Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Wood splitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood splitting (riving, cleaving) is an ancient technique used in carpentry to make lumber for making wooden objects, some basket weaving, and to make firewood. Unlike wood sawing, the wood is split along the grain using tools such as a hammer and wedges, splitting maul, cleaving axe, side knife, or froe.

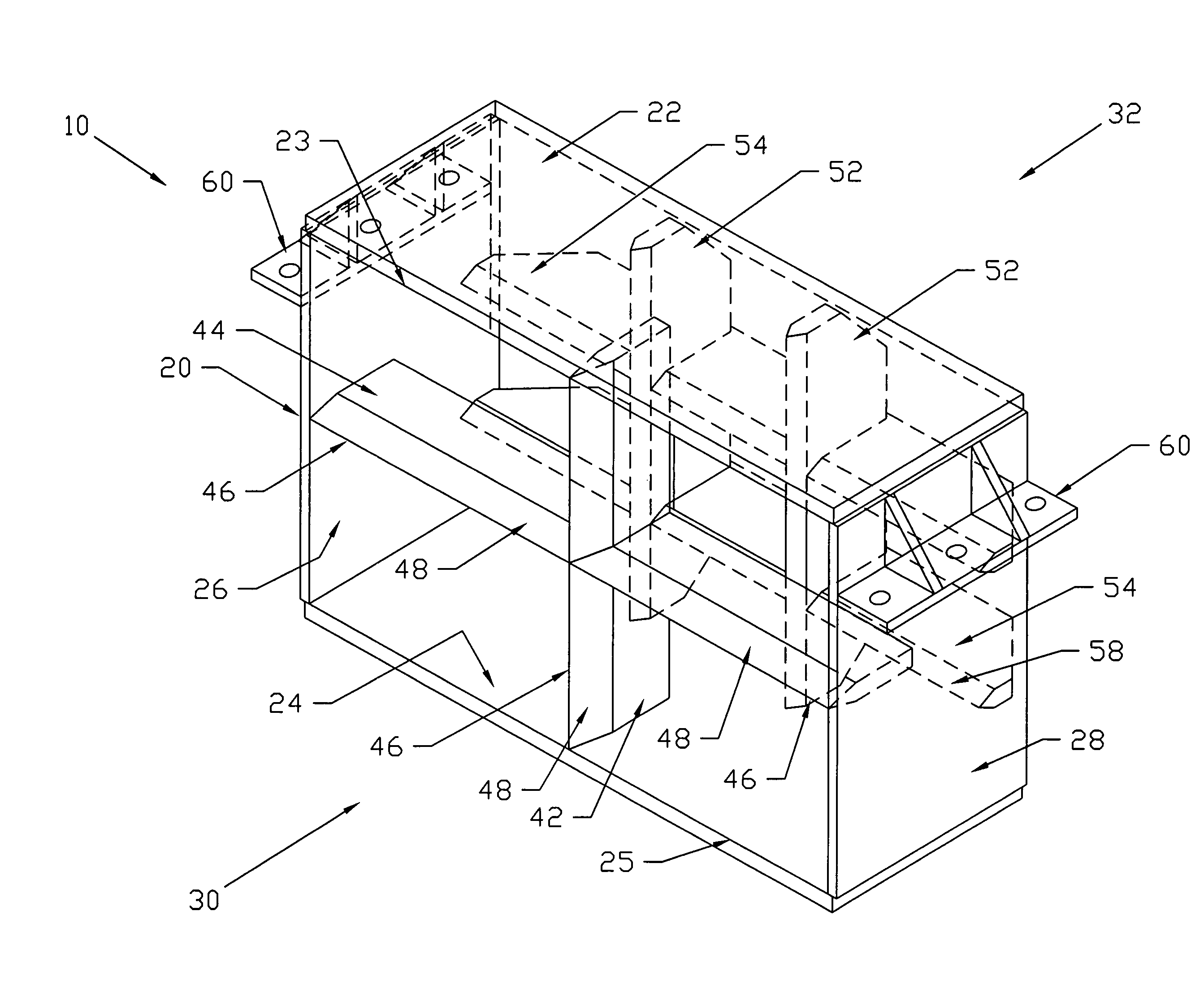

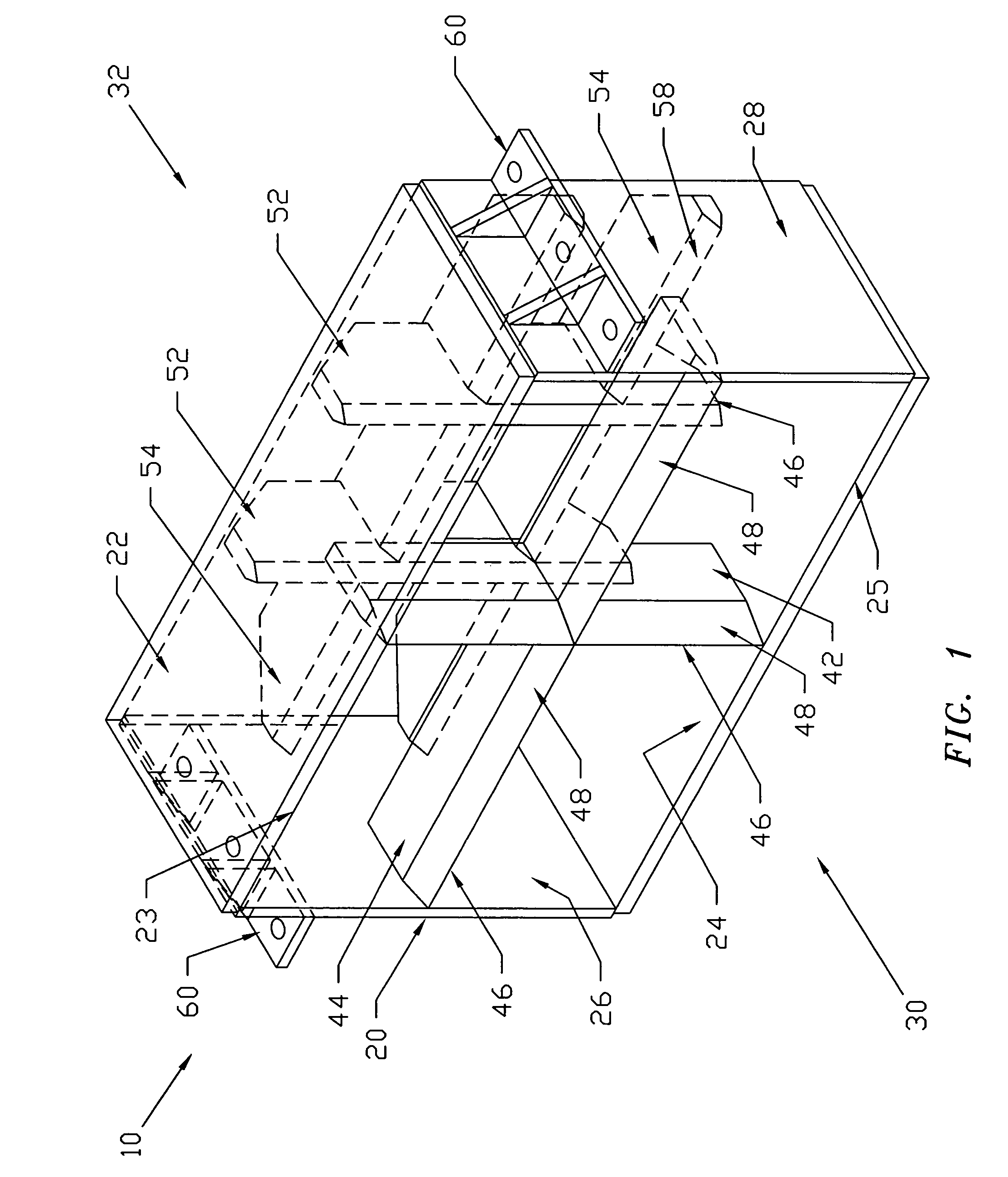

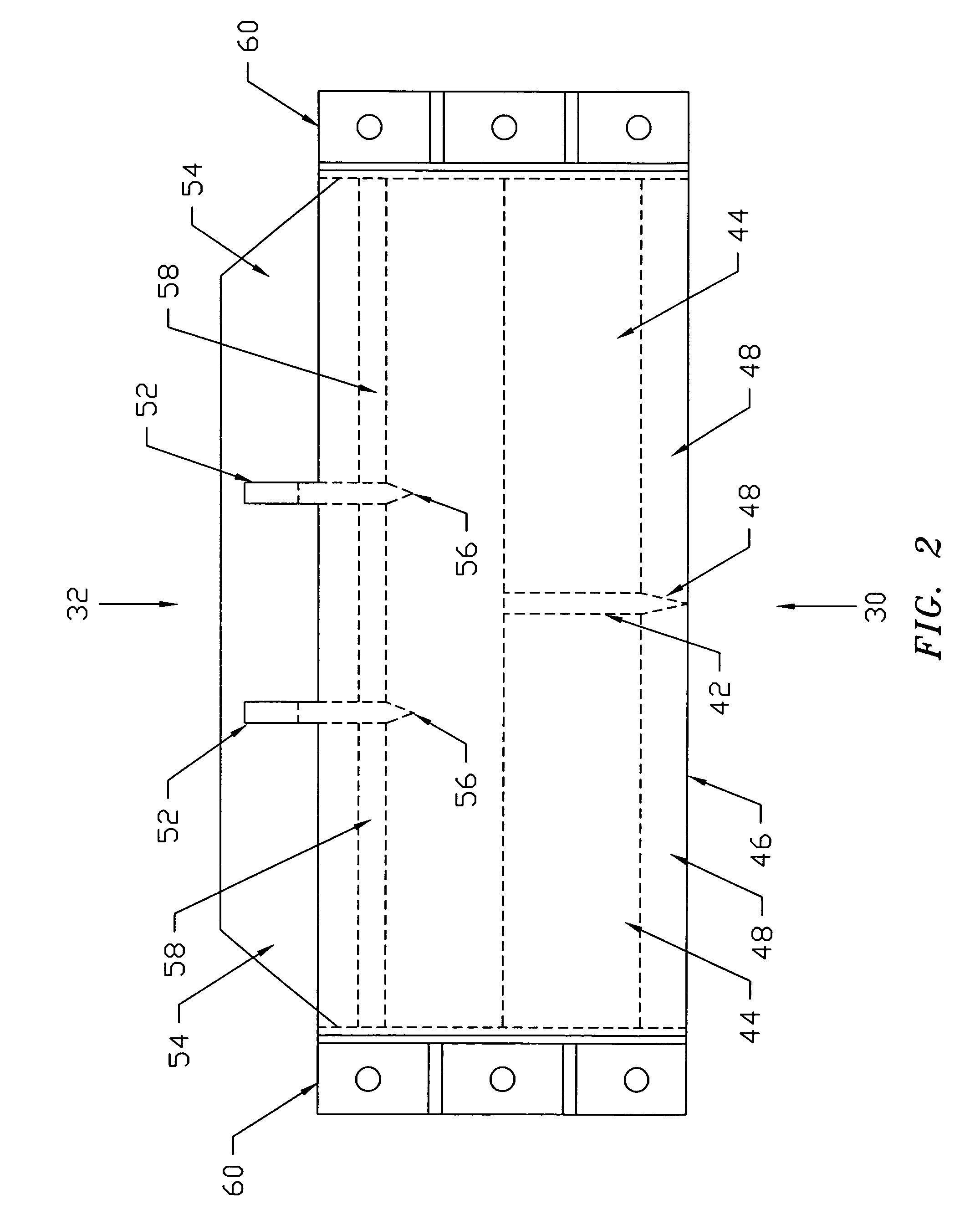

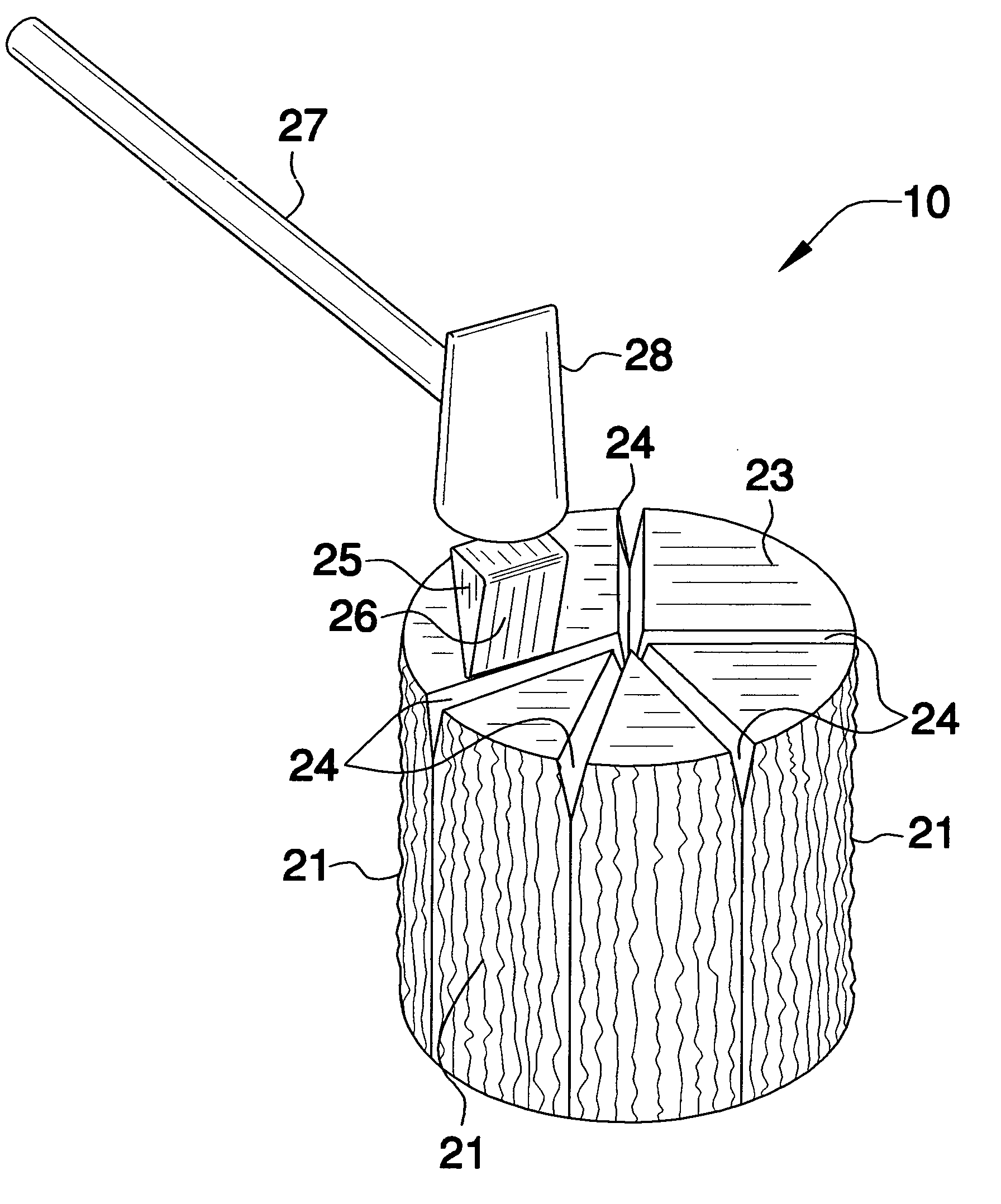

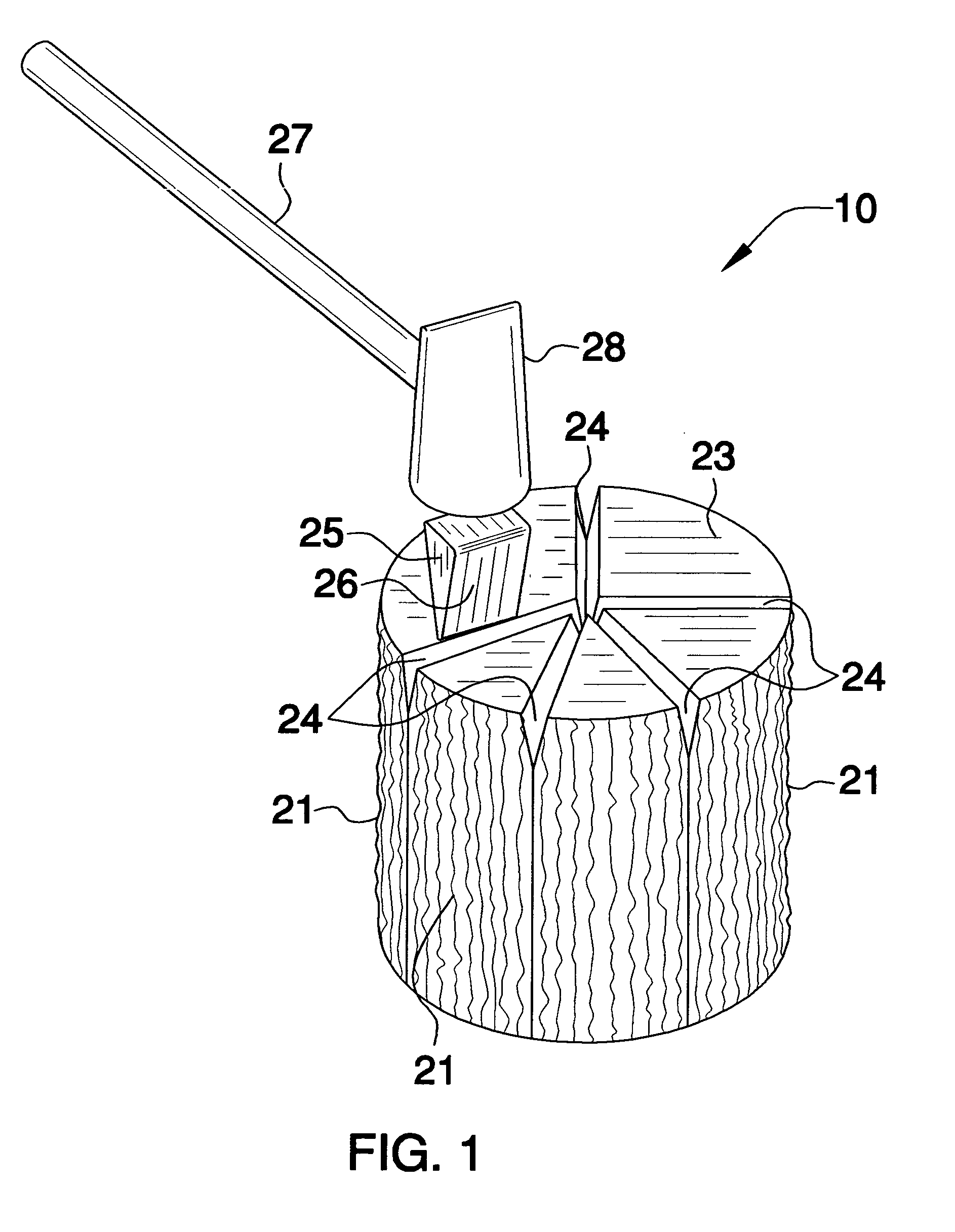

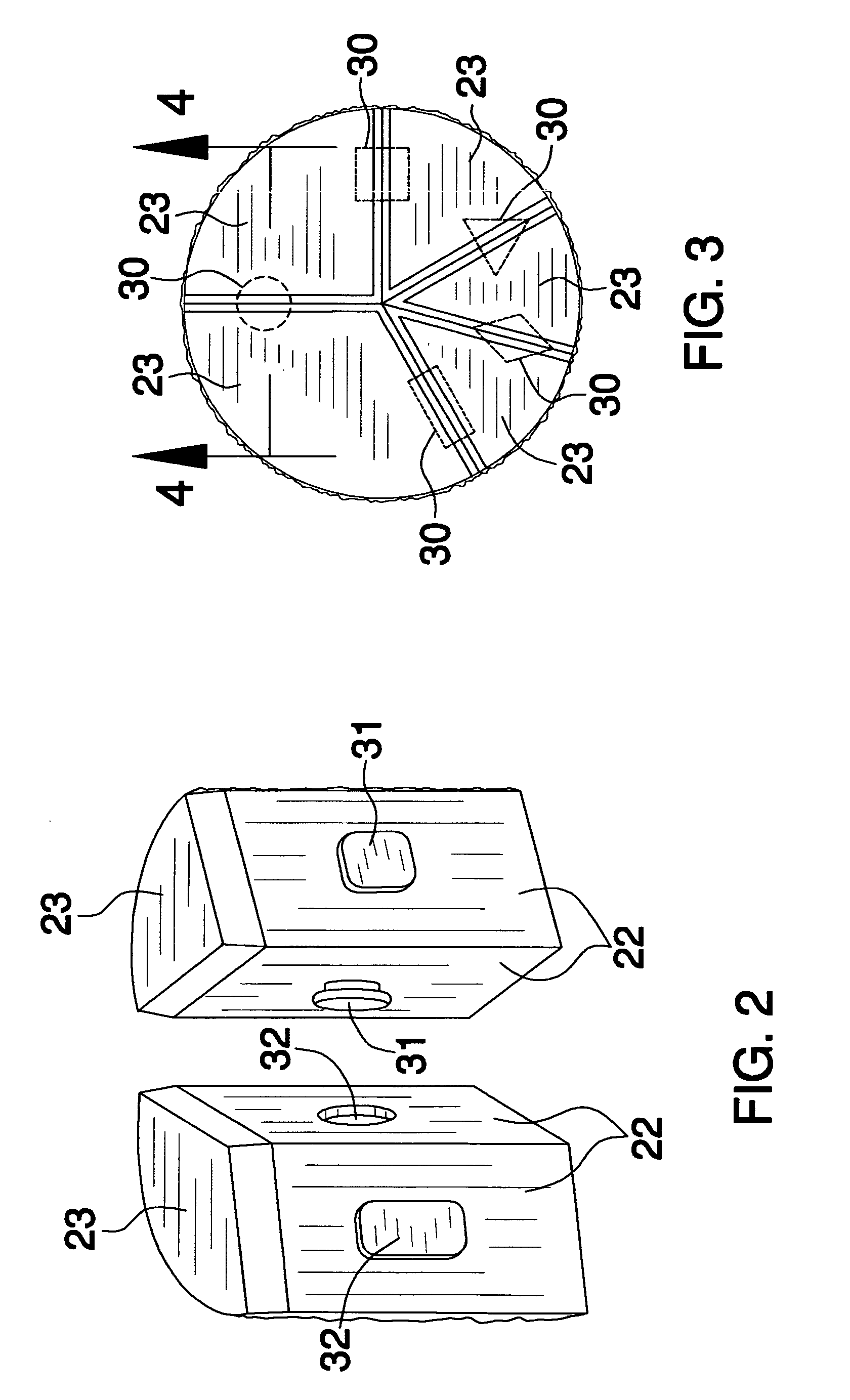

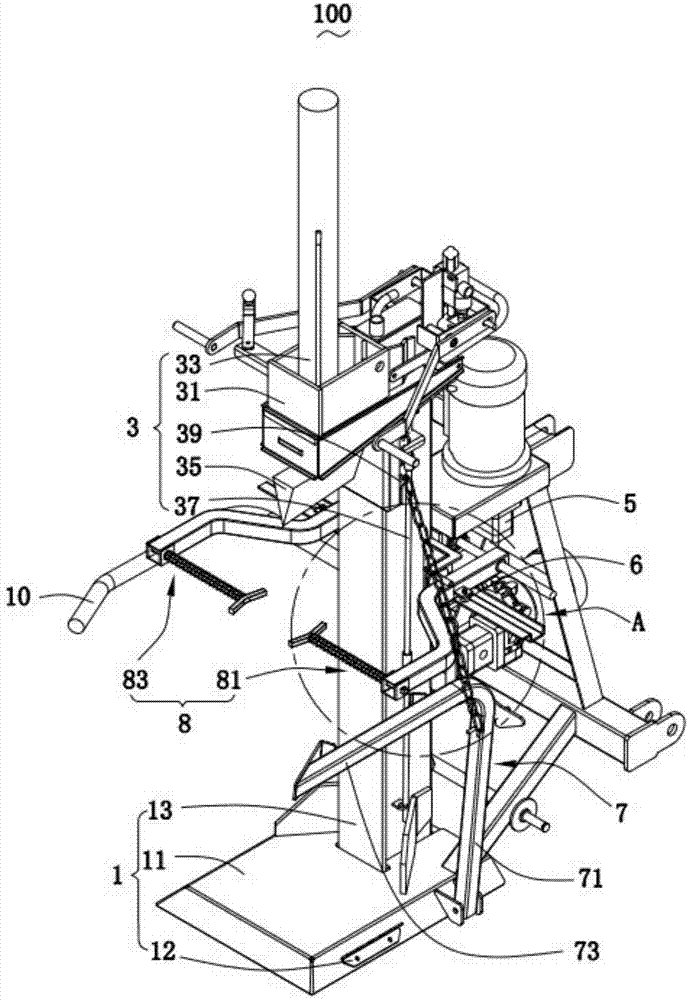

Two-stage two-stroke log splitting system

A log splitting system comprises a splitter box, having top, bottom and sidewalls, and open entrance and discharge ends. A first set of cutting blades secured adjacent to the entrance end divides the entrance end into at least two, first sections. A second set of cutting blades, secured adjacent to the first set of cutting blades and opposite the entrance end, further divides each splitter box's first section into at least two, second sections. A ram assembly with a force applying surface moveable toward the splitter box's entrance end contacts a log with the first set of cutting blades. The ram member's surface has a plurality of surface portions, each sized to fit into one of the splitter box's first section, to further contact the log with the second set of cutting blades, splitting the log into at least four pieces.

