Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Detachable connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

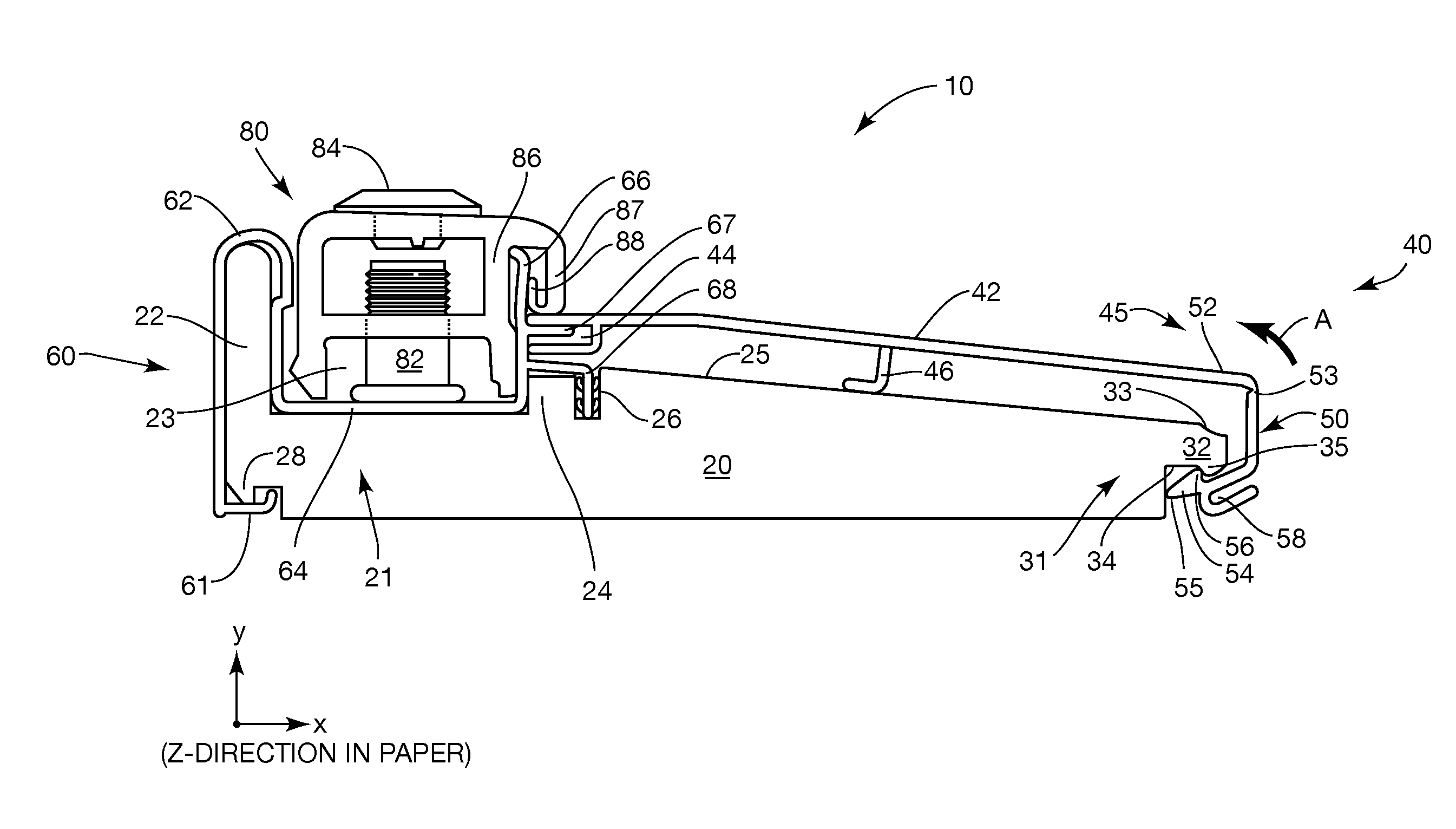

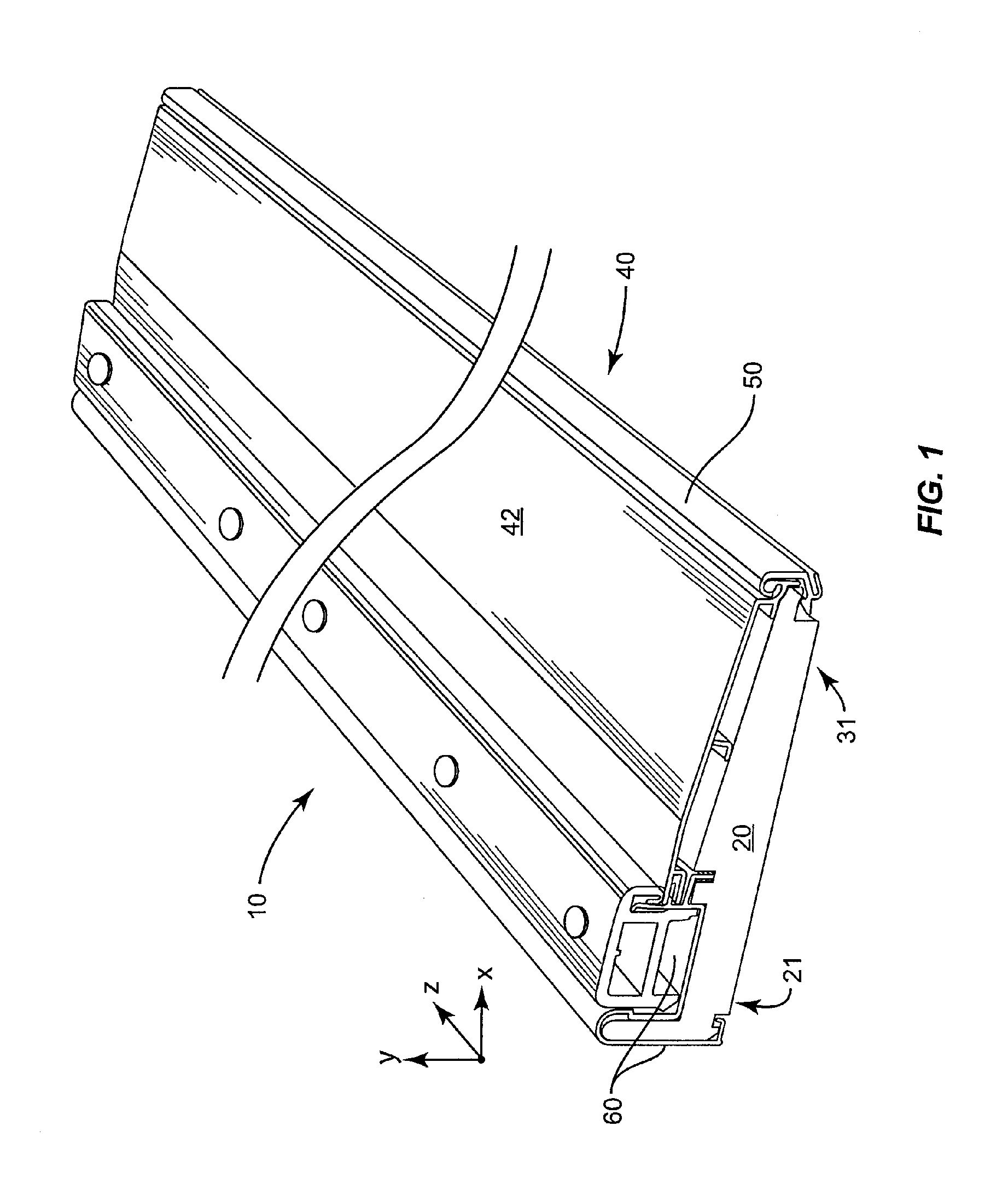

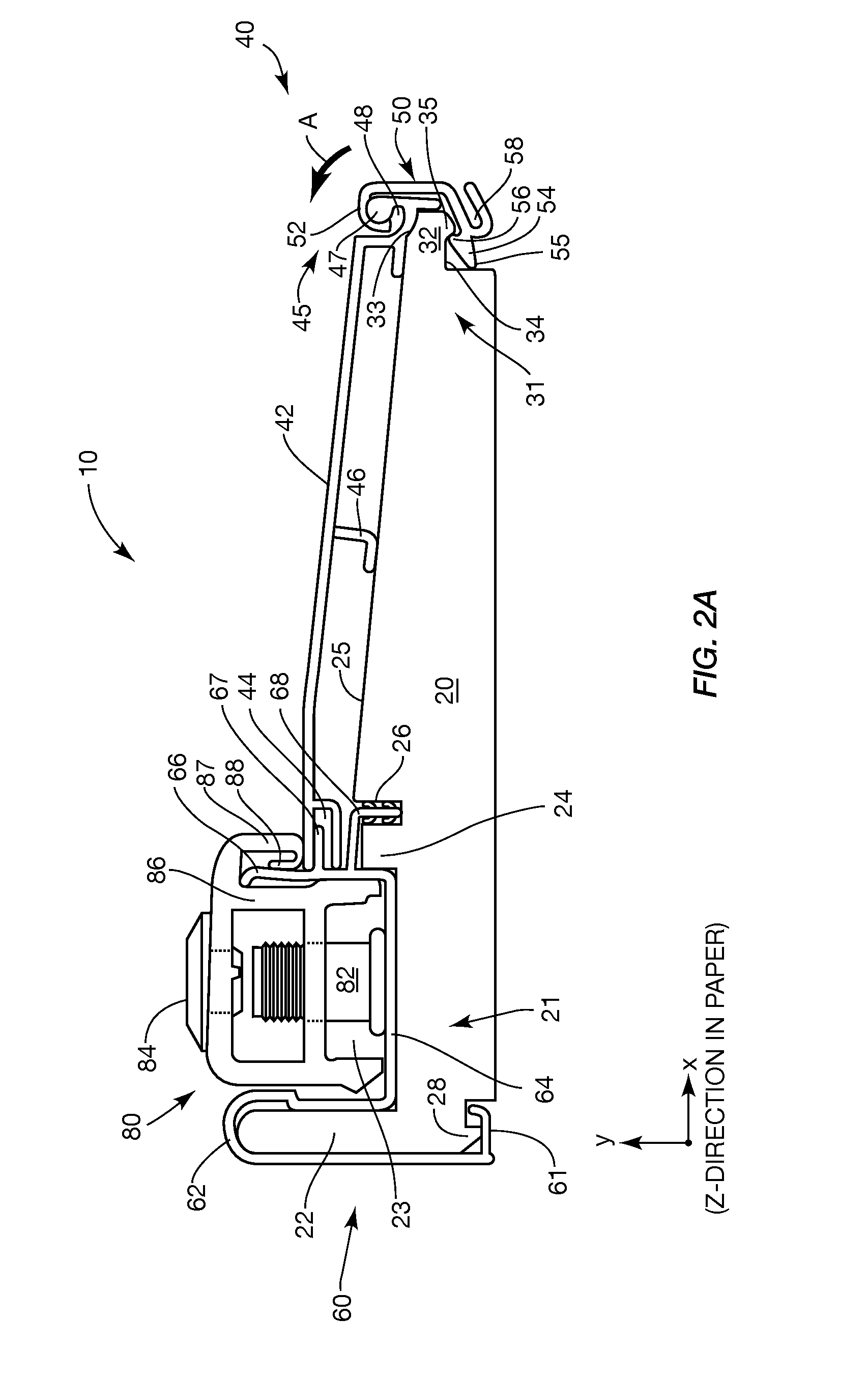

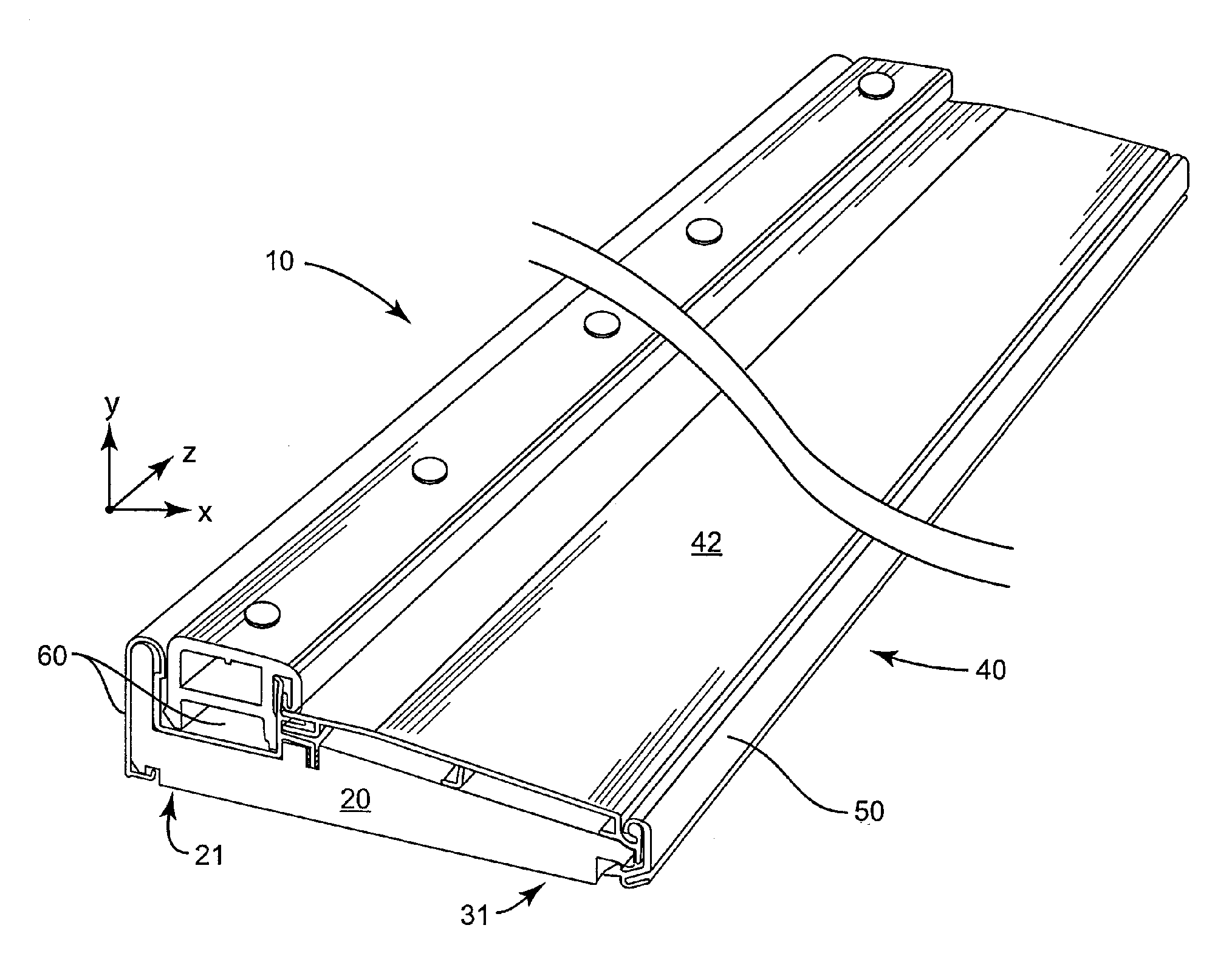

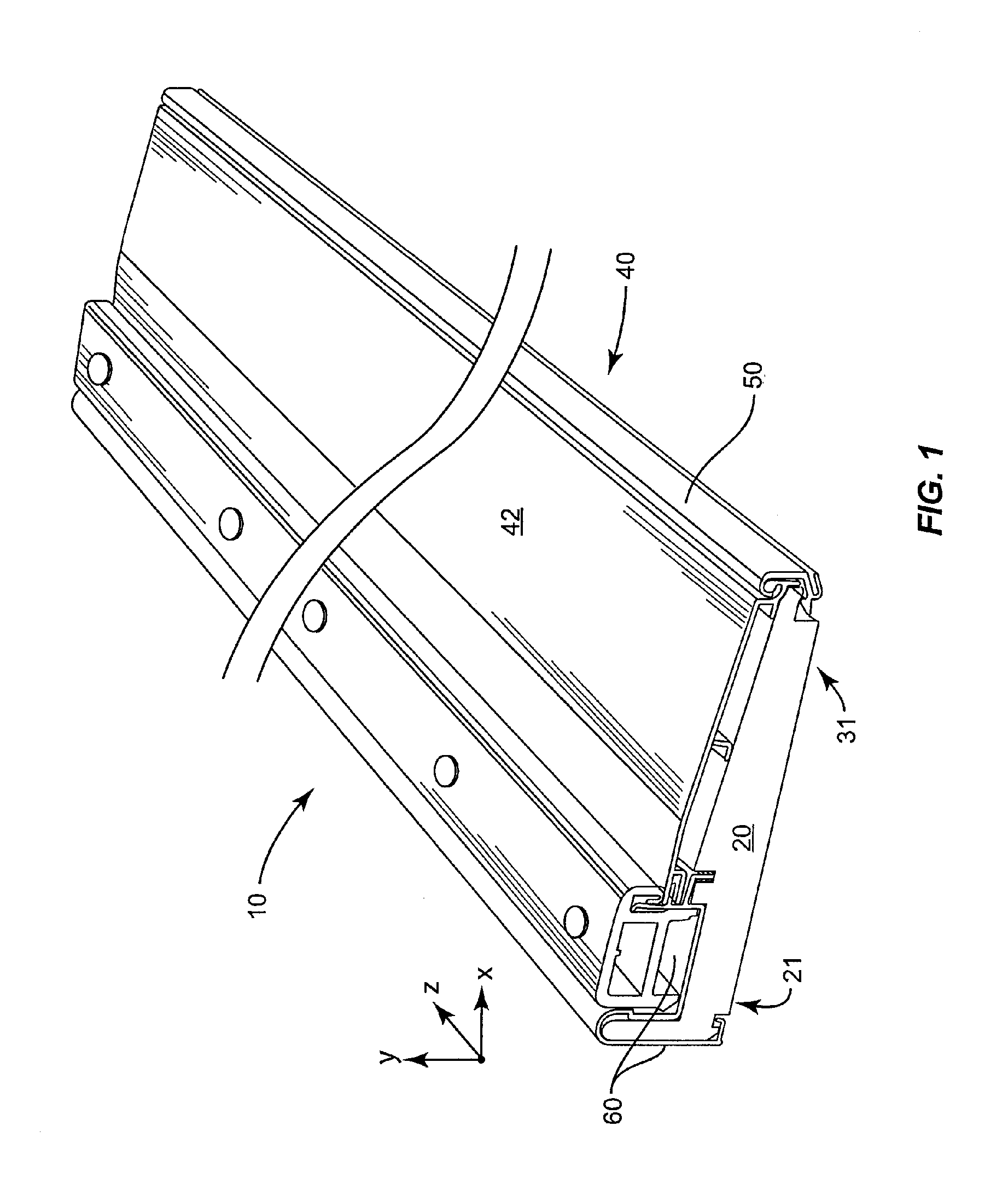

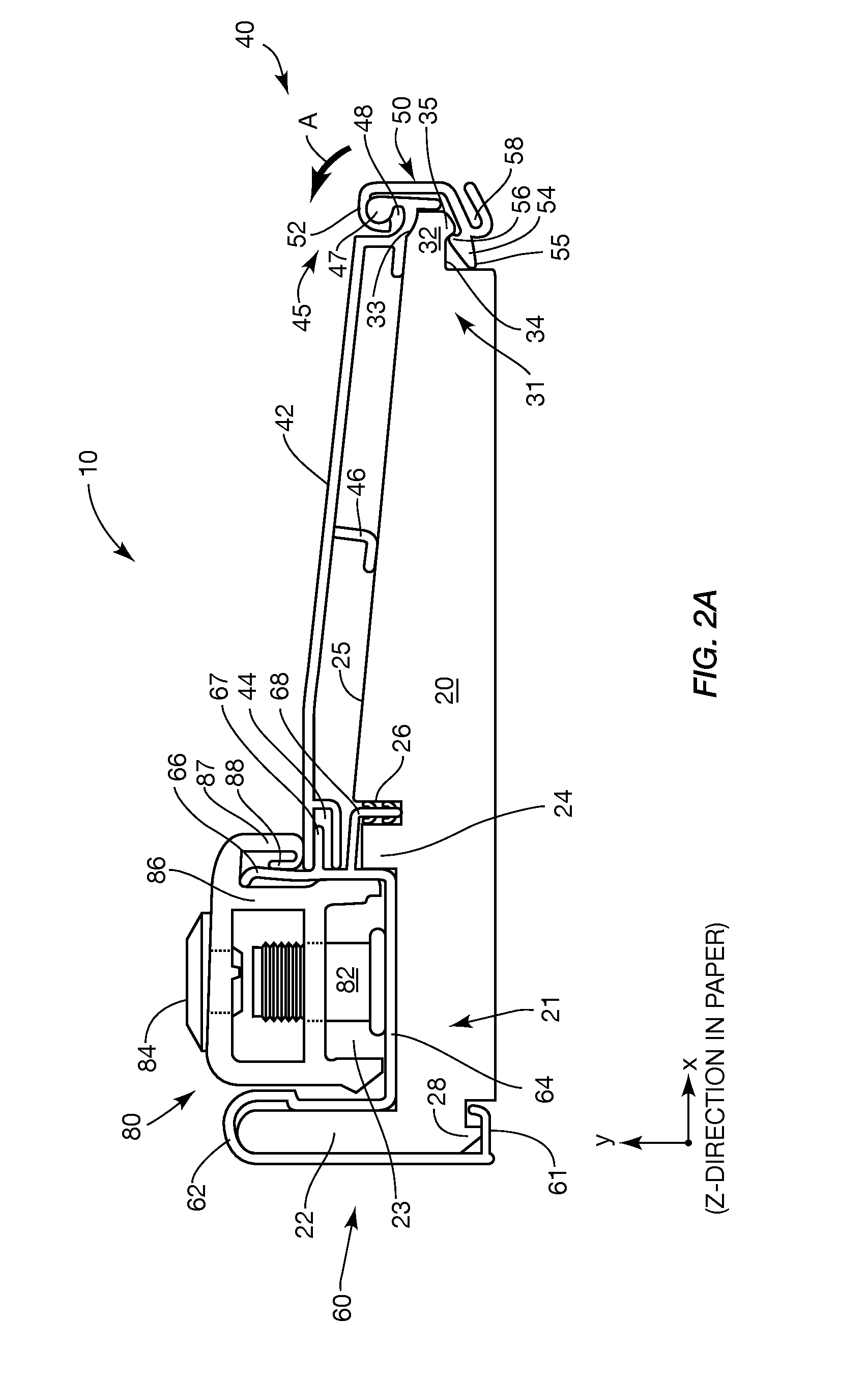

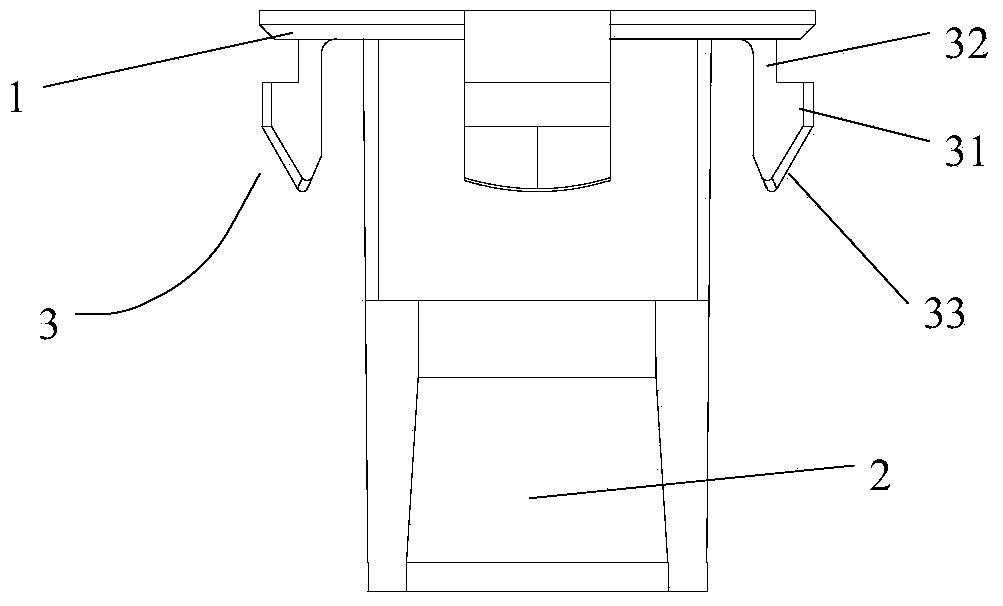

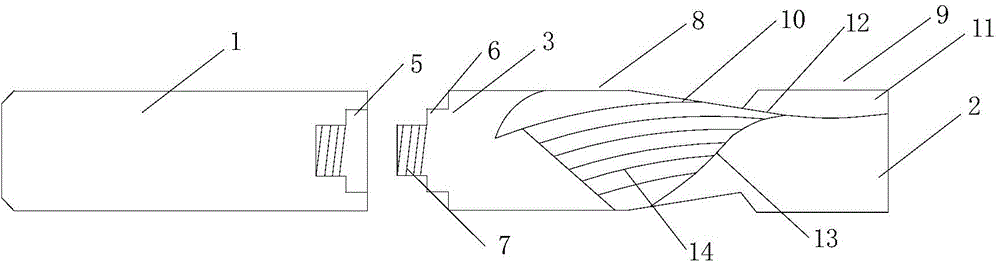

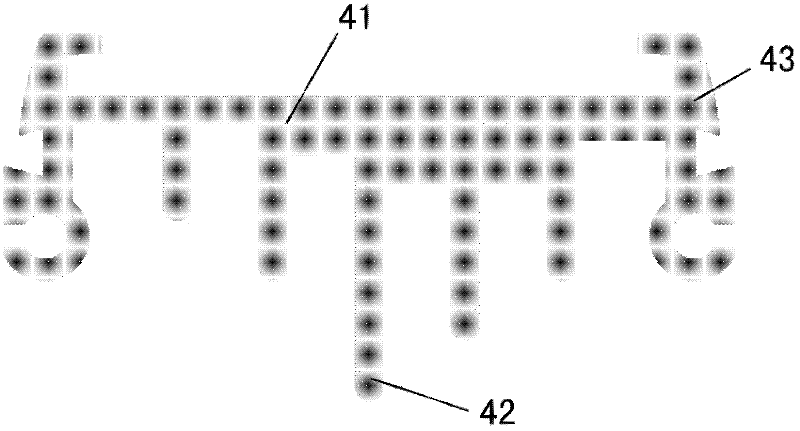

Door sill assemblies with replaceable sill decks

ActiveUS8567128B2Detachable connectionSills/thresholdSpecial door/window arrangementsEngineeringMechanical engineering

A door sill assembly for an entryway of a building can include a substrate having a nosing and a sill channel. A nosing cover can be attached to the substrate and extending over at least a portion of the nosing and over at least a portion of the sill channel. A sill deck can be on the substrate. The sill deck can include a deck and a clip. In an embodiment, the sill deck and clip are a unitary construction. The deck can be engaged with a portion of the nosing cover. The clip can be operably engaged with the deck. The clip can be removably attachable to the substrate. The sill deck is capable of removable attachment from the door sill assembly before or after the door sill assembly is installed in the entryway.

Owner:ENDURA PRODS

Door Sill Assemblies With Replaceable Sill Decks

ActiveUS20130091776A1Detachable connectionSills/thresholdSpecial door/window arrangementsEngineeringMechanical engineering

A door sill assembly for an entryway of a building can include a substrate having a nosing and a sill channel. A nosing cover can be attached to the substrate and extending over at least a portion of the nosing and over at least a portion of the sill channel. A sill deck can be on the substrate. The sill deck can include a deck and a clip. In an embodiment, the sill deck and clip are a unitary construction. The deck can be engaged with a portion of the nosing cover. The clip can be operably engaged with the deck. The clip can be removably attachable to the substrate. The sill deck is capable of removable attachment from the door sill assembly before or after the door sill assembly is installed in the entryway.

