Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177results about "Strap saws" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

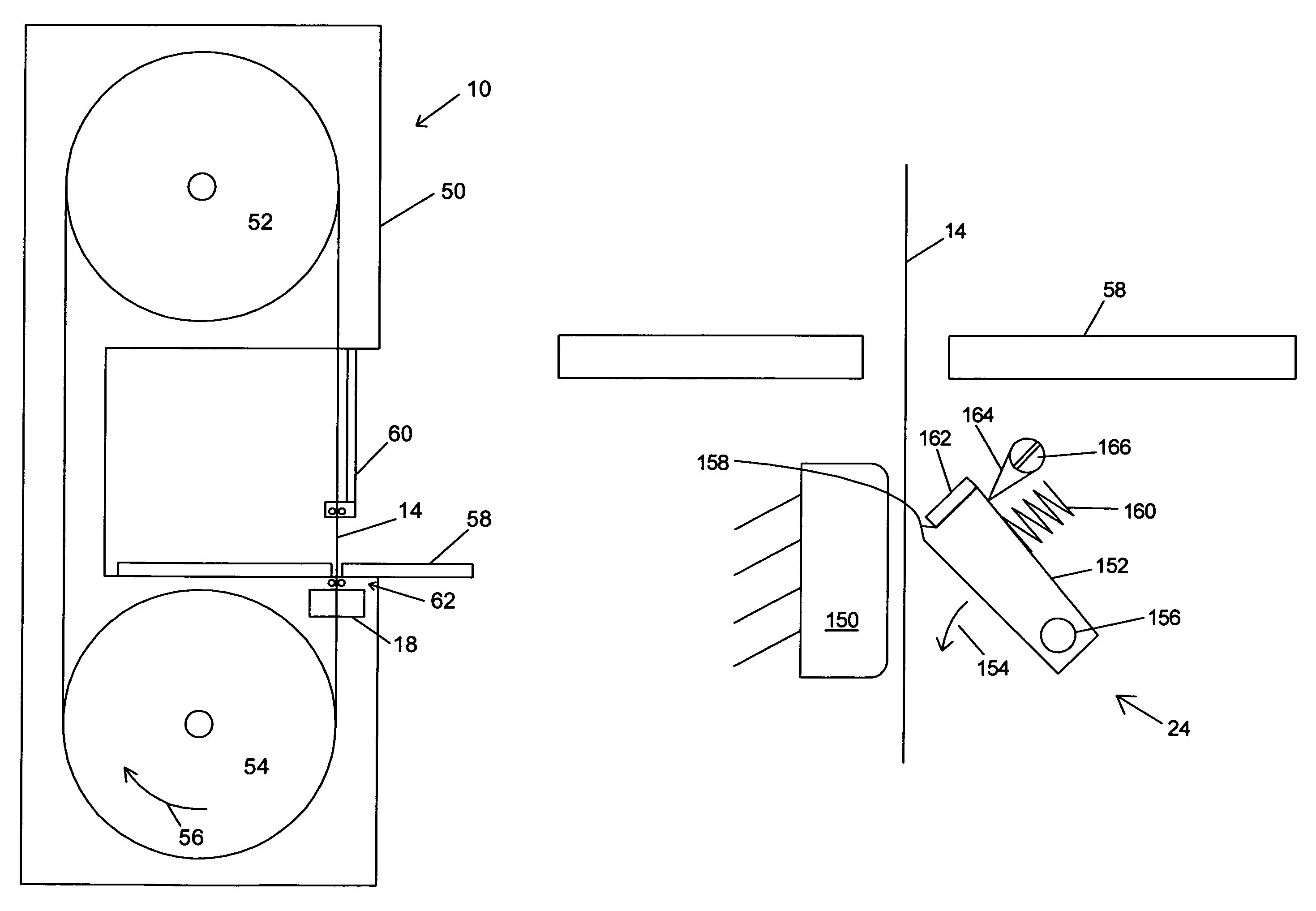

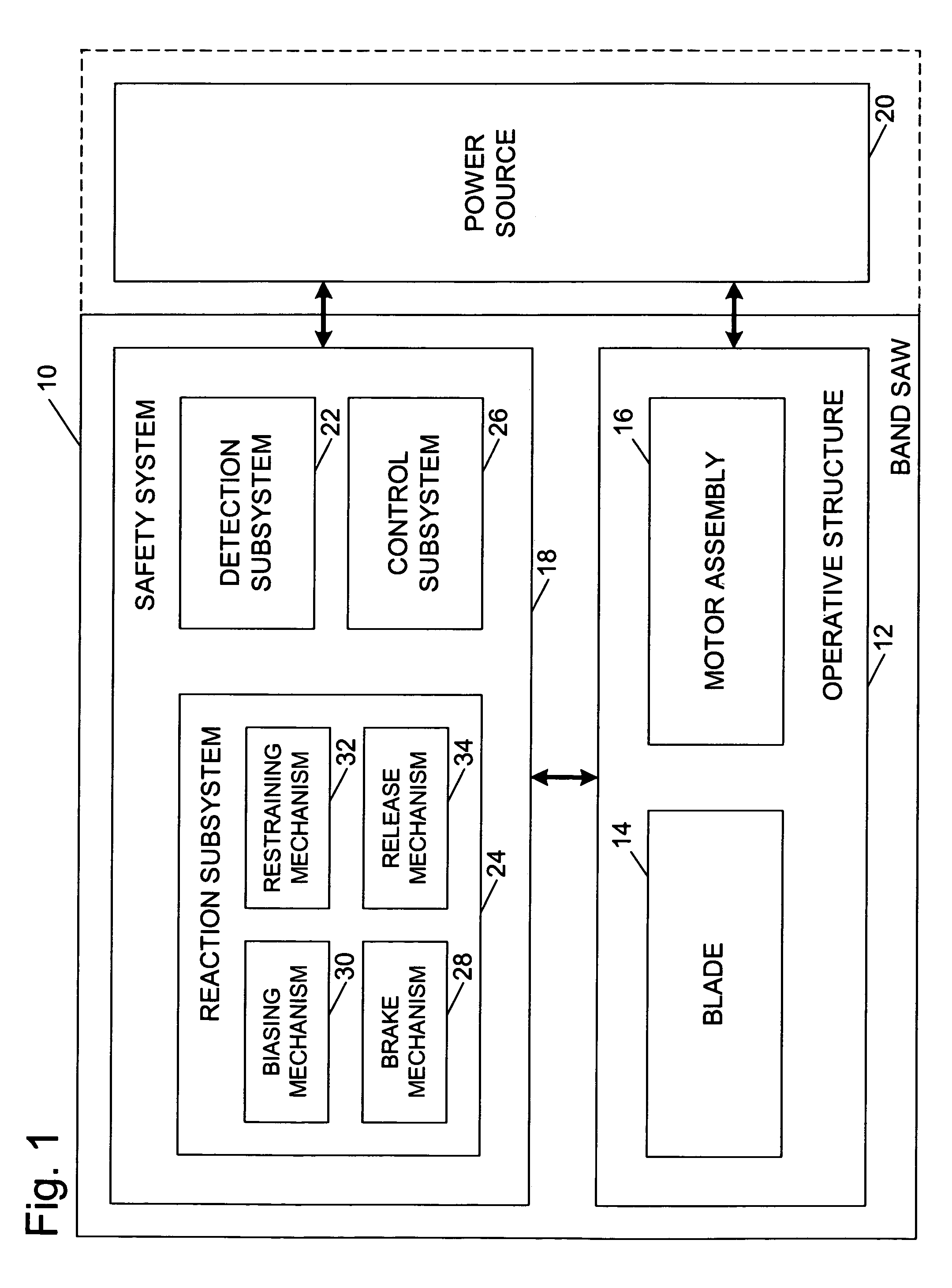

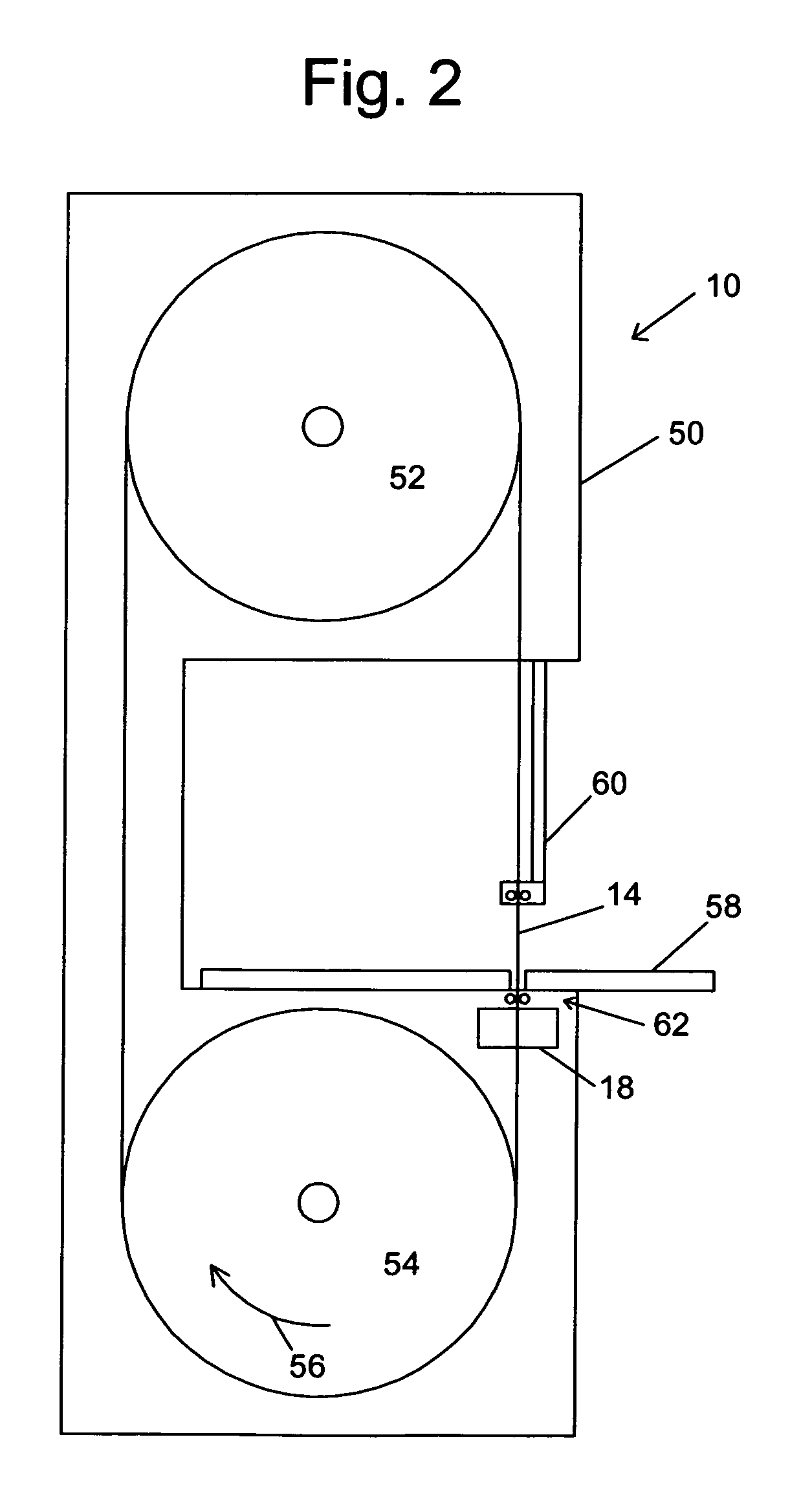

Safety systems for band saws

Owner:SAWSTOP HLDG LLC

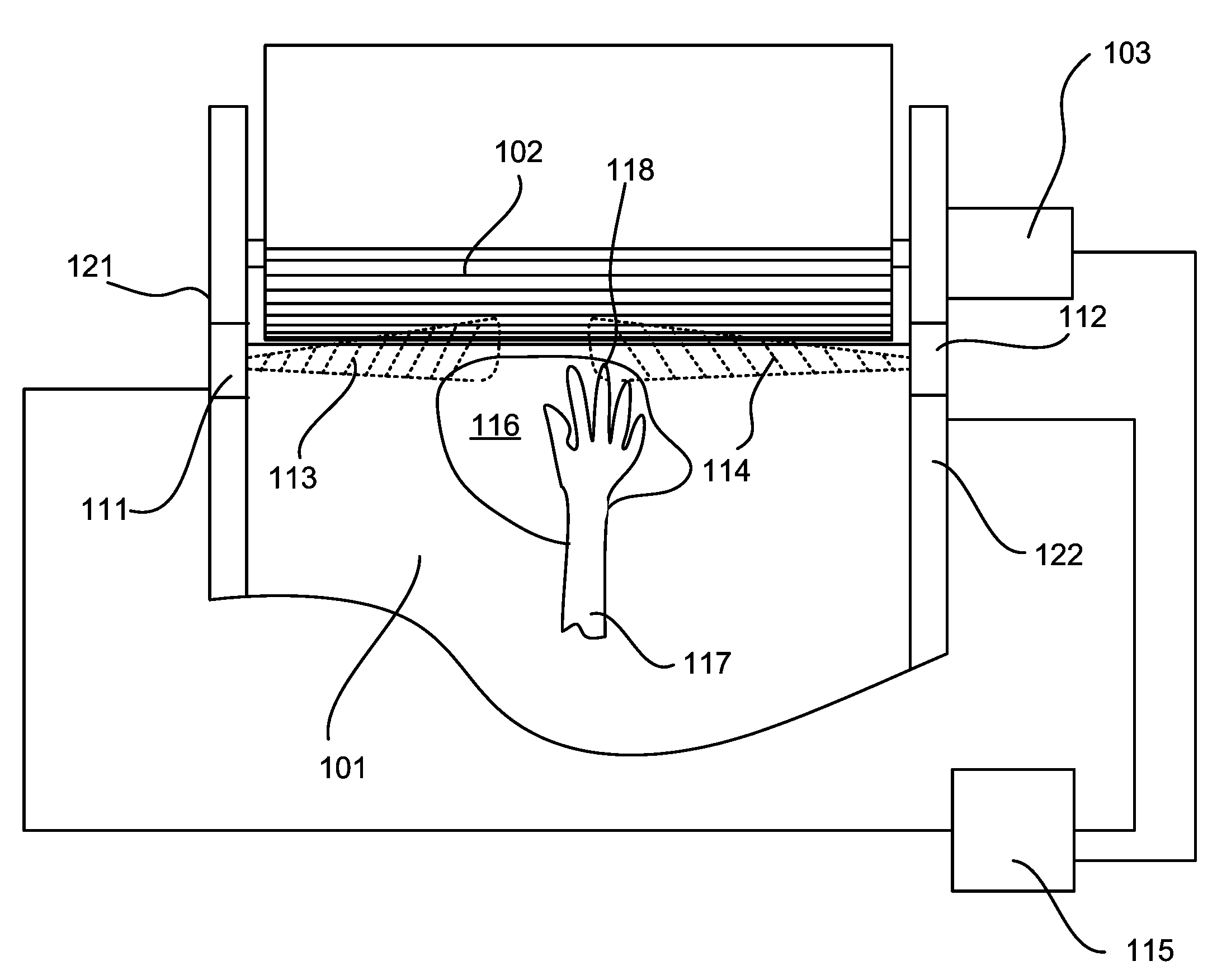

Operator safety device for a machine having sharp implements

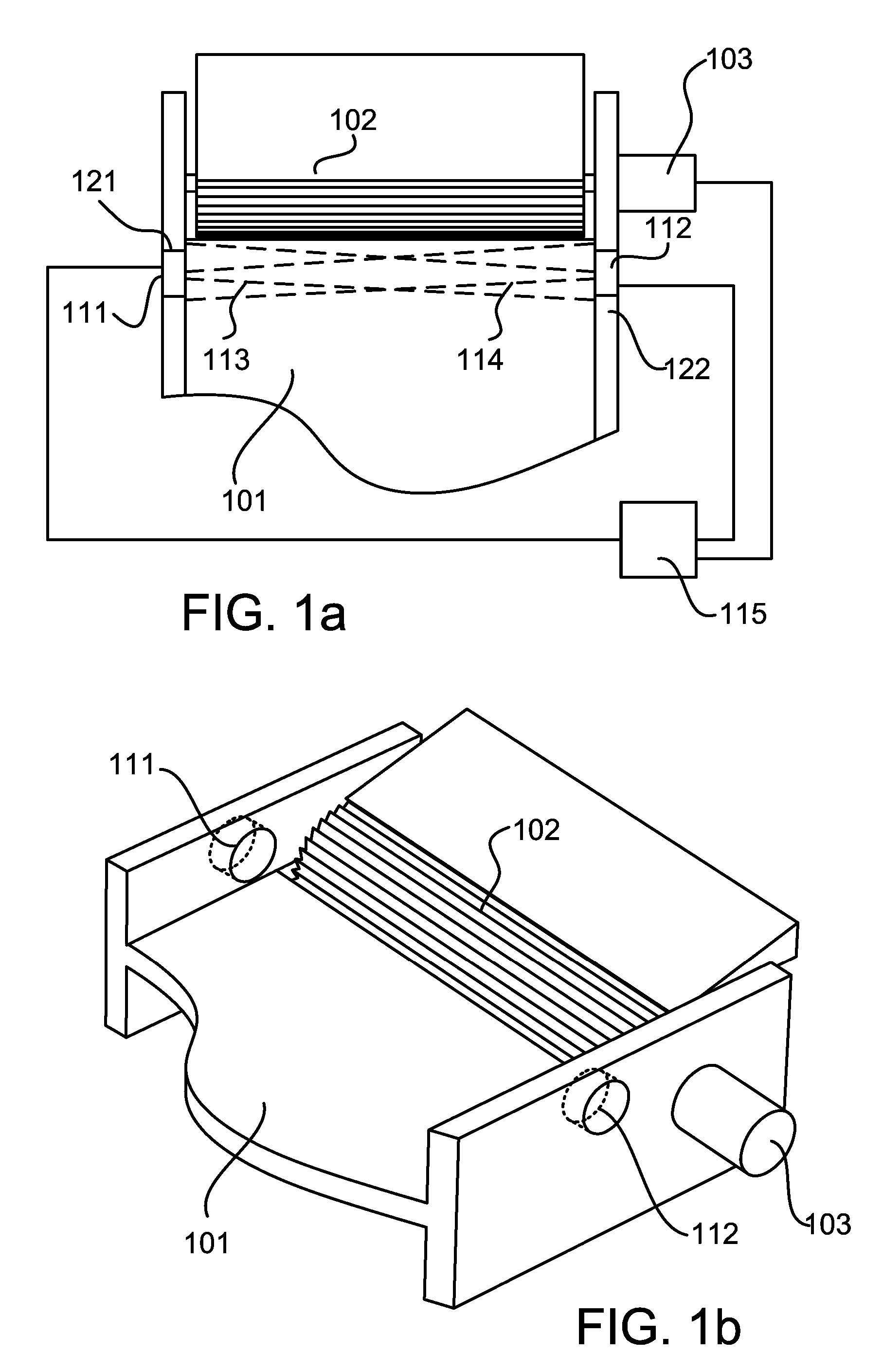

InactiveUS20060197020A1Providing operator safetySafer for operatorRadiation pyrometryMaterial analysis by optical meansEngineeringHuman operator

A novel human operator safety device is disclosed for use with motorized machines that have a danger zone that includes sharp cutting implements that can potentially cause operator harm. The operator safety device includes an optical or thermal sensor for either processing optically derived information to determine whether an extremity of an operator is within a predetermined proximity of the danger zone of the machine and processing thermal information to determine whether an extremity of an operator is within a predetermined proximity of the danger zone of the machine. If a presence is detected, at least a portion of the machine what may cause operator harm is stopped. For example, a thermal camera, an optical camera, laser or thermal sensor is used for determining whether an extremity of an operator is within a predetermined proximity of the danger zone.

Owner:TRZECIESKI MICHAEL A +1

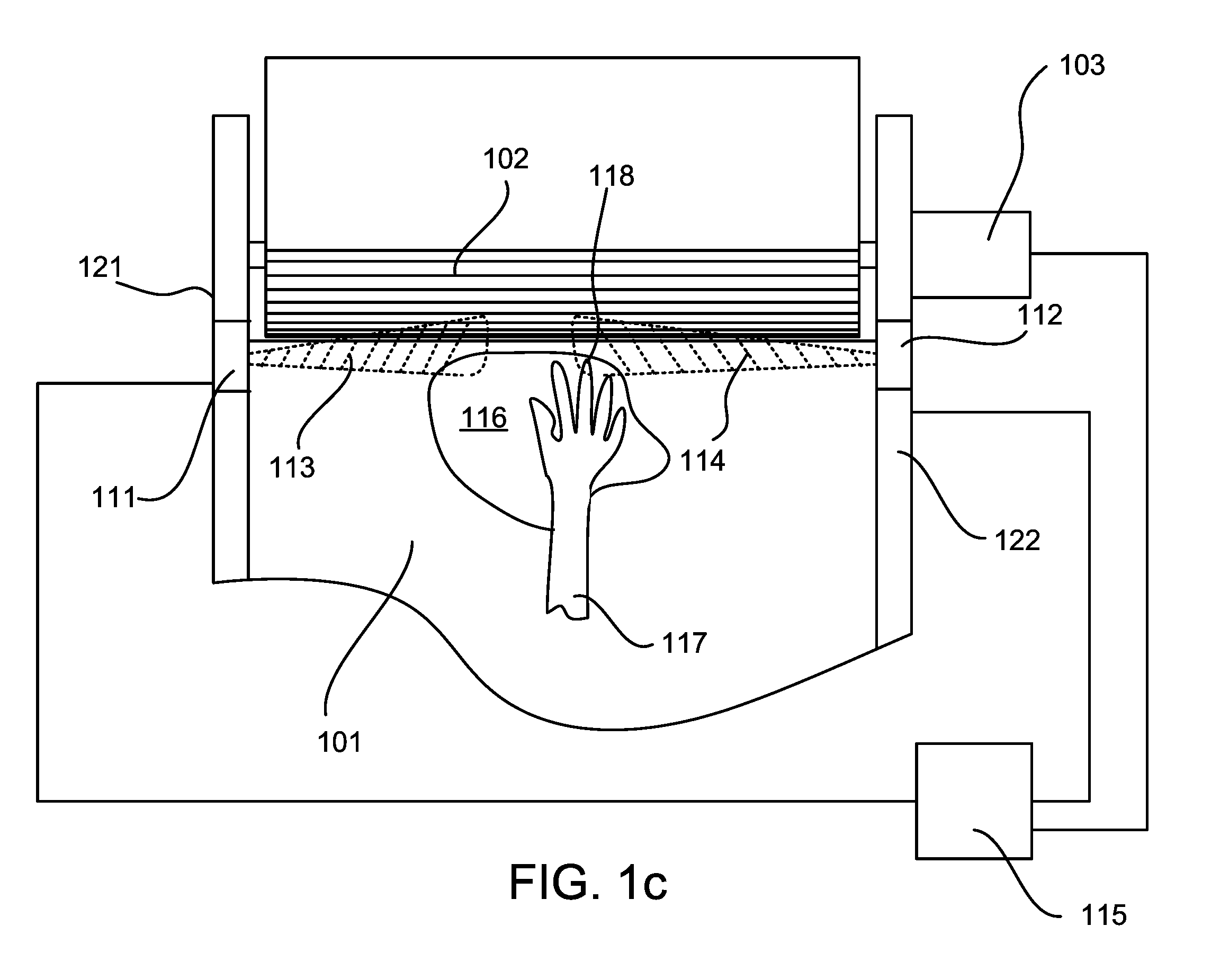

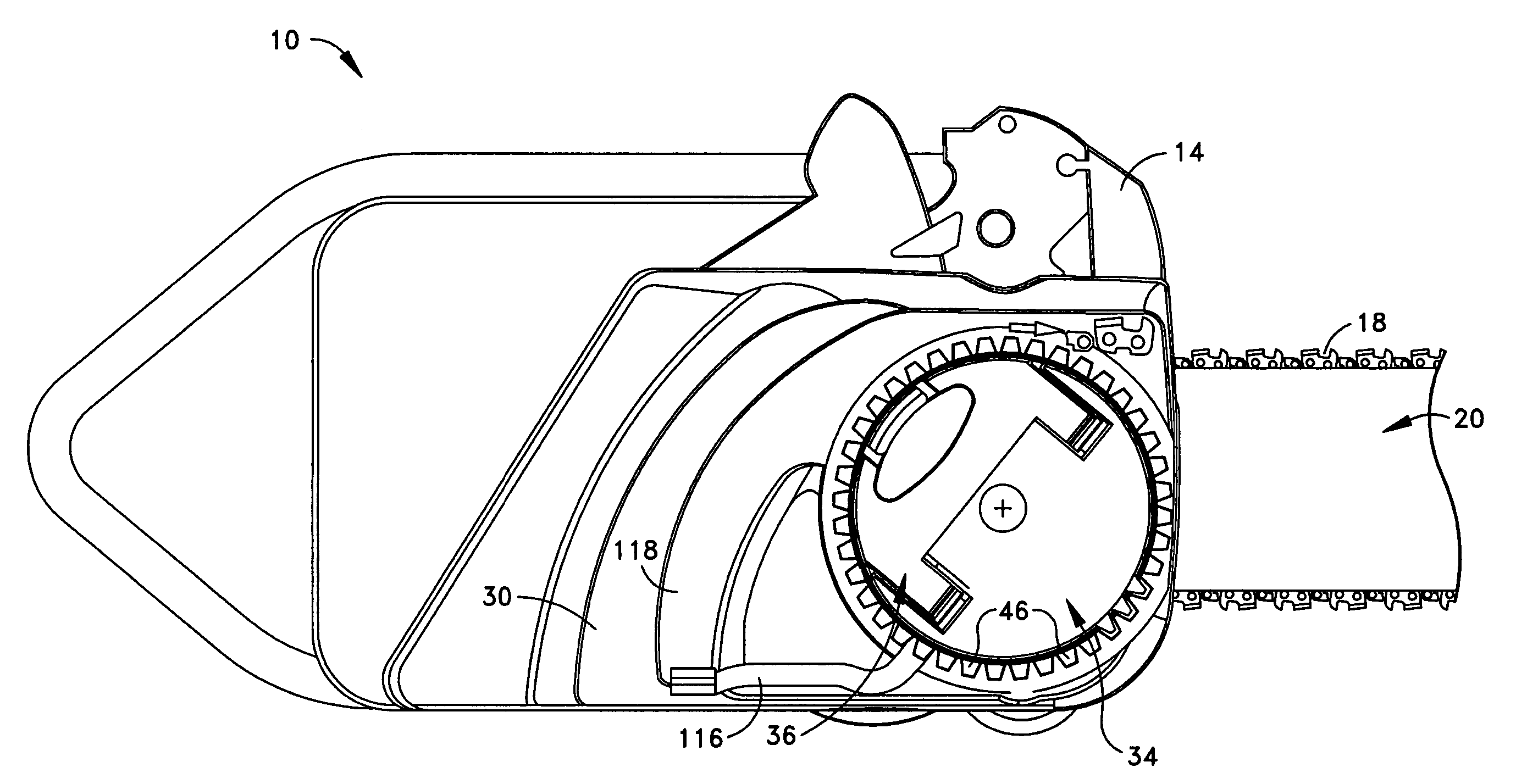

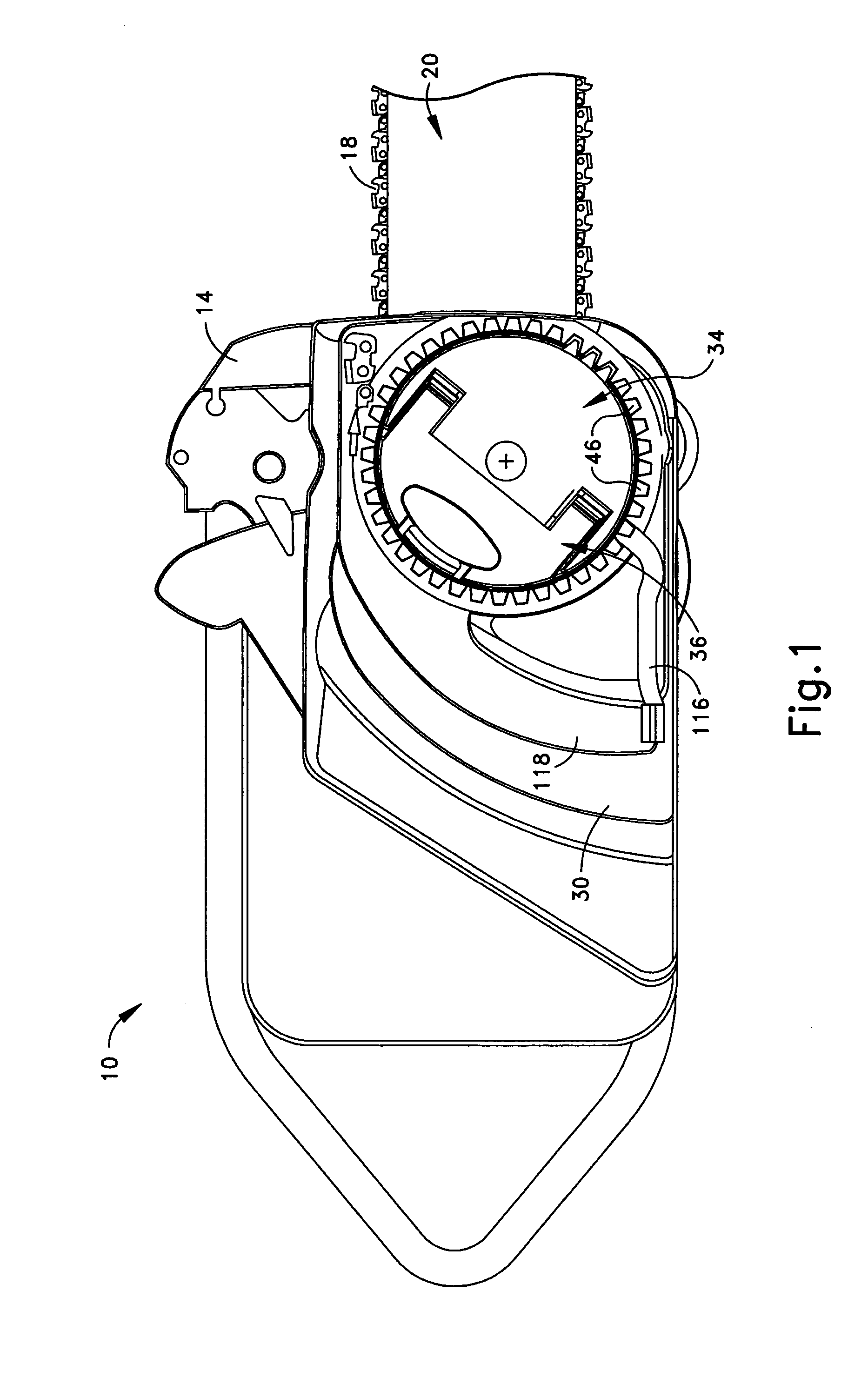

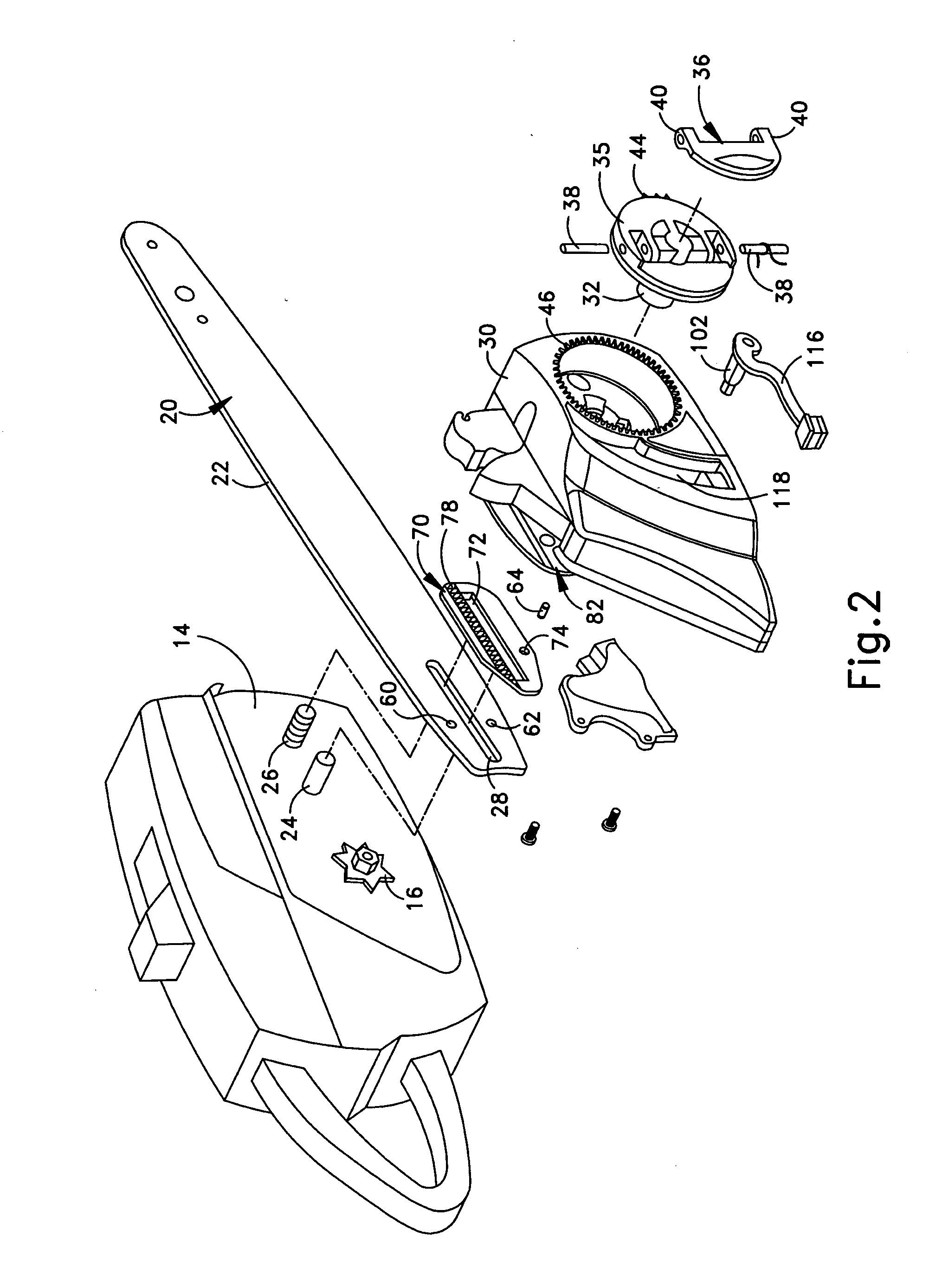

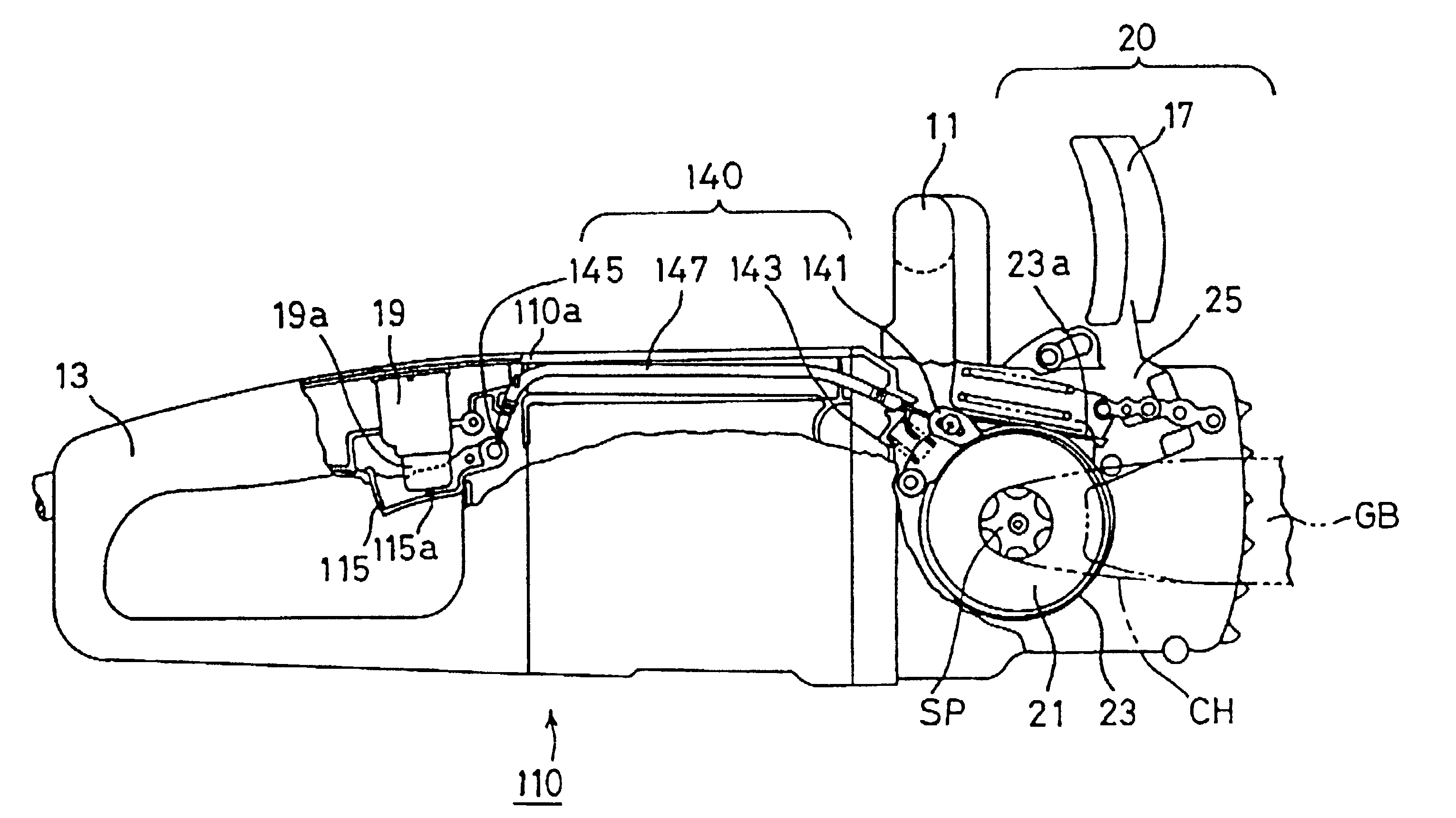

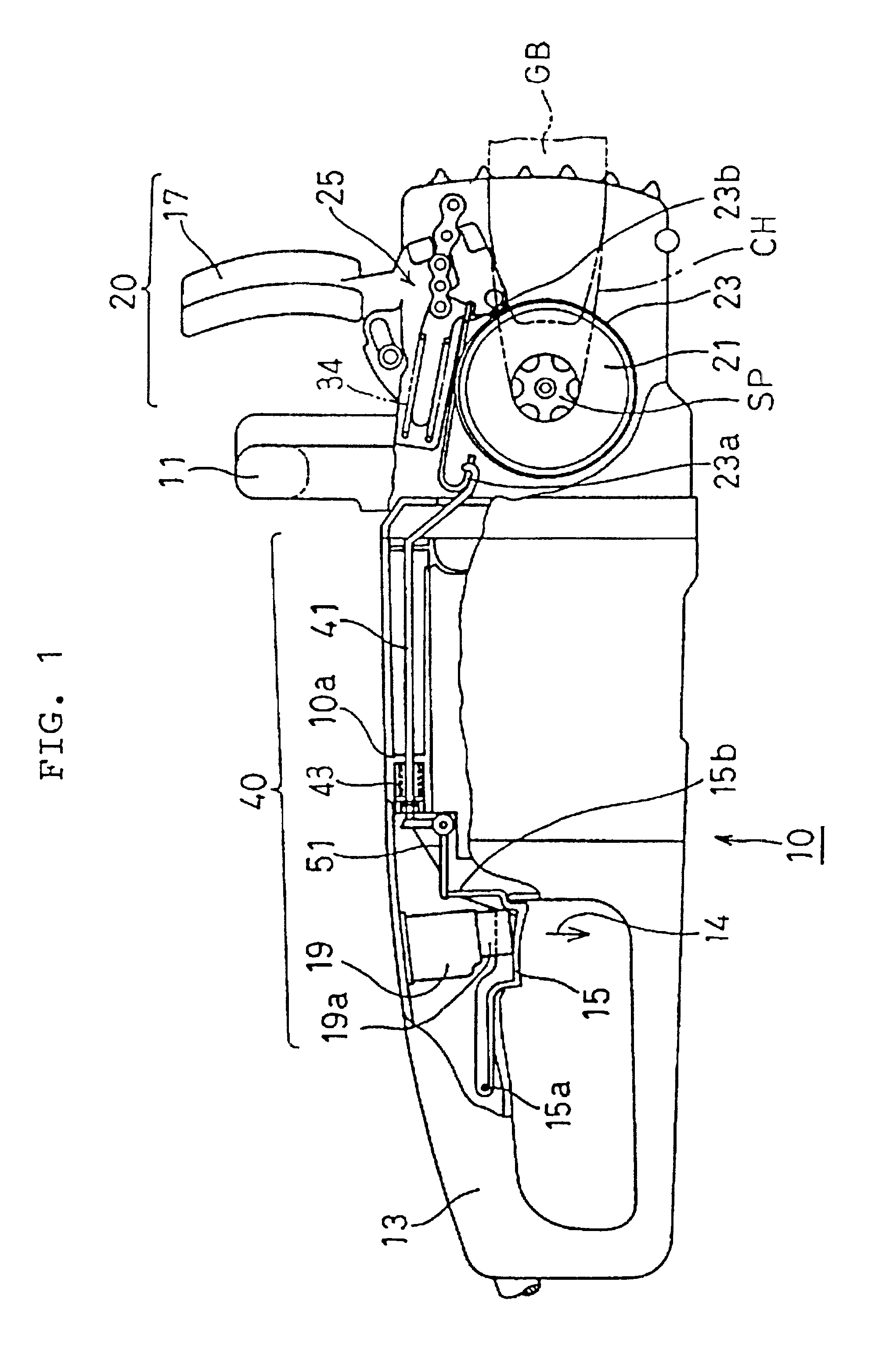

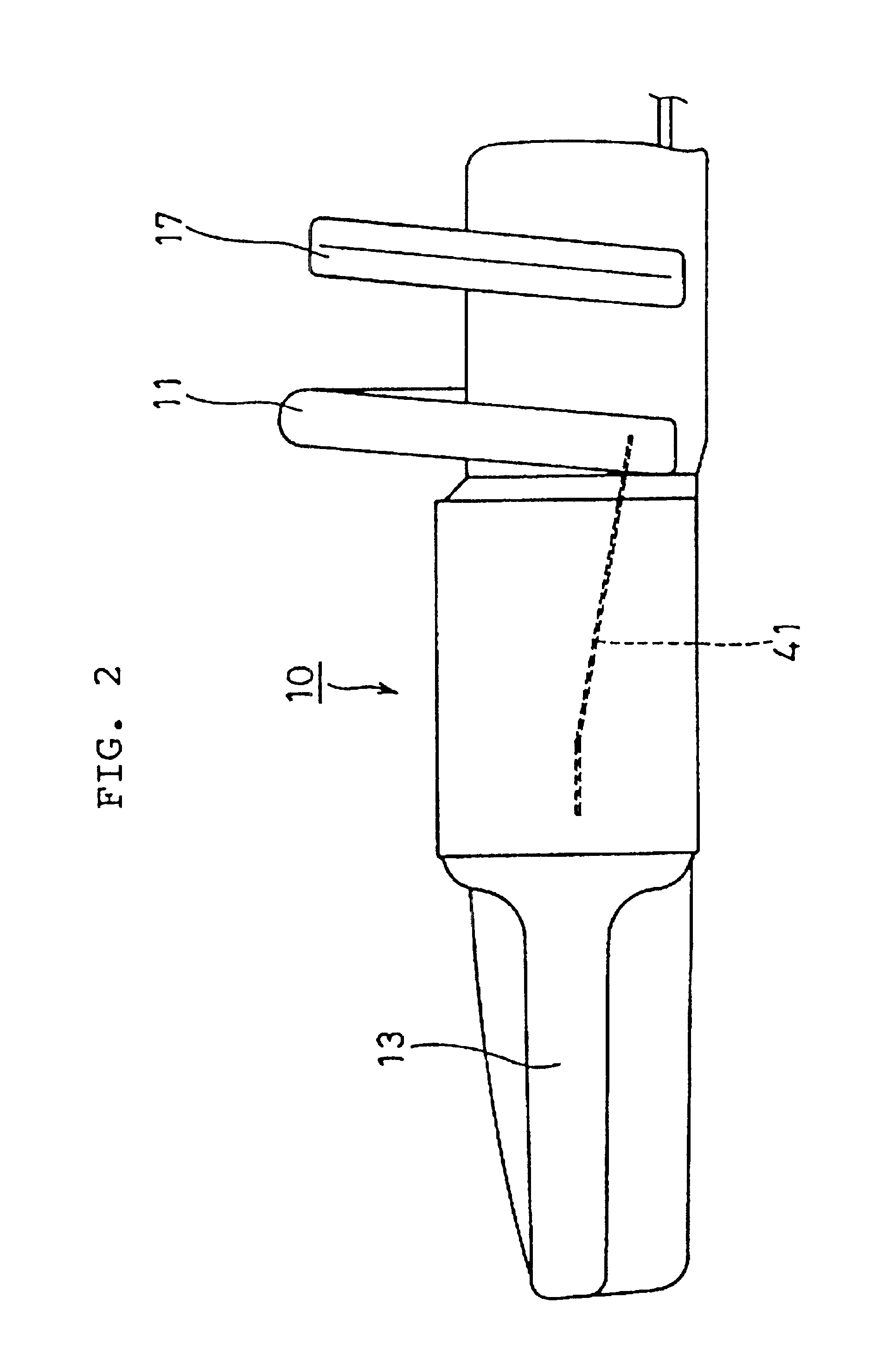

Chain saw

InactiveUS20020124421A1Reduce tensionStable positionMetal sawing devicesMetal sawing accessoriesSprocketEngineering

