Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176results about "Testing/calibration for volume measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

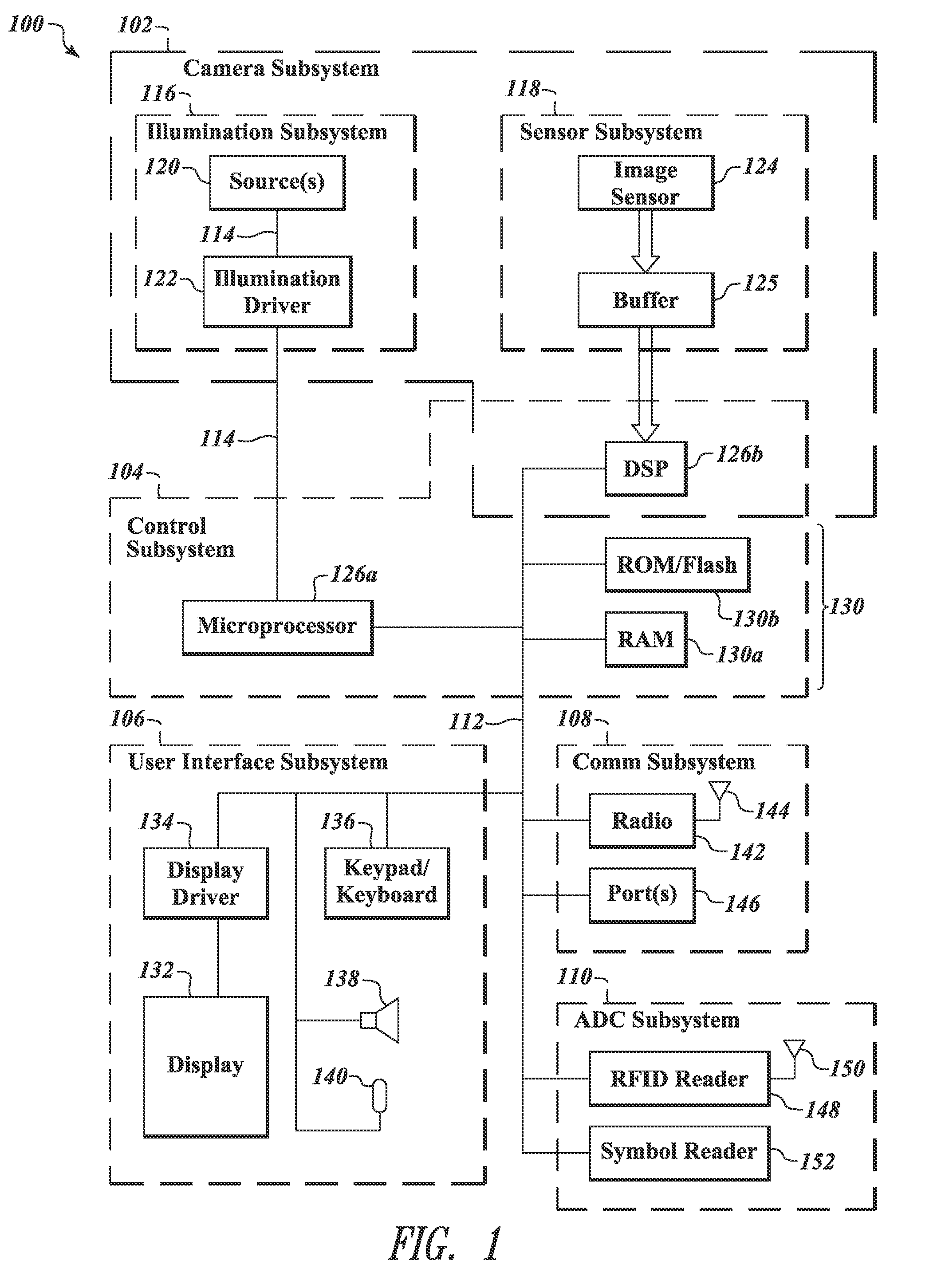

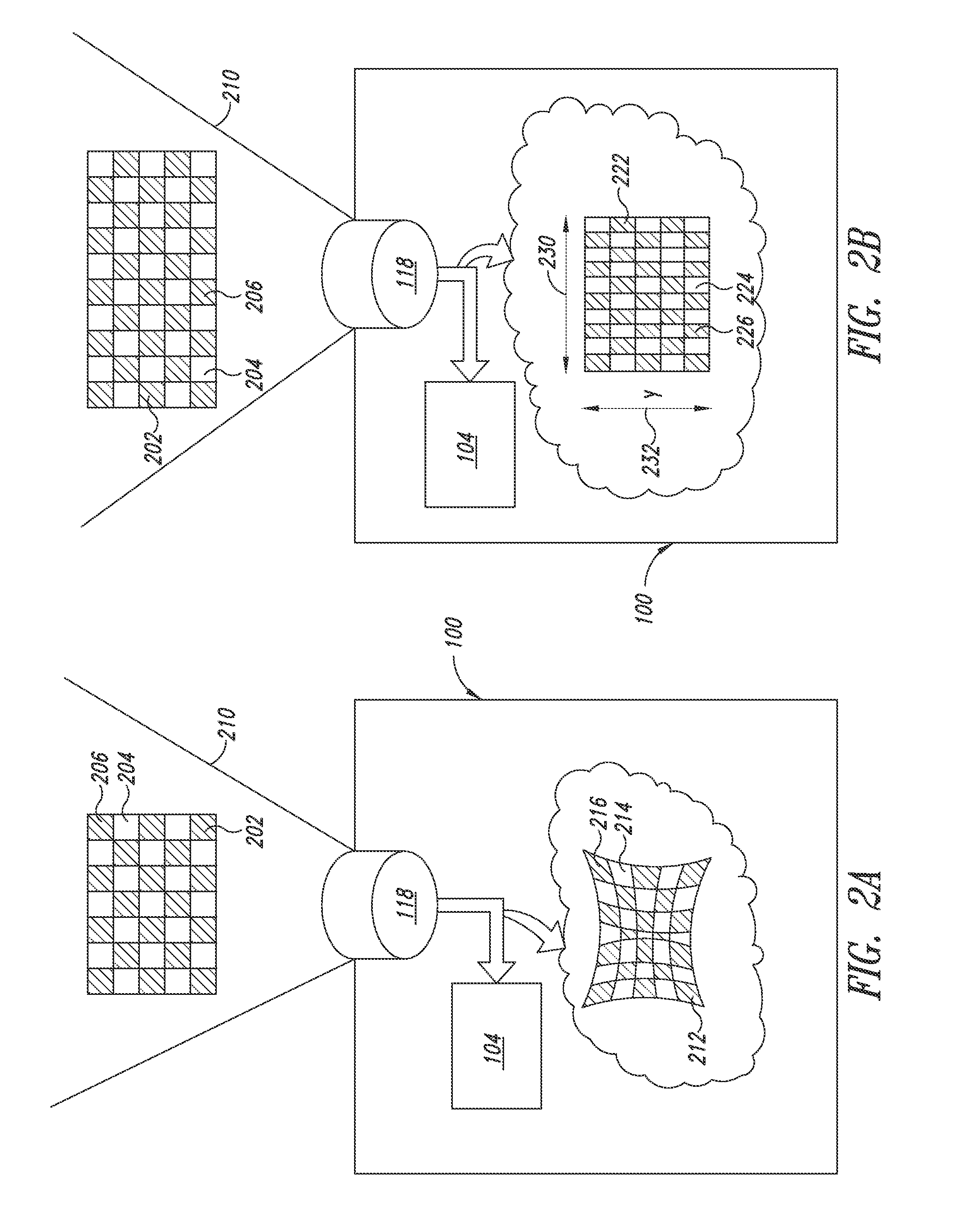

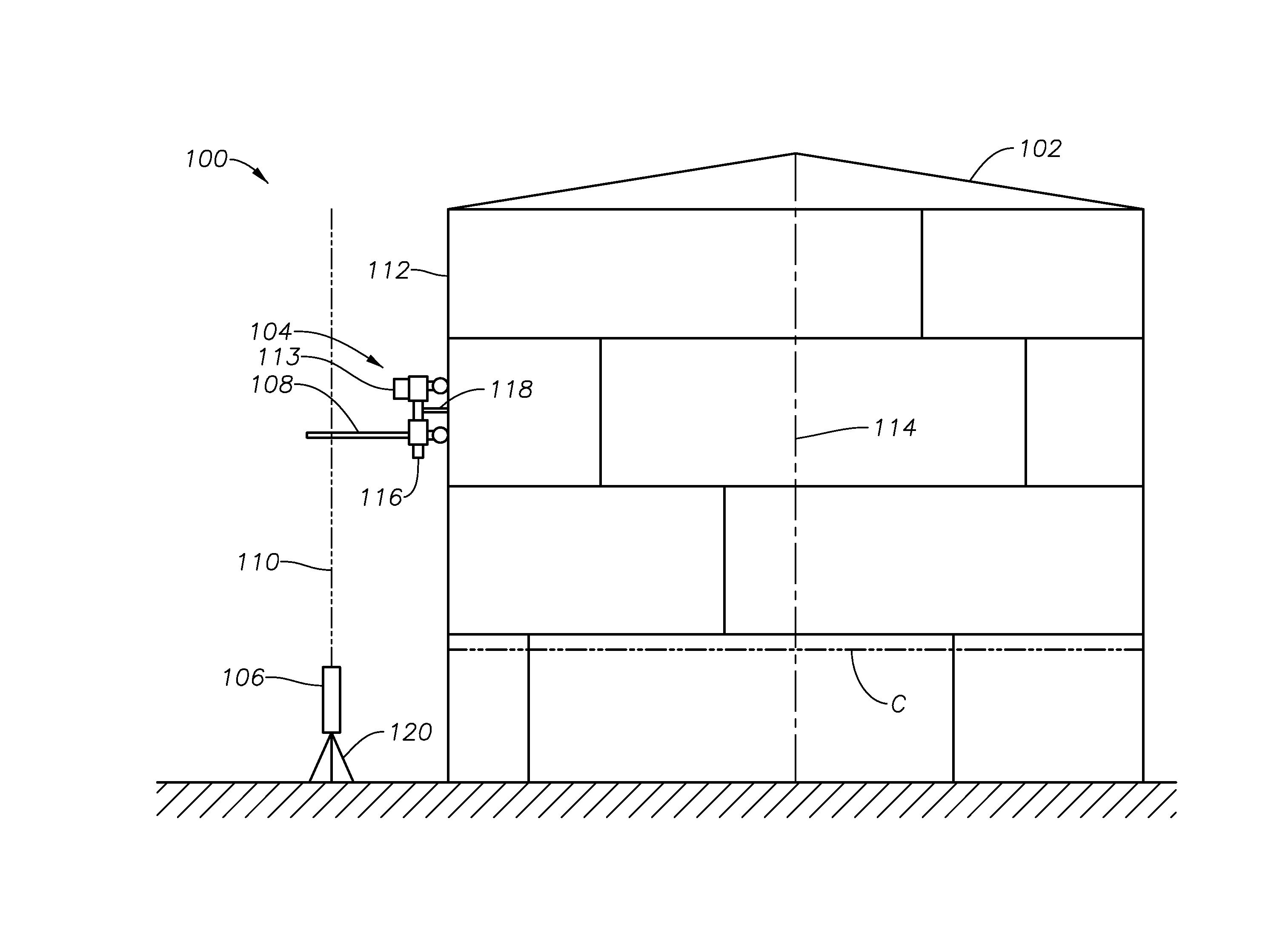

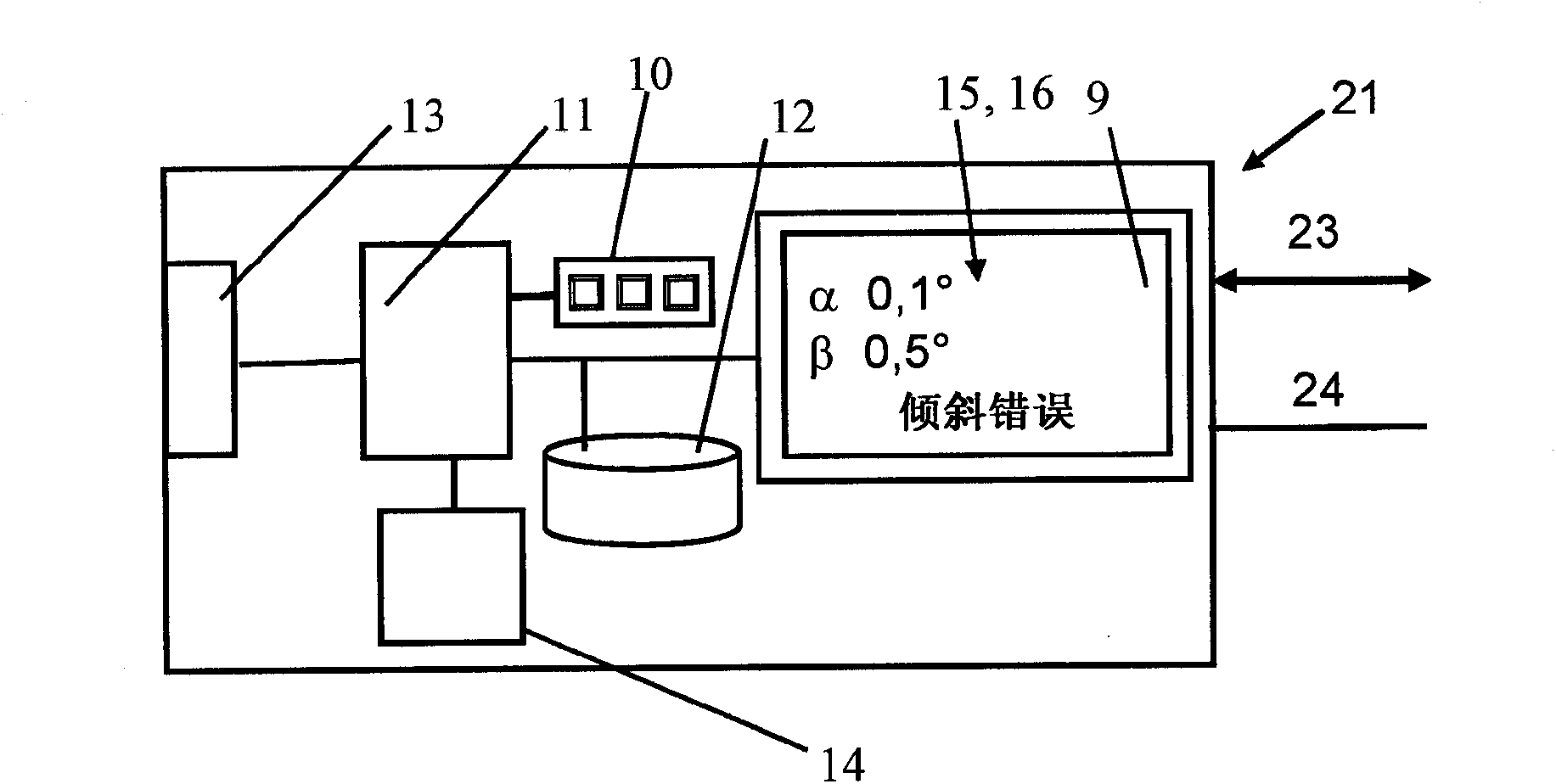

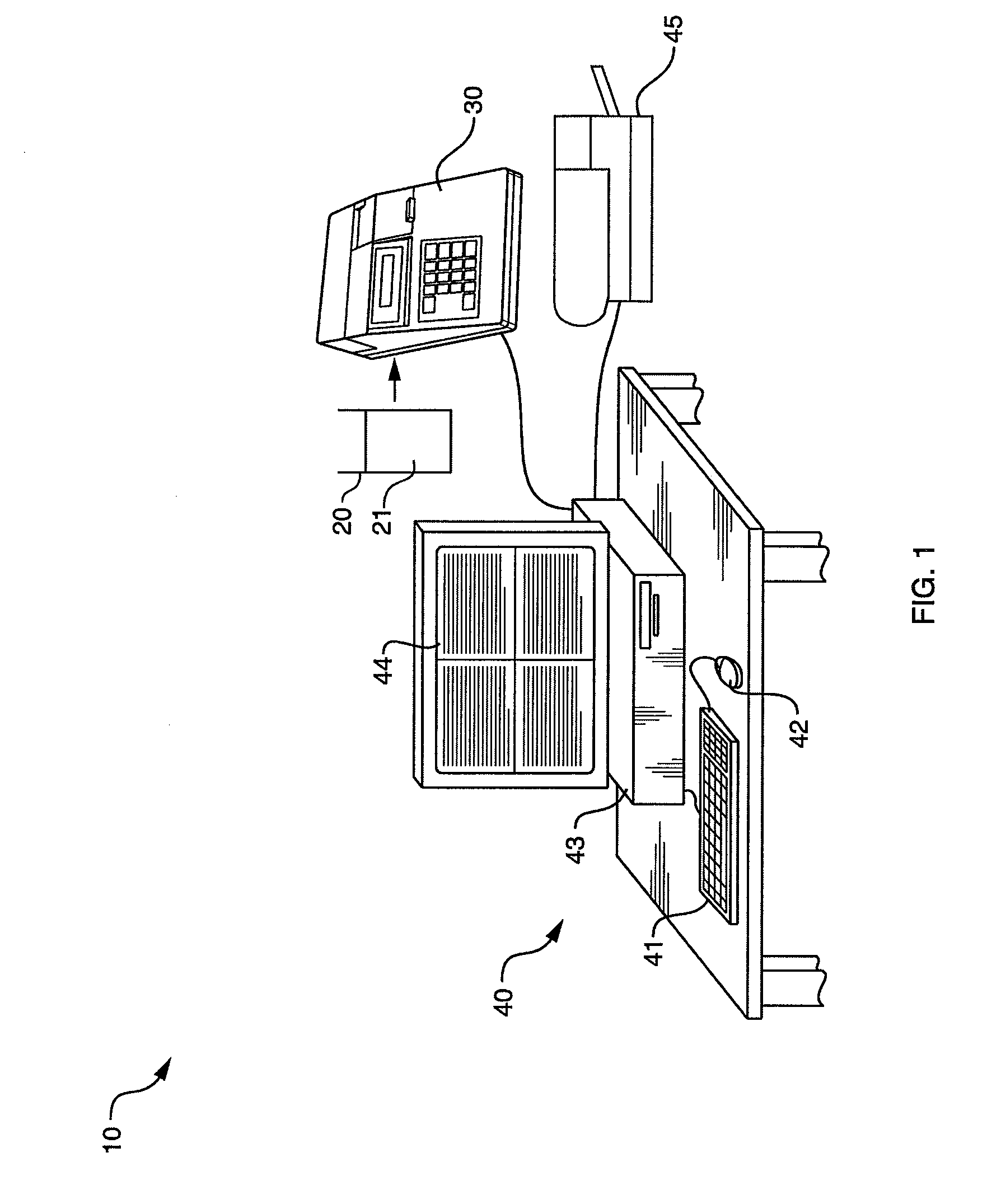

Volume dimensioning system calibration systems and methods

ActiveUS20140049635A1Small sizeFacilitate ongoing and operationally transparent and calibrationColor television detailsClosed circuit television systemsGuidelineTechnical standard

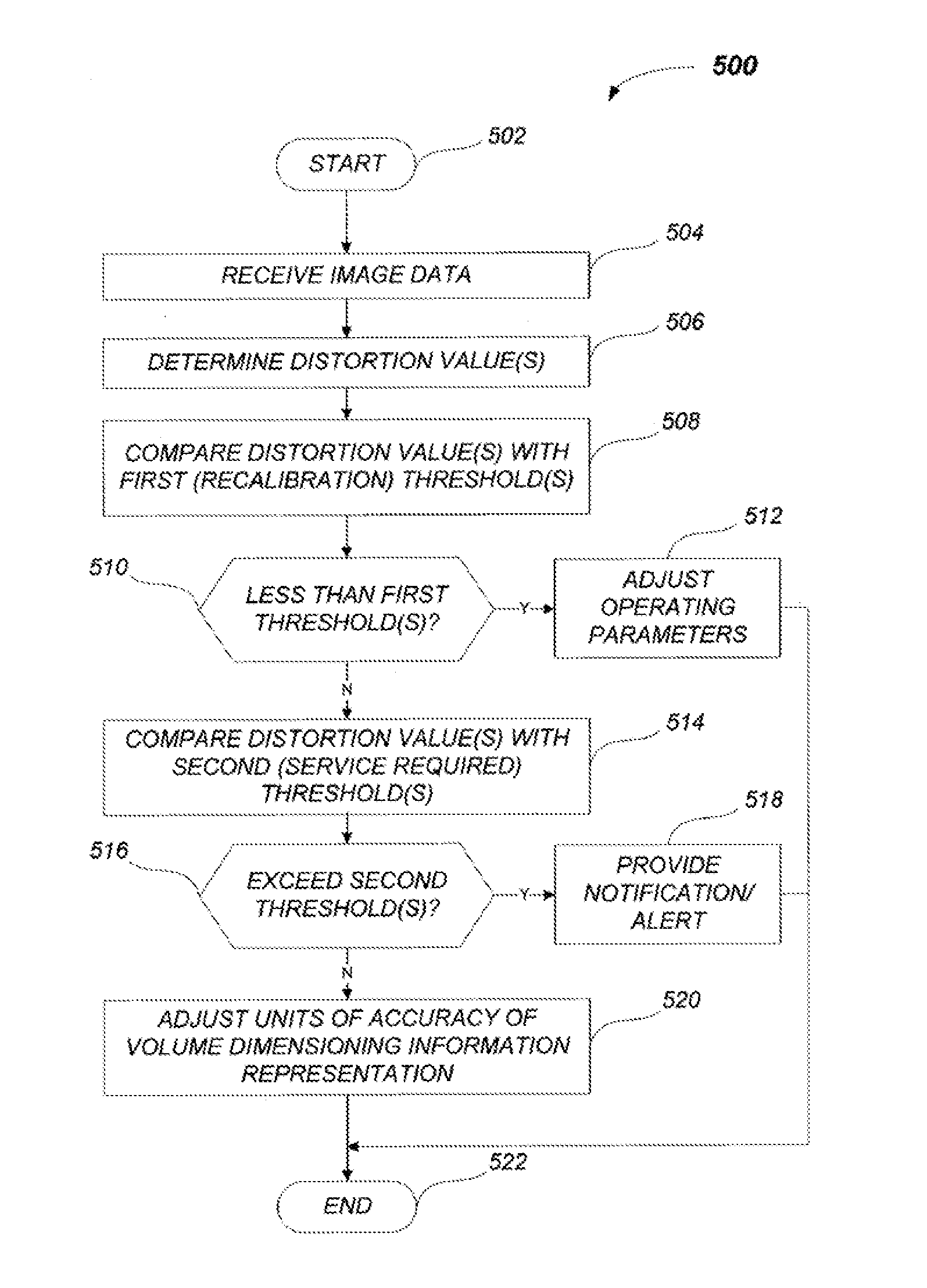

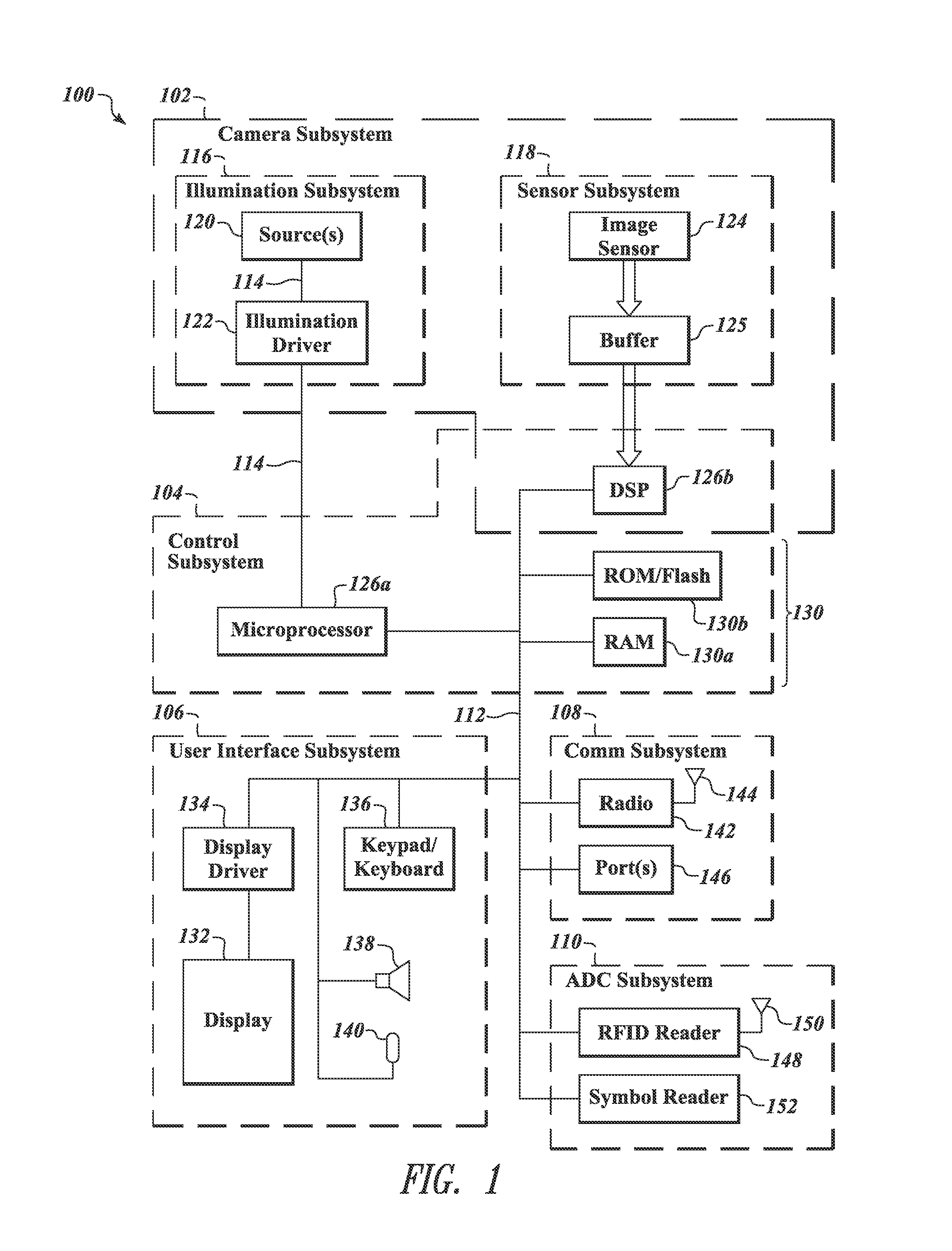

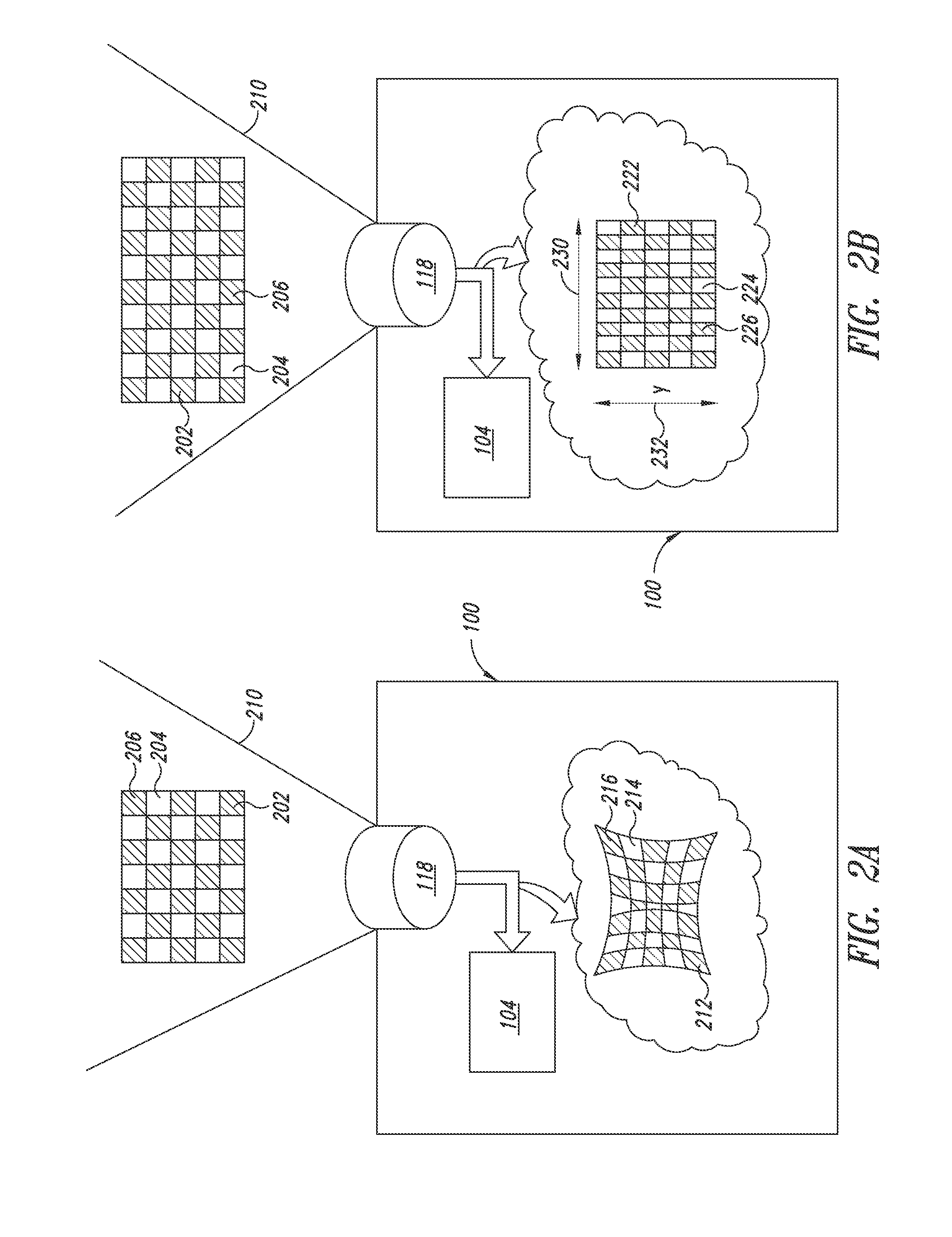

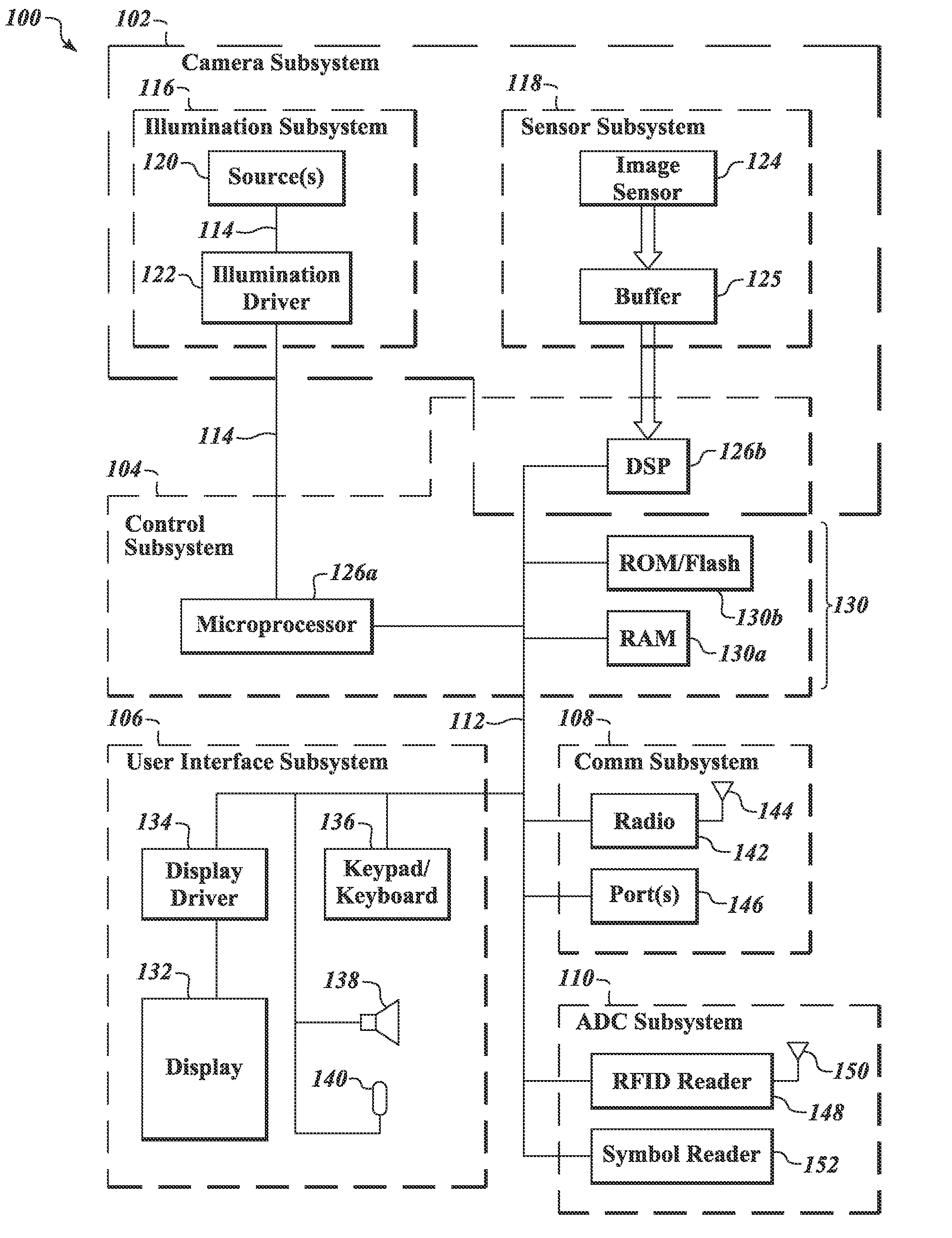

Various corporate, industry, and regulatory guidelines, best practices and standards are used in establishing acceptable levels of accuracy for volume dimensioning systems used in commerce. A volume dimensioning system can determine at least one distortion value that is indicative of an amount of distortion present in the system and responsive to the amount of distortion, autonomously alter or adjust the units of accuracy of information reported by the system. Such alteration or adjustment of units of accuracy may be performed based on an assessment of the distortion relative to a number of distortion thresholds. Responsive to the assessment, the volume dimensioning system can adjust a unit of accuracy in a representation of volume dimensioning related information.