Owner:ENDURA PRODS

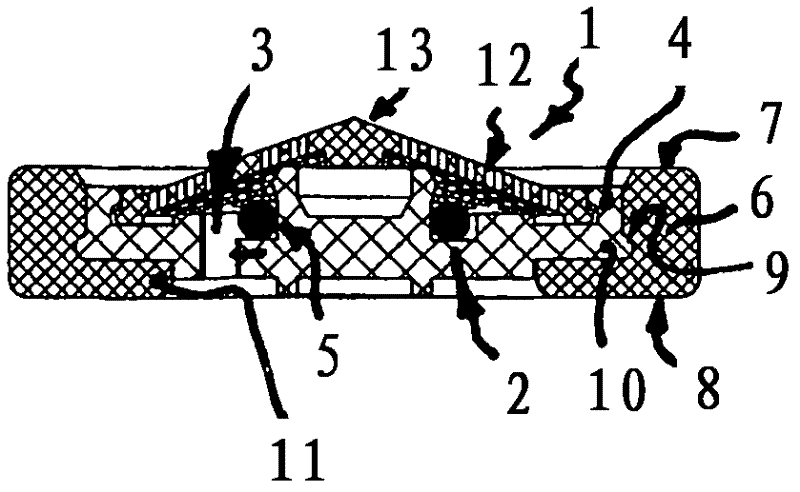

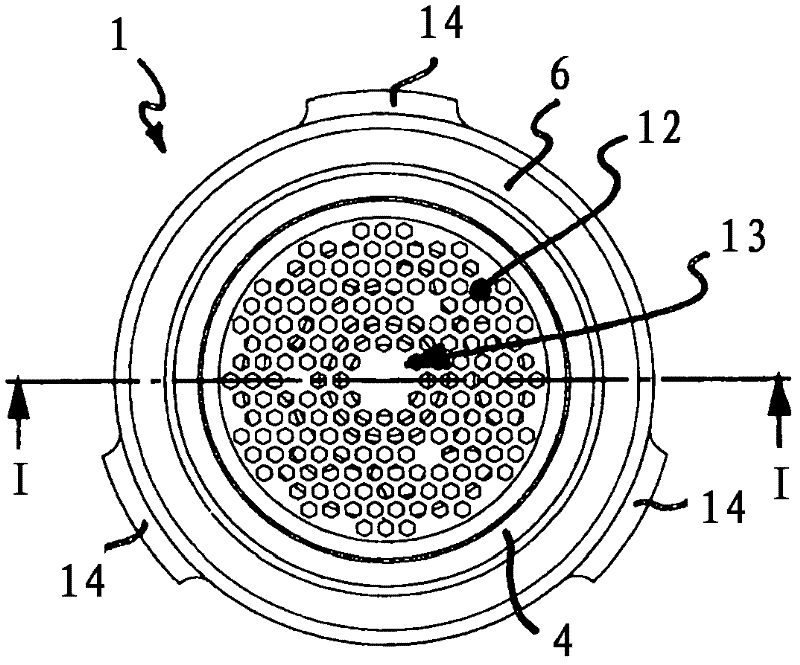

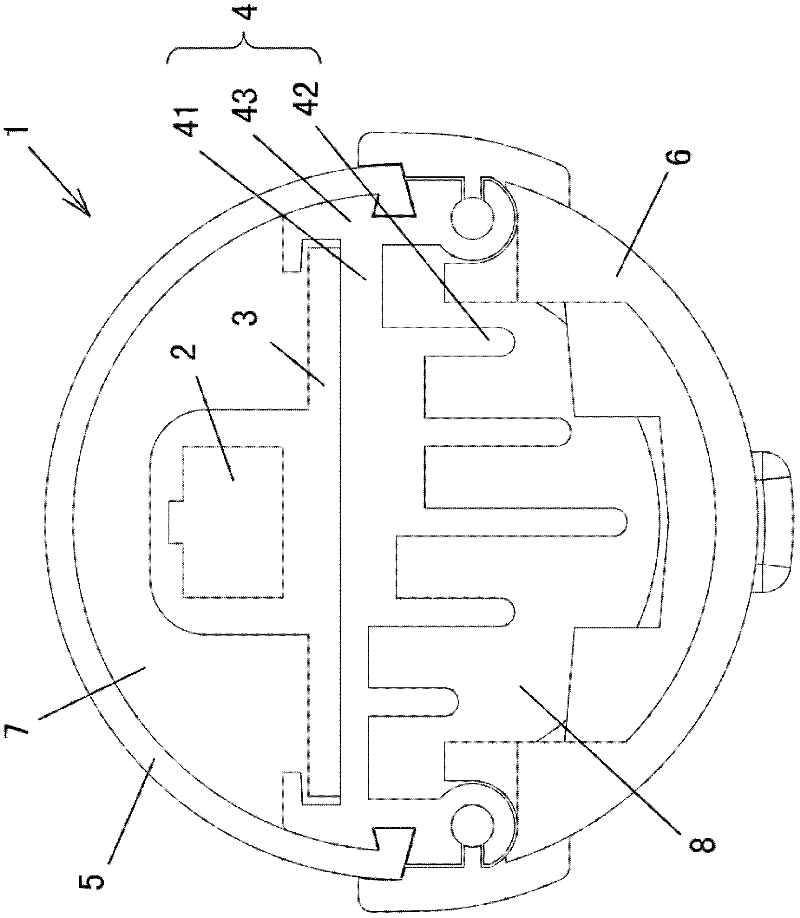

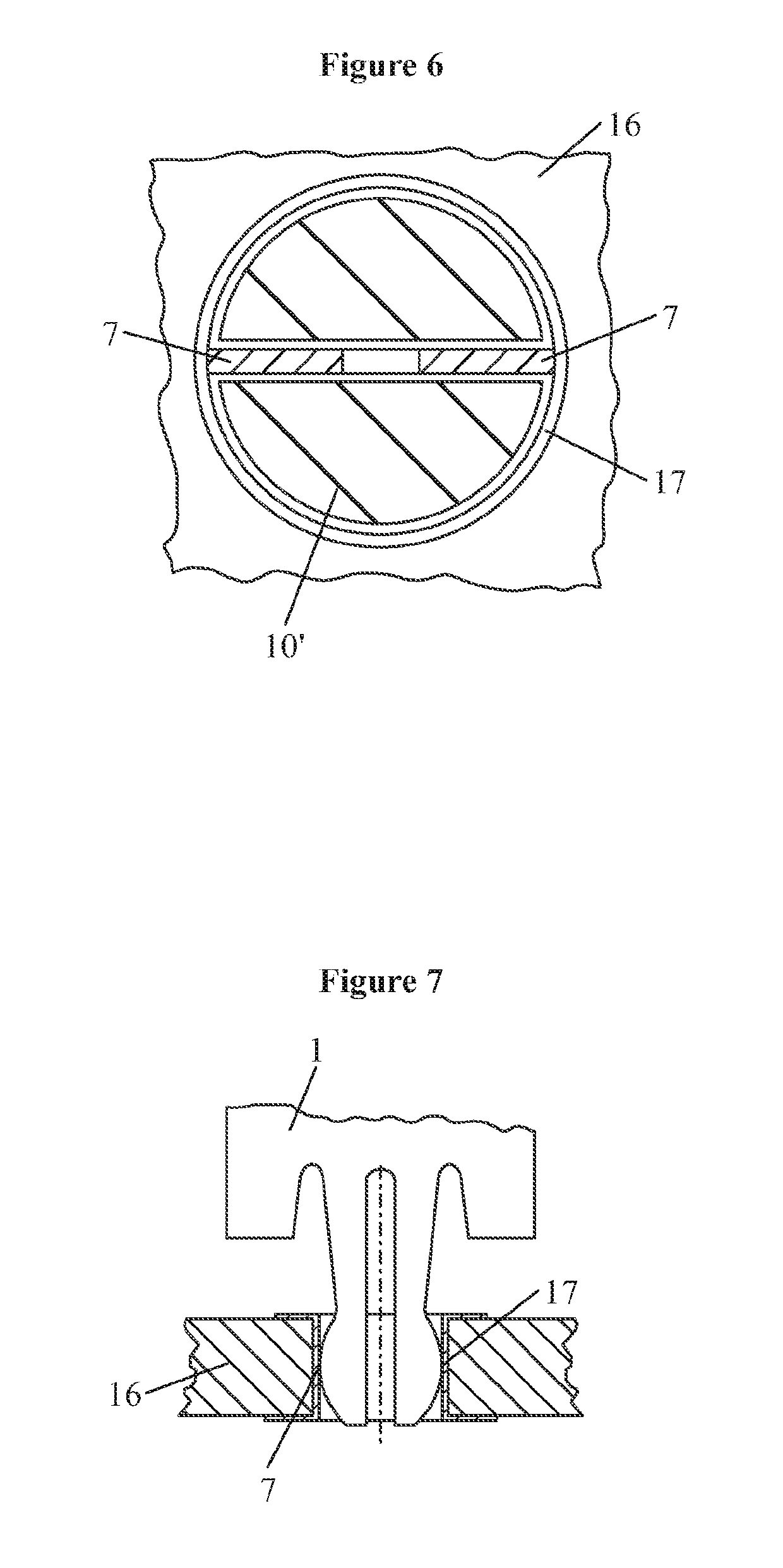

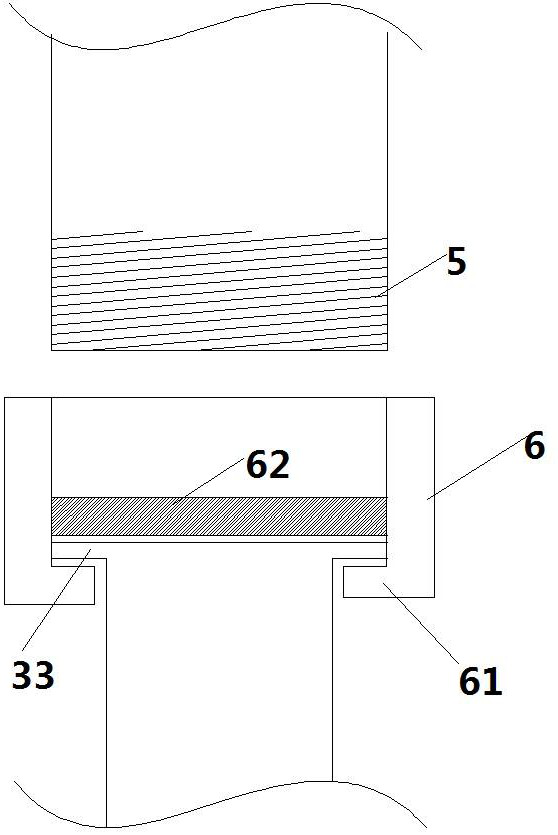

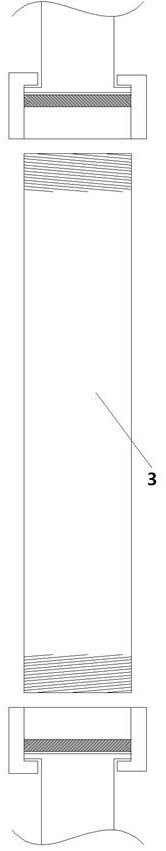

flow regulator

ActiveCN102272391AEasy to processFirmly connectedDomestic plumbingSpray nozzlesEngineeringStreamflow

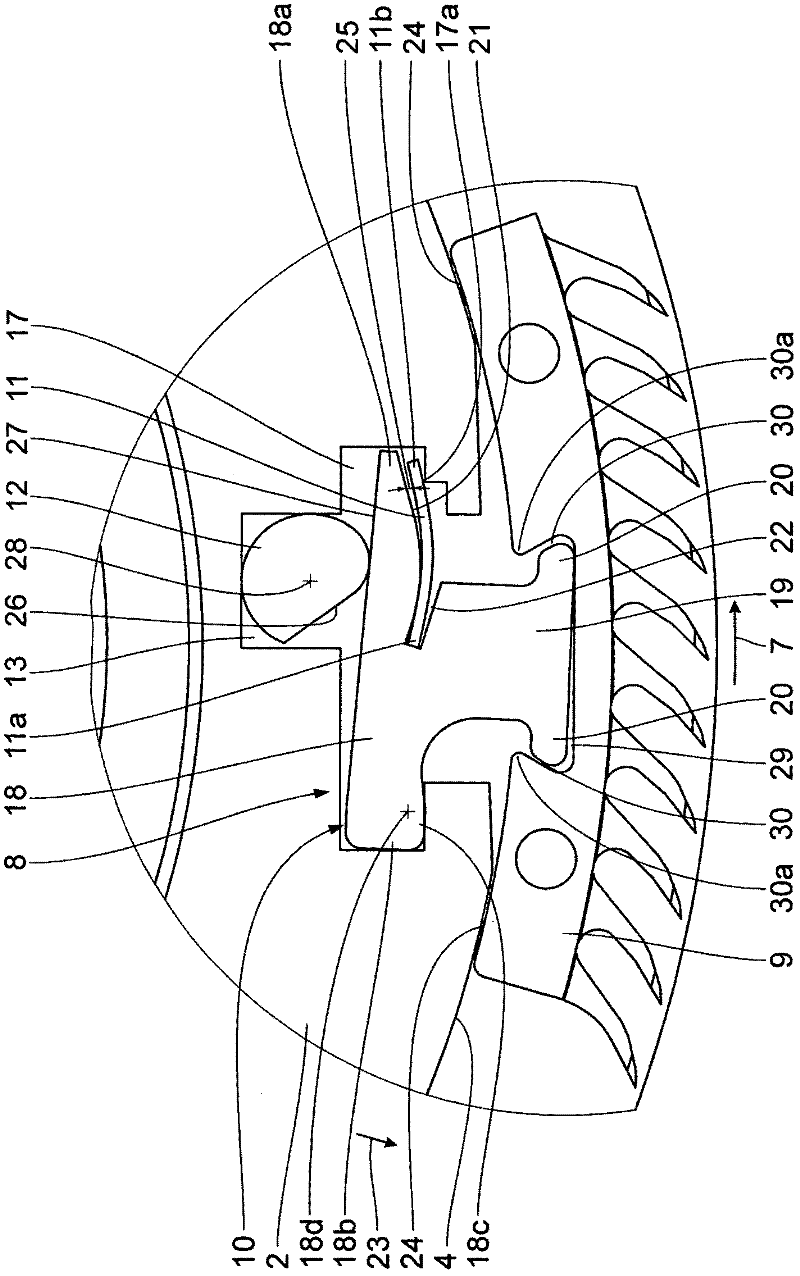

The invention relates to a flow quantity regulator (1) having at least one throttle body (2) made of elastically deformable material, disposed in the permeating channel (3) of a regulator housing (4) and delimiting a control gap (5) between the same and a control profile disposed on an inner and / or outer circumferential channel wall, said control gap (5) being changeable in the open flow cross section thereof, due to the throttle body (2) that can deform under the pressure of the permeating meidum, wherein the regulator housing (4) comprises a clamping edge area for clamping the flow quantity regulator (1) between two line segments or line components connected to each other. The flow quantity regulator (1) according to the invention is characterized in that the regulator housing (4) is disposed in the ring opening of a sealing ring (6) and that upstream and downstream face areas (7, 8) of the sealing ring (6) form the clamping edge area. The flow quantity regulator (1) according to the invention can easily be installed in a plumbing supply line, even under tight space conditions, wherein the sealing ring (6) provided as the clamping edge area of the regulator housing (4) externally seals off the end faces, facing each other, of the line segments to be connected to each other.

