Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Avoid print quality degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

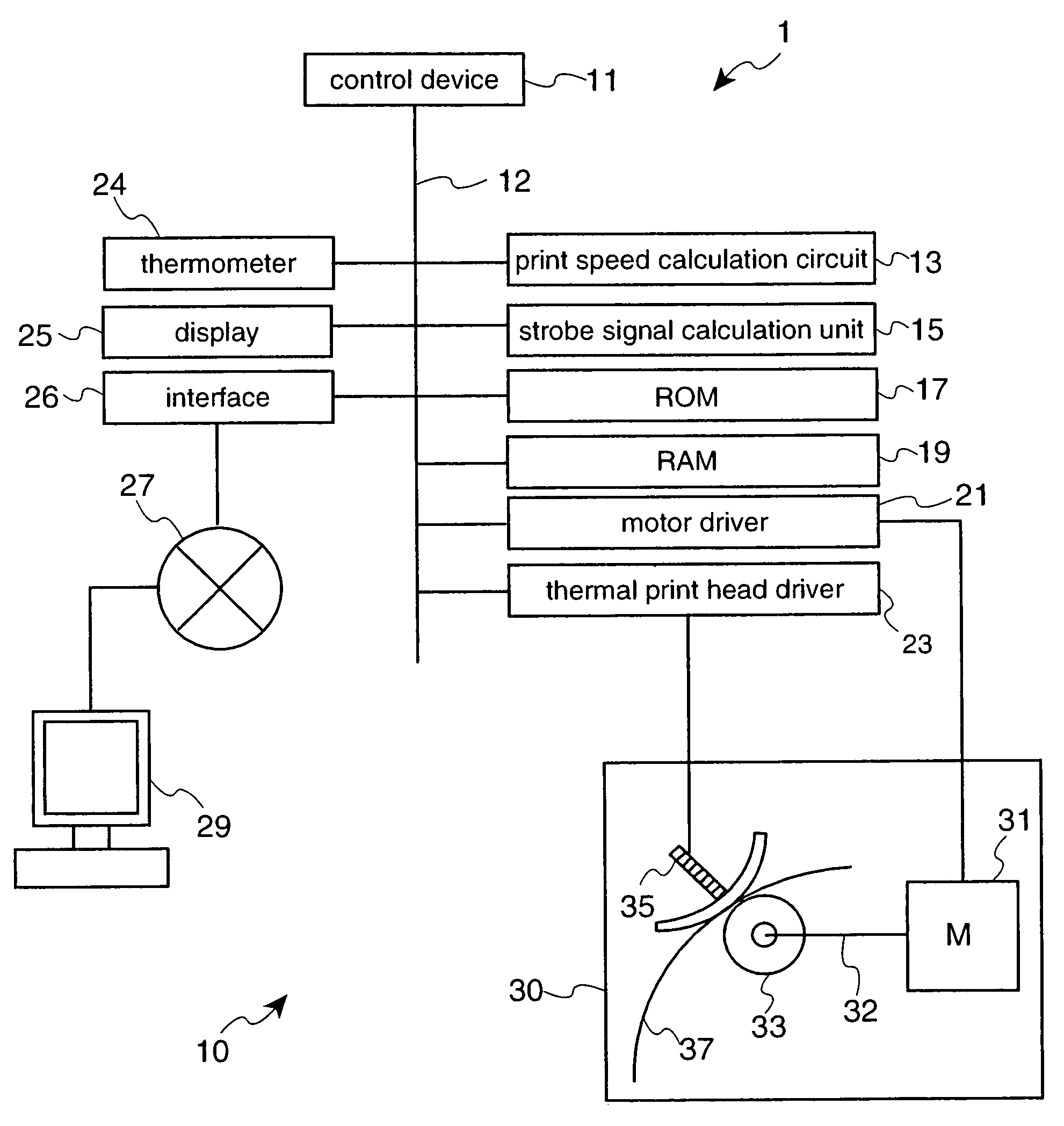

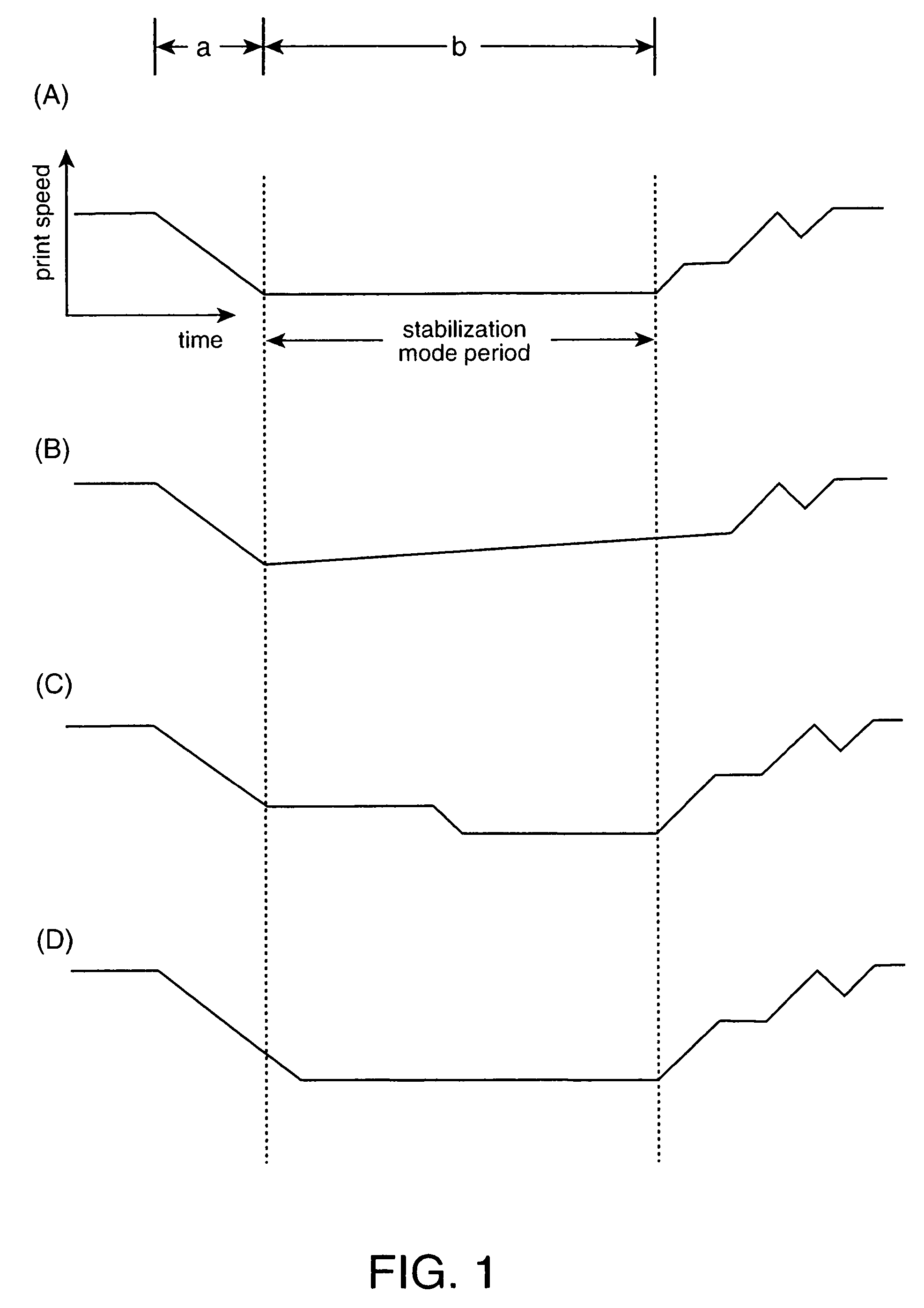

Thermal printer, thermal printer control method, and printing system

ActiveUS20070019061A1Control changesPrint speed to changeRecording apparatusOther printing apparatusComputer printingEngineering

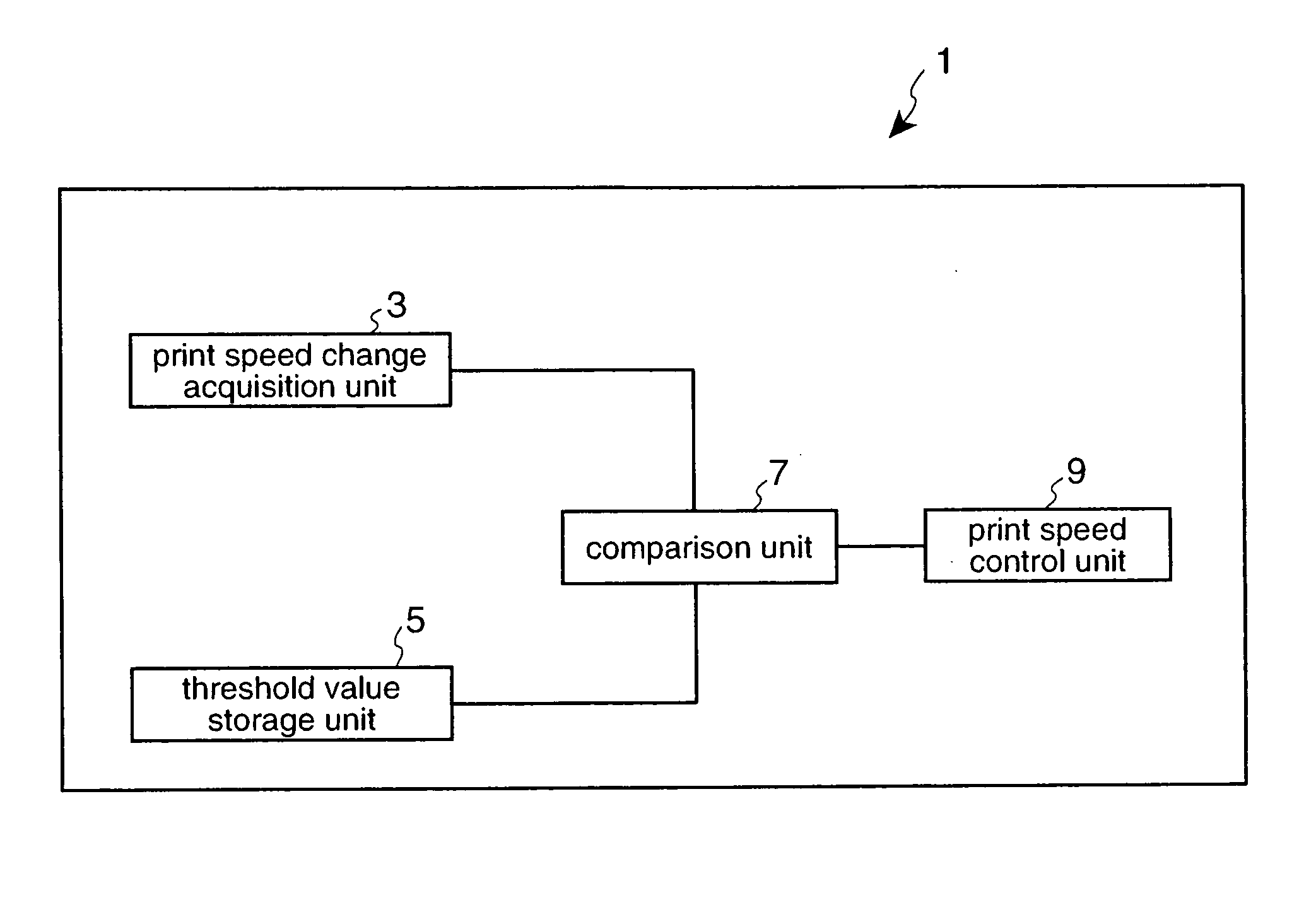

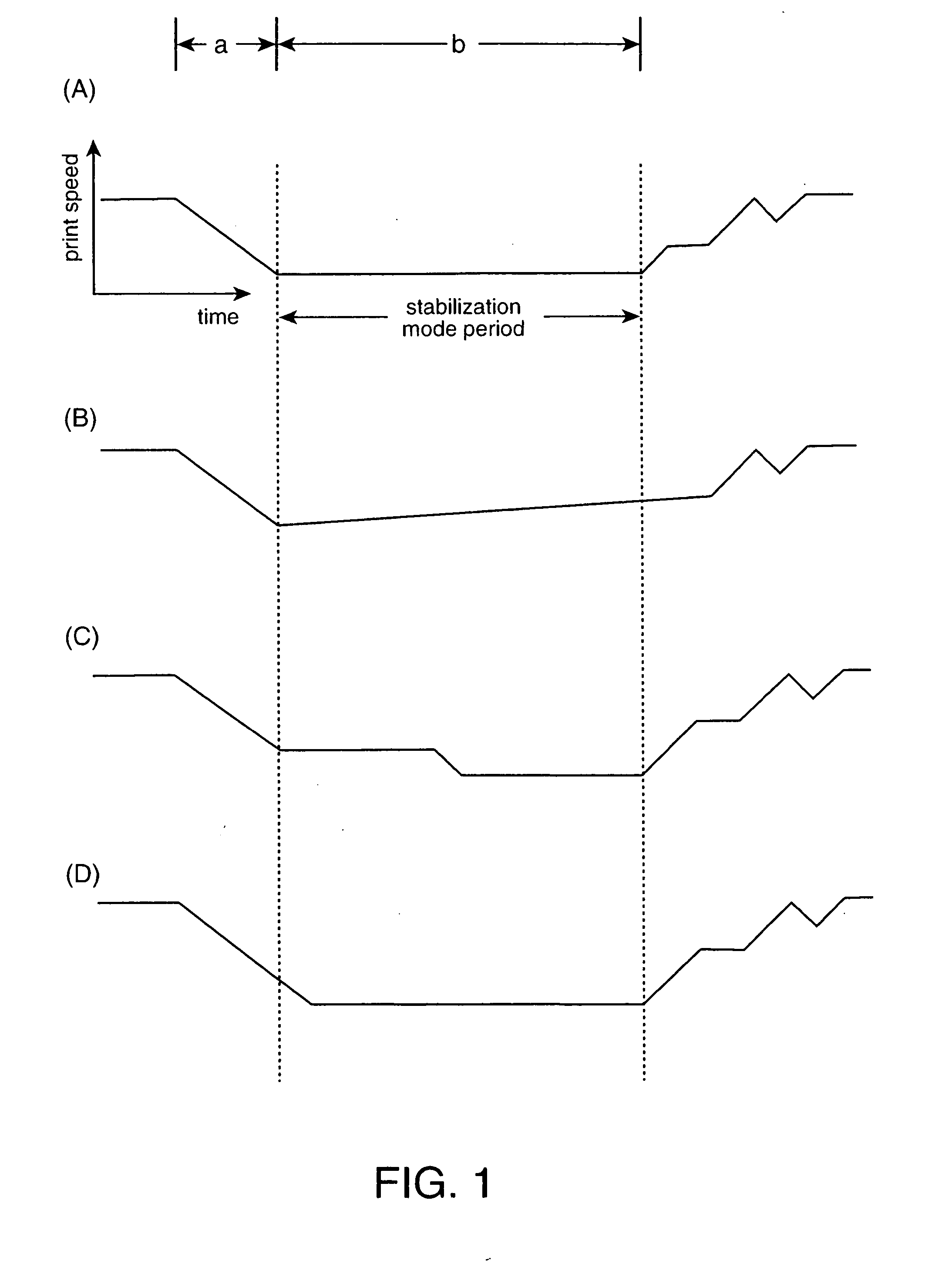

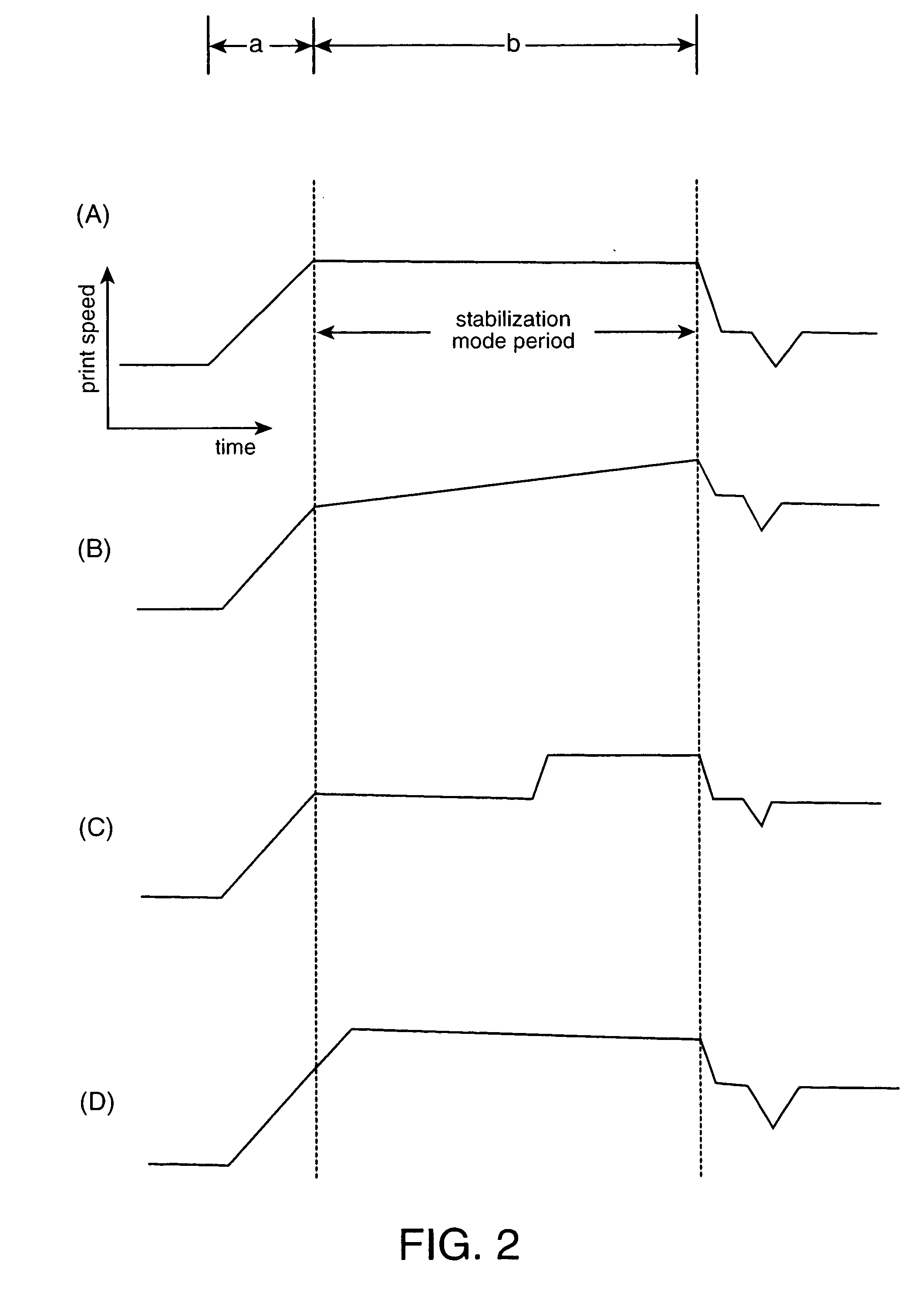

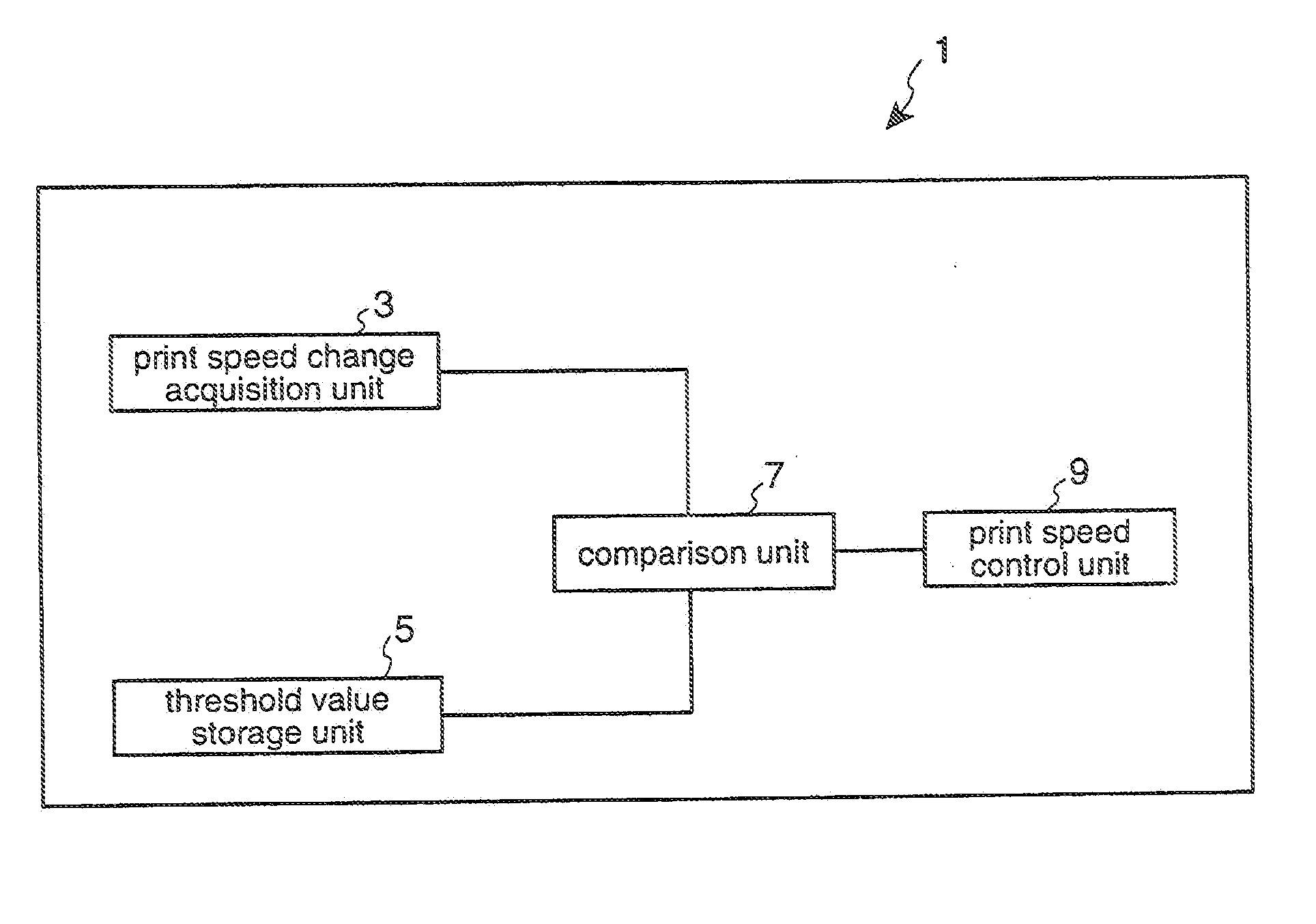

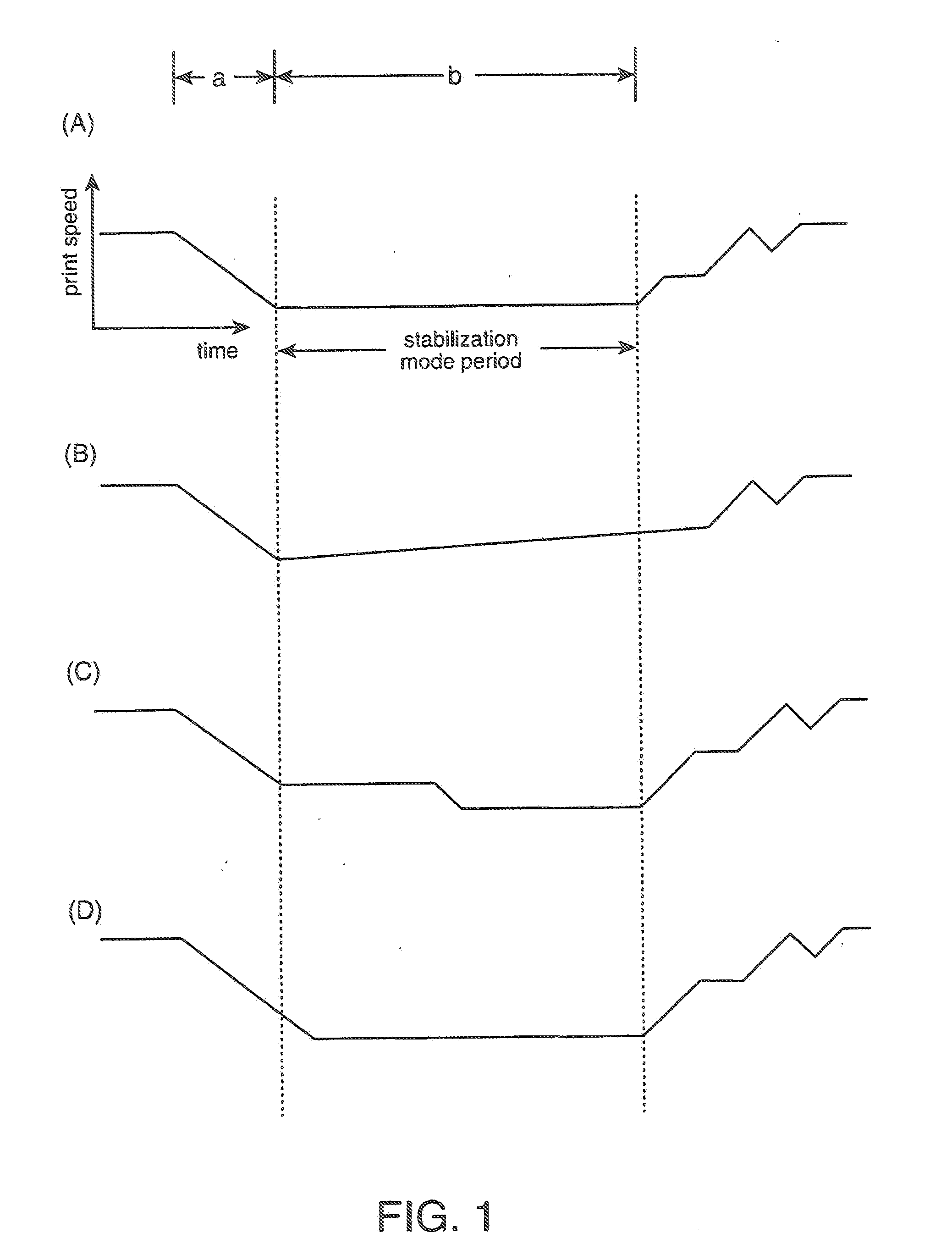

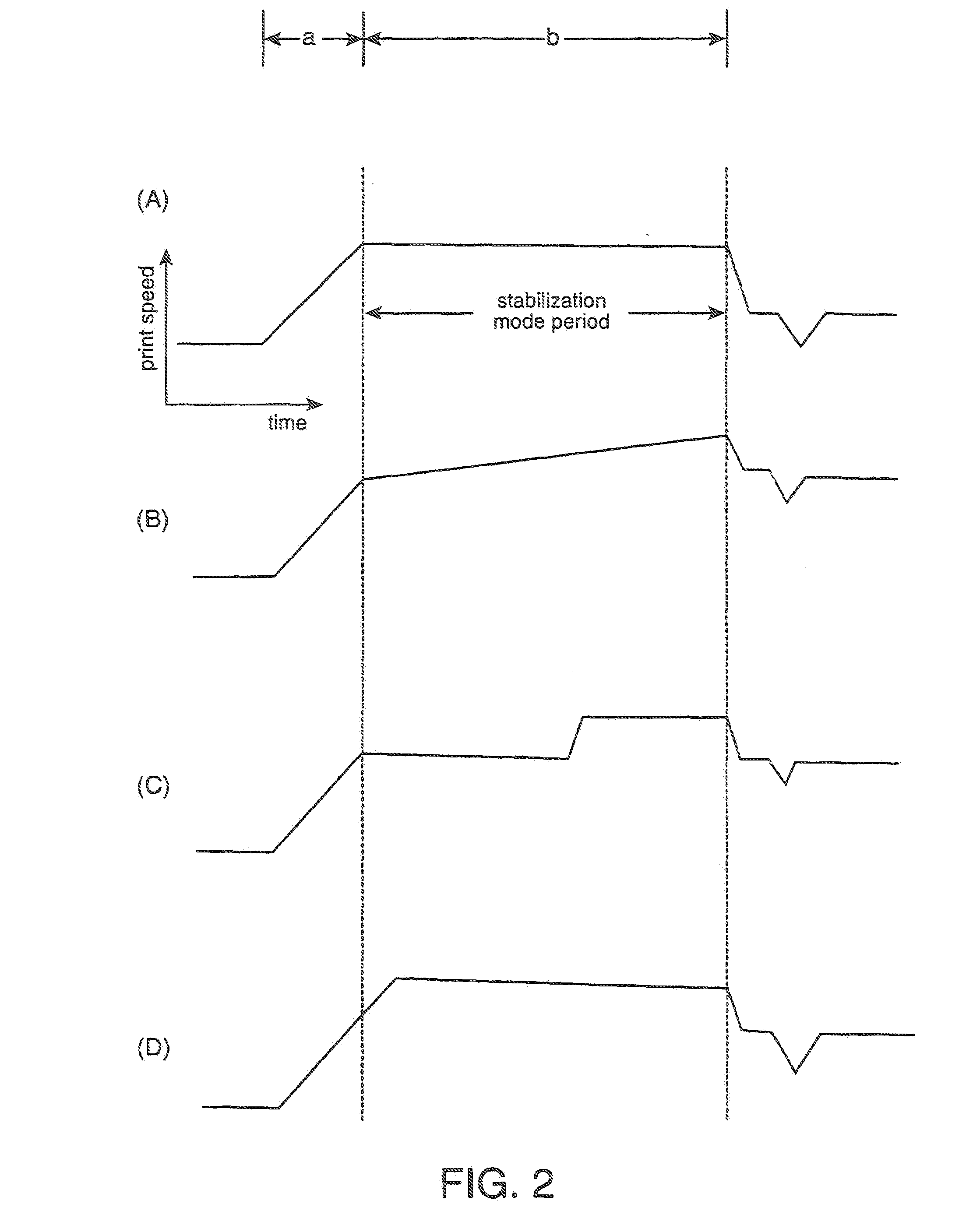

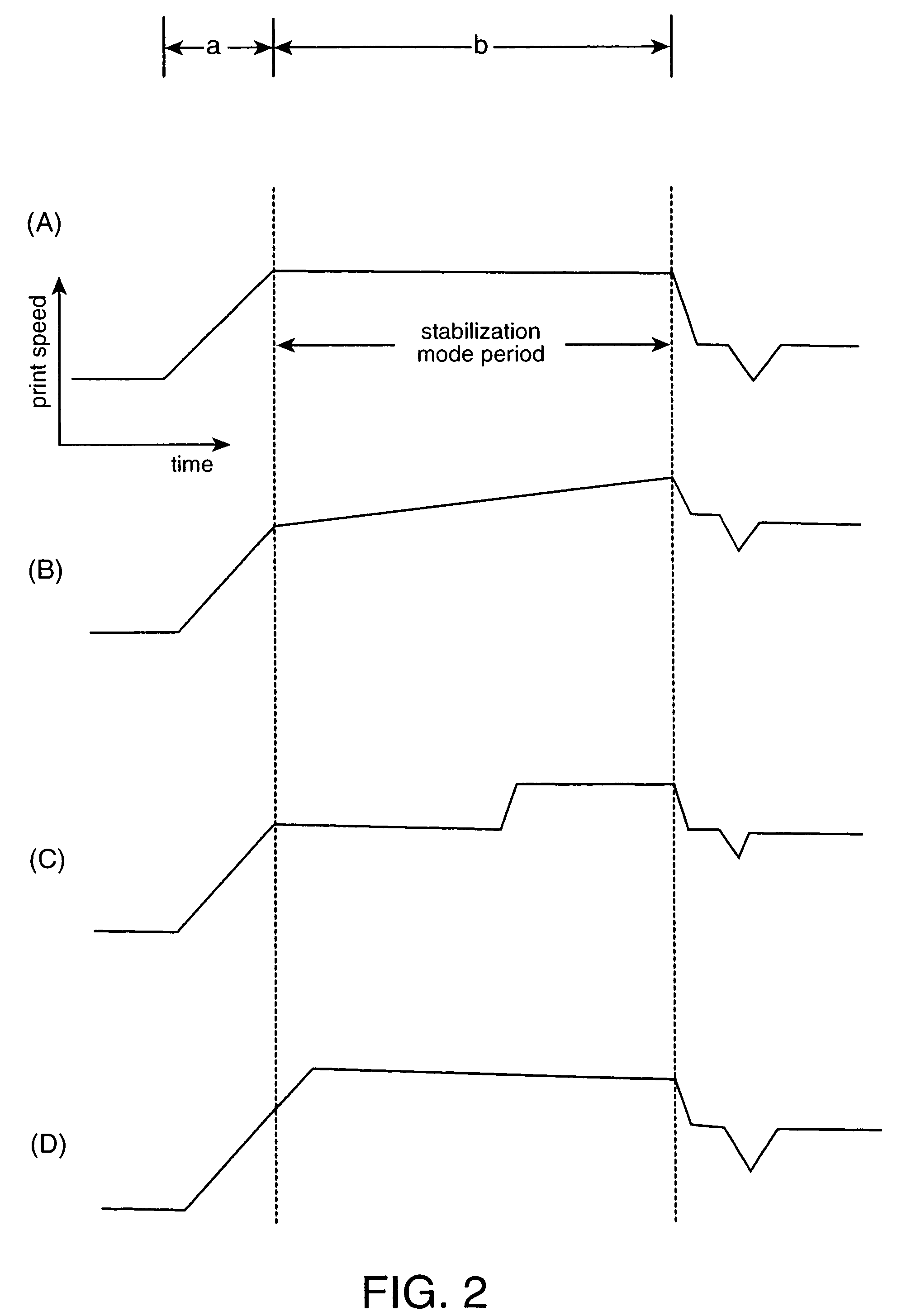

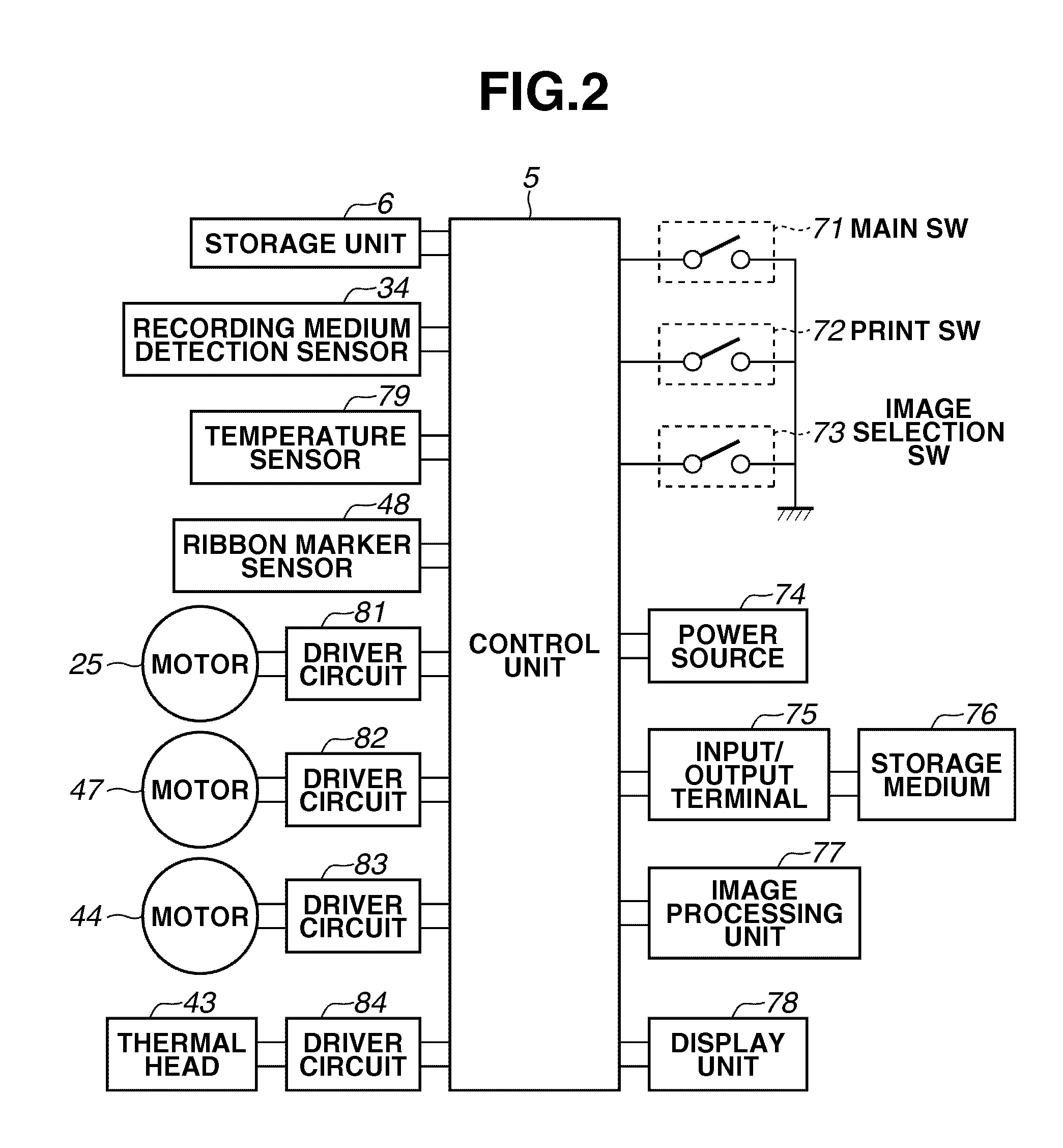

A thermal printer 1 and control method for controlling print speed to prevent variation in printing pitch due to frequent slight changes in the print speed following a significant change in print speed. The print speed, which is the speed at which the print medium i.e., paper is conveyed when printing, is controlled based on known print speed control factors. The thermal printer comprises a paper feed mechanism for conveying the print medium at a controlled print speed passed a thermal print head, a print speed control unit 9 for controlling the print speed of the paper feed mechanism based on the print speed control factors, a print speed change acquisition unit 3 for determining the change in the print speed over a predetermined time, and a comparison unit 7 for determining if the change in print speed exceeds a predetermined threshold value. The print speed control unit 9 limits change in the print speed based on the print speed control factors for a predetermined time after the comparison unit 7 determines that the change in print speed exceeds the threshold value.

