Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Ensure relative distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

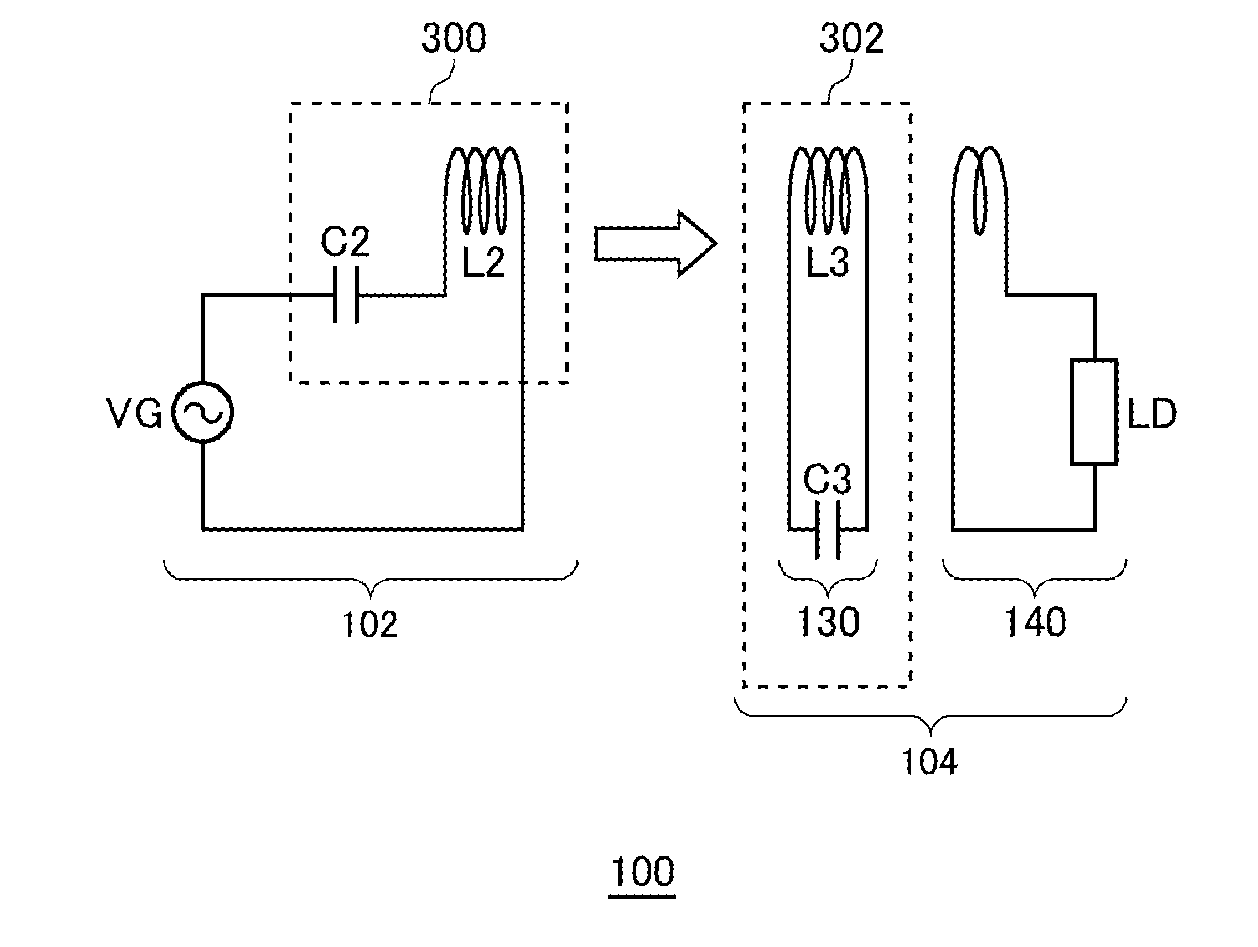

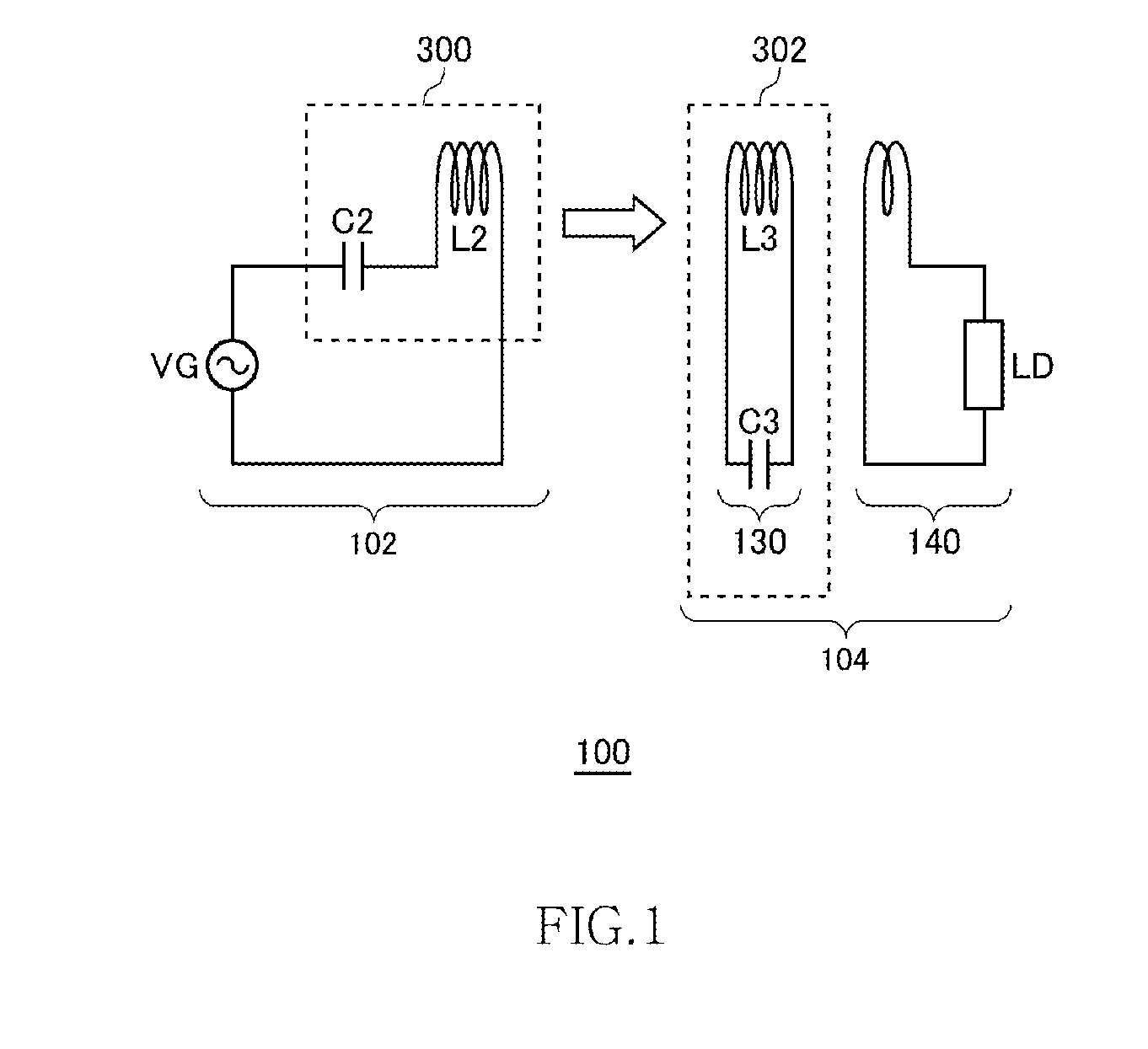

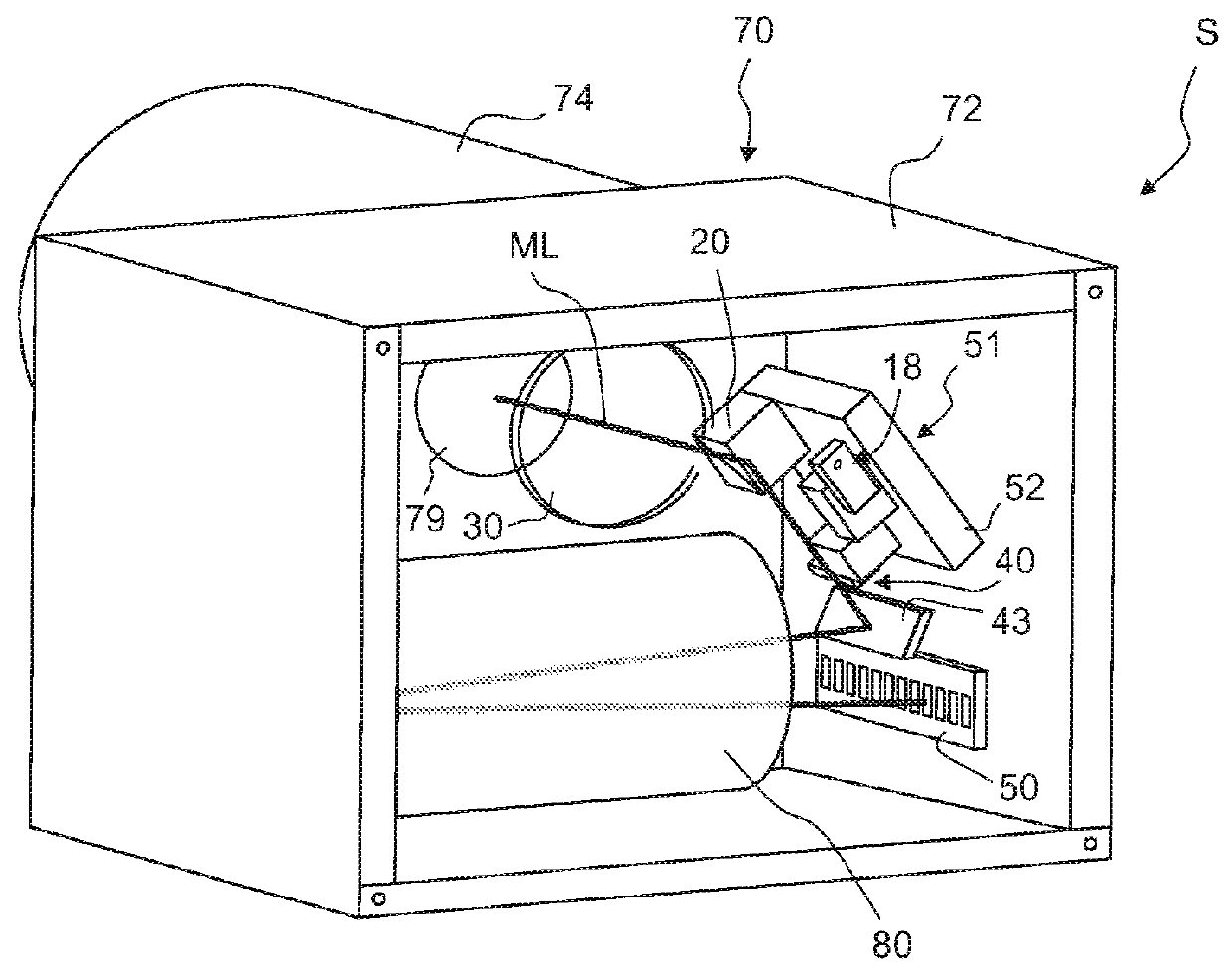

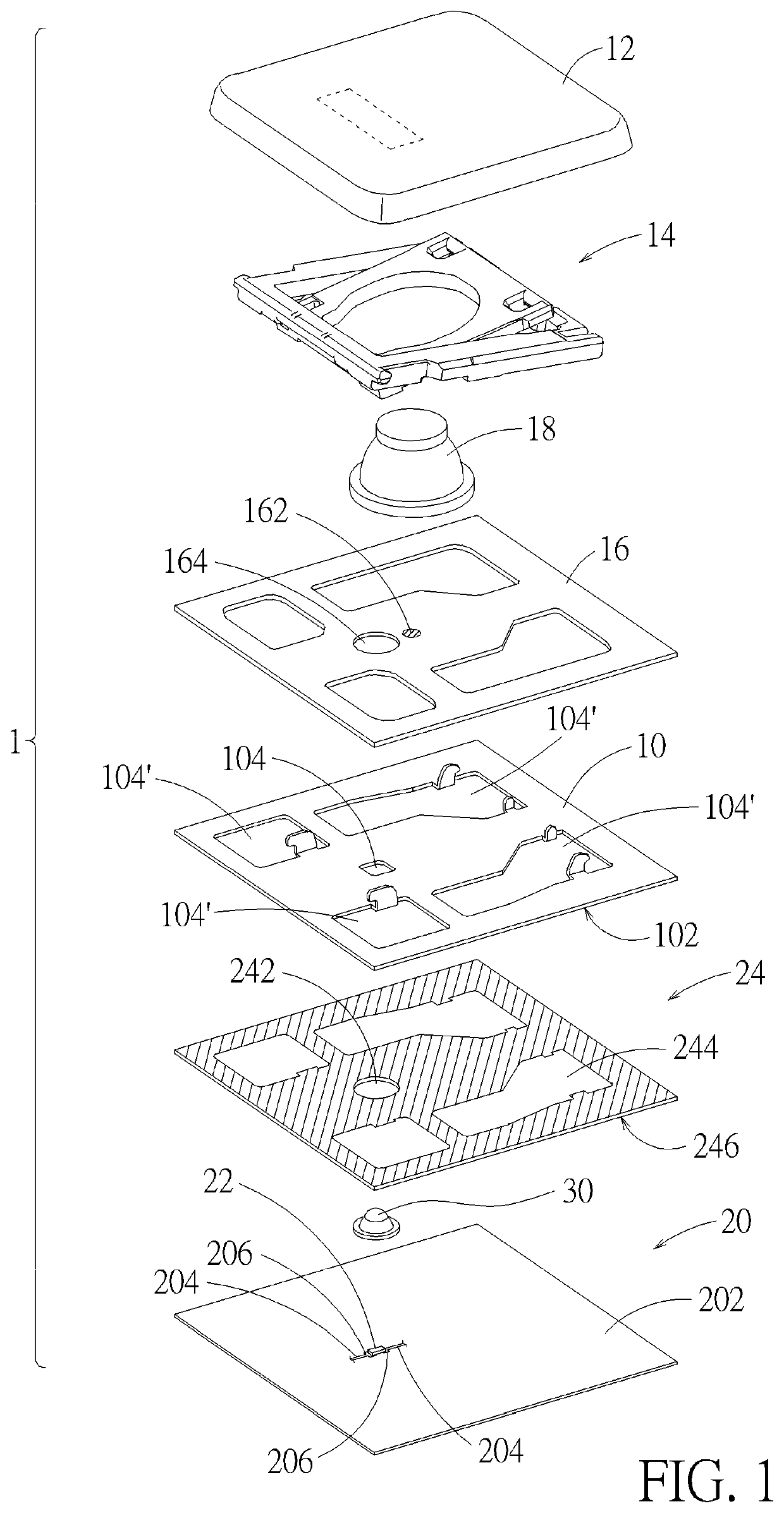

Wireless power feeder, wireless power receiver, and wireless power transmission system

ActiveUS20110198940A1Increase the number of windingsReduce sizeNear-field transmissionTransformersElectrical conductorResonance

Power is fed from a feeding coil to a receiving coil using magnetic resonance. The feeding coil is wound in a first layer substrate 144 of a multilayer substrate 116 with a space provided between the coil conductor thereof and further wound in a second later substrate 146 with a space provided between the coil conductor thereof. The feeding coil is wound such that a coil conductor 106a in the first layer and a coil conductive wire 106b in the second layer do not overlap each other as viewed in the axial direction (z-axis direction).