Owner:NEOPERL

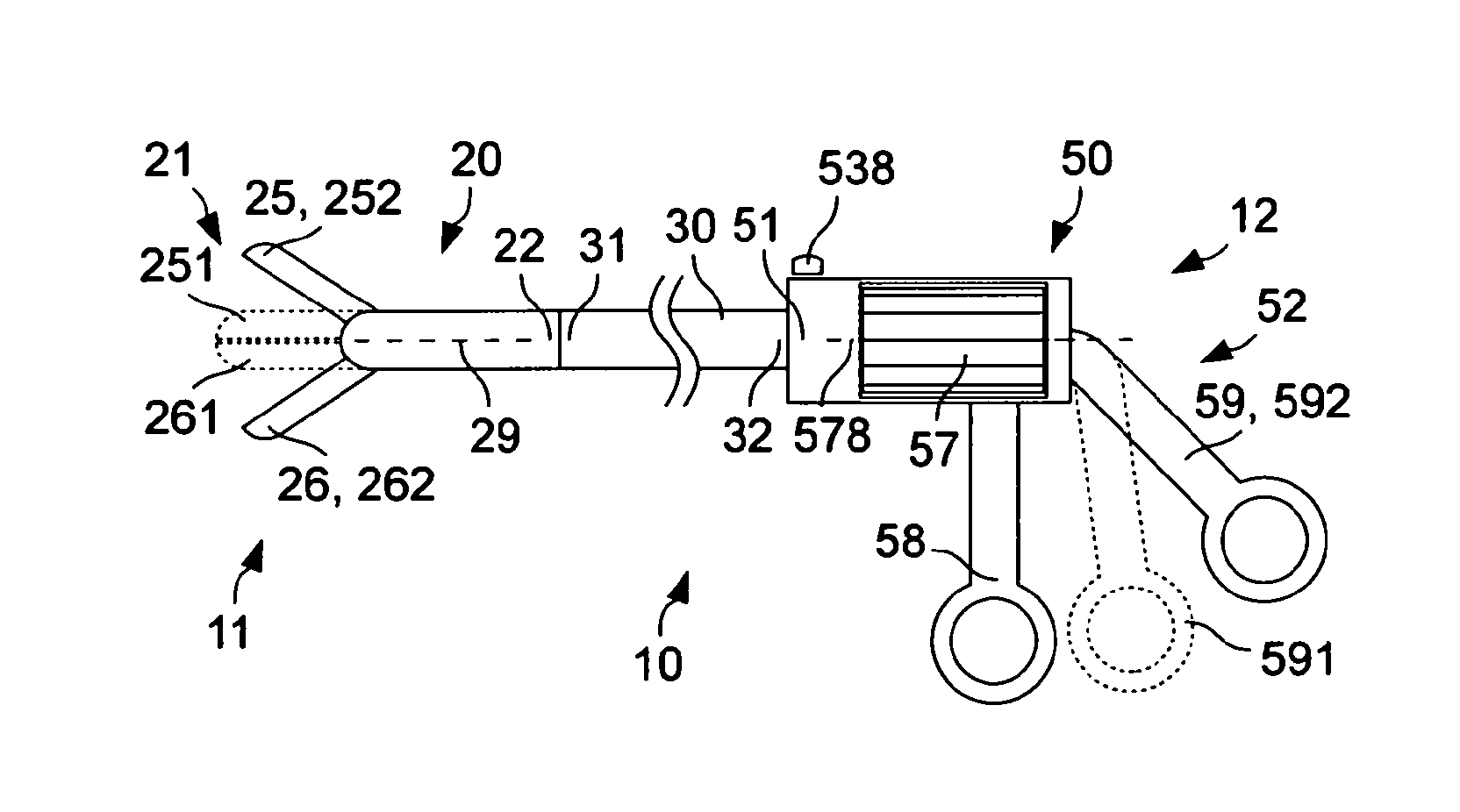

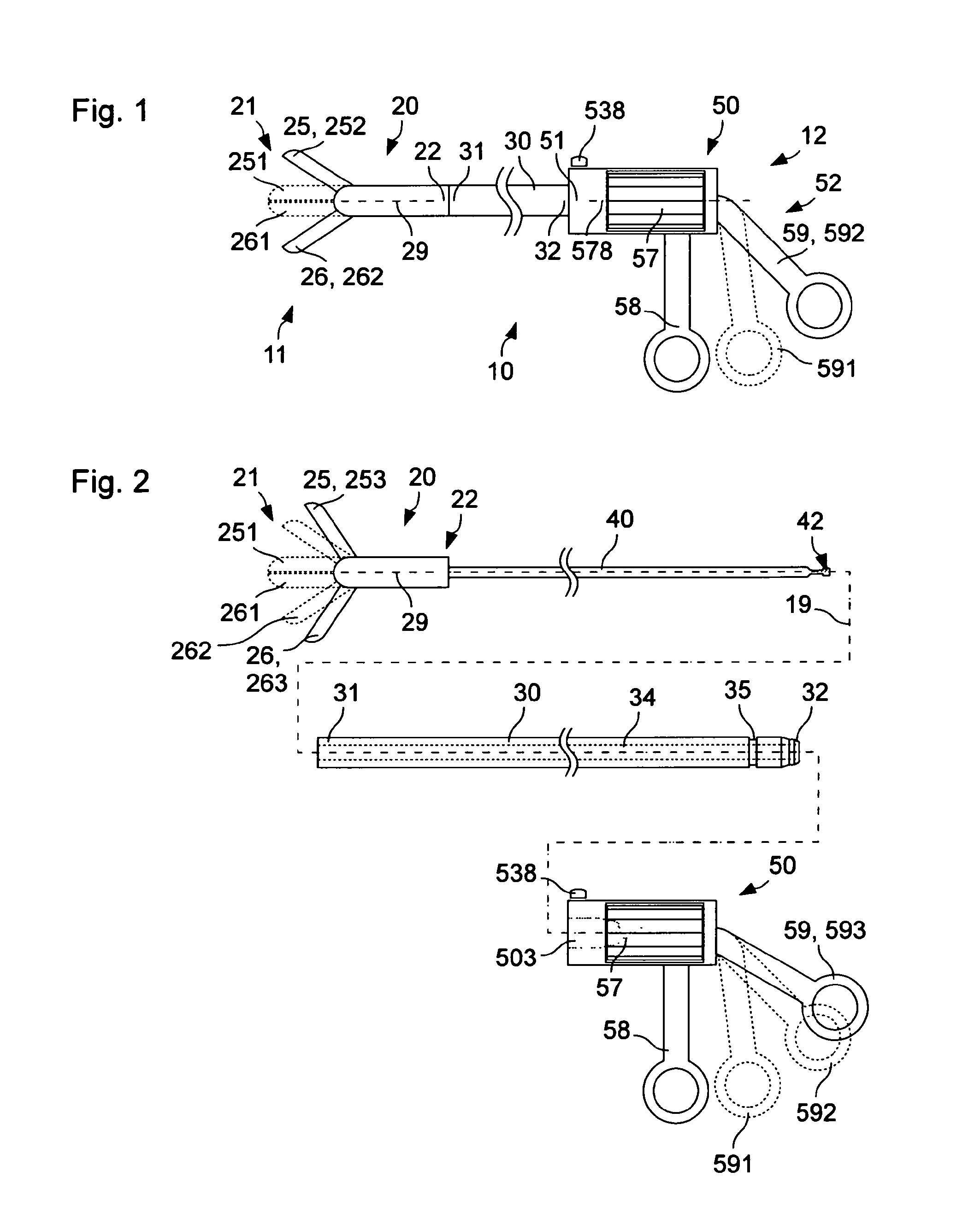

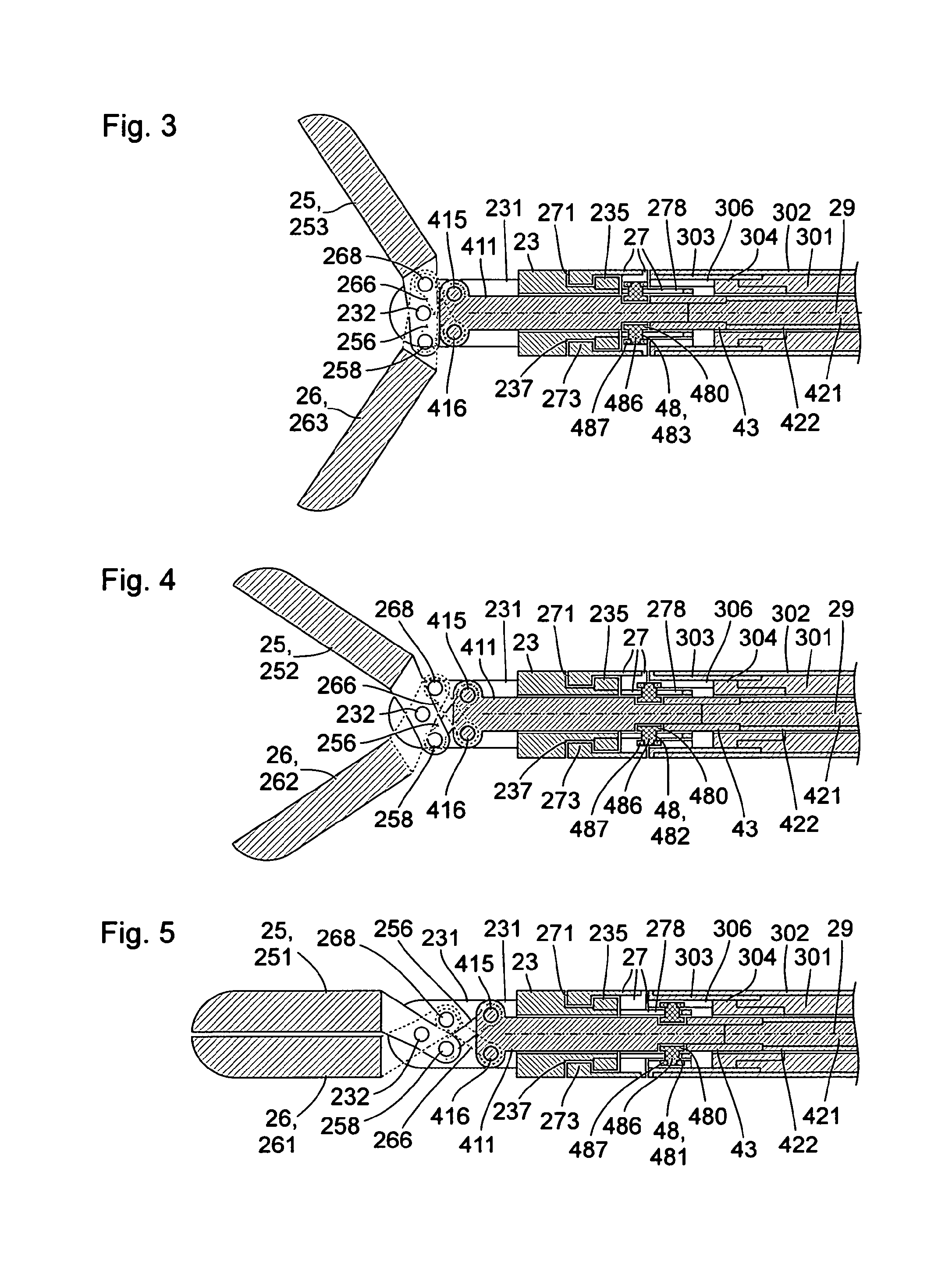

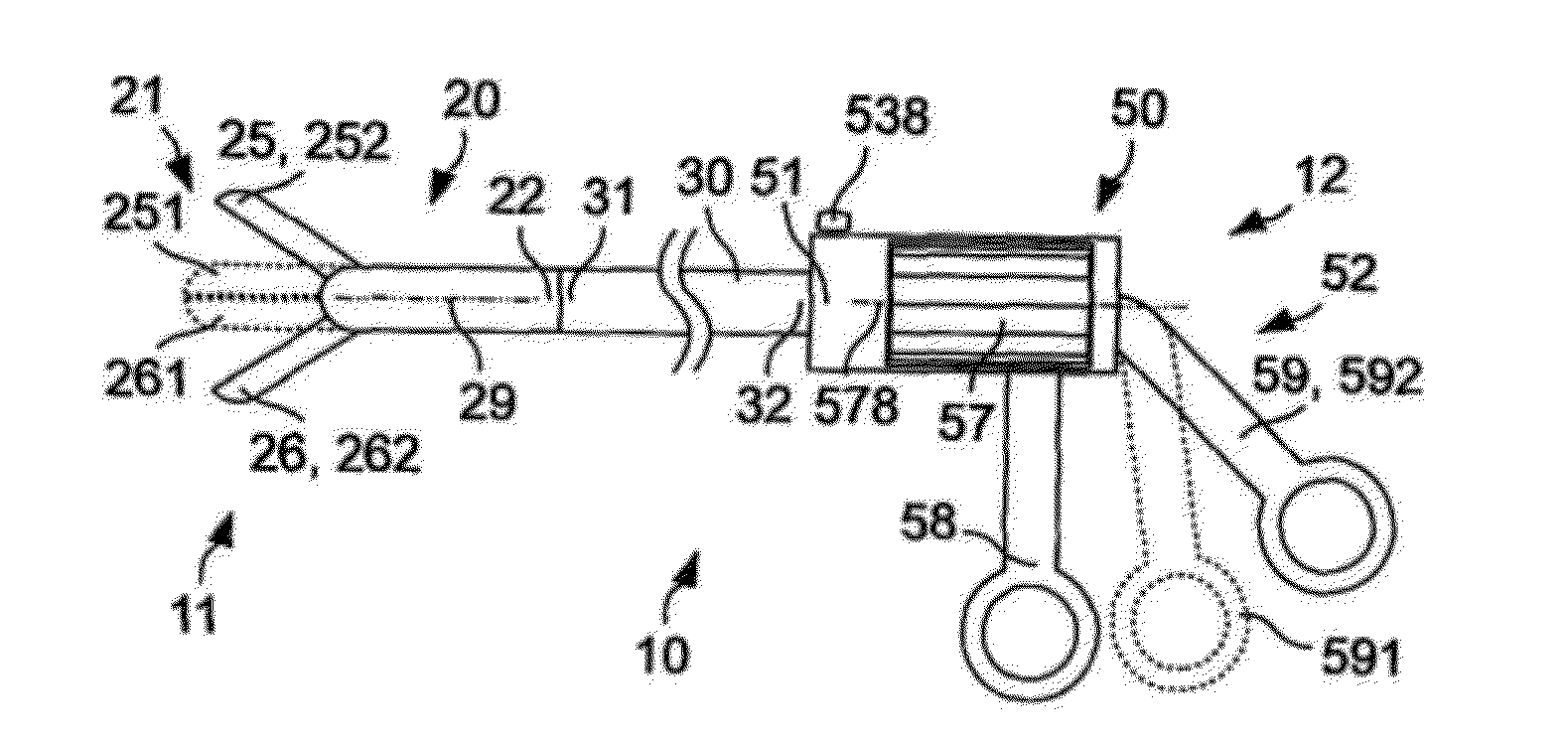

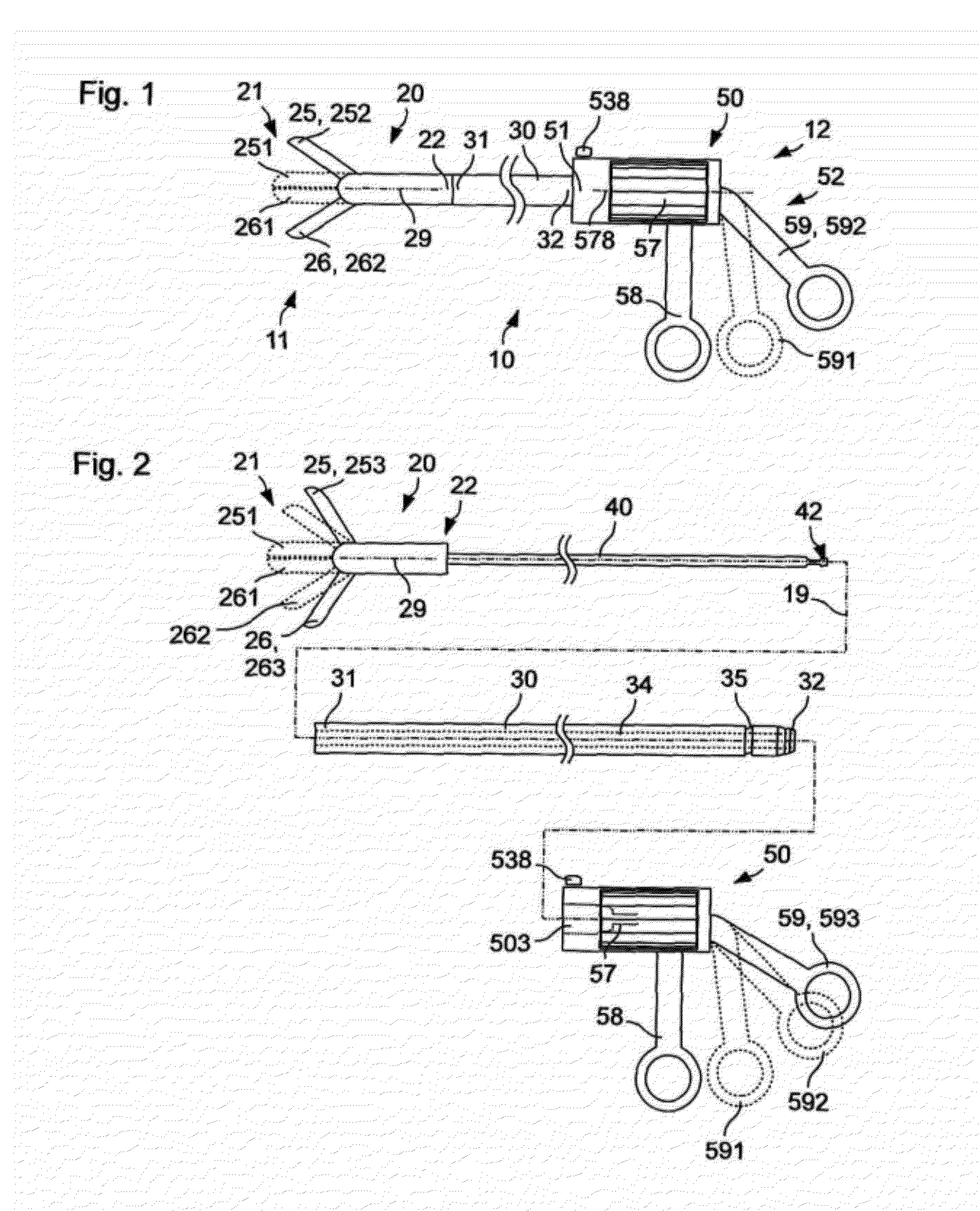

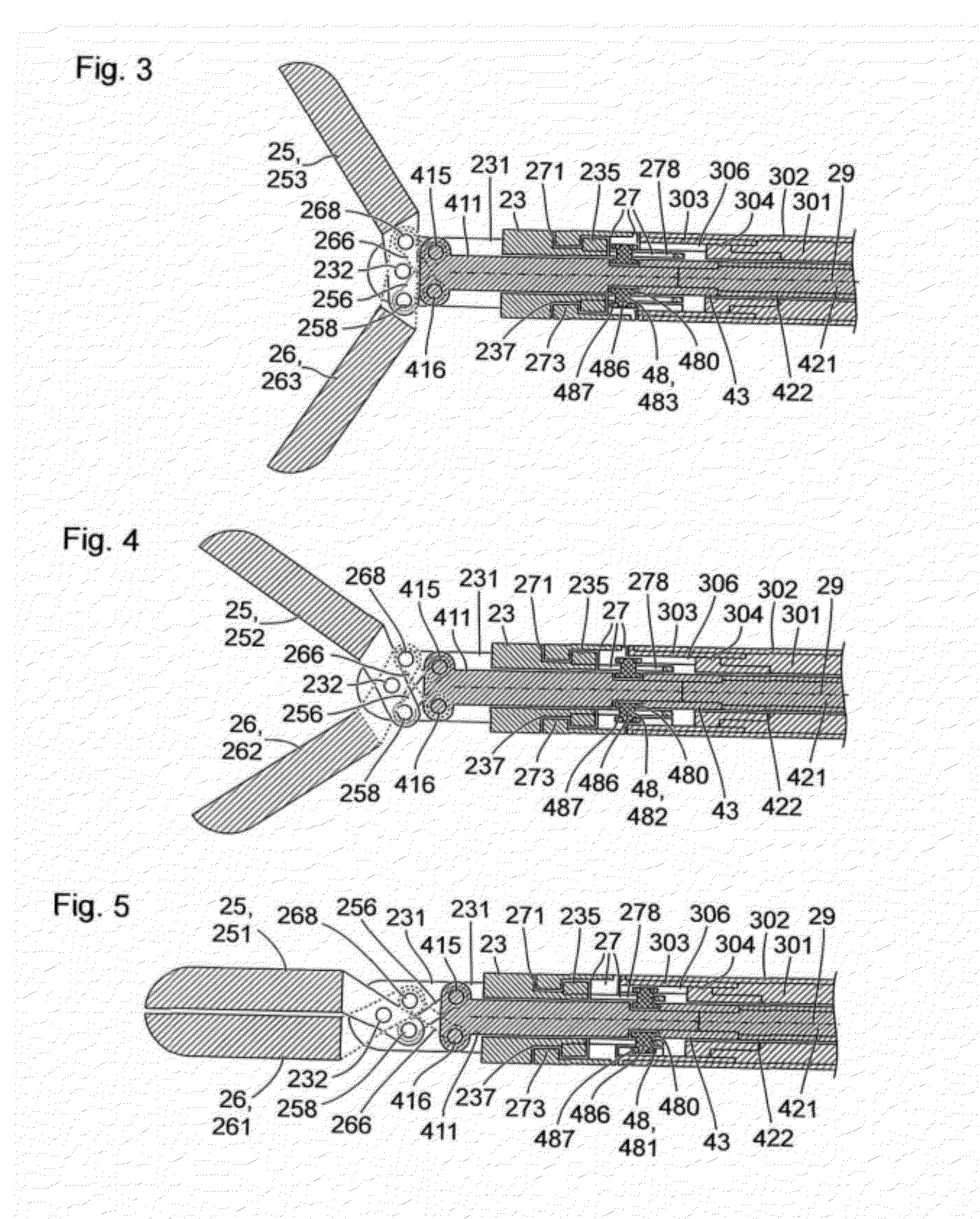

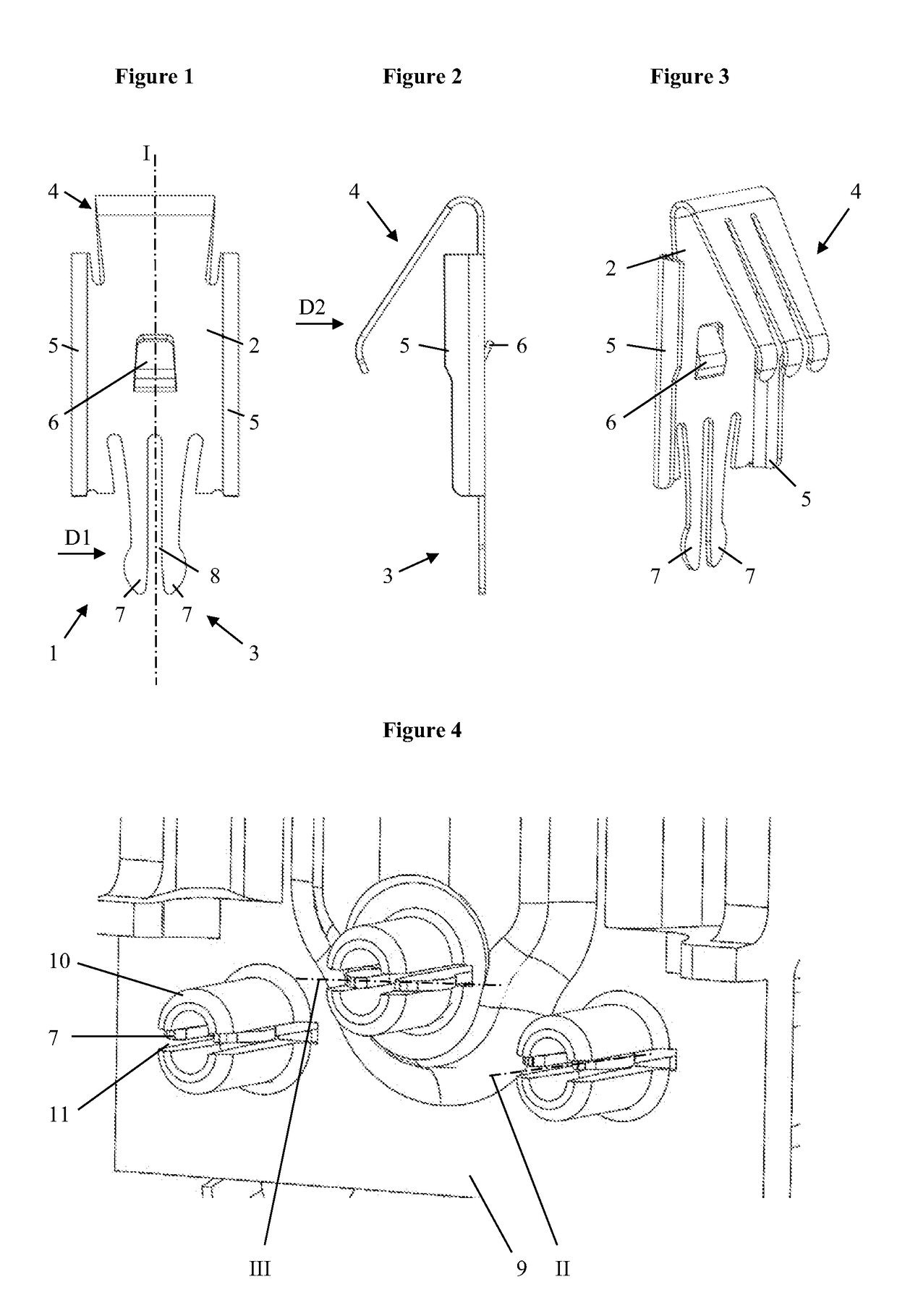

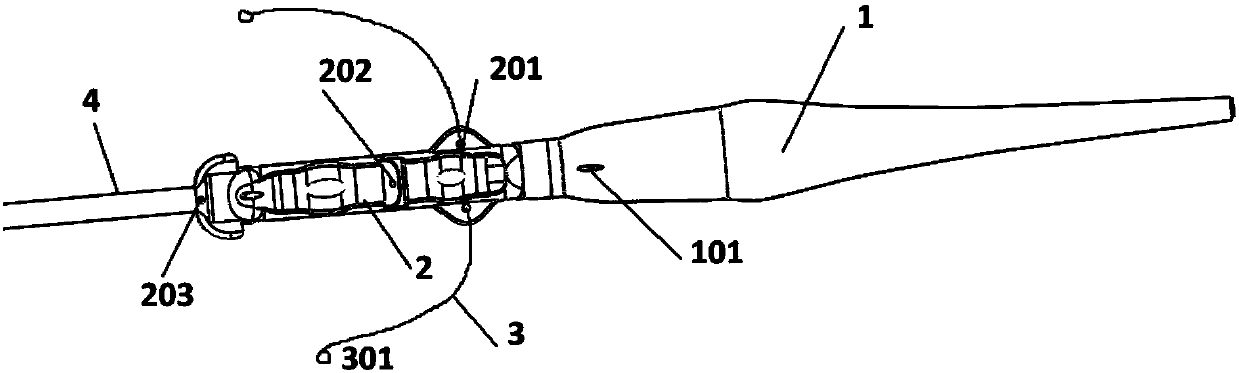

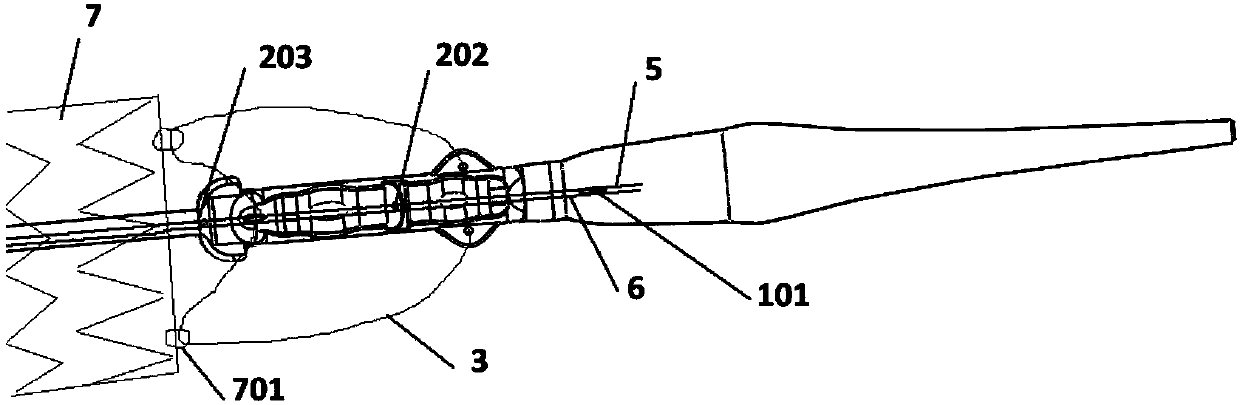

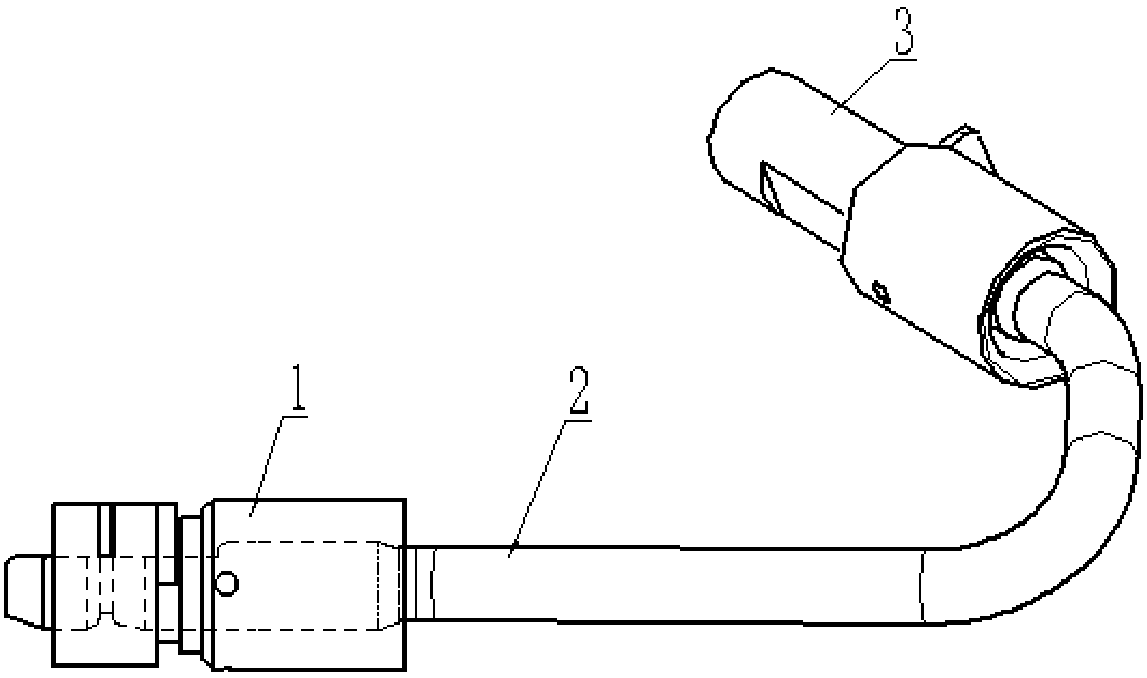

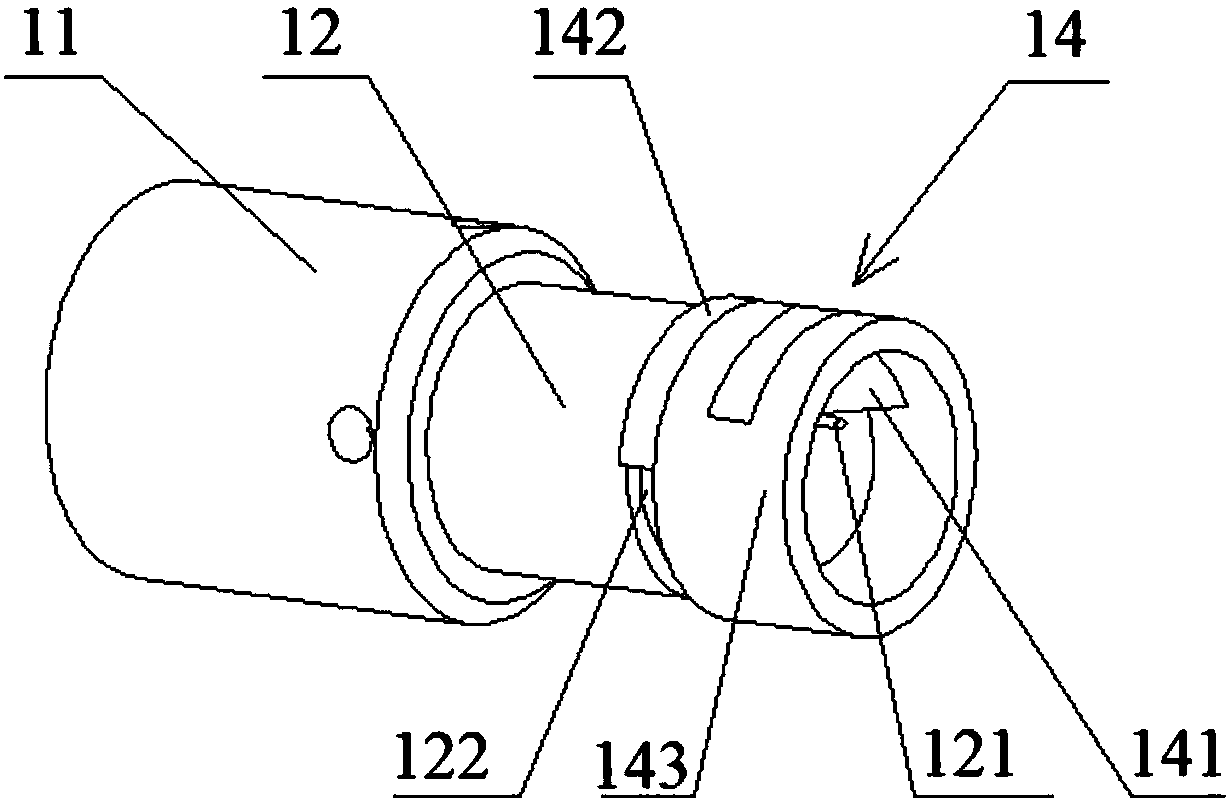

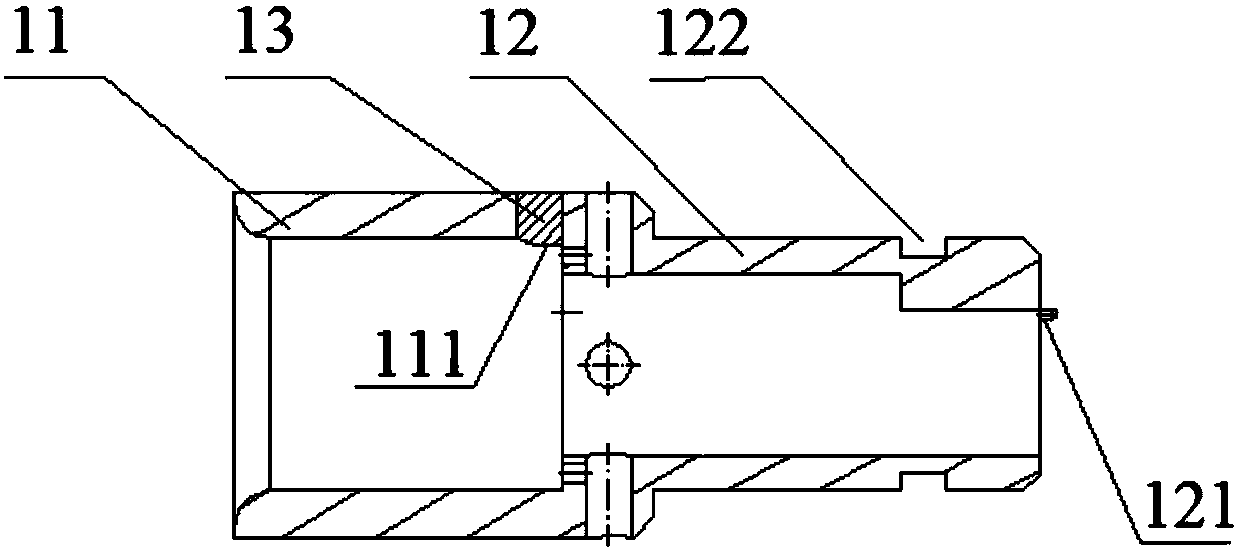

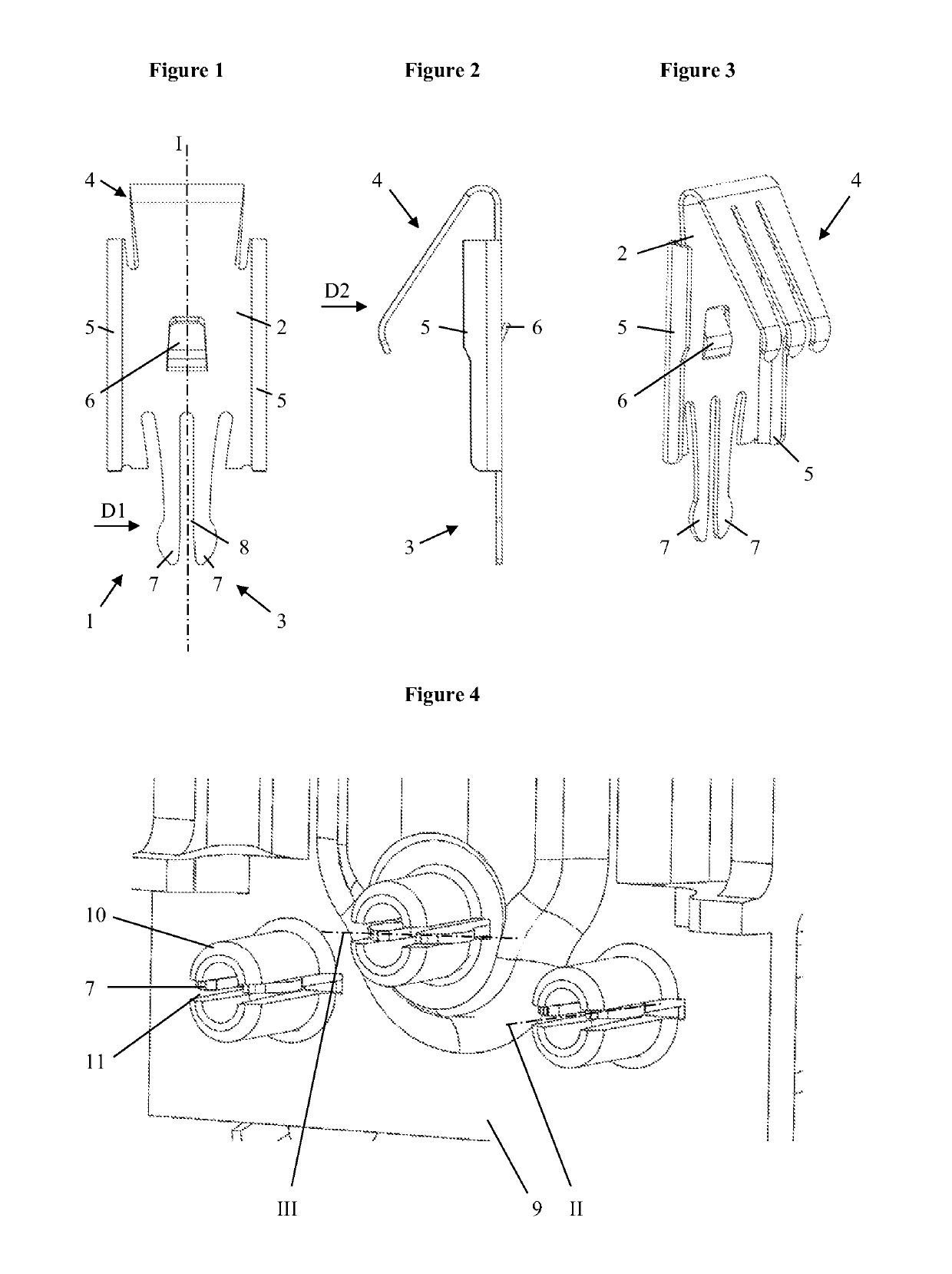

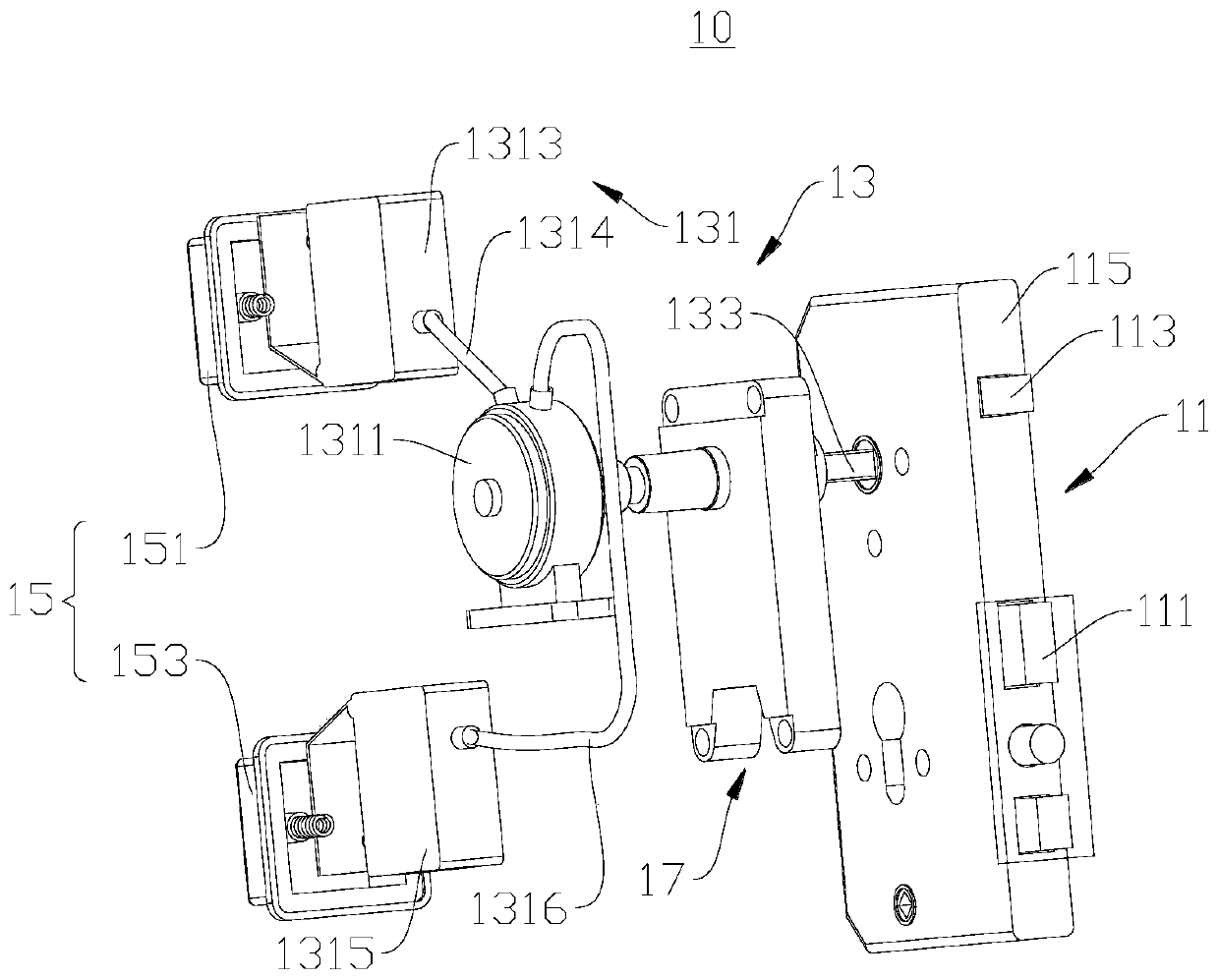

Tool for a micro-invasive surgical instrument

ActiveUS8882750B2Simplify and improve handlingDetachable connectionSurgical forcepsLess invasive surgeryCoupling

A tool, which is detachably coupleable with a shaft for a micro-invasive surgical instrument, includes an articulated device on which a jaw member or other active device is affixed, a connecting component that is rotatably connected with the articulated device and that includes a coupling device for detachable coupling with a distal end of a shaft, a transmission rod to transmit at least either a force or torque from one proximal end of a shaft detachably coupled with the tool to the jaw member or other active device, and a locking device that is coupled with the transmission rod in such a way that the locking device can be rotated with respect to the transmission rod but not slid axially, so that the locking device is mounted in the connecting component in such a way that it can be axially slid but not rotated in relation to the connecting component.

