Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Tone burst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

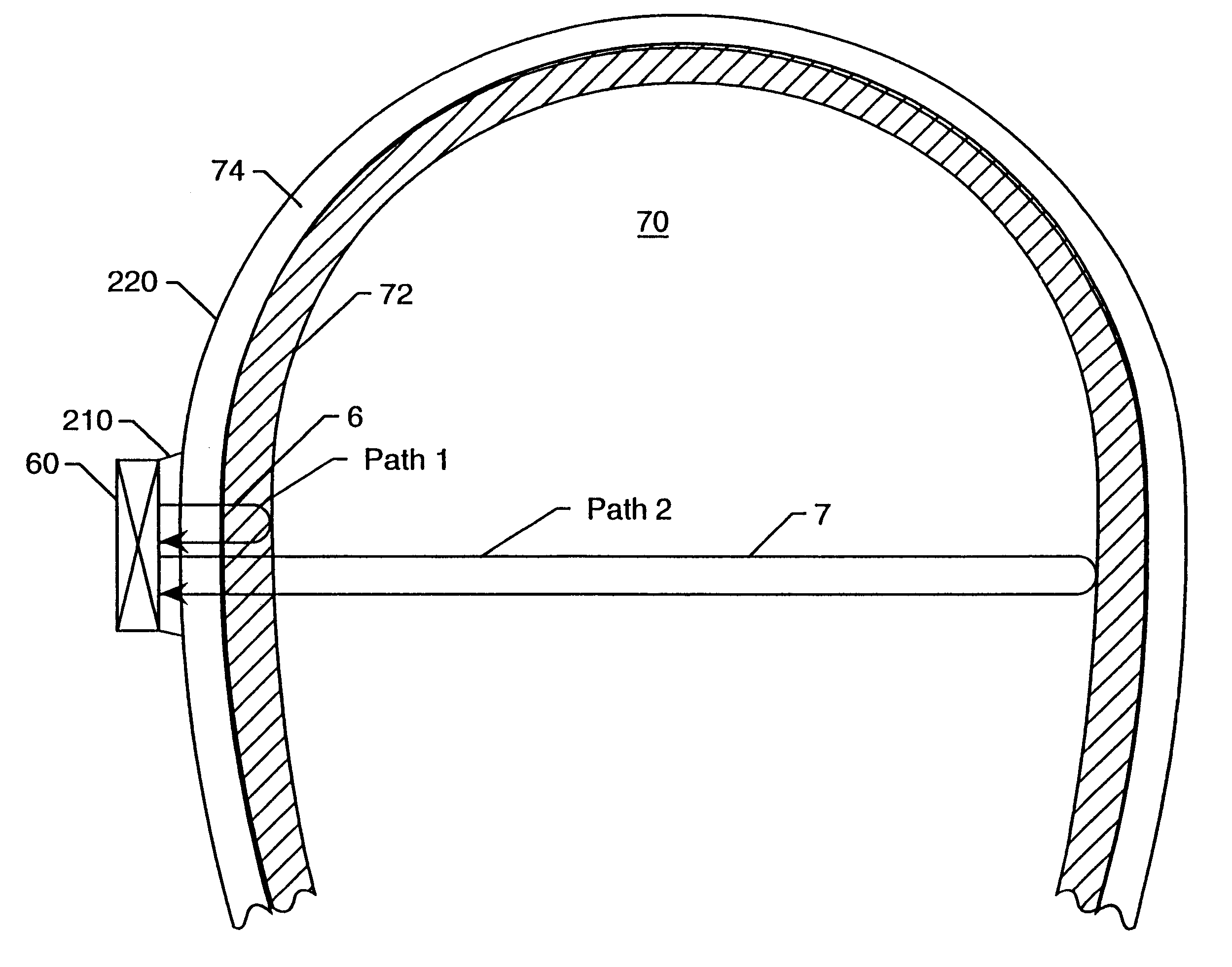

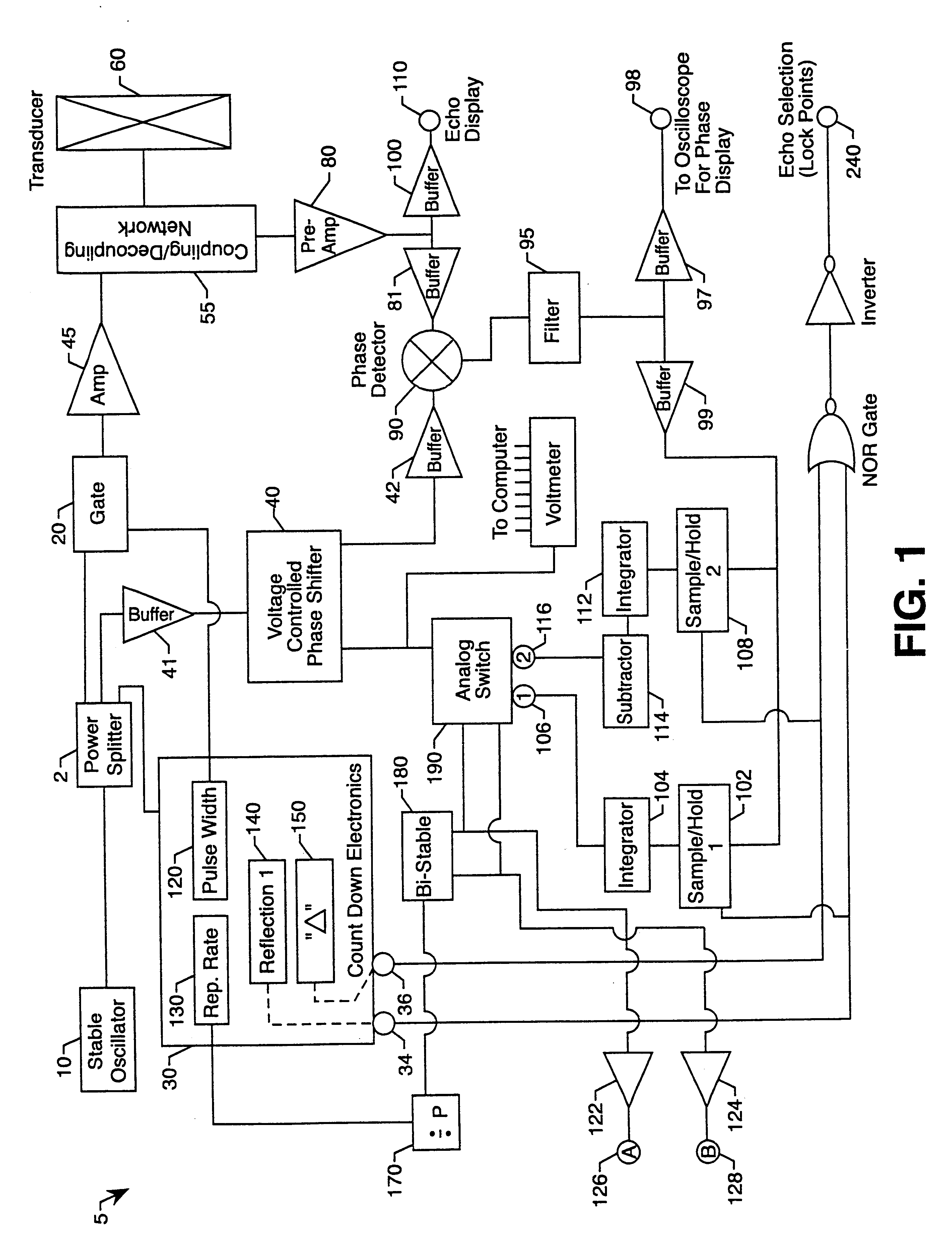

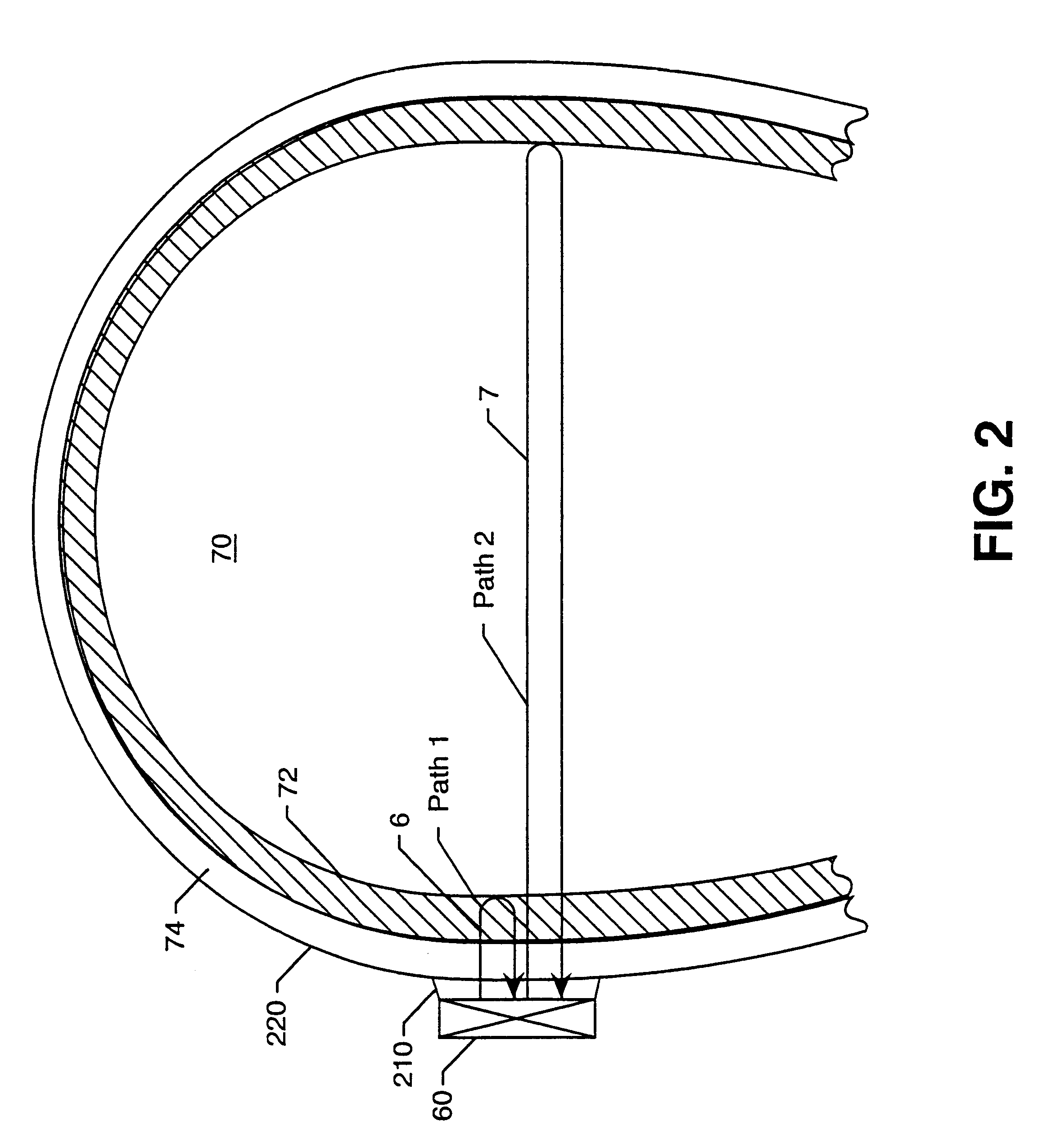

Method and apparatus for assessment of changes in intracranial pressure

InactiveUS6413227B1Eliminate the effects ofOrgan movement/changes detectionIntracranial pressure measurementElectricityPhase shifted

A non-invasive method and apparatus for monitoring changes in intracranial pressure which removes extracranial effects from the measurements. The method and apparatus can include the supplying of a fixed frequency electrical output to a transducer coupled to the patient's head, thereby generating an acoustical tone burst in the patient's head which generates a first echo and a second echo, the first echo reflecting from a first interface in the side of the patient's head coupled to the transducer, and the second echo reflecting from a second interface at the opposite side of the patient's head. The first and second echoes are received by the transducer which can generate a first electrical signal and a second electrical signal, wherein the first and second electrical signals vary in accordance with the corresponding first and second echoes. The counterbalancing phase shifts required to bring about quadrature between each of the first and second electrical signals and the fixed frequency electrical output can be measured, and values for the change in intracranial distance based on the changes in the counterbalancing phase shifts can be obtained.

