Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Crawl smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

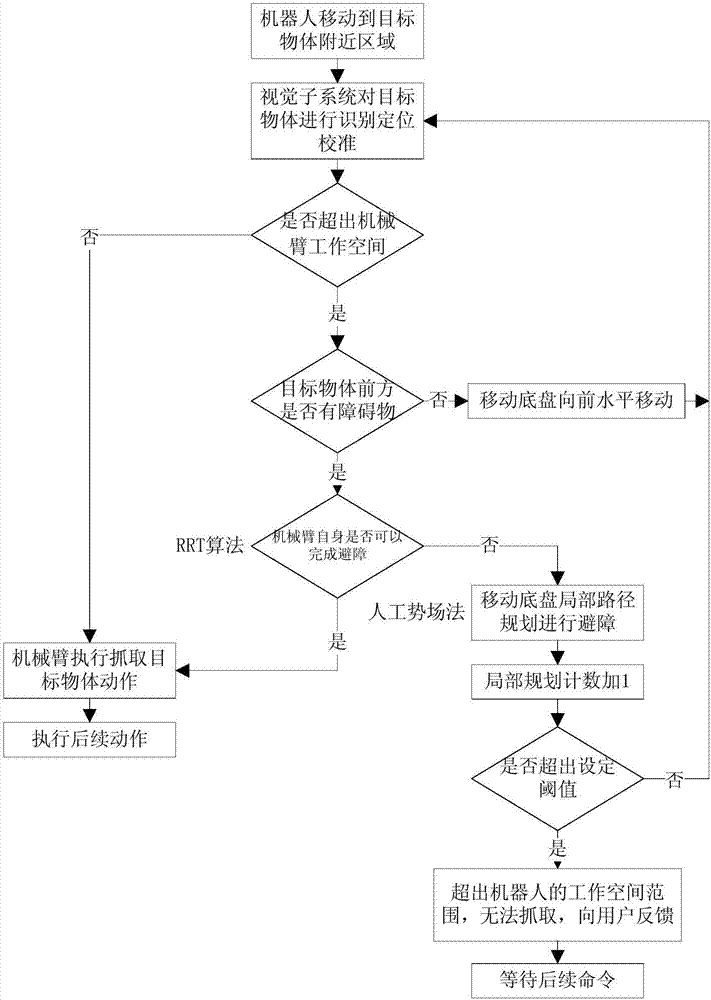

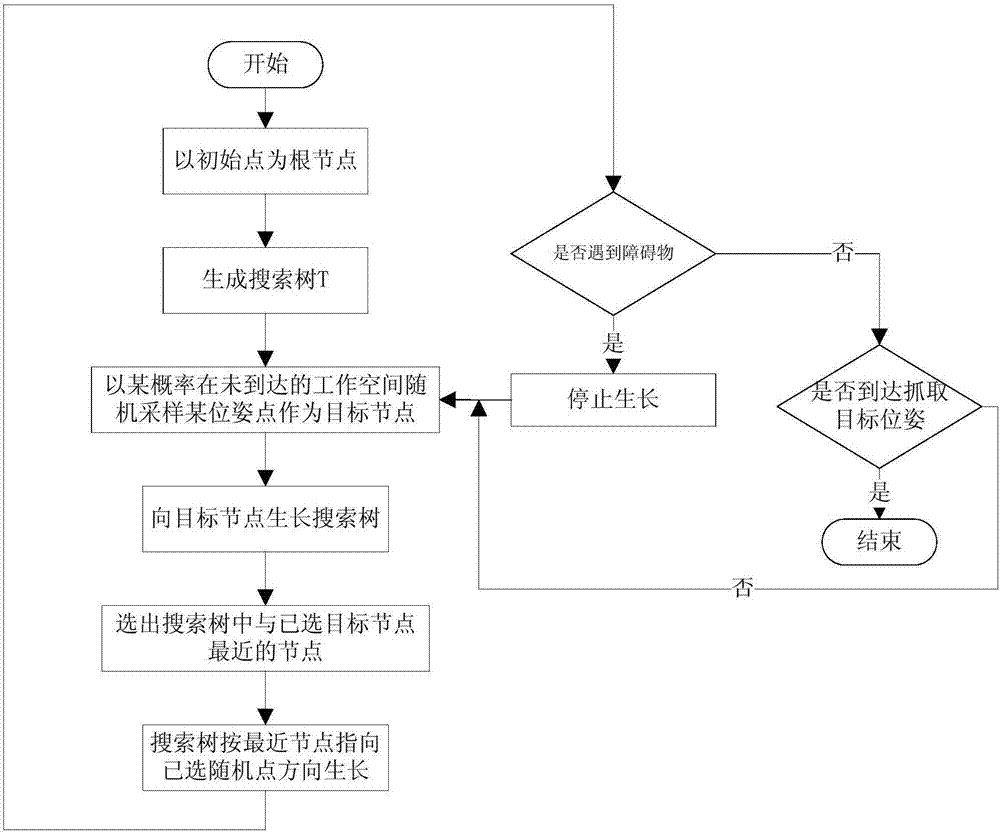

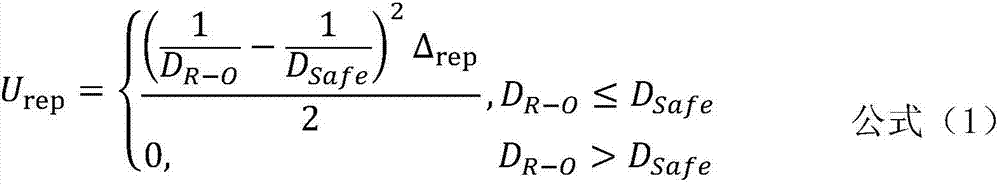

Robot local path planning method

InactiveCN106990777AAchieve crawlingAchieve placementProgramme-controlled manipulatorPosition/course control in two dimensionsPotential fieldSimulation

The invention provides a robot local path planning method which comprises following two parts: (1) a vision sub-system is adopted to perform closed-loop detection: a mechanical arm sub-system is separated from a mobile underpan sub-system, closed-loop detection control is performed through the closed-loop detection, and pick or place from the mechanical arm to a target object on the best substrate position is realized; (2) the local path plan is formed by a combination of the artificial potential field and the RRT algorithm, and mobile underpan and mechanical arm separation plan is realized through the local path plan; when the local path plan is performed, the mobile underpan adopts the artificial potential field to plan, and after every local path planning, the mechanical arm is planned through the RRT algorithm to judge if the movement of avoiding barrier and smoothly pick up a target object can be completed. According to the invention, the different plans for the mobile underpan and the mechanical arm are combined, so that overall coordination operation of the robot is realized.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

Industrial robot

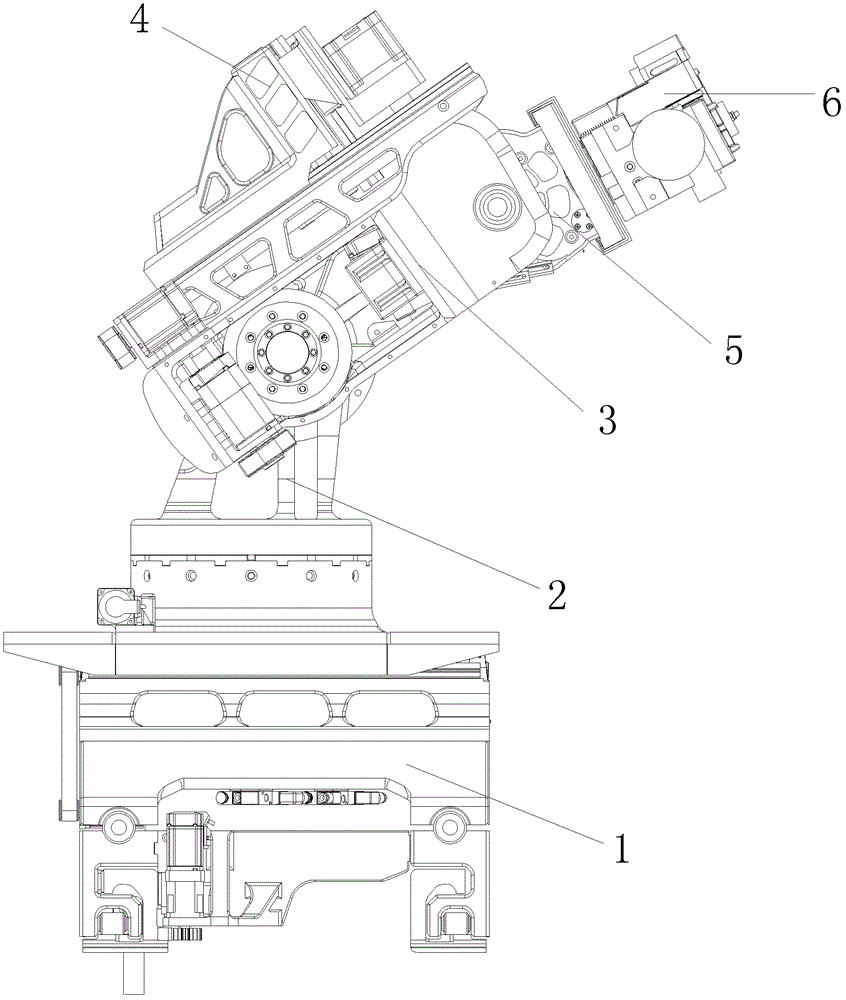

ActiveCN102658546ACrawl smoothlyRealize unmannedProgramme-controlled manipulatorJointsIndustrial engineeringIndustrial robot

The invention provides an industrial robot, which comprises a base guide rail component, a base component, a large arm component, an engraving and milling component, a wrist component and a claw component, wherein the lower end of the base guide rail component is matched with a guide rail I and can roll along the guide rail I; the lower end of the base component is matched with a guide rail II which is arranged at the upper end of the base guide rail component and can slide along the guide rail II; the base component consists of an upper component and a lower component, wherein the upper component can rotate around the lower component; a shoulder shaft on the large arm component is in floating fit with a shoulder shaft hole formed on the upper part of the upper component, and the large arm component realizes the action of lifting or lowering the arm; the lower part of the engraving and milling component is matched with a guide rail III which is arranged on the side of the large arm component, can slide along the guide rail III and realizes a drilling action; the wrist component is arranged in a mounting hole of the large arm component through a loop bar and finishes the action of lifting and lowering the wrist; and the side of the claw component is matched with a guide rail IV which is arranged on the wrist component, slides along the guide rail IV and realizes the action of opening and closing the claws.

Owner:刘朝龙

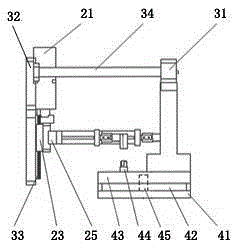

Electric cylinder hand grab used for grabbing battery pack

The invention discloses an electric cylinder hand grab used for grabbing a battery pack. The electric cylinder hand grab comprises a horizontal electric cylinder and a vertical electric cylinder connected with the horizontal electric cylinder. A hand grab body is arranged at the lower end of the vertical electric cylinder and comprises two double-end clamping air cylinders, and a clamping jaw is arranged at the stretchable end of each double-end clamping air cylinder. An auxiliary air cylinder is arranged at the head of one of the clamping jaws, and an auxiliary clamping block is arranged at the stretchable end of the auxiliary air cylinder. A vertical lifting air cylinder is arranged between the two double-end clamping air cylinders, the stretchable end of the lifting air cylinder faces downwards and is connected with a sucking disc fixing base, and a plurality of sucking discs are arranged on the lower side face of the sucking disc fixing base. The upper ends of the double-end clamping air cylinders and the upper end of the lifting air cylinder are fixedly connected through a connecting plate. A rotating air cylinder is arranged between the connecting plate and the lower end of the vertical electric cylinder. Therefore, the electric cylinder hand grab has the advantages of being capable of safely and stably grabbing the battery pack and smoothly achieving carrying and packing of the battery pack.