Owner:SEIKO EPSON CORP

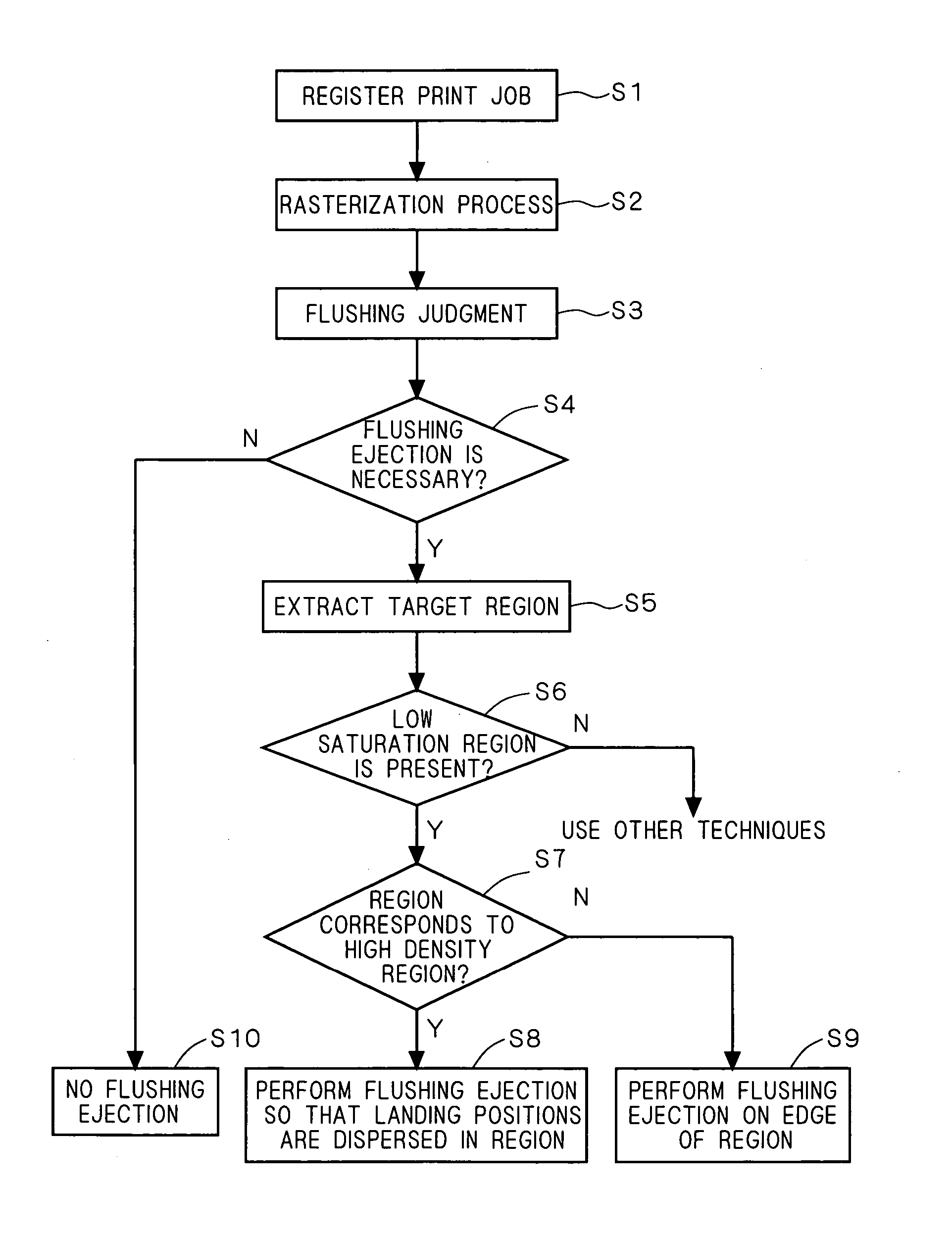

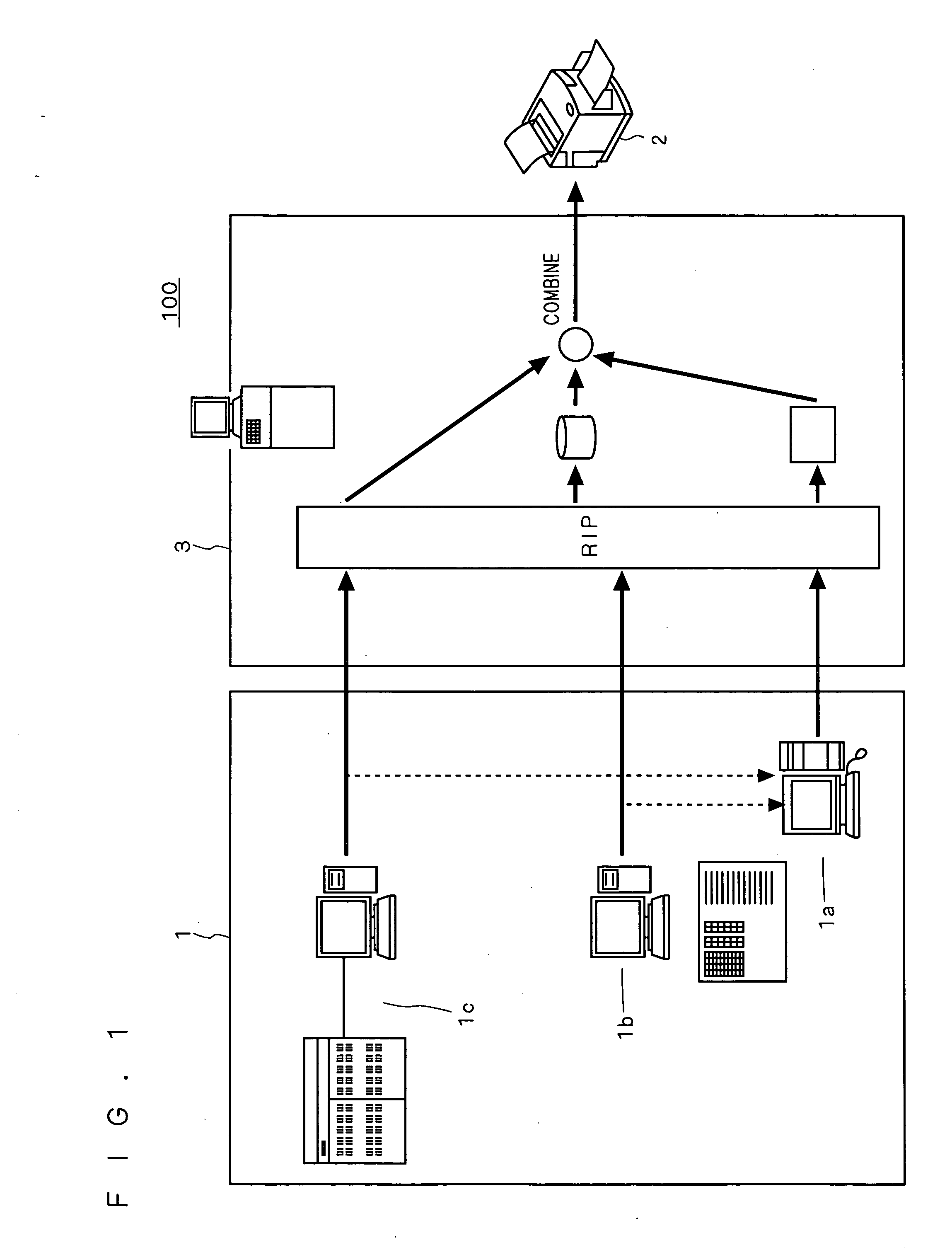

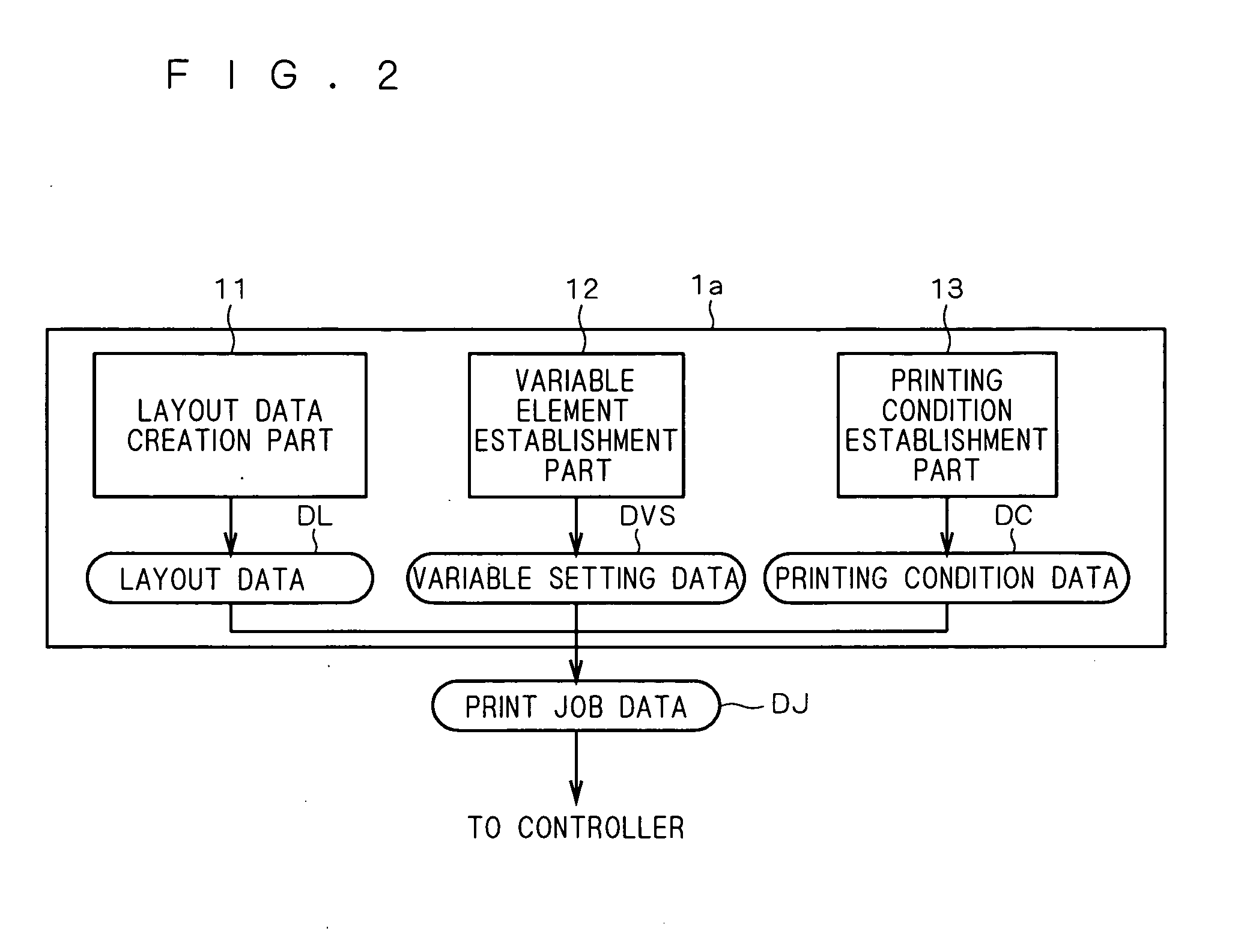

Printing system, controller for printing apparatus, method of executing printing process, and program

InactiveUS20060290739A1Improve processing effectivenessReliable flushingPrintingHigh densityEngineering

For a low saturation and high density region in a printed sheet identified based on rasterized data, flushing ejection is executed, with landing positions dispersed in the above-mentioned region. For a region which is low in saturation but is not high in density, an edge portion of the above-mentioned region is determined as the landing positions. During these processes, the adjustment is additionally made to the ejection from inkjet nozzles for color components which are not to be subjected to the flushing ejection, to thereby maintain the original hue of the above-mentioned region. This achieves the flushing ejection while minimizing the degradation of the quality of the printed sheet. Further, in the variable printing, whether the flushing ejection is necessary or not is judged based on details to be printed on a base page. This causes the execution of the flushing ejection whenever individual printed sheets are produced. Therefore, the print quality is held uniform during the production of a multiplicity of different printed sheets.

Owner:DAINIPPON SCREEN MTG CO LTD

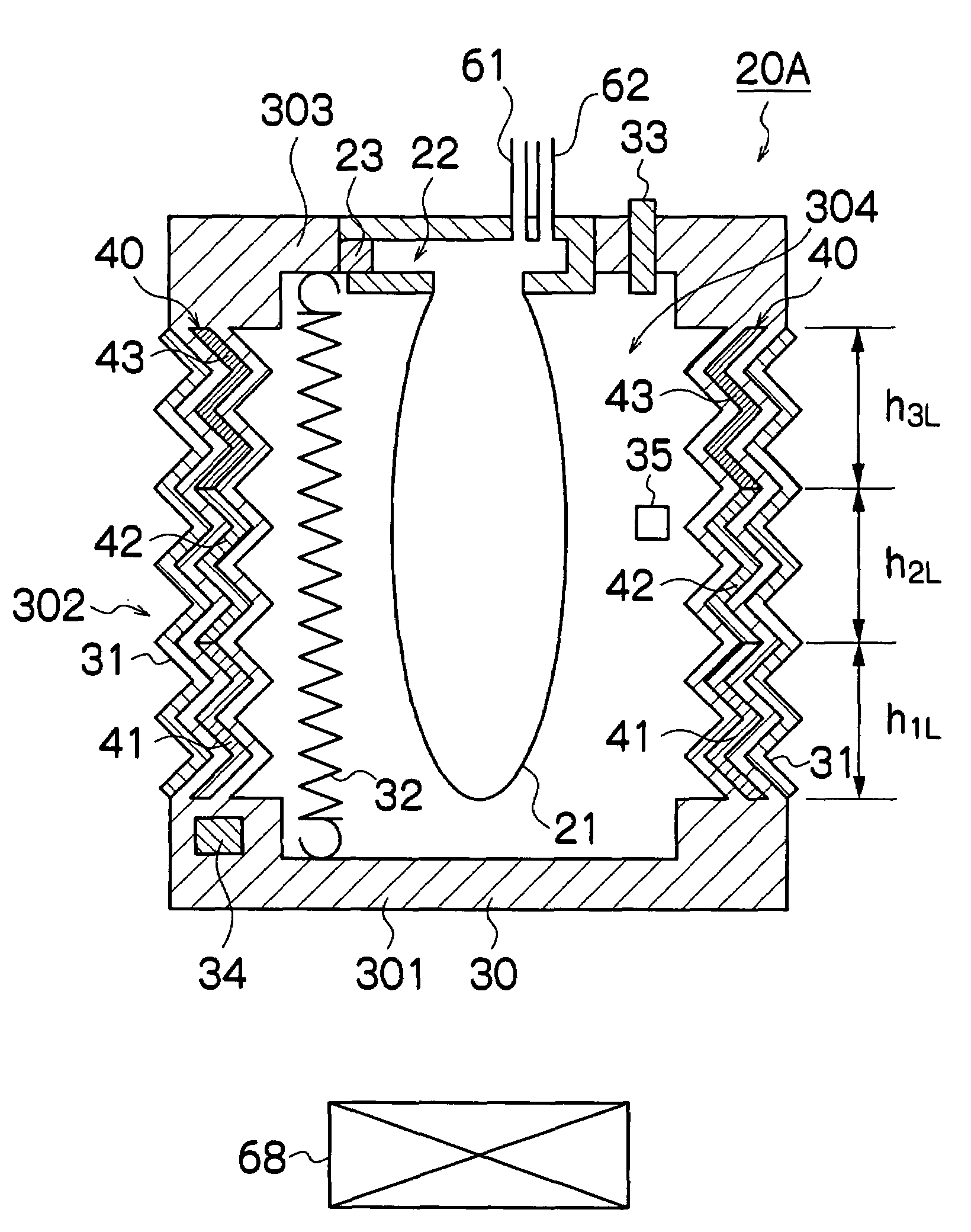

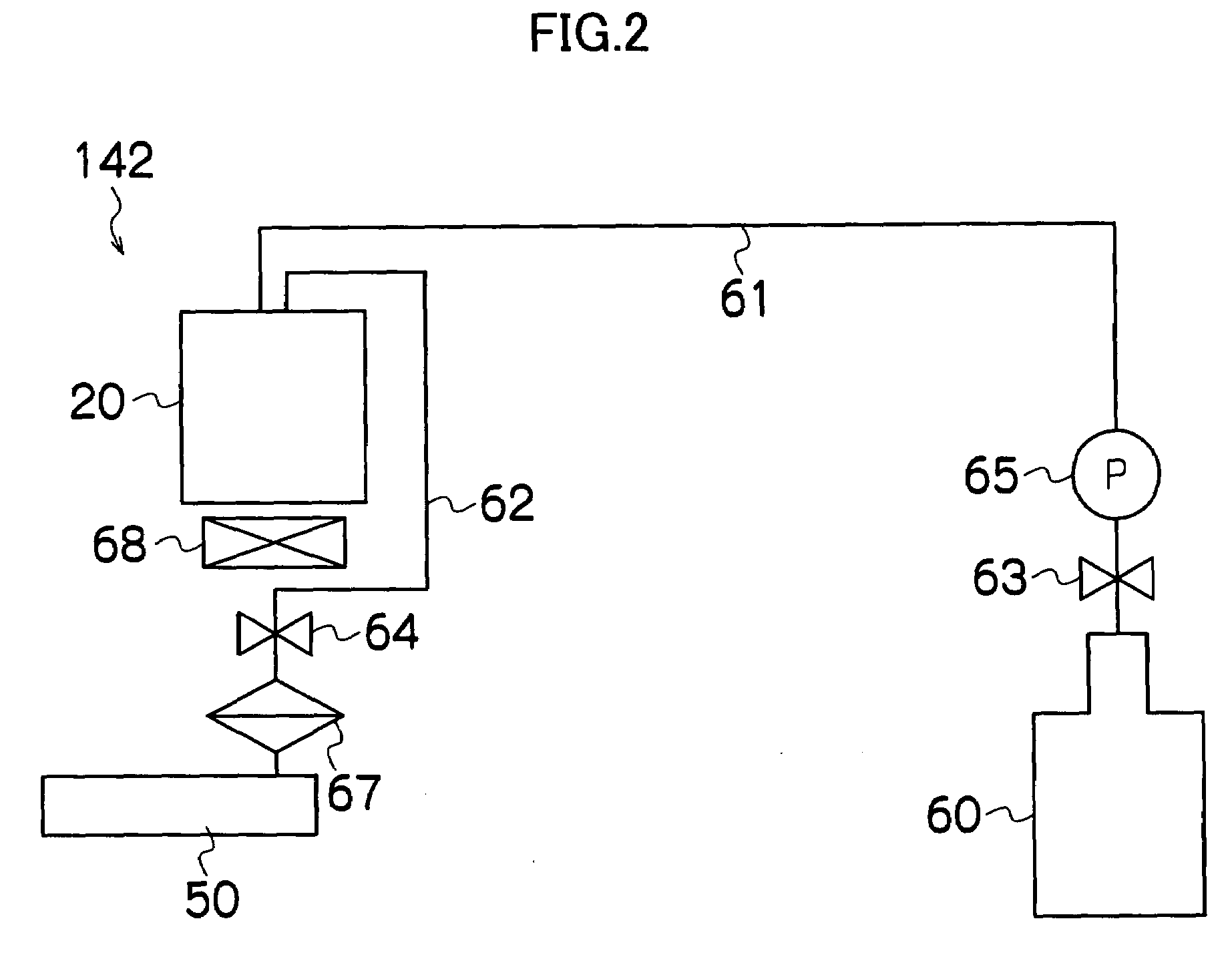

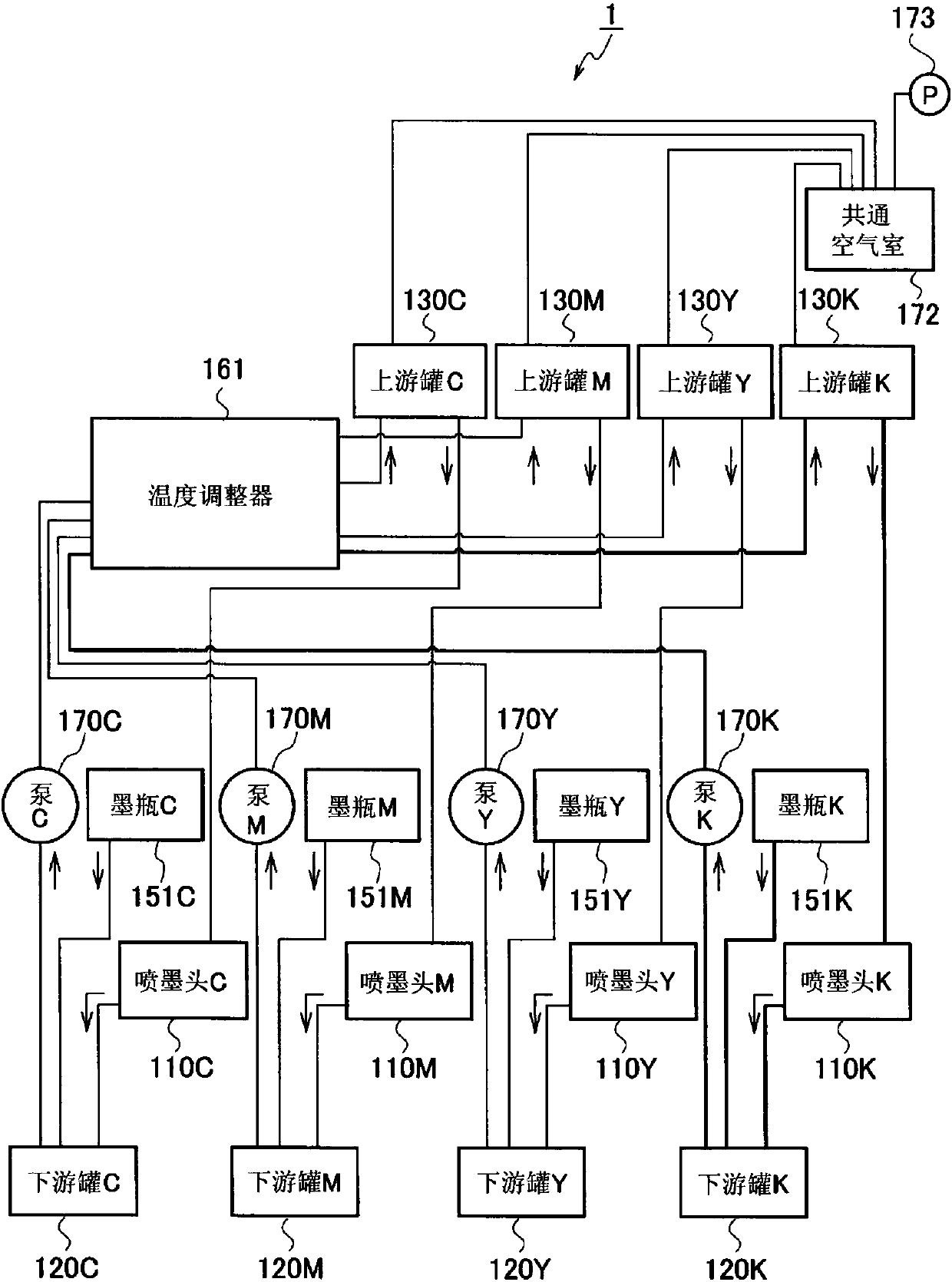

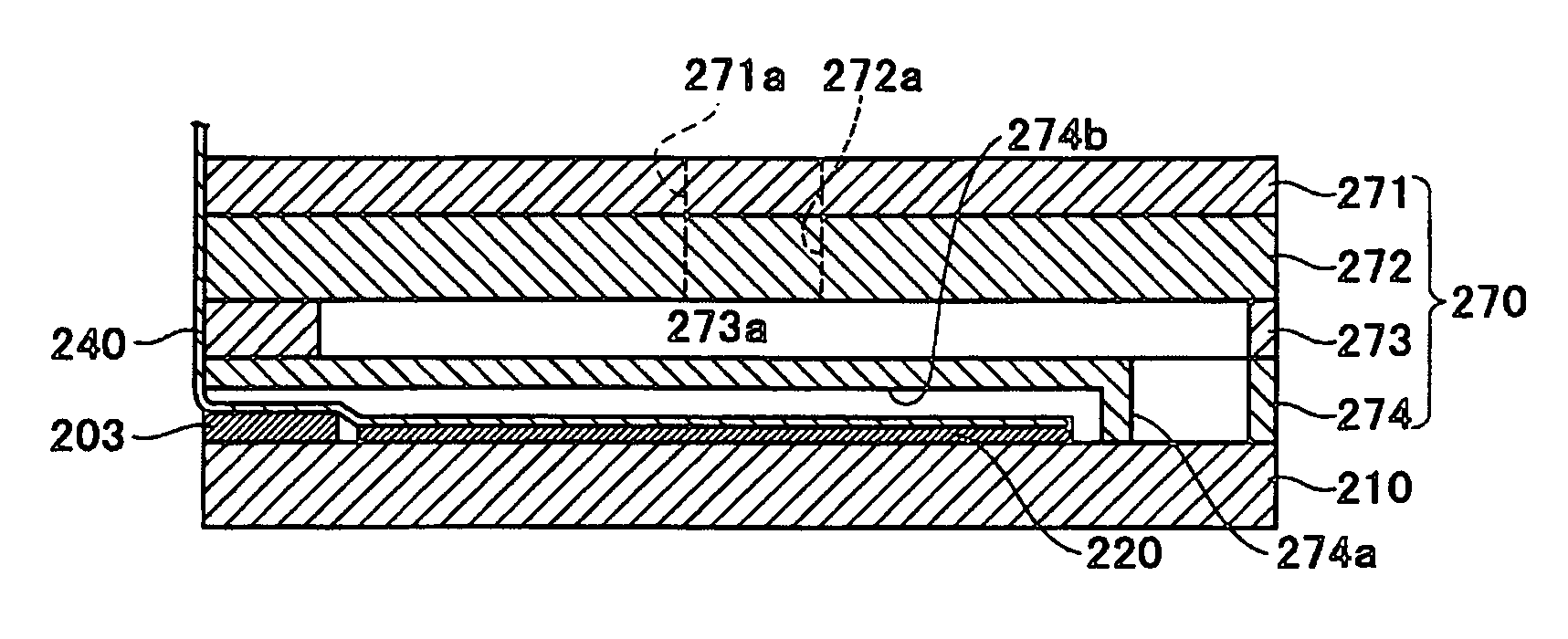

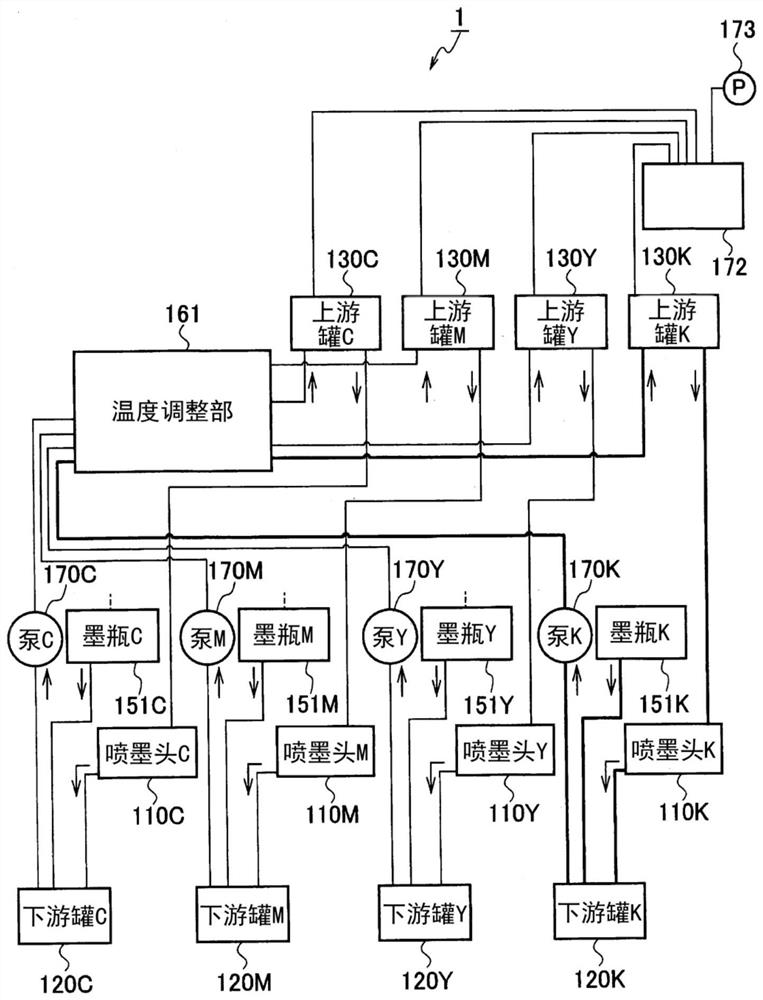

Liquid storage apparatus and image forming apparatus

InactiveUS20070280722A1Avoid it happening againAvoid print quality degradationTemperatue controlFlexible member pumpsHermetic sealImage formation

The liquid storage apparatus includes: a liquid storage chamber which is constituted by a flexible bag member and stores liquid; an exterior container which has walls constituted by a shape memory member and has a hermetically sealed space in which the liquid storage chamber is disposed, the shape memory member extending and contracting freely at temperatures not greater than a transformation temperature and recovering a memorized shape at temperatures not less than a shape recovery temperature; a forcing member which applies a contraction force to the walls of the exterior container in a direction in which the walls contract; and a temperature adjuster which adjusts a temperature of the shape memory member directly or indirectly so as to control a ratio of a portion of the shape memory member having temperatures not greater than the transformation temperature and deformed to a contracted shape by the contraction force of the forcing member and a ratio of a portion of the shape memory member having temperatures not less than the shape recovery temperature and recovering the memorized shape more extended than the contracted shape, so that a pressure in the liquid storage chamber is changed depending on a volume change of the exterior container due to deformation of the shape memory member.