Owner:TDK CORPARATION

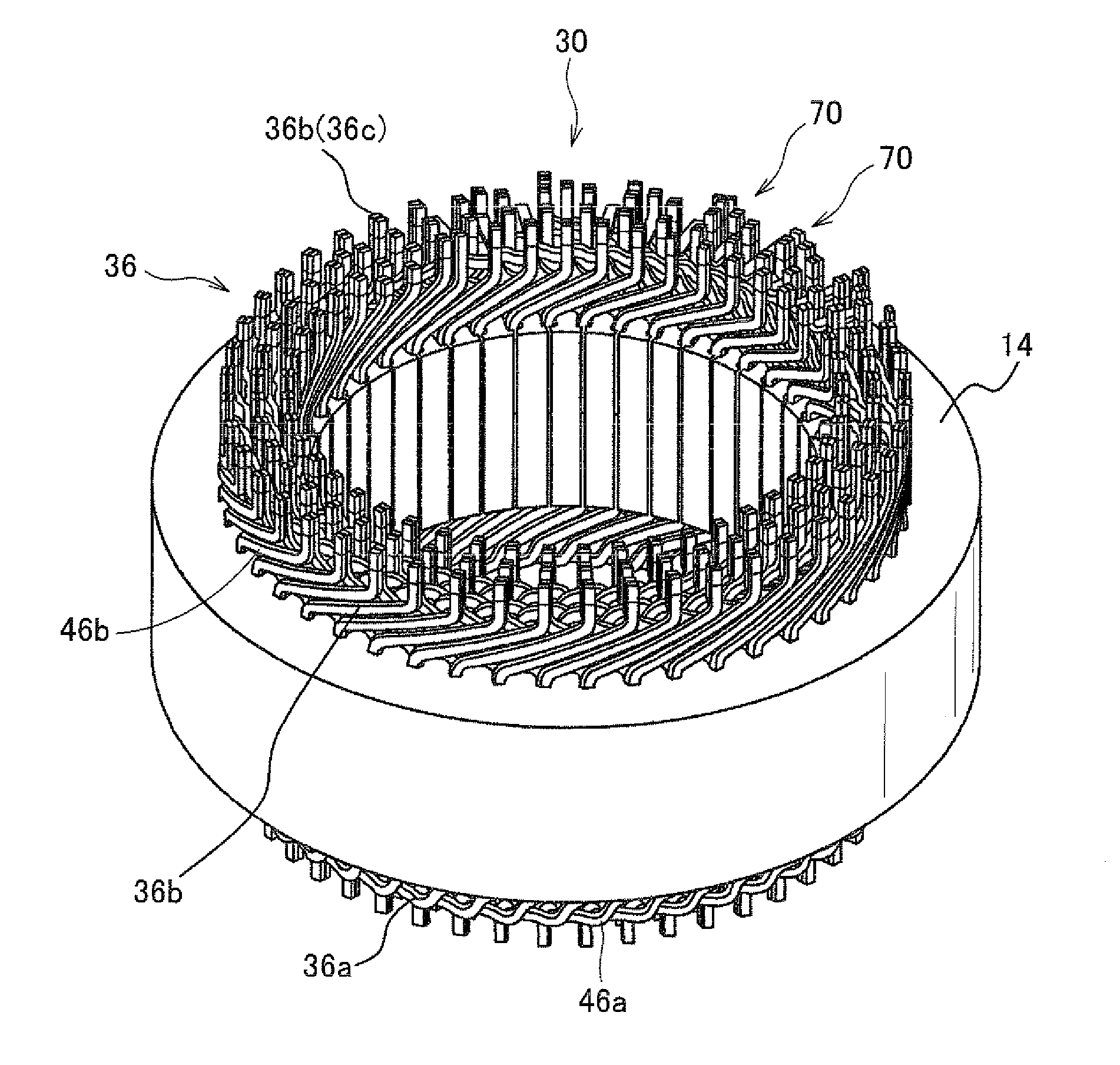

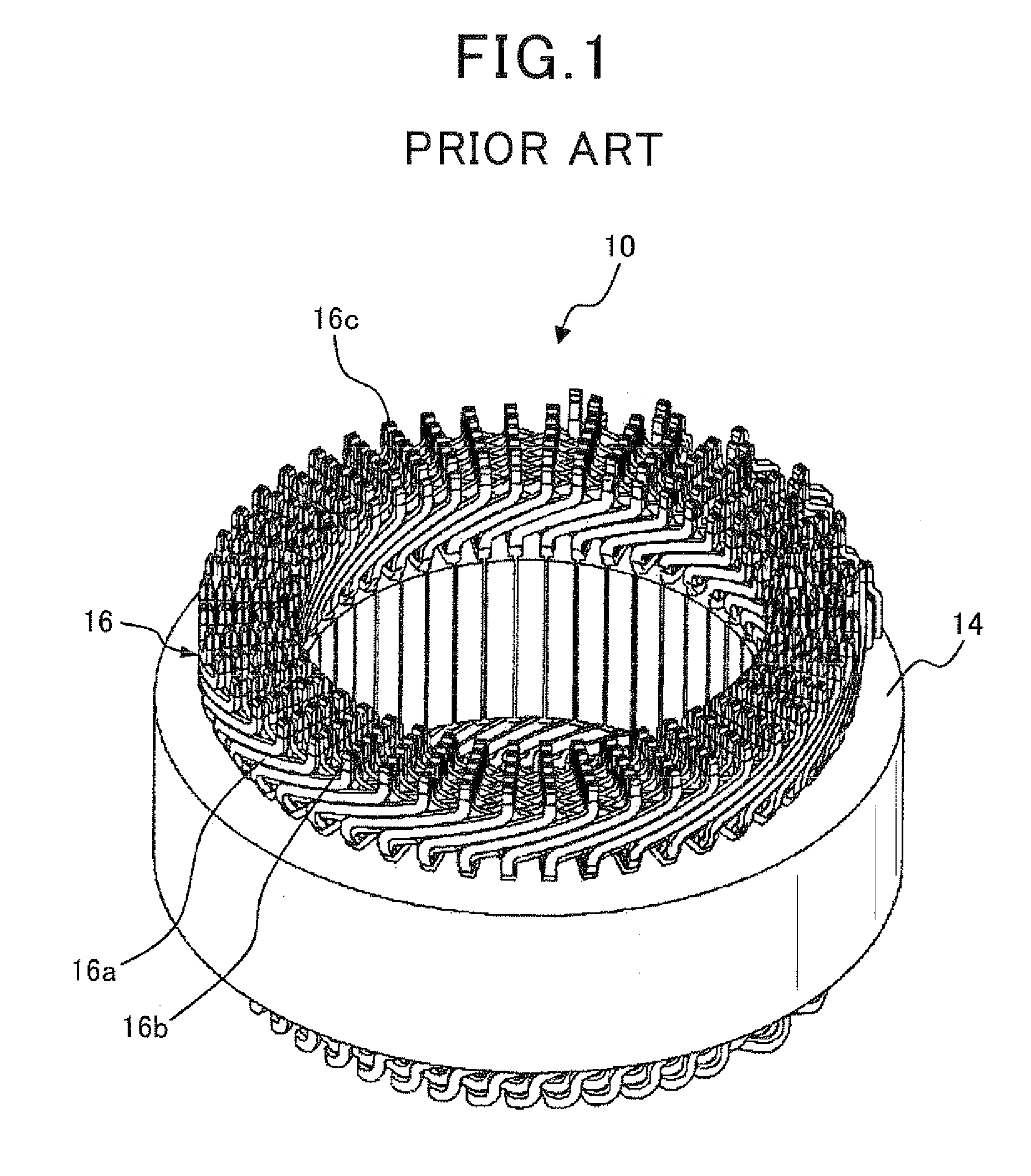

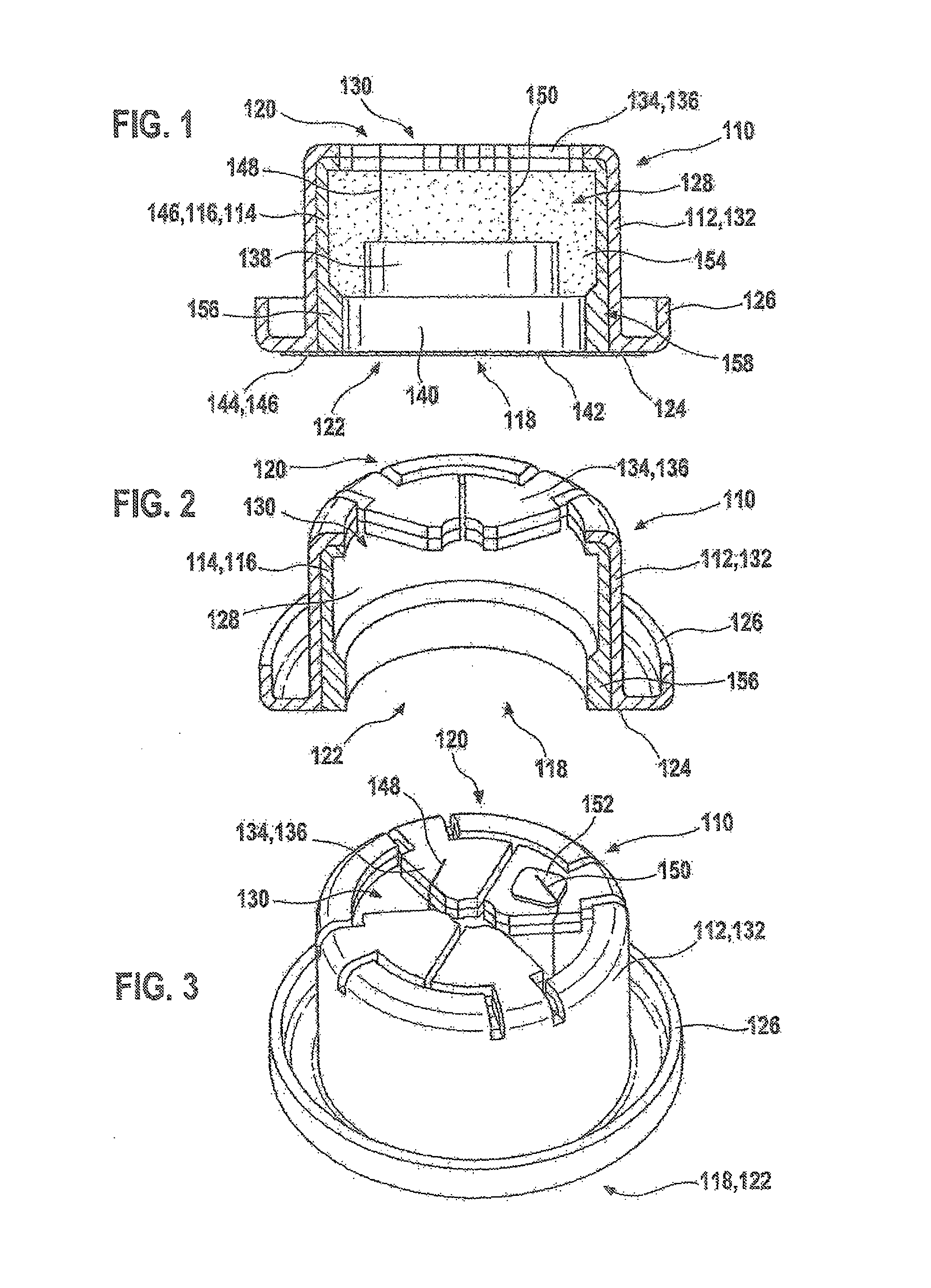

Stator for electric rotating machine

ActiveUS20110278973A1Simple structureDegreeManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectrical conductorEngineering

A stator for an electric rotating machine is equipped with a stator winding made up of a plurality of conductor segments. Each of the conductor segments has a head and two legs. The legs are inserted through their respective slots formed in a stator core, so that each of the conductor segments has leg ends protruding from either one of opposed end surfaces of the stator core and the head thereof protruding from the other end surface. Radially adjacent two of the leg ends are provided as a coil end pair to be welded. At least one of the heads is interposed between adjacent two of the coil end pairs, thereby ensuring a distance between the two adjacent coil end pairs which is great enough to provide a required degree of electric insulation between the coil end pairs when the leg ends of the conductor segments are welded electrically.

Owner:DENSO CORP

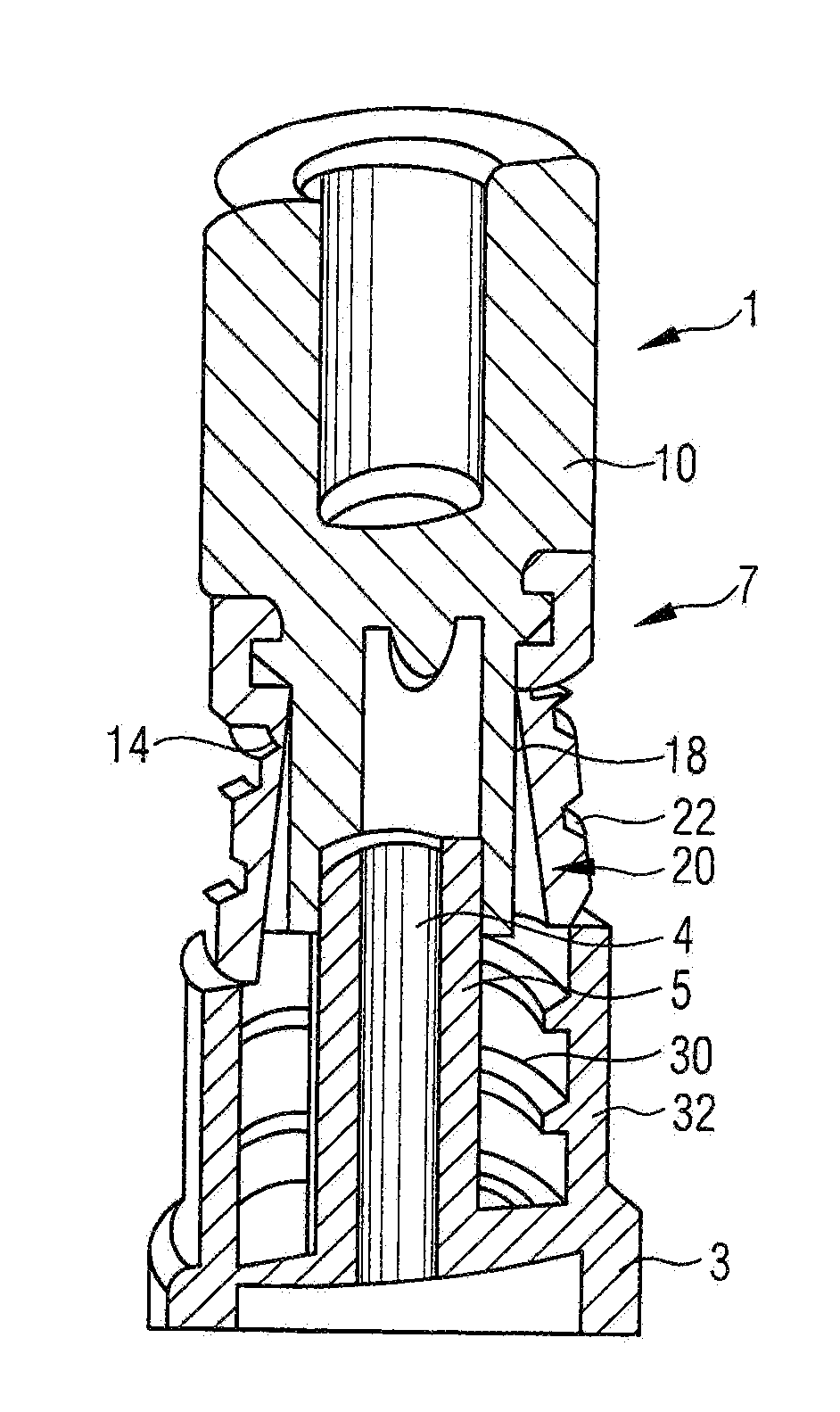

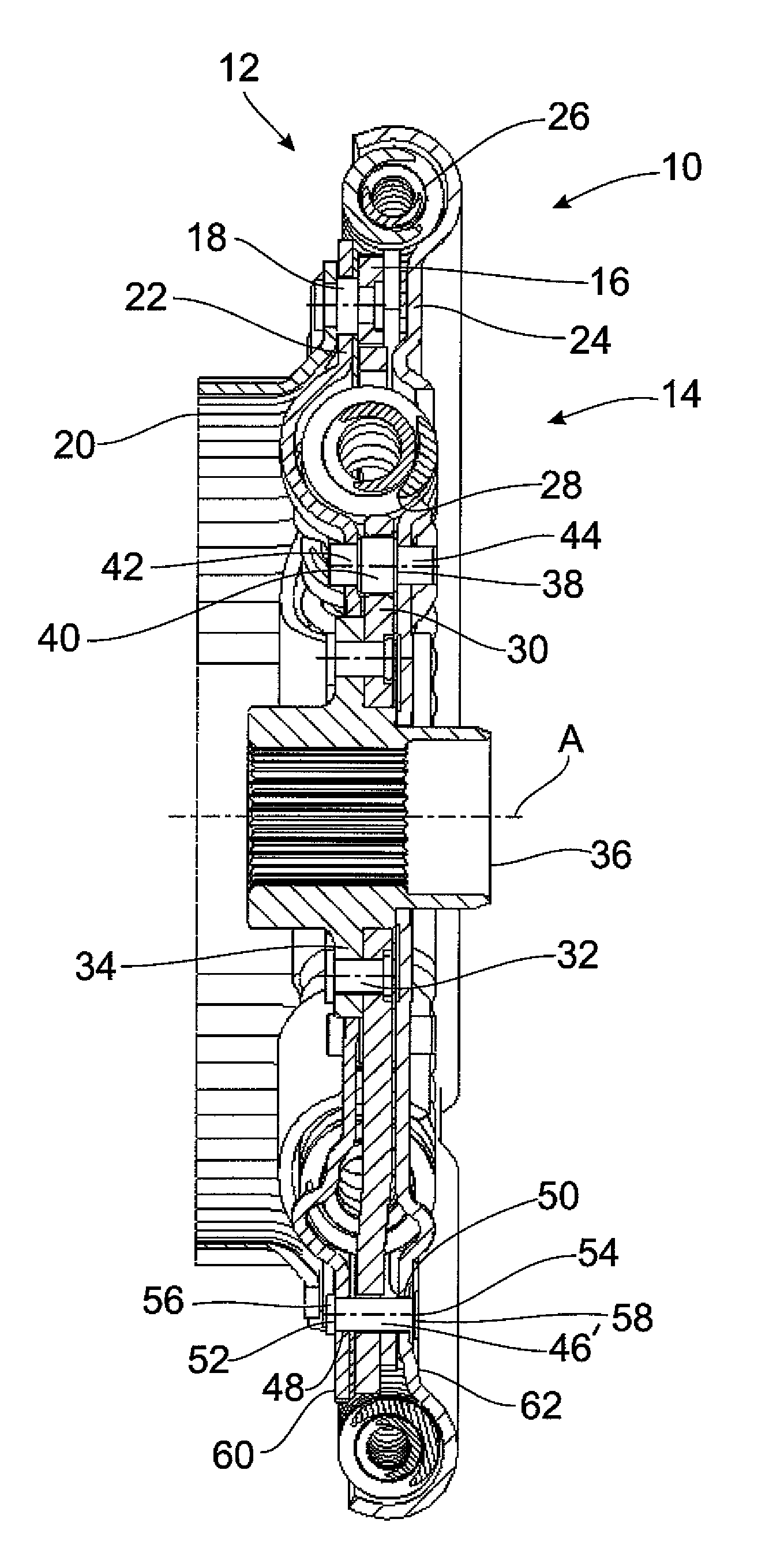

Ultrasonic transducer for use in a fluid medium

InactiveUS8596139B2Ensure relative distancePressure resistancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityUltrasonic sensor

Owner:ROBERT BOSCH GMBH

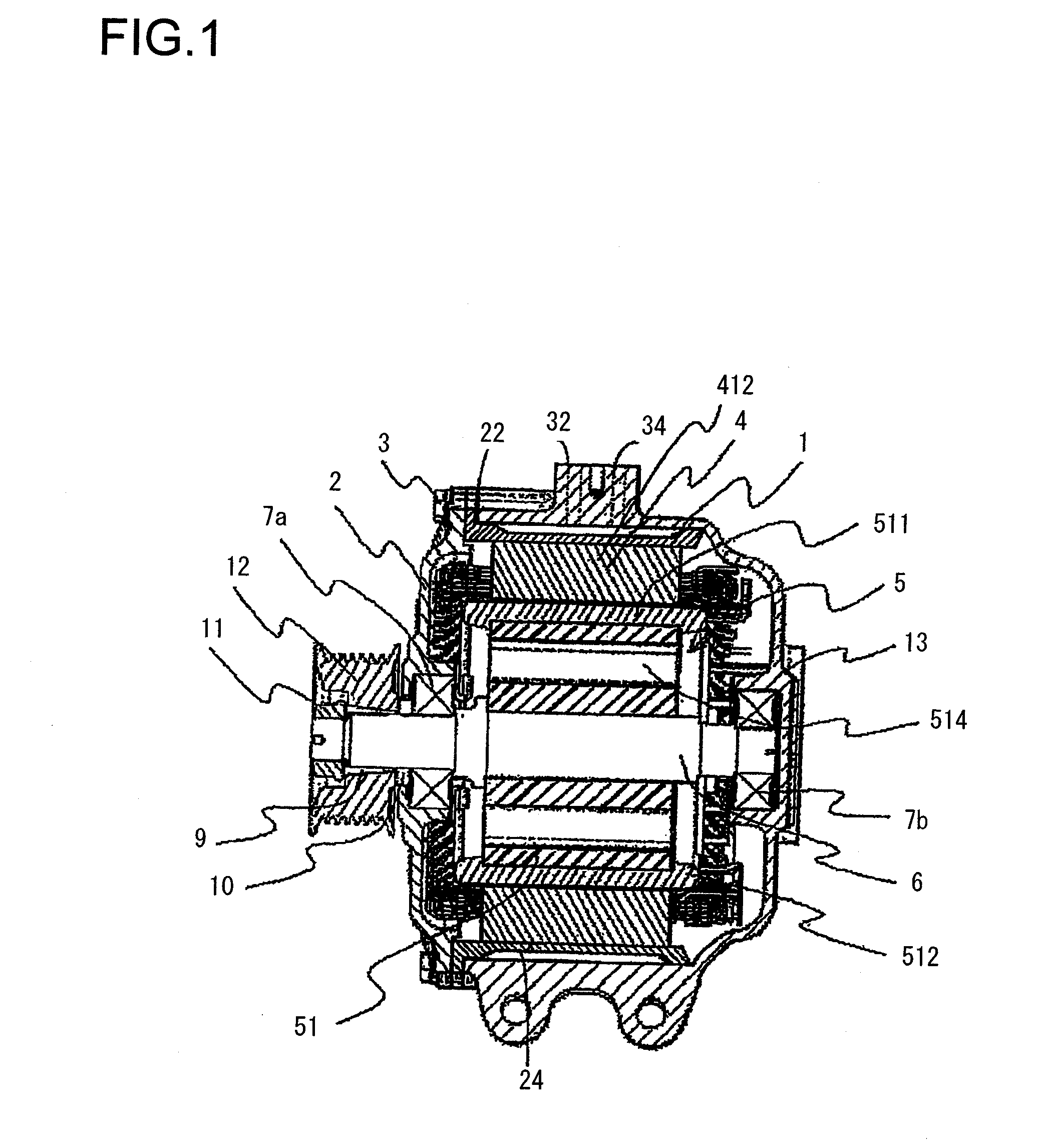

Rotating electric machine and production method for rotating electric machine

InactiveUS20120038230A1Small sizeCreepage distance distance ensuredWindings insulation shape/form/constructionMagnetic circuitElectric machineStator coil

A rotating electric machine includes: a stator in which a stator coil is mounted to a plurality of slots formed on a stator core; and a rotor that is rotatably disposed inside the stator. A slot groove, having a predetermined depth and a predetermined width from an end face of the stator core and forming a space between the stator coil and the stator core, is formed around each of the plurality of slots. The stator coil includes a straight-shaped straight section which is inserted into the slot and is provided with an insulating material, and a coil end section which extends outside of the slot and is bent at a same height as the end face of the stator core.

