Optical sensor, ink cartridge, and inkjet apparatus

An optical sensor and ink cartridge technology, applied in the direction of using optical devices, measuring devices, scientific instruments, etc., can solve the problems of ink clogging of nozzle holes, unsmooth ink ejection action, and difficulty in ensuring subtle color tone, etc., and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[Inkjet device]

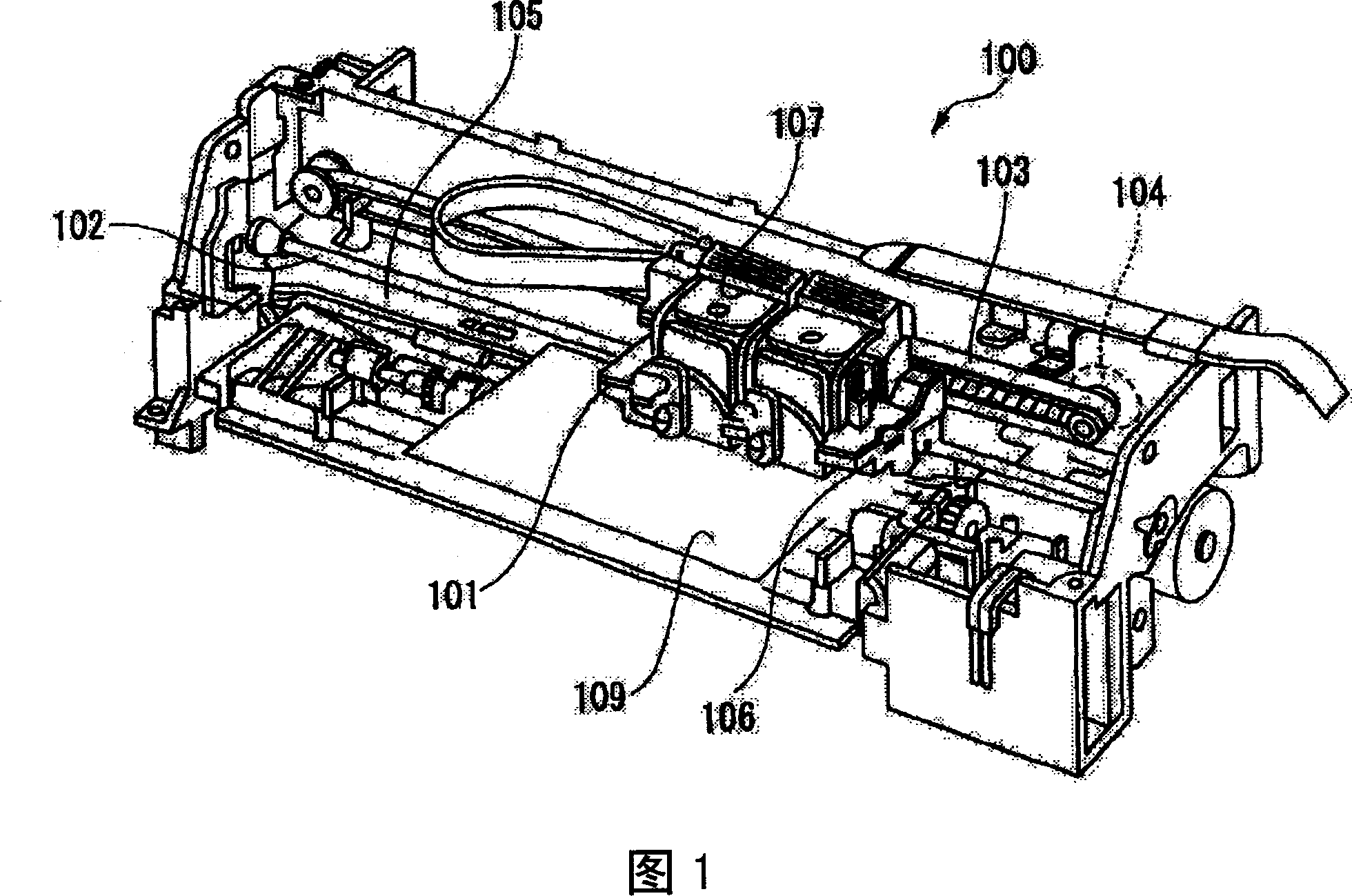

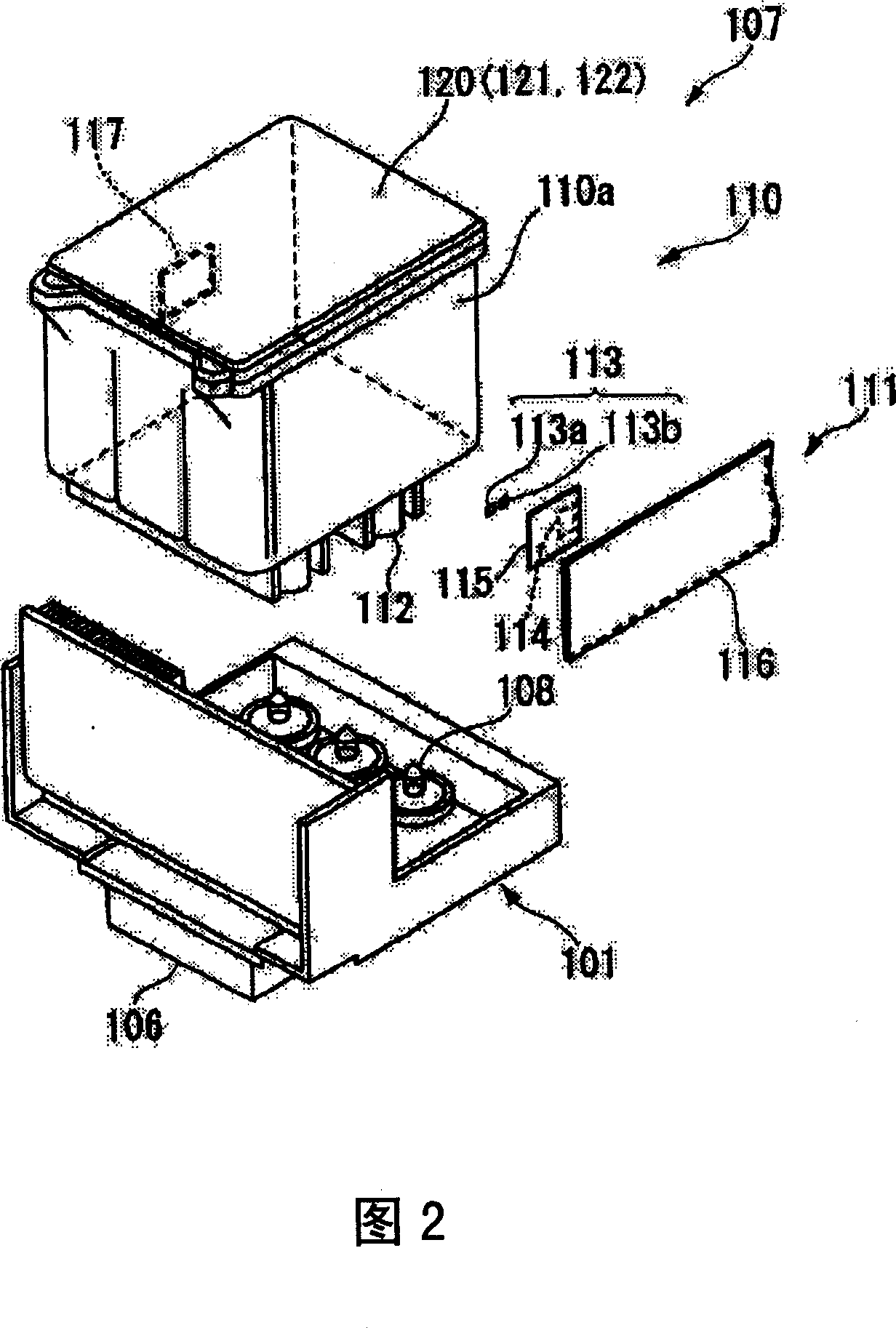

1 is a schematic perspective view showing an inkjet device including an ink cartridge according to a first embodiment of the present invention. In addition, FIG. 2 is an exploded perspective view showing main parts of a printing unit including an ink cartridge.

[0026]

As shown in FIG. 1 , an inkjet device 100 includes a carriage 101 on which ink cartridges are mounted, and an inkjet recording head 106 .

[0027]

The carriage 101 is supported by a guide member 102 and connected to a stepping motor 104 via a timing belt 103 so as to reciprocate parallel to the table 105 . An inkjet recording head 106 is mounted on the lower side of the carriage 101, and a printing unit 107 is mounted on the upper side in a detachable manner.

[0028]

As shown in FIG. 2 , the printing unit 107 includes an ink cartridge 110 and a carriage 101 on which the ink cartridge 110 is mounted.