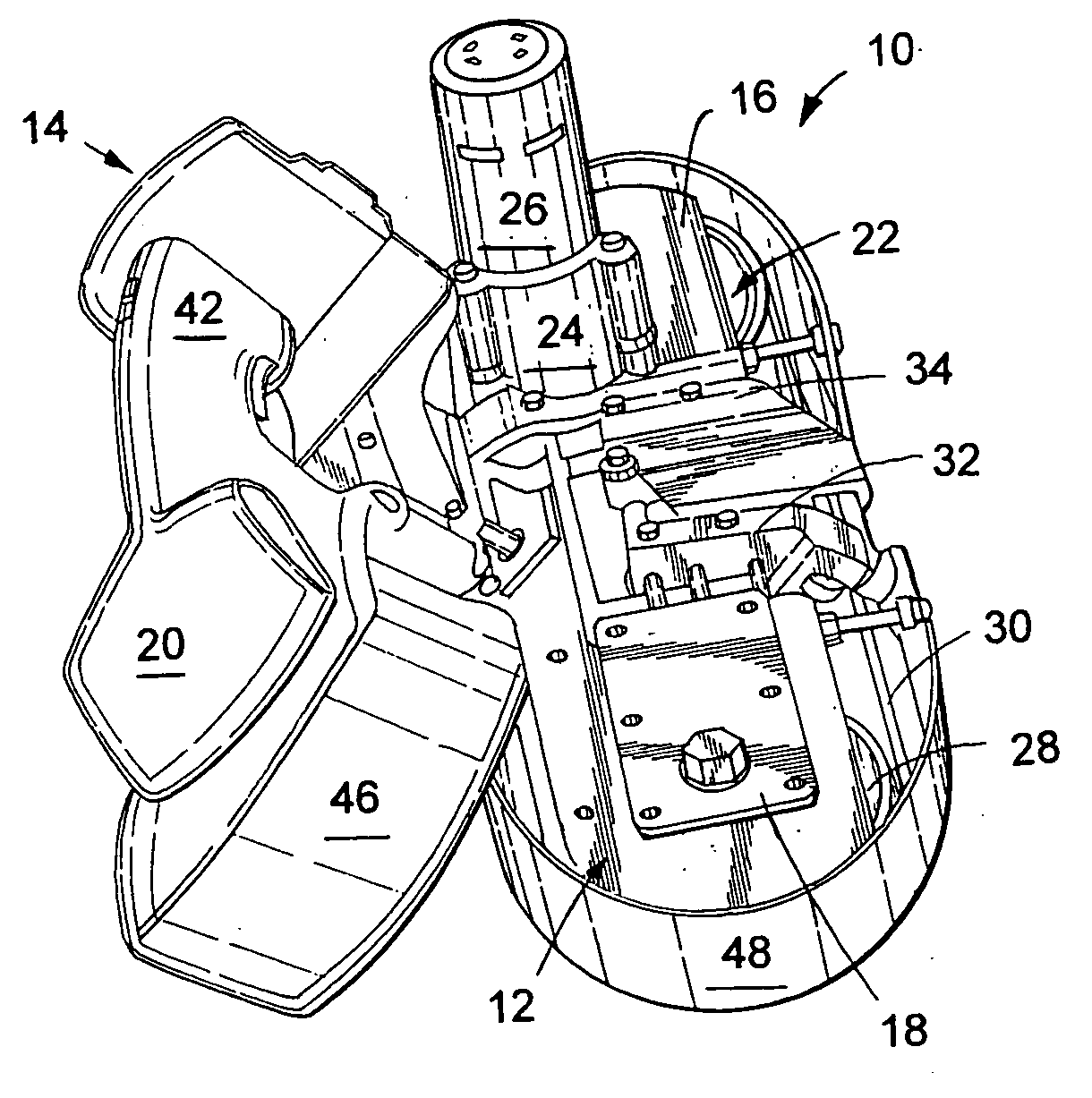

The chain tension of a motorized chainsaw (10) with a housing (12), a sprocket (22) mounted thereon, and a blade (14) that is aligned with this sprocket, which blade protrudes beyond the housing (12) and guides a saw chain (16) engaged with the sprocket (22) in a revolving manner, where the blade (14) is mounted such that it can be adjusted by means of longitudinal displacement in relation to the housing (12) and / or the sprocket (22) by means of a chain tensioning device (28) and where the chain tensioning device (28) has a stop (32) that can be fixed to the blade (14) and a cam (30) that can be rotated by means of a rotational member (36, 38) can be adjusted in a more comfortable and reliable fashion by virtue of the fact that the cam (30) can be locked in a form-fitting and rotationally secure manner in relation to the housing (12) by way of the rotational member (36, 38).

Owner:ROBERT BOSCH GMBH

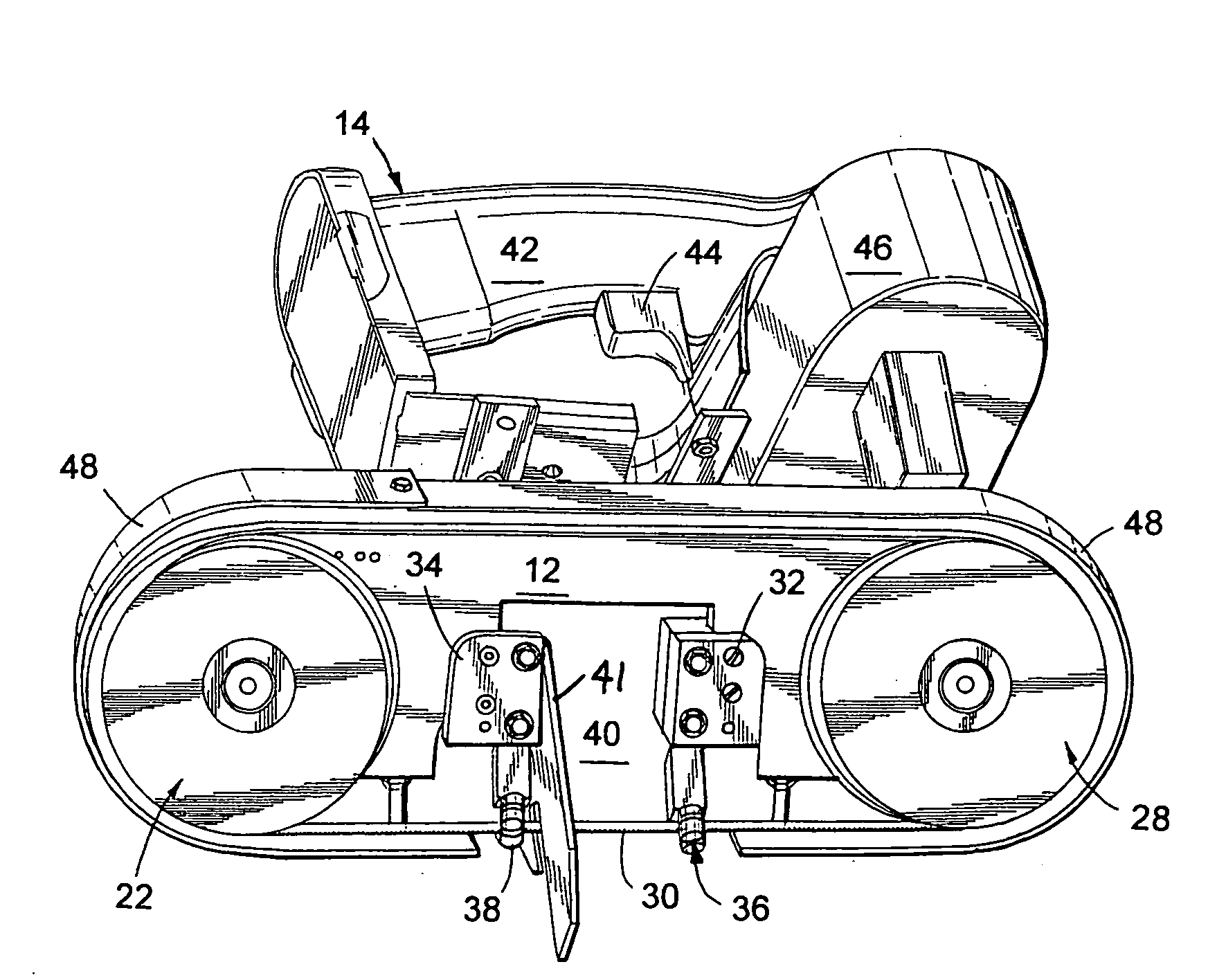

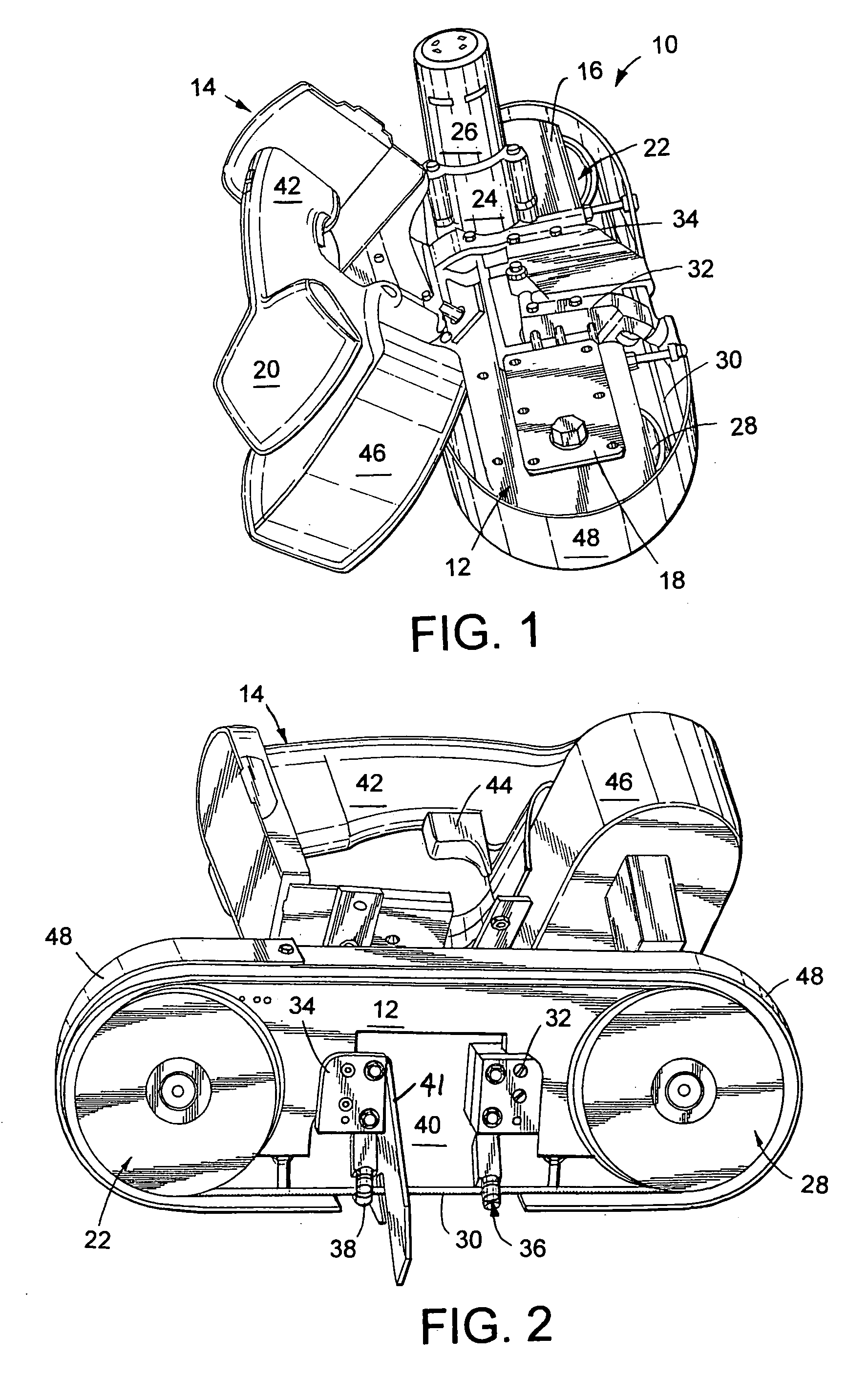

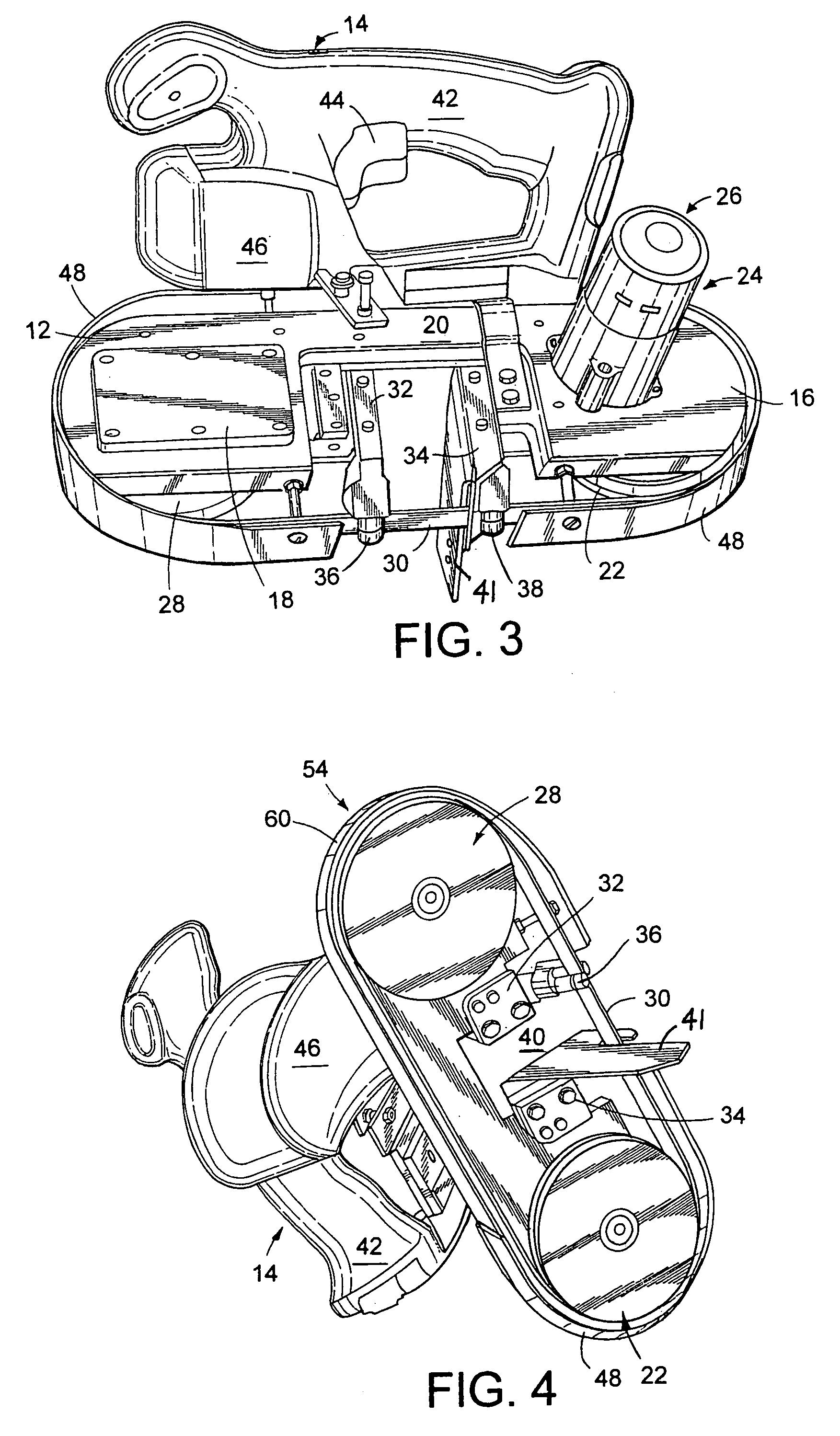

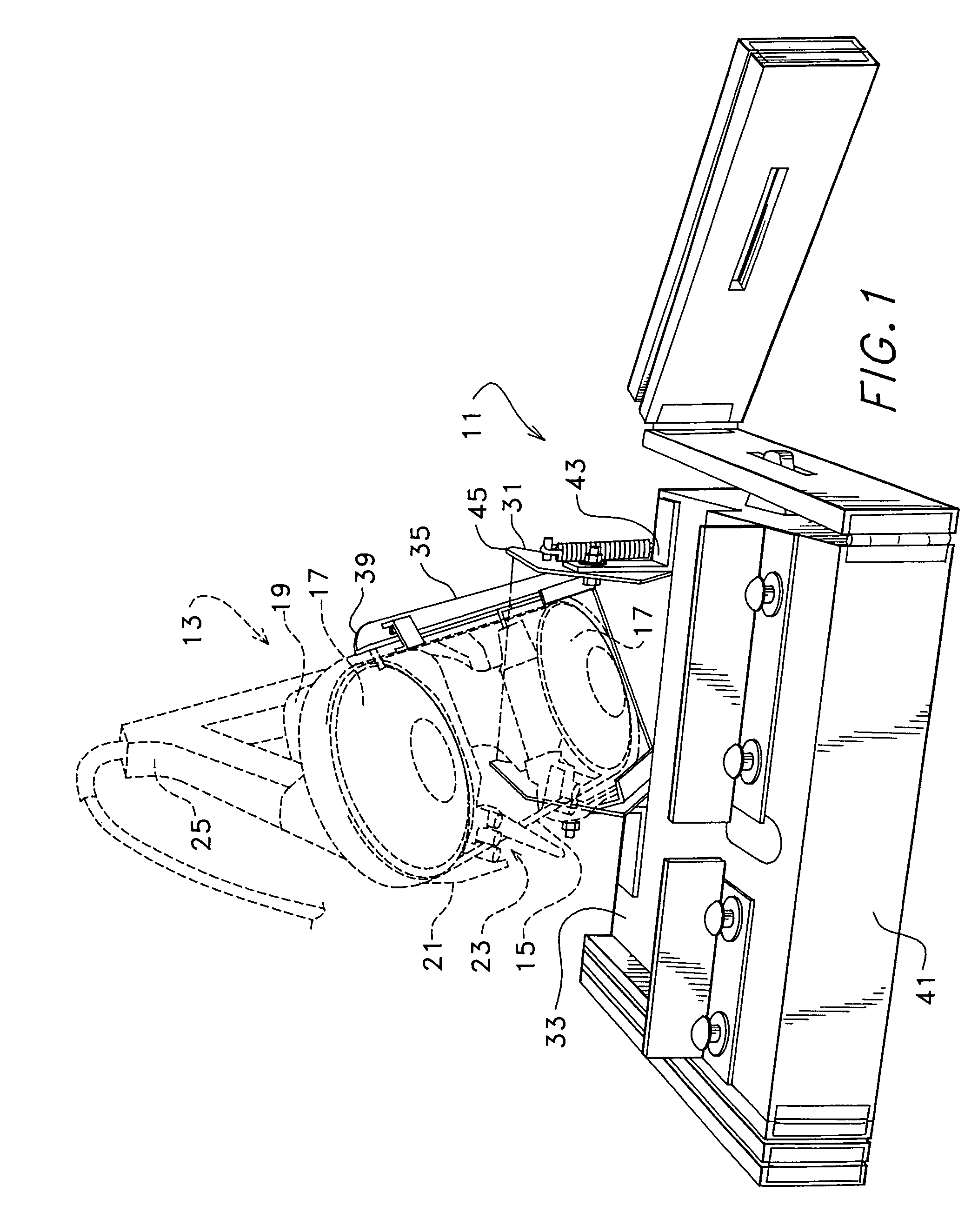

Hand-held band saw

ActiveUS20040158996A1Precise cuttingEasy to transportMetal sawing devicesBand sawsVertical planeAcute angle

A hand-held band saw is provided for one-hand operation. The band saw has a frame and a handle extending from a longitudinal edge of the frame at an acute angle and opposite an edge containing a throat for receiving the work piece. The orientation of the handle centers the mass of the saw below the hand and positions the cutting section of the blade in a vertical plane so it will engage a work piece at a preferred angle selected by the user.

