Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Log splitter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Many log splitters consist of a hydraulic or electrical rod and piston assembly and these are often rated by the tons of force they can generate. The higher the force rating, the greater the thickness or length of the rounds that can be split. The log splitter consists of all four major hydraulic components.

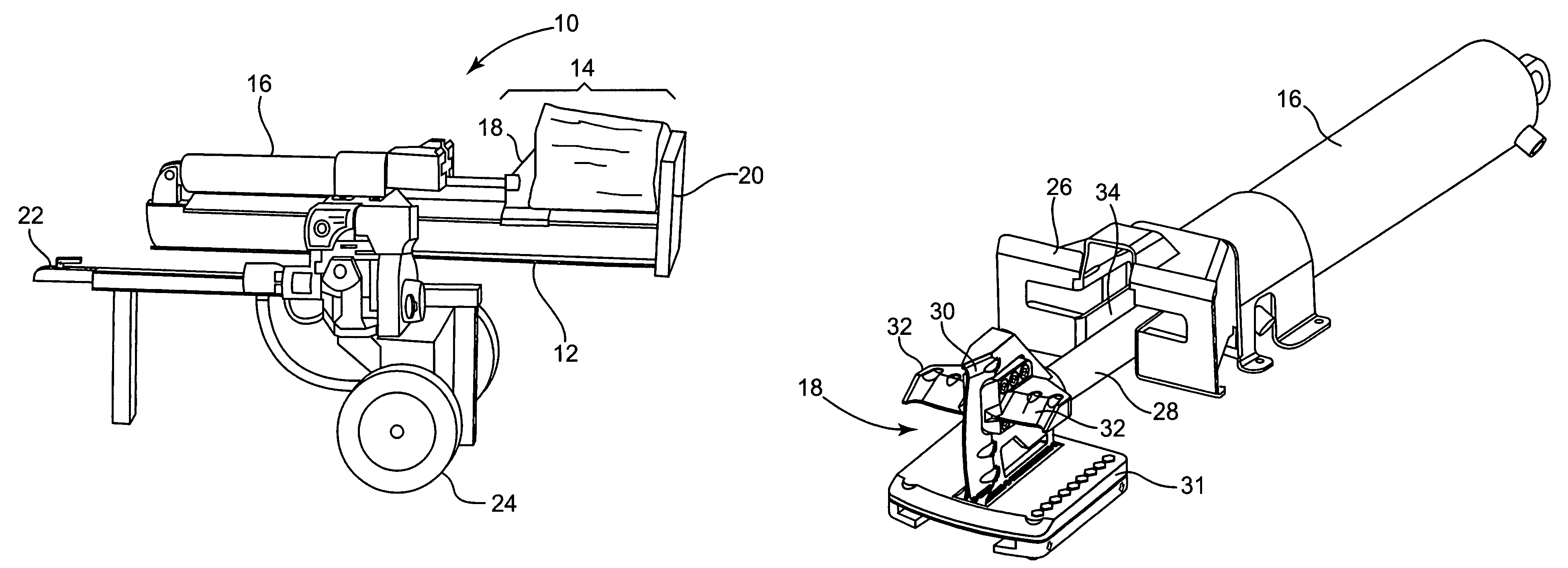

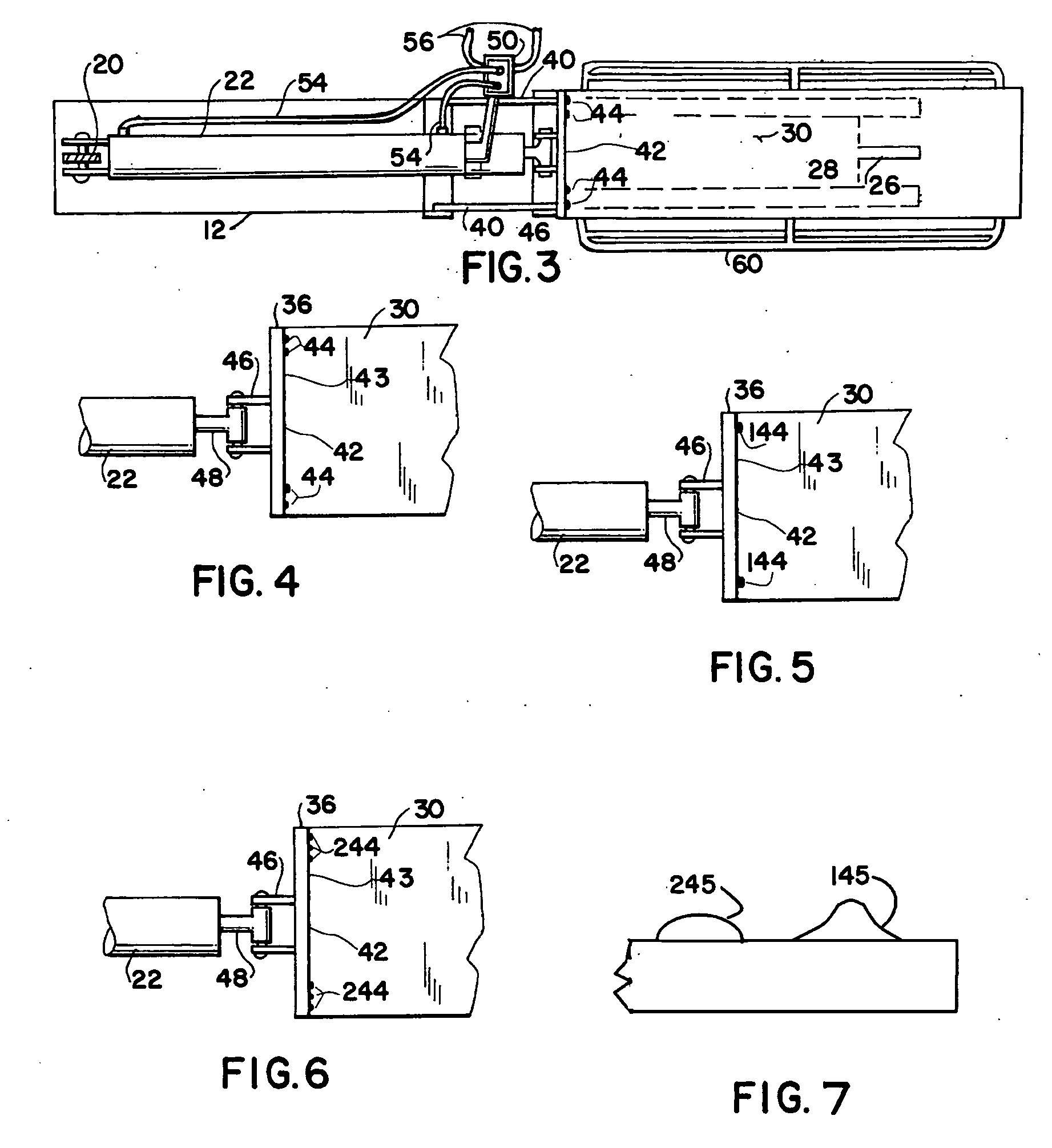

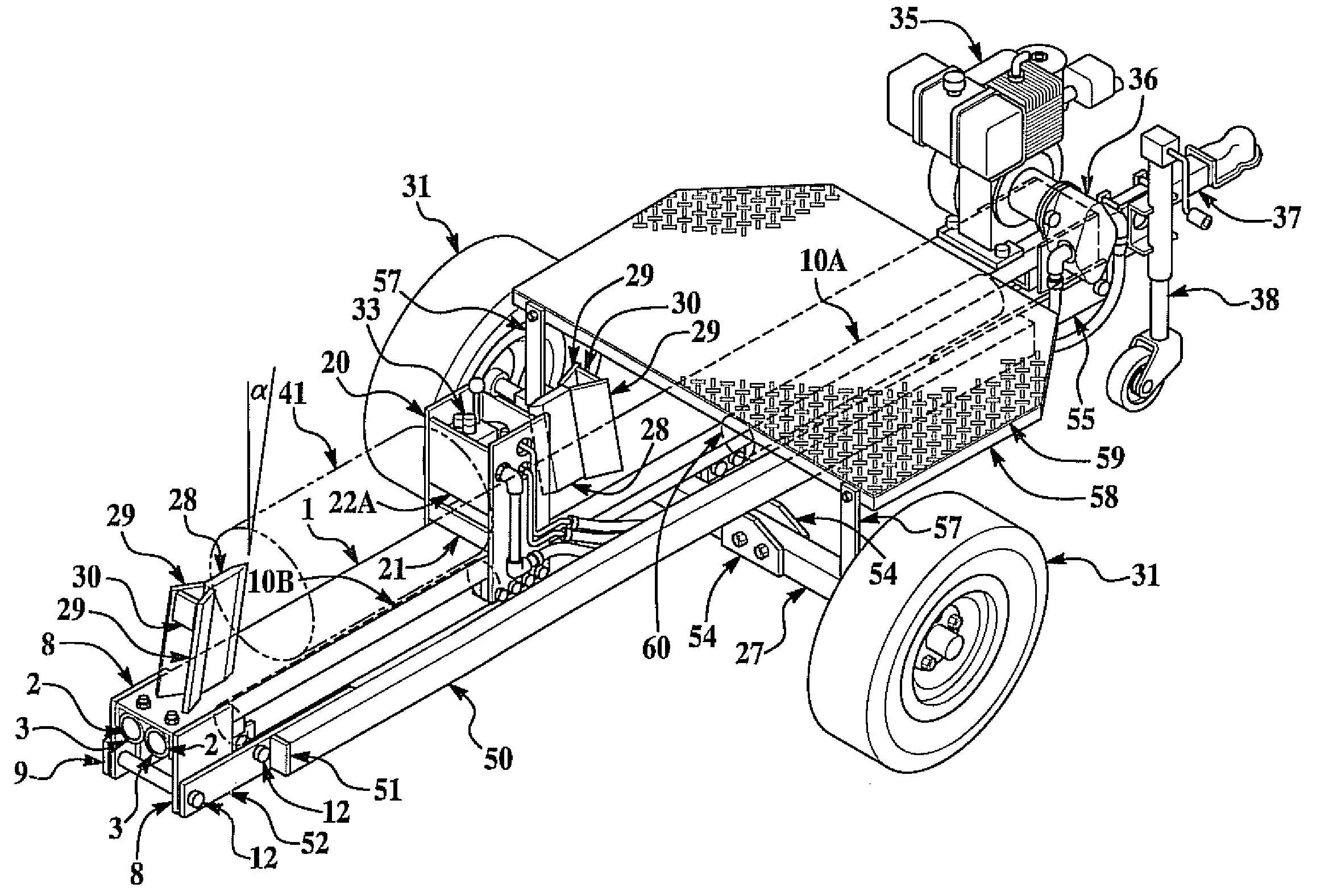

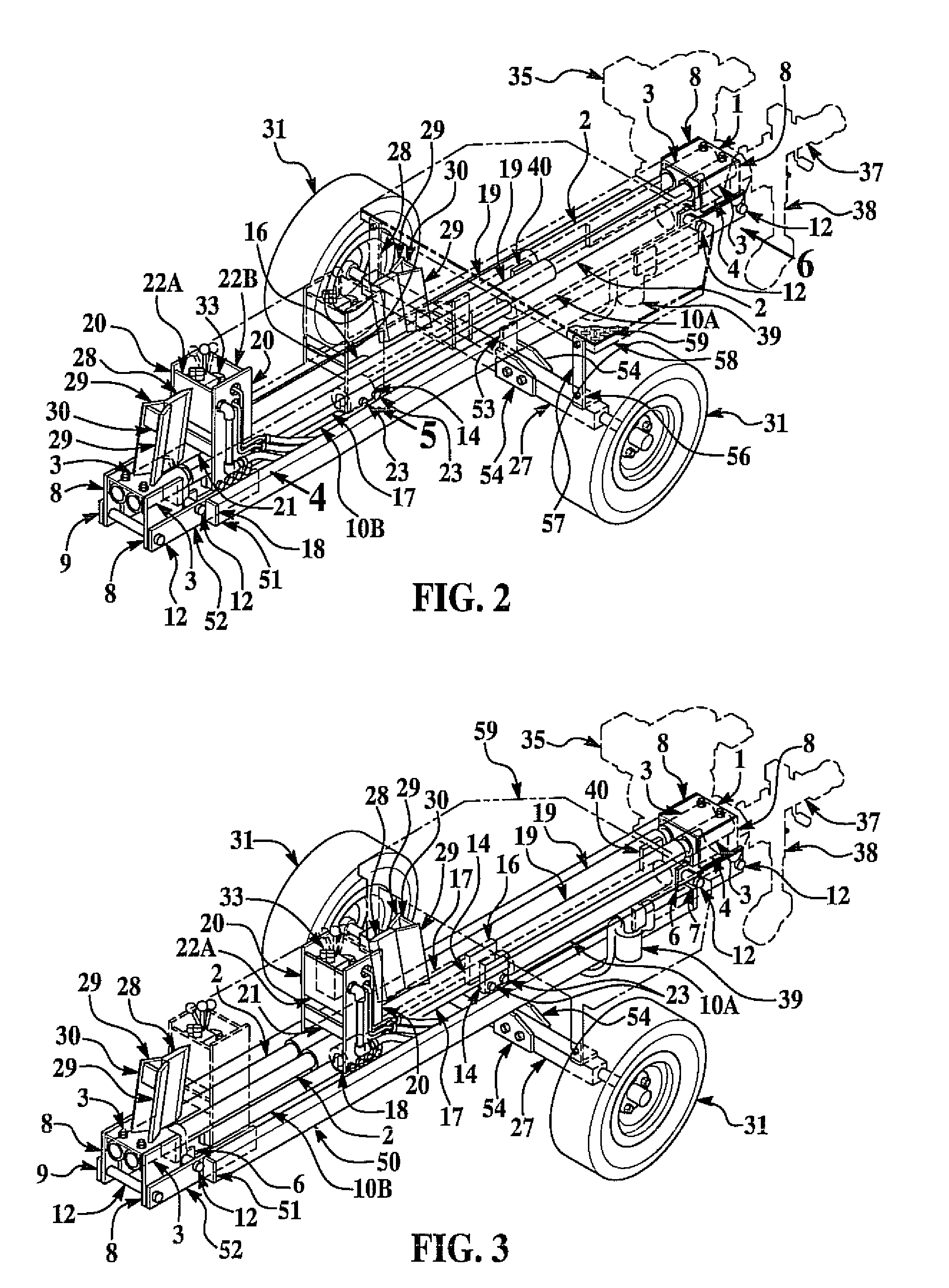

Quad wedge tip up log splitter

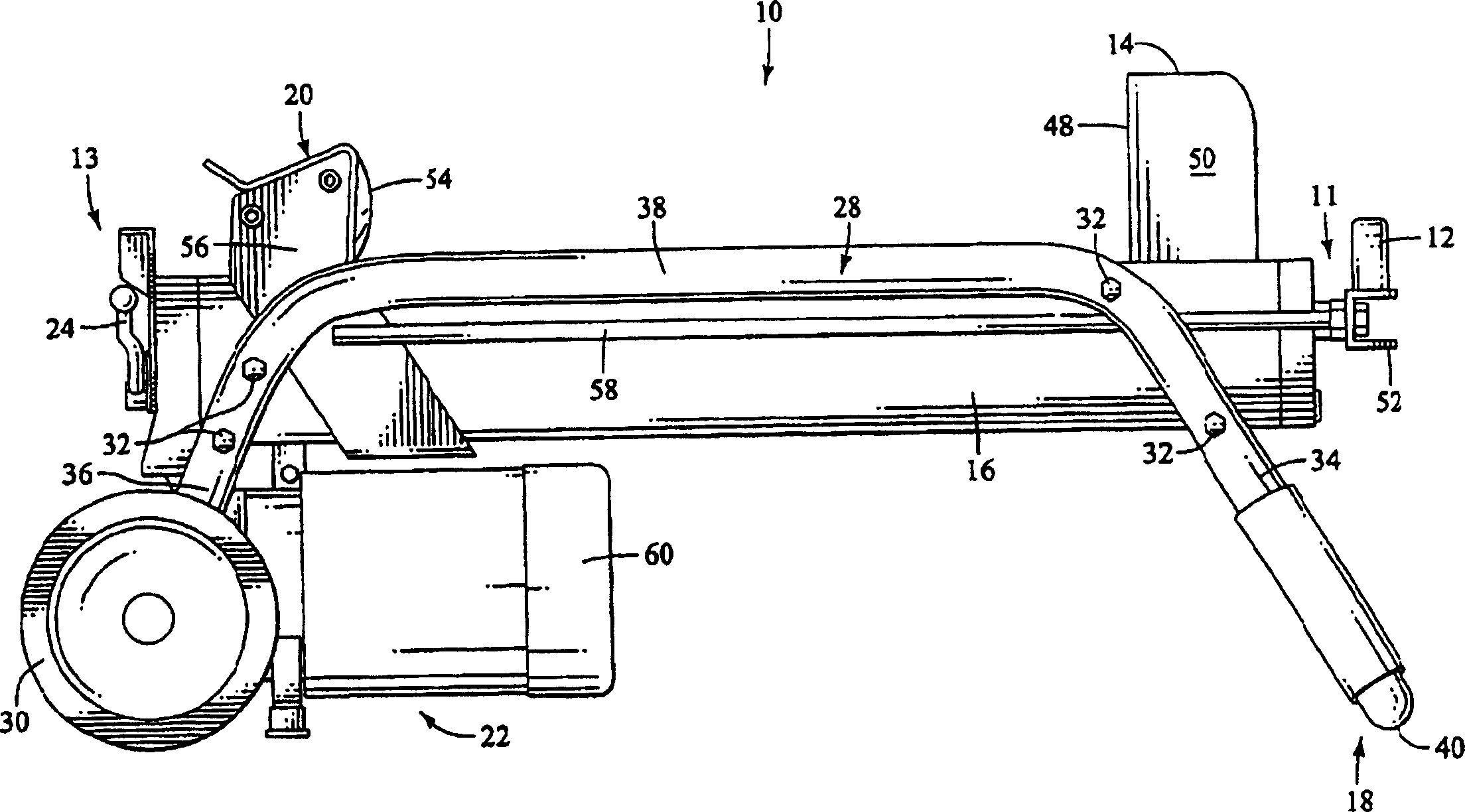

ActiveUS7255143B1Efficient executionProvide flexibilityWood splittingMulti-purpose machinesHydraulic cylinderEngineering

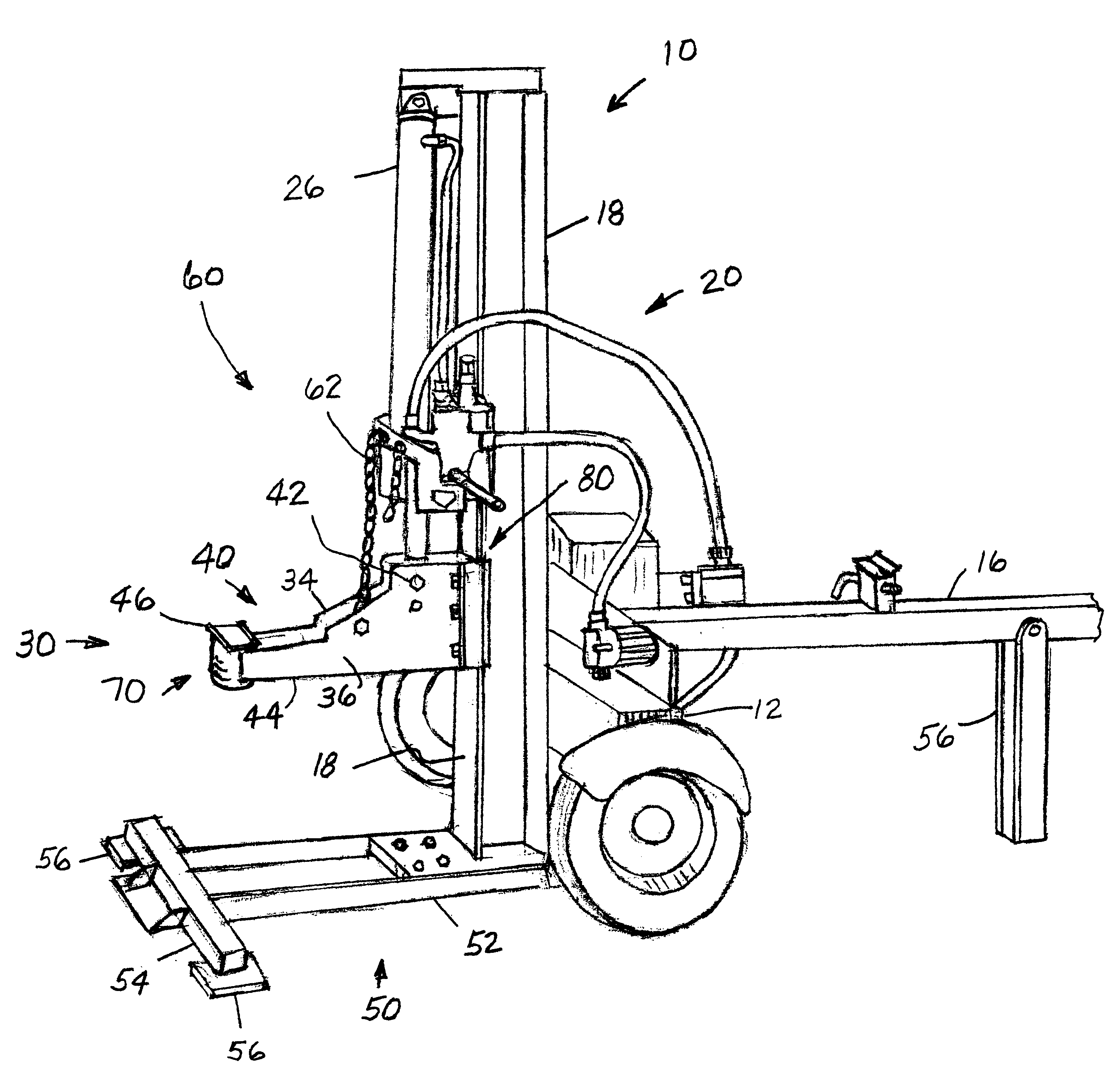

A uniquely configured quad wedge allows for the creation of a tip-up log splitter that is capable of multiple splits in a single stroke of the drive mechanism. The quad wedge is attached to the piston of a hydraulic cylinder, and is slidably mounted to a framework to allow for movement through a splitting zone. The quad wedge further includes a main splitting blade, along with a pair of splitting wings extending outwardly in a perpendicular manner. The blades each have structures on the ends thereof which are configured to help contain a log during splitting operations, thus avoiding undesired movement or wandering. The log splitter further includes a stripper mechanism positioned near the cylinder housing to allow jammed logs to be easily removed, which includes a recess to house the quad wedge when retracted. A jammed log will necessarily contact the stripper mechanism, causing it to be removed from the blade.

