Piezoelectric wafer eigenfrequency measurement method

A technology of piezoelectric wafer and eigenfrequency, which is applied in the field of measurement, can solve the problems of error in measurement results, difficulty in pre-determining, and time-consuming measurement, and achieve the effects of convenient operation, high measurement efficiency, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0025] Such as figure 1 As shown, a PZT-5 rectangular parallelepiped piezoelectric wafer is measured, and its size is 34mm (length L) × 14mm (width W) × 5mm (thickness T). The piezoelectric wafer is polarized in the thickness direction, and an excitation electric field is applied in the thickness direction.

[0026] 1) A device for measuring piezoelectric wafers using the method of the present invention is provided.

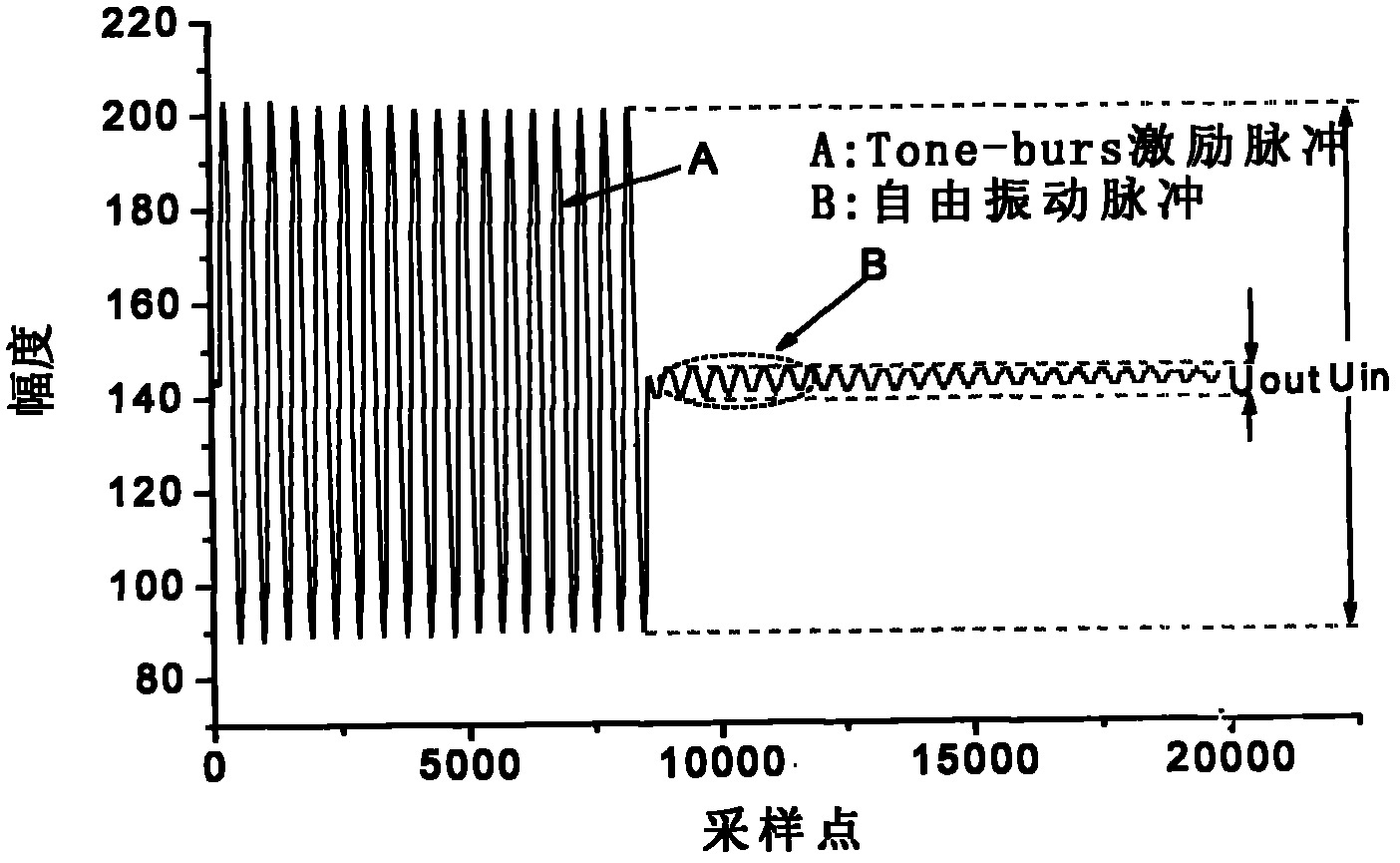

[0027] 2) if figure 2 As shown, the function generator 1 is turned on, and the function generator 1 generates a Tone-Burst sine wave signal A with 18 cycles (the part of the signal indicated by the arrow A in the figure). During this process, the function generator 1 controls the The piezoelectric wafer 2 is excited by electric pulses to make the piezoelectric wafer 2 vibrate. When the function generator 1 completes the number of cycles, the electric pulse excitation to the piezoelectric wafer 2 stops, and the piezoelectric wafer 2 starts to vibrate freely. Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com