Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Easy to tick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

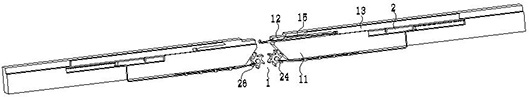

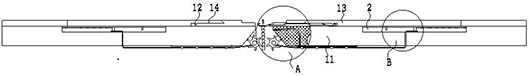

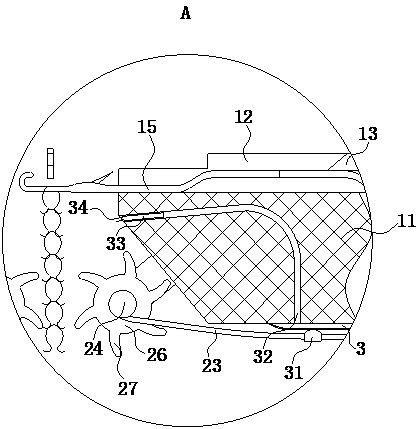

Mitral chordae sewing machine for implanting artificial chordae through minimally invasive technology and method of mitral chordae sewing machine

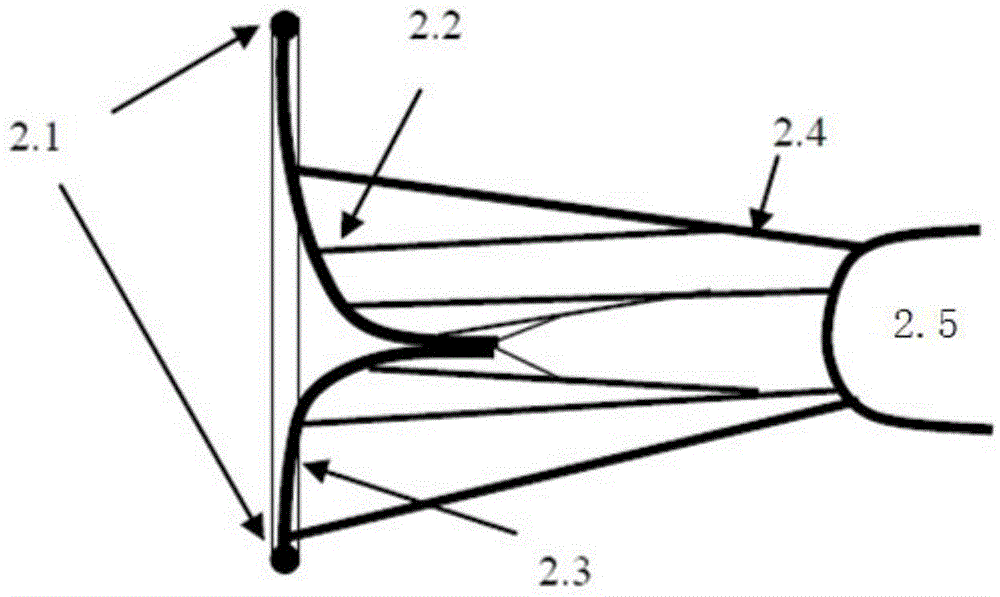

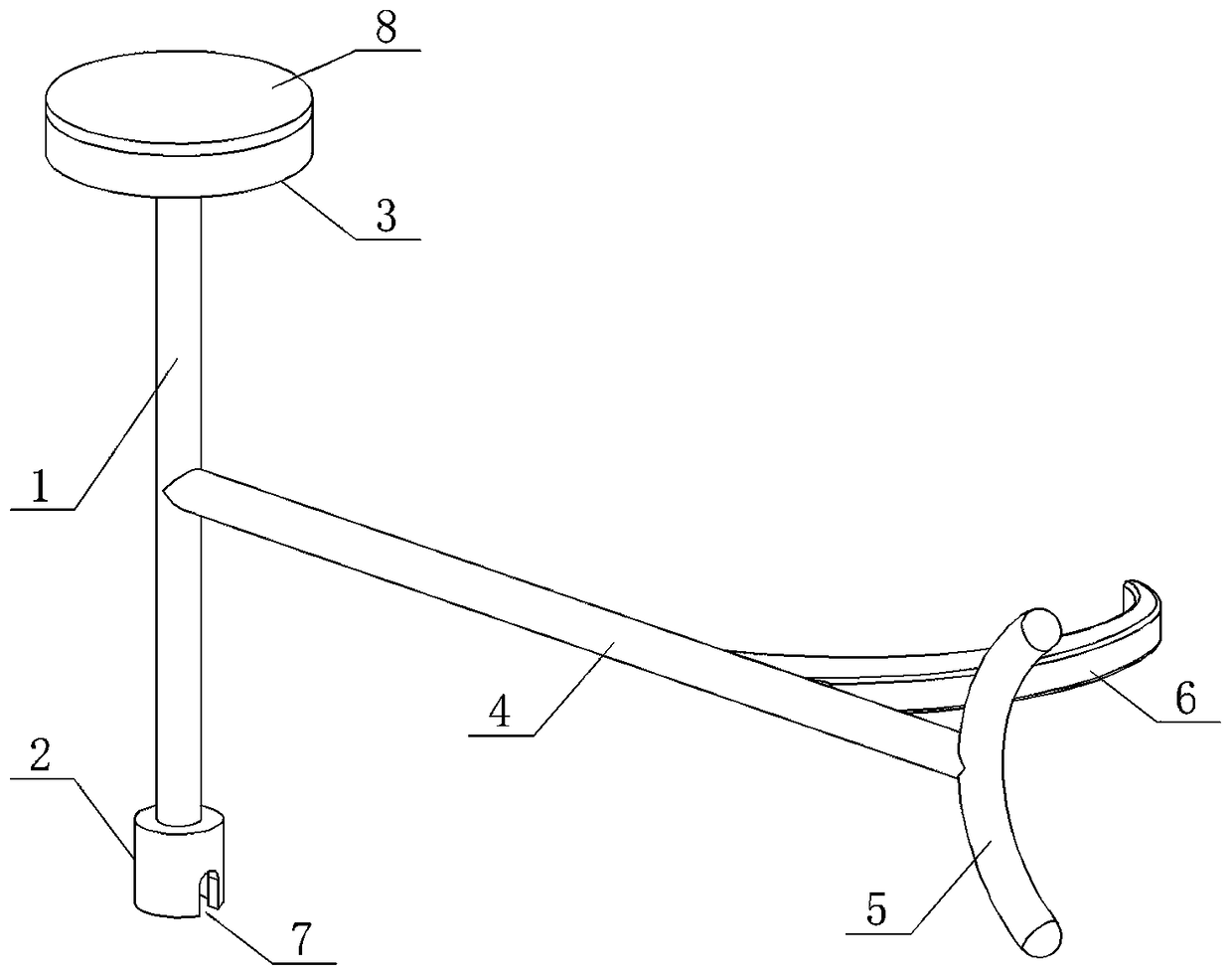

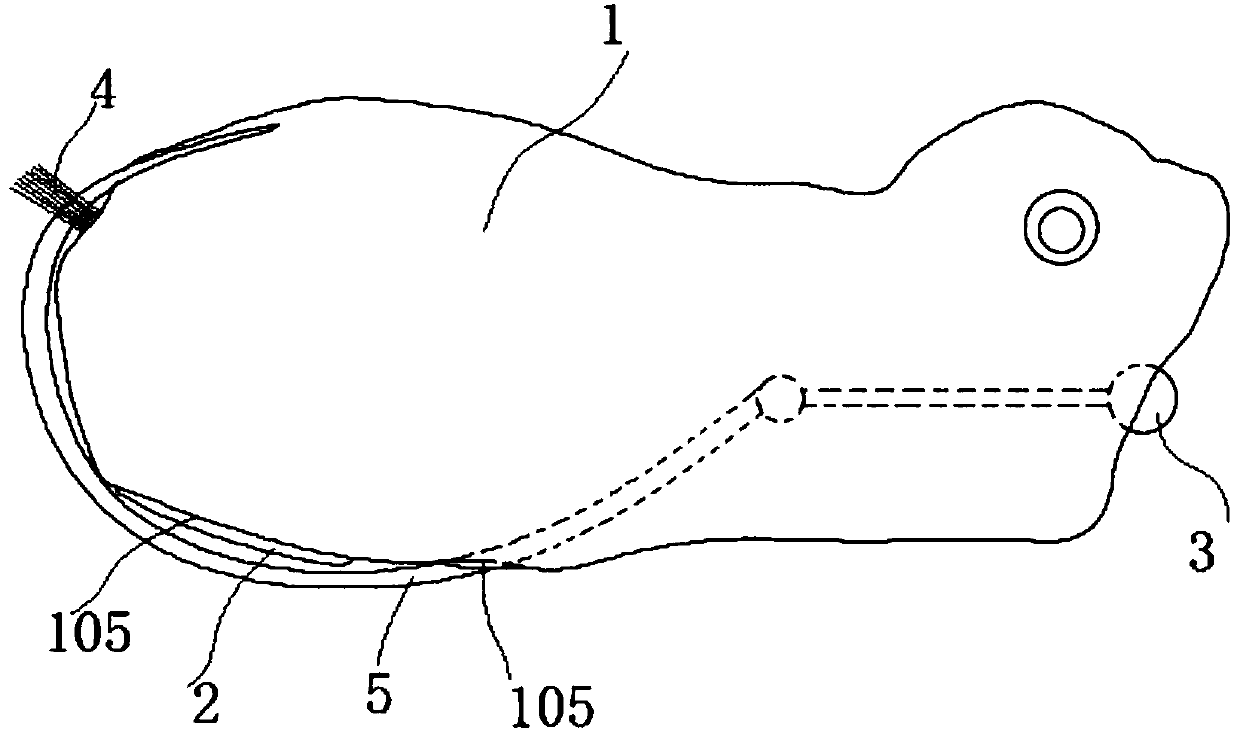

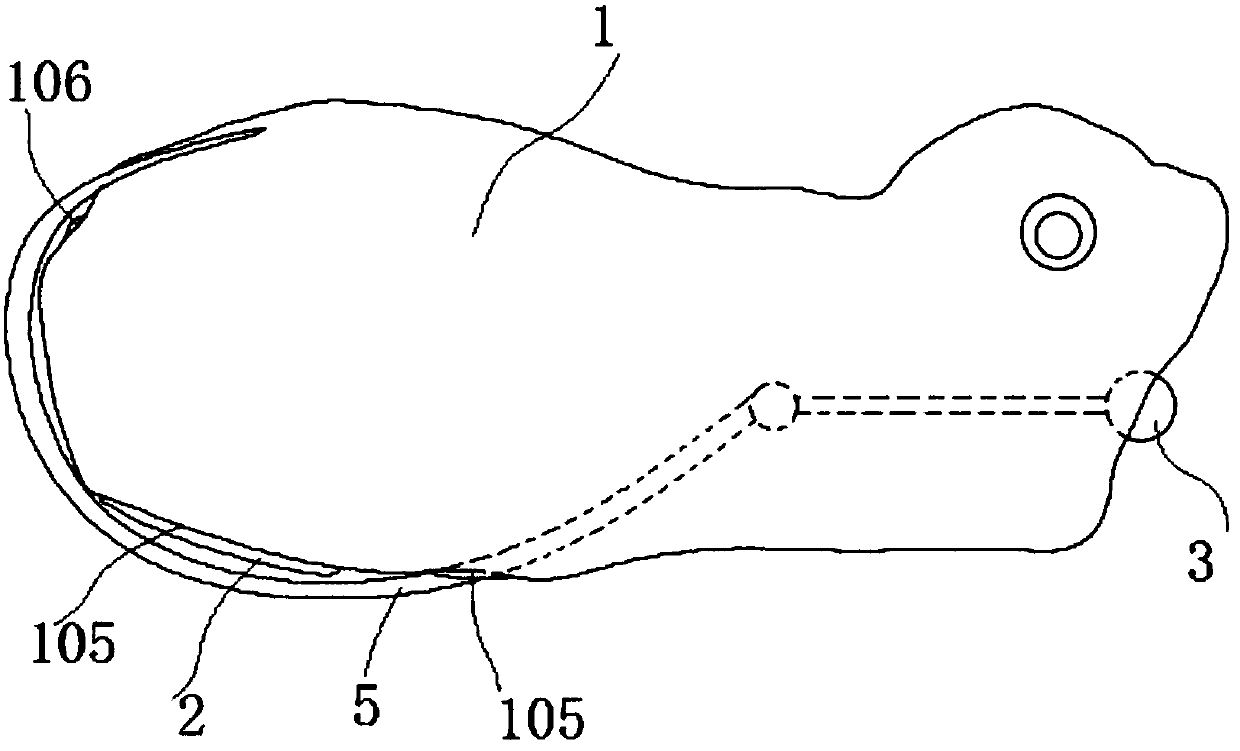

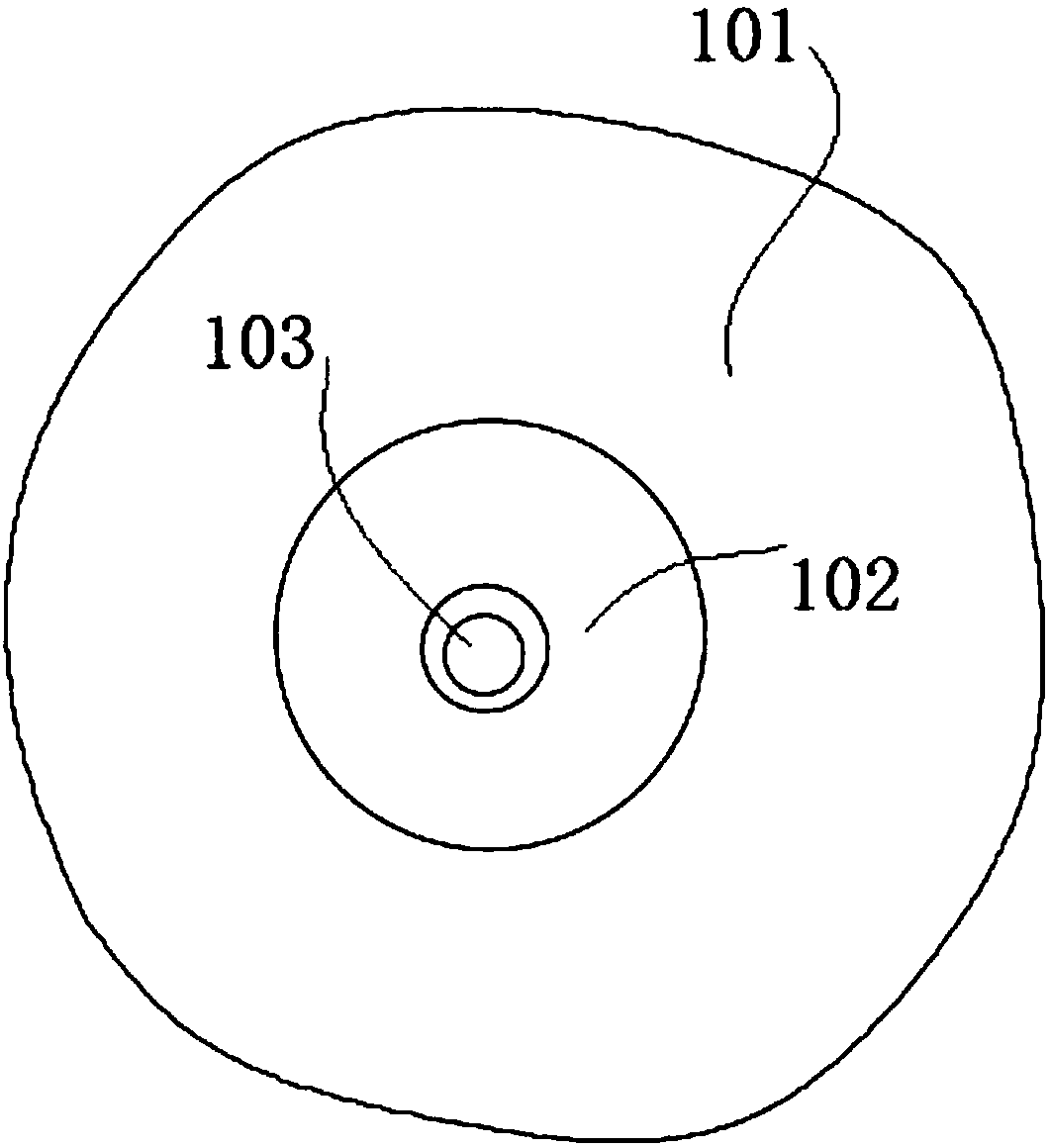

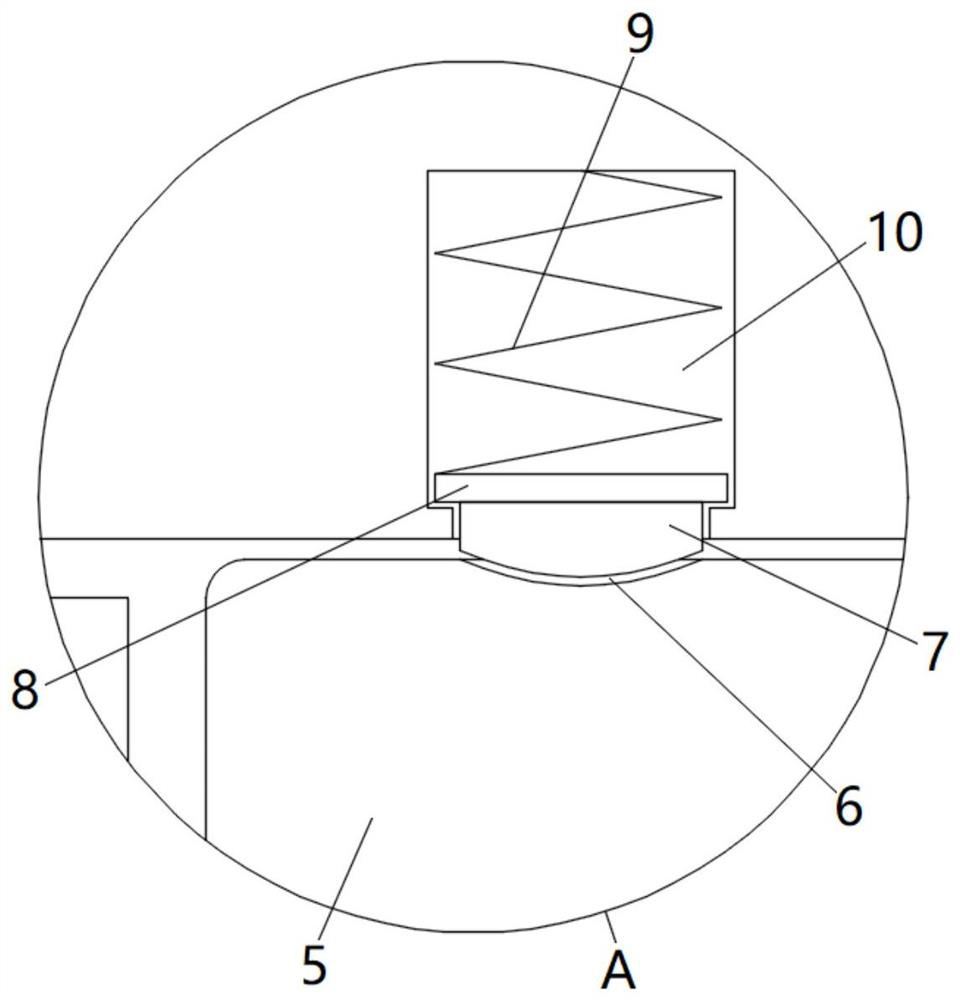

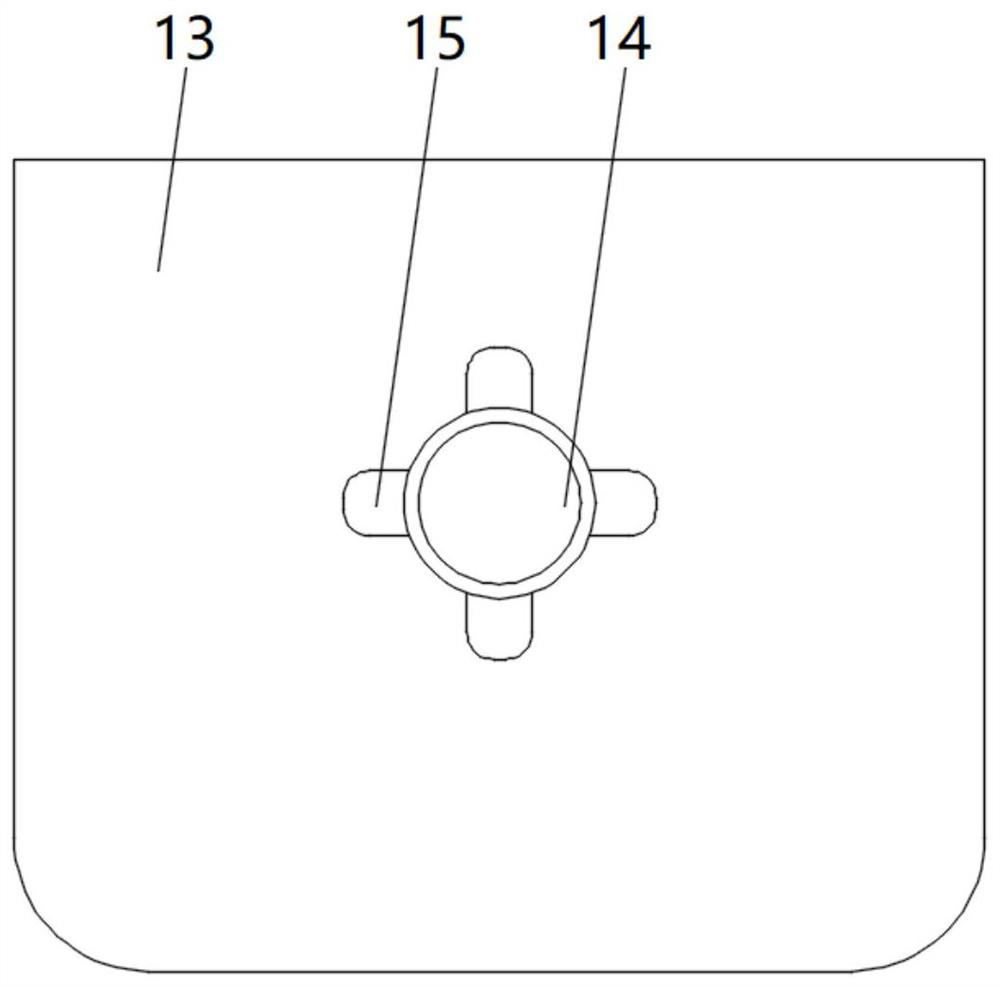

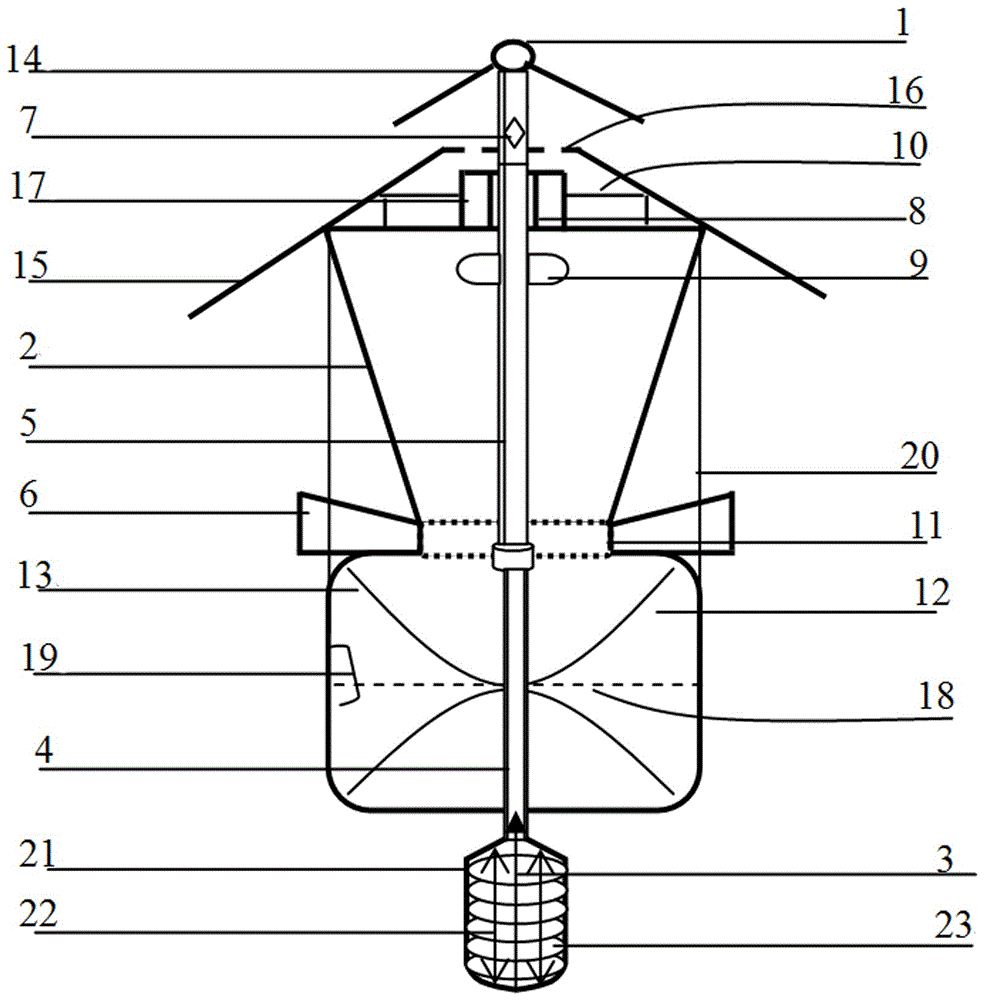

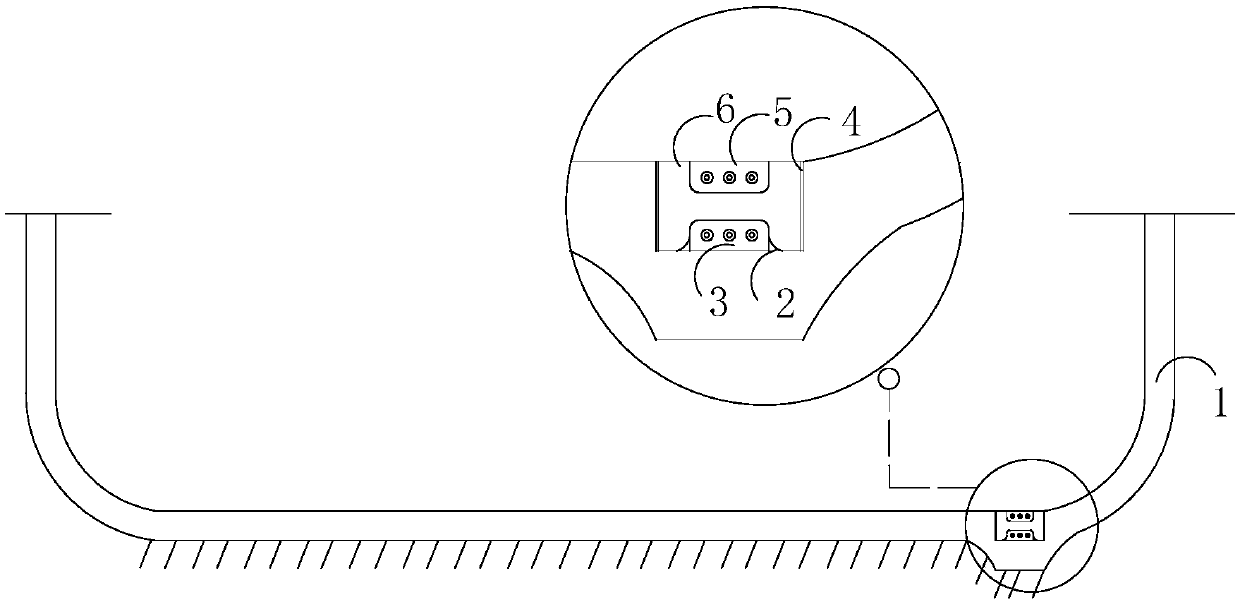

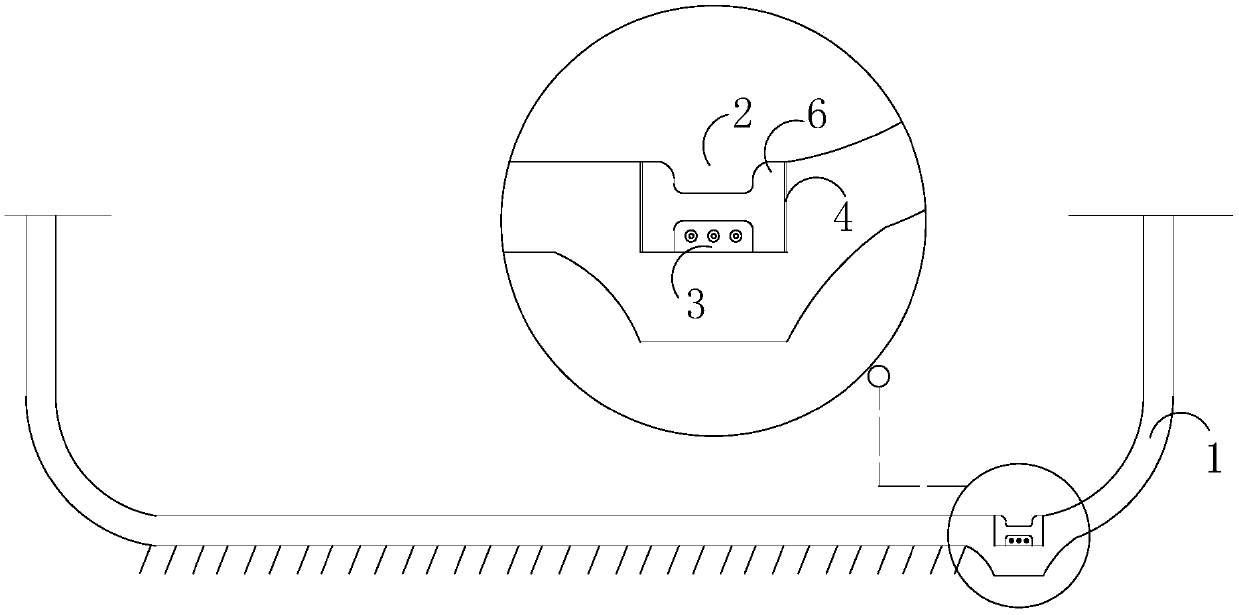

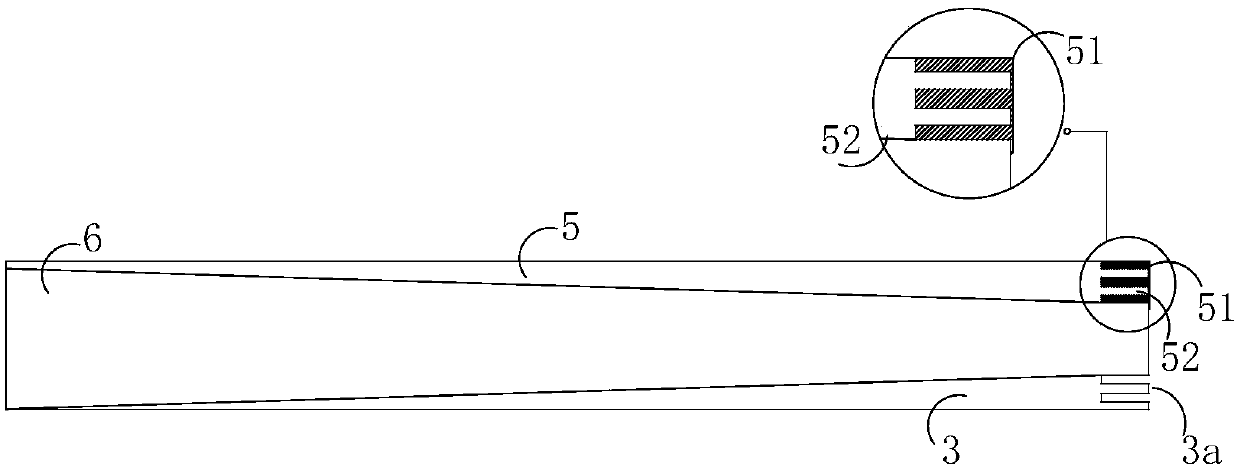

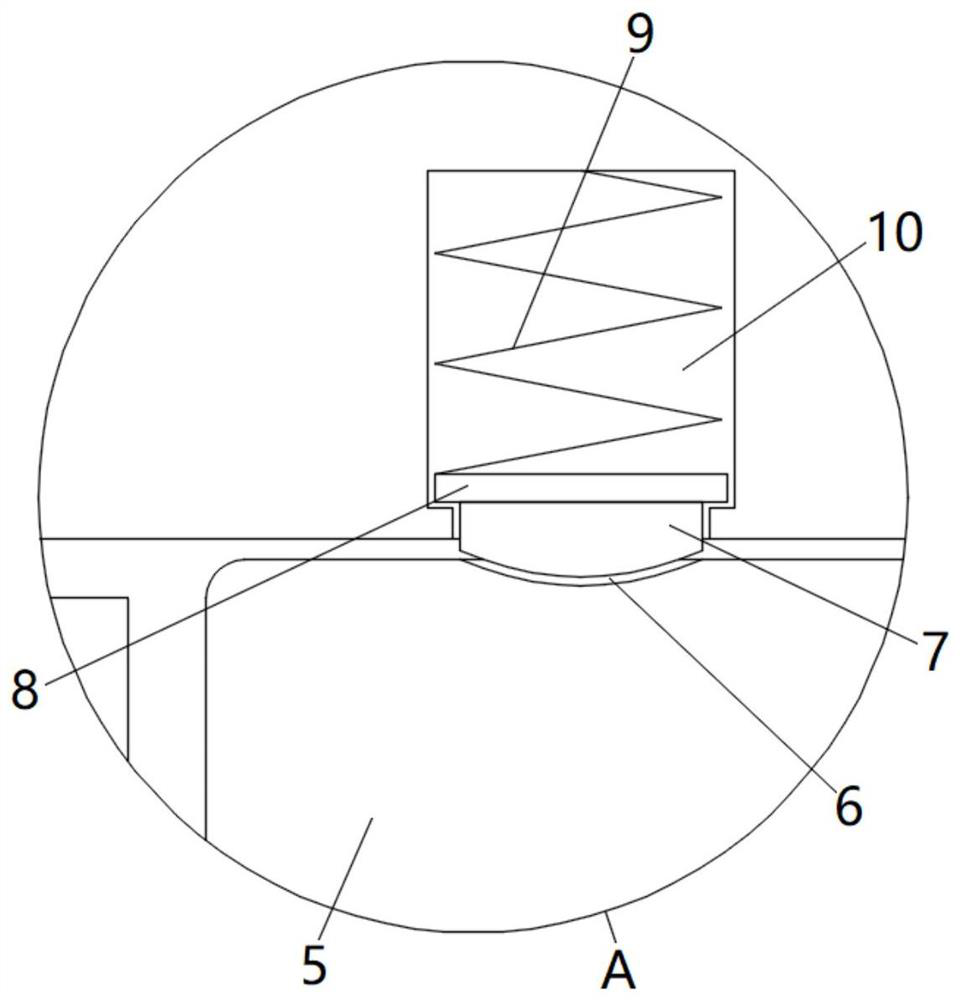

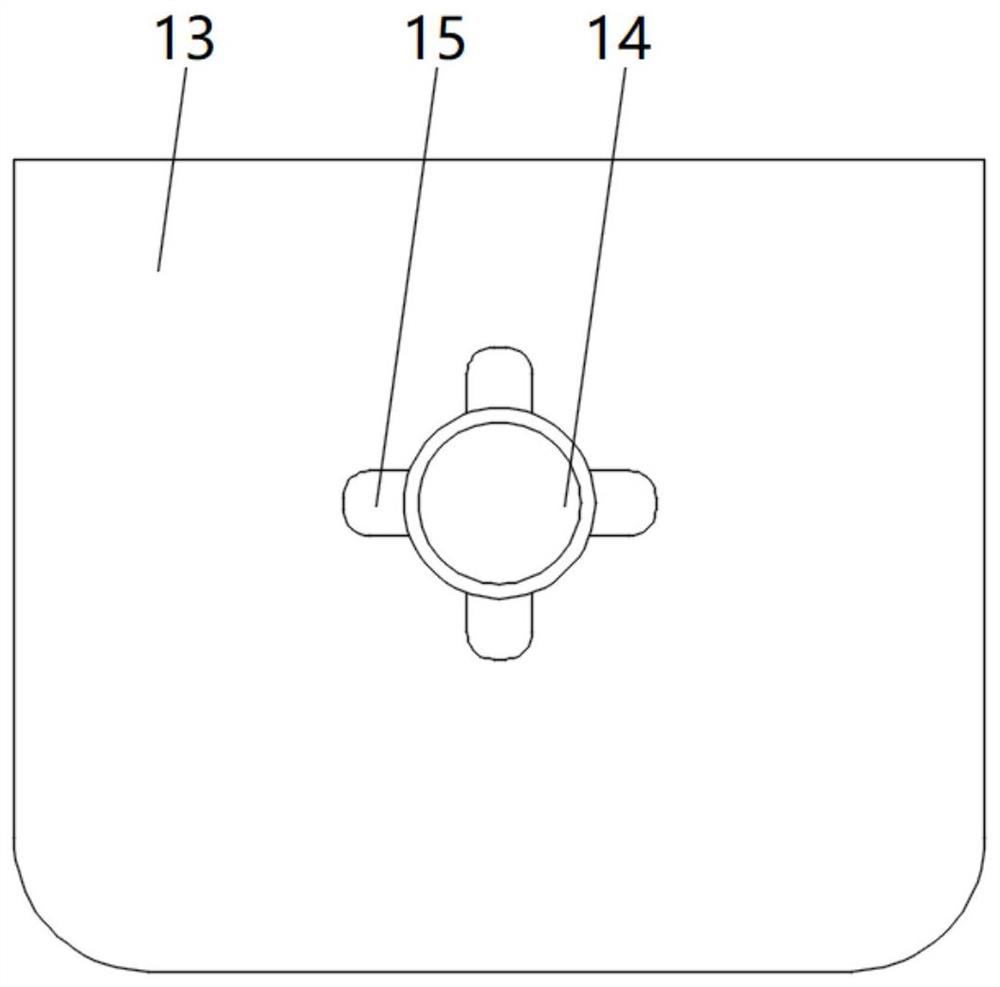

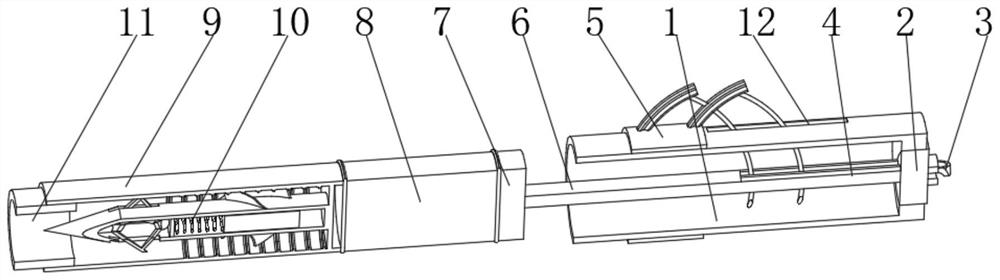

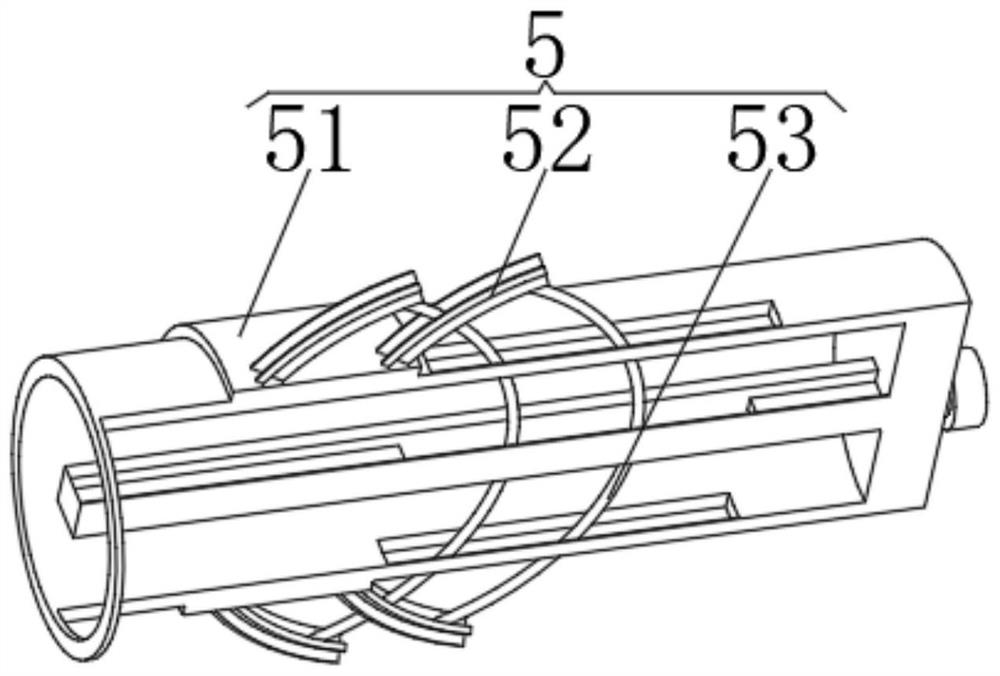

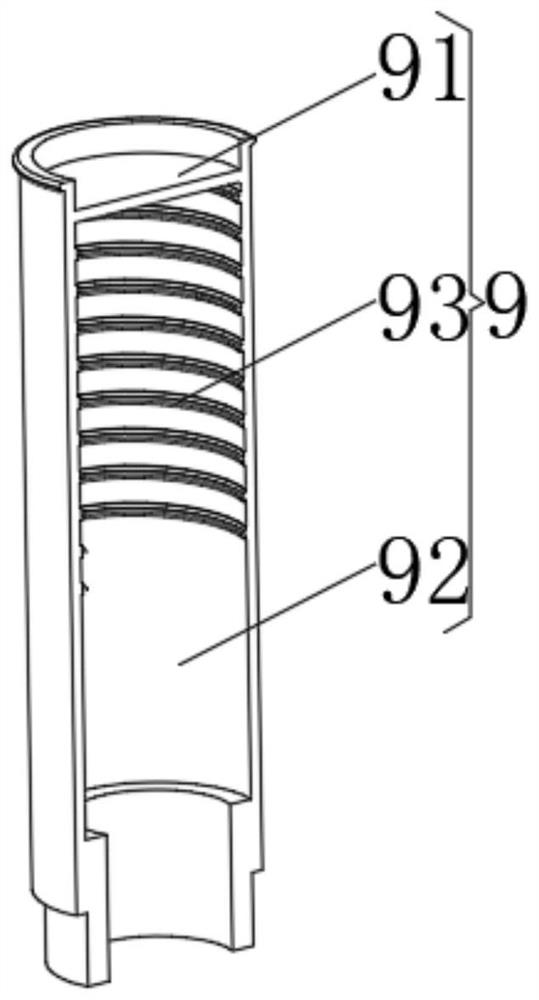

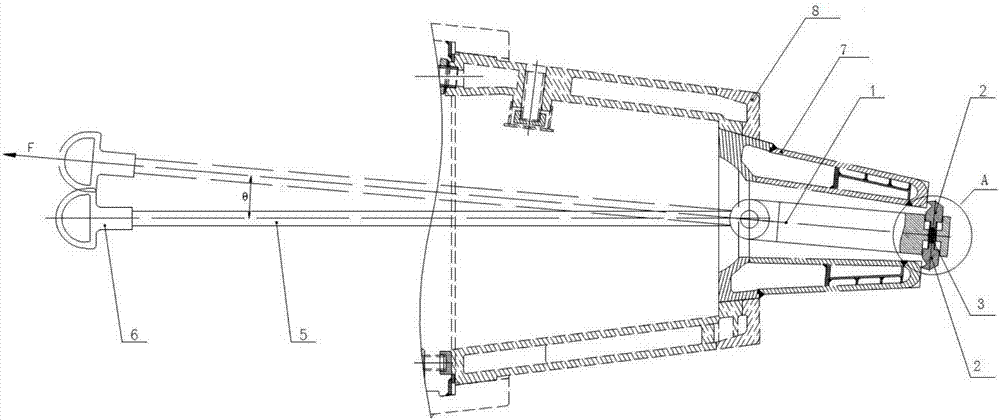

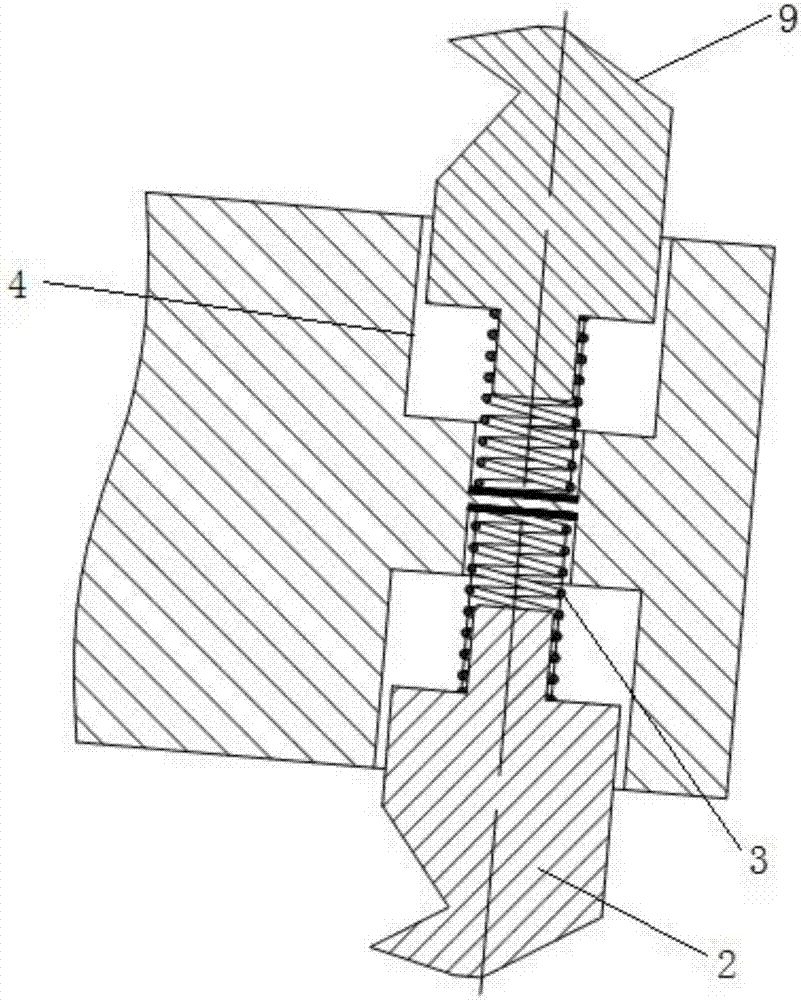

The invention discloses a mitral chordae sewing machine for implanting the artificial chordae through the minimally invasive technology and a method of the mitral chordae sewing machine in the field of medical apparatus and instruments. The mitral chordae sewing machine comprises a mitral forceps holder, sewing needles and a position detection device, wherein the mitral forceps holder is capable of clamping a mitral leaflet; the mitral forceps holder comprises an operating handle, a support rod and a clamping device of which the front end is opened and closed under the control of the operating handle; the number of the sewing needles is two; each sewing needle is designed to be of a barb structure, and the barb structures are used for hooking the artificial chordae; the position detection device is used for detecting the position, clamped by the mitral forceps holder, of the mitral leaflet; the mitral leaflet can be implanted into a human body through the small incision of left chest, and enters the ventriculus sinister from the apex cordis position to clamp the mitral leaflet; the sewing needles penetrate through the mitral leaflet to hook the artificial chordae, so that a liner is adhered to the mitral leaflet at one side of the atrium sinistrum, and two ends of the artificial chordae are fixed to the apex cordis position. According to the mitral chordae sewing machine and the method of the mitral chordae sewing machine disclosed by the invention, the goal that the artificial chordae is implanted through the minimally invasive technology is achieved, and patients with mitral regurgitation caused by the rupture of the mitral chordae are effectively treated.

