Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Adjust front and rear positions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

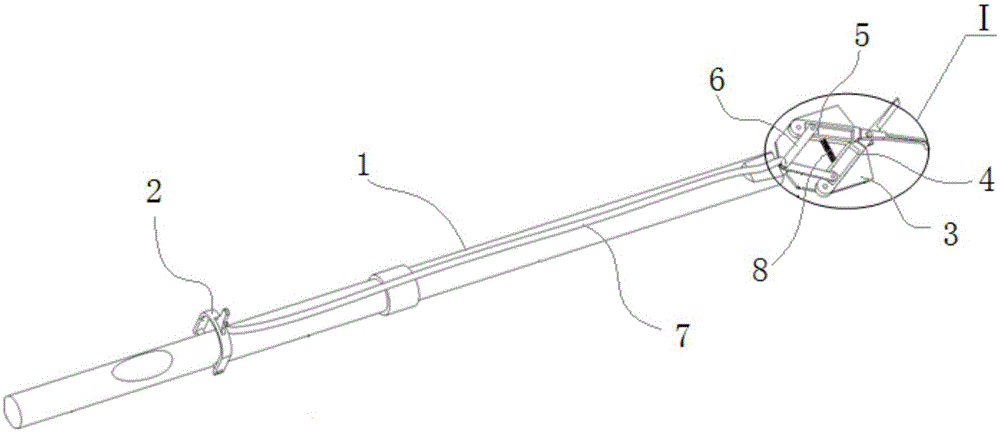

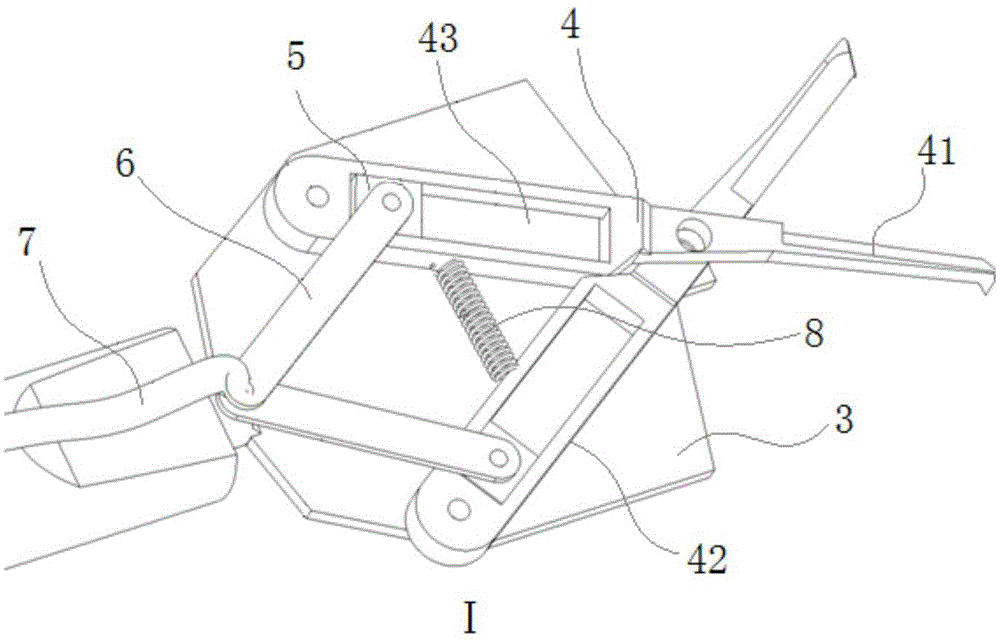

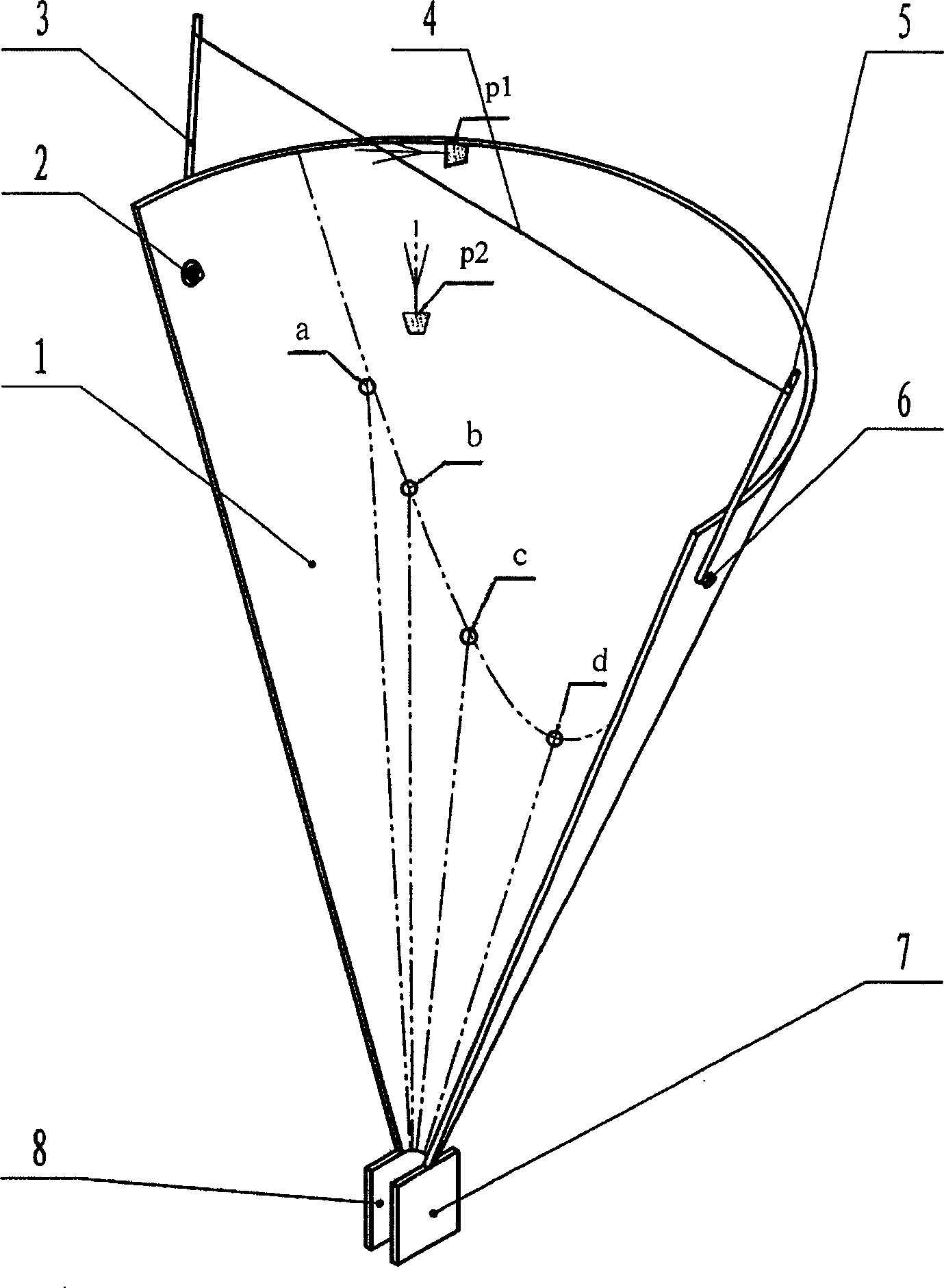

Orchard picking hand with arm of force adjustable

InactiveCN105103794AFix security issuesSolve physical exertionPicking devicesLocking mechanismEngineering

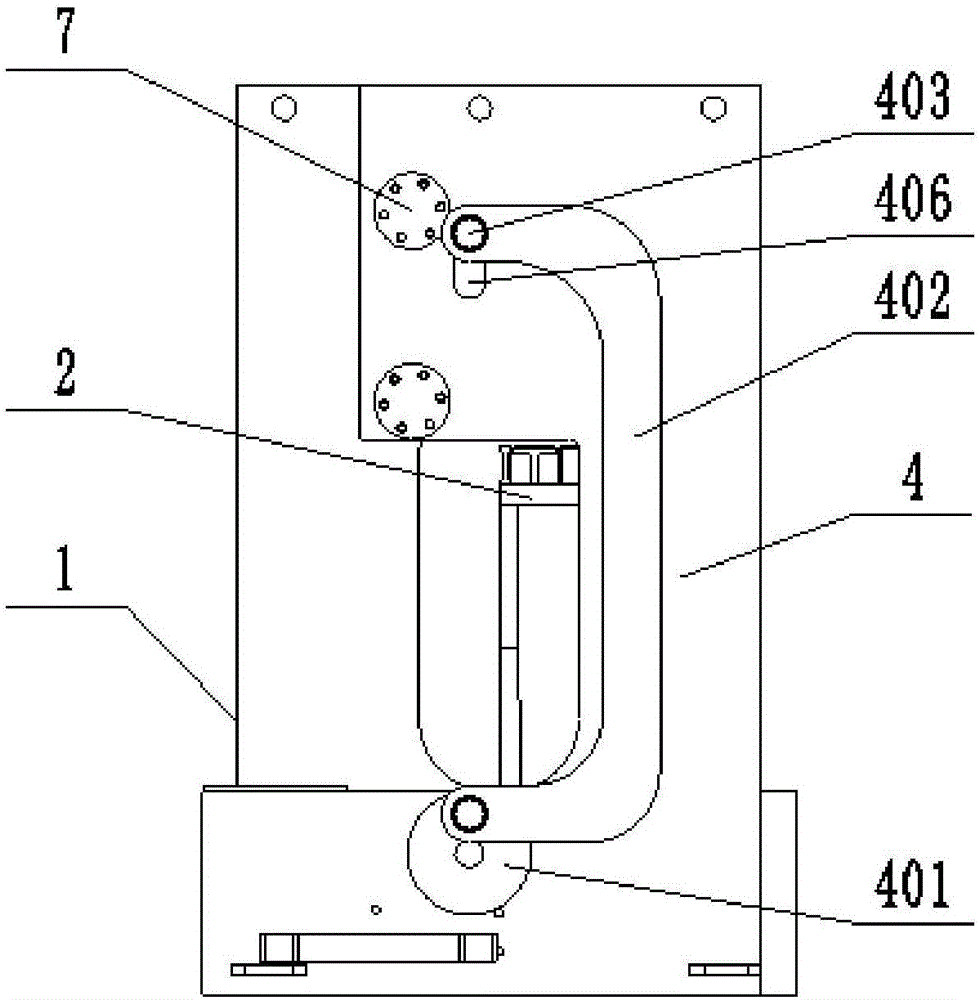

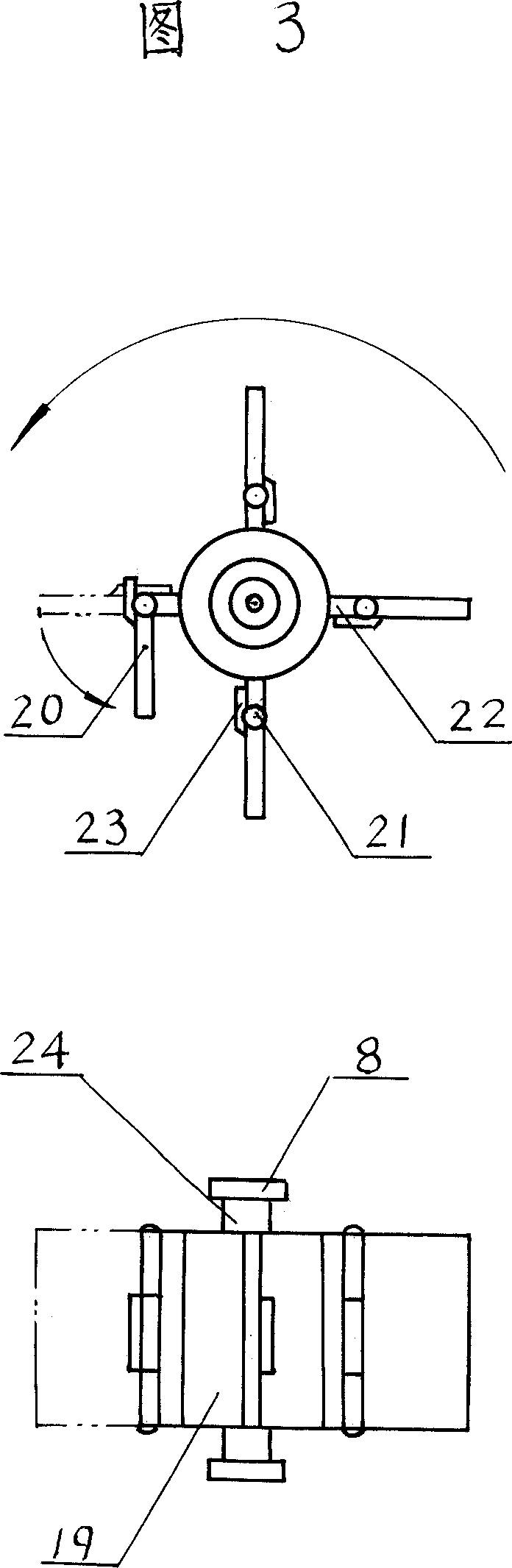

The invention discloses an orchard picking hand with the arm of force adjustable. The orchard picking hand comprises a supporting rod, a bottom plate, two shearing rods, a spring, two sliding blocks, two pull rods and a pull rope. A pull ring is arranged on the lower portion of the supporting rod, and the pull ring can swing front and back. The bottom plate is arranged at the top end of the supporting rod. The two shearing rods are crossed in the middle to be hinged to the bottom plate. Each shearing rod comprises an edge part and a rod part, wherein the edge part stretches forwards out of the bottom plate, and the rod part is provided with a sliding groove. The spring is clamped between the rod parts of the two shearing rods. The two sliding blocks are embedded in the two sliding grooves in a sliding mode respectively and fixed through locking mechanisms. The front ends of the two pull rods are hinged to the two sliding blocks respectively, and the rear ends of the two pull rods are hinged together. One end of the pull rope is connected with the hinged part of the two pull rods, and the other end of the pull rope is connected with the pull ring. According to the orchard picking hand, the arm of force of the two shearing rods can be adjusted by changing the positions of the sliding blocks in the sliding grooves, so that the orchard picking hand is suitable for picking different types of fruits, and thus adaptability is improved.

Owner:GUANGXI UNIV

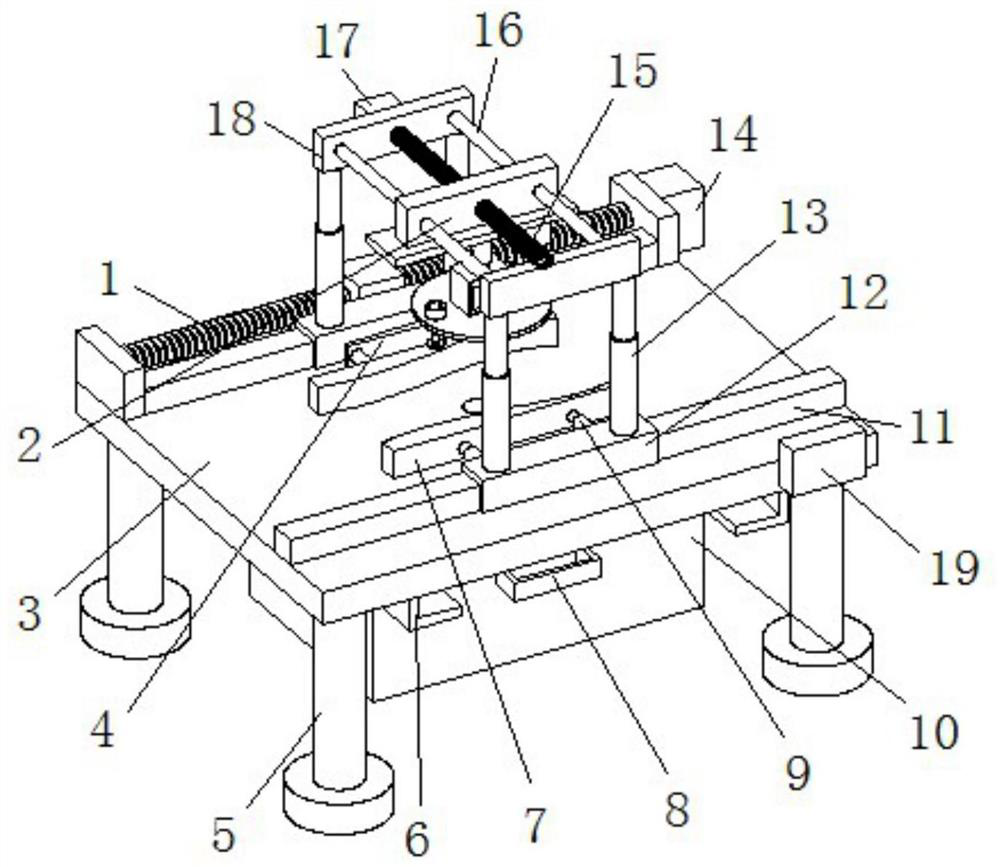

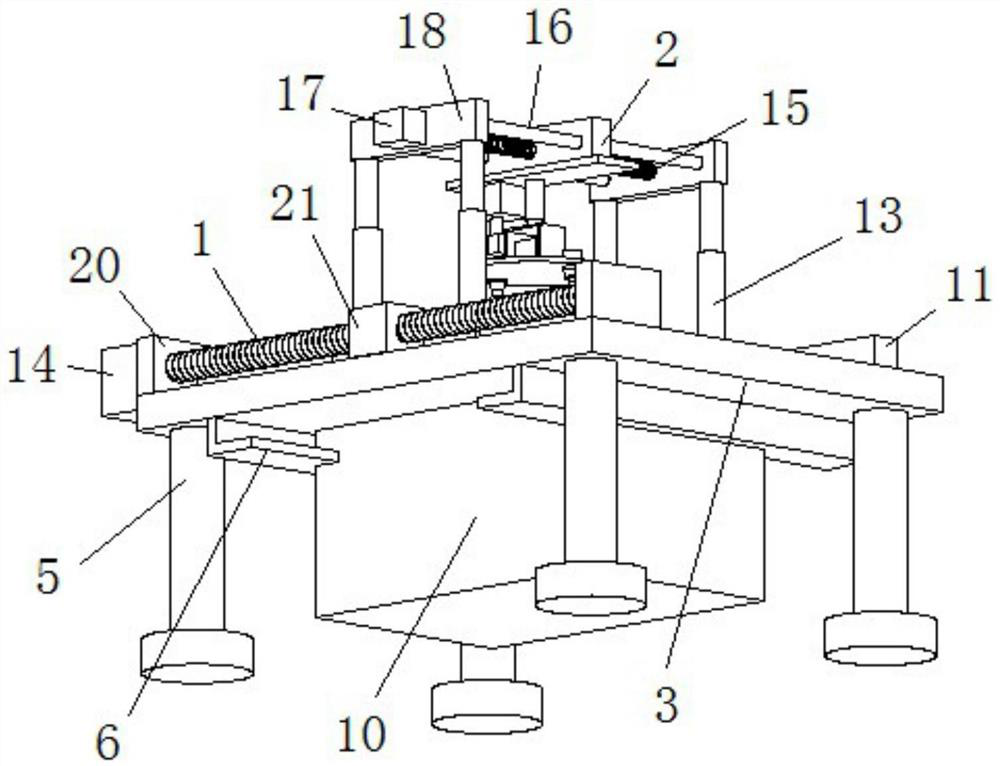

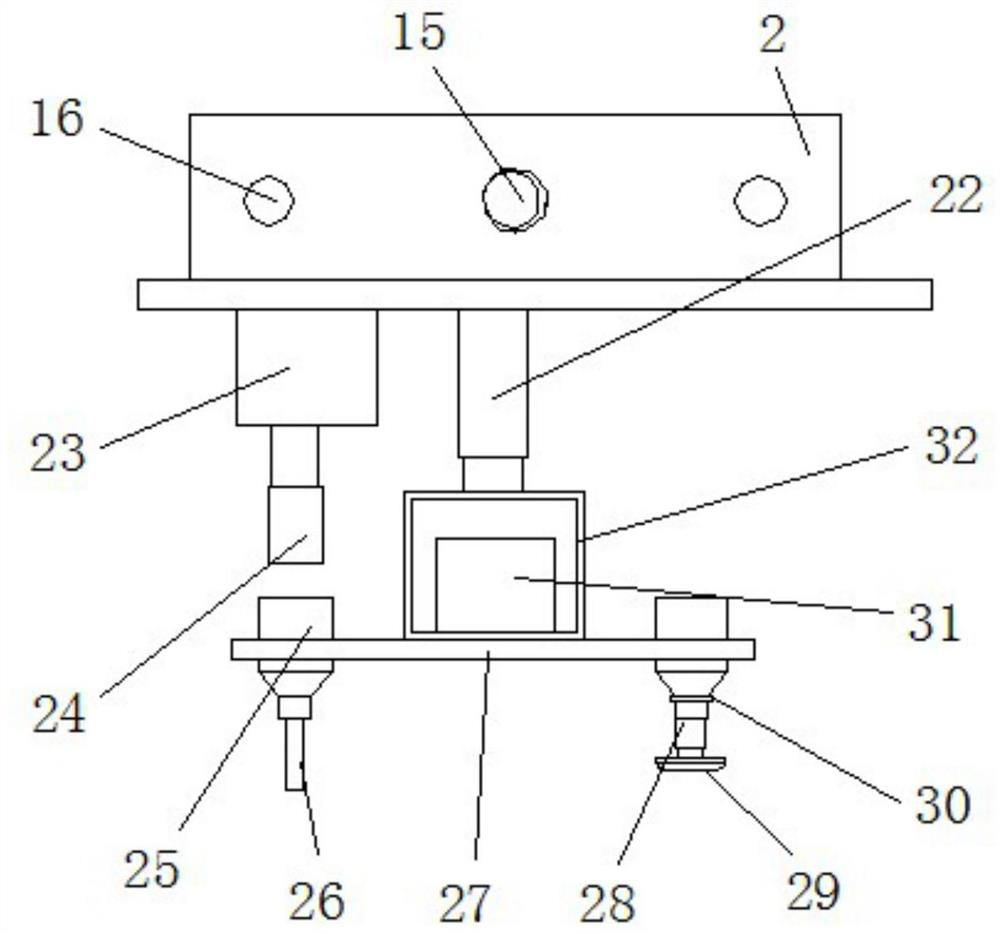

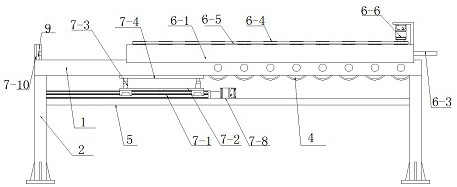

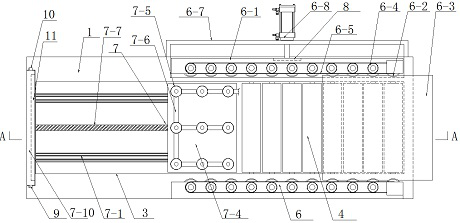

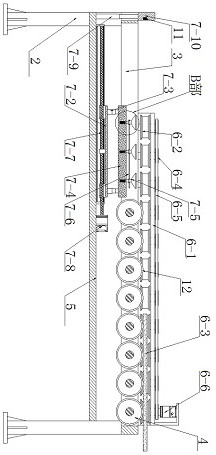

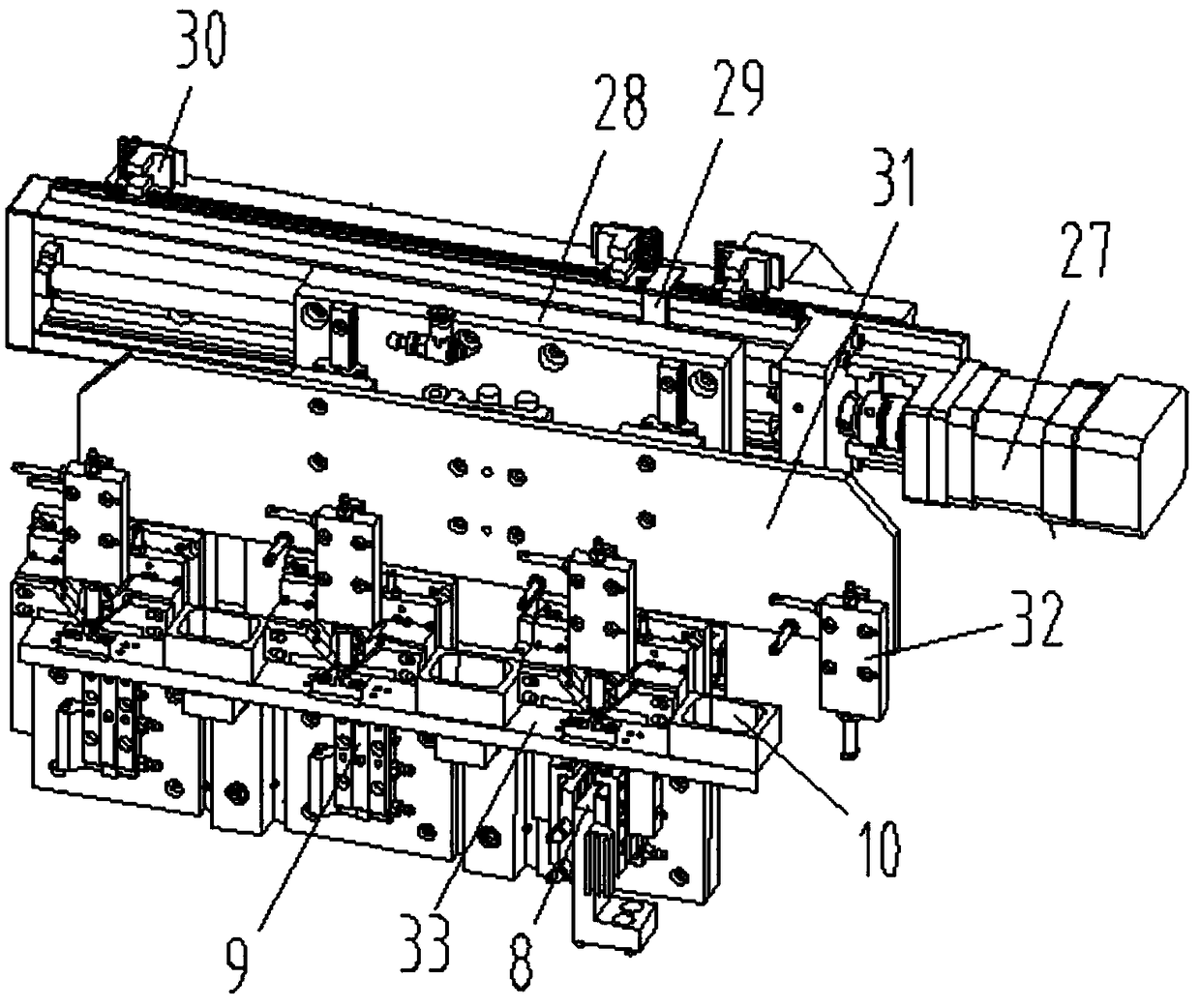

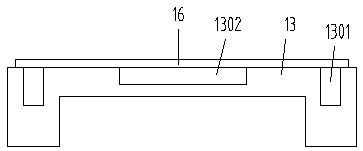

Full-automatic pliers head machining drilling and grinding machining production center