Owner:MULTITEK

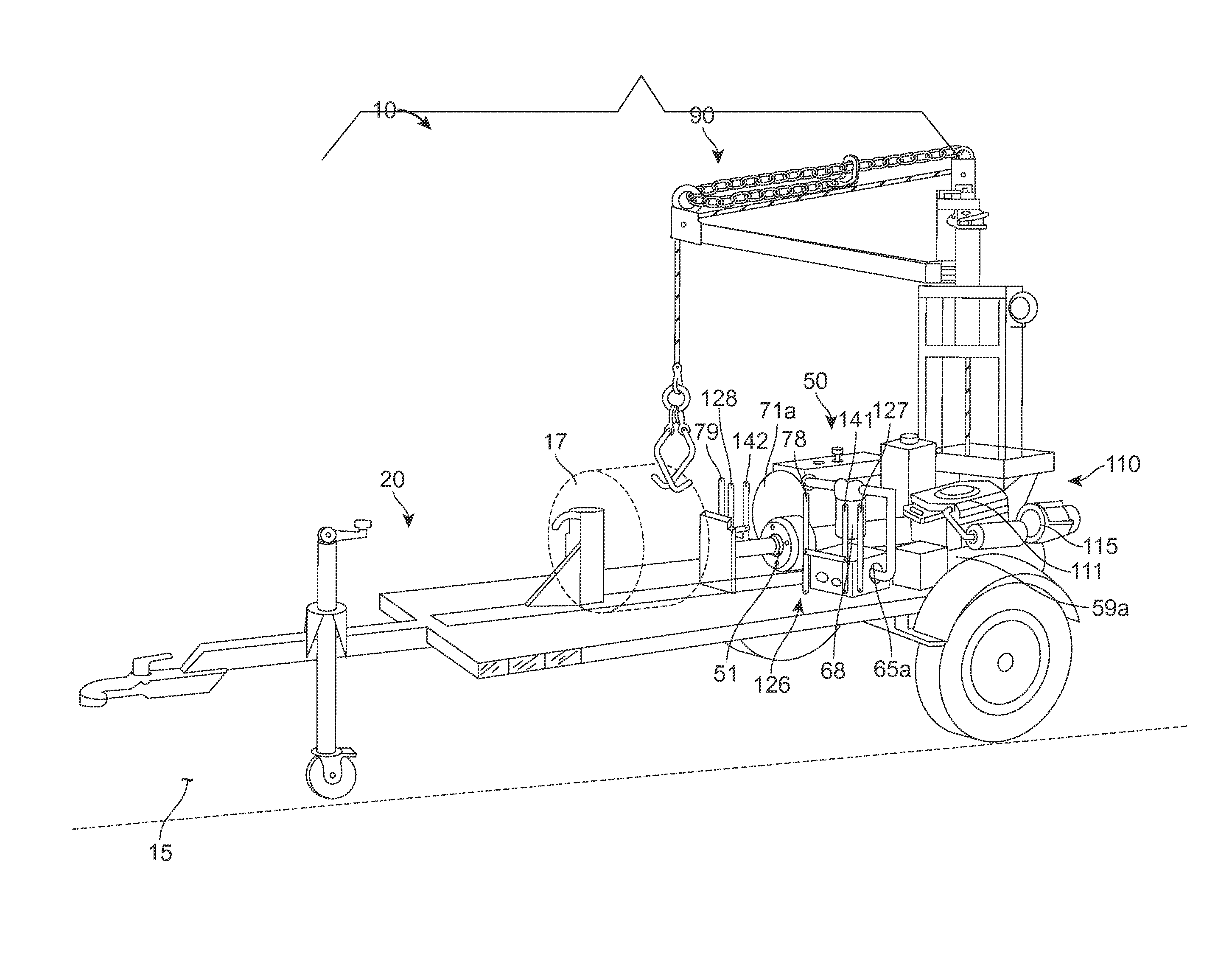

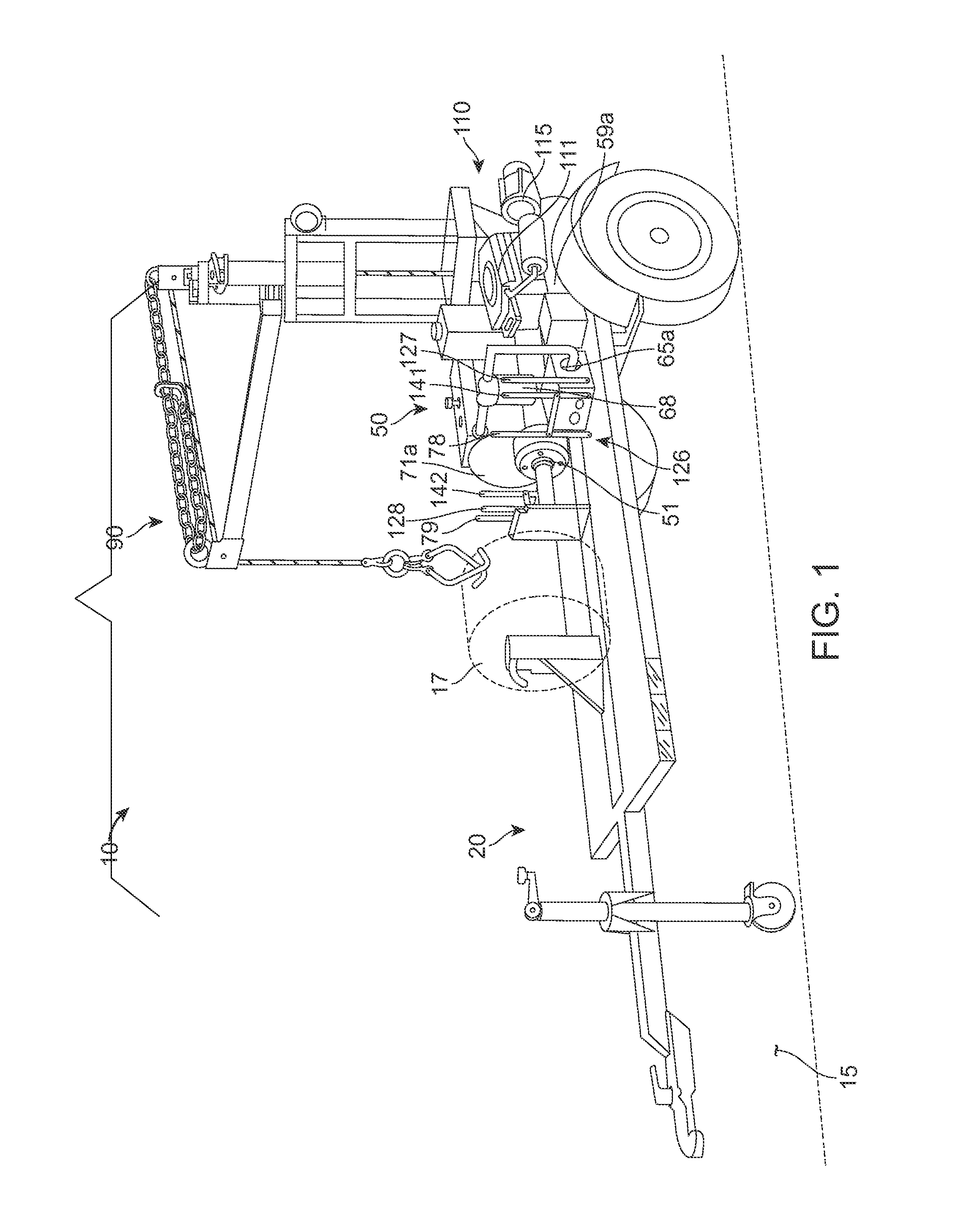

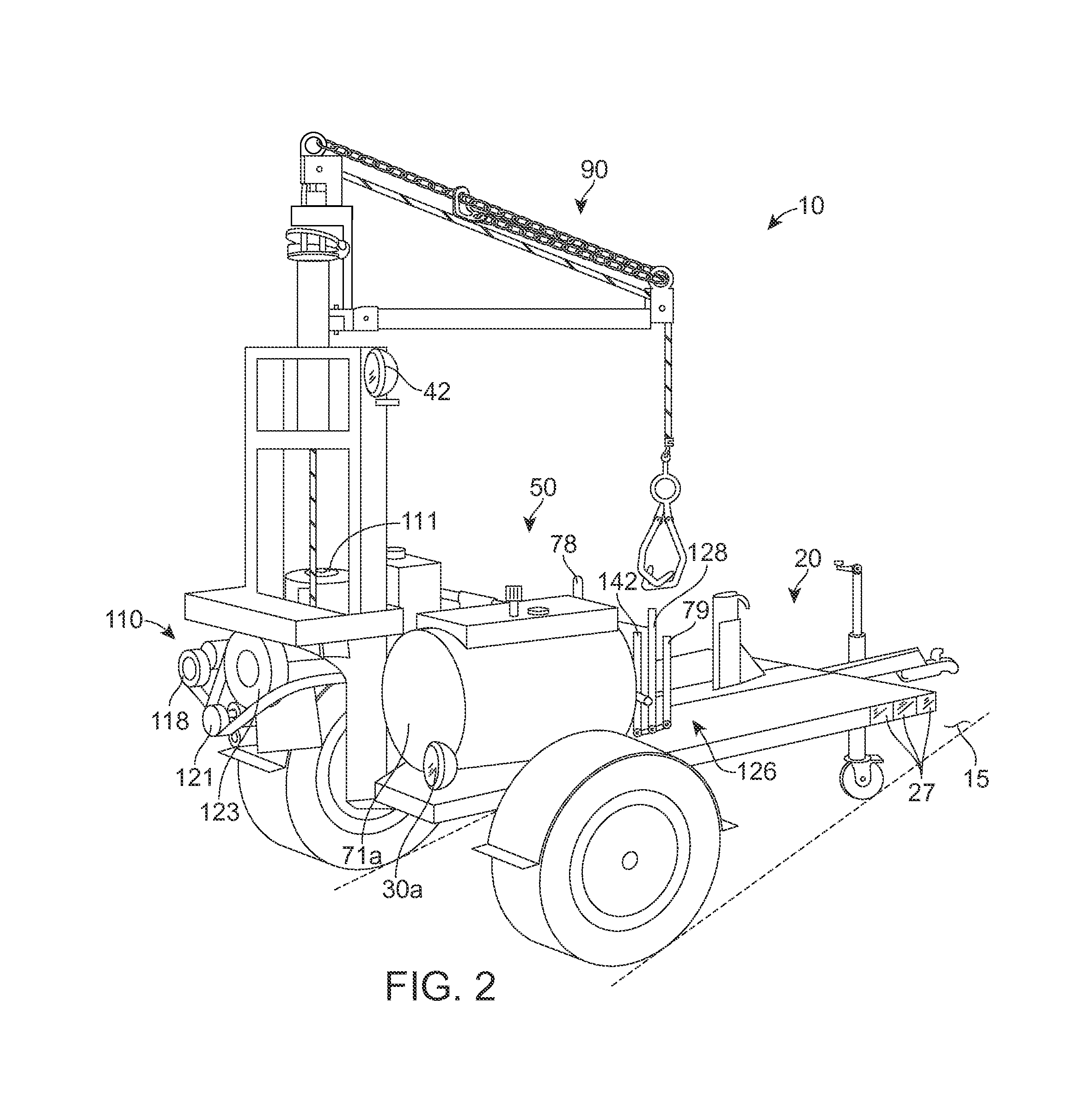

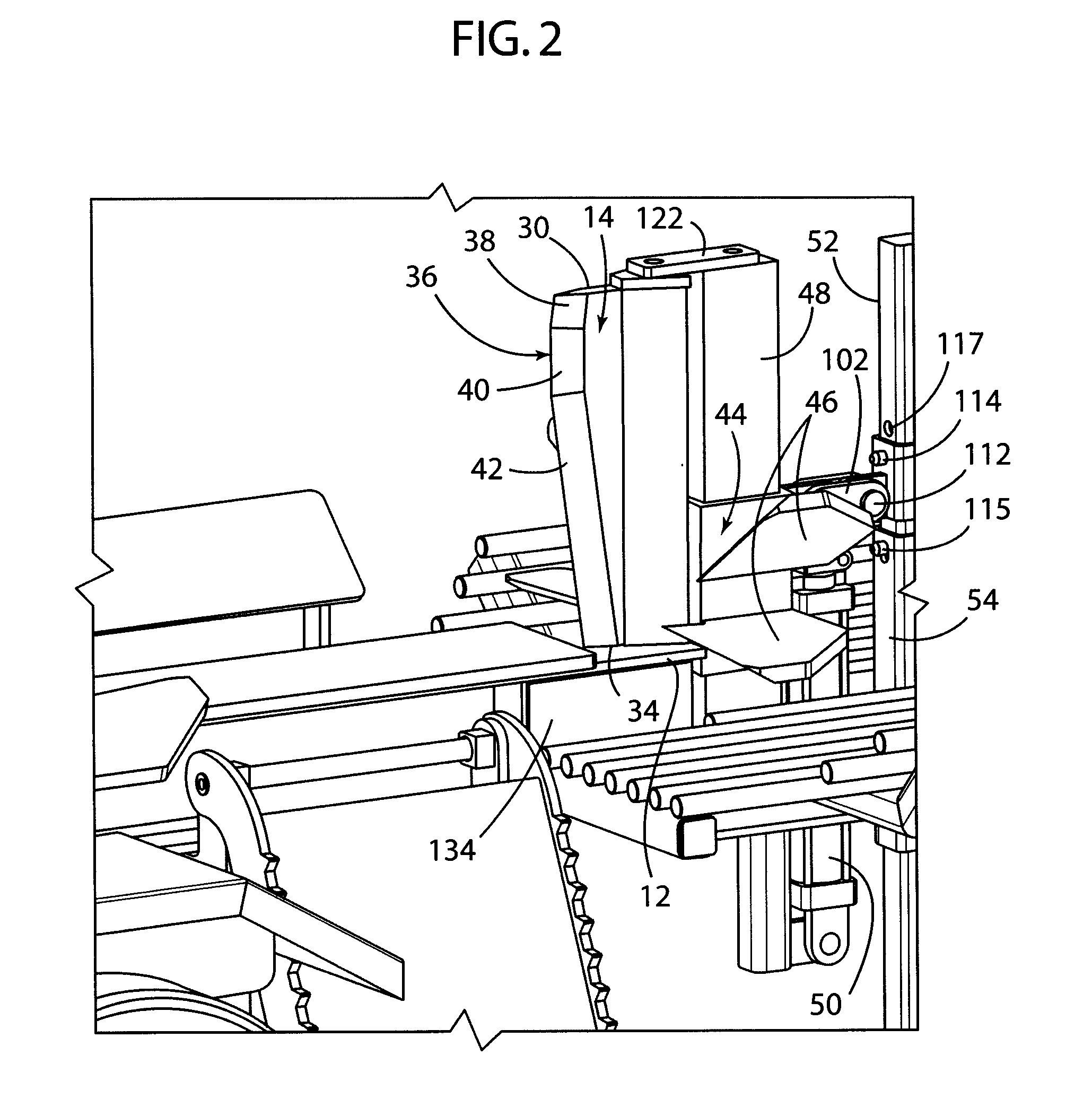

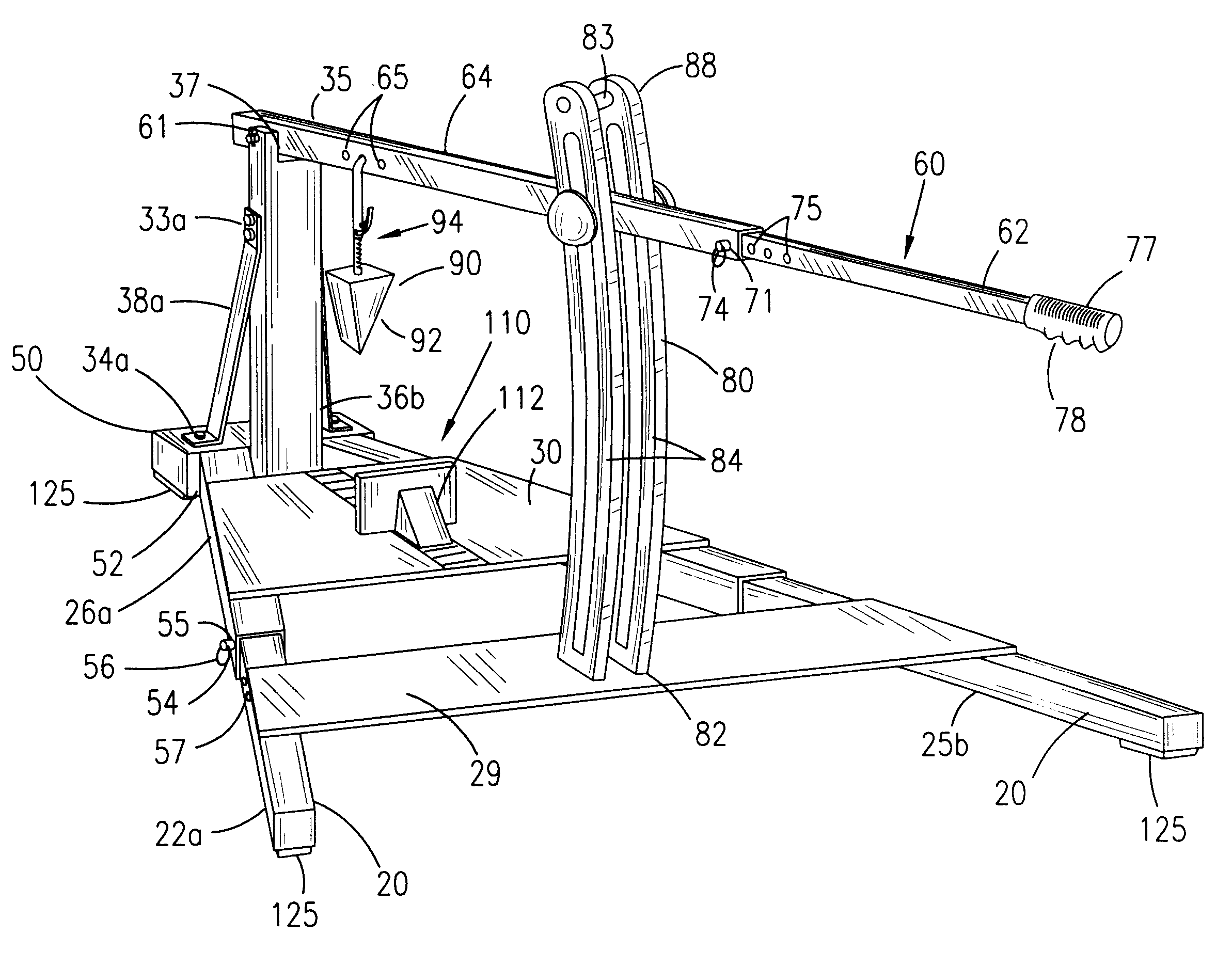

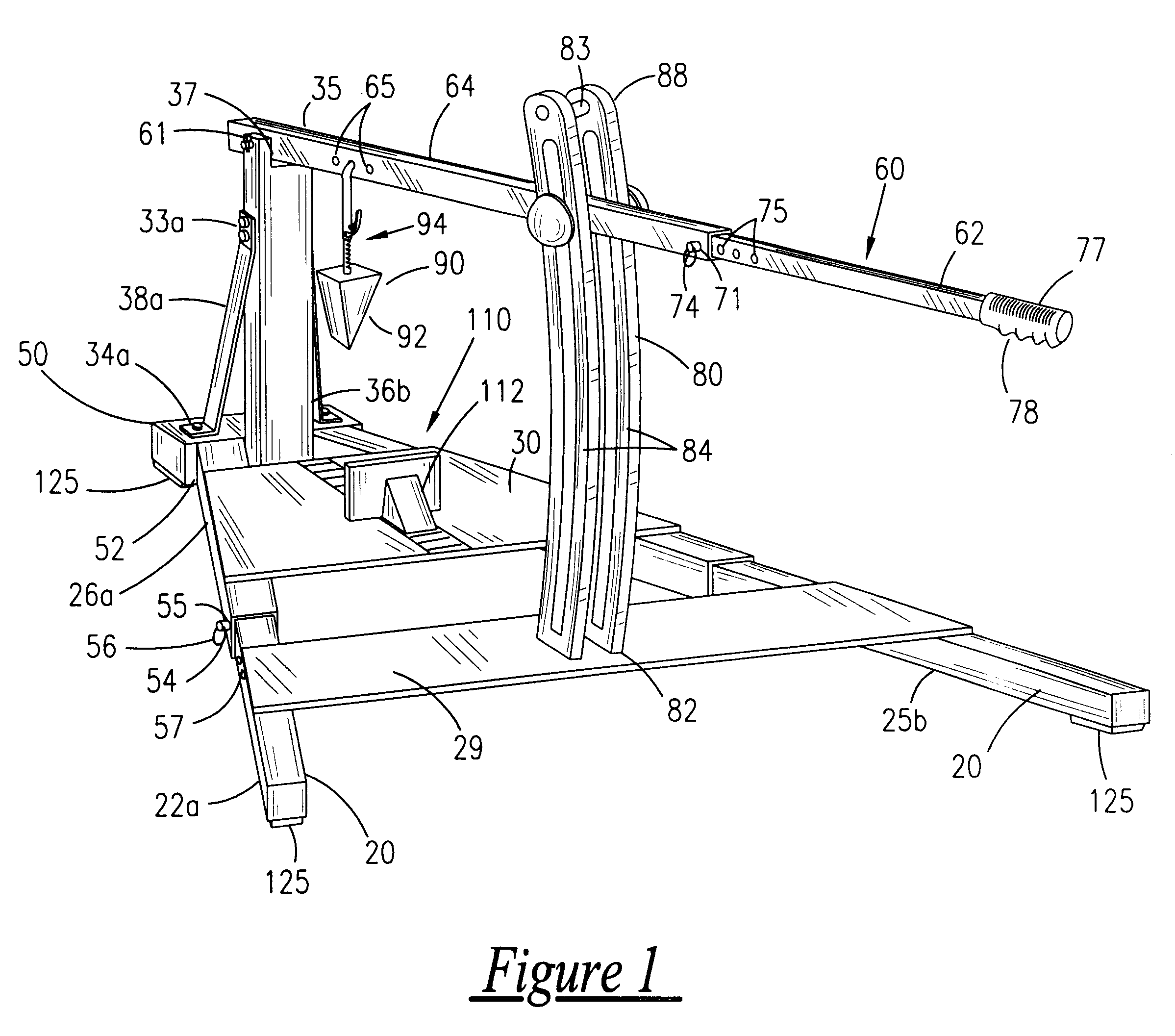

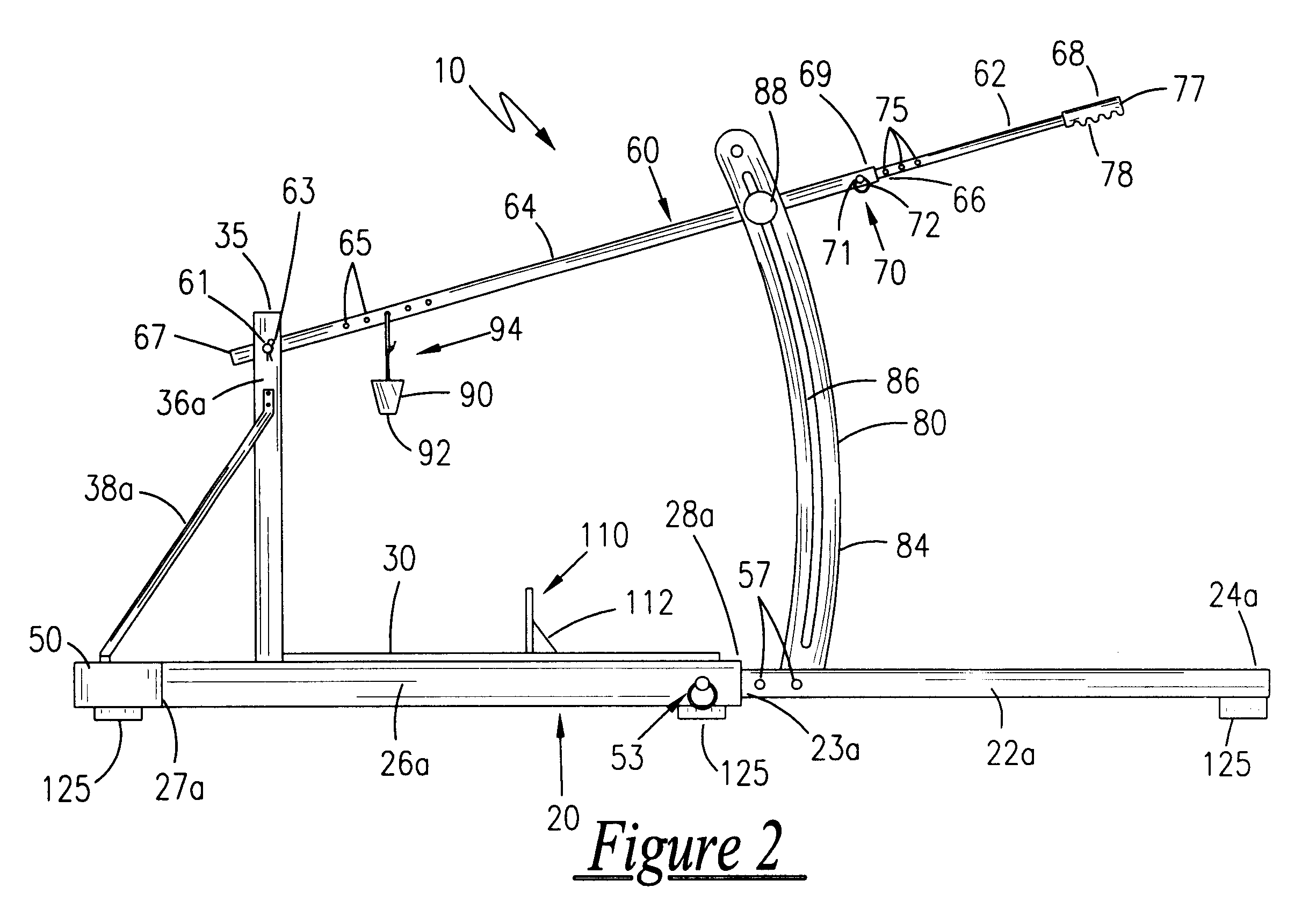

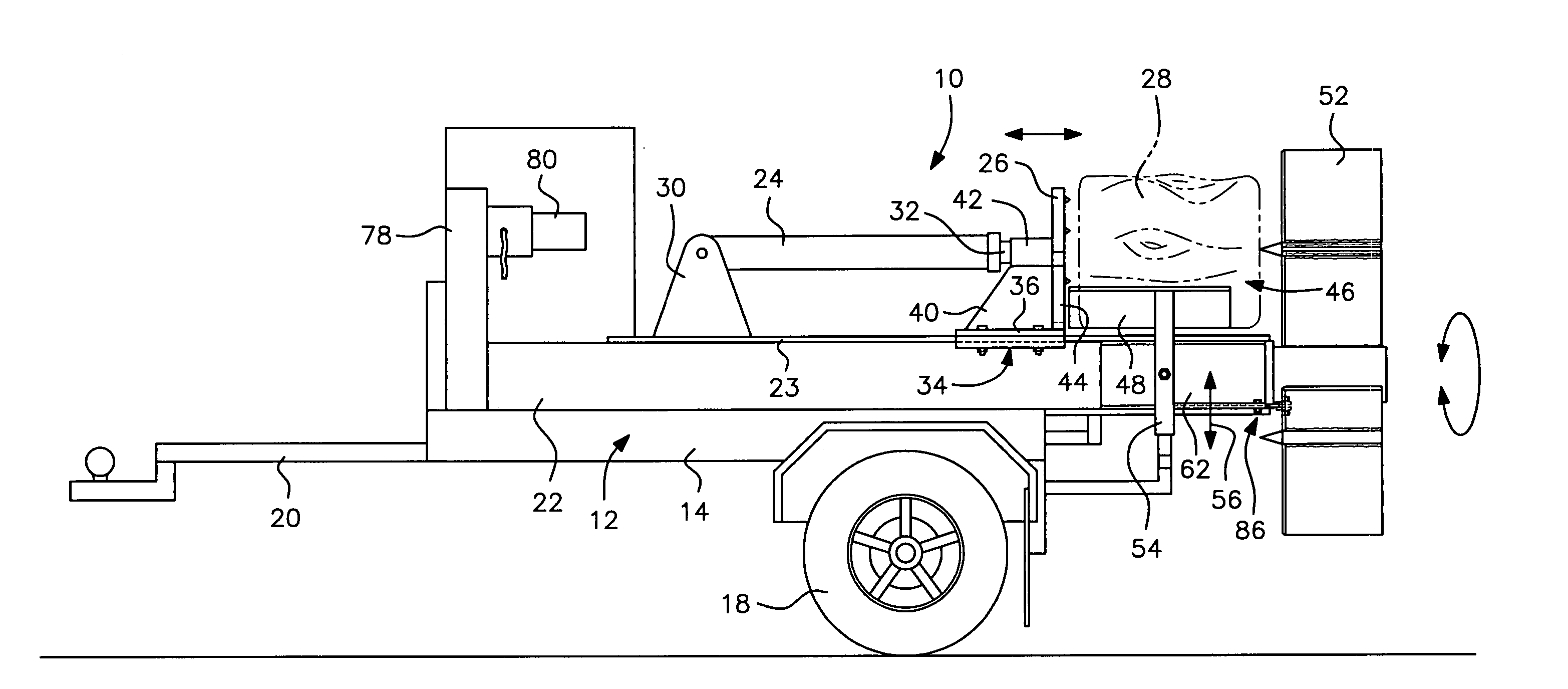

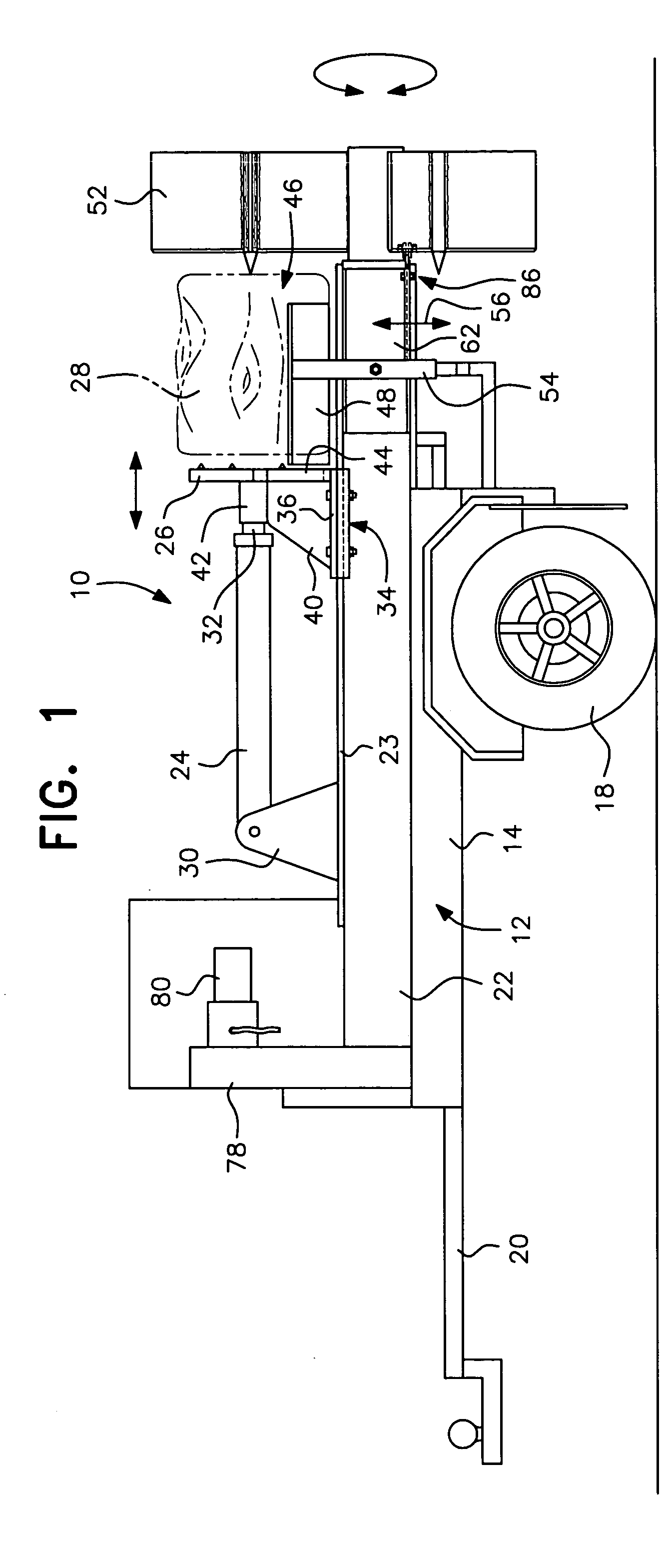

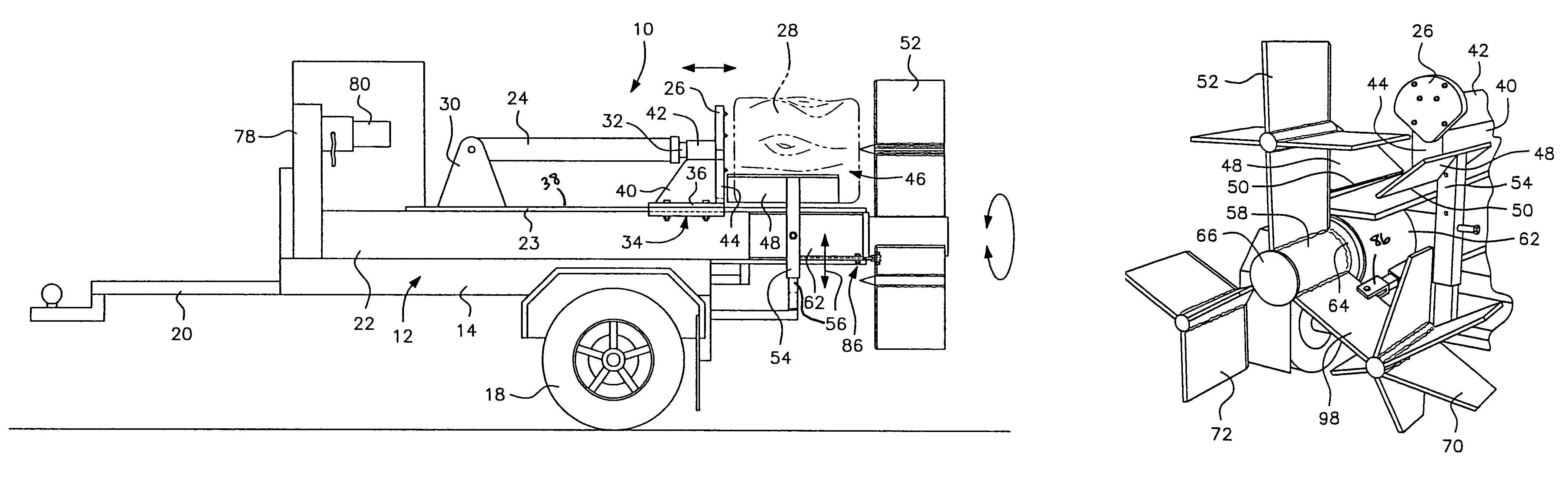

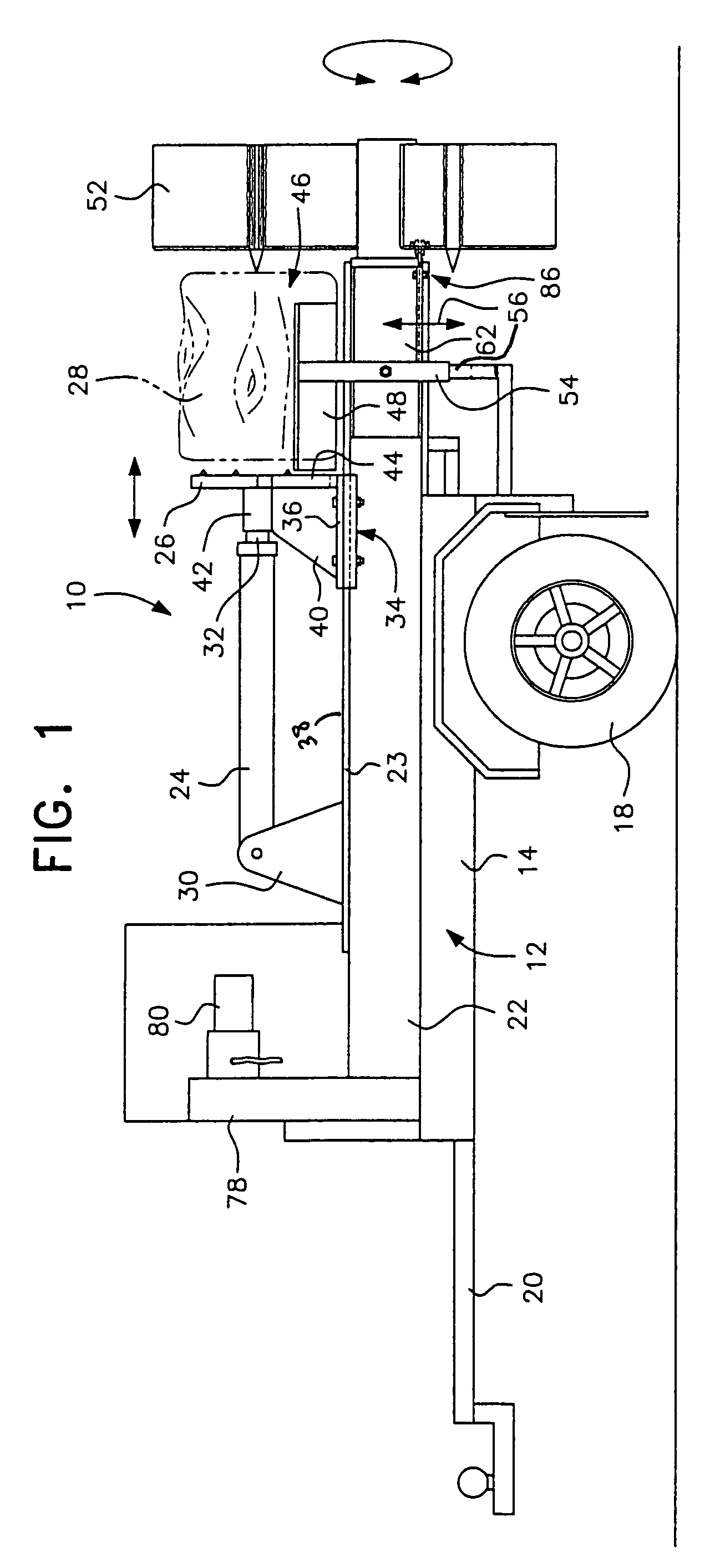

Trailer-mounted table wood splitter

A trailer-mounted wood splitter with an integral platform, log boom and grappler provides an extended table area to facilitate the splitting of wood. The apparatus comprises a hydraulic-powered wood splitting assembly operated by an internal combustion engine mounted to a trailer. A horizontal surface worktable is provided all around the upper surface of the wood splitting plane. In such a manner, any wood that is placed upon the platform for splitting does not fall off after splitting is complete. This allows the user to reposition any remaining sections of wood for additional splitting without having to pick them up off the ground. Once completely split, the wood can be directed to the side of the table or platform for stacking or transportation. The apparatus further comprises a log boom with a grappler attached to a far end for moving and manipulating felled logs.

