Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Easy to set up jobs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

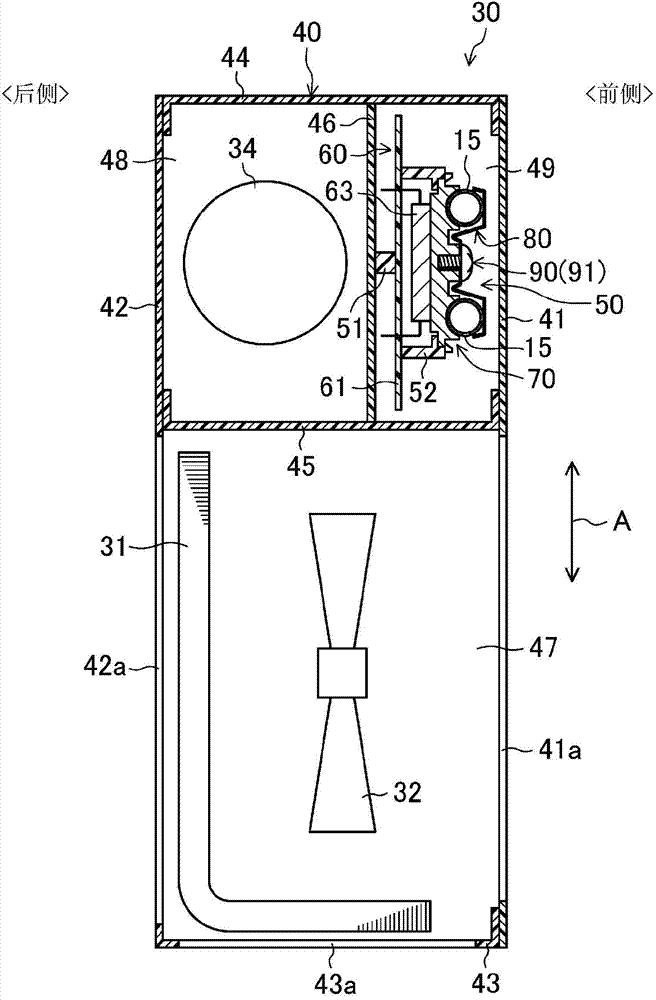

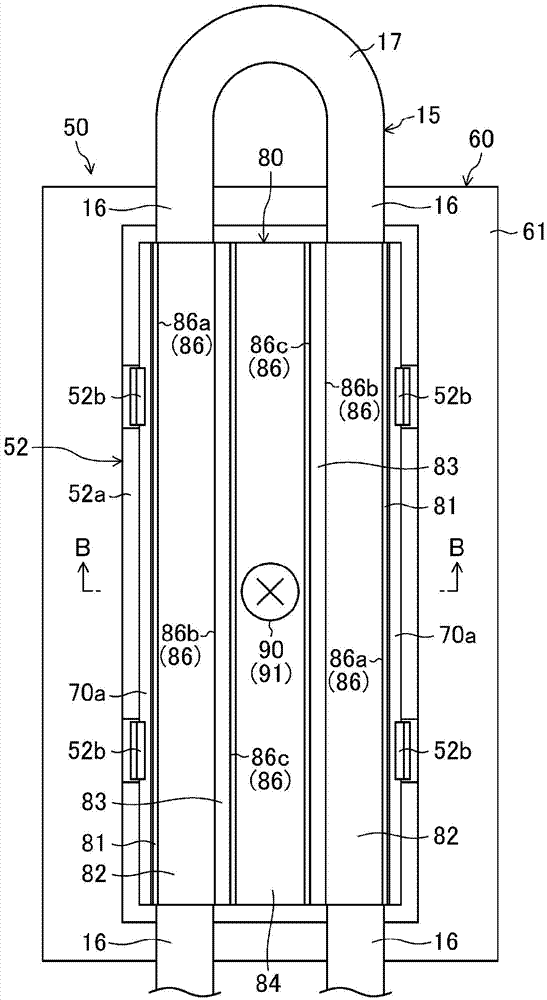

Installation structure for coolant pipe

ActiveCN103688605AIncrease contact areaReduce thermal resistanceCompressorSemiconductor/solid-state device detailsEngineeringRefrigerant

The present invention provides a coolant pipe installation structure which can reliably retain a coolant pipe and which can sufficiently decrease the thermal resistance between a coolant pipe and a heat-transmitting member. A heat-transmitting member (70) having a vertical groove part (72) into which a coolant pipe (15) fits, and which thermally contacts with a component to be cooled (63), is provided. An elastic member (80) formed in a long plate shape which extends in the extension direction of the coolant pipe (15), and having an opposing part (82) opposite the coolant pipe (15), is provided. A pushing structure (90) which pushes the elastic member (80) to the heat-transfer member (70) side is provided.

Owner:DAIKIN IND LTD

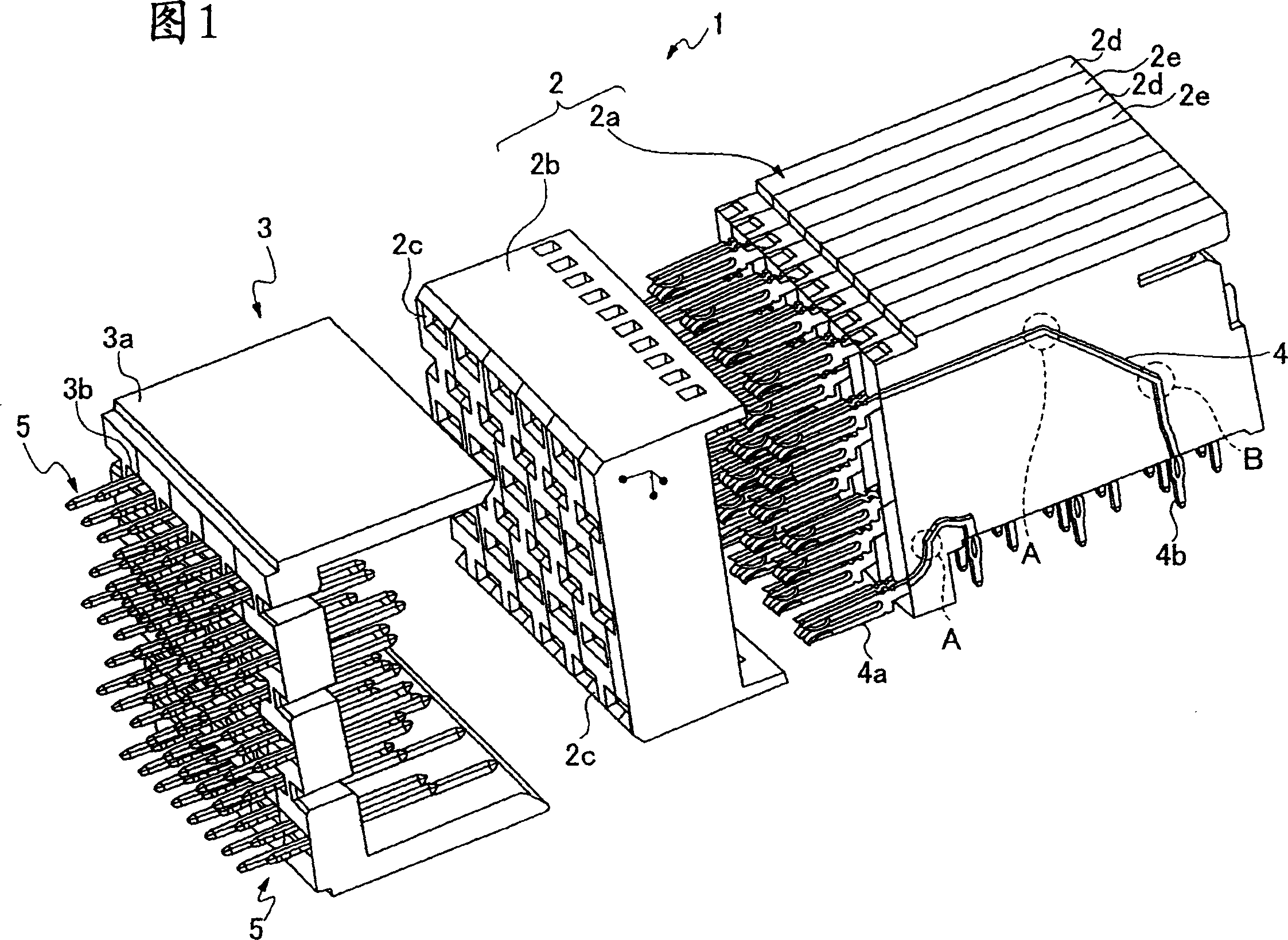

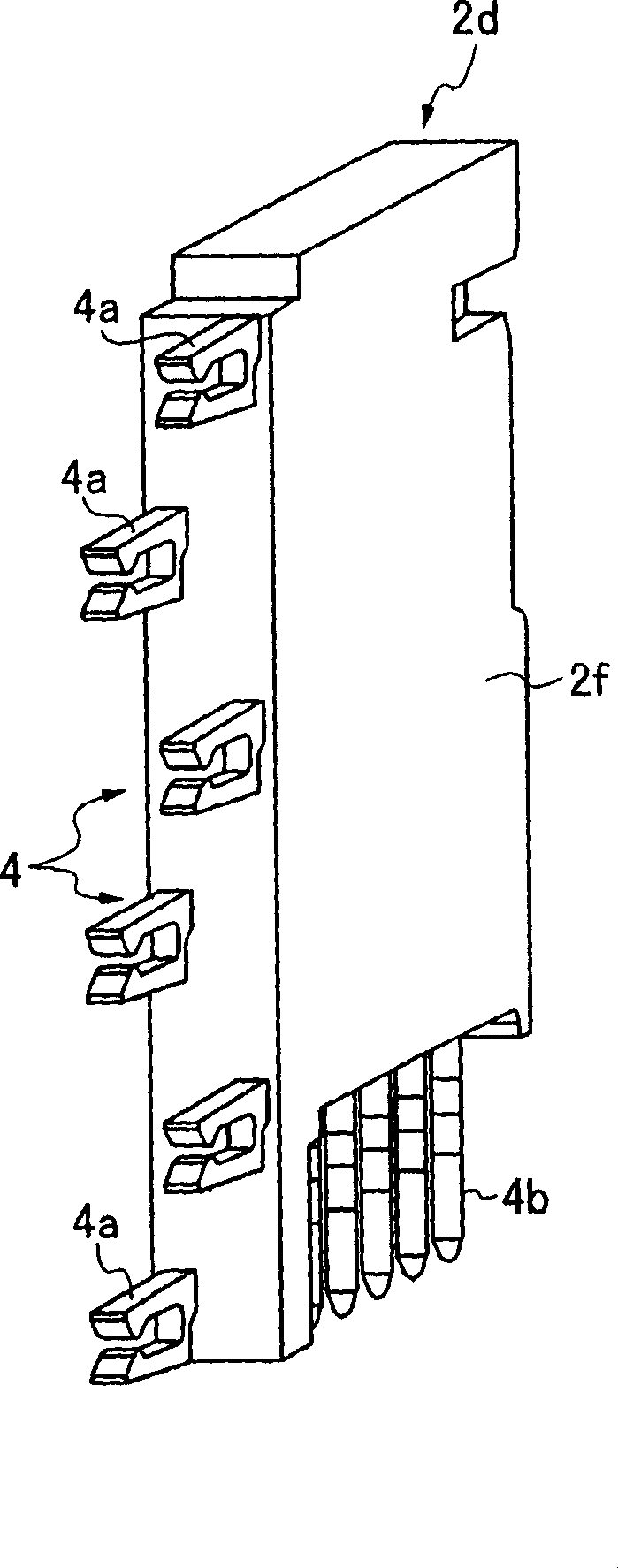

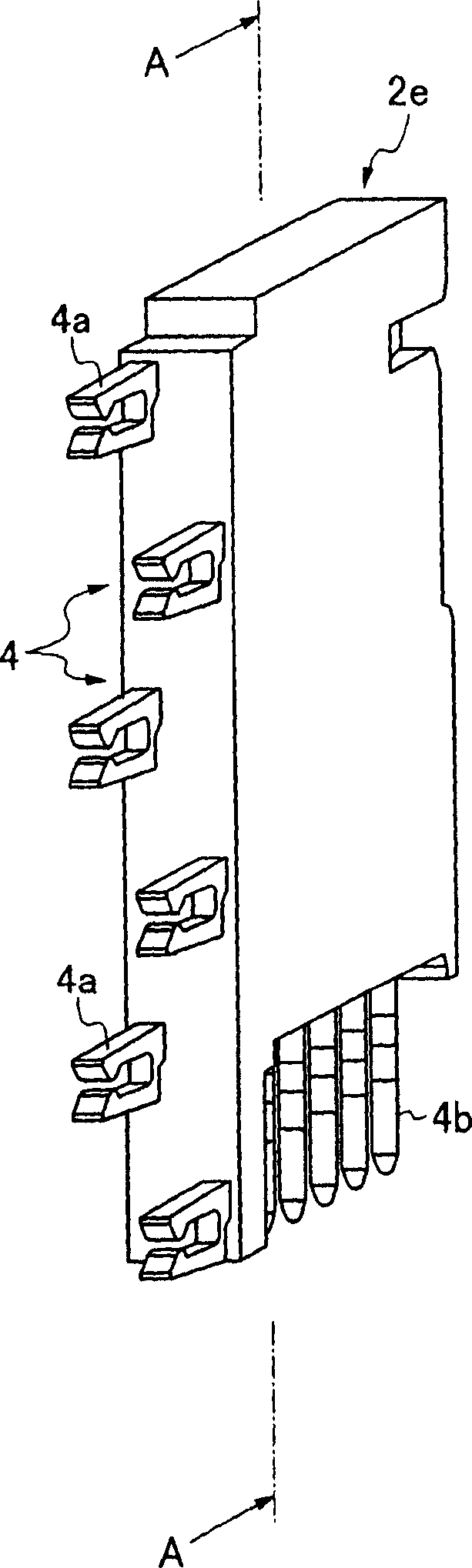

Electric connector

InactiveCN1771635AReduce intervalSpaced parallelCoupling protective earth/shielding arrangementsElectricityDifferential transmission

An electric connector for differential transmission principally transmitting a high-frequency electric signal where a ratio between the interval (a) between both signal terminals constituting a pair terminal being buried in a female contact housing and the interval (b) between the pair terminals is set ab. Since the both signal terminals are molded integrally while being buried separately in modular housings obtained by dividing the female contact housing along a vertical direction to match 1 / 2 of the interval (a) between both signal terminals, the interval (a) of both signal terminals can be kept small and in parallel. Consequently, crosstalk can be improved furthermore.

Owner:HONDA TSUSHIN IND

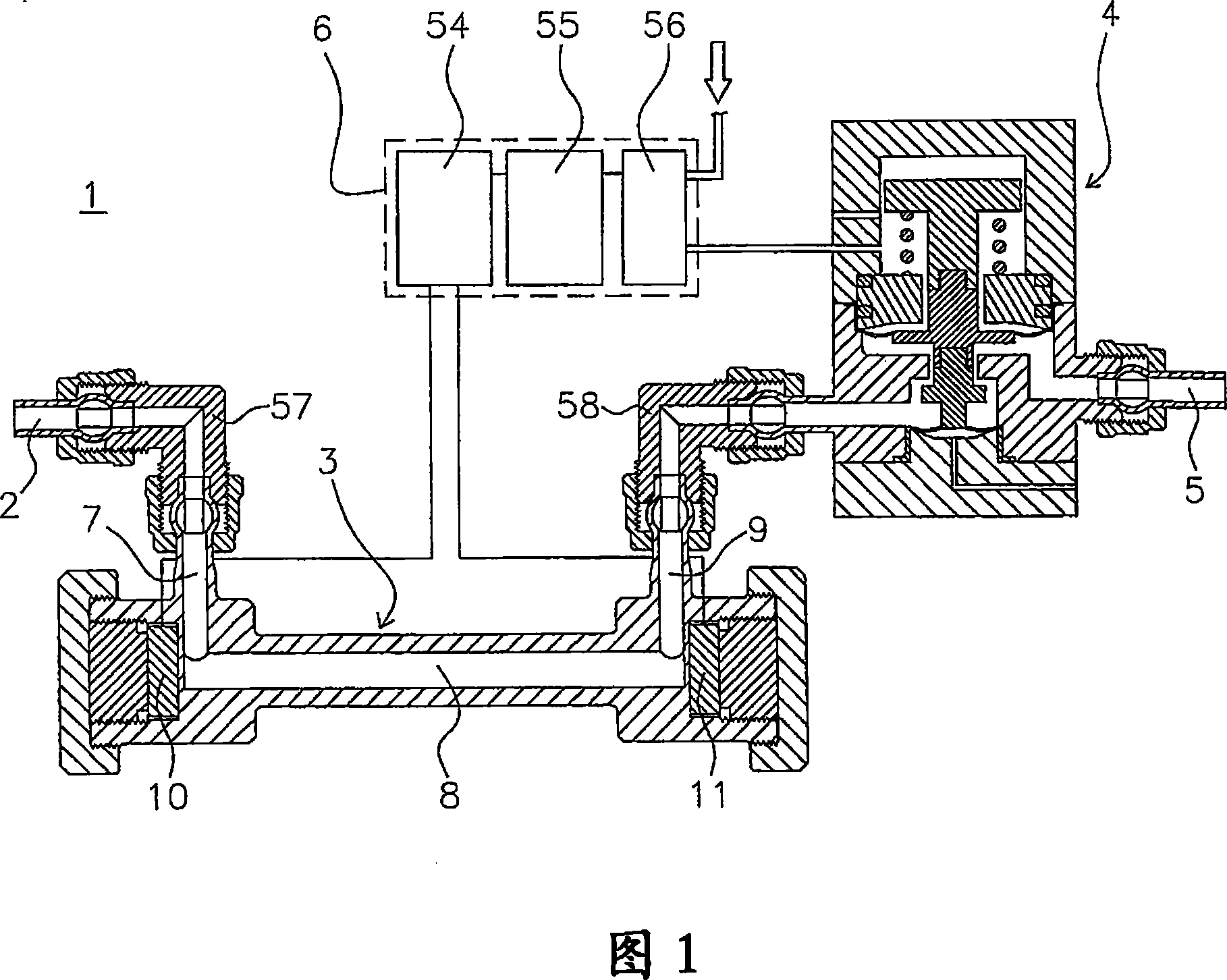

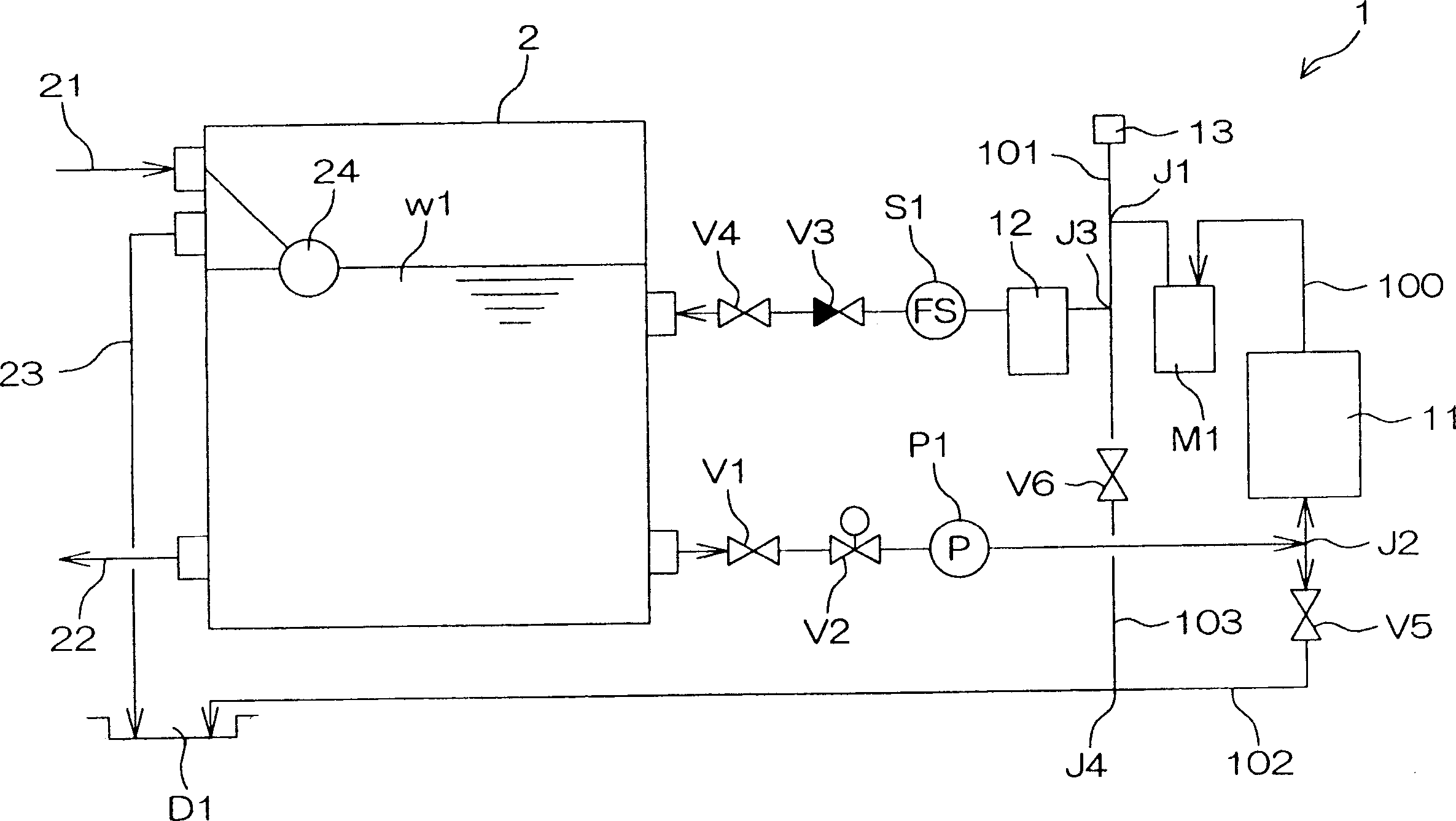

Fluid control apparatus

InactiveCN101243368AGood flow responsivenessAvoid resistanceSpindle sealingsDiaphragm valvesFluid controlEngineering

Owner:ASAHI YUKIZAI KOGYO CO LTD

Fluid control apparatus

InactiveCN101248402AImprove responsivenessAvoid resistanceSpindle sealingsOperating means/releasing devices for valvesFluid controlEngineering

A fluid control apparatus is provided with a fluid control valve for controlling the pressure of a fluid by pressure operation of a fluid for control; a flow volume measuring apparatus for measuring the flow volume of the fluid, converting the measured value of the flow volume into electric signals and outputting the signals; and a control section for outputting a command signal for controlling an opening area of the fluid control valve to the fluid control valve or to an apparatus which operates the fluid control valve, based on a deviation of the electric signal from a set flow volume outputted from the flow volume measuring apparatus.

Owner:ASAHI YUKIZAI KOGYO CO LTD

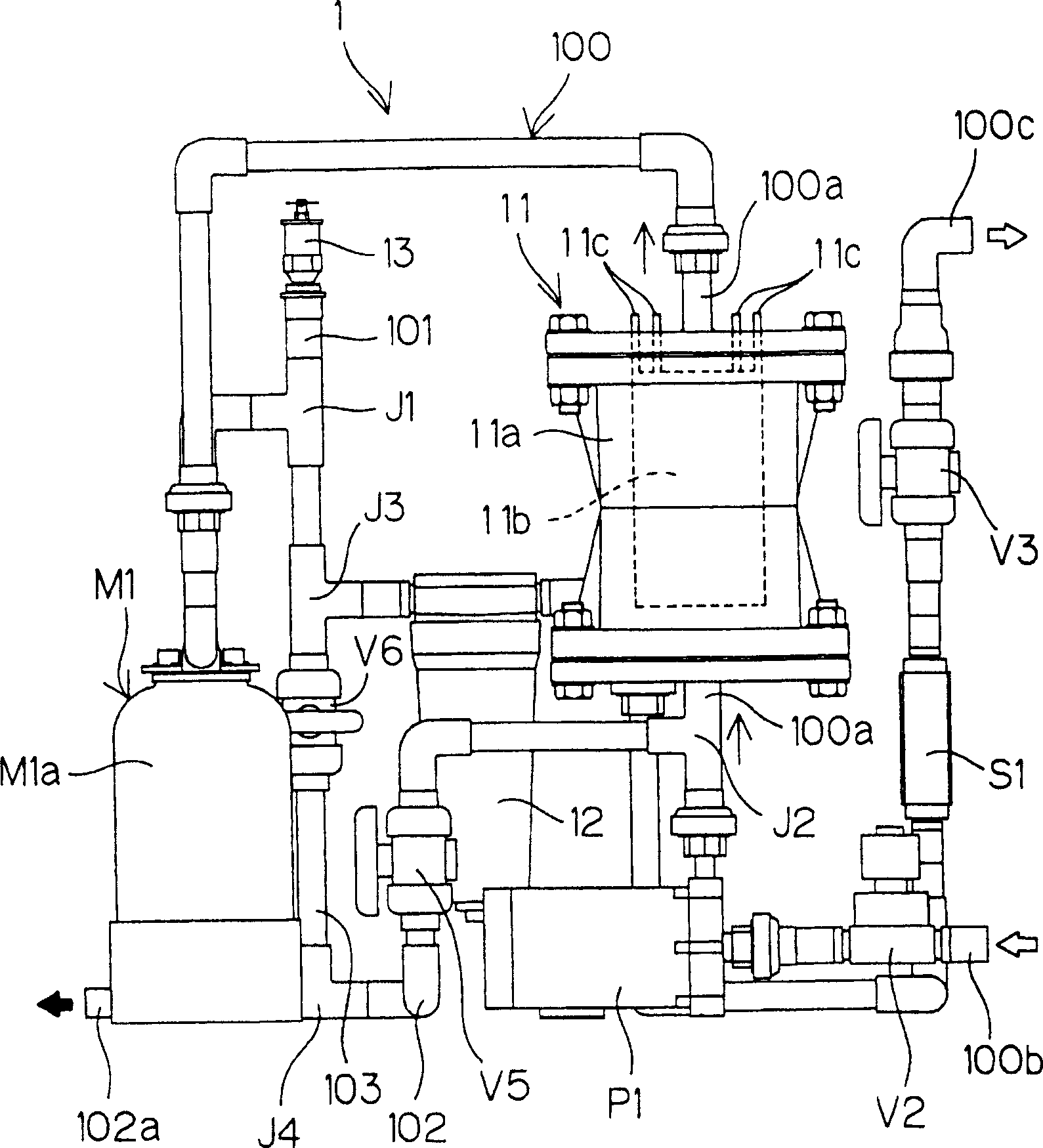

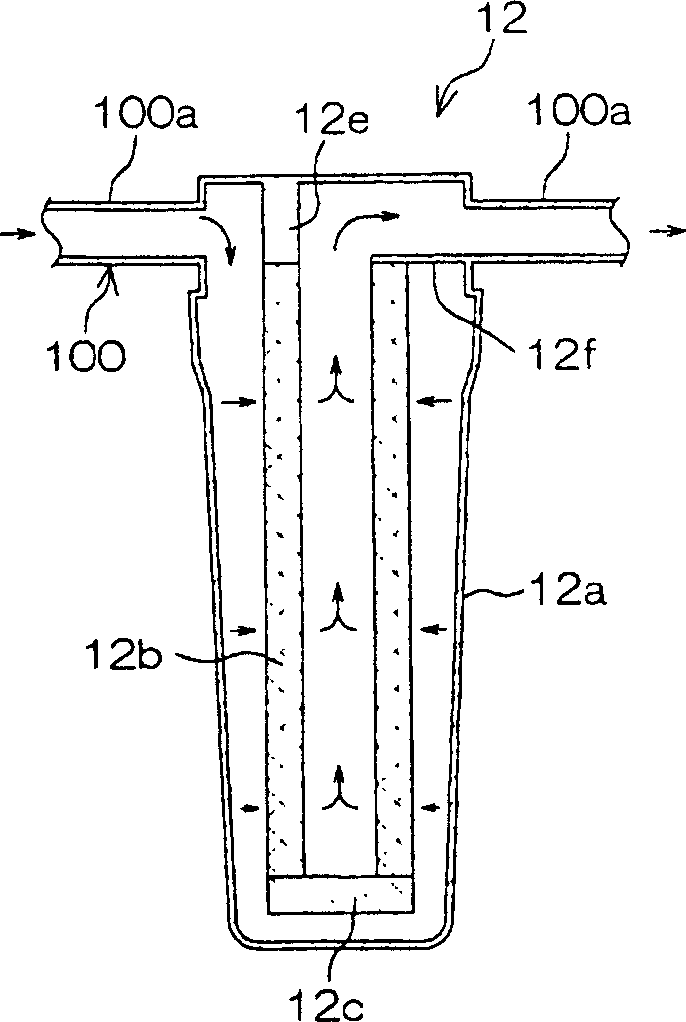

Water treatment unit

ActiveCN1498855AEfficient sterilizationQuality assuranceWater/sewage treatment by electrochemical methodsWater/sewage treatment using germicide/oligodynamic-processTemporary StoppingExhaust valve

Provided is a water treatment equipment which sterilizes water fed from a water supply inlet of a water supply system in a building etc. efficiently by electrolysis treatment to keep the water quality while keeping the airtightness of a water supply tank and preventing a gas storage problem.An automatic gas vent valve 13 for discharging a gas generated by the electrolysis treatment to the outside of a treated water passage 100 is connected onto the downstream side from an electrolysis treatment mean 11 of the treated water passage 100 connected with a water supply tank 2, and a function for accelerating the inflow of gas into the automatic gas vent valve 13 by stopping operation for a while is given. The gas generated by the electrolysis treatment can be collected in the automatic gas vent valve 13 by buoyancy of the gas during temporary stopping of the apparatus, and discharged outside of the treated water passage 100, which can surely prevent the gas from being stored in the water supply tank 2 while keeping the airtightness of the water supply tank 2.

Owner:SANYO ELECTRIC CO LTD

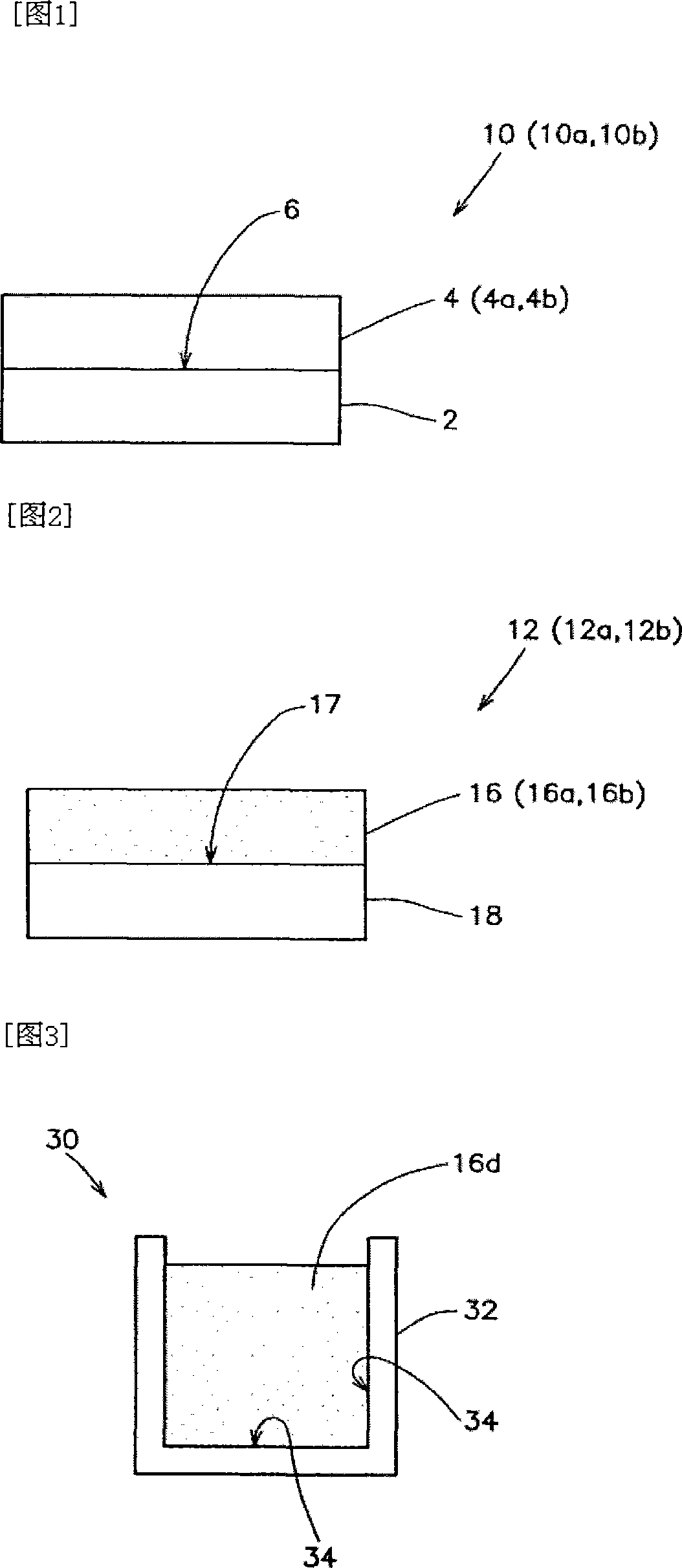

Composite ceramic structure, method for producing same and wall structure using such composite ceramic structure

InactiveCN101027266AAvoid heat island effectEasy to set up jobsCovering/liningsLayered productsCeramic sinteringComposite ceramic

The invention provides a composite ceramic structure comprising a porous ceramic and, bonded thereto by sintering, an ordinary fired material, and provide a process for producing the same. Further, it is intended to provide a novel product, such as tile or composite plant pot, constituted of this composite ceramic structure. Still further, it is intended to provide a wall surface structure that attains realization of a high added value of dry tile structure and is endowed with wall surface ornament and appearance beauty by plants, and that realizes energy saving through reduction of air conditioning load for buildings and other construction structure. There is provided a wall surface structure comprising a base wall surface and, detachable fitted thereto, a planar array of multiple tiles, wherein any parts devoid of tiles are fitted with pot-shaped tiles. In the wall surface structure, the tiles are arranged in lattice pattern lengthwise and crosswise to thereby form a tile surface, and the tiles are fitted above the corresponding parts devoid of tiles. Integer multiple of the width of pot-shaped tiles is made approximately equal to integer multiple of the crosswise width of tiles, and integer multiple of the height of pot-shaped tiles is made approximately equal to integer multiple of the lengthwise width of tiles, so as to effect fitting of pot-shaped tiles in the devoid parts. These tiles are composite tiles constituted of a composite ceramic structure comprising a fired material body and a porous ceramic body bonded to each other by sintering.

