Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Vitamin E product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Widespread in foods, especially vegetable oils and products containing oils such as salad dressings and margarine, vitamin E is easily destroyed by heat, so choose fresh or lightly processed sources such as seeds and nuts and leafy green vegetables. Other good sources include whole grains, liver and wheat germ.

Method for extracting natural vitamin E from blackberry seeds

The invention discloses a method for extracting a natural vitamin E from blackberry seeds, which comprises the following steps of: (1) solvent extraction: drying the seeds, extracting by using a mixed liquor of normal hexane and petroleum ether and concentrating extracting liquor to obtain a crude fat extract; (2) urea clathration: dissolving urea by using 95% ethyl alcohol, adding the fat extract, thermally extracting, standing at 0-4 DEG C, filtering, obtaining upper filtrate and carrying out reduced pressure distillation to obtain an oil phase; (3) silica gel column chromatography: carrying out the silica gel column chromatography on the oil phase, collecting eluant which is mixed liquor of absolute ethyl alcohol and normal hexane and concentrating to obtain a vitamin E concentrated solution; and (4) decoloration: decoloring the vitamin E concentrated solution by using a mixture of 7% of active carbon and atlapulgite to finally obtain a natural vitamin E product. The content and the yield of the vitamin E in the product obtained by using the method can be up to 50%.

Owner:江苏连恒生物科技有限公司

New extracting process for natural vitamin E

The new natural vitamin E extracting process has the technological steps of: esterification and separation of free fatty acid; saponification and esterification of pre-esterified oil; separation of sterol; separation of methyl fatty ester; and adsorbing separation. The present invention is suitable for the extraction of deodorized vegetable oil distillate with relatively low vitamin E content and preparation of natural vitamin E product with higher purity, and has high product yield and product purity over 95 %.

Owner:JIANGXI TEEMHIGH PHARMA

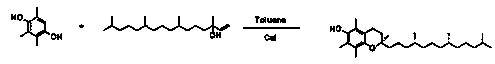

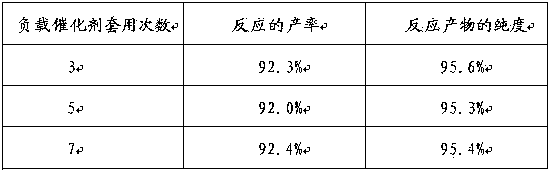

Environmentally-friendly synthesis method of vitamin E

ActiveCN103396392AHigh yieldHigh catalytic activityOrganic chemistryPhysical/chemical process catalystsSynthesis methodsDistillation

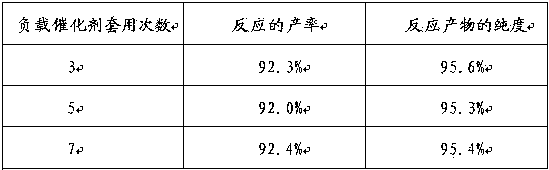

The invention relates to the fine chemistry industry synthesis field, and especially relates to an environmentally-friendly synthesis method of vitamin E. The method comprises the following steps: adding 150-200 parts by weight of toluene into a reaction device, sequentially adding 40 parts by weight of 2,3,5-trimethylquinhydrone and 40-80 parts by weight of isophytol under mechanical stirring, slowly adding 1.5-2.5 parts by weight of magnesium chloride and 0.8-1.2 parts by weight of a magnesium oxide supported silica catalyst after the above obtained reaction system is fully dissolved and clear, closing the reaction system, allowing the reaction system to undergo a reaction under a vacuum degree of -0.07 - -0.05MPa at a temperature of 55-65DEG C for 1.5-2.5h, and allowing toluene reflux to be maintained and generated water to be distilled out with the toluene reflux in the reaction to be in favor of the implementation of the reaction; and recovering the catalyst and the above solvent, and carrying out reduced pressure distillation of the solvent-distilled reaction system to obtain a required pale-yellow oily vitamin E product. The method has the advantages of repeated use of the supported catalyst, high yield, low energy consumption and environmental protection.

Owner:JILIN BEISHA PHARMA

A method of removing a plasticiser from vitamin E

ActiveCN105693683AReduce plasticizer contentReduce lossesOrganic active ingredientsOrganic chemistryPlasticizerIon-exchange resin

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Method for preparing natural vitamin E from crude oil of Maoyeshan tung tree seed

InactiveCN102229593AQuality improvementEasy and economical to makeOrganic chemistryChemical recyclingSolventEthyl acetate

The invention discloses a method for separating, purifying and preparing natural vitamin E from crude oil of Maoyeshan tung tree seed, which belongs to the field of medicines, foods and feeds. The method mainly comprises the steps of preparing through a chromatographic column, eluting and concentrating a solvent, treating active carbon, decompressing, drying and the like, wherein the vitamin E inthe crude oil of the Maoyeshan tung tree seed can be directly eluted, separated and purified by using the chromatographic column and a petroleum ether-ethyl acetate system through a low-pressure chromatography; after being concentrated properly, the vitamin E is treated by the active carbon; and a high-quality natural vitamin E product can be obtained by being dried at low temperature in a vacuumway. The method has the advantages that: the content of the vitamin E in the crude oil can be directly improved from about 0.1% to above 70% through a few operation steps; simultaneously, the processis simple and has a few operation steps and low equipment requirement; a high-temperature heating process is unnecessary; the separation residue can be used in other purposes of the oil of the Maoyeshan tung tree seed; the method is applicable for enterprises of different scales to product; and the method has a wide application prospect.

Owner:四川省毛叶山桐子科技股份有限公司 +1

Preparation method of vitamin E

InactiveCN102584770AGuaranteed purityGuaranteed yieldOrganic chemistryOrganic solventReaction system

The invention relates to a preparation method of vitamin E. The vitamin E is prepared by reacting 2,3,5-trimethylhydroquinone and isophytol serving as starting raw materials in an organic solvent in the presence of Lewis acid, hydrochloric acid and a metal reducing agent. In the technical scheme of the invention, a small amount of metal reducing agent is added into a reaction system for serving as a protective agent to prevent a generated vitamin E product to be oxidized, so that the purity and yield of a target product are ensured. Moreover, the technical scheme of the invention has the advantages of readily-available raw materials, simple and convenient process, low reaction low consumption and easiness for operating, so that the overall cost is reduced, and the method is suitable for industrial mass production.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