Owner:INTERMEC IP

Volume dimensioning system calibration systems and methods

InactiveUS20150009338A1Facilitate ongoing and operationally transparent and calibrationTelevision systemsTesting/calibration for volume measurementGuidelineTechnical standard

Owner:INTERMEC IP CORP

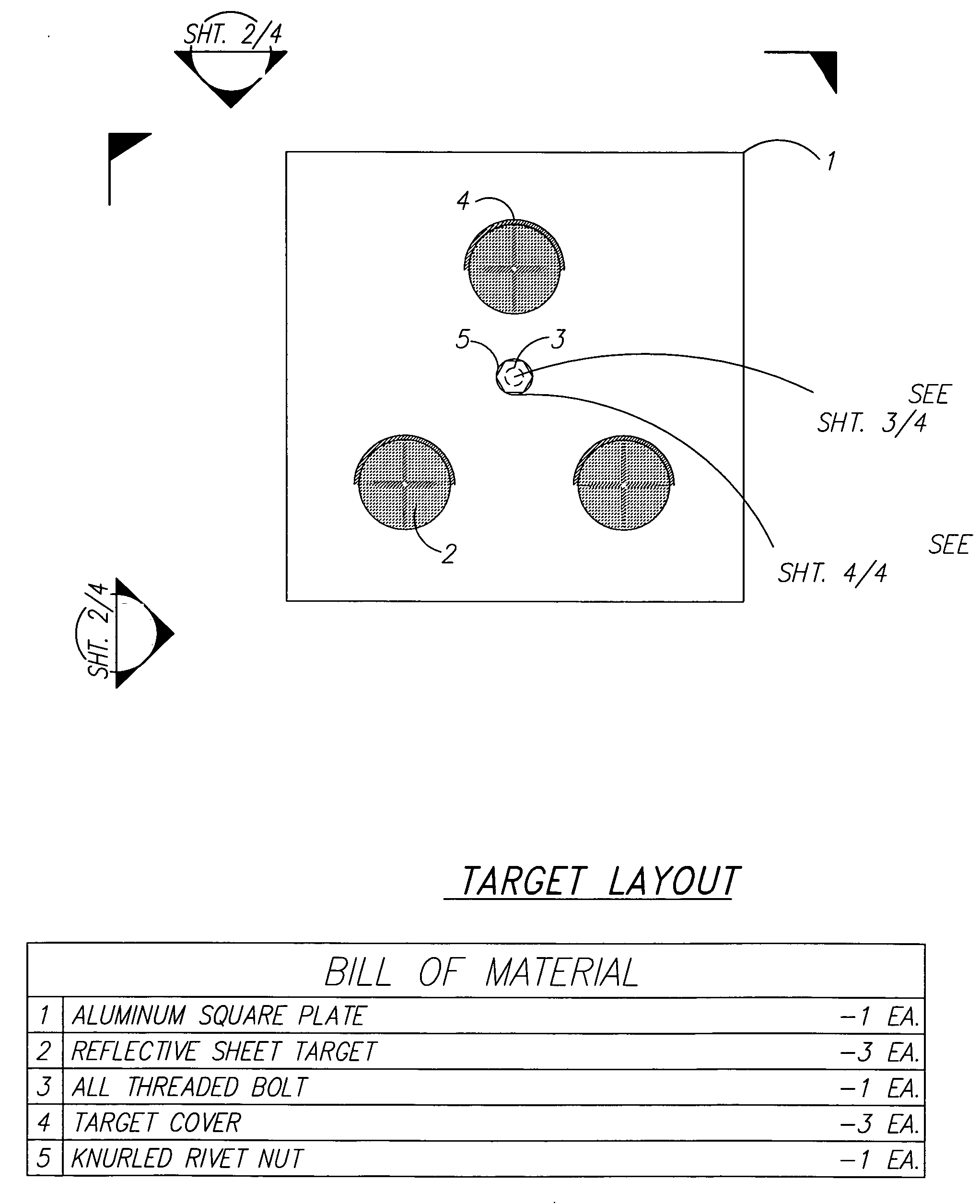

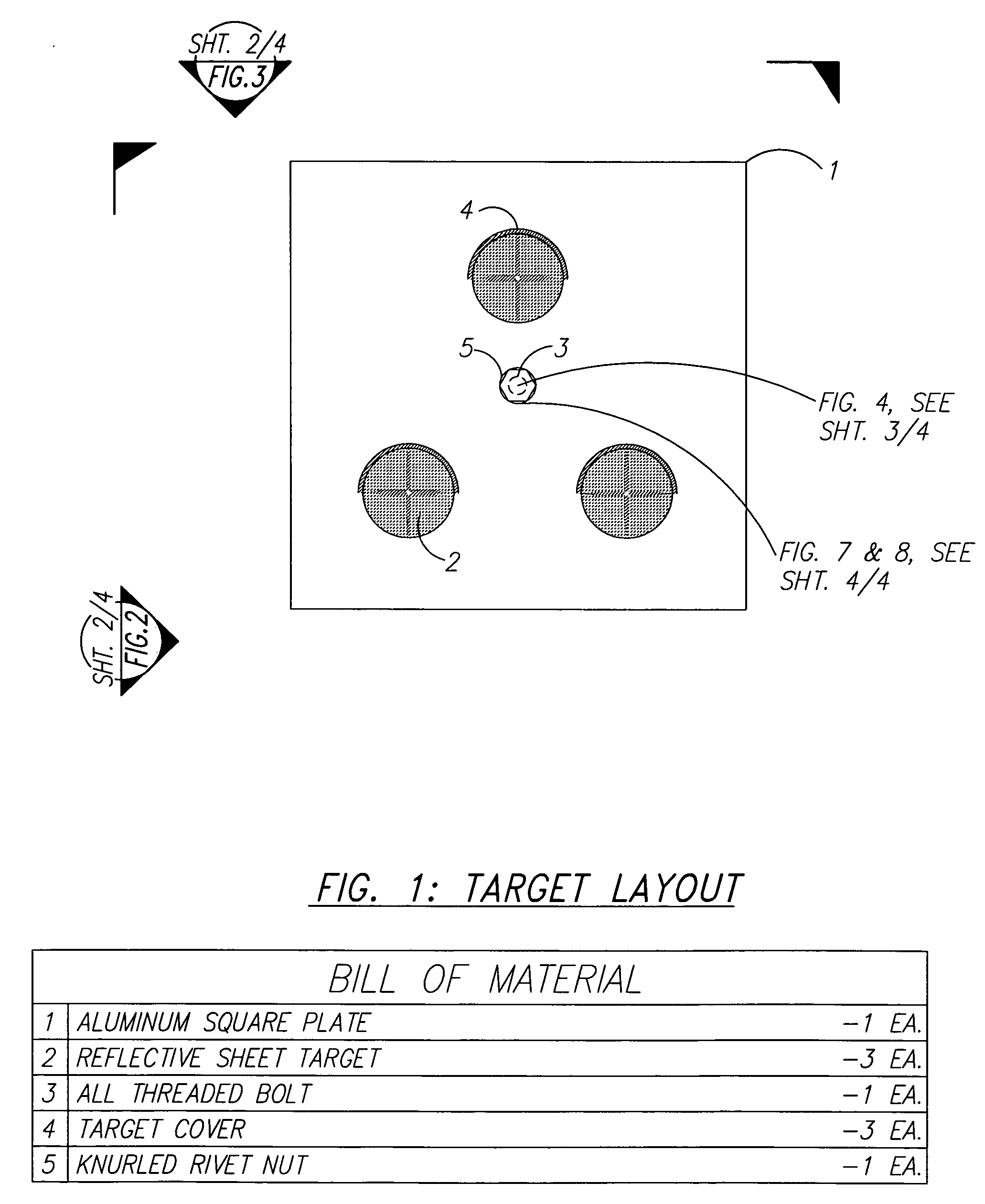

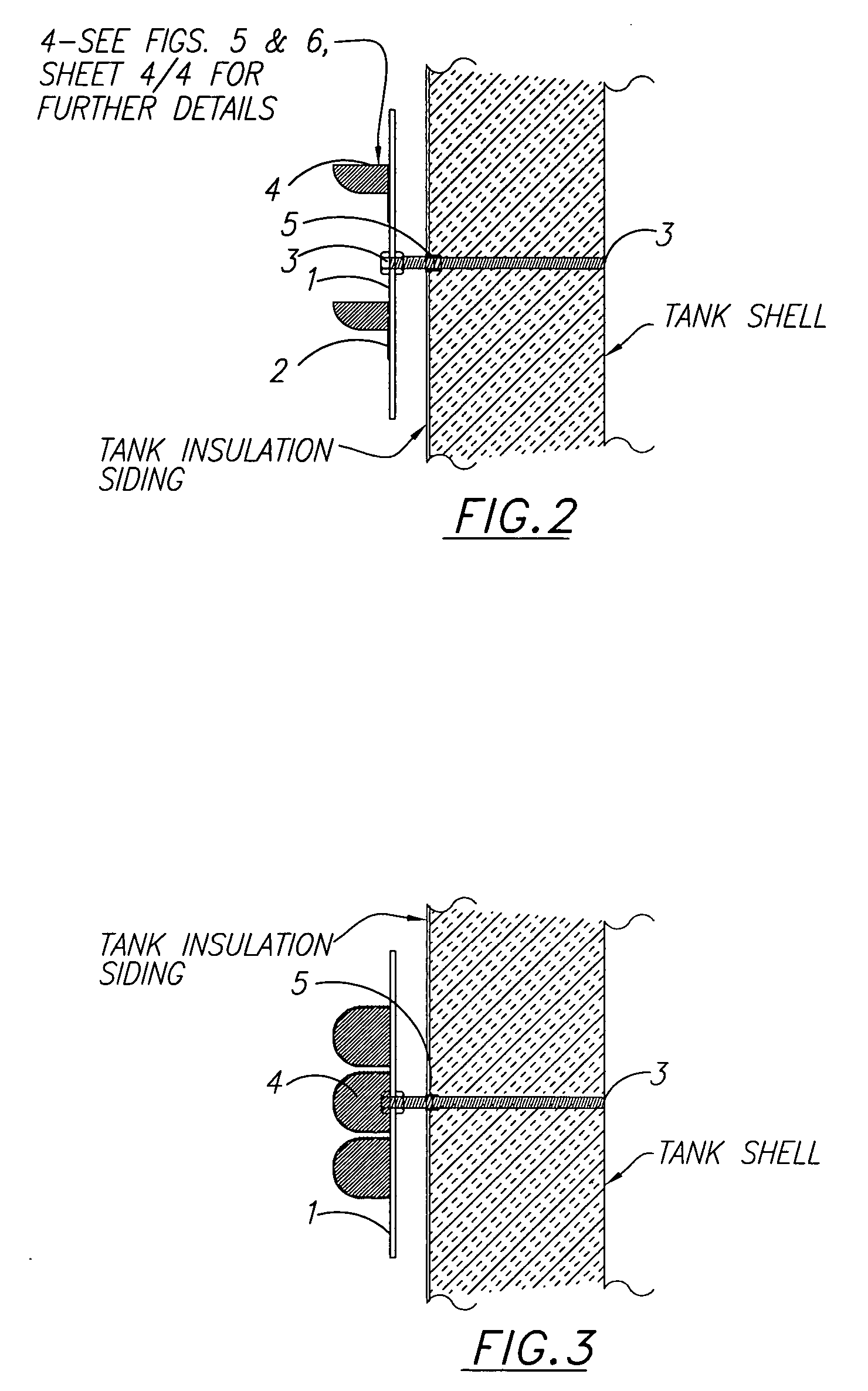

In-service insulated tank certification

InactiveUS20060009929A1Accurate measurementFlow propertiesFluid pressure measurement by mechanical elementsStrappingMeasurement point

A method for the accurate measurement of the true dimensions and true geometric shape of an insulated, or otherwise wrapped tank, and for the subsequent calculation of the strapping table (strap chart) thereof, for any desired liquid height increment, without removing the wrapping (insulation), or draining and cleaning the tank on the inside. A number of points are identified and located on the tank shell, for which 3D coordinates measurement is desired. A target is used for each desired measurement point. The method uses a total station to determine the 3D coordinates of a minimum of 3 points on a reflective target. The target is attached to a bolt that can be threaded through the tank insulation until the end of the bolt makes snug contact with the tank shell. The 3D coordinates of the 3 points on the target, measured with the total station, are converted to the coordinates of the point of contact between the tank shell and the tip of the bolt, which could not be sighted or measured otherwise, being covered by the insulation.

Owner:BOYETTE ROGER LEWIS JR +4

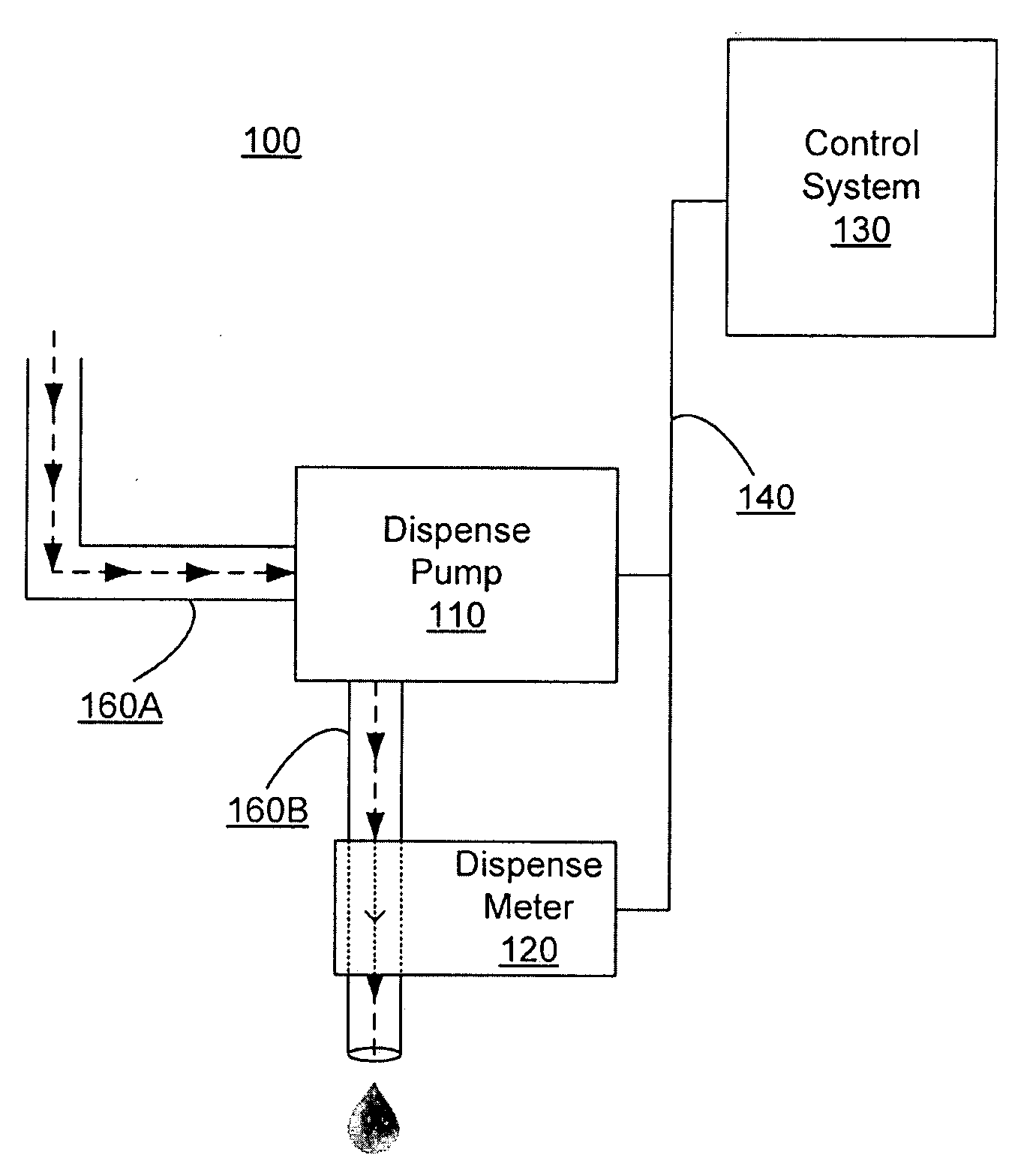

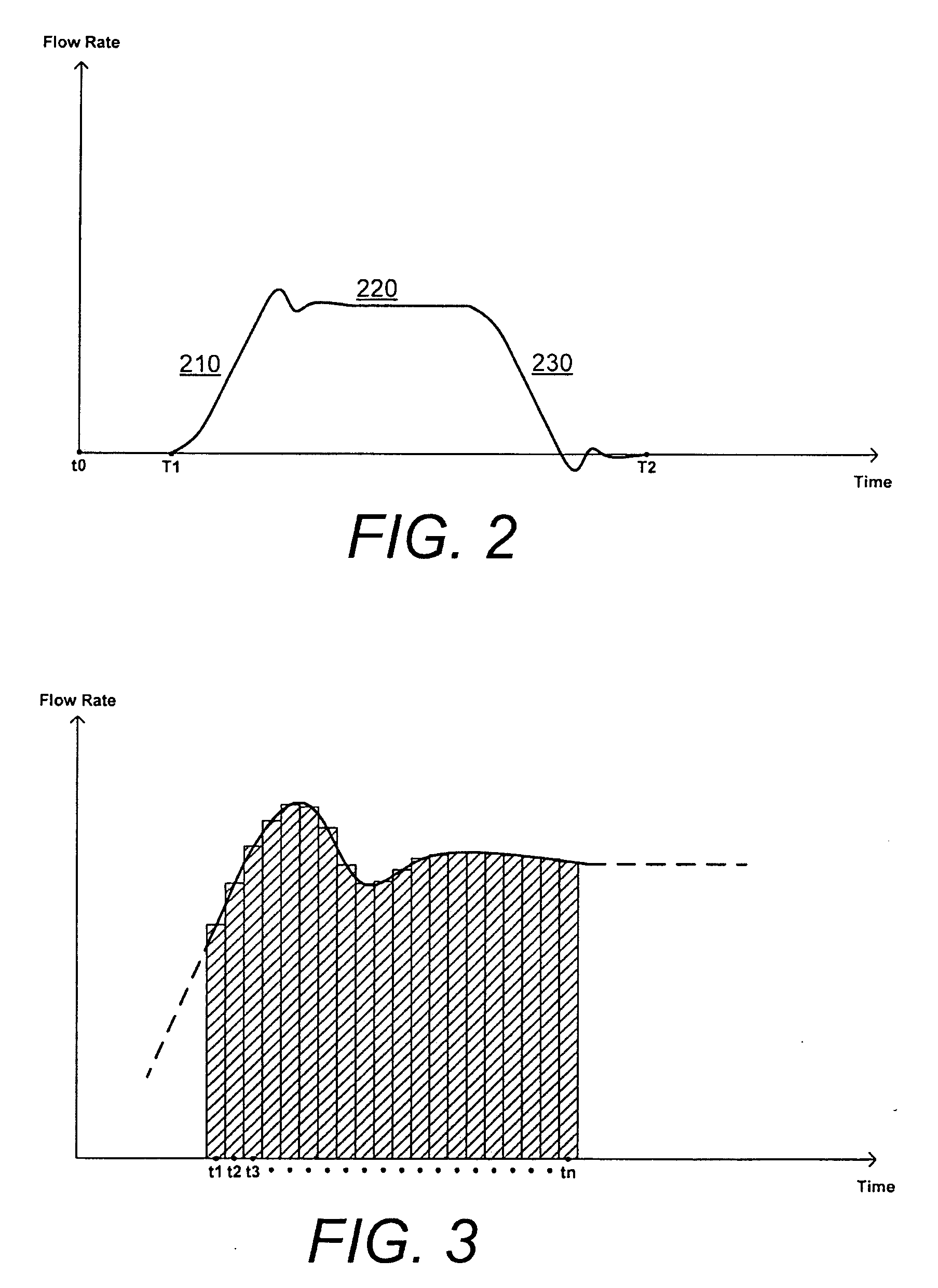

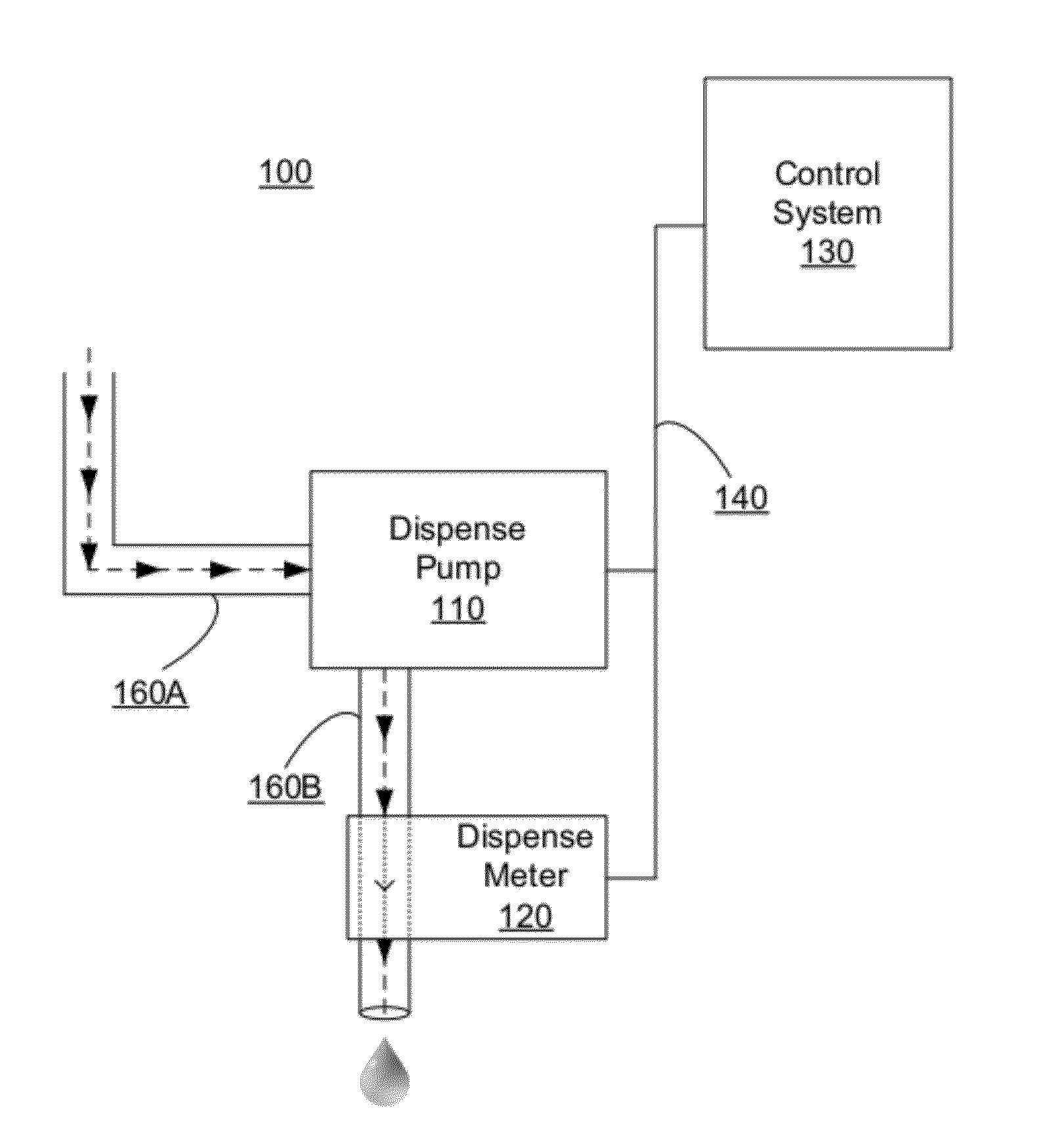

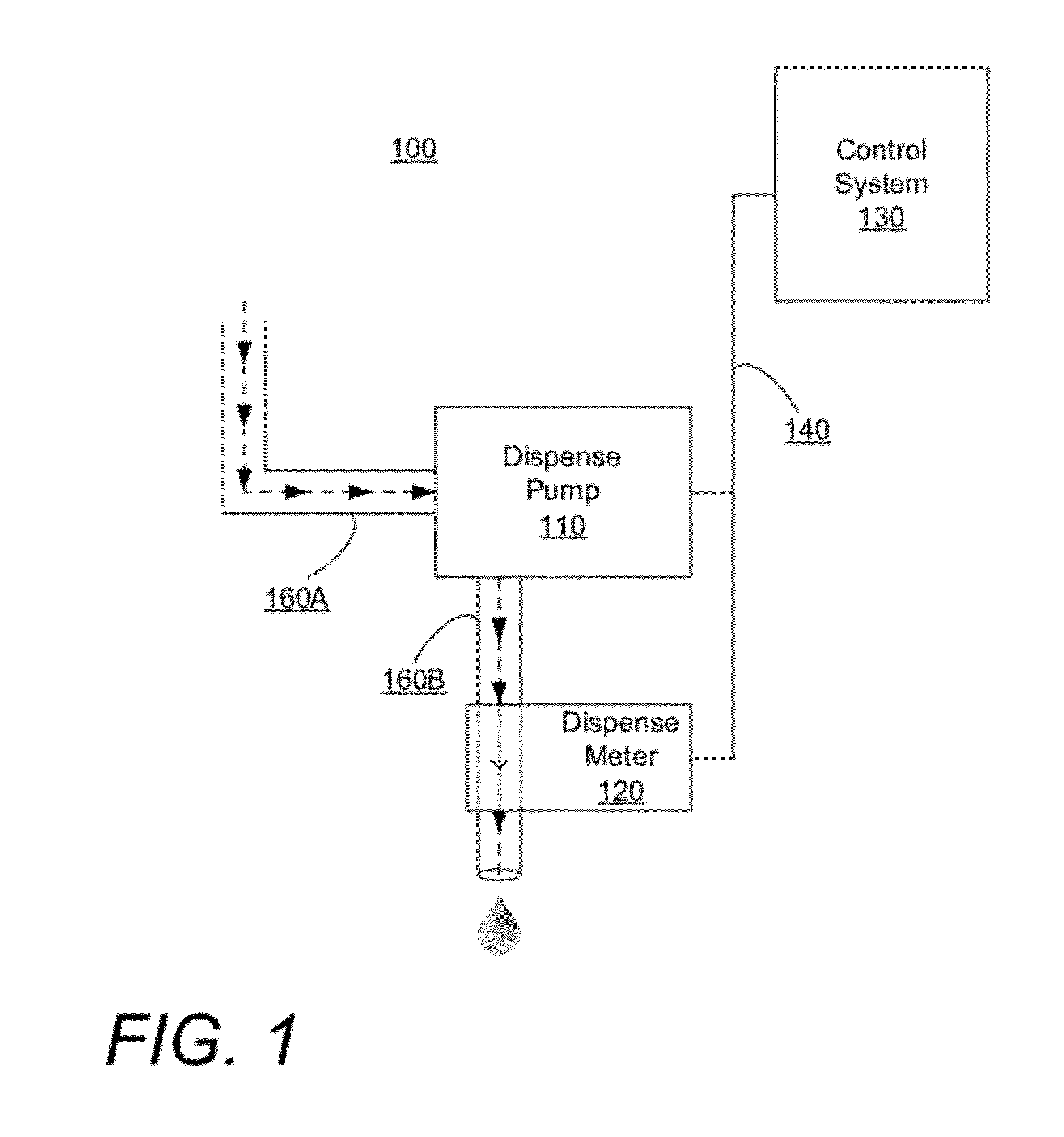

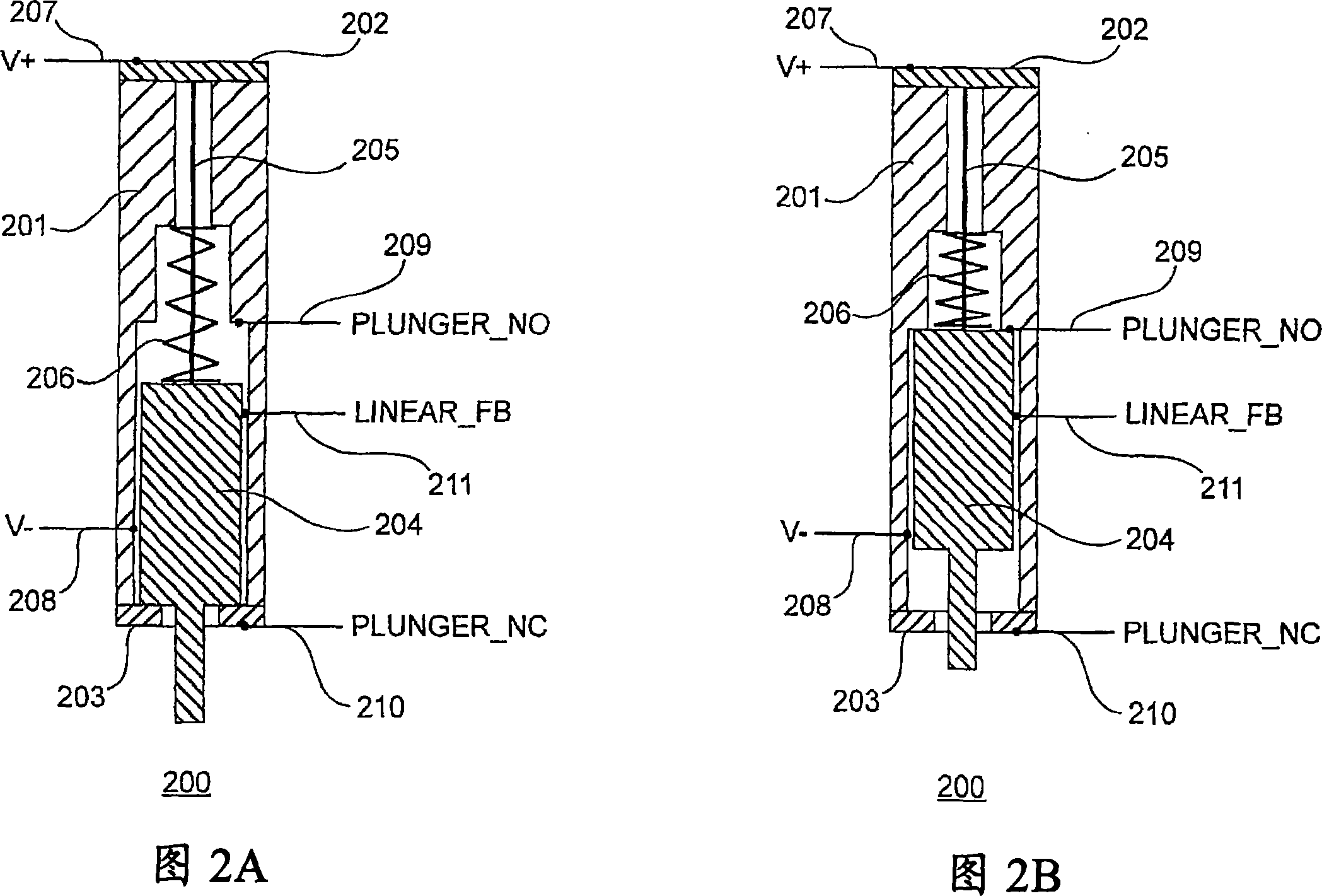

Dispense Verification Meters

ActiveUS20090171502A1Increase sampling rateOpening closed containersBottle/container closureComputer science