Owner:OMI CERAMIC CO LTD

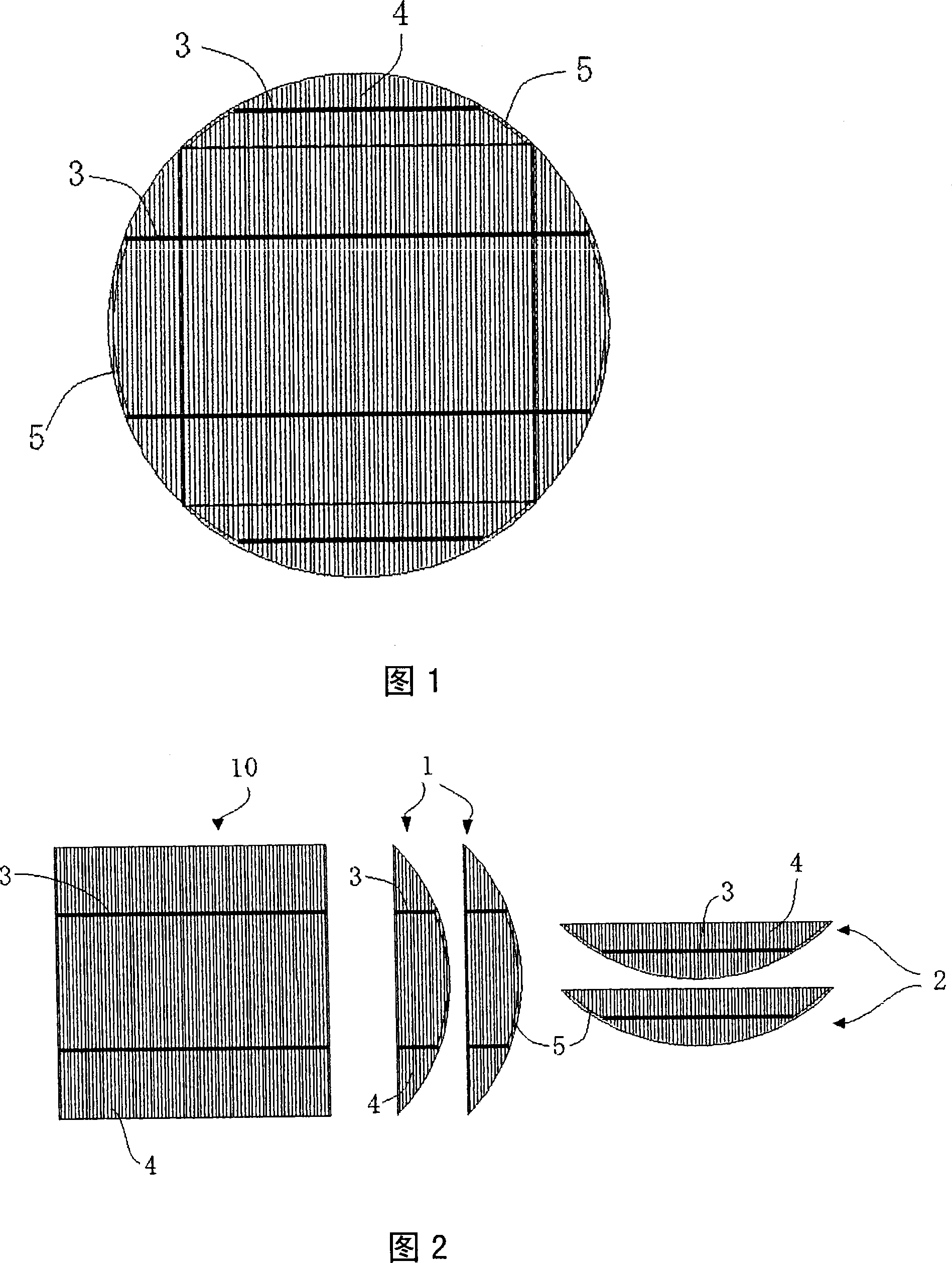

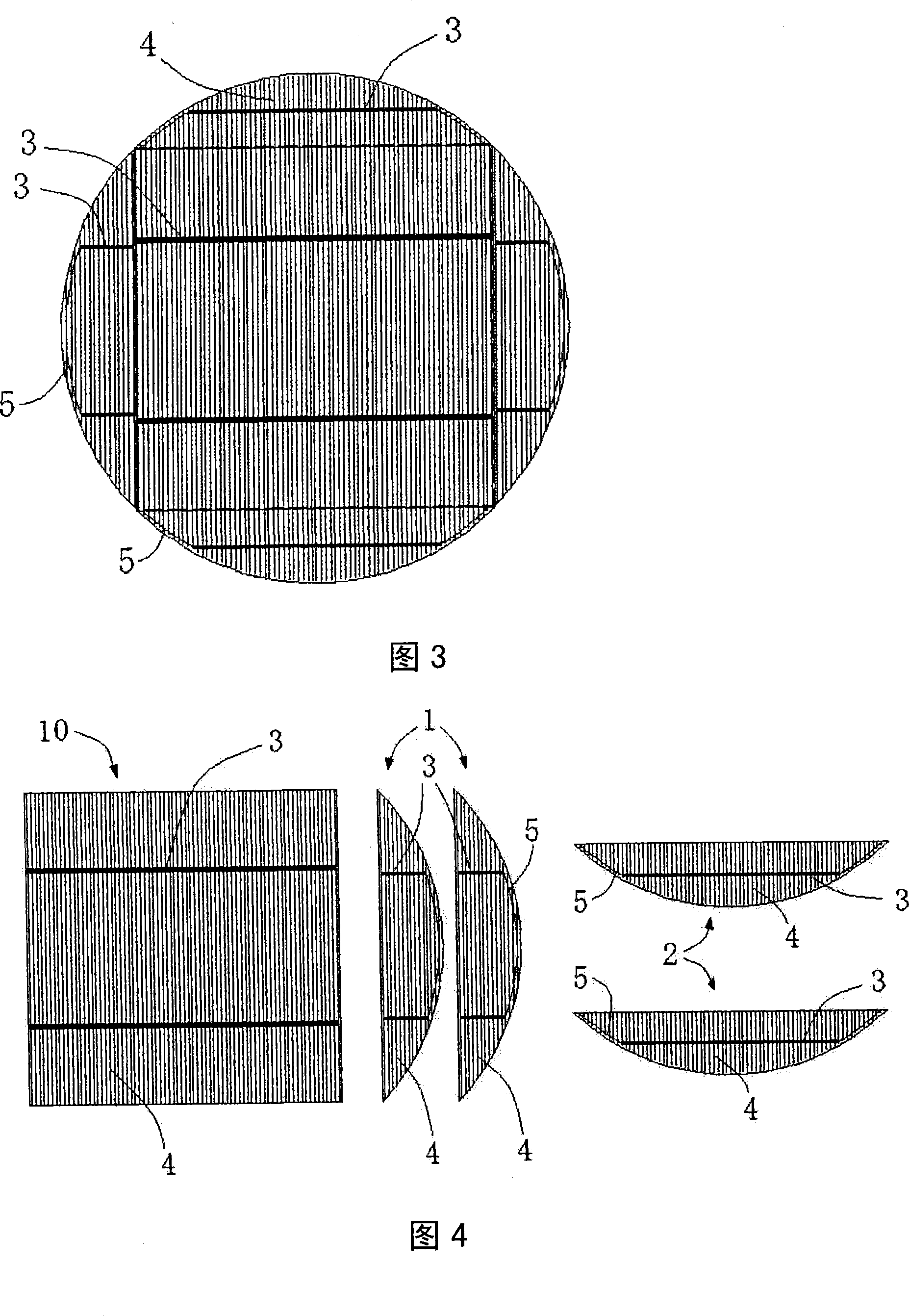

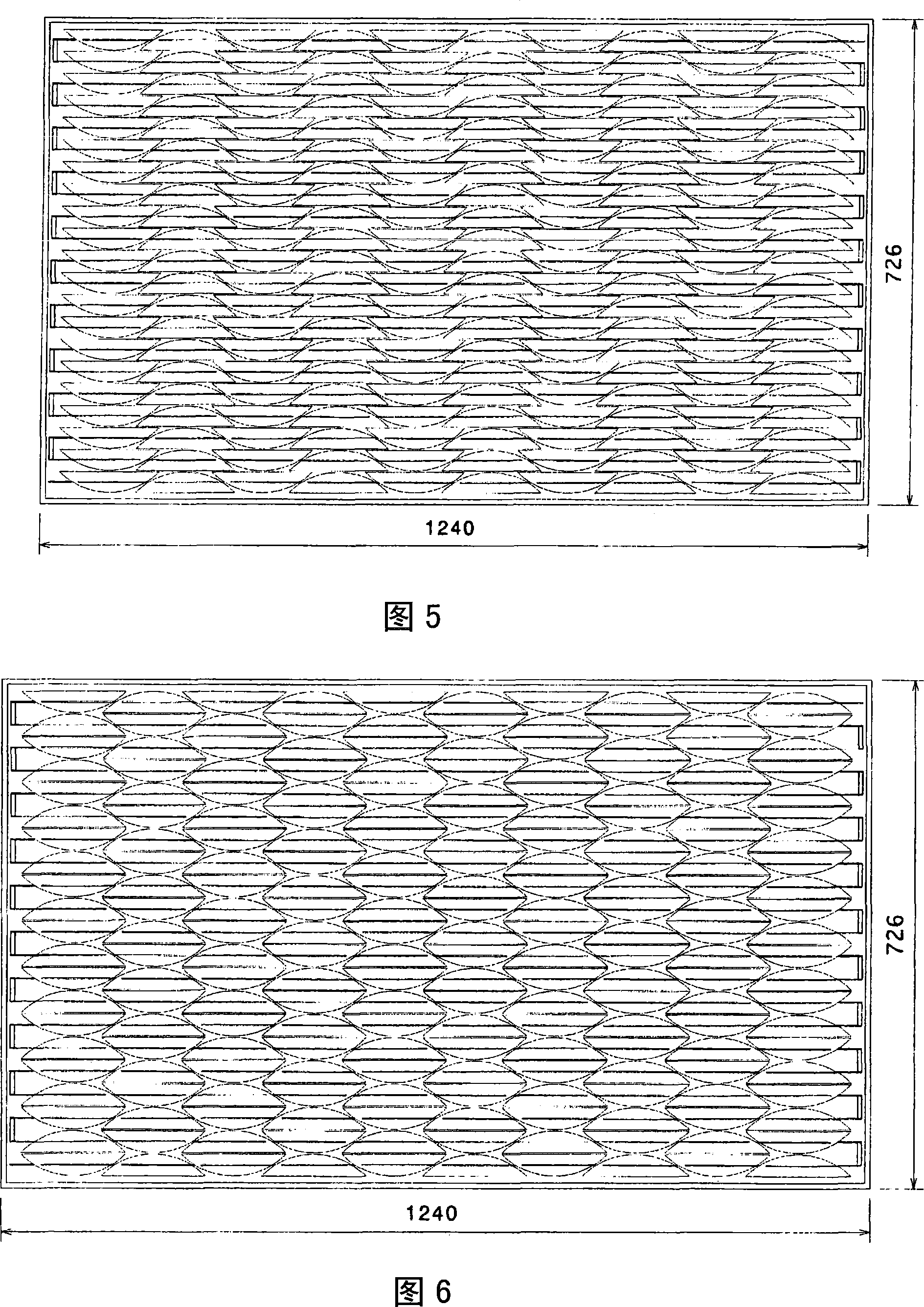

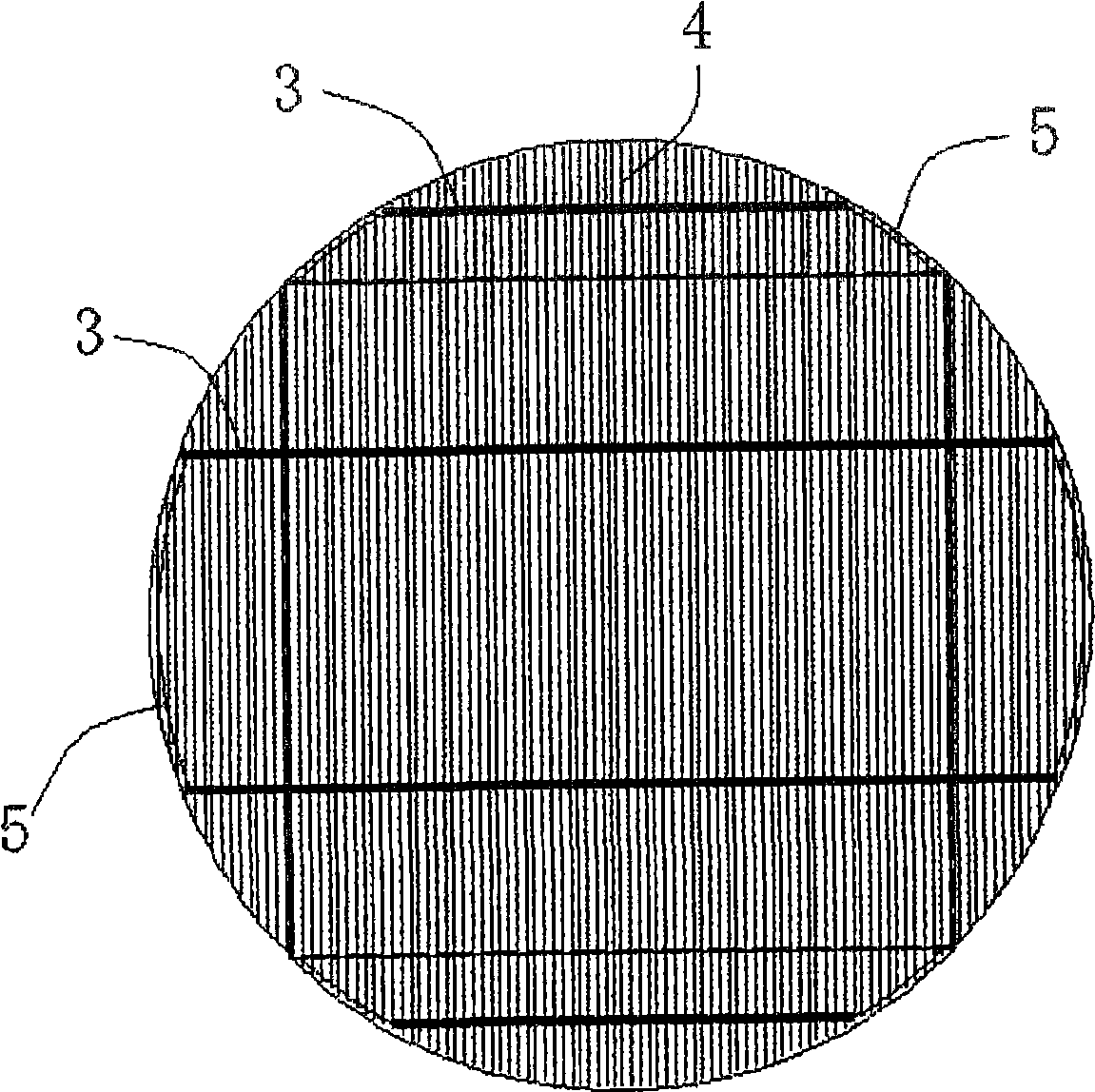

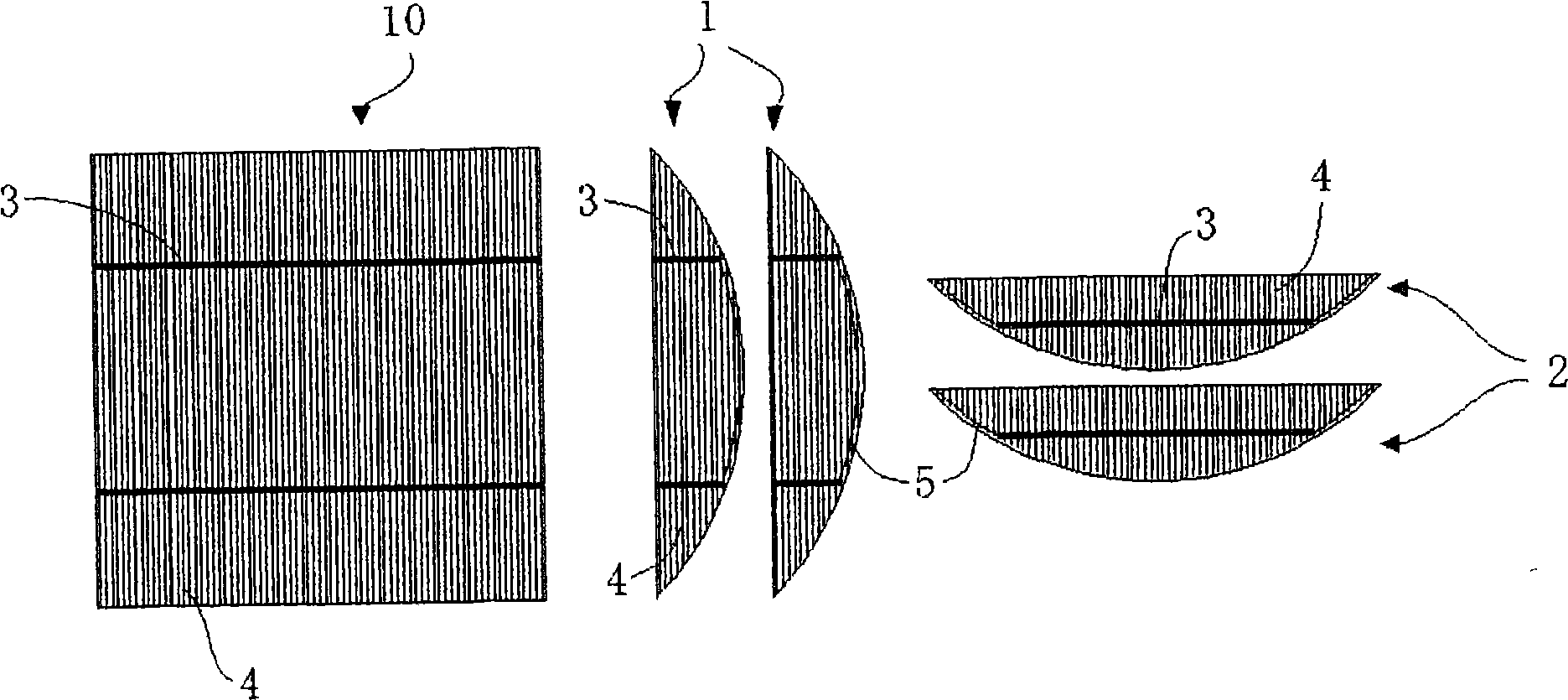

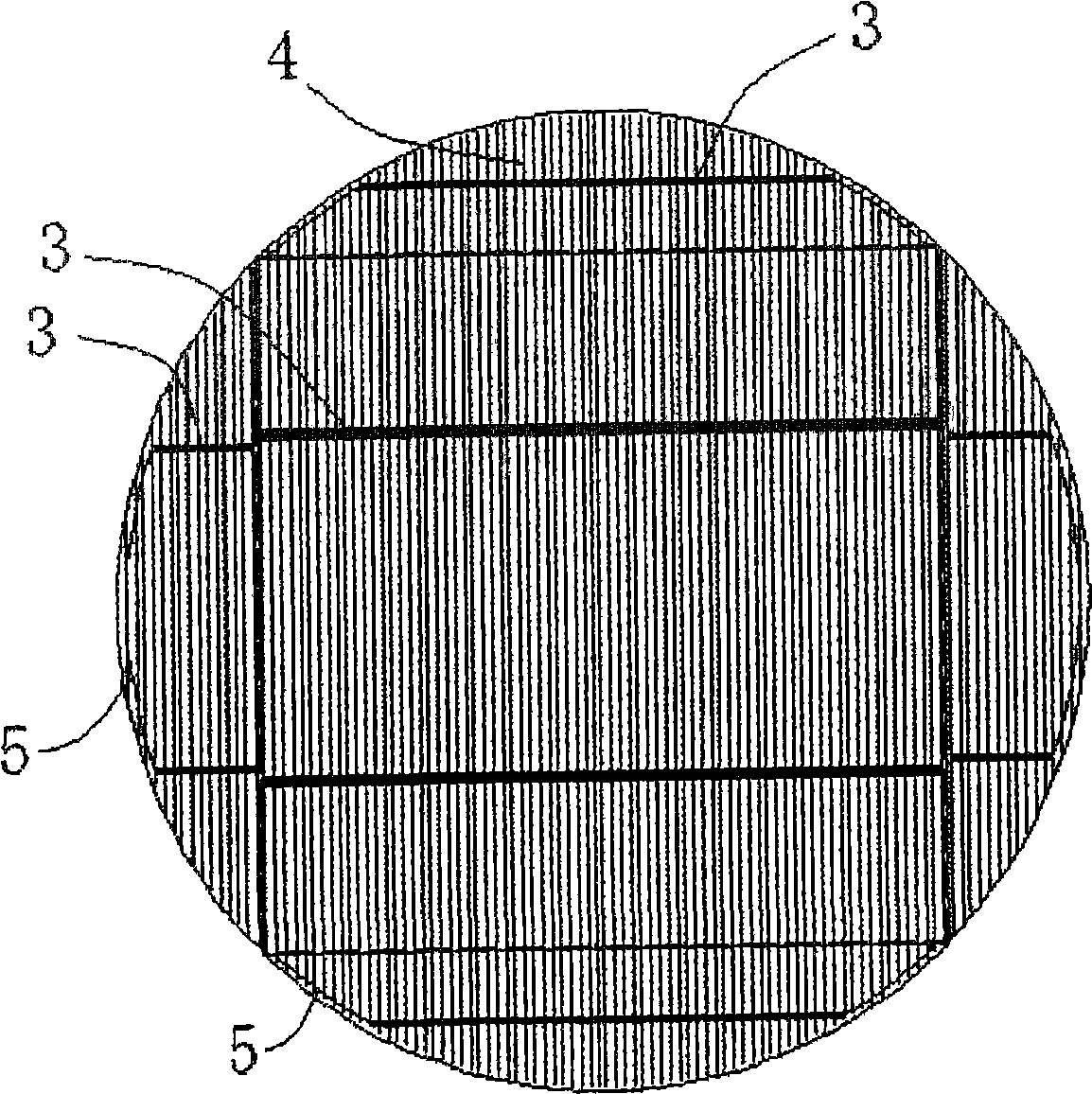

Module and system for solar electricity generation

ActiveCN101006589AReduce lossesEfficient use ofPhotovoltaic energy generationSemiconductor devicesResidenceEngineering

The aim of the invention is to provide a sunlight power generating module which has no loss of the circular monocrystaline wafer and can highly uses the arc battery that is not effectively utilized to this day and a sunlight power generating system using the module, a sunlight power generating module which provides high actuating electric voltage (''area voltage'') in each unit area and the sunlight power generating system using the module, a sunlight power generating module which can increase the configuration ratio of the module relative to the effective setting area of the residence roof and the sunlight power generating system using the module. The sunlight power generating module is composed of arc battery divided by the circular monocrystaline sunlight power generating battery, the arc battery has an arc with neutral angle 90 degrees, a grill orthogonal with the string and more than one generatrix orthogonal with the grill, and the arc battery is arranged to grill shape, and the sunlight power generating module is characterized in that the 14-42 pieces of arc battery with area 28-65cm<2> are arranged.