Owner:KARL STORZ GMBH & CO KG

Tool for a micro-invasive surgical instrument

ActiveUS20120259319A1Reliable and robust connectionReliable mannerSurgical forcepsSurgical instrumentActive devices

A tool, which is detachably coupleable with a shaft for a micro-invasive surgical instrument, includes an articulated device on which a jaw member or other active device is affixed, a connecting component that is rotatably connected with the articulated device and that includes a coupling device for detachable coupling with a distal end of a shaft, a transmission rod to transmit at least either a force or torque from one proximal end of a shaft detachably coupled with the tool to the jaw member or other active device, and a locking device that is coupled with the transmission rod in such a way that the locking device can be rotated with respect to the transmission rod but not slid axially, so that the locking device is mounted in the connecting component in such a way that it can be axially slid but not rotated in relation to the connecting component.

Owner:KARL STORZ GMBH & CO KG

Skirtboard lock and rail vehicle

ActiveCN103847755AEasy to observeDetachable connectionRailway transportAxle-box lubricationFastenerEngineering

The invention provides a skirtboard lock and a rail vehicle. The skirtboard lock comprises a lock shell provided with a hole in the center and a locking screw rod arranged in the lock shell in a penetrating mode; the tail end of the locking screw rod is a prismatic mounting section; the skirtboard lock also comprises a display fastener arranged between the lock shell and the mounting section; the bottom of the fastener is provided with a mounting hole matched with the mounting section in shape; the mounting section is coaxially clamped in the mounting hole; clamp hooks are fixedly arranged at the periphery of the top end of the display fastener; a clamping part is formed at the edge of the opening in the top end of the lock shell; the display fastener and the clamping part are clamped and fixed in the lock shell by the clamp hooks. The skirtboard lock has the beneficial effects that the synchronous rotation of the display fastener and the locking screw rod is realized by matching of the mounting hole and the tail end of the locking screw rod, so the loosening phenomenon of a locking rod screw rod is convenient to observe; the display fastener is fixed in the lock shell by clamping the clamp hooks and the clamping part. The display fastener is very convenient to assemble and disassemble due to the clamping mode.

Owner:CRRC TANGSHAN CO LTD +1

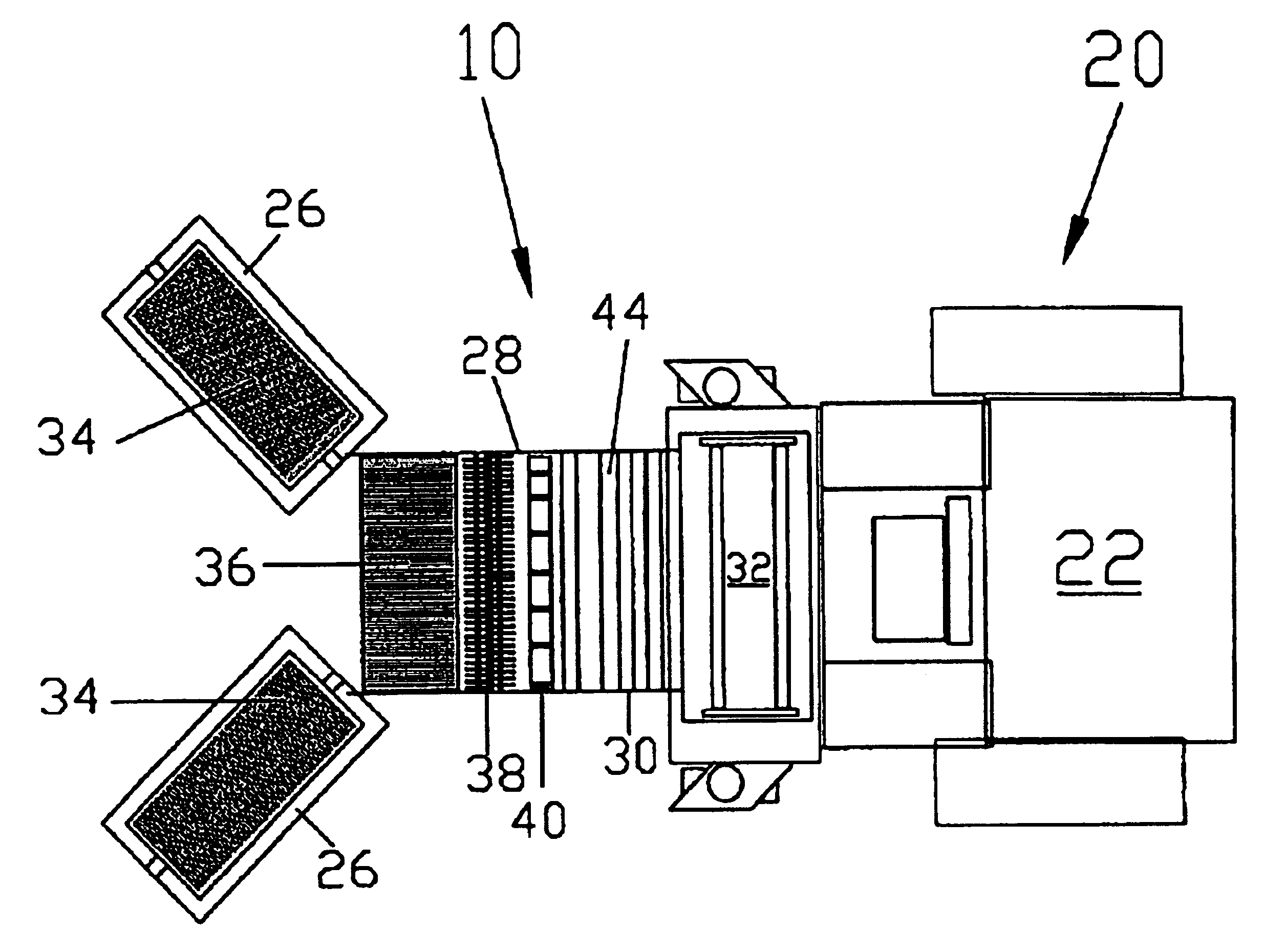

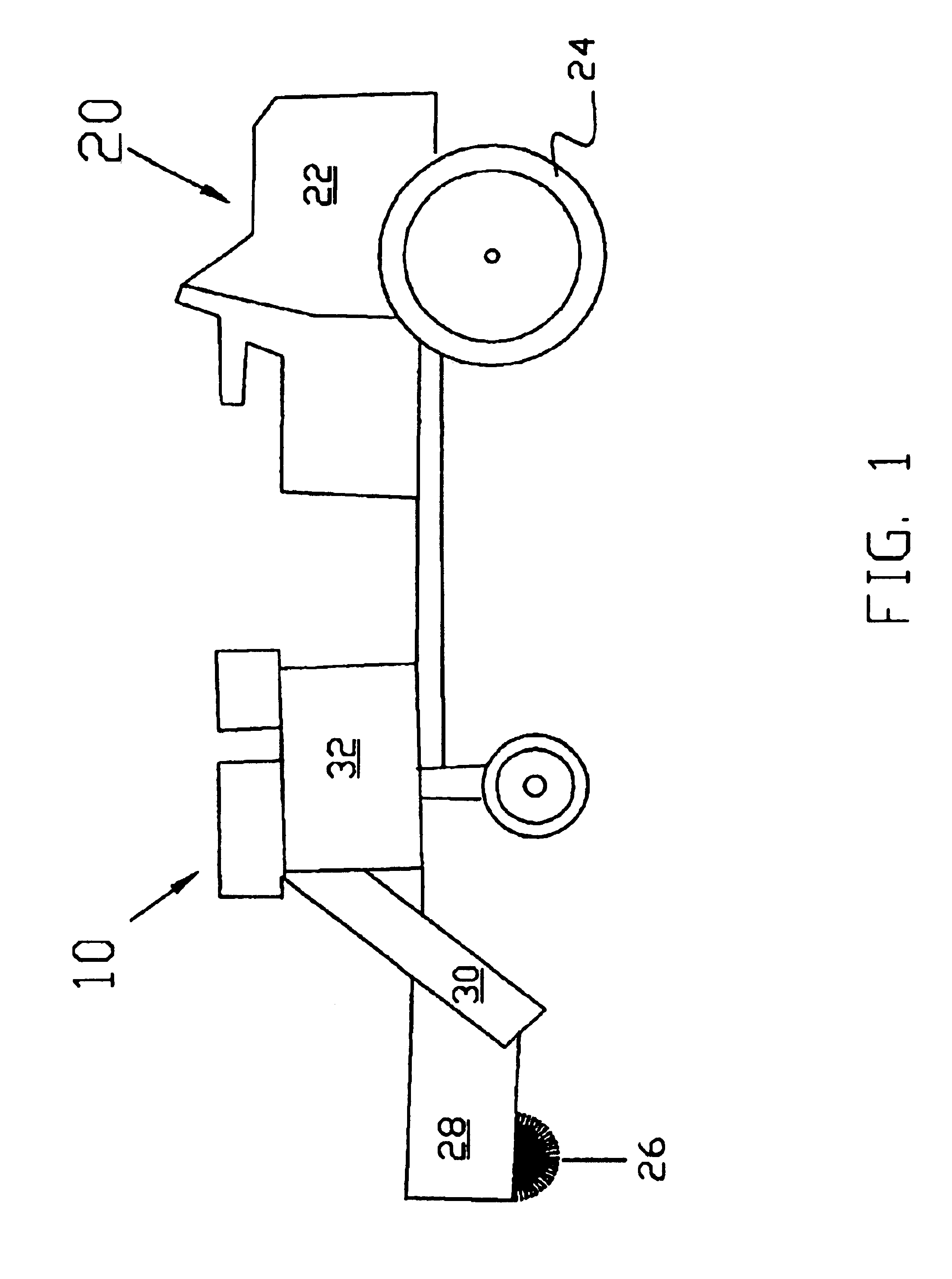

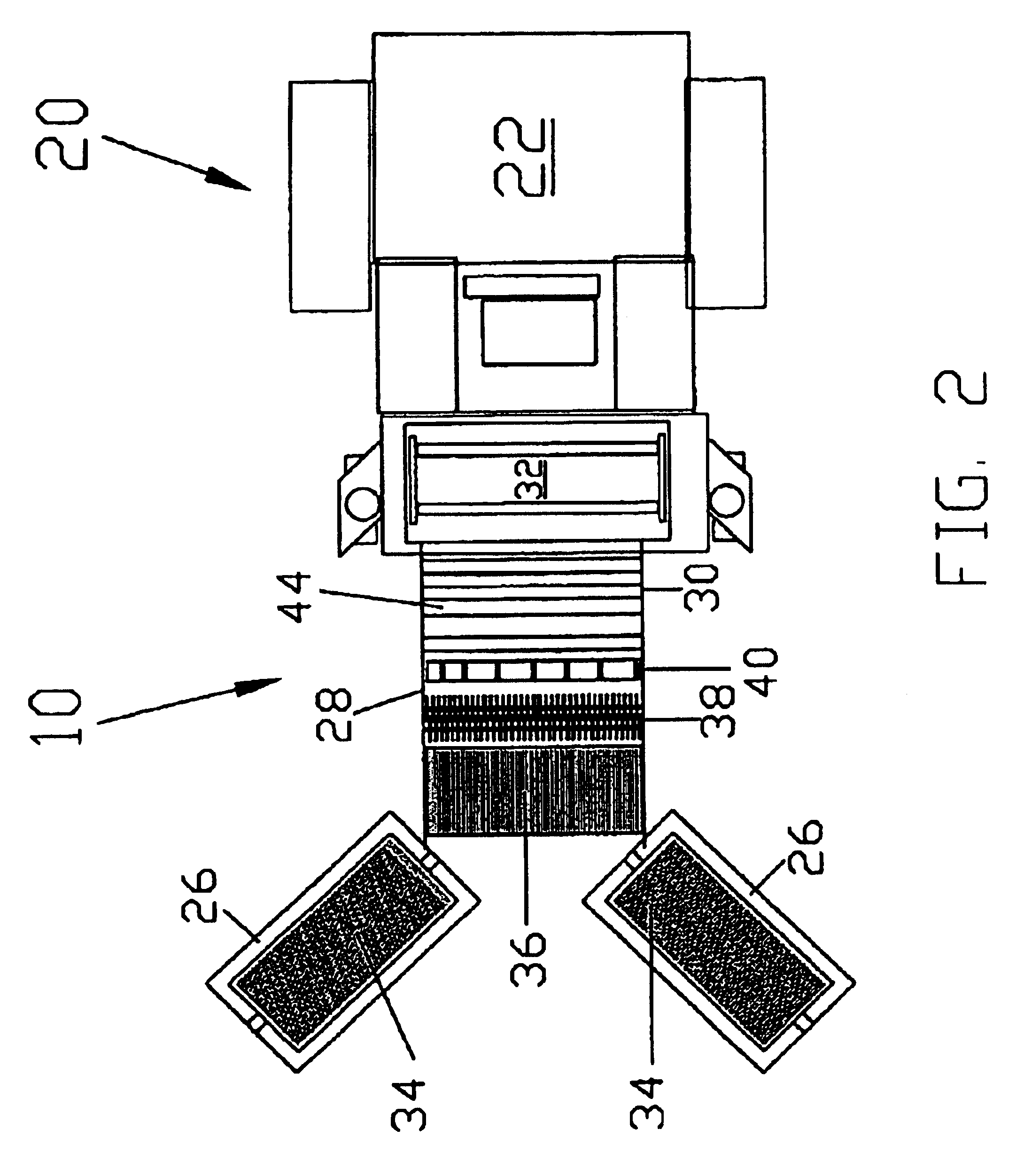

Leaf compactor and baler

InactiveUSRE40761E1Unlimited capacityConveniently carriedHops/wine cultivationBrush bodiesCrusherEngineering

An apparatus 10 for compacting and baling leaves, grass clippings, sticks, pine straw and other debris on lawns, yards, or fields is provided. The apparatus 10 may have diagonal brushes 26 to gather debris for processing though a crusher 28, a conveyor belt 30 to transport the crushed debris, and a baler 32 to compact and bale the debris. The baler 32 may compact the debris by rotating the debris in a continuous band 52, into which baling material 72 may be inserted to bale the debris. Alternatively, the debris may be gathered and feed into a crusher 28 that deposits the crushed debris directly into the baler 32 for compacting and baling. Further still, the apparatus 10 may gather the debris with brushes 26 and feed it onto a conveyor mechanism 30 that then introduces it into a crusher 28. The crushed debris may then be feed into a baling mechanism 32 that compacts and bales the debris for easy removal and disposal. In its various embodiments, the present invention may be connected to a prime mover 20 or alternatively connected to a portable base with a motor for driving the device 10.

Owner:TRUITT BOBBY L

Carrier element for pressure chamber of friction clutch

The present invention relates to a carrier element for a pressure chamber of a friction clutch. The carrier element is provided with at least a receiving element for a sealing device and a stopping element for an operation element of a pressure chamber. The carrier element is characterized by employing an integral structure. By employing the carrier element, a plurality of elements can be replaced by the carrier element which is very light in weight and simple in structure.

Owner:SCHAEFFLER TECH AG & CO KG

Connector Device With Connector And Assembly Method

ActiveUS20180309218A1Ensure electrical connection reliabilityReduce effortContact member manufacturingCoupling contact membersEngineeringElectric energy

A connector is disclosed comprising at least one contact clip. The contact clip comprises an electrically conductive substrate having a longitudinal axis, a first terminal located at a first end of the substrate, wherein the first terminal comprises at least two contact tongues between which a longitudinal slot is formed, which contact tongues are elastically deformable with respect to each other in a first direction which is perpendicular to the longitudinal axis, and a second terminal located at a second end of the substrate. The connector may further comprise a chassis and a PCB. In addition, a device comprising an energy consumer, an electrical energy source, a PCB and at least one connector is disclosed.