Owner:NORTHERN TOOL & EQUIP

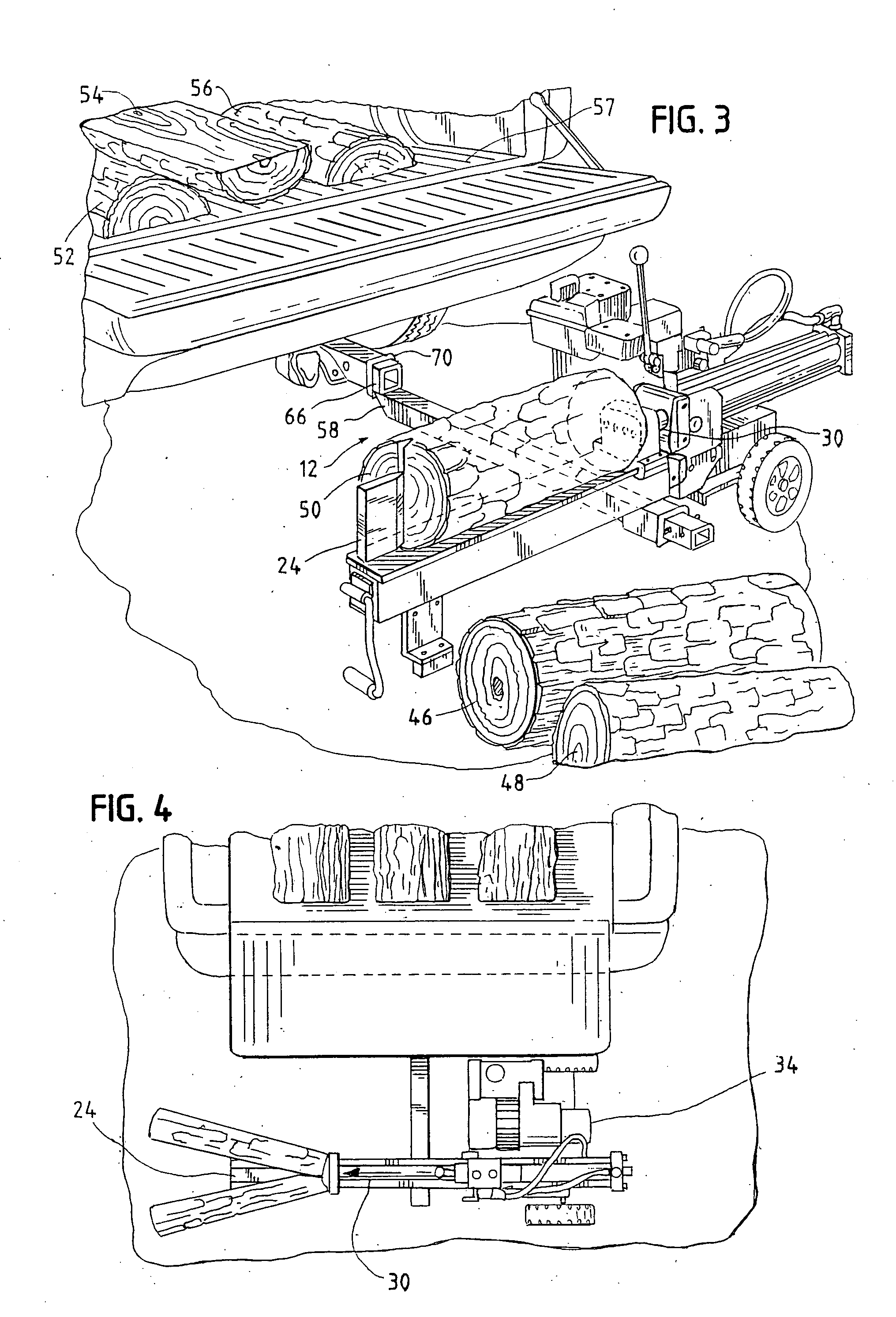

Compact log splitter

Owner:NORTHERN TOOL & EQUIP

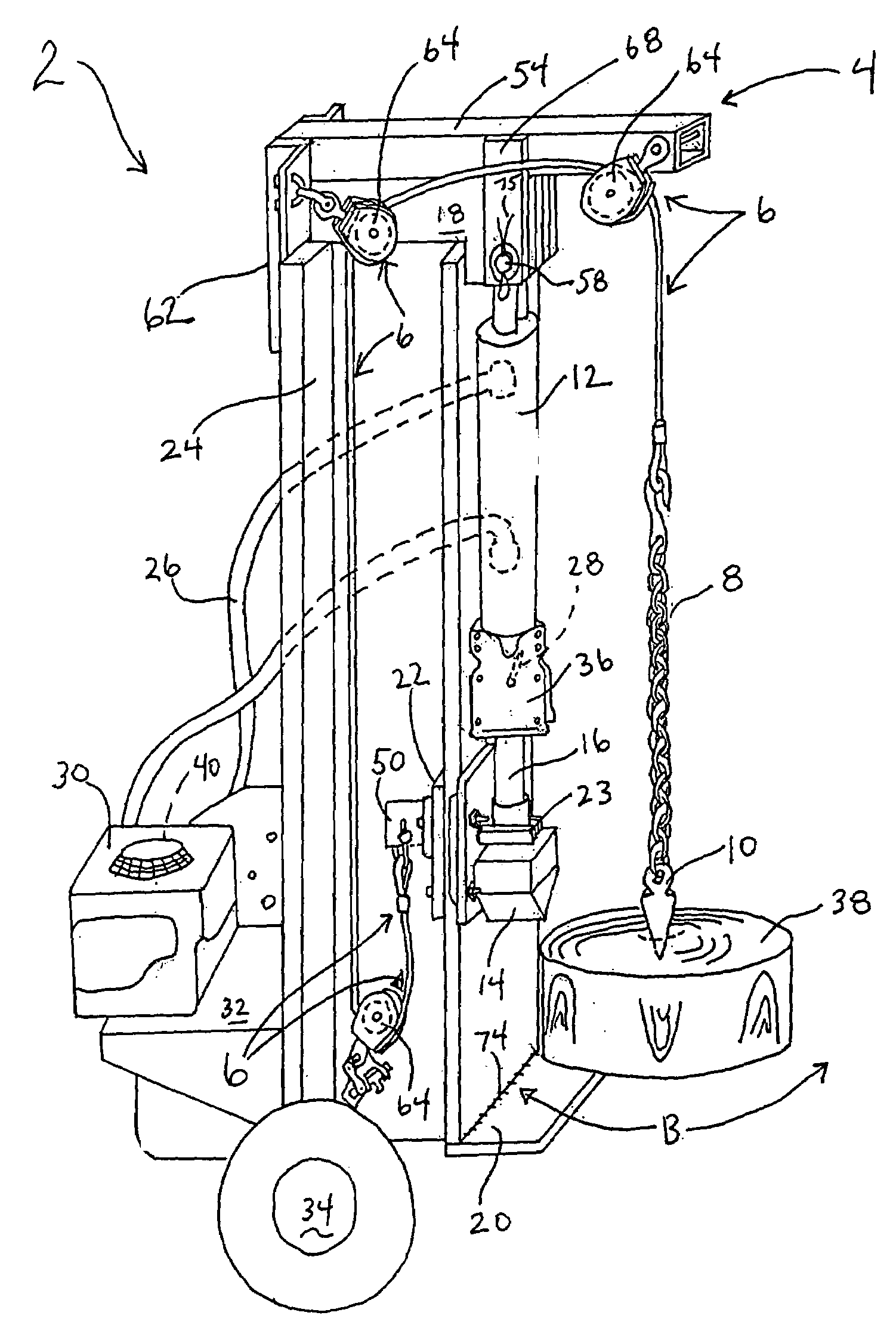

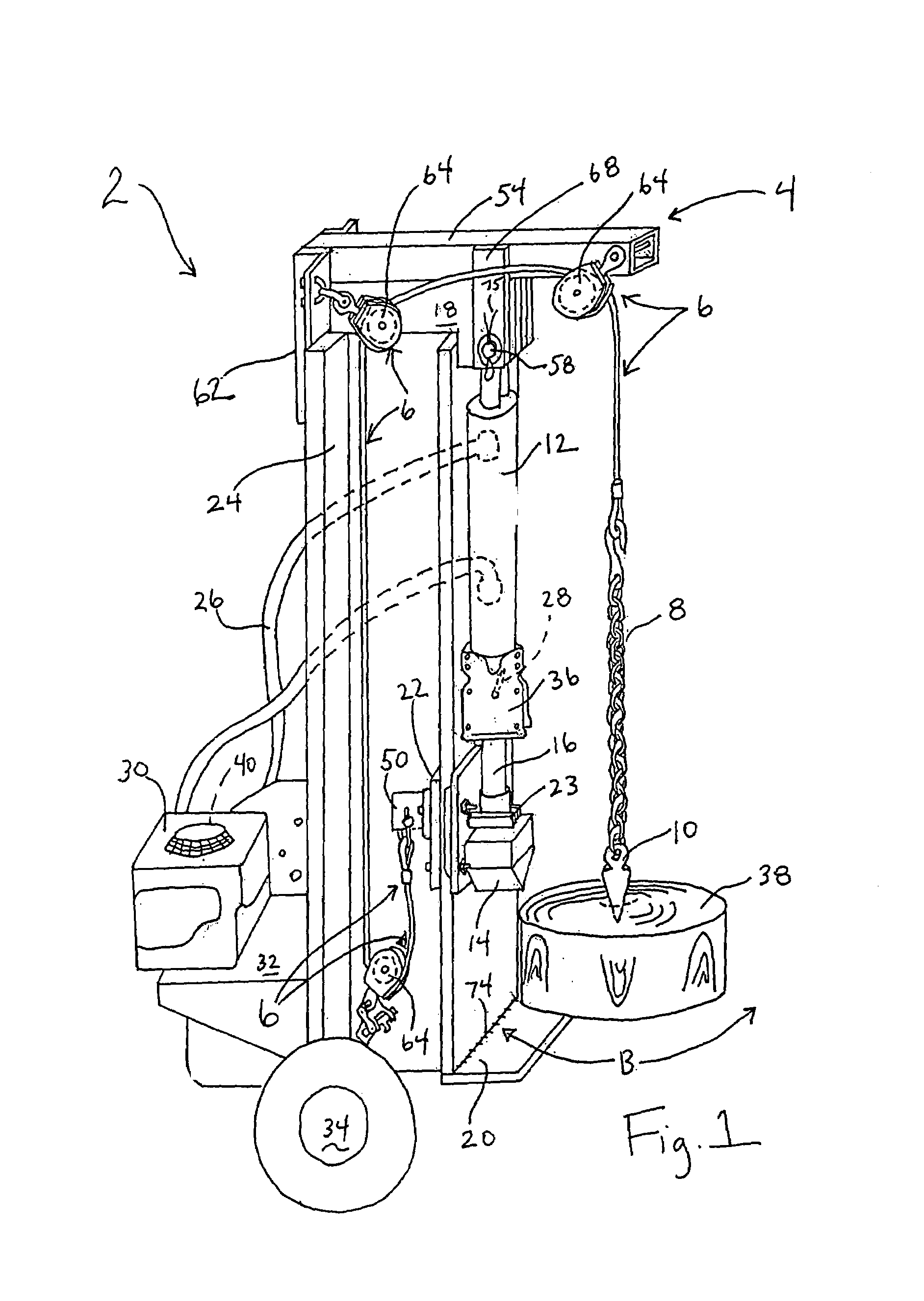

Block hoist

Owner:PETERSON BYRON

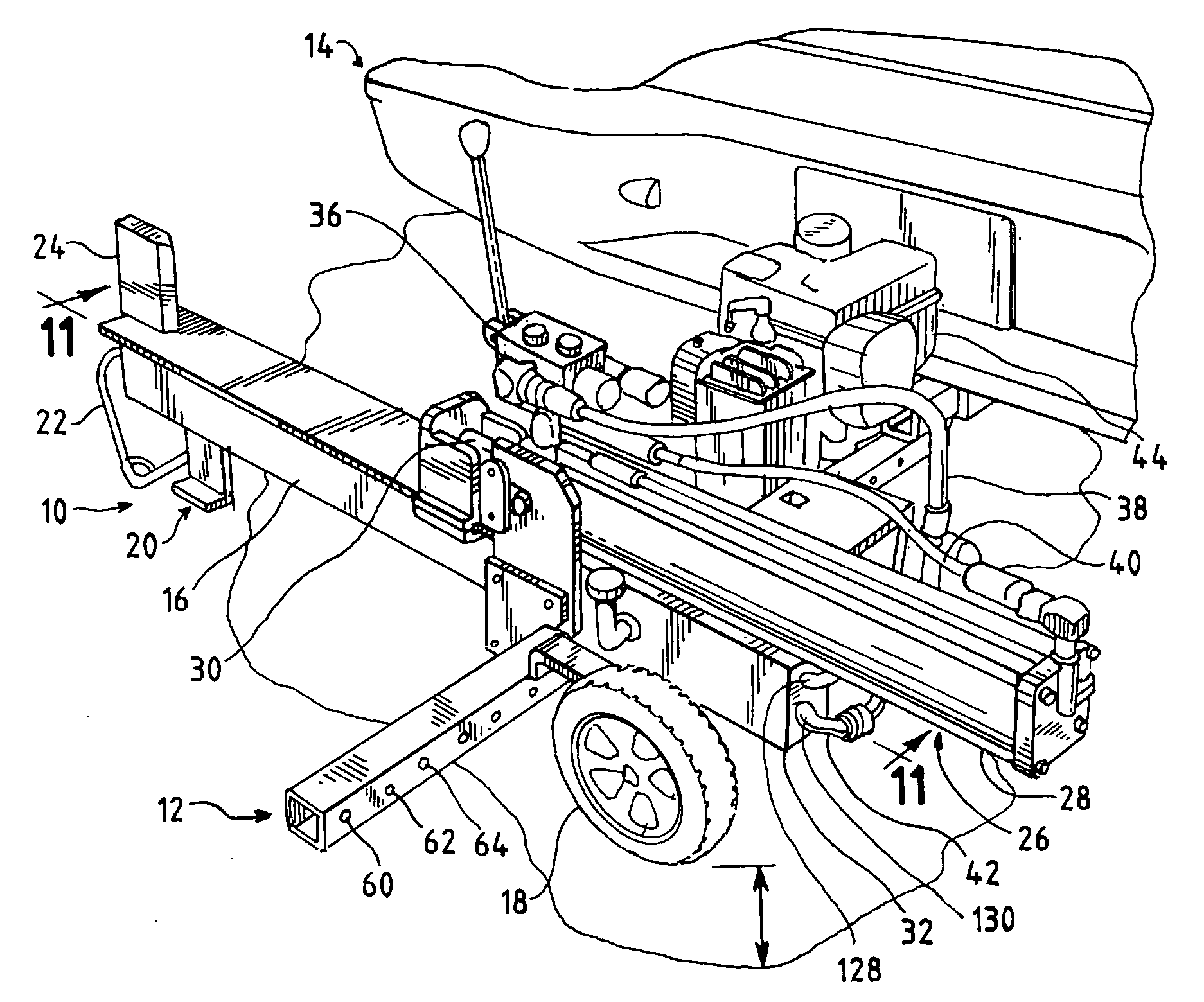

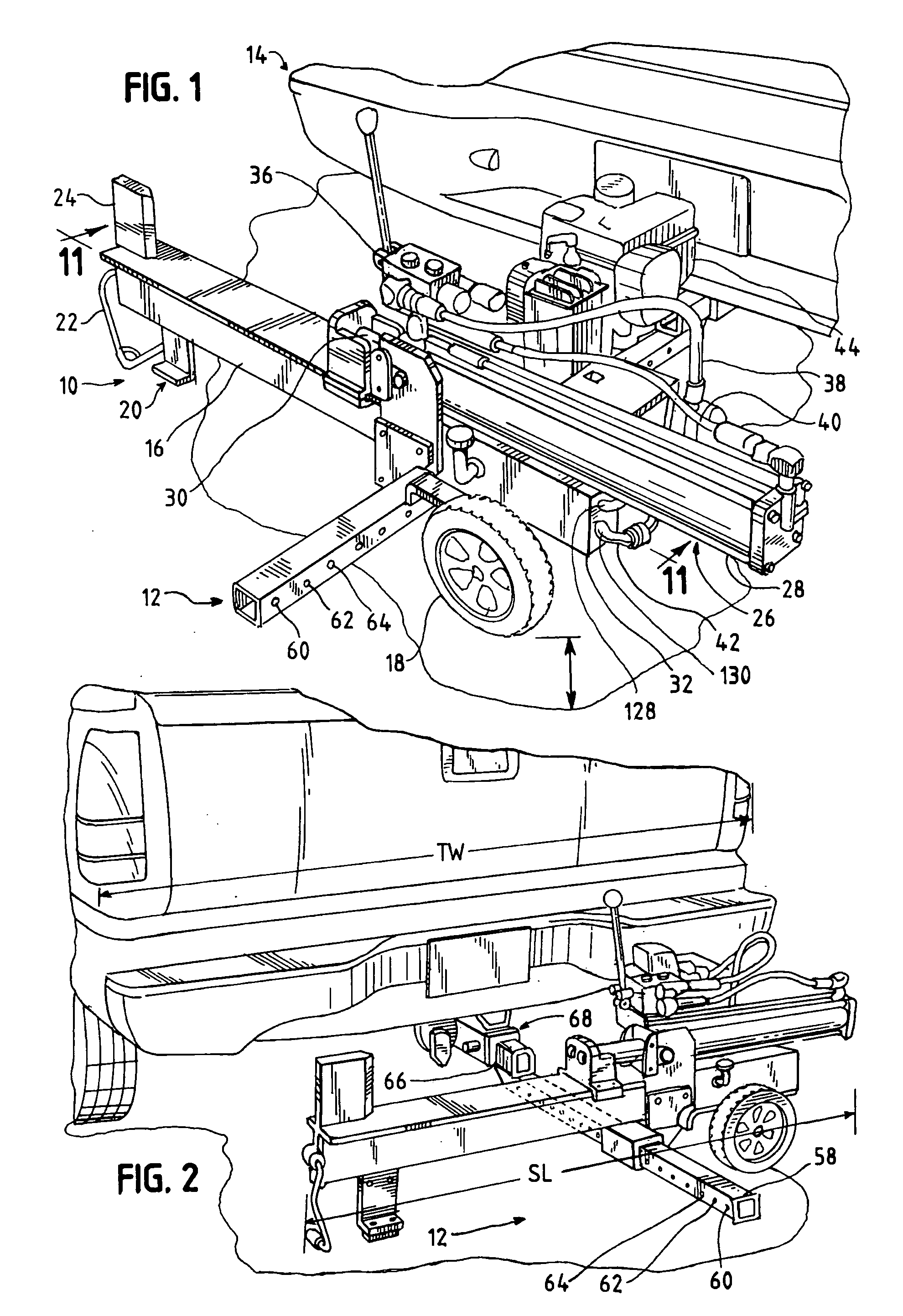

Log splitter

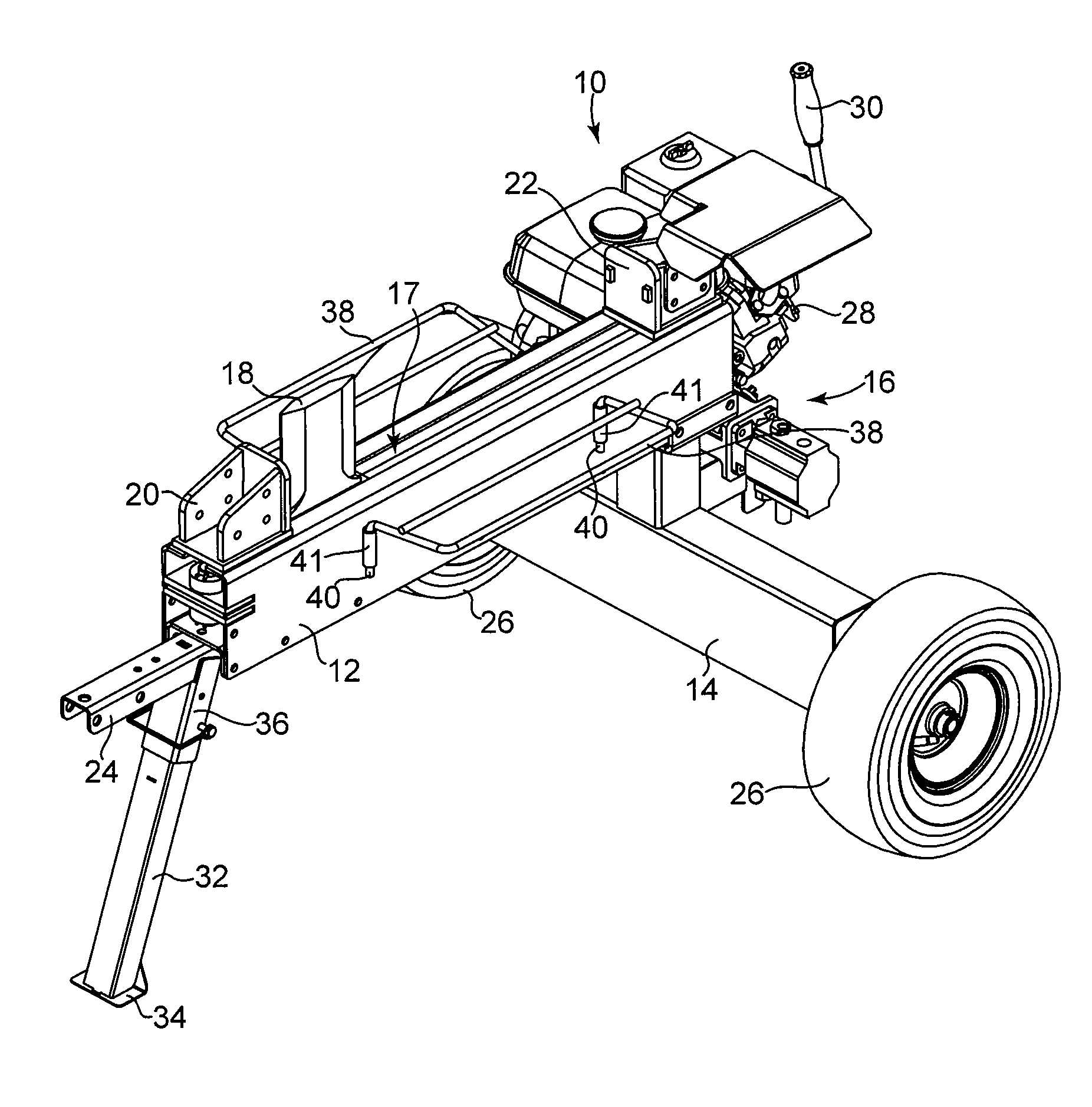

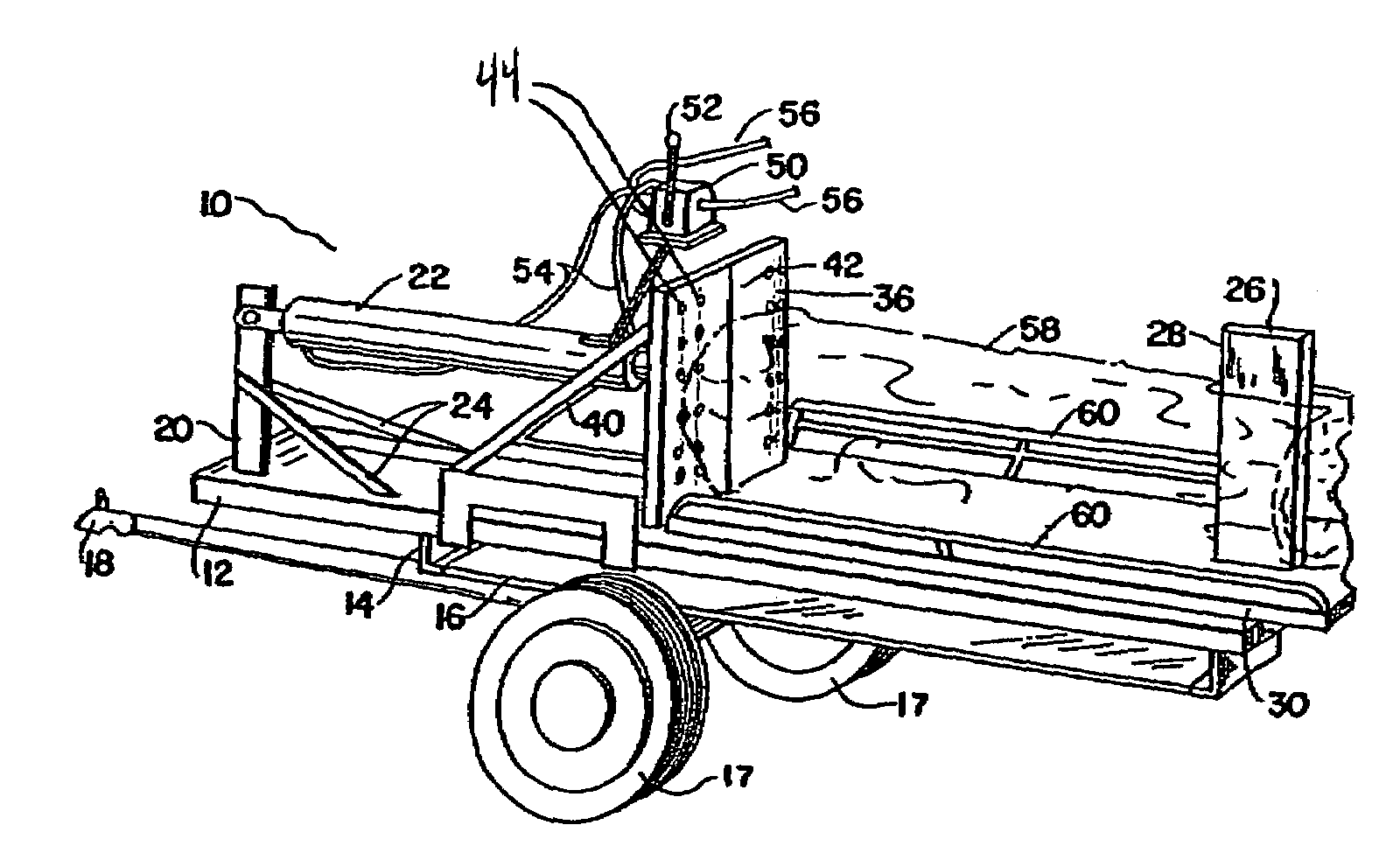

InactiveUS20050284541A1Maximize mixingMinimizes direct flow of fluidWood splittingMulti-purpose machinesHydraulic cylinderSet screw