A dispense verification meter for measuring and verifying dispense operations (e.g., actual dispensed volumes) of media dispense systems. The dispense verification meter preferably automatically corrects zero offset drift, preferably samples the flow rate of media being dispensed at a sufficiently high sample rate, and verifies whether the desired dispense operation has been achieved.

Owner:MALEMA ENG

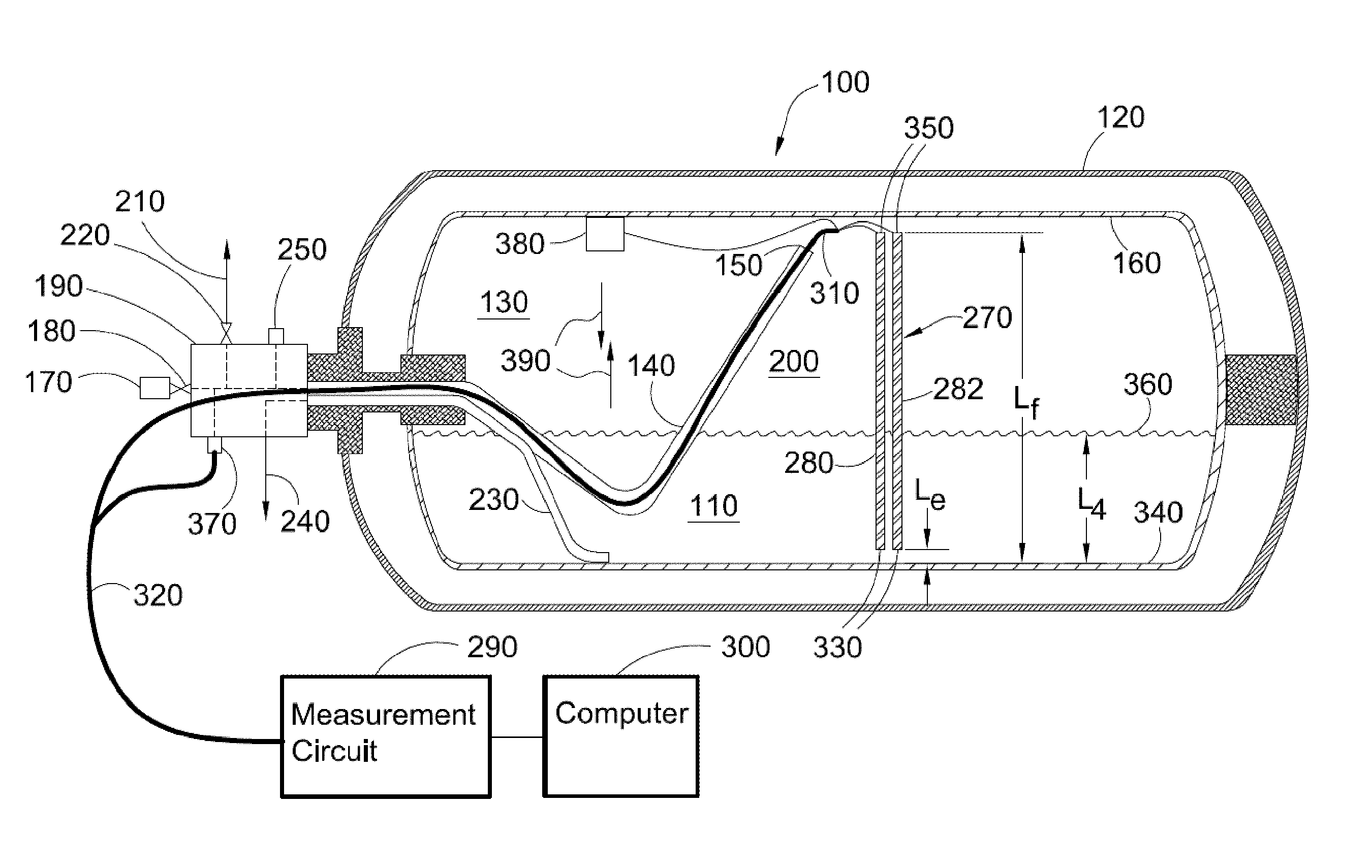

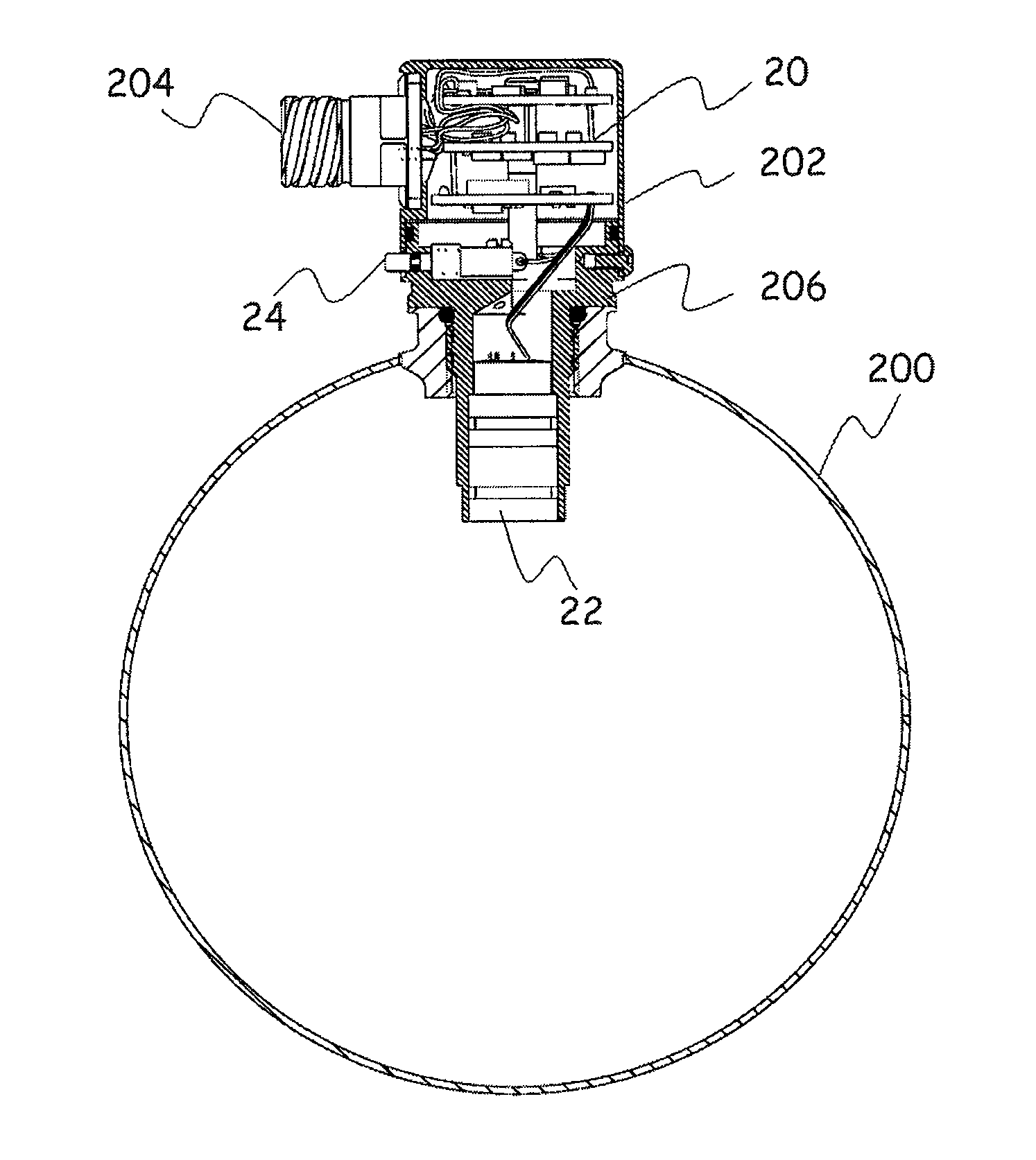

Apparatus And Method For Volume And Mass Estimation Of A Multiphase Fluid Stored At Cryogenic Temperatures

ActiveUS20140223992A1Quality improvementAnalysing fluids using sonic/ultrasonic/infrasonic wavesContainer filling methodsLevel sensorEngineering

An apparatus and method estimate fluid mass in a cryogenic tank that holds a multiphase fluid comprising a liquid and a vapor. The apparatus comprises a level sensor, a pressure sensor and a computer. The level sensor provides a parameter representative of a level of the liquid. The pressure sensor provides a pressure signal representative of vapor pressure inside the cryogenic tank. The computer is operatively connected with the level sensor and the pressure sensor to receive the parameter and the pressure signal, and is programmed to determine the level from inputs comprising the parameter, to calculate a first volume of the liquid from inputs comprising the level, and to calculate a first mass of the liquid from inputs comprising the first volume and the pressure signal.

Owner:WESTPORT FUEL SYST CANADA INC

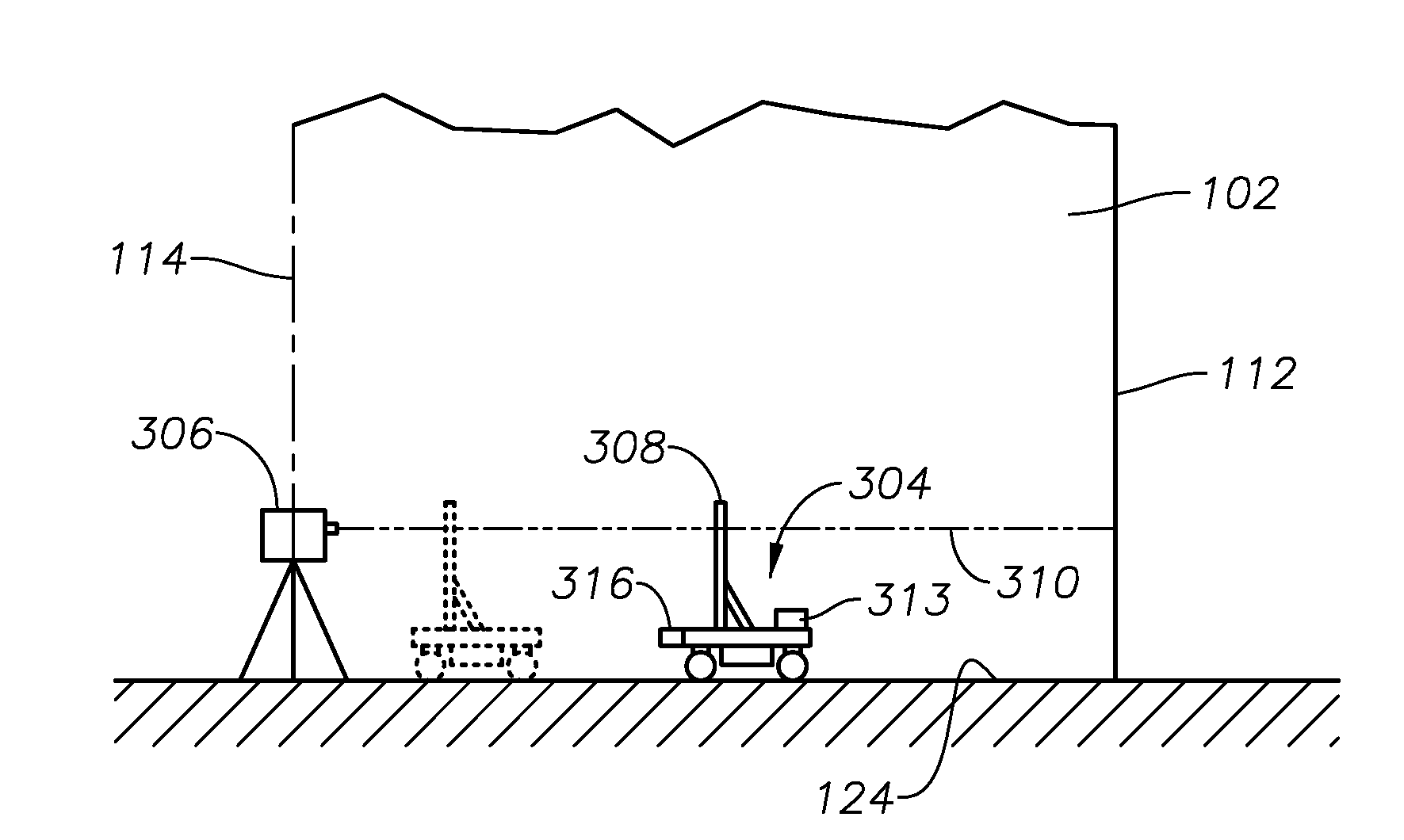

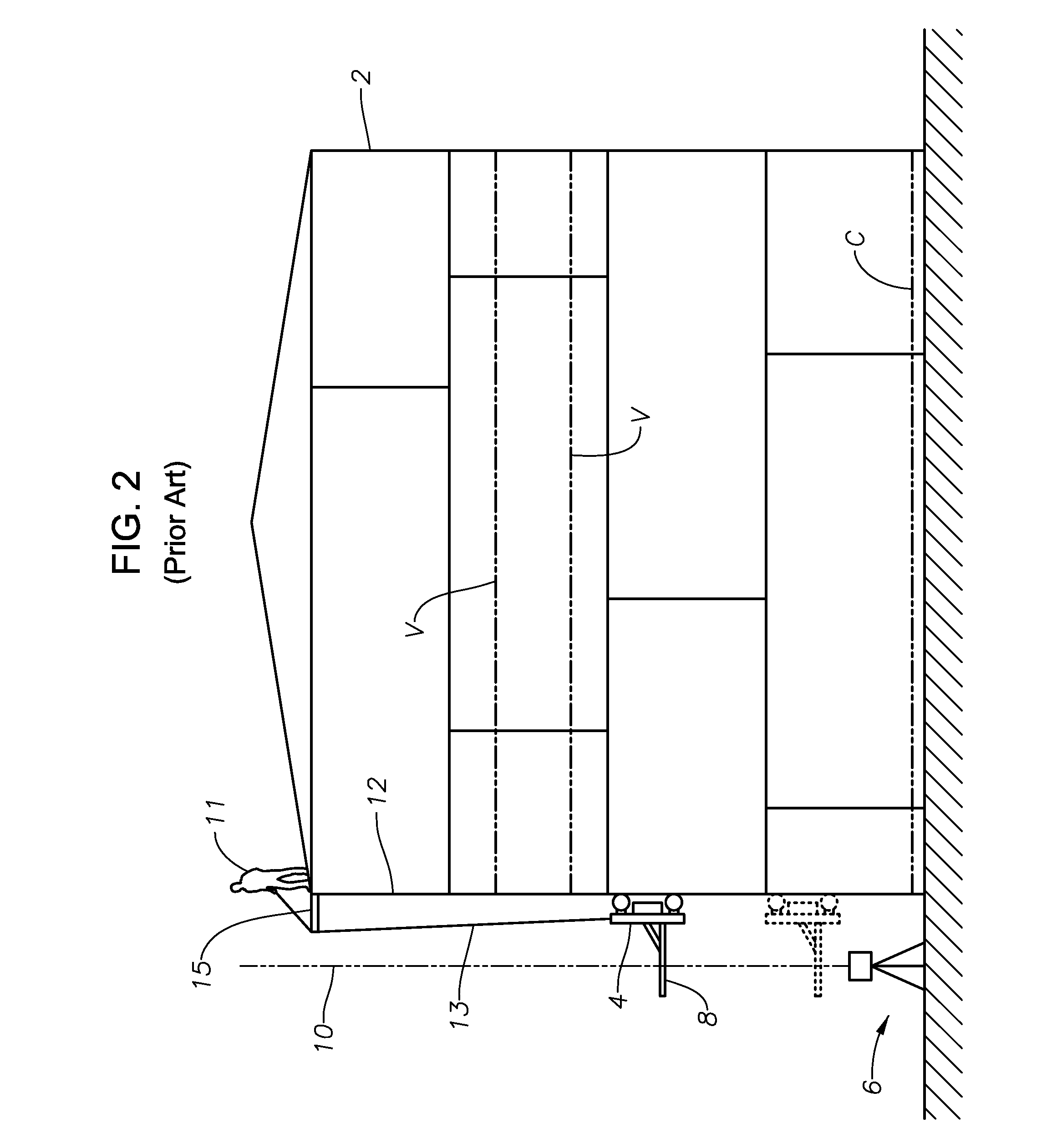

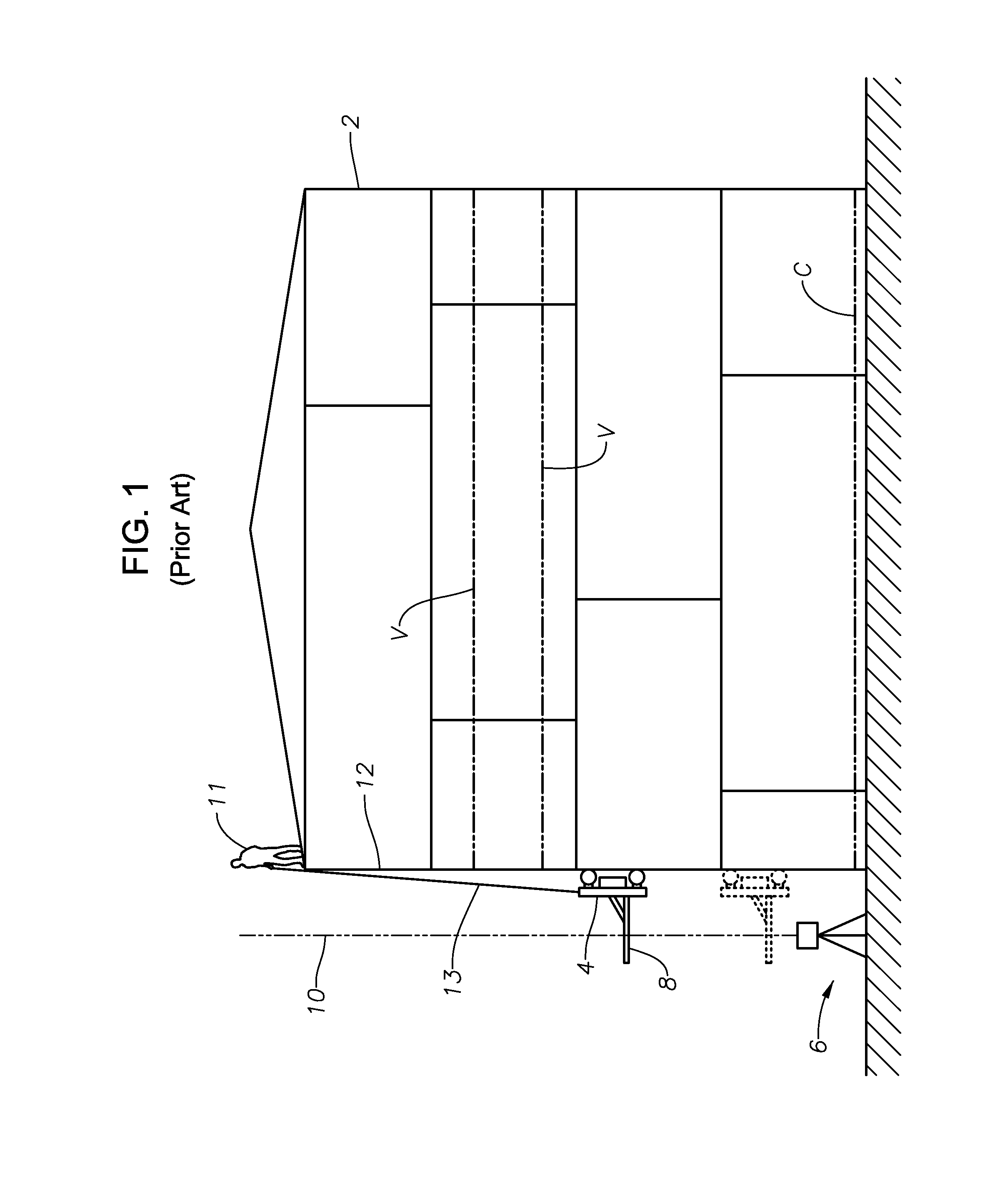

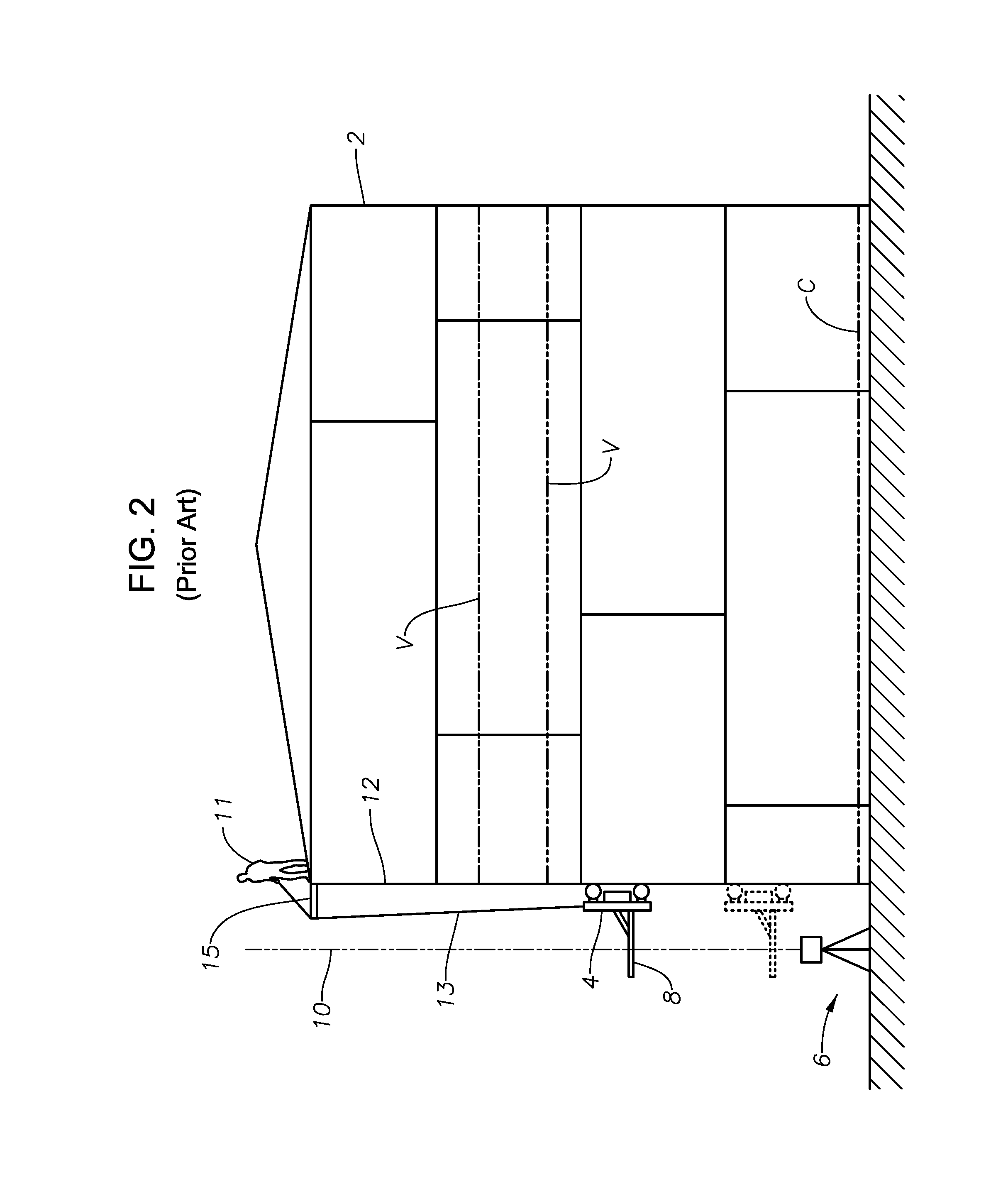

Enhanced Reference Line Tank Calibration Method and Apparatus

ActiveUS20140345375A1Improve stabilityImprove accuracyOptical rangefindersTesting/calibration for volume measurementReference lineLaser beams

A system for measuring the volume of a tank, including an optical device that emits a laser beam adjacent to a surface of the tank, and a magnetic trolley selectively moveable along the surface of the tank and configured to be remotely controlled by an operator. The magnetic trolley has a linear position sensor in communication with the laser beam to determine the position of the magnetic trolley relative to the laser beam as the magnetic trolley moves on the surface of the tank. A data processor communicates with the linear position sensor to calculate the volume of the tank based at least partially on the position data collected by the linear position sensor.

