Two-end synchronous cutting device

A technology of synchronous cutting and guiding devices, applied in metal processing and other directions, can solve problems such as low flexibility, low work efficiency, and difficulty in ensuring the quality of manual cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

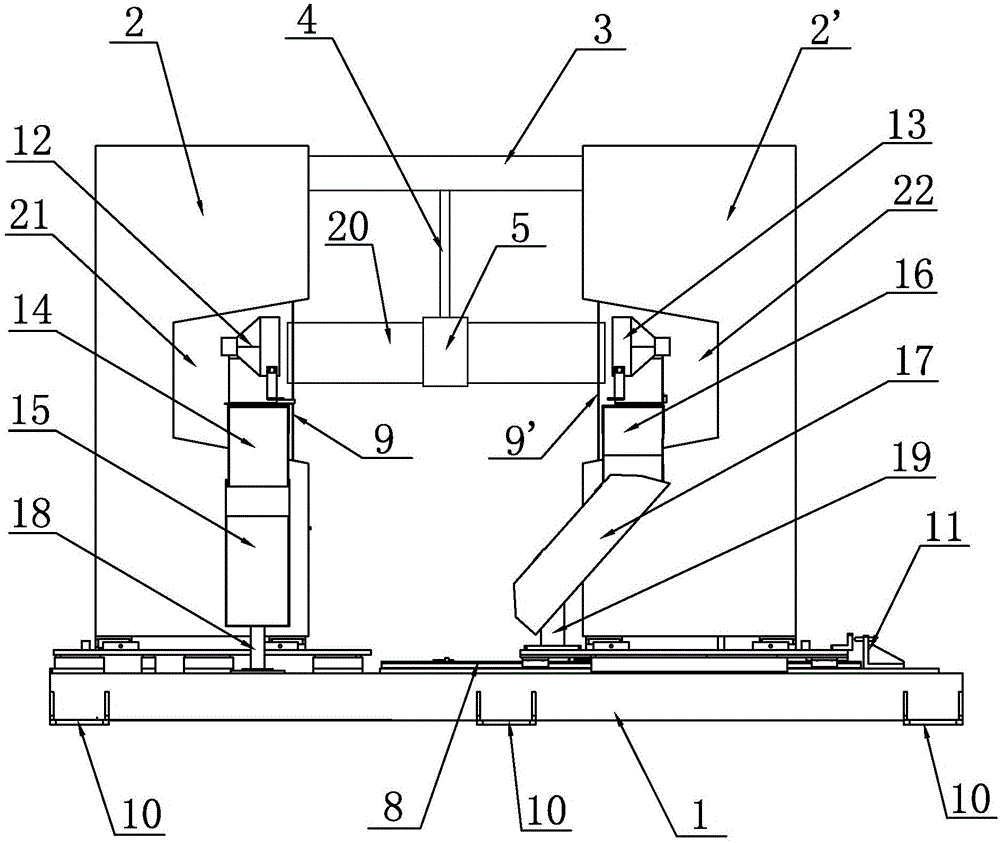

[0017] Such as figure 1 As shown, it is a front view of a synchronous cutting device at both ends of the present invention, including a base 1, a left sawing casing 2, a right sawing casing 2', a first cutting steel wire 9, a second cutting steel wire 9', a fixed Board 6, sliding board 7 and central controller. The base 1 is a flat plate structure placed along the horizontal direction, and a plurality of anti-slip pads 10 are uniformly arranged on the edge of the bottom end of the base 1 .

[0018] The left side of the top of the base 1 is vertically provided with a left sawing case 2 with a rectangular parallelepiped structure, and the left sawing case 2 is fixedly mounted on the top of the base 1 by screws, on the right side of the left sawing case 2 The middle position of wall is provided with the first groove 21 that section is trapezoidal, and the first cutting steel wire 9 is arranged vertically on the inner wall near the opening of first groove 21 inside first groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com