Owner:PERSAWVERE

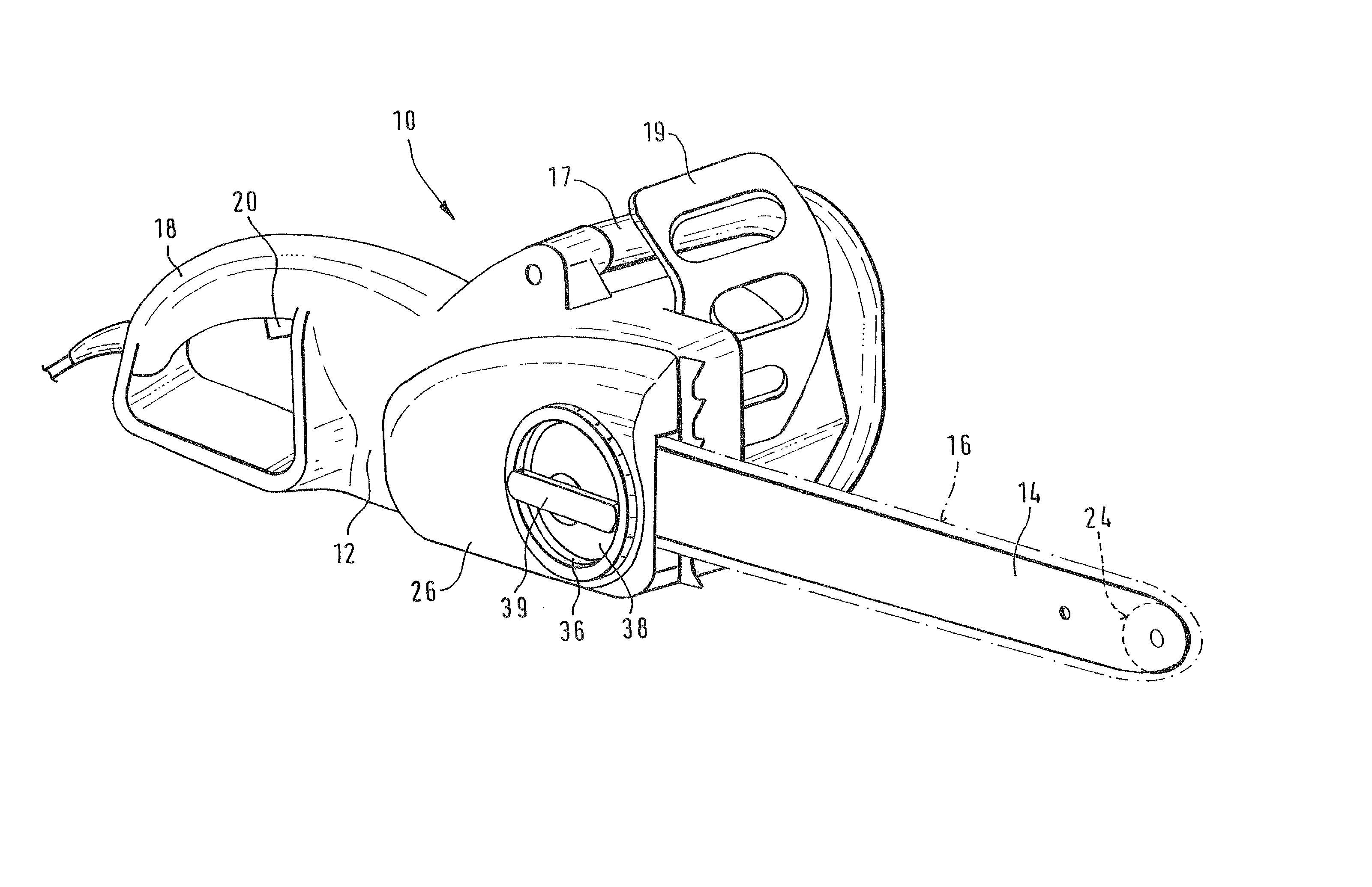

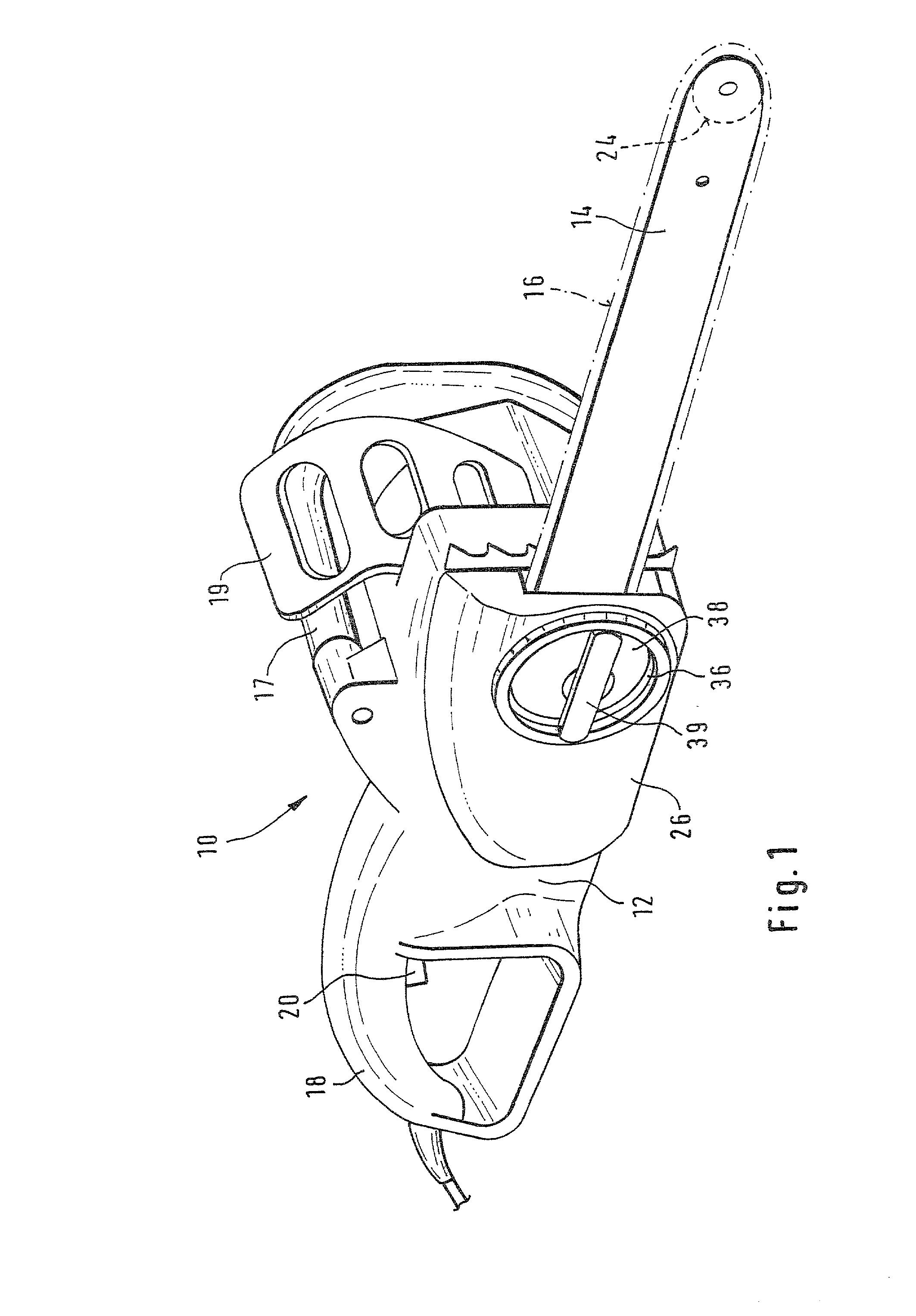

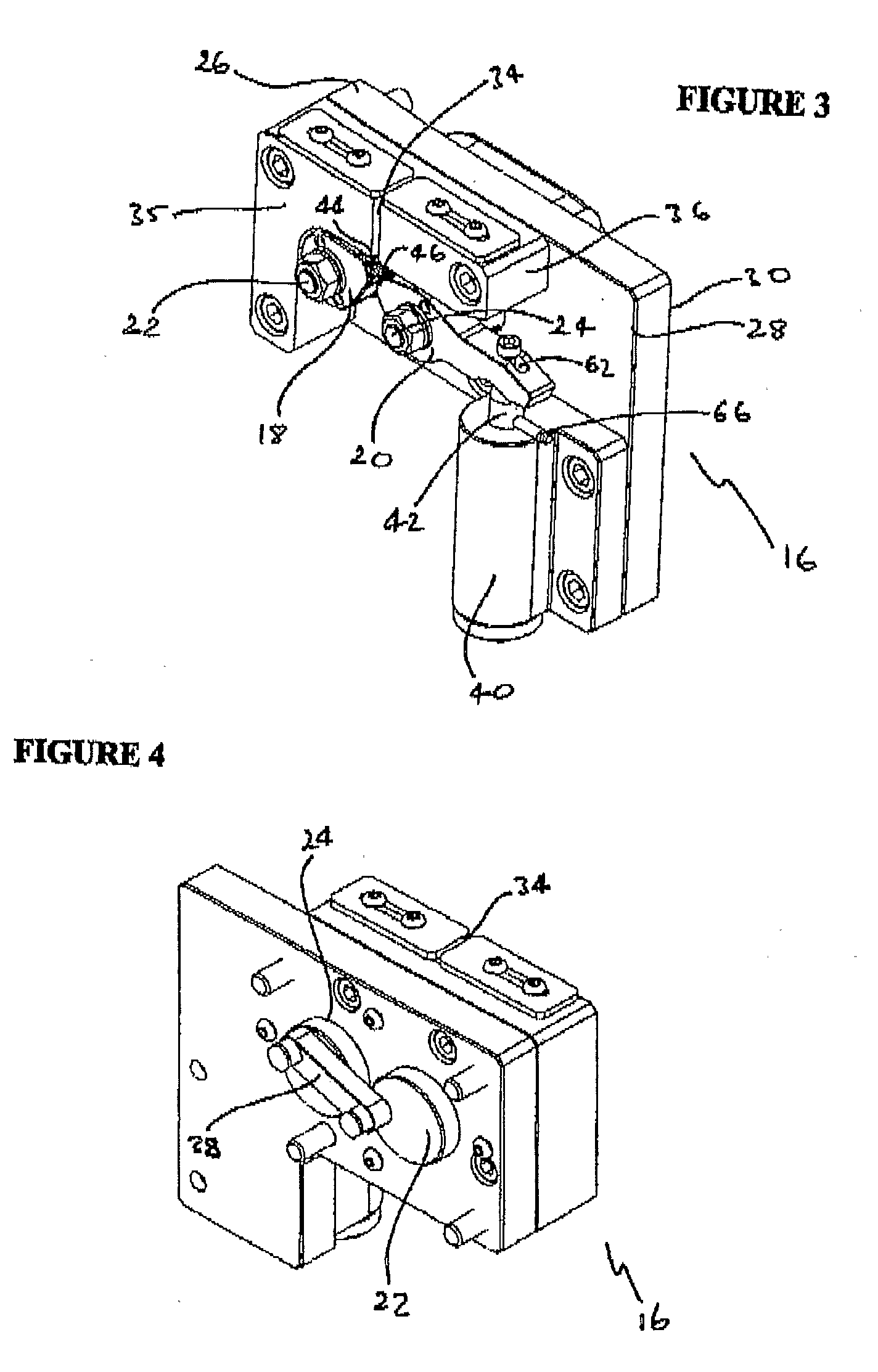

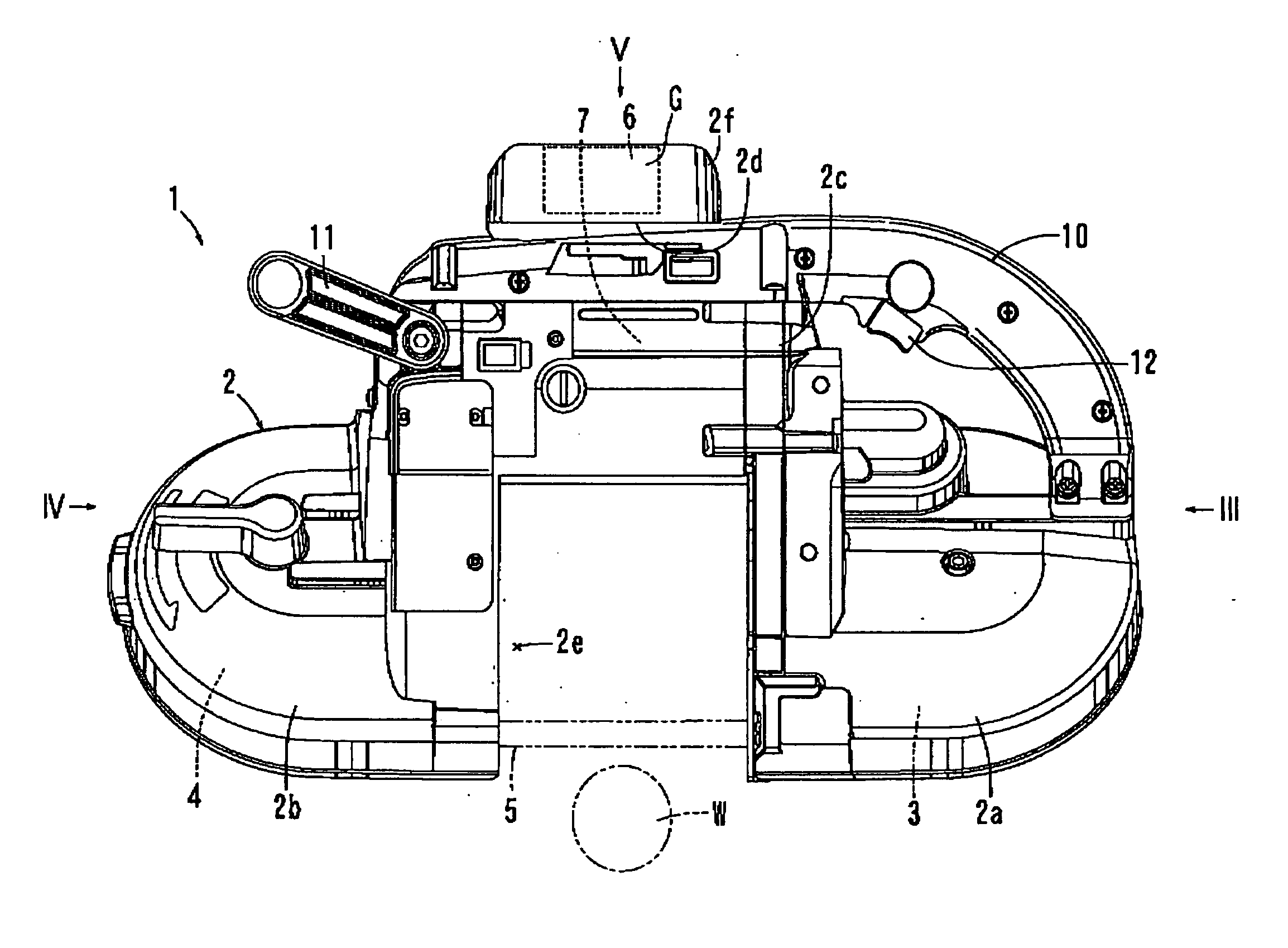

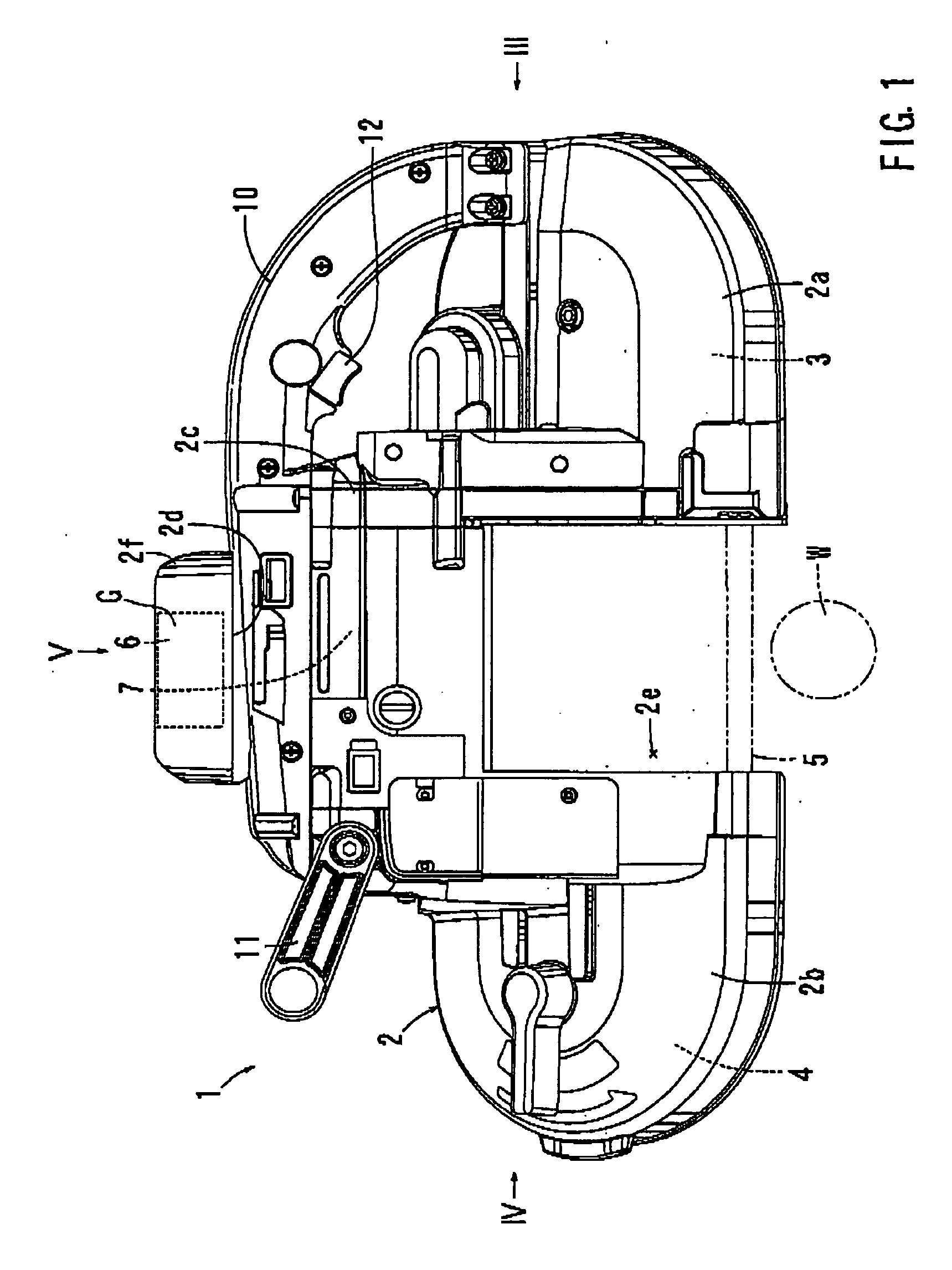

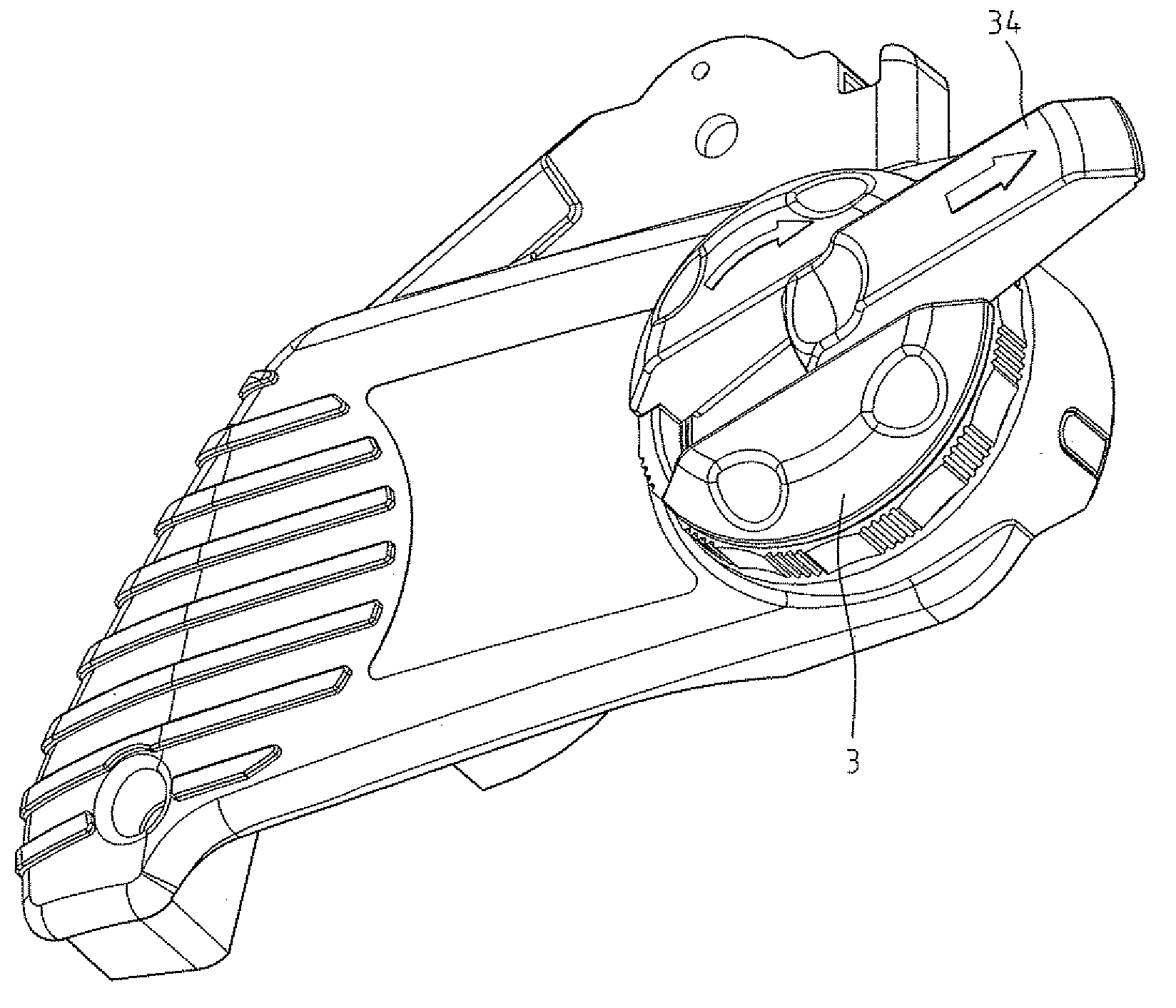

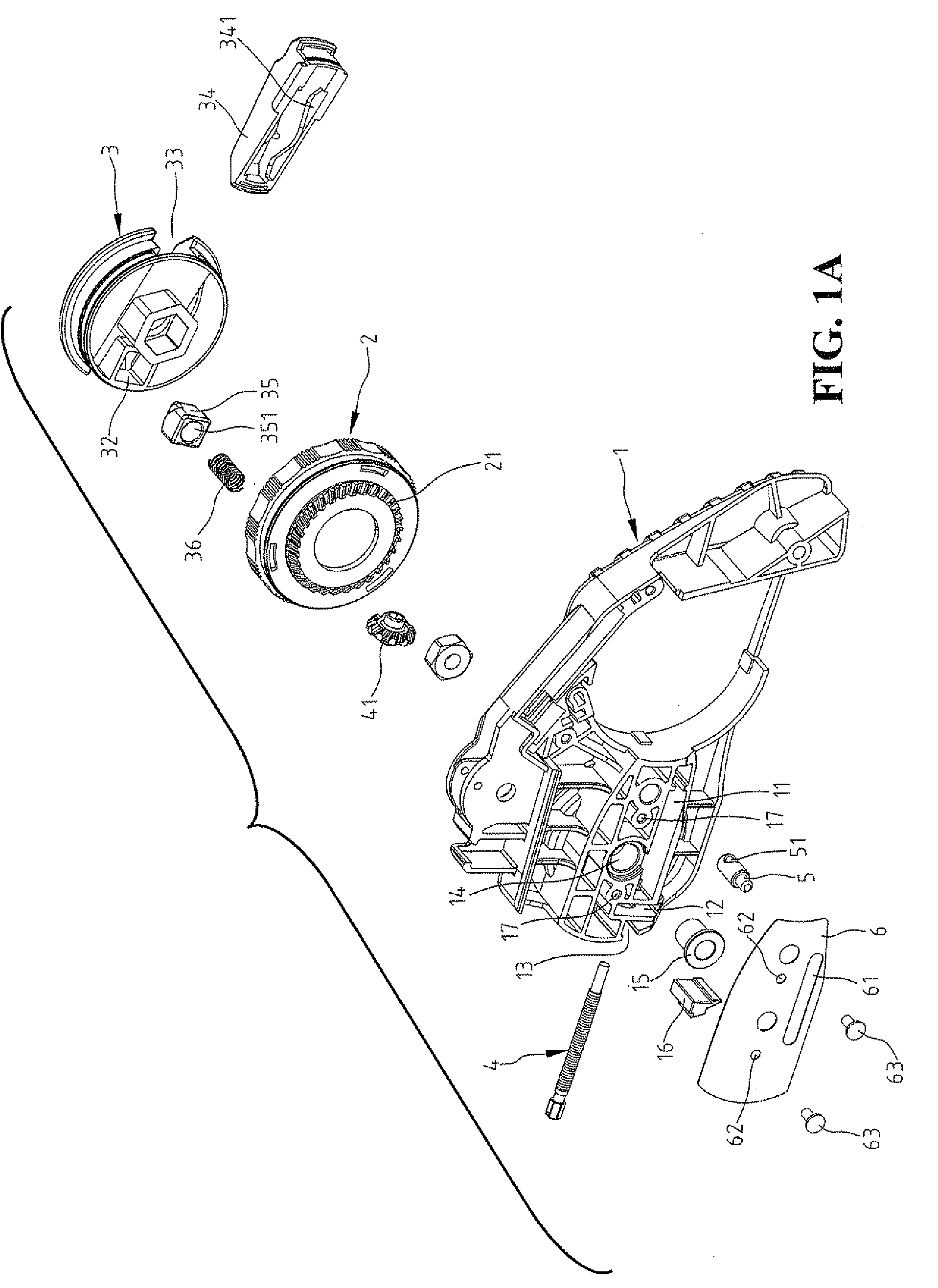

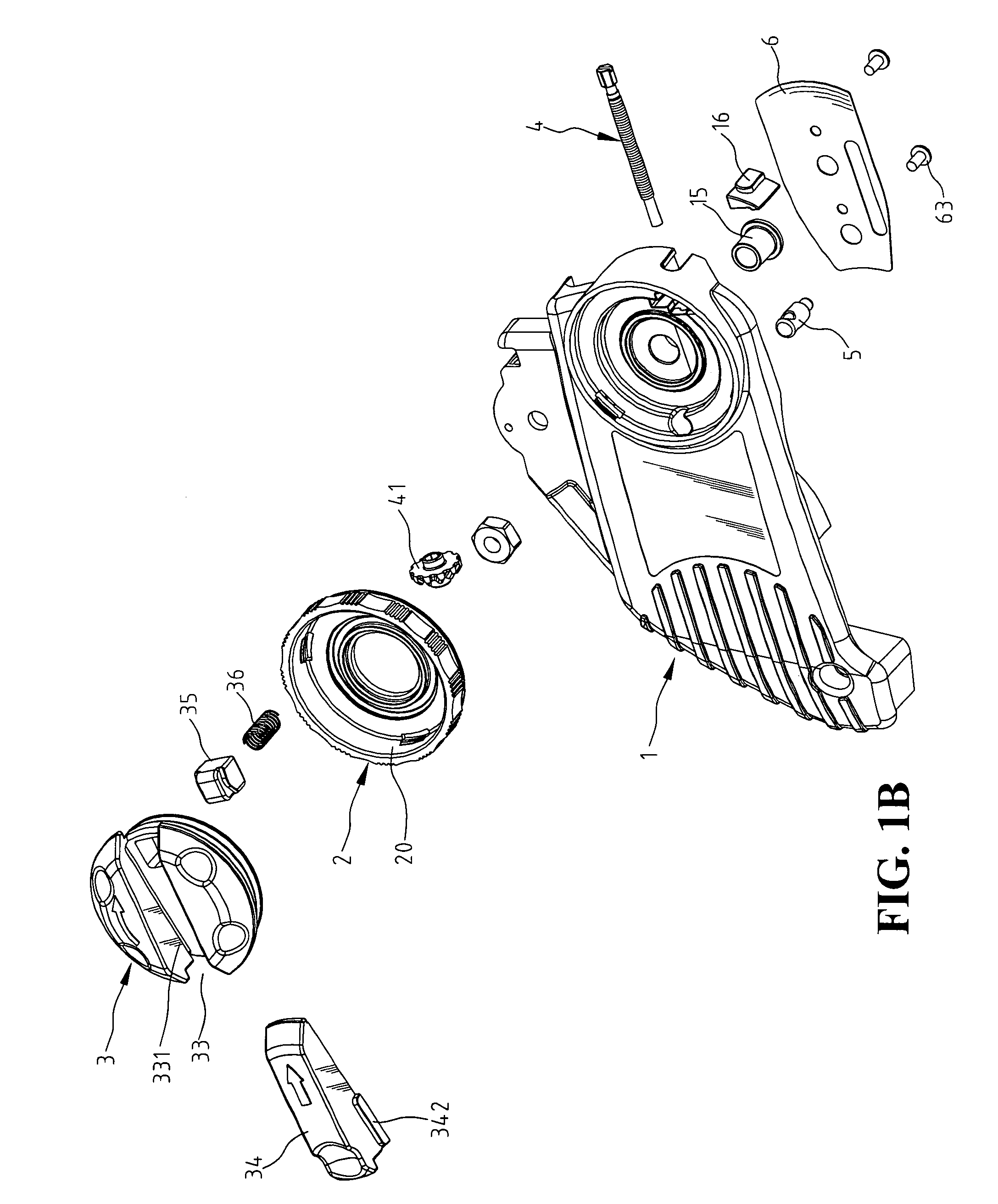

Bar knob with cam-operated locking mechanism

InactiveUS7434502B2Positive securing of the knobMetal sawing devicesMetal sawing accessoriesLocking mechanismEngineering

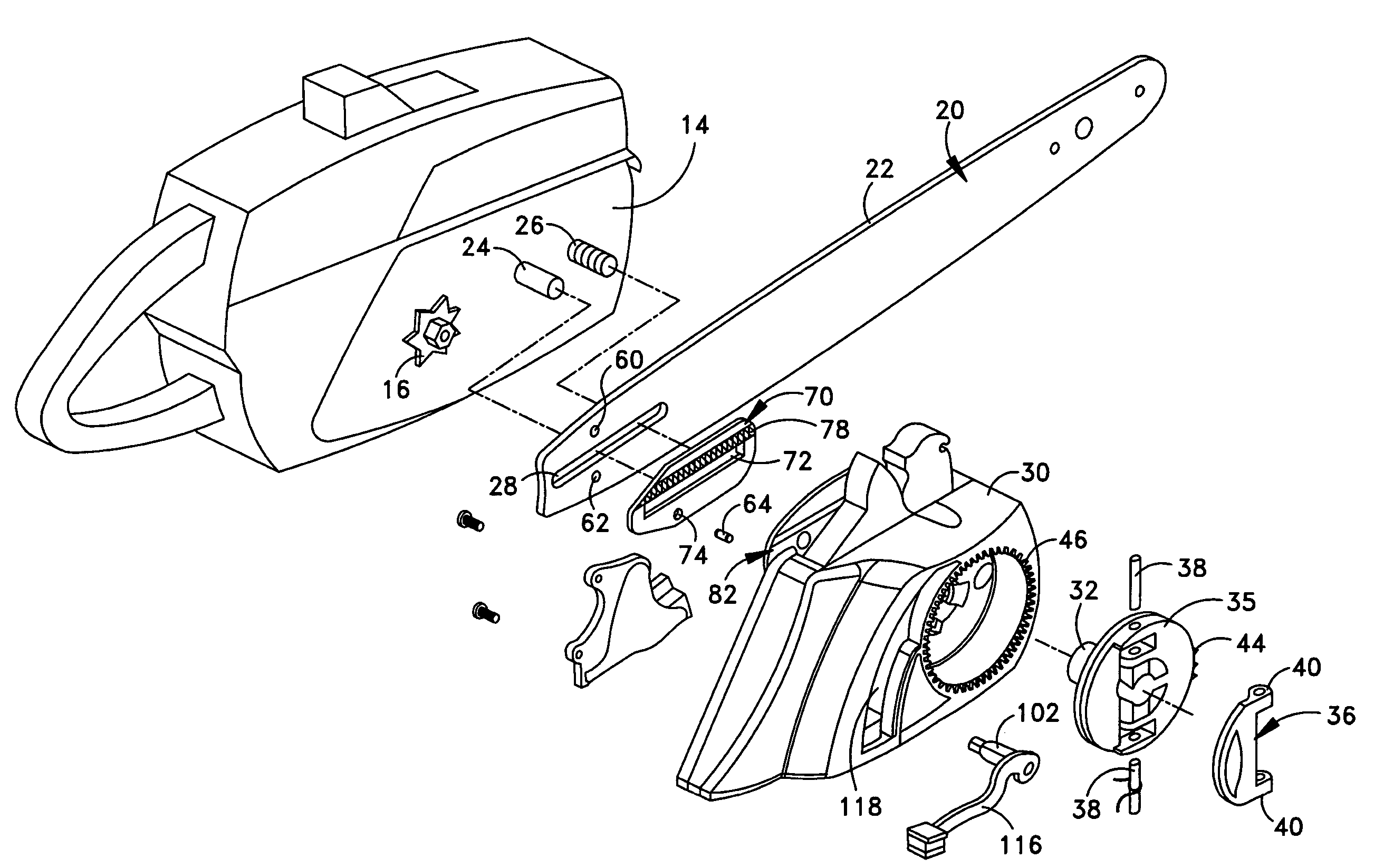

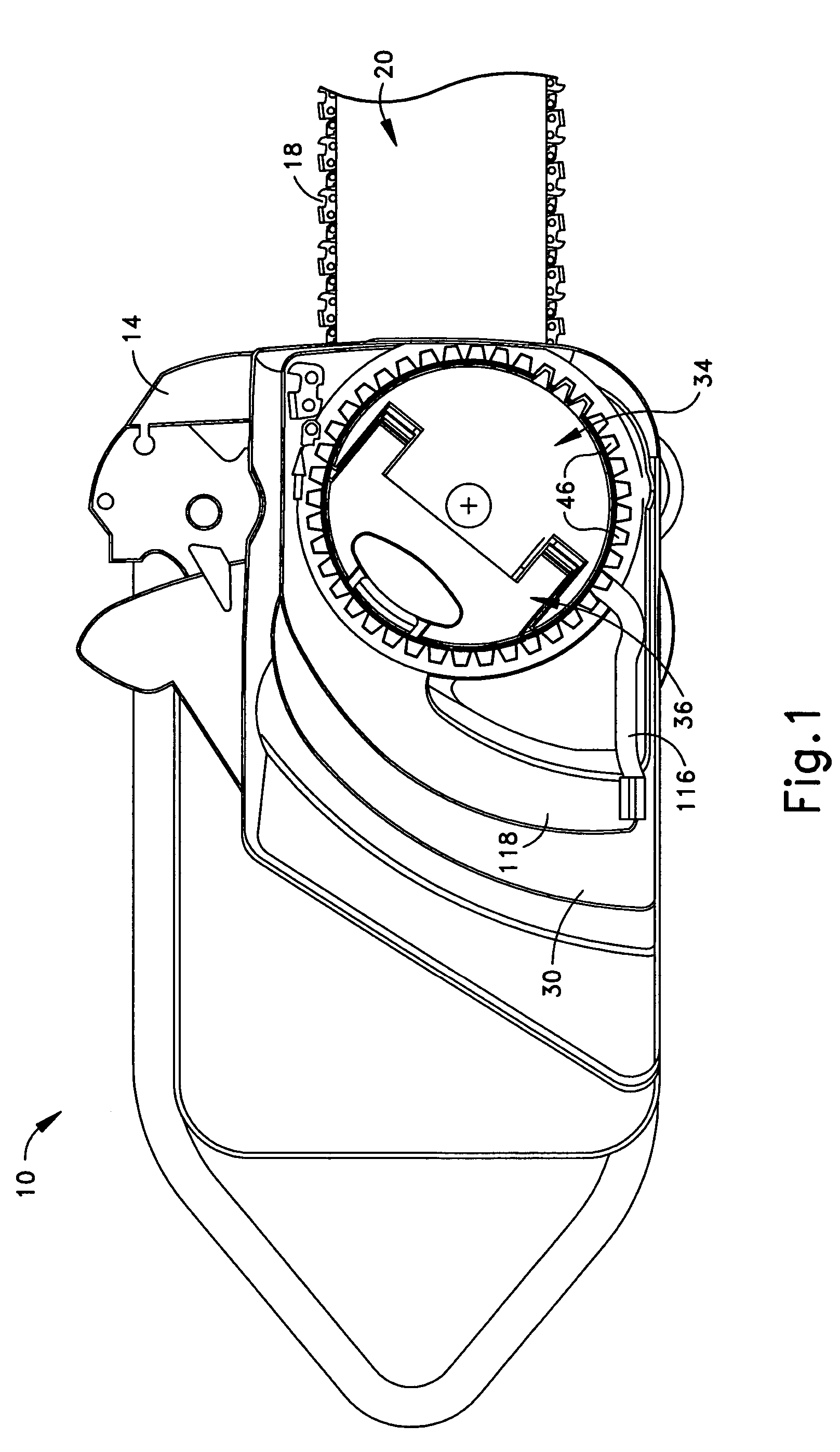

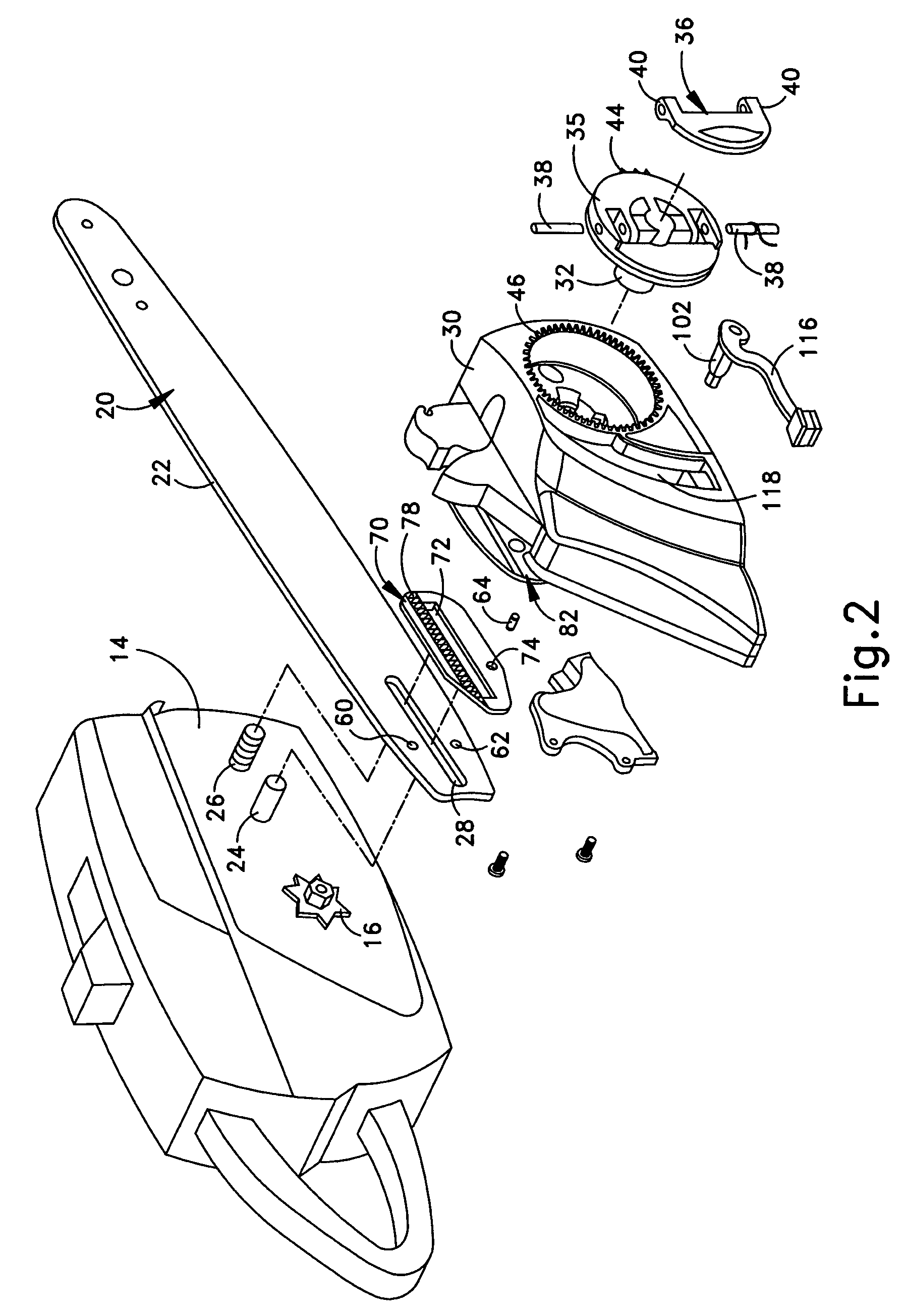

A chain saw includes a retaining assembly for a tensioning arrangement for adjusting the tension of the cutting chain in the chain saw. The retaining assembly includes a rotatable knob for operation with the chain saw's engine chassis, clutch cover, and guide bar and is rotatable about an axis of rotation between a tightening position for holding the guide bar in place and a loosening position enabling the guide bar to be repositioned whereby the tension in the cutting chain is adjusted. A locking mechanism is provided for locking and unlocking the knob. When the locking mechanism is in a locking position, moveable engagement points of the locking mechanism extended beyond the confines of the knob and engage fixed engagement points. When the locking mechanism is in the unlocking position, the moveable engagement points, having moved inwardly of the confines of the knob, are disengaged from the fixed engagement points.