Owner:NASA

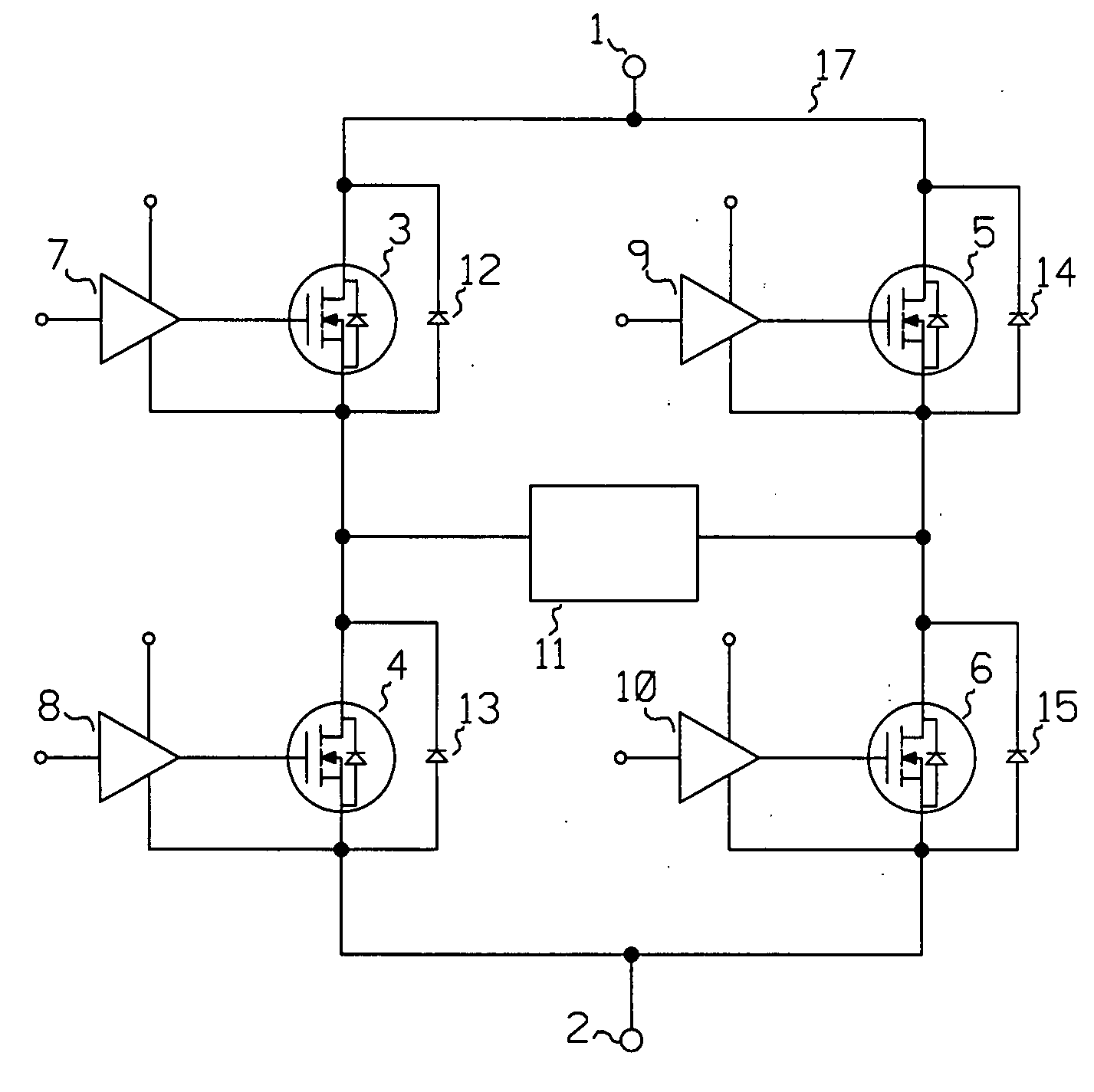

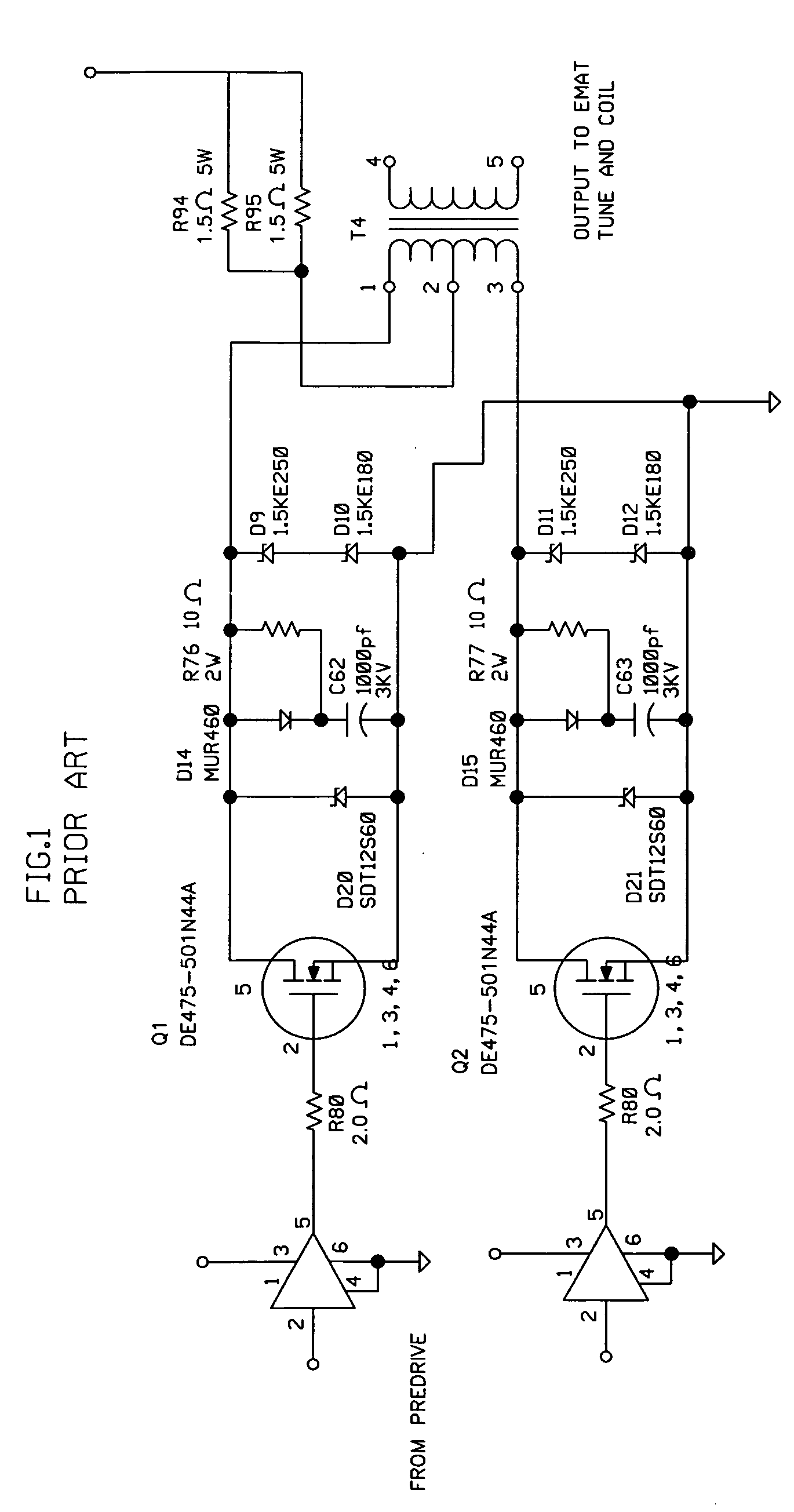

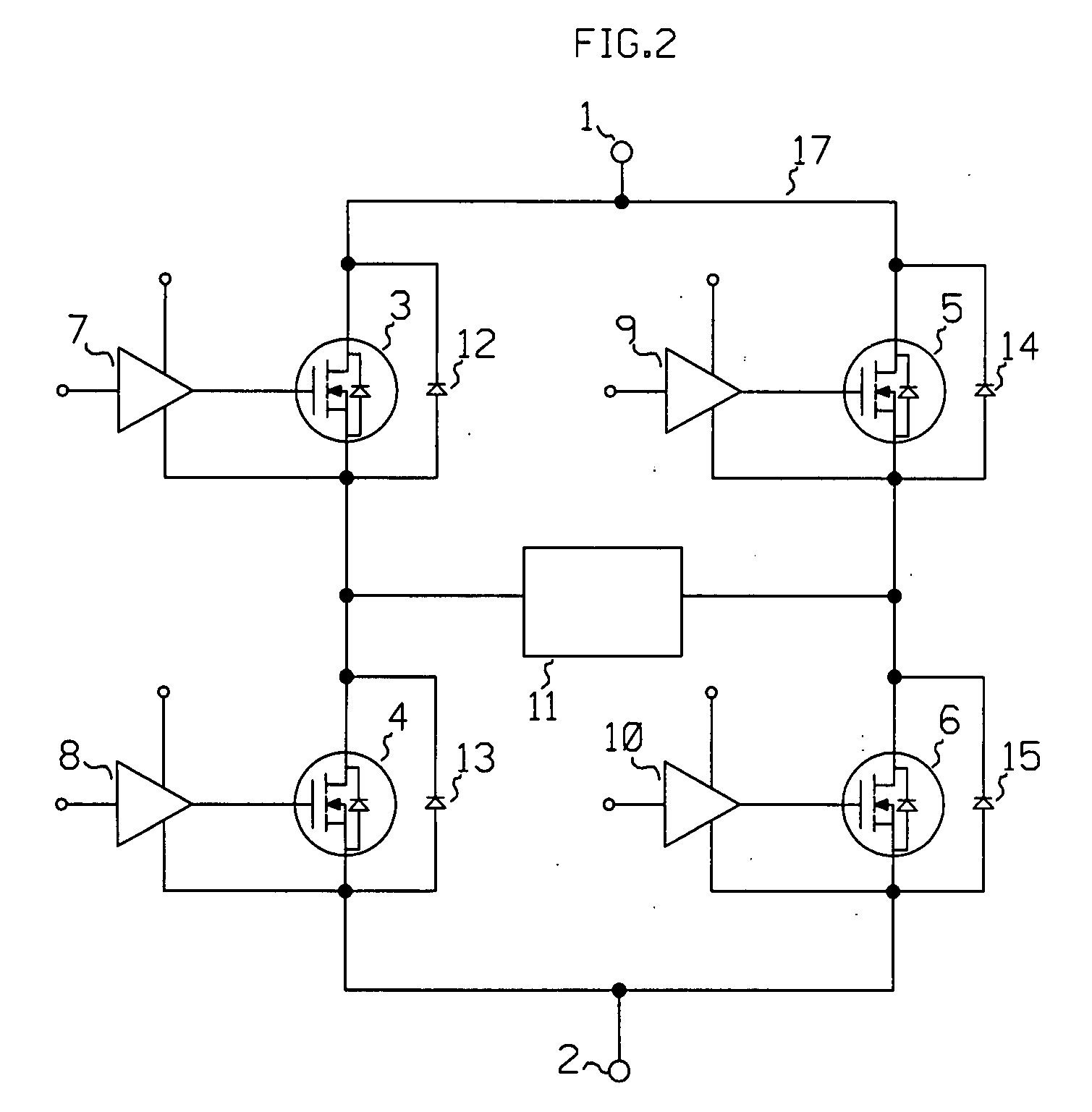

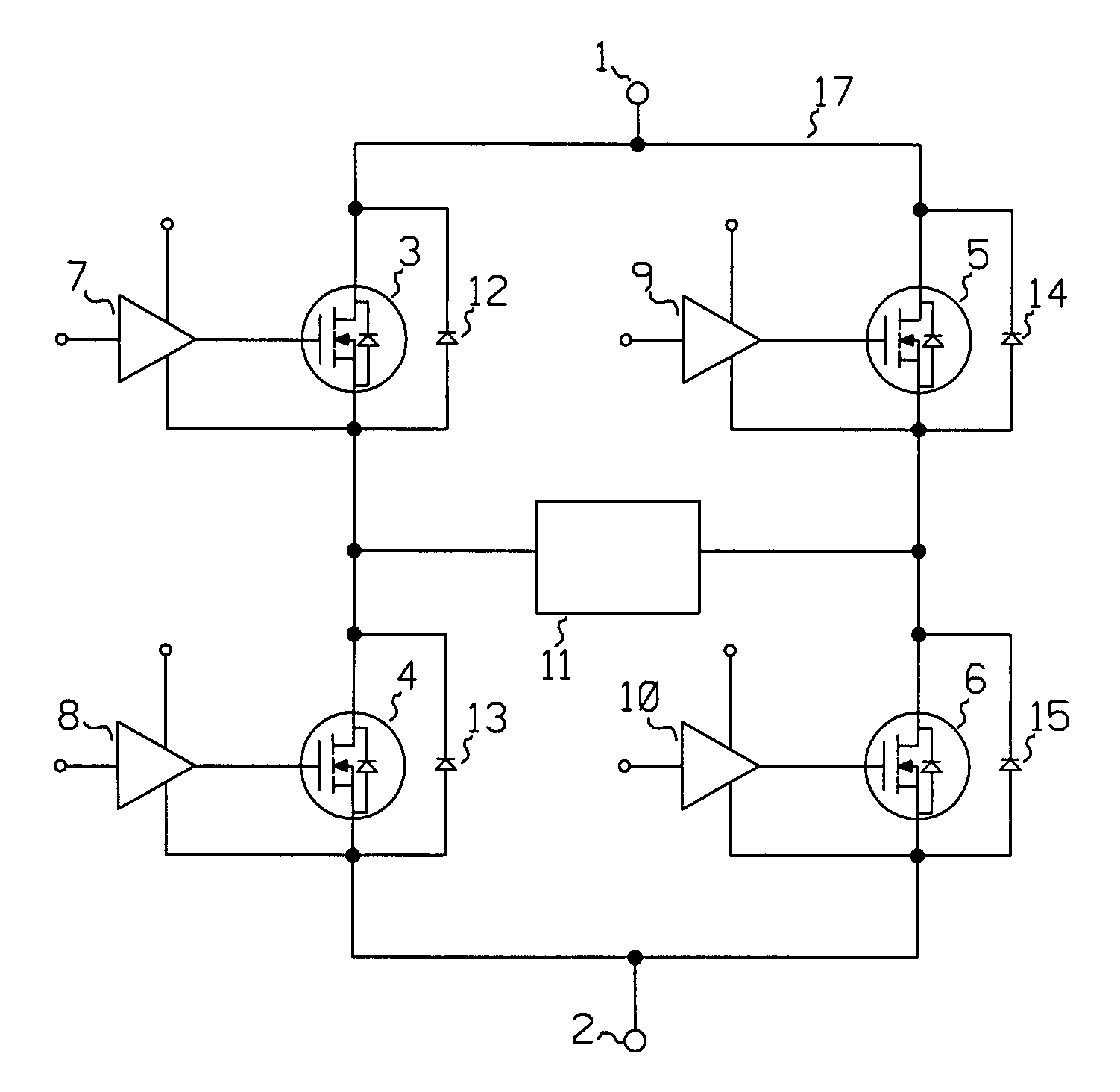

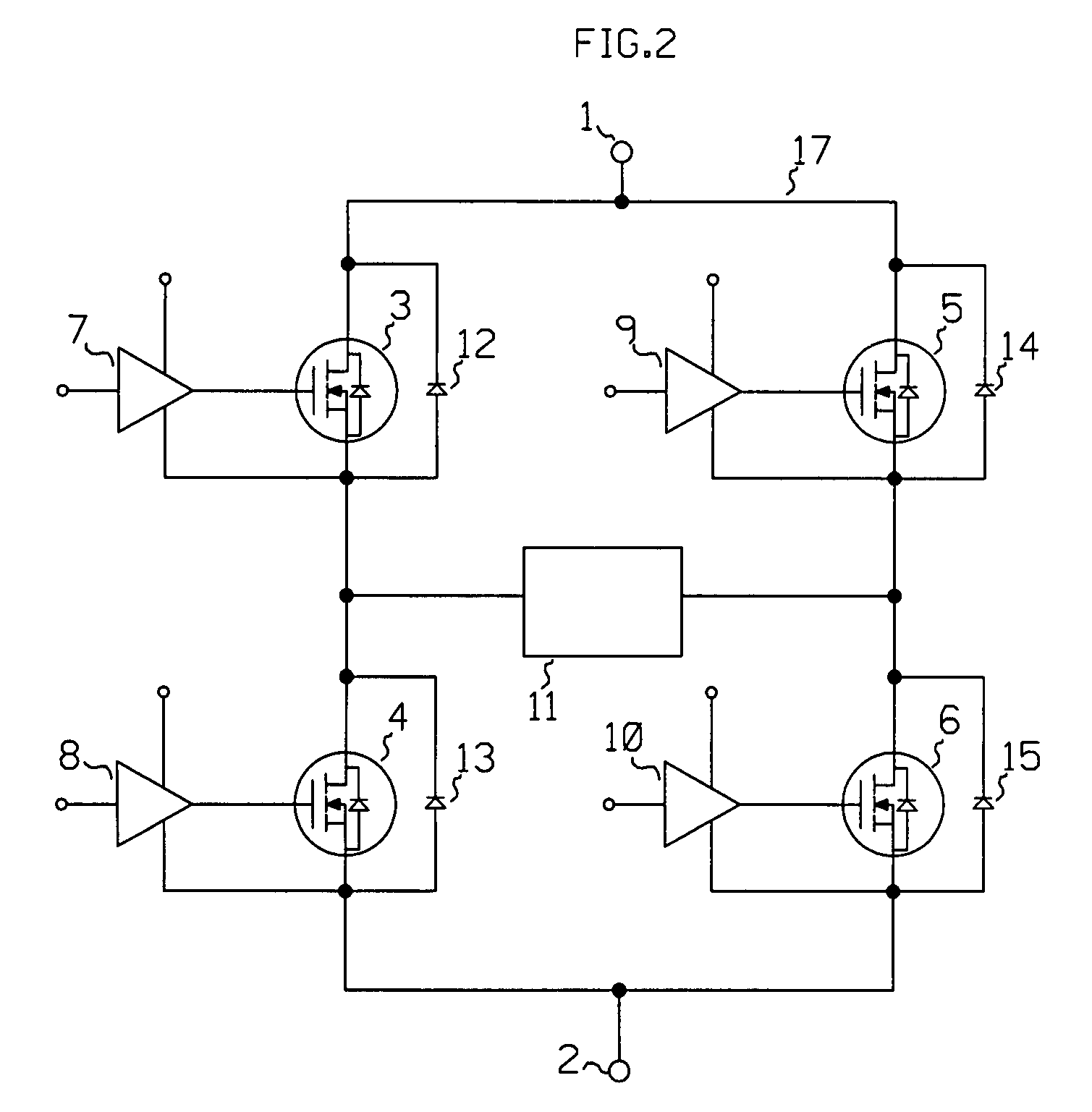

H-Bridge pulse generator

InactiveUS20100254221A1Reduce Propagation DelayAvoid failureMechanical vibrations separationTransmissionOutput transformerPeak value

Electronic circuitry for high-power, high-frequency excitation of electromagnetic acoustic transducers (EMAT) without the use of a matching transformer is described. This circuit contains a least 4 switching devices such as power Mosfet transistors, arranged in an H-Bridge configuration that are designed to drive various EMATs over a wide range of frequencies. The switching devices can be connected in parallel with respect to the H-Bridge and switched in sequence for greater power output and variety of wave forms. This circuit configuration can provide a many excitation waveforms including, Churp, Hemming window tone burst, rectangular tone burst and Barker Code wave forms.An improved electronic pulser circuit based on the H-bridge topology is designed for driving the sensor coils of an electromagnetic acoustic transducer (EMAT) to correct the disadvantages of conventional H-bridge pulsers and pulsers that require the use of an output transformer. A plurality of switching devices, primarily power Mosfets, are connected in parallel and augmented with support circuitry to provide improved performance in terms of increased power output, stability, reduced noise and complex output wave forms. This improved design provides for the application of modulated pulses such as multi-pulse, multi-frequency tone bursts of peak power outputs in excess of 20 thousand watts and frequencies in excess of 10 thousand Hertz.

Owner:SMITH STEPHEN

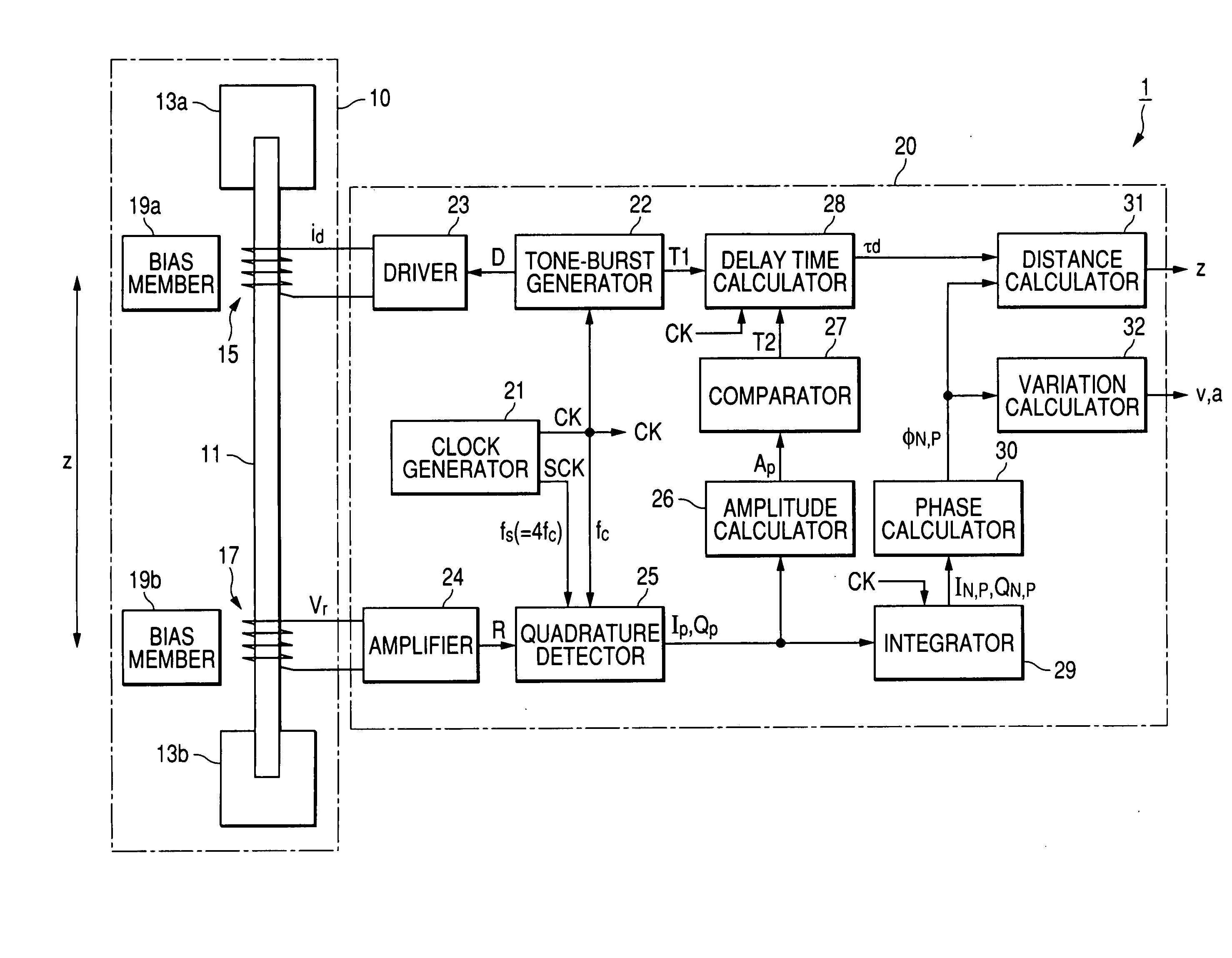

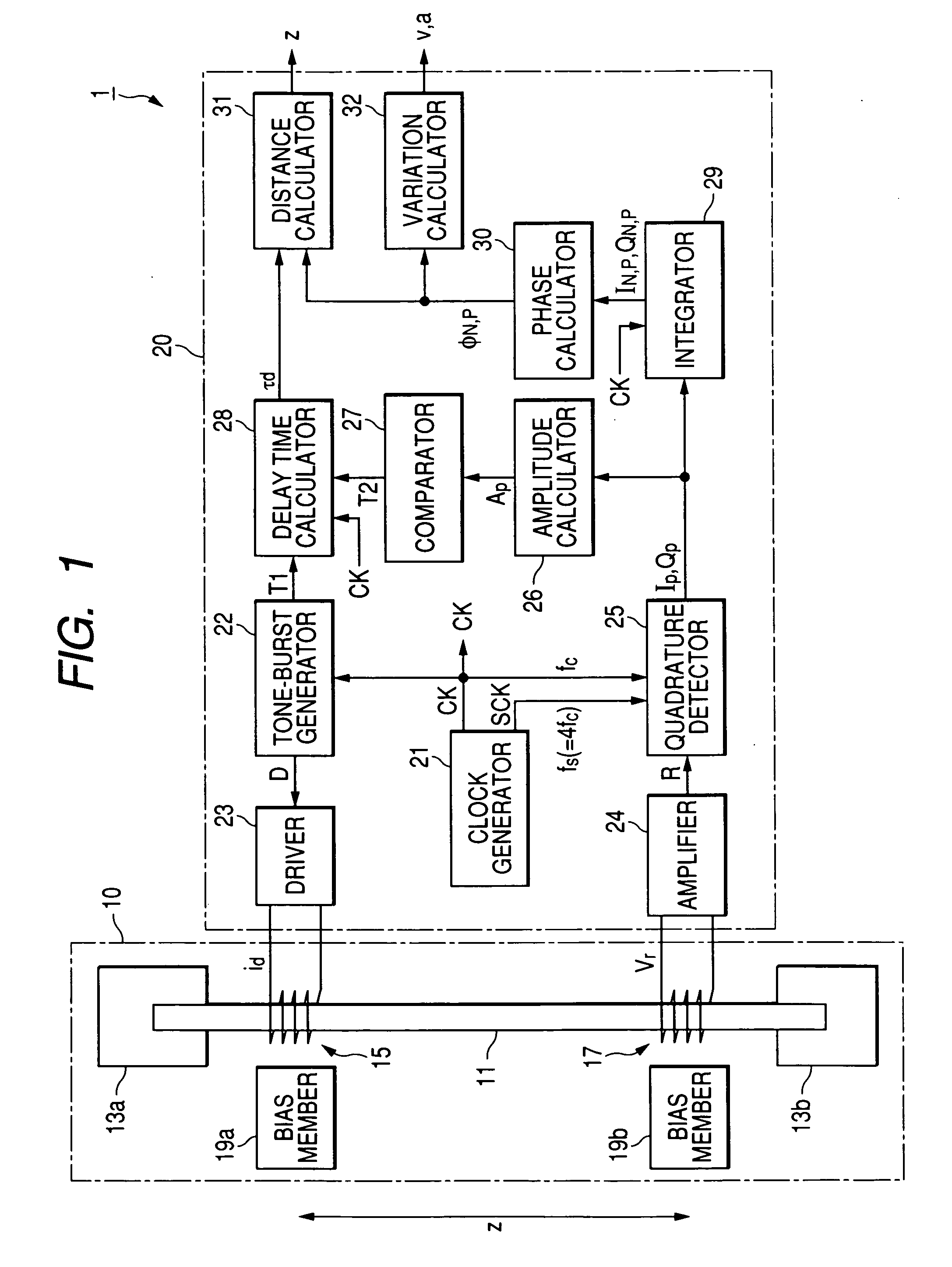

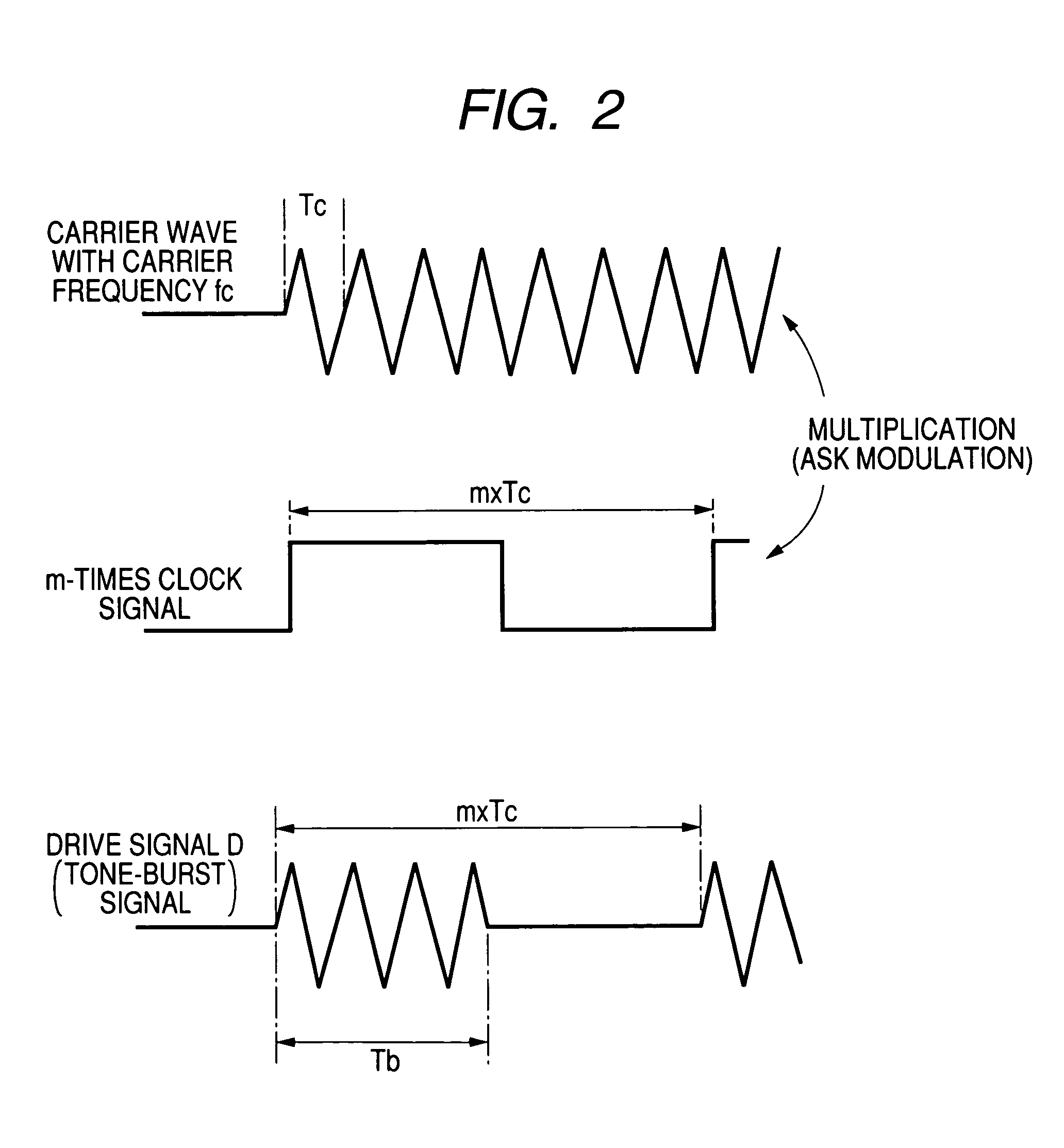

Positional information detecting method and device

InactiveUS20070203667A1High resolutionNoise figure or signal-to-noise ratio measurementUsing subsonic/sonic/ultrasonic vibration meansPropagation delayConstant frequency

In a positional information detecting device, a tone-burst signal propagating unit causes a tone-burst signal to propagate through a path. The tone-burst signal is composed of a continuous wave train, the continuous wave train including a plurality of cycles of a constant frequency. A detecting unit detects, at a predetermined position in the path, the tone-burst signal propagating through the path every one cycle of the tone-burst signal to measure a propagation delay time based on the detected signal. The propagation delay time represents a period for which the tone-burst signal has propagated through the path. A phase obtaining unit obtains a phase of the detected signal. A positional information obtaining unit obtains positional information associated with the predetermined position based on the measured propagation delay time and the obtained phase of the detected signal.