[0029]

The carriage 101 has a box-like shape with an open top, and an inkjet record...

no. 2 Embodiment approach

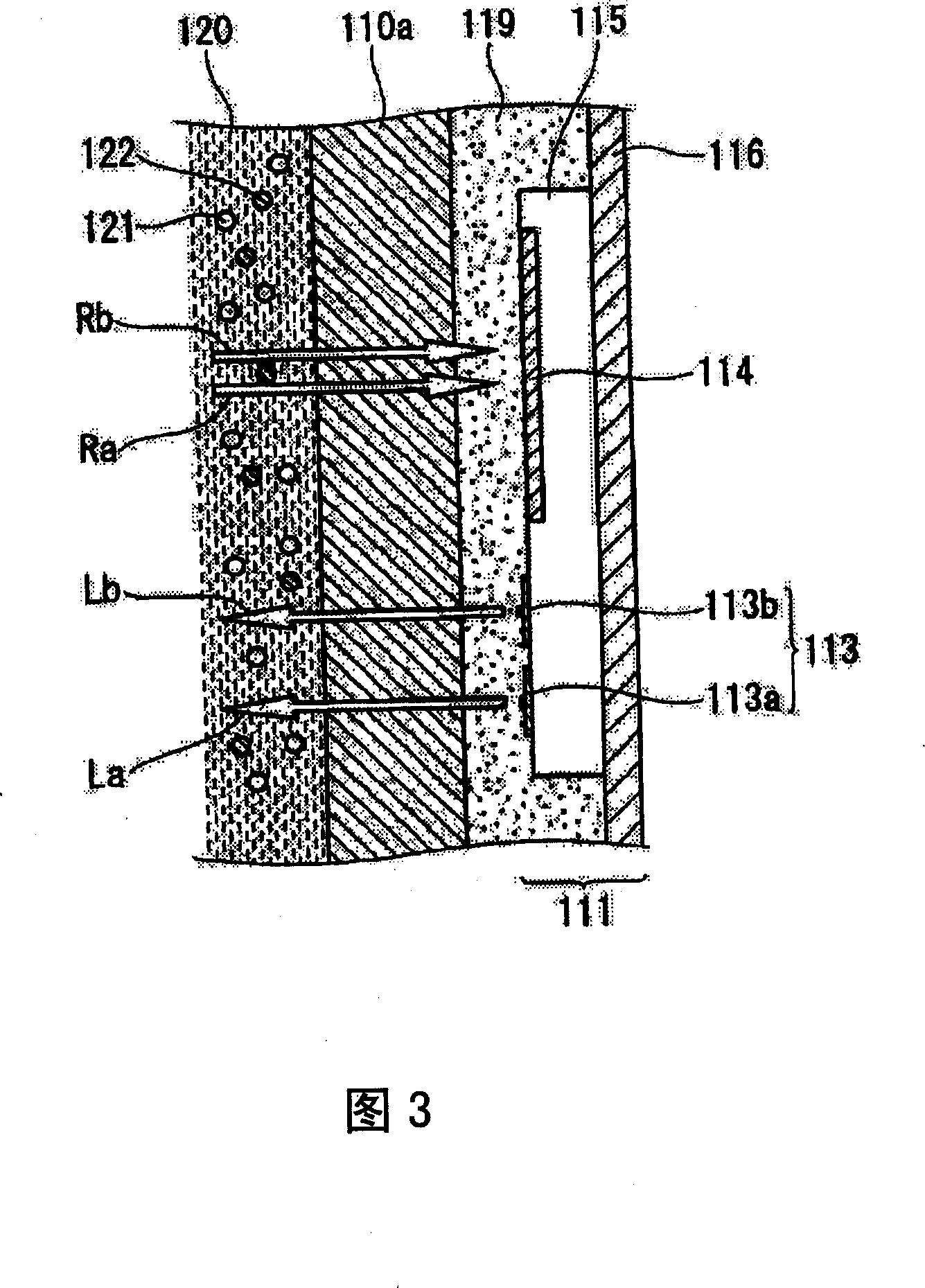

In addition, FIG. 20 is an exploded perspective view showing main parts including an optical sensor 211 according to the second embodiment of the present invention. The same reference numerals are assigned to the same components as those in the first embodiment, and the description thereof will not be repeated.

[0103]

As shown in FIG. 20, there are light-emitting elements 113a, 113b for irradiating reference light to the ink in the ink cartridge 110, a light-receiving element 114 for receiving reference light transmitted through the ink in the ink cartridge 110, and a first light-emitting element electrically connected to the light-emitting elements 113a, 113b. The integrated circuit board 215 , the second integrated circuit board 214 electrically connected to the light receiving element 114 , and the printed wiring board 216 electrically connected to the first integrated circuit board 215 and the second integrated circuit board 214 .

[0104]

On the first integrated circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com