InactiveCN111993081AAdjust front and rear positionsEasy to punchMeasurement/indication equipmentsOther manufacturing equipments/toolsElectric machineryMachining

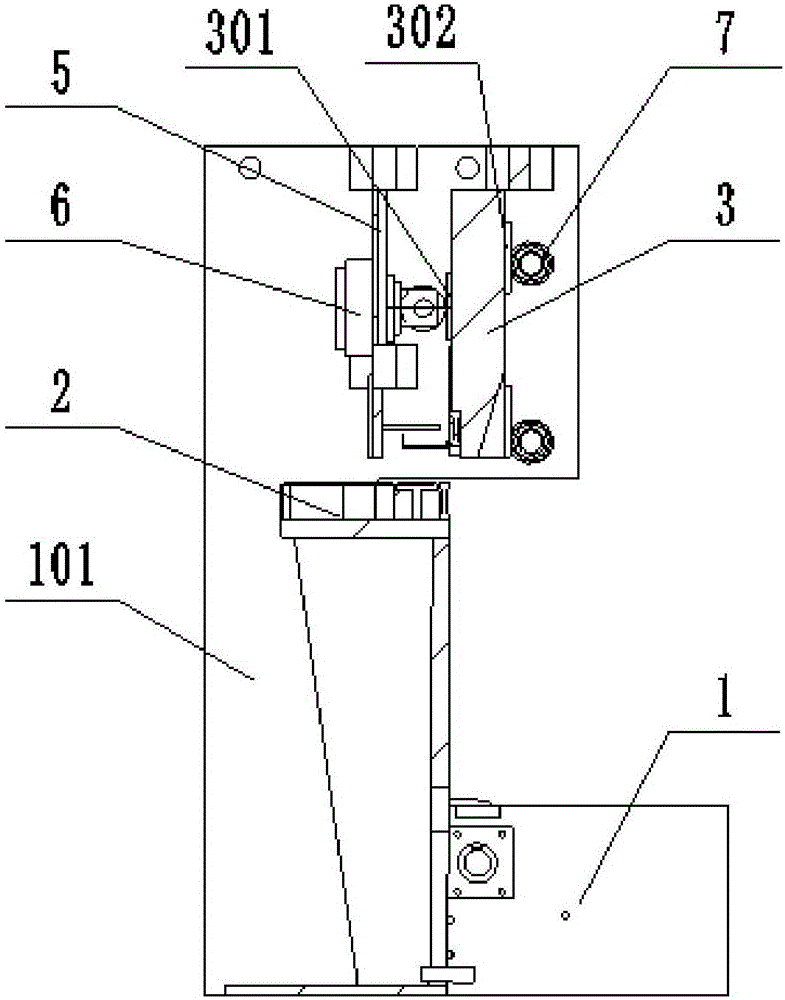

The invention discloses a full-automatic pliers head machining drilling and grinding machining production center. The full-automatic pliers head machining drilling and grinding machining production center comprises a machining working table. Two sliding rails are arranged on the front side and the rear side of the upper surface of the machining working table. A sliding connection seat in sliding connection is arranged on the sliding rails. Supporting lug plates are welded to the two ends of the rear side of the upper surface of the machining working table. A first threaded rod is connected between the two supporting lug plates in a bearing connection mode. One sides of the supporting lug plates are connected with a first motor through a bolt. An output shaft of the first motor penetrates through one sides of the supporting lug plates, and is connected with one end of the first threaded rod. The full-automatic pliers head machining drilling and grinding machining production center is simple in structure and easy and convenient to operate. A pliers head can be fixed more conveniently and can be drilled and ground, so that much manpower is saved, and convenience is brought to people.

Owner:东阳市俊华电器销售有限公司

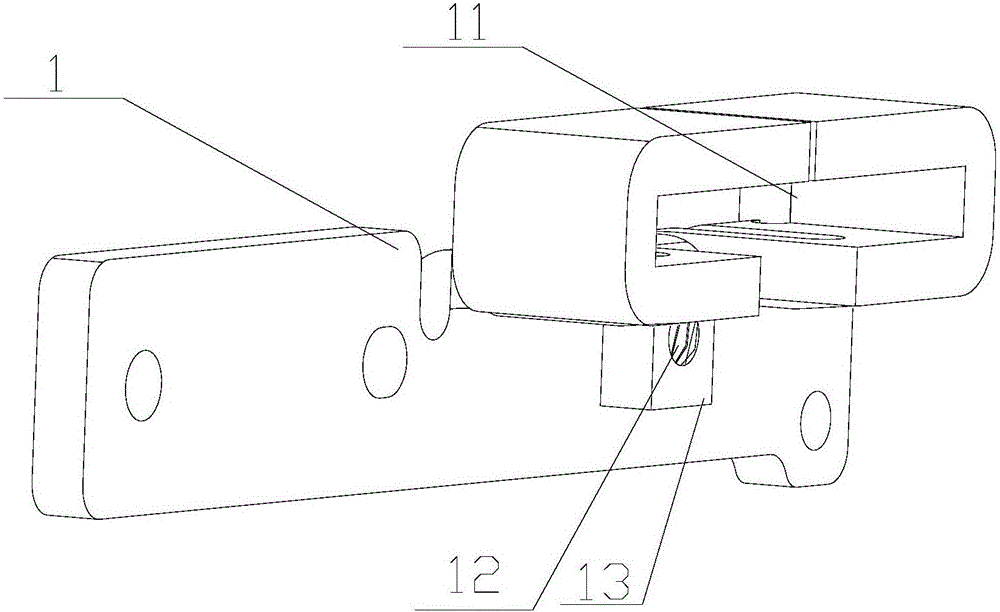

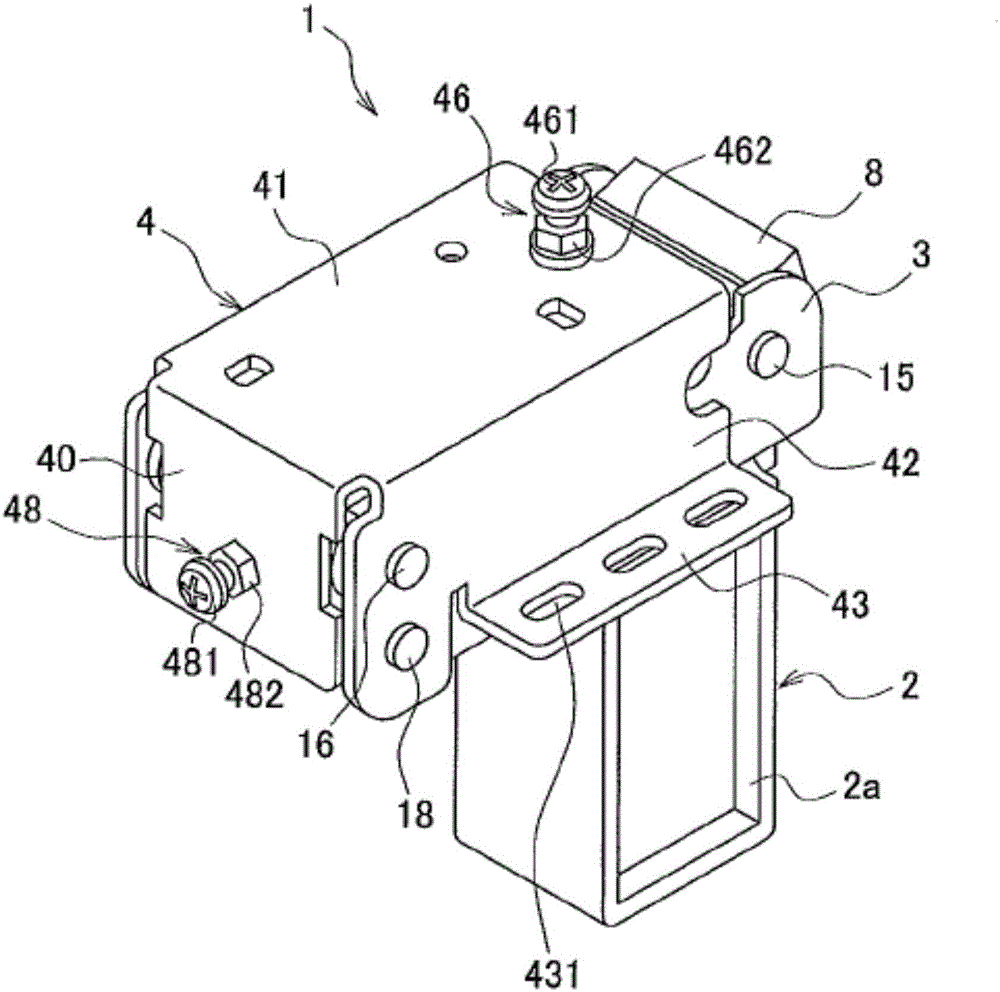

Middle hinge of refrigerator door and refrigerator with same

InactiveCN106837034ACorrect the problems on different sidesEasy to masterLighting and heating apparatusHingesEngineeringRefrigerated temperature