Owner:SUZHOU INNOMED MEDICAL DEVICE

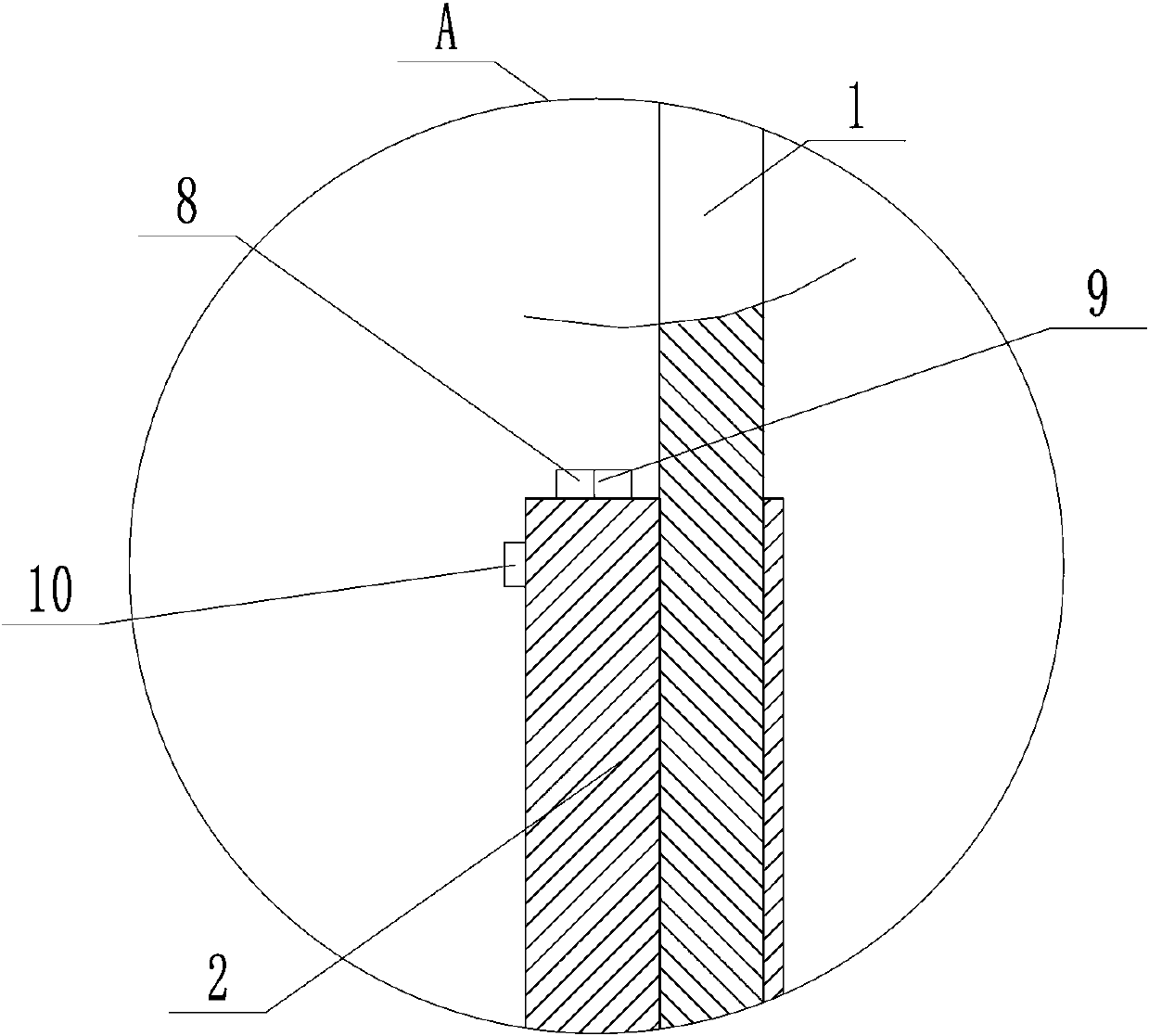

Anti-off quick-loading hook type short-circuit grounding wire clamp

PendingCN110137716AEffective clampingWhen clamping, it is effective to twist the double-ended threaded rod to disengage the second threaded rodElectric connection basesApparatus for overhead lines/cablesEngineeringScrew thread

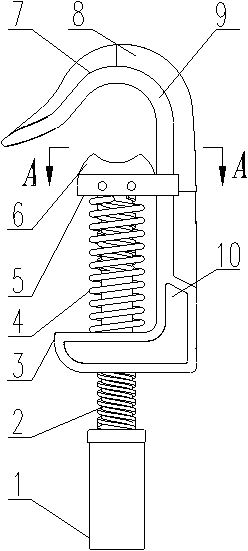

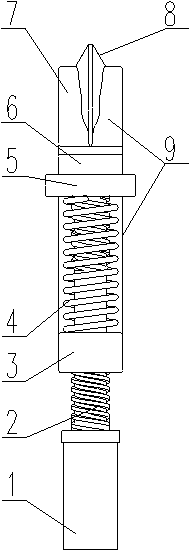

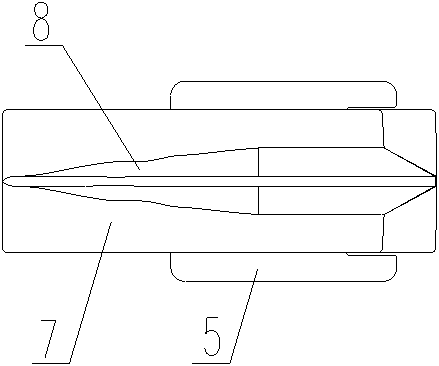

The invention belongs to the technical field of electric safety tools and particularly relates to an anti-off quick-loading hook type short-circuit grounding wire clamp. The anti-off quick-loading hook type short-circuit grounding wire clamp comprises a base, a double-head threaded rod is connected to a middle portion of a bottom surface of the base, the double-head threaded rod includes a first threaded rod, a polished rod and a second threaded rod, the first threaded rod and the second threaded rod are threadingly connected to the base, and the polished rod is slidingly connected to the base. A bottom end surface of the double-head threaded rod is fixedly connected to a connecting rod, a top end of the double-head threaded rod is rotatingly connected to a slider, and a top surface of theslider is fixedly connected to a pressing block. A compression spring is set between the slider and the base, and the compression spring sleeves the outside of the double-head threaded rod. The top of the base is fixedly connected with a tongue-shaped hook, the middle portion of a right end of the slider is provided with a guiding groove, and the slider is slidingly connected to a vertical portion of the tongue-shaped hook through a guiding groove. The overall structure of the wire clamp is reasonable, the operations of hanging and removing a grounding wire are simple, the wire can be effectively clamped, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:JIAOZUO POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER +1

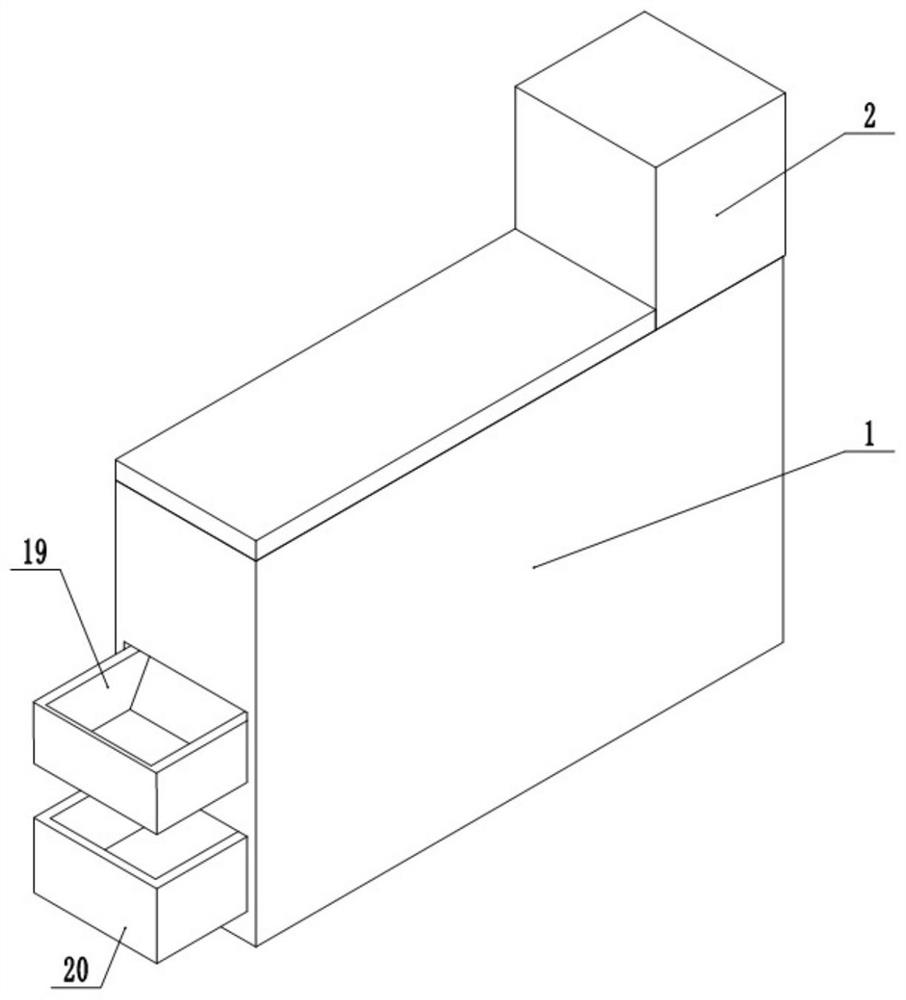

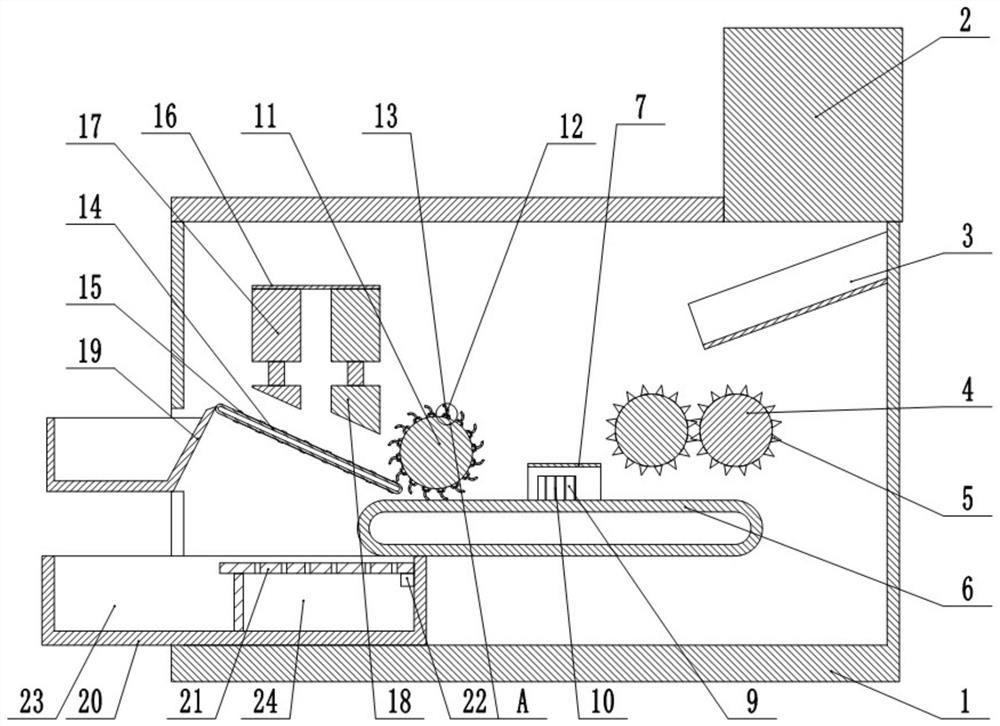

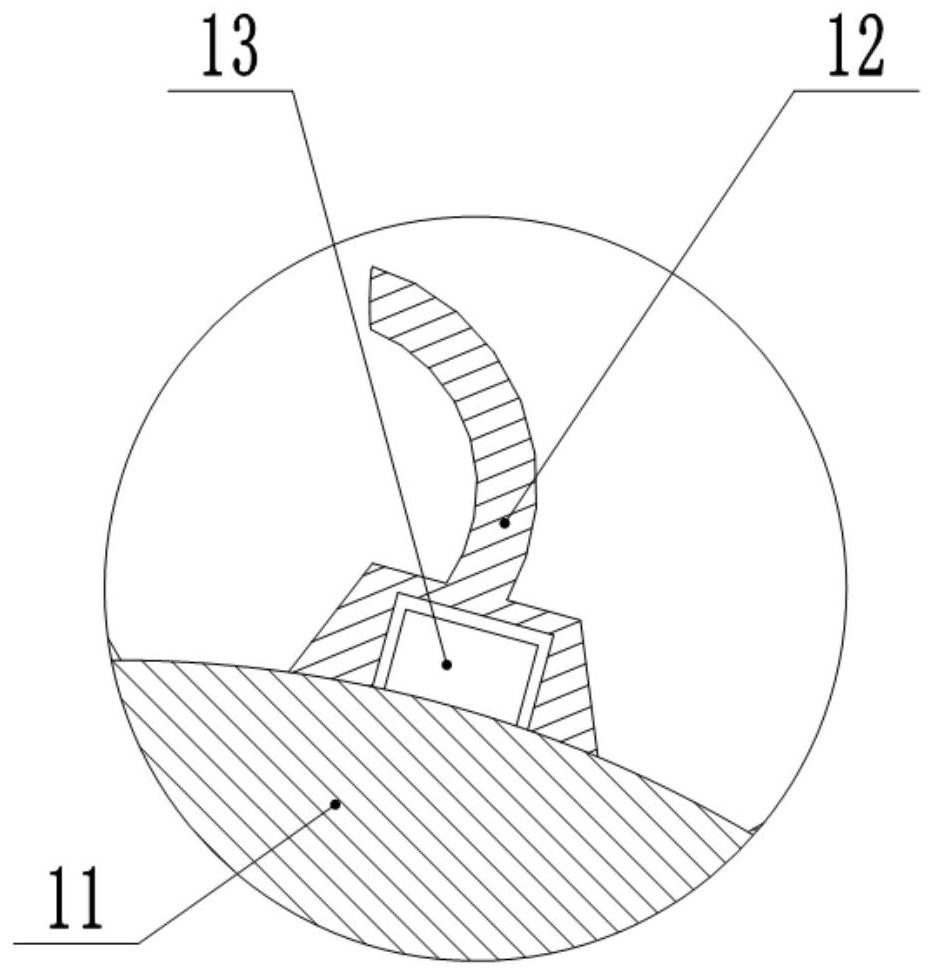

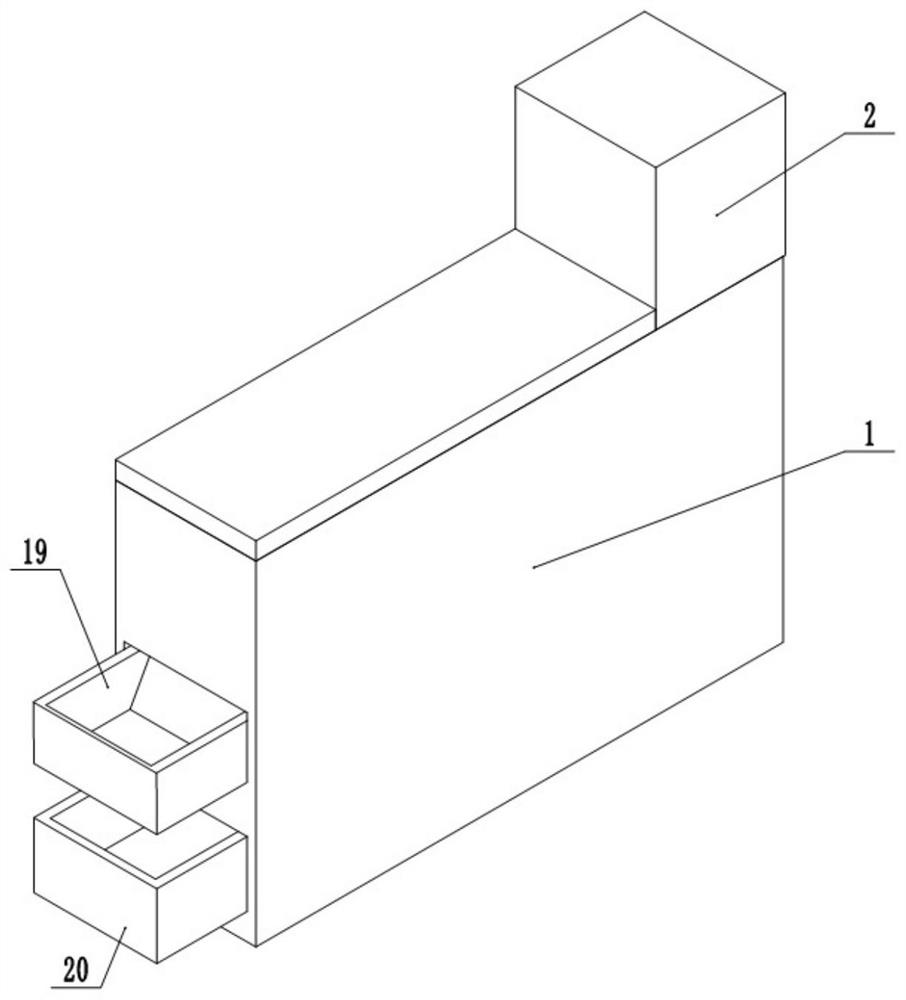

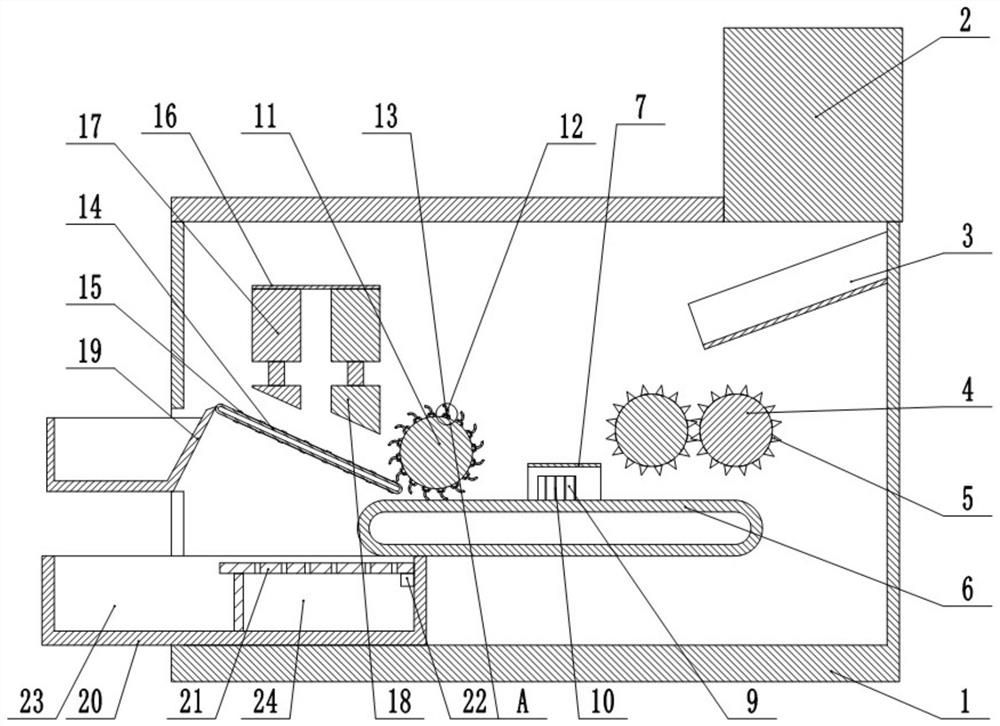

Reinforced concrete waste treatment device

ActiveCN111871494AAchieve separationEasy to tickMagnetic separationGrain treatmentsReinforced concreteArchitectural engineering

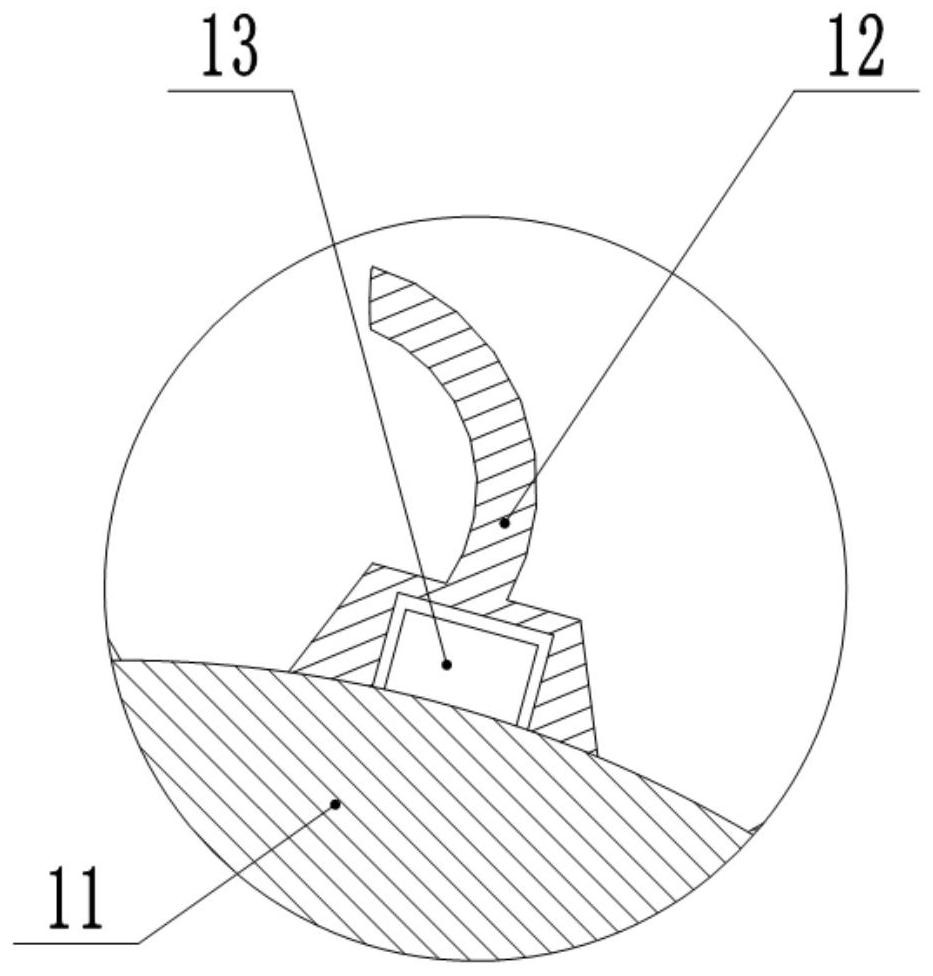

The invention relates to the field of building construction, and particularly discloses a reinforced concrete waste treatment device which comprises a crushing box. A coarse crusher is arranged in thecrushing box, an obliquely-arranged sliding way is fixed to the output end of the coarse crusher, and a crushing device is arranged at the lowest end of the sliding way and comprises two crushing rollers arranged in parallel; the crushing rollers are rotationally connected to the inner wall of the crushing box, the two crushing rollers rotate oppositely, a plurality of crushing thorns are distributed on the surfaces of the crushing rollers, and the crushing thorns of the adjacent crushing rollers are alternately distributed; a first conveying belt is fixed below the crushing rollers, a separation roller is arranged above the first conveying belt, the length of the separation roller is equal to the width of the first conveying belt, the separation roller is rotationally connected to the inner wall of the crushing box, and a plurality of staggered claws are fixed to the upper surface of the separation roller and make contact with the first conveying belt; and a second conveying belt which is obliquely arranged is fixed obliquely below the separation roller. The reinforced concrete waste treatment device aims to solve the problem of separation of steel bars and concrete in reinforcedconcrete waste.

