Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about "Mechanical transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

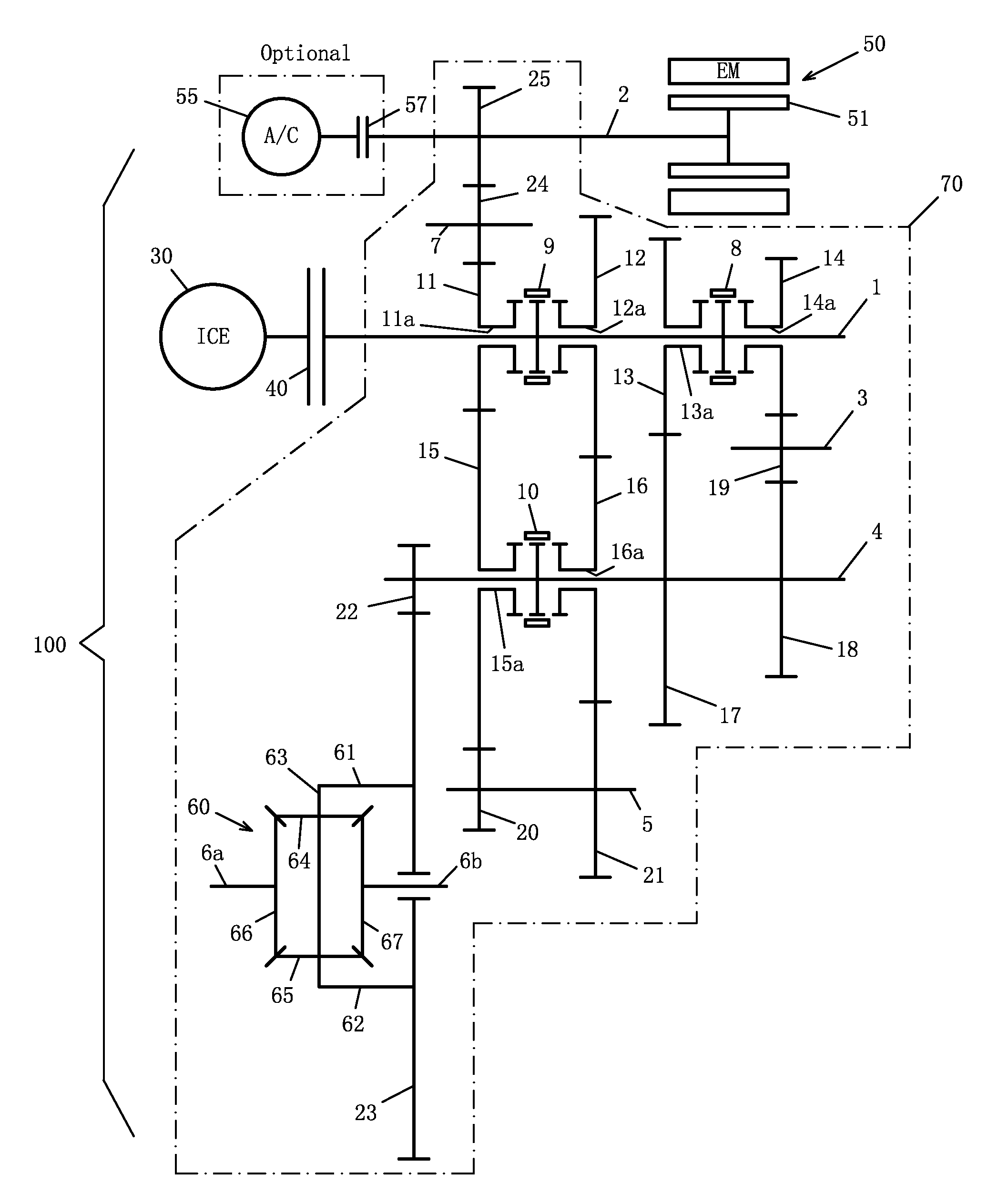

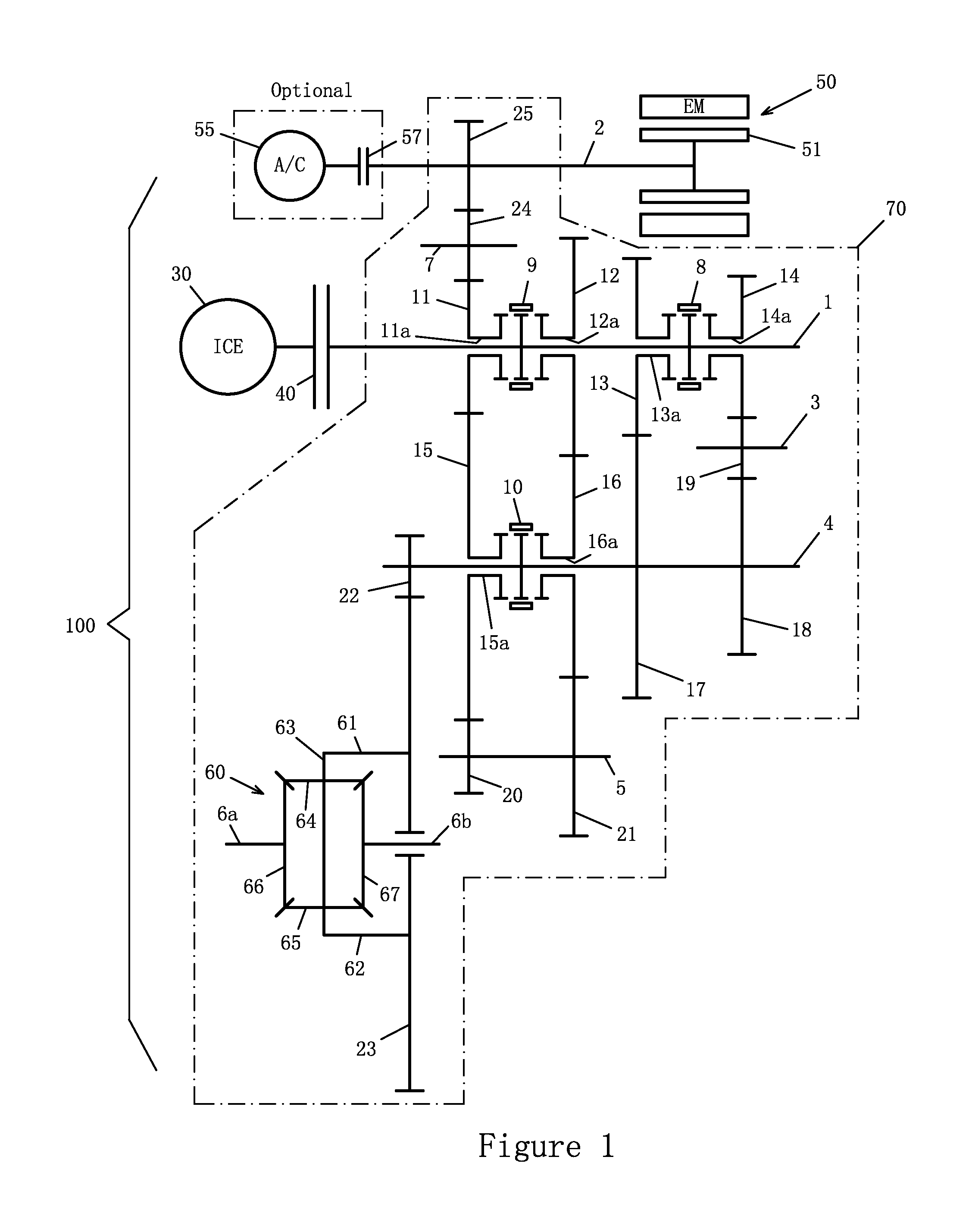

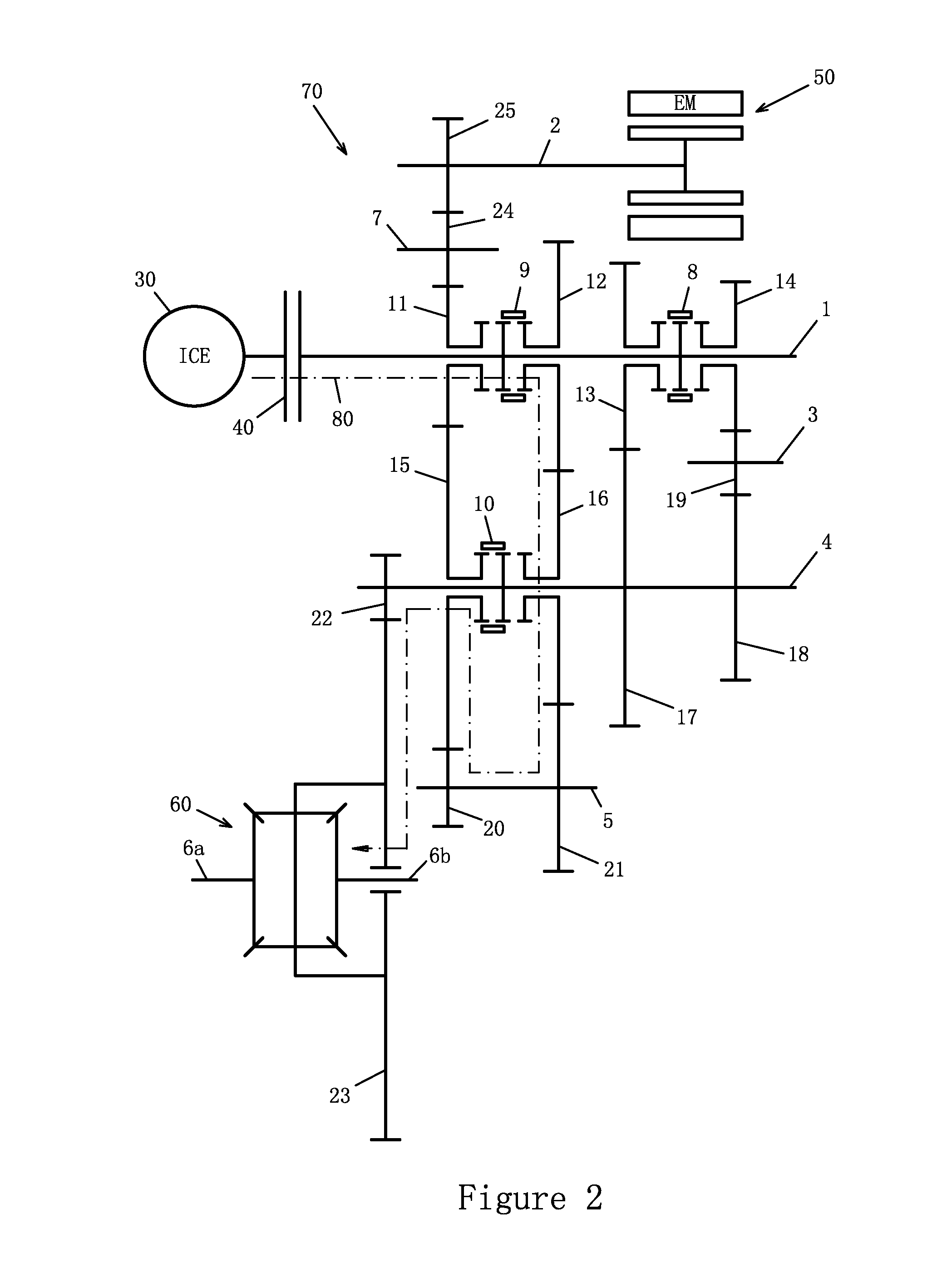

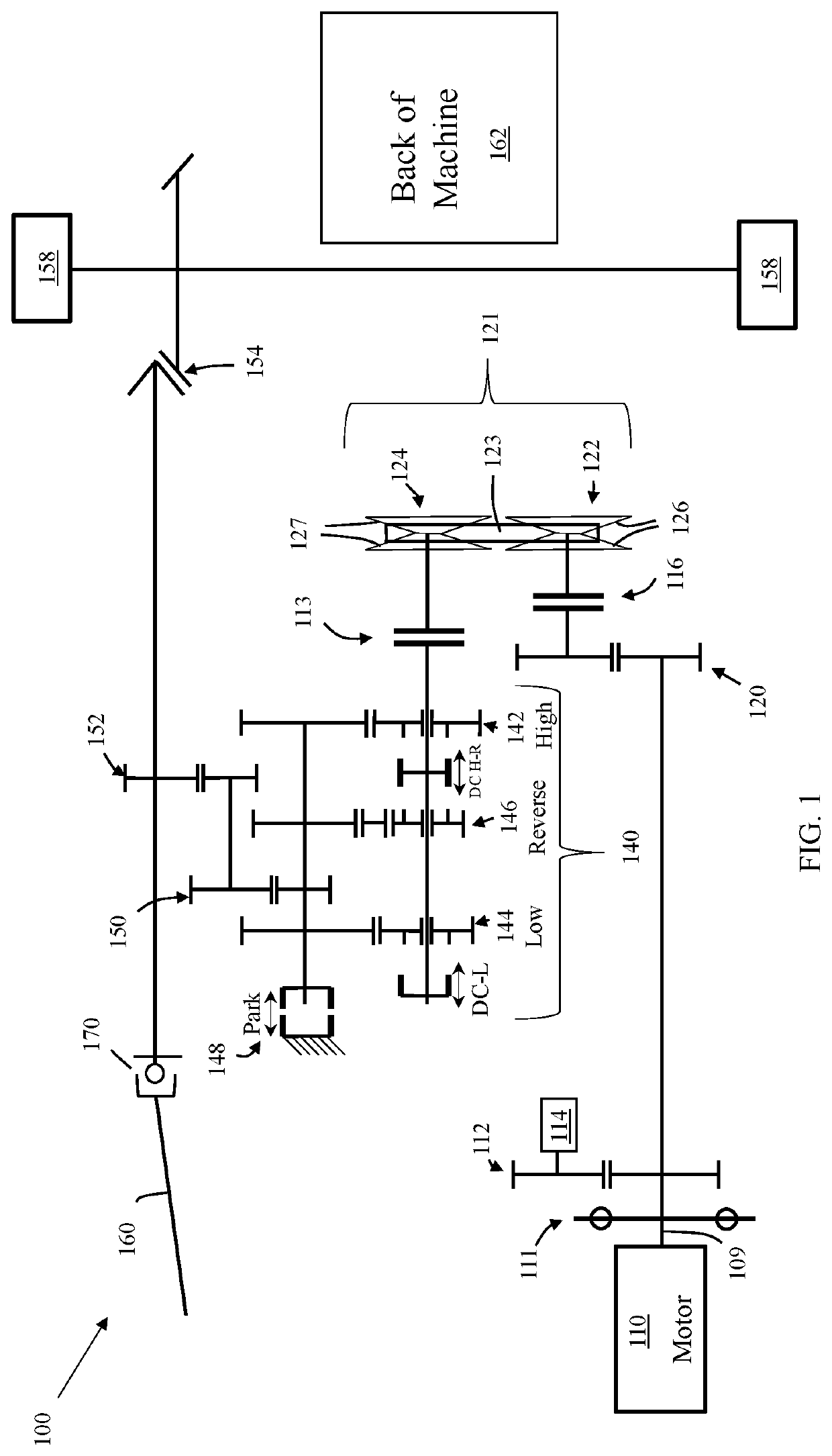

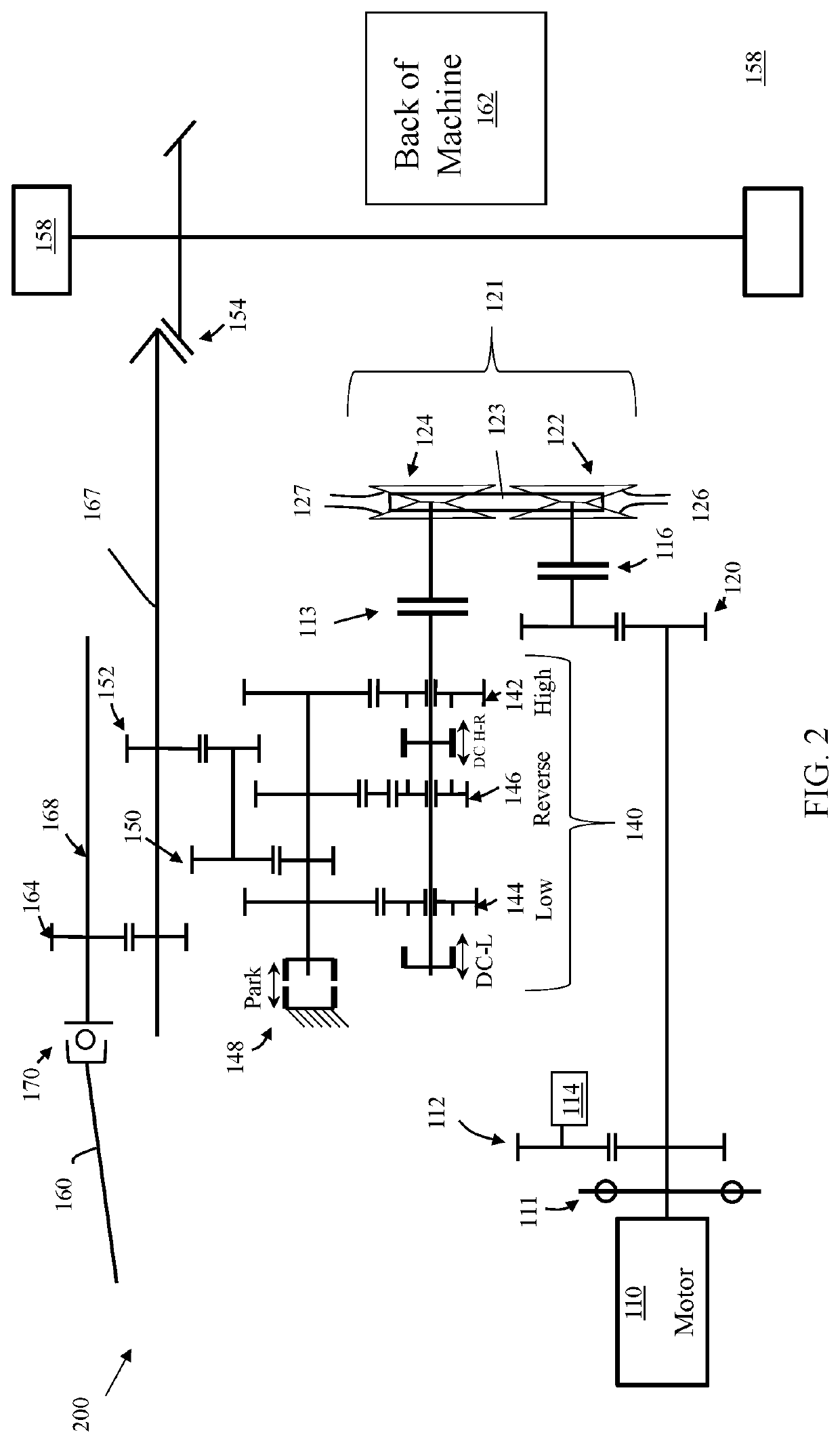

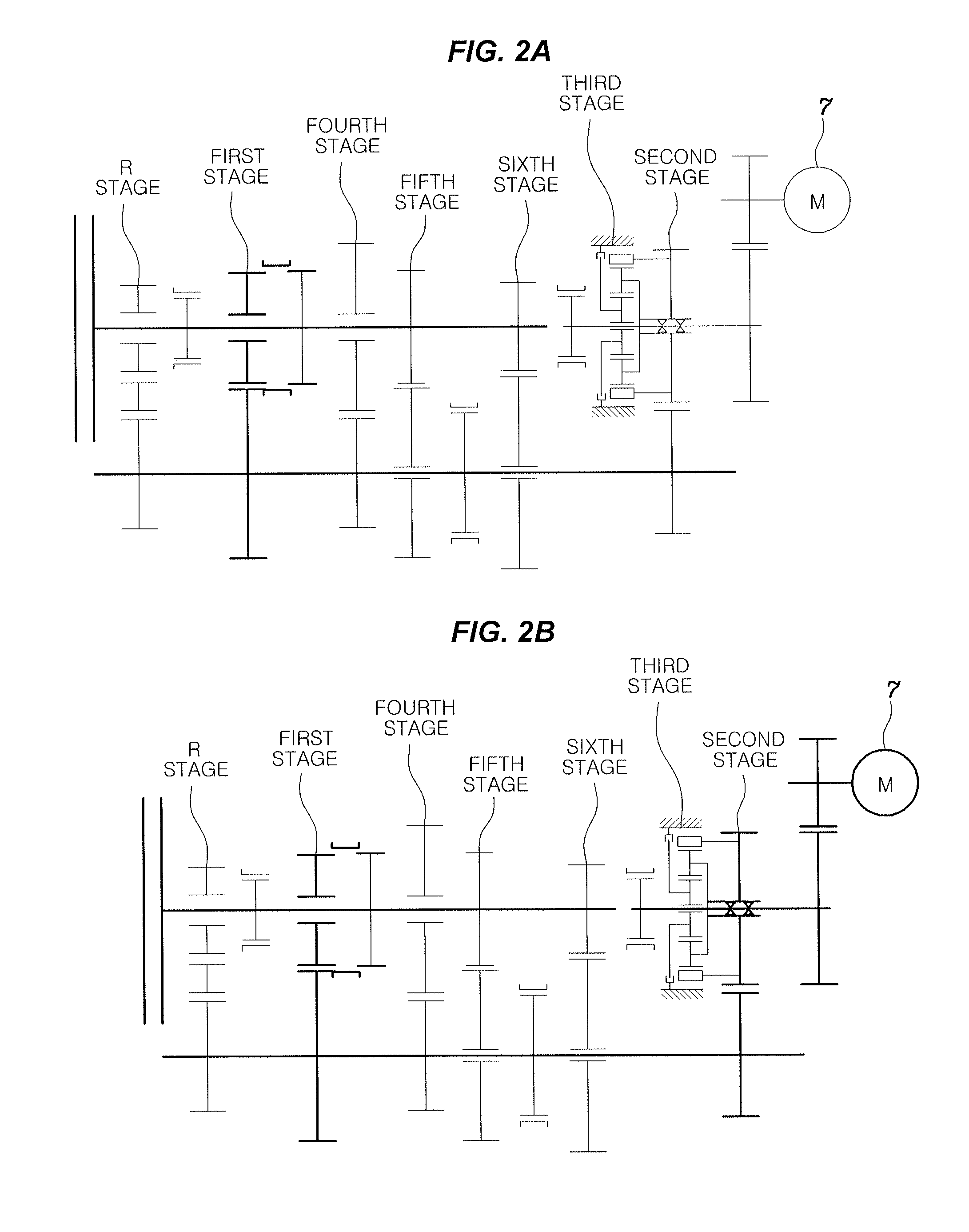

Hybrid-power driving system for a vehicle and a transmission thereof

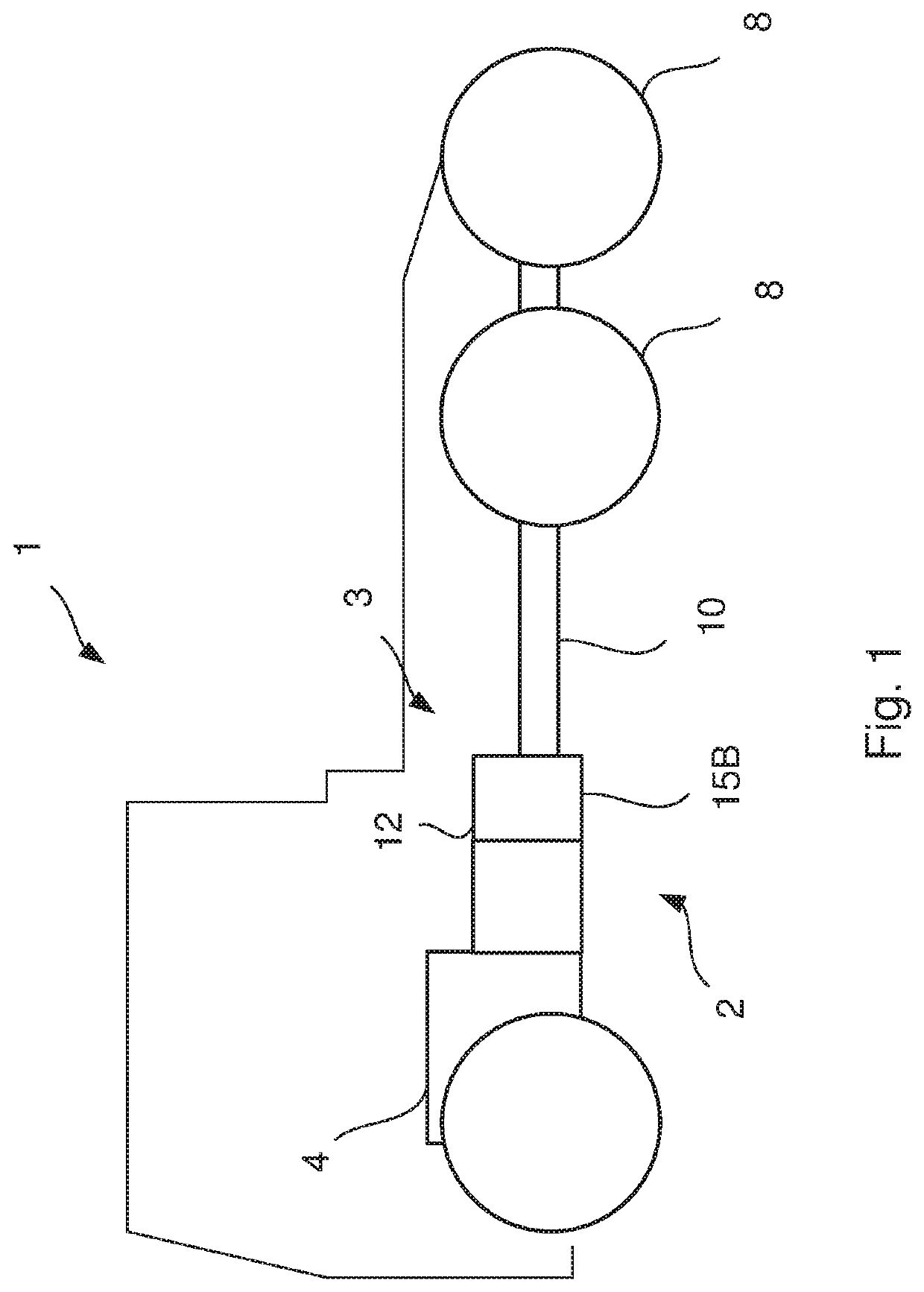

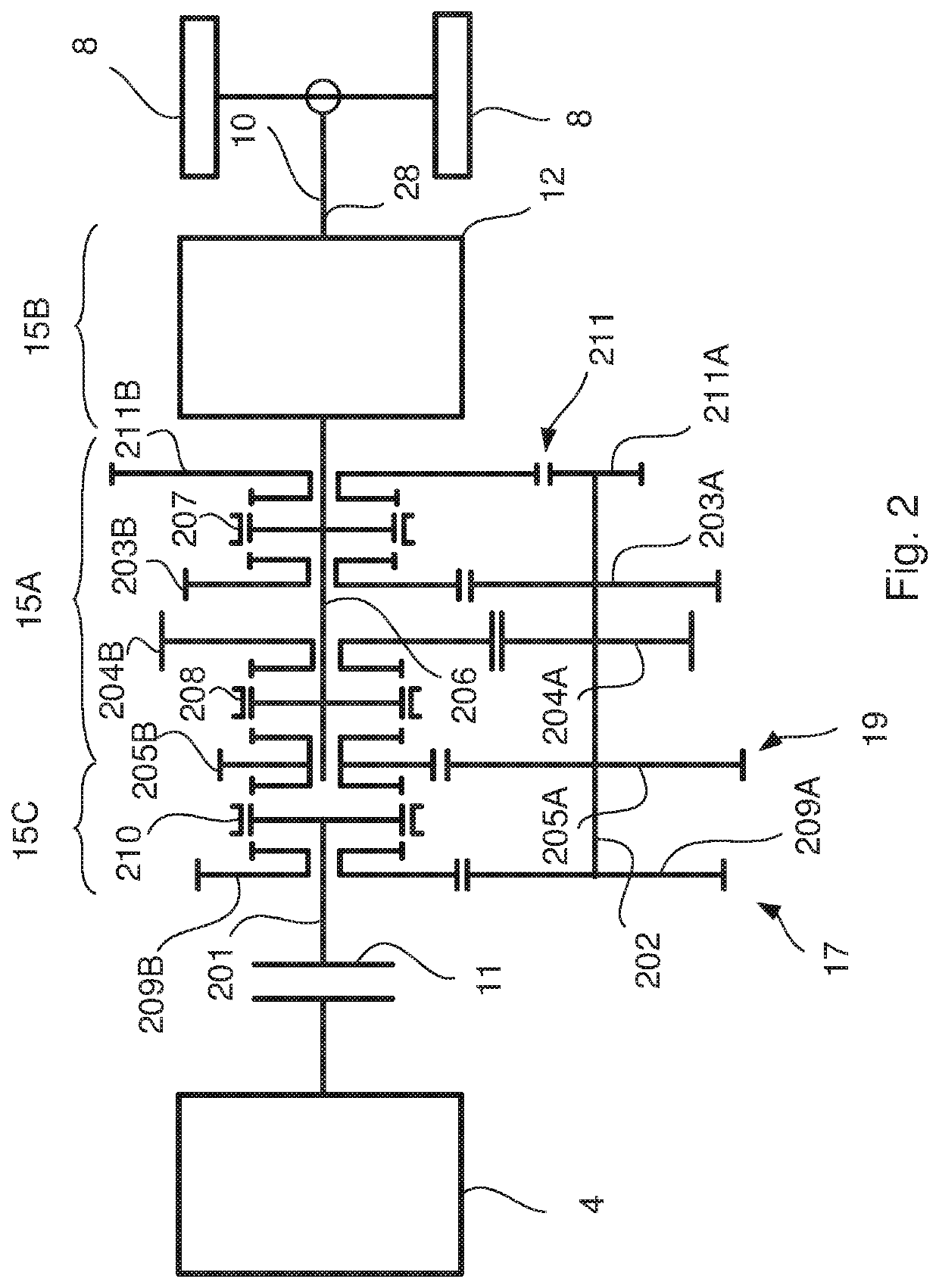

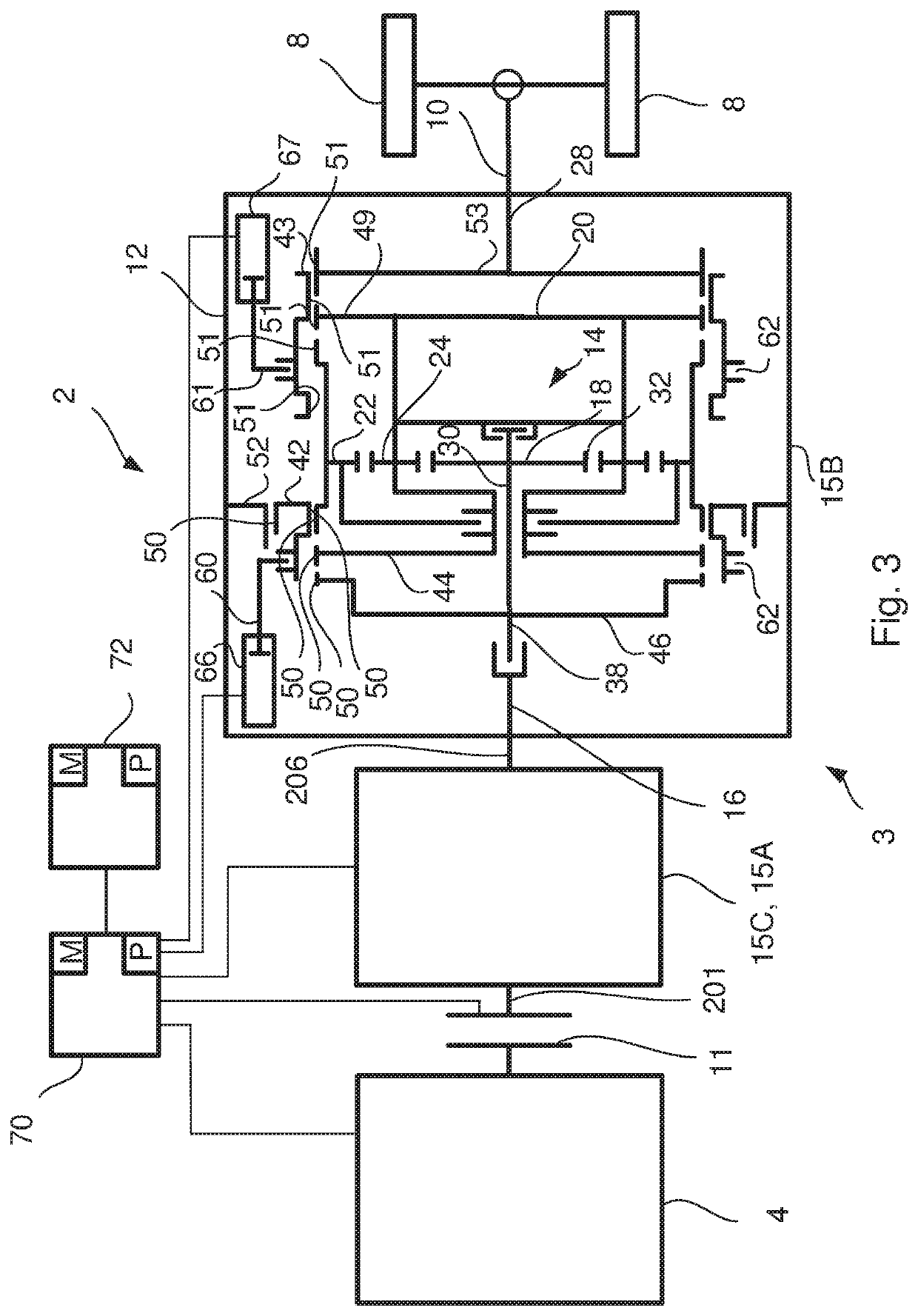

A hybrid-power driving system (HPDS) (100, 200) includes an engine, a motor, and a transmission. The HPDS may include a single clutch and the transmission can provide at least five forward speed ratios and can provide for at least one reverse speed ratio. The transmission can include three synchronizers and multiple gearwheels that are used in multiple speed ratios. In addition to a pure engine driving mode and a pure motor driving mode, the HPDS can operate using a hybrid-power driving mode (HDM). In the HDM, the HPDS can provide for shifting of gears without power interruption to the output shaft or half-axles and wheels of a vehicle. In the HDM, the continuous power being output can be achieved by keeping a synchronizer engaged with a gearwheel for two consecutive speed ratios.