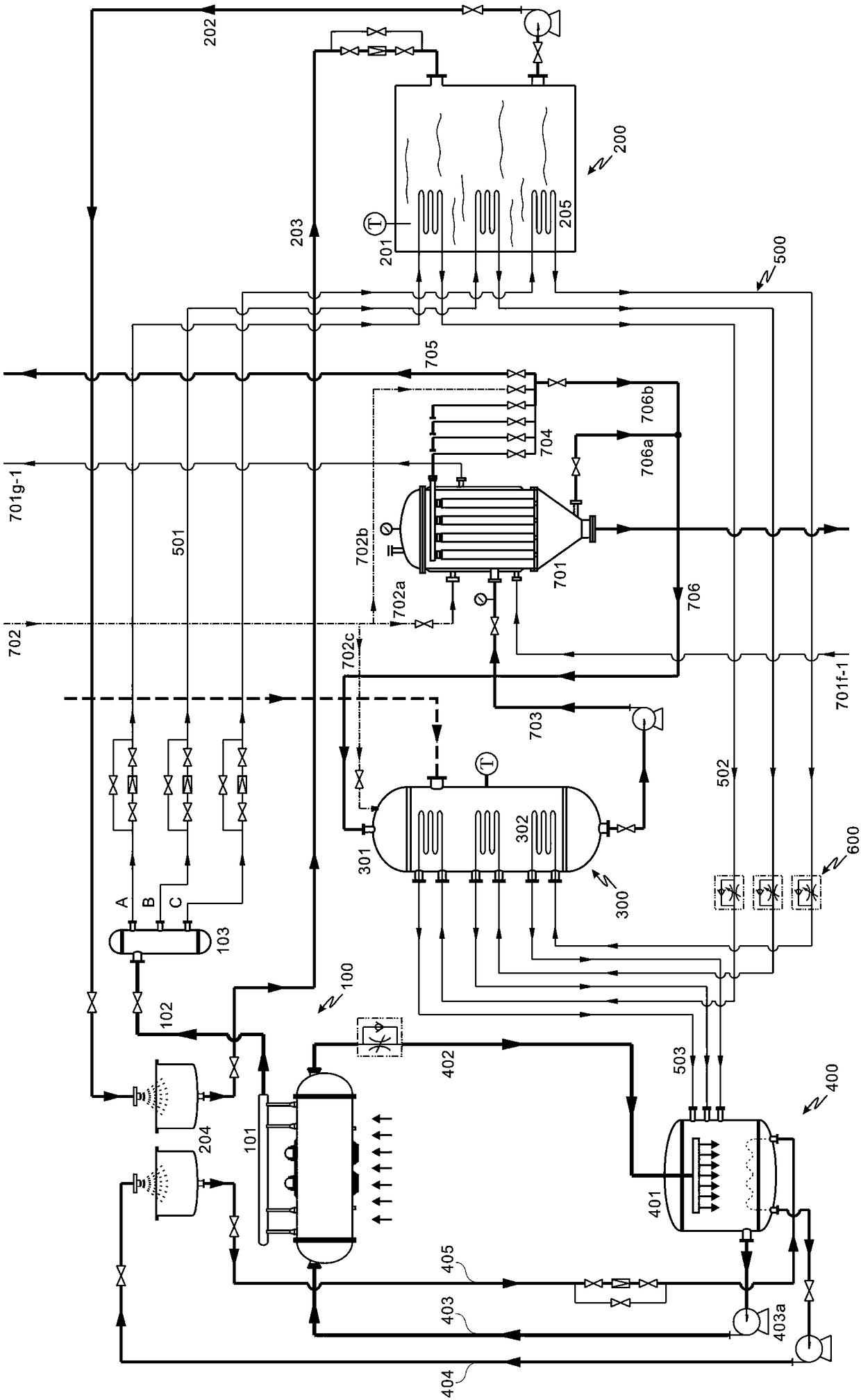

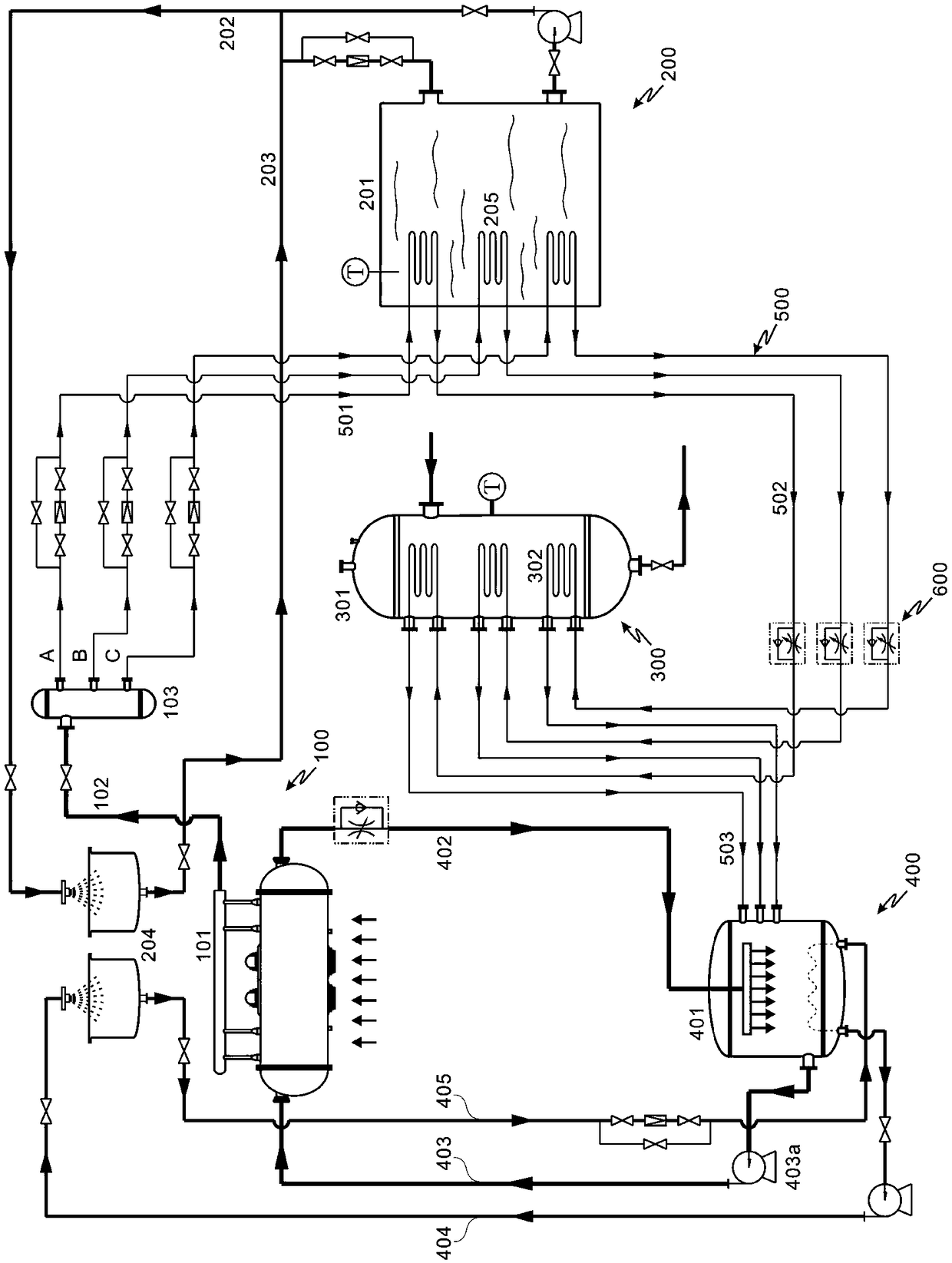

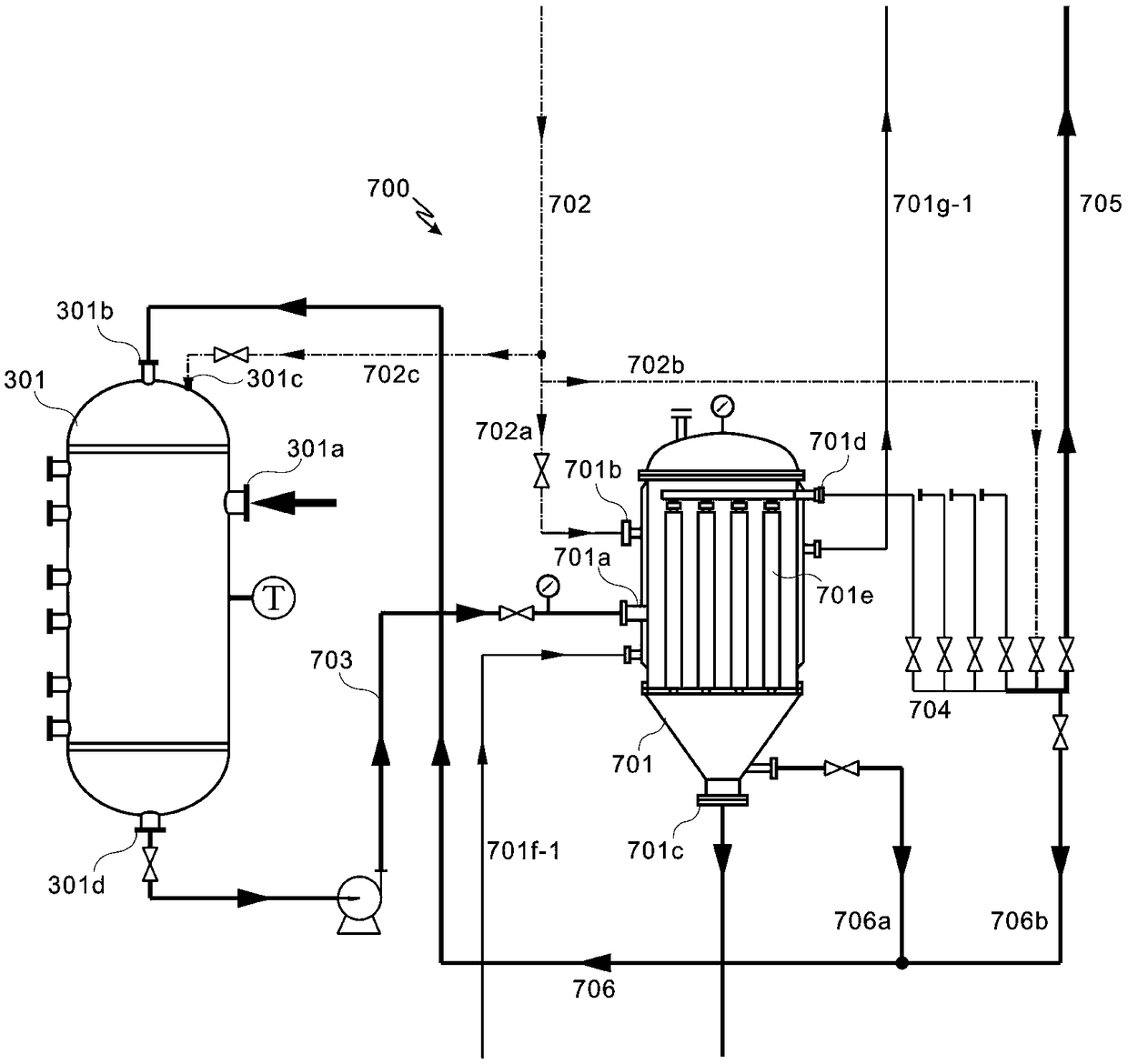

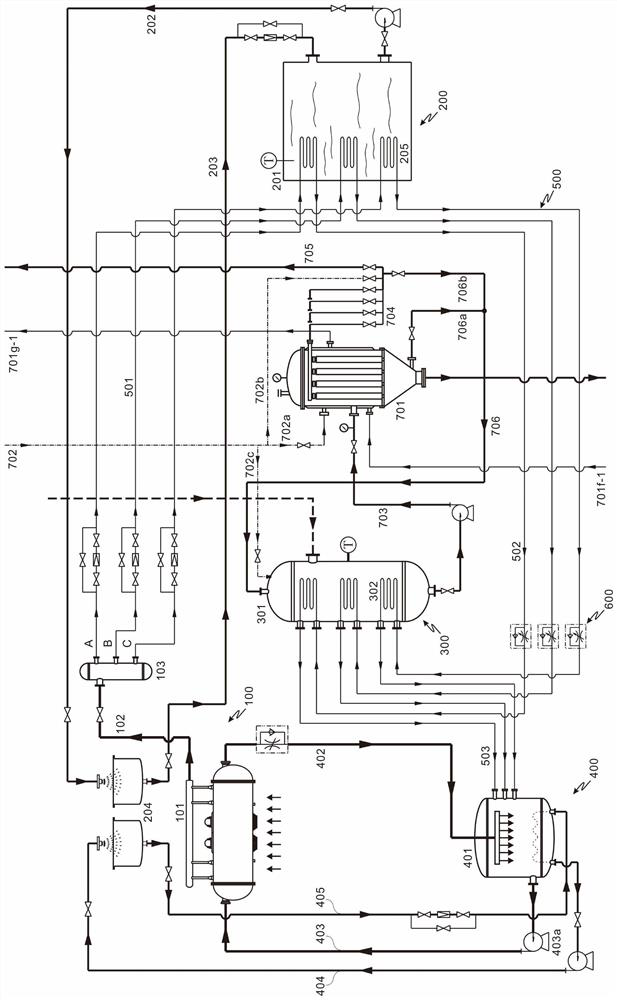

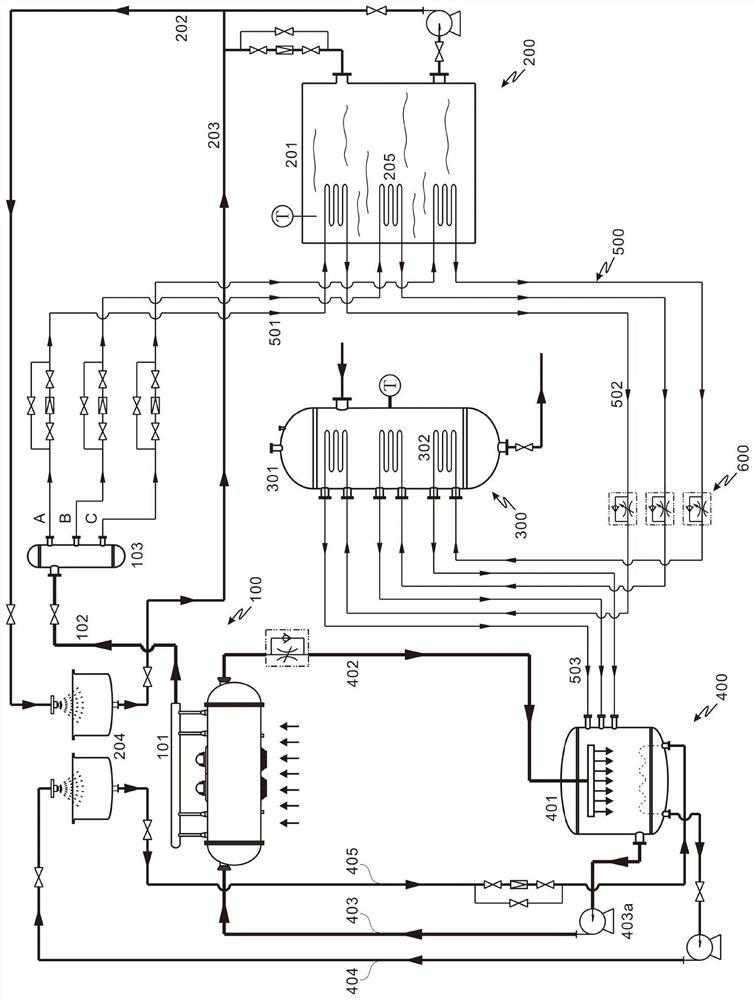

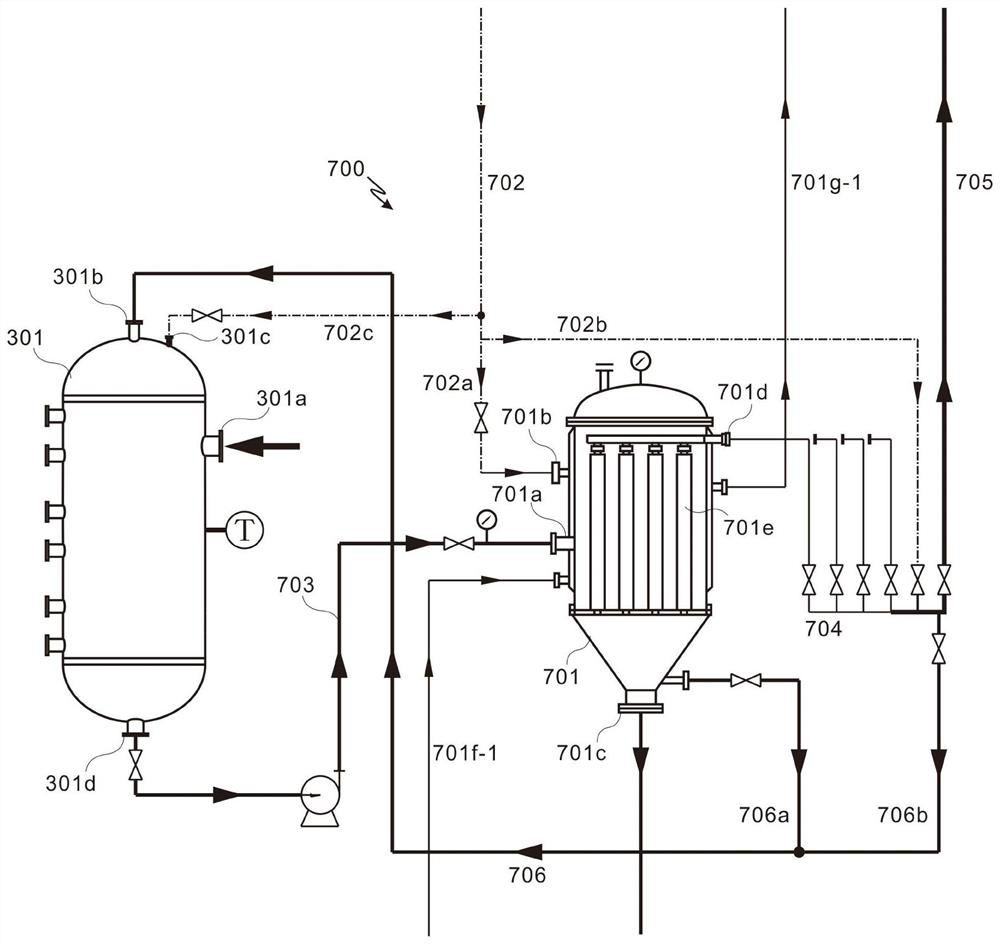

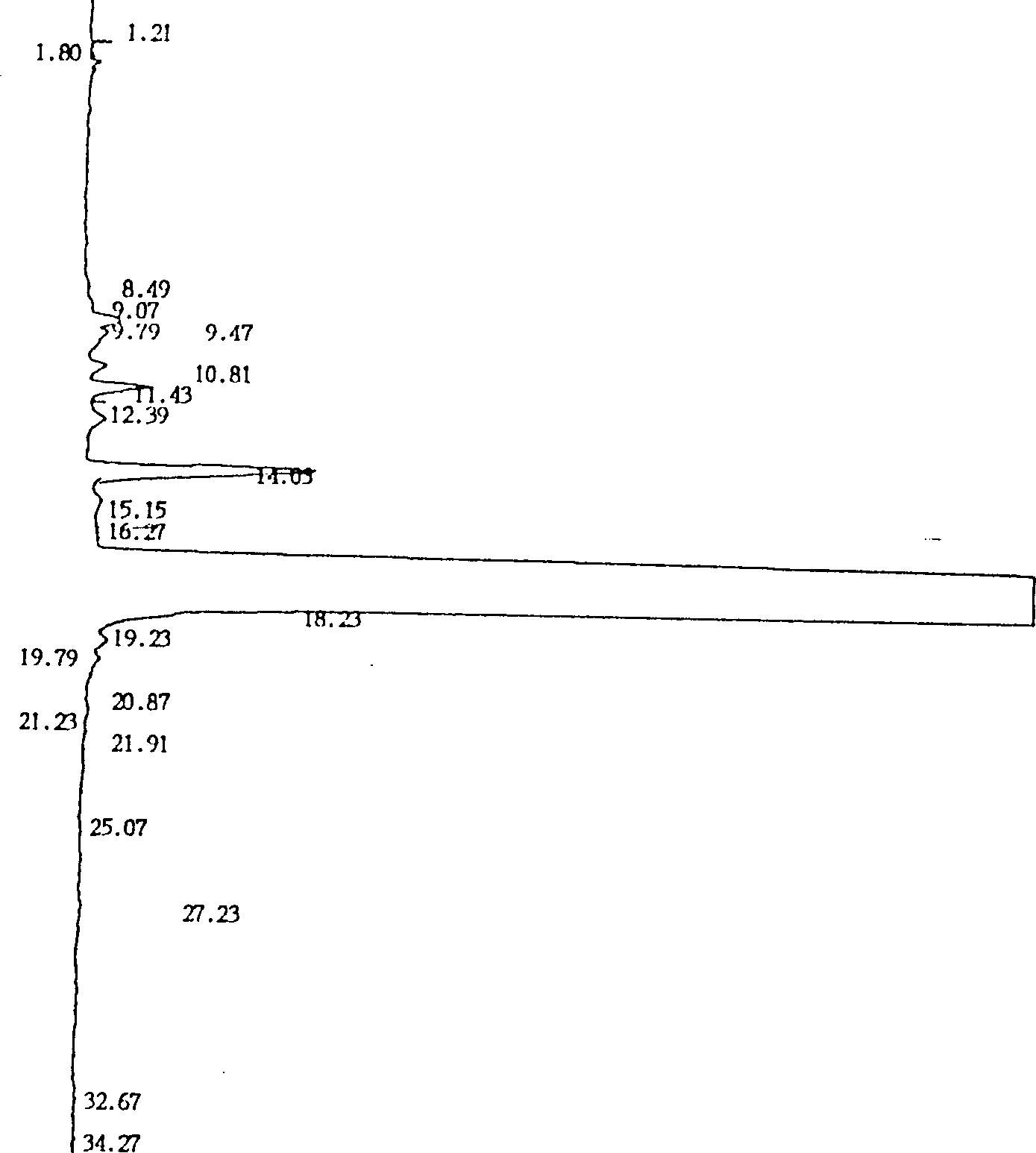

Method and system for low residual multi-stage stripping of vitamin E by-product fatty acid solvent

ActiveCN108771881AReaction is easy to controlHigh puritySteam distillationFractional distillationSterolSolvent

The invention discloses a method and a system for low-residual multi-stage stripping of a vitamin E by-product fatty acid solvent, and the method is as follows: distilling a deodorized distillate fromwhich sterol is removed to respectively obtain a distillate and a residual liquid; performing multi-stage stripping on the distillate, and evaporating a solvent to obtain a vitamin E product. The method has the advantages of extremely low residual capacity, low labor intensity, low environmental pollution, easy control of reaction, and high purity and high recovery rate of the vitamin E.

Owner:JIANGSU CONAT BIOLOGICAL PROD

Prepn of high-content vitamin E

The present invention relates to the preparation process of high-content vitamin E through condensation of trimethyl hydroquinone and isophytol. In polar ester solvent and in the presence of zinc halide and strong acid, trimethyl hydroquinone and isophytol produce condensation reaction. The