Owner:SHIN ETSU CHEM IND CO LTD +1

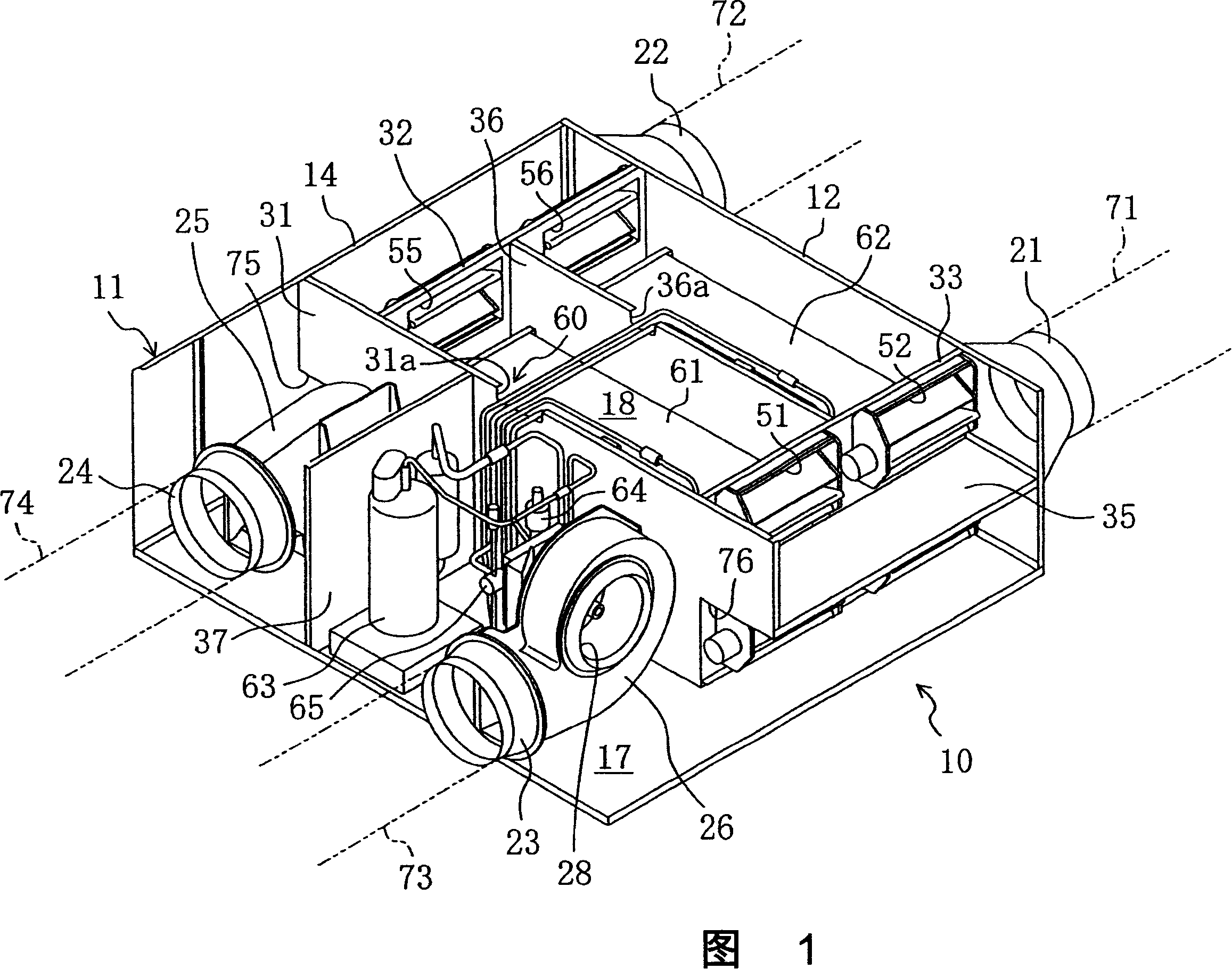

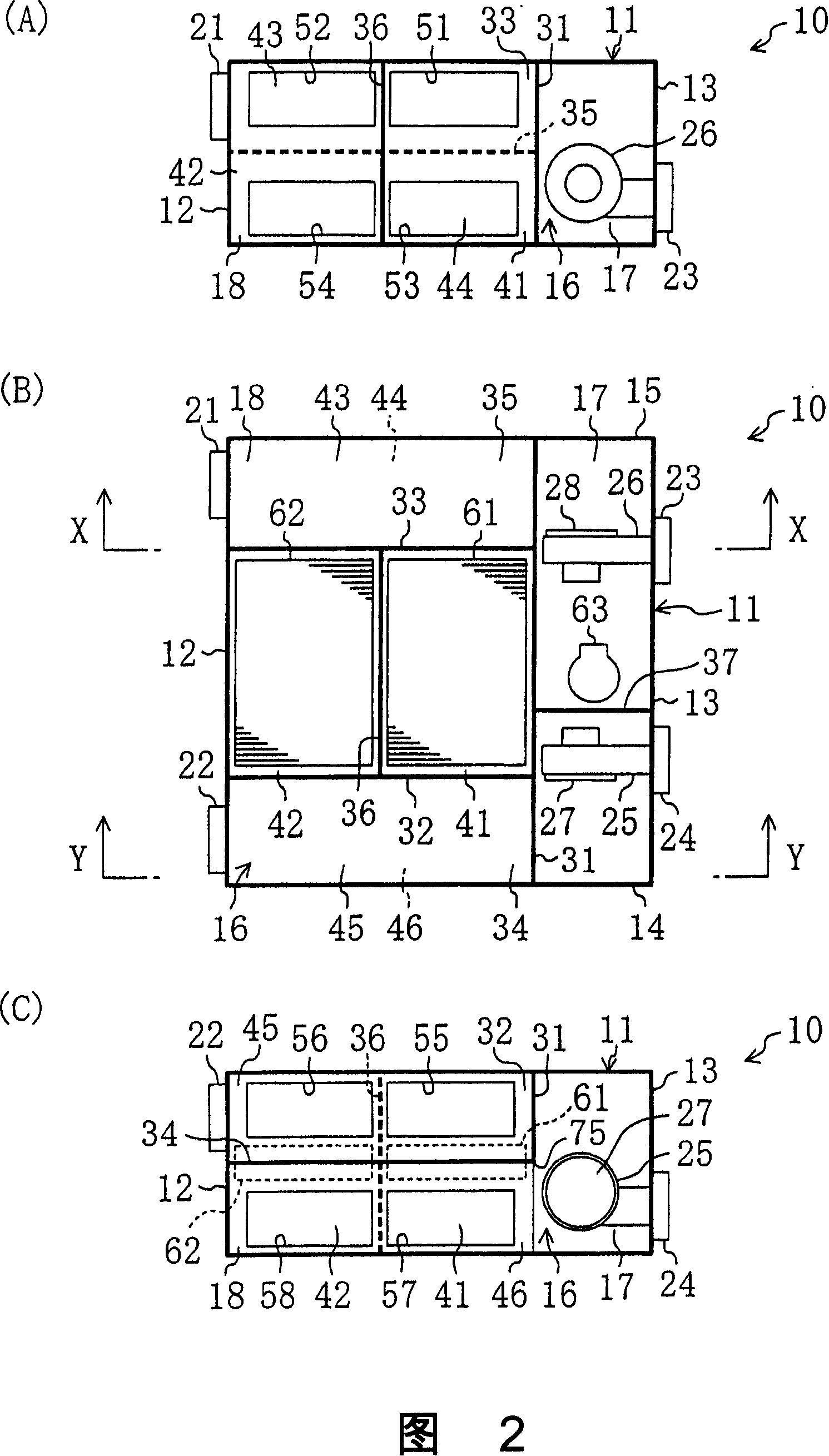

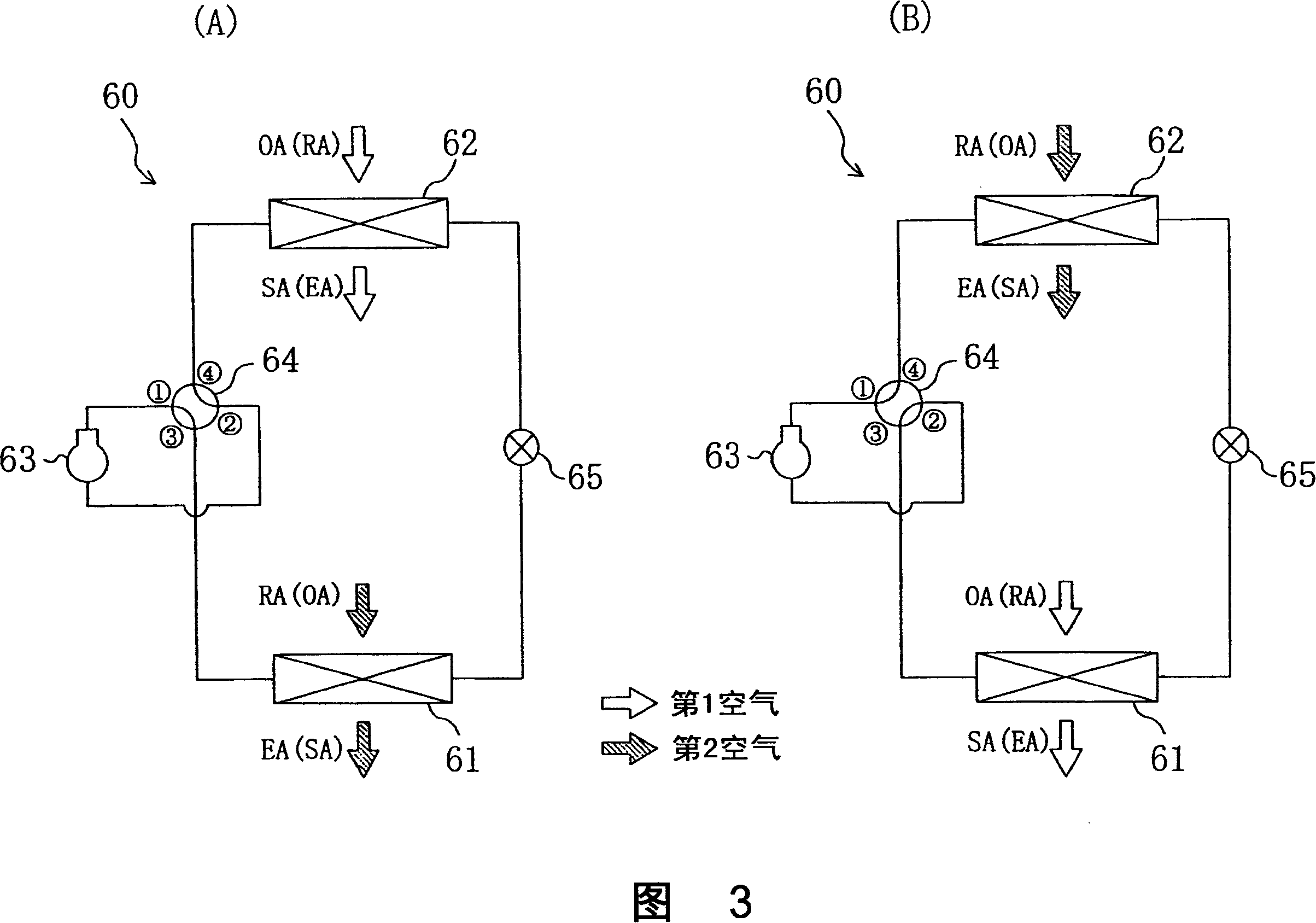

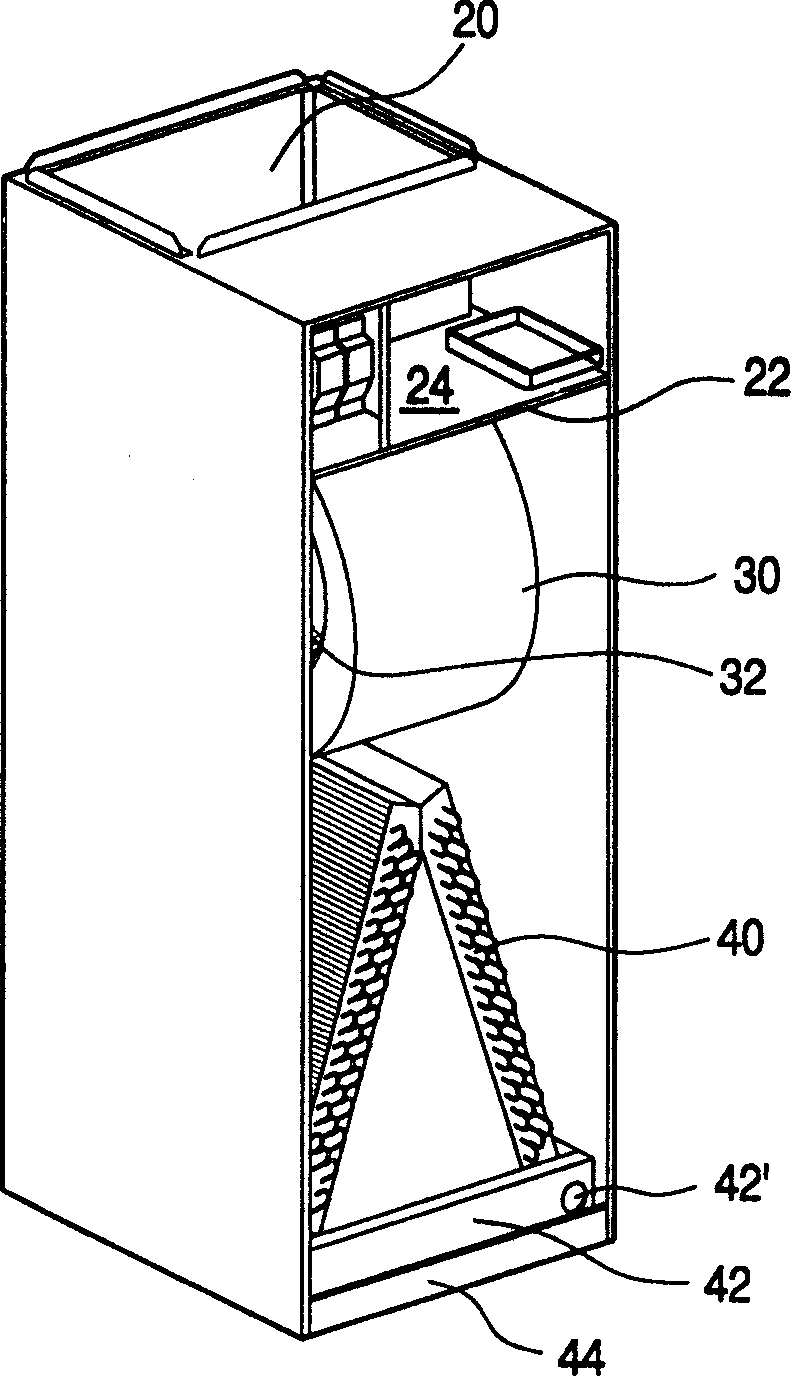

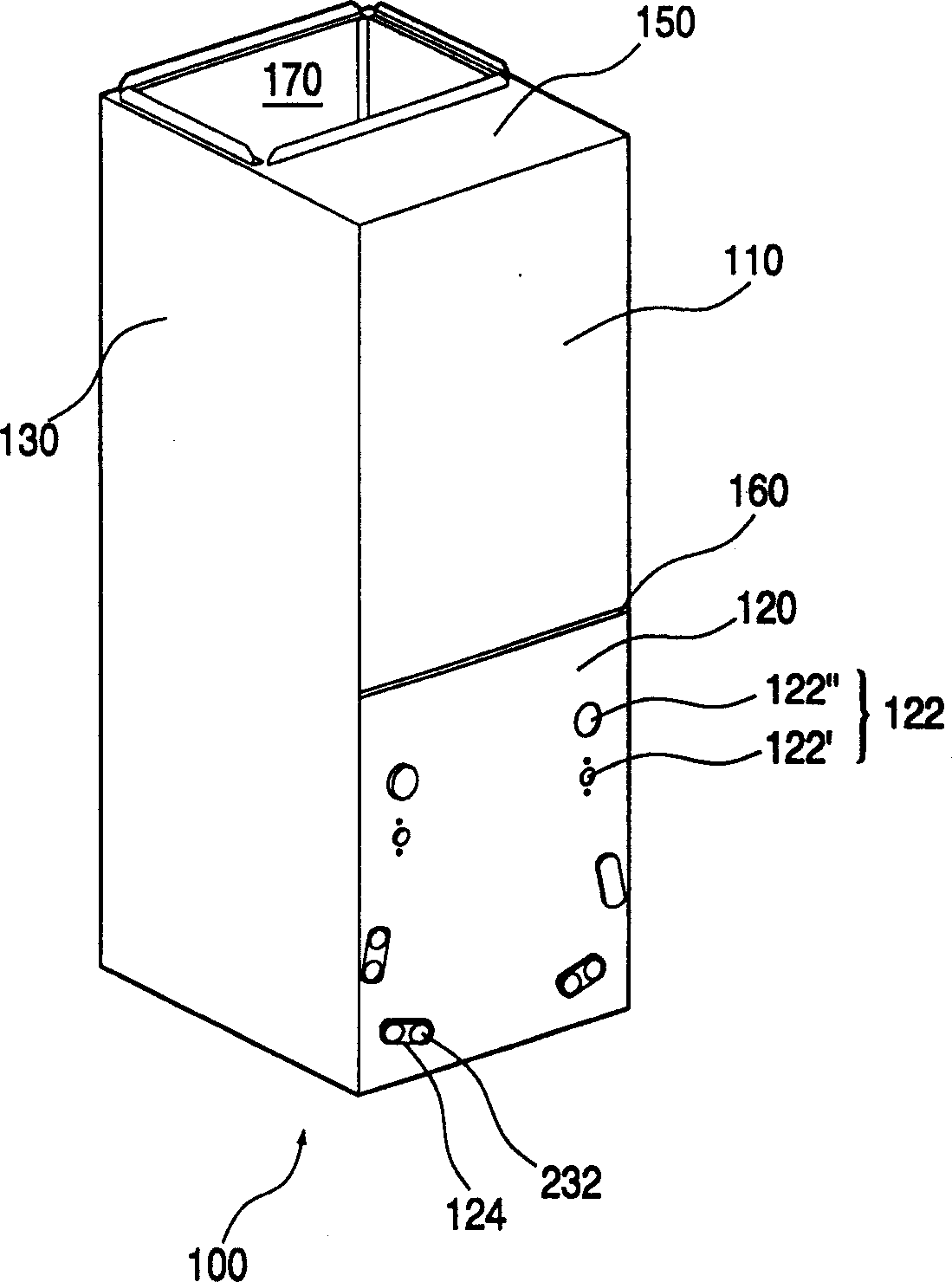

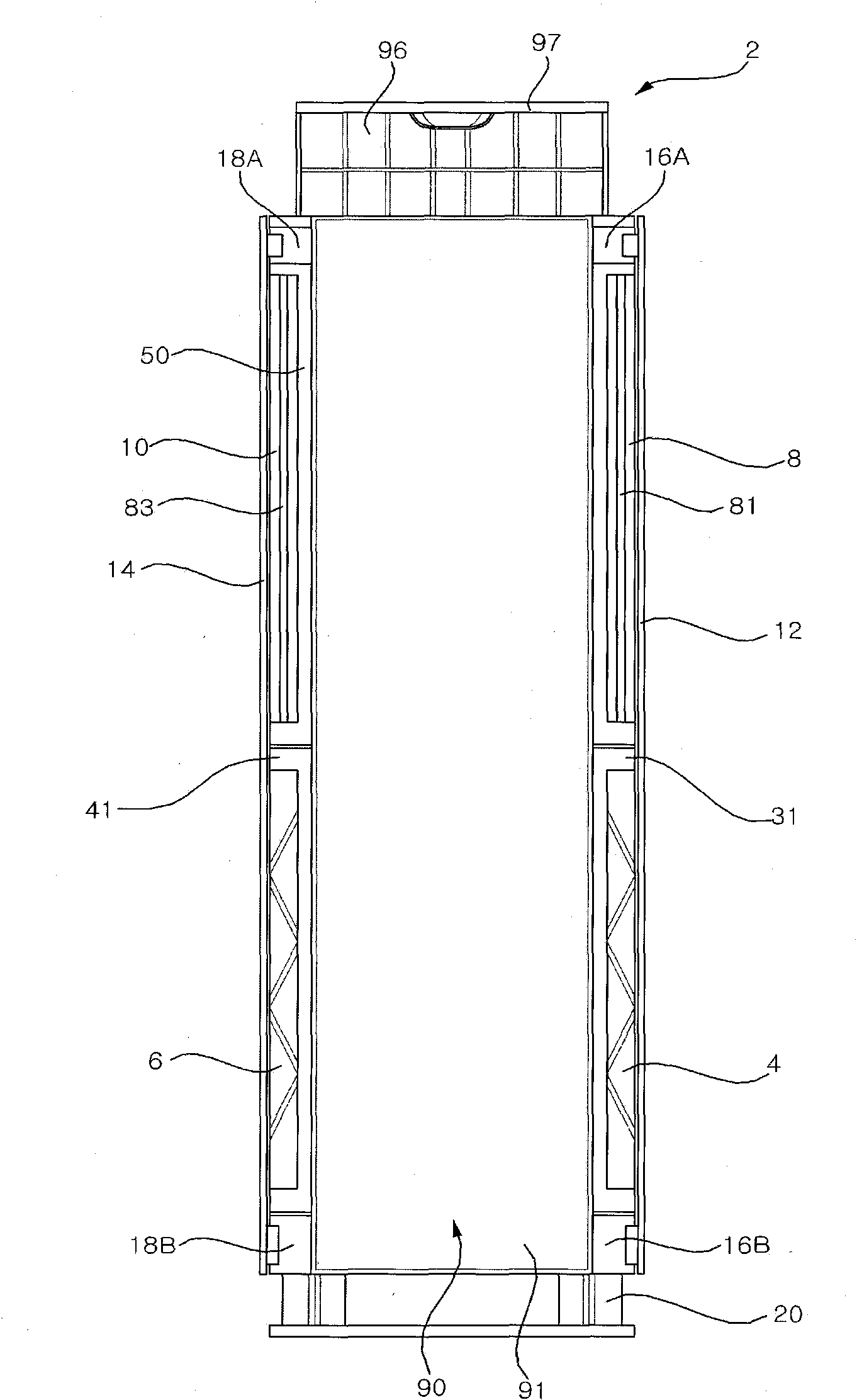

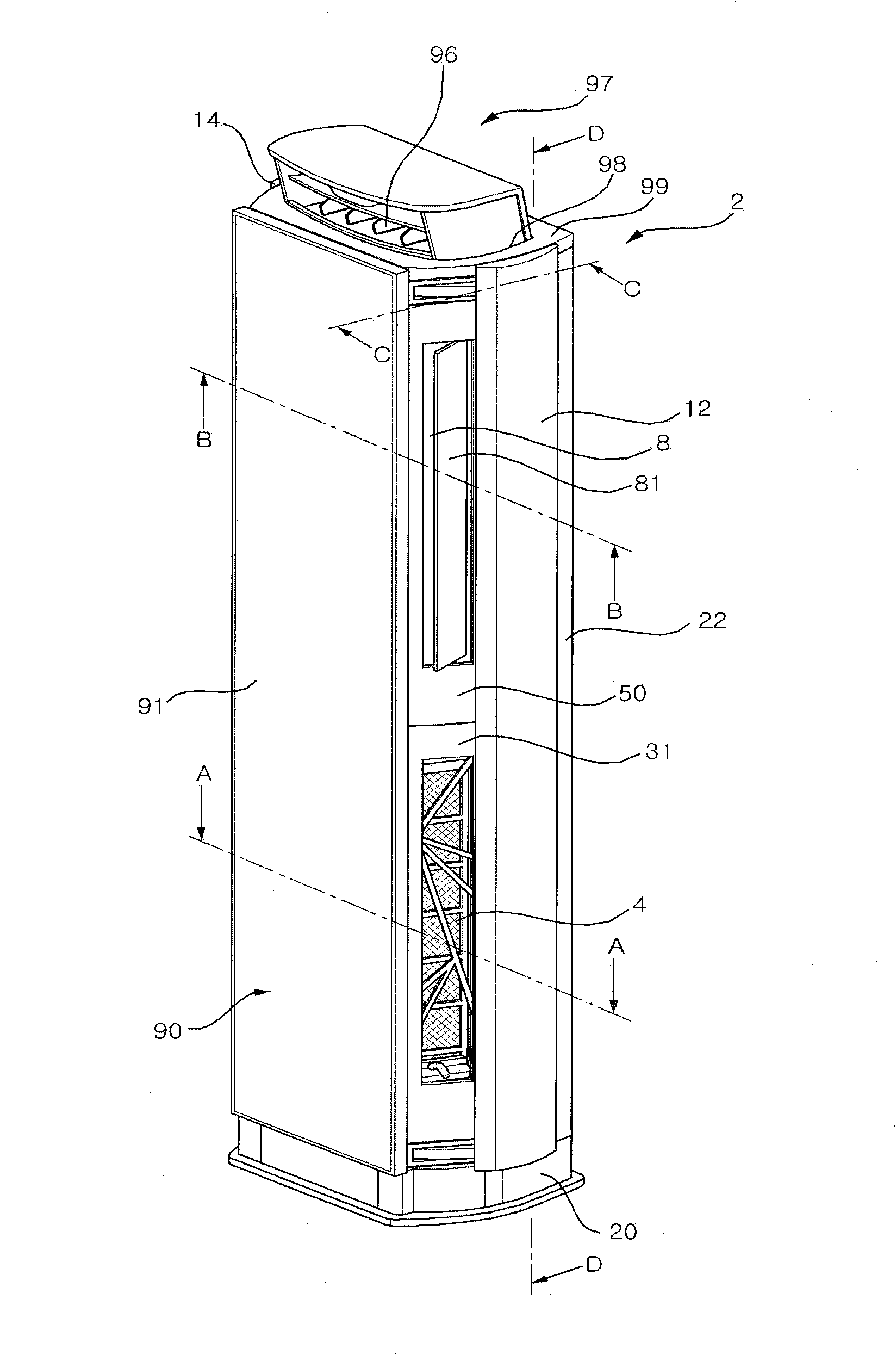

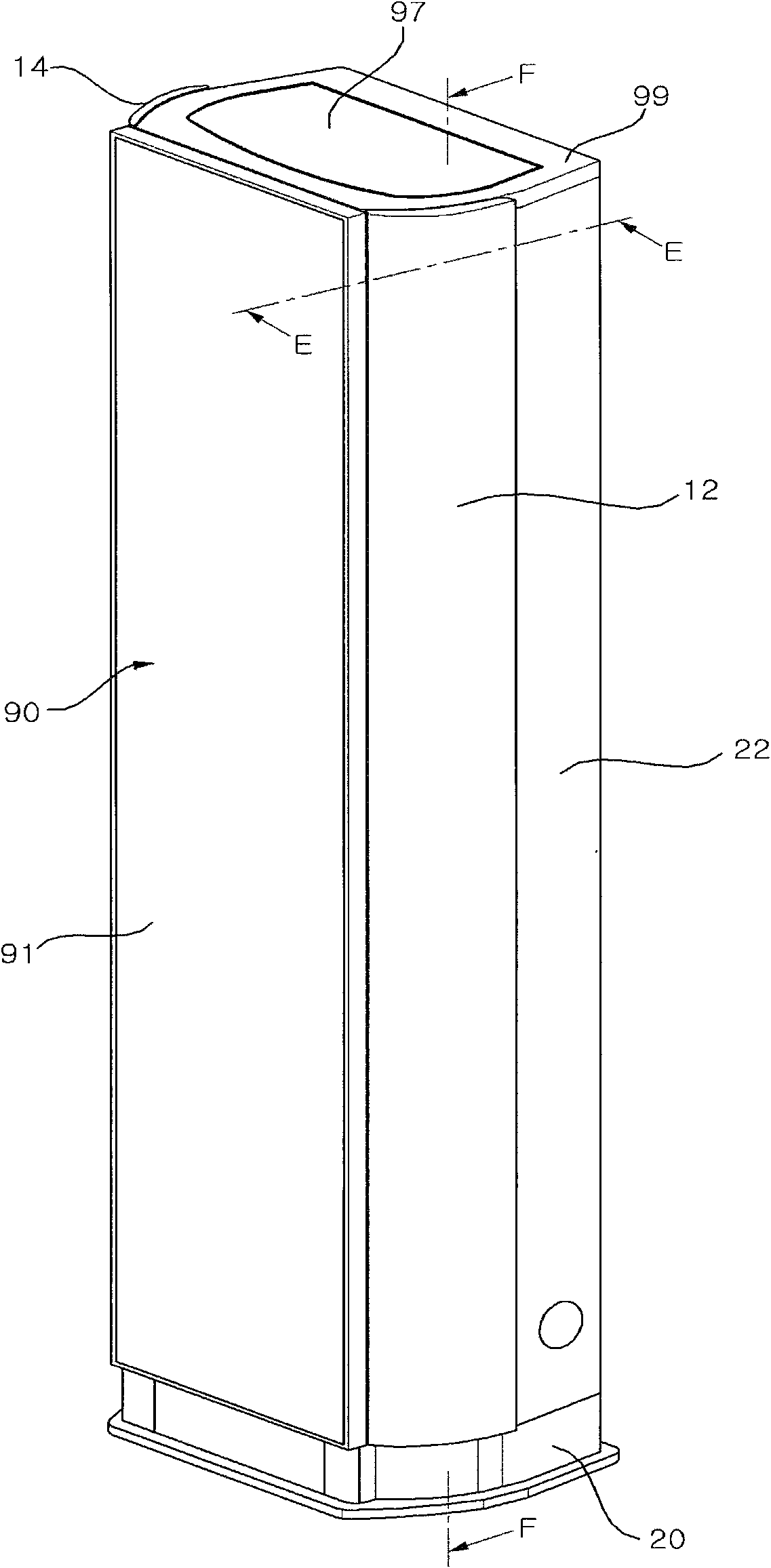

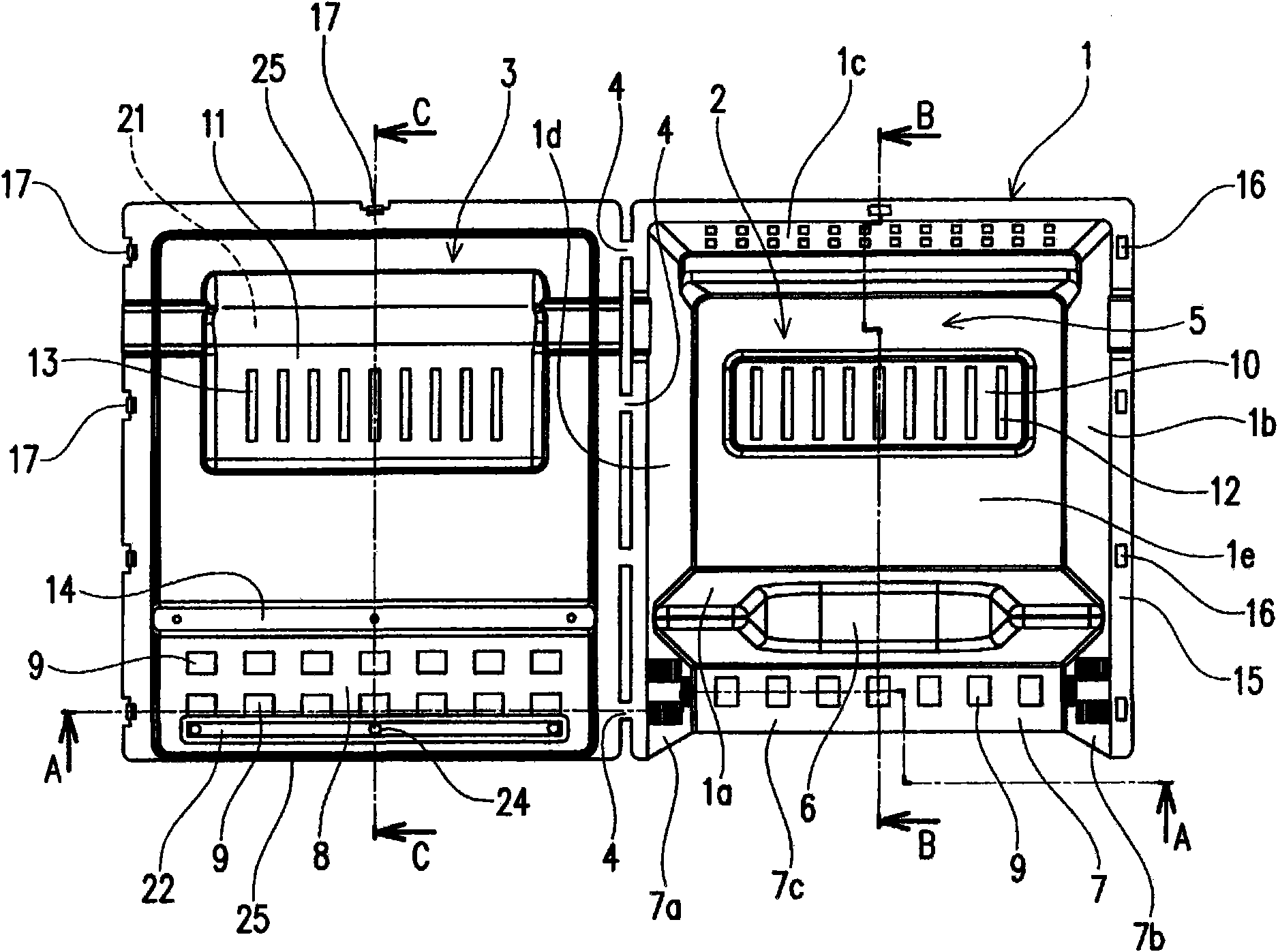

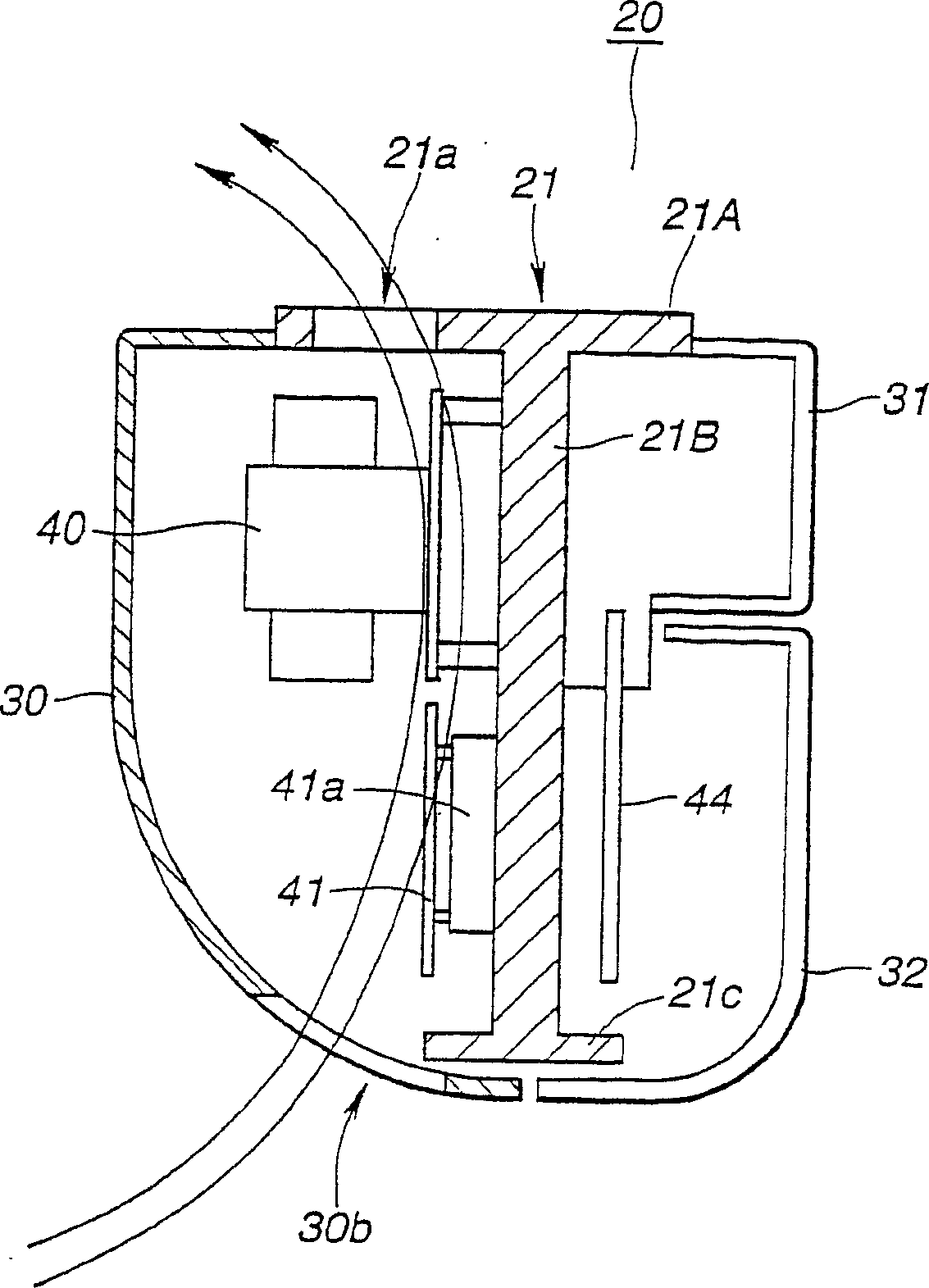

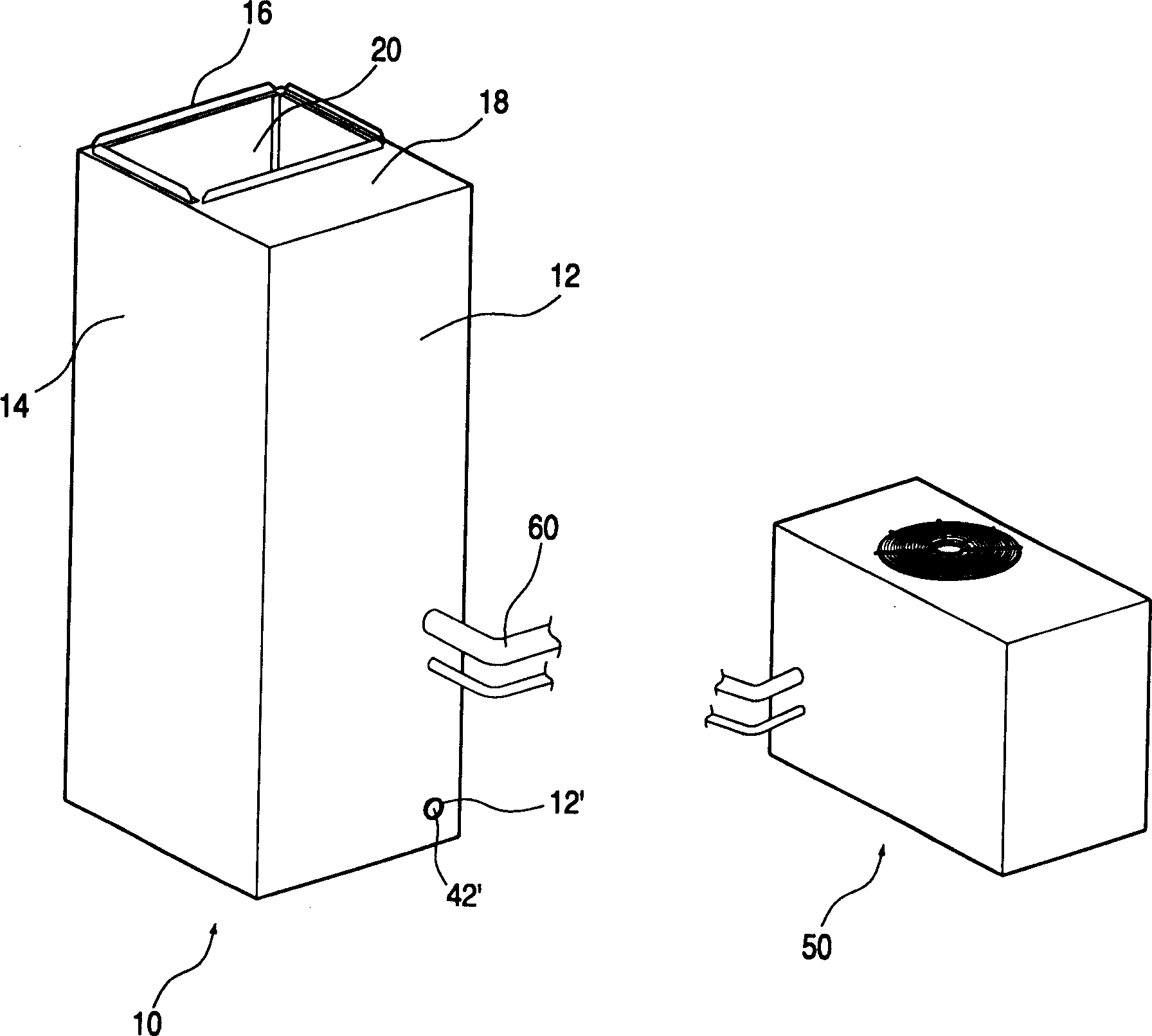

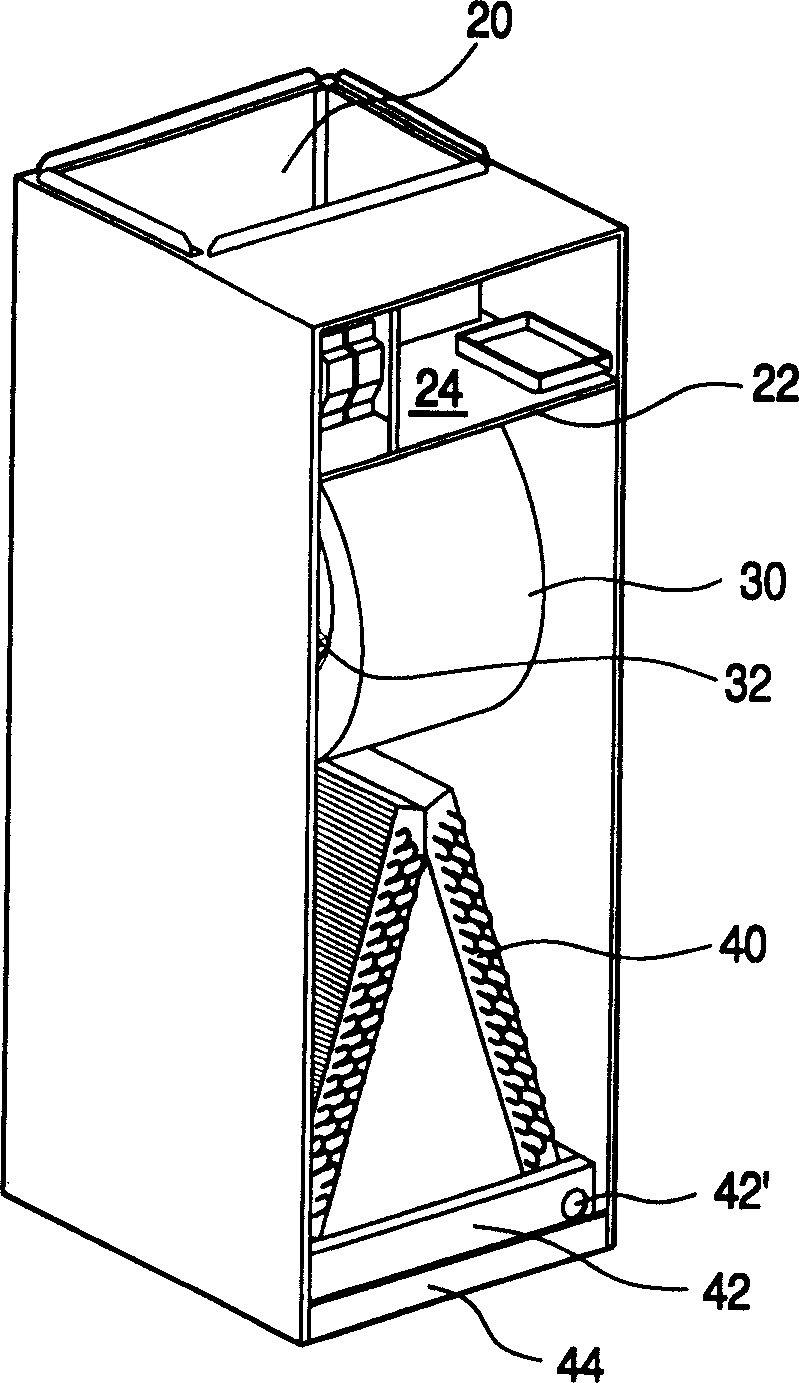

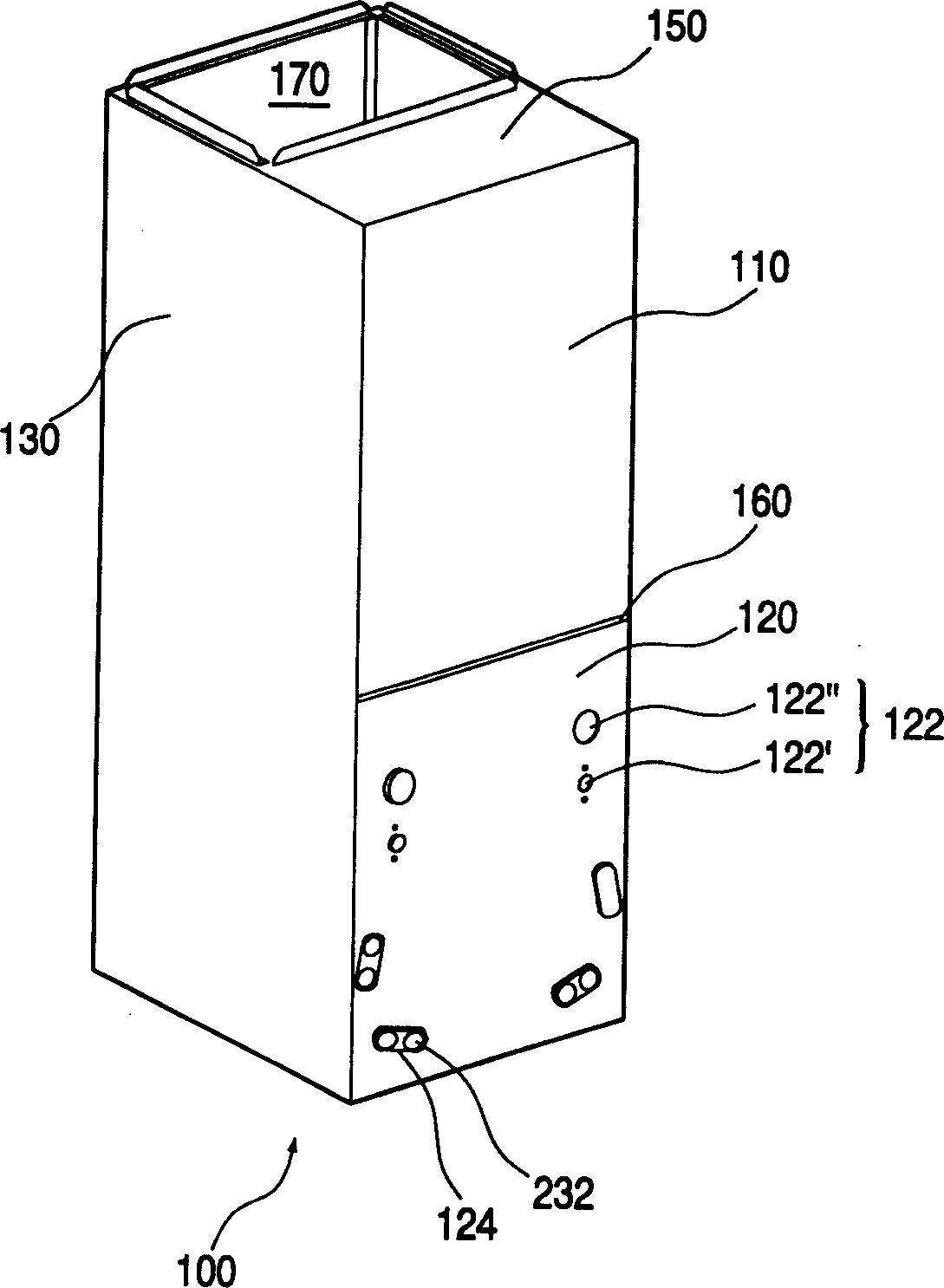

Humidity controller

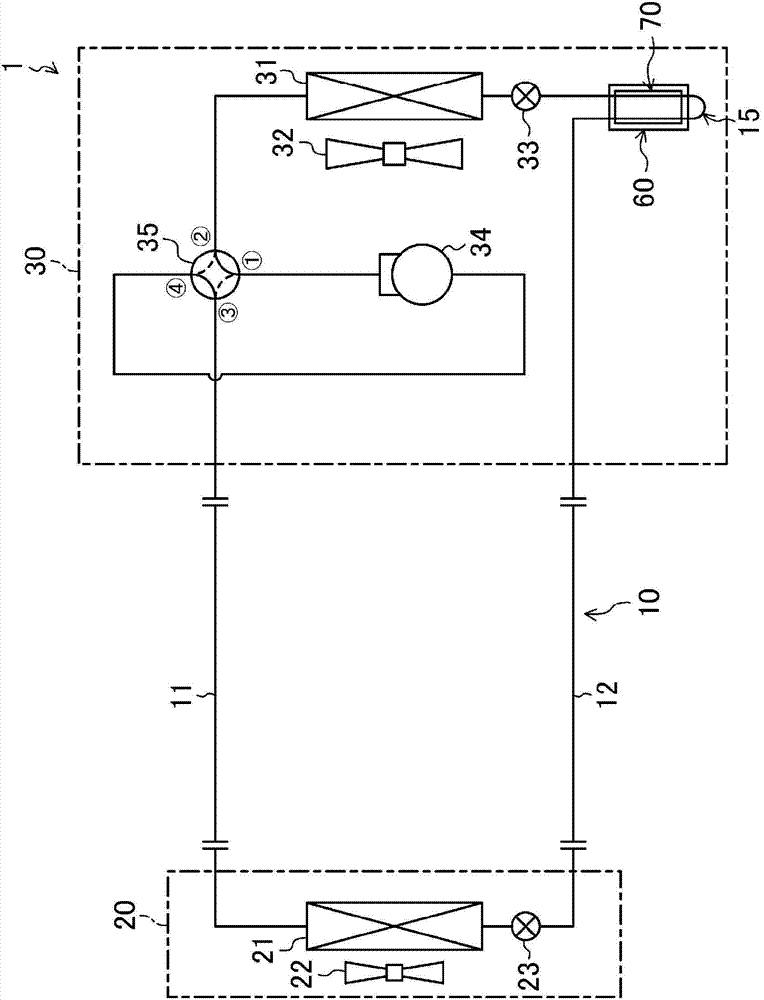

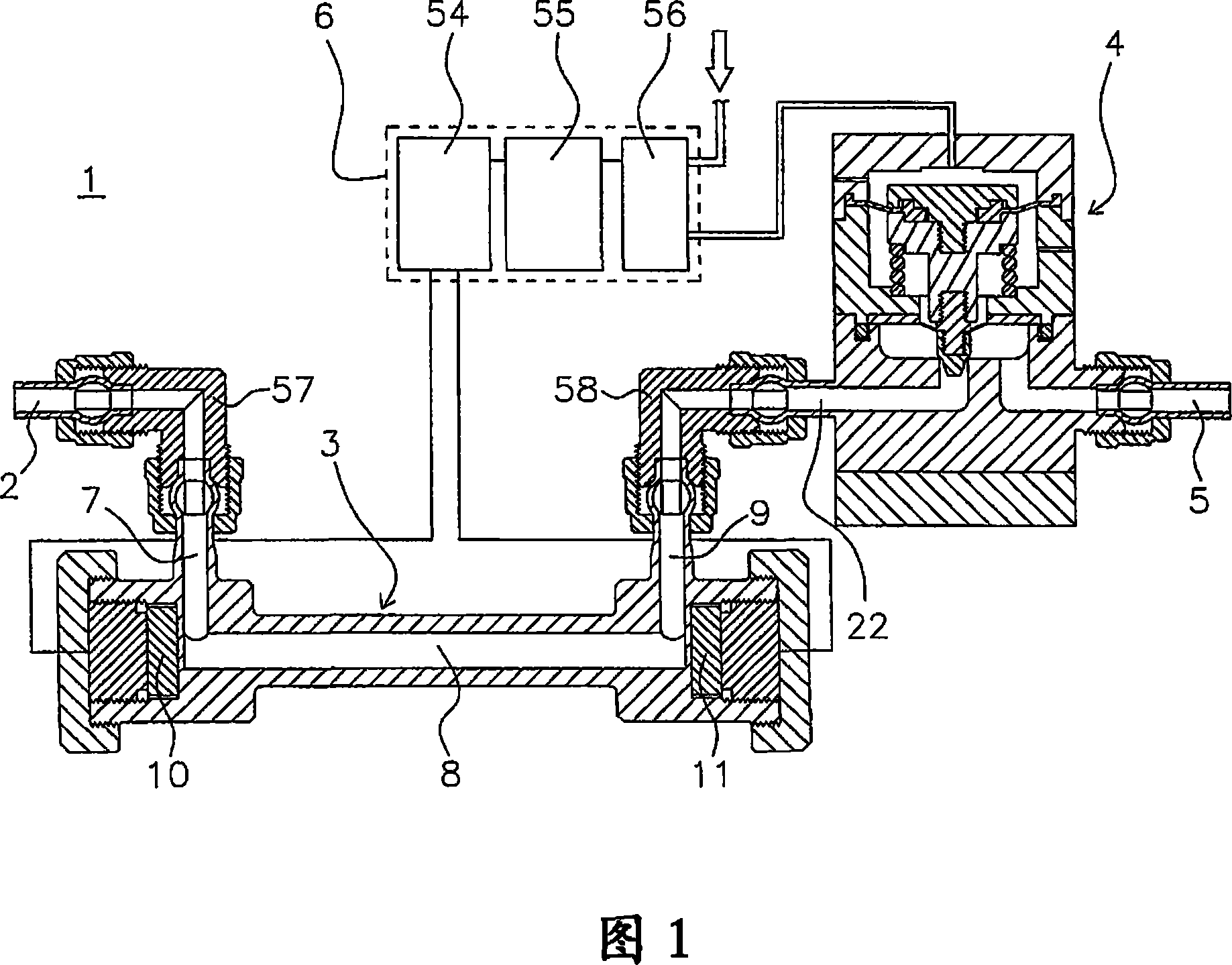

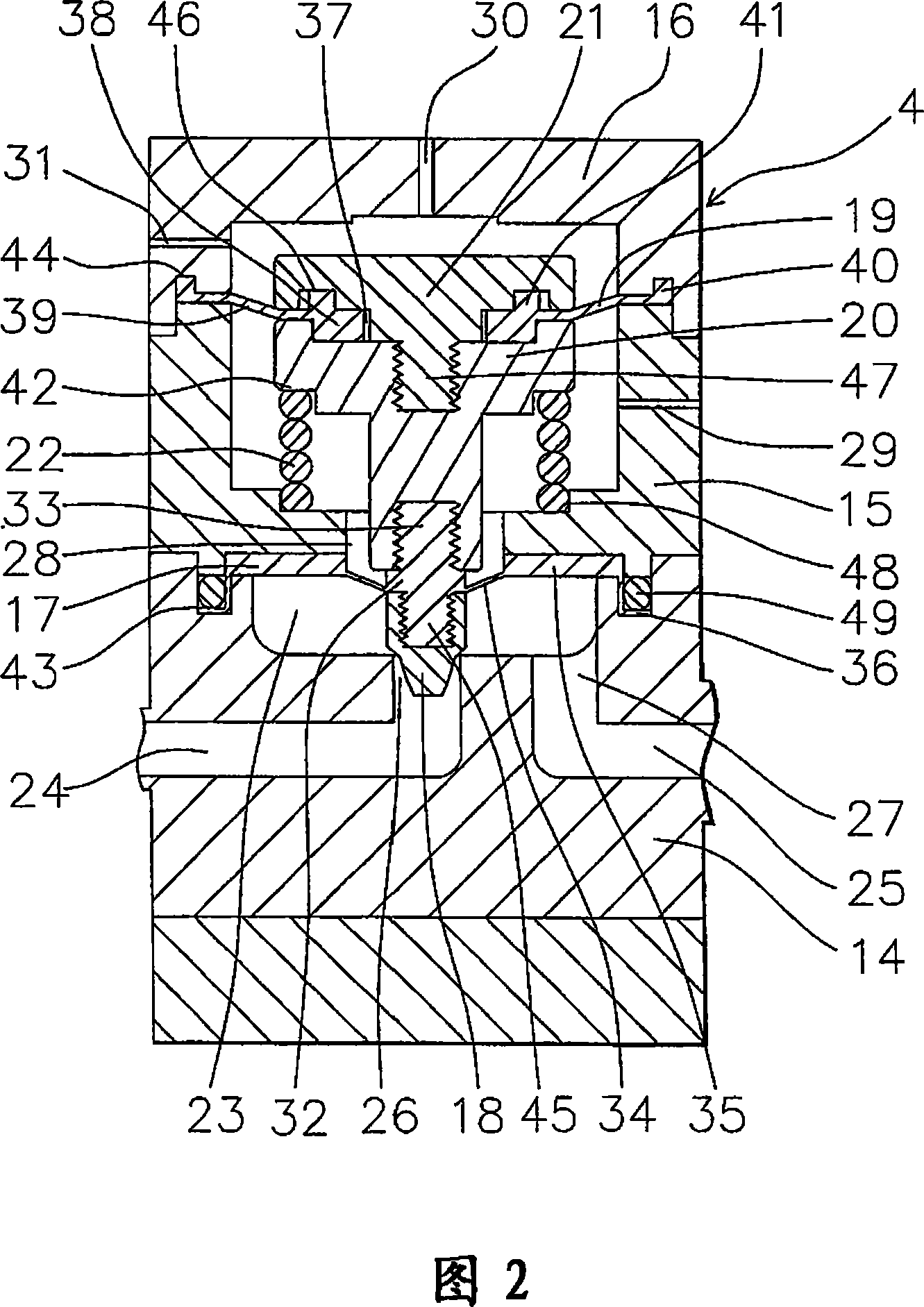

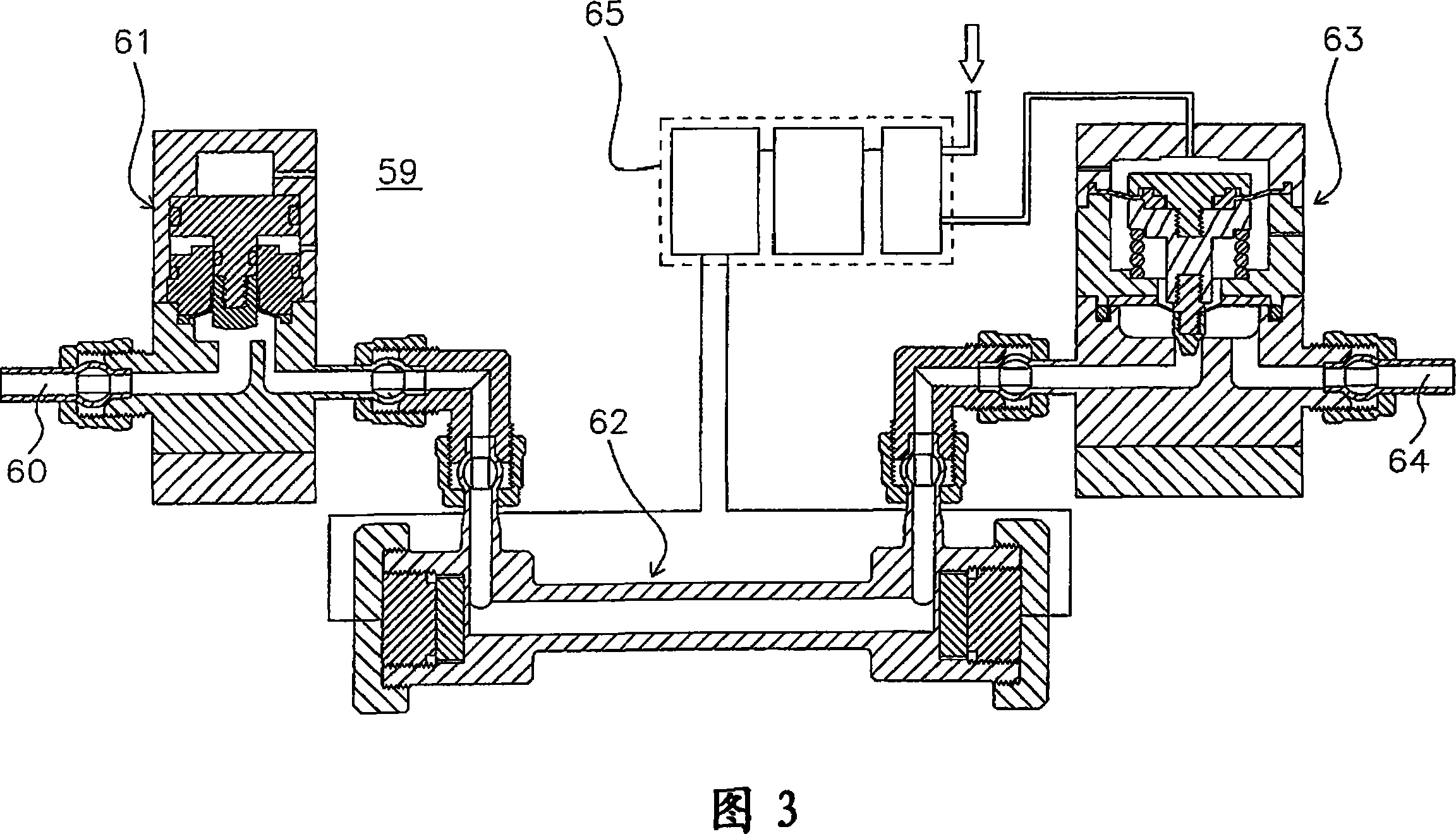

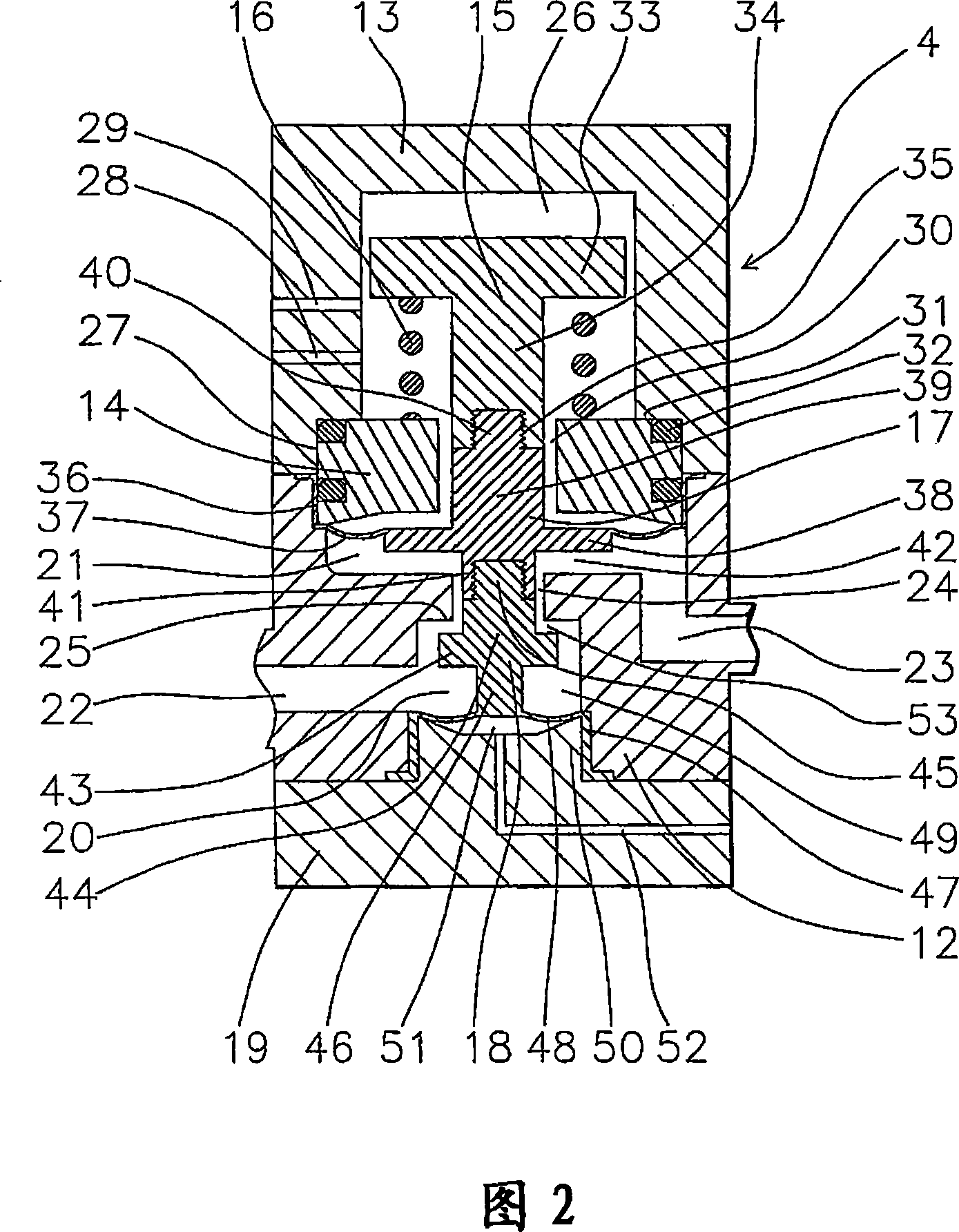

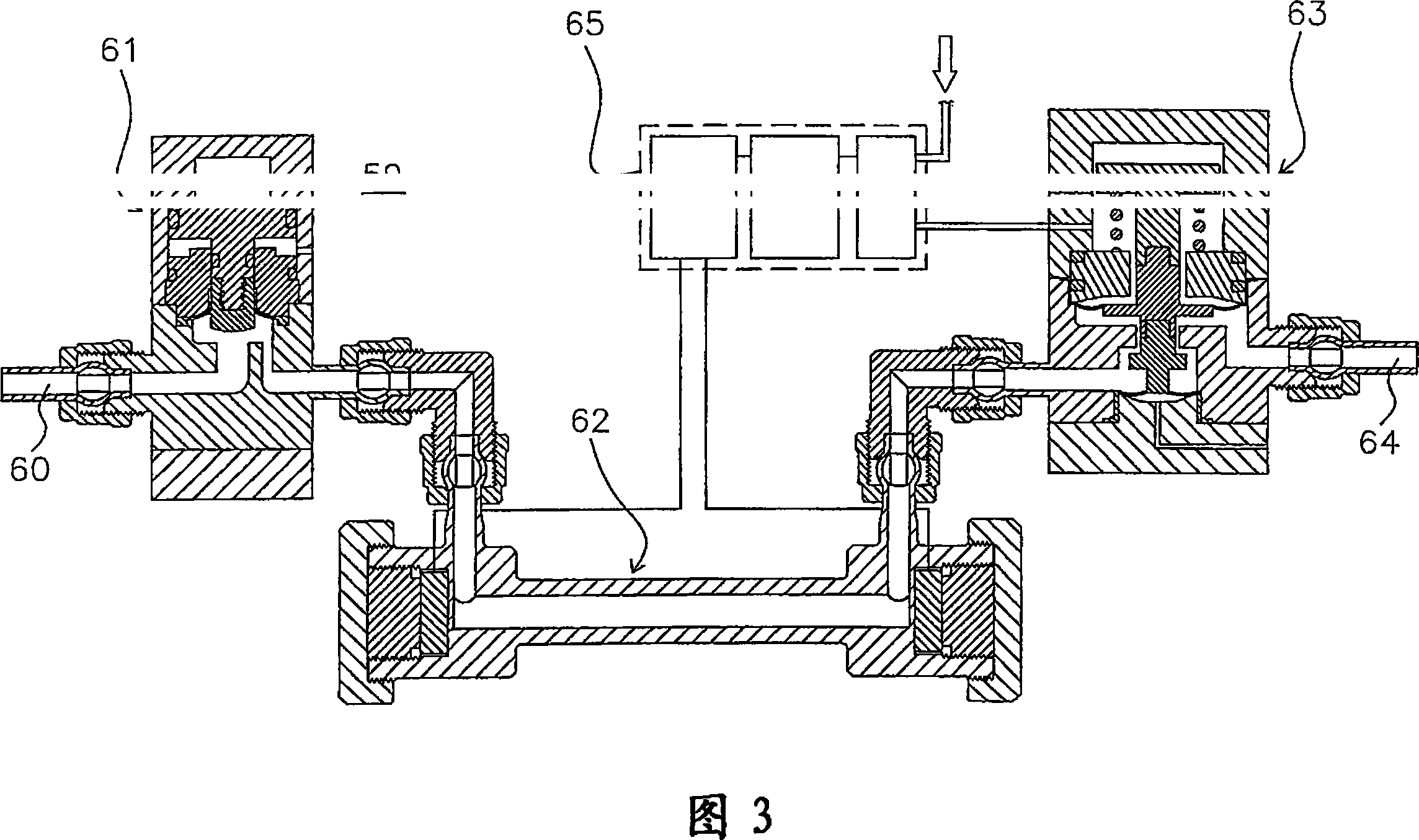

InactiveCN1922451AImprove efficiencyEasy to set up jobsCompressorDispersed particle separationEngineeringRefrigerant

A humidity controller (10) is provided with a refrigerant circuit (60). The refrigerant circuit (60) has first and second heat exchangers (61, 62) carrying an adsorptive agent and circulates a refrigerant to perform a freezing cycle. Further, in the refrigerant circuit (60), the direction of circulation of the refrigerant is reversible. The first and second heat exchangers (61, 62) are installed in a casing (11). In the humidity controller (10), air flow paths are switched so that first air passes through either of the heat exchangers (61, 62) that works as an evaporator and second air passesthrough the other that works as a condenser. A compressor (63), an expansion mechanism (65), and a four-way selector valve (64) of the refrigerant circuit (60) are installed in the casing (11) together with the heat exchangers (61, 62).

Owner:DAIKIN IND LTD

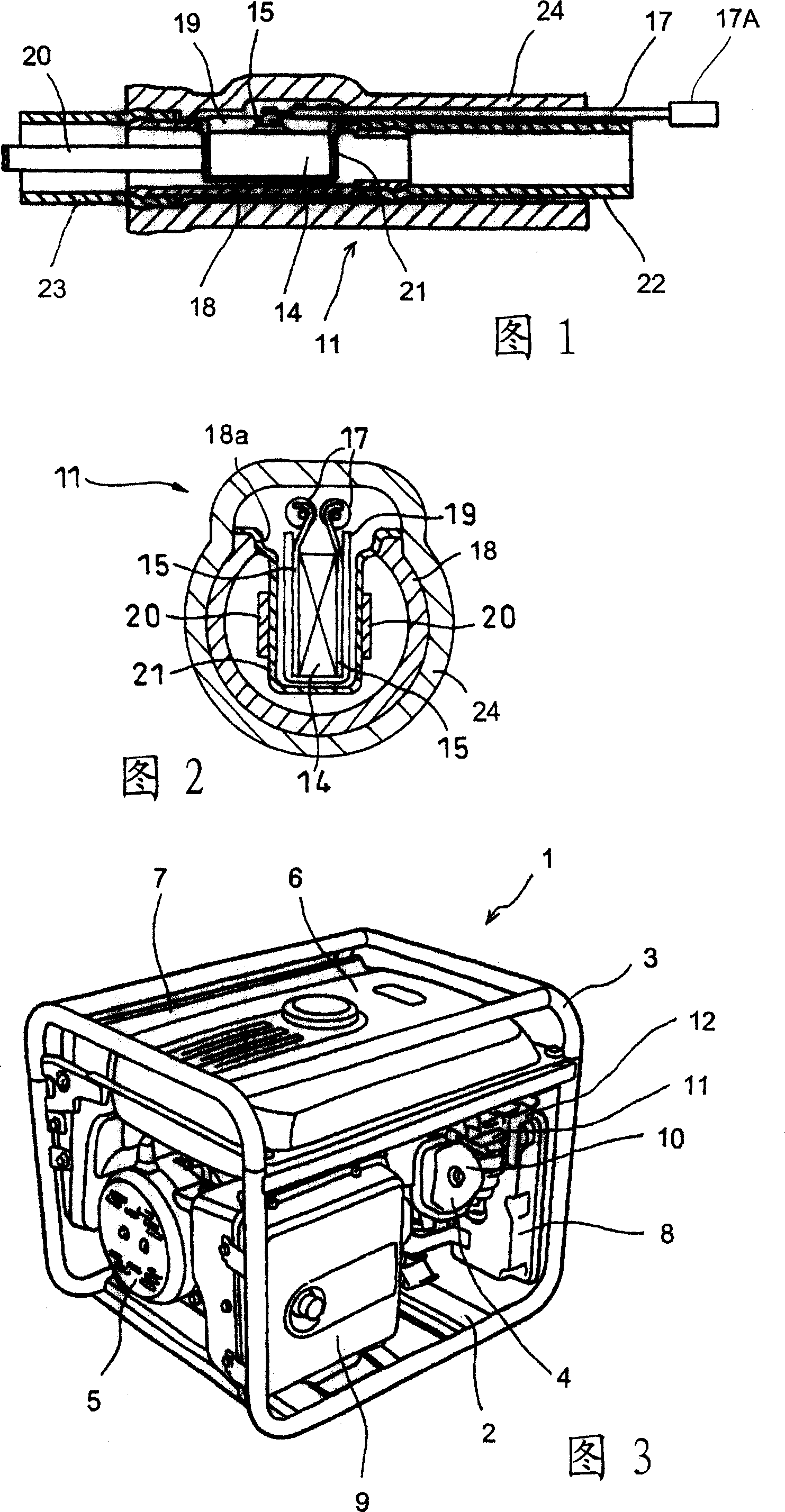

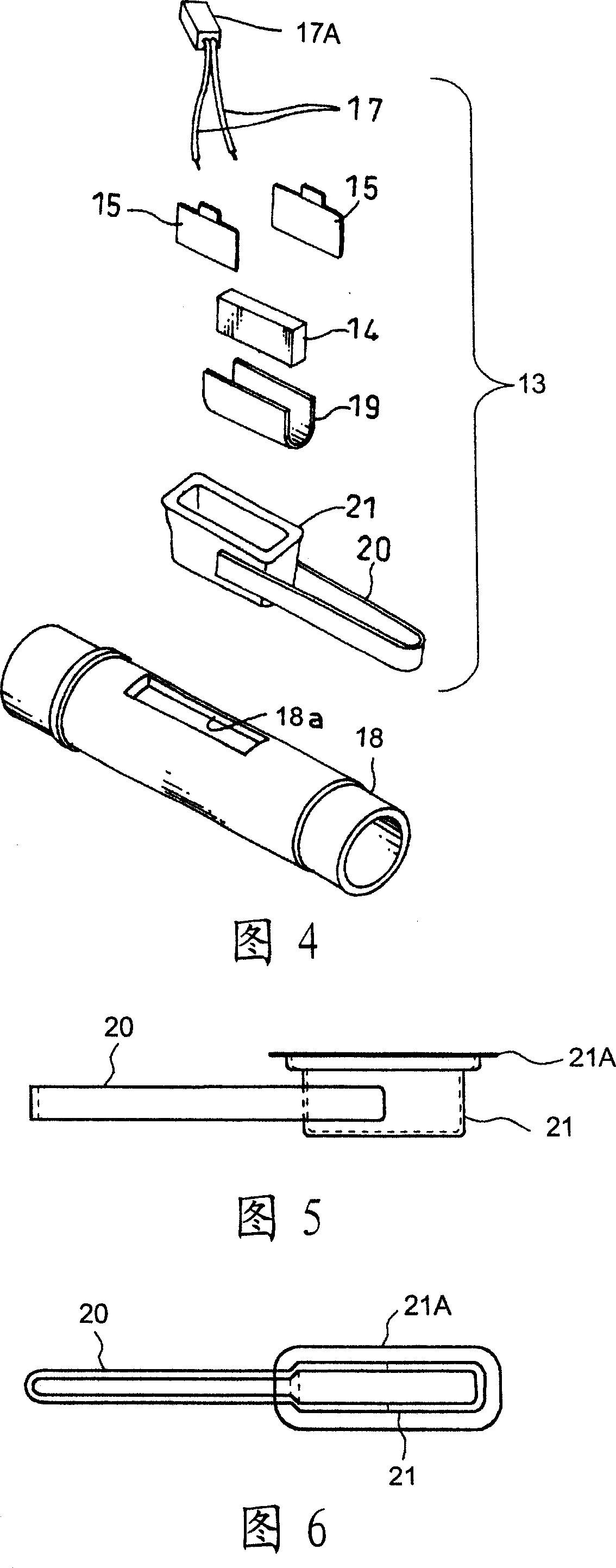

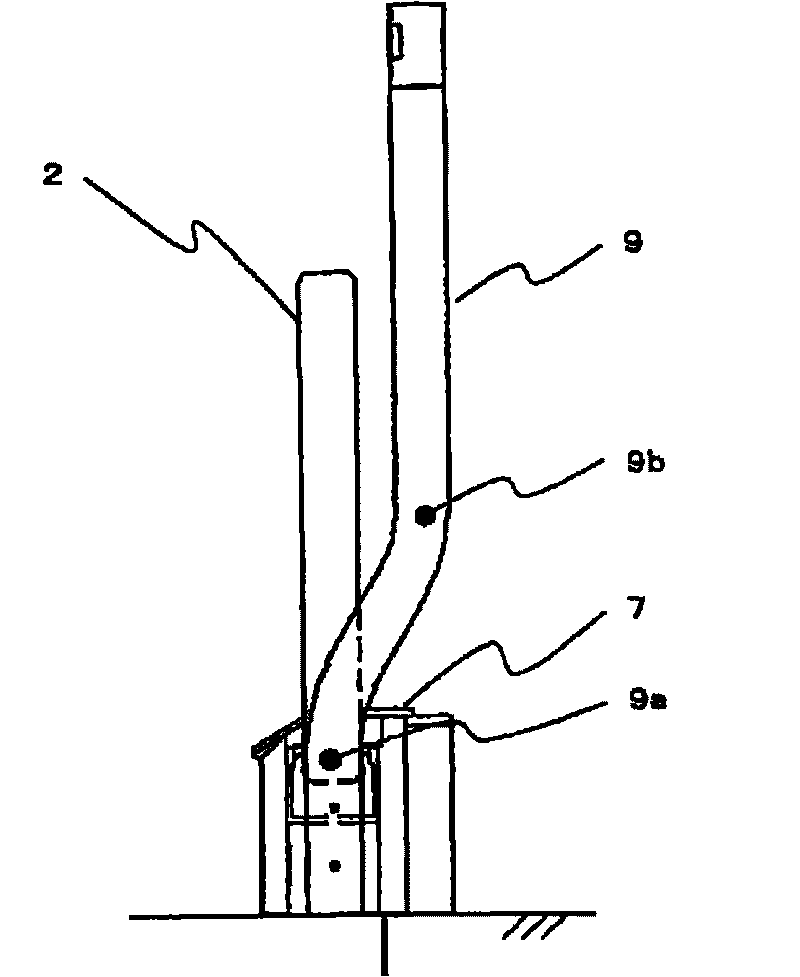

Engine with breather apparatus

InactiveCN101021174AIncrease contact timeEfficient heatingInternal combustion piston enginesCrankcase ventillationBreatherCylinder head

In order to suppress freezing of a water content within a breather tube, a heater ( 13 ) is arranged within a breather tube ( 11 ) joining a cylinder head cover ( 10 ) and an air cleaner ( 8 ). A main body of the breather tube ( 11 ) is constituted by a joint tube ( 18 ) arranged in a middle, and partial tubes ( 22, 23 ) connected to both ends thereof. The heater ( 13 ) has a heating element ( 14 ) corresponding to a heating element, and has a heater case ( 21 ) accommodating the heating element ( 14 ) in a state of being pinched by electrodes ( 15 ), and is arranged in a center portion of the joint 18 . A slot ( 18 a) for inserting the heater ( 13 ) is formed in the joint tube 18 . A heat radiating body ( 20 ) extended along the breather tube ( 11 ) is joined to the heater case ( 21 ). An outer peripheral portion of the breather tube ( 11 ) is covered by an insulative outer tube ( 24 ).