Owner:SAIC MOTOR

Gearbox for vehicles and vehicles comprising such a gearbox

InactiveUS20170089437A1Weaken energyReduce fuel consumptionToothed gearingsTransmission elementsCouplingEngineering

The invention relates to a gearbox for vehicles, comprising a planetary gear with a ring gear a sun gear and a planet carrier on which at least one planet gear is rotatable mounted, which ring gear and sun gear engages with the at least one planet gear by teeth; and a gearbox housing surrounding the planetary gear. A first axially movable coupling sleeve is in a first gear position arranged to engage the ring gear with the gearbox housing in a second gear position arranged to engage the sun gear with the planet carrier and in a third gear position arranged to engage the planet carrier with the gearbox housing. A second axially movable coupling sleeve is in the third gear position arranged to engage the ring gear with an output shaft. The invention also relates to a vehicle, which comprises such a gearbox.

Owner:SCANIA CV AB

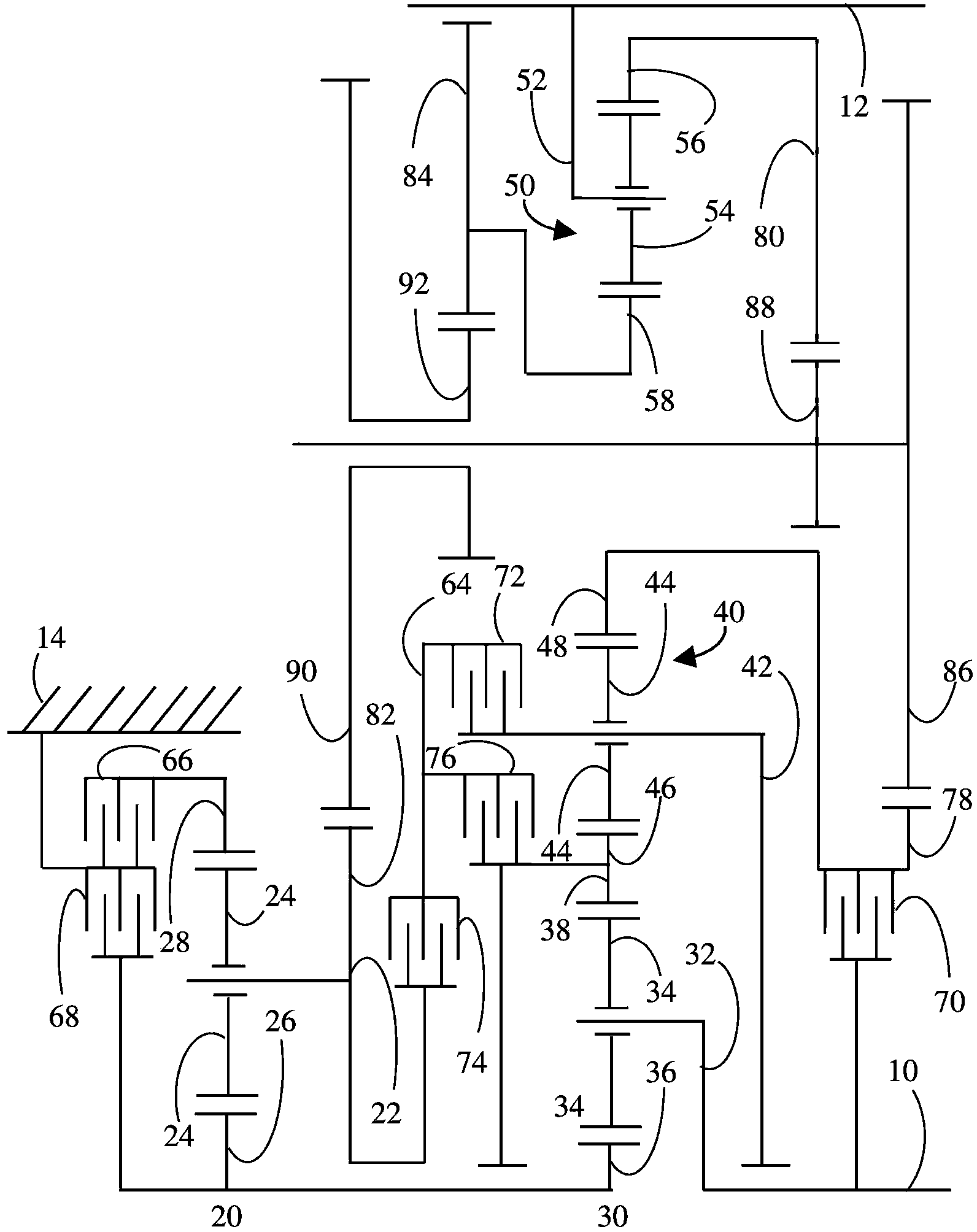

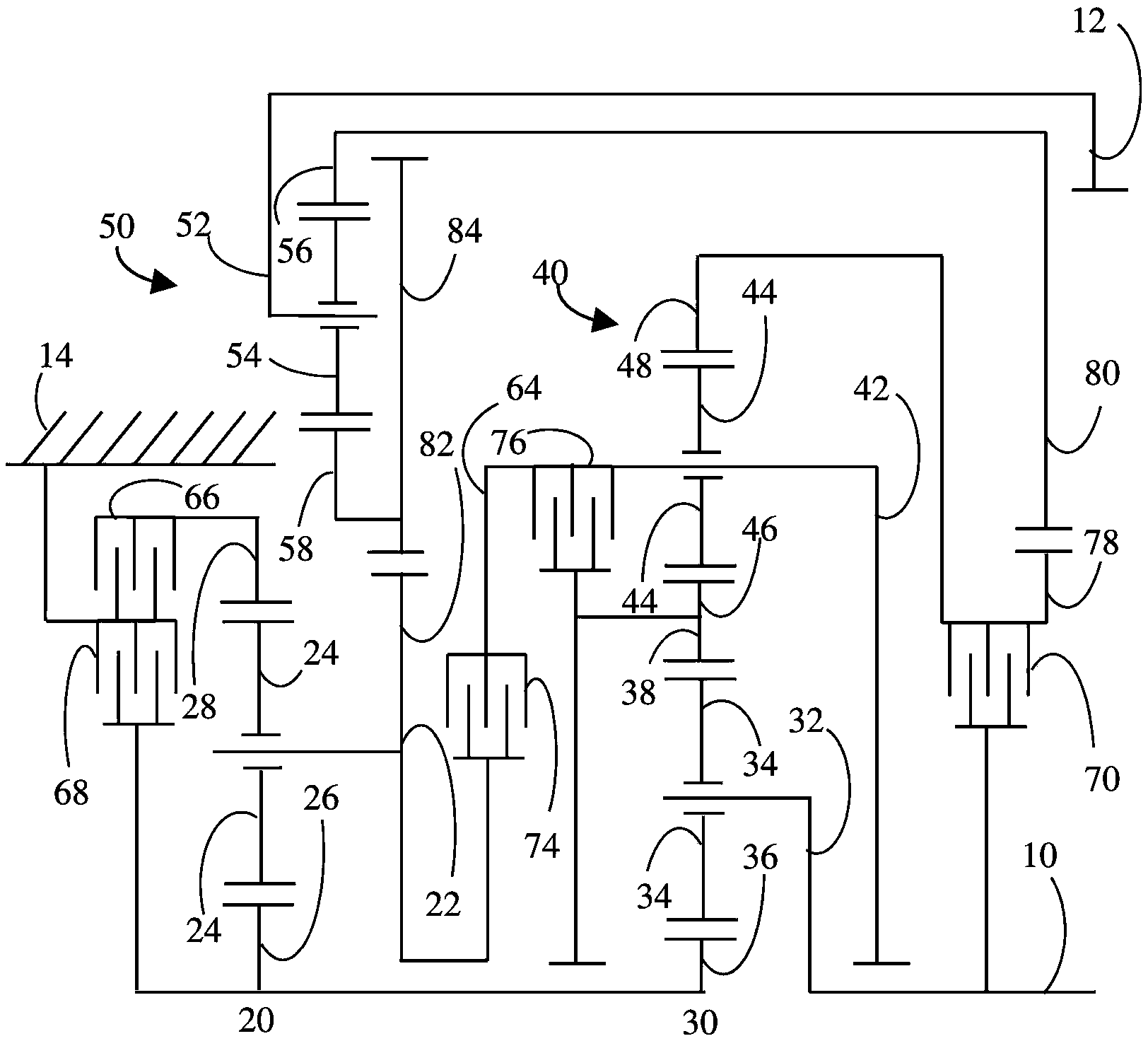

Multi-speed transmission

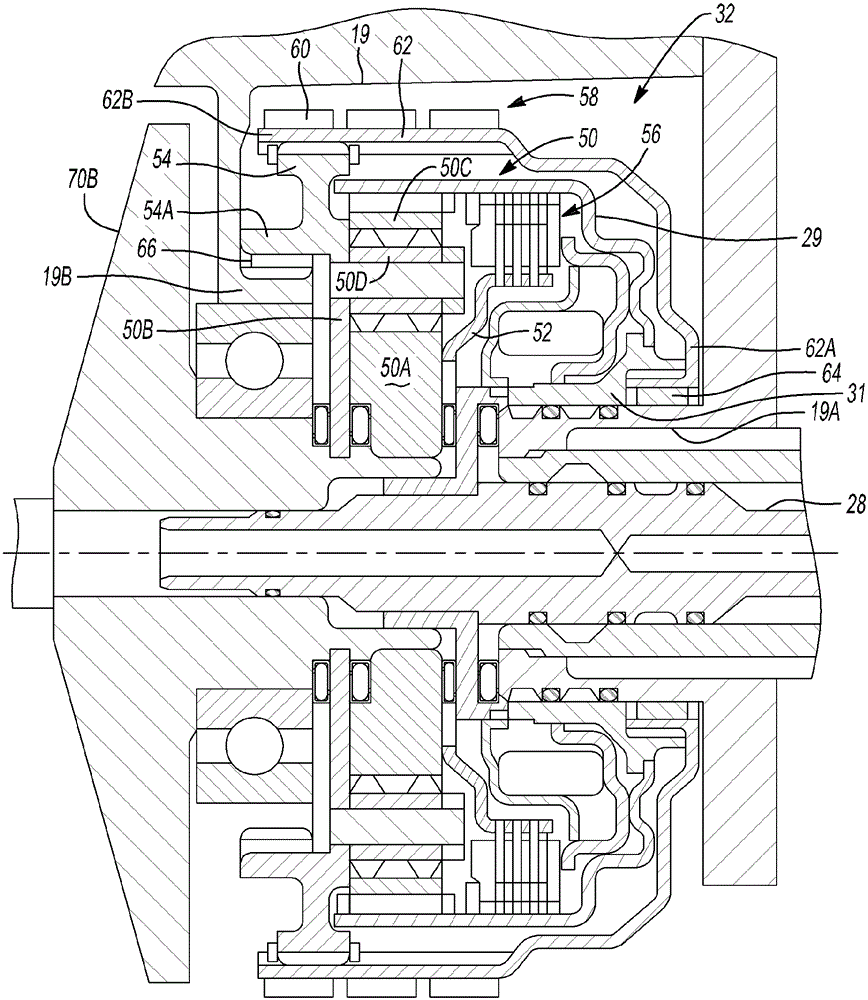

The invention relates to a multi-speed transmission. A family of transmission gearing arrangements provides between eight and ten forward speed ratios and a reverse speed ratio. Three planetary gear sets are located on the input axis and a fourth planetary gear set is located on an offset axis. Axis transfer gears convey power between the input axis and the offset axis. One axis transfer gear is supported by a front support while another is supported by a center support. The center support also supports a clutch module and supplies pressurized fluid to engage the clutches in the clutch module.

Owner:FORD GLOBAL TECH LLC

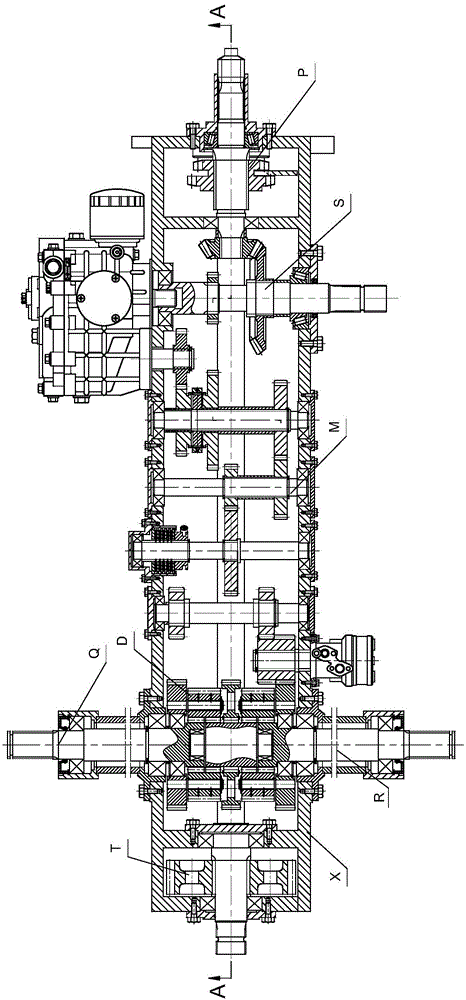

Integrated transmission for tracked vehicle

InactiveCN105090431AEasy to realize integrated controlReduce quality problemsFluid gearingsMechanical transmissionHydraulic motorEnergy consumption

The invention discloses an integrated transmission for a tracked vehicle. A power input mechanism, a double-power input mechanism, a middle transmission and brake mechanism, a differential type driving mechanism and a PTO power output mechanism are integrated to be mounted on a box body; a left track driving mechanism and a right track driving mechanism are of the same structure and are symmetrically mounted on the two sides of the box body, and the power input mechanism is connected with the PTO power output mechanism and the double-power input mechanism; the double-power input mechanism carries out transmission and is connected with the middle transmission and brake mechanism, and the middle transmission and brake mechanism is connected with the differential type driving mechanism; and the differential type driving mechanism outputs the power to drive the left track driving mechanism and the right rack driving mechanism. Through a conversion combination sleeve, the aim of combining mechanical direct transmission and hydraulic infinite type is achieved, and the transmission efficiency and the manipulation performance of the tracked vehicle can be effectively improved. Meanwhile, a steering device which integrates a brake device and a hydraulic motor to control positive rotation and negative rotation of a planet carrier gear effectively reduces the overall mass of the transmission, and the energy consumption is further reduced.