Owner:HUSQVARNA OUTDOOR PROD INC

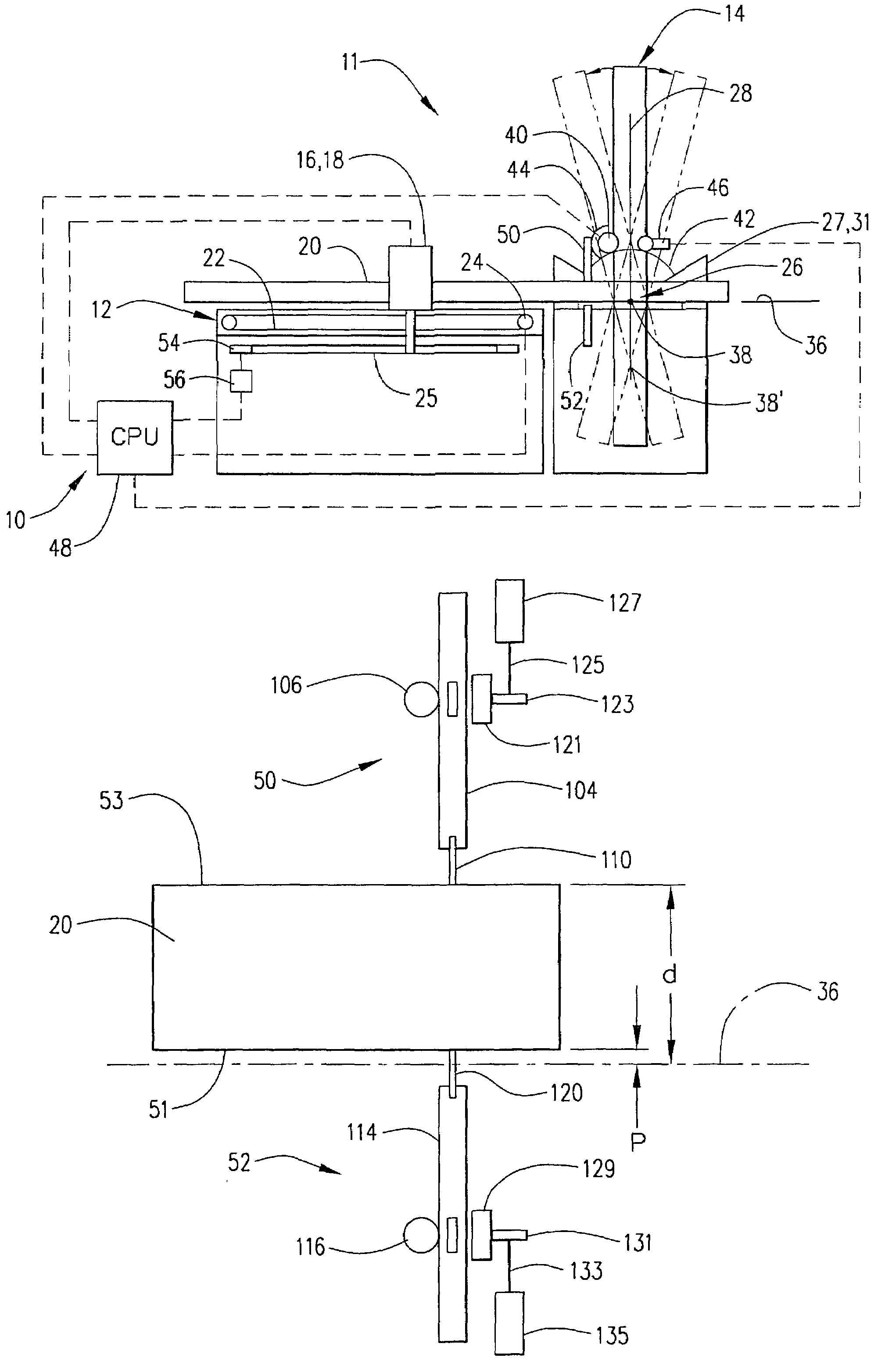

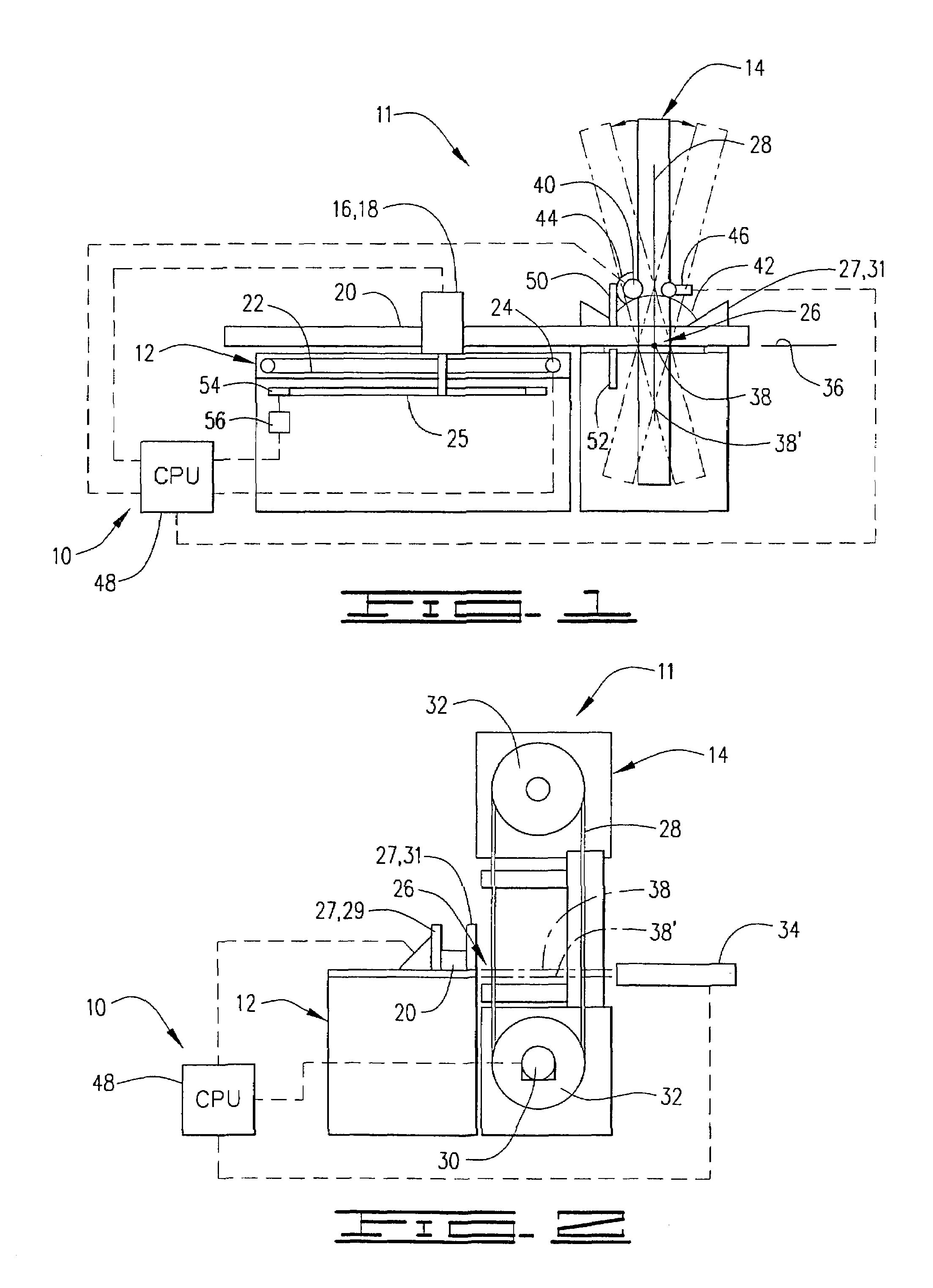

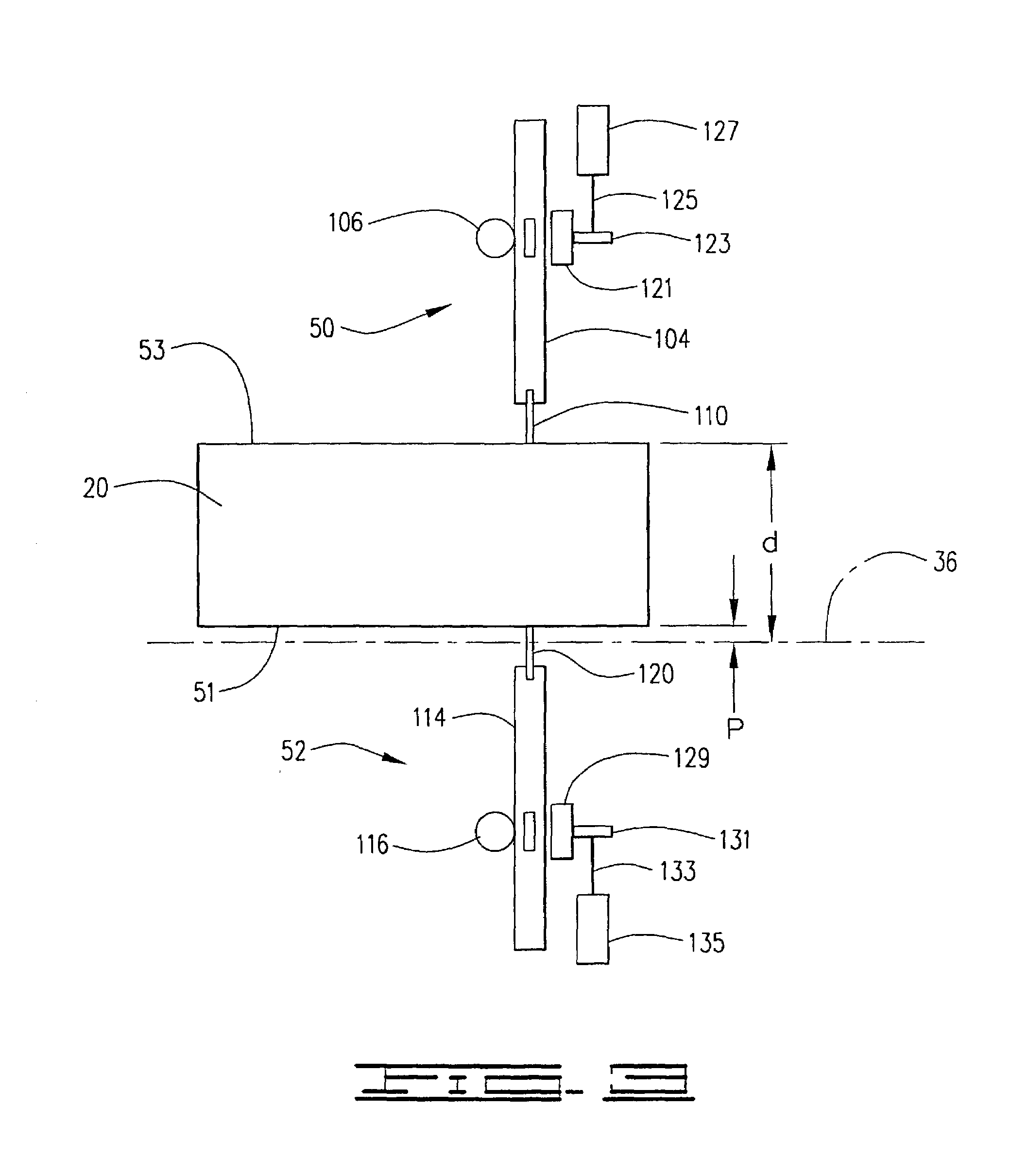

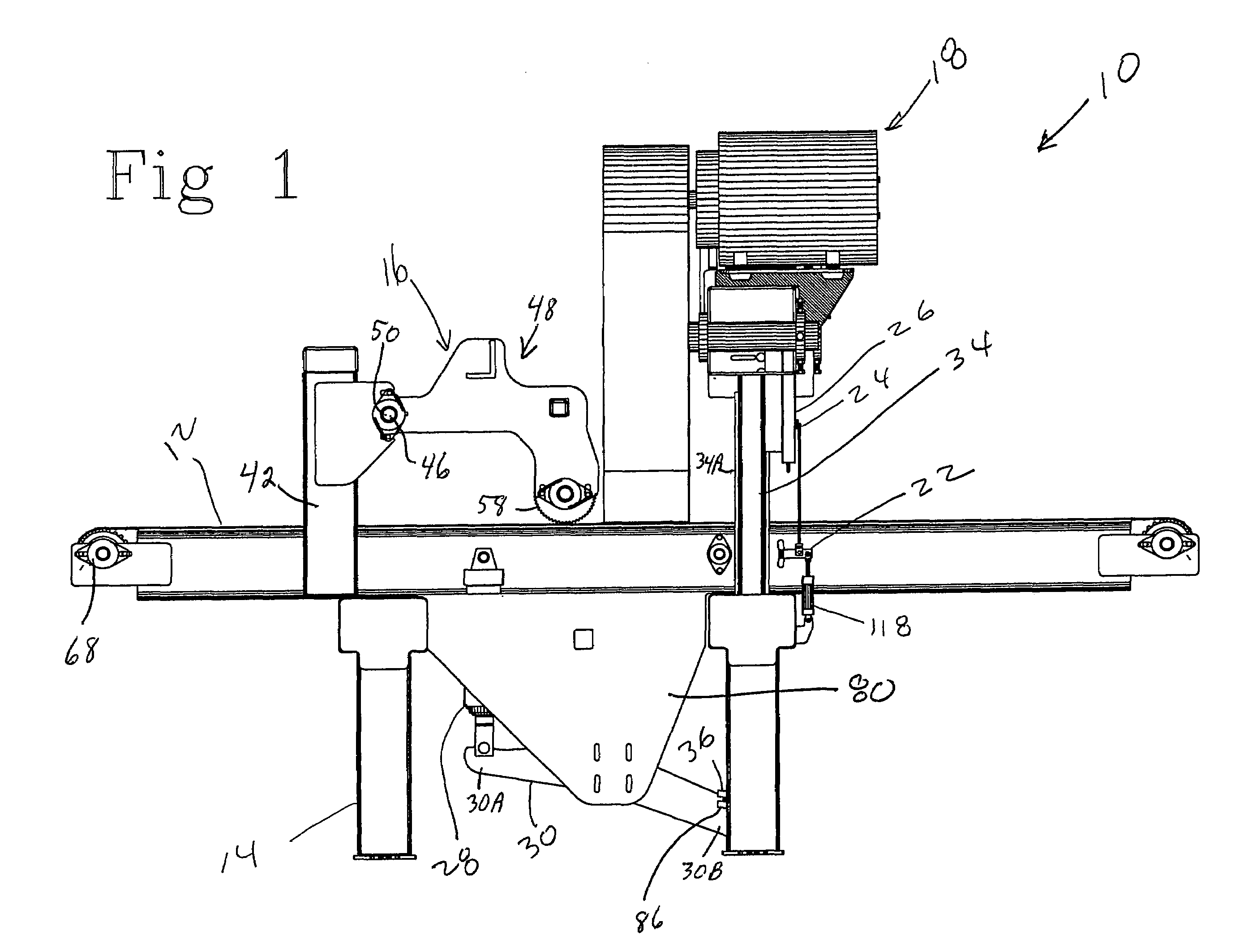

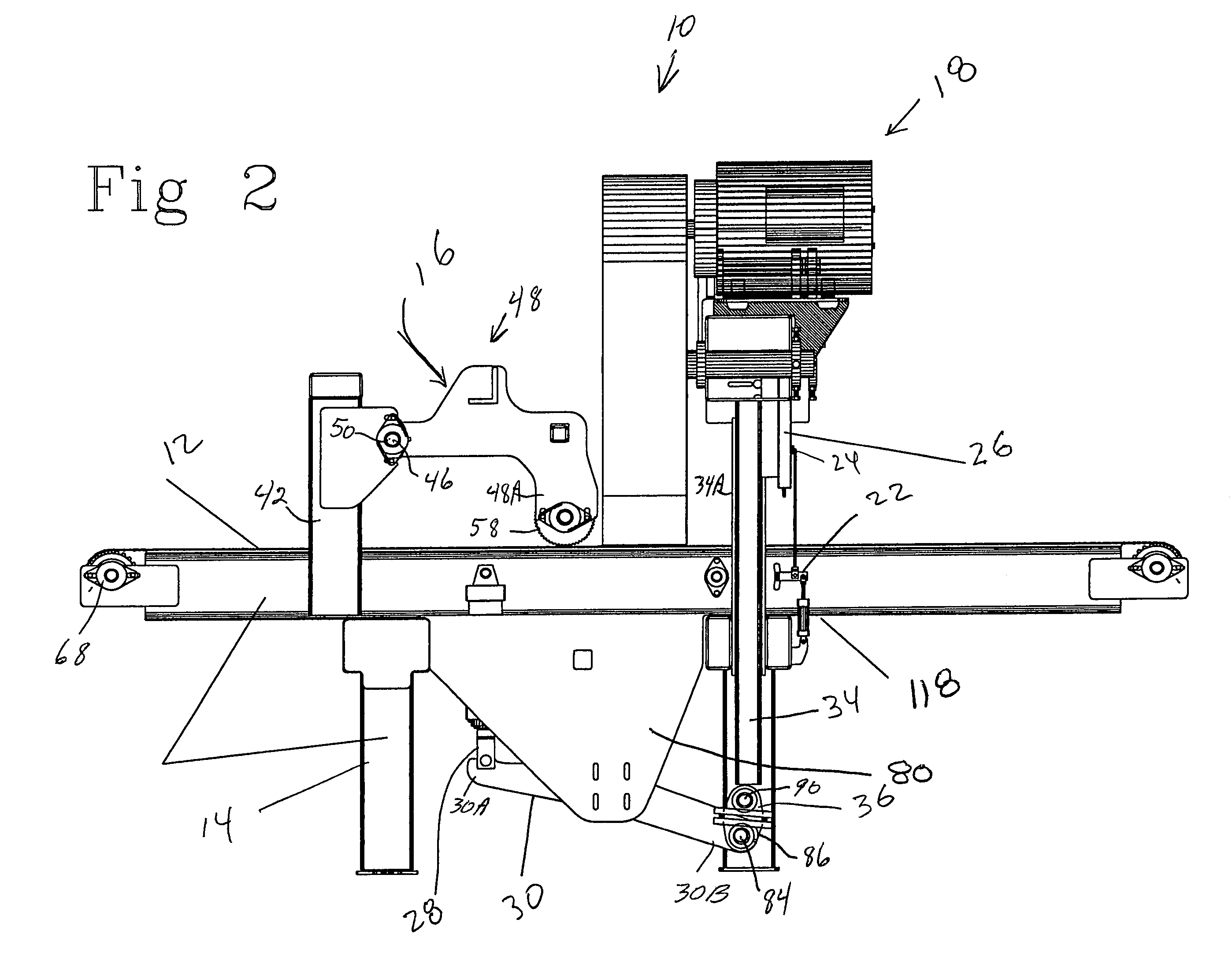

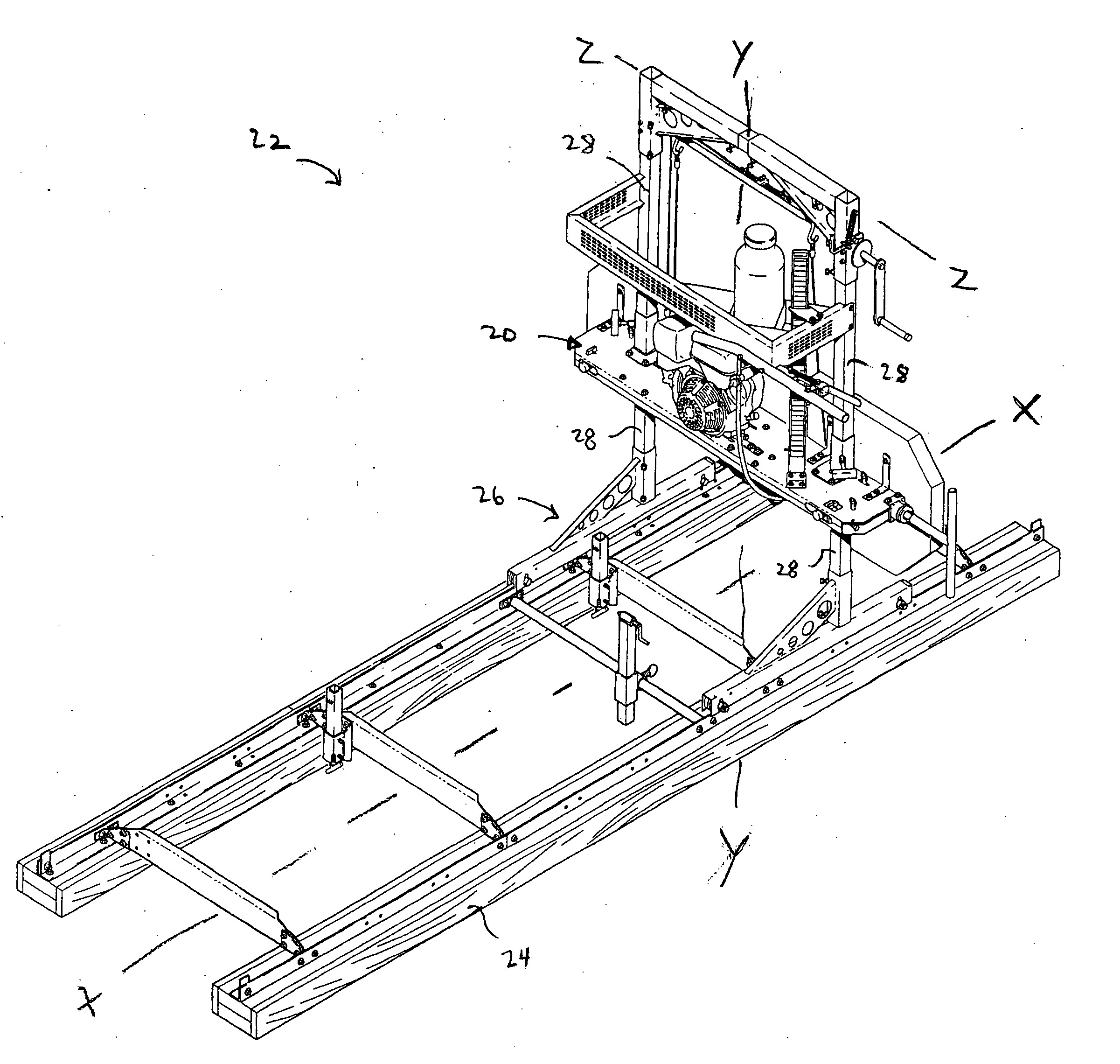

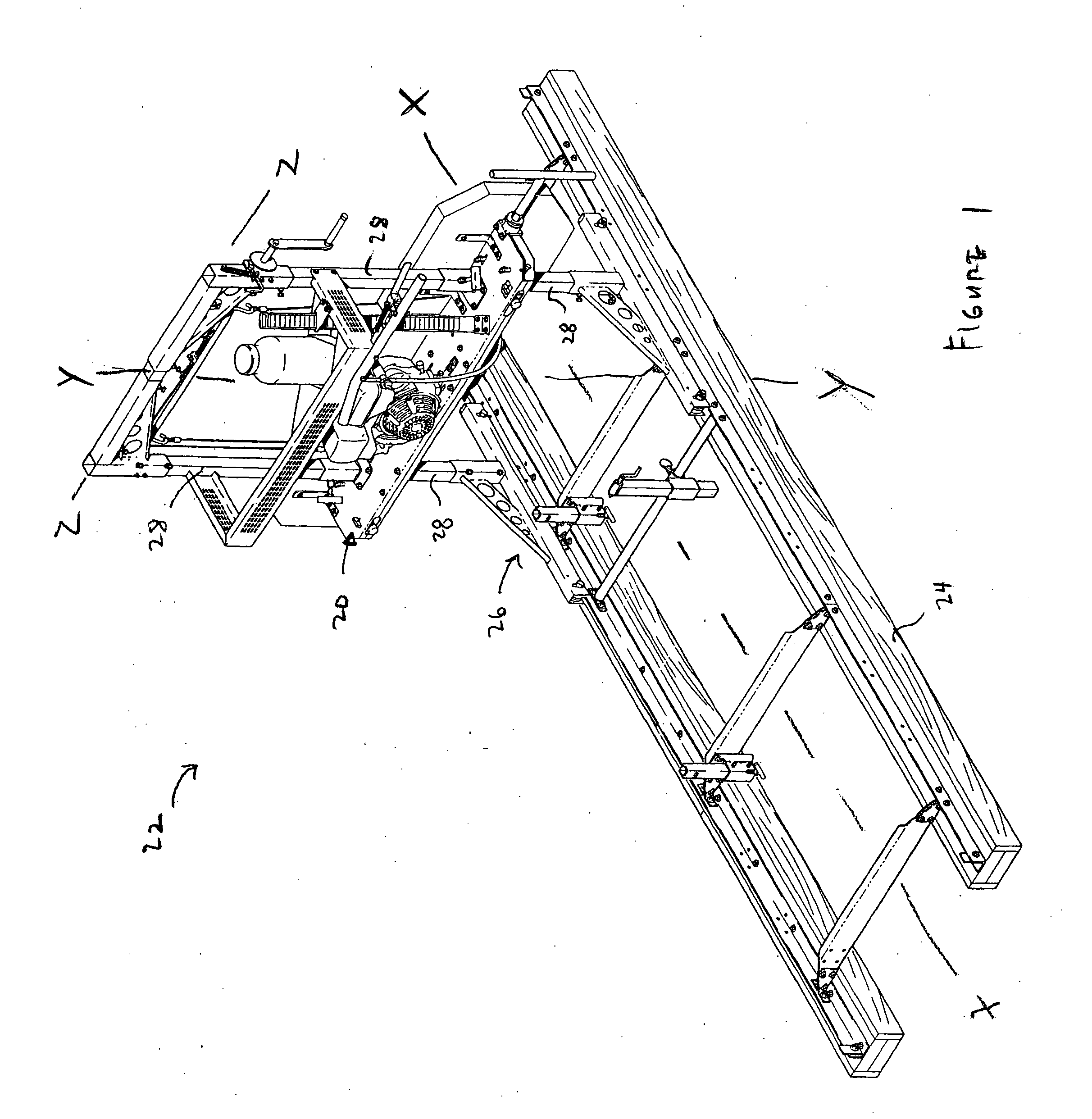

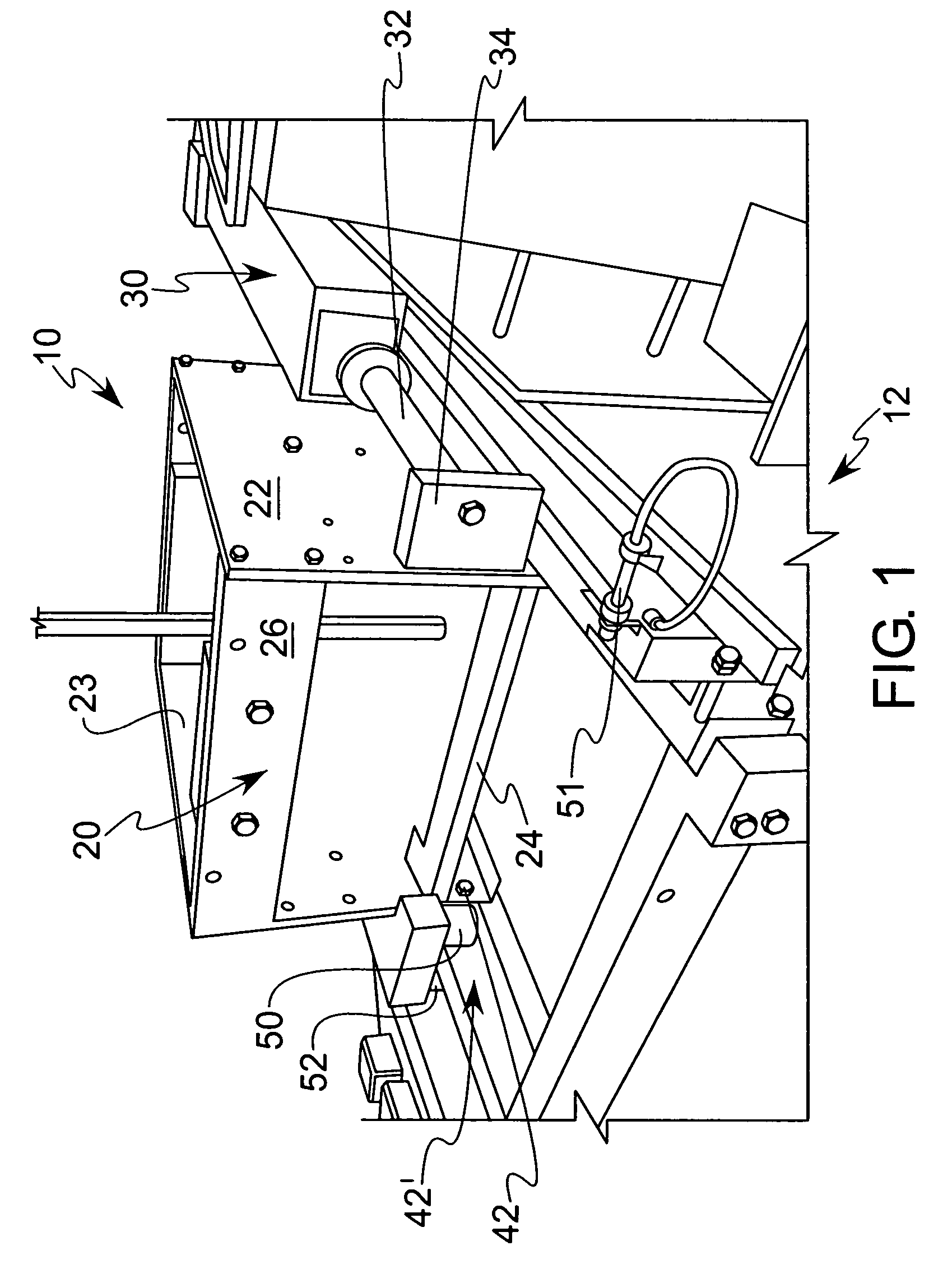

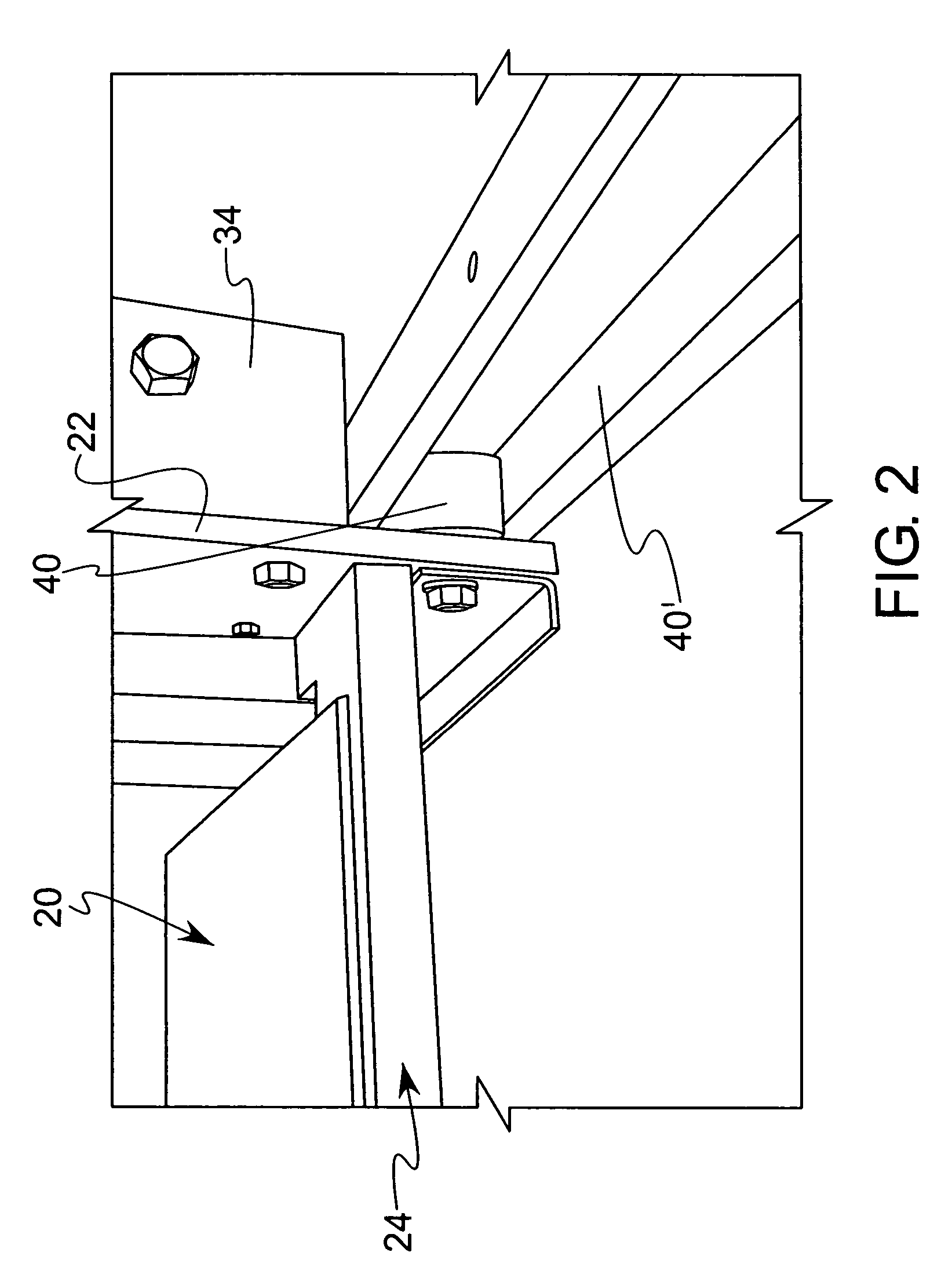

Active measurement and control system for a material cutting apparatus

An active measurement and control system for a material cutting apparatus. The apparatus comprises a cutting tool which may be pivoted for cutting a workpiece in a cutting area at a selectable angle. The cutting area defines a datum plane, and a feed table with a shuttle vise is used to move the workpiece toward the cutting area. A controller controls the feed distance of the shuttle vise and the cutting angle of the tool in response to a signal from a sensor used for sensing a transverse dimension of the workpiece relative to the datum plane. In this way, the feed distance and cutting angle are adjusted to compensate for variations in the transverse dimension. This transverse dimension can include a displacement from the datum plane of a distal and / or proximate surface of the workpiece. A method of cutting a workpiece is also disclosed.

Owner:HEM

Hand-held band saw

A hand-held band saw is provided for one-hand operation. The band saw has a frame and a handle extending from a longitudinal edge of the frame at an acute angle and opposite an edge containing a throat for receiving the work piece. The orientation of the handle centers the mass of the saw below the hand and positions the cutting section of the blade in a vertical plane so it will engage a work piece at a preferred angle selected by the user.

Owner:PERSAWVERE

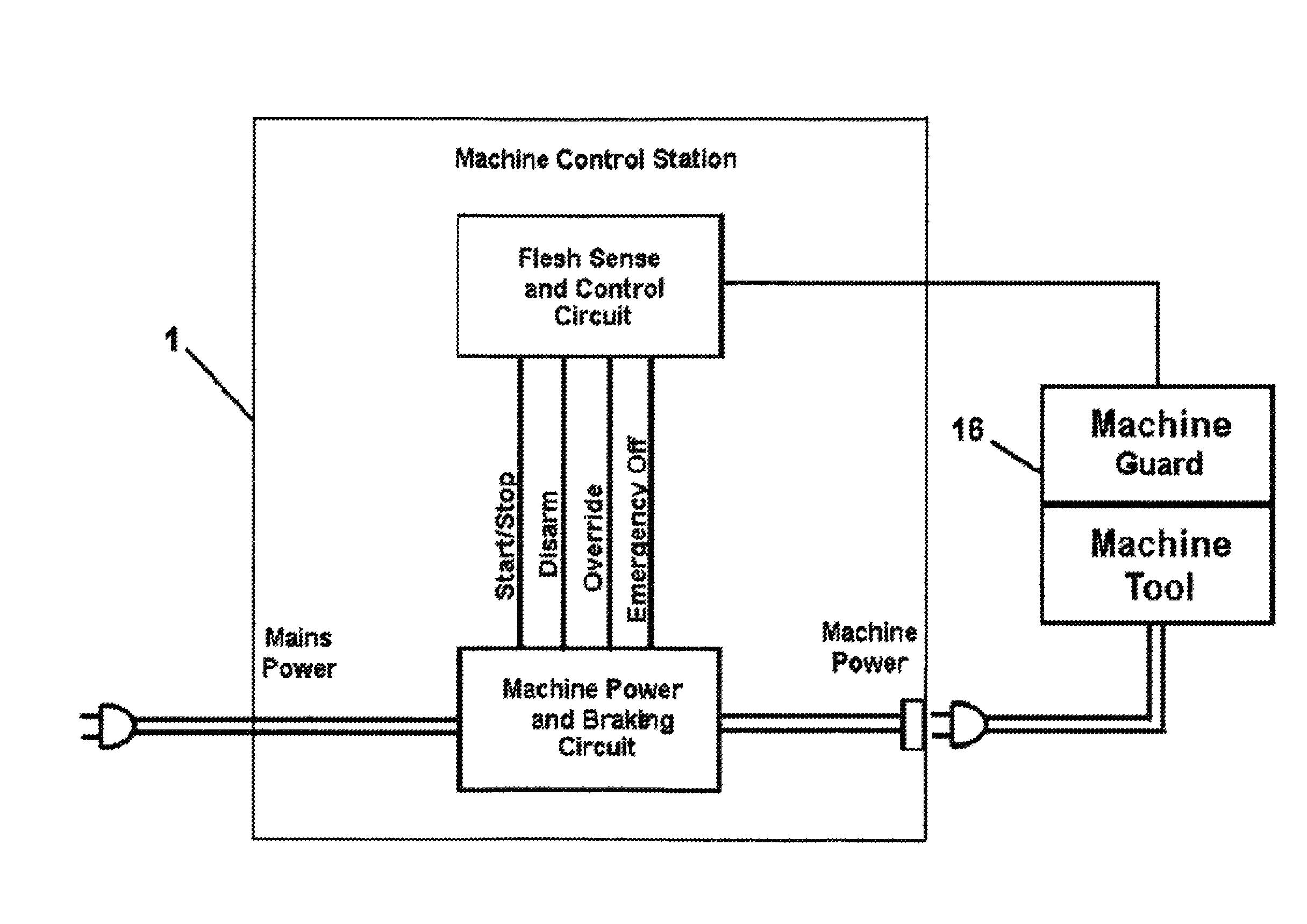

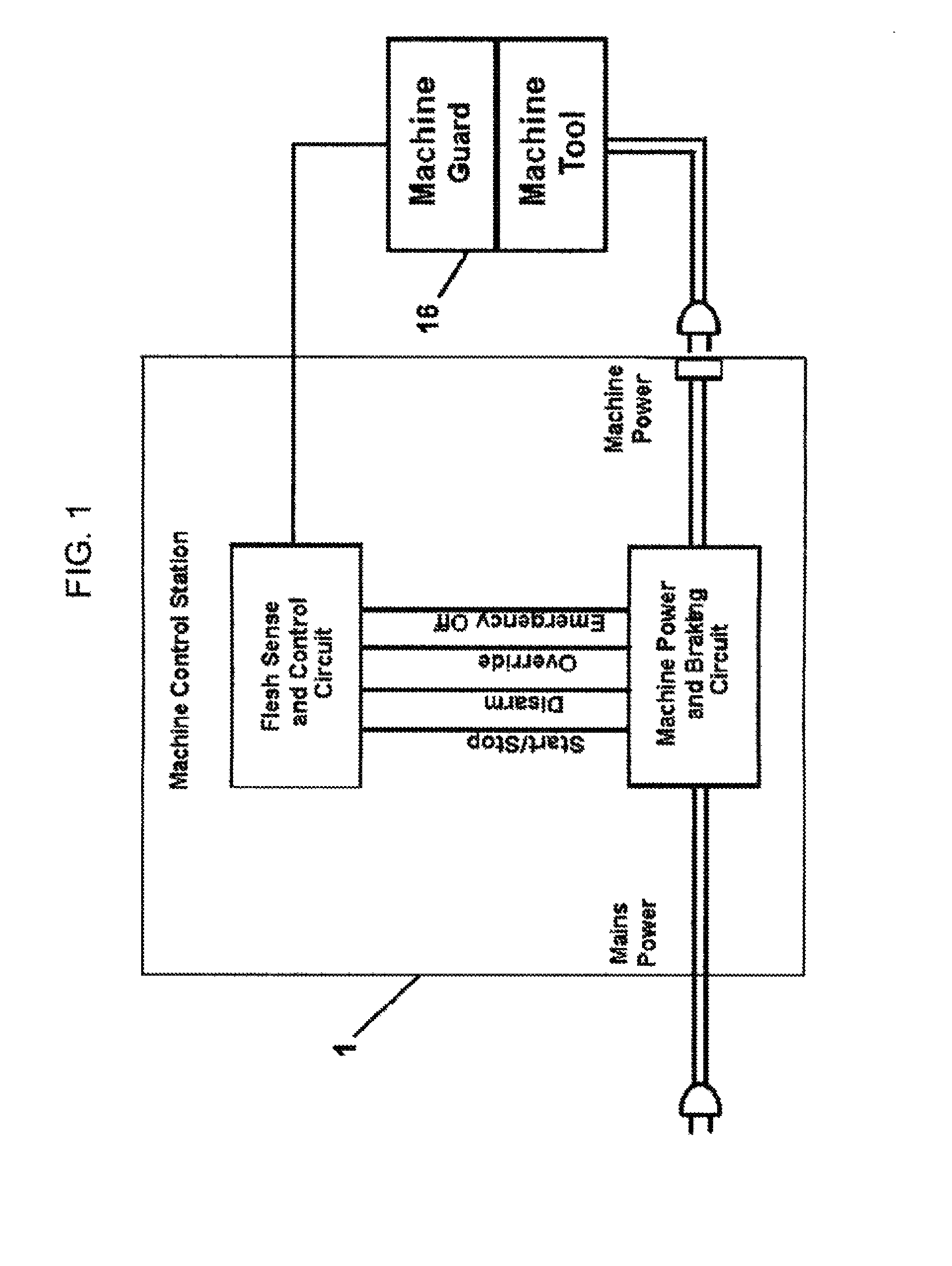

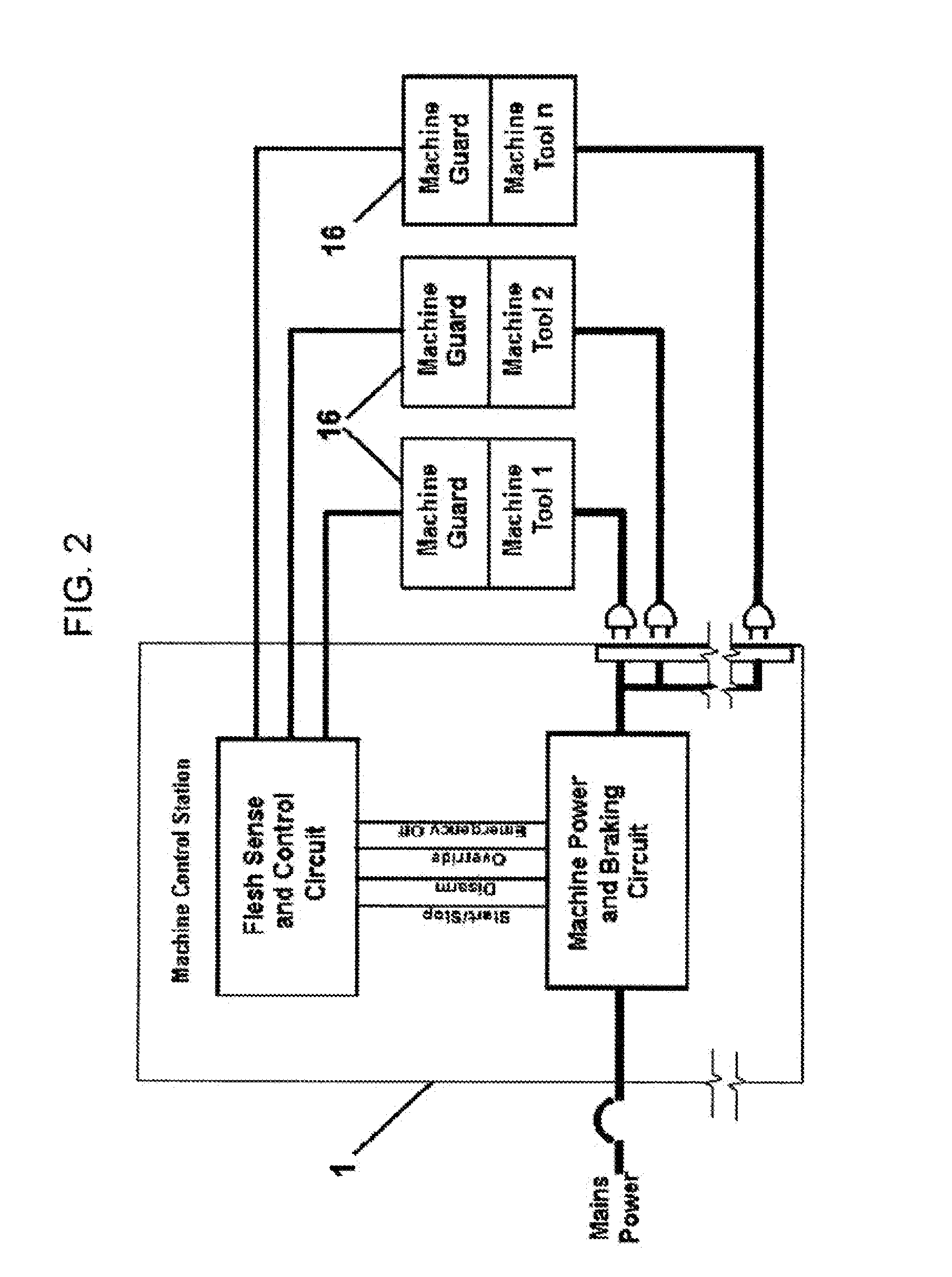

Safety system for machine tools

ActiveUS8336432B1Accurate measurementFast brakingMetal sawing accessoriesGuide fencesPower flowMachine parts

A safety system for a rotary saw or other dangerous machine tools features a flesh-sensing circuit (14, 19), located on a safety guard (16) surrounding a dangerous machine part, which generates an electronic signal to trigger emergency stopping of the machine before the operator can contact the dangerous machine part. The stopping means preferably employs DC injection, winding current direction reversal and / or electromagnetic motor braking, in the event of detection of operator contact with the safety guarding device. The system is adapted to be used both with newly-manufactured machine tools and by retrofitting onto previously-manufactured machine tools, by in-the-field modifications.