Owner:DENSO CORP

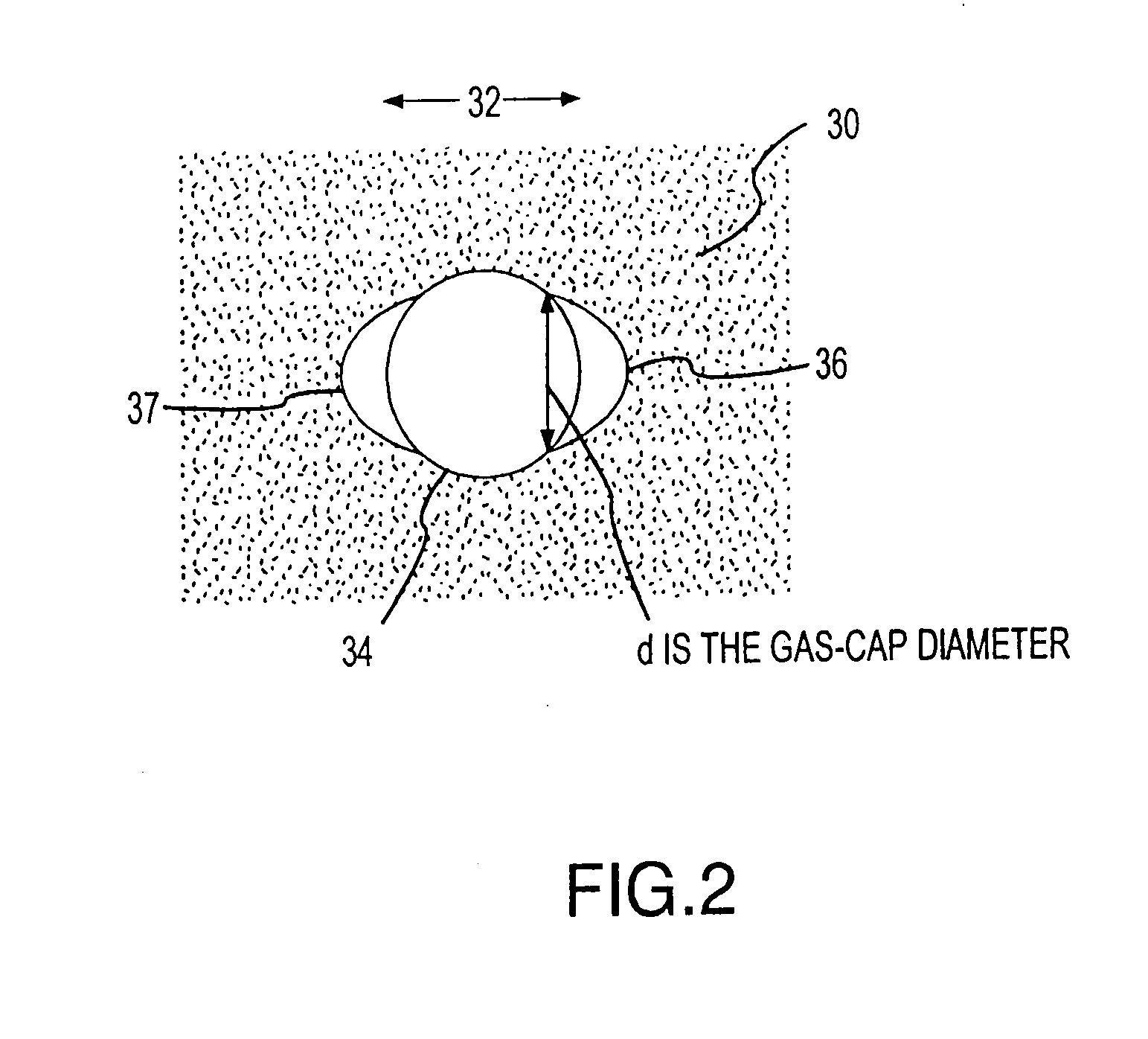

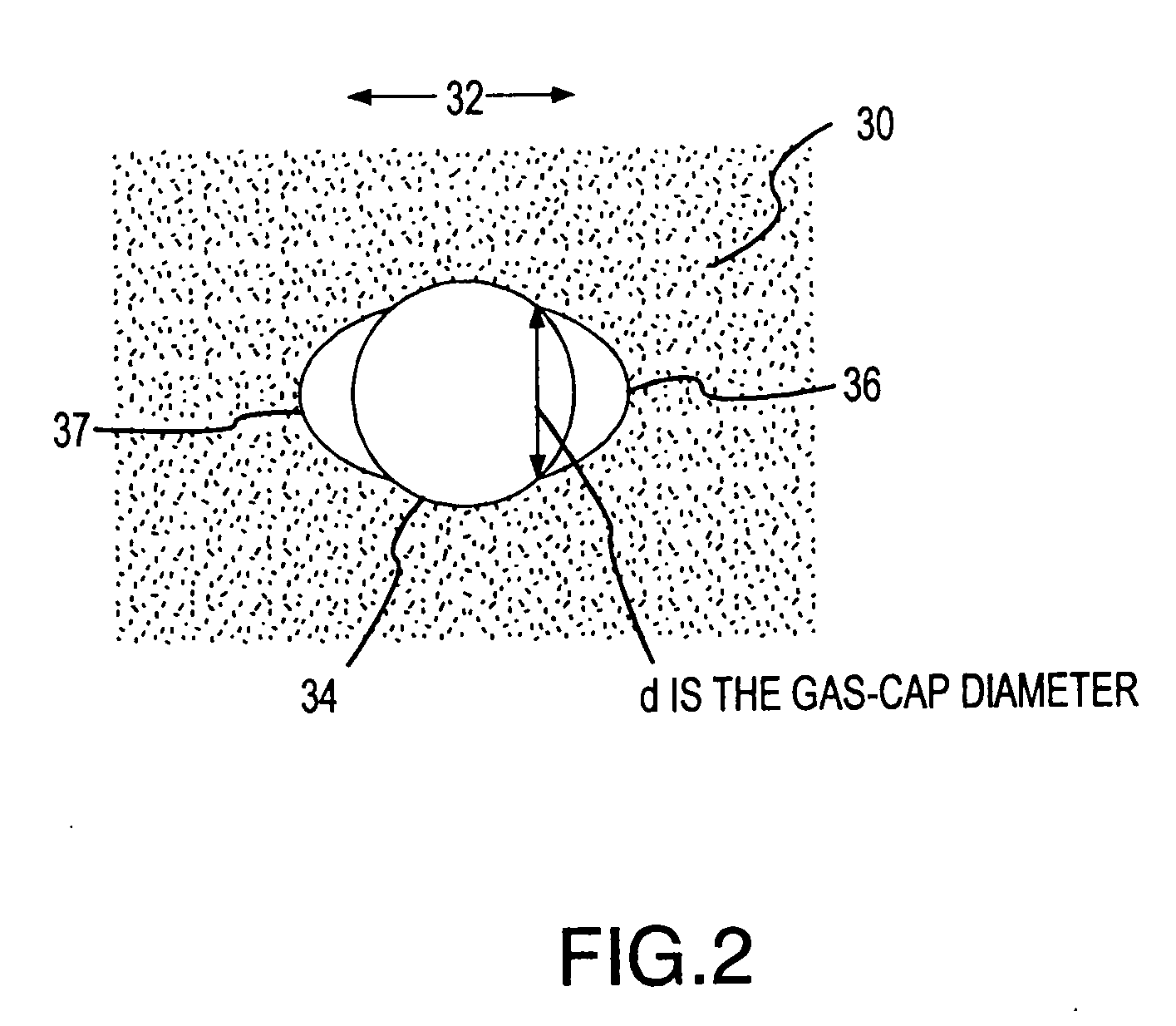

Noninvasive detection of corrosion, MIC, and foreign objects in fluid-filled pipes using leaky guided ultrasonic waves

InactiveUS6595059B2Fast and reliableDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationTransducer

Ultrasonic energy in the form of guided waves is launched into the wall of a fluid-filled container. The guided wave propagates around the circumference of the container from a transmitting transducer to a receiving transducer. Part of the guide wave energy leaks into the fluid in the form of bulk waves, reflects off the inner wall on the other side and enters back to the receiving transducer trailing the direct wave. Analysis of the received waves determines the presence of corrosion pitting and MIC nodules on the container inner wall, and fluid level. In addition, it determines whether foreign objects are inside the container. The guided waves are created with wideband transducers excited at certain frequencies that depend on the material and geometry of the part being measured. The leakage energy is maximized with a shaped tone burst pulse at the specified frequency. The energy and energy ratio of both the direct and leakage fields are measured and related to the container inner wall condition and the presence of any foreign objects in the fluid.

Owner:DIGITAL WAVE CORP

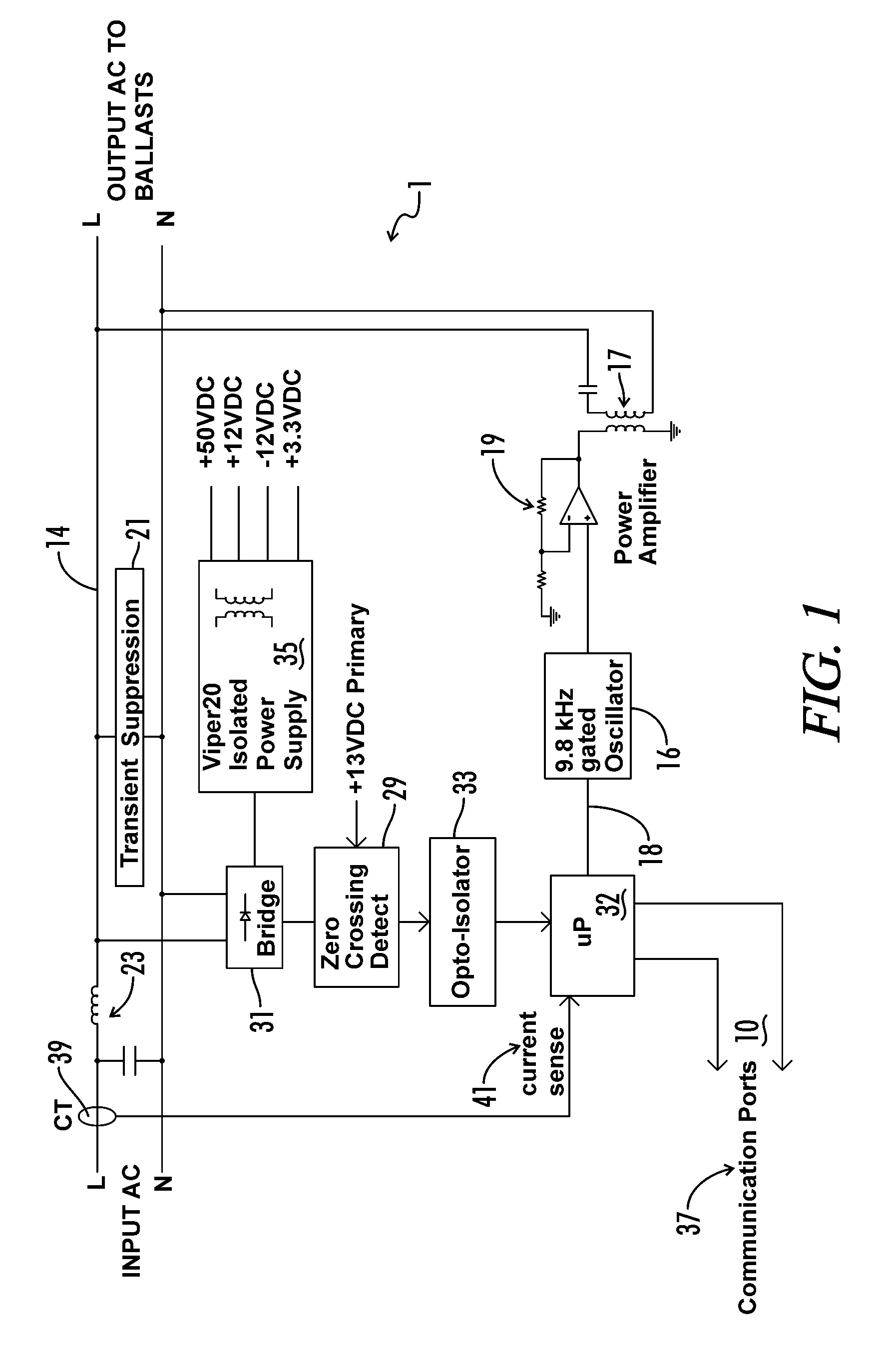

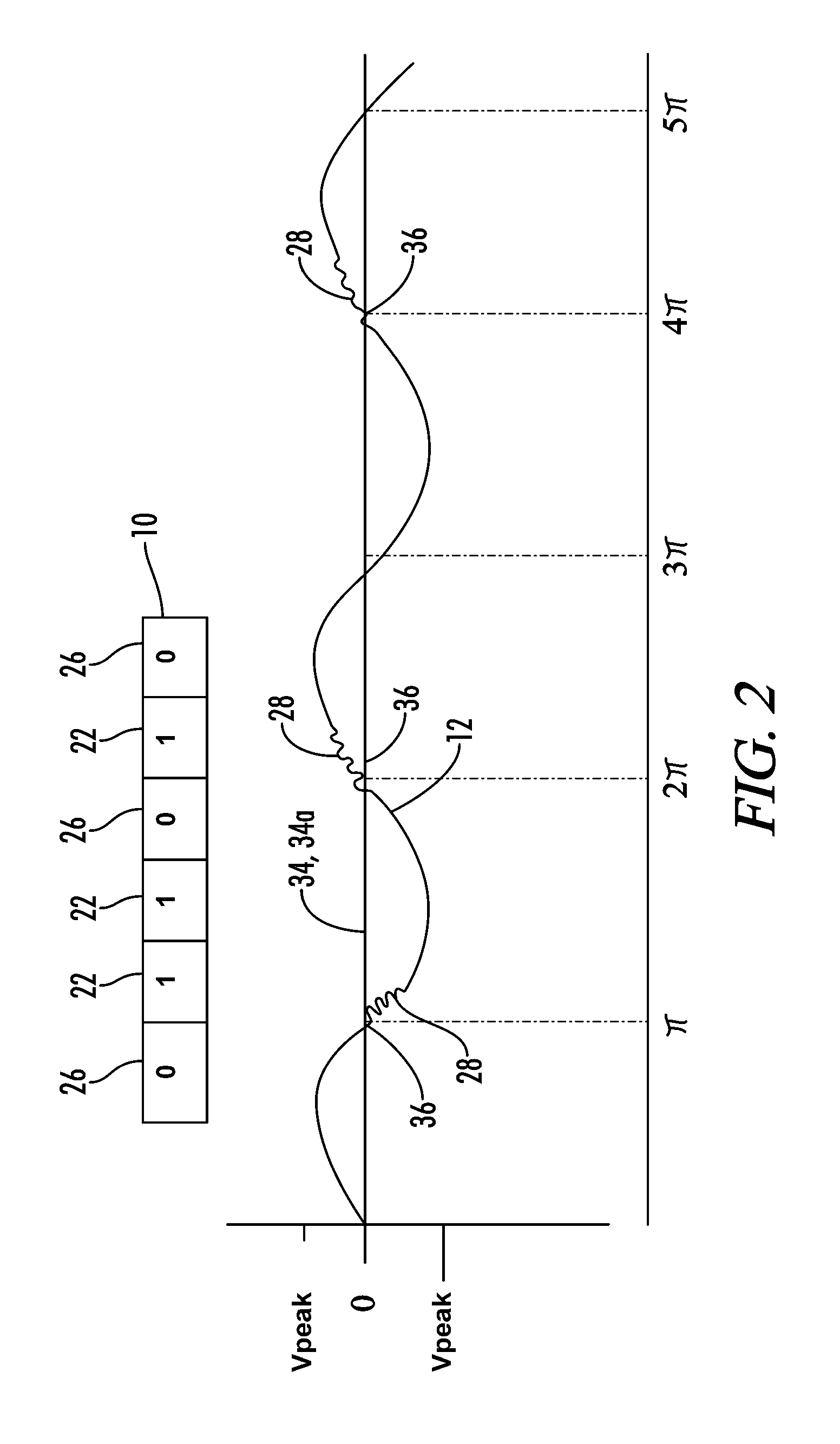

System and method for power line carrier communication using high frequency tone bursts

InactiveUS20080278295A1Low costSmall sizeElectric signal transmission systemsPower network operation systems integrationGas-discharge lampCommunications system

A communication system and method is utilized to communicate data over an AC power line. Tone burst are superimposed on an AC power signal at predetermined voltage reference levels or at predetermined phase angles to represent bit values. These bit values are represented by either the presence or the absence of the tone burst on the AC power signal. In this manner, control information can be communicated to an apparatus, such as a ballast for a gas discharge lamp.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