Owner:HONDA MOTOR CO LTD

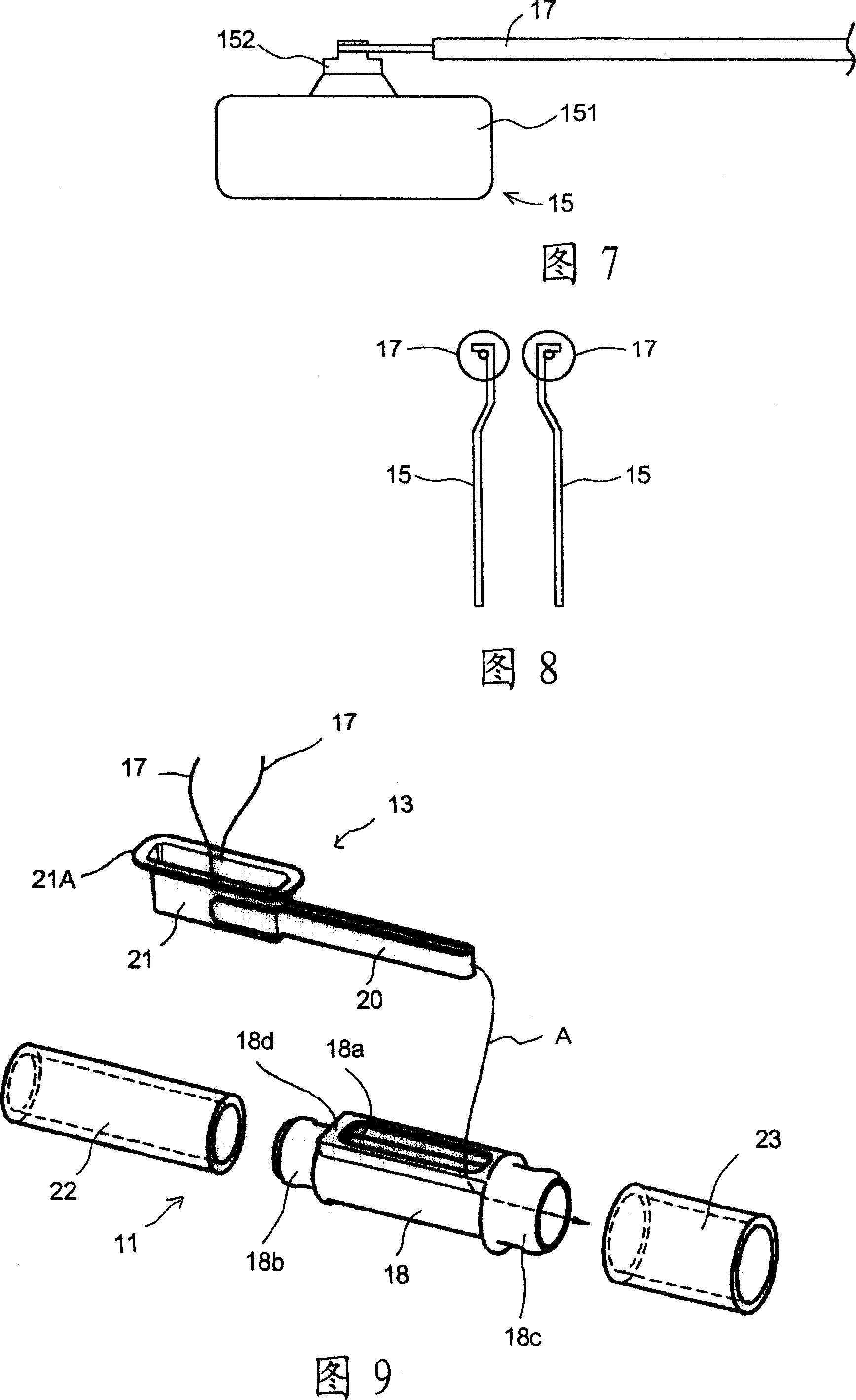

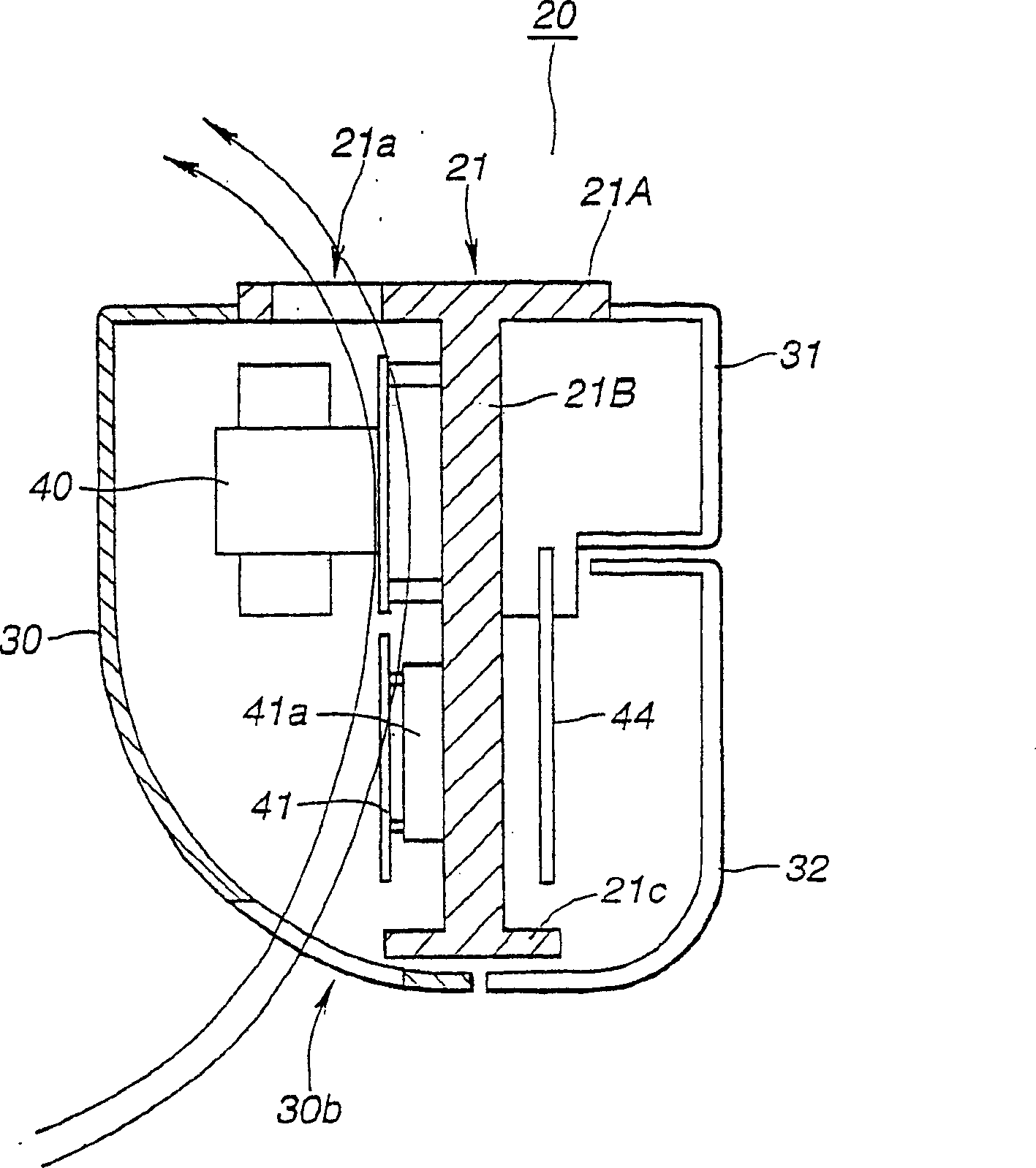

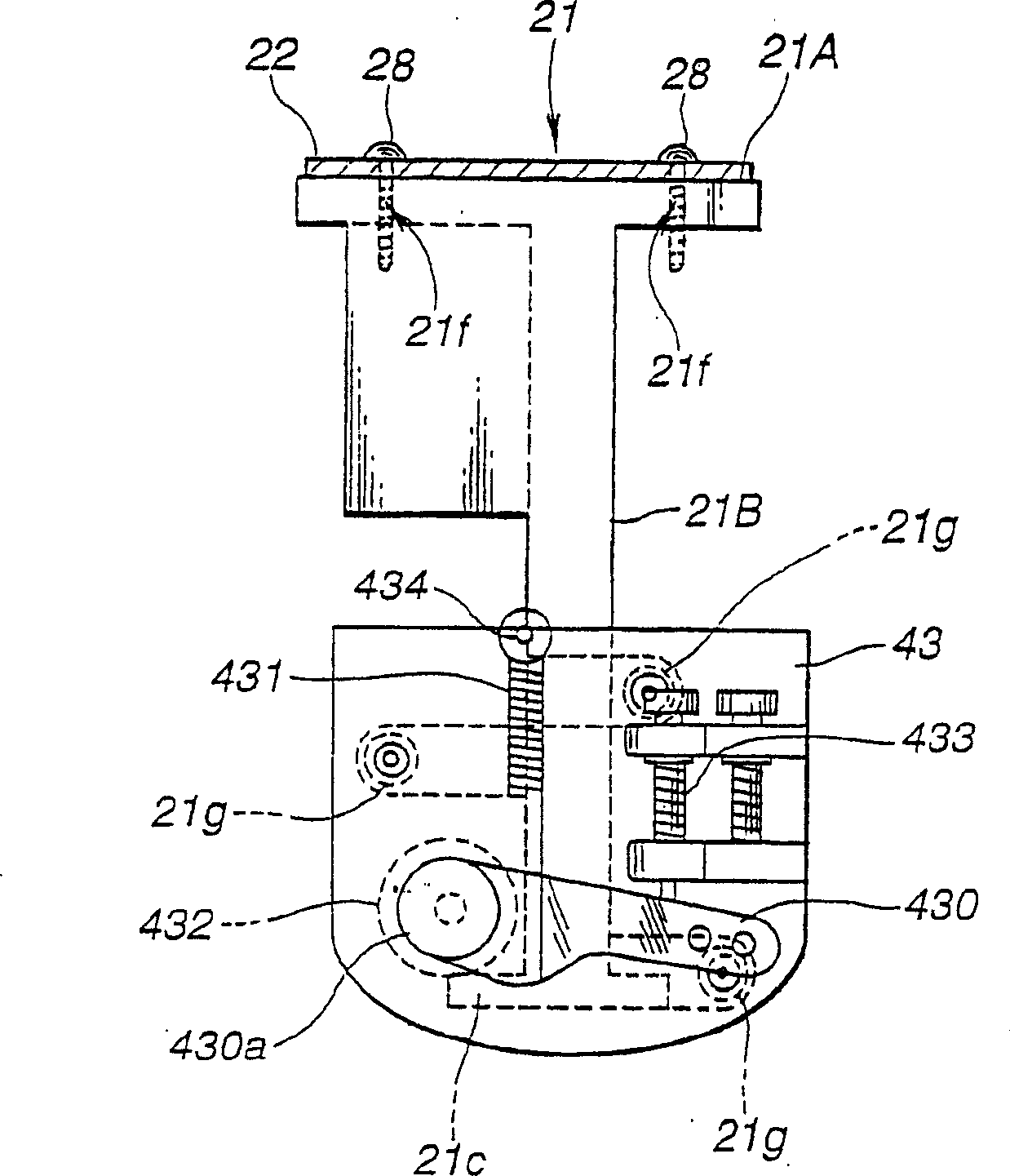

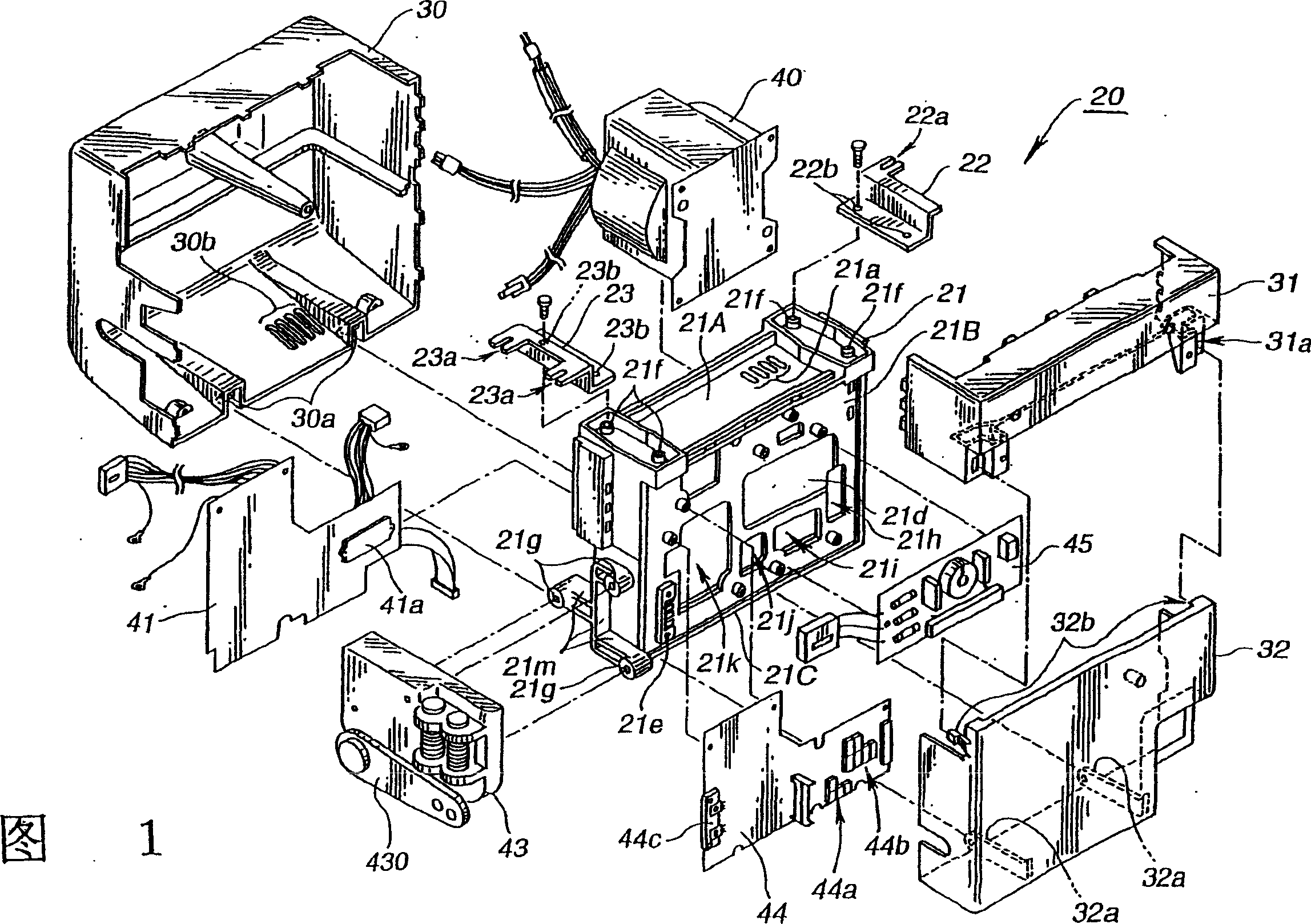

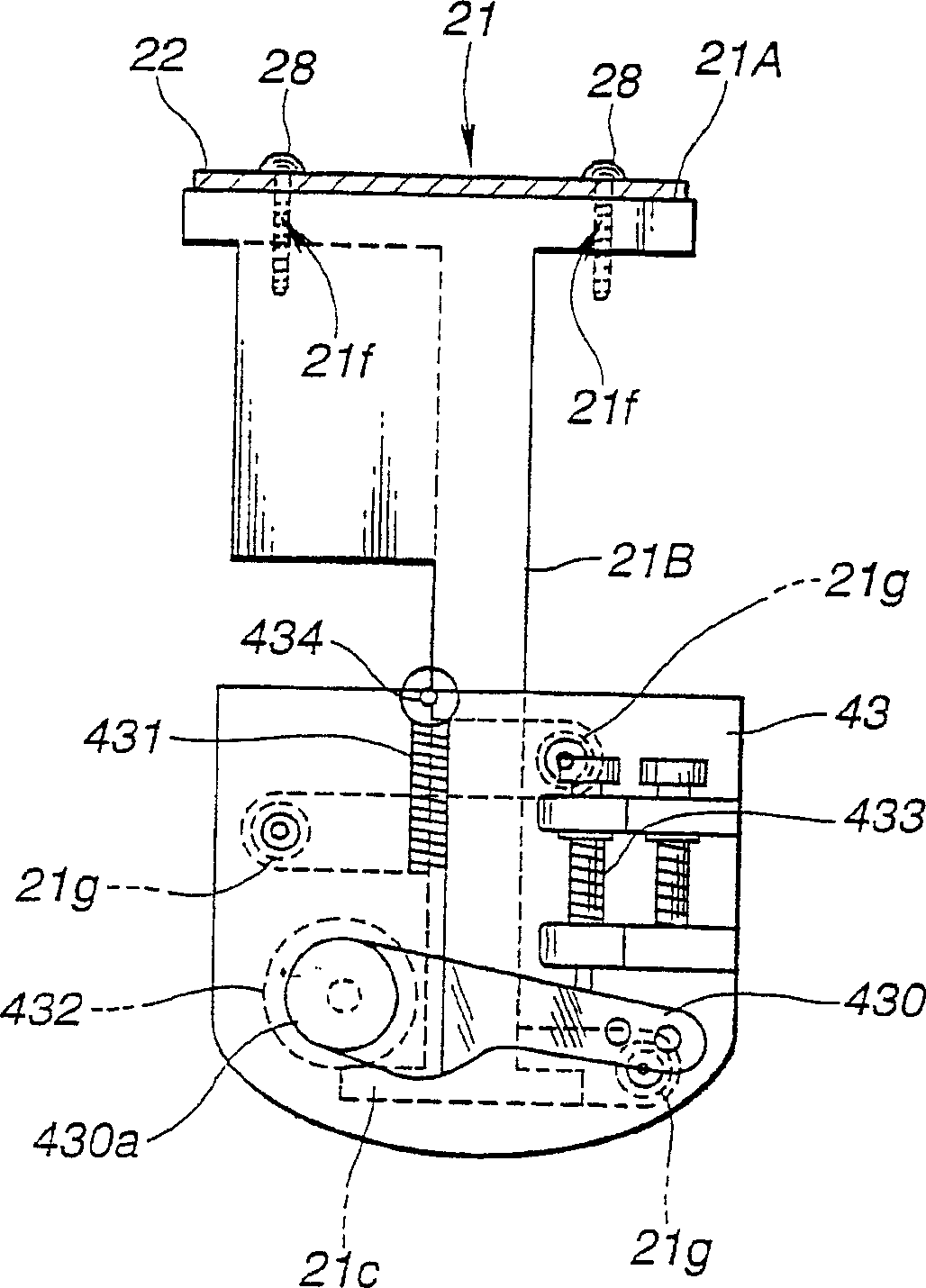

Control box device for sewing mechine

InactiveCN1495315ASmall sizeRich varietyLubrication/cooling devicesSewing-machine casingsMotor driveEngineering

To make a control box compact and to improve cooling efficiency of a heating part by providing a plate-like frame member vertically extending, and installing an electric part on both surfaces of the member in the control box arranged under a sewing machine table and housing a sewing machine control electric part. A frame 21 of a control box 20 of a sewing machine is made of metal, and is constituted in a cross-sectional view T shape out of the plate- like main frame part 21B extending in the vertical direction and the upper / lower frame parts 21A, 21C horizontally arranged above and below it. An electric part such as a motor drive circuit containing an inverter circuit for driving a power transformer 40 and a sewing machine motor is installed in the main frame part 21B. The opening parts 21h to 21k are formed in the main frame part 21 to improve weight reduction and gas permeability, the projecting parts 21d and 21e are arranged to receive heat radiation by contacting with a heating part containing the power transformer 40, and drive elements 41a, 44c are contacted with the respective projecting parts 21d, 21e.

Owner:JUKI CORP

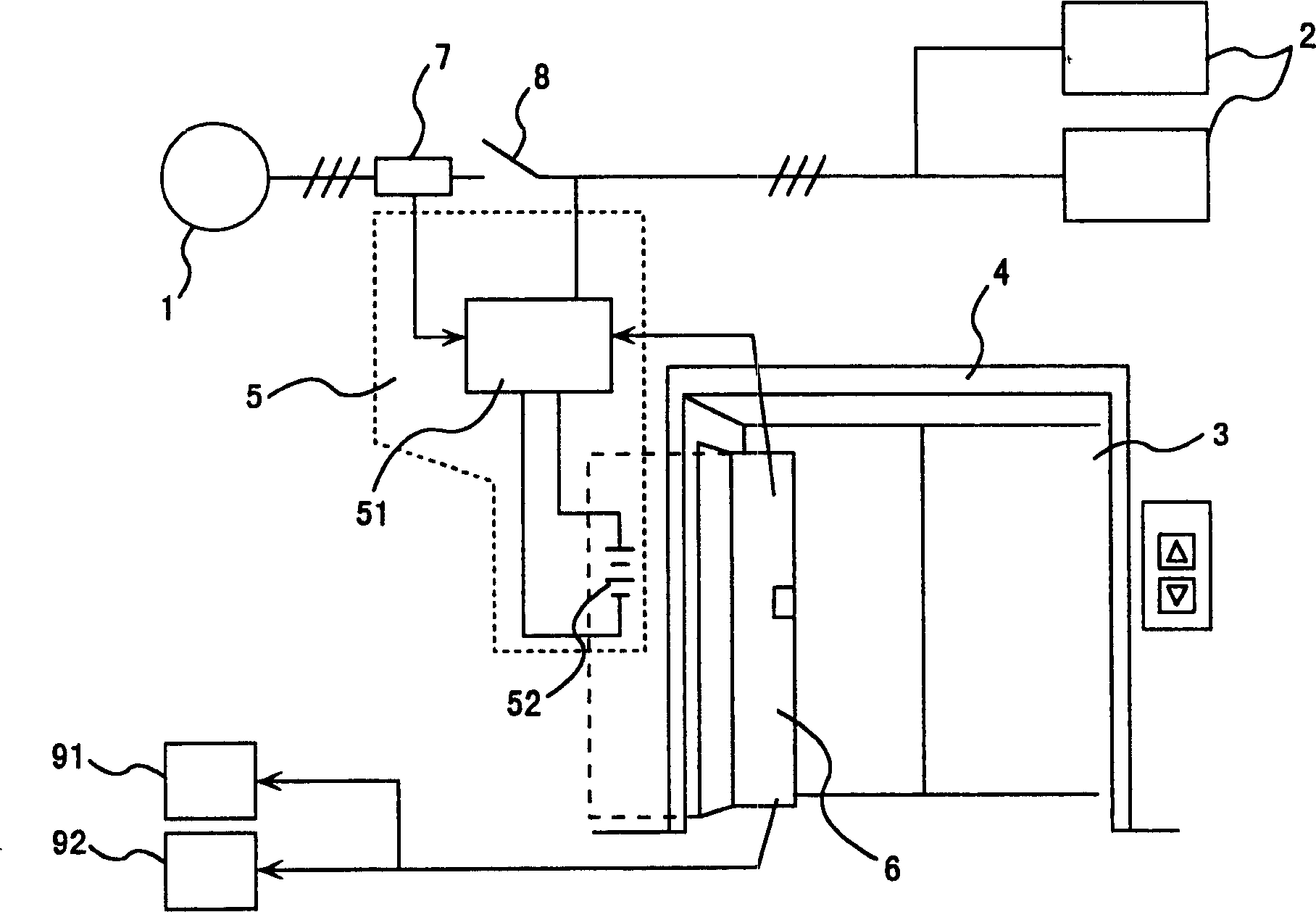

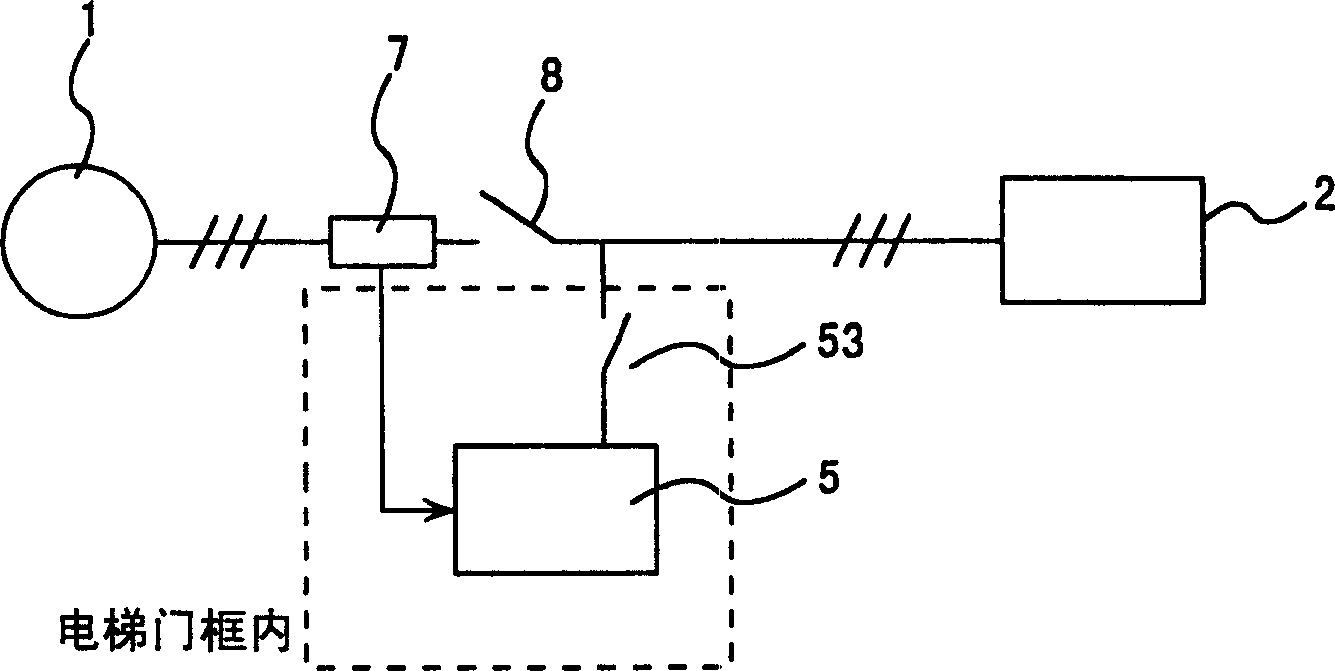

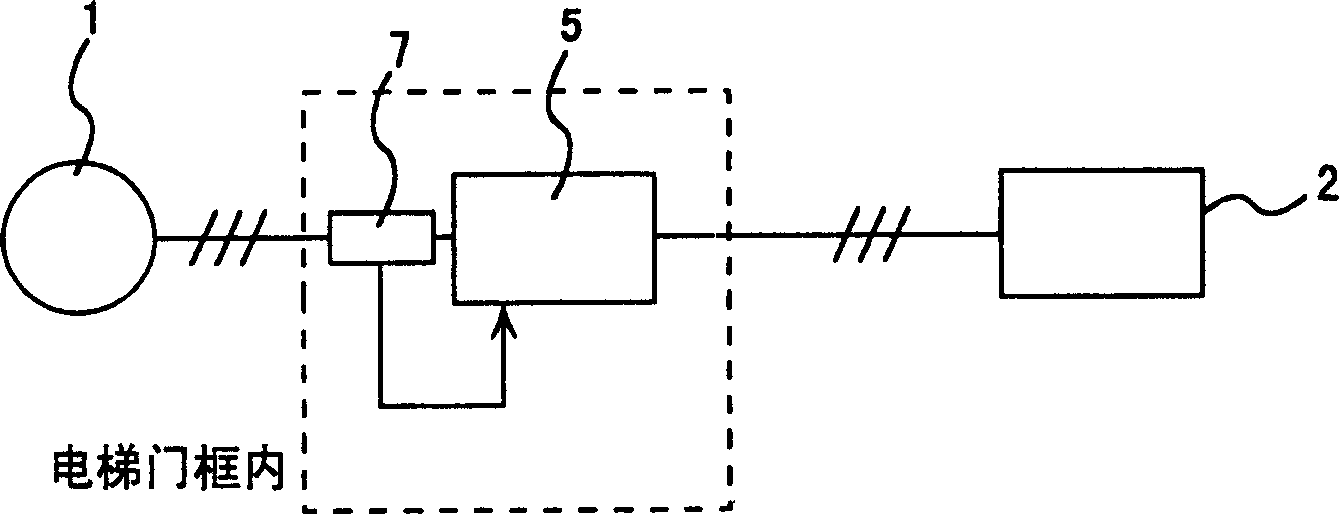

Power-supply system

InactiveCN1612836AImprove the decorative effectDecoration will not be affected by settingsElevatorsBuilding liftsPower sensorElectrical battery

A power supply system comprising a power supply having a secondary cell and a charging / discharging controller for controlling the charging / discharging of the secondary cell, characterized in that the power supply is connected to a power system of a building in series or parallel, and the power supply or a part of it is installed inside an entrance frame of a landing of an elevator. Since the power supply or a part of it is installed inside an entrance frame of a landing of an elevator, effective use of the building is achieved. Further, since the power supply or a part of it is installed inside the entrance frame of the elevator landing, the maintenance work is facilitated. The lead-in cable of the power supply installed inside of the elevator landing is only the power supply line and the signal line of a power sensor, thereby facilitating the installation work.

Owner:HITACHI LTD

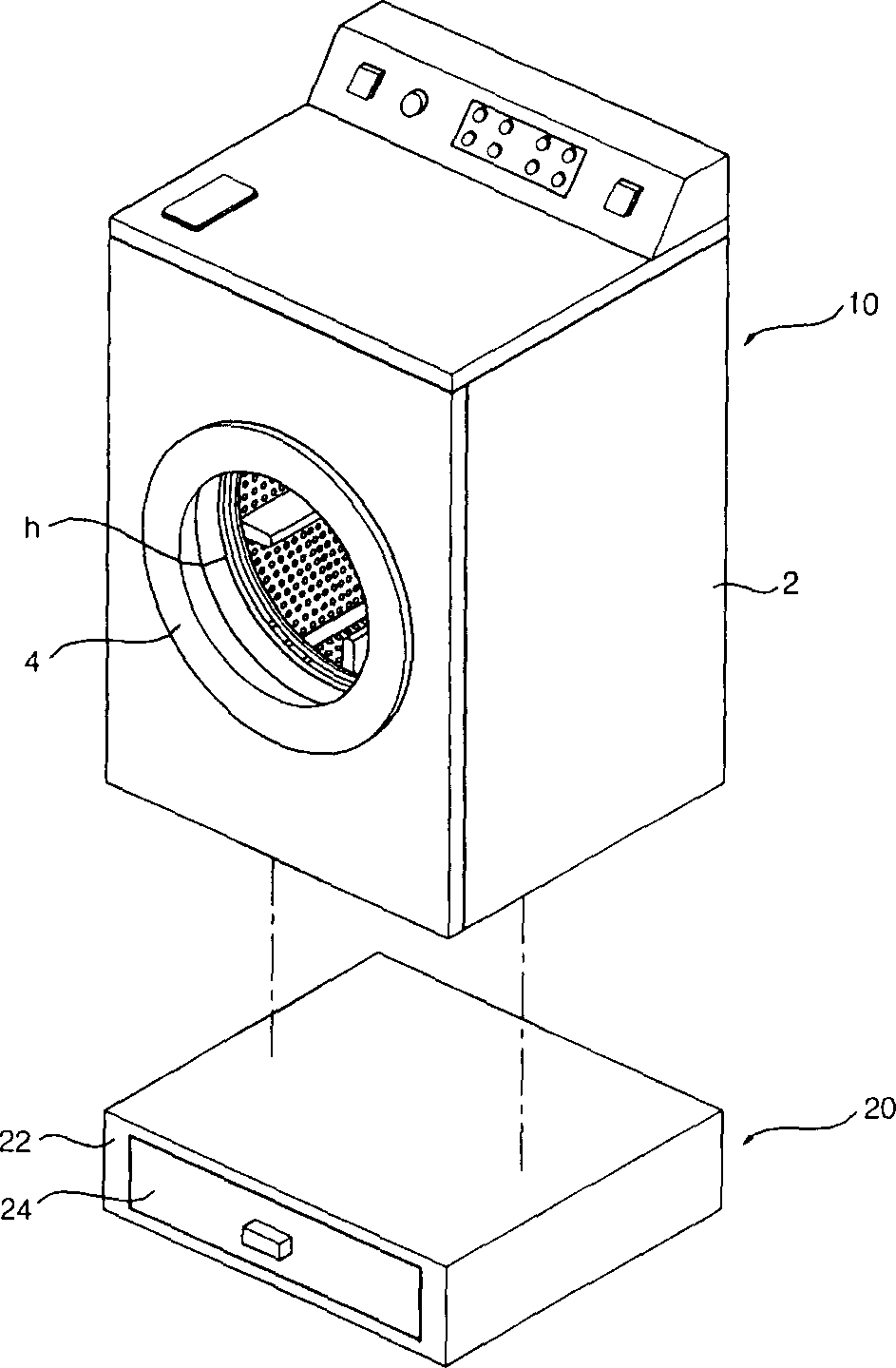

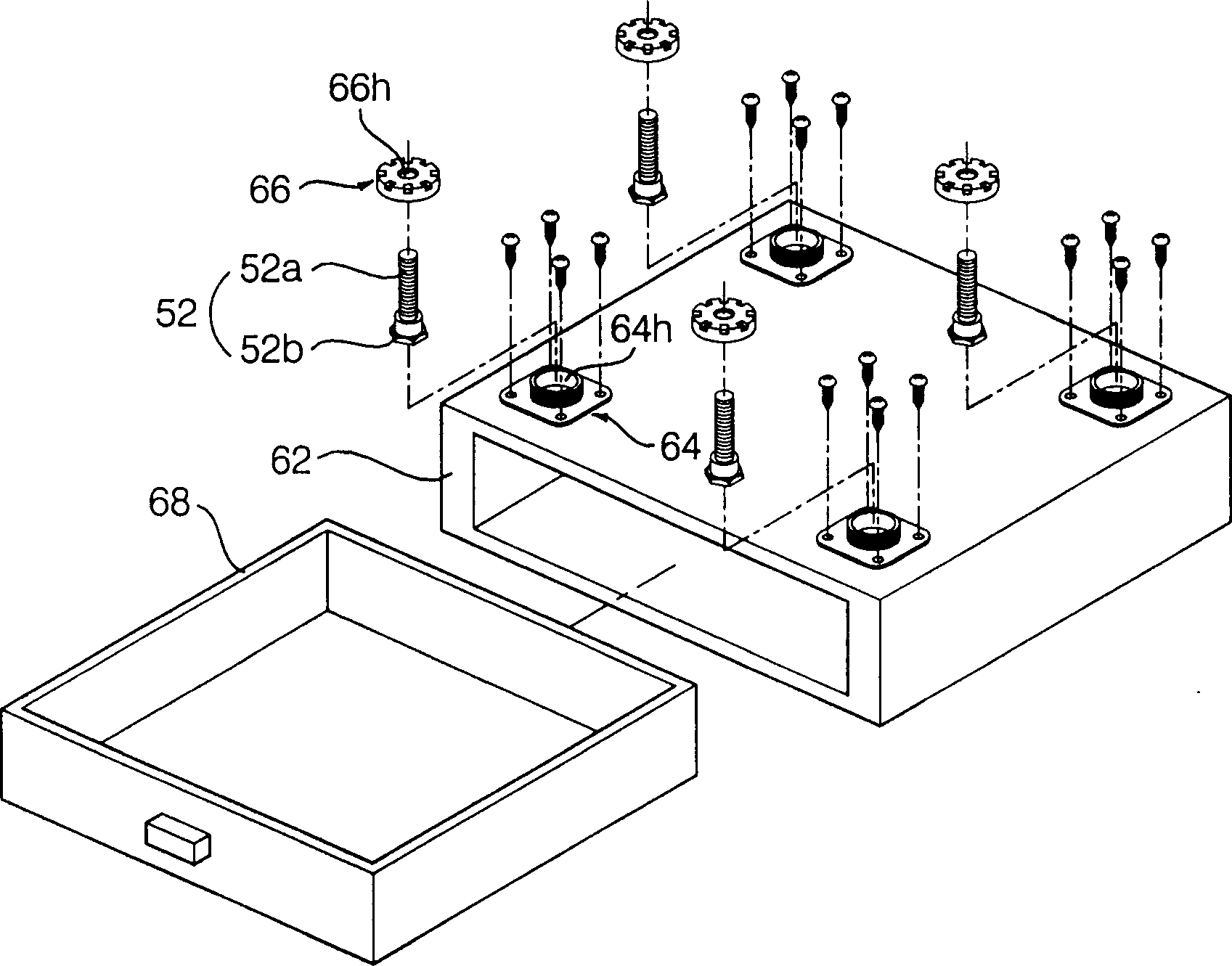

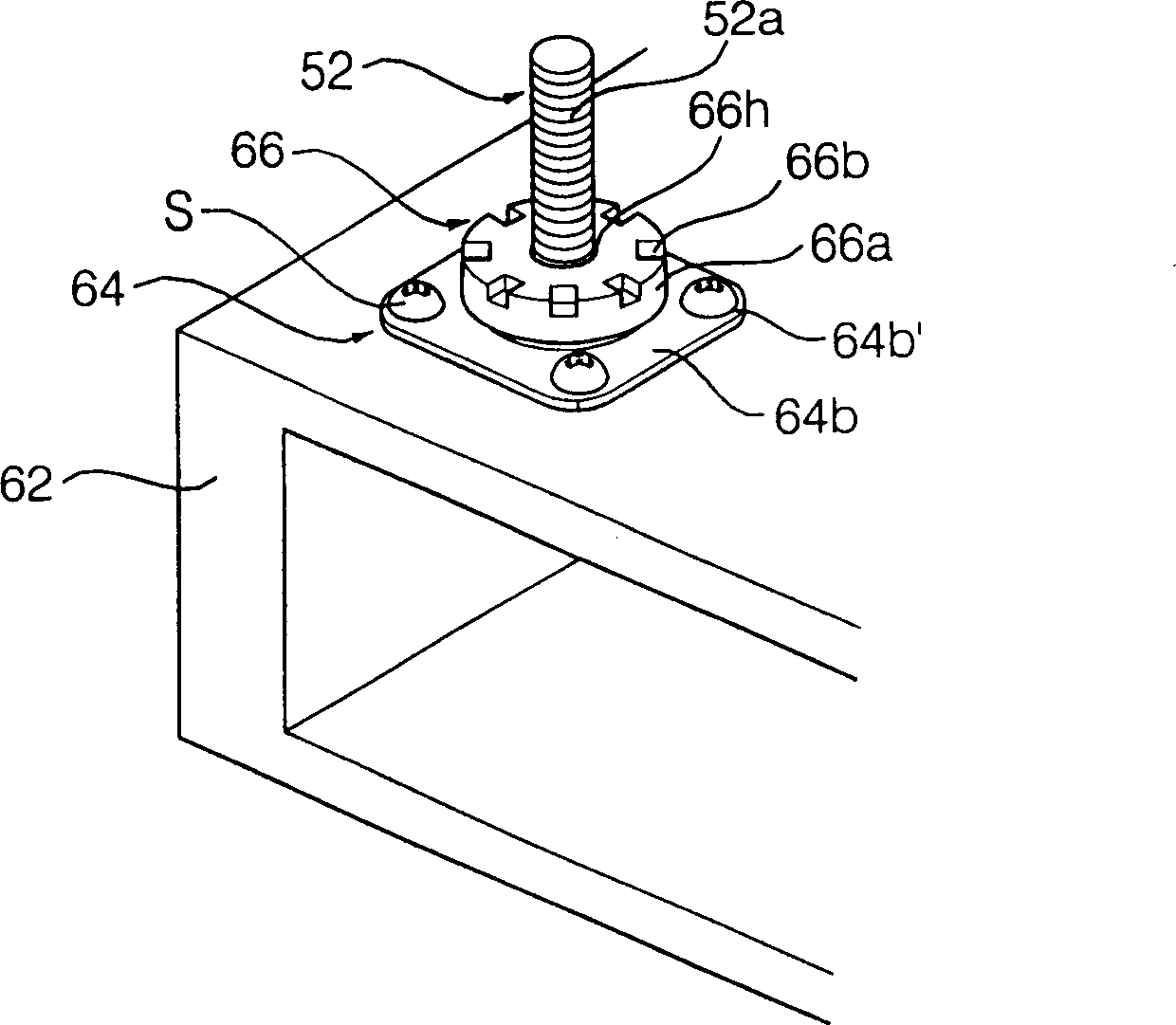

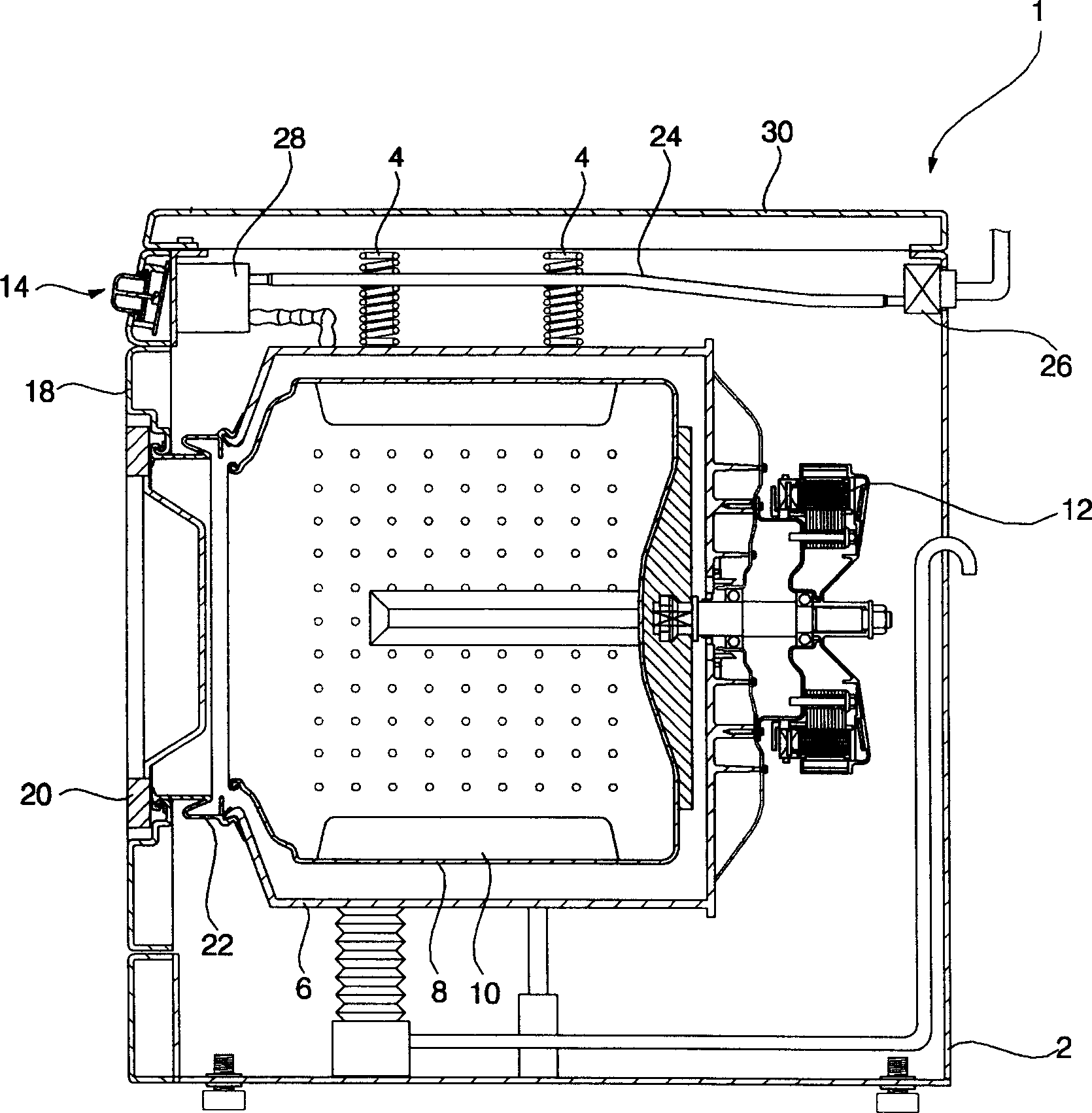

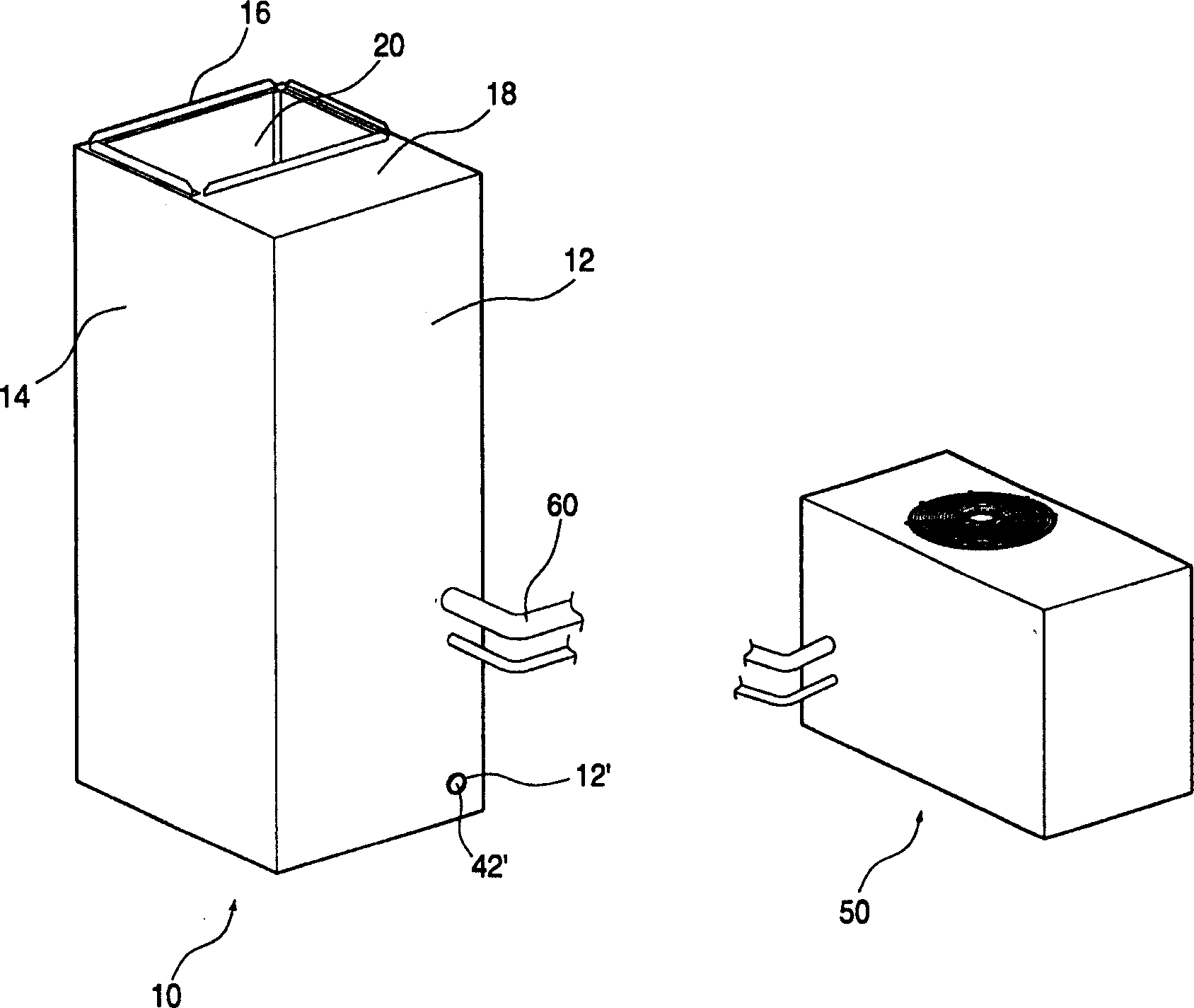

Washing machine pedestal

InactiveCN1683685AEasy to set up jobsReduce setup timeOther washing machinesStands/trestlesPulp and paper industry

The washing machine pedestal includes pedestal body, connecting screws and connecting nuts. The pedestal body can support washing machine in certain height; the connecting screws are fixed onto the pedestal body and have installation holes formed in center for installing the lower ends of the installing legs fixed to the lower part of the washing machine; and the connecting nuts are combined to the connecting screws, so as to combine the legs tightly onto the pedestal body and have in the center blocking holes for clamping the lower parts of the legs. Therefore, the present invention can raise the height of washing machine conveniently.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

