Chip flame storage box

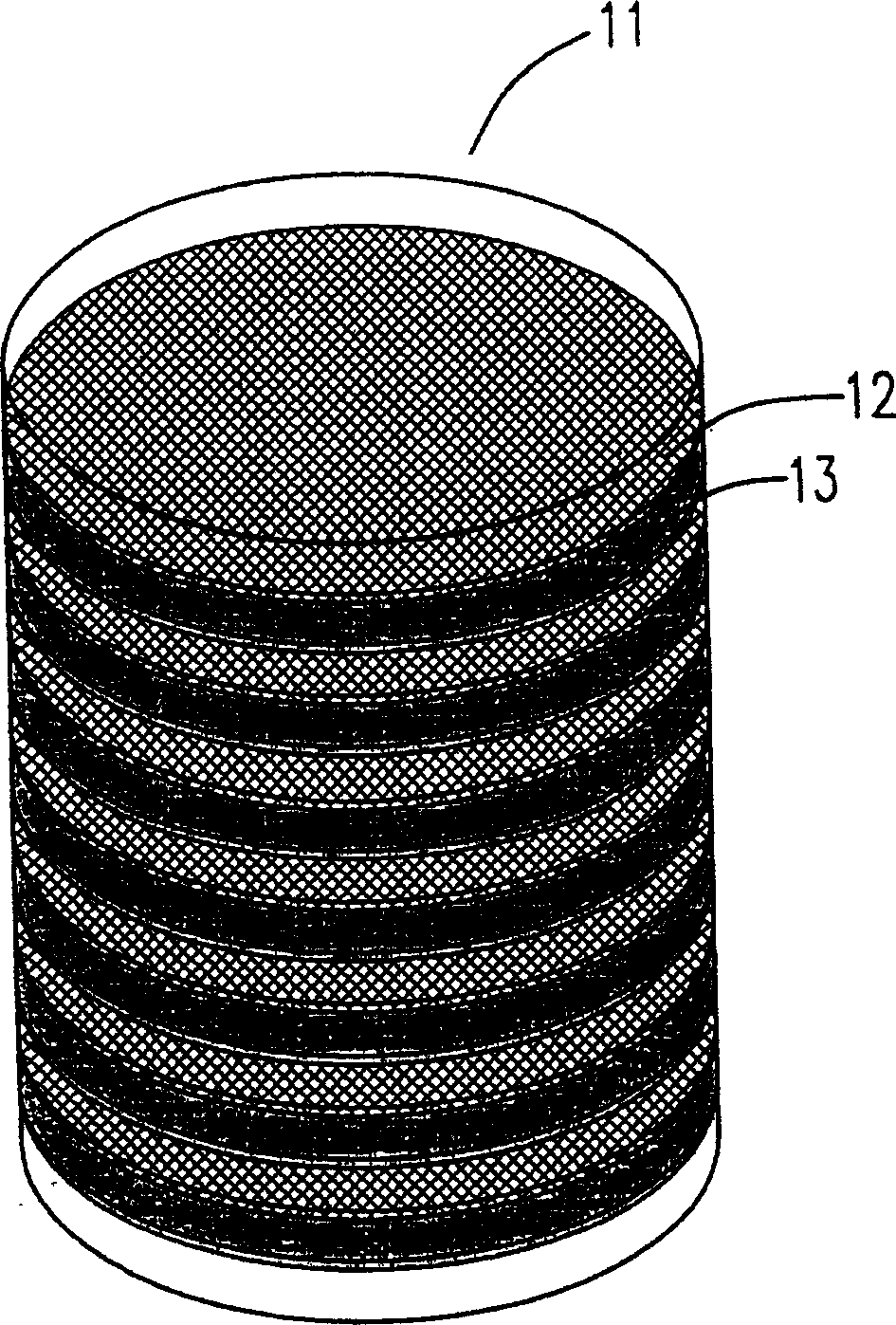

A technology for storing boxes and wafers, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., and can solve the problems of increasing manufacturing costs, affecting the quality of wafers 12, wasting wafers 12, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

