Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Avoid Manual Cleanup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

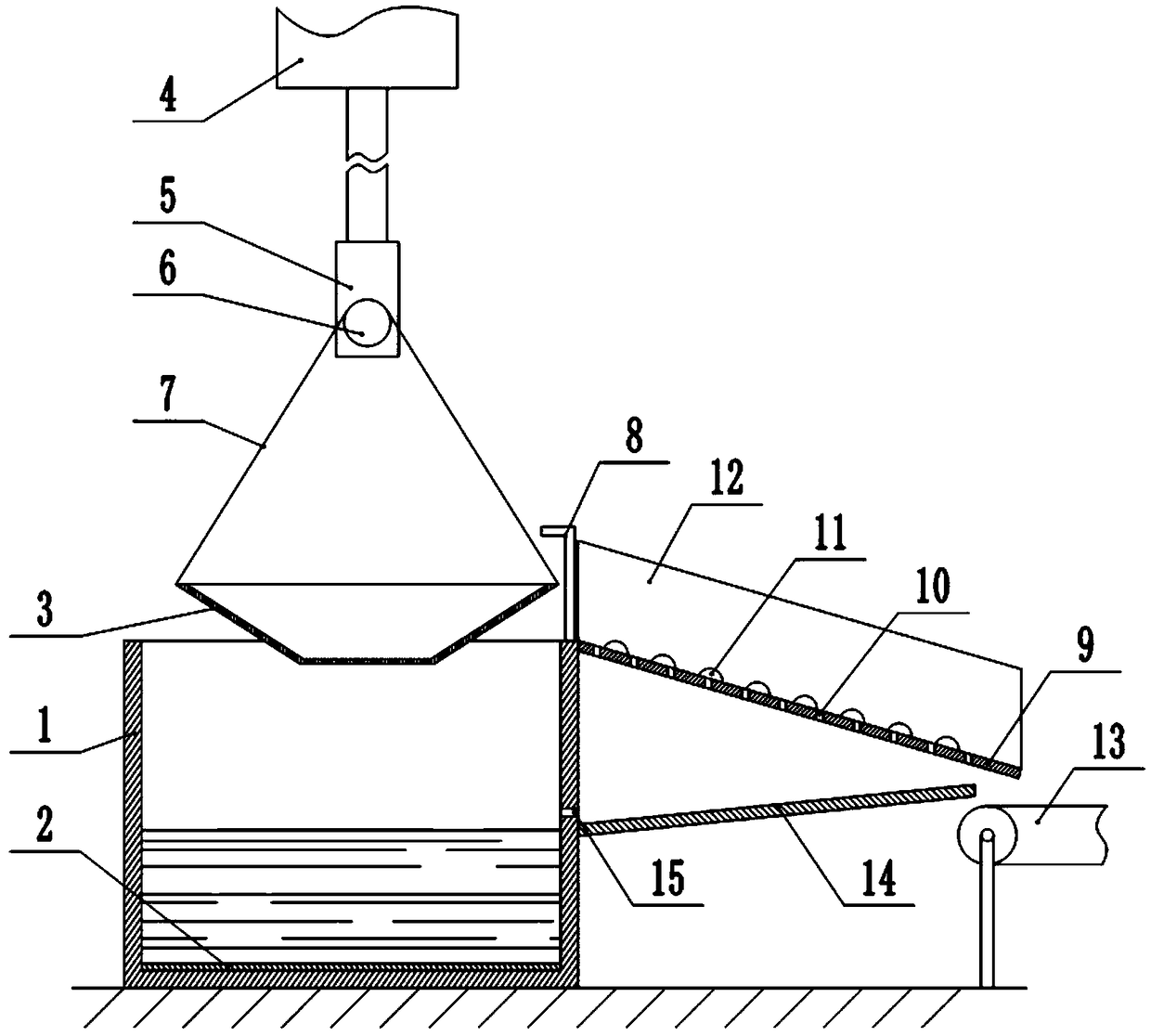

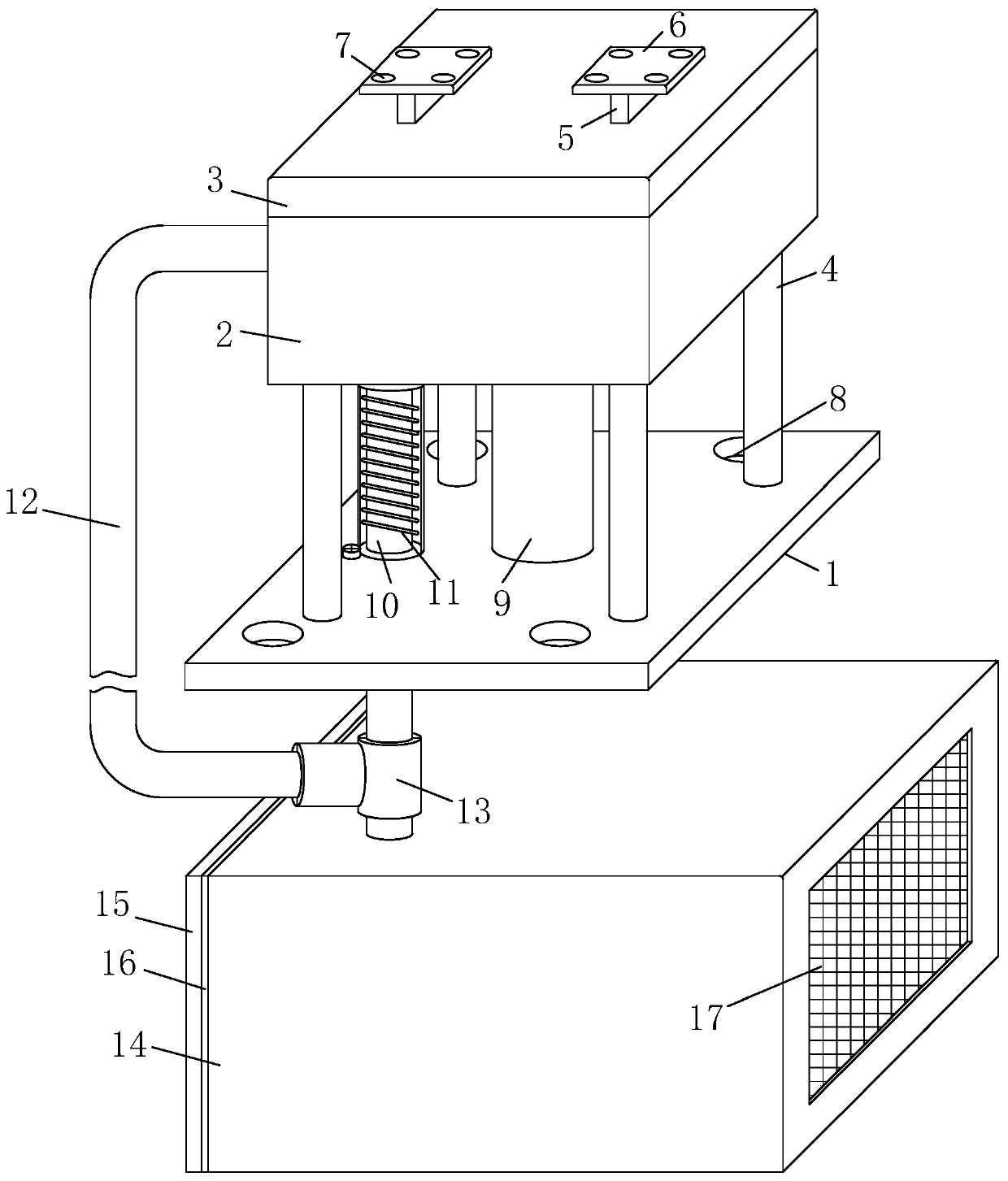

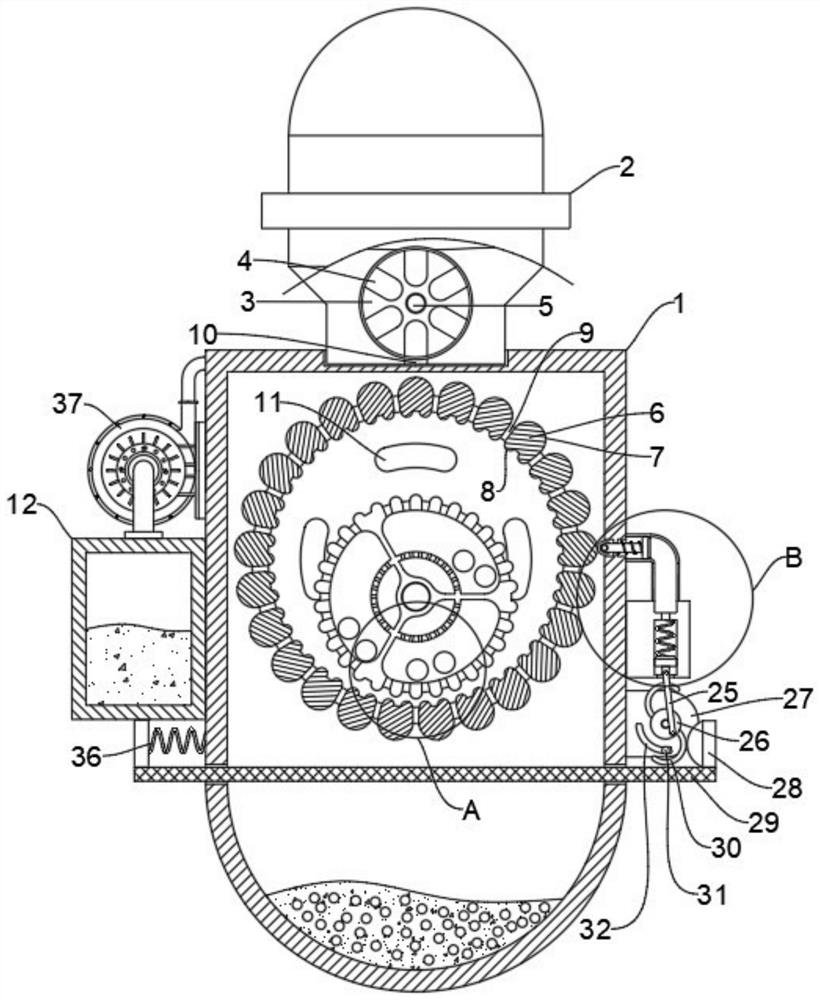

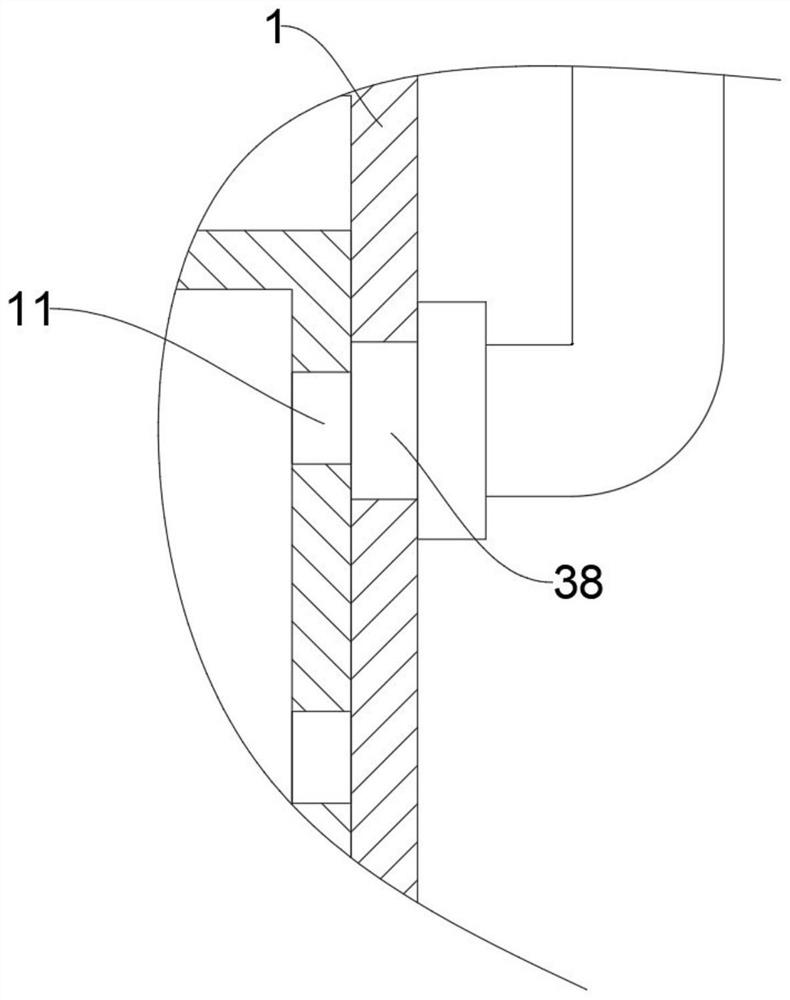

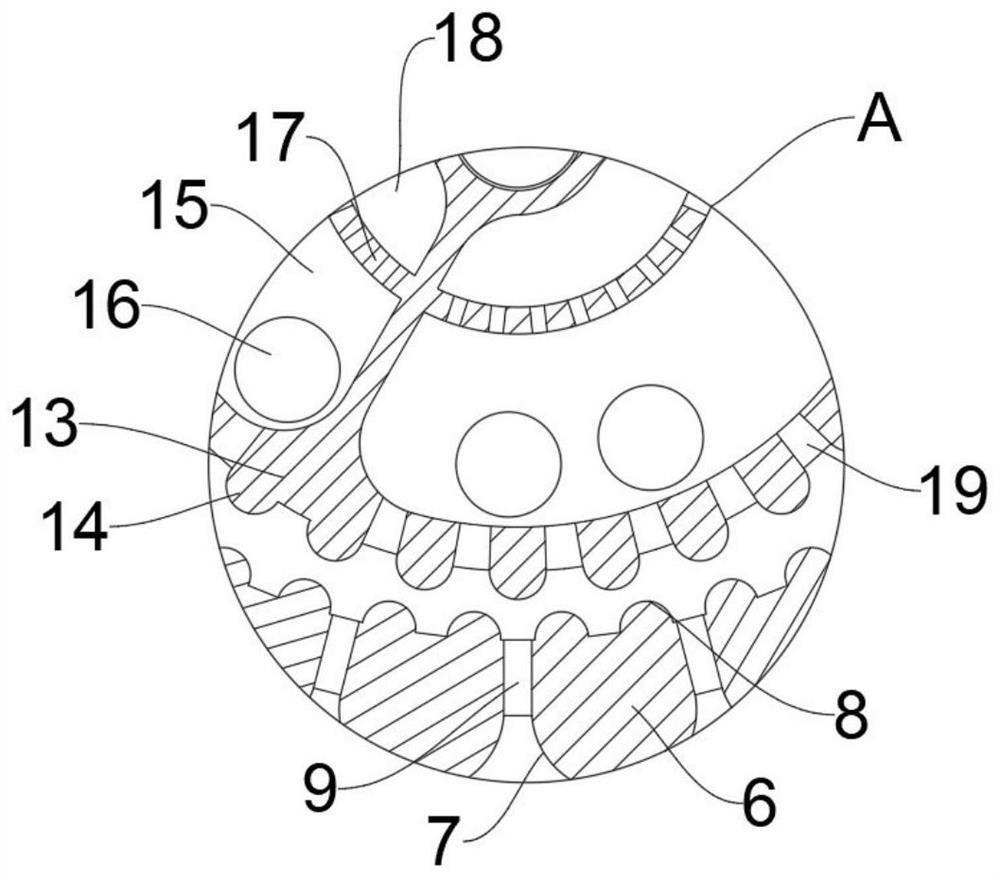

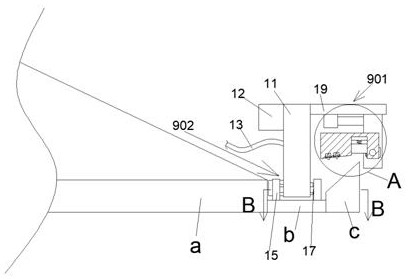

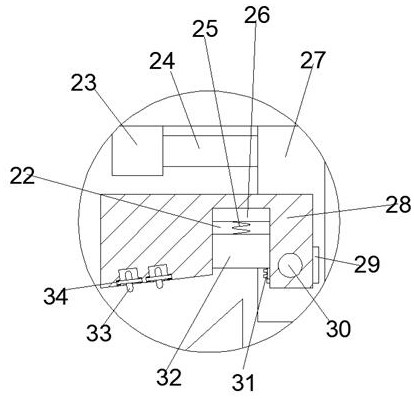

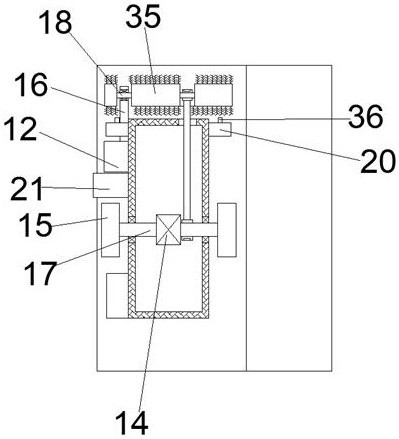

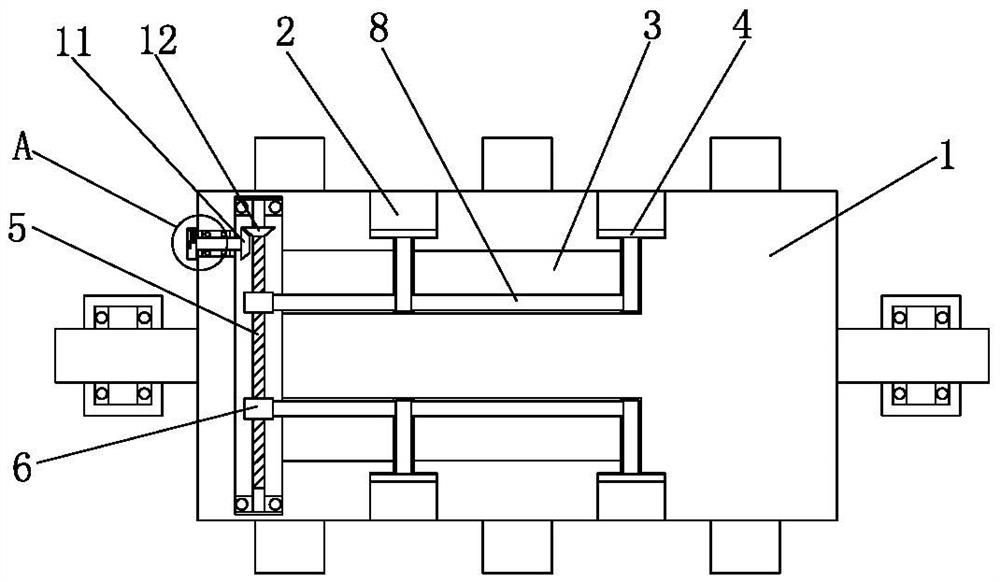

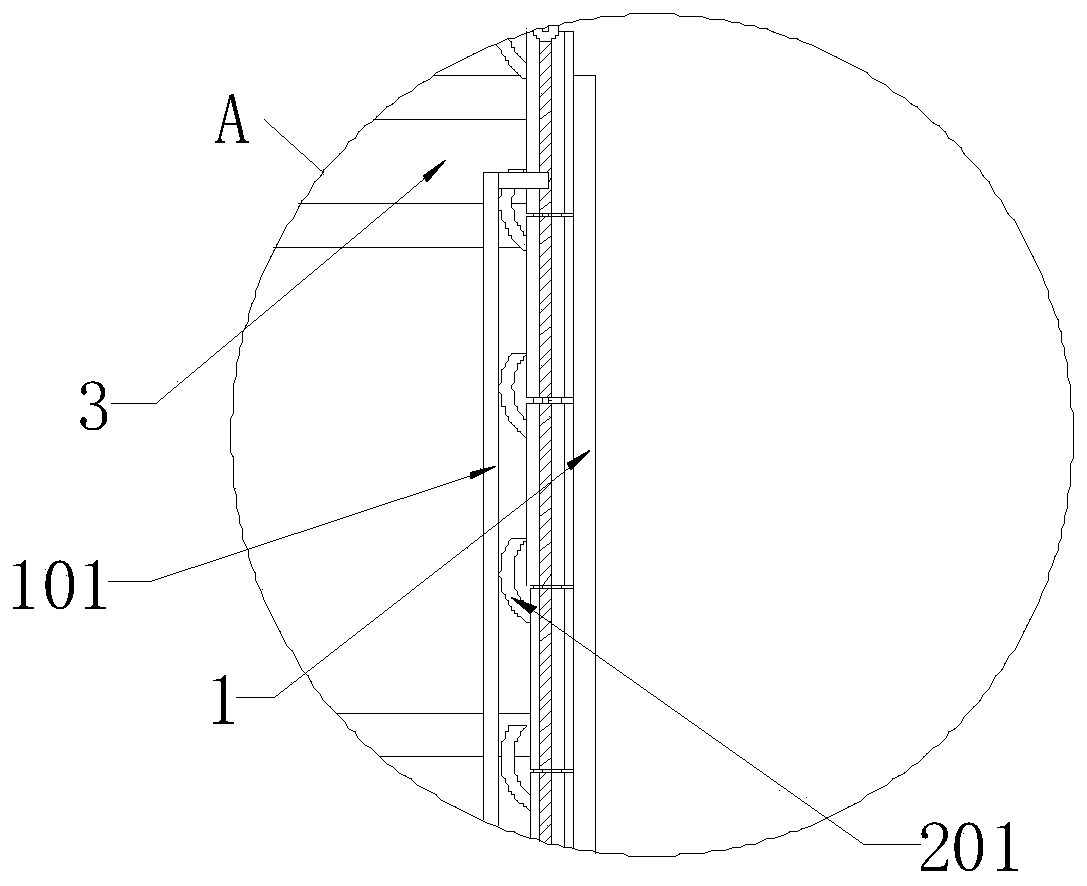

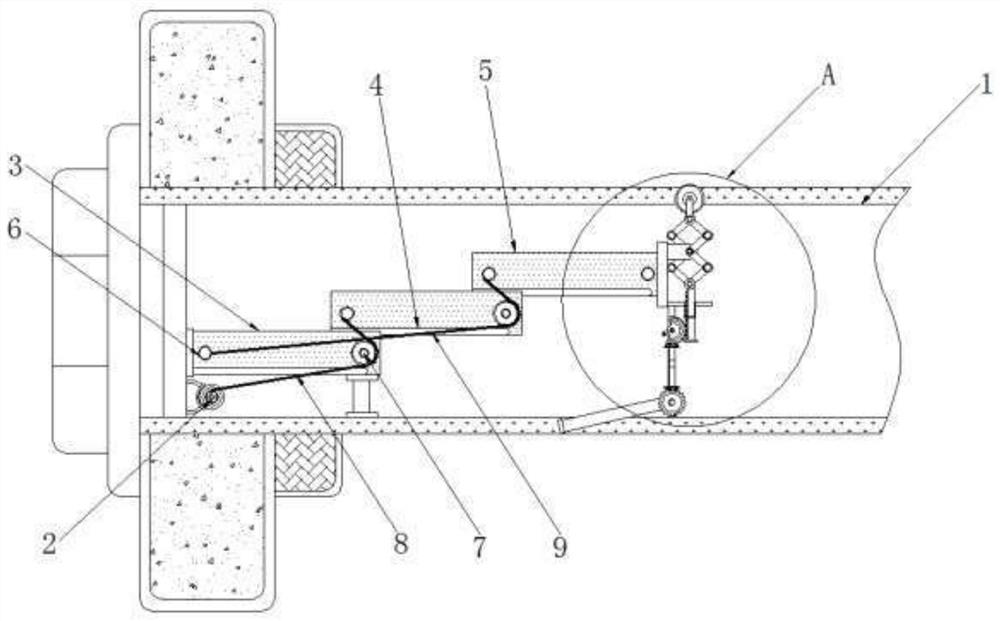

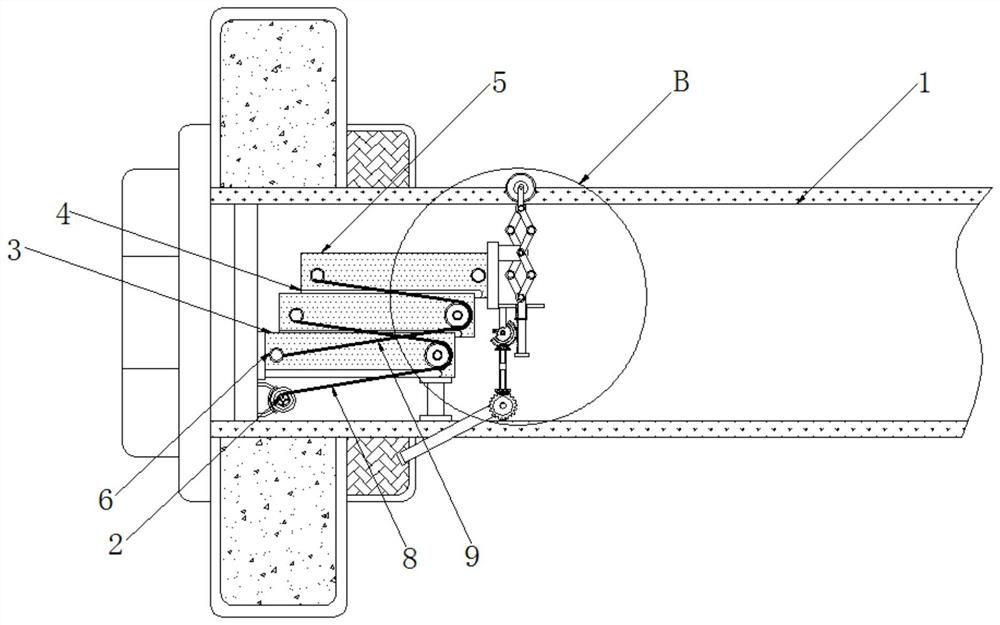

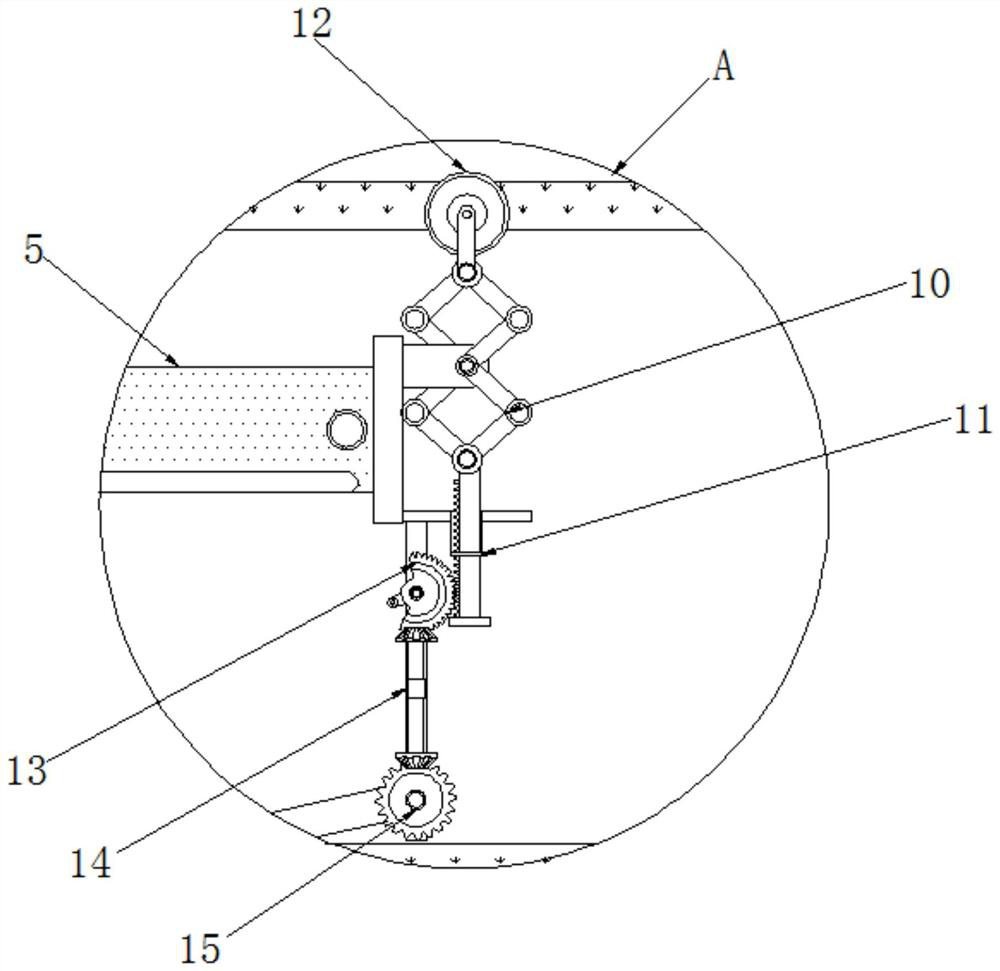

Oil-frying device

InactiveCN109329330AReduce wasteIncrease distanceOil/fat bakingCharging/discharging ovensEngineeringLarge distance