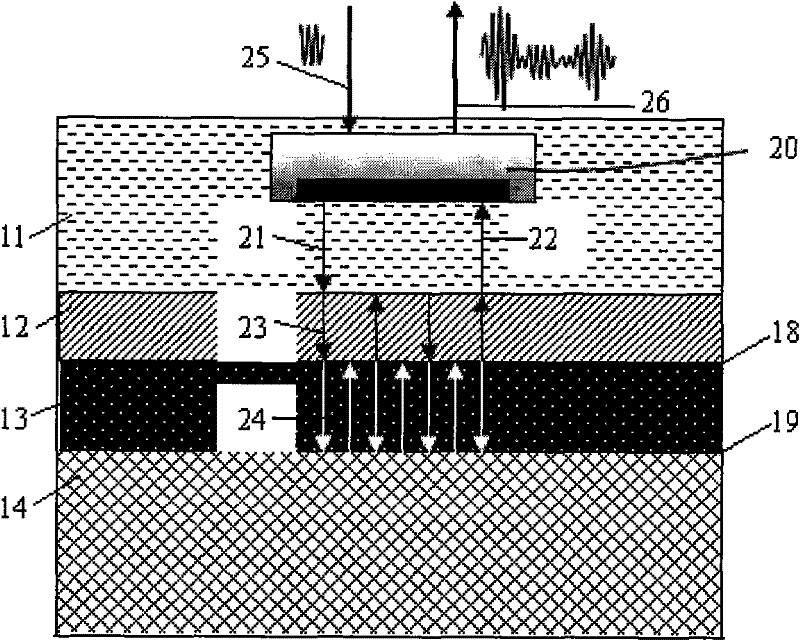

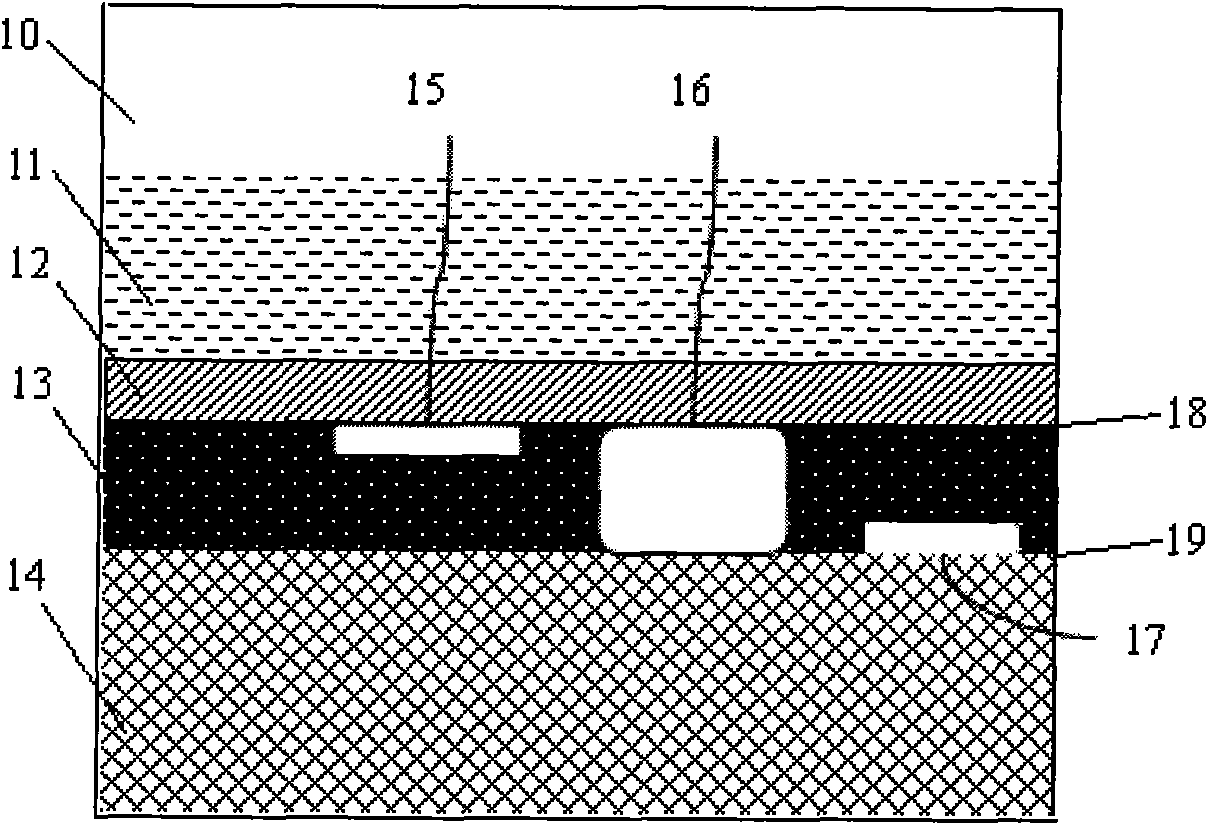

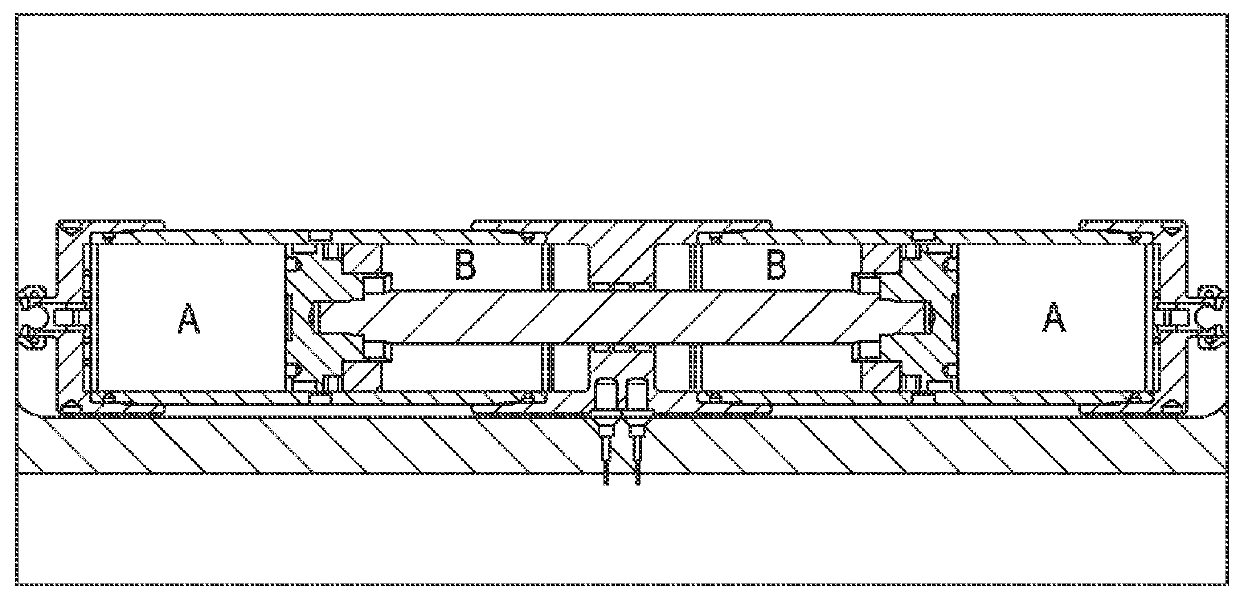

Double-interface ultrasonic detection imaging method for cased well

InactiveCN102128029AIncrease echoEffective detection and evaluation of bonding qualitySurveySonificationElectrical impulse

The invention relates to a double-interface ultrasonic detection imaging method for a cased well. In the method, a frequency-adjustable tone burst / electric pulse-excited broadband transducer is used; the control excitation frequency is the case thickness resonant frequency; under the excitation action of electric pulses, the transducer radiates narrowband ultrasonic pulses; the narrowband ultrasonic pulses perpendicularly enter the wall of the well and radially pass through each medium layer; simultaneously, each interface layer produces a reflection echo; the received echo is processed; the double-interface echo is separated to obtain double-interface bonding information; and when carrying out multi-point measurement and scanning on the wall of the case, the transducer can obtain double-interface bonding characteristic images. Compared with the prior art, the invention overcomes the disadvantage that the present ultrasonic pulse echo logging instrument and other logging instruments can not detect the double-interface bonding defects; and by separating the double-interface echo in the received signal, the invention can obtain the double-interface cement bonding quality images, andcan simultaneously obtain the detection result in the traditional pulse echo logging process.

Owner:TONGJI UNIV

System and method for power line carrier communication using high frequency tone bursts

InactiveUS7843145B2Low costSmall sizeElectric signal transmission systemsPower network operation systems integrationGas-discharge lampCommunications system

A communication system and method is utilized to communicate data over an AC power line. Tone burst are superimposed on an AC power signal at predetermined voltage reference levels or at predetermined phase angles to represent bit values. These bit values are represented by either the presence or the absence of the tone burst on the AC power signal. In this manner, control information can be communicated to an apparatus, such as a ballast for a gas discharge lamp.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

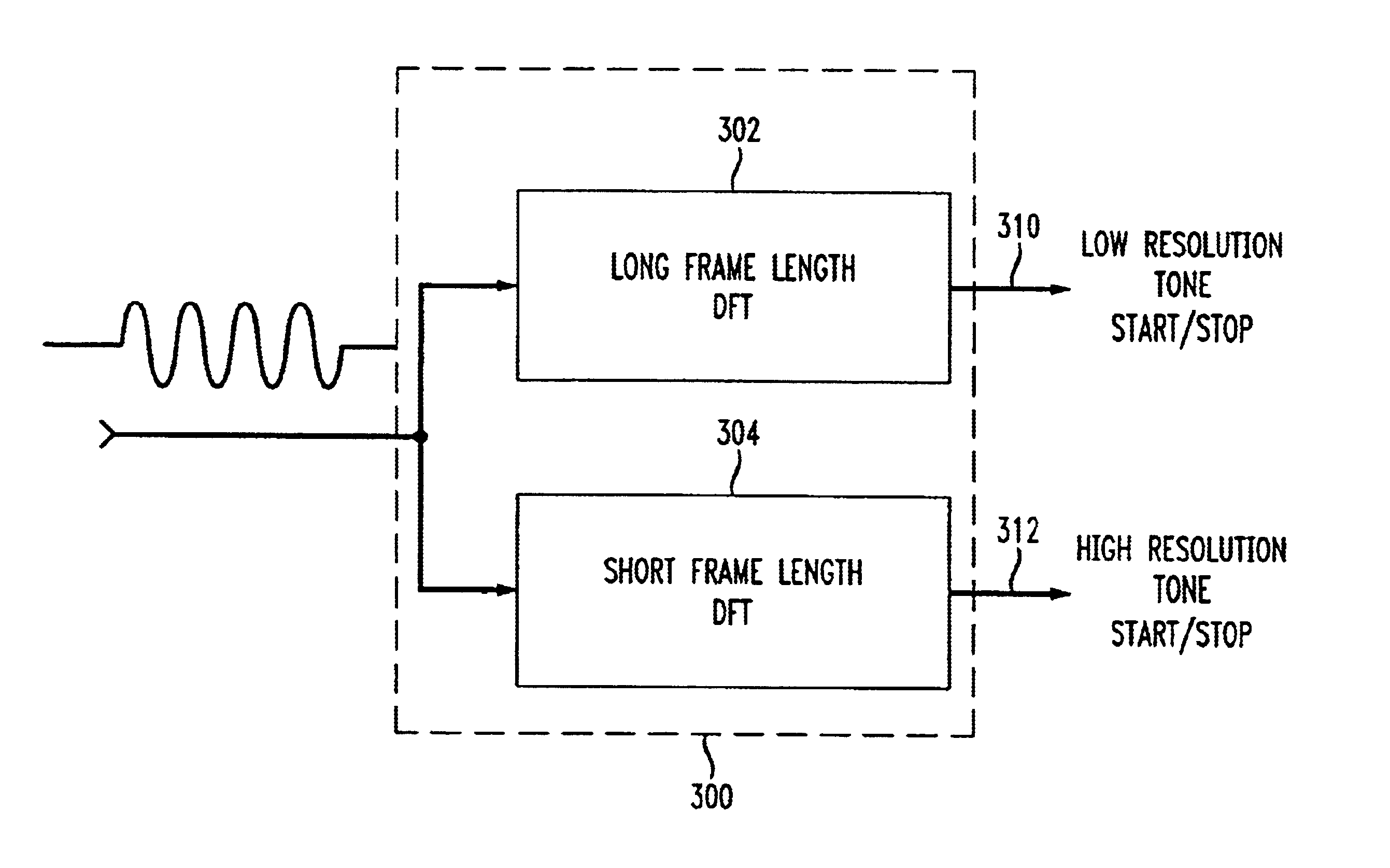

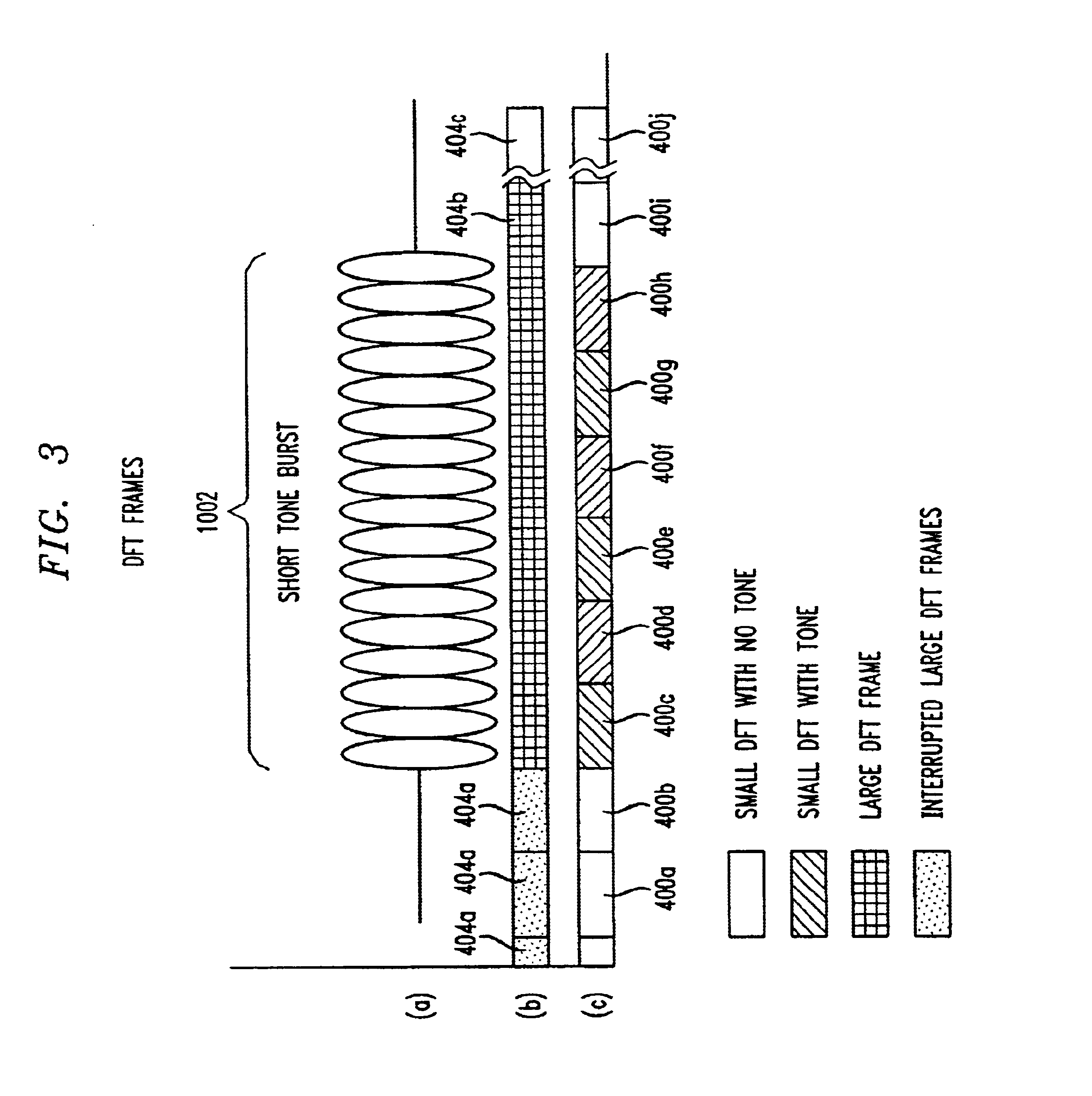

Robust signaling tone duration measurement

InactiveUS6671252B1Two-way loud-speaking telephone systemsFrequency-division multiplex detailsStart timeImage resolution

Apparatus and methods for adaptively, reliably, and accurately measuring the duration of an alerting or other signaling tone. A tone detector in accordance with the principles of the present invention accurately measures a duration of a tone burst (i.e., tone pulse) using a long frame length DFT and a short frame length DFT. Based on information obtained by the short frame length DFT, the long (i.e., standard) frame length DFT may be interrupted and reset to begin a new frame of data synchronized with the start of the next short frame corresponding to the processing by the short frame length DFT to minimize noise in the processing by the long frame length DFT and to greatly improve the resolution of the measurement of the duration of a particular tone to correspond to the lengths of the short frames used by the short frame length DFT. If desired, after a tone is initially detected, the frame length of the short frame length DFT can be iteratively reduced to increase a resolution of the measurement of a tone start time and a tone end time used to determine the duration of the detected tone burst.