Owner:HUNAN AGRICULTURAL UNIV

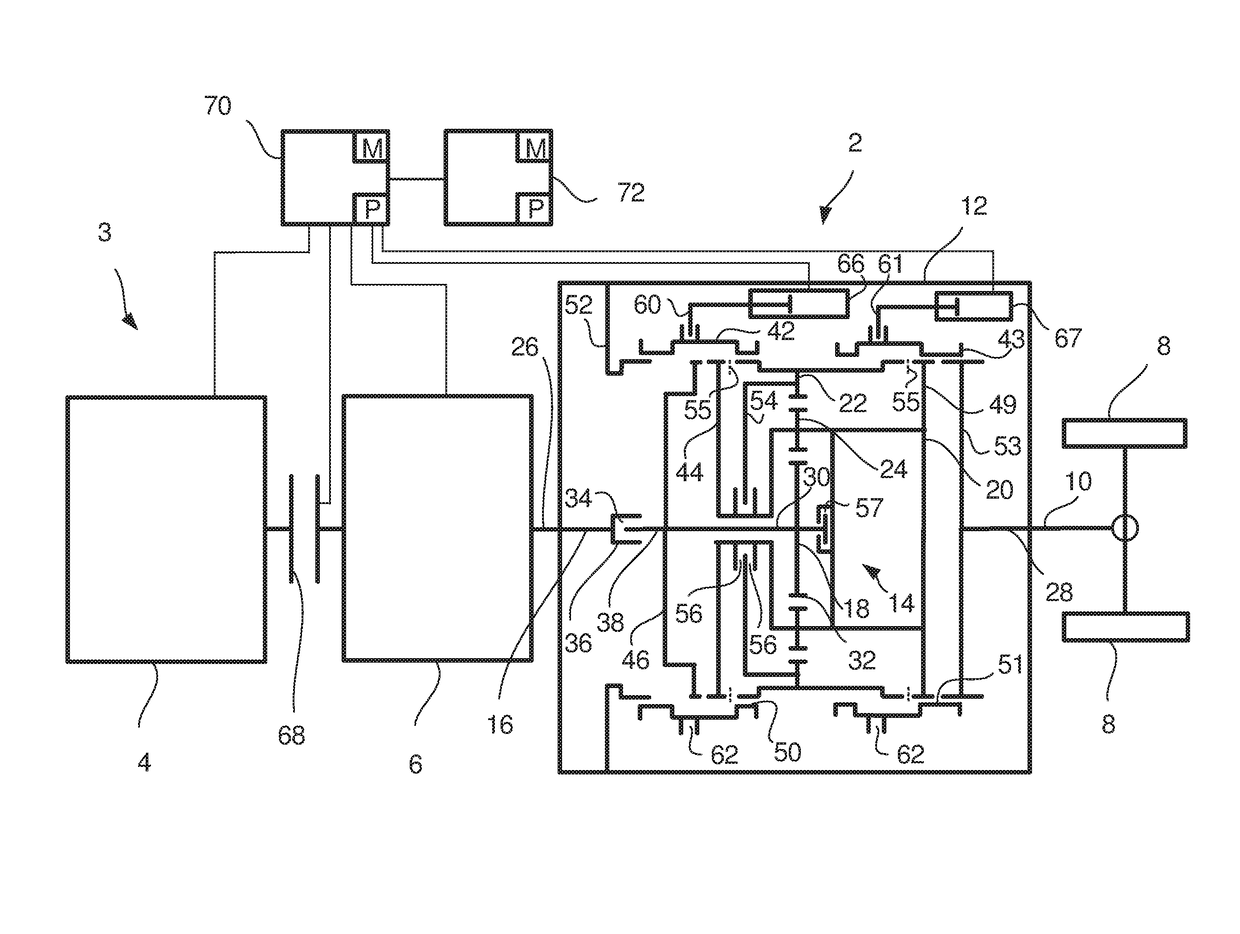

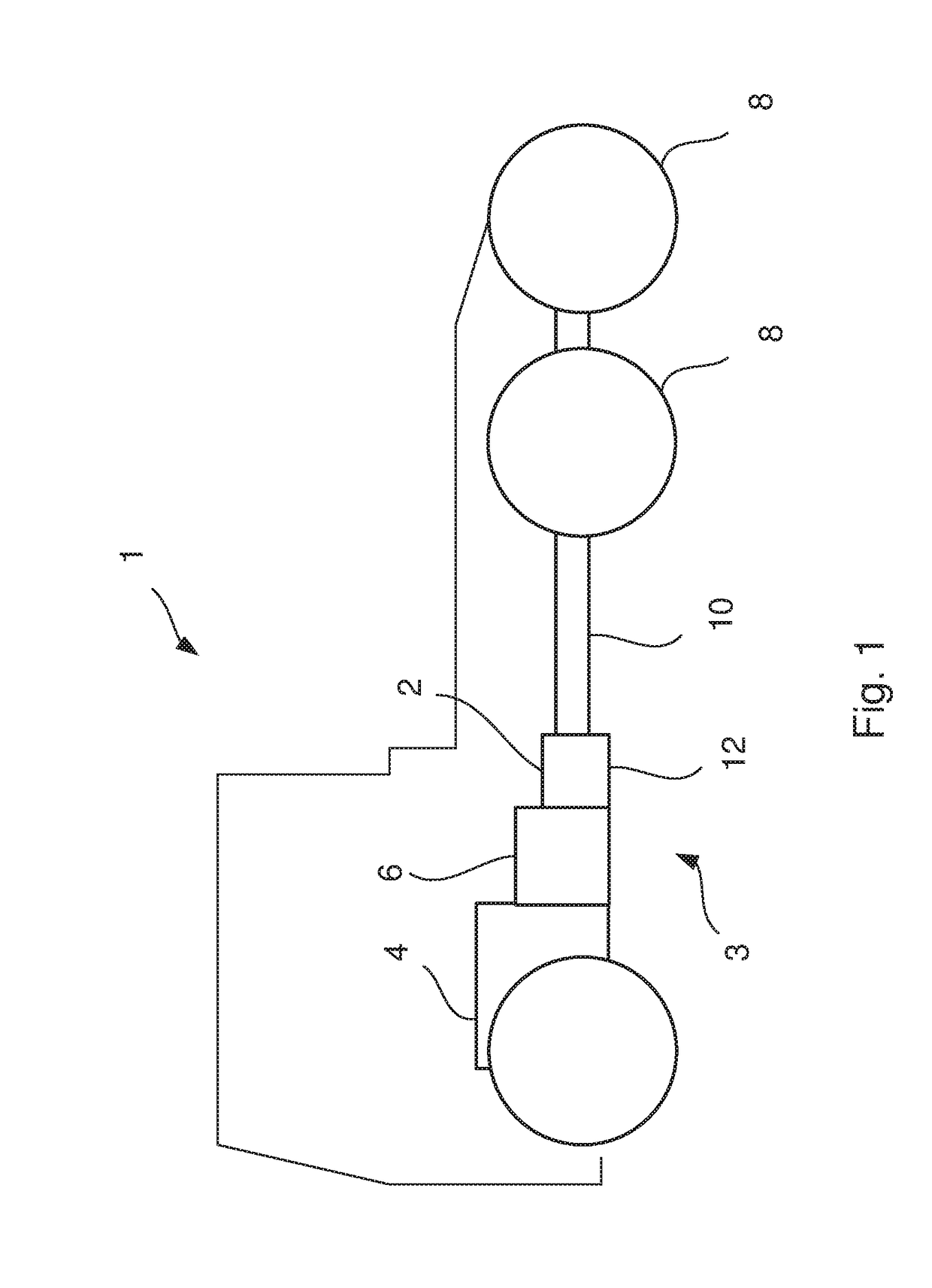

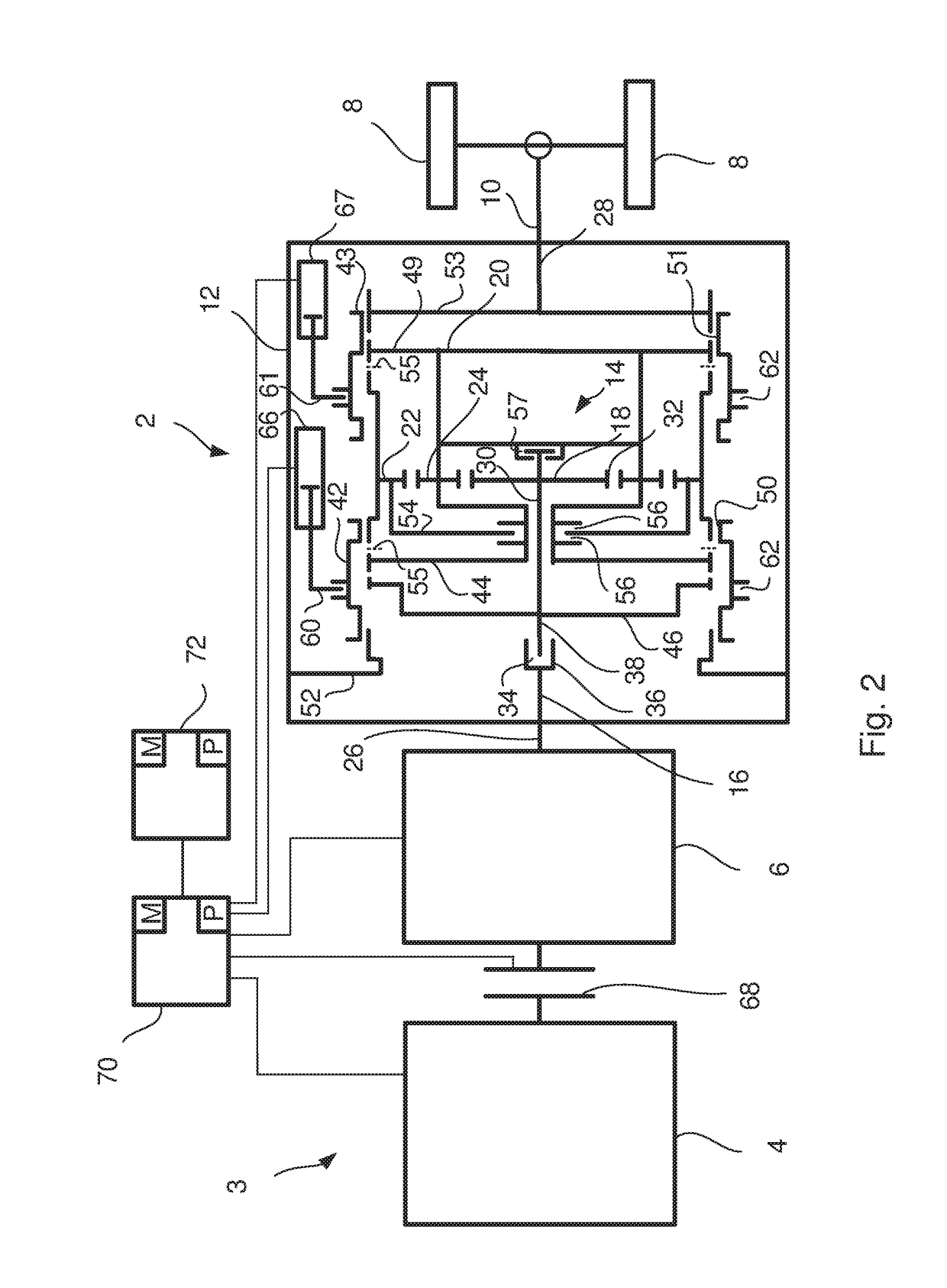

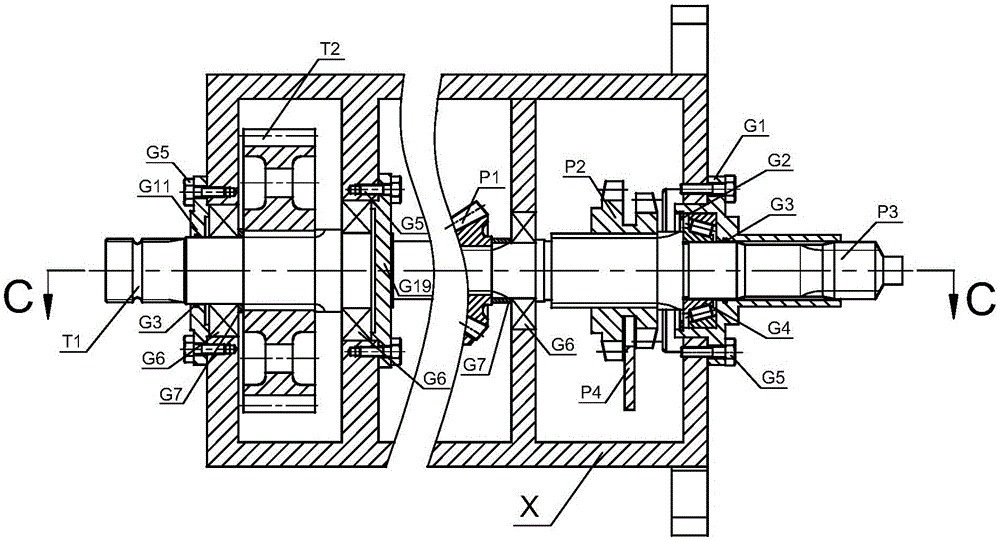

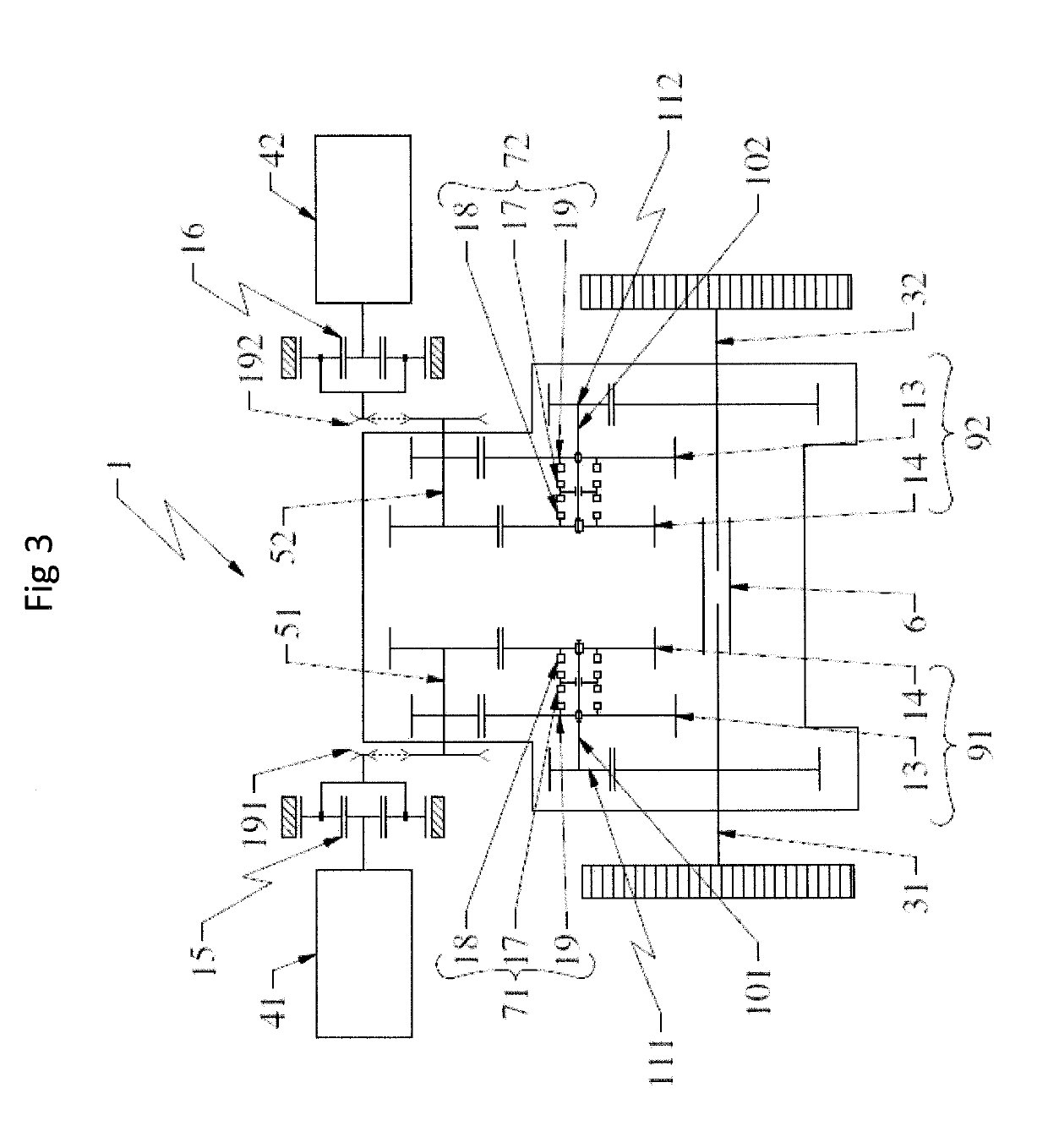

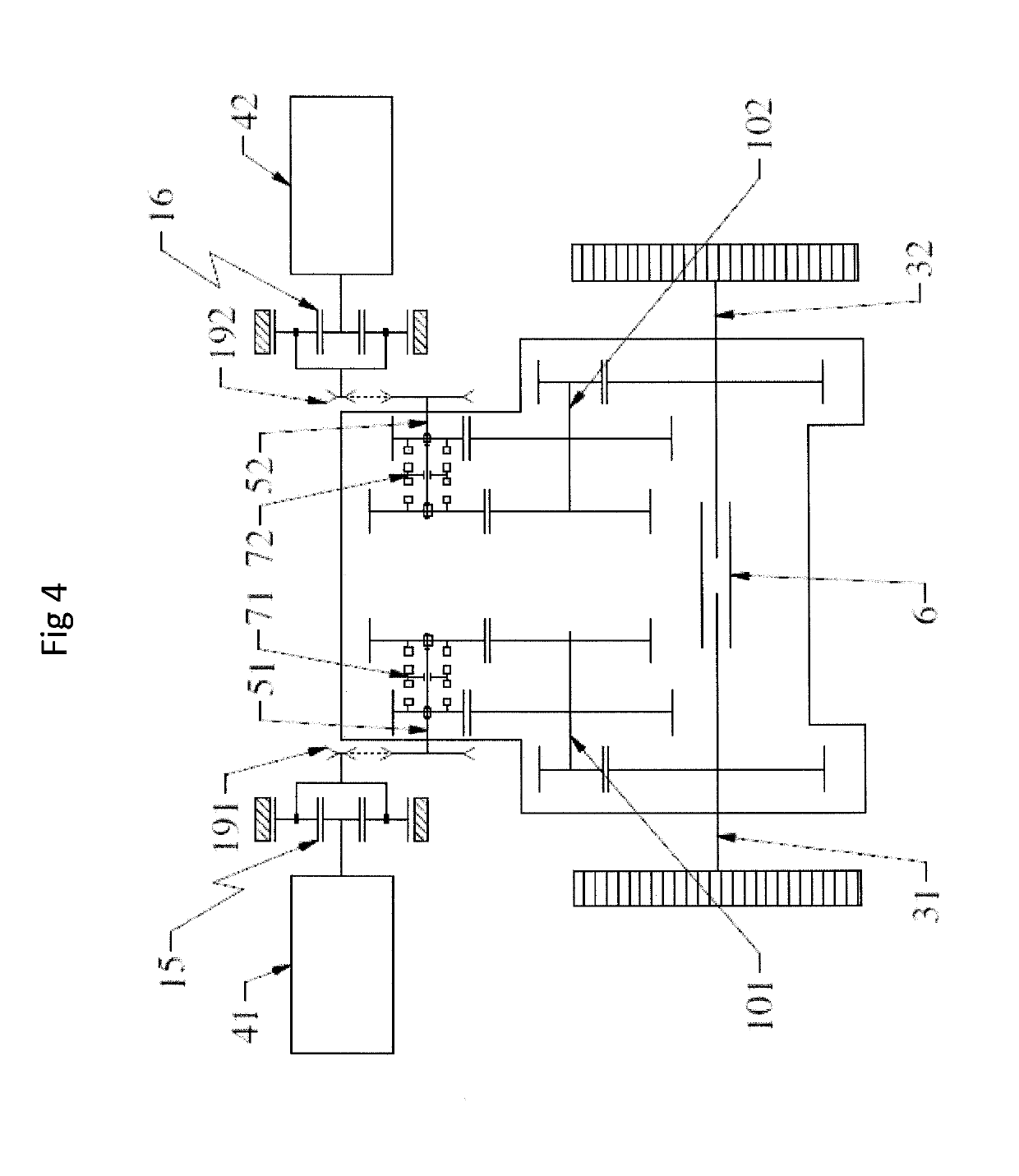

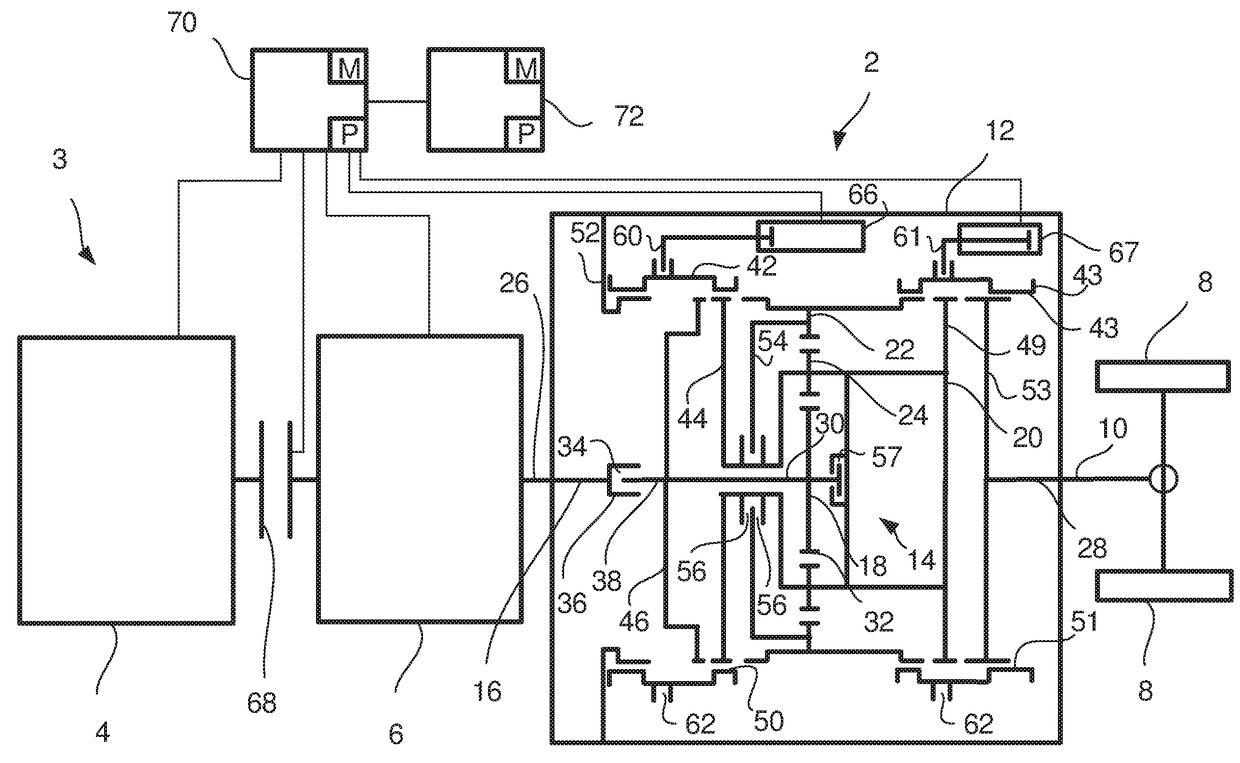

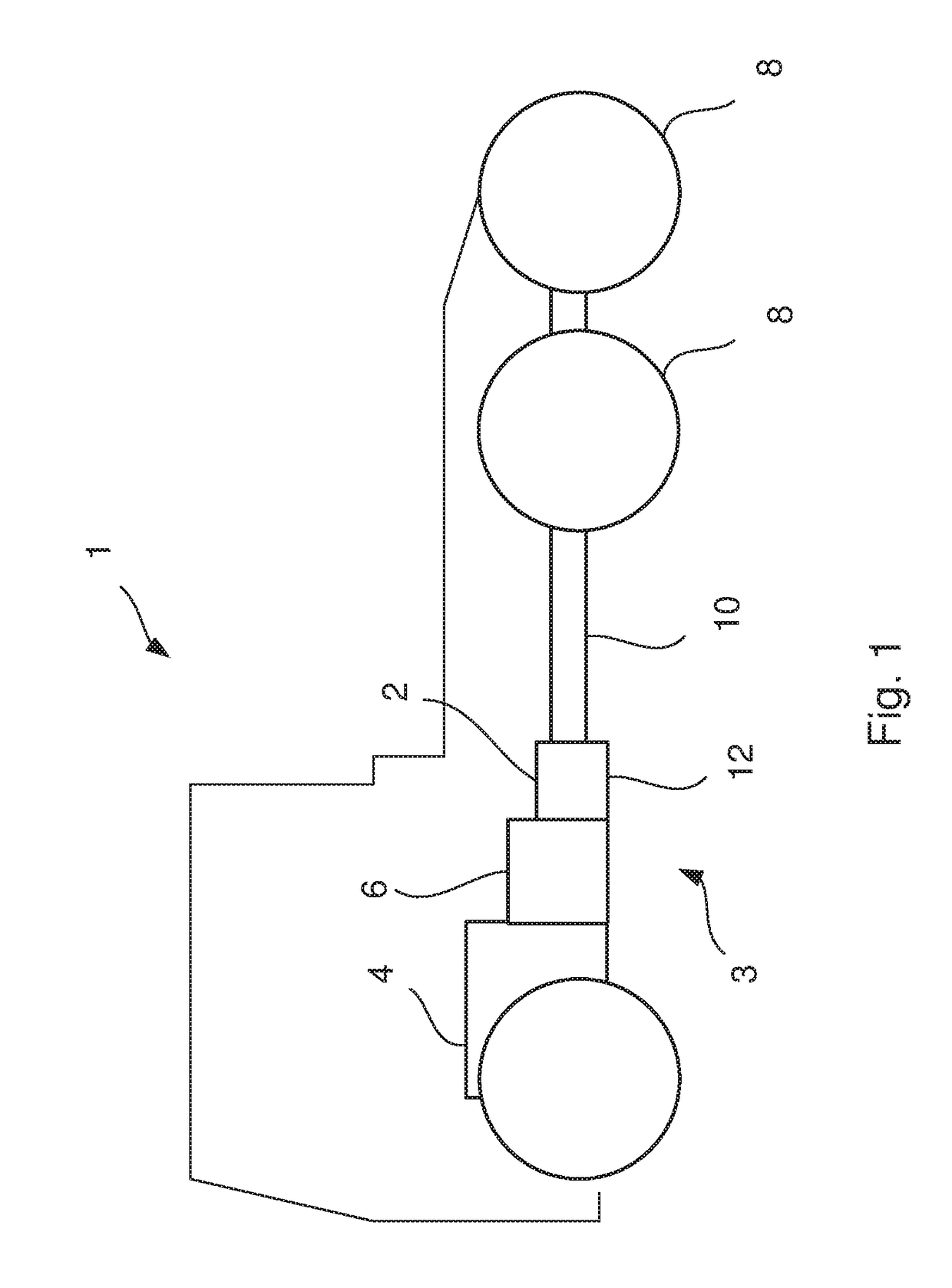

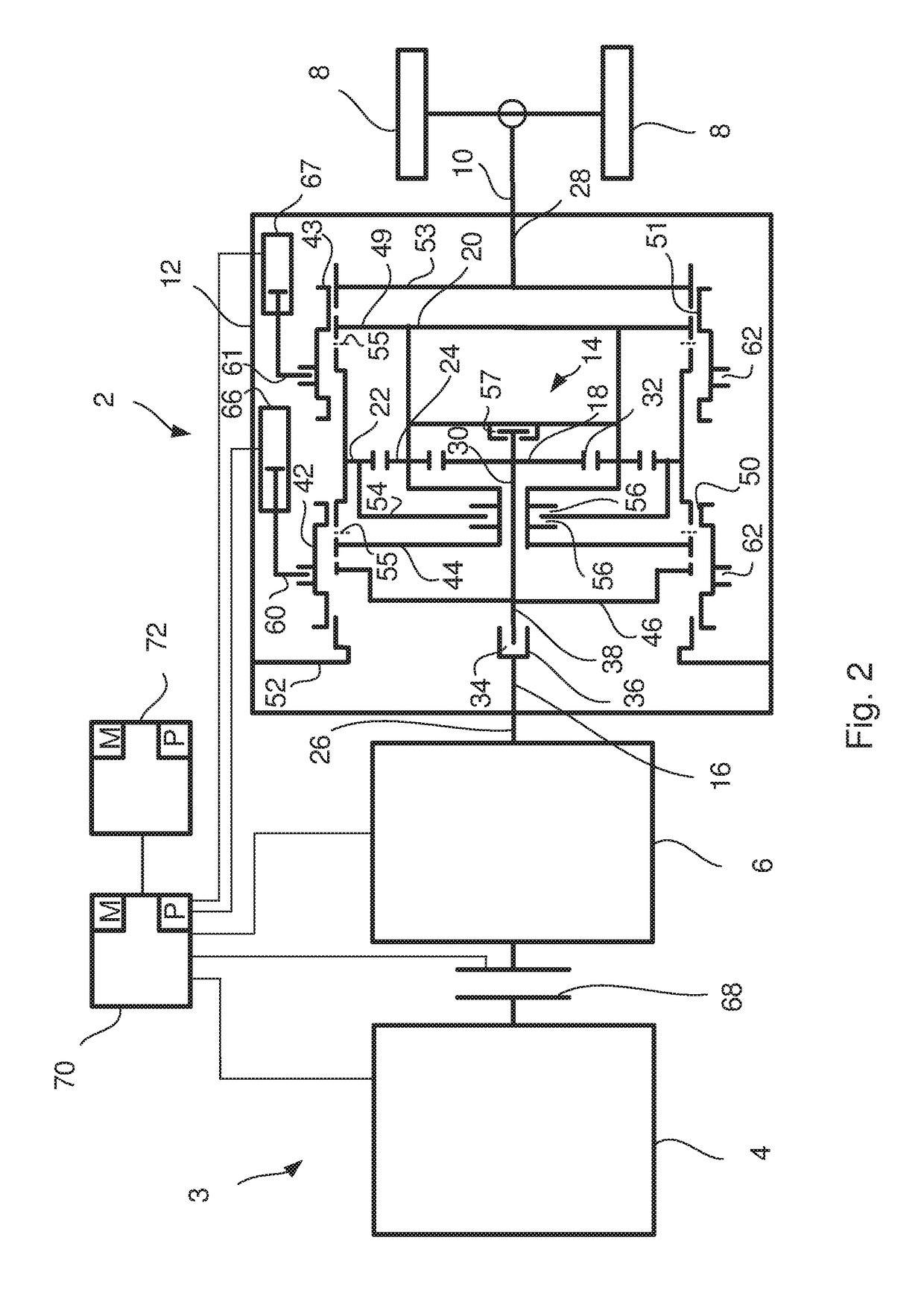

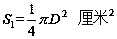

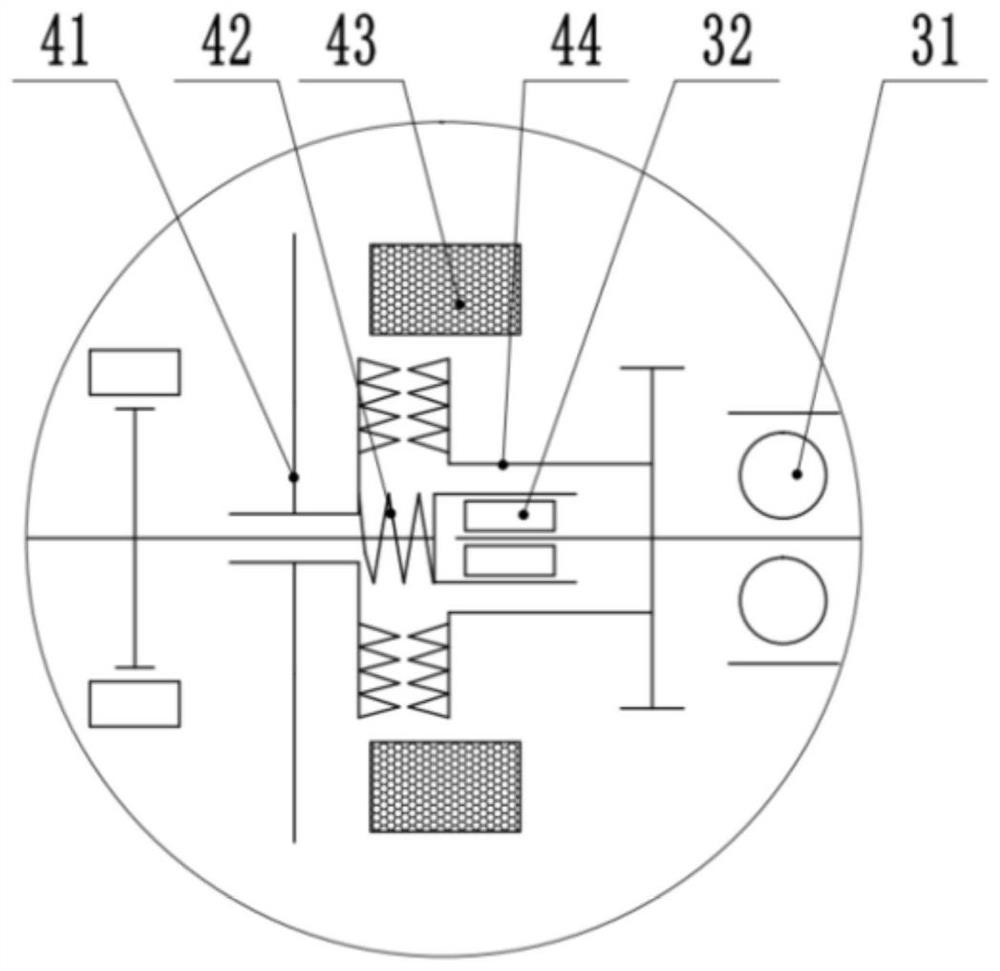

Transmission, particularly for a wheeled vehicle, and wheeled vehicle equipped with such a transmission

ActiveUS20190331200A1Reduce riskLow costAgricultural vehiclesElectric propulsion mountingClutch controlFree rotation

The transmission (1) comprises a housing (2), a first motor (41), a second motor (42), a first and a second input shaft (51, 52), respectively able to be driven in rotation, one (51) by the first motor (41), the other (52) by the second motor (42), two clutch mechanisms (71, 72) and two reduction gears (91, 92), wherein the output shaft (31, 32) is formed by two output shaft sections (31, 32) interconnected such that they rotate freely, the clutch mechanisms (71, 72) are each equipped with a clutch control member operable by a user for allowing the transmission, in the engaged state of the first clutch mechanism (71), of the rotational movement of the first input shaft (51) to the first output shaft section (31), and the transmission, in the engaged state of the second clutch mechanism (72), of the rotational movement of the second input shaft (52) to the second output shaft section (32), and the reduction gears (91, 92) are at least partially received inside the housing (2).

Owner:FRANCE REDUCTEURS SA

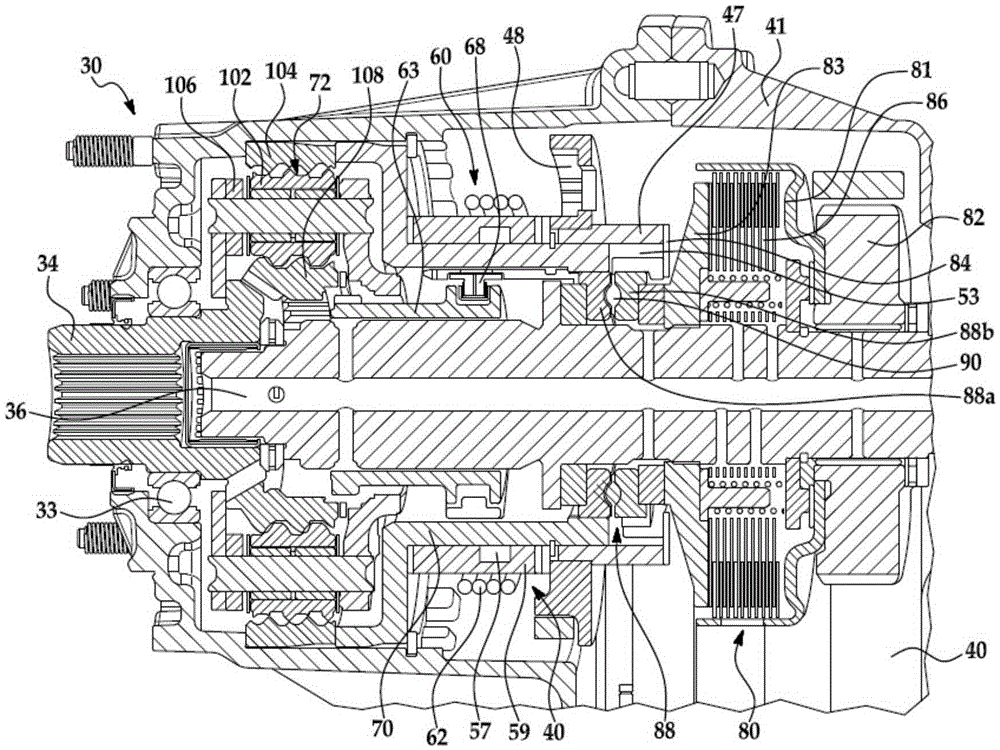

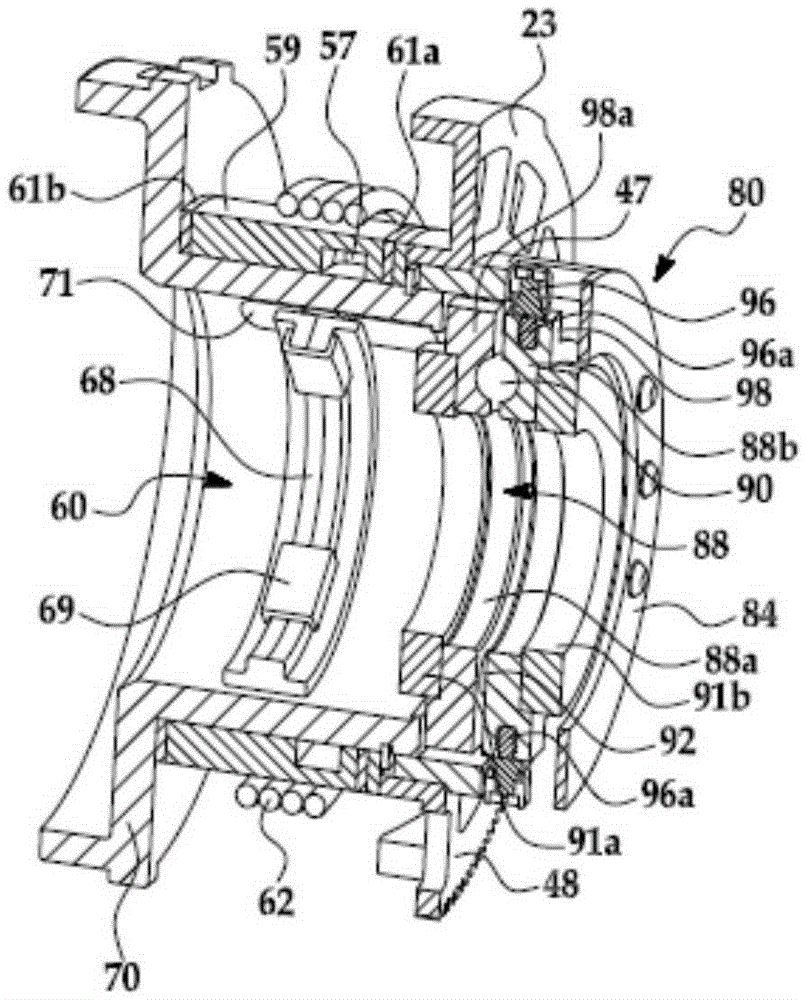

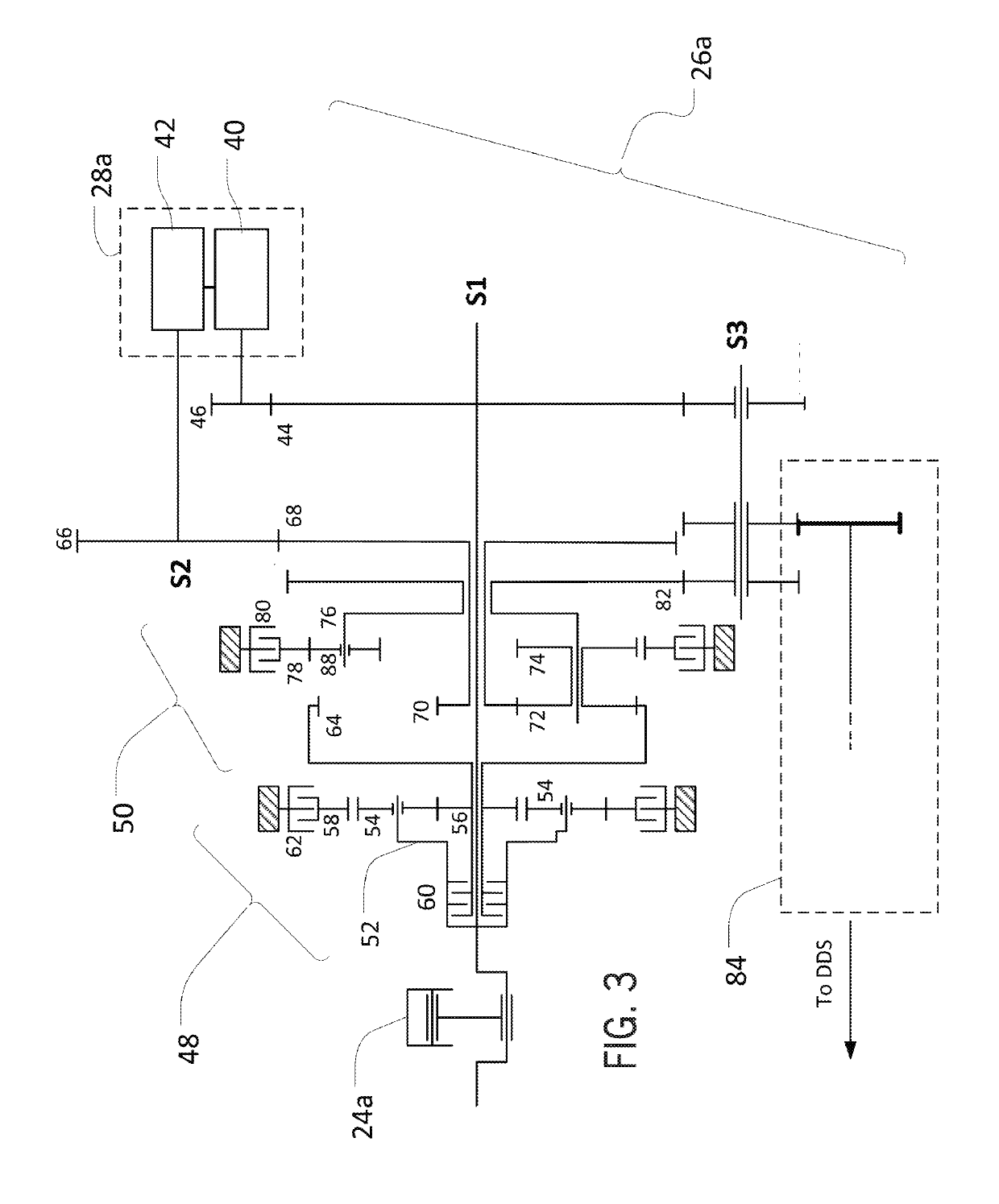

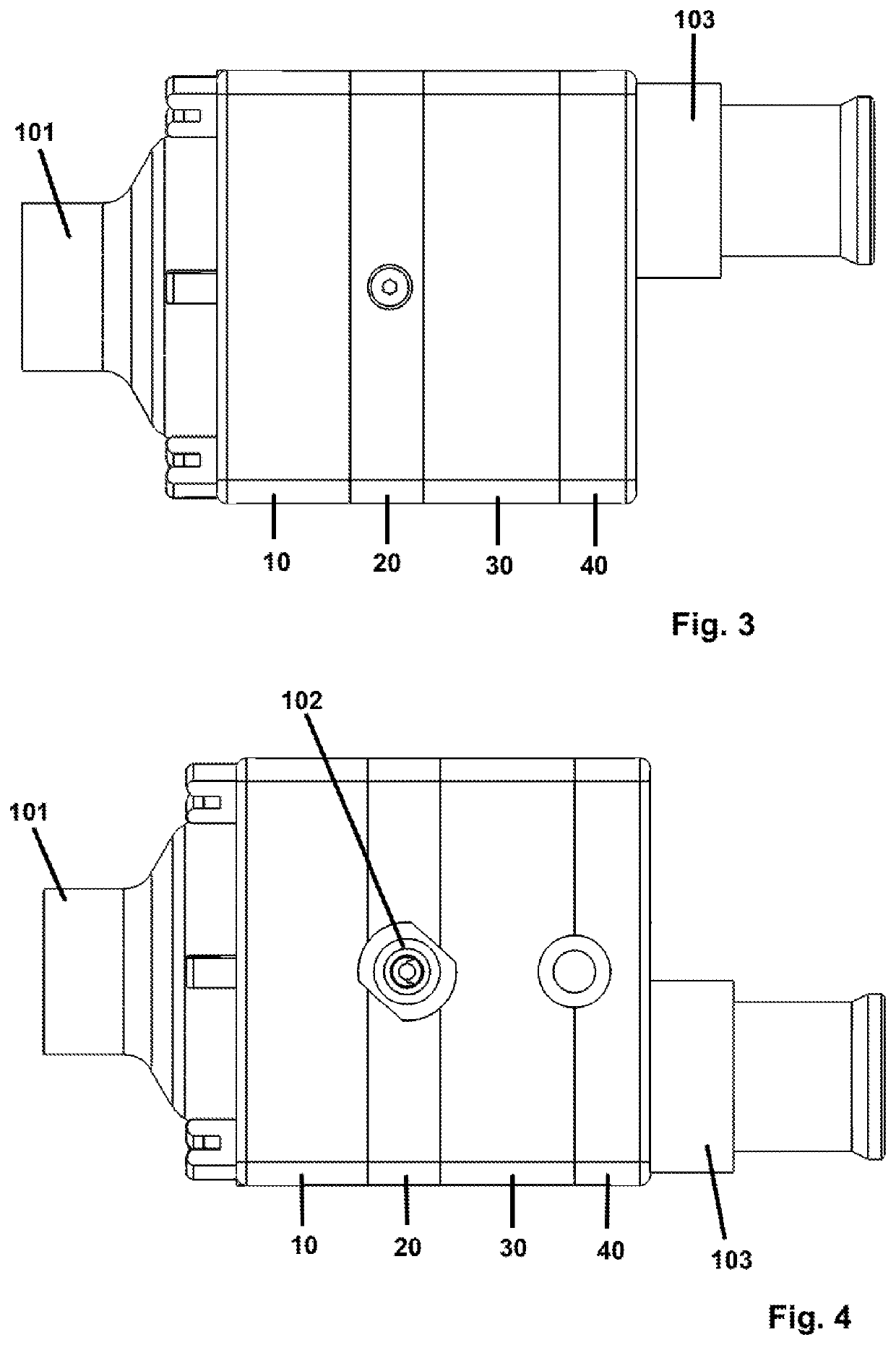

Motor driven transfer case with modular actuation

A transfer case (30) and a method of assembly in an all-wheel drive vehicle can include a range shifting assembly (60) for shifting between a low-range and high-range drive mode, a normally disengaged clutch assembly (80) for transferring drive torque to a first and second driveline, a clutch actuator (88), and an actuating gear (48). The clutch actuator (88) can be moveable between an expanded position and a contracted position and engageable with the clutch assembly (80) for engaging the clutch assembly (80) when in the expanded position. The actuating gear (48) can be reversibly rotatable through a predetermined angular arc of movement for operating the clutch actuator (88) between the contracted and expanded position for actuating the clutch assembly (80) and for shifting the range shifting assembly (60) between a low-range drive mode and a high-range mode when the clutch assembly (80) is in the disengaged position.

Owner:BORGWARNER INC

Continuously variable transmission

ActiveCN106989156ASimple structureImprove performanceTransmission elementsFluid gearingsEngineeringMechanical engineering

The invention provides a continuously variable transmission. The technical problem that the structure comprising an input end planetary gear set, an output end planetary gear set and a bucket wheel planetary gear set is complex is solved. The continuously variable transmission comprises an input end planetary gear set and an output end planetary gear set, a cavity planet carrier is arranged between the input end planetary gear set and the output end planetary gear set, the cavity planet carrier comprises a cavity input end cover and a cavity output end cover, the cavity input end cover is connected with the inner side of the input end planetary gear set, the cavity output end cover is connected with the inner side of the output end planetary gear set, a bucket wheel cavity shell is fixedly arranged between the cavity input end cover and the cavity output end cover, and a bucket wheel is fixed to a planet wheel connection shaft located inside the bucket wheel cavity shell. The continuously variable transmission can be widely applied in the drive field.