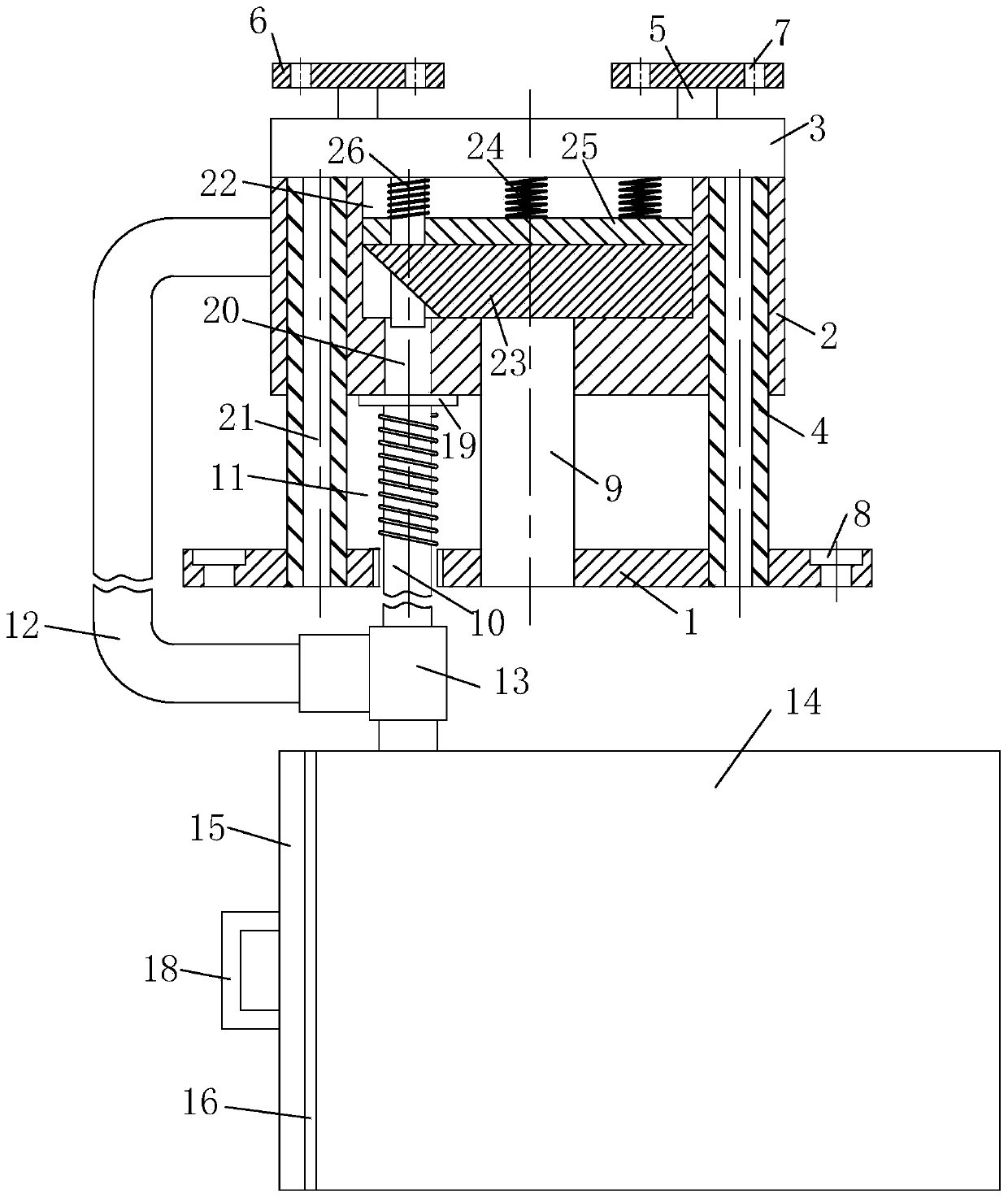

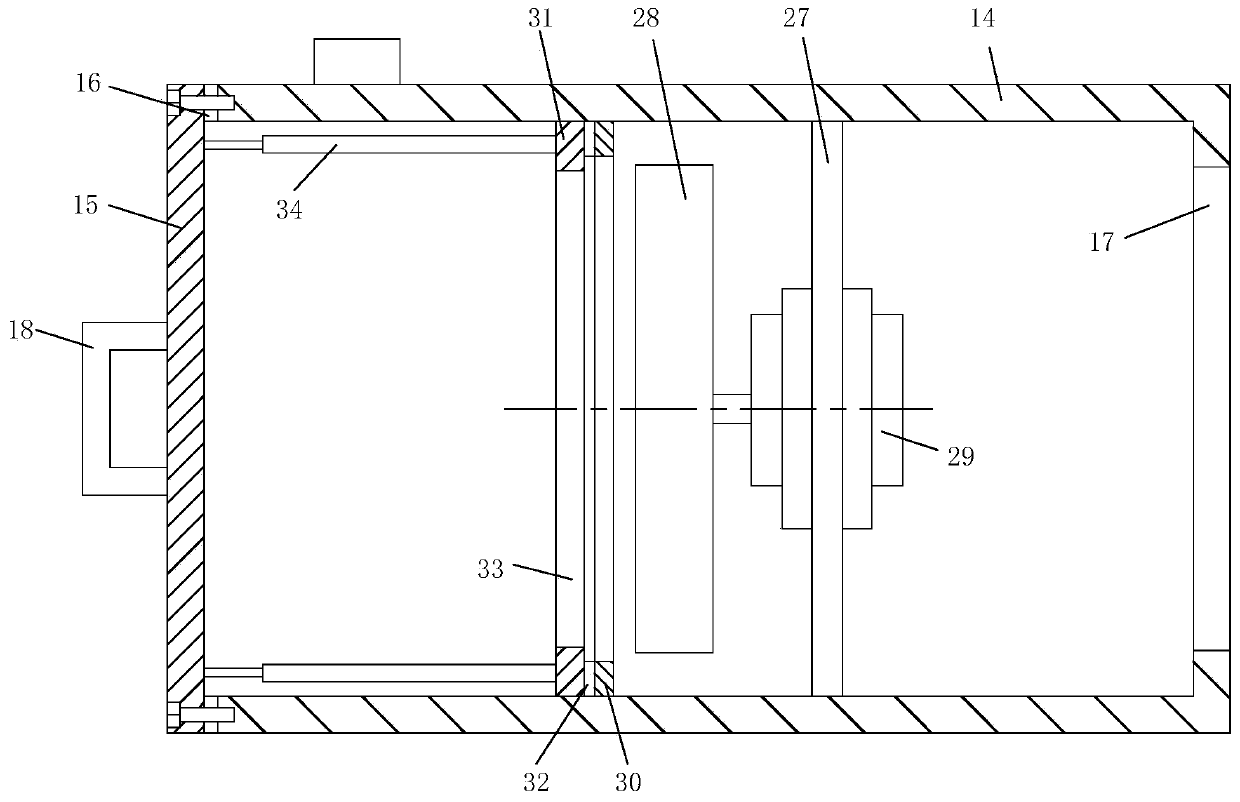

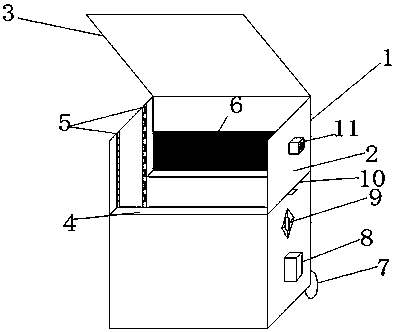

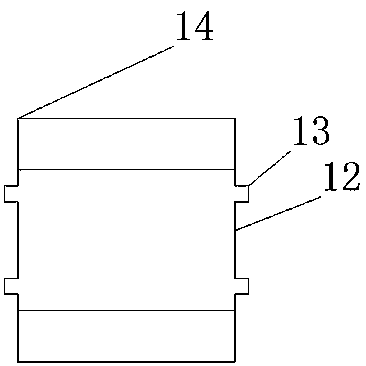

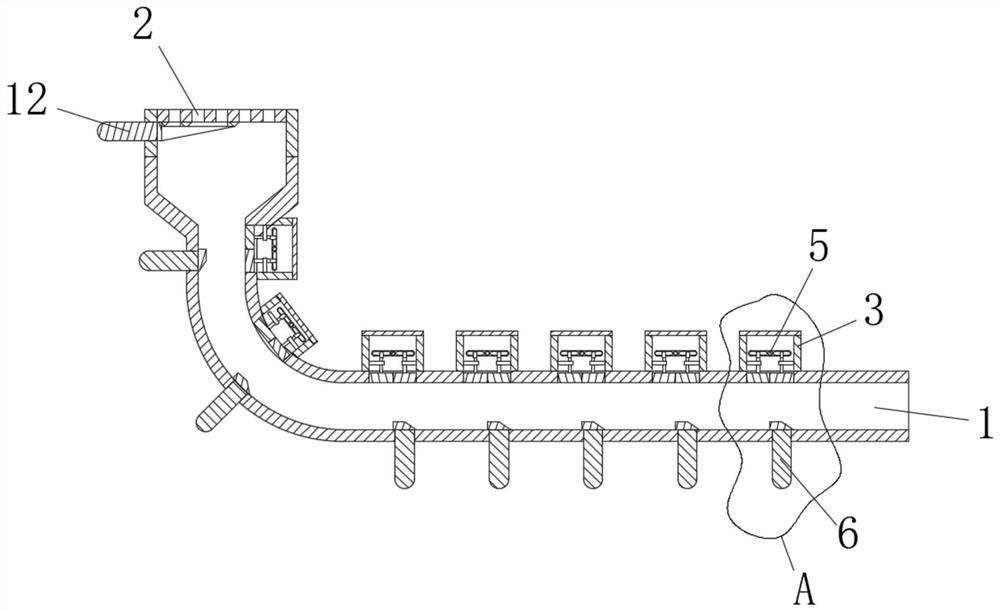

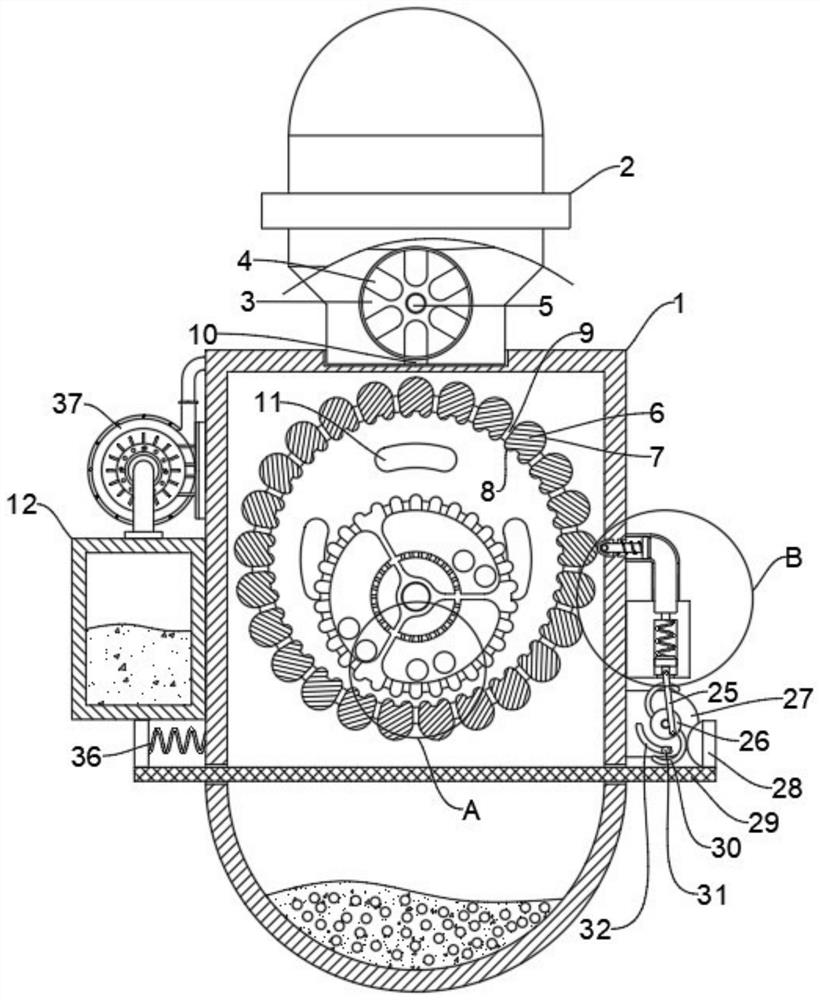

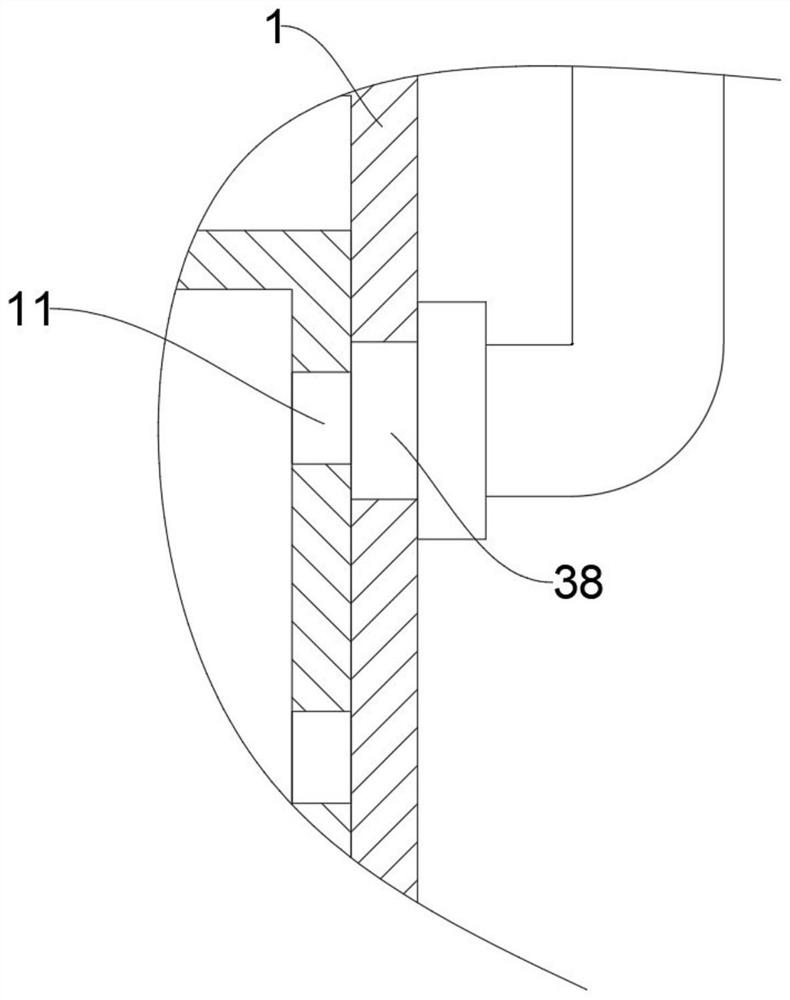

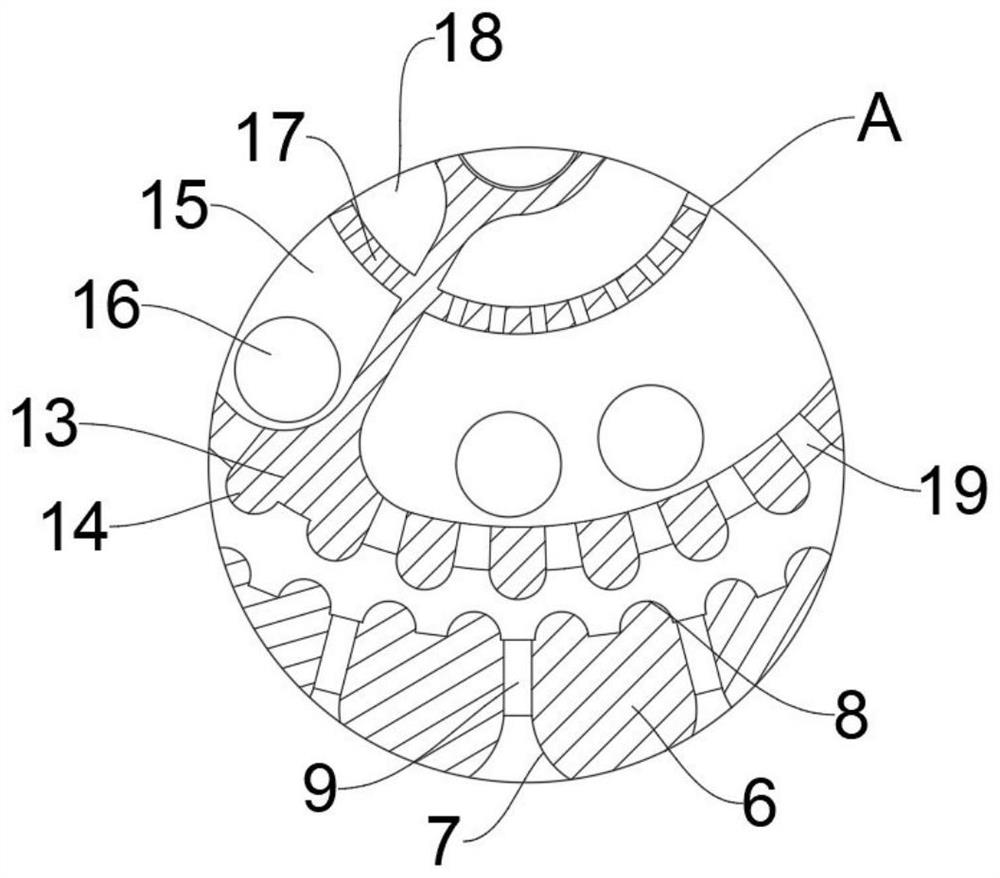

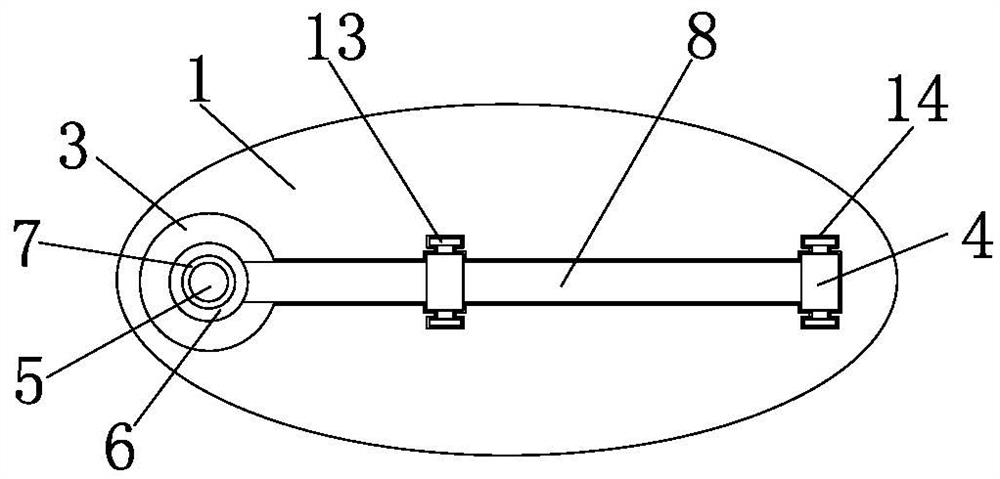

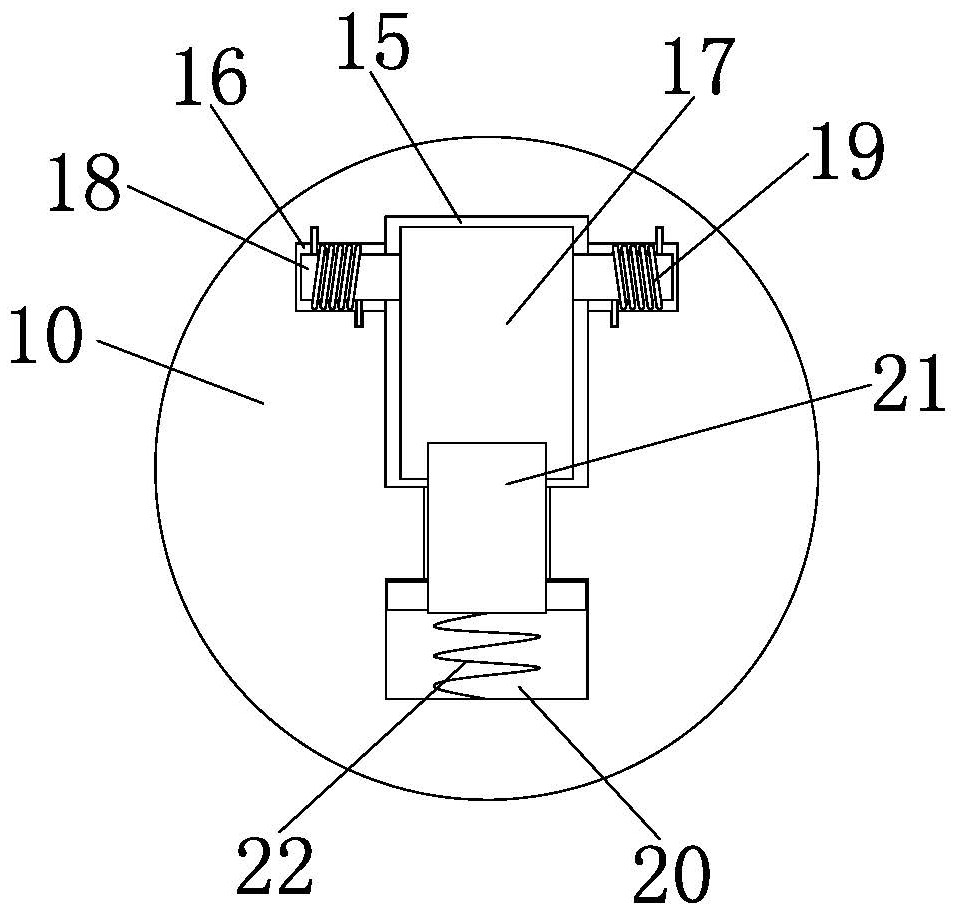

The present invention relates to the technical field of food production and particularly discloses an oil-frying device. The oil-frying device comprises an oil-frying pot; the oil-frying pot is internally provided with an oil-frying basket; the upper side of the oil-frying basket is fixedly provided with a telescopic cylinder; an output end of the telescopic cylinder is fixedly connected with a rotating roller frame; the rotating roller frame is rotatably connected with a rotating roller; a first chain and a second chain are wound around the rotating roller; both ends of the first chain and the second chain are respectively fixedly connected to the four end points of the top part of the oil-frying basket; and the top part of the side wall of the oil-frying pot, parallel to the rotating roller, is rotatably connected with a plurality of inverted L-shaped baffle bars. The oil-frying device realizes automatic material discharging of oil-fried materials, reduces workload and improves the work efficiency. At the same time, the oil-frying basket can completely enter into the oil-frying pot, so that the materials to be oil-fried in the oil-frying basket can be fully oil-fried to ensure the oil-frying quality; besides, the oil surface in the oil-frying pot has a large distance to the mouth of the oil-frying pot; hot oil is not easy to spill; scalding of workers is avoided; and at the same time, waste of oil is also reduced.