Owner:SHANGHAI NO 4 CONSTR

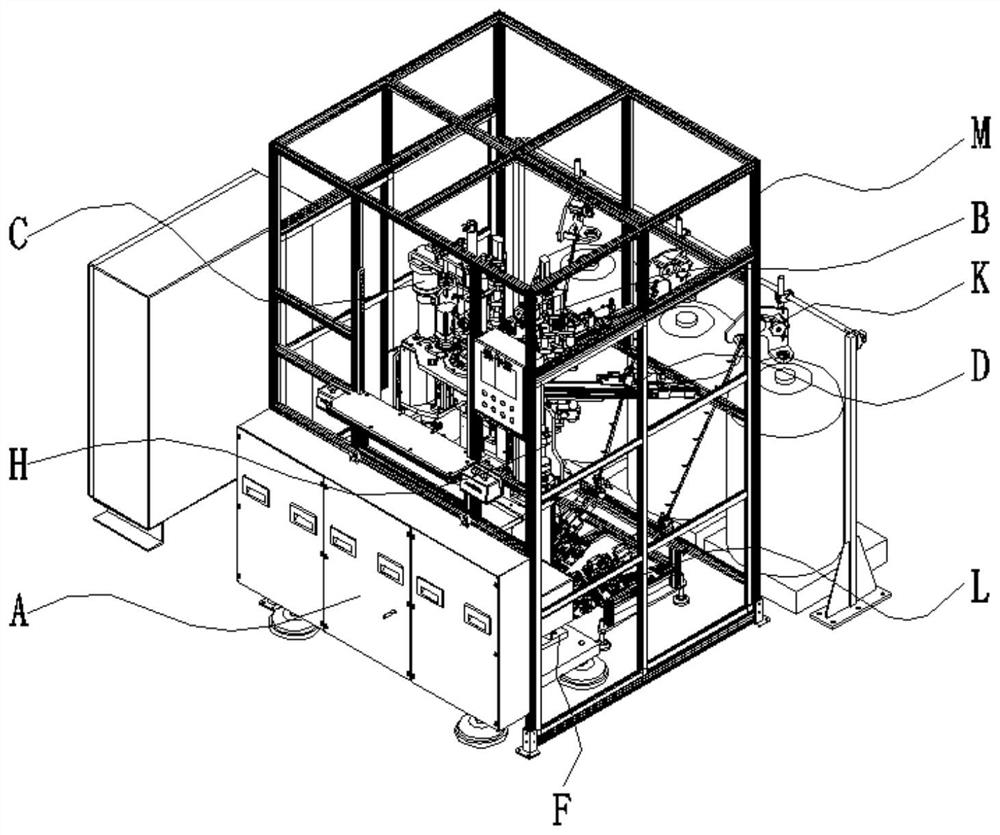

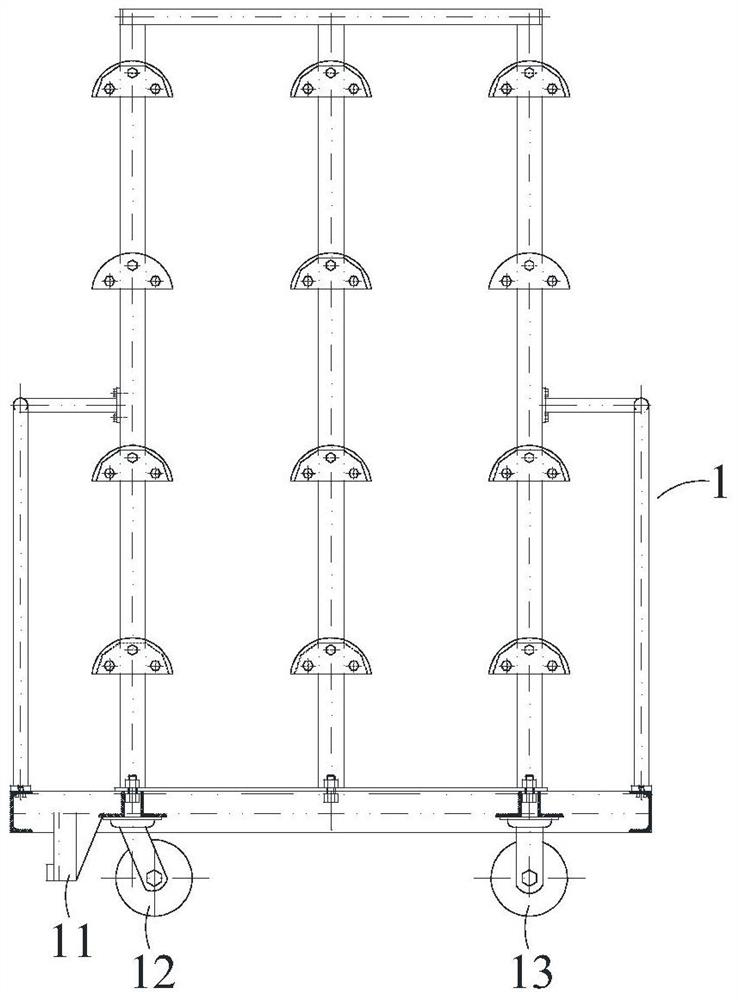

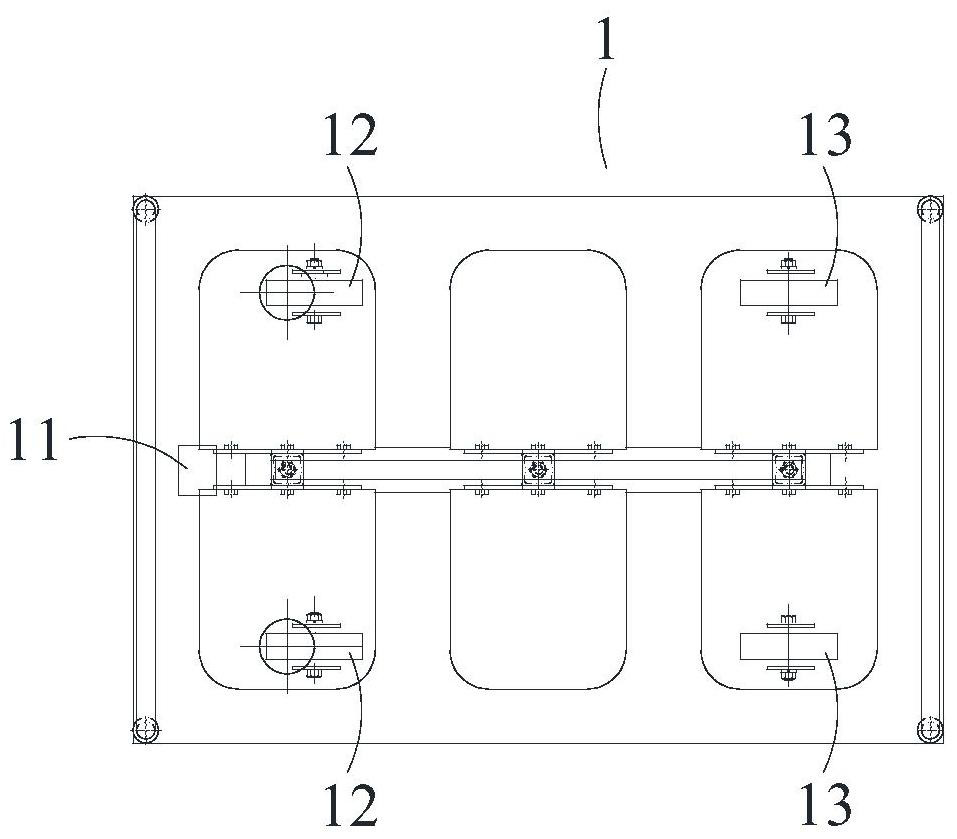

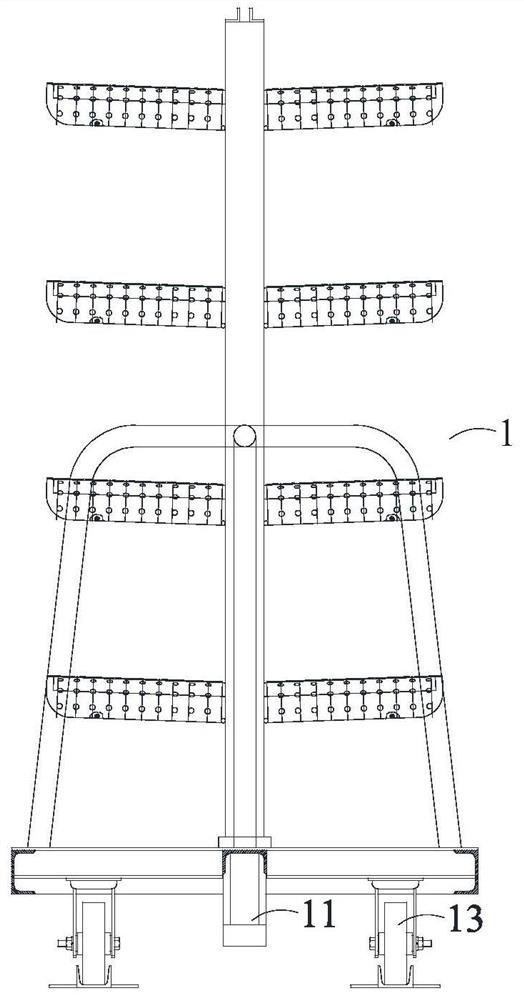

Three-wire parallel winding machine

The invention discloses a three-wire parallel winding machine. The machine comprises a rack assembly, a rotary disc jig assembly, a workpiece winding upper protective cover assembly, a main winding movement mechanism assembly, a transition wire hooking mechanism assembly, a wire drawing device assembly, a copper wire tension adjusting device assembly and a wire pressing device. The rack assembly is formed by welding iron plates, foot cups are arranged at the bottom of the rack assembly, the main winding movement mechanism assembly is vertically arranged in the rack, and the wire pressing device is arranged on a top plate in the rotary disc jig assembly. The invention relates to the technical field of winding machines. According to the three-wire parallel winding machine, vertical and linear integration of a mechanical structure for achieving main functions is achieved, the occupied area of equipment is greatly reduced, pollution is reduced. Meanwhile, the three winding heads are used for winding wires, other groove positions are automatically wound after winding of one set of wires is completed, a large amount of manpower and time needed in the period are reduced, and the production efficiency is improved.

Owner:广州桂电工控科技有限公司

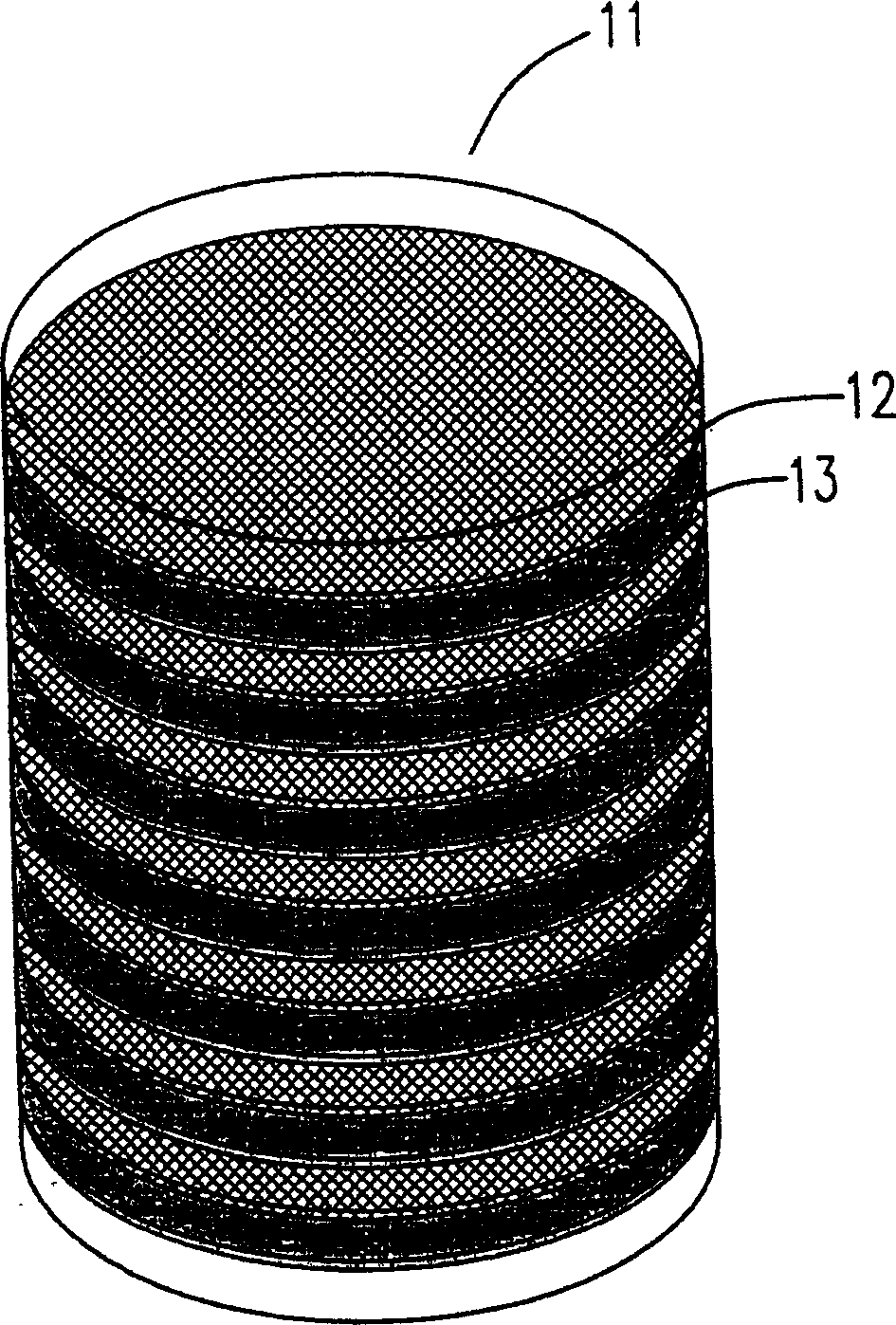

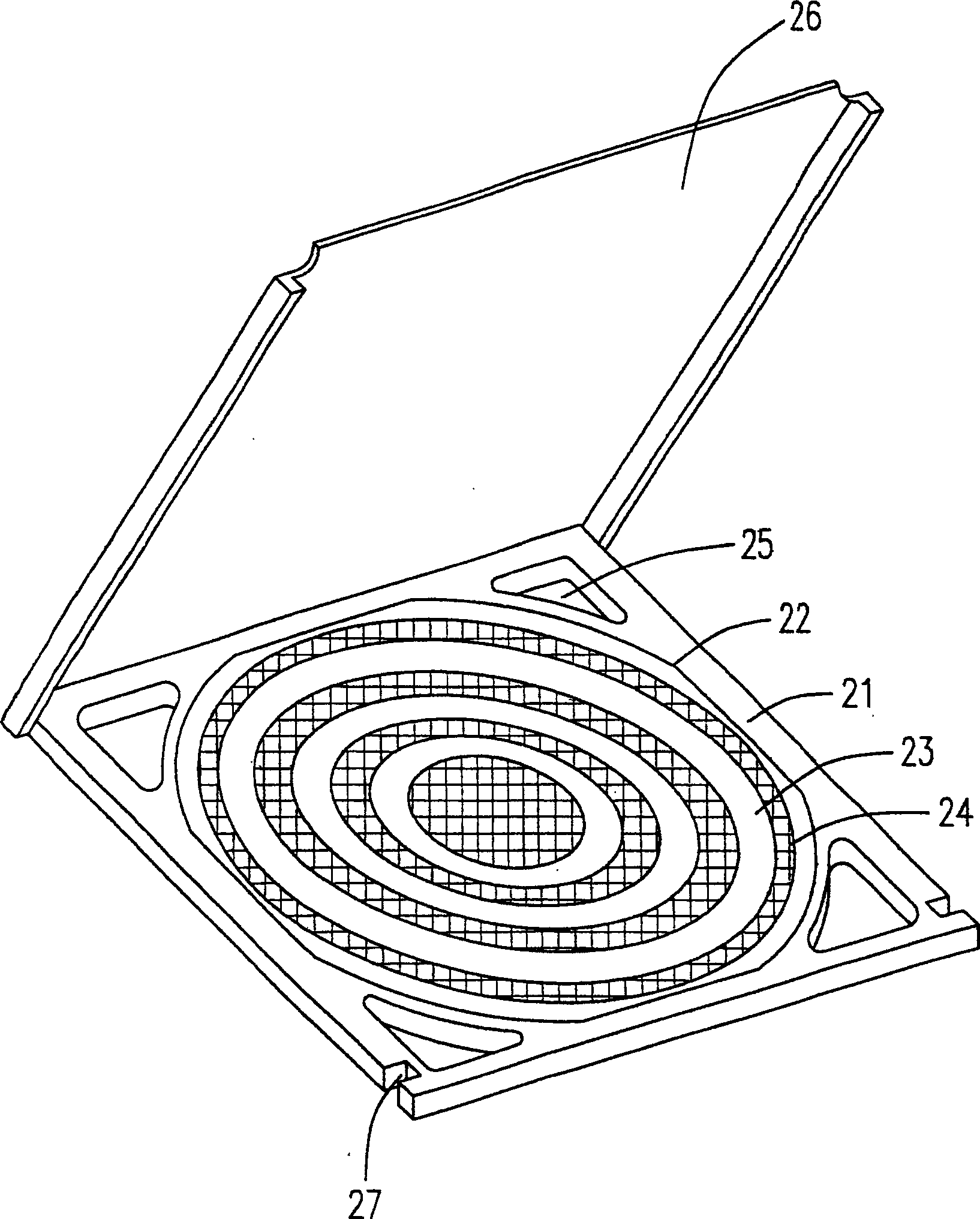

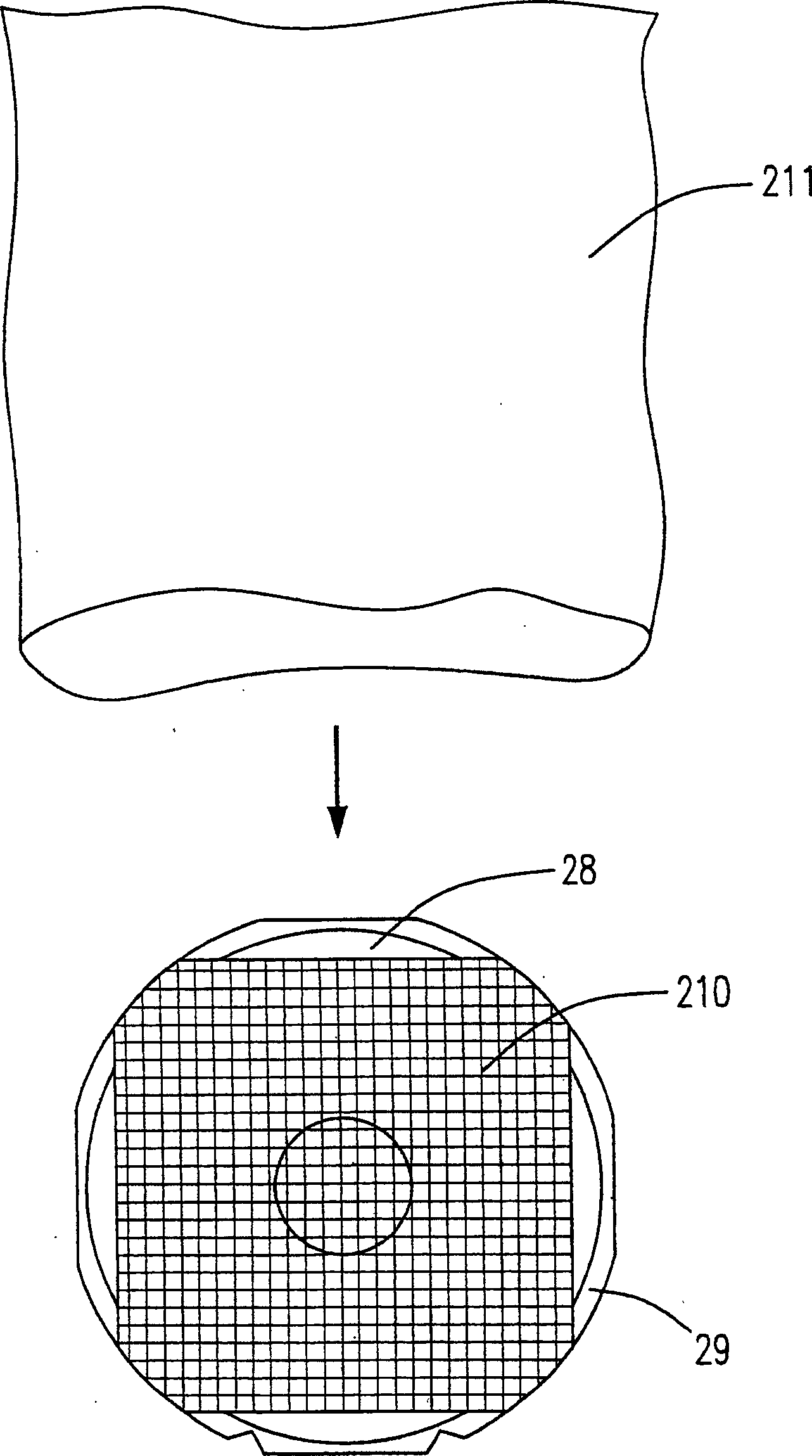

Chip flame storage box

InactiveCN1787198AReduce external impact forceReduce Fragmentation RateSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringEngineering

The invention relates to a wafer frame storage box, for storing a wafer, comprising: a main body with a holding space; plural saliencies formed on the bottom surface of the holding space to reinforce the main body; plural shockproof components arranged in the bottom surface of the holding space; and a cover body integrated with the main body. In the course of carrying wafers, it can reduce the received external shock force and thus effectively reduce the wafer chipping ratio so as to save the manufacturing cost.

