Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

262 results about "Food temperatures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In general, food should be cooked to a temperature of at least 75 °C or hotter. When food is cooked, it should be eaten promptly, kept hotter than 60 °C, or cooled, covered and stored in the fridge or freezer. Some people are more at risk from food poisoning than others.

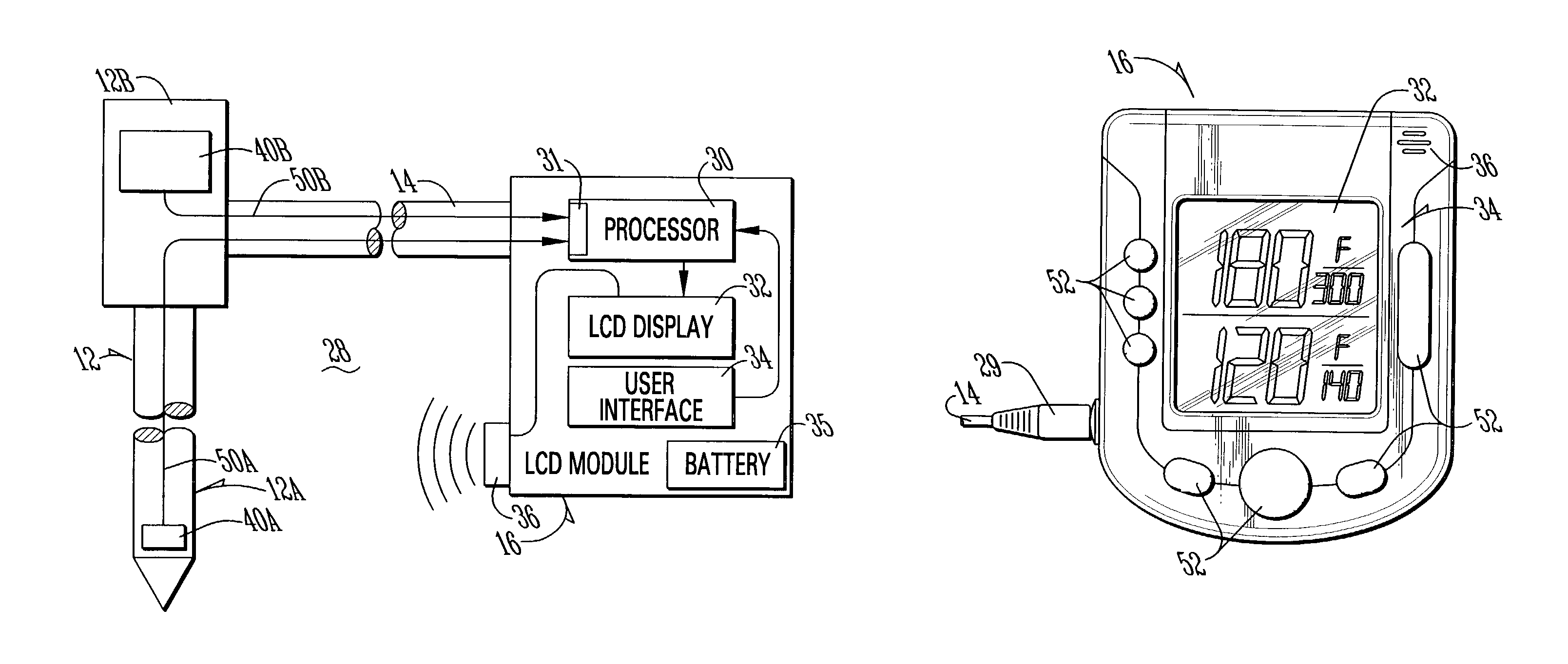

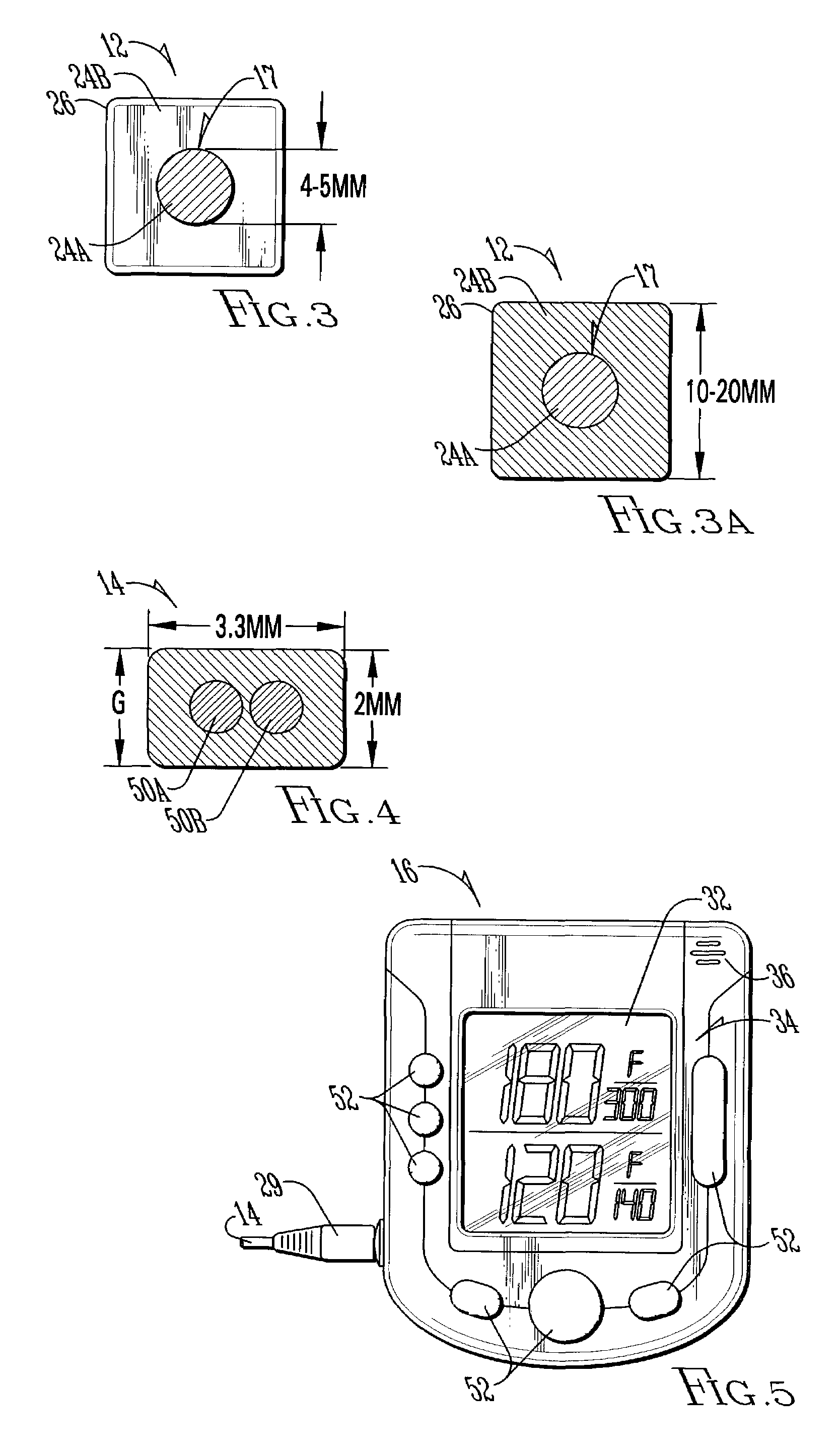

Dual thermometer system

InactiveUS7128466B2Quick measurementEasy to operateThermometer detailsDomestic stoves or rangesTwo temperatureEngineering

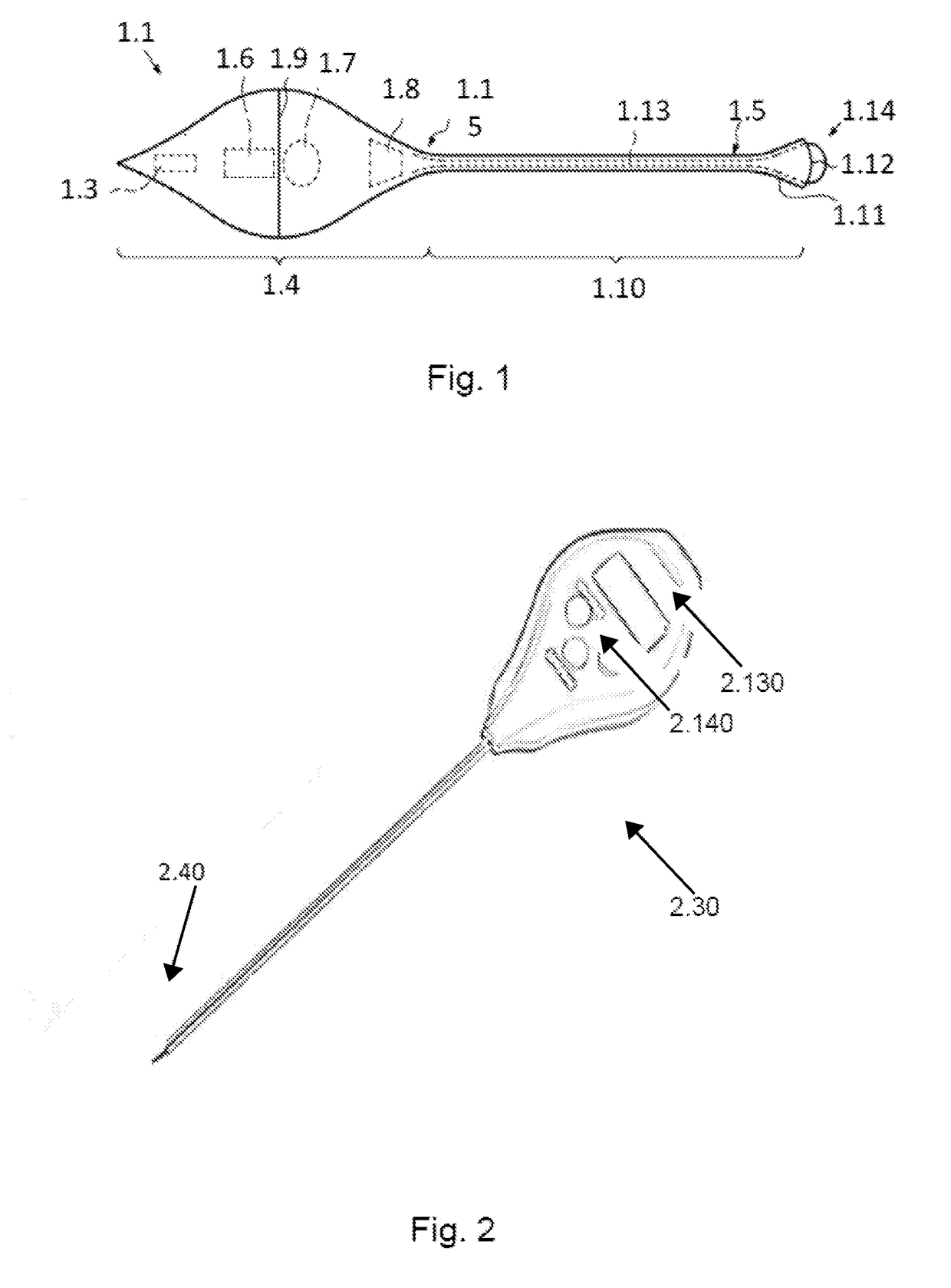

The invention provides a dual thermometer system for the measurement and display of temperature data taken at two separate locations within an oven. In one aspect, the invention provides an elongated probe connected with a flexible electronic cable. The probe houses two temperature sensors—one for sensing internal food temperature, one for sensing inside oven air temperature. The sensors are space apart within the probe such that the one sensor can be positioned substantially within a food item and the other sensor can positioned substantially outside of the food item and within the oven. Signals from the sensors are relayed from the probe and through the cable; external electronics may attach to the cable to acquire the signals and display associated temperatures. In another aspect, signals from temperature sensors are relayed from the probe and through the cable to a first wireless termination. The first wireless termination wirelessly relays signals from the probe to a second wireless termination coupled to module electronics, to acquire the wireless signals and to display associated temperatures. In operation, the probe is inserted into food within an operating oven, such that one of the sensors senses food temperature and such that the other of the sensors senses oven air temperature; the cable extends from the probe and through the door of the oven; the module electronics may be attached to a convenient location in the kitchen, usually near to the oven, to display temperatures from the probe.