Owner:CHONGQING NIANJI FOOD

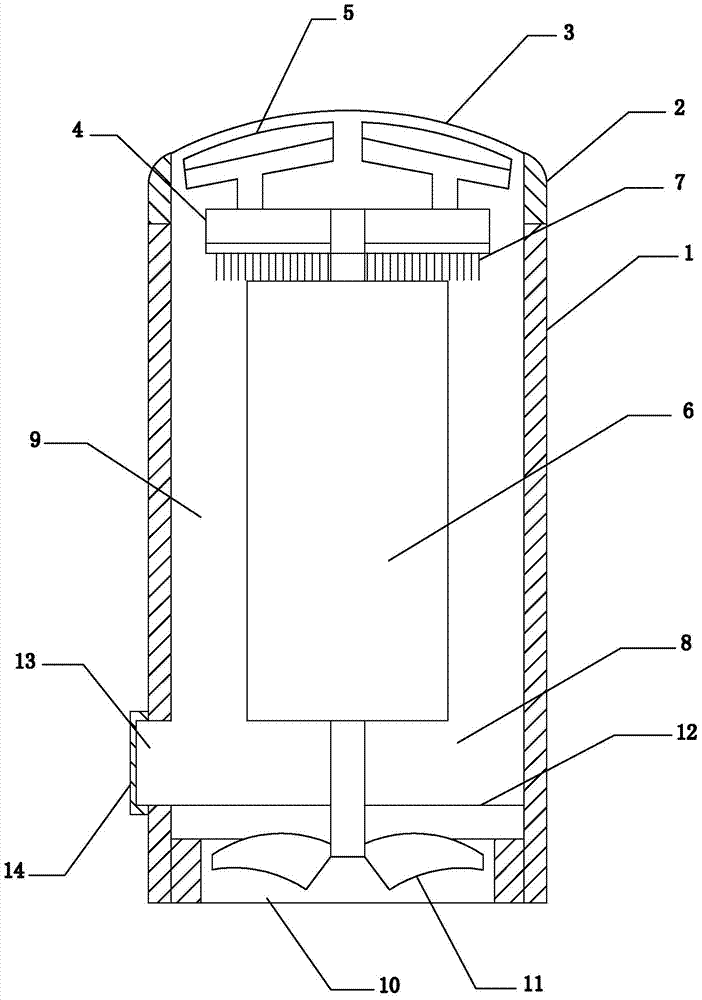

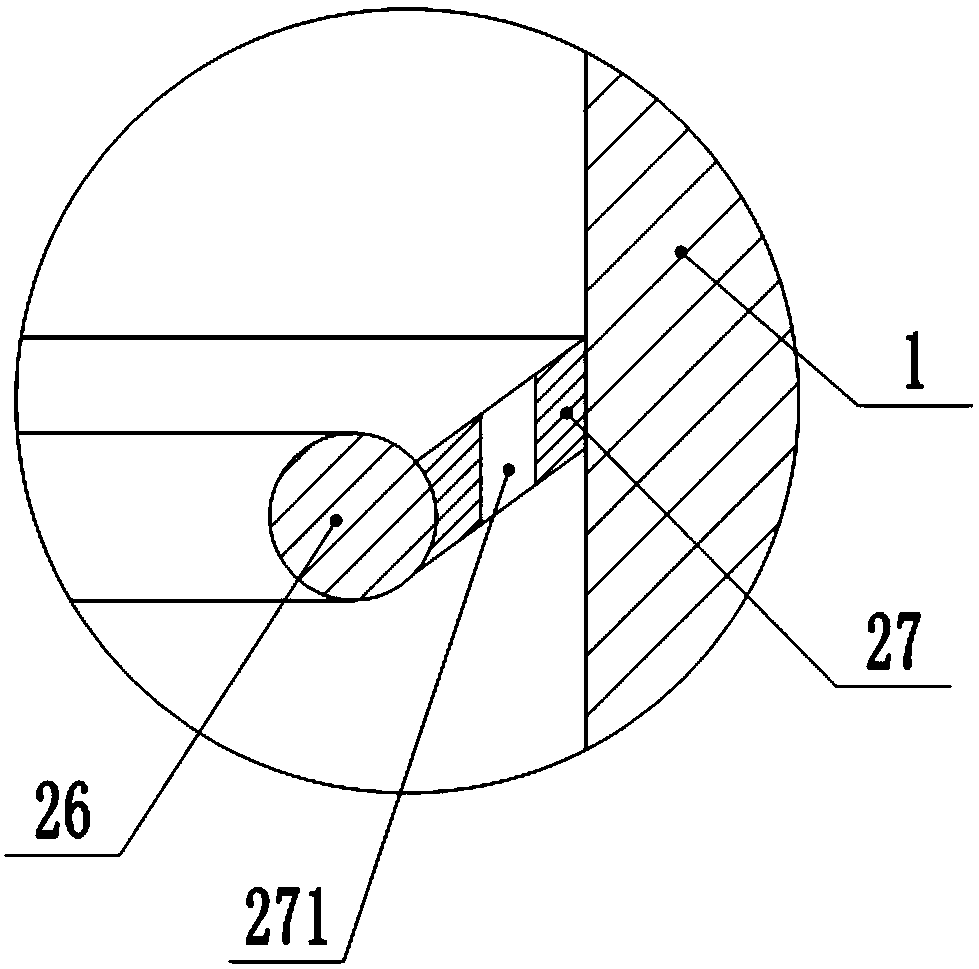

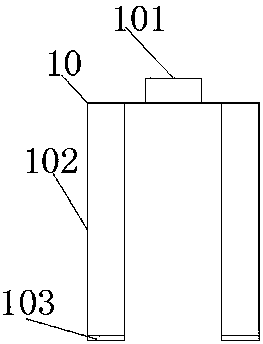

Electric shaver

InactiveCN103495994AEasy to cleanAvoid affecting useMetal working apparatusEngineeringElectric razors

The invention relates to the technical field of daily supplies, in particular to an electric shaver. The electric shaver comprises a body part, wherein a head part is installed at the top end of the body part, a mesh enclosure is installed at the top end of the head part, a blade rest is installed in the head part in a rotating mode, blades are installed on the blade rest, and beard cutting gaps are reserved between the blades and the mesh enclosure; a motor is installed in the body part, wherein a power output shaft of the motor is in transmission connection with the blade rest, and a beard storage cavity is formed between the motor and the blade rest; a cleaning brush is installed on the portion, located in the beard storage cavity, of the power output shaft of the motor; a beard storage box is arranged at the bottom of the body part, and a beard residue channel is arranged between the beard storage cavity and the beard storage box. When the electric shaver is used for shaving, an exhaust fan operates so that negative pressure can be formed in the beard storage box and a beard storage channel, beard residues in the beard storage cavity are sucked into the beard storage box, and therefore the beard residues in the beard storage box can be removed in a concentrated mode, and the situation that the usage is affected due to the fact that beard residues accumulate in the beard storage cavity and abrade the blades can be avoided.

Owner:刘振贵

Honey cleaning method

ActiveCN108782343AReduce wasteIncrease incomeHollow article cleaningHoney collectionMelenaEngineering

The invention relates to the technical field of honey production, and particularly discloses a honey cleaning method. The method comprises the following steps of: 1. removing a bee trough plate from abeehive and gently brushing the bees out on the bee trough plate with a soft brush; 2. putting the bee trough plate into a honey-shaking cavity, starting a motor, and shaking the honey while pressingthe outside air into an elastic airbag for storage; 3. after the shaking honey is finished, turning off the motor, putting the bee trough plate in the honey-shaking cavity back into the beehive, repeating steps 1 and 2; 4. after the last piece of the bee trough plate is processed, sending the air in the elastic air bag to a cavity provided in the side wall of a honey-shaking pot, and moving a blade to scrape off the adhered honey on the side wall of the honey-shaking pot; 5. pushing a push rod, moving the scraper set at the bottom of the honey-shaking cavity, and pushing the honey adhering tothe bottom wall of the honey-shaking pot to the honey outlet; 6. releasing the air in the cavity, resetting the blade, and pulling the push rod to reset; 7. taking away the honey. The honey cleaningmethod can scrape the honey adhered on the side wall and the bottom wall of the honey-shaking cavity, thereby reducing the waste of honey.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

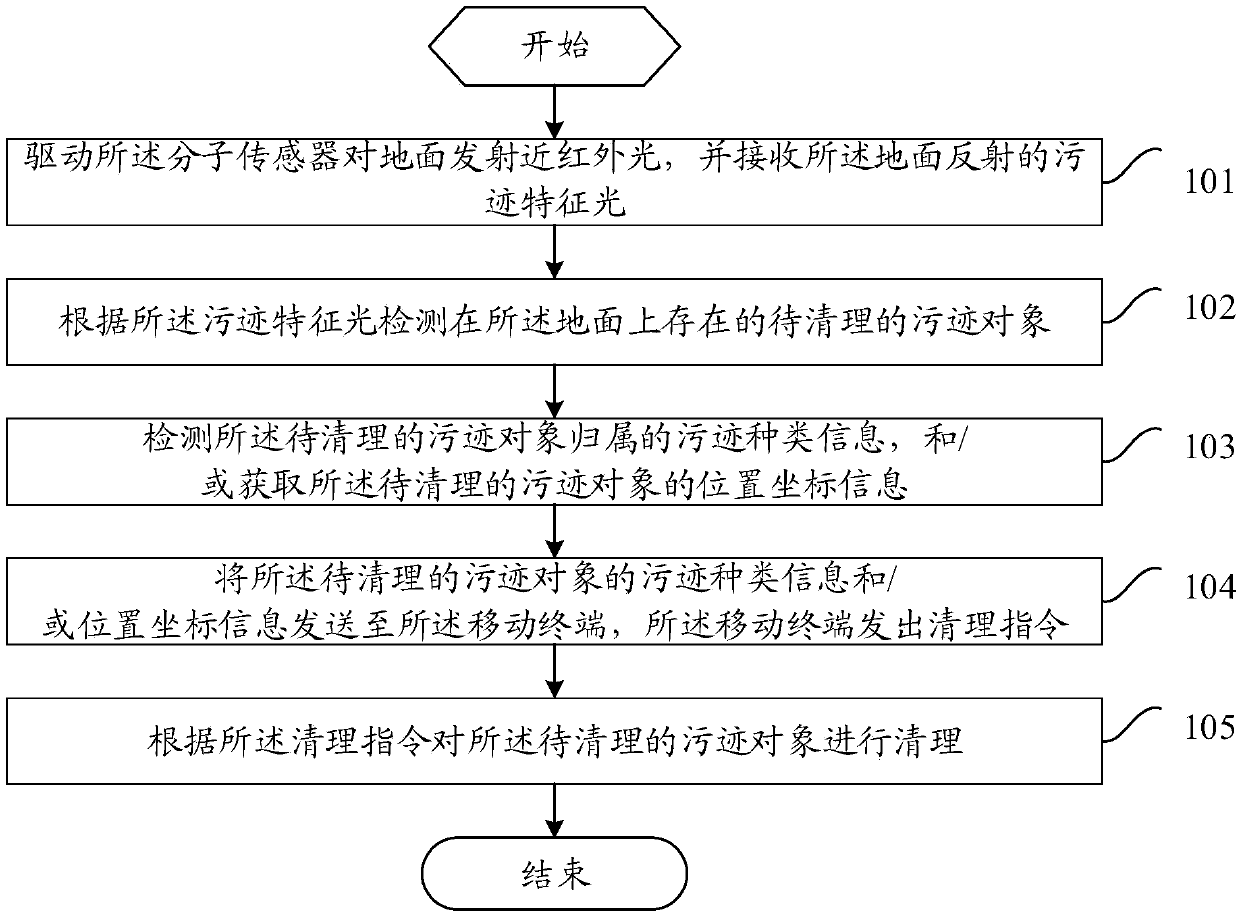

Stain clearing method and system

InactiveCN107669219AIncrease diversityAvoid Manual CleanupMachine detailsMaterial analysis by optical meansComputer scienceStain

The embodiment of the invention provides a stain clearing method and system. The method is applied to a mobile terminal and a relevant floor-sweeping robot, and the floor-sweeping robot is provided with a molecule sensor. The method comprises the steps that the molecule sensor is driven to transmit near-infrared light to the ground and receive stain characteristic light reflected by the ground; according to the stain characteristic light, a to-be-cleaned stained object existing on the ground is detected; stain type information the to-be-cleaned stained object belongs to is detected and / or theposition coordinate information of the to-be-cleaned stained object is obtained; the stain type information and / or the position coordinate information of the to-be-cleaned stained object is sent to the mobile terminal, and the mobile terminal sends out a cleaning instruction; according to the cleaning instruction, the to-be-cleaned stained object is cleaned. By adopting the method, targeted cleaning is performed, the diversity of cleaning functions is increased, manual stain clearing performed by a used is avoided, and the cleaning efficiency is improved.