Owner:SAUDI ARABIAN OIL CO

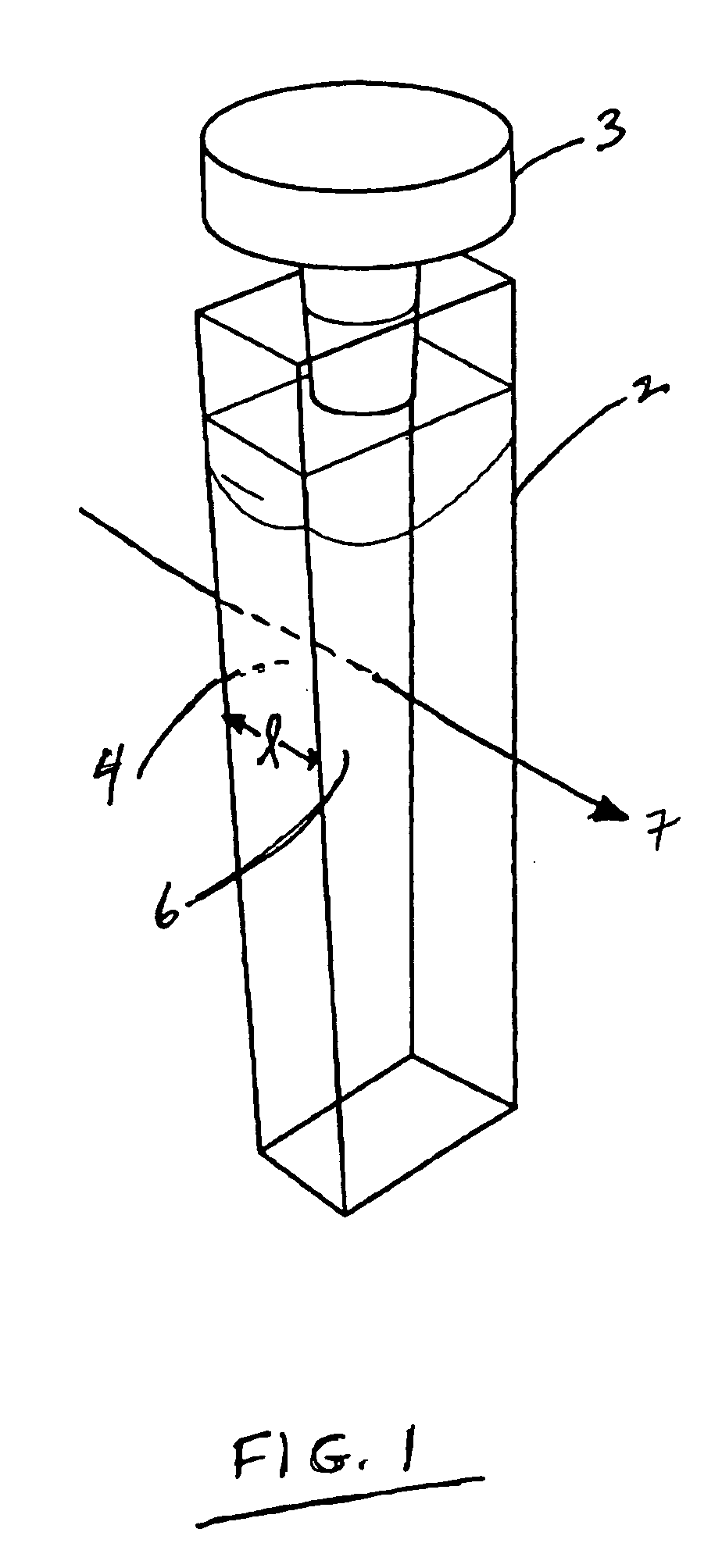

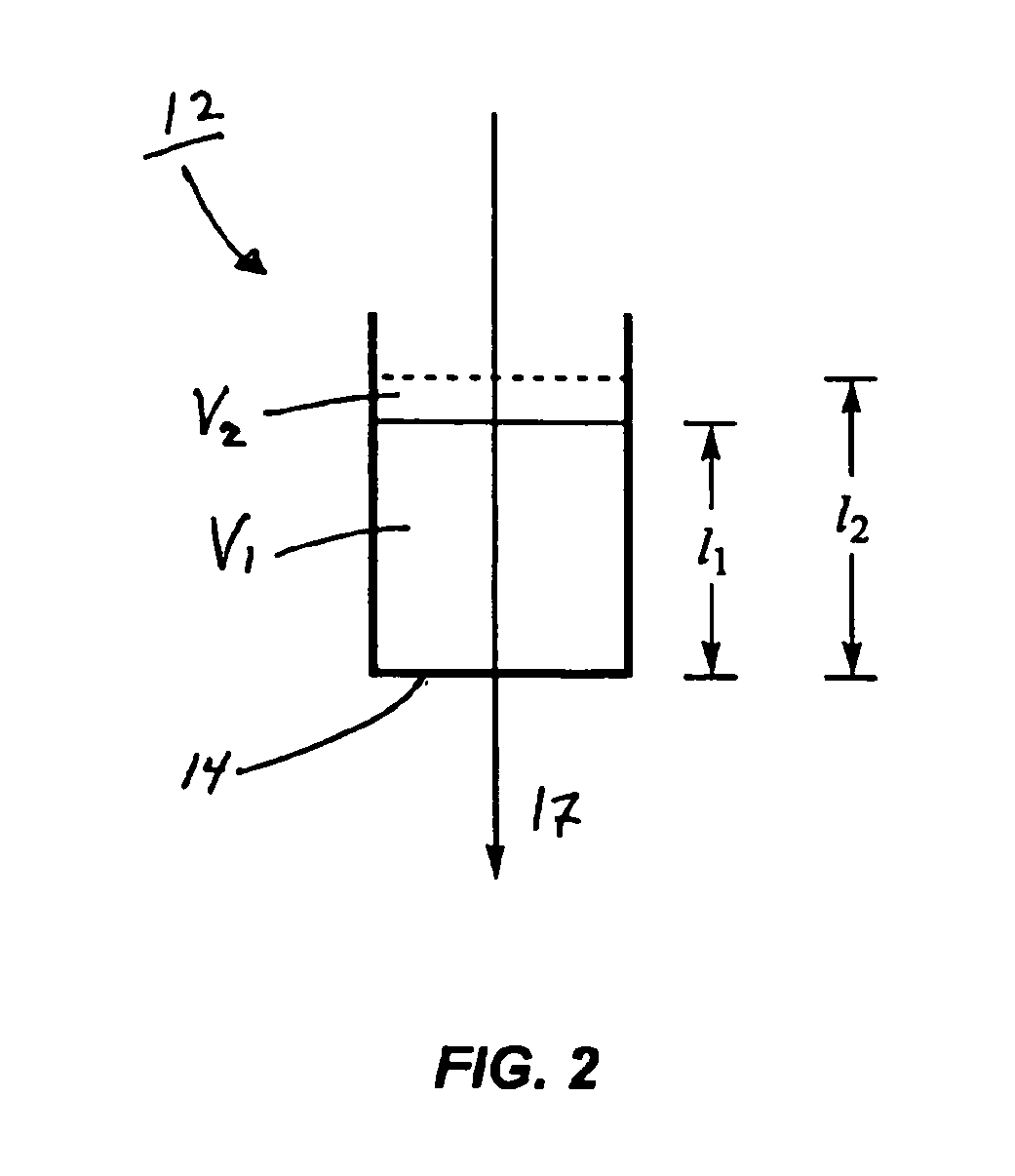

Photometric calibration of liquid volumes

InactiveUS7187455B2Easy to useSimple equipmentMaterial analysis by observing effect on chemical indicatorBurette/pipette supportsPath lengthLuminosity

A method and apparatus for measuring and calibrating the measurement of small volumes of liquids. The small volumes of liquid are typically dispensed from liquid delivery devices, the delivery device often having multiple channels to analyze many samples at once. The liquid samples are delivered to one or more cells, typically in a multi-well plate, and positioned in a spectrophotometer for determining an absorbance of a chromophore in the liquid sample. Based upon an absorbance measurement and the concentration of the chromophore, a path length of the liquid sample is determined, from which a volume of the sample may be calculated. The method and apparatus provide various means for correcting for differences in the dimensions and / or other factors causing a non-linear deviation from the Beer-Lambert law. A system or kit may be provided including sets of sample solutions of varying dilution ranges for calibrating different liquid volumes. The kit may further include software code for storing and analyzing the various sample solutions.

Owner:ARTEL

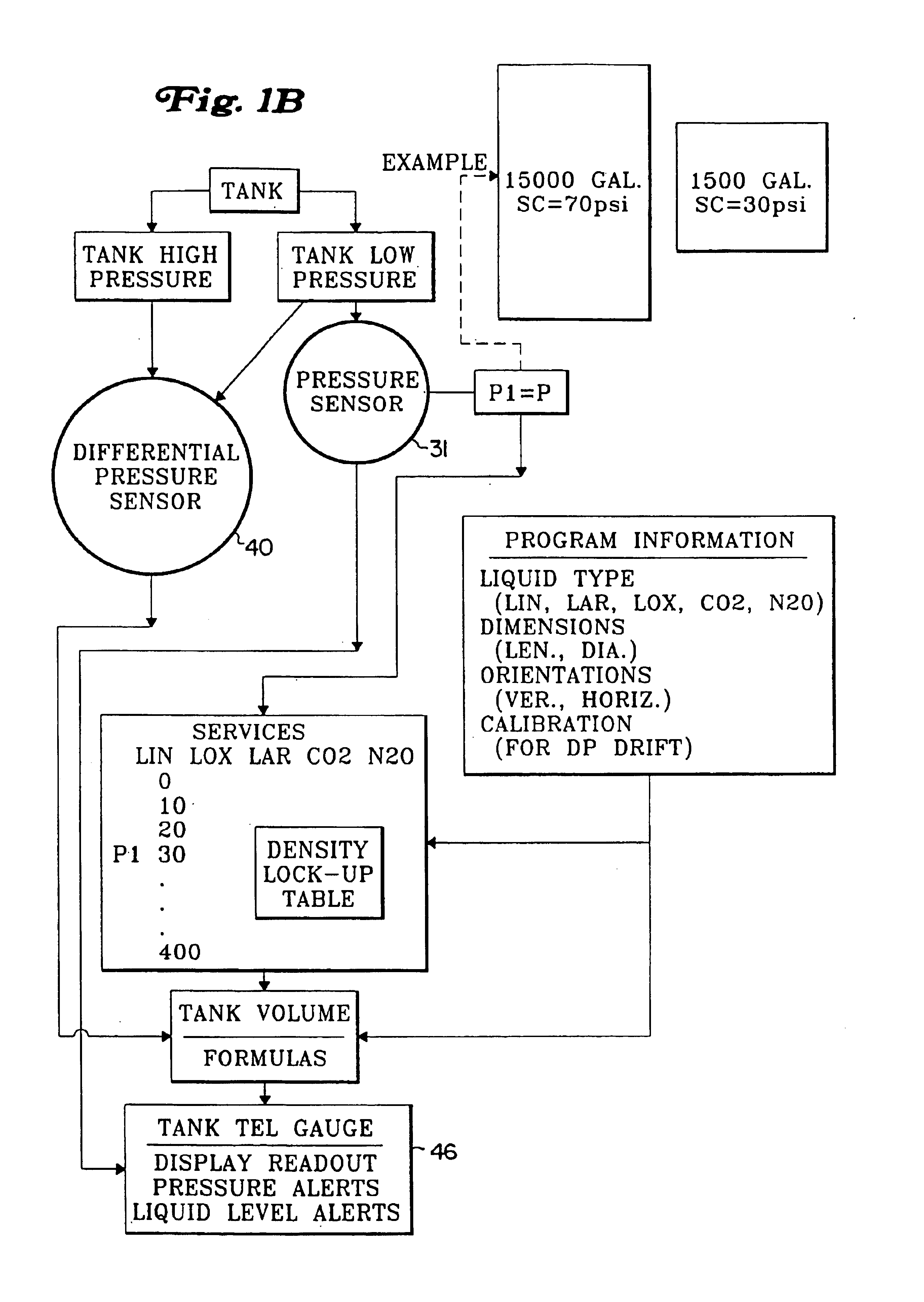

Differential pressure gauge for cryogenic fluids which selects a density value based on pressure measurement

InactiveUS6944570B2Minimizes supplyContainer filling methodsContainer discharging methodsDifferential pressureEngineering

A differential pressure gauge for a cryogenic storage tank provides onboard entry, by an operator, of tank dimensions, tank orientation stratification coefficient, and the type of liquid stored within the tank. A differential pressure sensor supplies a signal corresponding to a differential pressure. A pressure sensor supplies a signal corresponding to the head pressure. The gauge uses the information supplied by an operator, combined with stored formulas and liquid characteristics, to perform real-time liquid volume computations. The liquid volume may be displayed on the gauge itself or may be transmitted via telemetry to an external device.

Owner:U S BANK TRUST CO NAT ASSOC AS THE NOTES COLLATERAL AGENT

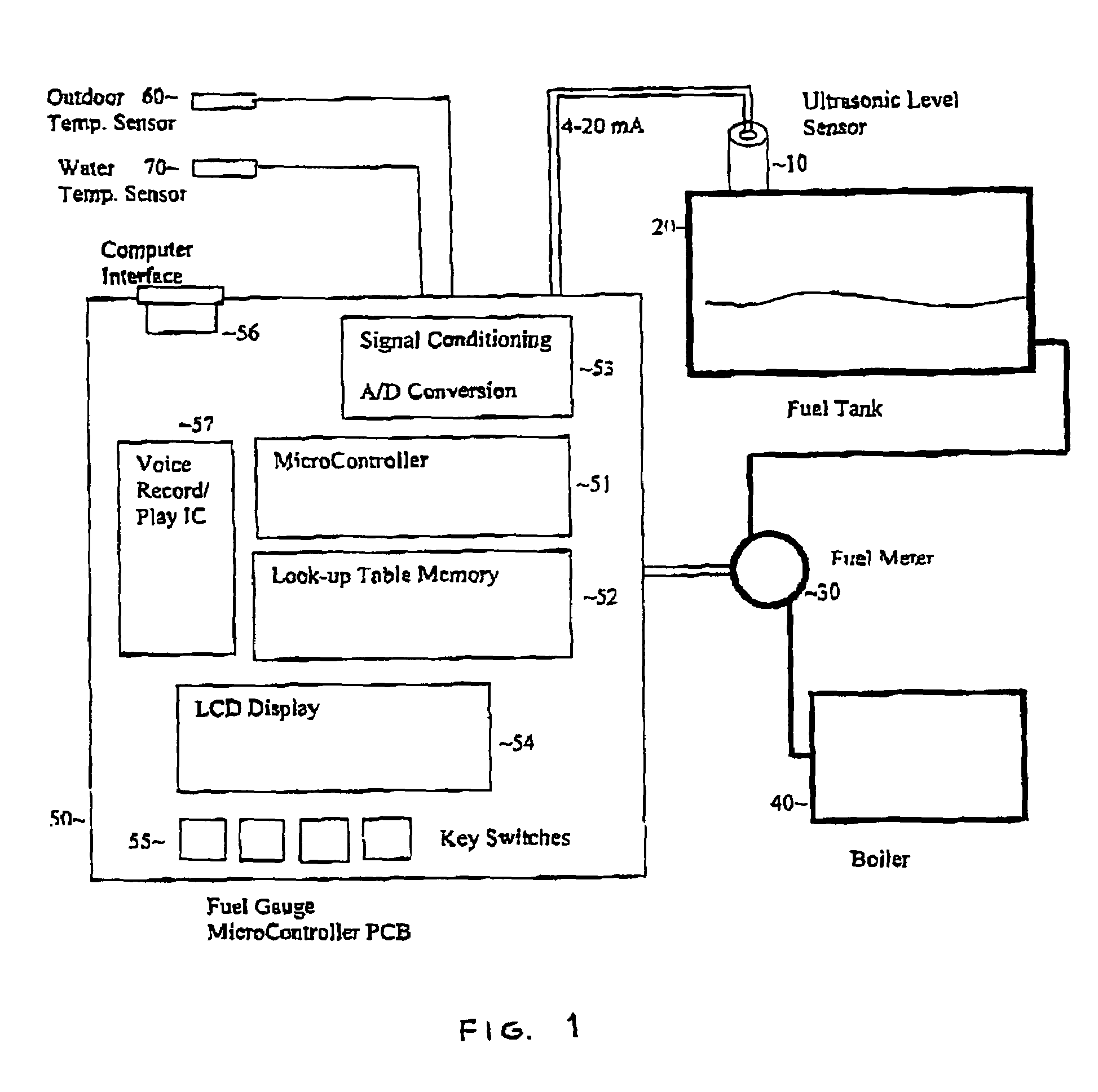

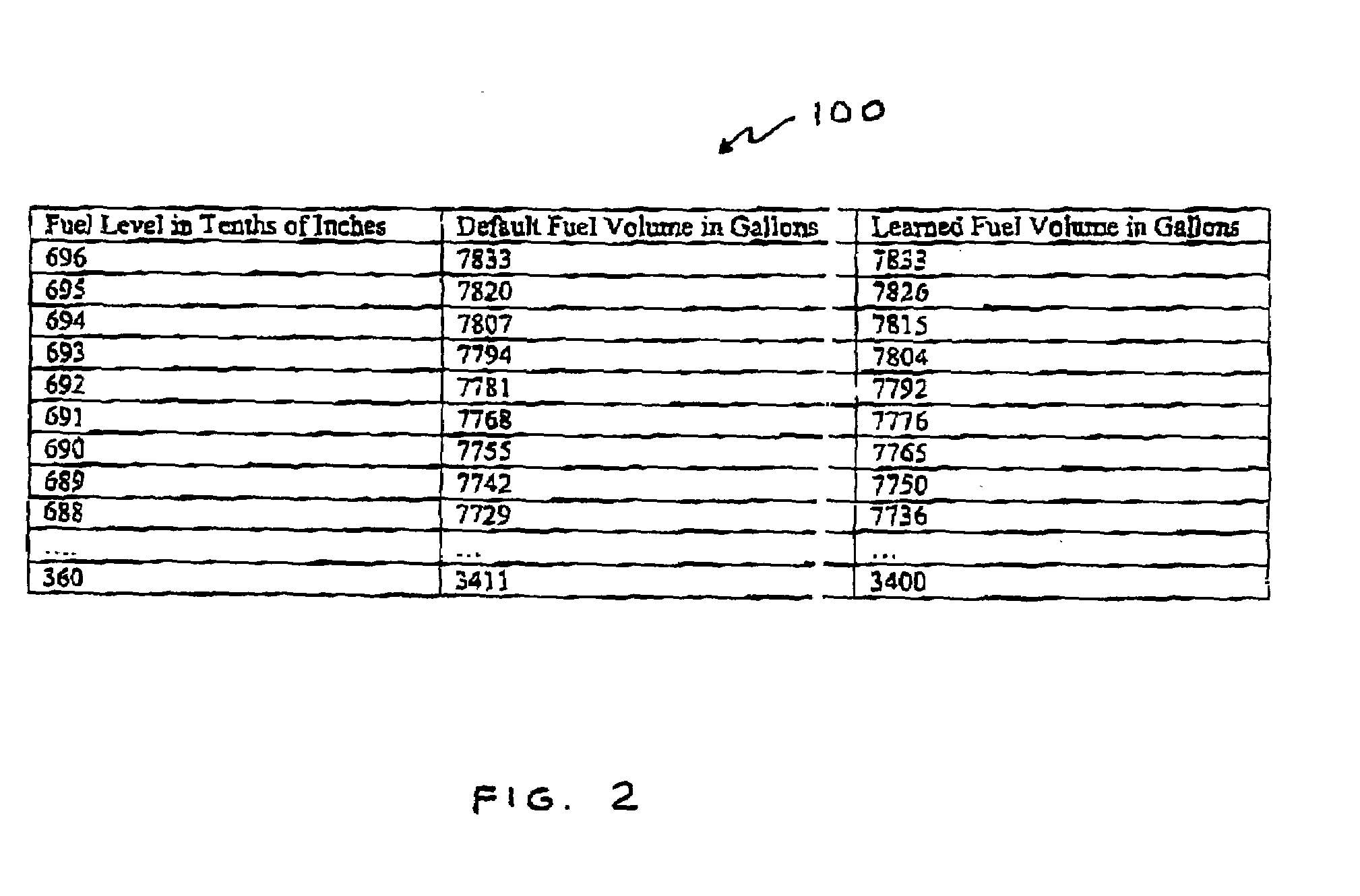

Method and apparatus for measuring the volume of fuel in a tank

InactiveUS7305875B1Testing/calibration for volume measurementContainer/cavity capacity measurementAutomotive engineeringFuel tank

An apparatus for dynamically measuring a volume of fuel in a fuel tank of unknown geometry includes a fuel level sensor mounted on the fuel tank, a fuel meter for measuring a volume of fuel being consumed, and a rewritable look-up table storing correspondence between volumes of fuel and levels of fuel in the fuel tank. The loop-up table is rewritten as the oil in the tank is consumed. A system website is used for remotely monitoring the fuel tank of a building.

Owner:MR GERALD PINDUS

Process and arrangement for calibrating and/or equilibrating single-channel and multi-channel liquid handling devices

InactiveUS20080083263A1Improve accuracyLaboratory glasswaresTesting/calibration for volume measurementHermetic sealEngineering

Owner:CYBIO AG

Enhanced reference line tank calibration method and apparatus

ActiveUS9188472B2Improve stabilityImprove accuracyOptical rangefindersTesting/calibration for volume measurementReference lineLaser beams

A system for measuring the volume of a tank, including an optical device that emits a laser beam adjacent to a surface of the tank, and a magnetic trolley selectively moveable along the surface of the tank and configured to be remotely controlled by an operator. The magnetic trolley has a linear position sensor in communication with the laser beam to determine the position of the magnetic trolley relative to the laser beam as the magnetic trolley moves on the surface of the tank. A data processor communicates with the linear position sensor to calculate the volume of the tank based at least partially on the position data collected by the linear position sensor.

Owner:SAUDI ARABIAN OIL CO

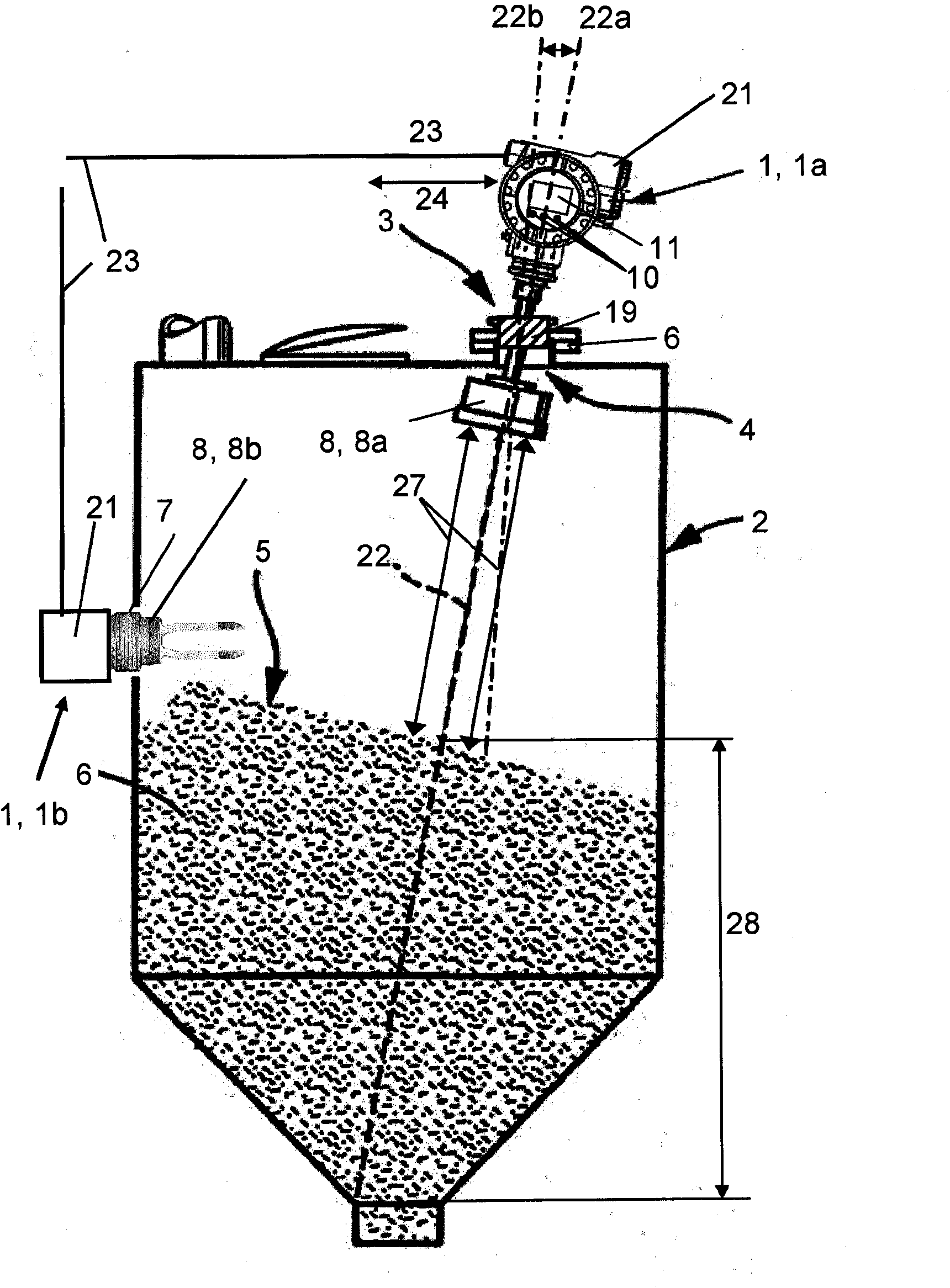

Method and apparatus for orienting measuring instrument

InactiveCN103348222AMachines/enginesTesting/calibration for volume measurementMeasuring instrumentEngineering

A measuring device featuring ascertaining and monitoring optimized orientation of the measuring device. Thus, the invention provides a measuring device for determining and / or monitoring limit level or fill level of a medium in a container, comprising at least one sensor unit and a measurement transmitter unit, wherein at least one inclination sensor is integrated in the measuring device for ascertaining orientation of the measuring device and / or the sensor unit on the container

