Movable industrial solid waste fiber composite material treatment system, working method and application

A fiber composite material, industrial solid waste technology, applied in solid materials, grain processing, packaging, etc., can solve the problems of long processing process, high processing cost, difficult cross-provincial transportation, etc., to achieve fast processing speed and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

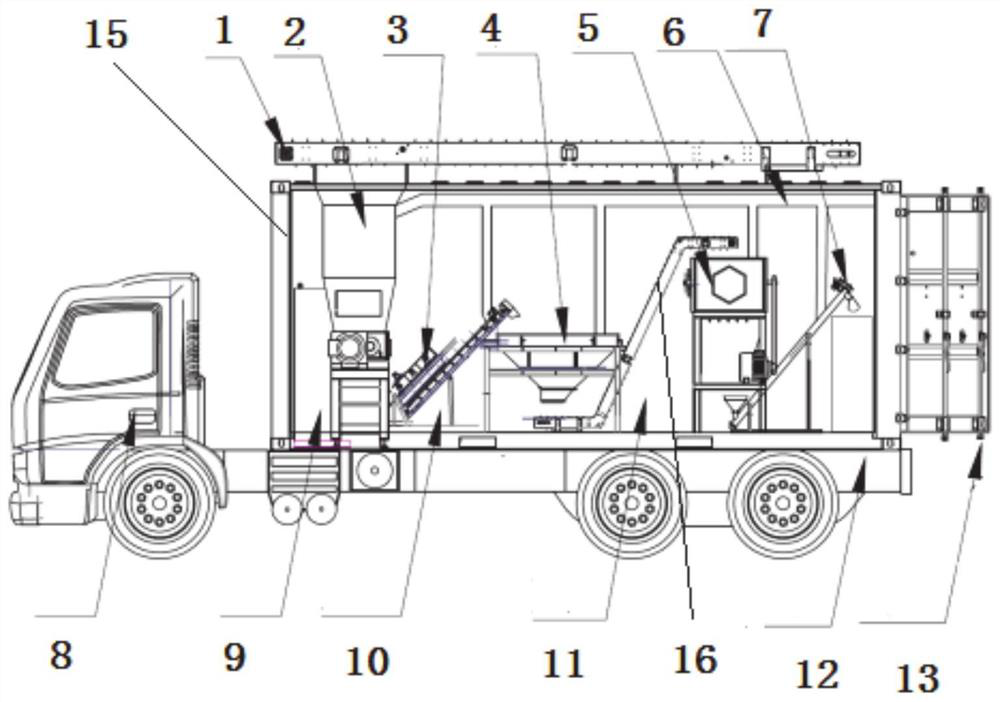

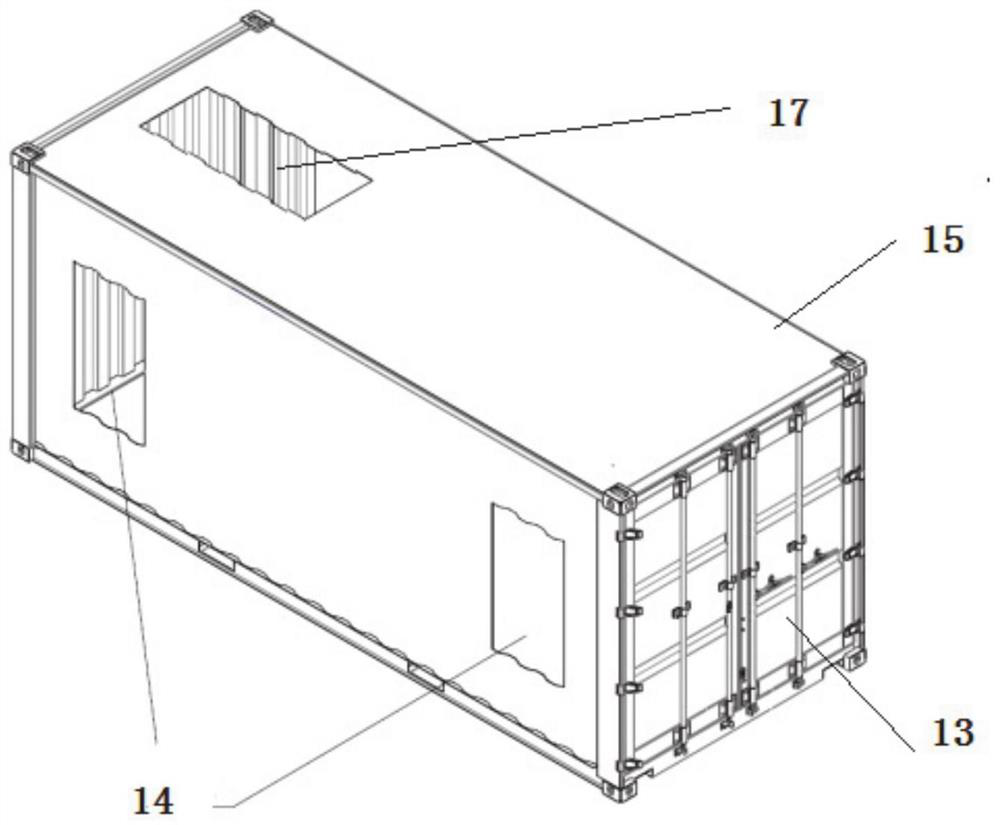

[0045] In a typical embodiment of the invention, reference figure 1 As shown, a mobile industrial solid waste fiber composite material processing system, including a tray 12, a tray mounted above the traveling mechanism 8 for supporting the upper casing 15 to achieve the processing system inside the housing 15 can move, walk away. The agency includes the cab that connects the control panel of the cab through the controller 9, which can drive the housing and the internal processing system thereof to achieve cross-regional effects, reduce the demand for the site, greatly reduce investment costs.

