Fluid delivery device with autocalibration

A fluid pumping and dispensing device technology, which is applied in liquid distribution, delivery or transfer devices, test/calibration devices, test/calibration volume flow, etc., can solve the problems of dose volume deviation, additional deviation enhancement, etc., and achieve economical and reliable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

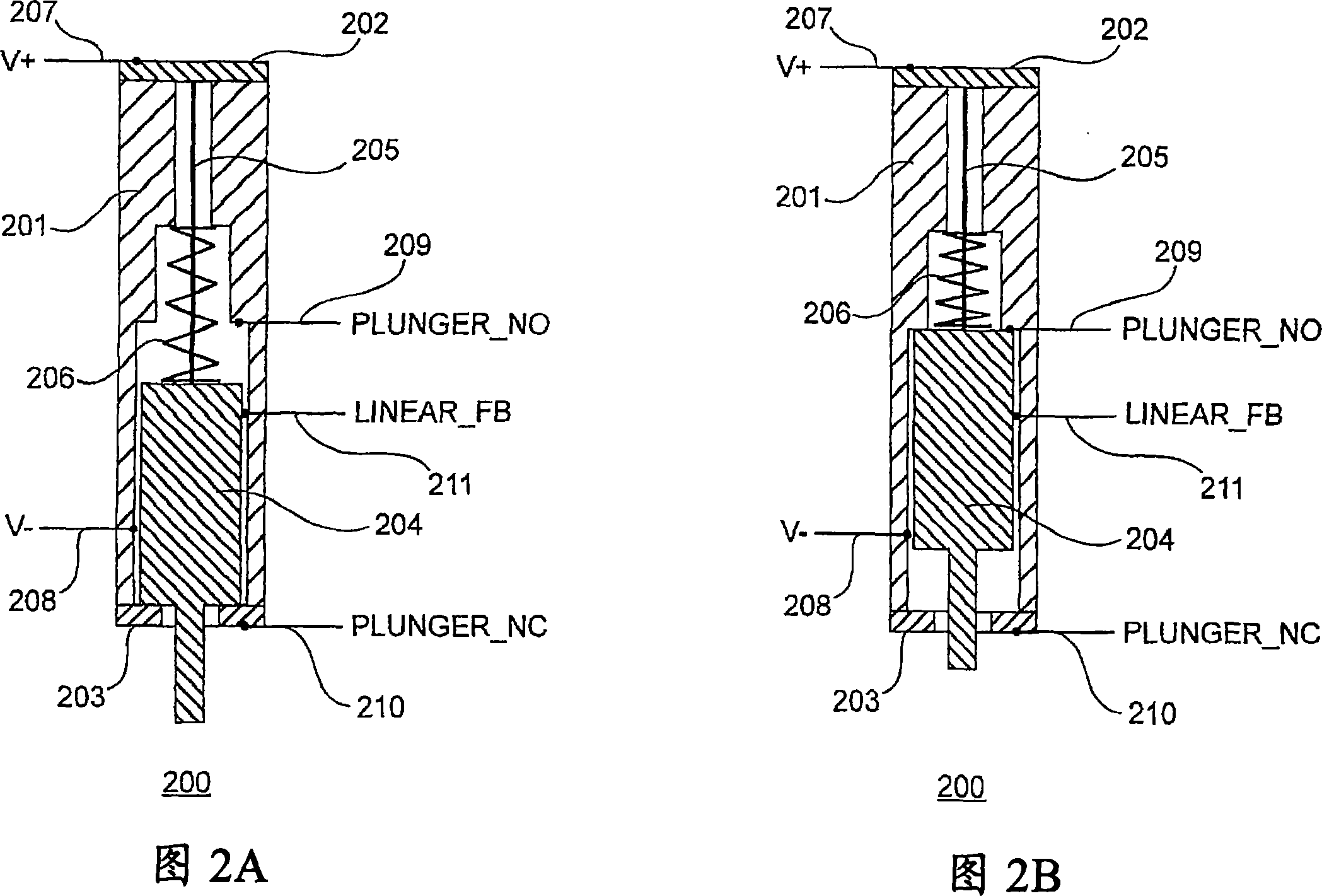

[0019] It is important to eliminate variations between one pump and another (of the same design), which are the result of manufacturing limitations. The present invention can be used to minimize the effects of these deviations and achieve precise delivery in any type of liquid pump.

[0020] As discussed in the Background, there is one type of liquid pump for which the present invention is particularly advantageous, namely the small piston type pump. Piston-diaphragm assemblies for small pumps require extremely high manufacturing tolerances in order to achieve reproducible dose volumes from one pump to another. Even when manufactured with high precision, there may be non-negligible deviations from one pump of a given design to another. This is not ideal, especially in applications involving pumps for drug delivery or other medical applications.

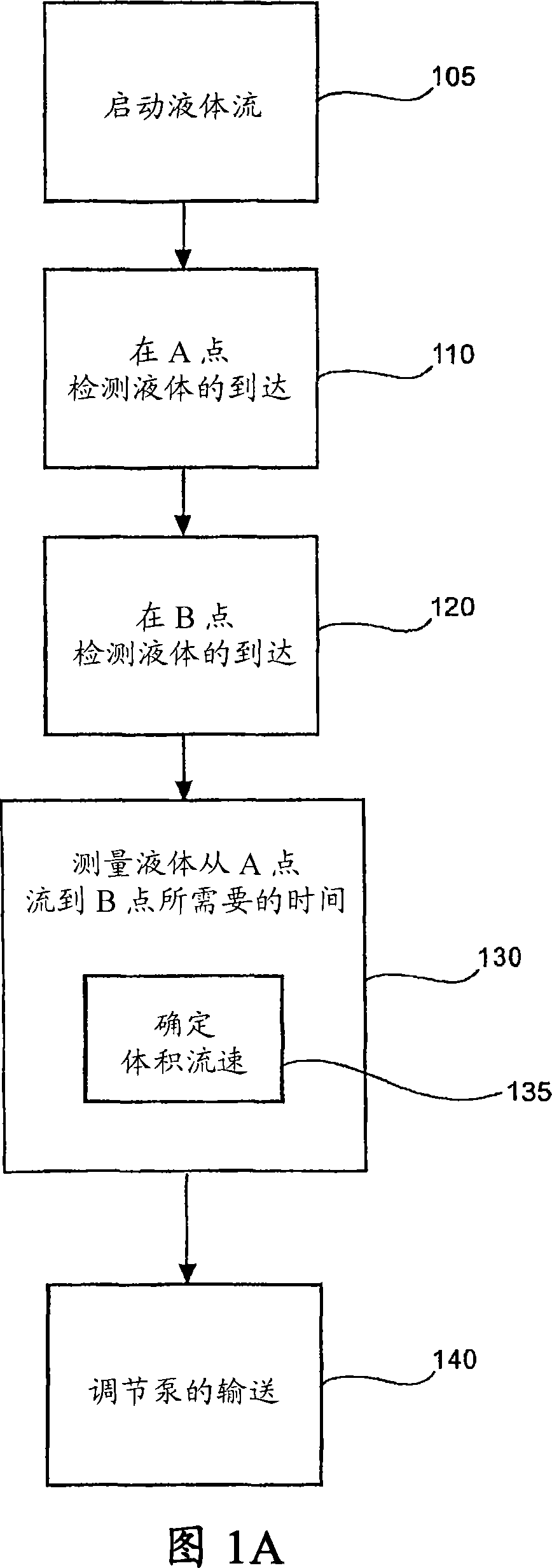

[0021] The present invention provides a simple, economical and reliable mechanism and method for minimizing or "zeroing out" pump-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com