present invention features that during condensation reaction, co-catalyst in the amount of 0.1-2.0 wt% of isophytol is added to inhibit the generation of dl-alpha-tocopherol isomer. The present invention can produce vitamin E product with vitamin E content over 98 % for corresponding medicinal use.

Owner:ZHEJIANG NHU CO LTD +3

Decoloration and purification method for vitamin E

ActiveCN105585552AIncrease contentLow viscosityOrganic chemistryOther chemical processesActivated carbonPurification methods

The invention provides a decoloration and purification method for vitamin E. The method includes the following steps: (a) providing a composite decoloration agent to perform decoloration to a vitamin E product; (b) eluting the decolored vitamin E in the step (a) through column chromatography by means of an eluting agent, and collecting an eluent component; and (c) concentrating the eluent component in the step (b) to prepare the decolored and purified vitamin E. In the step (a), the composite decoloration agent includes activated clay, activated carbon, diatomite and magnesium silicate according to 100:50-100:30-70:10-50 by mass. The decoloration and purification method can shallow the color and reduce the viscosity of vitamin E, thereby improving flowability and also increasing the purity of the vitamin E. The vitamin E is low in loss and has a high recovery rate during the decoloration and purification.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Preparation method of fortified vitamin E-containing fresh cheese

InactiveCN103783169AImprove food safetyPromote environmental protectionCheese manufactureBiological activationCow milk

The invention relates to reparation method of a fortified vitamin E-containing fresh cheese. The method comprises the following steps: 1, dissolving vitamin E and beta-whey protein in water, stirring with magnetic force so as to obtain a reaction solution, and dialyzing in a dialyzing bag so as to obtain a self-assembly beta-lacto globulin-fortified vitamin E product; 2, inoculating lactococcus in an M17 culture medium, carrying out continuous activation for three generations to obtain a bacterium solution, and inoculating the bacterium solution in a whey basal culture medium for culturing so as to obtain a fermentation agent; 3, mixing the self-assembly beta-lactoglobulin-fortified vitamin E product and fresh cow milk, adding calcium chloride, inoculating the fermentation agent, carrying out acid production, and curding so as to obtain the fortified vitamin E-containing fresh cheese. In the method, only beta-lactoglobulin serves as a carrier, no other coupling reagents, emulgators and organic solvents are added; on one hand, the food safety of the fortified vitamin E-containing fresh cheese is good, on the other hand, the edibleness and the utilization rate of the vitamin E are increased; the shelf life of the fresh cheese is prolonged.

