Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid deep reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

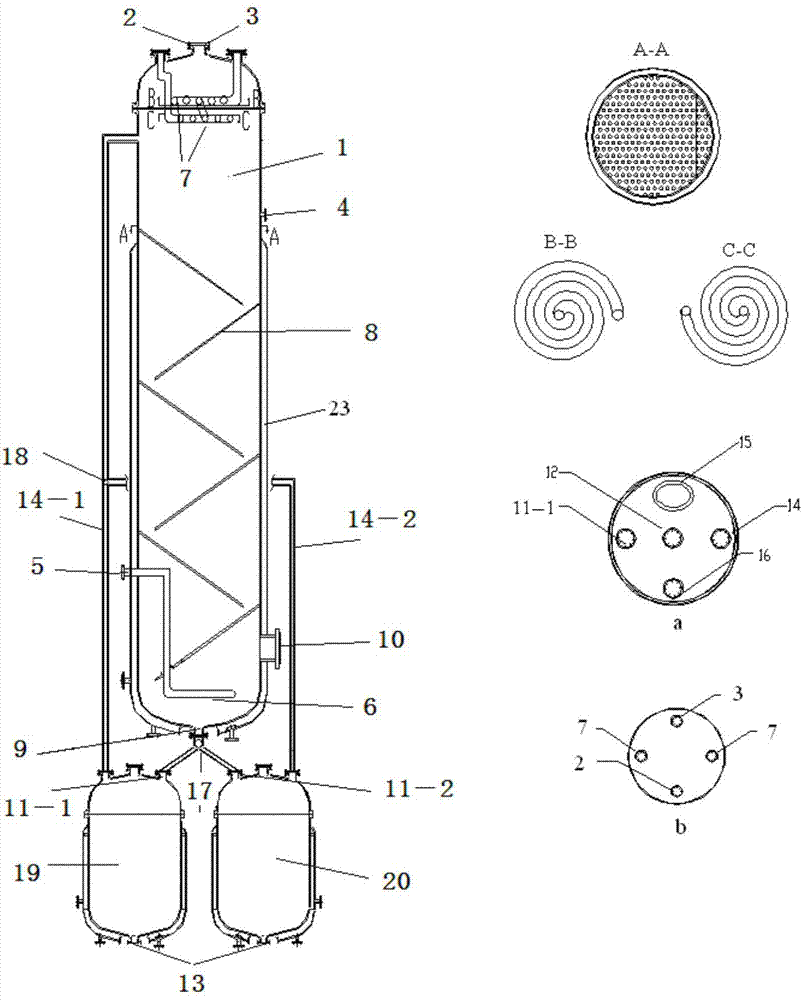

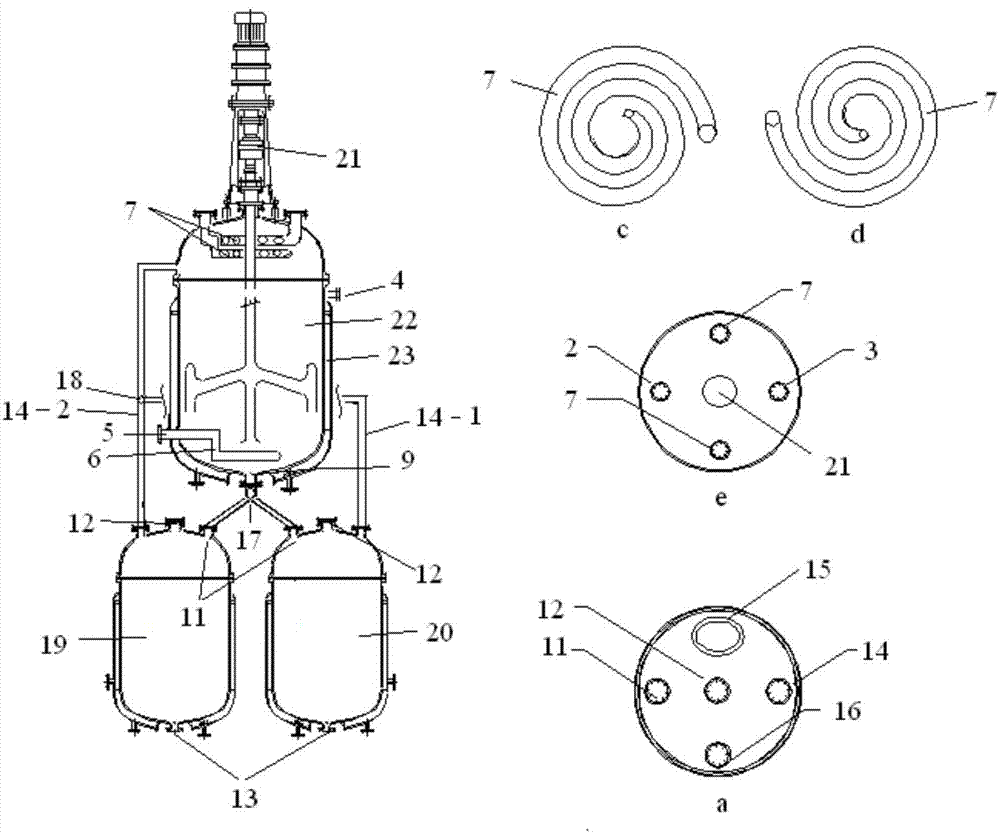

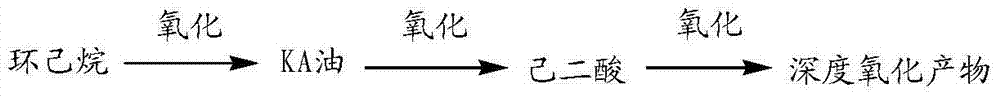

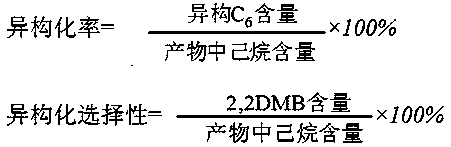

Method for producing adipic acid by oxidizing cyclohexane by utilizing air based on gas-liquid-solid multiphase reaction and separation synchronization reactor

ActiveCN103755543AHigh yieldImprove conversion rateOrganic compound preparationCarboxylic preparation by oxidationGas phaseAdipic acid

