Blasting construction method based on certain angle formed between boreholes and joints

A construction method and angle-fixed technology, applied in blasting and other directions, can solve problems such as labor-intensive, underutilized explosives, time-consuming, etc., and achieve the effect of a wide range of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

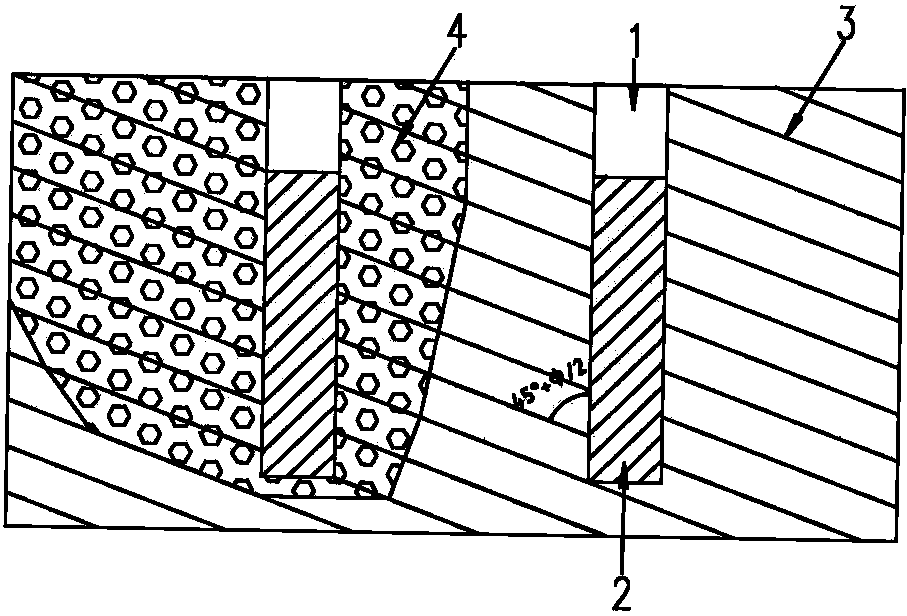

[0028] The blasting construction method in this embodiment, in which the drilling and the joints form a certain angle, is mainly applicable to the situation where the general rock occurrence of the whole mountain is not much different in the open-air step blasting site. If it is necessary to level the whole mountain, it is best It is to excavate along the inclination of the rock formation, so that the best excavation steps can be obtained, and it is the excavation direction with the best blasting effect. During construction, the following steps are included:

[0029] (1) Determine the mountain to be blasted, estimate the amount of rocks in the entire mountain and the height after blasting.

[0030] (2) Select several well-exposed rock formations in the entire mountain, and use a geological compass to measure the occurrence of the rock formations at these points—strike, dip and inclination X. Use the several groups of occurrences measured to make statistics to estimate the gen...

Embodiment 2

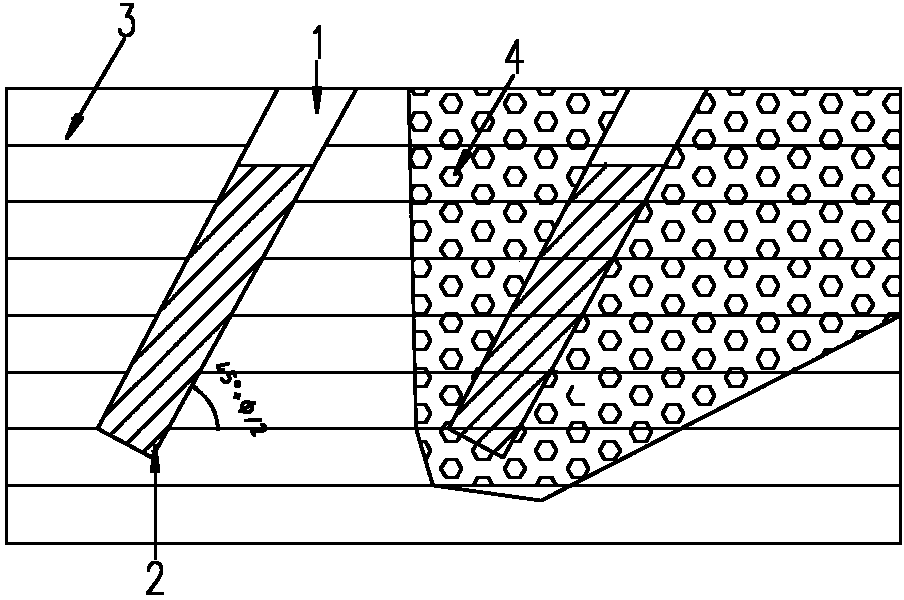

[0039] like image 3 As shown, the operation steps of this embodiment are basically the same as those of Embodiment 1, the difference being that the inclination angle of the mountain rock formation 3 to be blasted is 0°, and the angle between the drilling direction and the horizontal plane is 45°+φ / 2. After the hole is drilled, the charge 2 is put into it, and the plug 1 is installed at the hole, and the designed rock formation fragment 4 can be obtained after blasting.

[0040] Since the angle of the drilling hole is not perpendicular to the horizontal plane, the amount of charge can be better controlled. For example, for emulsion explosives, the tubes will not be skewed after being loaded into the hole, and they are all connected end to end and lie obliquely in the drilling hole.

[0041] It has been proved by engineering practice that the blasting construction method of the present invention can not only make full use of explosives, but also can obtain smaller rock blocks, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com