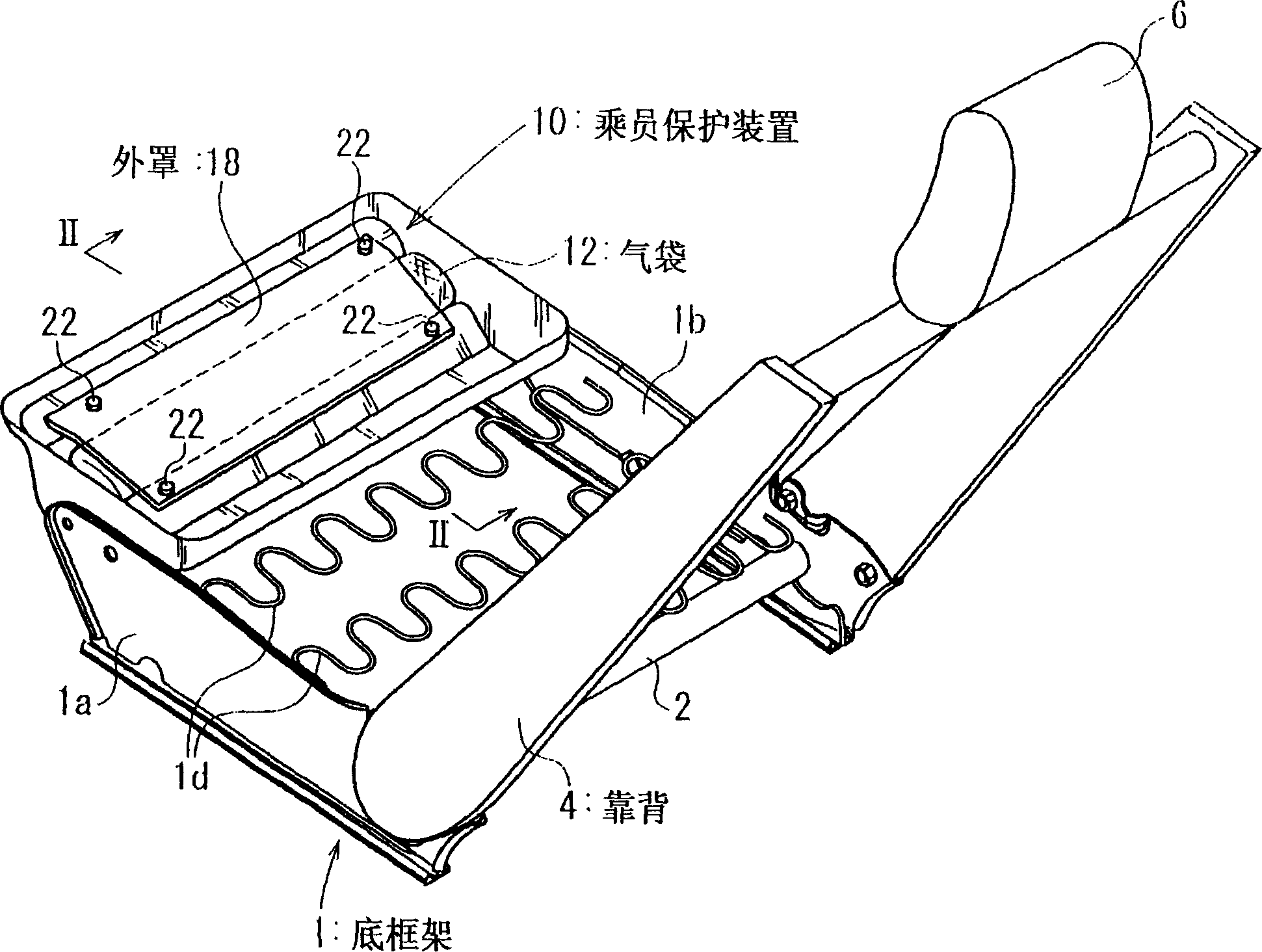

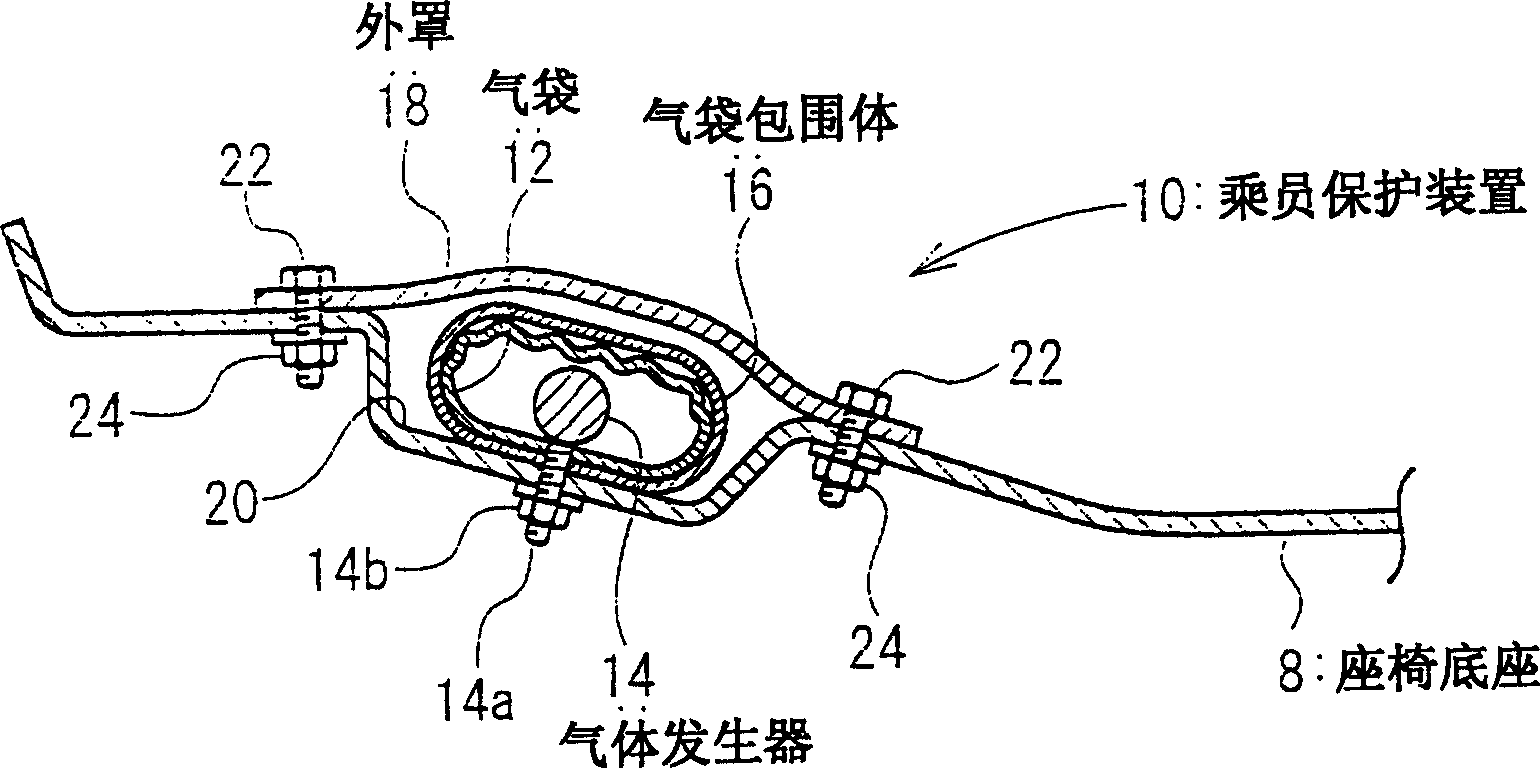

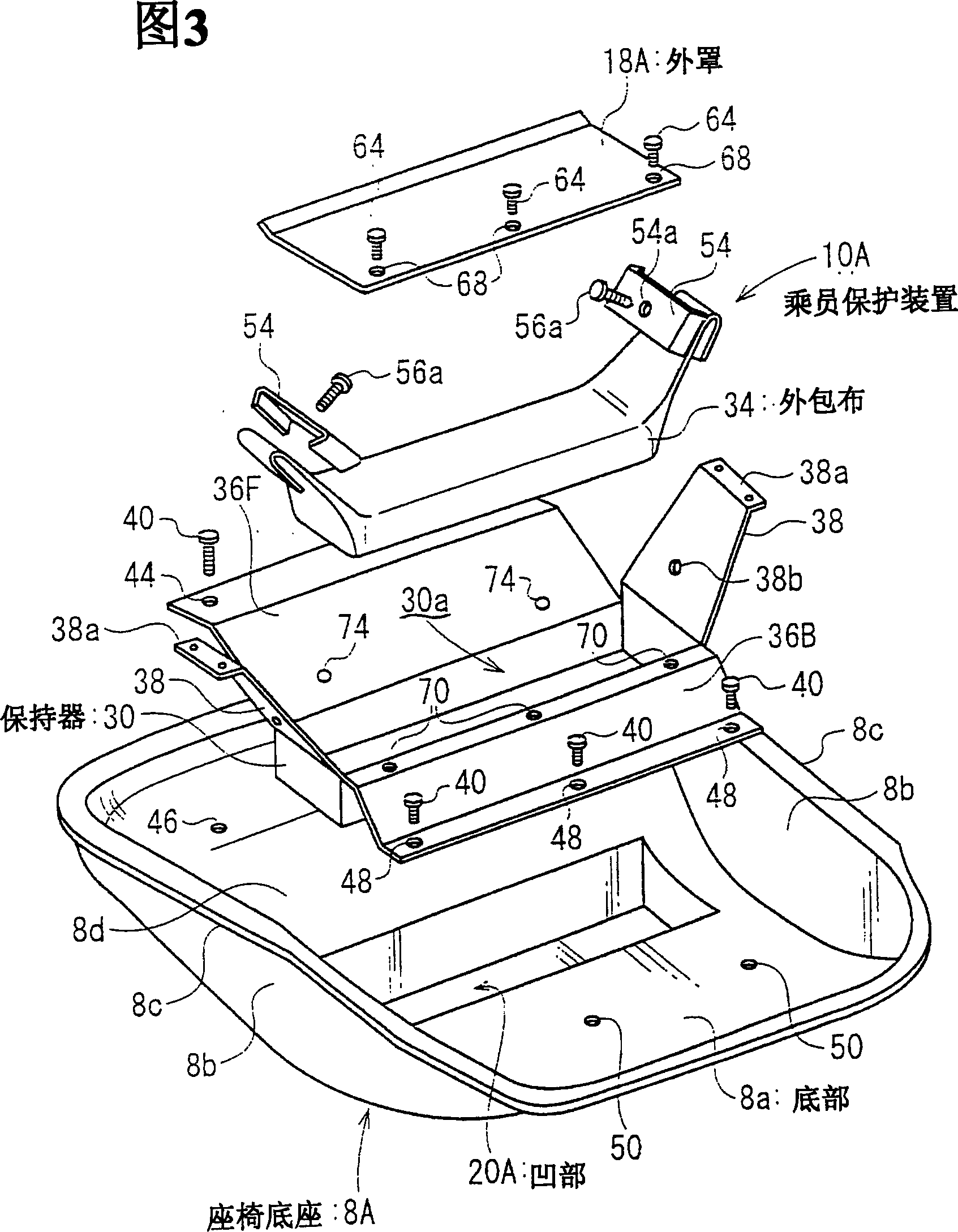

Passenger protecting device

InactiveCN1603175AAvoid damageReduced durabilityVehicle seatsPedestrian/occupant safety arrangementEngineeringGas generator

In order to provide a passenger protecting device having a configuration for preventing damage of a bag disposed underneath a cushion due to friction between a seat cushion and the bag, or the like, a passenger protecting device (10) includes the bag (12) disposed underneath a front portion of the seat cushion, a gas generator (14) for inflating the bag (12), a bag envelope (16) disposed so as to surround the bag (12), a cover (18) for covering the aforementioned components. A seat pan (8) disposed underneath the seat cushion includes a recess (20) on the upper face thereof, and the bag (12), the gas generator (14), and the bag envelope (16) are disposed within the recess (20). The cover (18) is disposed so as to cover the recess (20).

Owner:TAKATA CORPORATION

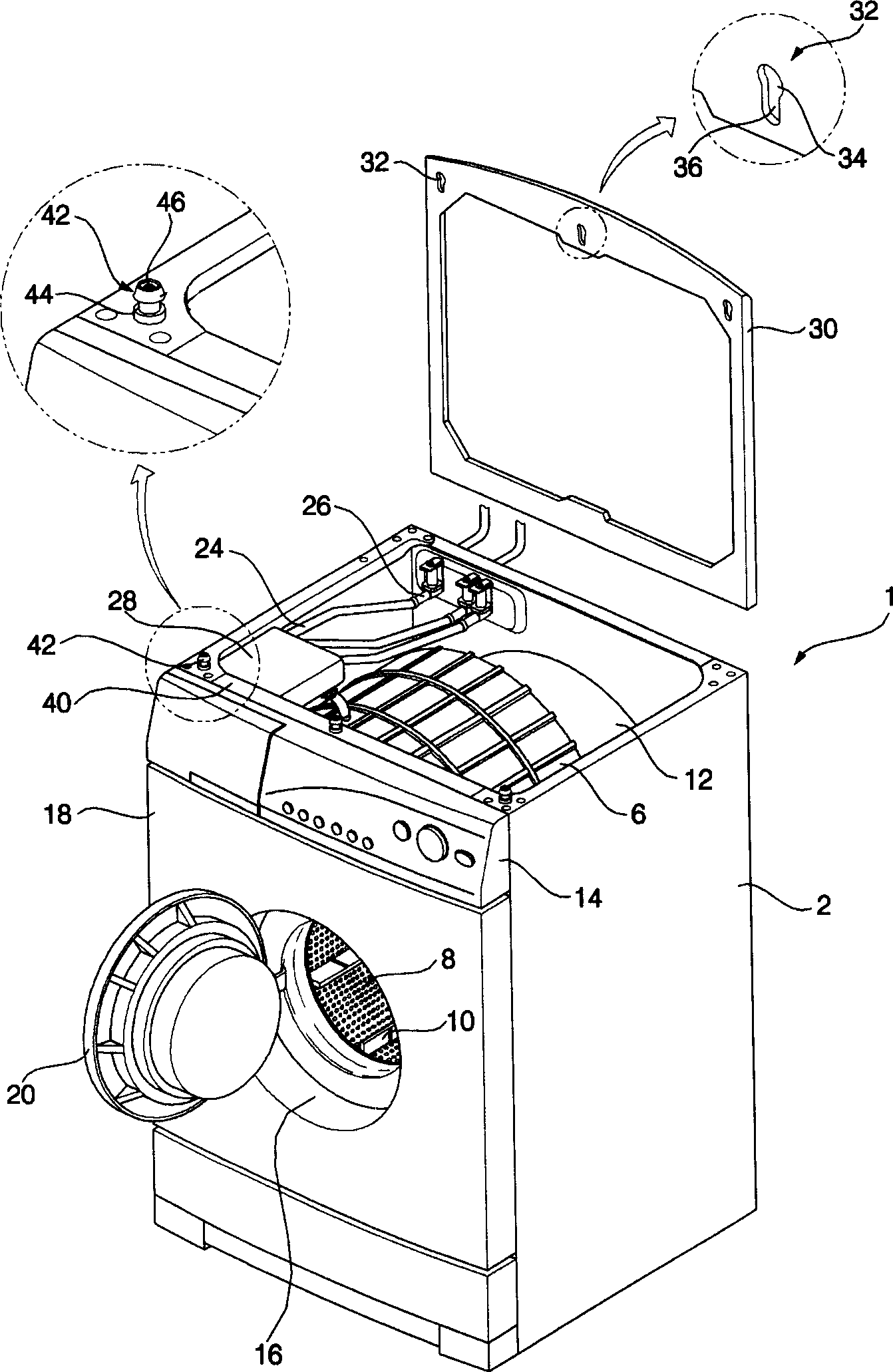

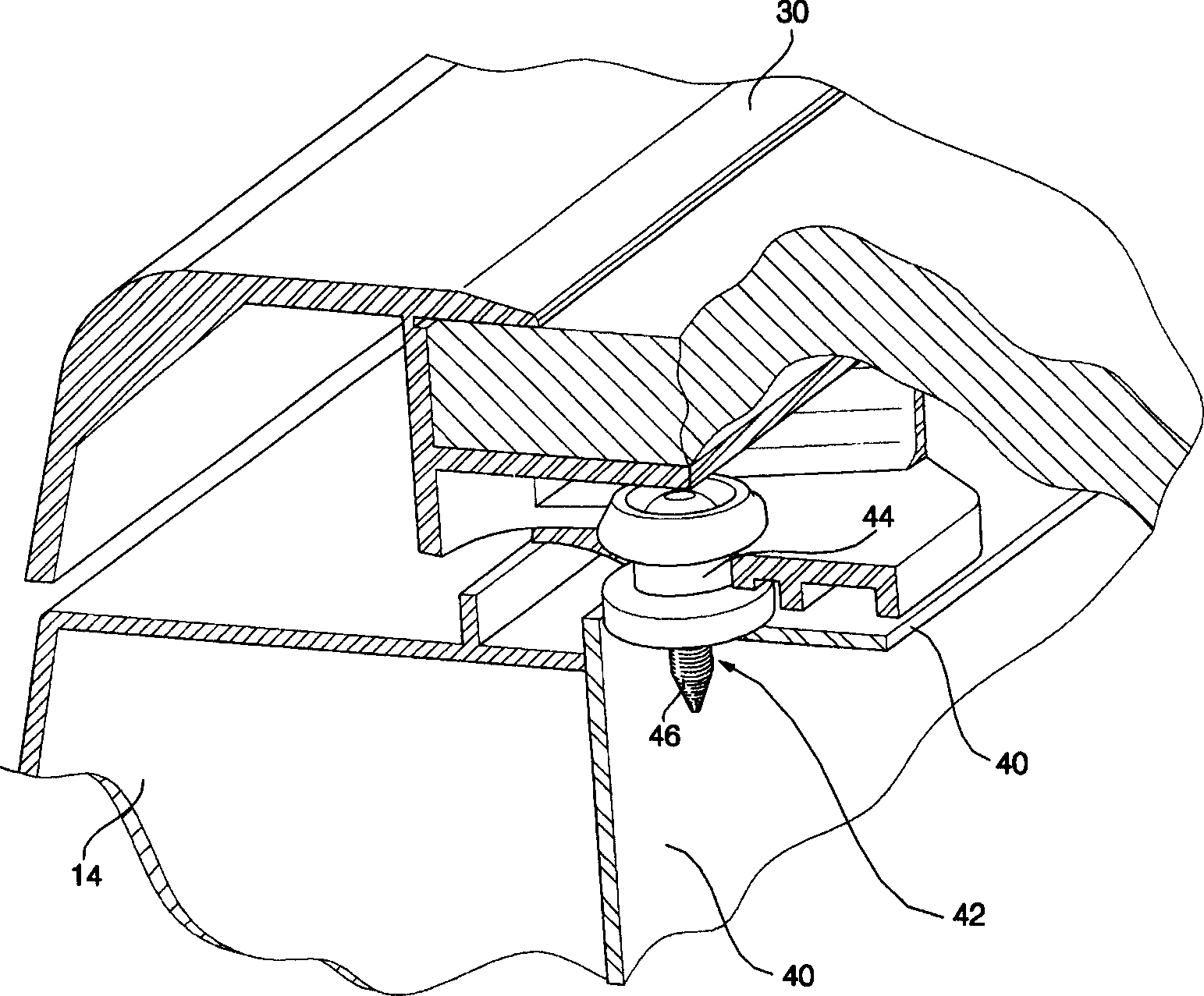

Top plate setting structure of drum washer

InactiveCN1779043AReduce setup processEasy to set up jobsOther washing machinesTextiles and paperEngineering

The invention opens a setting structure of the head plate for rolling washer including the shell, the control panel and the fixing hole. The fixing bracket is injected in the top of the control panel, so it can set the head plate directly after installing the control panel. Because of this, it simplifies the setting process of the head plate.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Indoor unit of air conditioner

InactiveCN1712790AEasy to set upEfficient use ofLighting and heating apparatusAir conditioning systems

An indoor unit of air conditioner has an external upper panel, a partition under said external upper panel, a control box containing a built-in circuit board fixed to said partition and an electric air heater, a fan housing able to slide back and forth under said control box, and a heater contained region formed on the back of said control box. Said electric air heater can be easily installed or detached via the internal space of control box.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

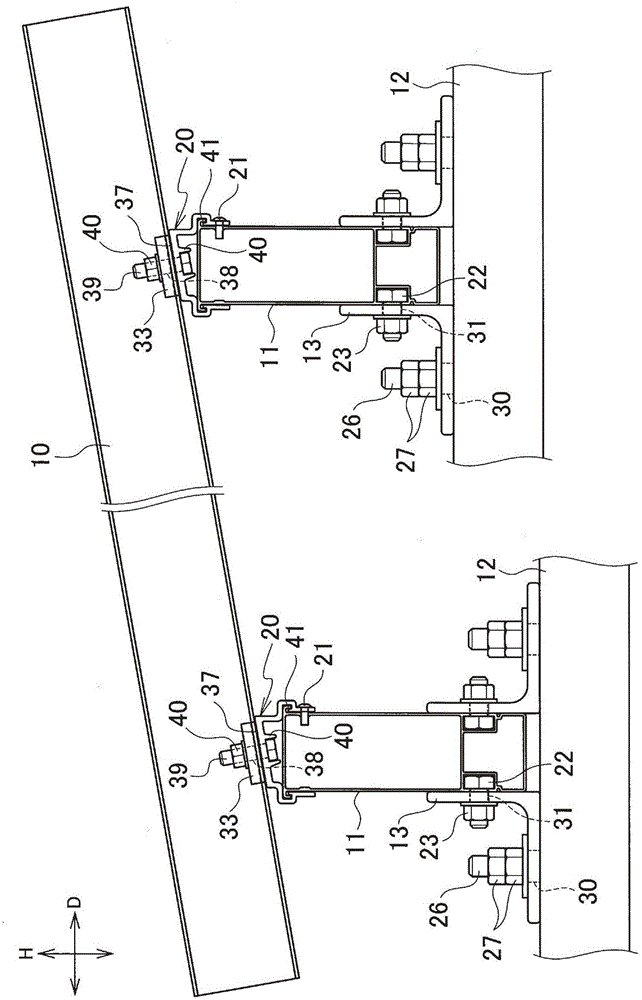

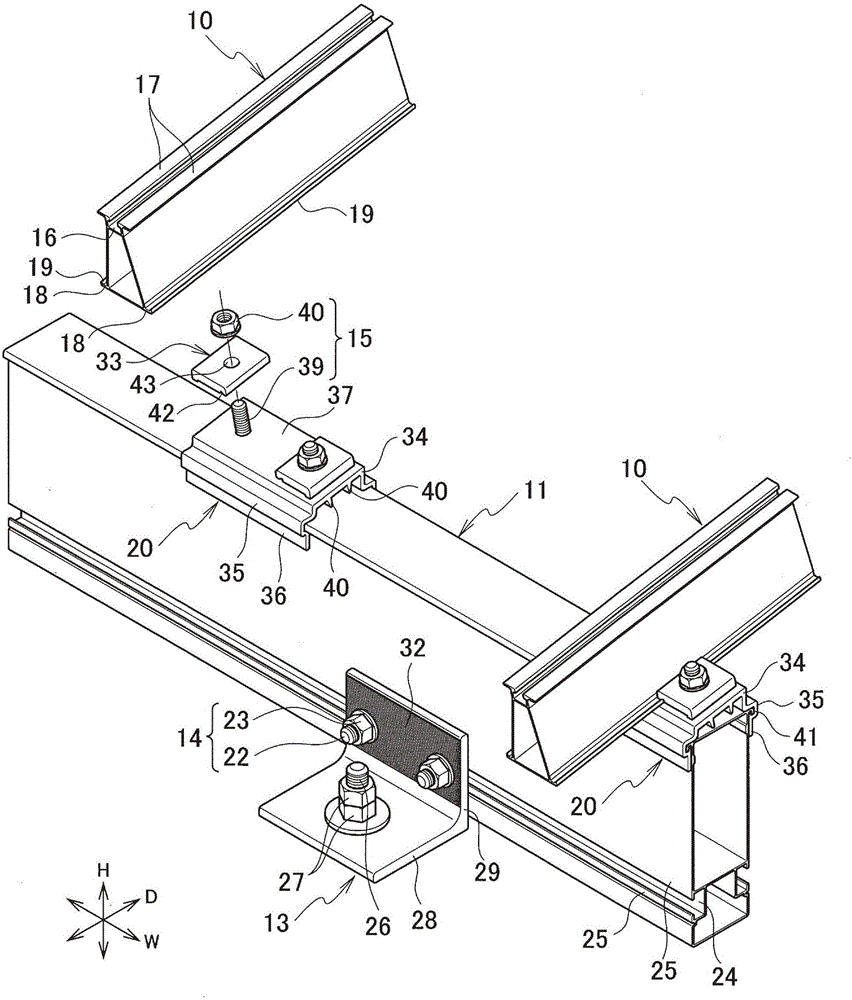

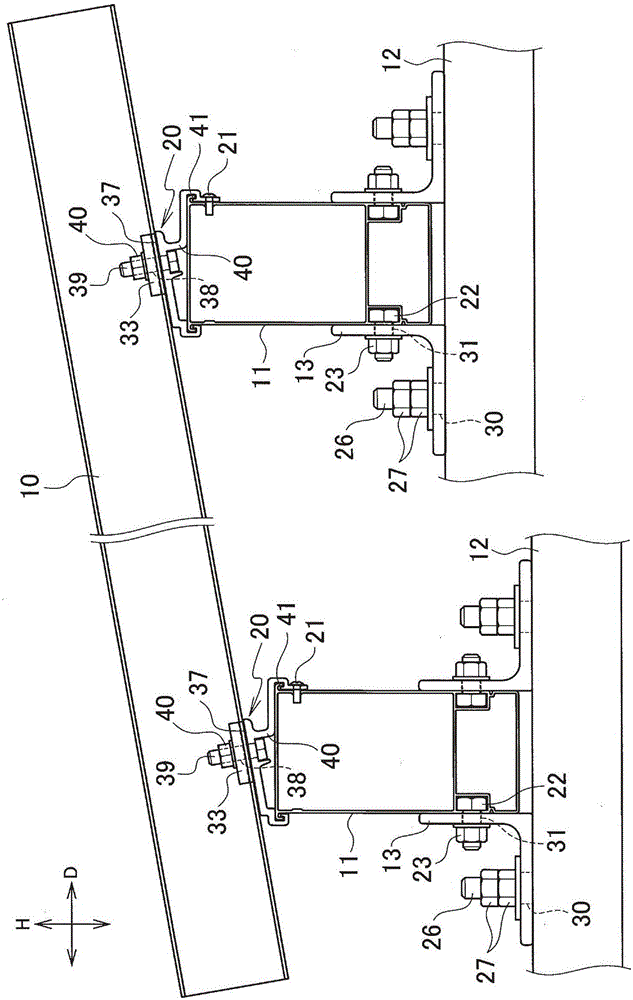

Solar panel stand

InactiveCN106330078AReduce the number of partsEasy to set up jobsPhotovoltaicsPhotovoltaic energy generationEngineeringStructural engineering

Owner:NIKKEIKIN ALUMINUM CORE TECH +6

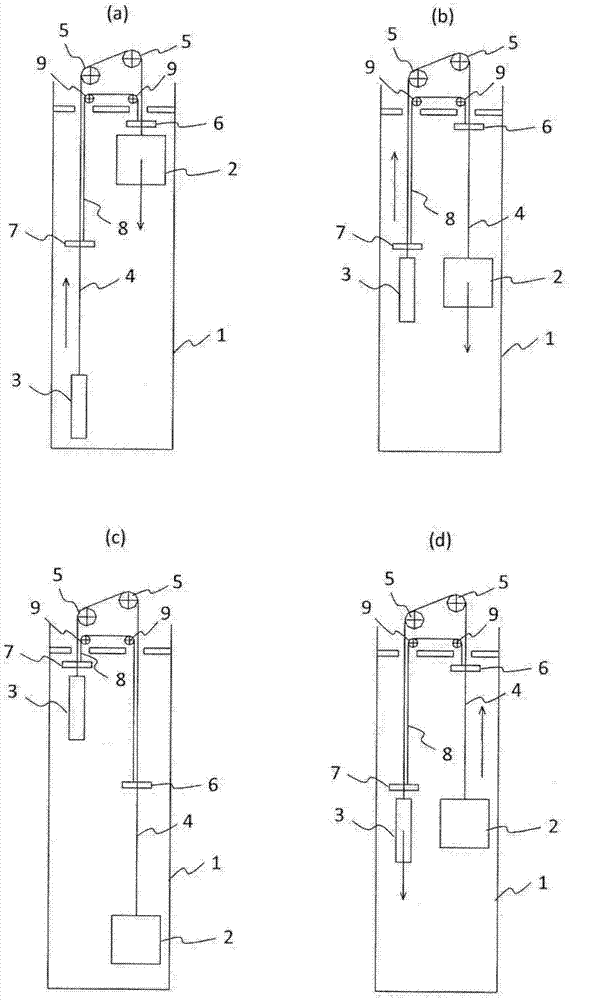

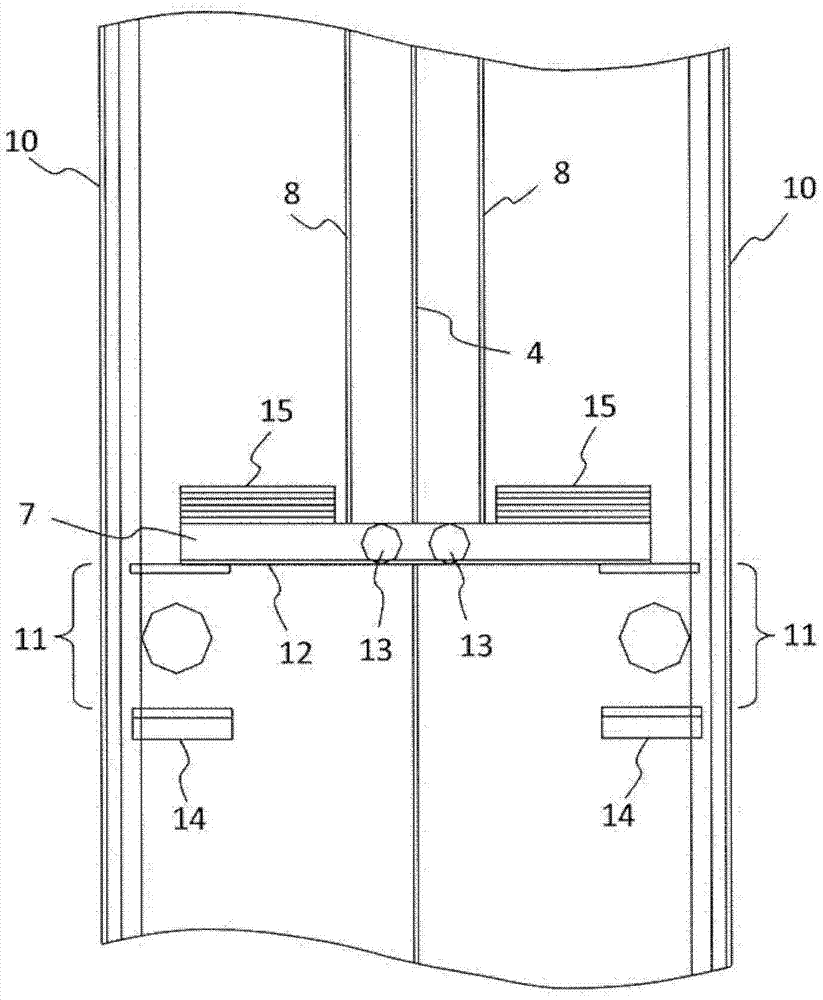

Elevator main suspension line shake preventing apparatus

The invention provides an elevator main suspension line shake preventing apparatus which can faithfully prevent the shakes of a main suspension line with a simple structure and conveniently perform setting operations. The apparatus comprises a car side shake preventor used for preventing shakes of the main suspension line on the elevator car side when a drive pulley with the main suspension line wound serves as a reference; a heavy side shake preventor used for preventing shakes of the main suspension line on the heavy side when the drive pulley serves as the reference; connecting slings connecting the shake preventors and having shake preventor rope wheels connected with slings wound thereon. The weights of the shake preventors are greater than the total weight of the shake preventor and the connecting slings. The shake preventors rise and fall inside an elevating channel in a way to not contact each other. When the shake preventors interfere with counterweights during a rising process, the shake preventors are pushed upwards so that the positions of the shake preventors are lowered.

Owner:HITACHI LTD

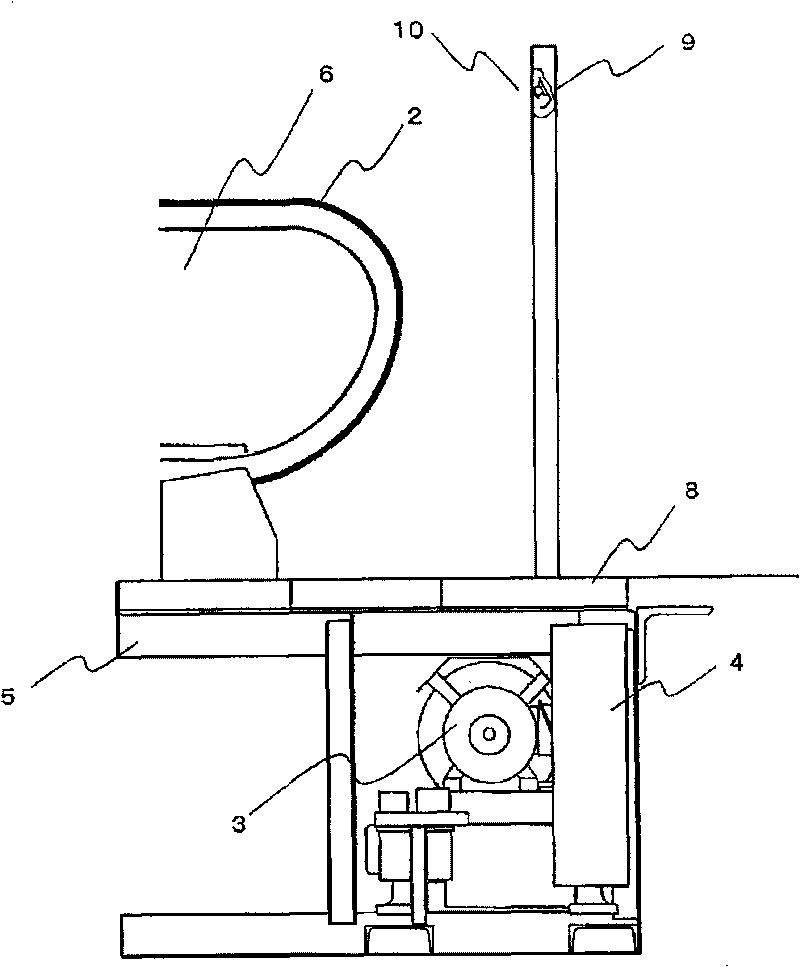

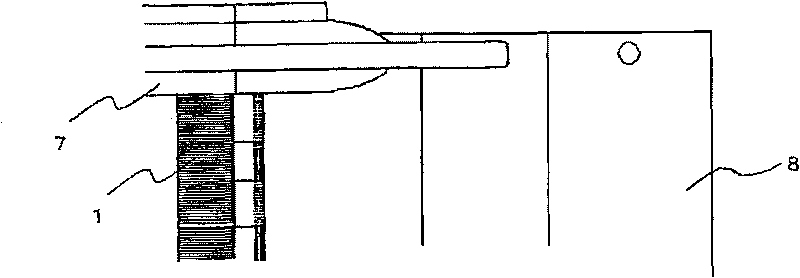

Passenger staircase

The invention provides a passenger staircase having no mechanical chamber and capable of shooting the use status of the passenger with on influence on the maintenance. The passenger staircase comprises a continuously annular armrest (2), a driving device (3) for driving steps and the armrest (2), a controlling means (4) for controlling the driving device (3), rails (6) vertically arranged at both ends of a frame (5) accommodating the armrest (2), the driving device (3) and the controlling means (4) side by side and having a guide for guiding the armrest (2), a deck (7) for filling the rails (6) and the gaps among the rails and the frame (5), and a cover plate (8) opened when the driving device (3) and the controlling means (4) in the frame (5) are repaired and a column (9) having an opening part (8a) of the cover plate (8) arranged on an extension line of the armrest (2) and detachably vertically arranged at the upper part of the opening part (8a) and having a video camera (10) therein.

Owner:HITACHI BUILDING SYST CO LTD

Air conditioner

InactiveCN101788166AEasy maintenanceEasy to set up jobsSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringElectrical and Electronics engineering

The invention relates to an air conditioner, comprising a bottom seat; a shell arranged at the upper side of the back part of the bottom seat; a discharge panel arranged at the front of the upper part of the shell to form an air discharge port and depressed to form a housing part; a suction panel arranged at the lower side of the discharge panel to form an air suction port; a door plate capable of simultaneously shading or opening the air suction port and the air discharge port; a drive connection rod connected with the door plate; a connection-rod rotary motor for making the drive connectionrod rotate; a conductor module for making the connection-rod rotary motor connected with the control part, wherein one part is housed in the housing part; and a maintenance cage combined with the discharge panel in way of shading the front part of the housing part. The door plate movable mechanism, such as the connection-rod rotary motor, is simply arranged and the door plate movable mechanism, such as the connection-rod rotary motor, is simply maintained without decomposing the air conditioner.