Owner:LUCENT TECH INC +1

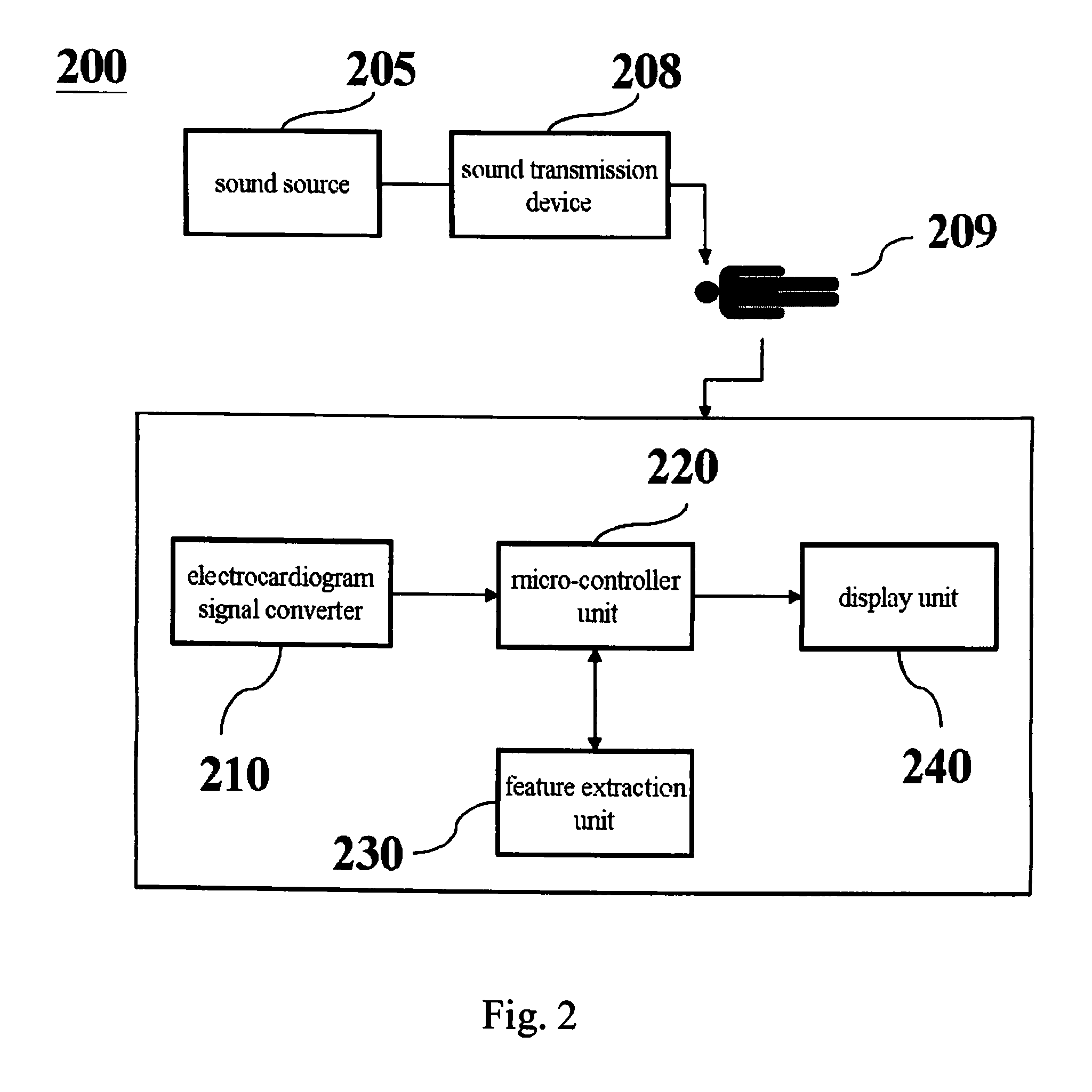

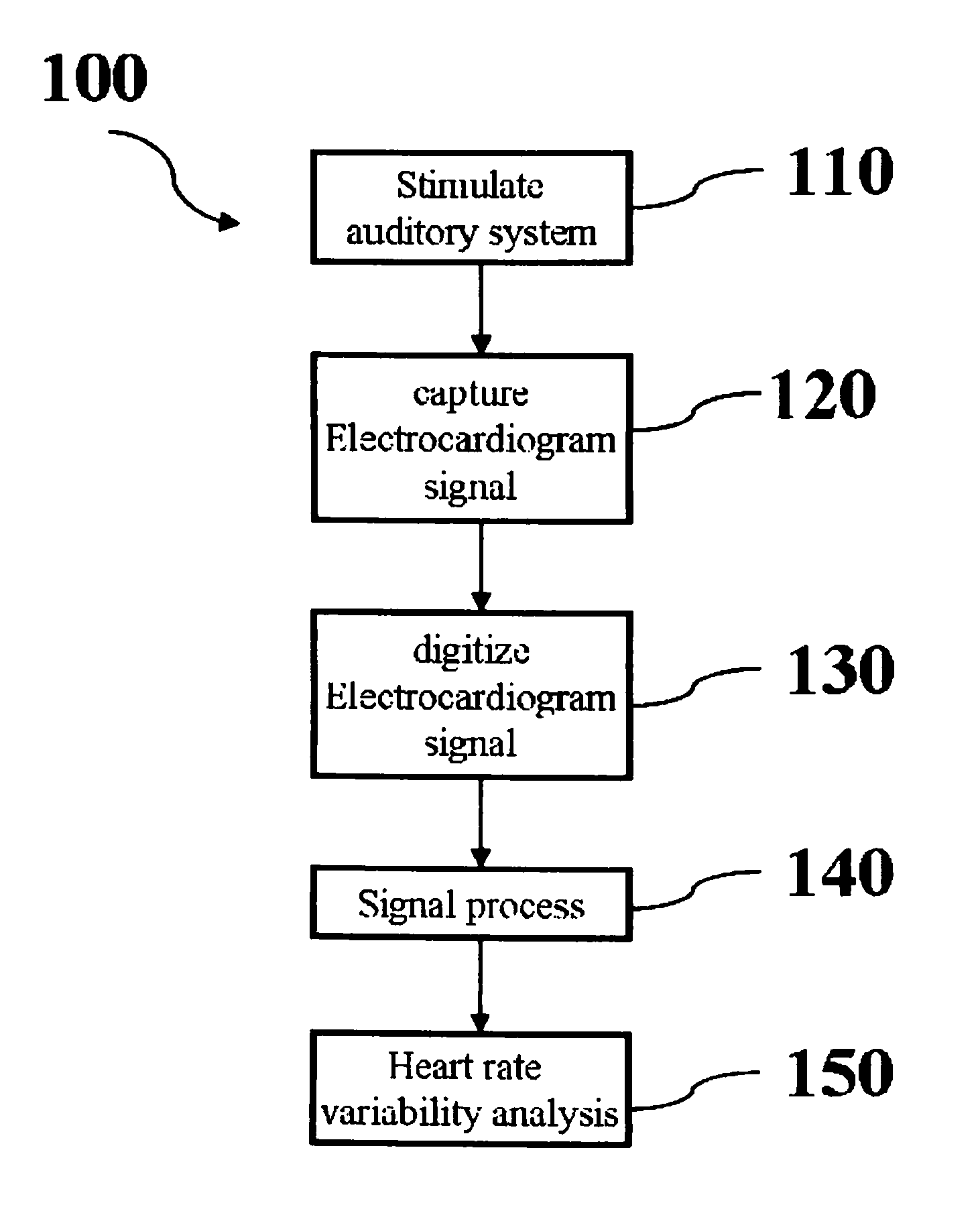

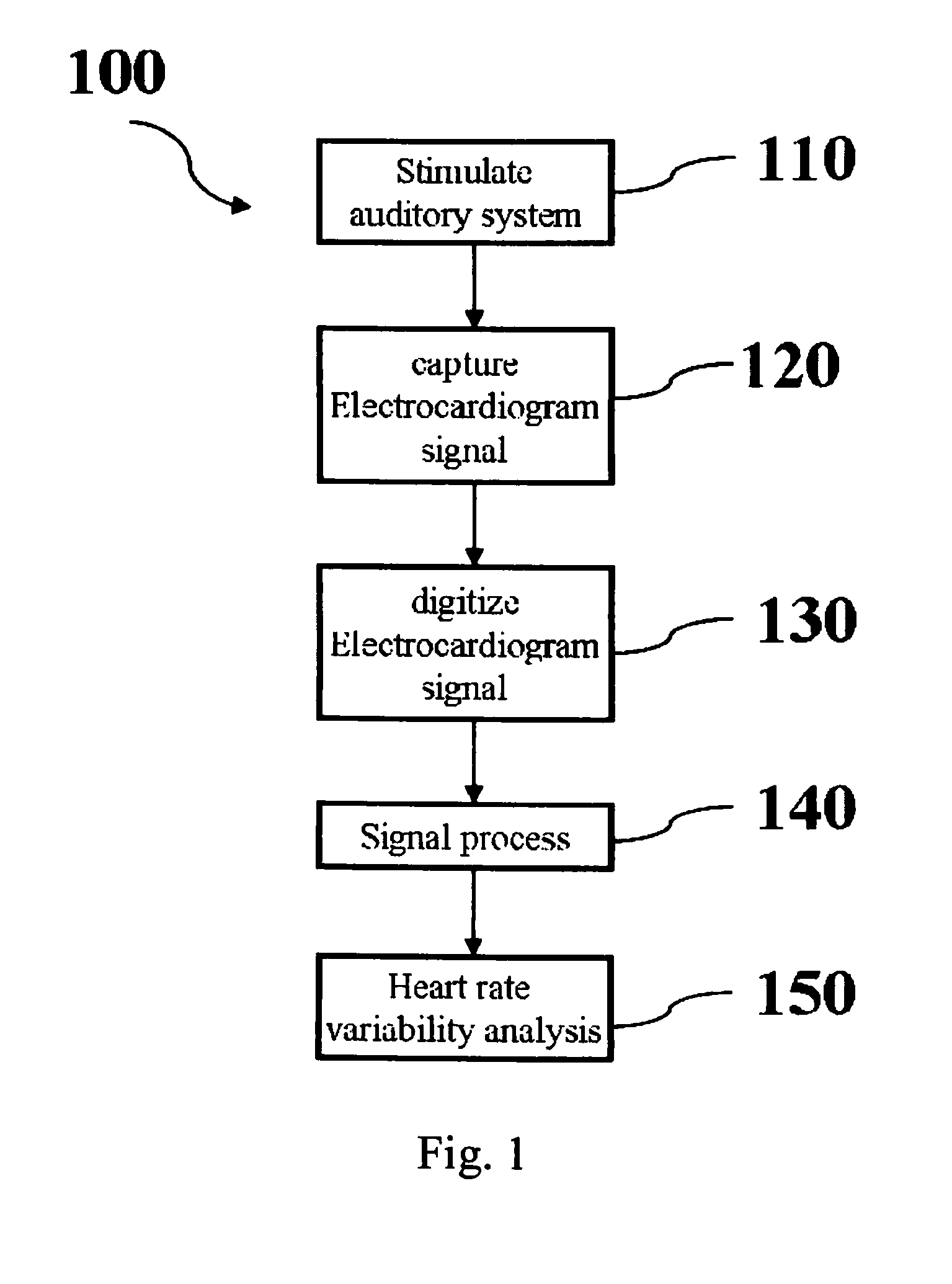

Method and system of auditory evoked heart rate variability analysis

InactiveUS20100268104A1High precisionSimplify analytical processingElectrocardiographyCatheterFrequency spectrumSOUND STIMULATION

The present invention provides a method and system of auditory evoked heart rate variability analysis having advantage of simply analytical process and portability. The disclosed method mainly includes the following steps of: stimulating the auditory system of a person by a sound through a sound transmission device, capturing an electrocardiogram signal of the person, performing analog-to-digital conversion of the electrocardiogram signal, selecting the peaks of the electrocardiogram signal and transforming the qualified peaks to a consecutive peak signal, and performing spectrum analysis to the peak signal in frequency domain, and obtaining the difference of the spectral parameters before and after the evoked sounds. Moreover, the sound further is selected from the group consisting of noise, short tone burst, click, and any other sound with the intensity of 30 dB to 100 dB. By comparing the heart rate variability analysis before or after sound stimulation in order to get the differences, the disclosed method and system of auditory evoked heart rate variability analysis can evaluate a changing index of stimulated autonomic functions.

Owner:NATIONAL YANG MING UNIVERSITY

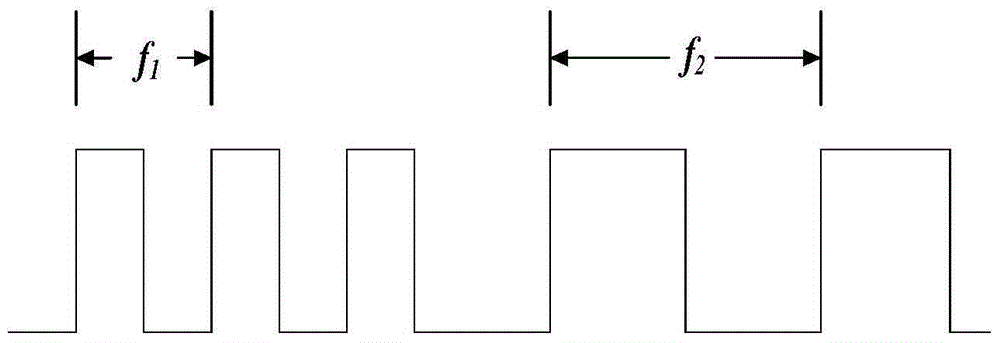

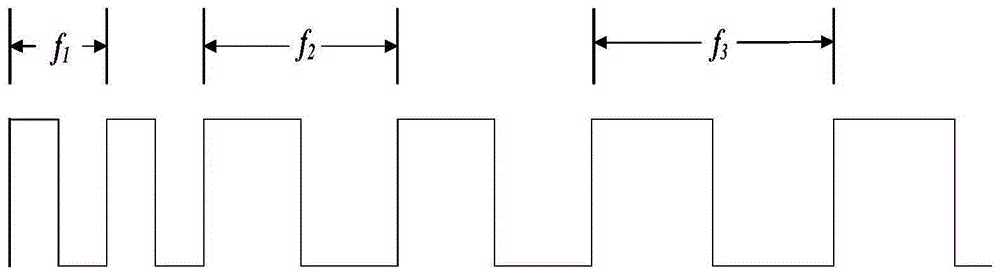

Electromagnetic ultrasonic metal material thickness measurement method

ActiveCN105180853ALow costImprove detection efficiencyUsing subsonic/sonic/ultrasonic vibration meansMetallic materialsPeak value

The invention provides an electromagnetic ultrasonic metal material thickness measurement method, which belongs to the field of metal material thickness measurement. The electromagnetic ultrasonic metal material thickness measurement method aims to avoid problems of low efficiency of electromagnetic ultrasonic energy conversion, unfixed occurrence moments of peak points of electromagnetic ultrasonic echoes and low thickness measurement accuracy. The specific electromagnetic ultrasonic metal material thickness measurement method comprises the steps that: an electromagnetic ultrasonic emitting tone burst pulse string and an electromagnetic ultrasonic receiving echo pulse string each comprises pulse signals of two or more kinds of frequencies, each pulse string comprises N1 consecutive pulse signals of frequency f1, N2 consecutive pulse signals of frequency f2, ...and Ni consecutive pulse signals of frequency fi, and N1 is greater than or equal to 1, N2 is greater than or equal to 1, and Ni is greater than or equal to 0; the time of a first cyclic wave cyclic wave initial zero-crossing point A or an initial peak point B of the pulse string of frequency f1 is obtained according to sequences of emission time and reception time, the time interval between the time of the first cyclic wave cyclic wave initial zero-crossing point A or the initial peak point B and the time of an initial emission point is the ultrasonic transmission time, and the thickness of metal materials is obtained through calculation. The electromagnetic ultrasonic metal material thickness measurement method is used for detecting thickness of metal materials.

Owner:HARBIN INST OF TECH

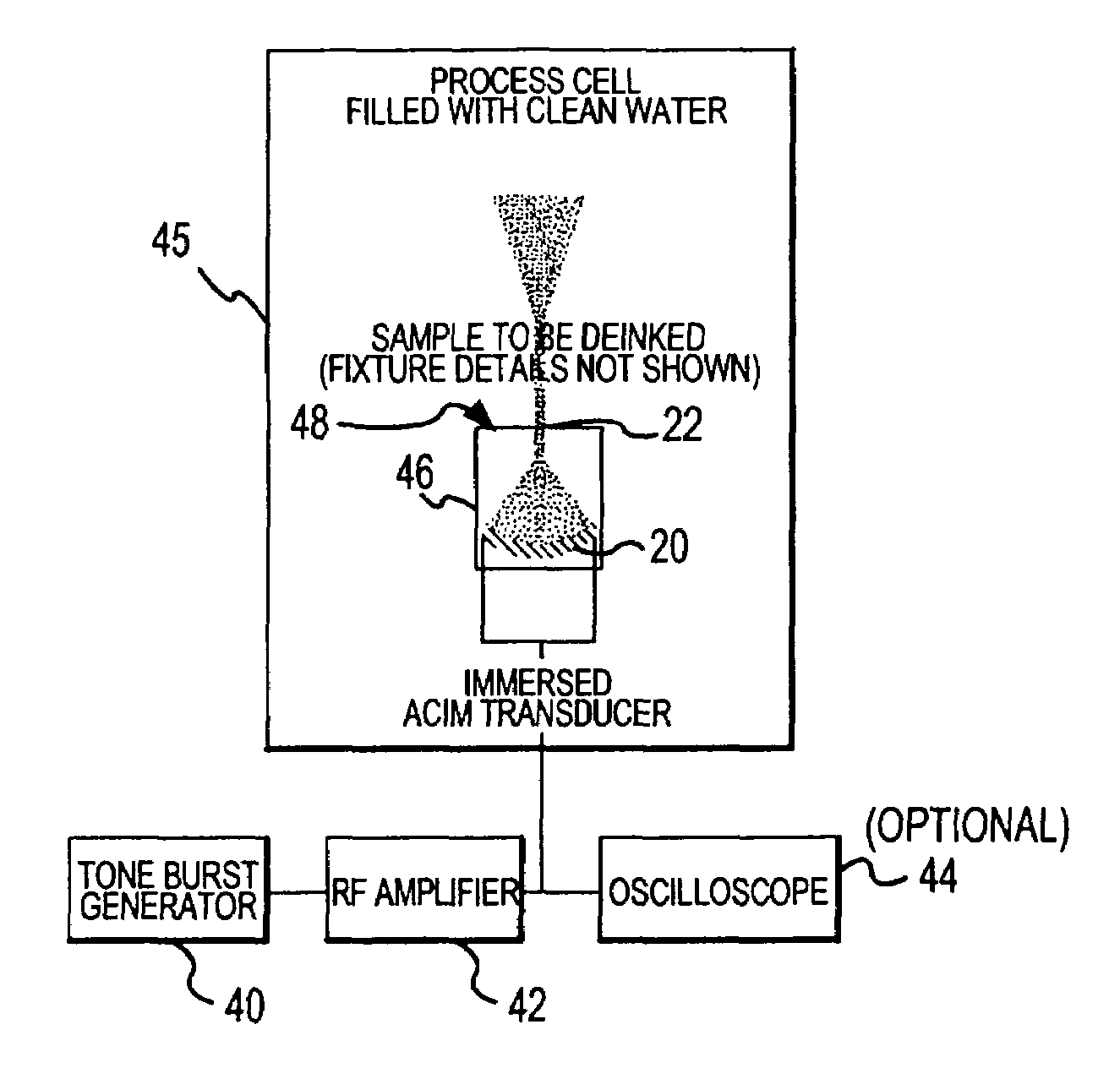

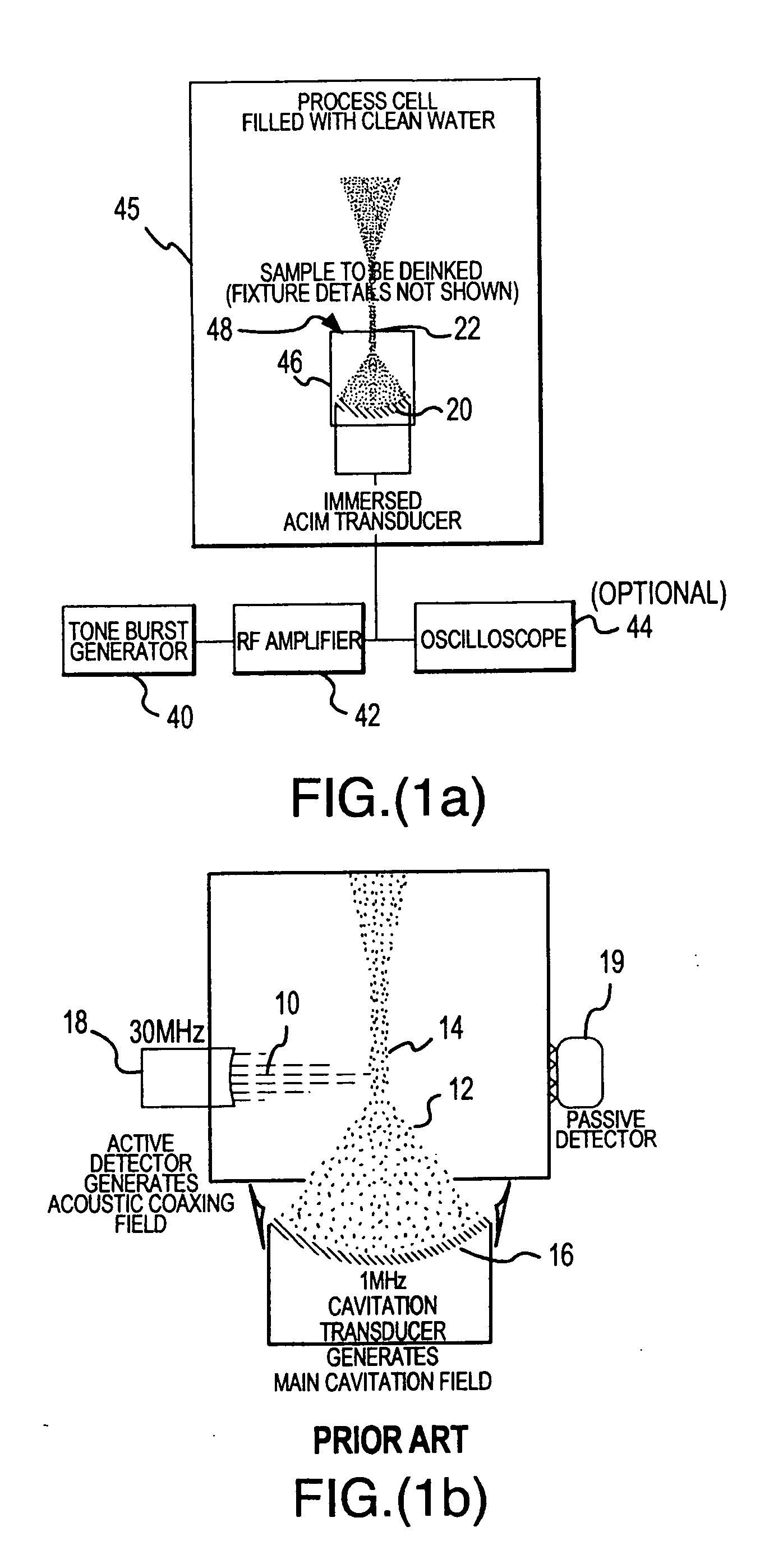

Apparatus to produce acoustic cavitation in a liquid insonification medium

InactiveUS20070262676A1Piezoelectric/electrostriction/magnetostriction machinesElectrostatic cleaningCavitationChemical reaction

An apparatus to produce acoustic cavitation by controlling cavitation events in a liquid insonification medium utilizing a waveform to excite a transducer with a series of bipolar inharmonic tone bursts having medium recovery intervals between respective bursts so that the medium repeatedly recovers from cavitation events between bursts. The apparatus may be used to clean a semiconductor wafer, to de-coat a painted surface having, to induce a chemical reaction, and / or to provide recycled paper made from inked paper de-inked by cavitation. Cavitation events are generated using a transducer and a waveform generator, e.g., square wave tone bursts, to excite the transducer with a signal controlled in frequency, burst repetition rate, duty-cycle and / or amplitude, e.g., utilizing bursts having a frequency between 500 KHz and 10 MHz, and a duty cycle between 0.1% and 70%.

Owner:OVIVO SWITZERLAND AG

Positional information detecting method and device

InactiveUS7529153B2High resolutionNoise figure or signal-to-noise ratio measurementUsing subsonic/sonic/ultrasonic vibration meansPropagation delayConstant frequency

In a positional information detecting device, a tone-burst signal propagating unit causes a tone-burst signal to propagate through a path. The tone-burst signal is composed of a continuous wave train, the continuous wave train including a plurality of cycles of a constant frequency. A detecting unit detects, at a predetermined position in the path, the tone-burst signal propagating through the path every one cycle of the tone-burst signal to measure a propagation delay time based on the detected signal. The propagation delay time represents a period for which the tone-burst signal has propagated through the path. A phase obtaining unit obtains a phase of the detected signal. A positional information obtaining unit obtains positional information associated with the predetermined position based on the measured propagation delay time and the obtained phase of the detected signal.

Owner:DENSO CORP

Apparatus to produce acoustic cavitation in a liquid insonification medium

InactiveUS7253551B2Piezoelectric/electrostriction/magnetostriction machinesElectrostatic cleaningSquare waveformCavitation

An apparatus to produce acoustic cavitation by controlling cavitation events in a liquid insonification medium utilizing a waveform to excite a transducer with a series of bipolar inharmonic tone bursts having medium recovery intervals between respective bursts so that the medium repeatedly recovers from cavitation events between bursts. The apparatus may be used to clean a semiconductor wafer, to de-coat a painted surface having, to induce a chemical reaction, and / or to provide recycled paper made from inked paper de-inked by cavitation. Cavitation events are generated using a transducer and a waveform generator, e.g., square wave tone bursts, to excite the transducer with a signal controlled in frequency, burst repetition rate, duty-cycle and / or amplitude, e.g., utilizing bursts having a frequency between 500 KHz and 10 MHz, and a duty cycle between 0.1% and 70%.