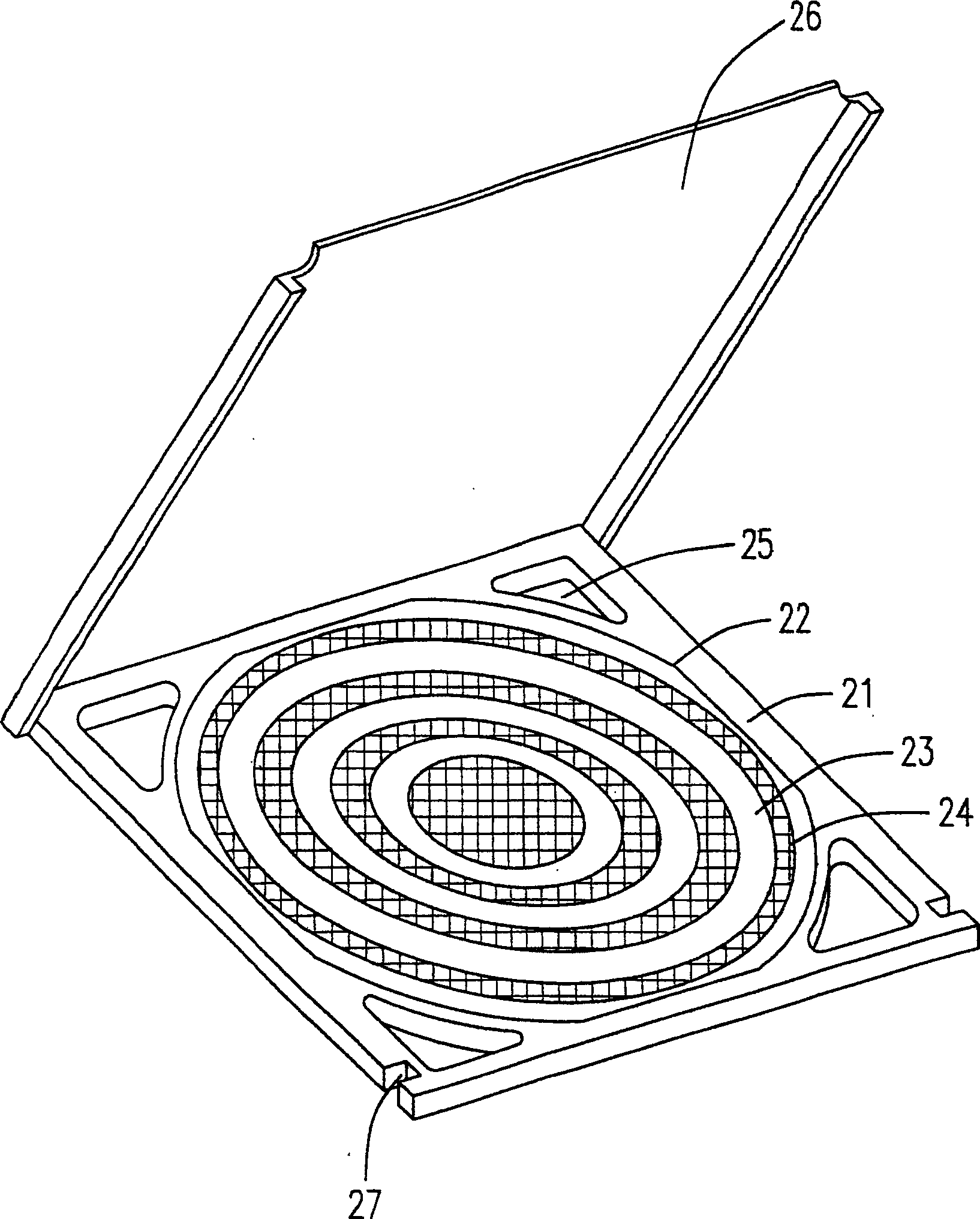

[0035] Please refer to FIG. 2( a ), which is a structural diagram of a Frame Storage Box (FSB) according to a preferred embodiment of the present invention. The wafer frame storage box includes a body 21 and a cover 26 , wherein the cover 26 is combined with the body 21 . The main body 21 has an accommodating space 22 , and a plurality of ring-shaped ribs 23 are formed on the bottom surface of the accommodating space 22 for strengthening the strength of the main body 21 . In addition, a plurality of anti-vibration pads 24 are arranged on the bottom surface of the accommodating space 22, and the anti-vibration pads 24 can reduce the external impact force received by the wafer during the process of transferring the wafer, thus effectively reducing the fragmentation rate of the wafer. To save manufacturing cost.

[0036] Four perforations 25 are provided at four corners of the main body 21 to facilitate the user to pick up the wafer frame storage box with fingers and reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com