a c 8 Preparation method of aromatic hydrocarbon isomerization catalyst

A technology for isomerization and catalyst of aromatic hydrocarbons, which is applied in the field of preparation of isomerization catalysts, can solve problems such as unreasonable pore structure, poor activity and diffusion performance, unsatisfactory location of hydrogenation active components, etc., to achieve increased diffusion speed, Enhanced activity and selectivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve chloroplatinic acid containing 0.3 g of platinum in 6 g of water, fully mix 10 g of 200-mesh cellulose with the above solution, and dry the mixture at 80°C for 6 hours to obtain platinum-loaded cellulose.

[0026] (2) 45 grams of EU-1 molecular sieve (particle size 0.3 microns, SiO 2 / Al 2 o 3 The molar ratio is 35), 72 grams (dry basis 76%) aluminum hydroxide is SB powder, the cellulose that loads platinum prepared in step (1), 50ml concentration is that the nitric acid solution of 0.2M and 30ml water are fully kneaded, make it become The paste-like plastic material is shaped into a cylindrical strip with a diameter of 1.5 mm on an extruder, and the cylindrical strip is dried at 110° C. for 8 hours, and then calcined at 650° C. for 4 hours in an air atmosphere to obtain a catalyst. The catalyst is composed of Pt: 0.3%, EU-1: 45%, pore-forming agent: 10%, alumina: balance. The pore volume of the catalyst with a pore diameter of 1-10nm accounts for 7.51% o...

Embodiment 2

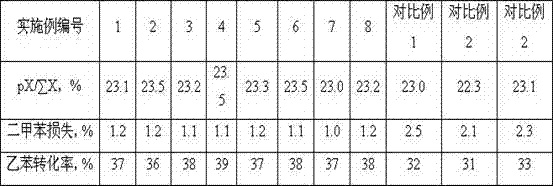

[0029] With embodiment 1, difference is that substance content is adjusted in each step, ZSM-50 (particle diameter is 0.7 micron, SiO 2 / Al 2 o 3 The molar ratio is 40) to replace the EU-1 molecular sieve to obtain a catalyst composition of Pt: 0.02%, ZSM-50: 30%, pore-forming agent: 10%, and alumina: the balance. See Table 2 for the evaluation results.

Embodiment 3

[0031] Same as Example 1, the difference is that the substance content in each step is adjusted, and the obtained catalyst composition is Pt: 0.02%, EU-1: 35%, pore former: 10%, alumina: balance. See Table 2 for the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com