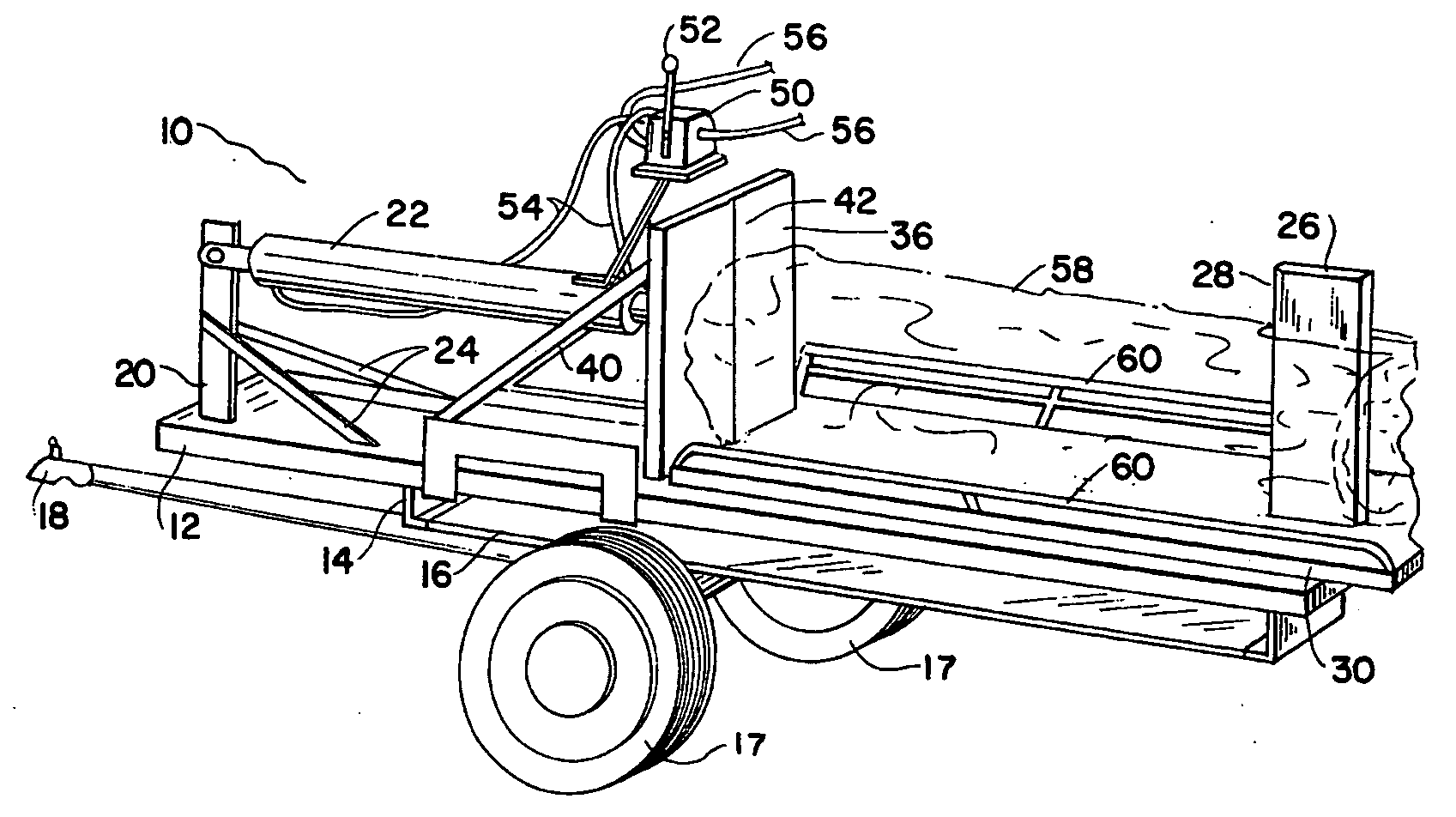

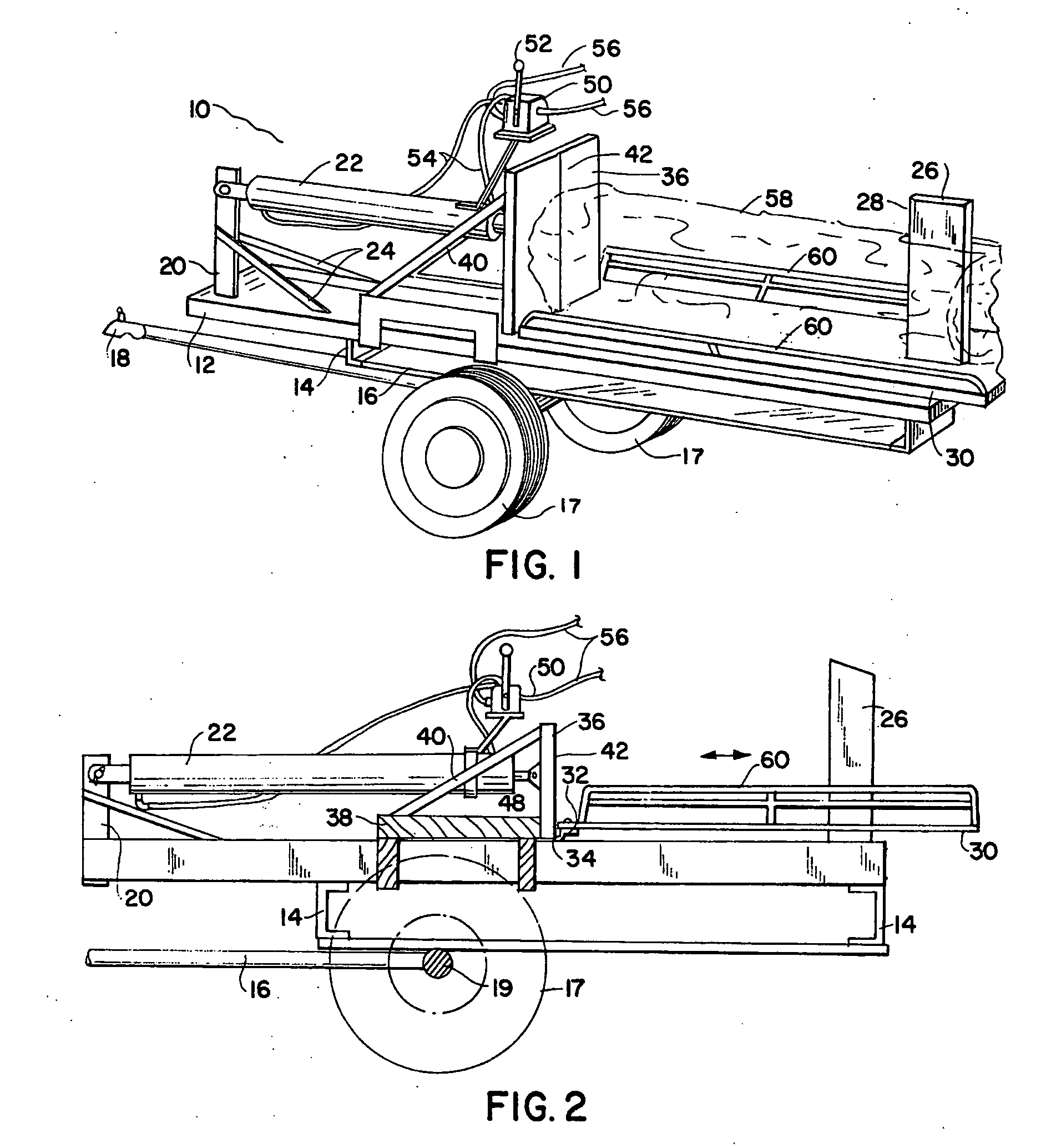

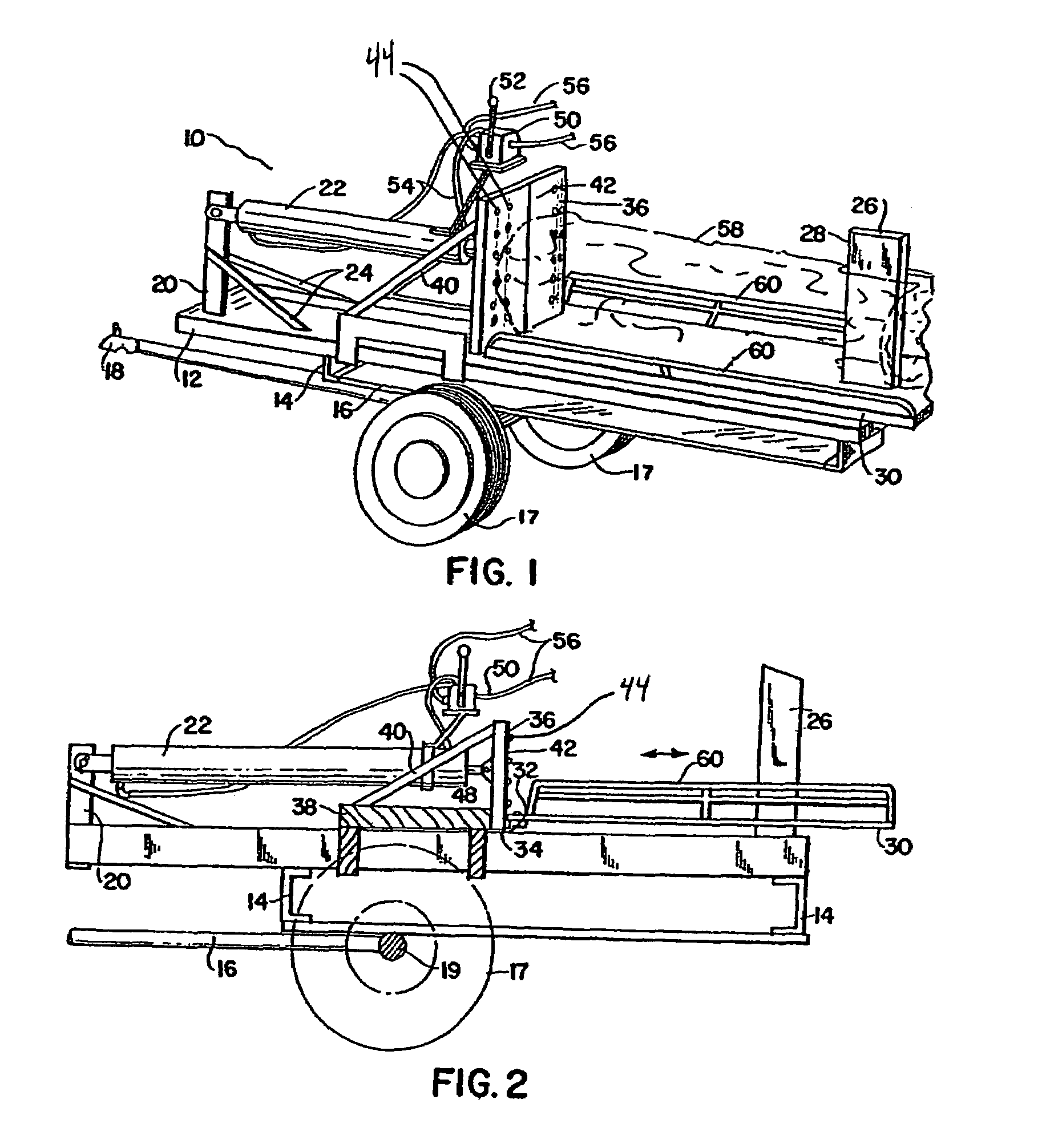

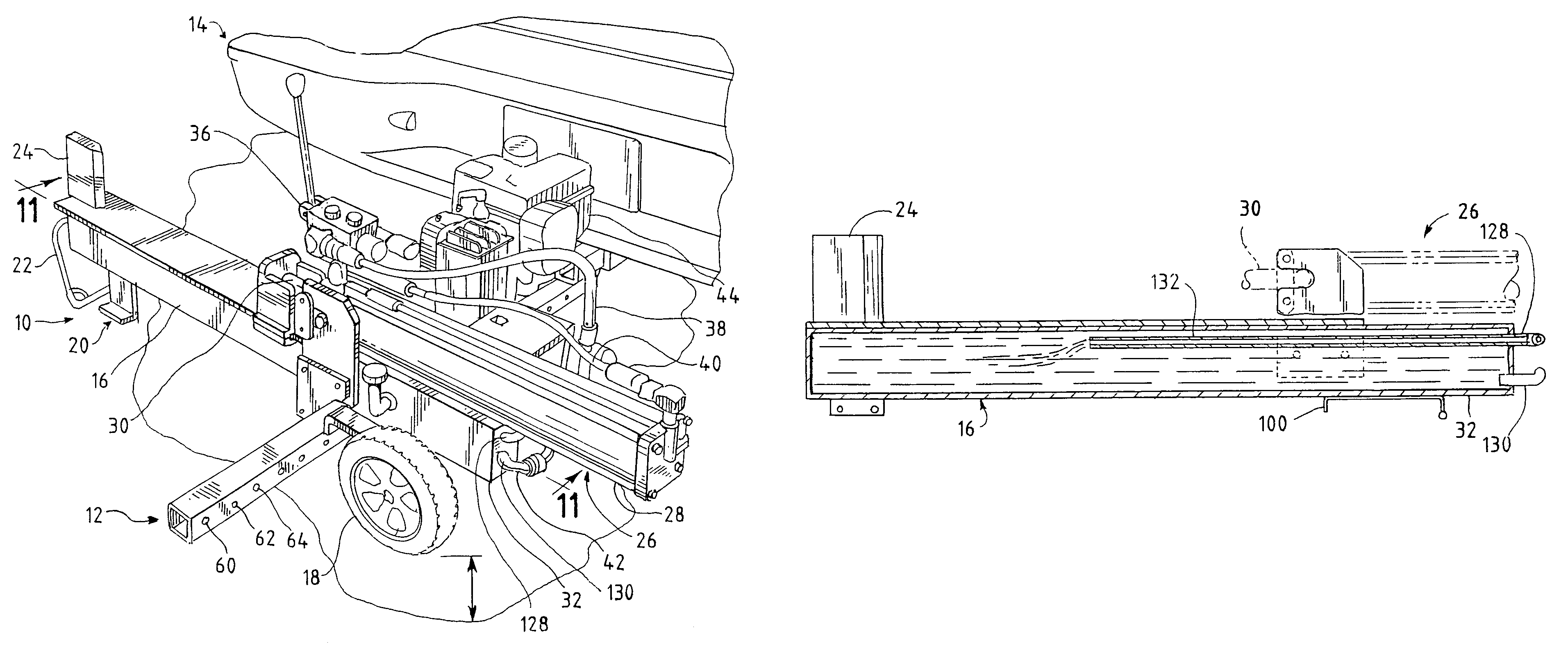

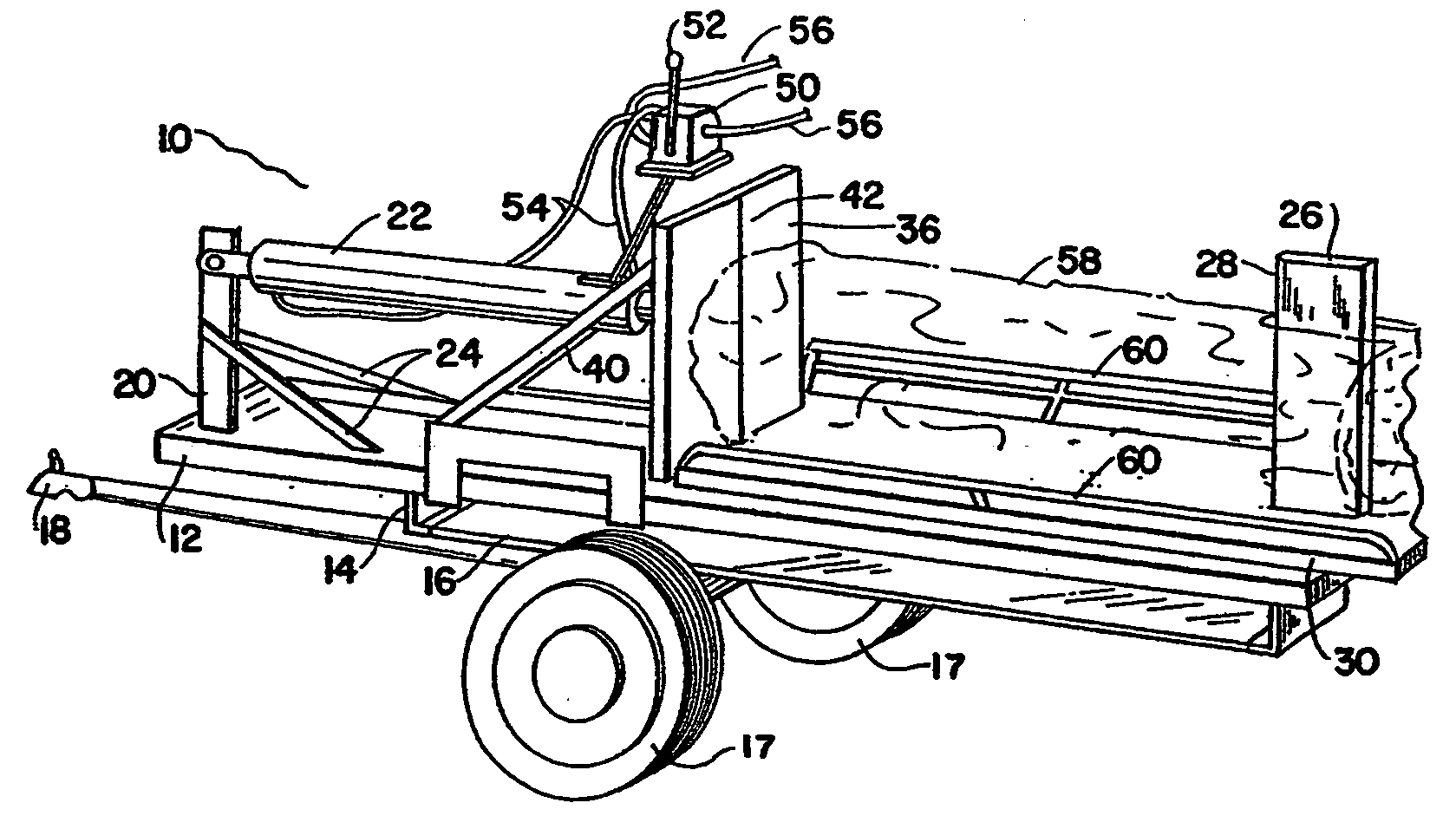

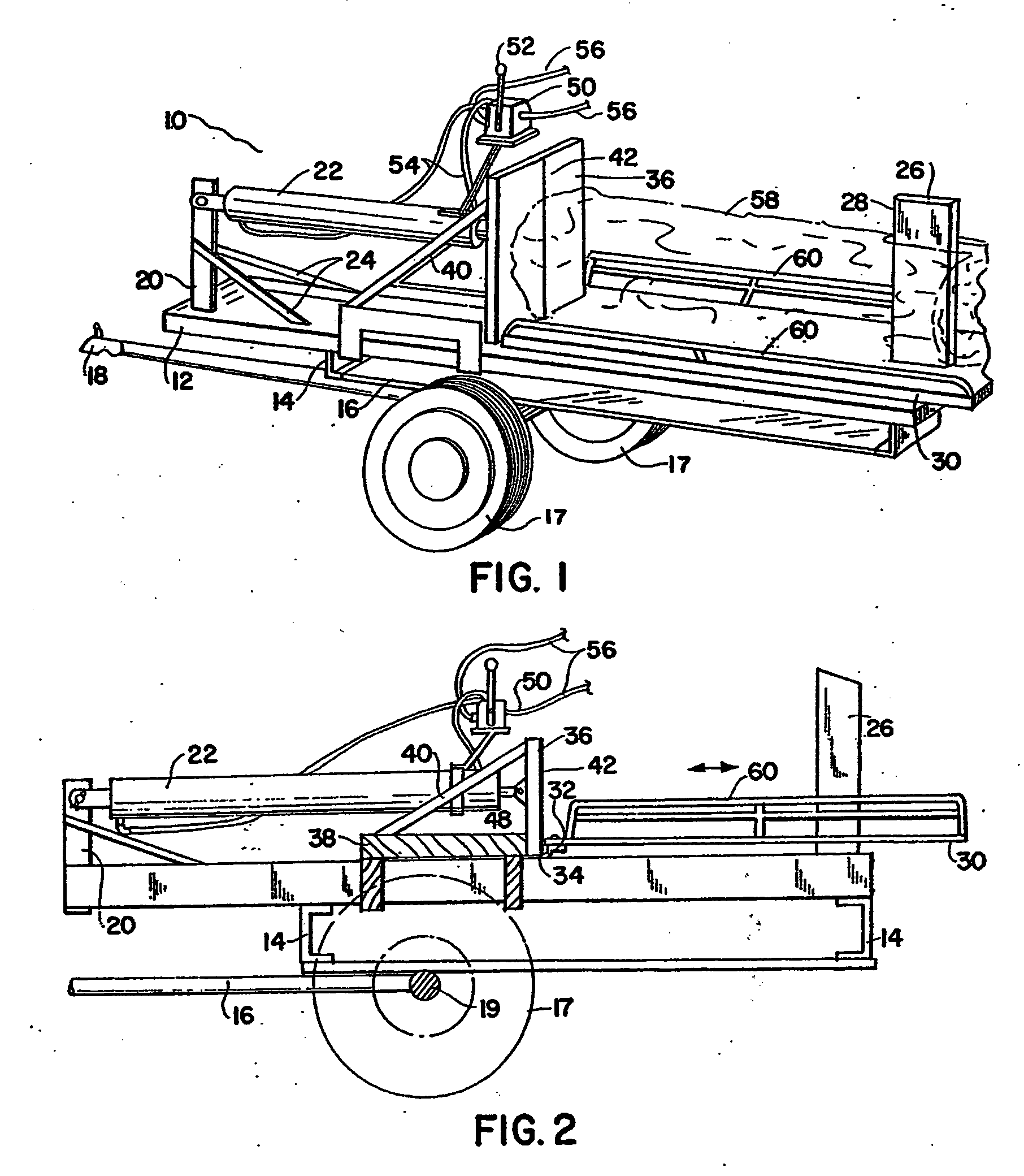

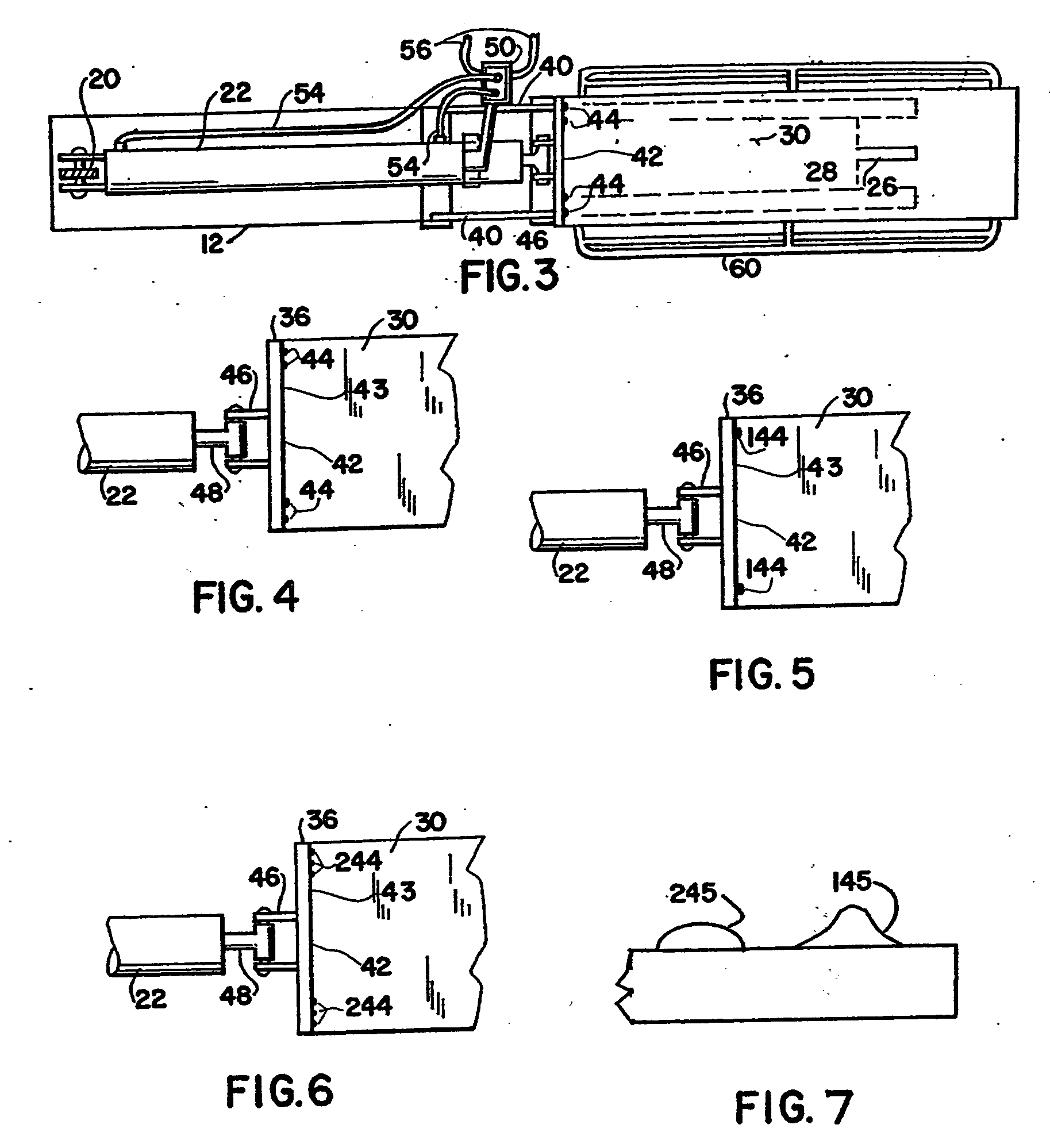

A log splitter which includes an elongated frame which defines a reservoir for hydraulic fluid. A log splitting wedge secured to one end of the frame and a hydraulic cylinder and ram / piston secured to the other end of the frame. The ram / piston being movable toward and away from the wedge. The reservoir includes an inlet and outlet and a discharge tube associated with the inlet having a length effective to discharge incoming fluid into the reservoir at a position remote from the inlet. The elongated tube may be associated with the reservoir outlet so as to draw fluid from the reservoir and thus maximize flow from the reservoir even if the reservoir, or log splitter is in a tipped position. A log splitter and arm for mounting the splitter to a vehicle having a hitch style receiver secured to the rear of the vehicle. The splitter has a substantially linear working action. The mounting system includes an elongated arm for securement to the receiver in a cantilever fashion. The splitter is adapted to be secured, by a pin or a set screw mechanism, to the arm and be supported above the ground. The splitter's linear working action is substantially normal to the vehicle's direction of movement and the support arm. This system permits the vehicle to travel at normal highway speeds and carry the splitter.

Owner:BRAVE PRODS

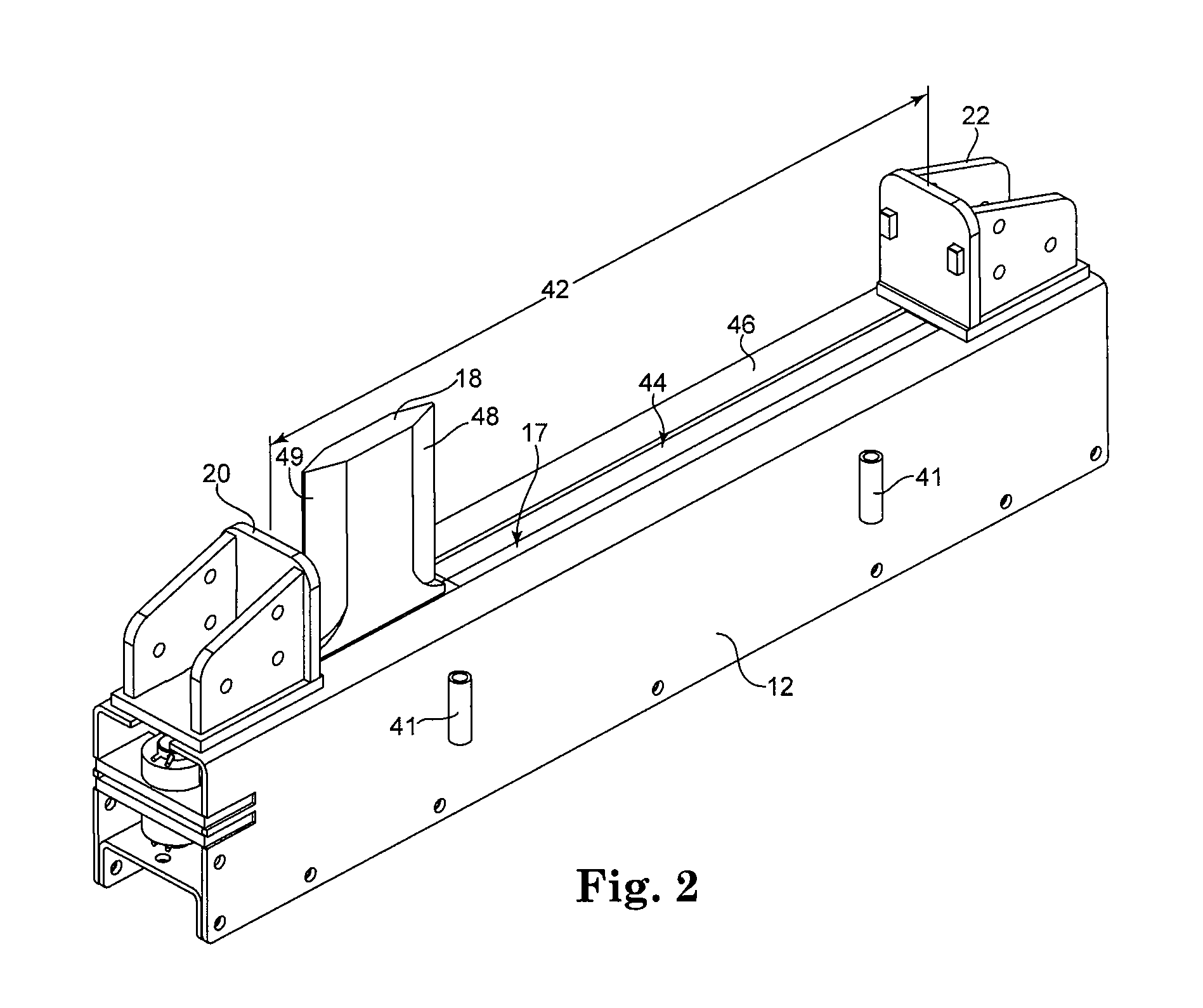

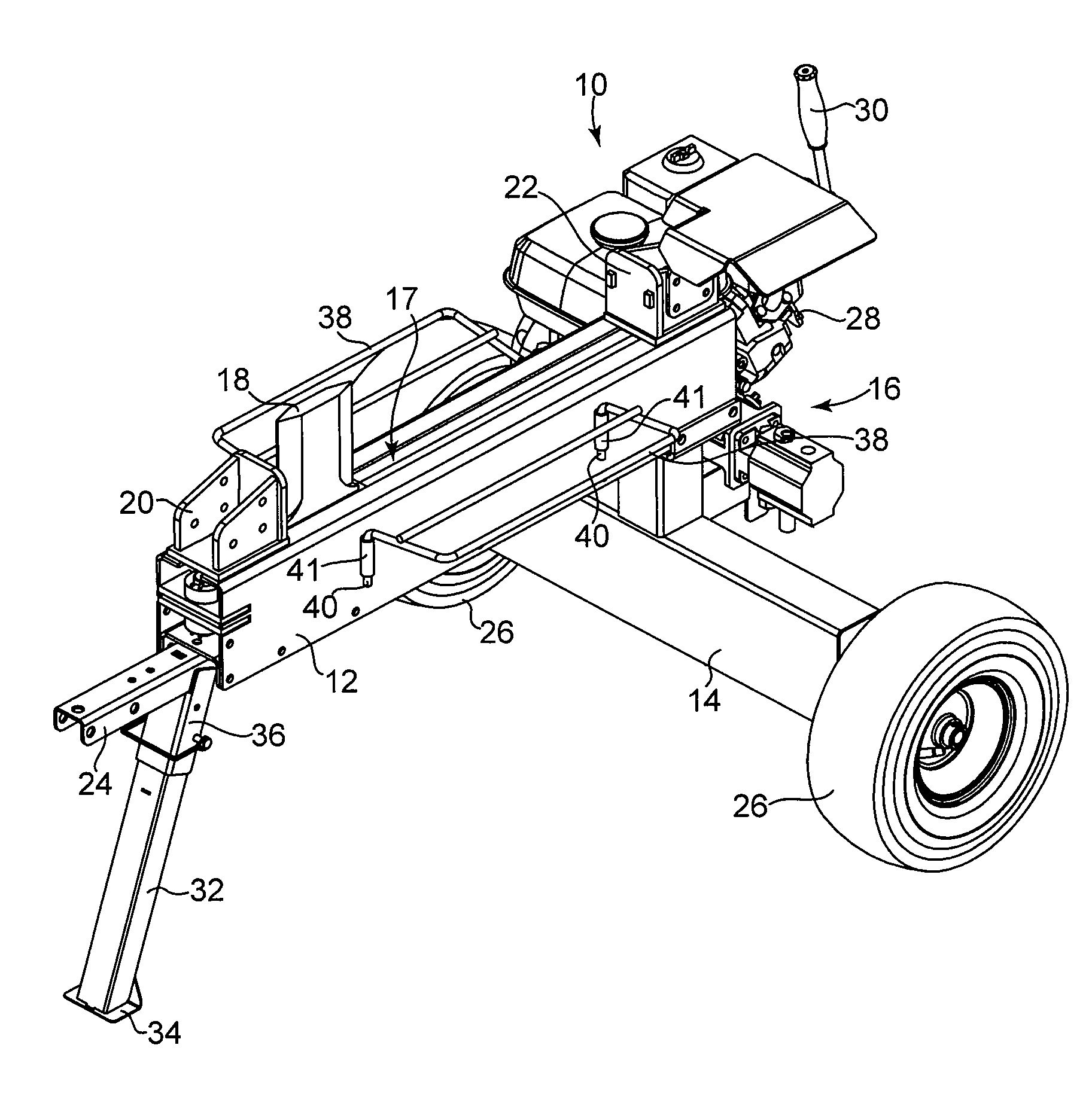

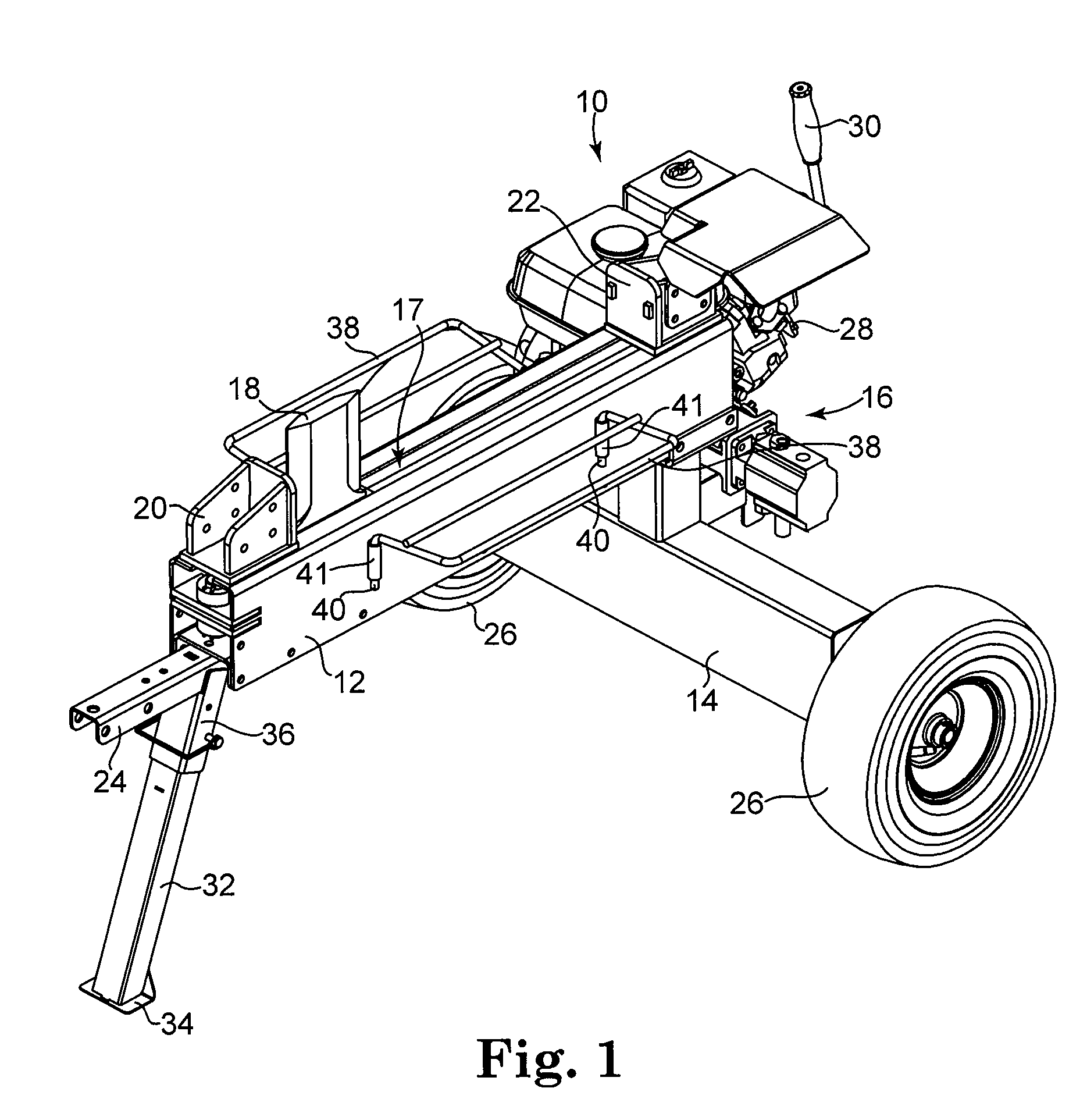

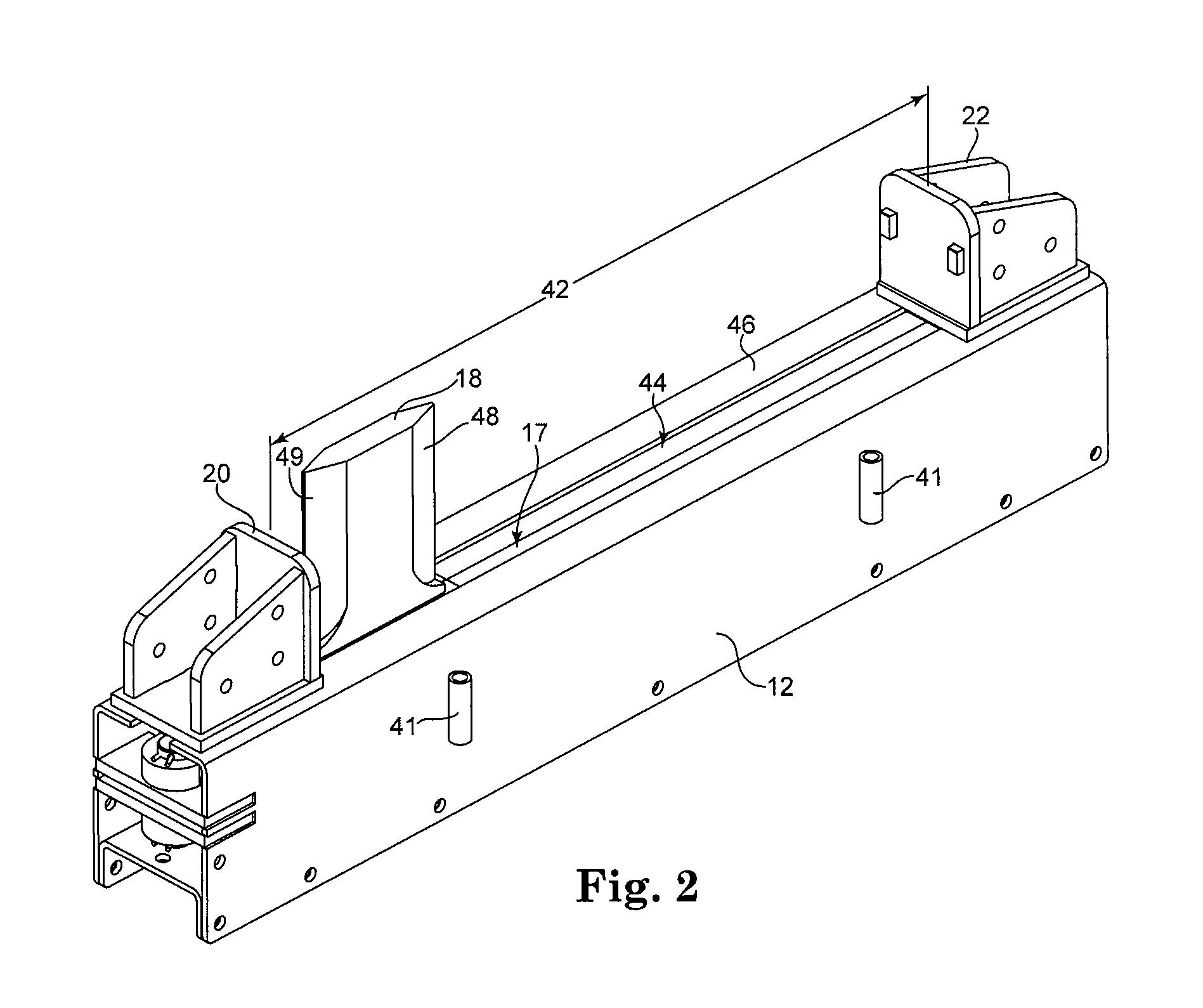

Compact log splitter

A log splitter comprises a support structure having a first end, a second end, and an open center portion defined therebetweeen, a splitting device slidably coupled to the support structure, and a drive mechanism for driving movement of the splitting device through a splitting zone. The splitting device comprises an elongate beam having an outer surface, a first end, a second end, and an open center portion between the first end and the second end, and a splitting wedge coupled to the outer surface of the elongate beam and having at least one splitting surface formed thereon. The elongate beam is disposed within the open center portion of the support structure. The drive mechanism is disposed within the open center portion of the elongate beam, and is coupled on a first end to the first end of the support structure and on a second end to the second end of the elongate beam.