Owner:EWIG INDS

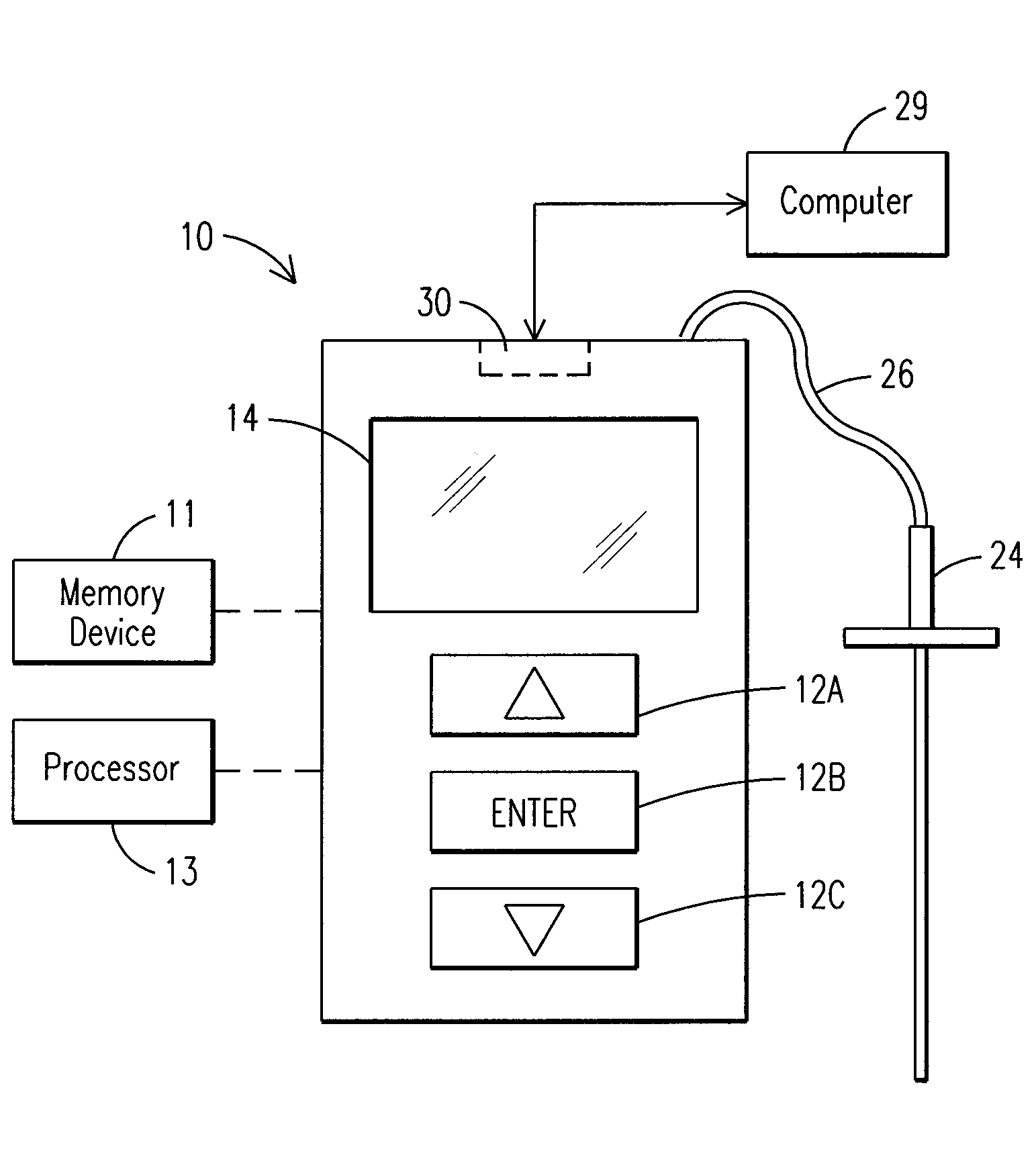

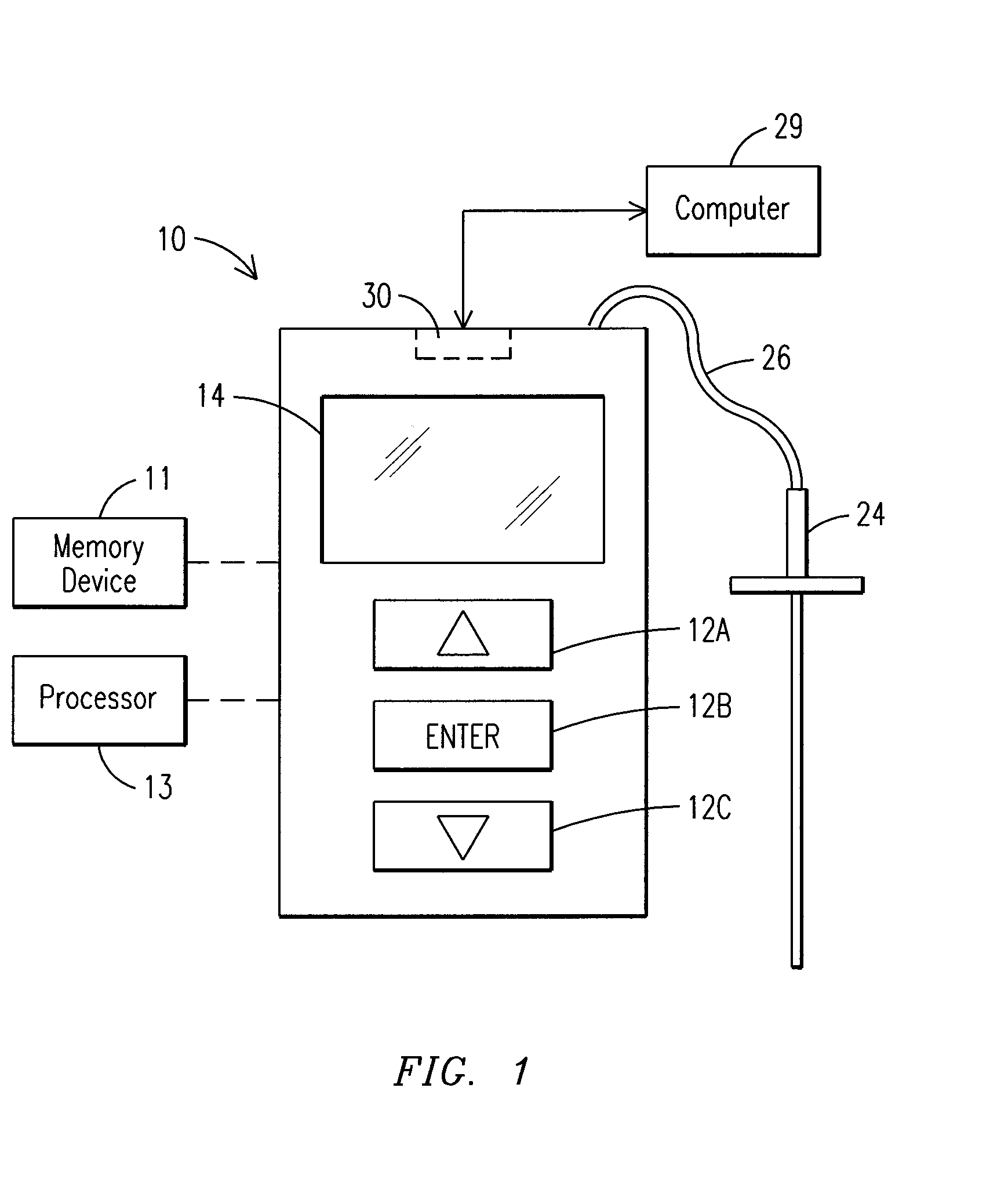

Food temperature collection, storage and retrieval system

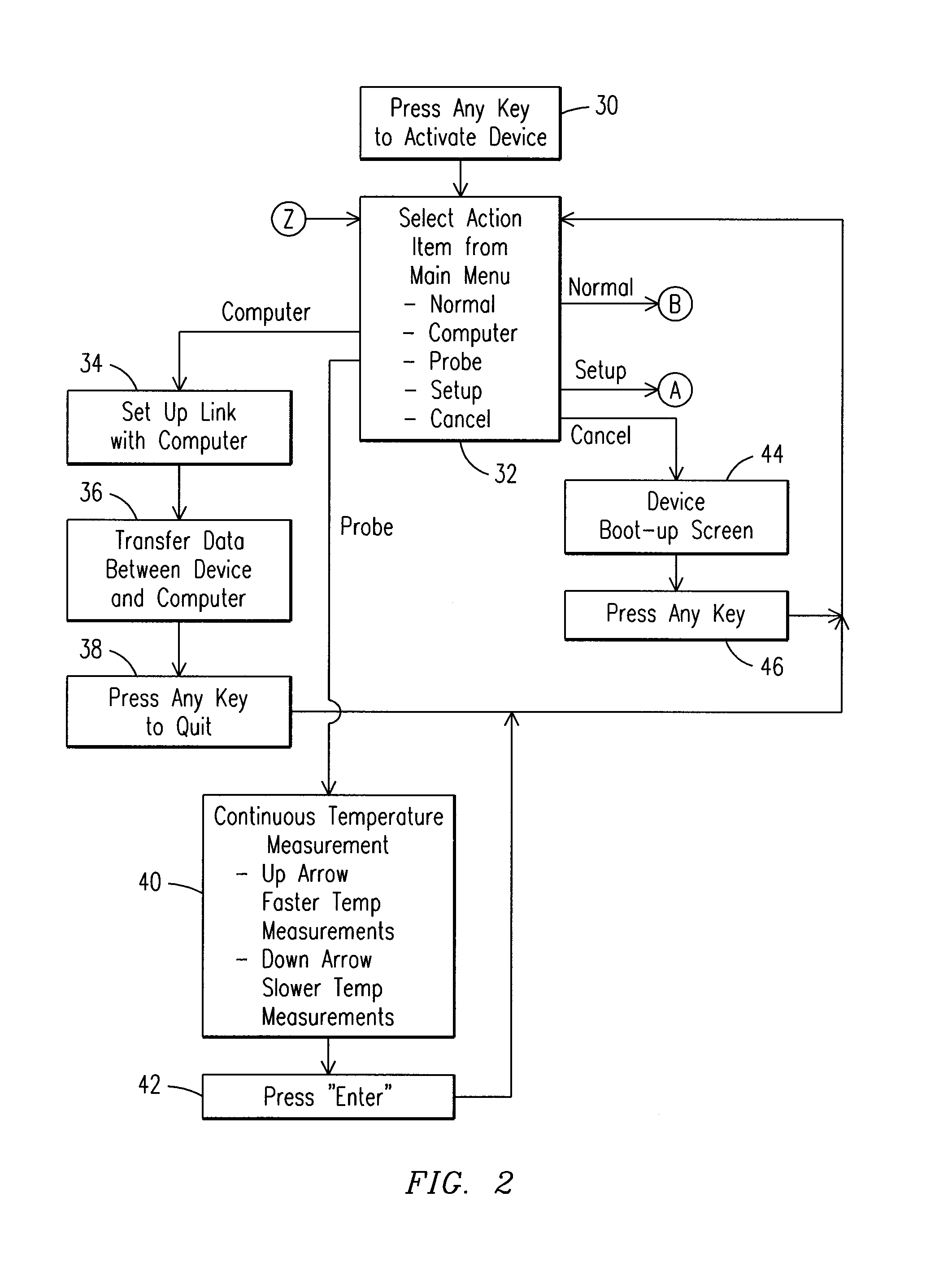

InactiveUS20080120188A1Thermometer detailsThermometers using material expansion/contactionHand heldDisplay device

An automated system for collecting, storing and retrieving temperature data relative to food items and food storage equipment includes a hand-held display and data input unit coupled to a temperature probe. The system may include, in the hand-held unit, a memory element for storing one or more predetermined temperature ranges for each one of a plurality of food items or food storage equipment items; and, the memory element maintains a log having temperature data relative to measured temperatures of food items and / or food storage equipment including the date and time when temperatures were measured. The system also comprises a processor that assigns a log number to a temperature measurement taken of a food item or the food storage equipment, and the memory element stores the log number with the date, time and measured temperature associated with the food item or food storage equipment.