Owner:FUJIFILM CORP

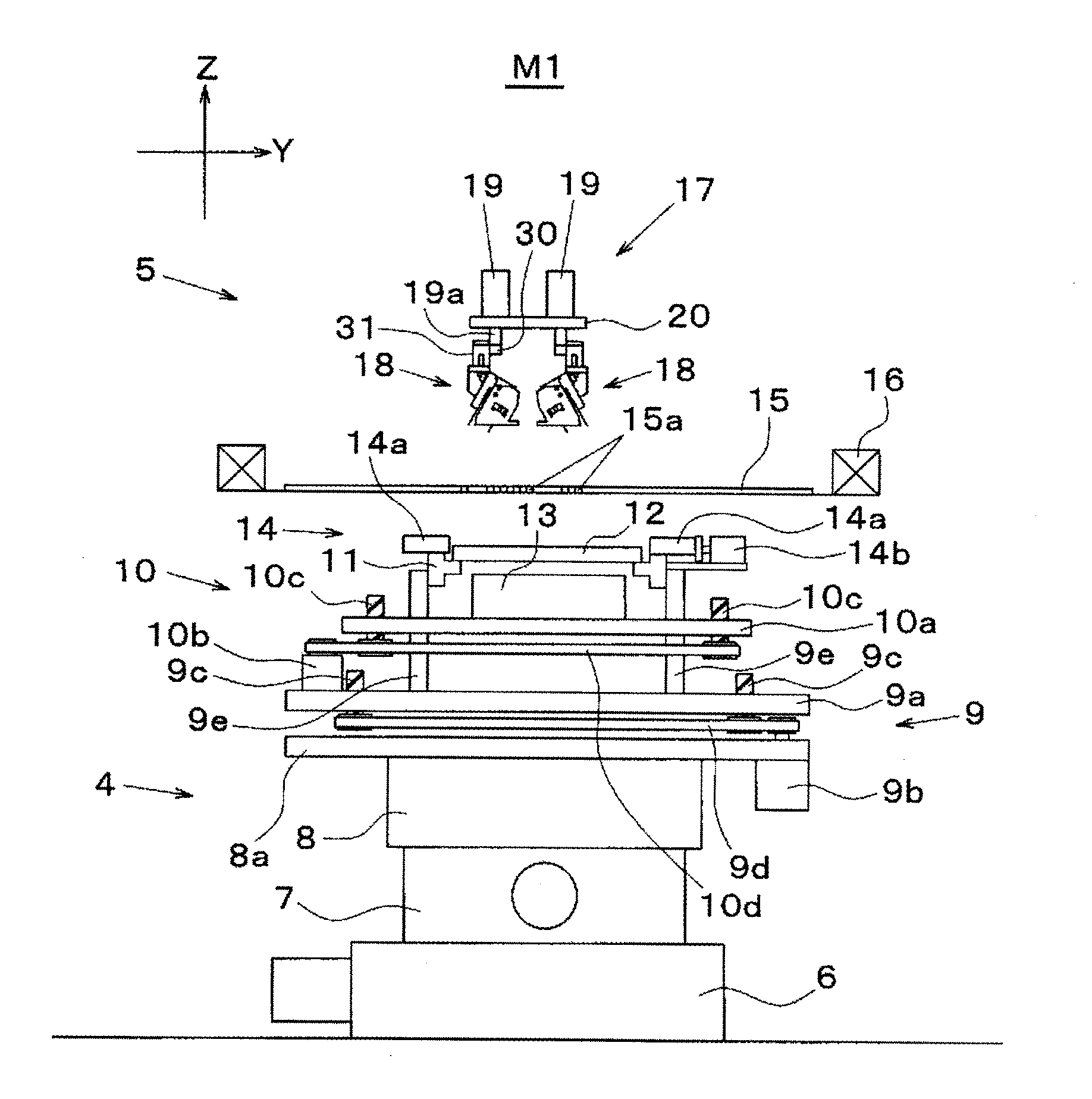

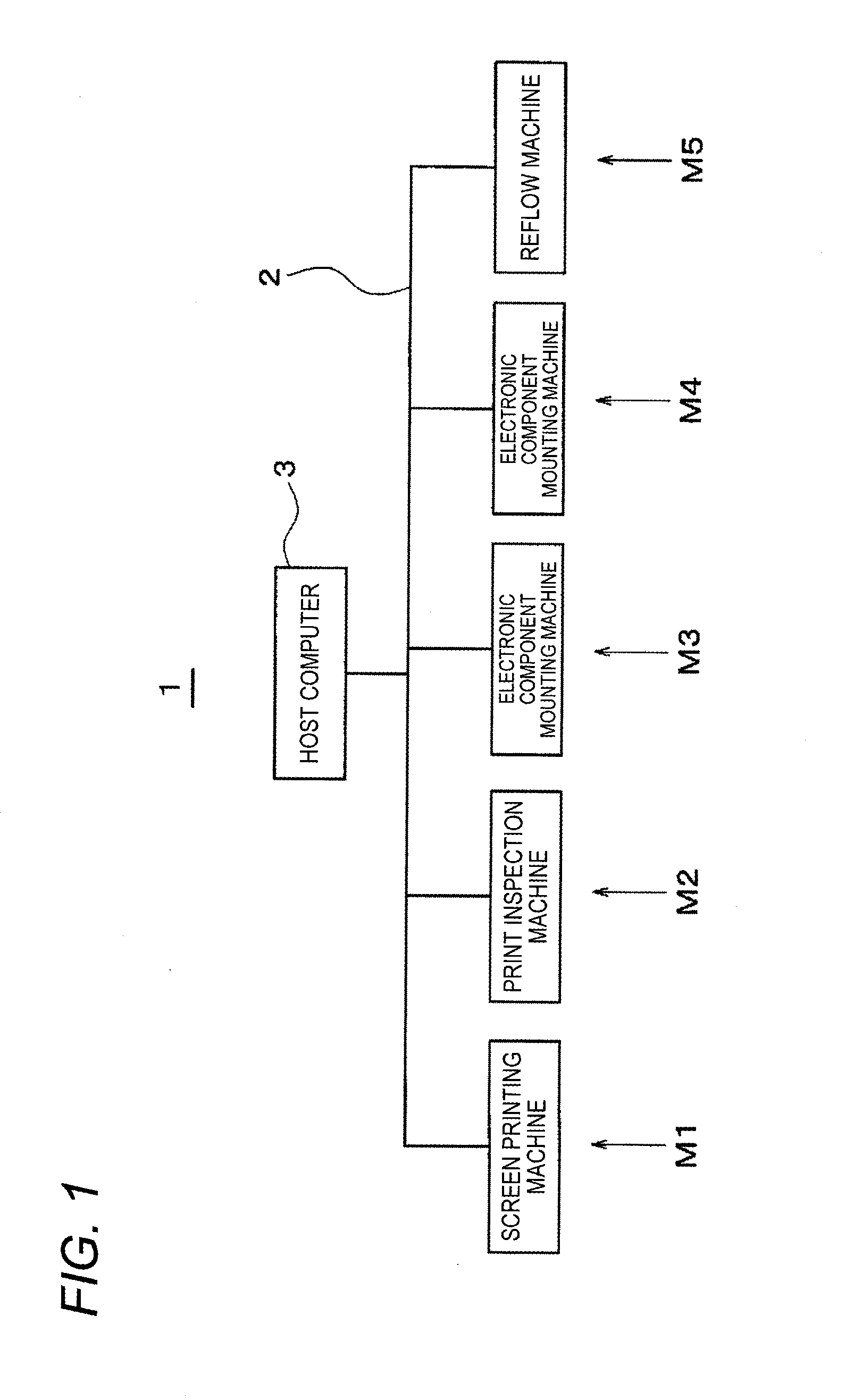

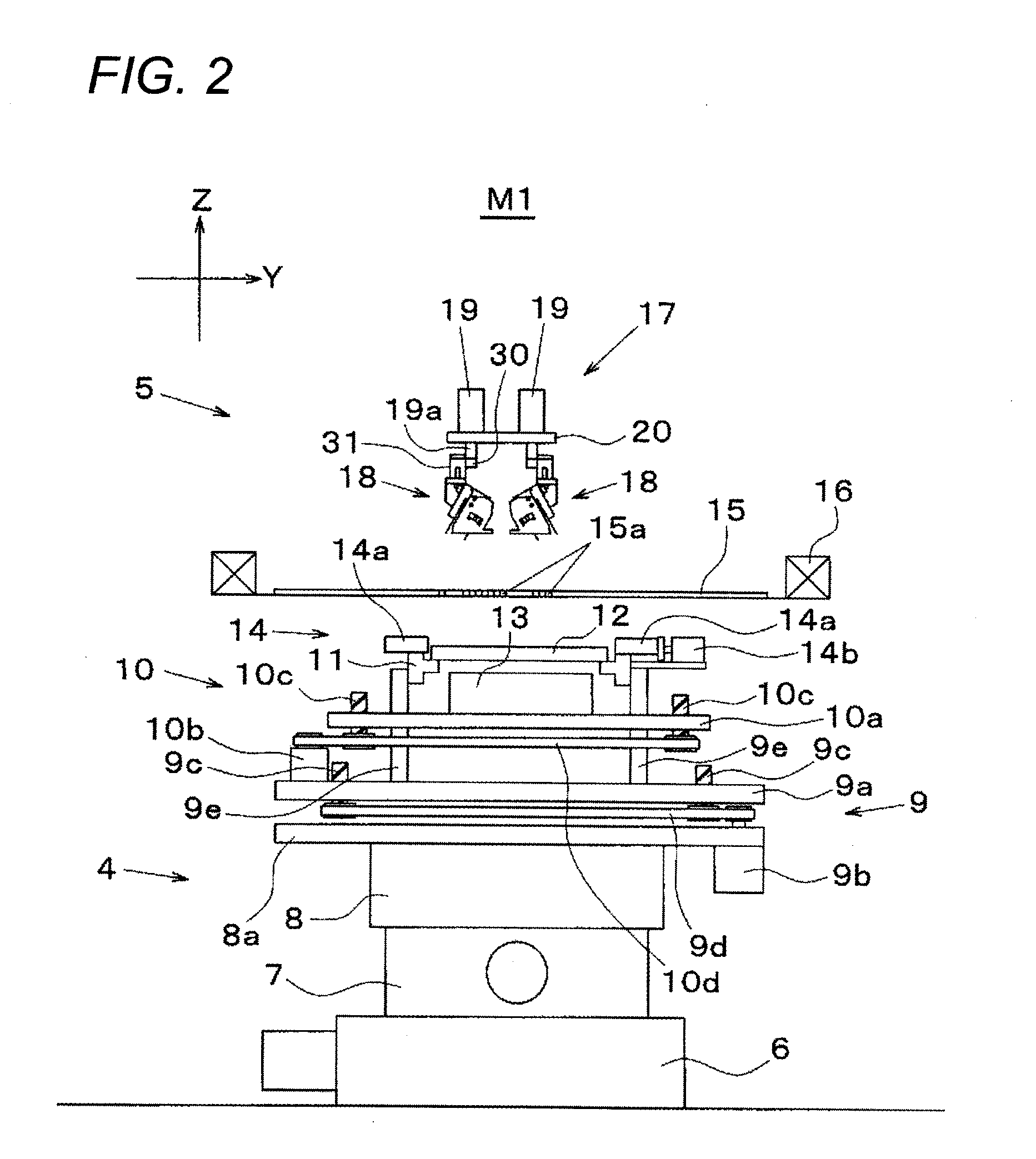

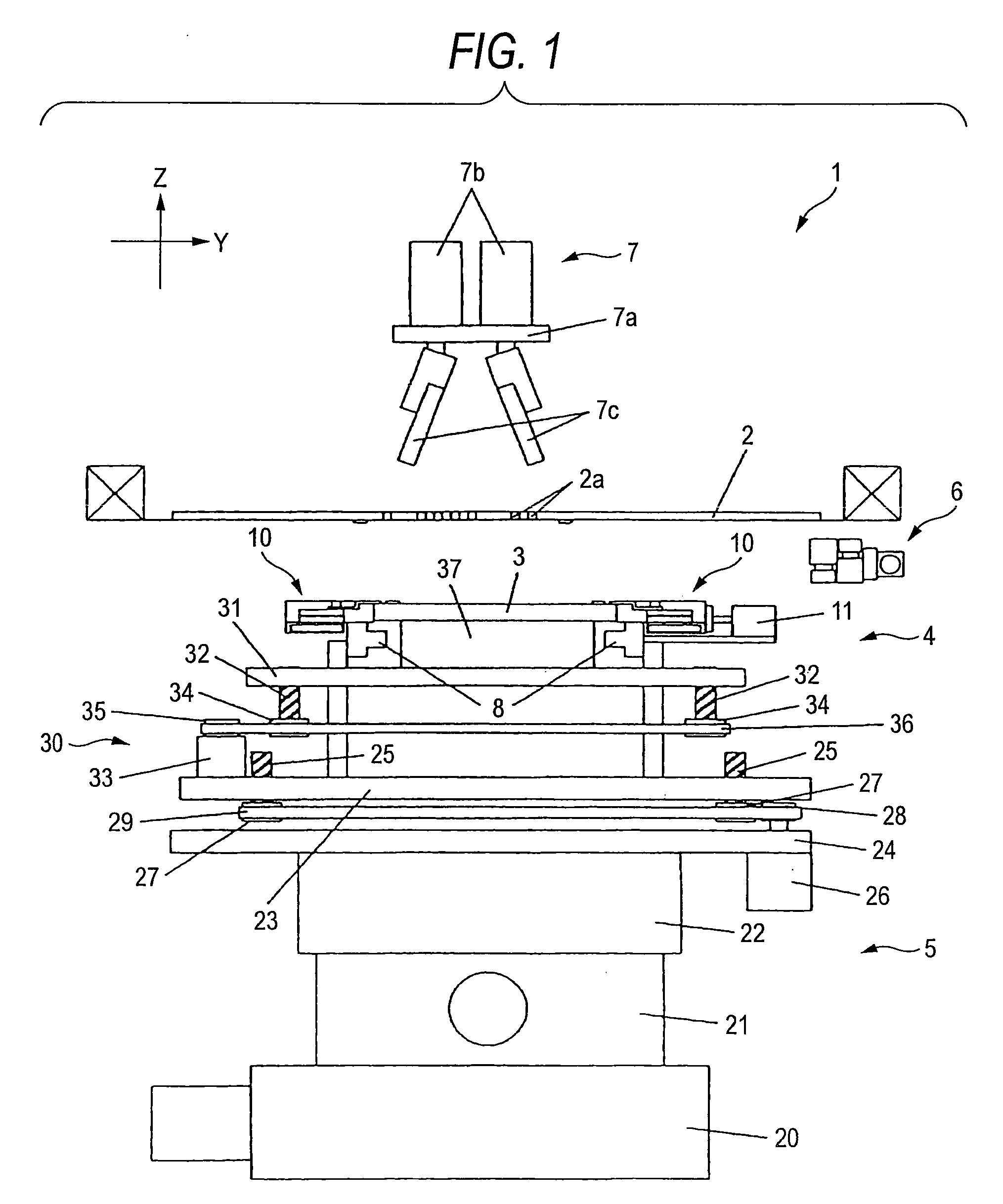

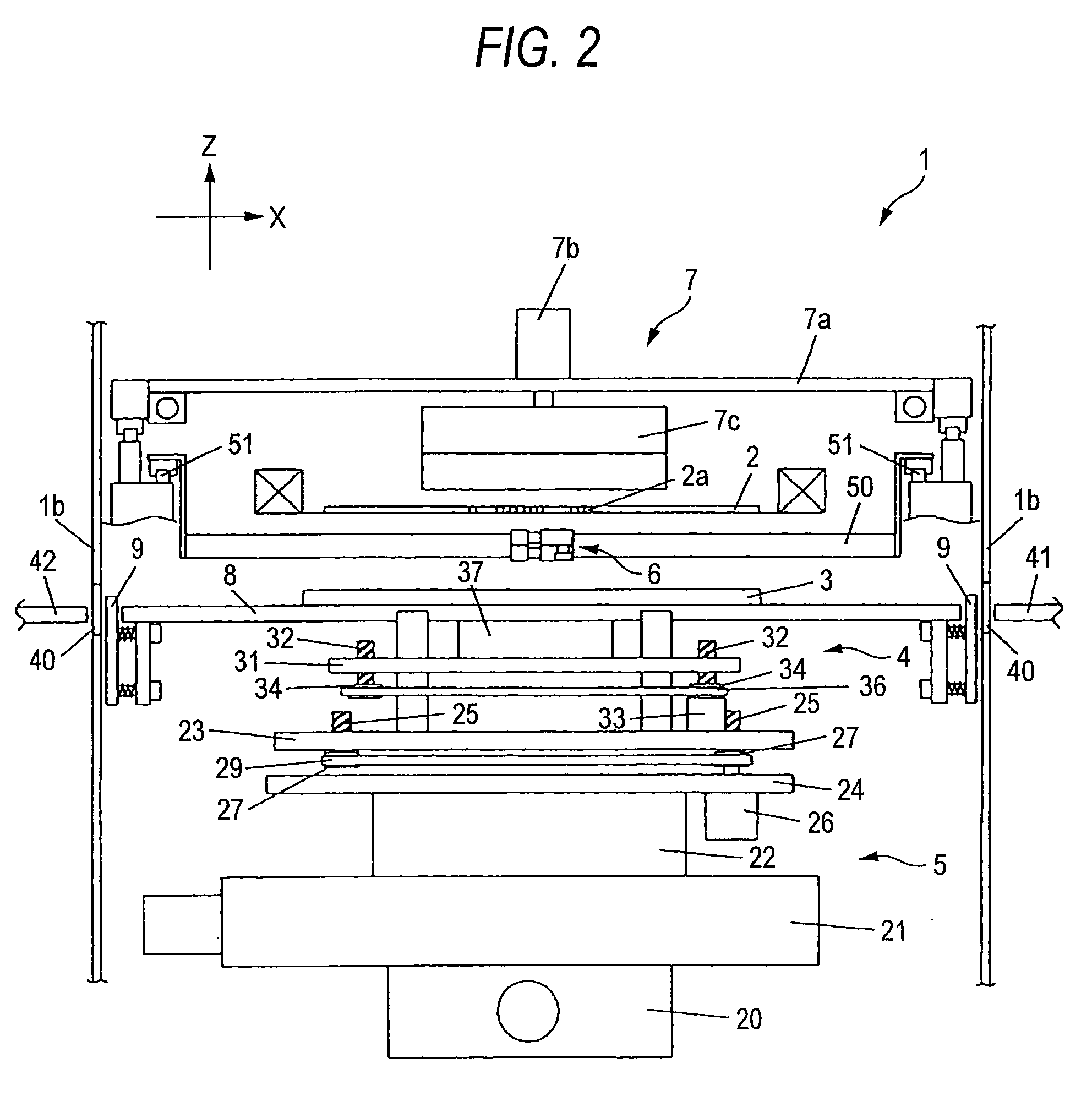

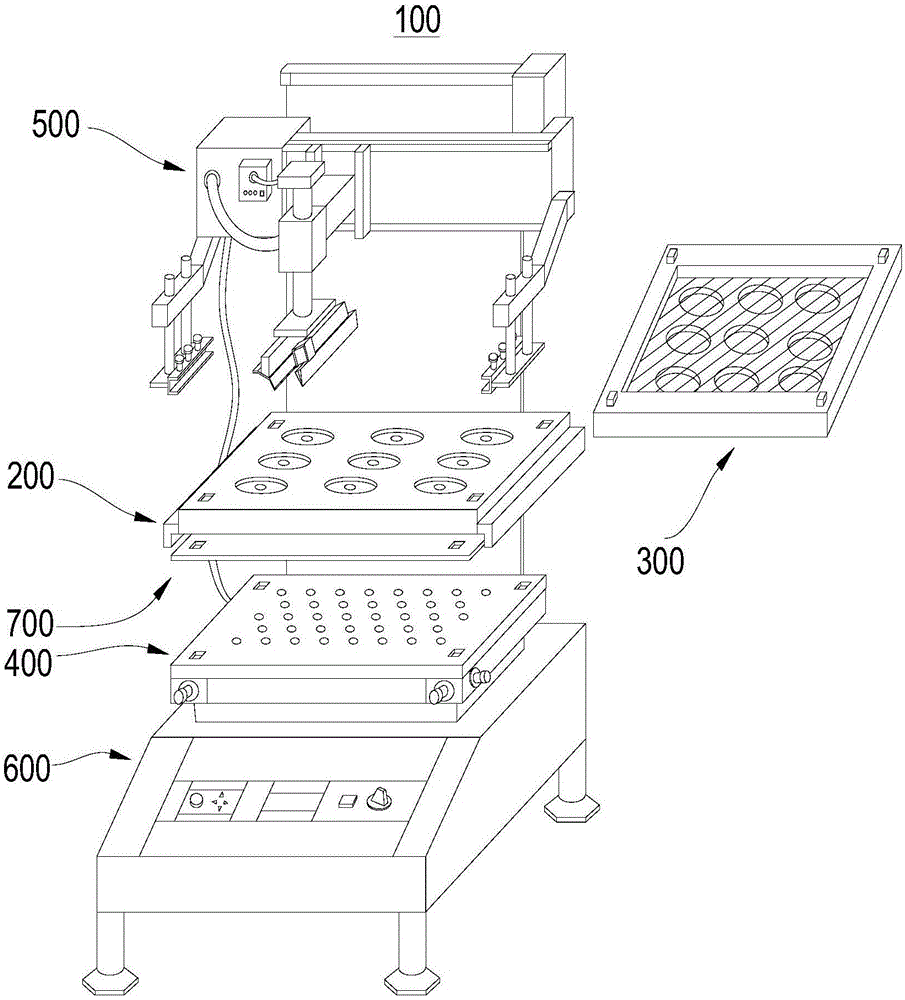

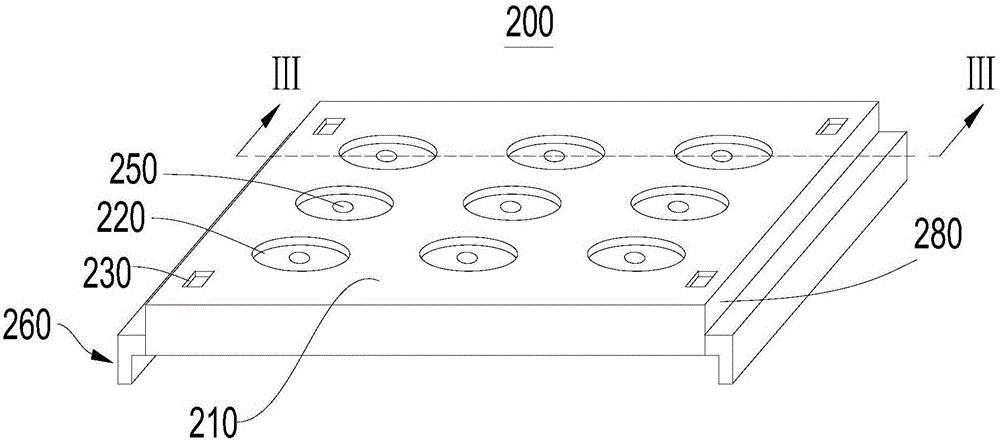

Screen printing machine, electronic component mounting system, and screen printing method

ActiveUS20150129641A1Prevent unevennessPrevent unevenness of formedPrinted circuit assemblingInking apparatusPrinting pressSilk-screen printer

A screen printing machine for forming a print of paste supplied to a mask plate having pattern holes, includes: a flexible filling squeegee which performs a squeegeeing operation in which the filling squeegee is moved relative to the mask plate in a printing direction; and a scraping squeegee which is held to maintain a given interval from the filling squeegee in the printing direction and to be movable together with the filling squeegee in the printing direction, and which scraps off the paste remaining on the mask plate after passage of the filling squeegee. In the squeegeeing operation, the filling squeegee is pushed up and bent by the paste to provide a clearance between a bottom end of the filling squeegee and the mask plate with the paste interposed therebetween so that the pattern holes are filled with paste with a prescribed filling pressure.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

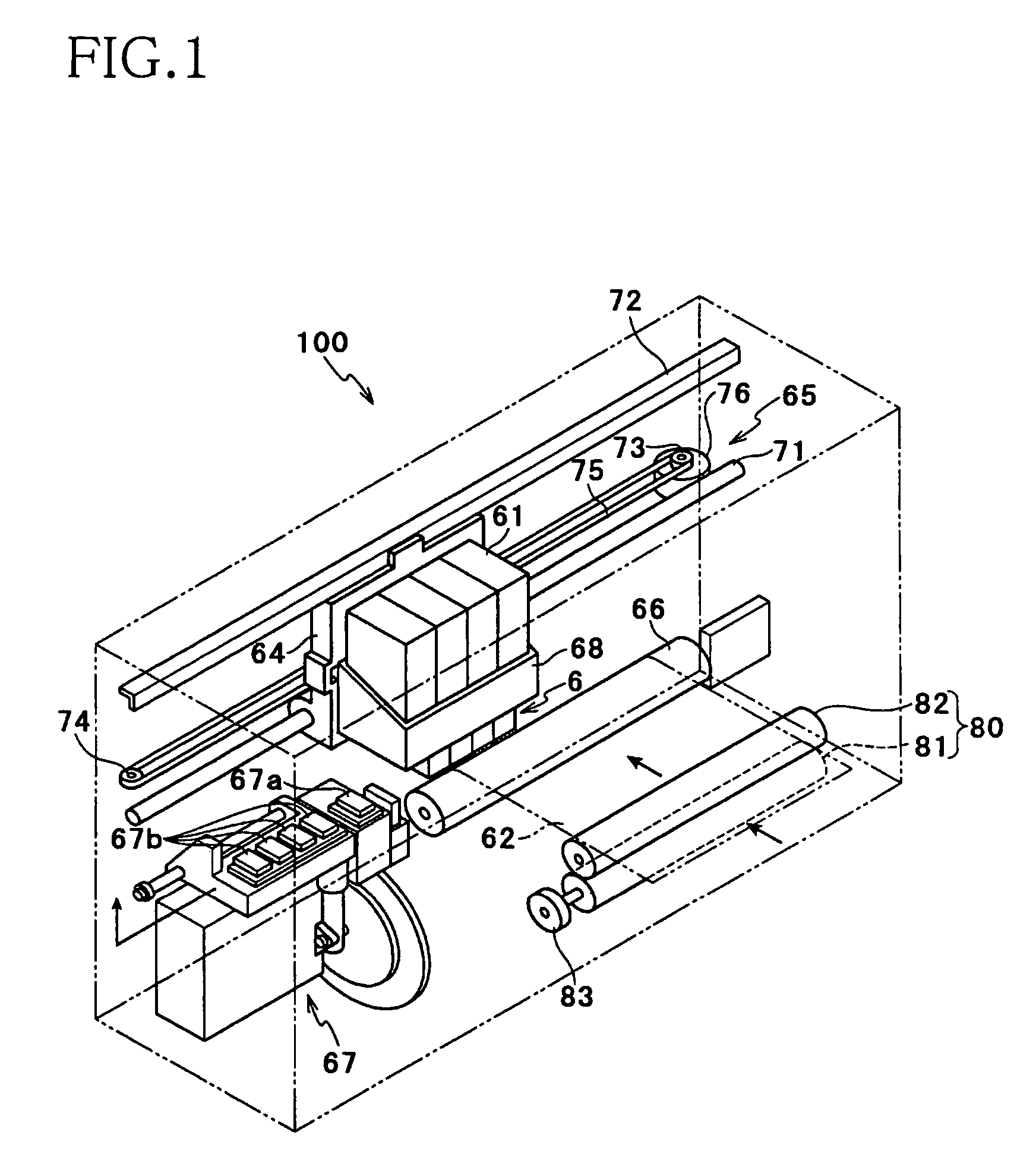

Ink-jet recording apparatus

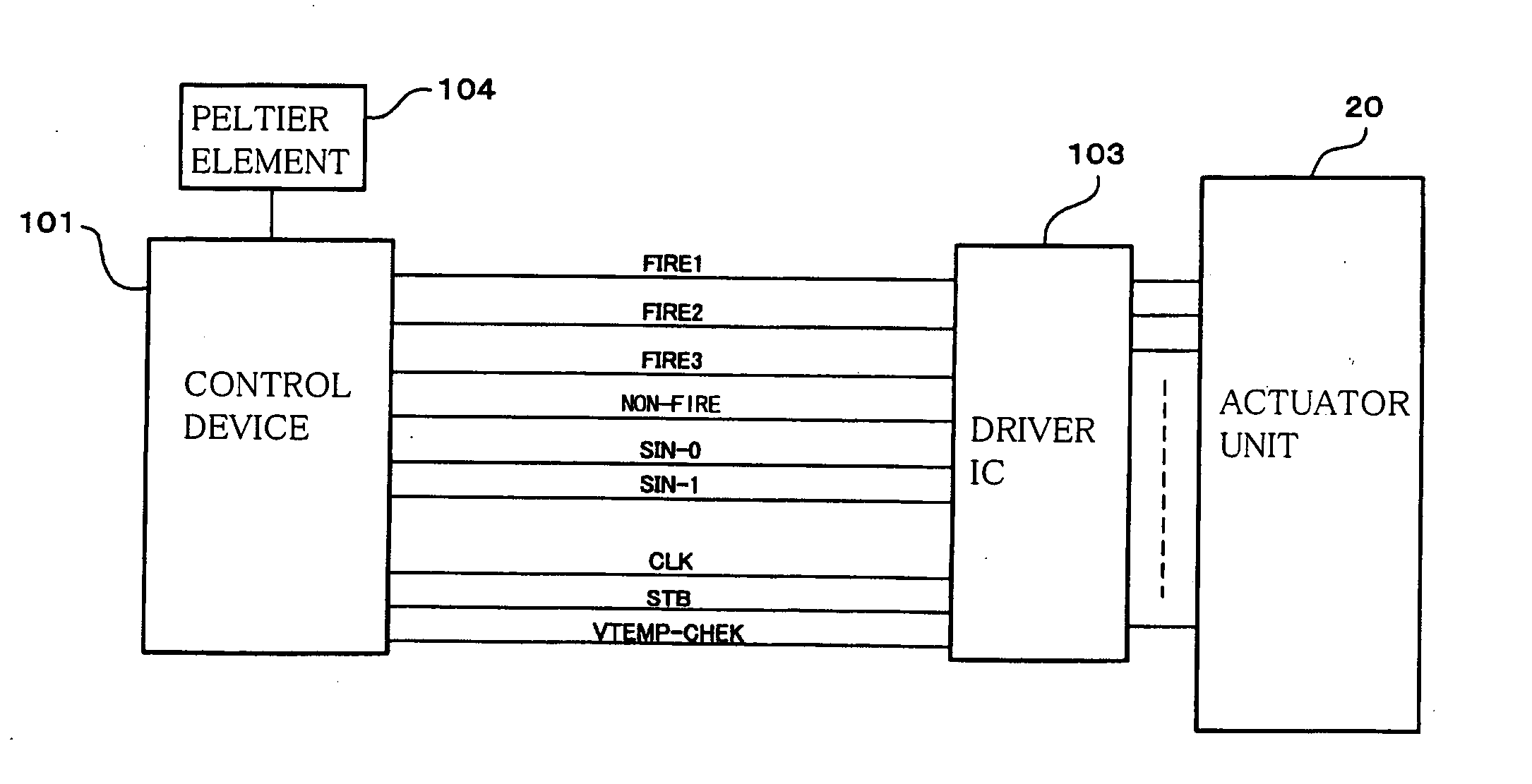

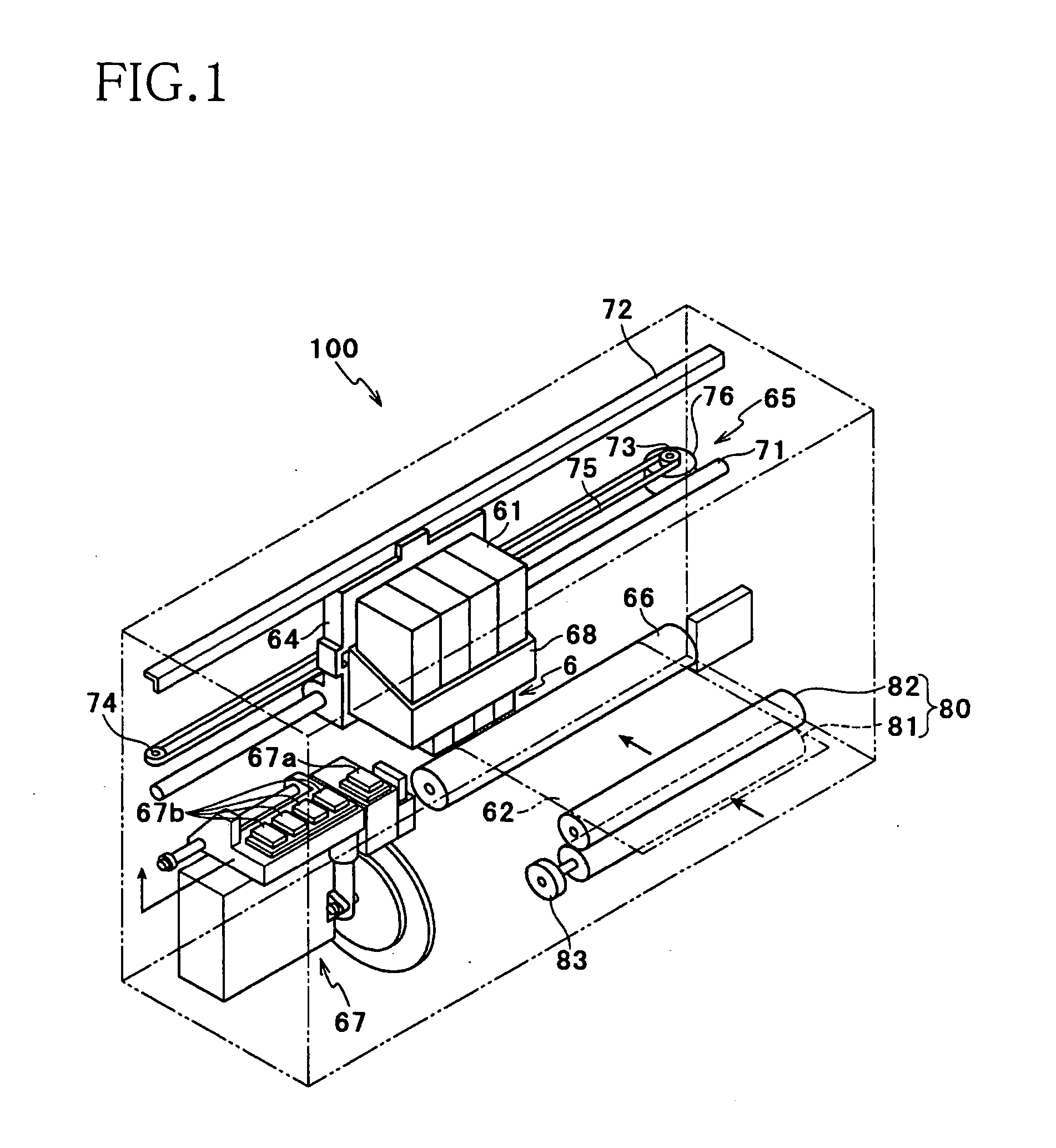

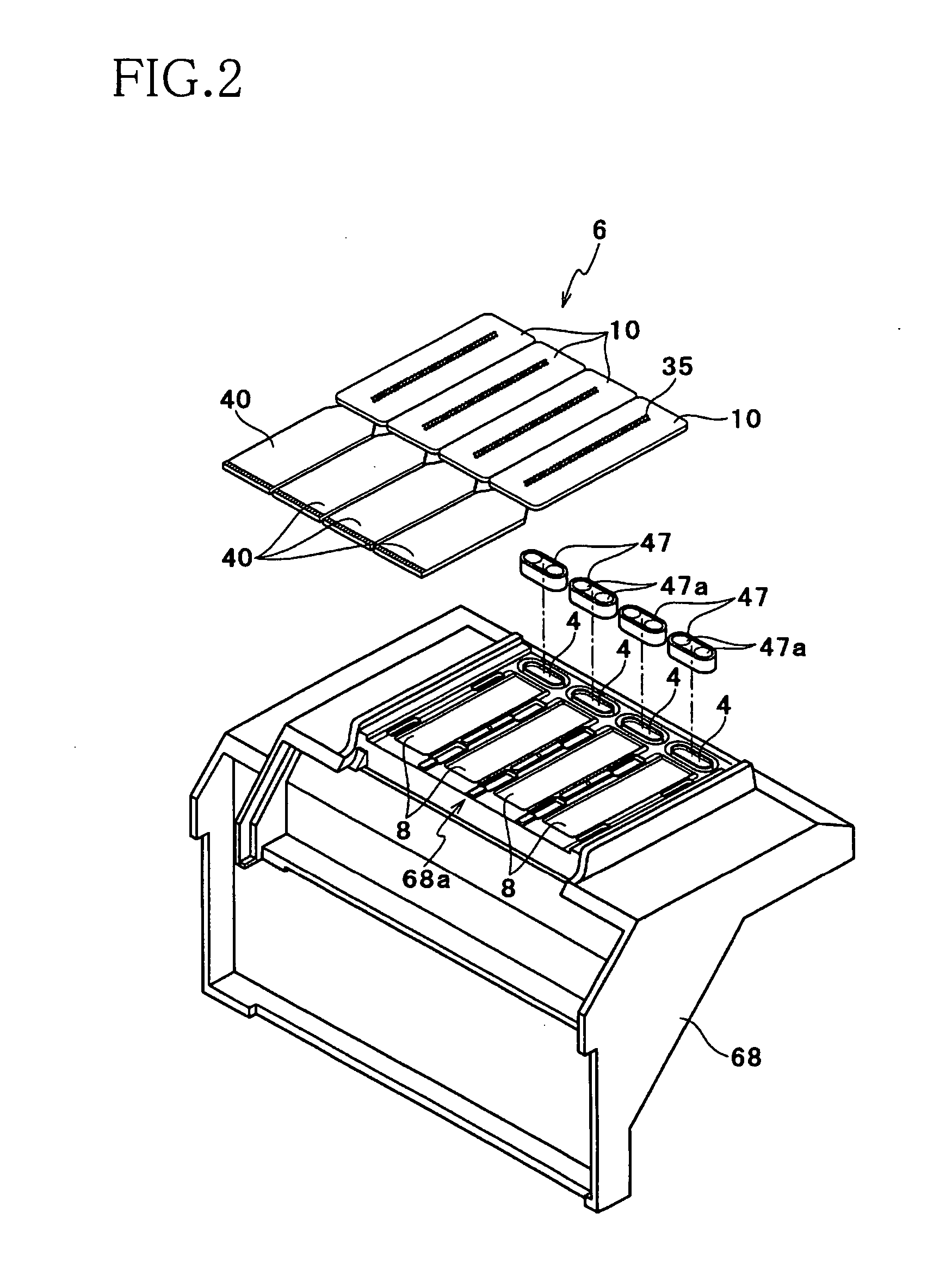

ActiveUS20060221112A1Avoid print quality degradationInking apparatusOther printing apparatusActuatorControl theory

An ink-jet recording apparatus including: (A) an ink-jet head which includes: a channel unit having a plurality of nozzles and a plurality of pressure chambers that respectively communicate with the plurality of nozzles; and an actuator unit which is disposed on the channel unit and to which drive signals are applied, thereby changing a volume of the plurality of pressure chambers; (B) a driver IC which is disposed on the ink-jet head and which includes: a drive-signal generating portion for generating the drive signals and applying the generated drive signals to the actuator unit; and a temperature sensor for detecting an environmental temperature of the actuator unit; and (C) a control device arranged to execute a low-temperature-condition control by controlling the drive-signal generating portion to generate the drive signals so as to change the volume of the plurality of pressure chambers, where the environmental temperature detected by the temperature sensor is not higher than a prescribed first temperature.

Owner:BROTHER KOGYO KK

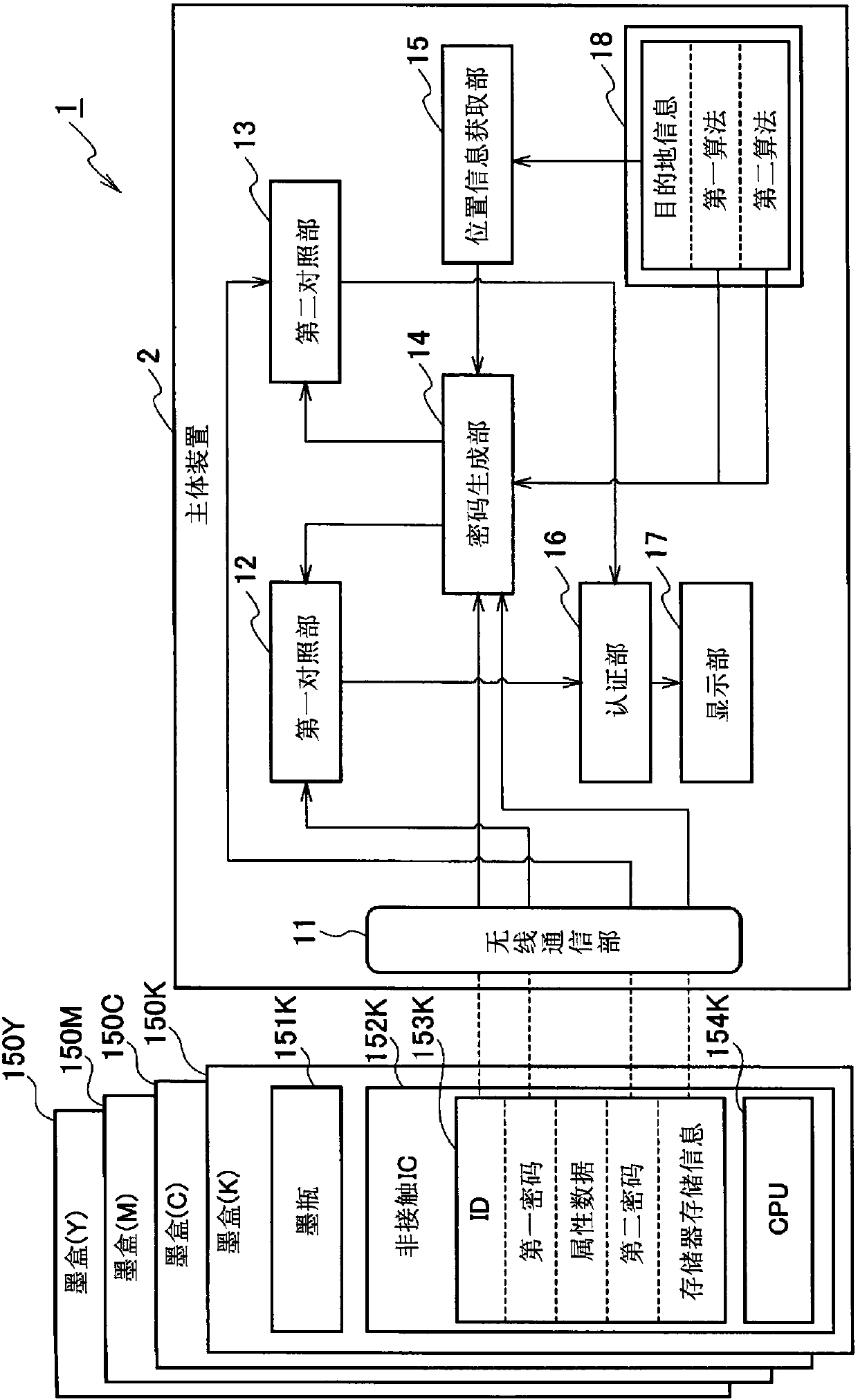

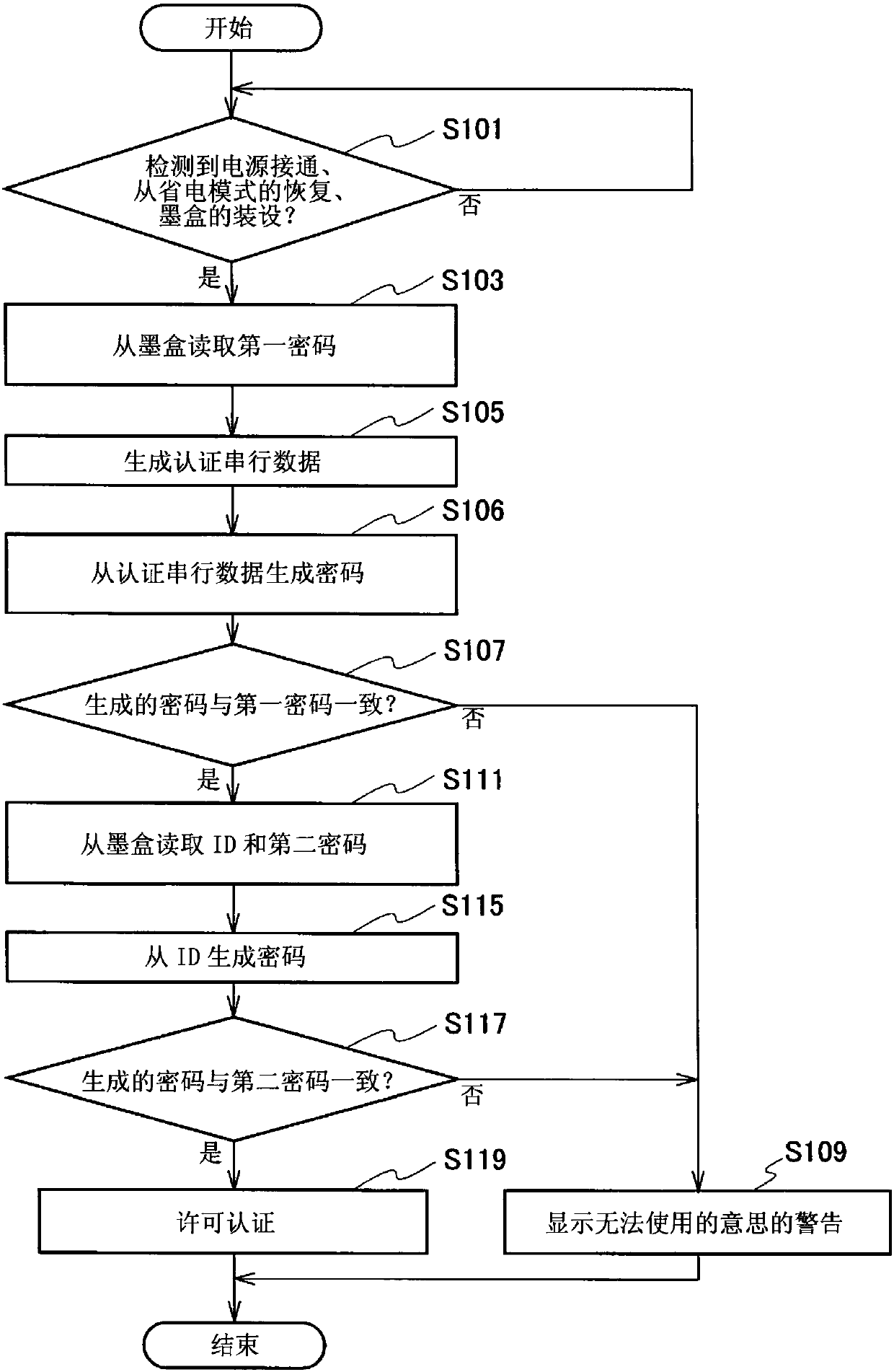

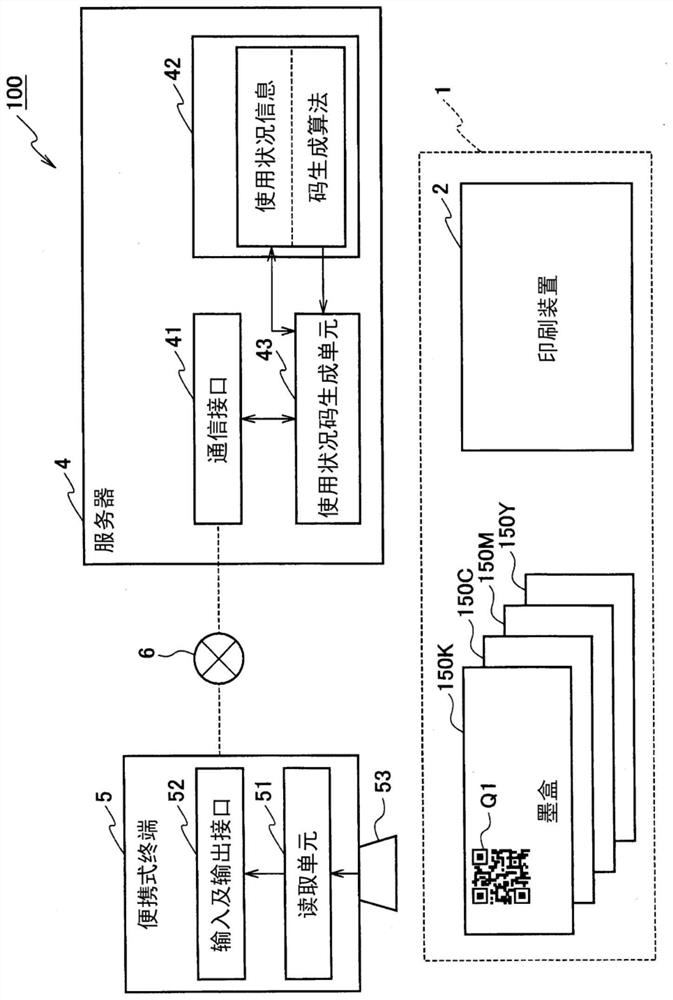

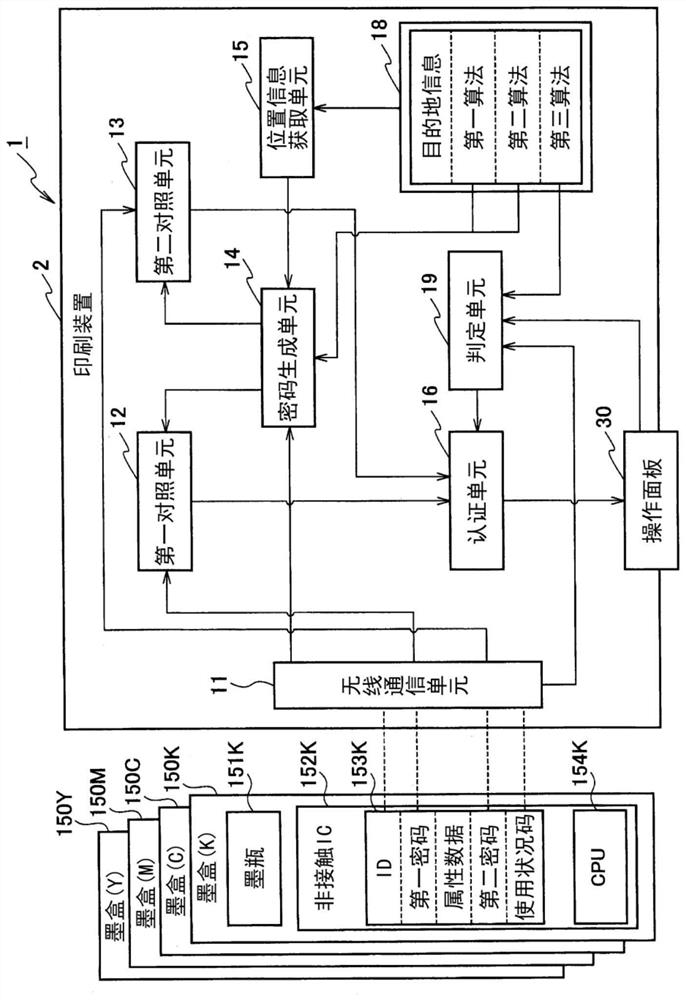

Authentication device

ActiveCN108025570AHigh precisionStrong passwordDigital data authenticationOther printing apparatusComputer hardwarePassword

A first comparison unit (12) compares a password which is static information generated by a password generating unit (14) of a main device (2) on the basis of authentication serial data read from a memory (18) in accordance with a reading pattern and a first password generated in advance on the basis of the authentication serial data and stored in advance in a memory (153K) a second comparison unit (13) compares a password generated by the password generating unit (14) of the main device (2) on the basis of an ID inputted to the main device (2) from an ink cartridge (150) and a second passwordgenerated in advance on the basis of the ID and stored in advance in the memory (153K) and an authentication unit (16) performs permission authentication of the ink cartridge (150) when it is determined that the results of comparison in the first comparison unit (12) match and it is determined that the result of comparison in the second comparison unit (13) match.