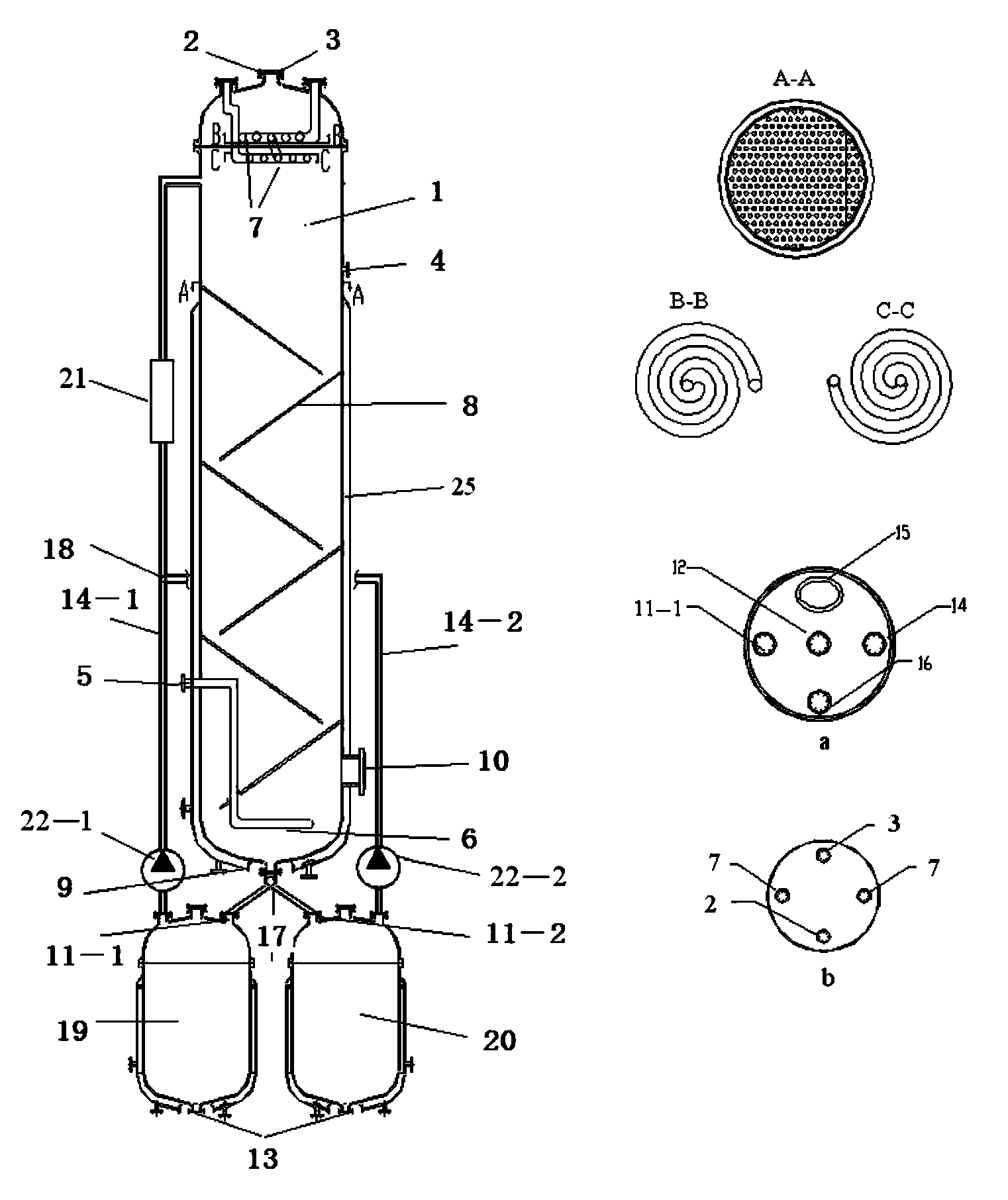

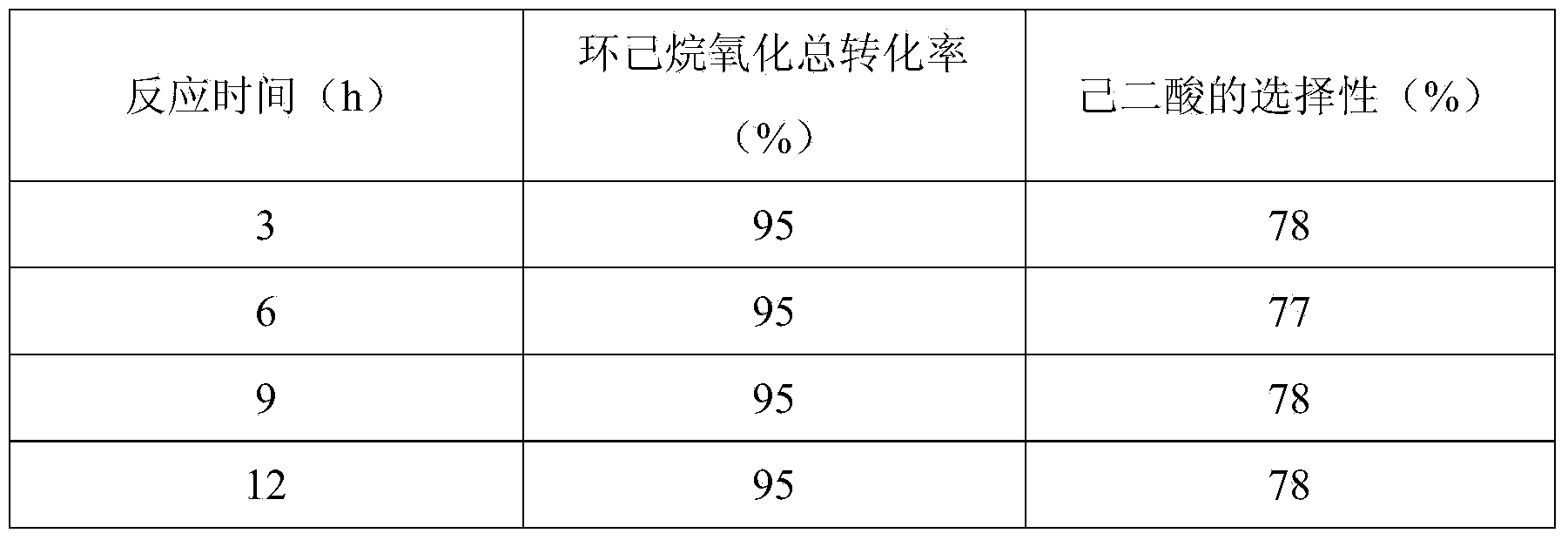

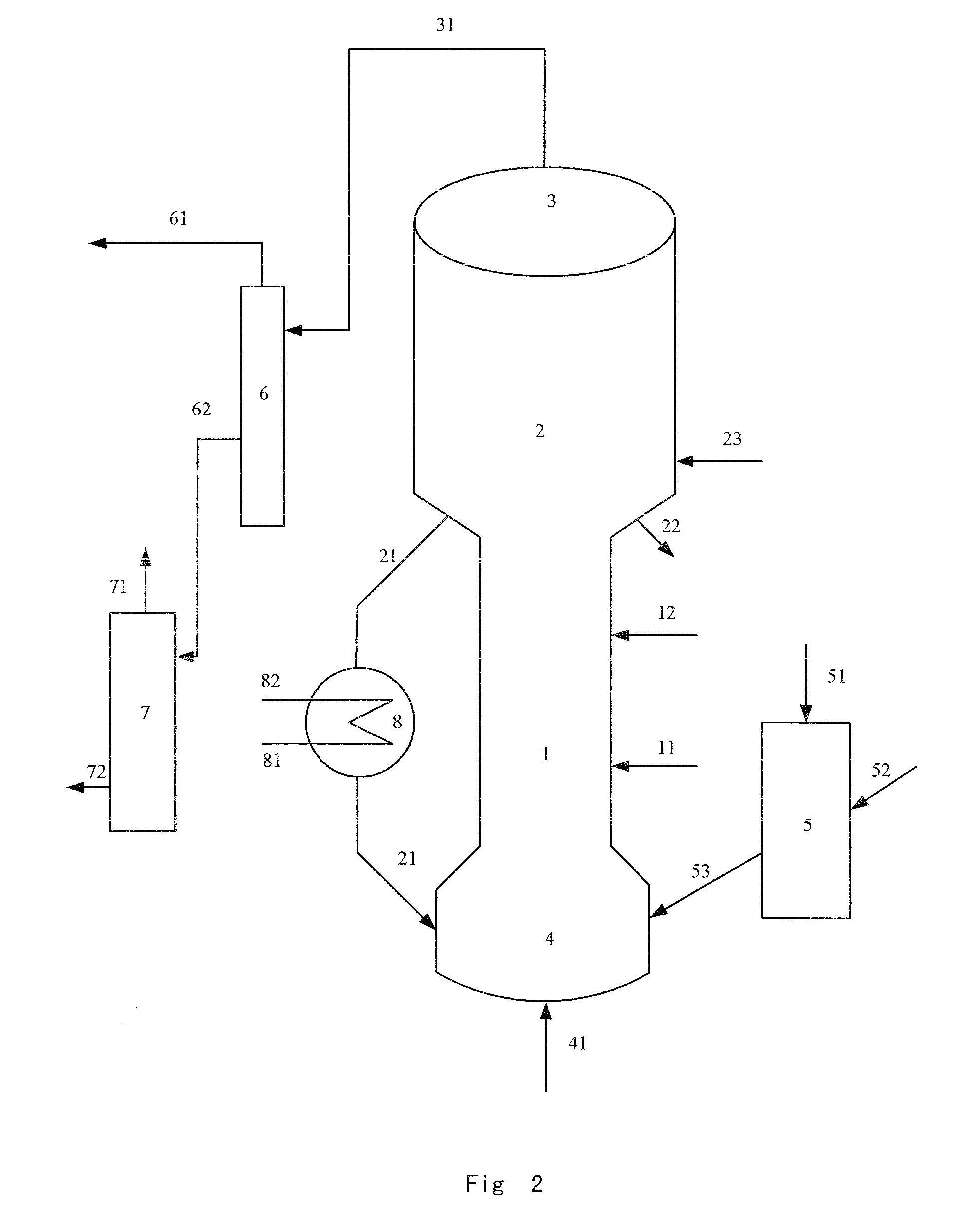

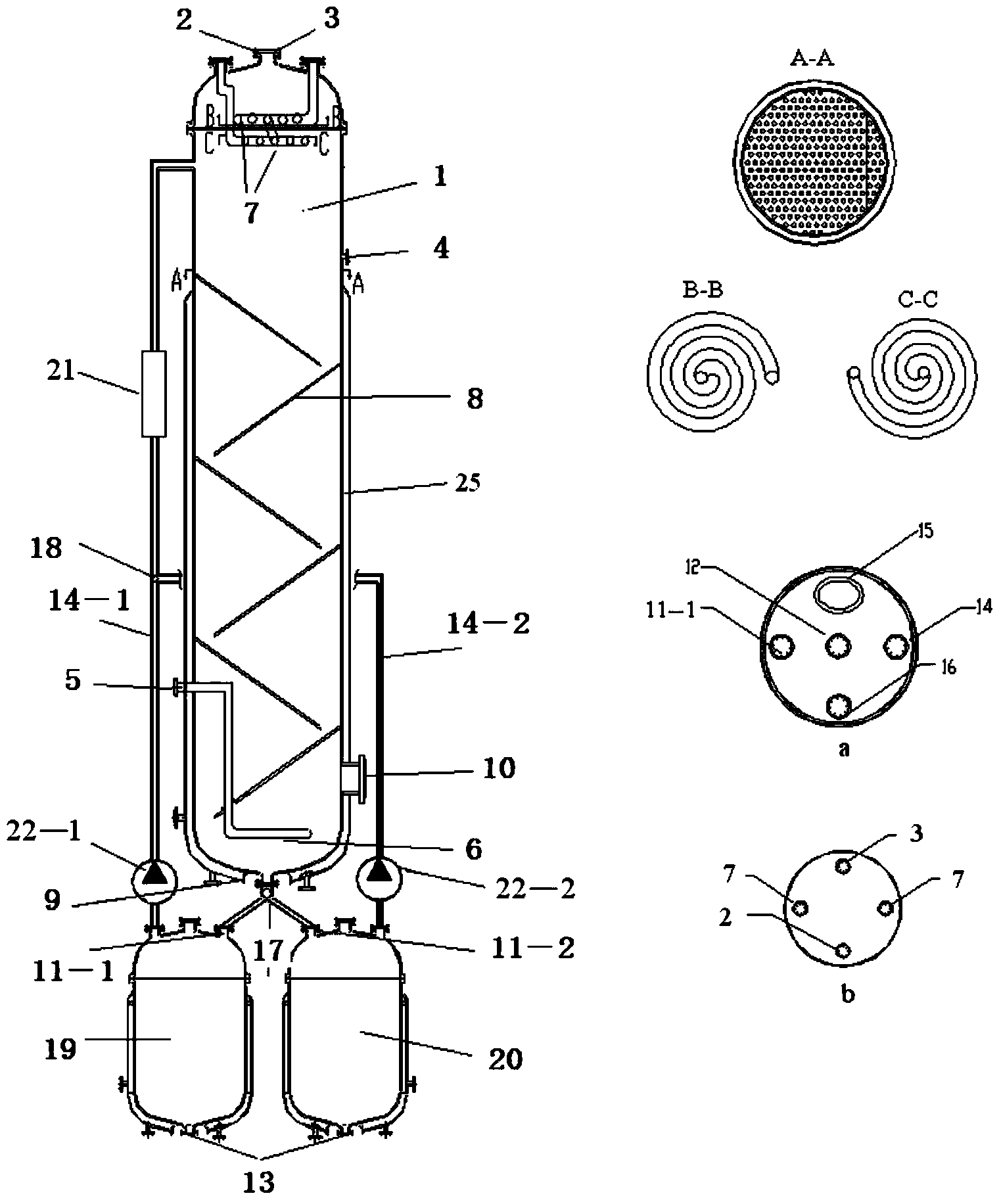

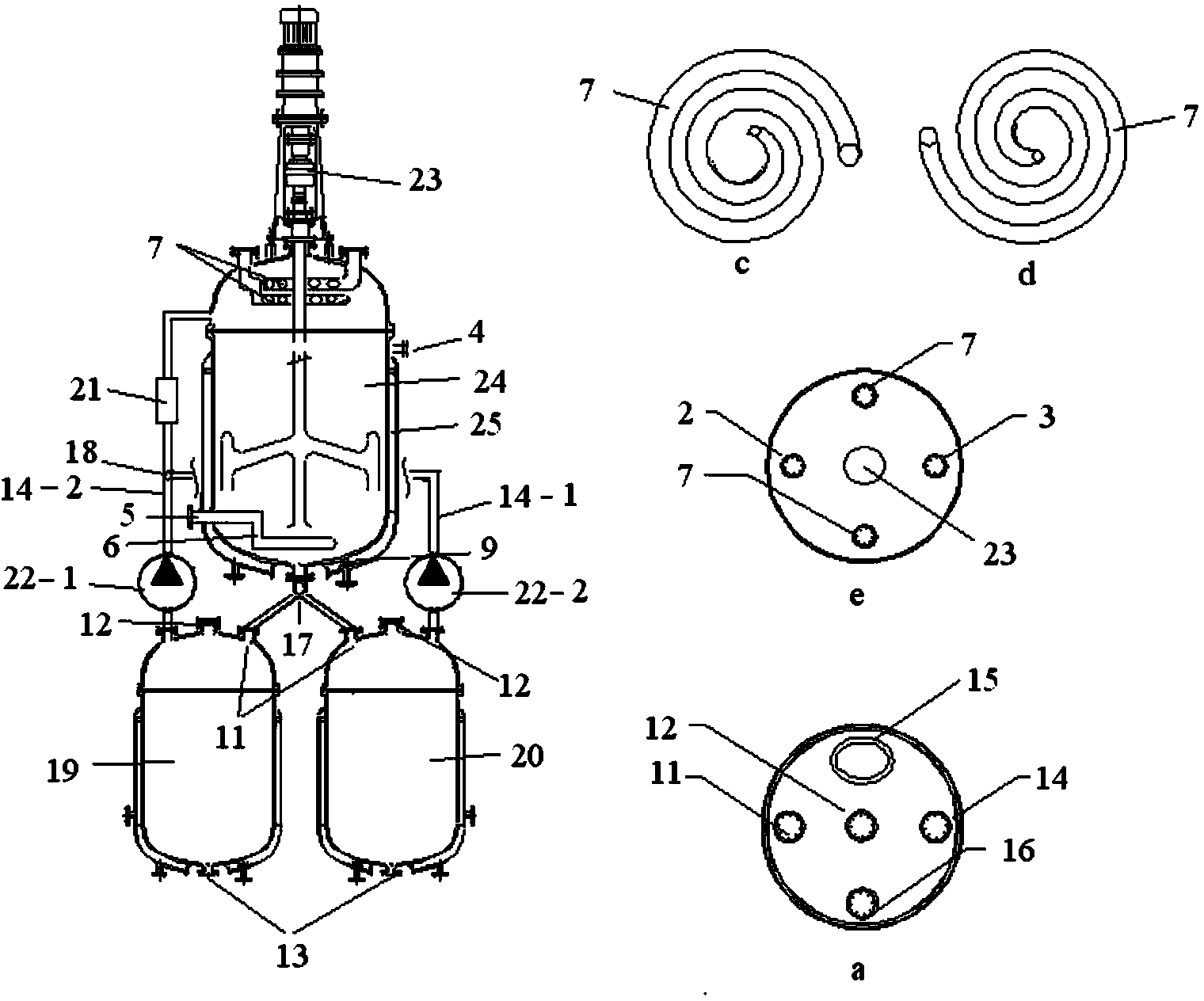

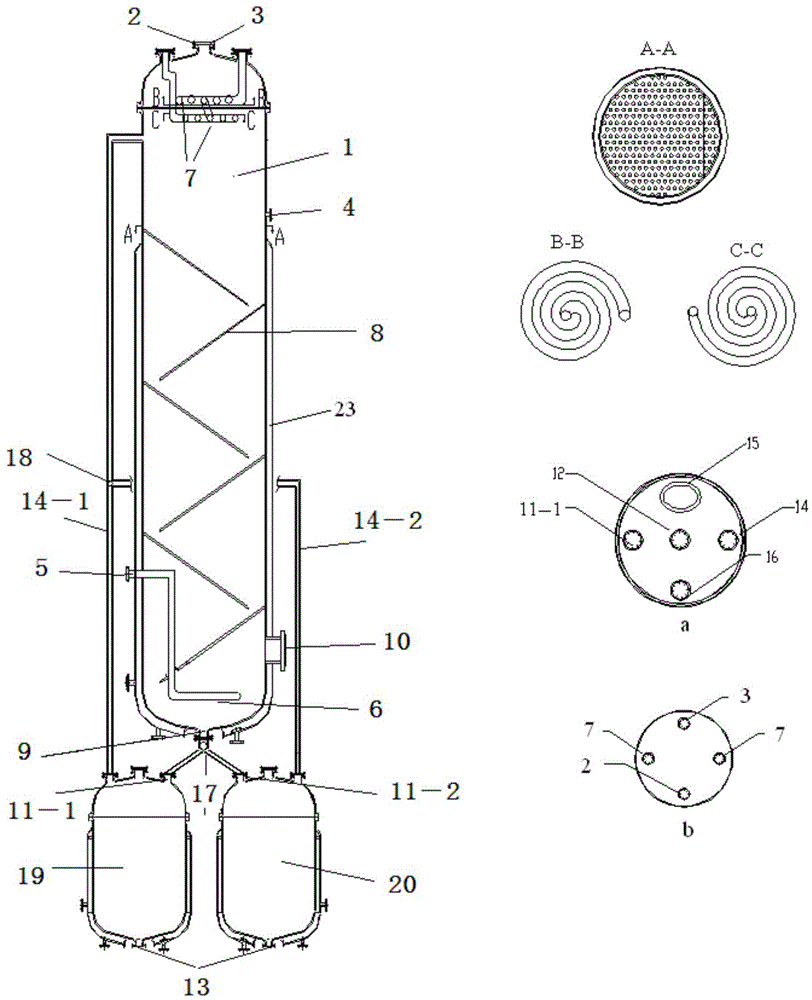

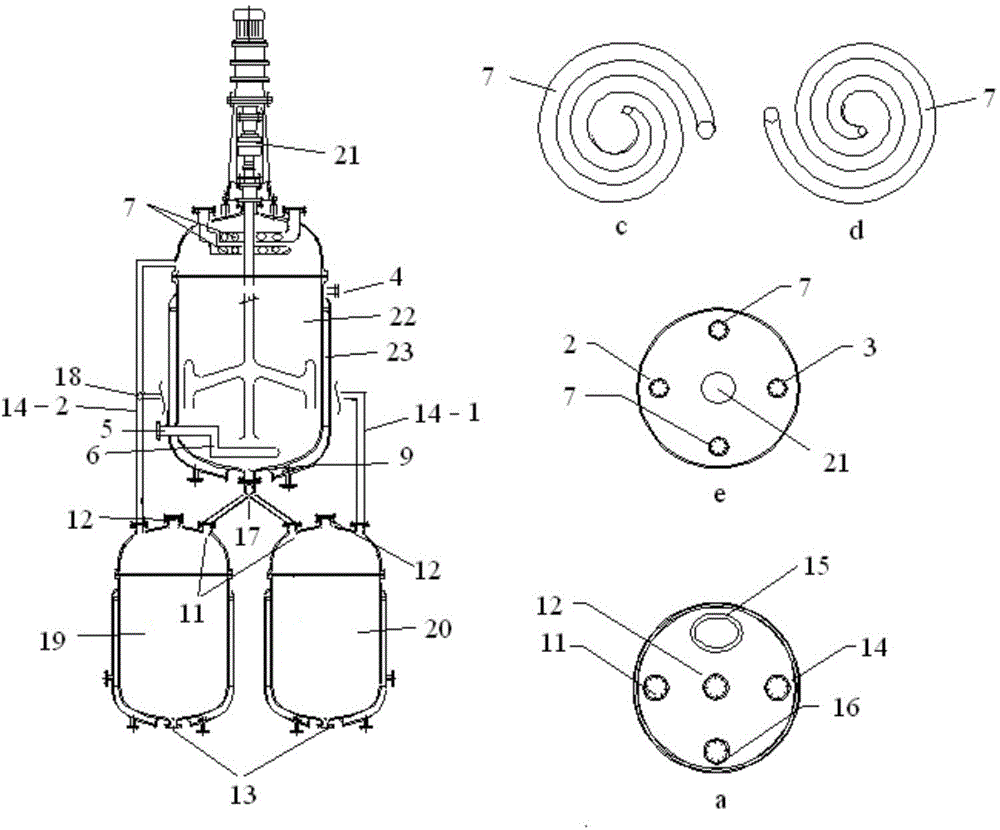

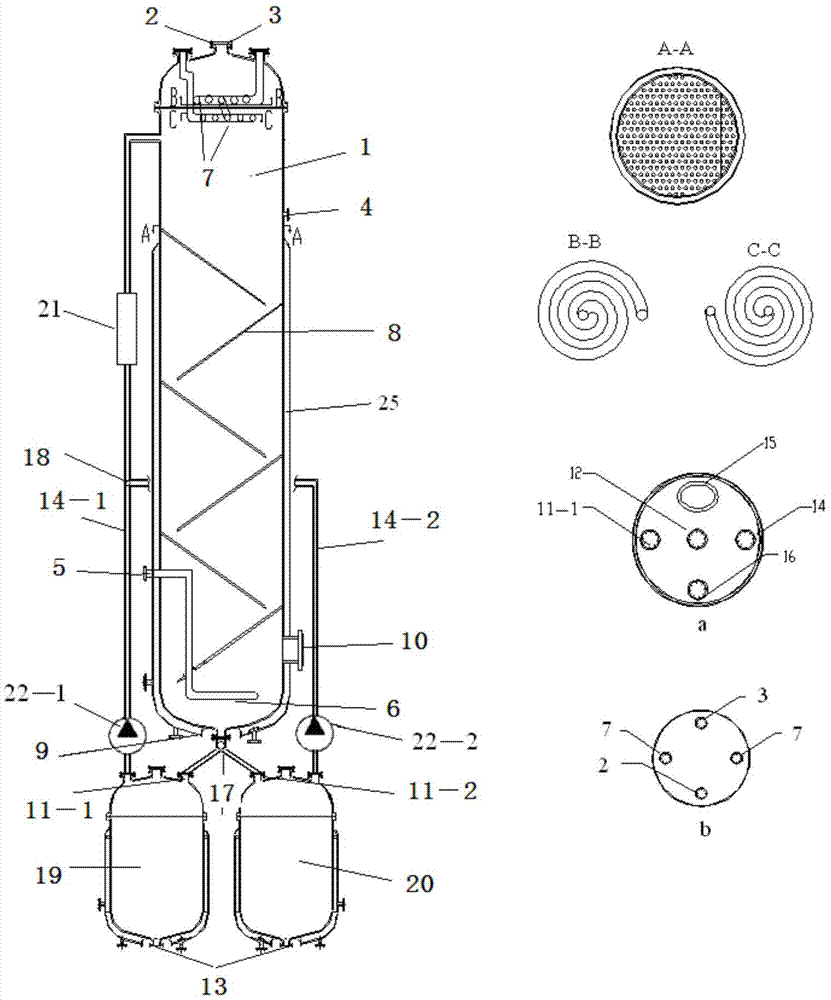

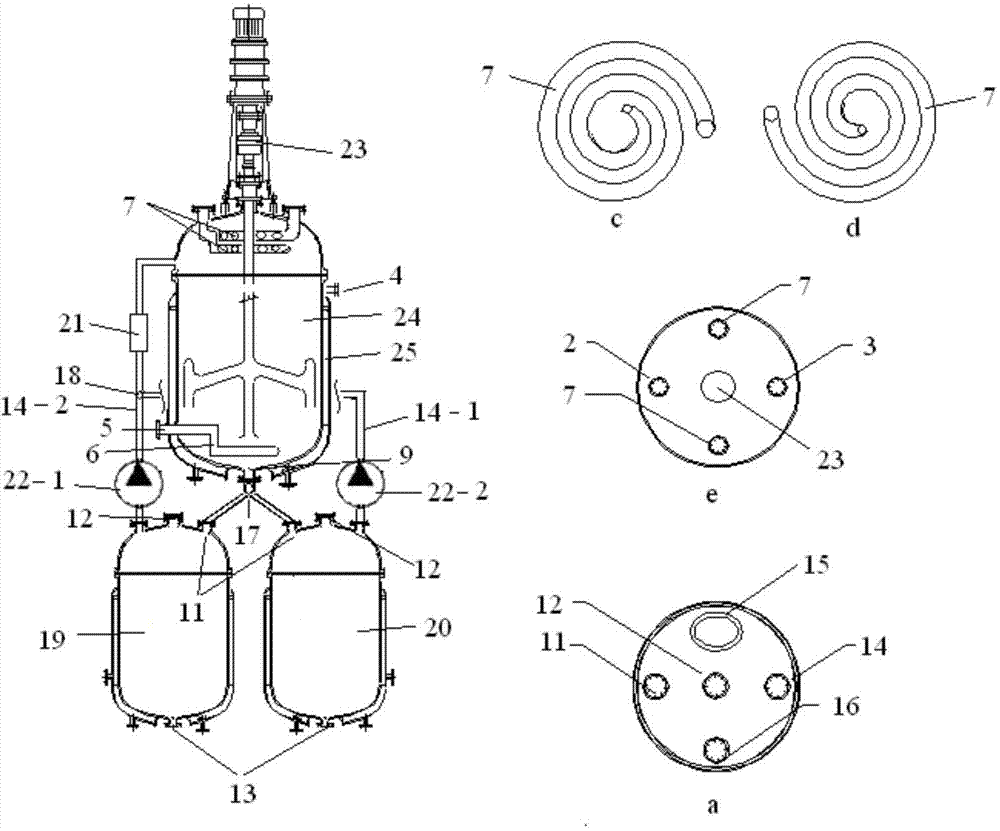

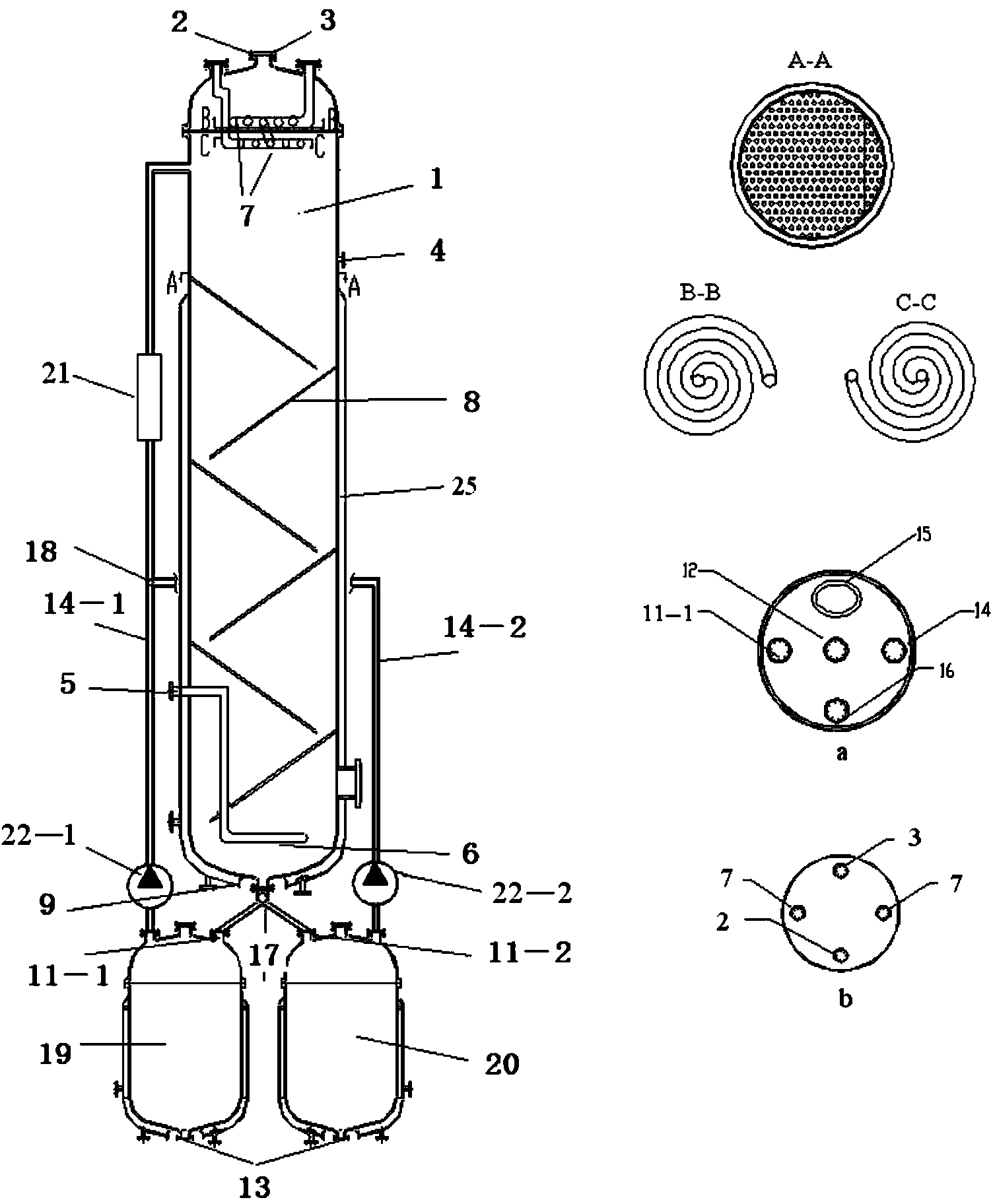

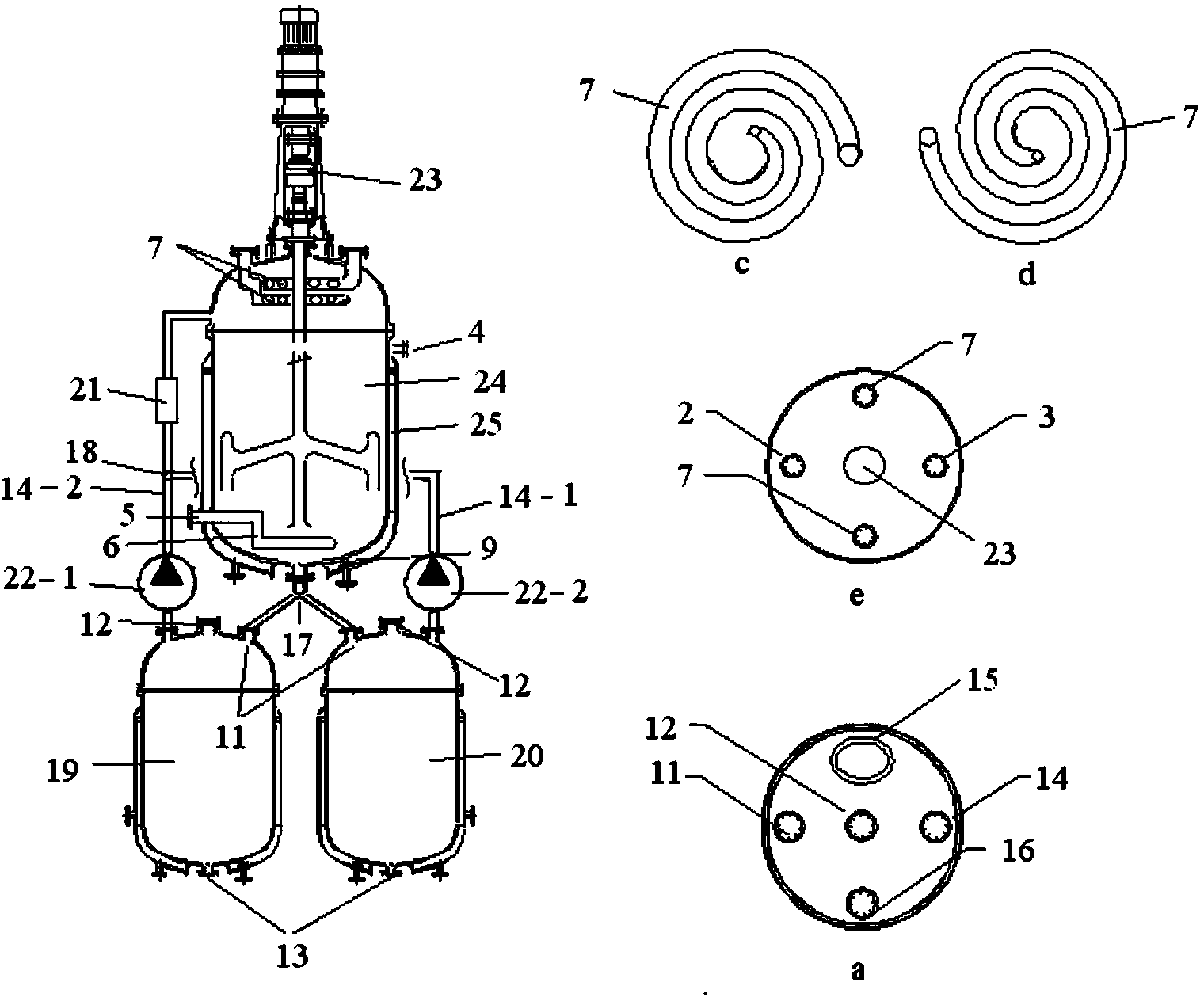

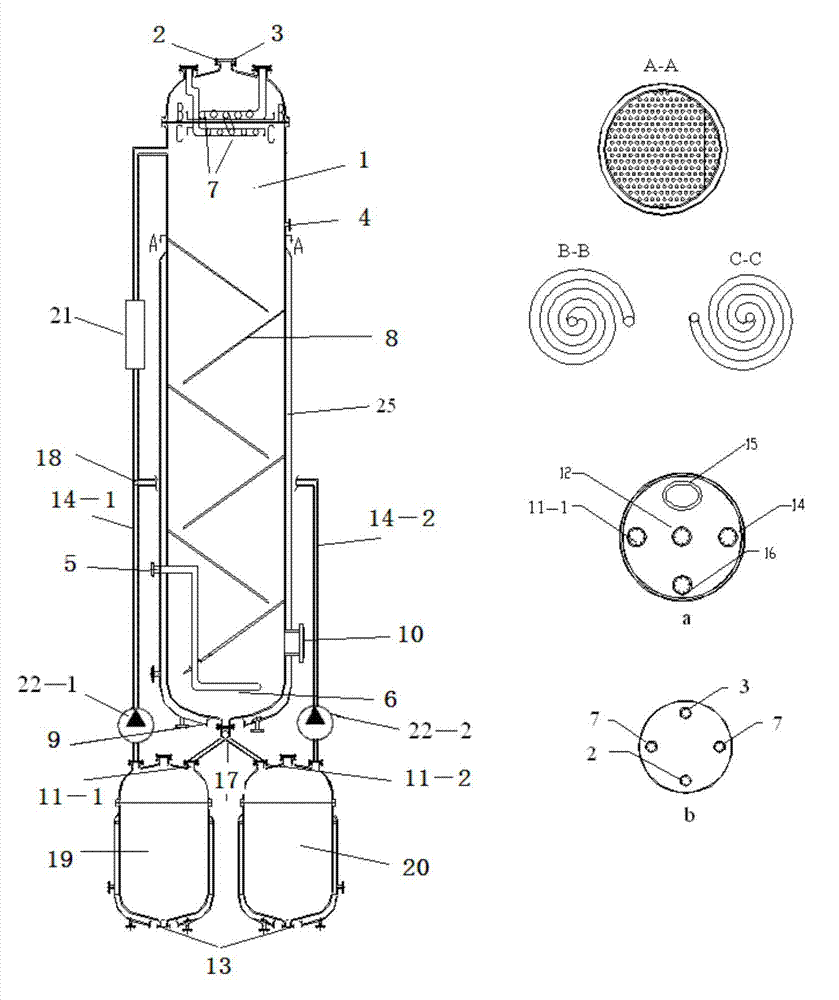

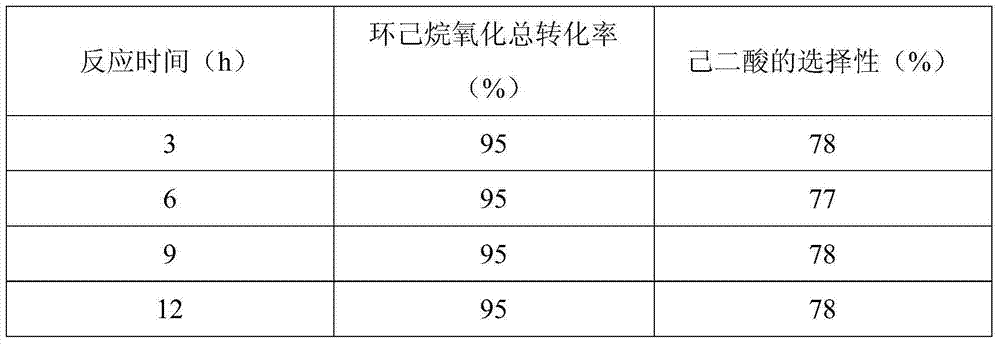

The invention discloses a method for producing adipic acid by oxidizing cyclohexane by utilizing air based on a gas-liquid-solid multiphase reaction and separation synchronization reactor. The method is characterized by adding cyclohexane to the gas-liquid-solid multiphase reaction and separation synchronization reactor, wherein the reactor comprises a reaction tower and at least two constant temperature settling towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase zone, an oxidation zone and a gas outlet; during reaction, filling the oxidation zone and constant temperature settling towers with cyclohexane, continuously pumping air from the bottom of the oxidation zone to come into contact with cyclohexane to carry out oxidation reaction, simultaneously enabling generated adipic acid solid to enter the constant temperature settling towers through settling, at the moment, enabling cyclohexane in the constant temperature settling towers to enter the oxidation zone via an external circulation system so that reaction is continuously carried out, enabling adipic acid to continuously settle in the constant temperature settling towers until the constant temperature settling towers are filled with the adipic acid phase, and switching a reaction tower to be communicated with the other constant temperature settling tower filled with cyclohexane, thus alternating the steps to carry out continuous production. The method can be used for continuously producing adipic acid with high conversion rate and high yield, and has the effects of improving the production efficiency and reducing the production cost.