Owner:HITACHI LTD

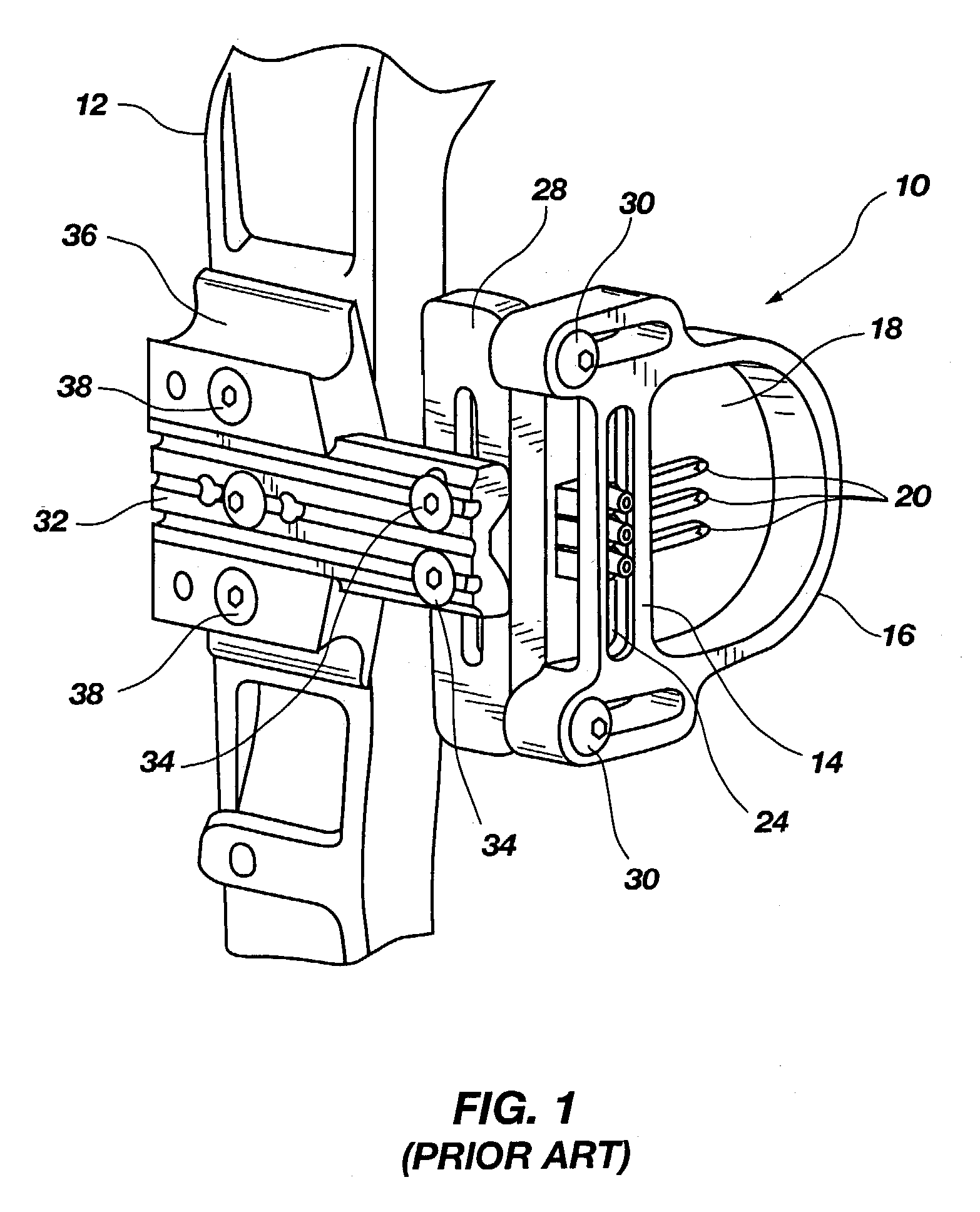

Fixed pin bow sight

InactiveUS7100291B2Vastly accurateAccurate placementBows/crossbowsSighting devicesEngineeringCircular segment

A fixed pin bow sight is comprised of a bow sight having an attachment portion, a sight pin mounting portion and a sight pin having a plurality of sight tips on said sight pin. Each of the sight tips are predisposed on the sight pin and spaced to provide accurate targeting of an arrow shot from a bow having a particular shooting speed. The spacing between sight tips is defined by the desired targeting distances from the bow. For example, the uppermost sight tip may be configured for a target that is twenty yards away with subsequent sight tips provided for ten yard increments (e.g., 30, 40, 50 and 60 yards). The sight tips are configured to be vertically aligned relative to the ground when firing the bow so that as the distance from target is increased the appropriate sight tip moves from top to bottom of the sight pin.

Owner:AFSHARI ABBAS BEN

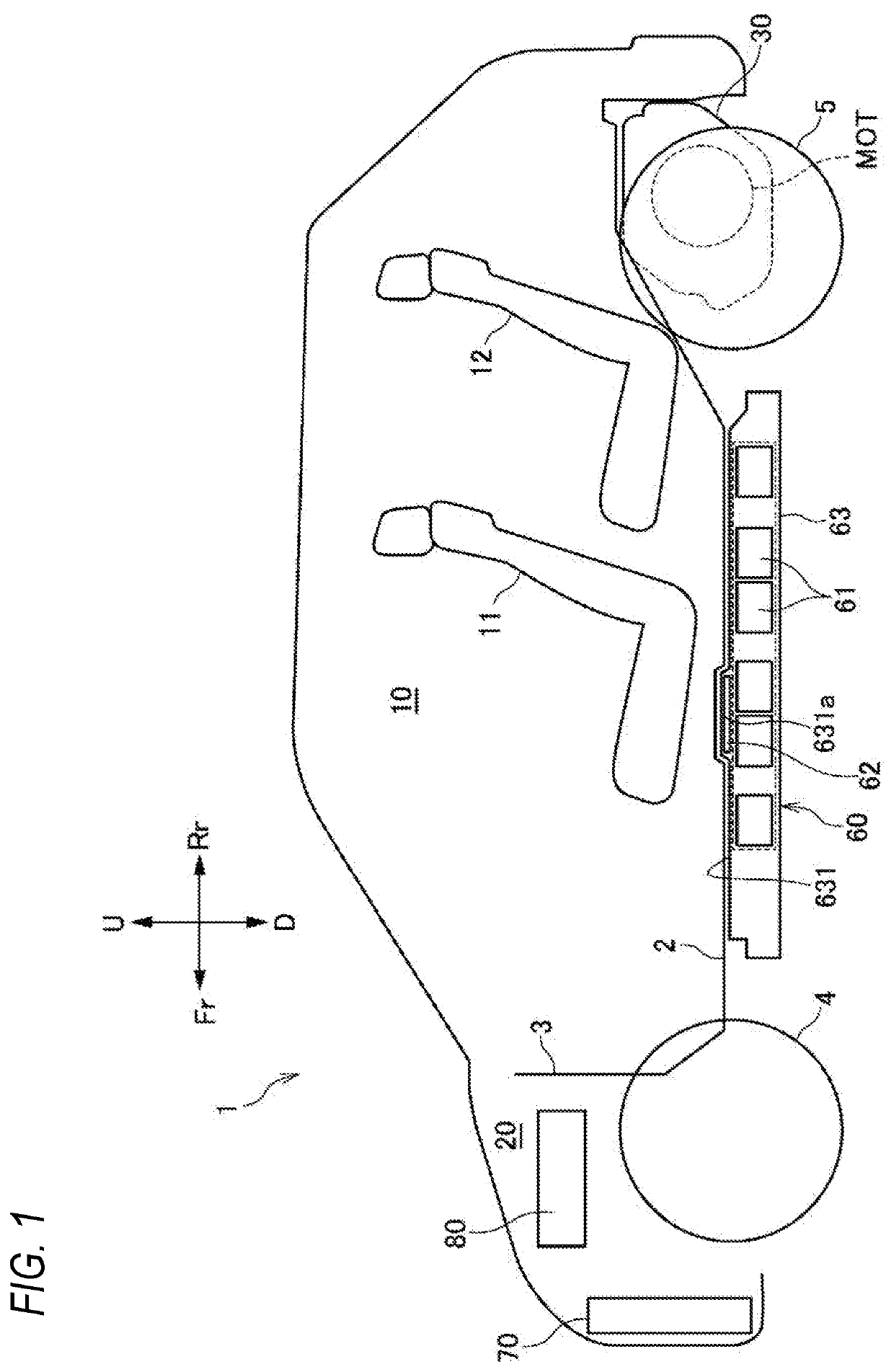

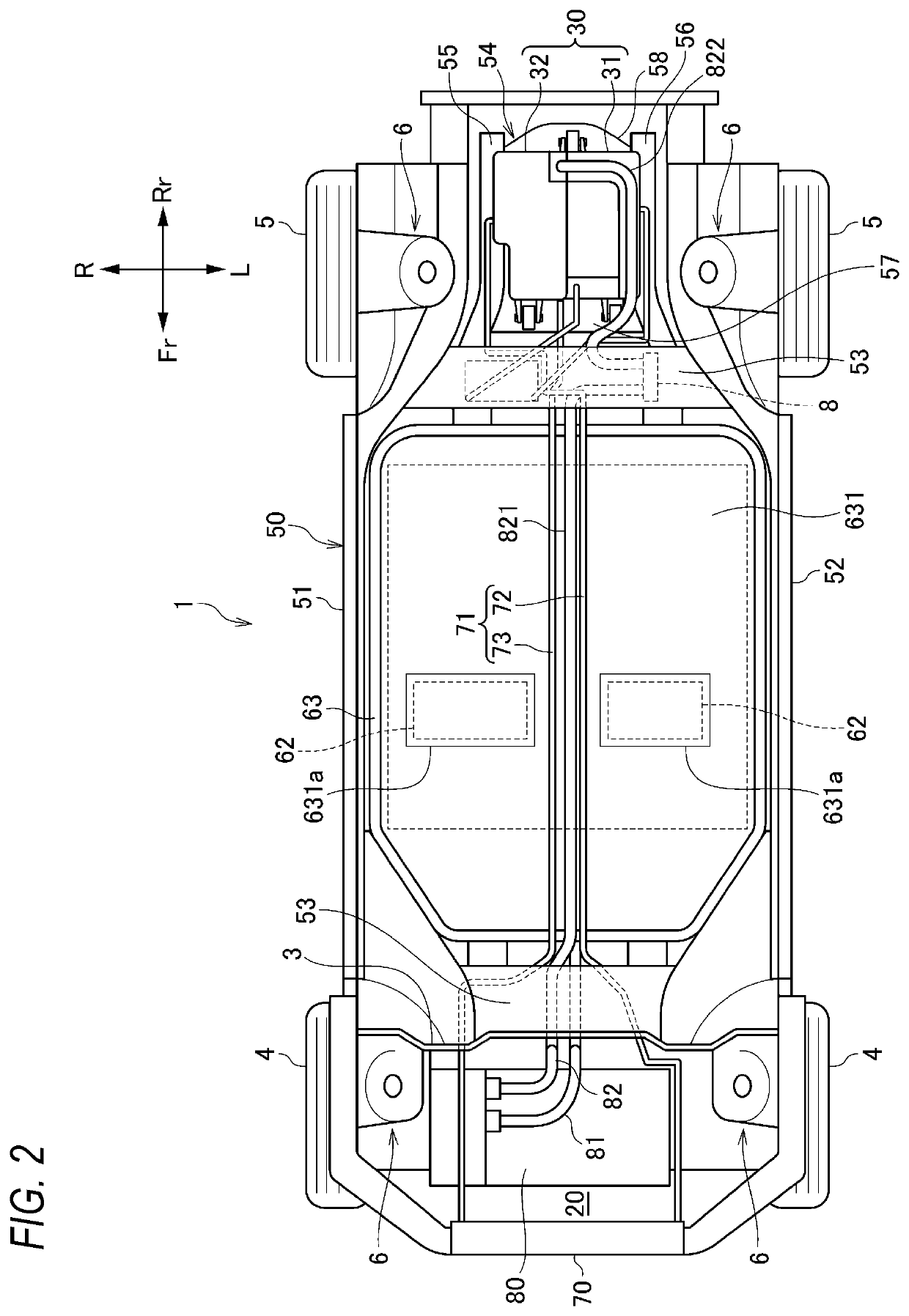

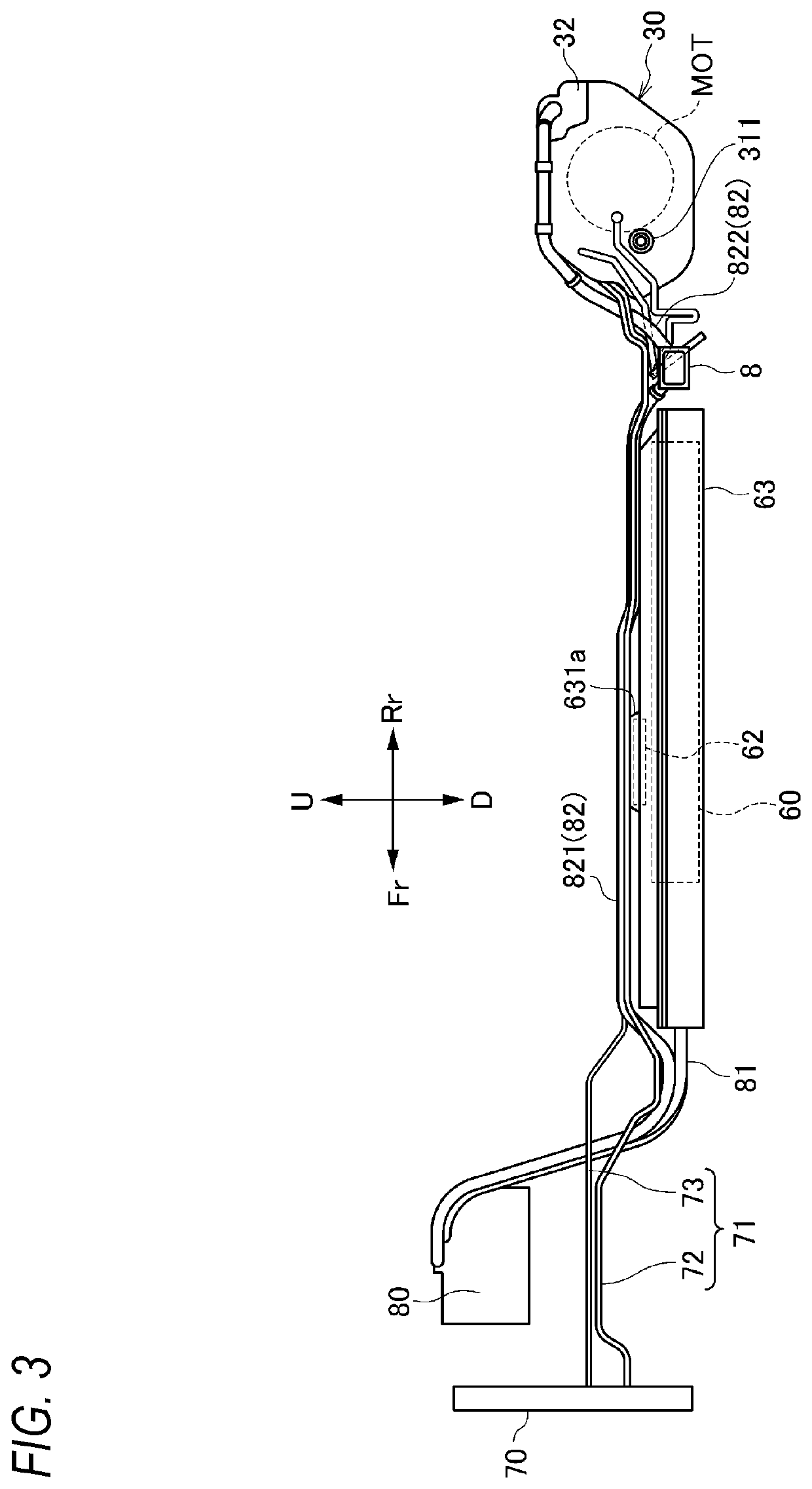

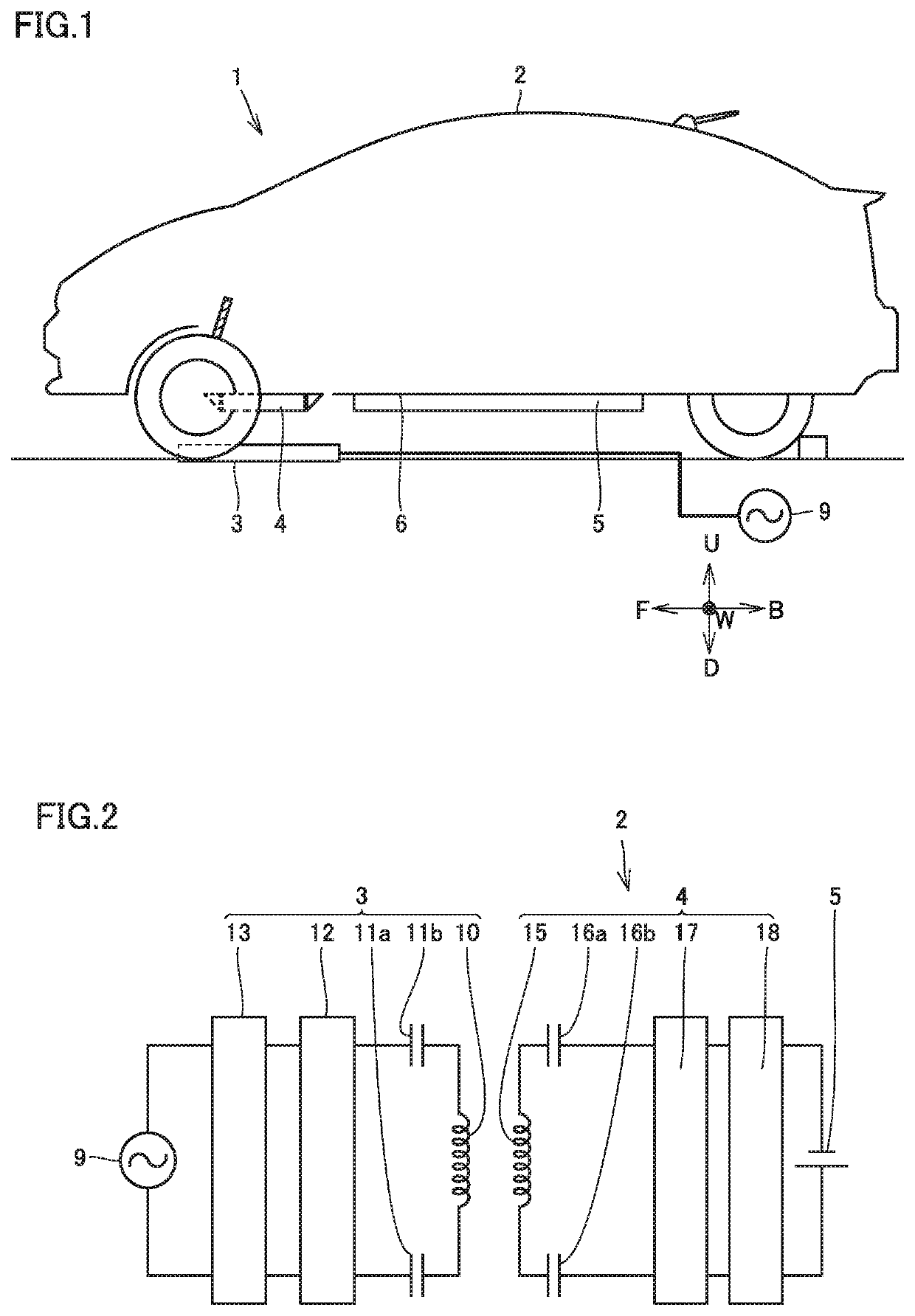

Vehicle

ActiveUS20200247225A1DistanceReduce distanceElectric propulsion mountingPropulsion by batteries/cellsElectrical batteryEngineering

A vehicle includes a vehicle interior; a front room provided in front of the vehicle interior; an electric motor control device provided at a rear side of the vehicle interior and below a floor panel; a battery provided below the vehicle interior and below the floor panel; a cooling device provided in the front room; a first cooling pipe configured to supply a refrigerant from the cooling device to the electric motor control device; and a second cooling pipe configured to discharge the refrigerant from the electric motor control device to the cooling device. The floor panel has a recessed portion recessed upwards, and the first cooling pipe and the second cooling pipe are accommodated in the recessed portion.

Owner:HONDA MOTOR CO LTD

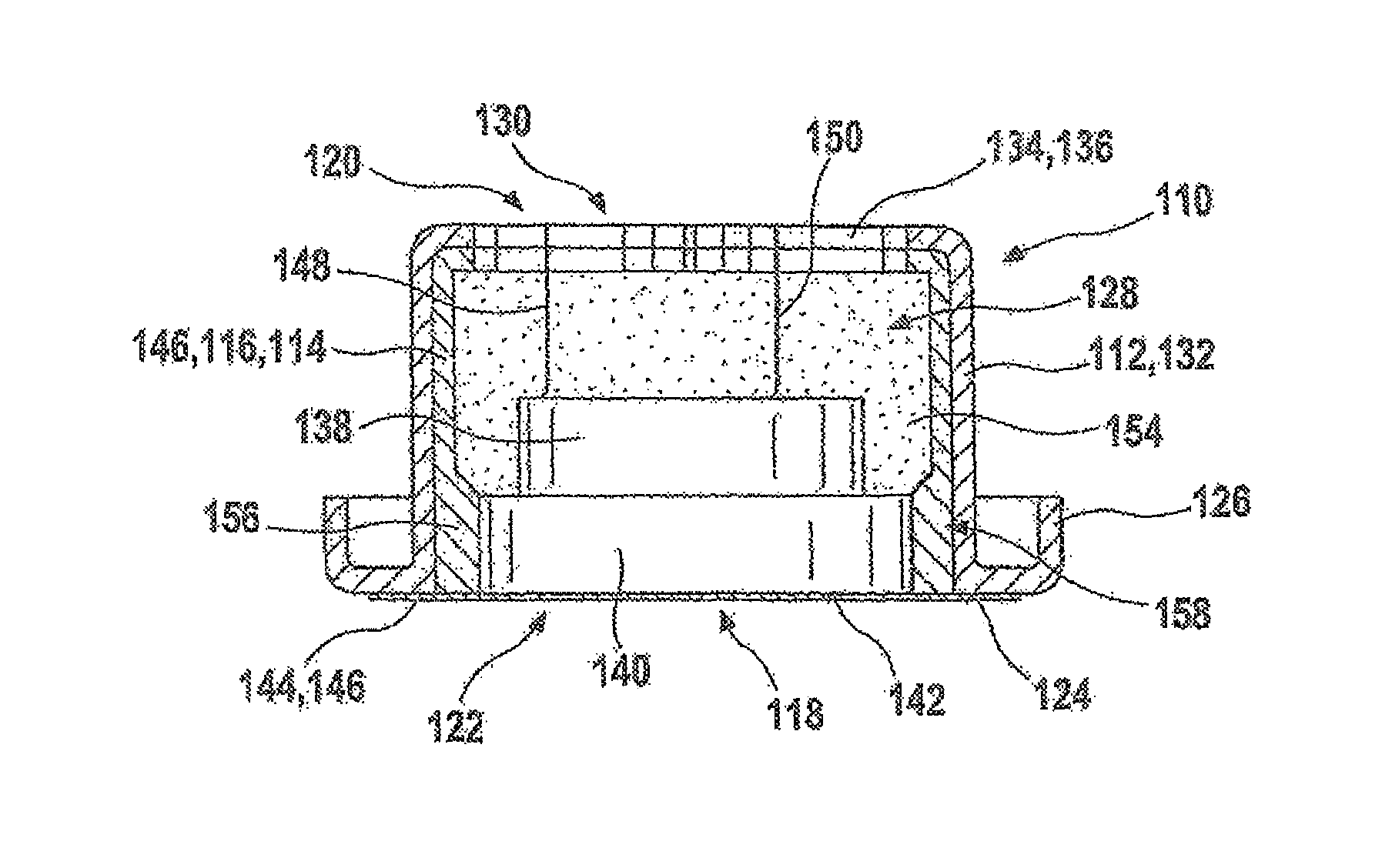

Closure, in particular a syringe closure for closing a distal opening of a syringe body in a sealing manner

InactiveUS20140358078A1Ensure relative distancePrevent fallingInfusion syringesIntravenous devicesEngineeringSyringe

A closure for closing in a sealing manner a distal opening on a syringe body is provided. The closure includes a fastening element that is or can be arranged on the syringe body around the distal opening and a closure cap that can be loosely connected to the fastening element and closing in a sealing manner the distal opening. The fastening element includes an inner thread that intermeshes with an outer thread on the closure cap, resulting in an initial state wherein the outer thread is formed on at least part of the closure cap. The part is under tension in such a way that after the closure cap is unscrewed from the inner thread the part under tension is pressed out over the inner thread of the fastening element such that the closure cap cannot be returned to the initial state once the closure cap is unscrewed.