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

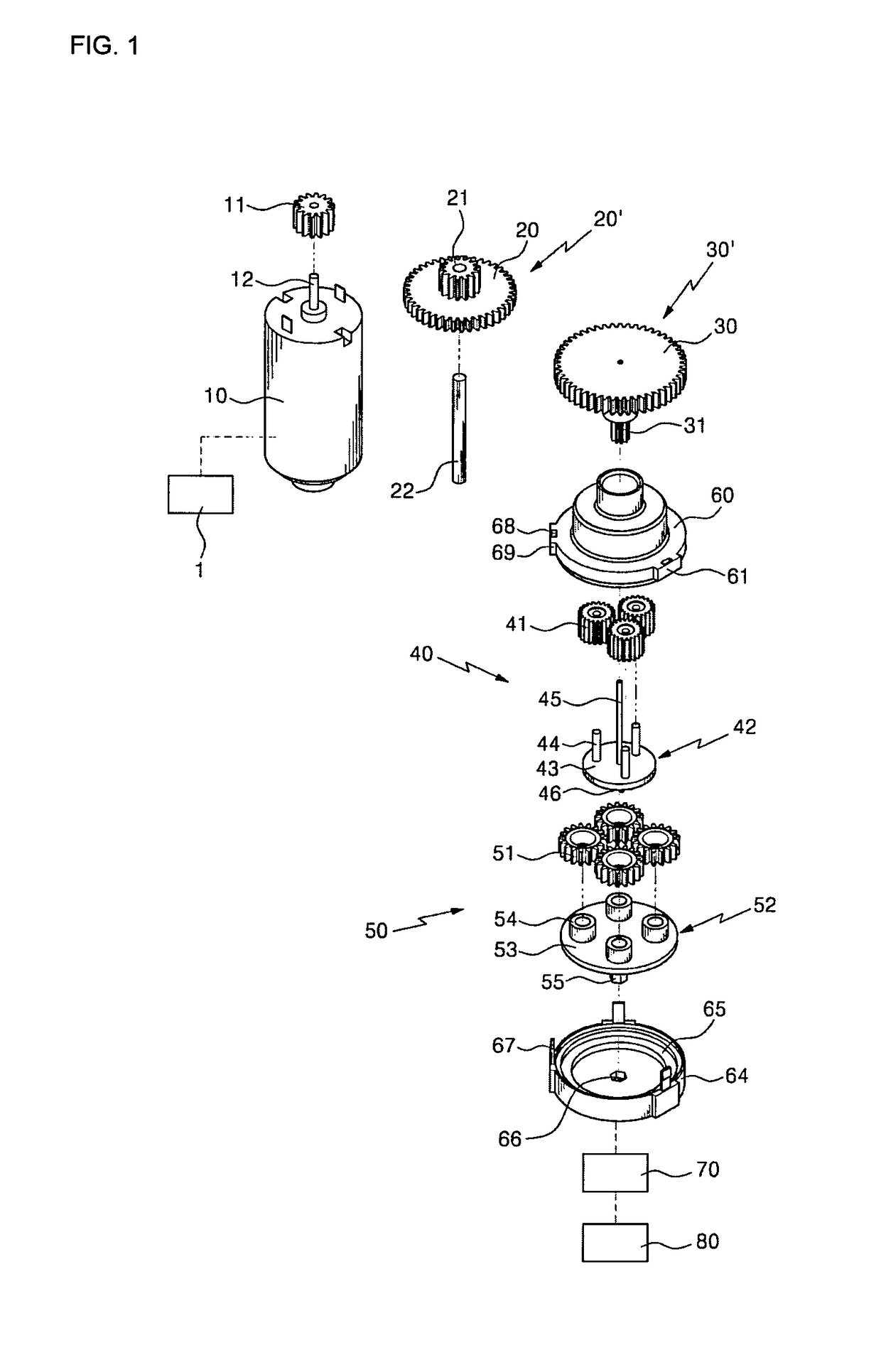

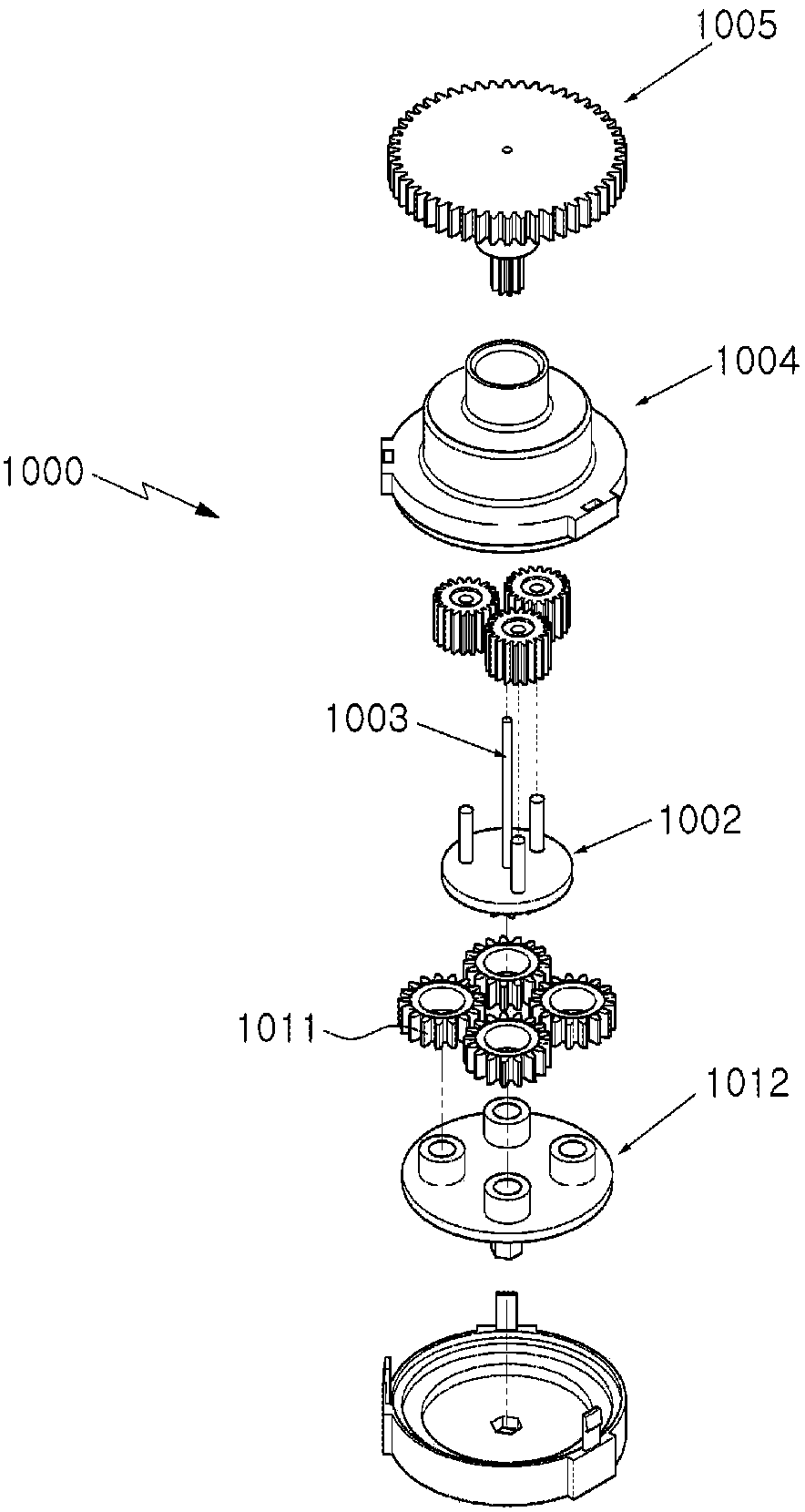

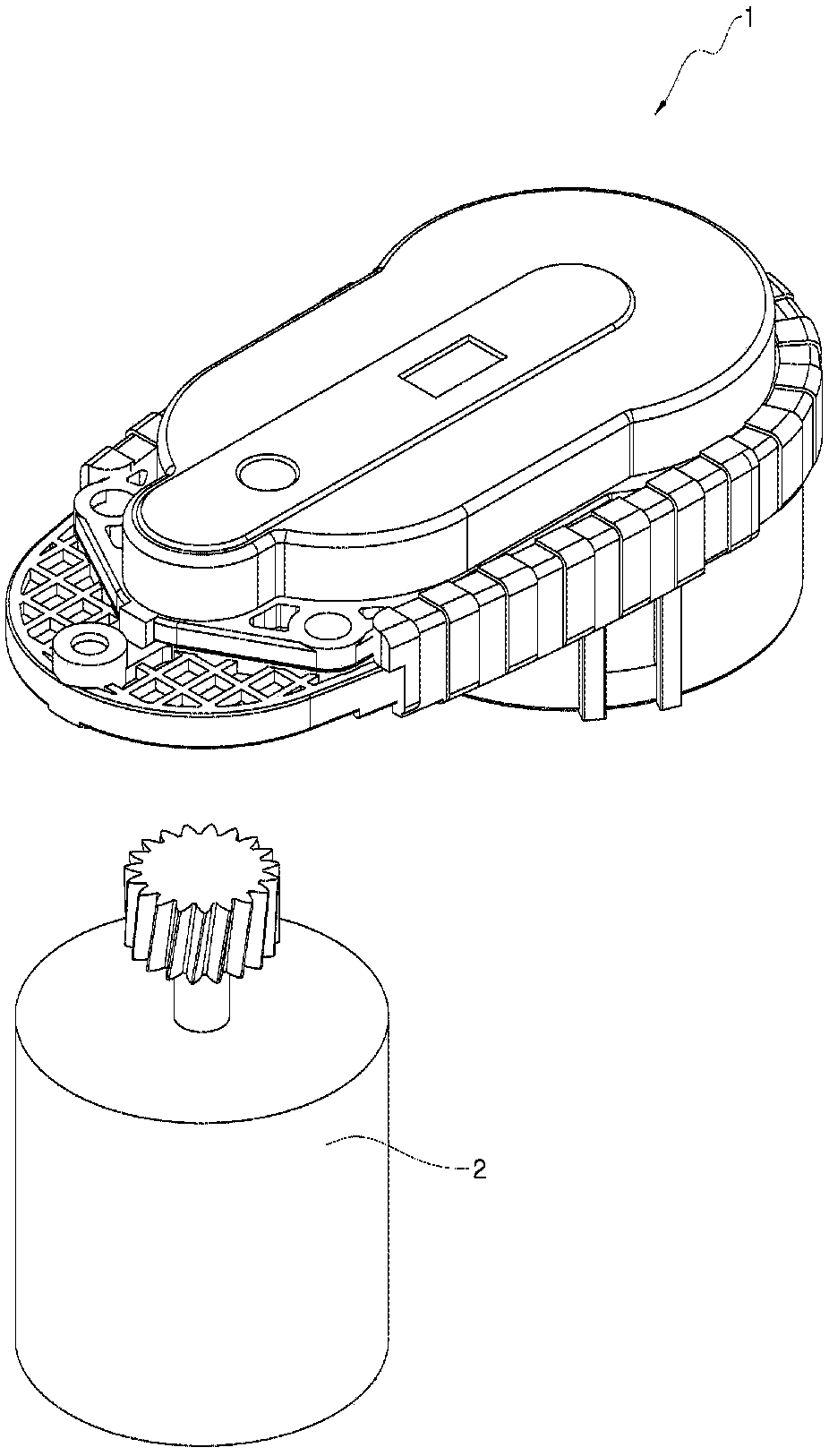

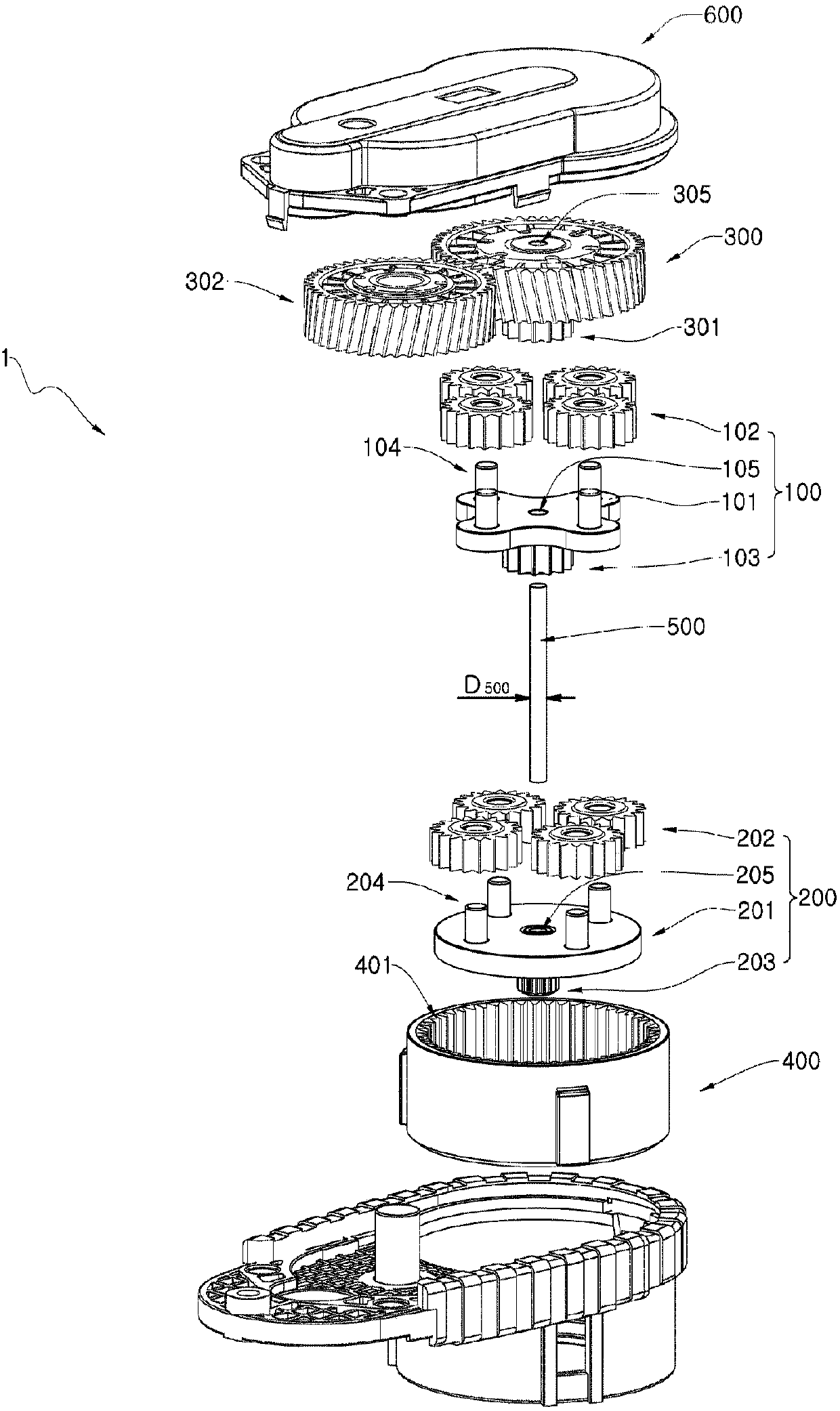

Actuator Assembly For Electronic Parking Brake

InactiveUS20180202517A1Increased durabilityImprove manufacturabilityBraking element arrangementsBraking action transmissionActuatorParking brake

An actuator assembly for an electronic parking brake in which a center pin is not fixed with the components of a planetary gear mechanism to prevent the deviation of the axis of the planetary gear mechanism, and in which the axial direction alignment of a planetary gear mechanism is stable, thereby increasing the output efficiency of the planetary gear mechanism and providing a noise attenuation function.