Owner:RISO KAGAKU CORP

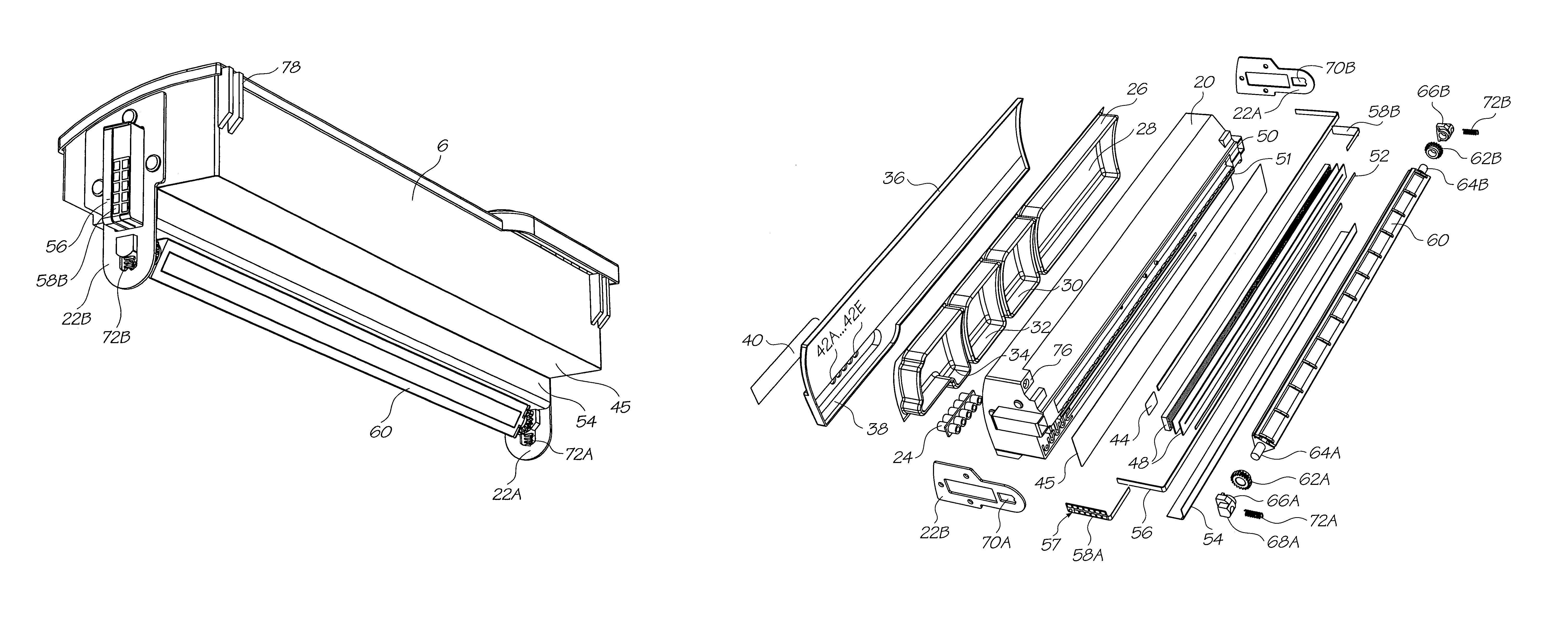

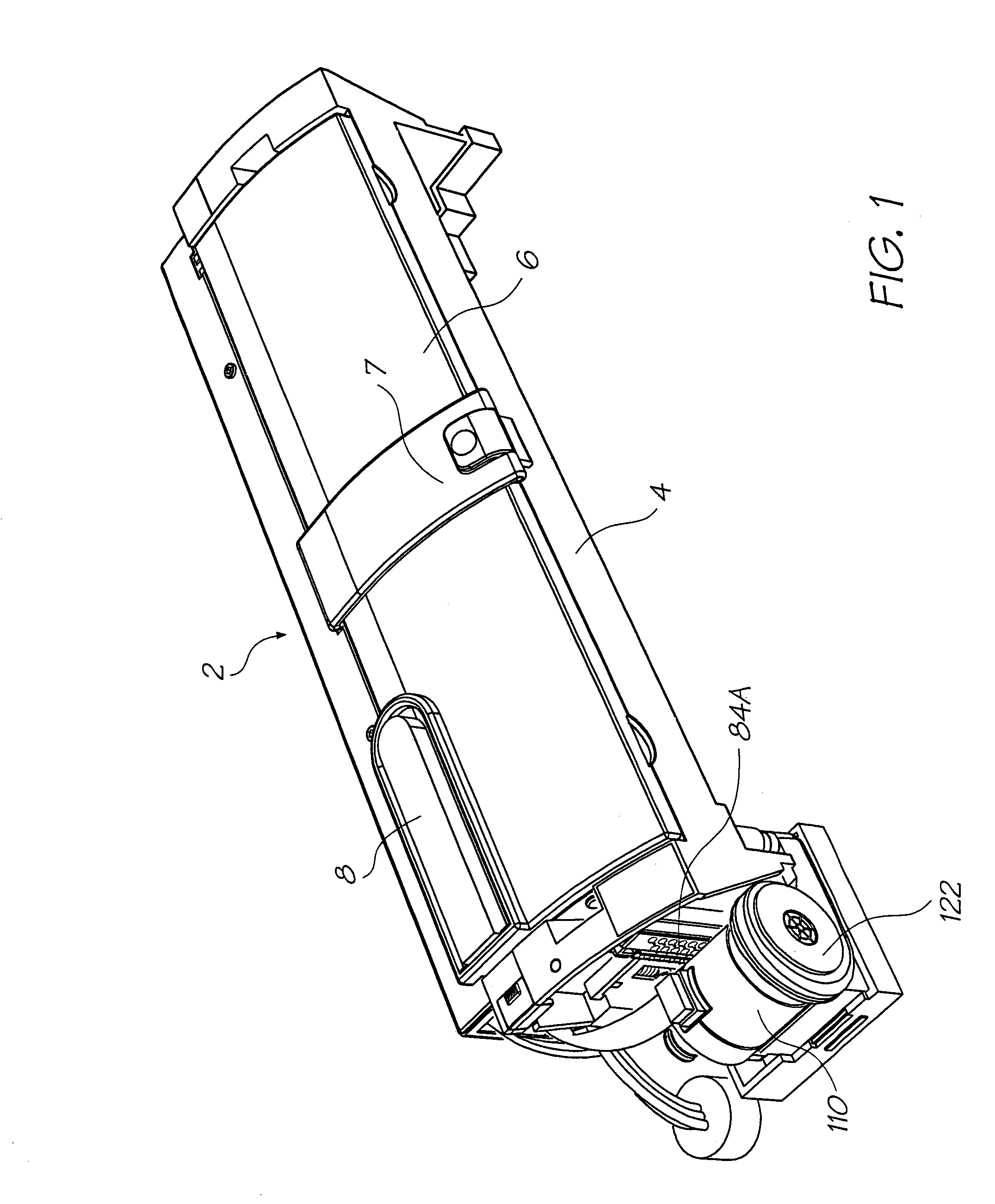

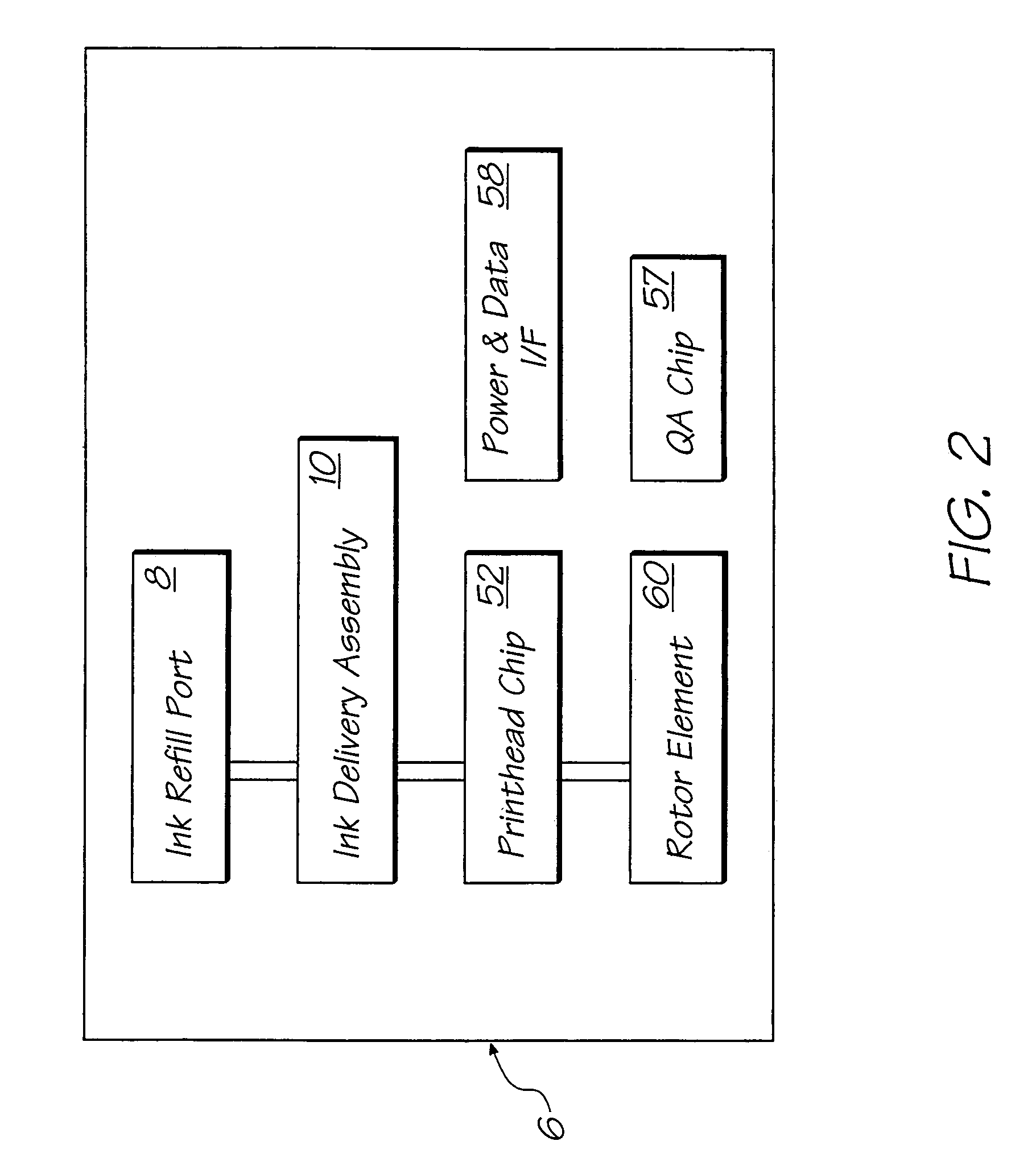

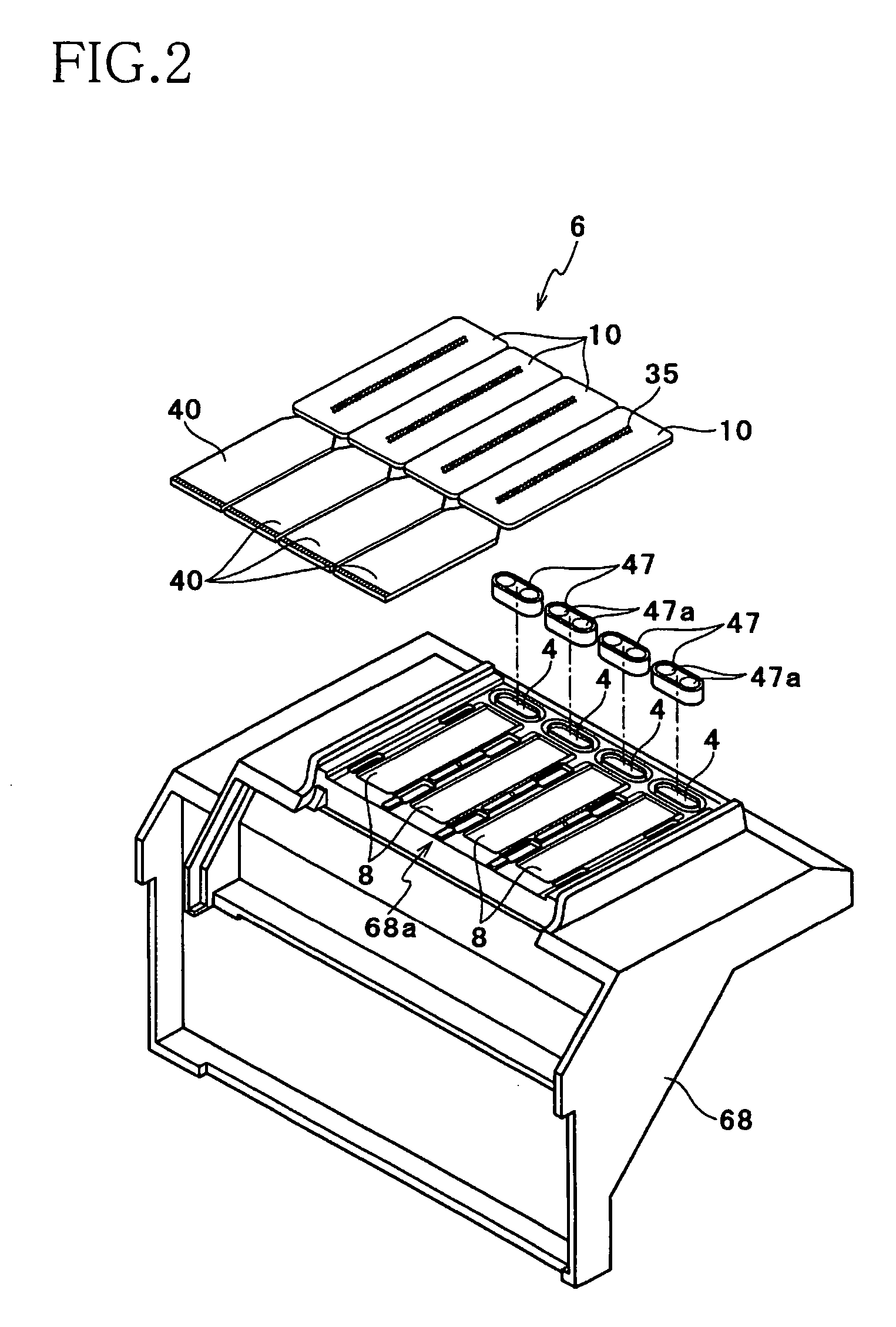

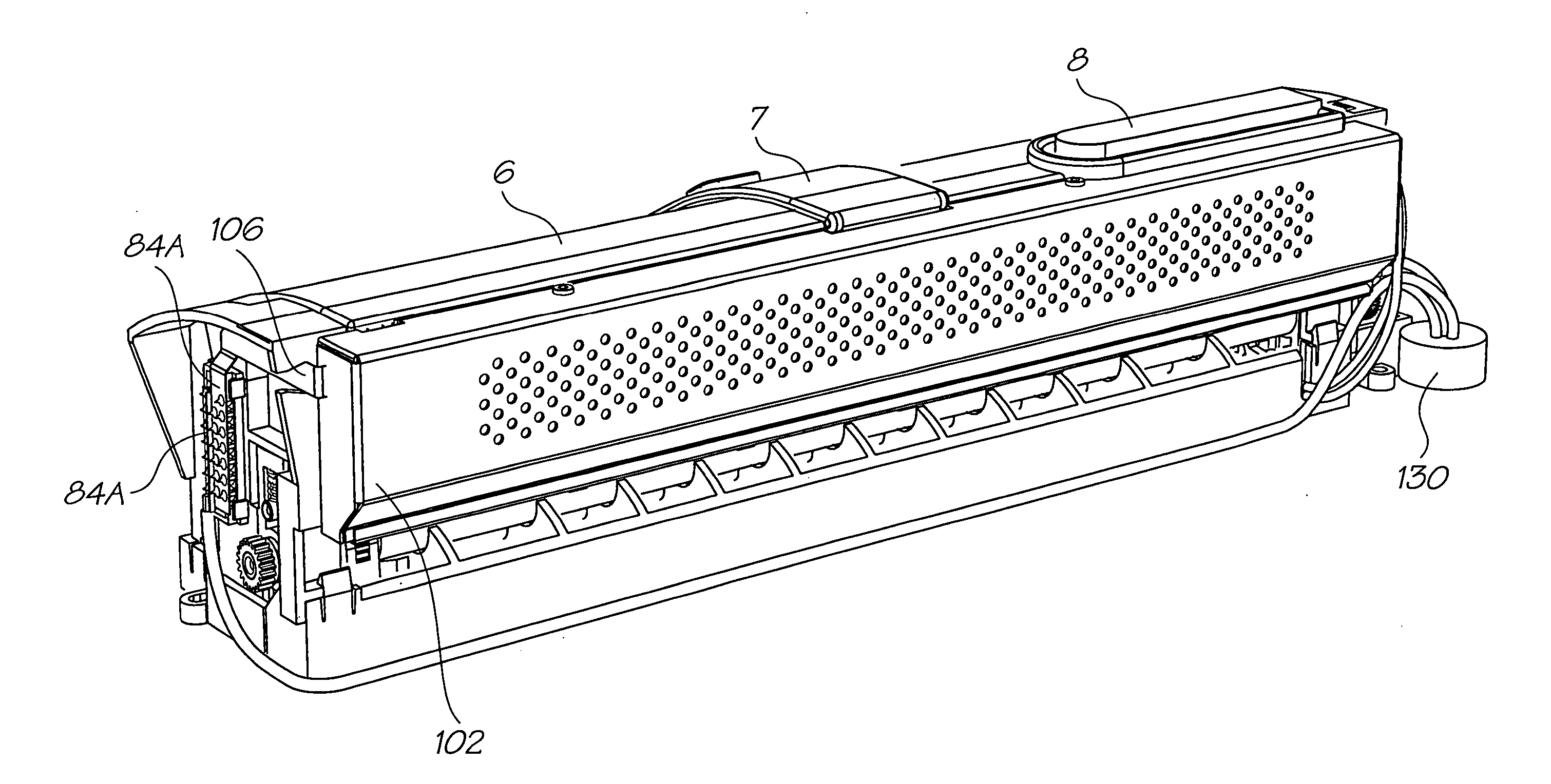

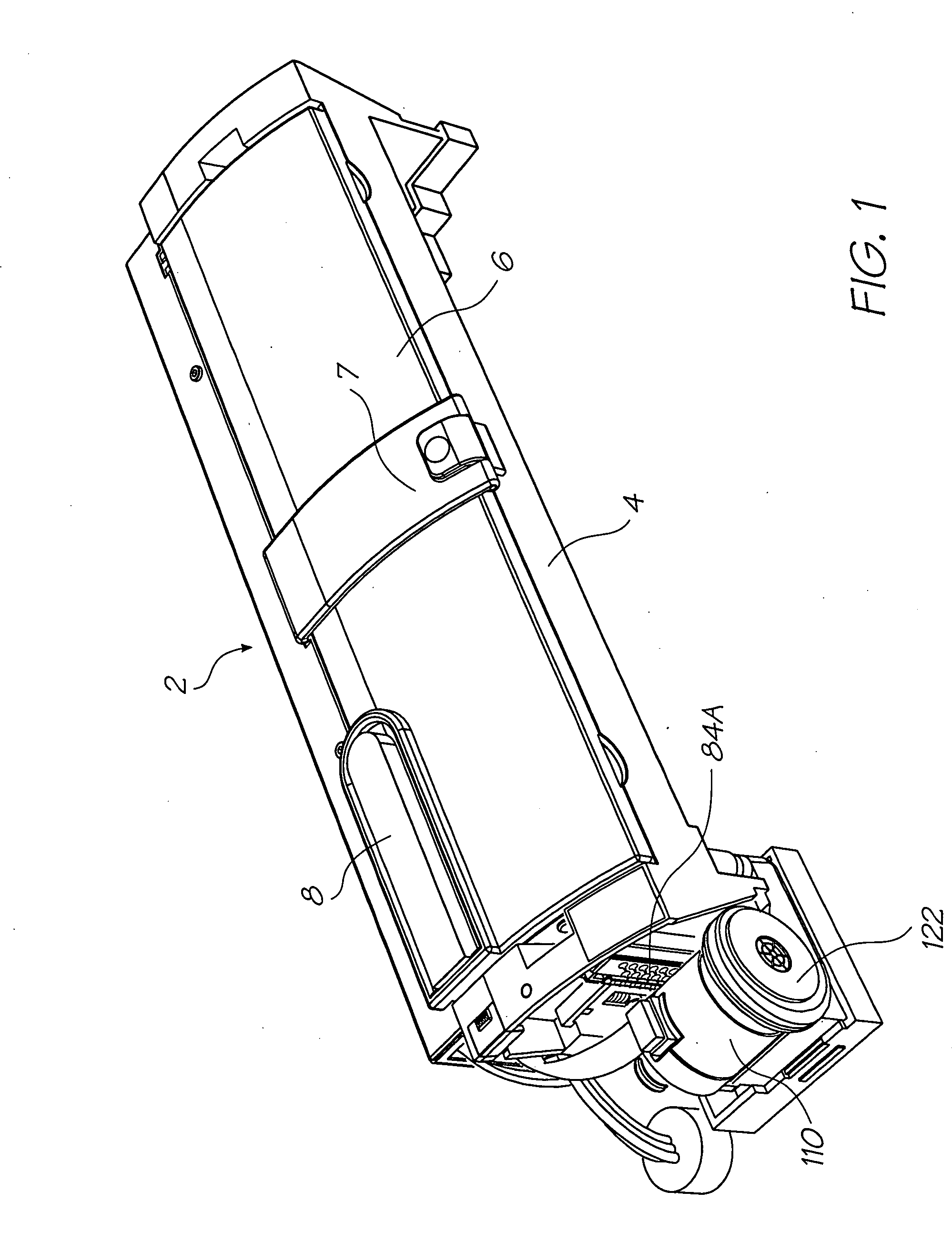

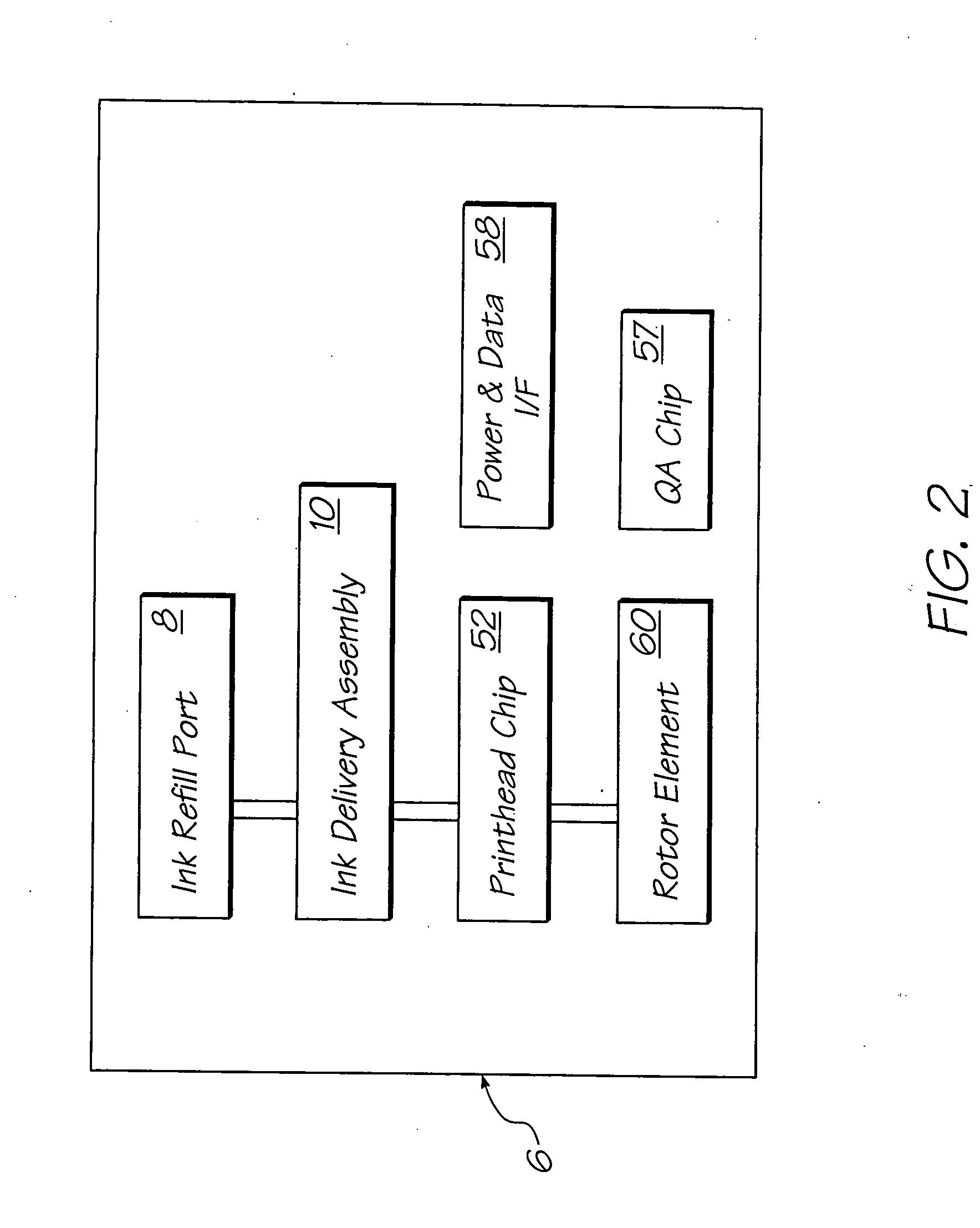

Inkjet printer cartridge with uniform compressed air distribution

ActiveUS7083273B2Easy to remove and replaceAvoid print quality degradationPrintingEngineeringCompressed air

An inkjet printer cartridge including an elongate body housing a printing fluid storage and adapted to be received within an inkjet printer cradle, a pagewidth printhead attached to the body and in fluid communication with the printing fluid storage, and an air distribution assembly arranged to evenly distribute compressed air along the pagewidth printhead.

Owner:SILVERBROOK RES PTY LTD +1

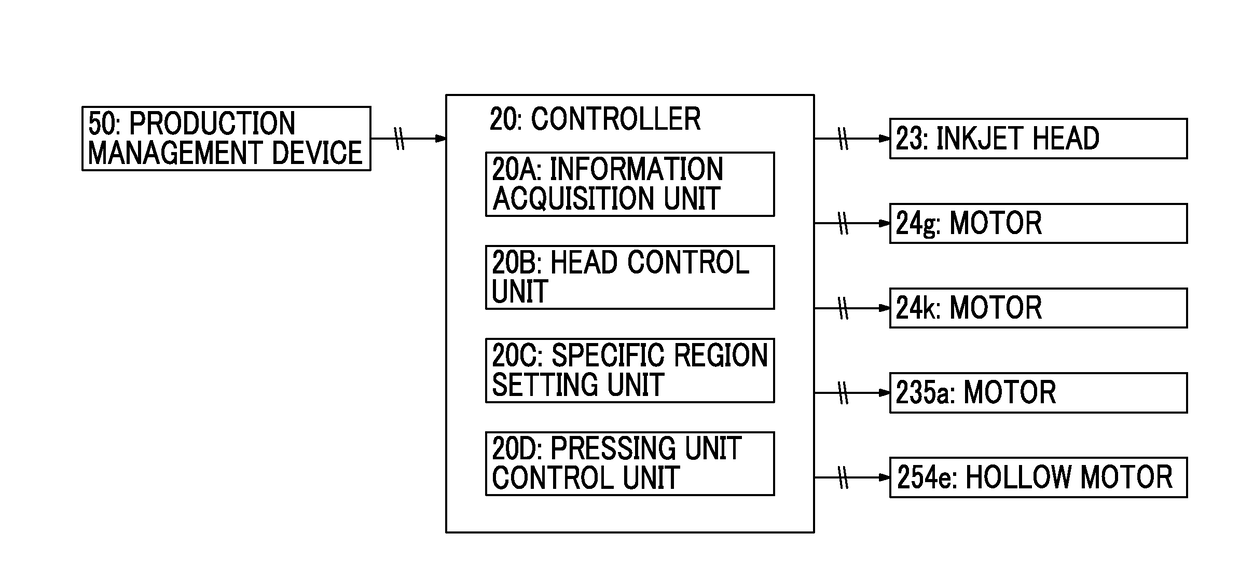

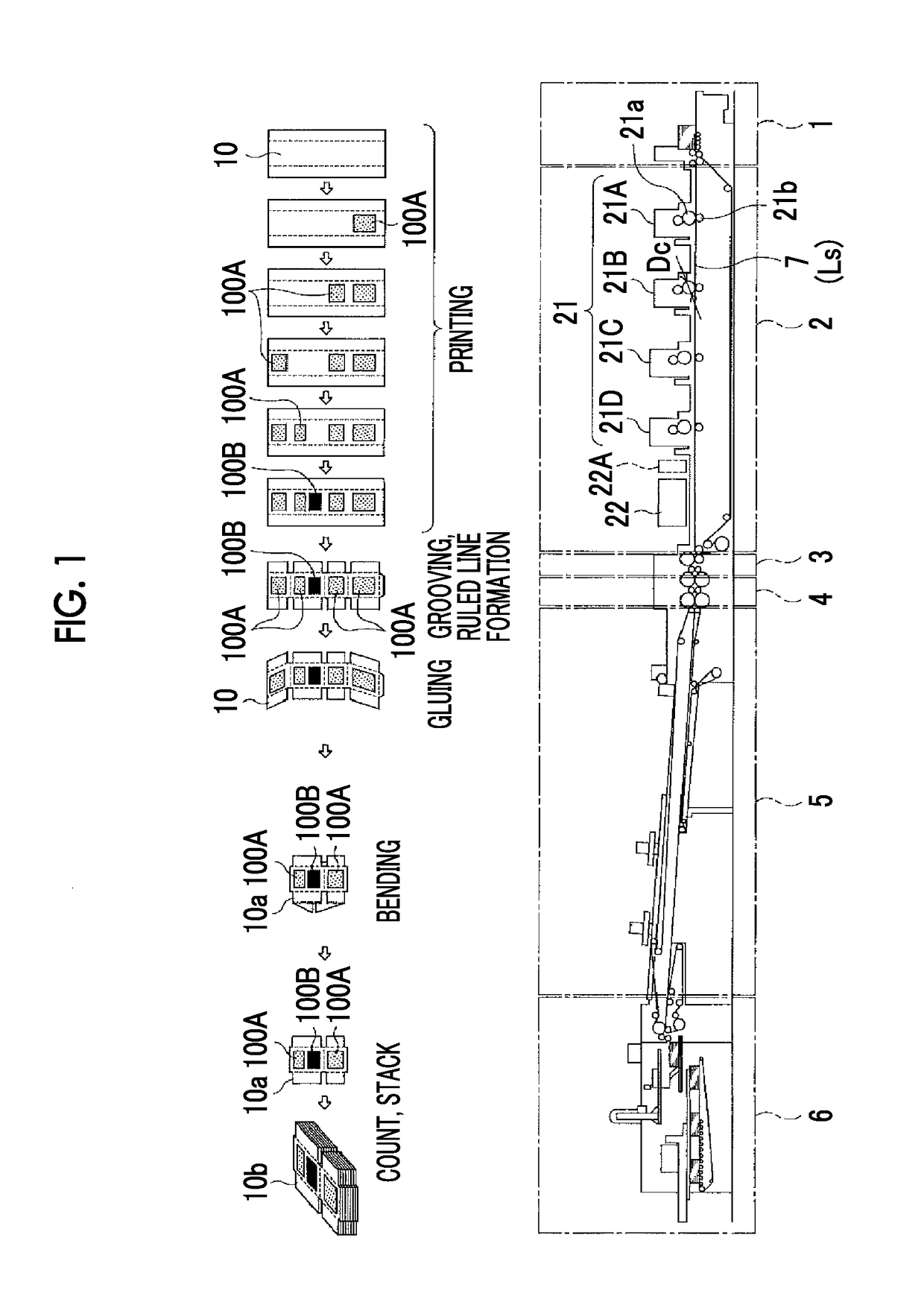

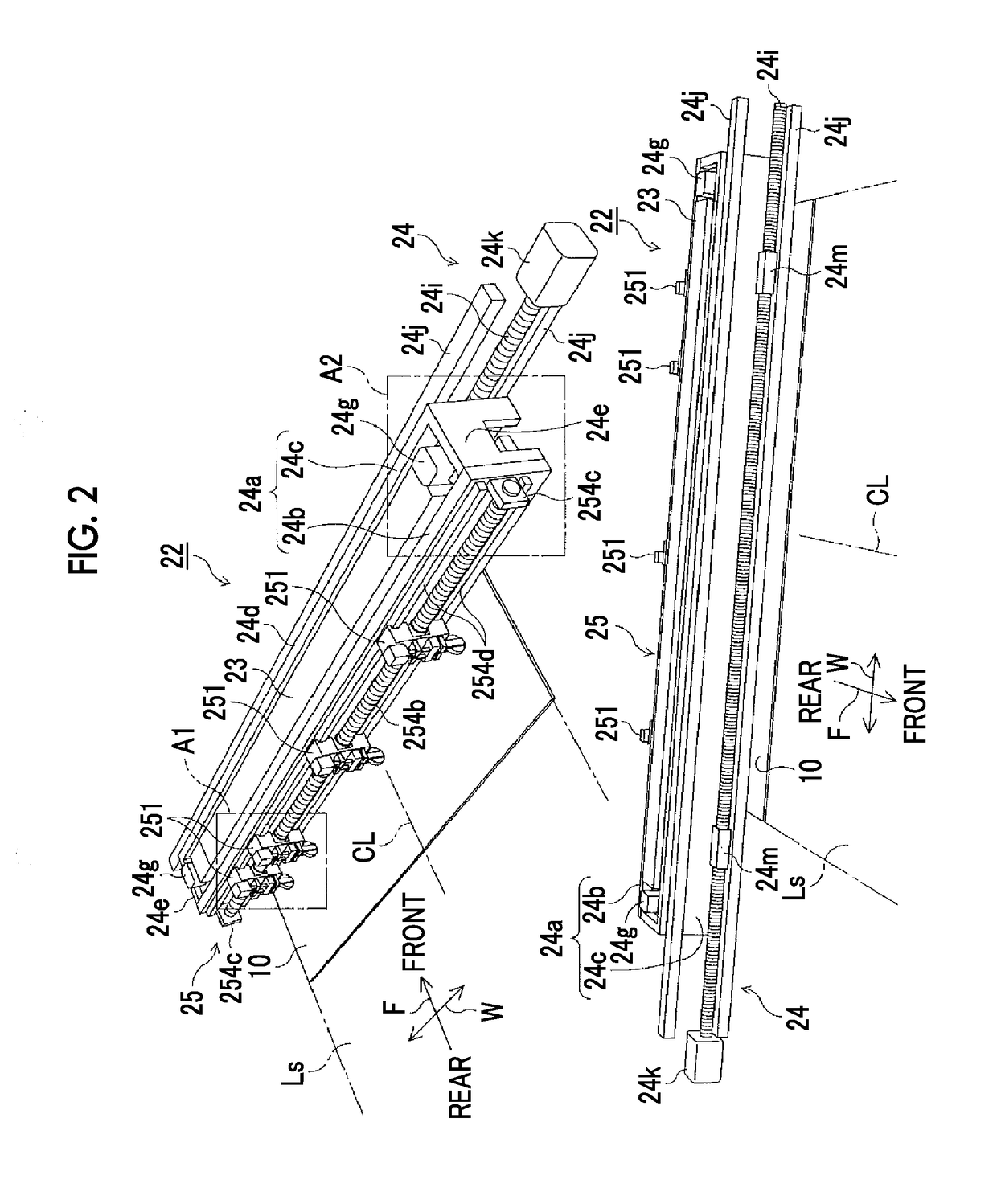

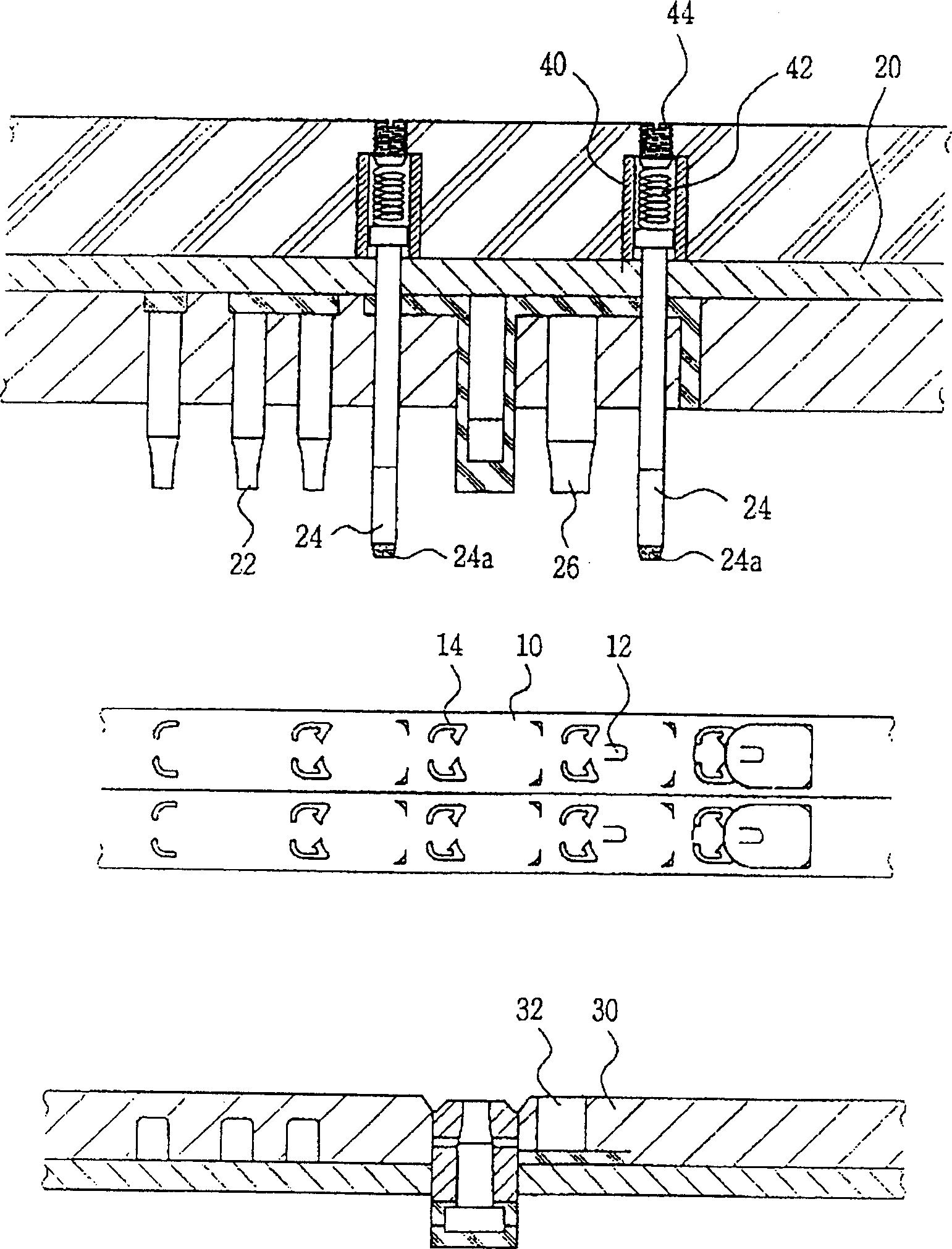

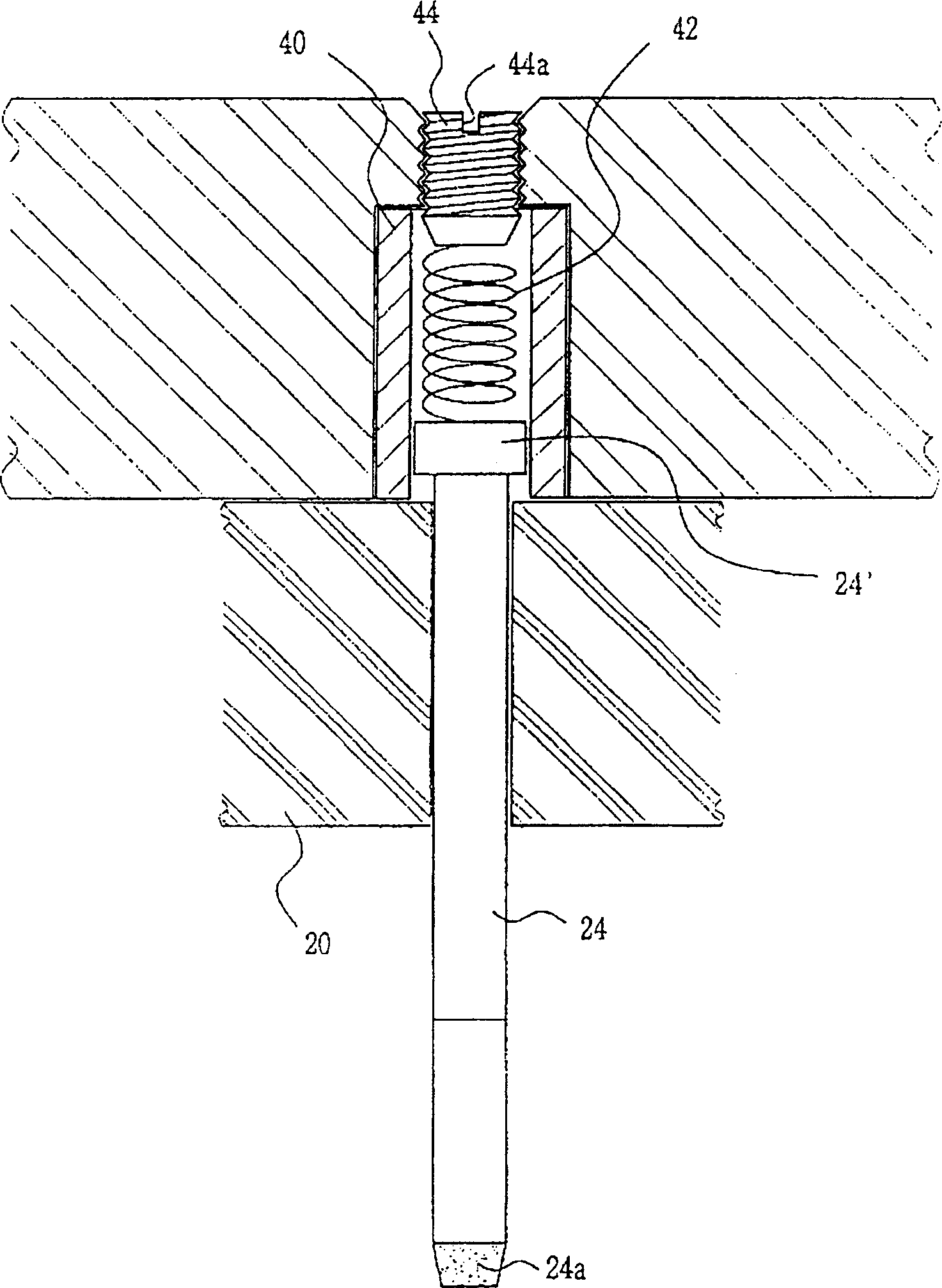

Corrugated fiberboard printing device and box-making machine having the same

ActiveUS20180215119A1Avoid print quality degradationQuality improvementPaper-makingBox making operationsEngineeringFiberboard