Owner:ANHUI AGRICULTURAL UNIVERSITY

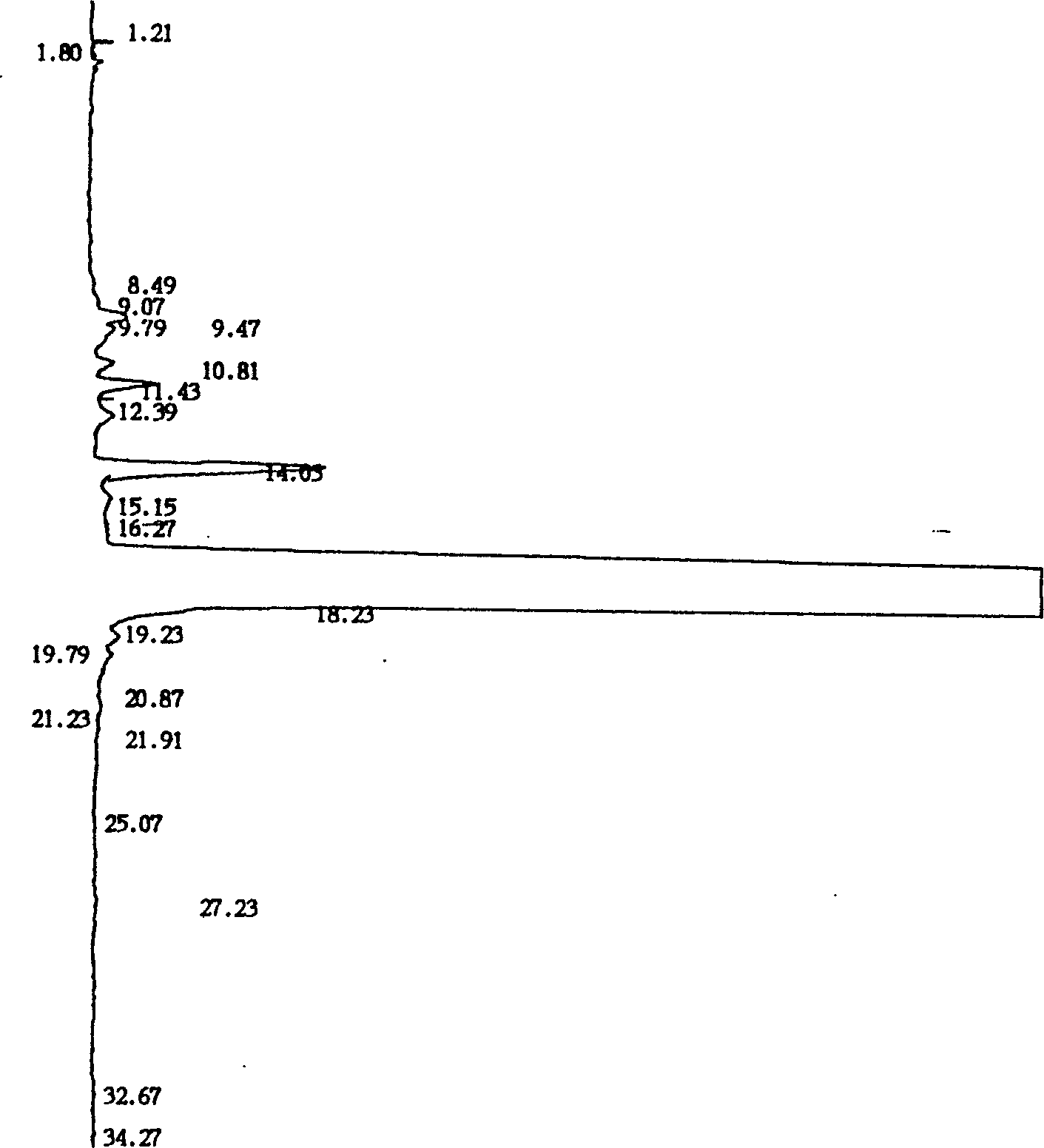

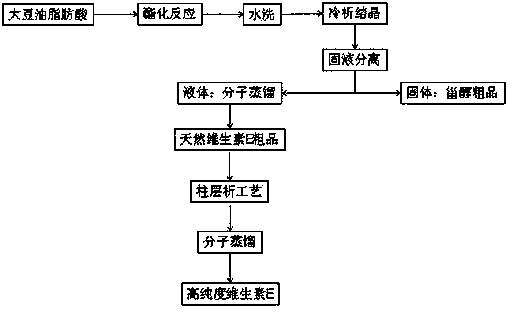

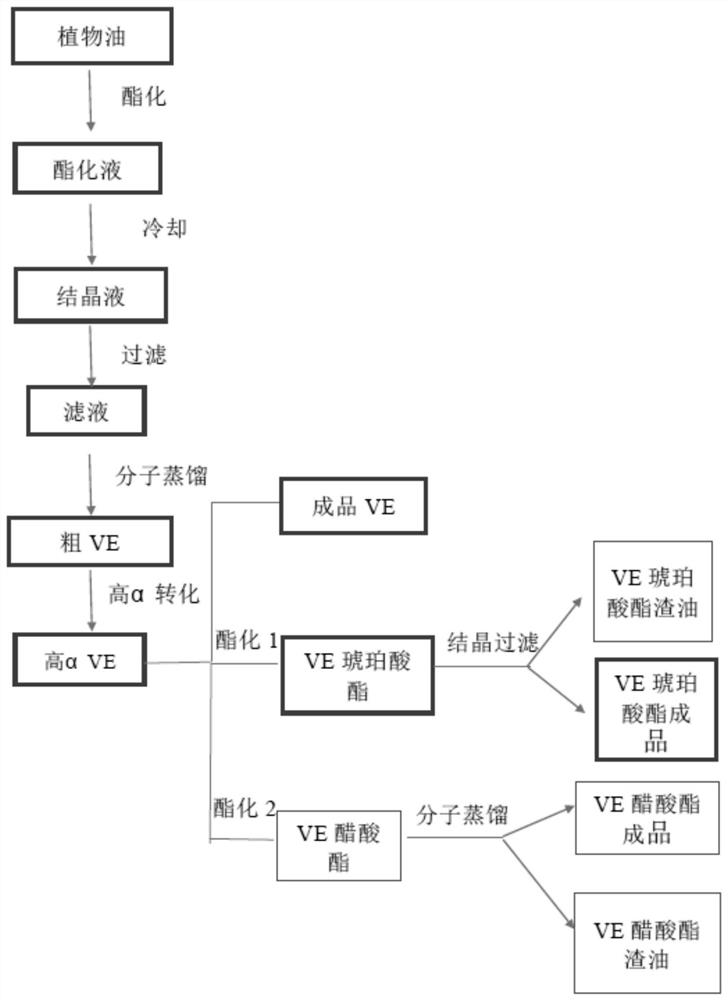

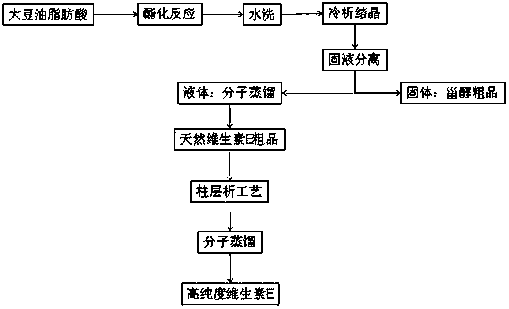

Preparation technology for natural vitamin E

The invention discloses a preparation technology for a natural vitamin E. The preparation technology comprises esterification, water washing, cold crystallization, solid-liquid separation, molecular distillation, column chromatography adsorption, and secondary molecular distillation and the like; according to the preparation technology for the natural vitamin E, the molecular distillation technology and the column chromatography technology are combined, so that the higher-purity natural vitamin E is prepared; the adsorption resin is a filling agent and used for purifying the natural vitamin E through column chromatography, the total content of the natural Vitamin E product prepared is 90% above, and the total yield is 80% above. Because the molecular distillation is performed for two times, by-products can be removed to the greatest extent, the natural vitamin E with good quality, more transparent color, qualified optical rotation, and high quality can be prepared; the process route has the characteristics that the steps are less, the yield is high, and the operation condition is mild; meanwhile, the process can be reduced greatly, the high-purity natural vitamin E can be obtained, the yield is higher, and the cost is reduced.

Owner:JIANGSU XIXIN VITAMIN

Method for extracting natural vitamin E from blackberry seeds

The invention discloses a method for extracting a natural vitamin E from blackberry seeds, which comprises the following steps of: (1) solvent extraction: drying the seeds, extracting by using a mixed liquor of normal hexane and petroleum ether and concentrating extracting liquor to obtain a crude fat extract; (2) urea clathration: dissolving urea by using 95% ethyl alcohol, adding the fat extract, thermally extracting, standing at 0-4 DEG C, filtering, obtaining upper filtrate and carrying out reduced pressure distillation to obtain an oil phase; (3) silica gel column chromatography: carrying out the silica gel column chromatography on the oil phase, collecting eluant which is mixed liquor of absolute ethyl alcohol and normal hexane and concentrating to obtain a vitamin E concentrated solution; and (4) decoloration: decoloring the vitamin E concentrated solution by using a mixture of 7% of active carbon and atlapulgite to finally obtain a natural vitamin E product. The content and the yield of the vitamin E in the product obtained by using the method can be up to 50%.