Owner:EHNDRESS KHAUZER GMBKH KO KG

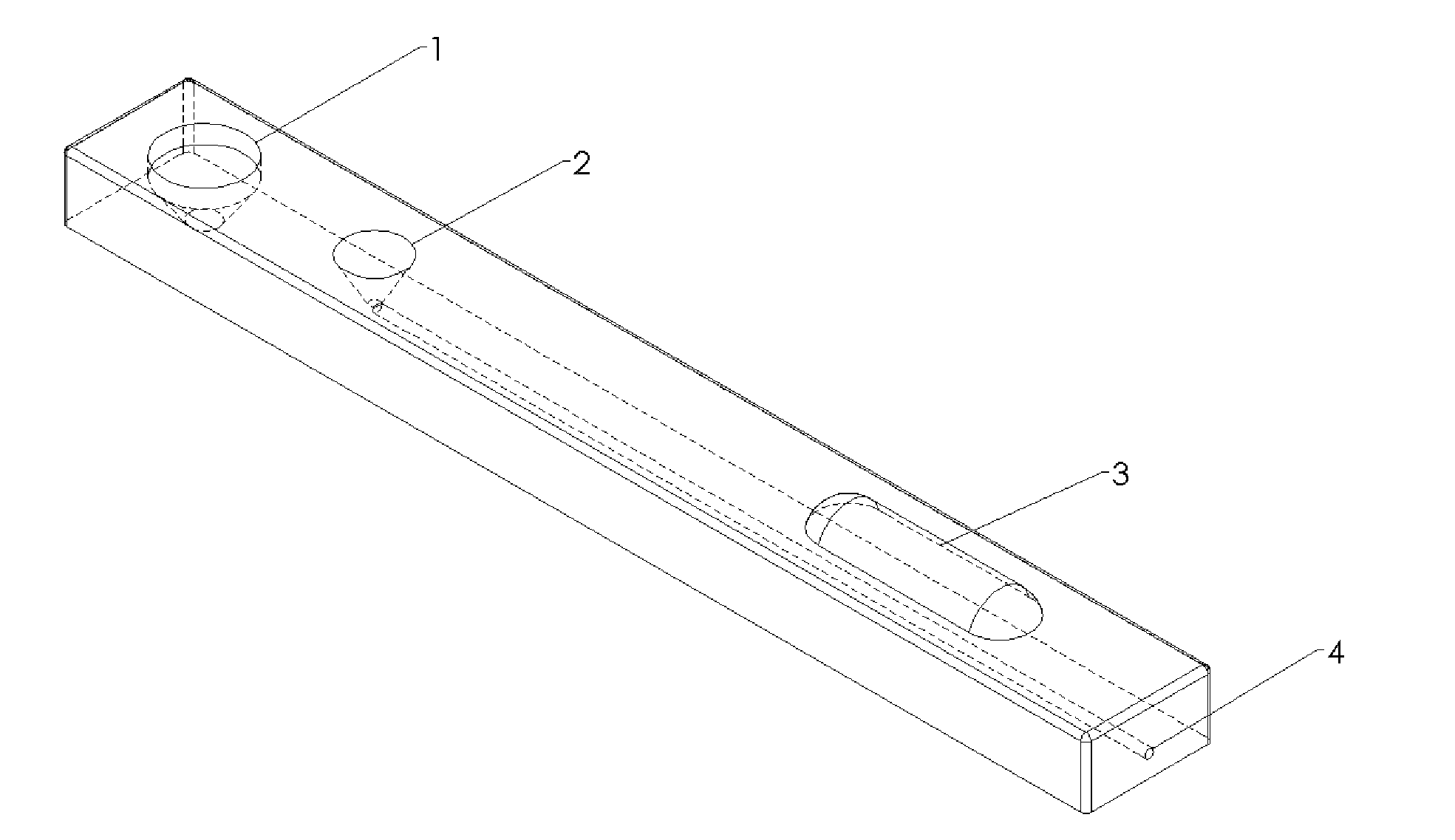

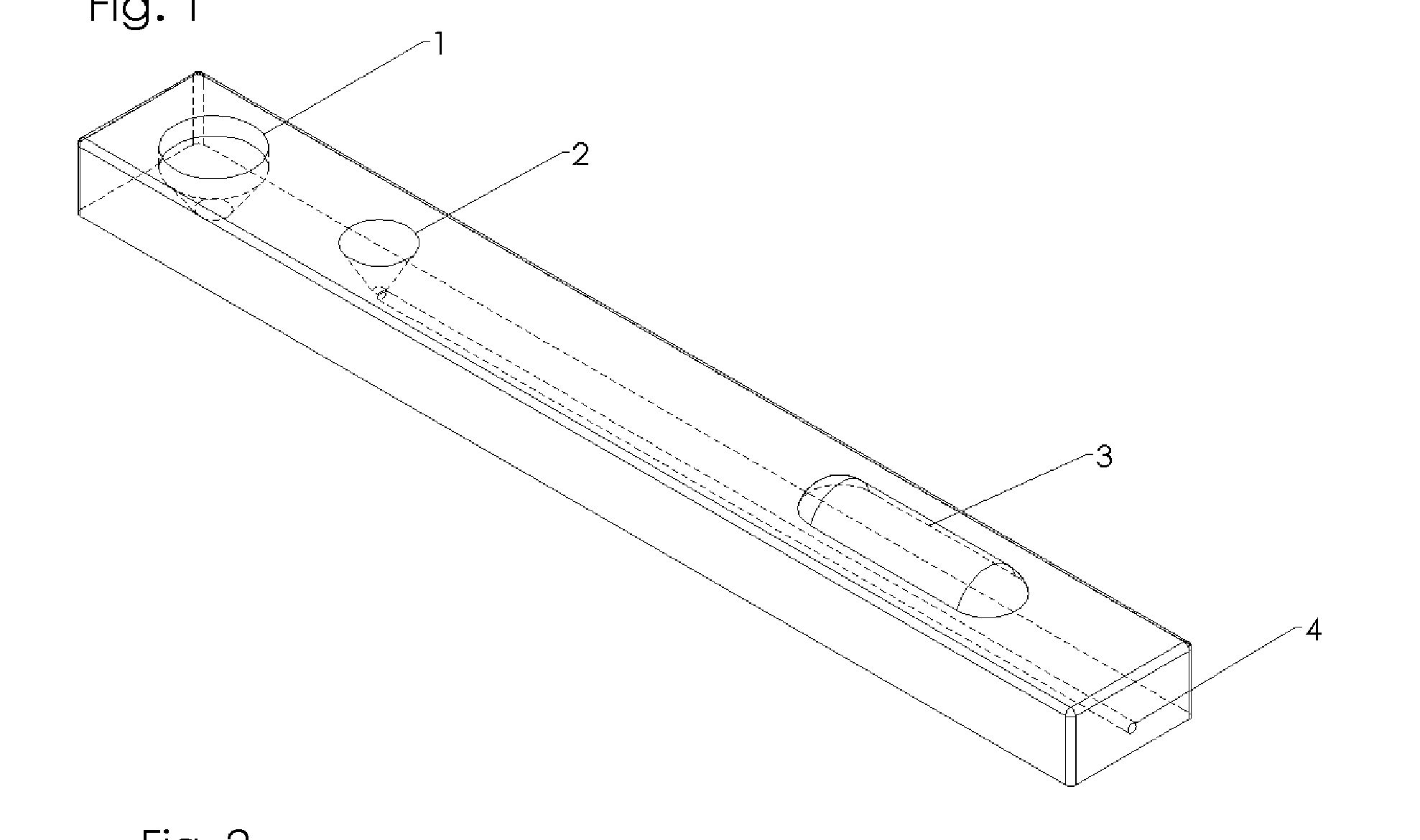

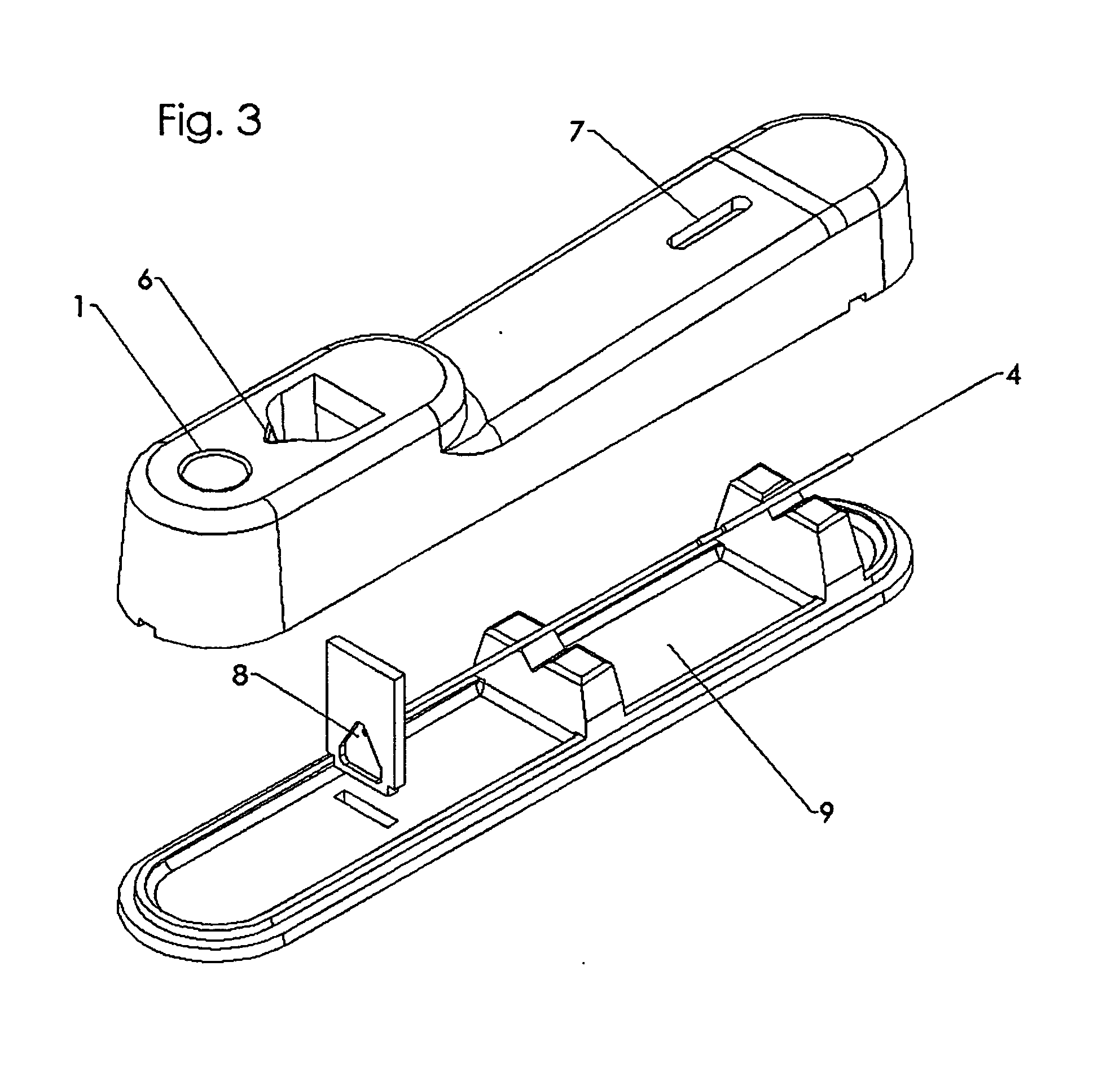

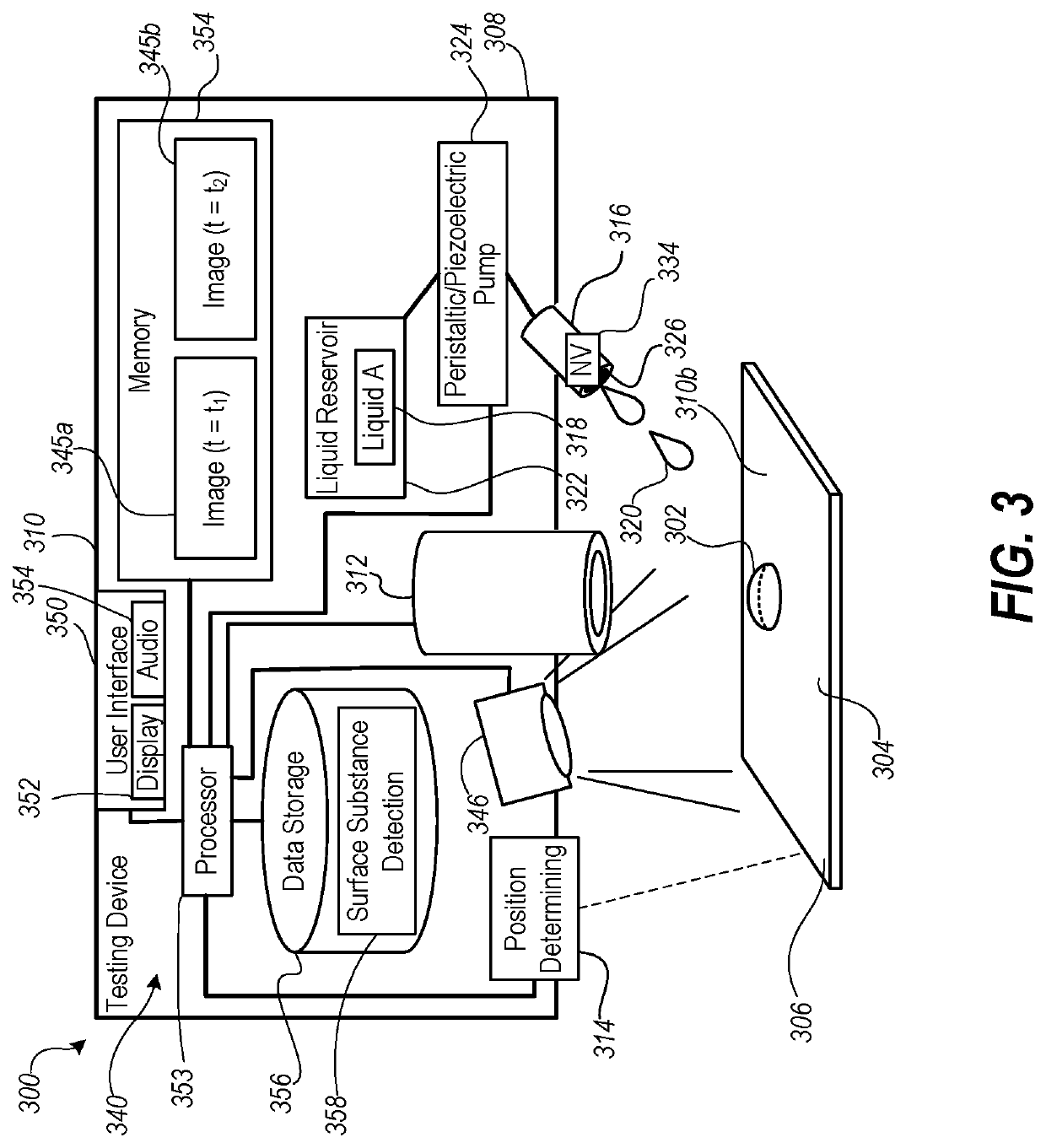

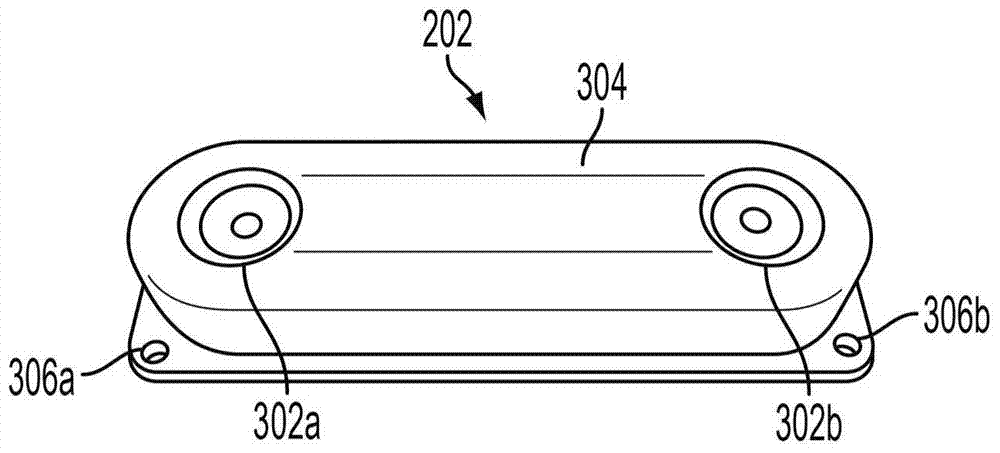

Dispensed Liquid Measurement Device

ActiveUS20140150522A1Accurately determineDisposable or reusableBurettes/pipettesTesting/calibration for volume measurementMeasurement deviceCapillary Tubing

A measurement device containing one or more capillaries to measure the volume of a dispensed fluid and determine the volumetric accuracy of the dispensing device. The measurement device can contain a reservoir containing the fluid to be measured and there may be an additional reservoir for a secondary fluid. A viewing window is necessary to complete a manual measurement and may include a magnifying lens. The liquid well by the capillary inlet may be shaped such that the measurement fluid is directed toward the capillary. The well may have features designed to position the dispensing device toward the capillary, or to position the well proximal to the capillary after it is filled. The well may also have surfaces or coatings which attract or do not attract various types of substances. The measurement device may interface with sensors to output measurement data.

Owner:FORWARD BIOTECH

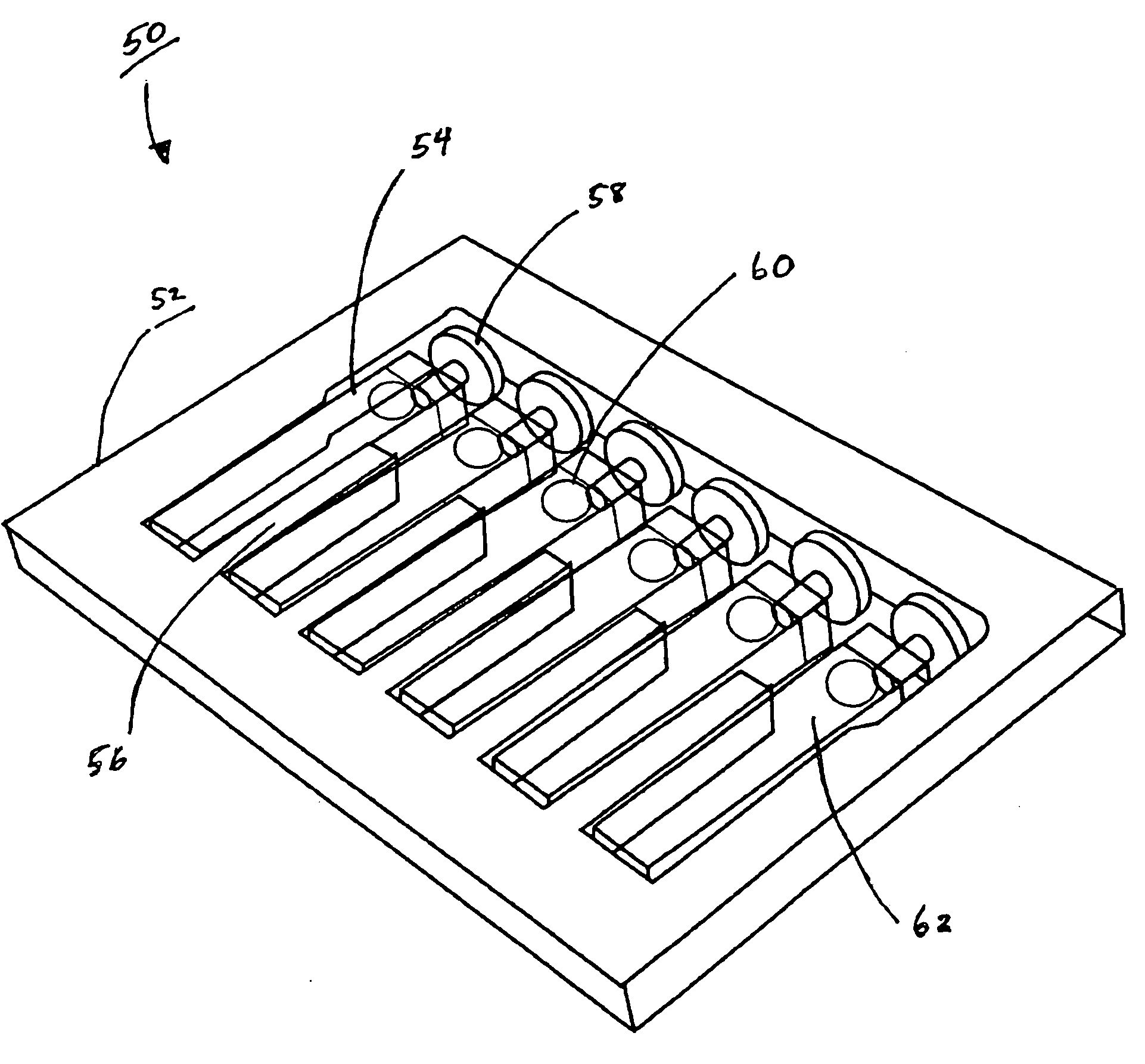

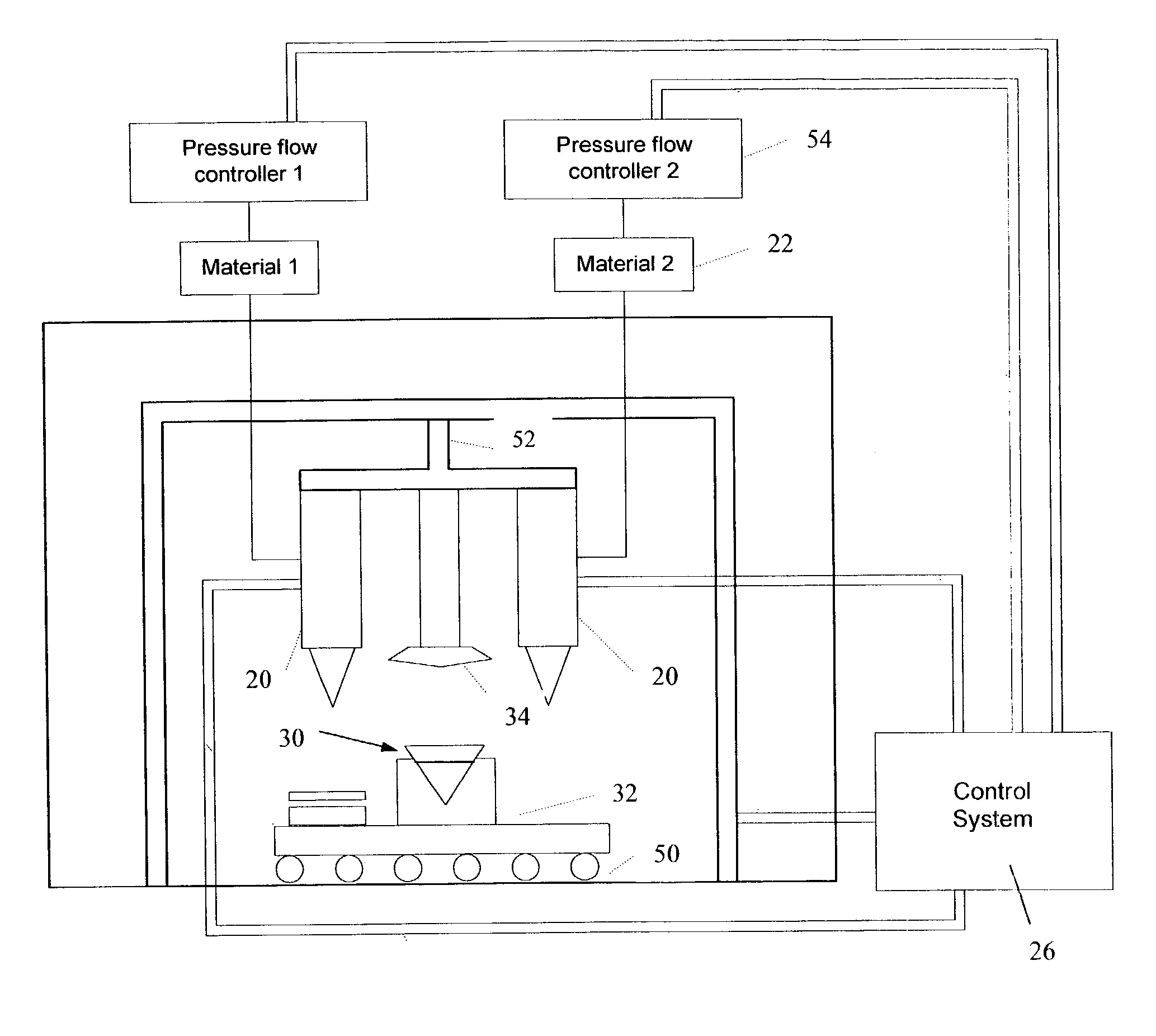

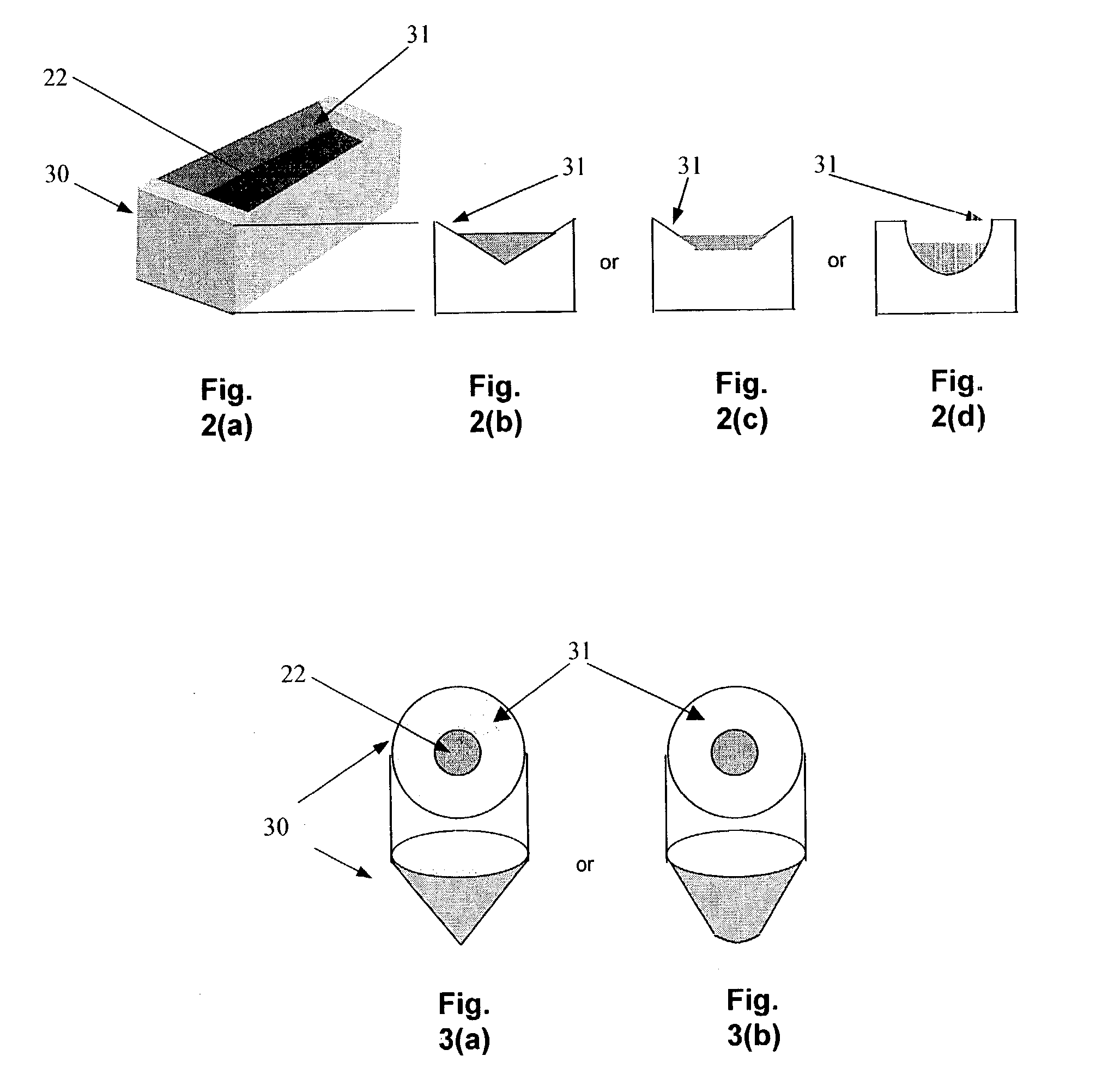

Apparatus and method for calibration of a dispensing system

ActiveUS7204960B2Layered productsSemiconductor/solid-state device manufacturingEngineeringVisual perception

The invention provides an apparatus and method for calibrating a dispensing system. A dispenser dispenses a controlled quantity of material into a container for receiving material. A system, preferably a vision system comprising an image capturing device and an imaging system, is adapted to capture an image of a physical dimension of a quantity of dispensed material in a given time. The physical dimension may be a width of a top surface area, a height or a cross-sectional area of the dispensed material. A calibrating system is adapted to calculate a volume of the quantity of material based upon said physical dimension.

Owner:ASM ASSEMBLY AUTOMATION LTD

Dispense Verification Meters

ActiveUS20120211518A1Volume measurement and fluid deliveryLiquid transferring devicesComputer science

A dispense verification meter for measuring and verifying dispense operations (e.g., actual dispensed volumes) of media dispense systems. The dispense verification meter preferably automatically corrects zero offset drift, preferably samples the flow rate of media being dispensed at a sufficiently high sample rate, and verifies whether the desired dispense operation has been achieved.

Owner:MALEMA ENG

System and method for liquid delivery evaluation using solutions with multiple light absorbance spectral features

ActiveUS20090251681A1Easy to testEasy CalibrationVolume measurement apparatus/methodsSamplingAbsorption ratioLuminosity

A system and related method for improved liquid delivery evaluation using a solution containing one or more dyes such that the solution exhibits multiple distinct detectable light absorbance spectral features for calibrating or testing over extended volume or dilution ranges are described. The system includes: a photometric instrument capable of measuring optical absorbance at multiple wavelengths; one or more sample solutions to be dispensed using the liquid delivery system whose performance is being tested or calibrated; and vessels optionally pre-filled, or filled by the user, with diluent solution. The sample solutions contain one or more dyes, chosen so that multiple distinct detectable light absorbance spectral features, such as peaks and / or valleys and / or plateaus of the solution can be distinguished for volume or dilution ranges of interest. The concentrations of the dyes may be chosen so that a large volume delivery device is calibrated using a spectral feature in the solution with a low absorbance per unit pathlength, while a small volume delivery device is calibrated with the same sample solution but using a different spectral feature with a high absorbance per unit pathlength.