Owner:VIVO MOBILE COMM CO LTD

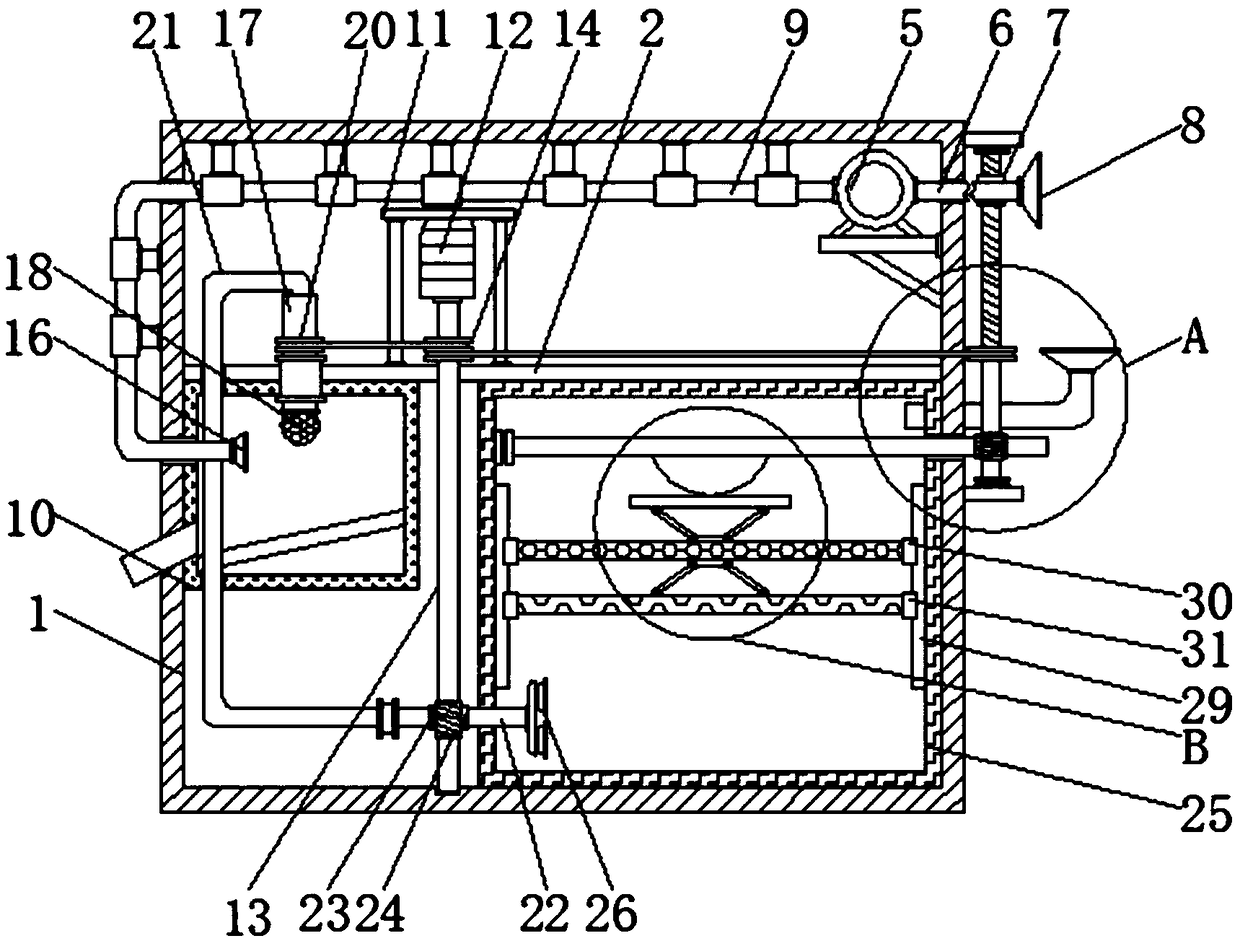

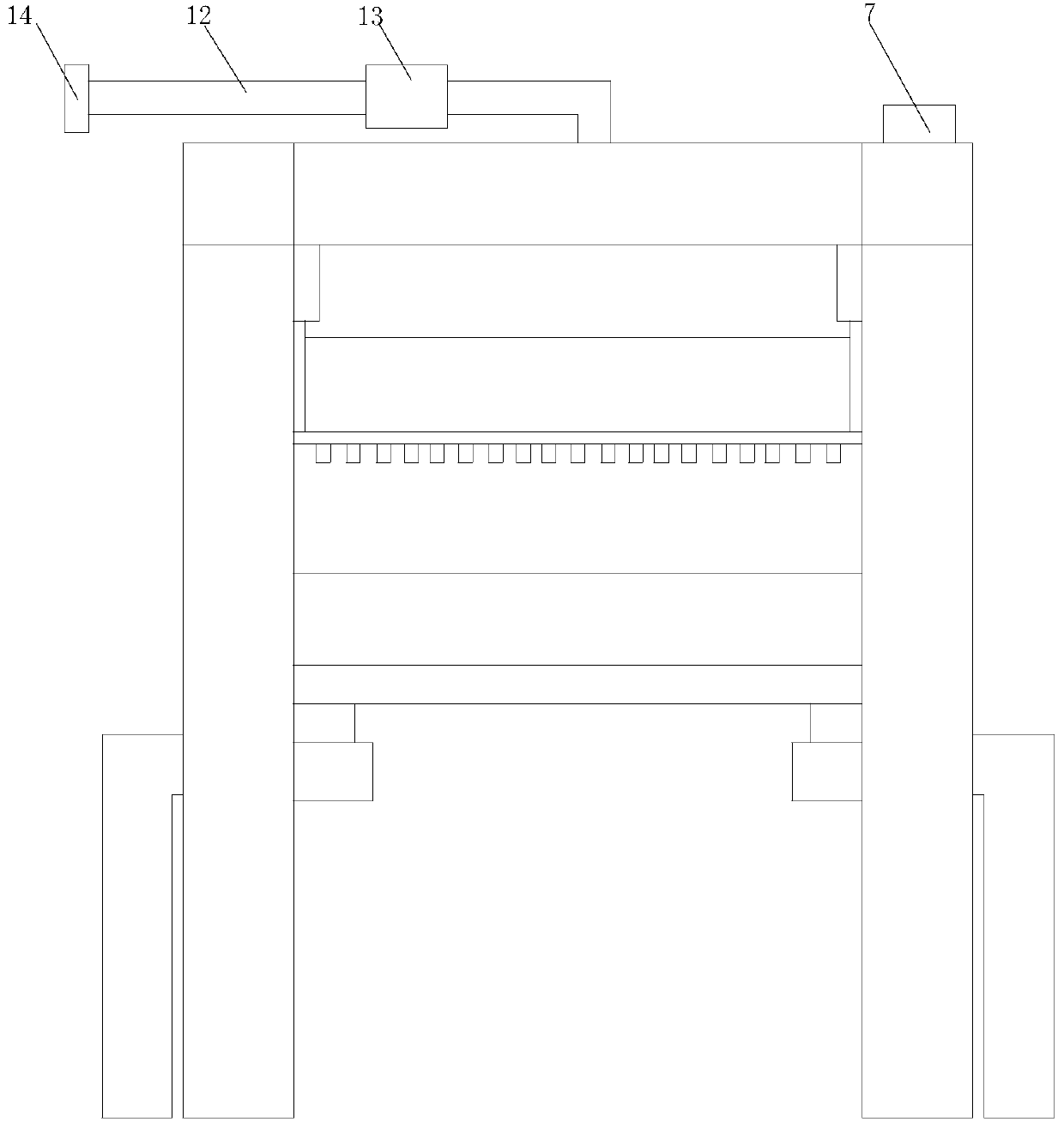

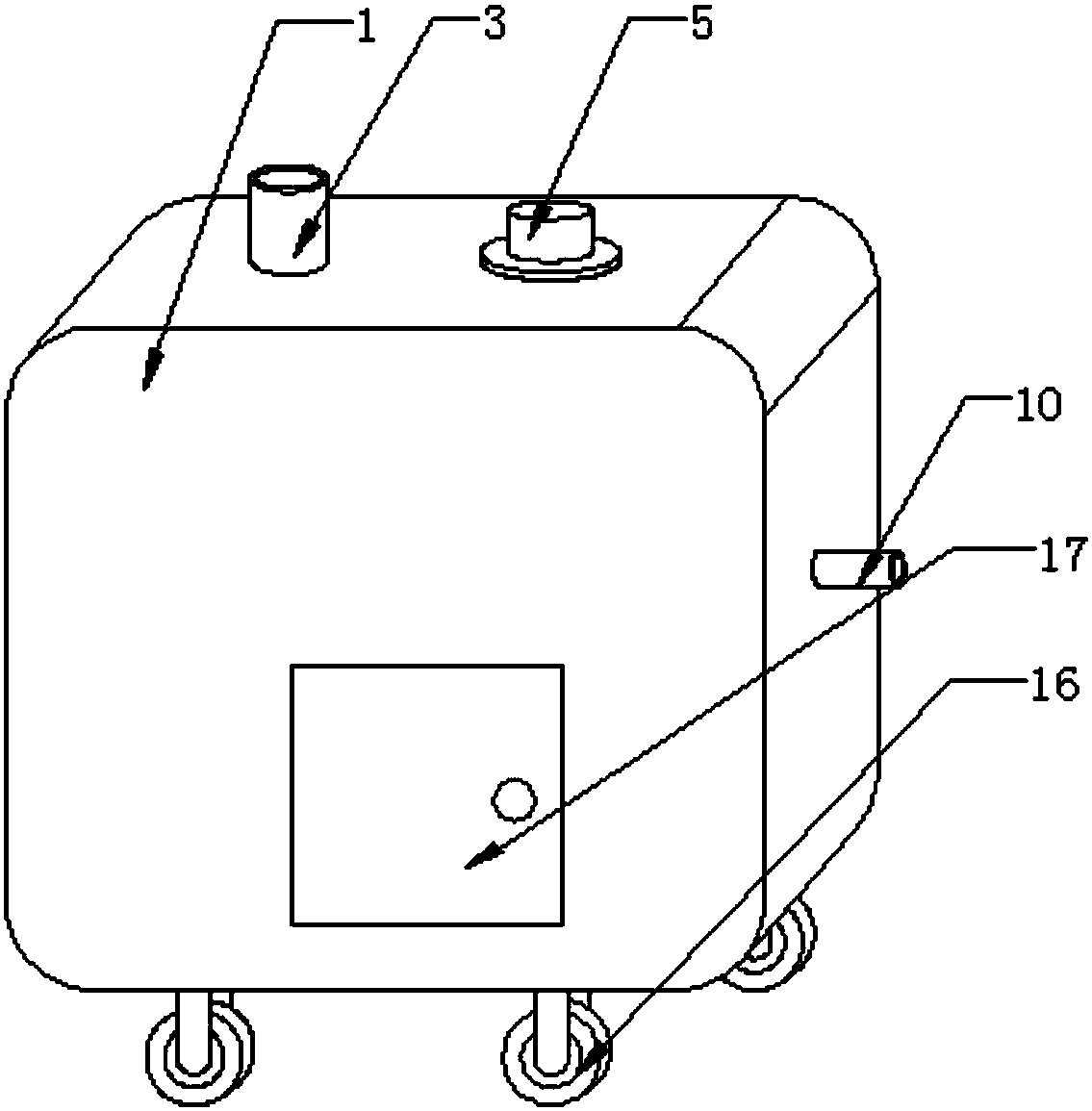

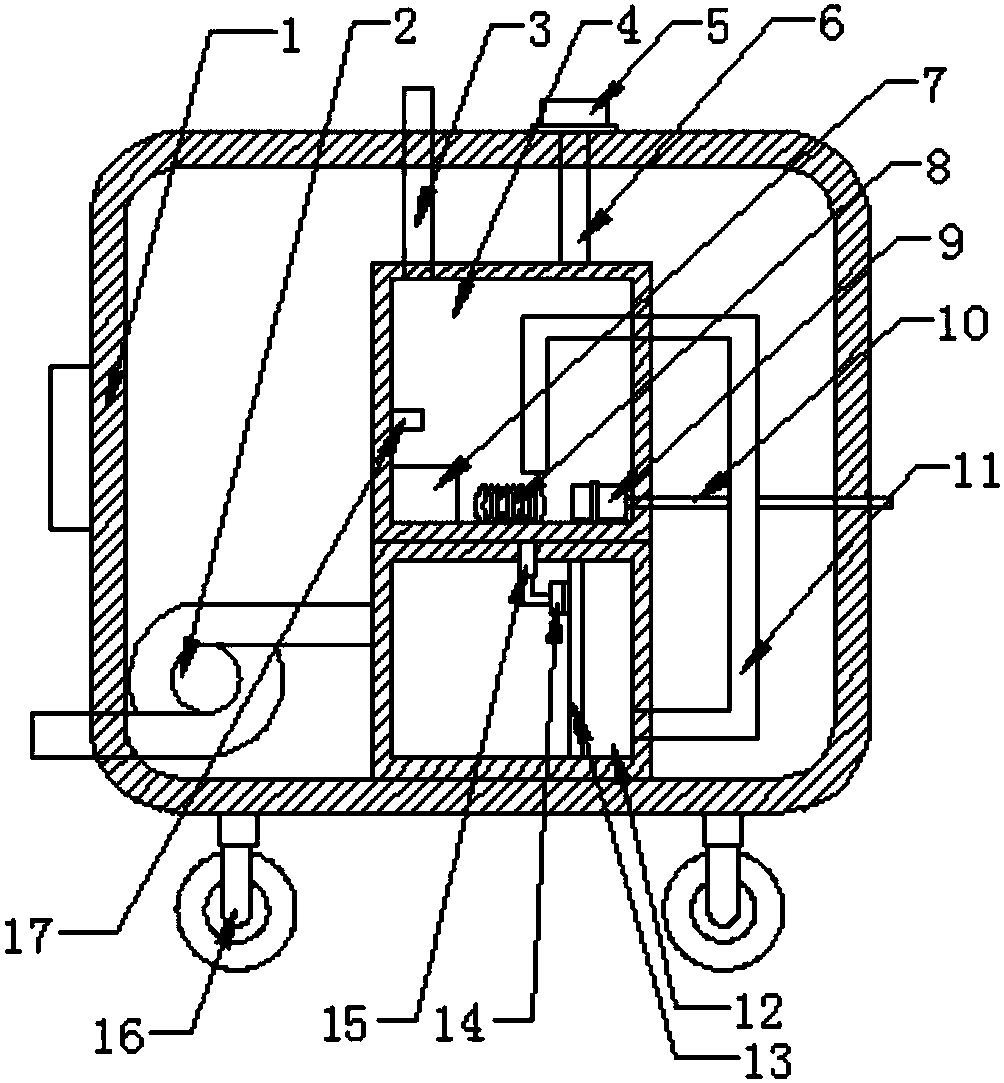

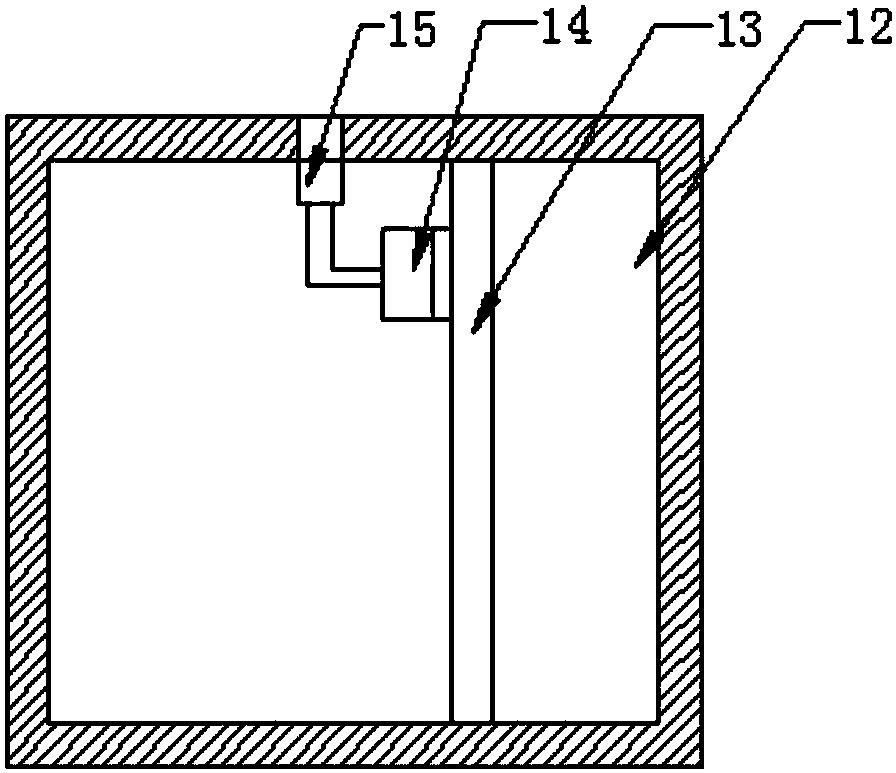

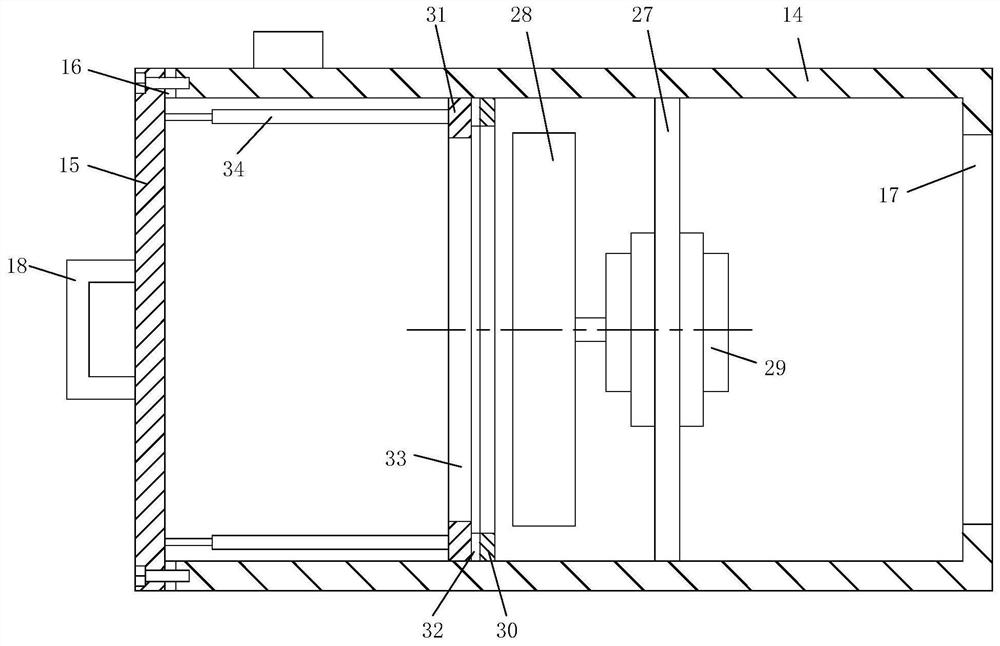

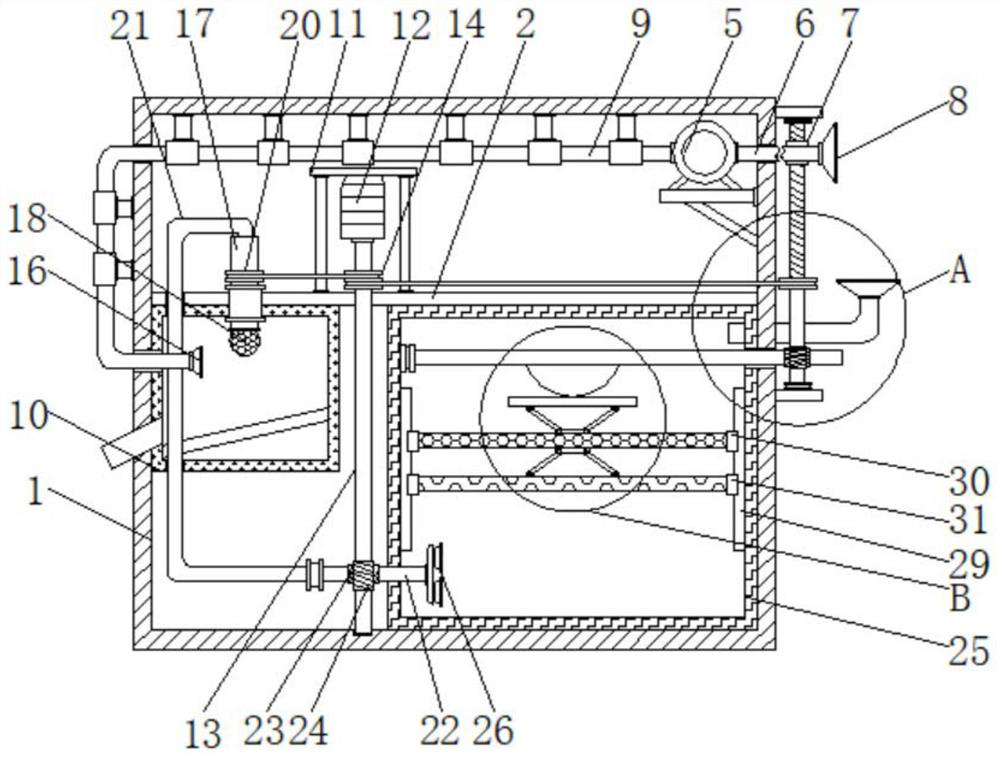

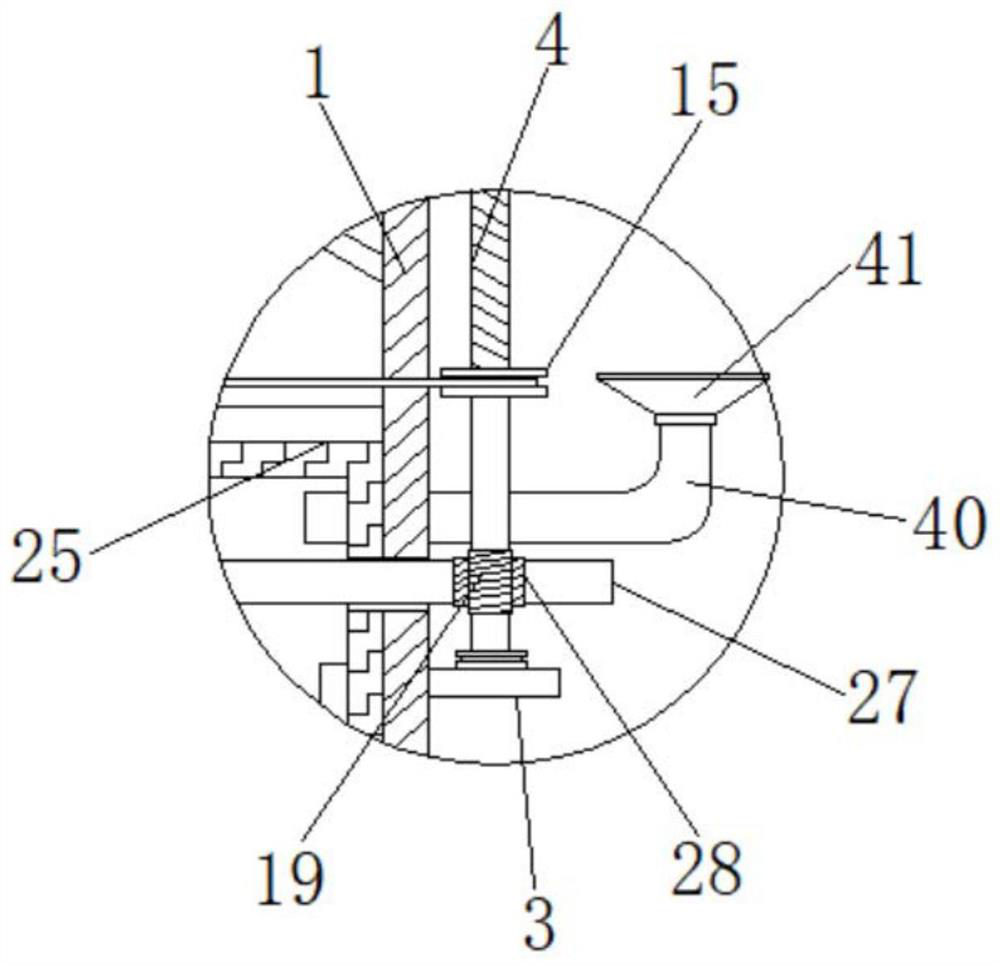

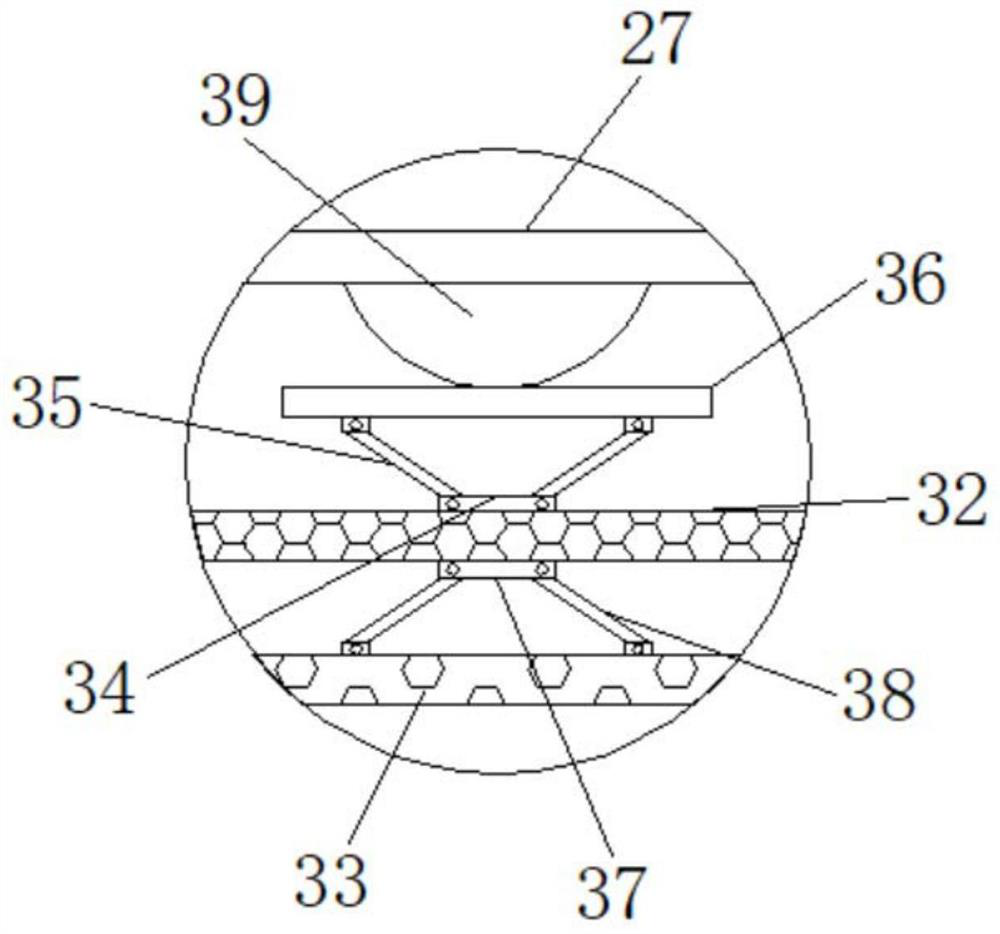

Welding smoke purifying device applied to welding machine tools and using method thereof

ActiveCN108355415AImprove adsorption capacityAvoid Manual CleanupDispersed particle filtrationWelding/cutting auxillary devicesEngineeringMachine tool

The invention discloses a welding smoke purifying device applied to welding machine tools. The welding smoke purifying device comprises a box body, wherein a partition plate is fixedly connected between the tops of two sides of the inner wall of the box body; the top and the bottom of one side of the box body are fixedly connected with support blocks; a screw rod is rotatably connected between theopposite sides of the two support blocks; the top of one side of the inner wall of the box body is fixedly connected with an air sucking machine; one end of an air inlet of the air sucking machine iscommunicated with a sucking pipe. The welding smoke purifying device relates to the technical field of purification of welding smoke. According to the welding smoke purifying device applied to welding machine tools and a using method thereof, the partition plate is fixedly connected to the tops between two sides of the inner wall of the box body; people do not need to take a lot of time to clean,so that the workload of the people is effectively reduced, and the working efficiency of the people is improved; a filtering box is fixedly connected to the bottom of the partition plate on one sideof the inner wall of the box body, so that large-sized particle impurities in the organic waste gas can be effectively removed; and the adverse influence on subsequent purification of the organic waste gas can be avoided.