Owner:HEFEI HUALING CO LTD +2

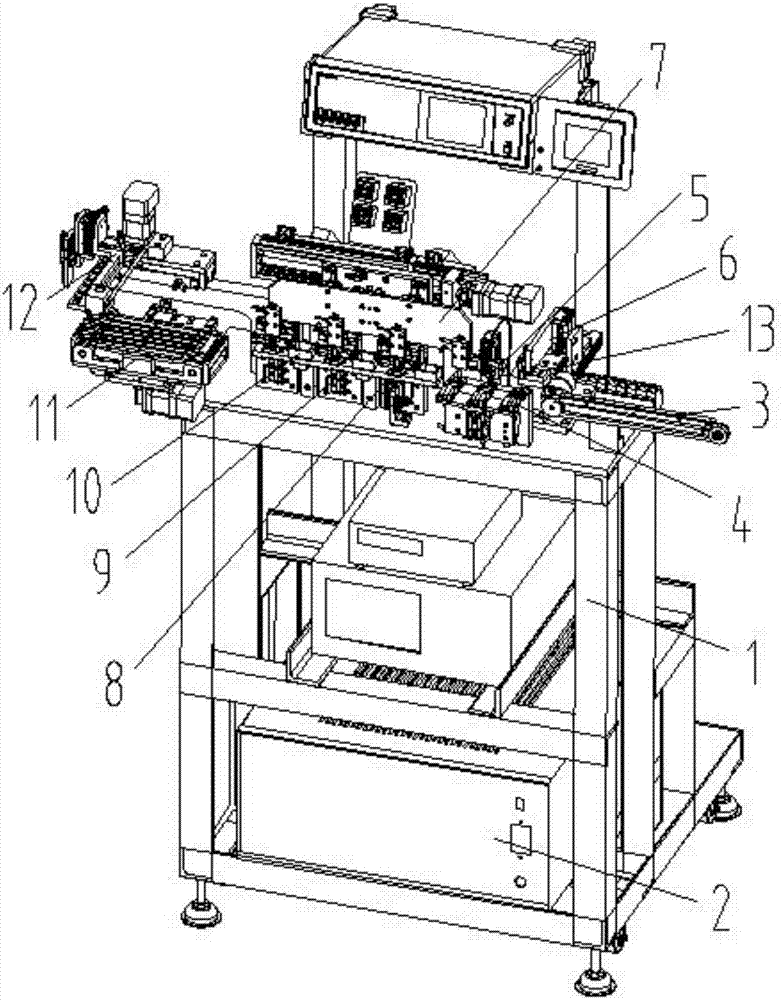

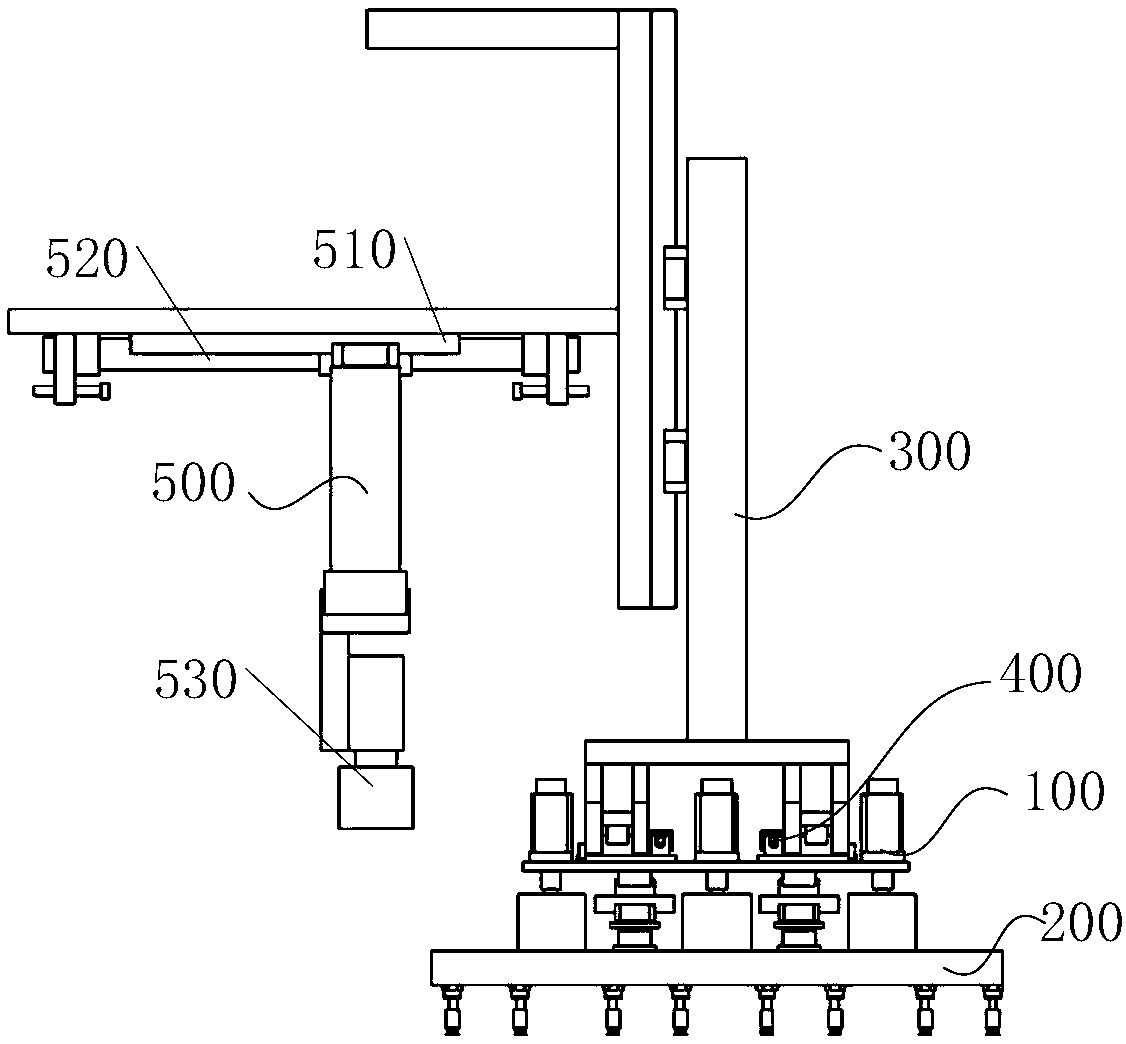

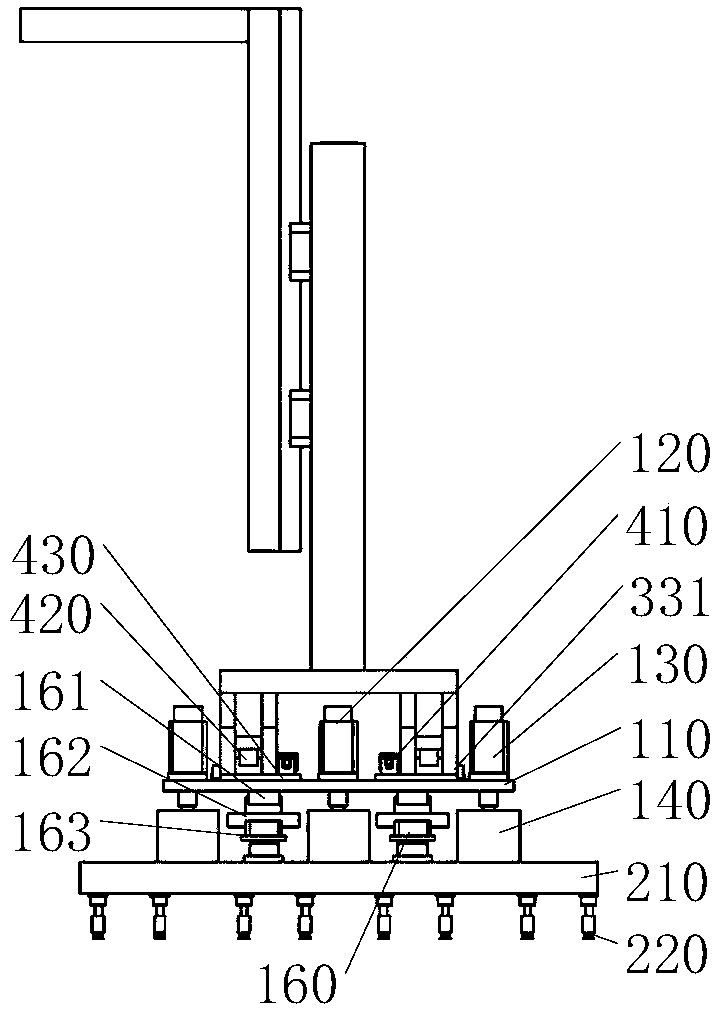

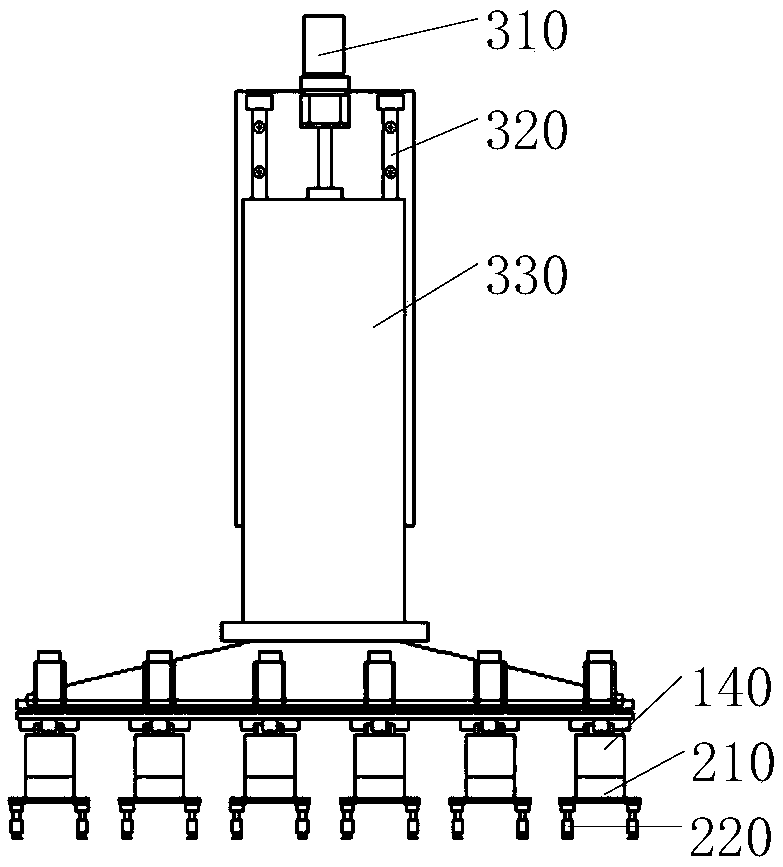

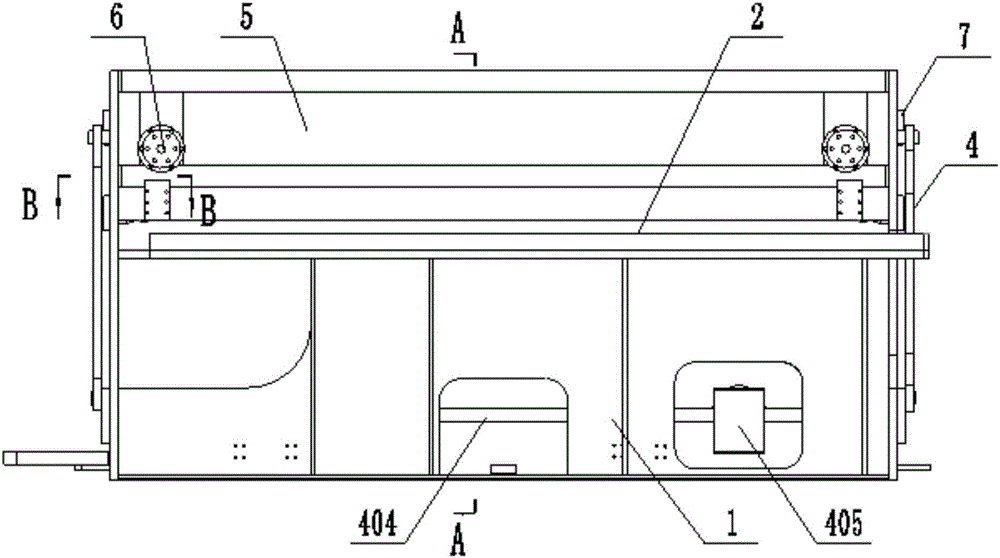

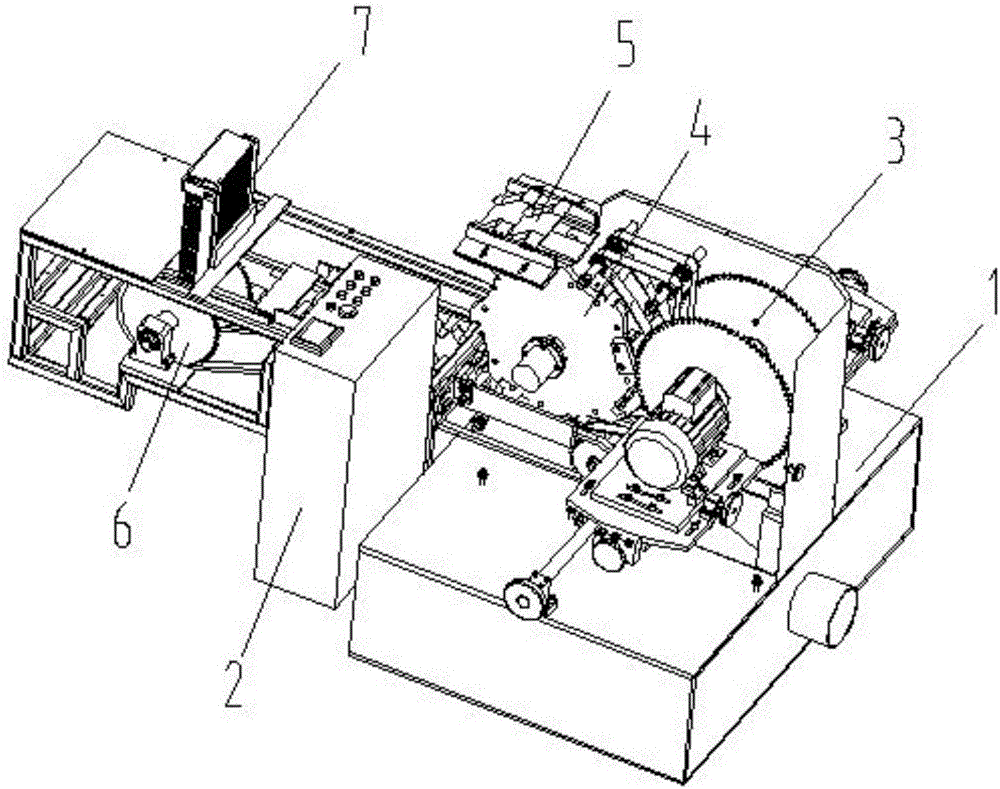

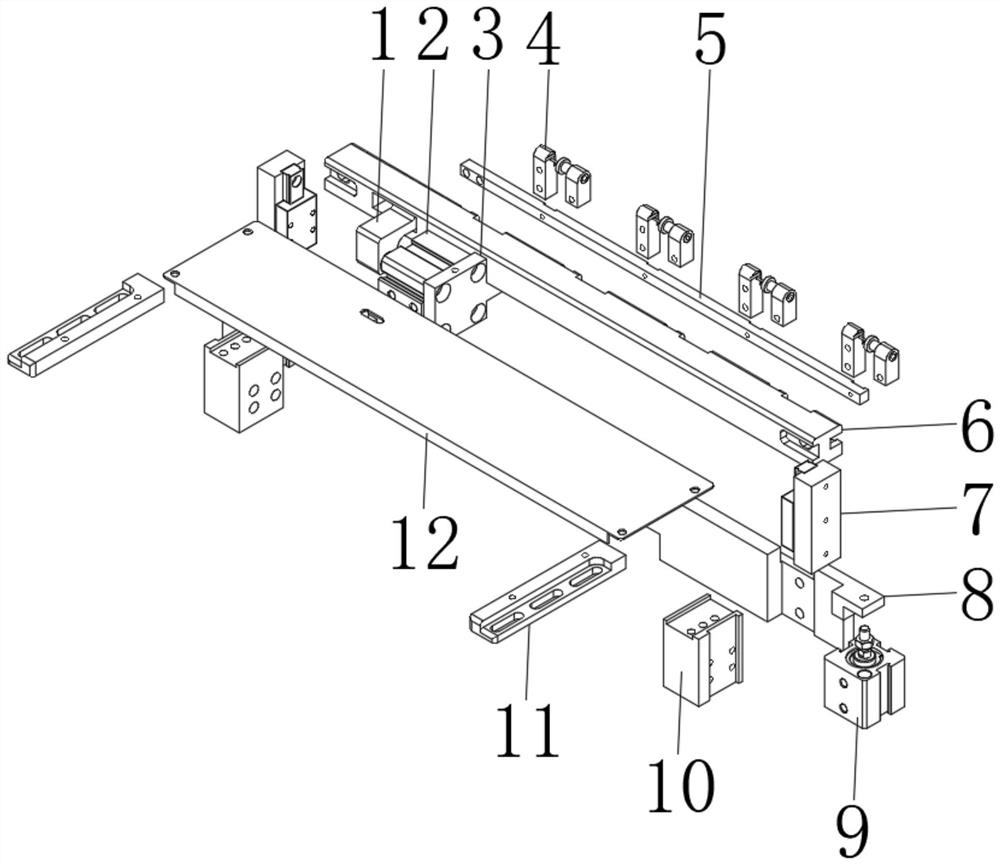

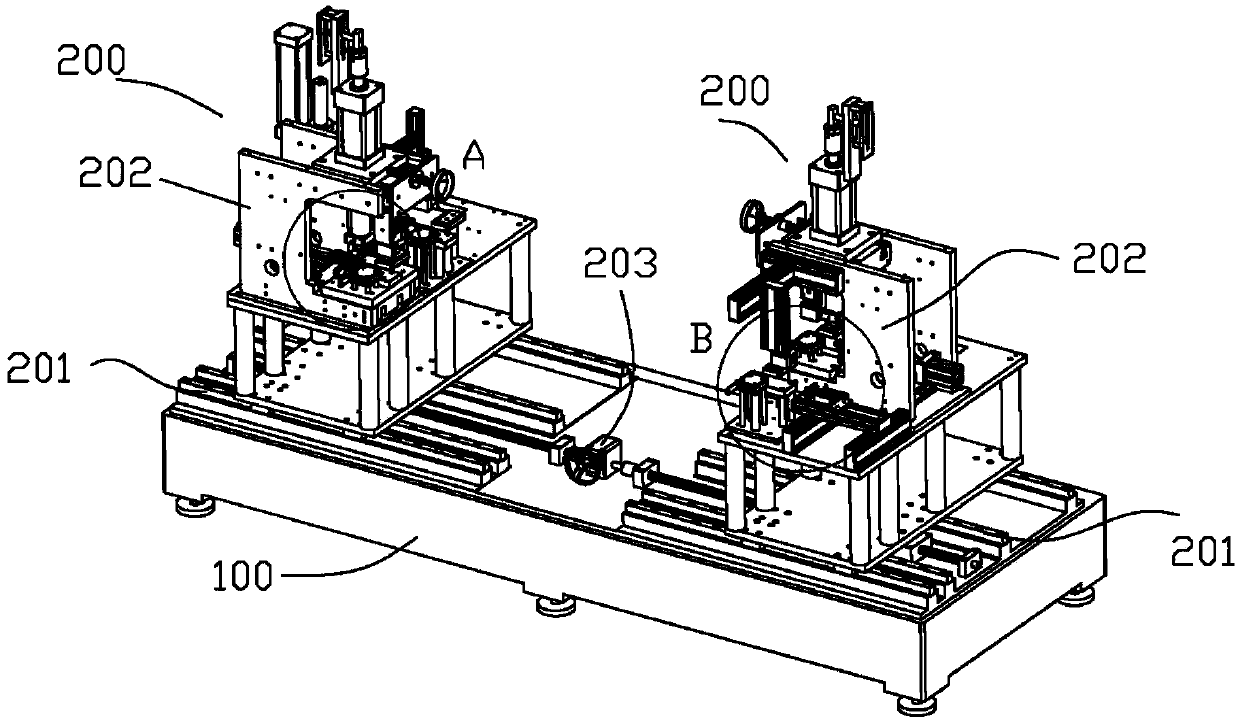

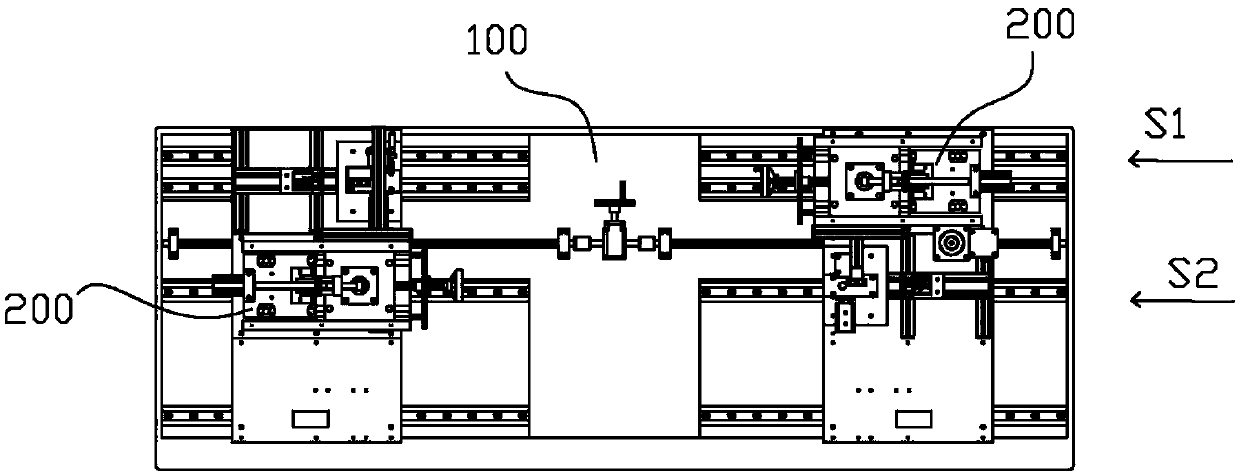

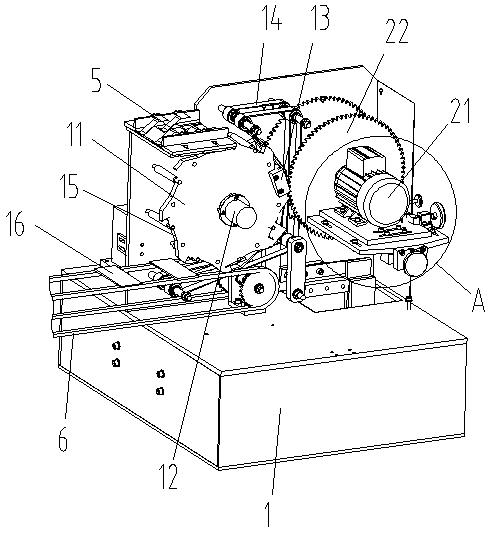

Chip resistor detecting sorting machine

ActiveCN106862101AGuaranteed accuracyGuarantee qualityElectrical testingSortingDistribution controlChip resistor

The invention relates to a chip resistor detecting sorting machine. The chip resistor detecting sorting machine comprises a machine frame and a power distribution control cabinet, wherein a feeding conveying device, an upper part detecting seat and a lower part detecting seat are sequentially arranged on the machine frame from right to left; the feeding conveying device and the upper part detecting seat are matched through an upper part detecting and taking device; the upper part detecting seat and the lower part detecting seat are matched through a lower part detecting and taking device; an upper part detecting device which is matched with products is arranged on the upper part detecting seat, wherein a CCD detecting head is used as a detecting component of the upper part detecting device; a lower part detecting device matched with the lower parts of the products is arranged on the lower part detecting seat; the lower part detecting device comprises a detecting and discharging seat arranged on the lower part detecting seat; an LCR detecting probe penetrating through the lower part of the detecting and discharging seat is arranged at the lower part of the detecting and discharging seat; and a first unqualified product collecting box is arranged at the lower part detecting seat. According to the chip resistor detecting sorting machine disclosed by the invention, automatic and integral detection for two sides of chip resistors is realized, so that the detecting accuracy is guaranteed, and the quality of subsequent finished products is guaranteed; and besides, the detecting efficiency is improved.

Owner:SHENZHEN MESTEK ELECTRONICS CO LTD

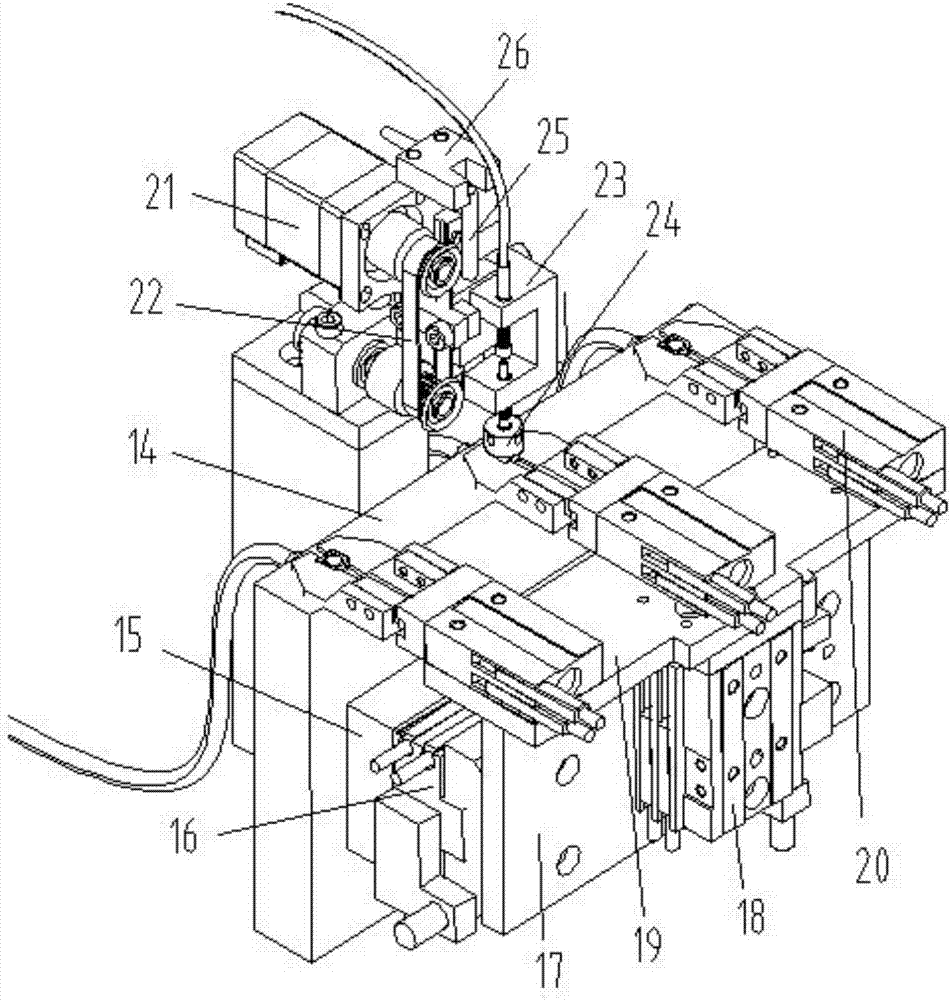

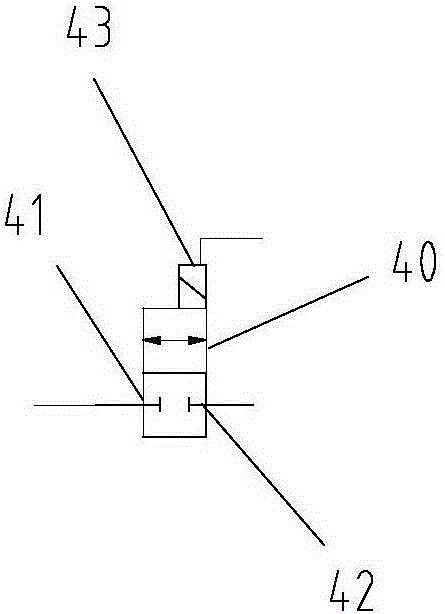

CCD regulating mechanism

The invention discloses a CCD regulating mechanism. The CCD regulating mechanism comprises a mounting base plate, a Y-direction adjusting component and a light source mounting plate, wherein the Y-direction adjusting component and the light source mounting plate are arranged on the mounting base plate. The Y-direction adjusting component is provided with an X-direction adjusting component and a camera rough positioning backup plate. The X-direction adjusting component is provided with a CCD camera component in a clamping mode. A height adjustment component is further arranged on the outer sidesurfaces of the CCD camera component and the X-direction adjustment component. The front and rear position, the photographic height and the yaw consistency of each angle during the CCD camera workingcan be adjusted and calibrated freely and flexibly by the Y-direction adjusting component, the X-direction adjusting component and the height adjusting component during operation in order to capturea target image on PCB board more accurately and record the coordinate information of each target more truthfully. By means of the CCD regulating mechanism, the positioning accuracy of a camera can beprimely improved, and the working stability of the camera by the way of mounting and fixing is primely ensured, so that the high quality and high efficiency production of the PCB circuit board is excellently guaranteed.

Owner:선전진신테크놀로지컴퍼니리미티드

Convenient-to-dismount outer lining steel bridge mounting mechanism

InactiveCN110829320AEasy to assemble and disassembleEasy to install and disassembleElectrical apparatusClassical mechanicsEngineering

Owner:ANHUI AUTOMATION INSTR

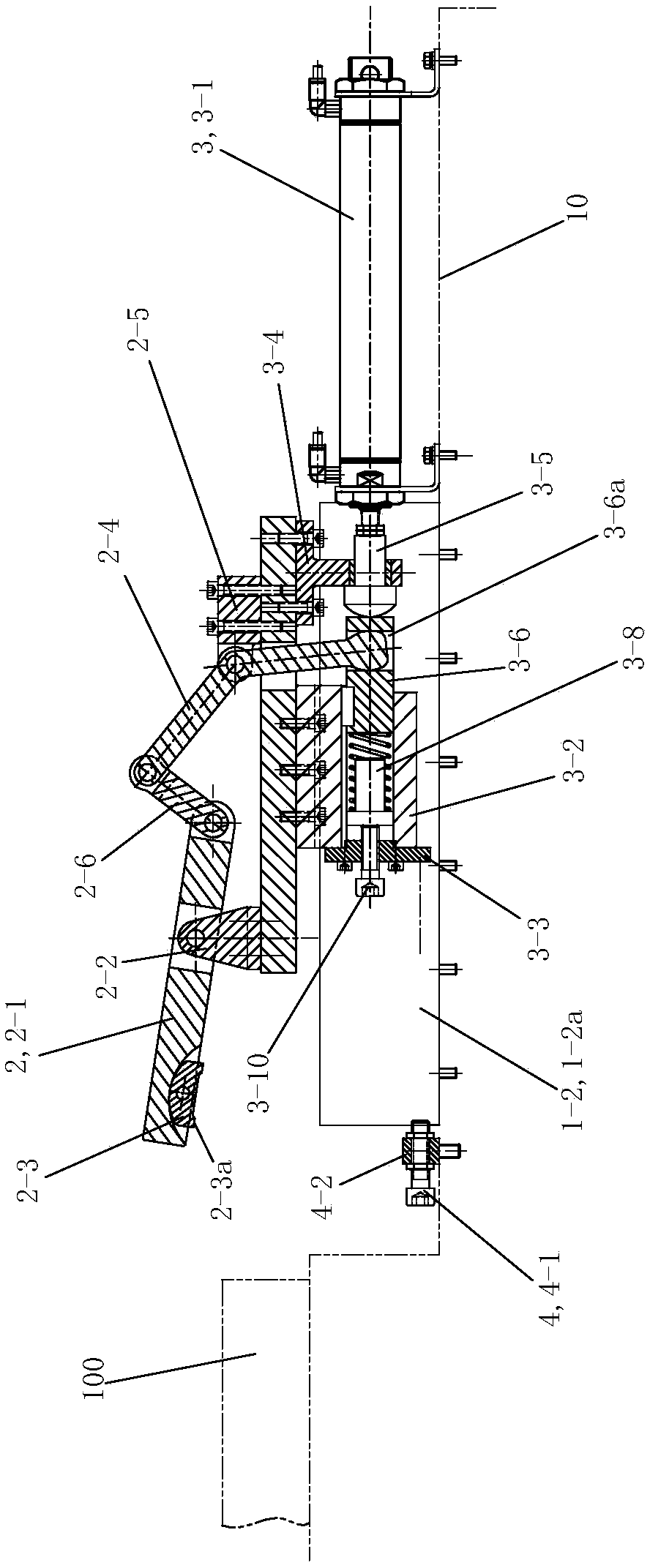

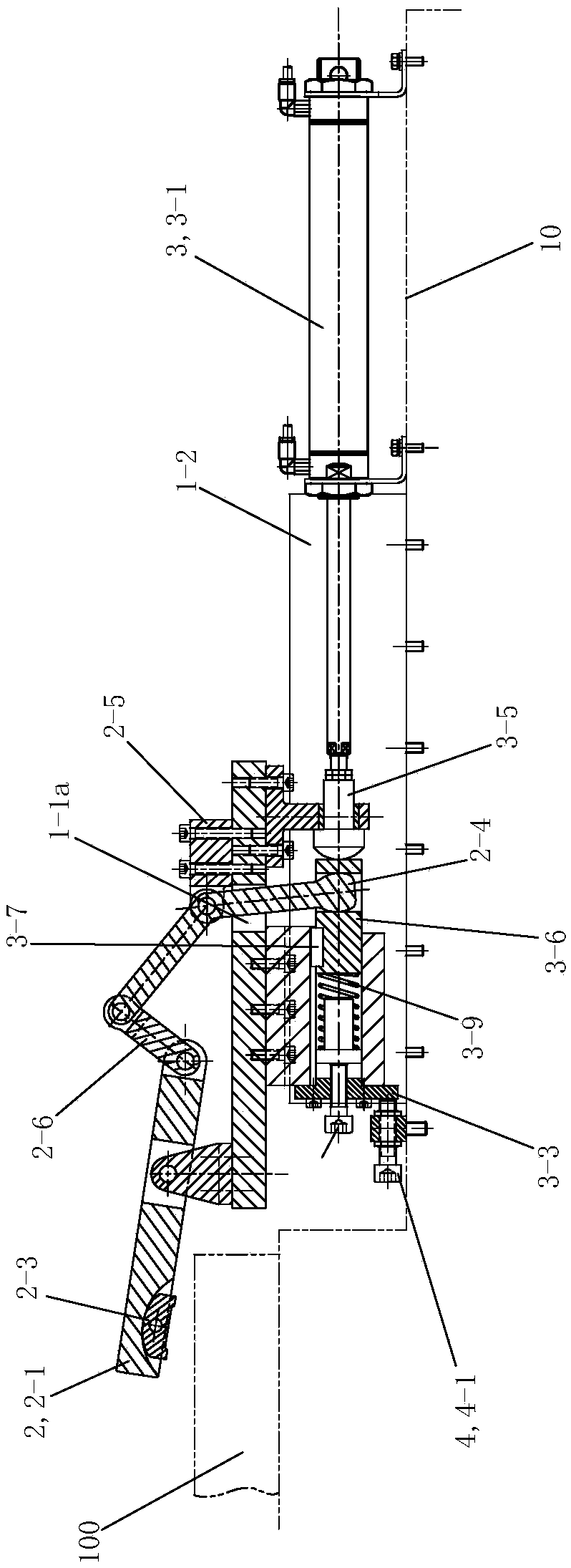

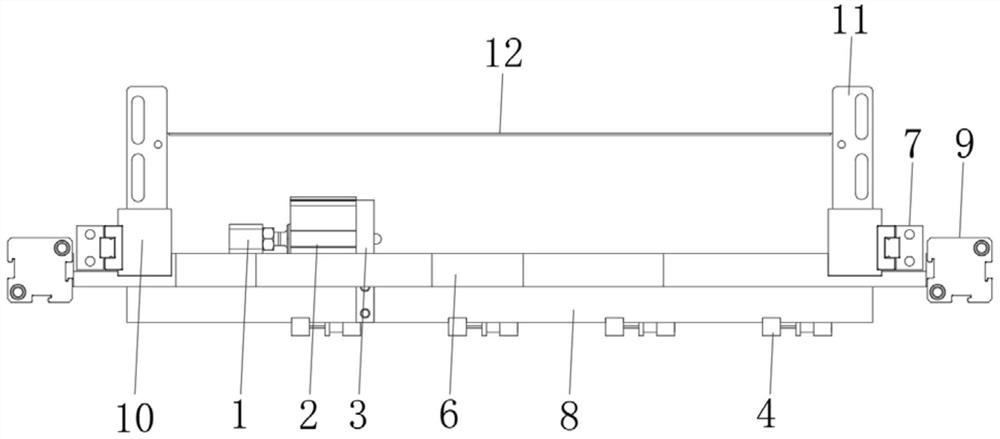

Deviation correcting device and bus bar welding all-in-one machine

PendingCN109366077AGuaranteed positioning accuracyFast solderingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringEngineering

The invention provides a deviation correcting device and a bus bar welding all-in-one machine, and relates to the technical field of battery manufacturing equipment. The deviation correcting device comprises a deviation correcting mechanism and an extracting mechanism; the deviation correcting mechanism comprises a mounting base, a first deviation correcting driving assembly and at least two setsof second deviation correcting driving assemblies; the extracting mechanism is connected with the mounting base; the first deviation correcting driving assembly is in transmission connection with theextracting mechanism and can drive the extracting mechanism to move in the left-right direction relative to the mounting base; at least two sets of second deviation correcting driving assemblies are in transmission connection with the extracting mechanism, at least two sets of second deviation correcting driving assemblies are used in a cooperated mode to each other, so that the extracting mechanism can be driven to move in the front-and-back direction and / or rotate relative to the mounting base. According to the bus bar welding all-in-one machine with the deviation correcting device, the problem that the bus bar welding all-in-one machine in the prior art cannot be used for correcting a battery string is solved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Ordered seedling-ejection guiding device

InactiveCN1742534AAccumulation-orientedAdjust the height positionTransplantingAgricultural engineeringGuide tube

The present invention discloses an orderly seedling-throwing and seedling-guiding device. It includes the following components: an inverted conical seedling-guiding tube, left and right rope bars and left and right rubber baffle plates. Said invention also provides their connection mode and concrete action of the above-mentioned every component. Said invention also provides its operation method.

