Textile mechanism of hosiery knitter

A sock knitting machine and textile technology, which is used in textiles and paper making, knitting, and circular knitting machines with separate action needles for weft knitting, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

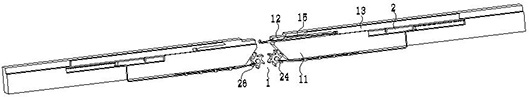

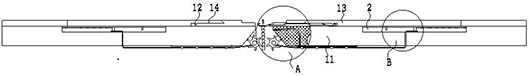

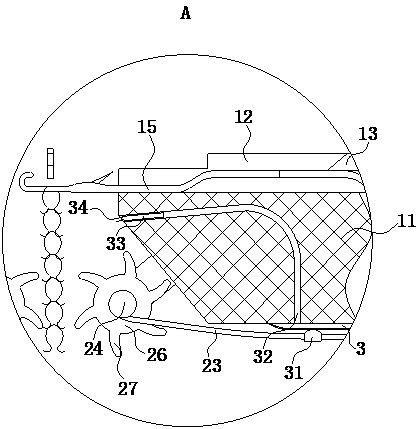

[0031] use Figure 1-Figure 6 The weaving mechanism of a sock knitting machine according to the present invention is described as follows.

[0032] like Figure 1-Figure 6 As shown, a kind of sock knitting machine textile mechanism according to the present invention includes a driving mechanism 1, and the number of driving mechanisms 1 is multiple and corresponding to each other; each of the driving mechanisms 1 includes two driving blocks 11, and the driving blocks 1 11 correspond to each other; the inner walls of the two drive blocks 11 are provided with a first chute 12, and the first chute 12 communicates with the space above the drive block 11; each of the first chute 12 passes through the controller A drive rod 13 is slidably connected, and the drive rod 13 is used to push the double-ended needle 15; the inner wall of the drive rod 13 near the first chute 12 is provided with a drive groove 14; the drive groove 14 is below the first slide A double-ended needle 15 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com