Owner:LG ELECTRONICS INC

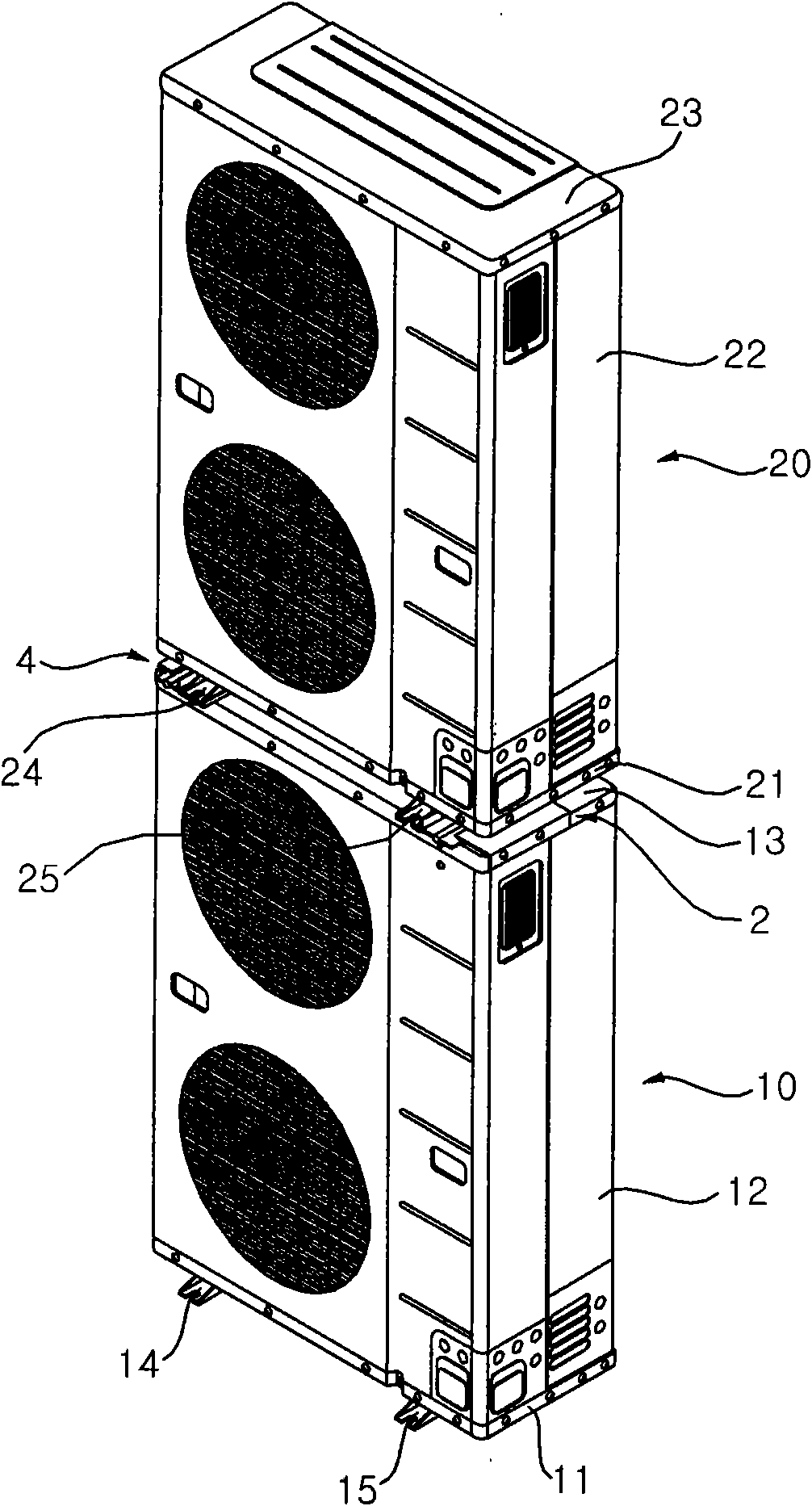

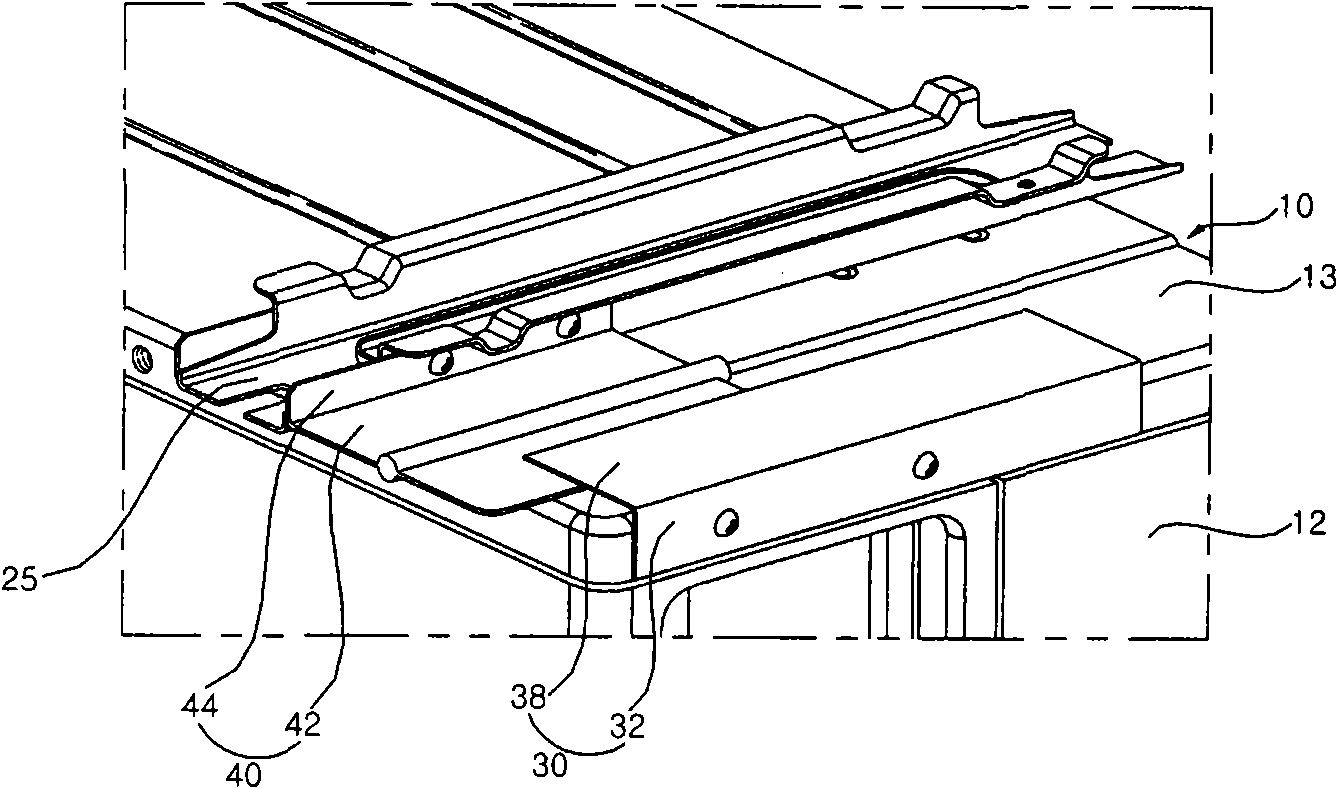

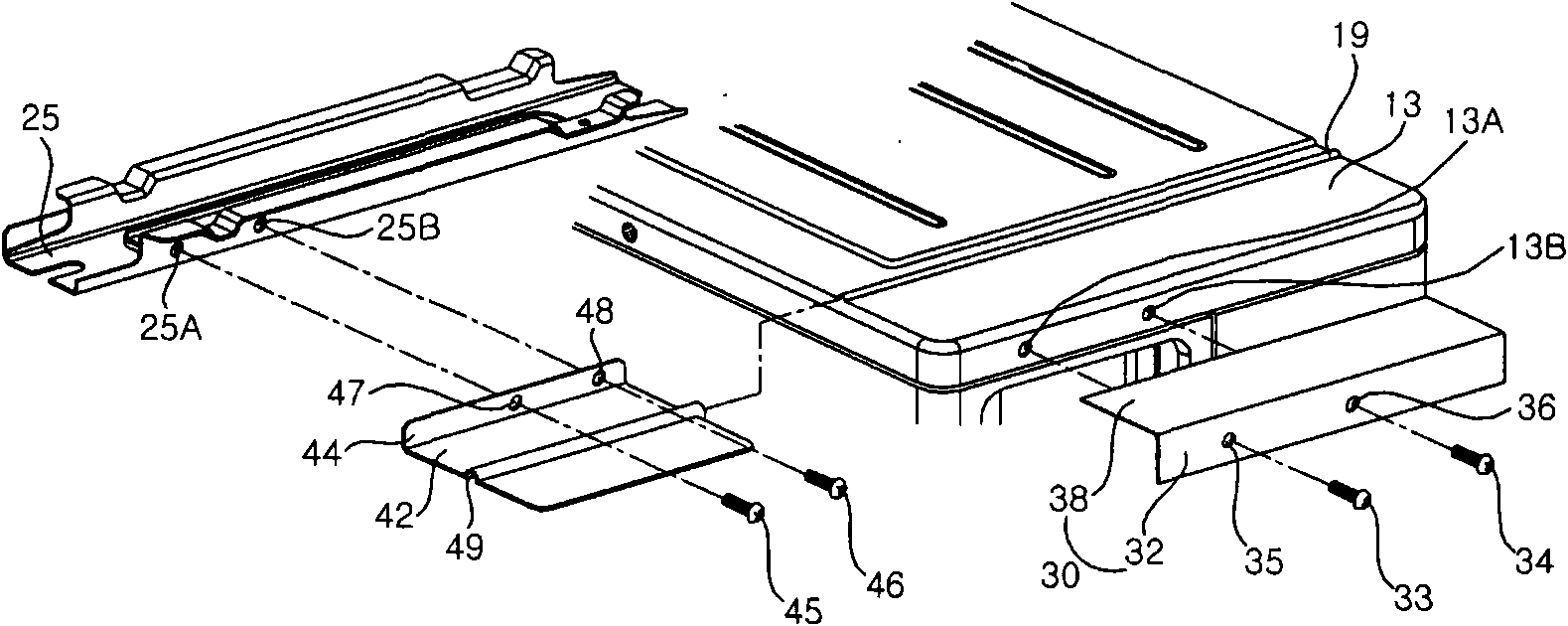

Stacking device of outdoor units of air conditioners and laminated structure of outdoor units

InactiveCN101592395AImprove stabilityEasy to fixLighting and heating apparatusSpace heating and ventilation detailsEngineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

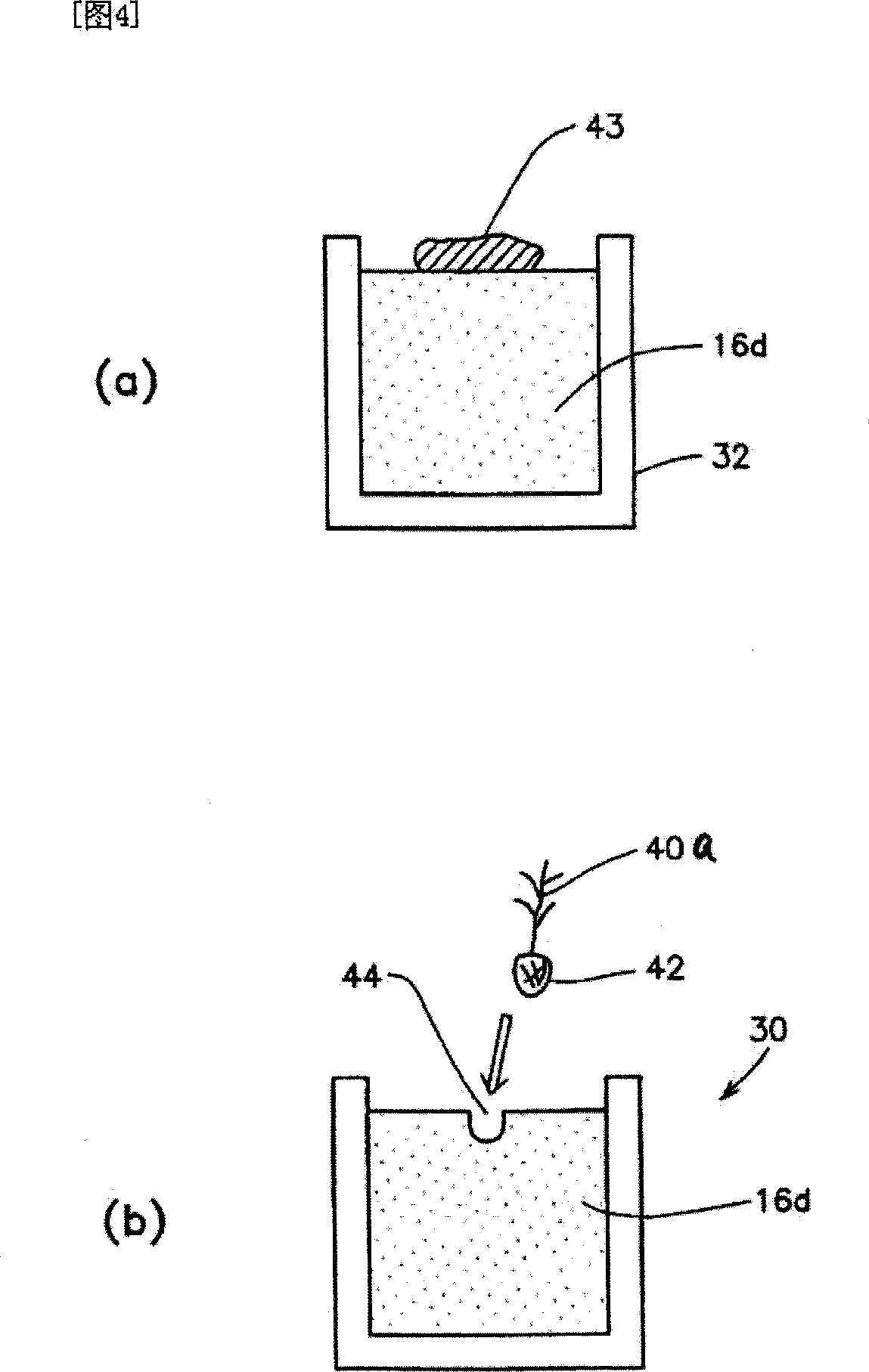

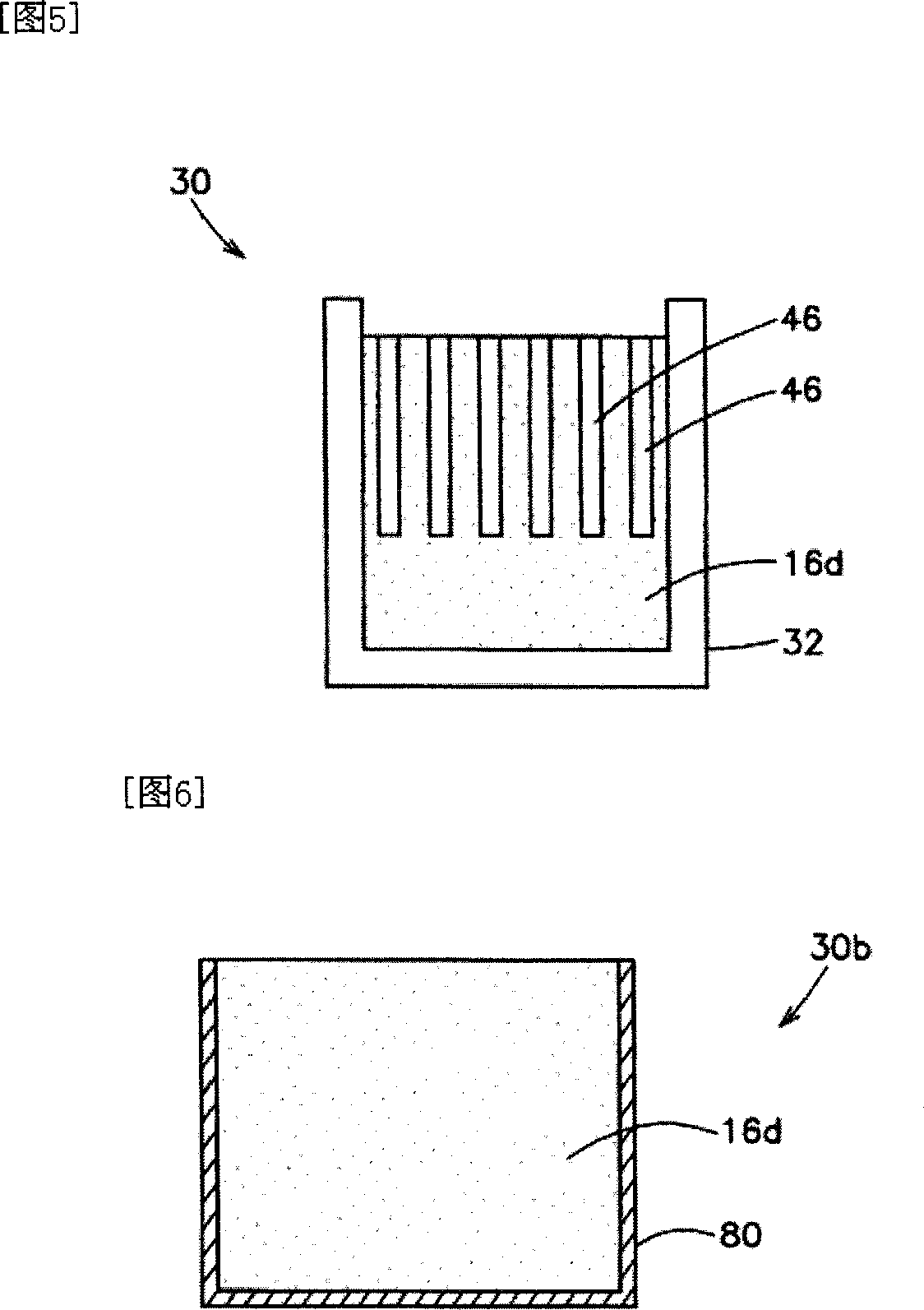

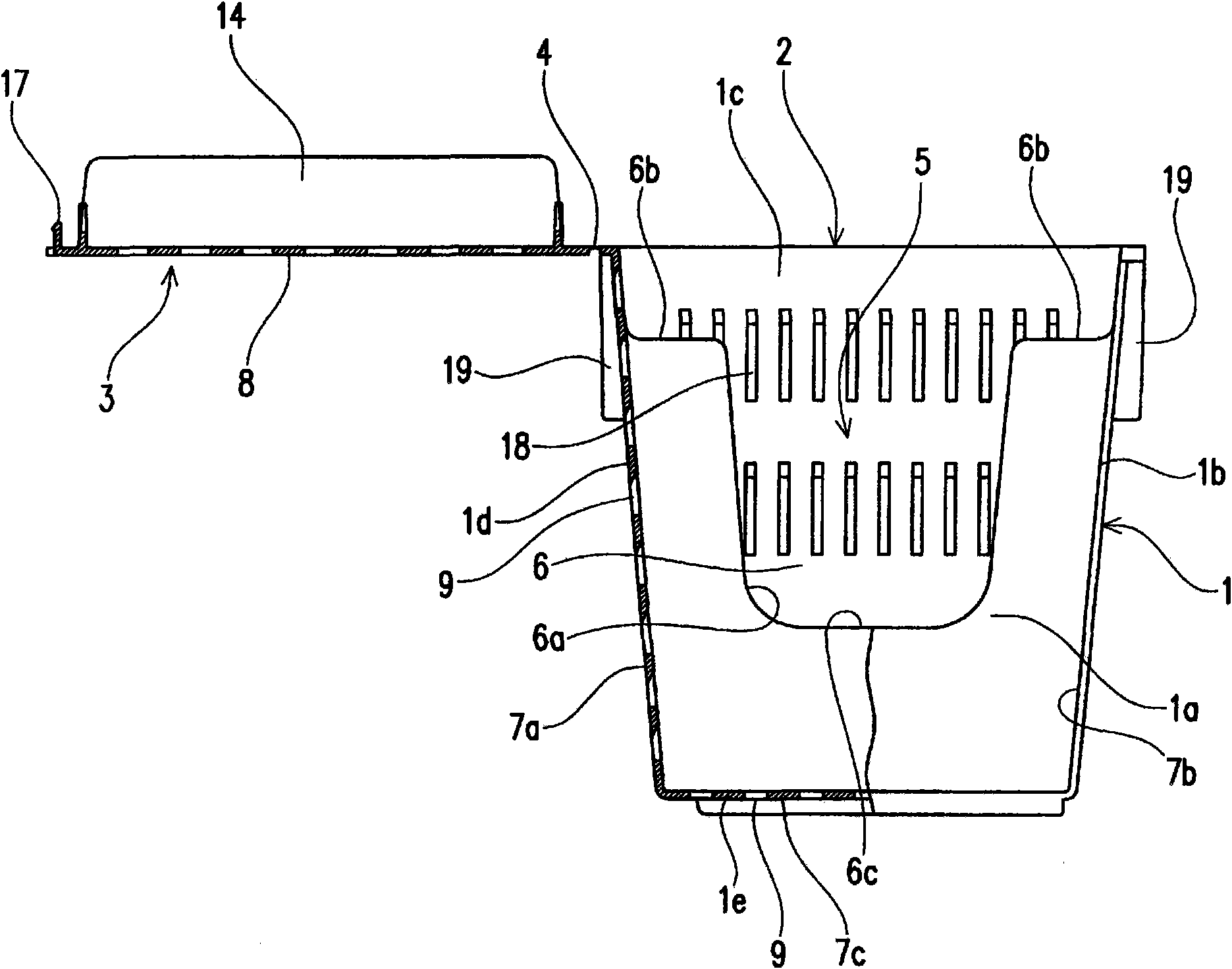

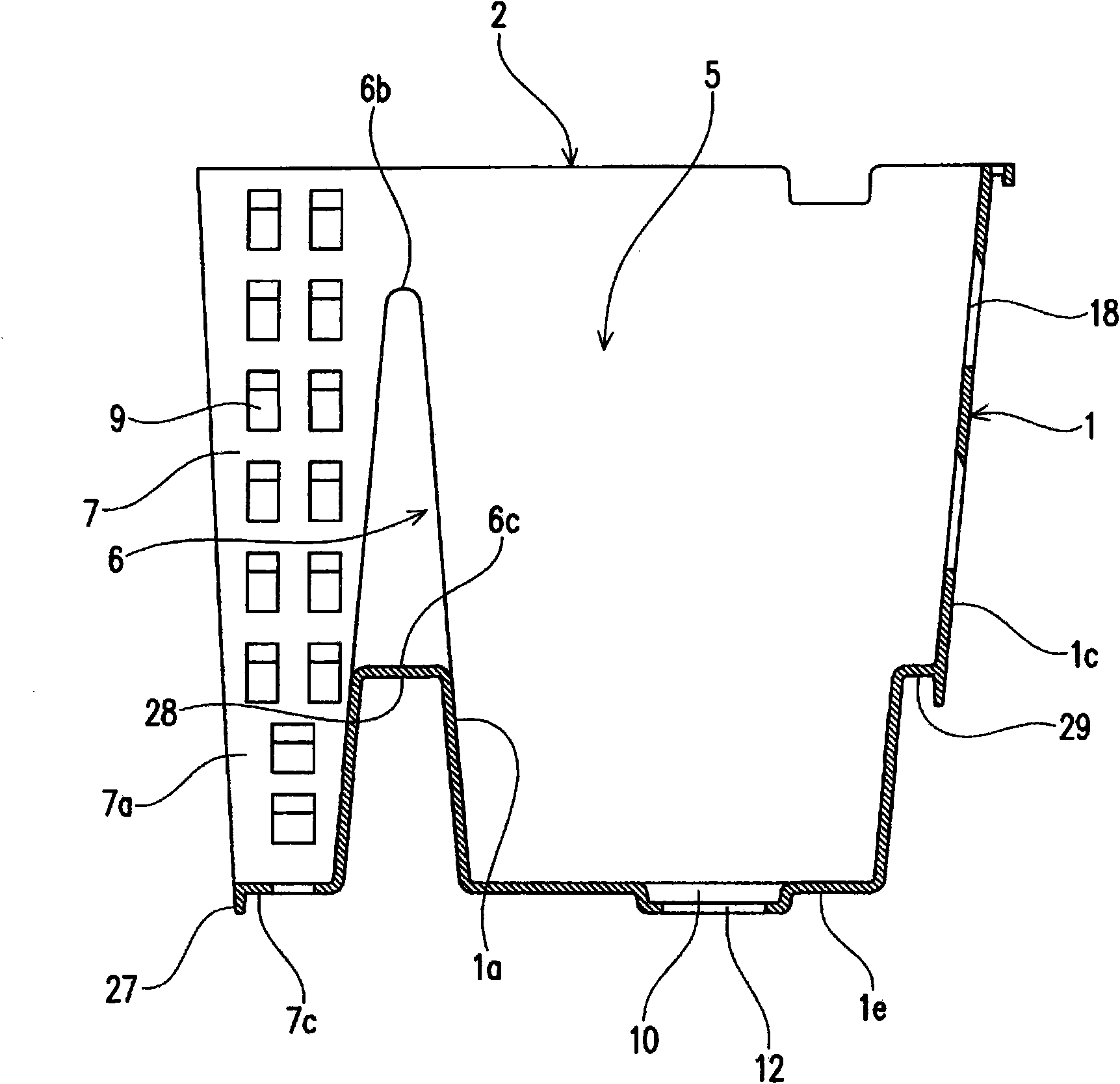

Container unit for greening and greening technique using the container unit

InactiveCN101909426AEasy to operateShort construction periodSelf-acting watering devicesCultivating equipmentsGreeningEngineering

Relating to a container unit for greening, for example, wall surface and a greening technique using the container unit, this object aims to provide a container unit for greening which can be easily handled, makes it possible to very easily undertake greening of, for example, wall surface within a short period of time, and has a low production cost; and a greening technique. A container unit is characterized in that an opening, through which a part of the plant body of a potted plant seedling to be packed in a container unit body can be guided outside, is formed in the one face side of the container unit body in which a planting base such as soil and the potted plant seedling can be packed. Separately from the opening through which a part of the plant body of the potted plant seedling can be guided outside, it is possible to form another opening for packing the planting base and the potted plant seedling in the container unit body.

Owner:TOHO LEO

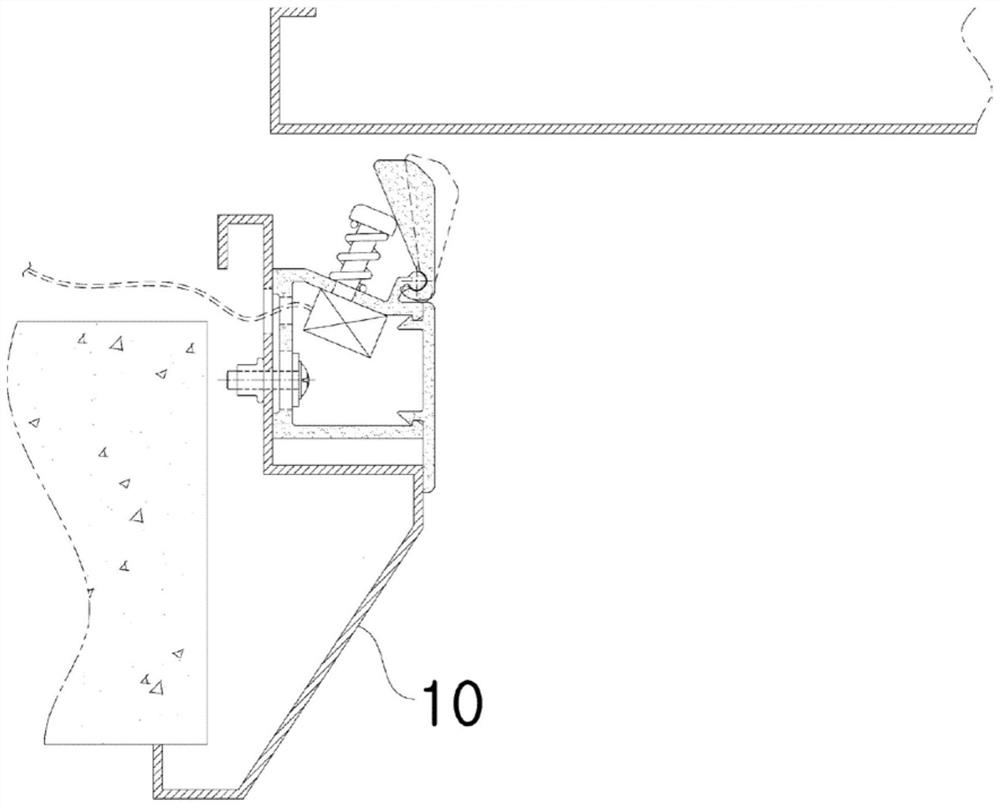

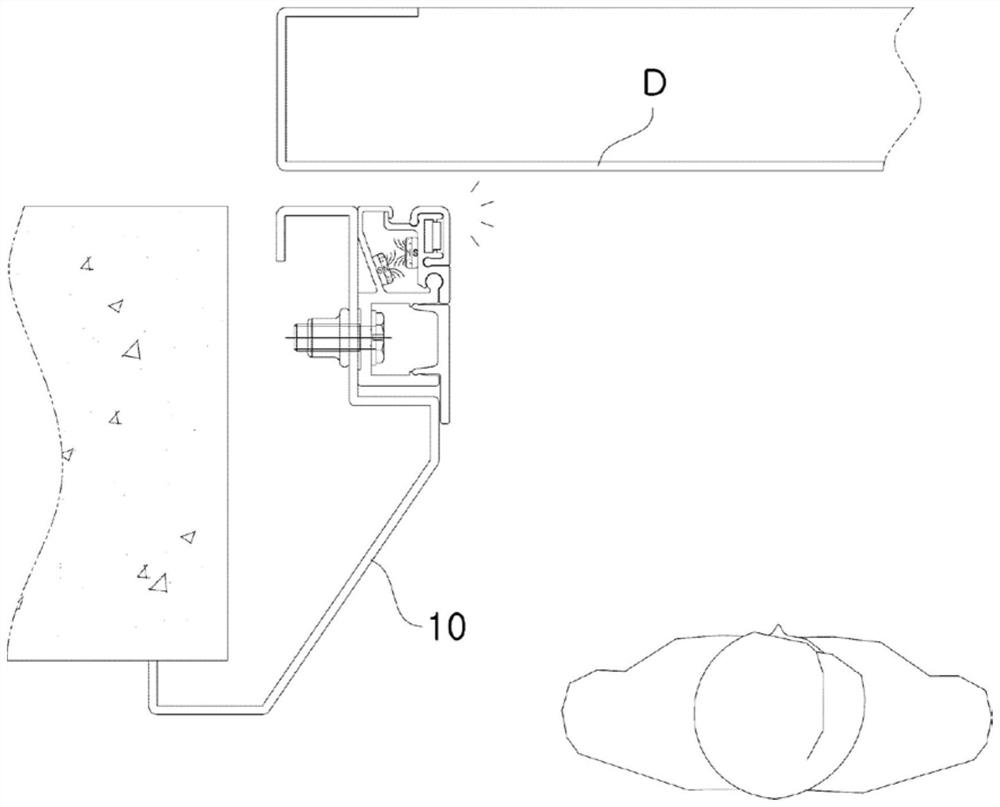

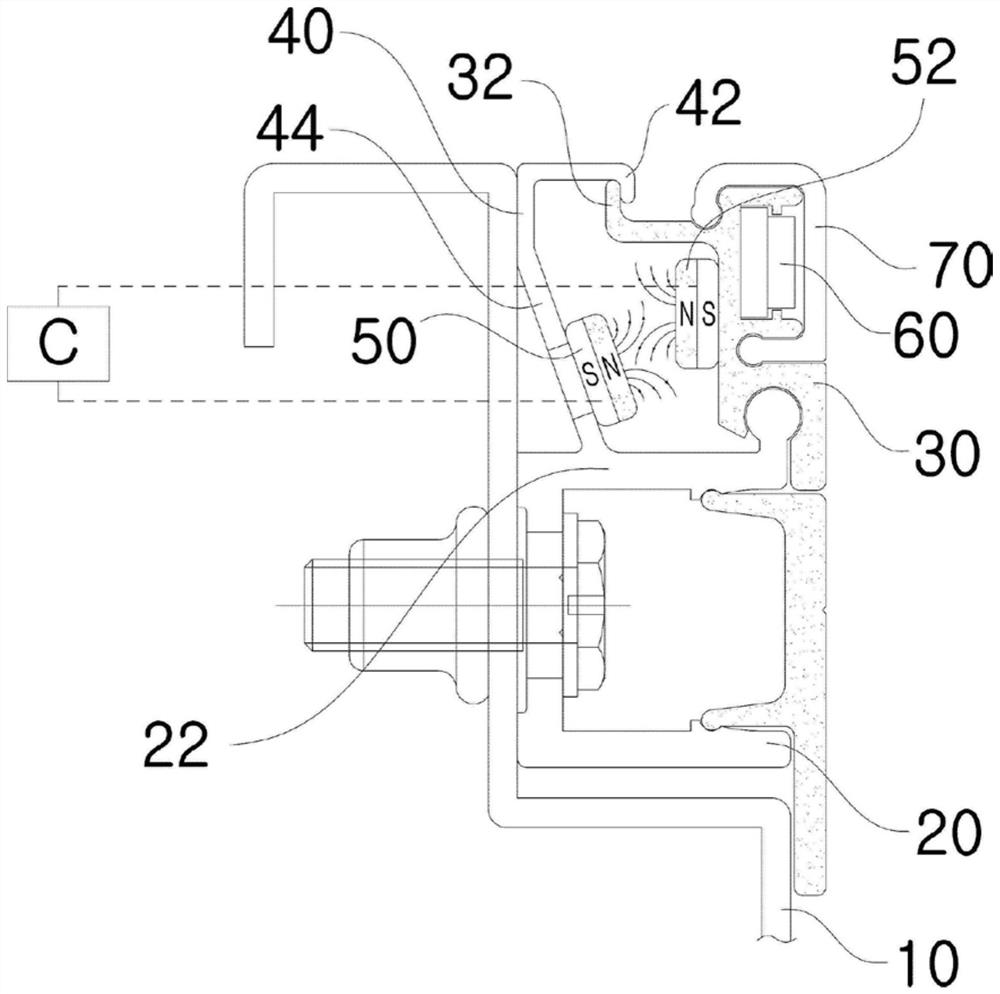

Safety device for preventing hand jamming in elevator

ActiveCN111819146APrevent protrudingPrevent inflowWing accessoriesElevatorsBraced frameMagnetic poles

The present invention relates to a safety device for preventing outward protrusions from an elevator door frame, and preventing hand jamming by giving off a warning light or a warning sound so as to warn a passenger of hand jamming while having a simple structure by using magnets, the safety device allowing a first magnet (50) and a second magnet (52) to approach each other such that current runstherethrough so as to stop the operation of an elevator hall door (D) or control the opening / closing speed thereof, while allowing a rotary frame (30) to rotate when the hand of a person is jammed ina gap between the door frame and a door, thereby preventing the hand of the person from entering the gap, and allowing the rotary frame (30) to rotate outward by a repulsive force between the same magnetic poles of the first magnet (40) and the second magnet (52) when external force acting on the rotary frame (30) disappears, and, at this point, allowing a stopping protrusion (32) of the rotary frame (30) to be caught by a stopper (42) of a support frame so as to prevent the rotary frame (30) from protruding outward from the door frame (10).