Owner:SCHOTT SCHWEIZ

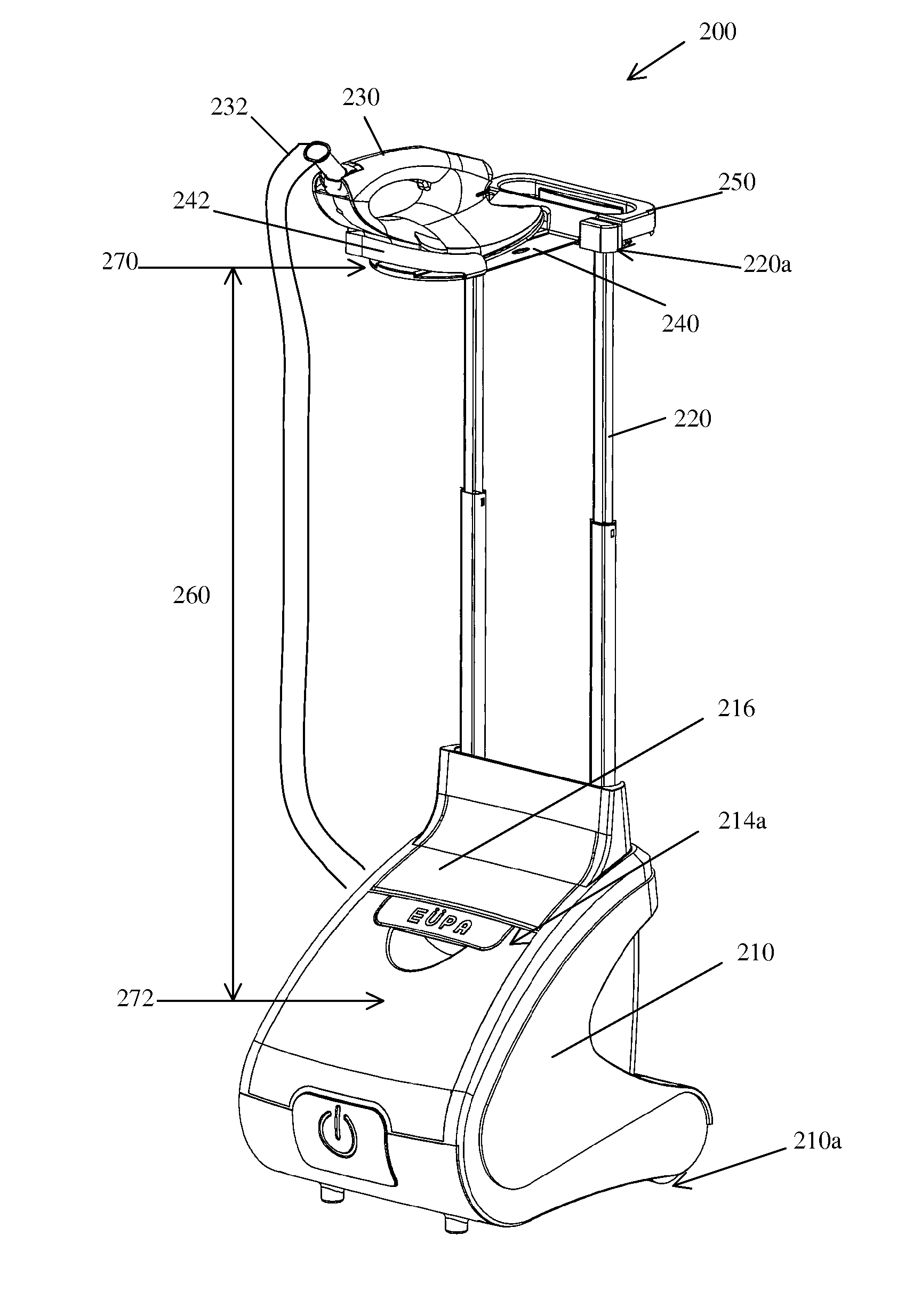

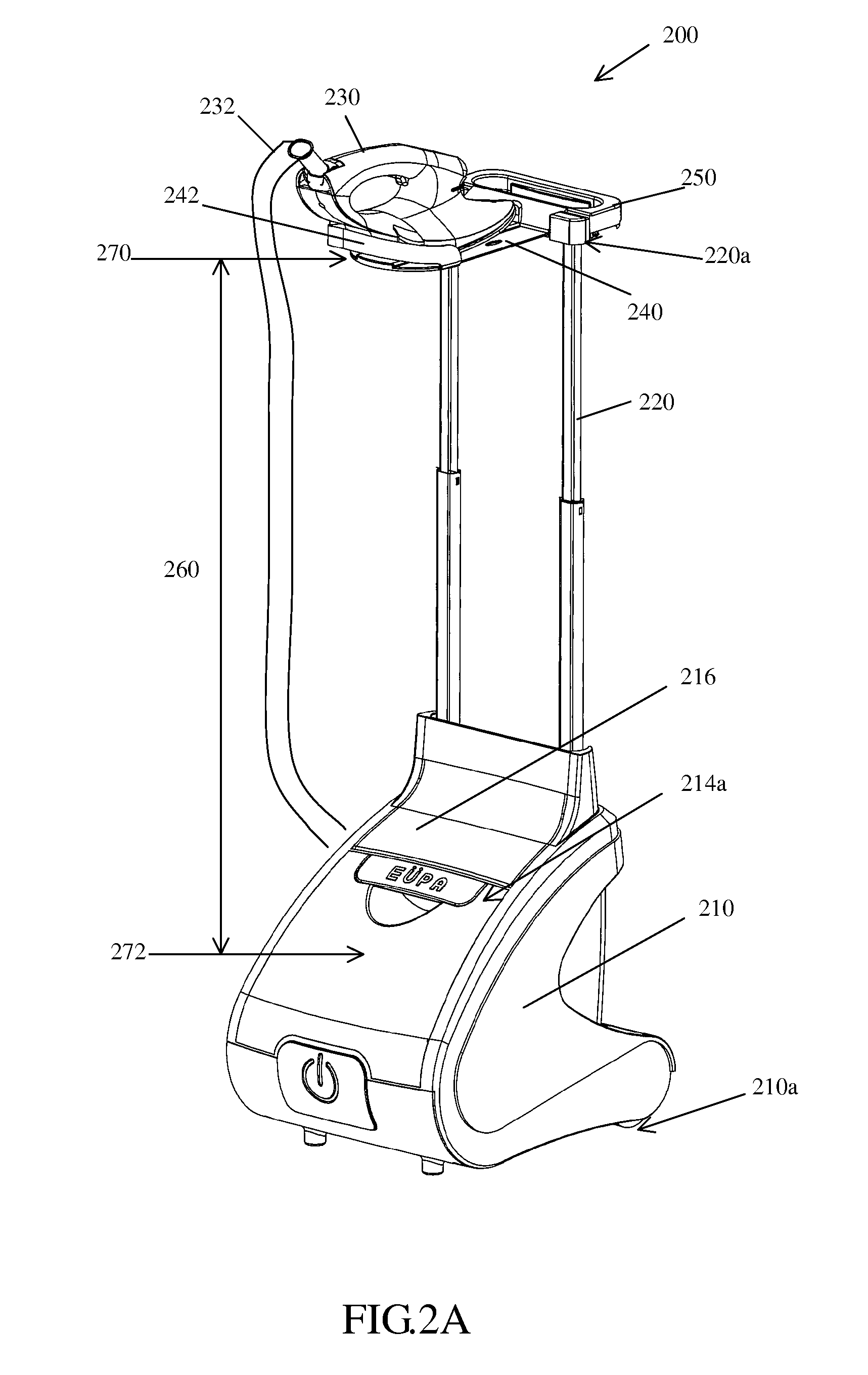

Steam ironing machine

A steam ironing machine, at least comprises a base, a telescopic shaft and an ironing device, wherein the base is provided with a steam generator and an outer case surrounding it. The telescopic shaft with a support seat mounted on its top end is disposed on the base and the support seat can move a distance relative to the base. The ironing device can detachedly be mounted on the support seat, wherein the steam generator in the base is attached to the ironing device.

Owner:TSANN KUEN CHINA ENTERPRISE

Semiconductor device and method for producing the same

ActiveUS7671453B2Increase in sizeEnsure relative distanceSemiconductor/solid-state device detailsSolid-state devicesShell moldingEngineering

Owner:MITSUBISHI ELECTRIC CORP

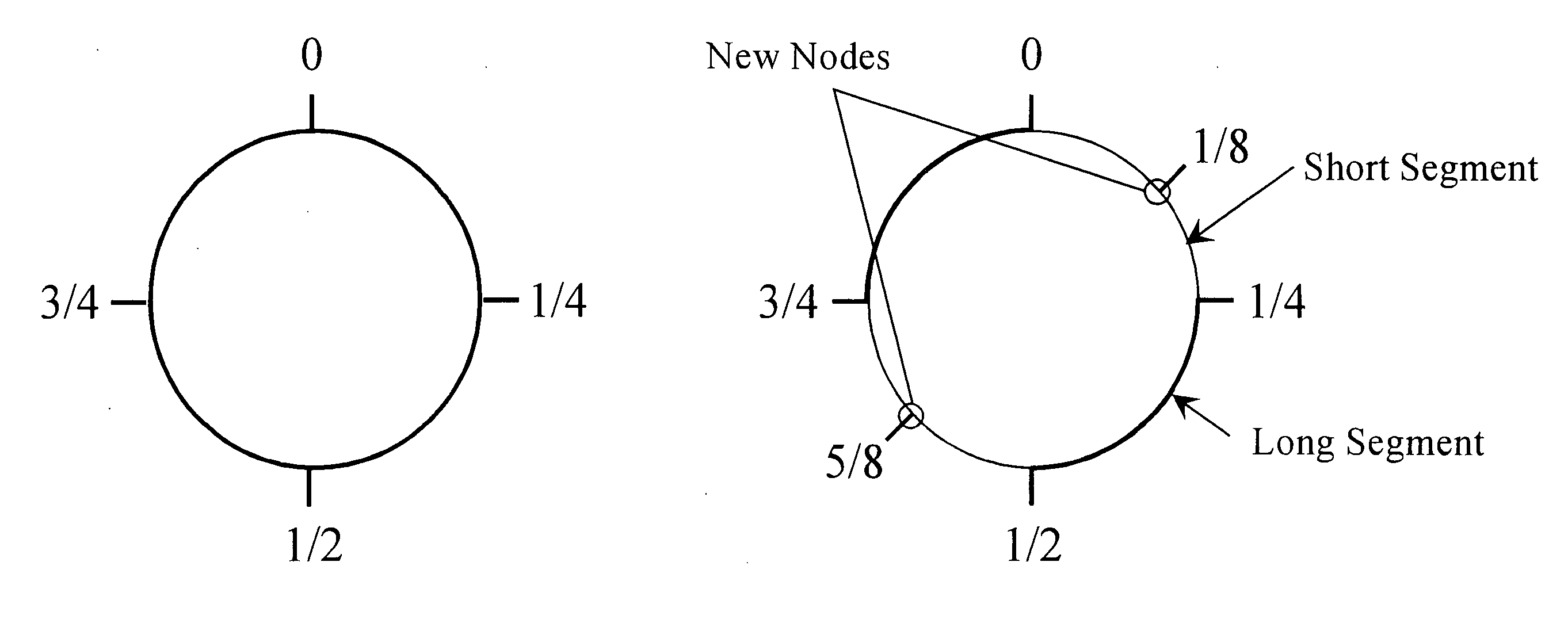

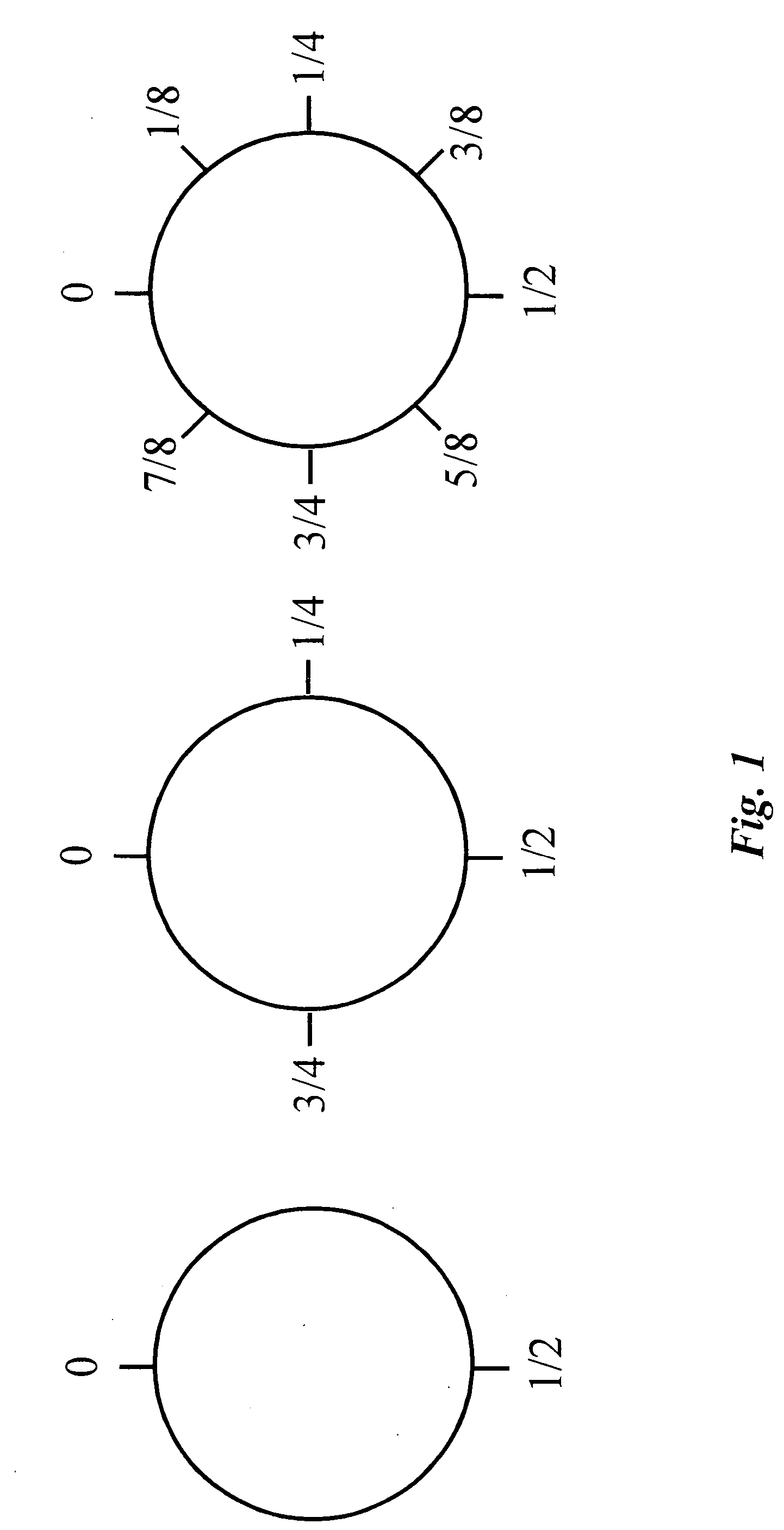

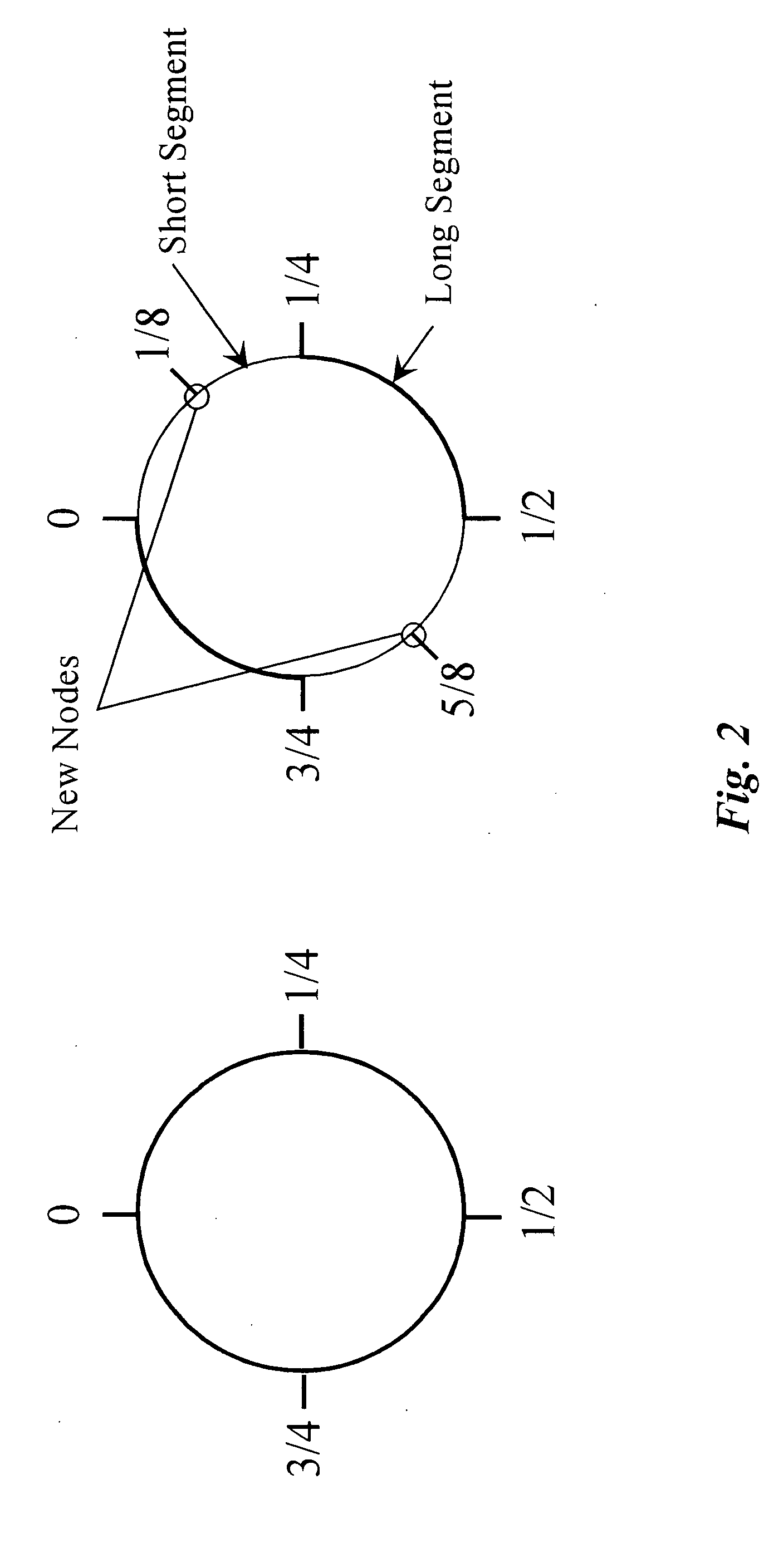

Distribution of identifiers in serverless networks

A method for assigning identifiers in a distributed system involves establishing a circle as a locus of all identifiers, with the value of any point on the circle being the portion of one complete revolution in a first direction around the circle to the point, measured from a first zero point, and selecting values to be assigned as identifiers as needed by rounds of assignment, wherein the beginning and end of any round of assignment has identifiers assigned with point values that divide the circle into equal-length sectors. The method is useful in and applied to serverless telephony systems.

