Machine for cutting a planar workpiece and method for pressing out a workpiece part that has been cut free

A technology for processing plates and workpieces, which is applied in the field of machinery and can solve problems such as oblique jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

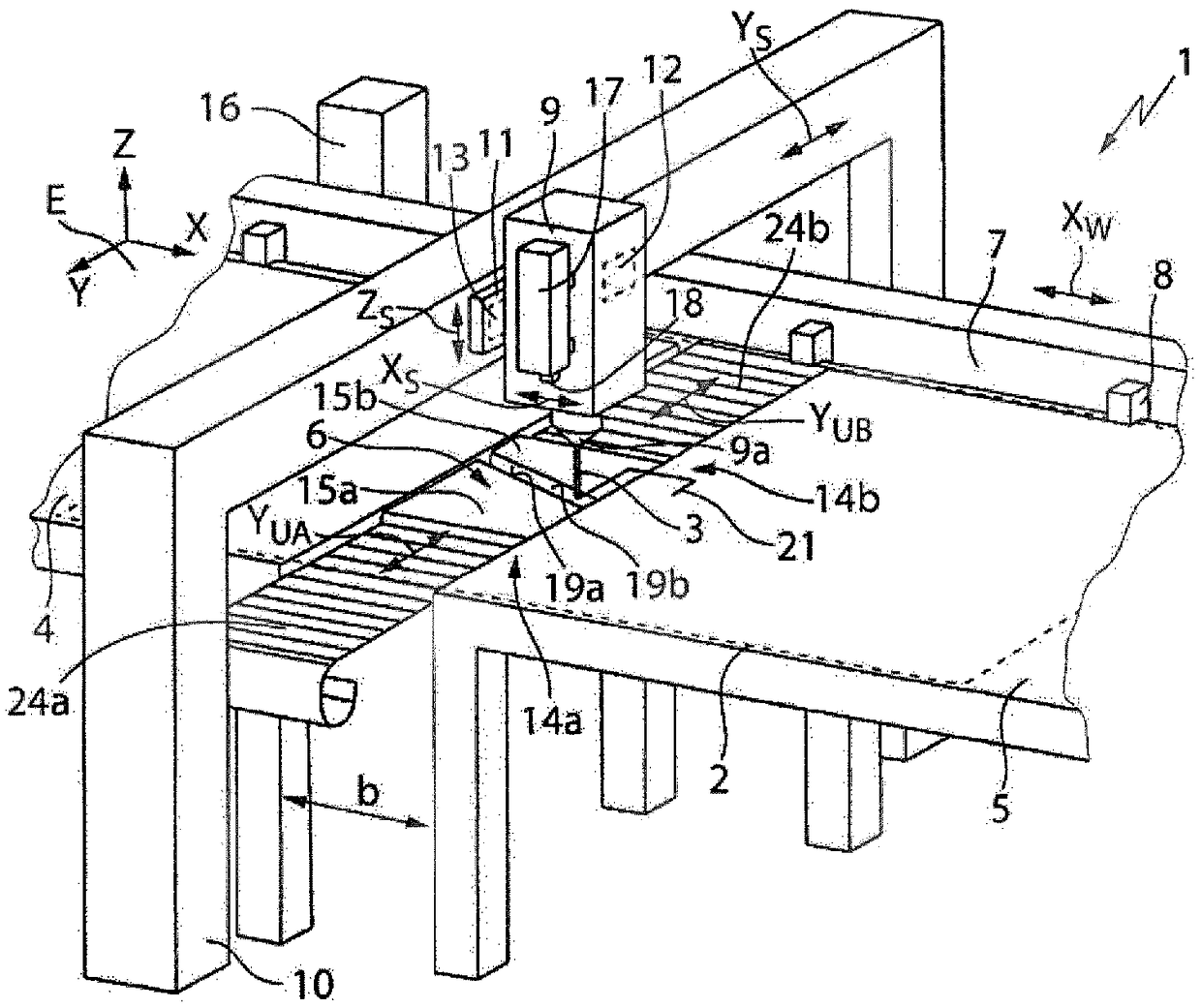

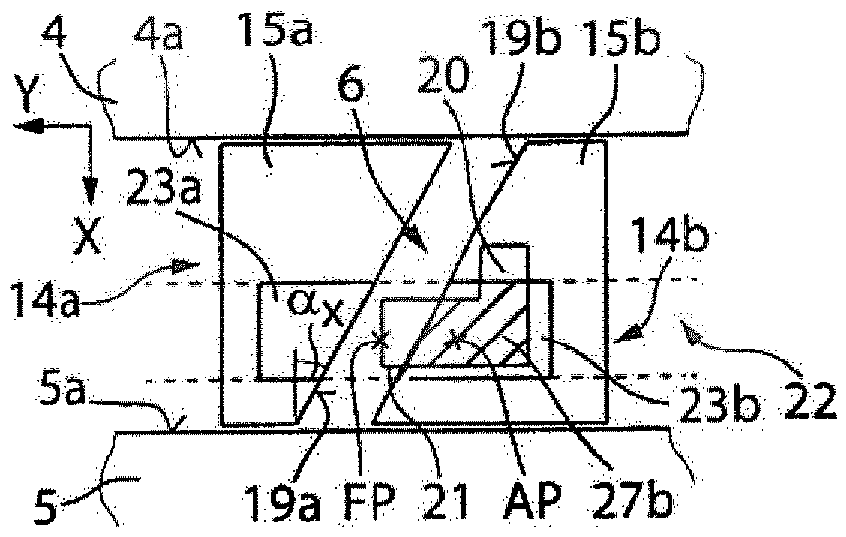

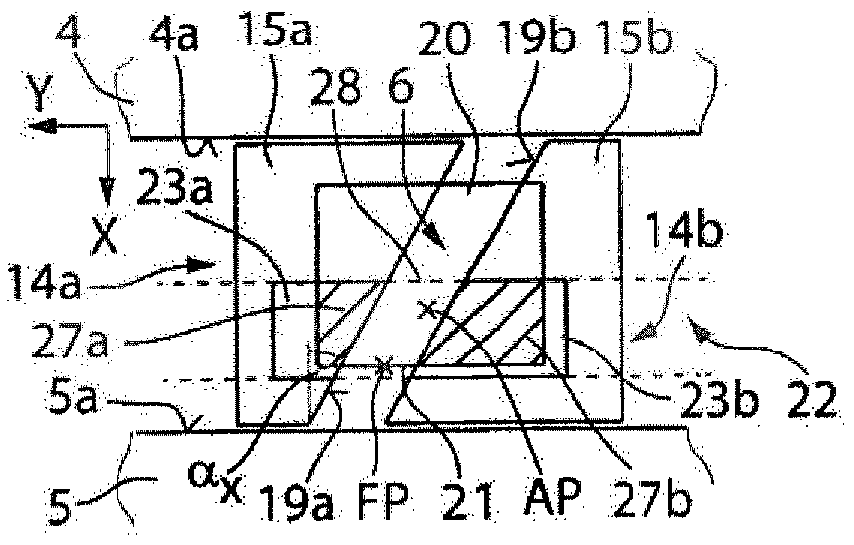

[0054] figure 1 An exemplary structure of a machine 1 for laser processing, more precisely laser cutting, of a plate-shaped workpiece 2 by means of a processing beam in the form of a laser beam 3 is shown. Instead of the laser beam 3 , other types of thermal processing beams, such as plasma torches or water jets, can also be used for cutting the workpiece 2 . Alternatively, the machine 1 can also be designed for the mechanical separation of workpieces 2 , for example as a punching machine or a punching-laser combination machine.

[0055] The workpiece 2 rests during processing on two fixed workpiece mounting surfaces 4, 5 which, in the example shown, form the upper sides of the two workpiece tables and define a The workpiece bearing plane E (X-Y plane of the XYZ coordinate system). The workpiece support surfaces 4, 5 can be formed by workbenches or by pin-shaped support elements (pins), support belts, brushes, rollers, balls, air cushions and the like.

[0056] By means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com