Owner:江苏连恒生物科技有限公司

Environmentally-friendly synthesis method of vitamin E

ActiveCN103396392BHigh yieldHigh catalytic activityPhysical/chemical process catalystsOrganic chemistryDistillationSynthesis methods

The invention relates to the fine chemistry industry synthesis field, and especially relates to an environmentally-friendly synthesis method of vitamin E. The method comprises the following steps: adding 150-200 parts by weight of toluene into a reaction device, sequentially adding 40 parts by weight of 2,3,5-trimethylquinhydrone and 40-80 parts by weight of isophytol under mechanical stirring, slowly adding 1.5-2.5 parts by weight of magnesium chloride and 0.8-1.2 parts by weight of a magnesium oxide supported silica catalyst after the above obtained reaction system is fully dissolved and clear, closing the reaction system, allowing the reaction system to undergo a reaction under a vacuum degree of -0.07 - -0.05MPa at a temperature of 55-65DEG C for 1.5-2.5h, and allowing toluene reflux to be maintained and generated water to be distilled out with the toluene reflux in the reaction to be in favor of the implementation of the reaction; and recovering the catalyst and the above solvent, and carrying out reduced pressure distillation of the solvent-distilled reaction system to obtain a required pale-yellow oily vitamin E product. The method has the advantages of repeated use of the supported catalyst, high yield, low energy consumption and environmental protection.

Owner:JILIN BEISHA PHARMA

Method for continuously removing dioxin from natural vitamin E

The invention discloses a method for continuously removing dioxin from natural vitamin E. The method comprises the following steps of: dissolving the natural vitamin E in a solvent of which the volume is 2-6 times that of the natural vitamin E; heating to 40-70 DEG C under the protection of nitrogen; uniformly mixing, and then continuously introducing the mixture into a fixed bed in which a filler is filled from the top end of the fixed bed; collecting effluent liquid after the solution stays for 0.5-5 hours; filtering; distilling and concentrating the filtrate; and refining through molecular distillation. The quality of a vitamin E product treated by the method can reach a limit standard to the dioxin by the European Union, the technological process is simple, and the running cost is low, so that the method is a relatively reliable treatment method and is suitable for industrial bulk production.

Owner:ZHONGGU TIANKE TIANJIN BIOENG

Method for industrial extraction of natural vitamin E

The invention provides a method for industrial extraction of natural vitamin E. The method is characterized by including the steps of: A. subjecting soybean oil leftover containing 4%-8% of natural vitamin E to vacuum deodorization dehydration treatment in a wiped-film evaporator; B. then adding a certain amount of ethanol into the treated oily matter for dissolution; C. then adding a catalytic amount of zinc chloride and a specified amount of tetrahydropyrane, and performing stirring at room temperature; D. filtering the precipitate; E. then dissolving the precipitate in ethanol; F. adding a catalytic amount of an organic weak acid water solution to carry out reaction at 45-55DEG C; G. at the end of the reaction, conducting filtering to remove sterol; and H. concentrating the mother liquor dry, thus obtaining natural vitamin E. The method provided by the invention can avoid multistage molecular rectification, and reduces the damage of long-time high temperature and high pressure on vitamin E. The natural vitamin E product extracted by the method provided by the invention has an effective content of greater than or equal to 50%. The employed solvent can be recycled and reused repeatedly. Being convenient and easy to operate, the method is suitable for industrialized production.

Owner:FUJIAN GLANNY BIO ENG

Method for preparing natural vitamin E from crude oil of Maoyeshan tung tree seed

InactiveCN102229593BQuality improvementEasy and economical to makeOrganic chemistryChemical recyclingSolventEthyl acetate

The invention discloses a method for separating, purifying and preparing natural vitamin E from crude oil of Maoyeshan tung tree seed, which belongs to the field of medicines, foods and feeds. The method mainly comprises the steps of preparing through a chromatographic column, eluting and concentrating a solvent, treating active carbon, decompressing, drying and the like, wherein the vitamin E inthe crude oil of the Maoyeshan tung tree seed can be directly eluted, separated and purified by using the chromatographic column and a petroleum ether-ethyl acetate system through a low-pressure chromatography; after being concentrated properly, the vitamin E is treated by the active carbon; and a high-quality natural vitamin E product can be obtained by being dried at low temperature in a vacuumway. The method has the advantages that: the content of the vitamin E in the crude oil can be directly improved from about 0.1% to above 70% through a few operation steps; simultaneously, the processis simple and has a few operation steps and low equipment requirement; a high-temperature heating process is unnecessary; the separation residue can be used in other purposes of the oil of the Maoyeshan tung tree seed; the method is applicable for enterprises of different scales to product; and the method has a wide application prospect.

Owner:四川省毛叶山桐子科技股份有限公司 +1

A kind of decolorization purification method of vitamin E

ActiveCN105585552BIncrease contentGood decolorizationOrganic chemistryOther chemical processesActivated carbonPurification methods

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

A method for extracting vitamin E from the deodorized distillate of jatropha oil

InactiveCN103467432BEfficient separationIncrease contentOrganic chemistryTransesterificationDistillation

The invention discloses a method for extracting vitamin E from the deodorized distillate of jatropha oil, comprising the following steps: (1) methyl esterification; (2) transesterification; (3) supplementary esterification; (4) water washing ; (5) cold analysis; (6) molecular distillation. The method of the invention can extract the product with high vitamin E content from the deodorized distillate of the jatropha oil, has simple operation, low cost and good application prospect.

Owner:SICHUAN RENDE PHARMA

Method for extracting vitamin E from vegetable oil deodorization distillate

InactiveCN101153035BNo pollution in the processEasy to recycleOrganic chemistryMicroorganism based processesVegetable oilDistillation

The present invention discloses a method of extracting vitamin E from plant oil deodorized and distilled substance of plant oil. The present invention has the technical proposal that: through crystallization of previously separated crude sterol and molecular distillation of sterol ester, two types of lipase are orderly used respectively to realize the methyl esterification of free fatty and the esterification of triglyceride in deodorized and distilled substance. Then the molecular distillation technology is used to realize the separation of methyl ester and vitamin E in the fatty acid so as to prepare the concentrated vitamin E product. The present invention uses lipase to replace the conventional strong acid and alkali. Two types of lipase are used to replace the methyl esterification of free fatty and the esterification of triglyceride in deodorized and distilled substance. Compared with the prior art, the reaction of the present invention occur in a mild circumstance; the reactionprocess is easy to be controlled, and conducive to the recycling and use of vitamin E. Besides, the operation is relatively simple and has no problems of environmental pollution. The purity of concentrated vitamin E can reach above 30 percent.

Owner:ZHEJIANG UNIV OF TECH

A method for removing mineral oil in natural vitamin E

ActiveCN107903236BReduce pollutionNo side effects and harmful reactionsOrganic chemistryElutionSolvent

The invention discloses a method for removing mineral oil in natural vitamin E, which comprises the following steps: (1) sample loading: take a separating agent, add eluent a, fill it into a chromatographic column, wash it with eluent a Decompress the chromatography column, dissolve and load the sample according to raw material: eluent a (m / v) = 2: 1; (2) Elution: elute with the eluent a described earlier after loading the sample, and then Elute with eluent b; (3) Collection: collect the eluate in sections and concentrate to obtain natural vitamin E products; (4) Regeneration: wash and regenerate the chromatographic column with eluent c; the raw material is natural Vitamin E; the eluent a is a weak polar solvent; the eluent b is a mixed weak polar solvent composed of the eluent a and the eluent c; the eluent c It is a strong polar solvent. The invention well solves the problem of trace residue of mineral oil in natural vitamin E by utilizing the polarity difference between mineral oil and natural vitamin E.

Owner:NINGBO DAHONGYING BIO ENG

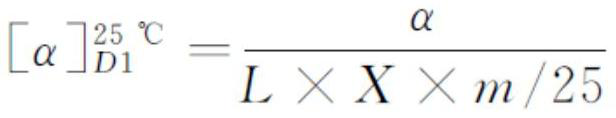

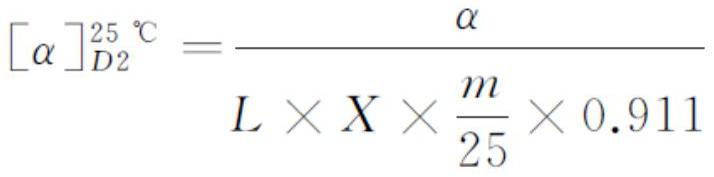

Method for extracting natural vitamin E from byproduct residual oil

PendingCN114644609AIncrease contentOrganic anion exchangersOrganic chemistry methodsVitamin E AcetateOrganosolv

The invention relates to a method for extracting natural vitamin E from by-product residual oil, which comprises the following steps: contacting the by-product residual oil dissolved in an organic solvent with strongly basic anion exchange resin HZ-202, eluting the resin, collecting the eluted fraction, and drying to obtain the natural vitamin E, wherein the byproduct residual oil contains vitamin E succinate and / or vitamin E acetate. By adopting the method disclosed by the invention, not only is the natural vitamin E efficiently recovered, but also the natural vitamin E product with relatively high purity can be obtained, and in addition, the specific rotation of the obtained natural vitamin E product is obviously improved.