Owner:蚌埠启邦科技信息咨询有限公司

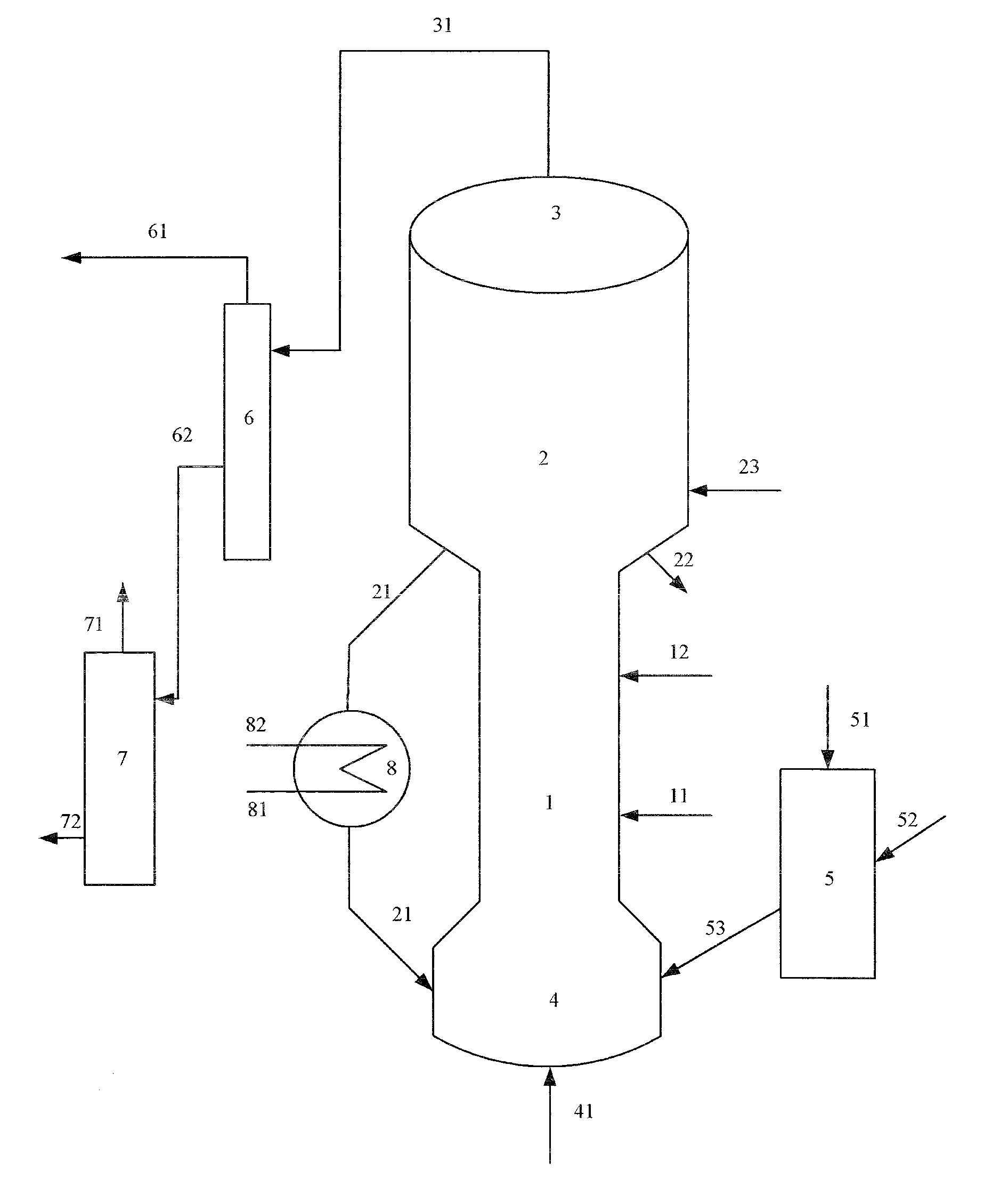

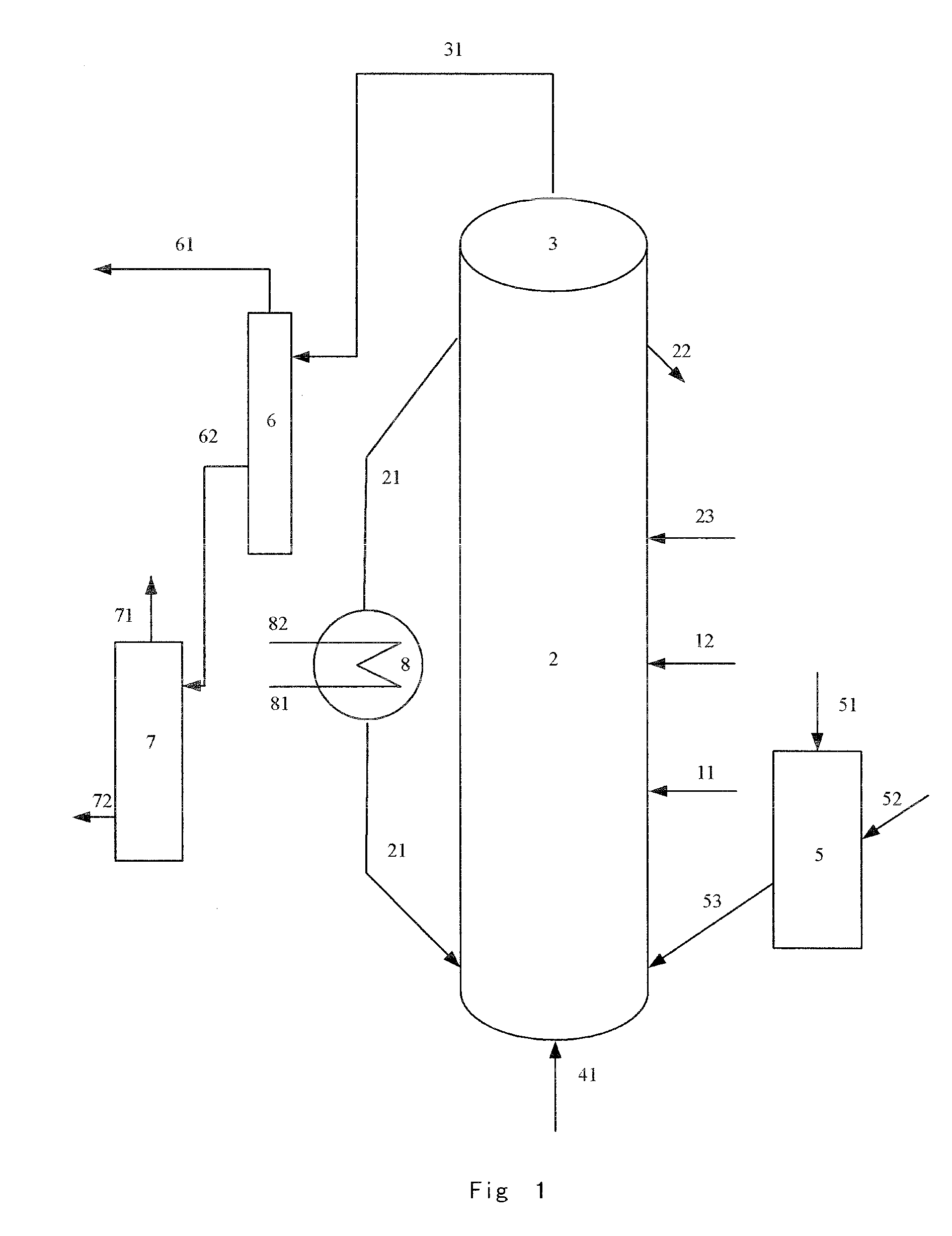

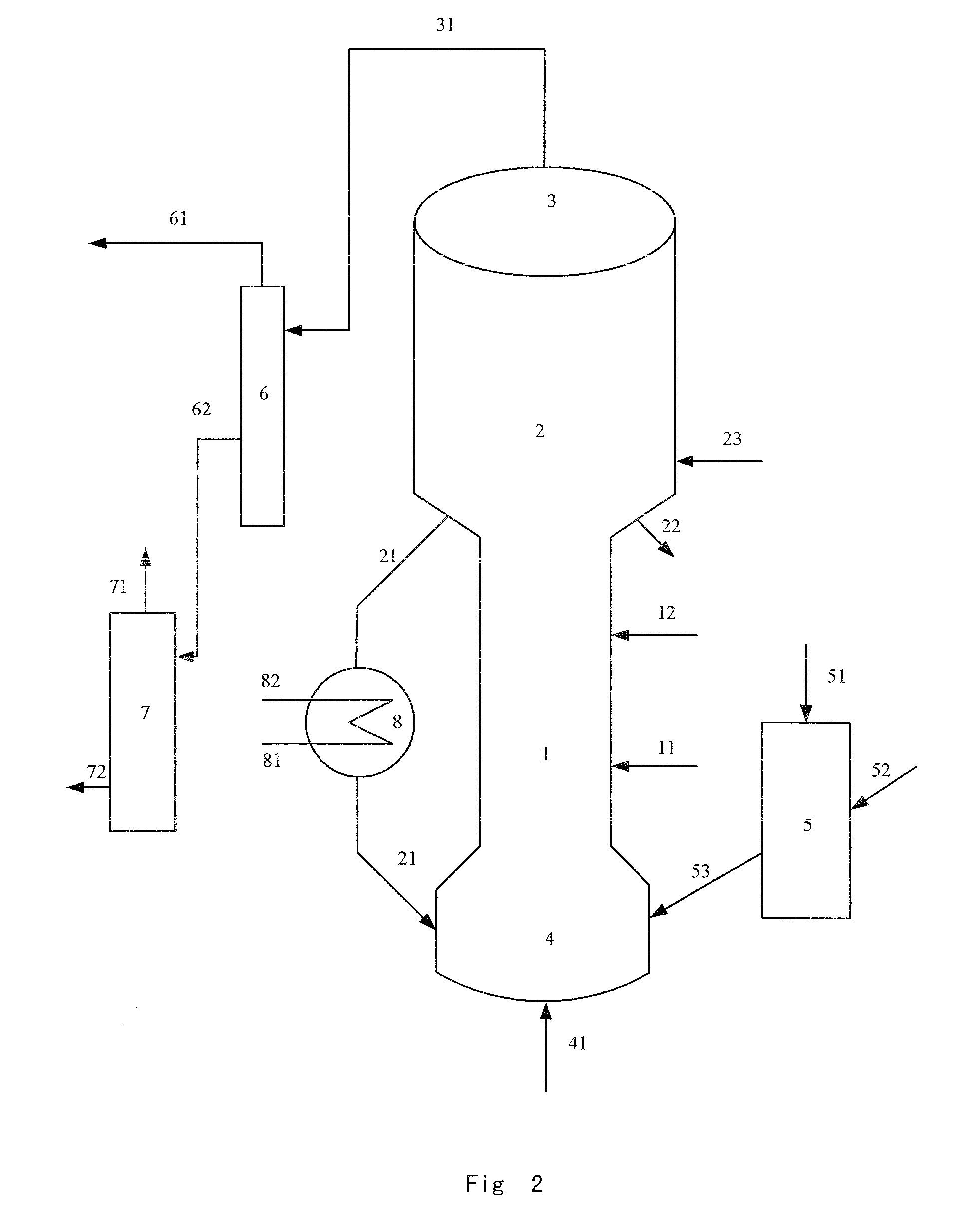

Fluidized catalytic process for production of dimethyl ether from methanol

ActiveUS20100076227A1Increase conversionsHigh selectivityMolecular sieve catalystsOrganic compound preparationDimethyl etherDehydration

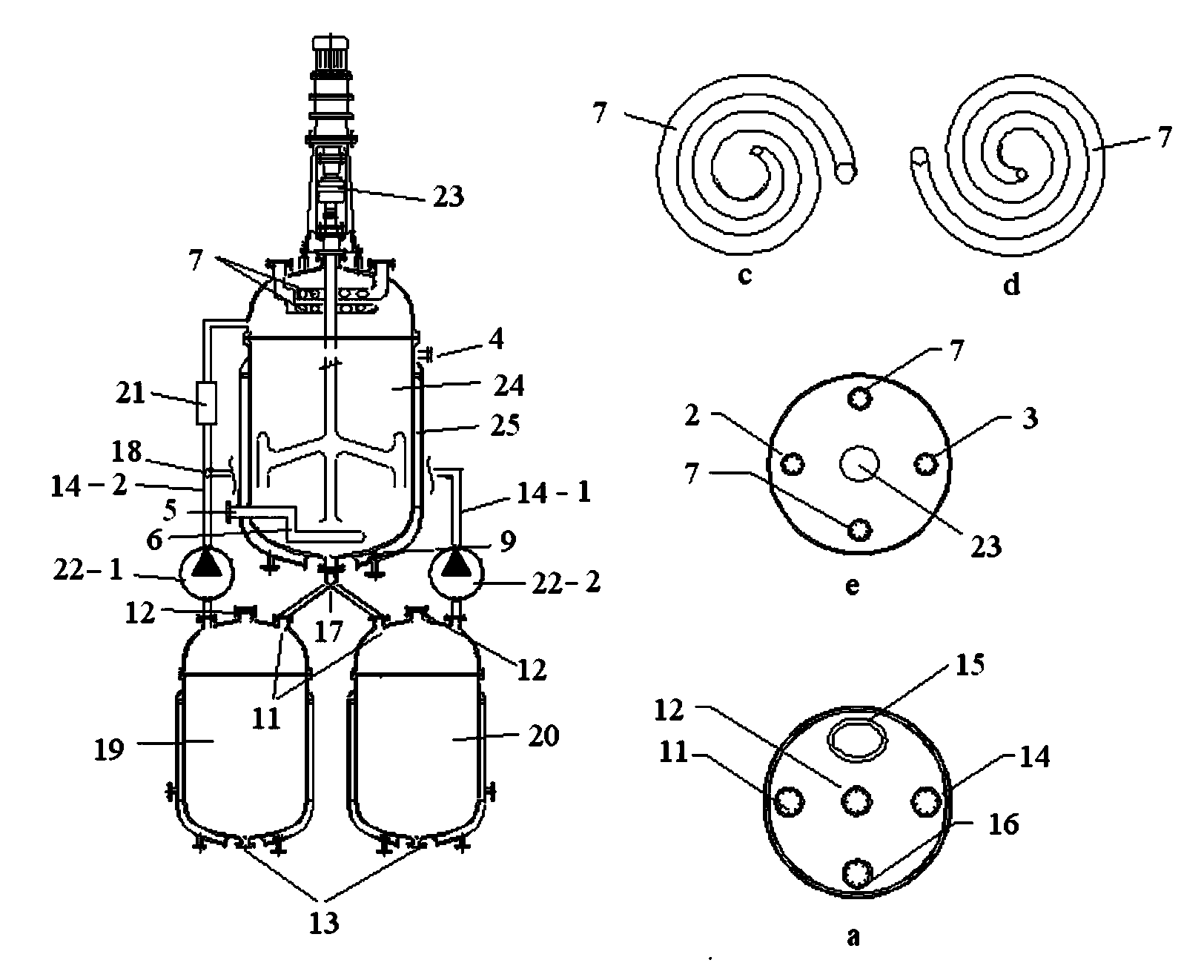

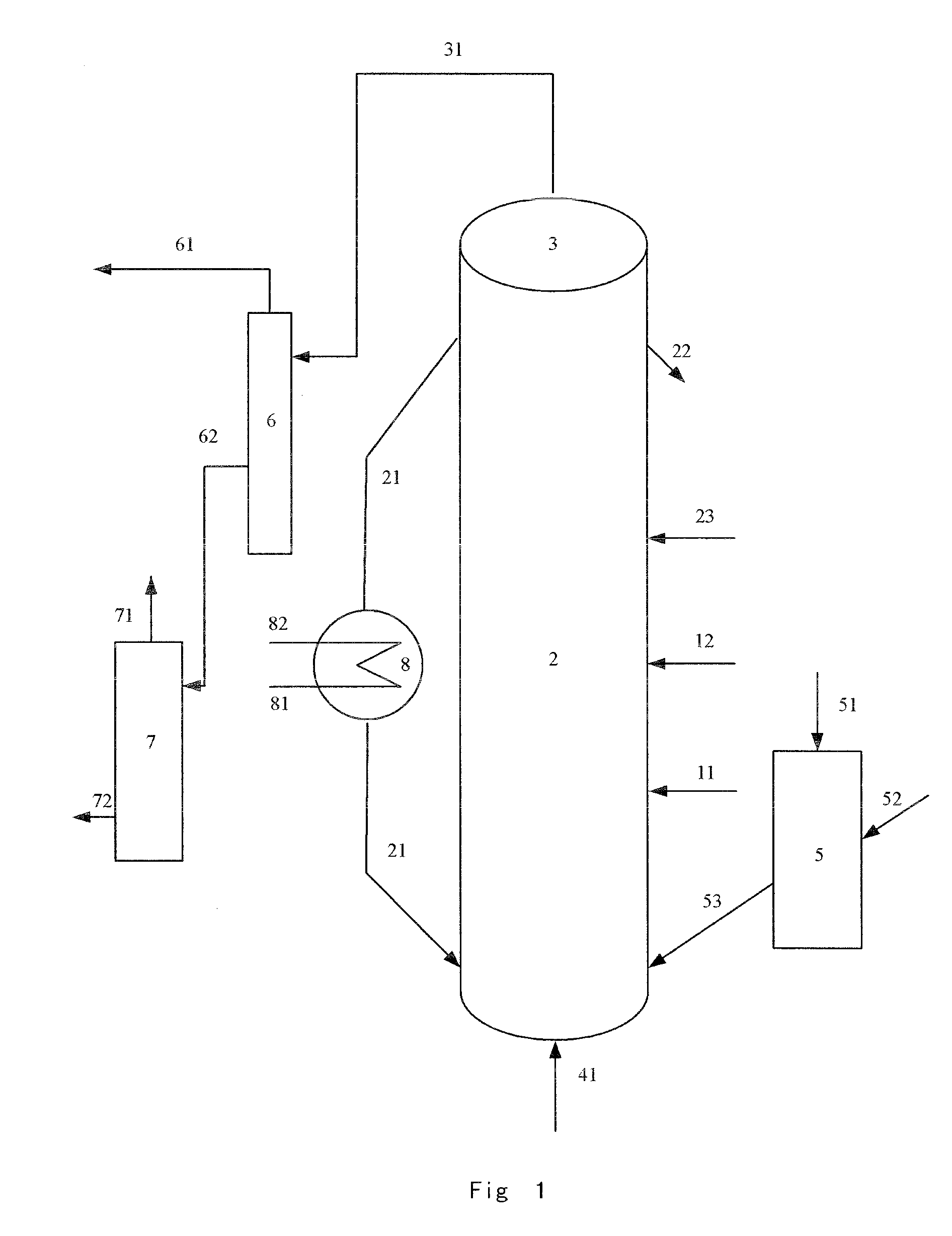

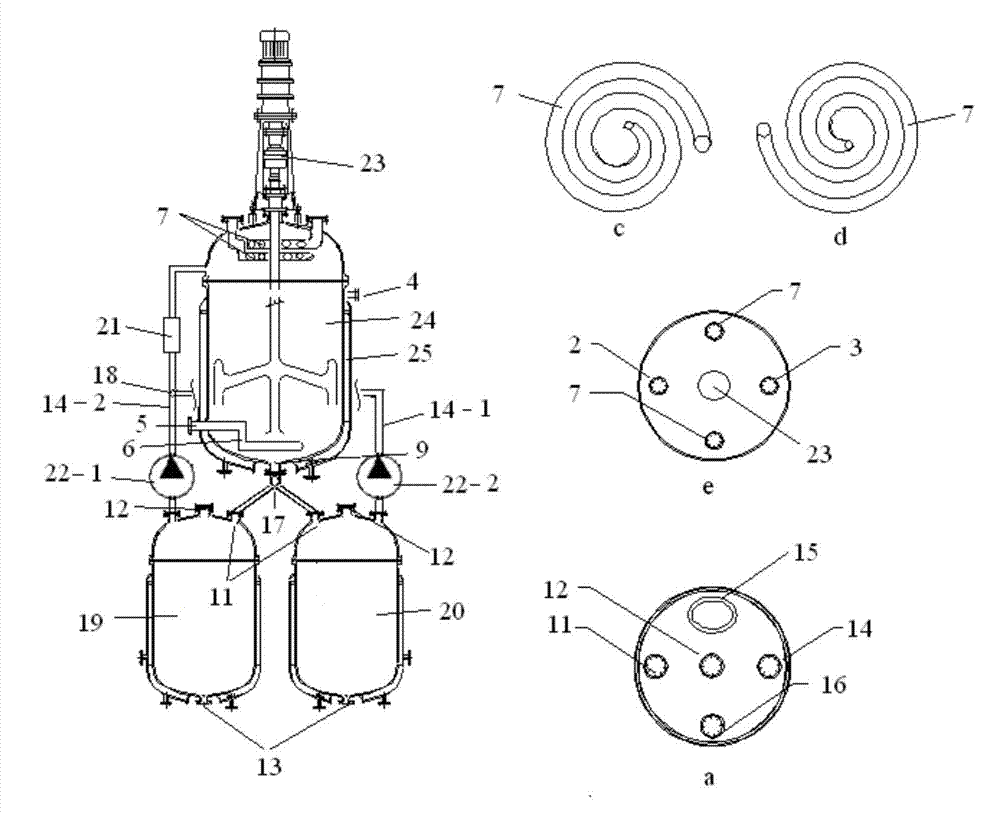

The present invention provides a fluidized catalytic process for production of dimethyl ether from methanol, wherein said process is carried out in a reactor in which the catalyst is in a fluidized state. Said process comprises the following steps of (1) feeding the methanol feedstock via two or more locations selected from the bottom, lower part, middle part and upper part of the reactor, contacting with the catalyst for preparation of dimethyl ether by methanol dehydration, carrying out the reaction of preparing dimethyl ether by methanol dehydration to obtain the reaction stream, separating said reaction stream to obtain a coked catalyst and a crude product primarily containing the target product, i.e. dimethyl ether; (2) totally or partially feeding the coked catalyst obtained in step (1) into a regenerator in a continuous or batch manner for regeneration via coke-burning, the regenerated catalyst being directly recycled to step (1) after being totally or partially cooled.