Owner:KEYANG ELECTRIC MACHINERY

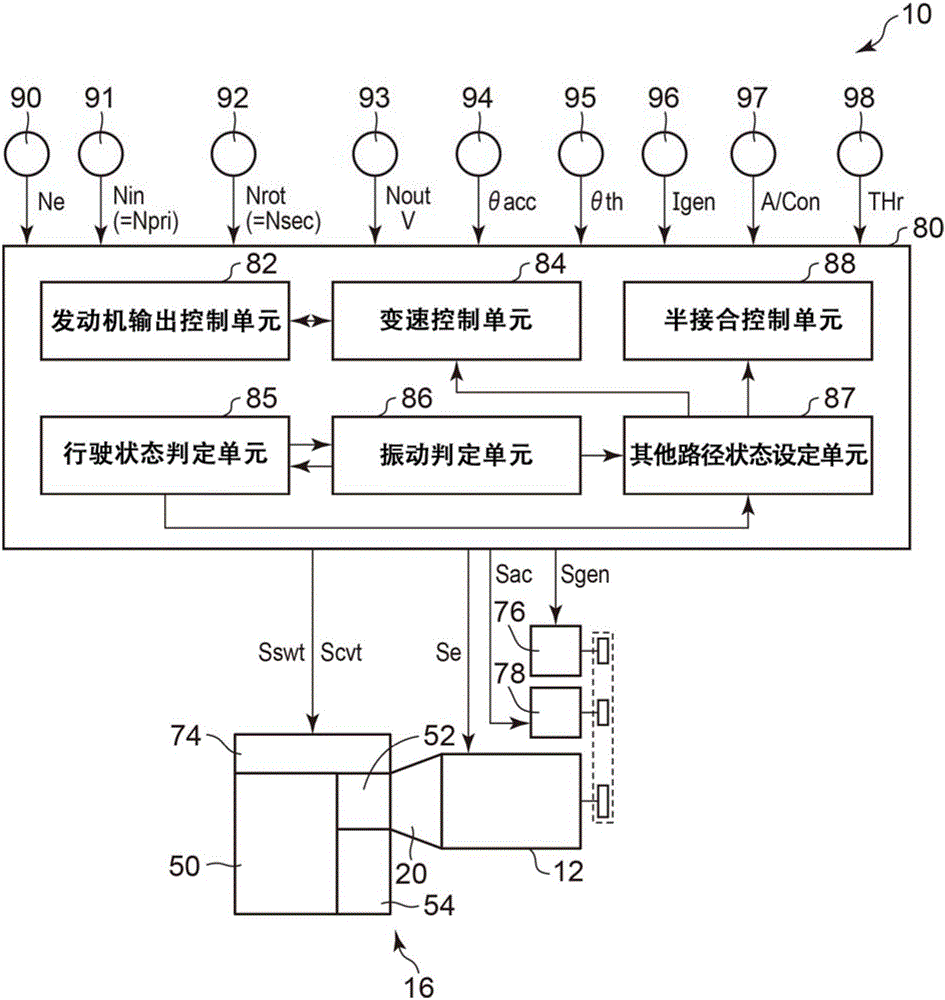

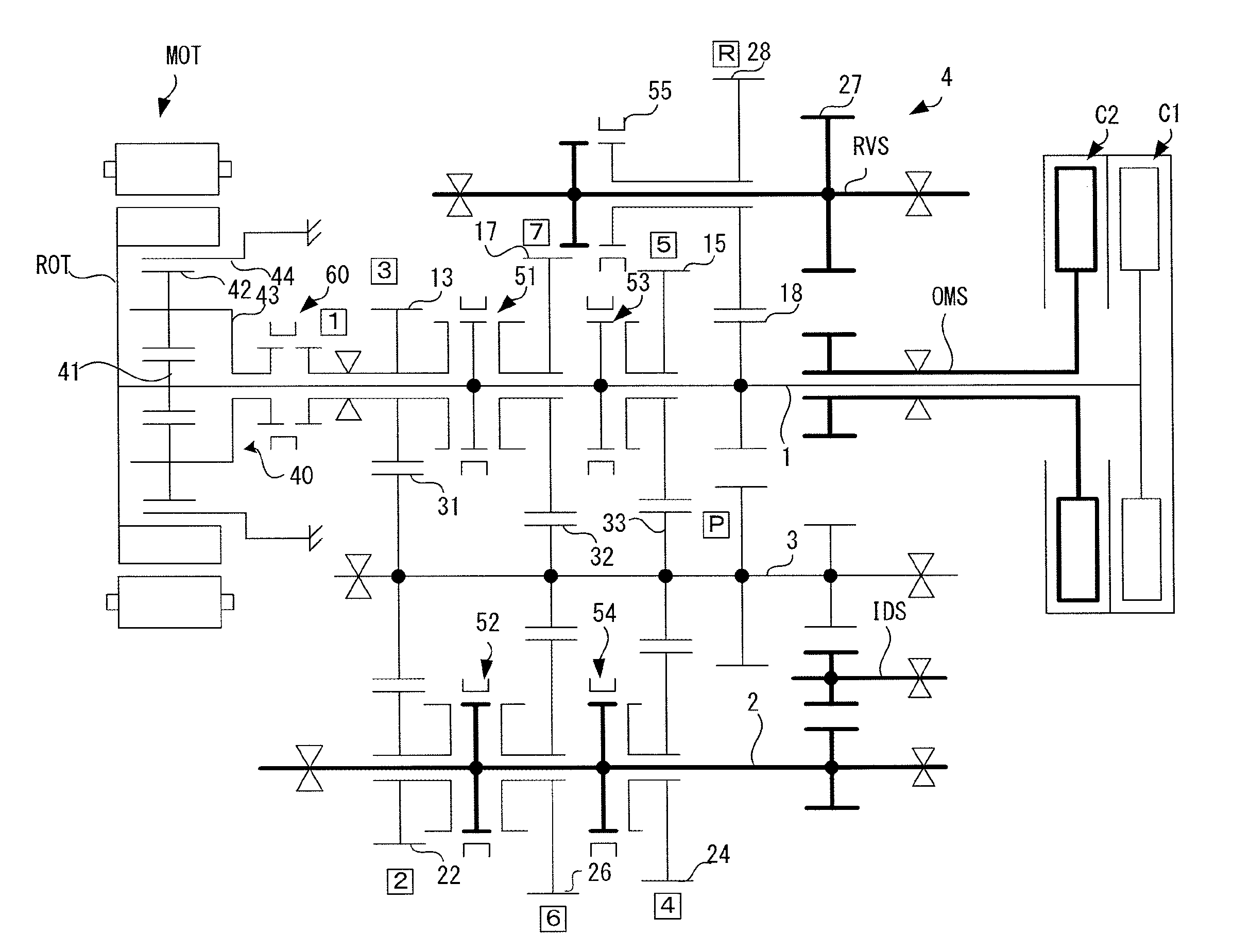

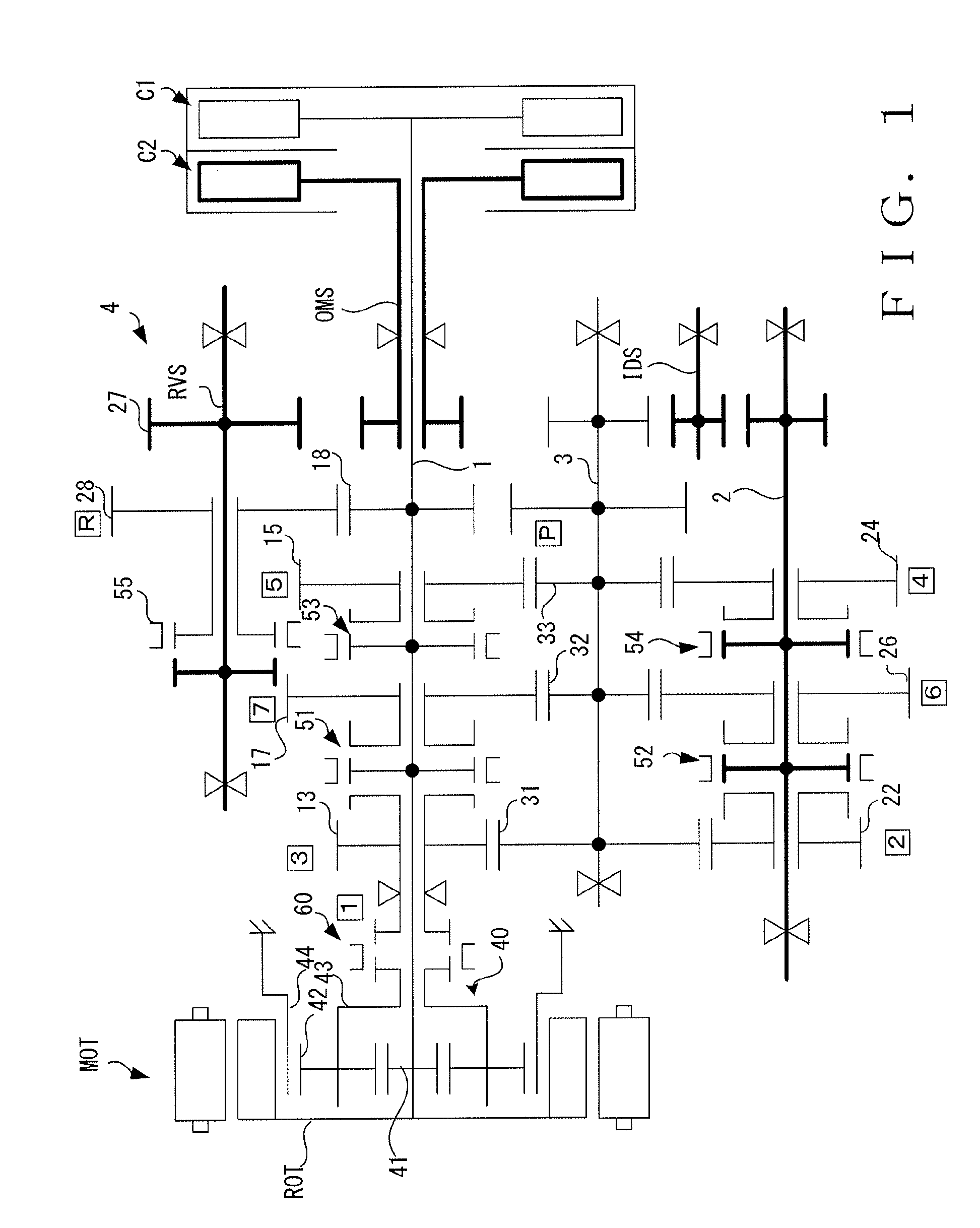

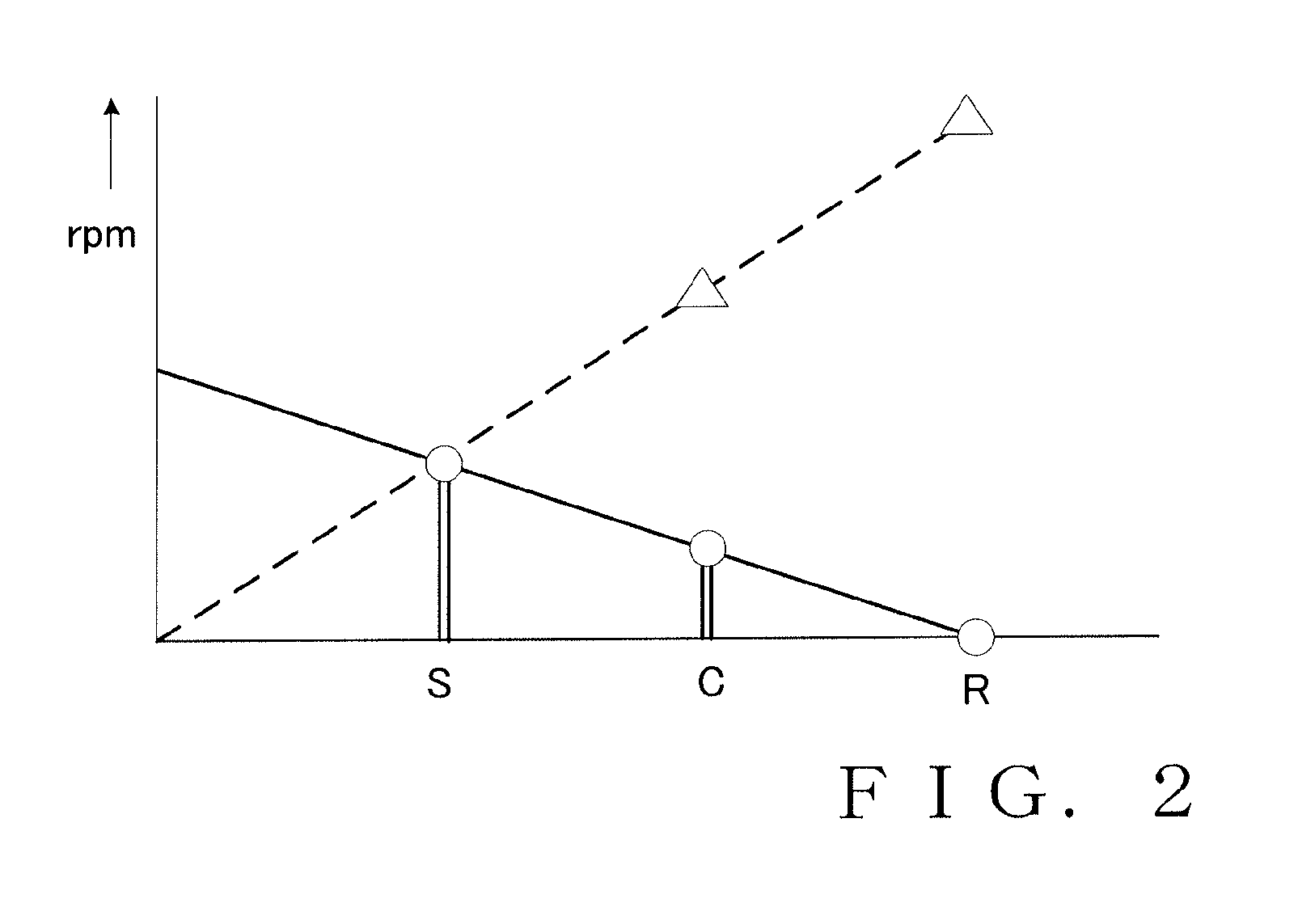

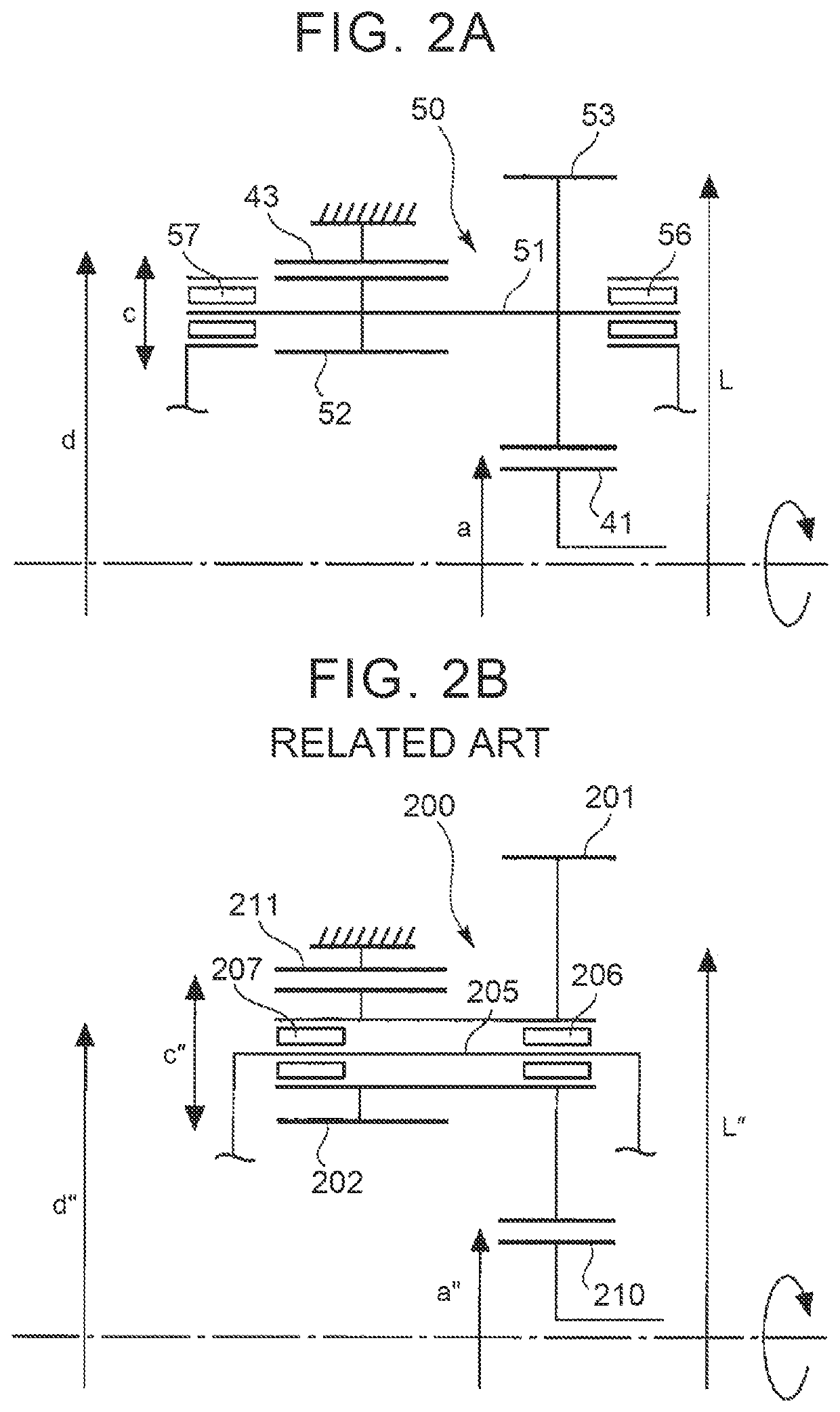

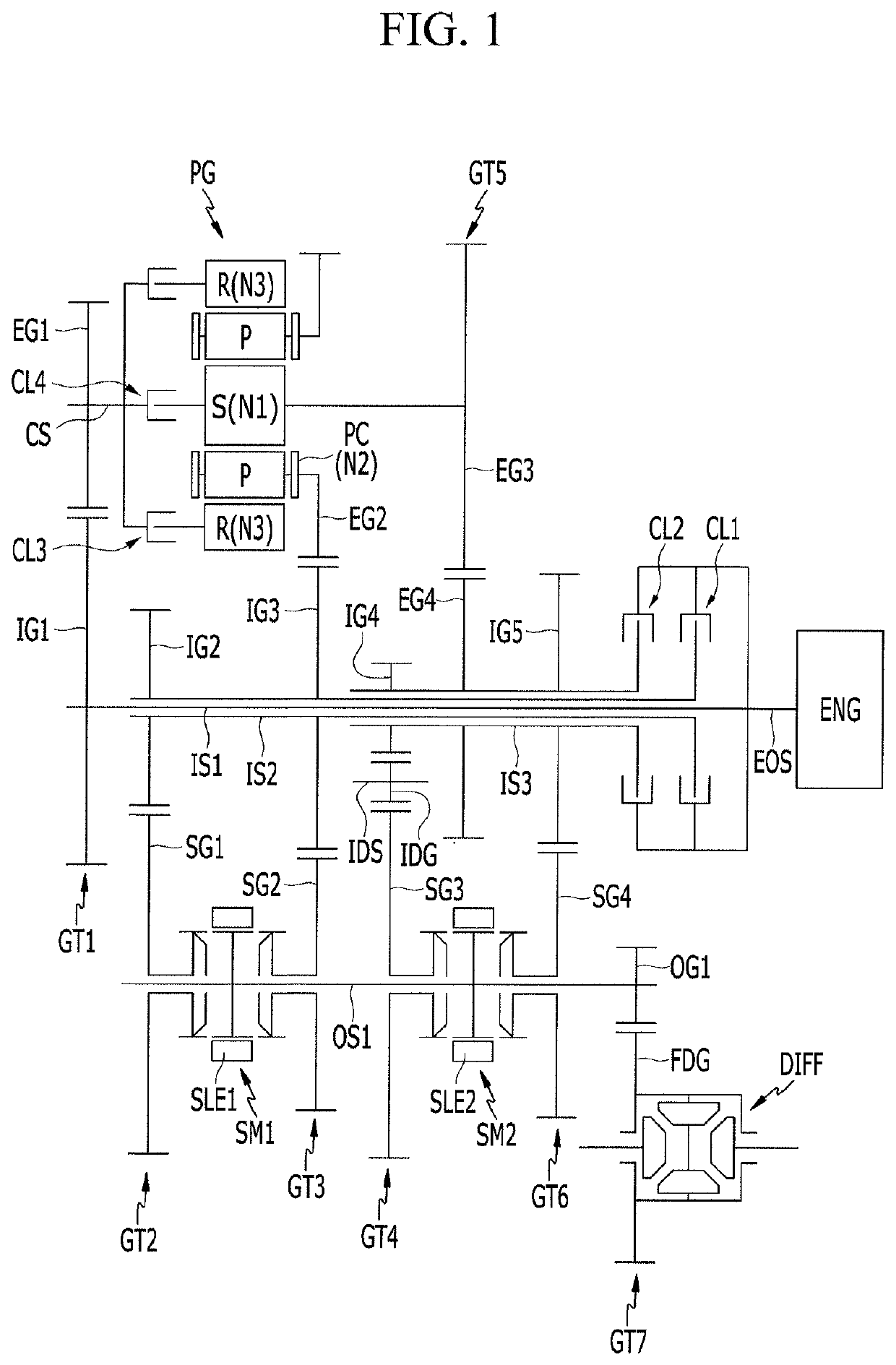

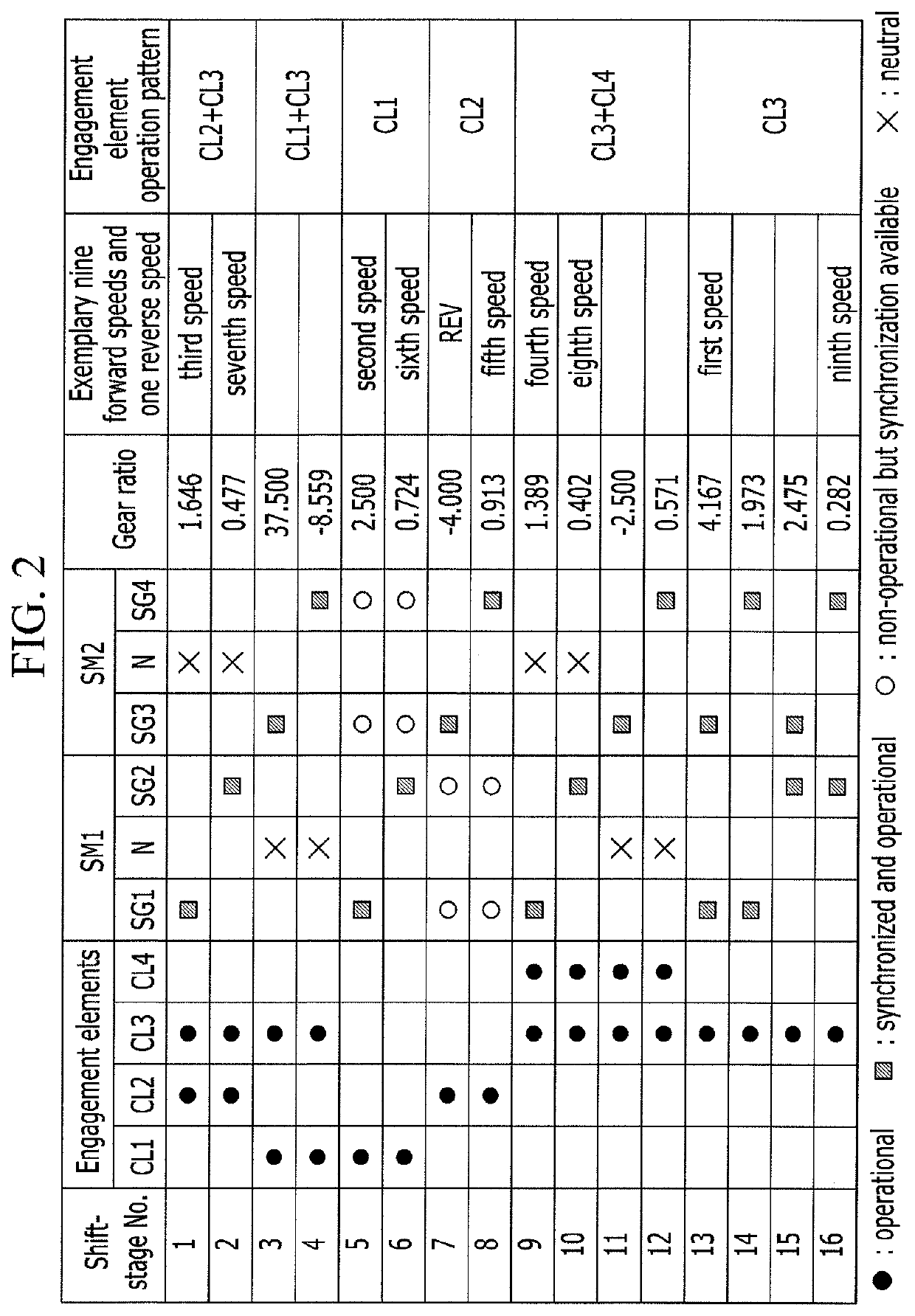

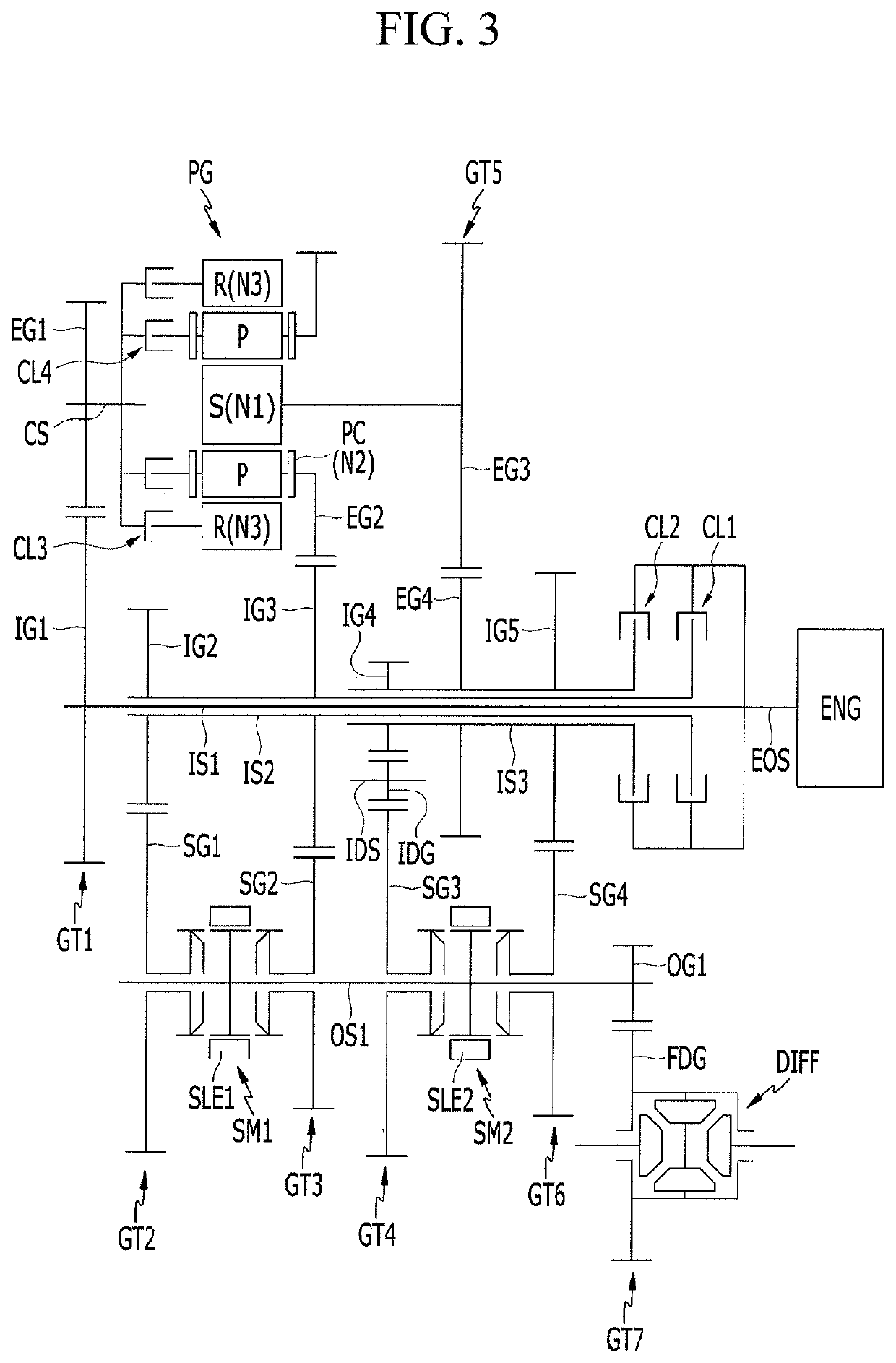

Control apparatus for power transmission system

InactiveCN106438985AReduce noiseReduce vibrationGear vibration/noise dampingToothed gearingsAutomatic transmissionControl theory

When a state of a vehicle is a predetermined state of the vehicle where vehicle vibration occurs, weak circulating torque is generated to fill backlash inside an automatic transmission and in a power transmission path by half-engaging a second clutch for establishing a second power transmission path while a first power transmission path remains established in the automatic transmission. A speed ratio of the second power transmission path is alternatively set to a lower vehicle speed-side speed ratio with respect to a speed ratio of the first power transmission path or a higher vehicle speed-side speed ratio with respect to the speed ratio of the first power transmission path in response to a traveling state. It is possible to generate weak circulating torque in a direction to increase an input shaft rotation speed or in a direction to reduce the input shaft rotation speed in accordance with the traveling state.

Owner:TOYOTA JIDOSHA KK

Gearbox for vehicles and vehicles comprising such a gearbox

InactiveUS10018259B2Reduce fuel consumptionReduce noiseToothed gearingsTransmission elementsCouplingEngineering

Owner:SCANIA CV AB

Stepless speed changer

PendingCN106996447ARealize automatic matchingRealize high-power flexible transmission occasionsTransmission elementsFluid gearingsControl theoryPower density

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

Transmission apparatus

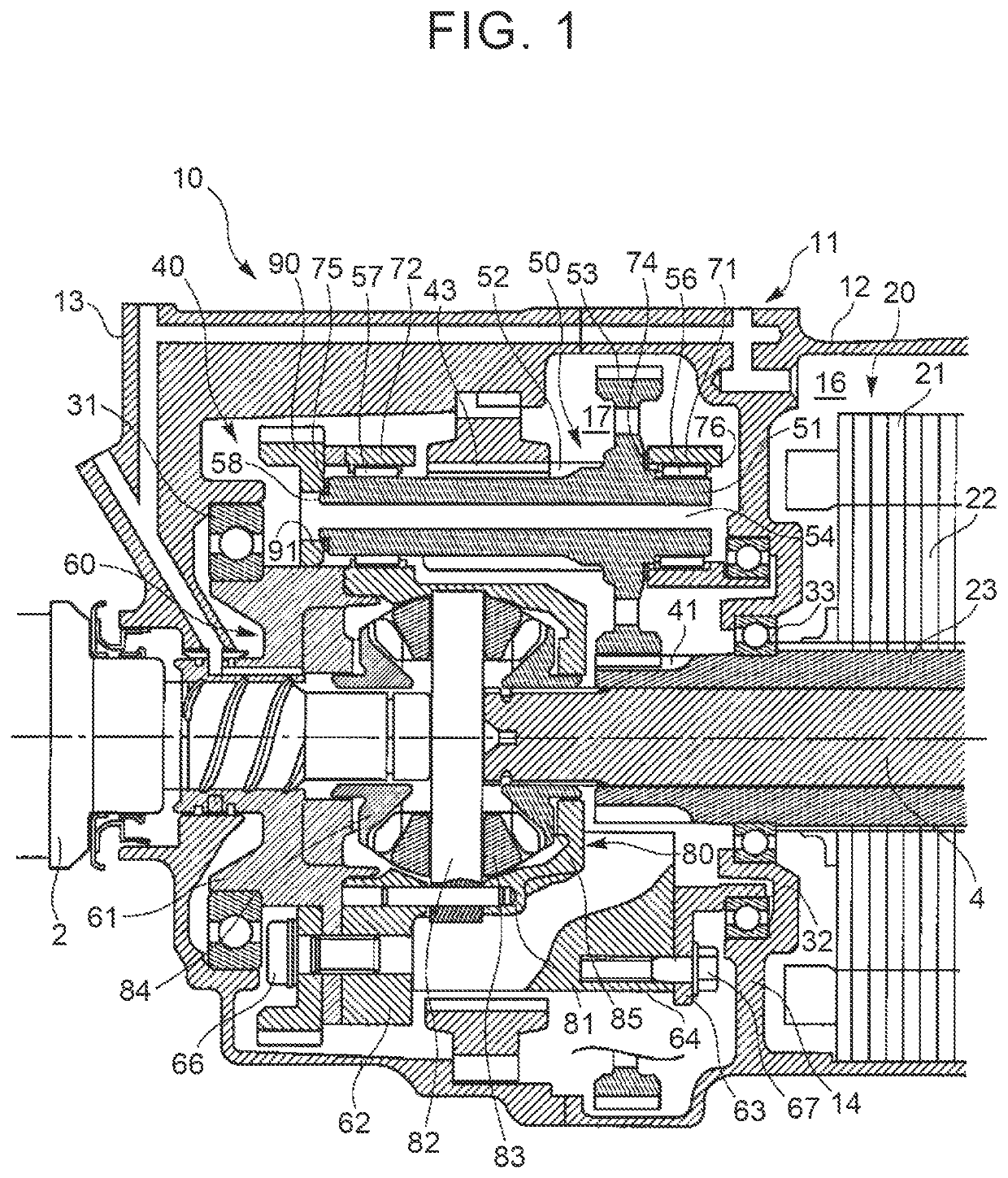

ActiveUS20150260268A1Process stabilityEliminate relative rotationHybrid vehiclesControlled membersExternal combustion engineEngineering

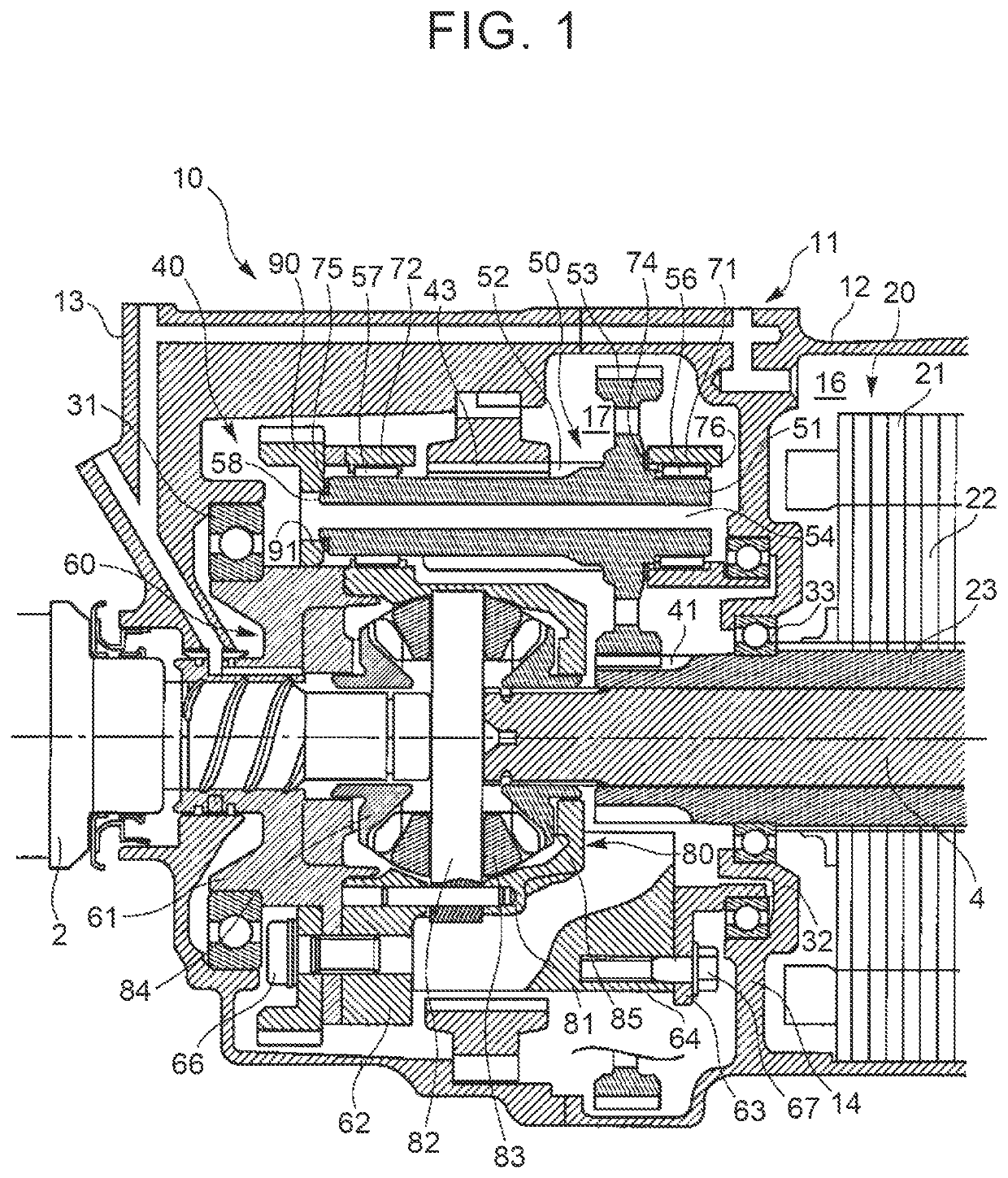

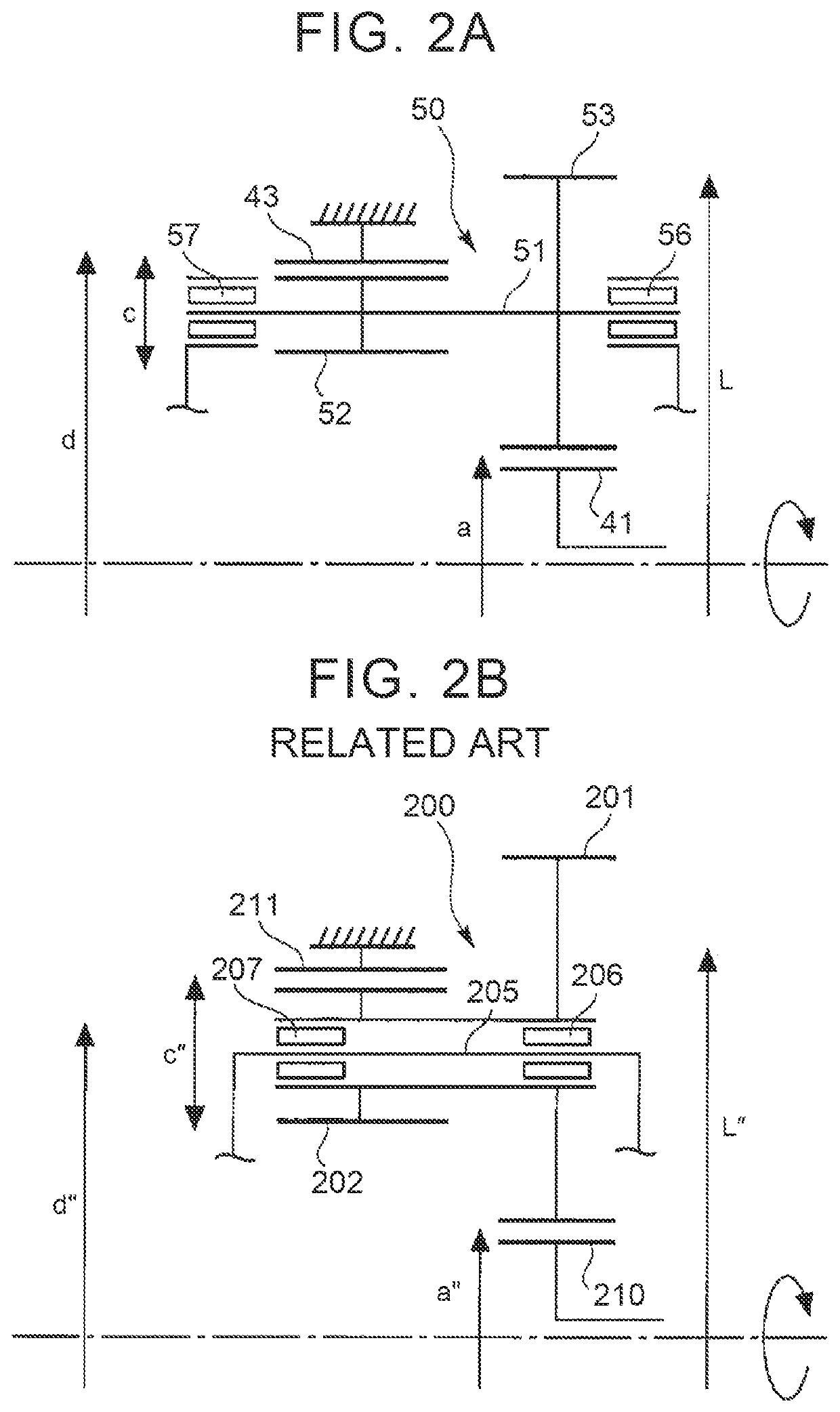

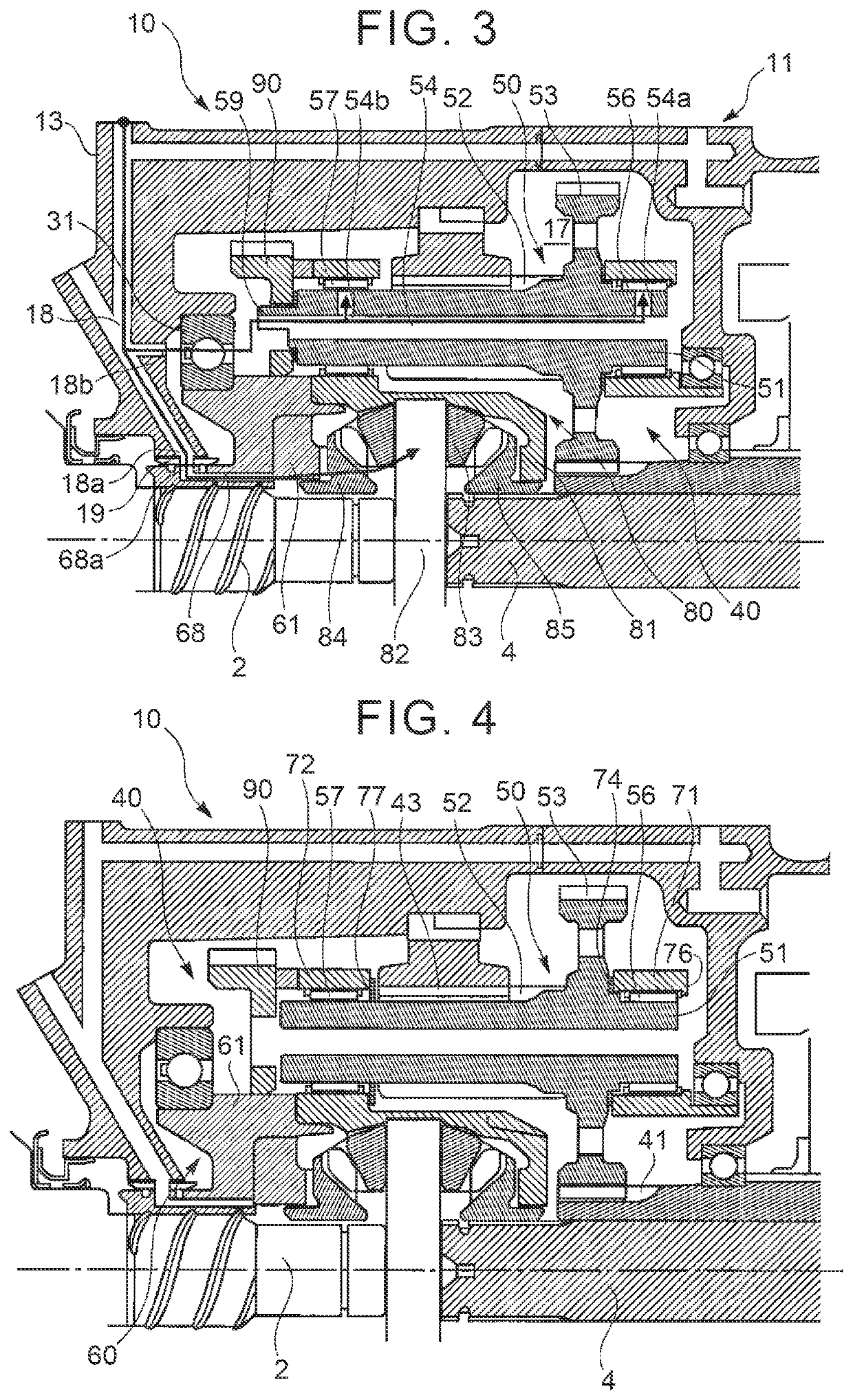

In a dual clutch transmission, on one end side of a first input shaft connectable to an internal combustion engine via a first clutch, a planetary gear mechanism for a predetermined speed stage is provided, and a sun gear thereof is provided to rotate integrally with the first input shaft and an electric motor. A ring gear is fixed to a case, and a synchromesh mechanism is provided connectably and disconnectably with respect to the planetary gear carrier for selecting the predetermined speed stage. When the synchromesh mechanism is connected to the planetary gear carrier, rotation of the carrier is transmitted to the countershaft. The ring gear is attached to an annular attachment member to be fixed to the case. In a circumferential side surface of the attachment member, openings for inserting a shift fork and an opening for inserting a finger for the convenience of assembly work are provided.

Owner:HONDA MOTOR CO LTD

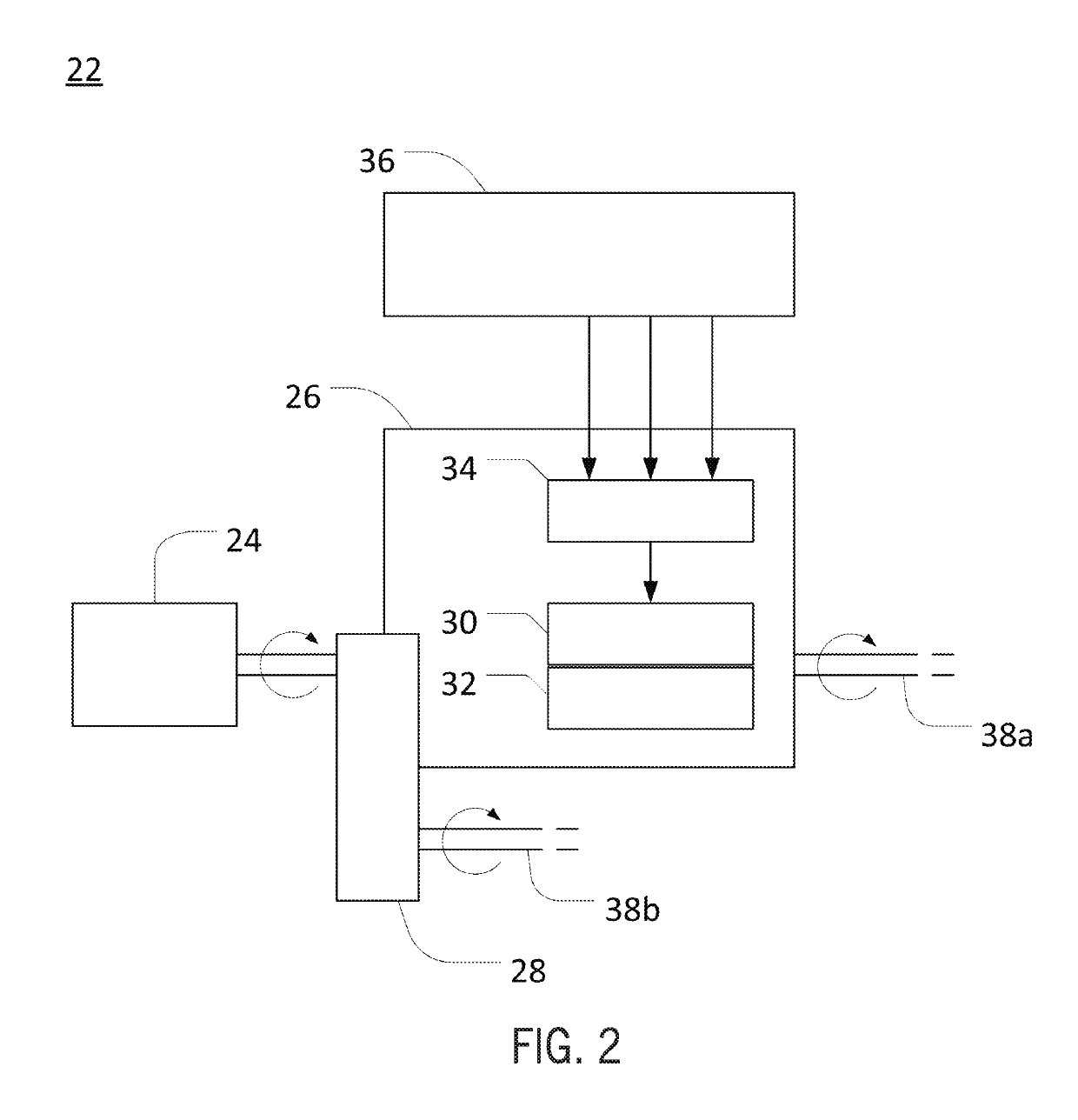

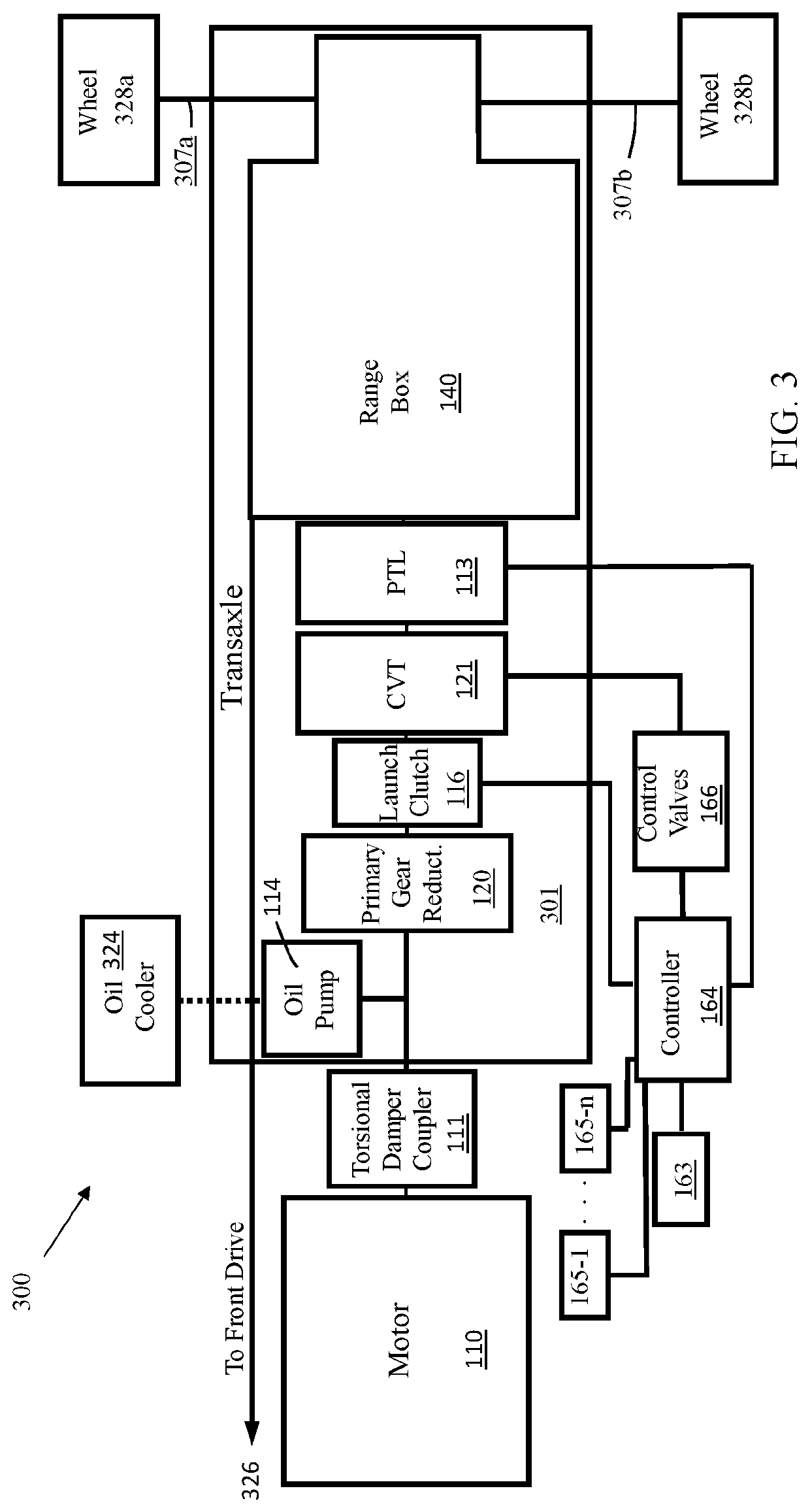

Drivetrain layout with cvt

A drivetrain layout that includes a primary gear reduction, a continuously variable transmission (CVT), a peak torque limiting (PTL) device and a range box is provided. The primary gear reduction is operationally engaged to an output of a motor. The CVT includes a primary pulley and a secondary pulley. The primary pulley of the CVT is operationally engaged to the primary gear reduction. The primary gear reduction reduces a rotational speed of the output of the motor that is coupled to the primary pulley of the CVT. The range box is operationally engaged with the secondary pulley of the CVT. The range box is configured to coupled torque between the CVT and wheels of a vehicle. The PTL device in operational engagement between the secondary pulley of the CVT and the range box, the PTL device configured to protect the drivetrain layout from torque transients.