Owner:OVIVO SWITZERLAND AG

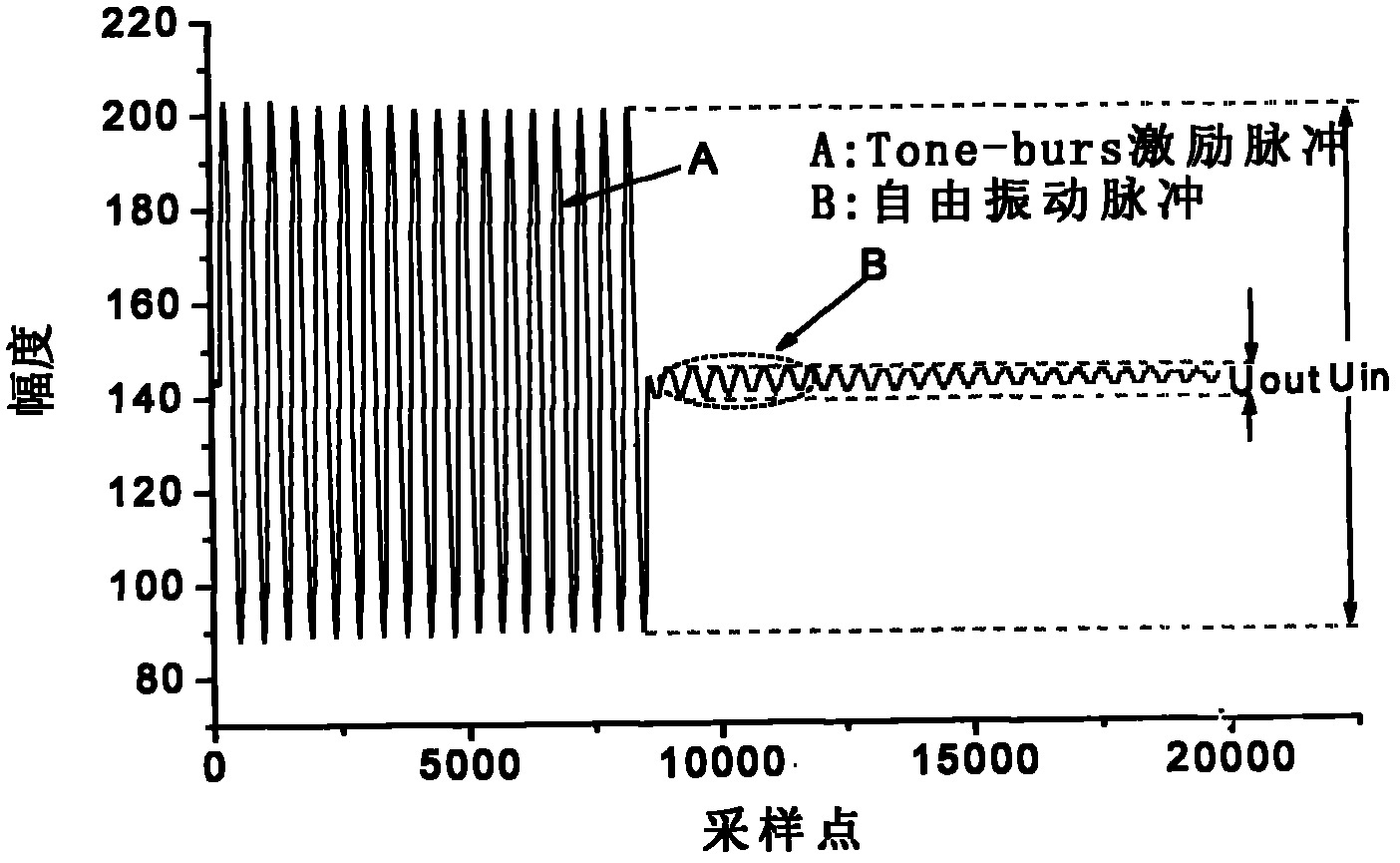

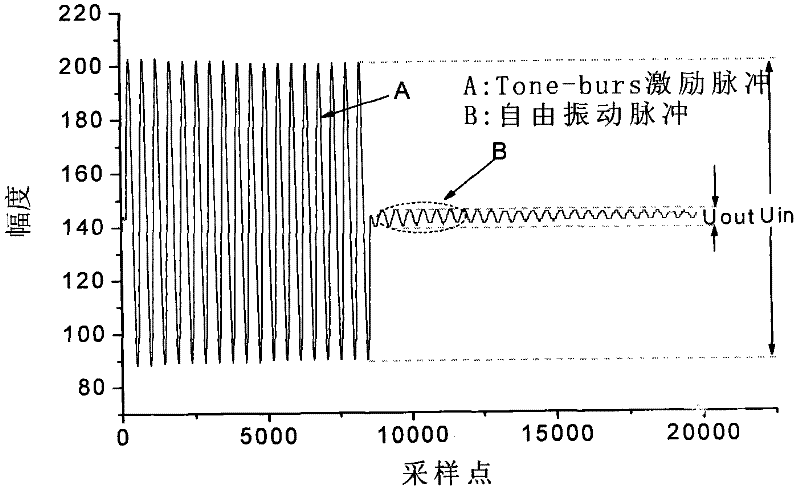

Piezoelectric wafer eigenfrequency measurement method

InactiveCN102095490AImprove measurement efficiencyHigh measurement accuracySubsonic/sonic/ultrasonic wave measurementUsing electrical meansFrequency spectrumMeasurement device

The invention relates to a piezoelectric wafer eigenfrequency measurement method. The method comprises the following steps: (1) arranging a measurement device including a function generator, a piezoelectric wafer and a digital oscilloscope; (2) starting the function generator to generate Tone-Burst sine wave signals with a certain period number, conducting electric pulse excitation to the piezoelectric wafer by the function generator at a frequency f, stopping the electric pulse excitation to the piezoelectric wafer when the function generator completes the period number, enabling the piezoelectric wafer to start vibrating freely, and collecting the free vibration signal between two electrodes of the piezoelectric wafer by the digital oscilloscope; (3) adjusting the digital oscilloscope to amplify the free vibration signal between the two electrodes of the piezoelectric wafer in the step (2), and processing the amplified signal by fast Fourier transform; (4) extracting the frequency of the peak on the spectrogram obtained by Fourier transform in the step (3) to obtain the eigenfrequency of the piezoelectric wafer to be tested; and (5) changing the frequency f of the function generator in the step (2), repeating the step (3) and step (4), and measuring each eigenfrequency of the piezoelectric wafer.

Owner:CHINA NAT OFFSHORE OIL CORP +1

H-bridge pulse generator

InactiveUS8509031B2High output powerImprove efficiencyMechanical vibrations separationTransmissionTransformerPeak value

Circuitry for high-power, high-frequency excitation of electromagnetic acoustic transducers (EMAT) without the use of a matching transformer is described. This circuit contains at least 4 switching devices, arranged in an H-Bridge configuration to drive EMATs over a range of frequencies. The switching devices can be connected in parallel with respect to the H-Bridge and switched in sequence for greater power output and variety of wave forms including, Churp, Hemming window tone burst, rectangular tone burst and Barker Code wave forms. A circuit for driving sensor coils of an EMAT to correct the disadvantages of conventional pulsers. A plurality of switching devices are connected in parallel and augmented with support circuitry to provide increased power output, stability, reduced noise and complex output wave forms. This design provides for the application of modulated pulses such as multi-pulse, multi-frequency bursts with peak power outputs over 20,000 watts and frequencies over 10,000 Hertz.

Owner:SMITH STEPHEN

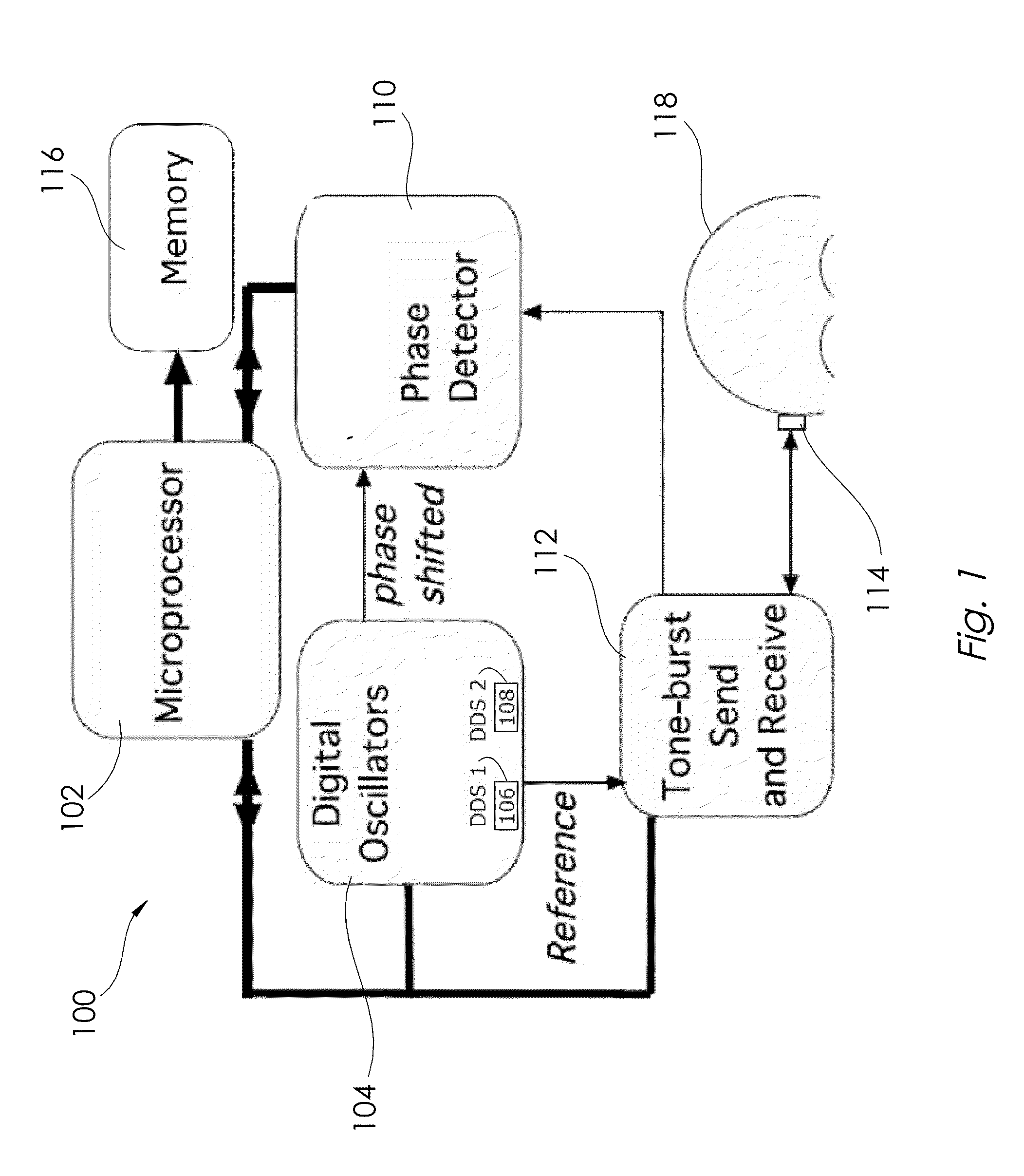

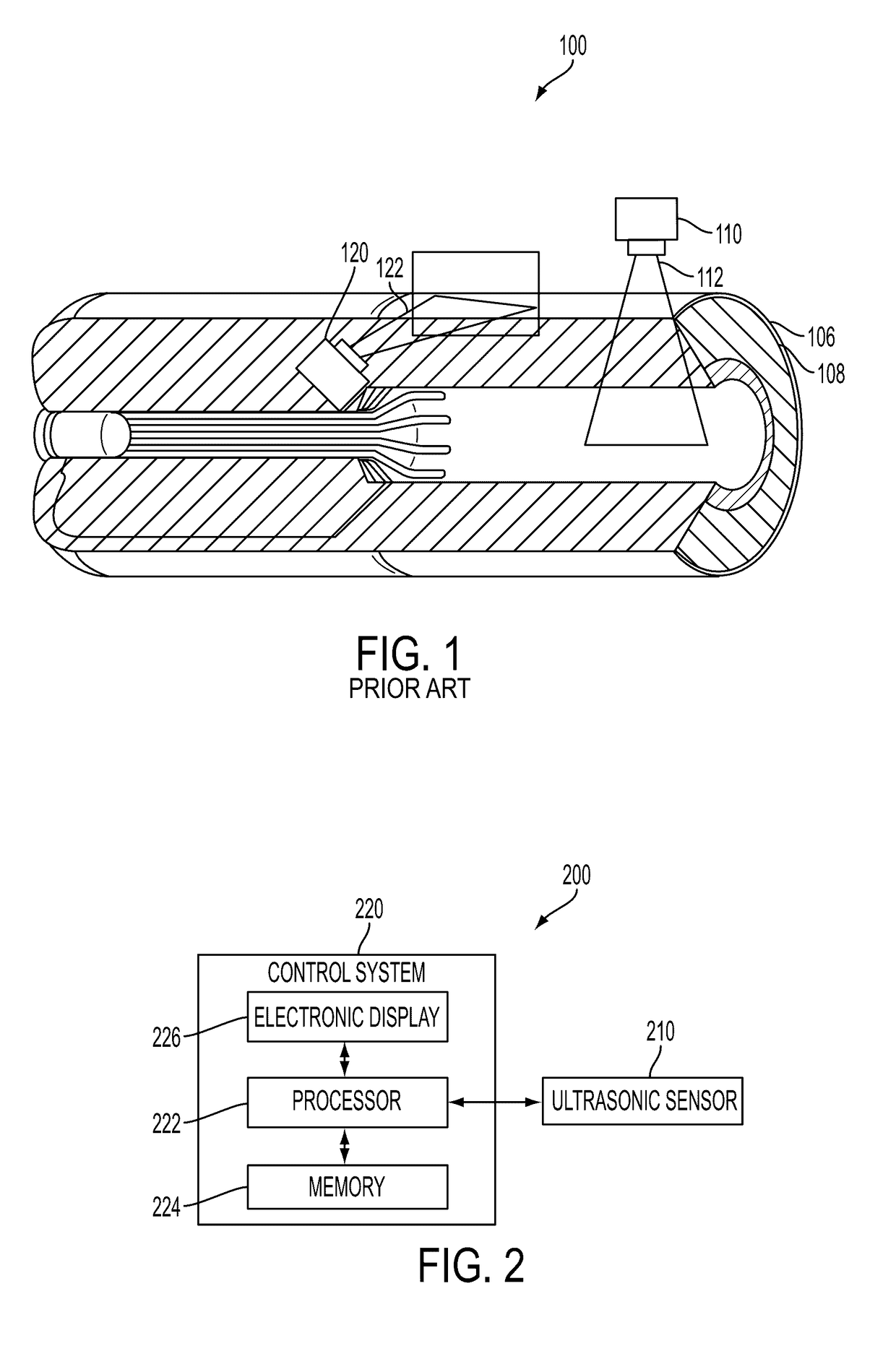

Systems and methods for measuring phase dynamics and other properties

ActiveUS20160262621A1Well formedDiagnostics using vibrationsIntracranial pressure measurementConstant frequencyPhase difference

Systems and methods for measuring phase dynamics and other properties (e.g. intracranial pressure) are disclosed. For example, the system may generate a reference waveform and a measurement waveform using digital synthesizers, each waveform having an identical constant frequency but also a relative phase shift. Next, system may send a tone-burst, via a transducer, into a sample (e.g. a skull or a bonded material), and then receive a reflected tone-burst in response. Then, a phase difference between the received tone-burst and the measurement waveform may be determined with a linear phase detector. Next, the phase shift of the measurement waveform may be adjusted, by the determined phase difference, such that there is no longer any phase difference between the received tone-burst and the adjusted measurement waveform generated by the appropriate digital synthesizer. A similar adjustment may occur after subsequent tone-bursts, allowing accurate monitoring of continuously variable phase relationships.

Owner:NASA

Double-interface ultrasonic detection imaging method for cased well

InactiveCN102128029BIncrease echoEffective detection and evaluation of bonding qualitySurveySonificationElectrical impulse

The invention relates to a double-interface ultrasonic detection imaging method for a cased well. In the method, a frequency-adjustable tone burst / electric pulse-excited broadband transducer is used; the control excitation frequency is the case thickness resonant frequency; under the excitation action of electric pulses, the transducer radiates narrowband ultrasonic pulses; the narrowband ultrasonic pulses perpendicularly enter the wall of the well and radially pass through each medium layer; simultaneously, each interface layer produces a reflection echo; the received echo is processed; the double-interface echo is separated to obtain double-interface bonding information; and when carrying out multi-point measurement and scanning on the wall of the case, the transducer can obtain double-interface bonding characteristic images. Compared with the prior art, the invention overcomes the disadvantage that the present ultrasonic pulse echo logging instrument and other logging instruments can not detect the double-interface bonding defects; and by separating the double-interface echo in the received signal, the invention can obtain the double-interface cement bonding quality images, andcan simultaneously obtain the detection result in the traditional pulse echo logging process.

Owner:TONGJI UNIV

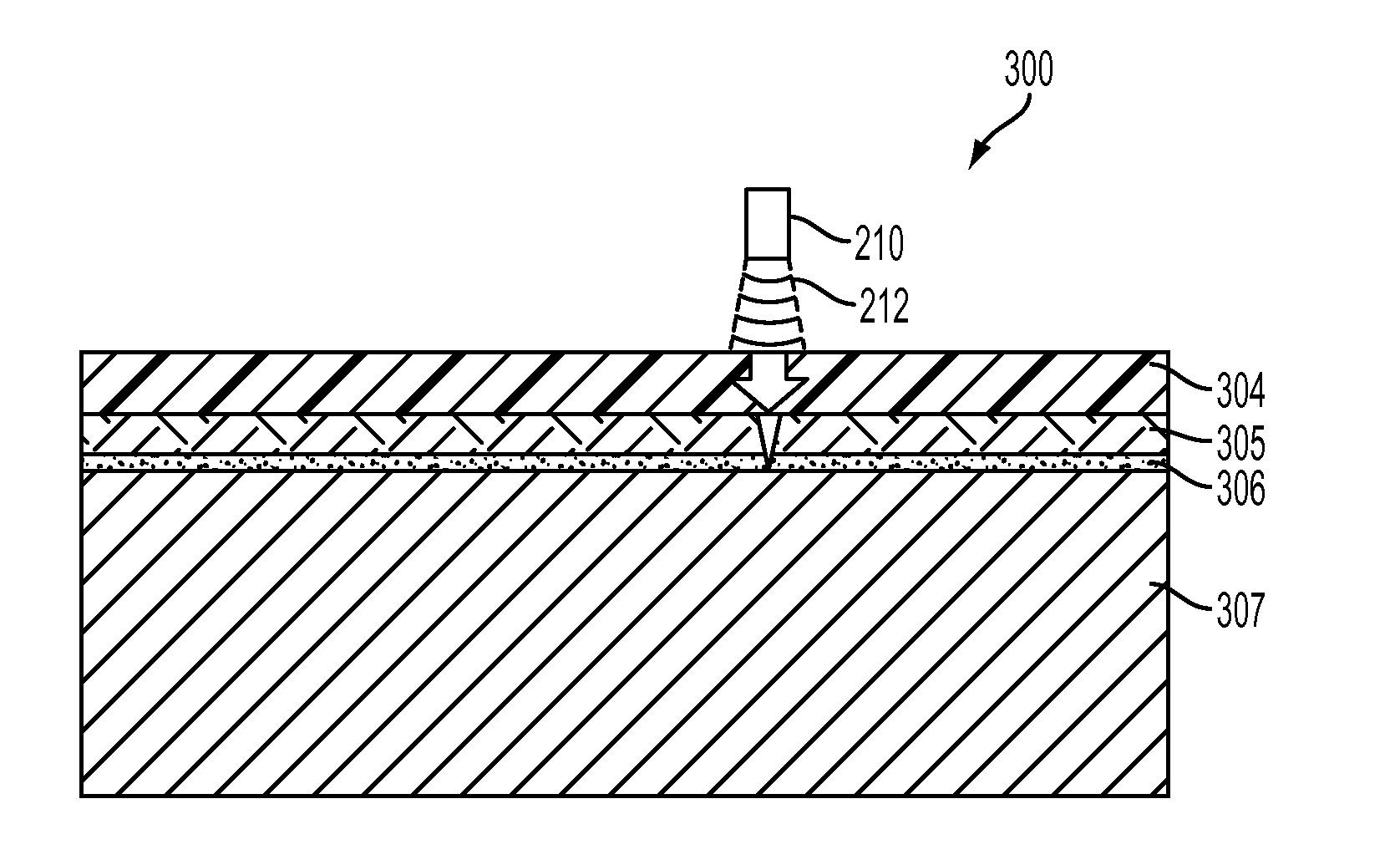

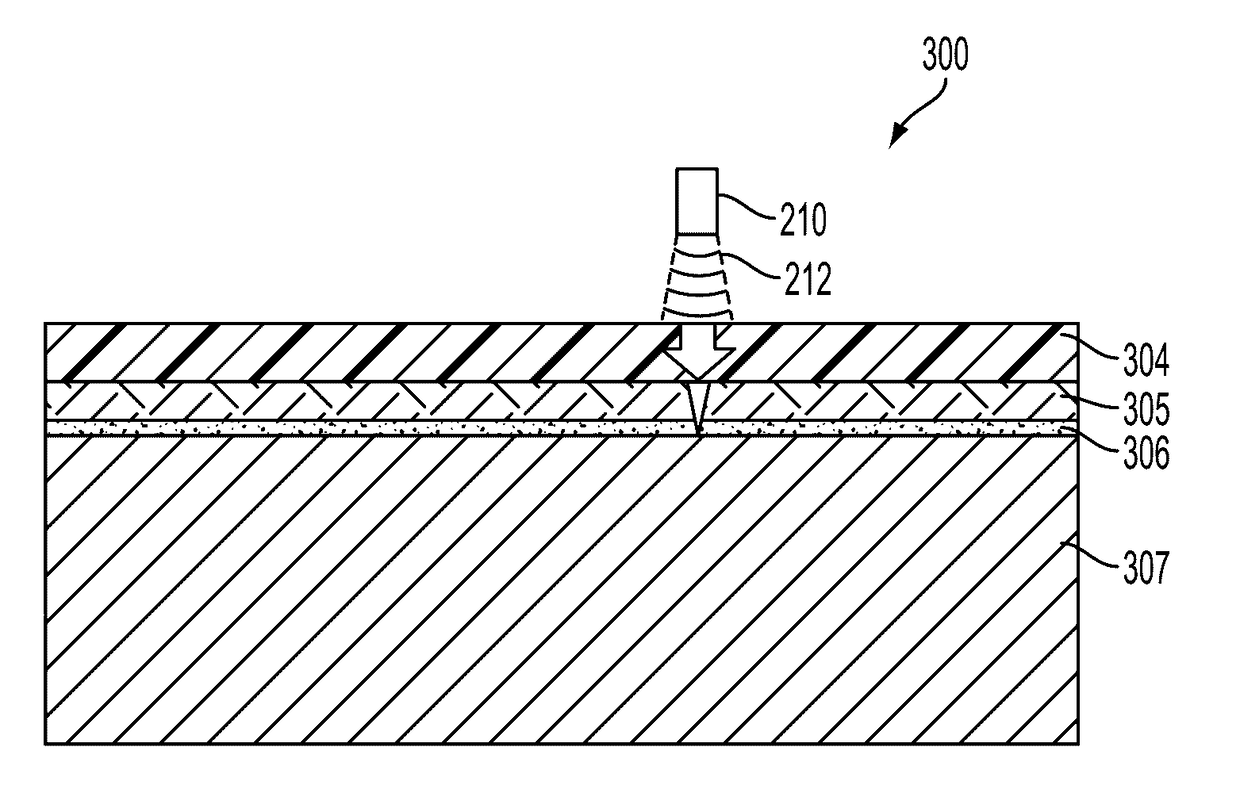

Methods and apparatus for detecting defects in an object of interest

ActiveUS20150226705A1Analysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansSonificationAcoustic impedance