Owner:BRAUN GMBH

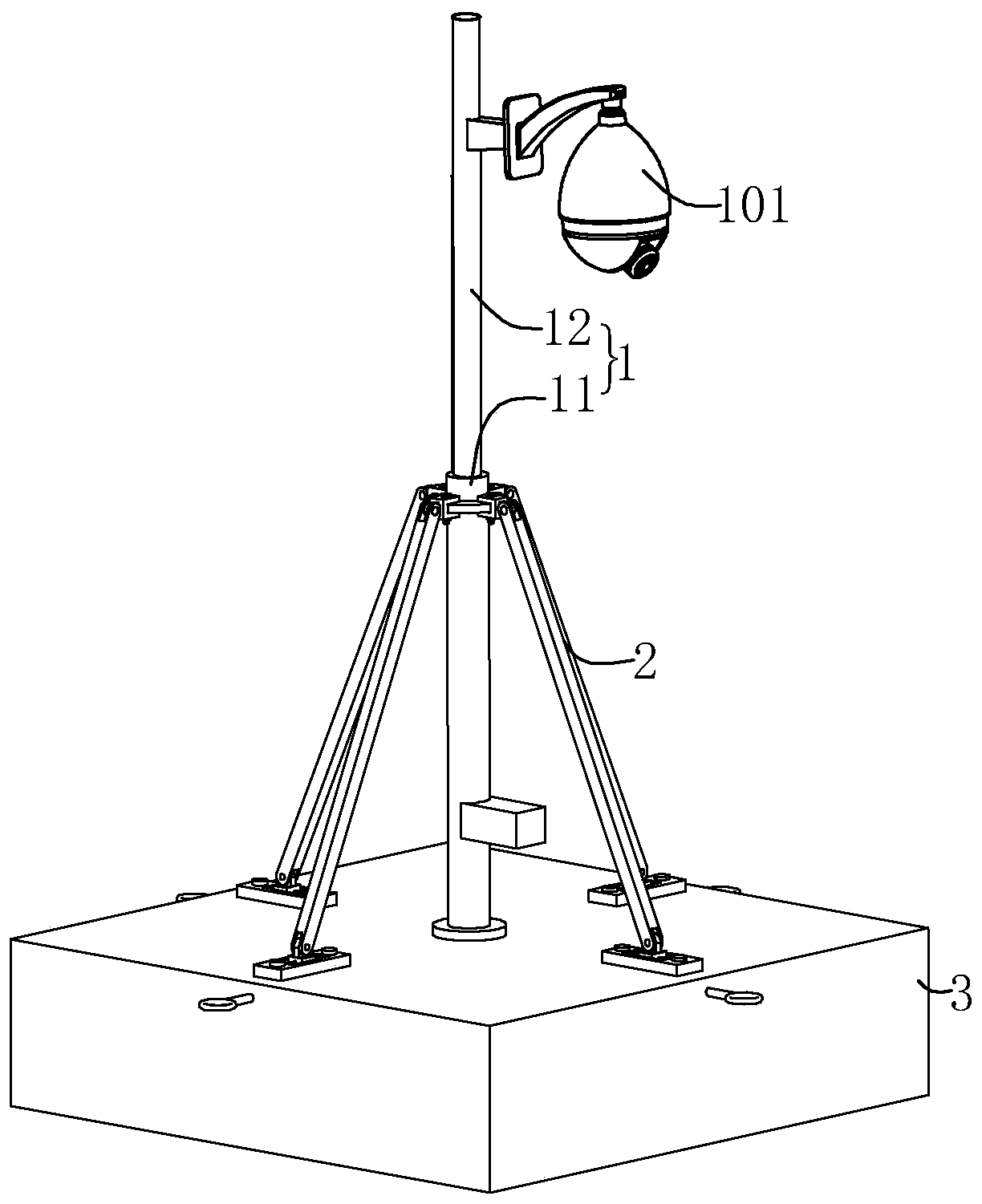

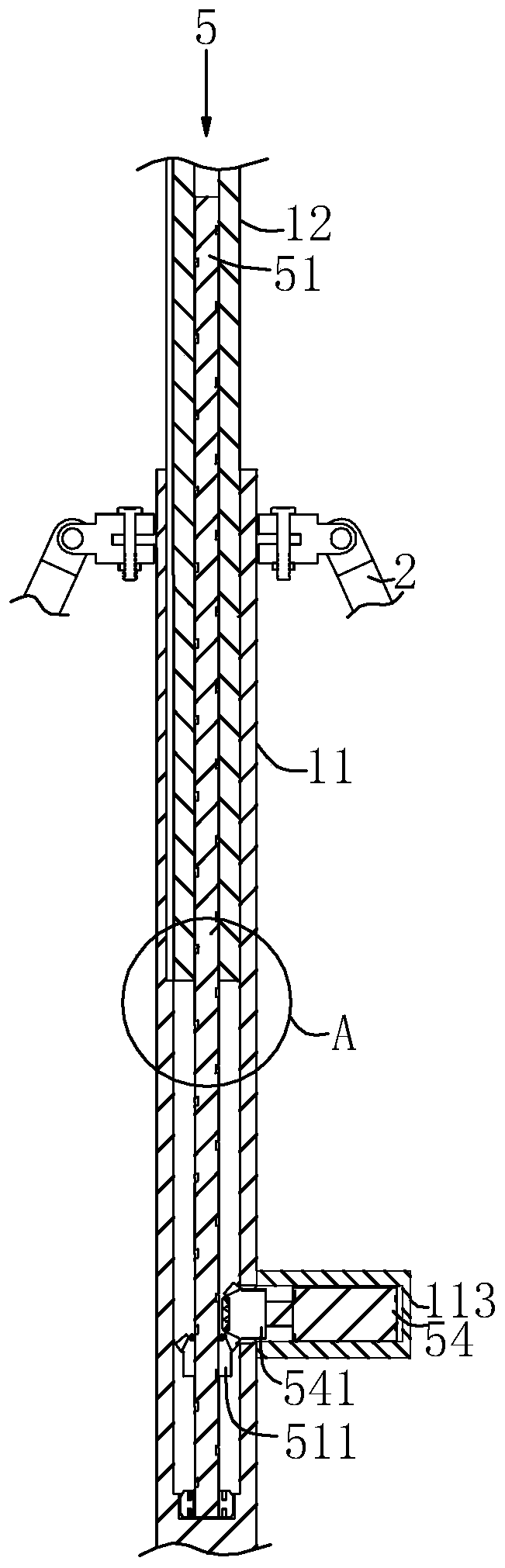

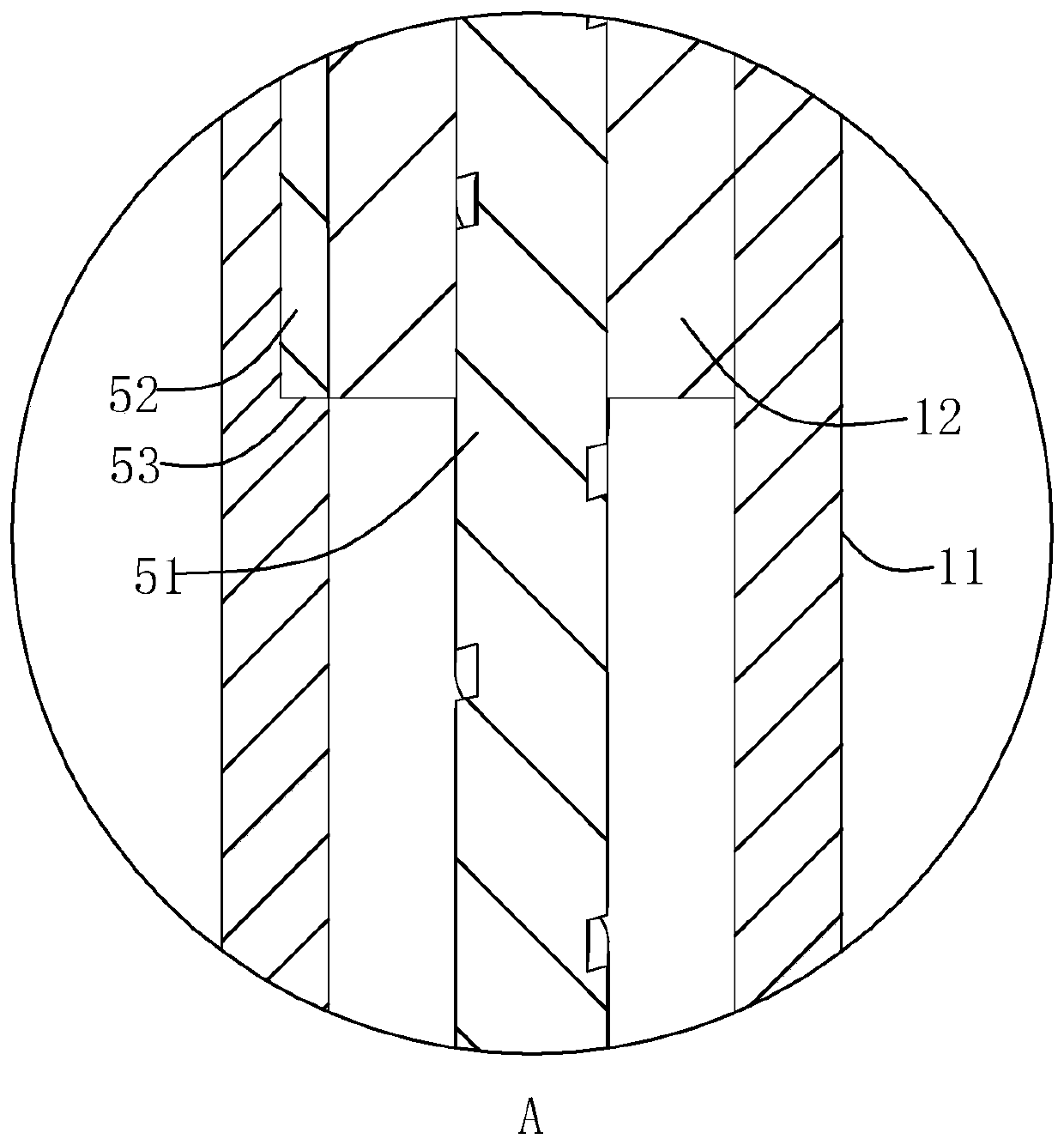

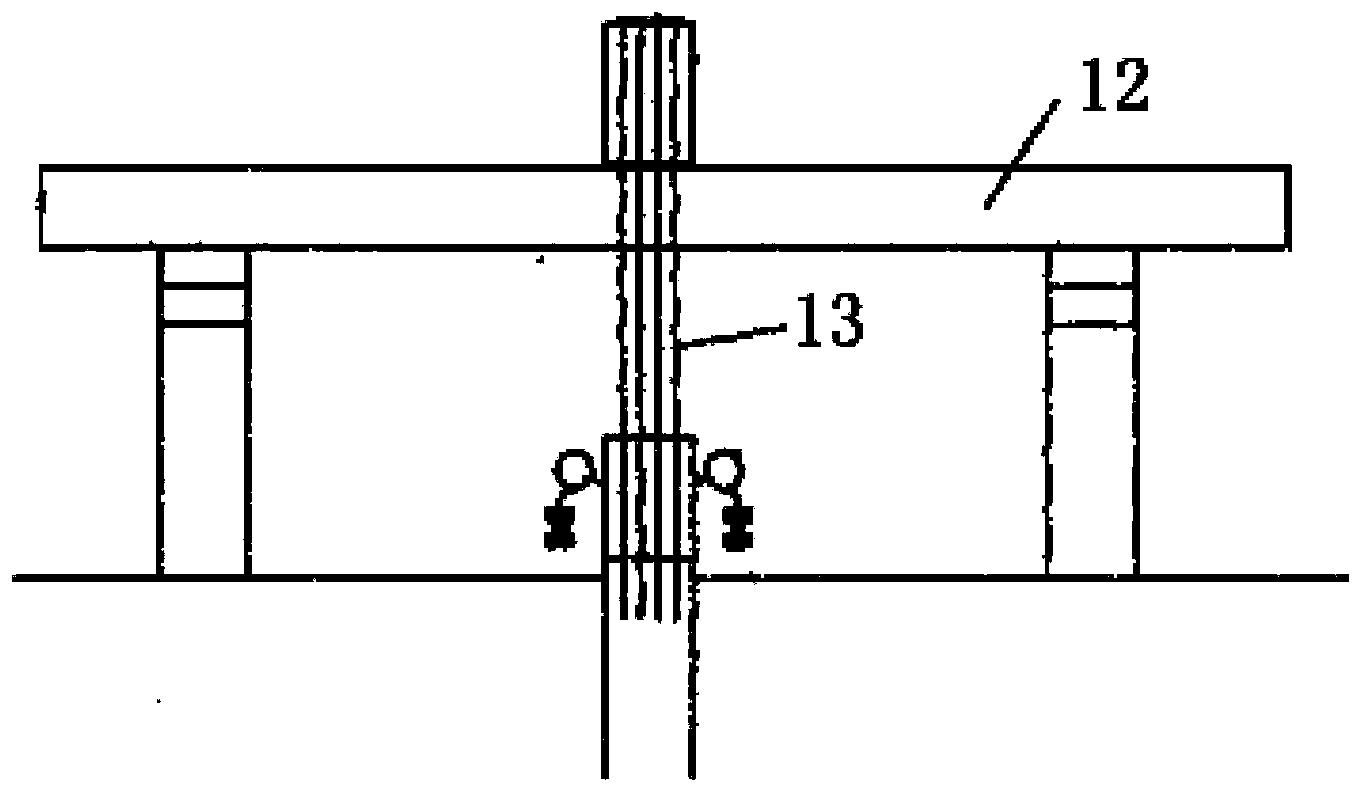

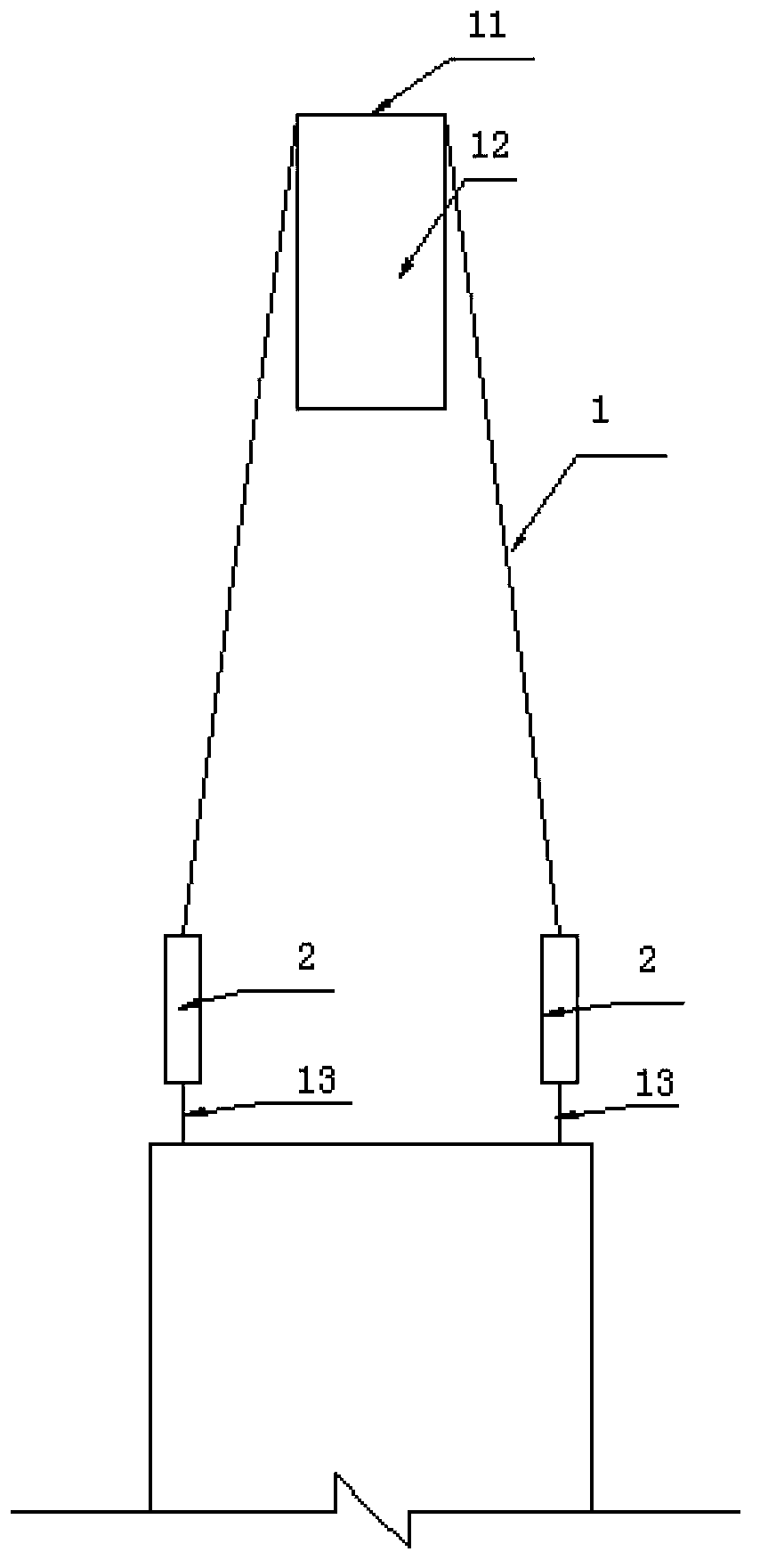

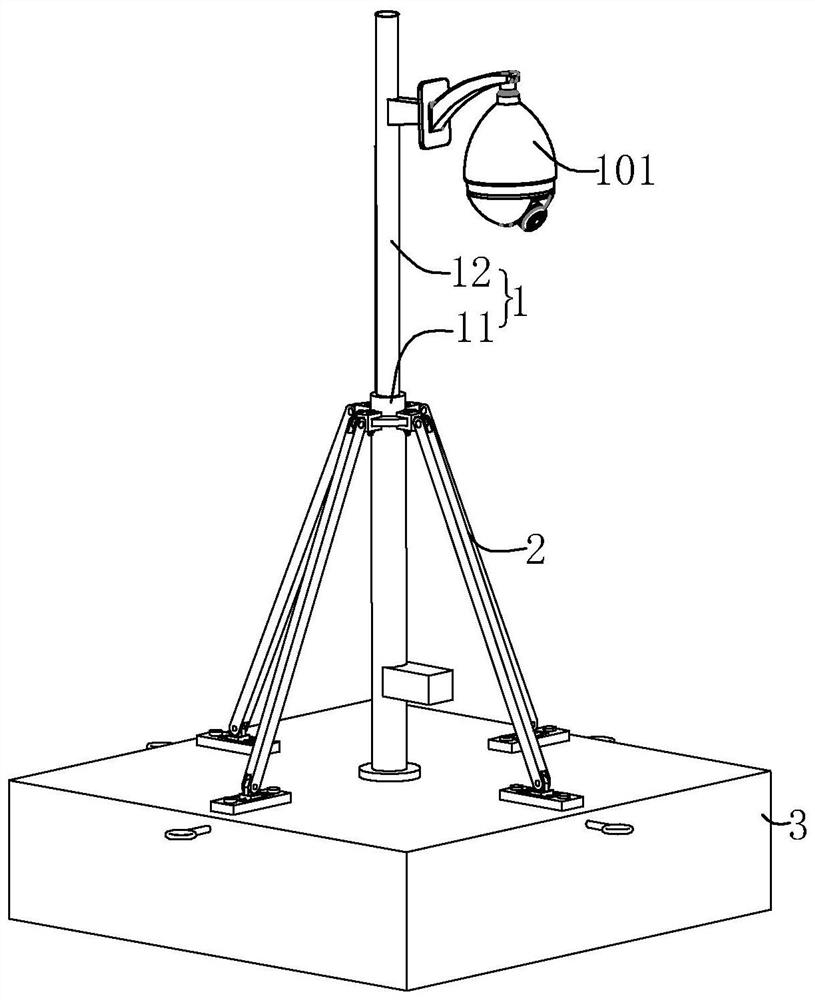

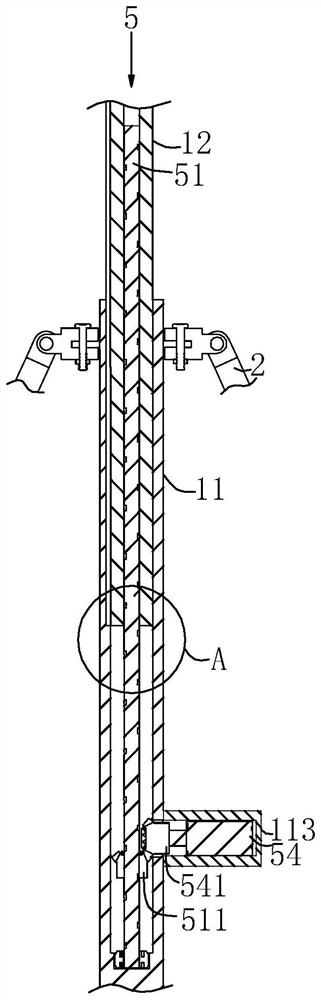

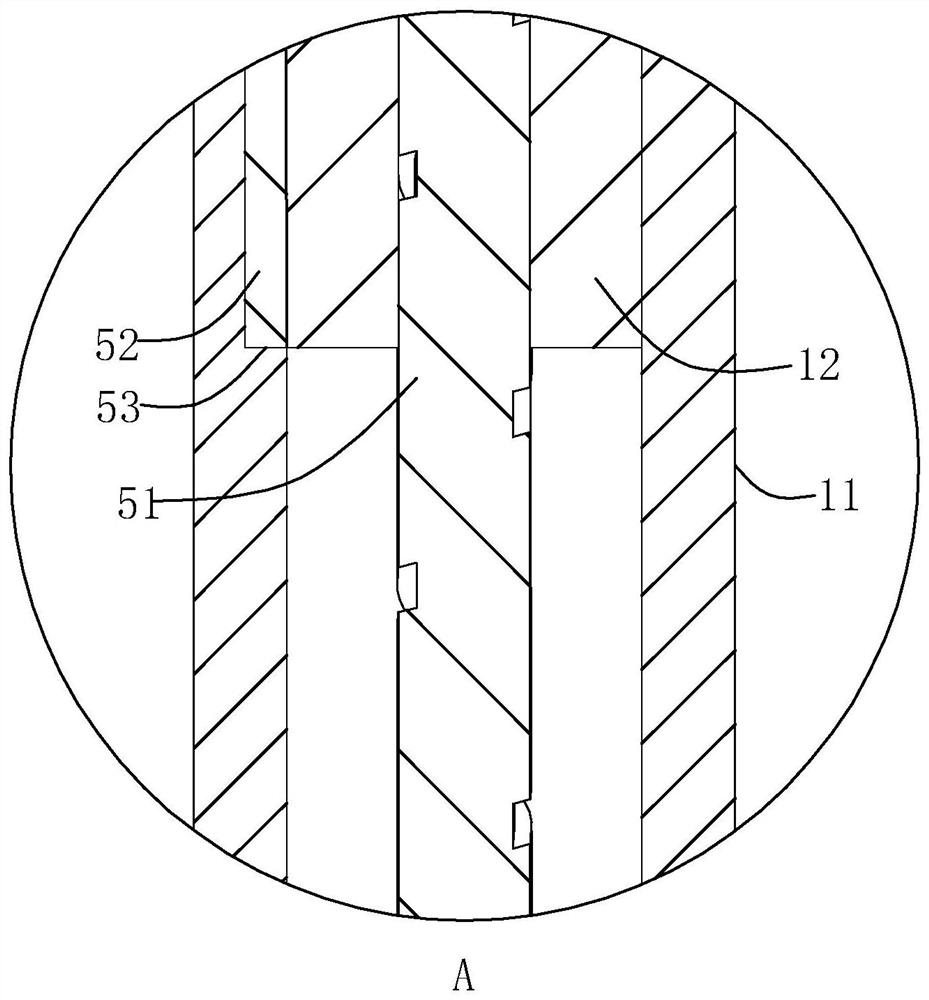

Novel monitoring device for monitoring municipal roads

InactiveCN110925569AImprove installation stabilityPrevent looseningStands/trestlesArchitectural engineeringWorkbench

The invention relates to a novel monitoring device for monitoring municipal roads. The monitoring device comprises a main supporting rod extending in the vertical direction, a monitoring device body mounted on the main supporting rod and a workbench for mounting the main supporting rod, wherein a plurality of inclined supporting rods are arranged on the side wall of the main supporting rod in thecircumferential direction, one ends of the inclined supporting rods are installed on the side wall of the main supporting rod through first connecting assemblies, and the other ends of the inclined supporting rods incline outwards and extend downwards, and the ends, away from the main supporting rod, of the inclined supporting rods are mounted on the workbench through second connecting assemblies.The novel monitoring device has the effect of improving the stability of the main supporting rod.

Owner:北京三和利贞科技有限公司

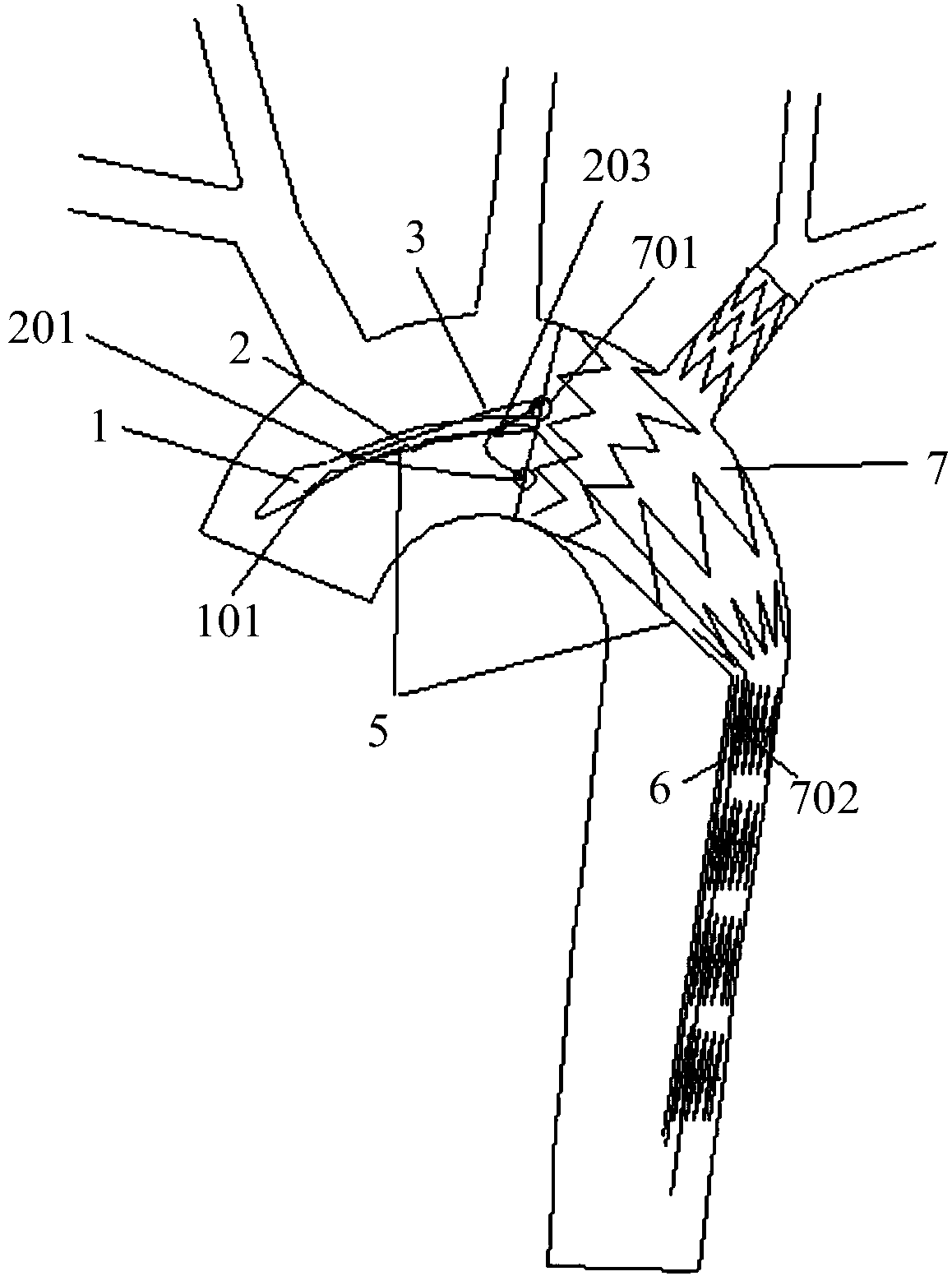

Scaffold system, conveying device thereof, rear release structure and scaffold

PendingCN109567981AGet rid of the bondageDetachable connectionStentsBlood vesselsEngineeringMechanical engineering

The invention provides a scaffold system, a conveying device thereof, a rear release structure and a scaffold. The near end of the scaffold is provided with one or more near end connecting parts, andeach near end connecting part is provided with one of corresponding through holes; the rear release structure comprises a rear release control piece, one or more far end connecting parts and one or more rear release constraint pieces; each far end connecting part is provided with the other corresponding through hole and arranged at one end of the corresponding rear release constraint piece; and when the other ends of the rear release constraint pieces are connected with a conveyor and one ends of the rear release constraint pieces penetrate through the through holes of the near end connectingparts, one end of the rear release control piece penetrates through the through holes of the far end connecting parts to be connected with the conveyor, then when the other end of the rear release control piece is pulled, one end of the rear release control piece is pulled out from the conveyor and the far end connecting parts, and then constraint of the rear release constraint pieces can be released. Thus, the near end of the scaffold and the conveyor are separably connected, and then when the scaffold is released, even if the near end of the scaffold is impacted by a high-speed blood flow, the near end of the scaffold is not turned over.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

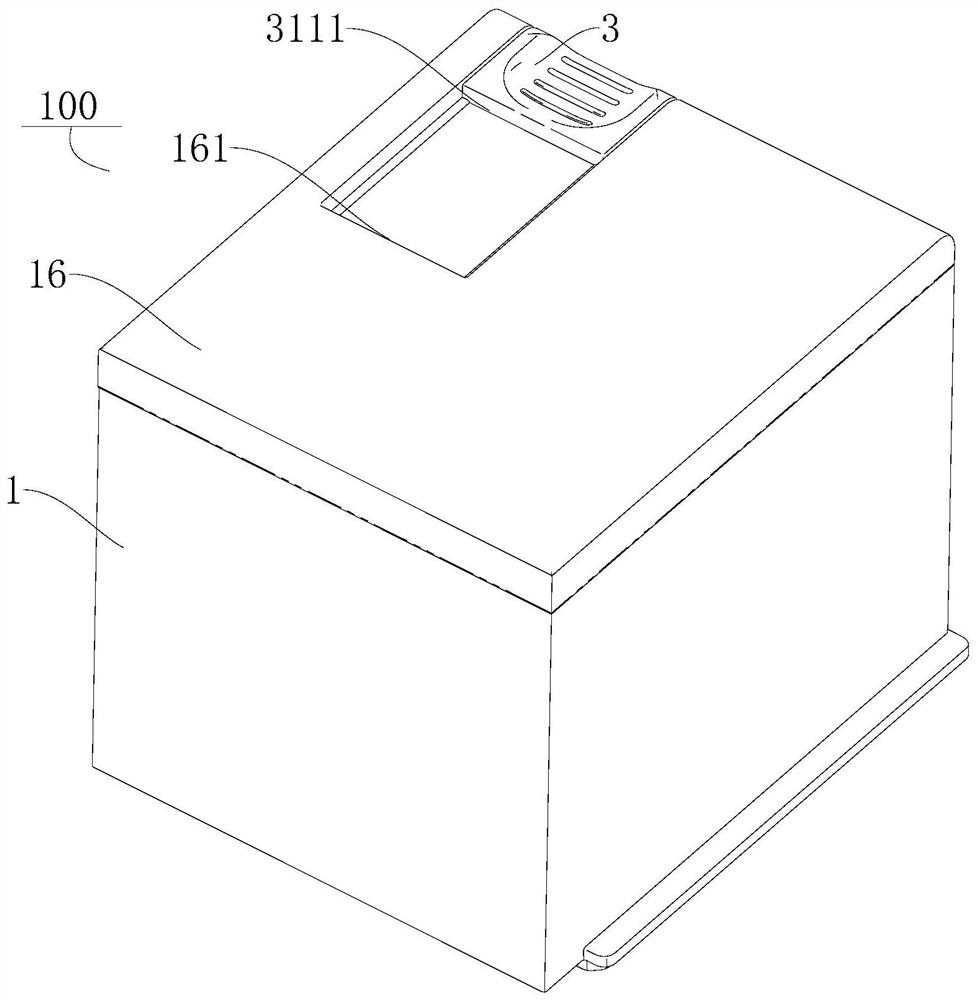

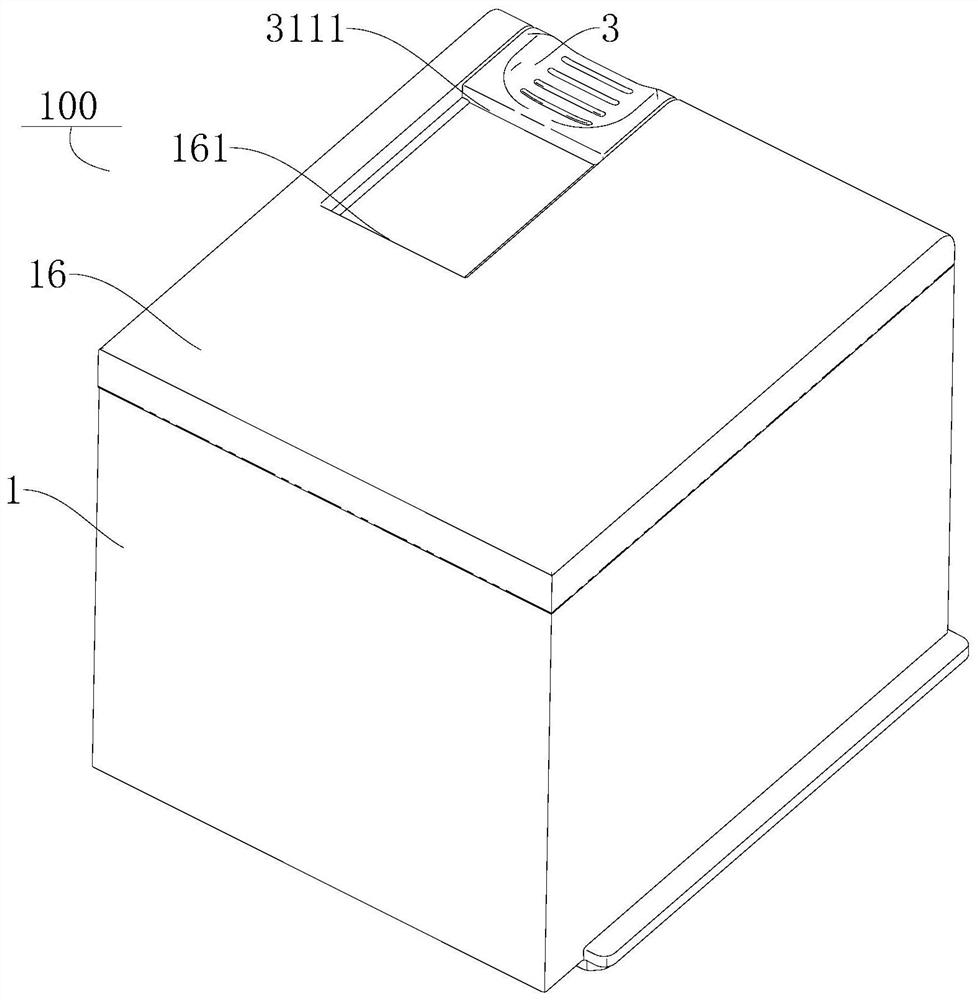

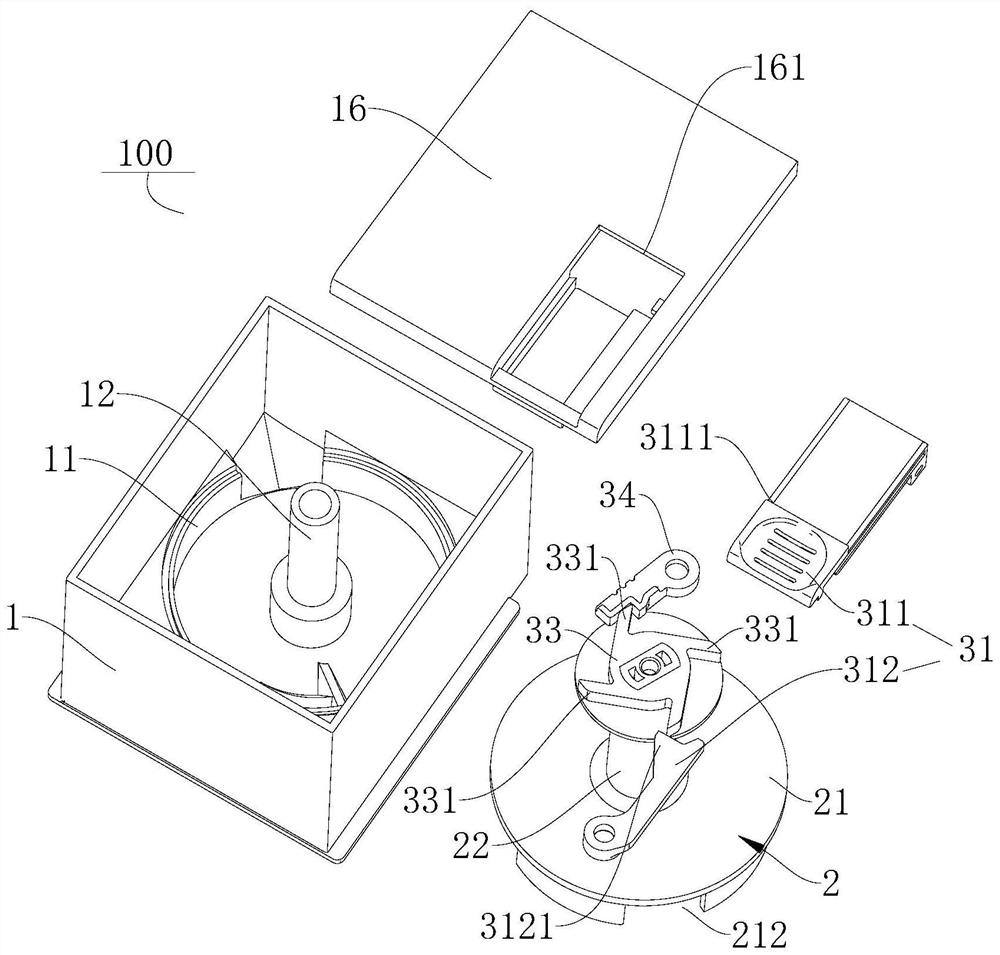

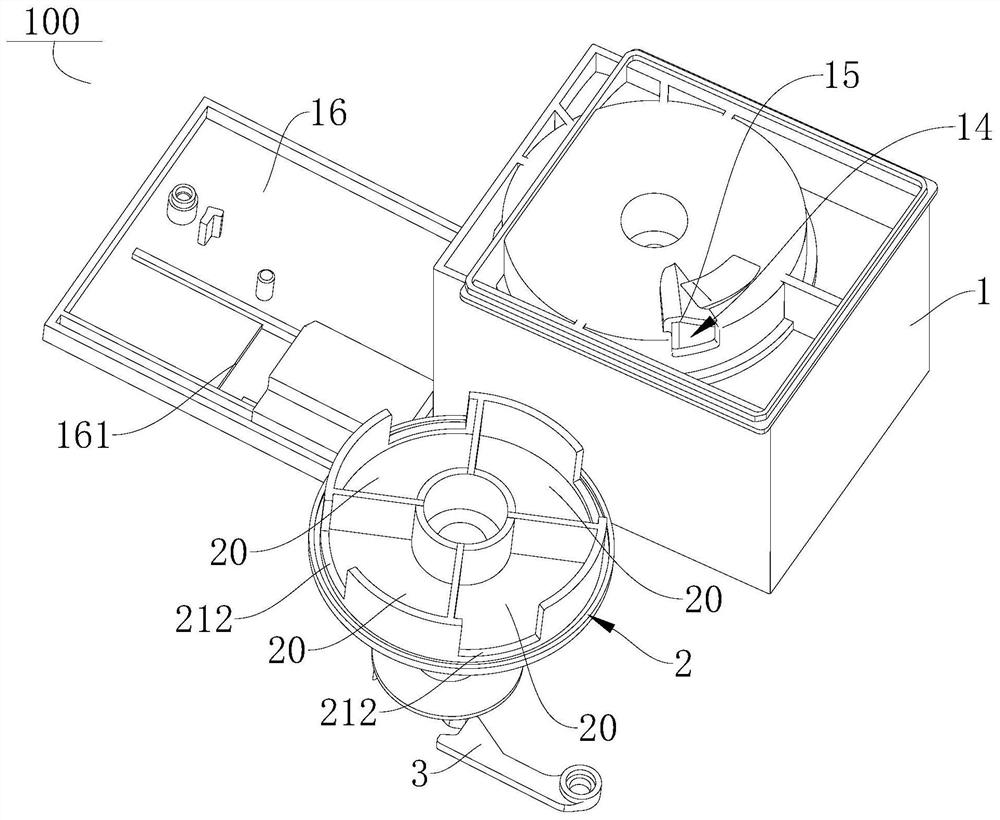

Feeding device, feeding assembly and washing equipment

ActiveCN113136705ADetachable connectionImprove delivery accuracyOther washing machinesTextiles and paperProcess engineeringMechanical engineering