A corrugated fiberboard printing device includes a protection device which regulates approaching of a corrugated fiberboard within a predetermined distance against an inkjet head, and a controller. The protection device includes multiple regulation devices which are juxtaposed in a width direction of the corrugated fiberboard, and a movement mechanism which moves each of the multiple regulation devices in the width direction. The controller includes a specific column setting unit which is set to classify a specific column, in which a printing quality is less influenced even when the specific column is regulated by the regulation device, with respect to the corrugated fiberboard in a sheet width direction based on order information, and a movement mechanism control unit which controls the operation of the movement mechanism and moves each of the regulation devices so as to regulate the corrugated fiberboard in the specific column.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

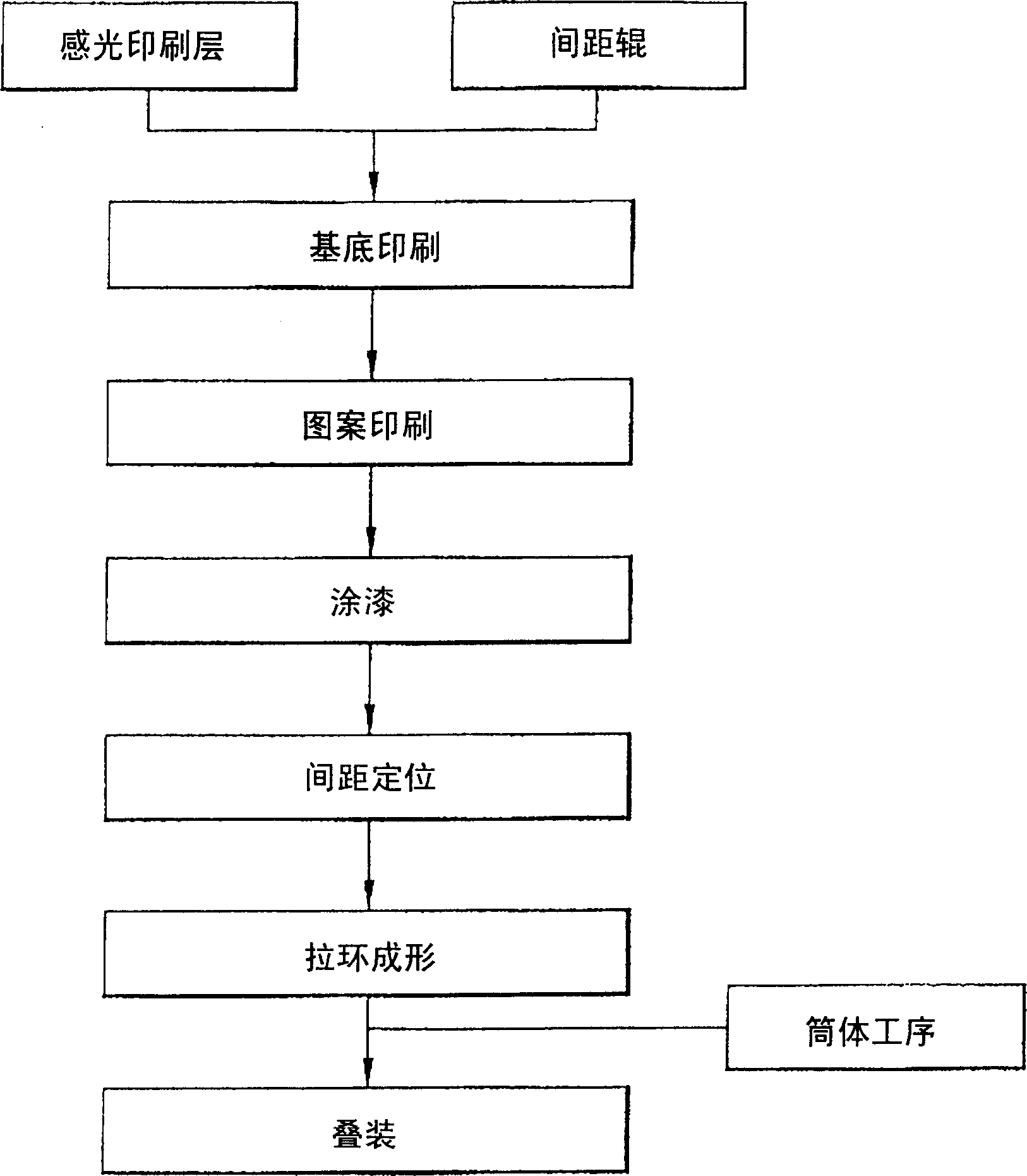

Method of manufacturing an aluminum design tab end for a beverage can

InactiveCN1503733AAvoid print quality degradationLiquid surface applicatorsClosure with auxillary devicesEngineeringVarnish

The present invention relates to a method for manufacturing a design tab end of a beverage can. The present invention is comprised of the steps of, painting a base color on an exact surface position of an aluminium tab coil that is to be formed to a tab through the tab forming process; printing a design on the surface of the tab coil on which the base color has been painted, according to a printing degree; coating a varnish for preventing a deterioration of printing quality during forming and distribution of a product, on the surface of the tab coil on which the design has been printed; arranging a pitch of the tab coil so as to determine an exact position of the tab coil that has been coated with the varnish; press-forming the arranged tab coil with a conversion press; and stacking the tab formed by the press-forming to join the tab on a center of a shell that has been fed previously.

Owner:3C TECH

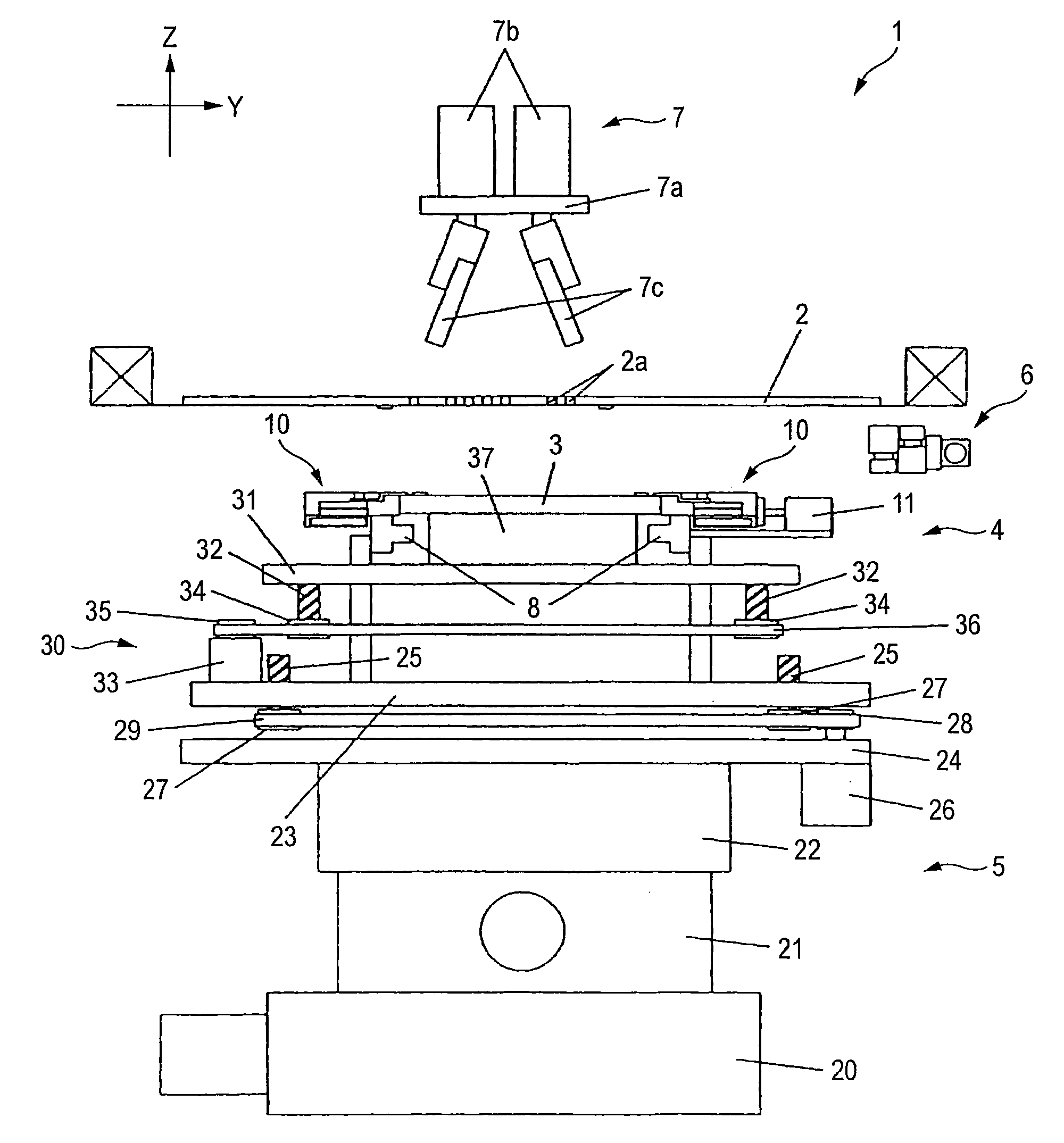

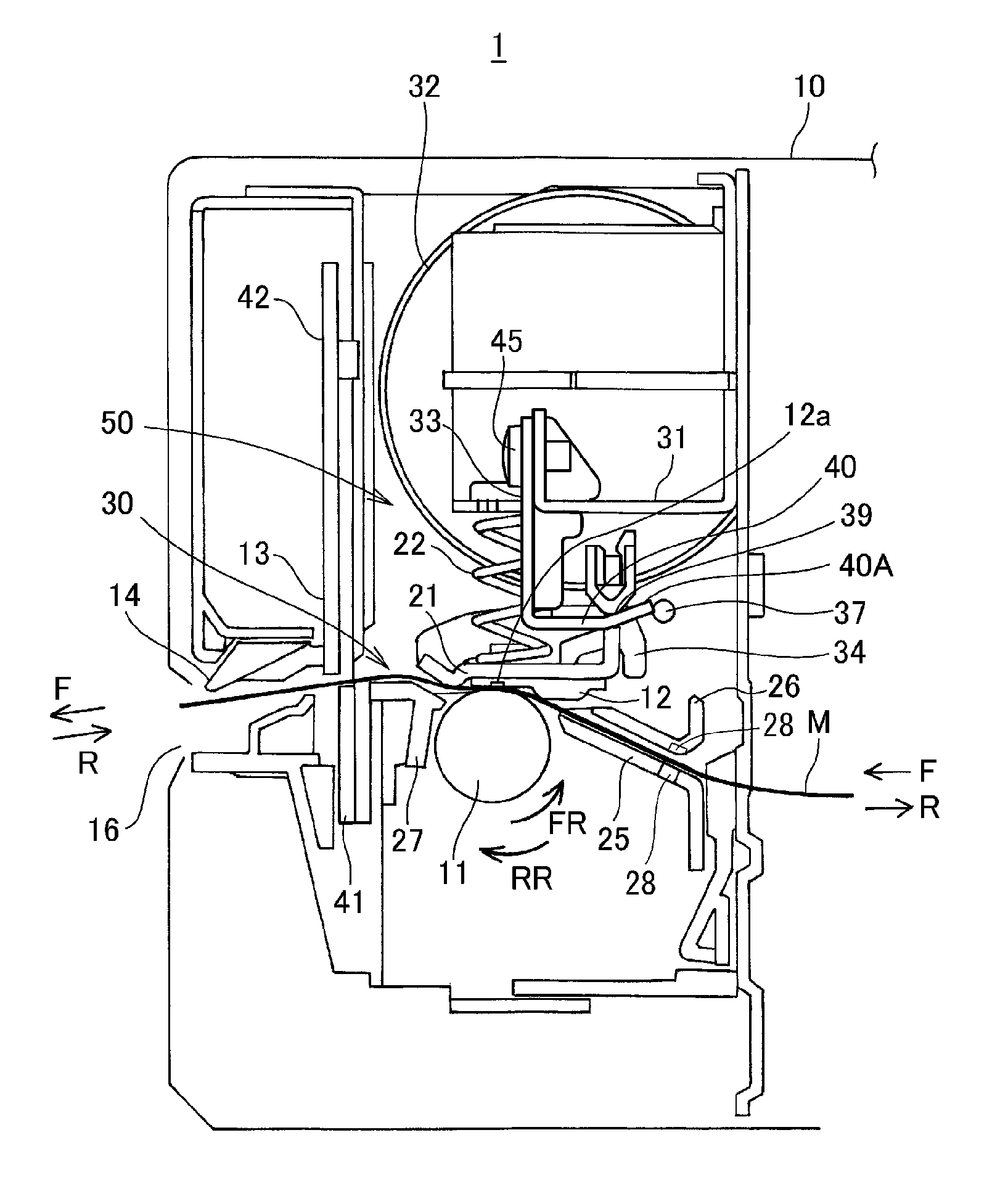

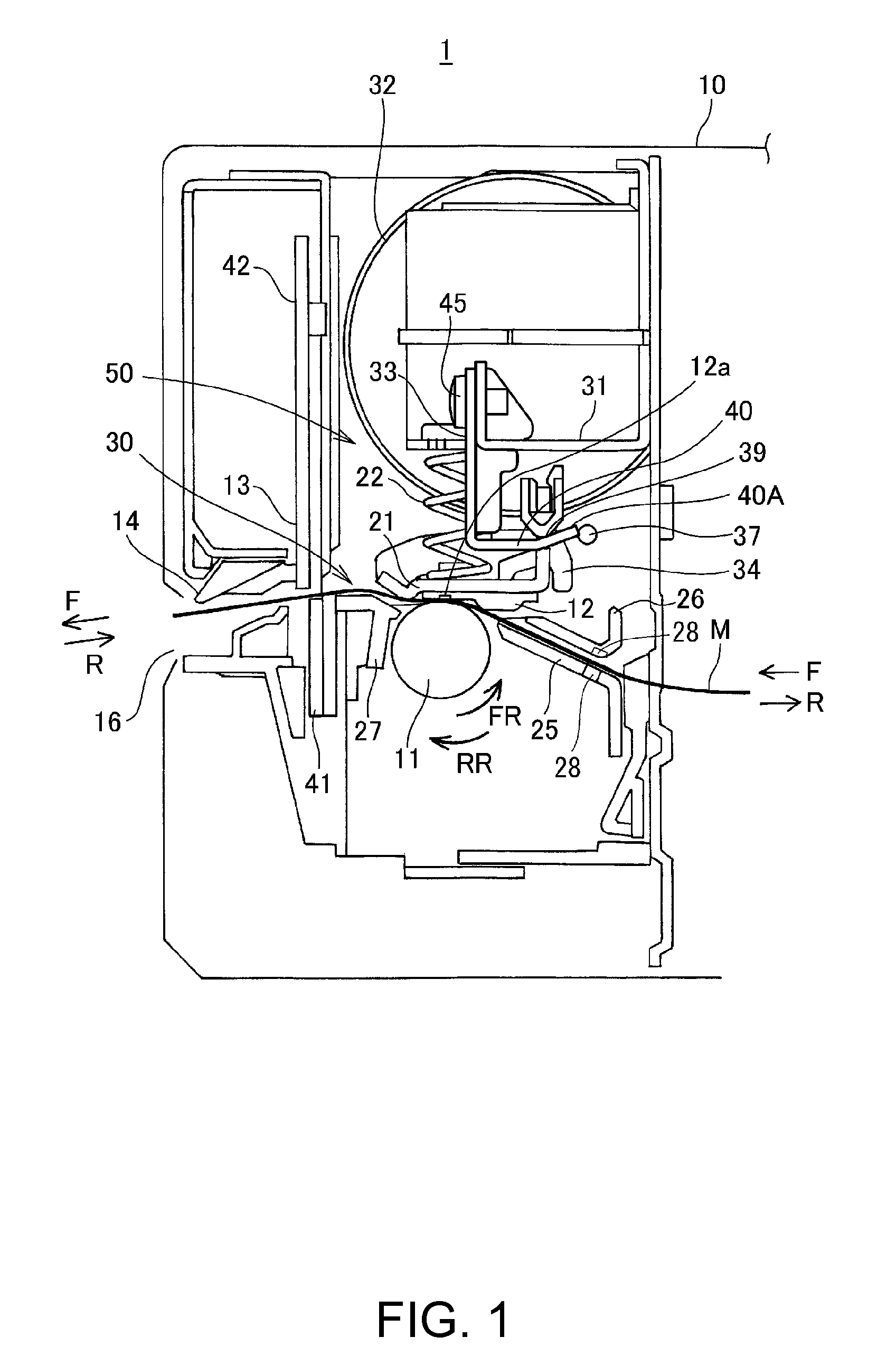

Screen printing apparatus and screen printing method

ActiveUS20090277348A1Operational securityHigh precision printingLiquid surface applicatorsScreen printersScreen printingMechanical engineering

Movable claws 13 are formed in dampers 10 holding a substrate 3 so that the movable claws can be selectively moved to a position where they have projected above the substrate 3, and to a position where they have retreated from above the substrate 3. Thereby, the safety of operation is ensured by causing the movable claws 13 to retreat during maintenance. Moreover, printing with high precision can be performed in a state where the surface of the substrate 3 and the rear face of the mask 2 are brought into surface contact with each other without any clearance by causing the movable claws 13 to retreat.

Owner:PANASONIC CORP

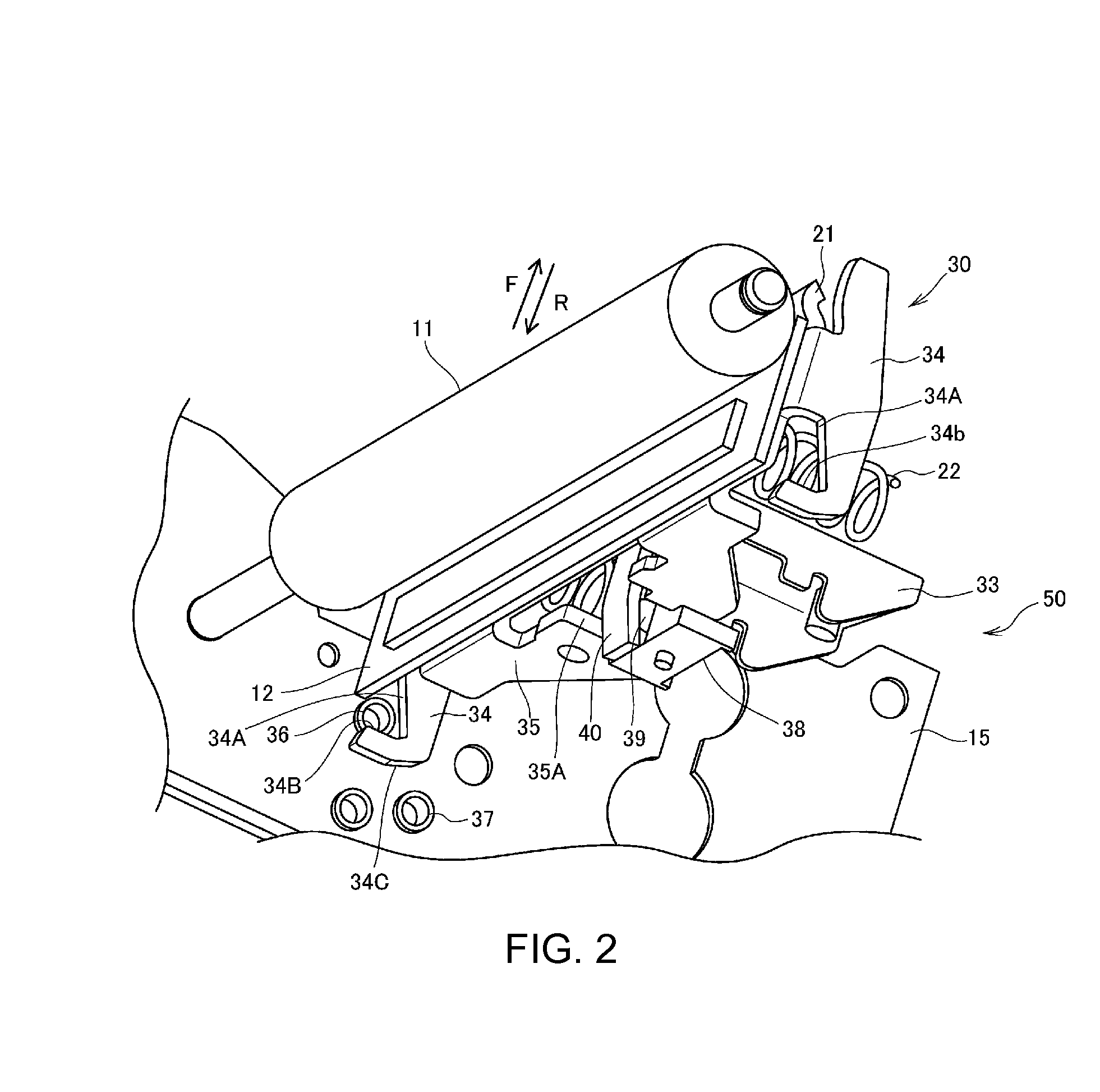

Printing device, printhead, and method of positioning print media in a printer

ActiveUS20150009257A1Accurate compensationCorrect deviationOther printing apparatusPrint mediaMechanical engineering

A printing device and a positioning method of a printing device can accurately compensate for deviation between the intended conveyance of the print medium, and the actual movement of the print medium when conveyed. A printer 5 has a conveyance motor 32 that can selectively convey print media forward and reverse; and a control unit 101 controls the conveyance motor 32 to convey the print medium. The control unit 101 executes a specific sequence, and calculates the difference in the conveyance amount of the print medium in each direction when the conveyance unit is operated the same amount in both directions. This sequence includes changing from forward to reverse and from reverse to forward the same number of times, a first conveyance of the continuous paper M forward or reverse, and a second conveyance in the opposite direction as the first conveyance.

Owner:SEIKO EPSON CORP

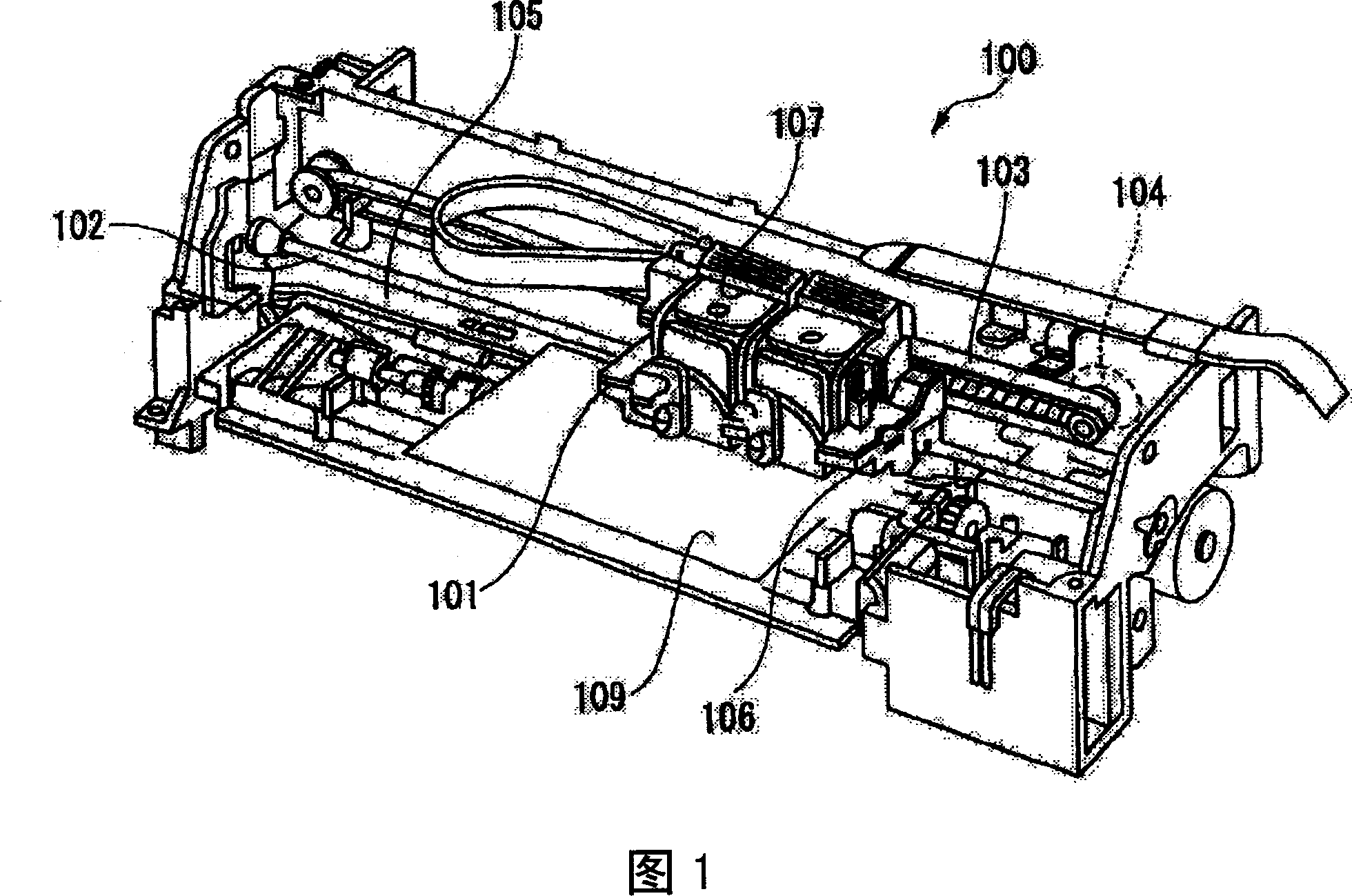

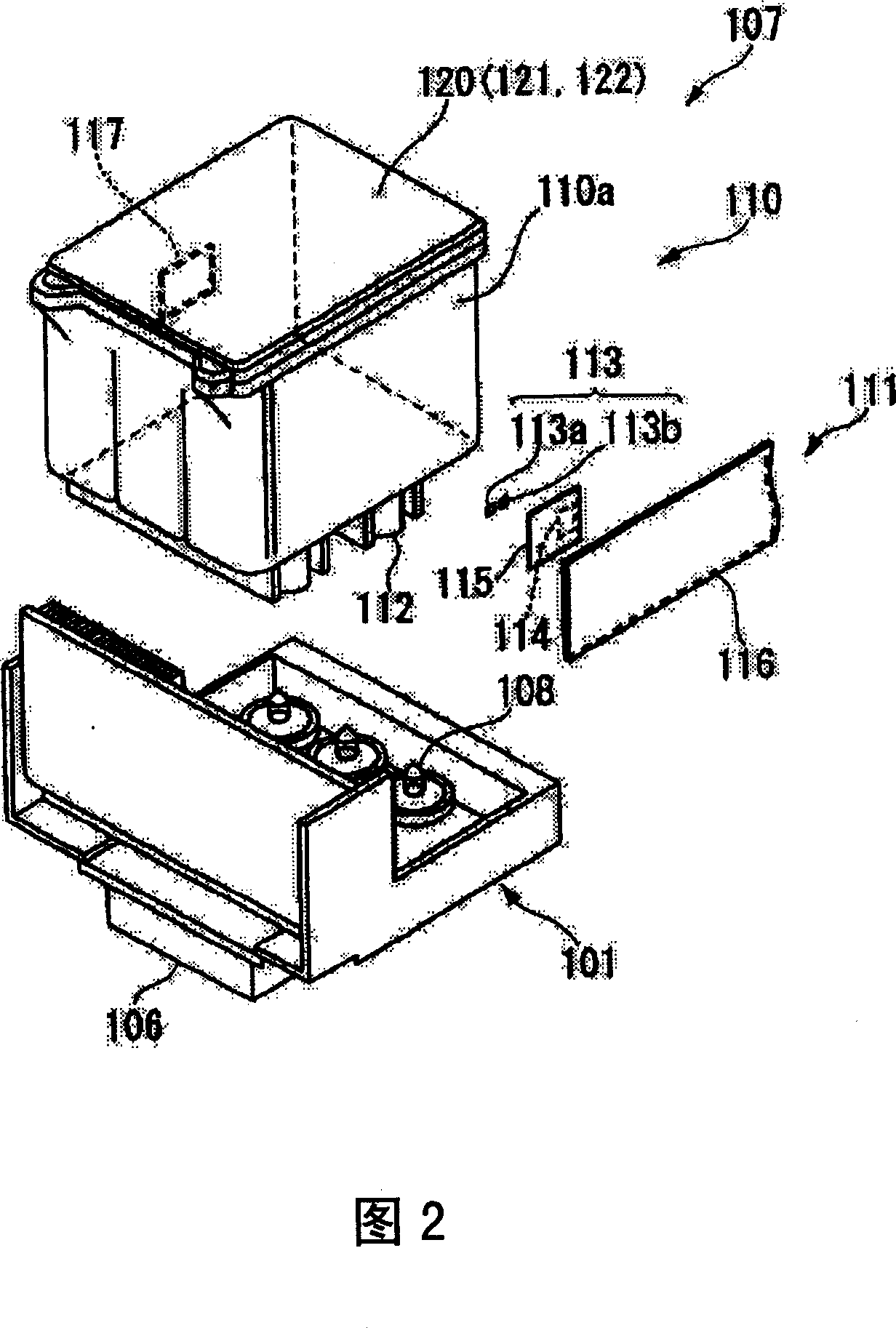

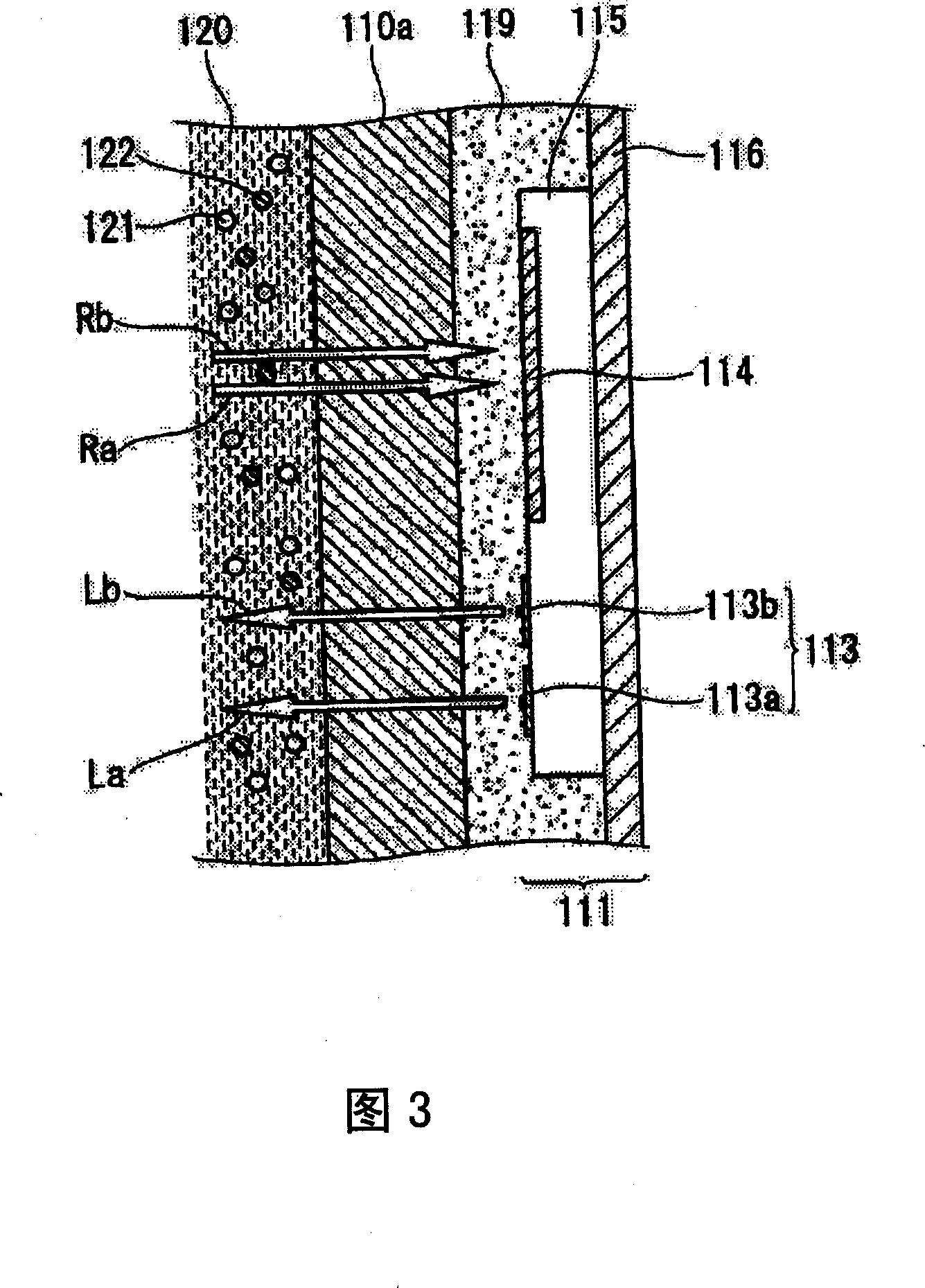

Optical sensor, ink cartridge, and inkjet apparatus

InactiveCN1967214AAvoid damageAvoid print quality degradationSolid-state devicesColor/spectral properties measurementsOptoelectronicsLength wave

An optical sensor 111 for identifying a subject 120 in accordance with the present invention is characterized in that, it has a light emitting device 113 for radiating reference light at a subject 120, and a light receiving device 114 used for receiving the reference light transmitted through the subject 120. Said reference light with light absorption characteristics of the light receiving material 121, 122 contained in said subject 120, has a peak wavelength in an absorption wavelength region of the light absorption materials 121, 122 adjusted independently from the subject. According to the light amount of the reference light transmitting through the subject, said light receiving material 121, 122 is capable of being identified. On the basis of the identifying results, a subject120 is capable of be identified. A high precision optical sensor for identifying a subject such as ink and the like is provided.