Owner:CHINA PETROCHEMICAL CORP +1

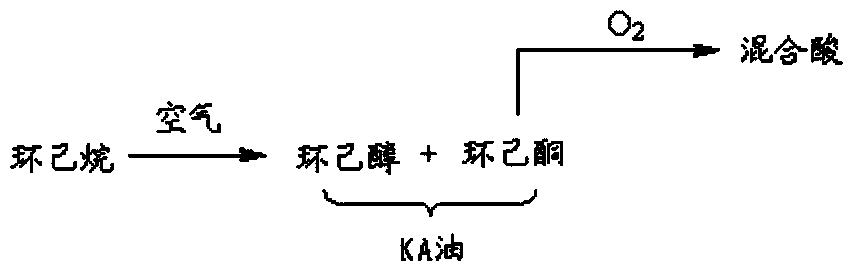

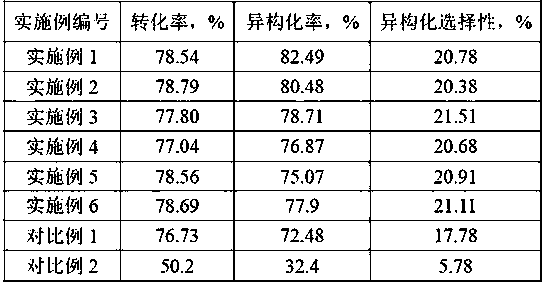

Method for producing KA oil through oxidizing cyclohexane by using air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755521AHigh yieldReduce the effect of settling velocityPreparation by oxidation reactionsOrganic compound preparationGas phaseOil phase

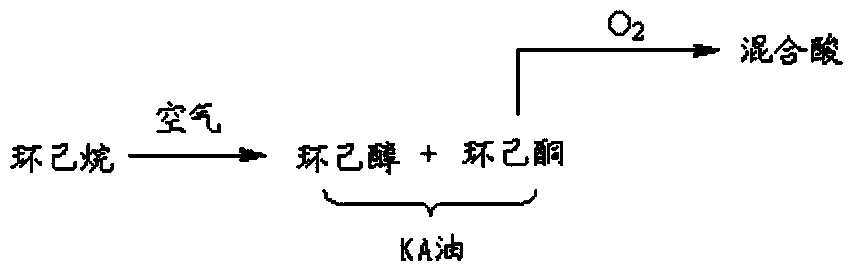

The invention discloses a method for producing KA oil through oxidizing cyclohexane by using air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing cyclohexane is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the cyclohexane in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the cyclohexane to carry out the oxidization reaction, meanwhile, the produced KA oil is blended with water to form a KA oil phase, the KA oil phase is settled into the constant temperature settlement tower, the cyclohexane in the constant temperature settlement tower at the moment enters the oxidization area through an external circulation system, so that the reaction is conducted continuously, the KA oil phase continues to settle in the constant temperature settlement tower until the constant temperature settlement tower is fully filled the KA oil phase, then the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the cyclohexane, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the KA oil. The method is used to continuously produce the KA oil with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:新疆普禾粟新型环保材料有限公司

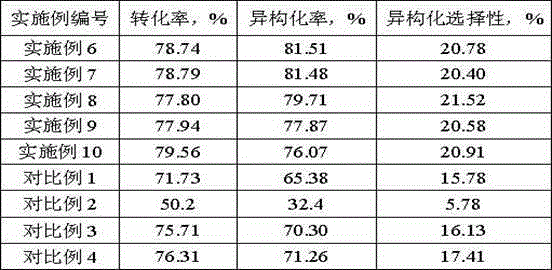

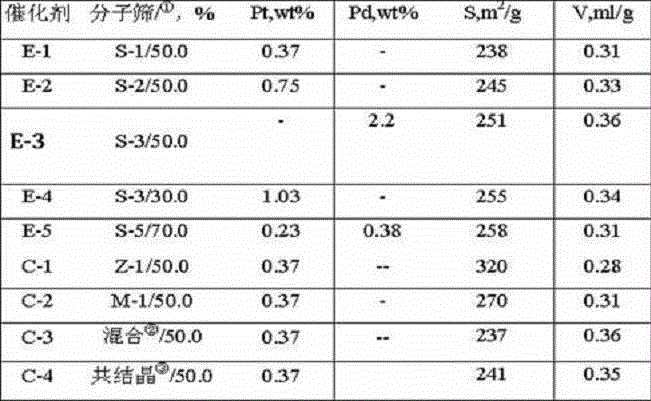

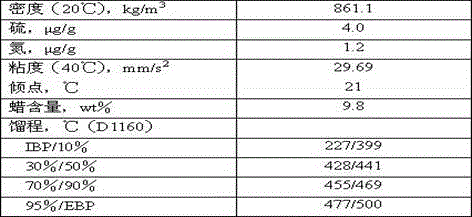

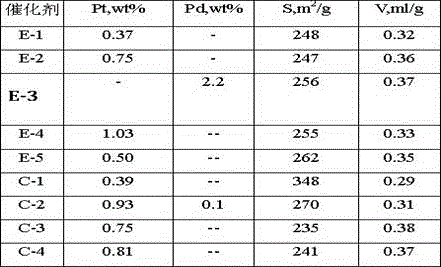

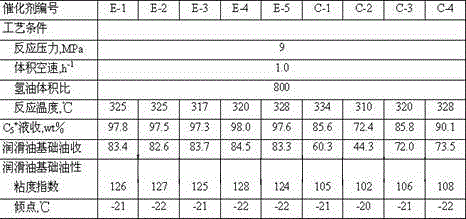

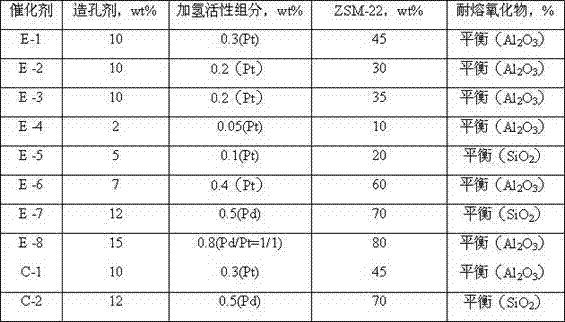

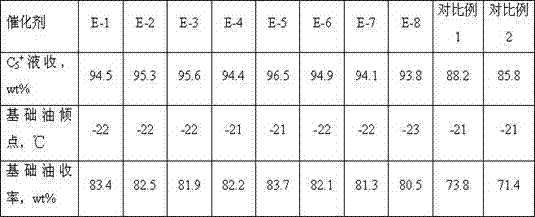

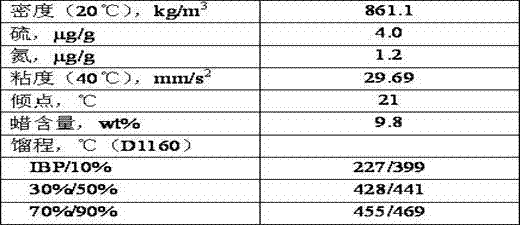

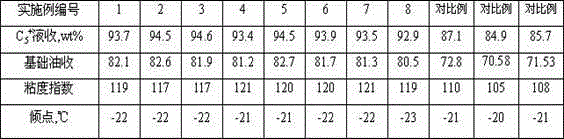

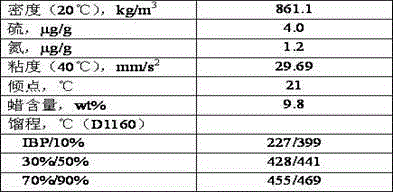

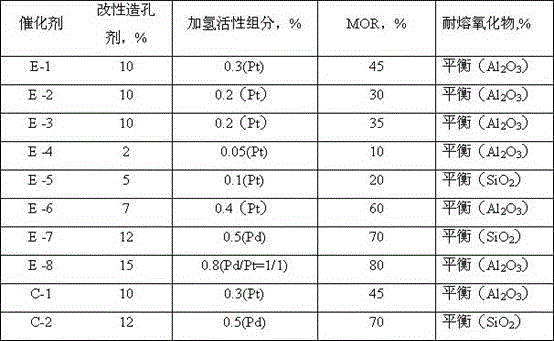

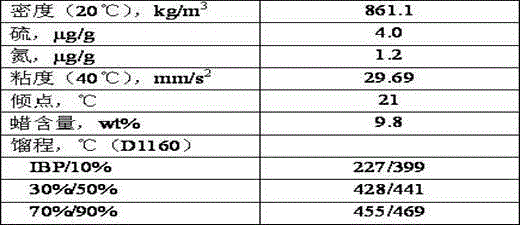

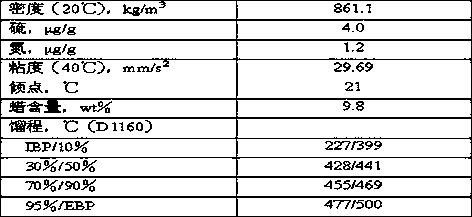

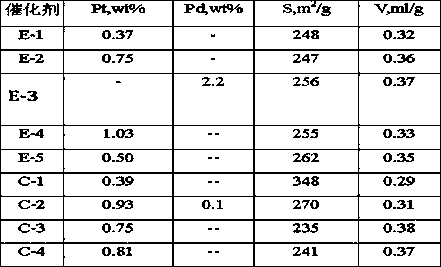

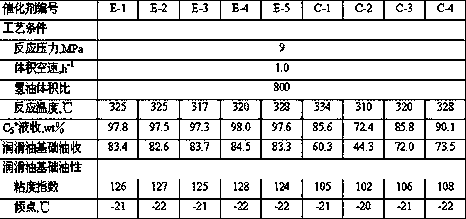

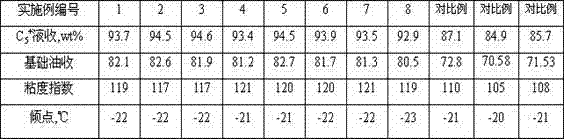

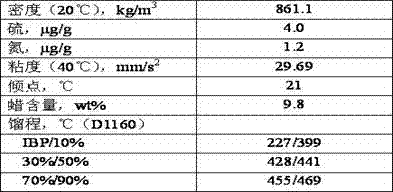

Isomerization dewaxing catalyst, and preparation method thereof

ActiveCN105709816AReduce usageReduce manufacturing costMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention discloses an isomerization dewaxing catalyst, and a preparation method thereof. According to the preparation method, TON-type molecular sieve loaded with a hydrogenation active ingredient is coated with an organic matter, an obtained product is uniformly mixed with a precursor of a high temperature resistant indifferent oxide, and an obtained mixture is subjected to moulding, drying, and roasting so as to obtain the isomerization dewaxing catalyst. The isomerization dewaxing catalyst is especially suitable for isomerization dewaxing of lubricating oil cut fractions. Compared with the prior art, the isomerization dewaxing catalyst possesses following advantages: molecular sieve using amount of the isomerization dewaxing catalyst is reduced greatly, so that catalyst production cost is reduced greatly, and discharge of wastewater difficult to process in molecular sieve synthesis process is avoided; target product yield is high; and pour point is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-carbon alkane isomerization catalyst and preparation method thereof

InactiveCN106669805AHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a low-carbon alkane isomerization catalyst and a preparation method thereof. The catalyst contains an MCM-22 / ZSM-35 composite molecular sieve and group-VIII precious metal active components, wherein counted by the weight content of the catalyst, the content of the MCM-22 / ZSM-35 composite molecular sieve is 1.0 to 90 percent, the content of group-VIII precious metals is 0.1 to 1.5 percent, an MCM-22 molecular sieve of the MCM-22 / ZSM-35 composite molecular sieve wraps a ZSM-35 molecular sieve, and the weight content of the MCM-22 in the MCM-22 / ZSM-35 composite molecular sieve is 1.0 to 50 percent. The catalyst can shorten the dwell time of a carbonium ion intermediate in pores of the catalyst, improves the activity and isomerization selectivity and stability of the catalyst, and also suppresses secondary reaction such as polymerization coking and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization catalyst, and preparation method and application thereof

ActiveCN106669804ADiffusion fastAvoid contactMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveLiquid product

The invention discloses an isomerization catalyst, and a preparation method and an application thereof. The catalyst includes, by weight, 10-90% of an MCM-22 / ZSM-23 compound molecular sieve, 0.1-5.0% of gallium oxide and 0.1-1.5% a group VIII precious metal, wherein the MCM-22 / ZSM-23 compound molecular sieve is obtained through wrapping ZSM-23 molecular sieve with MCM-22 molecular sieve, and the weight content of the MCM-22 in the MCM-22 / ZSM-23 compound molecular sieve is 1.0-50%. The catalyst reduces the condensation point of wax-containing raw oil, improves the yield of liquid products, and has the high viscosity index characteristic of lubricating oil base oil when especially used in the isodewaxing process of a lubricating oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized catalytic process for production of dimethyl ether from methanol

ActiveUS8304582B2Increase conversionsHigh selectivityMolecular sieve catalystsOrganic compound preparationDimethyl etherDehydration

The present invention provides a fluidized catalytic process for production of dimethyl ether from methanol, wherein said process is carried out in a reactor in which the catalyst is in a fluidized state. Said process comprises the following steps of (1) feeding the methanol feedstock via two or more locations selected from the bottom, lower part, middle part and upper part of the reactor, contacting with the catalyst for preparation of dimethyl ether by methanol dehydration, carrying out the reaction of preparing dimethyl ether by methanol dehydration to obtain the reaction stream, separating said reaction stream to obtain a coked catalyst and a crude product primarily containing the target product, i.e. dimethyl ether; (2) totally or partially feeding the coked catalyst obtained in step (1) into a regenerator in a continuous or batch manner for regeneration via coke-burning, the regenerated catalyst being directly recycled to step (1) after being totally or partially cooled.

