Method for producing substituted benzyl alcohol, substituted benzaldehyde and substituted benzyl acid through oxidizing substituted methylbenzene with air based on gas-liquid-solid heterogeneous reaction separation synchronization reactor

A multiphase reaction and air oxidation technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, separation/purification of carbonyl compounds, etc., can solve the problems of large energy consumption and increase the difficulty of product separation, so as to improve the conversion The effect of high-yield and high-yield continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

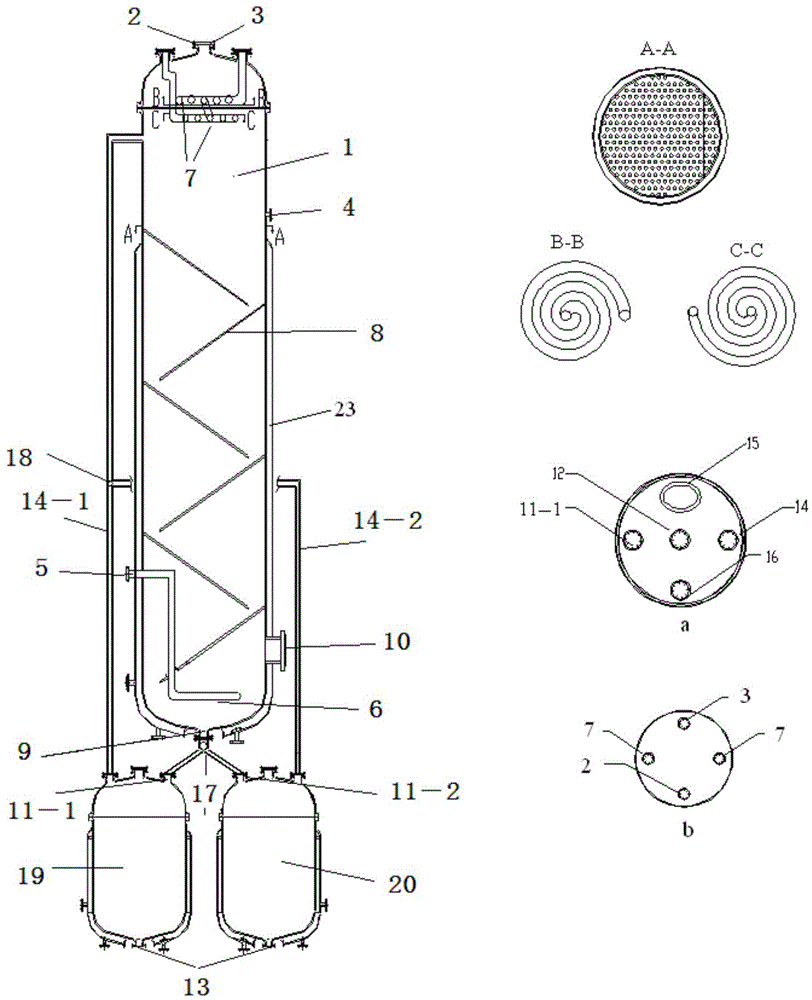

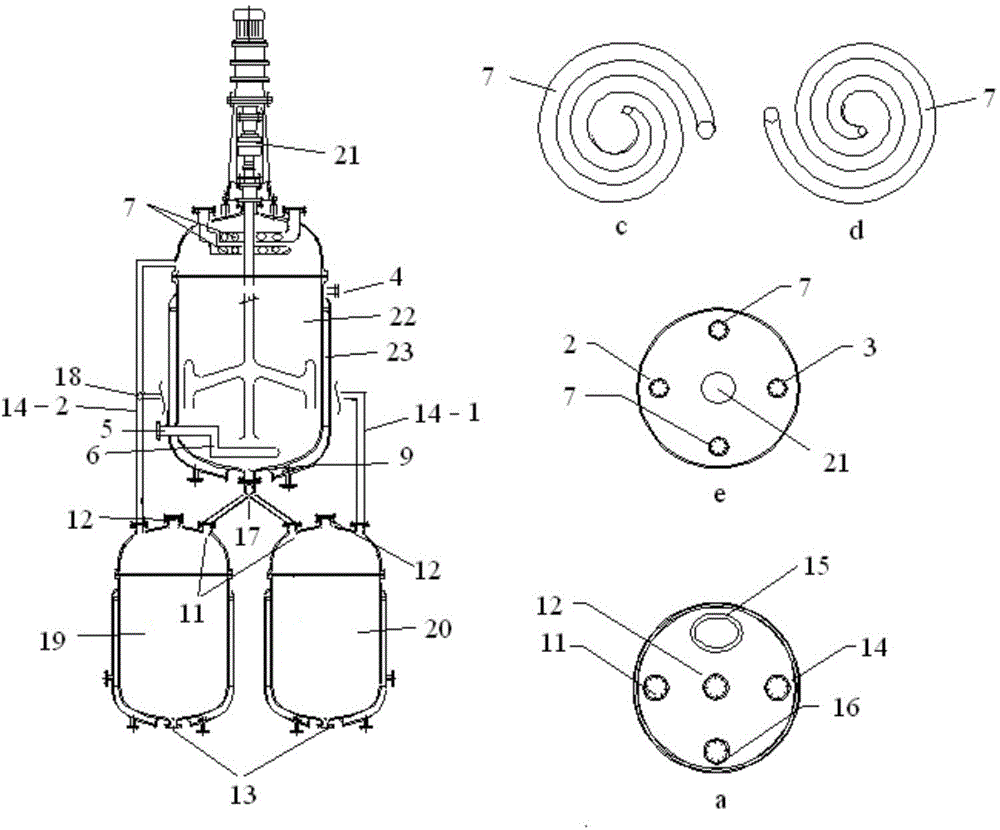

[0034] use figure 1 The shown gas-liquid-solid multiphase reaction separation synchronous reactor carries out the air oxidation of toluene to prepare benzyl alcohol, benzaldehyde and benzoic acid products; wherein, the ratio of diameter to height of the bubbling gravity reaction tower is 1:20; The diameter ratio is 1:0.8; the angle of the gravity settling plate along the tower axis is 75°; there is a constant temperature settling tower Ⅰ

[0035] Two constant temperature settling towers and constant temperature settling tower II; the outlet of the reaction liquid is 2 / 5 of the height of the tower body from the top of the reaction tower.

[0036] Cobalt tetraphenylporphyrin (concentration up to 10ppm) is added to the toluene raw material with a water content of 1wt% as a catalyst. In the oxidation zone of the settling tower Ⅰ and the bubbling gravity reaction tower, the tee on the pressure balance pipe and the tee pipe at the bottom of the bubbling gravity reaction tower are c...

Embodiment 2