Owner:INNOVATIVE TECH BY DESIGN

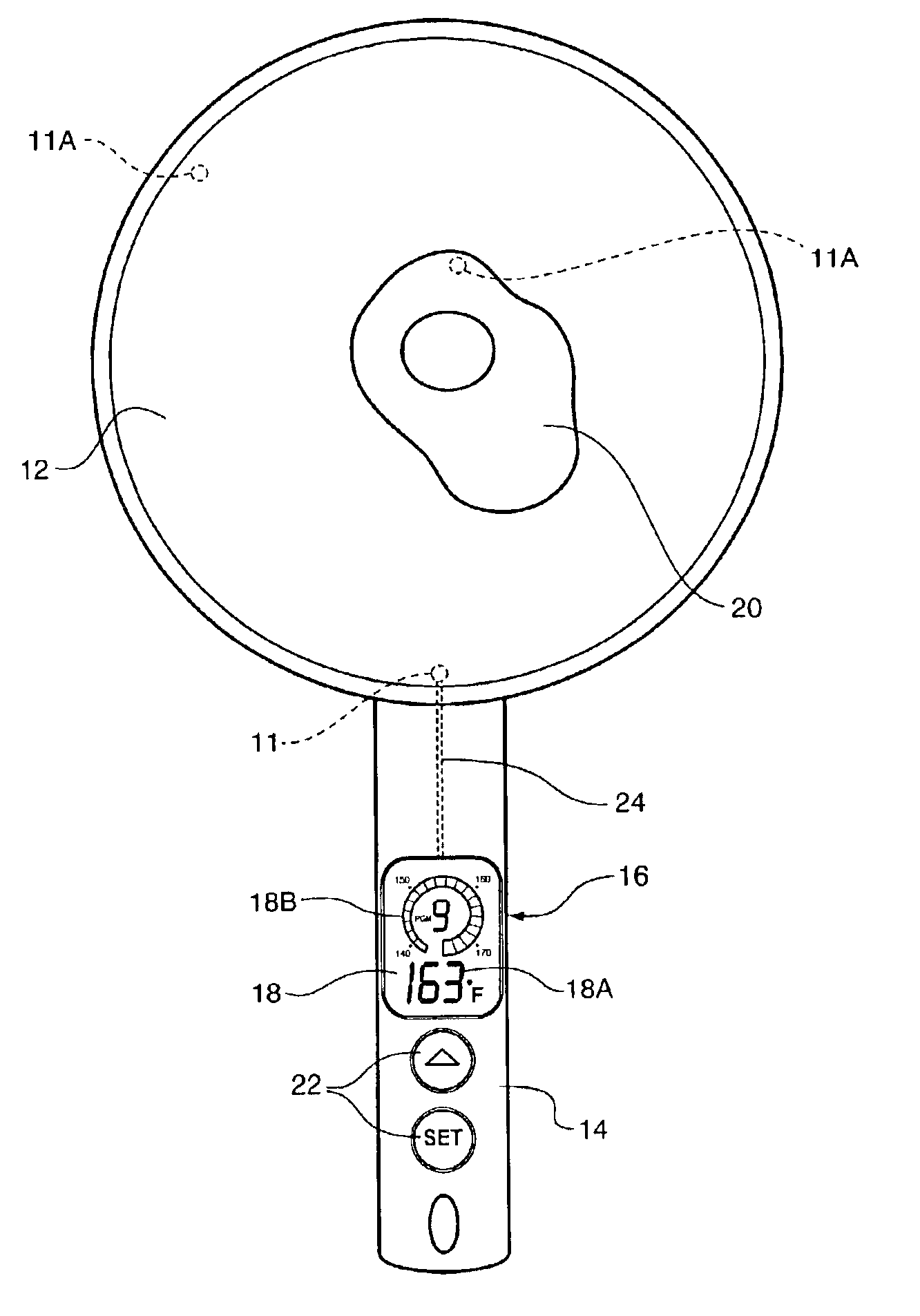

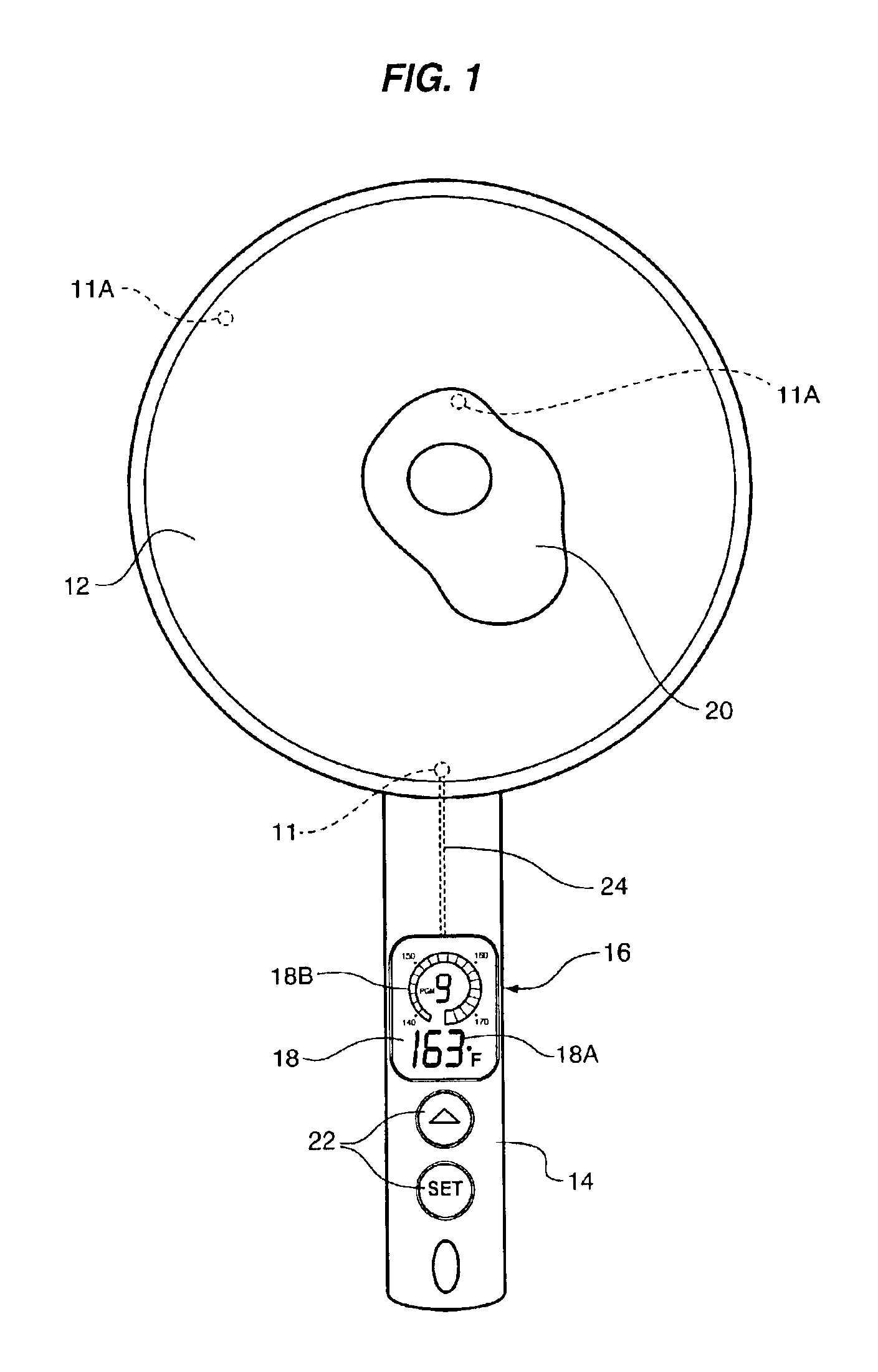

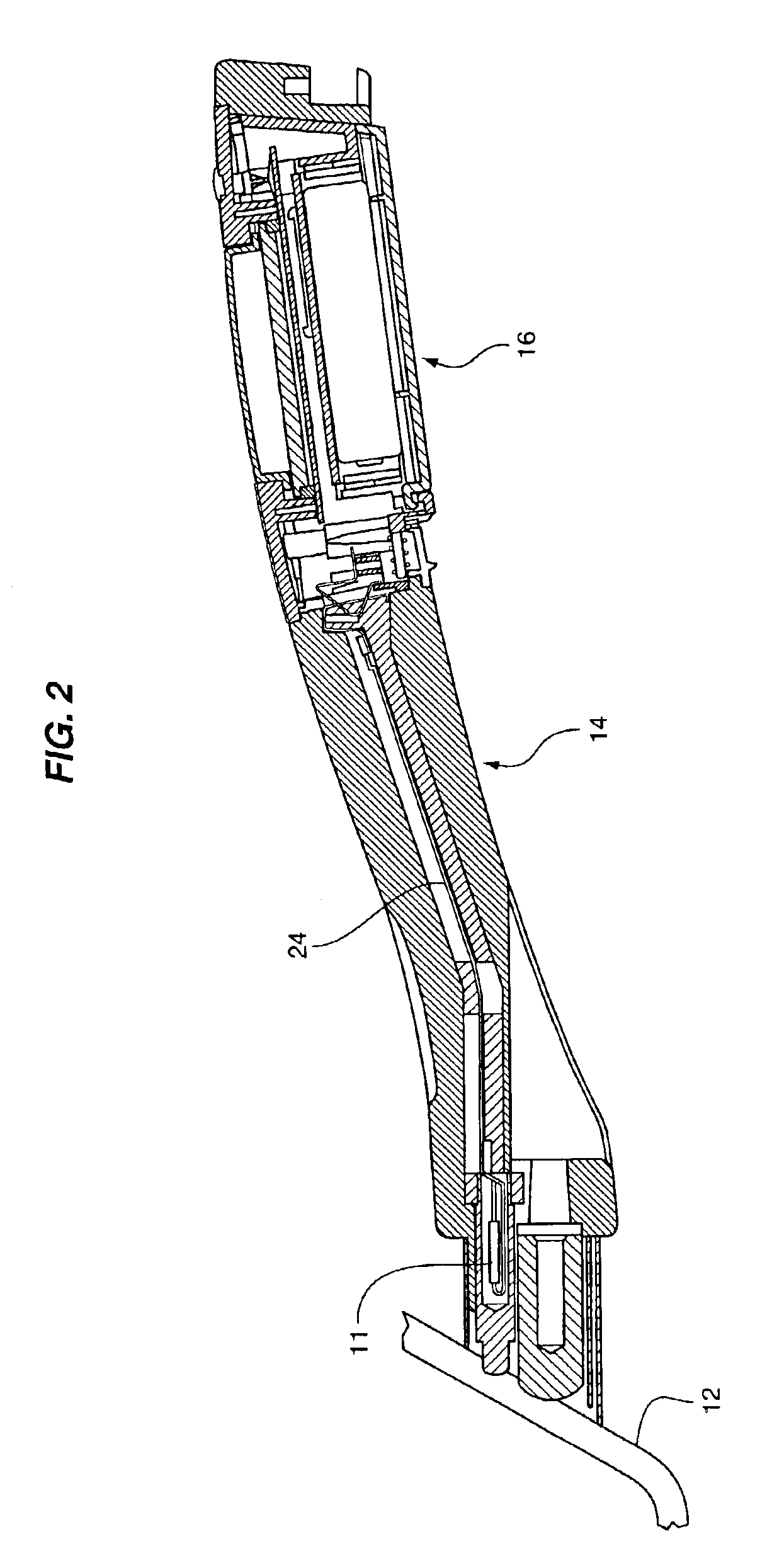

Electronic frying pan systems and methods

InactiveUS6860192B2Thermometer detailsThermometers using electric/magnetic elementsRemote systemEngineering

A digital frying pan provides temperature and / or food doneness information associated with food cooked within the pan. A thermal sensor coupled with the pan senses temperature and generates corresponding signals, and processing electronics coupled with the sensor convert the signals to data for display on a LCD. A warning buzzer or LED warns the user of completed cooking. The frying pan may be programmed to desired food types or personal temperatures or food doneness options. The invention also provides a remote sensing food doneness system for remotely viewing and then determining food temperature and / or food doneness. The remote system uses thermal imaging optics and thermal sensing techniques to remotely sense food temperature. Preferably a second optical element images the food onto a CCD to display an image of the food to a user. The system is mounted by a user who views the CCD to ensure appropriate placement in line of sight from the food. A warning is generated by the system to indicate food doneness or desired temperature.

