Rapid hydraulic oil cylinder

A hydraulic cylinder, fast technology, applied in the field of hydraulic cylinders, can solve the problems of long time spent, waste of energy, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

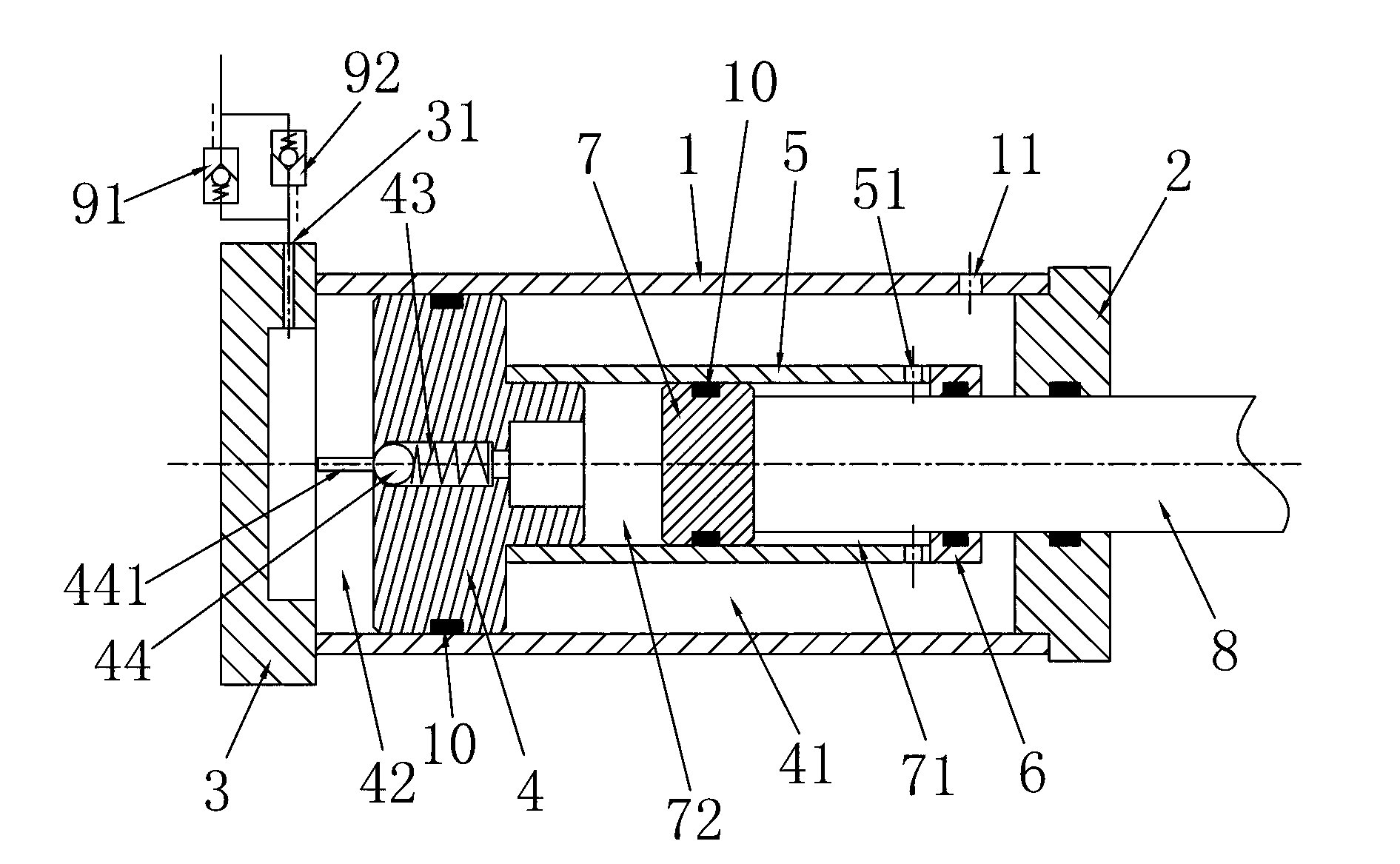

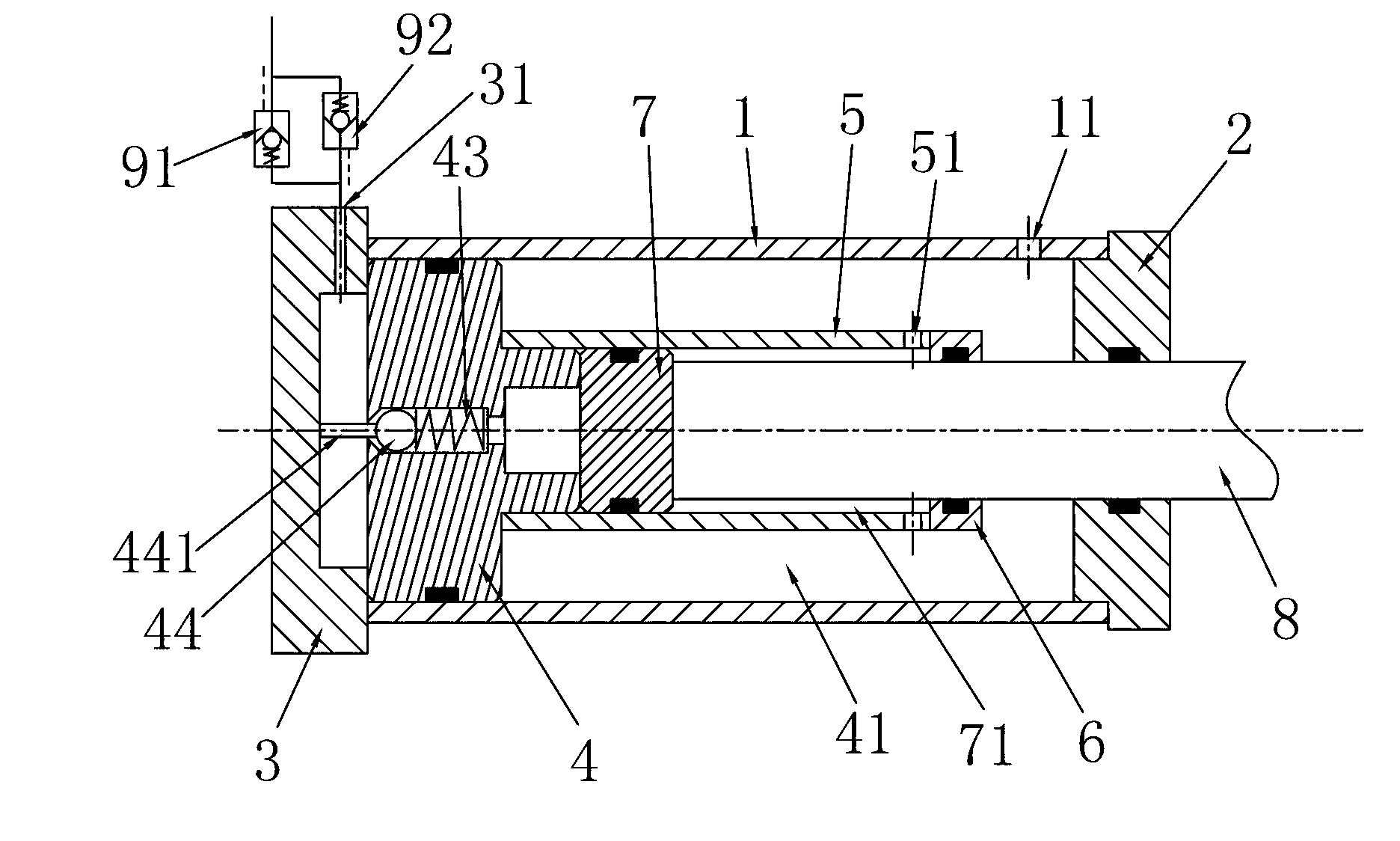

[0020] Such as figure 1 The first embodiment of the fast hydraulic oil cylinder shown in the present invention is the same as the ordinary oil cylinder, including a cylinder body 1, a front end cover 2 connected to the front end of the cylinder body 1, a rear end cover 3 connected to the rear end of the cylinder body 1, and a rear end cover 3 connected to the cylinder body 1. The first oil port 11 is provided on the front end side wall, and the first piston 4 is connected to the cylinder body 1 in a sealed and sliding manner. Between the cylinder body 1, the front end cover 2 and the rear end cover 3, a The first piston front chamber 41 and the first piston rear chamber 42, the first oil port 11 is connected to the first piston front chamber 41, the difference is that the front end surface of the first piston 4 is fixed with an inner cylinder arranged along the front and back direction 5. A second oil port 51 is provided on the front side wall of the inner cylinder body 5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com