Owner:ZHEJIANG LAOSHIDUN WELDING EQUIP

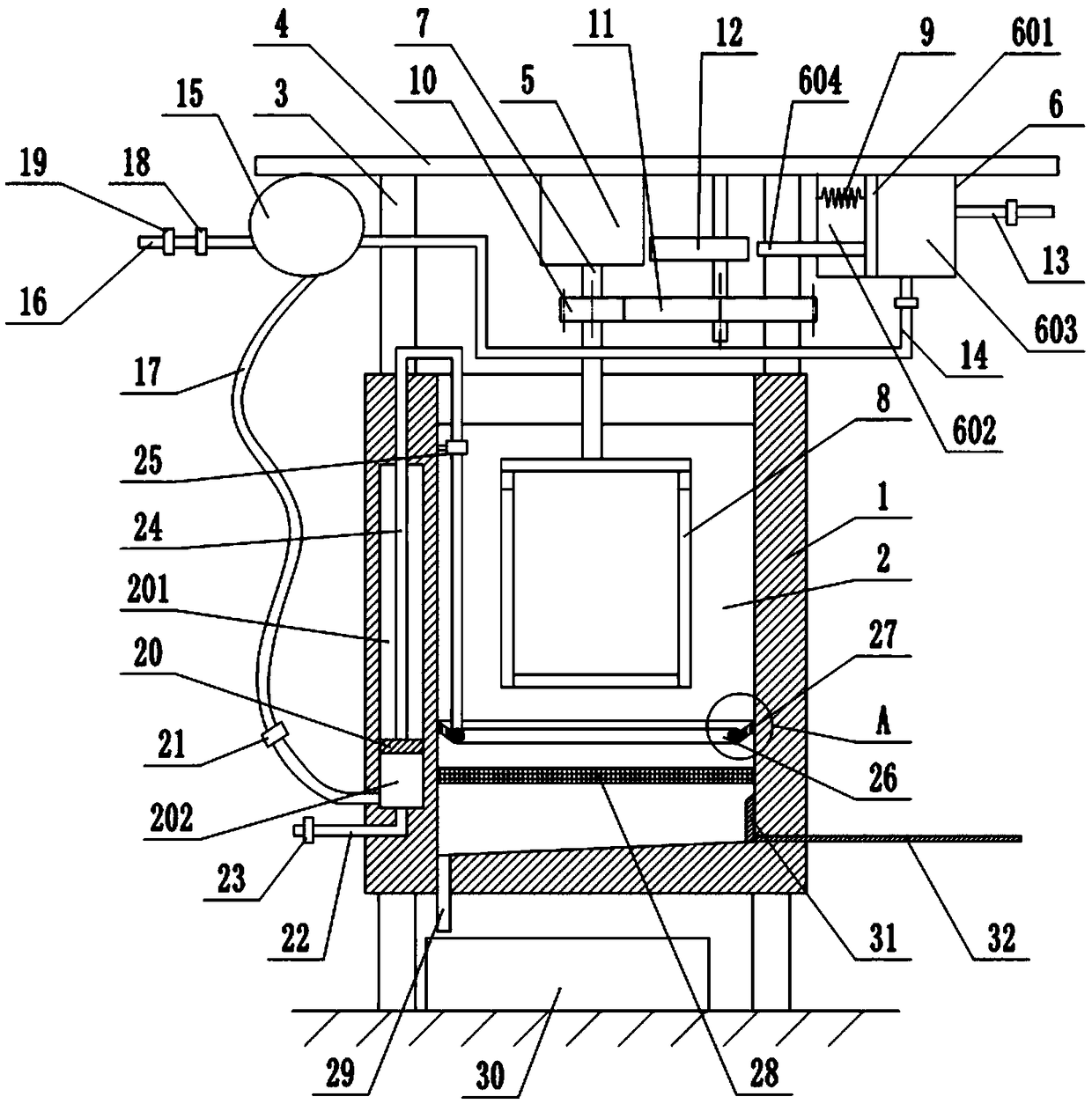

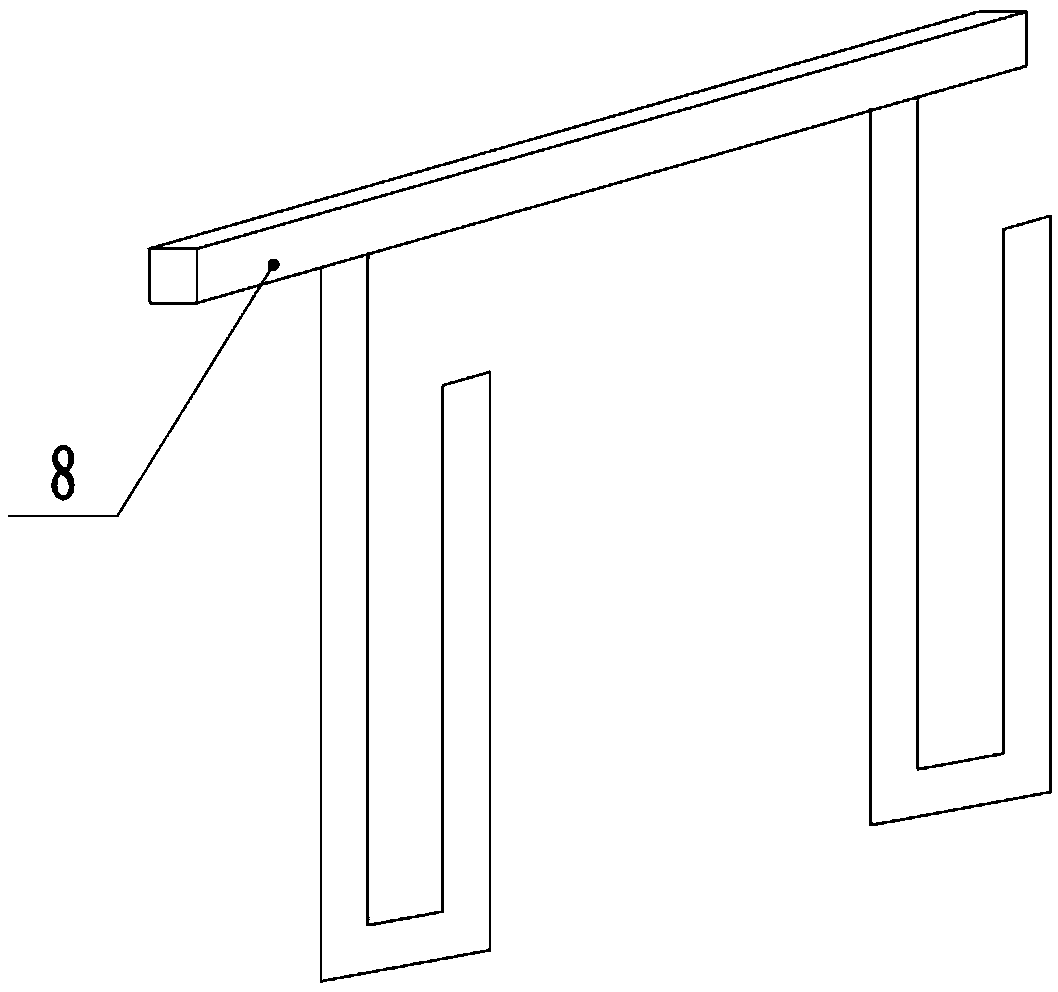

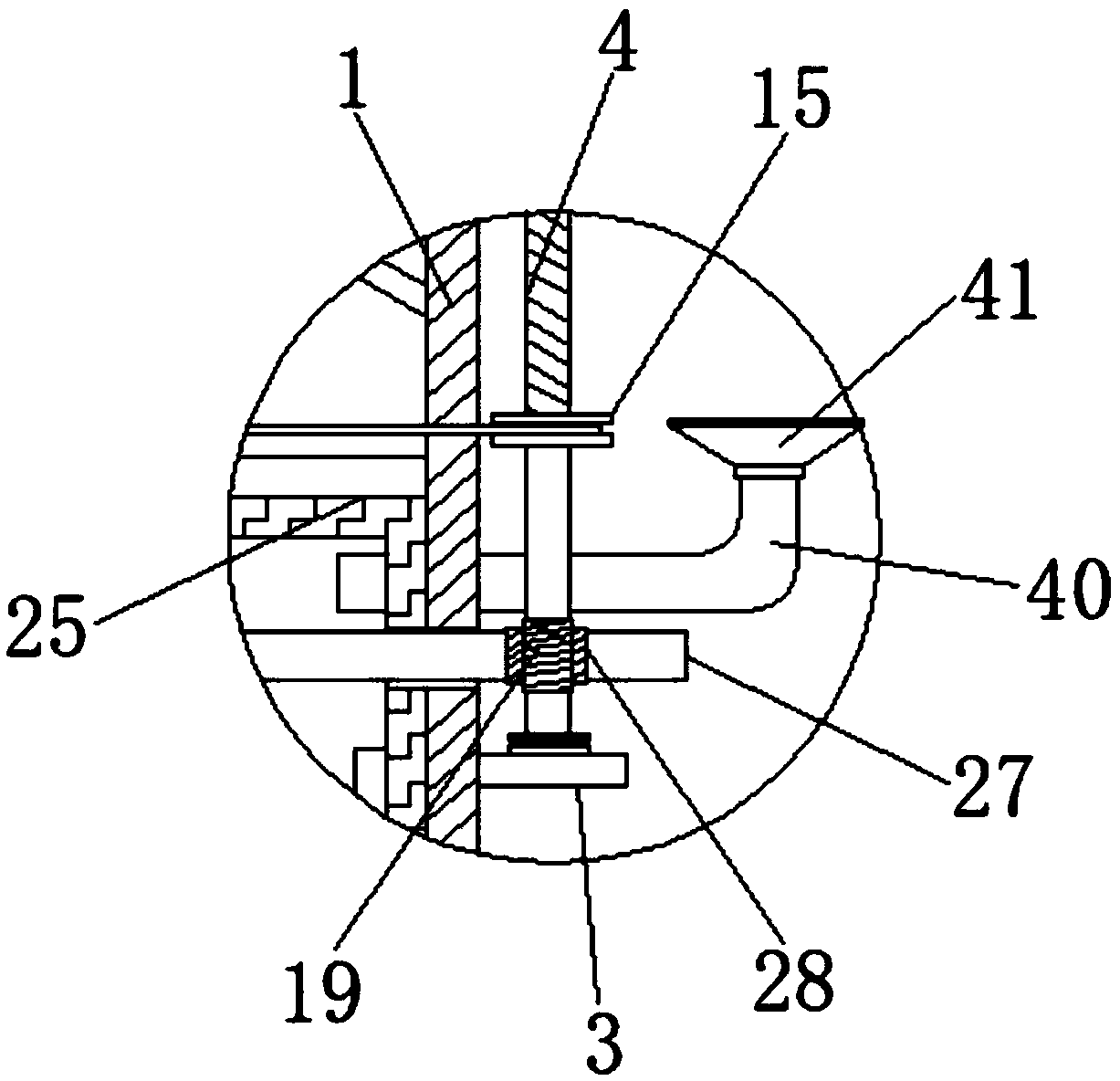

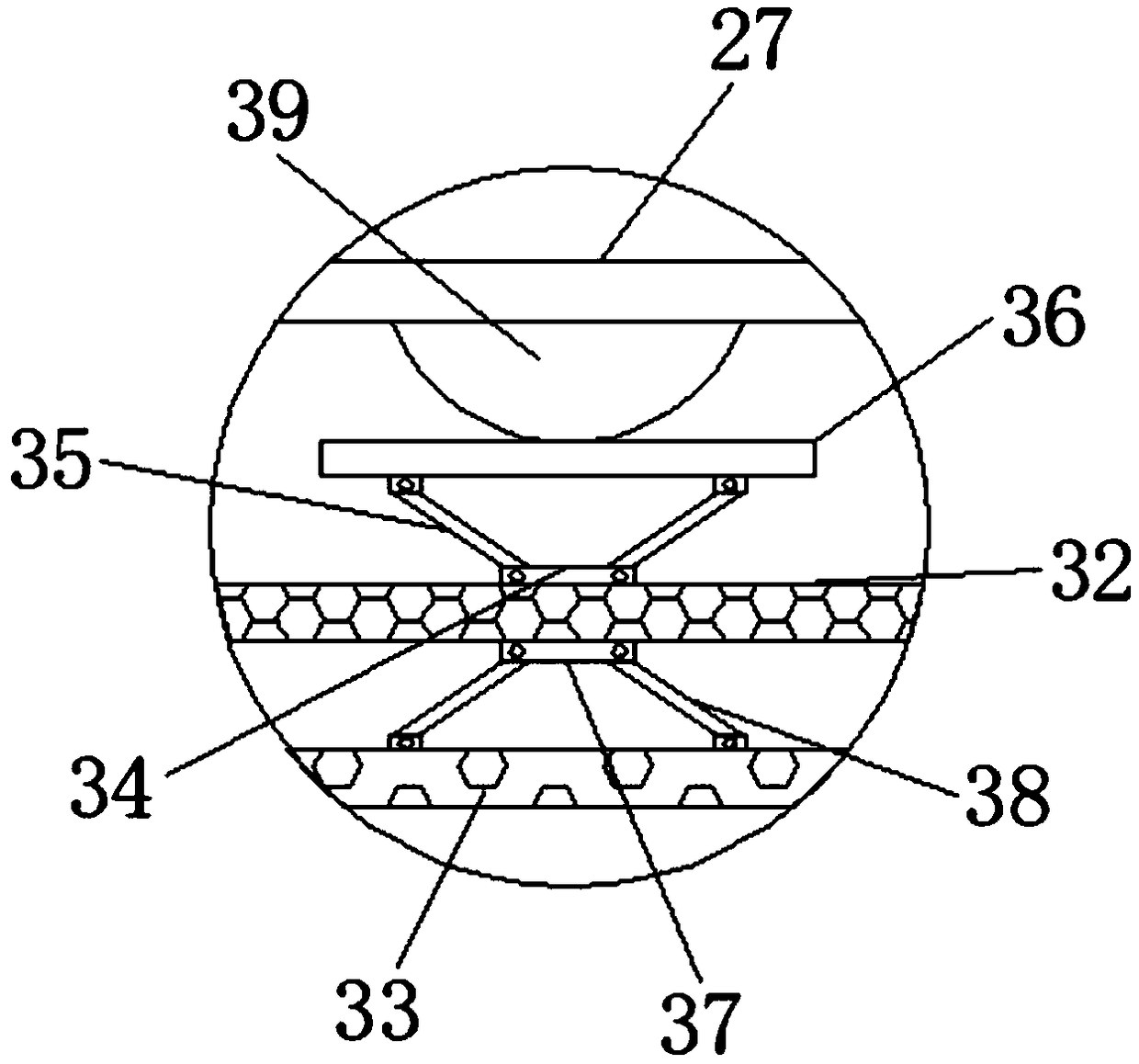

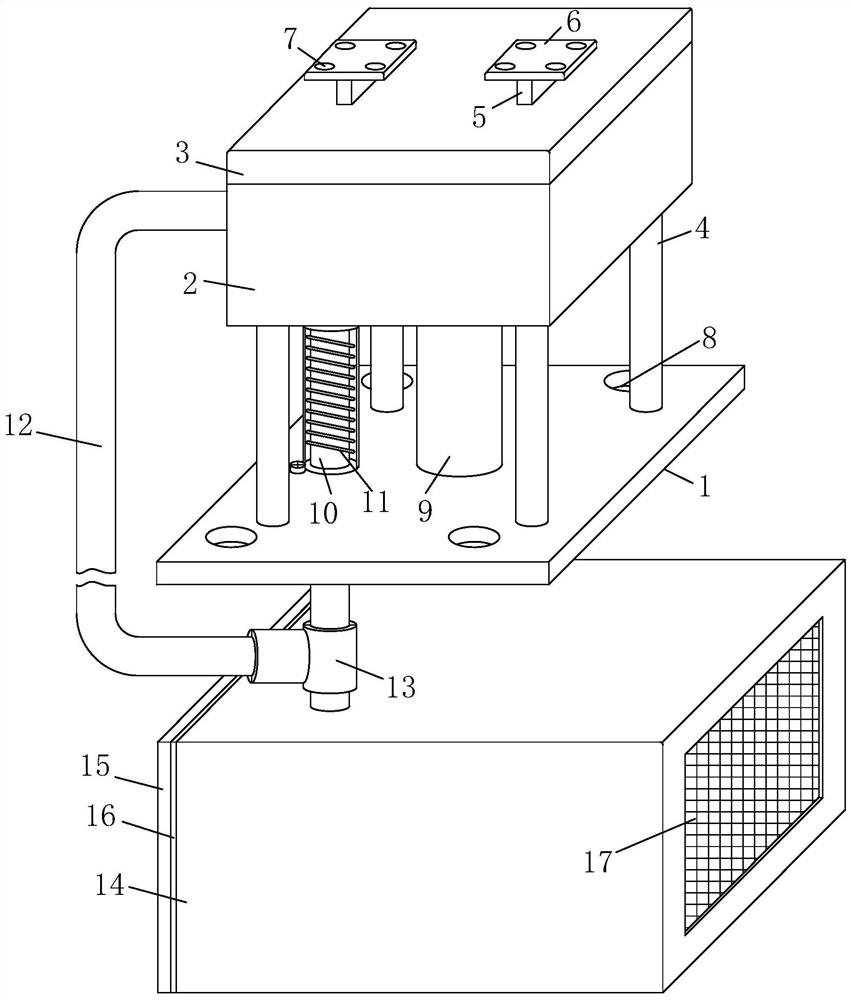

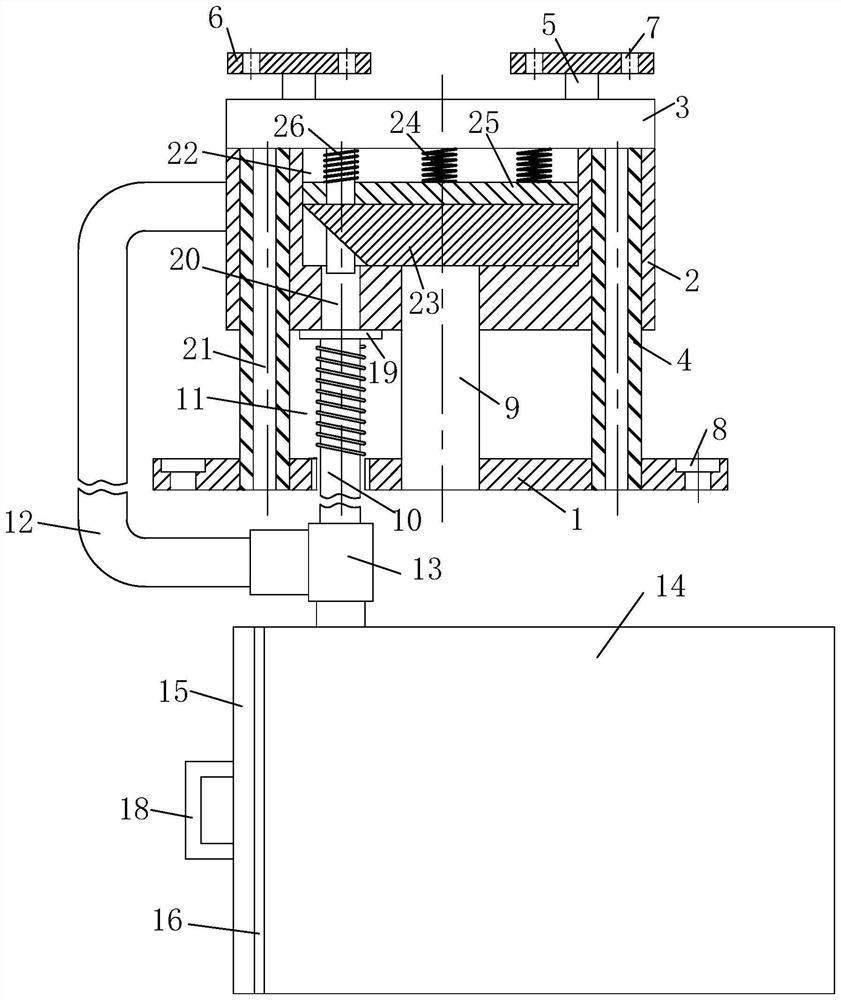

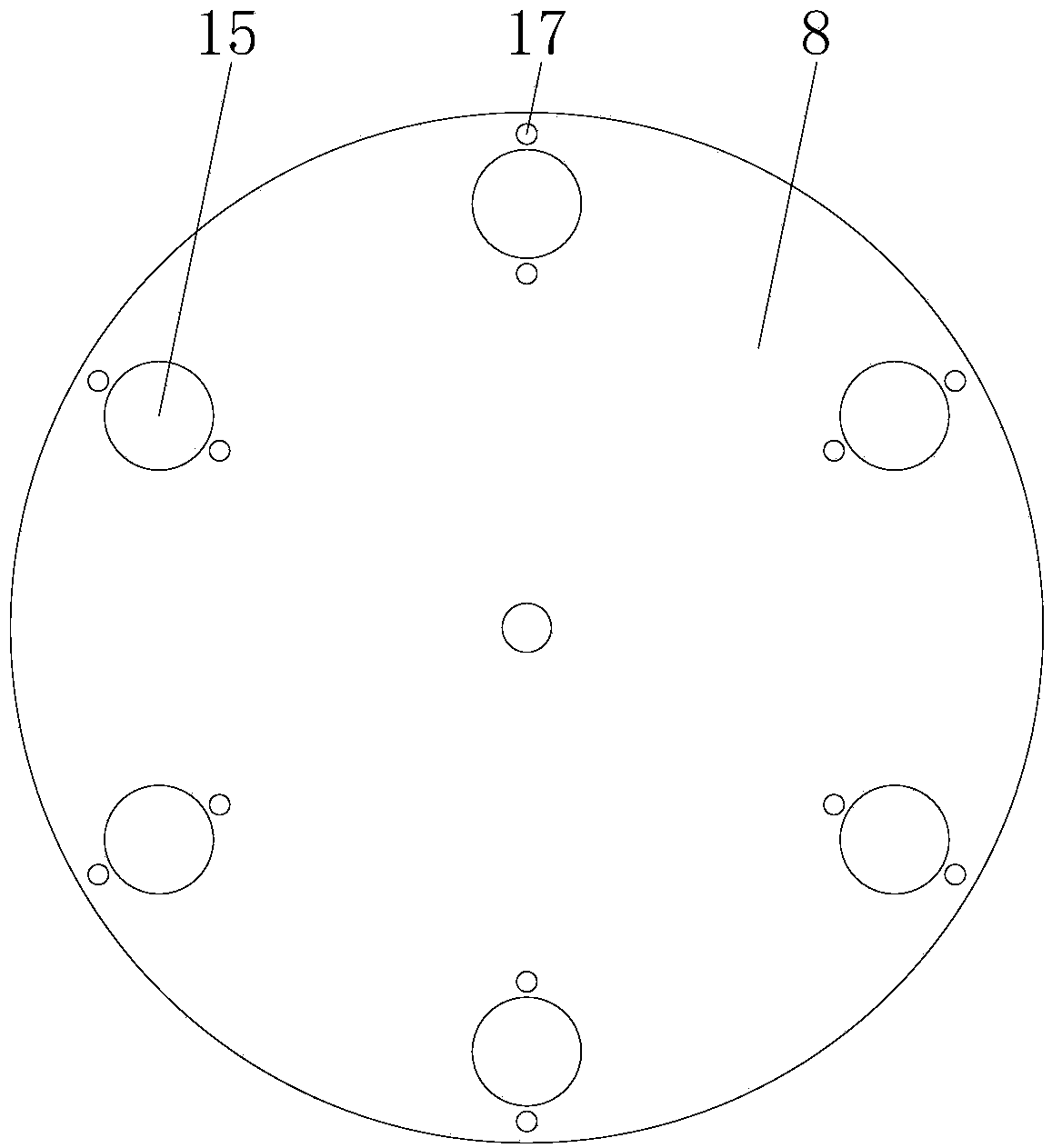

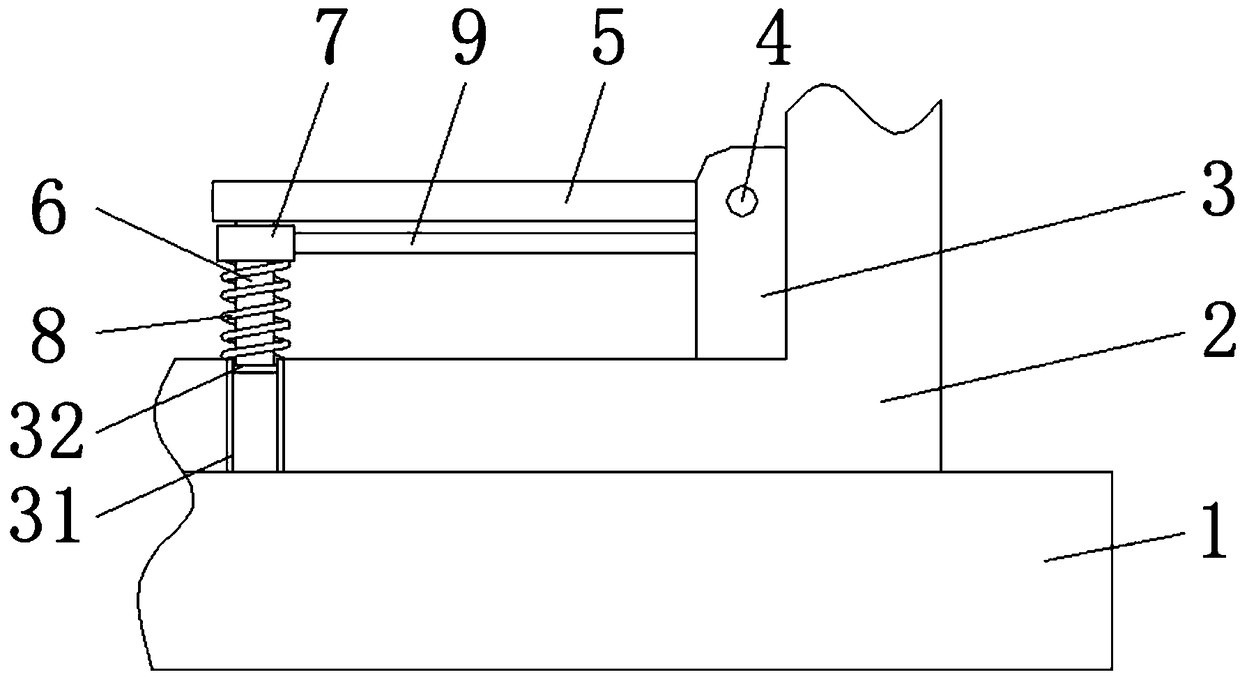

Metal punching die

ActiveCN110355278AImprove stabilityAvoid mobilityShaping toolsMetal-working feeding devicesRubber ringImpeller

The invention belongs to the technical field of dies, and particularly relates to a metal punching die. The metal punching die comprises a bottom plate, a lower die, an upper die, guide sleeves, connecting strips, a mounting plate, a first mounting hole, second mounting holes, a fixing sleeve, an electromagnet, a guide ring, a push block, a movable iron rod, a first spring, a material guide pipe,a second spring, a connecting pipe, a three-way pipe, a dust suction box, a side plate, a first rubber ring, a first filter screen, a handle, a circular ring, a discharge hole, guide rods, a punchingcavity, metal blocks, third springs, a pressing plate, a punching rod, a mounting frame, a centrifugal impeller, a motor, a baffle ring, a frame, a second rubber ring, a second filter screen and gas springs. The metal block punching device is reasonable in structure and suitable for punching and removing excess material on one side of the metal block; and during punching, the punching rod is in contact with the metal block, and the pressing plate and the multiple third springs are arranged, so that the pressing limit of the metal block can be carried out in advance, the stability of the metalblock during punching is improved, movement and upwarping are avoided, and the punching precision is improved.

Owner:上海东景工艺有限公司

Environmental sanitation garbage can

The invention belongs to the field of environmental sanitation facilities and particularly relates to an environmental sanitation garbage can. A base plate of the environmental sanitation garbage canis composed of two ascending-and-descending plates and a fixing plate, and a gap is formed between every two parts, so that water in garbage is drained through the gaps and prevented from being accumulated in the garbage. In addition, an exhaust opening is formed in one side of a garbage can body, and peculiar smell in the garbage can body can be removed in time. The environmental sanitation garbage can is further provided with electric wheels; sanitation workers do not need to push the environmental sanitation garbage can manually, and manpower is saved; the garbage can body is internally provided with a separating body, and when the garbage falls through the separating body, metal products are attracted by magnetic attraction devices; after a can cap is closed, the attracted metal products fall into containing boxes; when the garbage can body is cleaned, the containing boxes are shielded through a shielding plate, and metal in the containing boxes is prevented from being disposed together with other types of garbage; and after other types of garbage is disposed, the shielding plate is opened, and the metal in the containing boxes is cleaned.

Owner:常州蓝森环保设备有限公司

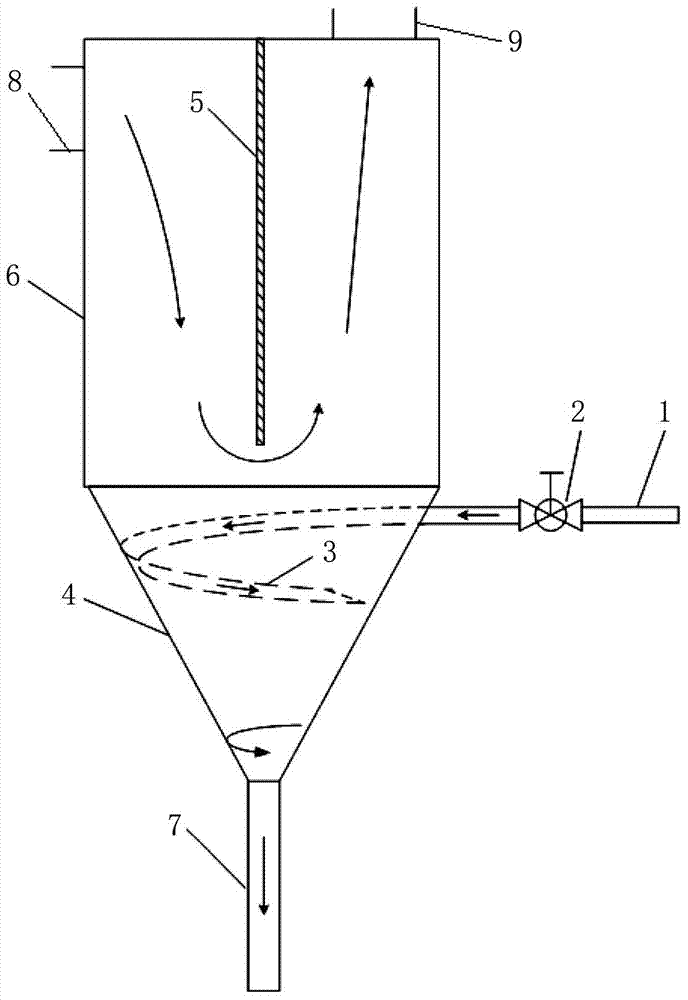

Blocking-preventing drop catcher and cleaning method thereof

ActiveCN103480205AEasy to cleanImprove the operating environmentDispersed particle separationTetrachlorideCleaning methods

The invention discloses a blocking-preventing drop catcher. The blocking-preventing drop catcher comprises a barrel body, a cone bottom and a drain pipe as well as a cleaning unit, wherein the cleaning unit comprises a feeding pipe, a pneumatic ball valve and a spiral pipe; one end of the feeding pipe is communicated with a titanium tetrachloride liquid storing unit, the other end of the feeding pipe is inserted into the drop catcher from the upper part of the outer wall of the cone bottom, the pneumatic ball valve is arranged on the feeding pipe, and the spiral pipe is paved on the inner wall of the cone bottom; the feeding port of the spiral pipe is connected with the other end of the feeding pipe, and the discharging port of the spiral pipe is positioned on the inner wall of the cone bottom. The cleaning method of the drop catcher provided by the invention is implemented based on the blocking-preventing drop catcher, the pneumatic ball valve arranged on the feeding pipe is switched on from time to time, titanium tetrachloride liquid enters the cone bottom of the drop catcher through the feeding pipe and can clean the inner wall of the cone bottom under the drainage action of the spiral pipe, and the titanium tetrachloride liquid after cleaning work and a hydrolysate thereof are discharged from the drain pipe. The blocking-preventing drop catcher provided by the invention has the advantages of being beneficial to cleaning the titanium tetrachloride and the hydrolysate thereof adhered on the inner wall of the cone bottom of the drop catcher, and improving and maintaining the operating environment of the drop catcher.

Owner:PANGANG GROUP TITANIUM INDAL

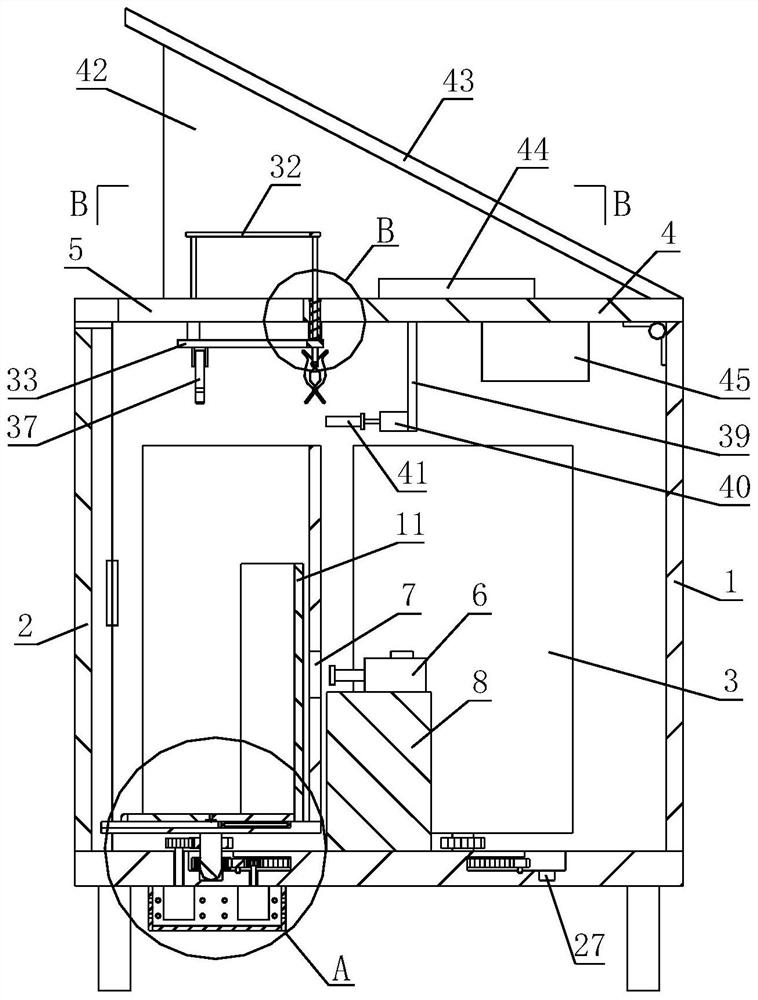

Glass processing device with automatic trimming function

InactiveCN112847004APrevent fallingAvoid displacementEdge grinding machinesGrinding drivesFixed frameElectric machinery

The invention discloses a glass processing device with an automatic trimming function. The glass processing device comprises a box body, a placing table is bolted to the center of the top of the box body, a lifting positioning mechanism is arranged in an inner cavity of the box body, a controller is bolted to the left side of the box body, and support frames are bolted to the periphery of the top of the box body; and fixing frames are connected to the centers of the front face and the back face of the supporting frame in a bolted mode. Through cooperation of an electric air cylinder, a lifting base and a lifting cylinder, the height of a suction cup can be adjusted, the lifting adjustment requirement of the glass trimming position is met, through cooperation of the suction cup, a suction pump, a hose, a three-way connector and a branch pipe, glass to be trimmed can be strongly and evenly adsorbed and fixed, falling and displacement in the glass trimming process are prevented, and a trimming accident at the glass edge is avoided, and through cooperation of a through groove, a sliding groove, a stepping motor, a lead screw, a threaded sleeve, a sliding rod, a connecting rod, a connecting frame and a trimming grinding roller, trimming operation can be conducted on the edge positions of the front face and the back face of the glass.