Owner:POWER GEODE TECH

Environment-friendly soil remediation method

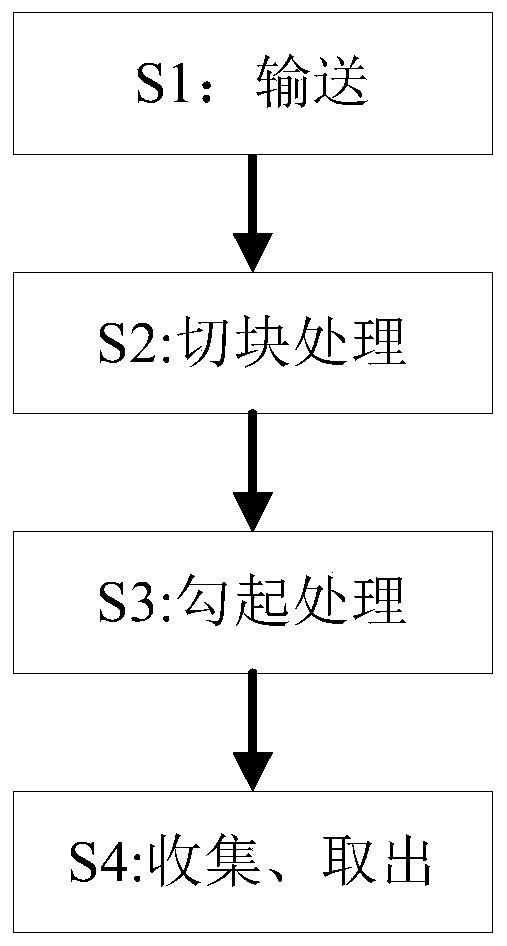

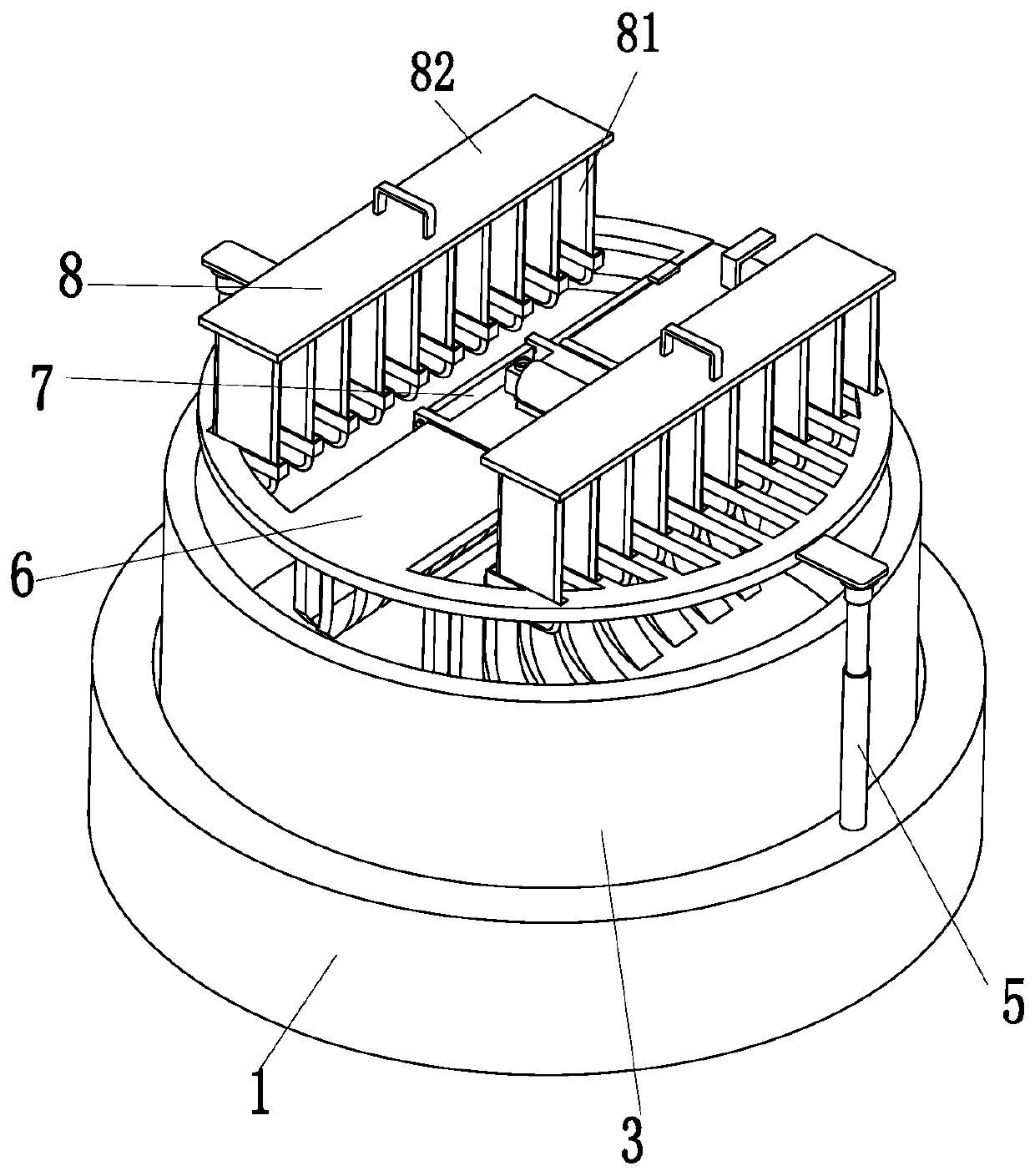

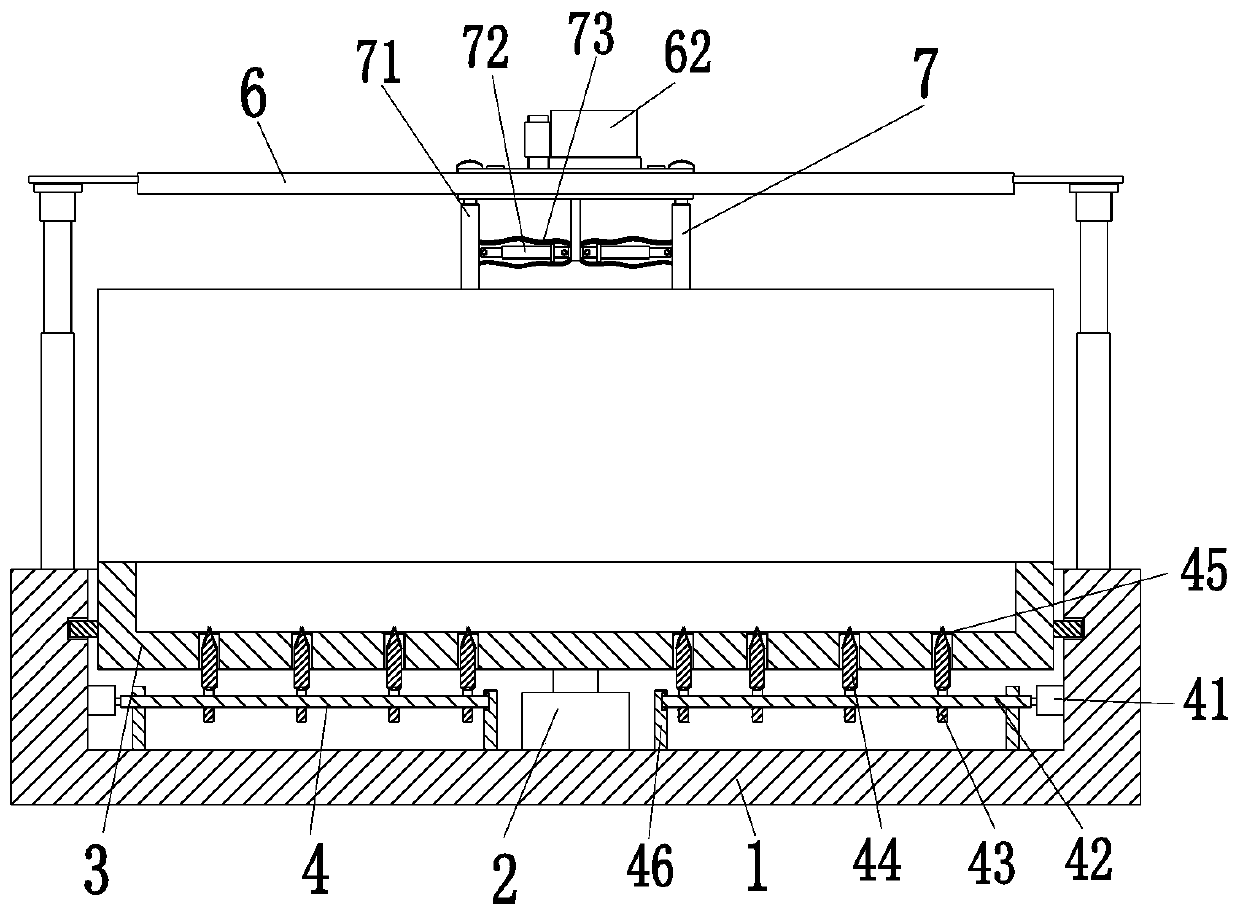

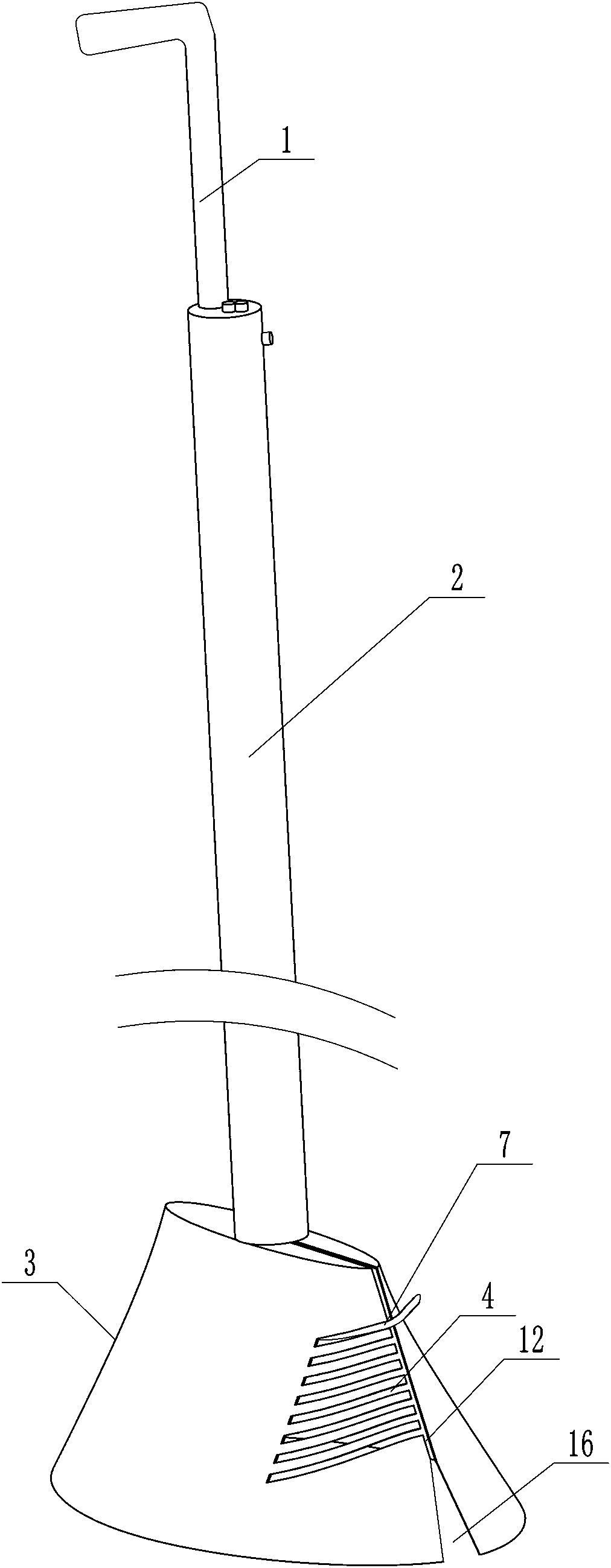

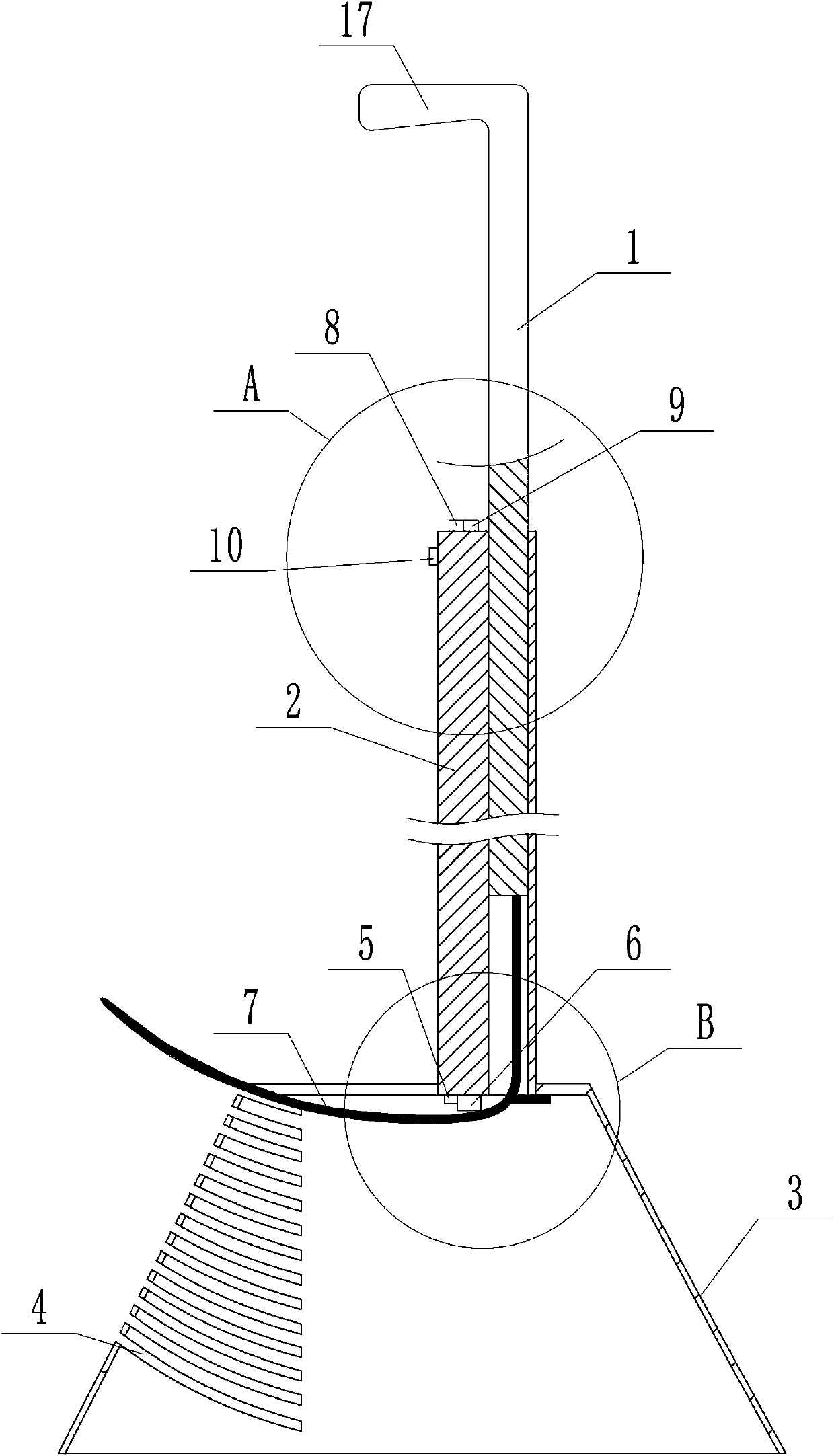

InactiveCN111052899AEasy to tickGuaranteed decentralizationContaminated soil reclamationGatherer machinesEnvironmental resource managementSoil remediation

The invention provides an environment-friendly soil remediation method. A fixed base, a rotating motor, a rotating frame, cubing devices, a lifting air cylinder, a circular cover group, two working devices and two partitioning devices cooperate to complete soil remediation operation. The environment-friendly soil remediation method can solve the problems that it is difficult for a worker to completely rake out plastic bags or flexible sheet objects by using an existing rake, and surfaces of the raked-out plastic bags or flexible sheet objects have a small amount of clay due to the conditions that the viscidity of the clay is relatively high, and the plastic bags or flexible sheet objects and the clay are stuck to each other to result in that the raked-out plastic bags or flexible sheet objects are still stuck to the existing rake, and need to be manually separated by the worker, the separation process is slow, and the like.

Owner:黄灏峰 +2

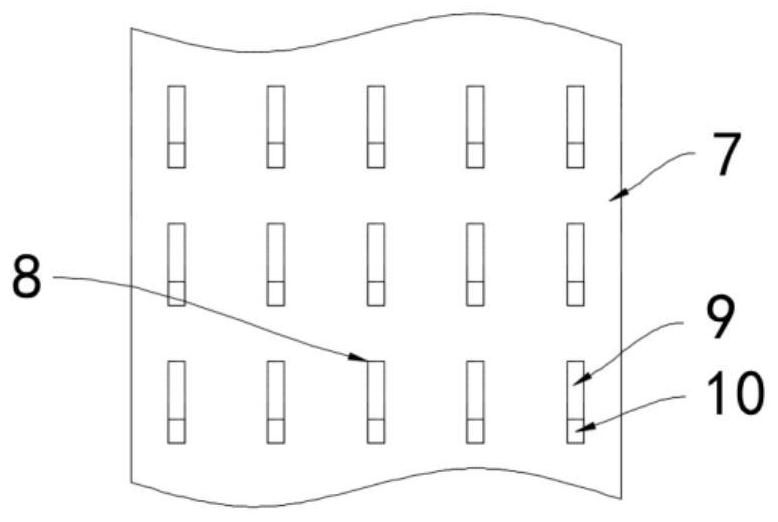

Warp-weft knitted double-sided fabric, preparation method and processing system thereof

PendingCN110815962AReduce transportationEasy to processLamination ancillary operationsLaminationPolymer scienceEngineering

The invention discloses a warp-weft knitted double-sided fabric, a preparation method and a processing system thereof, wherein a weft knitted fabric as a bottom cloth and a warp knitted fabric as a cloth surface are overlapped up and down and are subjected to needle punching compounding to form a warp-weft knitted composite double-sided fabric. According to the invention, the formed knitted warp-weft knitted double-sided composite fabric integrates the advantages of warp knitted fabrics and weft knitted fabrics, is stable in structure and soft in hand feeling, and can be used as various knitted garments or home textiles, wherein the weft knitted fabric layer is close to the body skin and is soft and skin-friendly, and the warp knitted layer as the outer layer is attractive and high in decorative property; and the outer layer of the composite fabric has napping effect, so that the obtained fabric is warm-keeping and comfortable.

Owner:WUHAN TEXTILE UNIV

Multifunctional pin taking-out device

The invention discloses a multifunctional pin taking-out device, and relates to the technical field of electric maintenance tools. The multifunctional pin taking-out device comprises a first connecting bar, a first hammer head, a stress balance block, a second connecting bar, a second hammer head and a pinch bar. The first hammer head is arranged at the lower end of the first connecting bar. The stress balance block is arranged at the upper end of the first connecting bar. The front end of the second connecting bar is arranged in the middle of the first connecting bar. The second hammer head is arranged at the rear end of the second connecting bar. The pinch bar is arranged on the rear portion of the second connecting bar. According to the multifunctional pin taking-out device, through thefirst connecting bar, the first hammer head, the stress balance block, the second connecting bar, the second hammer head and the pinch bar, strain insulator string pins W and R are replaced in an electrification manner; operation is simple, convenient and rapid; manpower and time are saved; power grid operation reliability is guaranteed; carrying is convenient; the situation that insulators of glass materials are damaged by vibration is avoided; and use is safe and reliable.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

Capsule bionic fishing bait

The invention discloses capsule bionic fishing bait, and relates to the technical field of bionic fishing bait production. The capsule bionic fishing bait includes a bionic capsule; a first through hole and a second through hole are successively formed in an abdomen portion of the bionic capsule; a balancing block is fixed on the second through hole in a sealed manner; third through holes are symmetrically formed in two sides of a tail end of the bionic capsule; a breathable hole is formed in a random position of the back portion of the bionic capsule; a colorful rubber line group is arrangedin the two adjacent third through holes; the colorful rubber line group passes through the two adjacent third through holes successively, and two ends of the colorful rubber line group are positionedoutside the bionic capsule; a groove is formed in one end surface of a head of the bionic capsule; a bulge is arranged on the bottom of the groove; a hole is formed in the bulge; a hanging ring is fixed on the hole; one end of the hanging ring passes through the hole and is positioned in the bionic capsule, and is fixed with a fishing hook; and a handle of the fishing hook passes through the firstthrough hole. The bionic capsule is fixed with the fishing hook; and when fishes are hooked, the fishing hook arranged on the capsule bionic fishing bait can easily hook the fishes.

Owner:界首市海德龙渔具有限公司

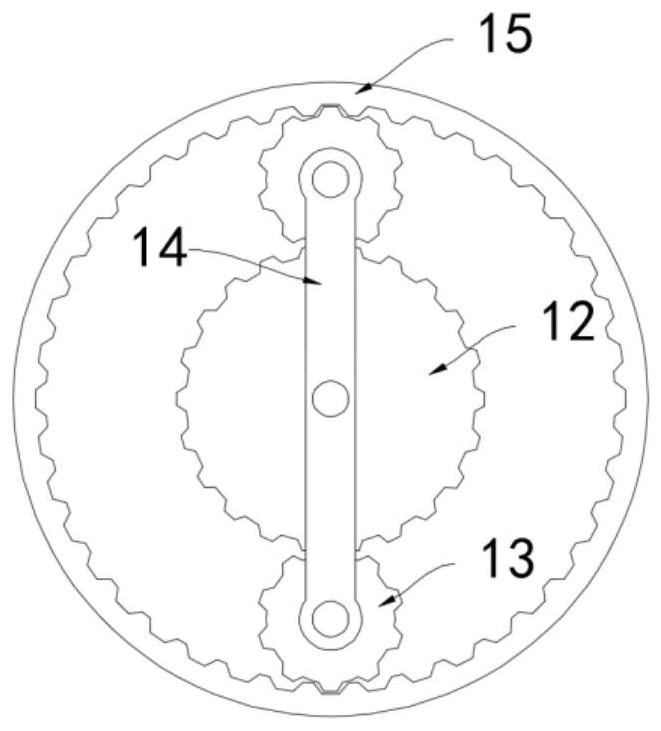

Drum-type leftover material recovery device for non-woven fabric production

InactiveCN111871546AExtend exercise timeImprove crushing effectGrain treatmentsDrive motorNonwoven fabric

The invention belongs to the technical field of non-woven fabric production, and particularly relates to a drum-type leftover material recovery device for non-woven fabric production. The drum-type leftover material recovery device comprises a cylindrical shell, a feeding hole is formed in the upper end of the cylindrical shell, and a crushing drum is arranged in the cylindrical shell in the axisdirection of the cylindrical shell; a plurality of crushing blades are installed on the outer side wall of the crushing drum and the inner side wall of the cylindrical shell at equal intervals, the multiple crushing blades are spirally arranged in a staggered manner, a driving motor is arranged above the cylindrical shell and connected with the crushing drum through a driving mechanism, and a collecting groove is rotatably connected to the bottom of the cylindrical shell; and a conveying belt is arranged in the collecting groove. By means of relative rotation of the crushing drum and the cylindrical shell, non-woven fabric is cut and crushed, the crushing effect is better, crushed non-woven fabric fragments can be screened and cut multiple times, the recycling requirement of the non-wovenfabric is met, a crushing device does not need to be adjusted or replaced, and the product quality and the working efficiency are greatly improved.

Owner:叶能

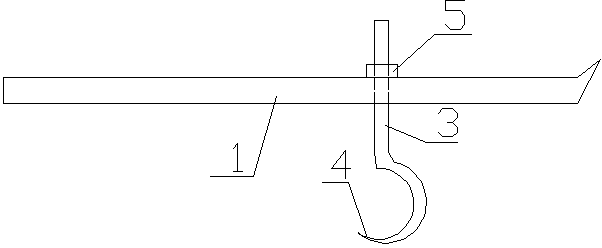

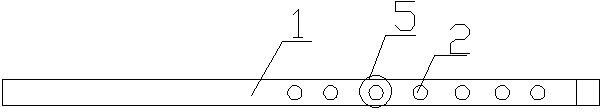

Multifunctional crowbar

The invention relates to a multifunctional crowbar comprising a crowbar body and a hook. The hook comprises a vertical part and a bent part. The vertical part of the hook is provided with a thread. The crowbar body is provided with ducts, the adjacent ducts are equally spaced, the vertical part of the hook is in clearance fit with the ducts, and the vertical part of the hook is perpendicularly connected with the crowbar body through a nut. The multifunctional crowbar is simple in structure and reasonable in design; the hook is added to the multifunctional crowbar, so that workers can hook and pull a spring through the crowbar conveniently.

Owner:SHANGQIU POWER SUPPLY CO OF STATE GRID HANAN ELECTRIC POWER CO

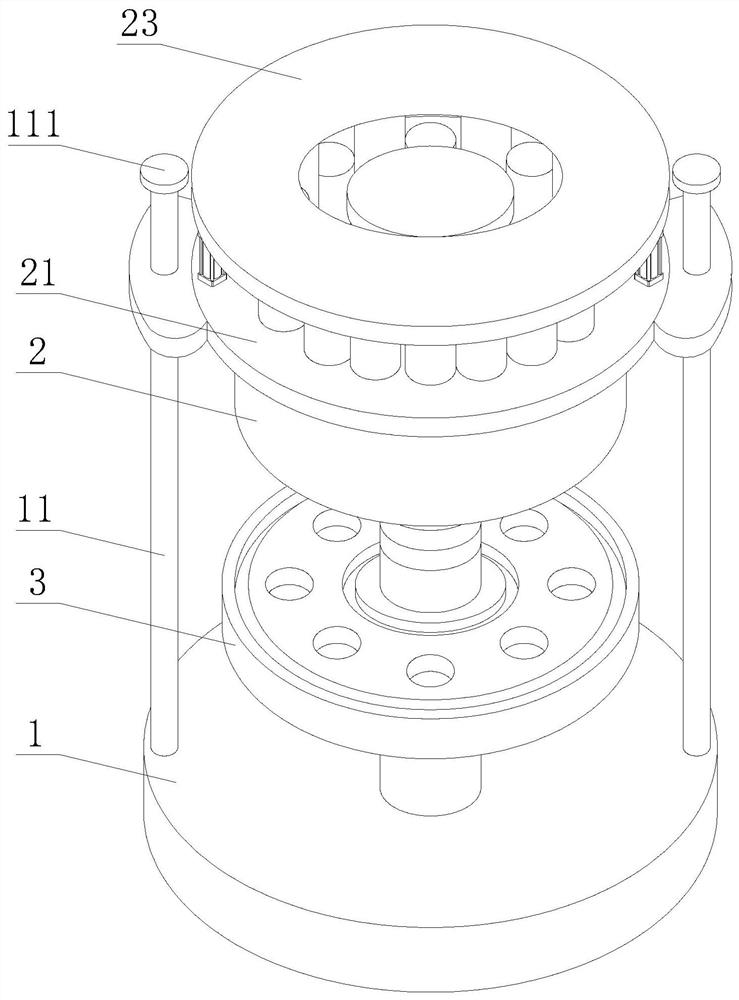

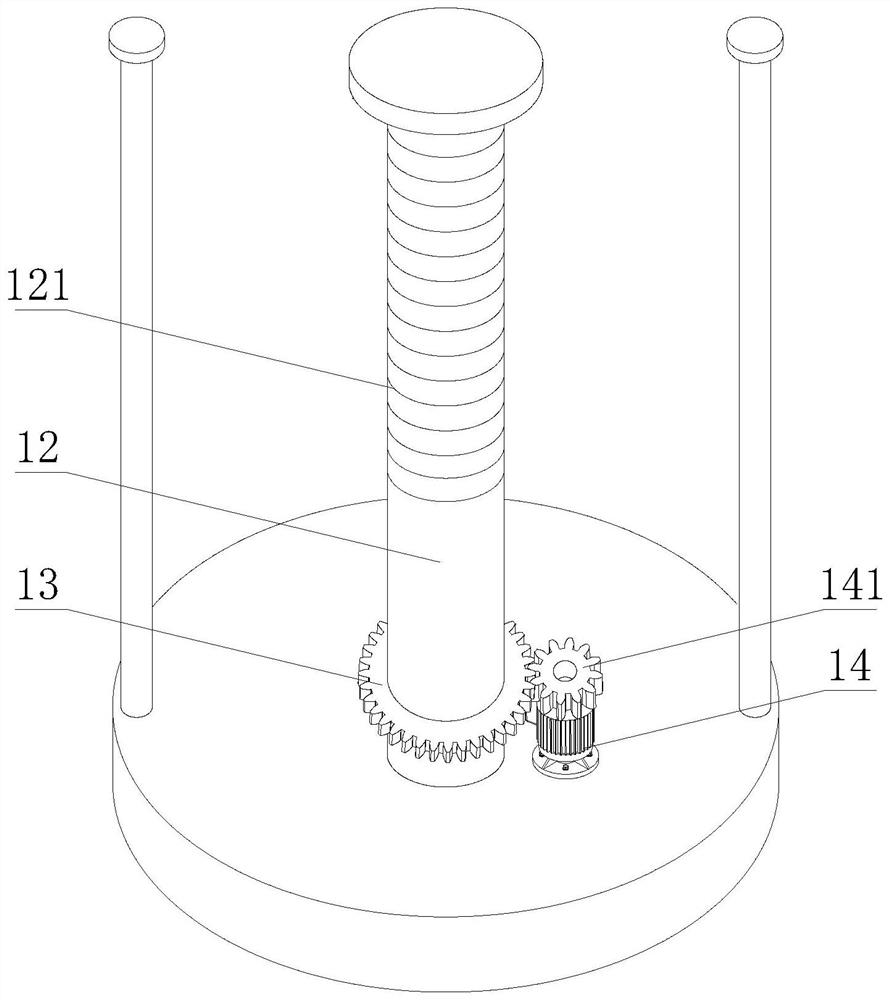

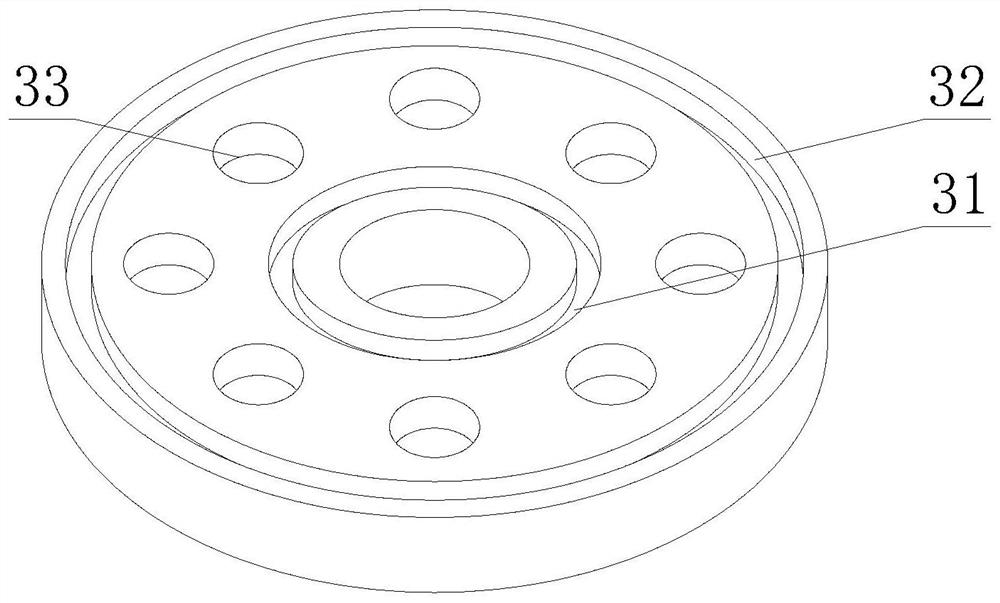

Can degassing device for canned aquatic product production and implementation method of can degassing device

InactiveCN112238967AEasy to tickEasy to get on and offPackaging under vacuum/special atmosphereGear wheelAquatic product

The invention discloses a can degassing device for canned aquatic product production and an implementation method of the can degassing device. The can degassing device comprises a base and a vacuum barrel, wherein guide rods are symmetrically connected to the two sides of the upper surface of the base, the vacuum barrel is movably connected to the guide rods, a rotating column is connected to thecenter of the upper surface of the base through a bearing, a first gear is fixedly connected to the lower end of the rotating column, a driving motor is fixedly connected to the position, on one sideof the rotating column, of the base, and a second gear is fixedly connected to the output end of the driving motor. According to the can degassing device for canned aquatic product production and theimplementation method of the can degassing device, the rotating column is adopted for controlling the vacuum barrel to move up and down, opening and closing of the vacuum barrel and an operation tableare achieved, the feeding and discharging process is achieved, meanwhile, the rotating column can drive the operation table to synchronously rotate, and a can containing groove sequentially passes through the front of an operator, so that cans are conveniently fed and discharged, leakage does not occur, and meanwhile, hooking by the operator is facilitated, an operation process is simplified, theuse is simple, and can body sealing covers are stacked in a sealing cover box.