Owner:丰益生物科技(江苏)有限公司

Method for continuously removing dioxin from natural vitamin E

The invention discloses a method for continuously removing dioxin from natural vitamin E. The method comprises the following steps of: dissolving the natural vitamin E in a solvent of which the volume is 2-6 times that of the natural vitamin E; heating to 40-70 DEG C under the protection of nitrogen; uniformly mixing, and then continuously introducing the mixture into a fixed bed in which a filler is filled from the top end of the fixed bed; collecting effluent liquid after the solution stays for 0.5-5 hours; filtering; distilling and concentrating the filtrate; and refining through molecular distillation. The quality of a vitamin E product treated by the method can reach a limit standard to the dioxin by the European Union, the technological process is simple, and the running cost is low, so that the method is a relatively reliable treatment method and is suitable for industrial bulk production.

Owner:ZHONGGU TIANKE TIANJIN BIOENG

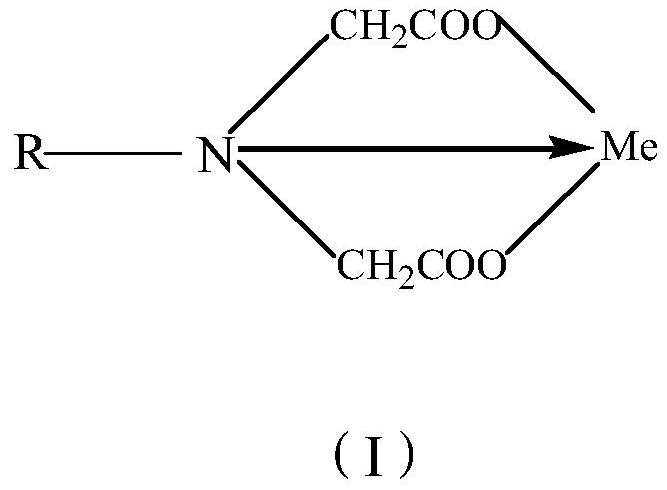

Method for removing zearalenone from natural vitamin E and products obtained by said method

ActiveCN113563297BCause secondary pollutionSimple processOrganic chemistrySpecific adsorptionVitamin products

The invention relates to a method for removing zearalenone from natural vitamin E and a pure vitamin E product obtained by the method. The method for removing zearalenone comprises the steps of pretreatment with iminodiacetic acid type chelating resin, column packing, adsorption, washing, separation and the like. The process of the method for removing zearalenone in the present invention is simple, does not introduce other substances, does not require other separation steps, and does not cause secondary pollution to vitamin E products; compared with adsorbents such as diatomite montmorillonite, the adsorption The efficiency is about 80-90% high, and the material loss is small.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

Preparation method of fortified vitamin E-containing fresh cheese

InactiveCN103783169BImprove food safetyPromote environmental protectionCheese manufactureBiological activationCulture mediums

The invention relates to reparation method of a fortified vitamin E-containing fresh cheese. The method comprises the following steps: 1, dissolving vitamin E and beta-whey protein in water, stirring with magnetic force so as to obtain a reaction solution, and dialyzing in a dialyzing bag so as to obtain a self-assembly beta-lacto globulin-fortified vitamin E product; 2, inoculating lactococcus in an M17 culture medium, carrying out continuous activation for three generations to obtain a bacterium solution, and inoculating the bacterium solution in a whey basal culture medium for culturing so as to obtain a fermentation agent; 3, mixing the self-assembly beta-lactoglobulin-fortified vitamin E product and fresh cow milk, adding calcium chloride, inoculating the fermentation agent, carrying out acid production, and curding so as to obtain the fortified vitamin E-containing fresh cheese. In the method, only beta-lactoglobulin serves as a carrier, no other coupling reagents, emulgators and organic solvents are added; on one hand, the food safety of the fortified vitamin E-containing fresh cheese is good, on the other hand, the edibleness and the utilization rate of the vitamin E are increased; the shelf life of the fresh cheese is prolonged.