Owner:HONNELL JAMES W

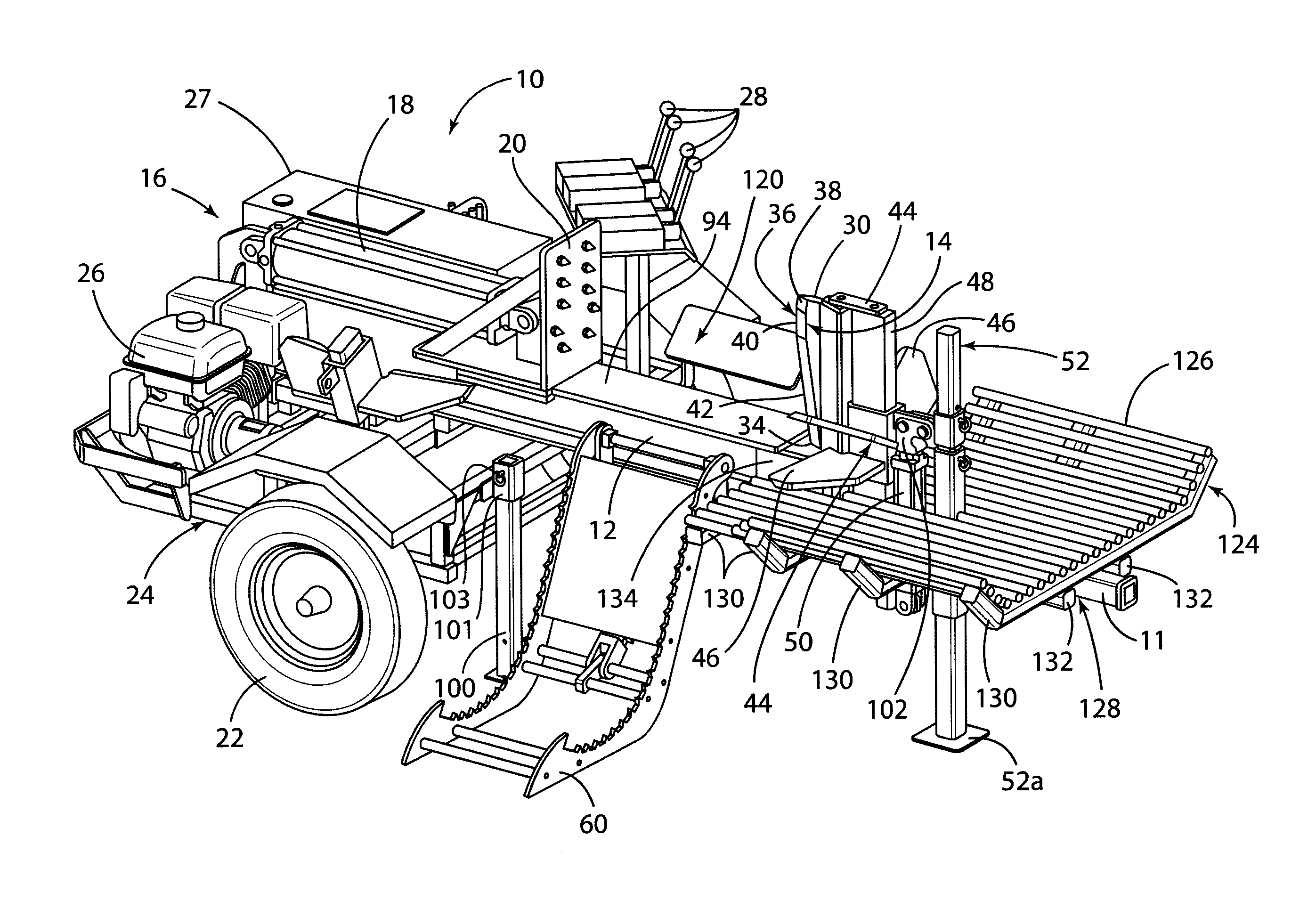

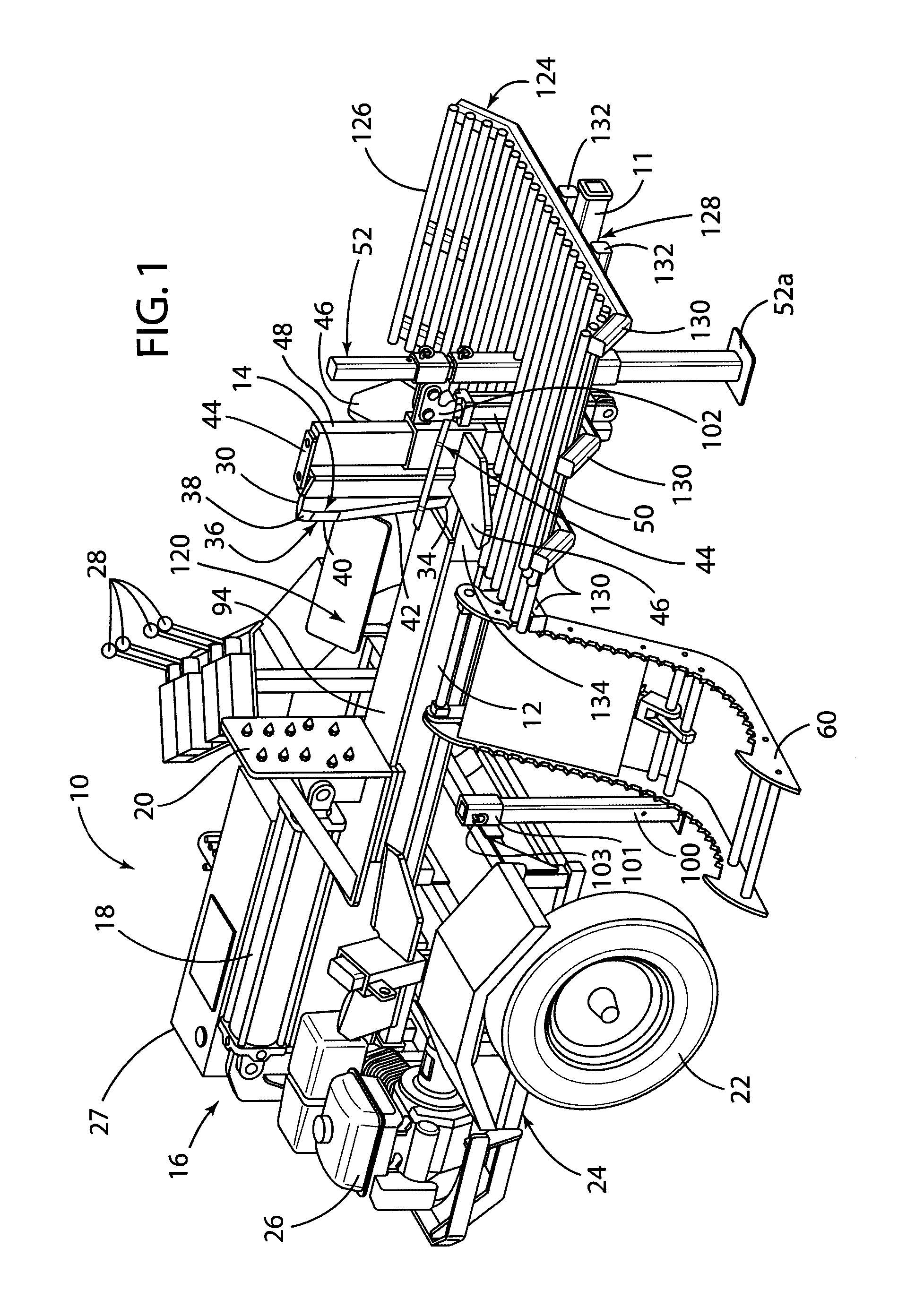

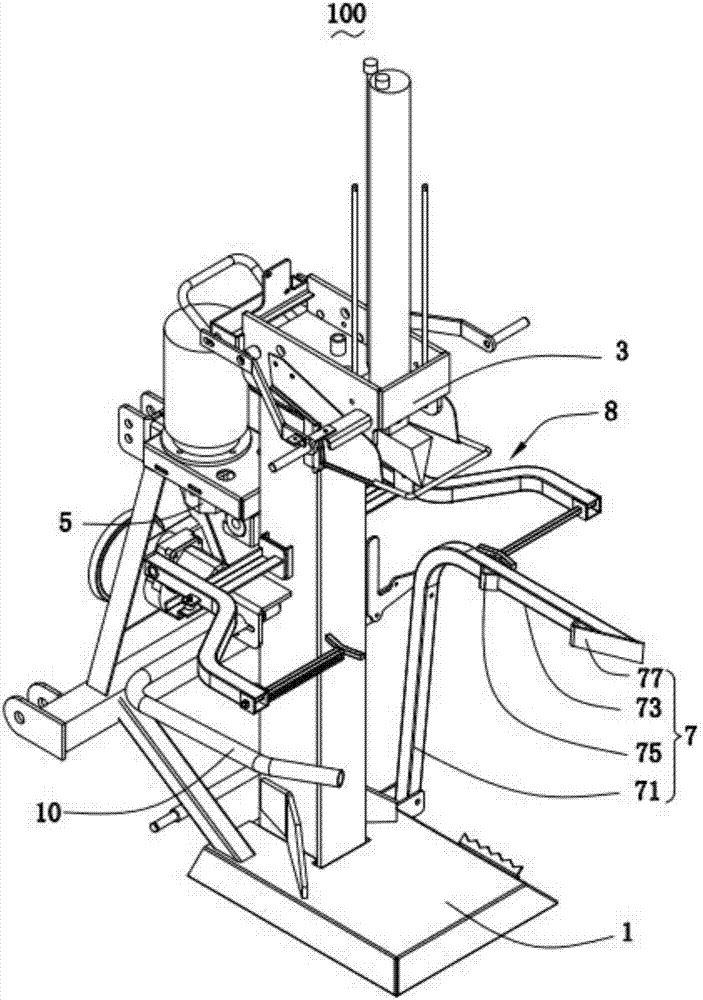

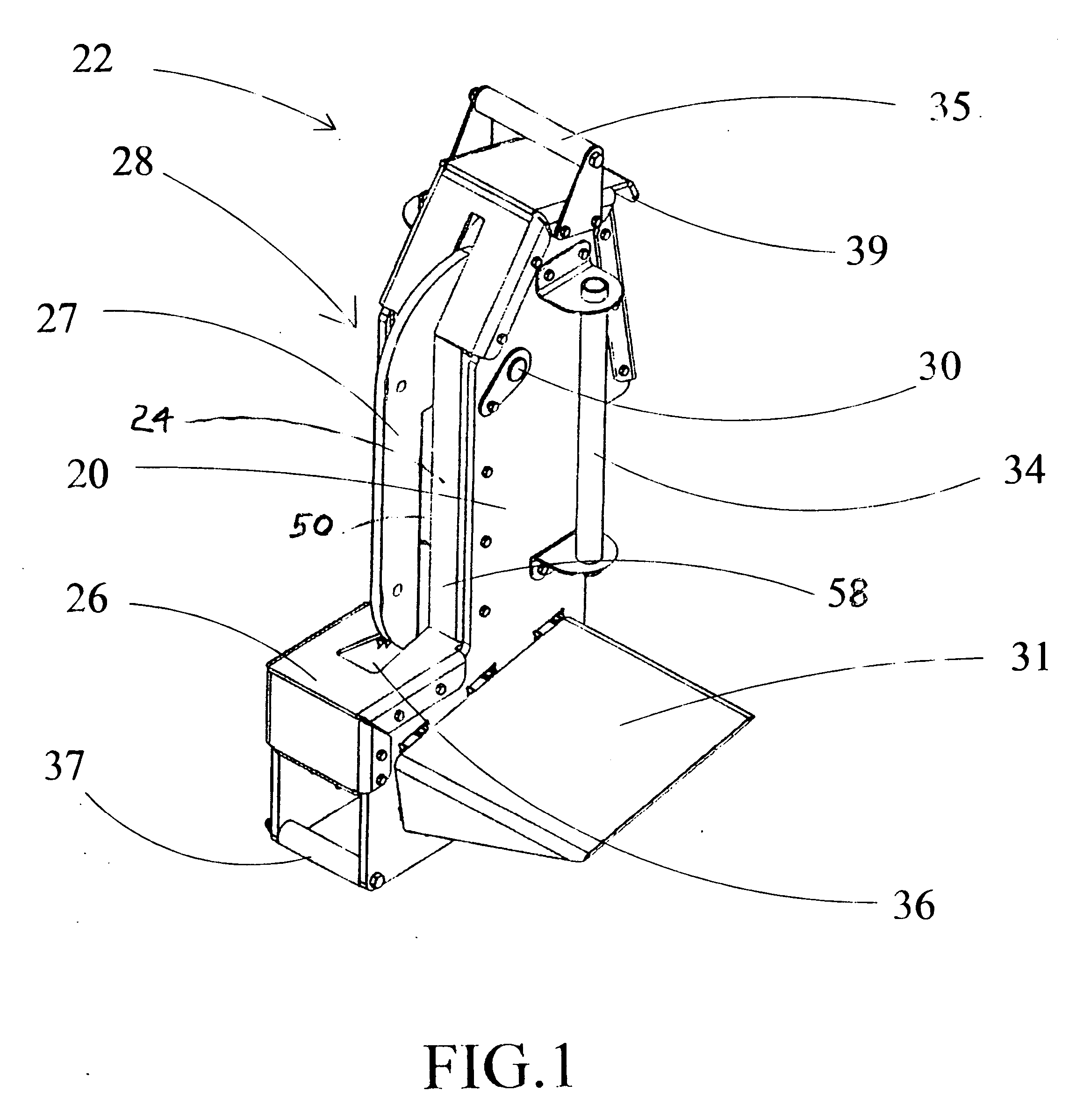

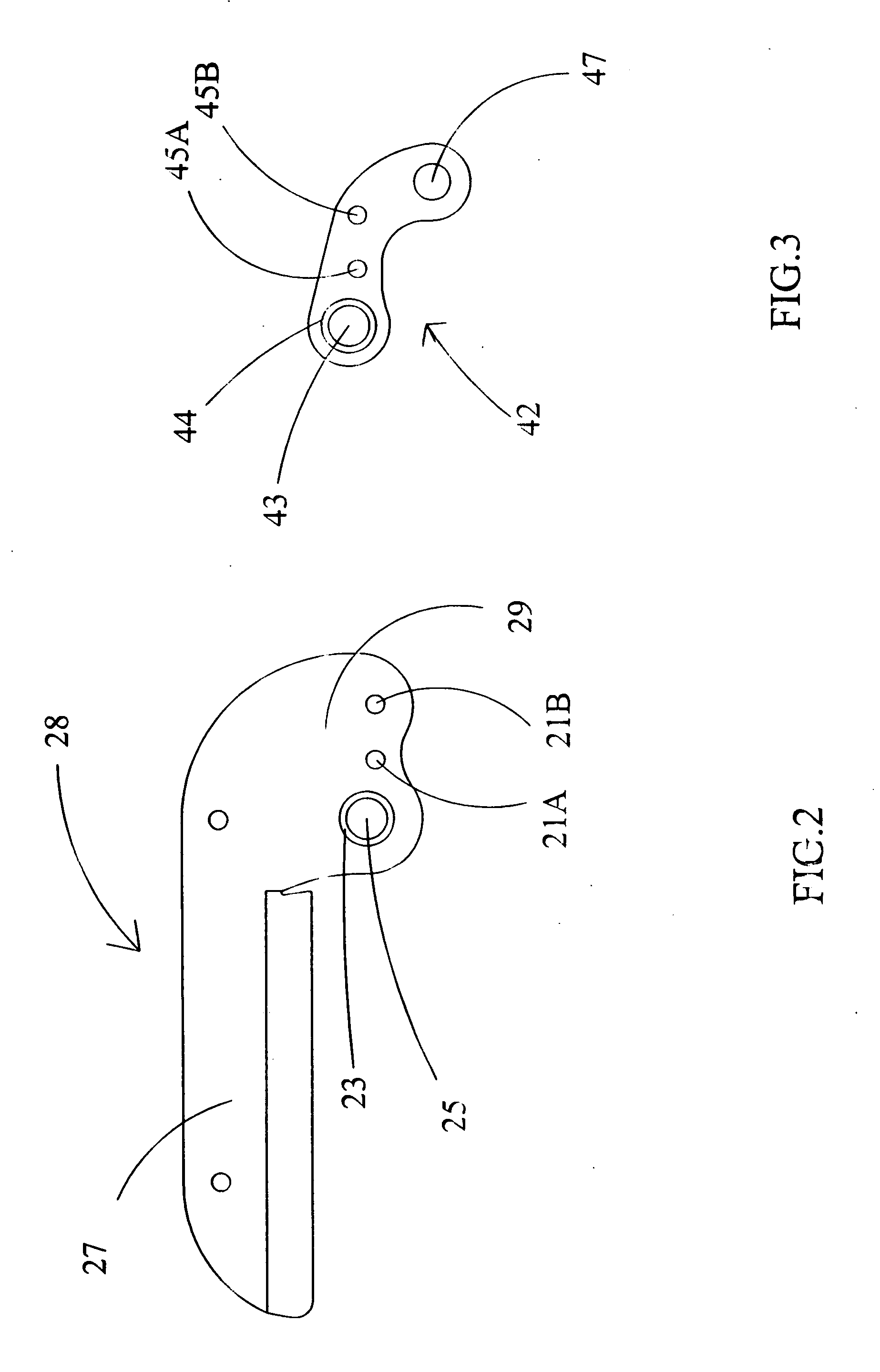

Wood Splitting Apparatus

A wood splitting apparatus having a splitting wedge mounted to a frame. The wedge configured to have multiple cutting edges that engage the workpiece. The apparatus further including a lift mechanism for transferring a workpiece to a workpiece carriage area adjacent the splitting wedge. The lift mechanism is pivotally connected to the frame whereby actuation of a power cylinder moves the lift mechanism from an initial position where a workpiece is loaded onto the lift mechanism and a second position wherein the workpiece is deposited from the lift mechanism into the workpiece carriage area.

Owner:GREEN KEVIN J

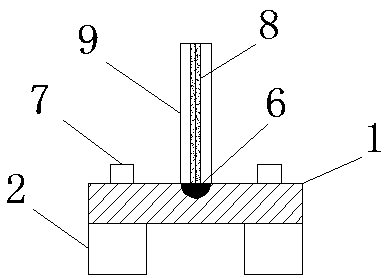

Manually operated apparatus for splitting wood

Manually operated apparatus for splitting wood includes at least one axe-shaped blade vertically arranged on a support base. The at least one axe-shaped blade has an upward facing cutting edge. The axe-shaped blade is structured and arranged to receive thereon a lower end of a piece of wood so that the piece of wood can be split by a hammer blow directed to an upper end of the piece of wood. A saddle member is coupled to the support base. The saddle member is structured and arranged to allow the piece of wood to lean against the saddle member and to hold the piece of wood upright at the moment when the piece of wood receives the hammer blow. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:WONDER LINK

Adjustable, portable wood splitting apparatus

InactiveUS6289955B1Great exercise for userQuiet operationWood splittingMulti-purpose machinesEngineeringWood splitting

An adjustable, portable wood splitting apparatus is provided having a pair of linearly elongated, telescoping cylindrical base members forming a V-shaped base diverging outwardly from an apex, a bracket base member, a linearly elongated, vertically extending handle support post, a linearly elongated, telescoping handle mounted above the apex and on a vertically extending handle support post, and a wedge vertically affixed to the handle.

Owner:WILHELM EUGENE

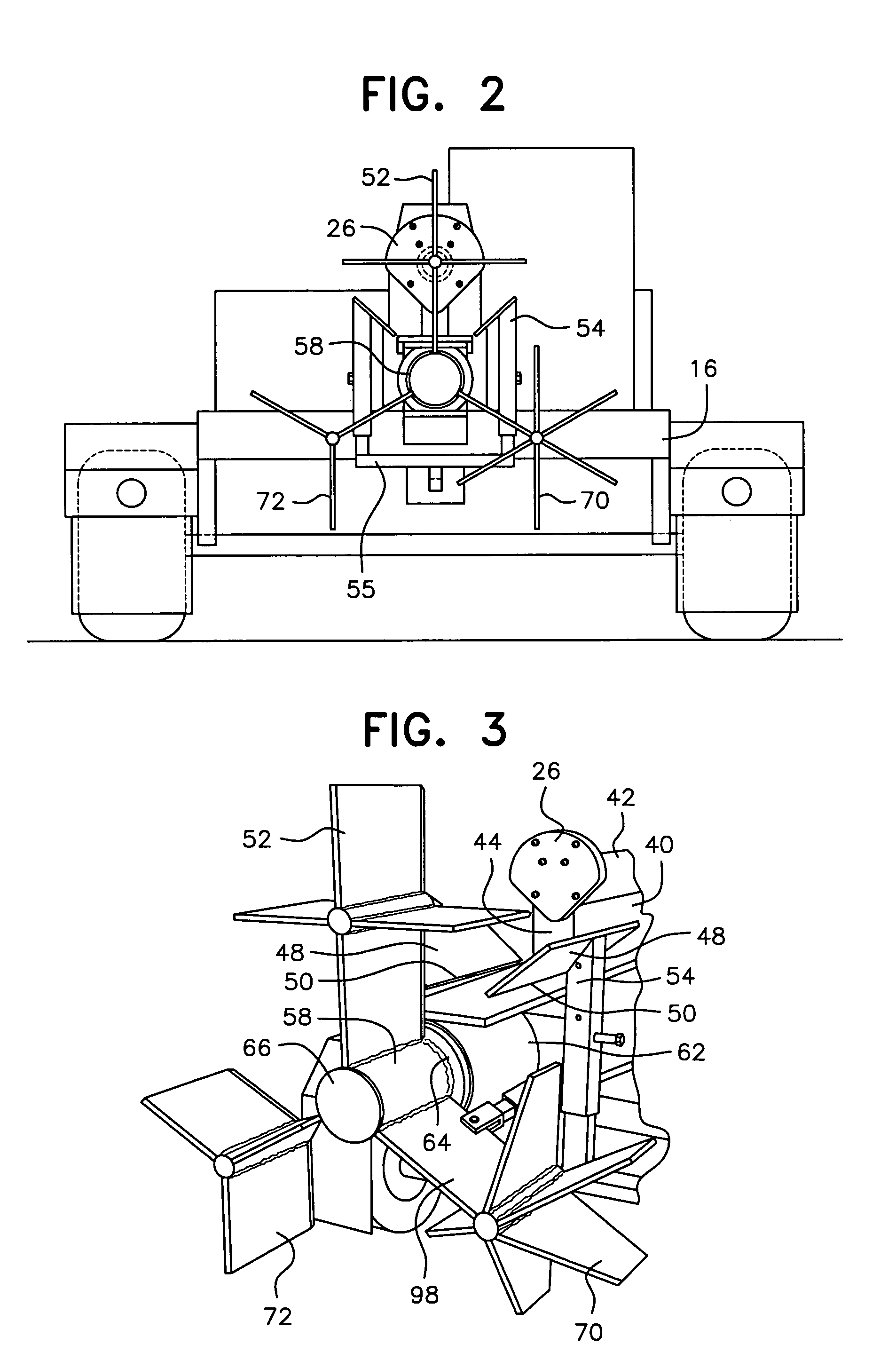

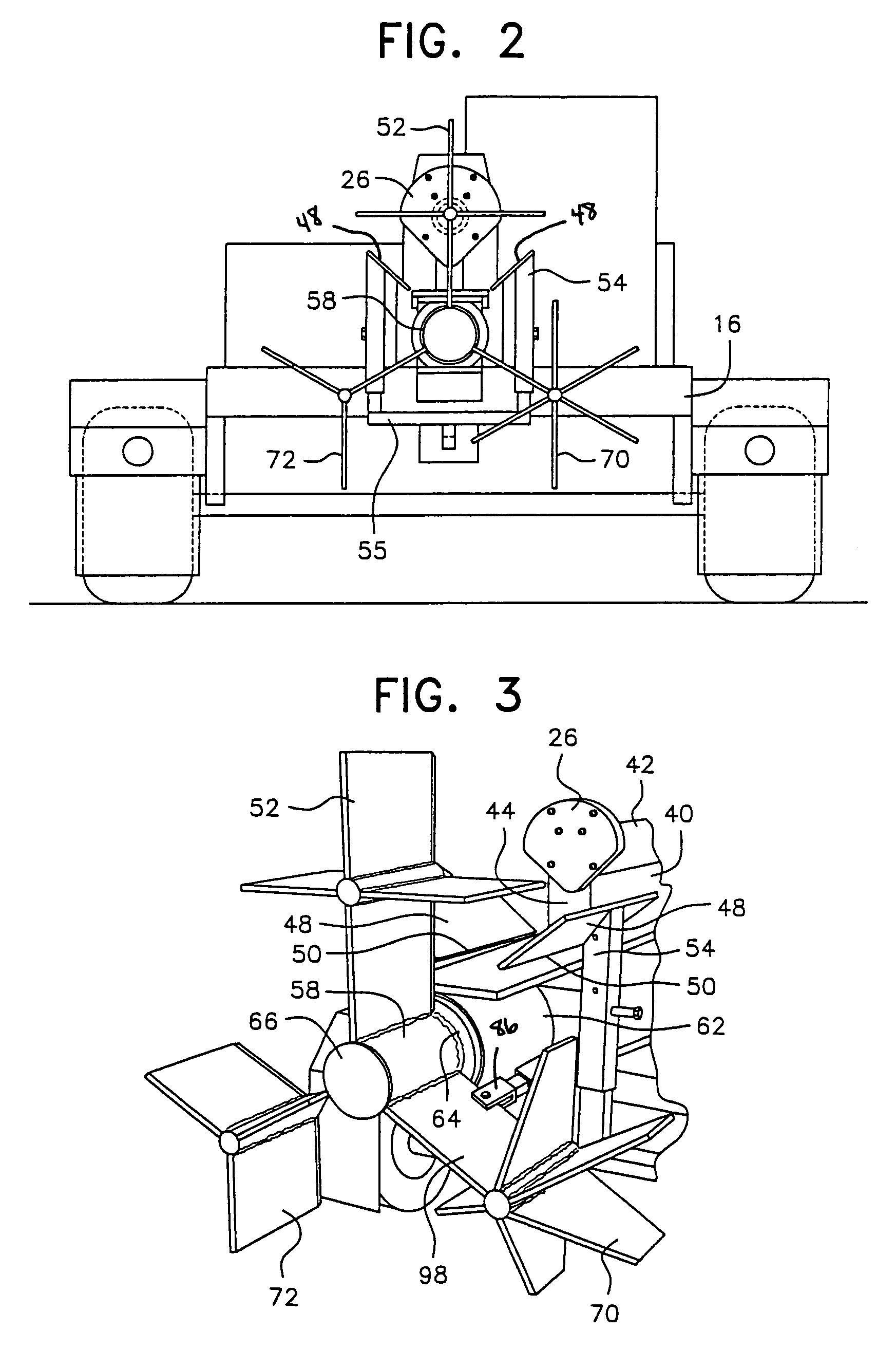

Wood splitter with multiple wood splitting wedges on a rotating member

InactiveUS20050279423A1Quickly and easily switchAccurate centerWood splittingMulti-purpose machinesEngineeringWood splitting

A woodsplitting machine has a plurality of wedges of various sizes radially attached to a rotational member mounted on the frame behind the log cradle such that an operator can quickly and easily rotate the appropriate wedge into position depending on the diameter of the log in the cradle to be split. The rotational member can be hydraulically actuated such that the wedges can be rotated around the longitudinal axis of the machine with little effort for the operator. An alternate embodiment provides that the rotational member be manually rotated such that the wedges can be rotated around the longitudinal axis of the machine by the hand of the operator.

Owner:ALBRIGHT DAVID B

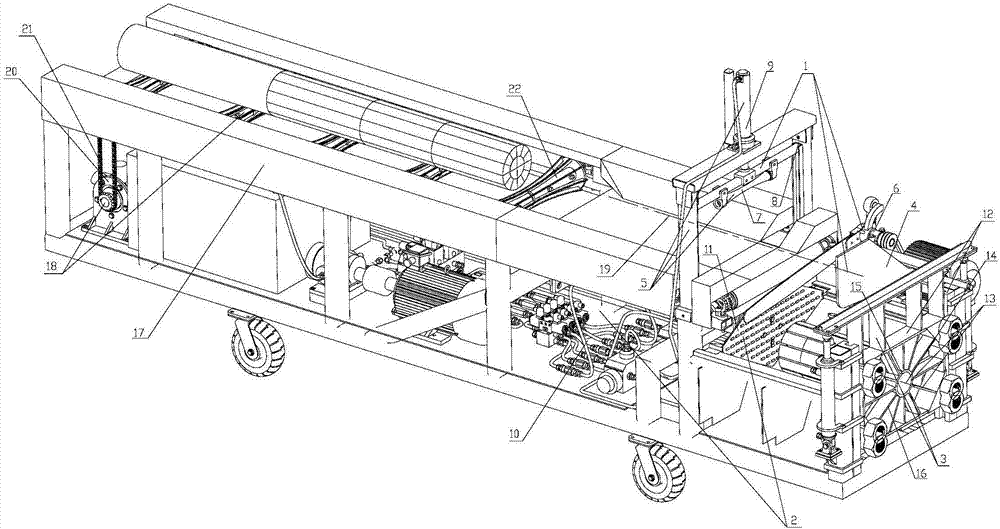

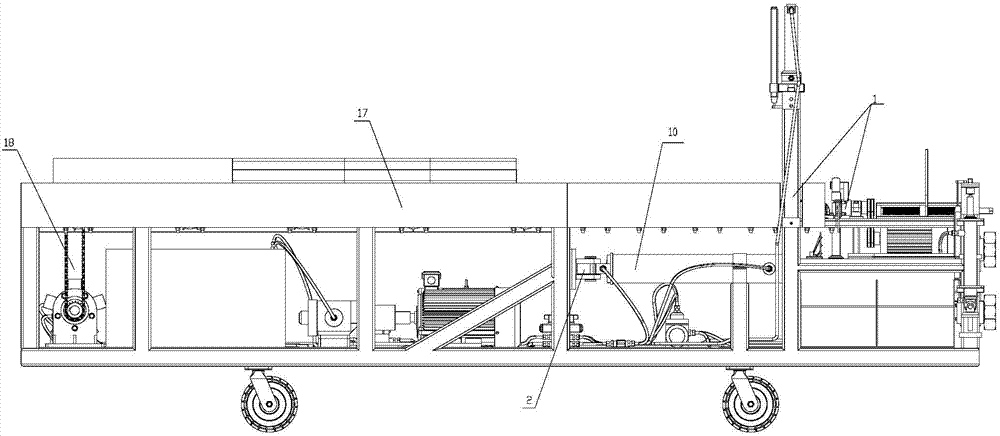

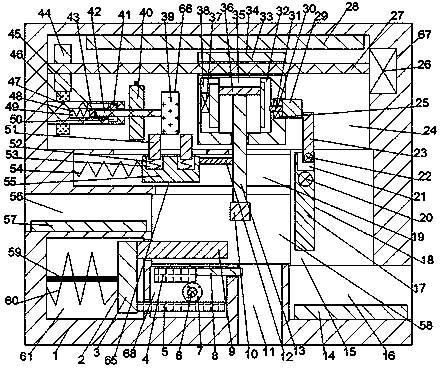

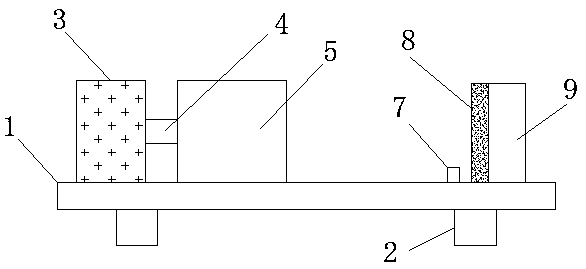

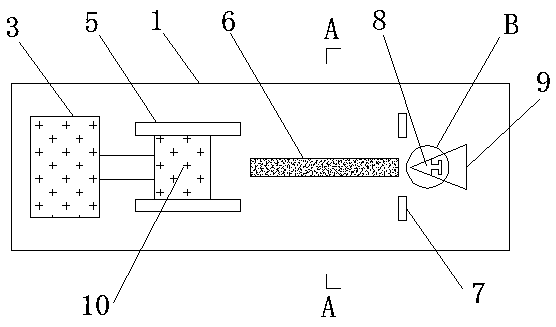

Full-automatic horizontal type wood splitting machine

PendingCN107139300AReduce labor intensityImprove labor productivityWood splittingWood splittingMachine

The invention discloses a full-automatic horizontal type wood splitting machine, belongs to the technical field of designing and manufacturing of new countryside production and living assisting equipment, and provides the full-automatic horizontal type wood splitting machine through which the man-made reference degree of an operator can be effectively reduced and further the automation degree of wood splitting work can be improved. The full-automatic horizontal type wood splitting machine comprises a shaping and cutting-off mechanism, a splitting and cutting driving mechanism and a splitting and hacking cutter. In the process of splitting and cutting wood, the wood which needs splitting and hacking is evenly shaped and cut by the shaping and cutting-off mechanism, and under the pushing of the splitting and cutting driving mechanism, the processed wood is split to small pieces of wood materials of a specified size by the splitting and hacking cutter.

Owner:PANZHIHUA UNIV

Method for cutting wood by utilizing wood splitting device

InactiveCN109203102AAutomatically reset and store powerRealize reset powerWood splittingProfiling/shaping machinesDrive shaftPulp and paper industry

The invention discloses a method for cutting wood by utilizing wood splitting device. The wood splitting device comprises a working block, a feeding space is arranged in the left end of the working block, a discharging space is arranged in the right end of the working block, a driving mechanism is arranged in the upper end of the feeding space, a hydraulic mechanism is arranged on a driving shaft,and a reset mechanism is arranged at the left end of the hydraulic mechanism. When the wood splitting device works, the device for pushing the wood can automatically achieve resetting and force storing, the wood can be automatically pushed after the force is stored well, the device can completely push the wood out each time, equal-length positioning and then automatic cutting of the wood are achieved, the automation degree in the whole wood cutting and delivering process is high, the stability of the device is good, multi-pass cutting of the wood can be achieved, the whole wood can be completely cut down, and after the wood is completely cut down, the last section of the wood can be automatically screened out if being unqualified.

Owner:方余香

Wood splitter with multiple wood splitting wedges on a rotating member

InactiveUS7108029B2Quickly and easily switchAccurate centerWood splittingMulti-purpose machinesEngineeringWood splitting

A woodsplitting machine has a plurality of wedges of various sizes and configurations radially attached to a rotational member mounted on the frame behind the log cradle such that an operator can quickly and easily rotate the appropriate wedge into position depending on the diameter of the log in the cradle to be split. The rotational member can be hydraulically actuated such that the wedges can be rotated around the longitudinal axis of the machine with little effort for the operator. An alternate embodiment provides that the rotational member be manually rotated such that the wedges can be rotated around the longitudinal axis of the machine by the hand of the operator.