Owner:ZHEJIANG SCI-TECH UNIV

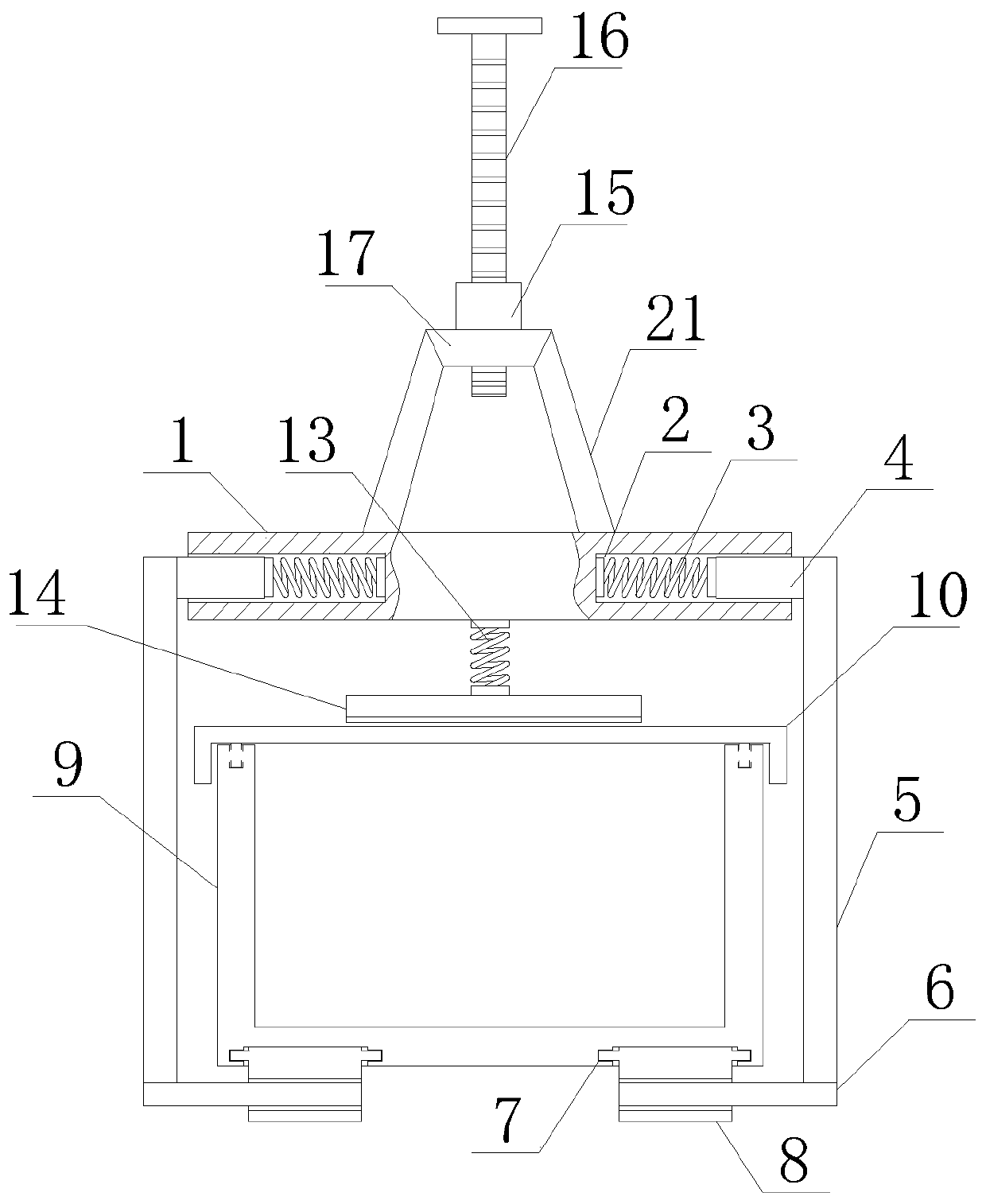

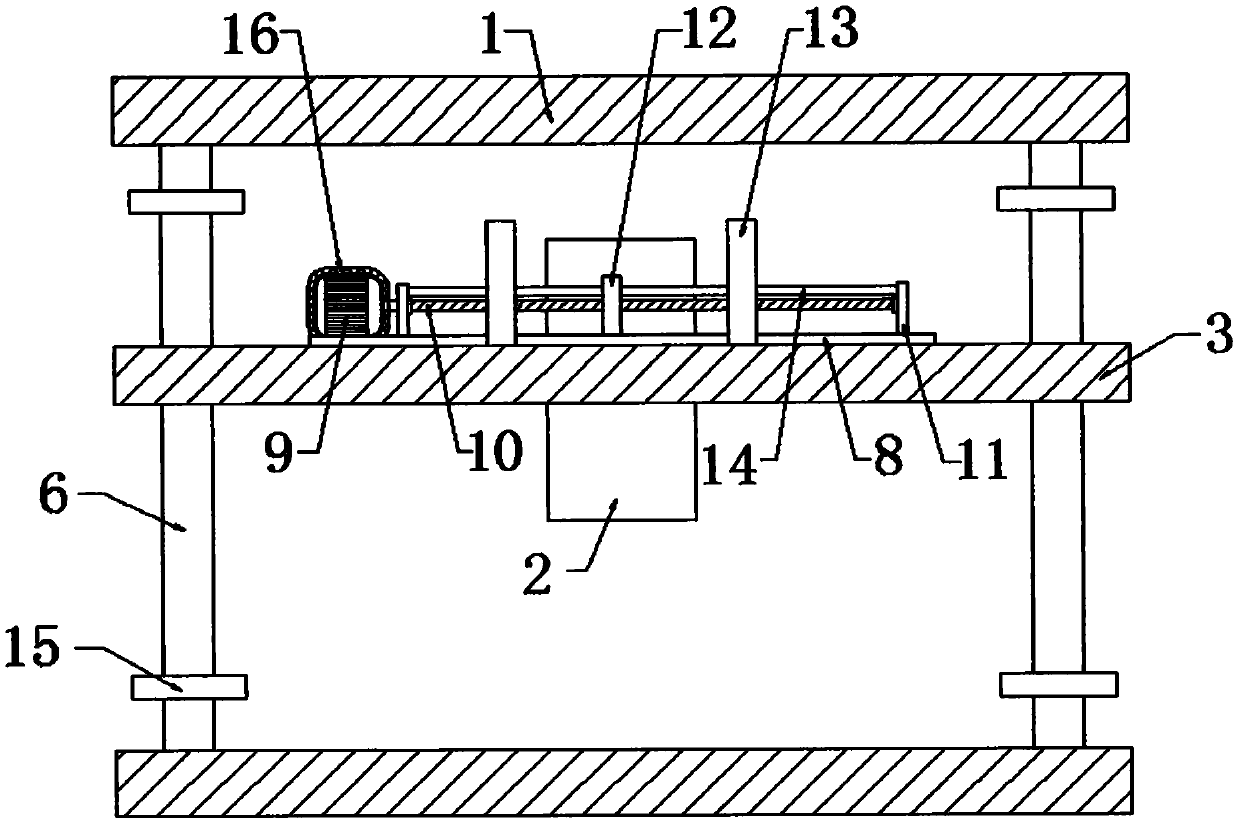

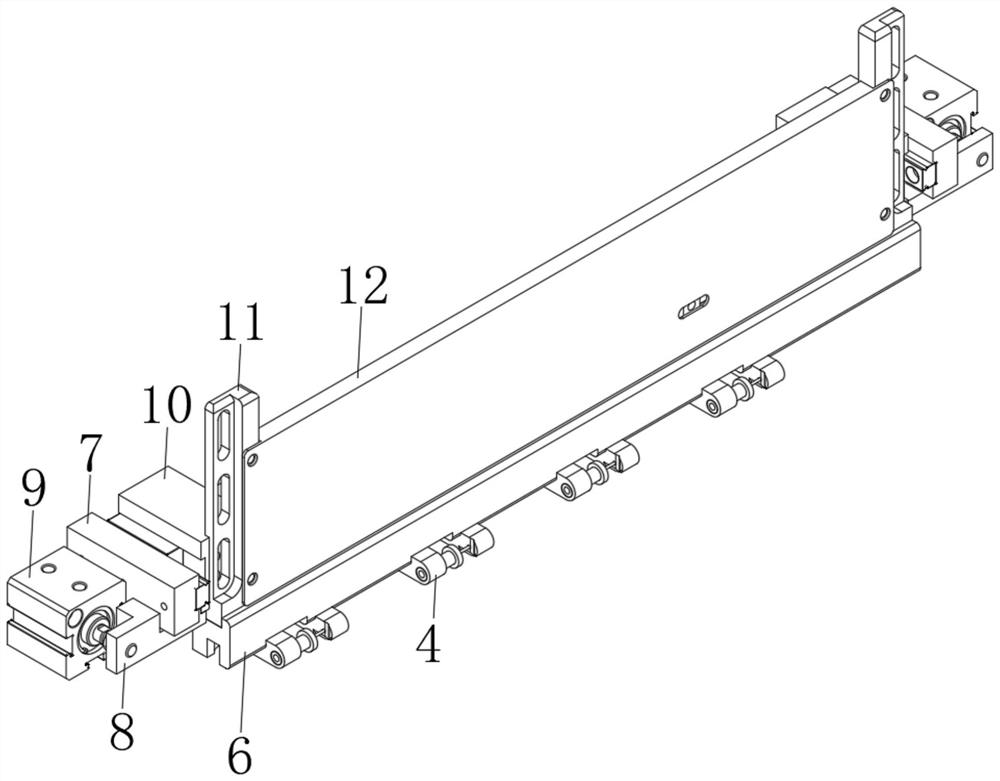

Positioning device for solar cell manufacturing

InactiveCN112259641AEasy to unloadAdjust front and rear positionsFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batteryEngineering

The invention relates to the technical field of solar cell production equipment, in particular to a positioning device for solar cell manufacturing. A plurality of conveying wheels are rotationally arranged in a mounting base at equal intervals through bearings and wheel shafts, a tempered glass plate is clamped between the conveying wheels on the front side and the rear side, and the top surfacesof conveying rollers make contact with the bottom surface of the tempered glass plate; the bottom surface of an adjusting plate is slidably arranged on a sliding rail through a sliding block; first electric push rods are symmetrically, vertically and fixedly arranged on the left side and the right side of the top face of the adjusting plate, the upper ends of the first electric push rods are fixedly arranged on the bottom face of a mounting plate, and a plurality of vacuum suction cups are arranged on the top face of the mounting plate in a matrix mode, in the conveying process of the tempered glass plate, the front and back positions of the tempered glass plate can be adjusted, and at the same time, the left and right positions of the tempered glass plate can be limited through limitingplates, the positioning accuracy is guaranteed, mechanical positioning is adopted, and the production efficiency is improved.