The invention discloses a feeding device, a feeding assembly and washing equipment. The feeding device is used for feeding a washing agent, and comprises a shell which is provided with a liquid inlet and a liquid outlet; a divided device provided with a plurality of divided areas, the divided device being used for distributing the washing agent; and a driving assembly used for moving under the action of an external force applied by a user, wherein the driving assembly is connected with the divided device, and the divided device is driven by the driving assembly to distribute the washing agent. According to the feeding device, the divided device is arranged, the divided device is provided with the plurality of divided areas, and the washing agent can be stored in the plurality of divided areas through the divided device; since the volume of each divided area is determined, the volume of the washing agent contained in each divided area is determined, and the volume of the fed washing agent is determined when the washing agent in the divided device is fed, so that the feeding precision of the feeding device can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

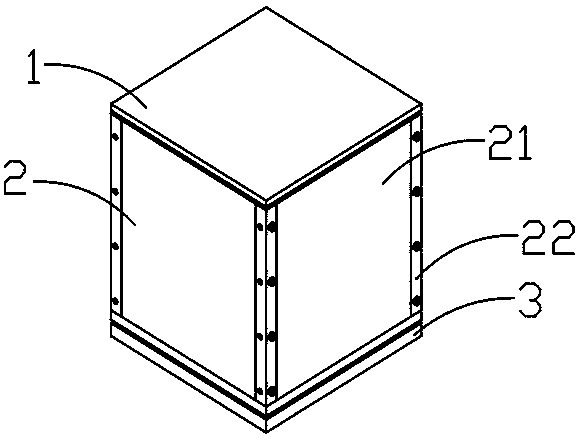

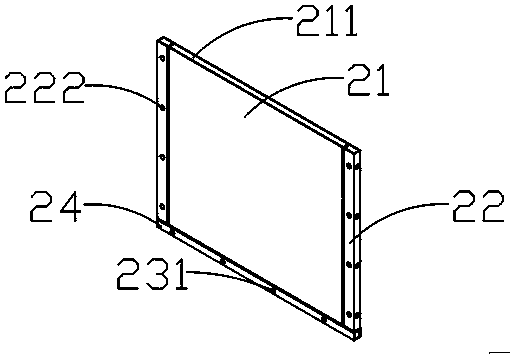

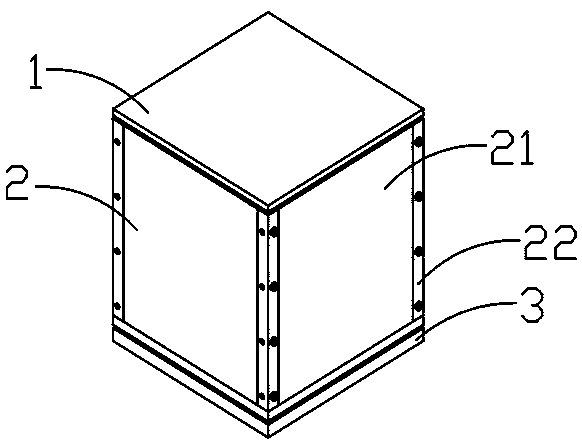

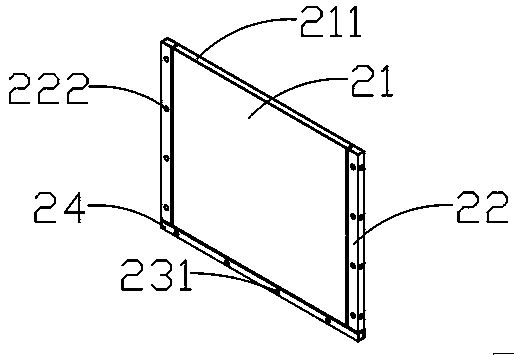

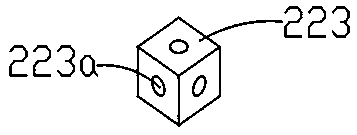

Jointing type paper packaging box

ActiveCN108163325AReduce manufacturing costRealize detachableRigid containersEngineeringRaw material

The invention mainly provides a jointing type paper packaging box which comprises a box cover and a box body. The bottom end of the box body is detachably provided with a base, the box body is formedby jointing four surrounding plates and a base plate, U-shaped steel plates are fixed to the peripheries of the surrounding plates and the two sides of the base plate, and screws penetrate the U-shaped steel plates to fix the four surrounding plates and the base plate one by one to form a box structure with an opened upper end; the base comprises an upper sealing plate and a bottom box, U-shaped steel plates are fixed to the peripheries of the upper sealing plate and the bottom box, the upper sealing plate and the bottom box are fixed together through screws, and the jointed base is fixed to the bottom end of the box body through screws. The jointing type paper packaging box is simple in structure and simple in manufacturing, achieves the detaching and jointing aim of the overall box bodythrough cooperation of the U-shaped steel plates, saves cost, reduces raw material waste, meanwhile can adjust the size of the box body according to actual needs, and meets the cargo transporting need.

Owner:ANQING SHENGHUA PAPER PACKAGING

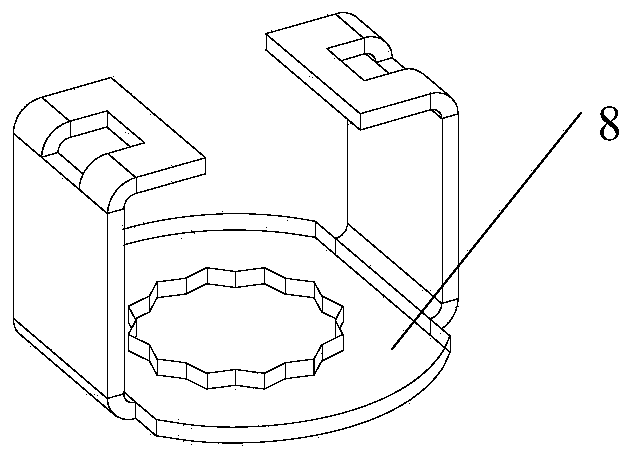

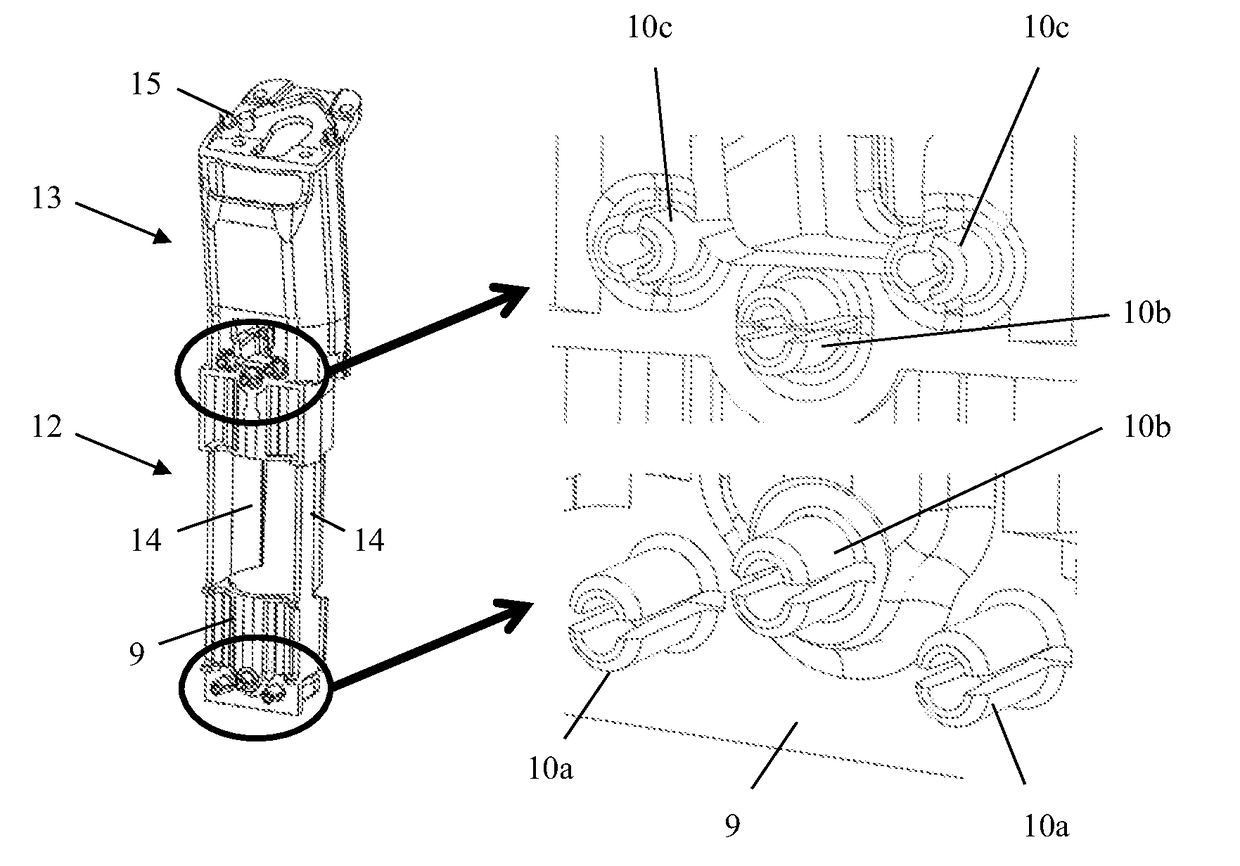

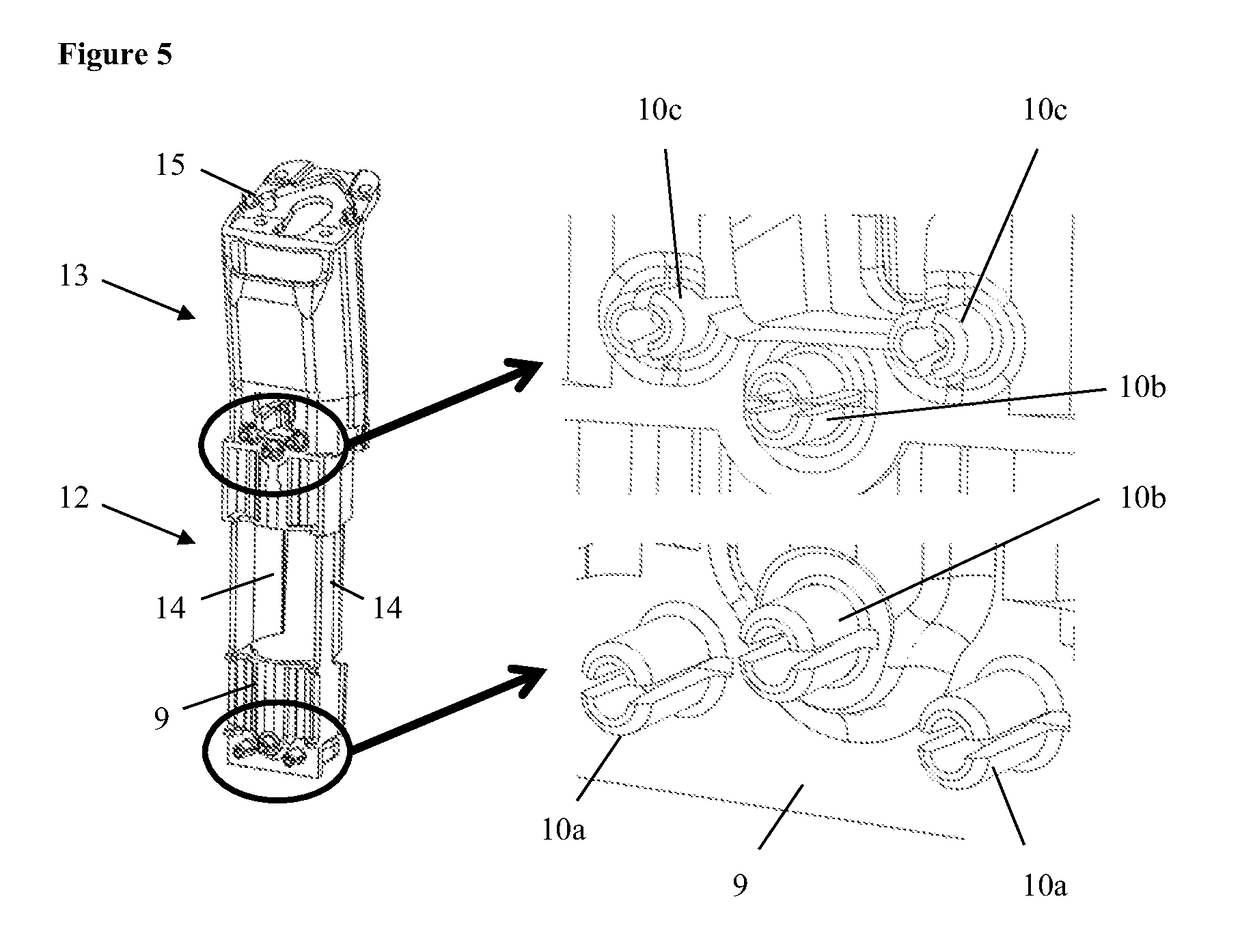

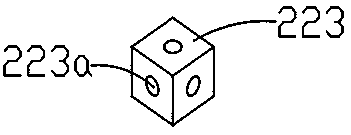

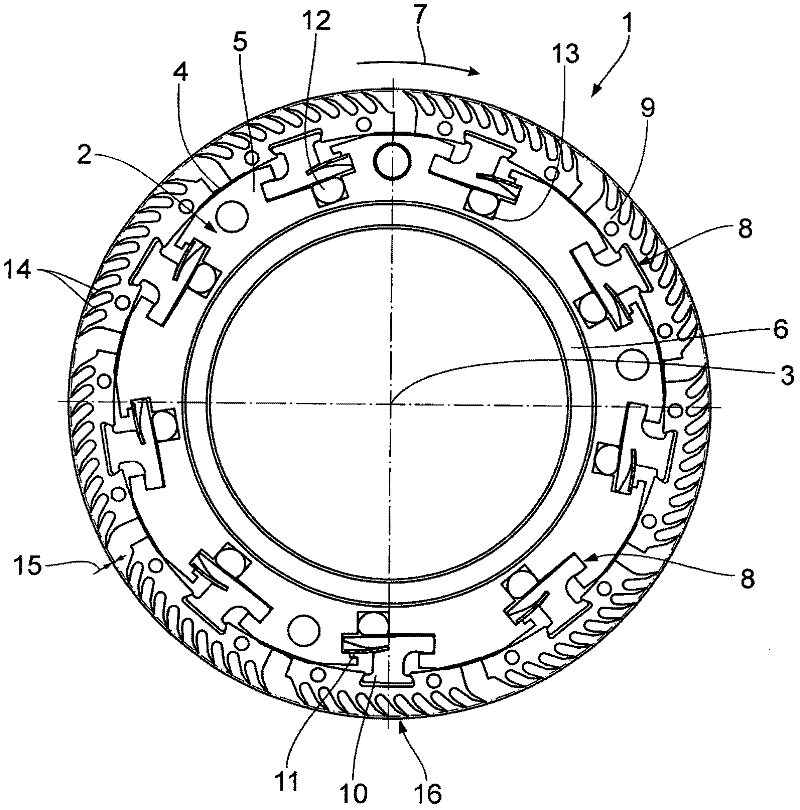

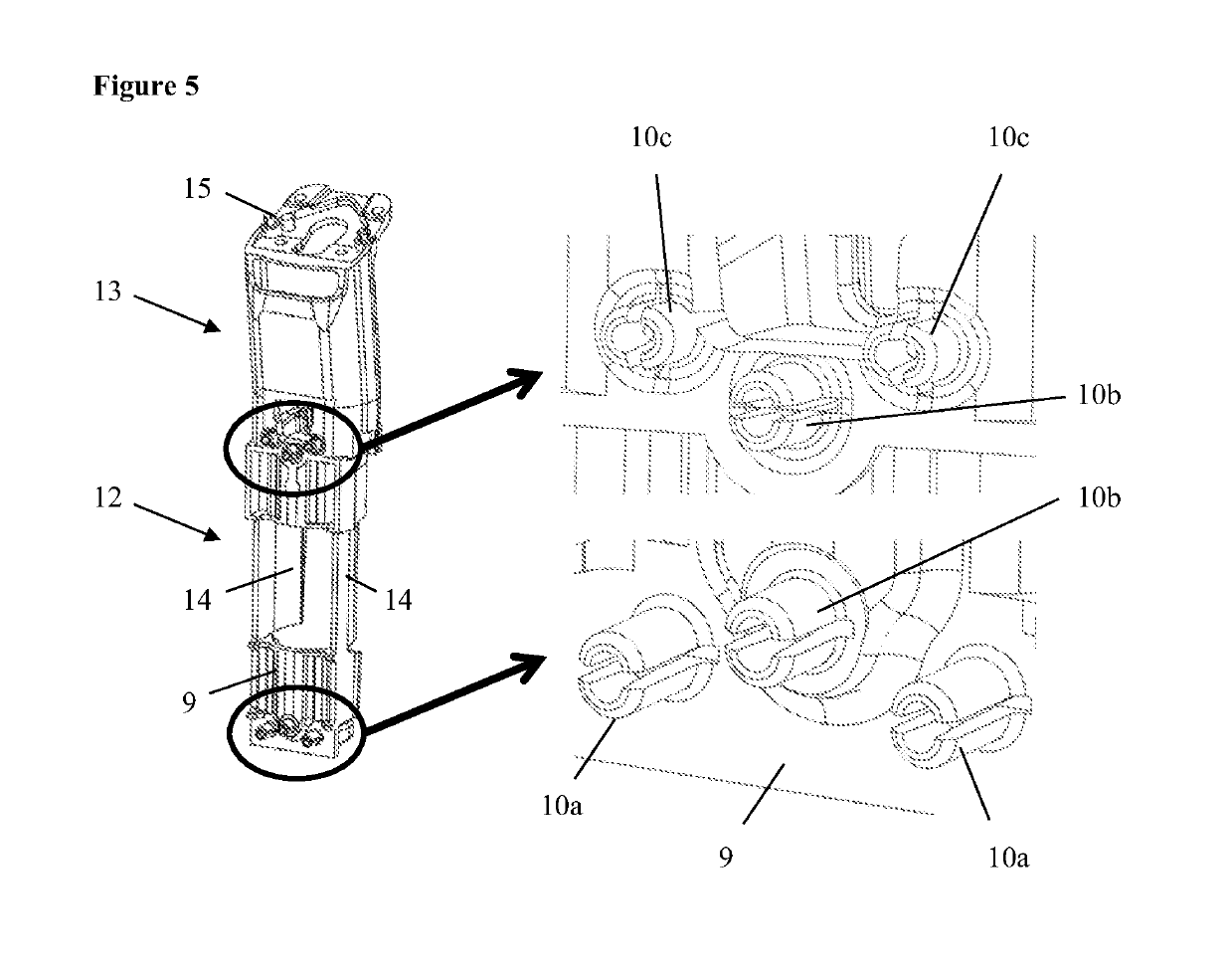

Circular comb

ActiveCN102414352AGeometry is not complicated to manufactureFirmly connectedCombing machinesCarding machinesEngineeringElectrical and Electronics engineering

A circular comb for a combing machine for combing textile fibres, comprising a basic body (2) with a centre longitudinal axis (3), a circumferential surface (4) and two end surfaces (5), a plurality of bar tacks (9; 32; 32a; 42) which are arranged on the circumferential surface (4) of the basic body (2) and fix a combing region of the circular comb, a plurality of fastening devices (8; 38) which are attached to the basic body (2) for the non-positive connection of in each case one of the bar tacks (9; 32; 32a; 42) to the basic body (2), and unlocking units for releasing the non-positive connections, wherein each unlocking unit has an unlocking device (13; 48) and an unlocking means (12) for actuating the unlocking device (13; 48), wherein the unlocking units are accessible from outside the combing regions, in particular from at least one of the end surfaces (5), and an additional positive securing connection is provided for securing the bar tacks (9; 32; 32a; 42) on the basic body (2).

Owner:STAEDTLER & UHL

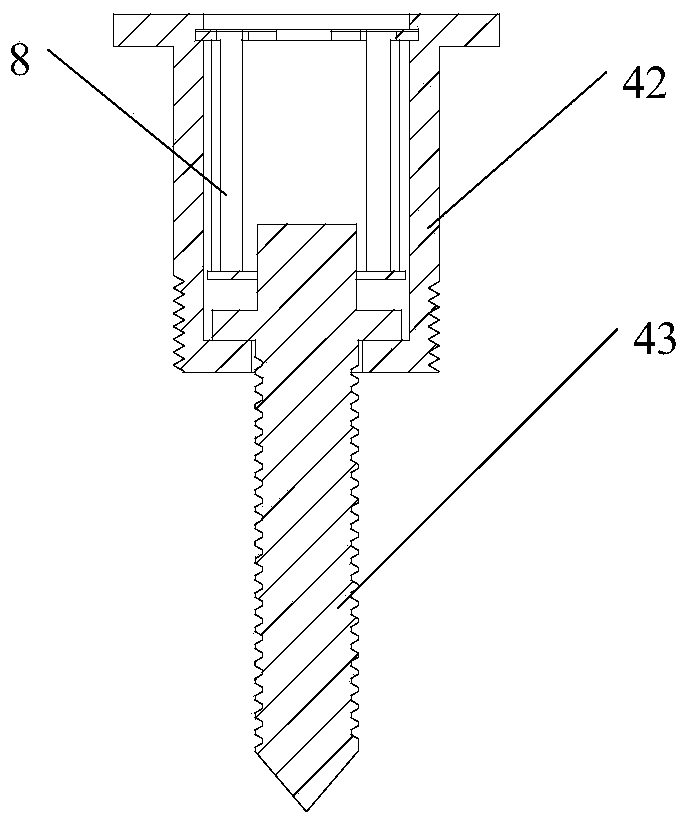

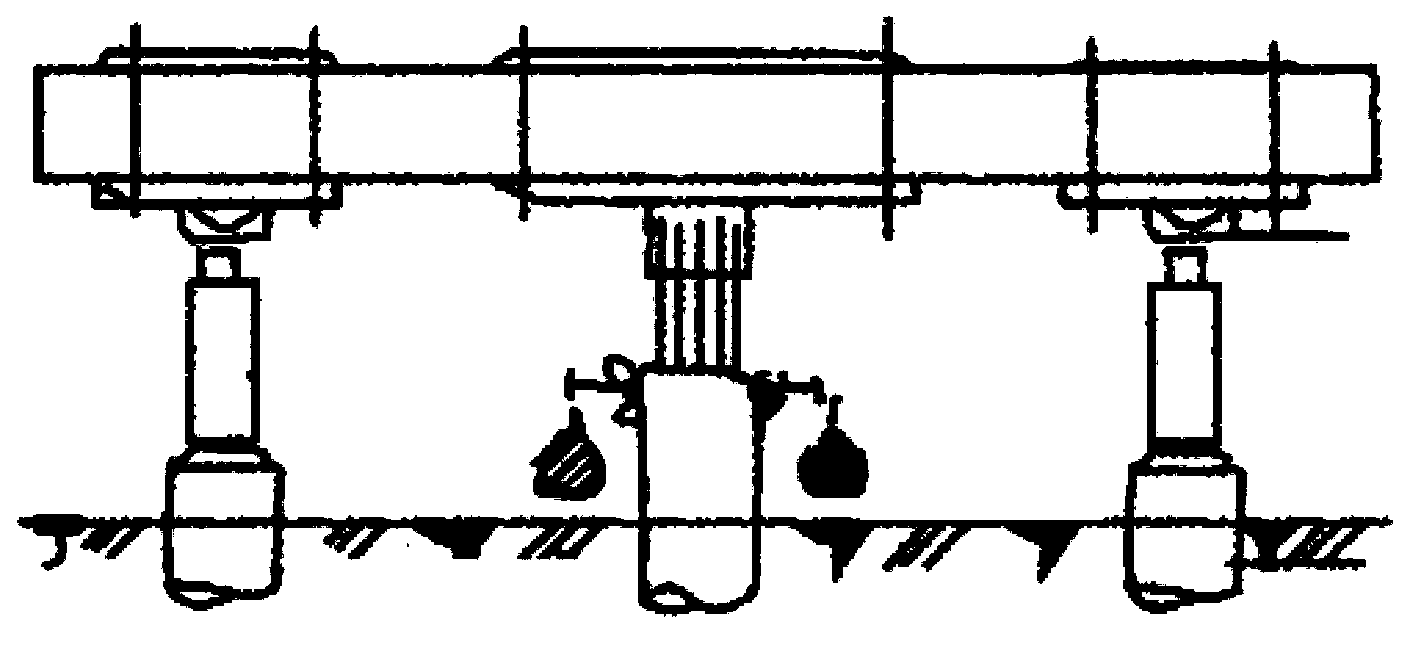

Quick connecting piece in pile foundation static load test

The invention discloses a quick connecting piece in a foundation static load test. The quick connecting piece comprises a connecting prestressing tendon and sub-connectors. At least one end of the connecting prestressing tendon can be in axial locking connection with the sub-connectors. The ends, back on to the connecting prestressing tendon, of the sub-connectors are provided with positioning holes, the diameter of the positioning holes can be decreased, the positioning holes are provided with adjusting pieces, and the diameter of the positioning holes can be adjusted through the adjusting pieces. The quick connecting piece can be in quickly detachable connection with a pile foundation rebar through the sub-connectors connected to one end of the prestressing tendon, the connecting speed is high, the junction between the rebar and the sub-connectors is convenient to adjust, and therefore it is guaranteed that the rebar on the top of a pile is stressed evenly. Furthermore, as the quick connecting piece is convenient to connect, high-lift operation can be avoided, work difficulty and work risks are lowered, materials are saved, material waste is avoided, repeated testing can be achieved, and the success probability of testing can be enhanced.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

Compound milling cutter

The invention relates to the technical field of mechanical cutters, and in particular relates to a compound milling cutter. The compound milling cutter comprises a cylindrical handle, and a cutter bit part connected with the handle; the cutter bit part comprises a conical cutter bit, and a cylindrical connecting part fixedly connected with the cutter bit; a concave groove is formed in the center of the end surface of the handle, closing to the connecting part; a screw hole is formed in the center of the bottom surface of the concave groove; a boss in match with the concave groove is arranged in the center of the end surface of one end of the connecting part, close to the handle; a screw used in match with the screw hole is arranged in the center of the boss; the cutter bit comprises a first cutting part connected with the connecting part, and a second cutting part connected with the first cutting part; two spiral first cutting edges are arranged on the conical surface of the first cutting part; two vertical second cutting edges are symmetrically arranged on the conical surface of the second cutting part; a circular arc surface is formed in the part in which the second cutting edge is connected with the conical surface of the second cutting part; the circular arc surface is connected with the bottom of a slag groove. The compound milling cutter has the advantages that the production cost is decreased, and the surface roughness is improved.