Owner:ALBRIGHT DAVID B

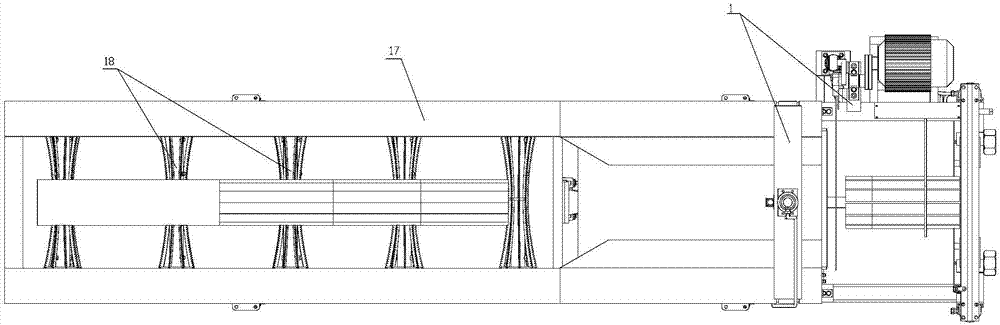

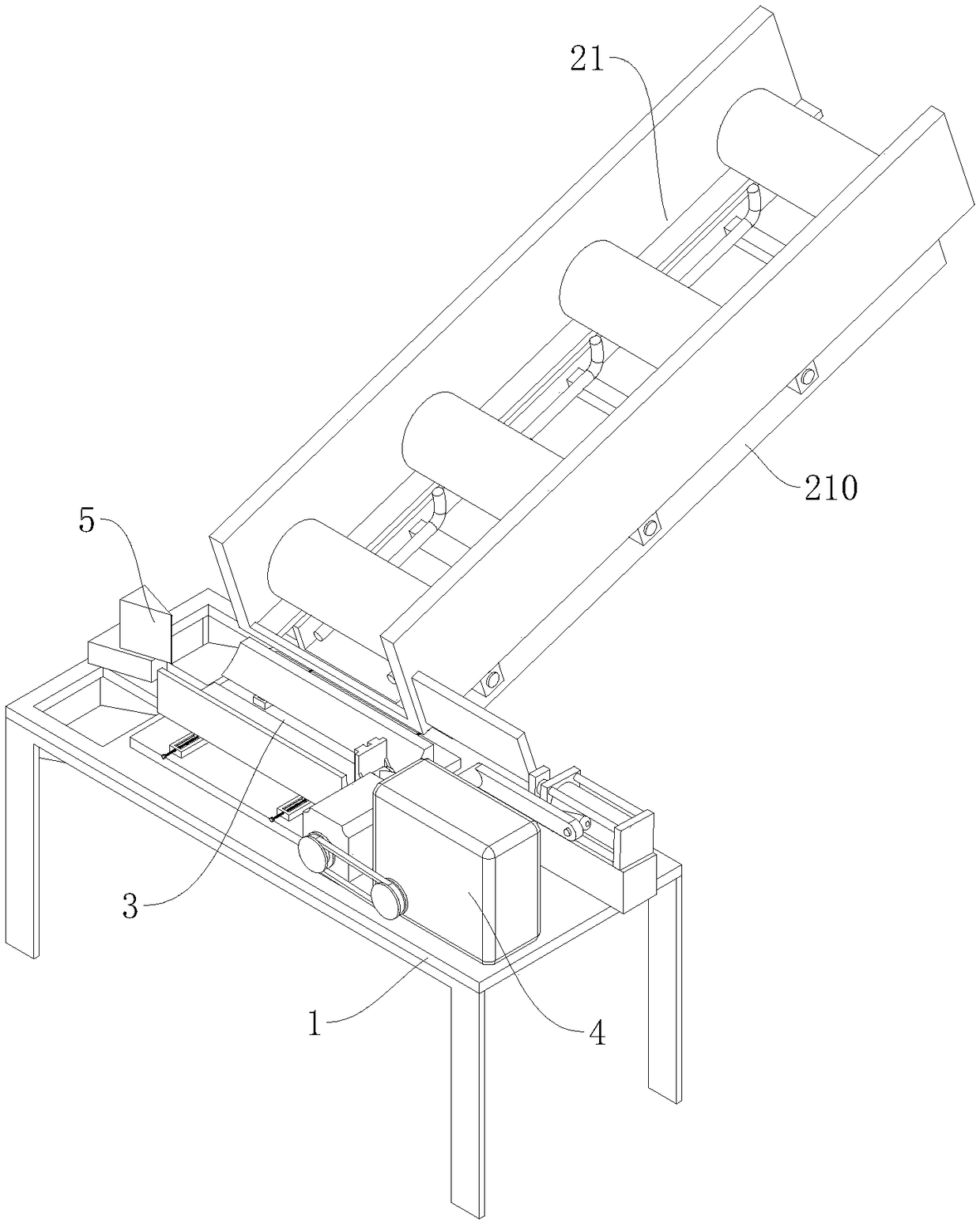

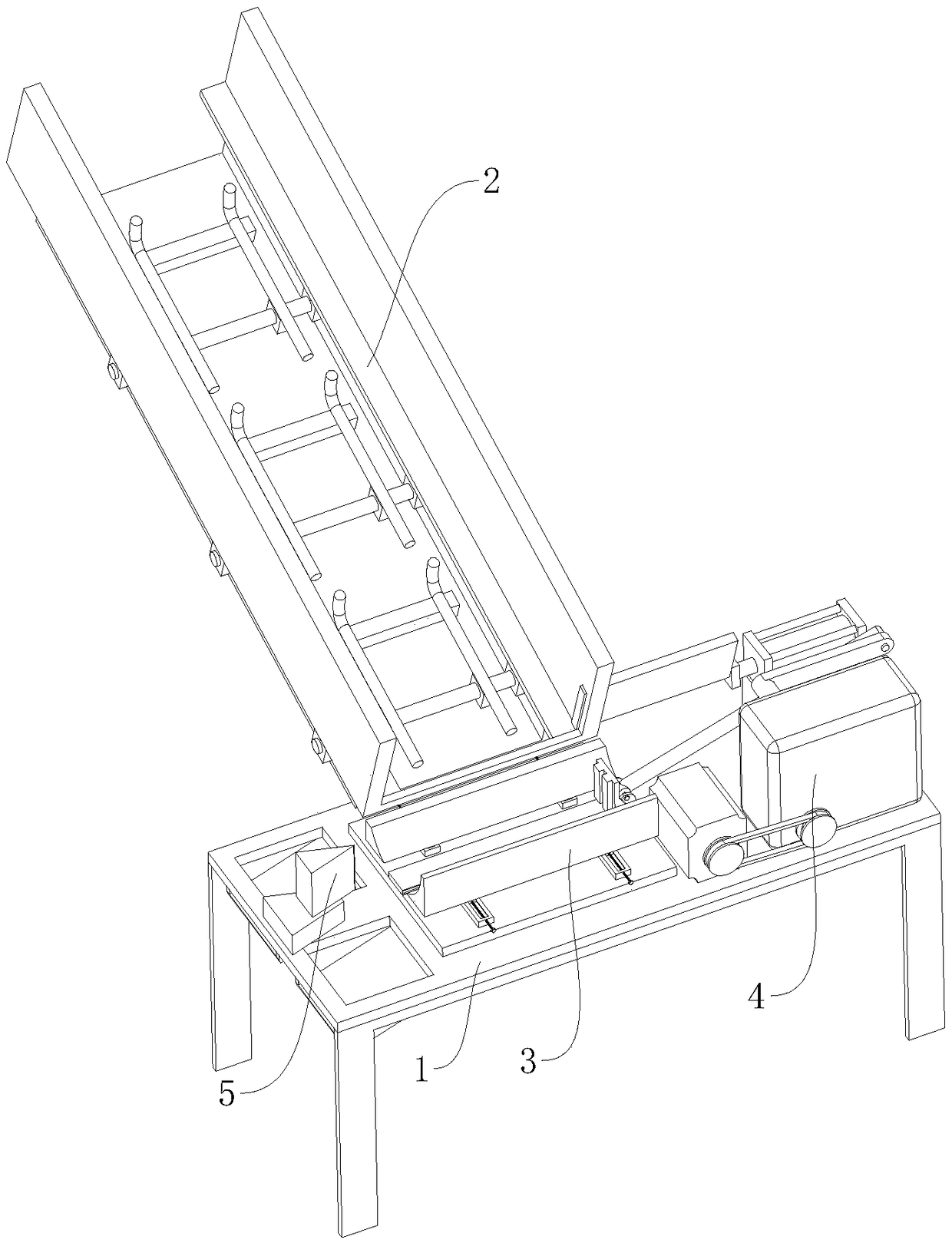

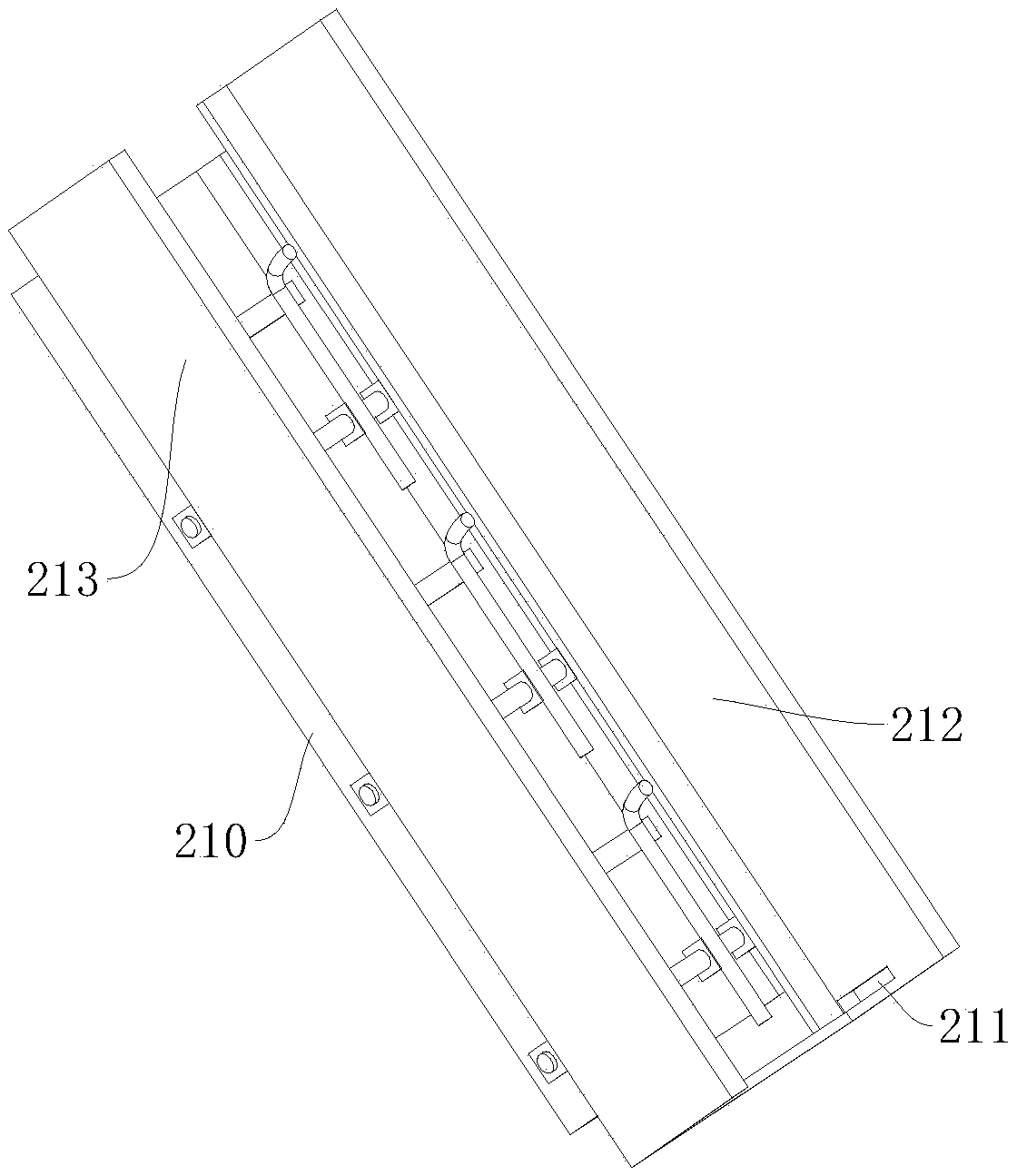

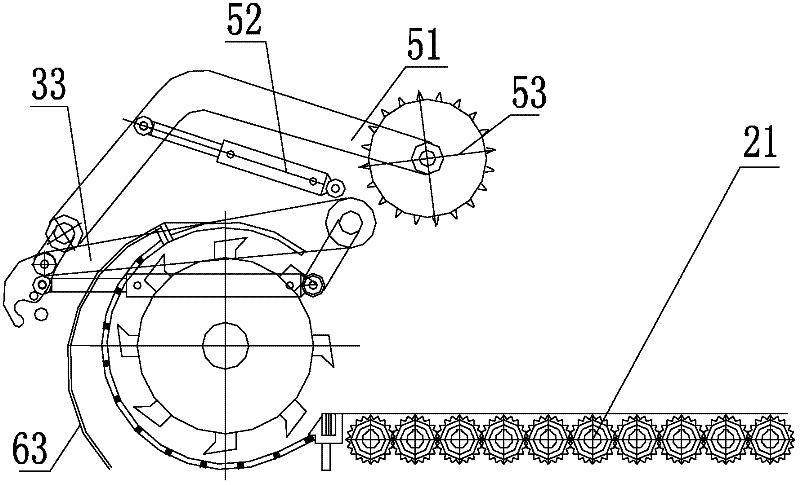

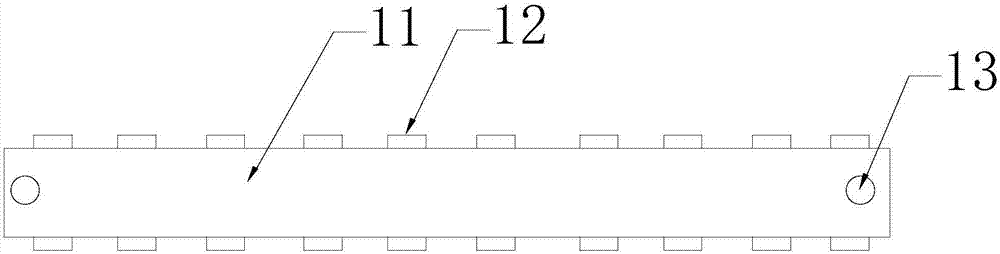

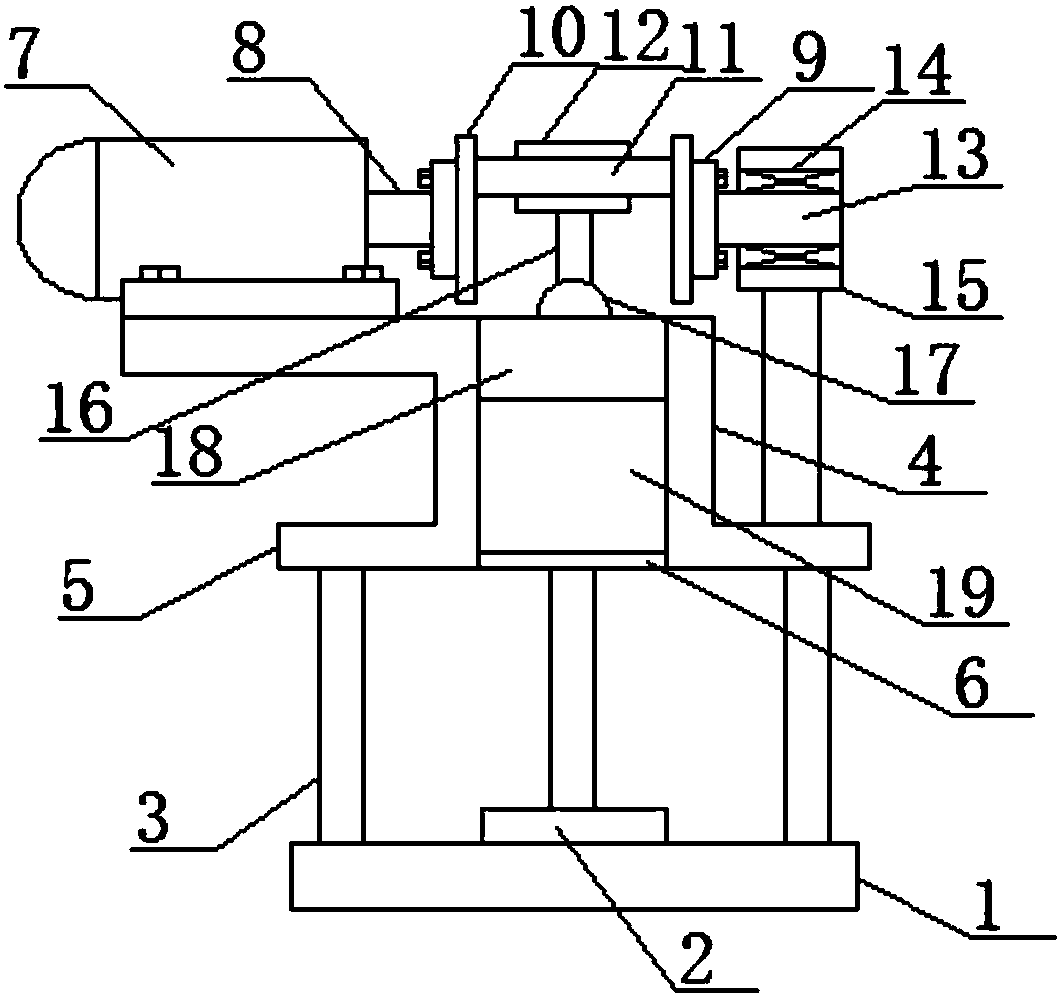

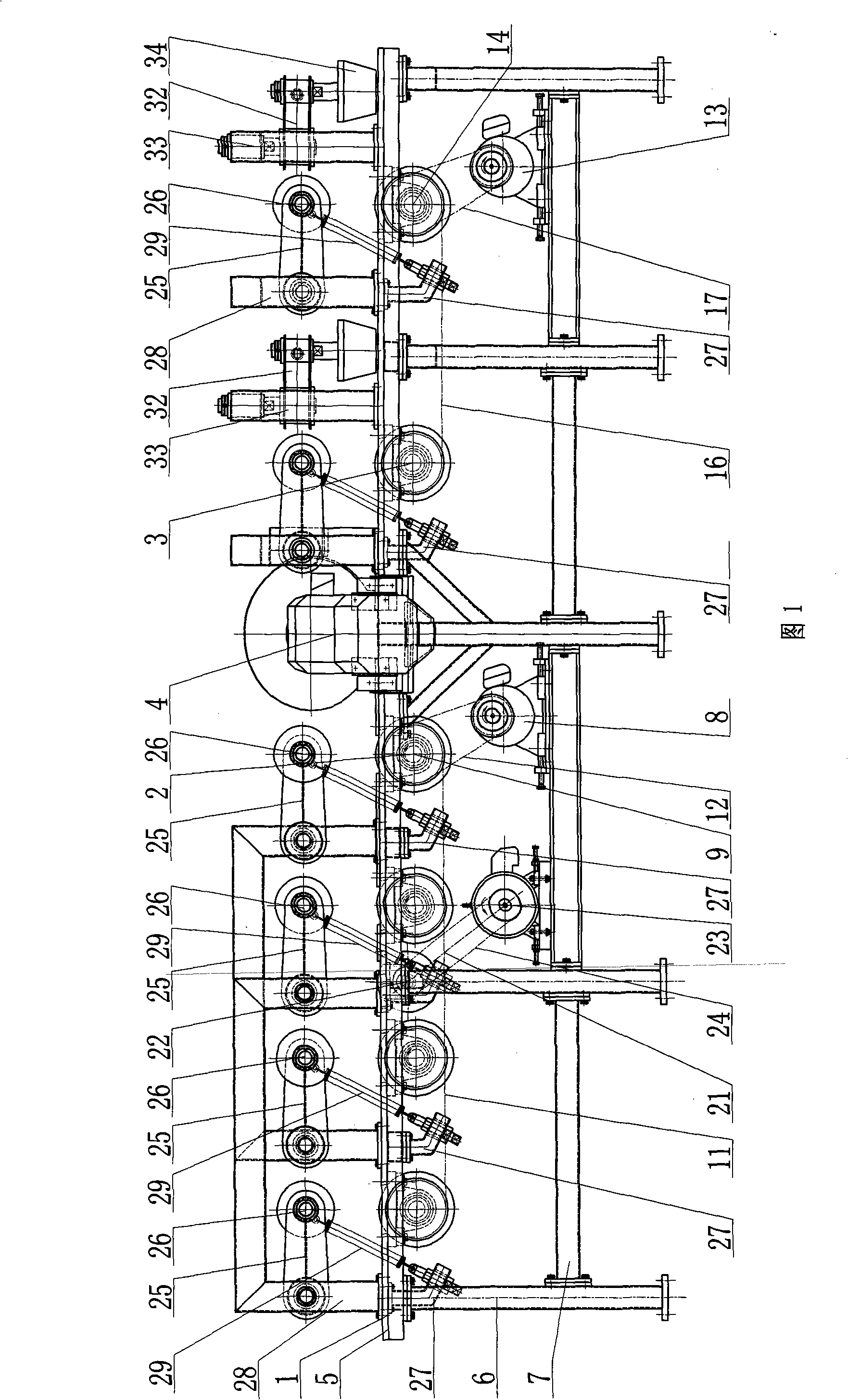

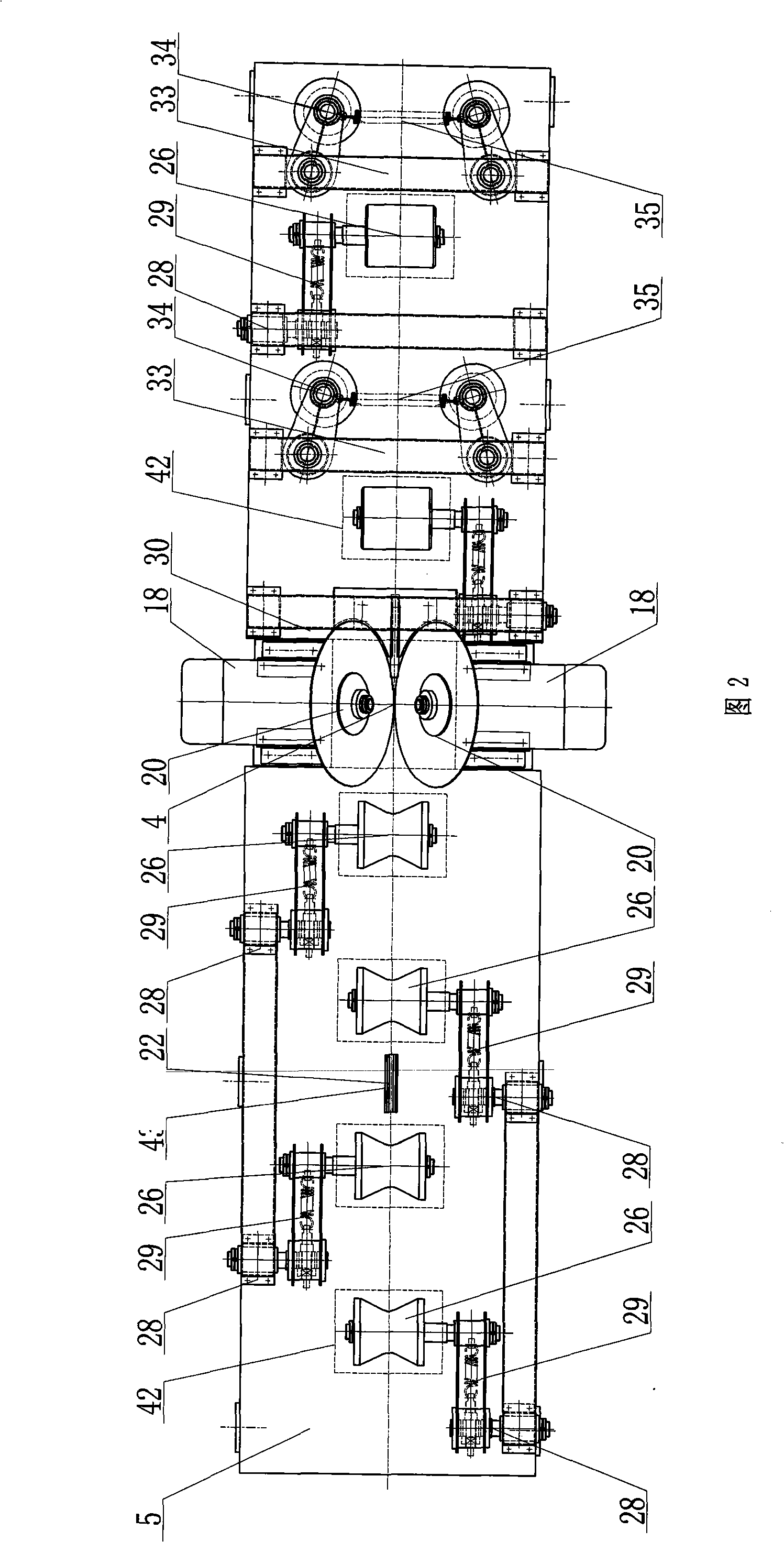

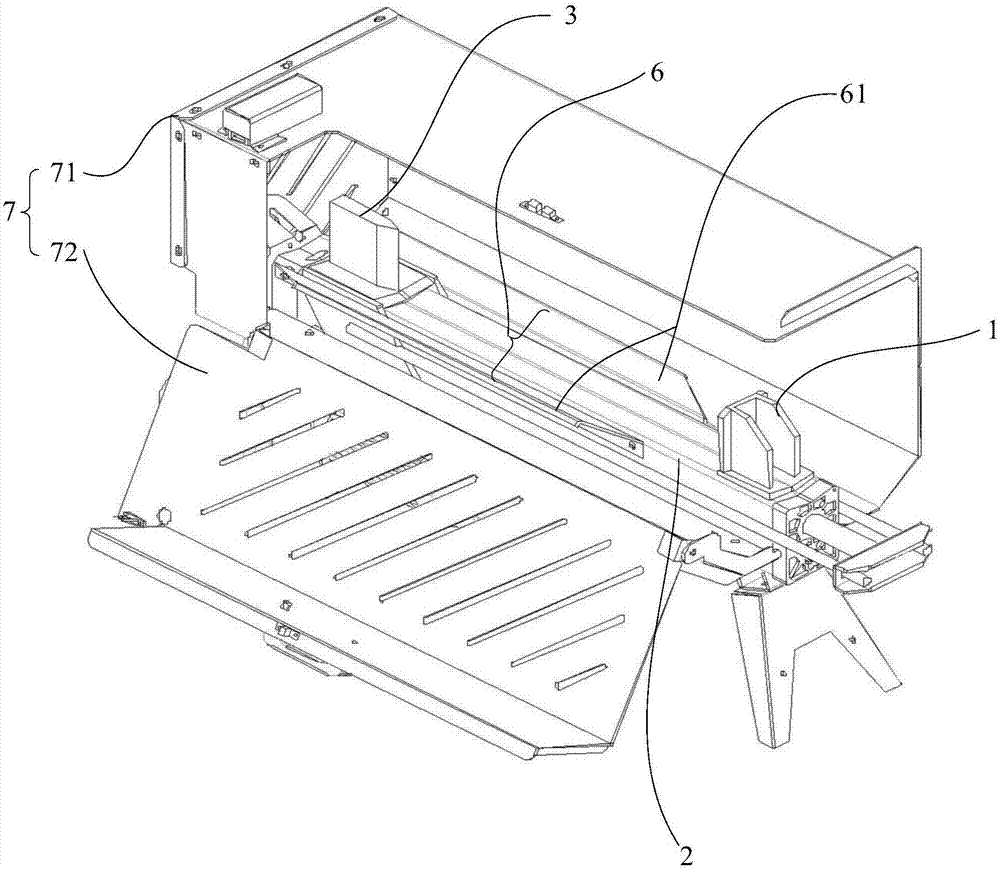

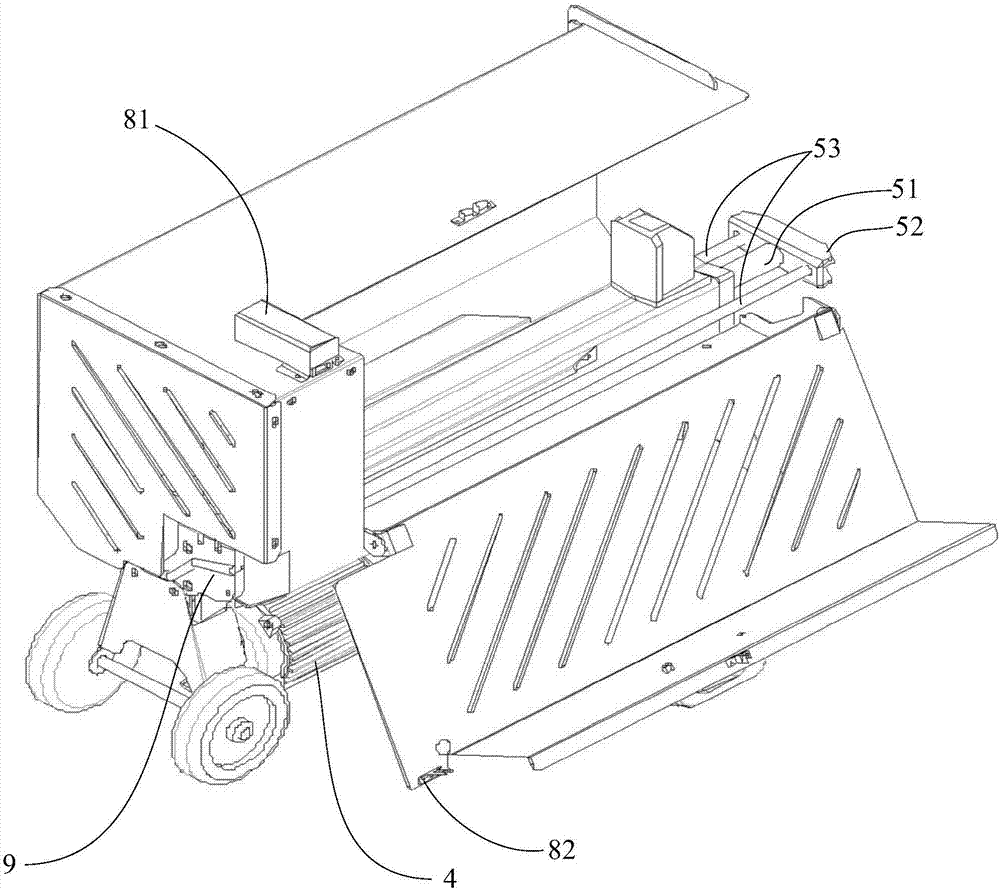

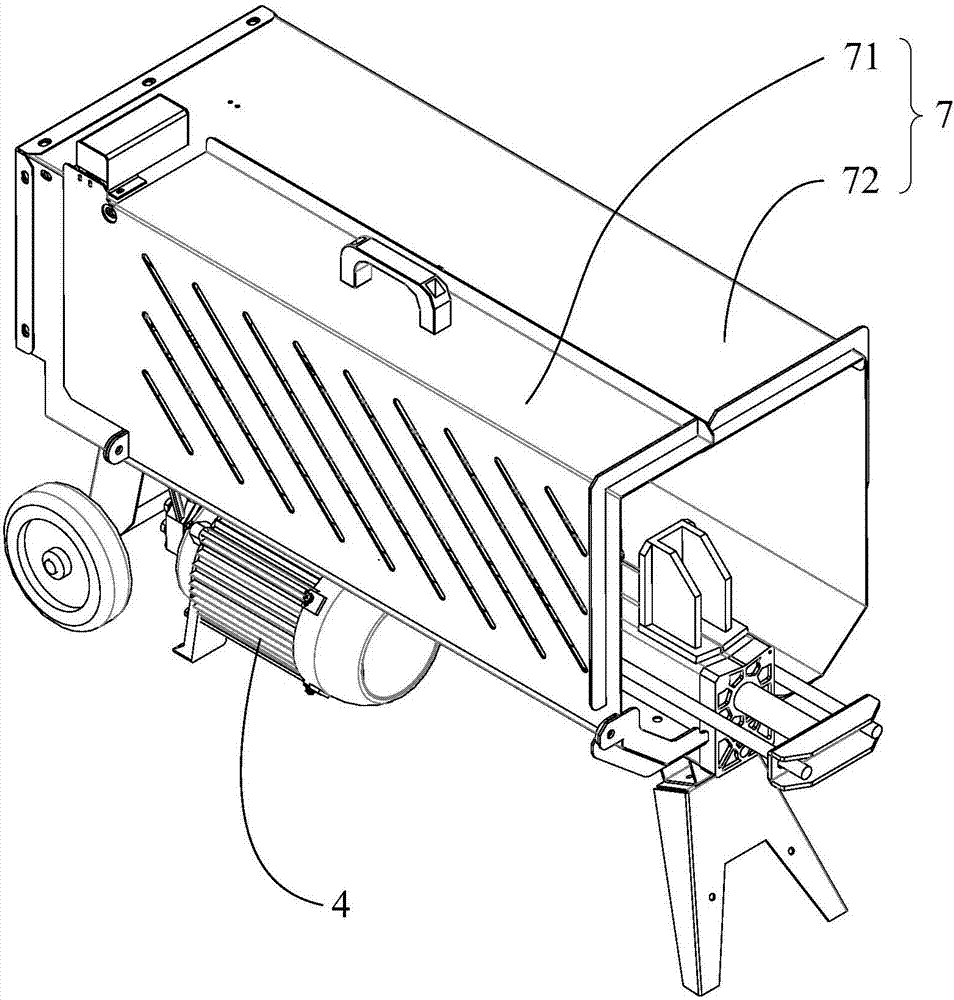

Automatic continuous wood splitting machine

The invention relates to the technical field of agricultural machinery, in particular to an automatic continuous wood splitting machine. The automatic continuous wood splitting machine comprises a workbench, a discharging device, a pushing device and a driving device. The pushing device is arranged at the top end of the workbench, a wood splitting cutter used for splitting wood is arranged at thetop end of the workbench, and the driving device is disposed at the top end of the workbench. The pushing device comprises a bearing bottom plate, a first limiting assembly, a second limiting assemblyand a pushing assembly, the bearing bottom plate is installed at the top of the workbench, the first limiting assembly and the second limiting assembly are separately mounted on one side of the top end of the bearing bottom plate, and the pushing assembly is disposed between the first limiting assembly and the second limiting assembly. The discharging device is disposed on the side of the workbench, and the discharging device and the first limiting assembly are arranged on the same side. The wood splitting operation with higher continuity is completed by the cooperation work between the discharging device, the pushing device and the driving device, the labor of personnel is reduced, and the efficiency is improved.