Owner:泗阳垠创运营管理有限公司

Garbage collecting device

ActiveCN113291660AMitigating Garbage SpillsAvoid the smellRefuse receptaclesGarbage collectionMechanical engineering

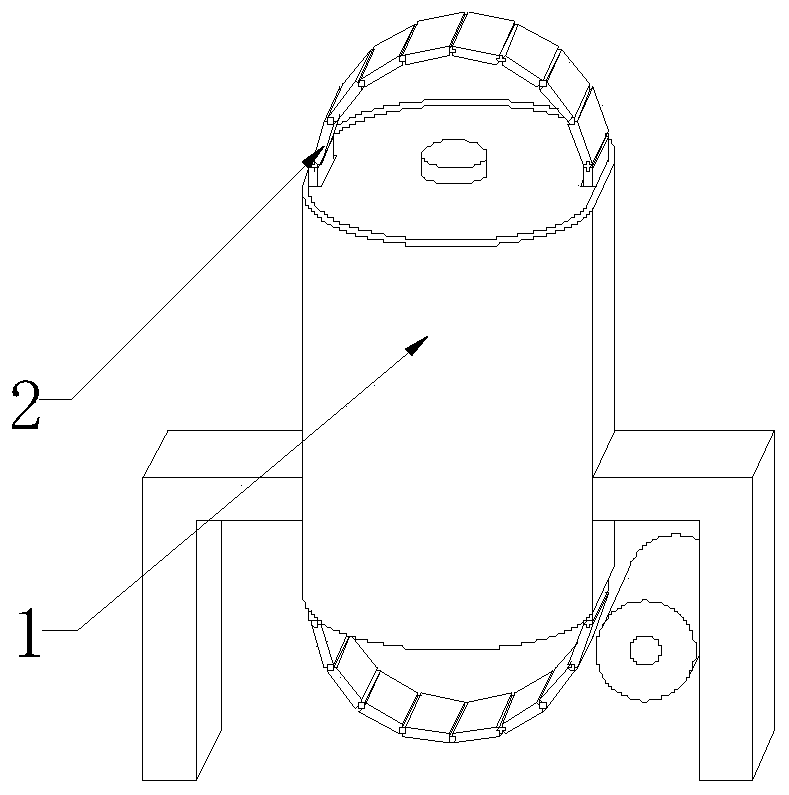

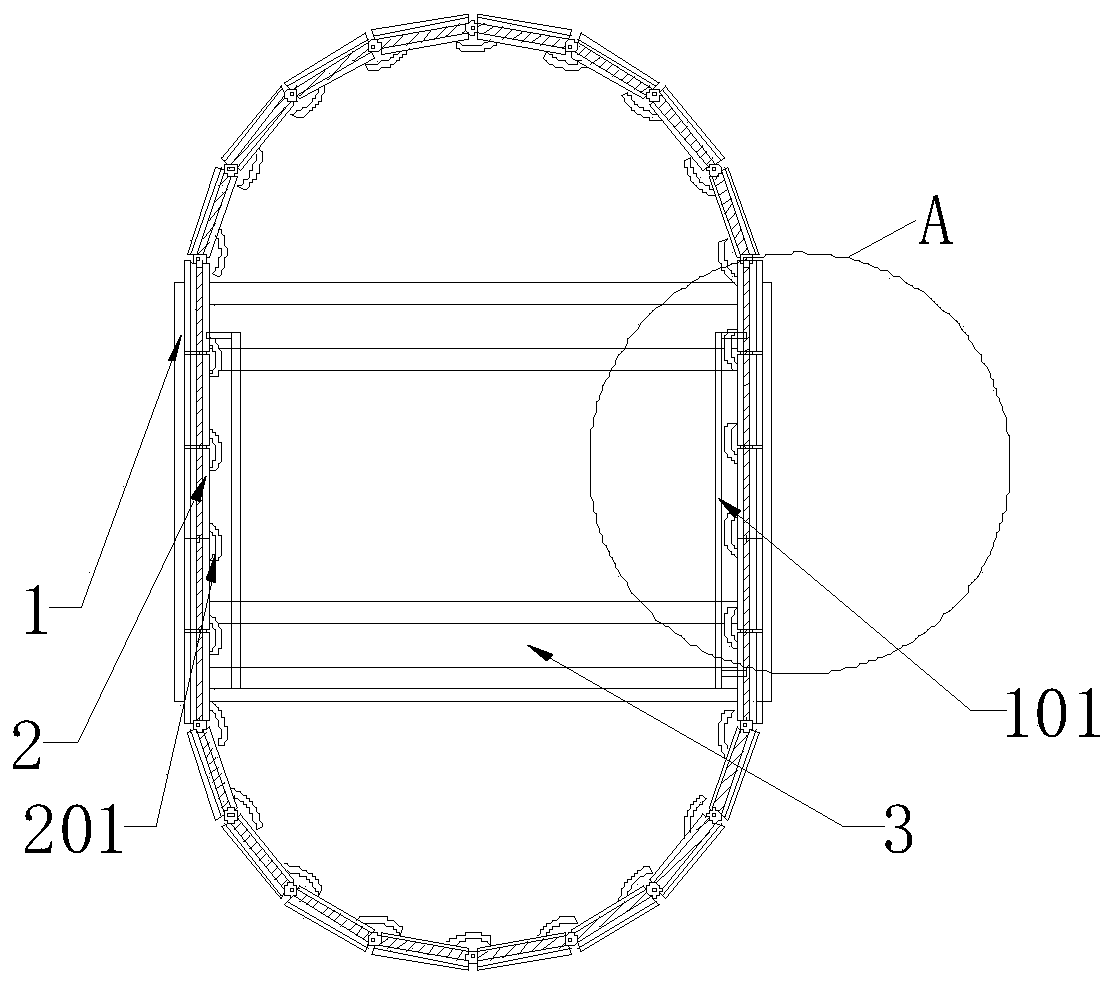

The invention relates to the technical field of garbage collection, in particular to a garbage collecting device. According to the specific technical scheme, a garbage collecting device comprises a garbage can and a can door hinged to one side of the garbage can, wherein a plurality of garbage cans which are annularly arranged are arranged in the garbage can, one side of each garbage can is provided with an opening, and a top cover of the garbage can is provided with a throwing opening corresponding to the top of one garbage can; a driving mechanism for driving all the garbage cans to rotate around the centers of bottom plates of the garbage cans and enabling a side opening in each garbage can to correspond to the can door is arranged on the bottom plate of each garbage can, a first push rod is arranged on the bottom plate in each garbage can; first through holes are formed in the side walls of the garbage cans; and the output ends of the first push rods correspond to the first through holes. The problem that in the prior art, garbage in the garbage cans overflows out of the garbage cans and to the outside of the garbage cans and is difficult to clean is solved.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Trash rack clearing device for water conservancy project

InactiveCN111287154AAvoid Manual CleanupImprove work efficiencyBarrages/weirsArtificial water canalsElectric machineryDrive motor

The invention discloses a trash rack clearing device for a water conservancy project. The trash rack clearing device for the water conservancy project comprises a clearing device supporting frame. First drive shafts are fixedly connected with the back faces of first drive motors. The end, far away from a first guide pipe, of each second guide pipe is fixedly connected with a connector. The tops ofconveyer belts are fixedly connected with trash rack supporting platforms. The bottoms of signal receivers are fixedly connected with a signal transmitter. The trash rack clearing device for the water conservancy project is provided with the two connectors, by means of the two connectors, a user connects the two connectors with a clear water pipe and a cleaning agent pipe correspondingly first ofall, when a trash rack moves to the middle portions of the conveyer belts, the clear water pipe is opened firstly, dirt on the surface of the trash rack is removed, then the user opens the cleaning agent pipe to clean residual dirt on the trash rack, the user opens the clear water pipe to conduct flushing finally, and therefore the work efficiency of cleaning is greatly improved. By means of thearranged conveyer belts, it is avoided that cleaning water splashes to a body of the work personnel during cleaning.

Owner:黄连明

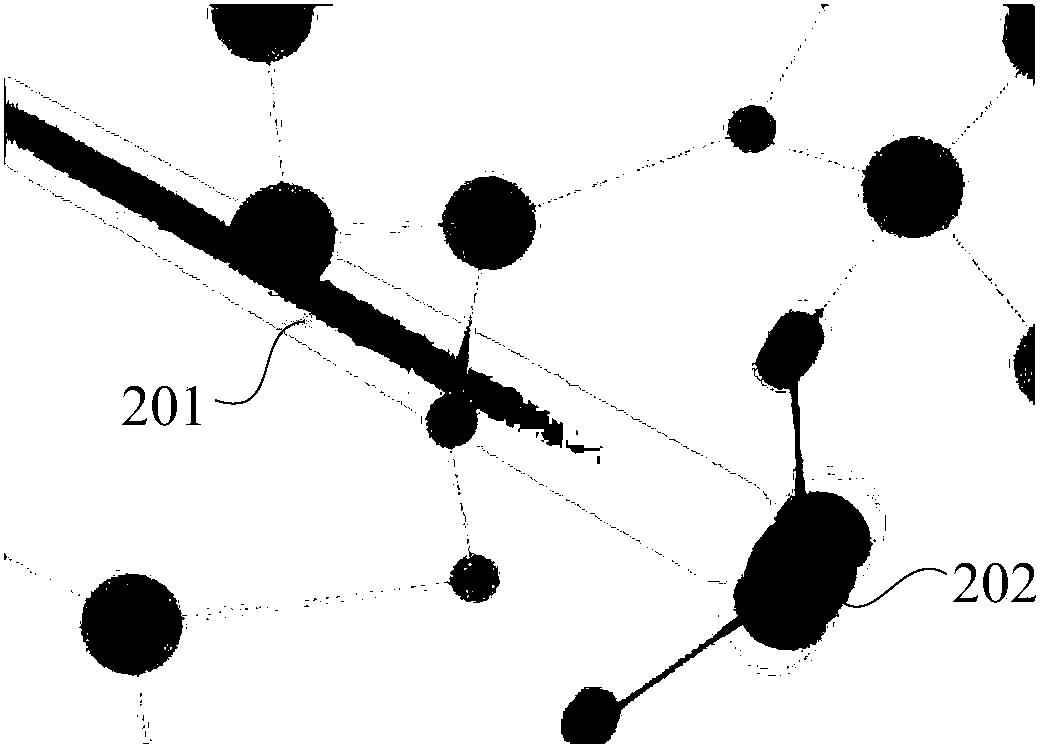

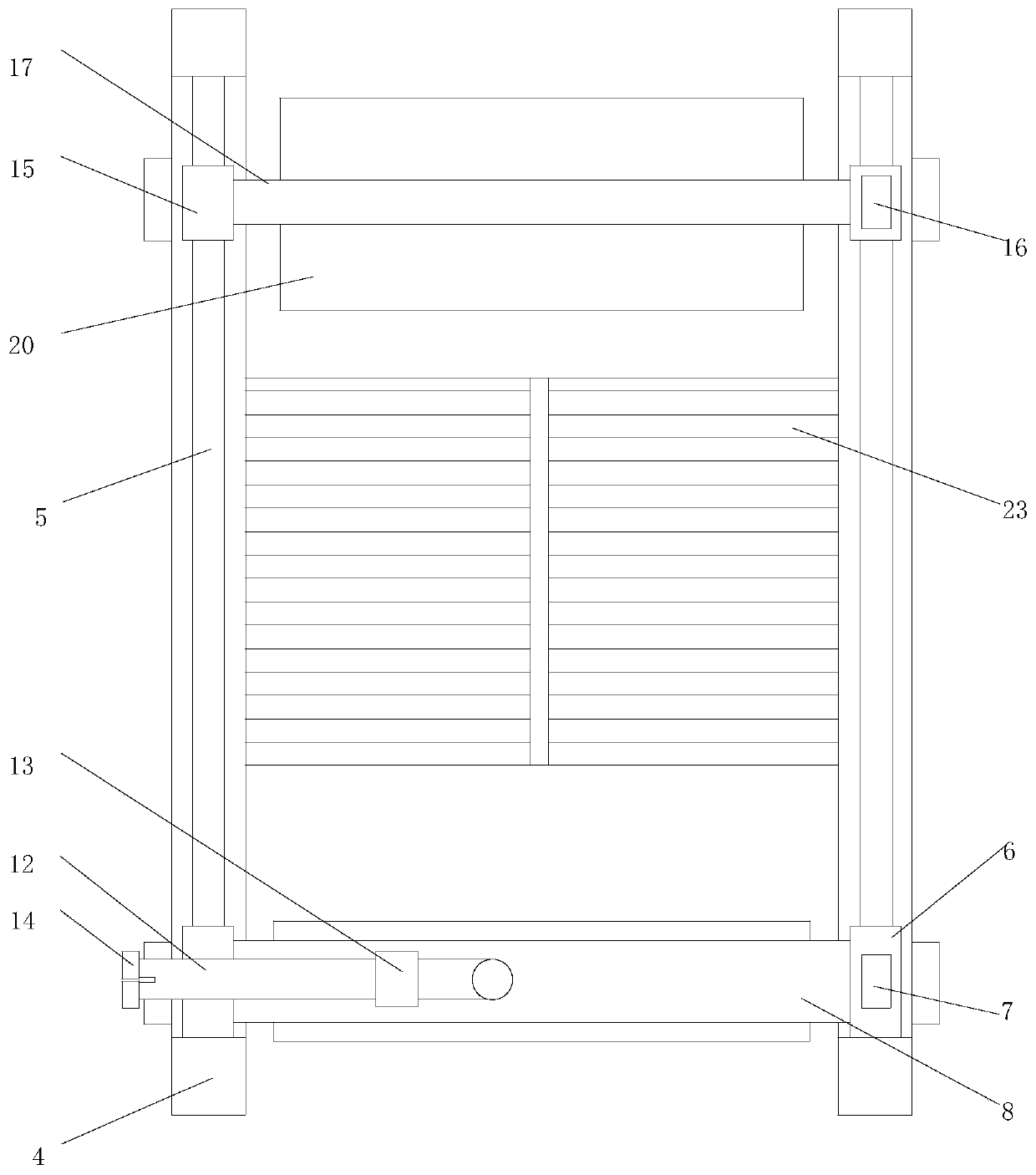

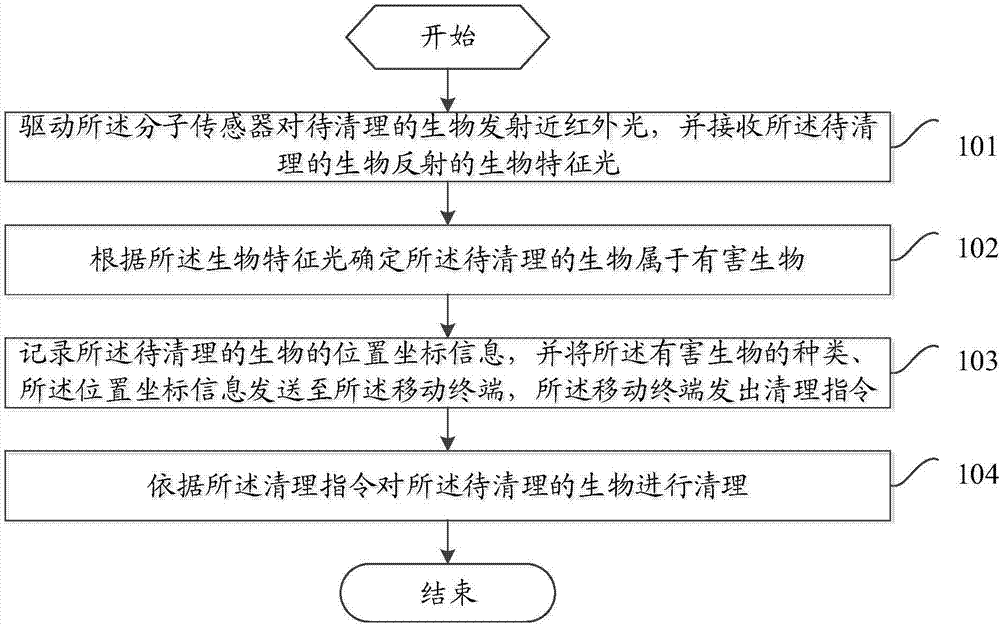

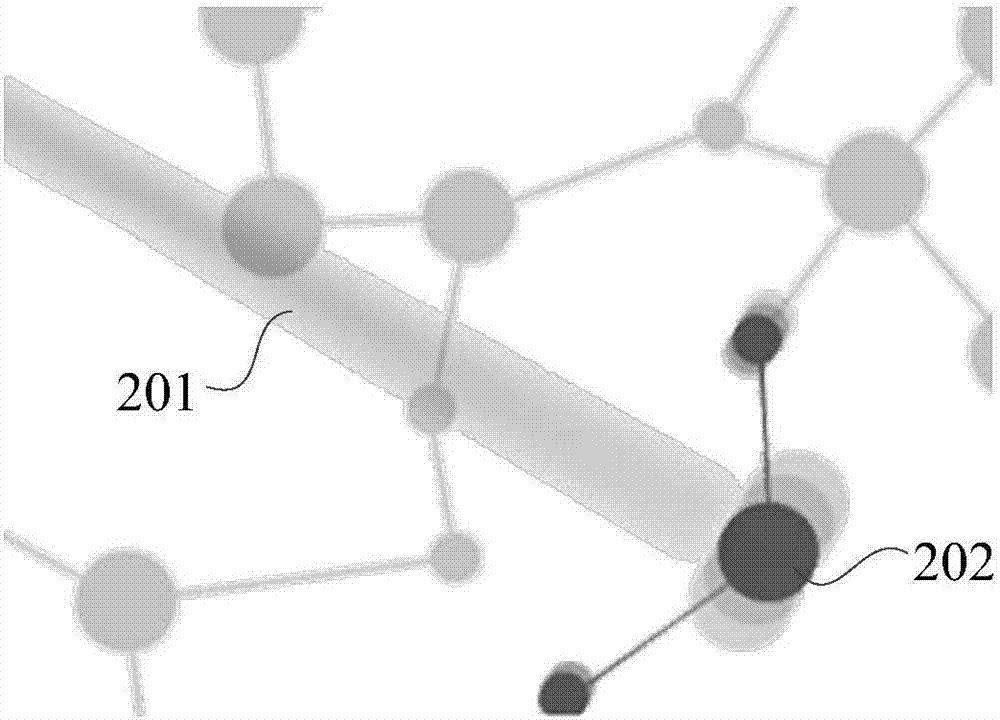

Harmful organism clearing method and system

InactiveCN107543802AAvoid Manual CleanupIncrease diversityMaterial analysis by optical meansCharacter and pattern recognitionOrganismEcology

The embodiment of the invention provides a harmful organism clearing method and system. The method is applied in a sweeping robot and a related mobile terminal, and the sweeping robot is provided witha molecular sensor. The harmful organism clearing method includes the steps that the molecular sensor is driven to emit near-infrared light to organisms to be cleared and receive biological feature light reflected by the organisms to be cleared; whether the organisms to be cleared belong to harmful organisms or not is determined according to the biological feature light; the position coordinate information of the organisms to be cleared is recorded, the kind of the harmful organisms and the position coordinate information are sent to the mobile terminal, and the mobile terminal sends out a clearing instruction; the organisms to be cleared are cleared according to the clearing instruction. Whether the organisms are the harmful organisms or not is verified accurately by detecting molecularproperties of the organisms through the molecular sensor, the organisms are cleared in a targeted mode, the diversity of clearing functions is improved, it is avoided that a user manually clear the harmful organisms, and the clearing efficiency is improved.

Owner:VIVO MOBILE COMM CO LTD

Environment-friendly dust removal device

InactiveCN108592225AAvoid Manual CleanupImprove cleanlinessMechanical apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses an environment-friendly dust removal device. The environment-friendly dust removal device comprises a housing, wherein one side inside the housing is fixedly equipped with an exhaust fan; an air inlet end of the exhaust fan penetrates through one side of the housing through a pipeline and communicates with the outside; an air outlet end of the exhaust fan communicates withone side of a filter box through a pipeline; and a filter screen is fixedly arranged inside the filter box. A cleaning brush is arranged, an electric telescopic pole drives the cleaning brush to clean, and the problem of manually dismounting a box door to manually clear is avoided; a water tank is arranged for filtering filtered air through water, so that water content of air can be increased; anda refrigerator and a heating wire are arranged for refrigerating or heating water inside the water tank according to real-time gas temperature, so that indoor temperature is increased. The environment-friendly dust removal device does not have a blockage phenomenon, can effectively absorb and treat dust in the room, and changes the temperature and humidity in the room.

Owner:南浔双林荣丰磁材厂

A metal stamping die

ActiveCN110355278BImprove stabilityAvoid mobilityShaping toolsMetal-working feeding devicesRubber ringImpeller