Owner:BUTLER DAVID J

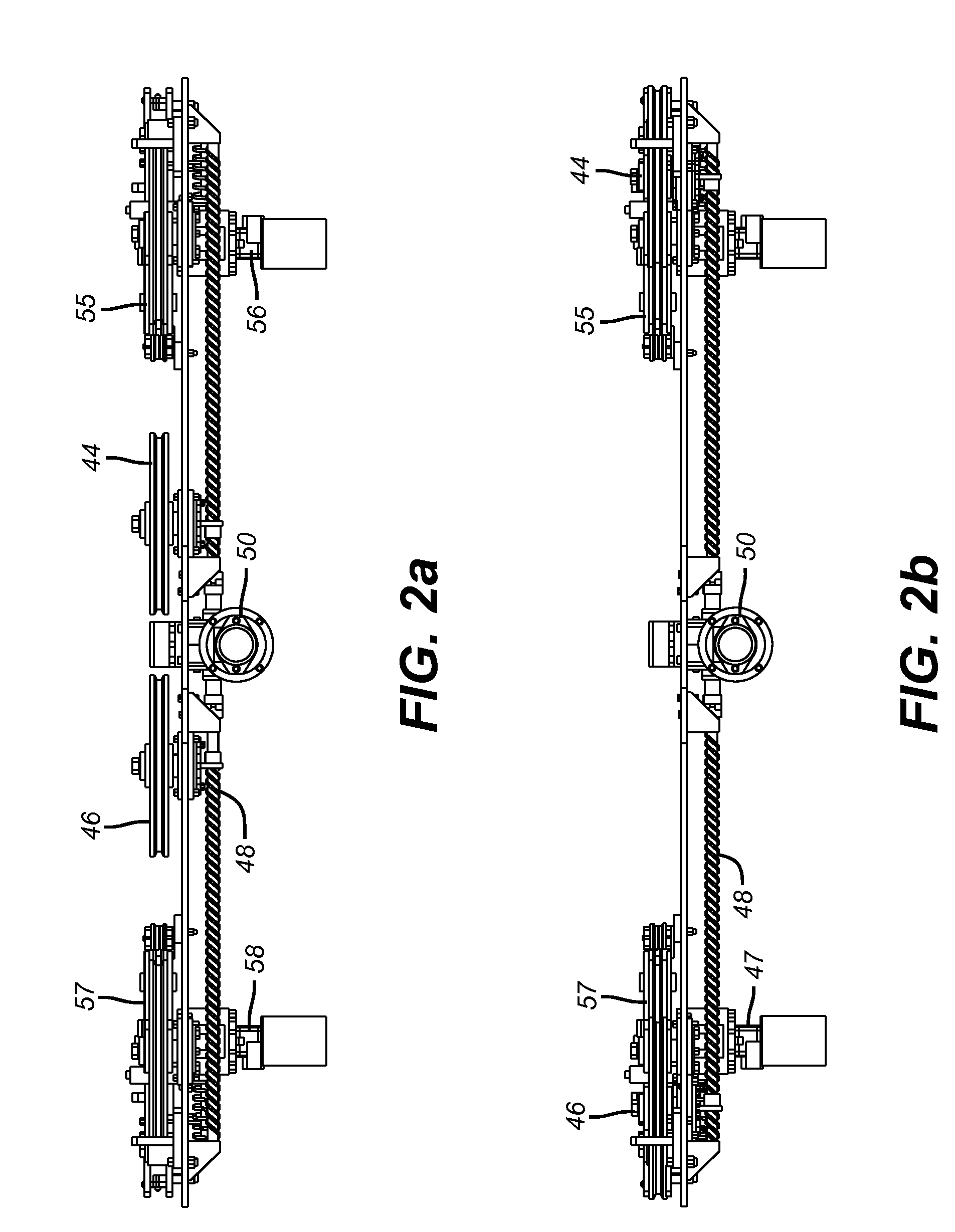

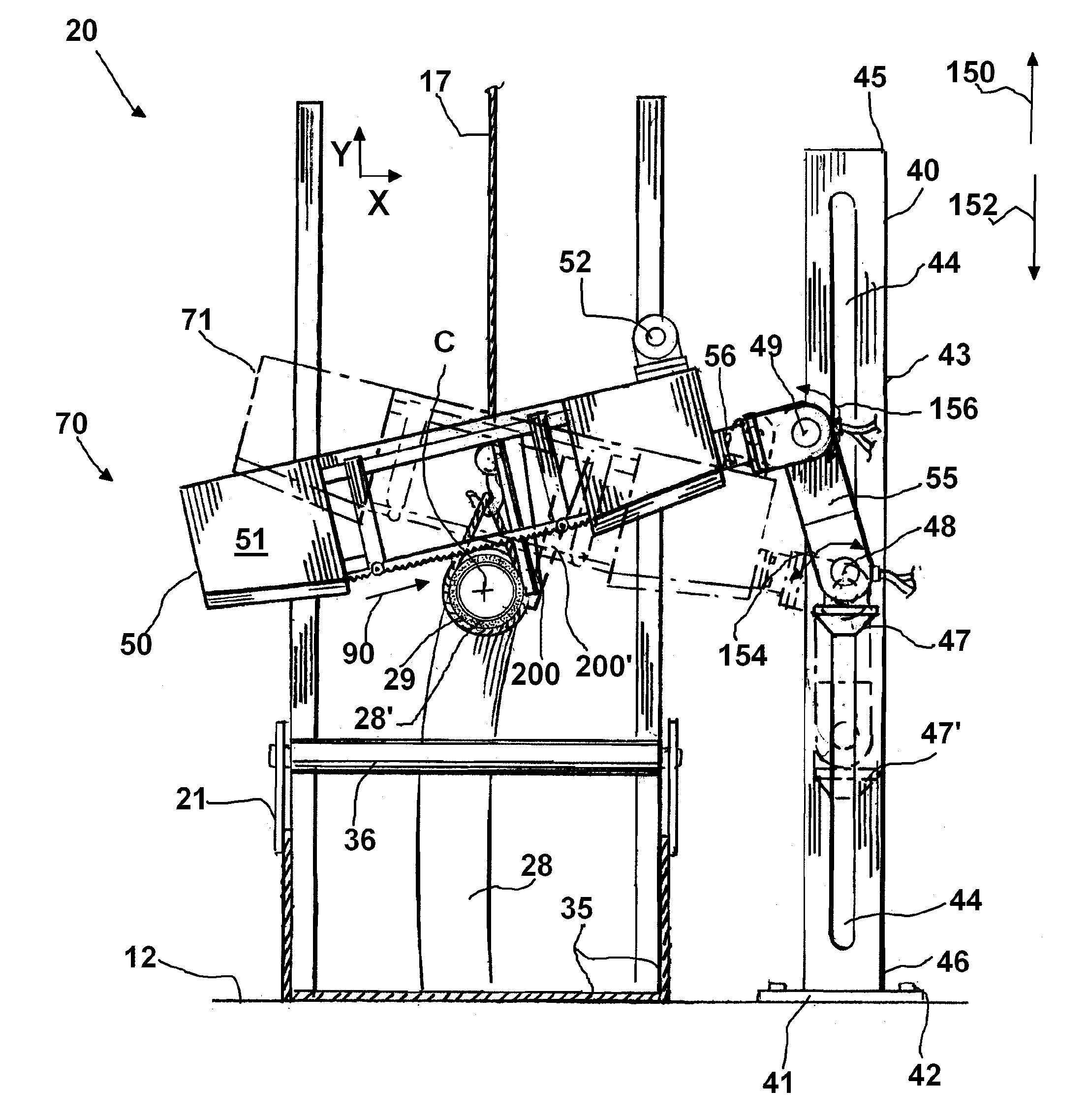

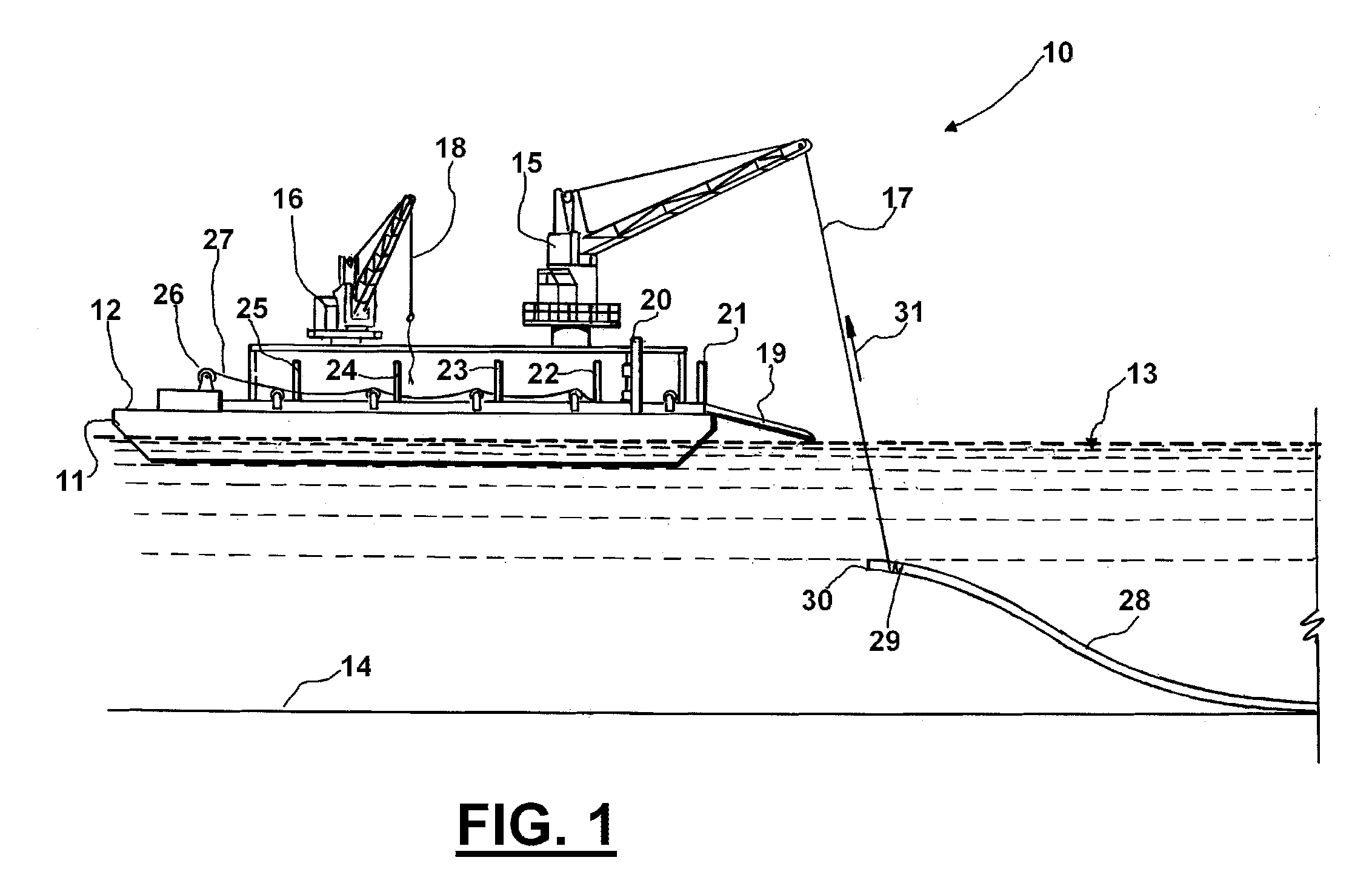

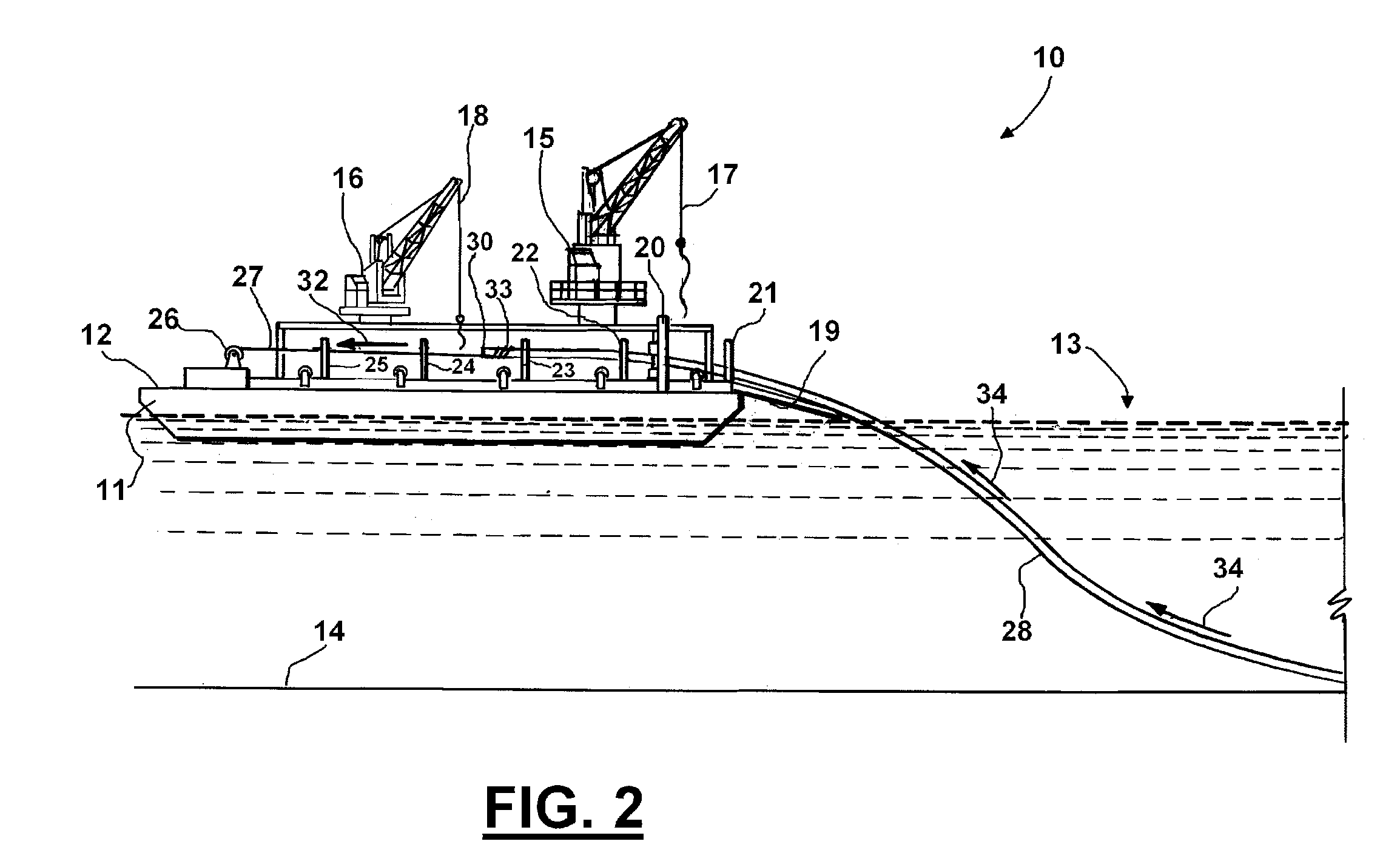

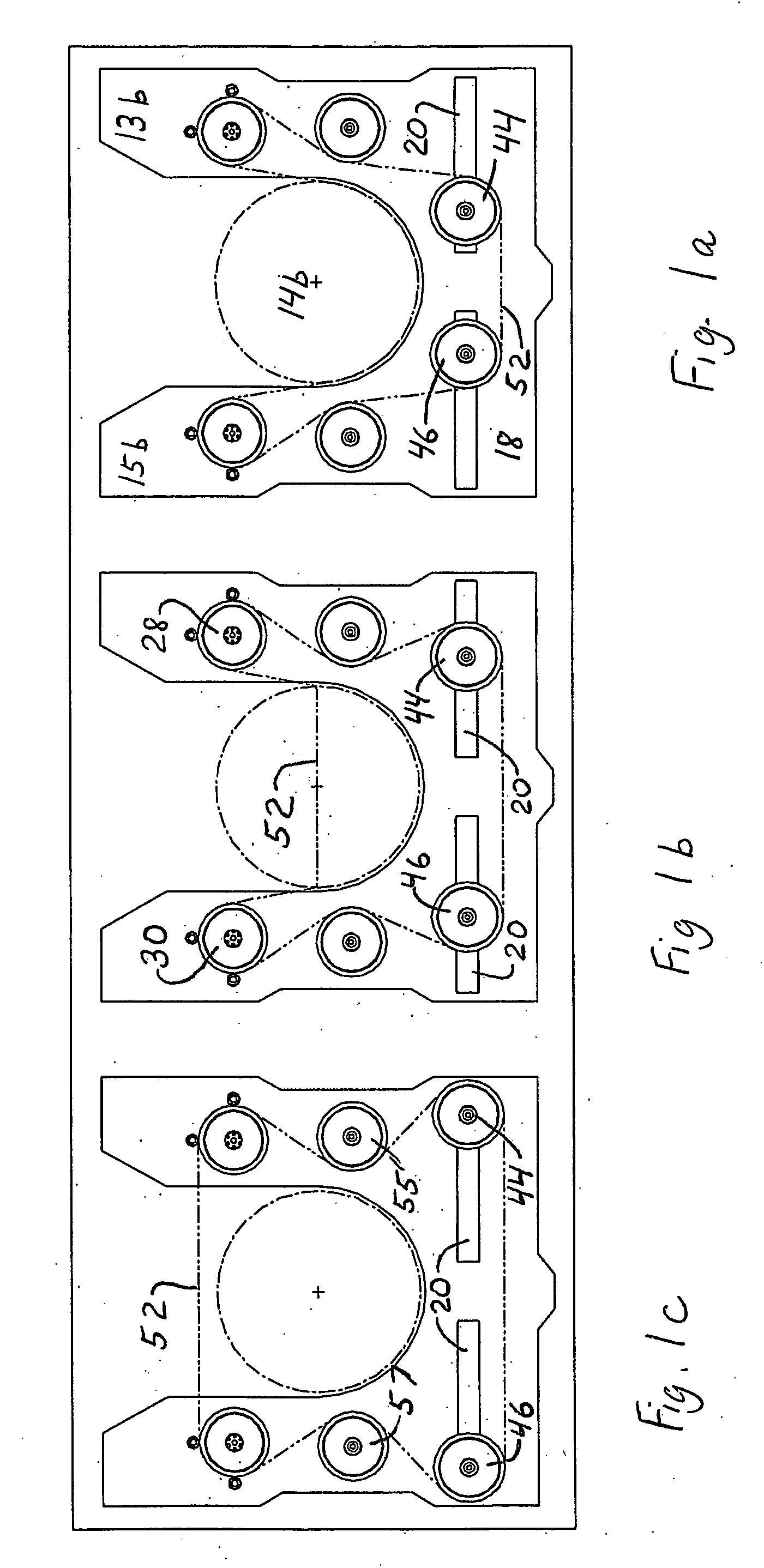

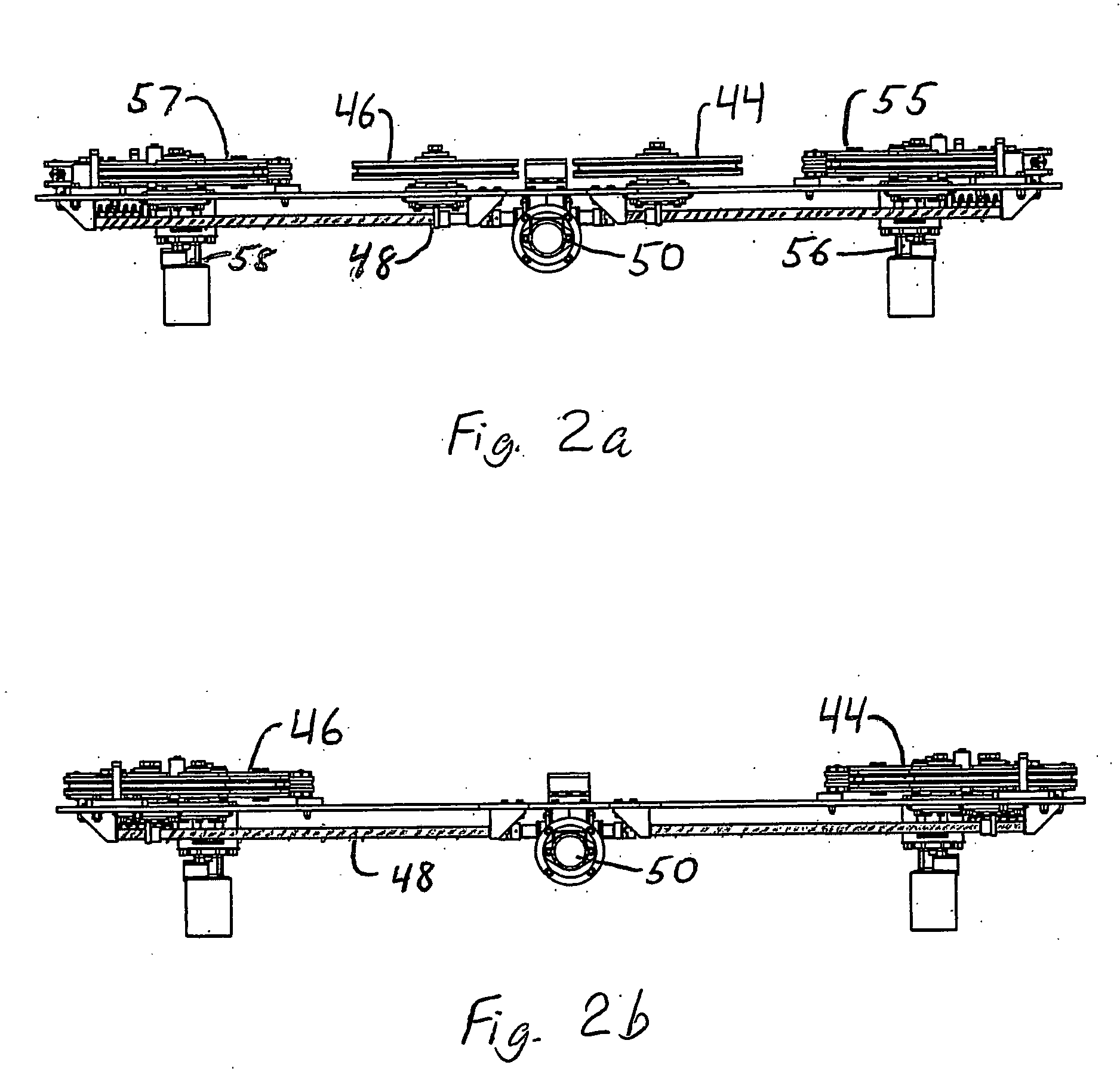

Articulating band saw and method

ActiveUS8475081B2Eliminate needImprove securityMetal sawing devicesPipe laying and repairDiamond wire sawActuator

An articulating band saw apparatus provides a frame that includes a vertically extending section having upper and lower end portions. An elevator moves between the upper and lower end portions of the frame. A first hydraulic actuator is supported on the elevator for movement therewith. A first arm provides arm end portions, the first arm supported by the first hydraulic actuator. An end of the first arm supporting a second hydraulic actuator that is spaced away from the first hydraulic actuator. The second hydraulic actuator supports a second arm. An endless band type saw is mounted on the free end of the second arm generally opposite the second actuator. The band saw is movable by articulation of the first and second actuators and resulting movement of the first and second arms. In one embodiment, the band saw is a diamond wire saw.

Owner:AES EOT EQUIP HLDG LLC

Electric Saw with Operator Protection System

InactiveUS20080245200A1Save from amputationLessens seriousnessAutomatic control devicesMetal sawing accessoriesControl systemEngineering

There is described a control system for an electrically powered saw of the type incorporating a table through which the blade of the saw passes. The control system comprises a clamping mechanism (16, 16a) having clamping members (18, 20) counter-rotatable relative to one another to clamp the blade (4) in use to stop travel of the blade in event of an operator coming into electrical contact with the blade during use of the saw. The control system monitors for an electrical signal conducted between the operator and the blade or the blade and the operator upon contact of the operator with the blade.

Owner:BLADESTOP

Bar knob with cam-operated locking mechanism

InactiveUS20060016081A1Positive securing of the knobMetal sawing devicesMetal sawing accessoriesLocking mechanismEngineering

A retaining assembly is provided for a tensioning arrangement for adjusting the tension of the cutting chain in the chain saw. The retaining assembly includes a rotatable knob that operates in conjunction with the chain saw's engine chassis, clutch cover, and guide bar and is rotatable about an axis of rotation between a tightening position for holding the guide bar in place and a loosening position enabling the guide bar to be repositioned whereby the tension in the cutting chain is adjusted. A locking mechanism is provided for locking and unlocking the knob for rotational movement. When the locking mechanism is in a locking position, moveable engagement points of the locking mechanism extended beyond the confines of the knob and engage fixed engagement points. When the locking mechanism is in the unlocking position, the moveable engagement points, having moved inwardly of the confines of the knob, are disengaged from the fixed engagement points.

Owner:HUSQVARNA OUTDOOR PROD INC

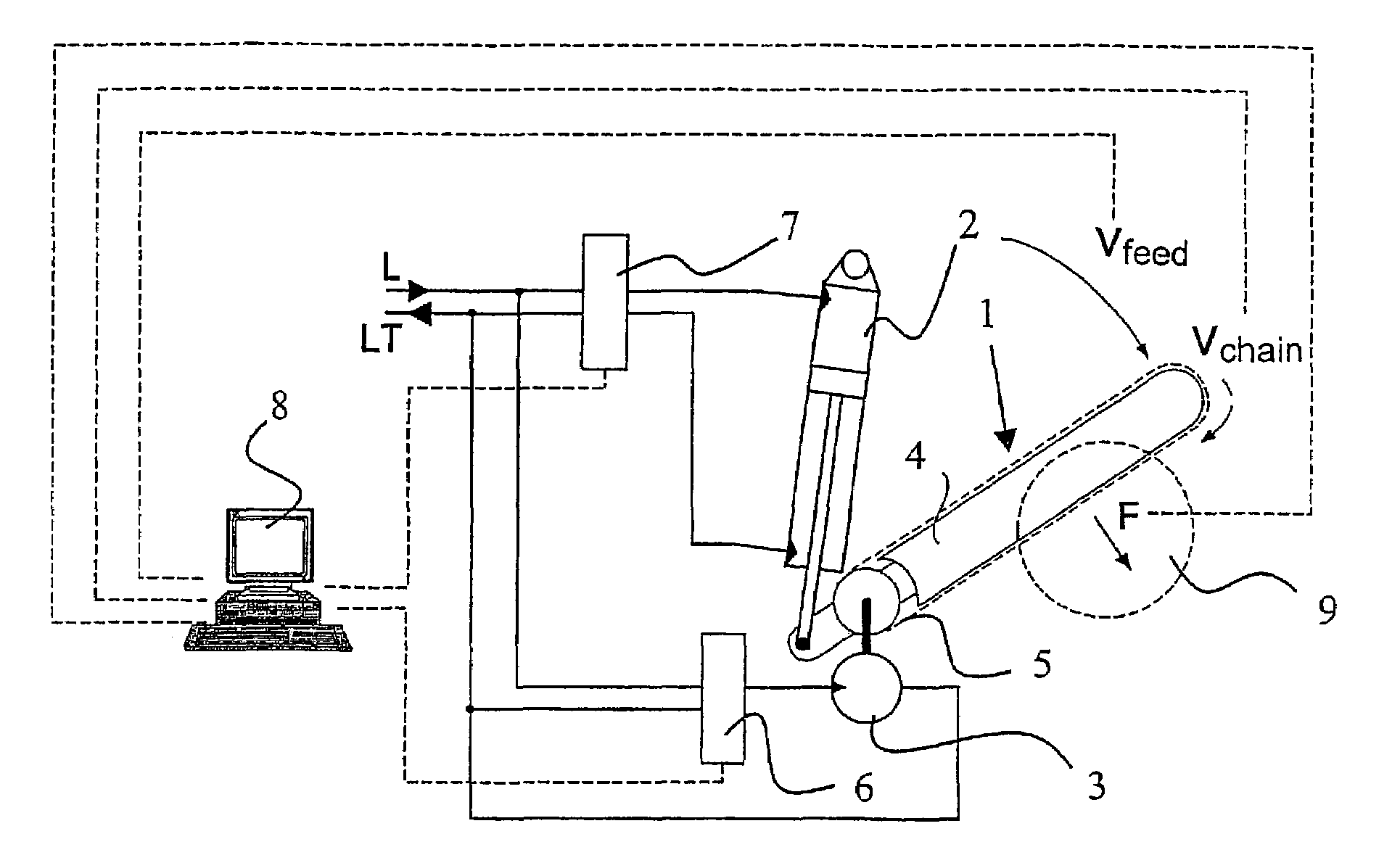

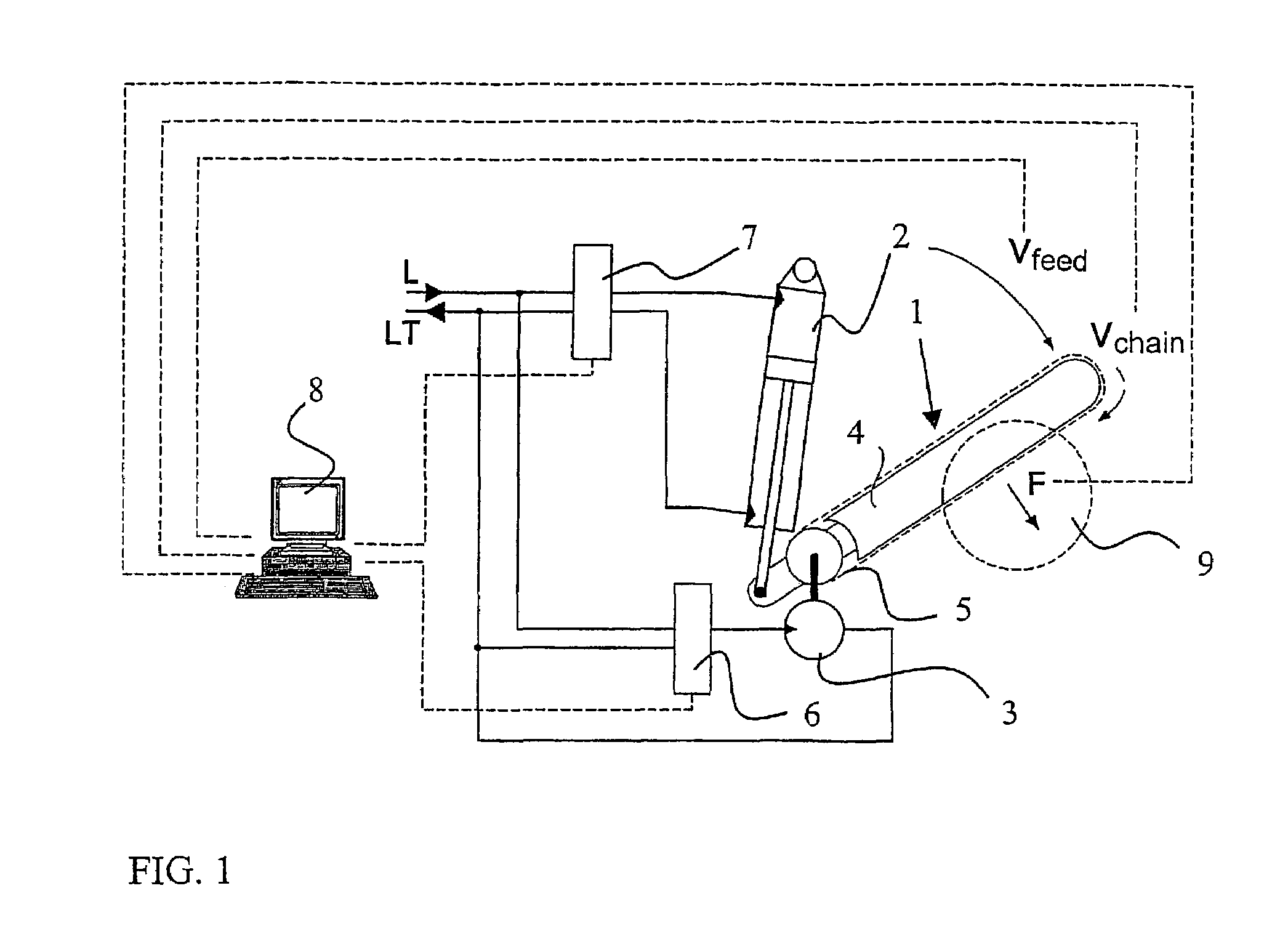

Method and arrangement for adjusting feed rate of a crosscut saw

InactiveUS7017460B2Limiting power neededImprove efficiencyMetal sawing devicesAutomatic control devicesFeeding forceActuator

A method and arrangement for adjusting a feed rate of a crosscut saw (1), in particular, in a harvesting head of a forest machine during the crosscutting of wood (9) in the apparatus. A feed force (F) of the crosscut saw and / or a rotating rate (vchain) of a cutter chain (5) revolving around a guide bar (4) are thus controlled. The control is implemented such that first the feed rate (vfeed) of the crosscut saw (1) is measured at given intervals. By adjusting thereafter the feed force of the actuator (2) controlling the crosscut saw and / or the rotating rate (vchain) of the cutter chain (5) and by determining the effect of the performed adjustment on the feed rate of the crosscut saw any change (δv) in the feed rate and the most advantageous adjustment measure to be performed next is concluded.

Owner:PONSSE

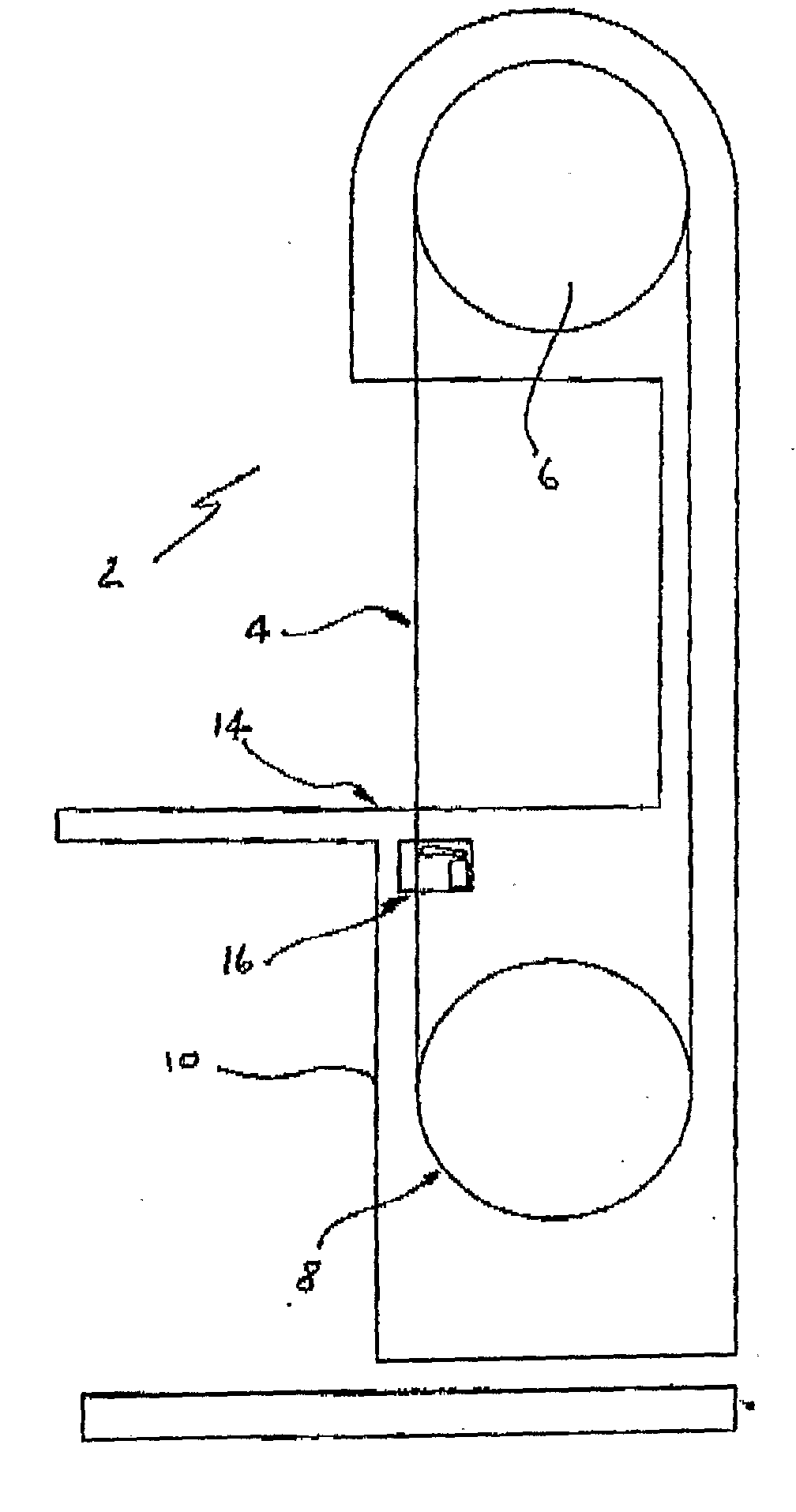

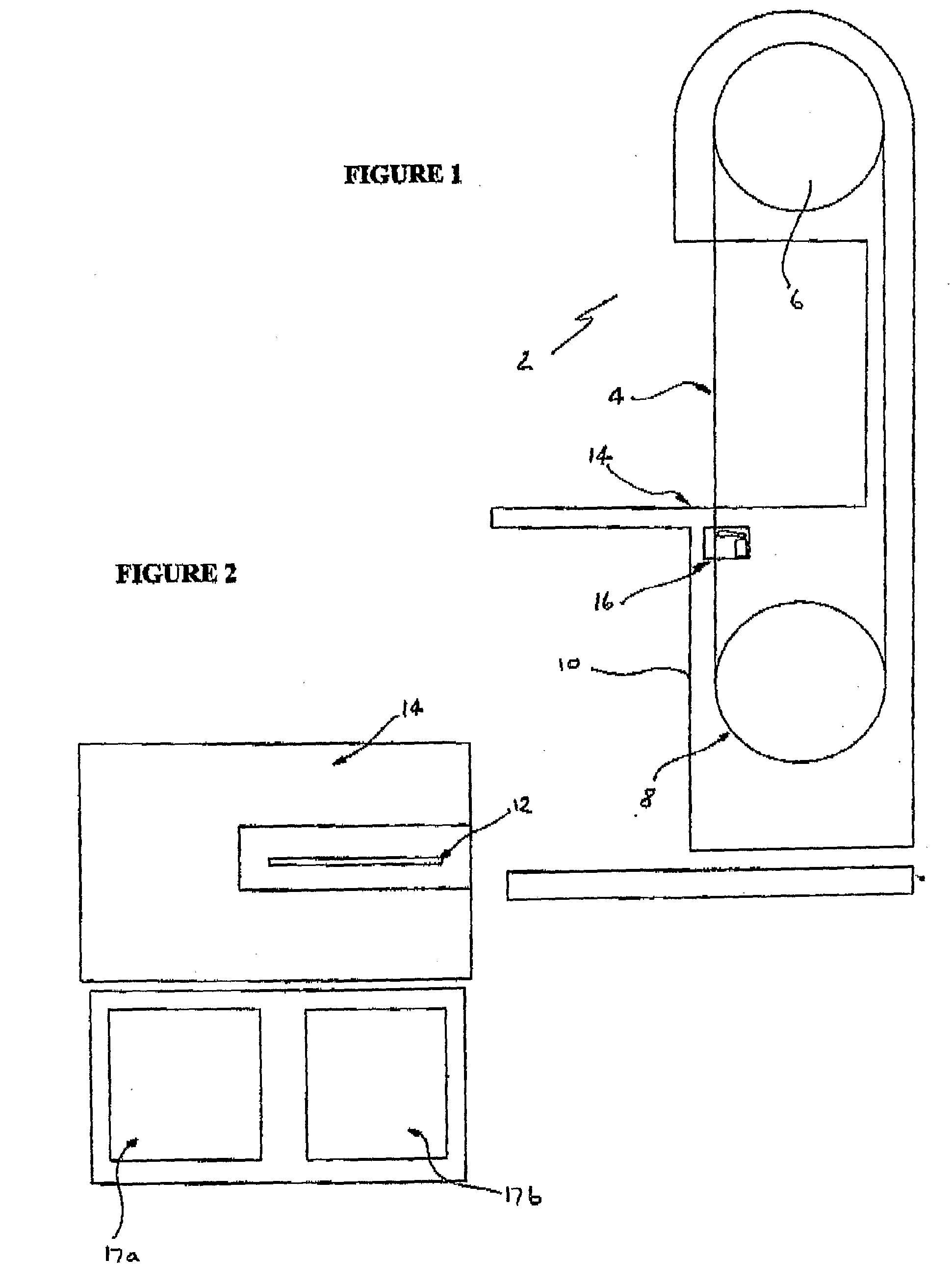

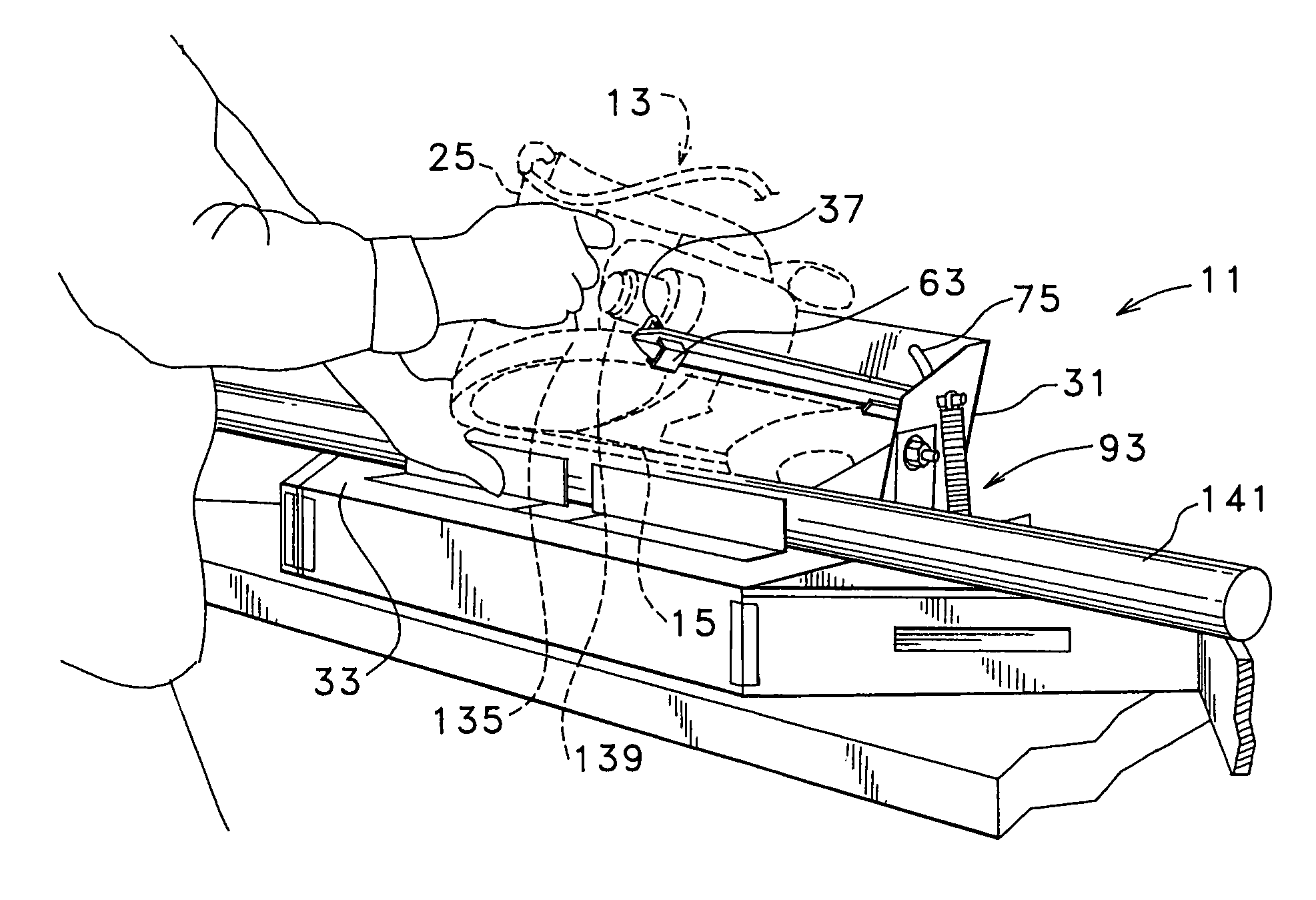

Operational support for portable band saw

InactiveUS7159499B1Improve surface stabilityMetal sawing devicesGang saw millsEngineeringMechanical engineering

Apparatus and methods for operational support and guidance of pivoting movement of portable band saws are disclosed. The apparatus includes a pivoting mount maintained at a work surface. A support is connected with the mount and includes a forward bracket adjacent to the mount for receiving a front portion of a blade housing structure of the portable band saw. An extension bar of the support supports a rear portion of the blade housing structure, a securing latch at the extension provided to releasably maintain the rear portion of the blade housing structure supported thereat.