Owner:CALLAHAN CELLULAR L L C

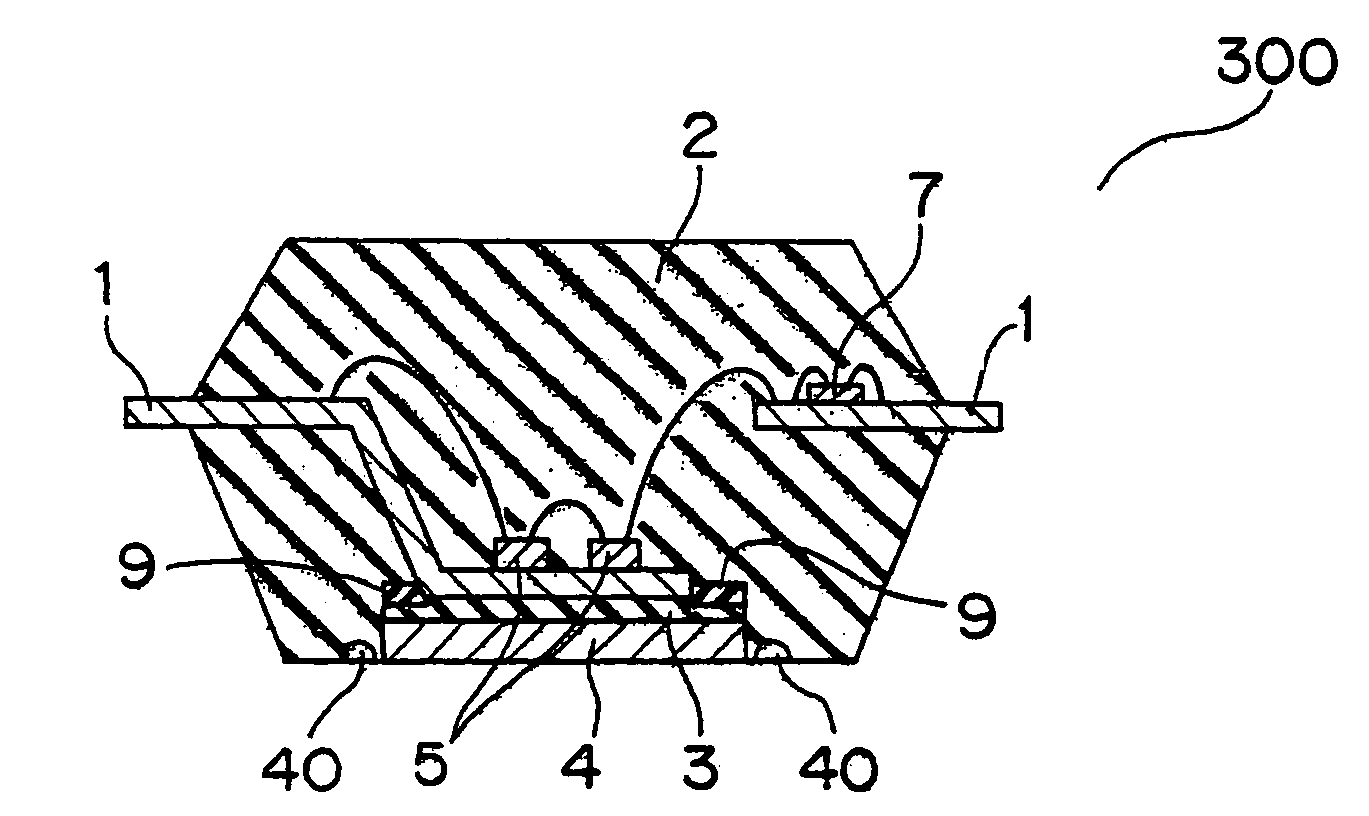

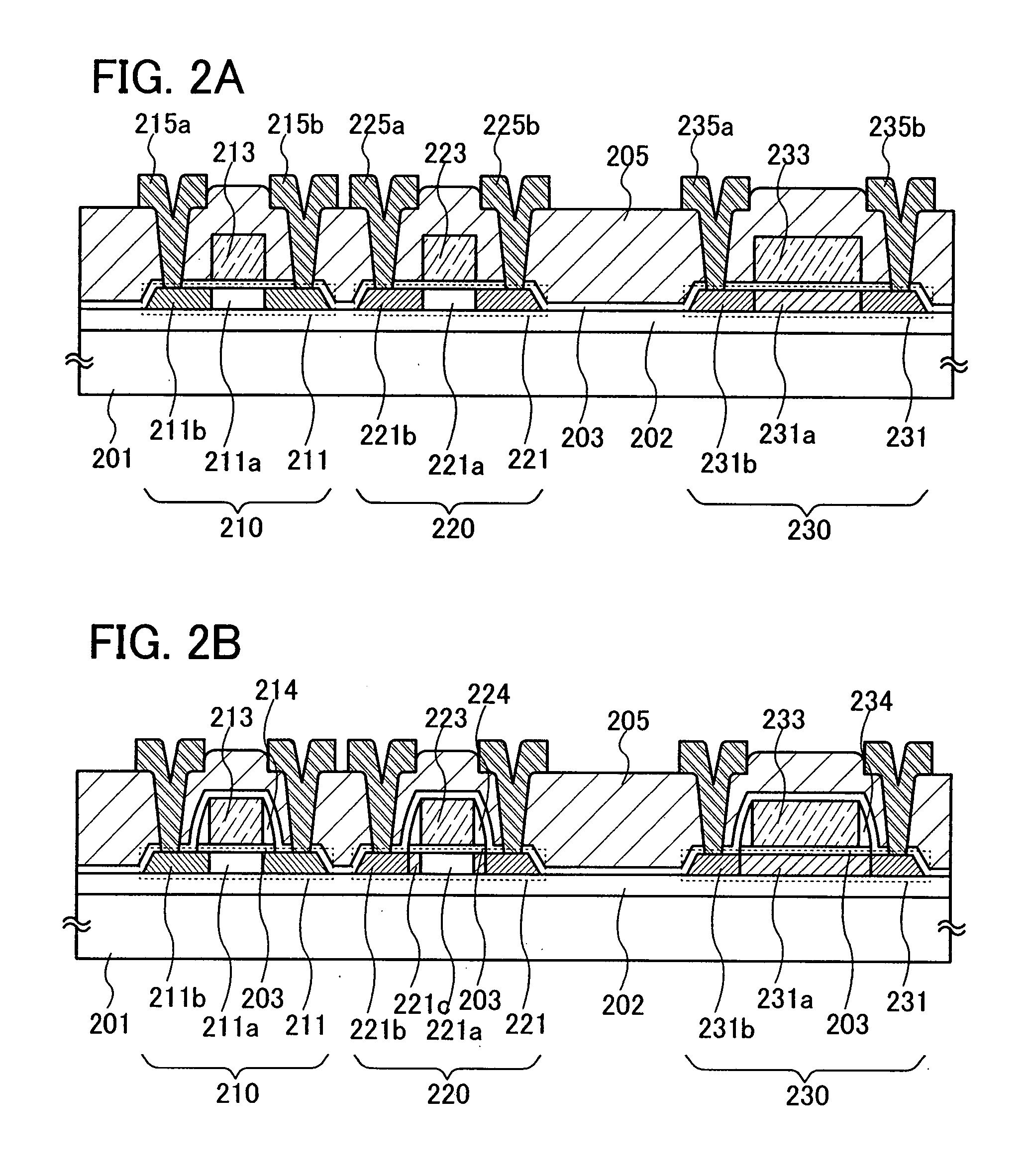

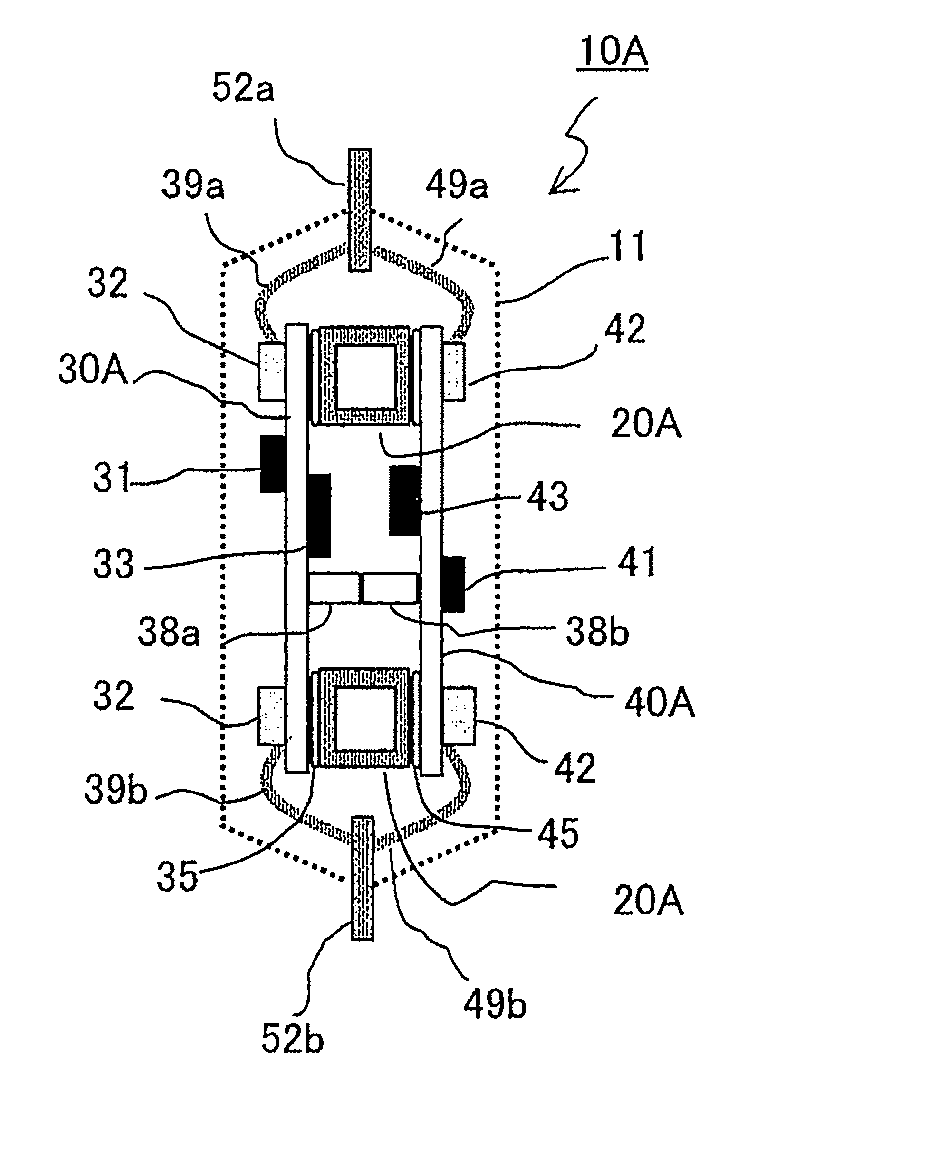

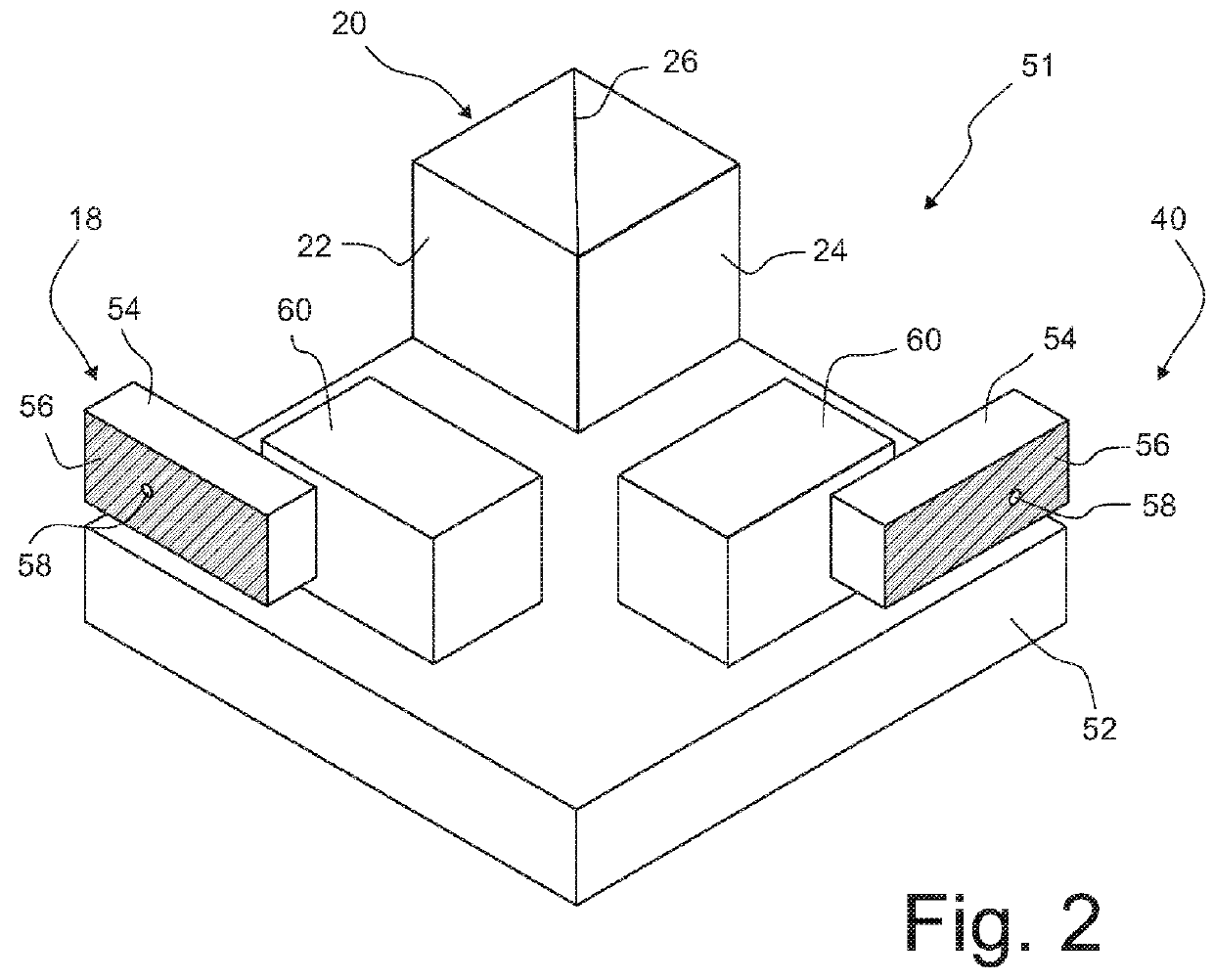

Resin-sealed electronic control device and method of fabricating the same

ActiveUS20110205701A1Increase the areaEnsure relative distanceCasings with connectors and PCBSemiconductor/solid-state device detailsElectronic boardExternal circuit

Provided is a resin-sealed electronic control device reduced in size, which includes a double-sided mounting board as at least one of a plurality of electronic boards obtained by division so that a large mounting surface with a small plane area is ensured. Each of a first electronic board (30A) and a second electronic board (40A) bonded onto an upper surface and a lower surface of each of a pair of separate beam members (20A) includes two surfaces on which outer circuit components (31, 32, 41, 42) and an inner circuit component (33, 43) are respectively mounted. A height of each of the inner circuit components is equal to or less than a thickness of each of the separate beam members (20A). Heat-generating components (32, 42) in the outer circuit components are provided to be adjacent to and opposed to the separate beam members (20A).

Owner:MITSUBISHI ELECTRIC CORP

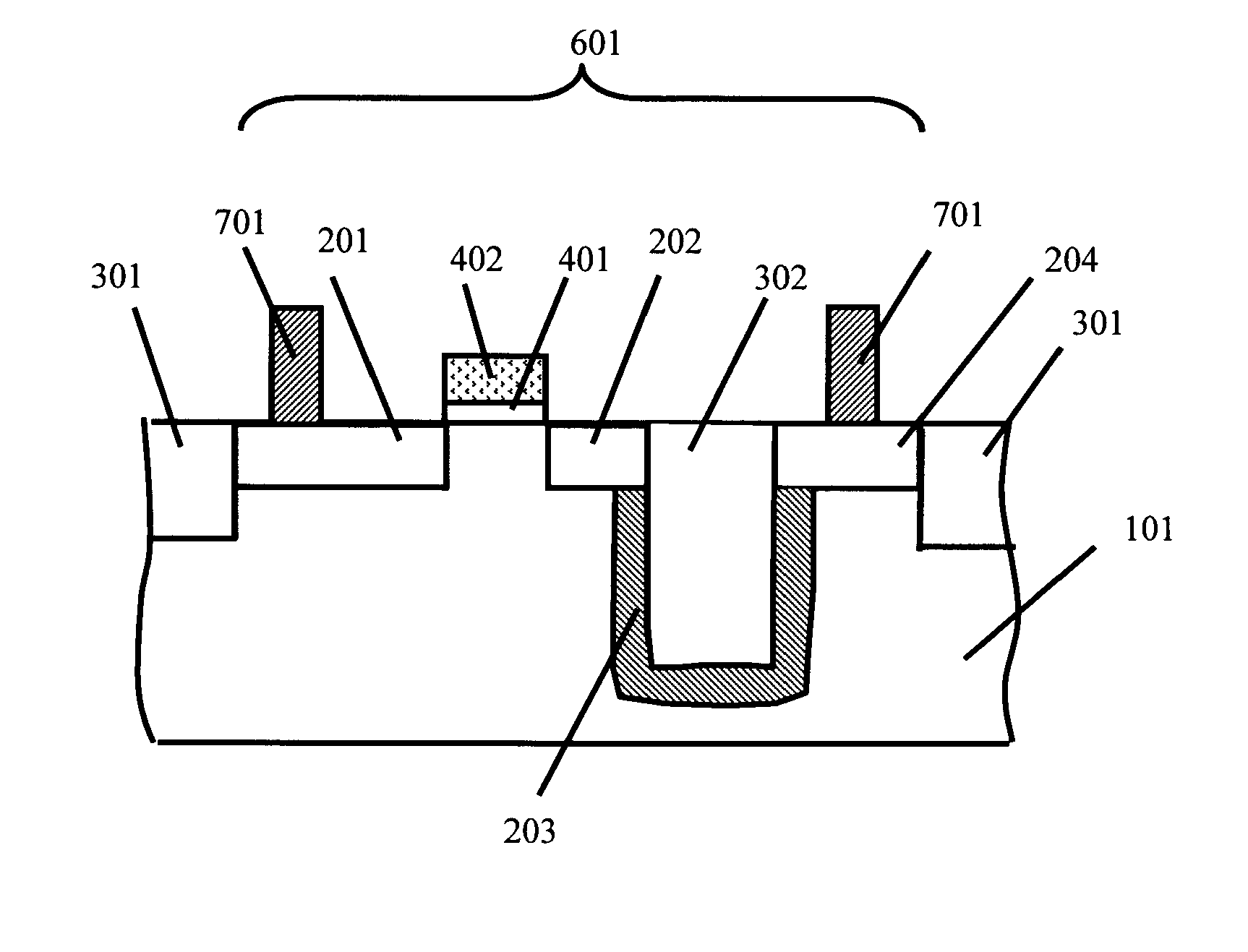

Semiconductor device and method for manufacturing semiconductor device

InactiveUS20070290207A1High signal processing speedCommunication distance can be ensuredTransistorSemiconductor/solid-state device detailsDevice materialCapacitor

In a semiconductor device including a digital circuit portion and an analog circuit portion having a capacitor portion provided over a substrate, the capacitor portion is provided with a first wiring, a second wiring and a plurality of blocks each having a plurality of capacitor elements. Further, each the plurality of capacitor elements provided in each block has a semiconductor film having a first impurity region and a plurality of second impurity regions provided apart with the first impurity region interposed therebetween, and a conductive film provided over the first impurity region with an insulating film therebetween. A capacitor is formed from the first impurity region, the insulating film, and the conductive film.

Owner:SEMICON ENERGY LAB CO LTD

Resin-sealed electronic control device and method of fabricating the same

InactiveUS20110205706A1Increase the areaLow costLine/current collector detailsSemiconductor/solid-state device detailsEngineeringElectronic board

Provided is a resin-sealed electronic control device reduced in size, which includes a double-sided mounting board as at least one of a plurality of electronic boards obtained by division so that a large mounting surface with a small plane area is ensured. Each of a first electronic board (30A) and a second electronic board (40A) bonded onto an upper surface and a lower surface of each of a pair of separate beam members (20A) includes two surfaces on which outer circuit components (31, 32, 41, 42) and an inner circuit component (33, 43) are respectively mounted. A height of each of the inner circuit components is equal to or less than a thickness of each of the separate beam members (20A). Heat-generating components (32, 42) in the outer circuit components are provided to be adjacent to and opposed to the separate beam members (20A).