Owner:TEAM INDS

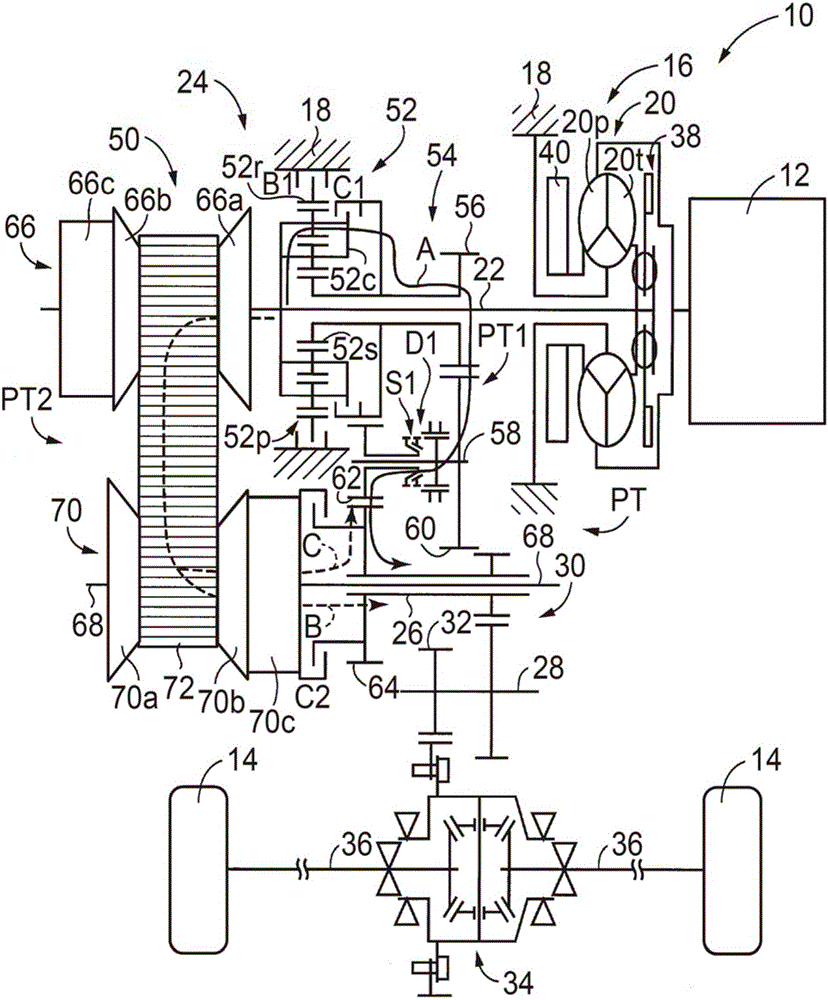

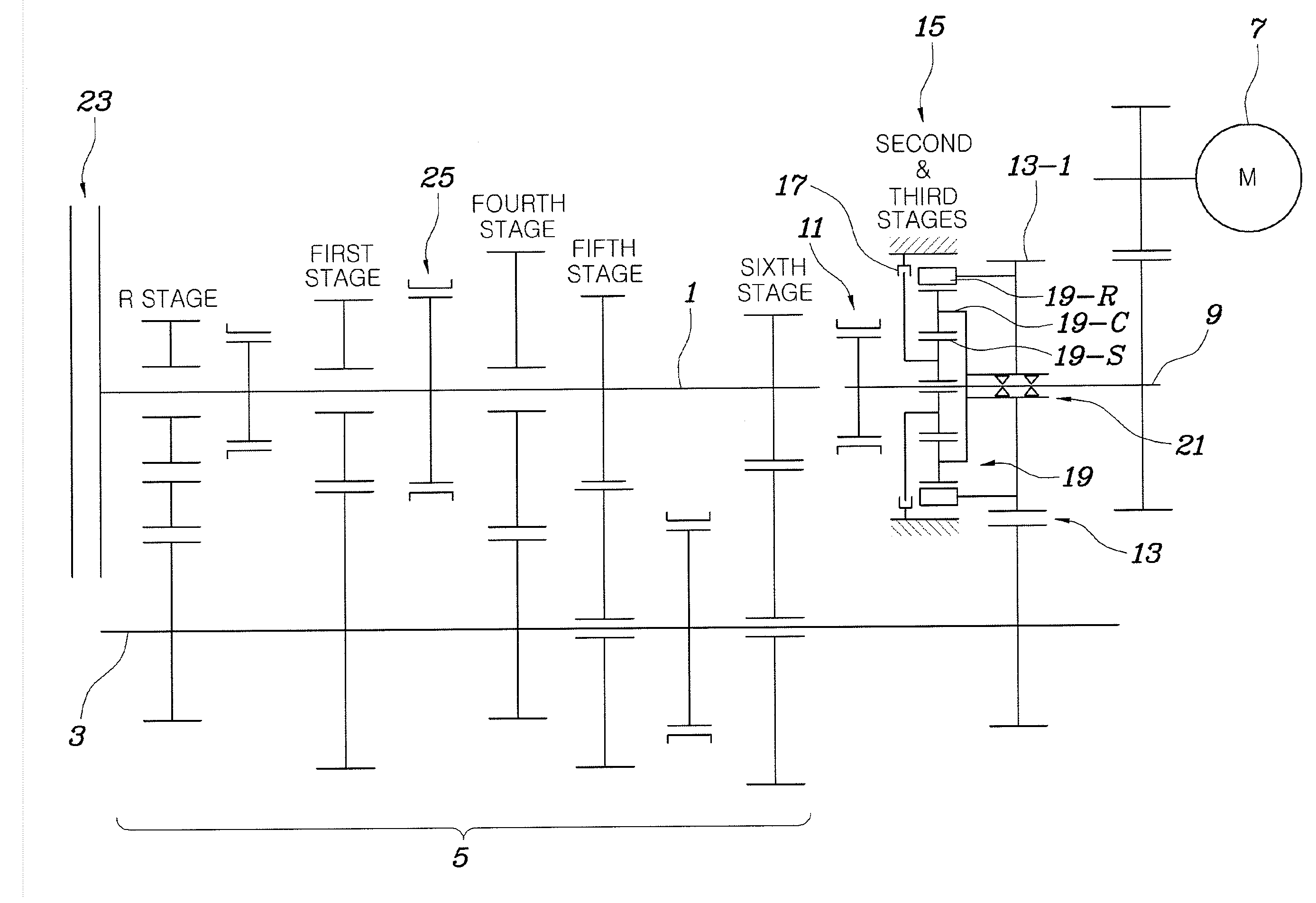

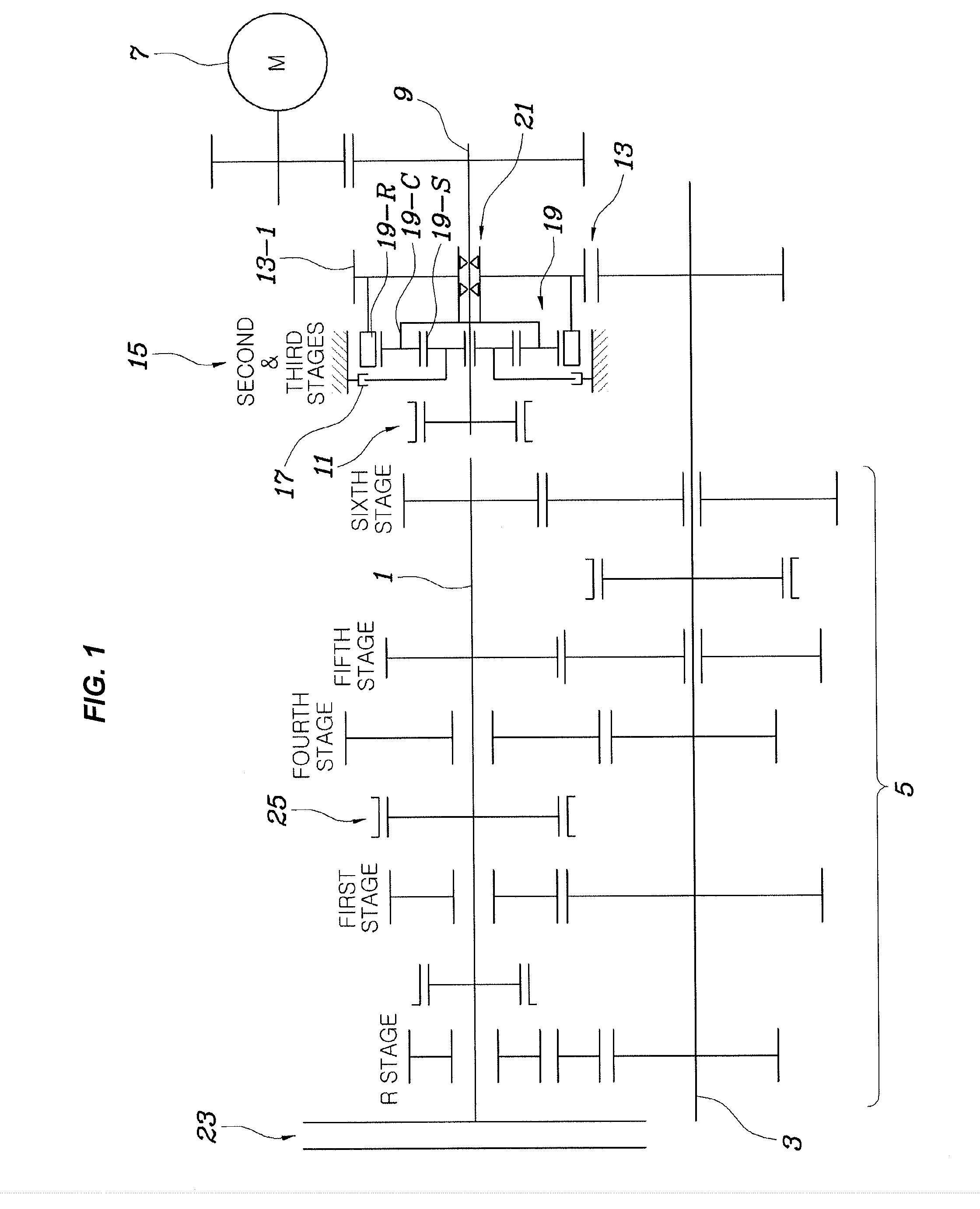

Hybrid power train for vehicle

ActiveUS20150119177A1Improve shift qualityImprove vehicle efficiencyHybrid vehiclesGas pressure propulsion mountingControl theoryClutch

A hybrid power train for a vehicle may include a gear module having a plurality of shift stages of a synchromesh type on a first input shaft and an output shaft arranged in parallel, a second input shaft driven by a motor and disposed coaxially with the first input shaft, a clutch means for connecting or disconnecting the second input shaft and the first input shaft, and variable shift ratio providing means for transmitting the torque of the second input shaft to the output shaft through an external engaged-gear pair selectively in two different shift ratios.

Owner:HYUNDAI MOTOR CO LTD

Transaxle

ActiveUS11279218B2Small sizeReduce the overall diameterBraking element arrangementsGearboxesNeedle roller bearingReduction drive

A transaxle includes a planetary gear reducer and a differential device. The planetary gear reducer includes a stepped pinion, a first needle bearing, a second needle bearing, and a carrier. The stepped pinion includes a pinion shaft with which a large diameter pinion and a small diameter pinion are integrated. The first needle bearing is fitted to a part of the pinion shaft outside the large diameter pinion. The second needle bearing is fitted to a part of the pinion shaft outside the small diameter pinion. The carrier is configured to support the stepped pinion via the first needle bearing and the second needle bearing such that the stepped pinion is rotatable with respect to the carrier, and to couple the stepped pinion and the differential device.

Owner:TOYOTA JIDOSHA KK

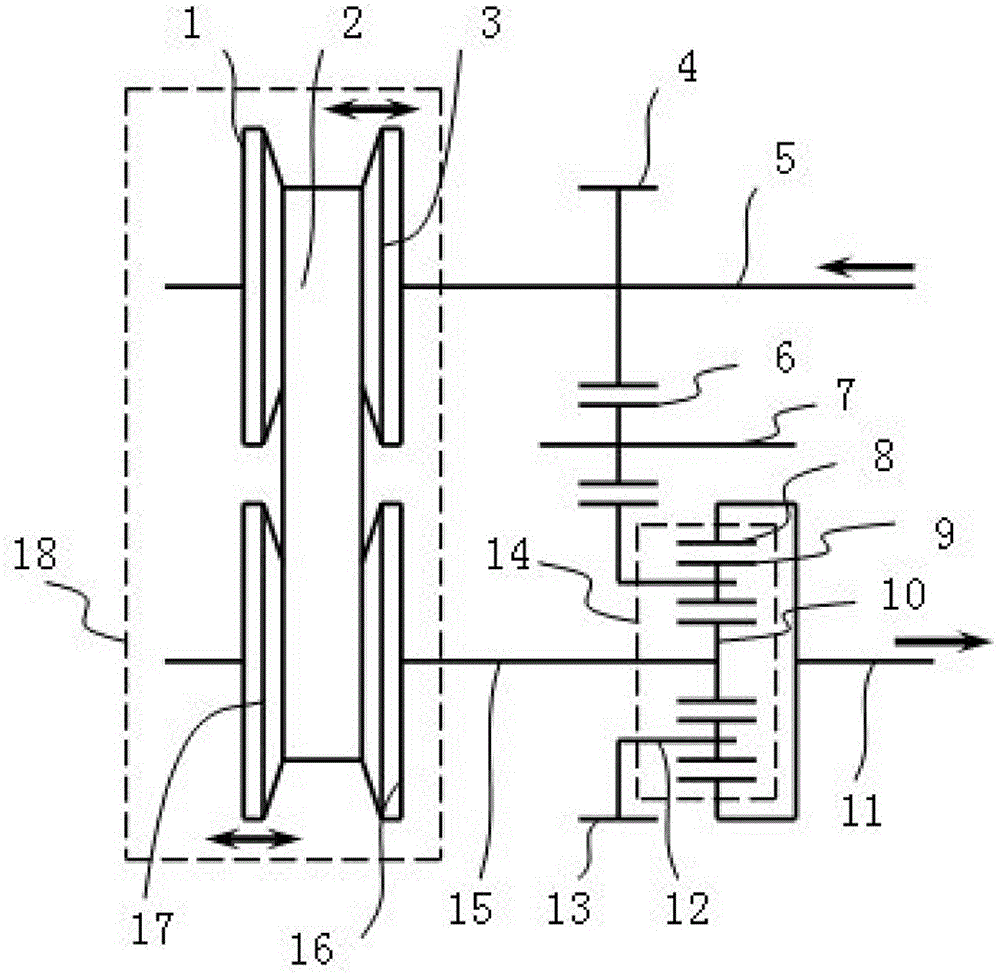

Stepless speed change transmission device for single row planetary gear mechanism

The invention discloses a stepless speed change transmission device for a single row planetary gear mechanism. The stepless speed change transmission device comprises a belt type stepless speed changer, the single row planetary gear mechanism, an input shaft and an output shaft. The single row planetary gear mechanism comprises a planet carrier, a tooth ring, a sun wheel and a planet wheel. The belt type stepless speed changer comprises a driving disc and a driven disc, the planet wheel is in transmission connection with a driving gear through an idle wheel, the sun wheel is connected with the driven disc of the belt type stepless speed changer, the tooth ring is connected with the output shaft, and the driving gear and the driving disc of the belt type stepless speed changer are installed on the input shaft. According to the stepless speed change transmission device, large-range changes of the speed changer transmission ratio is obtained by small-range control of the transmission ratio changes of the belt type stepless speed changer, so that the rotating speed of an engine is low when an automobile runs at a high speed, and the economy is improved. Besides, a reverse gear mechanism does not need to be arranged independently, the manufacturing and control difficulty of a control mechanism is reduced, and the cost of the speed changer and the failure rate are also reduced.