Owner:SHARPE RICHARD

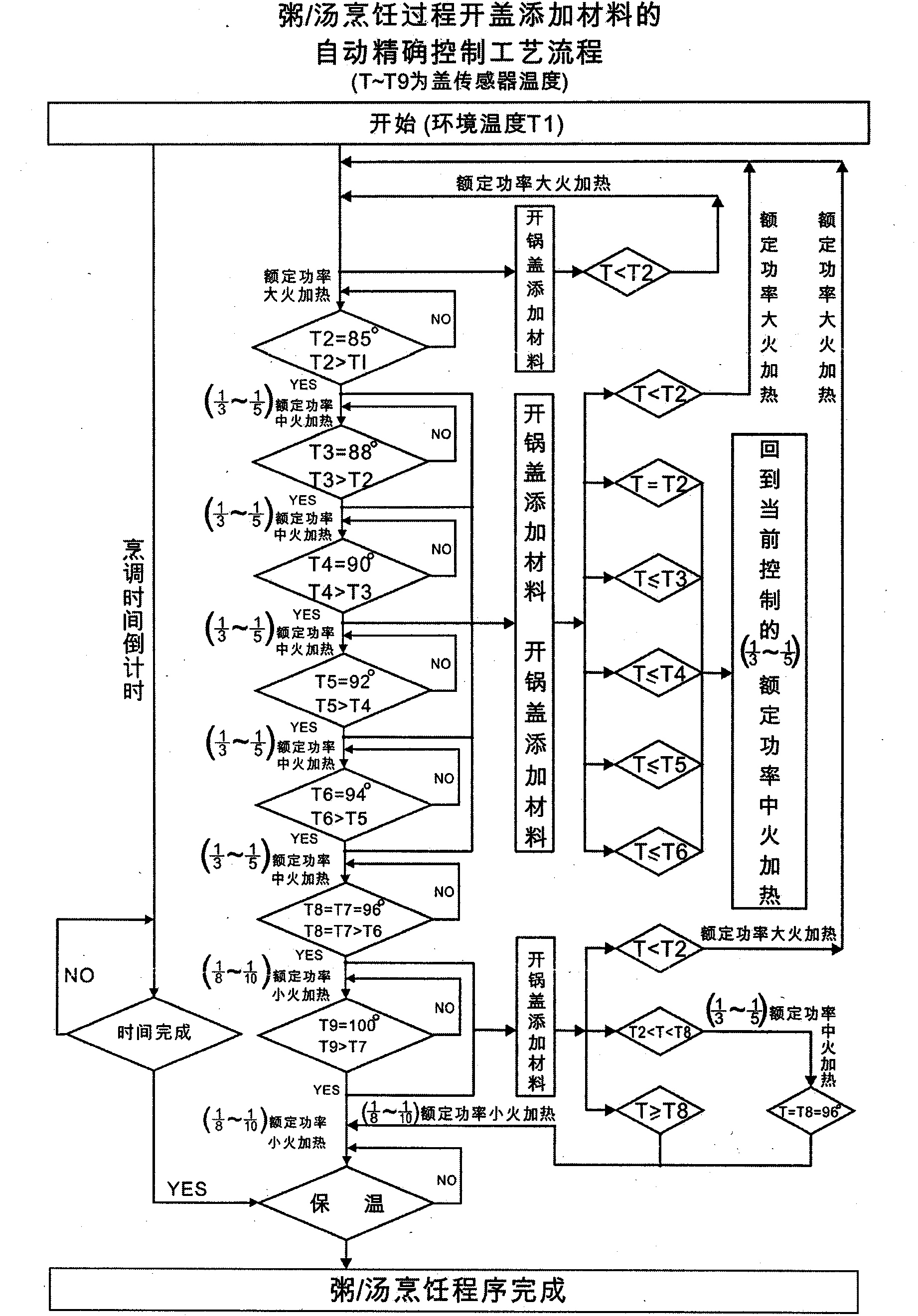

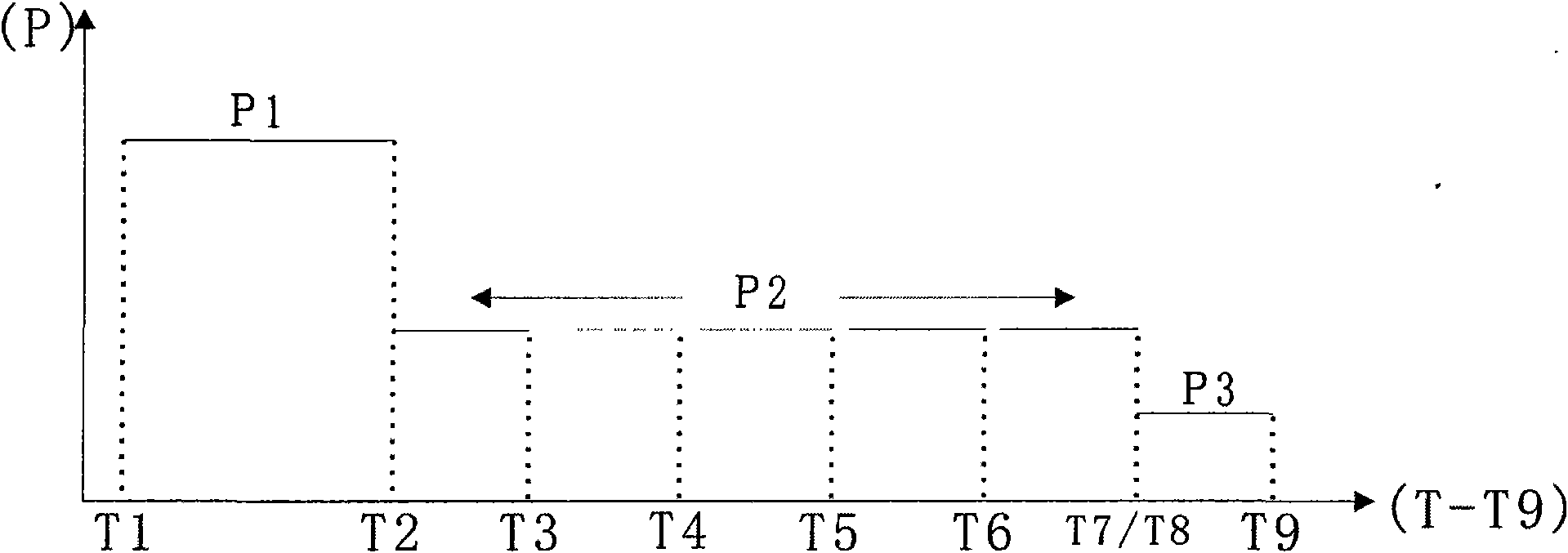

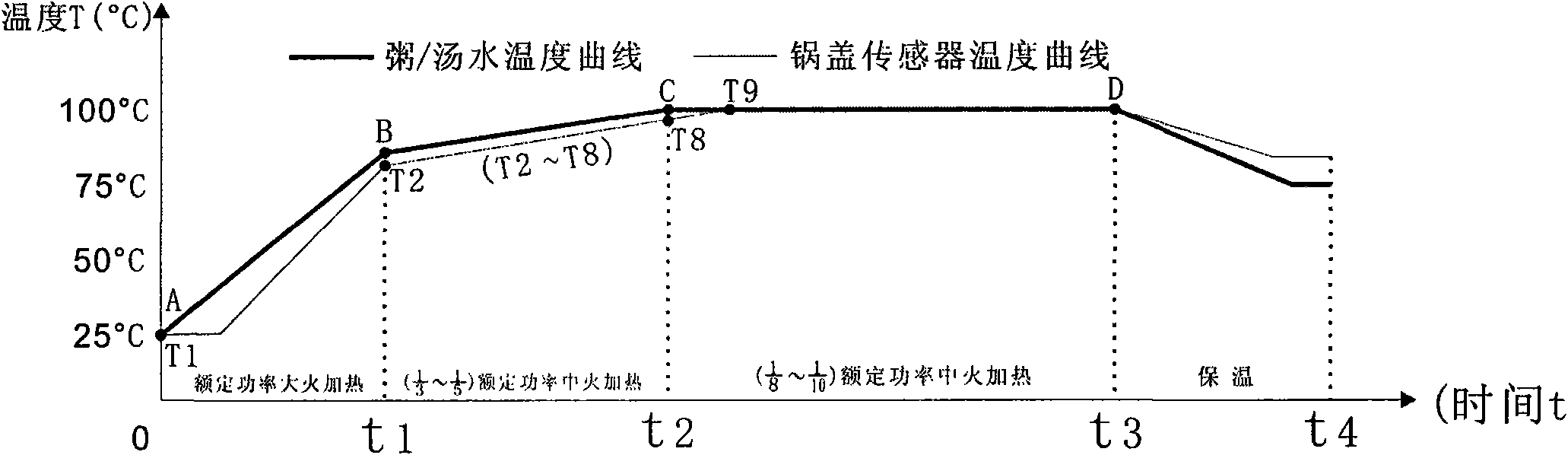

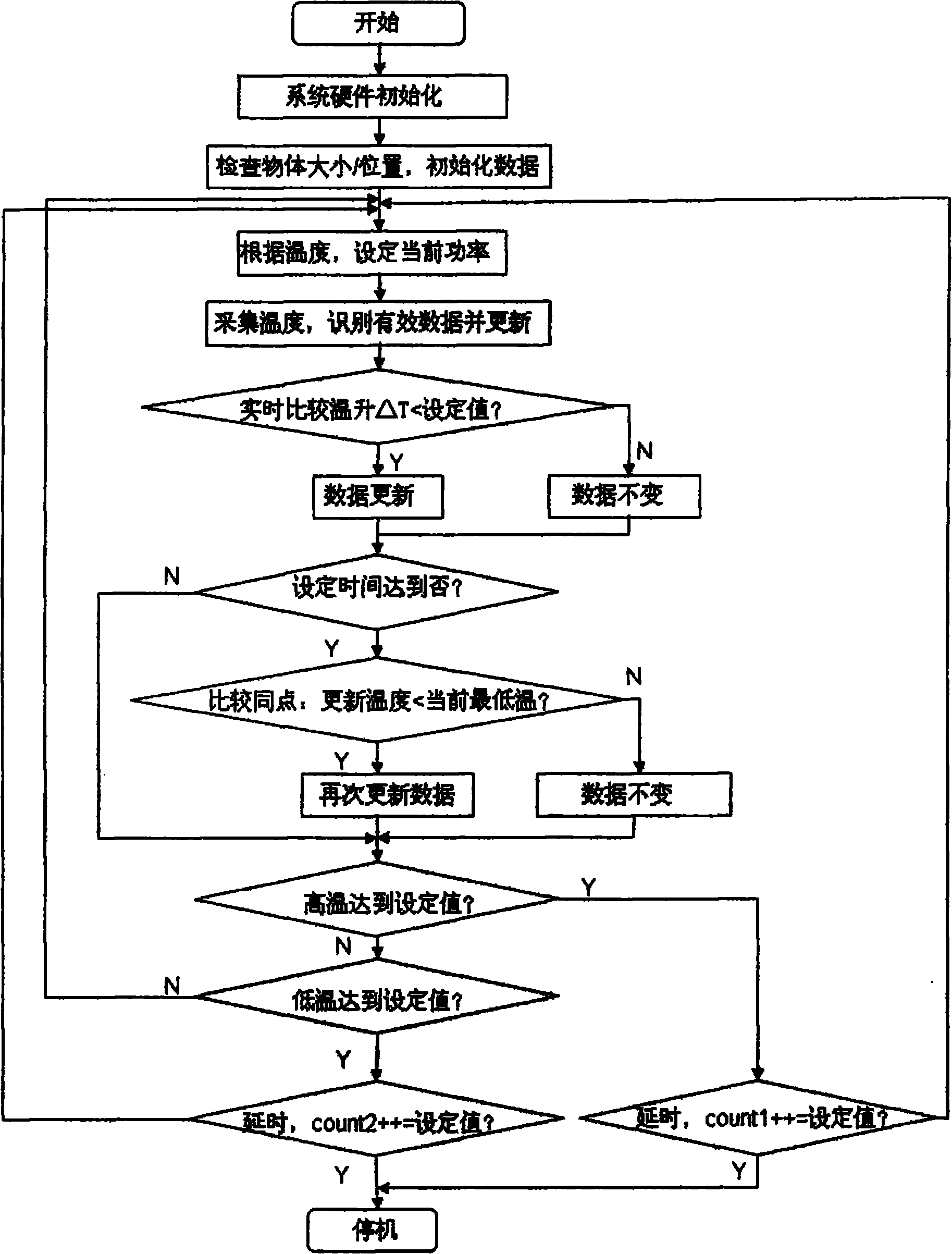

Automatic accurate temperature controlling technique for foodstuff adding process when cooking congee/soup with computerized electric cooker

InactiveCN102073329AGood cooking effectAuxillary controllers with auxillary heating devicesTemperature controlAutomatic control

The present invention relates to an automatic accurate temperature controlling technique for the foodstuff adding process when cooking congee / soup with a computerized electric cooker, which includes performing automatic accurate temperature control through increasing power or maintaining power to conduct rapid heat compensation during the random opening of a cooker lid to add foodstuff in high, medium or low flame heating phases. The invention adopts the automatic accurate temperature controlling technique capable of smartly controlling the temperature of the three cooking phases in cooking congee / soup in spite of randomly opening the cooker lid for foodstuff adding, thus, without increasing production cost, the application of the technique can accurately detect decreased values of in-pot food temperature and lid sensor temperature caused by the opening of the cooker lid for adding foodstuff, thereby automatically conducting heat compensation by controlling the power to increase or maintain so as to ensure sterilization to the later added foodstuff, in addition, improves the qualities of congee and soup cooked by the existing micro-computerized electric cooker, to make the congee or soup more delicious after more foodstuff is added during the cooking process. The automatic accurate temperature controlling technique for a micro-computerized electric cooker is new and practical, has good effect in cooking congee / soup because the lid can be randomly opened for foodstuff adding.