Owner:湖南旭昱新能源科技有限公司

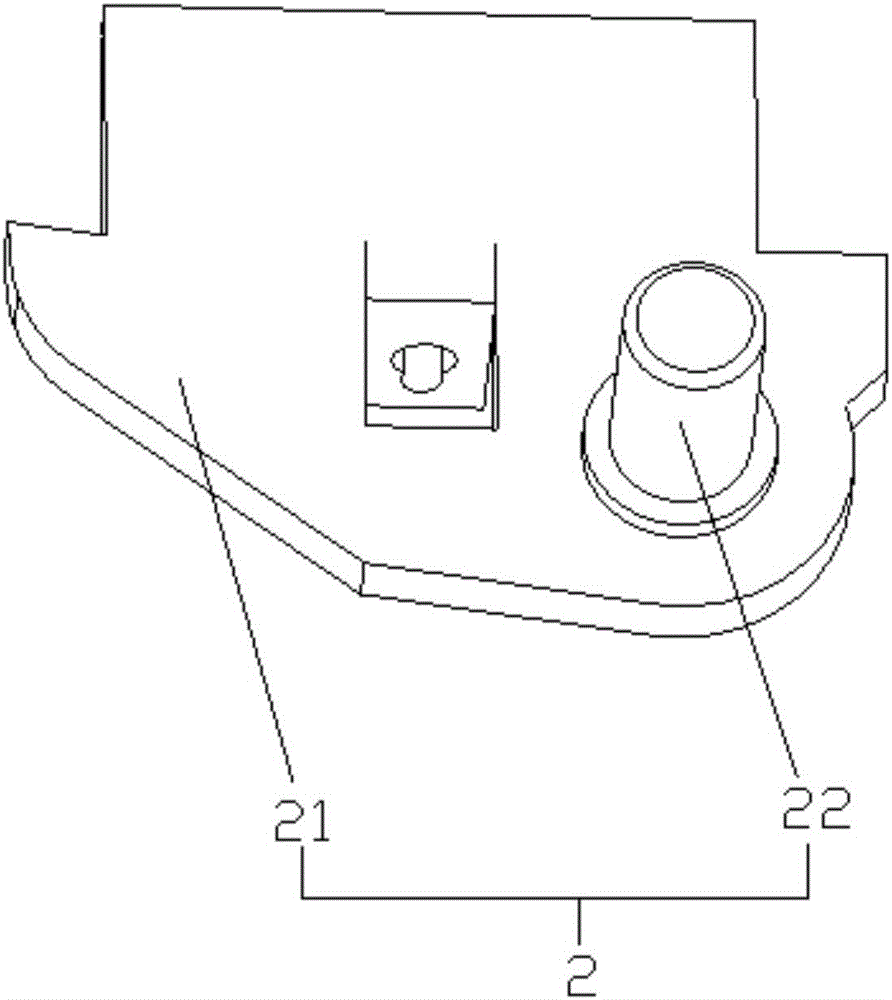

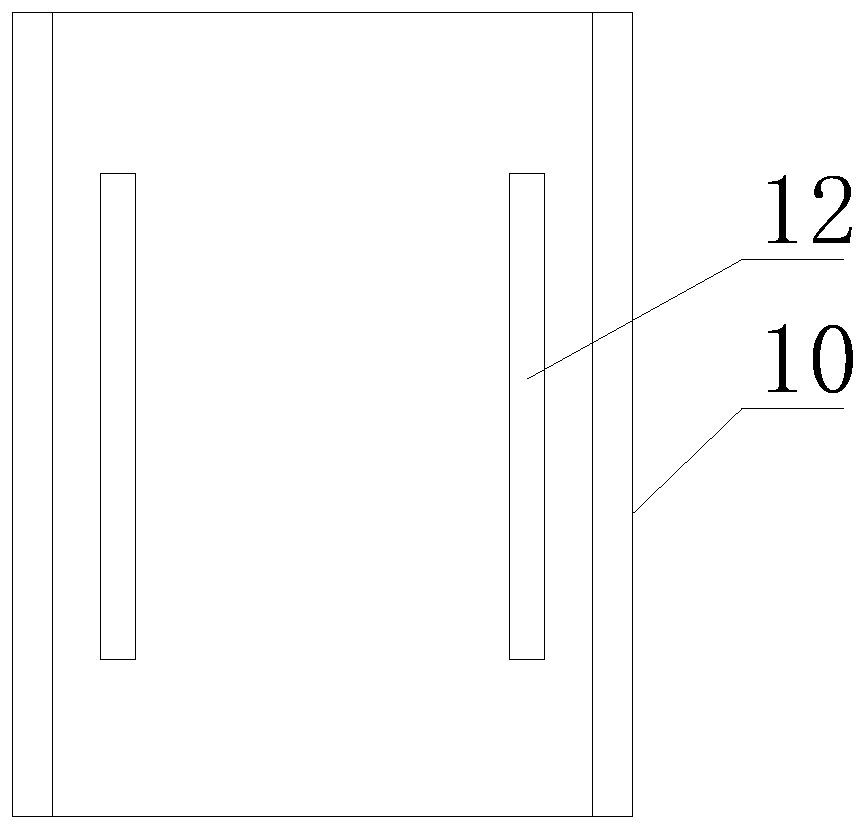

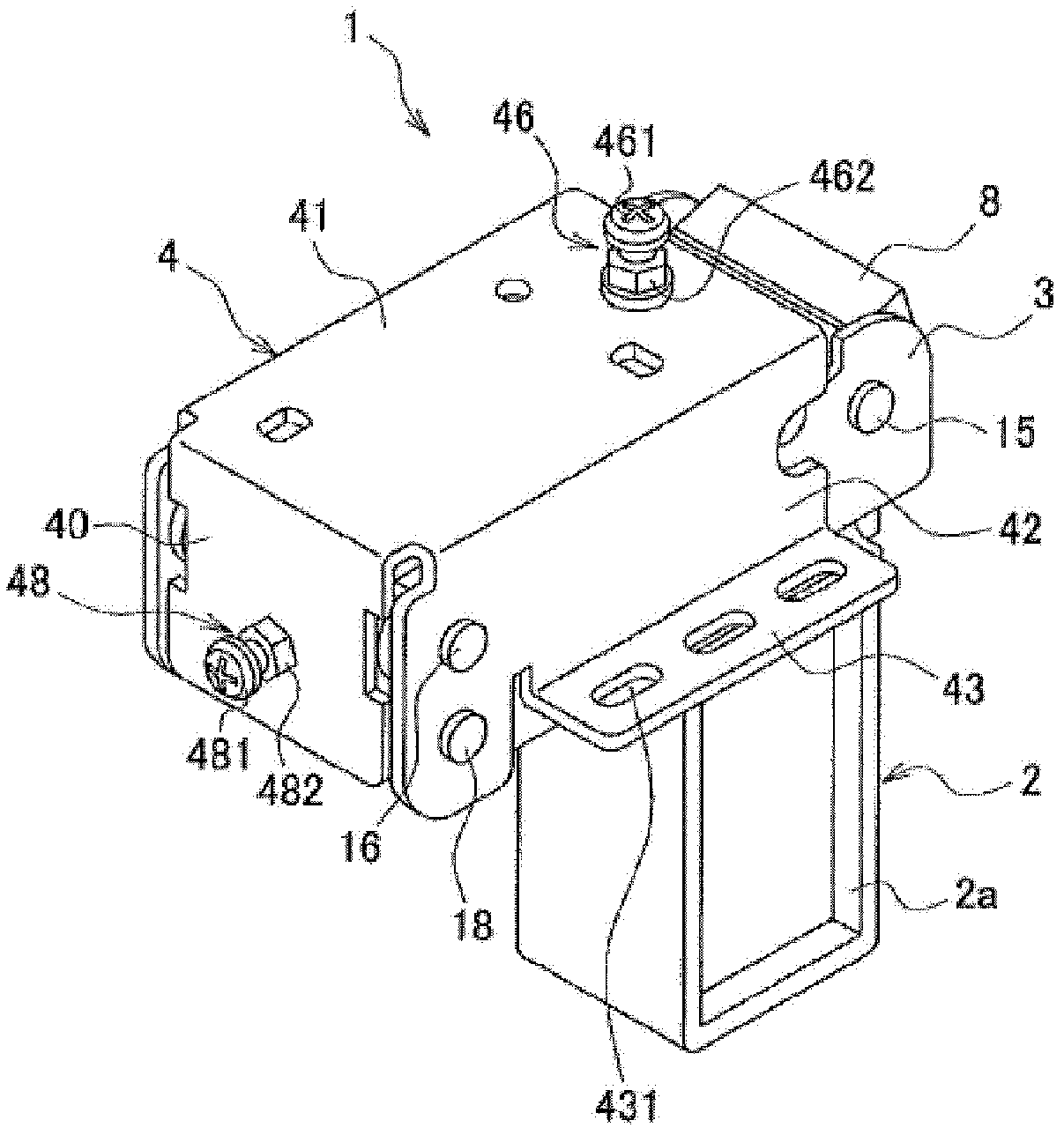

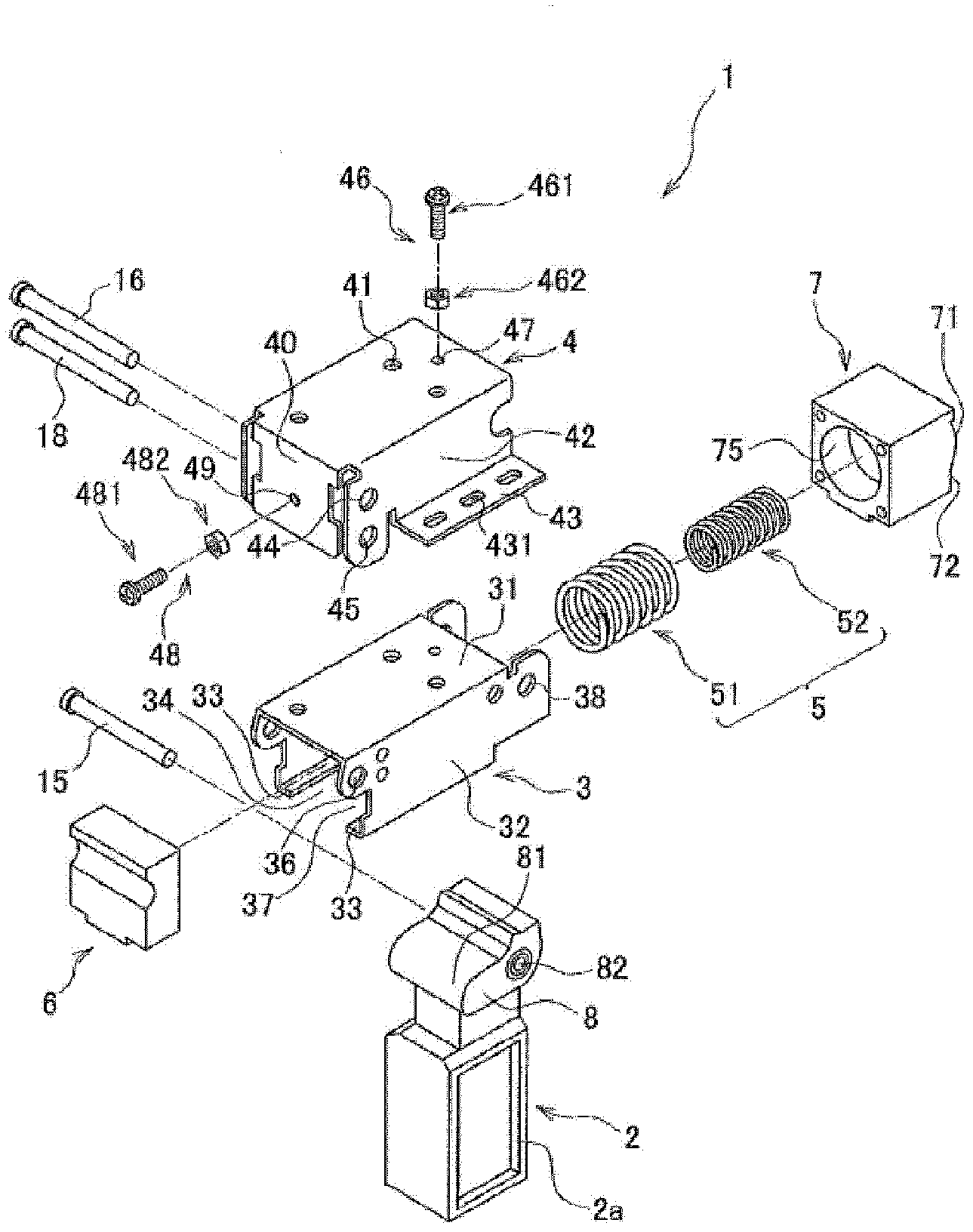

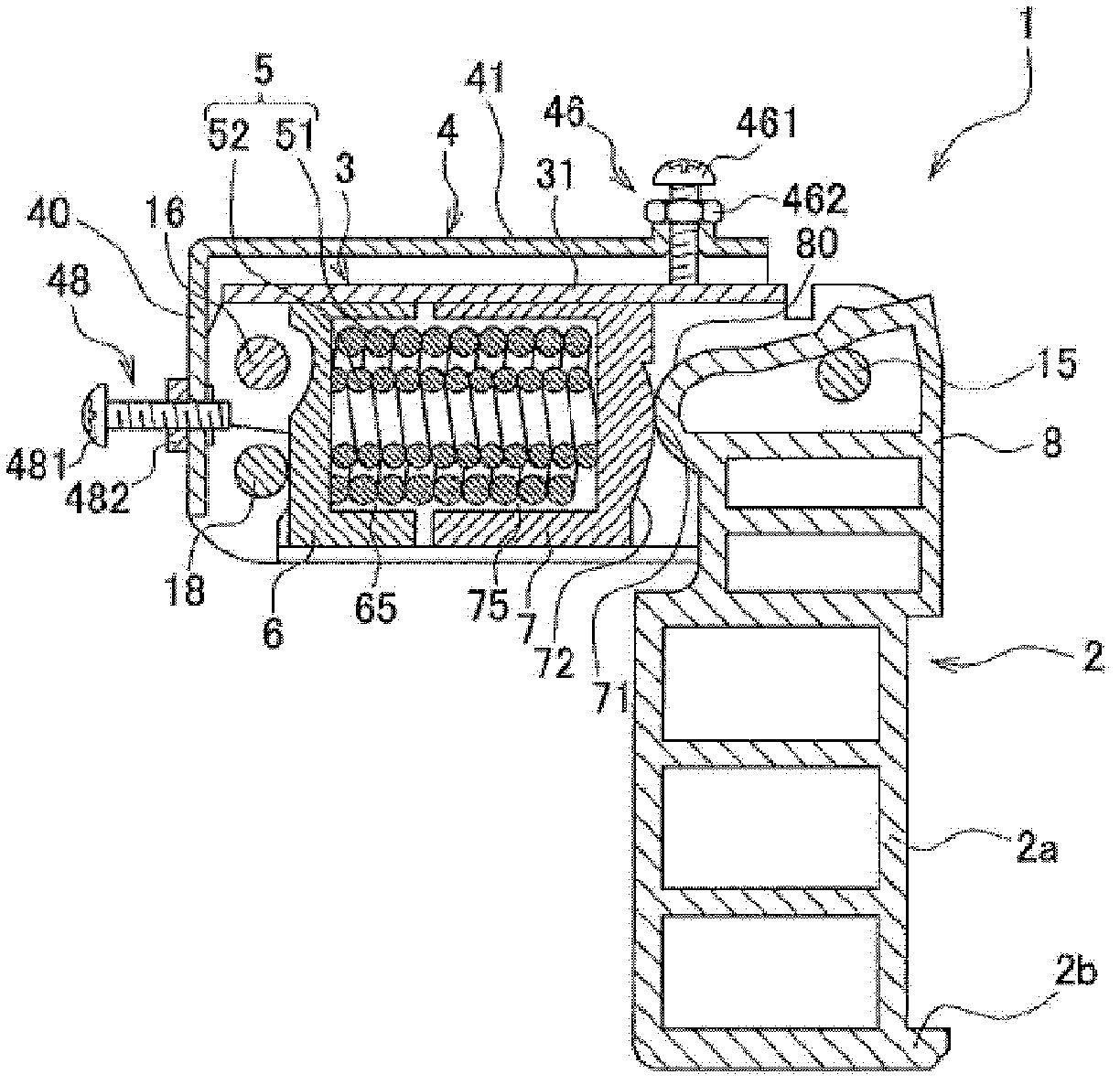

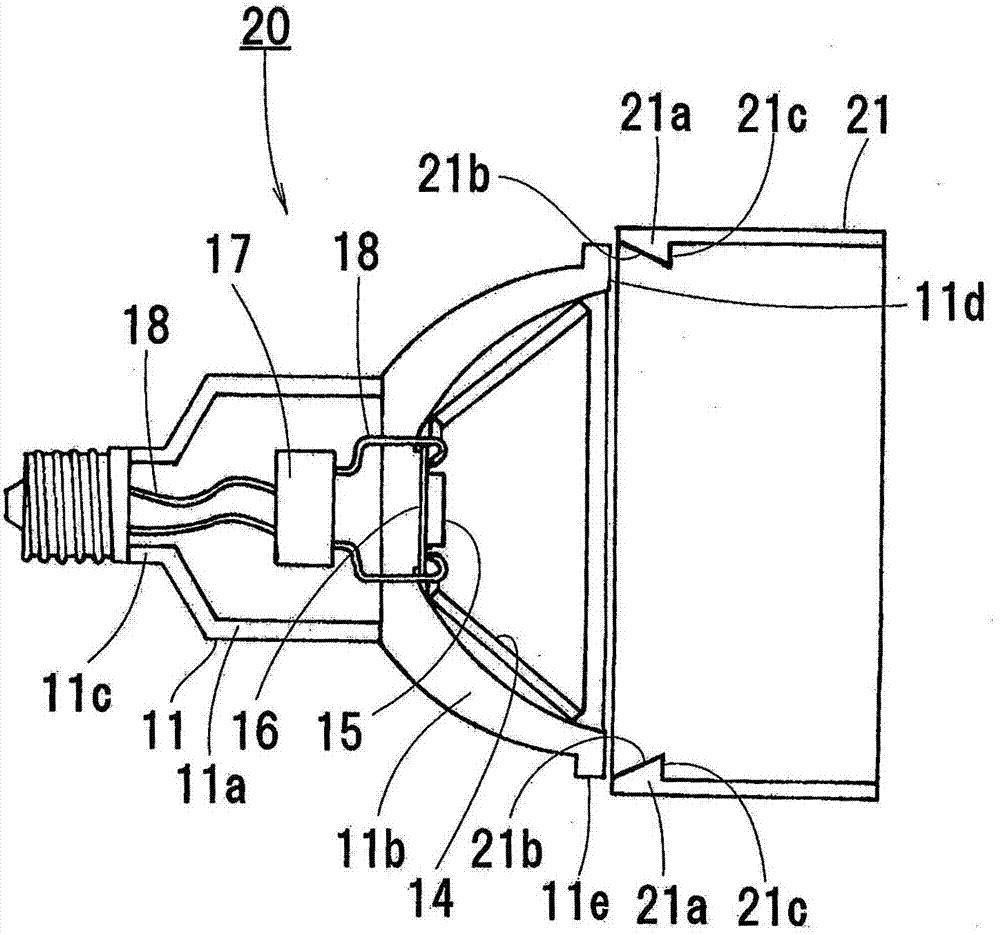

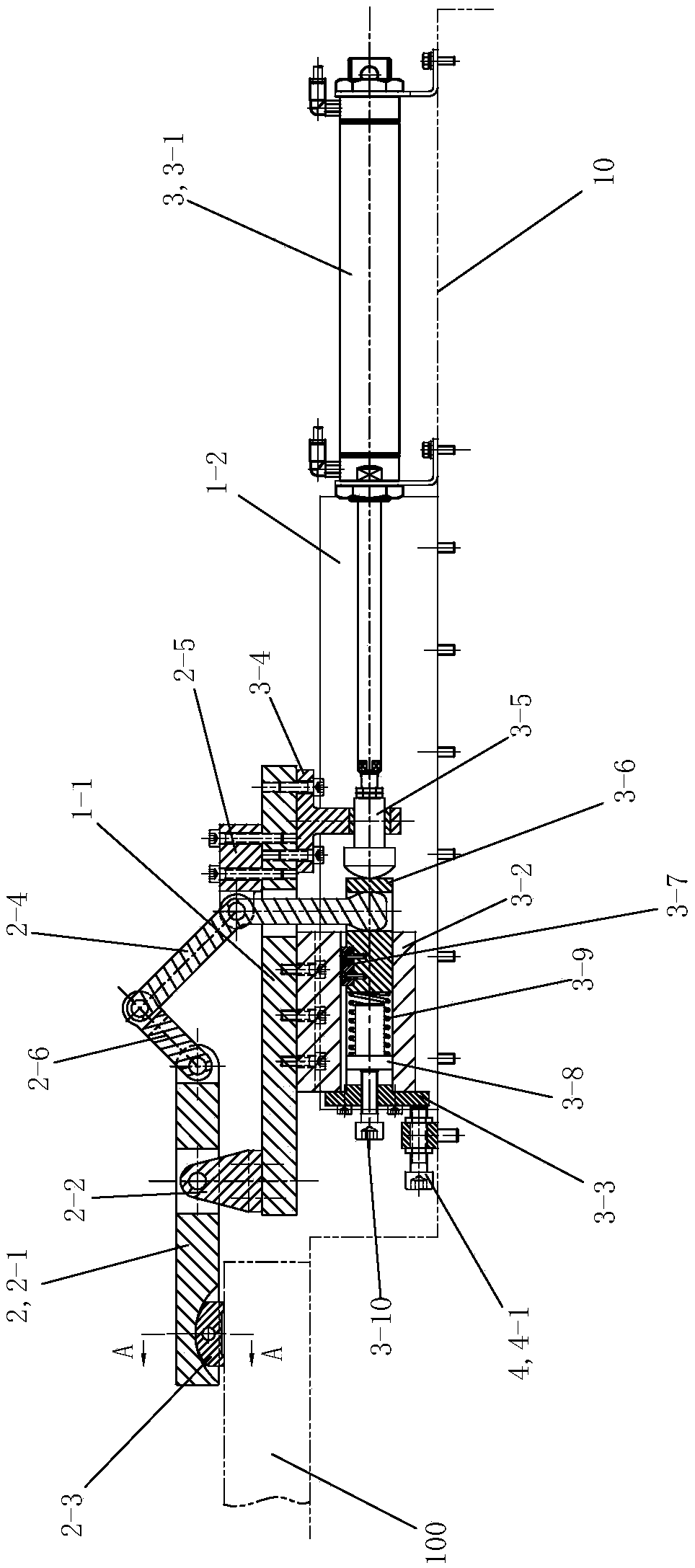

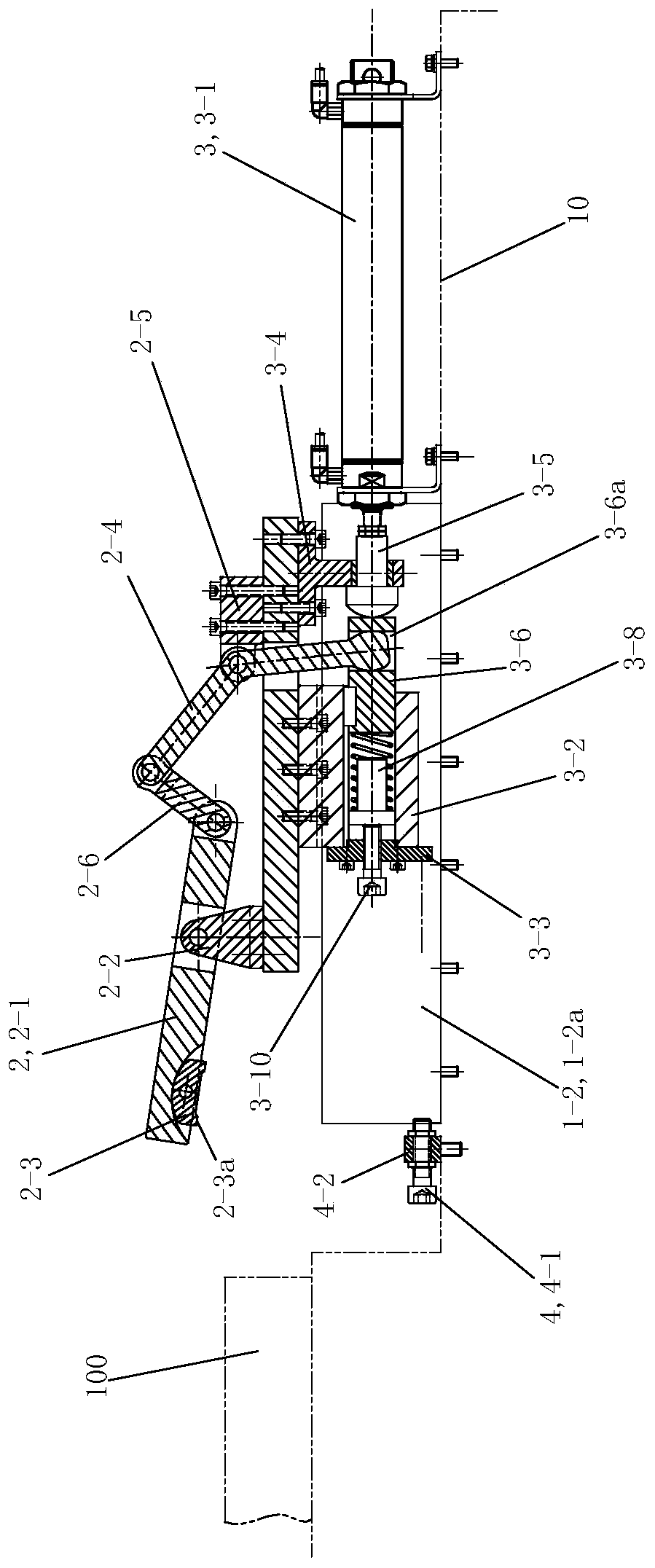

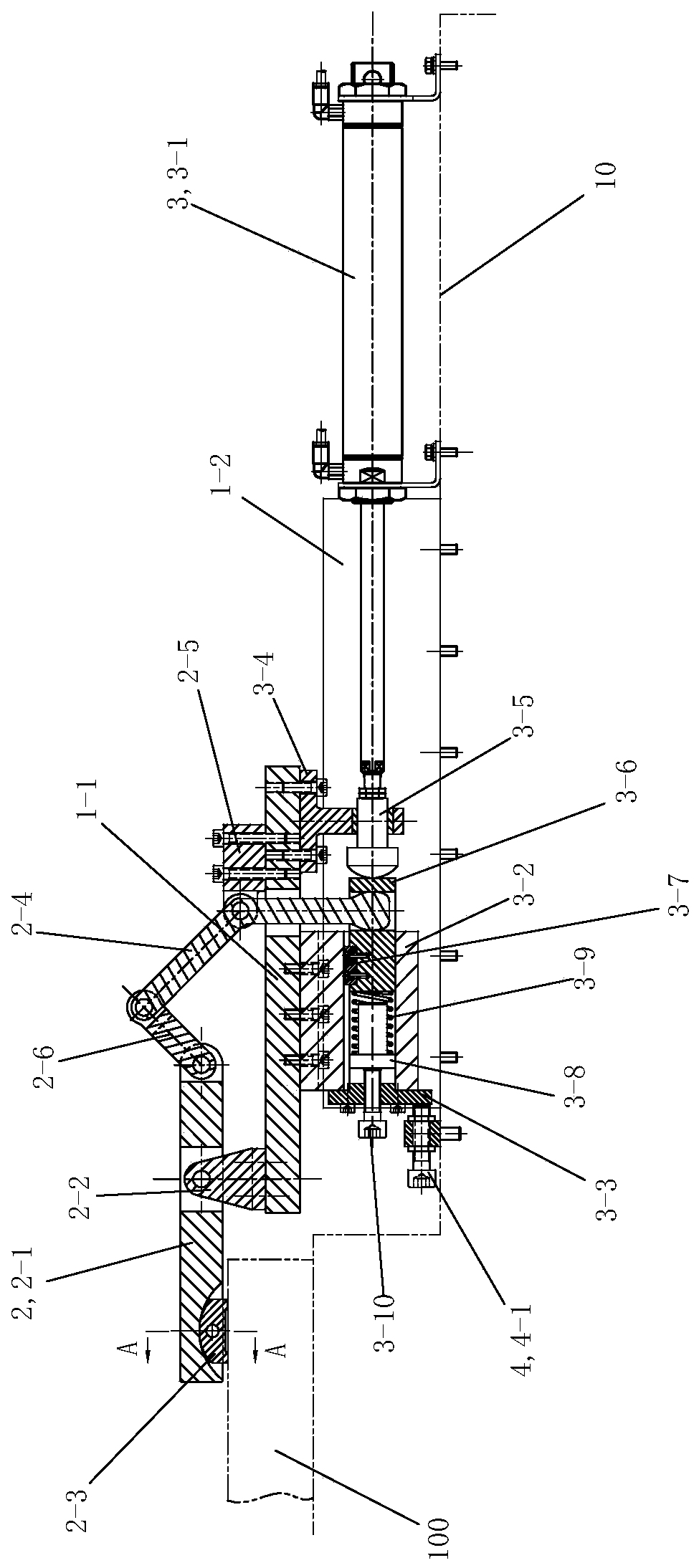

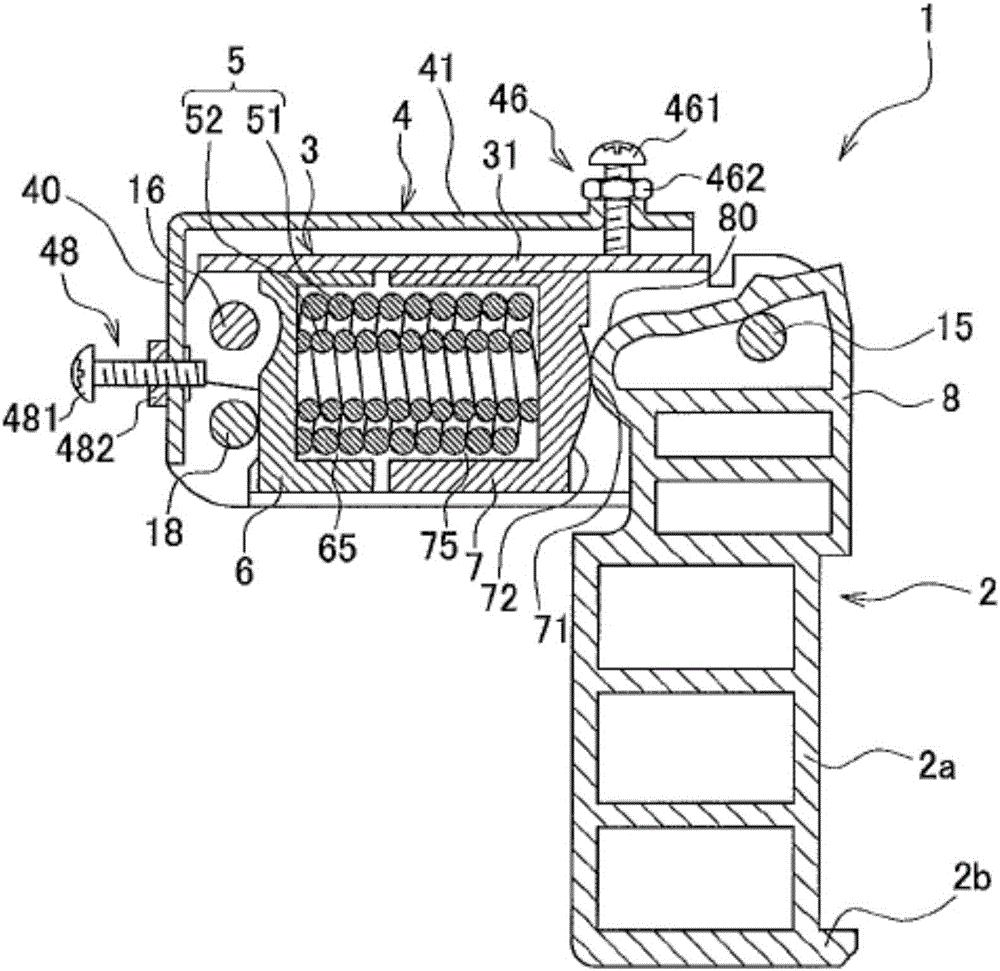

Device for opening and closing manuscript pressing plate and office machine

InactiveCN102621844AAdjust front and rear positionsLow costElectrographic process apparatusPictoral communicationEngineeringMechanical engineering

The invention provides a device for opening and closing a manuscript pressing plate. The device is capable of correctly adjusting the front-rear position of the manuscript pressing plate and allows a decrease in the number of elements so as to form a simple structure. In the invention, the manuscript pressing plate is assembled and can be opened and closed via the device relative to the body of the office machine. One of the means for adjusting the front-rear position of the manuscript pressing plate allows the adjustment of the assembling position between the manuscript pressing plate and the device in the front-rear direction. The means for adjusting the front-rear position of the manuscript pressing plate is directly arranged on a structural element of the device for assembling the manuscript pressing plate.

Owner:KEM HONGKONG

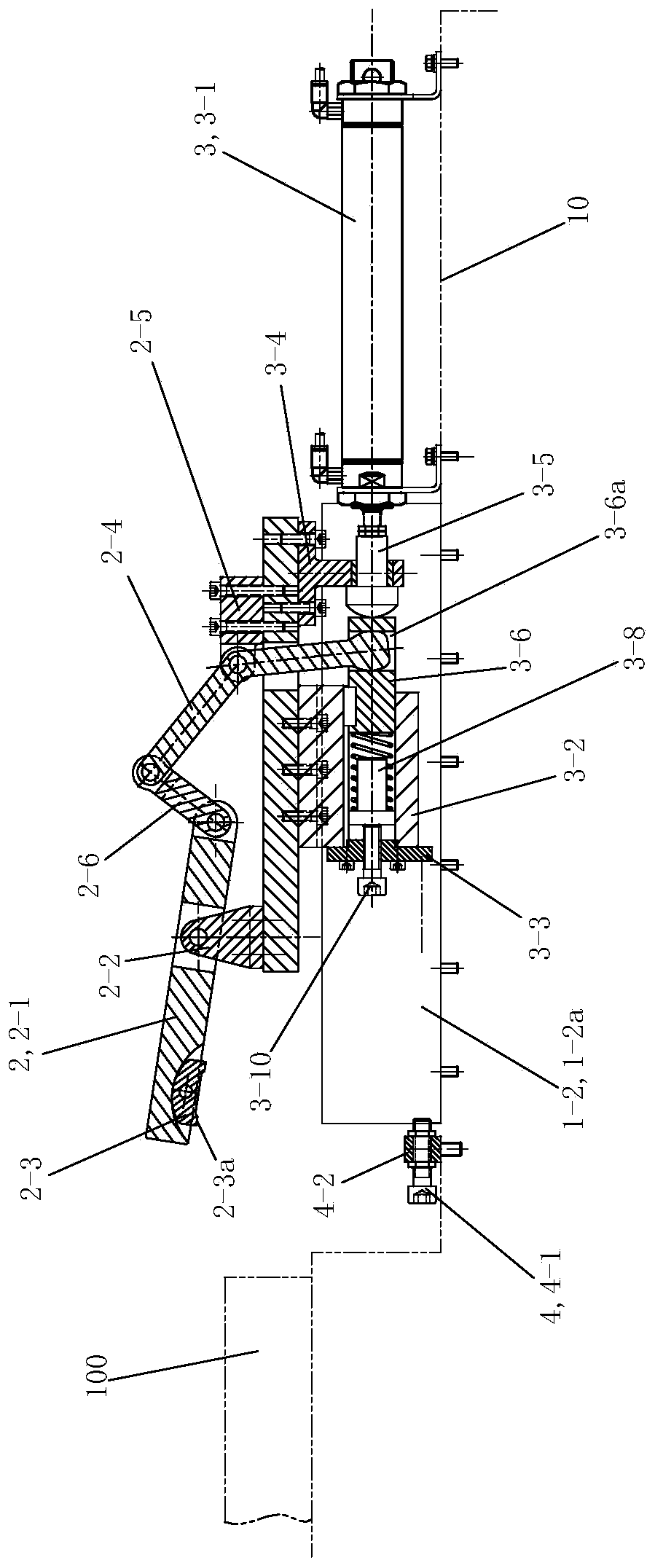

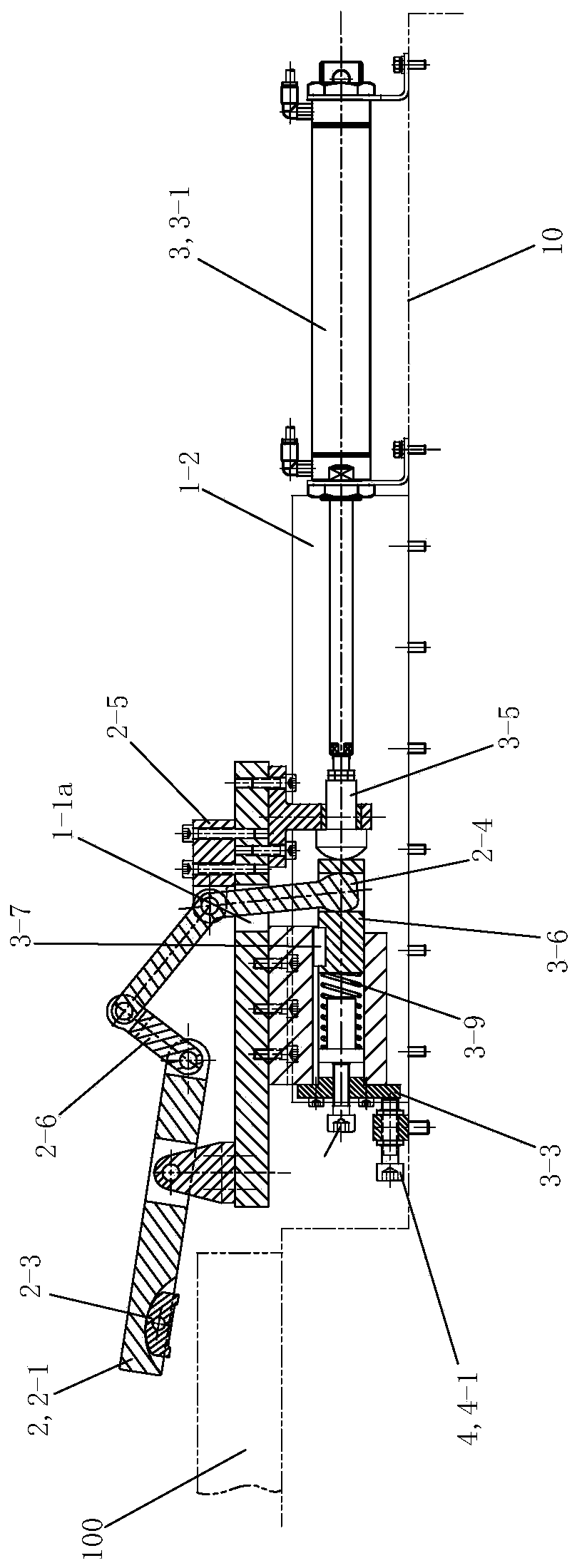

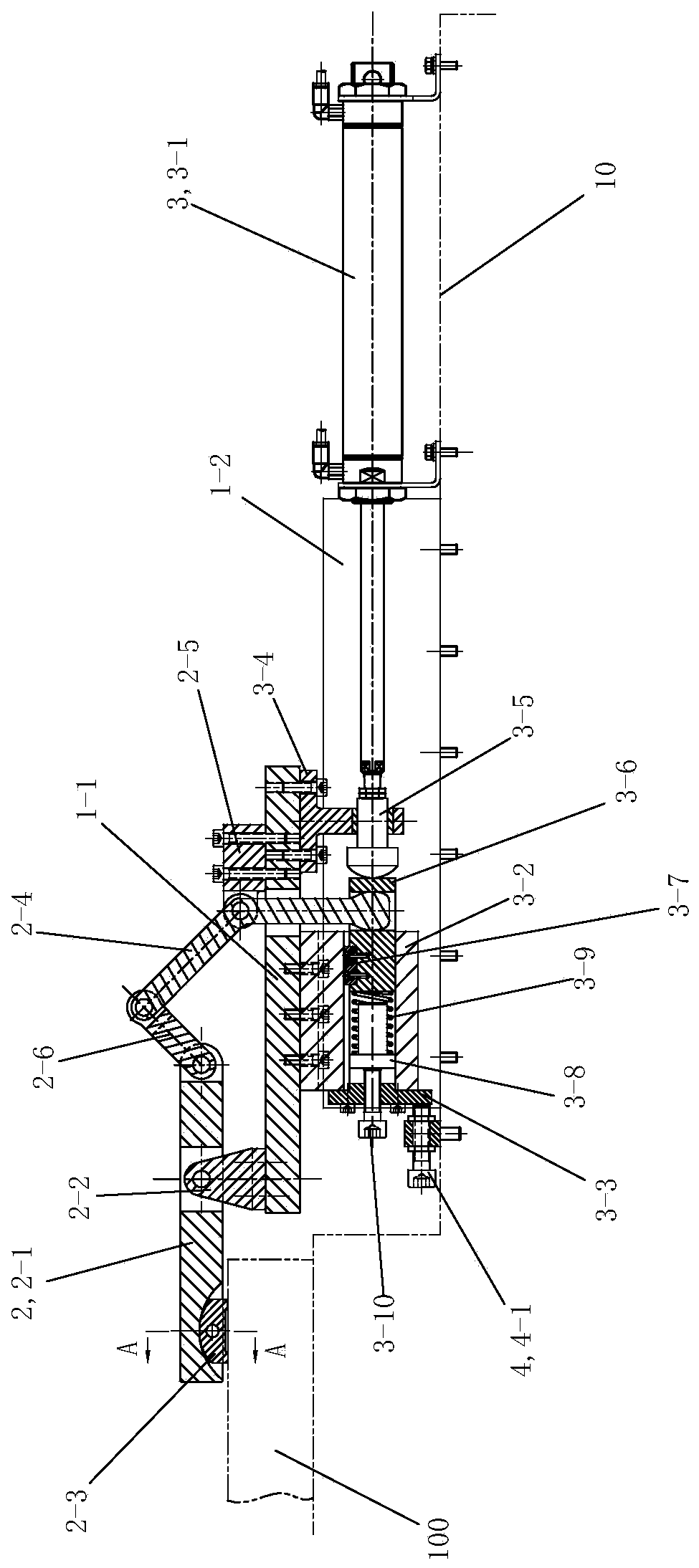

Balance weight adjustment device for engineering machinery and engineering machinery

ActiveCN104099855ASimple structureEasy to operateFluid-pressure actuator testingServomotorsHydraulic pumpControl engineering

