Special-shaped lumber splitting machine

An extension and wood technology, used in wood processing appliances, sawing equipment, circular saws, etc., can solve the problems of dry cracking and deformation, the impact of wood quality, inconvenience in board production and processing, and achieve good shape retention effect, simple structure, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

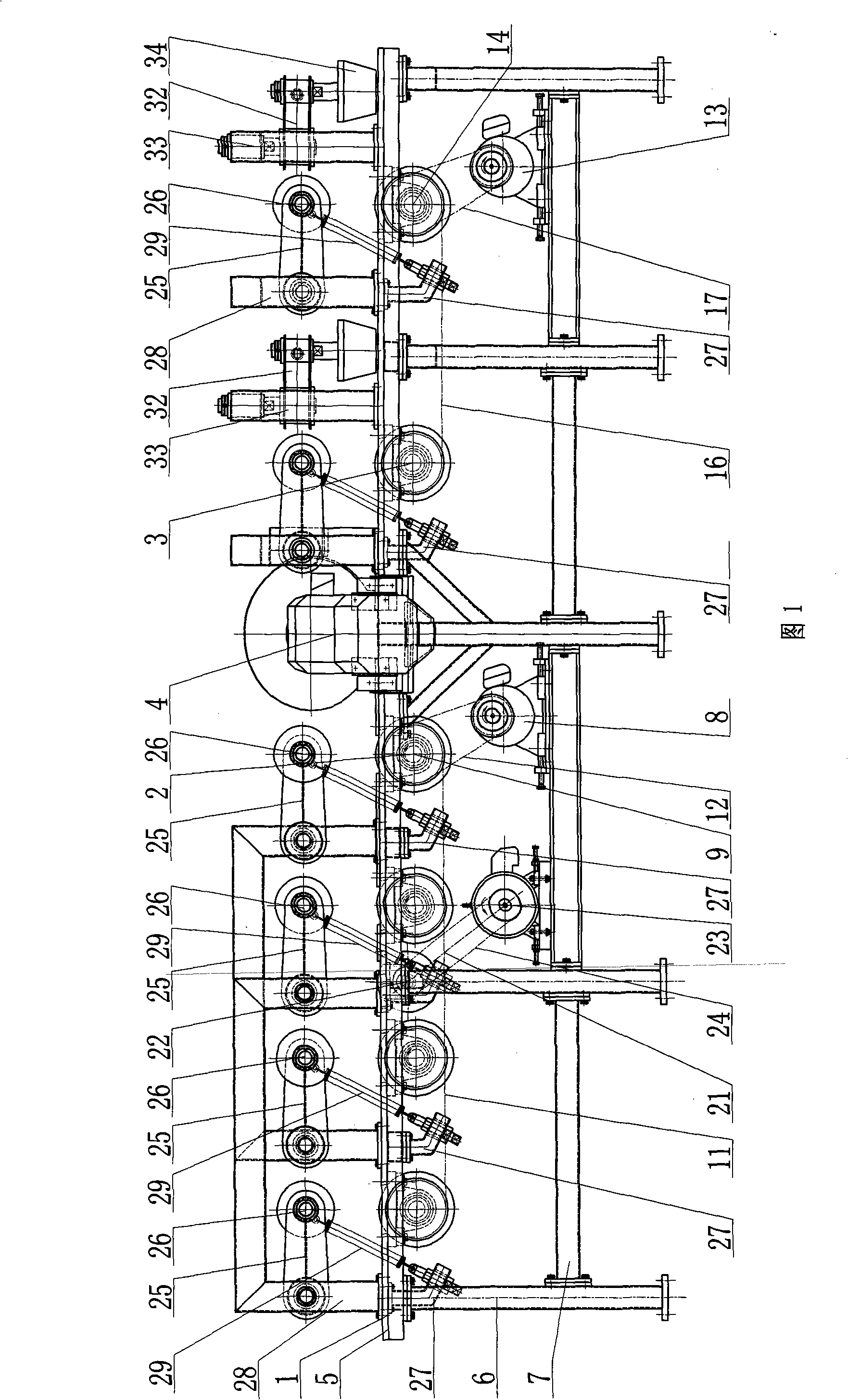

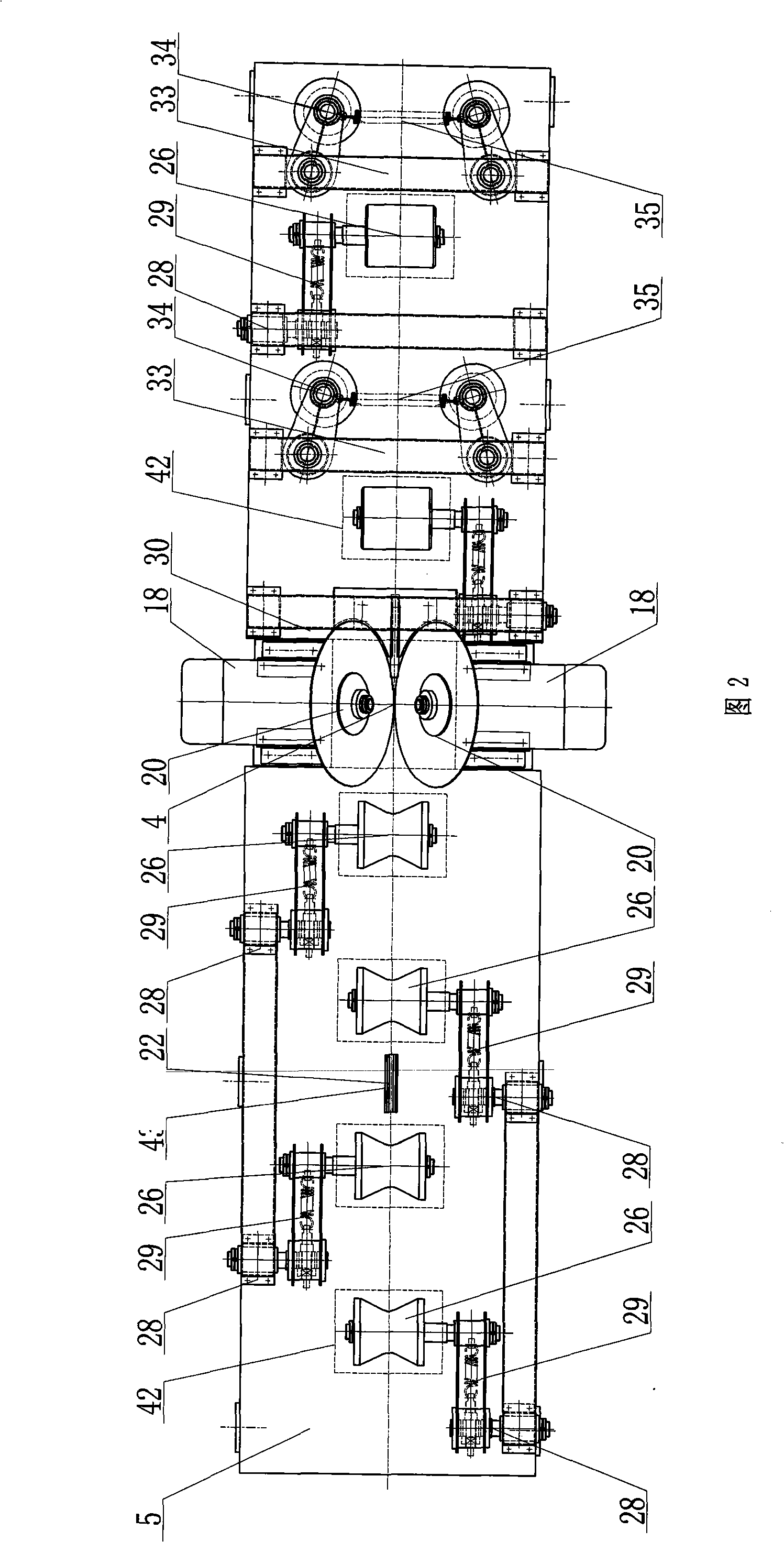

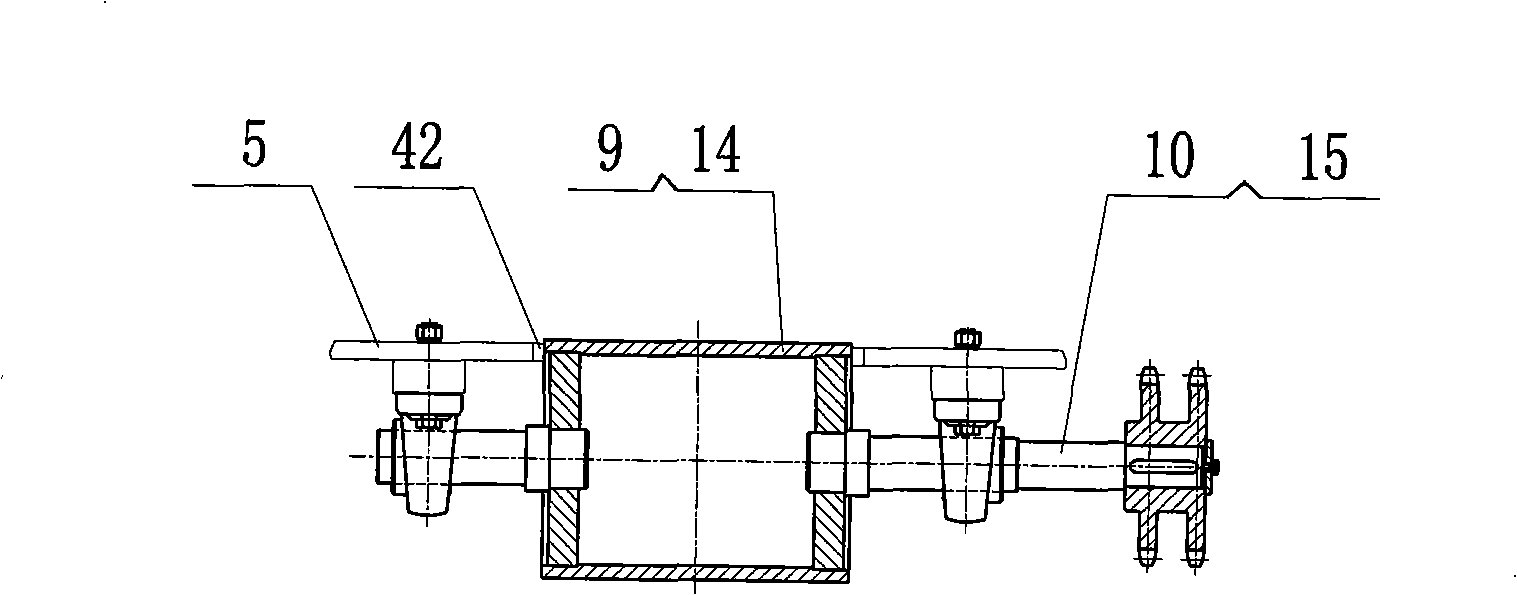

[0007] Specific implementation mode one: in conjunction with Fig. 1~ Figure 4 Describe this embodiment, this embodiment comprises frame 1, input driving roller assembly 2, output driving roller assembly 3 and two circular saw assemblies 4, described frame 1 is made up of platen 5, a plurality of supporting legs 6 Composed of a plurality of beams 7, the cross-section of the middle part of the platform 5 is trapezoidal, a number of holes 42 are opened on the longitudinal horizontal center line of the platform 5, and the plurality of supporting legs 6 are installed on the platform 5 On the lower end surface of the lower end face, the plurality of beams 7 are arranged between every two adjacent supporting legs 6; the input drive roller assembly 2 is composed of a first motor 8, at least two input drive rollers 9, a plurality of second A bearing sprocket 10, a first chain 11 and a second chain 12 are composed, the first motor 8 is installed on the beam 7 at the input end of the fr...

specific Embodiment approach 2

[0008] Embodiment 2: This embodiment is described with reference to FIG. 1 . The number of input drive rollers 9 in this embodiment is 2-6. With this setting, the operation is more stable. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific Embodiment 3: This embodiment is described with reference to FIG. 1 . The distance between two adjacent input drive rollers 9 in this embodiment is 300 mm to 500 mm. With this setting, the operation is more stable. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com