Owner:广东鸿智智能科技股份有限公司

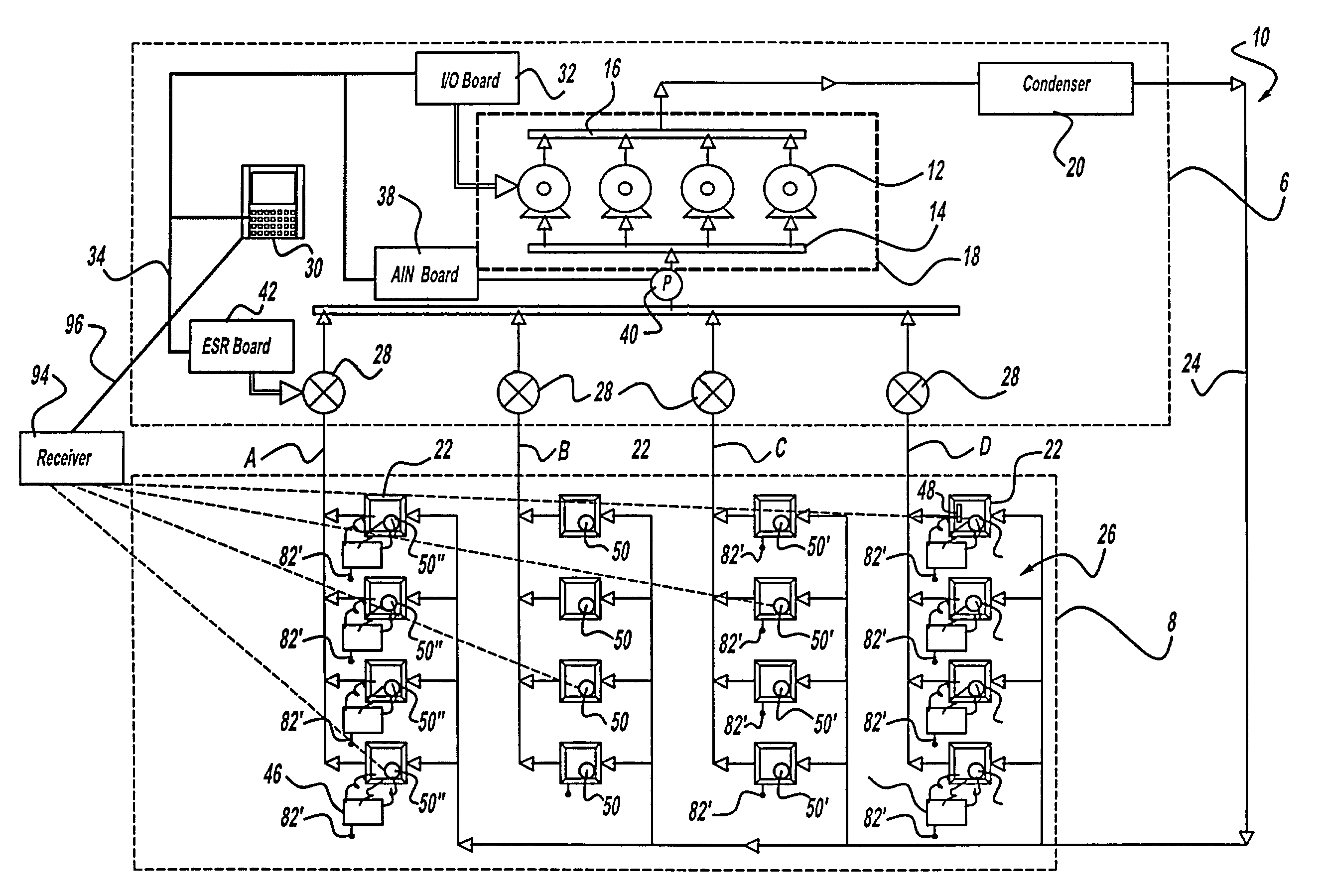

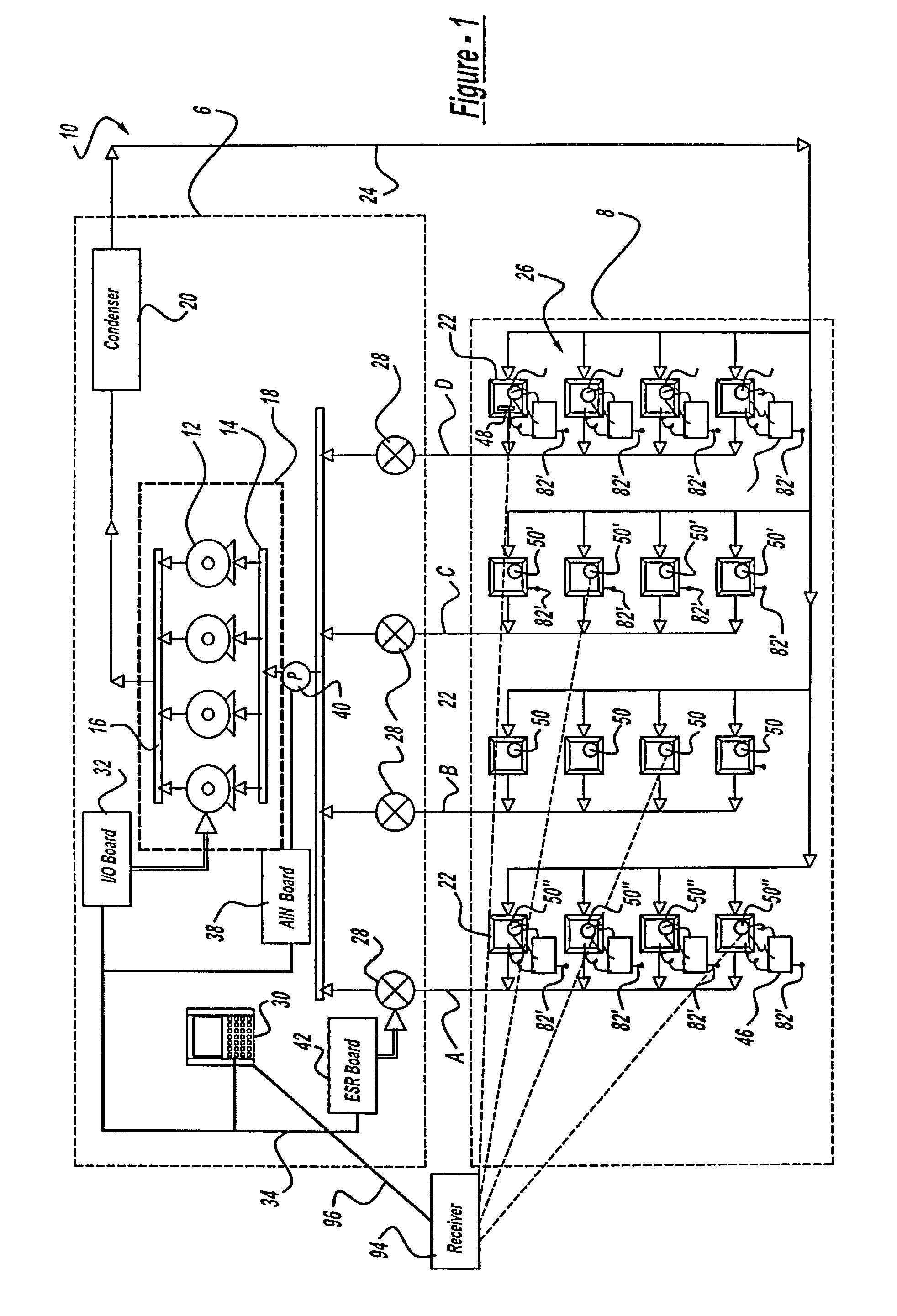

Wireless method for monitoring and controlling food temperature

InactiveUS7013661B2Mechanical apparatusTelemetry/telecontrol selection arrangementsData controlTransceiver

A method for controlling refrigeration including a simulated product temperature sensor operable to measure a simulated product temperature from a refrigeration case and a transceiver in communication with said simulated product temperature sensor and operable to wirelessly transmit data. A receiver receives the wirelessly transmitted data and a controller in communication with the receiver controls the refrigeration system based upon the wirelessly transmitted data from the refrigeration case.