Owner:HANGZHOU WAHAHA TECH

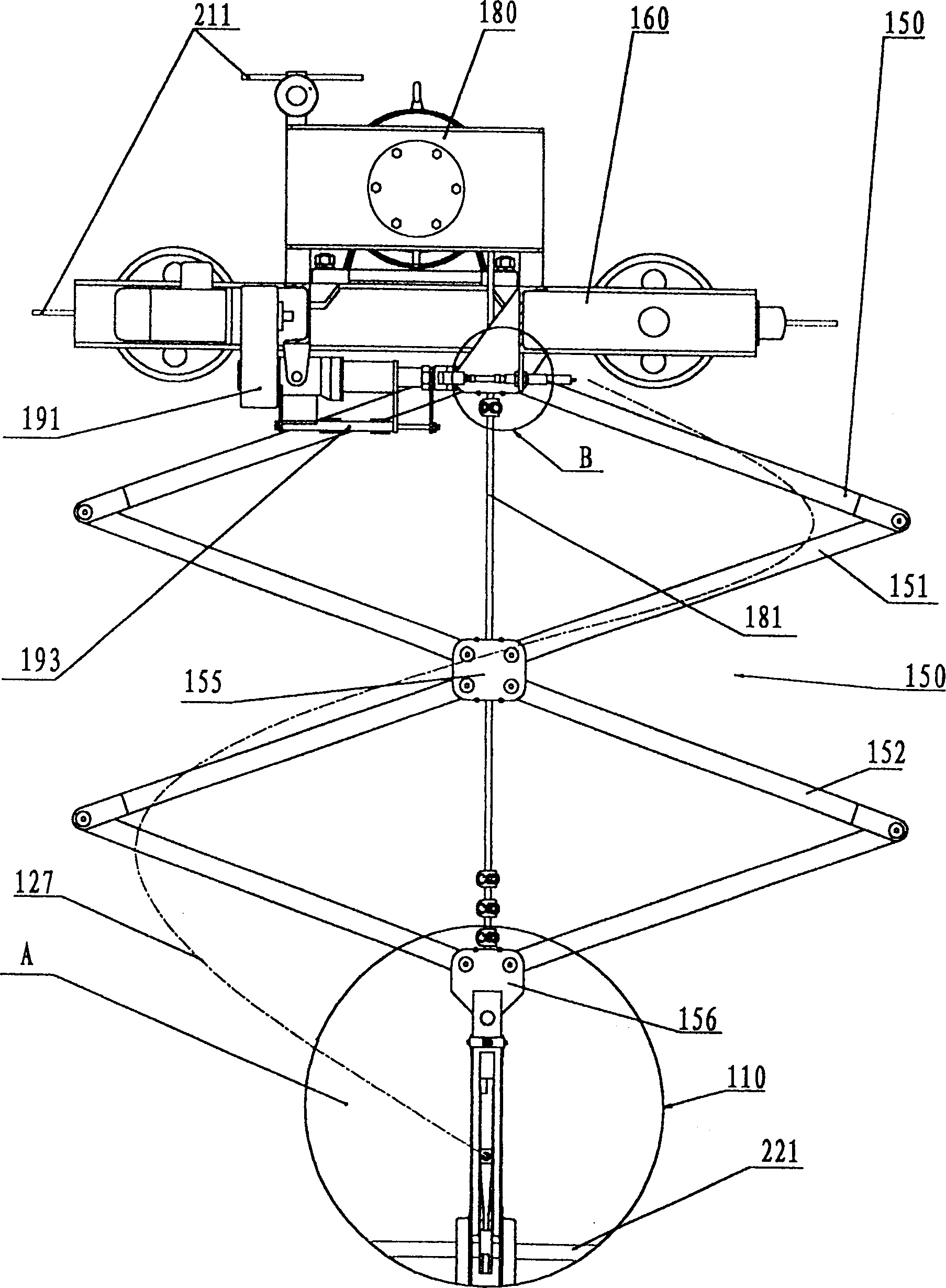

Adjustable deviation prevention device based on cable detection robot

The invention discloses an adjustable deviation prevention device based on a cable detection robot. The adjustable deviation prevention device comprises a support shaft connected with a cable detection robot support leg, a fixing frame arranged on the support shaft, a deviation prevention support frame connected with the support shaft, a stepped shaft connected with the deviation prevention support frame, and a deviation prevention wheel arranged on the stepped shaft. The support shaft passes through the fixing frame; meanwhile, two horizontal extension plates are arranged on the bottom side of the fixing frame, one side is clamped on the cable detection robot support leg, and the other side is clamped on the deviation prevention support frame, so that one face of the fixing frame is attached to the support leg, and the other face of the fixing frame is attached to the deviation prevention support frame.

Owner:SOUTHEAST UNIV

Hoisting and transport device extracting article from local high temperature area

InactiveCN1408634AAvoid empty grabsCaught accuratelyTravelling cranesManipulatorVehicle frameTouch Senses

The hoisting and transport equipment includes transport tracks, transport frame, hoister on the frame, frame driving drag and manipulator, suspended under the frame. The manipulator of whole metal structure includes link arm and grab, the link arm is two planar four-link mechanisms and the grab includes arm with guide mechanism, grabbing hook and hook opening and closing mechanism comprising bent link rod, pull-push flexible shaft and electric cylinder. The equipment is provided with touch sensing mechanism, hook opening sensing mechanism and manipulator elevating limit sensing mechanism, with the electric devices for the sensing mechanisms being far away from the manipulator. The equipment is matched with PLC and can grab article in preset position precisely while sending signal.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