Owner:尹一植

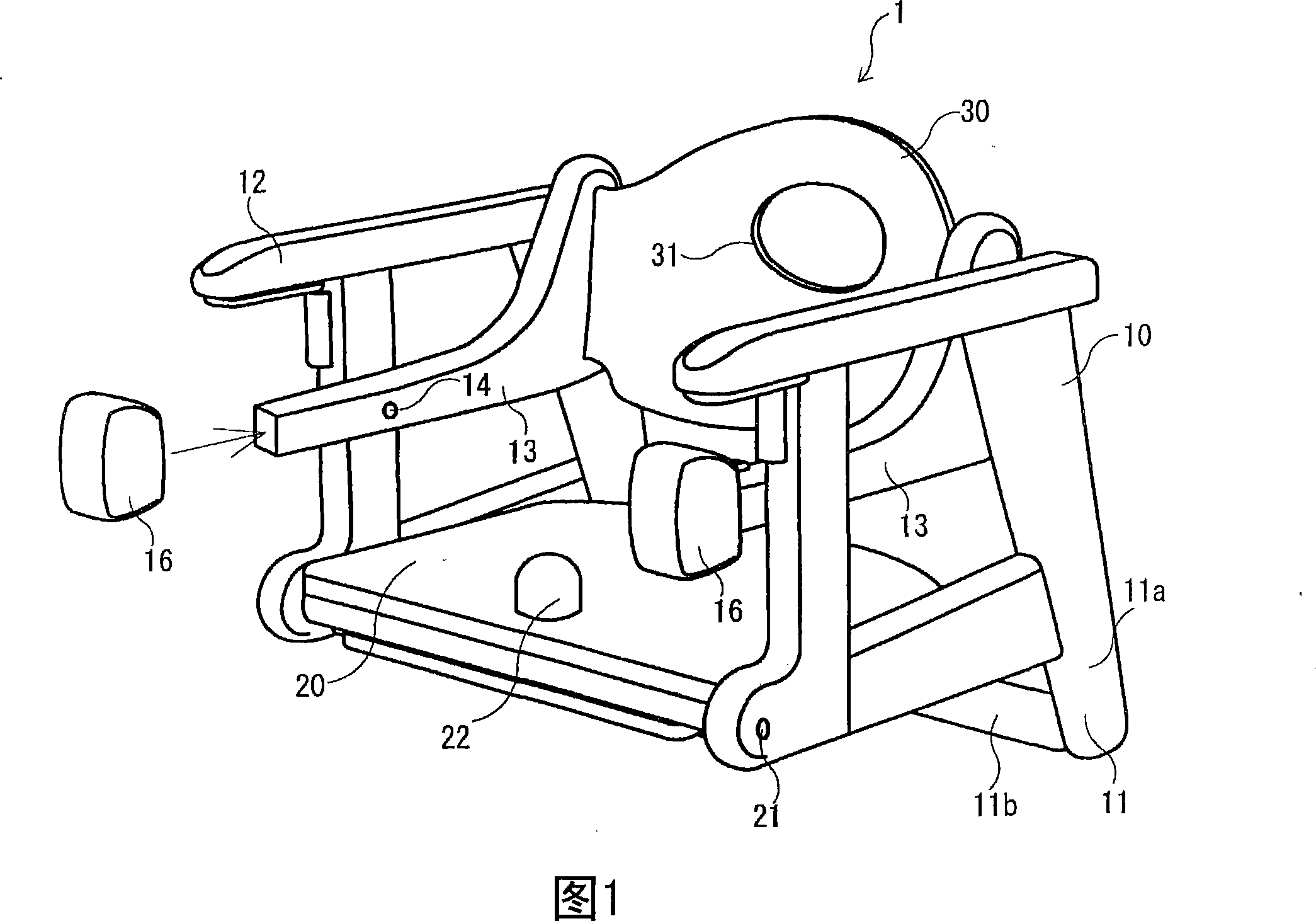

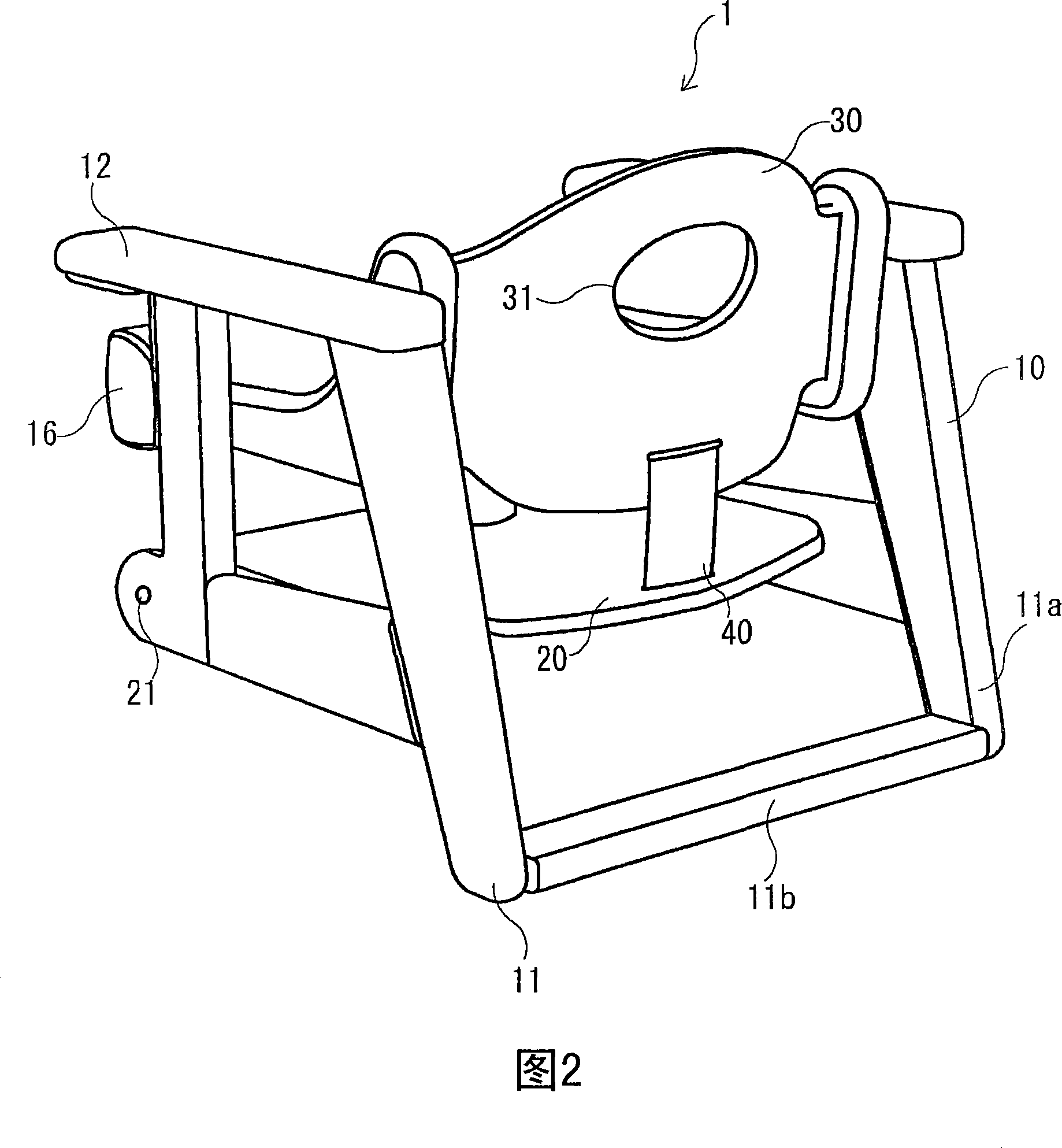

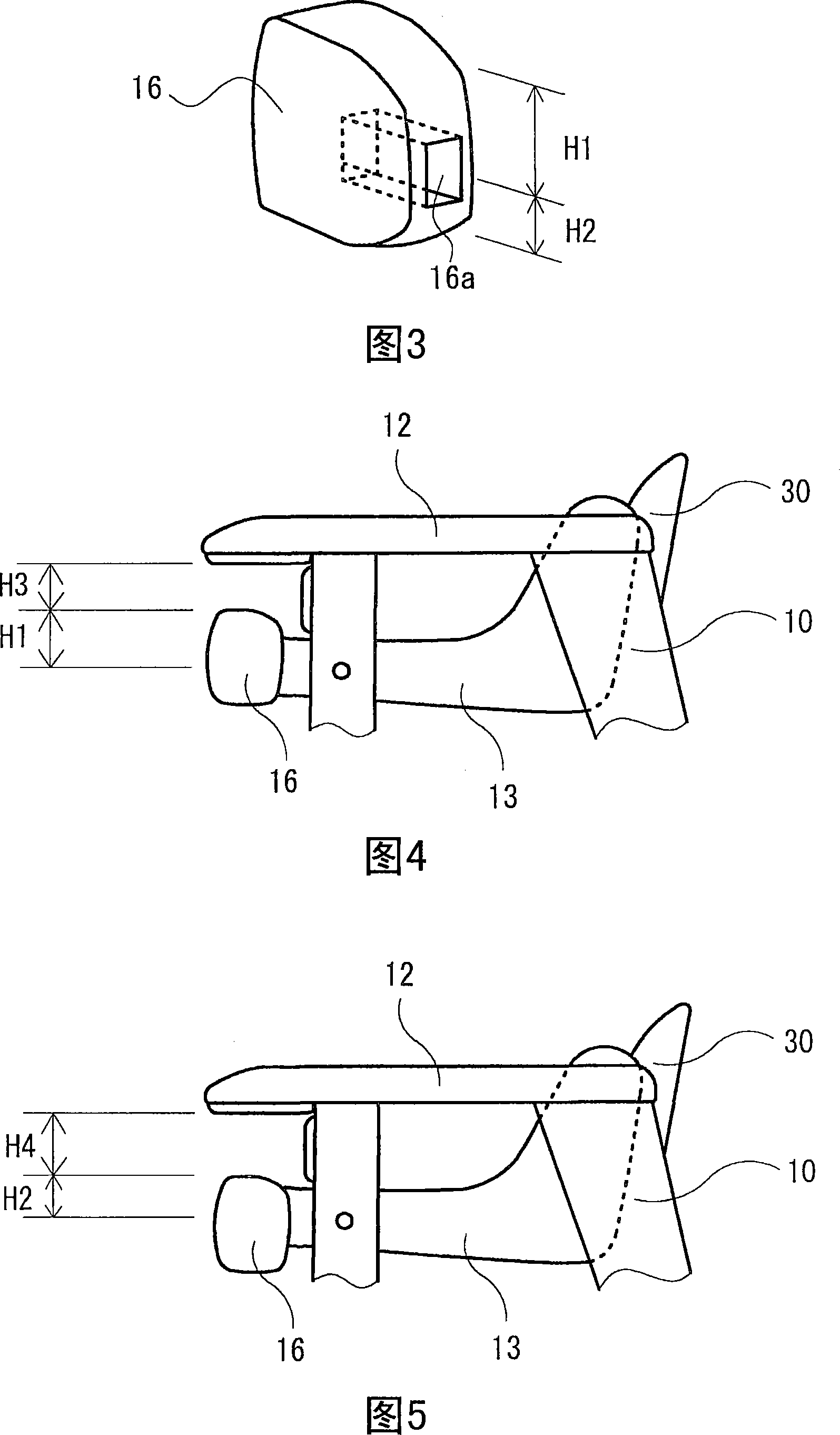

Chair for child

The present invention provides a chair for infants which can be easily placed on a seat close to a table in a stable state and which can prevent erroneous use. The chair for infants of the present invention is a chair for infants arranged on a seat close to a table, and has: a seat; a backrest; and a chair body for supporting the seat and the backrest. The top of the seat and the top of the seat are suspended and erected as fulcrums, so that the seat is hollowly supported on the seat.

Owner:COMBI CORP

Control box for sewing machine

InactiveCN1515729ASmall sizeRich varietyLubrication/cooling devicesSewing-machine casingsEngineeringCooling efficiency

The object of the present invention is to provide a control box of a sewing machine in which, by changing an arrangement of a frame of the control box, a size in X-Y direction of the control box can be compact, the cooling efficiency of heating parts can be increased, a deviated load which is caused by pedaling and loaded on the frame of the control box is eliminated, and further, it can be easily installed. The control box of the present invention is a control box of the sewing machine which is located under the table of the sewing machine, and in which control parts for use in the control of the sewing machine are accommodated. The control box is such structured that it has a vertically extending plate-like frame member, and on both sides of the frame member, the electric parts are fitted.

Owner:JUKI CORP

Module and system for solar electricity generation

ActiveCN100521252CReduce lossesEfficient use ofPhotovoltaic energy generationSemiconductor devicesSingle crystalActive solar

The object of the present invention is to provide a photovoltaic power generation module and a photovoltaic power generation system using the bow-shaped battery that has no loss of a disk-shaped single crystal wafer, and provide an operating voltage per unit area. (also referred to as "area voltage") high photovoltaic power generation modules and photovoltaic power generation systems using the same, and providing photovoltaic power generation modules and photovoltaic power generation systems that can increase the effective installation area ratio of modules relative to residential roofs Solar power generation system. The module for photovoltaic power generation is composed of arcuate cells divided from disc-shaped single-crystal silicon photovoltaic cells for photovoltaic power generation. more than one bus bar, and the arcuate cells are arranged in a grid shape, and the solar power generation module is characterized in that 14 to 42 arcuate cells with an area of 28 to 65 cm2 are arranged.

Owner:SHIN ETSU CHEM IND CO LTD +1

Indoor unit of air conditioner

InactiveCN1699868AFlexible interior spaceEasy to set upSpace heating and ventilation safety systemsLighting and heating apparatusInterior spaceComputer engineering

This invention provides an indoor device for air conditioner which can take down the part inside the control case easily. The indoor device includes the upper board, divider, control case, heater, and case assembly. The opposite sides of the control case forms the heater setting meatus; the wiring board fixes on the divider by the wiring board mounting device, and the device is composed by right side fixing protrusion, right side fixing slot, left side fixing protrusion and the molding part. This invention can make the part inside the control case set easily and use the inside space of the control case efficiently.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Overhead planting device

InactiveCN1146315CEasy to fillImprove work efficiencyCultivating equipmentsReceptacle cultivationFertilizerFilm material

The invention provided a highly equipment cultivated container, they can be stood up working, decreasing the amount of the cultivated soil, water, fertilizers, easy for installation and striking, minimizing the storage space and with a low cost. An elevated cultivating container 10, having a cultivated soil collector 13 which is partially formed by two sheets of laminating film material 11, 12 , a dust shape of the enhanced member 16 which is connected in the opening 14 of the cultivated soil collector 13 with a conjuntion gate 15, and a supporting pipe 17 which retains the cultivated soil collector 13 to tie the film material 11, 12 standing up on the ground.

Owner:FUKUOKA MARUMOTO KK

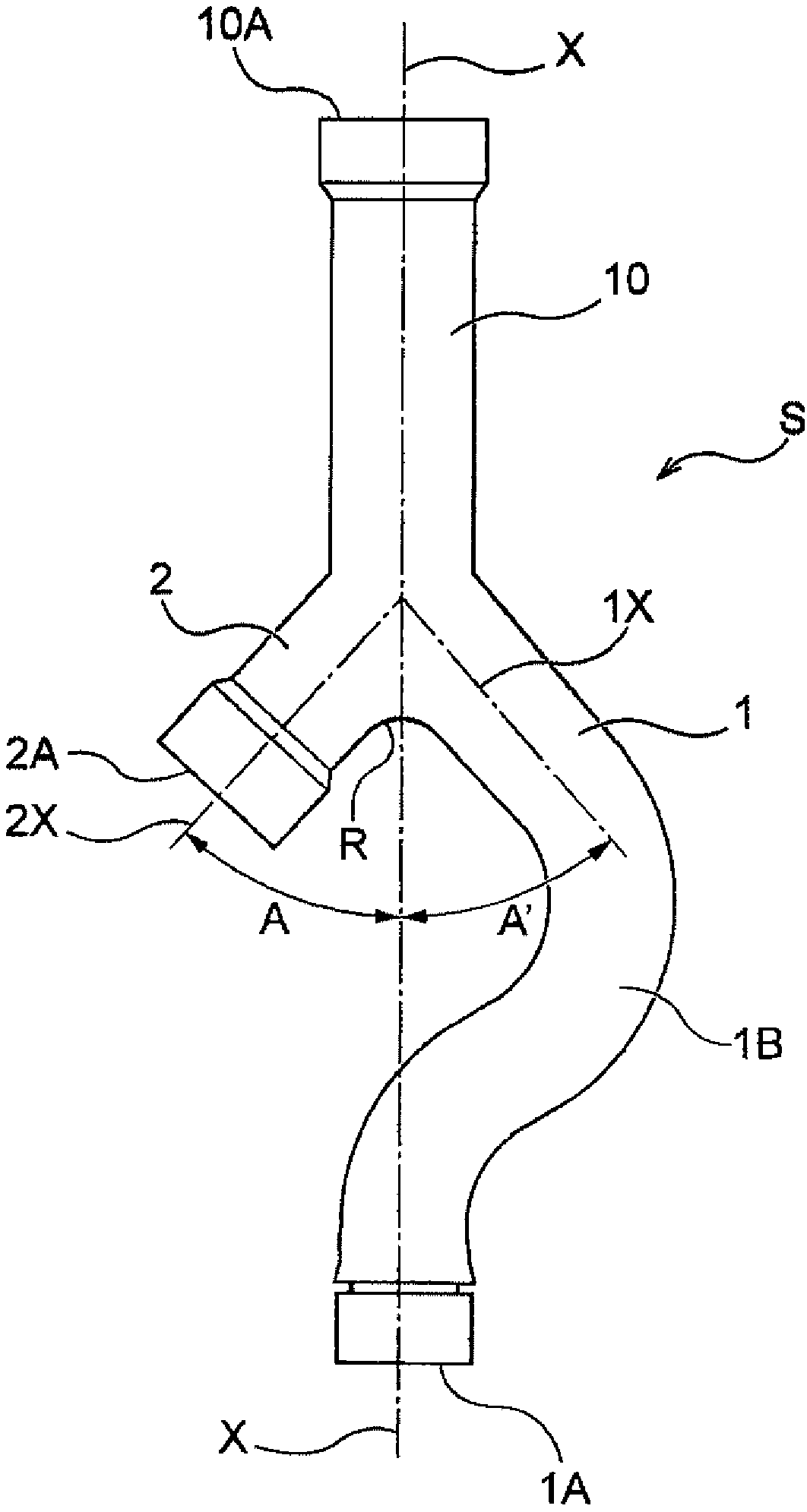

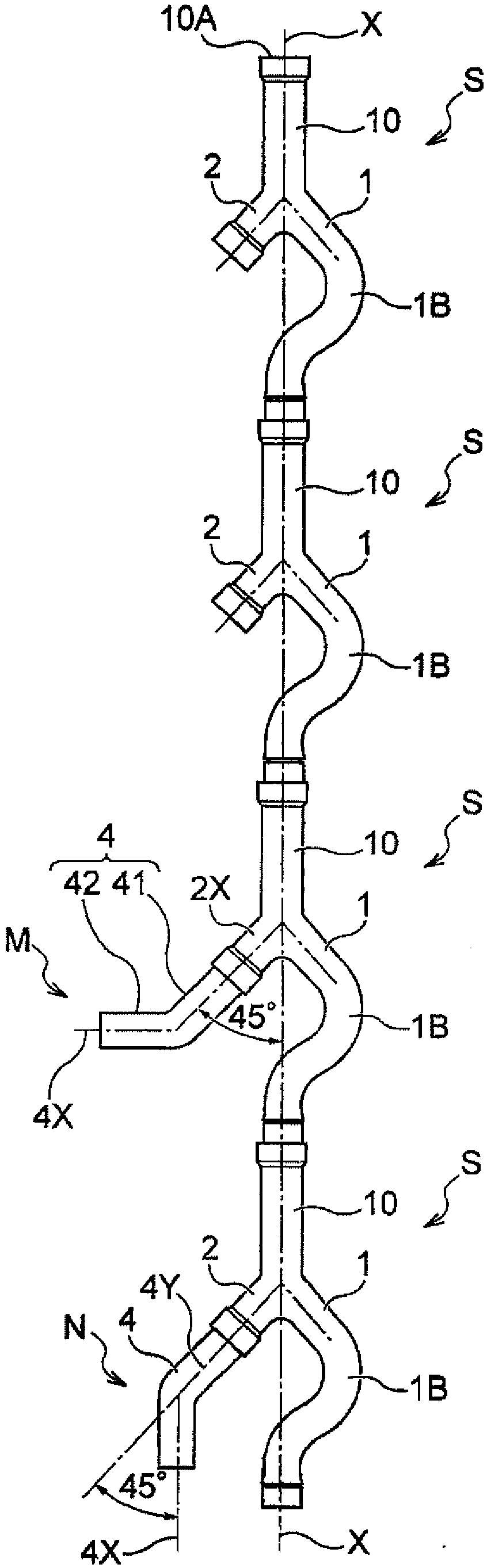

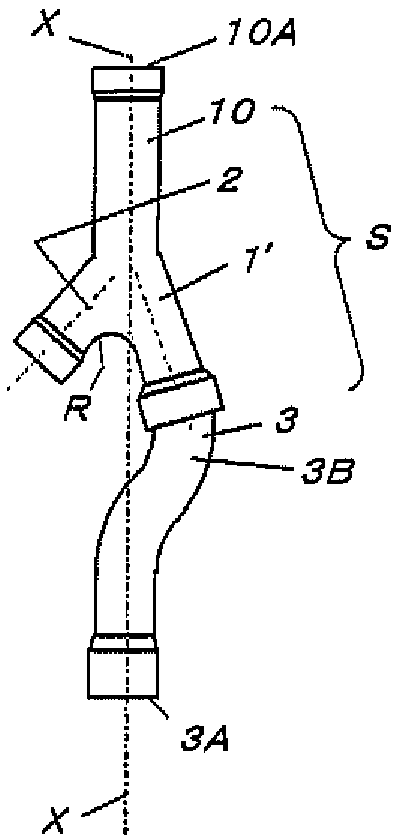

Branch pipe

InactiveCN108931082AEasy to useEasy to set up jobsThermal insulationFluid circulation arrangementMechanical engineeringMechanics

The invention aims to provide a branch pipe good in usage convenience. The branch pipe (S) branches fluid from an inflow portion (10) into a first outflow portion (1) and a second outflow portion (2).The middle portion of the first outflow portion (1) is curved so that the axis of the pipe at the outlet of the first outflow portion (1) is aligned with the axis of the pipe of the inflow portion (10).

Owner:KAKINUMA KINZOKU SEIKI

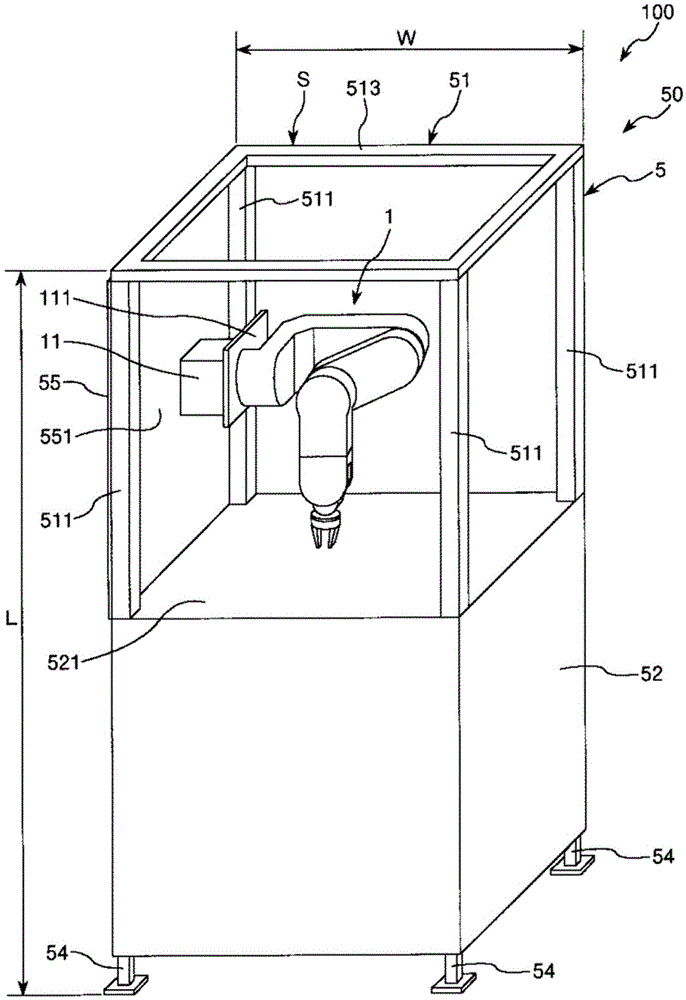

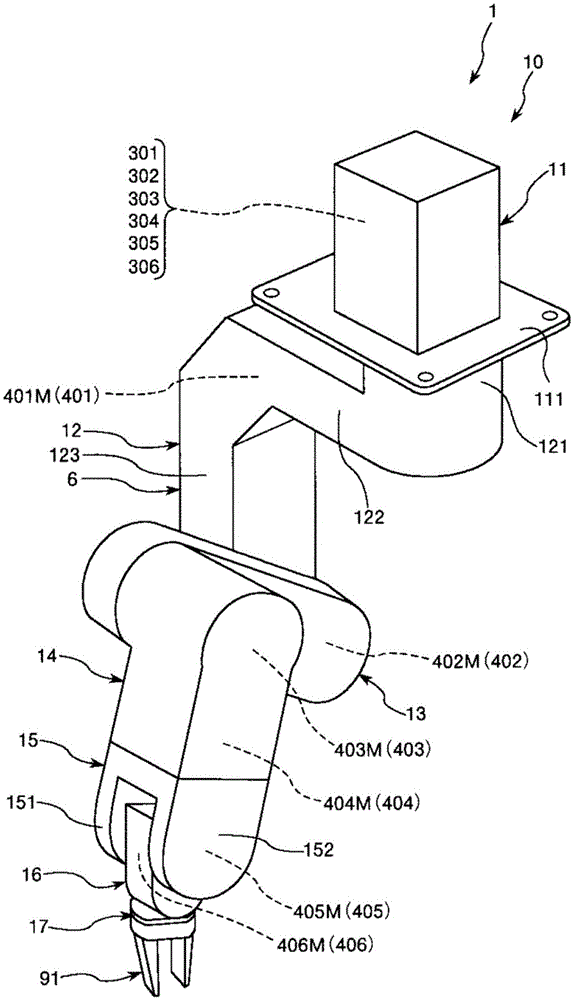

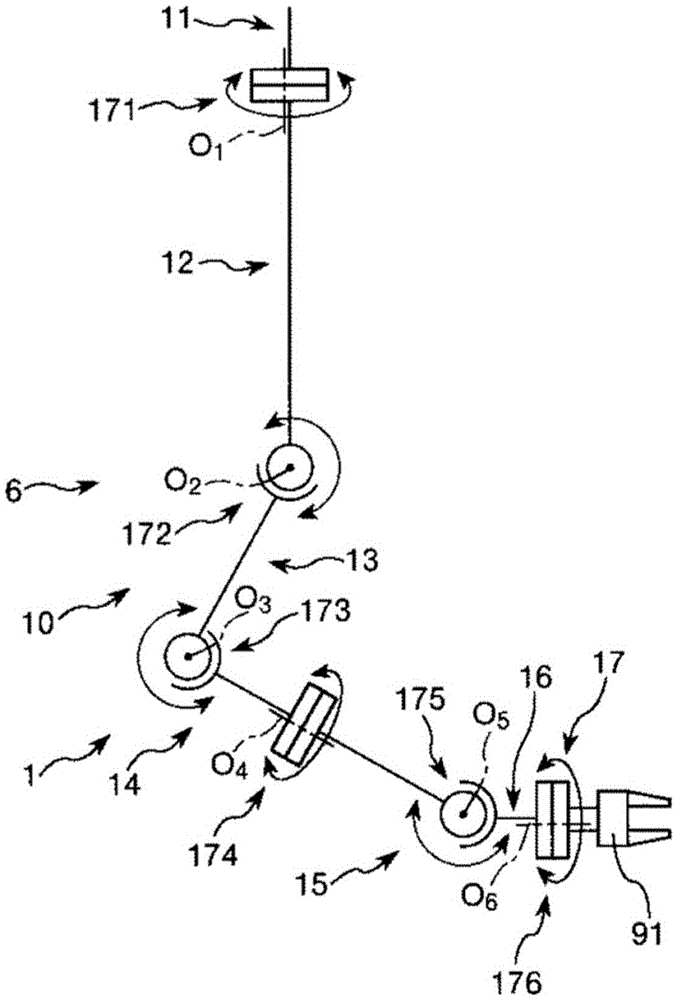

Robot system

InactiveCN106002933AEasy to set up jobsProgramme-controlled manipulatorArmsRobotic systemsEngineering

Owner:SEIKO EPSON CORP

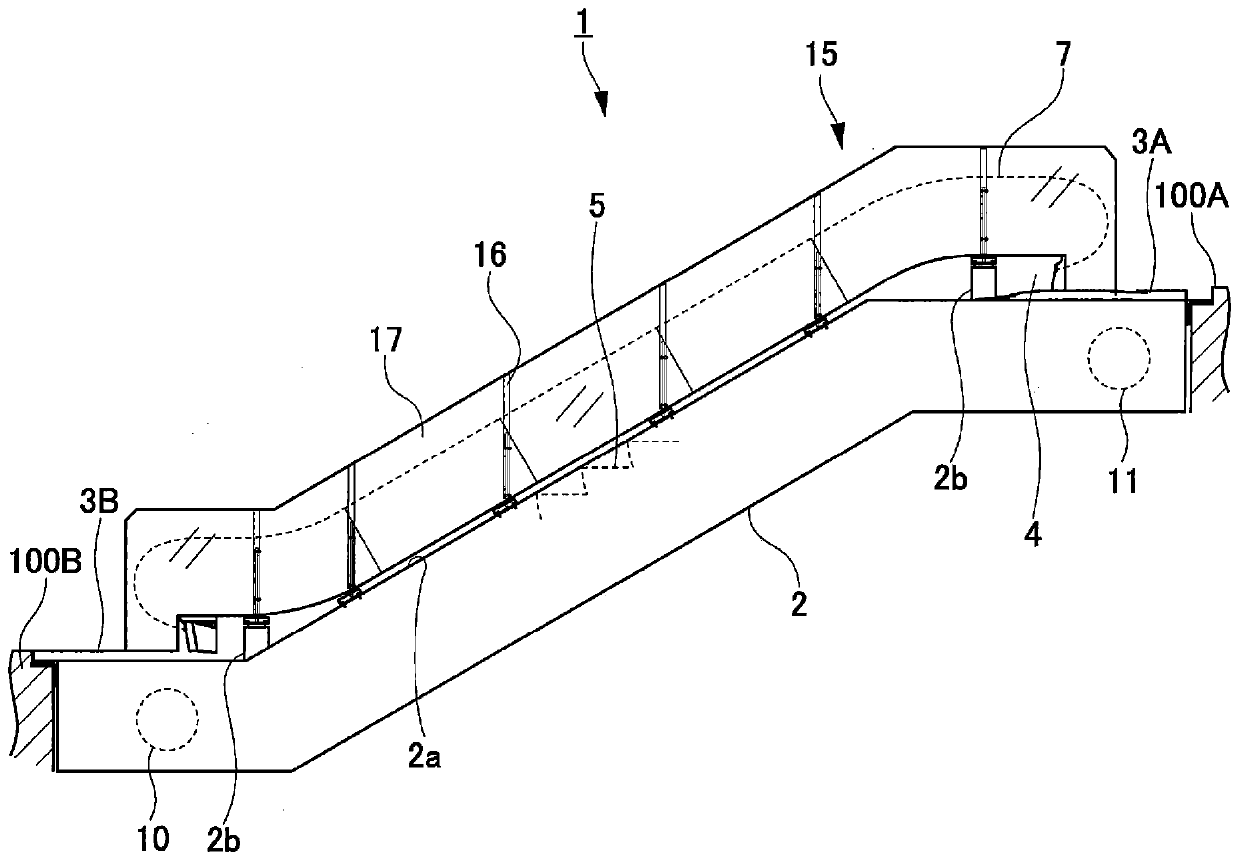

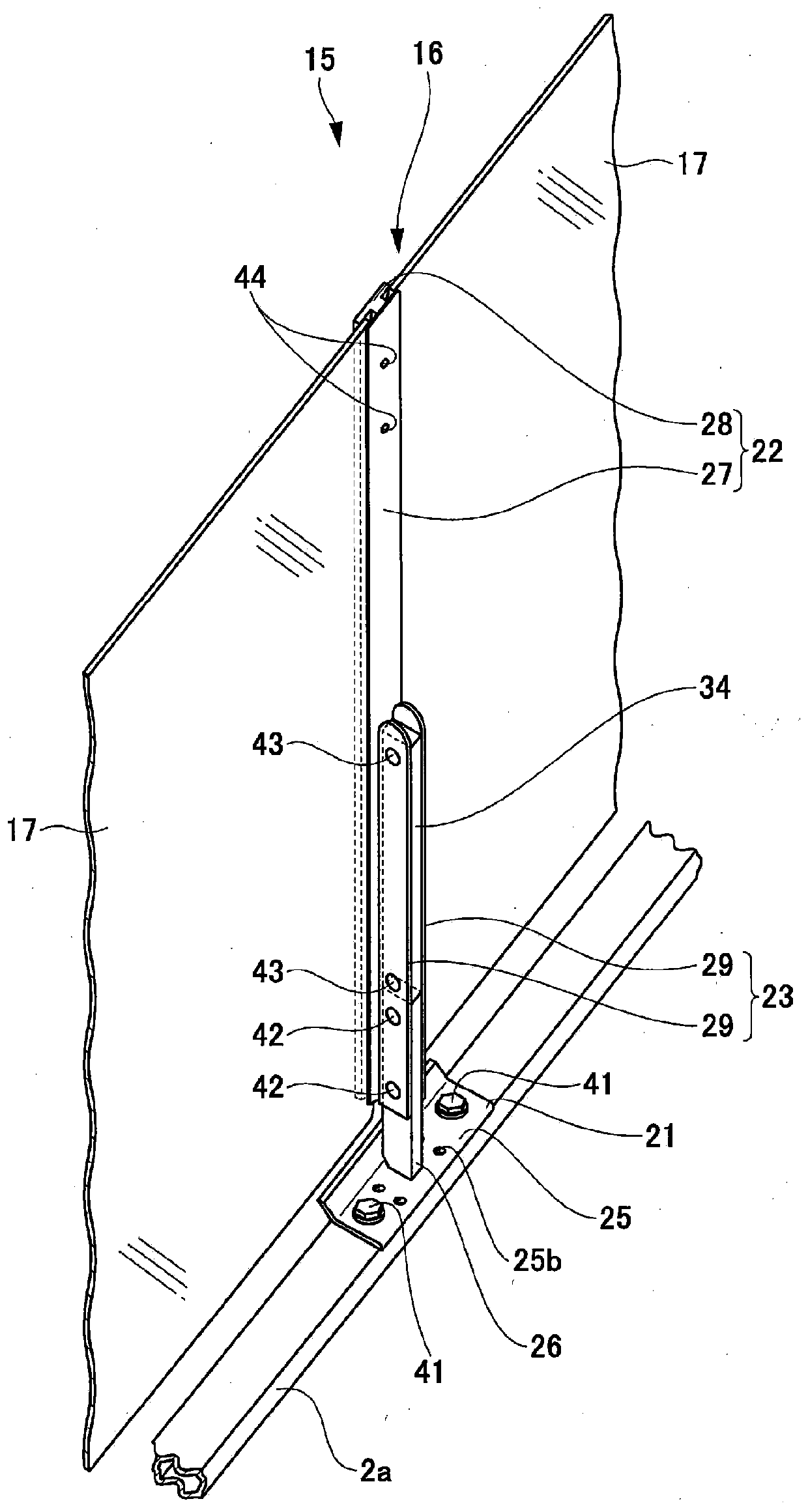

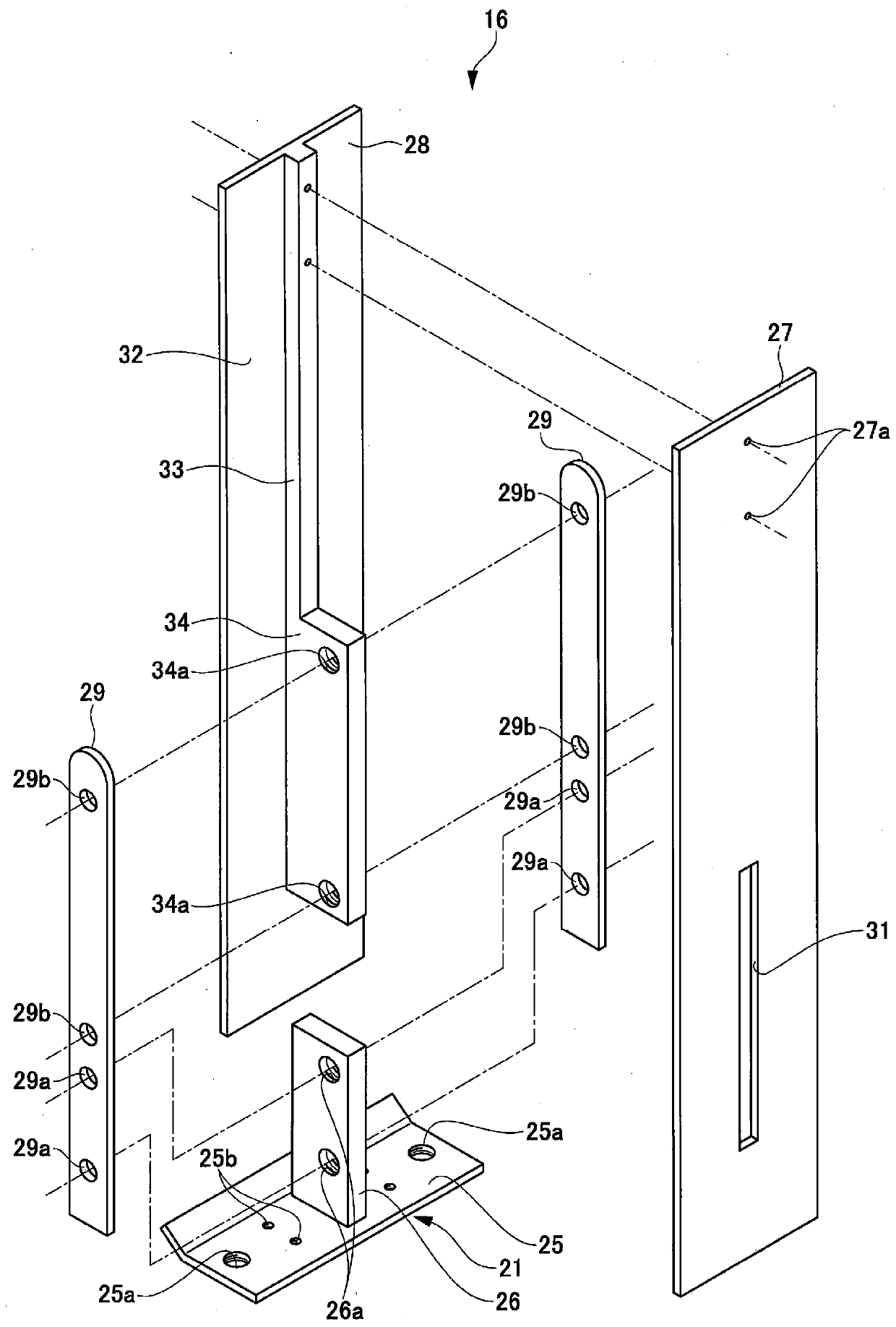

Falling object prevention guard rail of passenger conveyor belt and the passenger conveyor belt

The invention provides a falling object prevention guard rail of a passenger conveyor belt and the passenger conveyor belt, by which arrangement operation of pillars and a panel member can be carriedout easily. The falling object prevention guard rail (15) includes a pillar (16) and a panel member (17). In addition, the pillar (16) includes a pillar base (21), a supporting member (22) and a connecting member (23). The pillar base (21) is fixed to the upper surface of the frame (2) by fixing bolts (41). The supporting member (22) is arranged above the vertical direction of the pillar base (21), and supports the panel member (17). On the inner side in the width direction of the frame (2) than the panel member (17), the connecting member (23) connects the supporting member (22) and the pillar base (21) by connecting bolts (42, 43).

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com