Owner:CHANGZHOU YUJIA PACKAGING

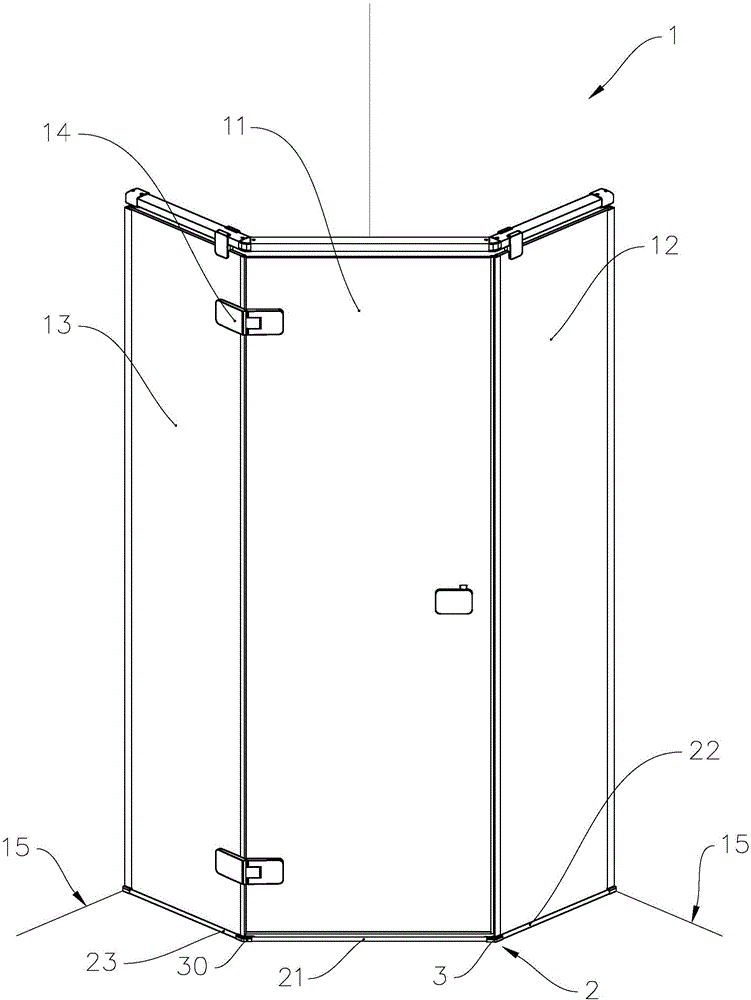

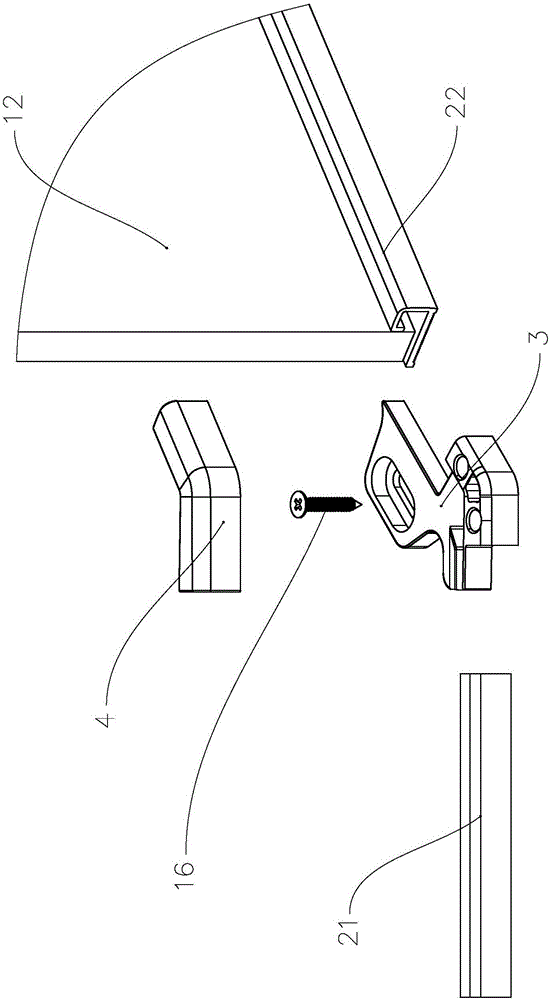

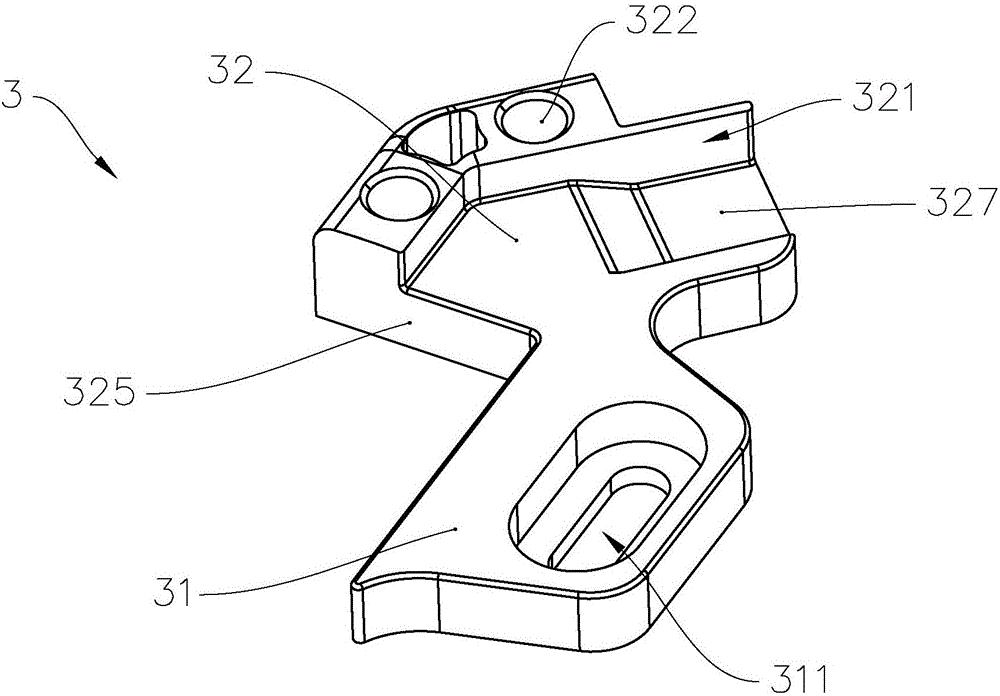

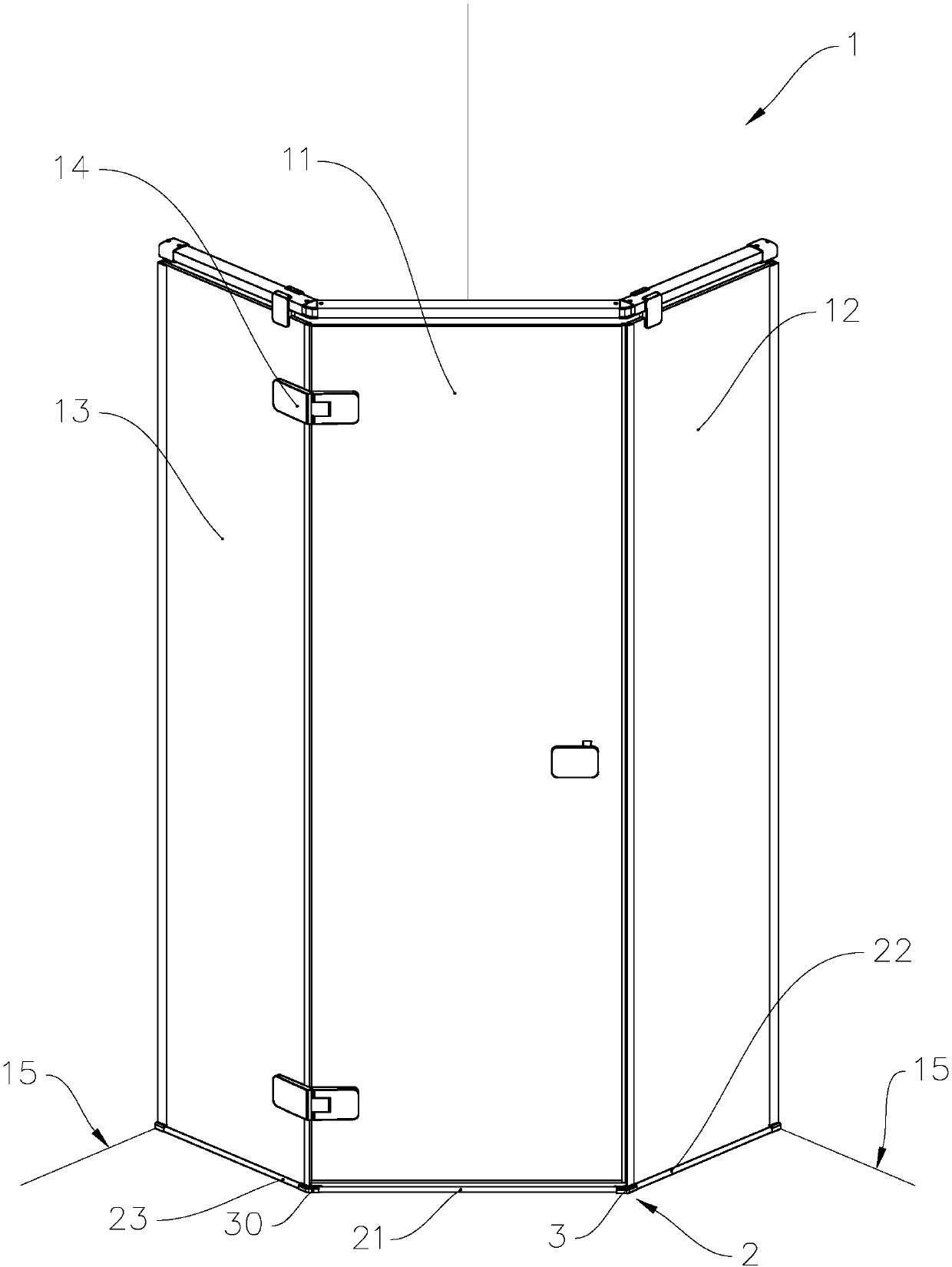

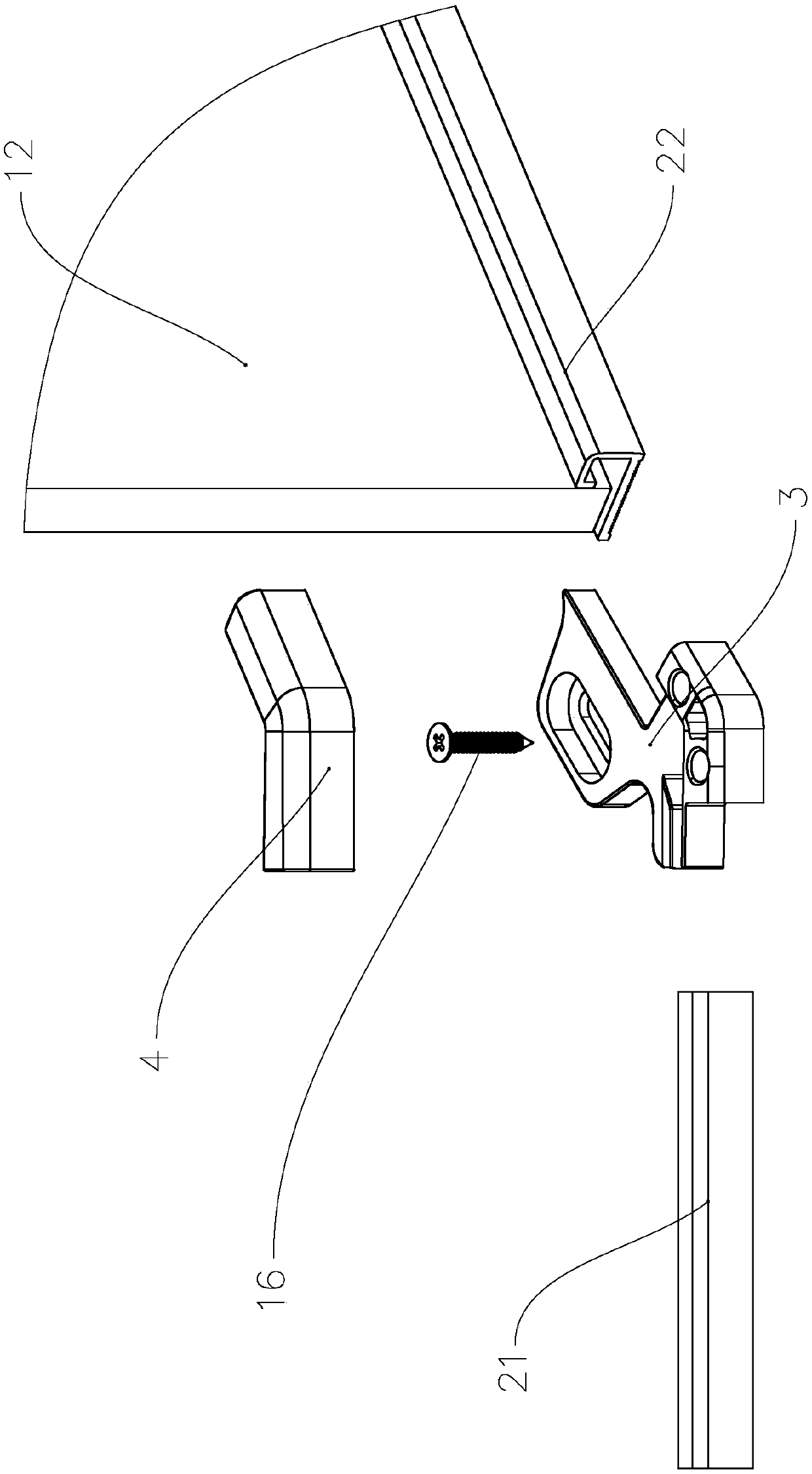

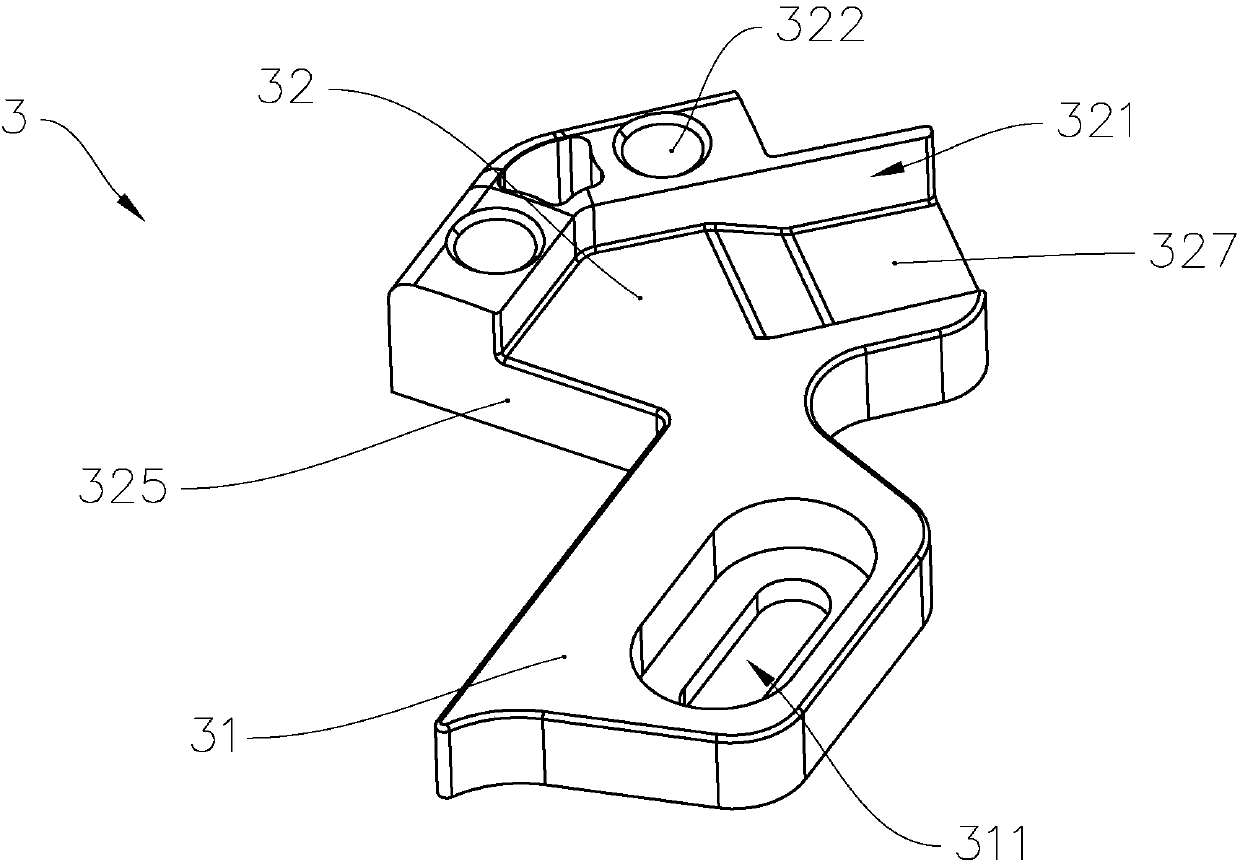

Shower door water-retaining strip connector and shower door water-retaining device

ActiveCN106437457ADetachable connectionTroubleshoot disassemblySealing arrangementsMechanical engineeringShower

The invention provides a shower door water-retaining strip connector and a shower door water-retaining device. The shower door water-retaining strip connector comprises a connector body, wherein the connector body is provided with an installing portion and a connecting portion connected with the installing portion, the installing portion is provided with a through groove, the upper surface of the connecting portion is provided with a protrusion, the connecting portion is provided with a first end face and a second end face which are connected with a water-retaining strip, the first end face is provided with an installing groove, and an installing position is formed between the second end face and the third end face of the installing portion. The shower door water-retaining device is provided with the shower door water-retaining strip connector. The shower door water-retaining strip connector and the shower door water-retaining device have the advantages of being simple in structure, convenient to install and capable of achieving rapid water-retaining strip installation.

Owner:IDEAL SANITARY WARE CO LTD

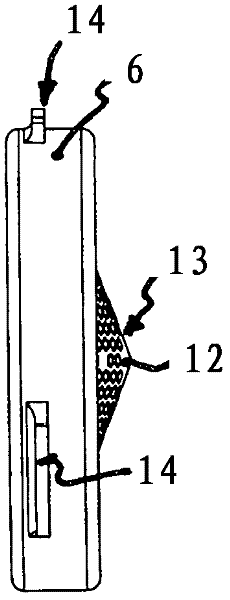

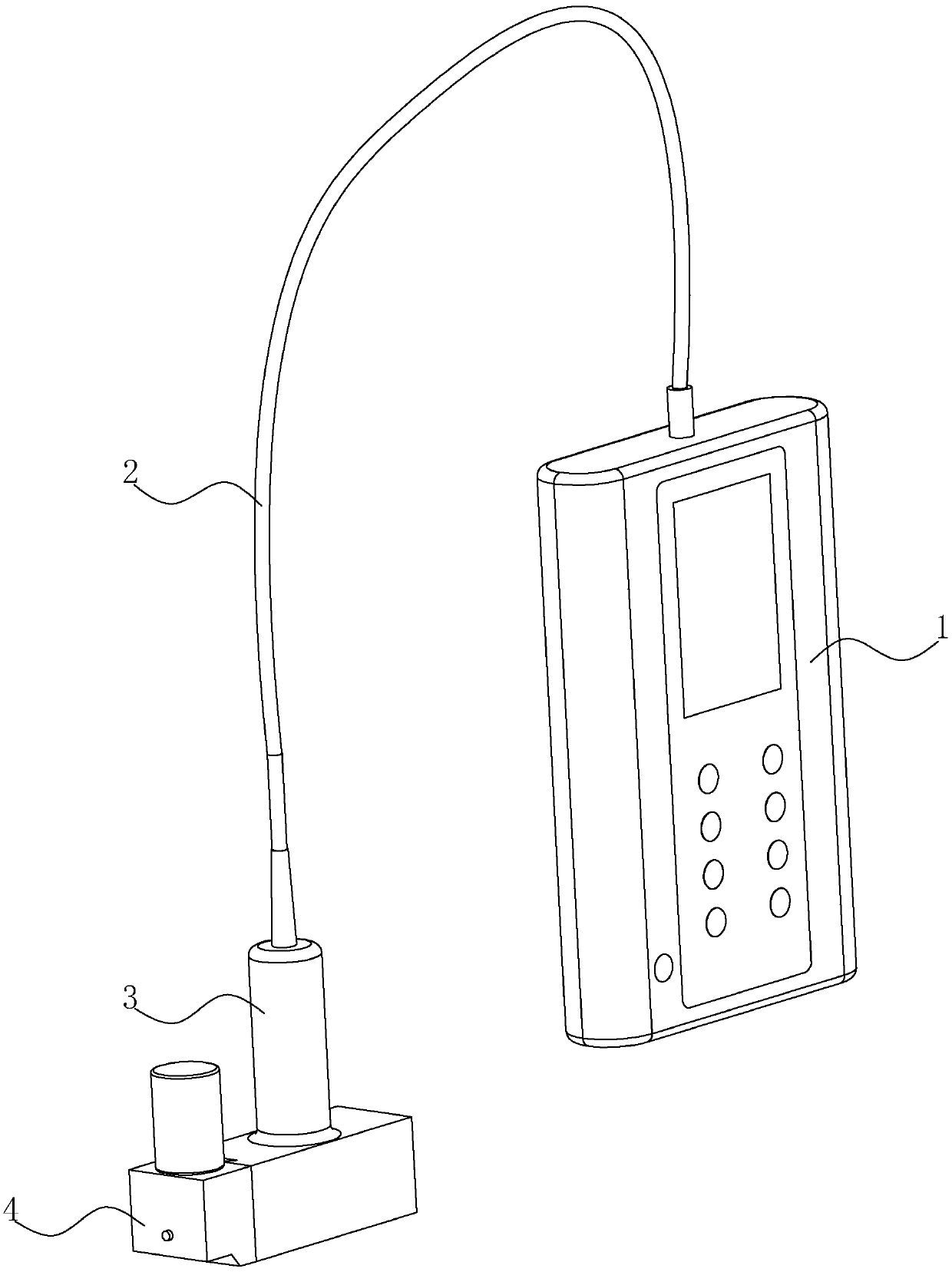

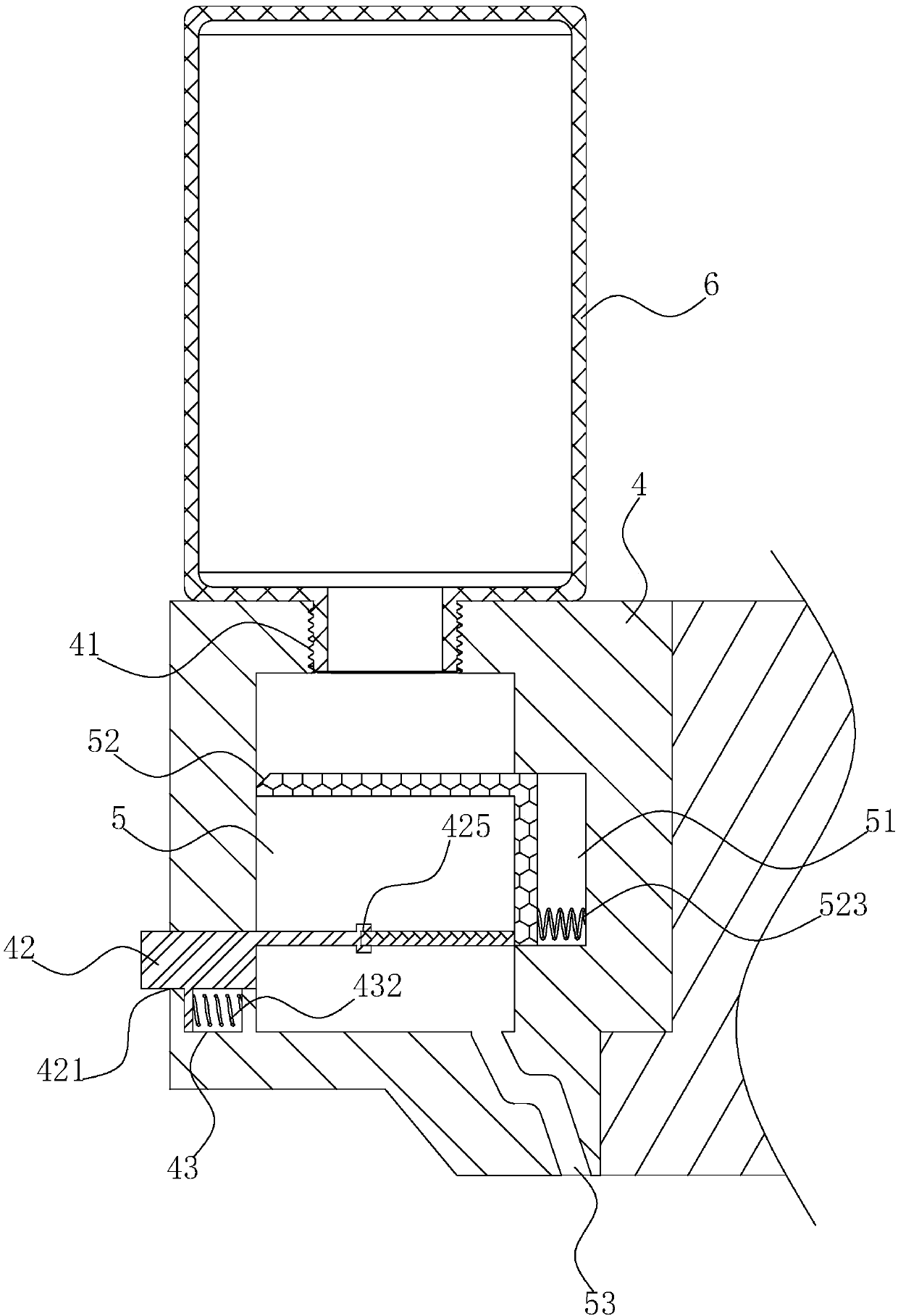

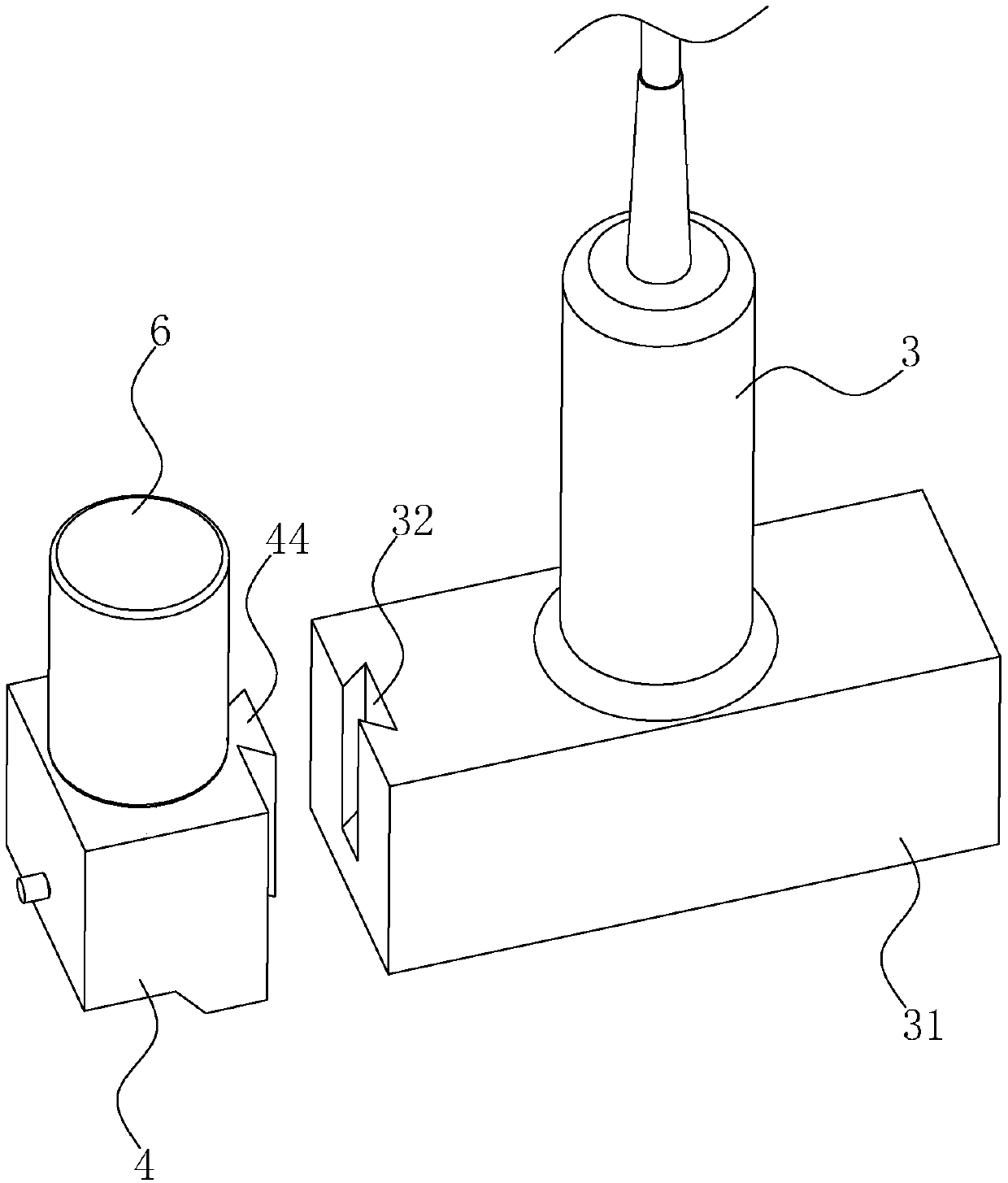

Ultrasonic flaw detector

InactiveCN109632967ARealize all-in-one connection settingsGuaranteed coatingMaterial analysis using sonic/ultrasonic/infrasonic wavesBottleNondestructive testing

The invention discloses an ultrasonic flaw detector, which relates to the technical field of nondestructive testing equipment, and solves the technical problem that the separation setting of a coupling agent bottle and a detection instrument is not convenient for detection by detection personnel. The ultrasonic flaw detector is technically characterized by comprising a detection host, a transmission line connected onto the detection host and a probe detachably connected onto the tail end of the transmission line, wherein the side wall of the shell of the probe is provided with a placement seat; the placement seat is internally provided with an accommodation cavity; the top of the placement seat is provided with a threaded through hole communicated with the accommodation cavity; a solvent bottle loaded with the coupling agent is in threaded connection to the threaded through hole; the cavity side wall, located at one side of the accommodation cavity, of the placement seat is provided with a sliding groove; the sliding groove is internally provided with a shielding assembly for sealing the accommodation cavity in a horizontal sliding mode; the cavity side wall, located at the other side of the accommodation cavity, of the placement seat is provided with a driving assembly for controlling the shielding assembly to slide along the sliding groove; and the bottom part of the accommodation cavity is provided with a liquid outlet channel communicated with the bottom surface of the placement seat. The ultrasonic flaw detector has the advantage of facilitating flaw detection by the detection personnel.