Owner:CHINA PETROCHEMICAL CORP +1

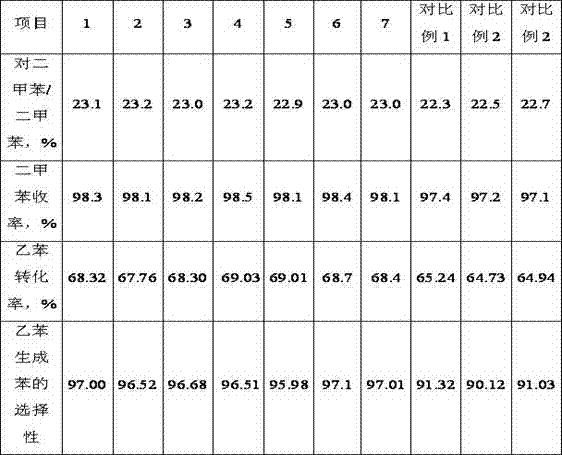

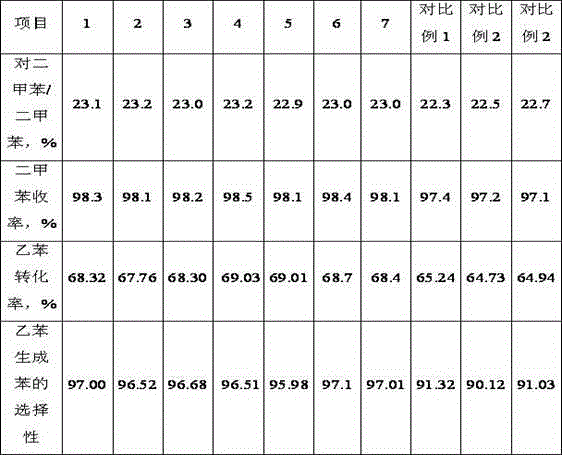

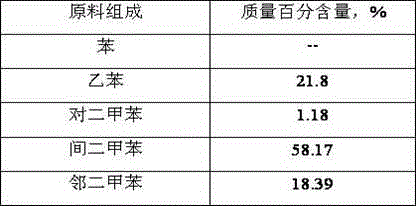

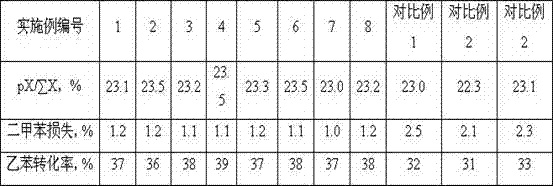

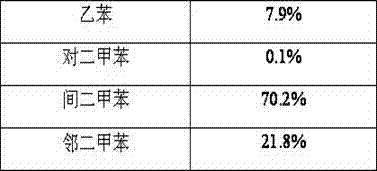

A kind of ethylbenzene dealkylation catalyst and preparation method thereof

ActiveCN105709809BReduce manufacturing costHigh selectivityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention discloses an ethylbenzene dealkylation catalyst and a preparation method thereof. In the method, the MOR type molecular sieve loaded with active metal components is embedded in the organic matter, then uniformly mixed with the precursor of the high-temperature resistant inert oxide, shaped, dried and calcined to obtain the ethylbenzene dealkylation catalyst. The catalyst of the invention is particularly suitable for the isomerization process of C8 mixed aromatics containing ethylbenzene. Compared with the existing technology, since the molecular sieve used is greatly reduced, not only the production cost of the catalyst is greatly reduced, but also the discharge of difficult-to-treat wastewater in the synthesis process of the molecular sieve is avoided, and it has a higher conversion rate of ethylbenzene and ethylbenzene The conversion of benzene to benzene is characterized by selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of ethylbenzene dealkylation catalyst

ActiveCN105582984BLow selectivityHigh selectivityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention discloses a preparation method of an ethylbenzene dealkylation catalyst, which includes the following contents: (1) loading active components on a macroporous pore-forming agent, and then drying to obtain a modified pore-forming agent; (2) adding MWW small-grain molecular sieves, precursors of refractory oxides, modified pore-forming agents, peptizers and water are kneaded, dried and calcined to obtain catalyst products. The preparation process of the method is simple and the cost is low, and the catalyst product is used in the isomerization process of C8 mixed aromatic hydrocarbons containing ethylbenzene, and has the characteristics of high conversion rate of ethylbenzene and selectivity of converting ethylbenzene into benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

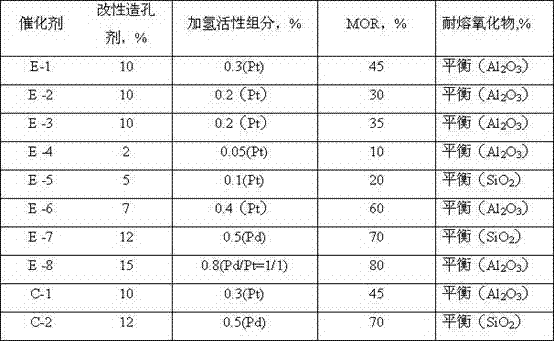

Preparation method of ethylbenzene dealkylation catalyst

ActiveCN105582984ALow selectivityHigh selectivityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method of an ethylbenzene dealkylation catalyst. The preparation method comprises the following steps: 1) supporting an active component onto a macro-pore forming agent, drying the macro-pore forming agent to prepare a modified pore forming agent; and 2) performing mix-kneading moulding to MWW-type small-crystalline-grain molecular sieve, a precursor of a melt-resistant oxide, the modified pore forming agent, a peptizer and water, and drying and roasting the mixture to prepare the catalyst. The preparation method is simple in processes and low in cost. The catalyst, when being used in isomerization on C8 mixed aromatic hydrocarbon containing ethylbenzene, is high in ethylbenzene conversion rate and is high in selectivity of converting the ethylbenzene into benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

a c 8 Preparation method of aromatic hydrocarbon isomerization catalyst

ActiveCN105582986BAvoid deep reactionIncrease the speed of diffusionHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method for a C8 aromatic hydrocarbon isomerization catalyst, which includes the following steps: 1) supporting an active component onto a macro-pore forming agent, and drying the macro-pore forming agent to prepare a modified pore forming agent; 2) performing mix-kneading moulding to an EUO-type small-crystal-grain molecular sieve, a precursor of a melting-resistant oxide, the modified pore forming agent, a peptizer and water, and drying and roasting the mixture to prepare the catalyst. The preparation method is simple in processes and low in cost. The catalyst, when being used in isomerization of C8 mixed aromatic hydrocarbon containing ethylbenzene, has high ethylbenzene conversion rate and low aromatic hydrocarbon loss rate.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

A kind of toluene and ethylene selective alkylation catalyst and preparation method thereof

ActiveCN105709815BEvenly distributedReduce manufacturing costMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

The invention discloses a catalyst for selective alkylation of toluene and ethylene and a preparation method thereof. The method is to embed the MWW type molecular sieve with small grains in the organic matter, then mix it evenly with the precursor of the high-temperature resistant inert oxide, form, dry and roast to obtain the selective alkylation catalyst of toluene and ethylene. The catalyst of the present invention is particularly suitable for the selective alkylation of toluene and ethylene to synthesize p-methylethylbenzene. Compared with the existing technology, since the amount of molecular sieve in the catalyst is greatly reduced, not only the production cost of the catalyst is greatly reduced, but also the discharge of difficult-to-treat wastewater in the synthesis process of the molecular sieve is avoided, and it has high catalytic activity and p-methylethylbenzene selectivity. Sexual characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing KA oil and adipic acid through oxidizing cyclohexane with air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755544BHigh yieldPrevent oxidationPreparation by oxidation reactionsOrganic compound preparationGas phaseAdipic acid

The invention discloses a method for producing KA oil and adipic acid through oxidizing cyclohexane with air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing cyclohexane is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the cyclohexane in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the cyclohexane to carry out the oxidization reaction, meanwhile, a mixed phase of the produced KA oil, adipic acid and water settles and enters the bottom of the constant temperature settlement tower, the cyclohexane in the constant temperature settlement tower is pushed and goes up into the oxidization area to lead to the continuous reaction, the mixed phase continues to settle in the constant temperature settlement tower until the constant temperature settlement tower is fully filled with the mixed phase, then the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the cyclohexane, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the KA oil and adipic acid. The method is used to continuously produce the KA oil and the adipic acid with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:蚌埠启邦科技信息咨询有限公司

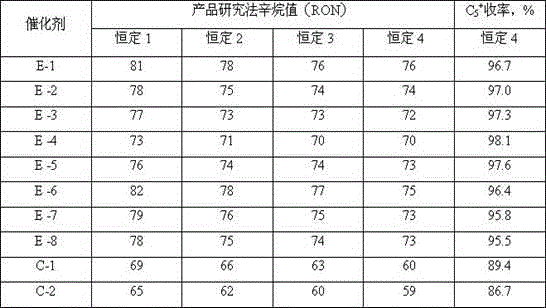

A kind of preparation method of naphtha isomerization catalyst

ActiveCN105521811BHigh activityHigh selectivityMolecular sieve catalystsNaphtha reformingMolecular sieveIsomerization

The invention discloses a preparation method of a naphtha isomerization catalyst, comprising the following contents: (1) loading active components on a macroporous pore-forming agent, and then drying to obtain a modified pore-forming agent; (2) Molecular sieve, refractory oxide, modified pore-forming agent, peptizer and water are kneaded to form a plastic body, extruded, dried and calcined to obtain a catalyst product. The method not only has the advantages of simple preparation process and low cost, but also the catalyst product is used in the naphtha isomerization reaction and has the characteristics of high yield of the target product and high octane number.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

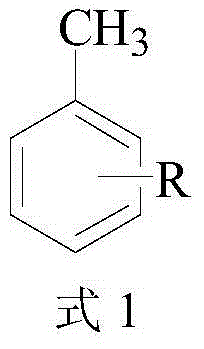

Method for producing substituted benzyl alcohol, substituted benzaldehyde and substituted benzyl acid through oxidizing substituted methylbenzene with air based on gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755520BHigh yieldRealize continuous productionPreparation by oxidation reactionsEther separation/purificationGas phaseBenzaldehyde

The invention discloses a method for producing substituted benzyl alcohol, substituted benzaldehyde and substituted benzyl acid through oxidizing substituted methylbenzene with air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing substituted methylbenzene is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the substituted methylbenzene in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the substituted methylbenzene to carry out the oxidization reaction, meanwhile, a mixed phase of the produced substituted benzyl alcohol, substituted benzaldehyde and substituted benzyl acid settles and enters the bottom of the constant temperature settlement tower, the substituted methylbenzene in the constant temperature settlement tower is pushed into the oxidization area to lead to the continuous reaction, the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the substituted methylbenzene when the constant temperature settlement tower is fully filled with the mixed phase, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the substituted benzyl alcohol, substituted benzaldehyde and substituted benzyl acid. The method is used to continuously produce the substituted benzyl alcohol, substituted benzaldehyde and substituted benzyl acid with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:YUANJIANG HUALONG CATALYST TECH

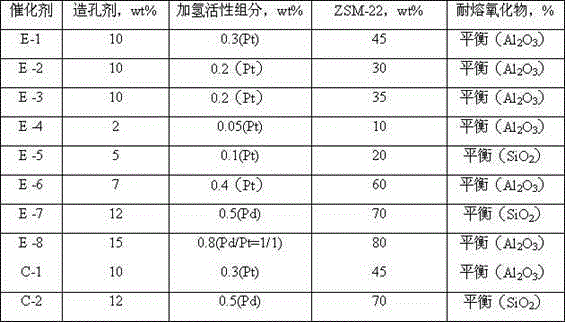

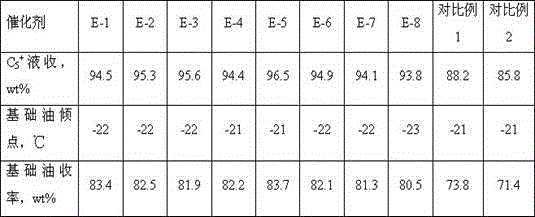

A kind of preparation method of paraffin hydrocarbon type-selective isomerization catalyst