Owner:SEIKO EPSON CORP

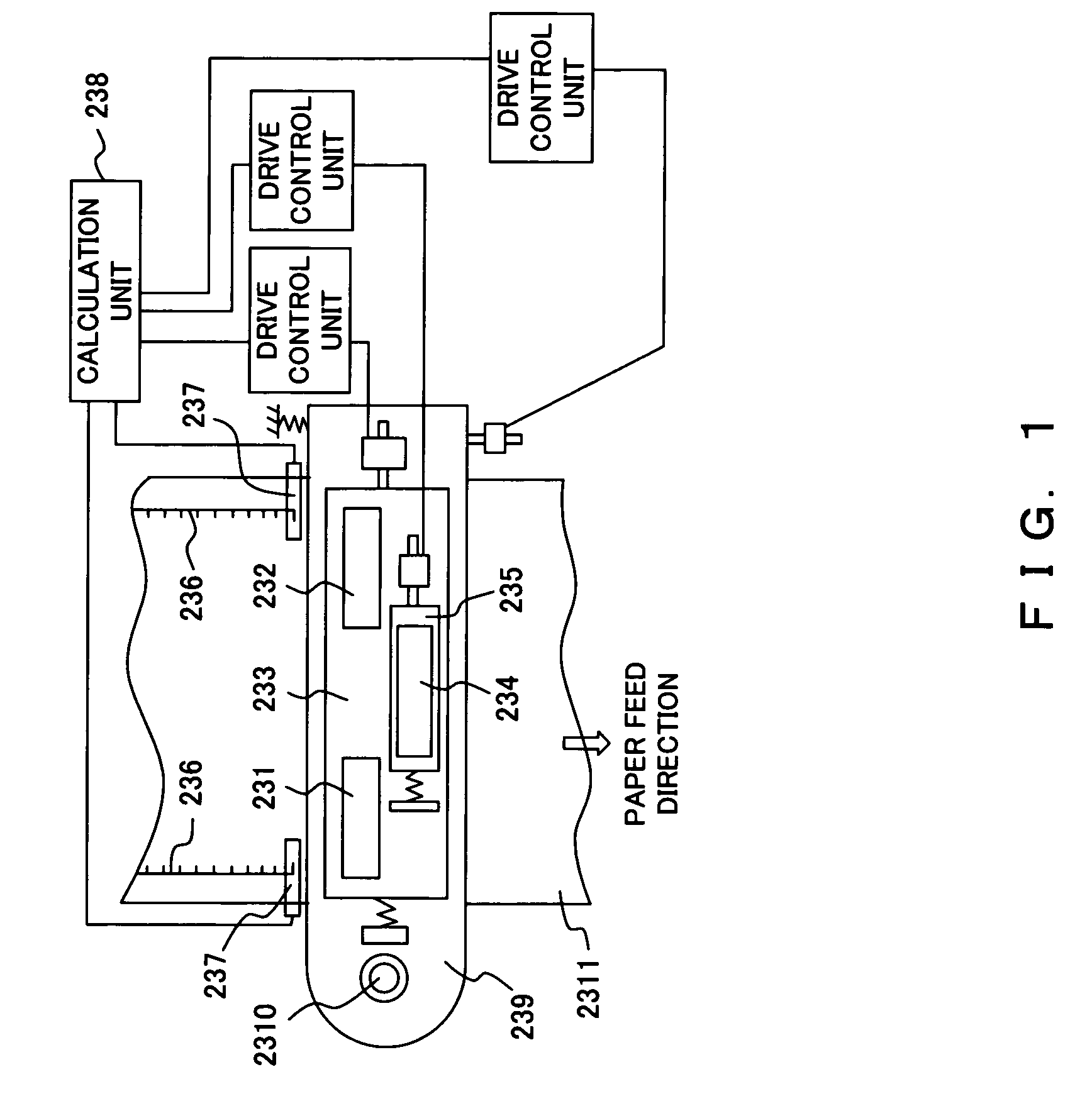

Thermal printer, thermal printer control method, and printing system

ActiveUS20090066778A1VariationQuality improvementRecording apparatusPrinting mechanismsThermal awareIndustrial engineering

A thermal printer 1 and control method for controlling print speed to prevent variation in printing pitch due to frequent slight changes in the print speed following a significant change in print speed. The print speed, which is the speed at which the print medium i.e., paper is conveyed when printing, is controlled based on known print speed control factors. The thermal printer comprises a paper feed mechanism for conveying the print medium at a controlled print speed passed a thermal print head, a print speed control unit 9 for controlling the print speed of the paper feed mechanism based on the print speed control factors, a print speed change acquisition unit 3 for determining the change in the print speed over a predetermined time, and a comparison unit 7 for determining if the change in print speed exceeds a predetermined threshold value. The print speed control unit 9 limits change in the print speed based on the print speed control factors for a predetermined time after the comparison unit 7 determines that the change in print speed exceeds the threshold value.

Owner:SEIKO EPSON CORP

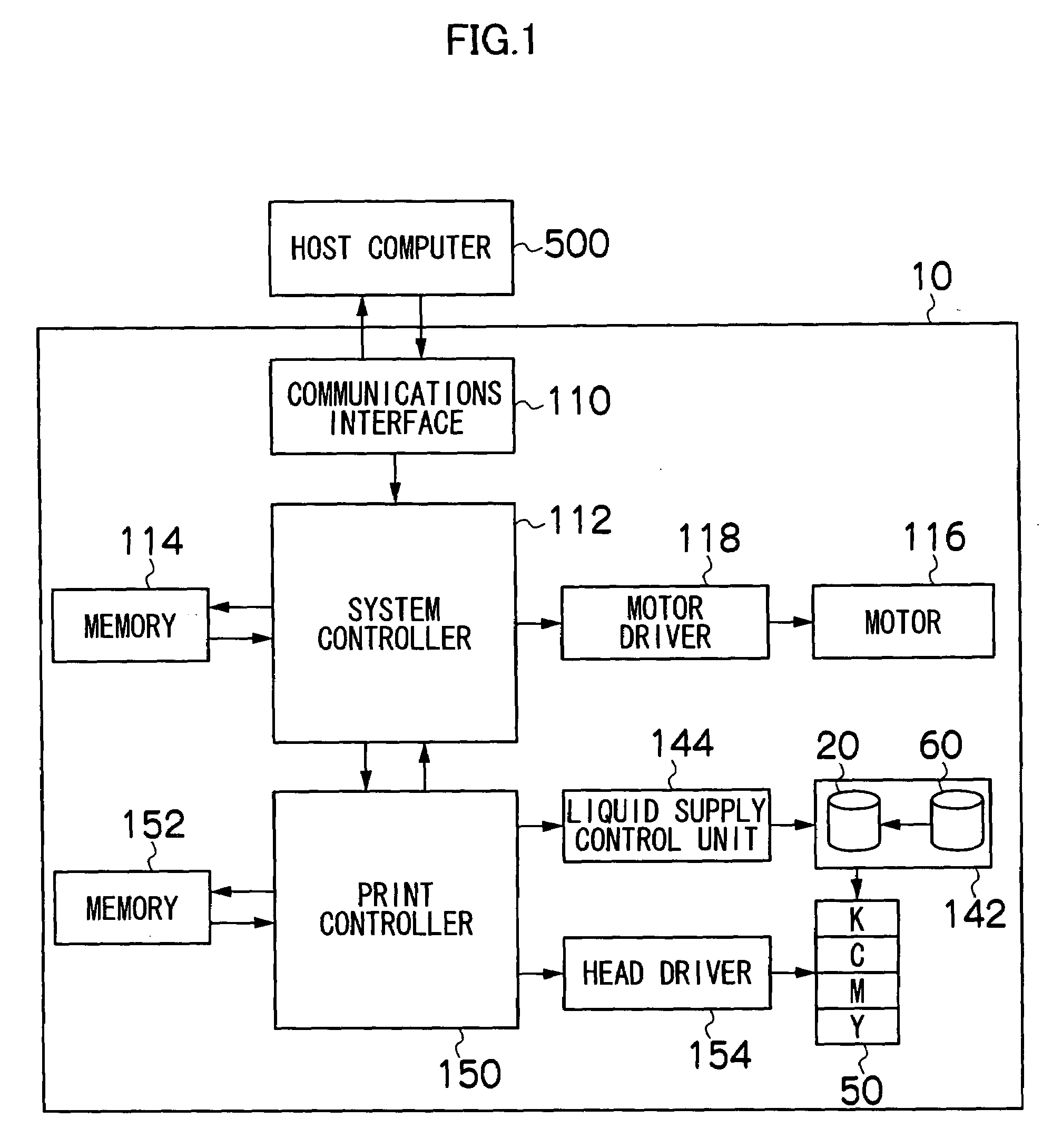

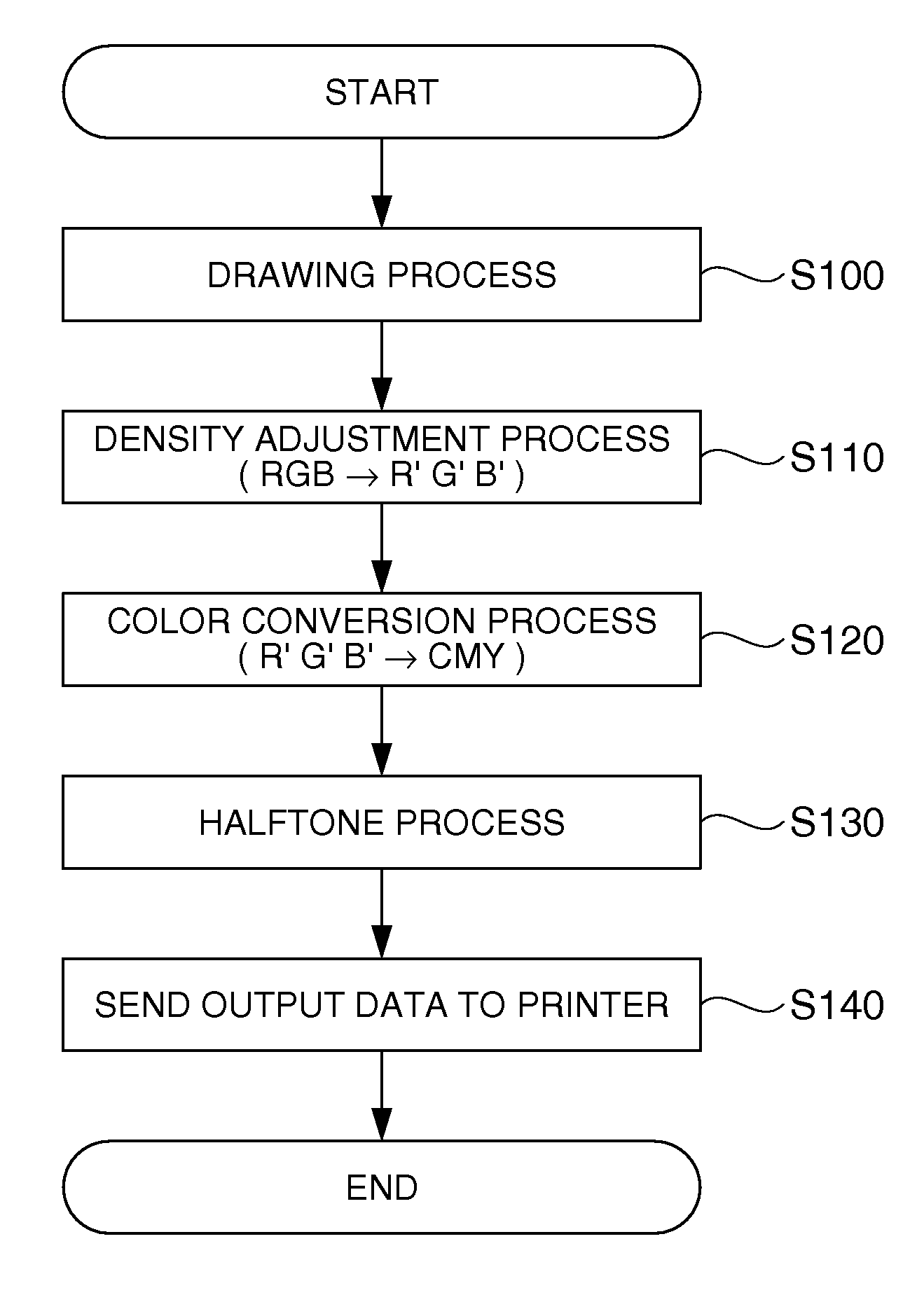

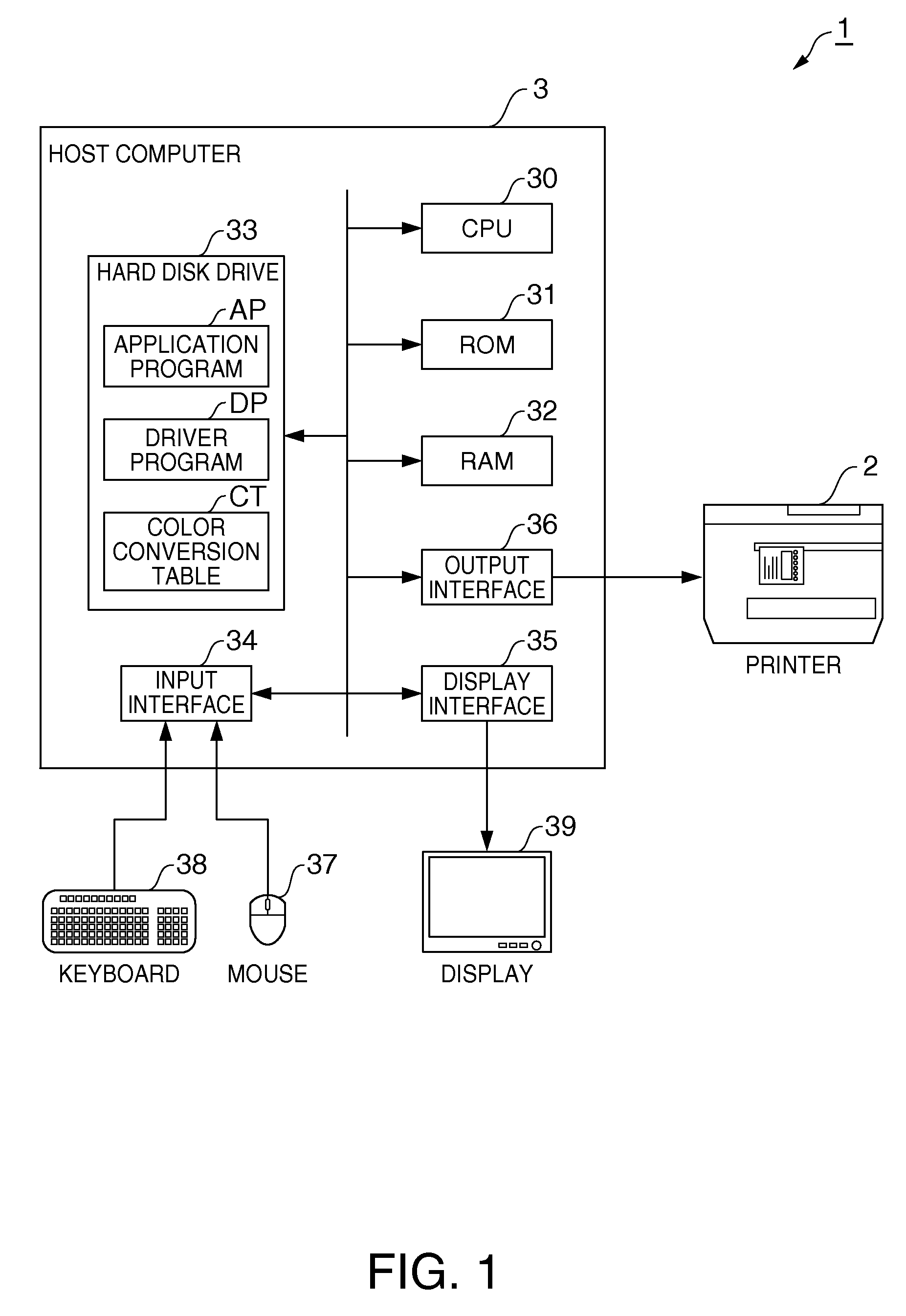

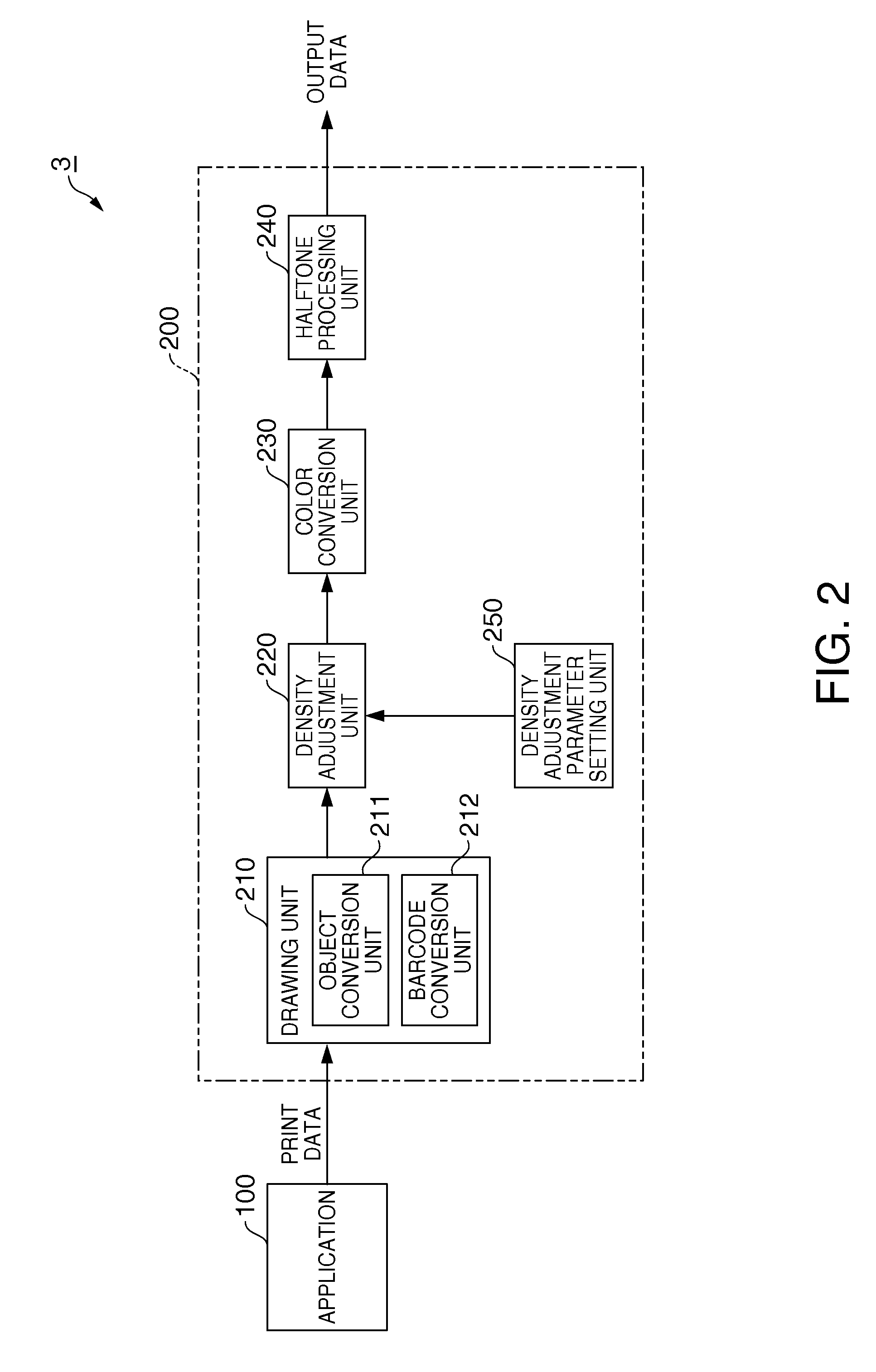

Applying density adjustment in processing barcode image data

ActiveUS8456710B2Quality improvementReduce consumptionImage enhancementDigitally marking record carriersImaging processingComputer printing

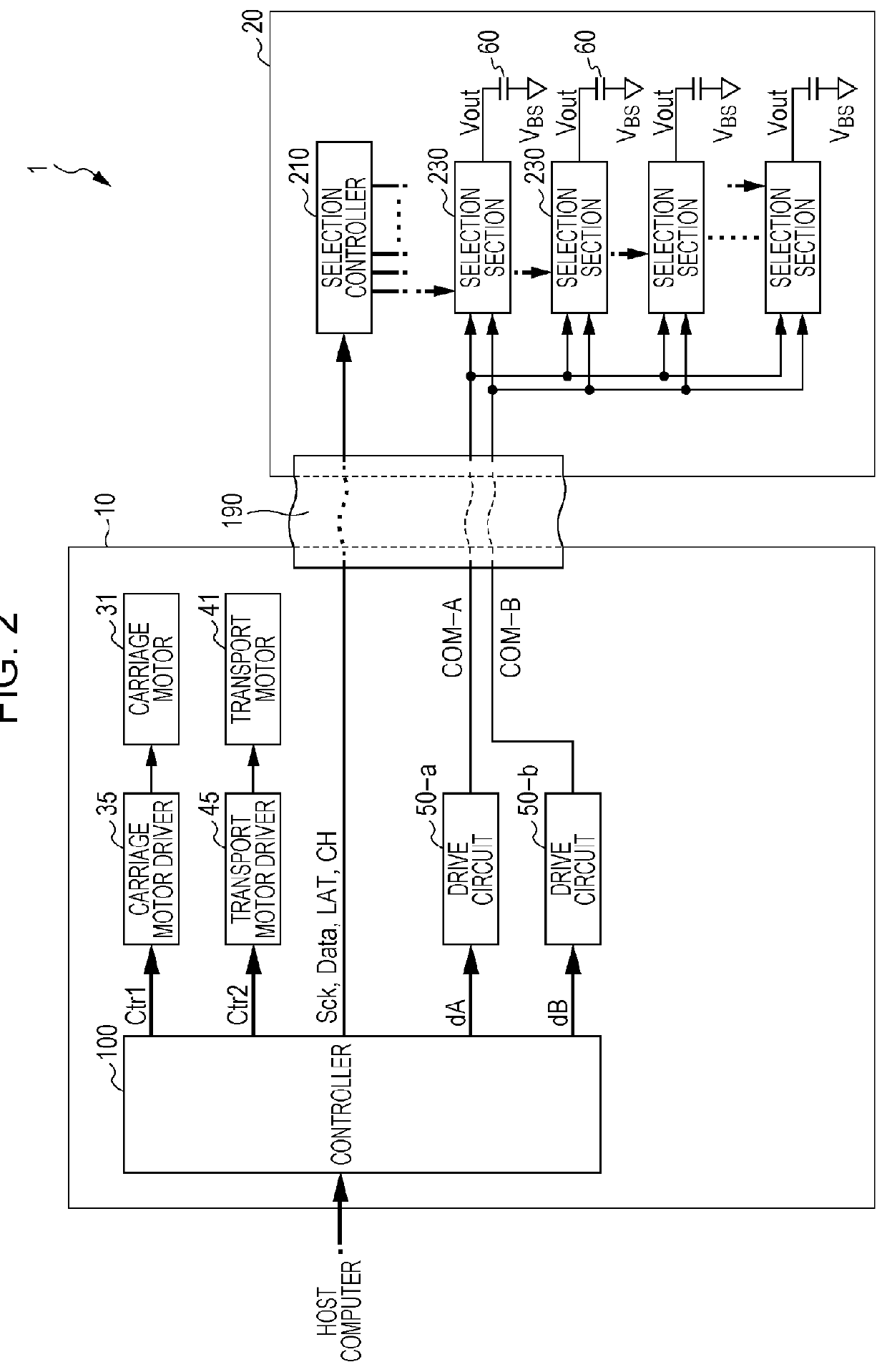

An image processing device and image processing method maintain hue and prevent a drop in print quality while also reducing consumption of recording materials. For example, a host computer 3 that outputs output data for printing to a inkjet printer 2 that uses cyan (C), magenta (M), and yellow (Y) inks has a drawing unit 210 that acquires bitmap data expressing the density of each channel in each pixel of an image to be printed, a density adjustment parameter setting unit 250 that sets an adjustment value according to the ink deposition level when the ink deposition level setting ink usage is received, a density adjustment unit 220 that adjusts the density of the bitmap data to a density corresponding to the set adjustment value, a color conversion unit 230 that converts the density-adjusted bitmap data to CMY image data expressing the usage of each ink, and a halftone processing unit 240 that generates the output data based on the CMY image data.

Owner:SEIKO EPSON CORP

Thermal printer, thermal printer control method, and printing system

ActiveUS7436418B2VariationQuality improvementRecording apparatusOther printing apparatusThermal awareIndustrial engineering

A thermal printer 1 and control method for controlling print speed to prevent variation in printing pitch due to frequent slight changes in the print speed following a significant change in print speed. The print speed, which is the speed at which the print medium i.e., paper is conveyed when printing, is controlled based on known print speed control factors. The thermal printer comprises a paper feed mechanism for conveying the print medium at a controlled print speed passed a thermal print head, a print speed control unit 9 for controlling the print speed of the paper feed mechanism based on the print speed control factors, a print speed change acquisition unit 3 for determining the change in the print speed over a predetermined time, and a comparison unit 7 for determining if the change in print speed exceeds a predetermined threshold value. The print speed control unit 9 limits change in the print speed based on the print speed control factors for a predetermined time after the comparison unit 7 determines that the change in print speed exceeds the threshold value.

Owner:SEIKO EPSON CORP

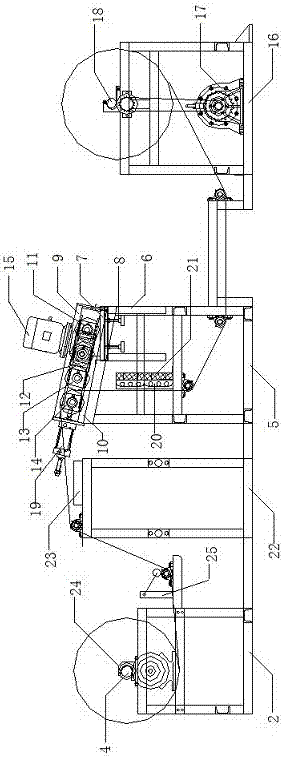

Printing machine for back flocked sand paper

ActiveCN107225852AGuaranteed normal printingAvoid print quality degradationRotary pressesPrinting press partsElectric machinerySand-paper

The invention provides a printing machine for back flocked sand paper. The printing machine sequentially comprises a feeding mechanism, a printing mechanism and a winding mechanism in the advancing sequence of the sand paper and further comprises guide rollers; the feeding mechanism comprises a feeding rack and a feeding shaft; the printing mechanism comprises a printing rack, an ink duct support, an ink duct and a printing piece; the winding mechanism comprises a winding rack, a winding motor and a winding shaft; and the guide rollers are distributed between the feeding mechanism and the printing mechanism and between the printing mechanism and the winding mechanism. With the printing machine, efficient and stable printing can be performed under the condition that the use performance of the back flocked sand paper and back flocked sand cloth is not affected; an ink transfer roller is added, so that clear printing can be guaranteed, and meanwhile, reduction of the printing quality due to relatively much ink can be avoided; the drying efficiency after printing is completed can be remarkably improved, and thus the overall printing quality can be guaranteed; and the printing machine is novel in structure and suitable for popularization and use.

Ink-jet recording apparatus with environmental temperature based drive-signal generation

ActiveUS7658461B2Avoid print quality degradationInking apparatusOther printing apparatusEngineeringActuator

An ink-jet recording apparatus including: (A) an ink-jet head which includes: a channel unit having a plurality of nozzles and a plurality of pressure chambers that respectively communicate with the plurality of nozzles; and an actuator unit which is disposed on the channel unit and to which drive signals are applied, thereby changing a volume of the plurality of pressure chambers; (B) a driver IC which is disposed on the ink-jet head and which includes: a drive-signal generating portion for generating the drive signals and applying the generated drive signals to the actuator unit; and a temperature sensor for detecting an environmental temperature of the actuator unit; and (C) a control device arranged to execute a low-temperature-condition control by controlling the drive-signal generating portion to generate the drive signals so as to change the volume of the plurality of pressure chambers, where the environmental temperature detected by the temperature sensor is not higher than a prescribed first temperature.

Owner:BROTHER KOGYO KK

Inkjet printer cartridge with a compressed air port

A printer cartridge for an inkjet printer including a printing fluid storage, a printhead in fluid communication with the printing fluid storage, an air inlet and one or more conduits arranged to direct air from the air inlet over the printhead.

Owner:SILVERBROOK RES PTY LTD +1

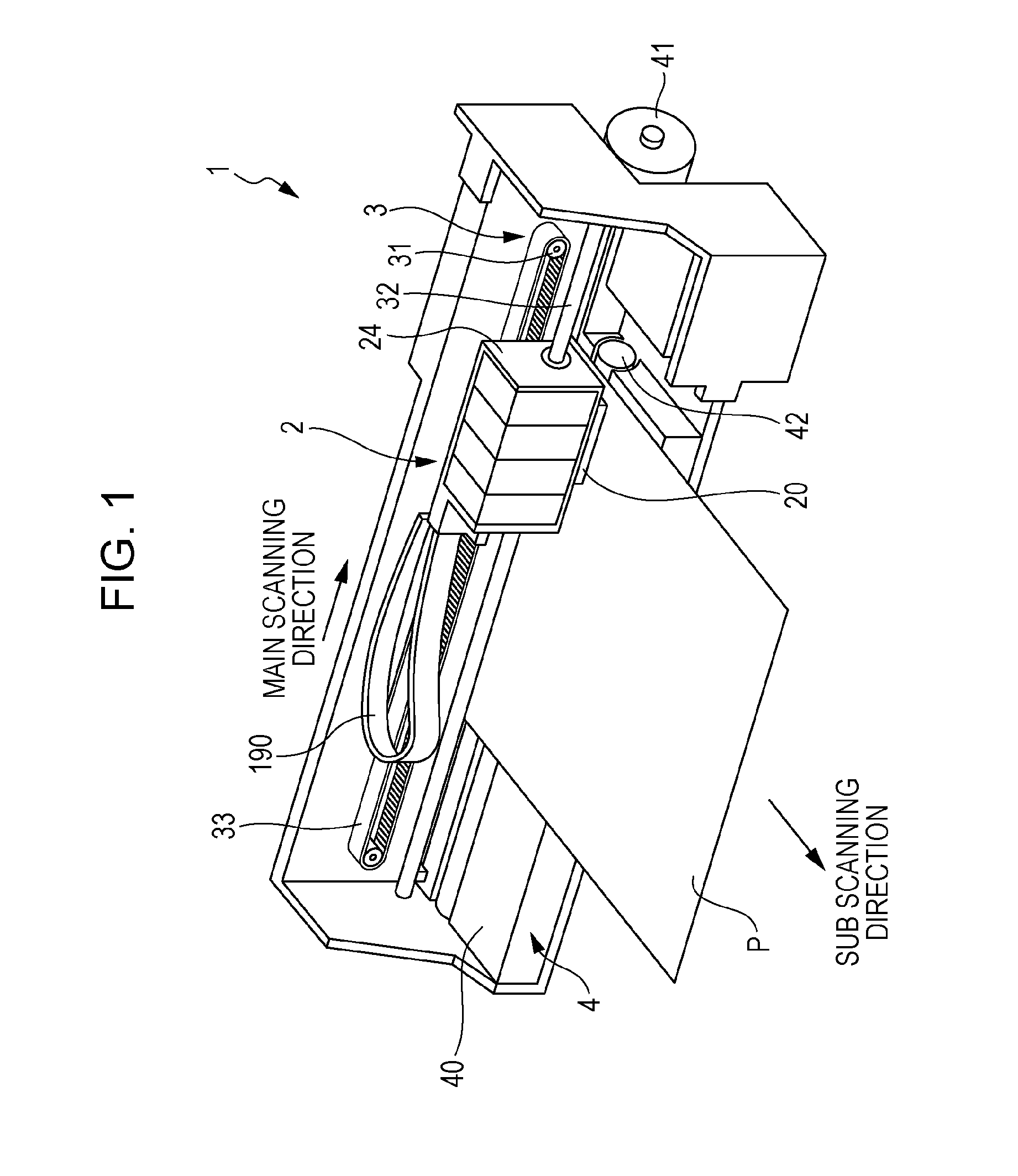

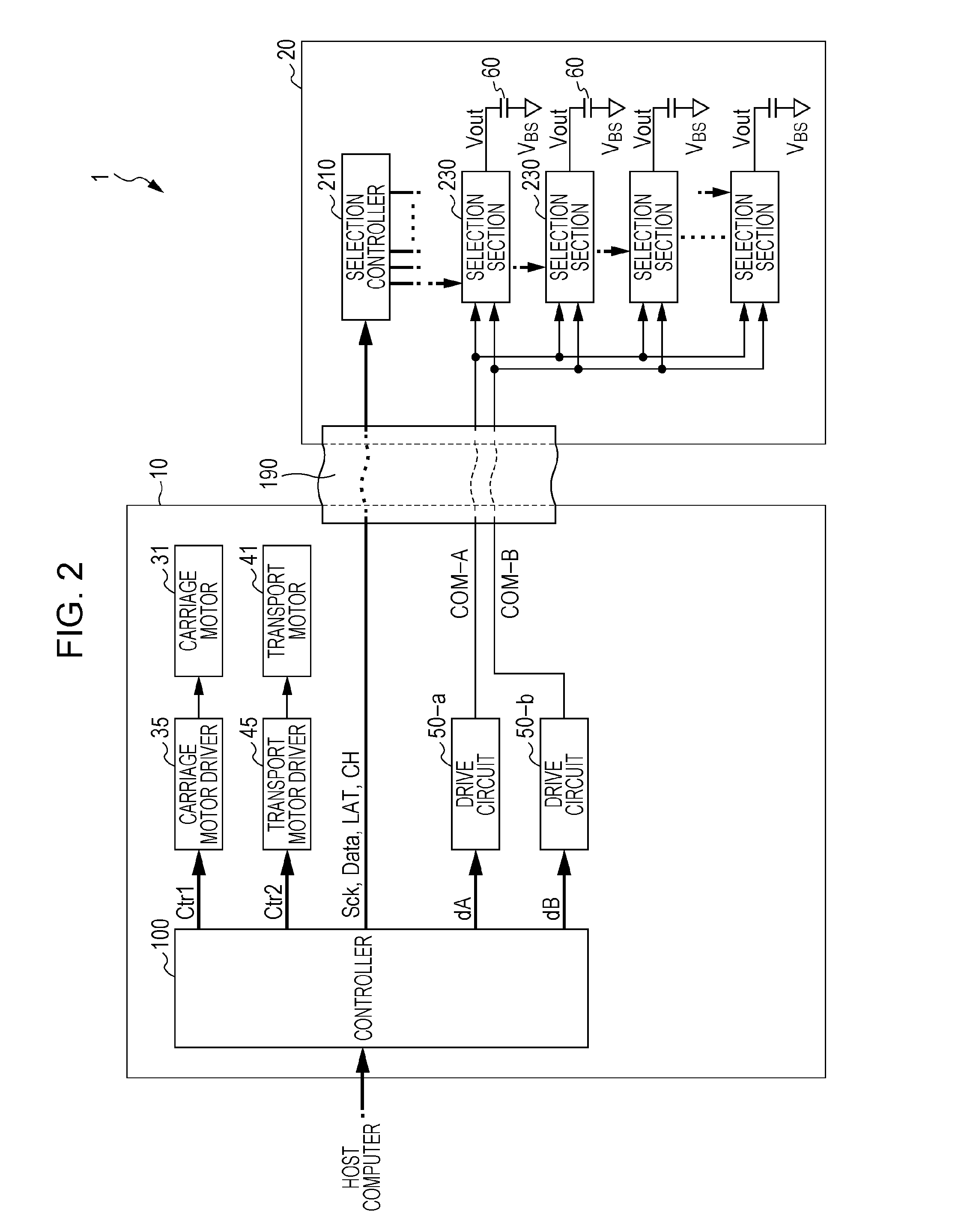

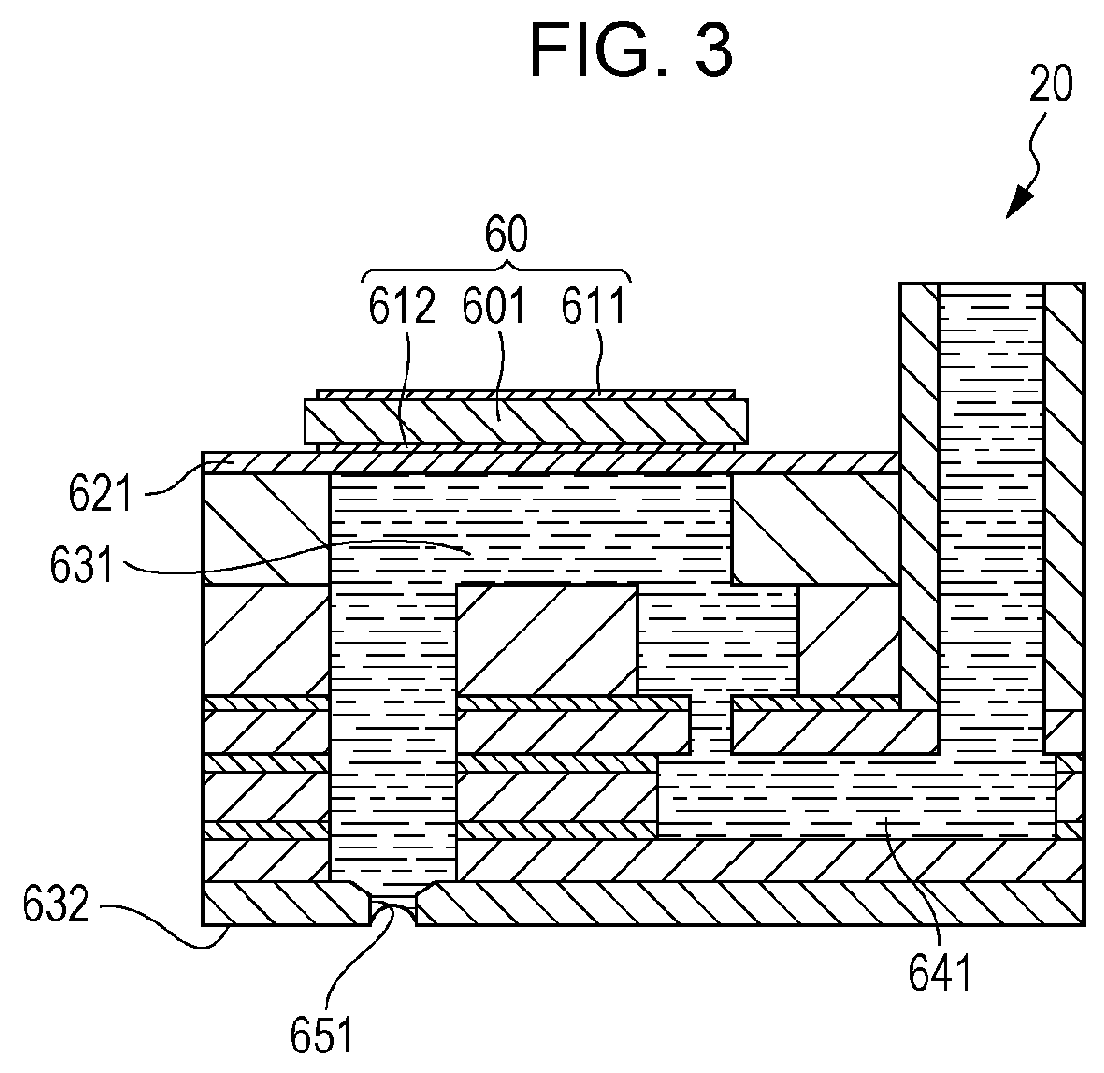

Liquid discharge apparatus and head unit

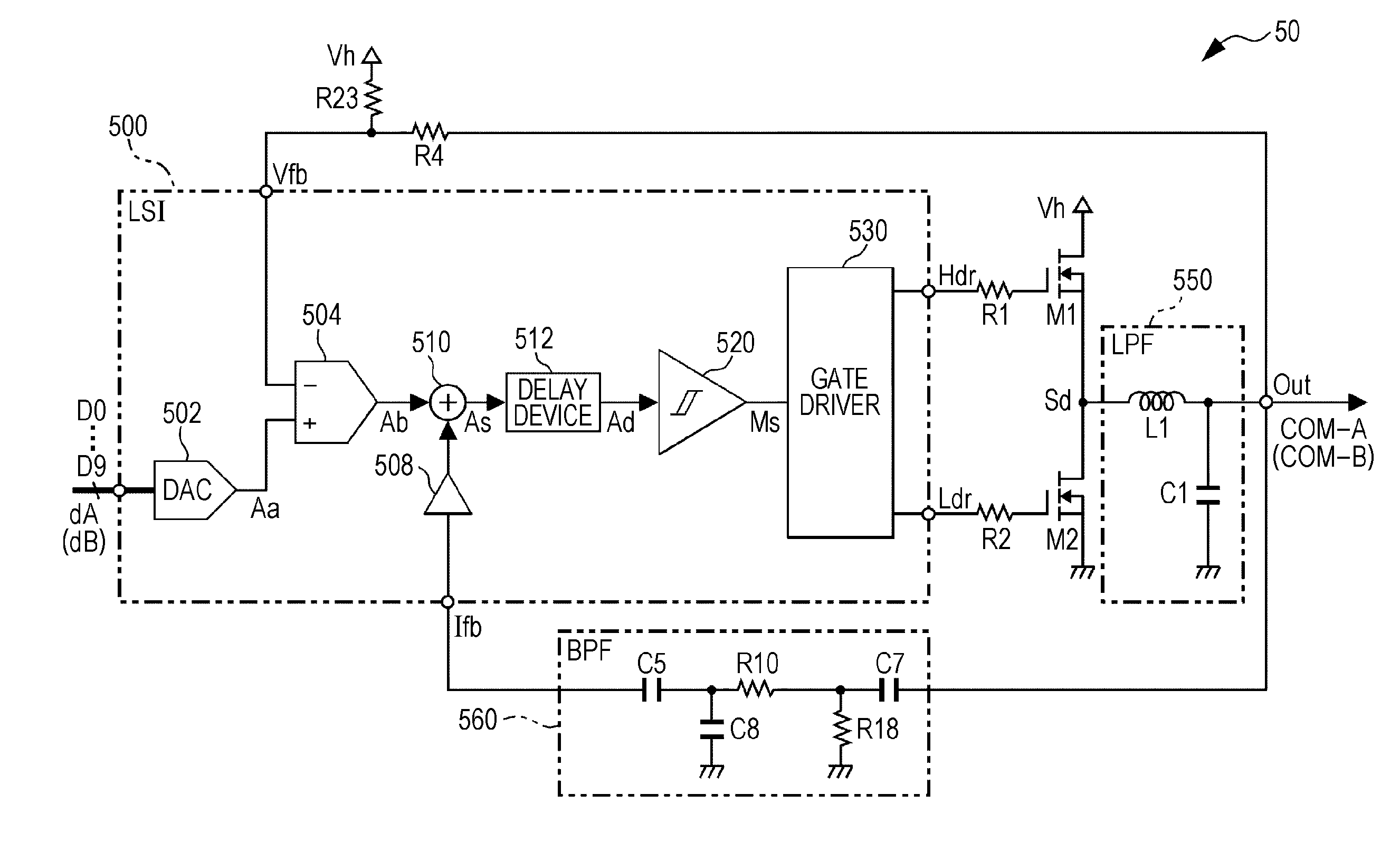

ActiveUS20160046122A1Inhibit deteriorationSimple configurationInking apparatusElectronic switchingSelf-oscillationLow-pass filter

A liquid discharge apparatus includes: a modulation circuit that generates a modulated signal by pulse-modulating a source signal through self-oscillation; a pair of transistors that include a high-side transistor and a low-side transistor and amplify the modulated signal to generate an amplified modulated signal; a low-pass filter that includes an inductor and a capacitor and smoothes the amplified modulated signal to generate a drive signal; a piezoelectric element that is displaced by application of the drive signal thereto; a cavity that is filled with a liquid inside and has an internal volume which changes when the piezoelectric element is displaced; and a nozzle that is provided to discharge the liquid inside the cavity in response to the change of the internal volume of the cavity. A shortest distance between the low-side transistor and the capacitor is shorter than a shortest distance between the high-side transistor and the capacitor.