Owner:ZOOMLION HEAVY IND CO LTD

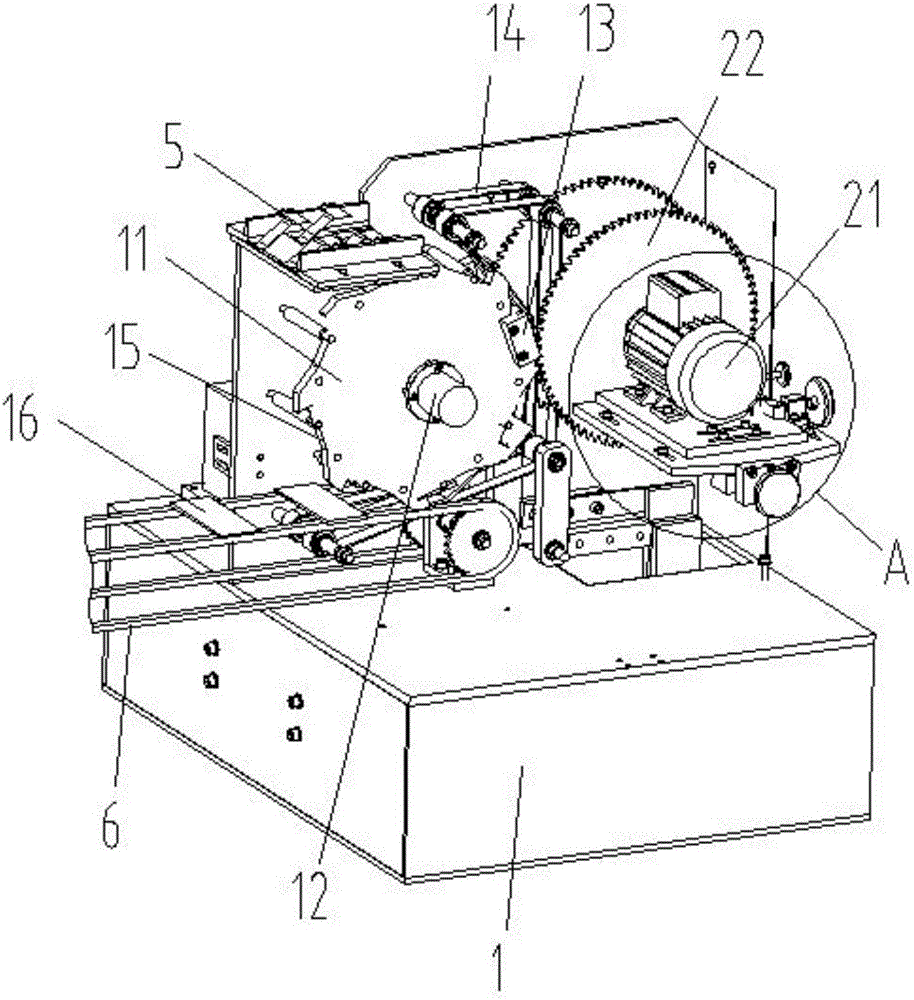

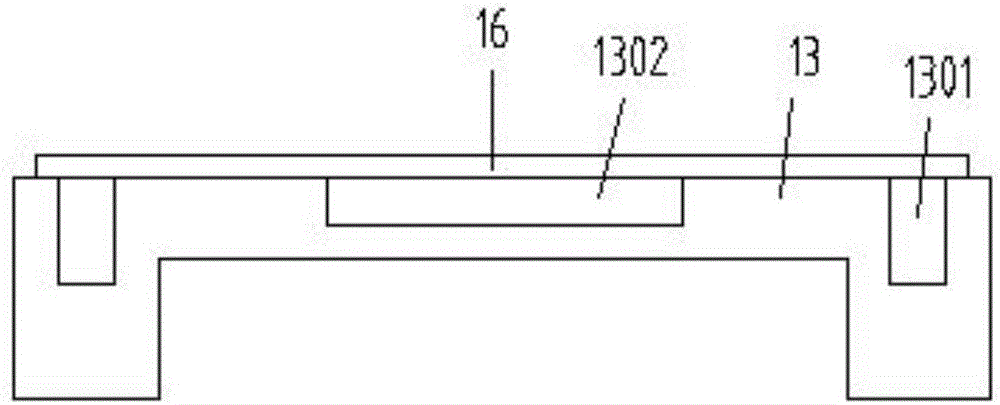

Nonmetal thin material shearing machine

InactiveCN106584541AIncrease cutting speedSmooth incisionMetal working apparatusElectric machineryWall plate

The invention discloses a nonmetal thin material shearing machine, and belongs to the field of soft thin material machining equipment. The nonmetal thin material shearing machine comprises a frame, a worktable provided with a lower blade, an upper cutter frame provided with an upper blade, and cutter frame driving mechanisms; the cutter frame driving mechanisms include driving wheels, connecting rods and motors; one ends of the connecting rods are eccentrically connected with the driving wheels, and the other ends are connected with the upper cutter frame through connecting shafts; the driving wheels are driven through the motors, and drive the connecting rods to drive the upper cutter frame to move up and down, so that the upper blade generates a shearing motion corresponding to the lower blade; two cutter frame driving mechanisms are provided, and are respectively arranged on the outer sides of two wall plates of the frame; two driving wheels are arranged on the wall plates through bearings, and are connected as a whole through driving shafts; and the motors are connected with the driving shafts through gear boxes. The nonmetal thin material shearing machine can finish shearing of such nonmetal thin materials as films, rubber and soft glass, is not easy to clamp cutters, is smooth in incision, high in quality of finished products and adjustable in edge gaps, can adapt to the cutting requirements of materials with different thicknesses, and is high in adaptability.

Owner:安徽汉邦重工机床制造有限公司

Underwater slide board

InactiveCN101028862AEliminate useless workLower center of gravityMuscle power acting propulsive elementsUnderwaterDriving mode

A water toboggan features its pedaling drive mode, an adaptive driver, small water skiing board, novel steering mechanism, and unidirectional movable blade.

Owner:刘丰

Fine waste battery sagger grinding device

InactiveCN109732459APlay a supporting roleAdjust the height positionGrinding carriagesGrinding machinesArchitectural engineeringTransverse beam

The invention belongs to the field of waste battery disposal and relates to a fine waste battery sagger grinding device which comprises a sagger placement table, a lifting rack and a grinding cutter,wherein the sagger placement table comprises a working flat plate, a vertical baffle edge, a support plate and a transverse baffle edge; the upper end of the working flat plate is fixedly connected with the vertical baffle edge and the transverse baffle edge; the vertical baffle edge and the transverse baffle edge form a right-angle shape; the left and right ends of the working flat plate are fixedly connected with the support plate; the lifting rack comprises vertical sliding rods, circular rail rods, sliding blocks and a transverse beam rod; four corners of the working flat plate are in sliding fit with the vertical sliding rods; one of the circular rail rods is connected between the two vertical sliding rods at the left end, and the other circular rail rod is connected between the two vertical sliding rods at the right end; the sliding blocks are fixedly connected with the left and right ends of the transverse beam rod; and the two sliding blocks are in sliding fit with the two circular rail rods separately.

Owner:广东山摩新材料科技有限公司

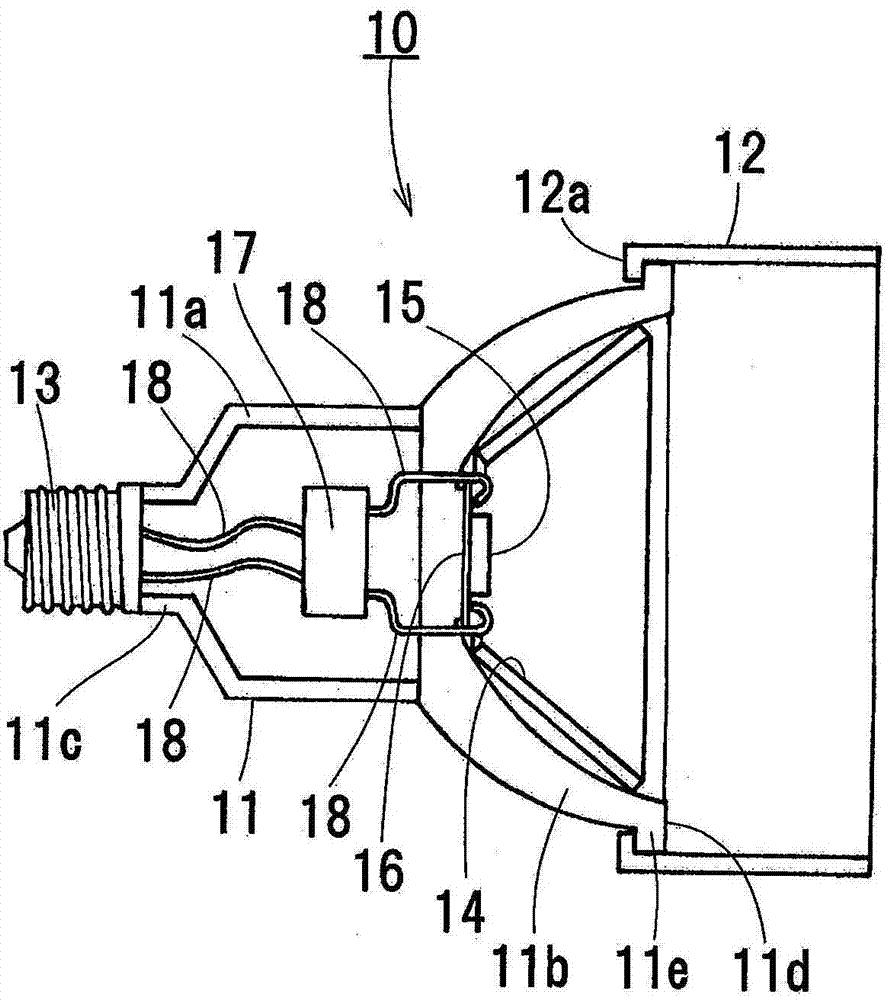

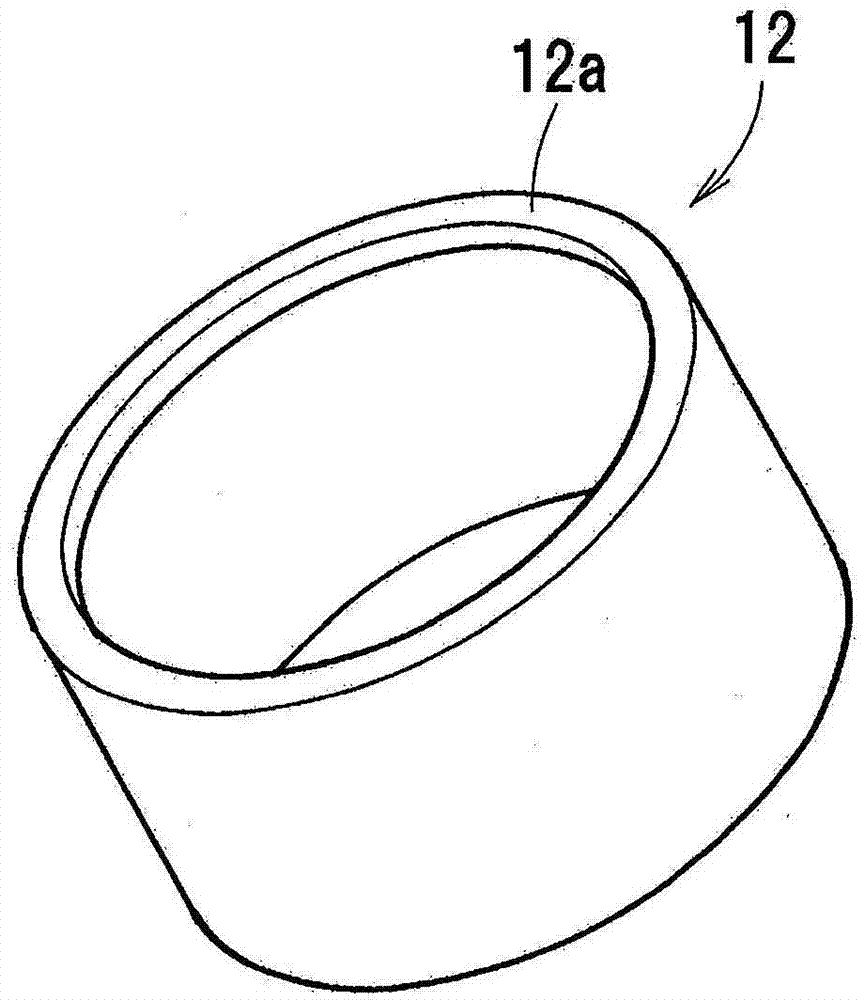

Led lamp

InactiveCN103032727AAdjustment amountInhibit sheddingPoint-like light sourceElectric lightingEngineeringLED lamp

An LED lamp includes a housing having a front end side formed into a cup shape and a rear end to which a cap is fixed, the cup-shaped portion having an inner peripheral surface formed with a reflection layer and an open end, a cap fixed to the rear end of the housing, an LED chip fixed to a bottom of the cup-shaped portion, a lighting circuit incorporated in the housing to supply electric power to the LED chip, the lighting circuit and the cap being electrically connected to each other, and a hood which is mounted to the open end of the cup-shaped portion so as to be movable forward and rearward in a direction of an imaginary center line of the cup-shaped portion.

Owner:BEAT SONIC

A chip resistor detection and sorting machine

ActiveCN106862101BQuality assuranceGuaranteed accuracyElectrical testingSortingElectrical resistance and conductanceDistribution control

The invention relates to a chip resistance detection and sorting machine, which includes a frame and a power distribution control box. The frame is provided with a feeding conveying device, an upper detection seat and a lower detection seat in sequence from right to left, and the feeding and conveying device Cooperate with the upper detection seat through the upper detection and reclaiming device, and cooperate with the upper detection seat and the lower detection seat through the lower detection and reclaiming device. The upper detection device that cooperates with the product and uses the CCD detection head as the detection part is arranged above the upper detection seat. The lower detection seat is provided with a lower detection device that cooperates with the lower part of the product. The lower detection device includes a detection discharge seat arranged on the lower detection seat. The lower part of the detection discharge seat is provided with an LCR detection probe that passes through it. The first unqualified product collection box is set on the top, and the invention realizes the automatic and integrated detection of both sides of the chip resistor, which ensures the accuracy of the detection, ensures the quality of the subsequent finished products, and improves the efficiency of detection at the same time.