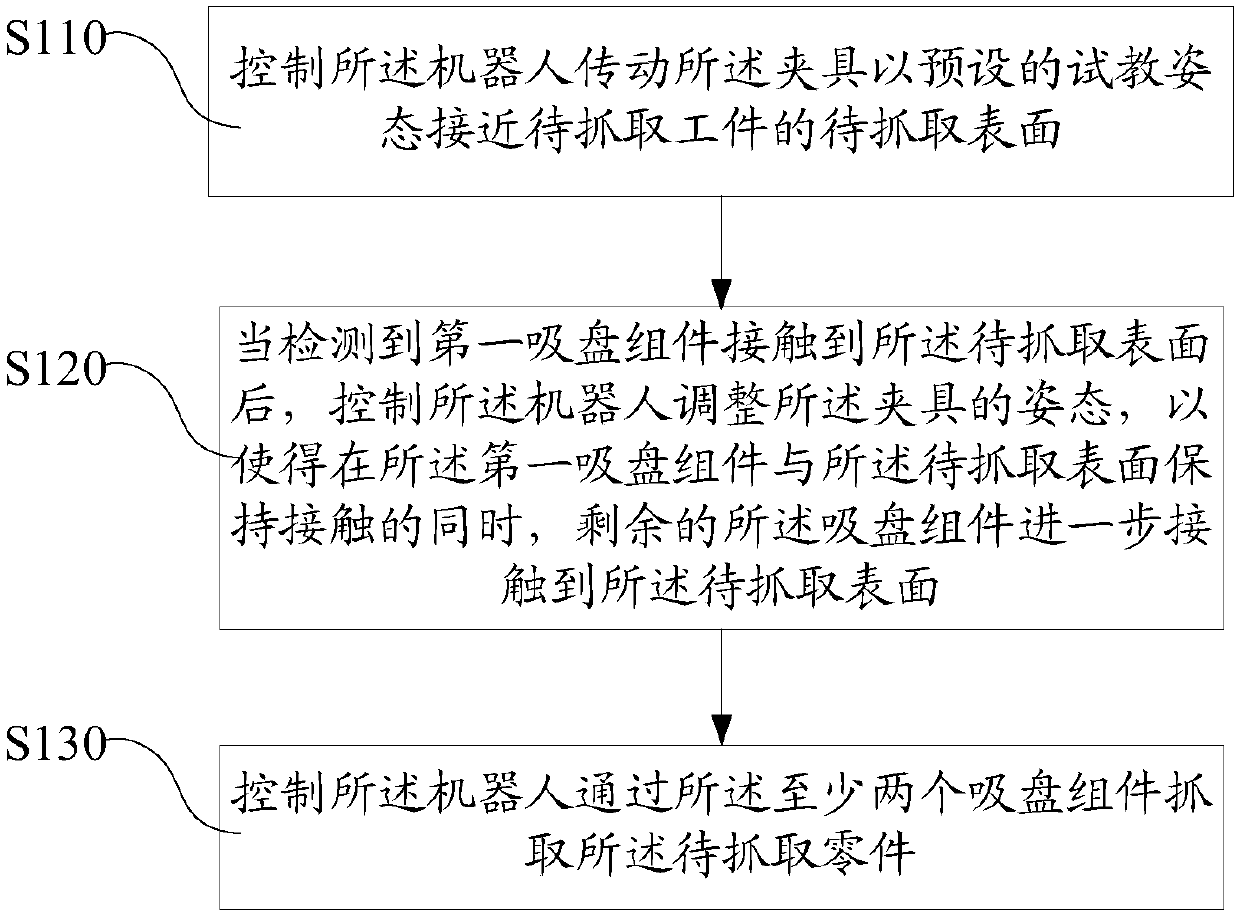

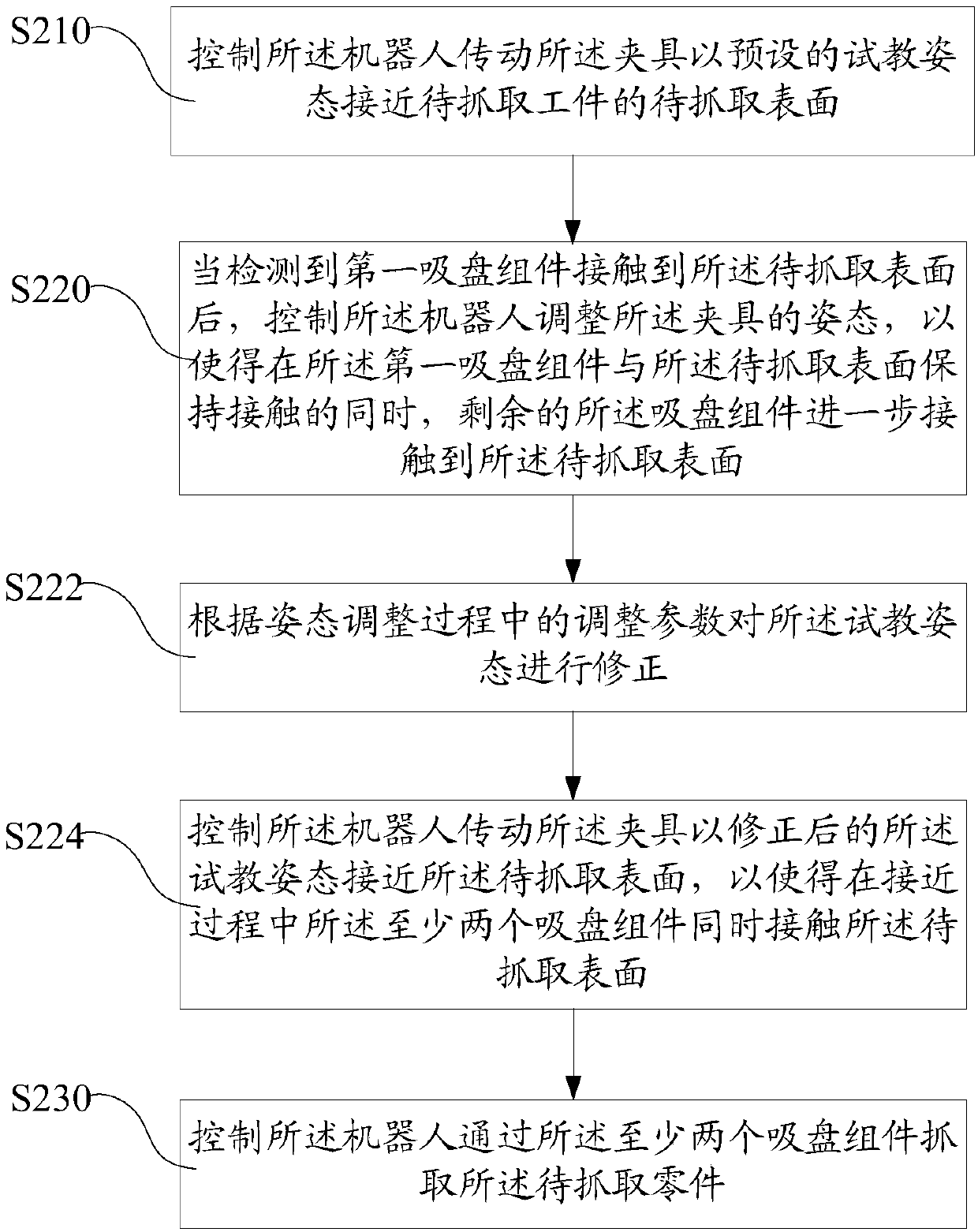

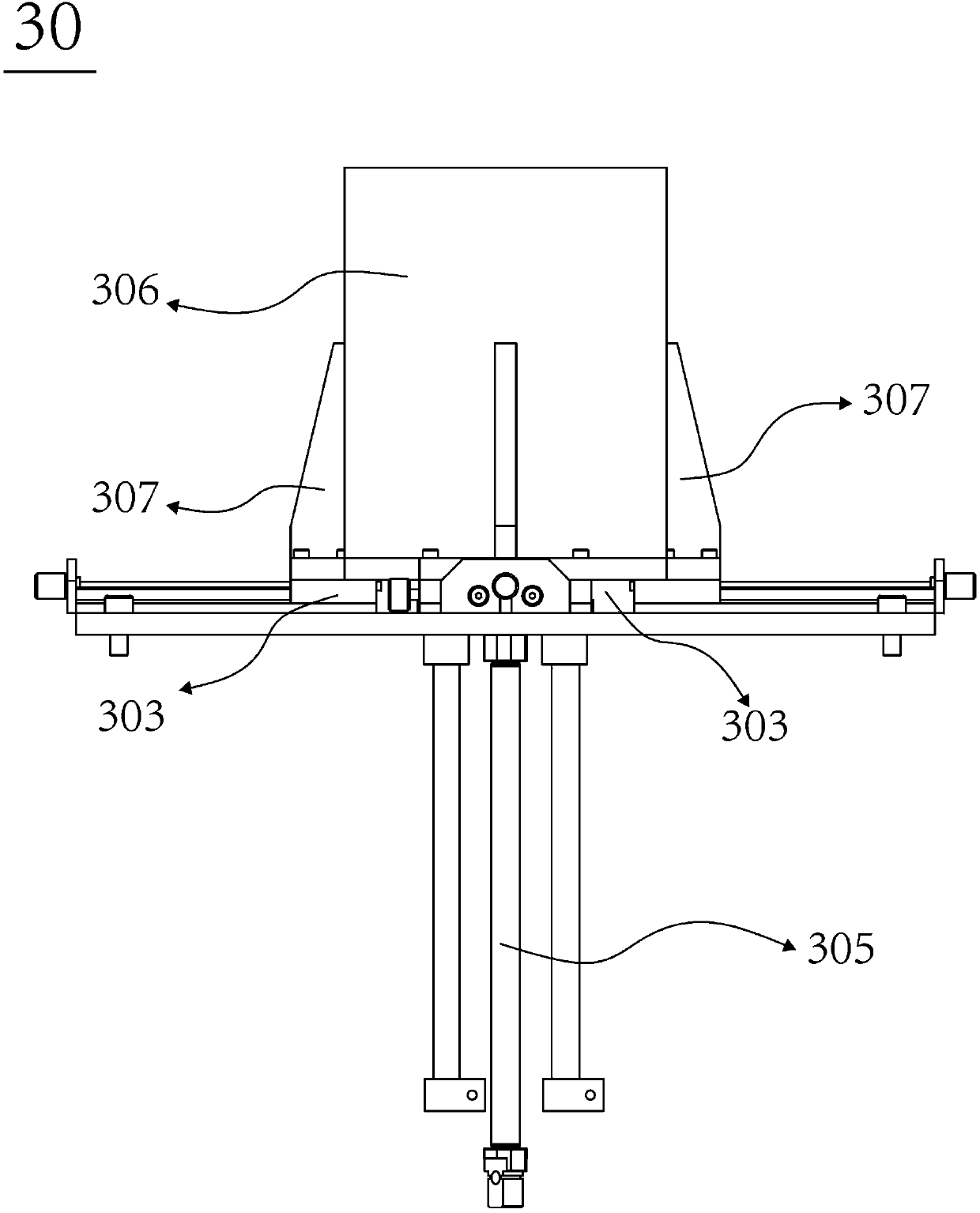

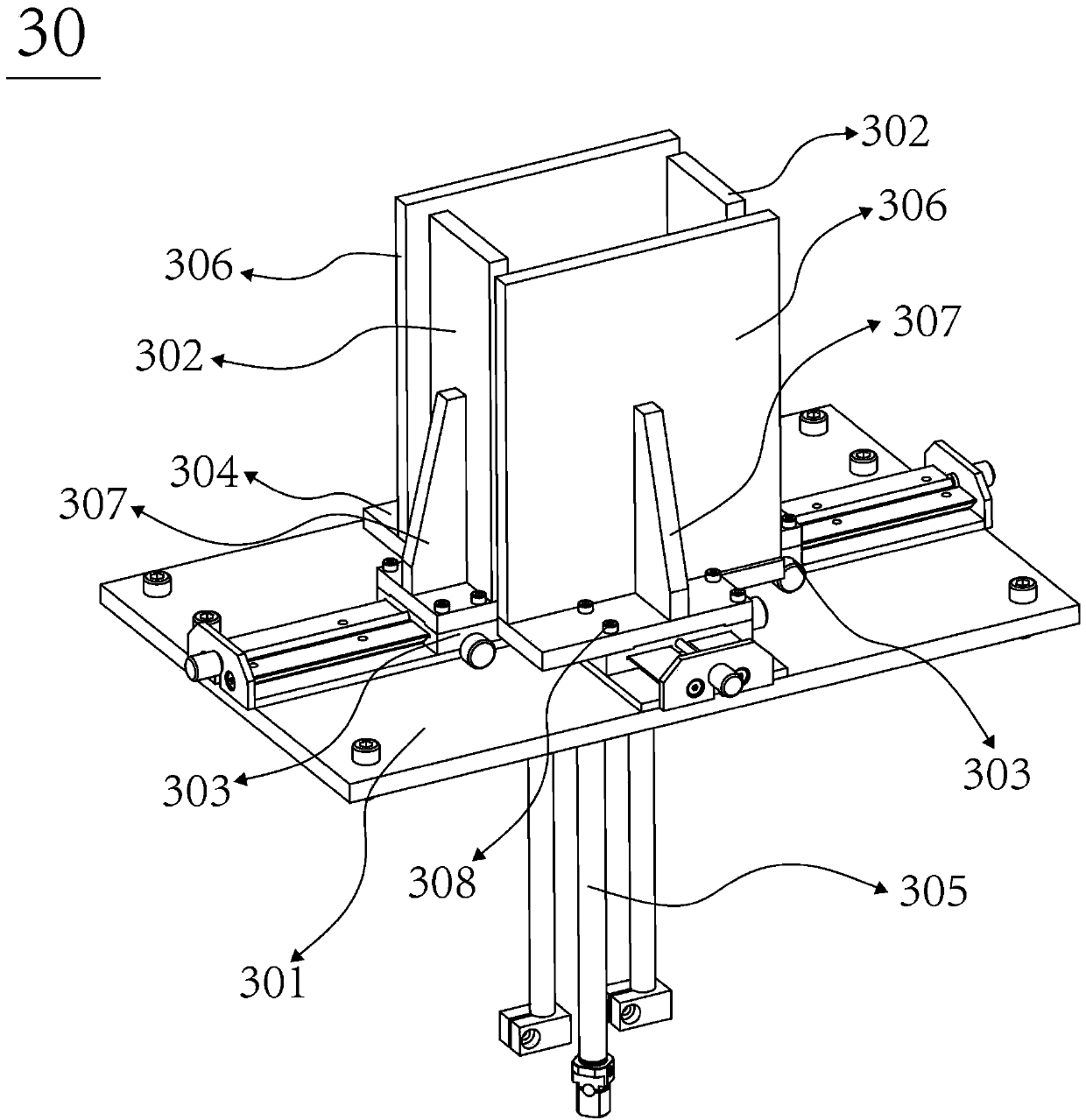

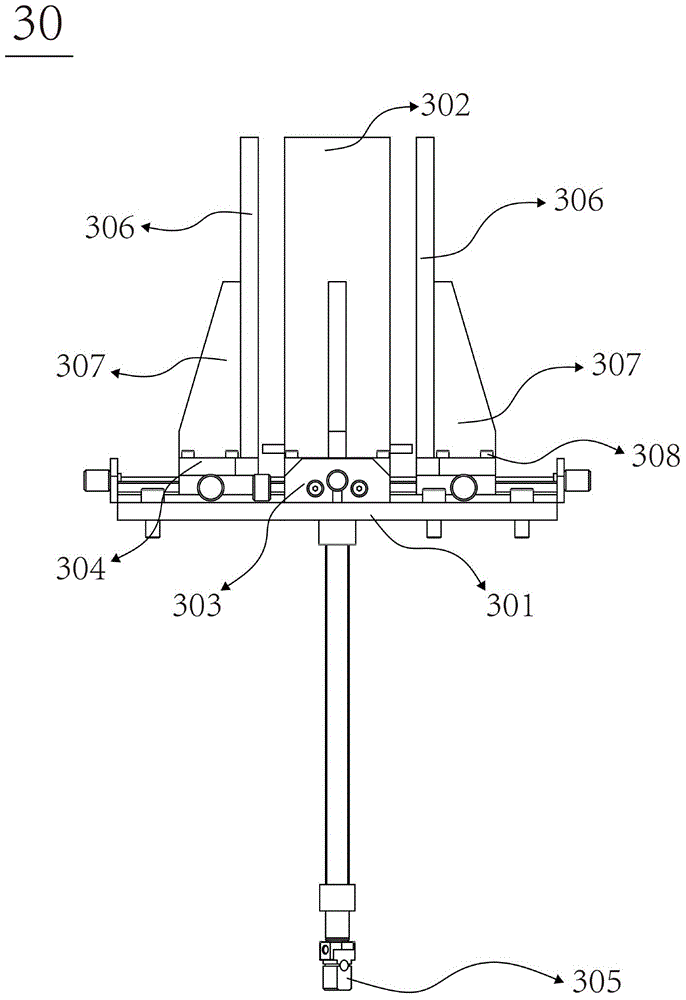

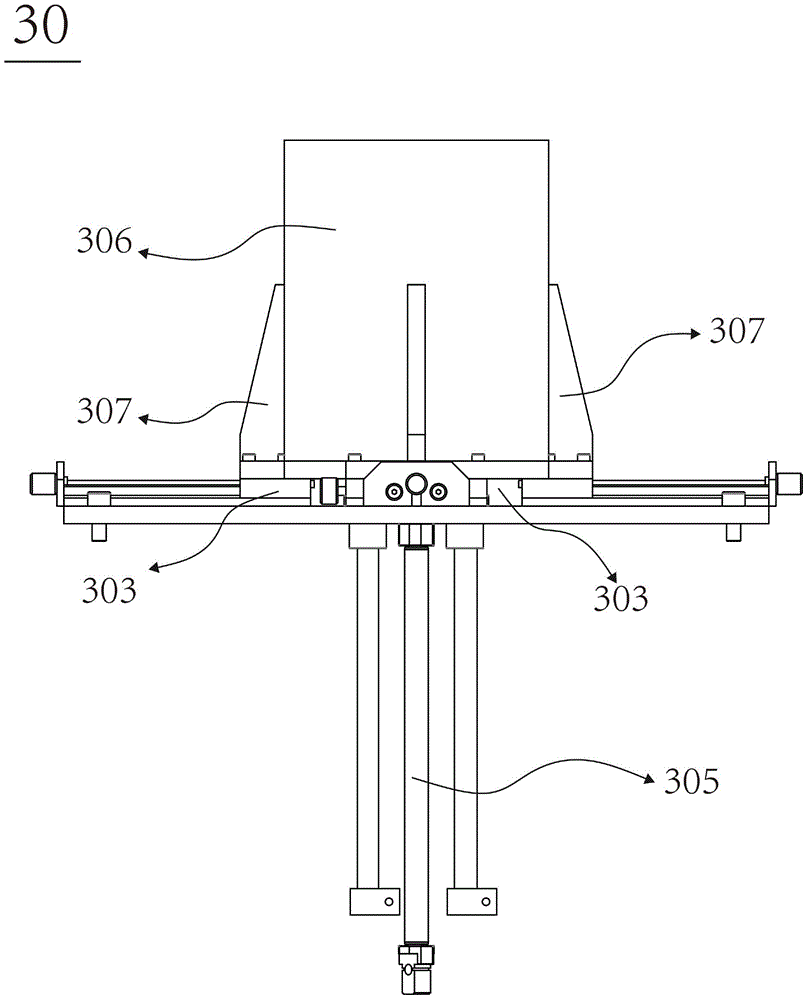

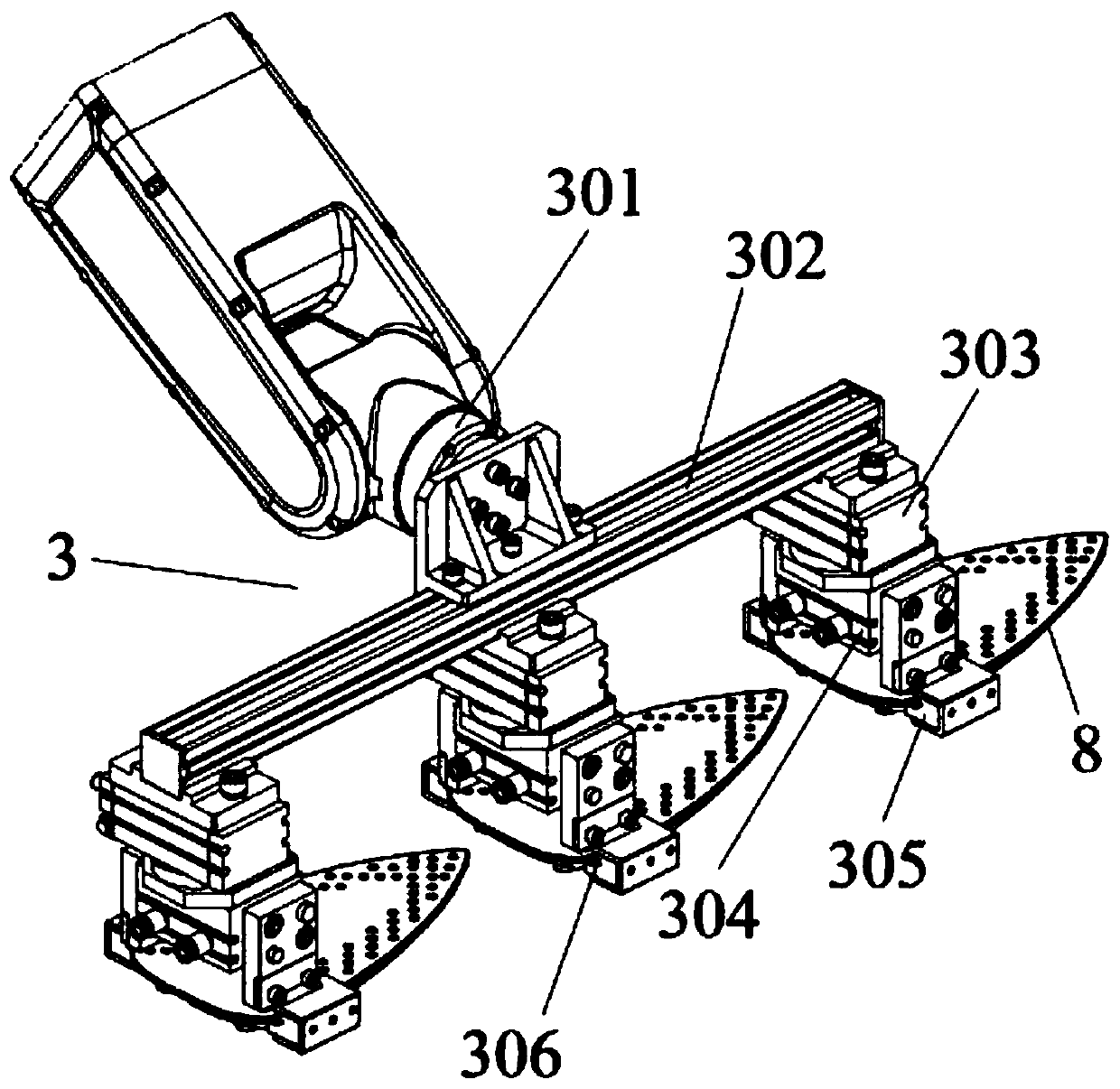

Robotic system-based part-grasping method and robot system, fixture

The invention discloses a part-grasping method based on a robot system comprising a robot (20) and a robot-driven clamp (30), wherein the clamp comprises at least two suction cup assemblies (31) arranged at intervals, the method comprising: Controlling the robot transmission fixture to approach the surface to be picked up of the parts to be picked up in a preset initial posture; controlling the posture of the robot to adjust the jig after detecting that the first suction pad assembly touches the surface to be picked up, While the first suction pad assembly remains in contact with the surface to be grasped, the remaining suction pad assembly further contacts the surface to be grasped; and the control robot grasps the part to be grasped through the at least two suction cup assemblies. The use of the parts crawling method can ensure the successful capture of parts in different poses. Also disclosed in the invention are a robotic system and a fixture.