Owner:FENGHUA NANFANG MACHINERY MANUFACTORY

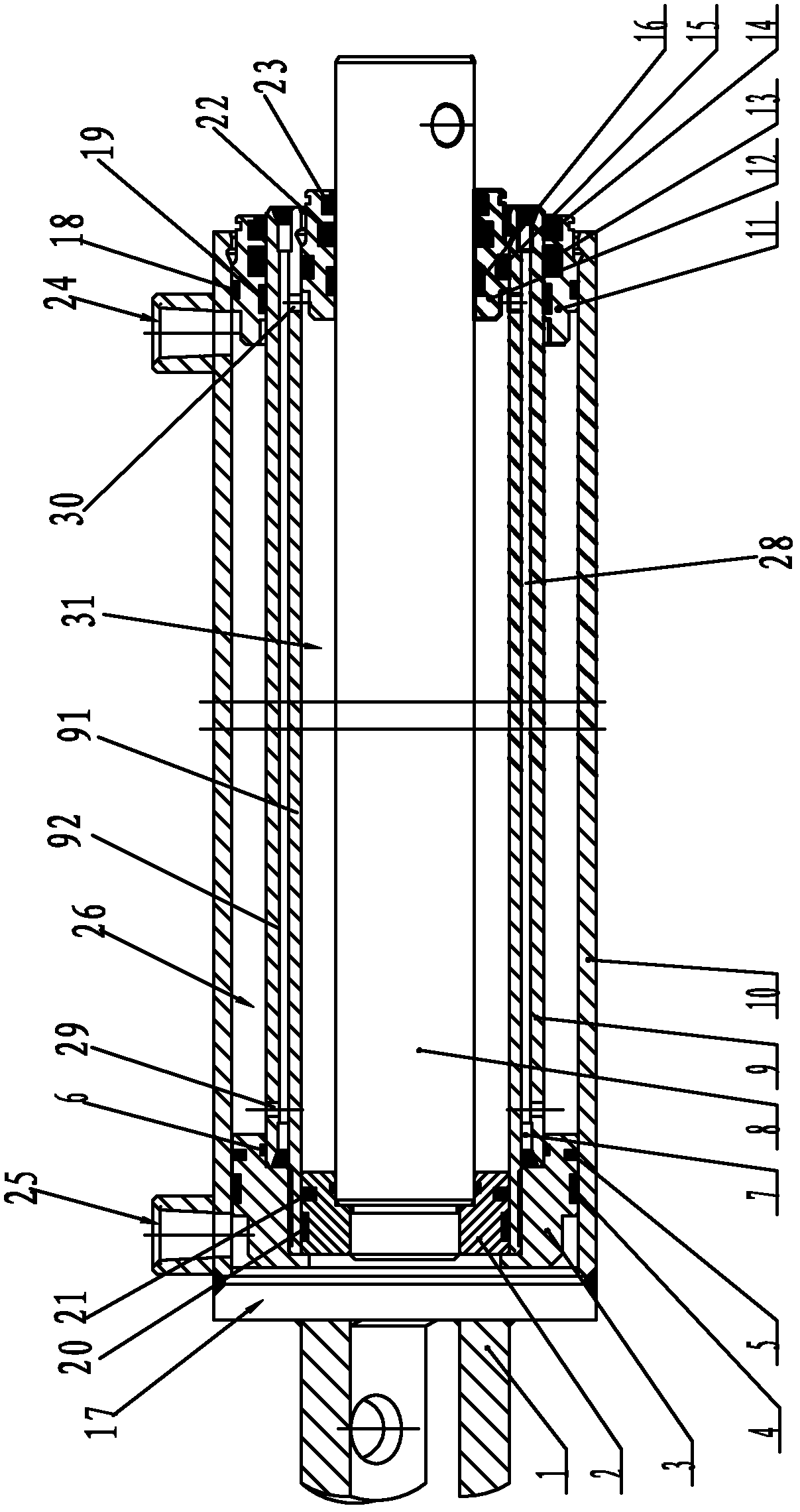

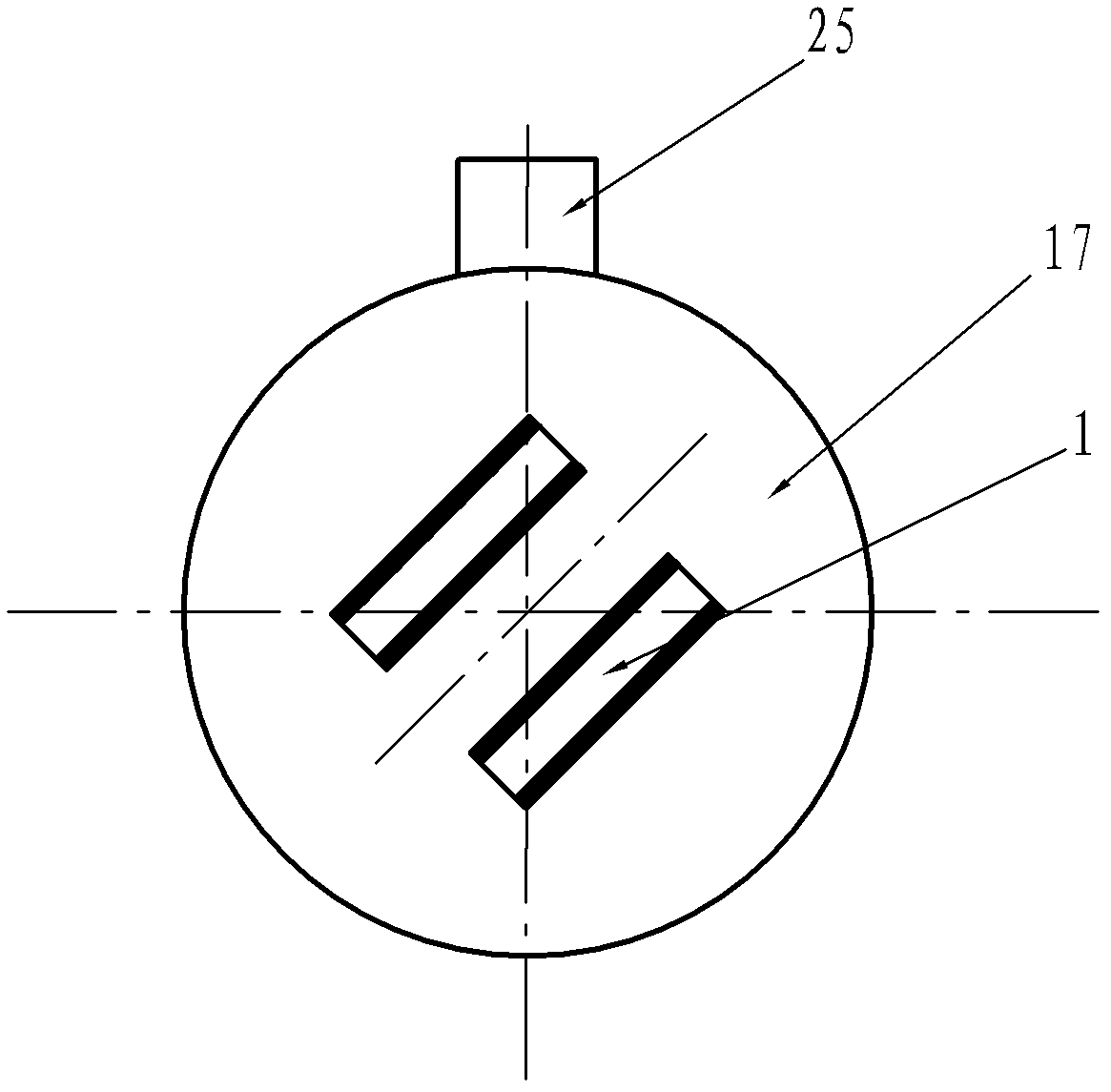

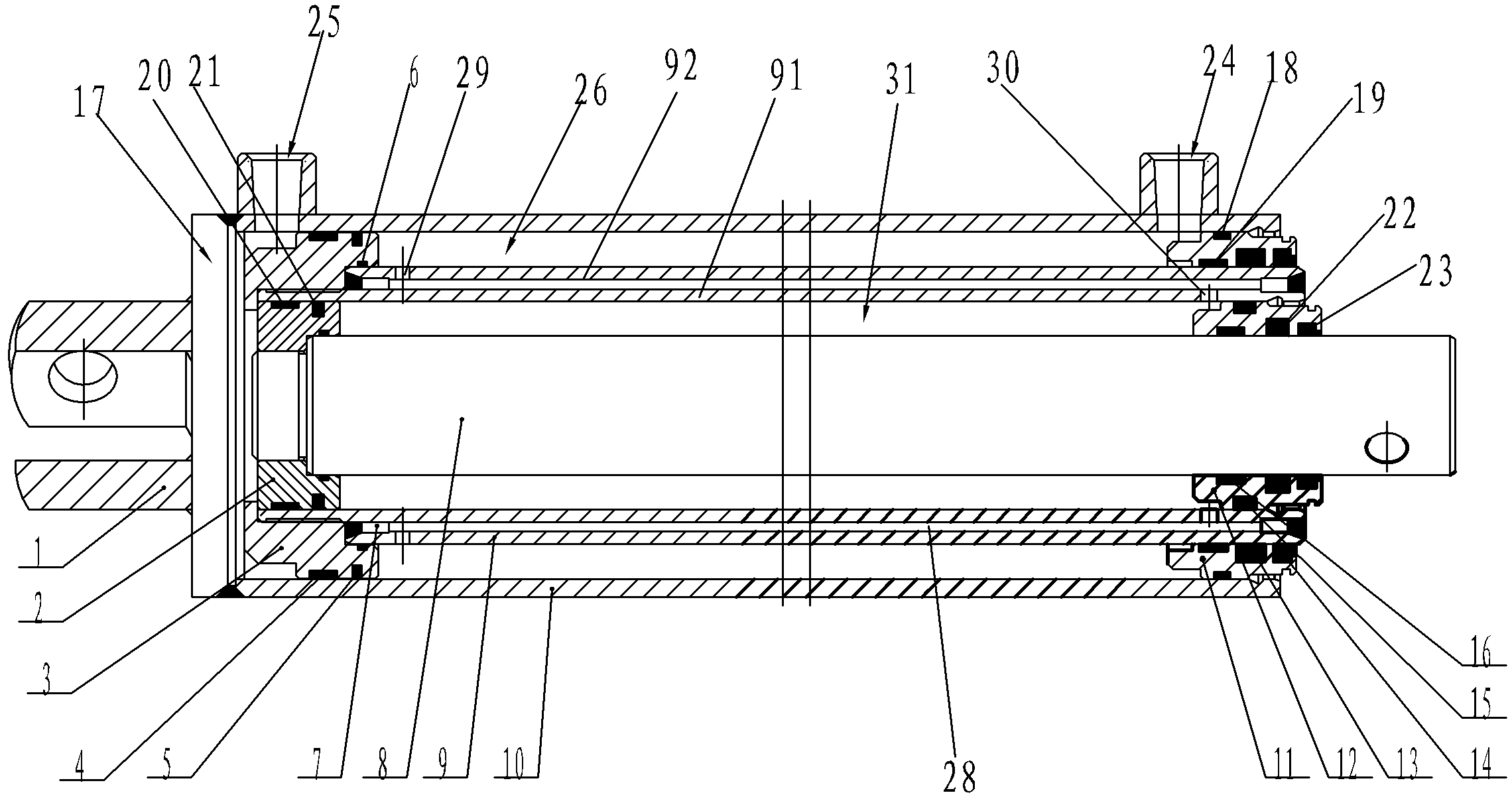

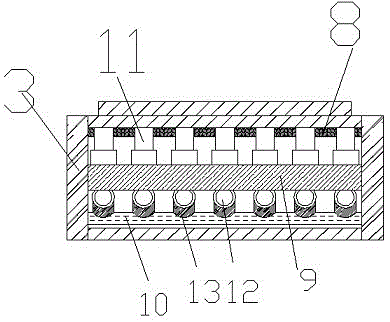

Secondary oil cylinder of wood splitting machine

InactiveCN102562710ASmall and light structureShorten the installation distance of the form factorFluid-pressure actuatorsPulp and paper industryWood splitting

The invention discloses a secondary oil cylinder of a wood splitting machine, which comprises a cylinder barrel, a cylinder base plate, a primary guiding sleeve, a primary piston, a primary piston rod, a secondary guiding sleeve, a secondary piston and a secondary piston rod. The primary piston is arranged in the cylinder barrel, the primary guiding sleeve is mounted at the top end of the cylinder barrel, the primary piston rod comprises an inner barrel and an outer barrel, bottom ends of the inner barrel and the outer barrel are respectively fixedly connected with the primary piston, the outer barrel penetrates through the primary guiding sleeve, the secondary piston is disposed in the inner barrel, the bottom end of the secondary piston rod is connected with the secondary piston, the secondary guiding sleeve is mounted inside the top end of the inner barrel, the secondary piston rod penetrates through the secondary guiding sleeve, the top end and the bottom end of the cylinder barrel are respectively provided with a first oil inlet and a second oil inlet, a first oil channel is arranged between the cylinder barrel and the outer barrel, a second oil channel is arranged between the inner barrel and the outer barrel, an external oil inlet is arranged at the bottom end of the outer barrel, an internal oil inlet is arranged at the top end of the inner barrel, a third oil channel is arranged between the secondary piston rod and the inner barrel, and the first oil inlet is successively communicated with the first oil channel, the external oil inlet, the second oil channel, the internal oil inlet and the third oil channel.

Owner:LAIZHOU XINGDA HYDRAULIC MACHINERY TECH

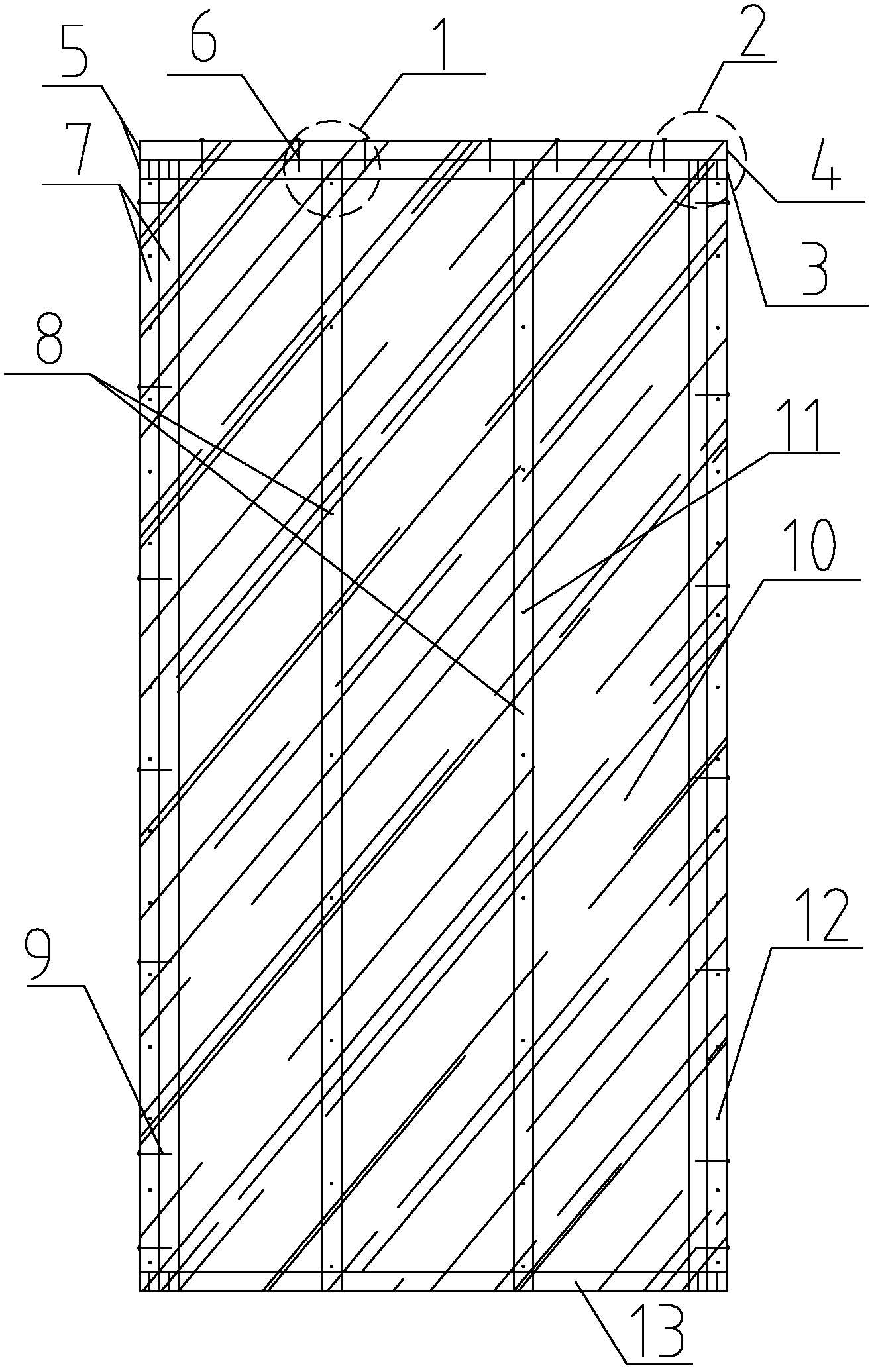

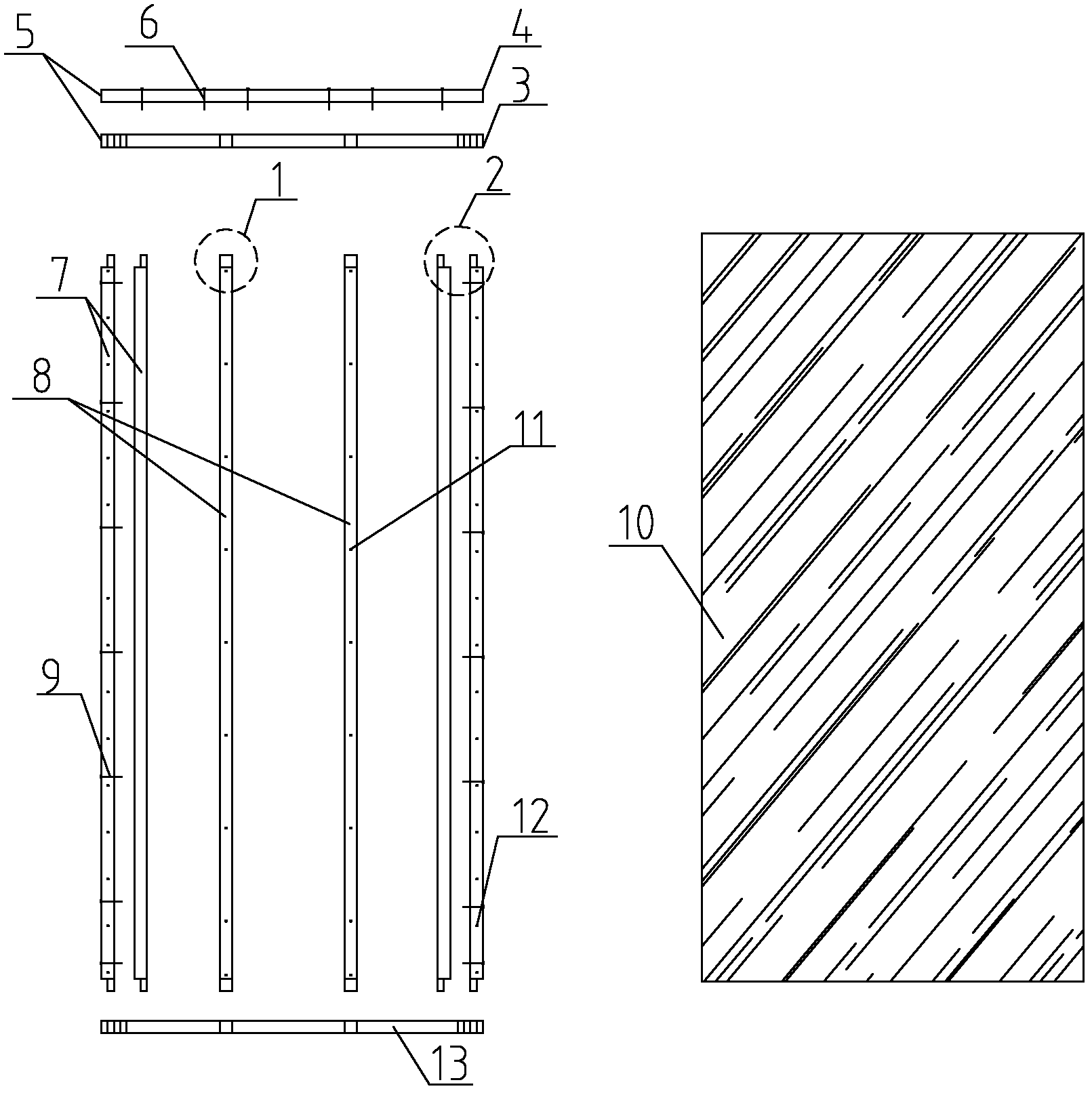

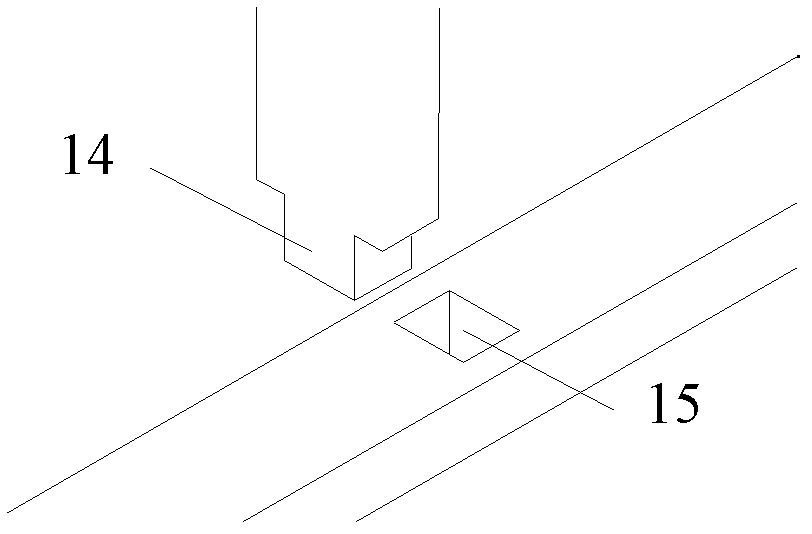

Novel shear wall with wood frame

The invention relates to a novel shear wall with a wood frame, which is composed of a cover panel and a wall frame, wherein the cover panel is fixed on a side face of the wall frame; the wall frame is composed of a top beam plate, a bottom beam plate and a plurality of wall skeletons; the wall skeletons are equidistantly arranged between the top beam plate and the bottom beam plate, thereby forming a frame structure. The novel shear wall with the wood frame is characterized in that two ends of the wall skeletons are fixed on the top beam plate and the bottom beam plate through mortise and tenon joint. The novel shear wall with the wood frame has the advantages of higher shearing resistance, bearing capacity, energy-consumption capacity, impact load resistance, better stressing and deforming capacity, and capability of avoiding the phenomena of invalid connection and wood splitting caused by a nail connecting joint which is bent after a nail is pulled out during loading and unloading processes.

Owner:国际竹藤网络中心

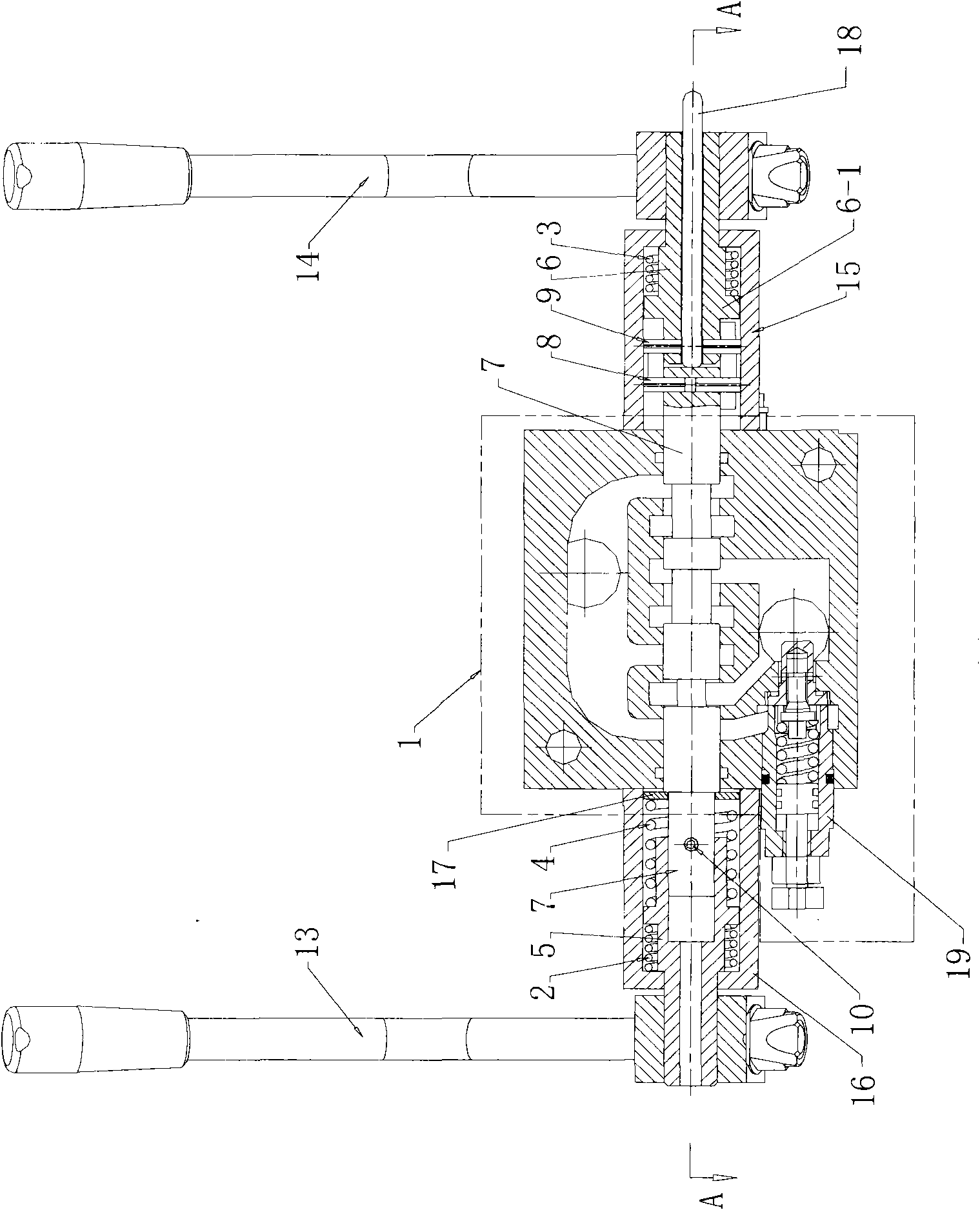

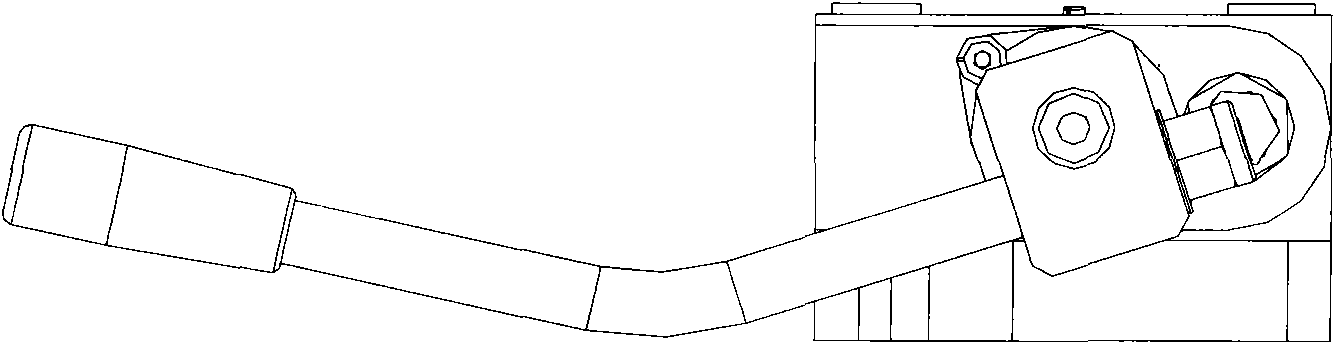

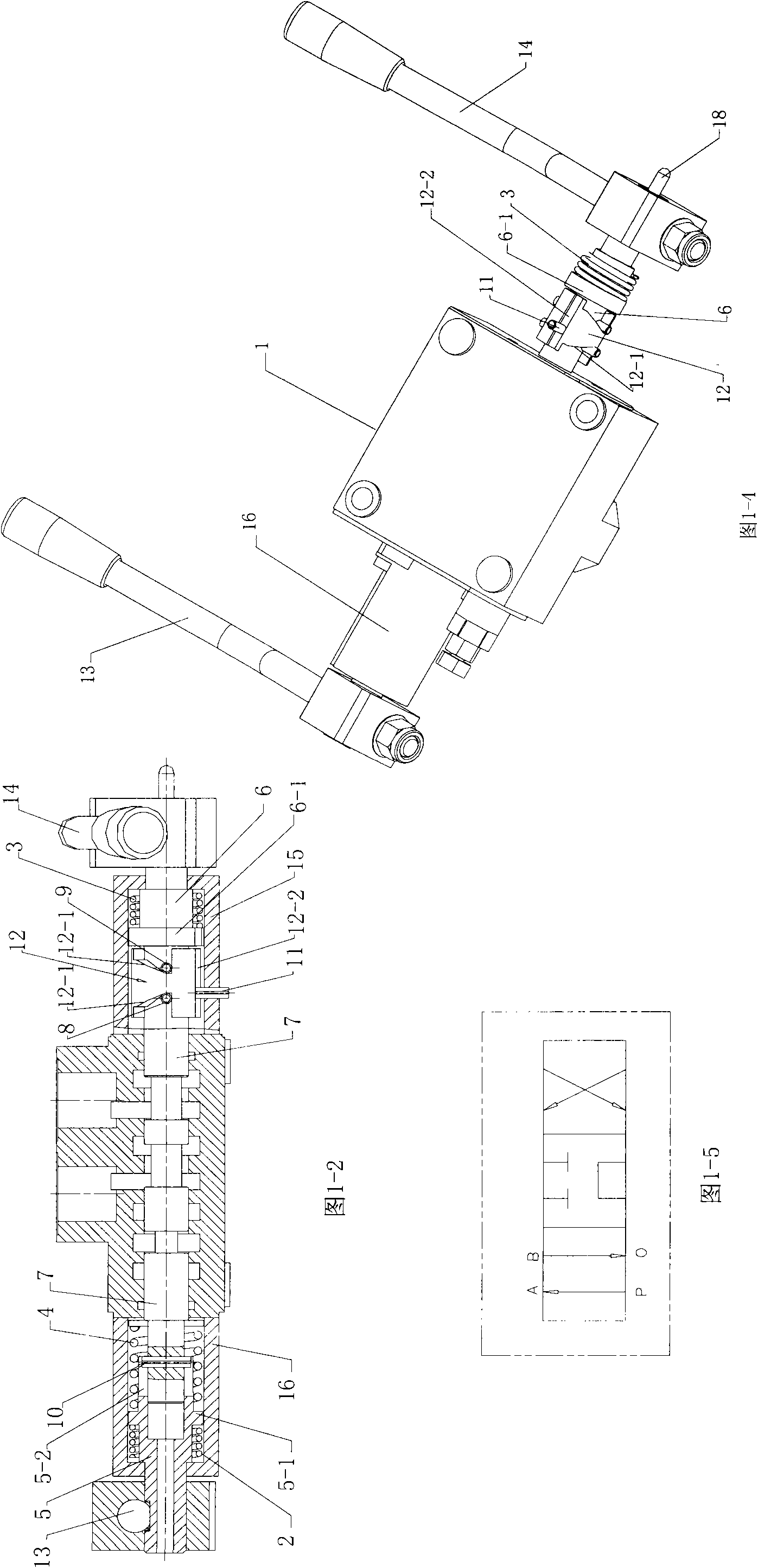

Manual drive control valve and wood splitting machine provided with same

InactiveCN101639129AFew partsSimple structureWood splittingOperating means/releasing devices for valvesWood splittingEngineering

The invention provides a manual drive control valve and a wood splitting machine provided with the same. The manual drive control valve can solve the problems that the prior art has lots of components, a complex structure, needs to add an adjusting mechanism and the like. The technical scheme of the invention is that one side of a main valve body and a handle is provided with a turning sleeve anda cam, the cam is sleeved on the turning sleeve and is provided with symmetrical cam curved surfaces, a pin of the turning sleeve and a pin of a valve core are positioned on the cam curved surfaces ofboth sides of the cam, the other side of the main valve body and the handle is provided with a turning sleeve which is provided with a torsional spring, one pin is inserted into the valve core, the top end of the pin is in a strip slot, and a compression spring is arranged between the end surface of the turning sleeve and the main valve body. The manual drive control valve has the characteristicsof fewer components, simplified structure, cost reduction, high mounting efficiency and the like.

Owner:昌信(五莲)林业机械有限公司

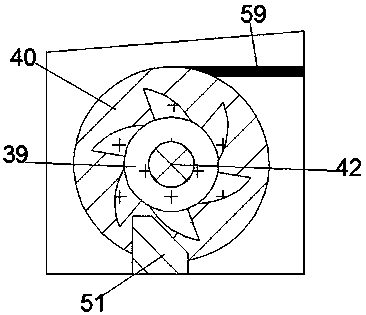

Plant crusher with spiral fly cutter drum

The invention is a plant crusher with a spiral fly cutter drum, which is used for cutting and crushing large timber, templates, tree roots, and straw plant raw materials. The main body is a plant crusher, and the cutter drum part of the plant crusher is a spiral fly cutter drum; the spiral fly cutter drum comprises a cutter drum and fly cutters distributed on the surface of the cutter drum, wherein the fly cutters or fly cutter edges orderly arranged along an extension direction of a central axis of a cutter drum are arranged in a spiral manner. The plant crusher can not only cut rigid, soft, and small wastes, but also perform primary crushing formation of large wastes, templates, and tree roots; the plant crusher can not only realize the processing of soft and rigid small materials, but also perform cutting of large wastes, templates, and tree roots; no other procedures are required, such as feeding and processing after large timber is splitted into small timber by a wood-splitting machine, which saves a lot of time and cost.

Owner:福建省闽武机械有限公司

Stump-cutting toy assembly

A children's educational toy includes a log section having a plurality of uniquely shaped and detachable log portions for defining altering portions of the log section. Each log portion has a top surface provided with a plurality of spaced notches for defining a striking area medially of the plurality of log portions respectively. The assembly further includes a wedge, a wood-splitting maul, and a mechanism for locking the plurality of log portions respectively. The locking mechanism includes a plurality of male portions extending outwardly from select ones of the plurality of sidewalls respectively and a plurality of female portions formed within adjacent ones of the plurality of sidewalls. The plurality of male and female portions are removably engageable when the plurality of sidewalls are positioned adjacent the axis.

