Core spinning device and new-structure core spinning method for full wrapping of macro core

A core-spun yarn and core-spun technology, which is used in yarn, electrospinning, textiles and papermaking, etc., can solve the problems of unstable structure, uneven core-spun, unimproved ring-spun core-spun yarn exposed core problem, etc. To achieve the effect of reducing flying flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific embodiments.

[0050] Here, it should also be noted that, in order to avoid obscuring the present invention due to unnecessary details, only the structures and / or processing steps closely related to the solutions of the present invention are shown in the specific embodiments, and the related Other details are not relevant to the invention.

[0051] Additionally, it should be noted that the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article or apparatus comprising a set of elements includes not only those elements, but also Other elements not expressly listed, or inherent to the process, method, article, or apparatus are also included.

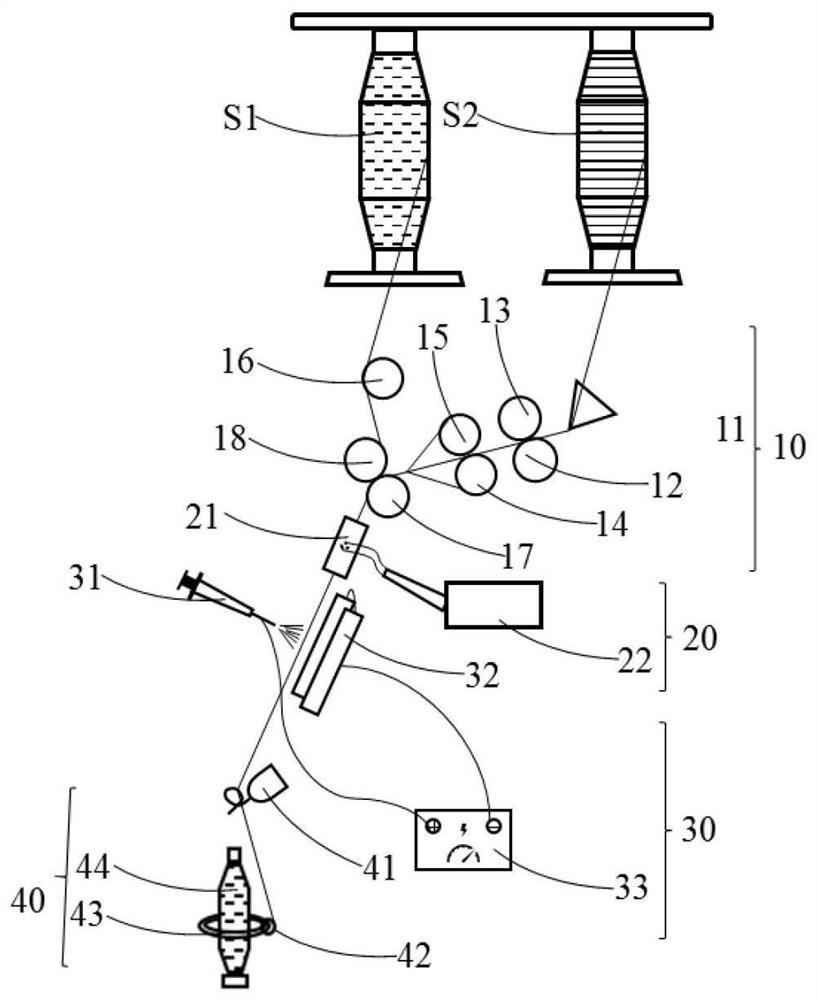

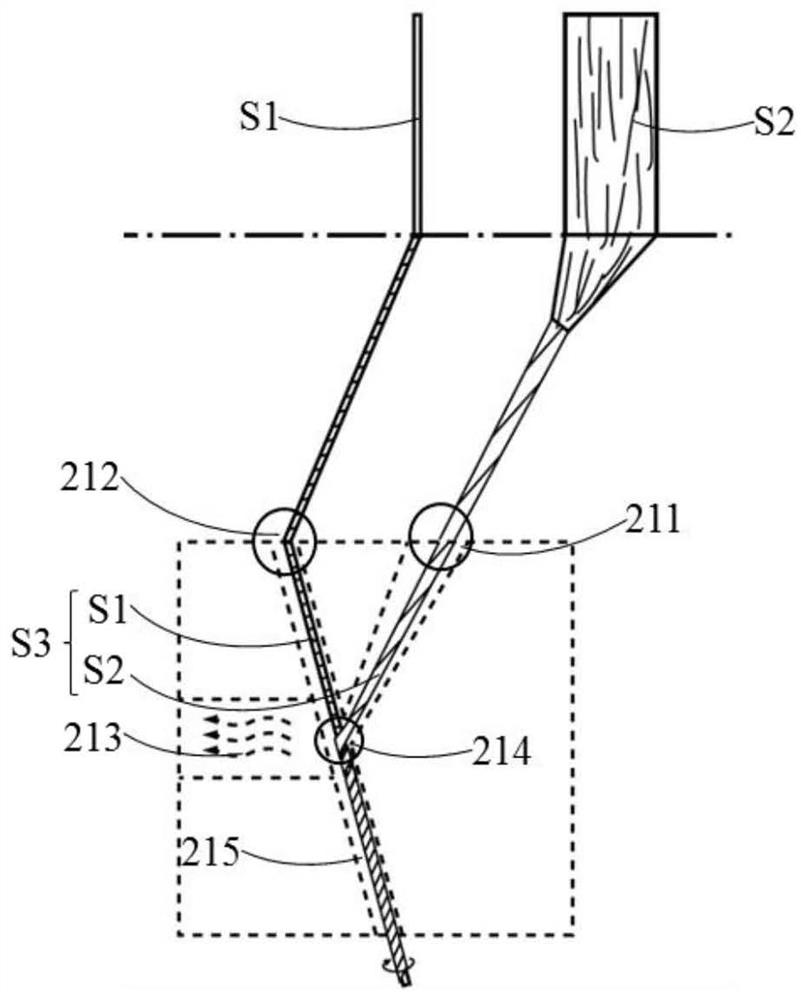

[0052] see Figures 1 to 7 As shown, in the core spinning dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com