Owner:SHENZHEN A&E INTELLIGENT TECH INST CO LTD

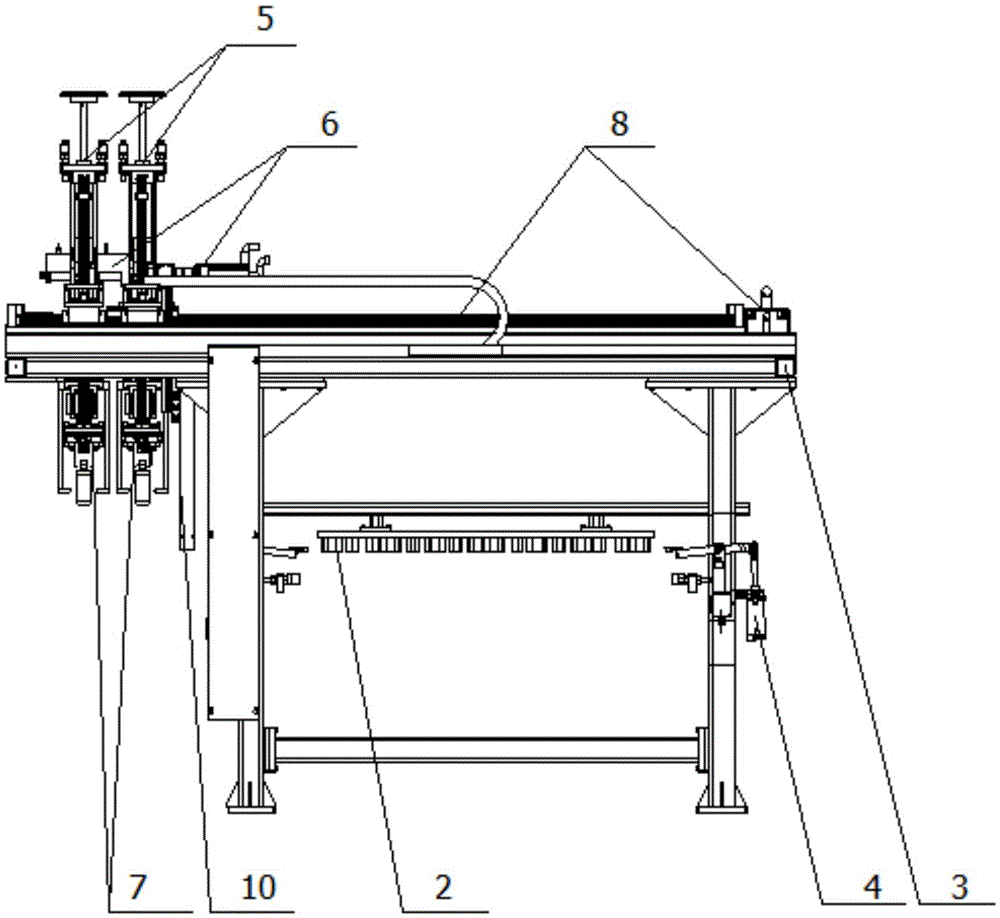

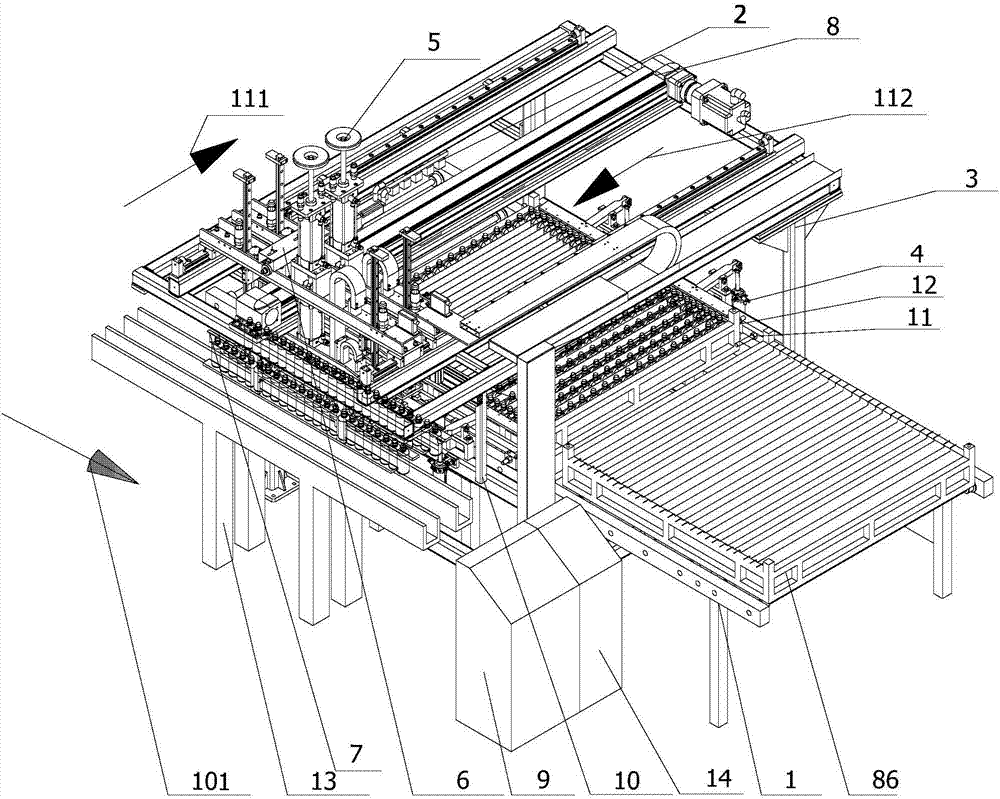

Automatic catching device, ironing machine and ironing method

ActiveCN104178987ACrawl smoothlySo as not to damageIroning apparatusTextiles and paperMechanical engineering

The invention discloses an automatic catching device, an ironing machine and an ironing method. The automatic catching device comprises a cloth clamping mechanism, a first driving mechanism for driving the cloth clamping mechanism to transversely move and a second driving mechanism for driving the cloth clamping mechanism to longitudinally move, wherein the cloth clamping mechanism is provided with at least two cloth chucks and an opening and closing driving mechanism for driving the cloth chucks to transversely move; the front ends of the cloth chucks are connected with a needle row. The ironing machine comprises the automatic catching device, an excessive ironing device and a workbench with a barrel plate; the excessive ironing device is connected to the workbench; the needle row faces the barrel plate. According to the automatic catching device and the ironing machine which are disclosed by the invention, automatic material catching is realized, the production efficiency is improved, and the labor and the time are saved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

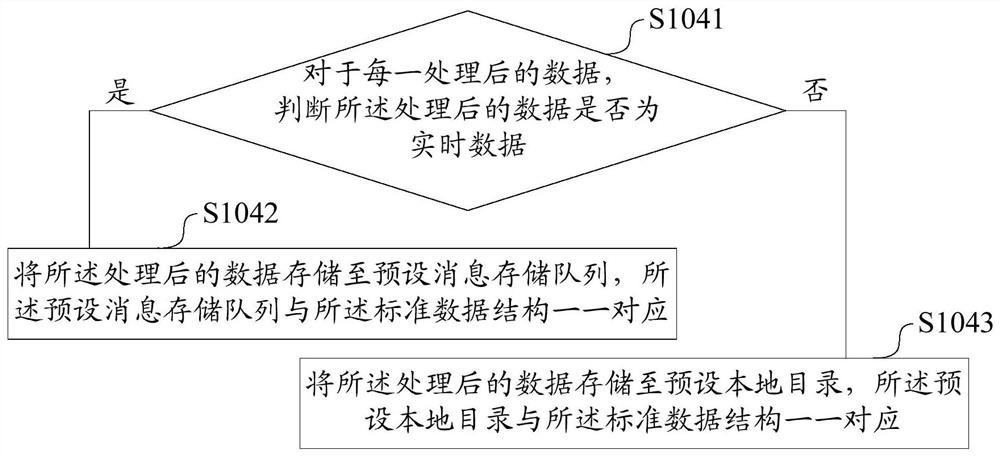

Multi-source heterogeneous data aggregation method and device, storage medium and terminal

PendingCN111782690AImprove compatibilityImprove versatilityRelational databasesSpecial data processing applicationsData classAlgorithm

The invention discloses a multi-source heterogeneous data aggregation method and device, a storage medium and a terminal, and the method comprises the steps of employing a preset plug-in to obtain original data from a data source, and enabling the preset plug-in to be in one-to-one correspondence with the data source; determining a standard data structure according to the data type of the originaldata, wherein the standard data structure comprises at least one field and the field type of the field; converting the original data according to the standard data structure to obtain processed data;and for a plurality of pieces of processed data, storing the plurality of pieces of processed data in a classified manner by taking the standard data structure as a reference, the plurality of piecesof processed data being obtained from the same or different data sources. Through the scheme provided by the invention, the complexity of system access and data conversion can be reduced, and the efficiency of synchronous processing of the multi-source heterogeneous data is improved.

Owner:JINGZAN ADVERTISING SHANGHAI CO LTD

Automatic cloth ironing machine and cloth ironing method thereof

The invention discloses an automatic cloth ironing machine and a cloth ironing method thereof. The automatic cloth ironing machine comprises an over-ironing device, a feeding device, a grabbing device, a lining cloth device, a correction device and a control system which are connected to a working panel. Action of automatic feeding is completed through cooperation of a feeding system and a pushing system; by designing the grabbing device, materials (such as barrel cloth) can be smoothly grabbed; through cooperation of the lining cloth rod and a rotating shaft, automatic feeding of lining rod can be realized automatically; through monitoring cooperation of the control system, a correction shaft and a sensor, the lining cloth deviating from a preset position can be automatically corrected timely. By the automatic cloth ironing machine, a full-automatic mode in the whole process of ironing of the barrel cloth is realized, manpower, material resources, time and resources are saved, and safety accidents are reduced greatly.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