A method for detecting defects in an object of interest comprises applying an ultrasonic signal including a tone burst having a predetermined frequency and number of cycles into an object of interest, receiving a return signal reflected from the object of interest, and processing the return signal to detect defects in the at least one inner material. The object may have an outer material and at least one inner material that have different acoustic impedances. An ultrasonic sensor system includes an ultrasonic sensor configured to generate an ultrasonic signal having a tone burst at a predetermined frequency corresponding to a resonant frequency of an outer material of an object of interest.

Owner:NORTHROP GRUMMAN SYST CORP

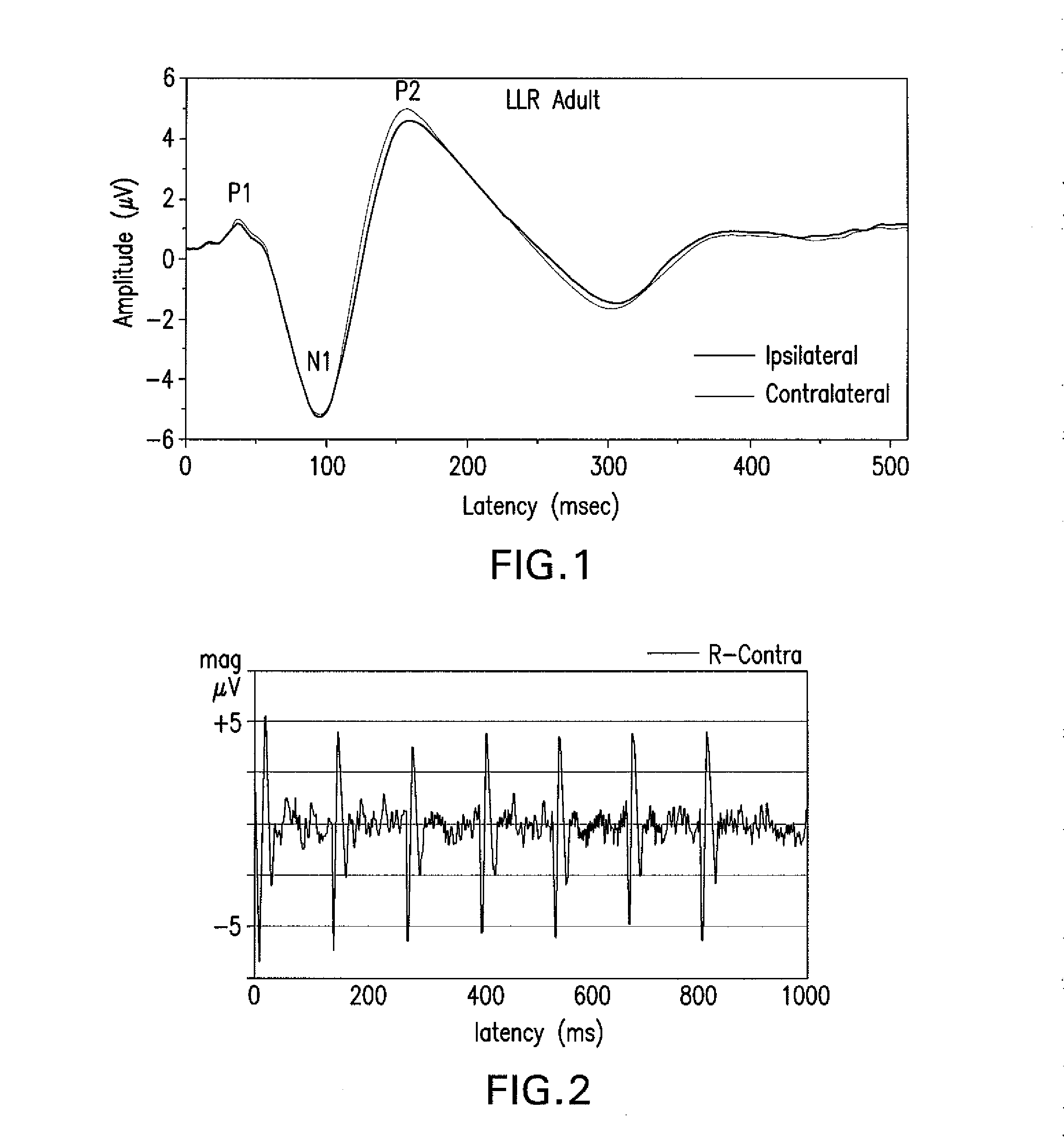

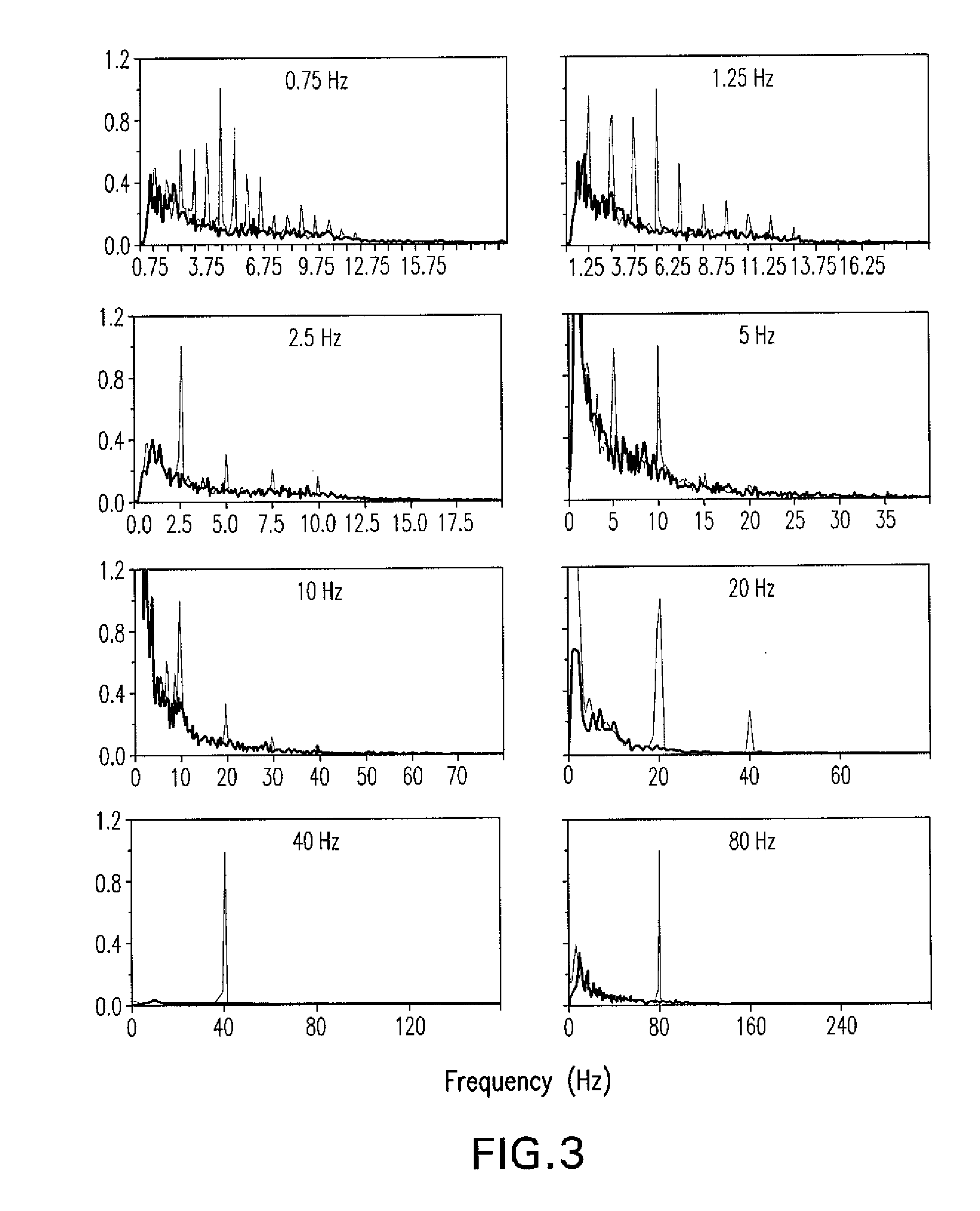

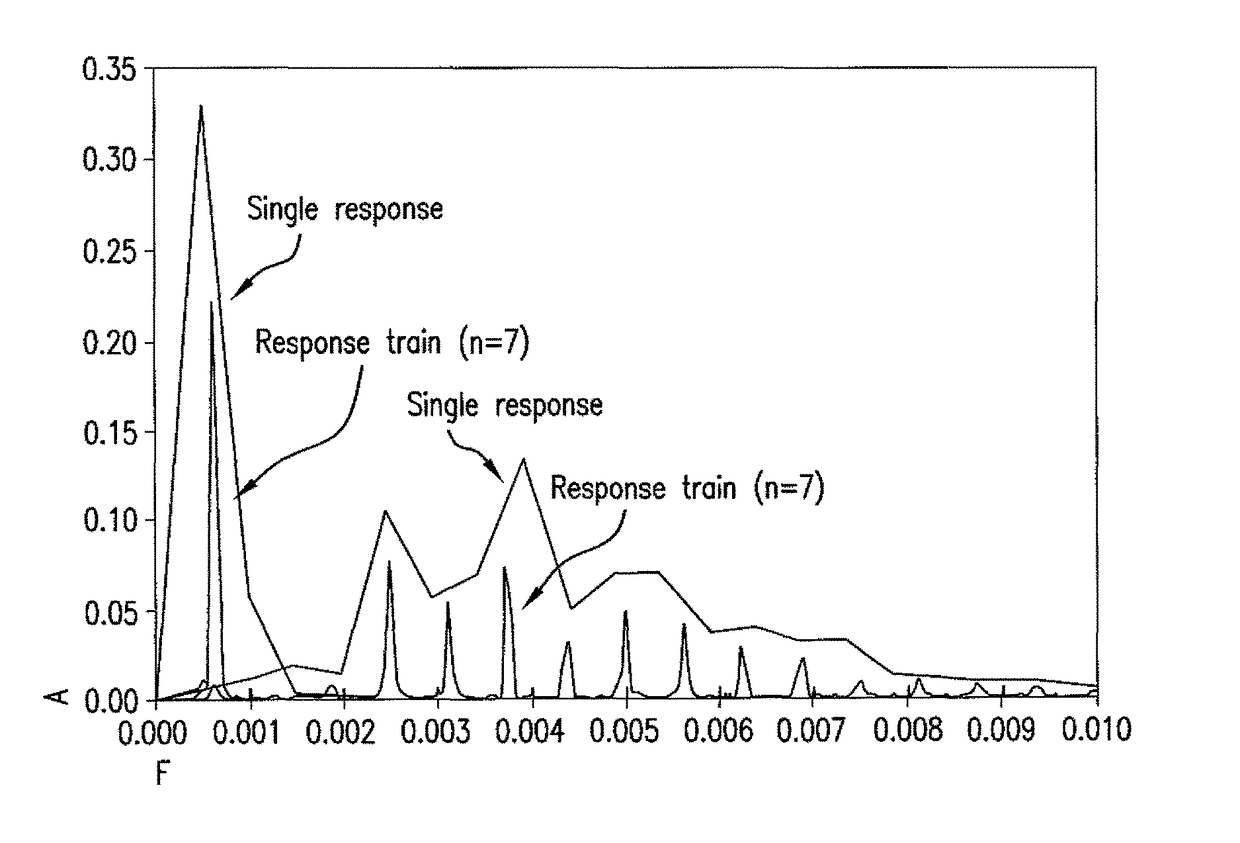

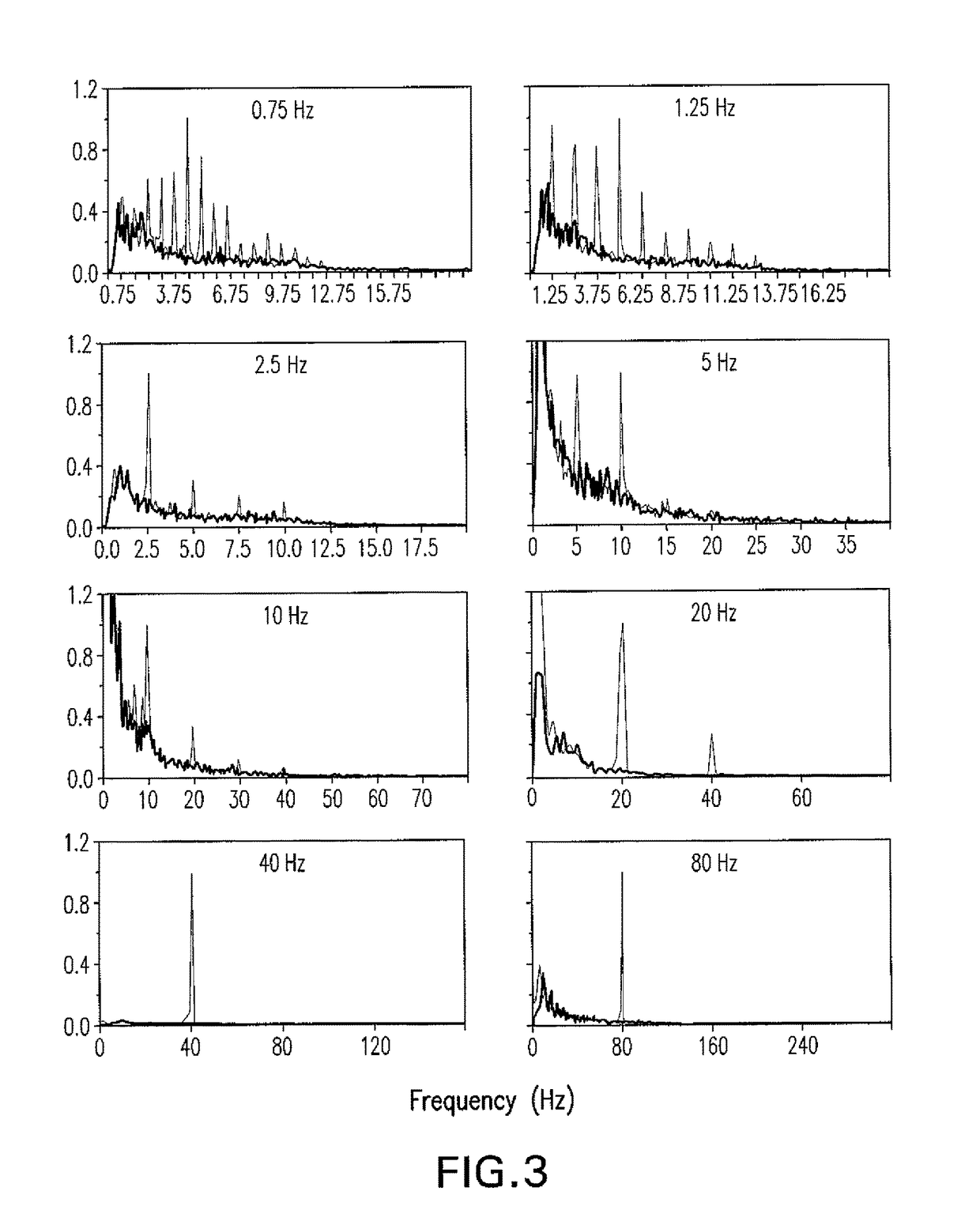

Steady state measurement and analysis approach to profiling auditory evoked potentials from short-latency to long latency

The present invention relates to methods and systems for profiling evoked potentials in brain electrical activity which apply steady state response concepts to analysis of longer latency responses reflective of activity of brain regions beyond the brainstem, up to an including the cortex. The use of repeated stimuli within a single analysis window produces a quasi steady-state response and permits a high-resolution spectral analysis. Response amplitudes were measured at repetition rates from 80 to below 1 Hz, using trains of repeated tone-burst stimuli. An amplitude measure introduced and defined as the harmonic sum was incorporated into the spectral power of the response carried by both the fundamental frequency, and the harmonics thereof. Additionally, time ensemble averaging can be employed to improve signal to noise ratio.

Owner:INTELLIGENT LEARNING SYST +1

Apparatus to produce acoustic cavitation in a liquid insonification medium

InactiveUS20060027254A1Piezoelectric/electrostriction/magnetostriction machinesElectrostatic cleaningCavitationChemical reaction

An apparatus to produce acoustic cavitation by controlling cavitation events in a liquid insonification medium utilizing a waveform to excite a transducer with a series of bipolar inharmonic tone bursts having medium recovery intervals between respective bursts so that the medium repeatedly recovers from cavitation events between bursts. The apparatus may be used to clean a semiconductor wafer, to de-coat a painted surface having, to induce a chemical reaction, and / or to provide recycled paper made from inked paper de-inked by cavitation. Cavitation events are generated using a transducer and a waveform generator, e.g., square wave tone bursts, to excite the transducer with a signal controlled in frequency, burst repetition rate, duty-cycle and / or amplitude, e.g., utilizing bursts having a frequency between 500 KHz and 10 MHz, and a duty cycle between 0.1% and 70%.

Owner:OVIVO SWITZERLAND AG

Systems and methods for measuring phase dynamics and other properties

InactiveUS10390704B2Diagnostics using vibrationsIntracranial pressure measurementPhase shiftedConstant frequency

Systems and methods for measuring phase dynamics and other properties (e.g. intracranial pressure) are disclosed. For example, the system may generate a reference waveform and a measurement waveform using digital synthesizers, each waveform having an identical constant frequency but also a relative phase shift. Next, system may send a tone-burst, via a transducer, into a sample (e.g. a skull or a bonded material), and then receive a reflected tone-burst in response. Then, a phase difference between the received tone-burst and the measurement waveform may be determined with a linear phase detector. Next, the phase shift of the measurement waveform may be adjusted, by the determined phase difference, such that there is no longer any phase difference between the received tone-burst and the adjusted measurement waveform generated by the appropriate digital synthesizer. A similar adjustment may occur after subsequent tone-bursts, allowing accurate monitoring of continuously variable phase relationships.