Owner:HEXIAN COUNTY JILONGSHAN CONDIMENT

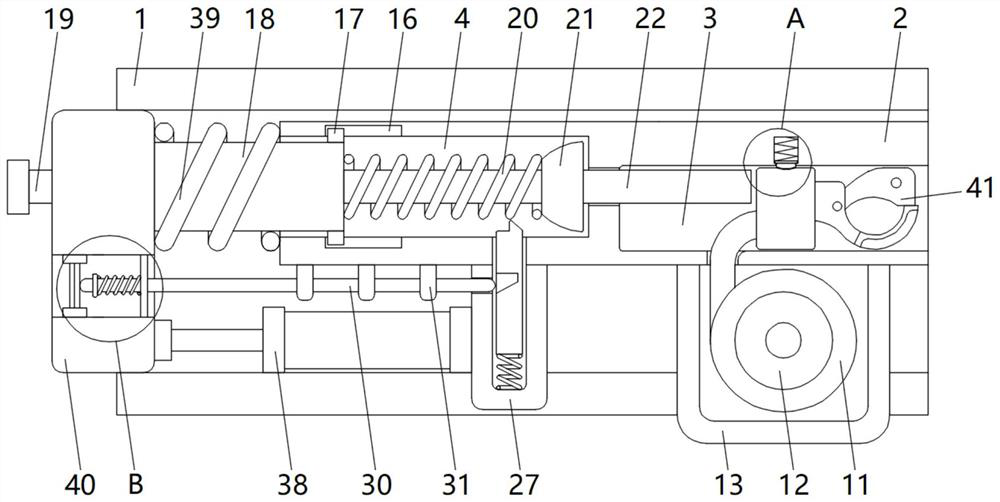

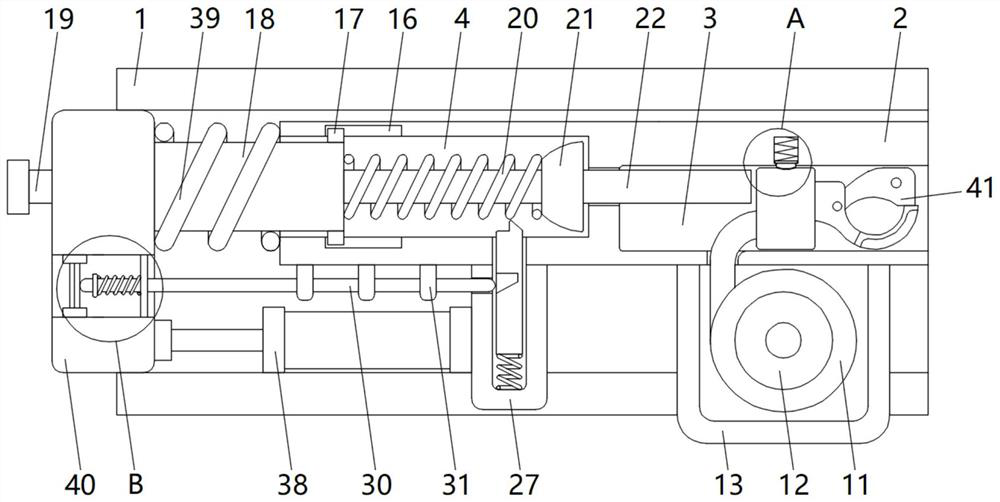

Automatic ejection hook for electric automobile

The invention relates to the technical field of automobile hooks and discloses an automatic ejection hook for an electric automobile. The automatic ejection hook comprises a thermal bimetallic plate;in a state of vehicle spontaneous combustion, the thermal bimetallic plate is heated to bend rightwards to push a trigger rod to move rightwards; the trigger rod moves rightwards to be inserted into apressing groove; a locking rod is pushed to move downwards under the action of the inclined surface of the inner bottom wall of the pressing groove; the locking rod moves downwards to drive a protruding part to move downwards. The locking of the projection part on the ejection block is relieved; at the moment, the ejection block impacts rightwards under the action of the elastic force of an ejection spring; a punching rod is driven to impact rightwards; a movable block and a hook are ejected out, a firefighter can hook the hook conveniently, then the spontaneous combustion vehicle is draggedaway more conveniently, the trailer is more convenient, the safety of the trailer is improved, and economic losses are reduced; the design is novel, the structure is simple, operation is easy, and theadvantage that the trailer hook can be ejected automatically when the vehicle spontaneously combusts is achieved.

Owner:周鹏

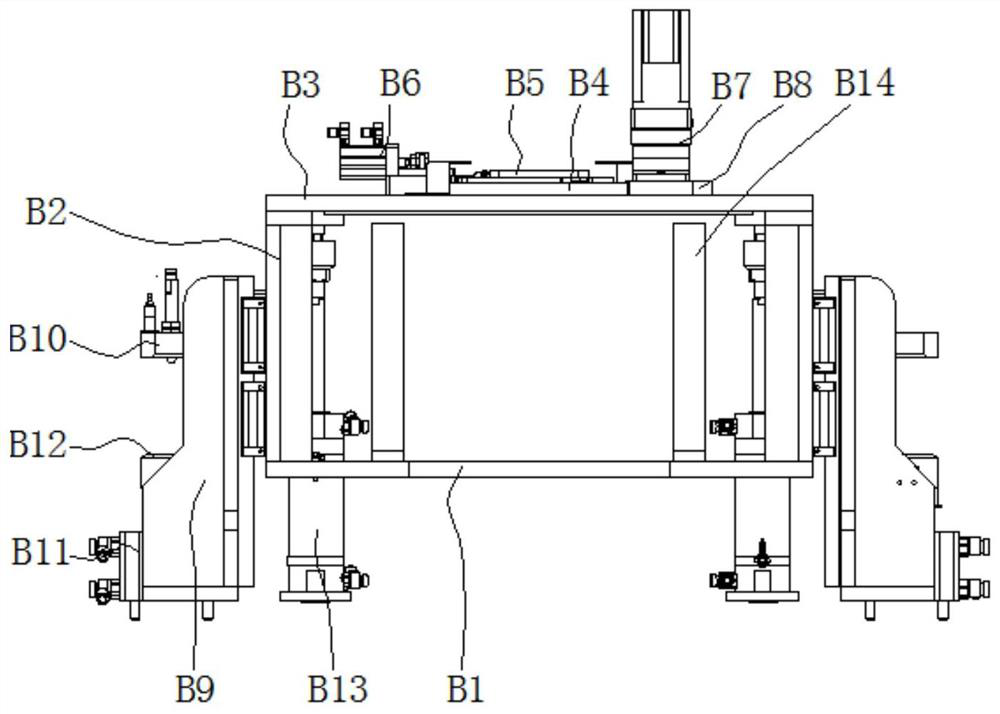

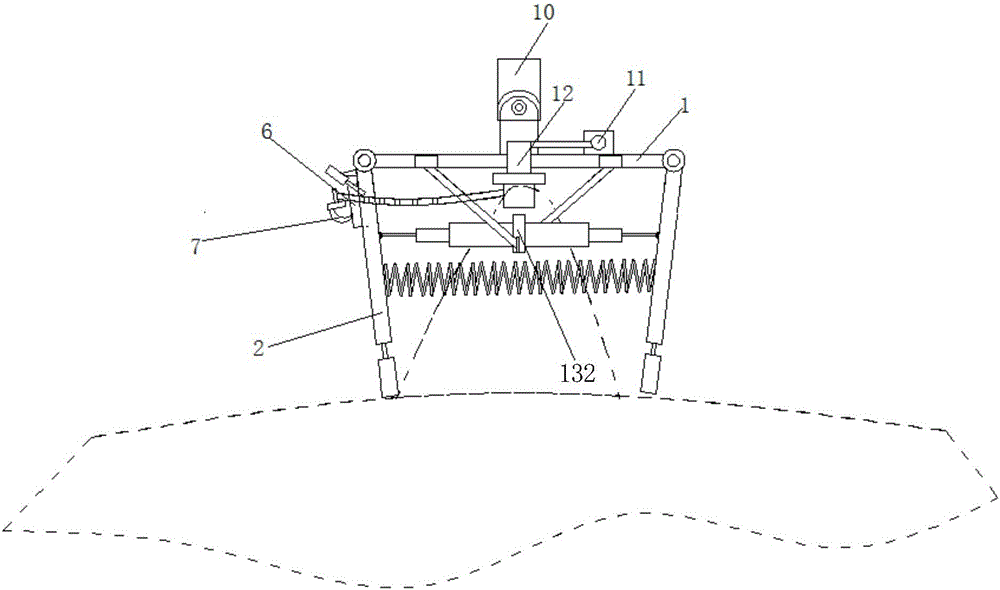

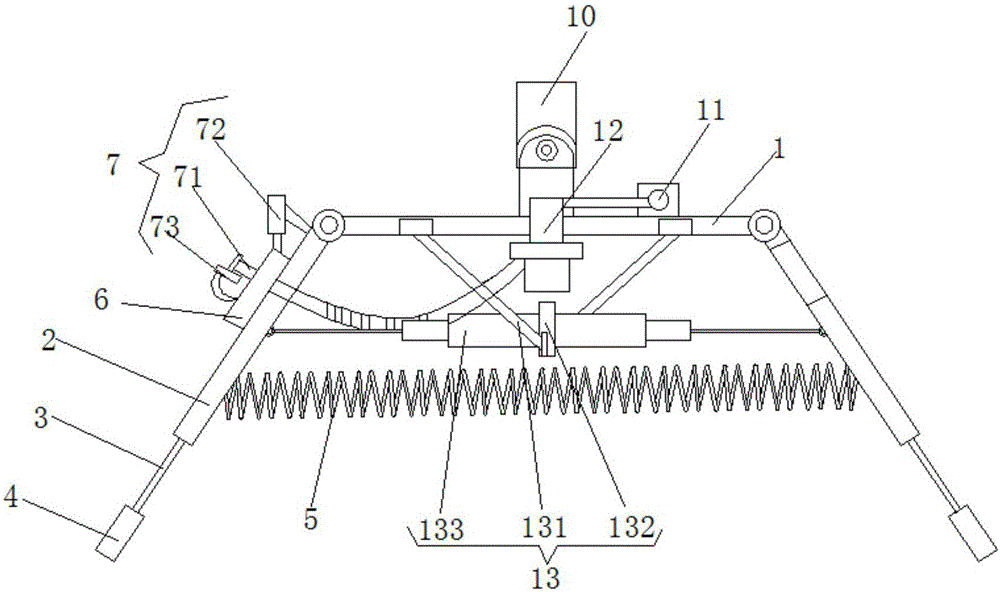

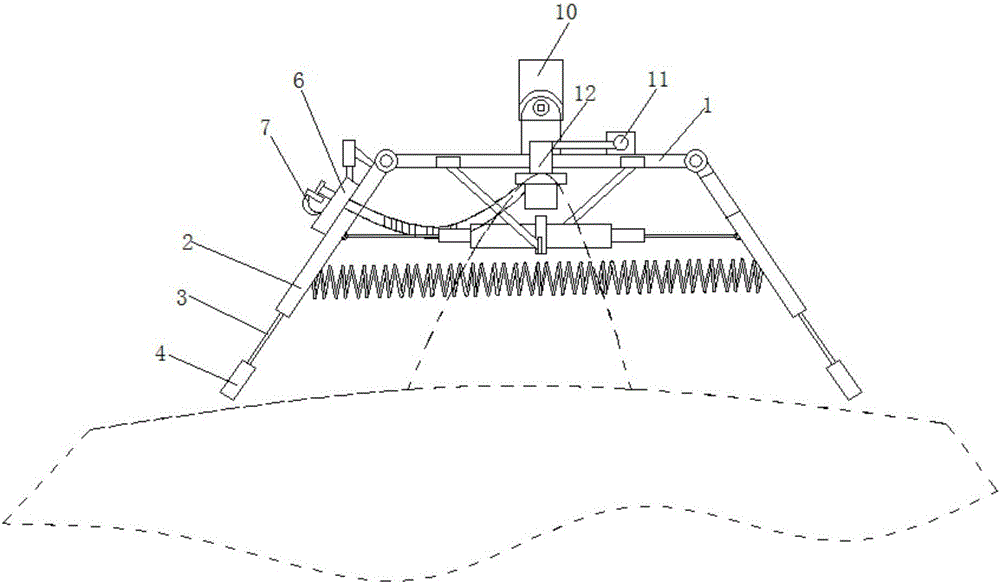

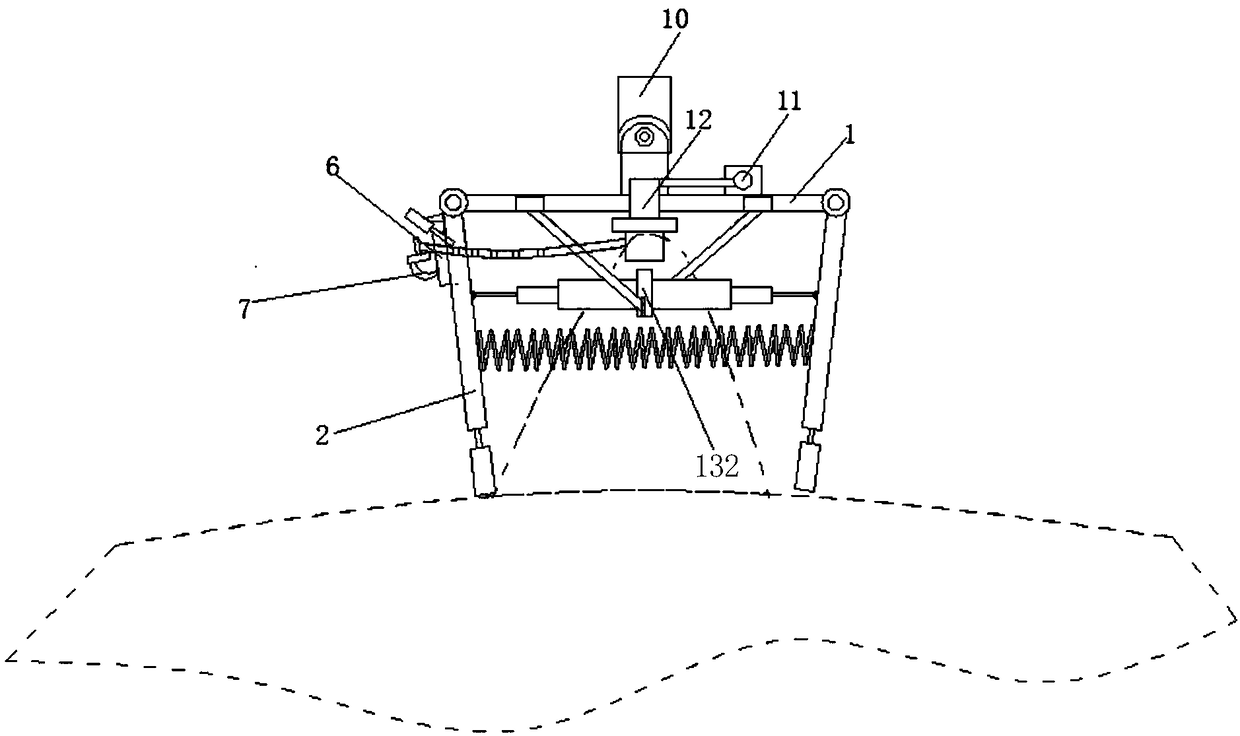

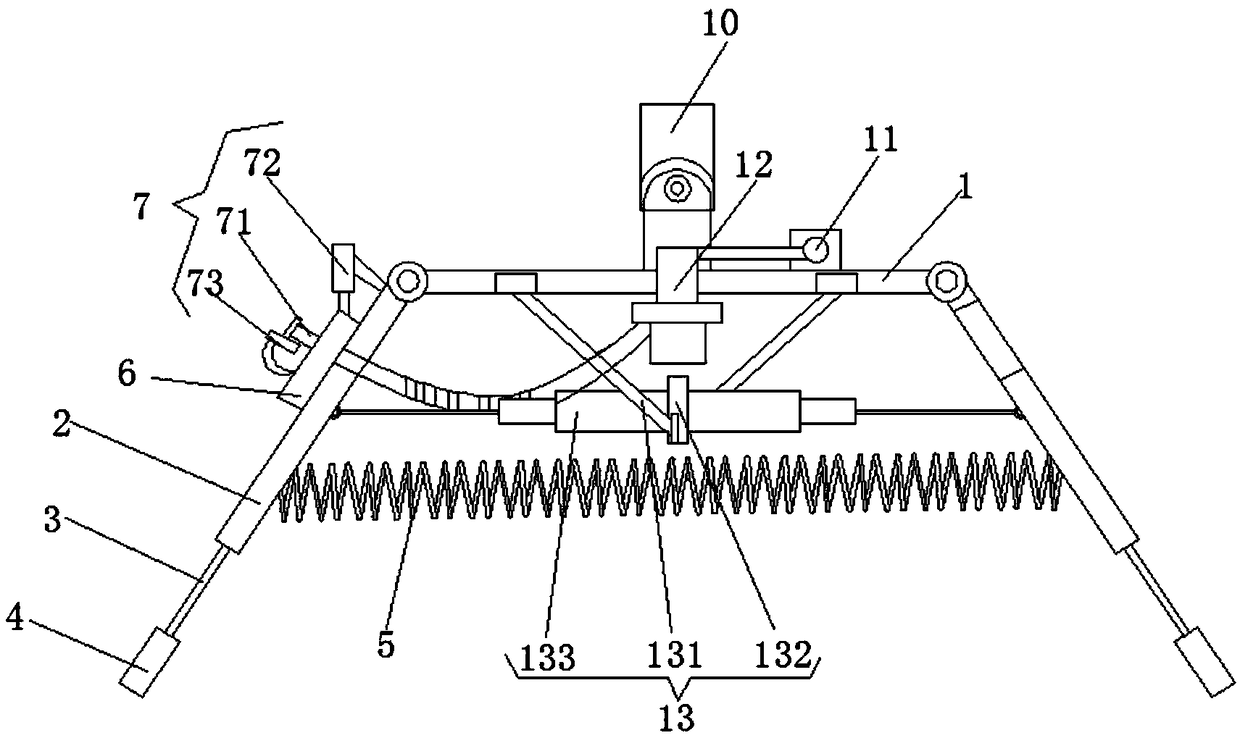

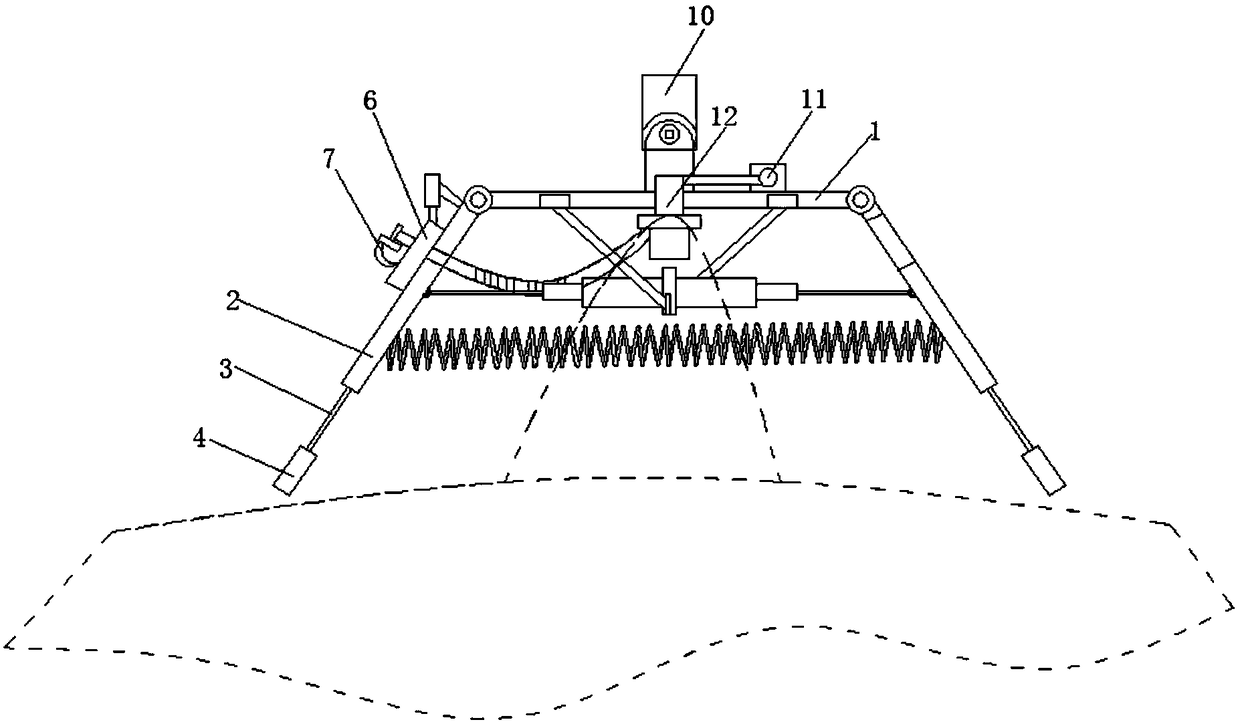

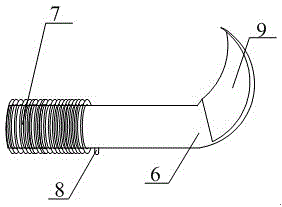

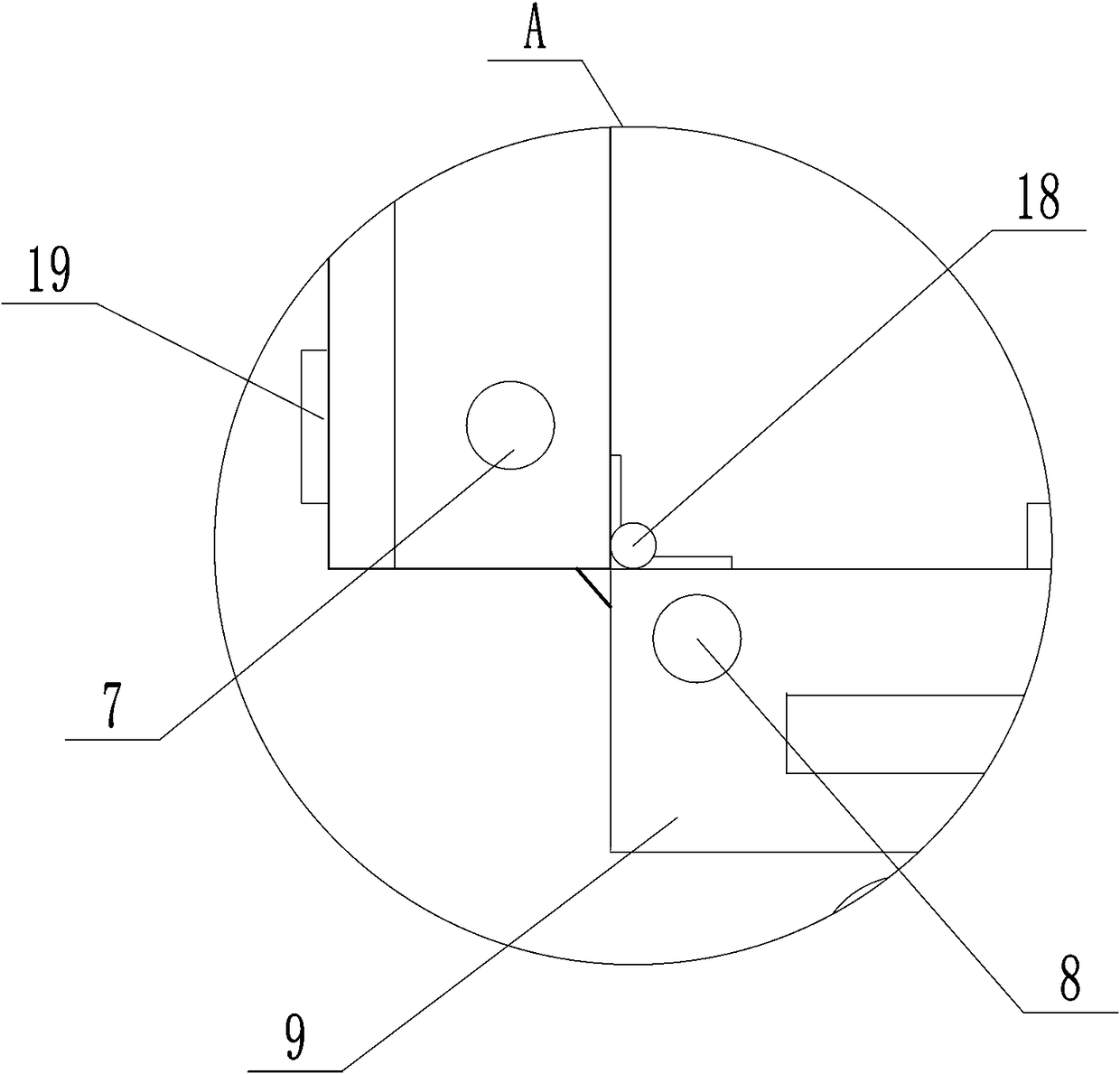

Mechanical arm suitable for automatically hooking ocean buoy

InactiveCN106041949AThe buoy is firmly clampedReduce riskProgramme-controlled manipulatorManipulatorEngineering

The invention discloses a mechanical arm suitable for automatically hooking an ocean buoy. The mechanical arm suitable for automatically hooking the ocean buoy comprises a guide rail device, wherein the two ends of the guide rail device are each hinged with a first positioning plate through a hinge, a first clamping groove used for tightly clamping the ocean buoy is formed between the two first positioning plates, the end, away from a rotation shaft, of each first positioning plate is fixedly connected with a second positioning plate through a telescoping mechanism, the opposite faces of the two first positioning plates are fixedly connected through a spring, a fixing base is further formed on the side face, away from the spring, of one first positioning plate, a hooking mechanism is further fixedly installed on the part, on one side of the fixing base, of the first positioning plate with the fixing base, an installation hole is formed in the top of the guide rail device, the top of the guide rail device is provided with two T-shaped guide rails, and the two T-shaped guide rails are arranged on the front side and rear side of the installation hole respectively. With the mechanical arm suitable for automatically hooking the ocean buoy, the risk in the work of recovering ocean buoys is reduced, and the uncertainty of the position of a dynamic buoy is eliminated so that a lifting hook can accurately hook a lug ring; and due to the fact that the positioning plates are designed to be telescoping, the mechanical arm is applicable to buoys with different sizes.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