Owner:LANSER JERRY L

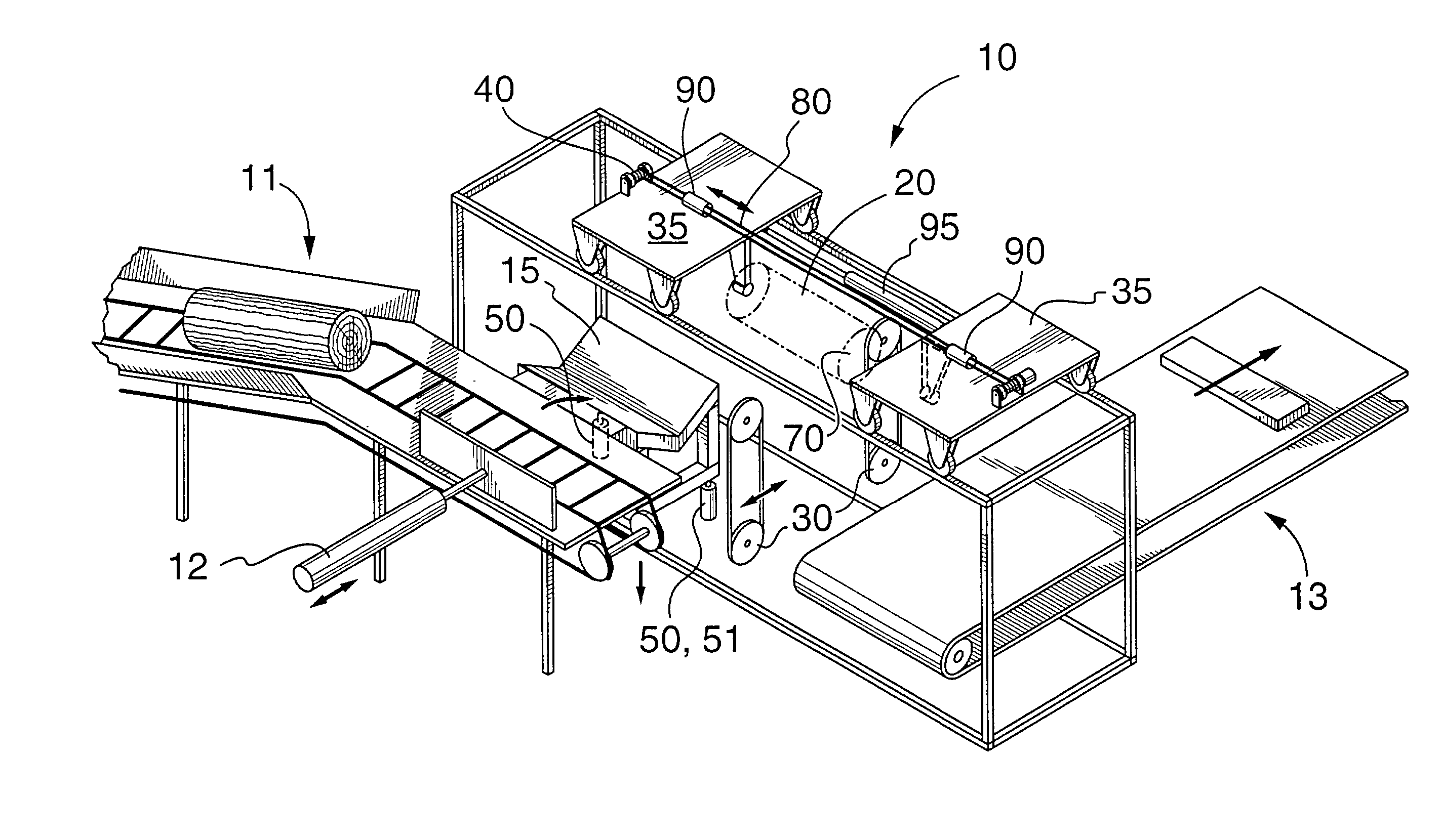

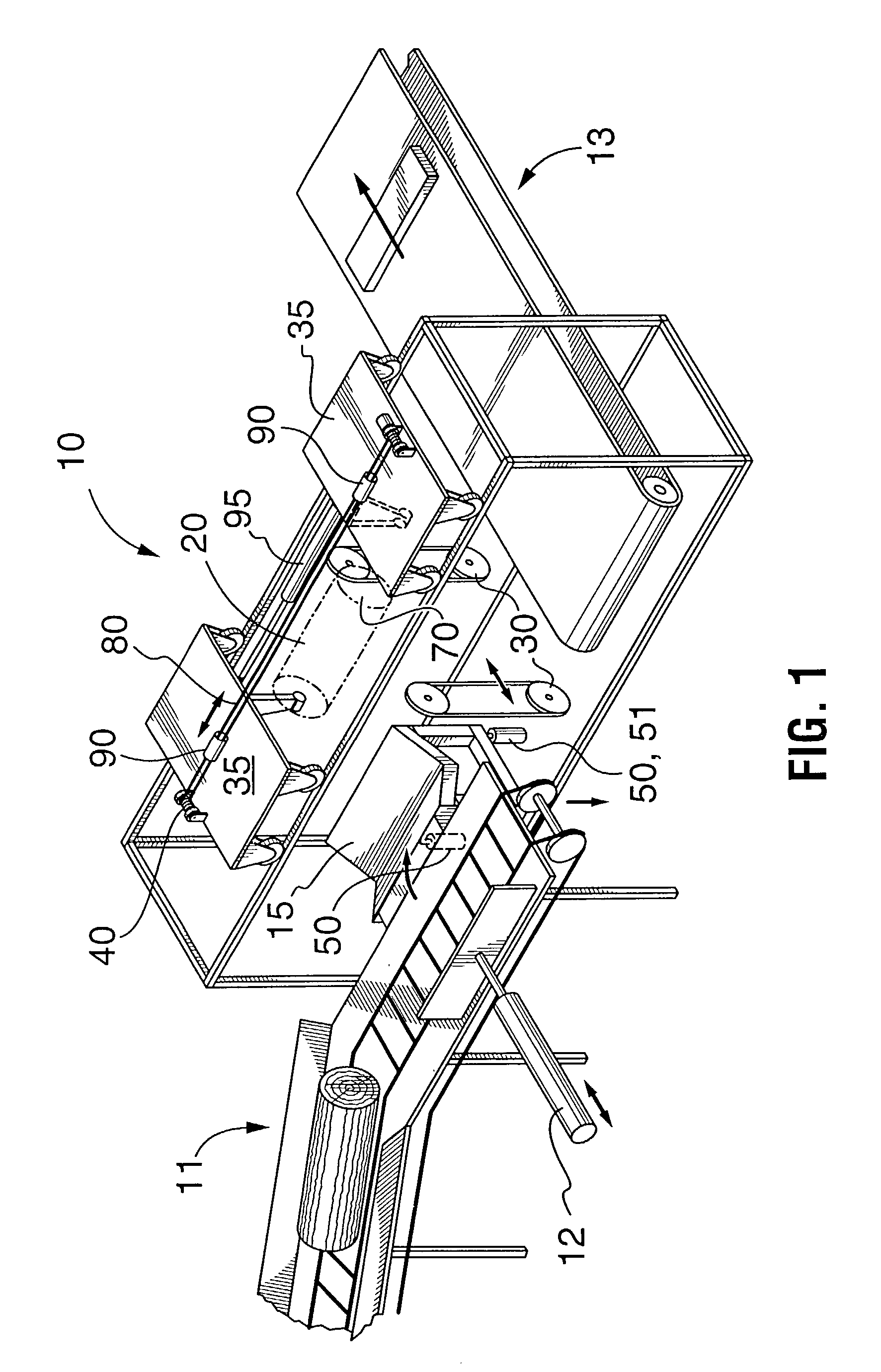

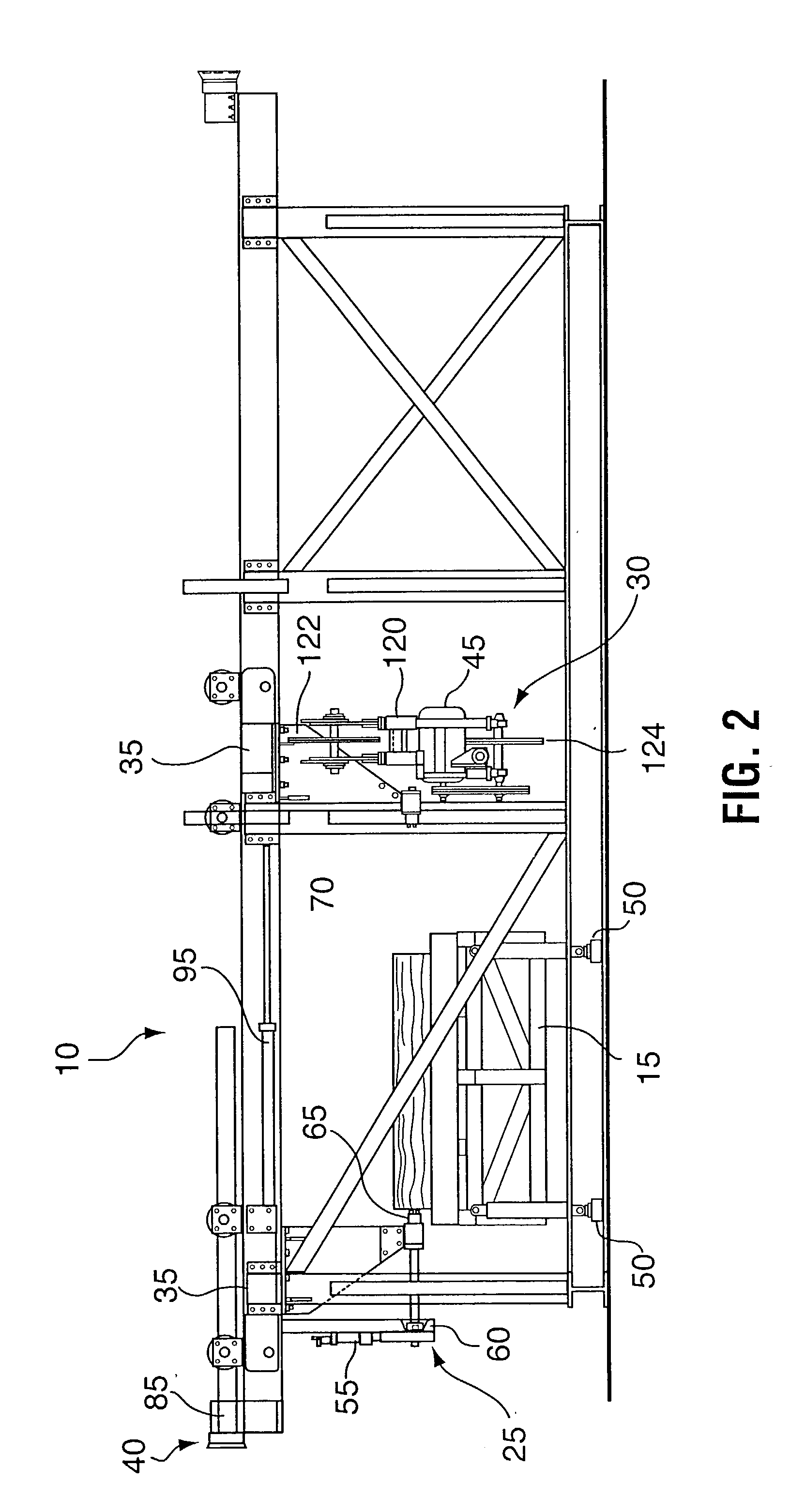

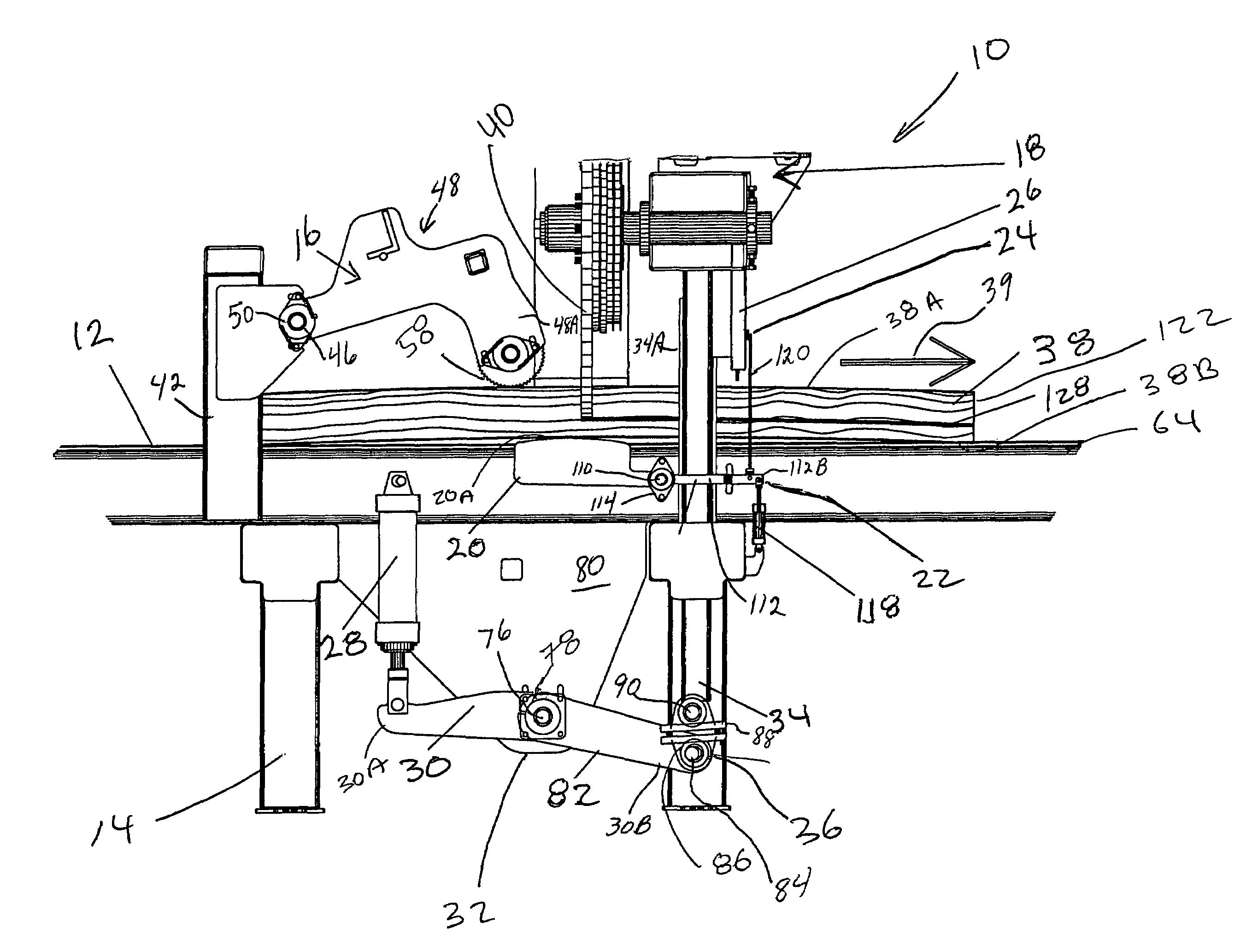

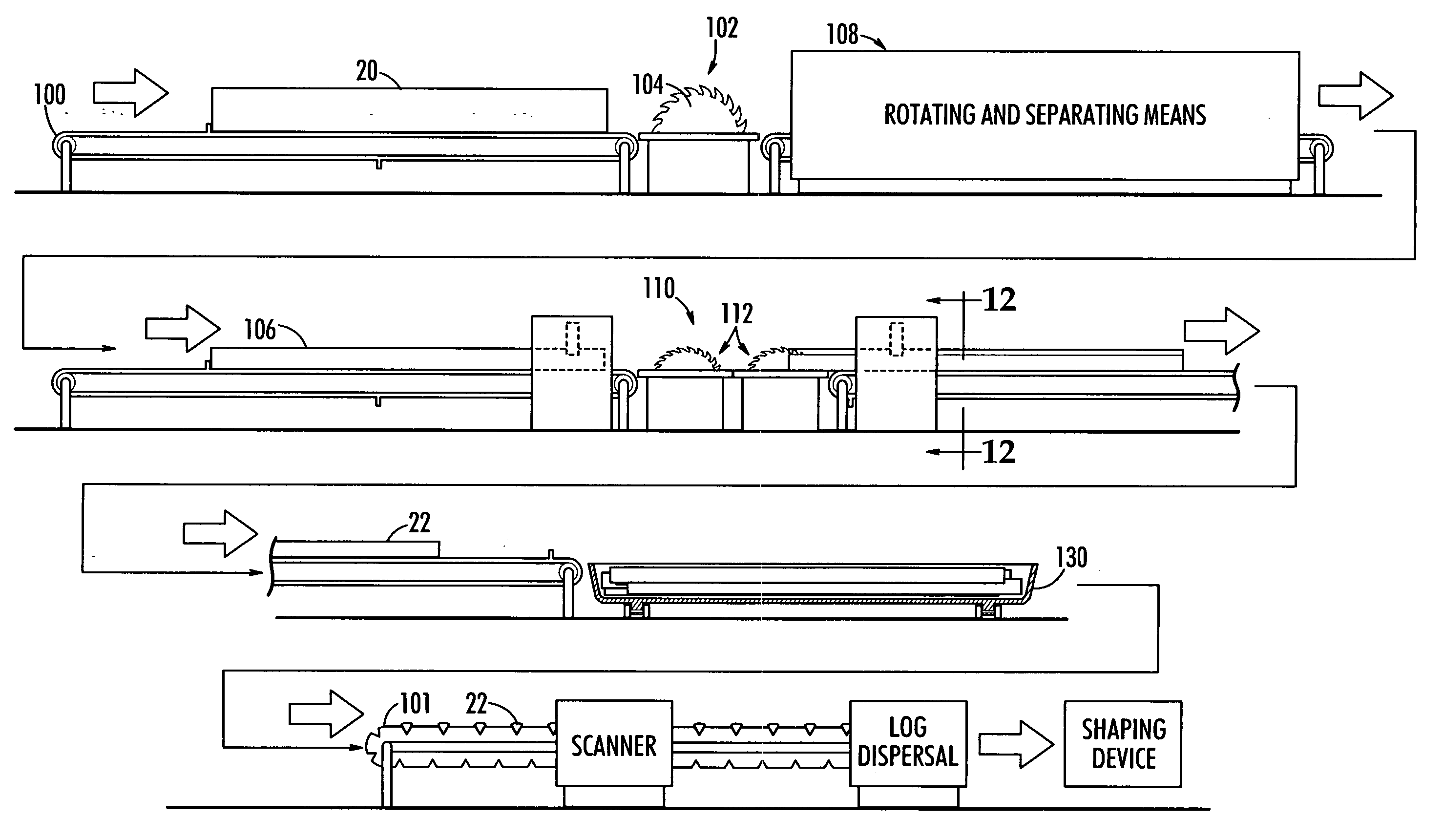

End-dogging head saw and method

InactiveUS20030015256A1Automatic control devicesPrecision positioning equipmentEngineeringMechanical engineering

An end-dogging head saw is disclosed comprising a log cradle for supporting a log, a log-turning device for rotating the log into proper alignment with a pair of band saws, the log-turning device depending from overhead log carriages which move the log into contact with the band saws, and a carriage drive for powering the overhead log carriages, whereby short logs can be quickly and efficiently processed. The invention also seeks to provide a method for using the apparatus, comprising rotation of a log through 360 degrees to allow for cutting at any desired angle along the length of the log. The method allows for maximal recovery of high-quality lumber.

Owner:9148 7520 QUEBEC

Horizontal curve sawing apparatus

InactiveUS7308921B1Smooth and precise cuttingEasy to trackMetal sawing devicesAutomatic control devicesMechanical engineering

Owner:BREWER SR CLARENCE R

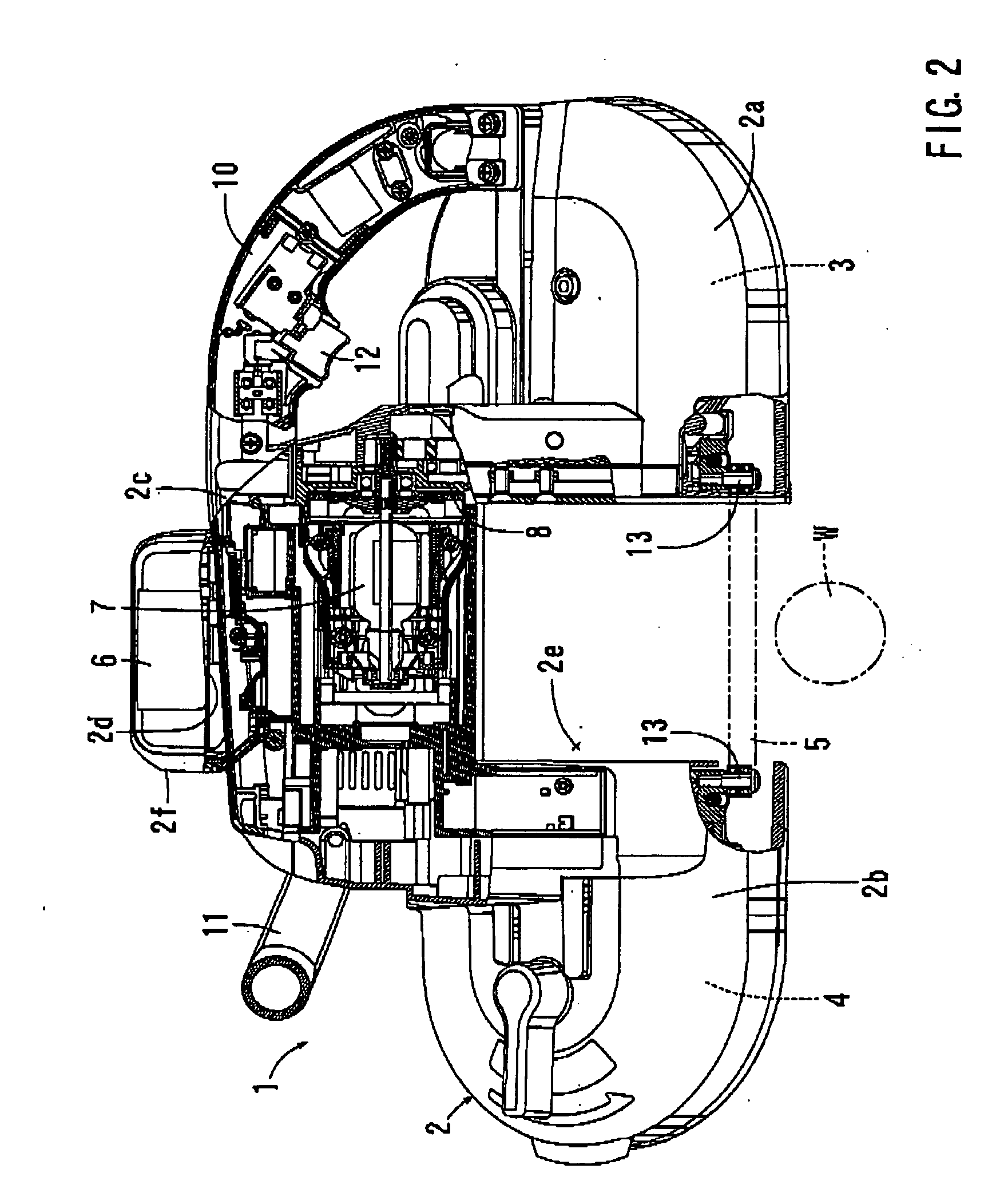

Electromotive chain saw

InactiveUSRE37832E1Durability is impairedIncreased durabilityMetal sawing devicesMetal sawing accessoriesCoil springEngineering

The chain of an electromotive chain saw is quickly stopped by the combined use of an electric brake and a mechanical brake when a trigger member is turned off. The rear end of a brake band disposed to tighten a brake drum by operating a hand guard is secured to a bent rod. When the trigger member is released, the brake band is normally tightened around the outer periphery of a brake drum by the urging force of a coil spring. When the trigger member is released, a circuit provided with a brake winding is closed, thereby applying a dynamic braking force. When the dynamic brake force is applied, a centrifugal clutch is released quickly and the speed of stopping the brake drum is accelerated.