Owner:SHUNDE POLYTECHNIC

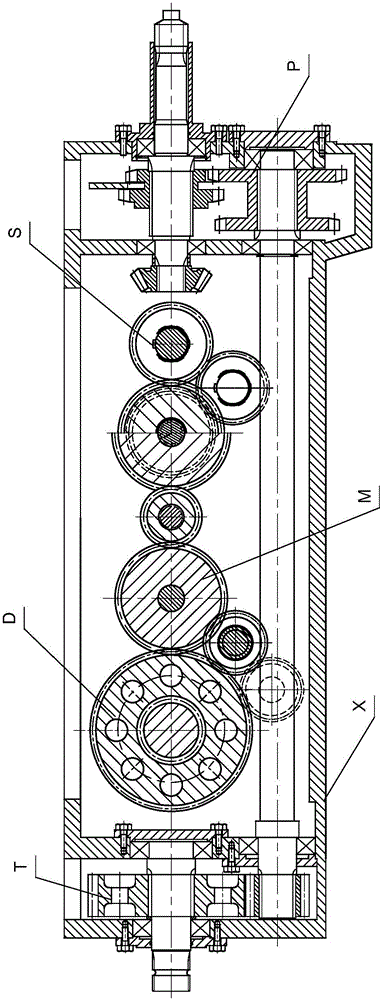

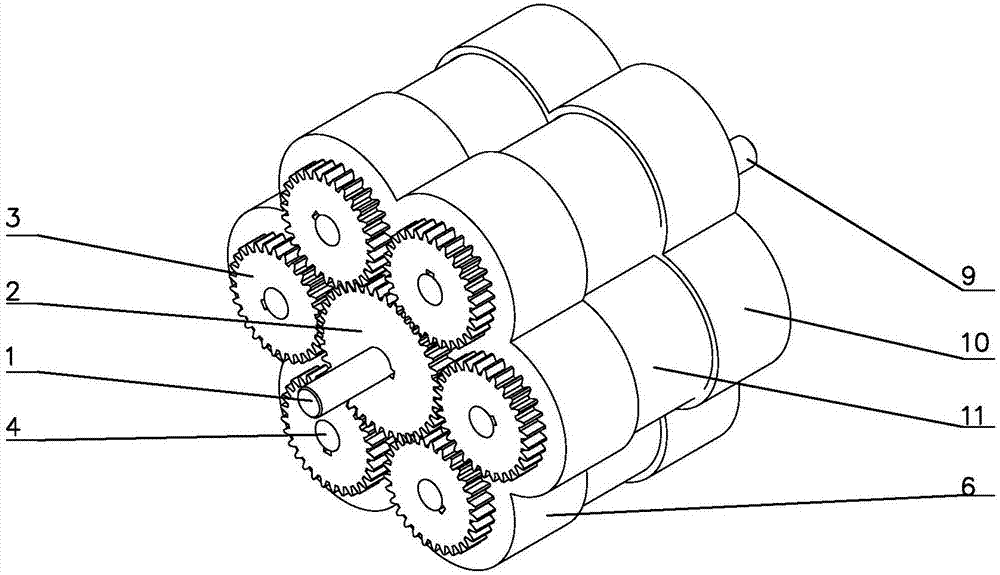

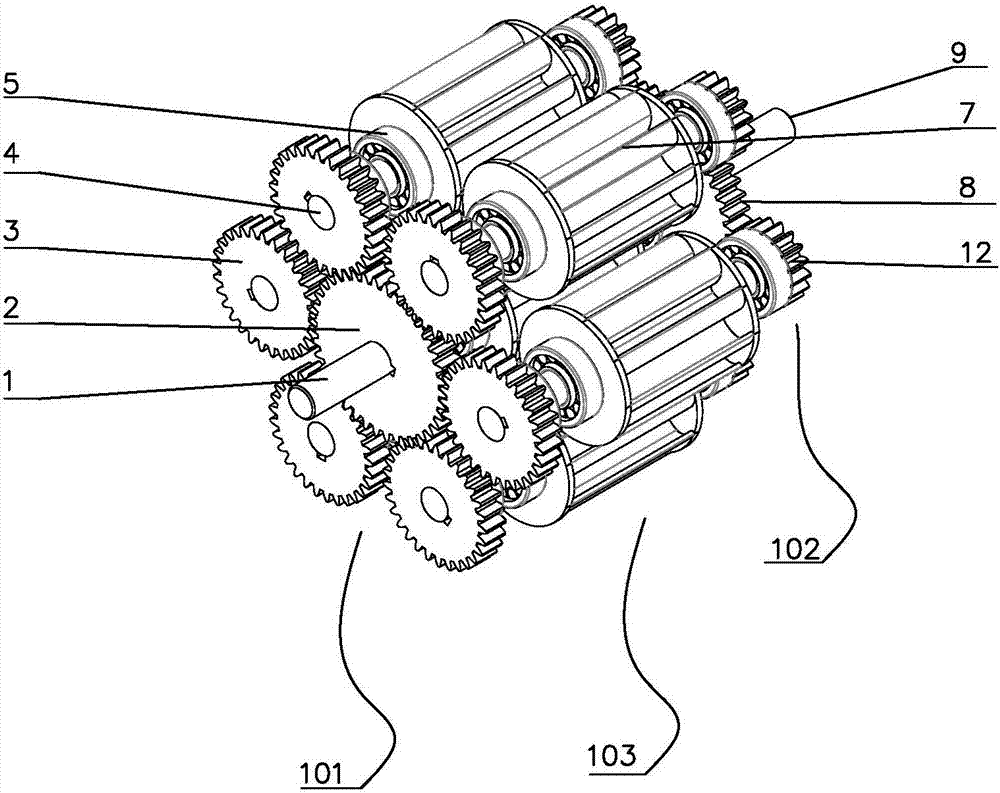

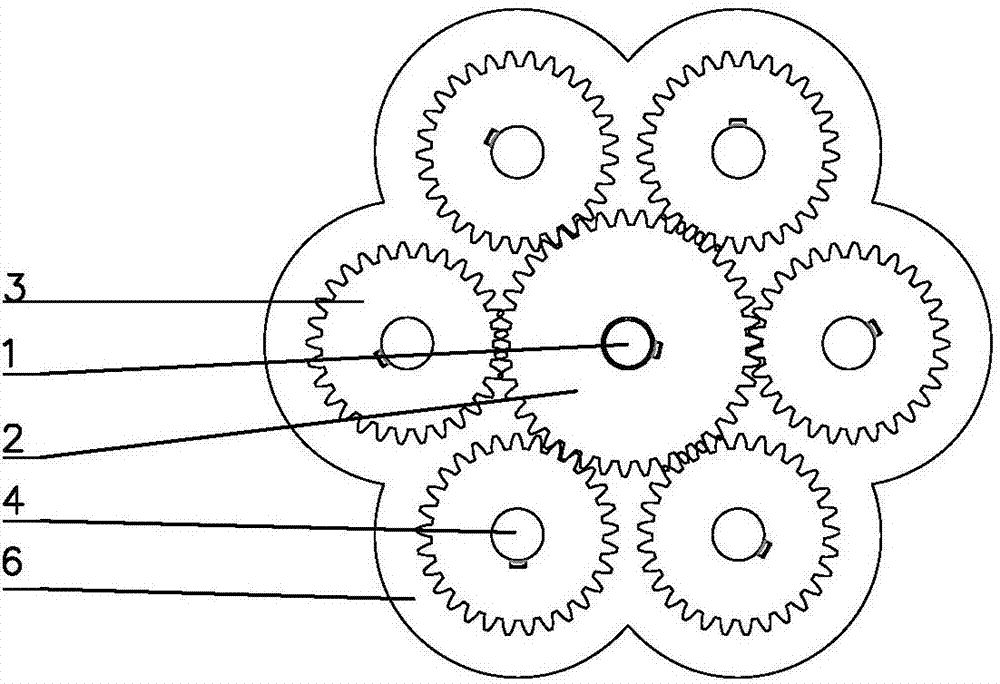

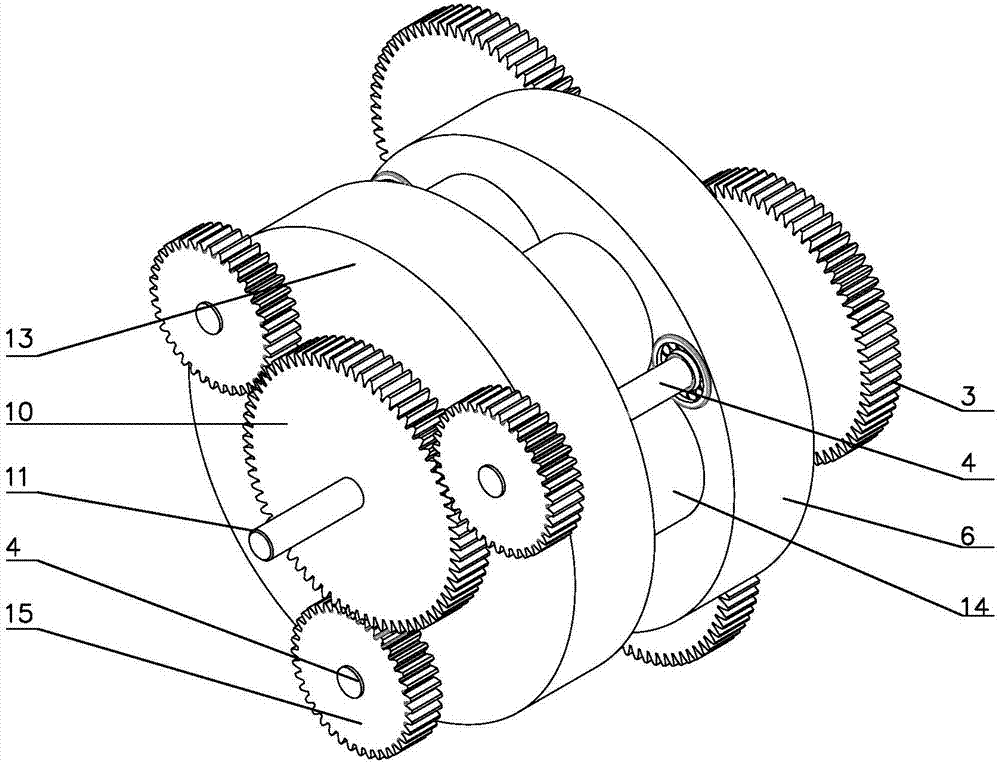

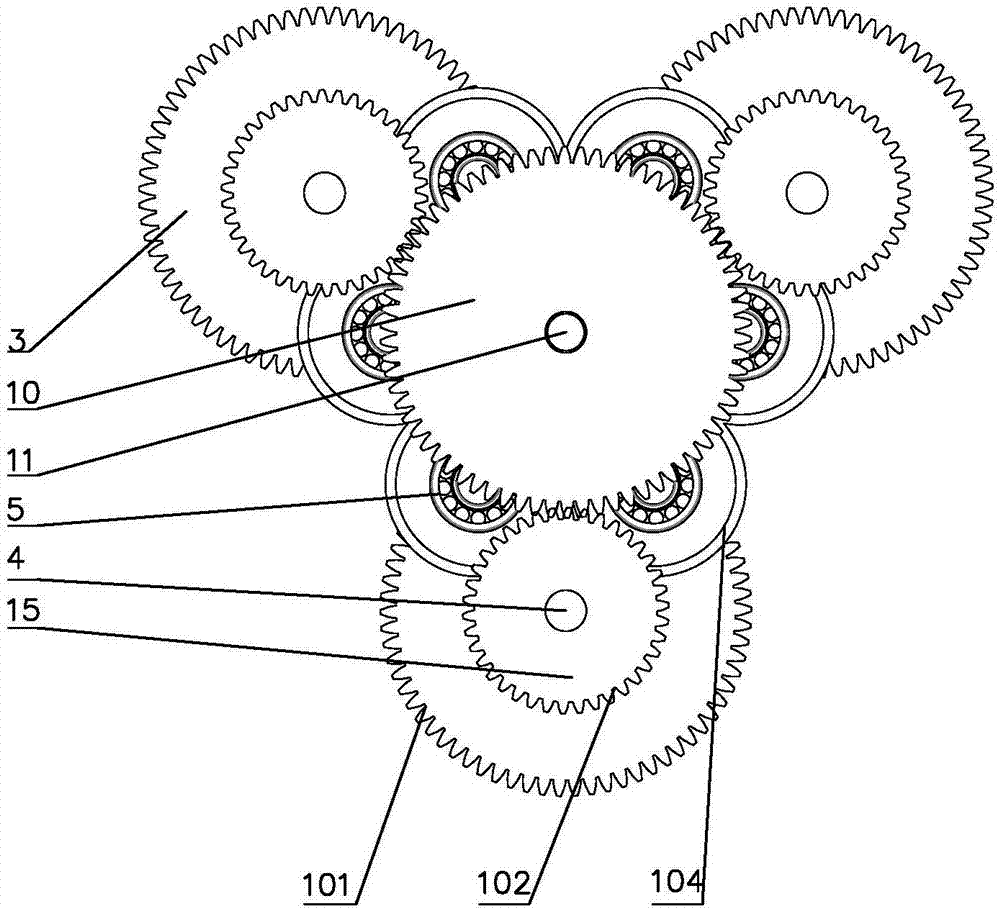

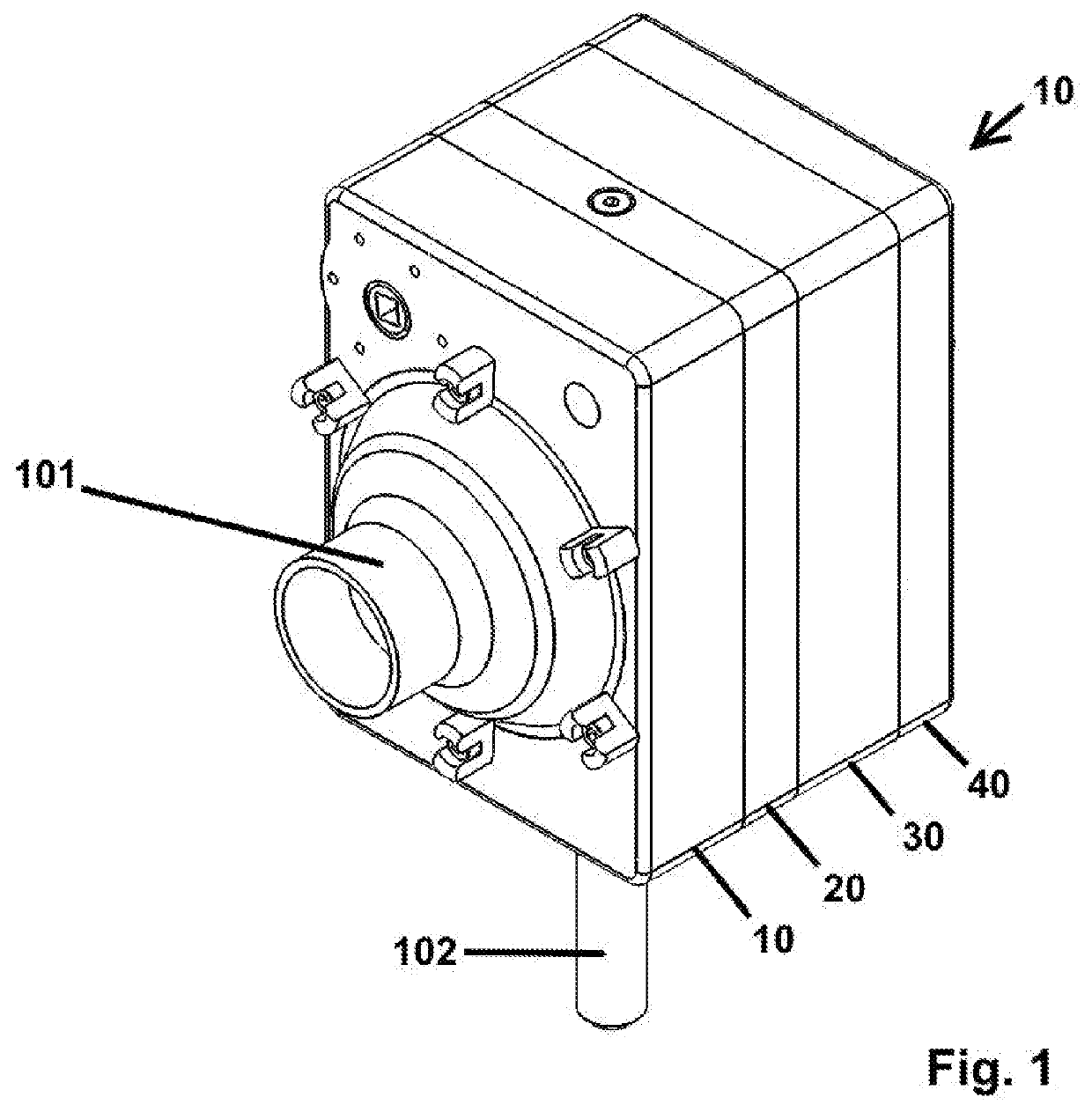

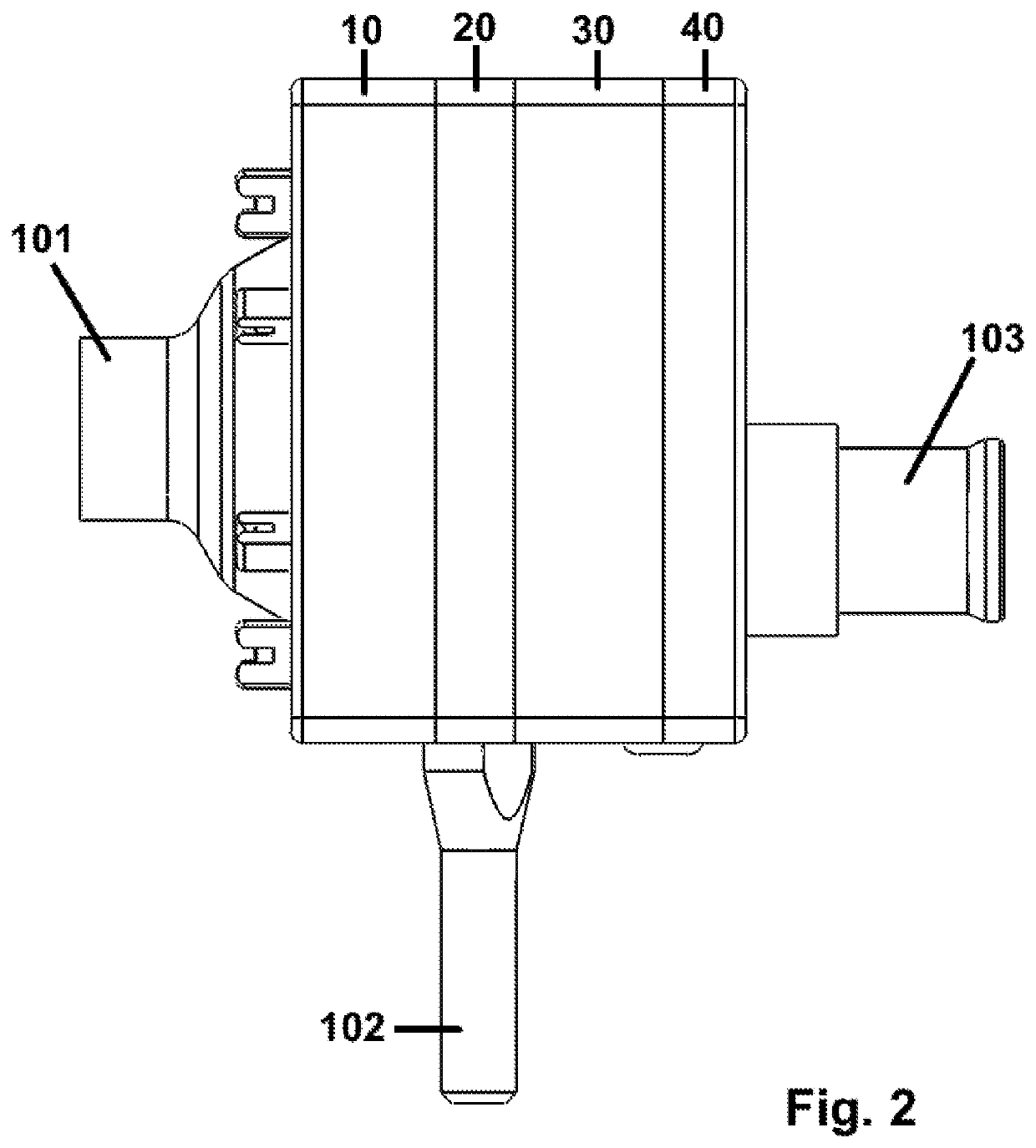

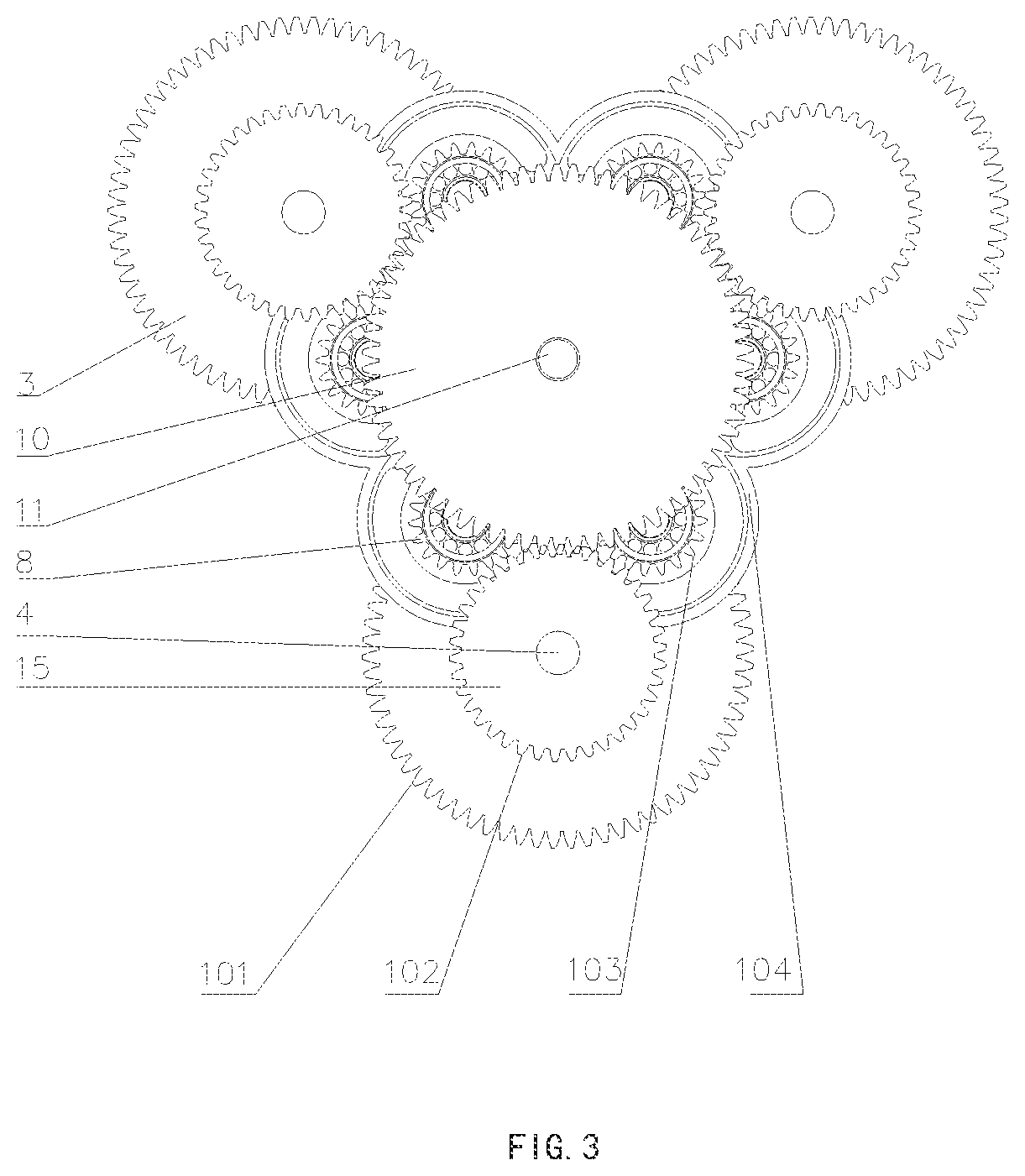

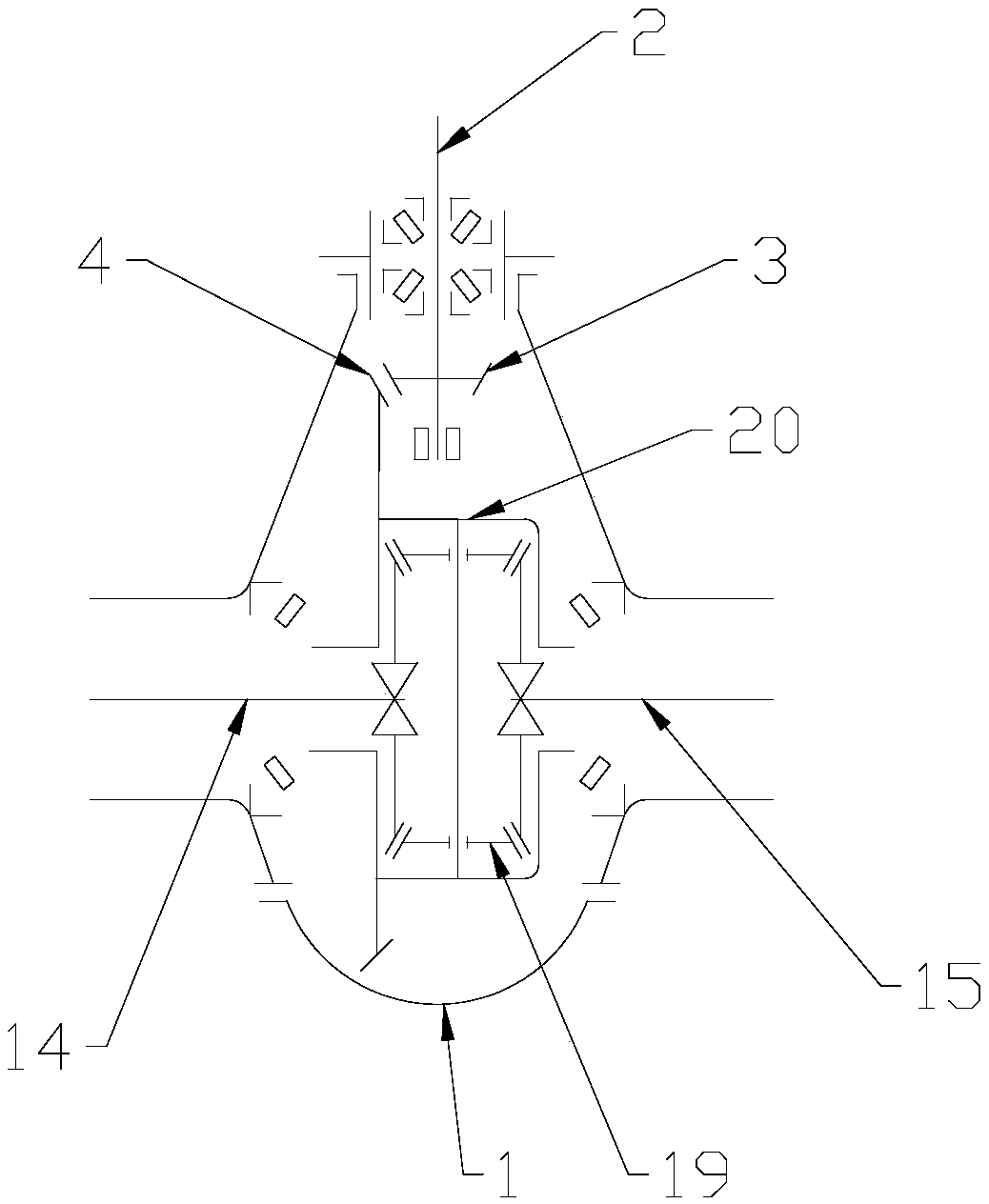

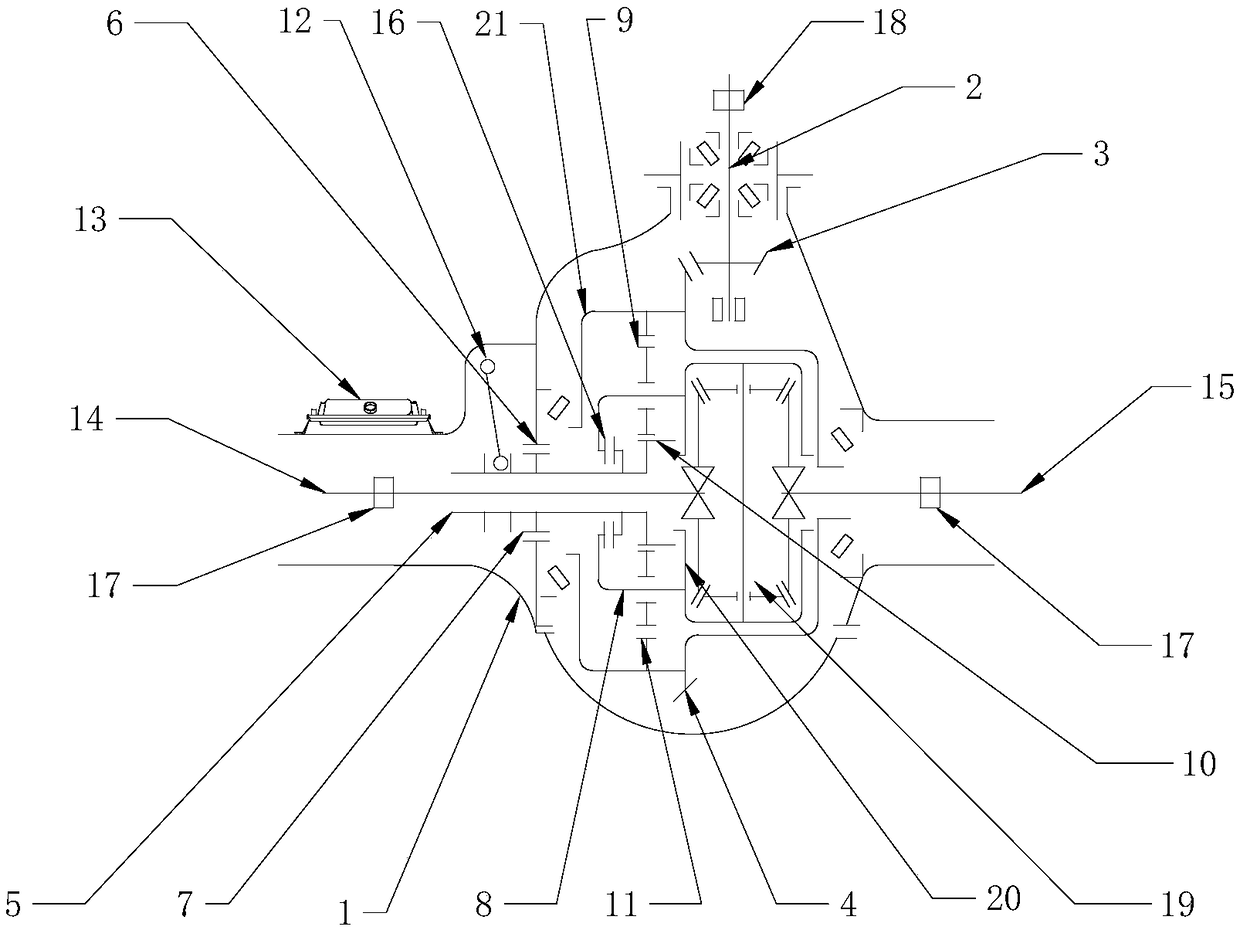

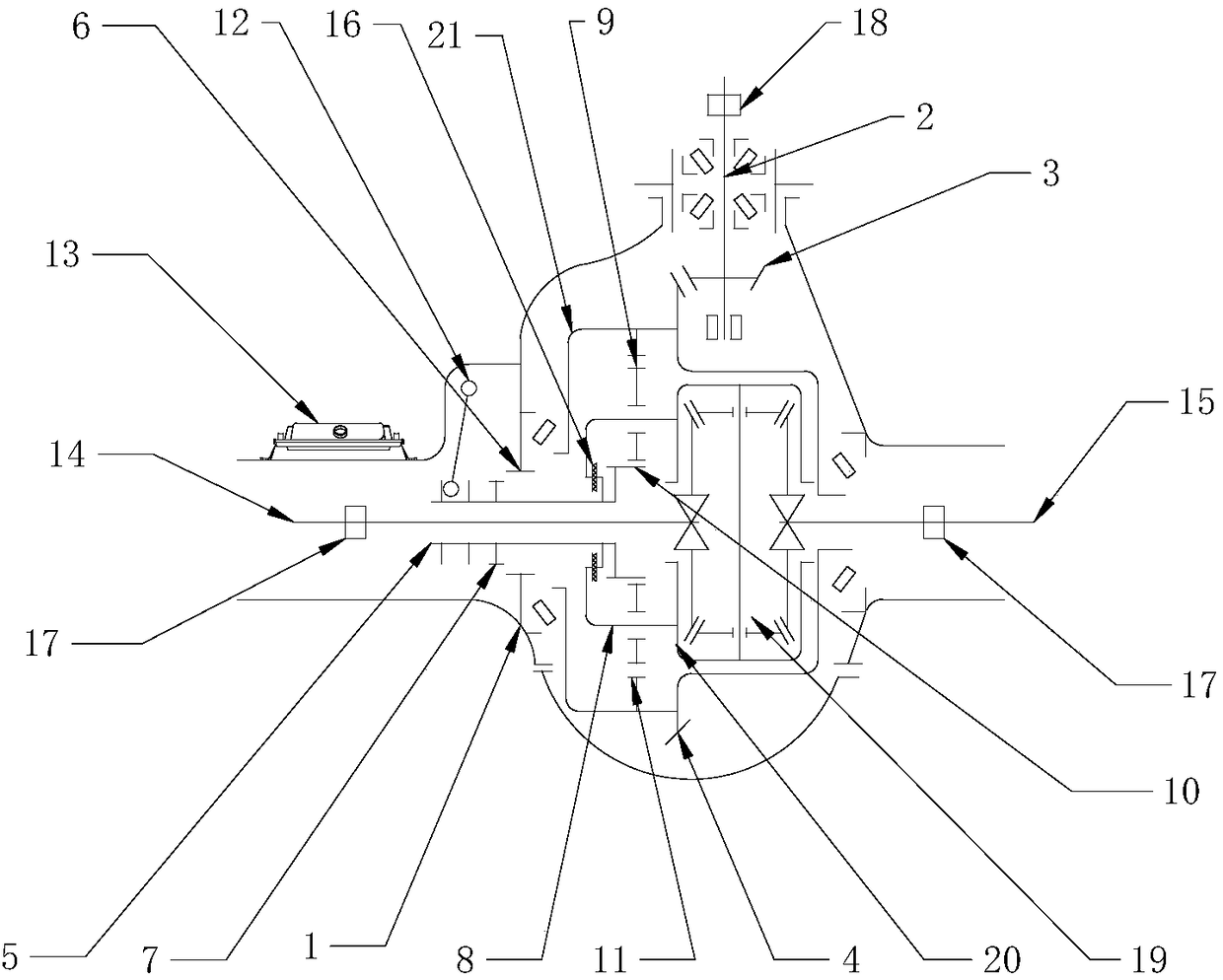

Continuously variable transmission

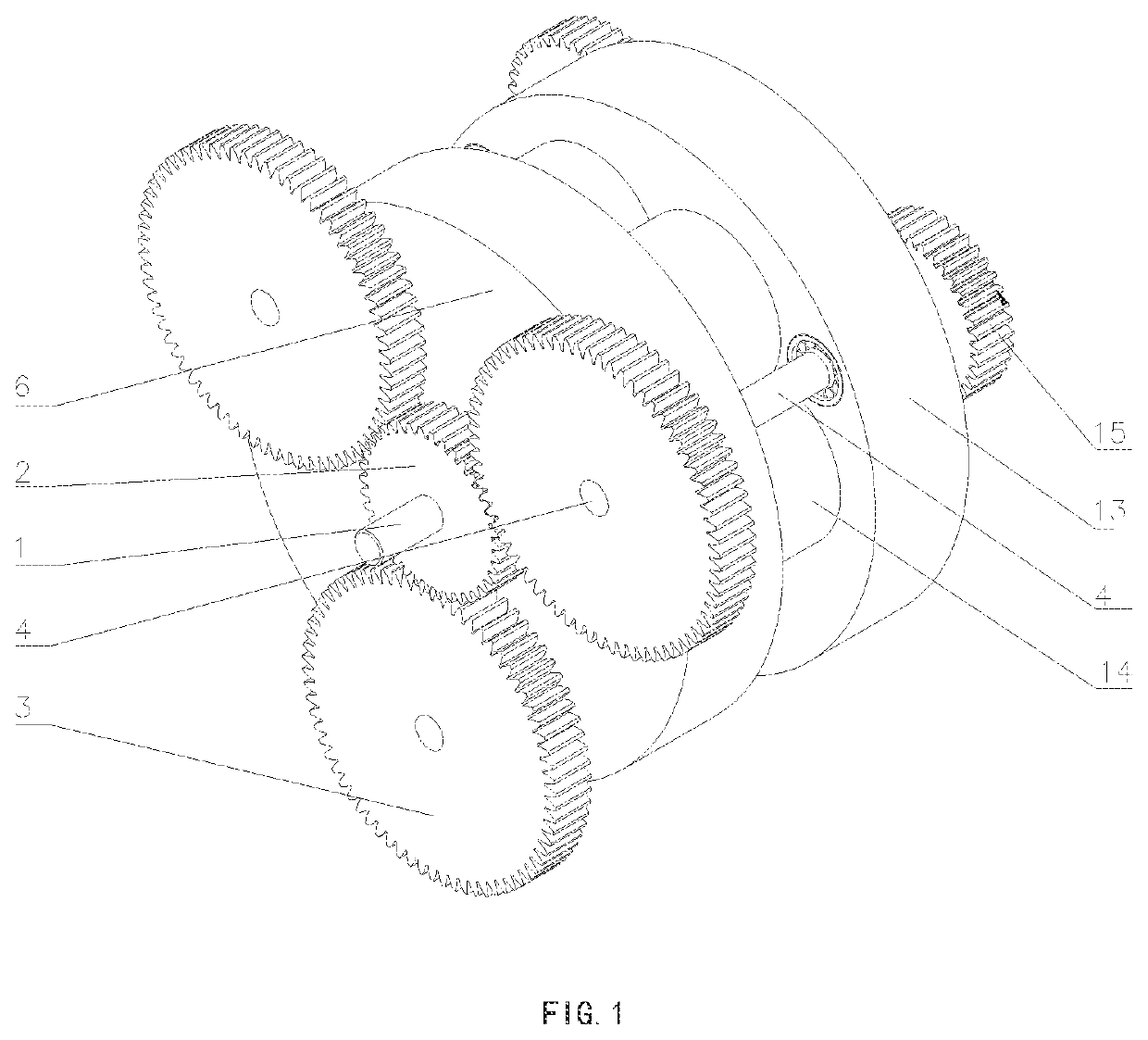

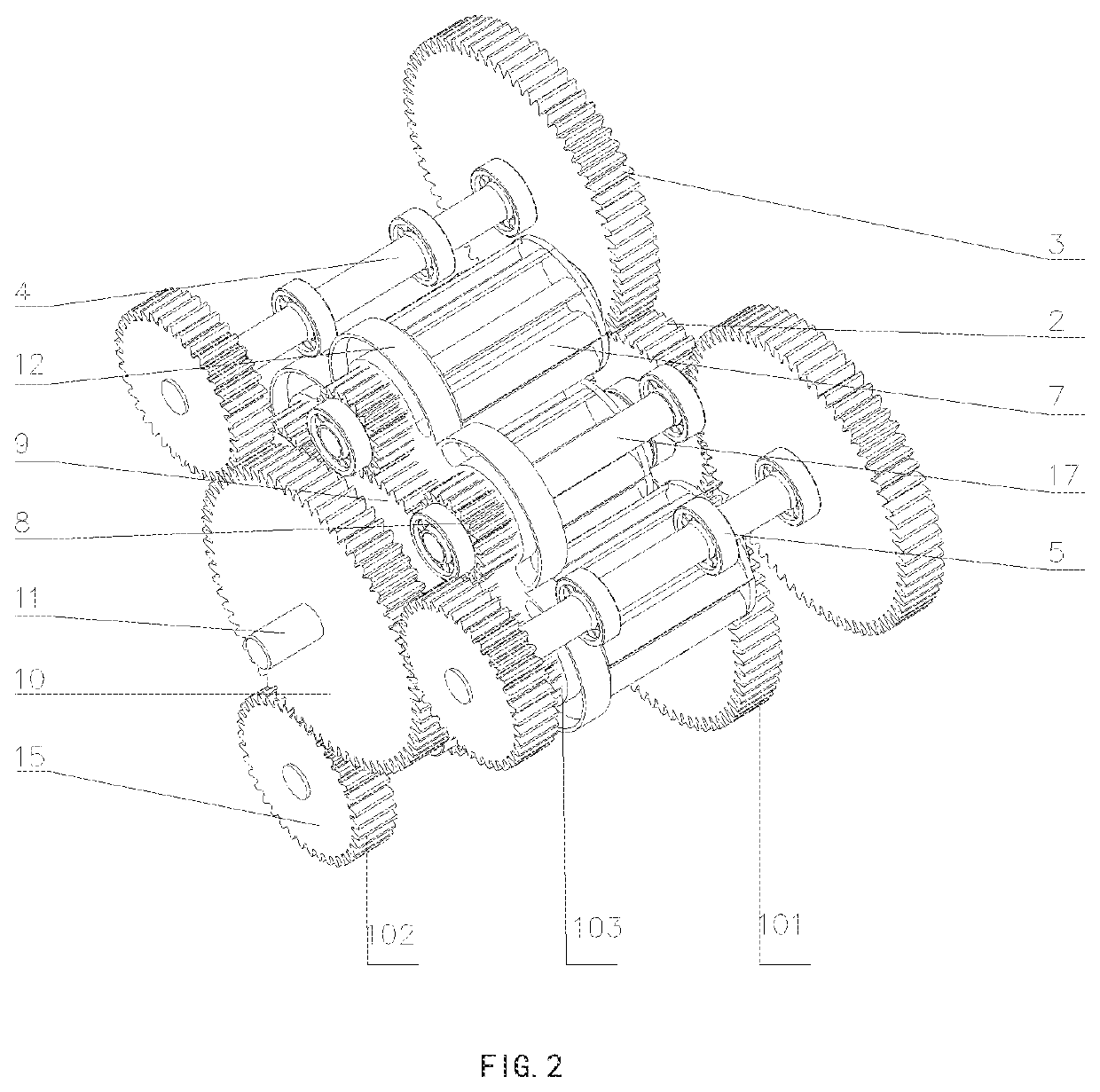

Provided is a continuously variable transmission capable of solving a technical problem of a complex structure comprising three planetary gear sets including a planetary gear set at an input end, a planetary gear set at an output end and a bucket wheel-based planetary gear set. The continuously variable transmission comprises a planetary gear set (101) at an input end and a planetary gear set (102) at an output end. A planetary carrier (103) having a cavity is provided between the planetary gear set (101) at the input end and the planetary gear set (102) at the output end. The planetary carrier (103) comprises an input end cover (6) and an output end cover (10). The input end cover (6) is connected to an inner side of the planetary gear set (101) at the input end. The output end cover (10) is connected to an inner side of the planetary gear set (102) at the output end. A bucket-wheel housing (11) having a cavity is fixed between the input end cover (6) and the output end cover (10). A bucket-wheel (7) is fixed to a planetary gear connecting shaft (4) located inside the bucket-wheel housing (11).

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

Transaxle

ActiveUS20210213819A1Reduce radial sizeReduce rateBraking element arrangementsElectric propulsion mountingNeedle roller bearingReduction drive

A transaxle includes a planetary gear reducer and a differential device. The planetary gear reducer includes a stepped pinion, a first needle bearing, a second needle bearing, and a carrier. The stepped pinion includes a pinion shaft with which a large diameter pinion and a small diameter pinion are integrated. The first needle bearing is fitted to a part of the pinion shaft outside the large diameter pinion. The second needle bearing is fitted to a part of the pinion shaft outside the small diameter pinion. The carrier is configured to support the stepped pinion via the first needle bearing and the second needle bearing such that the stepped pinion is rotatable with respect to the carrier, and to couple the stepped pinion and the differential device.

Owner:TOYOTA JIDOSHA KK

A gearbox for vehicles

ActiveUS20190376588A1Weaken energyReduce manufacturing costGearboxesToothed gearingsEngineeringRatio spread

A gearbox for vehicles that include a split gearbox, a main gearbox and a range gearbox. The range gearbox is shiftable into a low range gear, a high range gear and a reverse gear. The range gearbox includes a planetary gear, which may be shifted into a reverse gear. The split gearbox and the main gearbox are together arranged to have a combined ratio spread larger than 5, in that the split gearbox and the main gearbox are together arranged to have a combined largest gear ratio over 4:1, and in that the planetary gear in the range gearbox has a gear ratio less than 4:1 when shifted into the reverse gear.

Owner:SCANIA CV AB

Actuator assembly for electronic parking brake

InactiveCN107848518AStable alignmentIncreased durabilityBraking element arrangementsBraking action transmissionEngineeringActuator

Owner:KEYANG ELECTRIC MACHINERY

Seed-positioning device used in agricultural planting machines

PendingUS20210051844A1Increase planting speedCapacity lostGearingSeed depositing seeder partsSeederHydraulic motor

The seeding positioner device applied to agricultural planters comprising a structure consisted of a rotating seed pusher that directs the seeds to a labyrinth (14) moving in a opposite direction, allowing to control the seed release as the speed the assembly rotates, so that the discharge spacing will be commanded by a gears-driven compartment (22) which directs the seeds to a discharge tube (23), wherein the pneumatic system generates positive air pressure. Thus, the compressed air will push the seed against the soil in order to maintain the perfect line positioning and increasing the planting speed. The seeding positioner device can be driven by an electric motor, a pneumatic motor, a hydraulic motor, a cardan shaft, a pitch chain, or a twisting cable, according to the planter type. In addition, the device constructional shape prevents the seeds from being damaged and loses germination capacity when passing through the mechanism, allowing the equipment to be applied and adapted to work with any seed type.