Owner:上海东景工艺有限公司

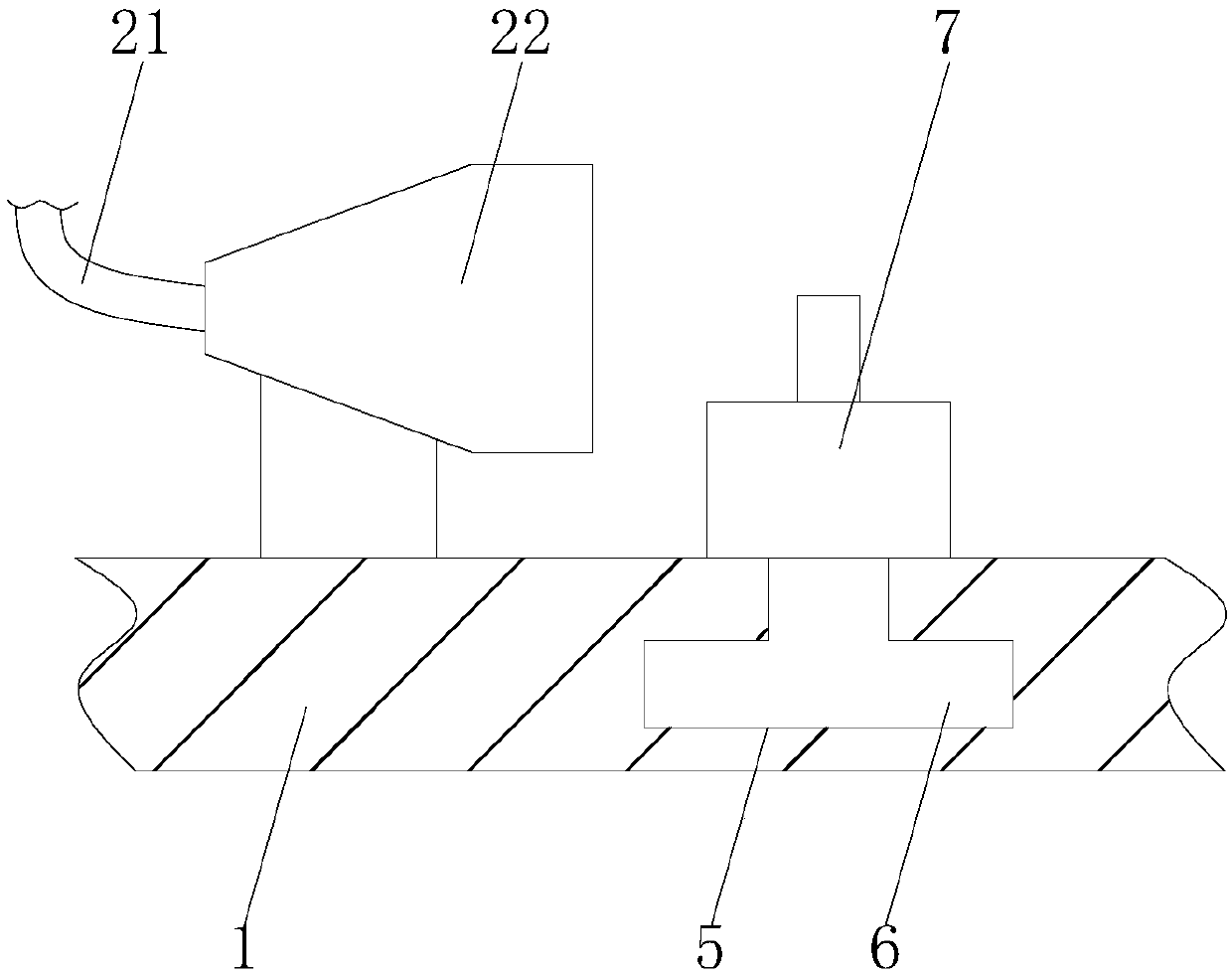

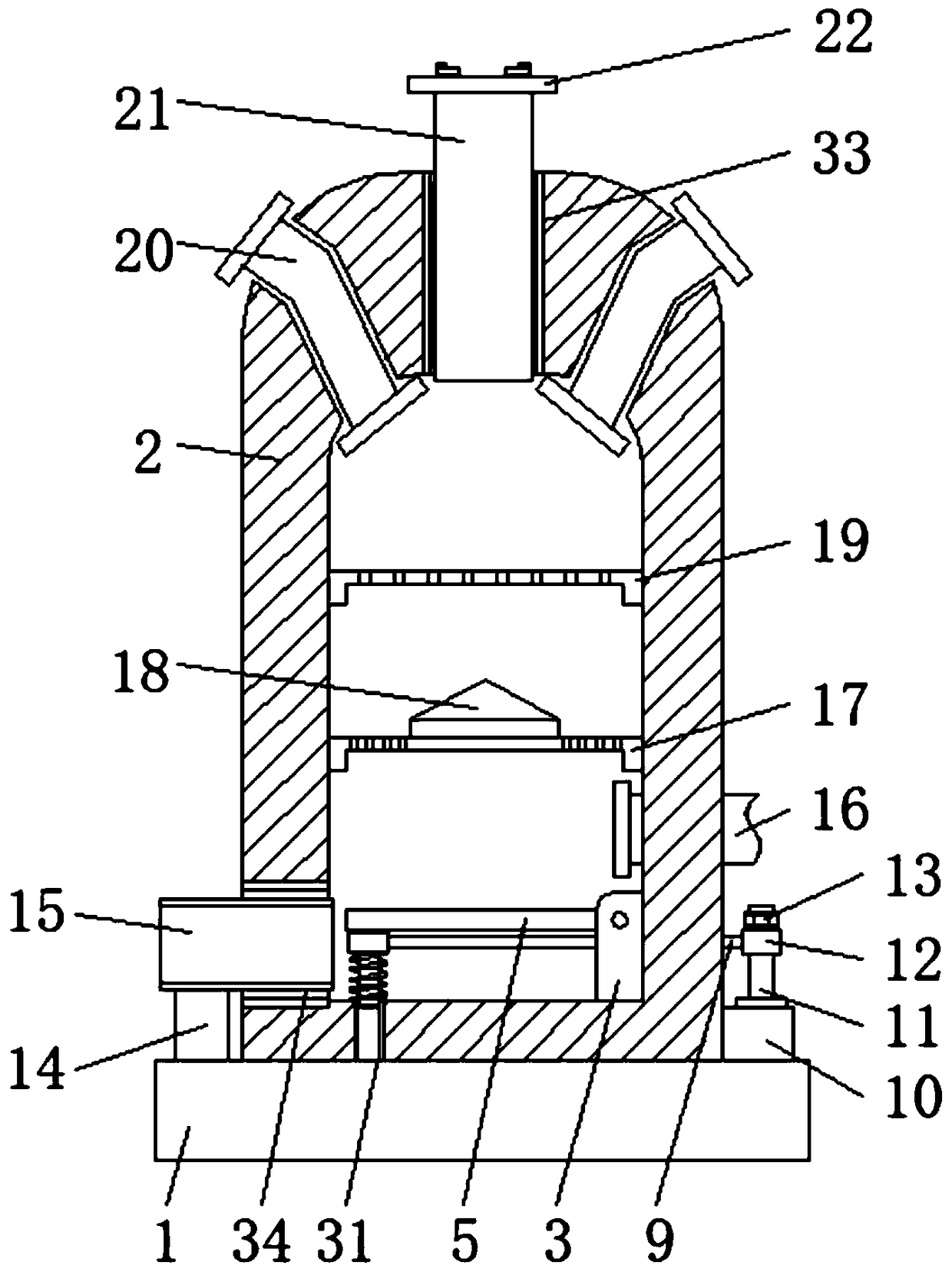

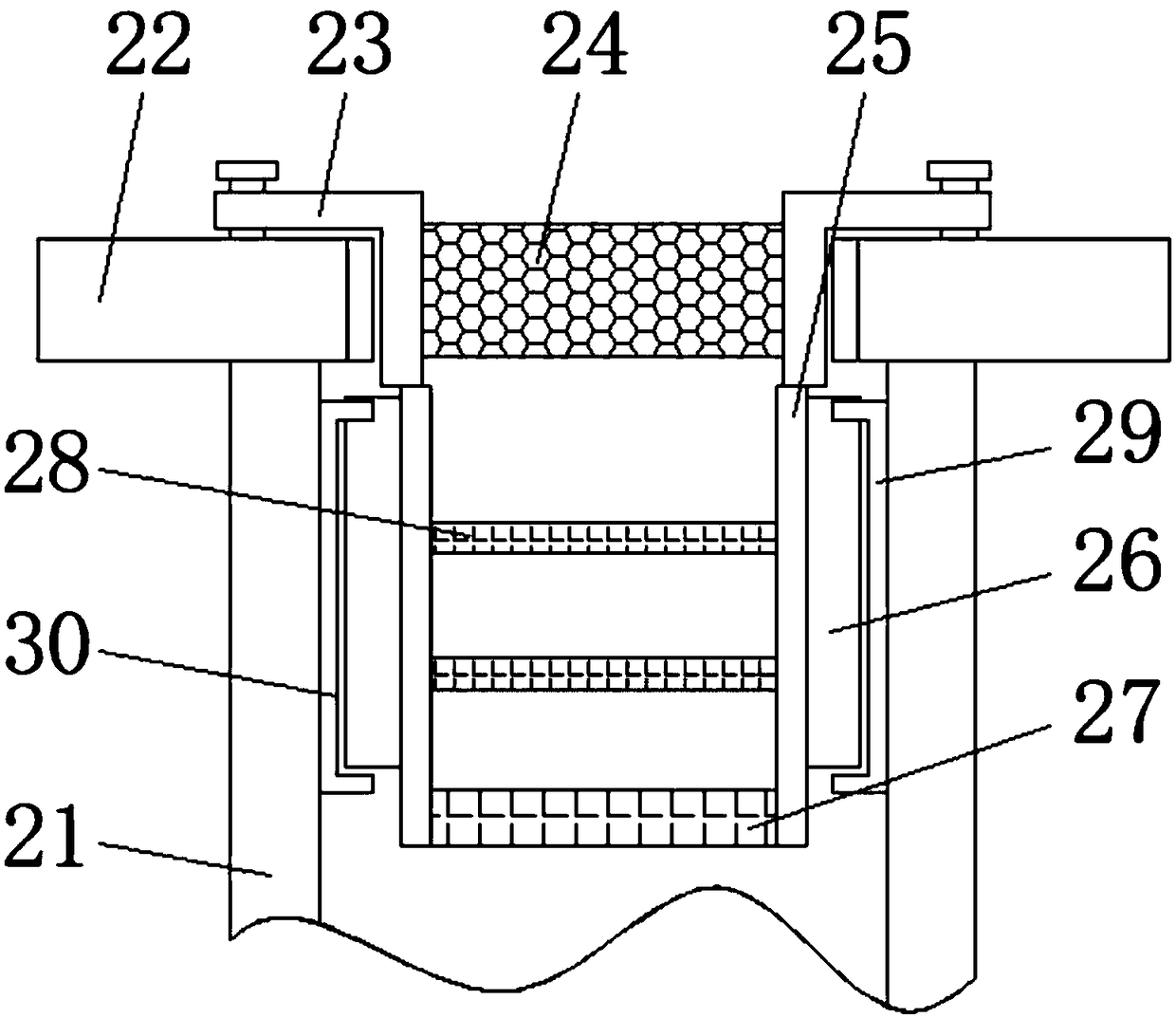

Aluminum shell finishing device for lithium battery for new energy

ActiveCN109514306AAvoid affecting the machining accuracyReduce processing timeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsMotor driveNew energy

The invention discloses an aluminum shell finishing device for a lithium battery for new energy. The aluminum shell finishing device comprises a slab, a first vertical plate, a second vertical plate,a first air cylinder, a sliding groove, a sliding block, a turning tool, a disc, a stepping motor, a rotary shaft, a second air cylinder, an inserting hole, a guide rod, a motor, an aluminum shell, athird air cylinder, a through hole, a supporting rod, a fourth air cylinder, a pressing plate, a dust suction pipe, a dust suction cover, a bottom cover, a straight pipe, a top shell, a vacuum pump, abend, connecting shafts, a pressing strip, a spring, a guide hole and a stepping motor driver. The aluminum shell finishing device is reasonable in structure, the edge of the end of the aluminum shell of the lithium battery can be cut, and oddments and burrs on the edge are removed; the multiple connecting shafts on the disc provide mounting positions for the aluminum shell, the stepping motor drives the disc to rotate to the top of the turning tool for machining, the machined aluminum shell can be replaced while machining is carried out, feeding is carried out, and machining time is saved.

Owner:苏州新睿琪金属科技有限公司

Energy-saving type coal-fired boiler

InactiveCN108644760APromotes secondary combustionBurn fullySolid fuel combustionCombustion apparatusSlagEngineering

The invention relates to the technical field of energy-saving environment-friendly equipment and discloses an energy-saving type coal-fired boiler which comprises a base. A boiler body is fixedly installed on the top of the base. A fixing plate is fixedly installed on one side of the bottom of an inner cavity of the boiler body. A shaft rod is fixedly installed on the middle portion of the fixingplate. The outer surface of the shaft rod is fixedly sleeved with an ash receiving plate. A first fire grate receives coal fragments falling off from a second fire grate, the coal fragments can be combusted for second time conveniently, coal resources can be combusted beneficially and fully, energy sources are saved, the energy source utilization rate is increased, a transverse rod drives a cushion block to move downwards, the cushion block extrudes a compression spring downwards, elastic deformation of the compression spring is utilized for generating reverse acting force, the ash receiving plate is turned over elastically along the shaft rod, waste slag on the ash receiving plate can be cleared beneficially and effectively, the situation that when direct manual clearing is used, the waste slag cannot be eliminated thoroughly, and the working efficiency is improved beneficially.

Owner:刘雪城

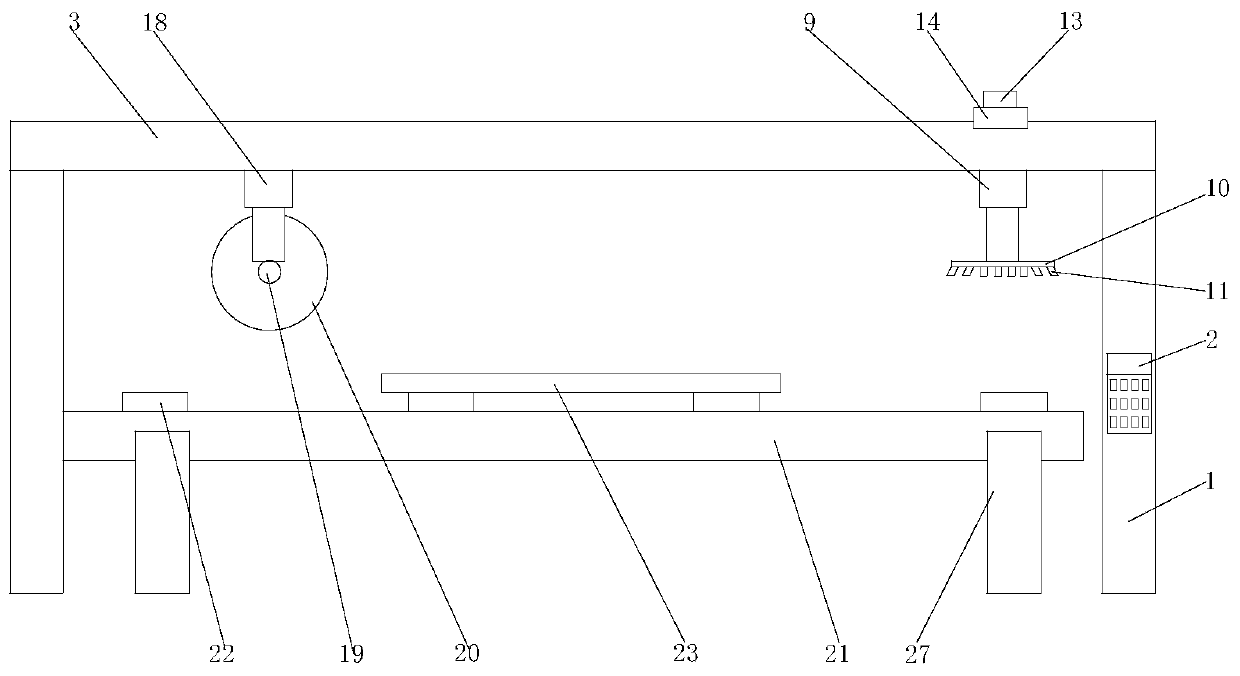

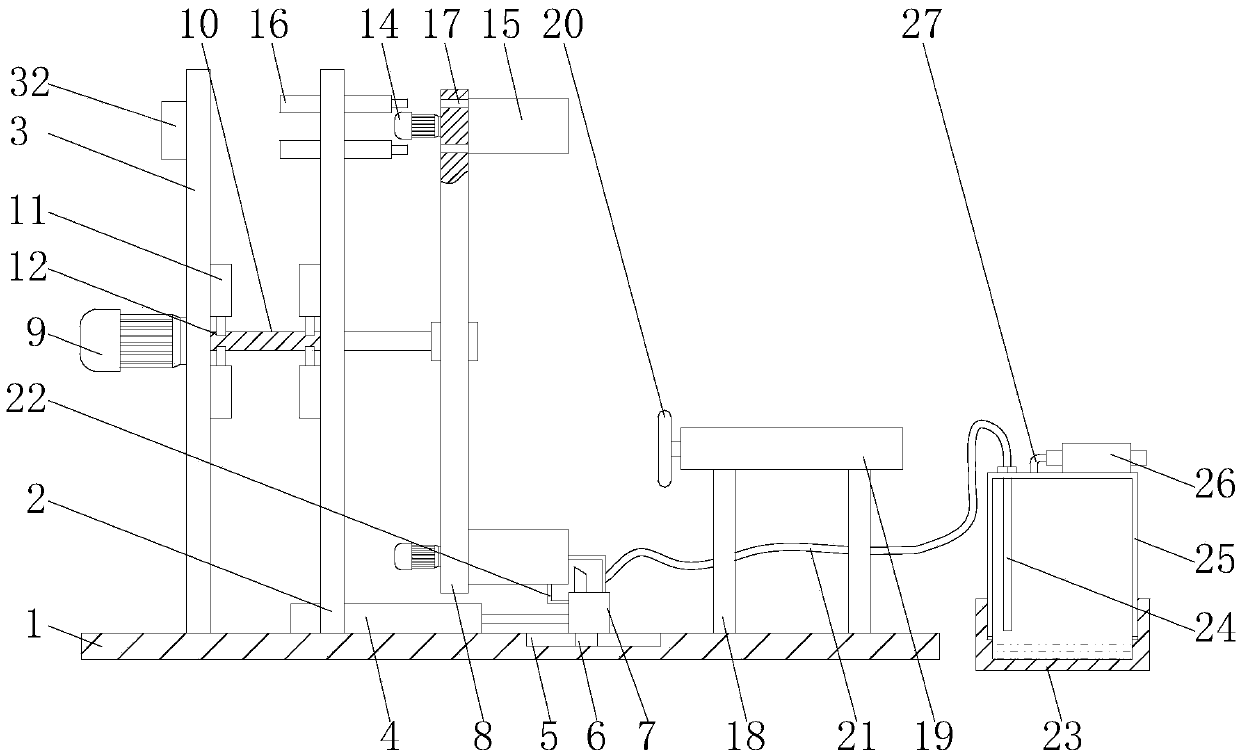

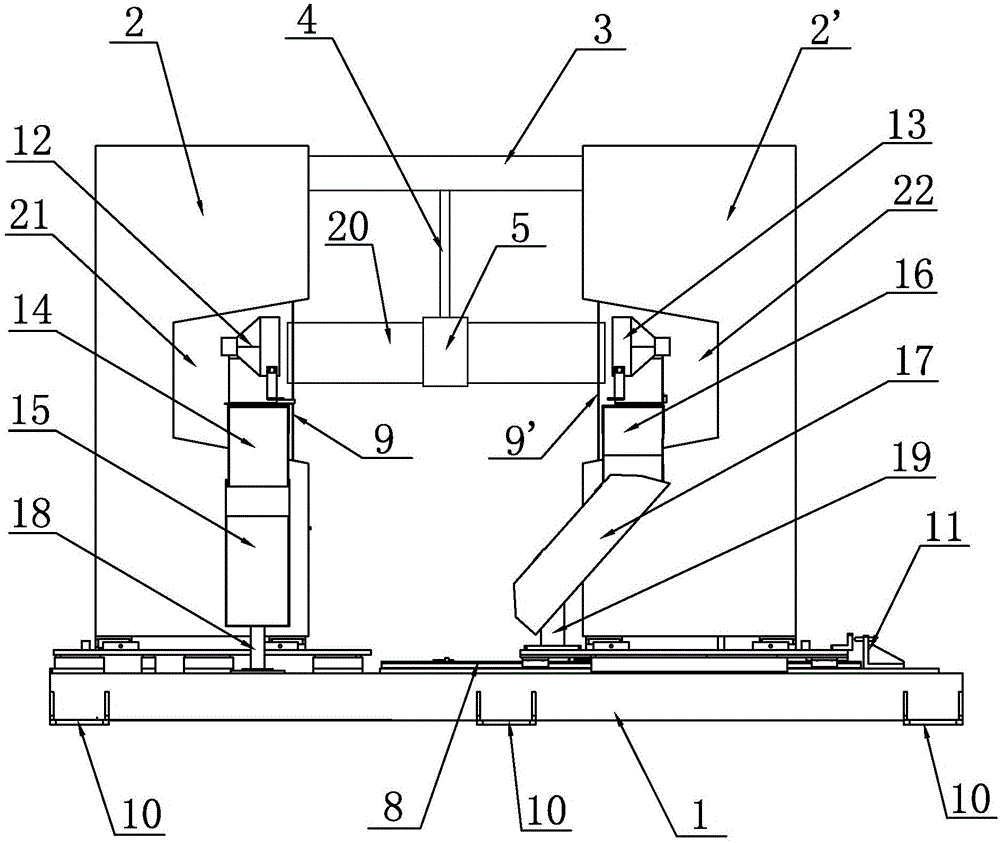

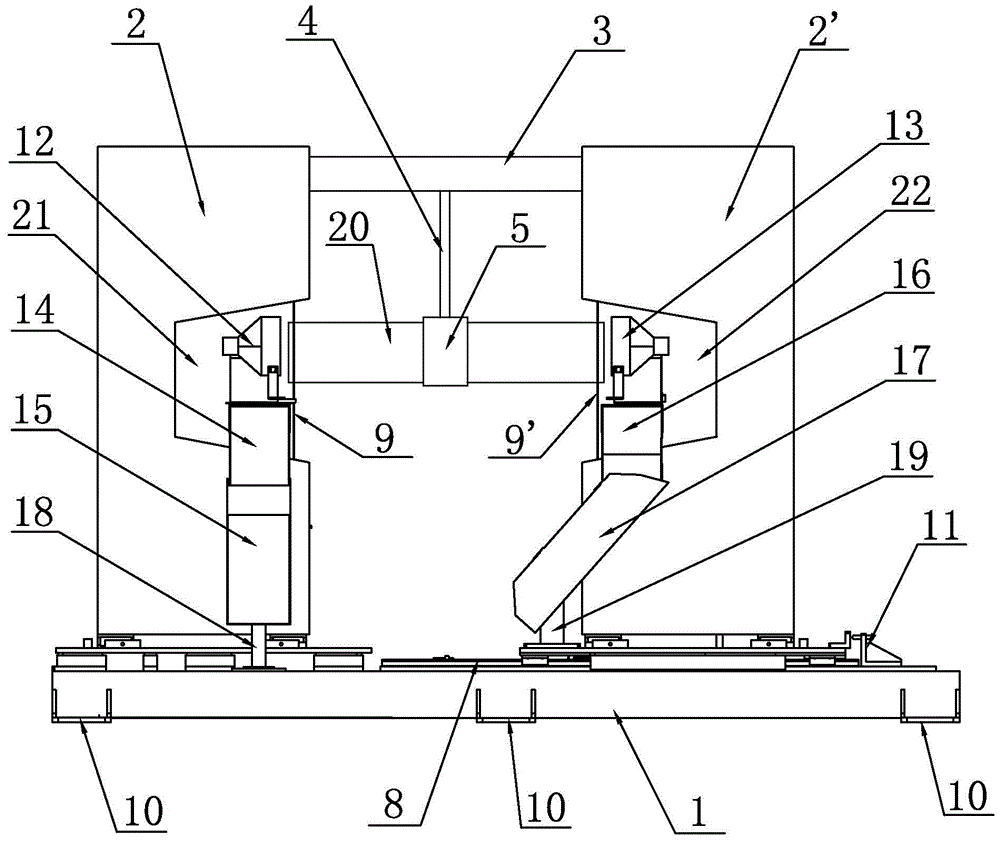

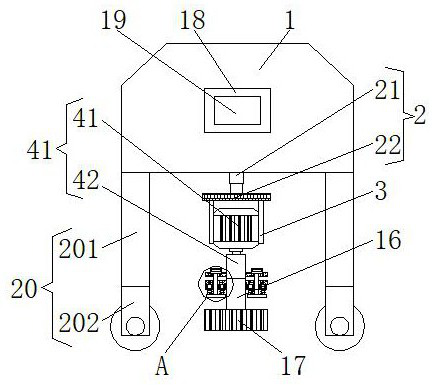

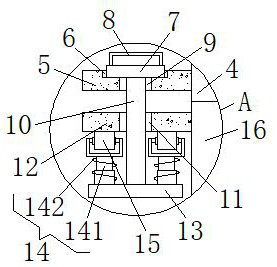

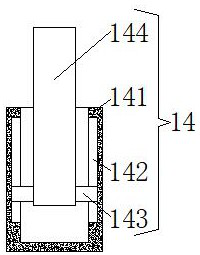

Two-end synchronous cutting device

ActiveCN105014725AAvoid Manual CleanupPrevent normal operation from affectingMetal working apparatusControl signalElectric machinery

The invention relates to a two-end synchronous cutting device, and aims at providing a catalyst cutting device which is high in working efficiency, low in cost and high in automatic degree. The two-end synchronous cutting device comprises a base, a left saw cutting shell, a right saw cutting shell and a central control unit. The fixed left saw cutting shell and the slideable right saw cutting shell are installed on the two sides of the top of the base respectively, and a first groove and a second groove are formed in the side walls of the left saw cutting shell and the right saw cutting shell respectively; and cutting steel wires are arranged in the two grooves respectively. Guide devices are arranged in front of the left saw cutting shell and the right saw cutting shell respectively, and outlets of the guide devices are located above the base. A rotating shaft is arranged between the left saw cutting shell and the right saw cutting shell, the rotating shaft is controlled through a second driving motor, and the control end of the second driving motor is connected with the control signal output end of the central control unit. The rotating shaft is connected with an electric clamping jaw through a connection rod, and the electric clamping jaw is controlled through the central control unit.

Owner:北京京城智通机器人科技有限公司

An anti-blocking floor drain

ActiveCN111962637BAvoid blockingAvoid the problem of not being snipped normallyFatty/oily/floating substances removal devicesSewerage structuresWater flowSlide plate

The invention relates to the technical field of sewer floor drains, and discloses an anti-blocking floor drain, which includes a drain pipe, and a floor drain plate is movably installed at one end of the drain pipe, which moves downward through the transmission of a transmission rod. One side of the cutout fits together so that when it moves downwards it fits against the cutout and creates a shearing force on the hair in the drain and cuts it. Since the main cutting devices are distributed in a rectangular array, the sliding plate is simple The second stroke can activate multiple cutting blocks so that the longer hair in the drain can be cut into multiple shorter hairs, which can be easily washed away by the water flow, thus avoiding the formation of a mesh-like structure of hair in the floor drain. The problem of clogging caused by the adhesion of dust and flocs, and cutting the long hair into multiple short lengths can avoid the problem of clogging caused by the long hair hanging on the wall after entering the sewer.

Owner:盐城市传臣精密铸造有限公司

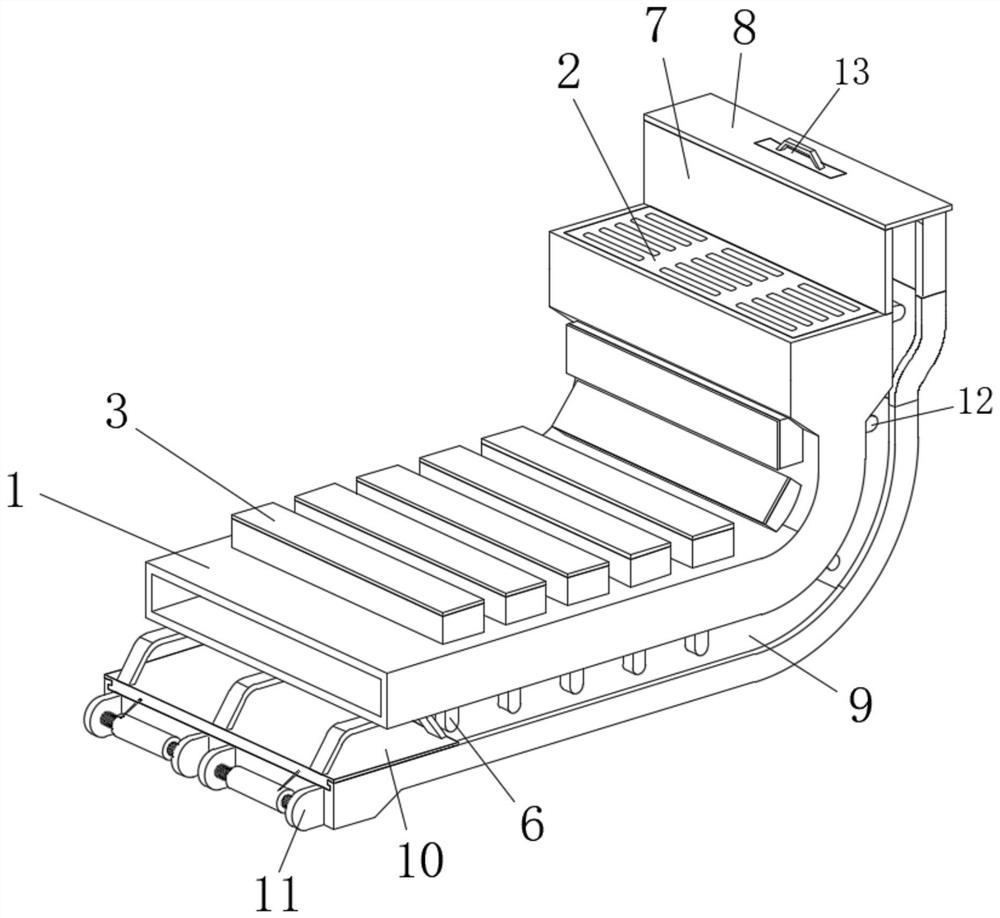

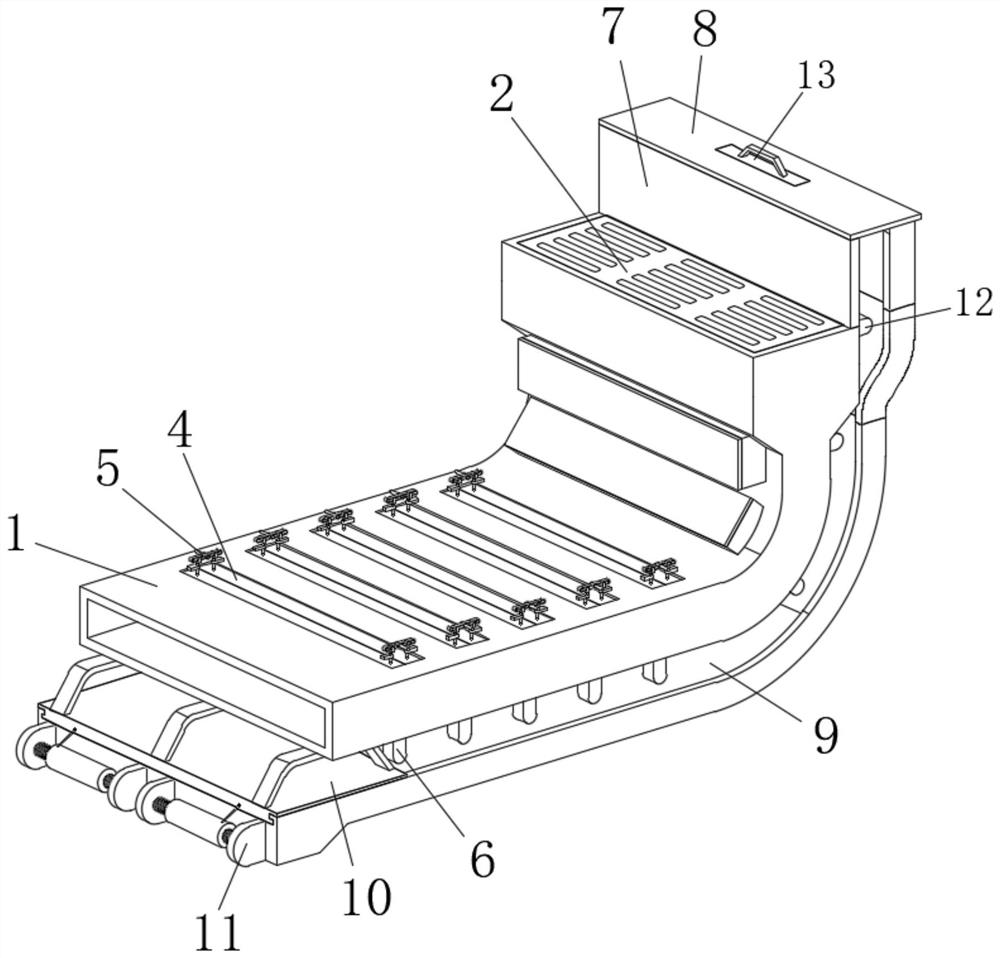

Soybean husking and screening processing device

ActiveCN112869213AAchieve the effect of crushing and recyclingAvoid manual cleanupSievingScreeningAgricultural engineeringStructural engineering

The invention relates to the technical field of primary processing of soybeans, in particular to a soybean husking and screening processing device which comprises a processing box and a bean pod storage barrel, the bean pod storage barrel is fixedly installed on the processing box, a discharging opening is formed in the bean pod storage barrel, a husking mechanism is arranged in the processing box, and the processing box is connected with the processing box. The husking mechanism comprises an outer husking barrel rotationally installed in the processing box, an inner husking barrel rotationally installed in the outer husking barrel and an impurity removing box fixedly installed on the outer wall of the processing box, a feeding port is formed in the side wall of the outer husking barrel in the circumferential direction, and a through hole matched with the feeding port is formed in the processing box; the through hole is communicated with the blanking port through a connecting pipe; by arranging the husking mechanism, husking treatment on soybean pods of different sizes is achieved, the effect of smashing and recycling the pods is achieved, manual cleaning work of workers in the later period is avoided, the labor intensity is reduced, and the automation degree is high.