Owner:厦门优而特技术咨询服务有限公司

Shower door water retaining strip connector and shower door water retaining device

ActiveCN106437457BDetachable connectionTroubleshoot disassemblySealing arrangementsEngineeringMechanical engineering

The invention provides a shower door water-retaining strip connector and a shower door water-retaining device. The shower door water-retaining strip connector comprises a connector body, wherein the connector body is provided with an installing portion and a connecting portion connected with the installing portion, the installing portion is provided with a through groove, the upper surface of the connecting portion is provided with a protrusion, the connecting portion is provided with a first end face and a second end face which are connected with a water-retaining strip, the first end face is provided with an installing groove, and an installing position is formed between the second end face and the third end face of the installing portion. The shower door water-retaining device is provided with the shower door water-retaining strip connector. The shower door water-retaining strip connector and the shower door water-retaining device have the advantages of being simple in structure, convenient to install and capable of achieving rapid water-retaining strip installation.

Owner:IDEAL SANITARY WARE CO LTD

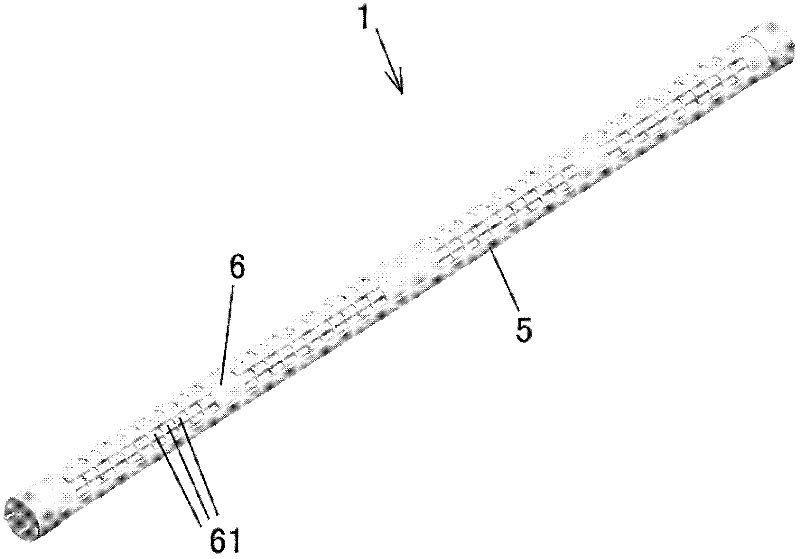

led lights

InactiveCN102261596ADetachable connectionImprove securityPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention relates to an LED lamp, which has a lampshade and a casing, the lampshade and the casing are connected to each other to define a cavity, and the cooling fins are connected to the inner side of the lampshade or the casing, so that the cooling fins divide the cavity into a cooling cavity and a housing. A light-emitting chamber of a PCB board installed with LED lamp beads, wherein the PCB board is connected to the base plate of the heat sink, and the base plate is configured to have different heat dissipation at different parts of the base plate. The invention also relates to a heat sink and a modular housing for the LED lamp.

Owner:霸士电器(上海)有限公司

Processing device and method for marking grooves at both ends of rubber hose

The invention relates to rubber pipe processing devices, in particular to a processing device for stamping groove marks at the two ends of a rubber pipe to solve the technical problem that a groove mark can only be stamped at one end of the rubber pipe. According to the scheme, the processing device comprises a positioning upper hoop, a core bar and a positioning lower hoop; a first protrusion is arranged on the positioning upper hoop, the positioning upper hoop is detachably connected with the first end of the core bar, and the position of the positioning upper hoop is fixed relative to the first end of the core bar; the positioning lower hoop is connected with the second end of the core bar, and a second protrusion is arranged on the inner wall of the positioning lower hoop; and the sizes of the first protrusion and the second protrusion are the same with the sizes of the groove marks located at the two ends of the rubber pipe correspondingly. The second end of the core bar is inserted into the positioning lower hoop, and after the relative positions of the second protrusion and the core bar are calibrated through a gauge, the core bar is welded to the positioning lower hoop; then the core bar is sleeved with a pipe blank, and then the first end of the core bar is sleeved with the positioning upper hoop; the structure is put into a vulcanizing pot to be vulcanized, after vulcanizing is completed, the groove marks are stamped at the two ends of the rubber pipe, and the purpose that the groove marks are stamped at the two ends of the rubber pipe is achieved.

Owner:TIANJIN PENGYI GRP CO LTD

A splicable paper packaging box

ActiveCN108163325BReduce manufacturing costRealize detachableRigid containersManufactured materialStructural engineering

Owner:ANQING SHENGHUA PAPER PACKAGING

Connector device with connector and assembly method

ActiveUS10424857B2Firmly connectedReduce effortContact member manufacturingCoupling contact membersEngineeringElectric energy

Owner:BRAUN GMBH

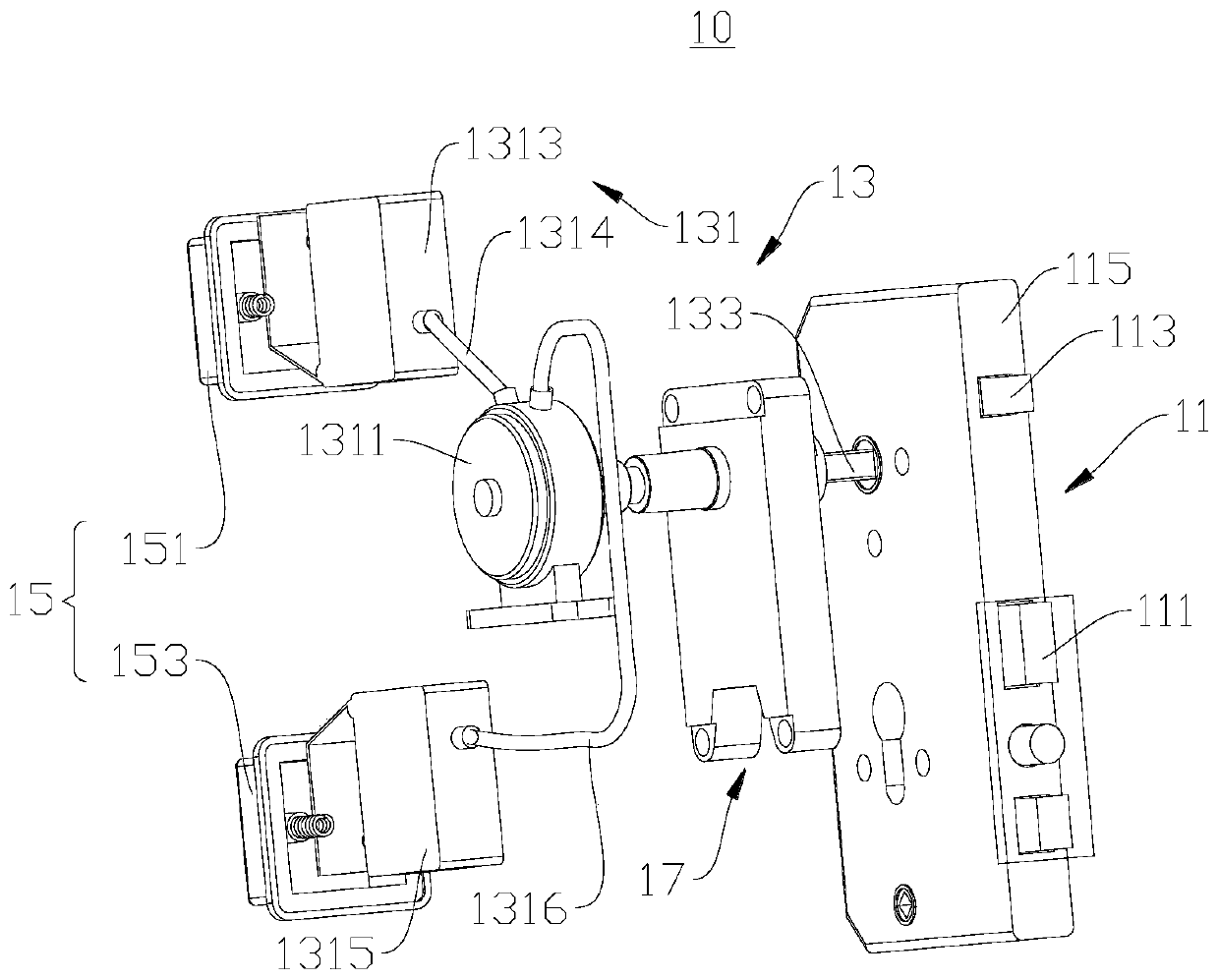

Intelligent door lock and intelligent door

ActiveCN110206392AOmit commutationSimple structureNon-mechanical controlsEngineeringElectrical and Electronics engineering

The invention relates to the technical field of locks, in particular to an intelligent door lock and an intelligent door. The intelligent door lock provided by the invention adopts a pressing device for driving a drive device to realize the extension or retraction of a first spring bolt, thereby realizing switching the intelligent door lock in the two states of locking and opening, and the pressing device is adopted to replace the traditional door handle, so a door handle reversing mechanism is saved and the structure is simplified. Because of comprising the above intelligent door lock, the intelligent door provided by the invention also has the above advantageous effects.

Owner:GREE ELECTRIC APPLIANCES INC +1

A new monitoring device for monitoring municipal roads

InactiveCN110925569BImprove installation stabilityPrevent looseningStands/trestlesArchitectural engineeringWorkbench

Owner:北京三和利贞科技有限公司

Dosing devices, dosing components and washing equipment

ActiveCN113136705BDetachable connectionImprove delivery accuracyOther washing machinesTextiles and paperLotionSurgery

The invention discloses a dispensing device, a dispensing assembly and washing equipment, wherein the dispensing device is used for dispensing lotion, comprising: a casing, on which a liquid inlet and a liquid outlet are formed; a grid divider, which has A plurality of compartments, the compartments are used to distribute lotion; drive components, the drive components are used to move under the external force applied by the user; the drive components are connected to the compartments, and the compartments are driven by the drive components to distribute lotion . According to the dispensing device of the present invention, a divider is provided, and the divider has a plurality of compartments, and the lotion can be accommodated in a plurality of compartments through the divider, since the volume of each compartment is determined , the capacity of the lotion contained in each compartment, when the lotion in the compartment is injected, the volume of the lotion to be injected is also determined, so the accuracy of the injection device can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

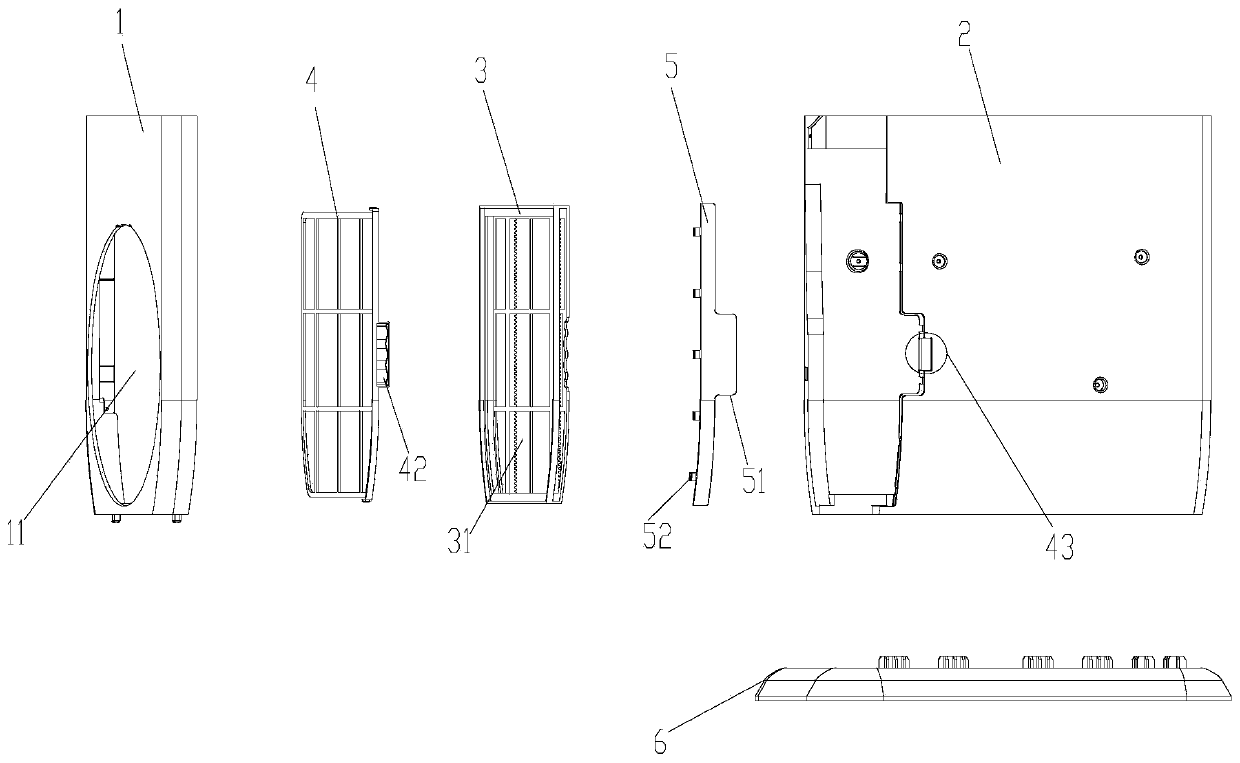

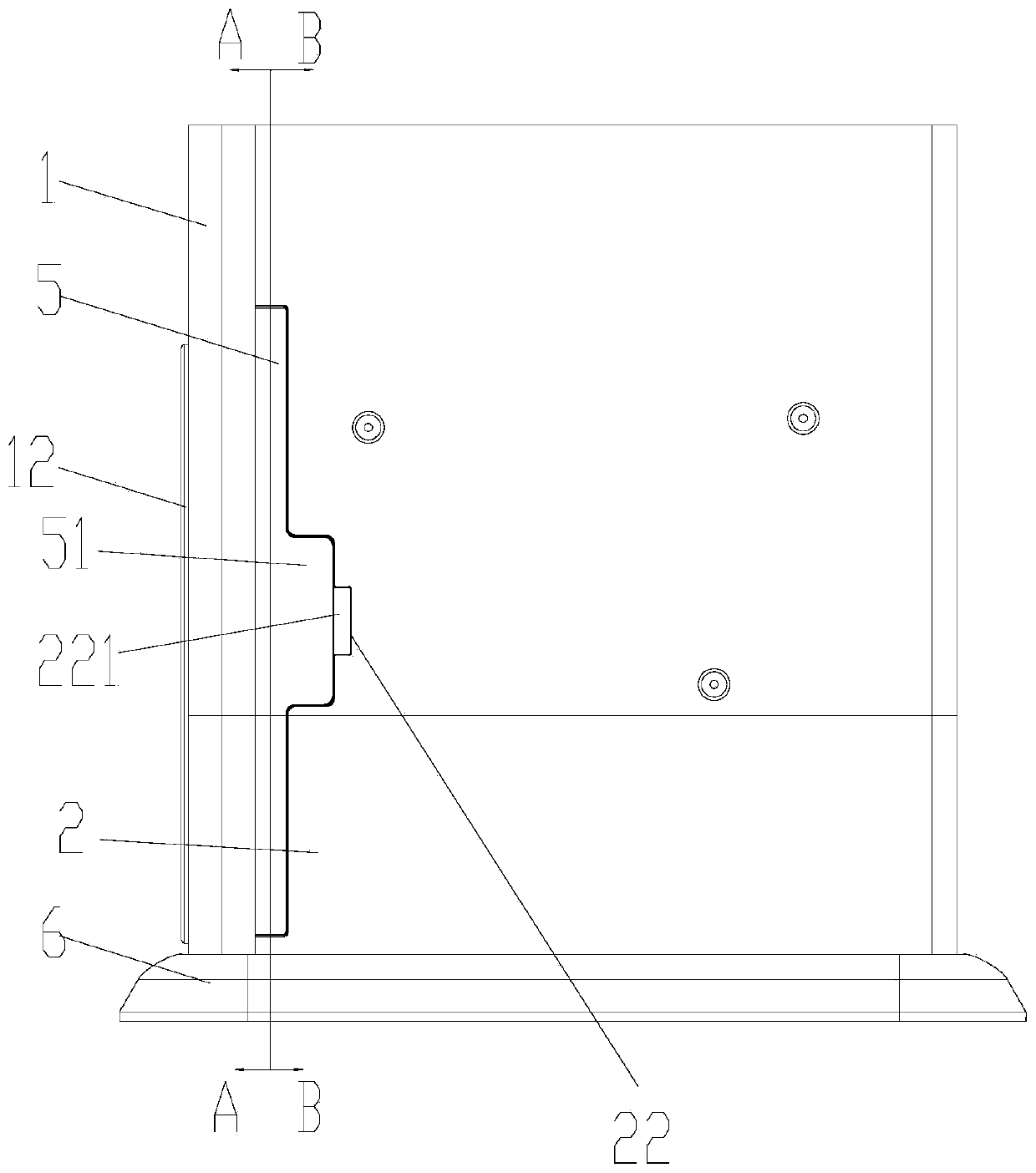

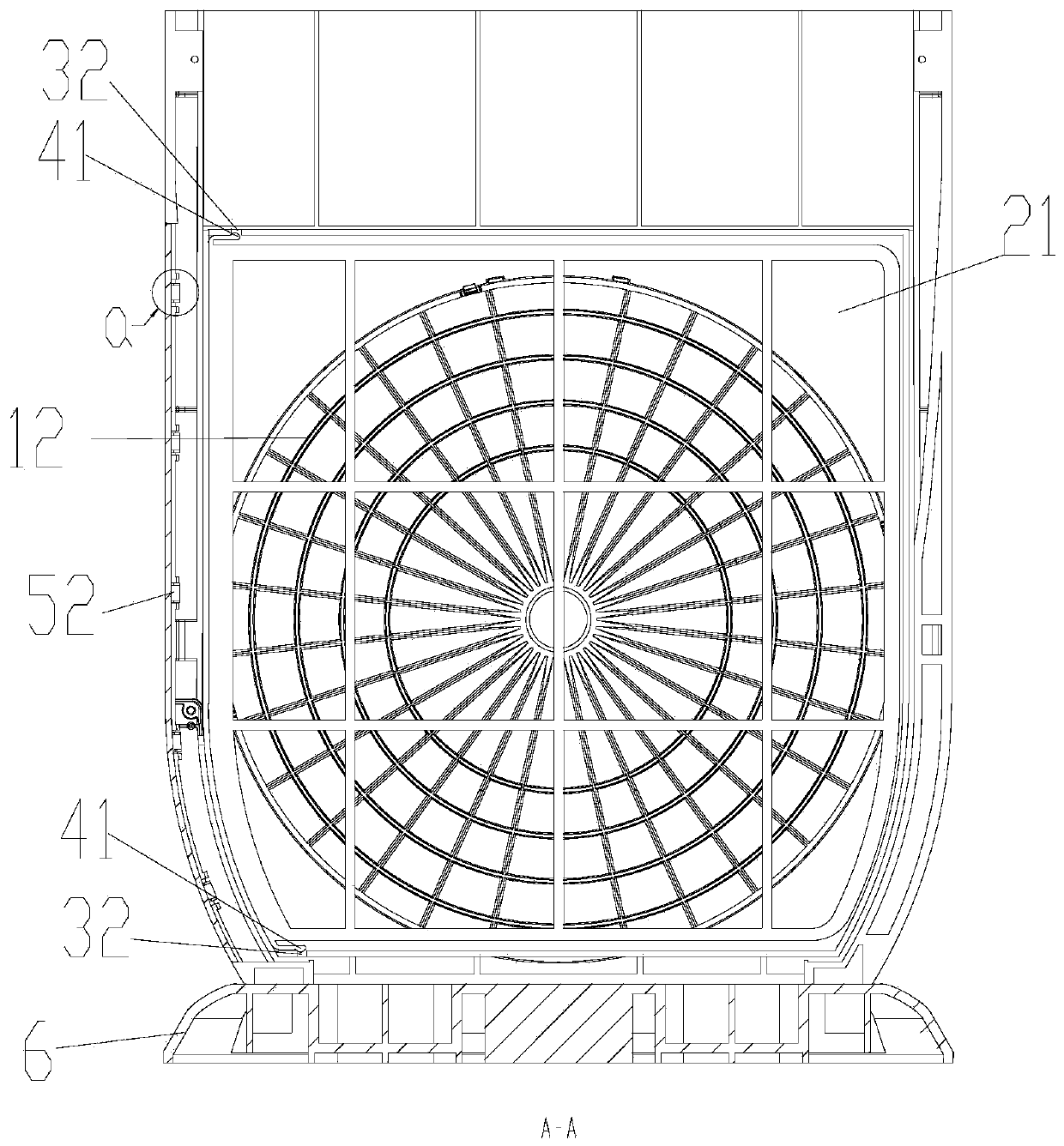

Mechanism with filter screen easy to disassemble and wash and air conditioner

PendingCN111006386ADetachable connectionEasy to assemble and disassembleLighting and heating apparatusHeating and ventilation casings/coversEngineeringMechanical engineering

The invention discloses a mechanism with a filter screen easy to disassemble and wash and an air conditioner. The mechanism with a filter screen easy to disassemble and wash comprises an air inlet panel, a shell, a filter screen mounting frame and a filter screen assembly, the shell is connected with the air inlet panel, an air duct is arranged in the shell, a first disassembly and assembly opening communicated with the air duct is formed in the side portion of the shell, the filter screen mounting frame is located in the air duct and connected with the air inlet panel, a second dismounting and mounting opening opposite to the first dismounting and mounting opening is formed in the side portion of the filter screen mounting frame, and the filter screen assembly is positioned in the filterscreen mounting frame, is detachably connected with the filter screen mounting frame, and can be pulled out of the shell through the first disassembly and assembly opening and the second disassembly and assembly opening. The shell and the filter screen mounting frame are improved, the filter screen assembly and the filter screen mounting frame are detachably connected, the filter screen assembly can be pulled out of the shell, the filter screen assembly is easy and convenient to disassemble and assemble, and the disassembling and washing work efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

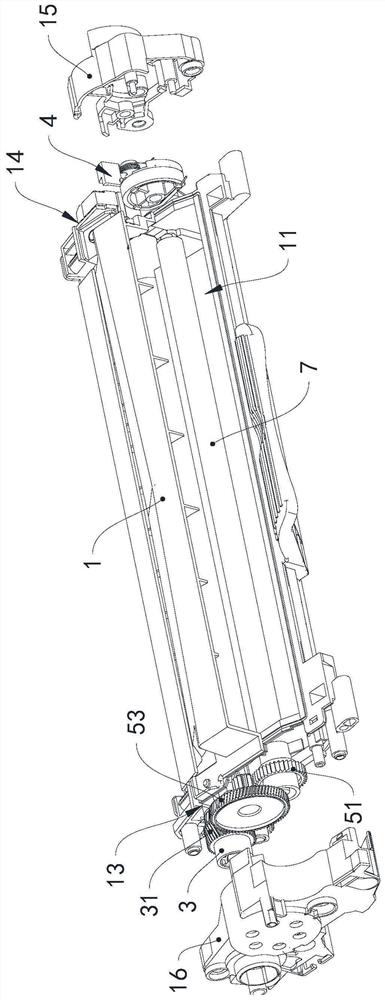

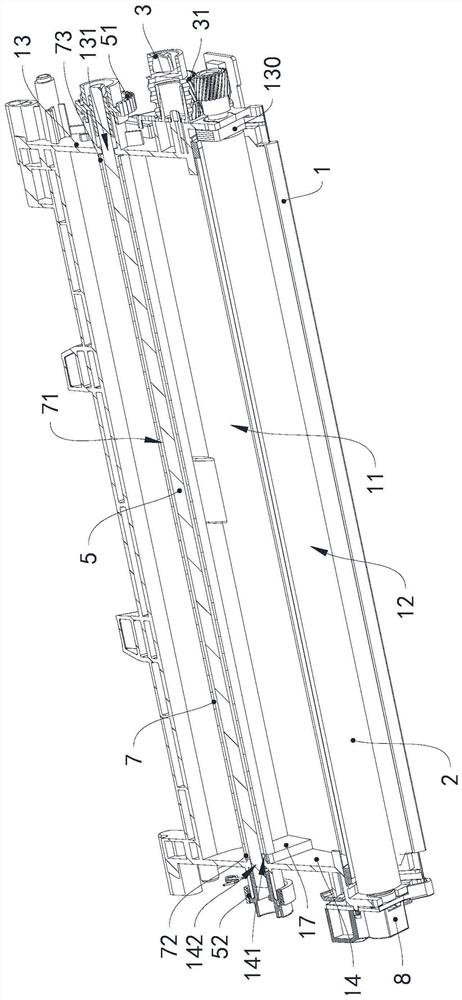

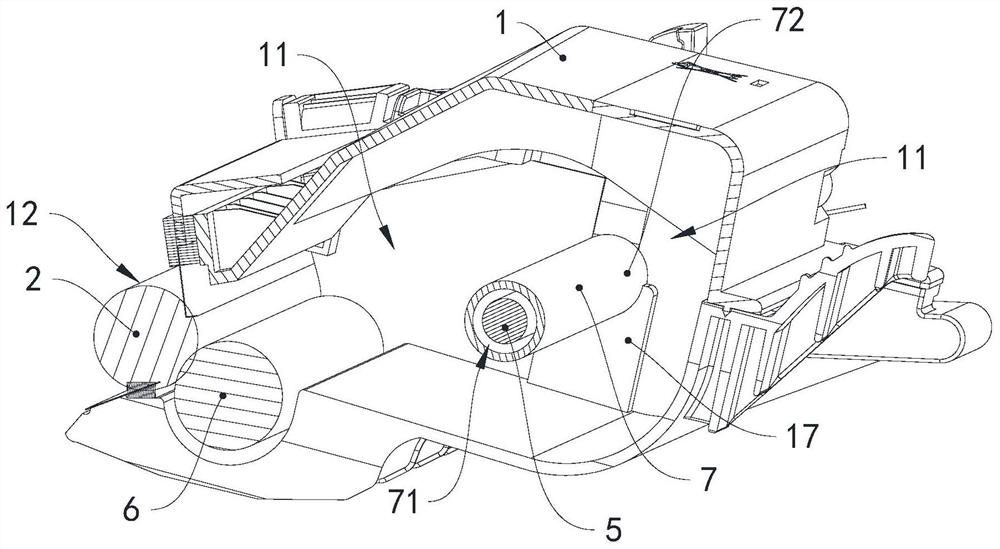

Developing box

PendingCN113608419ADetachable connectionEasy to replaceElectrographic process apparatusDrive wheelStructural engineering

The invention provides a developing box which comprises a box body, a developing roller, a driving force receiving head, a detection mechanism, a transmission shaft and a sleeve, the box body is provided with a carbon powder containing part and a powder outlet, the developing roller is rotatably supported at the powder outlet, the driving force receiving head is arranged on the first end wall of the box body, a tooth part is arranged on the peripheral wall of the driving force receiving head, the detection mechanism is arranged on the second end wall of the box body, the transmission shaft is columnar and extends in the length direction of the box body, the transmission shaft is rotatably installed in the carbon powder containing part, a first end of the transmission shaft is provided with a first driving wheel, the first driving wheel and the driving force receiving head are located on the same side of the box body, and the first driving wheel is in transmission connection with the driving force receiving head. The second end of the transmission shaft is provided with a second driving wheel which is matched with the rotating piece. A mounting cavity isolated from the carbon powder containing part is formed in the sleeve, and the transmission shaft is located in the mounting cavity and is in clearance fit with the sleeve. The developing box can reduce the torque generated by rotation.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Detachable loop heat pipe

ActiveCN114688904AQuick disassembly and replacementRealize long-distance transmissionIndirect heat exchangersHeat exchanger casingsThermodynamicsEngineering

The invention provides a detachable loop heat pipe which comprises an evaporation section, a condensation section and a heat insulation section, the heat insulation section comprises a steam heat insulation section and a liquid heat insulation section, fluid absorbs heat and evaporates in the evaporation section, enters the condensation section through the steam heat insulation section and then enters the evaporation section through the liquid heat insulation section after releasing heat in the condensation section, and the liquid heat insulation section is communicated with the liquid heat insulation section. The evaporation section, the condensation section and the heat insulation section are mutually independent parts, two end parts of the evaporation section are respectively connected with one end of the steam heat insulation section and one end of the liquid heat insulation section through detachable parts, and two end parts of the condensation section are respectively connected with the other end of the steam heat insulation section and the other end of the liquid heat insulation section through detachable parts. Therefore, the evaporation section, the condensation section and the heat insulation section form a loop heat pipe. According to the loop heat pipe, an existing loop heat pipe is improved, the detachable components are arranged to be connected with the evaporation section, the condensation section and the heat insulation section, so that all the components are rapidly detached and replaced, the requirements of different heat exchange occasions are met, the system structure is simple, and the cost is saved.

Owner:ZHONGBEI UNIV

A kind of intelligent door lock and intelligent door

ActiveCN110206392BOmit commutationSimple structureNon-mechanical controlsMechanical engineeringEmbedded system

Owner:GREE ELECTRIC APPLIANCES INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com