Owner:MITSUBISHI ELECTRIC CORP

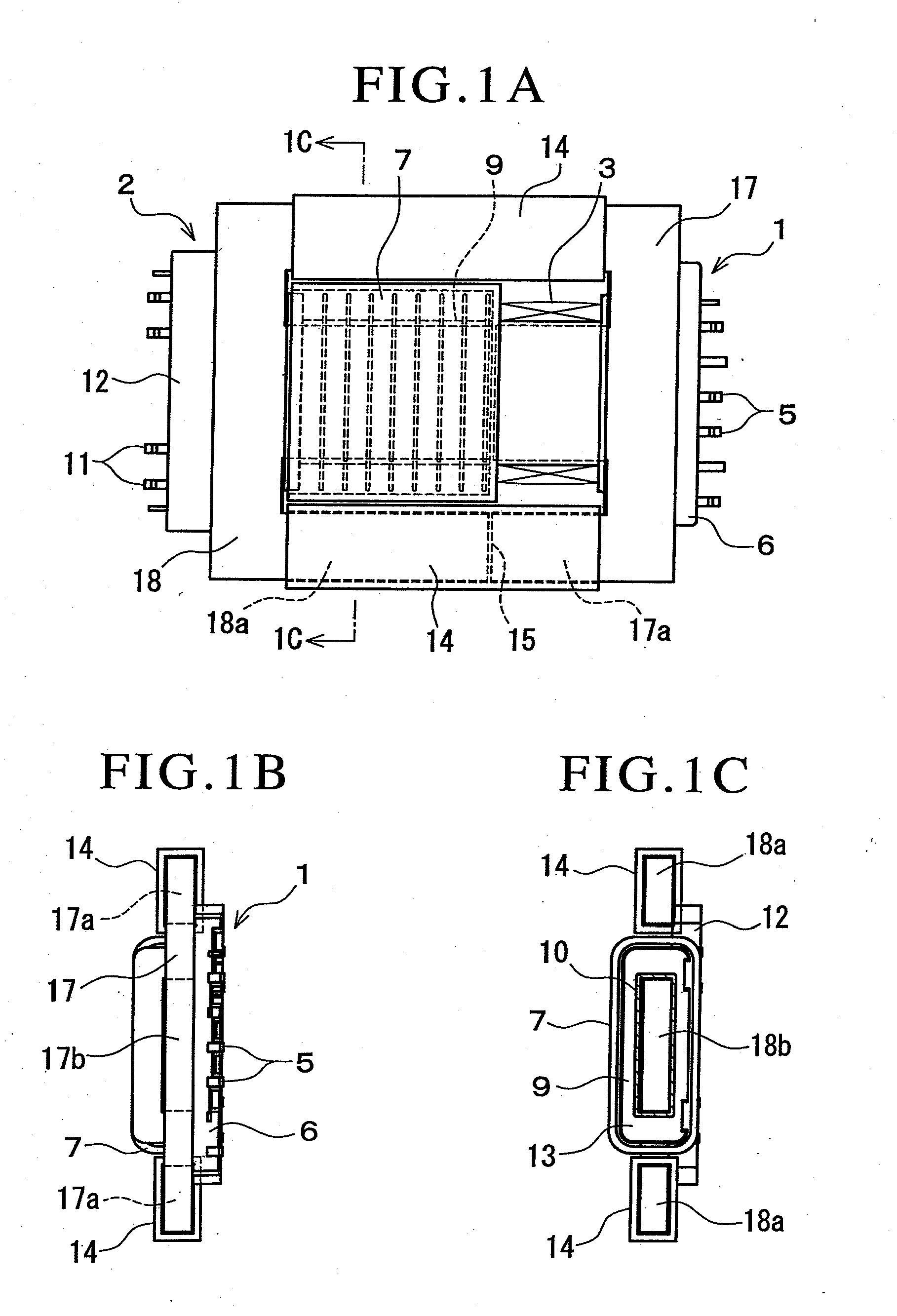

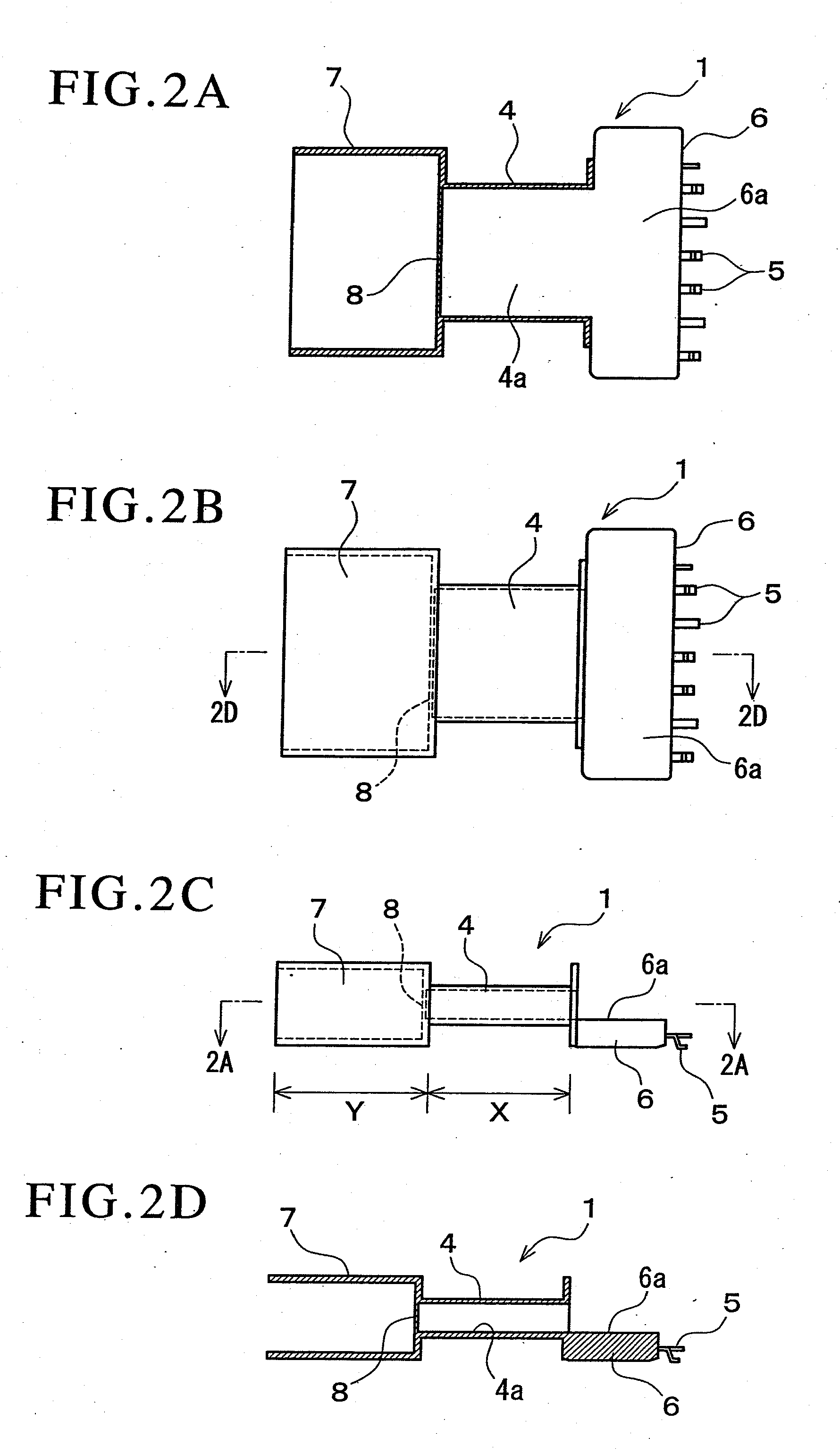

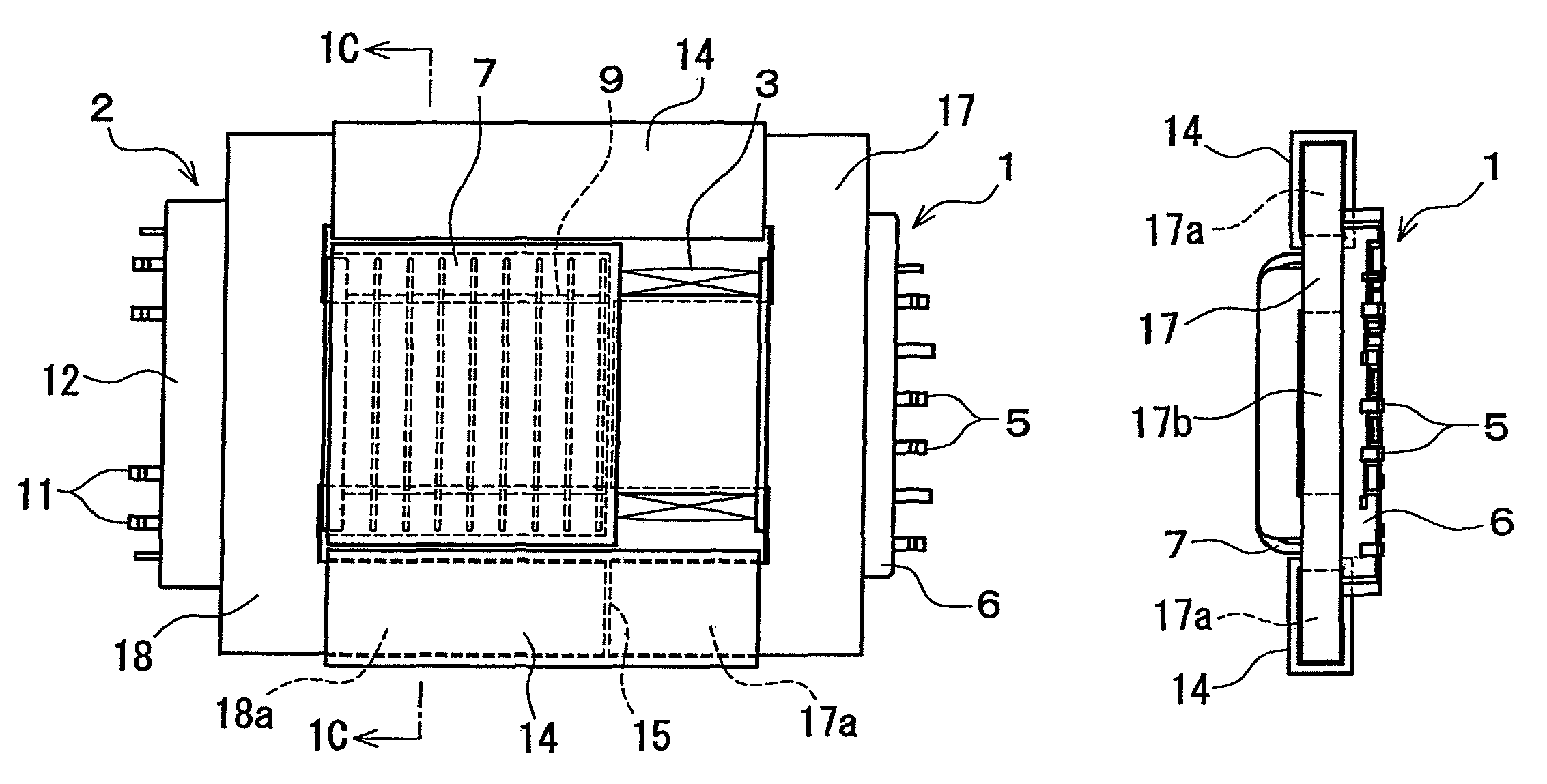

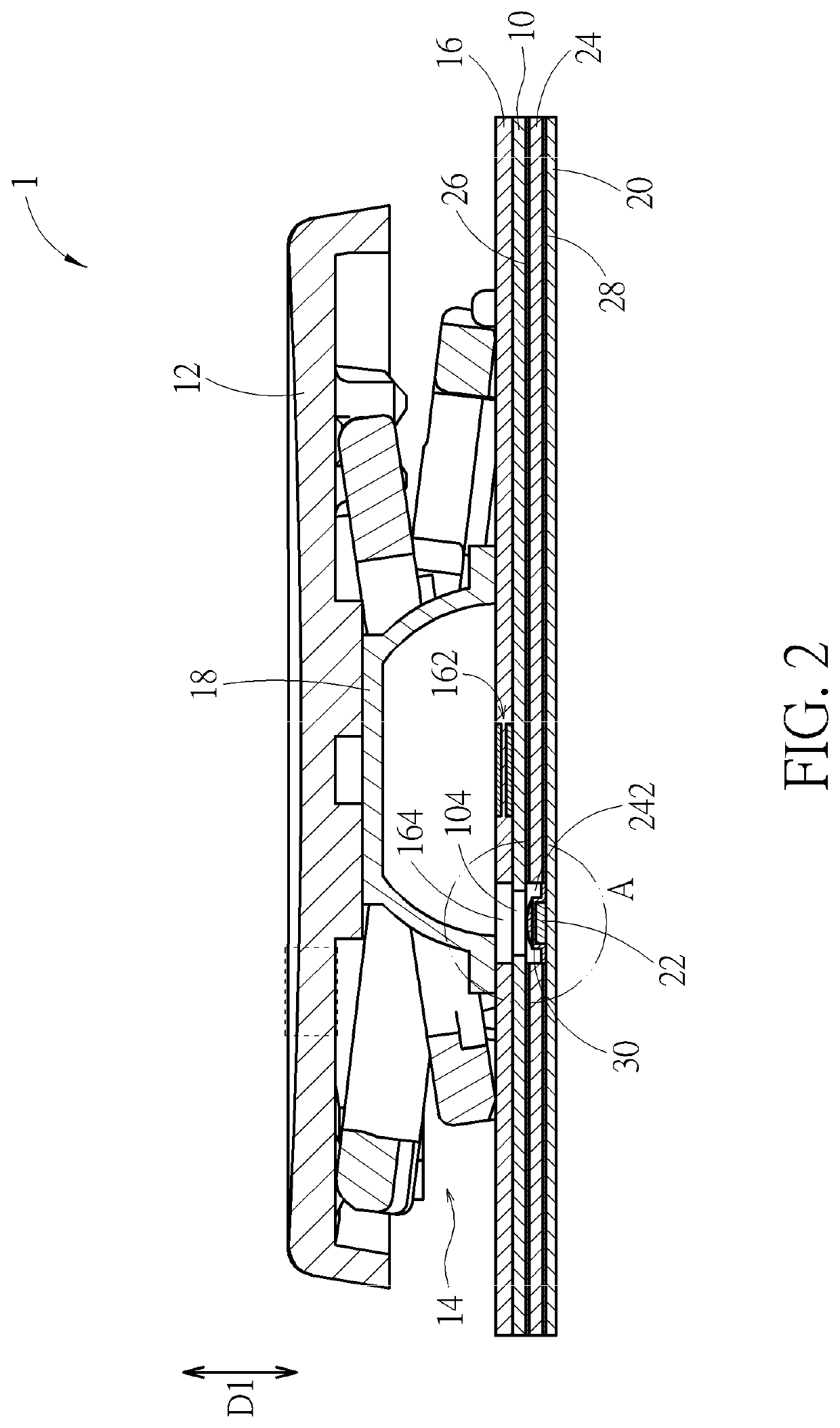

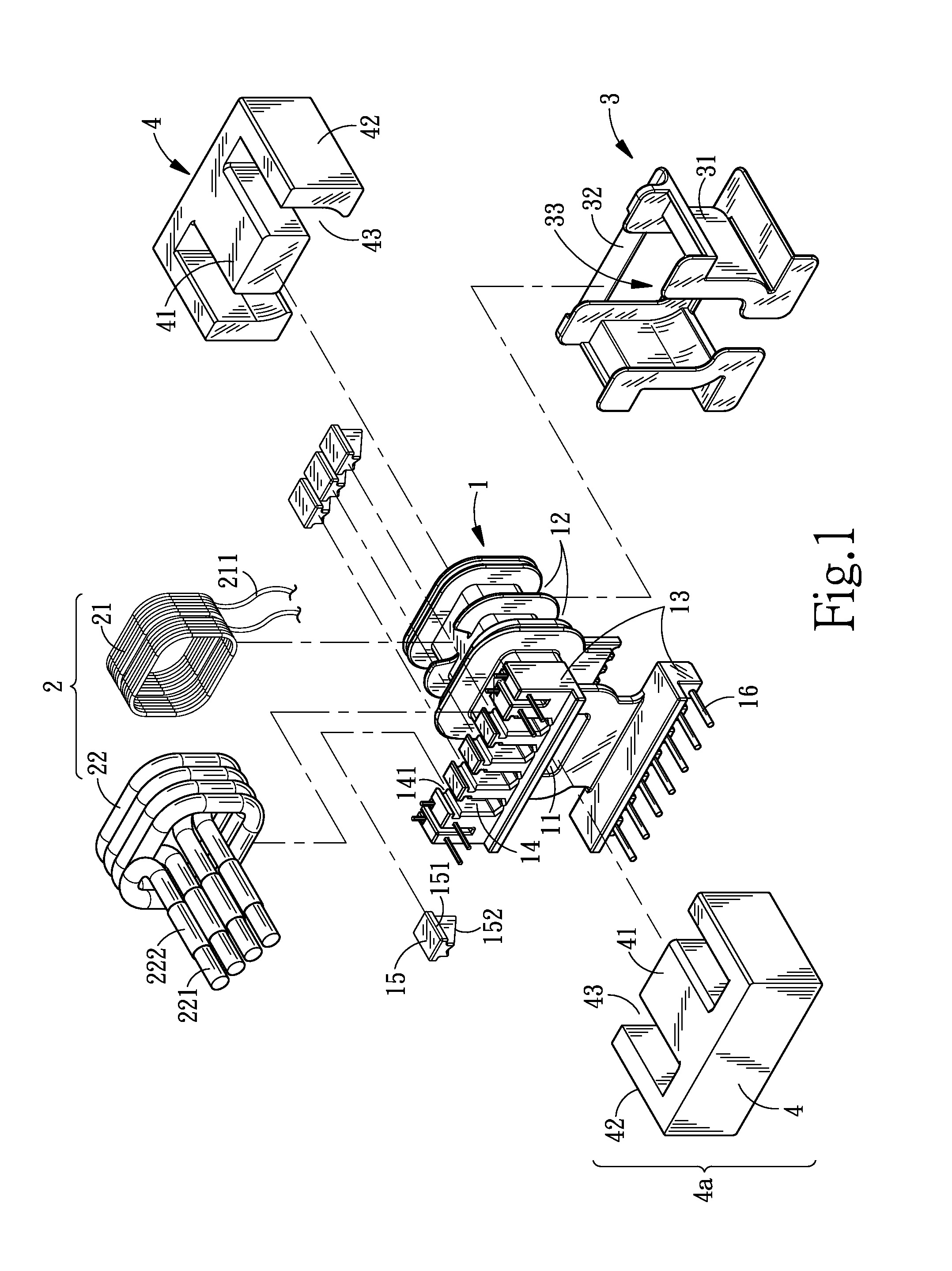

Transformer

ActiveUS20100245009A1Easy to operateSimple structureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresBobbinTransformer

The present invention provides a transformer including a first bobbin (1) around which a primary coil (3) is wound, a second bobbin (2) which is disposed adjacent to the first bobbin (1) and around which a secondary coil (9) is wound, a core disposed across the first and second bobbins and forming a closed magnetic path. The core is divided into a first core (17) positioned on the side where the first bobbin is present and a second core (18) positioned on the side where the second bobbin is present, and an insulating member (14) is interposed in a magnetically coupled portion between the first core (17) and the second core (18), the insulating member (14) including outer circumference sheaths (16a) and (16b) that cover at least one of the first and second cores and a barrier (15) interposed between the opposing surfaces of the first and second cores.