Owner:STEVENS GEOFFREY L

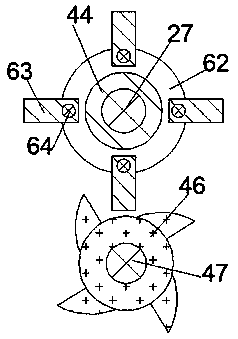

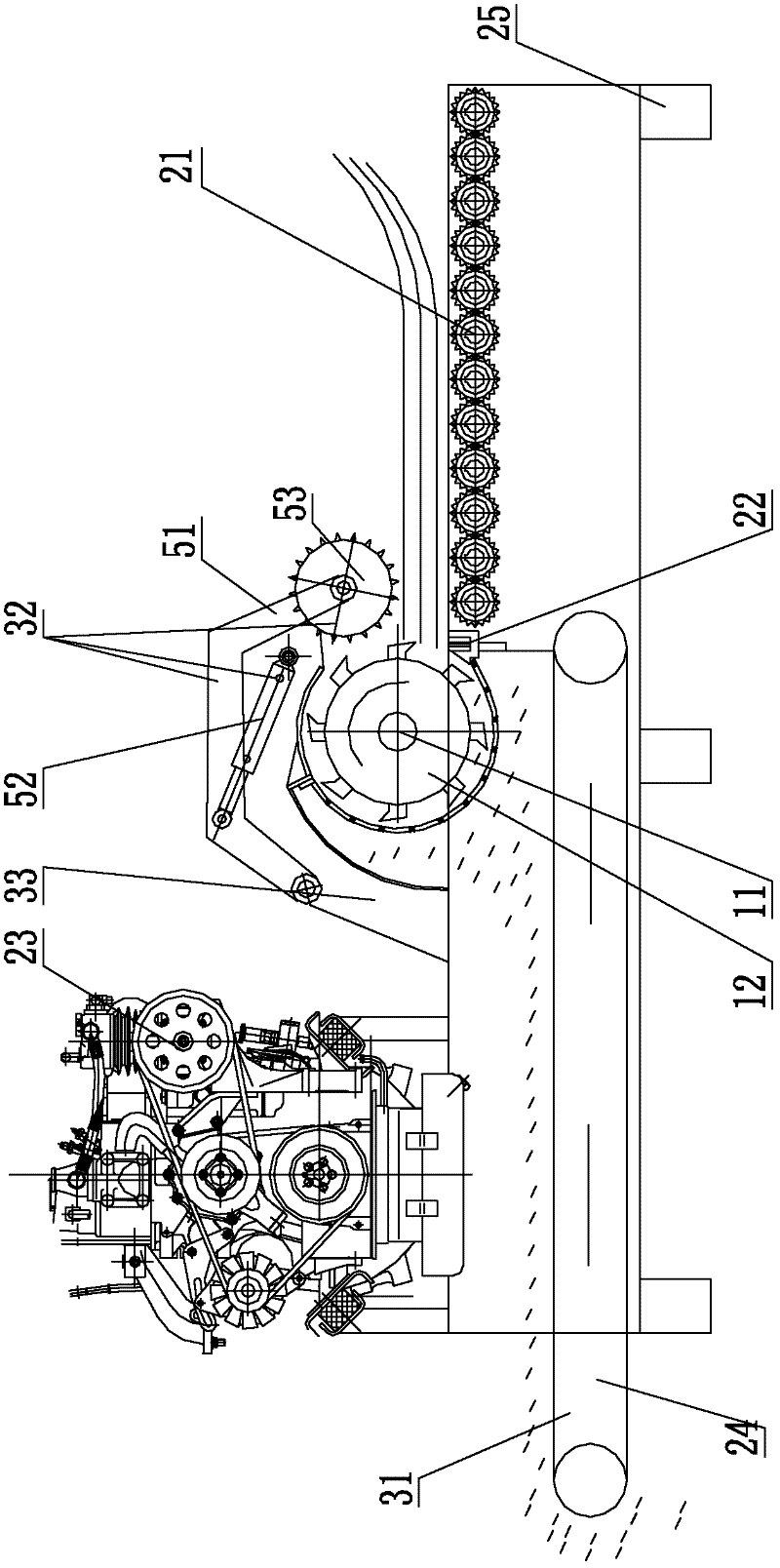

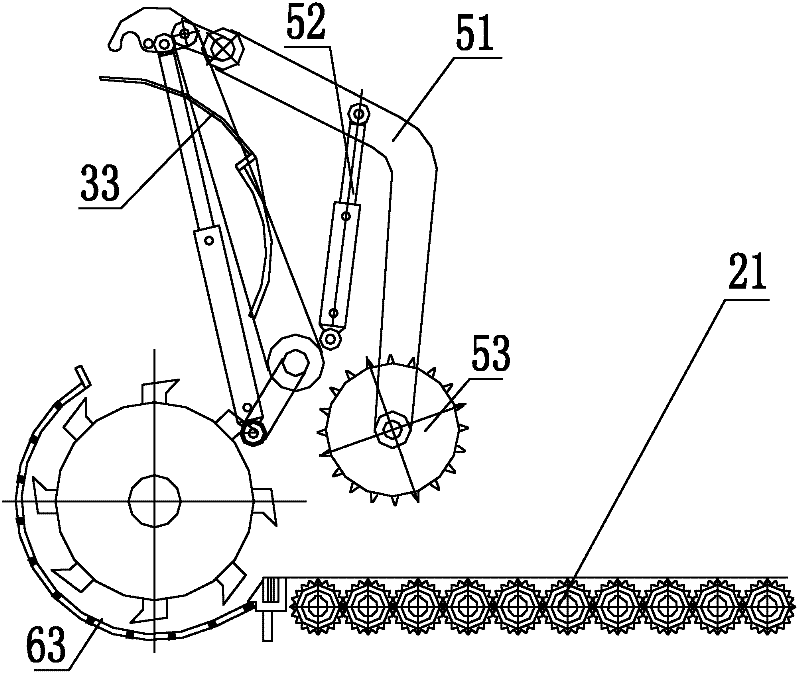

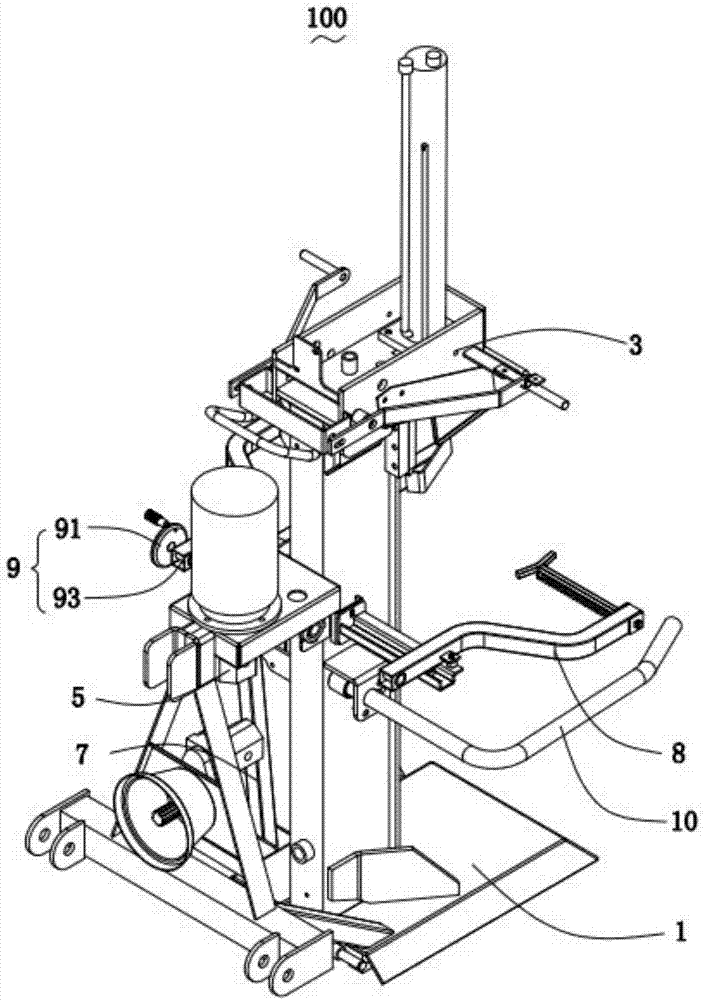

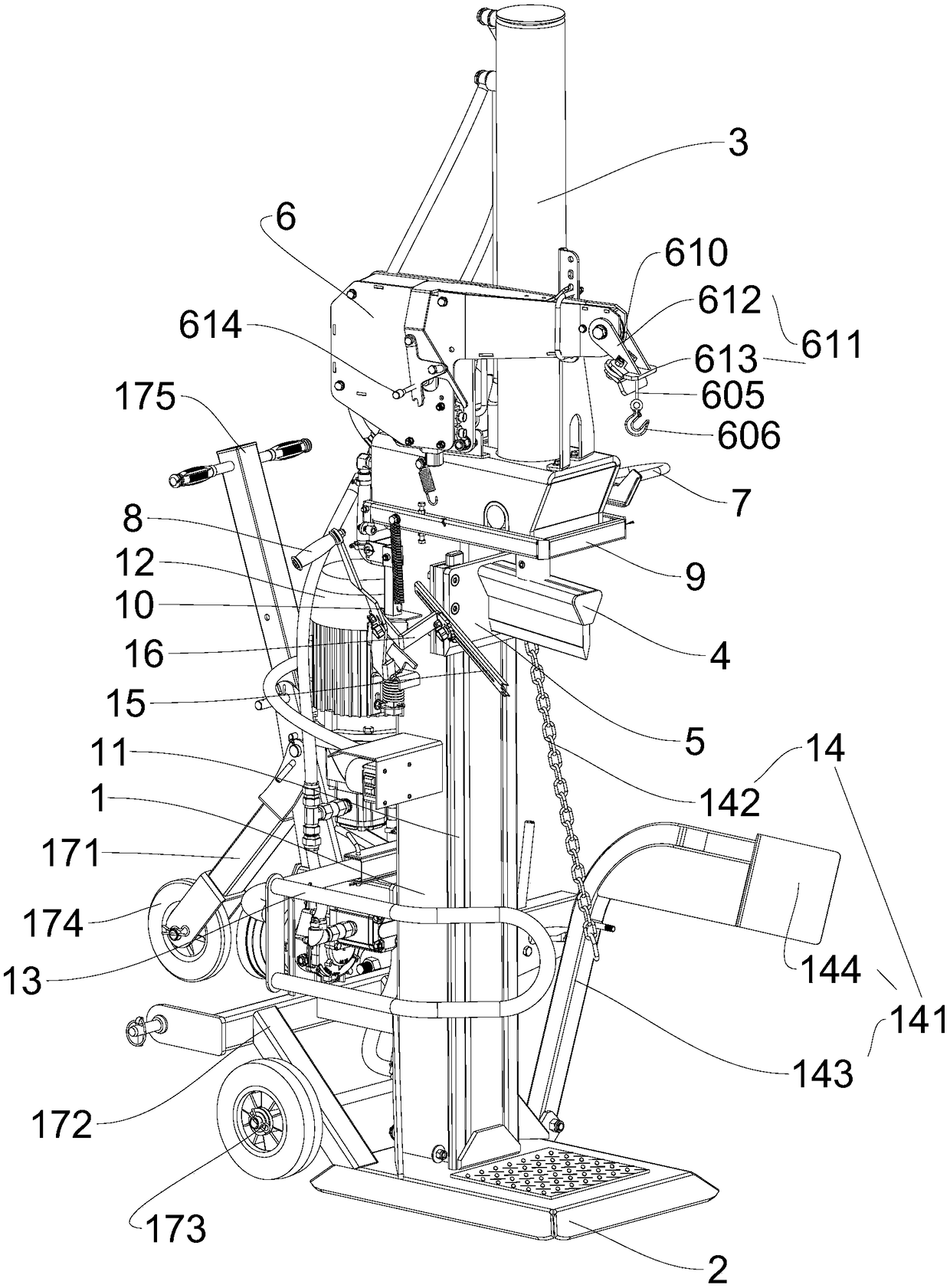

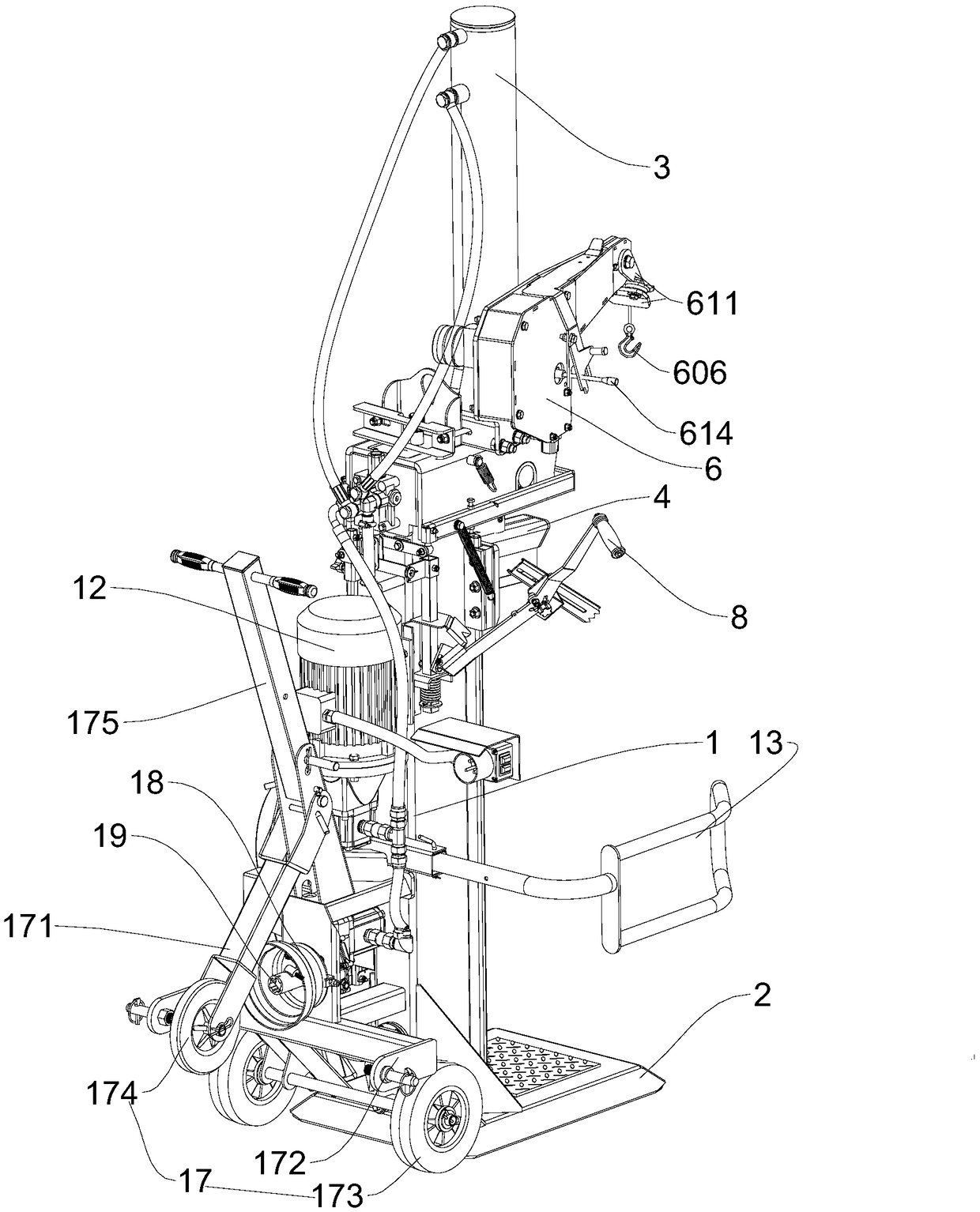

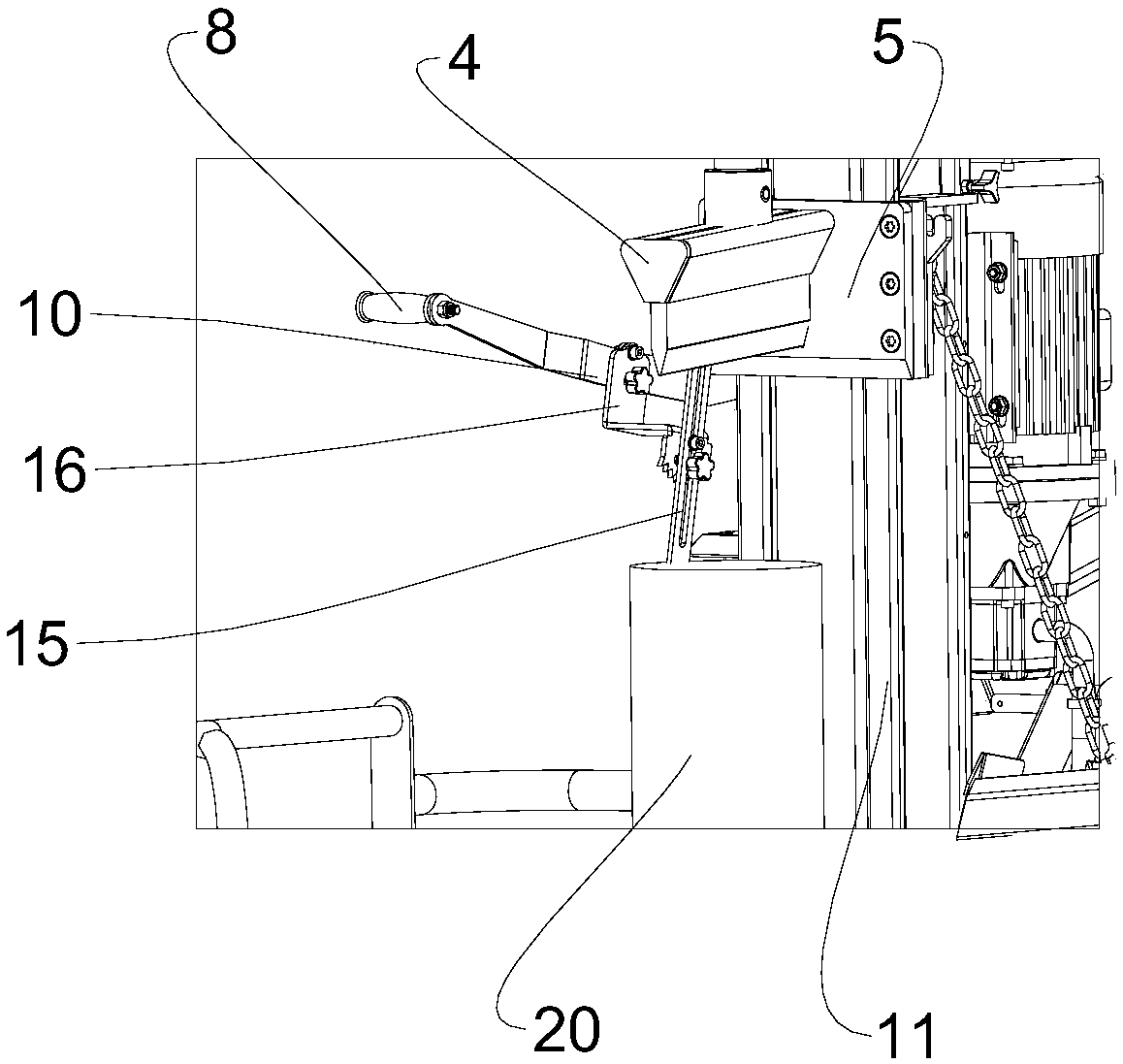

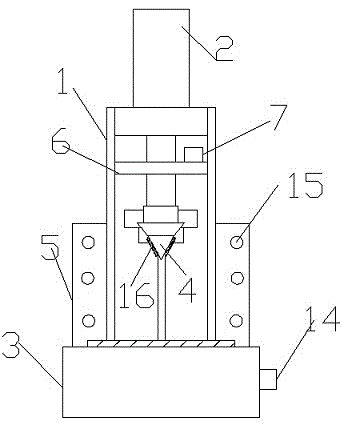

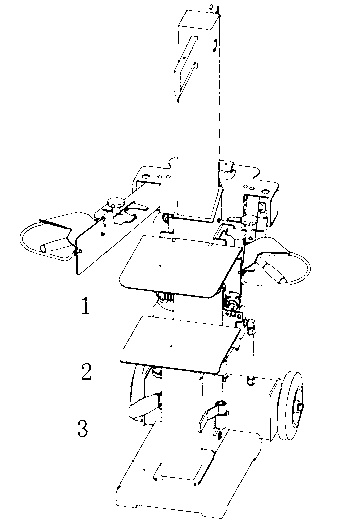

Combined driving vertical type machine for splitting wood

InactiveCN107283581AImprove wood chopping abilityExpand the scope of processingWood splittingWood processorSemi automatic

The invention is suitable for the technical field of wood processing machinery and equipment, and provides a combined driving vertical type machine for splitting wood. The combined driving vertical type machine comprises a rack, a knife rest, a double-stage pump, a wood holding device, a clamping device and a driving device, wherein the knife rest is arranged at the top end of the rack, and the double-stage pump is arranged on the rack; one end of the wood holding device is rotationally connected with the rack, and the other end of wood holding device is connected with the knife rest through a chain; the wood holding device can be driven by the knife rest to turn from horizontal to upright, and is used for pushing wood onto the rack; the clamping device is fixedly arranged at the rack and is used for clamping the wood pushed by the wood holding device; and the driving device is connected with the clamping device and is used for driving the clamping device to move. The wood is conveyed onto the rack through the holding device, so that the semi-automatic carry for the wood is realized, and the labor intensity is reduced. Meanwhile, the wood is clamped through the clamping device, so that the wood is effectively fixed, and therefore the safety performance of the wood splitting process is improved. The knife rest is driven to move through the double-stage pump, so that the wood splitting capacity of the combined driving vertical type machine is improved.

Owner:LAIZHOU XINHAIWEI MACHINERY

Agricultural wood splitter

InactiveCN107457867AEffective cleaving workReduce intensityWood splittingDynamo-electric machinesMicrocomputerAgricultural engineering

The invention discloses an agricultural wood splitter. The agricultural wood splitter comprises a base plate. A groove structure is formed in the center of the upper surface of the base plate. A connecting plate is fixed to one side of the upper surface of the base plate through a bolt. A longitudinal supporting rod which is of an integrated structure with the connecting plate is arranged in the center of the upper surface of the connecting plate. A transverse supporting plate which is of an integrated structure with the longitudinal supporting rod is arranged at the top of the longitudinal supporting rod. A 51 single chip microcomputer is fixed to the top of the transverse supporting plate. A hollow shell which is of an integrated structure with the transverse supporting plate is arranged in the center of the transverse supporting plate. An iron core sleeved with a coil is arranged at the inner top of the hollow shell. A movable chamber is arranged at the position, below the iron core, in the hollow shell. A permanent magnet is mounted in the movable chamber. The agricultural wood splitter can conduct wood splitting operation effectively and simultaneously splits wood in one effort, and thus the working efficiency can be effectively improved; and in addition, primary splitting operation is conducted by the device through the electromagnetic principle, and the intensity for splitting wood can be effectively relieved.

Owner:林南俊

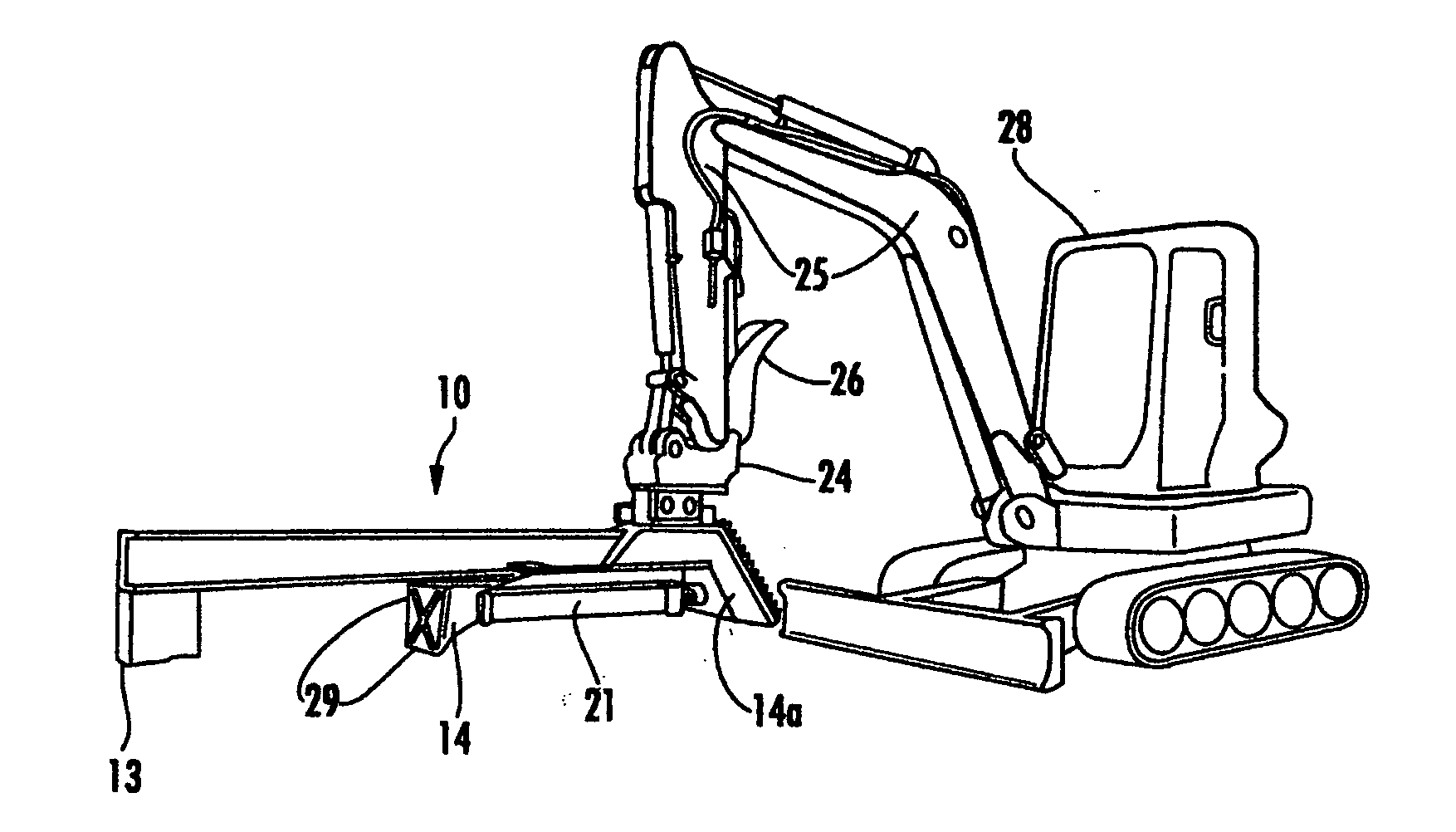

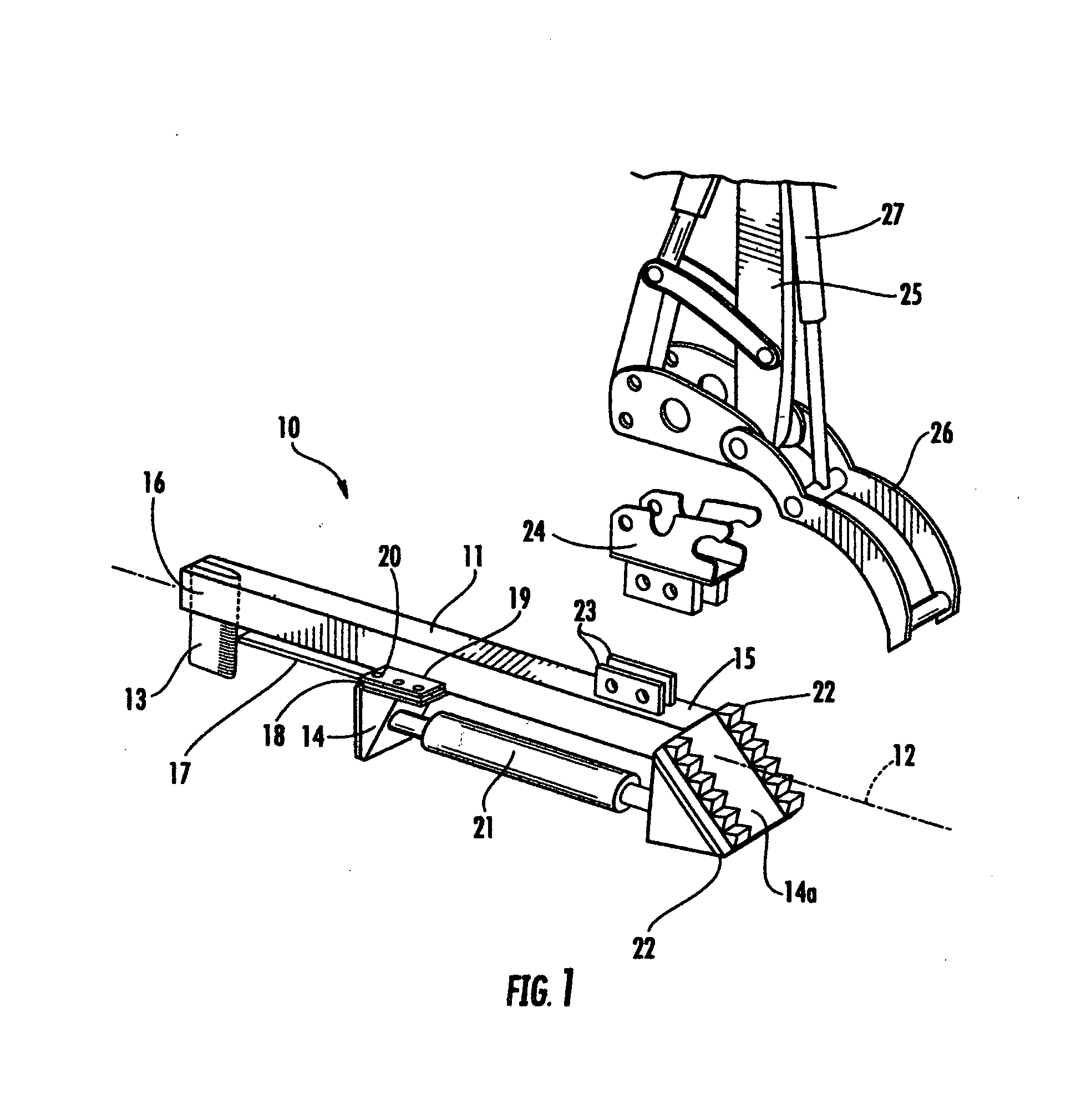

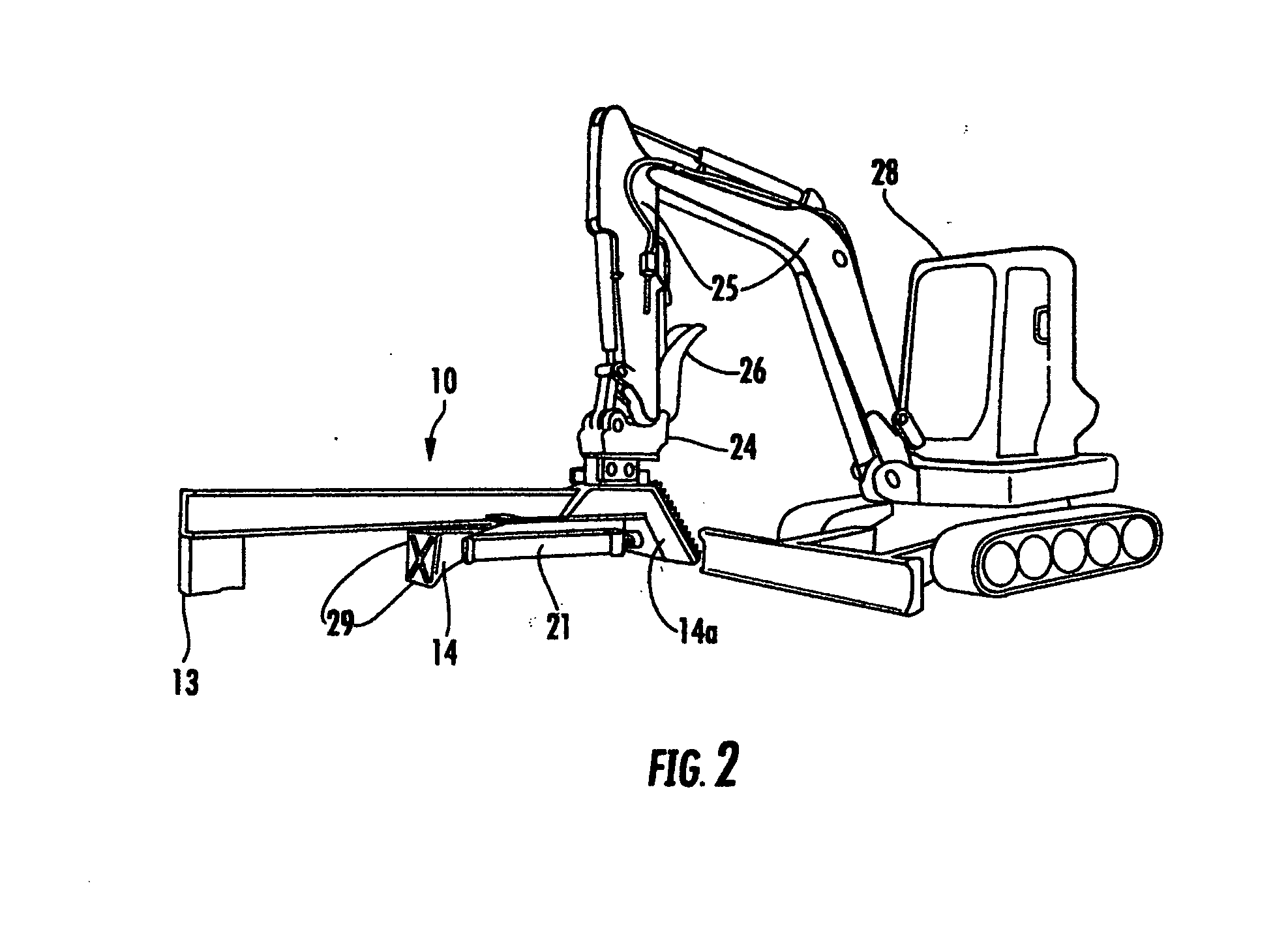

Apparatus for positioning and splitting wood

InactiveUS20090288737A1Readily observed in operationEnhanced couplingWood splittingMulti-purpose machinesWood splittingKnife blades

Apparatus for positioning and splitting wood. The apparatus includes: a beam having a longitudinal axis; a wood splitting blade attached at or near an of the beam; a workpiece slidably attached to the beam such that when wood is positioned between the splitting blade and the workpiece and the workpiece is slid in the direction of the longitudinal axis of the beam toward the splitting blade, the wood is forced into the splitting blade to split the wood; and a stationary jaw member attached at or near one end of the beam so that when the apparatus is attached to the boom of a backhoe or the like in place of the bucket thereof, wood can be grasped between the stationary jaw member and a jaw member attached to the boom of the backhoe or the like so that the wood can be positioned by movement of the apparatus.

Owner:M&G POWER ATTACHMENTS

Portable wood splitting device

InactiveCN107486911AEasy to assemble and disassembleSplit simpleWood splittingEngineeringWood splitting

The invention discloses a portable wood splitting device which comprises a cutter, a supporting frame and a cylinder; the cutter comprises a cutting edge at the upper part and a cutter body at the lower part; the cutter body is a pyramid frustum; the thickness of the upper end of the cutter body is less than that of the lower end of the cutter body; a plurality of bulges are uniformly distributed on the side surfaces of the cutter body; each bulge is thickened from the upper end to the lower end gradually; mounting holes are formed in the two ends of the cutter body; the supporting frame comprises four upright columns and a connecting ring; the four upright columns are distributed in a square manner; the connecting ring which is formed by hinging two semicircular rings is connected on the outer sides of the four upright columns by screws; the diameters of the upright columns are equal to the diameters of the mounting holes; grooves are symmetrically formed in a lower opening of the cylinder; the cutter is clamped in the grooves; and the inner side surface of the cylinder is in contact with the upright columns. The portable wood splitting device is convenient to carry; various components are very convenient to disassemble and assemble; and when the portable wood splitting device is in use, wood can be split very simply.