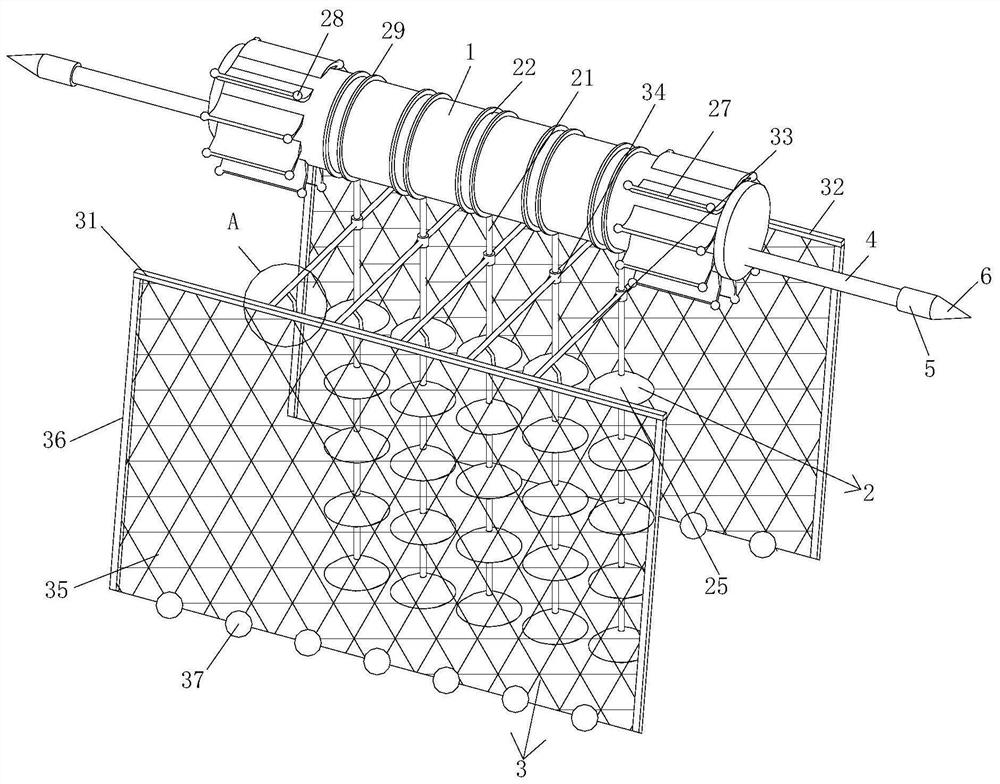

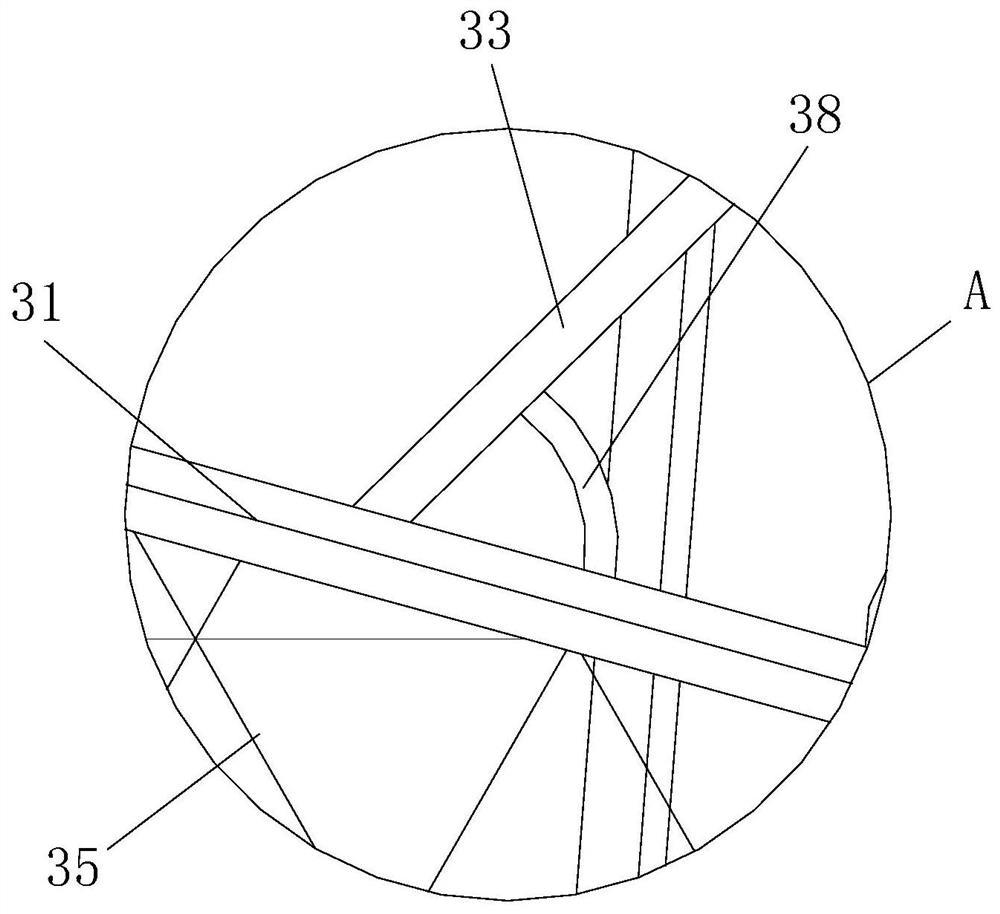

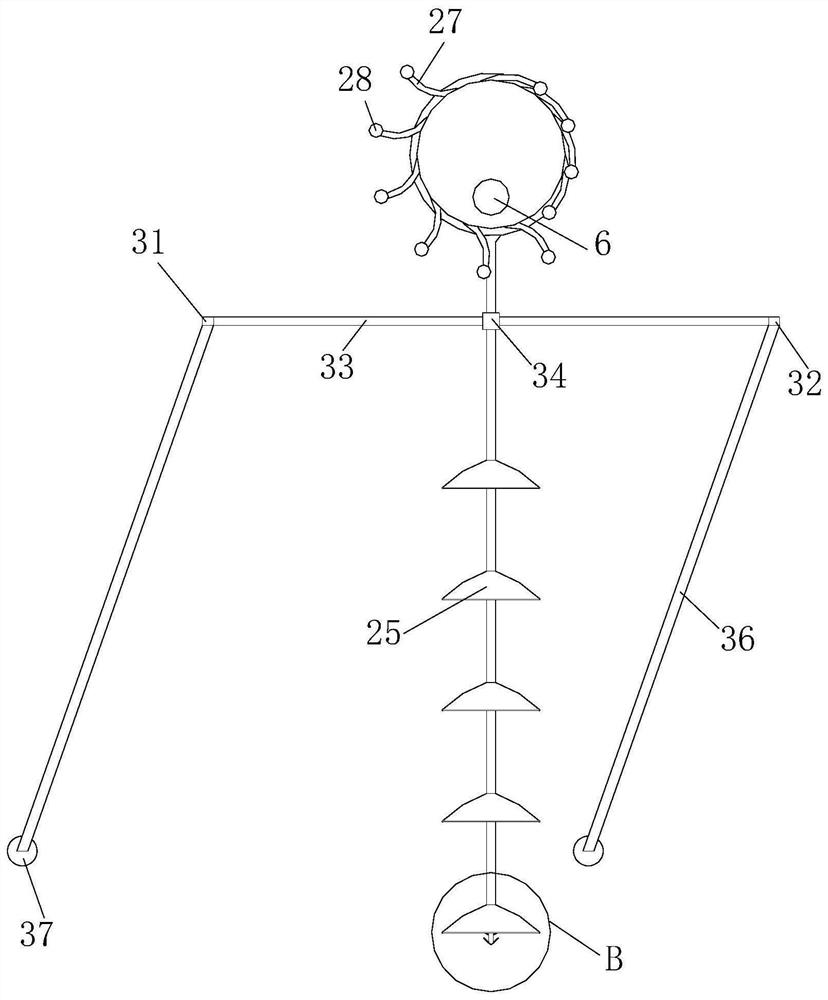

River environment ecological protection device

PendingCN113373886AAvoid going straight throughAvoid crossingWater cleaningRiver routingEnvironmental engineering

The invention provides a river environment ecological protection device. The river environment ecological protection device comprises a rotary floating pipe used for supporting equipment, a flapping cleaning mechanism used for cleaning the water bottom and a movable intercepting mechanism used for intercepting plastic bag garbage in water; the interior of the rotary floating pipe is hollow; the two ends of the rotary floating pipe are fixedly connected with rotary rods; and the rotary rods are located at the positions, deviating from the circle center, of the two ends of the rotary floating pipe. The invention relates to the field of ecological protection. According to the river environment ecological protection device, according to the problem that plastic bag garbage at the water bottom and in water of a river opening of an existing river cleaning device is difficult to clean, a special structure capable of conducting lifting, intercepting rubbing and multiple movable intercepting on the plastic bag garbage at the water bottom and in water at the same time is designed, and therefore the problems that a common river cleaning device cannot efficiently intercept the plastic bag garbage at the river opening, certain space limitation exists in cleaning of the plastic bag garbage at the water bottom, and the two manners cannot be conducted at the same time are effectively solved.

Owner:邓海燕

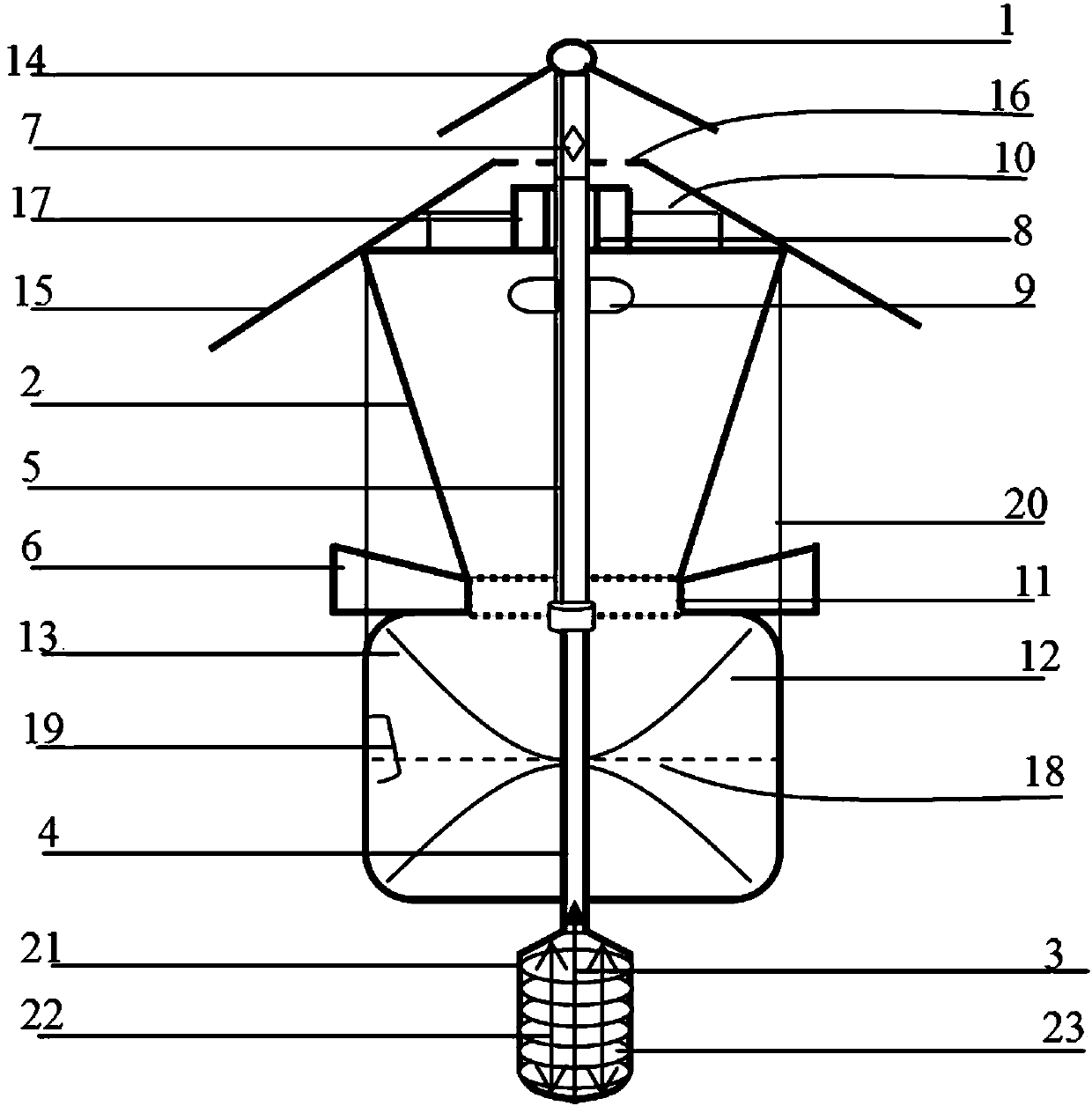

Mosquito eradication lamp box for fishing parks

InactiveCN106508842APrevent leakageEasy to installClimate change adaptationPisciculture and aquariaFishingShrub

Most fishing parks are located in a mountainous area or in the field, in such places, much grass and many shrubs exist, a large number of winged insects, mosquitoes and flies and moth move, fishy-smell bait also attracts the organisms easily, the organisms can easily spread diseases and bring trouble to fishing fans, and the fishing fans cannot enjoy fishing. A mosquito eradication lamp box for the fishing parks comprises a mosquito eradication box and a light source box and is characterized in that a whole mosquito eradication lamp is in an X type, a frame comprises the light source box on the upper portion and the mosquito eradication box on the lower portion, a horizontal shaft hole is formed in the top end of the mosquito eradication box, a rope connected with the two ends of a fish pond is arranged in the shaft hole, a lug hole is formed in the shoulder of the shaft hole, and a control rope is arranged in the lug hole. The mosquito eradication lamp box has the advantages that the structure is simple, use is convenient, the catching and killing efficiency of injurious insects is effectively improved, and the reproduction capacity of the injurious insects is reduced; a water baffle is arranged at the bottom of the mosquito eradication box, so that electric leakage is effectively prevented; the light source box can provide a light source in a night fishing environment.

Owner:中山市弘日电器有限公司

Drainage structure for defrosting and deicing of intelligent refrigerator

InactiveCN109631474ANot easy to dryEasy to tickLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention discloses a drainage structure for defrosting and deicing of an intelligent refrigerator. The drainage structure for defrosting and deicing of the intelligent refrigerator comprises a refrigerator inner container, arc-shaped notches, a constant base, a movable drainage ditch, a movable bolt and an overturning body, wherein the movable drainage ditch is arranged on one side of the ground of the refrigerator inner container; the constant base is vertically arranged in the middle of the bottom surface of the movable drainage ditch; the constant base is an inverted right-angle triangular prism body; the overturning body is of an irregular inverted I-shaped structure; the overturning body and the constant base are in sliding fit; and the arc-shaped notches are formed in the two side surfaces, in contact with the overturning body, of the constant base, the movable bolt is movably arranged at other end of the overturning body opposite to the constant base, and the overall size of the movable bolt is equal to that of the constant base. Through the cooperation of the arc-shaped notches, the constant base, the movable drainage ditch and the like, when the intelligent refrigerator defrosts or removes ice, the structure can be changed, water is diverted and drained, so that the problem that the ground is wet is solved due to convenient collection, and the daily use of the refrigerator cannot be influenced when defrosting is not performed.

Owner:吴国烘

A manipulator suitable for automatic hooking of buoys at sea

The invention discloses a mechanical arm suitable for automatically hooking an ocean buoy. The mechanical arm suitable for automatically hooking the ocean buoy comprises a guide rail device, wherein the two ends of the guide rail device are each hinged with a first positioning plate through a hinge, a first clamping groove used for tightly clamping the ocean buoy is formed between the two first positioning plates, the end, away from a rotation shaft, of each first positioning plate is fixedly connected with a second positioning plate through a telescoping mechanism, the opposite faces of the two first positioning plates are fixedly connected through a spring, a fixing base is further formed on the side face, away from the spring, of one first positioning plate, a hooking mechanism is further fixedly installed on the part, on one side of the fixing base, of the first positioning plate with the fixing base, an installation hole is formed in the top of the guide rail device, the top of the guide rail device is provided with two T-shaped guide rails, and the two T-shaped guide rails are arranged on the front side and rear side of the installation hole respectively. With the mechanical arm suitable for automatically hooking the ocean buoy, the risk in the work of recovering ocean buoys is reduced, and the uncertainty of the position of a dynamic buoy is eliminated so that a lifting hook can accurately hook a lug ring; and due to the fact that the positioning plates are designed to be telescoping, the mechanical arm is applicable to buoys with different sizes.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Uterine cavity cutter knife and connecting method of uterine cavity cutter knife

InactiveCN102920495BGuaranteed sharpAvoid cross infectionIncision instrumentsObstetrical instrumentsEngineeringOperative time

The invention discloses a uterine cavity cutter knife, which solves problems of complicated structure, difficult operation, large injury, long operation time and expensive cost and the problem that the damage can be caused easily of using hard shears or semi-hard shears in the prior art. The uterine cavity cutter knife mainly consists of an operating rod (1), a handle (2) and a cutter blade (3), wherein the handle (2) is arranged at the first end part of the operating rod (1), and the cutter blade (3) is arranged at and detachably connected to the second end part of the operating rod (1), the included angle between the cutter point of the cutter blade (3) and the operating rod (1) is 45-90 degrees; and the cutter blade (3) is in detachably connected with the operating rod (1) through a card slot or / and threads. On the basis of the structure, the invention also discloses a connecting method of the uterine cavity cutter knife. The uterine cavity cutter knife is simple in structure, low in cost and easy in operation, thereby being suitable for popularization.

Owner:成都锦江西囡诊所有限公司

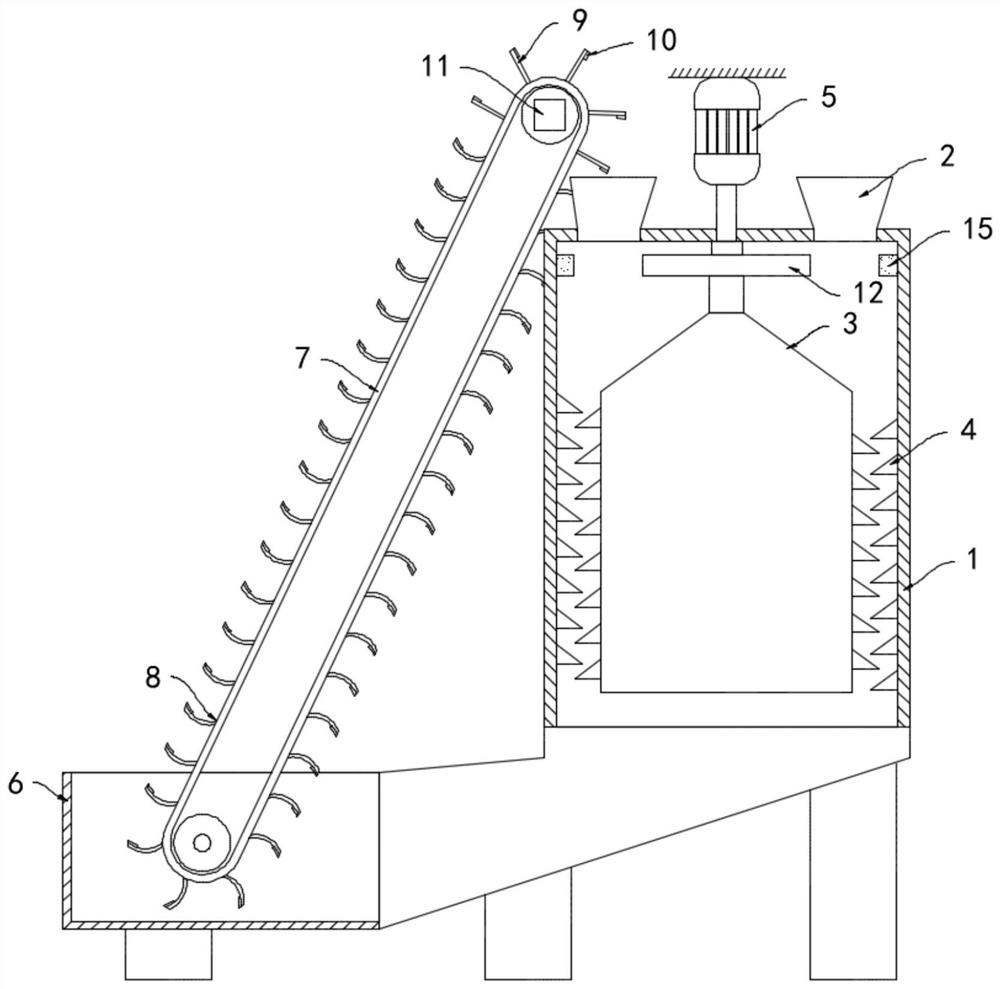

Reinforced concrete waste treatment device

ActiveCN111871494BAchieve separationEasy to tickMagnetic separationGrain treatmentsReinforced concreteArchitectural engineering

The invention relates to the field of building construction, and specifically discloses a reinforced concrete waste treatment device, which includes a crushing box, a coarse pulverizer is arranged in the crushing box, an inclined slideway is fixed at the output end of the coarse pulverizer, and the lowest end of the slideway There is a crushing device at the center, the crushing device includes two crushing rollers arranged in parallel, the crushing rollers are rotatably connected to the inner wall of the crushing box, the two crushing rollers rotate in opposite directions, and there are a number of crushing thorns distributed on the surface of the crushing rollers, and the adjacent crushing rollers The crushing thorns are distributed alternately; the first conveyor belt is fixed below the crushing roller, and the separation roller is arranged above the first conveyor belt. The length of the separation roller is equal to the width and length of the first conveyor belt. The separation roller is connected to the inner wall of the crushing box in rotation. A number of staggered claws are fixed on the upper surface of the separation roller, and the claws are in contact with the first conveyor belt; a second conveyor belt is fixed obliquely below the separation roller; the invention is intended to solve the problem of separation of steel bars and concrete in reinforced concrete waste .

Owner:SHANGHAI NO 4 CONSTR

An automatic ejection hook for electric vehicles

The invention relates to the technical field of automobile hooks, and discloses an automatic ejection hook for electric vehicles, which includes a thermal bimetallic plate. Move right and insert it into the pressure groove, and push the locking lever to move downward under the action of the slope of the inner bottom wall of the pressure groove. The downward movement of the locking lever drives the protrusion to move downward, releasing the locking of the protrusion to the ejection block. At this time, the ejection block will impact to the right under the elastic force of the ejection spring, and then drive the punch rod to impact to the right, ejecting the movable block and the hook, which is convenient for firefighters to hook the hook, and then tow the self-igniting vehicle away. The trailer is more convenient. Not only the safety of the trailer is increased, but also the economic loss is reduced. The invention has the advantages of novel design, simple structure, easy operation and the ability to automatically eject the trailer hook when the vehicle spontaneously ignites.

Owner:周鹏

Garbage pick-up device with LED lamps

Owner:泰州市海星环保设备安装有限公司

AGV system for drying furnace in wire drawing workshop

ActiveCN107272670BRealize dockingRealize complex job requirementsDrying solid materialsVehicle position/course/altitude controlIn vehicleIndustrial engineering

Owner:SHENZHEN CIMC TIANDA AIRPORT SUPPORT +1

A self-weight electromagnetic accelerated fire cleaning through fire hook

The invention discloses: a self-weight electromagnetic accelerated fire-fighting cleaning through fire hook, including a projecting cylinder, the middle position of the inner cavity bottom of the projecting cylinder is threadedly connected with a through-hole end cover, and the inner surface of the through-hole end cover is movably connected with a pull bolt , the middle position of the side of the pull bolt close to the projecting cylinder is fixedly connected with a clip, the inner surface of the clip is movably connected with a crossbow shooting mechanism, and the side of the clip away from the pull bolt is fixedly connected with a chain, and the chain One end away from the clip is fixedly connected with a hook rod, and one end of the hook rod away from the chain is fixedly connected with an energy rod, and the side of the energy rod far away from the hook rod is movably connected with an acceleration rod, and the inner cavity of the acceleration rod is movably connected with As for the claw mechanism, the end of the inner surface of the acceleration rod away from the energy rod is fixedly connected with an anti-collision protection mechanism. The invention relates to the technical field of fire hooks. Projectile hooking can be carried out at a long distance to avoid close contact between personnel and the fire scene and ensure the safety of personnel themselves.

Owner:湖州凌科智能技术有限公司

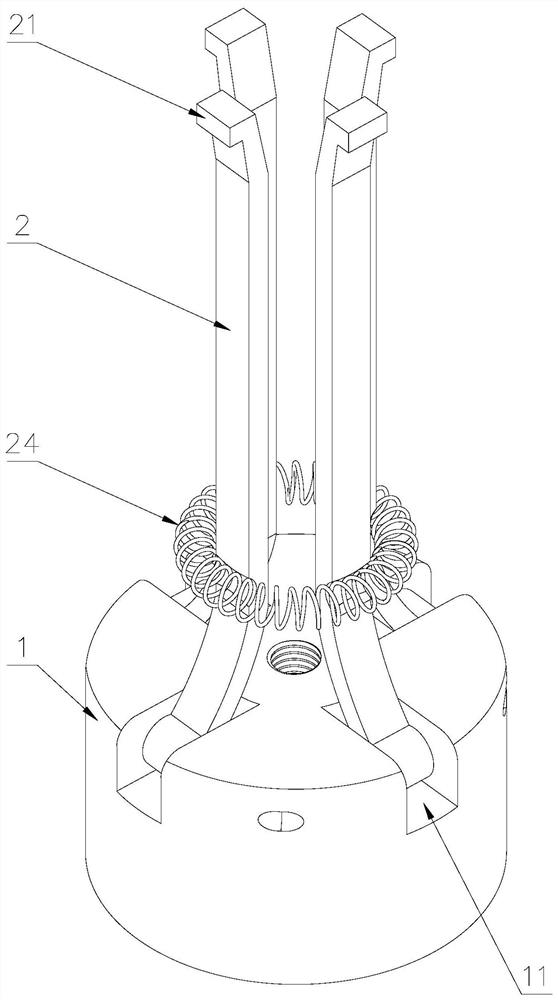

Disassembling mechanism and disassembling method for tuyere small sleeve and disassembling method for disassembling mechanism

The invention discloses a disassembling mechanism for a tuyere small sleeve. The disassembling mechanism comprises a push rod device, a cylinder body, a plurality of hook claws and elastic parts, wherein the cylinder body is arranged at the head part of the push rod device, the hook claws are embedded into the cylinder body and can extend relative to the cylinder body, the elastic parts are connected to the hook claws and the cylinder body, each hook claw is provided with one elastic part, one ends of the hook claws are provided with sharp-corner-shaped barbs which are used for hooking the tuyere small sleeve, when the hook claws extend out of the cylinder body, the barbs of the hook claws hook the tuyere small sleeve, and the cylinder body is hinged to the cylinder body through a hinge. The disassembling mechanism for the tuyere small sleeve is simple and reliable in structure and convenient to use.