Owner:NORTHERN TOOL & EQUIP

Block hoist

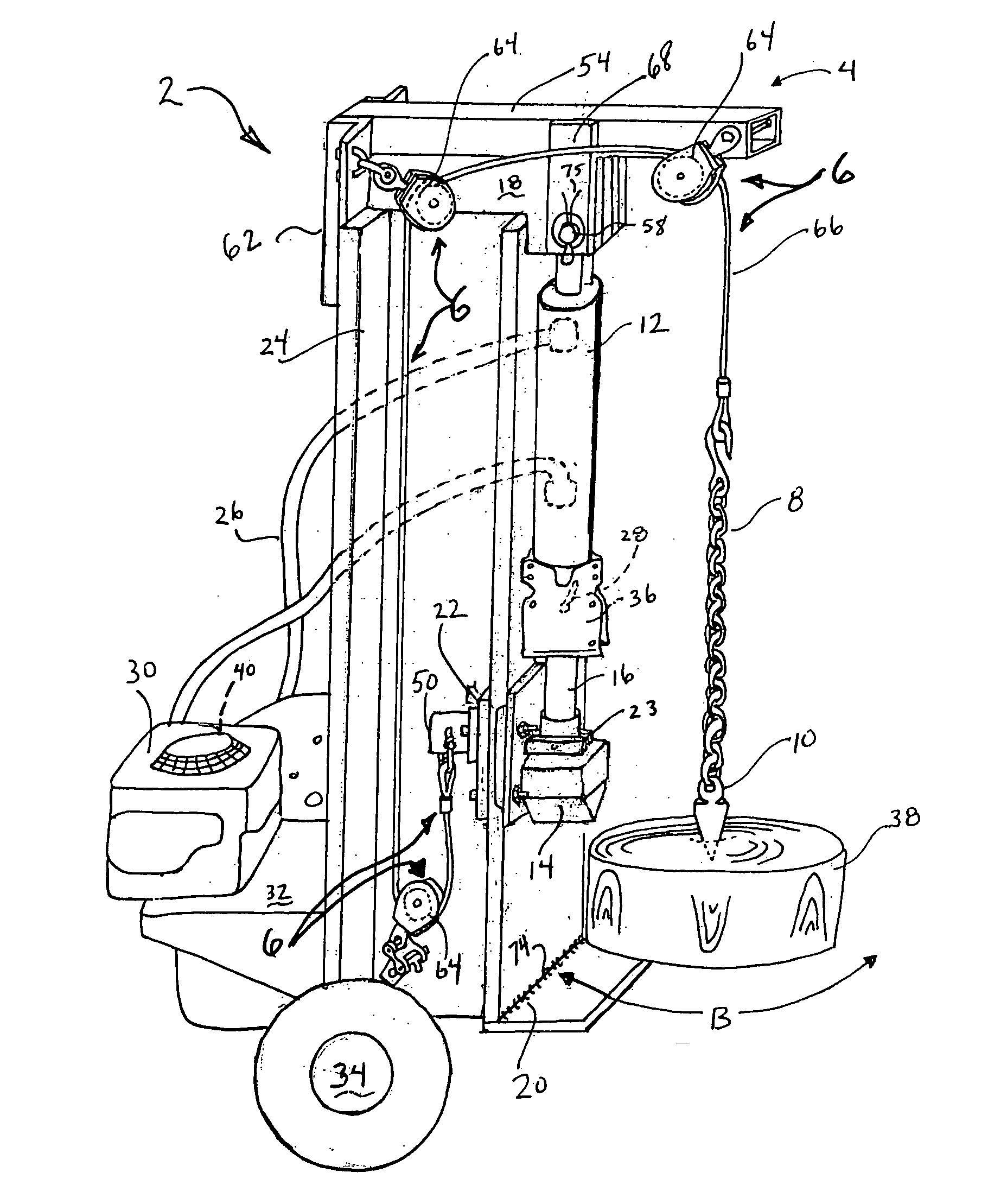

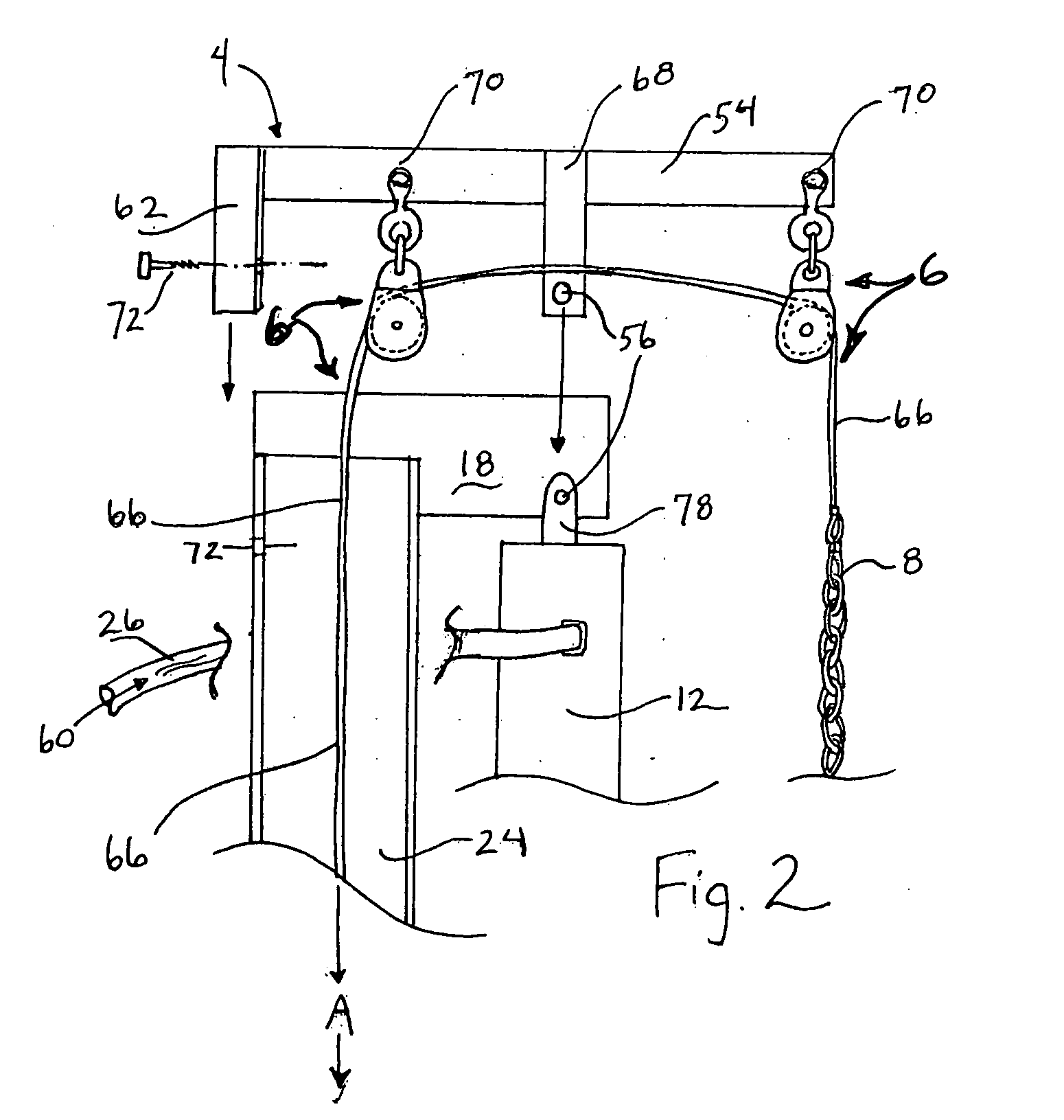

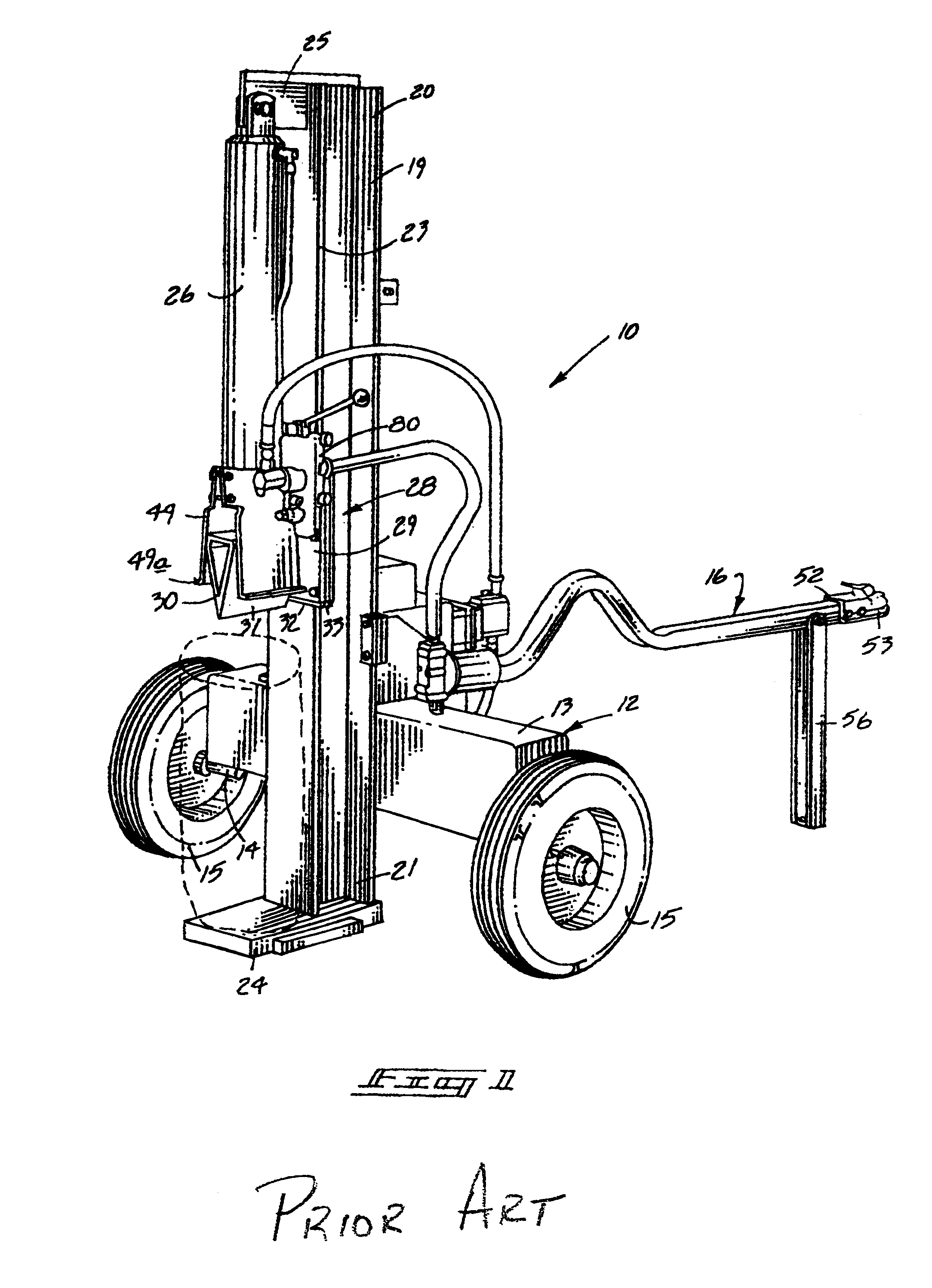

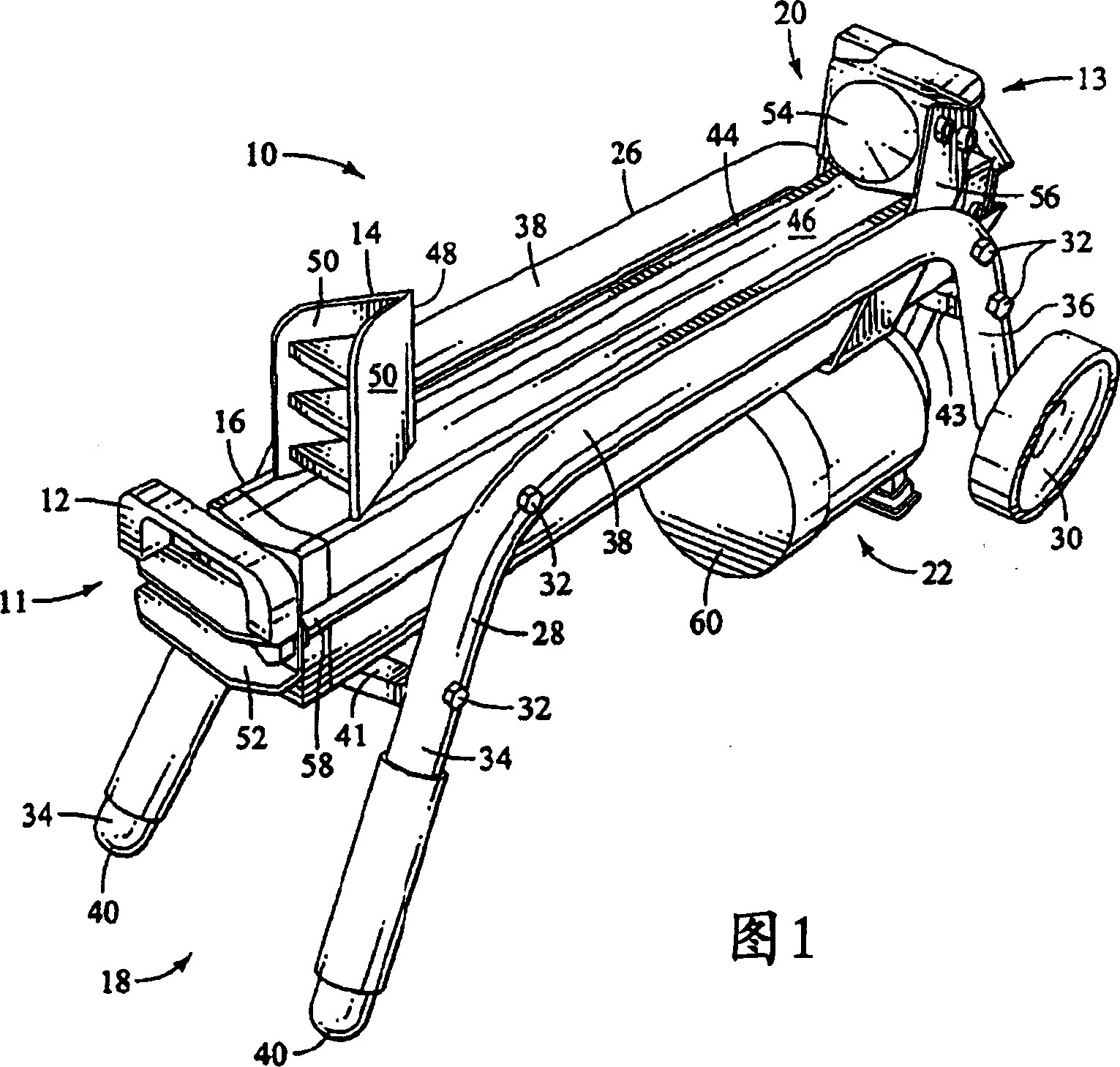

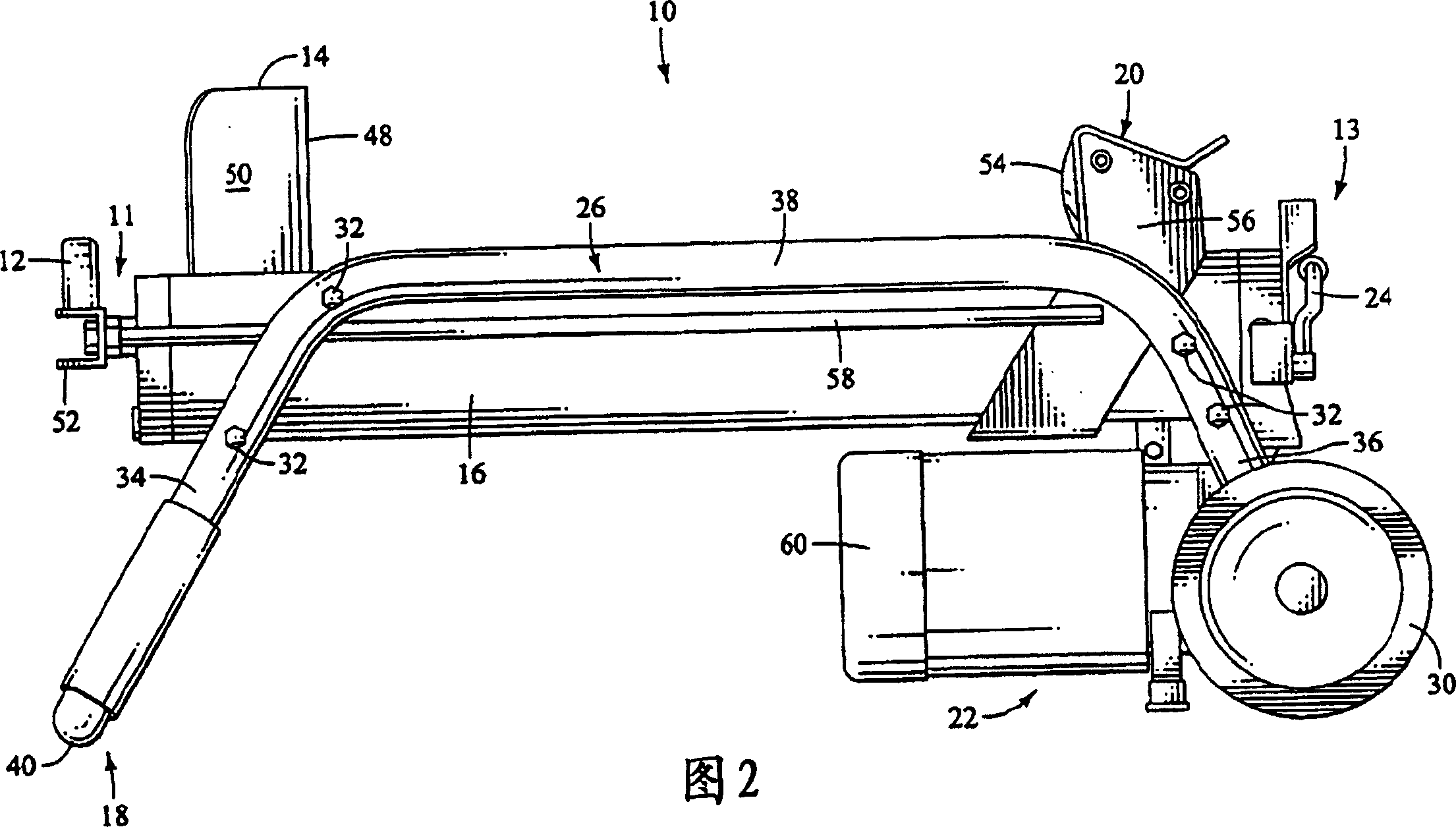

InactiveUS20050133114A1Assist in liftingAssist in maneuveringWood splittingMulti-purpose machinesEngineeringLog splitter

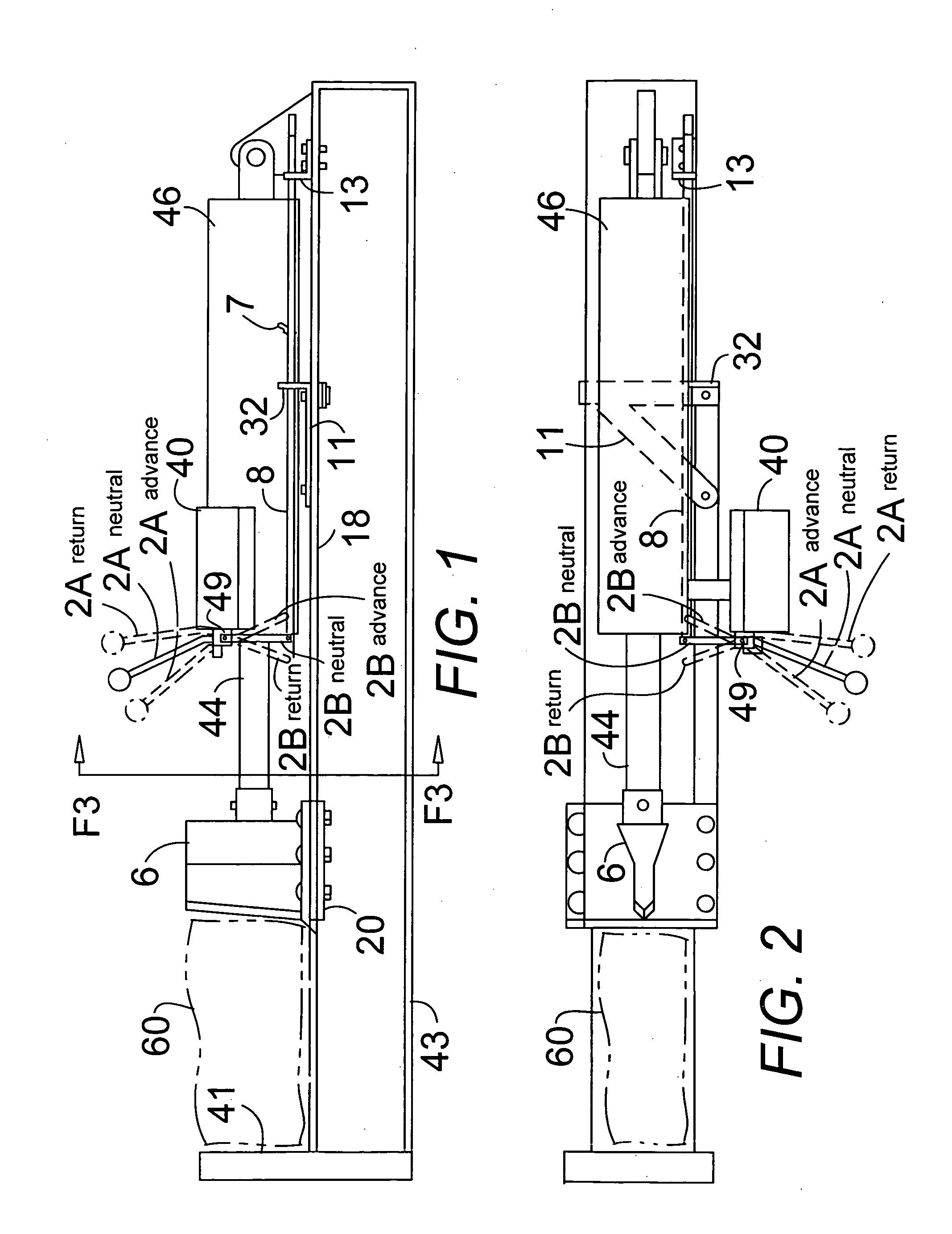

A new or retrofit block hoist for conventional, hydraulic-powered log splitters assists in the lifting, maneuvering, and positioning of large diameter, heavy logs that require multiple radial splits to section them for firewood, comprising a boom, pulley and cable system. A boom assembly is secured to the top end of the splitter guide beam and pulleys guide a lifting cable anchored to the wedge slide to a log section retainer means (dog or awl). The upward, hydraulically-powered movement of the cutting wedge along the I-beam lifts the log section as the wedge is raised into its upward, retracted position. Once lifted, the log is swung into position between the wedge and splitter foot plate. The wedge is then power extended (lowered), splitting the log. An optional turntable is securable to the footplate. The inventive block hoist can be provided as a kit.

Owner:PETERSON BYRON

Log splitter

A self-contained, or externally actuated, hydraulic log splitter which includes a frame on which is slidably mounted an assembly of a specially designed push plate secured at one end to a reversible hydraulic cylinder and at the other to a splitting table carrying logs which is pushed against a straight blade to split the logs. A plurality of lines of discrete nubs are integrally a part of the push plate along a majority of its entire height and positioned substantially parallel to the straight blade and spaced away from the edge of the push plate. These nubs to provide specialized and improved gripping of log segments as they are split thereby minimizing the tendency of the split log segments to fly away from the splitter. An electric or gas engine driving an hydraulic pump or the hydraulic system of a tractor is connected to drive the reversible hydraulic cylinder.

Owner:PARADISE ANTHONY

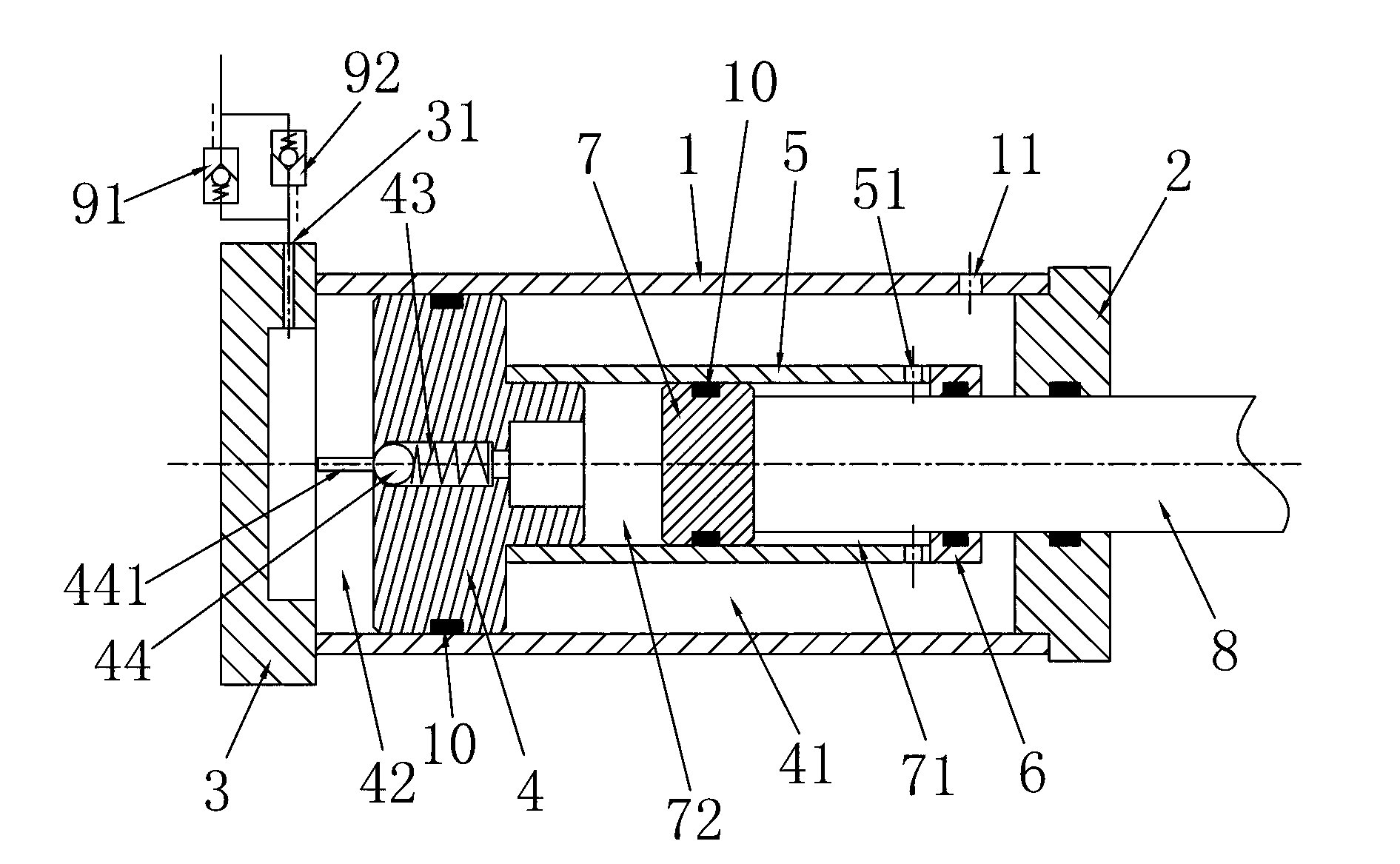

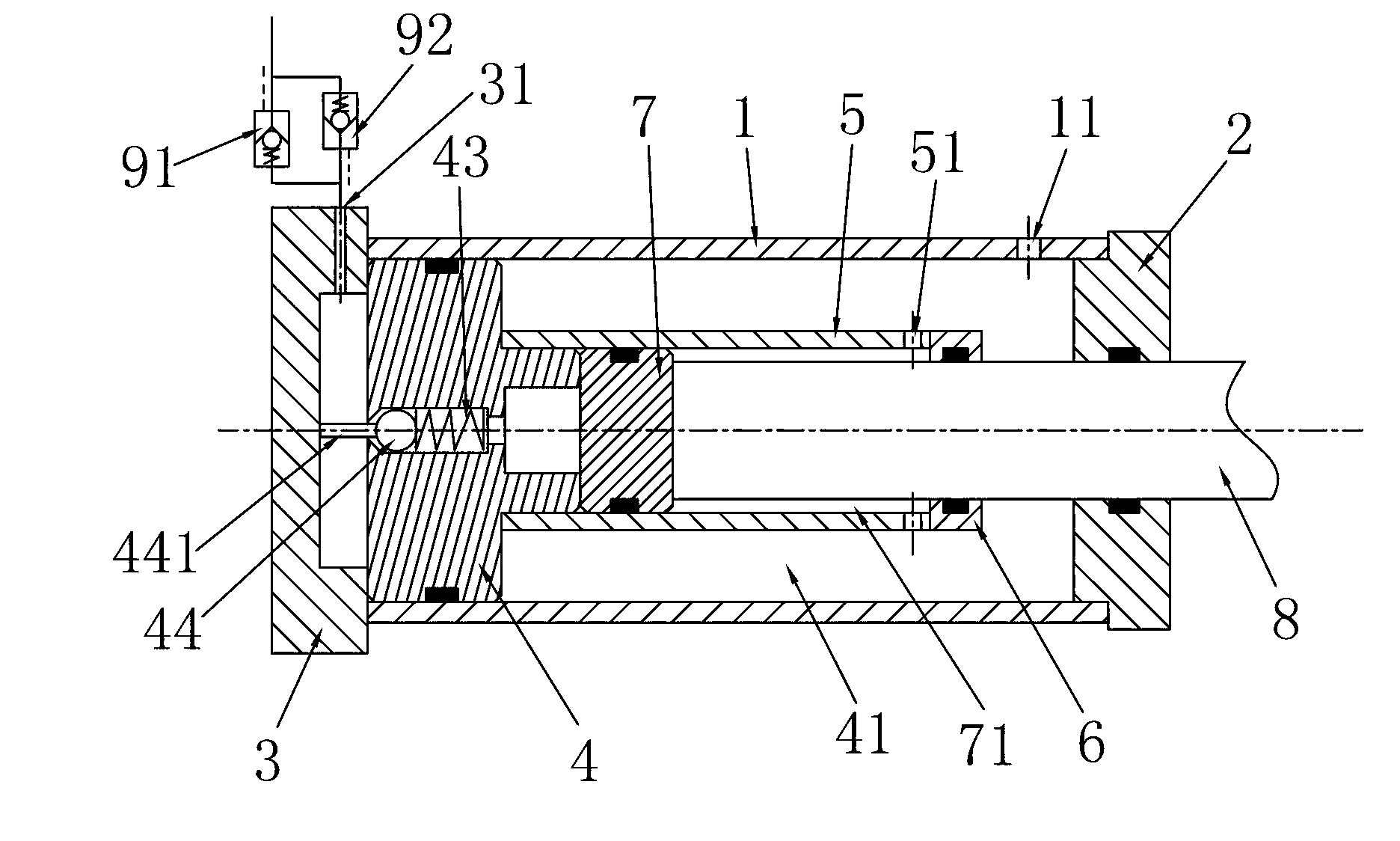

Rapid hydraulic oil cylinder

ActiveCN102937124AImprove work efficiencyShorten the timeFluid-pressure actuatorsHydraulic cylinderEngineering

The invention relates to a hydraulic oil cylinder, and particularly relates to a hydraulic oil cylinder provided with an inner cylinder body and an outer cylinder body and used for a log splitter. The invention aims to provide the rapid hydraulic oil cylinder with relatively high working efficiency and energy conservation. According to the improvement relatively to a common oil cylinder, the inner cylinder body (5) is fixedly arranged on a first piston (4); a second oil opening (51) is formed in the inner cylinder body; the inner cylinder body is further connected with an inner cylinder end cover (6); a second piston (7) is in sealing and sliding connection inside the first piston; a piston rod (8) passes through inner cylinder end cover and a front end cover (2), and is connected with the inner cylinder end cover and the front end cover (2) in a sealing and sliding manner; a one-way valve is arranged inside the first piston; an ejecting rod for ejecting the one-way valve when the first piston is located at the rearmost end inside the cylinder body is arranged between a one-way valve core (44) and a rear end cover (3); and a third oil opening (31) is formed in the rear end cover. The rapid hydraulic oil cylinder further comprises a first liquid control one-way valve (91) and a second liquid control one-way valve (92) which are mutually and inversely connected in parallel; and the positive conduction pressure difference of the first liquid control one-way valve and the one-way valve is large.

Owner:王广生

Log splitter

Owner:PARADISE ANTHONY

Cycle shortener for log splitters

InactiveUS20060060262A1Shorten the timeDifferent lengthWood splittingMulti-purpose machinesLog splitterLimiter

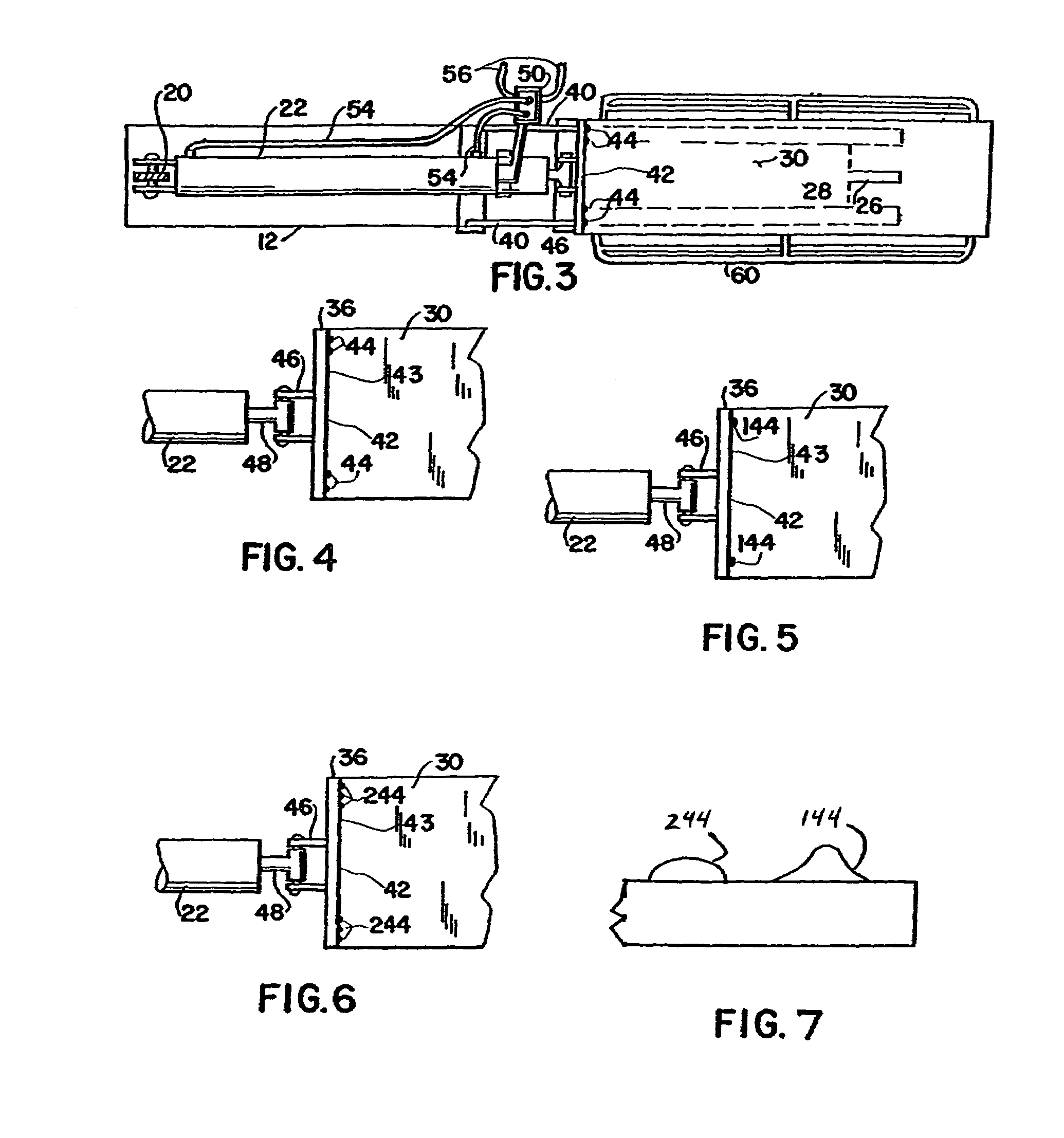

A length limiter rod is attached to an extended inward end of a control valve lever of a log splitter to allow it to stop at any point desired on a return cycle. A hitch pin on the rod contacting a shutoff guide attached to a slide wedge forces the rod rearward pulling the control valve lever to a neutral position stopping the return of the slide wedge to shorten the return length and thereby shorten the cycle time in splitting logs.