Owner:MAKITA CORP

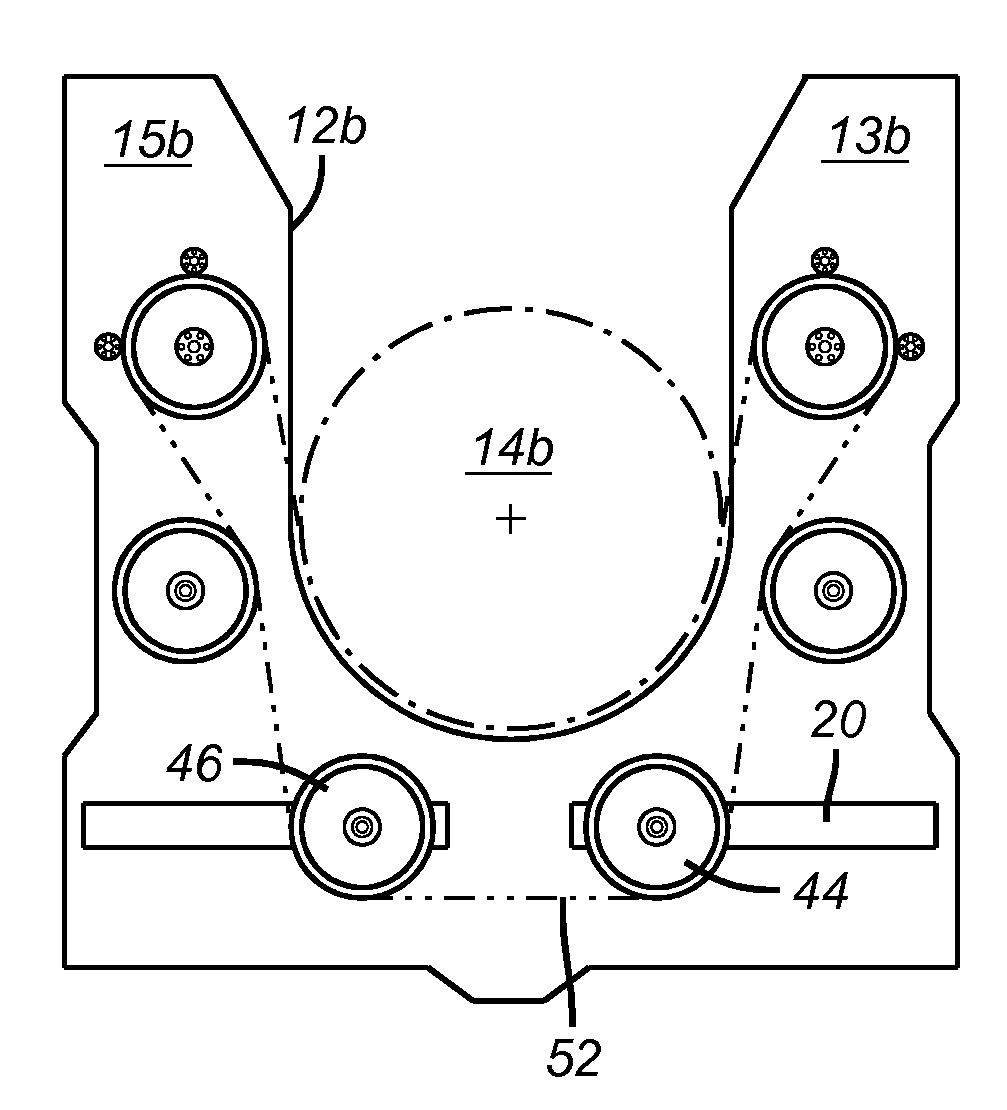

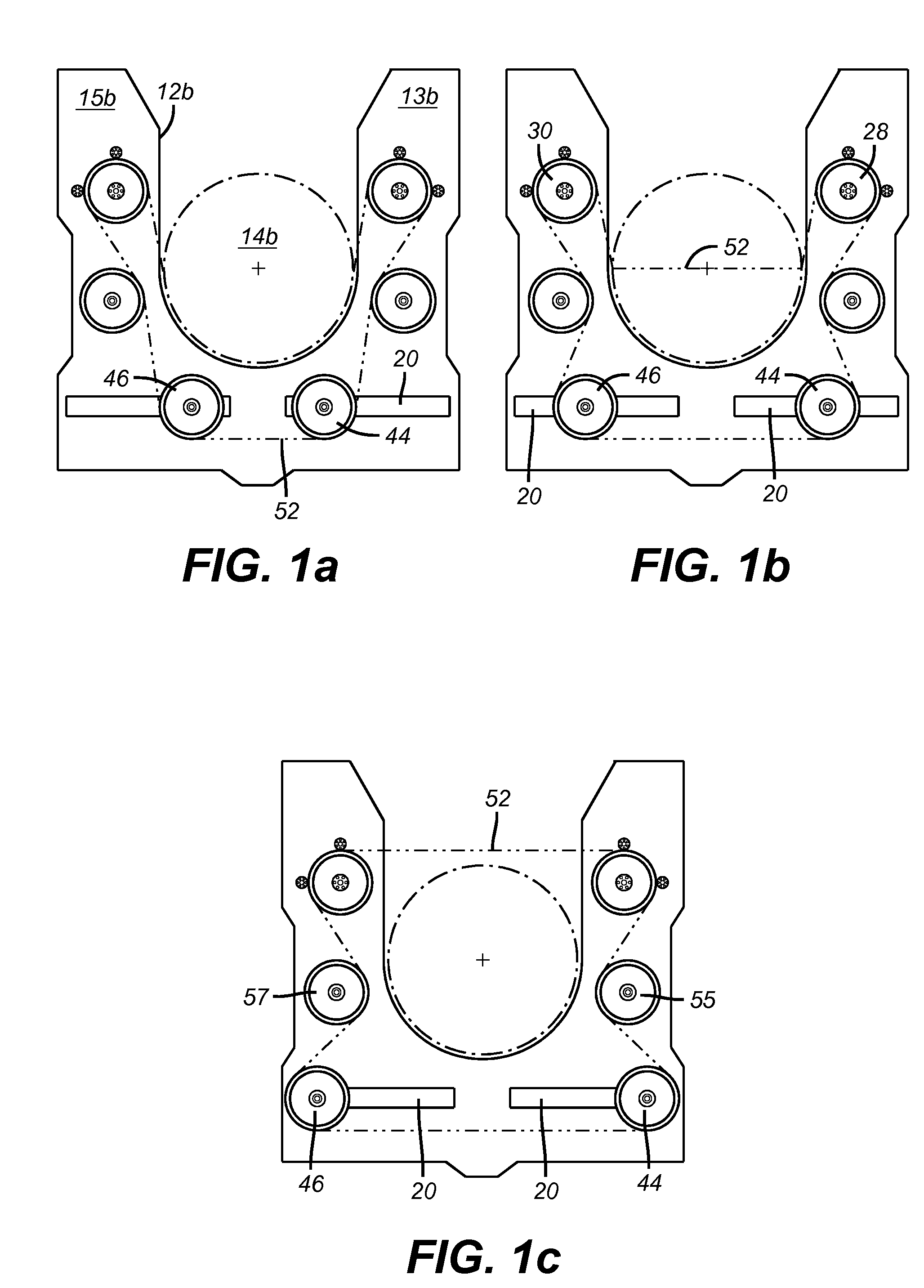

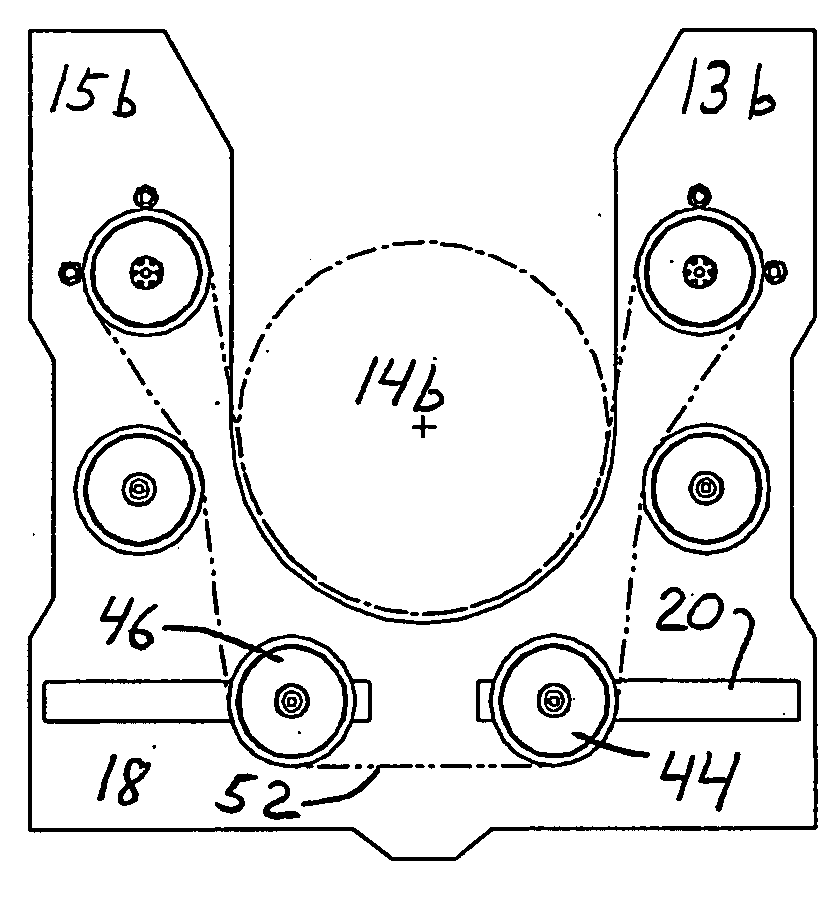

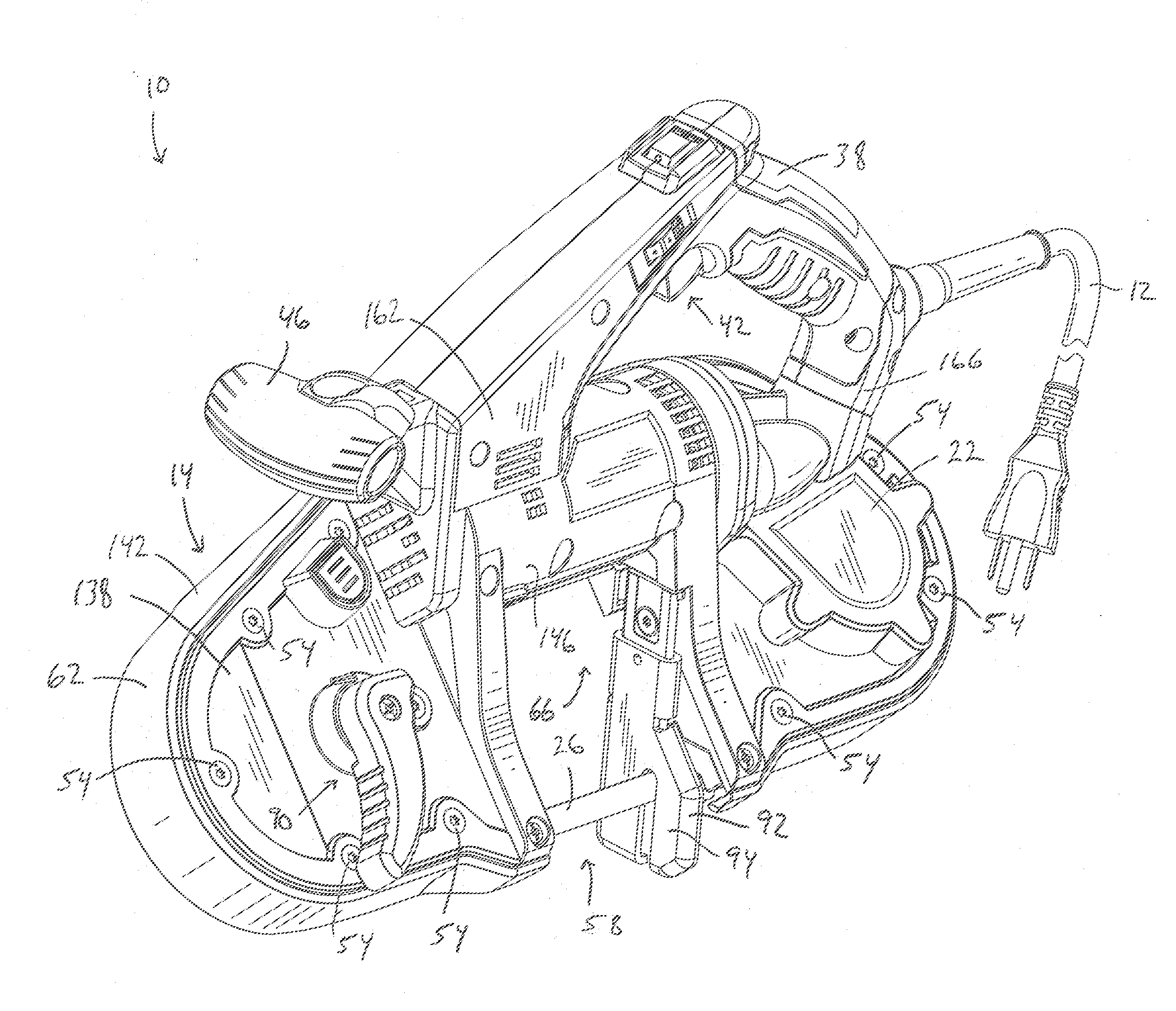

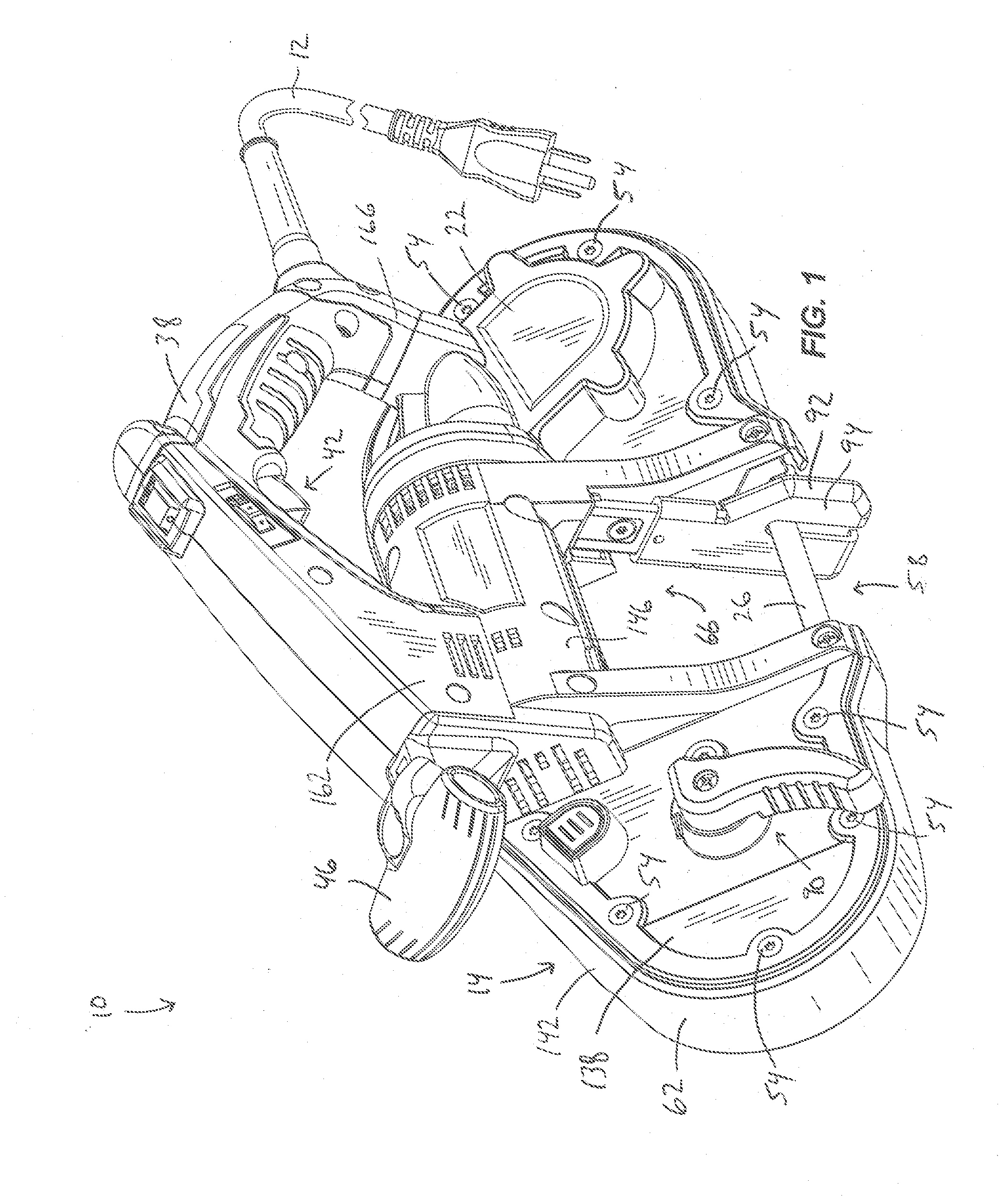

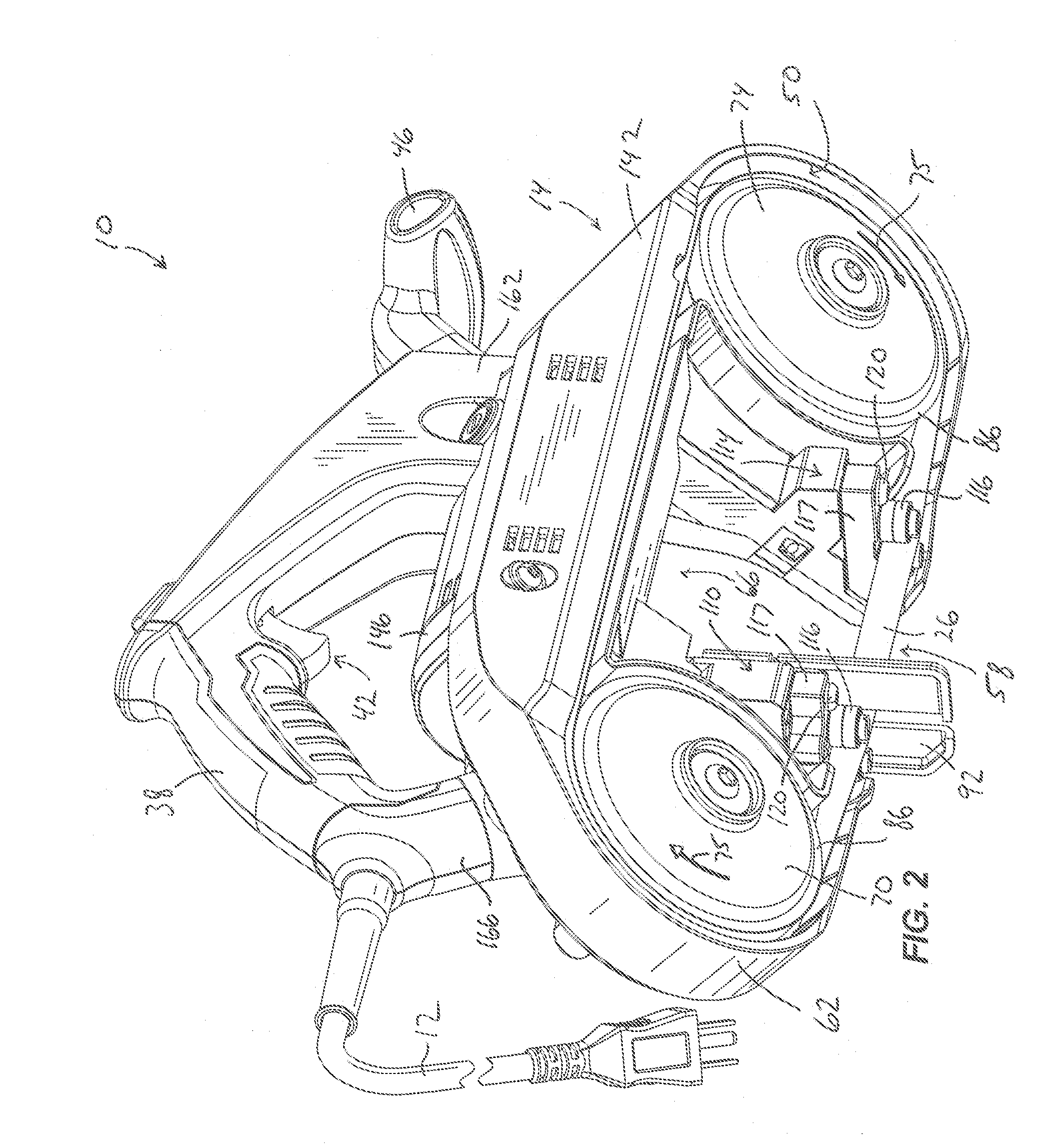

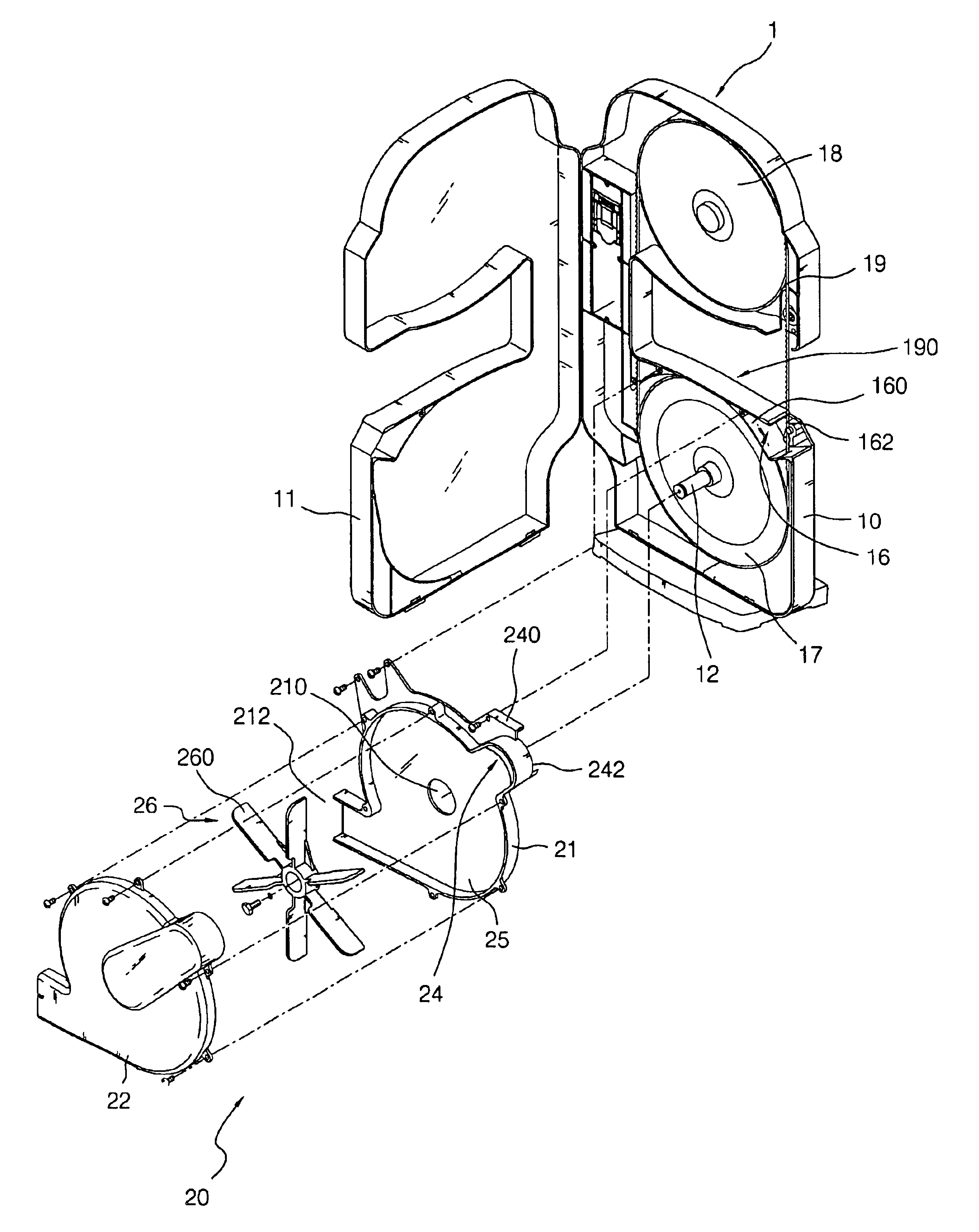

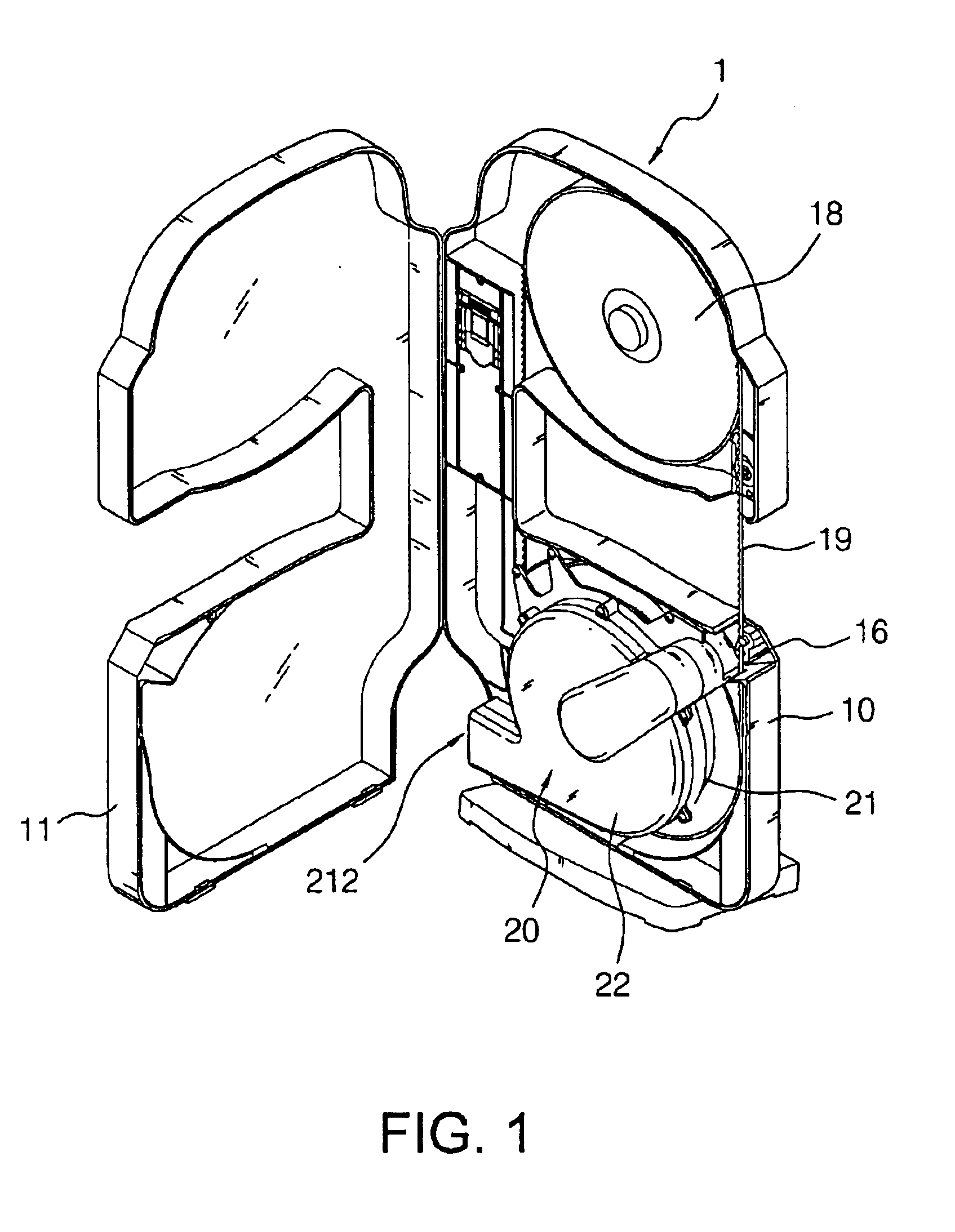

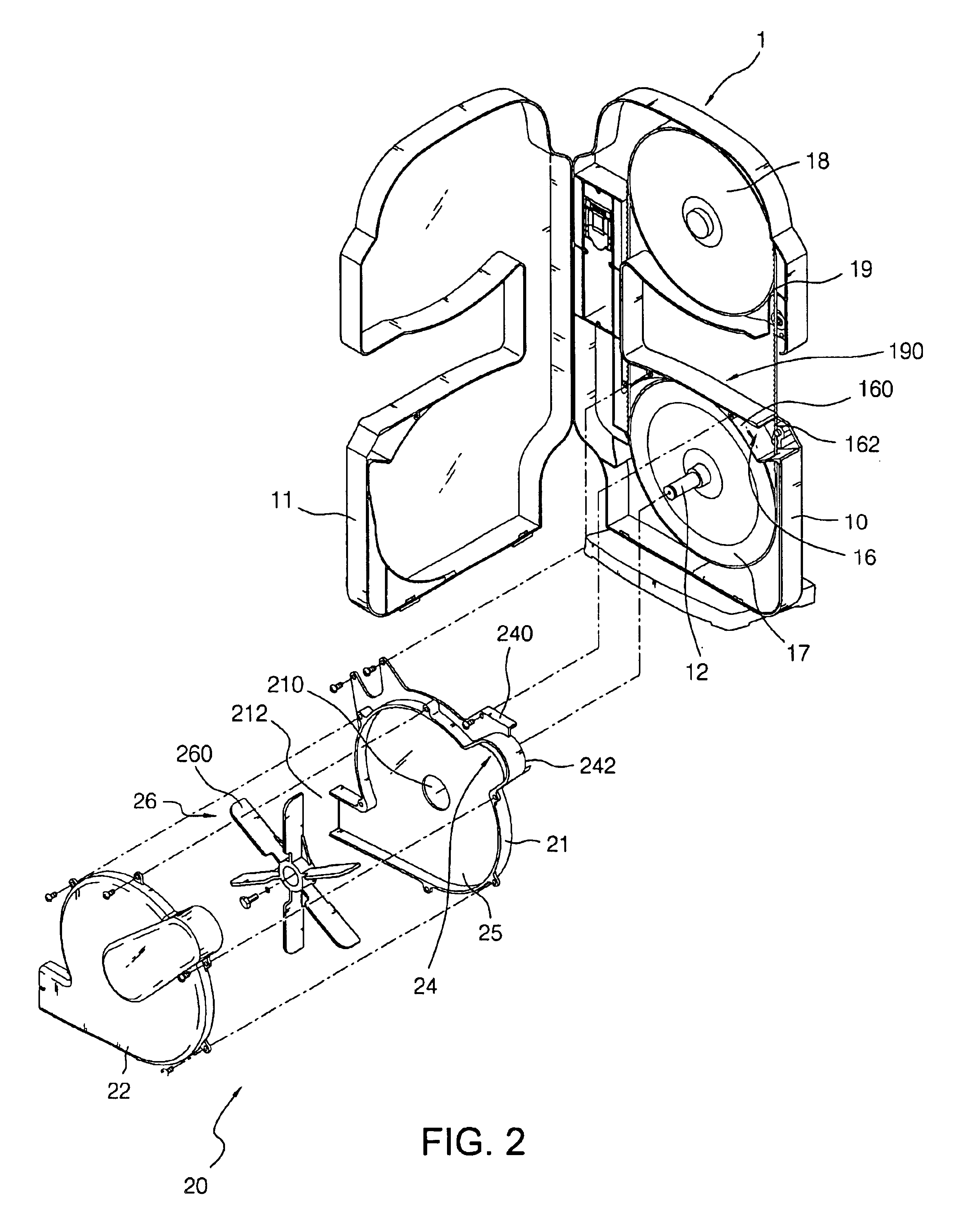

Band saw

A hand-held power tool includes a housing having an opening, first and second wheels supported by the housing for rotation about respective first and second parallel axes, a continuous saw blade supported by the first and second wheels, a first guide roller set coupled to the housing proximate a first side of the opening, and a second guide roller set coupled to the housing proximate a second side of the opening. The first and second wheels define respective first and second facing, parallel planes containing the first and second axes. The first and second guide roller sets define respective third and fourth facing, parallel planes that are also parallel to the first and second planes. A first dimension between the first plane and the third plane is less than about 3.3 inches. A second dimension between the second plane and the fourth plane is less than about 3.3 inches.

Owner:MILWAUKEE ELECTRIC TOOL CORP

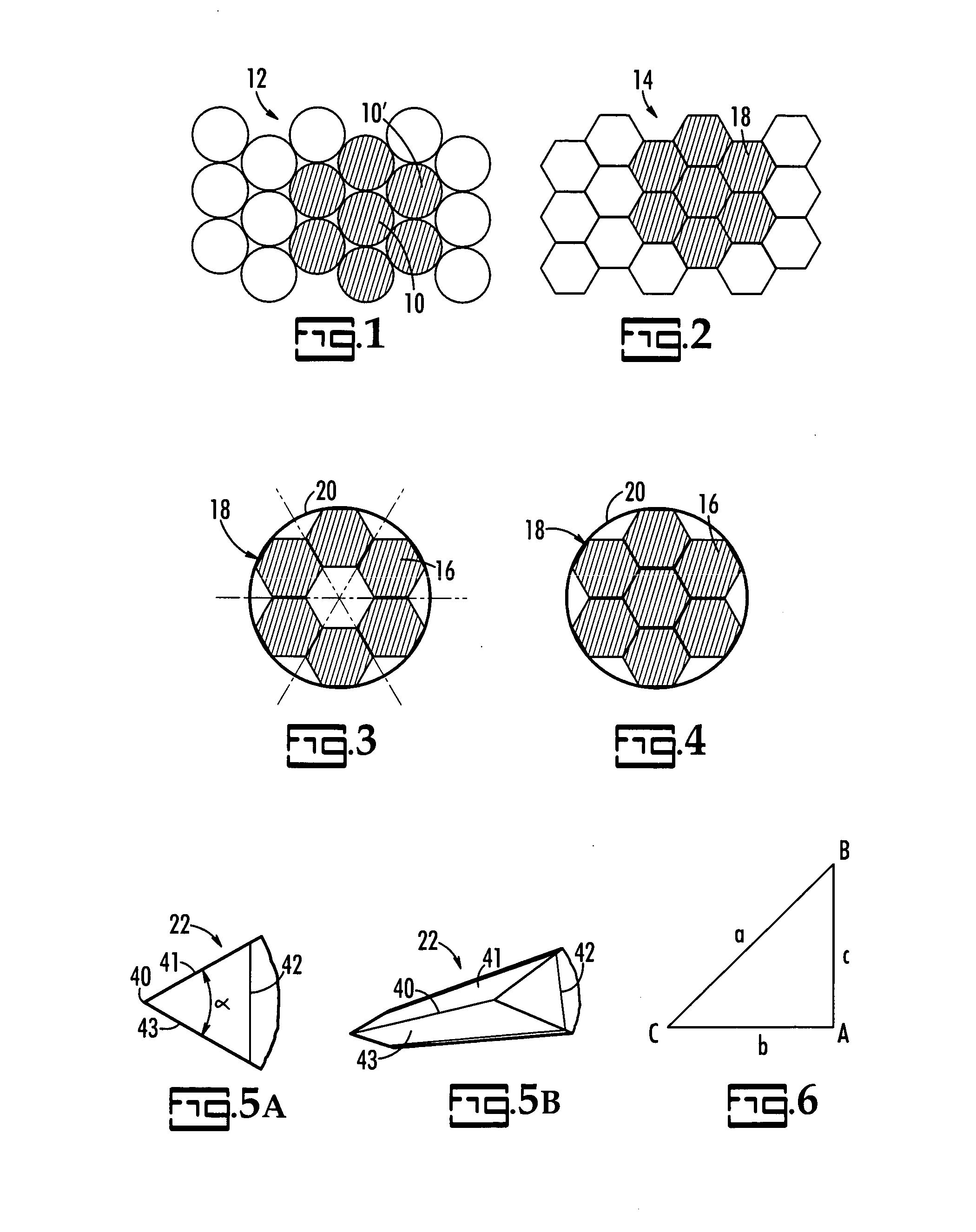

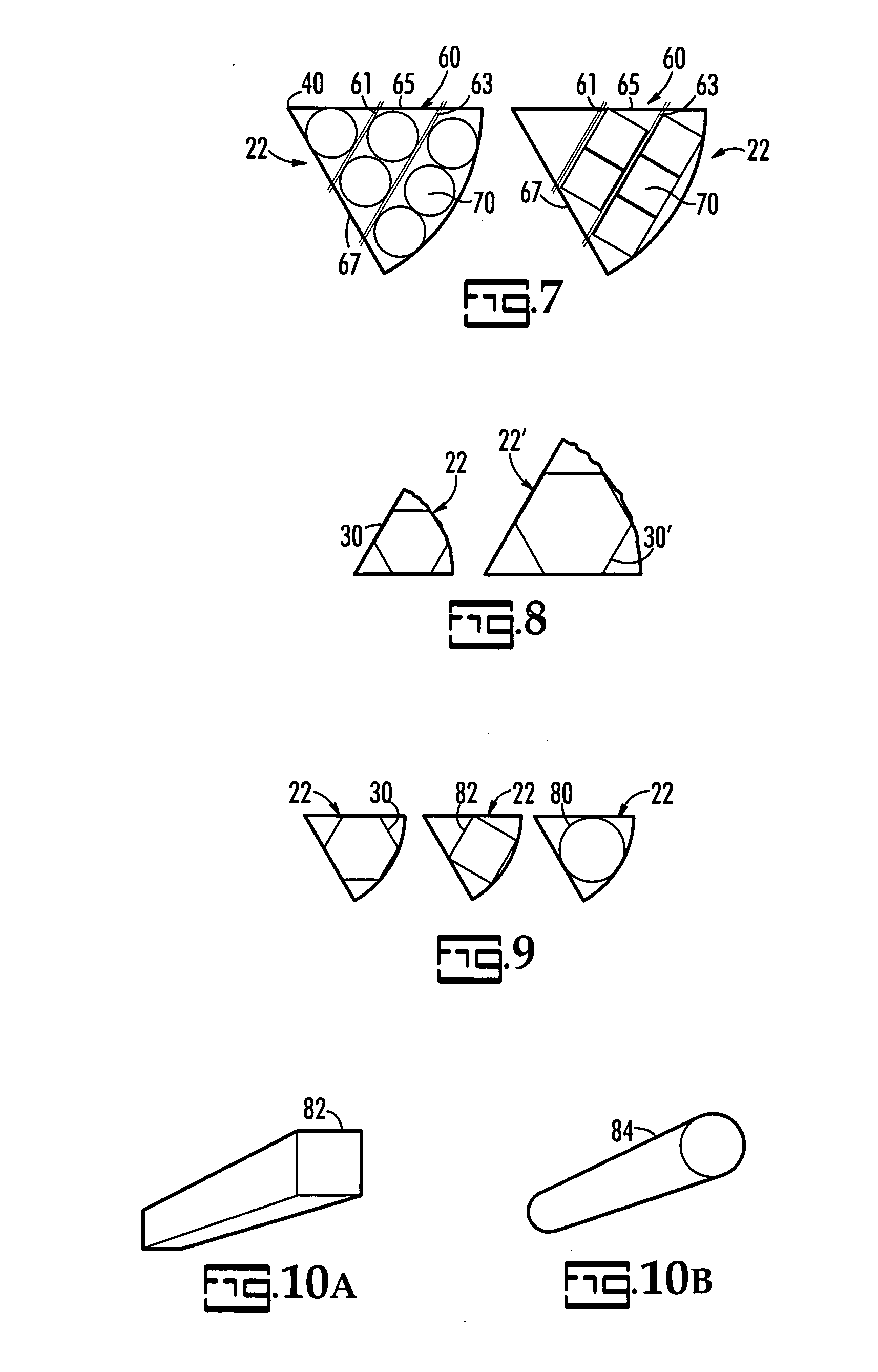

Radial sawing method

InactiveUS20050034786A1Efficient configurationReduce quality problemsWood splittingMulti-purpose machinesIsoetes triquetraEngineering

A radial sawing method for cutting a log into six sections. Each resulting section has a triangular wedge shape, such that in cross-section, an angle of approximately sixty-degrees (60°) at the interior edge of the log section is formed. The approximately 60° angle can be the point of an equilateral triangle. After the log has been formed into six pieces that are relatively equivalent in size and shape, each respective piece can then be fed into additional sawing machines for additional processing, such as to form symmetrically shaped pieces, include a circle, a square, a hexagon, an octagon, or other polygon pieces.

Owner:DARGAN SAMUEL G

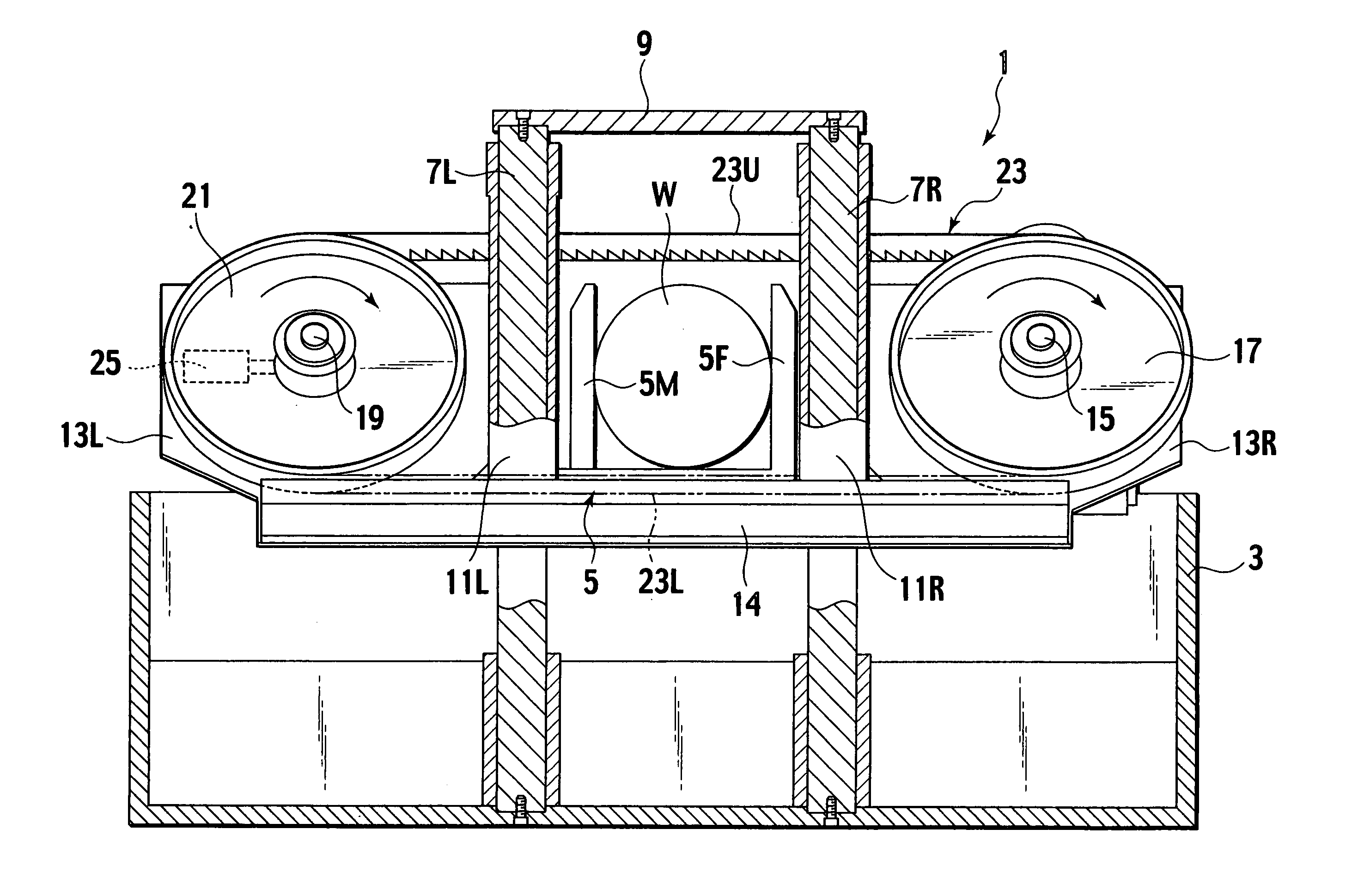

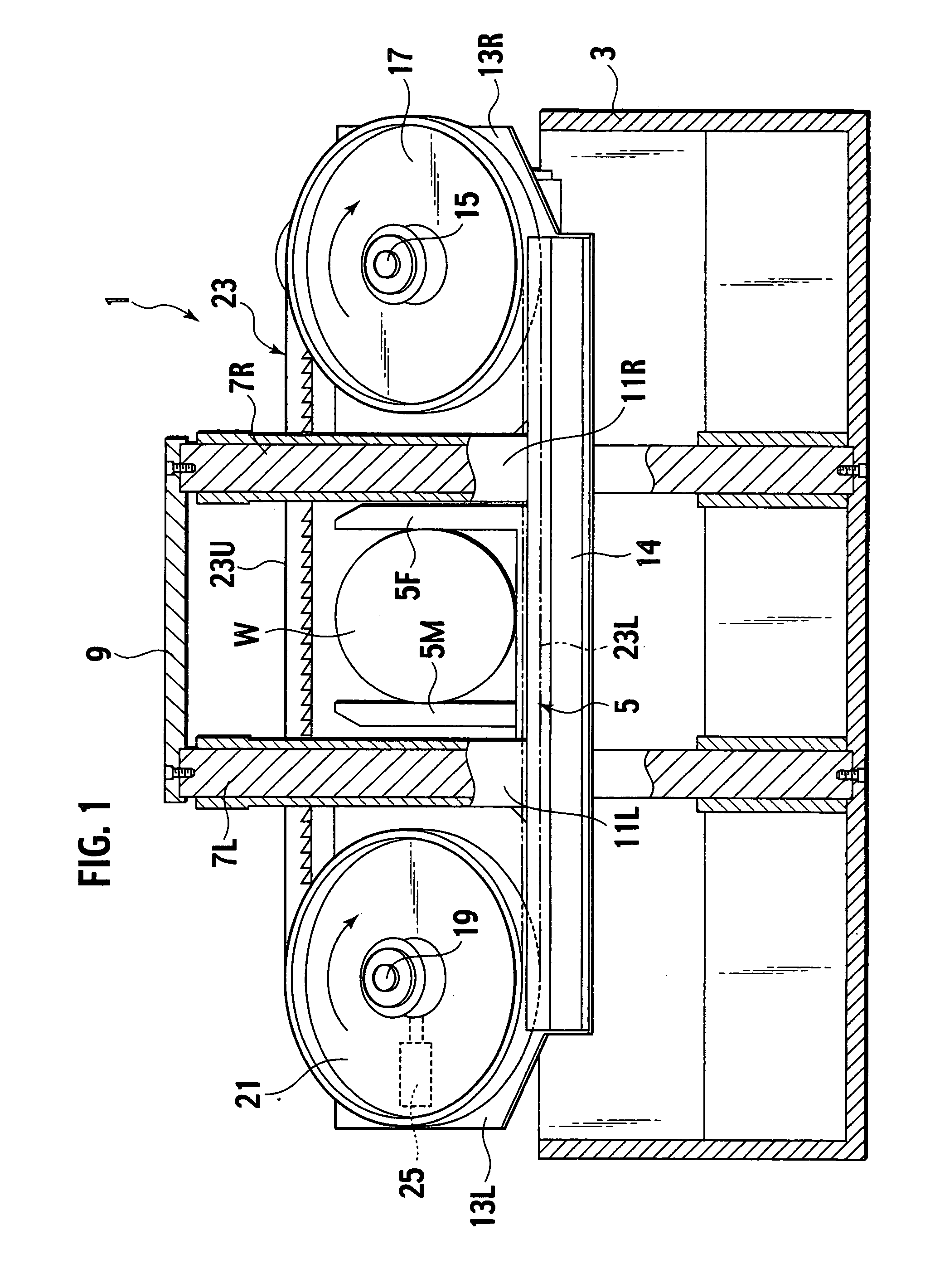

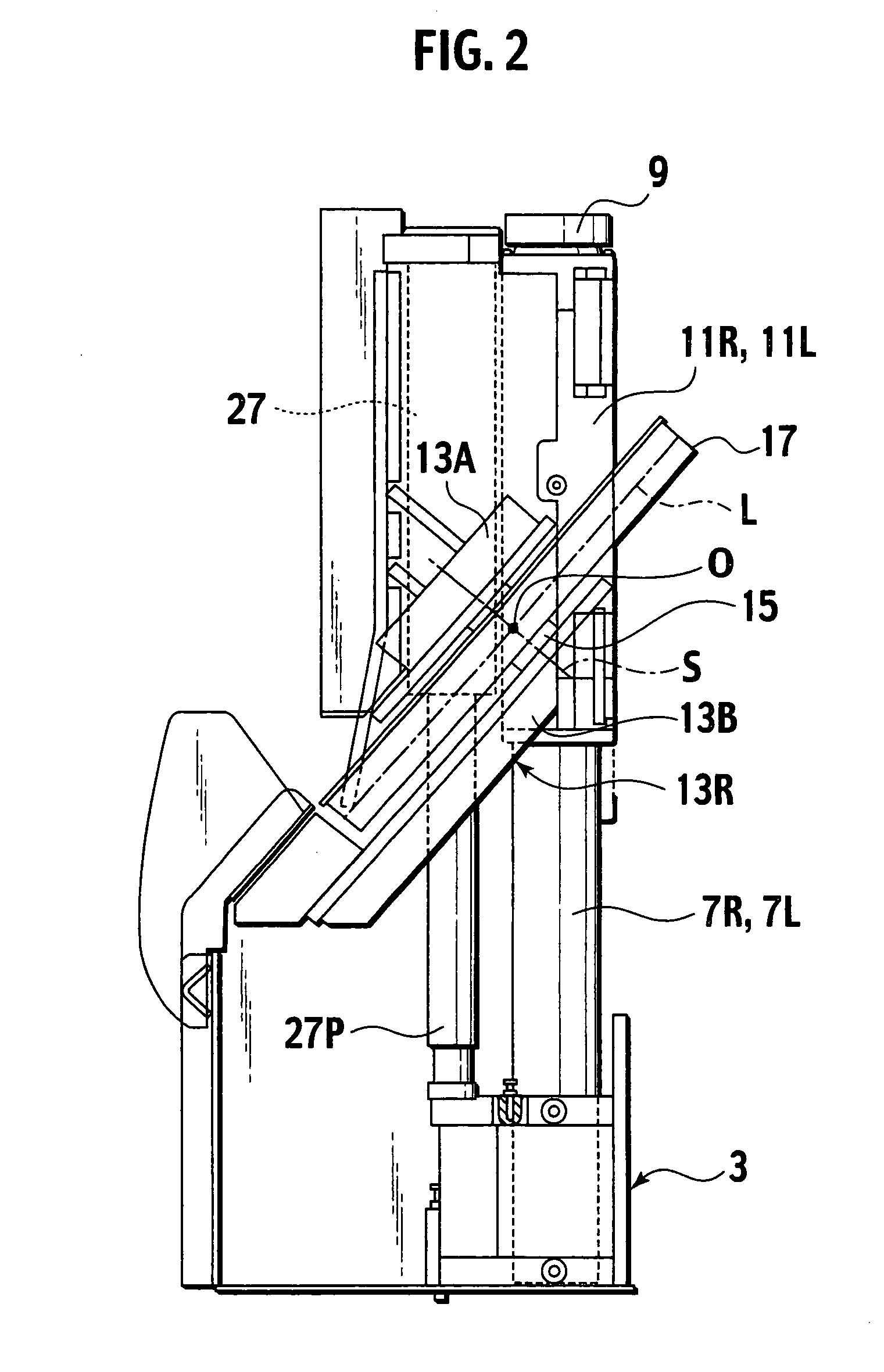

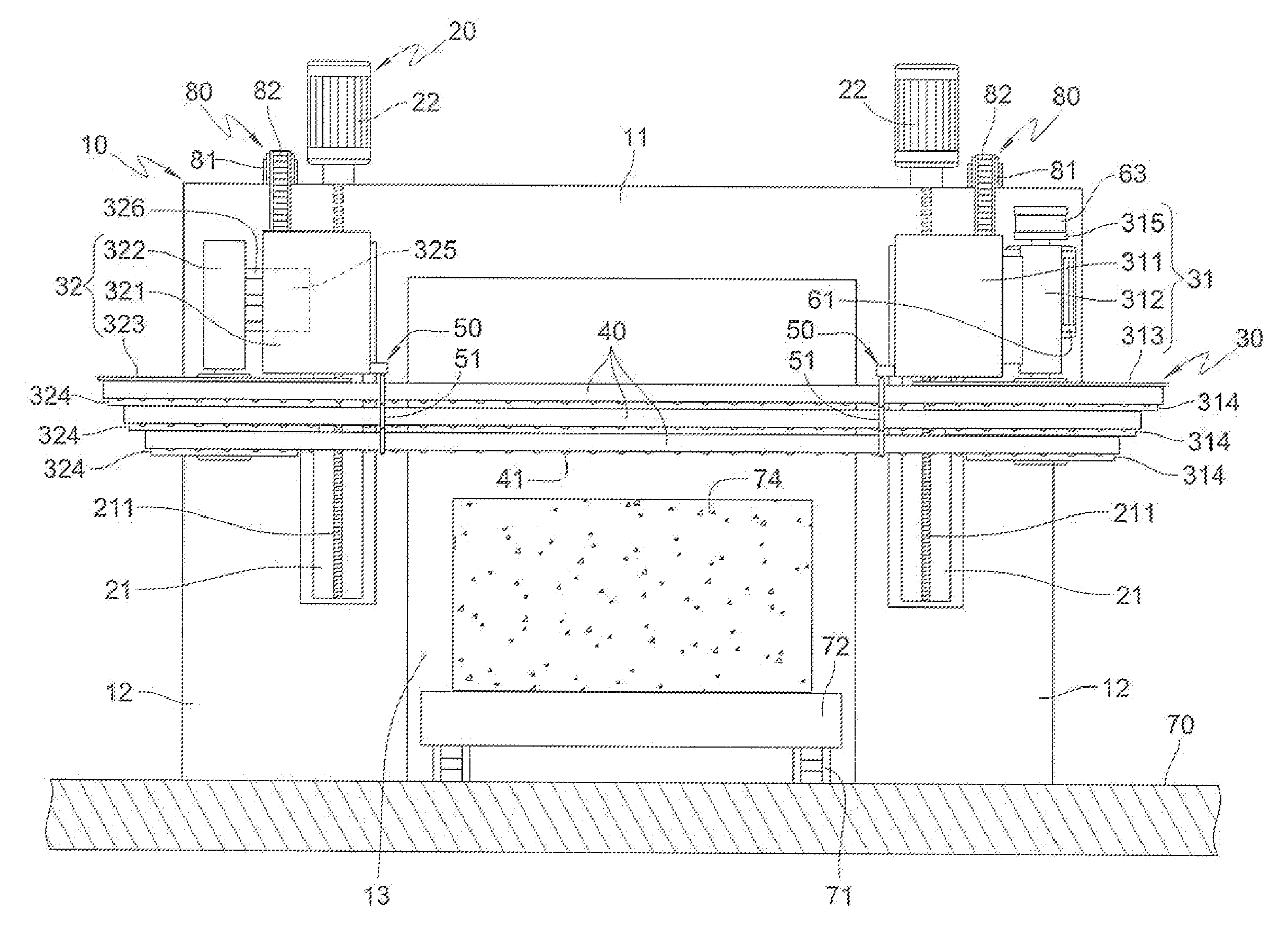

Band saw machine, saw blade installation method in band saw machine, saw blade driving method, and cutting method

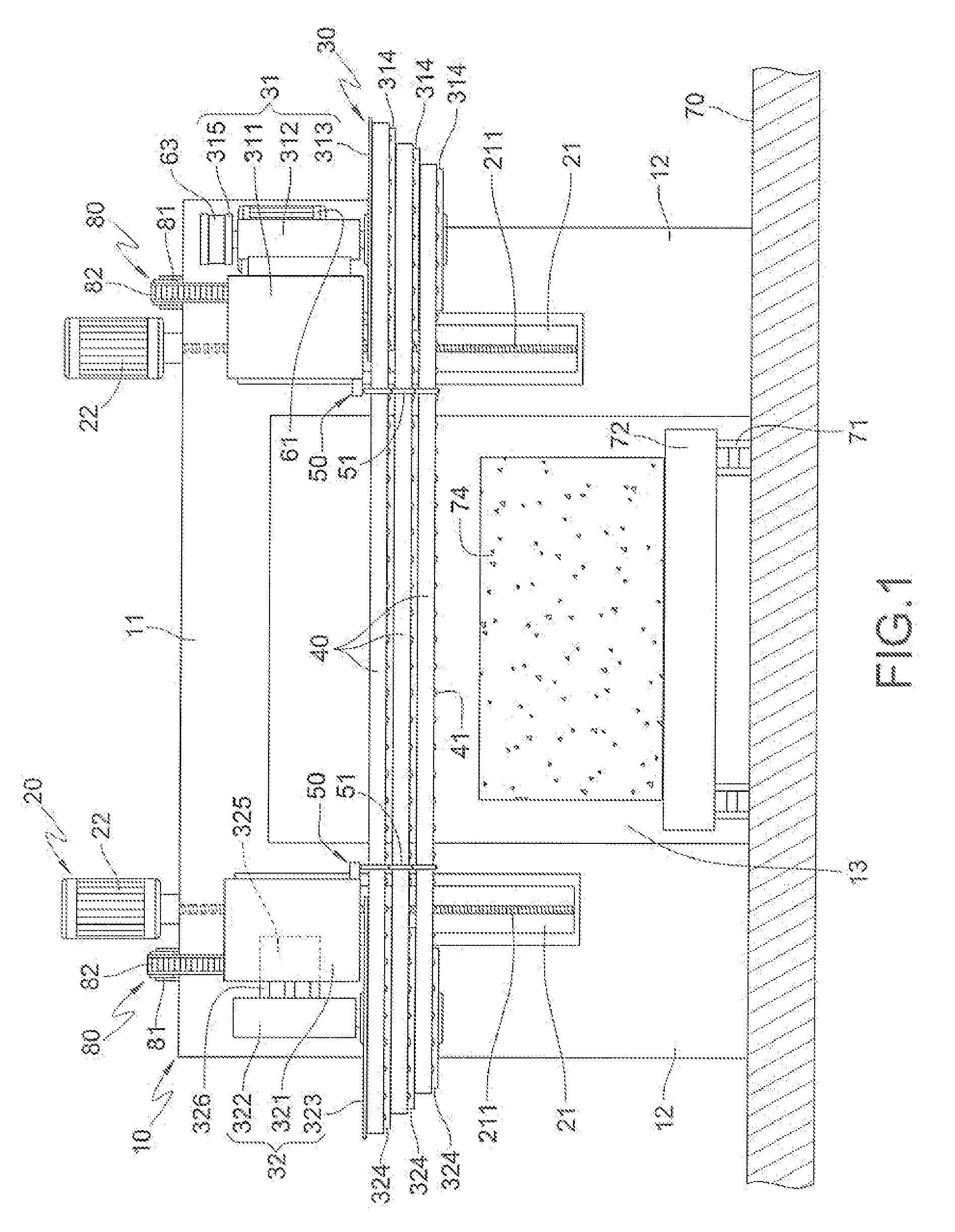

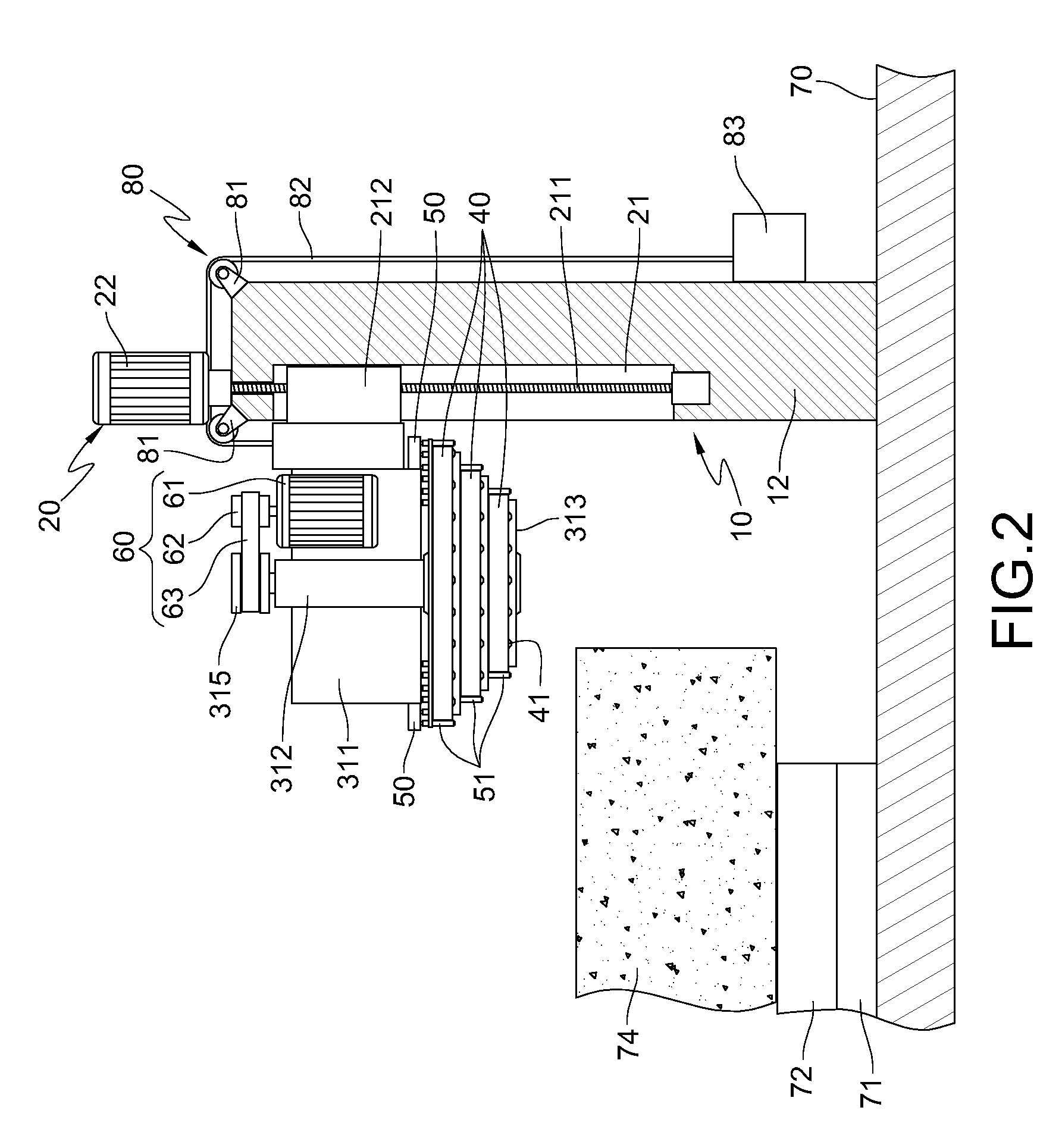

ActiveUS20070089576A1Damping reaction forceSmall sizeMetal sawing devicesAutomatic control devicesDrive wheelEngineering

In a band saw machine in which a pair of guide posts (7L, 7R) for guiding a saw blade housing that rotatably supports a driving wheel (17) and a driven wheel (21) and can vertically move in the vertical direction are provided between the driving wheel (17) and the driven wheel (21), an upper traveling part (23U) of a band saw blade (23) is disposed in the rear of the guide posts (7L, 7R) and a lower traveling part (23L) of a band saw blade (23U) is disposed in front of the guide posts (7L, 7R), when the band saw machine is viewed from the side, an intersection point between centers of the both wheels (17, 21) and the center line of the wheel width is almost equal to the width of the guide posts (7L, 7R).

Owner:AMADA CO LTD

Portable band saws

A portable band saw has a main housing and a saw band circulating within the main housing. A motor for driving the saw band is disposed within a motor housing that is mounted to the main housing. The main housing defines an opening across which the saw band moves in order to cut a workpiece. A battery for driving the motor is mounted to a motor receiving portion of the motor housing. The motor receiving portion has a width corresponding to the width of the opening and opposing to the opening in the forward and rearward directions.