Owner:ARTEL

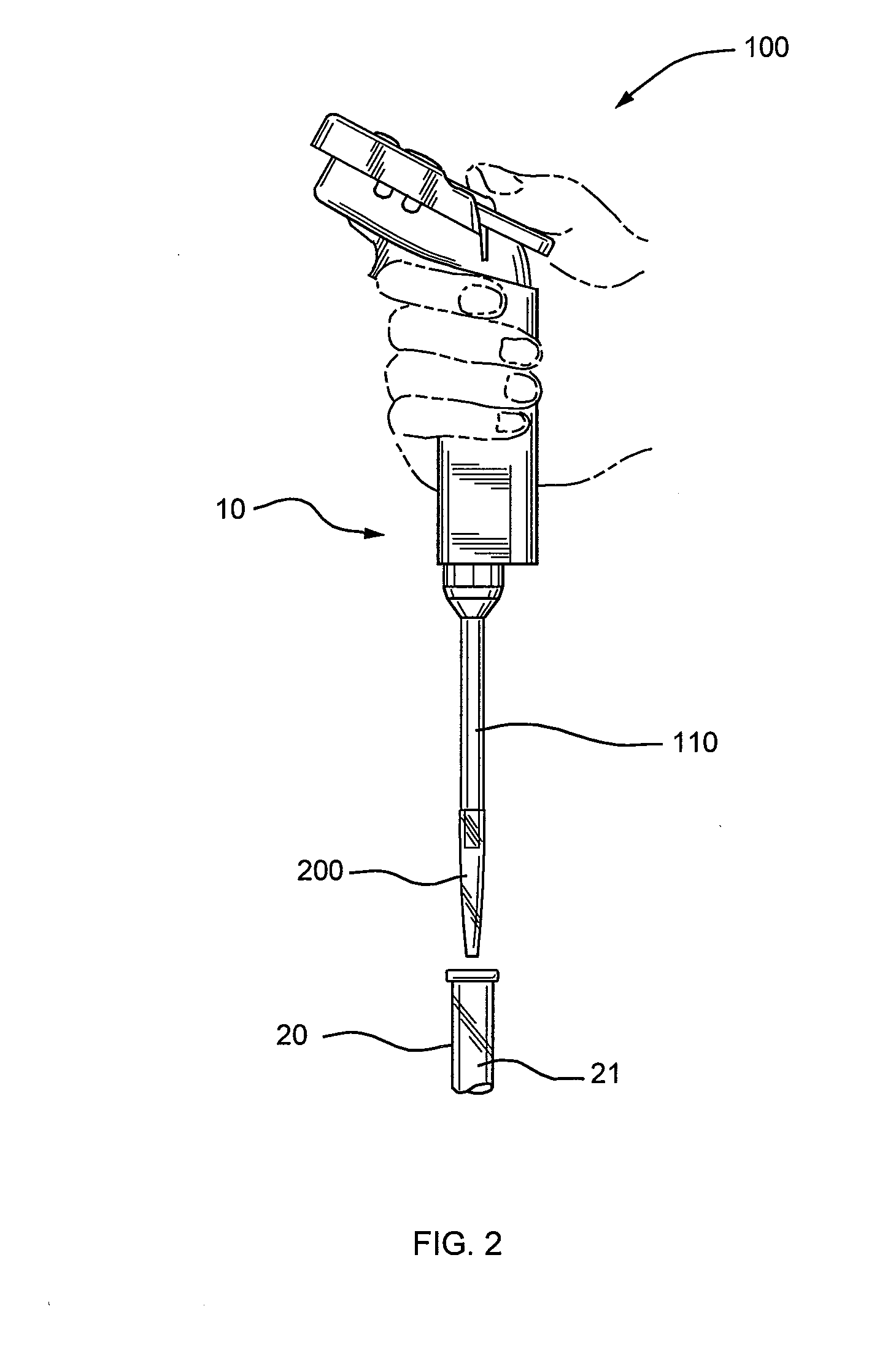

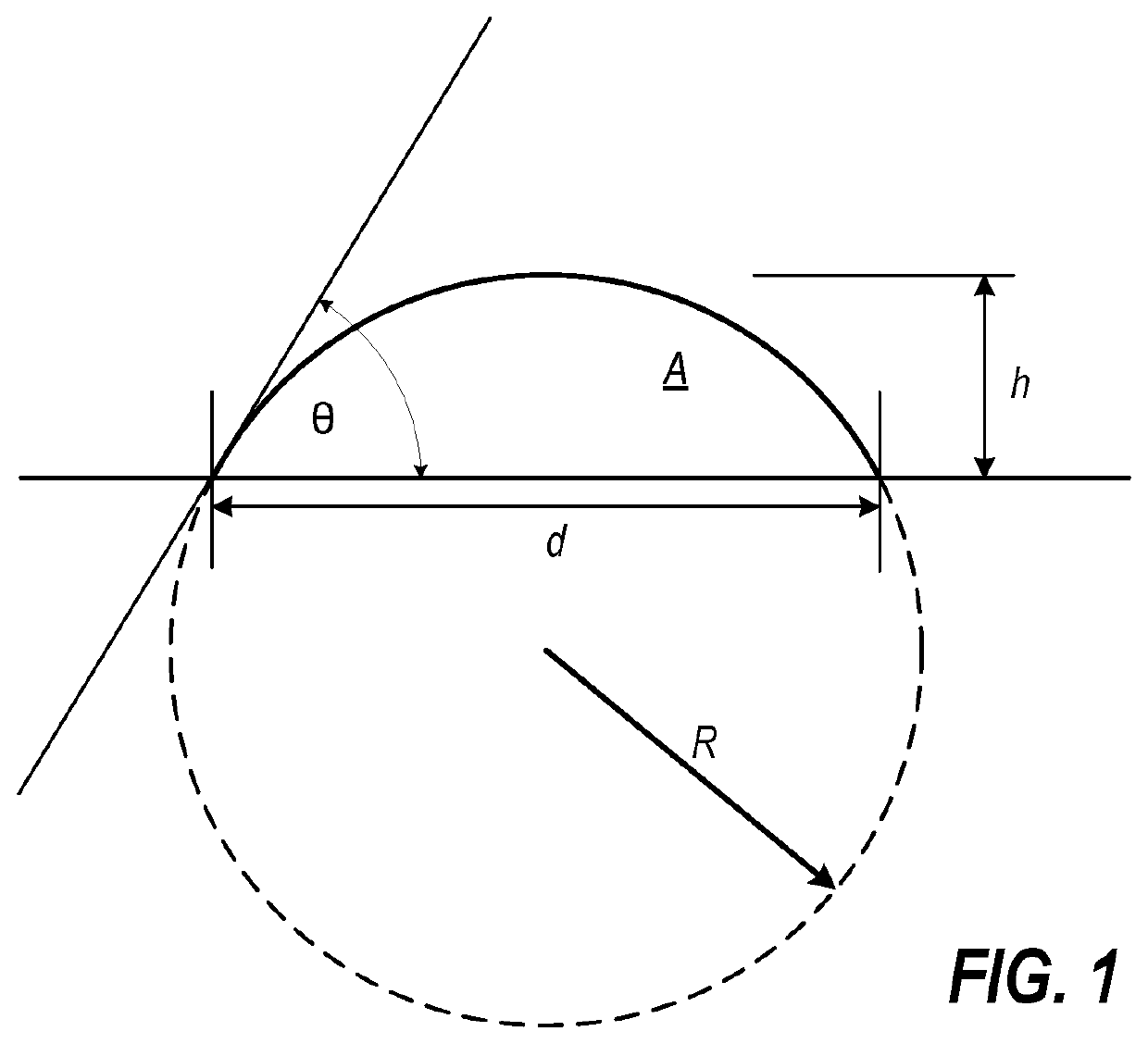

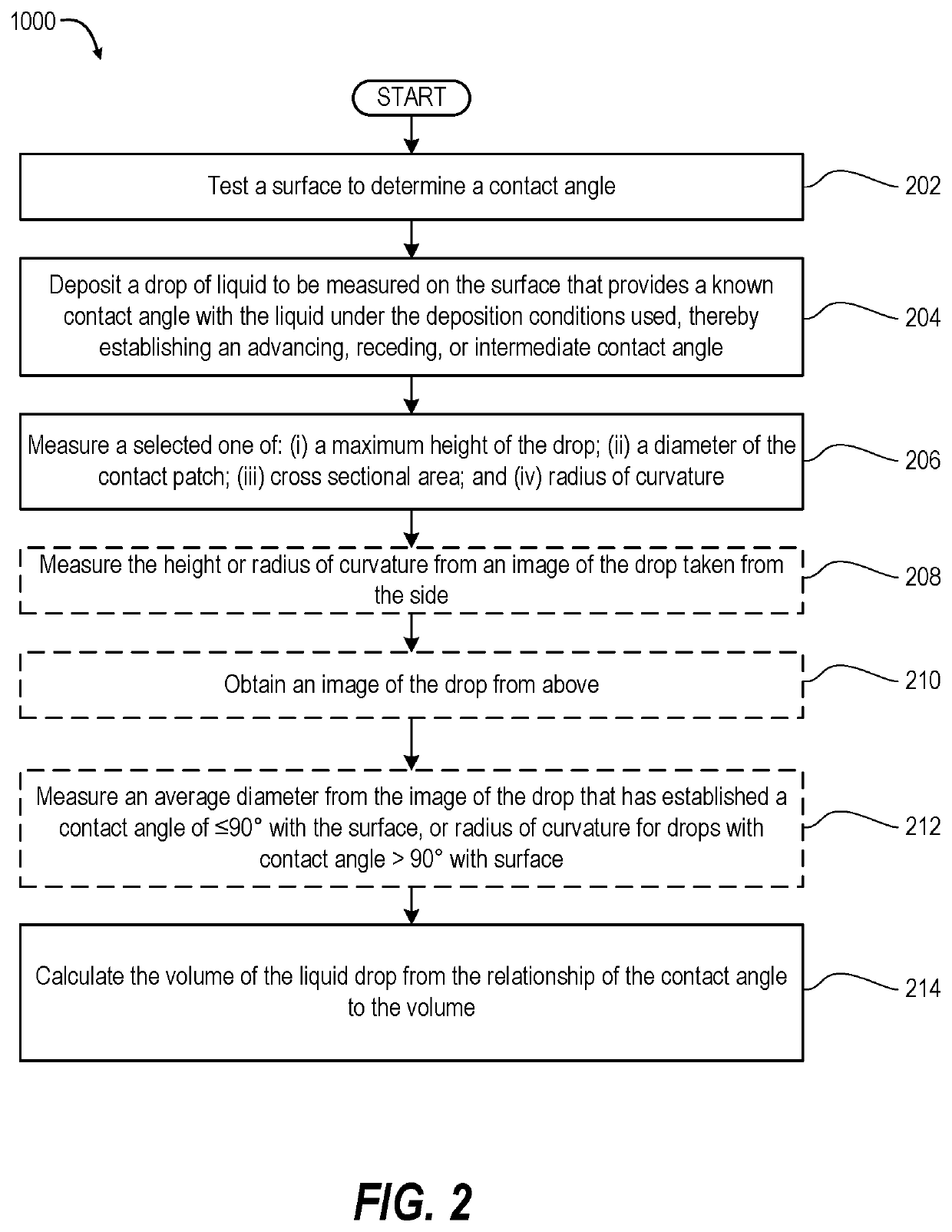

Method and device for measuring minute volume of liquid

InactiveUS20200080880A1Limit scopeVolume measurement apparatus/methodsImage analysisRadius of curvatureMechanical engineering

A method and test apparatus determines a volume of a droplet of liquid. The test apparatus deposits a drop of liquid to be measured on a surface that provides a known contact angle with the liquid under the deposition conditions used, thereby establishing one of: (i) an advancing, (ii) a receding, and (iii) an intermediate contact angle. The test apparatus images the drop. The test apparatus measures a dimension of height or diameter of the drop. In one embodiment, the test apparatus calculates a volume of the drop of liquid from the relationship of the contact angle to one or more parameters selected from the maximum height, the diameter of the contact patch, the radius of curvature, or the cross sectional area of the drop.

Owner:BRIGHTON TECH

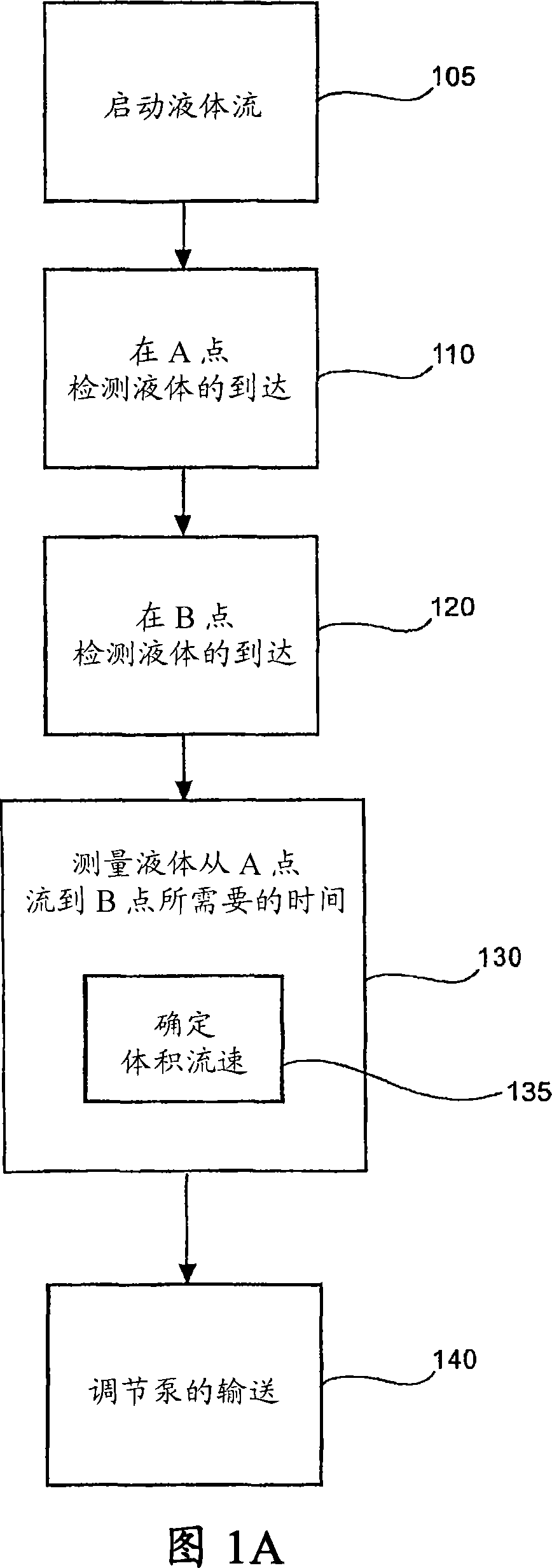

Fluid delivery device with autocalibration

ActiveCN101185042AVolume/mass flow measurementFlexible member pumpsControl systemBiomedical engineering

A micro fluid delivery device is particularly useful in medical applications. The device may be worn or carried by the user and may deliver drugs or other medicaments to the user or patient. The device has a control system that accepts input from the user and controls all aspects of operation of the device. The control system measures the output of the pump and adjusts the output of the pump to achieve the desired dosage rate and size. This eliminates differences from pump to pump that result from inevitable variations in the manufacturing of such small scale affordable devices.

Owner:ABBOTT DIABETES CARE INC

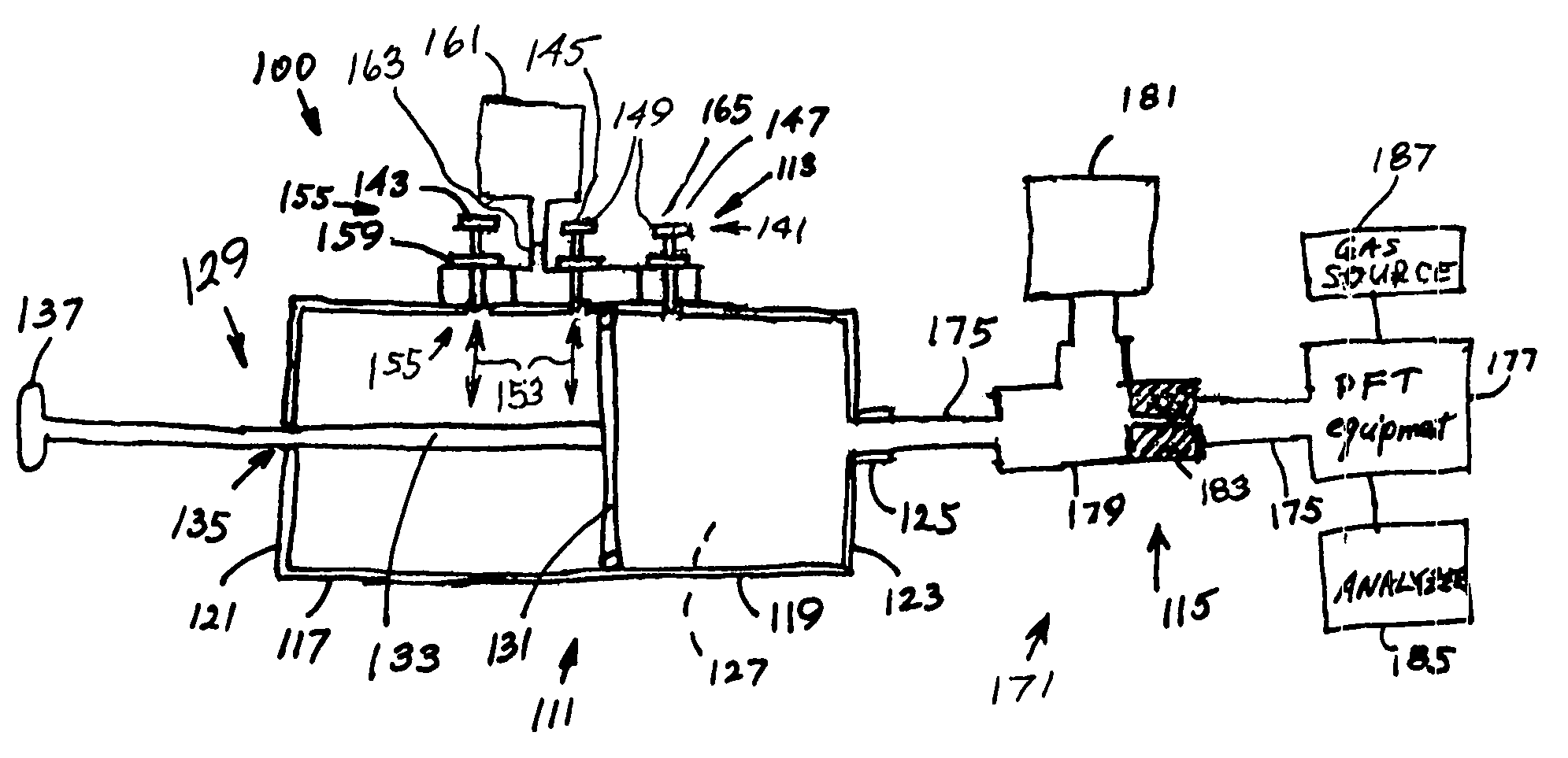

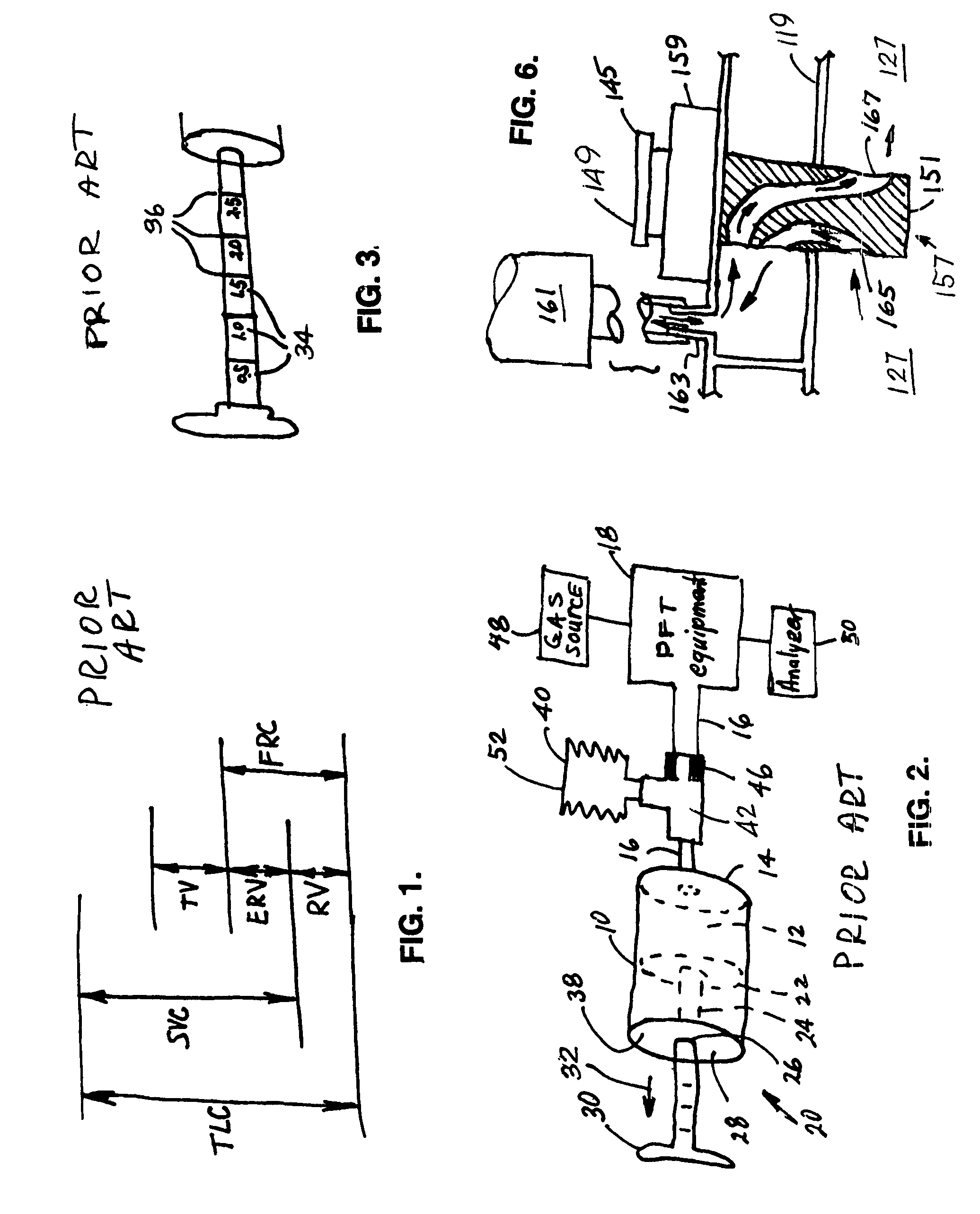

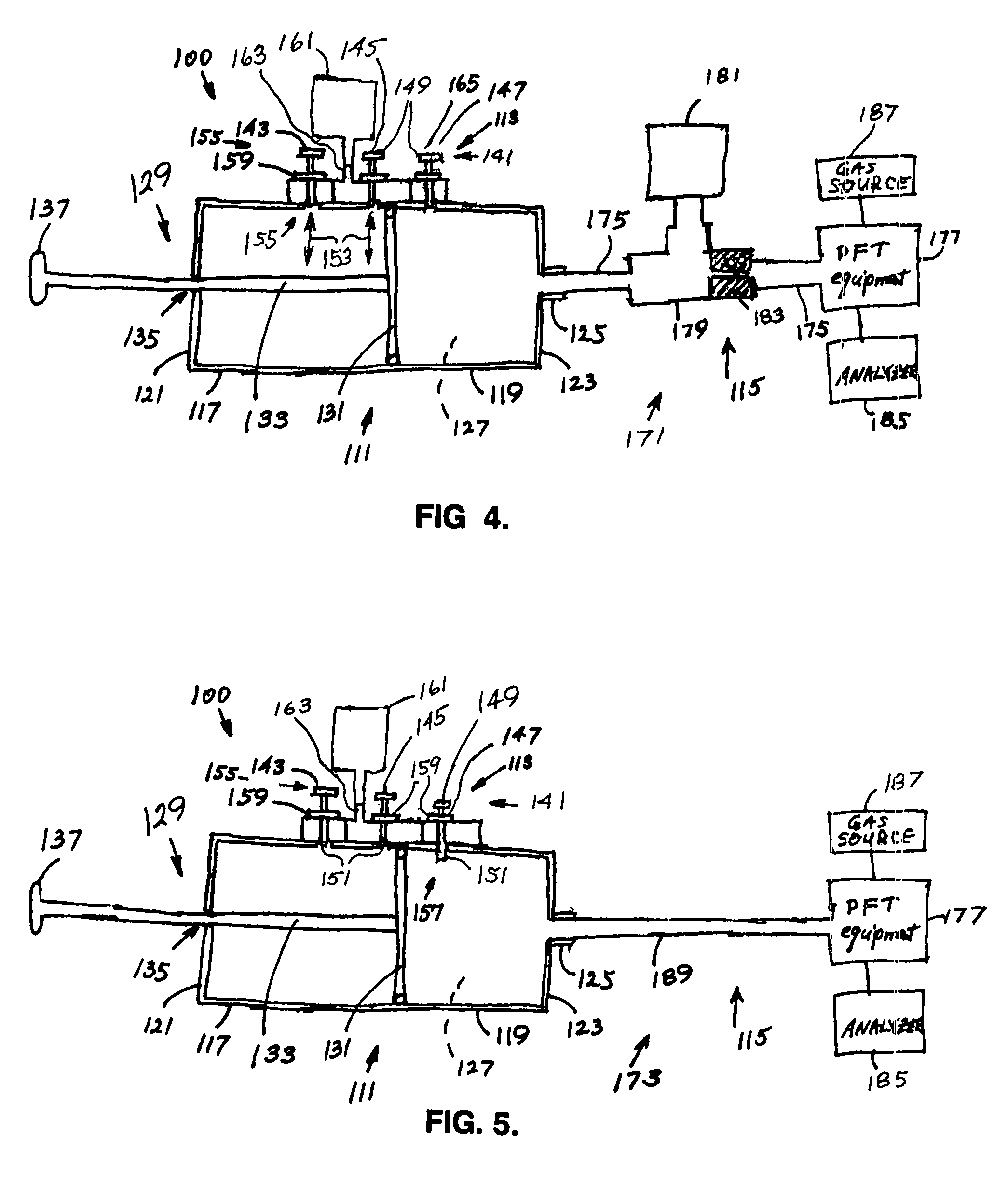

Pulmonary function test calibration system and method

InactiveUS7114367B1Accurate data collectionImprove performanceTesting/calibration for volume measurementTesting/calibration of speed/acceleration/shock measurement devicesPulmonary function testingTest equipment

A system for calibrating pulmonary function test equipment having syringe means, including a syringe having a cylindrically shaped sidewall, a proximal end with an centrally located orifice, a distal end with an output port, an interior cavity, and a plunger with a shaft slidably mounted through the orifice, a piston-type head mounted on one end of the shaft, and a handle mounted on an opposing end of the shaft; an FRC port; a rigid FRC bag connected in flow communication with the FRC port; control means having a plurality of stop mechanisms, including a first stop mechanism, a second stop mechanism structured to enable selective connection of the interior cavity in flow communication with the FRC port, and a third stop mechanism, and connection means structured to connect the syringe means to existing pulmonary function test equipment. A method of utilizing the system is also disclosed.