Owner:EMERSON CLIMATE TECH RETAIL SOLUTIONS

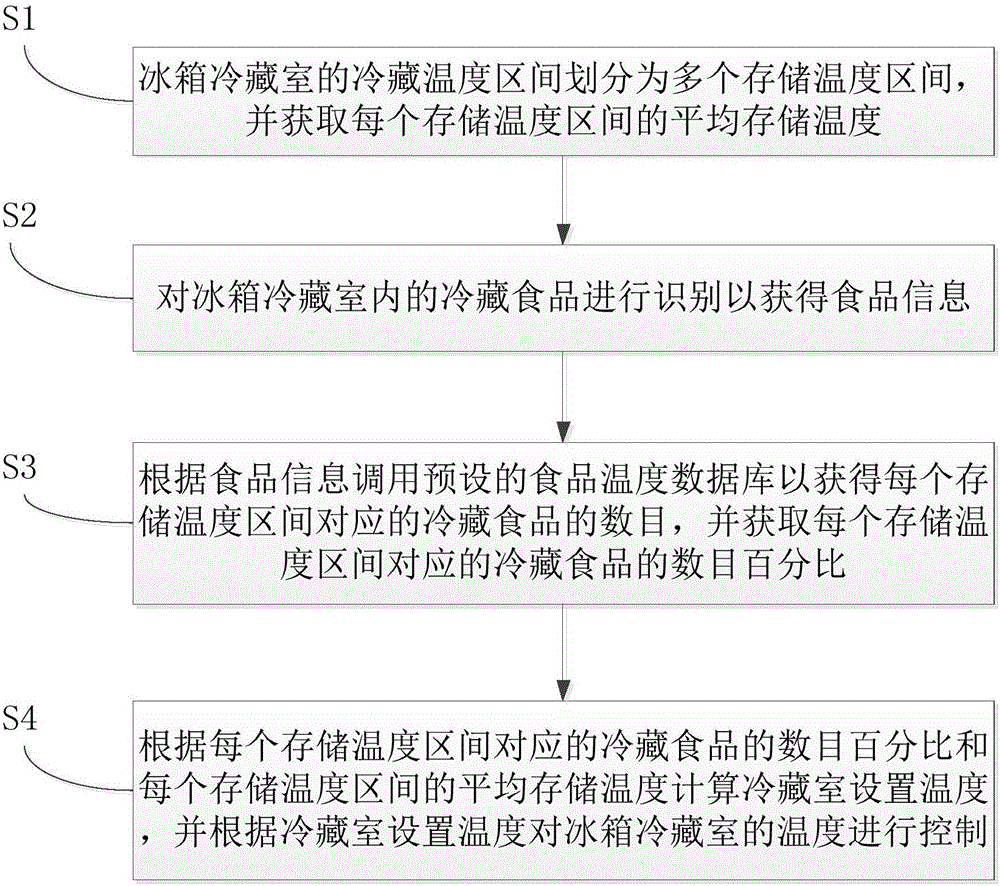

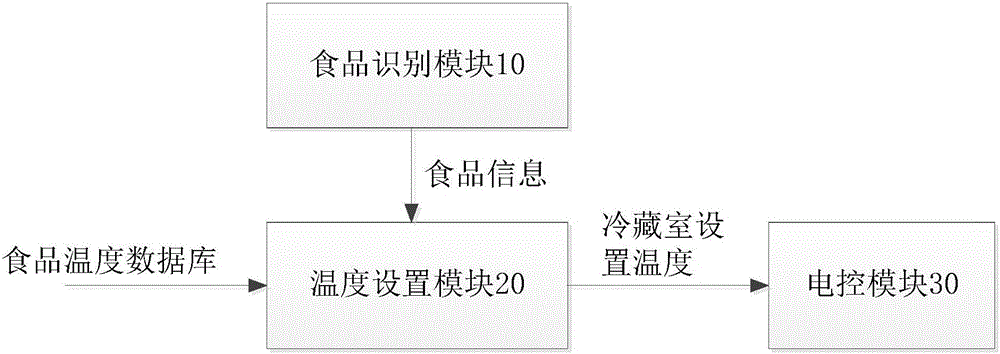

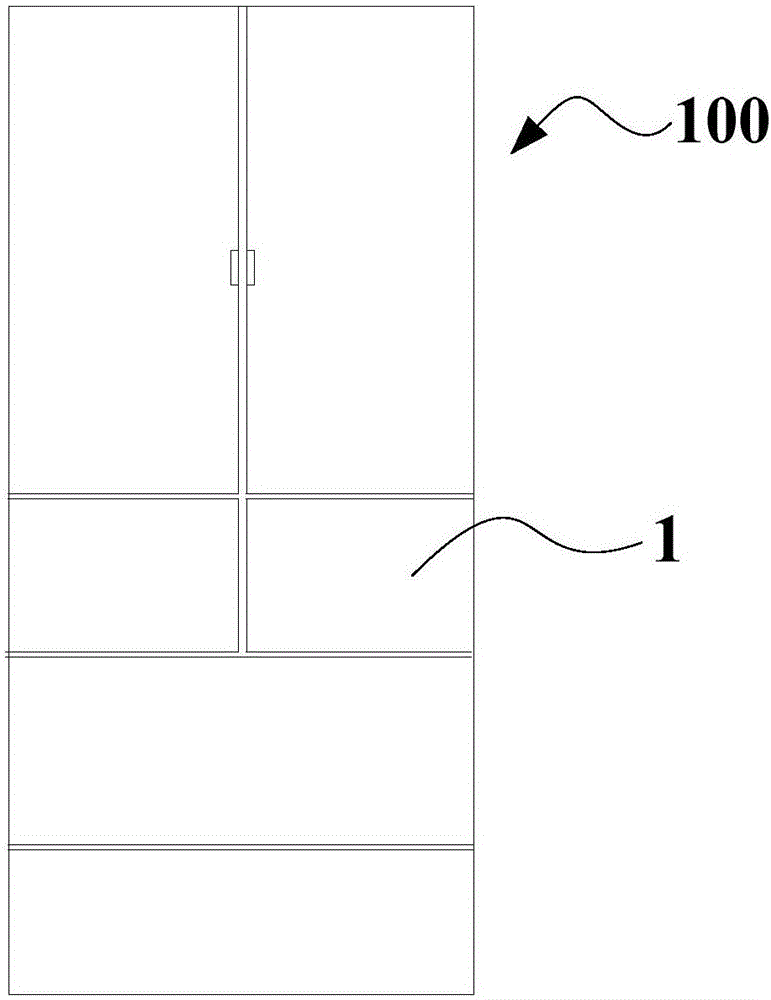

Intelligent temperature control method of fridge refrigerating chamber, device and fridge

ActiveCN106168432AGuaranteed refrigeration effectImprove the preservation effectLighting and heating apparatusCooling fluid circulationTemperature controlProcess engineering

The invention discloses an intelligent temperature control method of a fridge refrigerating chamber, a device and a fridge. The intelligent temperature control method includes the steps: dividing the refrigerating temperature range of the fridge refrigerating chamber into a plurality of storage temperature ranges, and acquiring average storage temperature of each storage temperature range; identifying refrigerated food to obtain food information; calling a preset food temperature database according to the food information to obtain the amount of the refrigerated food corresponding to each storage temperature range, and acquiring the percentage of the amount of the refrigerated food corresponding to each storage temperature range; calculating refrigerating chamber set temperature according to the percentage of the amount of the refrigerated food corresponding to each storage temperature range and the average storage temperature of each storage temperature range, and controlling the temperature of the fridge refrigerating chamber according to the refrigerating chamber set temperature. According to the intelligent temperature control method, the refrigerating chamber set temperature can be acquired according to storage temperature of various food materials in the fridge refrigerating chamber, and the fresh-keeping effect of the food is greatly improved.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