Owner:HICKS NORMAN A

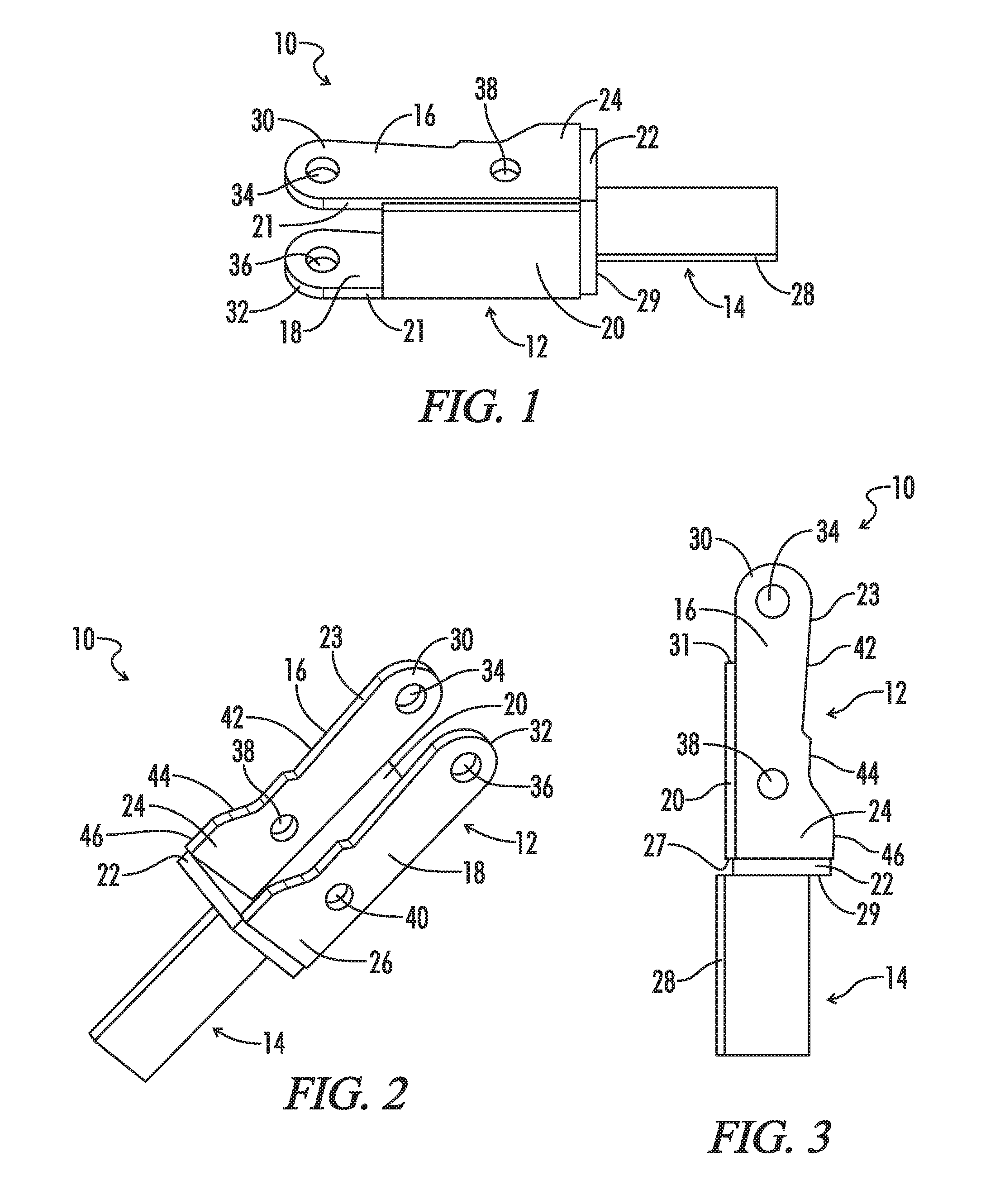

Lift adapter for log splitter

In combination with a portable log splitter having a wheel mounted support frame, a splitter frame mounted on the support frame, a power driven means disposed on the splitter frame for splitting wood, a towing bar engageable with the wheel mounted support frame and a brace disposed on the towing bar, an apparatus is provided for converting the portable log splitter into a hoisting mechanism. The apparatus for converting the log splitter includes a base member removeably attachable to the splitter frame adjacent the bottom thereof for preventing the portable log splitter from tipping over during lifting and a lift adapter that is slidingly engageable with the splitter frame and removeably attachable to the power driven means for engaging a predetermined object to be lifted.

Owner:LOUGHNER ROBERT J

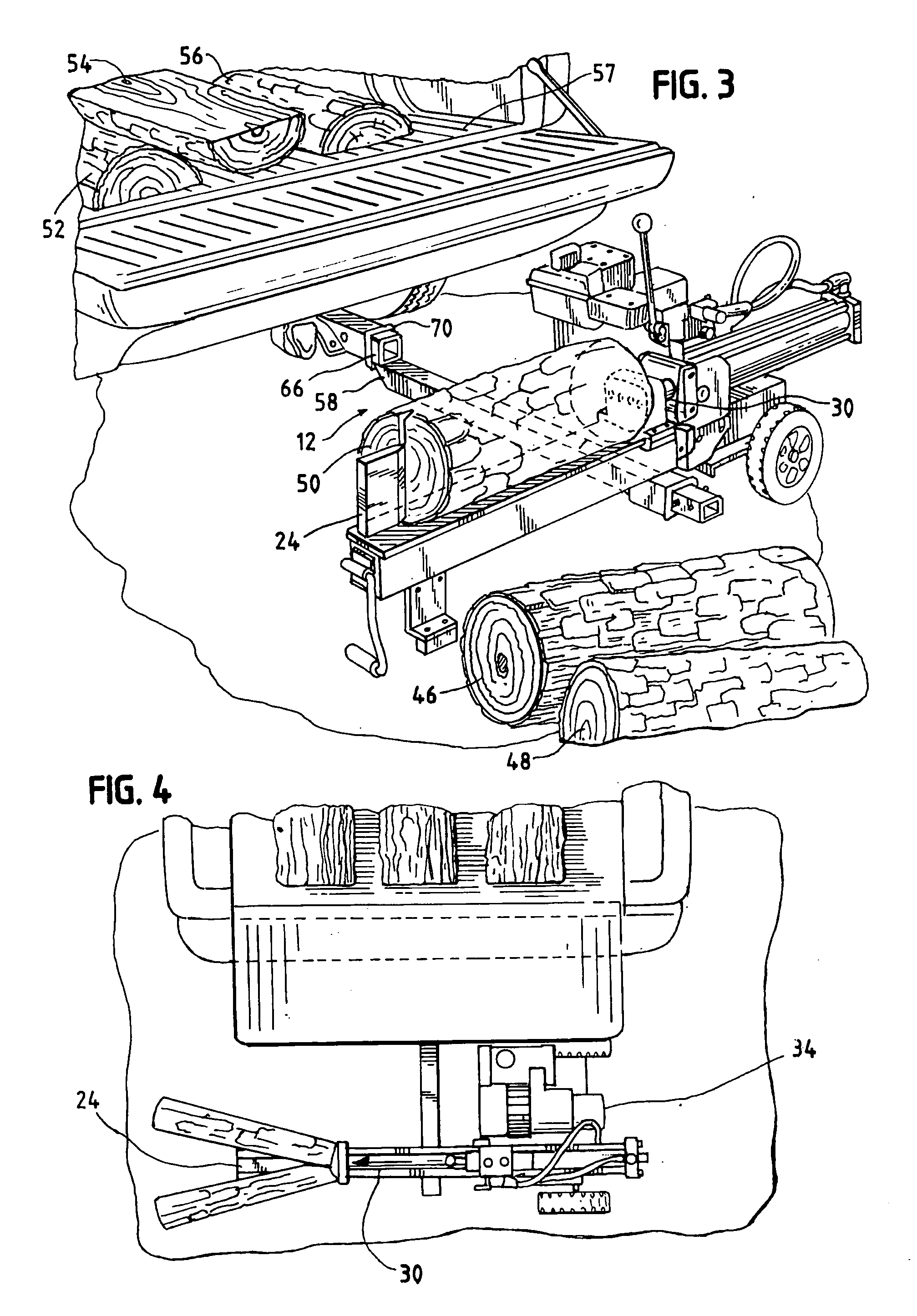

Log splitting apparatus

InactiveUS7066223B2Effective segmentationEasy to useWood splittingMulti-purpose machinesLog splitterPiston

Owner:STONE MARK O

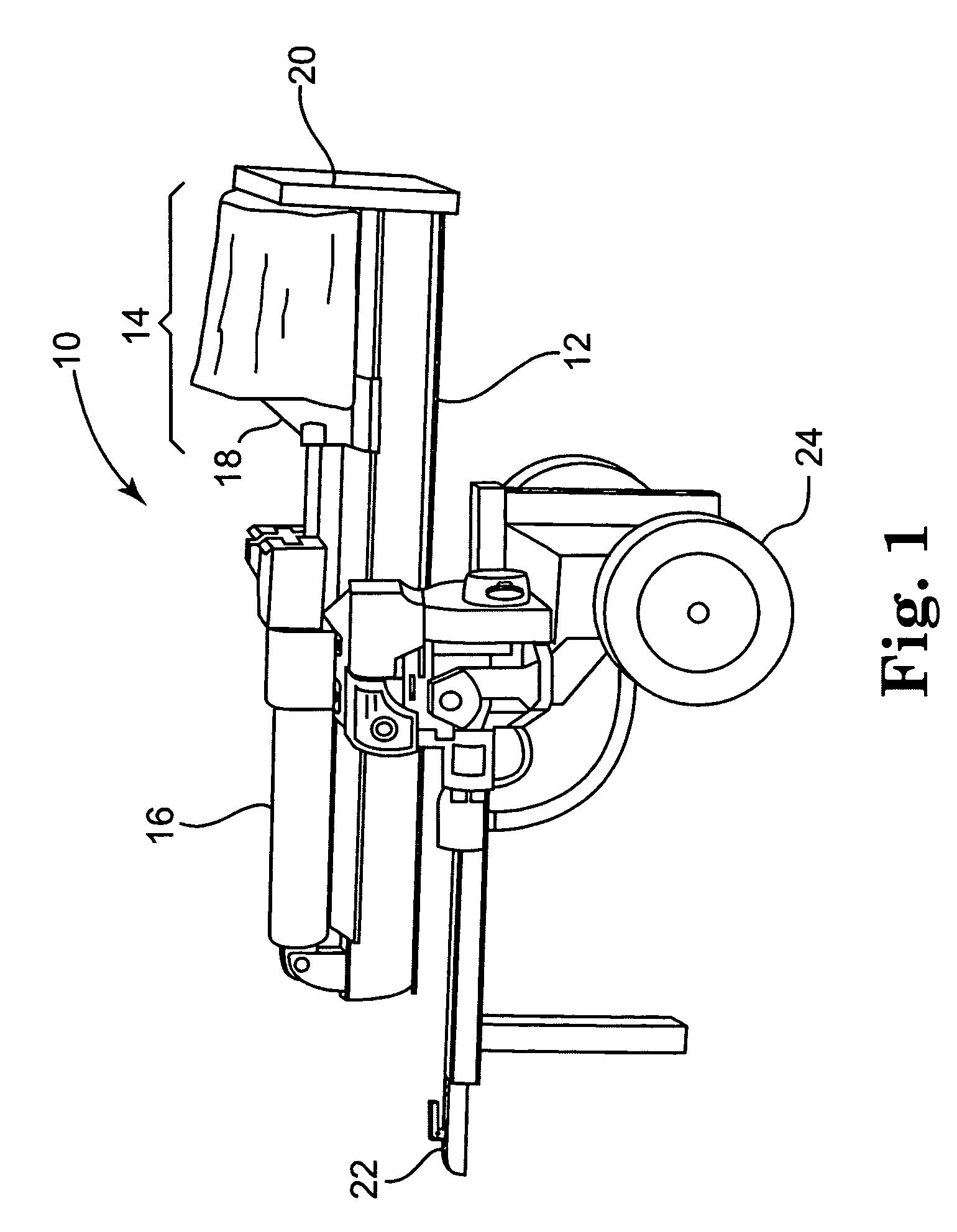

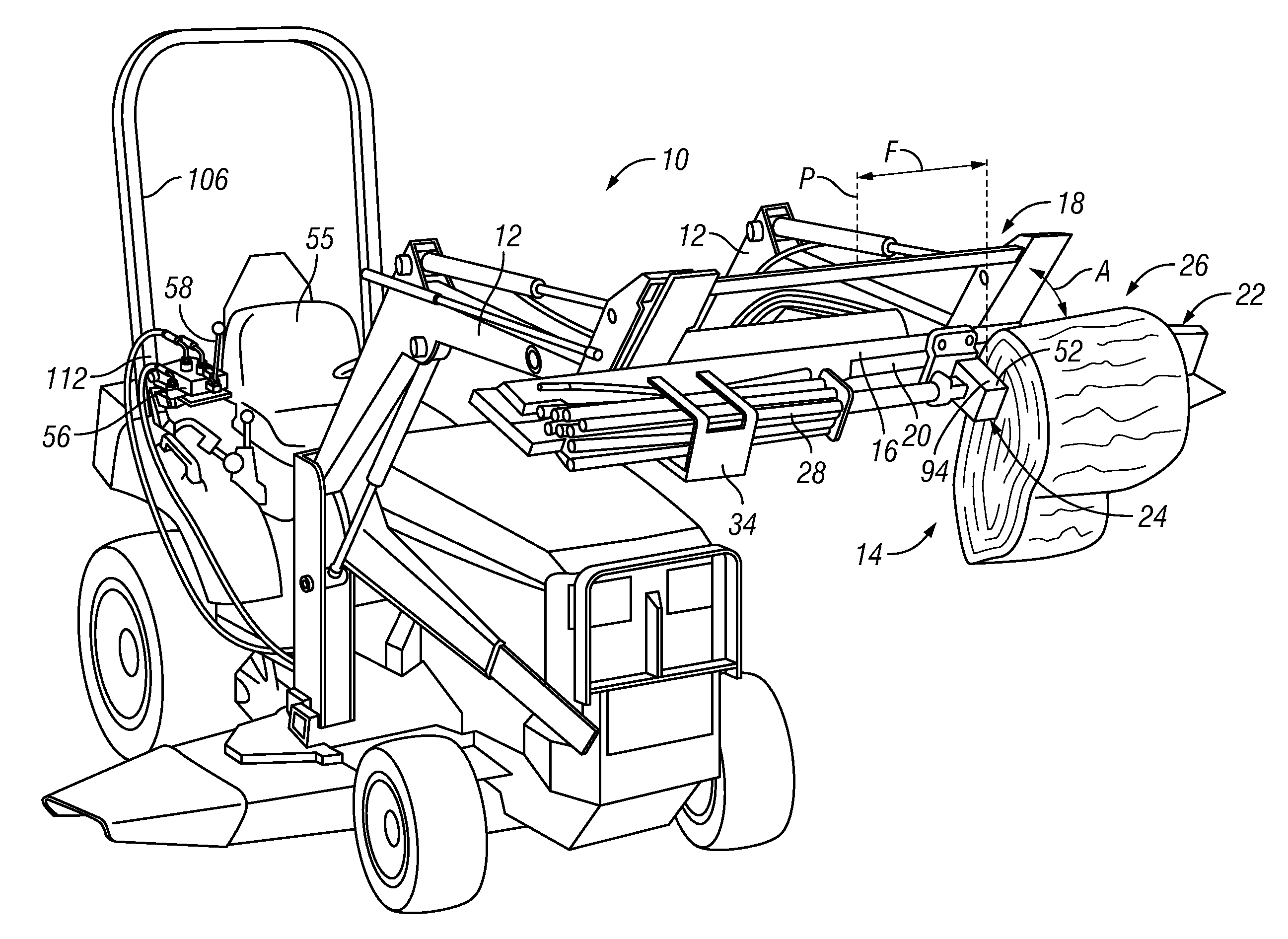

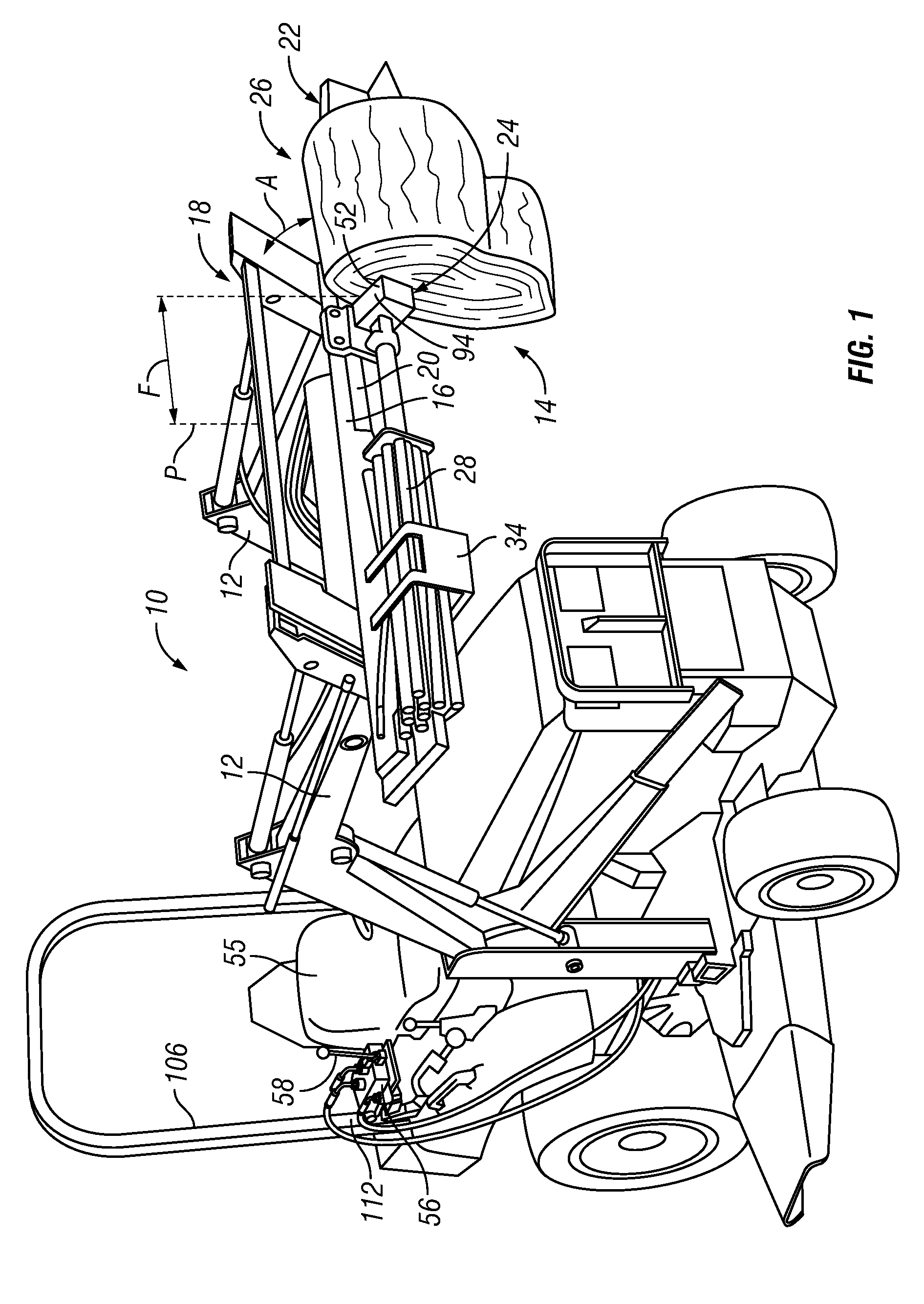

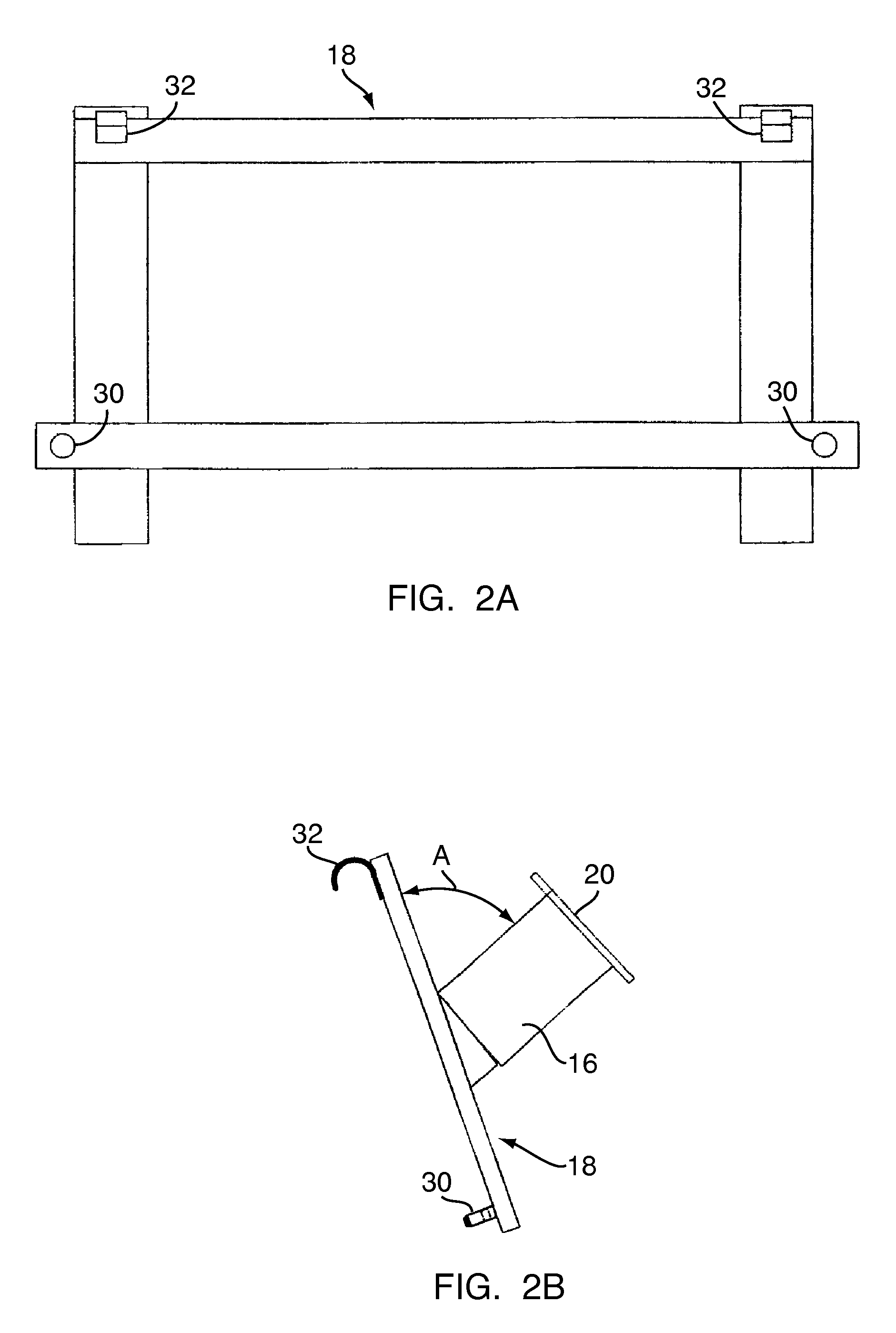

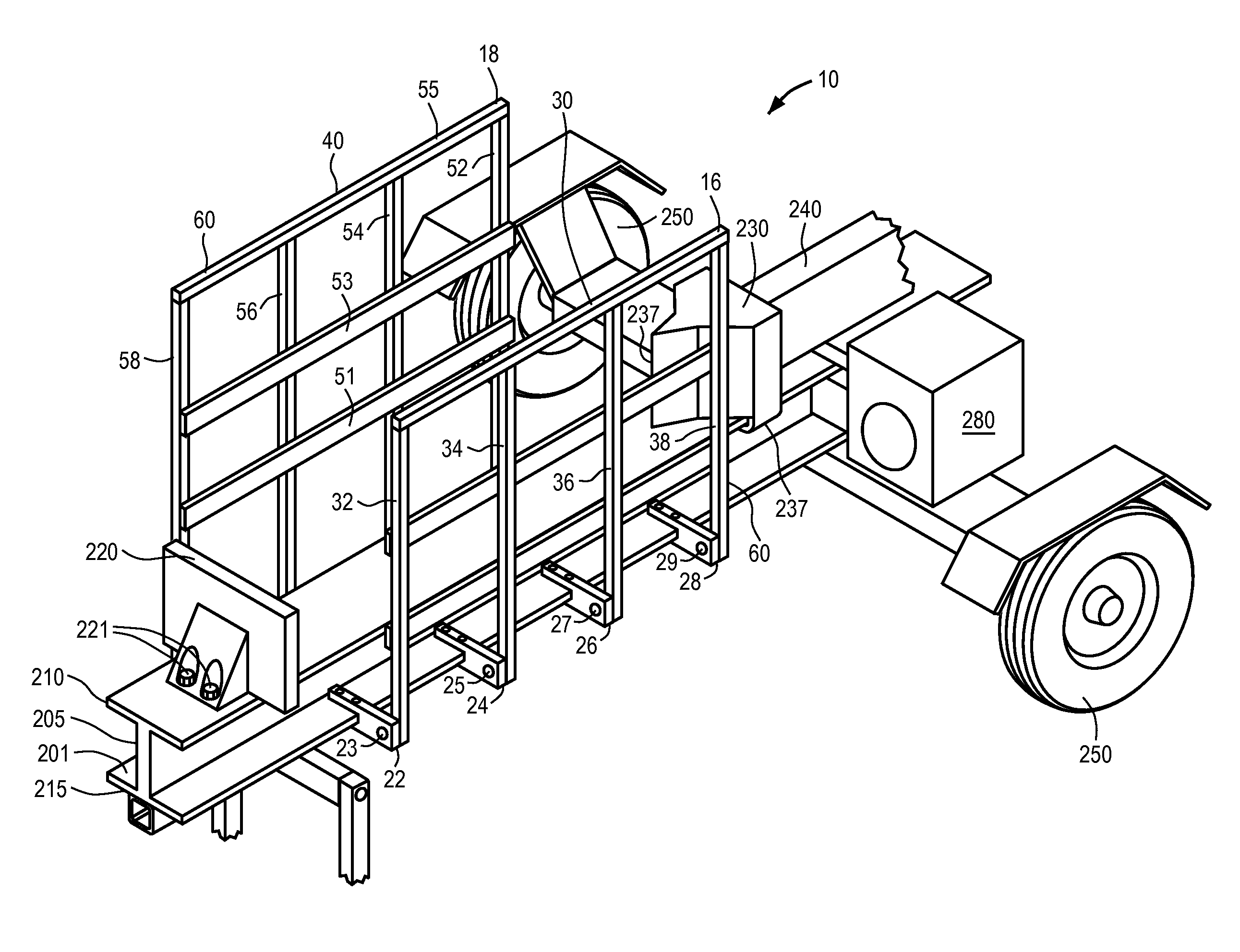

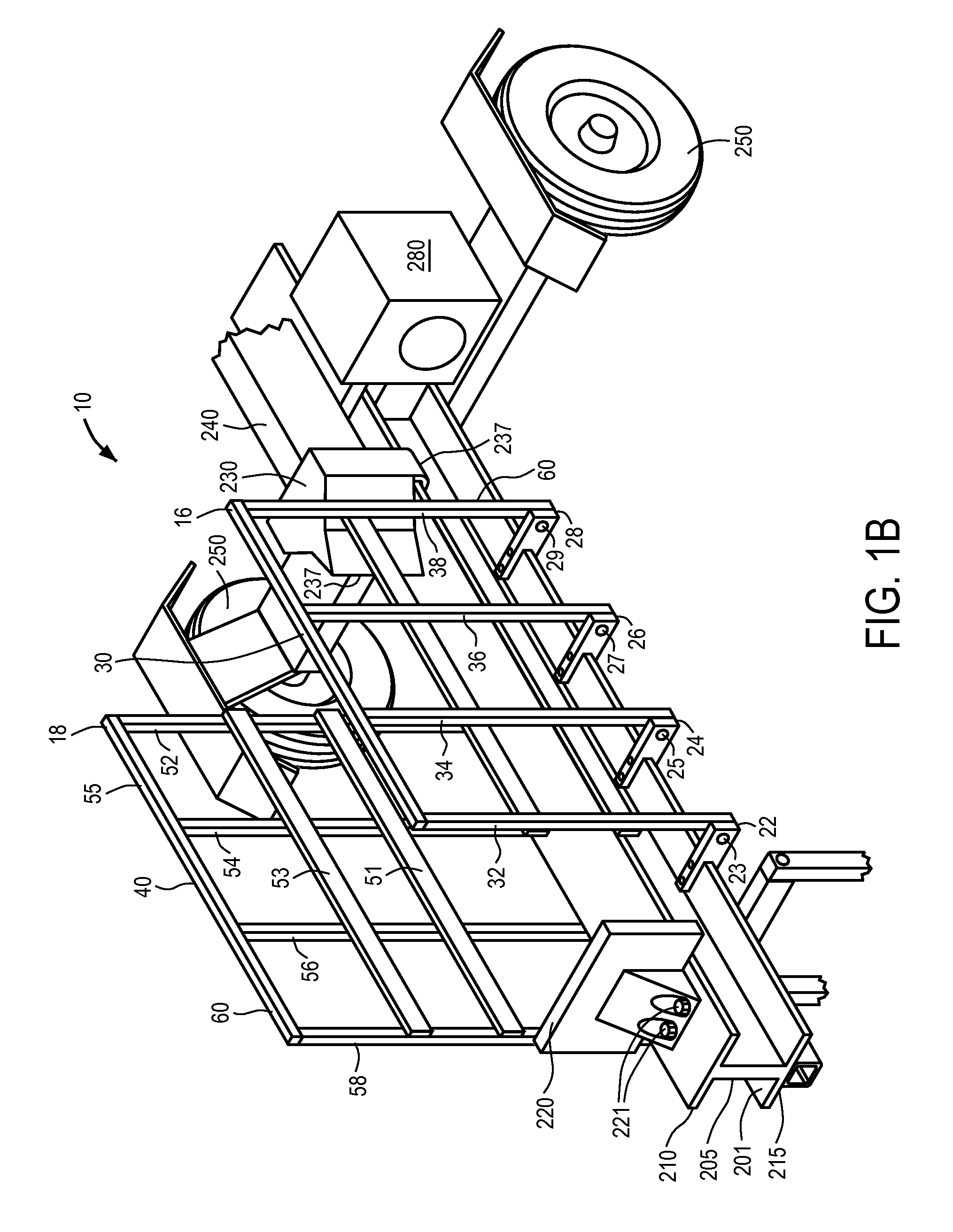

Log splitter system for a front-loader tractor

InactiveUS20080271817A1Minimize damageWide rangeAuxillary drivesAgricultural machinesFuel tankEngineering

