Electromotor of wood splitting machine

An electromechanical and motive technology, applied in the field of electric motors, can solve the problems of inability to guarantee sealing, large volume and high cost, and achieve the effect of light weight, small volume and reduced friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

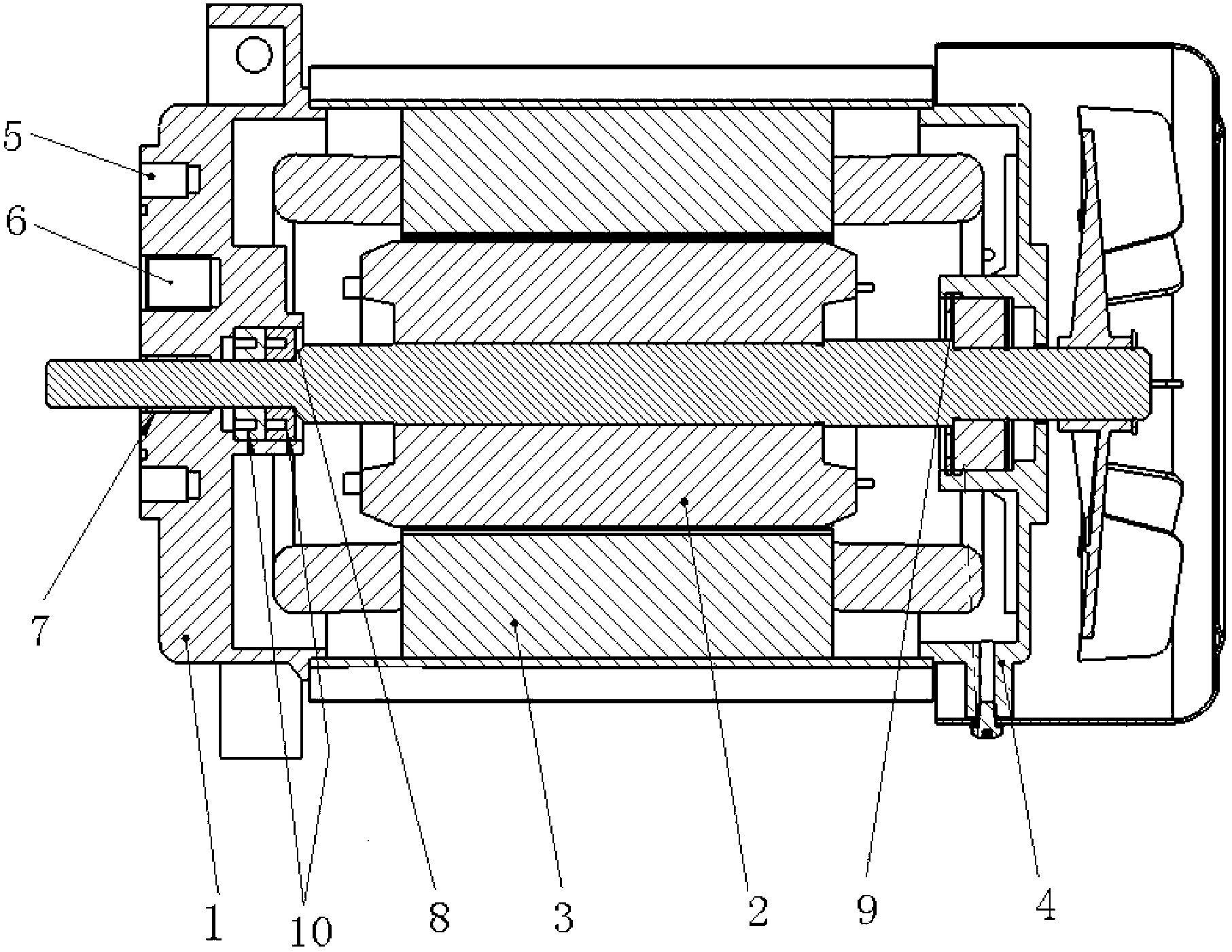

[0010] Such as figure 1 As shown, a wood splitter motor of the present invention includes a front cover 1, a rotor 2, a stator 3, a rear cover 4 and a control sleeve 7, and the front cover 1 is provided with a first oil hole 5 and a second oil hole. hole 6, the control sleeve 7 passes through the front cover 1, the rotor 2 and the rear cover 4 in turn, the control sleeve 7 includes a front part, a middle part and a rear part, the diameter of the middle part is larger than the diameter of the front part and the rear part, and the middle part and the front part There are front positioning shoulders 8 and rear positioning shoulders 9 at positions adjacent to the front and rear parts respectively, and an oil seal 10 is arranged between the front cover 1 and the front positioning shoulders 8 . The oil seal 10 is a mechanical element used to seal oil, and it isolates the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com