Owner:SEIKO EPSON CORP

Liquid discharge apparatus and head unit

ActiveUS9375917B2Inhibit deteriorationSimple configurationInking apparatusElectronic switchingElectricityLow-pass filter

A liquid discharge apparatus includes: a modulation circuit that generates a modulated signal by pulse-modulating a source signal through self-oscillation; a pair of transistors that include a high-side transistor and a low-side transistor and amplify the modulated signal to generate an amplified modulated signal; a low-pass filter that includes an inductor and a capacitor and smoothes the amplified modulated signal to generate a drive signal; a piezoelectric element that is displaced by application of the drive signal thereto; a cavity that is filled with a liquid inside and has an internal volume which changes when the piezoelectric element is displaced; and a nozzle that is provided to discharge the liquid inside the cavity in response to the change of the internal volume of the cavity. A shortest distance between the low-side transistor and the capacitor is shorter than a shortest distance between the high-side transistor and the capacitor.

Owner:SEIKO EPSON CORP

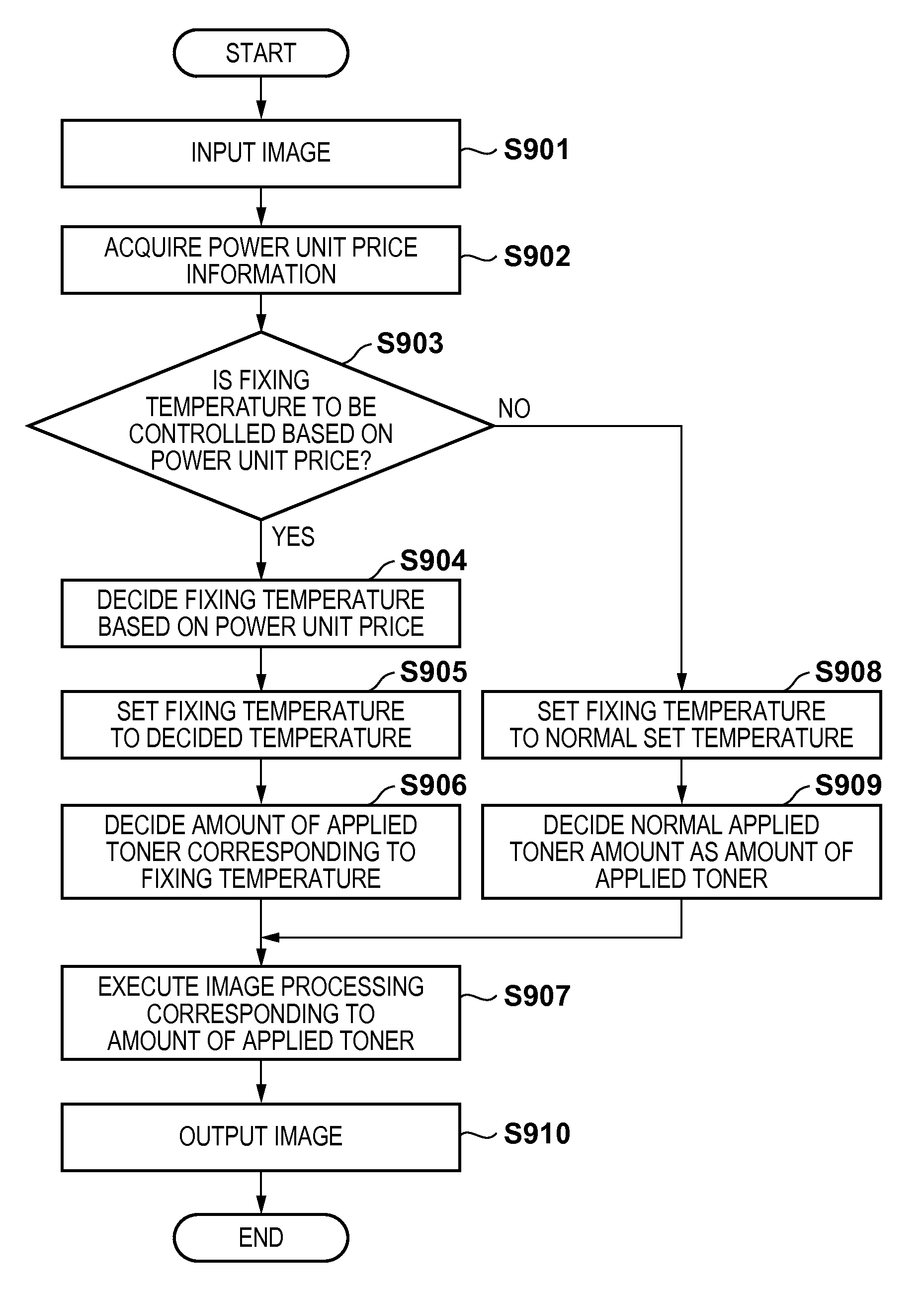

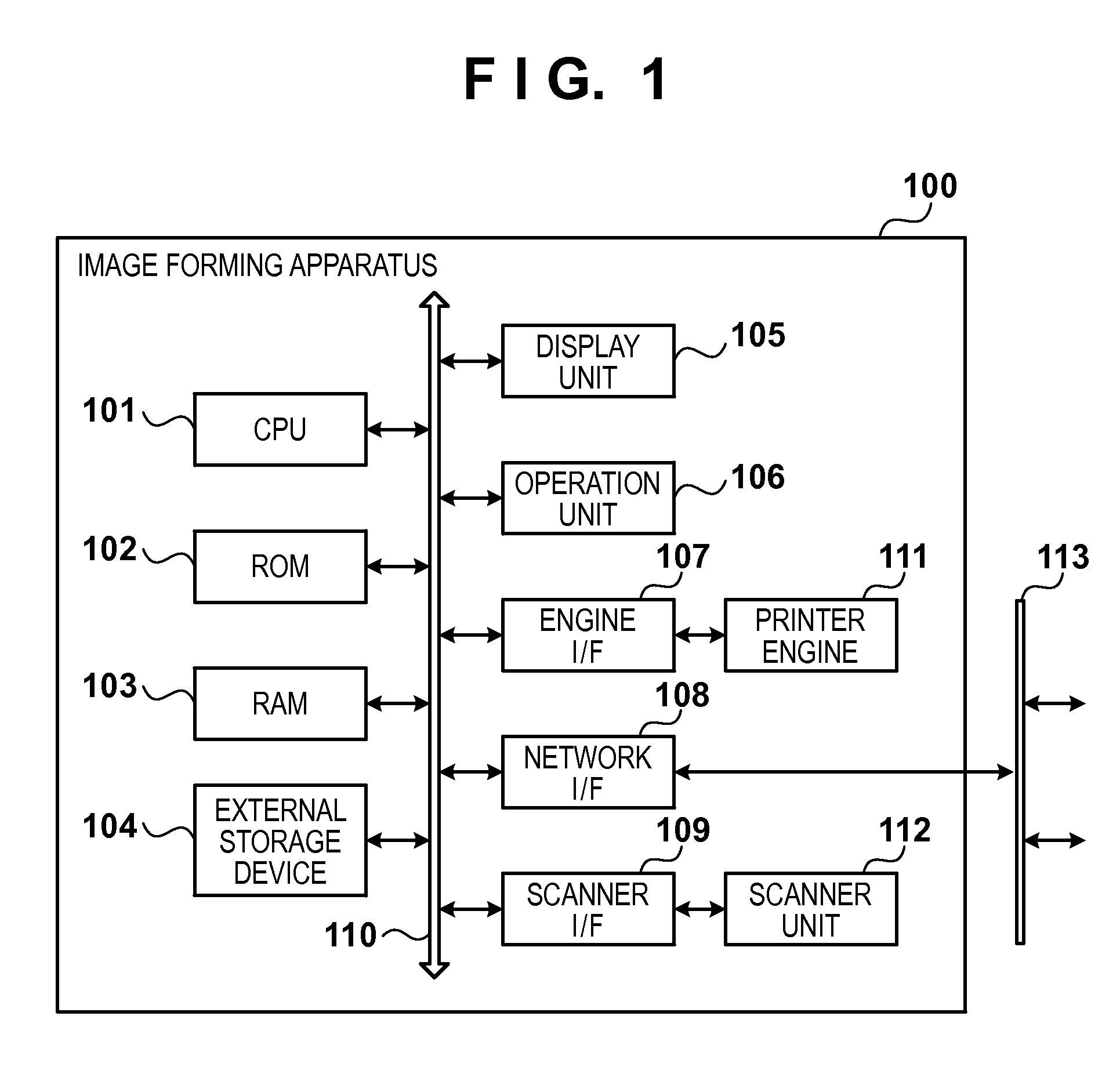

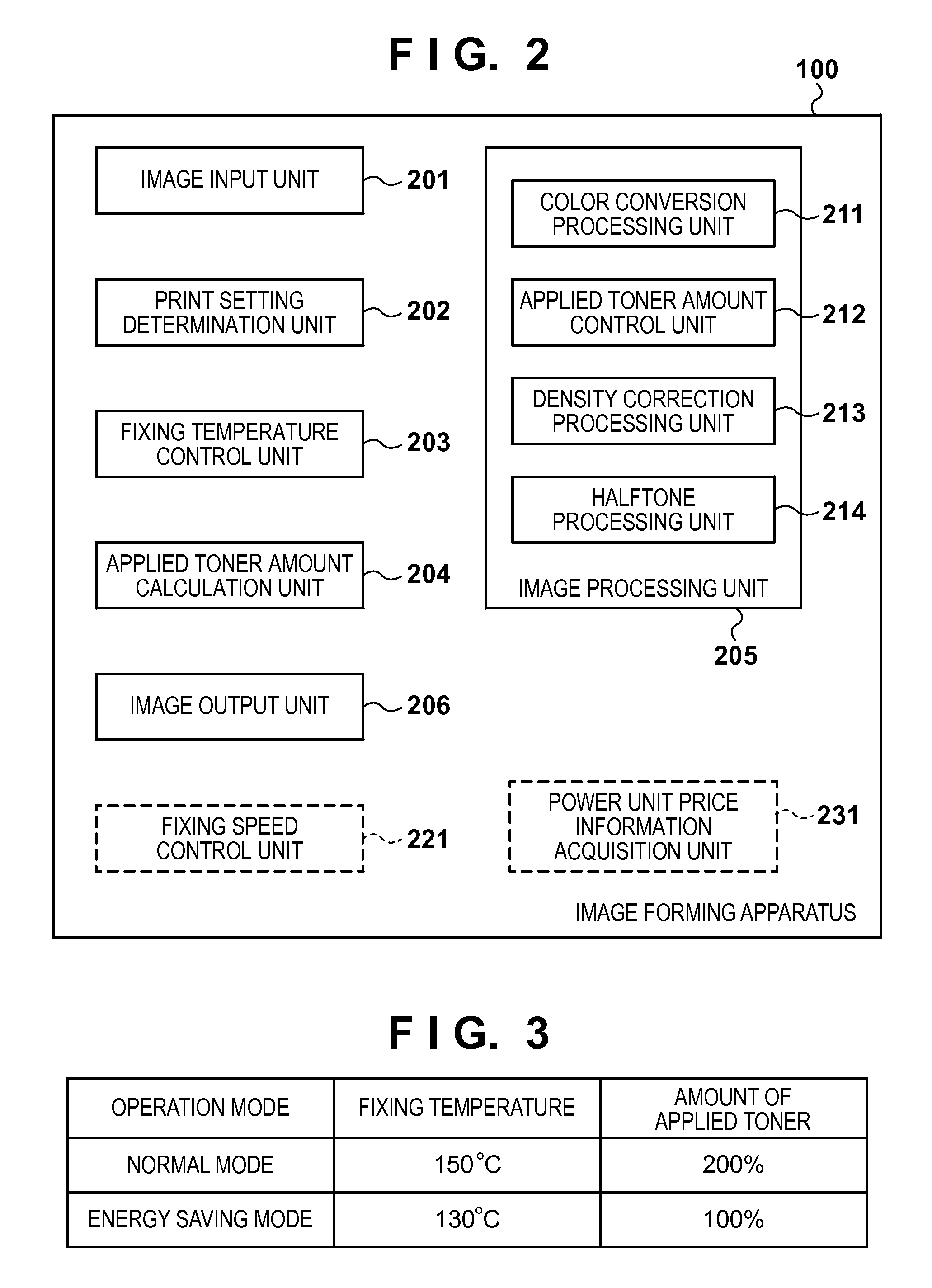

Image forming apparatus with controlled fixing temperature, control method and storage medium

InactiveUS9104147B2Reduce power consumptionAvoid print quality degradationElectrographic process apparatusNormal modeImage formation

An image forming apparatus according to an aspect of this invention controls a fixing temperature when a fixing device of a printer engine fixes an image on a recording material. More specifically, the image forming apparatus sets the fixing temperature to a value lower than that in a normal mode when printing an image in a power saving mode, and decides an amount of applied toner with which the fixing device can fix the image on the recording material at the set fixing temperature. Furthermore, the image forming apparatus generates print data corresponding to the decided amount of applied toner from input image data, and prints the image on the recording material based on the generated print data.

Owner:CANON KK

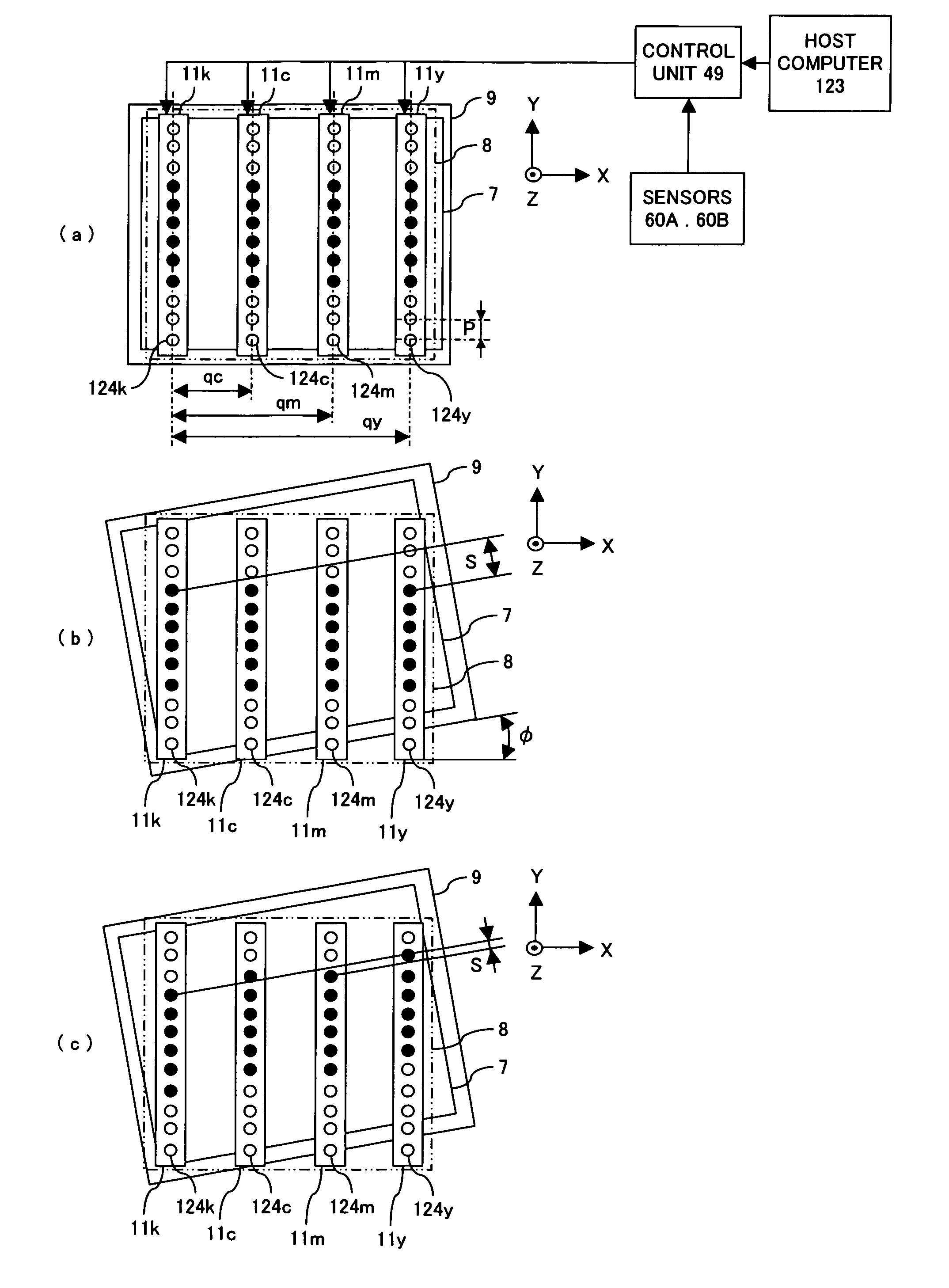

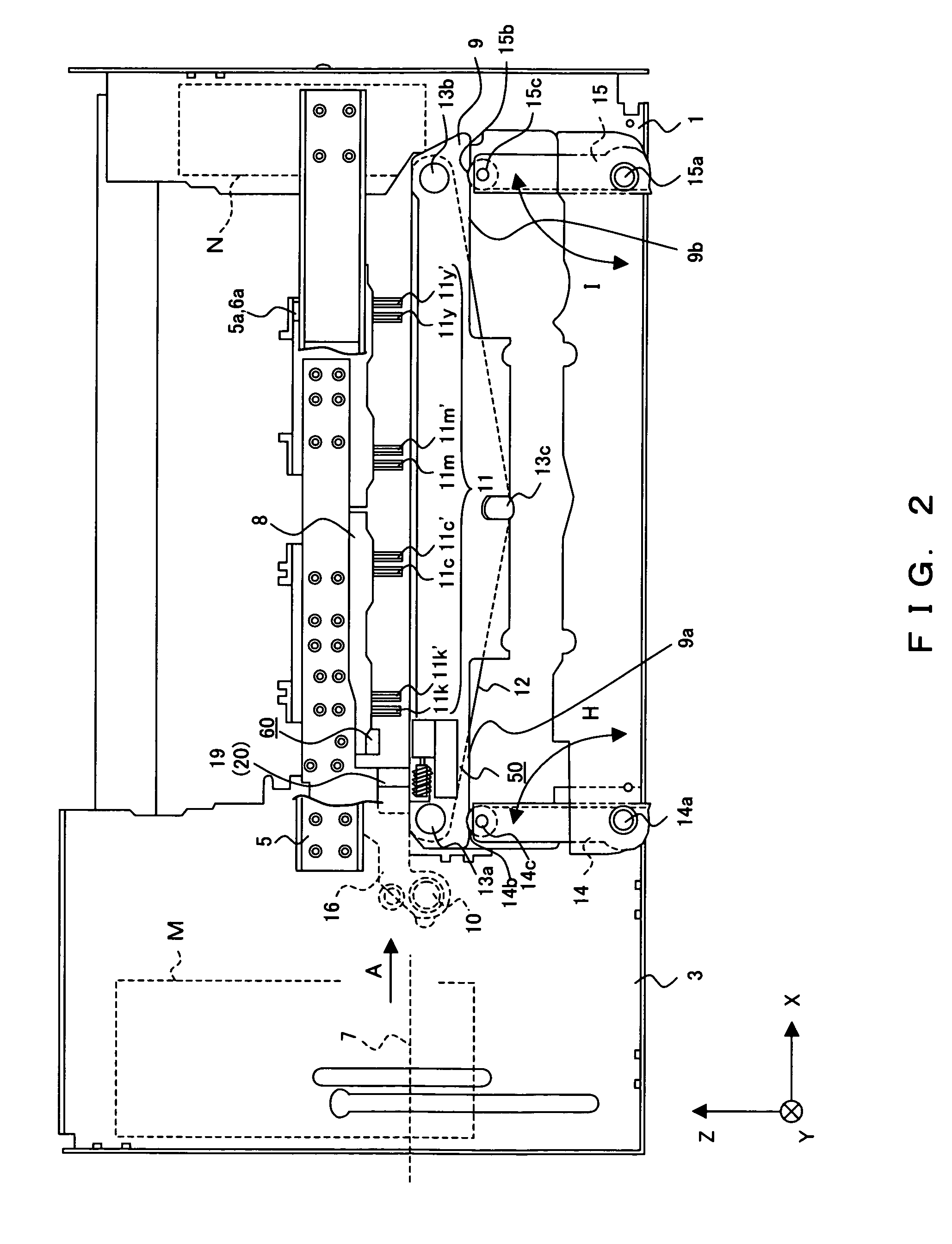

Image forming apparatus having position detection mechanism

ActiveUS7828400B2Avoid print quality degradationPower drive mechanismsOther printing apparatusImage formationRecording media

In an image forming apparatus having a recording head including a plurality of nozzle arrays for ejecting each ink droplet per color for plural colors respectively onto a transported recording medium, a positioning mechanism of the image forming apparatus having a detection mechanism for preventing a printing quality on a recording medium from degrading by comprising a transport mechanism for transporting in order to form an image on the recording medium, and a carriage placed on an opposite positions of the transport mechanism and a belt platen; placing a sensor for detecting a relative inclination between the transport direction and the recording head; detecting and calculating an inclination of the transport direction vis-à-vis the recording head, and controlling the relative inclination based on the calculation result.

Owner:RISO KAGAKU CORP

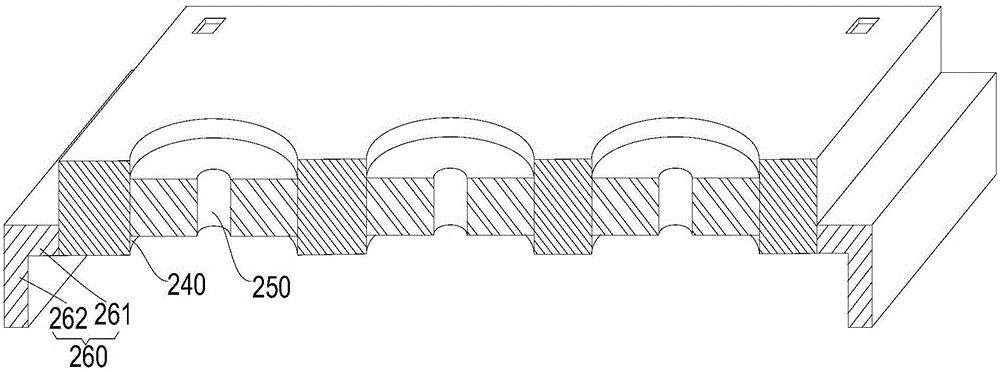

Mold used for electrode coating and electrode coating device provided with mold

The invention relates to a mold used for electrode coating and an electrode coating device provided with the mold, and belongs to the field of material coating. The mold comprises a first end face and a second end face opposite to the first end face. The first end face is provided with at least one first groove. The first end face and the second end face are provided with a first connecting part and a second connecting part correspondingly. The two opposite ends of the second end face are provided with third connecting parts correspondingly. Through the mold, samples can be fixed, the coating effect of slurry on the surfaces of the samples is improved, and the printing quality is improved. The electrode coating device comprises the mold, a screen mesh frame and a mold platform. The silk screen frame is provided with screen meshes corresponding to the at least one first groove in a one-to-one mode. The silk screen frame is detachably connected with the first connecting part. The mold platform is detachably connected with the second connecting part. The samples can be fixed by the device, the contact effect of the slurry and the samples during printing is improved, and the printing quality is improved.

Owner:YANCHENG INST OF TECH

Printing device, server device and consumables

ActiveCN111845089AAvoid print quality degradationAvoid failurePrintingSpecial data processing applicationsComputer scienceDatabase

A printing device, a server device and consumables are provided. The printing device includes: a first comparison unit that compares the first comparison information generated by the printing device based on the consumable storage information stored in a consumable storage with the second comparison information generated based on the consumable storage information and stored in a memory; and a second comparison unit that compares the third comparison information generated by the printing device based on the acquisition information of the printing device with the fourth comparison information generated based on the acquisition information of the consumables and stored in the memory; a determination unit that whether the consumables are installed in the printing device for the first time ornot based on the number of times of installation, corresponding to the printing device, acquired from a server; and an authentication unit that authenticates the consumables as permitted when the first and second comparison units determine that the first comparison information and the second comparison information are consistent and the third comparison information and the fourth comparison information are consistent, and the determination unit determines that the consumables are installed for the first time.