Owner:ANHUI XINRUI HEAVY IND

Agricultural mechanical type firewood chopping machine

The invention discloses an agricultural mechanical wood splitter, which comprises a placing base plate, a protruding structure is installed on the center of the upper surface of the placing base plate, a plurality of support rods are installed on the side of the upper surface of the placing base plate, and a plurality of the support bars The top of the rod is installed on the bottom of a hollow pipe body bottom plane structure, the center of the hollow pipe body is provided with a central hole, and a motor is installed on one side of the top of the hollow pipe body, and the motor spindle end of the motor is fixed A connecting plate, one end surface of the connecting plate is fixed with a circular plate by bolts. The invention is driven by a motor to drive the wood splitting cutter head mechanism to perform reciprocating up and down movements, thereby splitting the wood effectively. Time and labor are saved, and the device is controllable, which can effectively reduce potential safety hazards and improve the practicability of the device.

Owner:顾占从

Vertical type wood splitting machine

The invention relates to the technical field of wood splitting devices, and discloses a vertical type wood splitting machine comprising a wood pulling mechanism arranged on the upper portion of a machine body. The wood pulling mechanism comprises a drive assembly, a winch assembly and a rope. The drive assembly is connected with the winch assembly. The winch assembly is connected with the rope. The drive assembly drives the winch assembly to drive the rope to be tightened. The rope can pull to-be-split wood to a working table. According to the vertical type wood splitting machine, the to-be-split wood can be mechanically dragged and be placed on the working table, and operation is convenient and rapid.

Owner:厉承迪

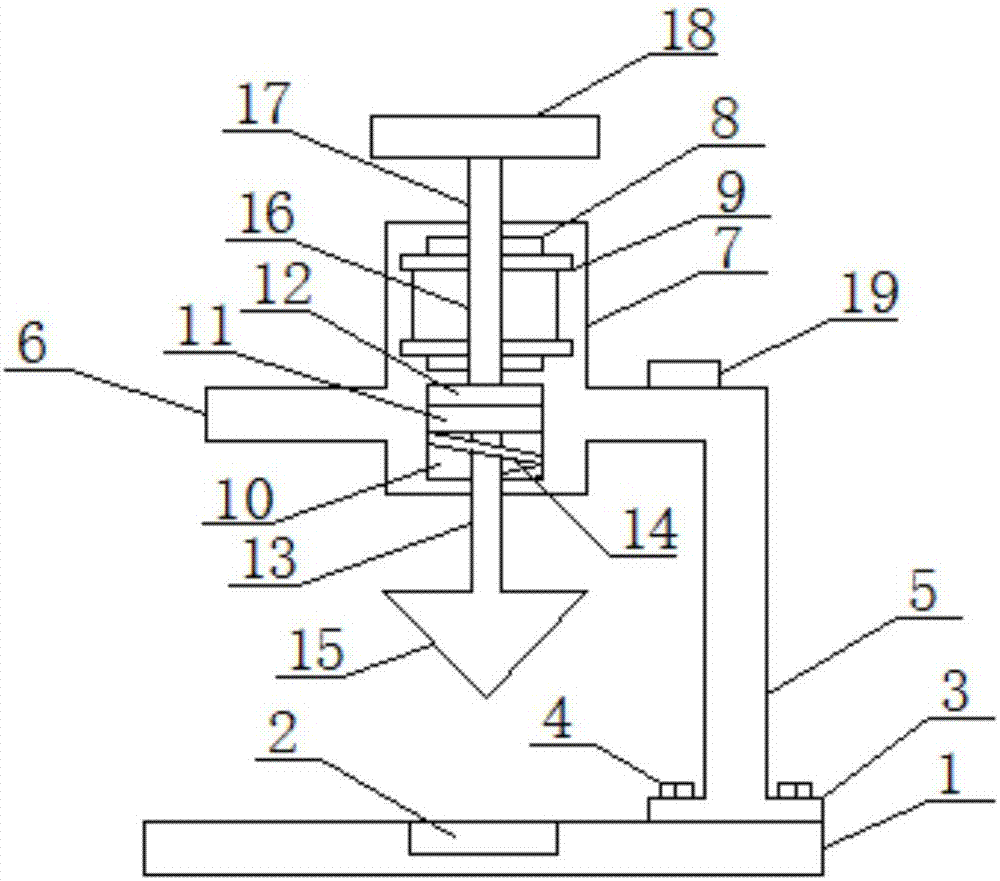

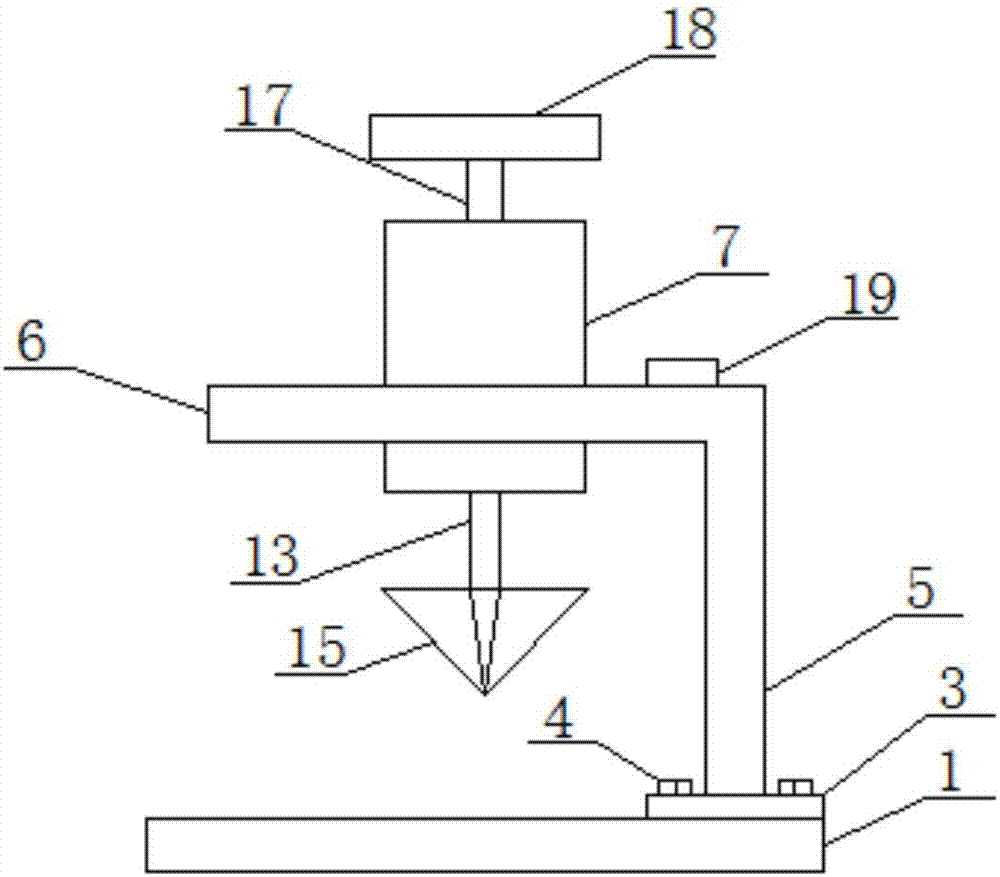

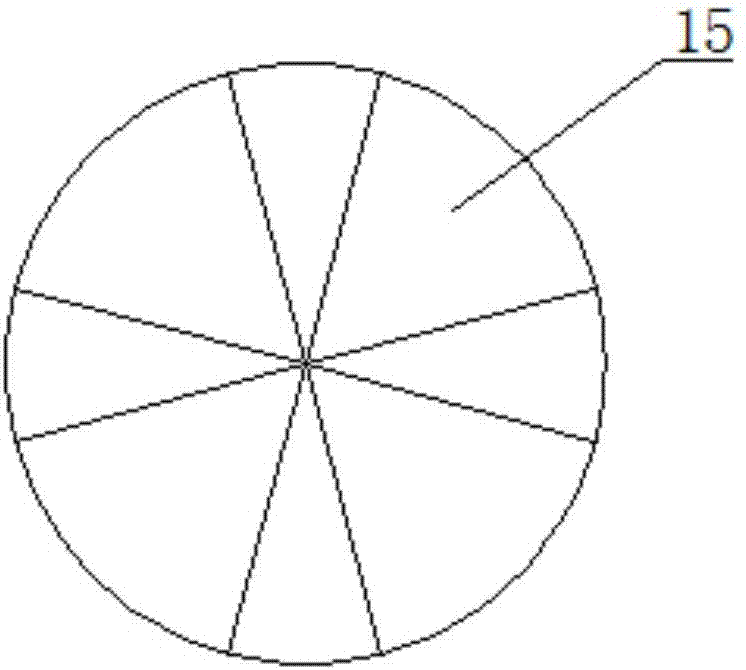

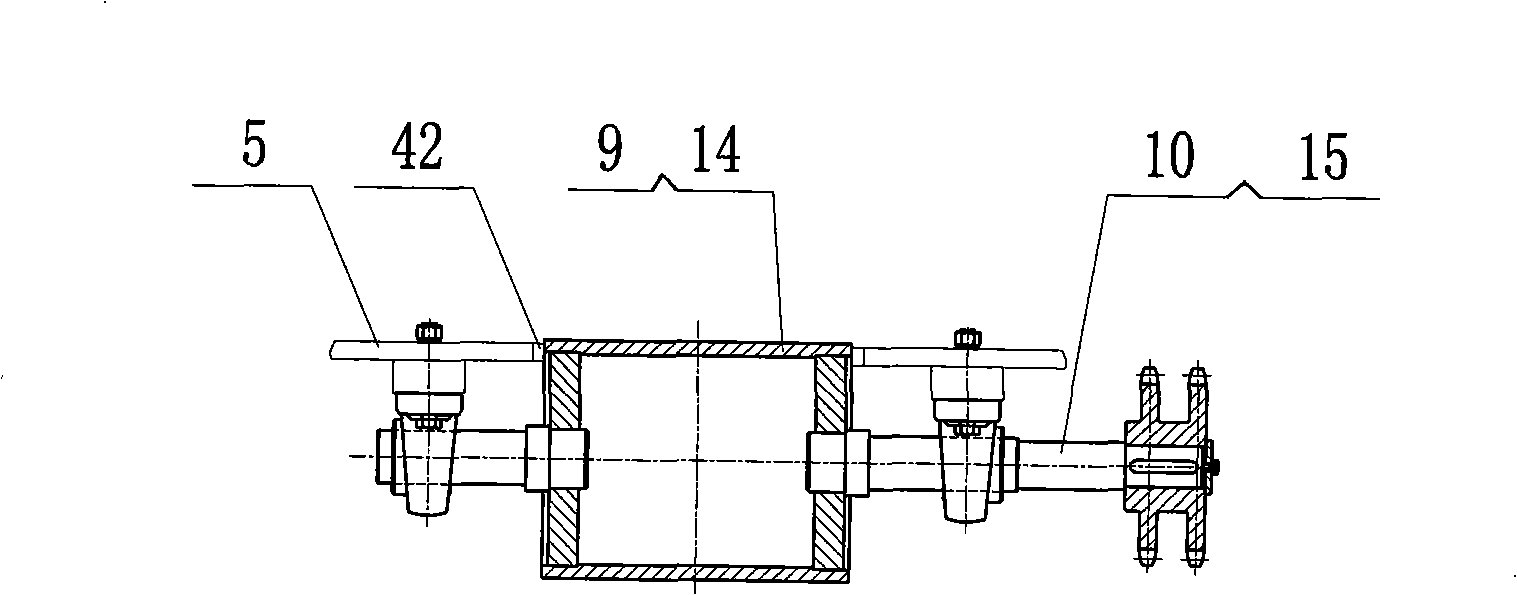

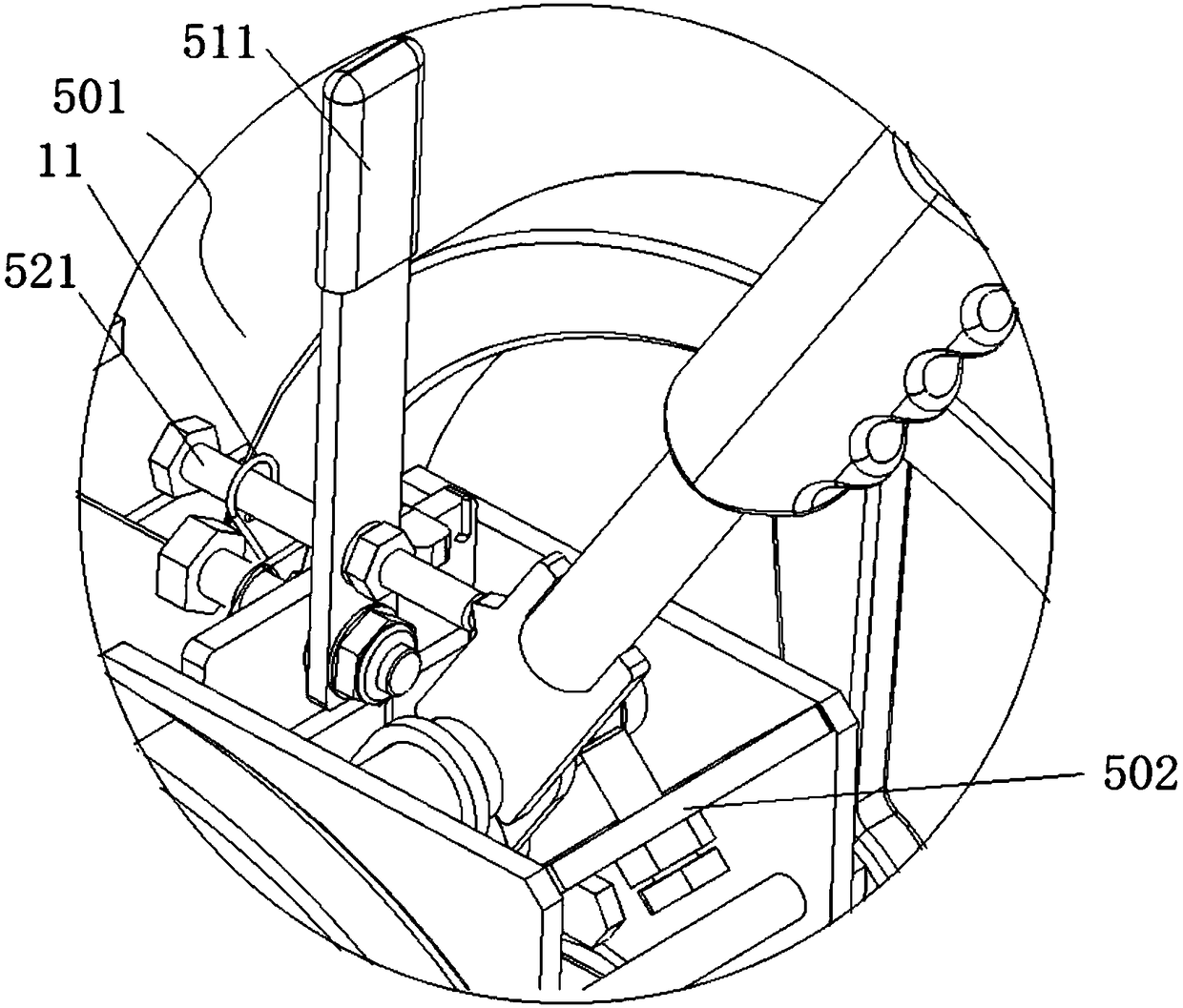

Wood splitting locating and anti-vibration mechanism of combined wood splitting device

InactiveCN105479567AFast and efficient wood splittingPrevent fallingWood splittingHydraulic cylinderEngineering

The invention provides a wood splitting locating and anti-vibration mechanism of a combined wood splitting device. The wood splitting locating and anti-vibration mechanism comprises a support frame, a hydraulic cylinder, an anti-vibration base plate and a riving knife, wherein baffle plates are arranged on the two sides of the support frame; the hydraulic cylinder is fixed at the top of the support frame, and a hydraulic shaft penetrates through a support plate to be connected with the riving knife for fixation; a location sensor is arranged on the support plate; a rubber mat, a plywood and a bottom plate are sequentially arranged in an inner cavity of the anti-vibration base plate; a plurality of anti-vibration strips sequentially extend from the top of the inner cavity of the anti-vibration base plate; the anti-vibration strips penetrate through the rubber mat to be fixedly connected with the plywood for fixation in a clamping manner; the bottom of the plywood is connected with a plurality of tooth rings; and each tooth ring is meshed in a corresponding tooth groove of the bottom plate. The wood splitting locating and anti-vibration mechanism has the benefits that the operation is convenient, the structure is stable and compact, a central point of the wood is quickly and effectively pinpointed, the locating is accurate, the anti-vibration effect is obvious, and the wood splitting effect is guaranteed.

Owner:王金青

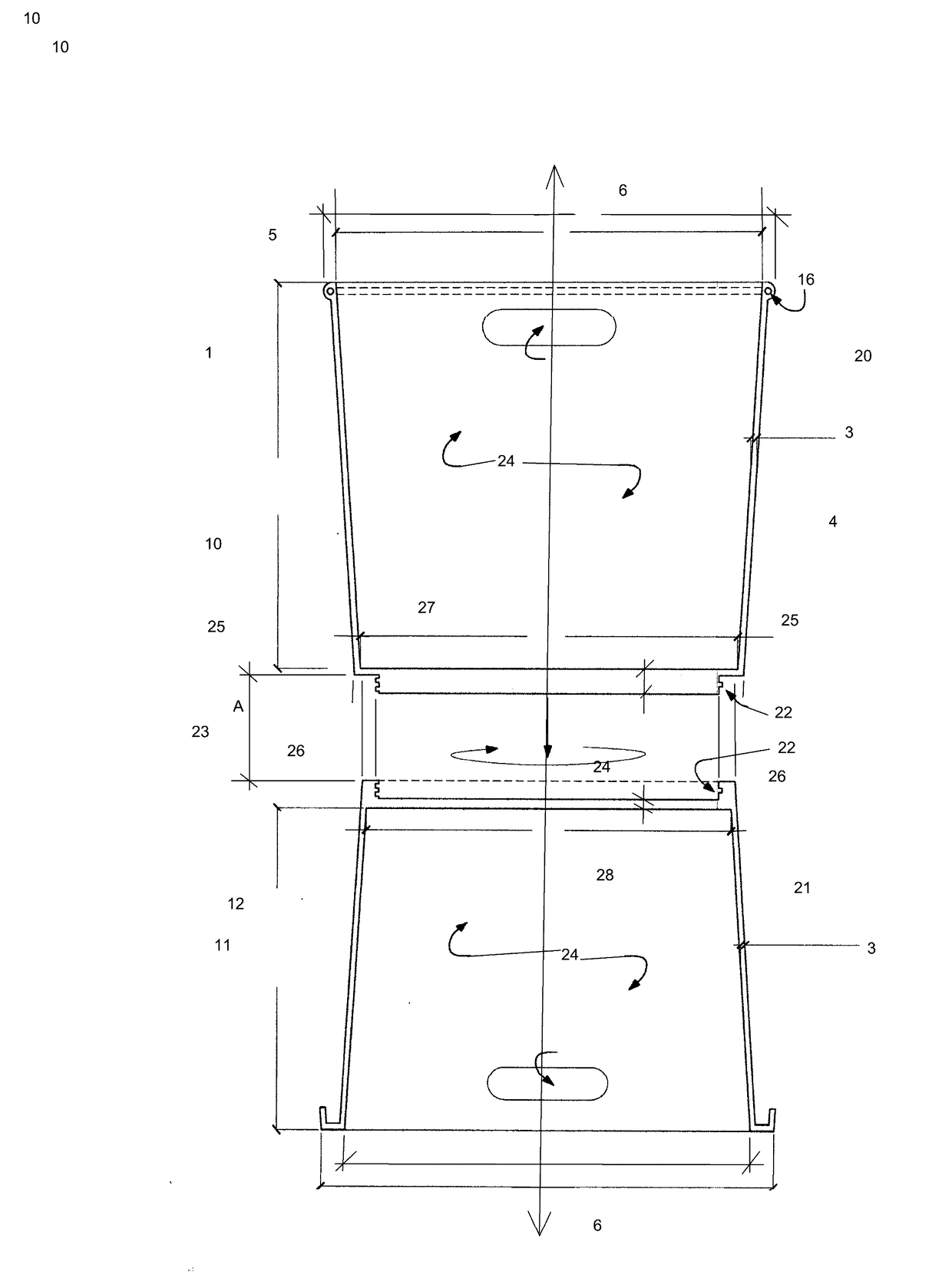

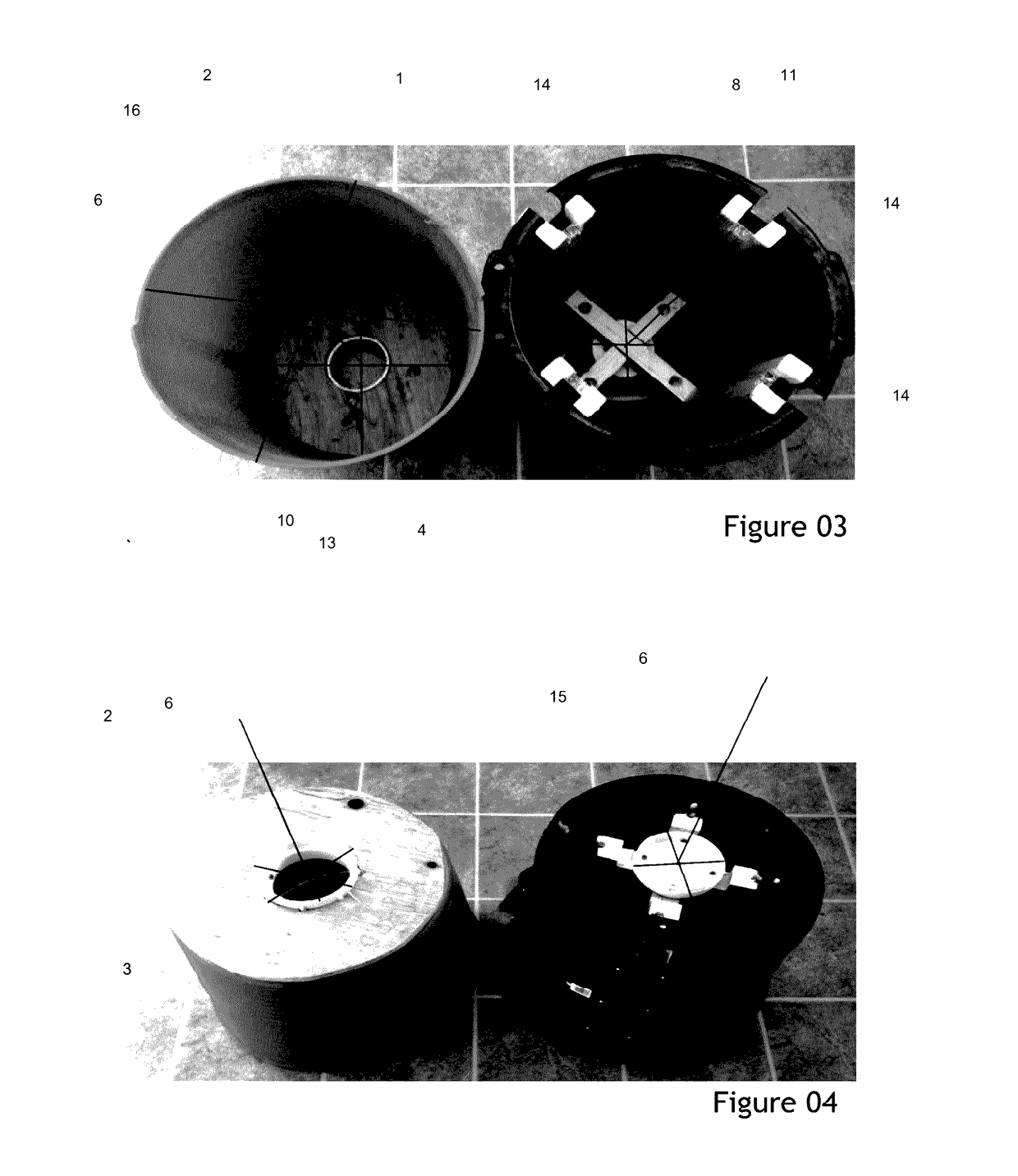

Wood splitting aid

The wood splitting aid of the invention includes a resilient bucket that attaches at its bottom to a base block bucket of similar shape and size to be used in conjunction with a hand-splitter such as an ax or splitting-mall. The resilient or flexible upper bucket holds a plurality of split pieces of corded firewood in an upright position for hand chopping and absorbs both horizontal and vertical forces of wood splitting. The split wood pieces are maintained in a general upright position adjacent their neighboring pieces. The base block bucket provides both a safe and ergonomic chopping height which absorbs and distributes the predominantly remaining vertical force of wood-splitting action against solid ground. The buckets are detachably connected bottom to bottom and are nesting when disconnected for easy portability, use, storage and reuse in an urban environment.