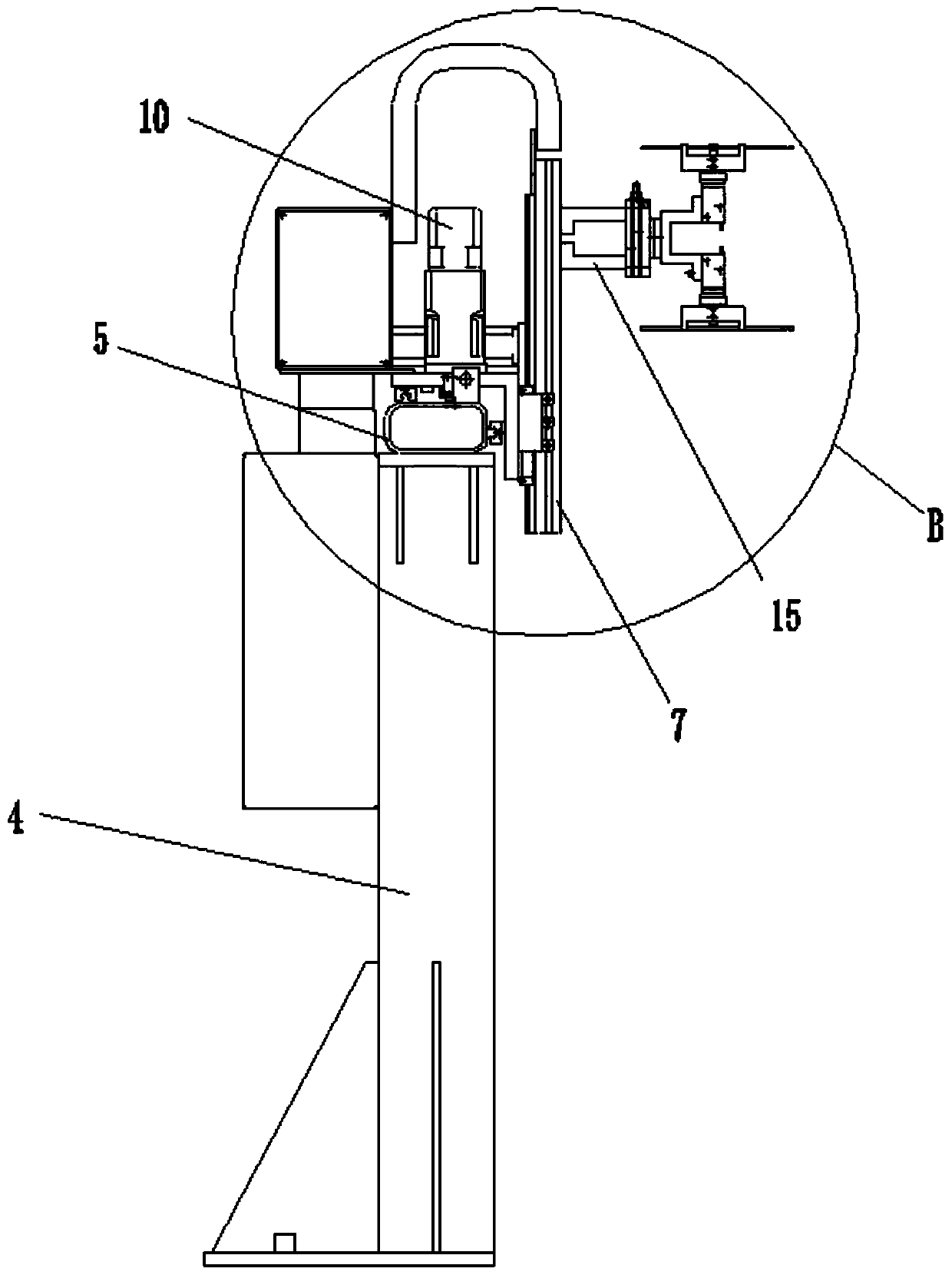

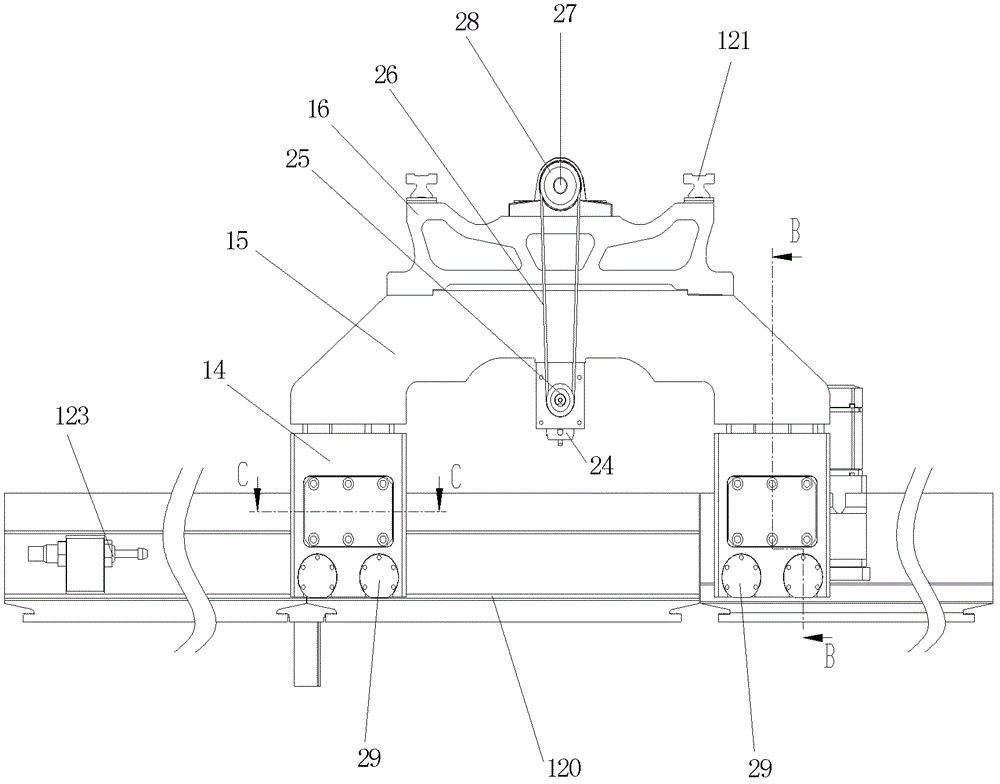

Automatic standing-bag unloading system and method

The invention discloses an automatic standing-bag unloading system and method. The automatic standing-bag unloading system is characterized in that a bottle unscrambler assembly is arranged at the front end of an automatic standing-bag unloading equipment frame assembly; the automatic standing-bag unloading equipment frame assembly is a mounting support frame of the automatic standing-bag unloading system; sterilization box partition plate pressing devices are arranged on two sides of the automatic standing-bag unloading equipment frame assembly; a horizontal travelling component is arranged at the top of the automatic standing-bag unloading equipment frame assembly; a horizontal gripper fine-adjustment combination is arranged above the horizontal travelling component; sterilization box locking and positioning devices are arranged on two sides of a sterilization box transferring track system; a travel switch is arranged at the bottom of the sterilization box transferring track system; a standing-bag conveyor body is correspondingly arranged near the automatic standing-bag unloading equipment frame assembly; and a vertical lifting component is connected with the automatic standing-bag unloading equipment frame assembly. The automatic standing-bag unloading system can automatically and directly take sterilized standing bag products out of a sterilization box and transfer the sterilized standing bag products onto a conveying line of the standing-bag conveyor body.

Owner:山东科伦药业有限公司

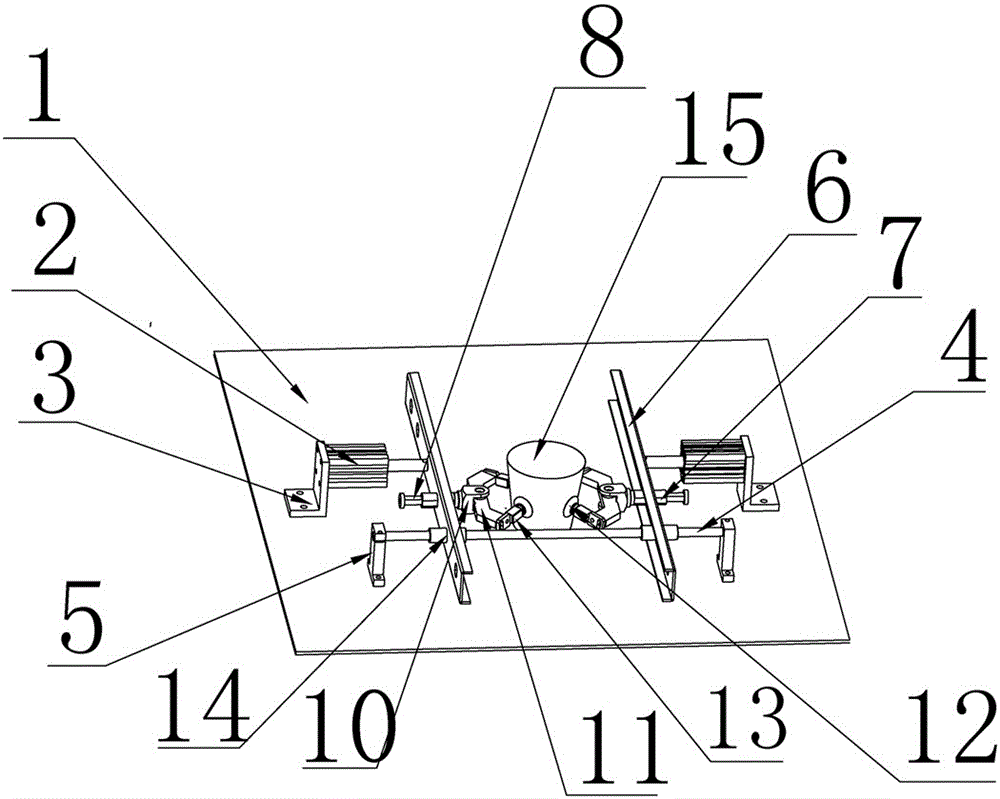

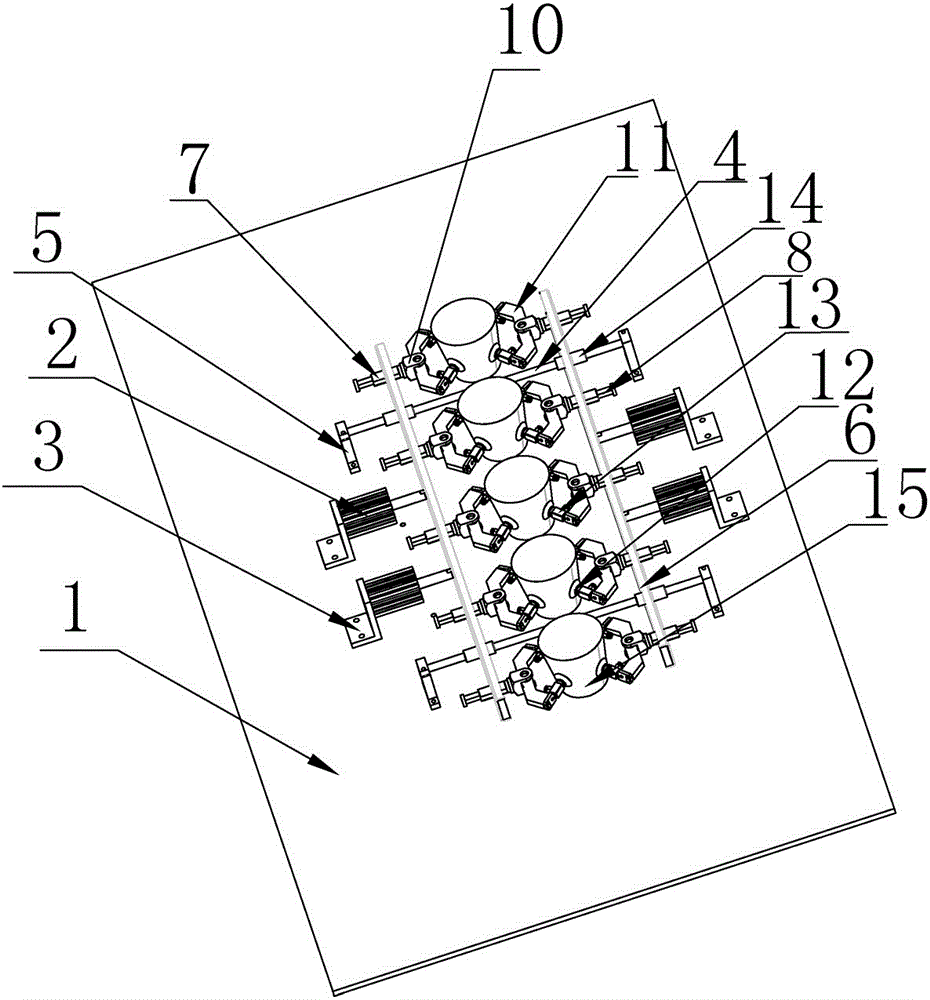

Bowl grabbing device of nutritive bowl separating machine

The invention relates to a bowl grabbing device for grabbing and separating nutritive bowls for seedling raising, in particular to a bowl grabbing device of a nutritive bowl separating machine. The bowl grabbing device comprises a base plate, wherein at least one group of air cylinders are symmetrically arranged on the top face of the base plate through air cylinder fixing plates, at least one cylindrical supporting rod is horizontally arranged on the same side of two air cylinder of the same group, the supporting rods are arranged on the top face of the base plate through supporting rod fixing frames arranged at two ends of each supporting rod, one connecting plate is arranged at the free ends of piston rods of the air cylinders respectively, the connecting plates are fixedly connected with the free ends of the piston rods of the air cylinders the connecting plates are close to, the supporting rods penetrate the side faces of two connecting plates, at least one group of grabbing assemblies is arranged on each connecting plate, and each group of grabbing assemblies includes two grabbing mechanisms oppositely arranged between the two connecting plates. The bowl grabbing device of the nutritive bowl separating machine has the advantages of being simple in structure, convenient to adjust, capable of effectively grabbing bowl bodies and high in bowl separating efficiency and automation degree, reducing manual operation and saving covering area.

Owner:ZHENGZHOU SHUNYI TECH CO LTD

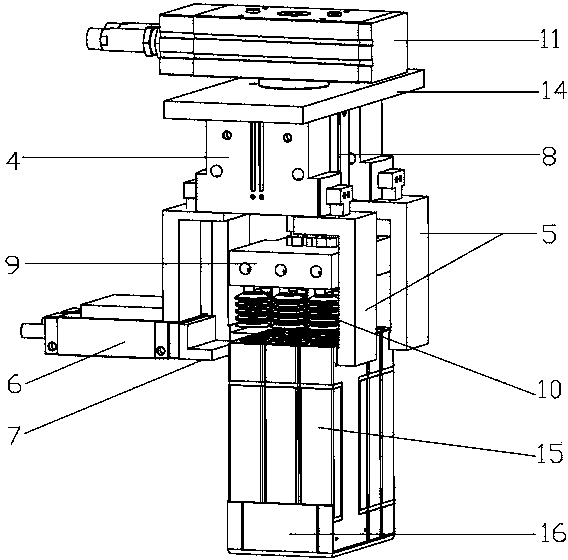

Production line vehicle accumulation battery installation device

ActiveCN104742711APrecise positioningCrawl smoothlyElectric propulsion mountingProduction lineEngineering

The invention discloses a production line vehicle accumulation battery installation device which can effectively lower labor intensity, reduce the number of operators for a production line and improve the degree of automation of the production line. The production line vehicle accumulation battery installation device comprises a bracket, a pallet limiting groove, a pallet, a transverse guide rail, transverse sliding blocks, a transverse moving execution device, a longitudinal guide rail, a longitudinal sliding block, a longitudinal moving execution device, an installation base, a first lifting execution device and a clamping positioning device, wherein the pallet limiting groove is formed in the top surface of the bracket, and the pallet is arranged in the pallet limiting groove; the transverse guide rail is arranged above the bracket, the transverse sliding blocks are arranged on the transverse guide rail in a slideable mode, and the transverse moving execution device is used for driving the transverse sliding blocks to move along the transverse guide rail; the longitudinal guide rail is arranged on the transverse sliding blocks, the longitudinal sliding block is arranged on the longitudinal guide rail in a slideable mode, and the longitudinal moving execution device is used for driving the longitudinal sliding block to move along the longitudinal guide rail; the installation base is arranged below the longitudinal sliding block, the first lifting execution device is arranged on the longitudinal sliding block and used for driving the installation base to lift vertically, and the clamping positioning device is arranged on the installation base.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Automatic height detecting device

PendingCN108759754ARealize fully automatic feedingImprove detection accuracyProgramme-controlled manipulatorMeasurement devicesMechanical engineeringTesting equipment

Owner:KUSN GUANGHE ELECTRONICS TECH

Plate discharging device and plate discharging method

ActiveCN112875241ACrawl smoothlyGuaranteed to workSortingConveyor partsControl engineeringProcess engineering

The invention provides a plate discharging device and a plate discharging method. The plate discharging device comprises a 90-degree plate rotating mechanism, a discharging conveying line, a discharging robot, a jacking transferring mechanism, a wrong material storage station, a plate centering mechanism, a moving stopping mechanism and a control module, and the 90-degree plate rotating mechanism, the discharging conveying line, the discharging robot, the jacking transferring mechanism, the wrong material storage station, the plate centering mechanism and the moving stopping mechanism are all electrically connected with the control module. According to the plate discharging device, through the automatic production process, the plate production efficiency is improved, manual participation in production is reduced, the quality loss caused by manual operation can be reduced, and the labor cost is reduced.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

High-altitude wall decoration device capable of replacing climbing operation

InactiveCN108487614AGuaranteed to operateGuarantee the safety of lifeBuilding constructionsBrickEngineering

