Robot workstation for feeding and discharging iron base plates in space between polishing process and sand blasting process

A robot and workstation technology, applied to used abrasive processing devices, grinding/polishing equipment, abrasives, etc., can solve problems such as labor-intensive, impacted product quality, workpiece bumps, etc., to ensure safety, avoid Bump and surface scratches, convenient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

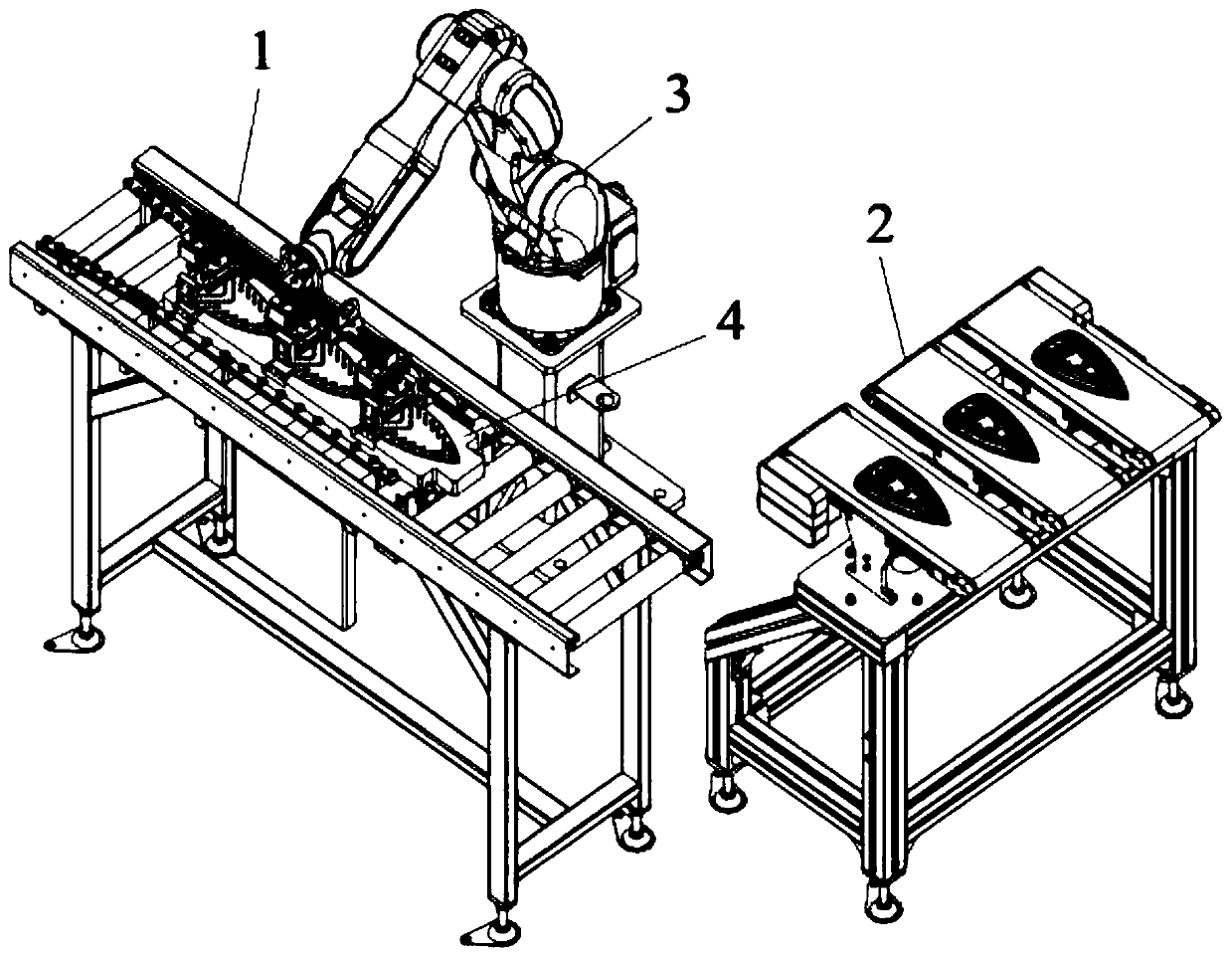

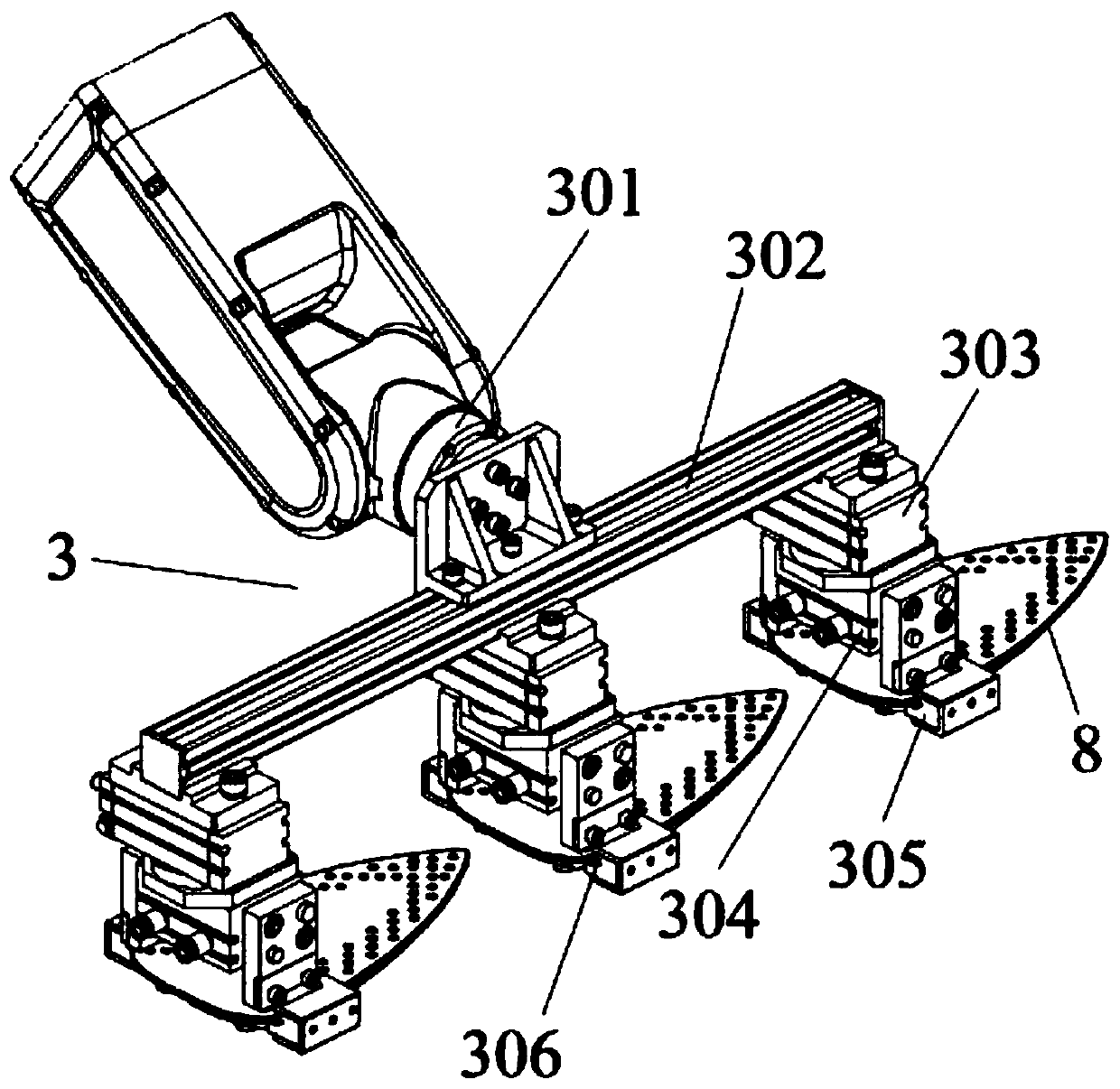

[0026] like Figure 1 to Figure 9 As shown, this embodiment provides a robot workstation for loading and unloading iron soleplates between polishing and sandblasting, which includes a robot 3; the driving end of the robot 3 is fixed with a mounting beam 302; the mounting beam 302 The bottom side is equipped with at least one second rotating mechanism 303 for 90-degree rotation of the soleplate 8 of the iron; the rotating end of the bottom side of the second rotating mechanism 303 is equipped with a clamping mechanism 304; A clamping block 305 is installed on the clamping end; the inner side of the clamping block 305 is provided with a clamping groove 306 for clamping the edge of the soleplate of the iron; .

[0027] In the robot workstation of this embodiment for loading and unloading iron soleplates between polishing and sandblasting, the robot 3 is a six-axis robot.

[0028] In a robot workstation of the present embodiment, which is used for loading and unloading iron sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com