Owner:COUTO PEDRO LUIS PEREIRA +1

Power transmission apparatus for vehicle

ActiveUS10837534B1Easy to optimizeImprove installabilityToothed gearingsTransmission elementsGear wheelTorque transmission

Owner:HYUNDAI MOTOR CO LTD +1

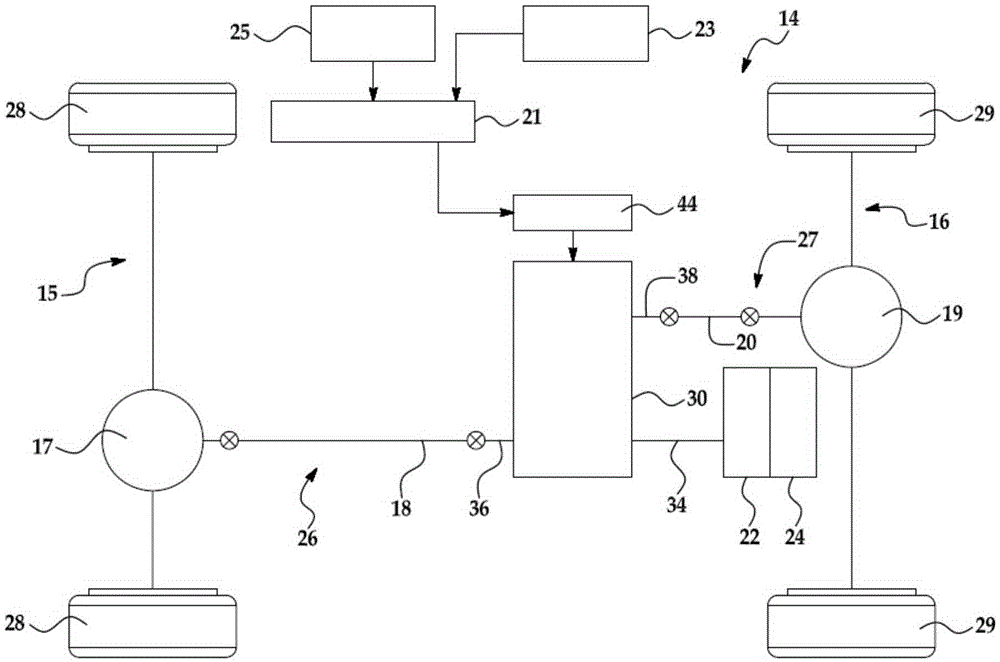

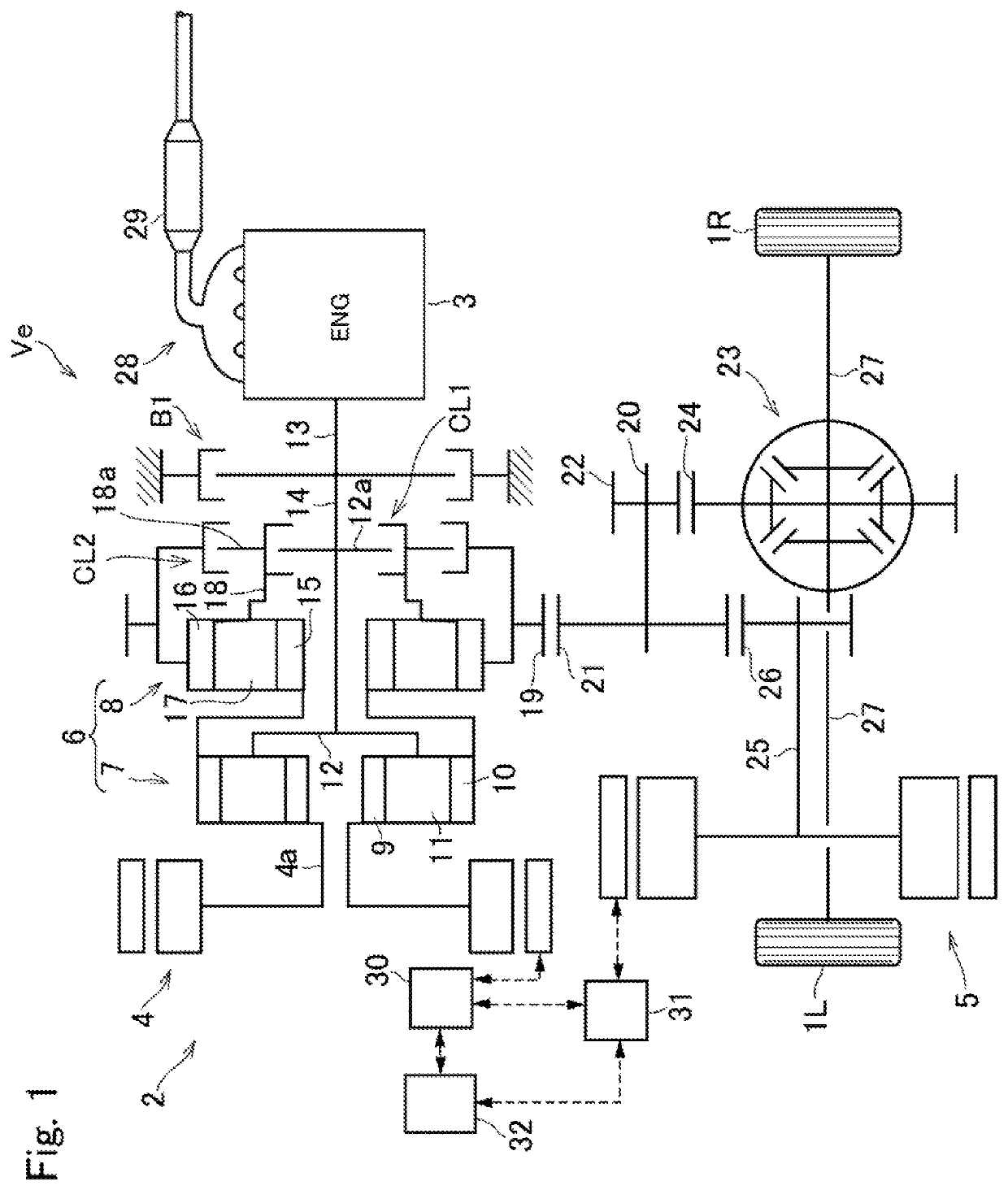

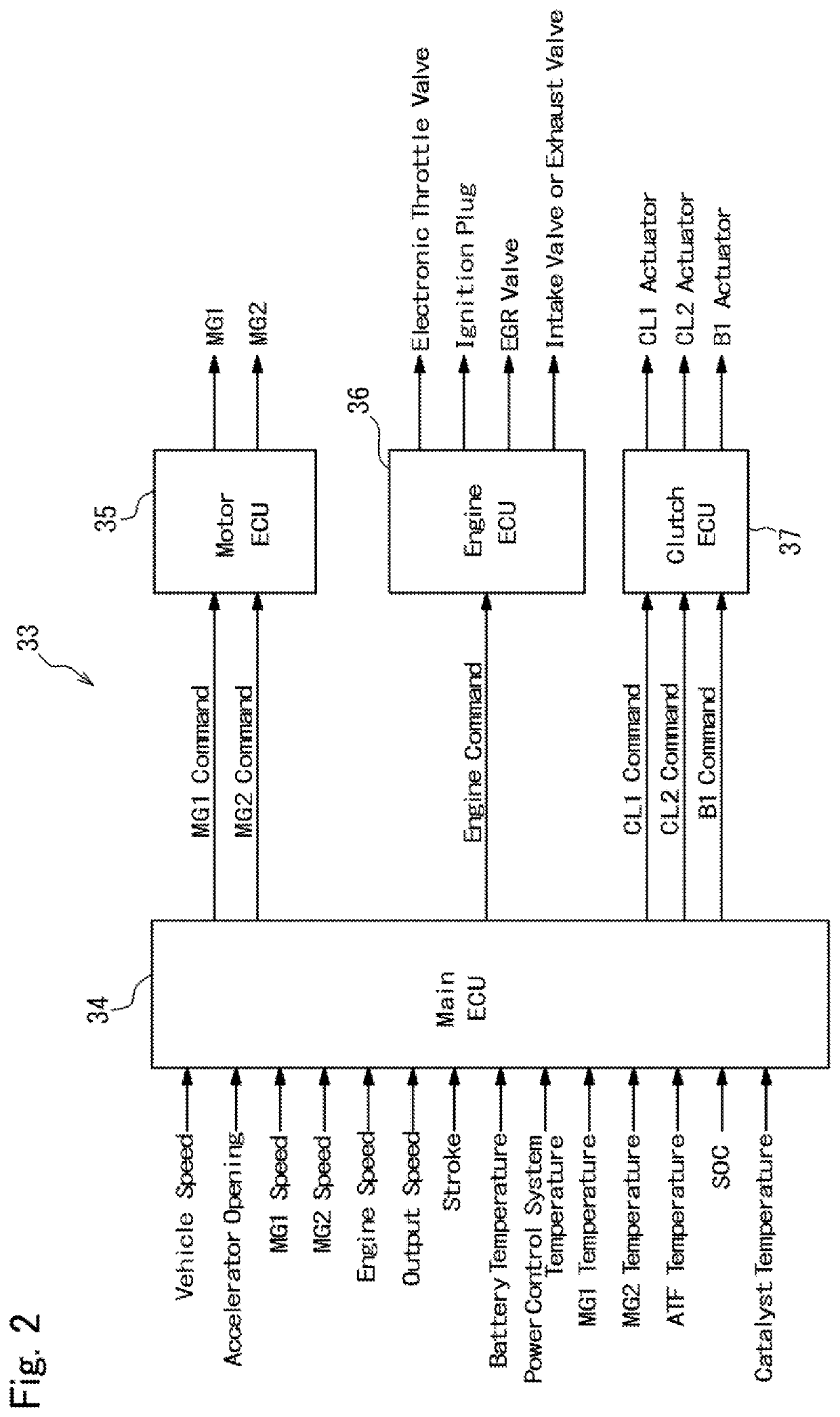

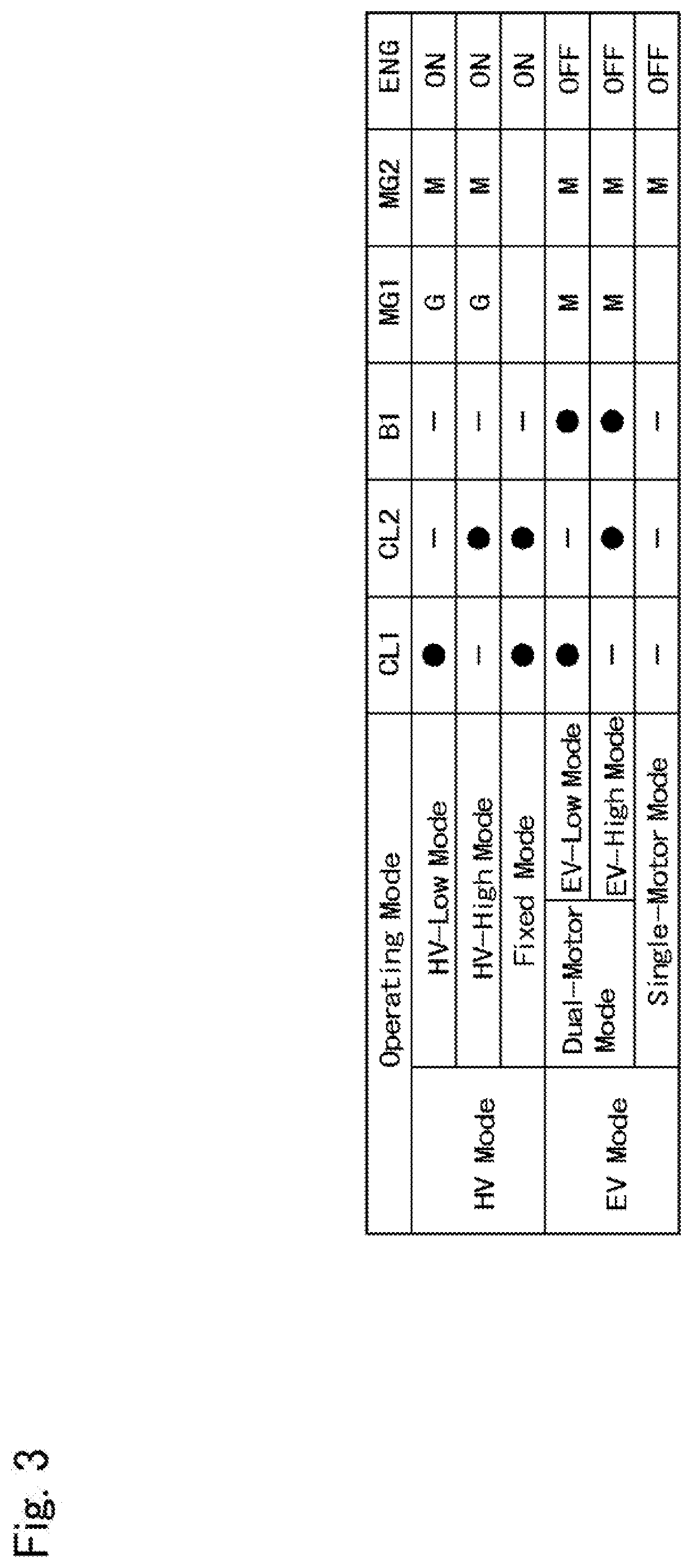

Control system for hybrid vehicle

ActiveUS20200148190A1Lower performance requirementsIncrease temperatureHybrid vehiclesElectrical controlControl systemControl engineering

A control system for a hybrid vehicle configured to prevent a reduction in the purifying performance of the catalyst in a predetermined operating mode. An operating mode of the hybrid vehicle can be selected from a first hybrid vehicle mode, a second hybrid vehicle mode, and a fixed mode. A controller that is configured to restrict a shifting operation between the first hybrid vehicle mode and the second hybrid vehicle mode via the fixed mode, when the purifying device is being warmed or the purifying device has to be warmed.

Owner:TOYOTA JIDOSHA KK

Positive-pressure self-adaptive power split type continuously variable transmission of planetary ring bevel gear

The invention provides a positive pressure adaptive planetary bevel gear power split type continuously variable transmission, the structure includes a planetary bevel gear train, a differential gear train and a hydraulic system; the planetary bevel gear train structure includes: a planetary bevel gear, Speed regulating ring, planetary ring conical conical surface, driving center bevel gear and driven center bevel gear; differential gear train includes: output center wheel, planet carrier, synchronous planetary gear, planetary gear, synchronous internal meshing gear, synchronous cylindrical gear, Fixed shaft gear, central inner cylindrical gear, cylindrical gear; hydraulic control system includes power output shaft, torque sensor, hydraulic cylinder, displacement sensor (pressure sensor), control system, drive circuit, motor, hydraulic pump, servo amplifier and electro-hydraulic servo valve. The present invention selects complete power split transmission, and finally synthesizes the output at the planetary gear, which effectively improves the problem of being unable to provide constant positive pressure in the prior art.

Owner:ZHONGBEI UNIV

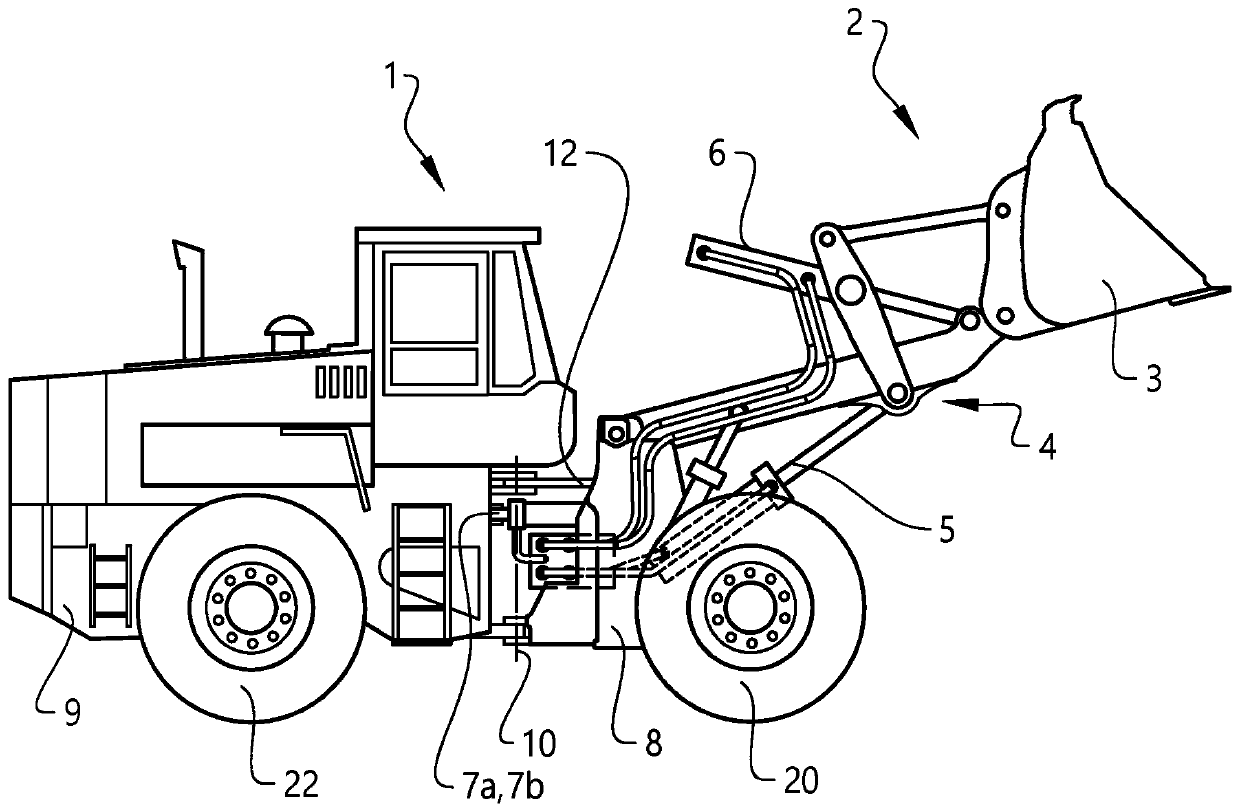

A transmission for a vehicle

InactiveCN110023648ASmall sizeToothed gearingsTransmission elementsElectrical and Electronics engineeringPlanet

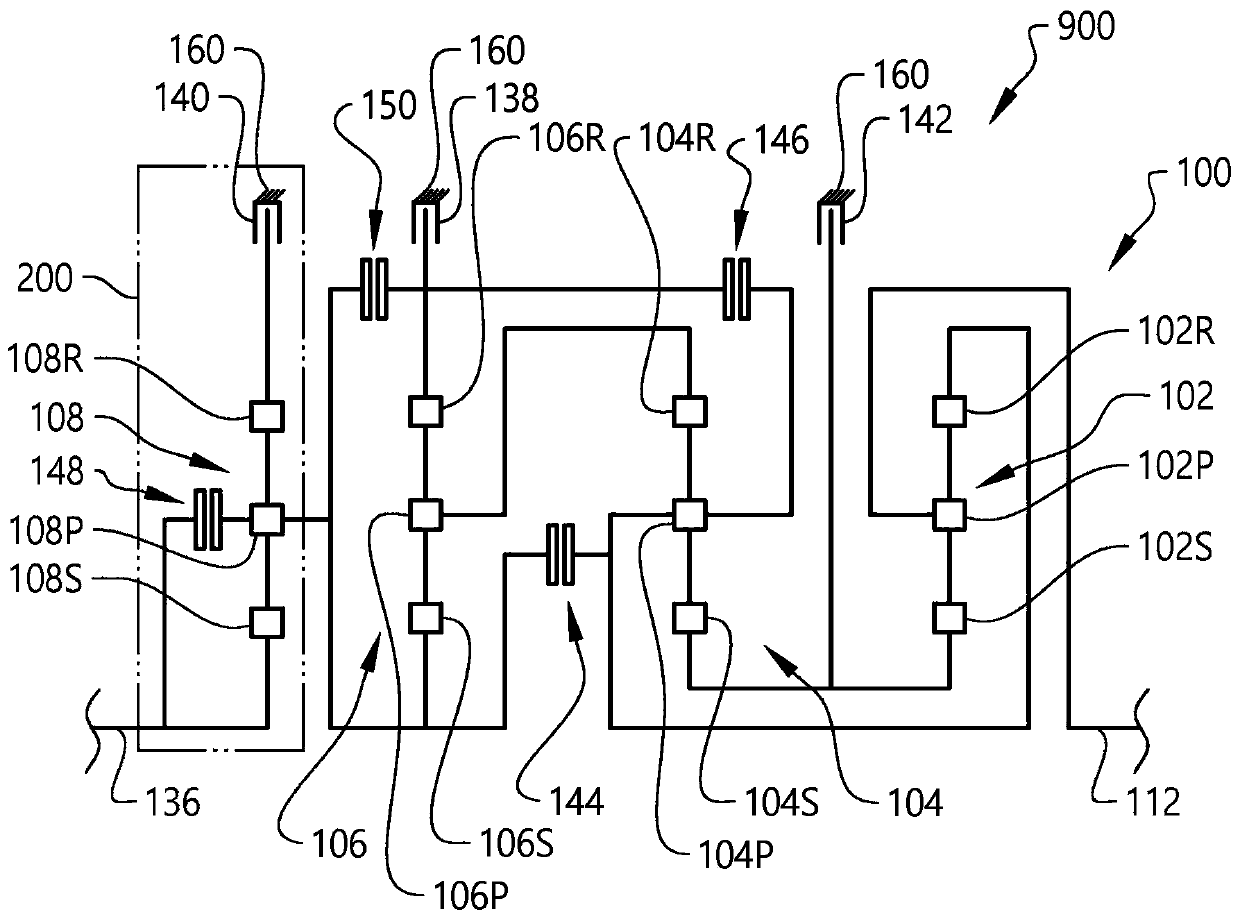

The present invention relates to a transmission (100) for a vehicle, the transmission comprising a primary transmission arrangement (900), a transmission housing (160), an input shaft (136), and an output shaft (112), the primary transmission arrangement (900) comprising a first (102), a second (104) and a third (106) planetary gear set each comprising a first, a second and a third planetary member, said planetary members being a sun gear, a planet carrier and a ring gear, the primary transmission arrangement further comprising five shift elements (138, 142, 144, 146, 150) engageable in combinations of two to obtain six forward gear stages, wherein the ring gear (102R) of the first planetary gear set (102) and the planet carrier (104P) of the second planetary gear set (104) are operativelyconnected to each other, the ring gear (104R) of the second planetary gear set (104) and the planet carrier (106P) of the third planetary gear set (106) are operatively connected to each other, and two planetary members of the third planetary gear set (106) are selectively connectable to each other.

Owner:VOLVO CONSTR EQUIP

One Mode Continuously Variable Transmission With Low Loss Configuration

The invention provides a one mode continuously variable transmission with low loss configuration. The one mode, front wheel drive continuously variable transmission includes a transmission input member interconnected to an engine of the motor vehicle, a transmission output member, a continuously variable unit having a first pulley pair, a second pulley pair, and a chain wrapped around the first pulley pair and the second pulley pair. A planetary gear set includes a first member, a second member, and a third member. The first member is connected to the first pulley pair and the third member is connected to the transmission input member. A clutch is selectively engageable to connect the first member of the planetary gear set with the transmission input member. A band brake selectively engageable to connect the second member with a stationary member. The transmission output member is interconnected to a differential supported by sets of ball bearings.

Owner:GM GLOBAL TECH OPERATIONS LLC

Continuously variable transmission

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

Electric control automatic speed changing main reducing gear

InactiveCN108361329AImprove climbing abilityPowerfulToothed gearingsTransmission elementsHigh accelerationDrive motor

The invention discloses an electric control automatic speed changing main reducing gear which comprises a housing, an input shaft, a driving bevel gear, a driven bevel gear, a splicing sleeve, a firstgear ring, a short tooth splicing ring, a planet carrier, a planet gear, a long tooth splicing ring, a second gear ring, a shifting fork, a controller, a first output shaft, a second output shaft anda clutch. Compared with a direct-driven type driving system with a fixed velocity ratio, the involved electric control automatic speed changing main reducing gear has higher power, high gradeabilityand high acceleration performance, easily adapts to various road conditions such as a mountainous area, an overpass bridge and a steep slope, and is wide in applicable regions; a driving motor can work in a high efficiency area for a long time, energy consumption of a finished automobile is lowered effectively, the continuous voyage mileage of the automobile is increased by 10-15% on the equivalent conditions; and the electric control automatic speed changing main reducing gear has high performance and economy. Compared with a gearbox type driving system, no gearbox is required, the electric control automatic speed changing main reducing gear is simple in structure, low in cost and good in reliability, the automobile is low in total weight and small in overall size and overall layout of the automobile is facilitated.

Owner:浙江华亦海汽车电子科技有限公司

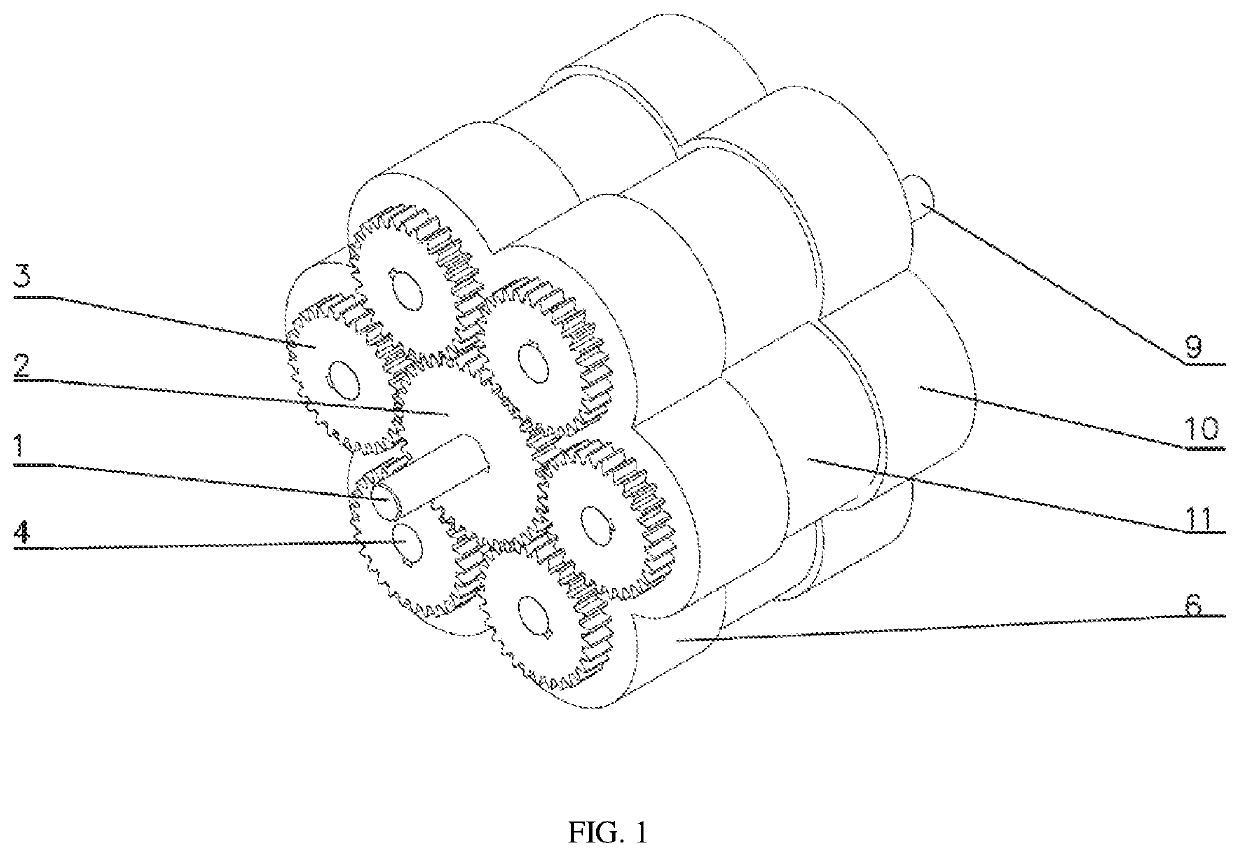

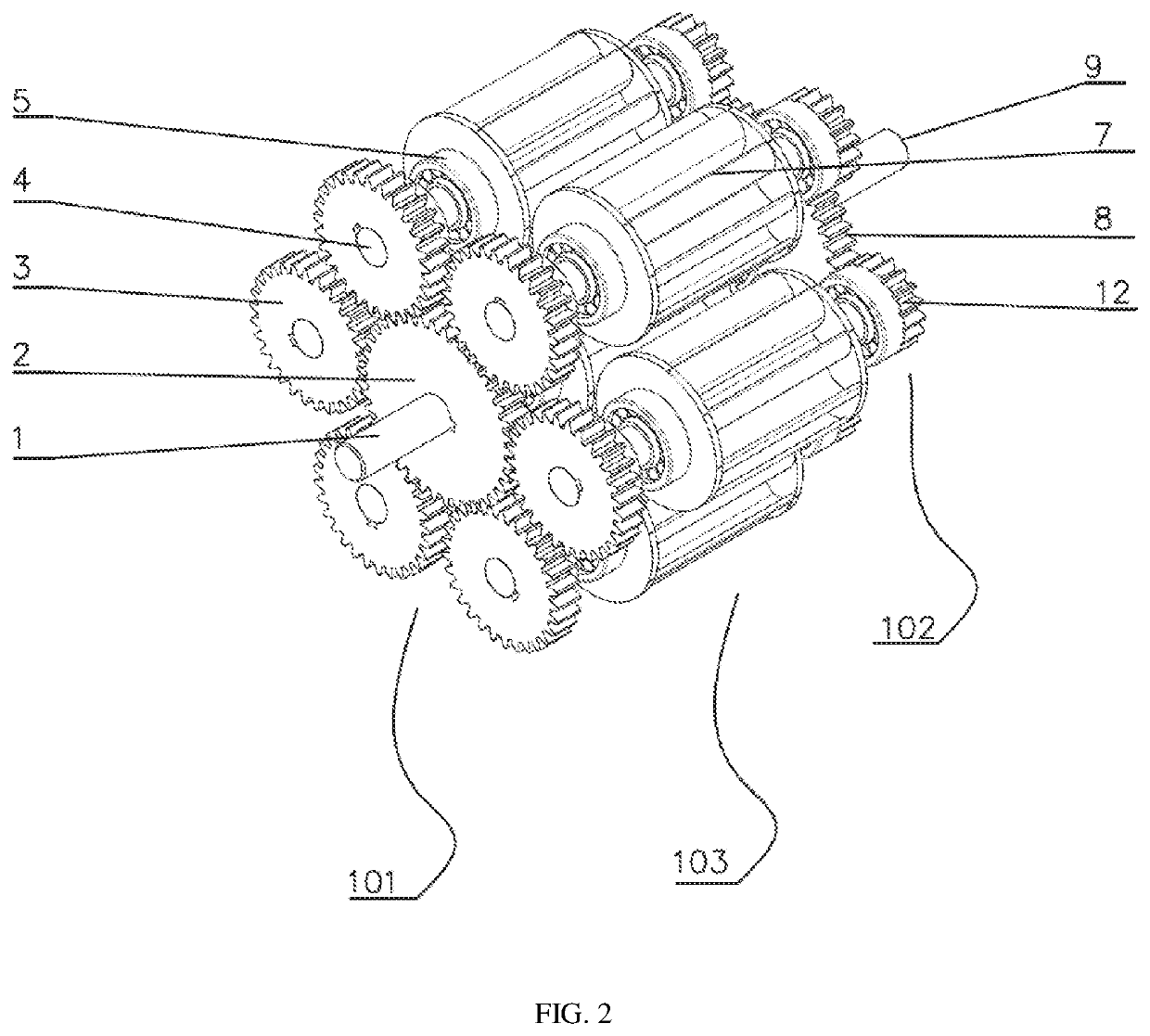

Dual-motor driving system

PendingCN111762010AImprove escape performanceReduce axial sizeElectric propulsion mountingDifferential gearingsGear wheelCoupling

The invention discloses a dual-motor driving system. The dual-motor driving system comprises a first motor, a second motor, two sets of gear speed reducing mechanisms, a differential lock and a parking mechanism, wherein the first motor and the second motor are coaxially arranged, primary gears of the two sets of gear speed reducing mechanisms are arranged on an output shaft of the first motor andan output shaft of the second motor respectively, and the differential lock mechanism is arranged at the tail ends of the output shaft of the first motor and the output shaft of the second motor; thedifferential lock mechanism comprises a movable fluted disc assembly, a fixed fluted disc assembly and a fixed armature assembly, and when relative rotation between the two motors needs to be locked,the movable fluted disc assembly and the fixed fluted disc assembly are meshed and locked in the axial direction; and when parking is needed, the differential lock mechanism and the parking mechanismcan be combined to achieve the parking function. According to the structure of the dual-motor driving system, the axial size of a gearbox can be reduced, the coupling of dual-motor output power is achieved through the differential lock mechanism, the maximum output power is improved, and the escape capacity of a vehicle is improved.

Owner:JING JIN ELECTRIC TECHNOLOGIES (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com