Owner:湖北骏源豆制品股份有限公司

Electronic rearview mirror capable of avoiding influence of severe weather on use of commercial vehicle

PendingCN114013370AImprove protectionAvoid blockingVehicle cleaningOptical viewingSnowpackEngineering

The invention provides an electronic rearview mirror capable of avoiding influence of severe weather on use of a commercial vehicle, and relates to the technical field of electronic rearview mirrors. The electronic rearview mirror comprises an outer protective shell. The outer protective shell comprises outer heating strips, side scraping strips and upper inclined blocks, the outer heating strips are vertically arranged in the middle of the outer protective shell in an array mode, the side scraping strips are fixedly arranged on the side face of the outer protective shell, and the upper inclined blocks are arranged on the top of the outer protective shell in a circular array mode; a base is fixedly installed on the lower portion of the outer protective shell through screws and comprises a driving connecting shaft and a lower scraping strip, the driving connecting shaft is fixedly embedded in a main shaft of the driving motor, and the lower scraping strip is fixedly arranged in the middle of the base through screws. Rainwater or ice and snow substances outside the inner protective shell are scraped through the side scraping strips and the lower scraping strips, accumulated snow deposited outside the inner protective shell is shaken and bumped up and down in a reciprocating mode through the inner protective shell, and the problems that the electronic rearview mirror is prone to being covered by the accumulated snow and inconvenient to use after severe rain and snow weather are solved.

Owner:深圳市昂星科技有限公司

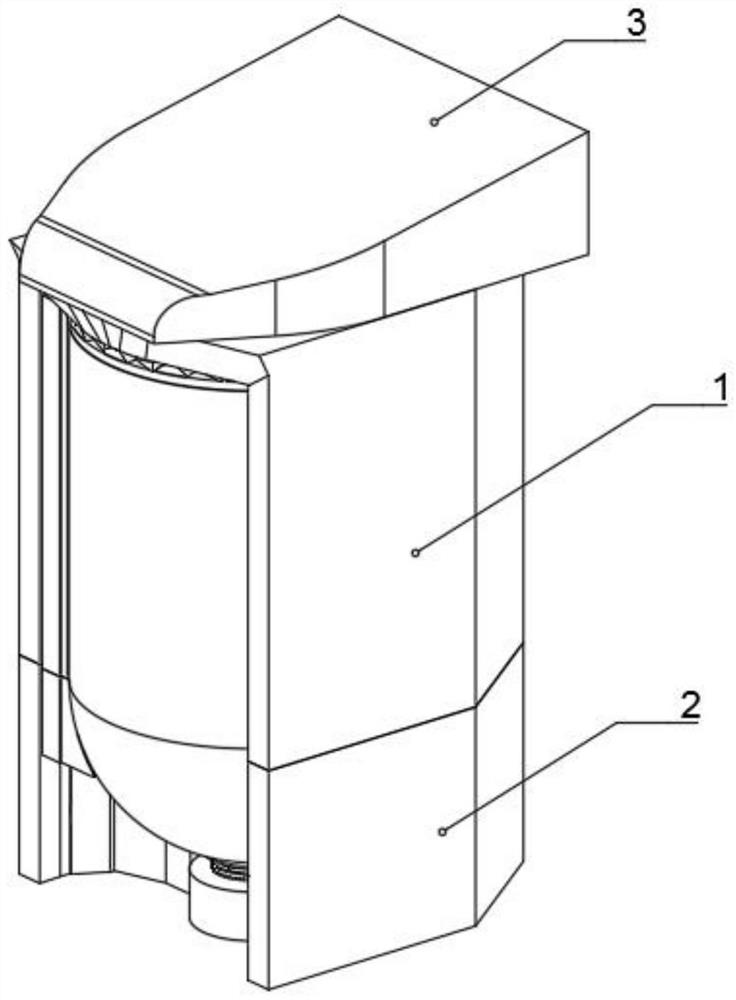

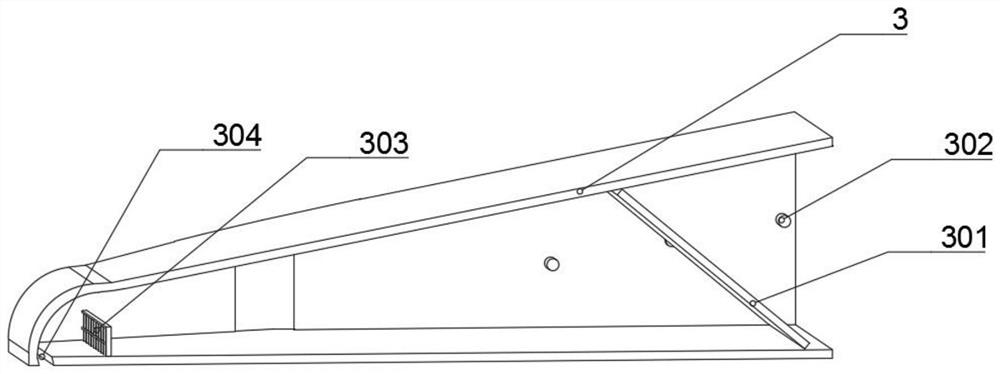

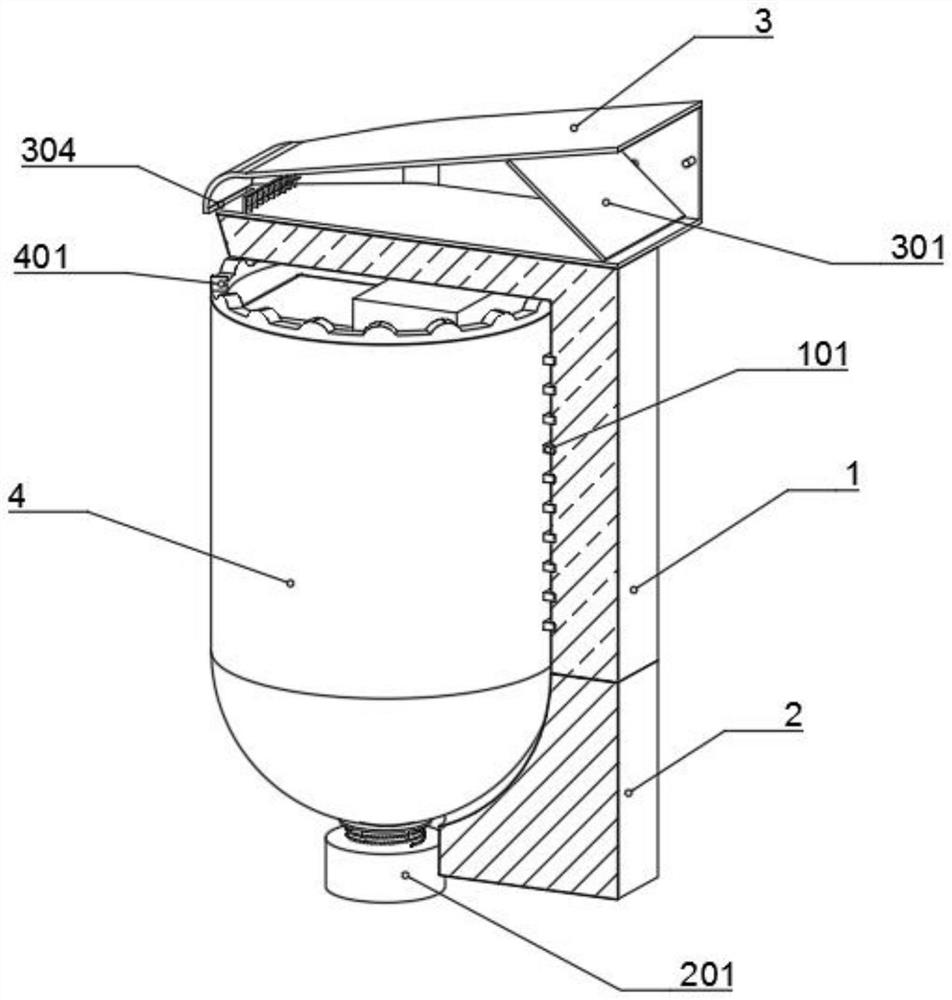

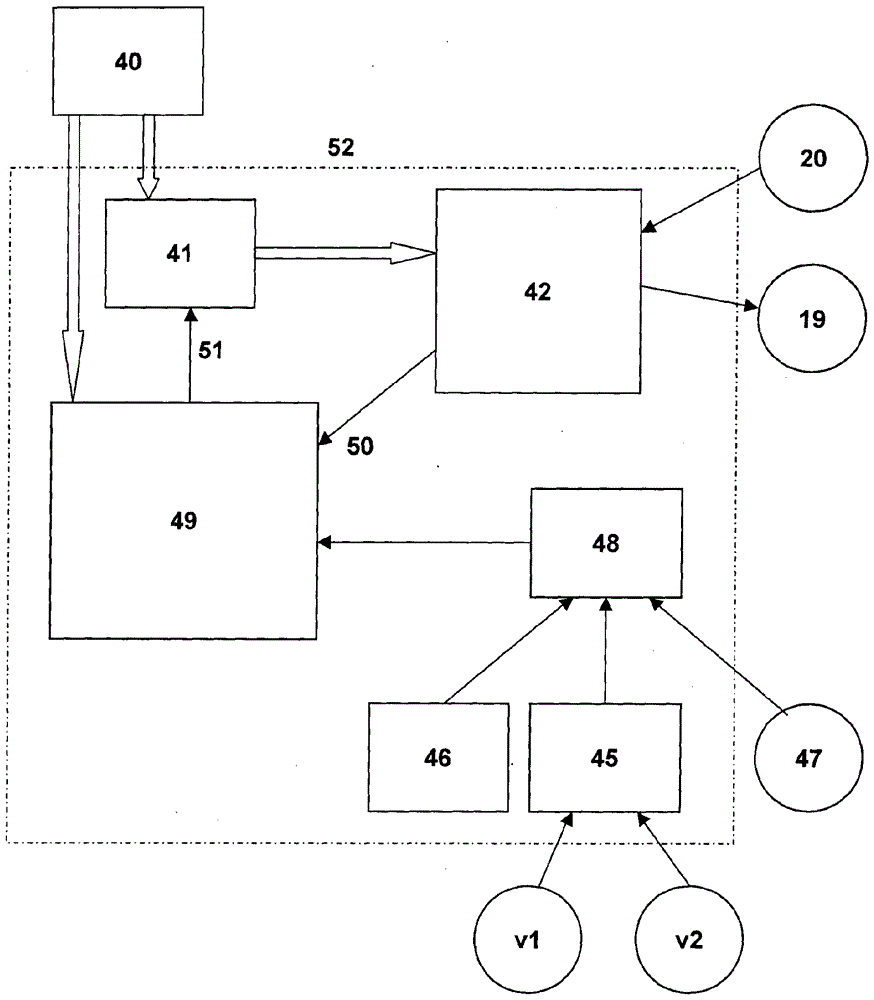

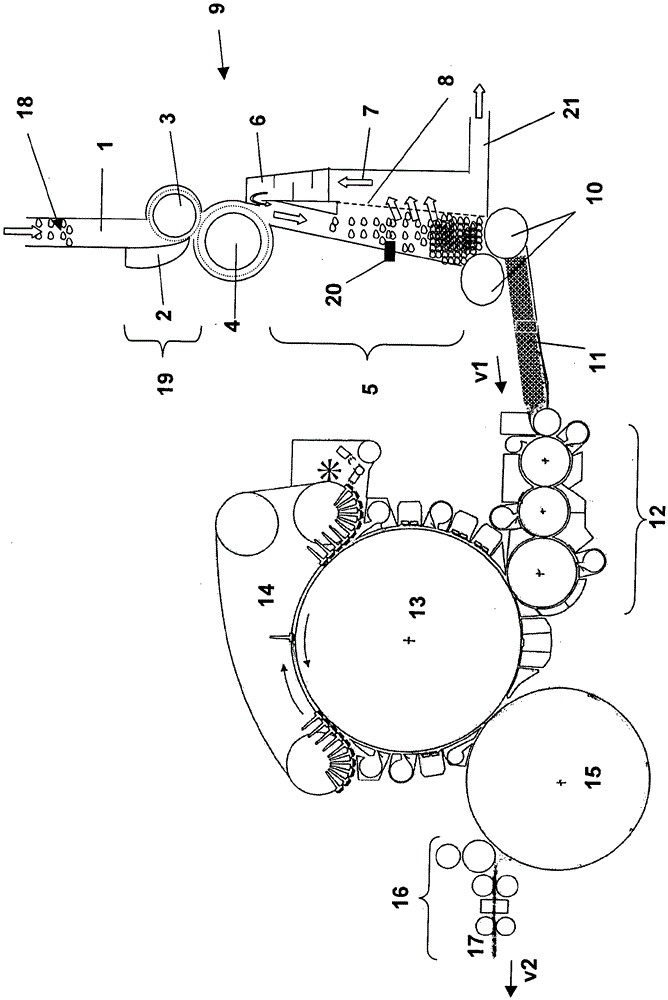

Method and device for adjusting fiber feed to carding machine

The invention relates to a device and a method for controlling the fiber feed to a carding machine having a filling shaft. The filling shaft is divided into an upper shaft and a lower shaft, wherein fiber flocks are fed into the upper shaft and are transported into the lower shaft (5) by means of a feeding device (19). The fiber flocks are compressed into wadding having a certain wadding weight in the lower shaft under a certain pressure. A target value for the wadding weight is predefined, with which target value a pressure for the lower shaft is associated. Then an actual value of the wadding weight is determined and the target value for the pressure is corrected on the basis of a comparison of the target value and actual value of the wadding weight.

Owner:MASCHINENFABRIK RIETER AG

A kind of soybean peeling, screening and processing device

ActiveCN112869213BAchieve the effect of crushing and recyclingAvoid manual cleanupSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to the technical field of soybean primary processing, more specifically, a soybean shelling and screening processing device, comprising a processing box and a pod storage bucket, the pod storage bucket is fixedly installed on the processing box, and the pod storage bucket is fixed on the processing box. A blanking port is provided, and a shelling mechanism is provided in the processing box, and the shelling mechanism includes an outer shelling barrel rotatably installed in the processing box, an inner shelling barrel rotatably installed in the outer shelling barrel, and a fixed installation The miscellaneous box on the outer wall of the processing box, the side wall of the outer hulling barrel is provided with a material inlet in the circumferential direction, and a through hole matching the material inlet is provided in the processing box, and the through hole is connected to the The pipe is connected to the discharge port; by setting the shelling mechanism, not only the shelling of soybean pods of different sizes is realized, but also the effect of crushing and recycling the pods is achieved, avoiding the manual cleaning work of the later staff and reducing the It reduces labor intensity and has a high degree of automation.

Owner:湖北骏源豆制品股份有限公司

Welding smoke purifying device for welding machine tool and using method thereof

ActiveCN108355415BImprove adsorption capacityAvoid Manual CleanupDispersed particle filtrationWelding/cutting auxillary devicesExhaust fumesProcess engineering

The invention discloses a welding smoke purifying device applied to welding machine tools. The welding smoke purifying device comprises a box body, wherein a partition plate is fixedly connected between the tops of two sides of the inner wall of the box body; the top and the bottom of one side of the box body are fixedly connected with support blocks; a screw rod is rotatably connected between theopposite sides of the two support blocks; the top of one side of the inner wall of the box body is fixedly connected with an air sucking machine; one end of an air inlet of the air sucking machine iscommunicated with a sucking pipe. The welding smoke purifying device relates to the technical field of purification of welding smoke. According to the welding smoke purifying device applied to welding machine tools and a using method thereof, the partition plate is fixedly connected to the tops between two sides of the inner wall of the box body; people do not need to take a lot of time to clean,so that the workload of the people is effectively reduced, and the working efficiency of the people is improved; a filtering box is fixedly connected to the bottom of the partition plate on one sideof the inner wall of the box body, so that large-sized particle impurities in the organic waste gas can be effectively removed; and the adverse influence on subsequent purification of the organic waste gas can be avoided.

Owner:ZHEJIANG LAOSHIDUN WELDING EQUIP

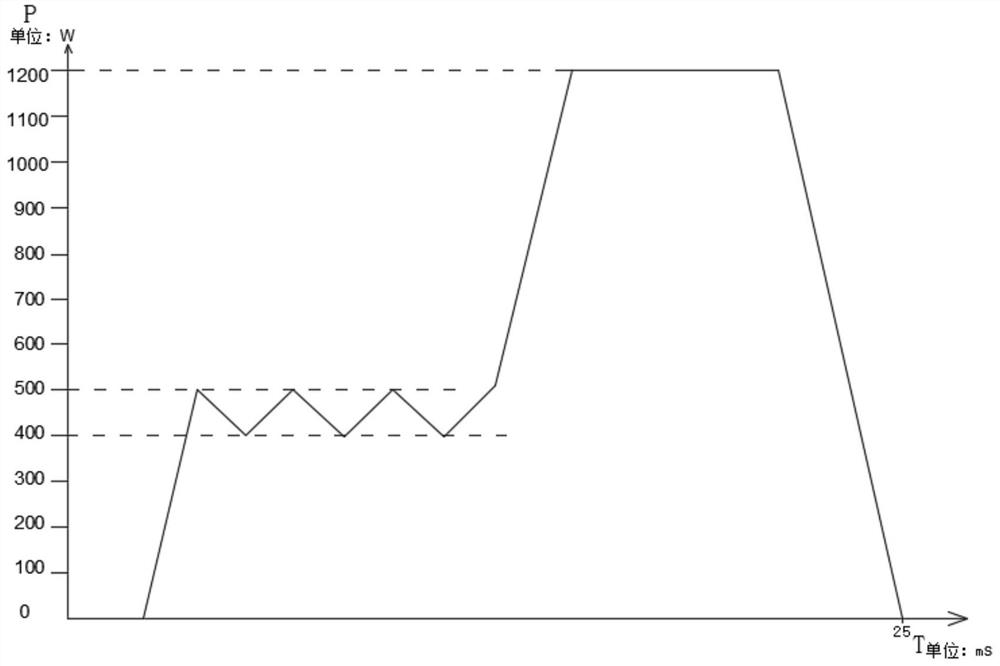

Laser welding method capable of reducing welding burst points

PendingCN112222618AReduce welding costsImprove welding efficiencyLaser beam welding apparatusLaser power densityLaser soldering

The invention discloses a laser welding method capable of reducing welding burst points, and belongs to the technical field of laser welding. The welding method comprises the two steps of cleaning andwelding, and a to-be-welded position of a workpiece is welded at the preset output power during cleaning. The laser power density corresponding to the preset output power is smaller than a welding threshold value of the workpiece, the preset output power has a certain amplitude in the cleaning process, and stains can be effectively evaporated before the workpiece is normally welded. The purposesof cleaning the stains and welding the workpiece can be achieved at the same time only through one-time welding, so that welding burst points are reduced, the welding operation efficiency and the welding operation success rate are greatly improved, and the welding cost is reduced.

Owner:SHANGHAI FEIBO LASER TECH CO LTD

Roof ditch garbage cleaning vehicle with self-adaptive stabilizing function

InactiveCN112942697AWon't fallAvoid manual cleanupRoof coveringAgricultural engineeringStructural engineering

The invention provides a roof ditch garbage cleaning vehicle with a self-adaptive stabilizing function. The roof ditch garbage cleaning vehicle comprises a cleaning vehicle shell, wherein the cleaning vehicle shell is provided with a self-adaptive stabilizing mechanism for cleaning garbage on a roof and a peripheral ditch; the cleaning vehicle shell is provided with a cleaning mechanism; the cleaning mechanism comprises a horizontal bracket which is fixedly arranged on the cleaning vehicle shell; and the horizontal bracket is provided with a linkage slide block in a sliding manner. According to the roof ditch garbage cleaning vehicle provided by the invention, a rotary block capable of carrying out horizontal position adjustment according to the height of an inclined plane convex block at the edge of the roof ditch is arranged; when the rotary block rotates, two abutting wheels can abut against the inclined plane of the inclined plane convex block at the edge of the roof ditch, so that the roof ditch garbage cleaning vehicle does not topple over when transverse wind comes; and a cleaning wheel brush capable of rotating is arranged and the ditch is brushed through the cleaning wheel brush, so that the ditch can be cleaned and manual cleaning work with a relatively high risk coefficient is avoided.

Owner:杭州用磊贸易有限公司

Main shaft roller of scrap steel crusher

The invention discloses a main shaft roller of a scrap steel crusher; the roller comprises a main shaft roller body and crushing grooves, the crushing grooves are formed in the upper end and the lower end of the outer wall of the main shaft roller body, an ejection device is arranged in the main shaft roller body, a first movable groove is formed in the main shaft roller body, and an ejection rod is arranged in each crushing groove in a sleeved mode; the left end of the first movable groove is connected with a lead screw through a rotating shaft, the outer wall of the lead screw is sleeved with two sets of movable nuts, threaded holes are formed in the movable nuts, movable rods are welded to the right ends of the movable nuts, the opposite ends of the ejector rods are welded to the movable rods, and a rotating hole is formed in the left end of the main shaft roller body. And a rotating rod is connected into the rotating hole through a rotating shaft. The main shaft roller of the scrap steel crusher is provided with the ejector rods, the lead screws, the movable nuts, the movable rods, a first bevel gear and a second bevel gear, the situation that workers spend time in manual cleaning is avoided, and the practicability of the main shaft roller is improved.

Owner:JIANGSU HUAHONG TECH STOCK

Waste incineration residue treatment furnace

The invention provides a waste incineration residue treatment furnace. The waste incineration residue treatment furnace comprises an incineration barrel, a wall cleaning belt and a wall cleaning ring,wherein the wall cleaning belt is arranged inside the incineration barrel, the wall cleaning ring is arranged on one side of the wall cleaning belt, and transposition holes can be blocked through spring buckles, so that the wall cleaning ring stays on the spring buckles, then the wall cleaning ring can be supported on the spring buckles in the upward process, and the inner wall of the wall cleaning ring can be stably cleaned through the spring buckles; when the wall cleaning ring reaches the top end of the incineration barrel, shifting rolling wheels are in contact with racks on the inner walls of the transposition holes to rotate, so that the shifting rolling wheels rotate to drive locking wheels to rotate, then the locking wheels are popped off from the support of abutting rods, and then the wall cleaning ring is separated from the support of the abutting rods; and meanwhile, a directional falling area can be provided for the wall cleaning ring falling down from the top of the incineration barrel through positioning rods and sliding grooves formed in the inner wall of the wall cleaning belt, so that the wall cleaning ring falls from the top end of the incineration barrel to clean the interior of the incineration barrel.

Owner:东莞粤丰环保电力有限公司

Mechanical device for removing wound yarn from warp beam of textile machinery

PendingCN112320491AAvoid Manual CleanupDecrease productivityFilament handlingMetal working apparatusYarnRatchet

The invention relates to the technical field of textile fabrics, and discloses a mechanical device for removing wound yarn from a warp beam of textile machinery. A third fixing rod and a second fixingrod are driven to slide towards the left side through a first connecting rope and a second connecting rope, so that a cutter installed at the right end of the third fixing rod is pulled to move towards the left side, when yarn wound on the warp beam is cut, and the situations that the yarn wound on the warp beam needs to be manually cleaned by workers, the working efficiency is reduced and the workload is reduced are avoided. A sector gear rotates to push a toothed bar to move upwards, a folding rod is extended, the cutter is pushed out of the warp beam from the inner side of the warp beam, the sector gear drives a double-ratchet rod, the double-ratchet rod drives a first gear to rotate, a wiring rod is installed on the outer side of the first gear, and the wiring rod is driven by the first gear to rotate to the outer side of the warp beam from the inner side of the warp beam, so that tightly-wound yarn is mechanically cut, and the cut yarn falls onto the wiring rod.

Owner:厦门瓯耶烨纺织机械有限公司

A synchronous cutting device with both ends

ActiveCN105014725BAvoid Manual CleanupPrevent normal operation from affectingMetal working apparatusControl signalEngineering

The invention relates to a two-end synchronous cutting device, and aims at providing a catalyst cutting device which is high in working efficiency, low in cost and high in automatic degree. The two-end synchronous cutting device comprises a base, a left saw cutting shell, a right saw cutting shell and a central control unit. The fixed left saw cutting shell and the slideable right saw cutting shell are installed on the two sides of the top of the base respectively, and a first groove and a second groove are formed in the side walls of the left saw cutting shell and the right saw cutting shell respectively; and cutting steel wires are arranged in the two grooves respectively. Guide devices are arranged in front of the left saw cutting shell and the right saw cutting shell respectively, and outlets of the guide devices are located above the base. A rotating shaft is arranged between the left saw cutting shell and the right saw cutting shell, the rotating shaft is controlled through a second driving motor, and the control end of the second driving motor is connected with the control signal output end of the central control unit. The rotating shaft is connected with an electric clamping jaw through a connection rod, and the electric clamping jaw is controlled through the central control unit.

Owner:北京京城智通机器人科技有限公司

A housekeeping robot that facilitates the replacement of cleaning brushes

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com