Owner:NASA

Method for measuring ultrasonic nonlinearity generated by high-voltage pulser

InactiveCN109196347APurely nonlinear parameters can be determinedEffective Health Maintenance ManagementAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationHarmonicFundamental frequency

The present invention relates to a method for measuring ultrasonic nonlinearity generated by a high-voltage pulser. More specifically, the method comprises: a calibration step for transmitting and receiving an ultrasonic signal to / from an object to be inspected having a reception probe attached thereto, the calibration step being performed by a receiving unit; a harmonic measurement step for transmitting a tone burst signal to the object to be inspected having a transmission / reception probe attached thereto, and receiving a tone burst signal that has passed through the object to be inspected,the harmonic measurement step being performed by the receiving unit; a harmonic measurement step for transmitting a tone burst signal to the object to be inspected having a transmission probe attachedthereto, and receiving the transmitted tone burst signal, the harmonic measurement step being performed by a transmitting unit; a calibration step for transmitting and receiving an ultrasonic signalto / from the object to be inspected having the transmission probe attached thereto, the calibration step being performed by the transmitting unit; and a step for measuring the ultrasonic nonlinearity of the object to be inspected by comparing fundamental frequency and harmonic components measured by the receiving unit and fundamental frequency and harmonic components measured by the transmitting unit.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Steady state measurement and analysis approach to profiling auditory evoked potentials from short-latency to long latency

The present invention relates to methods and systems for profiling evoked potentials in brain electrical activity which apply steady state response concepts to analysis of longer latency responses reflective of activity of brain regions beyond the brainstem, up to an including the cortex. The use of repeated stimuli within a single analysis window produces a quasi steady-state response and permits a high-resolution spectral analysis. Response amplitudes were measured at repetition rates from 80 to below 1 Hz, using trains of repeated tone-burst stimuli. An amplitude measure introduced and defined as the harmonic sum was incorporated into the spectral power of the response carried by both the fundamental frequency, and the harmonics thereof. Additionally, time ensemble averaging can be employed to improve signal to noise ratio.

Owner:INTELLIGENT LEARNING SYST +1

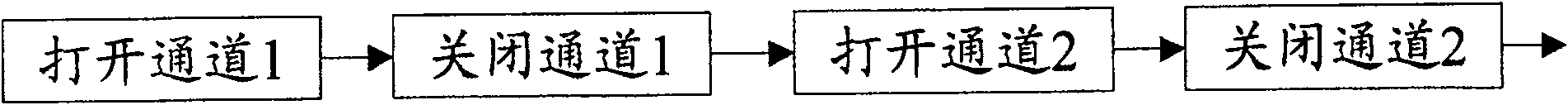

Player method for spurt tone in digital interface of musical instrument

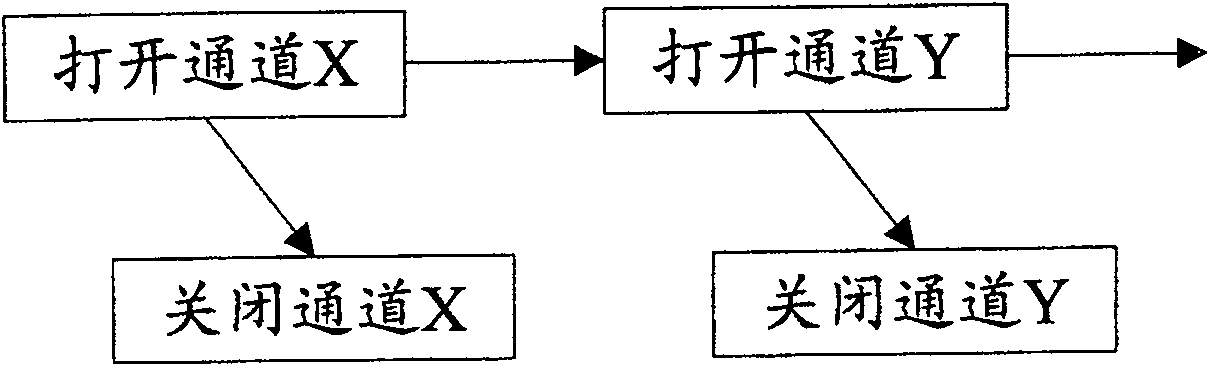

InactiveCN100562923CResolve delayImprove playbackElectrophonic musical instrumentsDigital interfaceTransmission channel

The invention discloses a method for playing a sudden sound in a digital interface of a musical instrument. In the method, a corresponding timing device is set for each channel in advance; property, generate an open channel event according to the property of the burst sound, and execute the open channel event, open the channel corresponding to the event, and play the burst sound on it; at the same time, the system will set the duration in the burst sound property to Send it to the timing device corresponding to the burst sound channel; when the duration ends, the timing device sends a closing instruction to the corresponding channel to close the channel. In the present invention, by setting a corresponding timing device for each channel, after the user generates a burst sound, the system controls the closing of the opened channel through the timing device, which solves the delay problem of burst sound playback and improves the burst sound quality. playback effect.

Owner:VIMICRO CORP

Method and system of auditory evoked heart rate variability analysis

InactiveUS8452385B2High precisionSimplify analytical processingElectrocardiographyCatheterFrequency spectrumSOUND STIMULATION

The present invention provides a method and system of auditory evoked heart rate variability analysis having advantage of simply analytical process and portability. The disclosed method mainly includes the following steps of: stimulating the auditory system of a person by a sound through a sound transmission device, capturing an electrocardiogram signal of the person, performing analog-to-digital conversion of the electrocardiogram signal, selecting the peaks of the electrocardiogram signal and transforming the qualified peaks to a consecutive peak signal, and performing spectrum analysis to the peak signal in frequency domain, and obtaining the difference of the spectral parameters before and after the evoked sounds. Moreover, the sound further is selected from the group consisting of noise, short tone burst, click, and any other sound with the intensity of 30 dB to 100 dB. By comparing the heart rate variability analysis before or after sound stimulation in order to get the differences, the disclosed method and system of auditory evoked heart rate variability analysis can evaluate a changing index of stimulated autonomic functions.

Owner:NATIONAL YANG MING UNIVERSITY

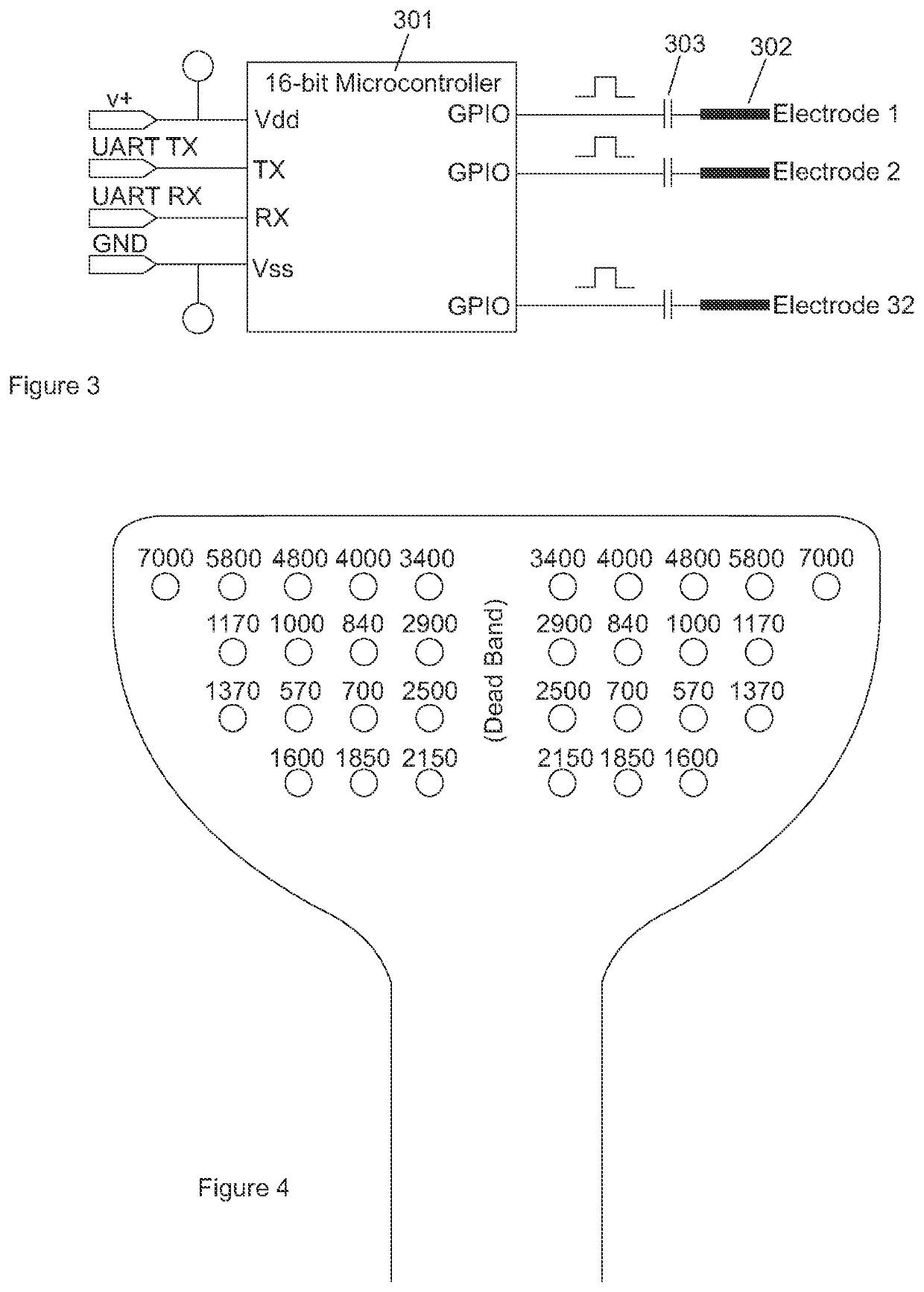

Apparatus and method for treating a neurological disorder of the auditory system

ActiveUS10893371B2Improve performanceImprove customizabilityHead electrodesEar treatmentNoiseAuditory system

An apparatus for use in treating a neurological disorder of the auditory system, including a stimulus generation unit and a somatosensory stimulation unit. The stimulus generation unit operable to analyse an audio signal including a first component comprising a broadband or white noise component and a second component including a plurality of complex tone bursts, and generate a plurality of actuation signals representative of at least one of the first or second component of the audio signal and further to spectrally modify the audio signal to generate a binaural modified audio signal for delivery to a subject. The somatosensory stimulation unit includes: an array of stimulators to apply a somatosensory stimulation to the subject with the modified audio signal, and an input for receiving the plurality of actuation signals from the stimulus generation unit and directing individual actuation signals in a predetermined pattern to individual stimulators in the array.

Owner:NEUROMOD DEVICES

Acoustic determination of piston position in a modular dynamics tester displacement pump and methods to provide estimates of fluid flow rate

Owner:SCHLUMBERGER TECH CORP

Methods and apparatus for detecting defects in an object of interest

ActiveUS9594061B2Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationSonificationAcoustic impedance

A method for detecting defects in an object of interest comprises applying an ultrasonic signal including a tone burst having a predetermined frequency and number of cycles into an object of interest, receiving a return signal reflected from the object of interest, and processing the return signal to detect defects in at least one inner material. The object may have an outer material and the at least one inner material that have different acoustic impedances. An ultrasonic sensor system includes an ultrasonic sensor configured to generate an ultrasonic signal having a tone burst at a predetermined frequency corresponding to a resonant frequency of an outer material of an object of interest.

Owner:NORTHROP GRUMMAN SYST CORP

Piezoelectric wafer eigenfrequency measurement method

InactiveCN102095490BImprove measurement efficiencyHigh measurement accuracySubsonic/sonic/ultrasonic wave measurementUsing electrical meansFrequency spectrumMeasurement device

The invention relates to a piezoelectric wafer eigenfrequency measurement method. The method comprises the following steps: (1) arranging a measurement device including a function generator, a piezoelectric wafer and a digital oscilloscope; (2) starting the function generator to generate Tone-Burst sine wave signals with a certain period number, conducting electric pulse excitation to the piezoelectric wafer by the function generator at a frequency f, stopping the electric pulse excitation to the piezoelectric wafer when the function generator completes the period number, enabling the piezoelectric wafer to start vibrating freely, and collecting the free vibration signal between two electrodes of the piezoelectric wafer by the digital oscilloscope; (3) adjusting the digital oscilloscope to amplify the free vibration signal between the two electrodes of the piezoelectric wafer in the step (2), and processing the amplified signal by fast Fourier transform; (4) extracting the frequency of the peak on the spectrogram obtained by Fourier transform in the step (3) to obtain the eigenfrequency of the piezoelectric wafer to be tested; and (5) changing the frequency f of the function generator in the step (2), repeating the step (3) and step (4), and measuring each eigenfrequency of the piezoelectric wafer.

Owner:CHINA NAT OFFSHORE OIL CORP +1

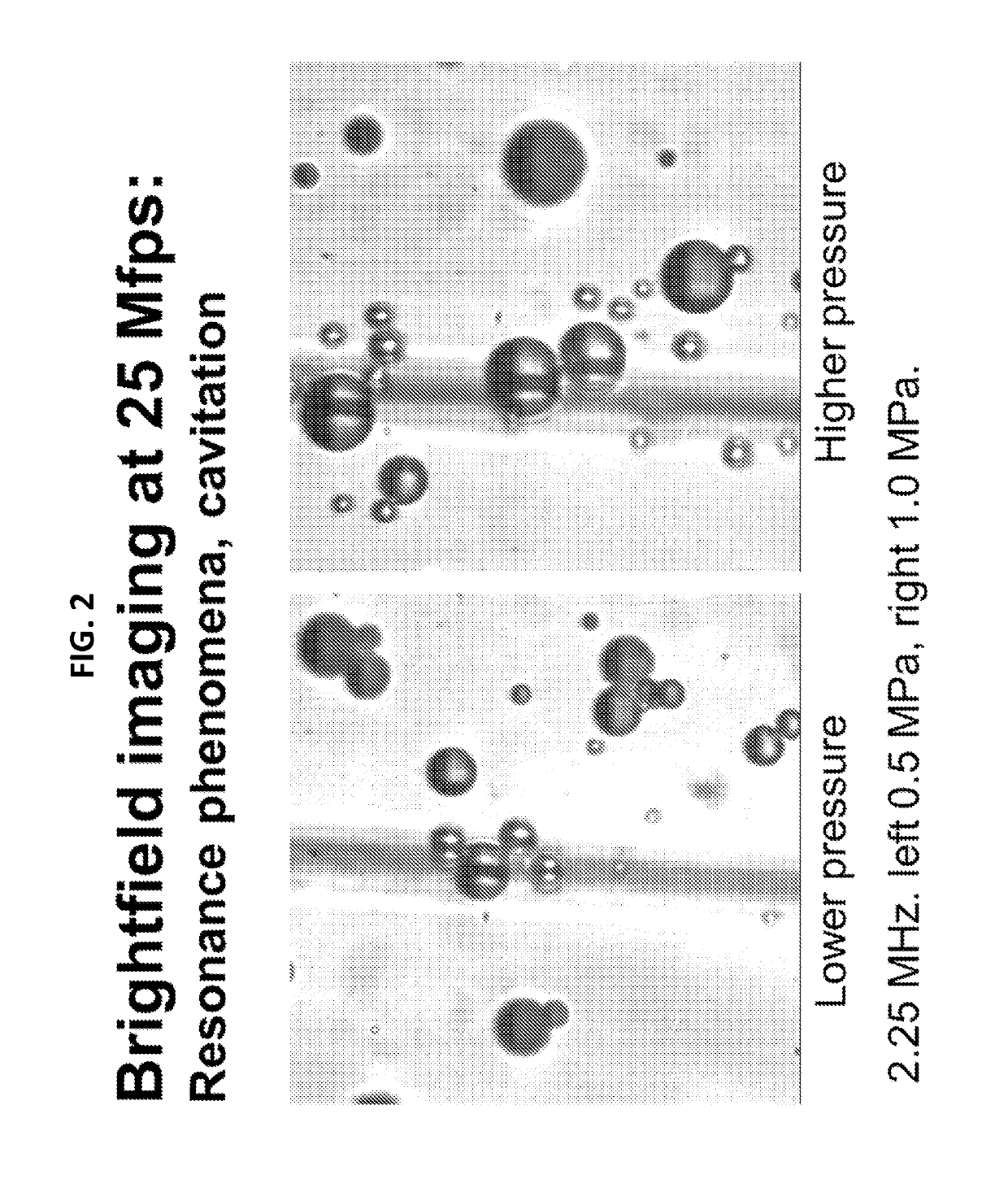

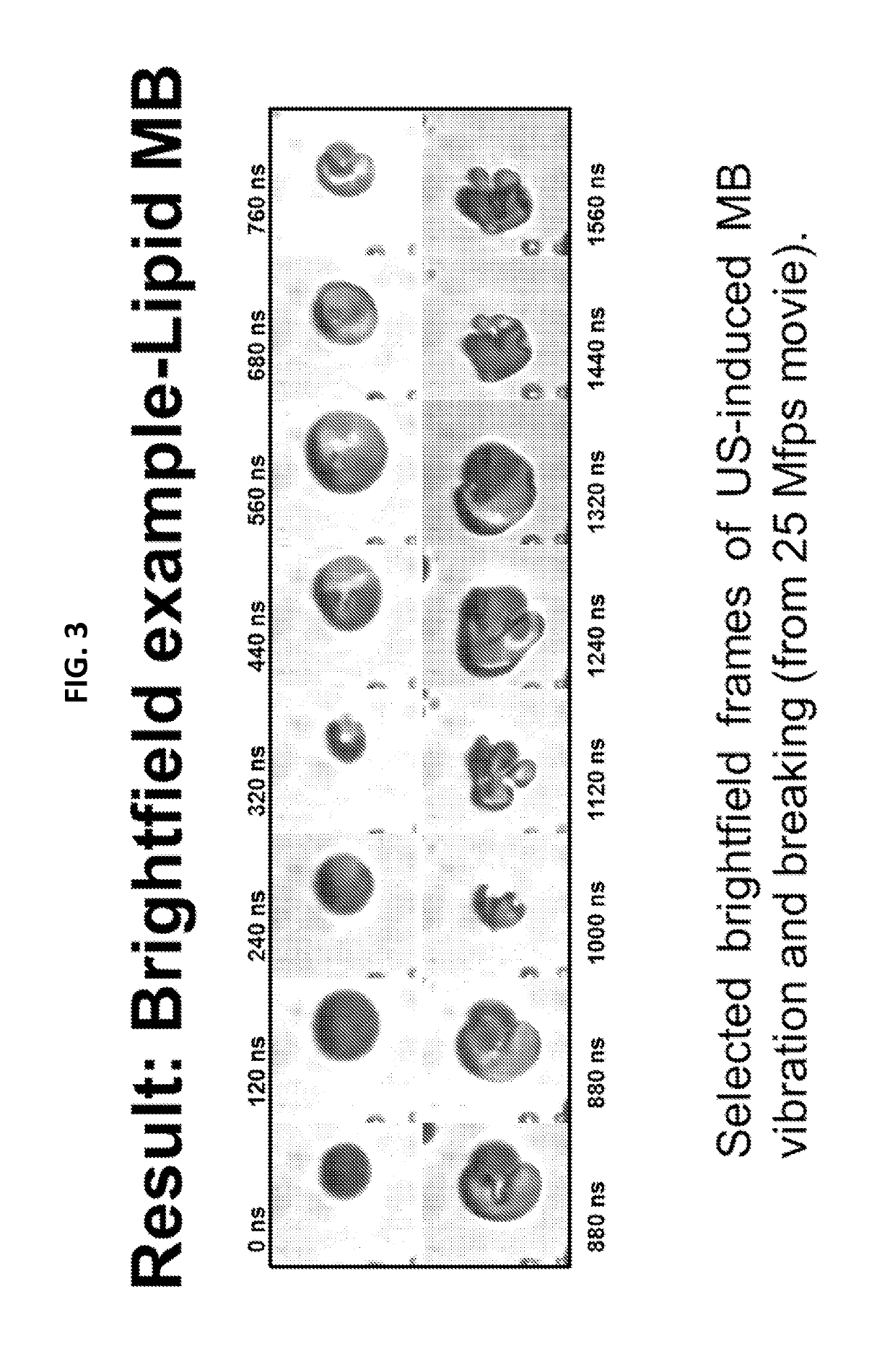

Methods and devices for ultrasound contrast-assisted therapy

ActiveUS10413278B2Ultrasound therapyOrgan movement/changes detectionUltrasound contrast mediaMedicine

Various methods of performing ultrasound contrast assisted therapy are provided. One such method includes delivering a plurality of microbubble-based ultrasound contrast agents to a target area and disrupting the microbubble-based ultrasound contrast agents by delivering tone bursts of ultrasound to the target area. The oscillation of the microbubble-based ultrasound contrast agents can be achieved by delivering ultrasound tone bursts of greater than 5 acoustic cycles with a pulse repetition frequency of between 0.01 and 20 Hz, with pressure greater than 0.3 MPa.

Owner:UNIVERSITY OF PITTSBURGH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com