Owner:NJ COMPONENTS CO LTD

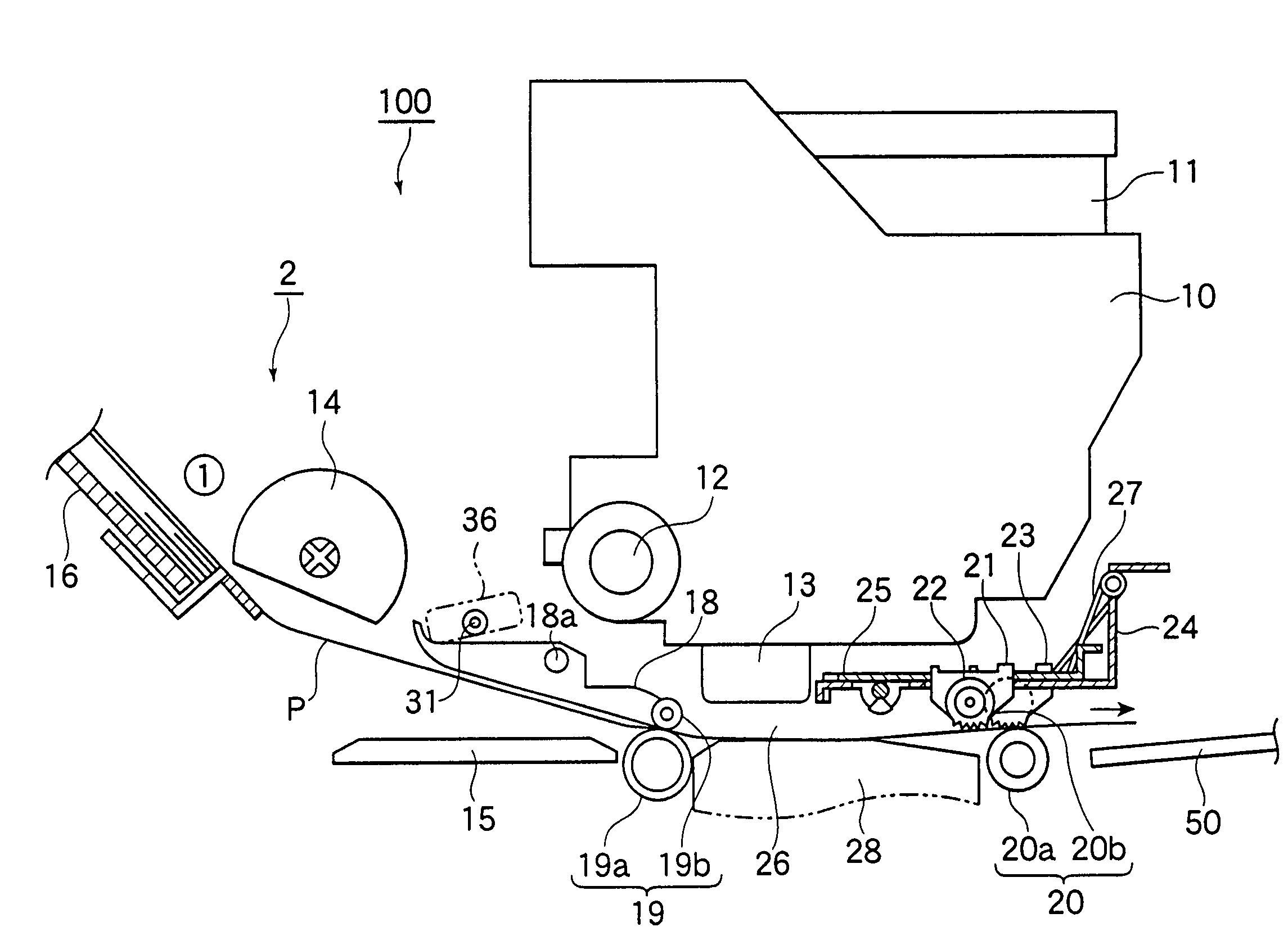

Recording apparatus

InactiveUS7309123B2High quality printingEnsure relative distancePower drive mechanismsOther printing apparatusMechanical engineeringRecording head

A recording apparatus includes: a feeder, provided in an upstream in a transfer path for transferring a medium, for feeding the medium to a downstream in the transfer path one by one, the medium being stacked at an angle; a recording head, provided in the downstream of the feeder, for performing recording for the medium; a carriage, on which the recording head is mounted, for reciprocating in a main scanning direction along a carriage guide axis; a transfer roller for transferring the medium by rotating, the transfer roller including a transfer-driving roller and a transfer-driven roller; a stacker having a medium-placed surface, the stacker being positioned at a first position allowing the medium to be substantially horizontally fed from the medium-placed surface to a position under the recording head and be substantially horizontally discharged from the position under the recording head onto the medium-placed surface, or a second position for receiving and stacking the medium fed by the feeder, the second position being on a lower level than the first position, the medium-placed surface being arranged substantially horizontally when the stacker is positioned at the first position and is arranged at an angle when the stacker is positioned at the second position; and a first link mechanism for displacing the stacker to cause the carriage guide axis to displace. The carriage guide axis can be displaced upward and is prevented from moving downward when the stacker is positioned at the first position.

Owner:SEIKO EPSON CORP

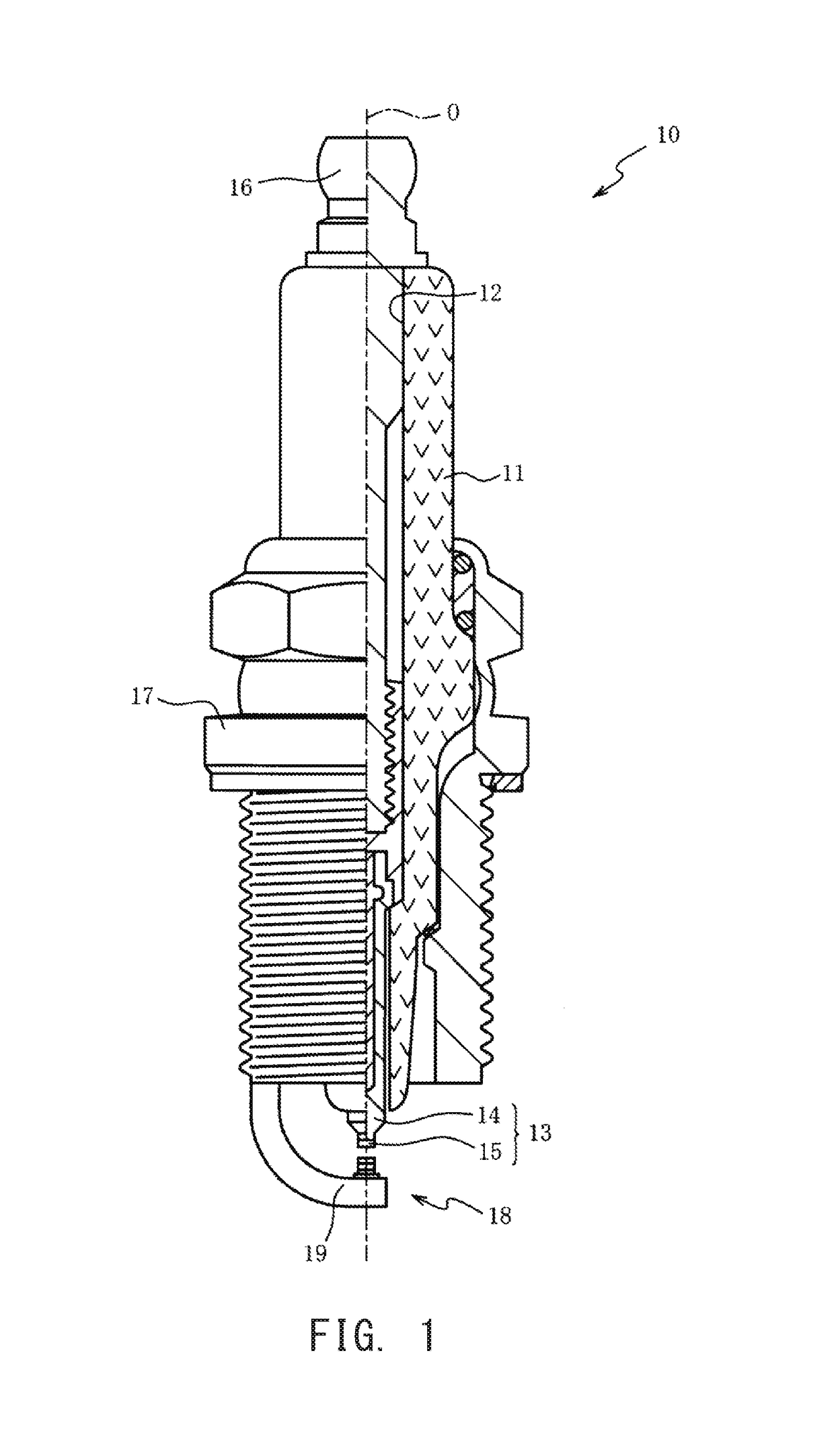

Spark plug

A spark plug having a tip formed of an alloy containing Pt. The tip contains not less than 6 mass % of Rh, at least one element selected from an R group consisting of Rh, Re, Ir, Ru, W, Mo, and Nb, not less than 5 mass % of Ni, and at least one element selected from an N group consisting of Ni, Co, Fe, and Cu. The tip contains Rh most among the elements of the R group, and contains Ni most among the elements of the N group. The total of contents of Pt, Rh, and Ni is not less than 91 mass %, and the total of contents of Pt, the R group, and the N group is not less than 95 mass %. A value obtained by dividing the content of the R group by the content of the N group is not less than 0.7 and not greater than 8.

Owner:NGK SPARK PLUG CO LTD

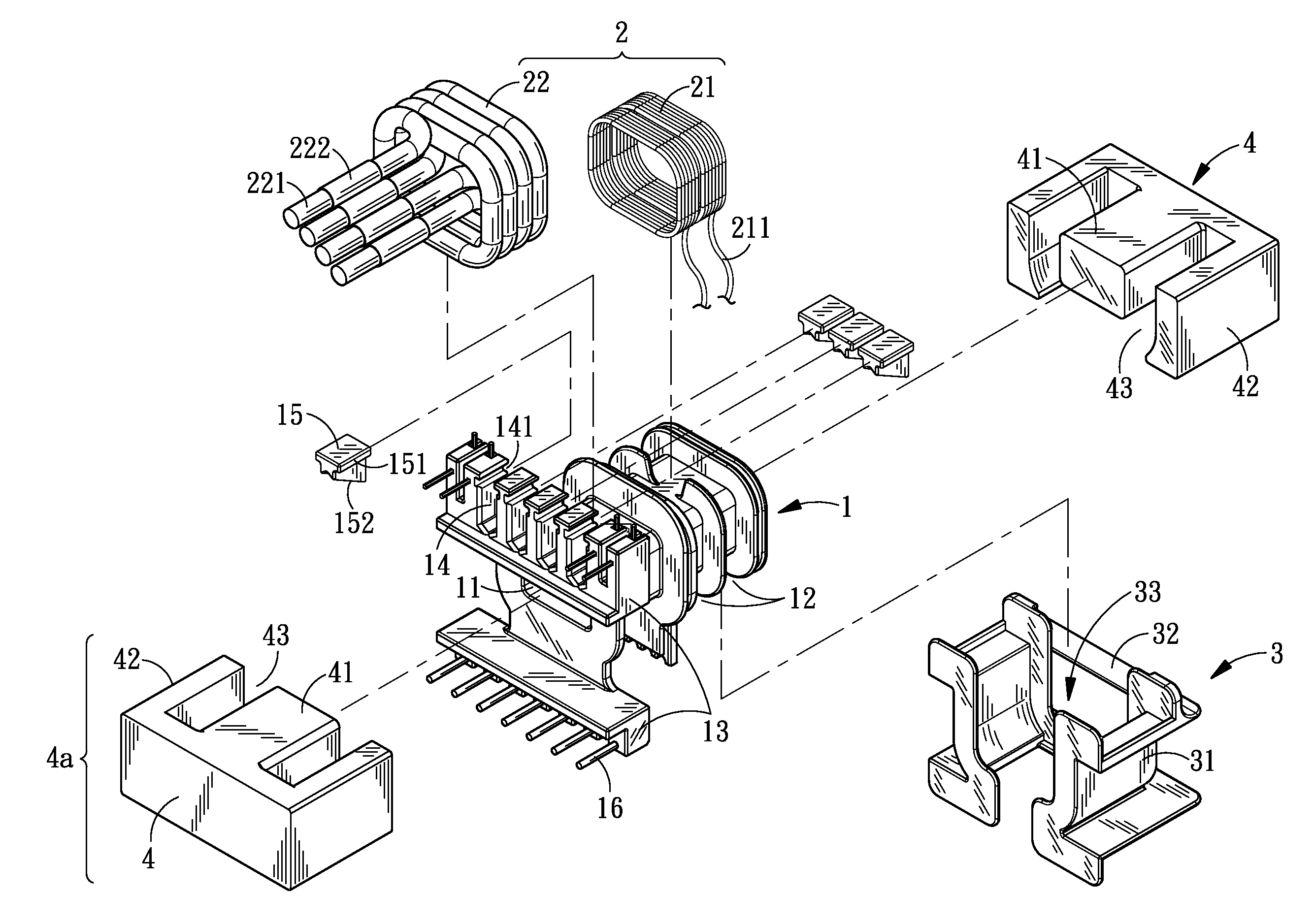

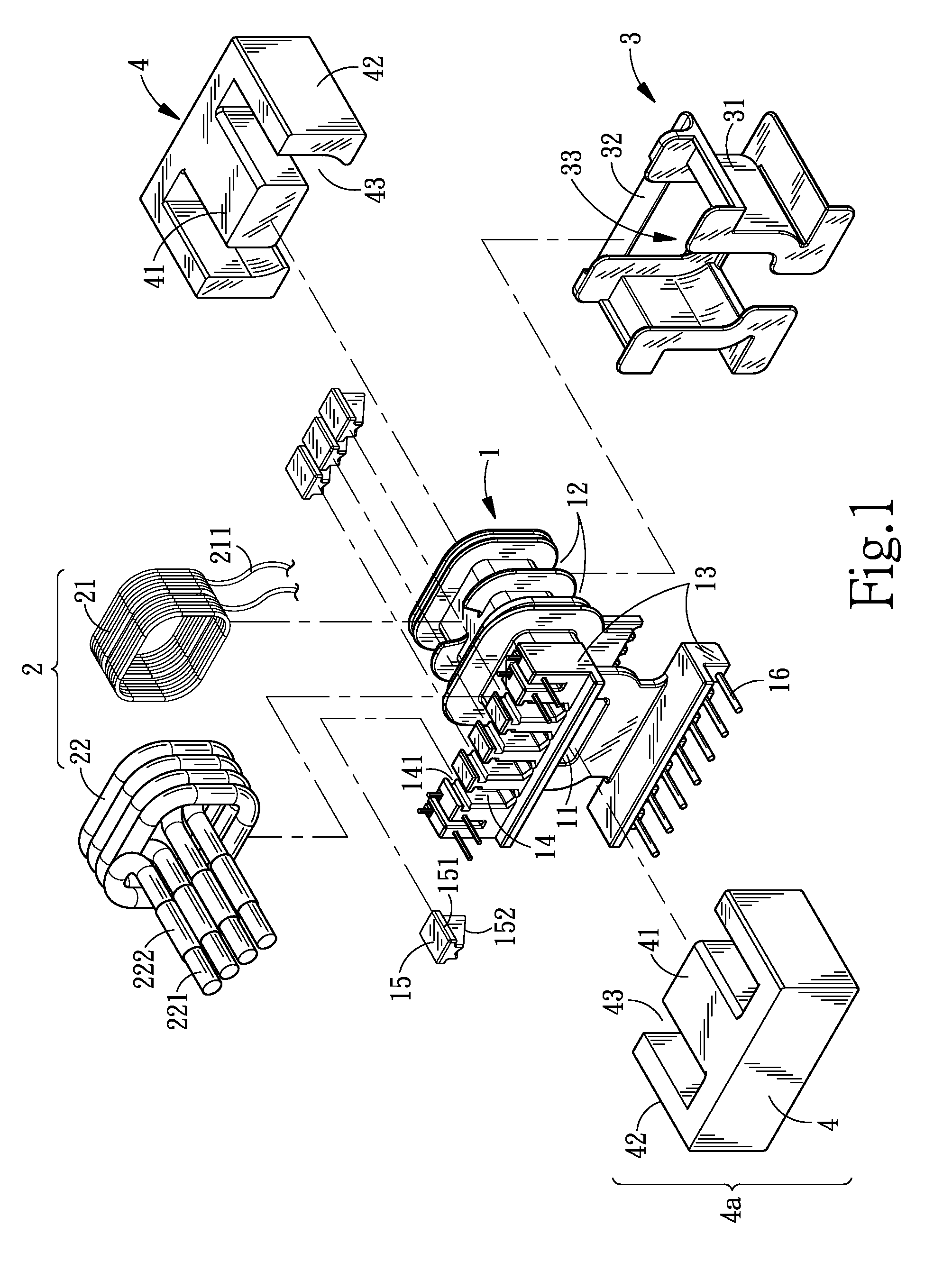

Structure of transformer

ActiveUS20150302979A1Simple structureSimplify the assembly processTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMagnetic coreAirflow

An improved structure of a transformer includes a bobbin covering at least a portion of a magnetic core set which has a magnetic loop passing through the bobbin, wherein winding grooves and at least one connecting portion extending sideways are provided on the outer peripheral side of the bobbin, and a plurality of notches with lateral openings are provided on the connecting portion. Coils are wound in the winding grooves of the bobbin. The coils have at least a plurality of line ends, each line end passing through a different notch. One positioning pin is embedded in each of the winding grooves near the lateral opening. The positioning pins hold the respective line ends in place by pressing against them. A casing is fitted on the outer peripheral side of the coils to create separation between the coils and the magnetic core set. The casing is provided with a hollow opening such that the outer peripheral side of the coils facing the airflow is exposed to improve the overall heat dissipating efficiency.

Owner:YUJING TECH CO LTD

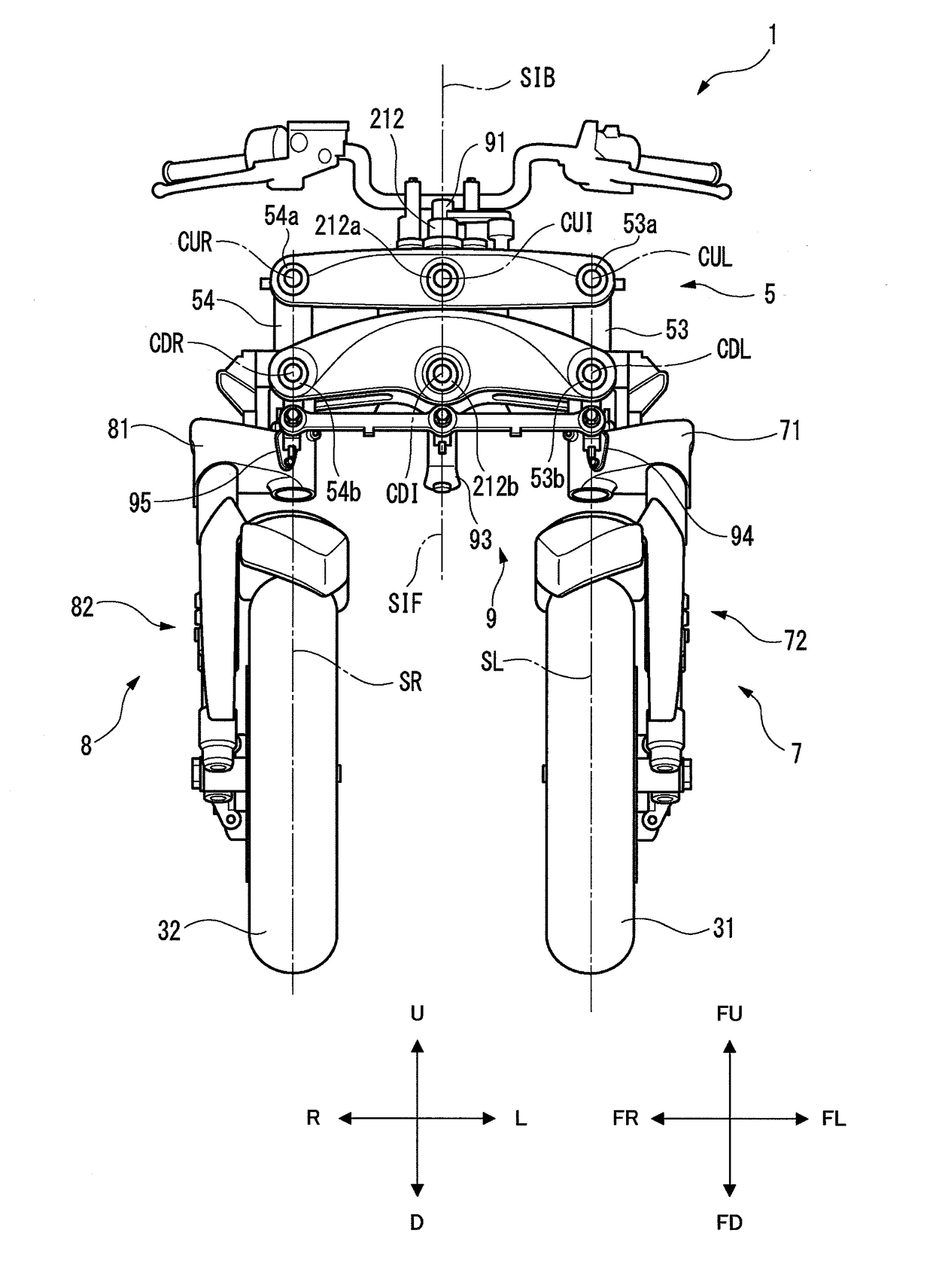

Vehicle

ActiveUS20170088223A1Preventing and significantly reduce intrusion of foreign matter intoEnlarge sizeCyclesInterconnection systemsEngineeringBody frame

In a vehicle, a left cover attached to a left side member covers at least one of a left upper edge of an upper cross member, a left lower edge of the upper cross member, a left upper edge of a lower cross member, and a left lower edge of the lower cross member, from the left in a left-right direction of a body frame together with at least a portion of the left side member. A right cover attached to a right side member covers at least one of a right upper edge of the upper cross member, a right lower edge of the upper cross member, a right upper edge of an upper edge of the lower cross member, and a right lower edge of the lower cross member, from the right in the left-right direction of the body frame together with at least a portion of the right side member.