Owner:RISO KAGAKU CORP

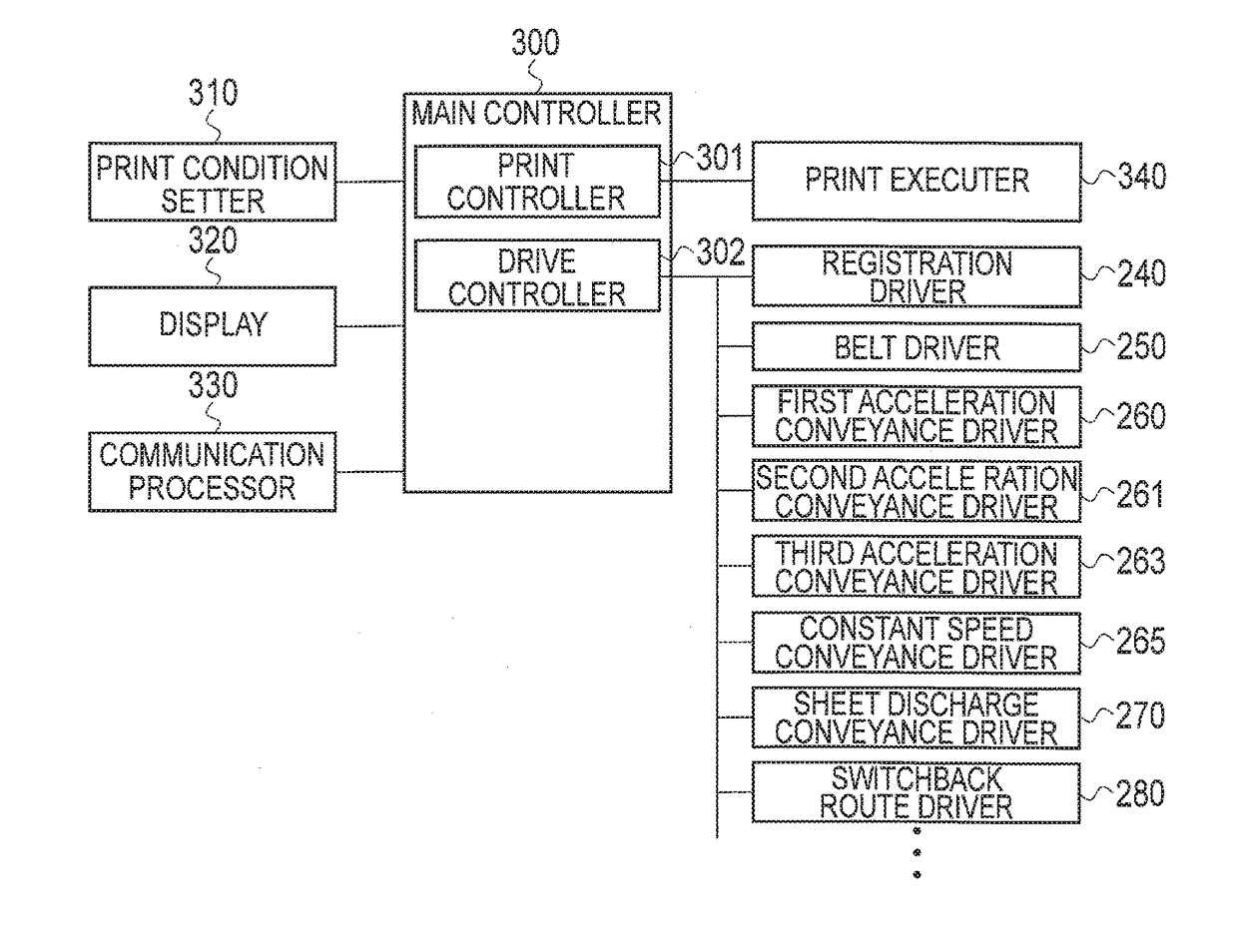

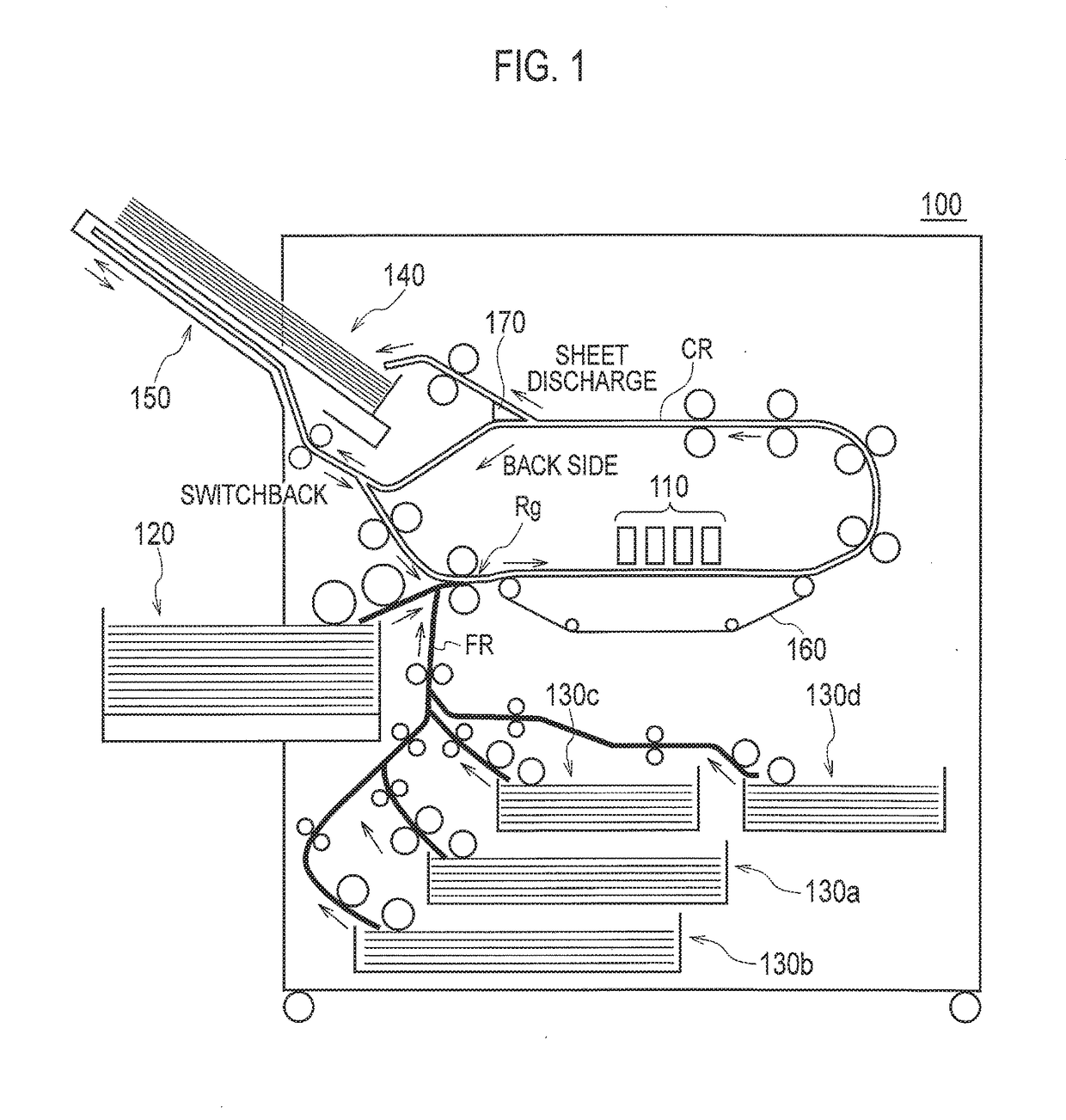

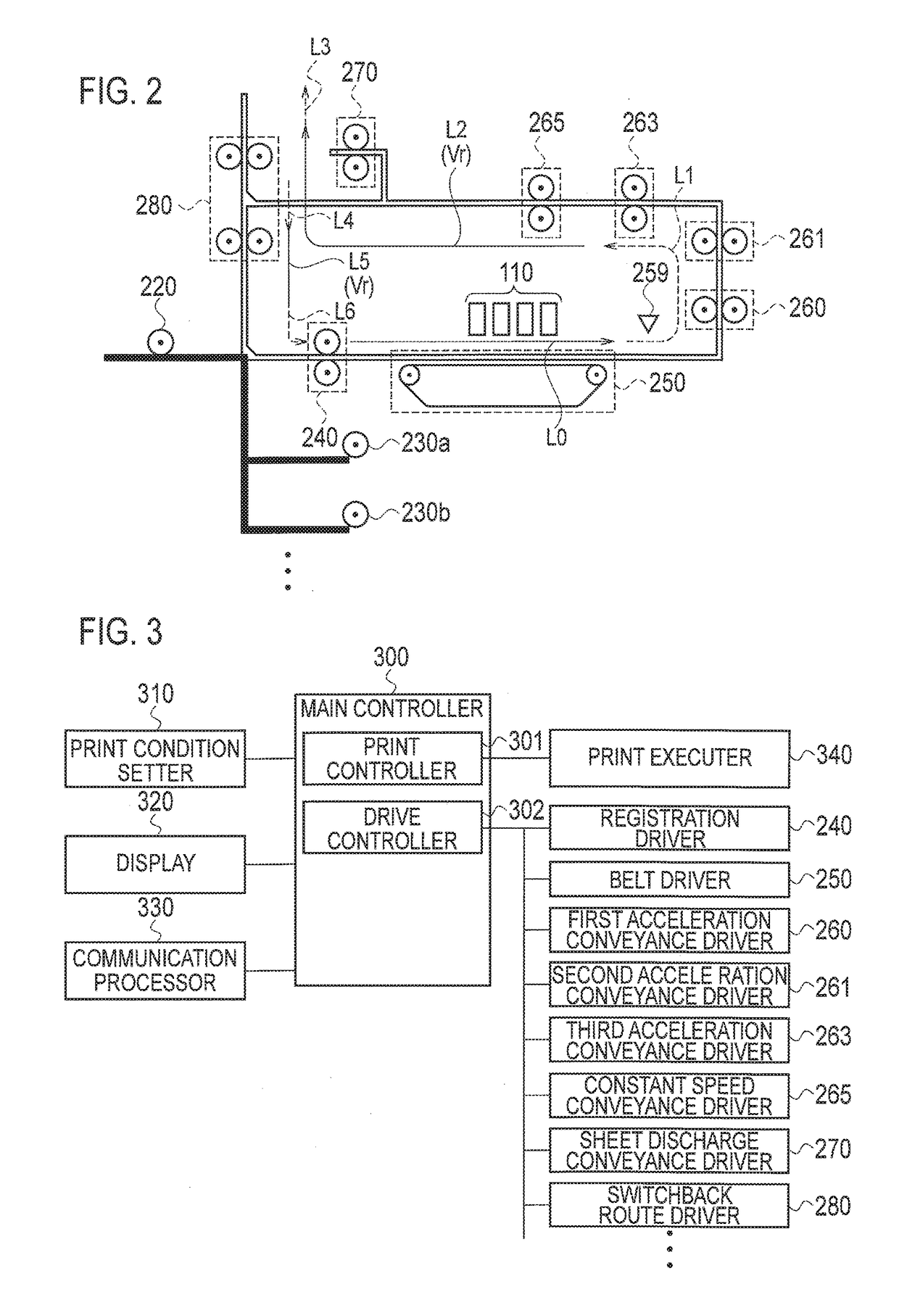

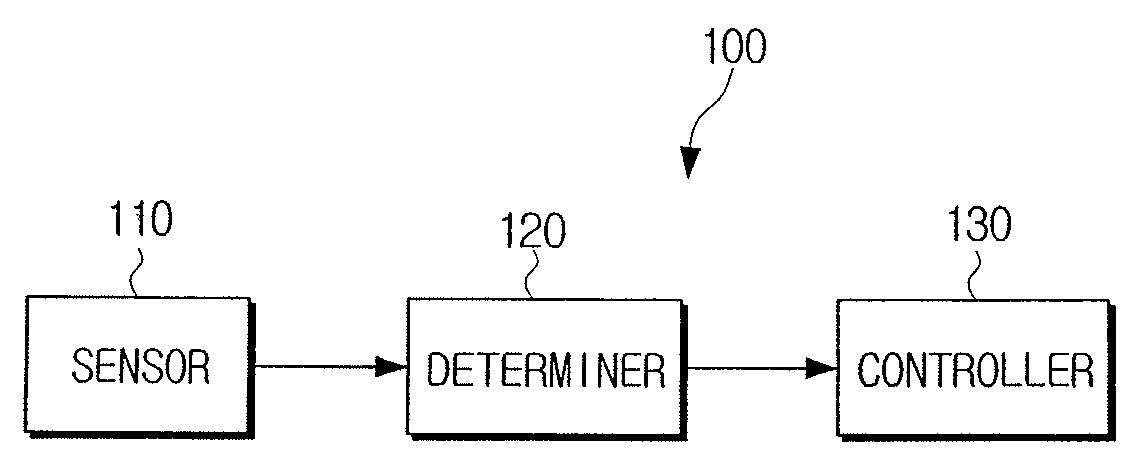

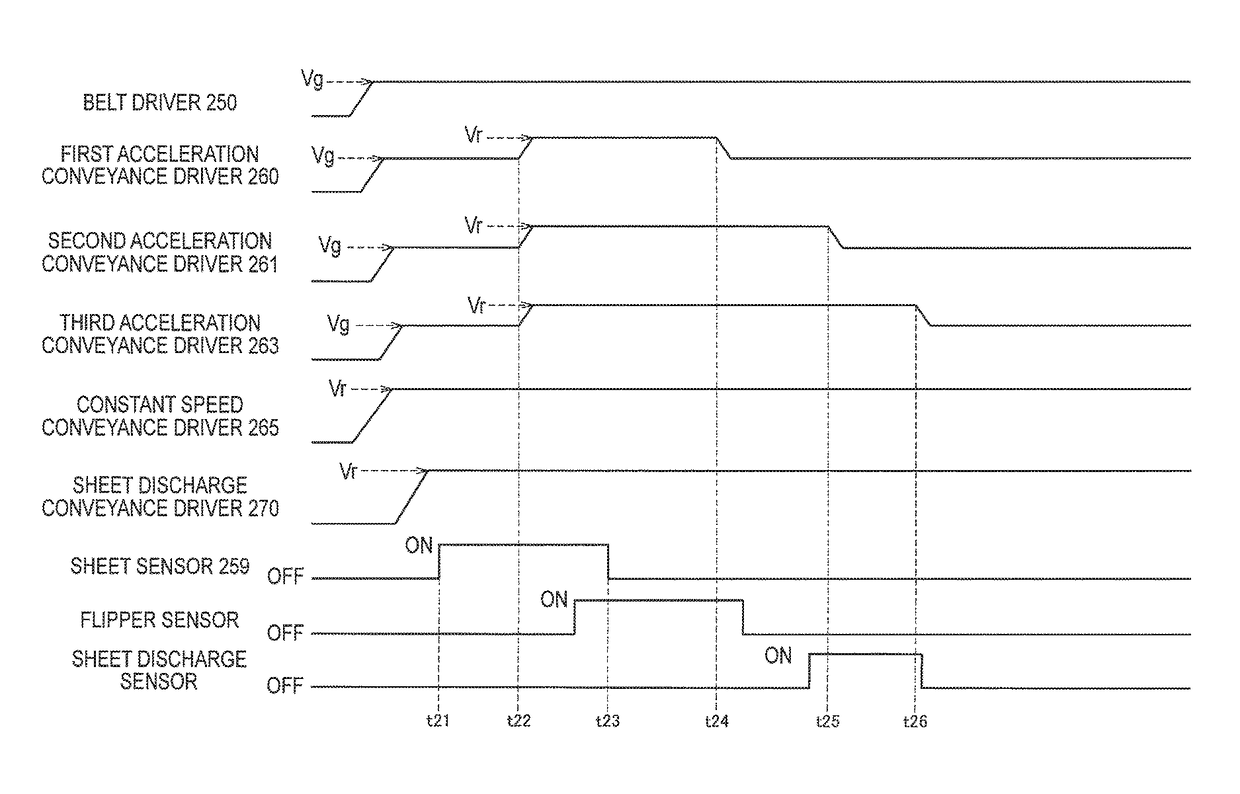

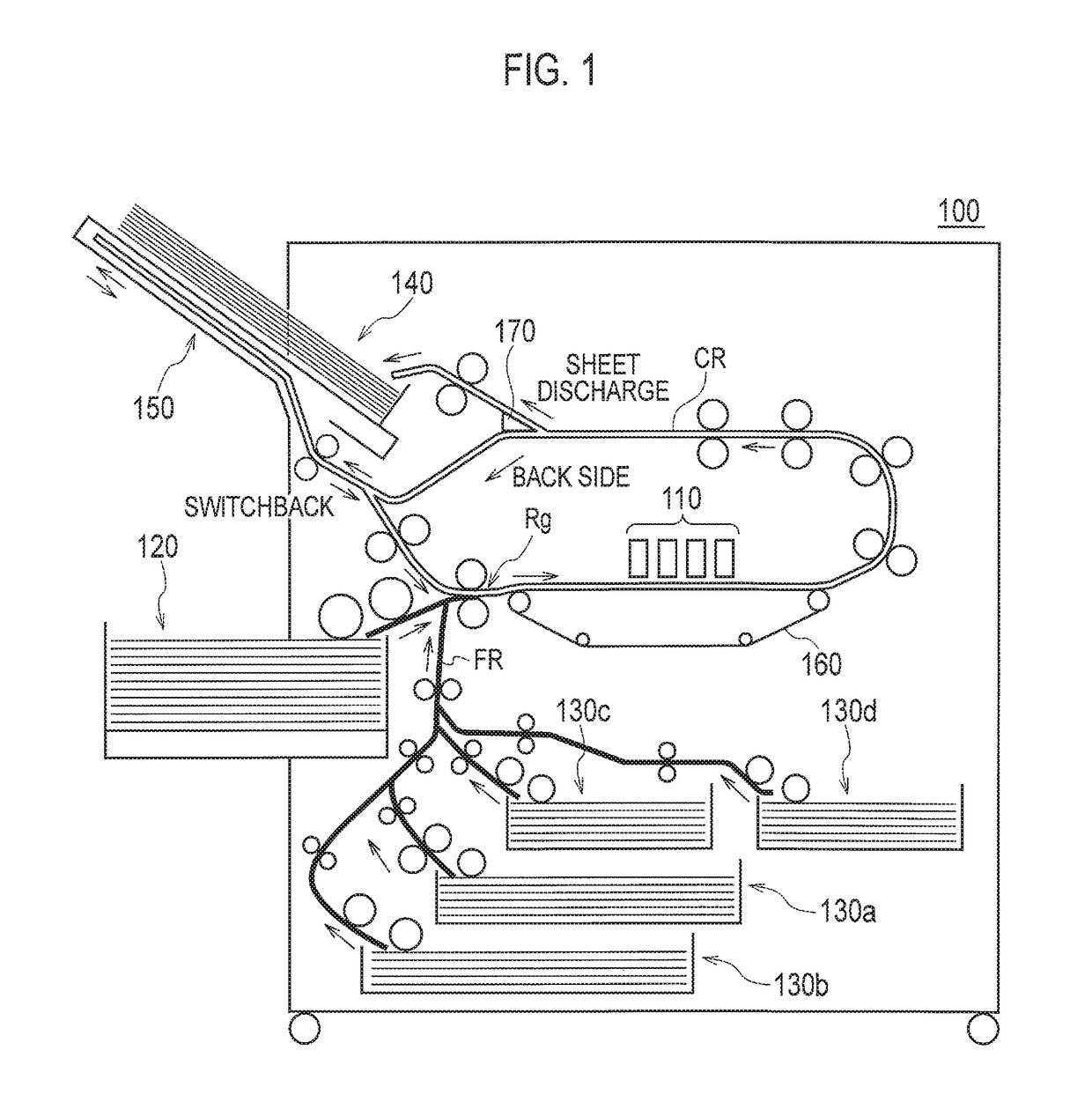

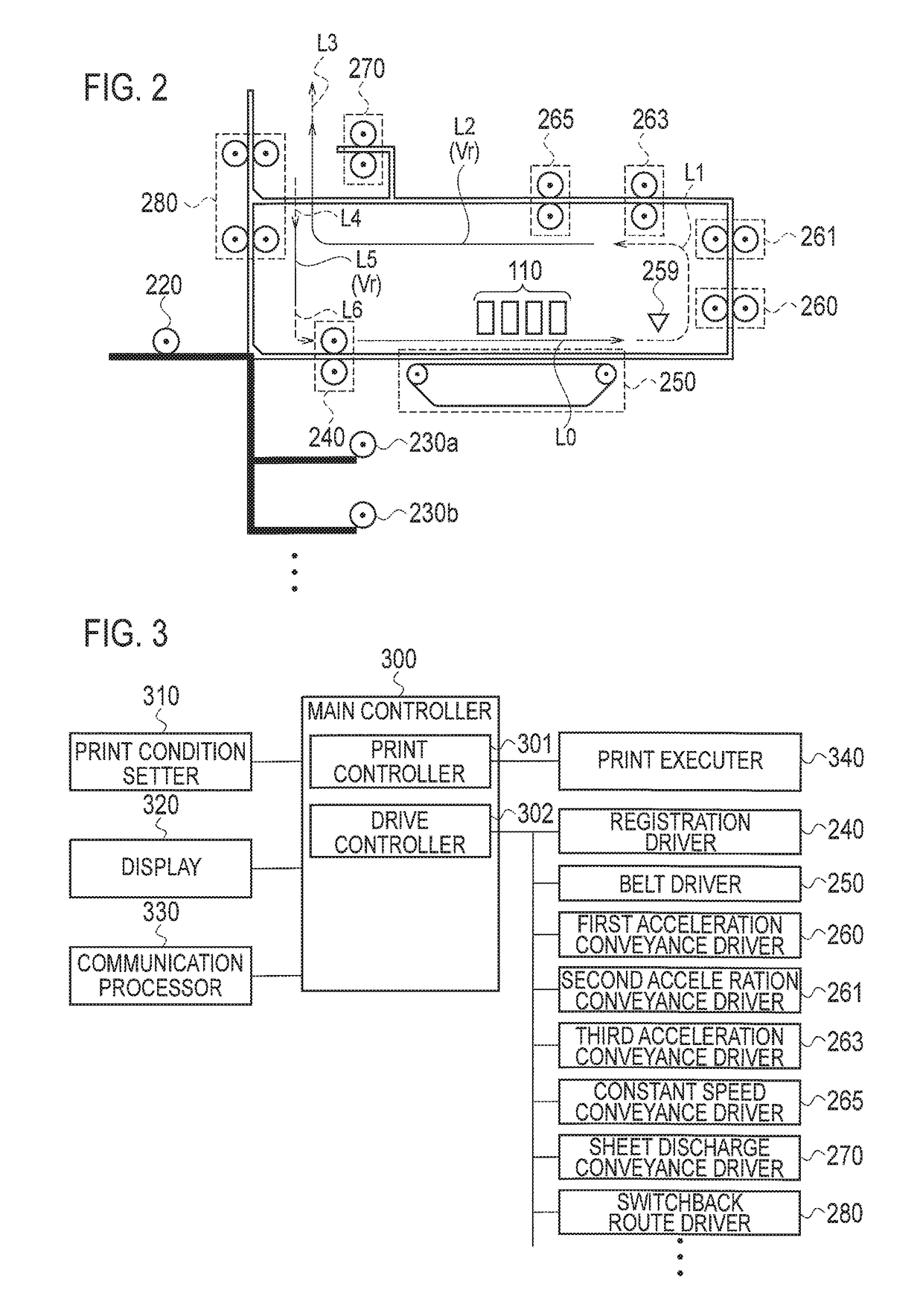

Printer with different conveyance speeds of recording medium

ActiveUS20180056677A1Improve productivityImprove printing qualityTypewritersElectrographic process apparatusLeading edgeImage formation

A printer includes: a first conveyor configured to convey a recording medium during image formation by an image former at a first conveyance speed based on a print condition of the image formation by the image former; a second conveyor configured to convey the recording medium at a second conveyance speed higher than the first conveyance speed; and a third conveyor arranged between the first conveyor and the second conveyor on a conveyance route. The third conveyor is configured to start acceleration of the recording medium after a recording region trailing end of the recording medium passes the image former and accelerate the recording medium such that a speed of the recording medium increases to the second conveyance speed not later than a time point when a leading edge of the recording medium reaches the second conveyor.

Owner:RISO KAGAKU CORP

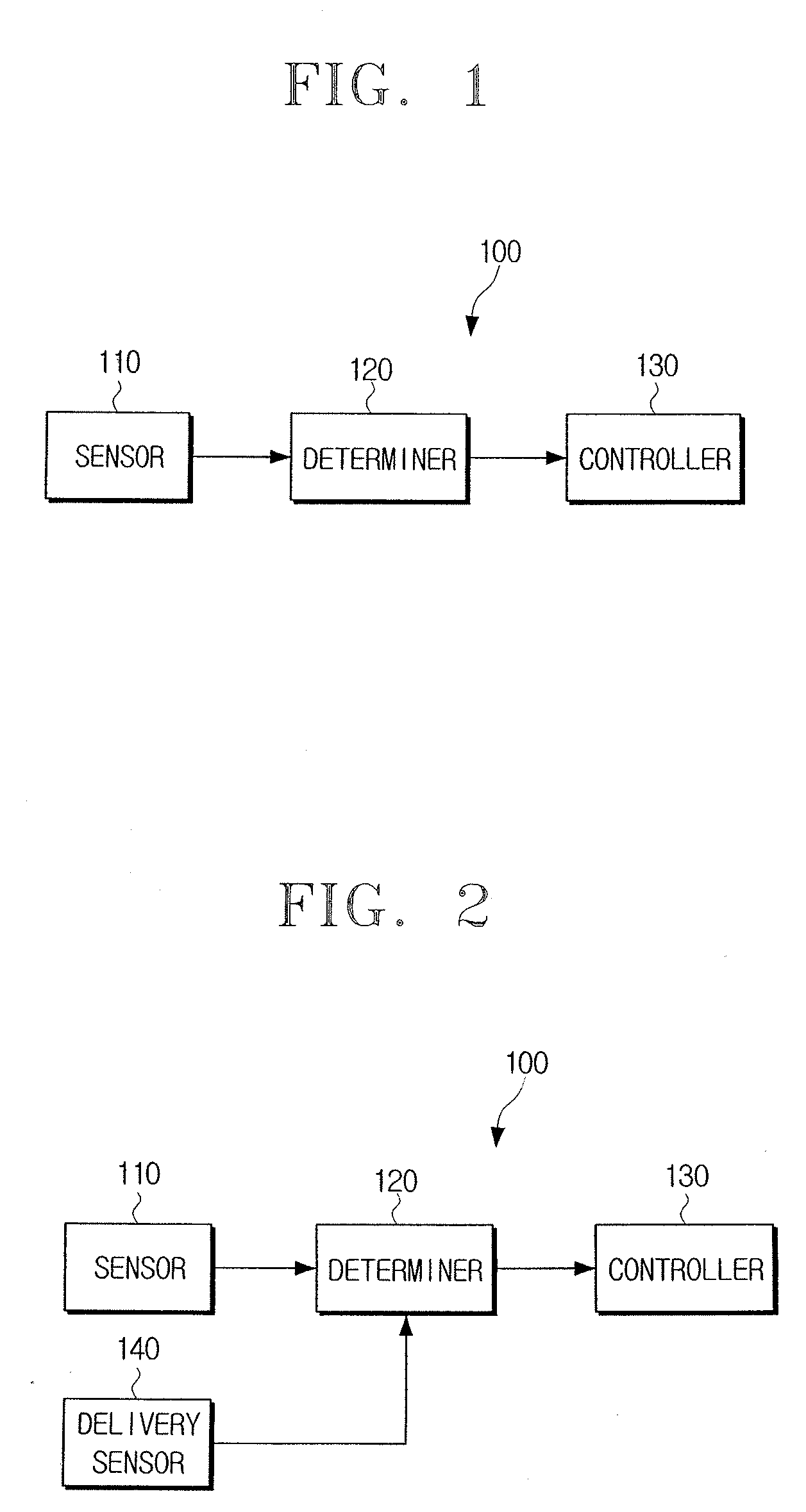

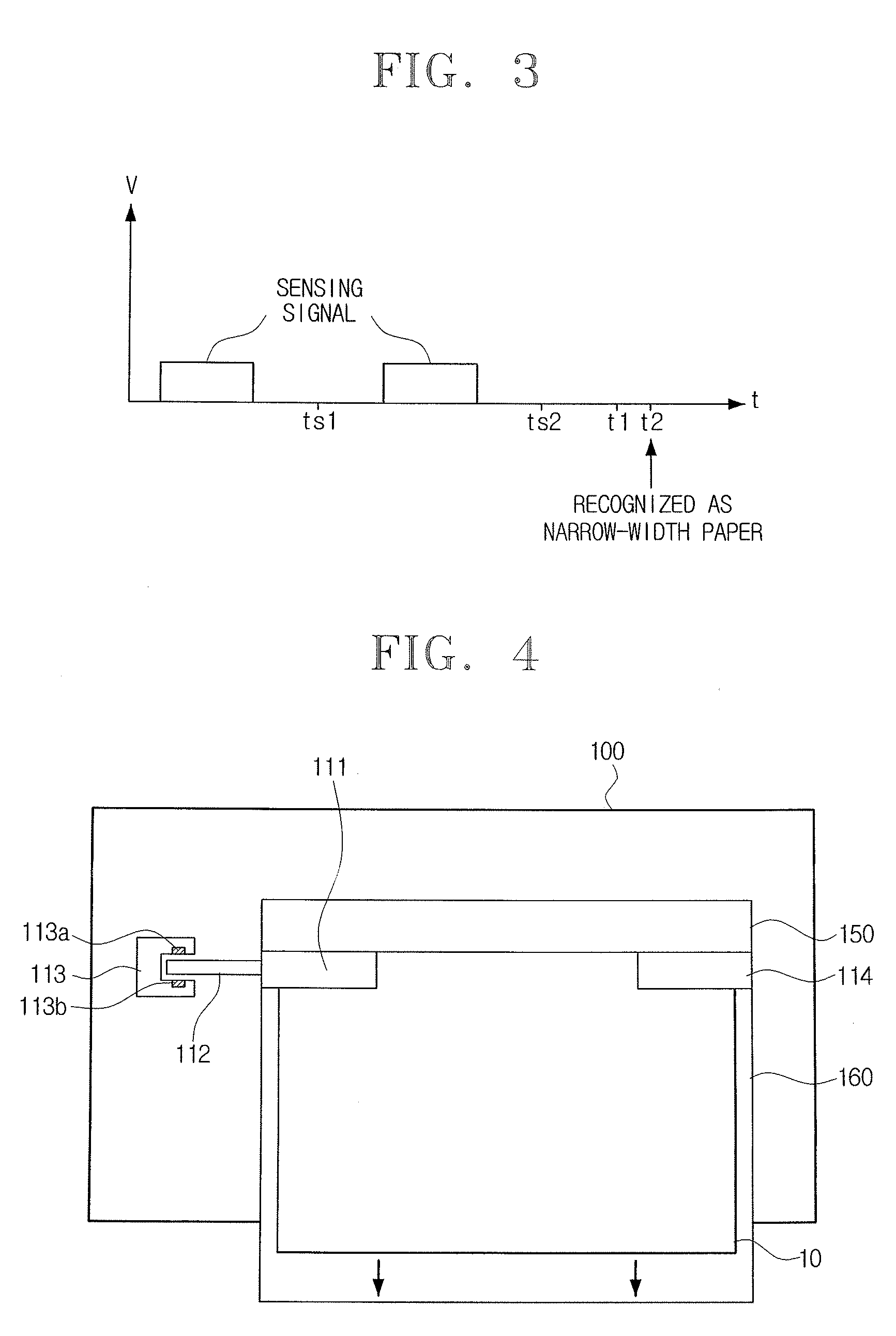

Image forming device to determine paper width and image forming method thereof

InactiveUS20080152368A1Avoid component damageAvoid print quality degradationElectrographic process apparatusImage formationEngineering

An image forming device includes a sensor to detect whether a paper is discharged or not, a determiner to determine a paper width according to whether a sensing signal is output from the sensor when a printing job is executed, and a controller to control a subsequent printing operation according to the determination result of the determiner. After the printing job is initiated, the determiner determines a normal width when the sensing signal is output within a preset time, and the determiner determines a narrow width when the sensing signal is not output within the present time. Accordingly, using an existing sensor, the paper width can be detected and the appropriate printing process can be performed.

Owner:S PRINTING SOLUTION CO LTD

Reclamation method of hollow and used ink cartridge of ink-jet printer

InactiveCN1803457AImprove recycling efficiencyAvoid print quality degradationPrintingEngineeringHigh pressure

The invention discloses an old- regenerating method of print cartridge in the ink-ejecting printer, which adapts high-pressure hot air to blow and wash the old hollow print cartridge through scouring agent. The method improves the utility of old print cartridge greatly, which possesses high effective economical character.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Printer with different conveyance speeds of recording medium

ActiveUS10131164B2Improve printing qualityAvoid print quality degradationTypewritersElectrographic process apparatusLeading edgeImage formation

A printer includes: a first conveyor configured to convey a recording medium during image formation by an image former at a first conveyance speed based on a print condition of the image formation by the image former; a second conveyor configured to convey the recording medium at a second conveyance speed higher than the first conveyance speed; and a third conveyor arranged between the first conveyor and the second conveyor on a conveyance route. The third conveyor is configured to start acceleration of the recording medium after a recording region trailing end of the recording medium passes the image former and accelerate the recording medium such that a speed of the recording medium increases to the second conveyance speed not later than a time point when a leading edge of the recording medium reaches the second conveyor.

Owner:RISO KAGAKU CORP

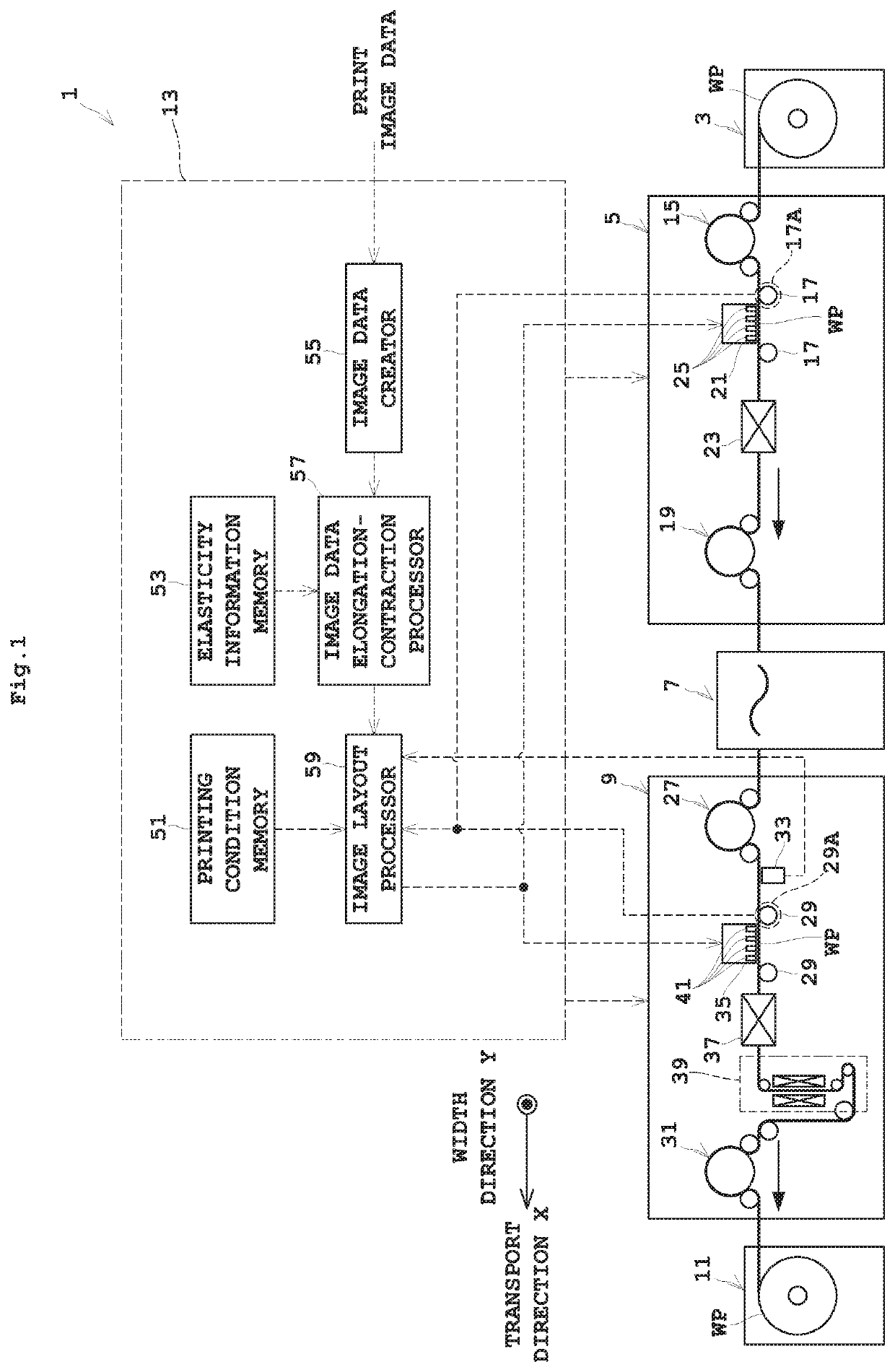

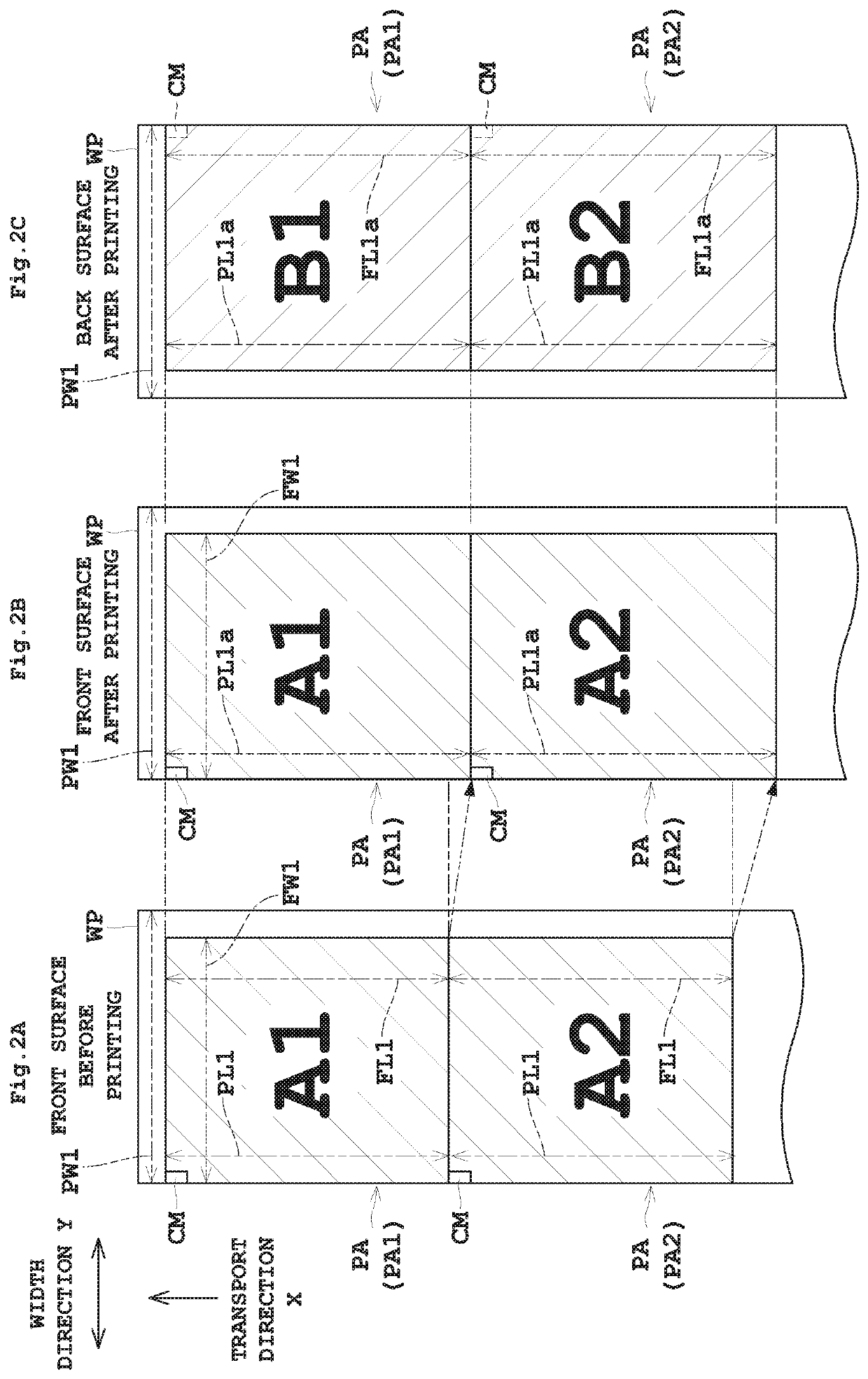

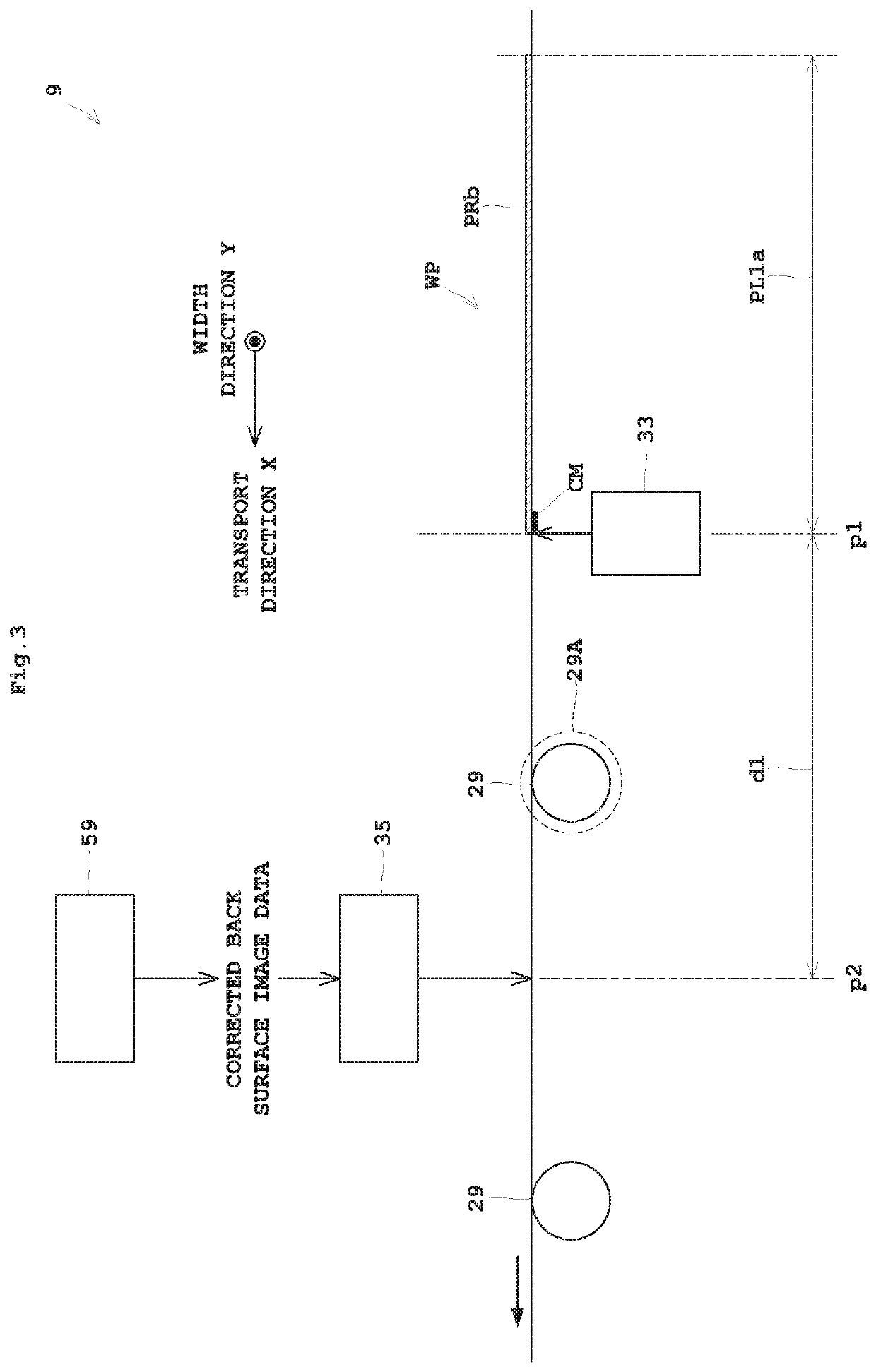

Printing apparatus

ActiveUS11110724B2Quality improvementAvoid print quality degradationTypewritersVisual presentationComputer graphics (images)Engineering

Owner:DAINIPPON SCREEN MTG CO LTD

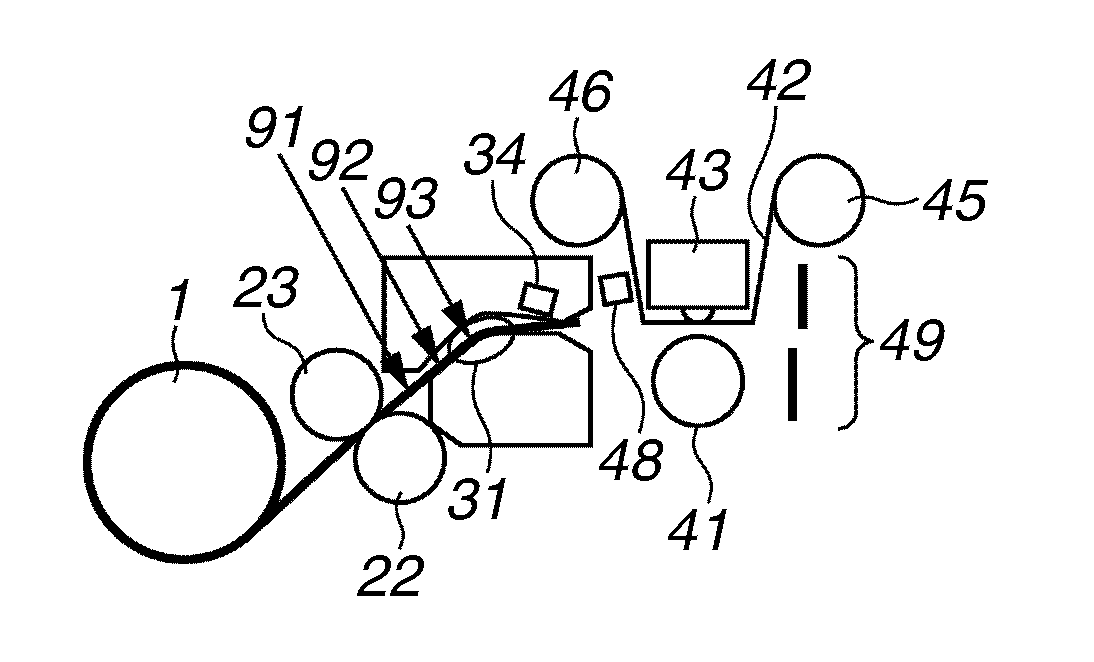

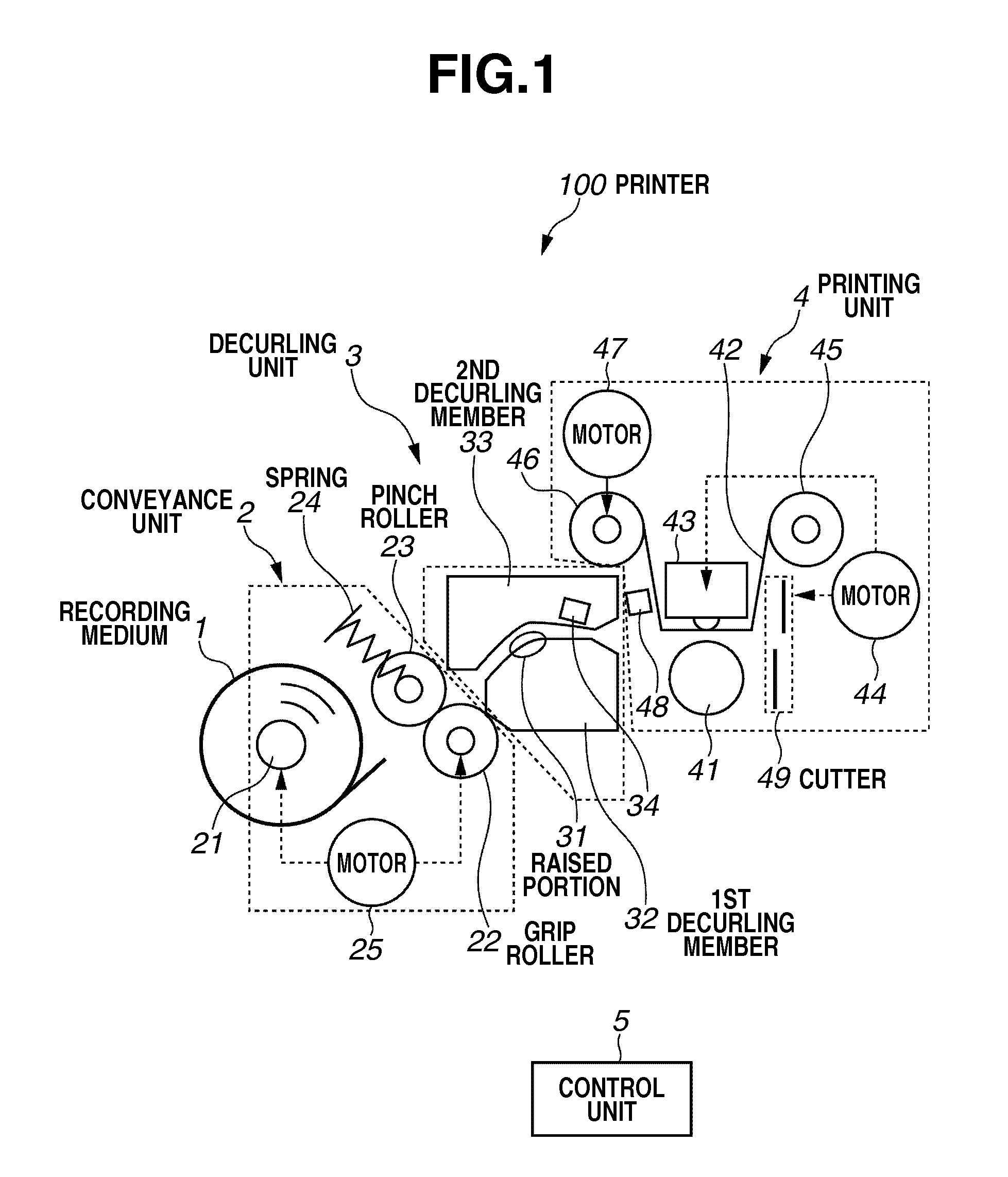

Printer and printing method which prevents a decurling unit from deteriorating a print quality

InactiveUS8540443B2Avoid print quality degradationRecording apparatusInking apparatusLeading edgeControl unit

A printer is provided that includes a conveyance unit configured to nip and simultaneously convey the roll recording medium; a print unit configured to print an image by sequentially transferring a plurality of color inks on the recording medium while nipping the recording medium conveyed by the conveyance unit; a decurling unit disposed between the conveyance unit and the print unit, and configured to include a raised portion that decurls the recording medium by contacting the recording medium conveyed by the conveyance unit; and a control unit configured to control the conveyance unit to convey the recording medium to a waiting position after ending the transfer of one color ink, wherein the waiting position is a position where an area on a leading edge side of the recording medium is in contact with the raised portion.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com