Owner:SHENZHEN MESTEK ELECTRONICS CO LTD

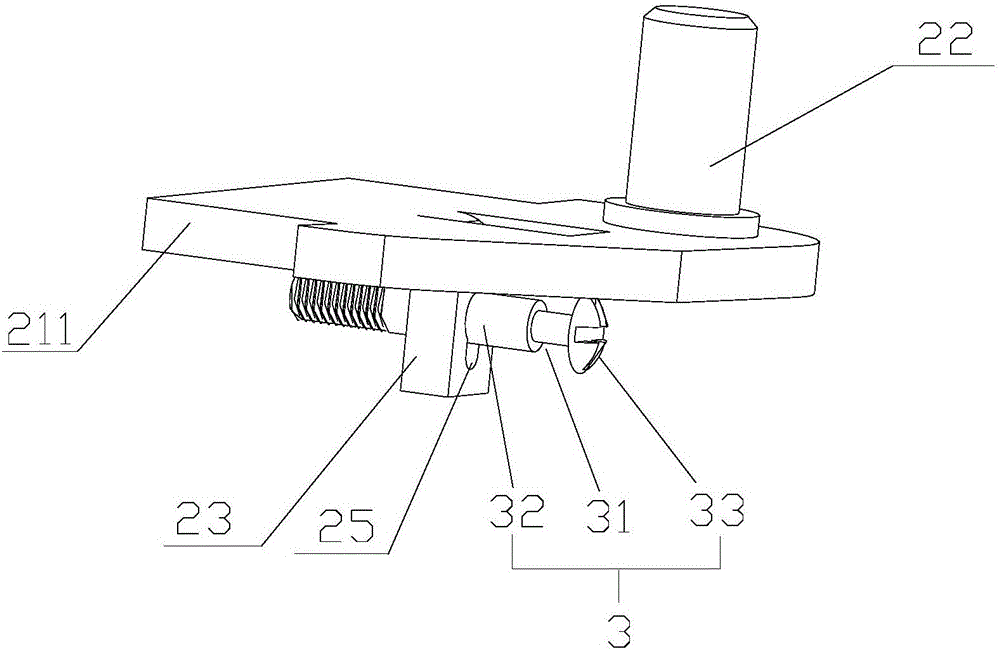

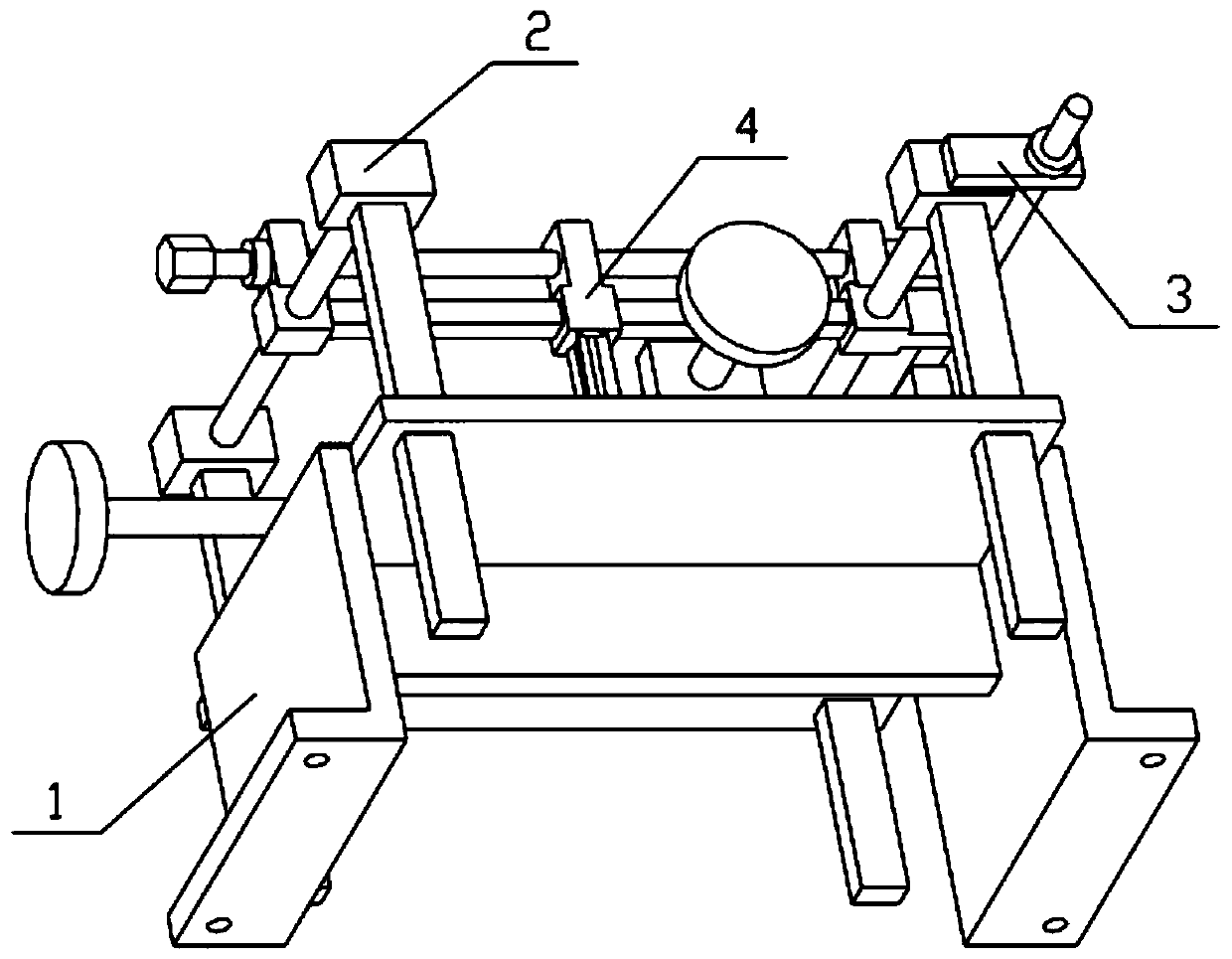

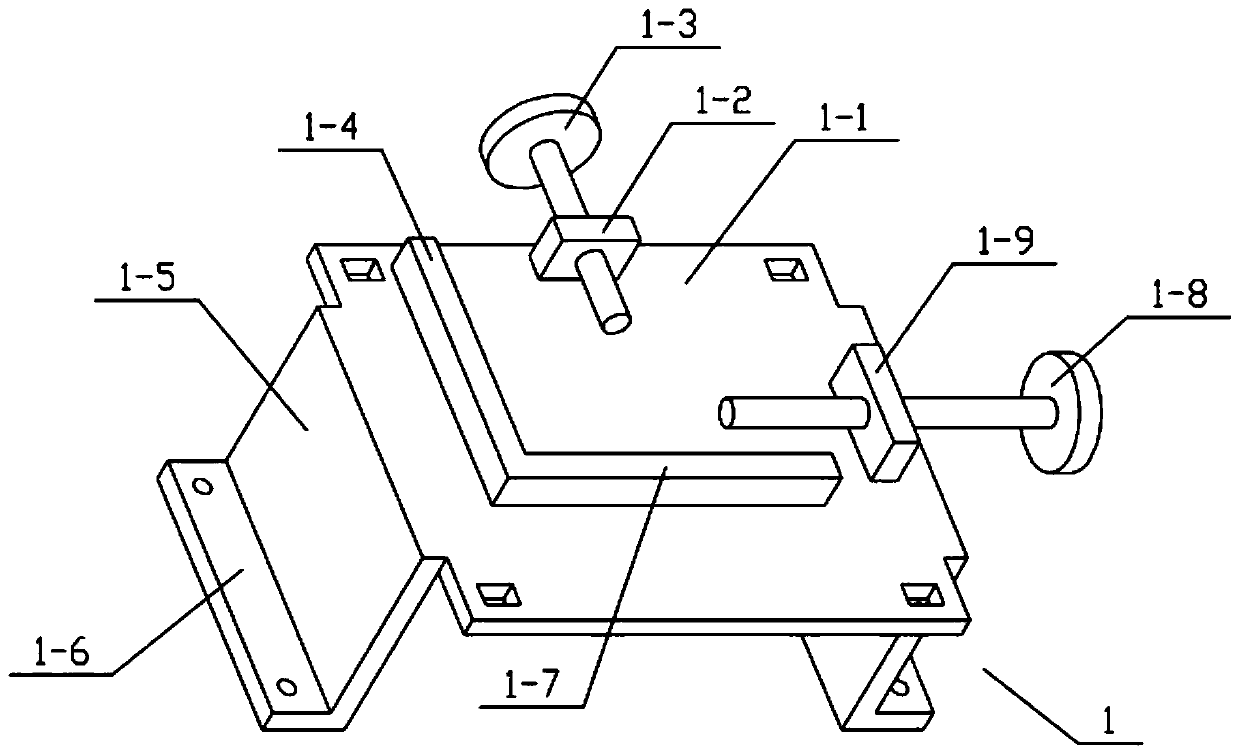

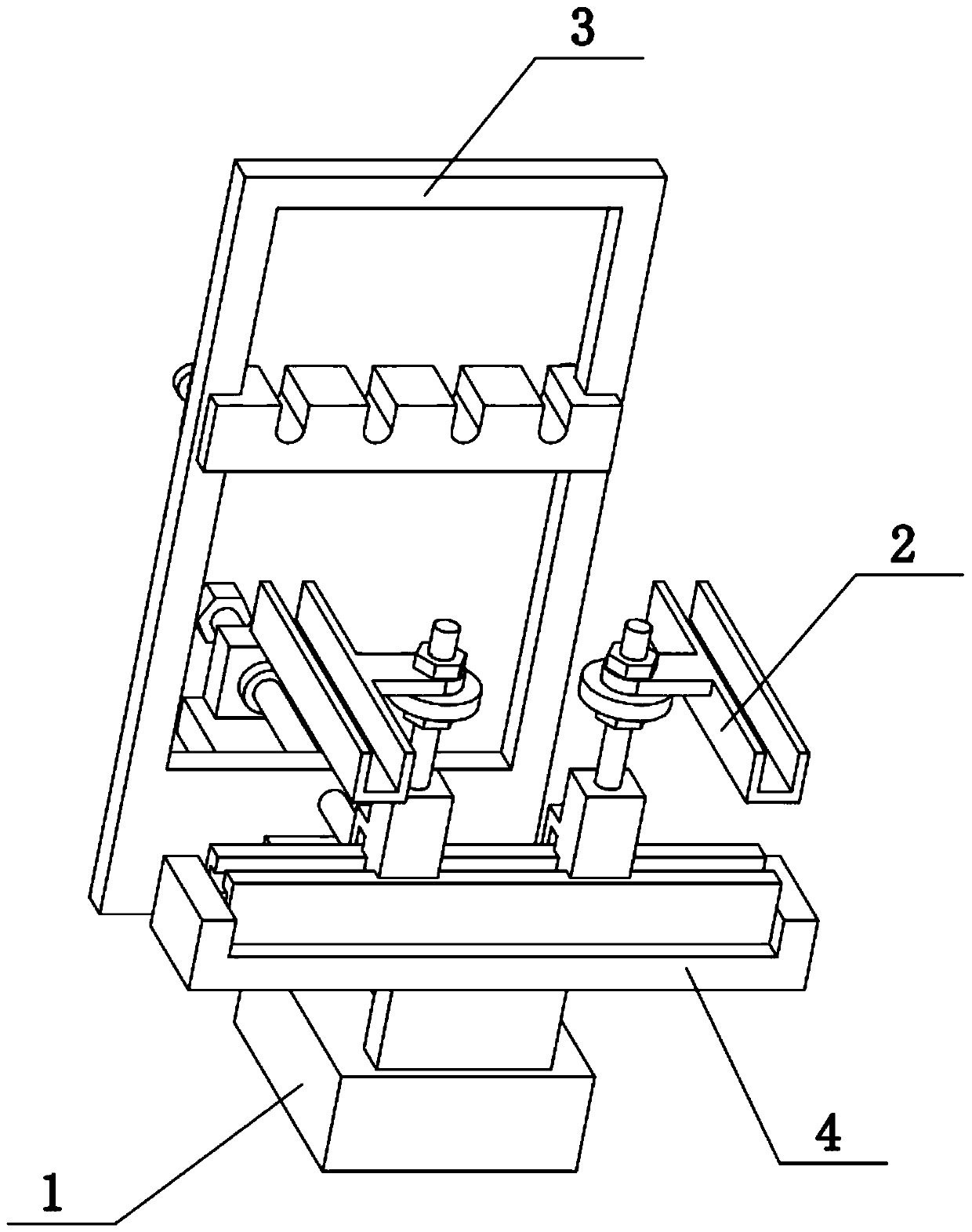

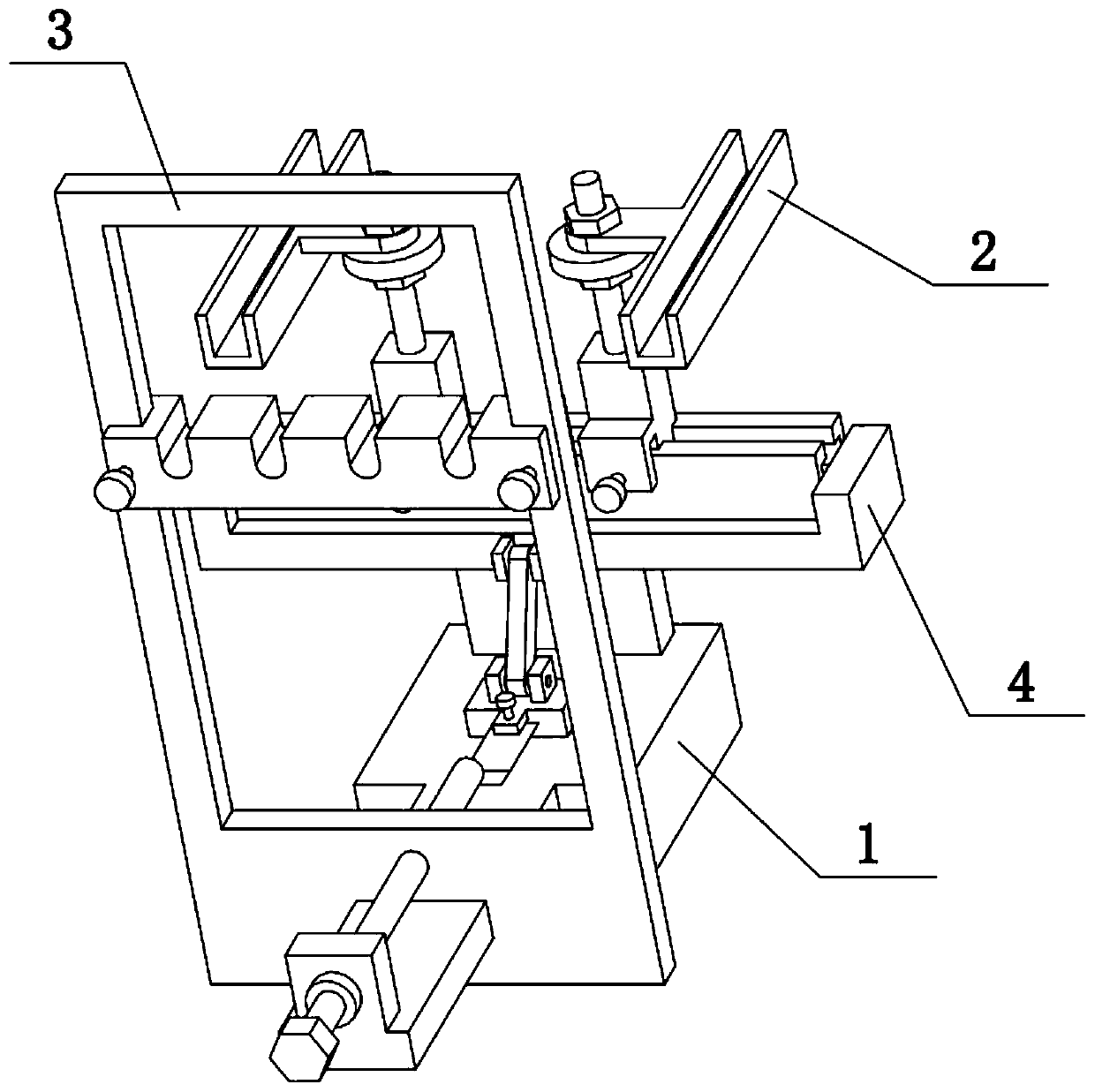

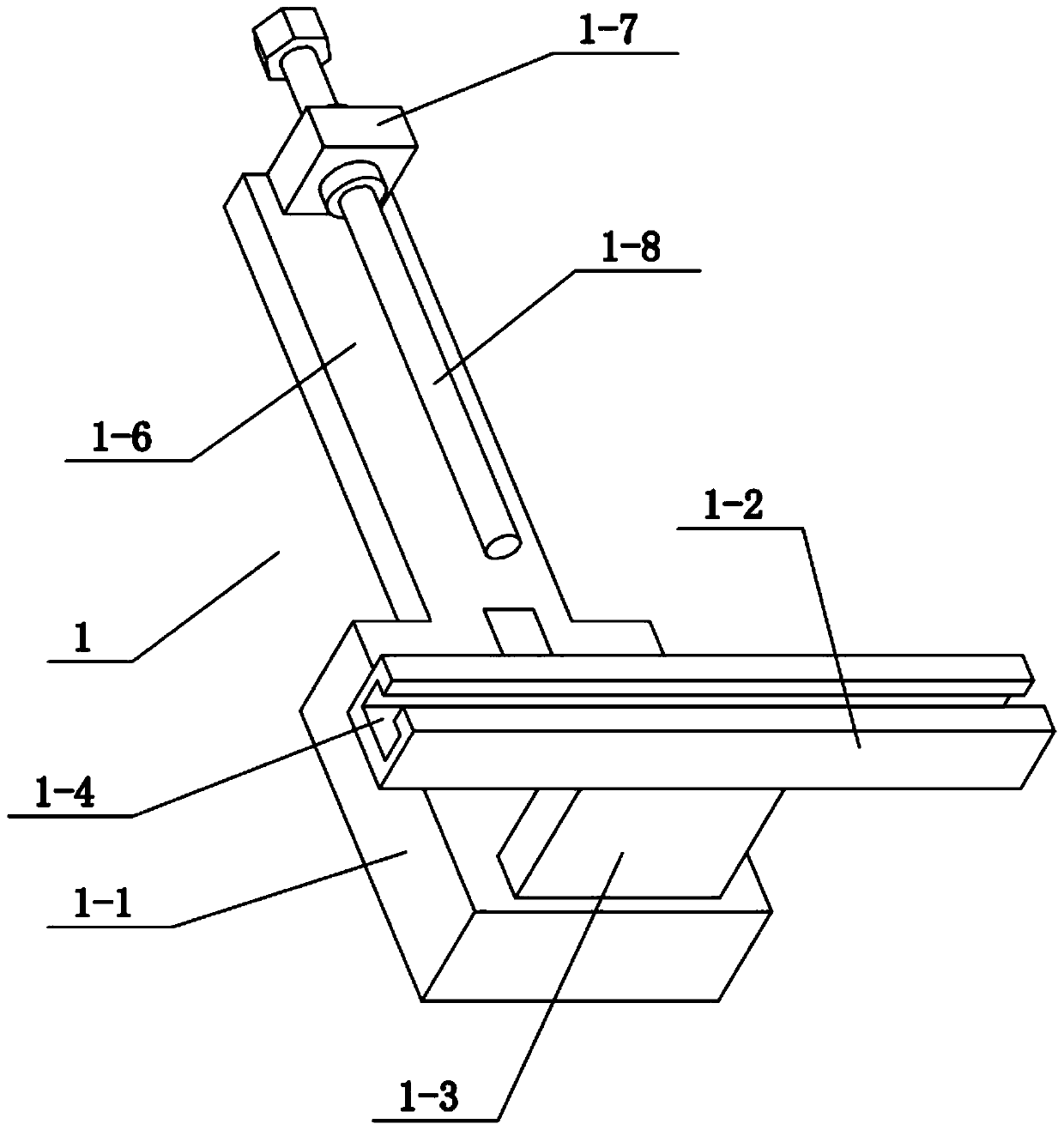

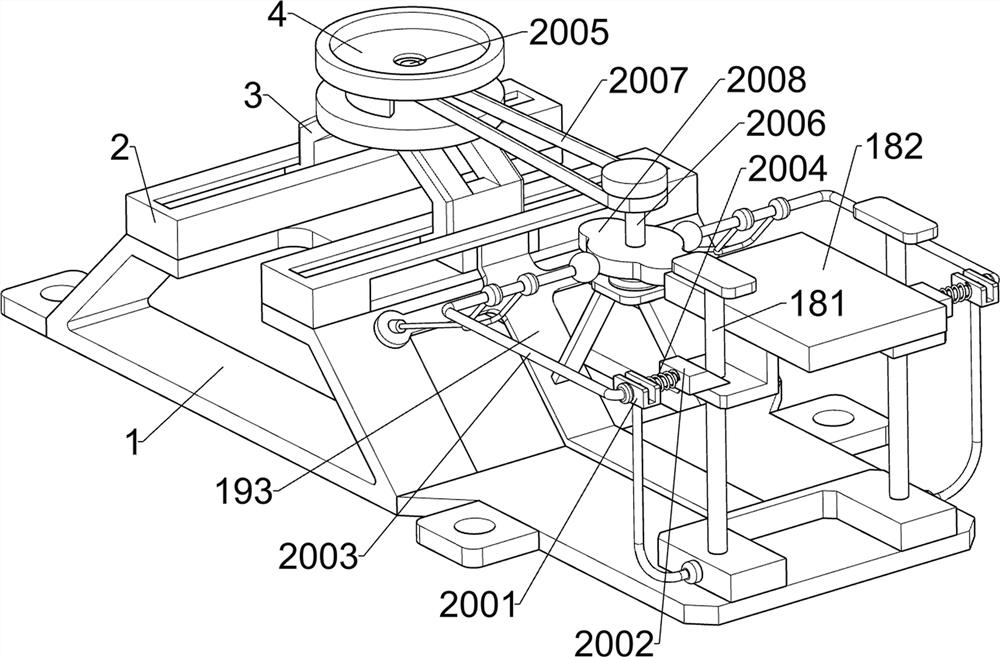

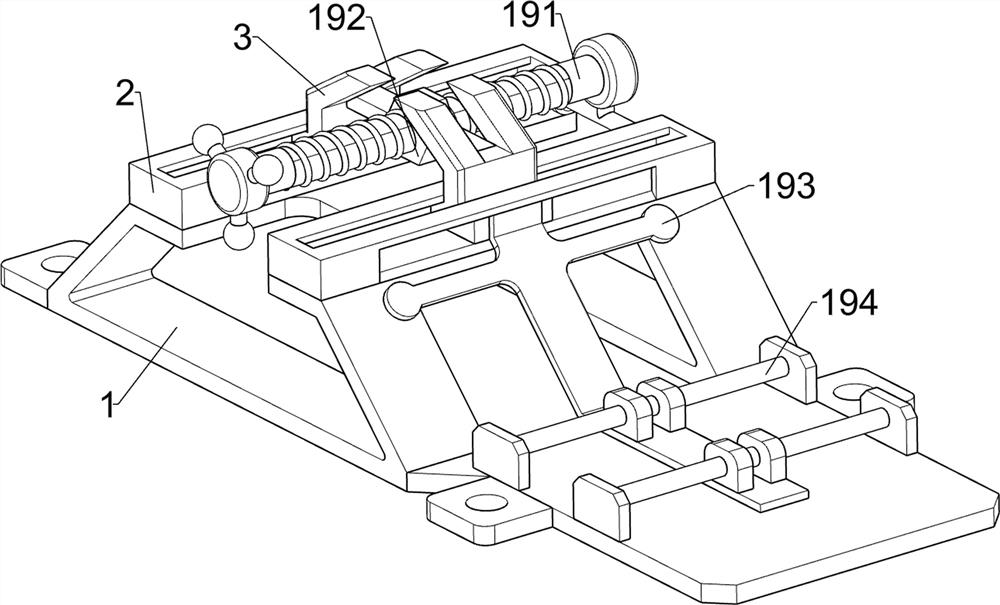

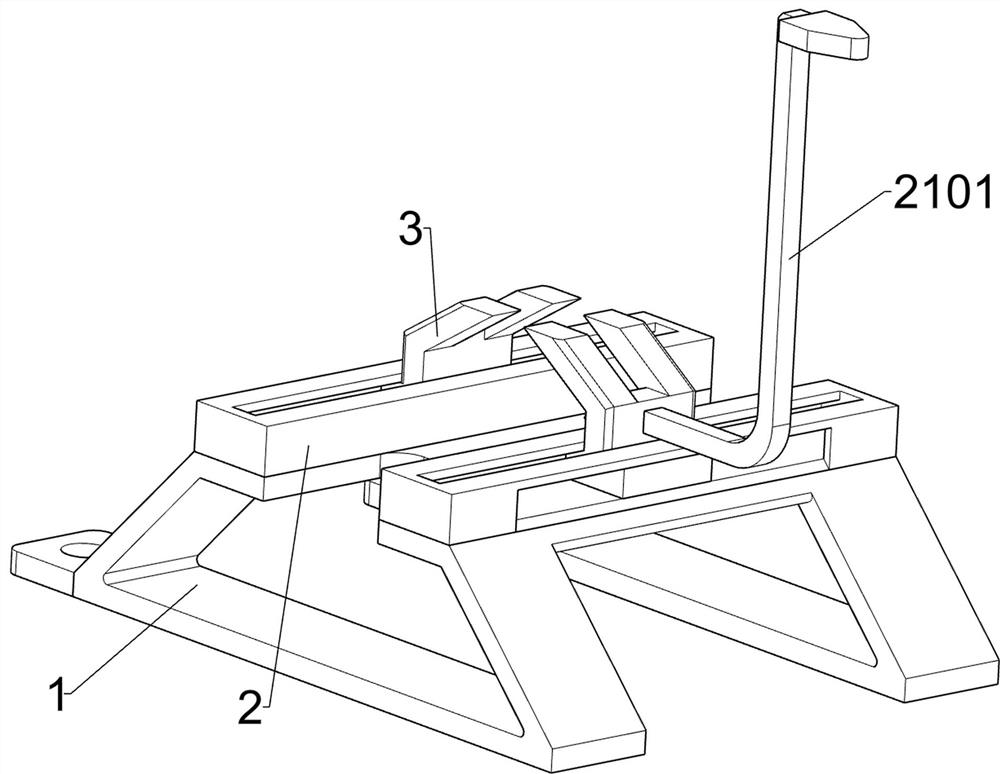

Labor-saving slide table fixture

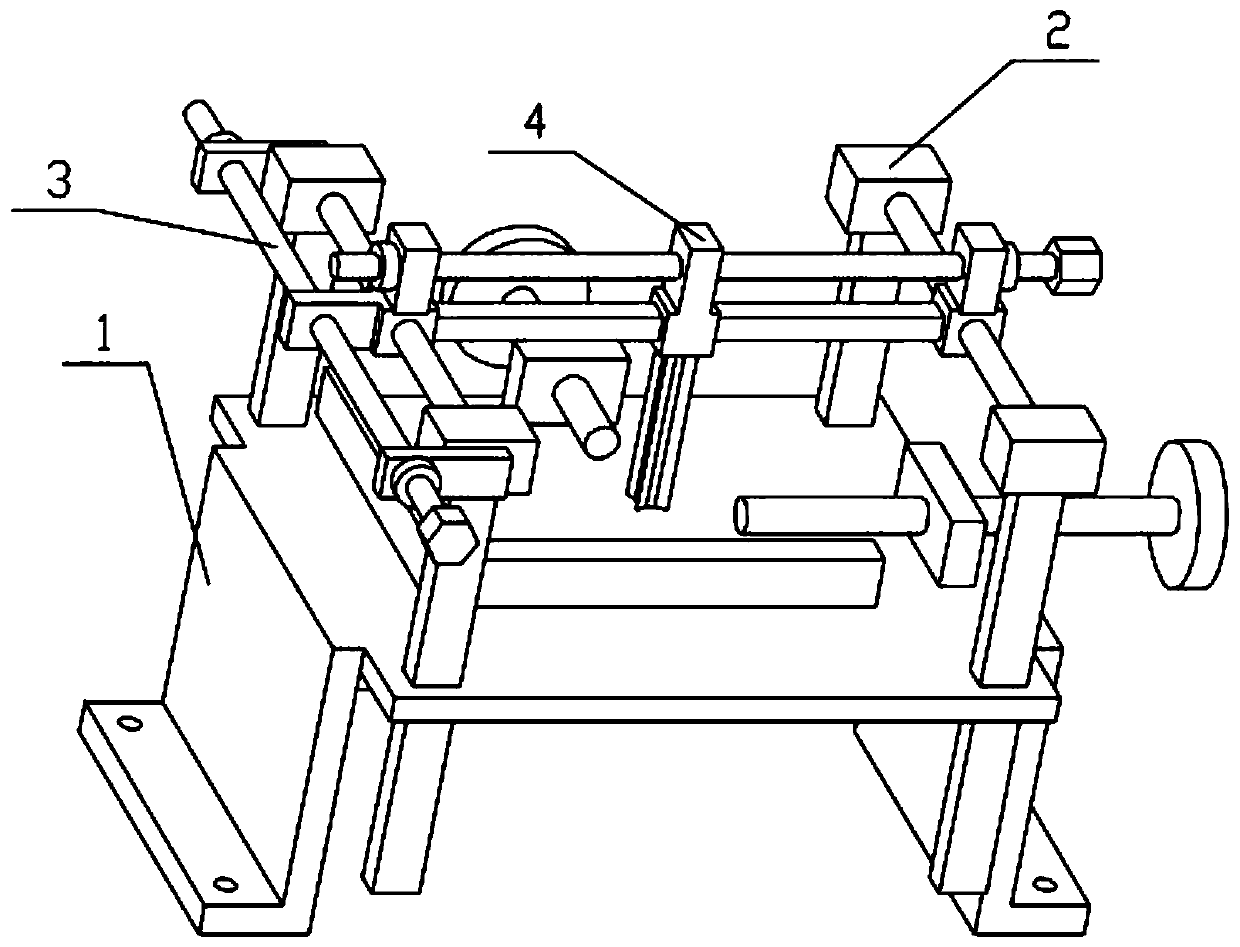

InactiveCN108655785ASimple structureReduce volumePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a labor-saving slide table fixture. The essential is as follows: the labor-saving slide table fixture comprises a slide table assembly, a compression assembly, a drive assemblyand a limit assembly. The slide table assembly comprises a slide table and a linear guide rail. A lever hole penetrating through the top and bottom of the slide table is formed in the middle part inthe front-rear direction of the slide table. The slide table is fixedly arranged on a slide block of the linear guide rail. The stroke of the slide table is limited by the limit assembly. The compression assembly comprises a press rod, a press rod support seat, a press head, a lever, a lever support seat and a connection rod. The drive assembly comprises a power source, a drive seat, a drive seatend cover, a guide seat, a rod joint, a push rod, a guide flat key, a spring seat, a compression spring and an adjustment screw. The cylinder force needed during workpiece compression can be adjustedthrough the adjustment screw. After the slide table is driven to reach a limit part by the drive assembly, the lever of the compression assembly starts to be driven through the push rod, and the leveris enabled to rotate around the fulcrum of the lever support seat, so that the press head presses downwards the corresponding workpiece.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

More labor-saving slide fixture

InactiveCN108655785BSimple structureReduce volumePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

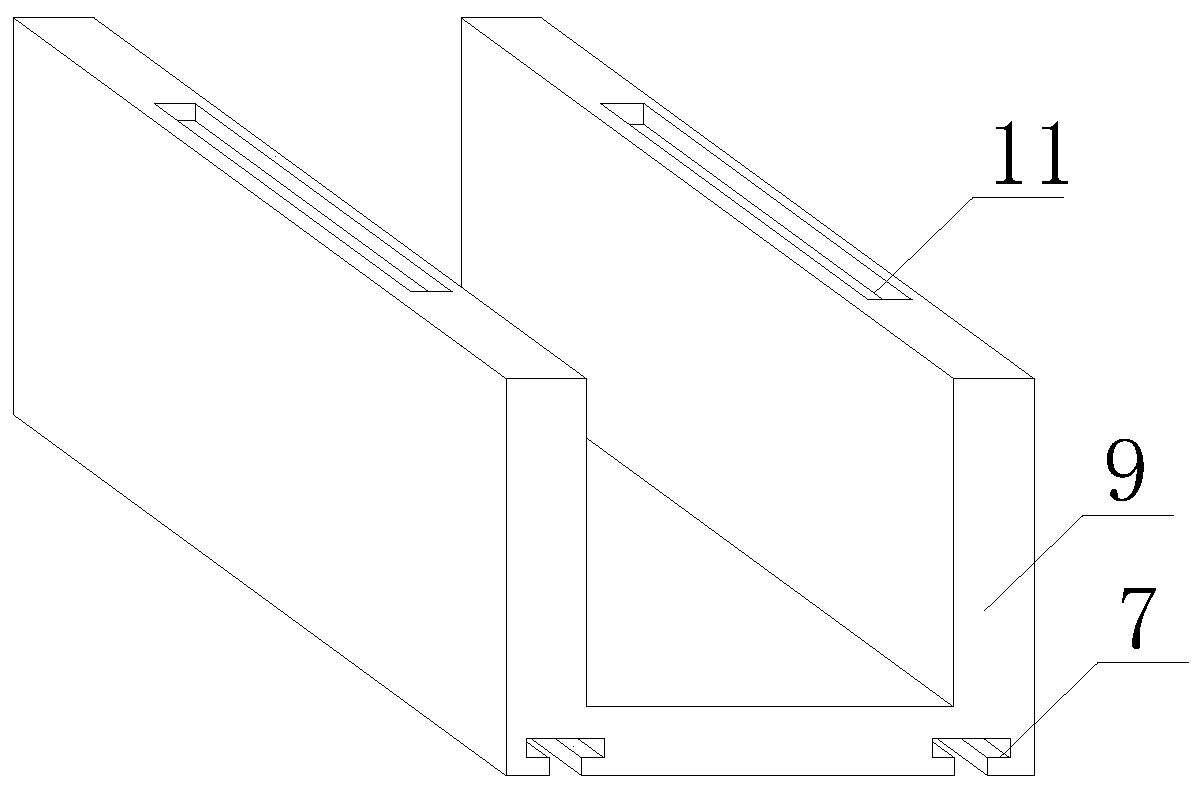

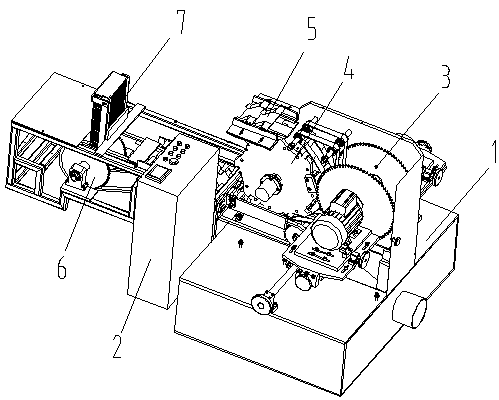

Convenient batten coiling trimmer

ActiveCN106827073AEasy loading and unloadingImprove efficiencyGuide fencesFeeding devicesCharge and dischargeDistribution control

The invention relates to a convenient batten coiling trimmer. The convenient batten coiling trimmer comprises a machine frame and a distribution control box. A coiling device and a trimming device are arranged on the machine frame. The coiling device comprises a coiling wheel vertically arranged on the machine frame. A coiling shaft of the coiling wheel is connected to a coiling output shaft. The coiling wheel rotate anticlockwise. A material holding frame is arranged under the coiling wheel. Mounting notches are evenly formed in the coiling wheel. Material pressing bases matched with battens are mounted on the mounting notches. A material pressing belt matched with the coiling wheel is arranged on the right side of the coiling wheel. The lower end of the material pressing belt is located under the material holding frame, and the upper end of the material pressing belt is located above the middle of the coiling wheel. The material pressing bases evenly arranged on the coiling wheel and the material pressing belt matched with the right side of the coiling wheel are adopted for achieving the effect that the battens rotate around the coiling wheel, then trimming of the battens is achieved through edge trimmers arranged on the right side of the coiling wheel, products do not need to be fixed to the coiling wheel, charging and discharging are greatly facilitated, and thus the total trimming efficiency is improved.