[0040] Attached figure 1 The shown gas-liquid-solid multiphase reaction separation synchronous reactor carries out the air oxidation of p-chlorotoluene to prepare p-chlorobenzyl alcohol, aldehyde and acid products; wherein, the diameter-to-height ratio of the bubbling gravity reaction tower is 1:40; the length of the gravity settling plate The ratio to the diameter of the tower is 1:1.2; the included angle of the gravity settling plate along the tower axis is 45°; there are two constant temperature settling towers, the constant temperature settling tower I and the constant temperature settling tower II; the outlet of the reaction liquid is 3 / 7 away from the top of the reaction tower At the height of the tower.

[0041] Add tetra-p-chlorophenylporphyrin iron μ-dimer (concentration up to 5ppm) and tetraphenylporphyrin manganese (concentration up to 5ppm) into the p-chlorotoluene raw material with a water content of 2wt% as a compound catalyst, and the mixture starts from The re...

Embodiment 3

[0045] Attached figure 1 The shown gas-liquid-solid multiphase reaction separation synchronous reactor carries out the air oxidation of p-nitrotoluene to prepare p-nitrobenzyl alcohol, aldehyde and acid products; wherein, the ratio of diameter to height of the bubbling gravity reaction tower is 1:35; gravity sedimentation The ratio of the length of the plate to the diameter of the tower is 1:1.2; the inclination angle of the gravity settling plate along the tower axis is 55°; there are two constant temperature settling towers, the constant temperature settling tower I and the constant temperature settling tower II; the outlet of the reaction liquid is 1 / 3 at the height of the tower.

[0046] Cobalt acetate (concentration up to 100ppm) is added as a catalyst to p-nitrotoluene raw material with a water content of 2wt%. In the oxidation zone of tower I and the bubbling gravity reaction tower, connect the tee on the pressure balance pipe and the tee pipe at the bottom of the bub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com