Owner:MAKITA CORP

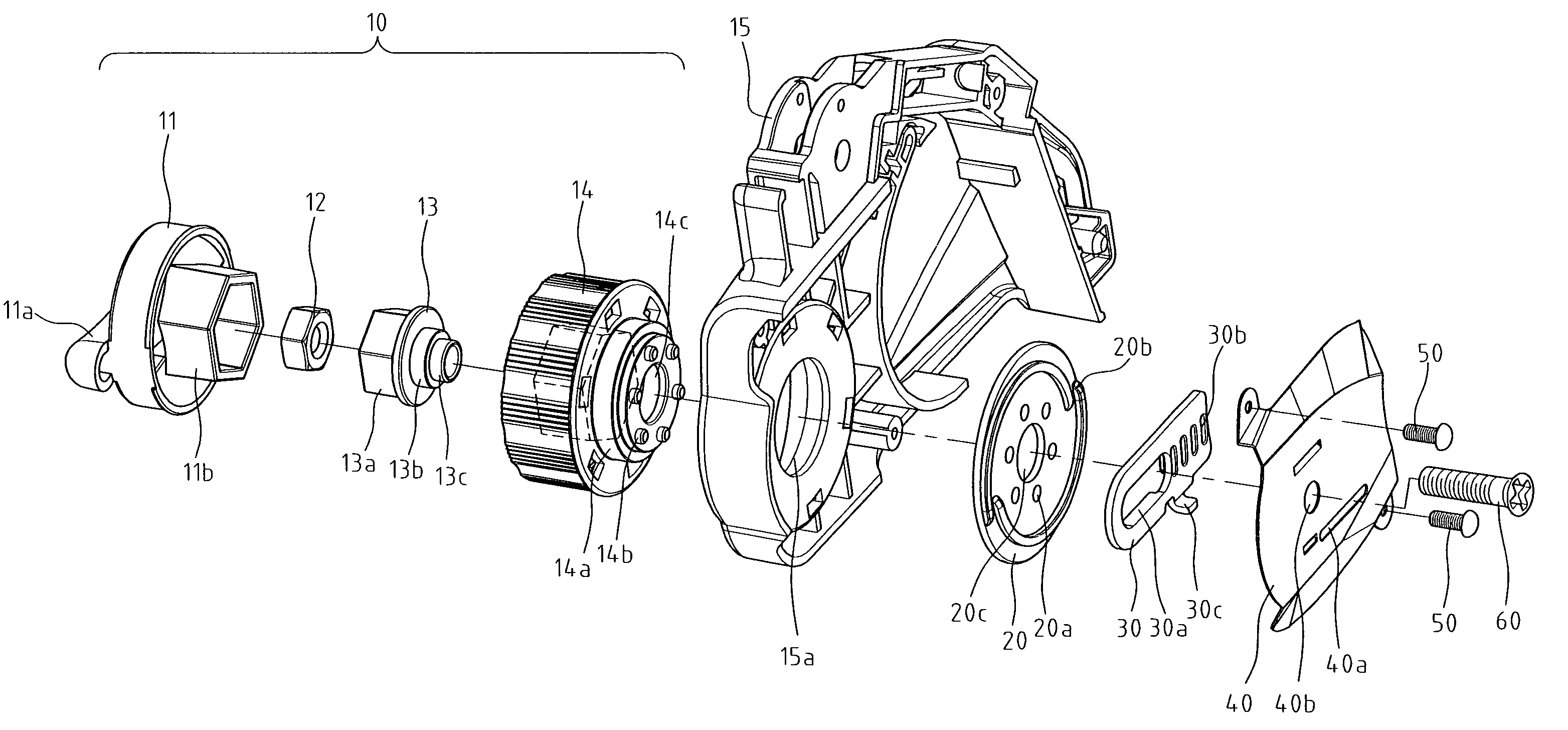

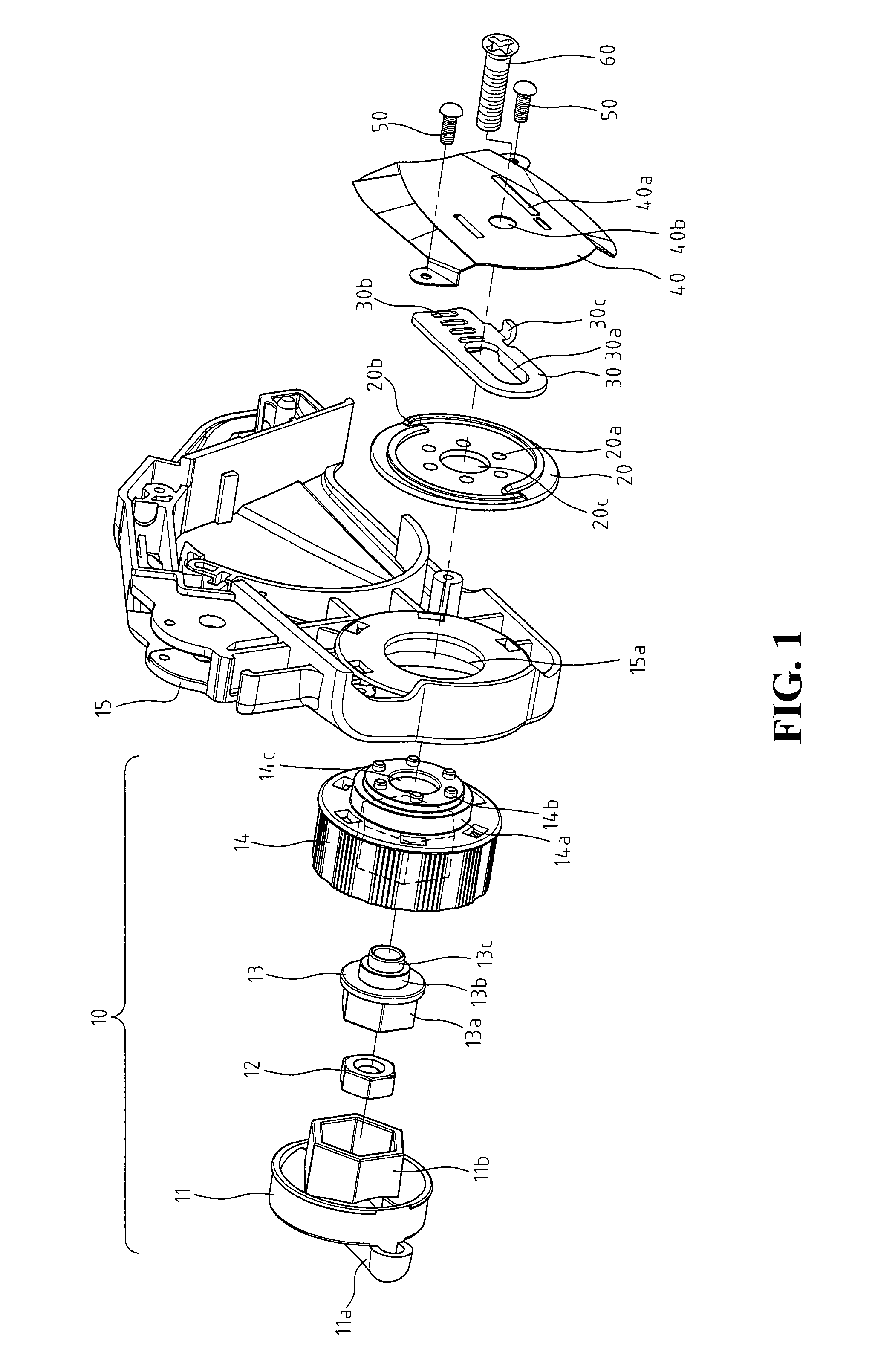

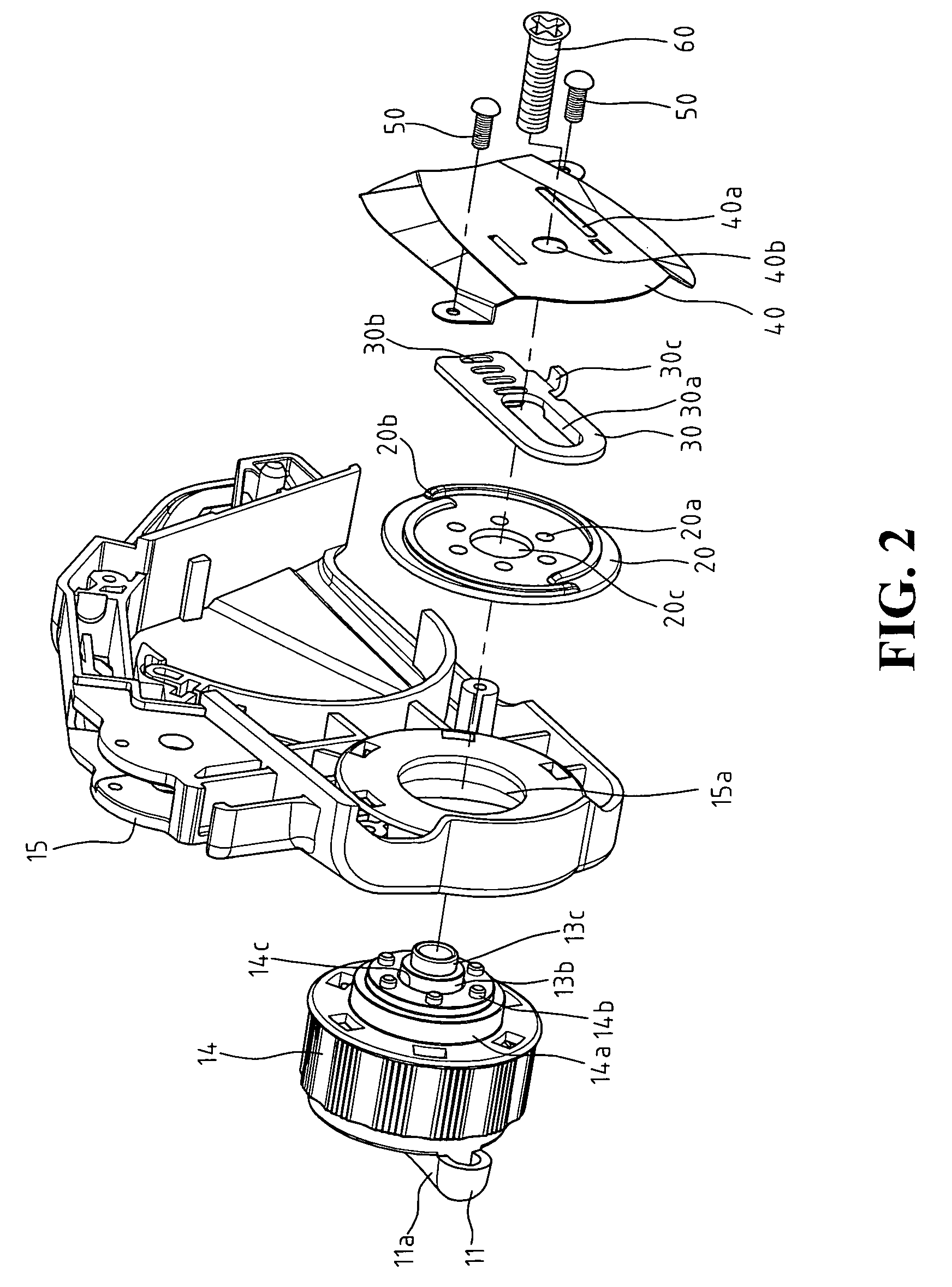

Tension-adjusting device for a chain in chain saw

InactiveUS7350301B2Simple structureEasy to assembleMetal sawing devicesMetal sawing accessoriesEngineeringChain saw

Owner:HUSQVARNA AB

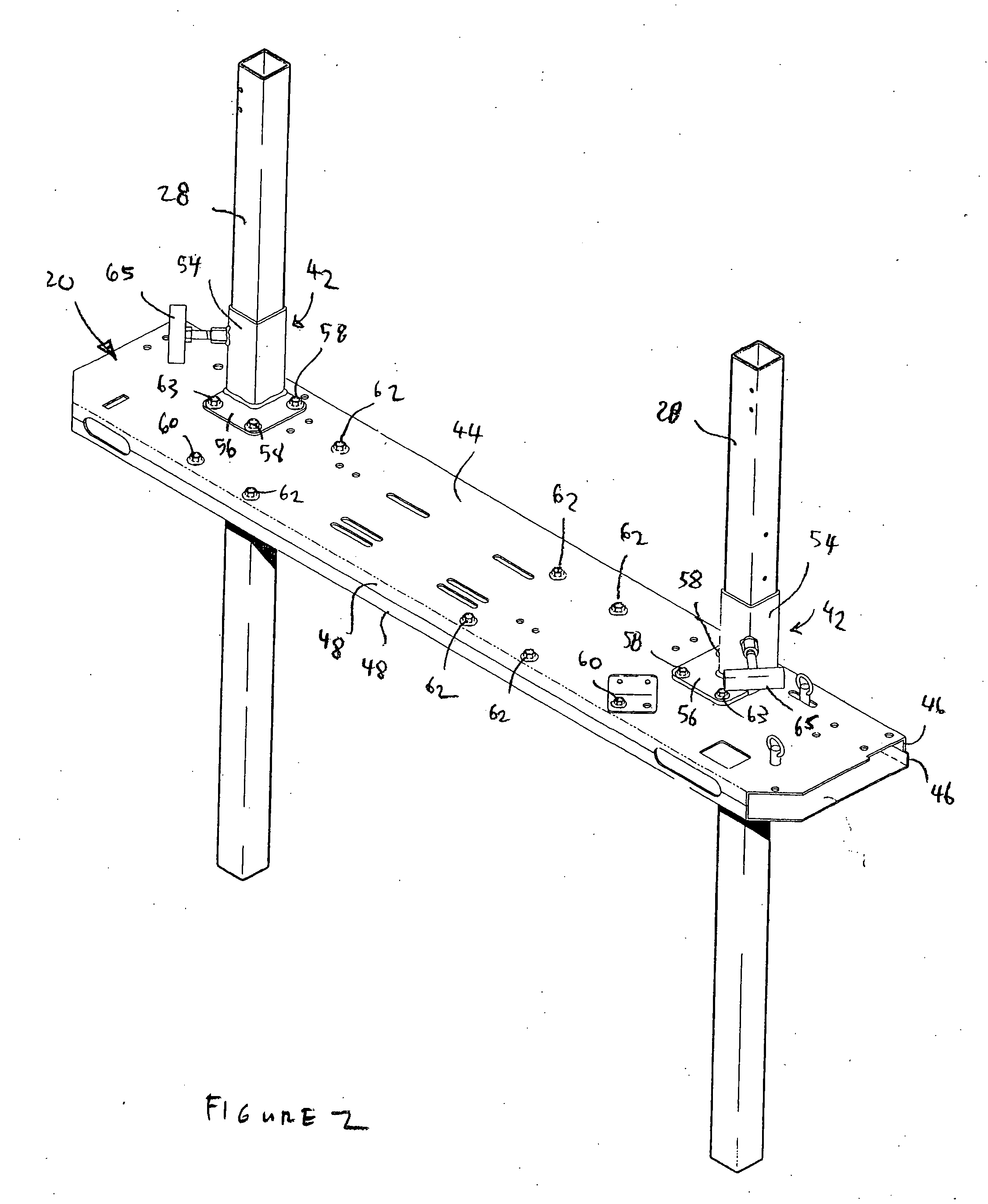

Sawmill construction

ActiveUS20060117926A1Avoiding and minimizingShearing machinesGang saw millsMechanical engineeringBuilding construction

A kit for constructing a sawhead is disclosed. The kit comprises two or more plates adapted to be stacked upon and secured to one another by bolts to form a plate stack. The kit further comprises two or more elongate guide receivers. Each guide receiver has a longitudinal axis and an interior wall which defines a bore extending through said each guide receiver and through which bore said longitudinal axis extends. The interior wall has a cross-section which is substantially constant along the length of said each guide receiver. The guide receivers are adapted to be mounted to the plate stack by bolts at respective operative positions whereat the longitudinal axes are oriented parallel to one another and whereat the guide receivers are spaced from one another in a direction transverse to said axes. An improved band sawmill employing a sawhead constructed from the kit is also disclosed.

Owner:NORWOOD IND

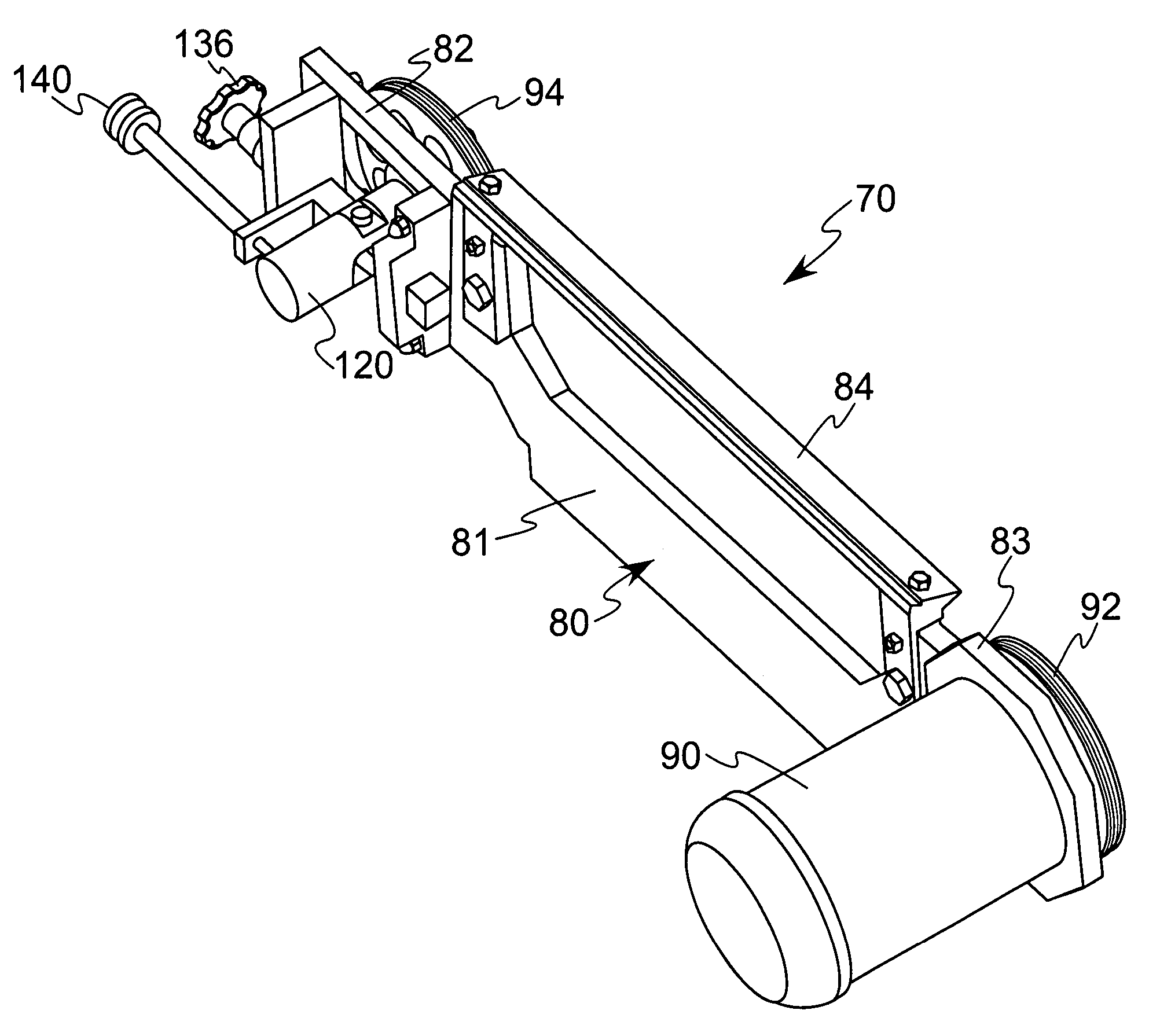

Drive mechanism and slicing apparatus for food slicing machine

ActiveUS7600459B2Metal sawing devicesAutomatic conveying/guiding stockReciprocating motionEngineering

A food slicing machine using a linear servo motor to reciprocate a carriage holding food products through a path that includes a slicing blade. The slicing apparatus is a modular apparatus that can be mounted to and removed from slicing machines as a unit without the need for disassembly of the components of the slicing apparatus. An adjustment mechanism for the blade guide uses two shafts that extend from a bearing plate into a finger that is mounted to the blade guide. The lower shaft has a cam nut that displaces the finger about the upper shaft to bend the blade guide. There is also an adjustment mechanism for the idler pulley of the band blade apparatus.

Owner:J E GROTE

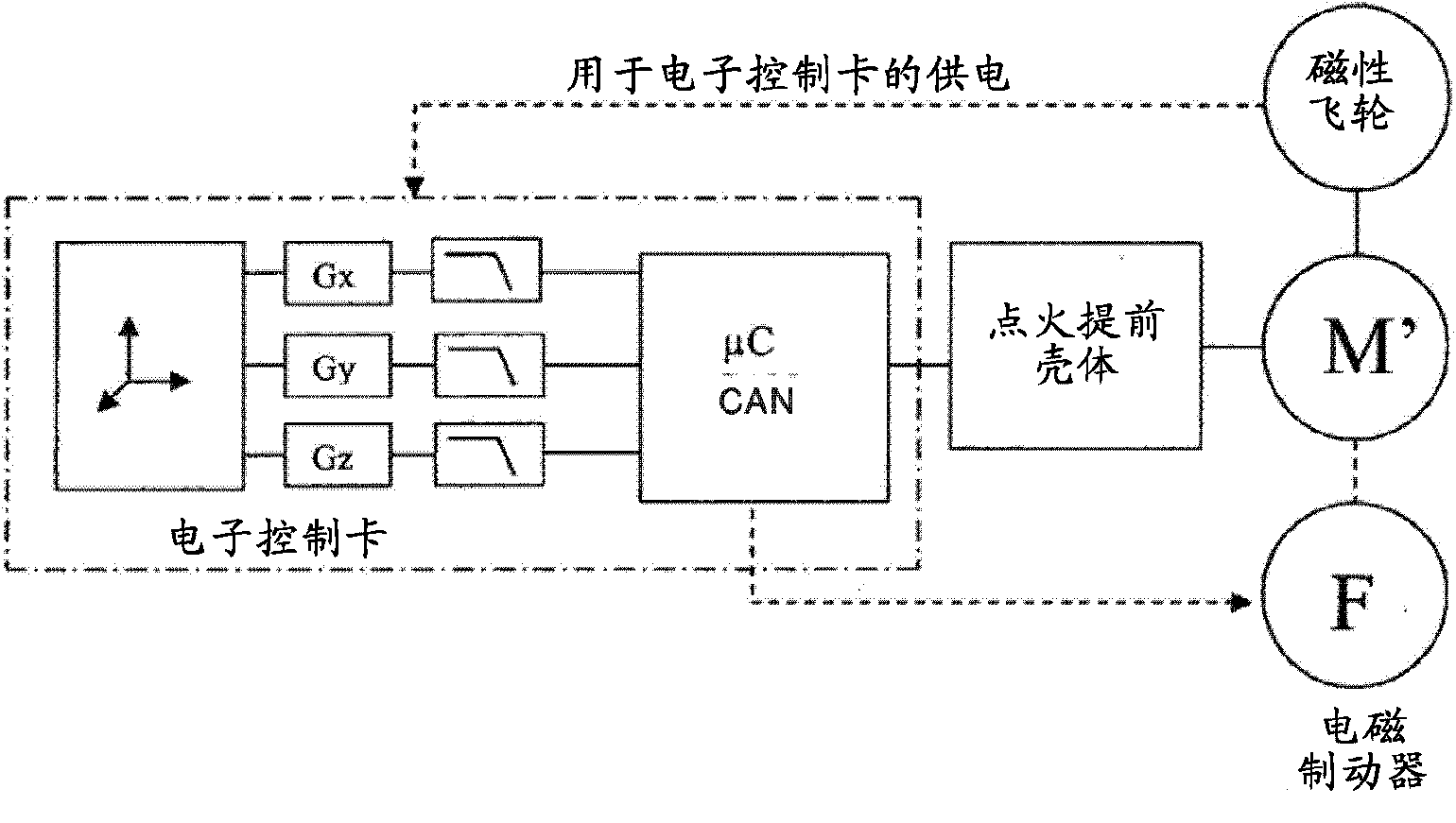

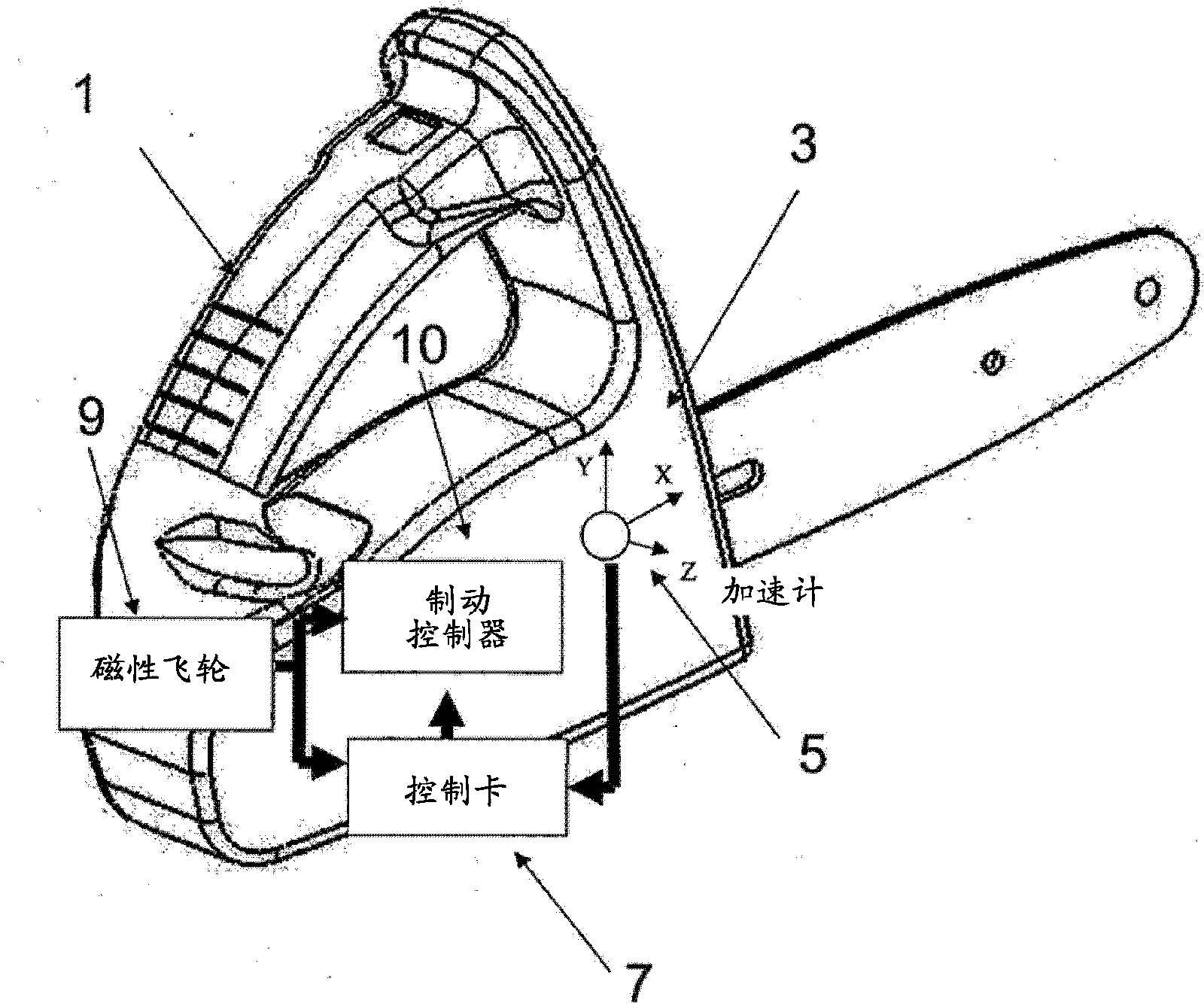

Safety device for portable tools with a heat engine, capable of stopping the operation thereof after sudden, violent movements

InactiveCN102137742ALower jump pointNo inertial mass involvedEngineering safety devicesChain sawsAccelerometerEngineering

The present invention relates to a safety device for portable tool with a heat engine that is capable of stopping, almost instantly, the operation of said tool after unexpected, sudden, and violent movements, said device including at least one electronic accelerometer (5) enabling the measurement of the acceleration along at least one plane or axis (X, Y, Z), the output(s) of said accelerometer (5) being connected to an electric and / or electronic monitoring means (7), wherein said electric and / or electronic monitoring means consists of an electric and / or electronic management card (7), the latter and the accelerometer being supplied with electric voltage by an electric current generator (9) known per se and actuated by the heat engine, said electric and / or electronic management card being configured to process analog or digital electrical data from the accelerometer and activate a means ensuring that said heat engine stops almost instantly.

Owner:PELLENC SA

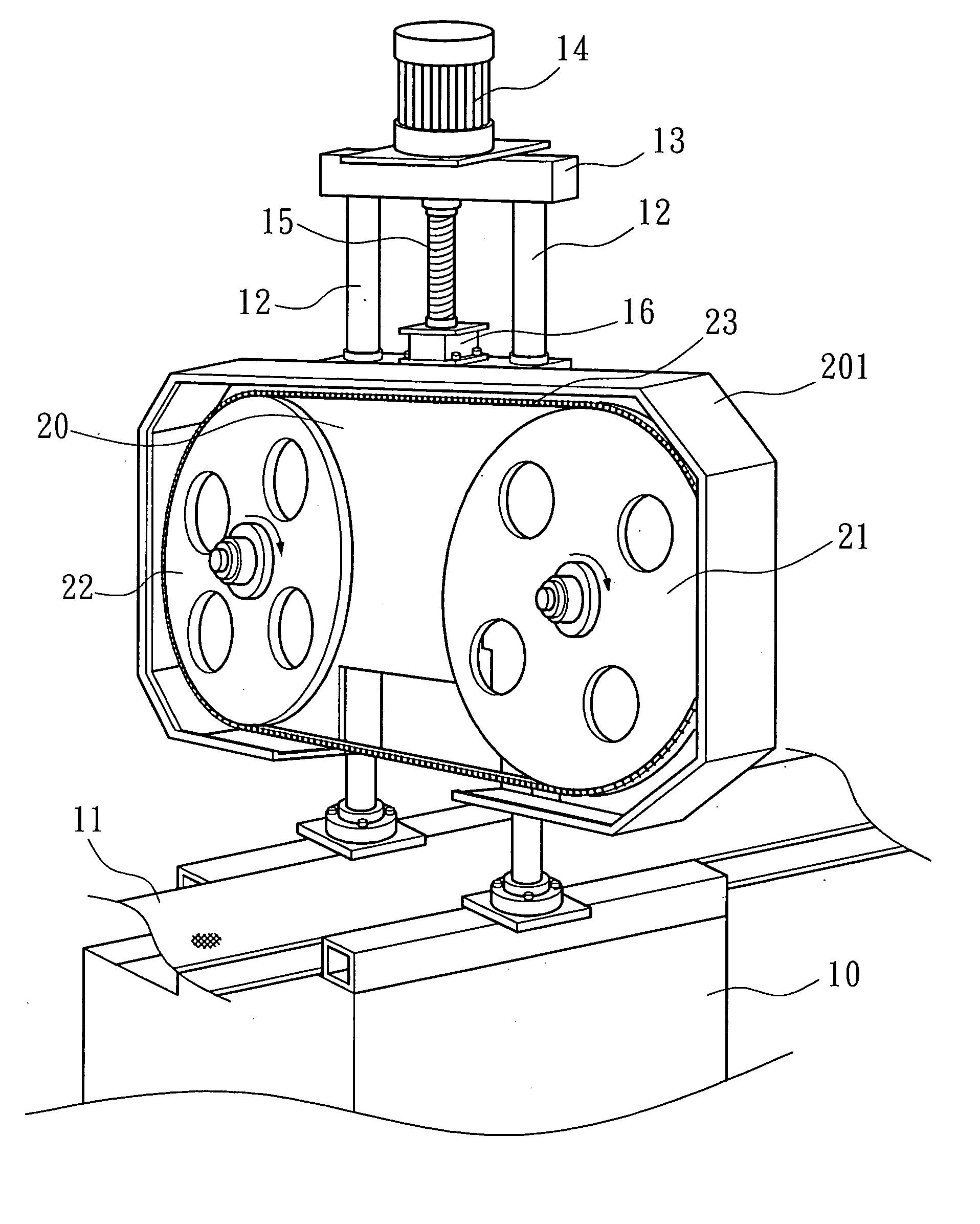

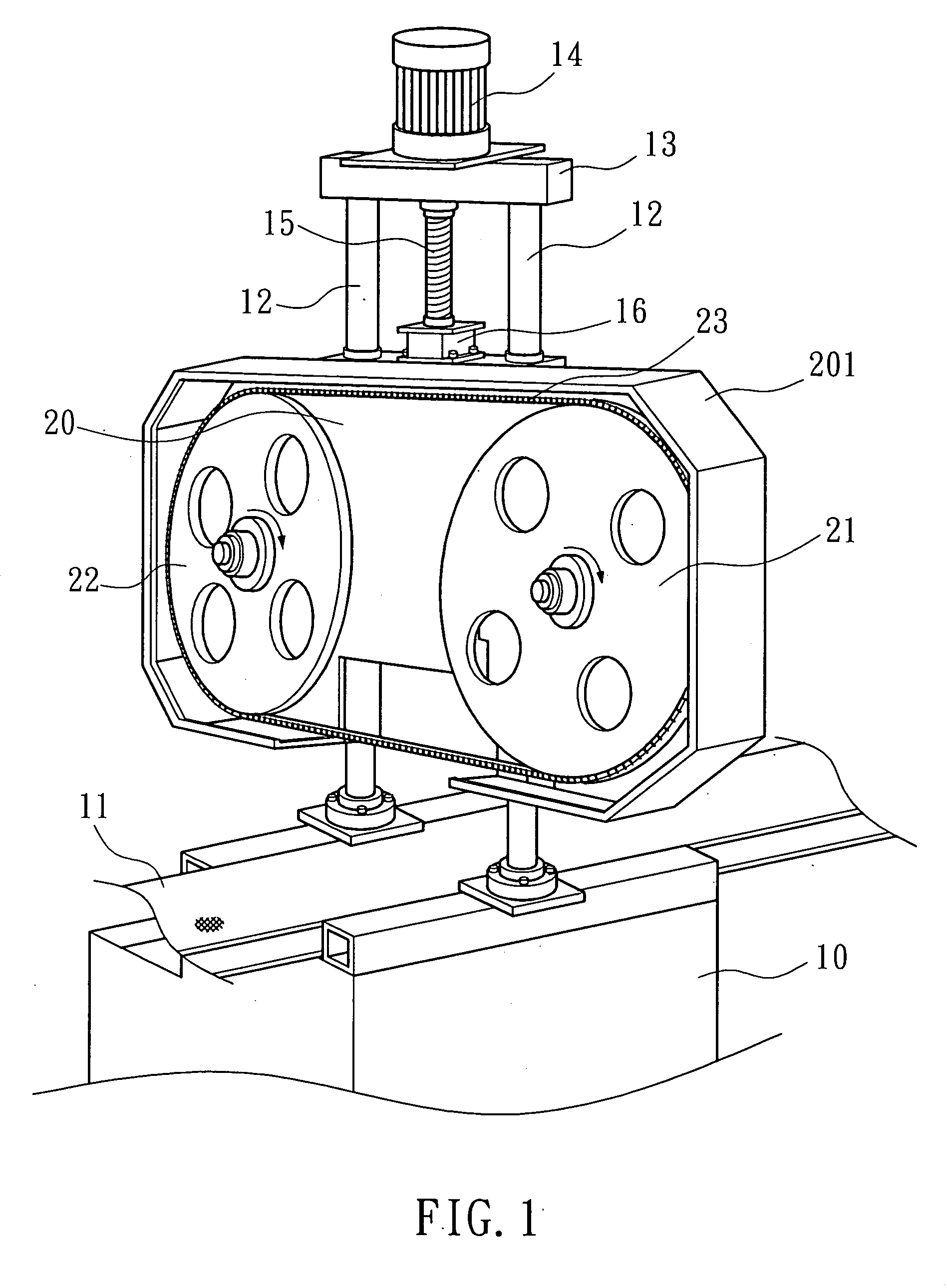

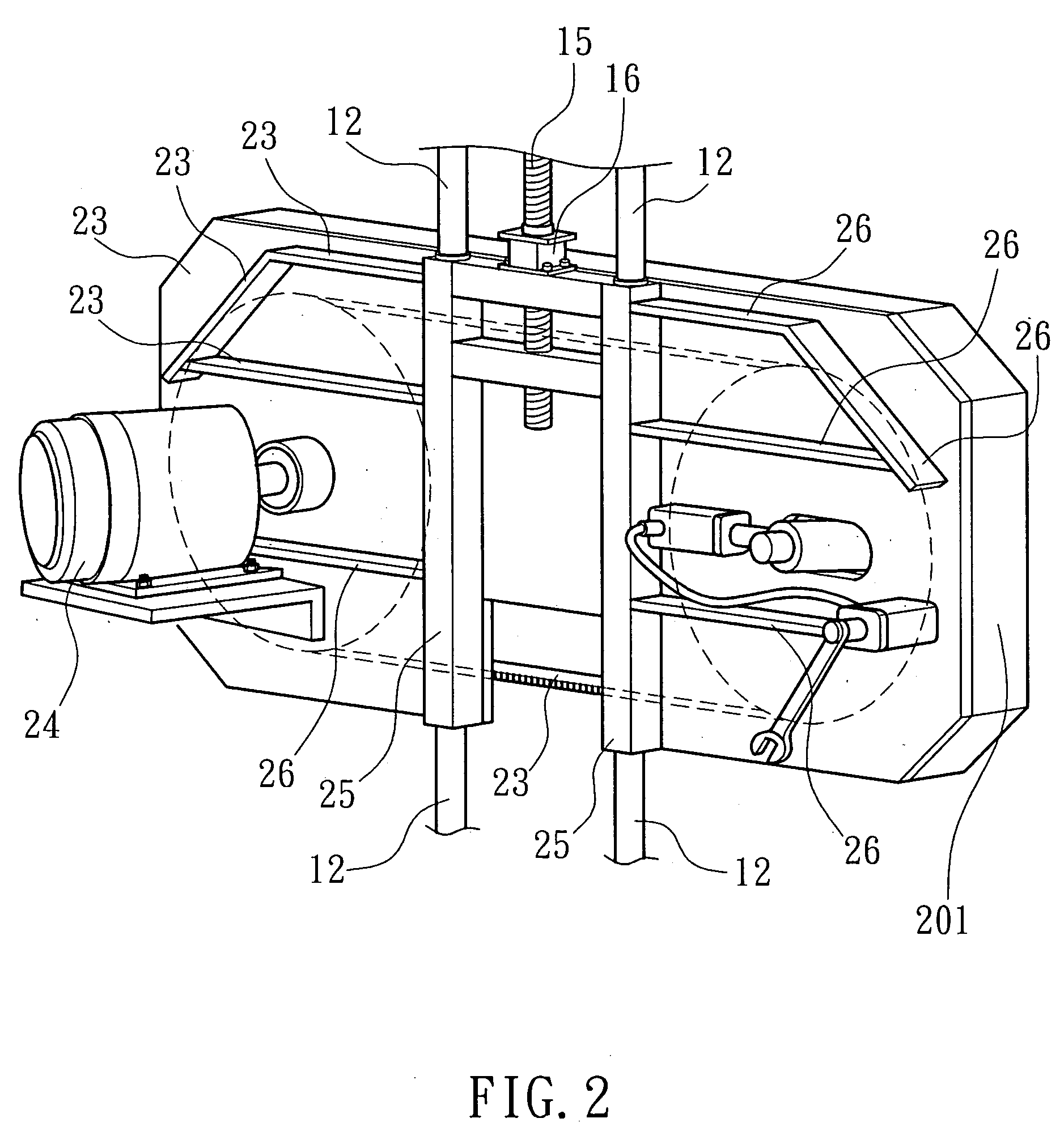

Band saw

InactiveUS20070028745A1Improve structural strengthConveniently and rapidly adjustedMetal sawing devicesBand sawsMechanical engineering

A band saw is disclosed to includes a holder frame, which is movable along two vertical guide rods above the machine base and holds a saw blade and a saw blade driving mechanism, a nut fixedly provided at the top of the holder frame, a vertical motor mounted on a connecting frame at the top of the guide rods, and a screw rod threaded into the fixed nut and rotatable by the vertical motor to move the holder frame along the guide rods to the desired elevation.

Owner:WANG VIVIAN

Multi-Bandsaw Machine

InactiveUS20110000355A1Cutting efficiency can be affectedIncrease manufacturing costMetal sawing devicesGang saw millsSingle processEngineering

A multi-bandsaw machine includes several bandsaws, for cutting a material into a plurality of plates in a single process. At least one side edge of each bandsaw has a plurality of diamond grits, and the bandsaws rotate in a single direction on the multi-bandsaw machine, so as to cut the material with the diamond grits and form a cutting notch on the material. The cutting notch has a depth to kerf ratio at least larger than 100:1 during the process of cutting the material with the diamond grits in each hour.

Owner:KINIK

Keyless adjusting mechanism for chain saw

InactiveUS7676934B2Simple structureMetal sawing devicesMetal sawing accessoriesEngineeringScrew thread

A keyless adjusting mechanism for a chain saw is disclosed herein, which comprises a protection cover, an adjusting bolt, an adjusting stud, and an adjusting ring with a driver gear, wherein the adjusting bolt is coupled with a driven gear for engaging with the driver gear of the adjusting ring, the adjusting stud is coupled with a chain board and has a threaded hole for engaging with the corresponding adjusting bolt. Accordingly, when the adjusting ring is rotated, the driver gear can bring the driven gear to let the adjusting stud move axially along the adjusting bolt such that the chain could be adjusted to tighten or loosen. In addition, a knob with a handle is coupled to the adjusting ring. The handle can be withdrawn in the knob or extended out of the knob for convenient twist.

Owner:HUSQVARNA AB +1

String saw having dust collection and chip drainage mechanism

InactiveUS6837134B2Mitigate and obviate disadvantageMetal sawing devicesMetal sawing accessoriesEngineeringElectrical and Electronics engineering

A string saw includes a housing, and an air box. The housing includes a first casing and a second casing combined with each other. The air box is mounted in the housing and has an inside formed with a receiving chamber communicating with the storage space of the first casing, so that the cut chips during the sawing process can be introduced from the storage space of the first casing into the receiving chamber of the air box. Thus, the string saw can provide the dust collection and chip drainage function.

Owner:CHIN CHIN CHANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com