Owner:ANHUI AGRICULTURAL UNIVERSITY

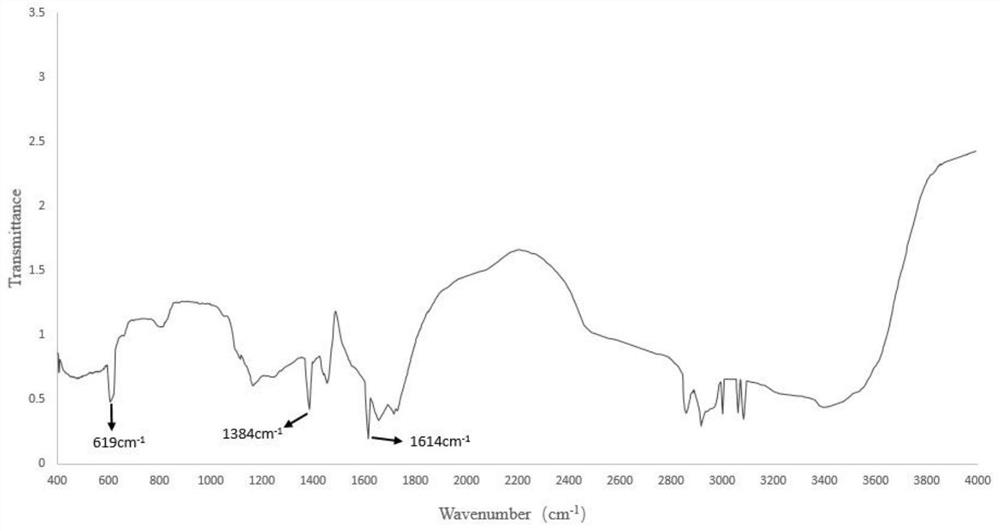

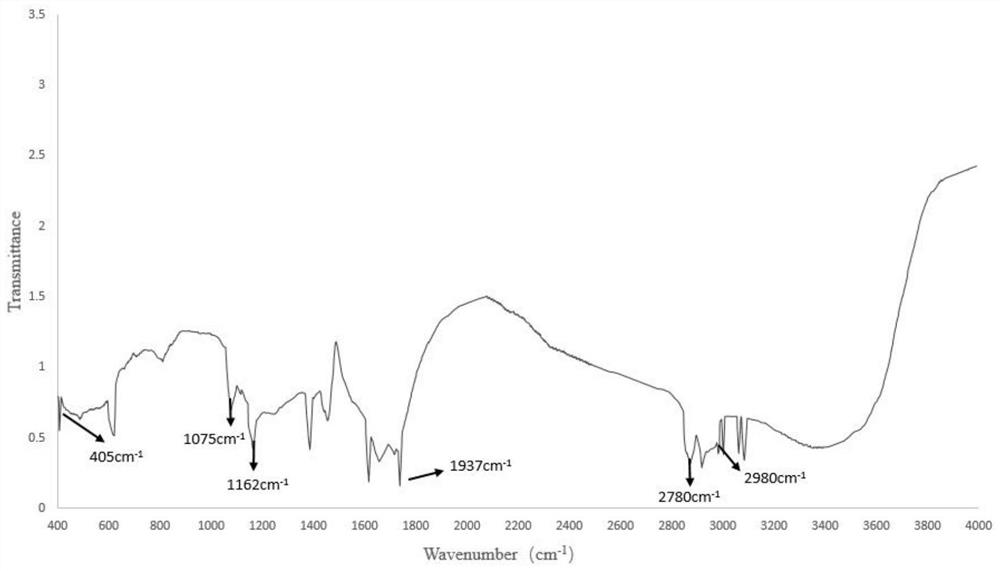

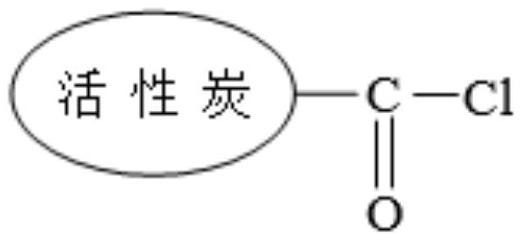

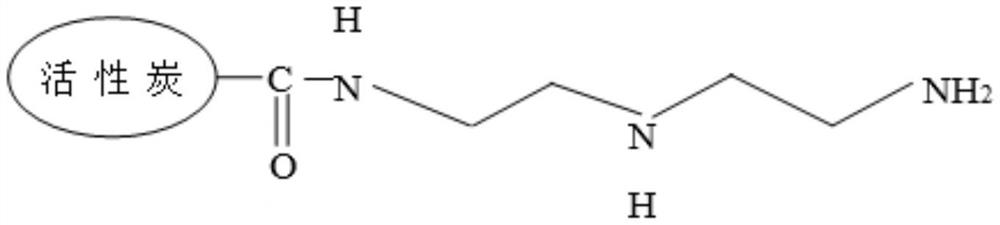

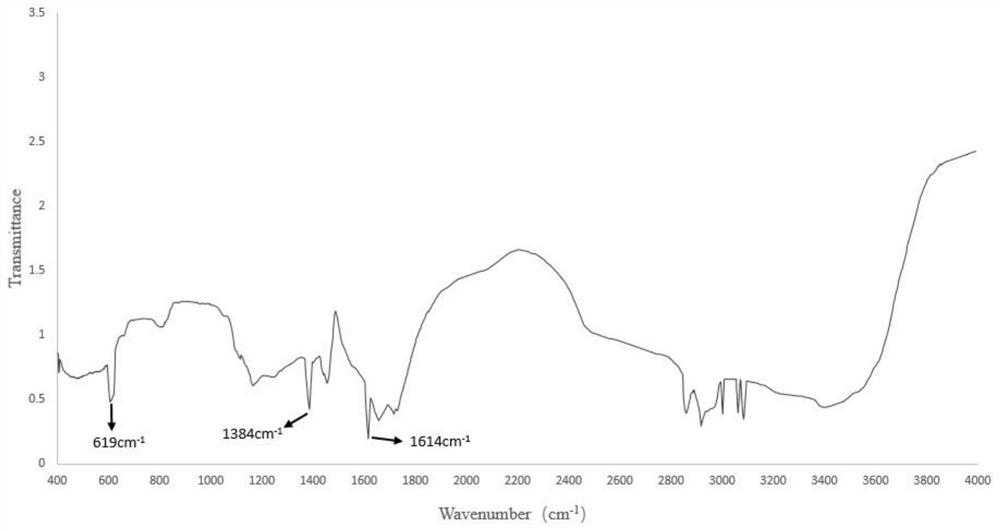

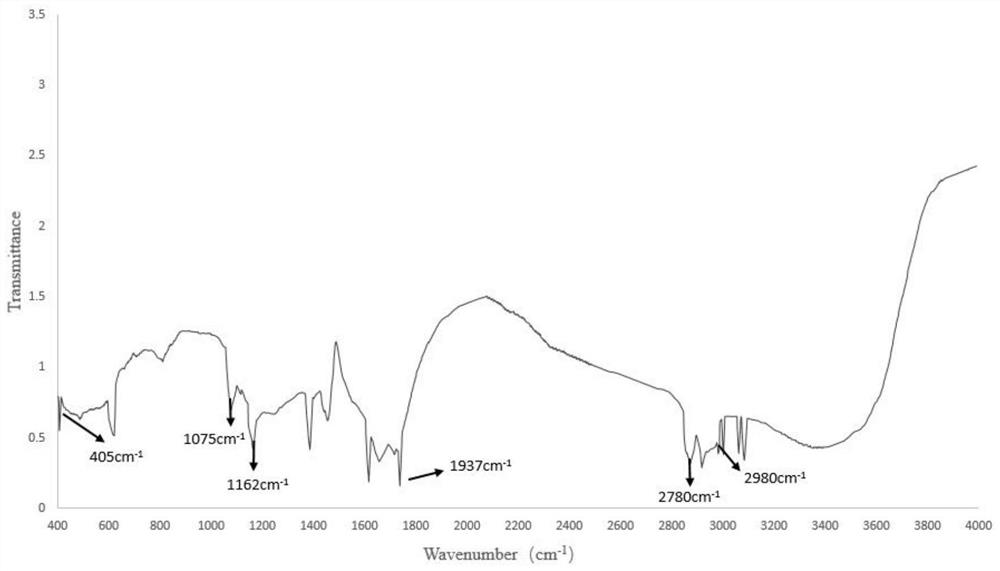

Method for removing glycidyl ester, 3-chloropropanediol and esters thereof from natural vitamin E and obtained product

ActiveCN114516852ACause secondary pollutionSimple processOrganic chemistryOther chemical processesActivated carbonVitamin products

The invention relates to a method for removing natural vitamin E containing glycidyl ester, 3-chloropropanediol and esters thereof and a high-purity vitamin E product obtained by the method. The removal method comprises the steps of activated carbon acid treatment, activated carbon acylating chlorination, activated carbon amination, adsorption, separation and the like. The technical process is simple and easy to implement, no secondary pollution is caused to the natural vitamin E product, and compared with the used natural vitamin E raw material, the glycidyl ester content and the total content of 3-chloropropanediol and 3-chloropropanediol ester of the high-purity vitamin E product obtained through the method are reduced by 85% or above and 88% or above respectively.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

Method for removing zearalenone from natural vitamin E and product obtained by method

ActiveCN113563297ACause secondary pollutionSimple processOrganic chemistrySpecific adsorptionVitamin products

The invention relates to a method for removing zearalenone from natural vitamin E and a pure vitamin E product obtained by the method. The method for removing zearalenone comprises the steps of imino diacetic acid type chelate resin pretreatment, column packing, adsorption, leaching, separation and the like. The method for removing zearalenone is simple in process, does not introduce other substances, does not need other separation steps, and does not cause secondary pollution to the vitamin E product; and compared with adsorbents such as diatomite and montmorillonite, the adsorption efficiency of the method is about 80-90% higher, and the material loss is small.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

Method for removing plasticizer from vitamin E

ActiveCN105693683BReduce plasticizer contentReduce lossesOrganic active ingredientsOrganic chemistryPlasticizerIon-exchange resin

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

A kind of preparation technology of natural vitamin E

The invention discloses a preparation technology for a natural vitamin E. The preparation technology comprises esterification, water washing, cold crystallization, solid-liquid separation, molecular distillation, column chromatography adsorption, and secondary molecular distillation and the like; according to the preparation technology for the natural vitamin E, the molecular distillation technology and the column chromatography technology are combined, so that the higher-purity natural vitamin E is prepared; the adsorption resin is a filling agent and used for purifying the natural vitamin E through column chromatography, the total content of the natural Vitamin E product prepared is 90% above, and the total yield is 80% above. Because the molecular distillation is performed for two times, by-products can be removed to the greatest extent, the natural vitamin E with good quality, more transparent color, qualified optical rotation, and high quality can be prepared; the process route has the characteristics that the steps are less, the yield is high, and the operation condition is mild; meanwhile, the process can be reduced greatly, the high-purity natural vitamin E can be obtained, the yield is higher, and the cost is reduced.

Owner:JIANGSU XIXIN VITAMIN

Method and system for low-residue multi-stage stripping of vitamin E by-product fatty acid solvent

ActiveCN108771881BReaction is easy to controlHigh puritySteam distillationFractional distillationSterolBiochemical engineering

The invention discloses a method and a system for low-residual multi-stage stripping of a vitamin E by-product fatty acid solvent, and the method is as follows: distilling a deodorized distillate fromwhich sterol is removed to respectively obtain a distillate and a residual liquid; performing multi-stage stripping on the distillate, and evaporating a solvent to obtain a vitamin E product. The method has the advantages of extremely low residual capacity, low labor intensity, low environmental pollution, easy control of reaction, and high purity and high recovery rate of the vitamin E.

Owner:JIANGSU CONAT BIOLOGICAL PROD

Prepn of high-content vitamin E

The present invention relates to the preparation process of high-content vitamin E through condensation of trimethyl hydroquinone and isophytol. In polar ester solvent and in the presence of zinc halide and strong acid, trimethyl hydroquinone and isophytol produce condensation reaction. The present invention features that during condensation reaction, co-catalyst in the amount of 0.1-2.0 wt% of isophytol is added to inhibit the generation of dl-alpha-tocopherol isomer. The present invention can produce vitamin E product with vitamin E content over 98 % for corresponding medicinal use.

Owner:ZHEJIANG NHU CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com