Owner:OWENS NORMAN L

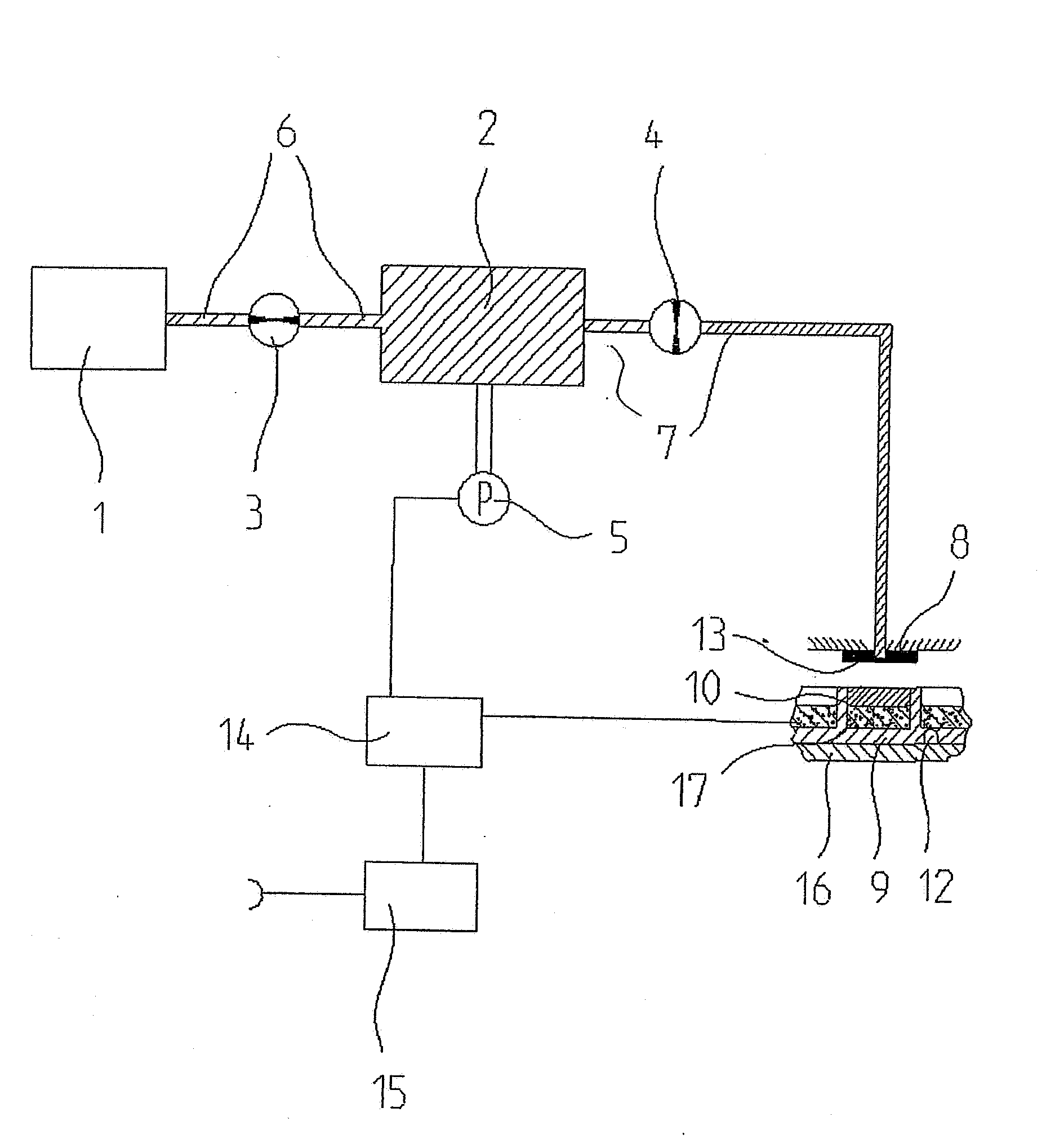

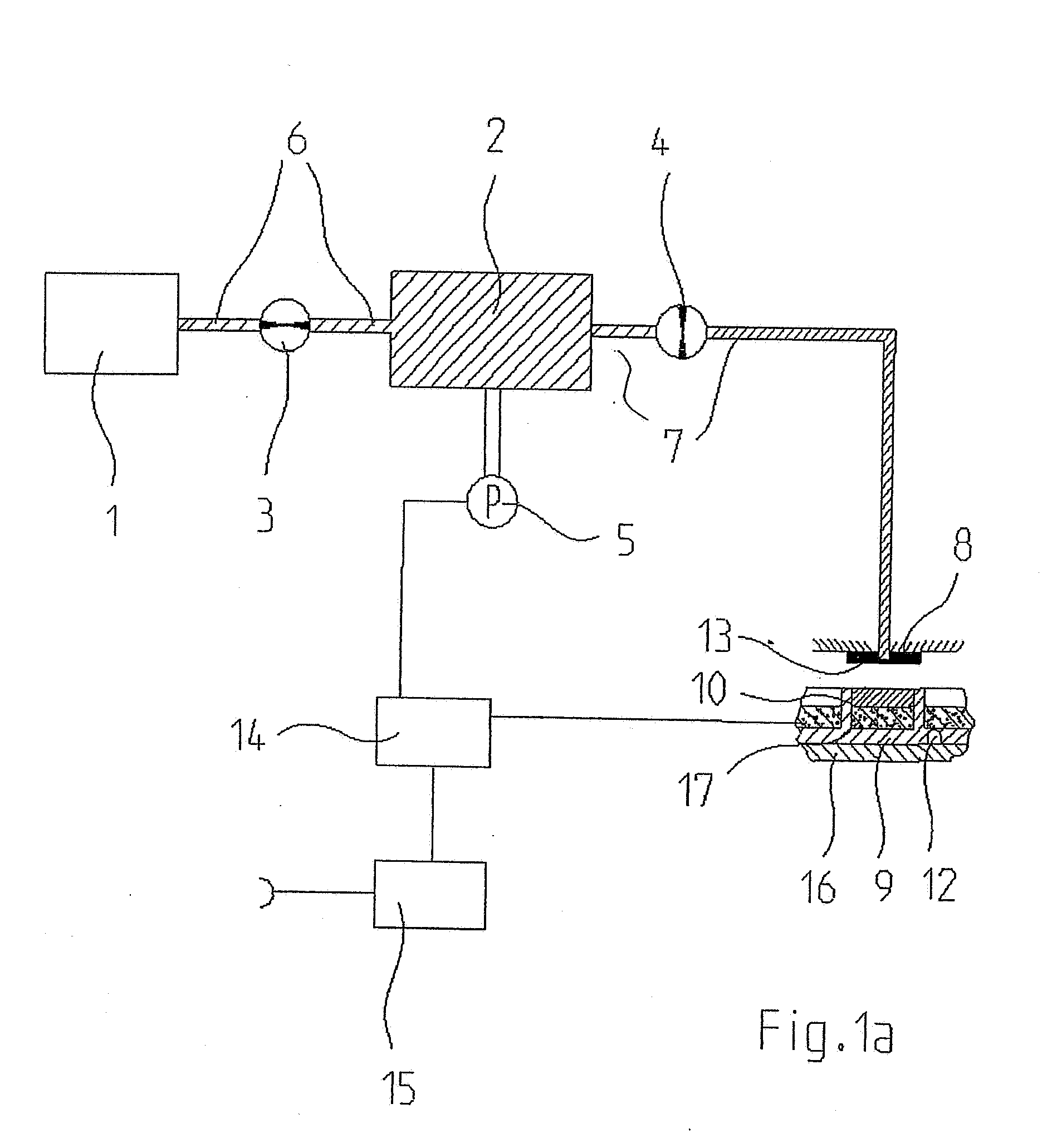

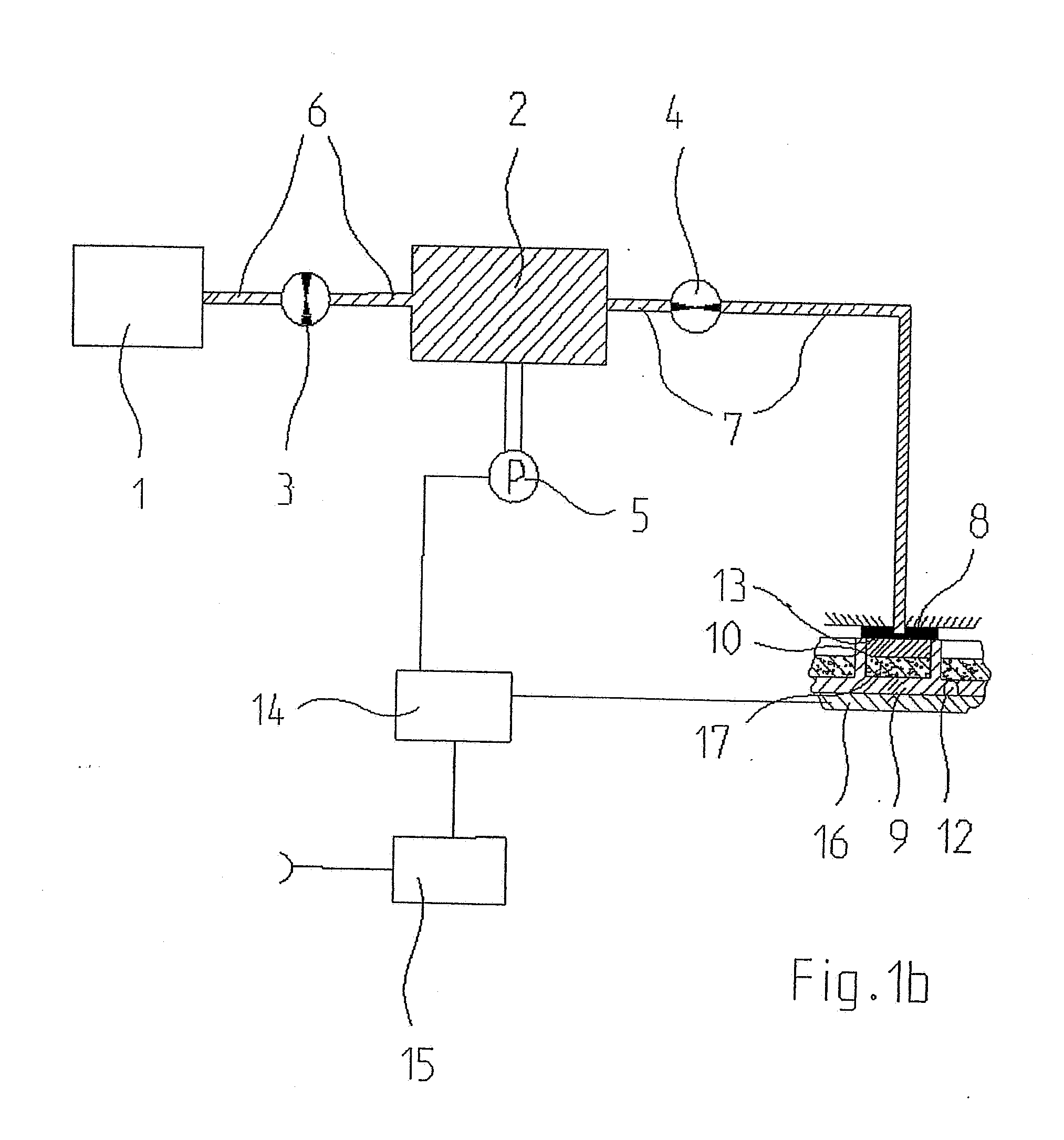

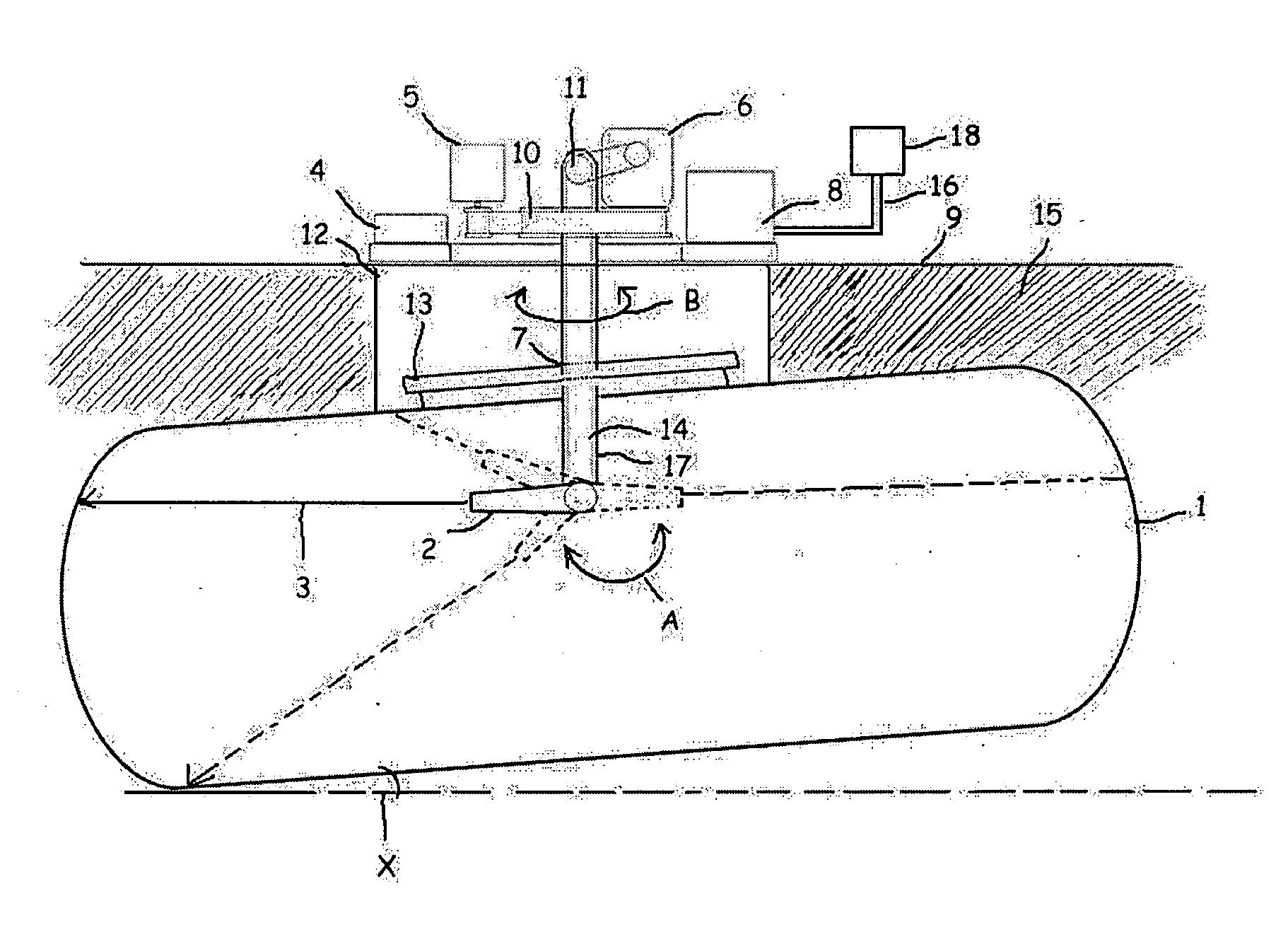

Method and Apparatus for Forming the Calibration Chart for the Underground Fuel Tanks

ActiveUS20100212397A1Faster performance of calibrationShort timeFlow propertiesFluid pressure measurement by mechanical elementsMarine engineeringFuel tank

The invention relates to the method and apparatus for forming the calibration chart used to measure the amount of fuel inside the fuel tanks (1) which comprises at least one laser distance measurement device (2) positioned inside said fuel tank (1) and measuring the distance between itself and the inner wall of said fuel tank (1) at separate points, at least one main shaft (14) providing said distance measurement device (2) with rotational movement circularly in the direction of B through up to 360 degrees and in the upward-downward direction of A through up to 270 degrees and at least one inclinometer (4) positioned on the surface (9) and measuring the angle X between said fuel tank (1) and the ground on which it is located.

Owner:ASIS OTOMASYON VE AKARYAKIT SISTEMLERI ANONIM SIRKETI

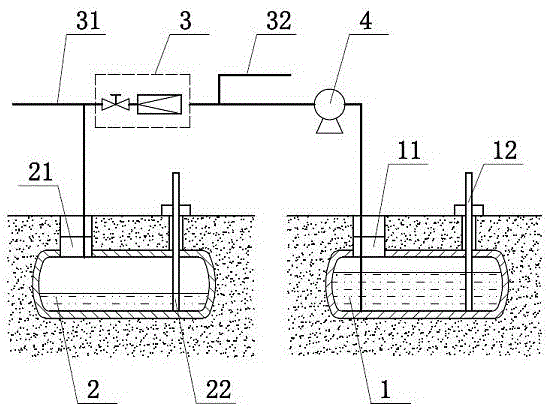

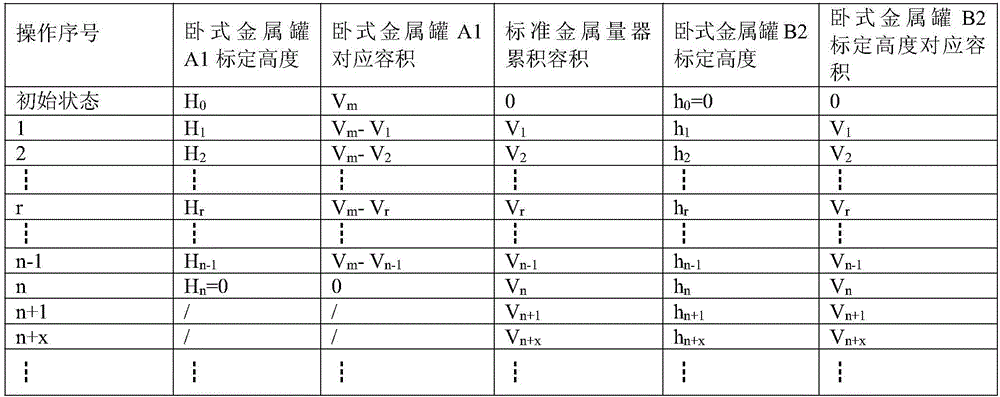

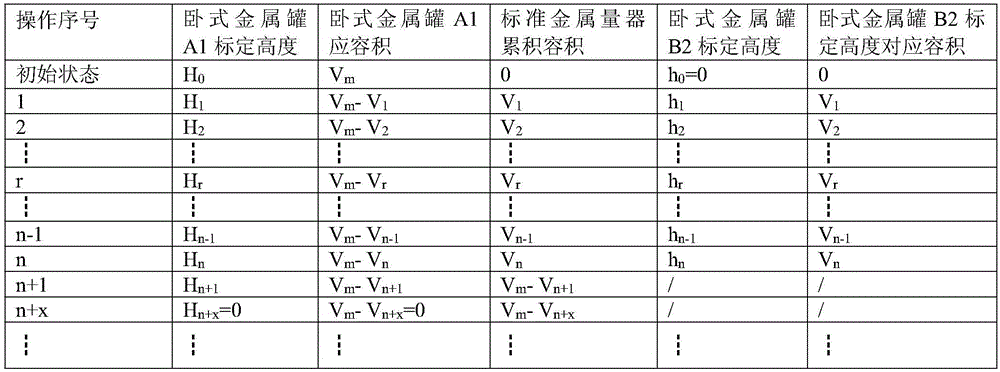

Meter-in and meter-out dual calibration device and method for calibrating volume of horizontal metal tank

ActiveCN105784076AReduce investmentImprove calibration efficiencyTesting/calibration for volume measurementWater volumeEngineering

The invention provides a meter-in and meter-out dual calibration device and method for calibrating the volume of a horizontal metal tank, and relates to the technical field of measuring. The initial volume of a tank A filled with water is Vm, a tank B is empty totally, and a numerical value of a liquidometer A and the numerical value of a liquidometer B are recorded respectively; water is sucked from the tank A, metered through a standard and injected into the tank B repeatedly, and numerical values of the liquidometers A and B are recorded respectively; the liquidometer B of the tank B corresponds to the injection water volume, and calibrated tank volume data is obtained after calibration is completed; the initial volume value Vm is obtained after water in the tank A is sucked completely, the each reading of the liquidometer A corresponds to the remaining water volume in the tank obtained by subtracting the volume of sucked water from Vm, the volume is converted after calibration is completed, and calibrated tank volume data is obtained. The technical problem that an existing metal storage tank volume is large in volume calibration error and low in efficiency is solved. The device and method have the advantages that equipment input is saved, energy consumption is lowered, calibration efficiency is high, the meter-in and meter-out working modes are calibrated, a result is reliable, operation is easy, and adaptability is good.

Owner:GUANGZHOU INST OF ENERGY TESTING

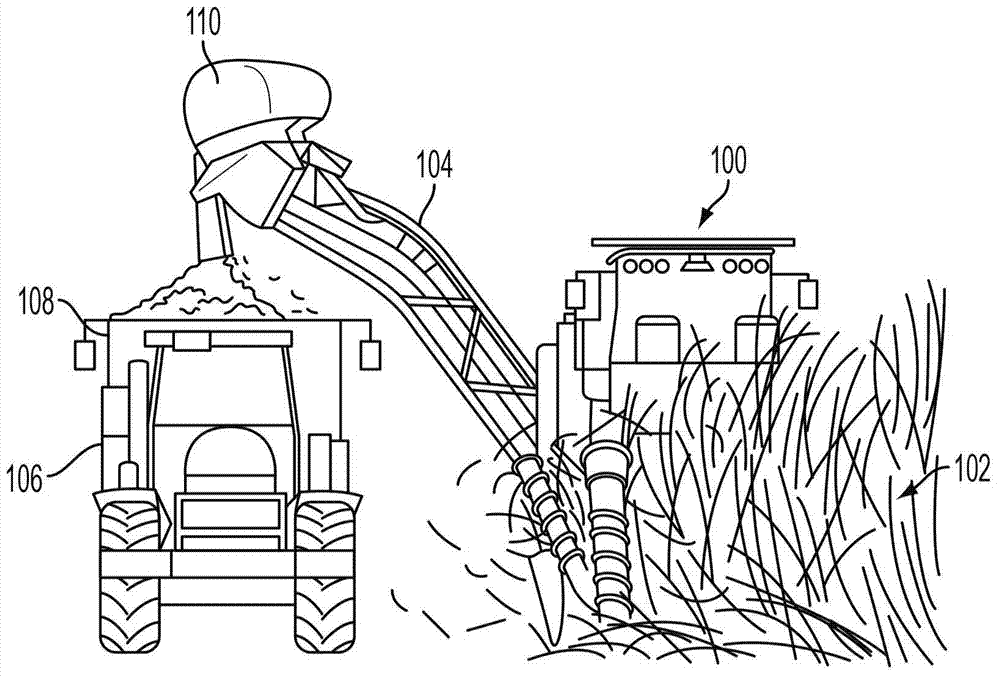

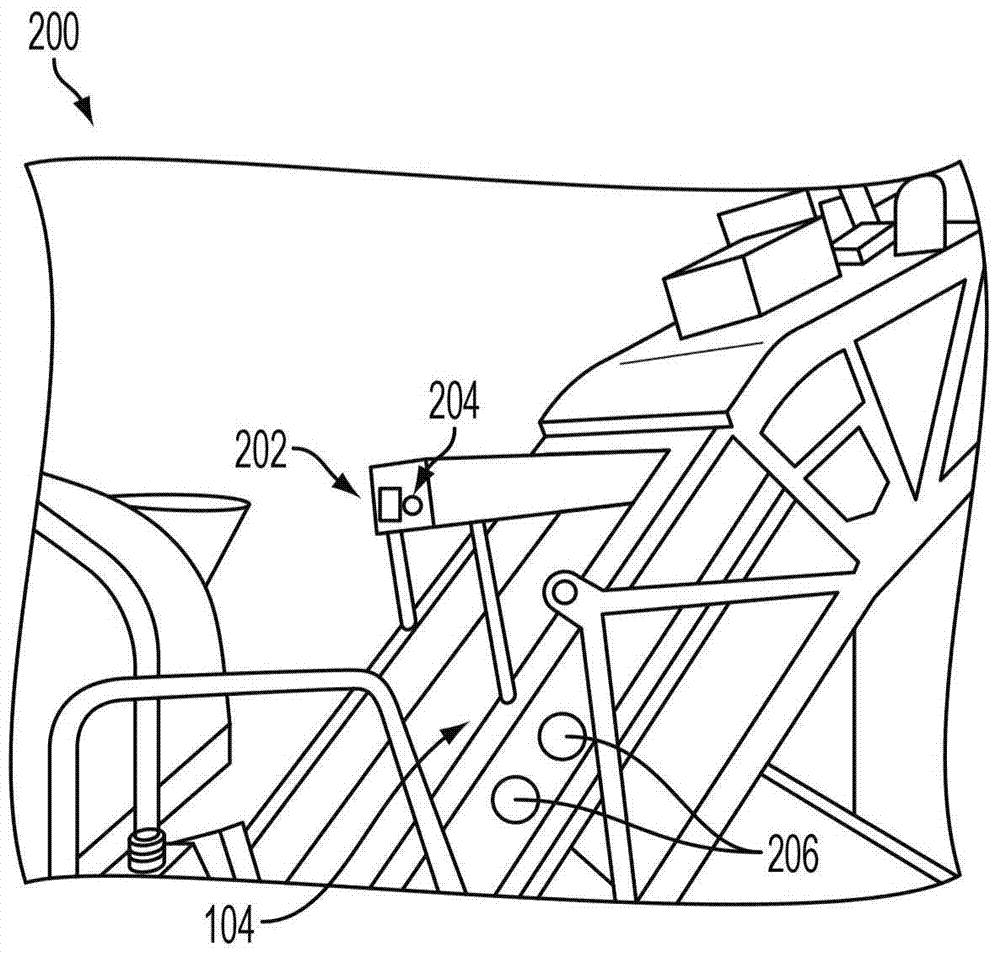

Yield measurement and base cutter height control systems for a harvester

A system is provided that can include a 3D sensor. The 3D sensor can be configured to detect an area of an elevator on a harvester. The 3D sensor can further be configured to transmit a first signal associated with the area. The system can also include a processing device in communication with the 3D sensor. The system can further include a memory device in which instructions executable by the processing device are stored for causing the processing device to receive the first signal and determine a volume of a material on the elevator based on the first signal.

Owner:IOWA STATE UNIV RES FOUND +2

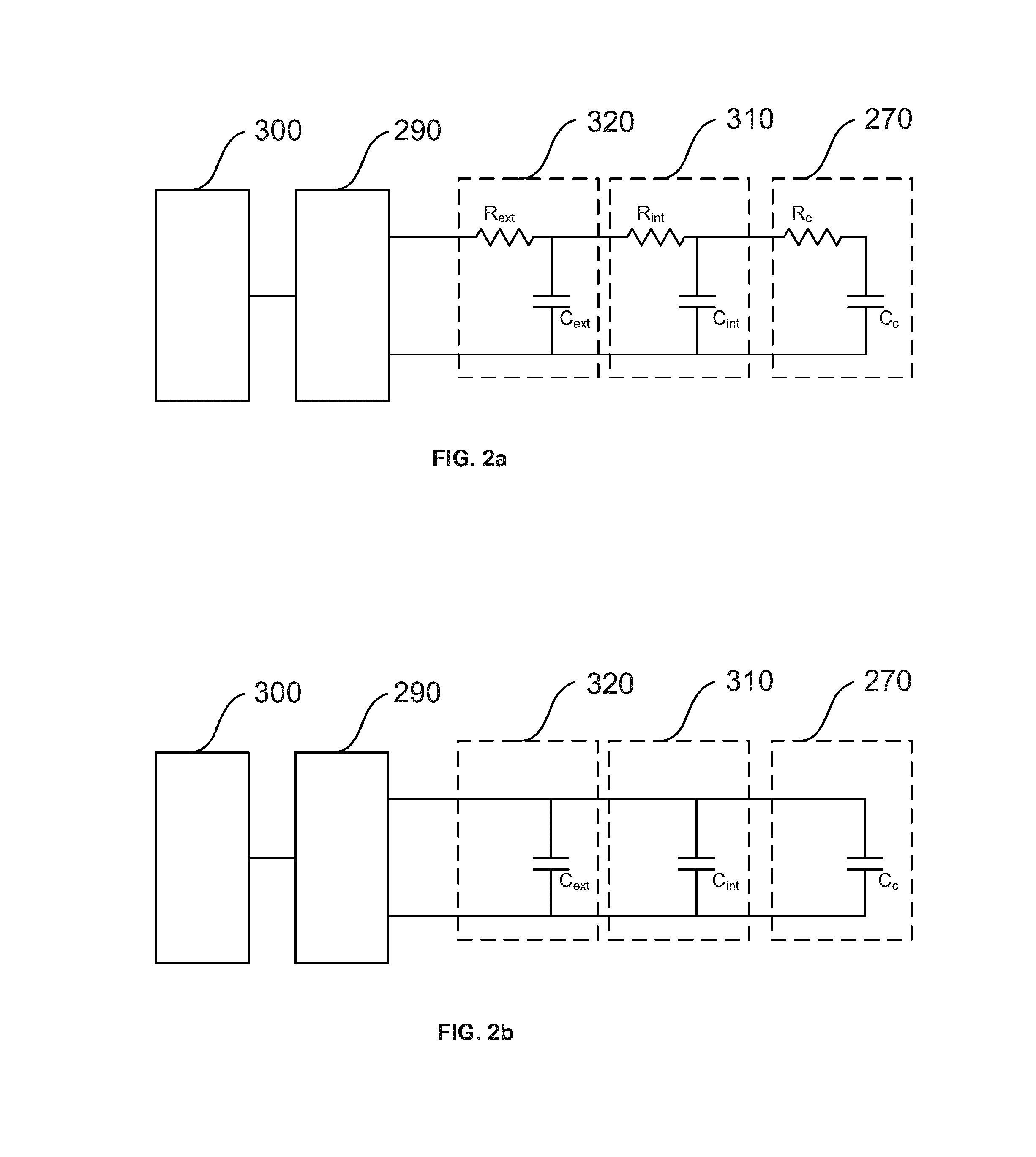

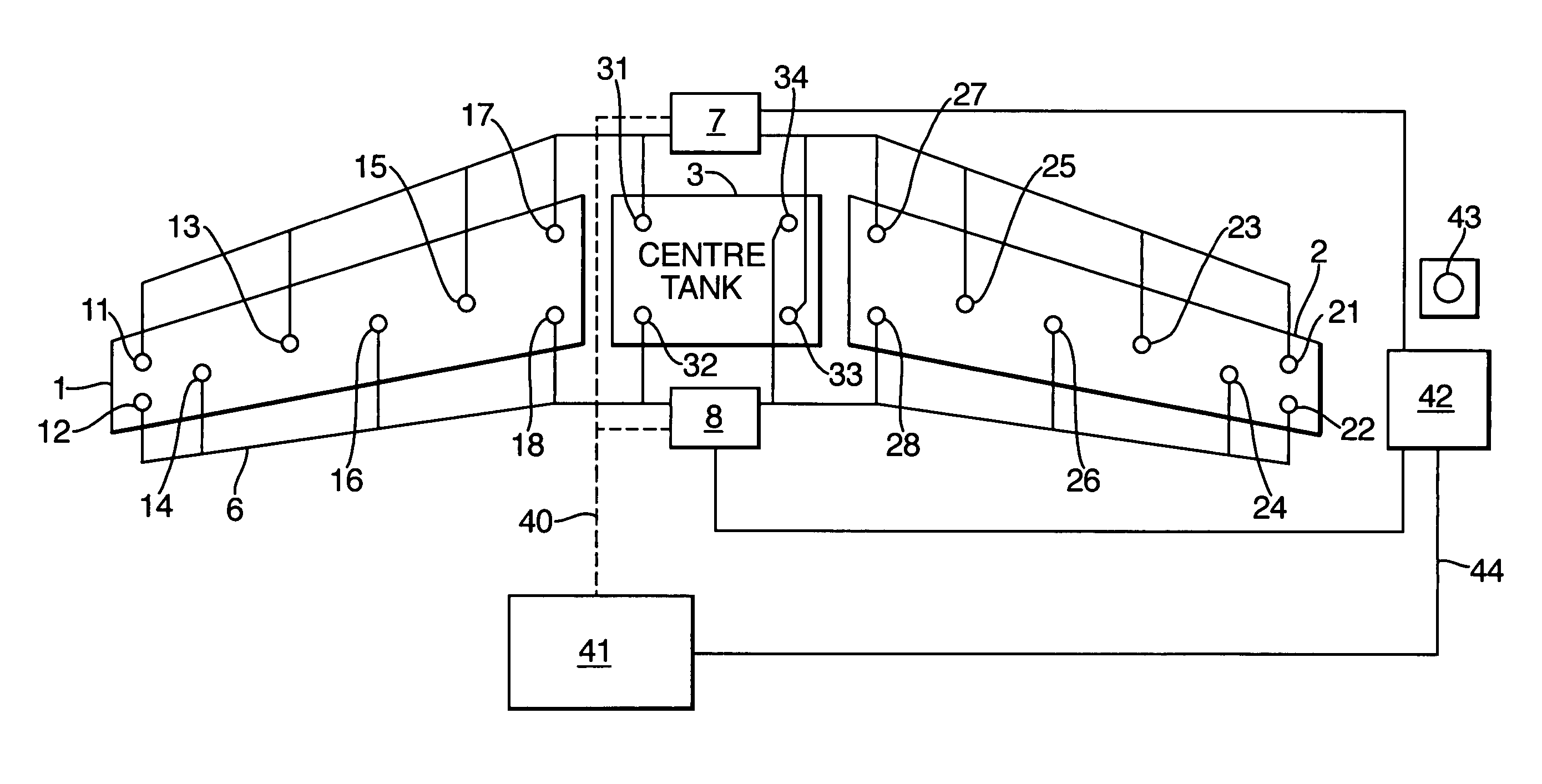

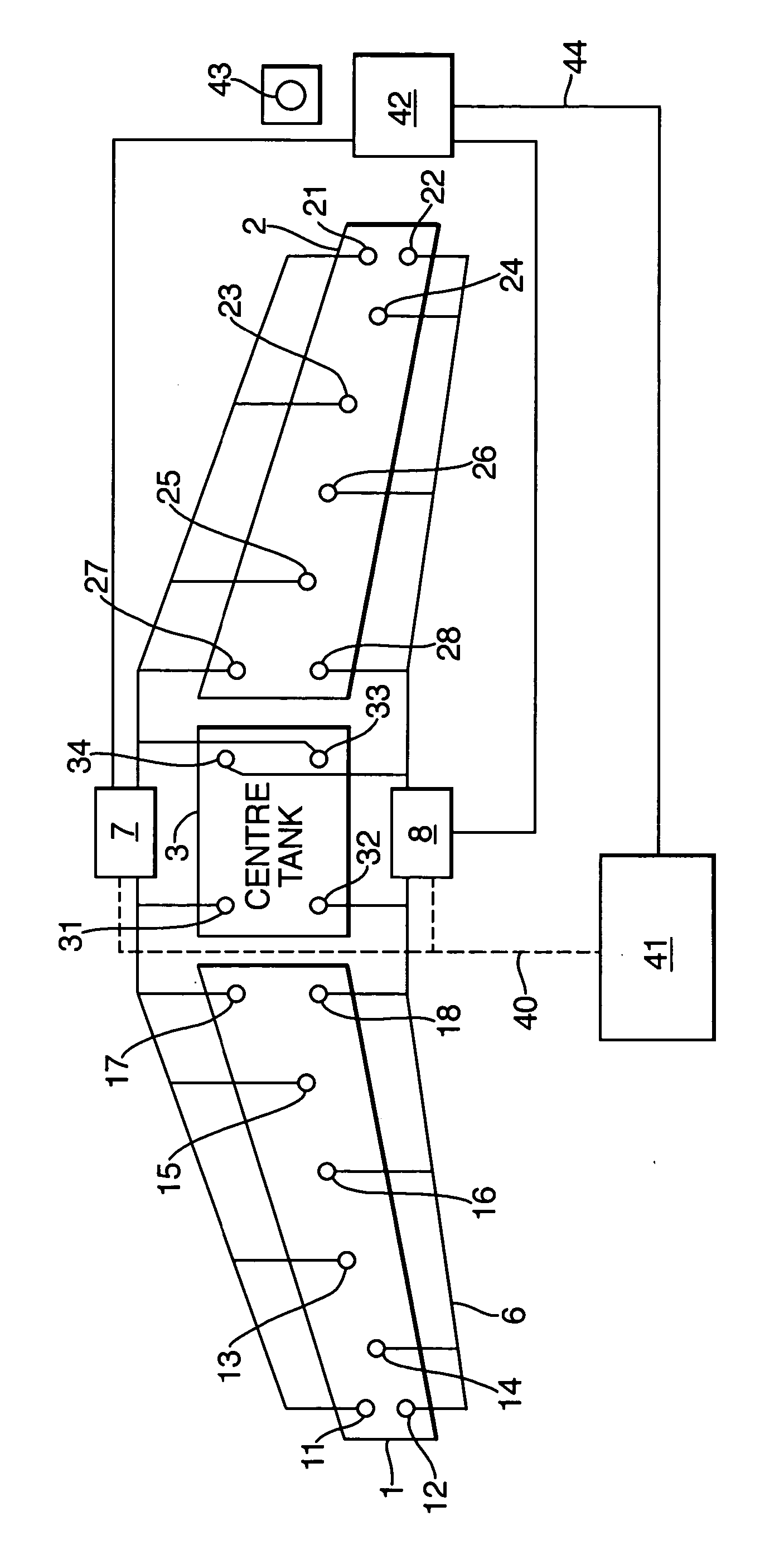

Fluid-gauging systems

An aircraft fuel-gauging system has multiple gauging sensors in each tank divided into two groups. Each group of sensors connects with a respective processor. The processors are linked to provide a display in the cockpit to give an indication of fuel quantity derived from all the sensors. The two processors also provide separate, nominally-identical display indications of fuel quantity on a refuel panel on the exterior of the aircraft. The refueller can compare these two separate quantity indications with the flow meter in the fuel dispenser to confirm that the correct quantity has been dispensed.

Owner:SMITHS GRP PLC

Temperature compensated pressure switch (TCPS)

ActiveUS8443650B2Testing/calibration for volume measurementContainer/cavity capacity measurementEngineeringPressure data

A temperature compensated pressure switch (“TCPS”) with thermal lag compensation, trend indication, and forecast analysis. The TCPS has a first control unit, a pressure sensor connected to the first control unit outputting a first pressure data, a temperature sensor connected to the first control unit outputting a first temperature data, and a first storage unit connected to the first control unit storing: minimum and maximum pressure data corresponding to temperature data and rate of temperature change values. The first control unit can substitute a second temperature data, for the first temperature data for a period of time. The first control unit also outputs a first signal indicating the amount of material is acceptable when the first pressure data is above the minimum pressure data and outputs a second signal indicating the amount of material is unacceptable when the first pressure data is not above the minimum pressure data.