Owner:闫光

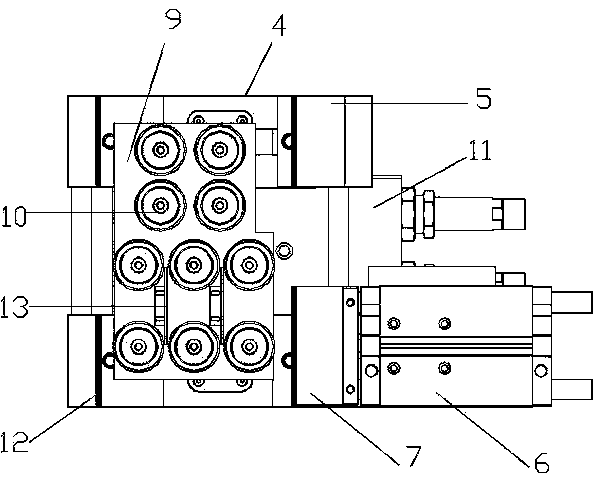

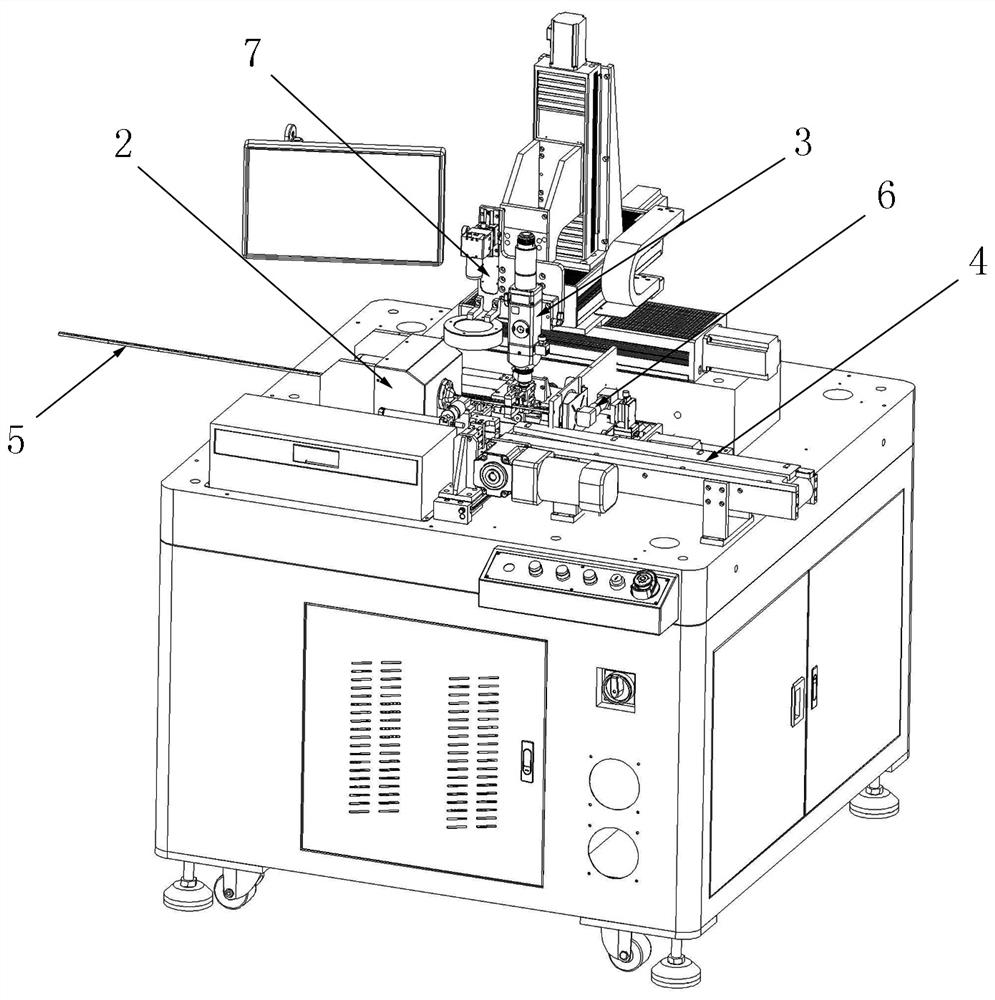

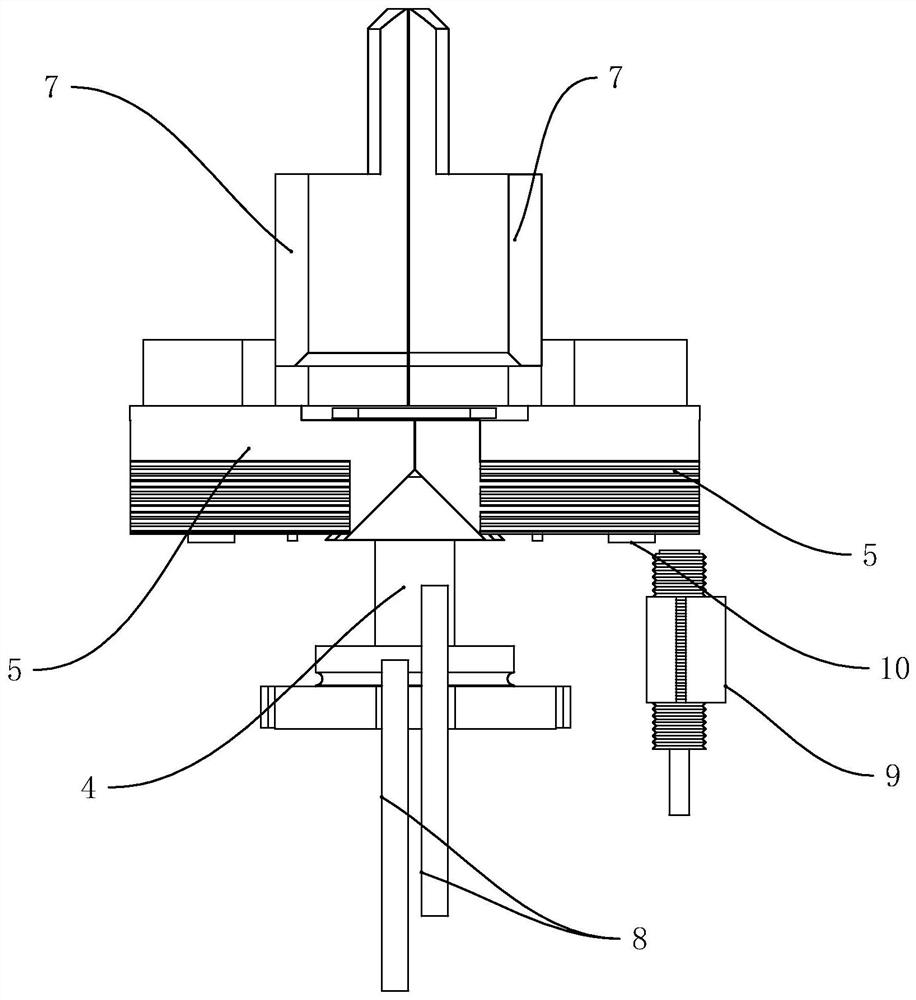

Automatic bolt distributing and feeding mechanism

PendingCN108098296AImprove work efficiencyReduce labor intensityMetal working apparatusMechanical engineeringUltimate tensile strength

The invention discloses an automatic bolt distributing and feeding mechanism and belongs to the field of assembly of clamps. The automatic bolt distributing and feeding mechanism structurally comprises a vibration disk, a main material channel, an automatic material distributing mechanism, two branch material channels, automatic grabbing and feeding mechanisms, a clamp positioning mechanism and asupporting frame; the tail end of the vibration disk is connected with the main material channel; the two branch material channels are symmetrically arranged on the left side and the right side of therear portion of the supporting frame; the automatic material distributing mechanism is arranged between the main material channel and the branch material channels; the automatic grabbing and feedingmechanisms and the clamp positioning mechanism are arranged on the supporting frame; and the automatic grabbing and feeding mechanisms are arranged on the rear portions of the branch material channelsand the upper portion of the clamp positioning mechanism. Compared with the prior art, the automatic bolt distributing and feeding mechanism has the characteristics of replacing manual operation, achieving automatic assembly of fire fighting pipe clamps, improving the working efficiency, relieving labor intensity of workers and the like, thereby having the great application and popularization value.

Owner:山东爱通代代良智能科技有限公司

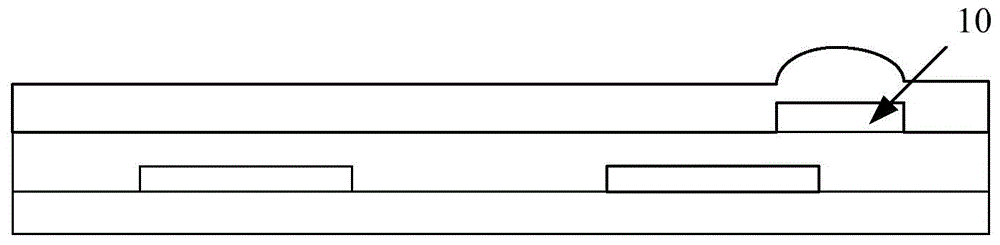

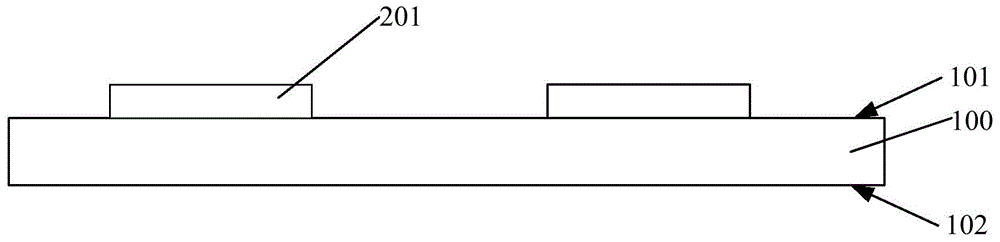

Semiconductor structure and forming method thereof

ActiveCN106185790ACrawl smoothlyImprove reliabilityDecorative surface effectsSolid-state devicesTectorial membraneSemiconductor structure

The invention relates to a semiconductor structure and a forming method thereof. The forming method for the semiconductor structure comprises the following steps of: providing a substrate, which is provided with a first surface and a second surface opposite to the first surface; forming a first device on the first surface of the substrate; forming a buffer layer covering the first surface of the substrate and the first device; and sticking a protective film on the surface of the buffer layer, wherein the protective film is provided with a hole structure; and the hole structure comprises multiple holes. By means of the forming method for the semiconductor structure, gas bump formed between the buffer layer and the protective film can be avoided; and the protection performance of the protective film and the reliability when the substrate is grabbed by a machine in a following process can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

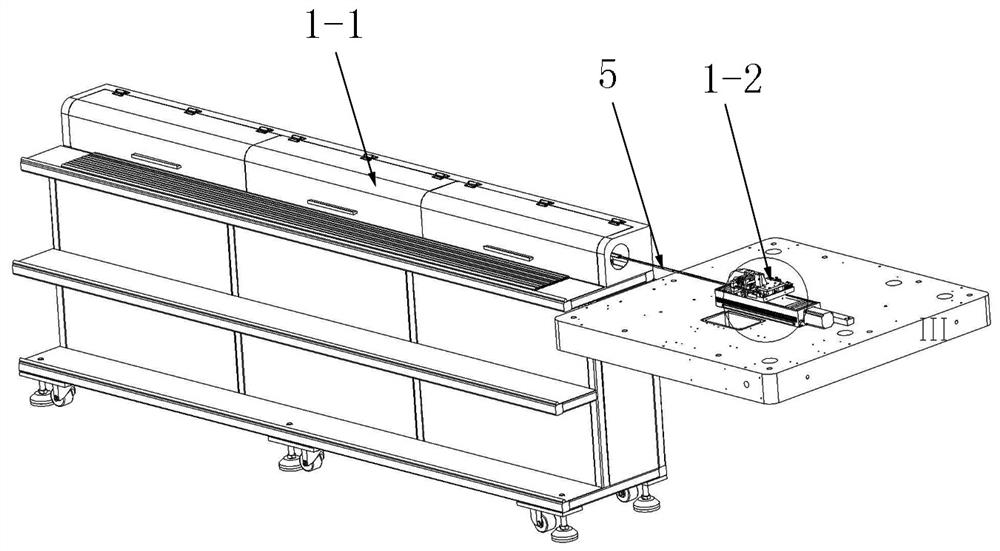

Strip-shaped workpiece automatic inspection device

PendingCN110125027AGuaranteed continuitySolve pain points and difficultiesSortingEngineeringMechanical engineering

The invention relates to a strip-shaped workpiece automatic inspection device. The strip-shaped workpiece automatic inspection device comprises a multi-station bin, a grabbing device and an inspectiondevice. An inspection station and a storage station are arranged on the inspection device. The grabbing device comprises two material grabbing claws, one of the material grabbing claws firstly grabsone front strip-shaped workpiece on the multi-station bin, places the strip-shaped workpiece onto the inspection station, and then grabs a rear strip-shaped workpiece on the multi-station bin, thereafter the other material grabbing claw grabs the front strip-shaped workpiece with inspection completed on the inspection station according to the inspection result, and places the front strip-shaped workpiece onto the storage station or a discharging station which is used for conveying materials to the next station, and at last, one of the material grabbing claws places the grabbled rear strip-shaped workpiece on to the inspection station for inspection. According to the strip-shaped workpiece automatic inspection device, after the grabbing device automatically grabs the strip-shaped workpieceon the multi-station bin, can go on to grab the strip-shaped workpiece on the inspection station, and the production efficiency is greatly improved.

Owner:GUILIN GUANGLU MEASURING INSTR CO LTD

Fully automatic sponge glue-rolling composite assembly line

PendingCN110370774AFully automatedReduce manual laborLaminationLamination apparatusEngineeringAssembly line

The invention relates to a fully automatic sponge glue-rolling composite assembly line, which comprises a composite rack. A glue rolling station, a compositing station, a press-fit station and a transferring station are sequentially distributed on the composite rack in the conveying direction of sponges; the glue rolling station comprises a glue-rolling conveying part and a sponge glue-rolling machine; the compositing station comprises a composite conveying part, a detection mechanism and a sponge grasping mechanism, wherein the composite conveying part comprises a main sponge conveying part arranged on the composite rack and an auxiliary sponge conveying part arranged on the lateral side of the composite rack; the press-fit station comprises a press-fit conveying part and a sponge composite press; and the transferring station comprises a transferring conveying platform. The fully automatic sponge glue-rolling composite assembly line has the advantages that the glue rolling station, the compositing station, the press-fit station and the transferring station which are distributed side by side are adopted, the detection mechanism is matched, thus the positions of the main sponge andthe auxiliary sponge are detected, the two sponges are automatically fitted through the sponge grasping mechanism, whole sponge compositing automation is achieved, and manual labor is effectively reduced.