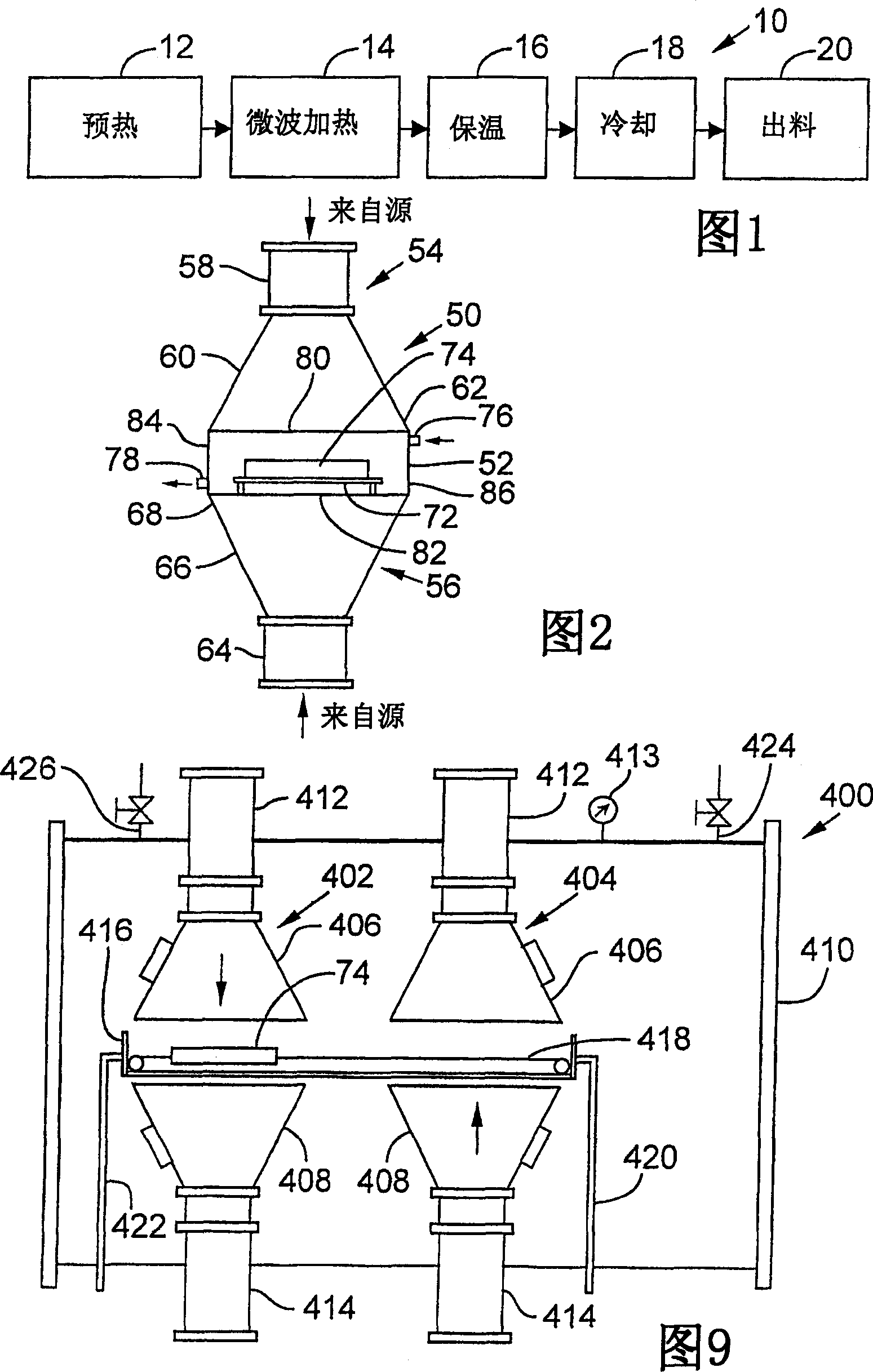

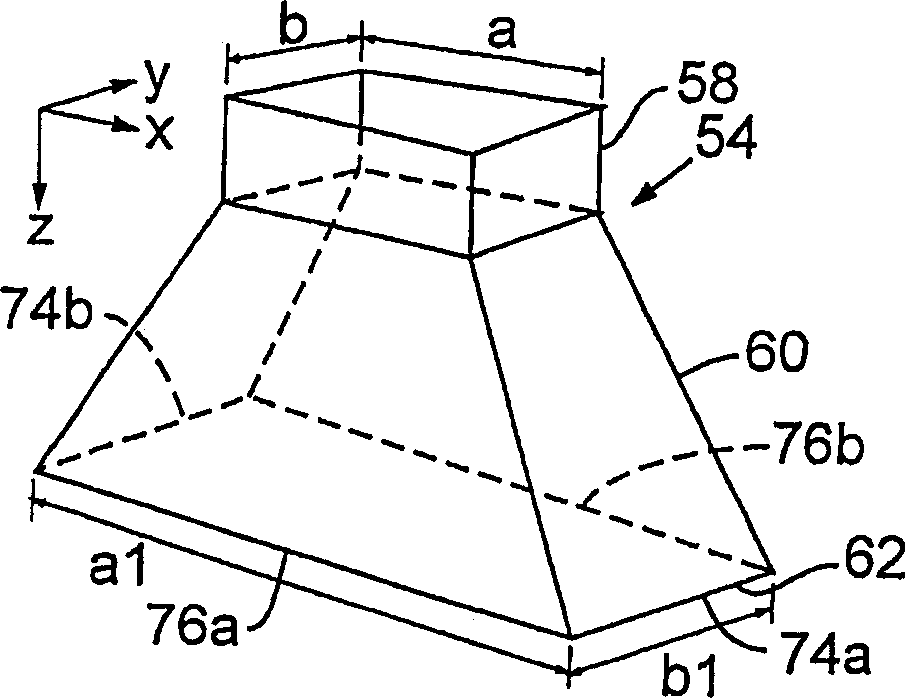

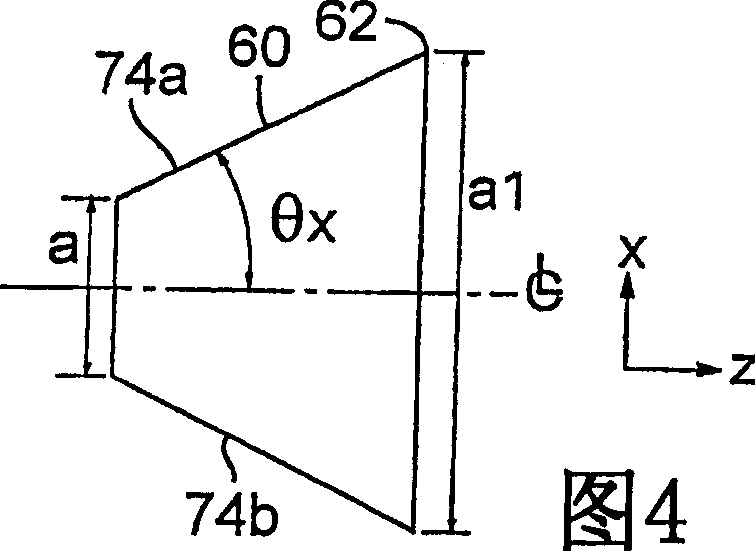

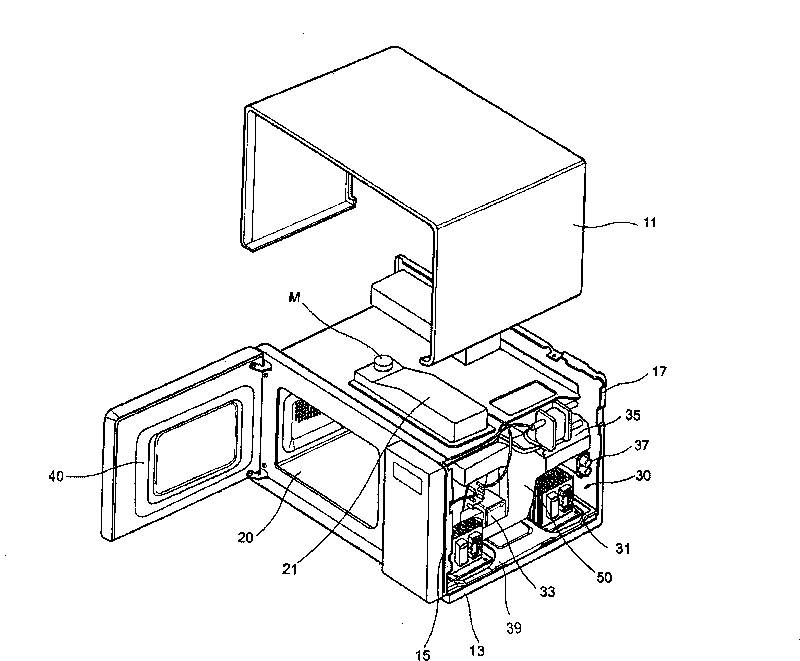

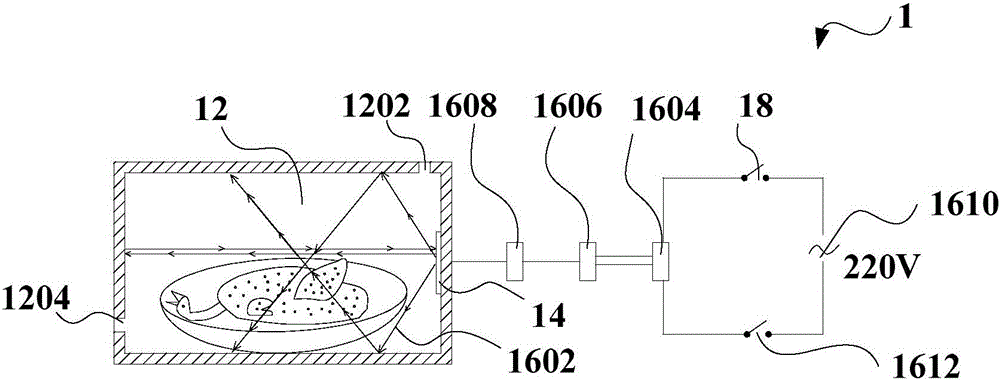

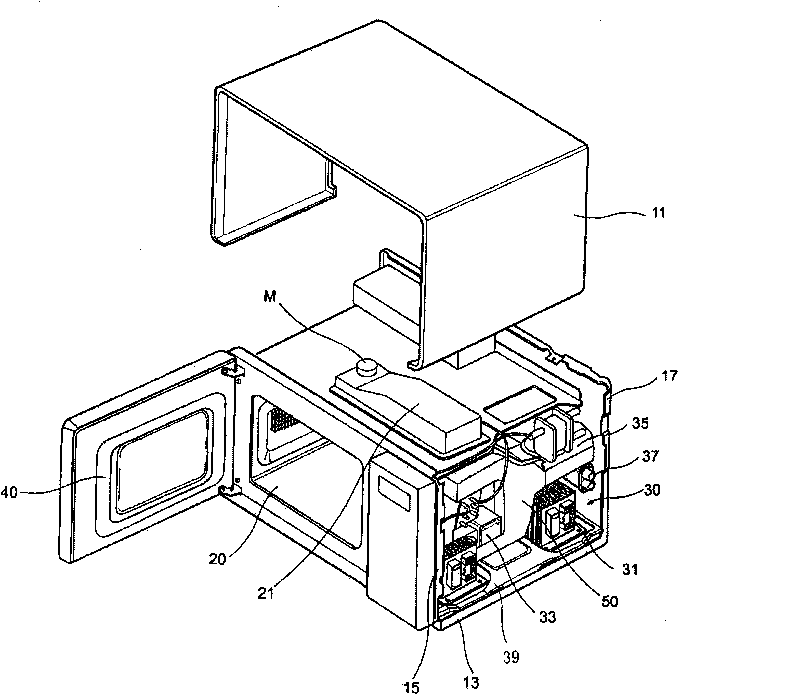

Apparatus and method for heating objects with microwaves

The present invention relates to a device for pasteurization and / or high temperature sterilization of food products. In a typical embodiment, the pasteurized or high-temperature sterilized food packaging device includes at least one cavity, in which pasteurized or high-temperature sterilized food is placed. The cavity is configured to operate as a single cavity when microwave energy is injected into the cavity, pasteurizing or autoclaving food. The present invention also relates to optimizing microwave systems for pasteurization or high temperature sterilization of food products.

Owner:WASHINGTON STATE UNIV RES FOUND INC

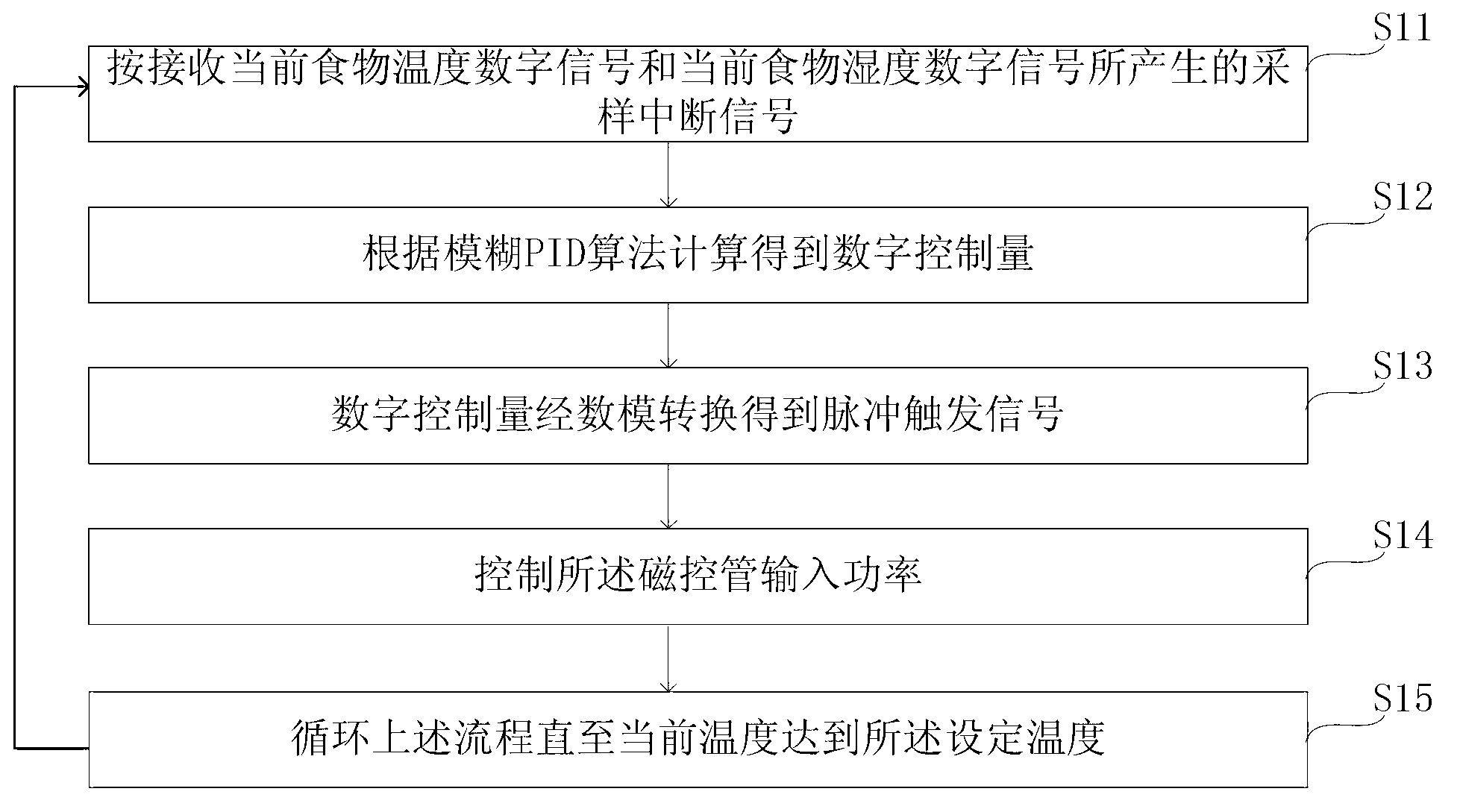

Micro-wave oven control method, control equipment and micro-wave oven

InactiveCN103017217AHigh precisionImprove convenienceDomestic stoves or rangesLighting and heating apparatusControl signalClosed loop

The embodiment of the invention discloses a micro-wave oven control method, micro-wave oven control equipment and a micro-wave oven. The method comprises the following steps: receiving a sampling interruption signal generated by a digital signal of the current food temperature and a digital signal of the current food humidity according to a pre-set period; responding to the sampling interruption signal, calculating the current food temperature , the current food humidity and the received setting temperature to obtain the amount of digital control according to a fuzzy PID (proportion integration differentiation) algorithm, and performing digital to analog conversion and PWM (pulse-width modulation) on the amount of digital control to obtain an analog pulse control signal; utilizing the analog pulse control signal to control the input power of a magnetron; and circulating the process until the current temperature reaches the setting temperature. According to the invention, through the closed-loop control method for continuously acquisition, calculation and output, the precision for temperature control is increased; and meanwhile, a user can obtain a pre-set heating effect without setting the heating time and heating manner of food according to experience, so that the convenience for use is further improved.

