Positive-pressure self-adaptive power split type continuously variable transmission of planetary ring bevel gear

A continuously variable transmission, planetary ring cone technology, applied in the direction of vehicle gearbox, belt/chain/gear, fluid pressure actuating device, etc. The effect of transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

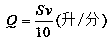

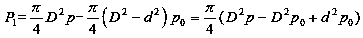

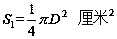

[0031] Such as figure 1As shown, the present invention is a positive pressure self-adaptive planetary ring bevel gear power-split continuously variable transmission. When working, the input torque can be directly transmitted from the input shaft 7 or through the reduction mechanism to the input shaft 7, and most of the power is directly transmitted to the input shaft 7. Transferred to the planetary carrier 18, a small part is transferred to the active central bevel gear 5, and the active central bevel gear 5 and the input shaft 7 do not rotate relative to each other, the active central bevel gear 5 directly meshes with the planetary ring bevel pinion 29, and then, through the speed regulation The frictional force between the ring 2 and the conical surface 3 of the planet ring is transmitted to the planet ring bevel gear 32, and then meshed with the driven central bevel gear 28 to transmit power to the differential gear train. The annular body 31 on the planetary ring bevel gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com