ActiveCN105521816BHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveParaffin wax

The invention discloses a preparation method of a paraffin hydrocarbon shape-selective isomerization catalyst, which is characterized in that it includes the following content: (1) loading active components on a macropore pore-forming agent, and then drying to obtain a modified pore-forming agent ; (2) The catalyst product is obtained by kneading TON-type small-grain molecular sieves, refractory oxides, modified pore-forming agents, peptizers and water, and drying and roasting. The preparation process of the method is simple, the cost is low, and the catalyst product is used in the paraffin hydrocarbon type-selective isomerization reaction, and has the characteristics of high yield of the target product and low pour point.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Method for producing terephthalic acid through oxidation of p-xylene by using air based on gas-liquid-solid heterogeneous reaction separation synchronizing reactor

ActiveCN103772182BHigh yieldPrevent oxidationOrganic compound preparationChemical/physical processesGas phaseTower

The invention discloses a method for producing a terephthalic acid through the oxidation of p-xylene by using air based on a gas-liquid-solid heterogeneous reaction separation synchronizing reactor, which comprises the following steps that: p-xylene is added into the gas-liquid-solid heterogeneous reaction separation synchronizing reactor, wherein the reactor comprises a reaction tower and at least two constant-temperature subsidence towers communicated with the bottom of the reaction tower, a gaseous phase area, an oxidation area and a gas outlet are arranged in the reaction tower; in the process of reaction, the oxidation area and the constant-temperature subsidence tower are filled with p-xylene, air is continuously fed from bottom of the oxidation area so as to contact and react with the p-xylene, and generated terephthalic acid solids enter the constant-temperature subsidence tower by settling, and meanwhile, the p-xylene in the constant-temperature subsidence tower enters the oxidation area through an outer circulatory system, so that the reaction is running continuously, the p-xylene continues to be settled in the constant-temperature subsidence tower until the constant-temperature subsidence tower is filled, then the reaction tower is switched to be communicated with the other constant-temperature subsidence tower filled with p-xylene, in such an alternate way, continuous production is achieved. According to the method, a terephthalic acid can be continuously produced at high conversion rate and high yield, so that the production efficiency is improved, and the production cost is reduced.

Owner:湖北骏捷新材料股份有限公司

Preparation method of paraffin hydrocarbon shape-selective isomerization catalyst

ActiveCN105582983AHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveParaffin wax

The invention discloses a preparation method of a paraffin hydrocarbon shape-selective isomerization catalyst. The method includes the following steps: (1) supporting an active component onto a macro-pore forming agent, drying the macro-pore forming agent to obtain a modified pore forming agent; (2) performing mix-kneading moulding to MTT micro-crystal-grain molecular sieve, a precursor of a melt-resistant oxide, the modified pore forming agent, a peptizer and water, and drying and roasting the mixture to prepare the catalyst. The preparation method is simple in processes and low in cost. The catalyst, when being used in a paraffin hydrocarbon shape-selective isomerization reaction, has high target product yield and low pour point.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing naphtha isomerization catalyst

ActiveCN105521811AHigh activityHigh selectivityMolecular sieve catalystsNaphtha reformingMolecular sieveNaphtha

The invention discloses a method for preparing a naphtha isomerization catalyst. The method comprises the following steps: 1) active ingredients are loaded to a macropore pore-forming agent, then drying the active ingredients to obtain a modified pore-forming agent; and 2) a molecular sieve, a refractory oxide, the modified pore-forming agent, a peptizing agent and water are mixed, a mixture is shaped, striped, dried, and calcinated to obtain the catalyst product. The method has the advantages of simple process flow and low cost, and the catalyst product used in a naphtha isomerization reaction has the characteristics of high target product yield and high octane number.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

Method for preparing paraffin hydrocarbon shape-selective isomerization catalyst

ActiveCN105521816AHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningParaffin waxPARAFFIN HYDROCARBONS

The invention discloses a method for preparing a paraffin hydrocarbon shape-selective isomerization catalyst. The method comprises the following steps: 1) active ingredients are loaded to a macropore pore-forming agent, then the active ingredients are dried to obtain a modified pore-forming agent; and 2) a TON-type small grain molecular sieve, a refractory oxide, the modified pore-forming agent, a peptizing agent and water are mixed, a mixture is shaped, dried, and calcinated to obtain the catalyst product. The method has the advantages of simple process flow and low cost, and the catalyst product used in a paraffin hydrocarbon shape-selective hydrocarbon reaction has the characteristics of high target product yield and low pour point.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

A kind of isomerization dewaxing catalyst and preparation method thereof

ActiveCN105709816BReduce usageReduce manufacturing costMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a heterogeneous dewaxing catalyst and a preparation method thereof. The method is to embed the TON type molecular sieve loaded with hydrogenation active components in the organic matter, then mix evenly with the precursor of the high temperature resistant inert oxide, form, dry and roast to obtain the isomerization dewaxing catalyst. The catalyst of the present invention is particularly suitable for use in the isomerization dewaxing process of lubricating oil fractions. Compared with the existing technology, since the amount of molecular sieve in the catalyst is greatly reduced, not only the production cost of the catalyst is greatly reduced, but also the discharge of difficult-to-treat wastewater in the synthesis process of the molecular sieve is avoided, and it has the advantages of high yield of the target product and low pour point features.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization dewaxing catalyst and preparation method thereof

ActiveCN105709817AReduce usageReduce manufacturing costMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention discloses an isomerization dewaxing catalyst, and a preparation method thereof. According to the preparation method, MTT-type molecular sieve loaded with a hydrogenation active ingredient is coated with an organic matter, an obtained product is uniformly mixed with a precursor of a high temperature resistant indifferent oxide, and an obtained mixture is subjected to moulding, drying, and roasting so as to obtain the isomerization dewaxing catalyst. The isomerization dewaxing catalyst is especially suitable for isomerization dewaxing of lubricating oil cut fractions. Compared with the prior art, the isomerization dewaxing catalyst possesses following advantages: molecular sieve using amount of the isomerization dewaxing catalyst is reduced greatly, so that catalyst production cost is reduced greatly, and discharge of wastewater difficult to process in molecular sieve synthesis process is avoided; target product yield is high; and pour point is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

a c 8 Aromatic hydrocarbon isomerization catalyst and preparation method thereof

ActiveCN105709818BReduce loss rateReduce manufacturing costHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention discloses a C8 aromatic hydrocarbon isomerization catalyst, and a preparation method thereof. The preparation method comprises following steps: EUO-type molecular sieve loaded with a hydrogenation active ingredient is coated with an organic matter, an obtained product is uniformly mixed with a precursor of a high temperature resistant indifferent oxide, and an obtained mixture is subjected to moulding, drying, and roasting so as to obtain the C8 aromatic hydrocarbon isomerization catalyst. The C8 aromatic hydrocarbon isomerization catalyst is especially suitable for isomerization of C8 mixed aromatic hydrocarbons containing ethylbenzene. Compared with the prior art, the C8 aromatic hydrocarbon isomerization catalyst possesses following advantages: molecular sieve using amount of the C8 aromatic hydrocarbon isomerization catalyst is reduced greatly, so that catalyst production cost is reduced greatly, and discharge of wastewater difficult to process in molecular sieve synthesis process is avoided; and ethylbenzene conversion rate is relatively high, and aromatic hydrocarbon loss ratio is relatively low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization dewaxing catalyst and preparation method thereof

ActiveCN105709817BReduce usageReduce manufacturing costMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses an isomerization dewaxing catalyst, and a preparation method thereof. According to the preparation method, MTT-type molecular sieve loaded with a hydrogenation active ingredient is coated with an organic matter, an obtained product is uniformly mixed with a precursor of a high temperature resistant indifferent oxide, and an obtained mixture is subjected to moulding, drying, and roasting so as to obtain the isomerization dewaxing catalyst. The isomerization dewaxing catalyst is especially suitable for isomerization dewaxing of lubricating oil cut fractions. Compared with the prior art, the isomerization dewaxing catalyst possesses following advantages: molecular sieve using amount of the isomerization dewaxing catalyst is reduced greatly, so that catalyst production cost is reduced greatly, and discharge of wastewater difficult to process in molecular sieve synthesis process is avoided; target product yield is high; and pour point is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of low carbon alkane isomerization catalyst

ActiveCN105582980BHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveAlkane

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

A kind of isomerization catalyst and its preparation method and application

ActiveCN106669804BDiffusion fastAvoid contactMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveLiquid product

The invention discloses an isomerization catalyst and its preparation method and application. The catalyst contains MCM-22 / ZSM-23 composite molecular sieve, gallium oxide and Group VIII noble metal active components. Based on the weight content of the catalyst, MCM- The content of 22 / ZSM-23 composite molecular sieve is 10~90%, the content of calcium oxide is 0.1%~5.0%, and the content of Group VIII noble metal is 0.1%~1.5%. The MCM-22 / ZSM-23 composite molecular sieve is It means that MCM-22 molecular sieve is wrapped around ZSM-23 molecular sieve. The weight content of MCM-22 in MCM-22 / ZSM-23 composite molecular sieve is 1.0~50%. The catalyst can not only reduce the freezing point of waxy raw oil, but also improve the yield of liquid products. It is especially used in the isomerization dewaxing process of lubricating oil fractions and has the characteristics of high viscosity index of lubricating oil base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing KA oil through oxidizing cyclohexane by using air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755521BHigh yieldReduce the effect of settling velocityPreparation by oxidation reactionsOrganic compound preparationGas phaseProduct gas

The invention discloses a method for producing KA oil through oxidizing cyclohexane by using air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing cyclohexane is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the cyclohexane in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the cyclohexane to carry out the oxidization reaction, meanwhile, the produced KA oil is blended with water to form a KA oil phase, the KA oil phase is settled into the constant temperature settlement tower, the cyclohexane in the constant temperature settlement tower at the moment enters the oxidization area through an external circulation system, so that the reaction is conducted continuously, the KA oil phase continues to settle in the constant temperature settlement tower until the constant temperature settlement tower is fully filled the KA oil phase, then the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the cyclohexane, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the KA oil. The method is used to continuously produce the KA oil with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:新疆普禾粟新型环保材料有限公司

A kind of low-carbon alkane isomerization catalyst and preparation method thereof

ActiveCN105709814BReduce manufacturing costHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningAlkaneIsomerization

The invention discloses a low-carbon alkane isomerization catalyst and a preparation method thereof. The method is to embed the FER type molecular sieve loaded with hydrogenation active components in organic matter, then mix evenly with the precursor of high-temperature-resistant inert oxide, shape, dry and roast to obtain a low-carbon alkane isomerization catalyst. The catalyst of the invention is used in the isomerization process of C5-C10 alkanes. Compared with the existing technology, because the amount of molecular sieve in the catalyst is greatly reduced, not only the production cost of the catalyst is greatly reduced, but also the discharge of difficult-to-treat wastewater during the synthesis of molecular sieves is avoided, and it has the characteristics of high catalytic activity and isomeric olefin selectivity. , can be used to produce blending components of high-octane gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing adipic acid by utilizing air oxidation of cyclohexane based on gas-liquid-solid heterogeneous reaction separation synchronous reactor

ActiveCN103755543BHigh yieldImprove conversion rateOrganic compound preparationCarboxylic preparation by oxidationGas phaseAdipic acid

The invention discloses a method for producing adipic acid by oxidizing cyclohexane by utilizing air based on a gas-liquid-solid multiphase reaction and separation synchronization reactor. The method is characterized by adding cyclohexane to the gas-liquid-solid multiphase reaction and separation synchronization reactor, wherein the reactor comprises a reaction tower and at least two constant temperature settling towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase zone, an oxidation zone and a gas outlet; during reaction, filling the oxidation zone and constant temperature settling towers with cyclohexane, continuously pumping air from the bottom of the oxidation zone to come into contact with cyclohexane to carry out oxidation reaction, simultaneously enabling generated adipic acid solid to enter the constant temperature settling towers through settling, at the moment, enabling cyclohexane in the constant temperature settling towers to enter the oxidation zone via an external circulation system so that reaction is continuously carried out, enabling adipic acid to continuously settle in the constant temperature settling towers until the constant temperature settling towers are filled with the adipic acid phase, and switching a reaction tower to be communicated with the other constant temperature settling tower filled with cyclohexane, thus alternating the steps to carry out continuous production. The method can be used for continuously producing adipic acid with high conversion rate and high yield, and has the effects of improving the production efficiency and reducing the production cost.

Owner:蚌埠启邦科技信息咨询有限公司

A kind of preparation method of paraffin hydrocarbon type-selective isomerization catalyst

ActiveCN105582983BHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningIsomerizationActive component

The invention discloses a preparation method of a paraffin hydrocarbon type-selective isomerization catalyst, which includes the following contents: (1) loading active components on a macropore pore-forming agent, and then drying to obtain a modified pore-forming agent; (2) ) MTT-type small-grain molecular sieves, precursors of refractory oxides, modified pore-forming agents, peptizers and water are kneaded, dried and roasted to obtain catalyst products. The preparation process of the method is simple, the cost is low, and the catalyst product is used in the paraffin hydrocarbon type-selective isomerization reaction, and has the characteristics of high yield of the target product and low pour point.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com