Owner:望江县南山刷业有限公司

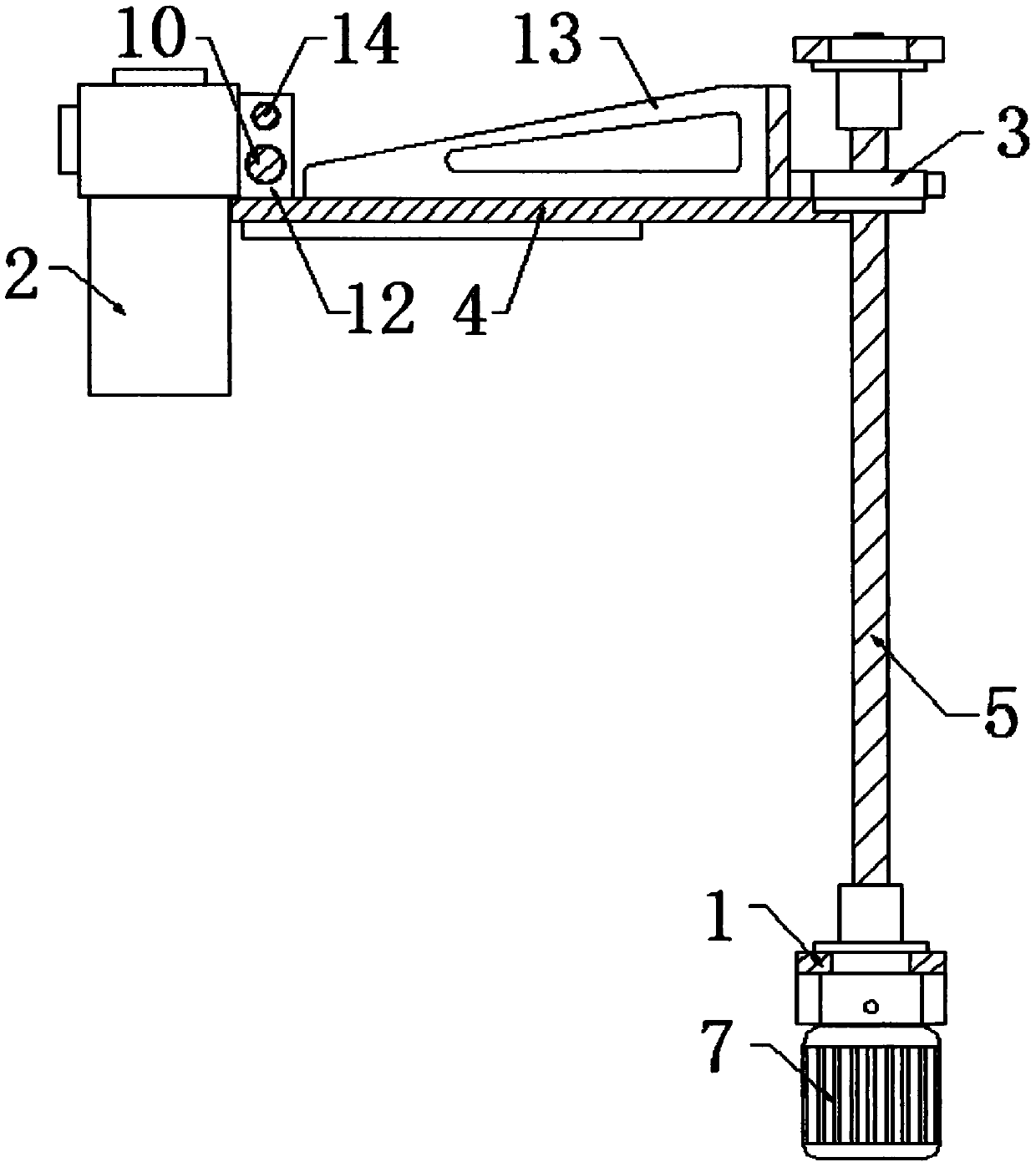

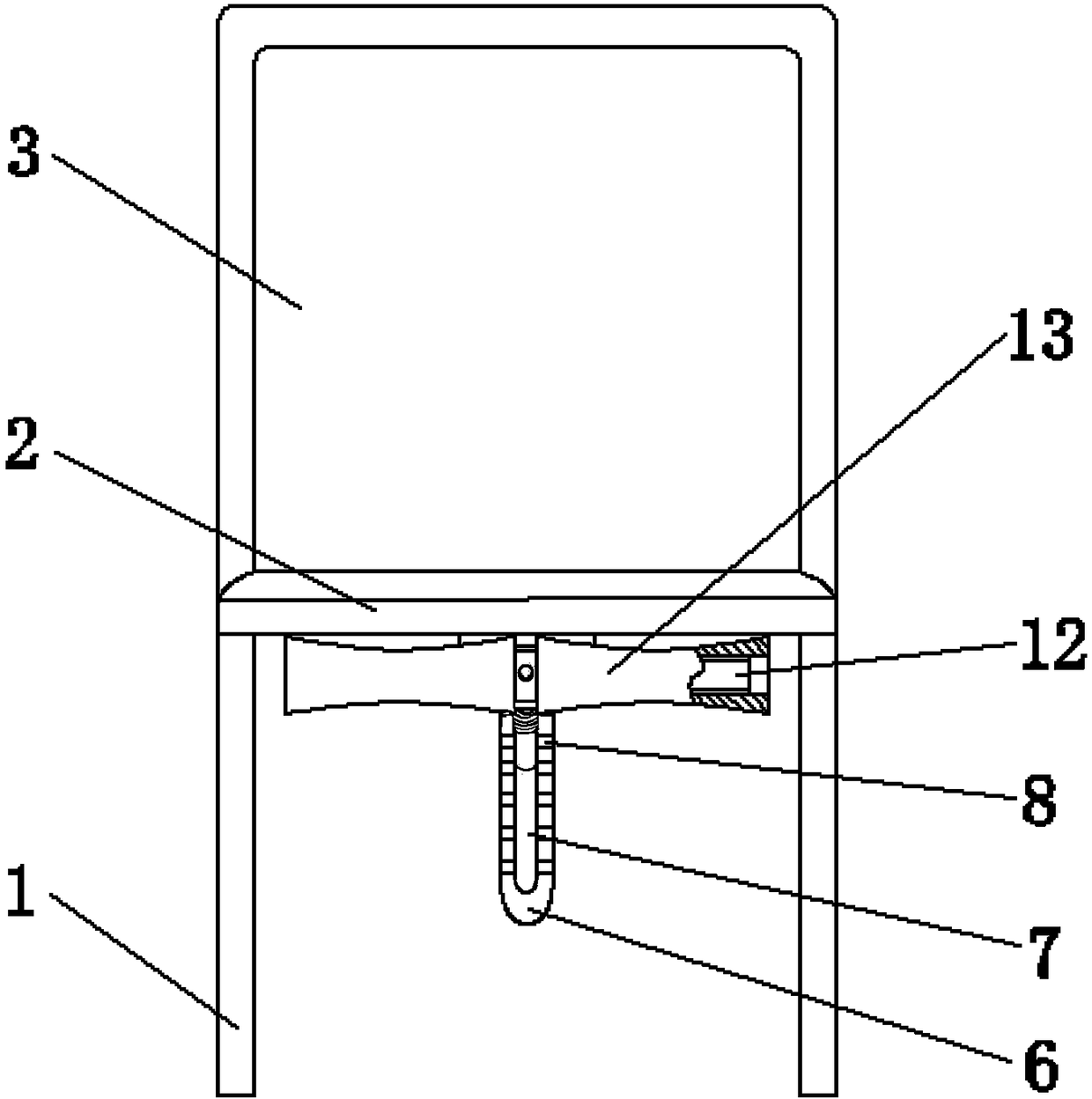

Convenient-to-adjust CCD camera for glass printing size AOI inspection

PendingCN110185896AAdjust up and down positionAdjust front and rear positionsMaterial analysis by optical meansStands/trestlesCcd cameraThreaded rod

The invention relates to the technical field of base station antennas, and discloses a convenient-to-adjust CCD camera for glass printing size AOI inspection. The convenient-to-adjust CCD camera comprises an upper fixing plate, a lower fixing plate and a detection camera, wherein a movable plate is arranged between the upper fixing plate and the lower fixing plate, the side wall of the movable plate is fixedly connected with a supporting plate, the movable plate is provided with an up-and-down adjusting mechanism, a front-and-rear adjusting mechanism is arranged on the supporting plate, the up-and-down adjusting mechanism comprises a first threaded rod, two supporting columns and a first motor, the two ends of each of the two supporting columns are fixedly connected with the top of one fixing plate and the bottom of the other fixing plate correspondingly, the two supporting columns are located on the two sides of the fixing plates, the two ends of the movable plate are movably connected with the two supporting columns in a sleeve mode, and the two ends of the first threaded rod are correspondingly and rotationally connected with the side walls of the two fixing plates through firstbearings. According to the CCD camera, the upper and lower and front and rear positions of the detection camera can be adjusted, so that the detection effect by the detection camera is improved, andpeople can conveniently use the camera.

Owner:苏州天目光学科技有限公司

Counterweight adjustment device for construction machinery and construction machinery

ActiveCN104099855BAdjust the weightAdjust the center of gravityFluid-pressure actuator testingServomotorsWeight adjustmentHydraulic pump

The invention provides a balance weight adjustment device for engineering machinery and the engineering machinery. The balance weight adjustment device comprises a pumping device, a first liquid storage box and a second liquid storage box, wherein the pumping device comprises a hydraulic pump; the first liquid storage box is communicated with the second liquid storage box; a hydraulic loop is formed among the first liquid storage box, the second liquid storage box and the hydraulic pump; the first liquid storage box and the second liquid storage box are mounted at different positions of the machine body of the engineering machinery; the pumping device is controlled to adjust the weight of counterweight liquid in the first liquid storage box and the second liquid storage box so as to adjust the center of gravity of the engineering machinery. According to the invention, when the balance weight adjustment device is mounted in the engineering machinery, the weight of the counterweight liquid in the first liquid storage box and the second liquid storage box is adjusted to more conveniently adjust the balance weight at the first liquid storage box and the second liquid storage box, so that the weight state of the engineering machinery can be effectively improved, the center of gravity of the engineering machinery is adjusted, and the adaptation of the engineering machinery to the working condition is improved.

Owner:ZOOMLION HEAVY IND CO LTD

An adaptable smart device access device

ActiveCN110601105BFunction as a support columnAdaptableElectrical apparatusStructural engineeringMechanical engineering

Owner:南京庞瑞科技有限公司

Original pressing board opening and closing device and office machine

InactiveCN102621844BAdjust front and rear positionsLow costElectrographic process apparatusPictoral communicationEngineeringMechanical engineering

The invention provides a device for opening and closing a manuscript pressing plate. The device is capable of correctly adjusting the front-rear position of the manuscript pressing plate and allows a decrease in the number of elements so as to form a simple structure. In the invention, the manuscript pressing plate is assembled and can be opened and closed via the device relative to the body of the office machine. One of the means for adjusting the front-rear position of the manuscript pressing plate allows the adjustment of the assembling position between the manuscript pressing plate and the device in the front-rear direction. The means for adjusting the front-rear position of the manuscript pressing plate is directly arranged on a structural element of the device for assembling the manuscript pressing plate.

Owner:KEM HONGKONG

Automatic cover mold grapnel device for high-end equipment manufacturing

InactiveCN113333610AAdjust front and rear positionsEasy to collectMetal-working feeding devicesPositioning devicesCircular discElectric machinery

The invention relates to a grapnel device, in particular to an automatic cover mold grapnel device for high-end equipment manufacturing. The technical problem to be solved by the invention is to provide the automatic cover mold grapnel device for high-end equipment manufacturing, which can prevent a cover mold from being damaged. The automatic cover mold grapnel device for high-end equipment manufacturing comprises a bottom plate, first sliding groove plates, a sliding plate, a disc, a rotating cylinder, a connecting block, a first connecting plate, a second sliding groove plate, a motor, a first lead screw, a bevel gear set, a second lead screw, a first nut, a first connecting rod, a special-shaped plate, a clamping assembly, a rotating assembly and a placing assembly, wherein the first sliding groove plates are arranged on the two sides of the bottom plate correspondingly, and the sliding plate is arranged between the first sliding groove plates in a sliding mode; the disc is arranged on the sliding plate; and the rotating cylinder is rotationally arranged on the disc. The automatic cover mold grapnel device is provided with a front-back moving assembly, so that the front-back positions of the clamping assembly and the placing assembly can be integrally adjusted, and then the front-back positions of a grapnel are adjusted.

Owner:田小会

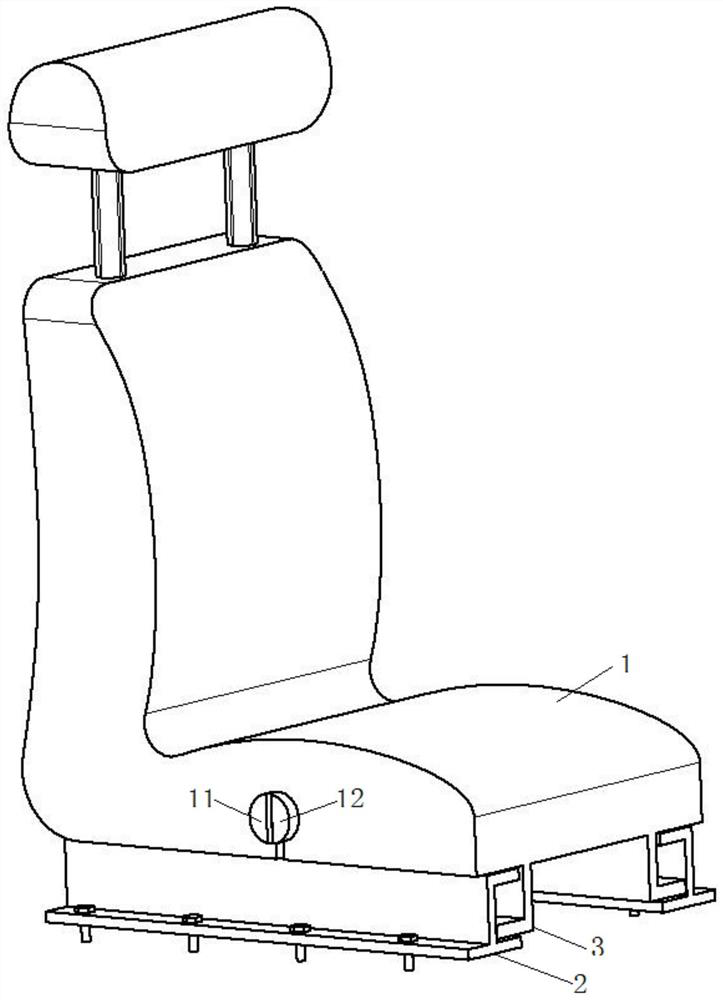

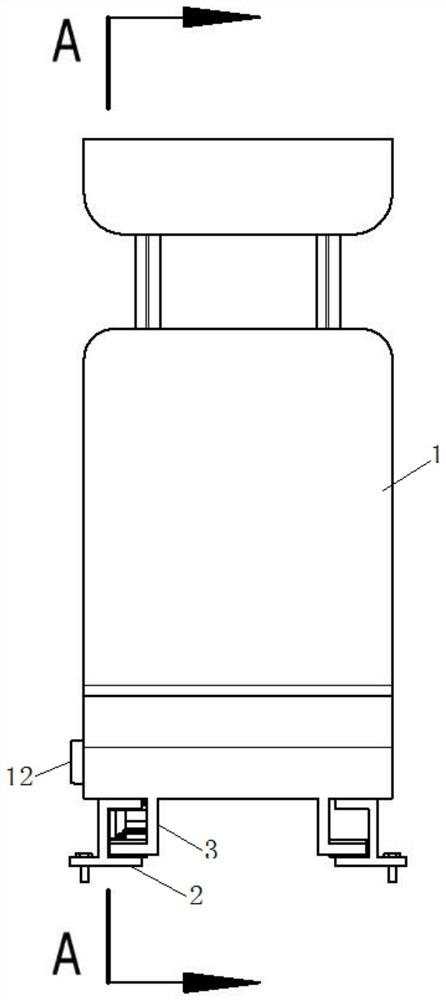

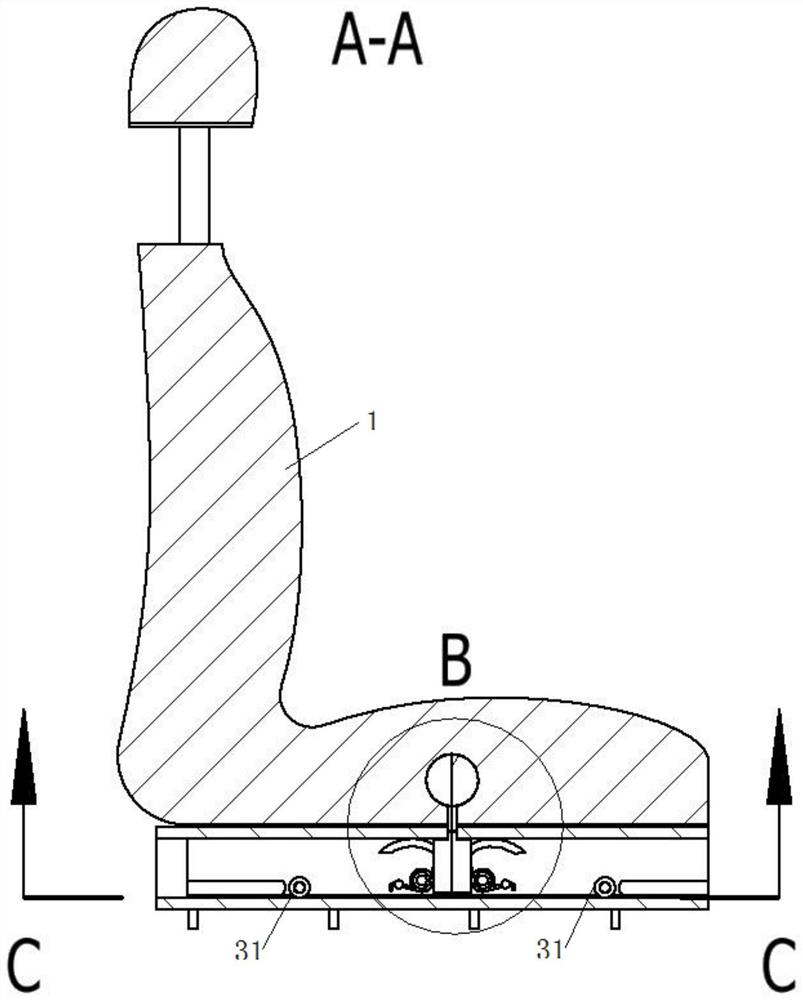

A stepless adjustable car seat

Owner:TAIYUAN CITY TAIHANG CHANGQING AUTOMOBILE SAFETY EQUIP

Multi-shaft wire clamping retaining device

PendingCN112809582AAdjust front and rear positionsWork holdersStructural engineeringClassical mechanics

The invention discloses a multi-shaft wire clamping retaining device. The multi-shaft wire clamping retaining device comprises an air cylinder fixing seat, a fixing rod, a fixing end mounting seat and a cross beam; clamping fingers are fixed on the fixing rod; one end of the fixing rod is fixedly connected with an adapter block; the adapter block is connected with a clamping air cylinder; the clamping air cylinder is fixedly connected with the air cylinder fixing seat; the air cylinder fixing seat is fixedly connected with the fixing end mounting seat; a front-back adjusting block is fixed to the side, away from the clamping fingers, of the fixing end mounting seat; a wire rod protection cover is clamped and fixed to the fixing end mounting seat through a front-back adjusting block; the cross beam is fixed to the lower surface of the fixing end mounting seat; moving air cylinders are fixed to the two ends of the cross beam; and sliding rail fixing bases and connecting blocks are fixed to the positions, on the inner sides of the moving air cylinders, of the cross beam. The multi-shaft wire clamping retaining device has the advantages that flexible clamping is achieved through a conventional air cylinder and a linkage mechanism, and only one air cylinder is needed as power regardless of the number of shafts before the limiting force of the air cylinder is exceeded.

Owner:深圳市易准数控系统有限公司

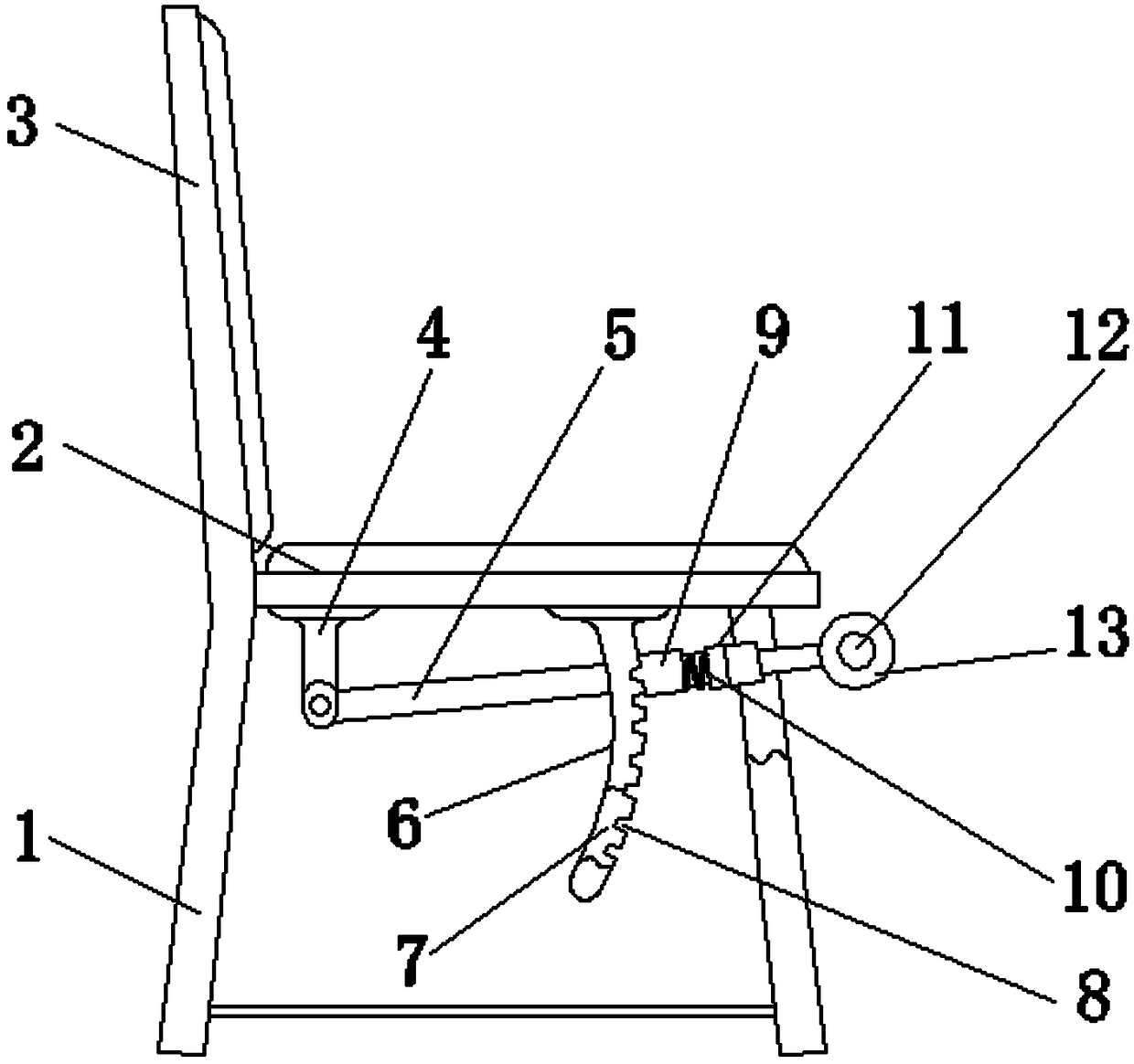

Chair with massaging function

PendingCN108784062AImprove massage effectSimple structureVehicle seatsRoller massageAirplaneEngineering

A chair with a massaging function comprises a chair body consisting of chair legs, a chair seat and a backrest, wherein a hinging seat is arranged at a position, near the back part, of the middle partof the lower side of the chair seat, and a longitudinal rod is hinged; a vertical arc-shaped rod is arranged at a position, near the front part, of the middle part of the lower side of the chair seat; a vertical rod slot and vertically arranged clamping slots are formed in the arc-shaped rod; the longitudinal rod runs through the vertical rod slot; a clamping sleeve matched with the clamping slots, a clamping sleeve spring matched with the clamping sleeve and a spring baffling ring matched with the clamping sleeve spring are assembled on the longitudinal rod; a transverse roll shaft is fixedly connected to the front end of the longitudinal rod; a pair of massaging rolls are arranged on the roll shaft in bilateral symmetry; the longitudinal rod is a telescopic rod; the massaging rolls areconcave arc rolls; salient points are distributed on the roll surfaces of the massaging rolls. The chair with the massaging function is simple in structure and convenient to use, has the characteristics of small space occupancy and light weight, and is suitable to be used on occasions having relatively high requirements on the space and the weight, such as airplanes, vehicles and ships.

Owner:张云峰

Staggered aluminum profile stamping device

PendingCN109622708AAdjust clamping widthAdjust front and rear positionsMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a staggered aluminum profile stamping device. The staggered aluminum profile stamping device comprises a base; the base is provided with a pair of machining units; the machining units are arranged on the base in a staggered mode; each machining unit comprises an adjustment rail and a stamping assembly; the stamping assemblies are slidably arranged on the adjustment rails; each stamping assembly comprises a stamping base and a stamping air cylinder; the head of each stamping air cylinder is provided with a detachable stamping head; one side of each machining unit is provided with a near end positioning assembly and a near end clamping air cylinder; and the other side of each machining unit is provided with a far end positioning assembly, a far end clamping air cylinder and a far end adjustment air cylinder. When the width of profile changes, a user can adjust the clamping width of the near end positioning assembly and the far end positioning assembly; and when the length of the profile changes, the user can adjust the front-back position of the far end adjustment air cylinder, and rapidness and convenience are achieved.

Owner:扬州丛宇自动化科技有限公司

Material coiling conveying mechanism for wood strip trimming

The invention relates to a material coiling conveying mechanism for wood strip trimming. The material coiling conveying mechanism for wood strip trimming comprises a machine frame and a power distribution control box. A material coiling device and a trimming device are arranged on the machine frame. The material coiling device comprises a material coiling wheel arranged vertically on the machine frame, a material coiling shaft of the material coiling wheel is connected to material coiling output shaft, and the material coiling wheel rotates counterclockwise.A material discharging frame is arranged under the material coiling wheel, and installation notches are evenly formed in the material coiling wheel. Material pressing seats matched with wood bars are installed on the installation notches, a material pressing belt matched with the material coiling wheel is arranged on the right side of the material coiling wheel, the lower end of the material pressing belt is located under the material discharging frame, and the upper end of the material pressing belt is located above at the middle and right part of the material coiling wheel. According to the material coiling conveying mechanismfor wood strip trimming, the rotation of the wood bars around the material coiling wheel is realized by using the uniformly arranged material pressing seat on the material coiling wheel and the material pressing belt matched with the right side of the material coiling wheel, then the trimming of the wood bars is realized through a trimming cutter arranged on the right side of the material coilingwheel, a product is not required to be fixed to the material coiling wheel, feeding and discharging are greatly facilitated, and the efficiency of the whole trimming is improved.

Owner:JIAXING DAMING INDAL

Work clamping device

InactiveCN108637938BSimple structureReduce volumeWork holdersPositioning apparatusClassical mechanicsEngineering

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com