Owner:MASS SYST A UNIT OF AMERON GLOBAL

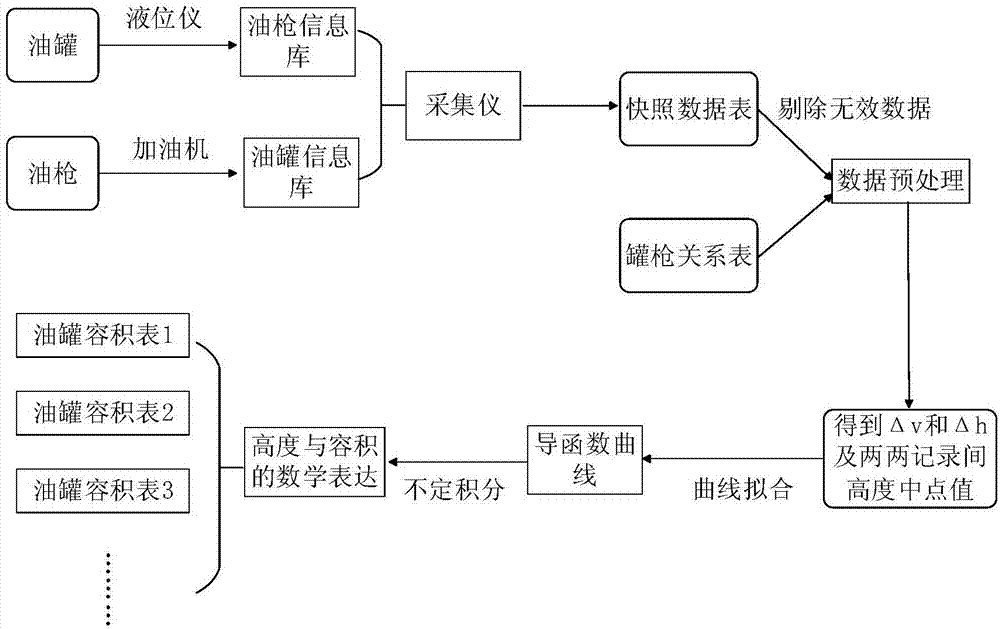

Data processing method of calibration of oil tank volume table with integral

ActiveCN107462299AGood technical effectImprove the inaccurate phenomenon of volume tableTesting/calibration for volume measurementContainer/cavity capacity measurementVolume tableCurve fitting

The invention discloses a data processing method of calibration of an oil tank volume table with integral. The method comprises the steps that first, oil tank oil gun data is collected and stored in a database; second, screening is conducted on the collected data, and meanwhile a tank gun relation table of every oil tank in a gas station is obtained; third, data preprocessing is conducted on the screened data based on the tank gun relation table, and effective data pairs are obtained; fourth, curve fitting is conducted on the effective data pairs, then integral is conducted on the fitted curve formula to obtain the mathematical expression of the height and volume of each oil tank, and the volume table is generated; fifth, error analysis is conducted on the volume table generated. Through implementation of the data processing method, in the condition that closure and tank emptying are not needed, normal operation of the gas station is ensured, and management of quantity and quality of the gas station is improved.

Owner:杭州信雅达三佳系统工程股份有限公司

Fluid-gauging systems

An aircraft fuel-gauging system has multiple gauging sensors in each tank divided into two groups. Each group of sensors connects with a respective processor. The processors are linked to provide a display in the cockpit to give an indication of fuel quantity derived from all the sensors. The two processors also provide separate, nominally-identical display indications of fuel quantity on a refuel panel on the exterior of the aircraft. The refueller can compare these two separate quantity indications with the flow meter in the fuel dispenser to confirm that the correct quantity has been dispensed.

Owner:SMITHS GRP PLC

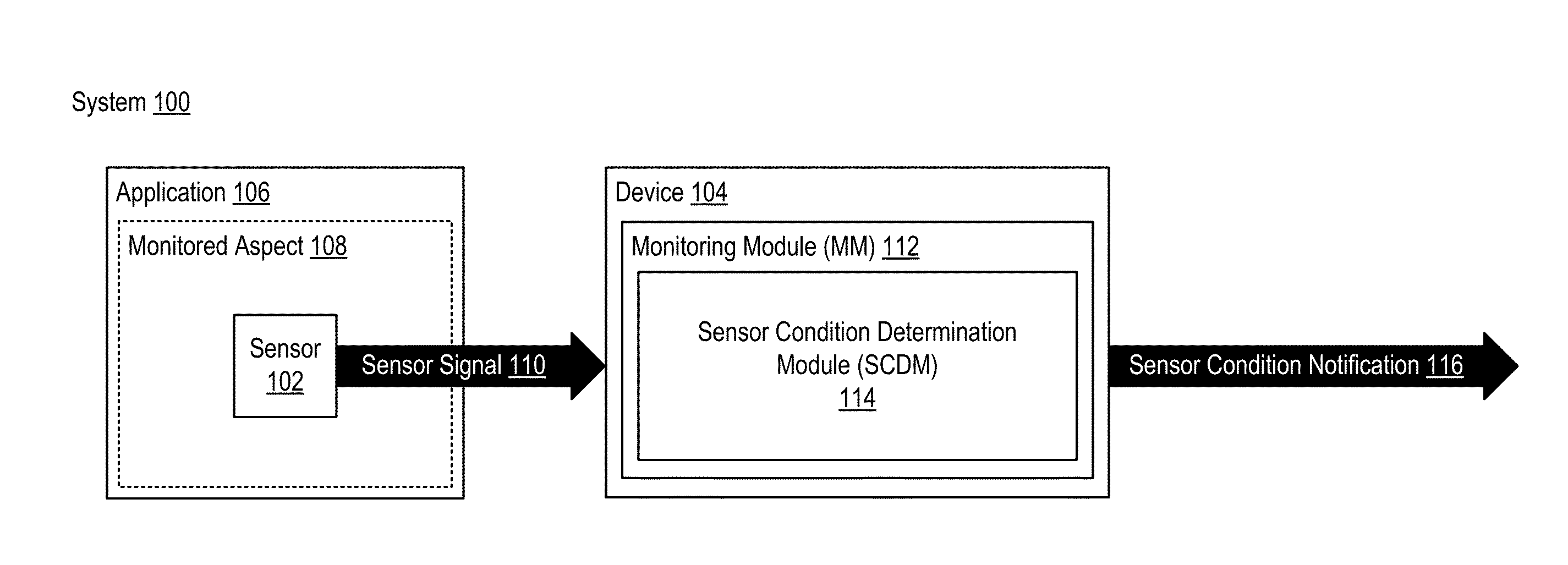

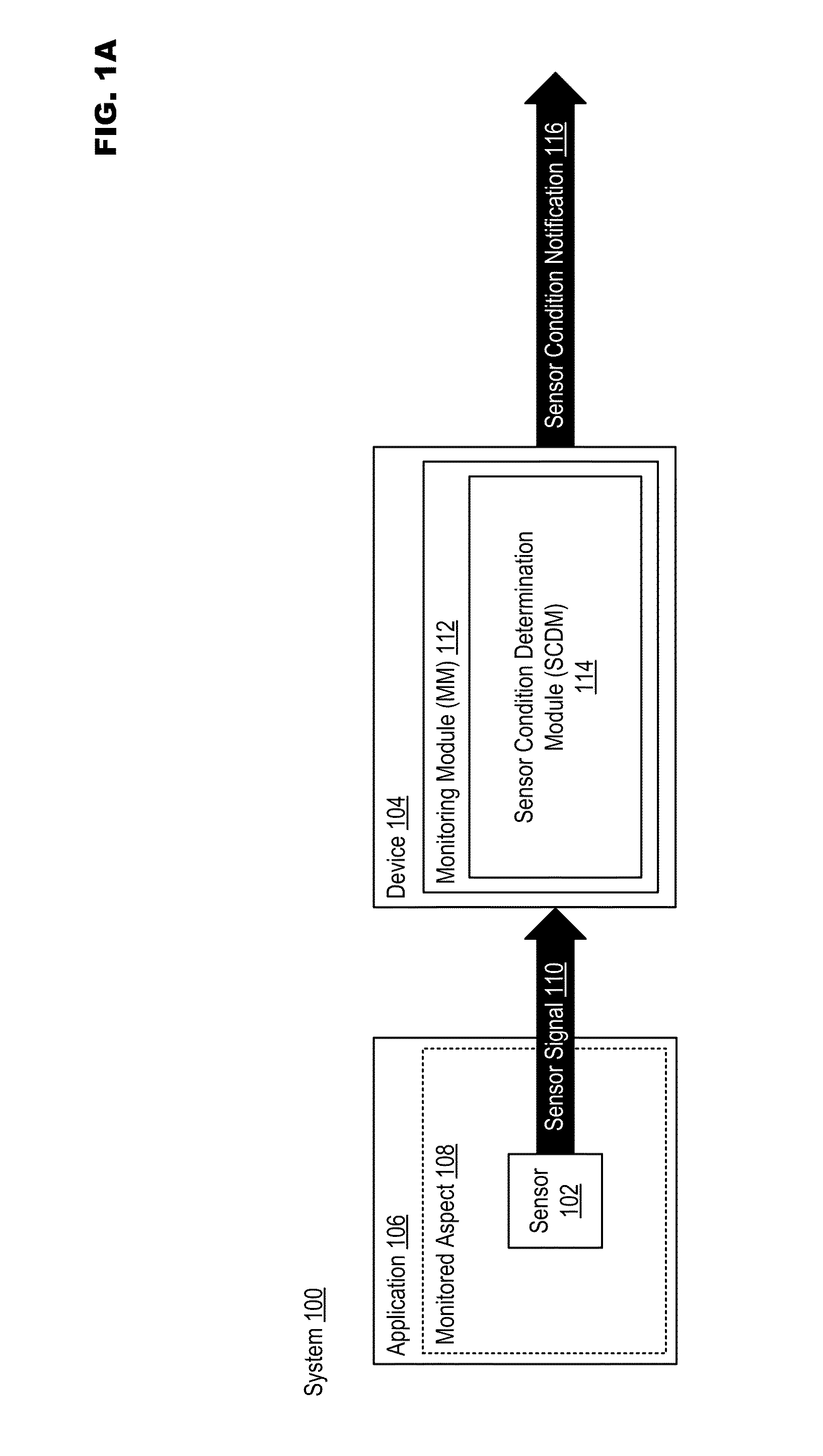

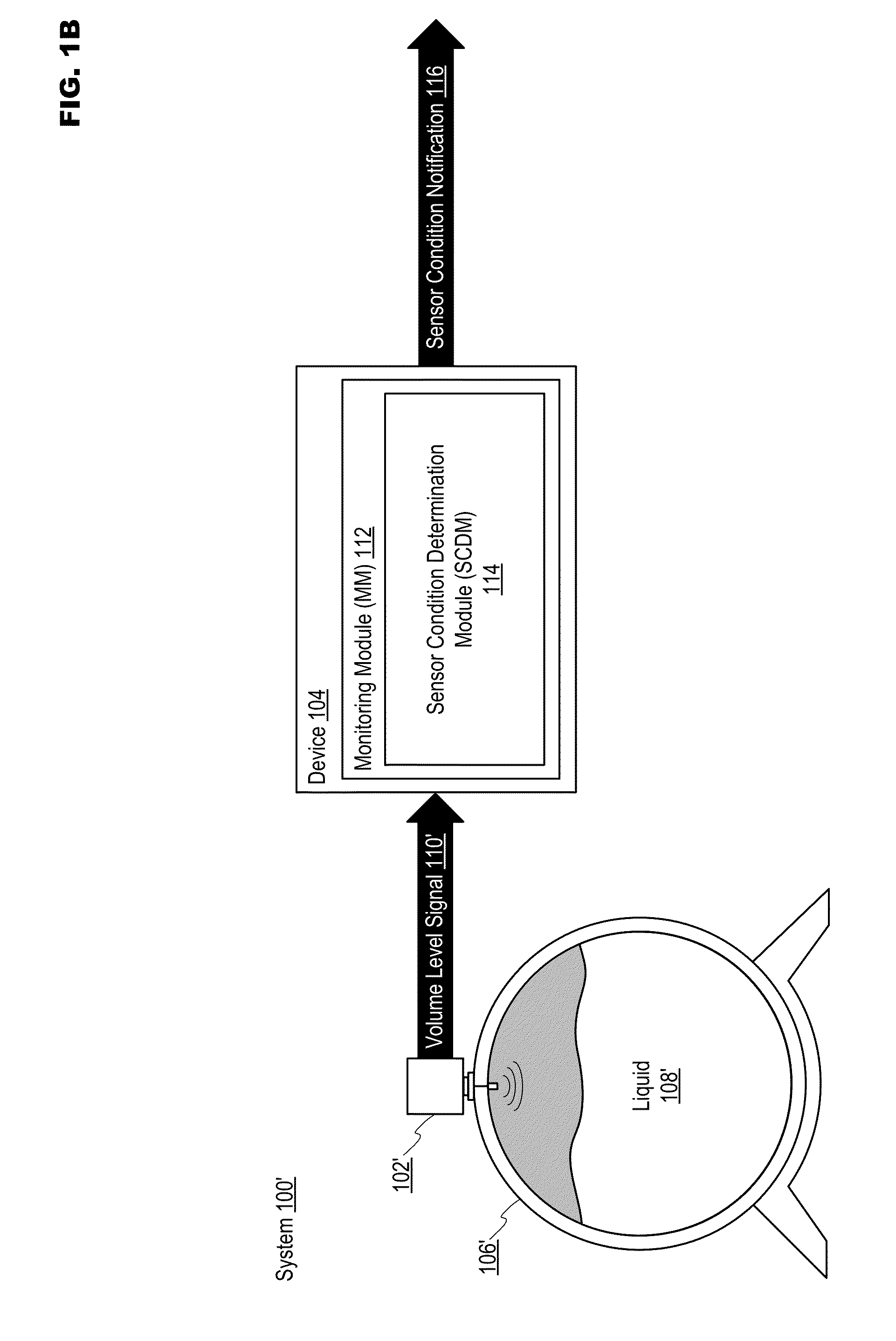

System for determining sensor condition

ActiveUS20160125720A1Testing/calibration for volume measurementAlarmsSupport vector machineFeature extraction

The present disclosure is directed to a system for determining sensor condition. A sensor signal generated by a sensor to communicate the current condition of an aspect being monitored by the sensor may also be employed to determine the condition of the sensor itself. For example, a device capable of determining if the sensor condition is normal or malfunctioning (e.g., erratic, stuck, etc.) may comprise a monitoring module (MM) to receive the sensor signal. The MM may comprise a sensor condition determination module (SCDM) to determine sensor condition. The SCDM may include a feature extraction engine to determine various characteristics of (e.g., to “extract features” from) the sensor signal and a model to determine sensor condition based on the extracted features. The model may include a support vector machine (SVM) taught to determine sensor condition utilizing sampled sensor signals correlated with annotations of sensor condition.

Owner:INTEL CORP

Method and arrangement for indirectly determining fill characteristics of a fluid tank on a marine vessel

InactiveUS7059167B2Avoid confusionImprove data qualityTesting/calibration apparatusFlow propertiesPosition dependentEngineering

Method and arrangement for accommodating indirect ascertainment of fill-characteristics of fluid tanks on marine vessels. The invention includes providing an experientially-based mapping of volume characteristics of a fluid tank positioned on a marine vessel that are correlated with respect to measurable fluid surface positions within the fluid tank. In consideration of this volume characteristic mapping, fluid fill condition information is output for operator use based on quantification of a parameter other than sensed fluid level in the fluid tank. While it is contemplated that the other parameter may be any characteristic that readily reads back to the volume characteristic mapping, it is particularly advantageous, and a preferred embodiment of the invention, that the other parameter be a volumetric quantification of fluid consumed out of the tank that can be compared to an earlier ascertained tank volume.

Owner:VOLVO PENTA AB

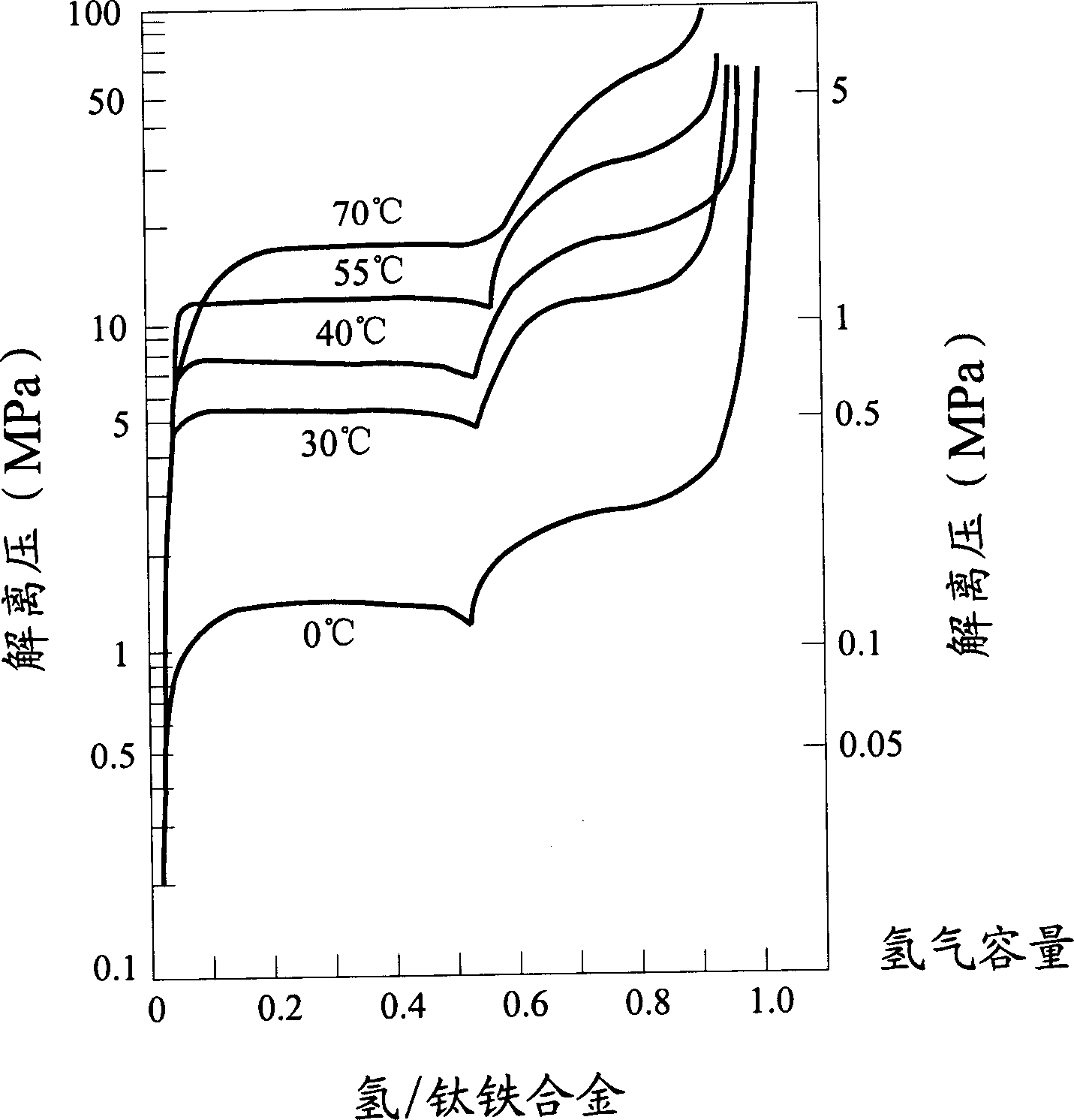

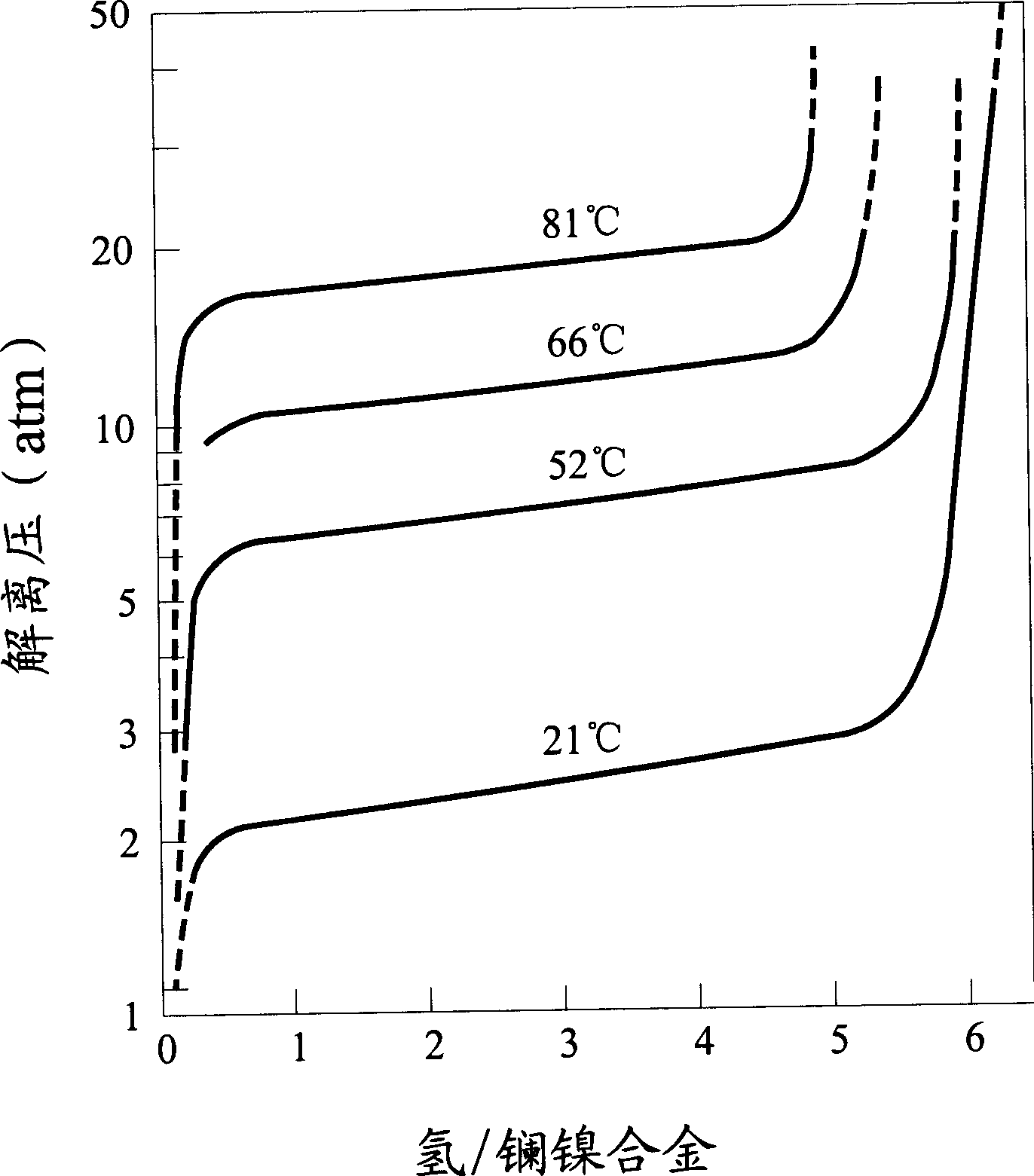

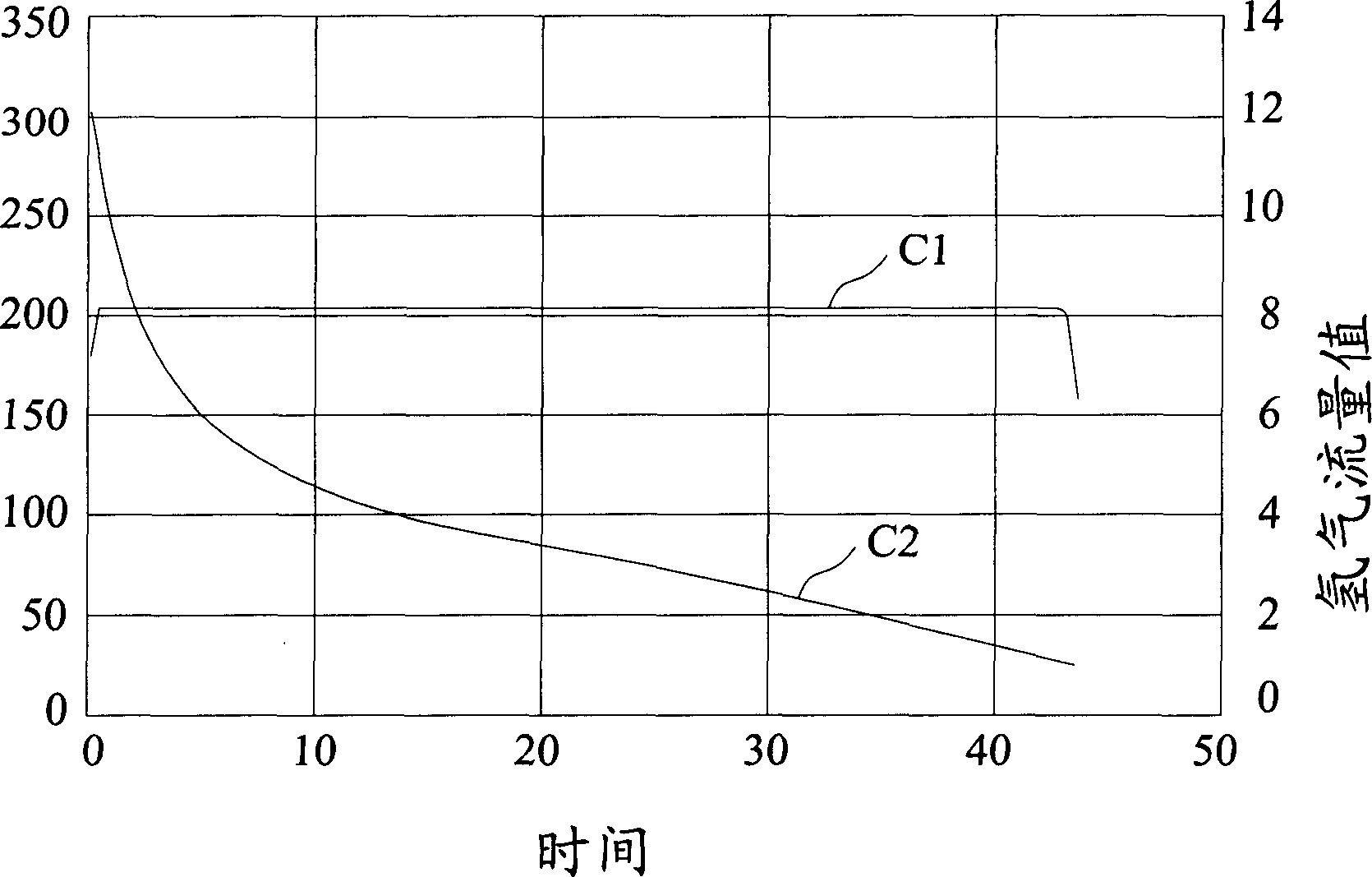

Residual hydrogen-storage account measuring method of hydrogen-storage container

ActiveCN1854692AOvercome the error problem of hydrogen capacityAvoid errorsTesting/calibration for volume measurementContainer/cavity capacity measurementChemistryHydrogen storage

A method for measuring out usable residual-hydrogen amount stored in hydrogen container includes fetching service circulation frequency of hydrogen container, fetching hydrogen stock of hydrogen container and consumed hydrogen amount of hydrogen container, then applying calculation formula to calculate out usable residual-hydrogen amount stored in hydrogen container.

Owner:ASIA PACIFIC FUEL CELL TECH

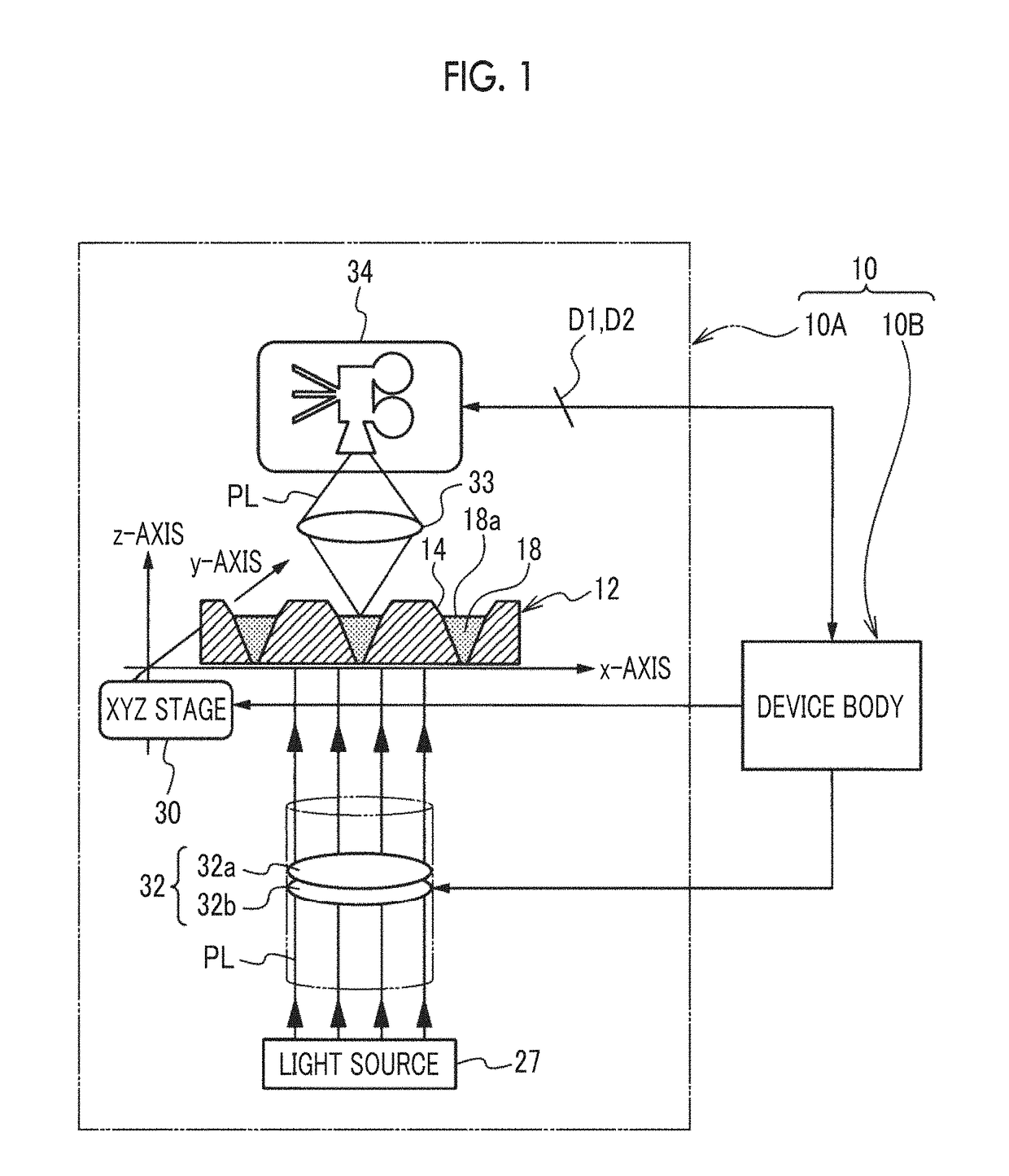

Measurement method, measurement device, and program

ActiveUS20180066938A1Improve accuracyShorten speedInfusion syringesMicroneedlesMeasurement deviceAqueous solution

The present invention provides a measurement method, a measurement device, and a program capable of non-destructively measuring a volume of an aqueous solution of a drug in each needle-like recess of a mold with high accuracy. A measurement method according to a preferred embodiment of the present invention includes a measurement wave intensity acquisition step of acquiring, for each needle-like recess, an intensity of a measurement wave transmitted through a drug in a needle-like recess, absorbed by the drug by an amount according to a distance by which the measurement wave is transmitted through the drug, and emitted from the drug; and a volume acquisition step of acquiring a volume for each needle-like recess on the basis of the intensity of the measurement wave for each needle-like recess acquired in the measurement wave intensity acquisition step.

Owner:FUJIFILM CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com