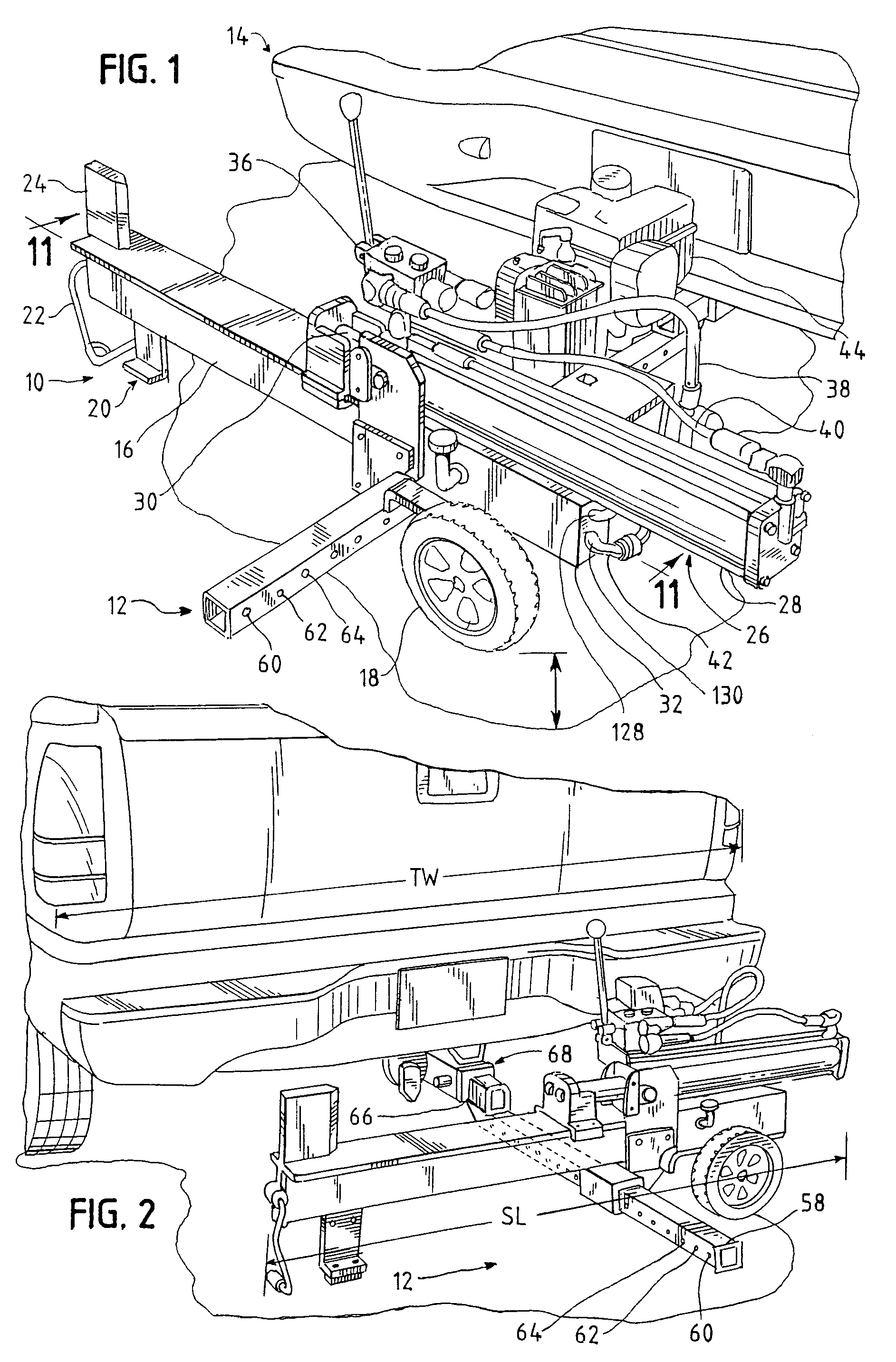

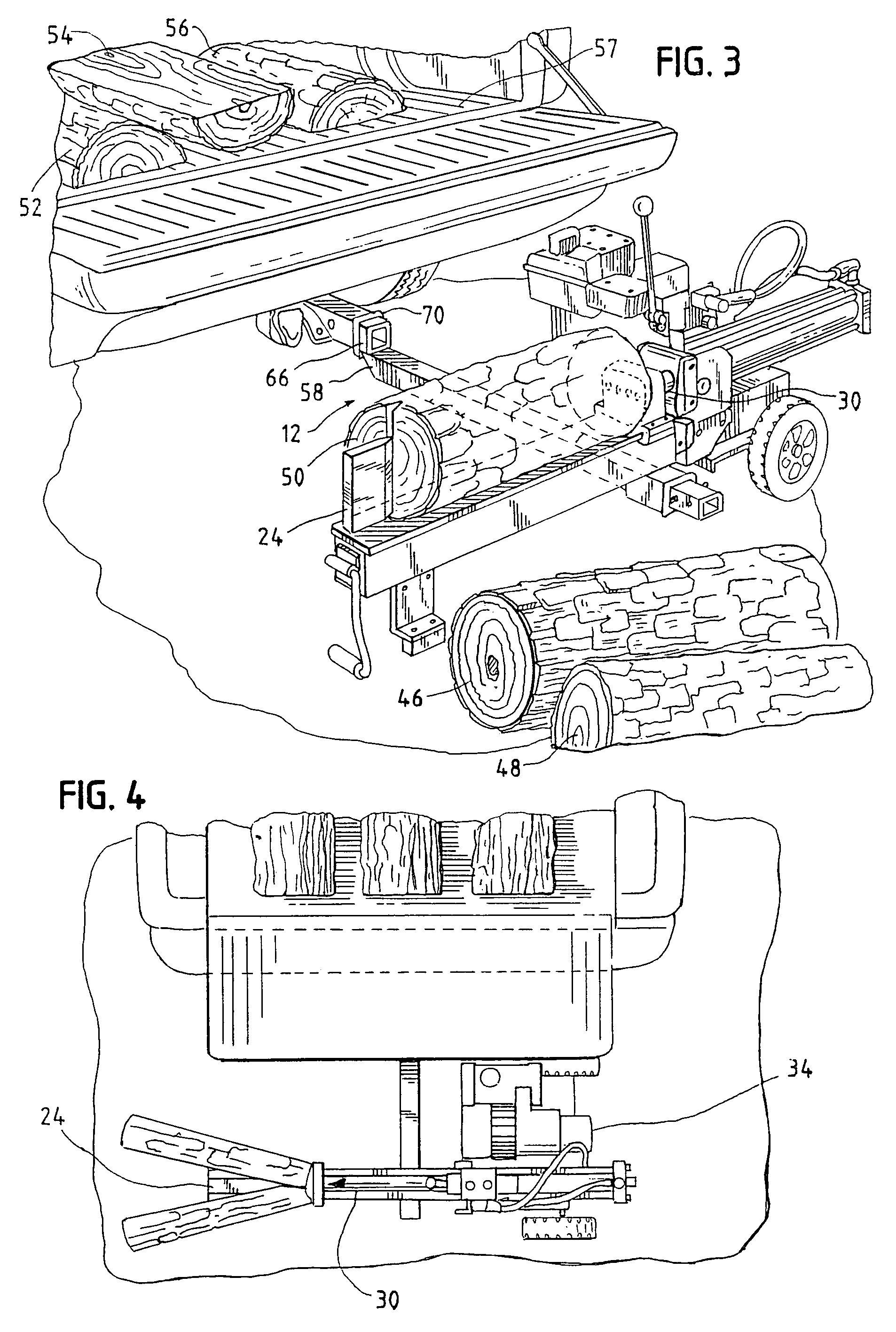

A tractor has a log splitter installed on two loader arms pivoted at a front end of the tractor. The log splitter includes a frame for attachment to the loader arms. The frame includes a surface, to which a ram and a wedge are coupled. An actuator mounted to the frame moves the ram and / or the wedge to split a log received between the ram and the wedge. The wedge includes a main blade and a cross blade perpendicular to the main blade. An edge of the cross blade is offset from an edge of the main blade so as to reduce the force required to achieve a four-way split of the log. The wedge and the frame are designed to enable inverting the log splitter to grasp a log, then raising the inverted log splitter to split the log directly into a truck bed. The uniquely designed hydraulic tank—ballast box combination provides an owner an external high volume hydraulic system without impeding the capability of the tractor hydraulic system. The tank and ballast box hitch assembly can also integrate the pump mounted to the hitch frame allows one to remove all components together.

Owner:PRIEBE DEAN R

Log splitter system for a front-loader tractor

InactiveUS7934524B2Minimize damageImprove efficiencyAuxillary drivesAgricultural machinesFuel tankEngineering

A tractor has a log splitter installed on two loader arms pivoted at a front end of the tractor. The log splitter includes a frame for attachment to the loader arms. The frame includes a surface, to which a ram and a wedge are coupled. An actuator mounted to the frame moves the ram and / or the wedge to split a log received between the ram and the wedge. The wedge includes a main blade and a cross blade perpendicular to the main blade. An edge of the cross blade is offset from an edge of the main blade so as to reduce the force required to achieve a four-way split of the log. The wedge and the frame are designed to enable inverting the log splitter to grasp a log, then raising the inverted log splitter to split the log directly into a truck bed. The uniquely designed hydraulic tank-ballast box combination provides an owner an external high volume hydraulic system without impeding the capability of the tractor hydraulic system. The tank and ballast box hitch assembly can also integrate the pump mounted to the hitch frame allows one to remove all components together.

Owner:PRIEBE DEAN R

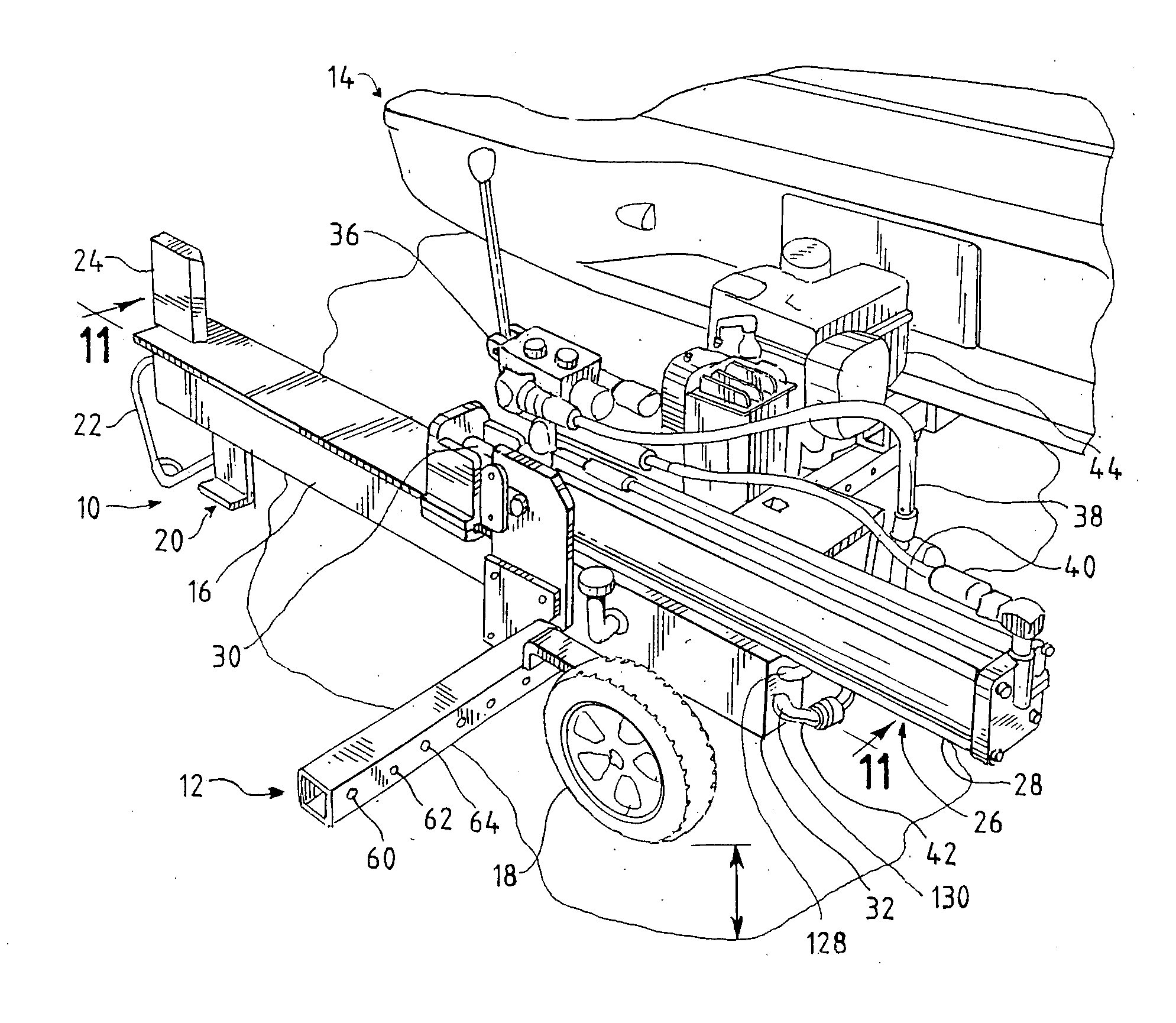

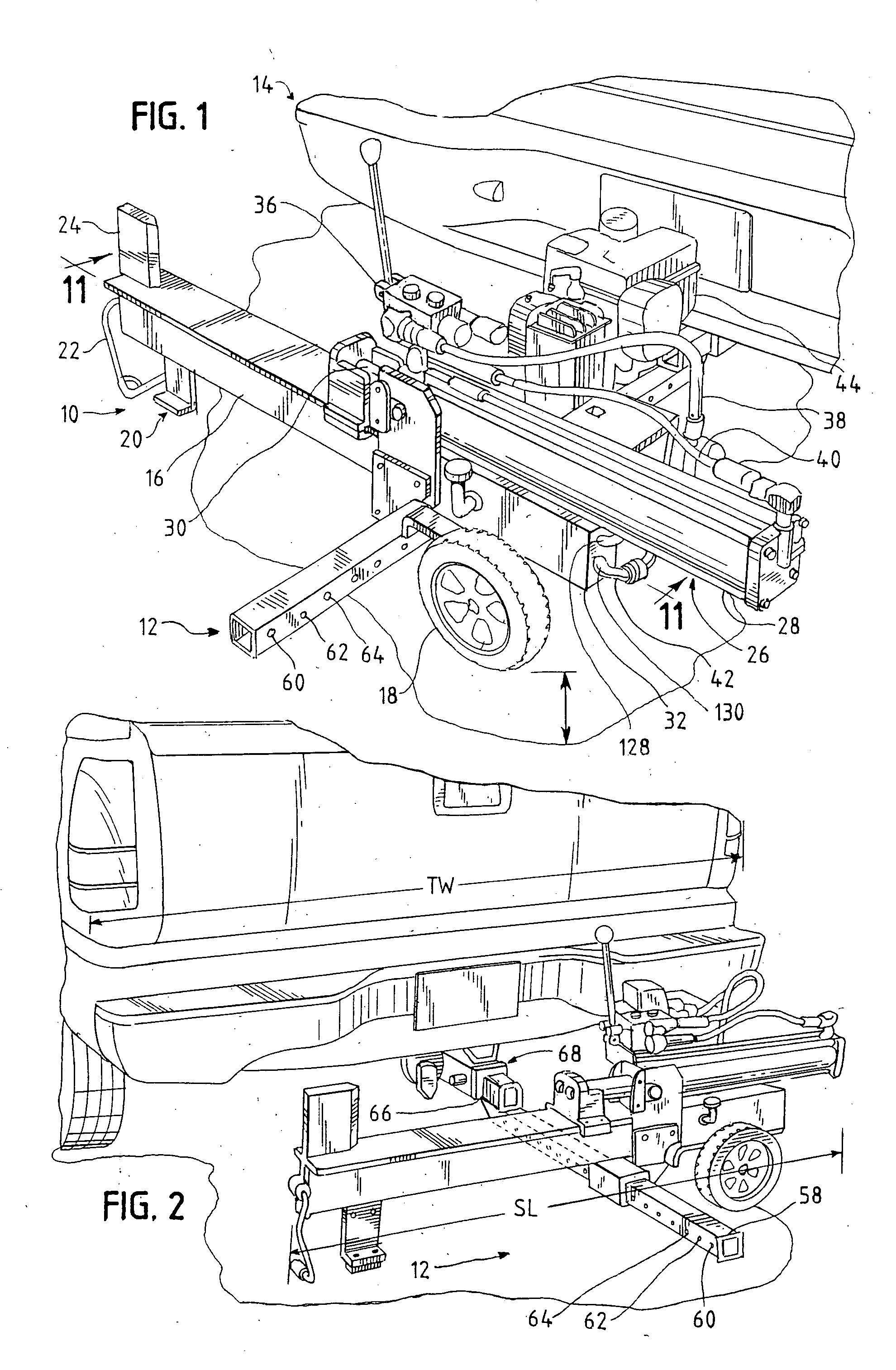

Log splitter

InactiveUS20050284540A1Maximize mixingMinimizes direct flow of fluidWood splittingMulti-purpose machinesHydraulic cylinderLog splitter

A log splitter which includes an elongated frame which defines a reservoir for hydraulic fluid. A log splitting wedge secured to one end of the frame and a hydraulic cylinder and ram / piston secured to the other end of the frame. The ram / piston being movable toward and away from the wedge. The reservoir includes an inlet and outlet and a discharge tube associated with the inlet having a length effective to discharge incoming fluid into the reservoir at a position remote from the inlet. A log splitter and arm for mounting the splitter to a vehicle having a hitch style receiver secured to the rear of the vehicle. The splitter has a substantially linear working action. The mounting system includes an elongated arm for securement to the receiver in a cantilever fashion. The splitter is adapted to be secured to the arm and be supported above the ground. The splitter's linear working action is substantially normal to the vehicle's direction of movement and the support arm. This system permits the vehicle to travel at normal highway speeds and carry the splitter.

Owner:BRAVE PRODS

Log splitter

InactiveUS7134464B2Maximize mixingMinimizes direct flow of fluidWood splittingMulti-purpose machinesHydraulic cylinderEngineering

A log splitter which includes an elongated frame having a reservoir for hydraulic fluid a wedge secured to one end of the frame and a hydraulic cylinder and ram / piston secured to the other end of the frame. The ram / piston being movable toward and away from the wedge. The reservoir includes an inlet and outlet and a discharge tube associated with the inlet or outlet and having a length effective to discharge incoming fluid into the reservoir at a position remote from the inlet to prevent short circuiting. A log splitter and arm for mounting the splitter to a vehicle having a hitch style receiver secured to the rear of the vehicle. The splitter is adapted to be secured to an elongated arm and supported above the ground. The splitter's linear working action is substantially normal to the vehicle's direction of movement.

Owner:BRAVE PRODS

Bi-directional equal force log splitter

ActiveUS7124794B2Increase productionImprove certaintyWood splittingMulti-purpose machinesEngineeringLog splitter

A bi-directional log splitter having at least two stationary splitting wedges and a moveable ram therebetween for splitting wood, said splitter being mounted on a trailer where the splitter exerts a substantially equal force for both the exertion and the retraction strokes to increase the production of split wood.

Owner:MARX DANIEL A

Log splitter

A portably log splitter is provided. The log splitter comprises a base having a pair of one-piece side members , and a support member to which the one-piece side members are attached. The support member and the one-piece side members form a seat that is adapted to receive a log. The log splitter also includes a splitting wedge that is attached to the support member and a contact member that is configured to translate in a reciprocal manner adjacent to the support member in order to move the log. The log splitter also includes a control assembly operated by a switch to actuate the contact member in the reciprocal manner.

Owner:TECHTRONIC OUTDOOR PRODS TECH

Gear-rack log splitter with clutch

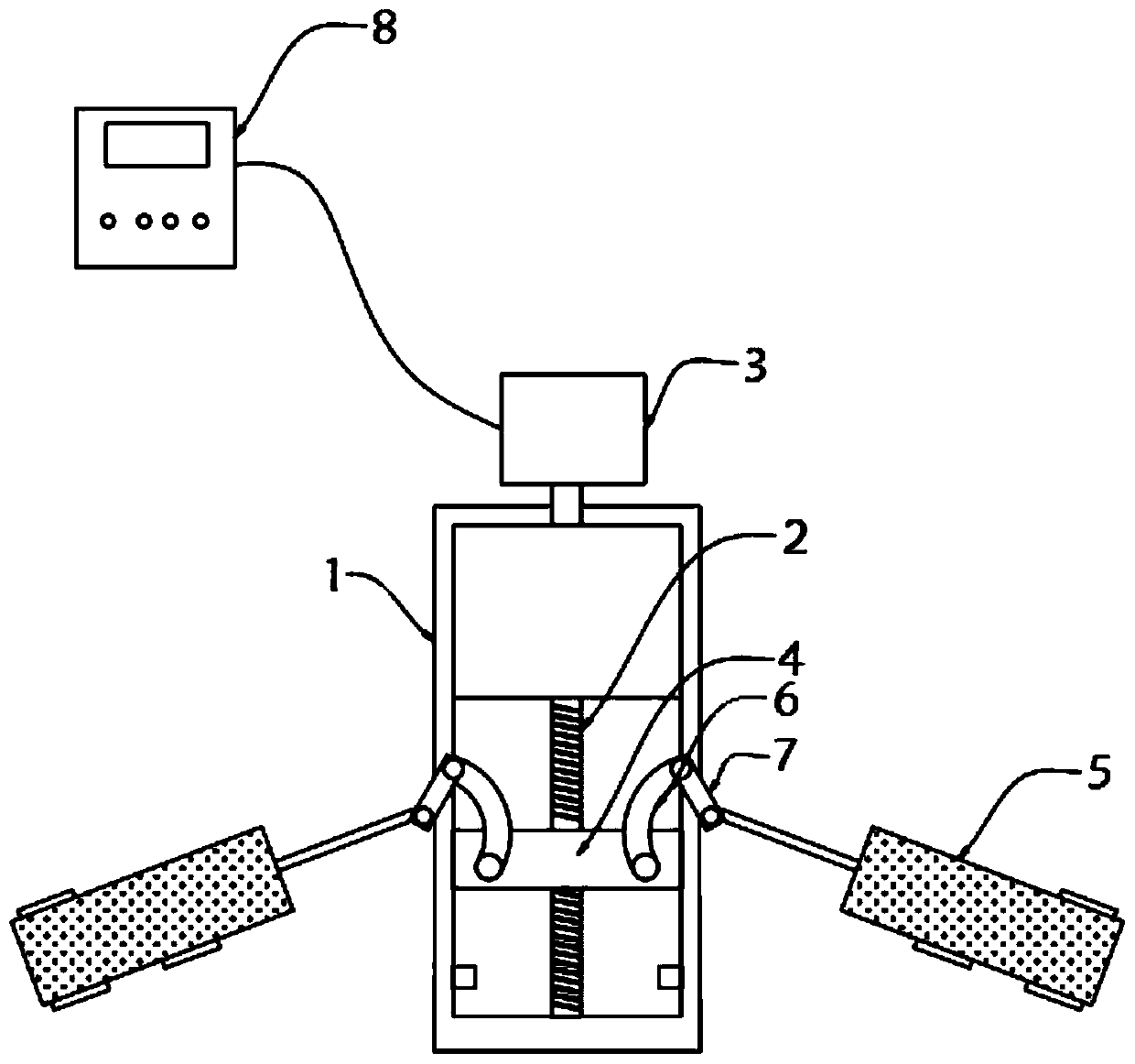

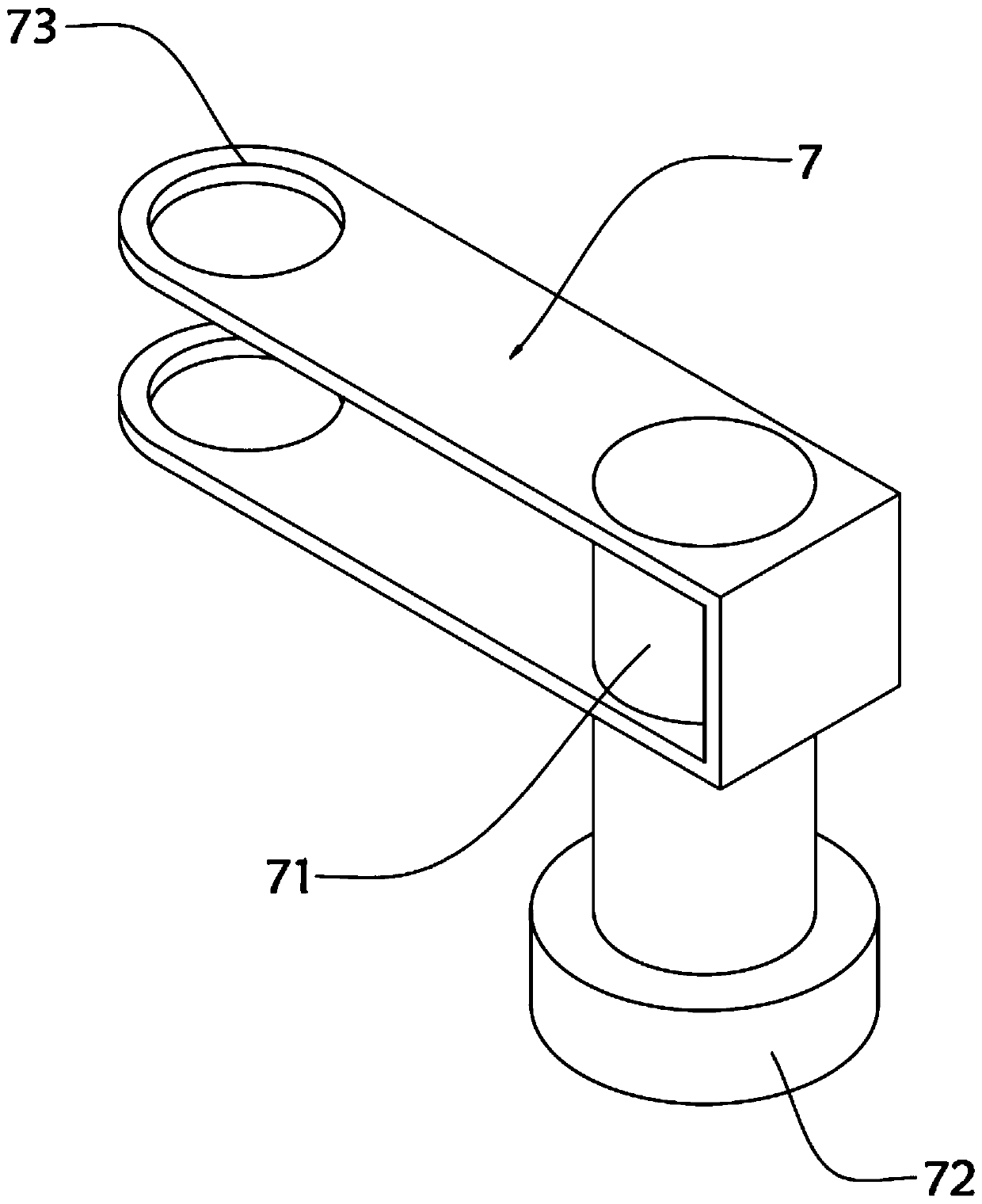

The invention discloses a gear-rack log splitter with a clutch. The gear-rack log splitter comprises an engine holder, an engine, a tool and a push plate. The engine is arranged on the engine holder. A frame is disposed at the front end of the engine holder. The gear-rack log splitter is characterized in that a power input shaft and a gear shaft are disposed on the frame, a flywheel and a first sprocket are disposed on the power input shaft, the engine is connected with the flywheel through a belt, a second sprocket, the clutch and an operating handle are disposed on the gear shaft, an input portion of the clutch is connected with the flywheel, the operating handle is connected with an output portion of the clutch, the first sprocket and the second sprocket are connected through a chain, a rack is disposed on the frame, the push plate is disposed on the rack, the bottom of the rack is connected with the frame through a tension spring, and the rack meshes with the gear shaft. The gear-rack log splitter with the clutch has the advantages that the tool can be reset fast, the service life of the tool is longer, and the gear-rack log splitter is suitable for wide popularization and application.

Owner:JIASHAN SUPERPOWER TOOLS

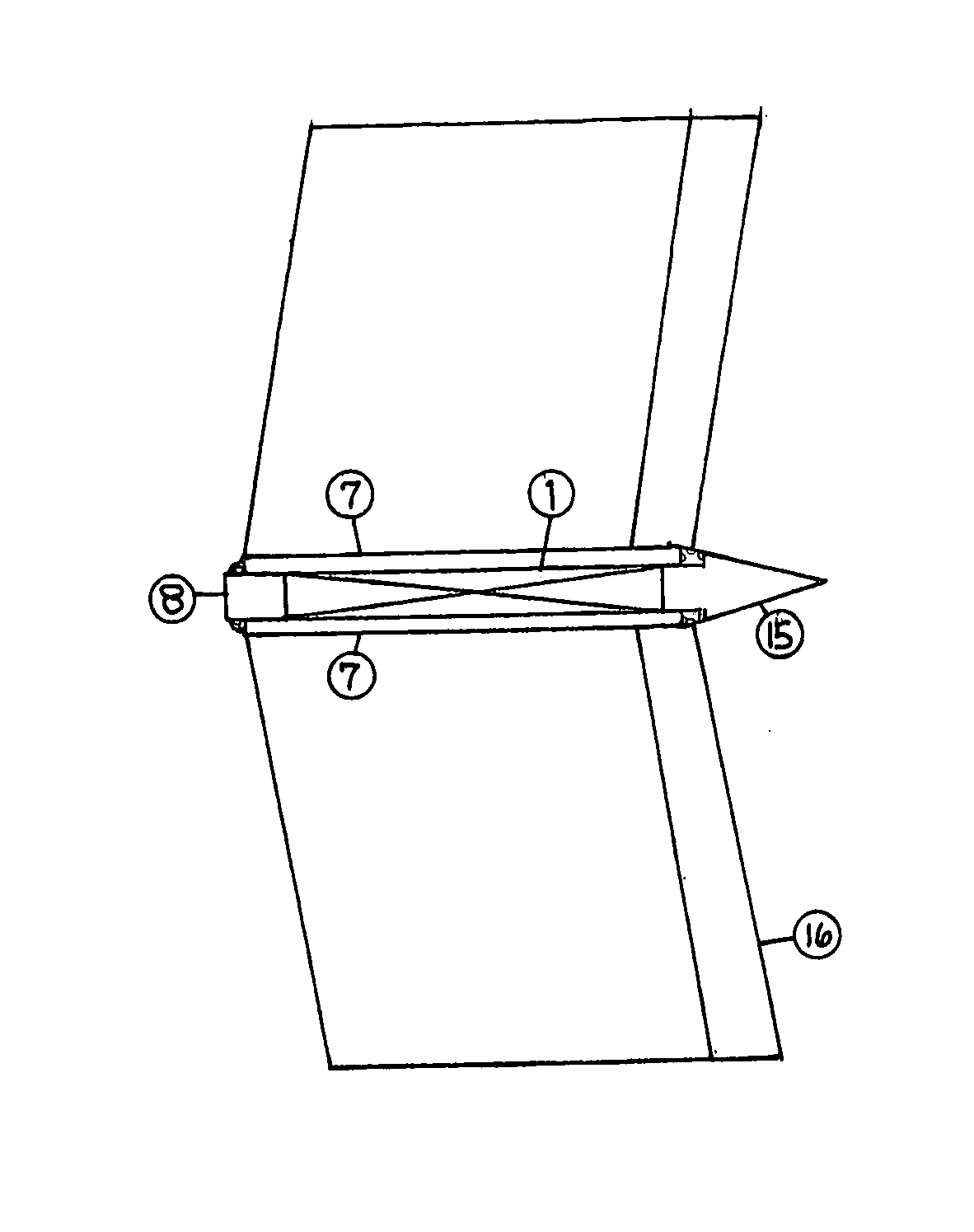

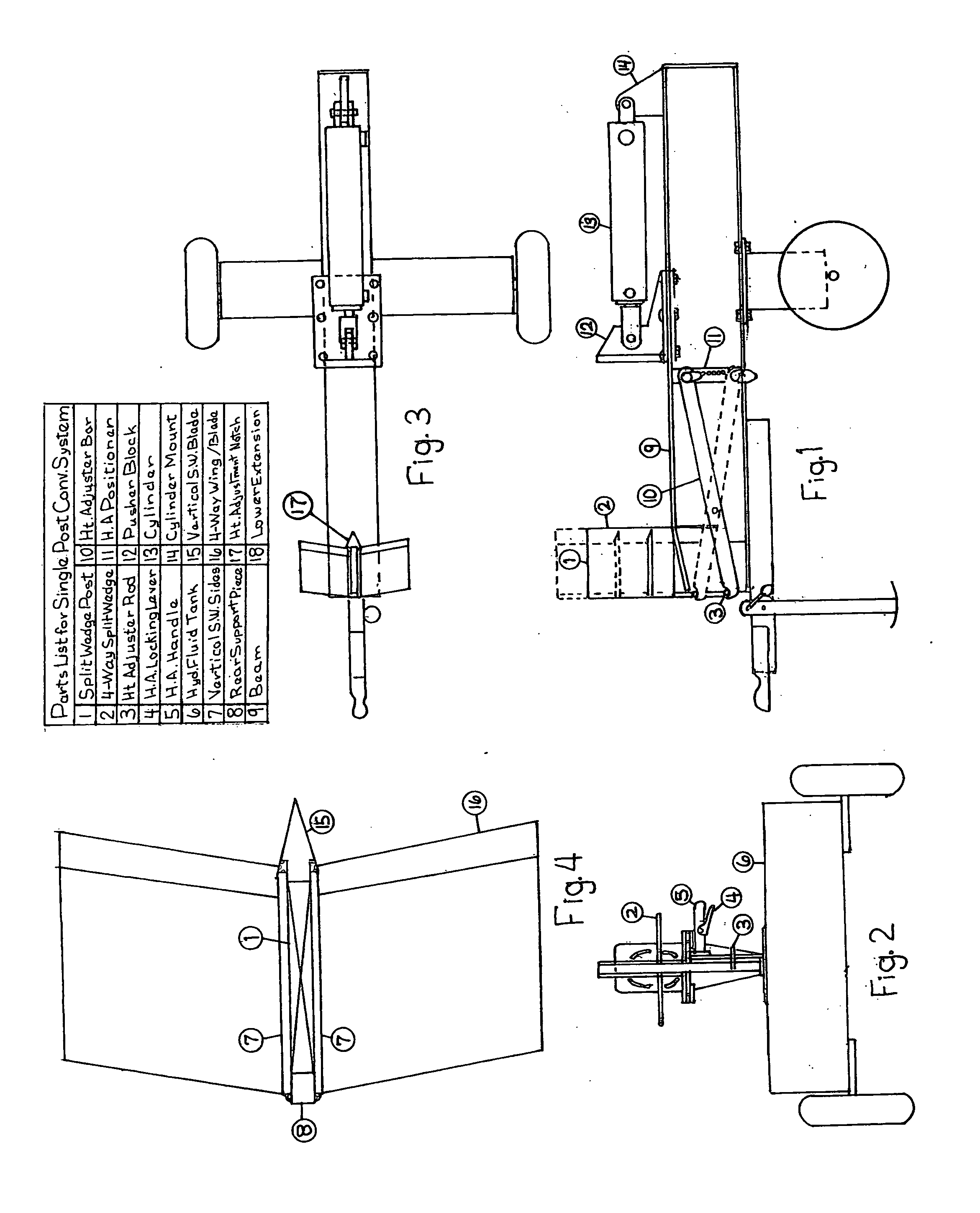

Single post convertible split wedge system

InactiveUS20110048581A1Less powerLess expensiveWood splittingMulti-purpose machinesEngineeringLog splitter

This log splitter is designed to work very fast and efficiently, yet be less expensive to construct than comparable splitters. By using a single, vertical, rectangular post to support all the split wedges including the two-way, these wedges can be of a simpler, less expensive, yet as strong construction. Secondly, by angling the Split Wedge Post slightly forward, it retains the split wedges during splitting operations, limits them to rise only slightly as the wood passes through, yet allows them to be freely and easily placed and removed by hand by the operator. The manually operated Height Adjuster Bar located conveniently on the side of the beam, allows the operator to easily and quickly raise and lower the split wedges as necessary to accommodate different sized logs and to retain the wedges in place with a simple latch type arrangement.

