Stand-up pouch automatic unloading system and method

A stand-up pouch, automatic technology, applied in the stand-up pouch automatic bag-down system, plastic packaging large infusion pharmaceuticals, stand-up pouch combing bottle and sterilization box positioning, partition pressing, soft field, can solve the problem that the combing bottle method does not have Involved, did not completely solve the problems of fully automatic bottle unloading, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

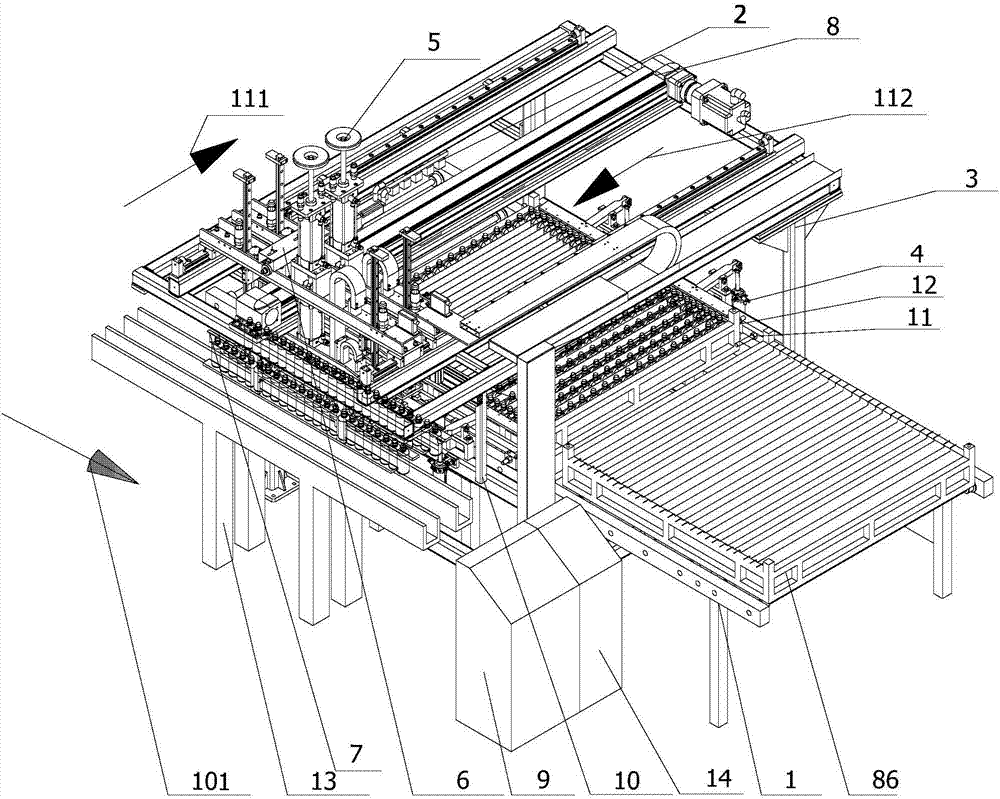

[0025] Such as figure 1 , figure 2 As shown, a stand-up pouch automatic unloading system includes a sterilizing box transfer track system 1, a bottle comb assembly 2, a stand-up pouch automatic unloading equipment frame assembly 3, a stand-up pouch conveyor body 13, and a handle Combination 7 and vertical lifting assembly 5, sterilization box transfer track system 1 is slidably installed with sterilization boxes, and several rows of standable bags are arranged in the sterilization box separated by partitions; The front end of the bag automatic bottle unloading equipment frame assembly 3, the vertical bag automatic bottle unloading equipment frame assembly 3 is the installation support frame of the vertical bag automatic unloading bag system, and the bottle comb assembly 2 is used to clean the bottles in the sterilization box The stand-up pouch can be used for combing and sorting the bottles; on both sides of the stand-up pouch automatic bottle unloading equipment frame assem...

Embodiment 2

[0037] Such as figure 1 , figure 2 As shown, the present invention comprises a sterilizing box transfer track system 1, a stand-up pouch automatic bottle unloading equipment frame assembly 3, and the bottle comb assembly 2 is arranged at the front end of the stand-up pouch automatic bottle unloading equipment frame assembly 3, so The sterilizing box partition pressing device 4 is arranged on both sides of the frame assembly 3 of the stand-up bag automatic bottle-loading equipment, and the horizontal walking assembly 8 is arranged on the top of the frame assembly 3 of the stand-up bag automatic bottle-loading equipment. The hand level fine-tuning assembly 6 is arranged on the upper part of the horizontal walking assembly 8, the photoelectric scanning switch assembly 10 is arranged on the horizontal walking assembly 8 and arranged in parallel with the gripper assembly 7, and the gripper assembly 7 is arranged The lower part of the horizontal walking assembly 8 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com