[0046] Considering environmental issues, in this embodiment, select a closed housing, one end of the housing has an opening door for repair and maintenance of various mechanisms within the processing system; specifically, the tray 12 is threaded with the housing 15, Implementing the overall deployment mode, the housing can also be disassembled separately to the ground, so that the overall ...

Embodiment 2

[0072] This embodiment provides a working method of a mobile industrial solid waste fiber composite material treatment system, and the specific method is as follows:

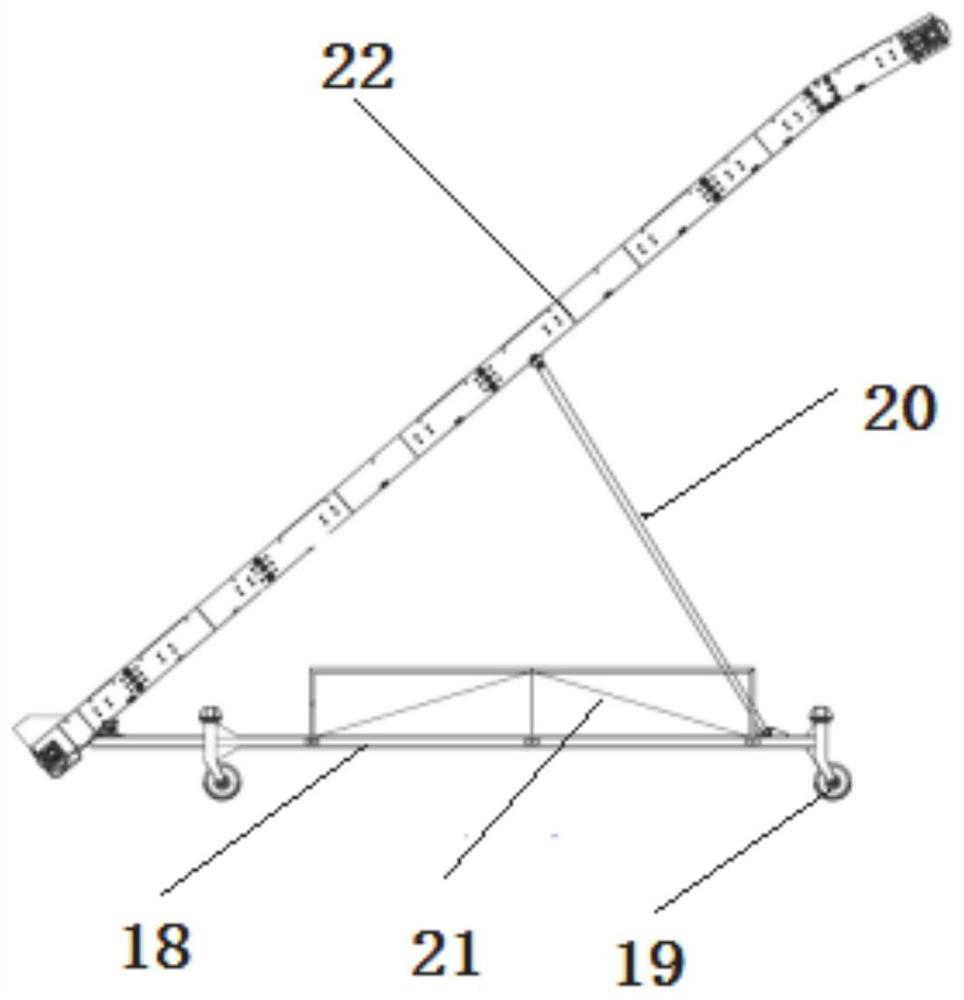

[0073] By the traveling mechanism drives the tray to the set position; the injection conveying unit is adjusted to ensure that the industrial solid waste is delivered to the upper portion of the housing;

[0074] Industrial solid waste enters the first group of crushing units, the primary crushing unit is primarily broken;

[0075] After the crushing material enters the magnetic option, the metal in the straw is separated, and the separated metal is collected by the discharge package collection unit;

[0076] The disgoriatable material after separating the metal enters the screening unit for screening, and collecting the strand smaller than the set particle size by the discharge package collecting unit, greater than the crushed material of the setting particle size is delivered to the next set of crushing units The ...

Embodiment 3

[0078] This embodiment provides a use of a mobile industrial solid waste fiber composite material treatment system, mainly used in waste glass steel, wind power blades, rail transit interior plates, cruise boats, and aerospace panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com