Owner:WISDRI ENG & RES INC LTD

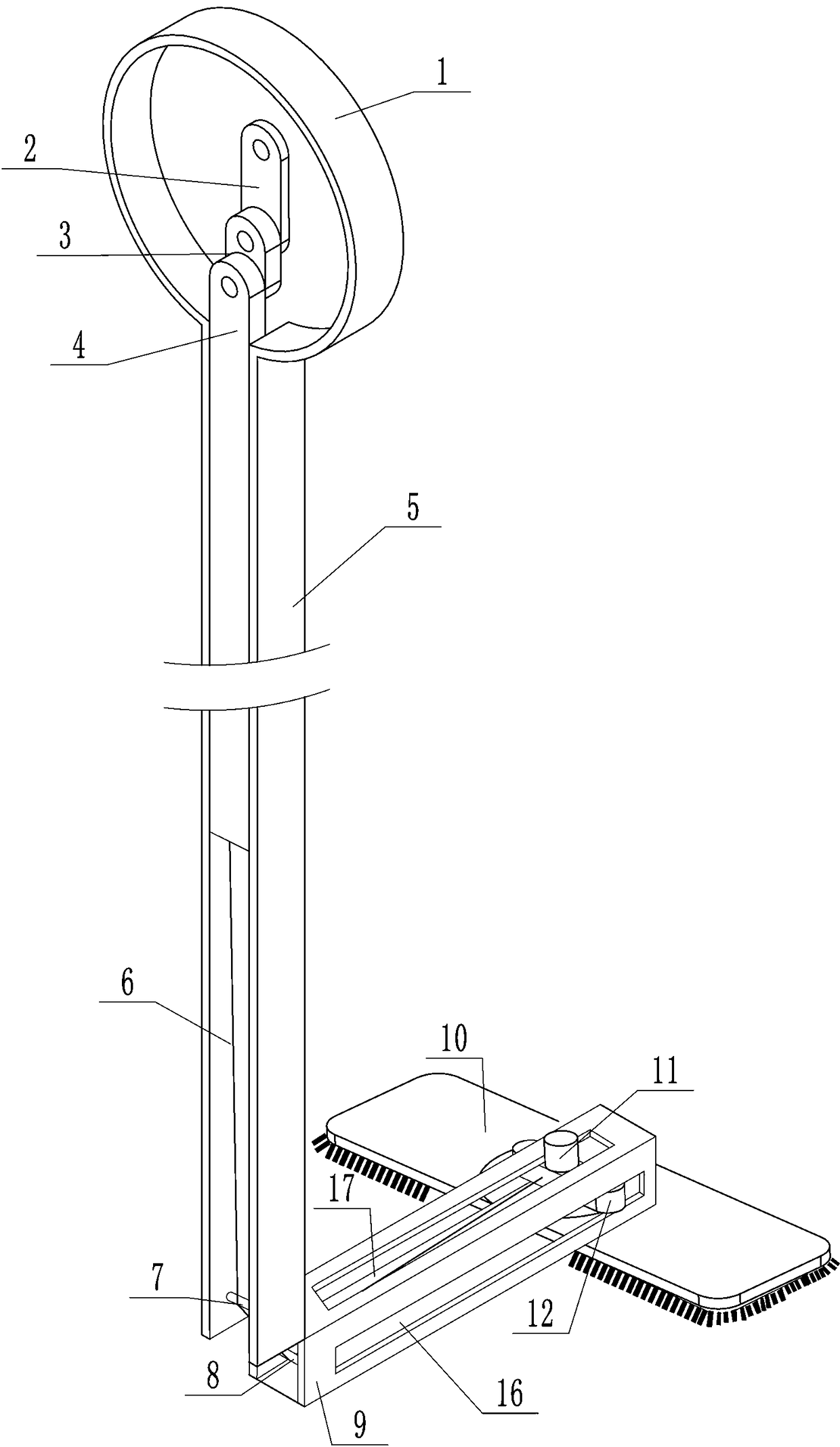

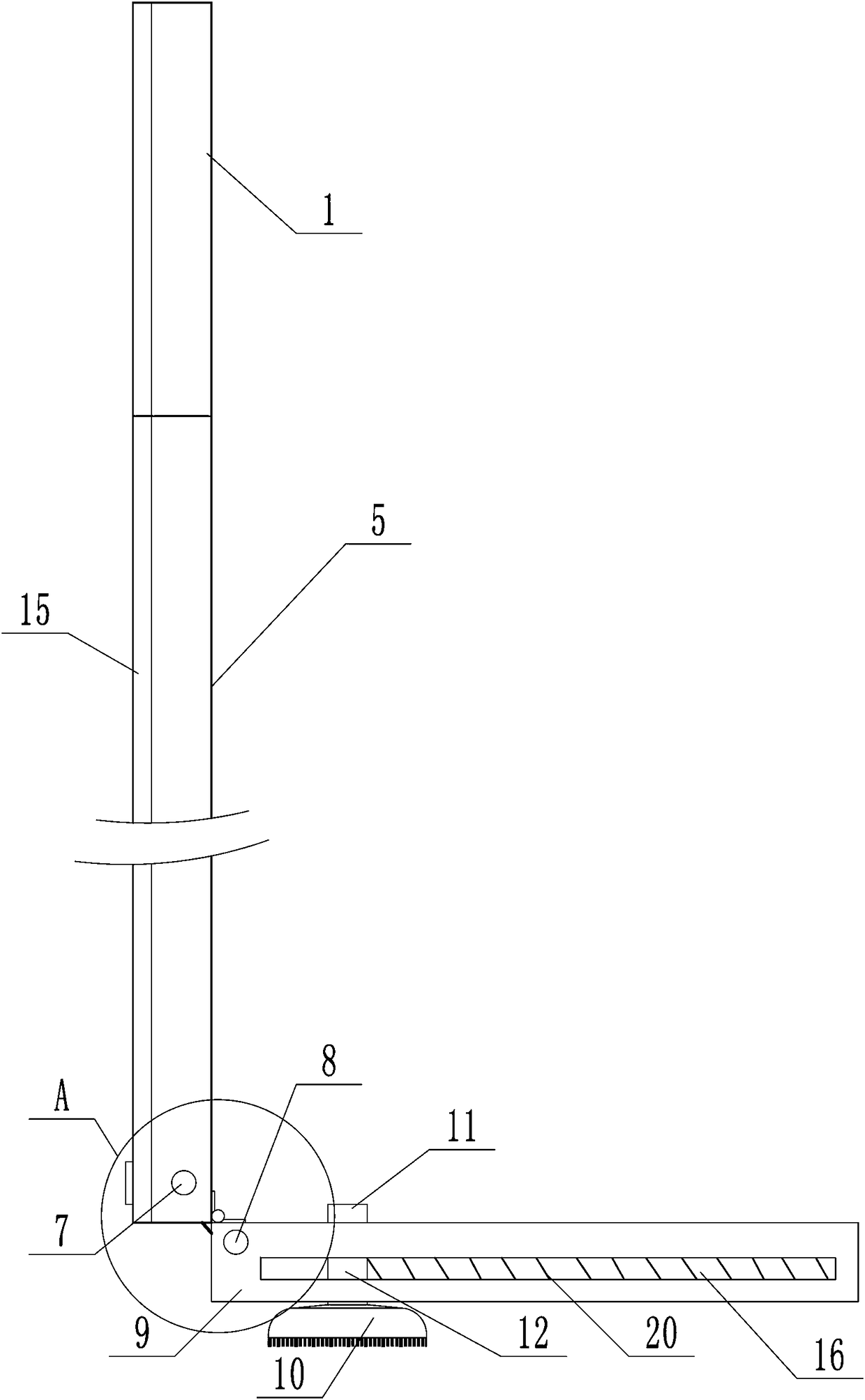

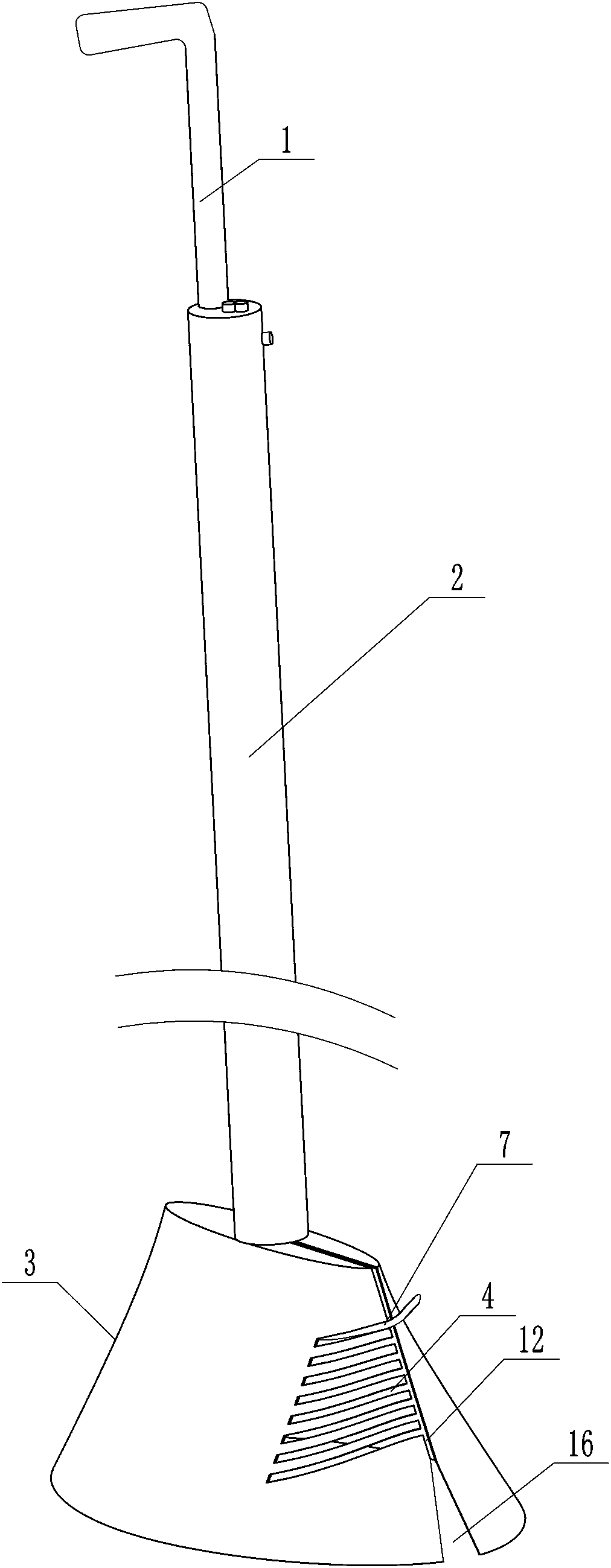

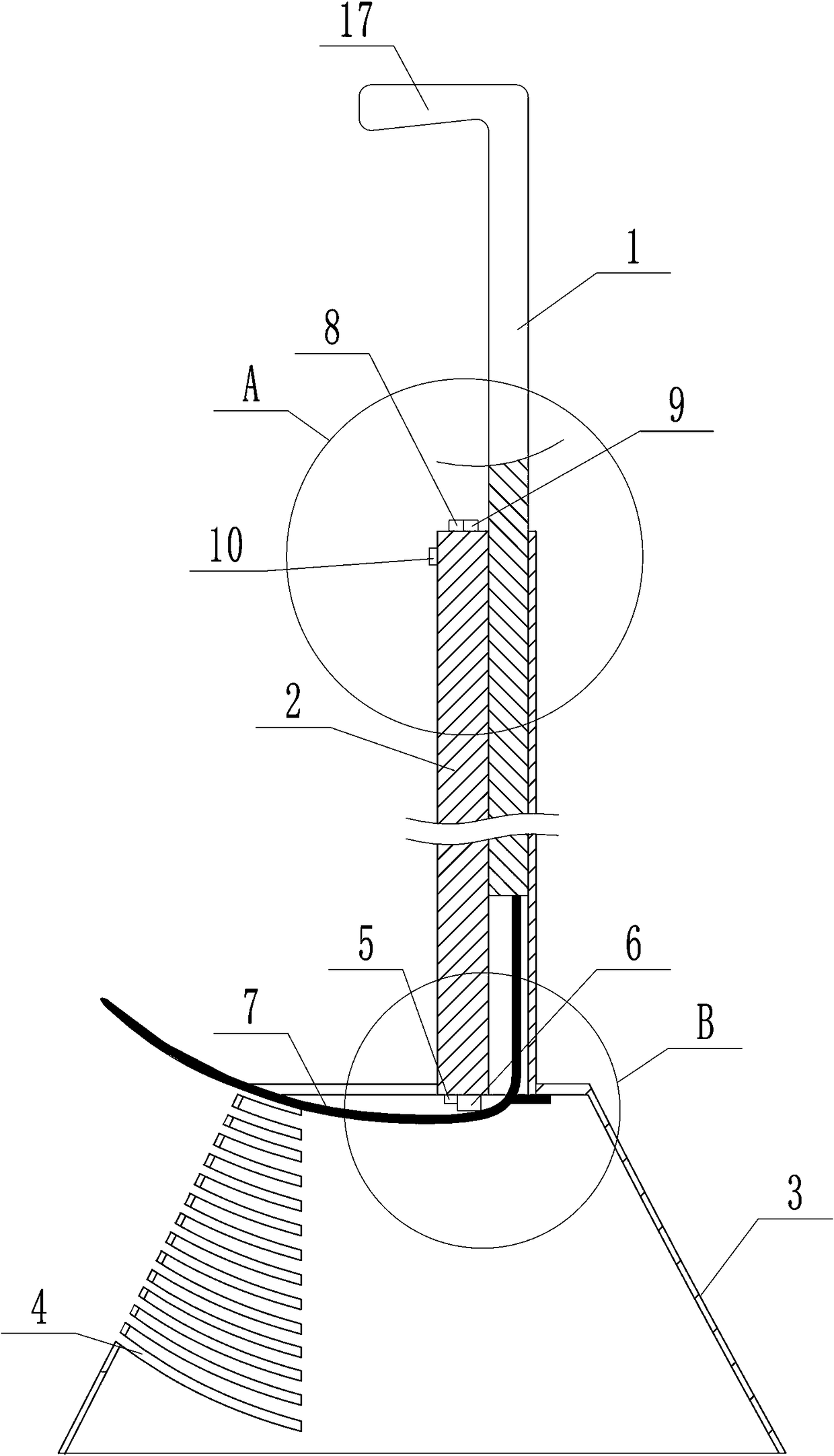

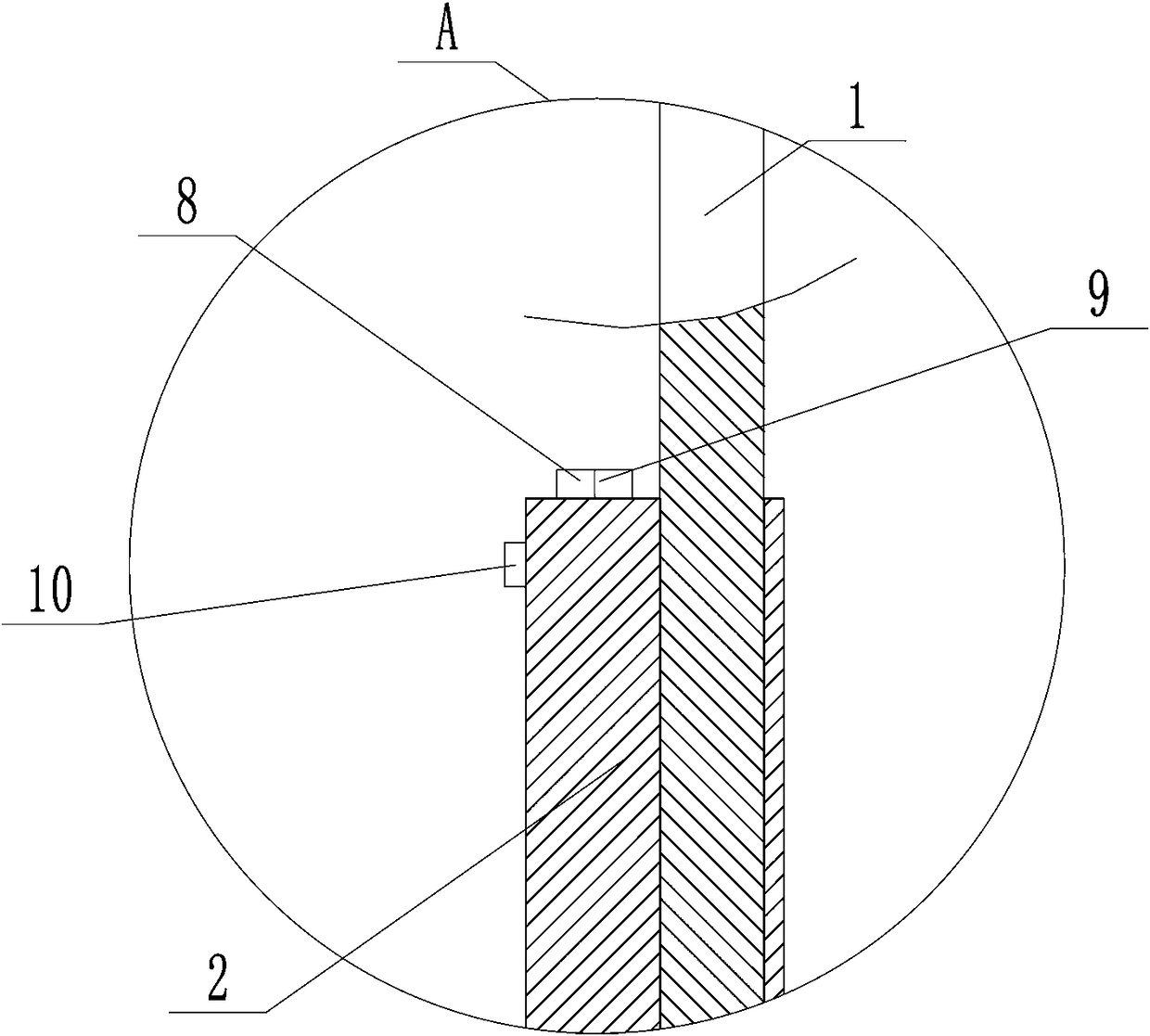

A special mop for library bookshelves

ActiveCN107854053BIncrease the lengthEasy to tickCarpet cleanersFloor cleanersMechanical engineering

The invention relates to a mop special for a library bookshelf. The mop comprises a ground cleaning device which can rotate around the lower portion of a mop bar device, and a driving device arrangedon the mop bar device. The mop bar device comprises a map bar top cavity and a mop bar body connected with the mop bar top cavity; the cleaning device comprises a mop cloth connecting rod and a movable mop cloth arranged on the mop cloth connecting rod, and an elastic reset piece is arranged between the mop cloth connecting rod and the movable mop cloth; the driving device comprises a driving rodpiece arranged on the mop bar top cavity, a connecting rope connecting the driving rod piece with the movable mop cloth and a driver driving the driving rod piece; the driving rod piece comprises a driving rod, a connecting rod connected with the driving rod and a movable rod connected with the connecting rod; the movable rod is clamped into the mop body and can move up and down inside a mop bar body inner cavity.

Owner:临沂高新人才教育发展集团有限公司

A kind of anti-mosquito light box for fishing garden

InactiveCN106508842BEasy to tickOptimize layoutClimate change adaptationPisciculture and aquariaEngineeringFishing

Owner:中山市弘日电器有限公司

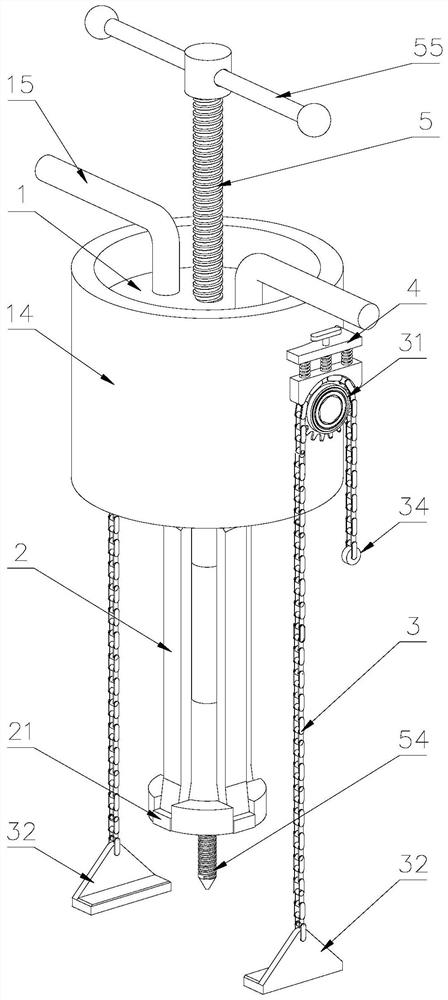

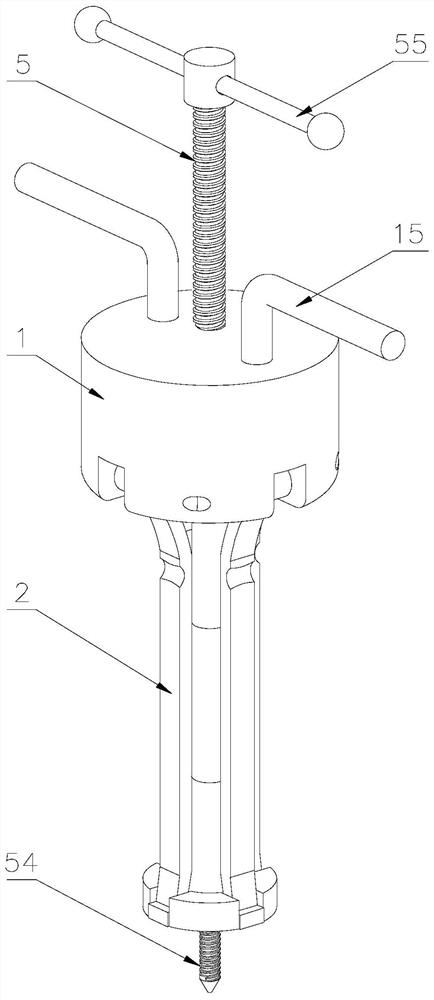

Dismounting device for in-hole bearing

The invention discloses a dismounting device for an in-hole bearing. An inner barrel is in threaded connection with the interior of an outer barrel, a plurality of second handles are arranged on the upper portion of the inner barrel, an ejector rod is in threaded connection with the middle of the inner barrel, a conical head is arranged at the lower end of the ejector rod, and a first handle is arranged at the upper end of the ejector rod; at least two mounting grooves are formed in the lower portion of the inner barrel, clamping arms are movably connected to the mounting grooves, and a firstclamping hook is arranged at one end of each clamping arm; and at least two sets of chain wheels are arranged on the outer barrel, the chain wheels are mounted on the outer wall of the outer barrel through fixed shafts, chains are arranged on the chain wheels, and second clamping hooks are arranged at the lower ends of the chains. When the in-hole bearing is dismounted, the second clamping hooks are clamped on a bearing pedestal or other fixing structures, then the clamping arms are inserted into a bearing inner ring, the first handle is rotated, the first clamping hooks at the lower ends of the clamping arms are opened through the conical head and hook the lower end face of the bearing, then the second handles are rotated, the inner barrel ascends, the clamping arms are driven to move upwards, and therefore the in-hole bearing is dismounted, the dismounting stability of the in-hole bearing is guaranteed, and the bearing is prevented from being damaged.

Owner:冠县恒祥轴承制造有限公司

A trash picker with led lights

Owner:泰州市海星环保设备安装有限公司

Textile mechanism of hosiery knitter

The invention belongs to the technical field of hosiery knitters, and particularly relates to a textile mechanism of a hosiery knitter. The textile mechanism of the hosiery knitter comprises multiple driving mechanisms, wherein the driving mechanisms correspond to one another; each driving mechanism comprises two driving blocks, and the driving blocks correspond to each other; first sliding grooves are formed in the inner walls of the two driving blocks correspondingly, and the first sliding grooves communicate with spaces above the driving blocks correspondingly; and a driving rod is slidably connected to the interior of each first sliding groove through a controller, and the driving rods are used for pushing double-end needles; The textile mechanism of the hosiery knitter provided by the invention is mainly used for solving the problems that in the sock weaving process of an existing hosiery knitter, due to the fact that the weight of yarns is light, the yarns on the double-end needles are prone to being supported, so that the double-end needles cannot hook the yarns easily, and the woven sock is lack of yarns; and meanwhile, when some cotton socks are woven, due to the fact that yarns of the cotton socks are thick and expand, when the double-end needles hook the yarns, hooks on the double-end needles are prone to being hooked into the yarns, so that the quality of the socks is affected due to the fact that the yarns are dispersed.

Owner:诸暨市众创机械设备厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com