Owner:HICKS NORMAN A

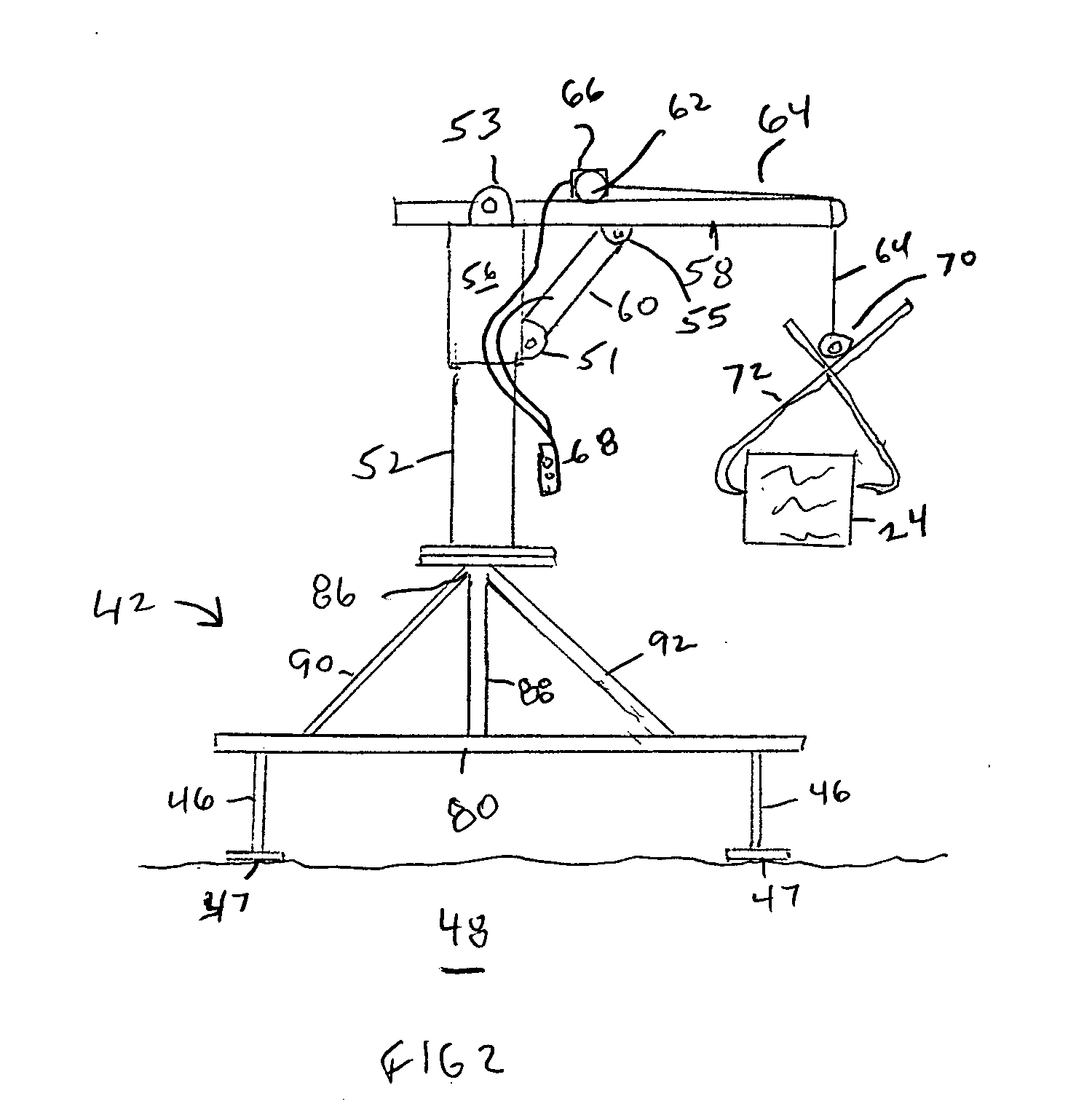

Log lift and pulling apparatus for cooperation with log splitter

InactiveUS20160009532A1Easily manipulated and positionedWood feeding arangementsWood splittingEngineeringLog splitter

A lift apparatus cooperable with a log splitter for lifting log sections onto and positioning the log sections on the log splitter for splitting, the lifting apparatus having a frame member removably secured to the frame of the log splitter and supported by the underlying substrate, the frame defining an upwardly extending pedestal having a vertical post member secured thereto having a transverse lifting boom secured to the upper end of the vertical member, the lifting boom supporting a cable spool and electric motor, the lifting boom articulating in the vertical frame in response to a hydraulic control, the lifting boom rotatable about said support post, the cable having a lifting tong secured to its end for engaging log sections and lifting onto said log splitter, or for engaging log sections a distance from the log splitter and dragging them to the log splitter for lifting.

Owner:BENNETTE JOHN

Special pipe forming technology and die replacing device for log splitter oil cylinder

The invention relates to a special pipe forming technology for a log splitter oil cylinder. The technology comprises the steps that 1, uncoiling is carried out, and particularly a steel belt coil is uncoiled; 2, leveling is carried out, and particularly the uncoiled steel belt is leveled and conveyed to a next station; 3, end flattening and butt welding are carried out, particularly, the head andthe tail of the leveled steel belt are sheared and flattened, and the tail of the sheared and end-flattened steel belt and the head of a next sheared and end-flattened steel belt are welded together;4, prestoring is carried out, and particularly the but-connected steel belts are conveyed into a loop storage bin; 5, forming is carried out, particularly, the steel belts in the loop storage bin areconveyed into a forming machine, and the steel belts are gradually bent in sequence to form pipe blanks to be welded; 6, high-frequency welding is carried out, and particularly high-frequency weldingis carried out after the two butt-connected ends of the pipe blanks are extruded to the certain opening angle; 7, water cooling is carried out, the steel pipes welded at a high frequency are cooled toroom temperature in a spraying mode; 8, special gradient sizing is carried out, and particularly the water-cooled steel pipes are sized through a sizing unit; and 9, contour machining is carried out,and particularly the sized steel pips are cut to specific lengths.

Owner:山东舜世高科实业有限公司

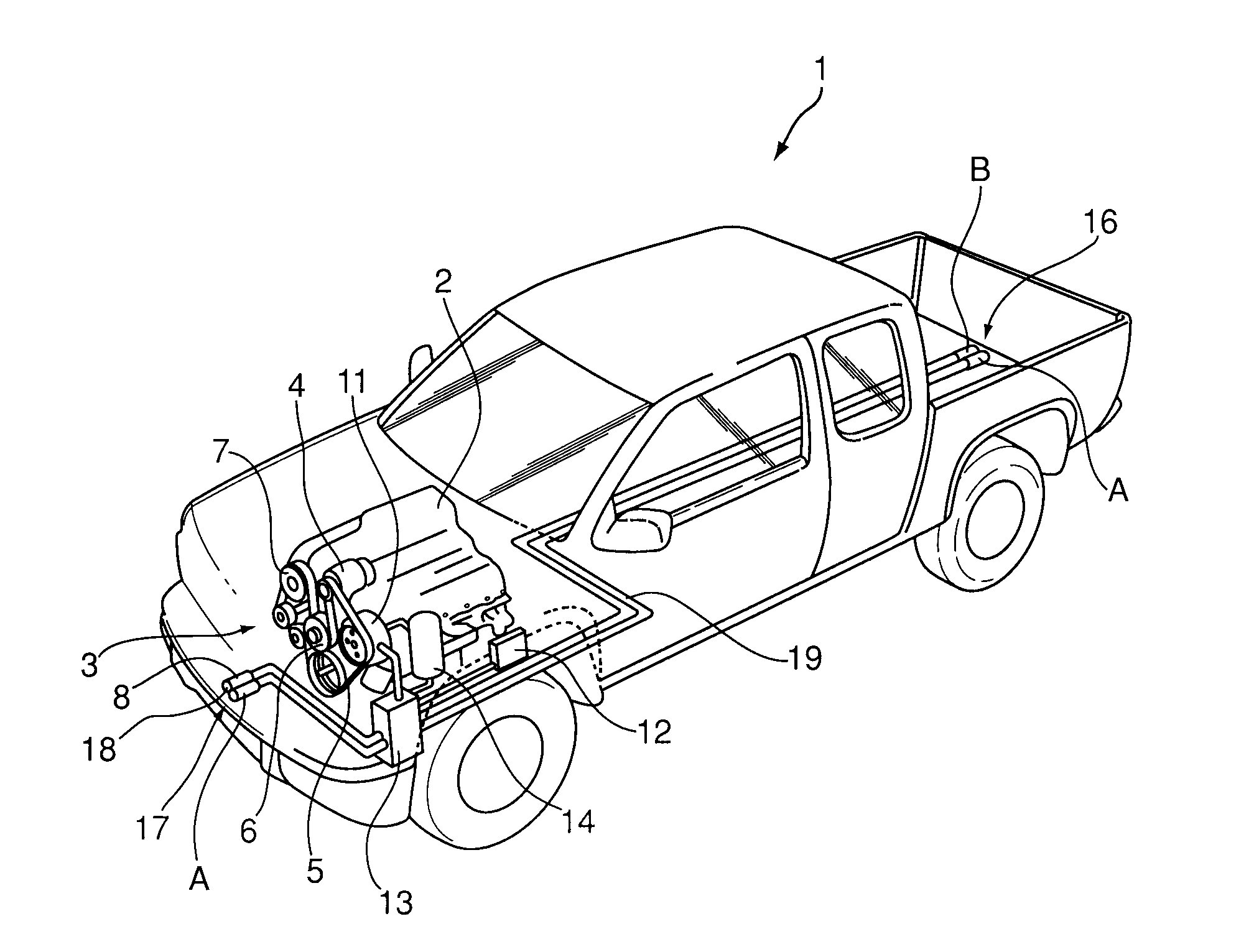

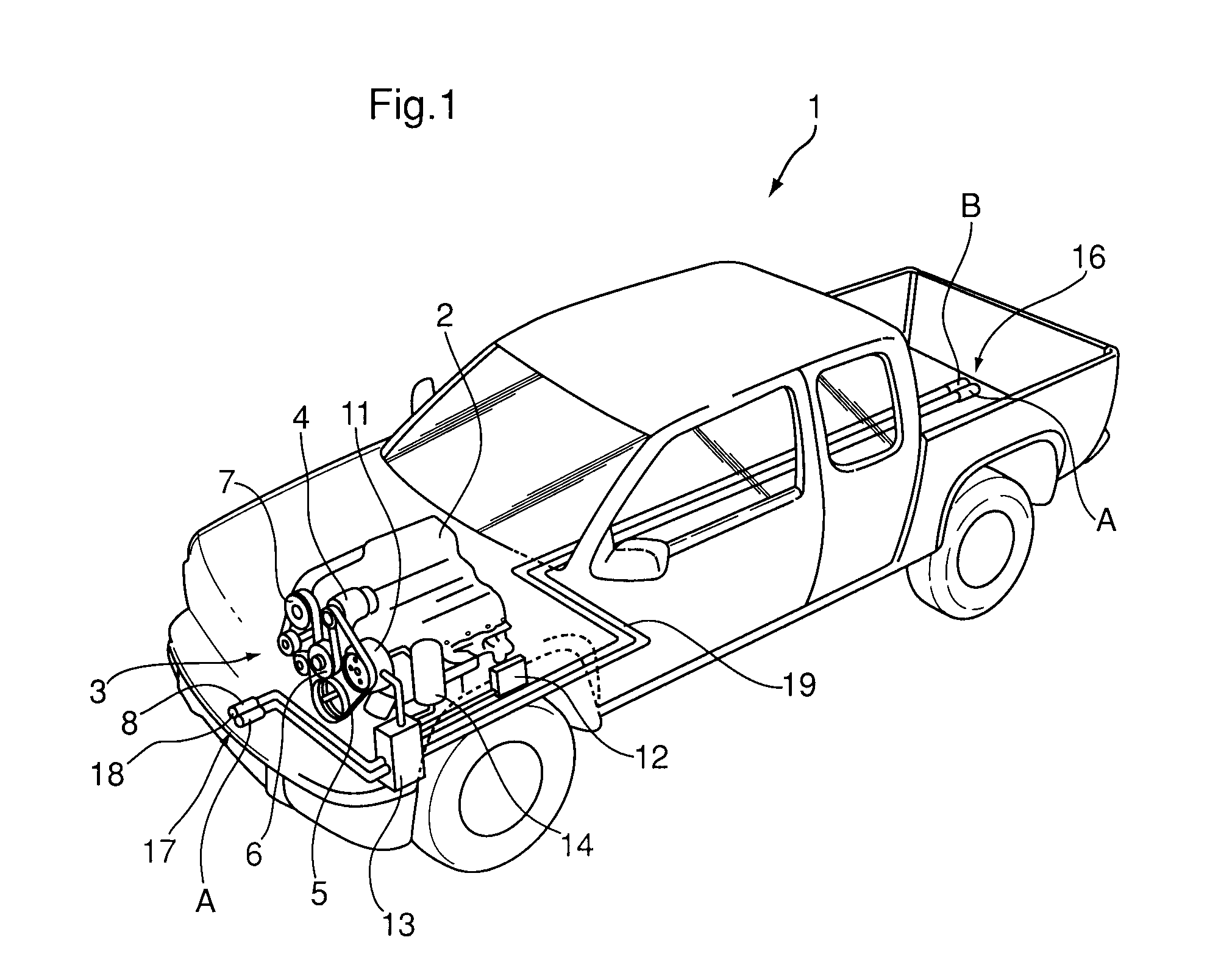

Vehicle auxiliary hydraulic system

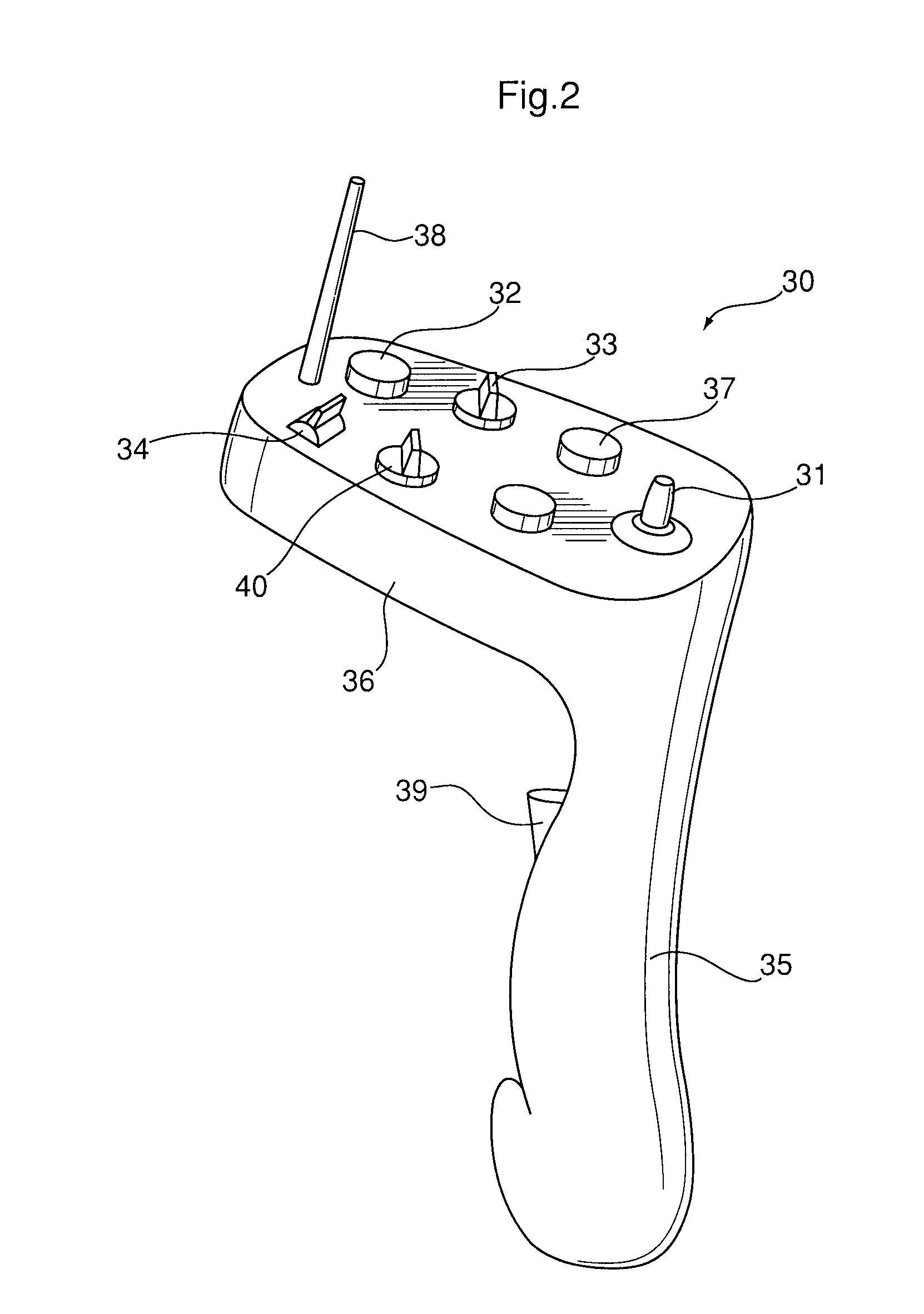

ActiveUS8589026B2Eliminate requirementsFacilitates variable outputAuxillary drivesDigital data processing detailsOn boardMicroprocessor controller

An auxiliary hydraulic system for vehicles, in particular pick-up trucks, is configured to supply hydraulic fluid under pressure to both on-board and off-board auxiliary equipment such as snow plows, dump boxes and wood splitters. The auxiliary hydraulic system includes a multi-piston fluid pump with electrically selectable poppet valves and an associated microprocessor control that facilitates variable output so that a desired proportional flow can be supplied to the auxiliary equipment. The system also provides a switchable valve arrangement for directional control and an arrangement of fluid distribution pipes and detachable couplings so that a range of different auxiliary equipment can be quickly and simply connected to the system. A simple user interface is also included so that the operator can command the auxiliary equipment from either within or in close proximity to the vehicle.

Owner:MULTIMATIC INC

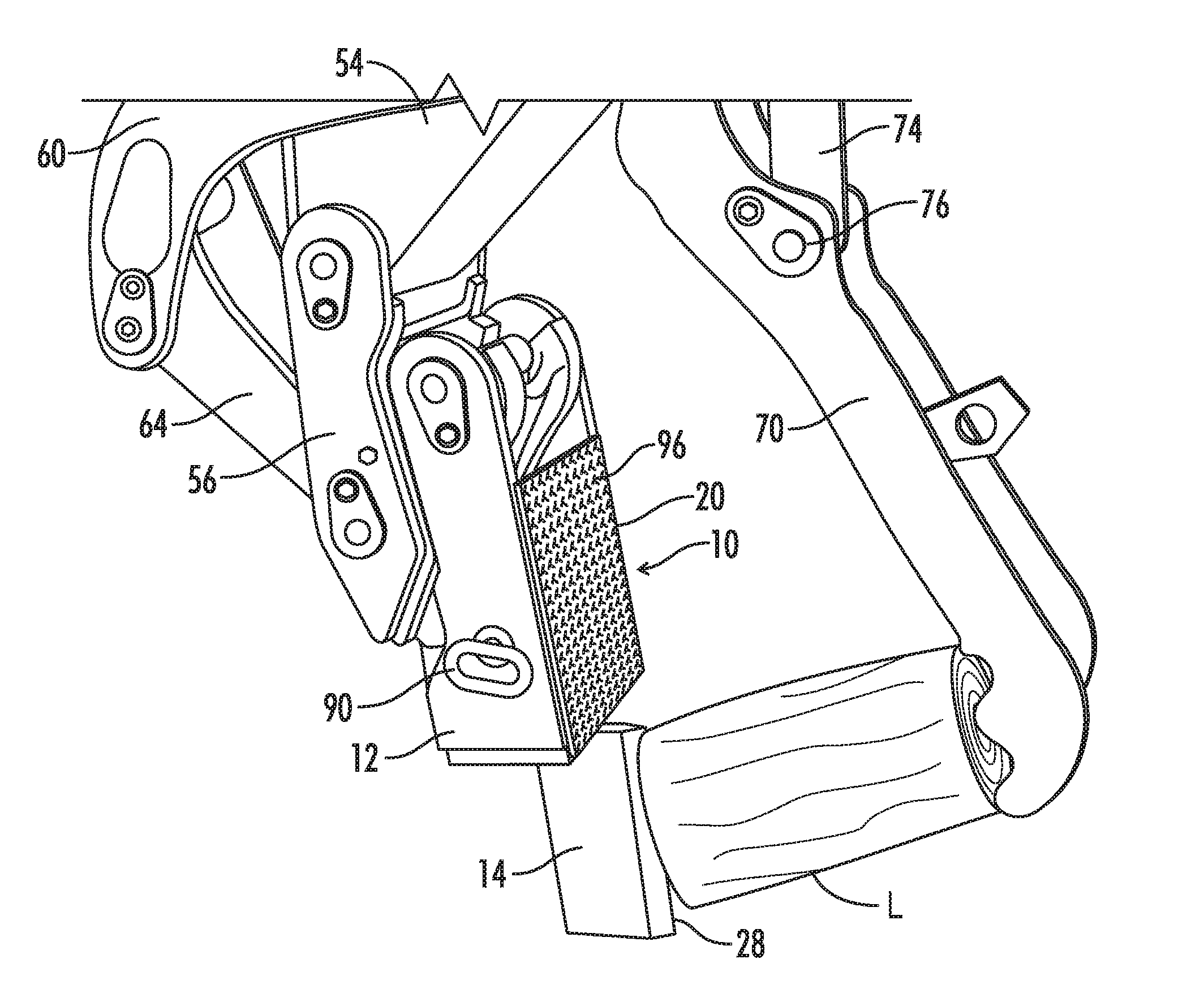

Log splitter

A self-contained, or externally actuated, hydraulic log splitter which includes a frame on which is slidably mounted an assembly of a specially designed push plate secured at one end to a reversible hydraulic cylinder and at the other to a splitting table carrying logs which is pushed against a straight blade to split the logs. A plurality of lines of discrete nubs are integrally a part of the push plate along a majority of its entire height and positioned substantially parallel to the straight blade and spaced away from the edge of the push plate. These nubs to provide specialized and improved gripping of log segments as they are split thereby minimizing the tendency of the split log segments to fly away from the splitter. An electric or gas engine driving an hydraulic pump or the hydraulic system of a tractor is connected to drive the reversible hydraulic cylinder.

Owner:PARADISE ANTHONY

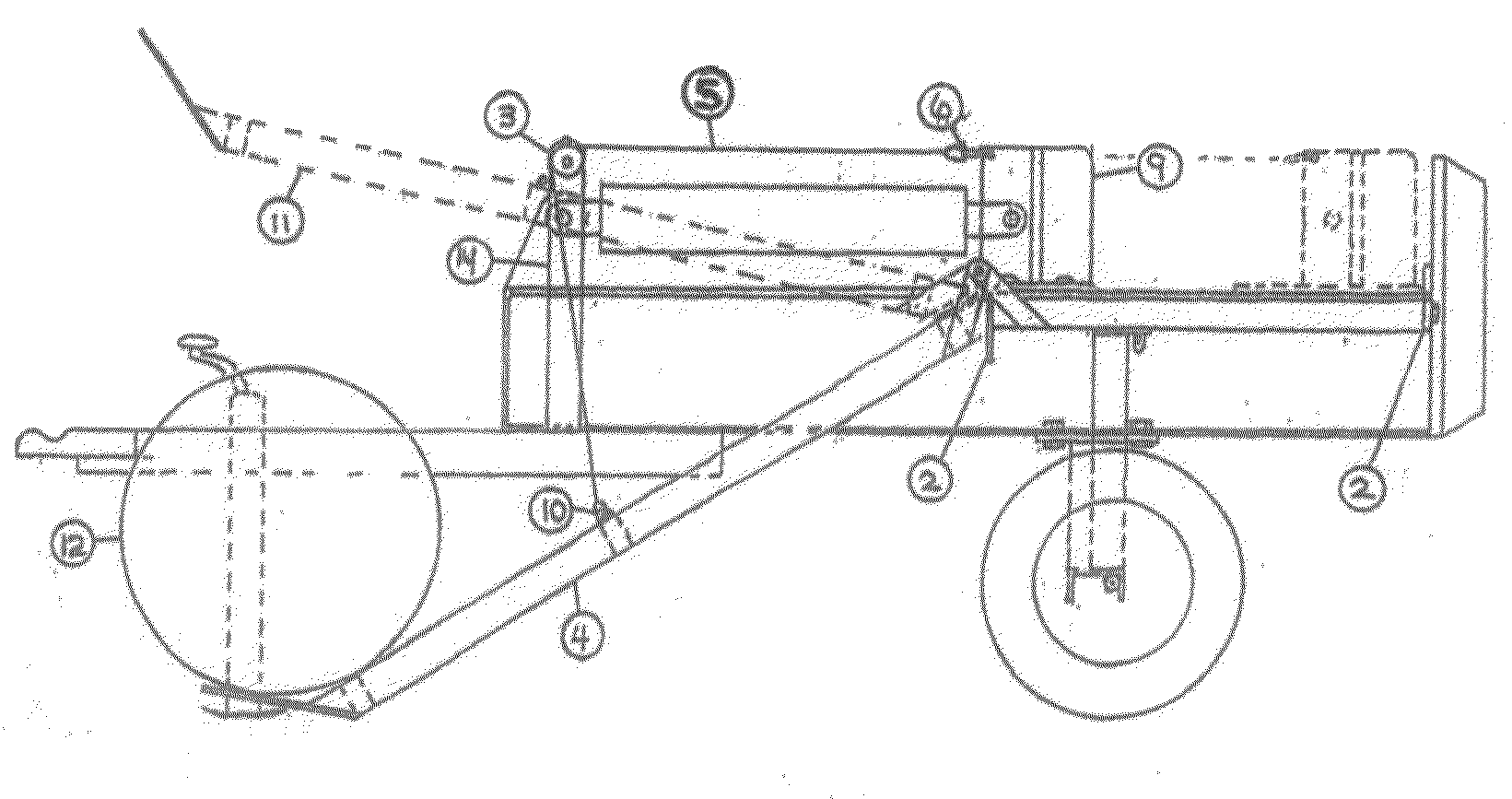

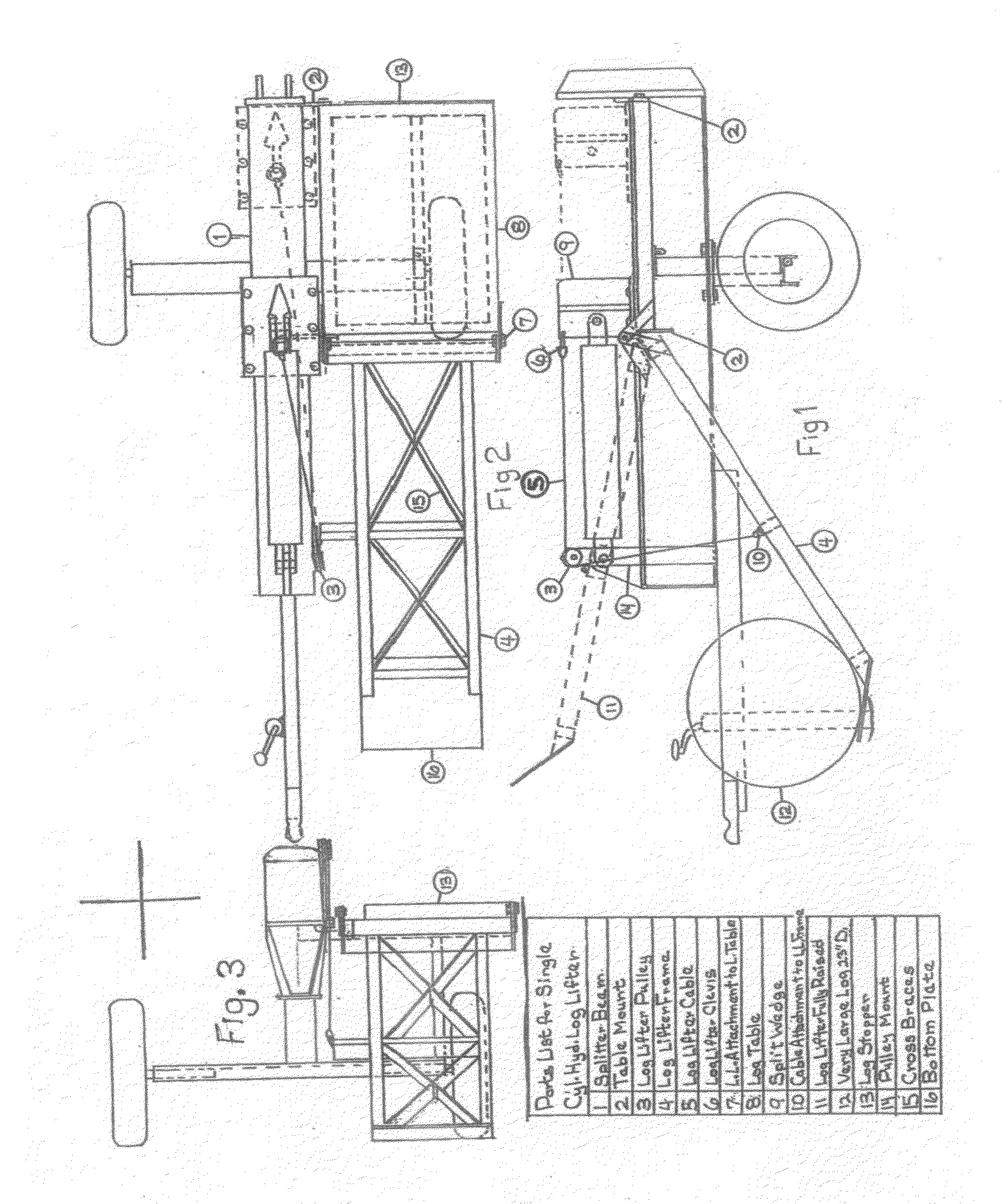

Single cylinder hydraulic log lifter

This invention adds a very large (24×32 inch or larger) log table permanently mounted to the log splitter. This alone adds immeasurably to the efficiency and convenience of splitting. It allows for the true, convenient, and safe one-man operation of a splitter because it catches and stores the far side of the log and log pieces while the operator is free to handle the near side with one hand and the control valve with the other hand. The log lifter is powered hydraulically with the same cylinder, control valve, hoses and fittings that power the split wedge. Very simply, a cable and a pulley are used to direct the force of the existing cylinder to raise the log lifter. This simplicity lowers the cost of the log lifter considerably and makes it and the log table and the convenience of splitting in a more comfortable, standing position more readily available to the splitting public.