Owner:南通恒康数控机械股份有限公司

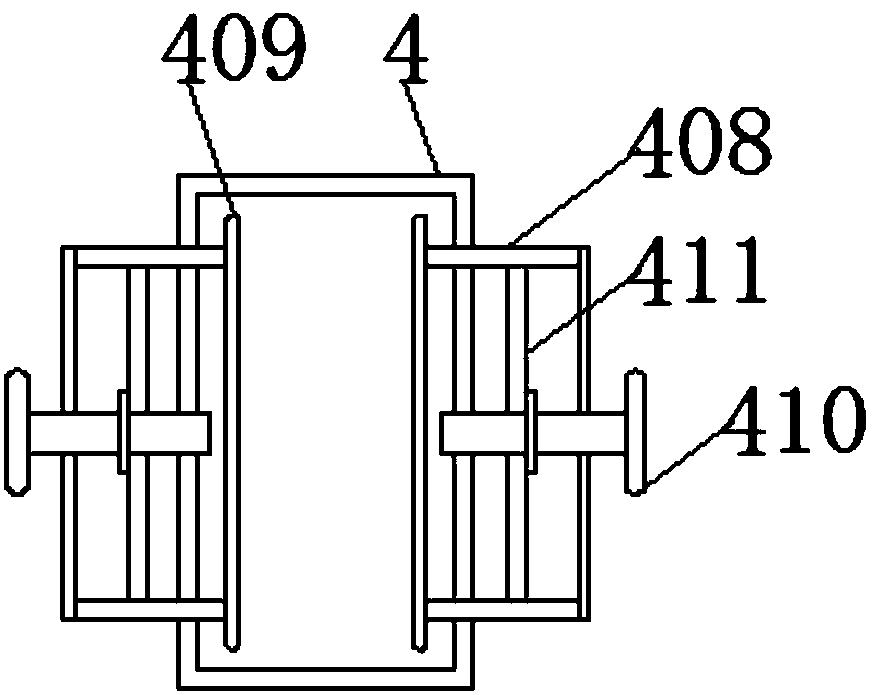

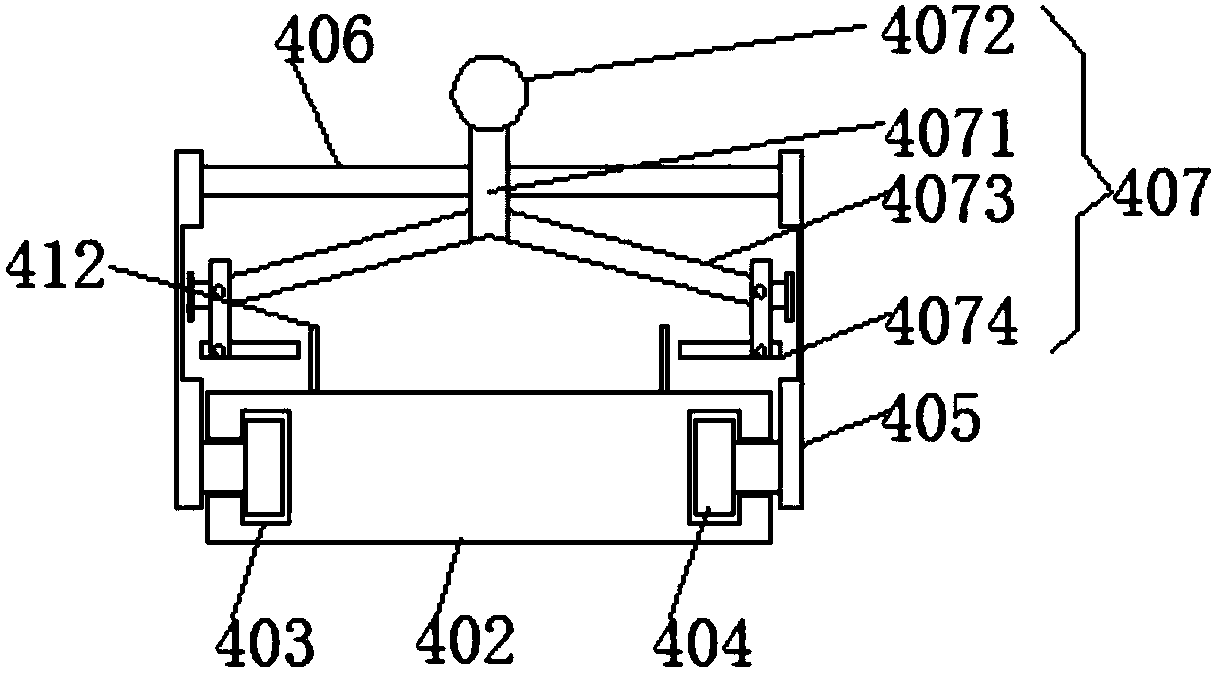

Floating lifting appliance and battery replacing equipment

PendingCN114368670ACrawl smoothlyEasy to grabLoad-engaging elementsEngineeringMechanical engineering

The invention provides a floating lifting appliance and battery replacing equipment, and the floating lifting appliance comprises a first tool, a second tool, a connecting piece, a posture adjusting assembly and a grabbing assembly; the first tool is movably connected with the second tool through a connecting piece, the posture adjusting assembly is clamped between the first tool and the second tool, and the grabbing assembly is arranged on the side, away from the first tool, of the second tool. And under the driving of the posture adjusting assembly, the second tool can deflect relative to the first tool. Under the driving of the posture adjusting assembly, the second tool can deflect relative to the first tool, that is, the levelness of the second tool can be adjusted, so that the levelness of the second tool is the same as that of the to-be-grabbed object, and the grabbing assembly can grab the to-be-grabbed object smoothly. According to the floating lifting appliance, the grabbing assembly can be adjusted to be parallel relative to the to-be-grabbed object according to the levelness of the to-be-grabbed object, the floating lifting appliance can adapt to various complex working conditions, grabbing and lifting are convenient, and the lifting efficiency is high.

Owner:三一锂能有限公司

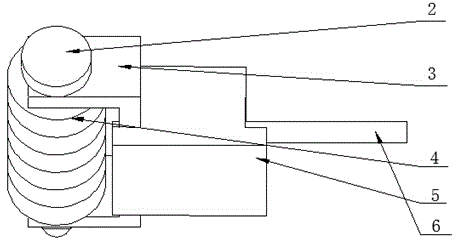

Device and process for roll coating inner wall of pipe part

ActiveCN108940749ACompact structureReasonable structurePretreated surfacesCoatingsEngineeringElectric control

The invention relates to a device and a process for roll coating the inner wall of a pipe part. The device comprises multiple electric control cabinets arranged in parallel at intervals, wherein a working table is arranged on the top parts of the electric control cabinets; a frame is arranged on the upper surface of the working table; multiple fans are arranged on the top part of the frame; and multiple groups of drying mechanisms, glue rolling mechanisms, detecting devices and three-axle linkage manipulators are arranged at one end of the upper surface of the working table in the frame in parallel at intervals from back to front. The work reliability is good, the glue coating operation of the inner wall surface of the pipe part can be conveniently accomplished, and the work efficiency ishigh.

Owner:无锡牧宇智能科技有限公司

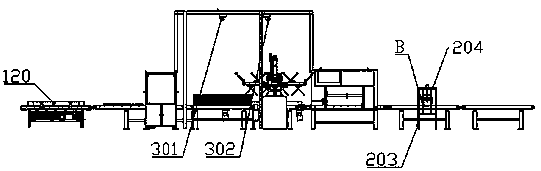

High-precision special pipe laser cutting equipment

ActiveCN113695765AEnsure initial angular positioning accuracyAvoid stickingMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses high-precision special pipe laser cutting equipment. The high-precision special pipe laser cutting equipment comprises a feeding mechanism, a clamping and rotating mechanism, a laser cutting device and a discharging mechanism, the feeding mechanism is used for clamping a to-be-cut product and conveying the to-be-cut product to the clamping and rotating mechanism, the clamping and rotating mechanism is used for clamping the to-be-cut product to rotate, the laser cutting device cooperates with the clamping and rotating mechanism and is used for providing cutting laser beams, and the discharging mechanism is used for discharging the cut product. The high-precision special pipe laser cutting equipment is characterized in that a first positioning mechanism is arranged by corresponding to the advancing end of the to-be-cut product, and the first positioning mechanism comprises a first image acquisition device used for acquiring an end image of the to-be-cut product; and a second positioning mechanism is arranged by corresponding to the laser cutting side of the to-be-cut product, and the second positioning mechanism comprises a second image acquisition device used for acquiring an image of the cut side of the to-be-cut product. The high-precision special pipe laser cutting equipment has the advantage of being higher in cutting precision, the initial angle positioning precision before cutting reaches 0.05 degree, and the positioning precision during cutting reaches 0.01 mm.

Owner:广东国玉科技股份有限公司

Sealing ring grabbing device and system and sealing ring forming and assembling system

The invention provides a sealing ring grabbing device and system and a sealing ring forming and assembling system, and relates to the technical field of sealing ring assembly. The sealing ring grabbing device comprises: a grabbing clamp lower working platform, wherein the working surface thereof is provided with a plurality of contact pin through holes and vacuum adsorption air holes; a grabbing clamp upper working platform provided with a plurality of grabbing contact pins suitable for penetrating through the contact pin through holes in the grabbing clamp lower working platform; a first driving mechanism used for driving the grabbing clamp upper working platform to move in the direction close to the grabbing clamp lower working platform, so that the grabbing contact pins penetrate out of the contact pin through holes to be inserted into the sealing rings, or the grabbing clamp upper working platform is driven to move in the direction away from the grabbing clamp lower working platform, so that the grabbing contact pins are retreated from the sealing rings and then drive the grabbing clamp lower working platform to move together; and a limiting mechanism. The technical problems that in the prior art, a sealing ring grabbing device is poor in reliability, and a sealing ring is prone to partially or integrally falling off in the grabbing or transferring process are solved.

Owner:北京新研创能科技有限公司

Robot grabbing device

PendingCN112372624AJudgment accuracyCrawl smoothlyProgramme-controlled manipulatorGripping headsStructural engineeringControl theory

The invention discloses a robot grabbing device which comprises a flange and a connecting rod. An air cylinder base is fixed onto the connecting rod; an air cylinder is fixed onto the air cylinder base; a pair of sliding blocks are arranged on the air cylinder base in a sliding mode; the telescopic end of the air cylinder is connected with the two sliding blocks in a sliding mode through a pair ofsliding grooves distributed in a V shape; the air cylinder can control the two sliding blocks to be separated or close through stretching and retracting; each sliding block is provided with a connecting plate; each connecting plate is provided with a grabbing finger deviating from the center of the corresponding connecting rod; the air cylinder base is provided with a pair of electromagnetic induction switches for detecting the stretching and retracting distance of the air cylinder; a proximity switch for detecting the moving distance of one sliding block is further arranged on the air cylinder base; and a detection block matched with the proximity switch for detection is arranged on the sliding block detected by the proximity switch.

Owner:宝鸡忠诚机床股份有限公司

Industrial intelligent robot bionic manipulator grabbing equipment

PendingCN114310855AImprove stabilityImprove reliabilityProgramme-controlled manipulatorGripping headsKnuckleHuman body

The industrial intelligent robot bionic manipulator grabbing equipment comprises a supporting frame, a U-shaped fixing base capable of sliding up and down is arranged on the side wall of the supporting frame, a height adjusting mechanism used for driving the fixing base to move up and down is arranged on the supporting frame, and a horizontally-distributed guide rail is fixedly arranged on the fixing base; the three finger mechanisms are used for simulating the thumb, the index finger and the middle finger of a human body, and under the cooperation of the knuckles and the flexible ropes, the three finger mechanisms can be used for simulating the thumb, the index finger and the middle finger of the human body, so that the three finger mechanisms can be used for simulating the thumb, the index finger and the middle finger of the human body. The degree of freedom of all knuckles is achieved, the grabbing stability is greatly improved, reliability is high, and the manipulator is suitable for being widely used and popularized in the society.

