Can degassing device for canned aquatic product production and implementation method of can degassing device

A degassing device, aquatic product technology, applied in vacuum/special atmosphere packaging, packaging objects under special gas conditions, packaging, etc., can solve the problems of no specific structure, inconvenient removal of the tank body, etc., to achieve convenient up and down Canned food, simple structure, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

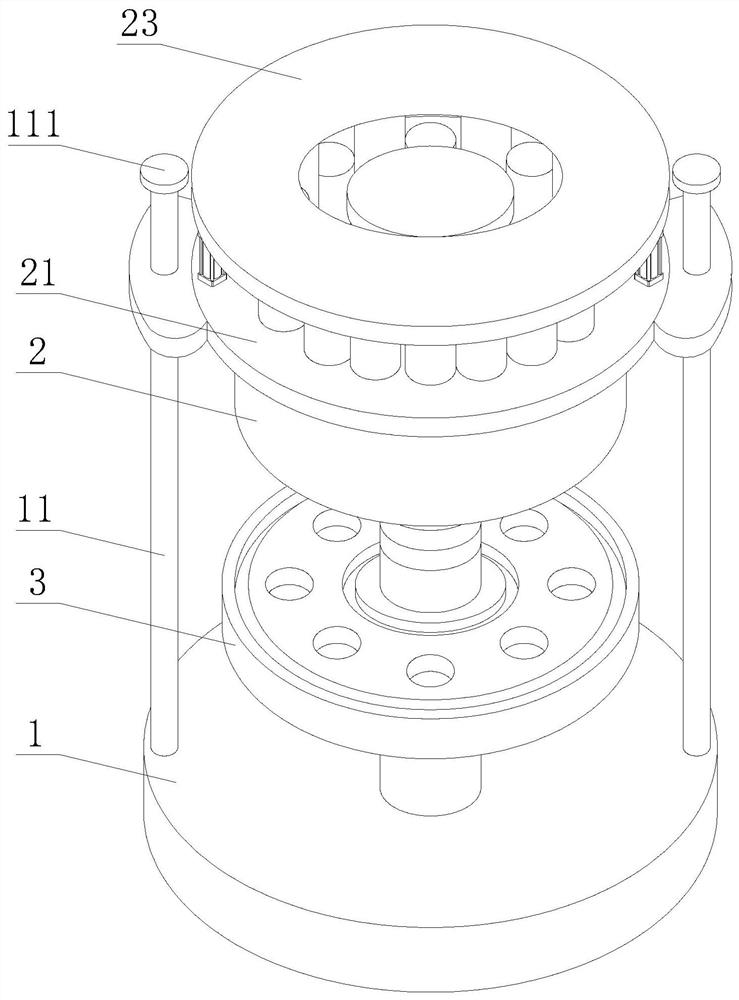

[0037] In order to better demonstrate the implementation process of the tank body degassing device for the production of canned aquatic products, this embodiment now proposes an implementation method of the tank body degassing device for the production of canned aquatic products, including the following steps:

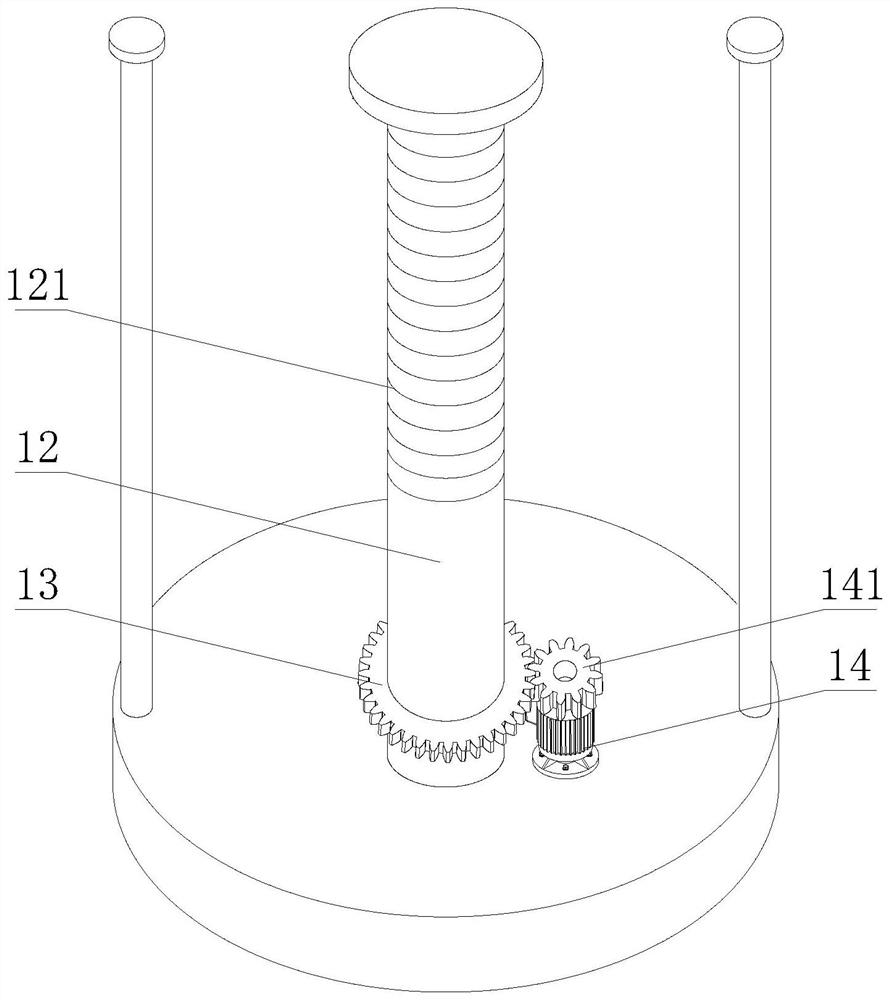

[0038] Step 1: The driving motor 14 drives the rotating column 12 to rotate, and under the joint action of the guide rod 11 and the stop ear 211, the vacuum cylinder 2 moves up to the upper end of the guide rod 11, and the distance between the vacuum cylinder 2 and the operating table 3 is opened to facilitate Put canned aquatic products into the operation platform 3;

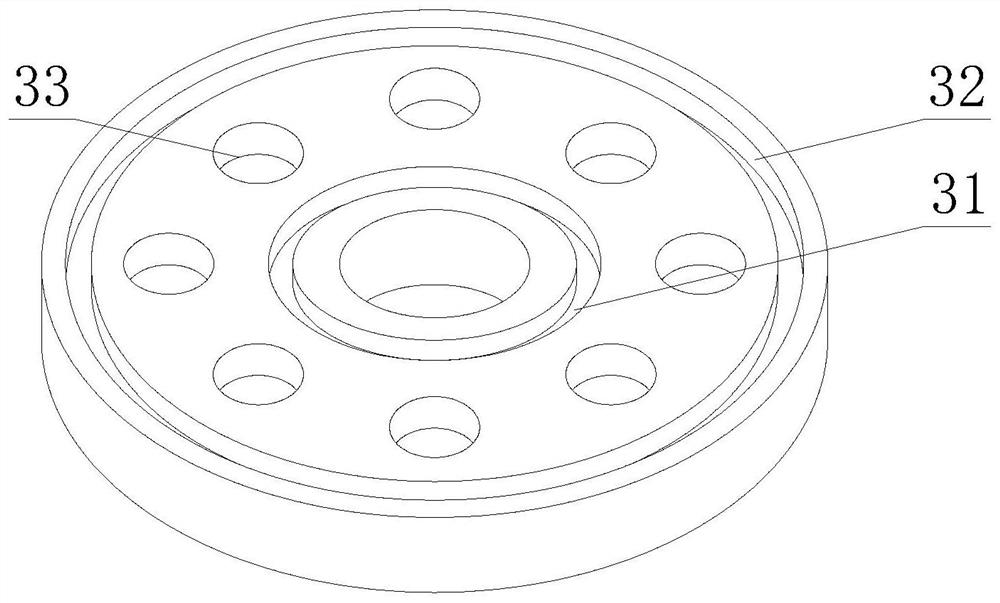

[0039] Step 2: Drive the motor 14 to rotate in the opposite direction, the vacuum cylinder 2 moves down, and the operating platform 3 rotates accordingly, and puts the canned aquatic products into the canned food storage tank 33 on the operating platform 3 in sequence. side can realize the operation pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com