Owner:YAMAHA MOTOR CO LTD

Shaft rod and heald shaft

InactiveUS20070062596A1Prevents shaft rod breakageImprove scratch resistanceHealdsOther shedding mechanismEngineeringMechanical engineering

The shaft rod (2) according to the invention has, at one of its narrow sides, at least one recess (21) which is later provided in the shaft rod and in which a reinforcing element (24) is glued. The material externally of the shaft rod forms securing zones (32, 33) which serve for the attachment of additional elements. The recesses are preferably applied in such a manner that hollow spaces free from Eloxal coating are exposed which may be utilized as recesses into which reinforcing elements are glued.

Owner:GROZ BECKERT KG

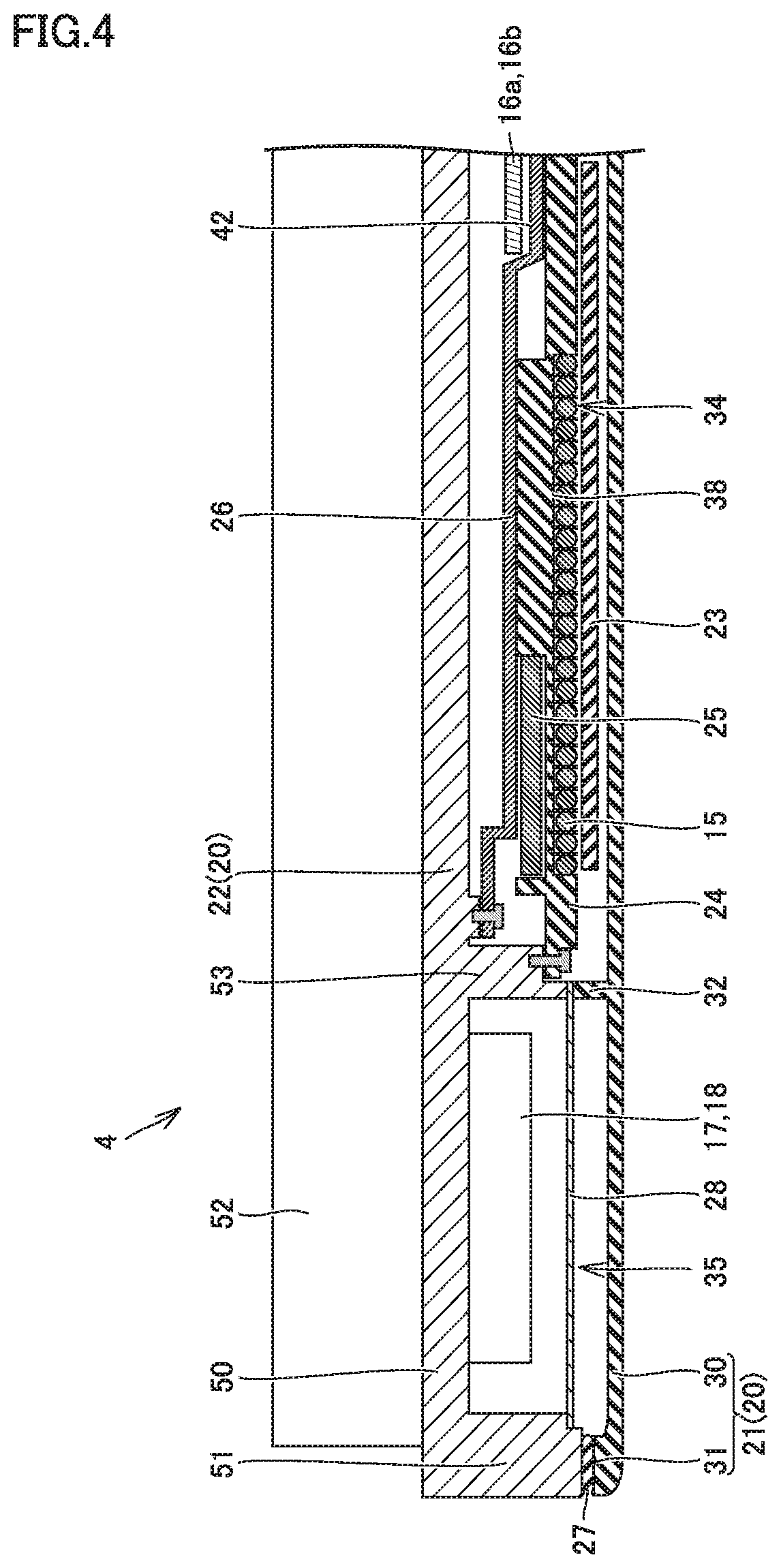

Wireless power feeder, wireless power receiver, and wireless power transmission system

ActiveUS8901776B2Increase the number ofSmall sizeNear-field transmissionTransformersElectric power transmissionElectrical conductor

Power is fed from a feeding coil to a receiving coil using magnetic resonance. The feeding coil is wound in a first layer substrate 144 of a multilayer substrate 116 with a space provided between the coil conductor thereof and further wound in a second later substrate 146 with a space provided between the coil conductor thereof. The feeding coil is wound such that a coil conductor 106a in the first layer and a coil conductive wire 106b in the second layer do not overlap each other as viewed in the axial direction (z-axis direction).

Owner:TDK CORPARATION

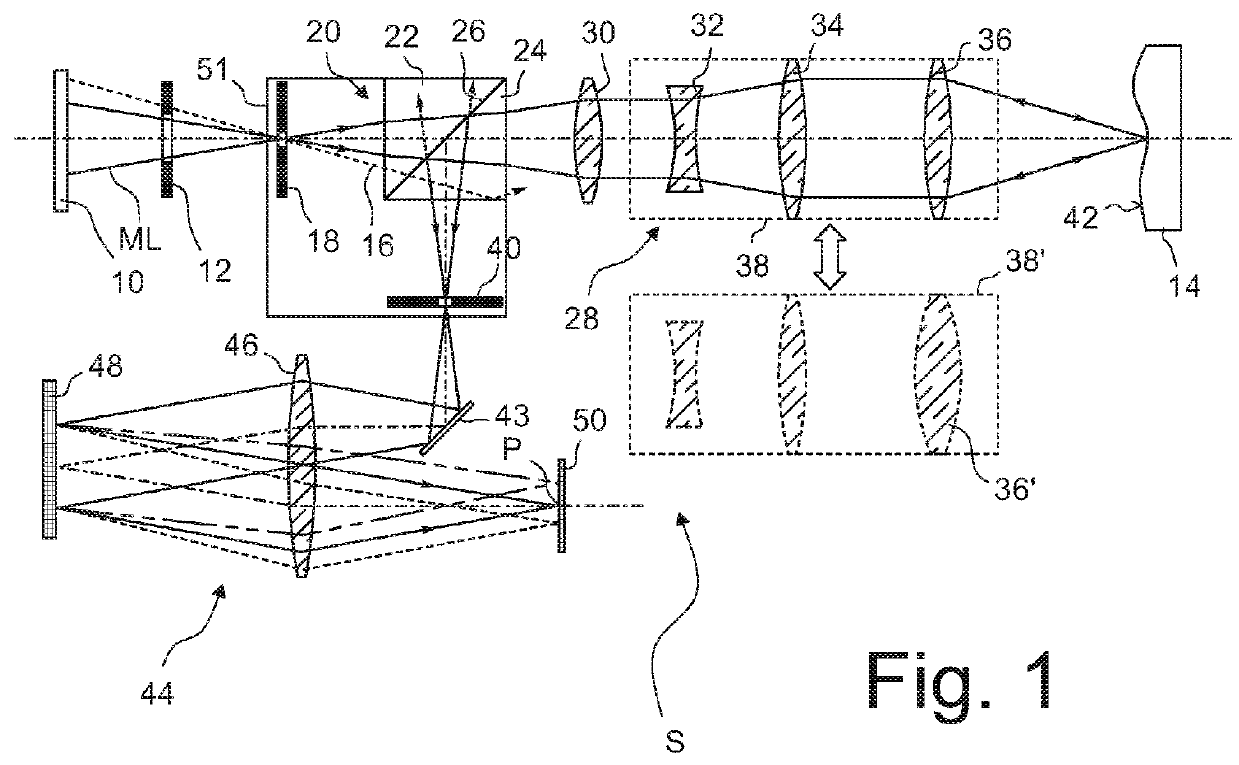

Chromatic confocal distance sensor

ActiveUS20180094975A1High measurement accuracyEnsure relative distanceRadiation pyrometryUsing optical meansBeam splitterThermal expansion

A chromatic confocal distance sensor has a housing in which a polychromatic light source, imaging optics having a longitudinal chromatic aberration, a spectrometer and a planar beam splitter surface are arranged. These lie in the light path of the measurement light between the light source and the imaging optics and between the imaging optics and the spectrometer. A first diaphragm is arranged in the light path between the light source and the beam splitter surface, and a second diaphragm is arranged in the light path between the beam splitter surface and the spectrometer. The diaphragms are arranged mirror-symmetrically with respect to the beam splitter surface. The measurement light propagates as a free beam inside the housing. The beam splitter surface, the first diaphragm and the second diaphragm are fastened together on a carrier which has an isotropic thermal expansion coefficient. This way, temperature changes cannot significantly affect the measurement accuracy.

Owner:PRECITEC OPTRONIK GMBH

Transformer

ActiveUS8284009B2Ensure relative distanceSmall and simple structureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresBobbinTransformer

The present invention provides a transformer including a first bobbin around which a primary coil is wound, a second bobbin which is disposed adjacent to the first bobbin and around which a secondary coil is wound, a core disposed across the first and second bobbins and forming a closed magnetic path. The core is divided into a first core positioned on the side where the first bobbin is present and a second core positioned on the side where the second bobbin is present, and an insulating member is interposed in a magnetically coupled portion between the first core and the second core, the insulating member including outer circumference sheaths that cover at least one of the first and second cores and a barrier interposed between the opposing surfaces of the first and second cores.

Owner:NJ COMPONENTS CO LTD

Semiconductor device

InactiveUS20130187232A1Solve the lack of functionIncrease in occupation areaSemiconductor/solid-state device detailsSolid-state devicesImpurity diffusionEngineering

In the semiconductor device including an ESD protection N-type MOS transistor having a sufficient ESD protective function, a drain region of the ESD protection N-type MOS transistor is electrically connected to a drain contact region via a drain extended region. The drain extended region is provided on a side surface and a lower surface of an ESD protection trench isolation region, and is formed of an impurity diffusion region of the same conductivity type as that of the drain region. The drain contact region is formed of an impurity diffusion region of the same conductivity type as that of the drain region.

Owner:SEIKO INSTR INC

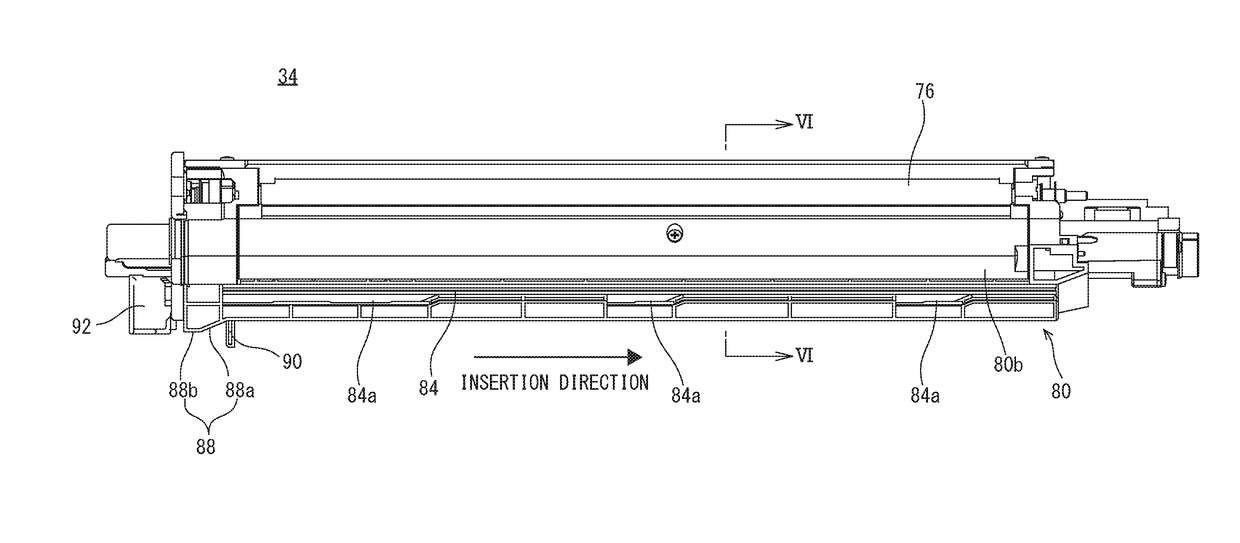

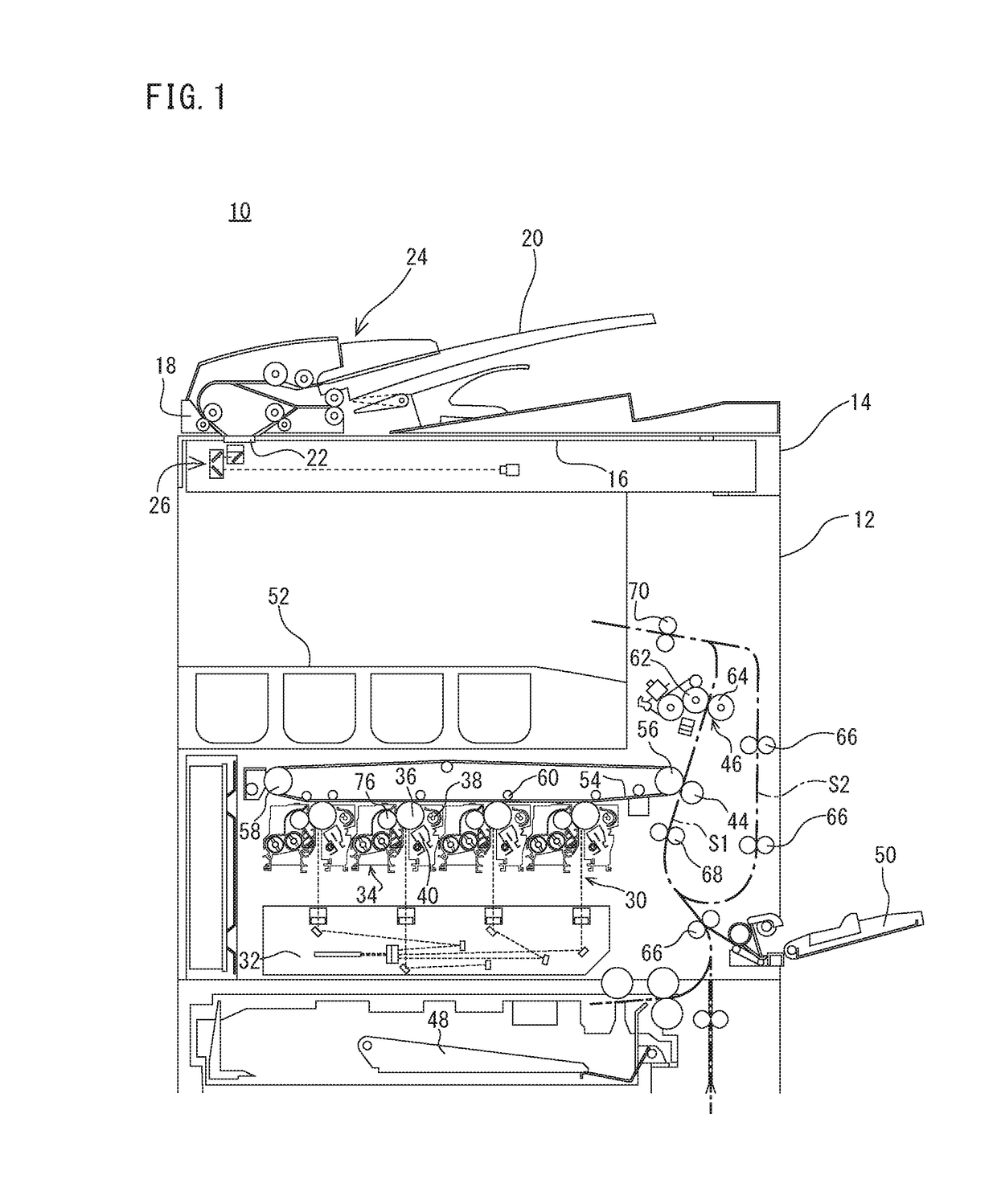

Image forming apparatus

ActiveUS20170075291A1Reducing size of apparatusLow number of componentsElectrographic process apparatusImage formationEngineering

An image forming apparatus comprises a developing unit and a developing unit attaching portion that is provided in an apparatus main body. The developing unit and the developing unit attaching portion are provided with an insertion guide. The insertion guide makes the developing unit a state it is inclined from a normal posture so as to be moved on a position departed from a photoreceptor drum during a period from a start of insertion of the developing unit into the developing unit attaching portion until just before completion of the insertion, and makes, during a period from just before completion of the insertion until completion of the insertion, the developing unit turn according to an insertion operation of the developing unit so as to be brought close to the photoreceptor drum, whereby the developing unit is positioned so as to take the normal posture.

Owner:SHARP KK

Coil unit

InactiveUS20200152376A1Increase distanceEnsure relative distanceCharging stationsTransformersElectrically conductiveEngineering

Owner:TOYOTA JIDOSHA KK

Method for riveting two structural component parts, in particular cover plate elements of a torsional vibration damper arrangement, at a distance from one another

ActiveUS20110035929A1Distance to be maintained between the two structural component parts can be ensuredEnsure relative distanceSpringsRopes and cables for vehicles/pulleyEngineeringTorsional vibration

A method for riveting two structural component parts arranged with their inner sides facing one another and with their outer sides facing away from one another at a distance from one another by at least one spacer rivet element. Positioning the at least one spacer rivet element at the two structural component parts such that rivet element end areas extend through rivet openings provided in the structural component parts to be associated with the rivet element end areas. Supporting a rivet element end area at the outer side of one of the structural component parts. Supporting the other of the structural component parts at its inner side. Applying a riveting force to the other rivet element end area to deform at least one rivet element end area and to form a rivet head.

Owner:ZF FRIEDRICHSHAFEN AG

Resin-sealed electronic control device and method of fabricating the same

ActiveUS8274791B2Increase the areaEnsure relative distanceCasings with connectors and PCBSemiconductor/solid-state device detailsEngineeringElectronic board

Owner:MITSUBISHI ELECTRIC CORP

Illuminated keyswitch structure and illuminating module thereof

ActiveUS20220351921A1Small sizeEnsure relative distanceContact mechanismsLegendsMechanical engineeringDriving circuit

Owner:DARFON ELECTRONICS CORP

Objective lens, optical pickup device having the same, and recording and/or reproducing apparatus for optical recording medium, equipped with the optical pickup device

InactiveUS20090129242A1Small sizeReduce weightRecord information storageOptical beam guiding meansOptical pickupOptical recording

An objective lens 8 consists of a single lens element. A light source side surface 8a is formed into a convex surface having a large curvature, and an optical recording medium side surface 8b has a small curvature. Also, the objective lens satisfies the following expressions (1) and (2)ΦA / ΦB<5.0 (1)7.69≦ΦA / ΦB+19.33×bf′ / f′≦9.45 (2)where ΦA denotes an effective diameter (mm) of the light source side surface of the objective lens 8, ΦB denotes an effective diameter (mm) of the optical recording medium side surface of the objective lens 8, bf′ denotes a back focal length (mm) of the objective lens 8, andf′ denotes a focal length (mm) of the objective lens 8.

Owner:FUJI PHOTO OPTICAL CO LTD

Structure of transformer

ActiveUS9437360B2Simple structureSimplify the assembly processTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinTransformer

An improved structure of a transformer includes a bobbin covering at least a portion of a magnetic core set which has a magnetic loop passing through the bobbin, wherein winding grooves and at least one connecting portion extending sideways are provided on the outer peripheral side of the bobbin, and a plurality of notches with lateral openings are provided on the connecting portion. Coils are wound in the winding grooves of the bobbin. The coils have at least a plurality of line ends, each line end passing through a different notch. One positioning pin is embedded in each of the winding grooves near the lateral opening. The positioning pins hold the respective line ends in place by pressing against them. A casing is fitted on the outer peripheral side of the coils to create separation between the coils and the magnetic core set. The casing is provided with a hollow opening such that the outer peripheral side of the coils facing the airflow is exposed to improve the overall heat dissipating efficiency.

Owner:YUJING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com