Owner:ZHAOQING UNIV

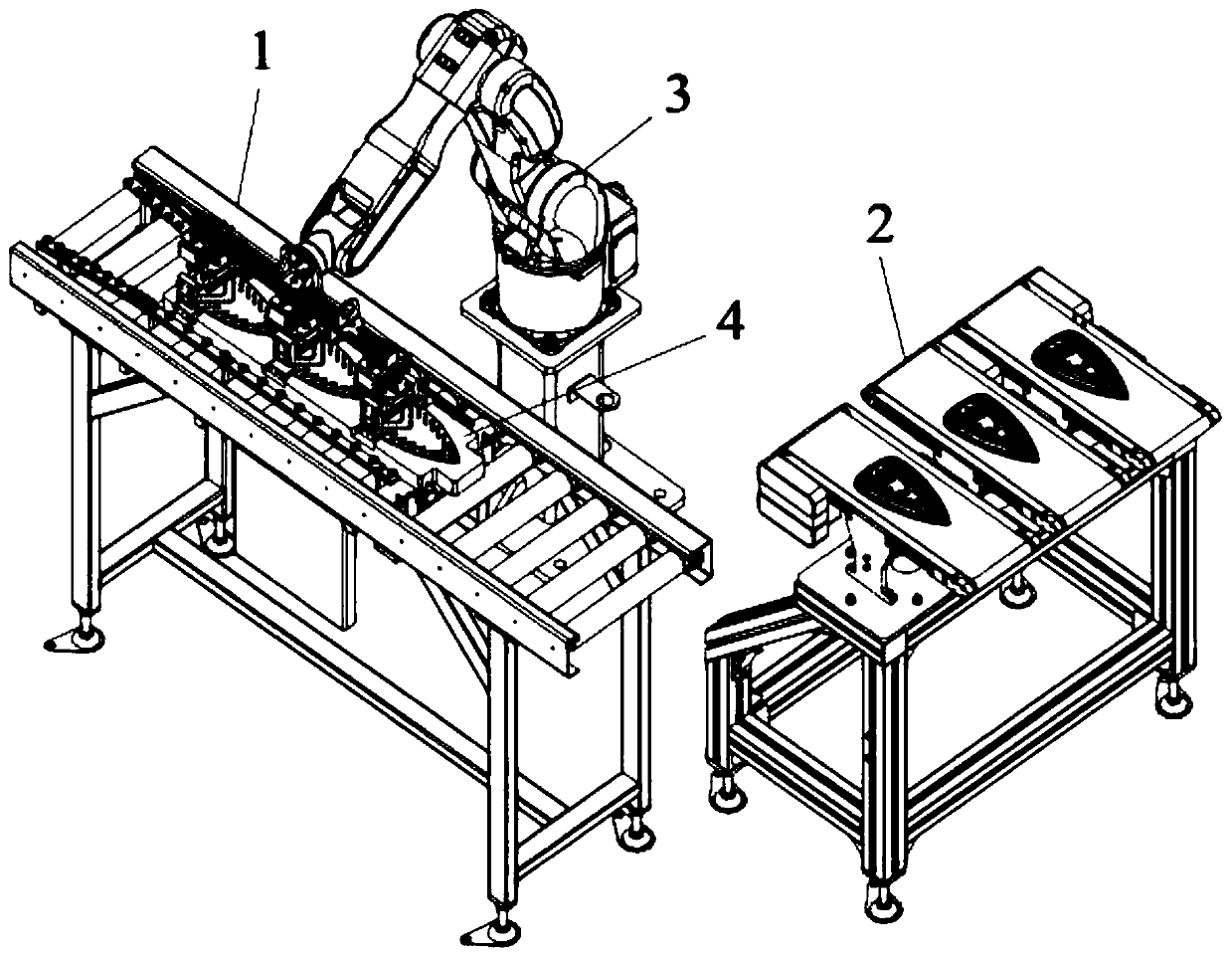

Robot workstation for feeding and discharging iron base plates in space between polishing process and sand blasting process

PendingCN110937392ACrawl smoothlyQuality assuranceAbrasive machine appurtenancesGrinding feedersSand blastingEngineering

The invention relates to a robot workstation for feeding and discharging iron base plates in the space between the polishing process and the sand blasting process. The robot workstation comprises a robot. A transverse installation beam is fixedly arranged at the driving end of the robot. At least one second rotating mechanism which is used for rotating the iron base plates is installed on the bottom side of the transverse installation beam. Clamping mechanisms are installed at the rotating ends of the bottom sides of the second rotating mechanisms, clamping blocks are installed at the two clamping ends of each clamping mechanism, and clamping grooves which are used for clamping the edges of the iron base plates are formed in the inner sides of the clamping blocks. The robot further comprises a first rotating mechanism which fulfills the function of turning over the iron base plates. By the adoption of the robot workstation for feeding and discharging the iron base plates in the space between the polishing process and the sand blasting process, the automatic feeding and discharging operation conducted in the space between the iron base plate bottom surface polishing process and theiron base plate inner cavity sand blasting process is achieved, the manpower is replaced, and the labor cost is reduced. The bump and the surface scratch caused by the manual operation of workers areavoided, the quality of the iron base plates is guaranteed, the processing efficiency of the iron base plates is improved, and the time and the labor are saved.

Owner:HANGZHOU GUOCHEN ROBOT TECH CO LTD

Blank material table for high-speed notching machine

InactiveCN109604426ARealize automatic notchingAchieve separationMetal-working feeding devicesPositioning devicesEngineeringManipulator

The invention discloses a blank material table for a high-speed notching machine. The blank material table comprises a material stack mounting and positioning mechanism for motor blank sheets, motor blank sheet separation device, a blank stack height sensor, a blank material table lifting system and the like. For the blank material table provided by the invention, through the motor blank sheet separation device, separation of a motor blank sheet at the topmost layer between a blank stack is realized, and damages on other motor blank sheets in the grasping process of a manipulator is prevented;through matching use of the blank stack height sensor and the blank material table lifting system, the height of the top surface of a blank stack is guaranteed, and the manipulator is ensured to perform successful grasping; and due to ingenious structure design, very great convenience and rapidness are provide to realization of automatic notching to the motor blank sheet by the high-speed notching machine.

Owner:WUHU ELECTROTECHN MACHINERY

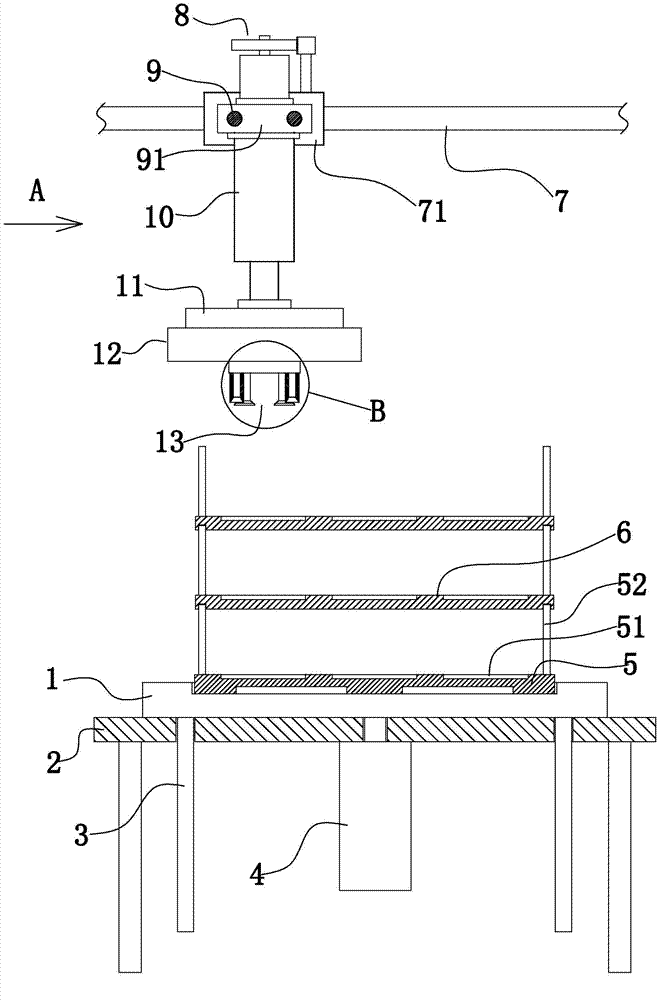

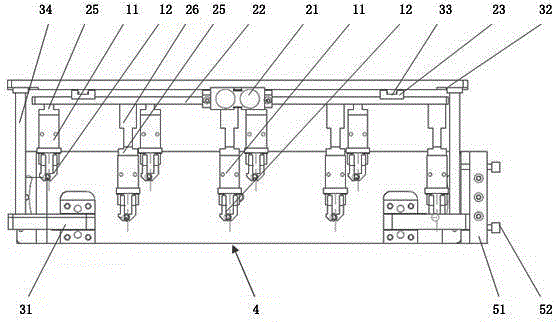

Robot Assembly Fixture

ActiveCN103331598BCrawl smoothlyLow labor intensity of automatic operationMetal working apparatusEngineeringManipulator

The invention provides a manipulator-assembling jig, which can effectively lower the labor intensity and improve the production efficiency, has a simple and reasonable structure and low device cost and is simple to maintain. The manipulator-assembling jig comprises manipulator devices and a pedestal and is characterized in that a plurality of groups of positioning pieces for fixing parts to be machined are arranged on the pedestal, the manipulator devices are installed on a fixed plate, a plurality of groups of manipulator devices are arranged on the fixed plate, the group number of the manipulator devices is equal to that of the positioning pieces, each group of manipulator device comprises manipulators with the number which is equal to that of plug-ins needing to be plugged into the parts to be machined, the fixed plate is connected with and driven by a lifting device to upwards and downwards move, the lifting device is supported on the pedestal through a supporting structure, the manipulator comprises a clamping jaw and a mechanical arm, and the clamping jaw is driven to make forward and backward telescopic movement by the mechanical arm.

Owner:WUXI MATEX PRECISION

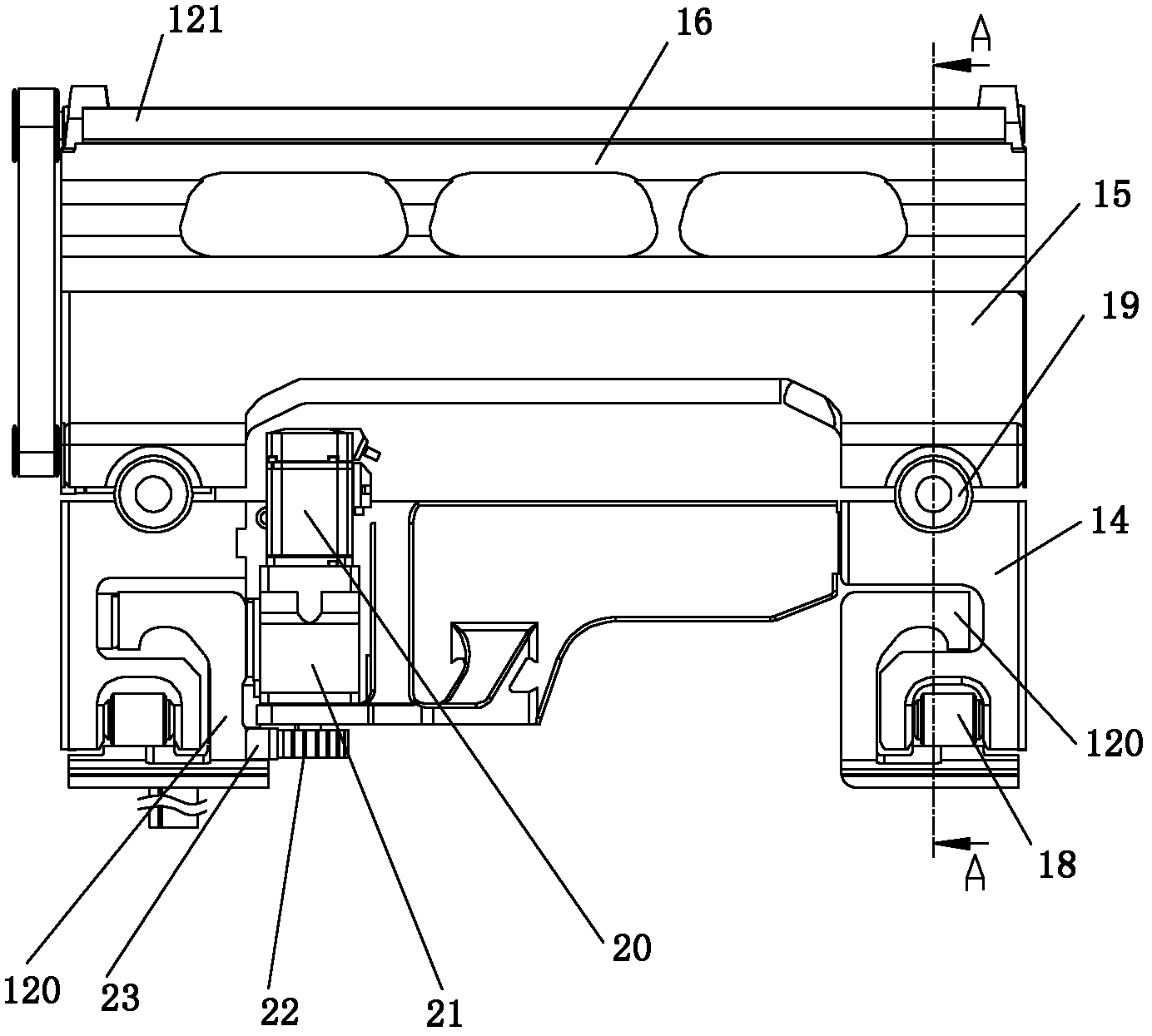

Industrial robot

ActiveCN102658546BCrawl smoothlyMove horizontallyProgramme-controlled manipulatorJointsIndustrial engineeringIndustrial robot

The invention provides an industrial robot, which comprises a base guide rail component, a base component, a large arm component, an engraving and milling component, a wrist component and a claw component, wherein the lower end of the base guide rail component is matched with a guide rail I and can roll along the guide rail I; the lower end of the base component is matched with a guide rail II which is arranged at the upper end of the base guide rail component and can slide along the guide rail II; the base component consists of an upper component and a lower component, wherein the upper component can rotate around the lower component; a shoulder shaft on the large arm component is in floating fit with a shoulder shaft hole formed on the upper part of the upper component, and the large arm component realizes the action of lifting or lowering the arm; the lower part of the engraving and milling component is matched with a guide rail III which is arranged on the side of the large arm component, can slide along the guide rail III and realizes a drilling action; the wrist component is arranged in a mounting hole of the large arm component through a loop bar and finishes the action of lifting and lowering the wrist; and the side of the claw component is matched with a guide rail IV which is arranged on the wrist component, slides along the guide rail IV and realizes the action of opening and closing the claws.

Owner:刘朝龙

Stand-up pouch automatic unloading system and method

The invention discloses an automatic standing-bag unloading system and method. The automatic standing-bag unloading system is characterized in that a bottle unscrambler assembly is arranged at the front end of an automatic standing-bag unloading equipment frame assembly; the automatic standing-bag unloading equipment frame assembly is a mounting support frame of the automatic standing-bag unloading system; sterilization box partition plate pressing devices are arranged on two sides of the automatic standing-bag unloading equipment frame assembly; a horizontal travelling component is arranged at the top of the automatic standing-bag unloading equipment frame assembly; a horizontal gripper fine-adjustment combination is arranged above the horizontal travelling component; sterilization box locking and positioning devices are arranged on two sides of a sterilization box transferring track system; a travel switch is arranged at the bottom of the sterilization box transferring track system; a standing-bag conveyor body is correspondingly arranged near the automatic standing-bag unloading equipment frame assembly; and a vertical lifting component is connected with the automatic standing-bag unloading equipment frame assembly. The automatic standing-bag unloading system can automatically and directly take sterilized standing bag products out of a sterilization box and transfer the sterilized standing bag products onto a conveying line of the standing-bag conveyor body.

Owner:山东科伦药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com