Owner:HICKS NORMAN A

Log splitter apparatus and related methods

InactiveUS20120255650A1Avoid interferenceWood splittingMulti-purpose machinesEngineeringLog splitter

A guard for a log splitter apparatus is disclosed herein. In various aspects, the guard includes a support member adapted to be secured to a rail of a log splitter apparatus, and a panel hingedly secured to the support member. The panel may be lockably positionable at least between a collapsed position and an extended position. The panel is adapted to capture at least portions of a log, in various aspects. In various aspects, a plurality of support members are located about the panel to secure the panel to the rail of the log splitter apparatus. The support members may be located such that the support members and the panel avoid interference with mechanisms of the log splitter apparatus with the guard secured to the rail. This Abstract is presented to meet requirements of 37 C.F.R. §1.72(b) only. This Abstract is not intended to identify key elements of the apparatus and methods disclosed herein or to delineate the scope thereof.

Owner:EFAB ERIK FRISELL

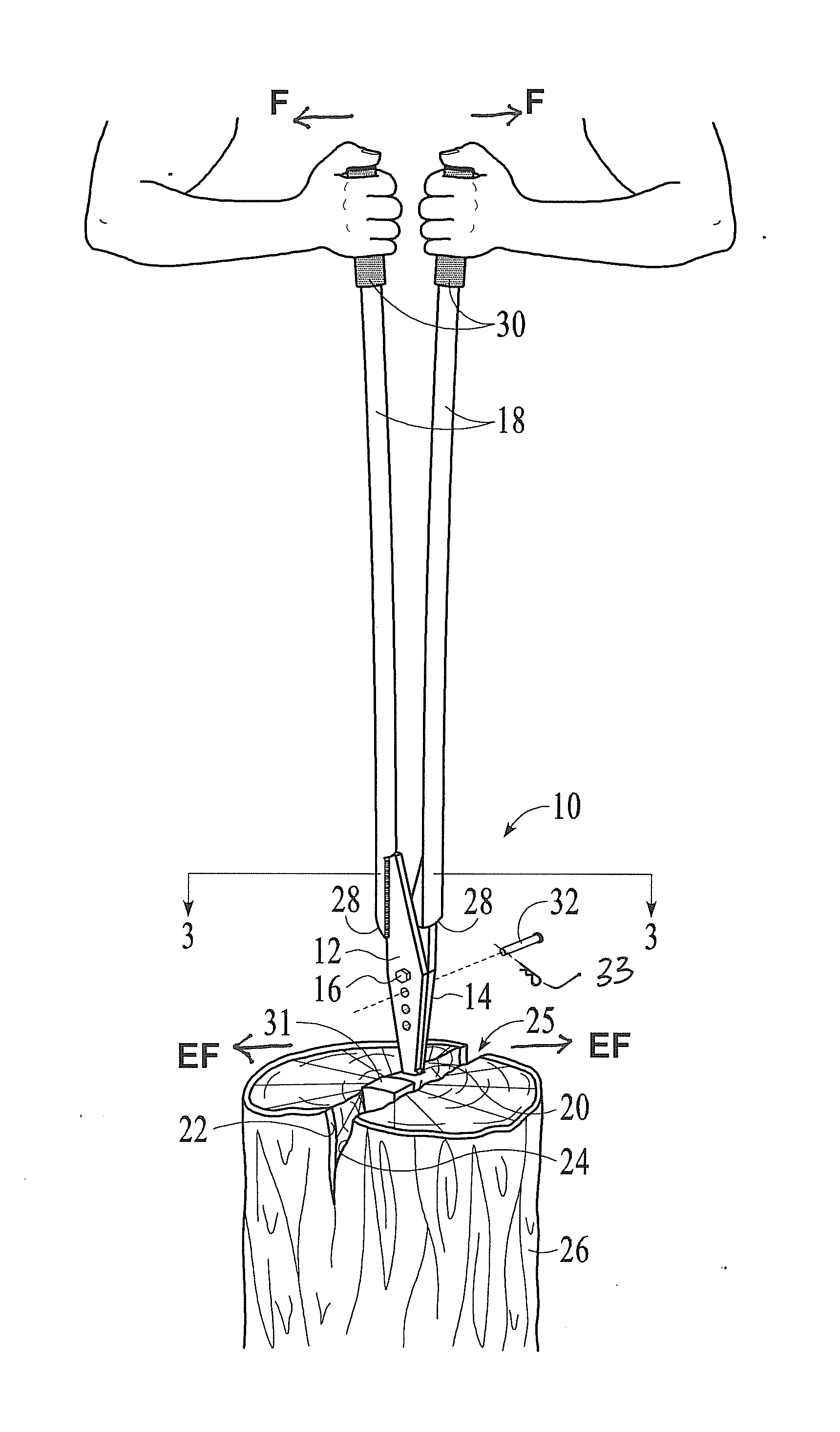

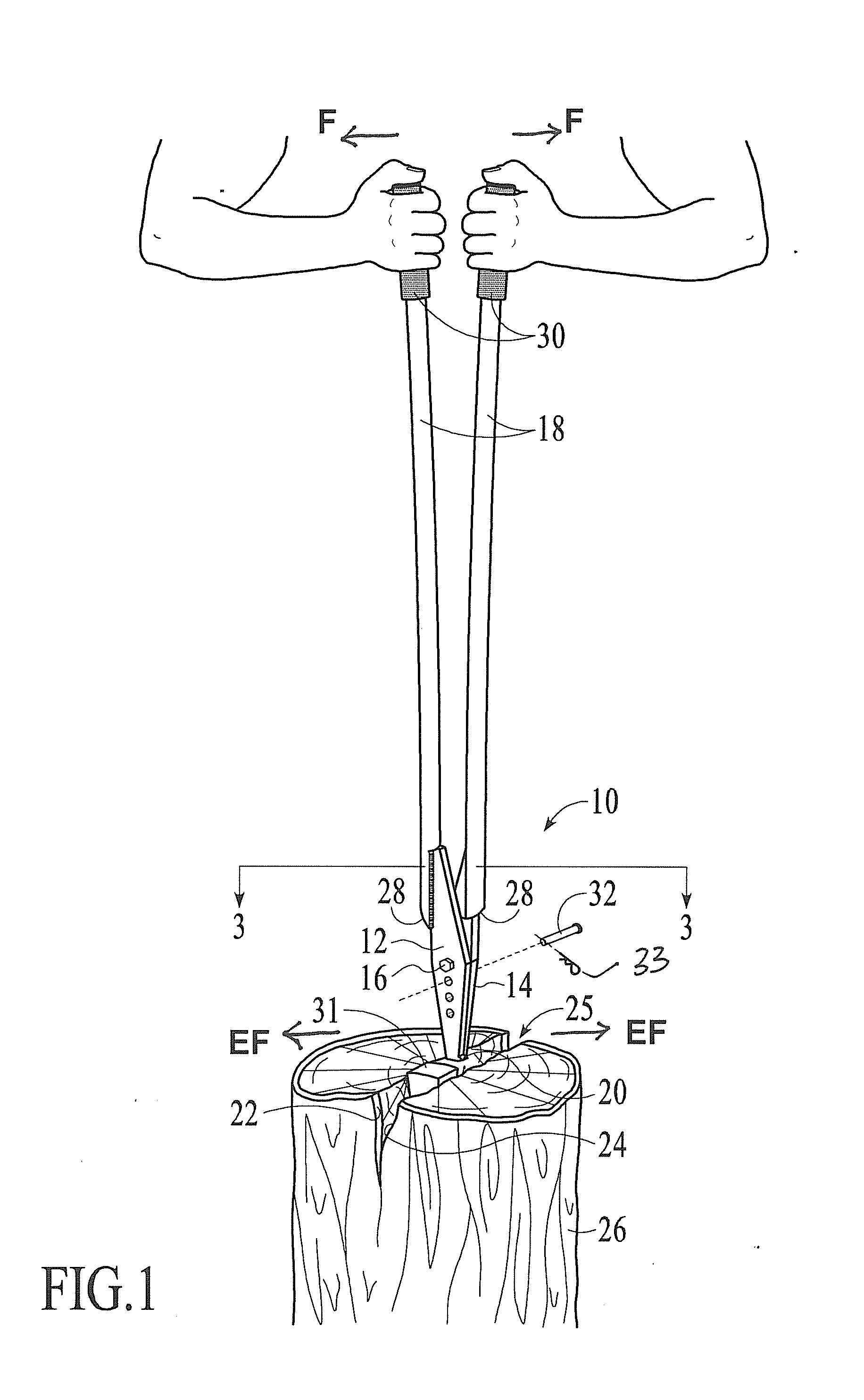

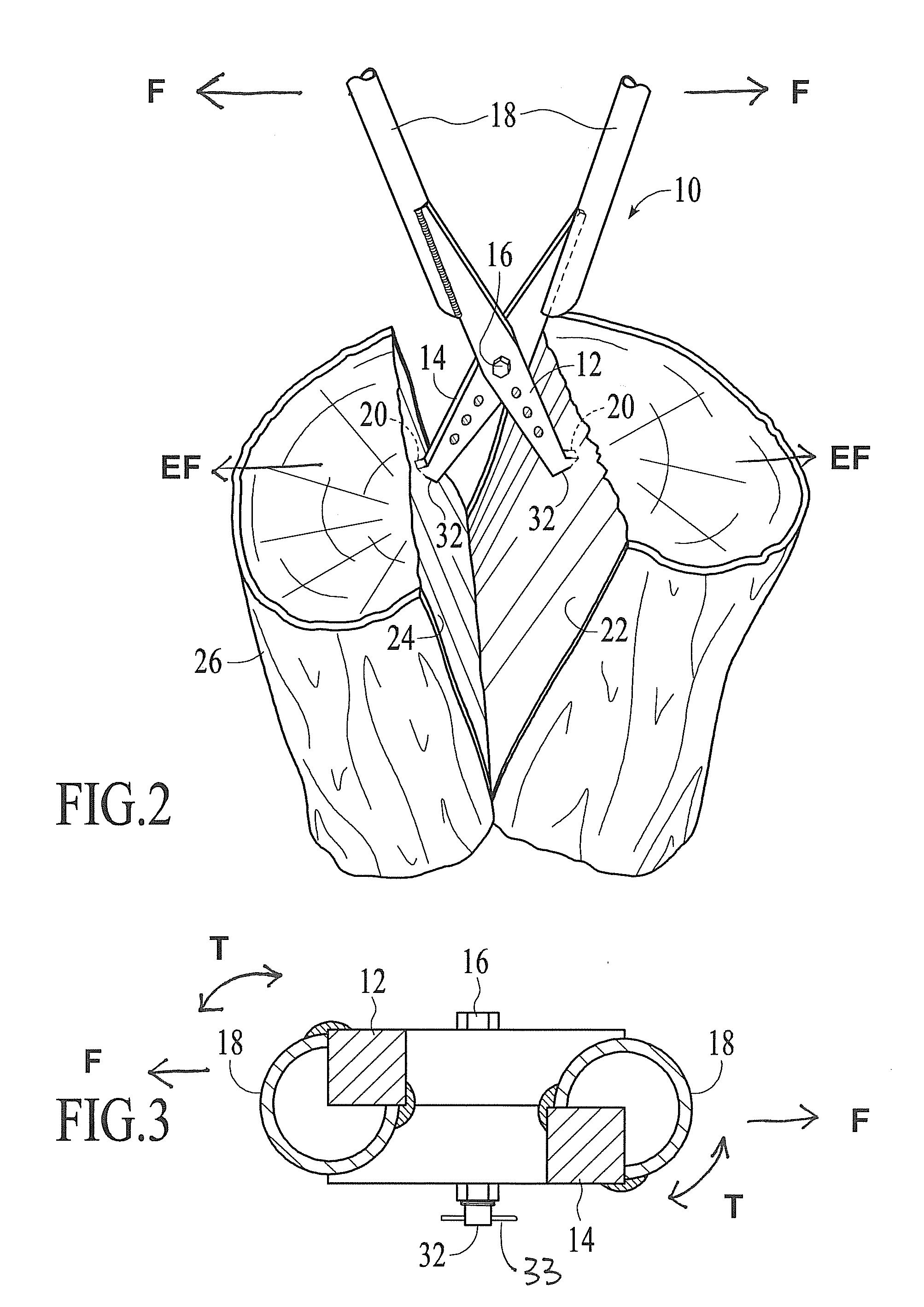

Manually Operable Log Splitter

InactiveUS20110126942A1Low costIncrease ratingsWood splittingMulti-purpose machinesFlow diverterEngineering

A manually-operable log splitter for use with a splitting wedge has a pair of jaws pivotable about a point. Each jaw is connected to a handle extending away from its associated jaw from the pivot point. The jaws have a tip smaller than a width of the splitting wedge with which the splitter is used. The jaws and handles are dimensioned and configured for insertion beside the splitting wedge when embedded in a log. Manual application of force F on each handle outward from the pivot point spreads the jaws and provides sufficient force for splitting the log. This tool is particularly suited for small scale log splitting, such as by a home owner for personal use.

Owner:LARSON MARCUS R +1

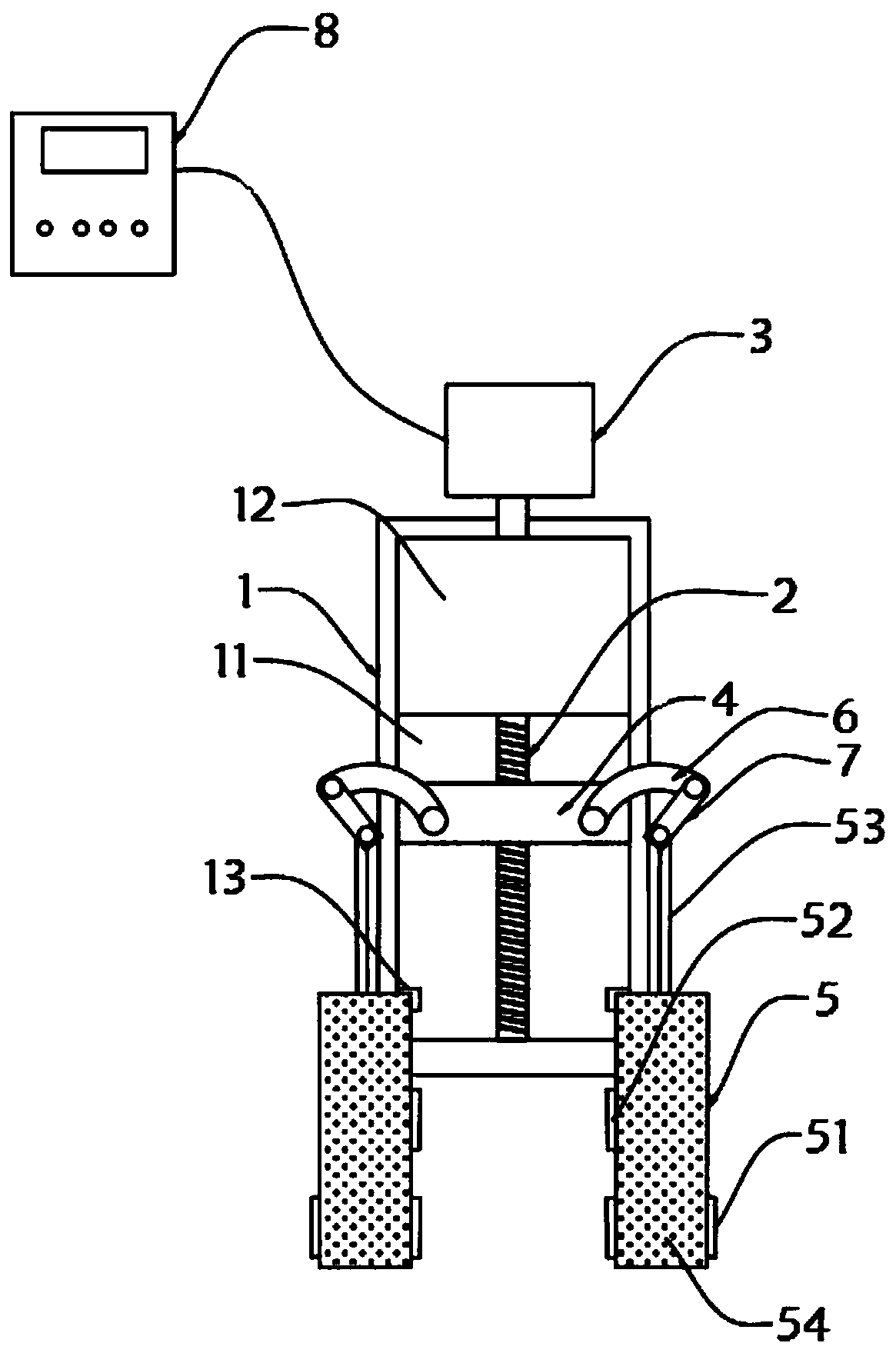

Full-automatic intelligent adductor leg splitter

InactiveCN110353941AStretch out at a constant speedGuaranteed to open normallyChiropractic devicesEngineeringLog splitter

The invention relates to the technical field of leg splitters, in particular to a full-automatic intelligent adductor leg splitter. The leg splitter includes a sliding table, a sliding groove is formed in the sliding table, the sliding groove is internally provided with a screw rod, the outside of one end of the sliding table is provided with a motor, the output end of the motor is in drive connection with the screw rod, a slider is arranged on the screw rod and is in threaded connection with the screw rod, the outer wall of the slider is slidably connected with the inner wall of the sliding groove, the outer wall of the side of the slider is symmetrically provided with connection rods, one ends of the connection rods are rotationally connected with the slider through rotation shafts, theother ends of the connection rods are provided with connection pieces, the ends, away from the connection rods, of the connection pieces are provided with leg support plates, and support rods are arranged between the leg support plates and the connection pieces. In the full-automatic intelligent adductor leg splitter, the screw rod and the slider can slowly slide at a constant speed, it is ensuredthat the leg support plates can be unfolded rapidly and can move repeatedly, thus the rehabilitation effect is ensured, the leg support plates can fix the legs well, and it is ensured that the legs are stable and not easy to slip at the time of stretching and withdrawing.

Owner:梅宇波

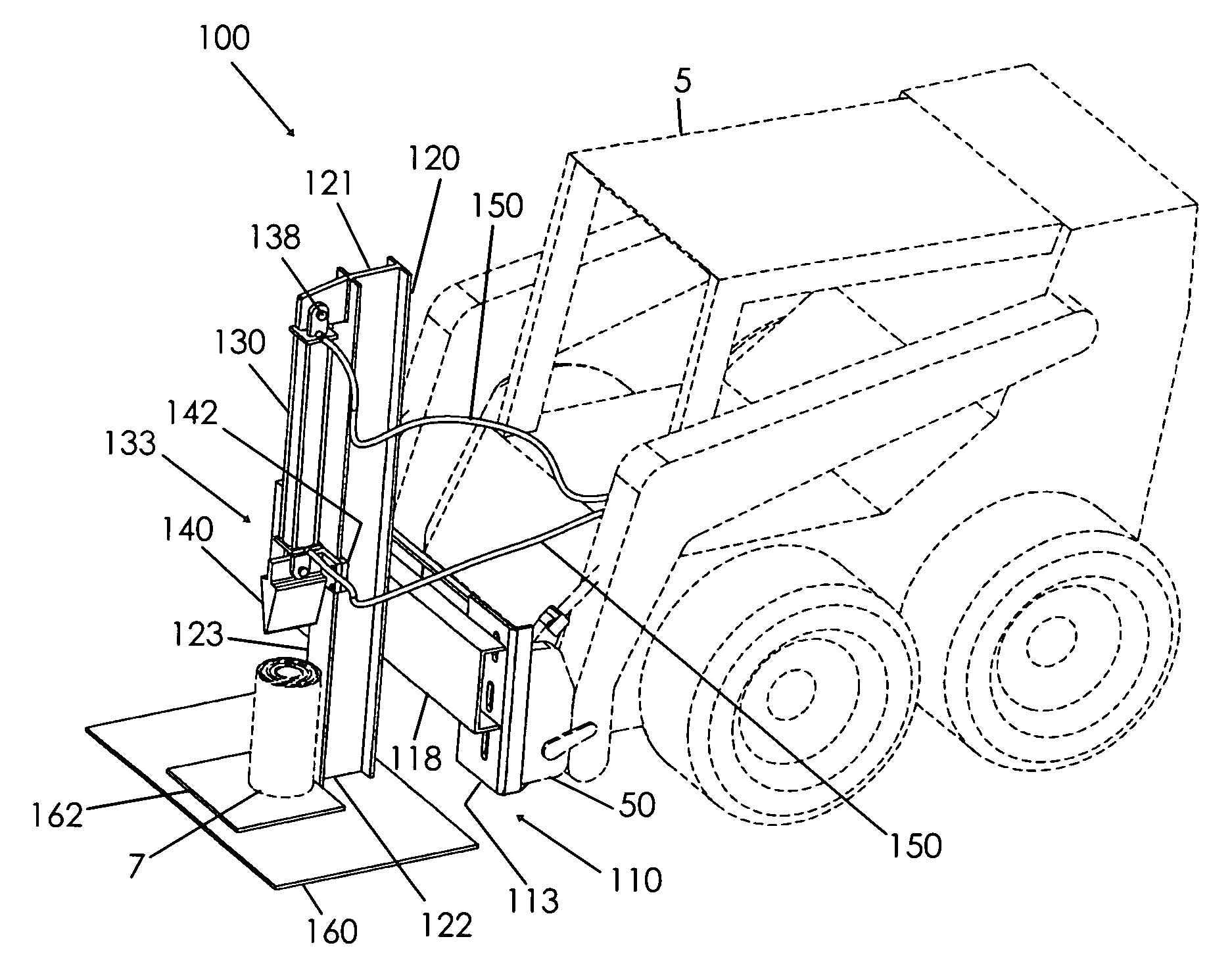

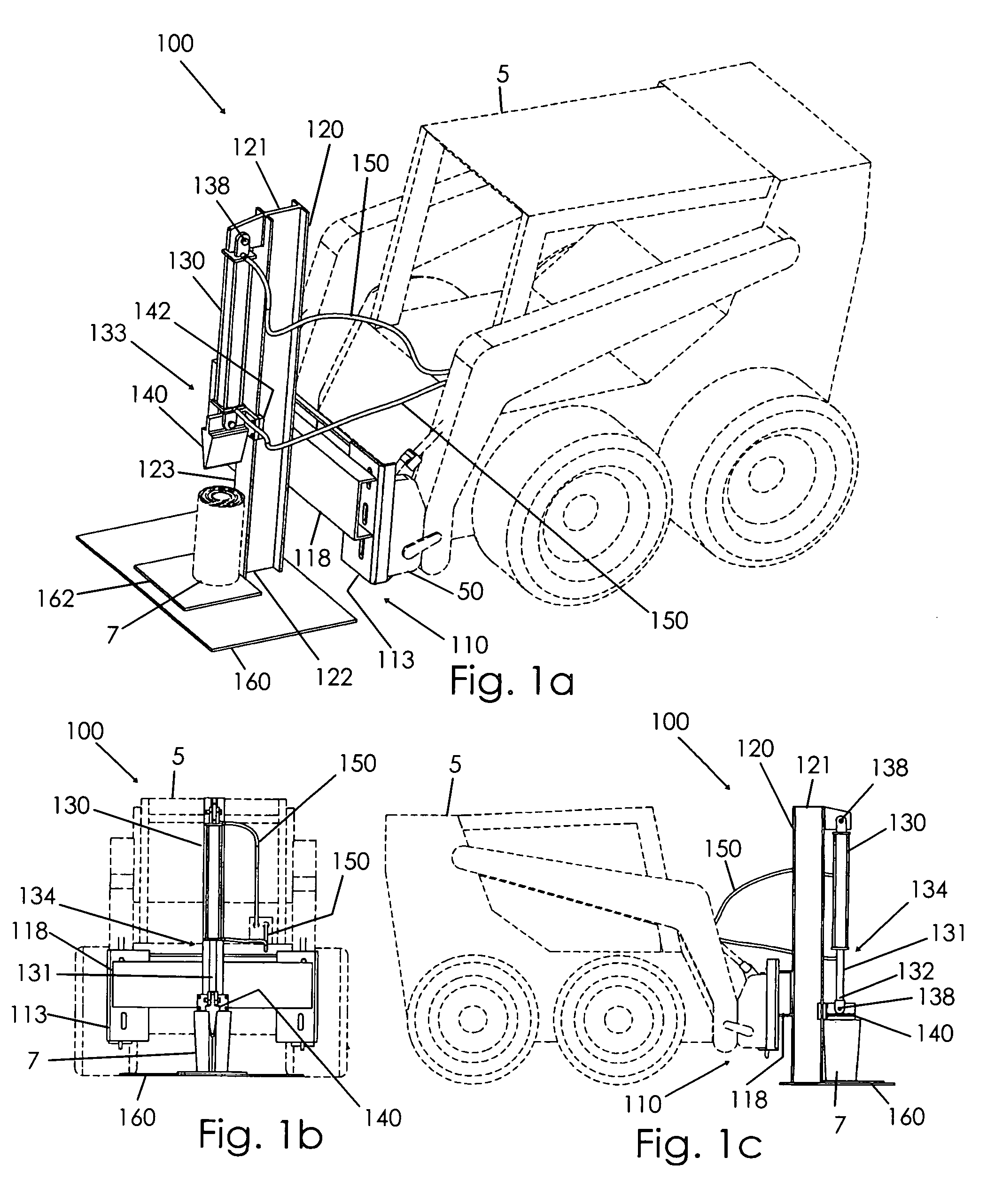

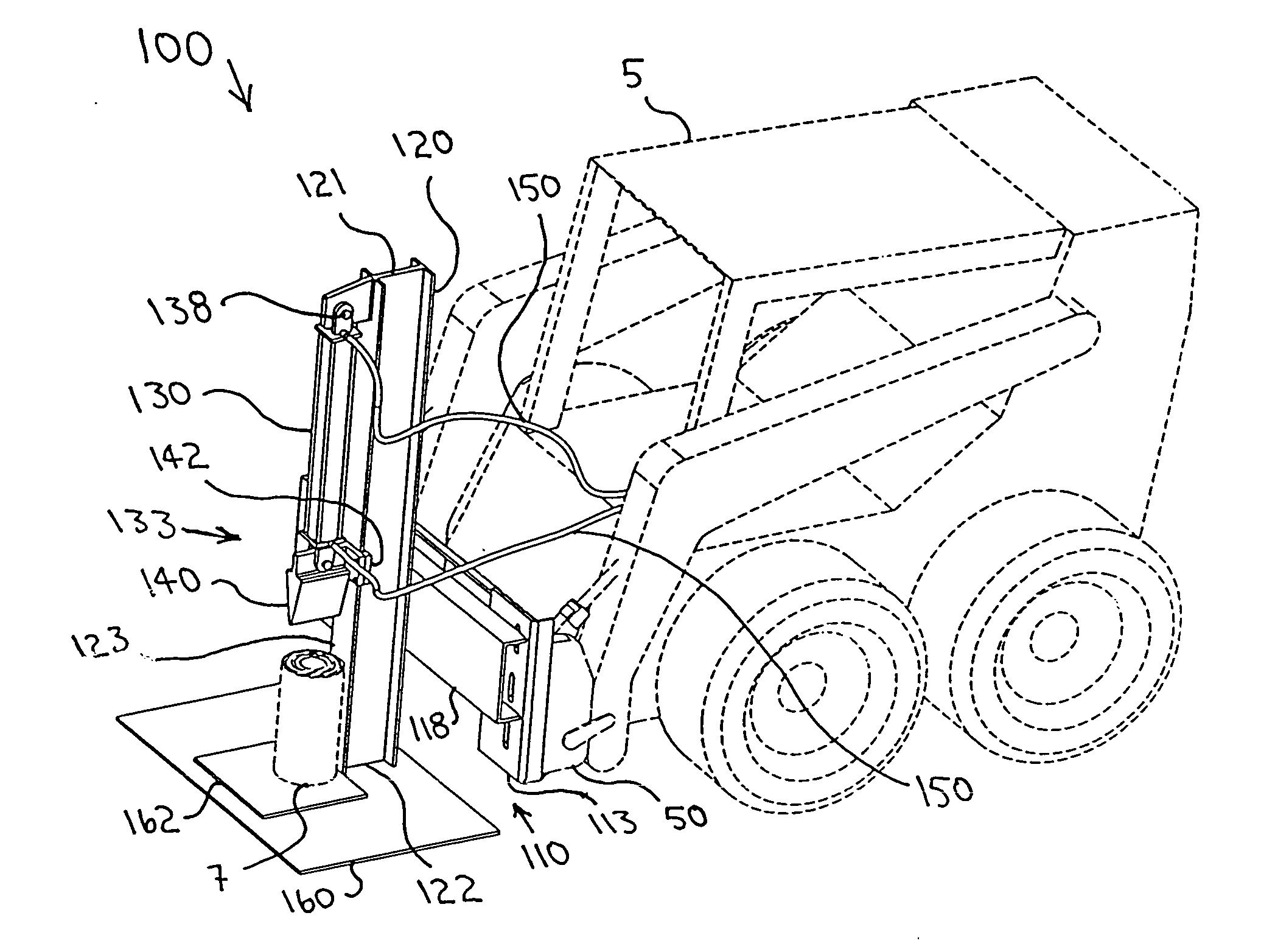

Log splitting apparatus

InactiveUS20050284542A1Effective segmentationEasy to useWood splittingMulti-purpose machinesEngineeringLog splitter

A hydraulic log splitter attachment for a skid steer loader includes a mounting framework attached to a vertical elongate beam. A piston / cylinder combination with a rod for movement between retracted and downwardly extended configurations mounts to the beam. A wedge attaches to a lower end of the rod. A base plate attaches to the beam adjacent the lower end; storage wall assemblies and stabilizing plates optionally attach to the base plate. Hoses connect the piston / cylinder combination to the loader's hydraulic system. Wedge guides slidably attach the wedge to the beam. The wedge guides optionally include wedge guide rollers; the wedge optionally includes wedge rollers. The loader secures to the mounting framework. Wood is placed on the base plate while the rod is in the retracted configuration. The rod moves to the downwardly extended configuration, thus splitting the wood with the wedge. The storage wall assemblies provide split wood storage.

Owner:STONE MARK O

Backhoe log splitter attachment tool

A log splitting attachment tool adapted for use in combination with a material moving machine having a boom and dipper stick for lifting and moving as well as splitting logs which tool can alternatively be secured directly to a dipper stick and hydraulic bucket cylinder or to a quick connect mechanism secured thereto.

Owner:NEWMAN JOSEPH E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com