Owner:SEED NICHOLAS HYSNI

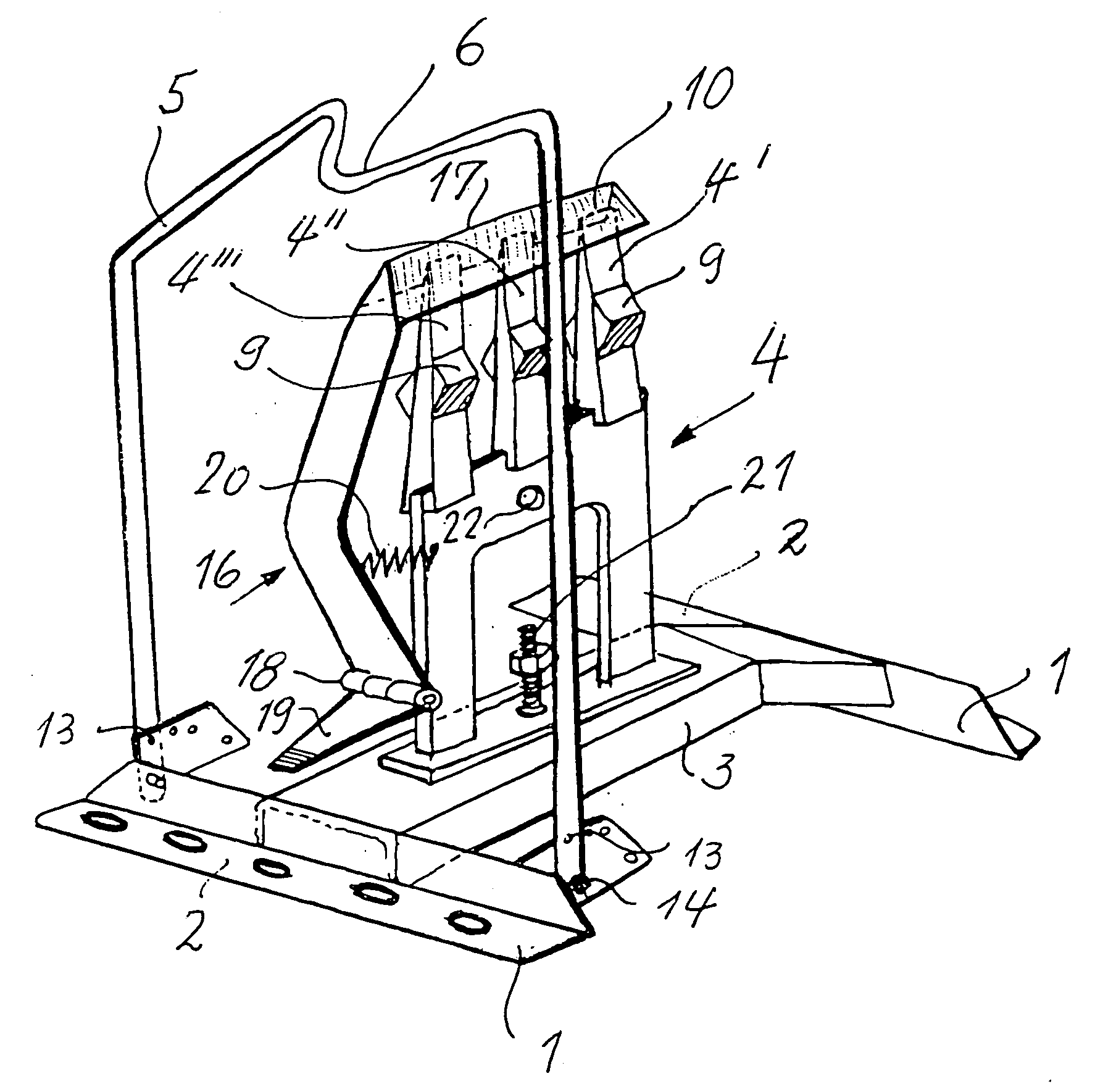

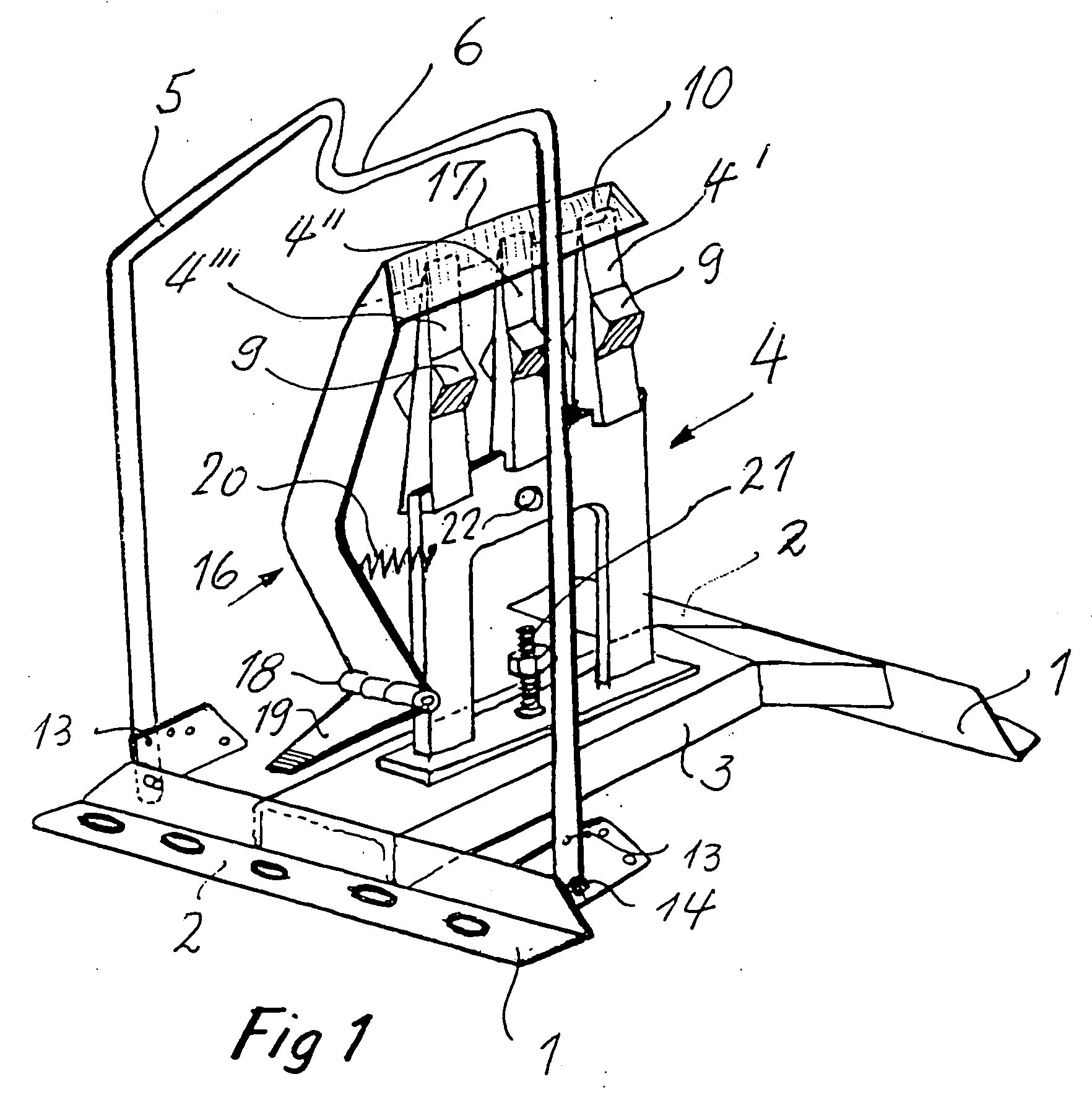

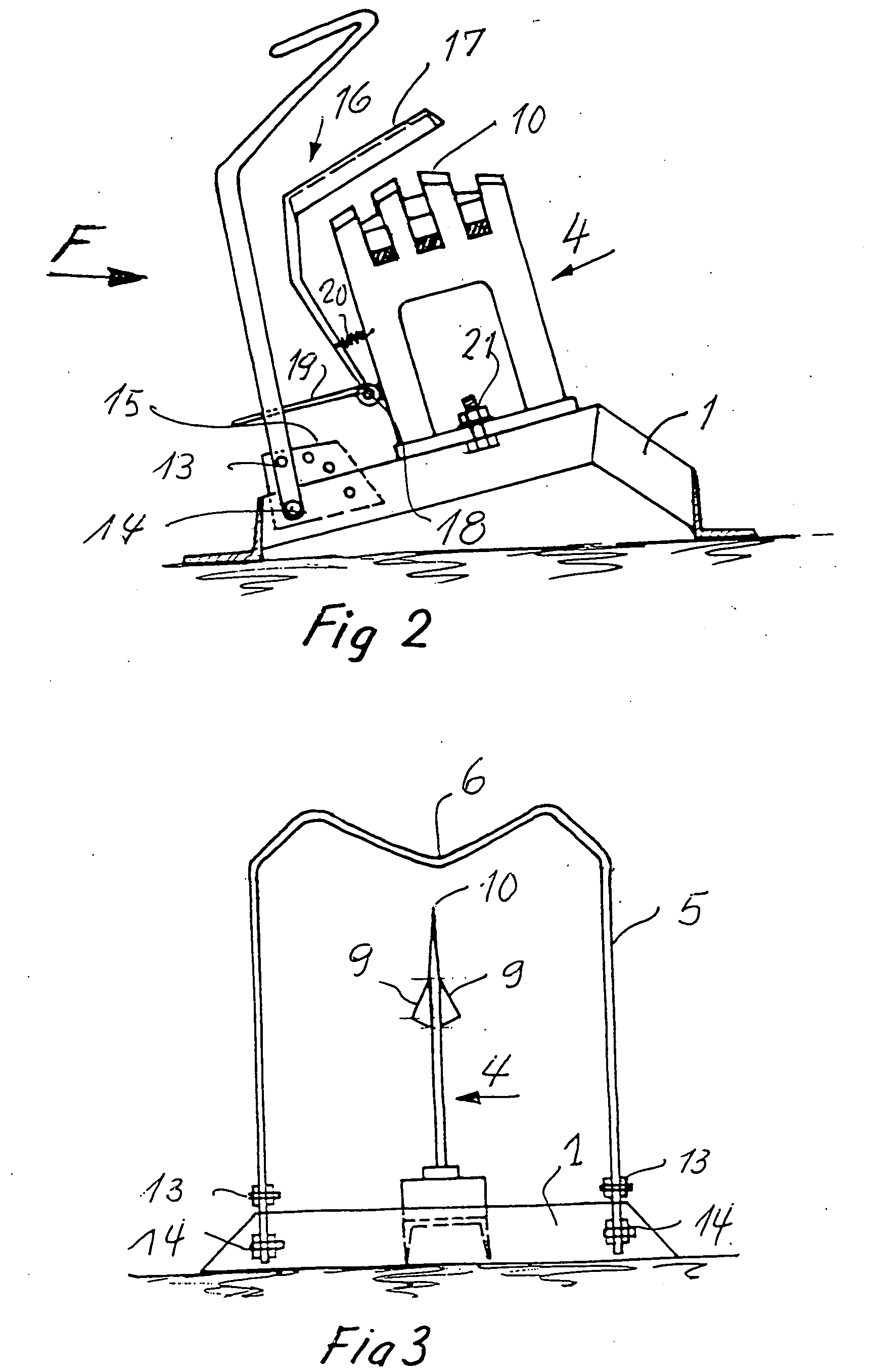

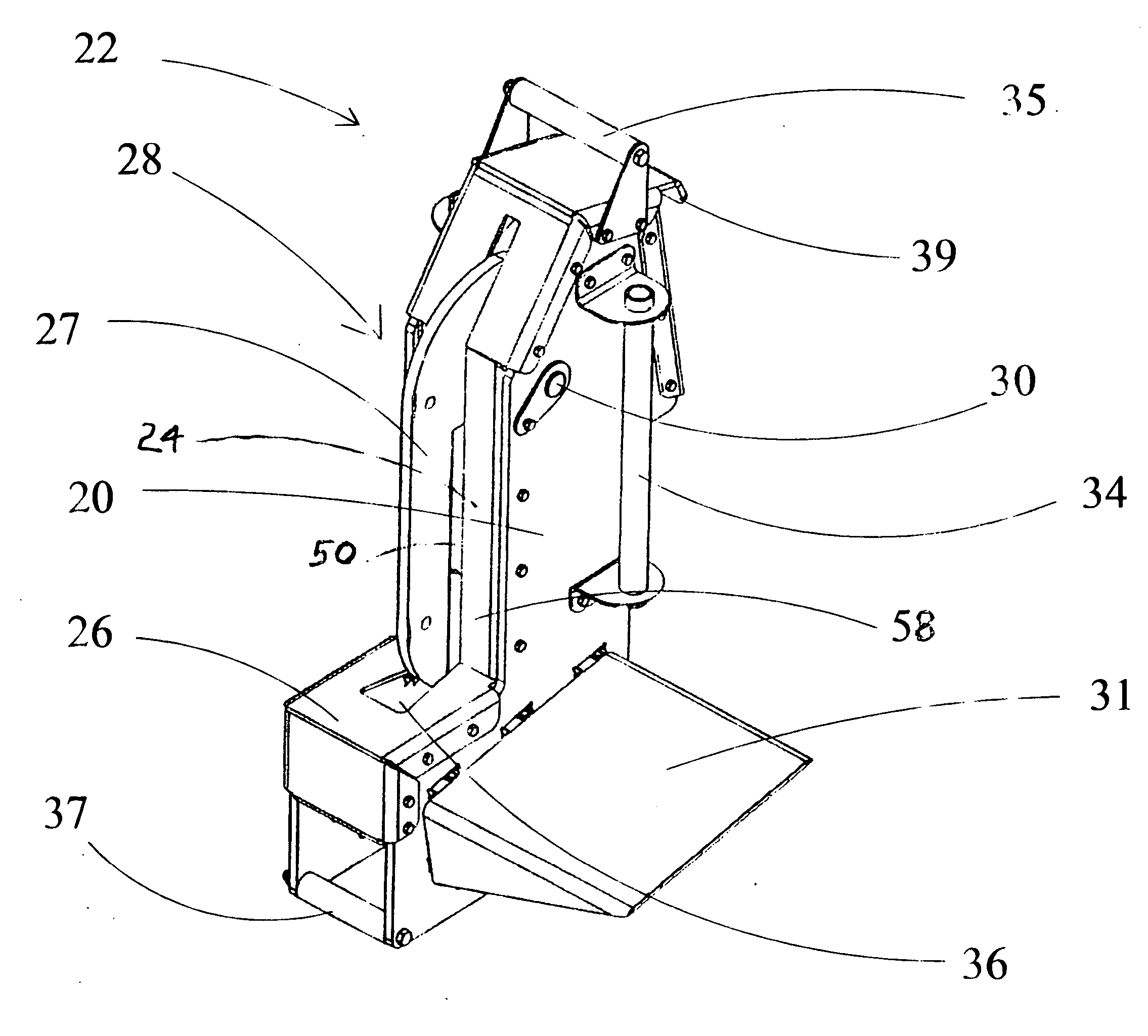

Compact and portable wood splitter

InactiveUS20070107805A1Easy to carryLight weightWood splittingMulti-purpose machinesHydraulic cylinderEngineering

The present invention concerns a compact, portable, lightweight, easily transportable, quickly operating wood splitting apparatus, using a knife which cuts a log or piece of wood that is deposed on a platform. This compact and portable wood splitter is actuated by a hydraulic cylinder transmitting a pendulum movement to a knife and onto an upright piece of wood. The apparatus may be attached to a truck box, to a trailer or to a wall by means of a vertical, horizontal, fixed or mobile fixture. The splitter apparatus is compact and portable and it can easily be stored in a car trunk or in a shed.

Owner:LESSARD MARTIN

Convenient wood splitting device

The invention discloses a convenient wood splitting device which comprises a workbench and support legs arranged at the bottom of the workbench. A hydraulic device body is mounted on the left side ofthe top of the workbench, a piston rod is connected to the output end of the hydraulic device body, and an impact head is fixedly connected to the end of the piston rod. Baffles are symmetrically arranged on the two sides of the impact head. A tool rest is fixedly mounted on the right side of the top of the workbench, a tool body is arranged on the left side of the tool rest, and arc-shaped positioning grooves are further formed between the tool body and the baffles. Two limiting plates are further arranged between the positioning grooves and the tool body and are symmetrically arranged with respect to the workbench, the distance between the limiting plates is smaller than the width of the impact head, and the transverse distance between the limiting plates and the tool body is 5-10 mm. The convenient wood splitting device is novel in structure and convenient to operate, manual operation is replaced by mechanical operation, work efficiency is high, and the labor intensity is lowered.

Owner:高巧锦

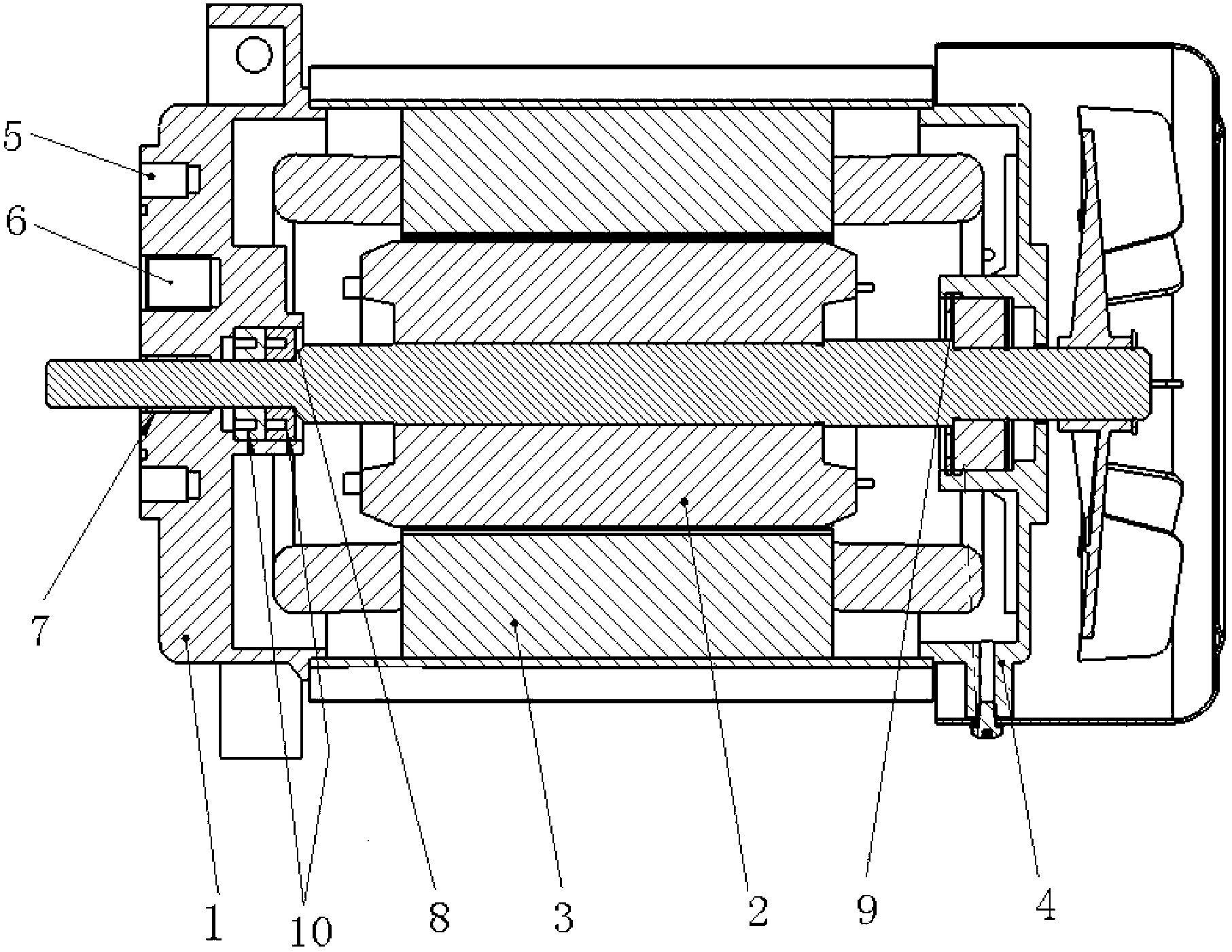

Electromotor of wood splitting machine

InactiveCN102842981APrevent leakageReduce frictionSupports/enclosures/casingsFriction reductionFuel tank

The invention discloses an electromotor of a wood splitting machine. The electromotor comprises a front cover, a rotor, a stator, a back cover and a pipe control sleeve, wherein the front cover is provided with a first oil hole and a second oil hole; and the pipe control sleeve passes through the front cover, the rotor and the back cover in sequence. The pipe control sleeve comprises a front part, a middle part and a rear part, wherein the diameter of the middle part is greater than those of the front part and the rear part respectively; a front positioning shoulder and a rear positioning shoulder are arranged in the positions of the middle part adjacent to the front part and the rear part respectively; and oil seals are arranged between the front cover and the front positioning shoulder. According to the invention, the pipe control sleeve is used and the oil holes are formed in the front cover to replace bearings, so that lubricating oils can flow into the pipe control sleeve through the oil holes, thereby reducing frictions; the oil seals are arranged to prevent oils at the oil holes leaking into the electromotor; particularly, a double oil seal structure can achieve preferable seal, thereby decreasing oil leakage possibilities; and the front cover is used as a part of a gear case, and the front cover and an oil tank are formed integrally, thereby reducing the cost. The electromotor provided by the invention has the advantages of small volume, smooth operation, simplicity in maintenance and repair and the like.

Owner:扬州市华天电机有限公司

Special-shaped lumber splitting machine

InactiveCN101402209AGood shape retentionFacilitate follow-up productionCircular sawsCircular sawWood machining

The invention provides a profiled wood splitting machine, which relates to a wood splitting machine. The invention solves the problems that a sheet material processed by the prior wood processing device is easily cracked and deformed after drying, thereby generating serious impact on the quality of wood, and causing inconvenience for post-producing and processing of the sheet material. At least two input driving rollers are arranged on the lower end surface of the input end of a bedplate; the upper end of each of at least two input driving rollers passes through a corresponding hole on the bedplate; at least two output driving rollers are arranged on the lower end surface of the output end of the bedplate; the upper end of each of at least two output driving rollers passes through a corresponding hole of the bedplate; and seat boards of two buzzsaw assemblies are relatively arranged on an inclined surface in the middle of the bedplate. The sheet plate which is completed by processing of the wood splitting machine has a flat surface and good forming effect, thereby providing convenience for post-producing and processing of the sheet material. The wood splitting machine also has the advantages of simple structure, stable operation and strong practicality.

Owner:HEILONGJIANG ACAD OF FORESTRY

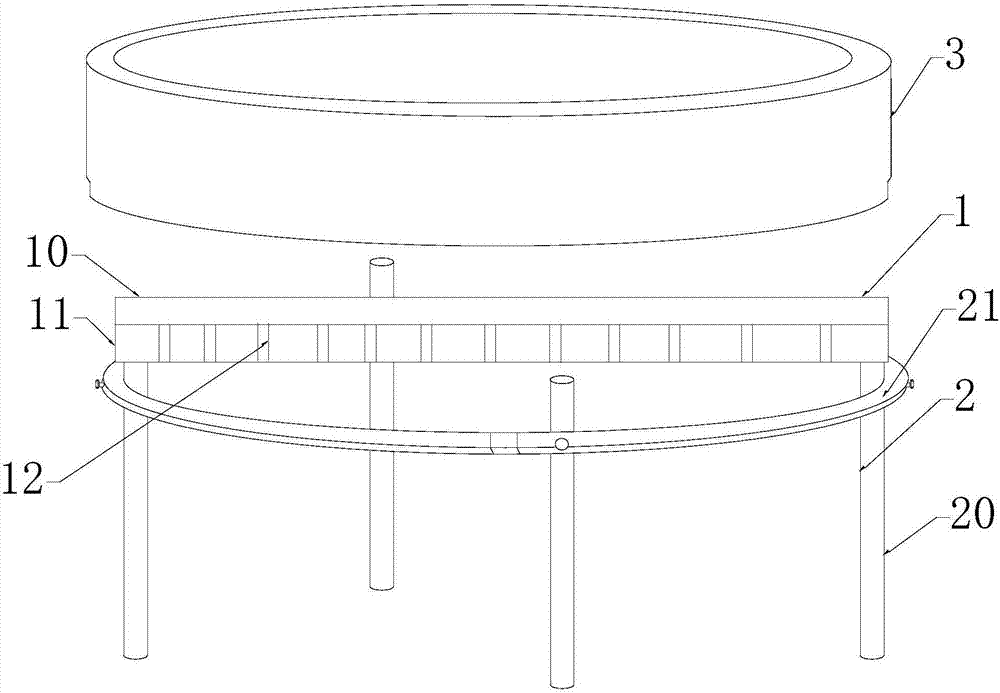

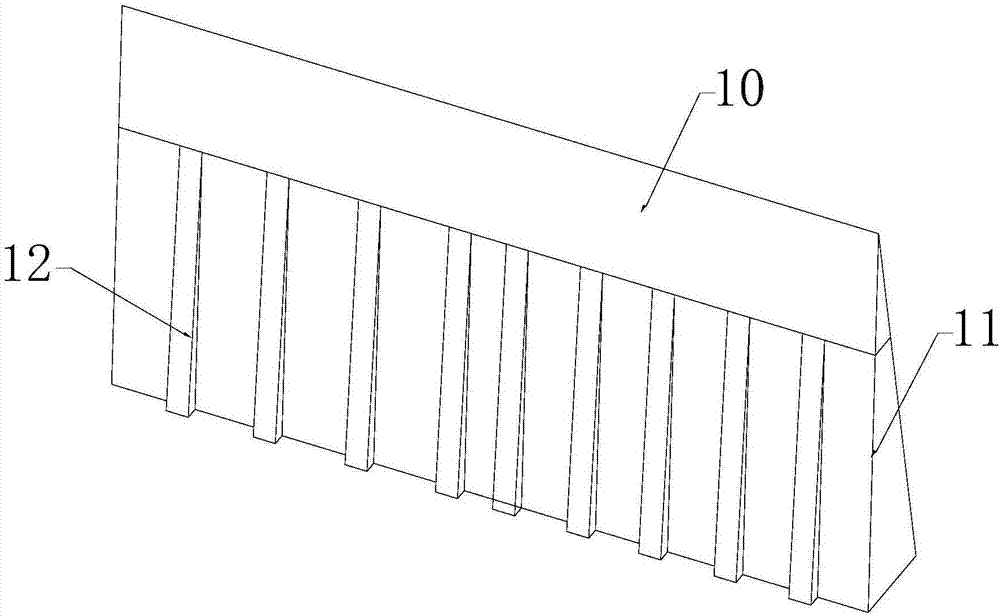

Rotary working table of vertical wood splitting machine

InactiveCN103317570AEasy to useIncreased chopping speedWood splittingWood splittingPulp and paper industry

The invention discloses a rotary working table of a vertical wood splitting machine. The rotary working table of the vertical wood splitting machine comprises a rack, an upper working table, the rotary working table and a fixed working table, wherein the fixed working table is arranged at the bottom of the rack, the detachable upper working table is arranged at the upper part of the rack, and the moveable rotary working table is arranged between the upper working table and the fixed working table. The three gear positions of the working tables of the wood splitting machine can be switched quickly, so that the wood splitting speed is increased and convenience is brought to users.

Owner:YANGZHOU XINGYI MACHINERY

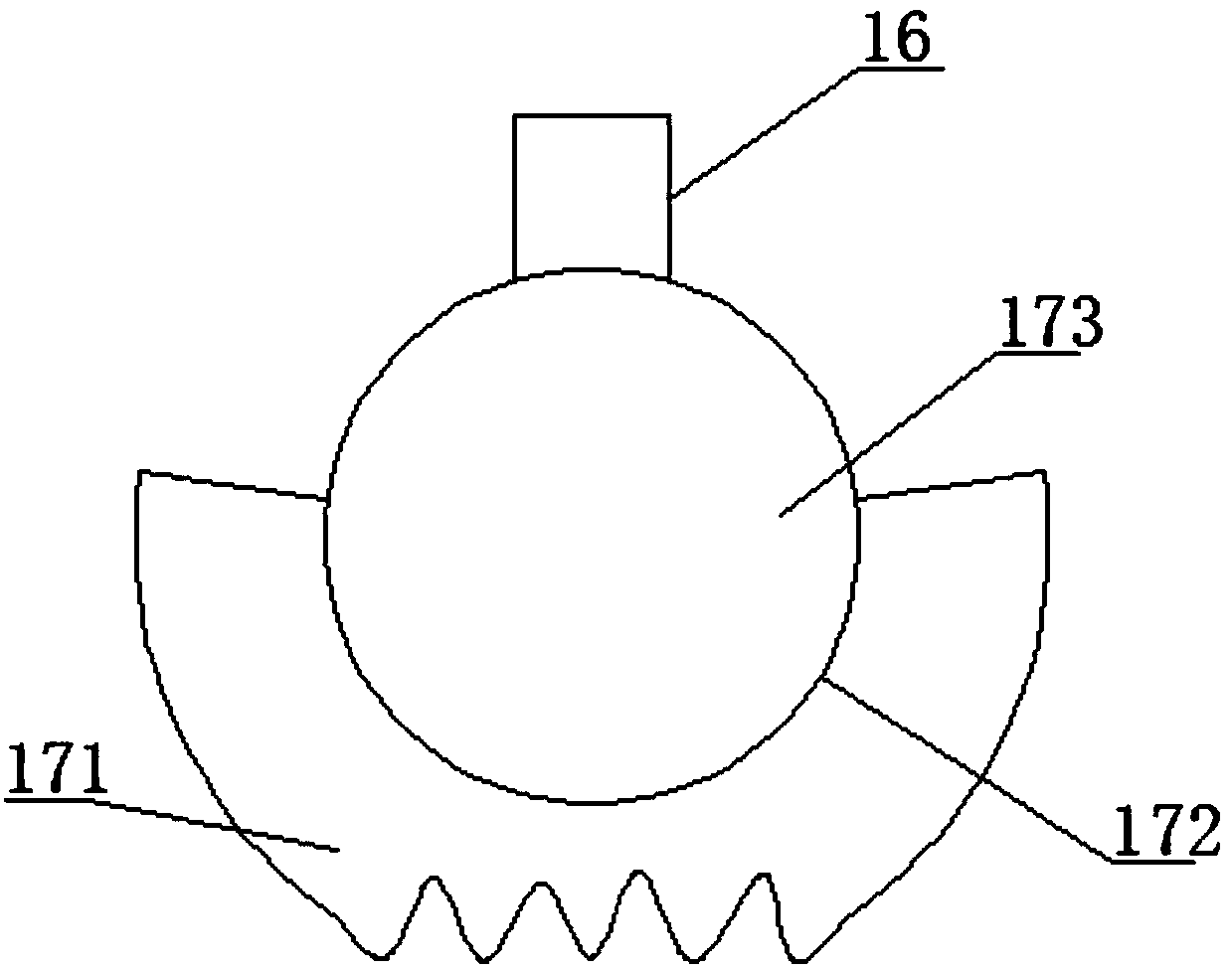

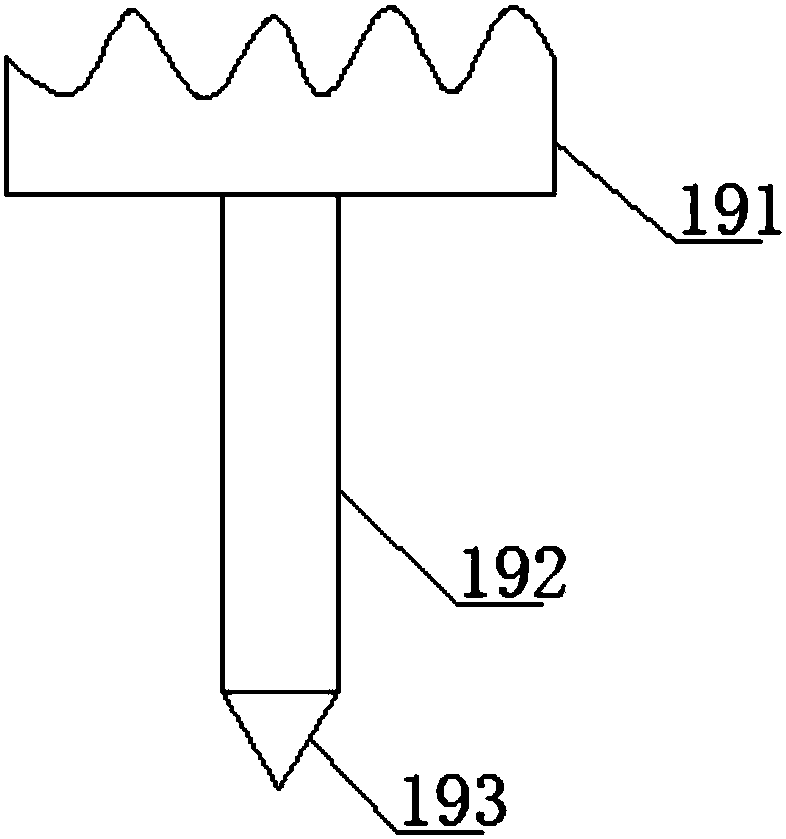

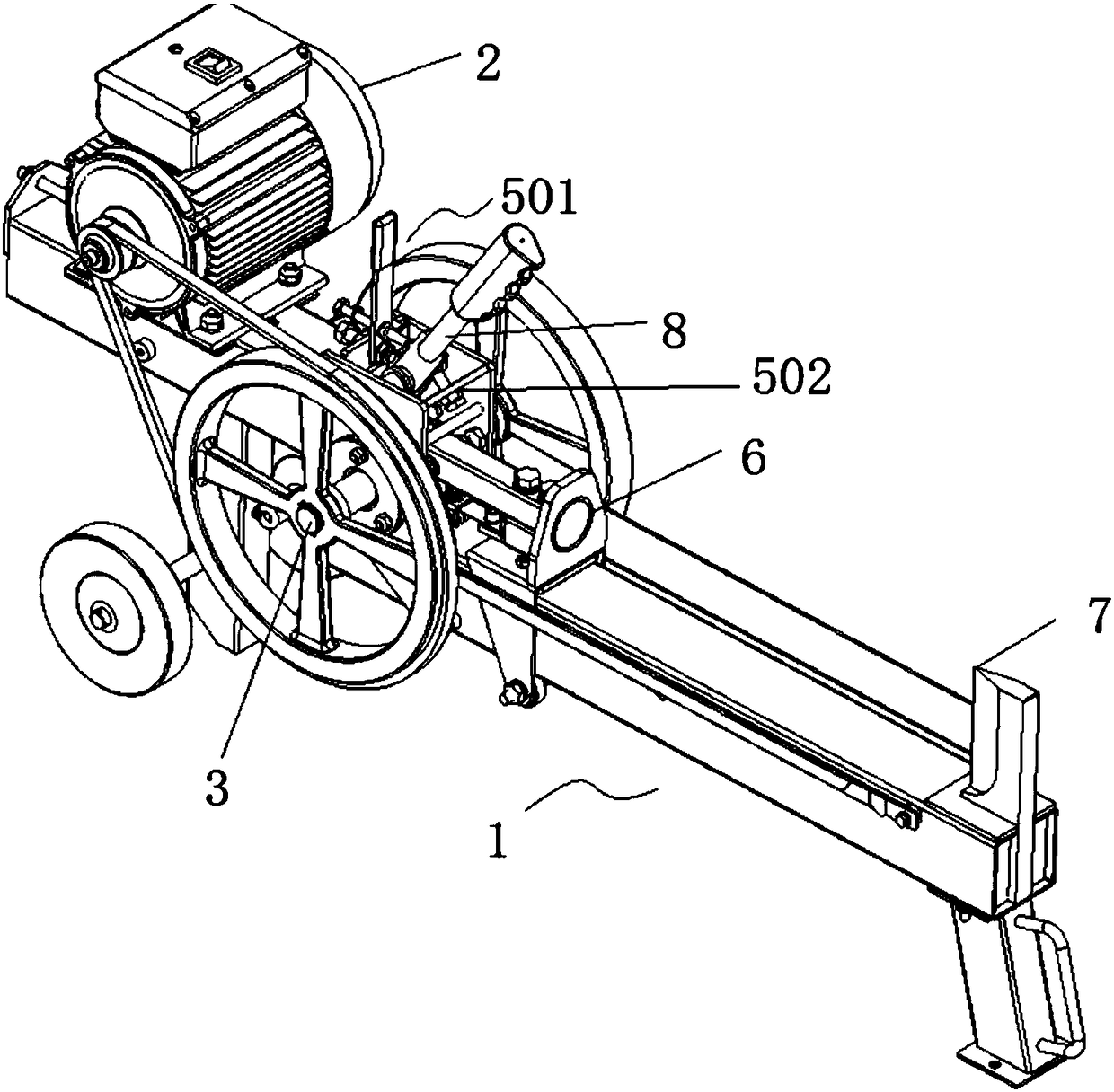

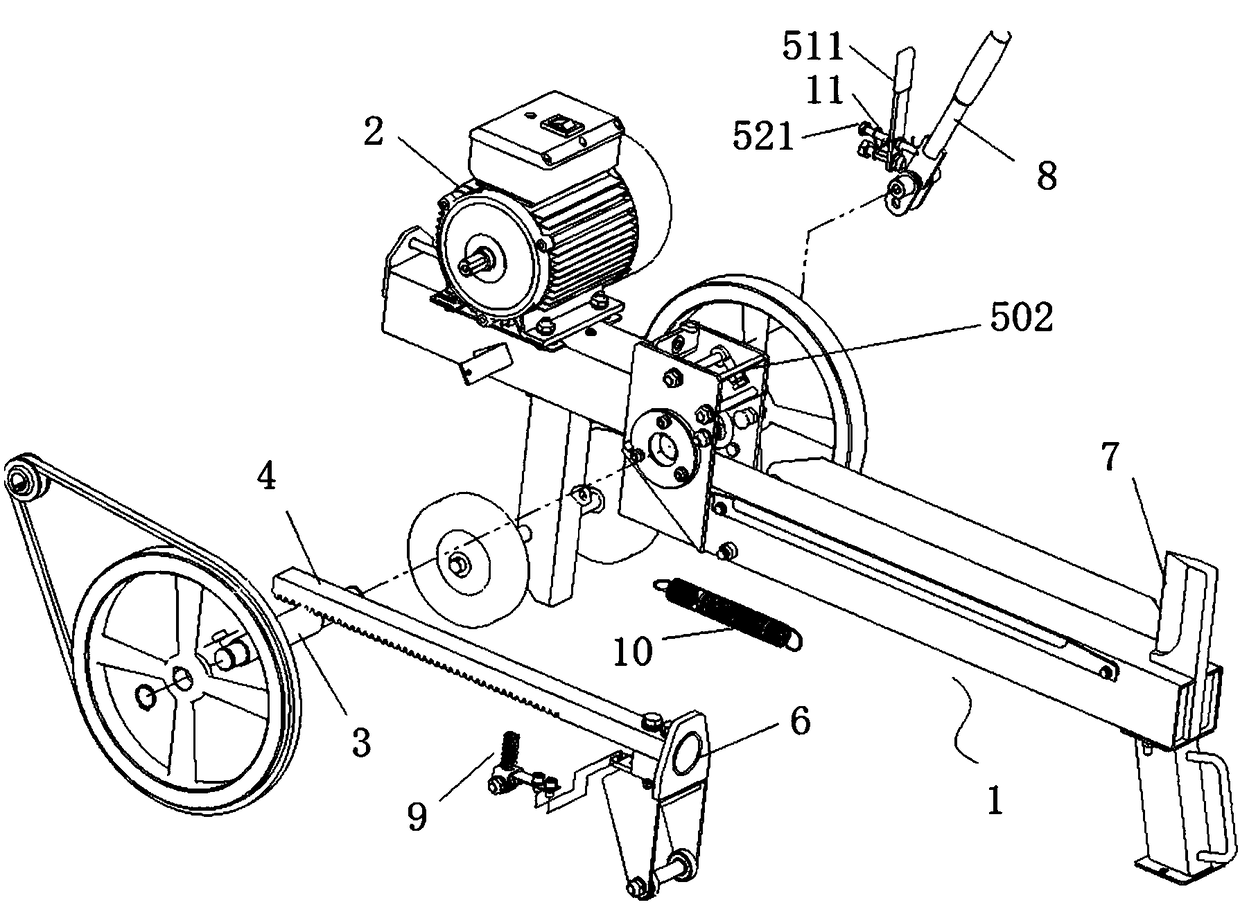

Flywheel wood splitting machine

The invention discloses a flywheel wood splitting machine. The flywheel wood splitting machine comprises a frame, a motor, a transmission main shaft, a transmission toothed bar and a toothed bar control component, wherein the transmission main shaft is in connection transmission with the motor, the transmission toothed bar is located on the rotating direction of the transmission main shaft, the toothed bar control component controls the transmission toothed bar to make contract with / be separated from the transmission main shaft, when the transmission toothed bar makes contract with the transmission main shaft, the transmission toothed bar is in connection transmission by being engaged with a toothed edge of the transmission main shaft, a material pushing plate is arranged on the transmission toothed bar, the transmission extending position of the transmission toothed bar is provided with a chopper, and a toothed edge reset spring and a material pushing reset spring are arranged betweenthe transmission toothed bar and the frame. The flywheel wood splitting machine has the advantages that wood splitting is realized utilizing discontinuous engaging of the toothed bar and a toothed wheel through man-made operations, discontinuous wood splitting can be performed at will according to actual requirements of operators, after each wood splitting stroke is finished, the flywheel wood splitting machine resets automatically, immediate / latish wood splitting operations are conveniently performed, phenomena of oil leak and insufficient pressure do not exist, the safety performance is high, and the wood splitting speed is fast.

Owner:YANGZHOU XINGYI MACHINERY

Wood splitting machine with 5T acting force

InactiveCN107097319ANot easy to dropSolve the problem of increased volume and increased costWood splittingMotor driveReciprocating motion

The invention belongs to the field of wood processing equipment, and provides a wood splitting machine with the 5T acting force. The wood splitting machine comprises a sliding rail, a fixing base, a wood splitting cutter body, a hydraulic transmission system and a motor, wherein the fixing base is arranged at one end of the sliding rail, the wood splitting cutter body is arranged on the sliding rail and can move in a reciprocating mode along the sliding rail, the hydraulic transmission system drives the wood splitting cutter body to move along the sliding rail, and the motor drives the hydraulic transmission system. According to the wood splitting machine, displacement of wood can be prevented through the fixing base, the motor is adopted for providing power, and the hydraulic transmission system is adopted for transmission so as to drive the wood splitting cutter body to move along the sliding rail towards the fixing base so that the wood which is placed between the wood splitting cutter body and the fixing base can be split; due to the fact that the wood does not generate displacement under the action of the fixing base, the wood cannot fall off from the wood splitting machine easily, a receiving device does not need to be additionally arranged, and therefore the problems that in the prior art, a wood splitting machine with the 5T acting force needs to be additionally provided with the receiving device, and then the size of equipment is increased and the cost is increased can be solved.

Owner:LAIZHOU XINHAIWEI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com