Owner:ORISE TECHNOLOGY CO LTD

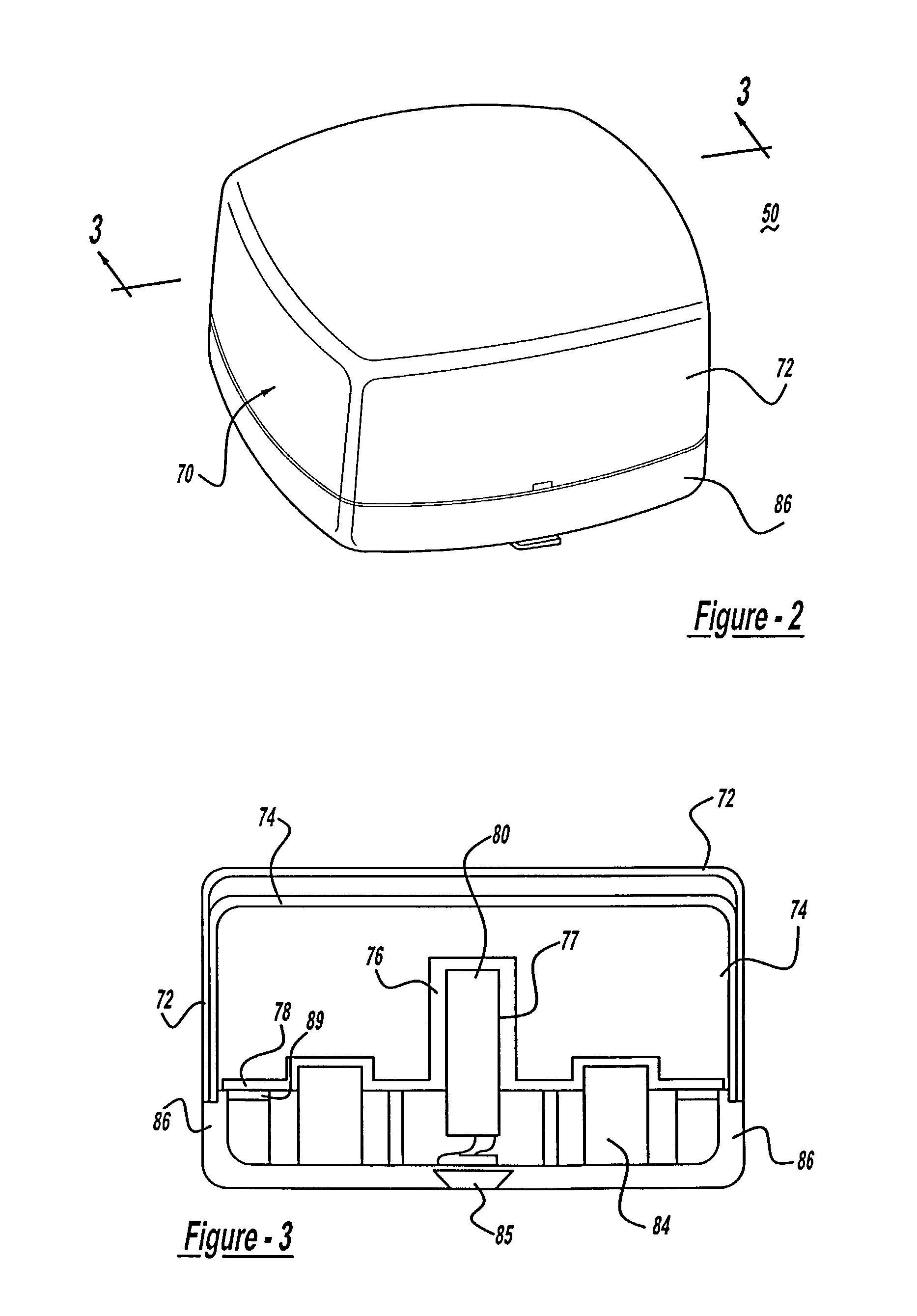

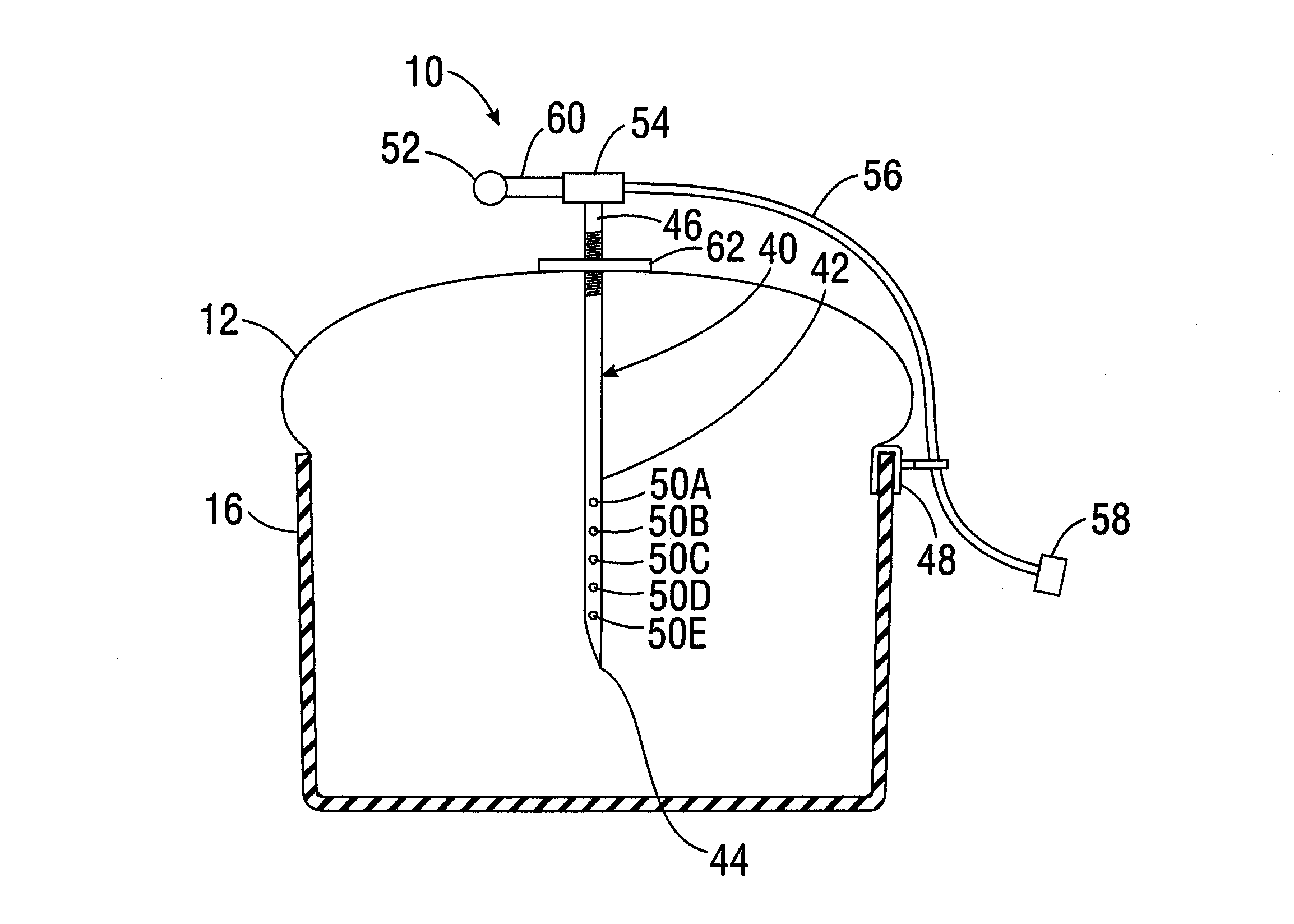

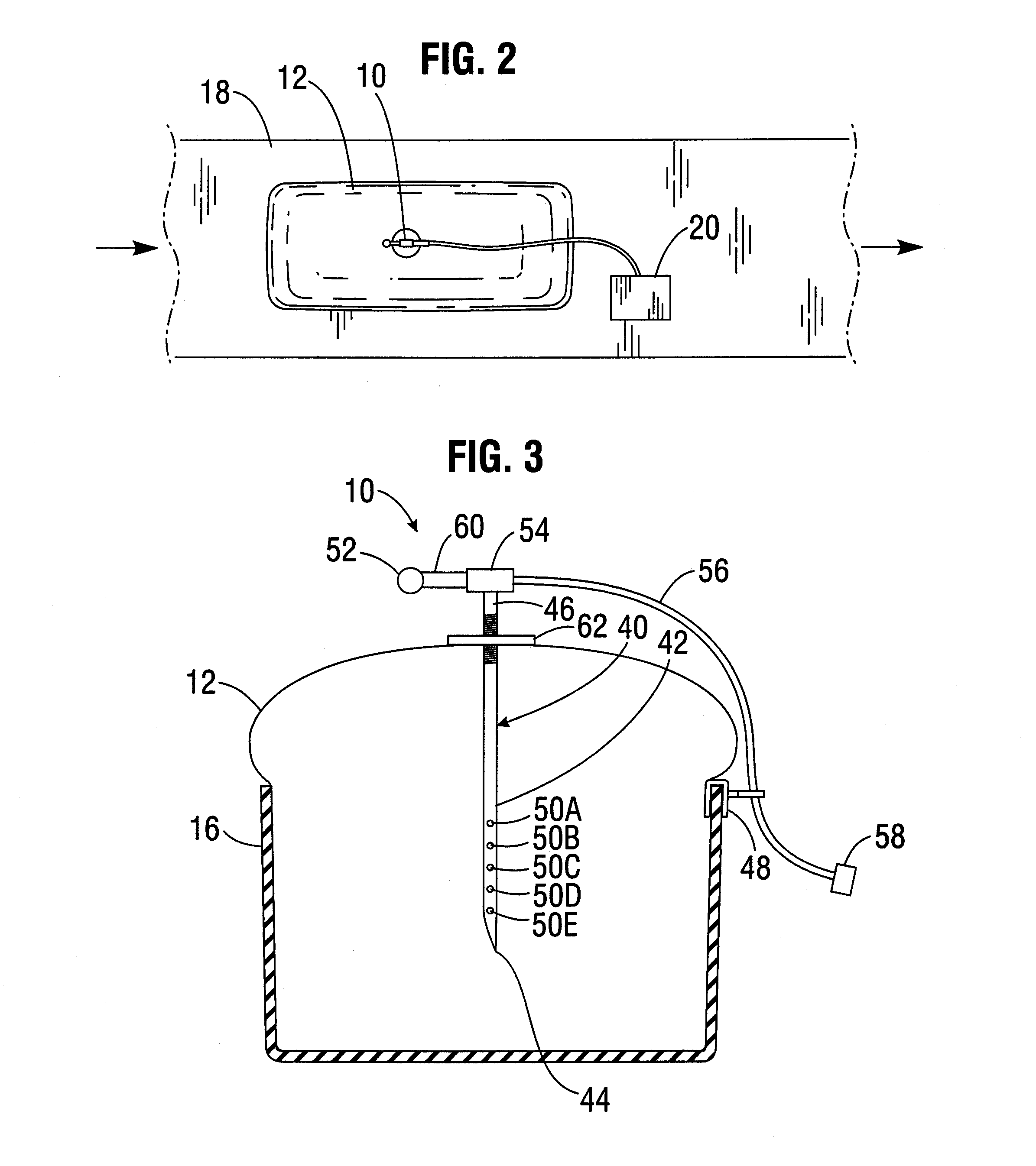

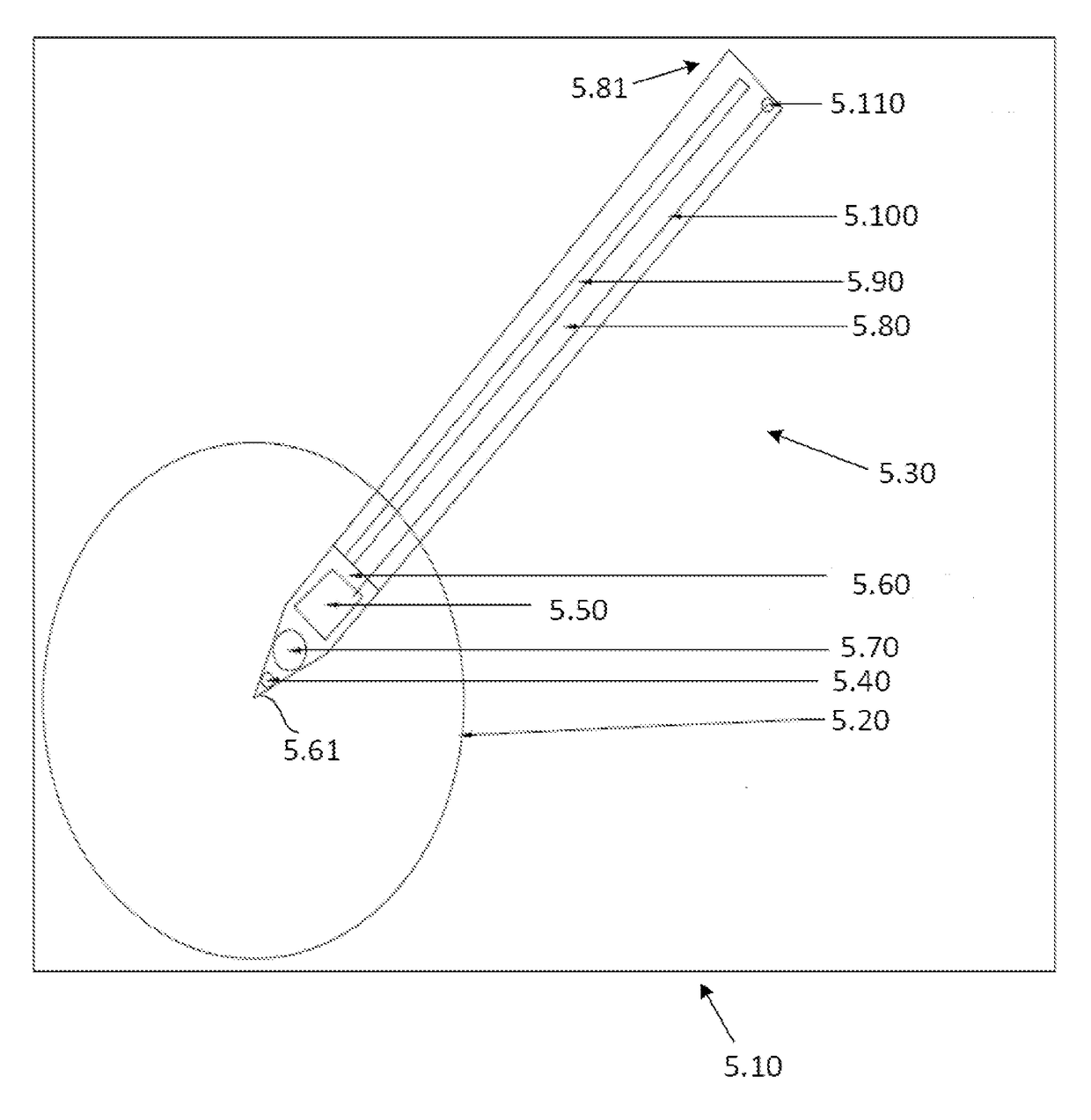

Food temperature probe

ActiveUS20130128919A1Easy and more consistentThermometer detailsTemperature measurement in household appliancesTwo temperatureEngineering

An exemplary embodiment of a temperature probe comprises an elongated shaft having a first portion and a second portion, the first portion being configured for insertion into a unit of food and the second portion being configured to extend outside of the unit of food. The probe further comprises at least two temperature sensors positioned at different longitudinal locations along the first portion of the shaft that are configured to measure temperatures of the unit of food at different locations within the unit of food while the unit of food is being processed thermally. The probe further comprises at least one ambient temperature sensor coupled to the shaft and configured to measure ambient temperature adjacent to the unit of food.

Owner:ELECTRONICS CONTROLS DESIGN

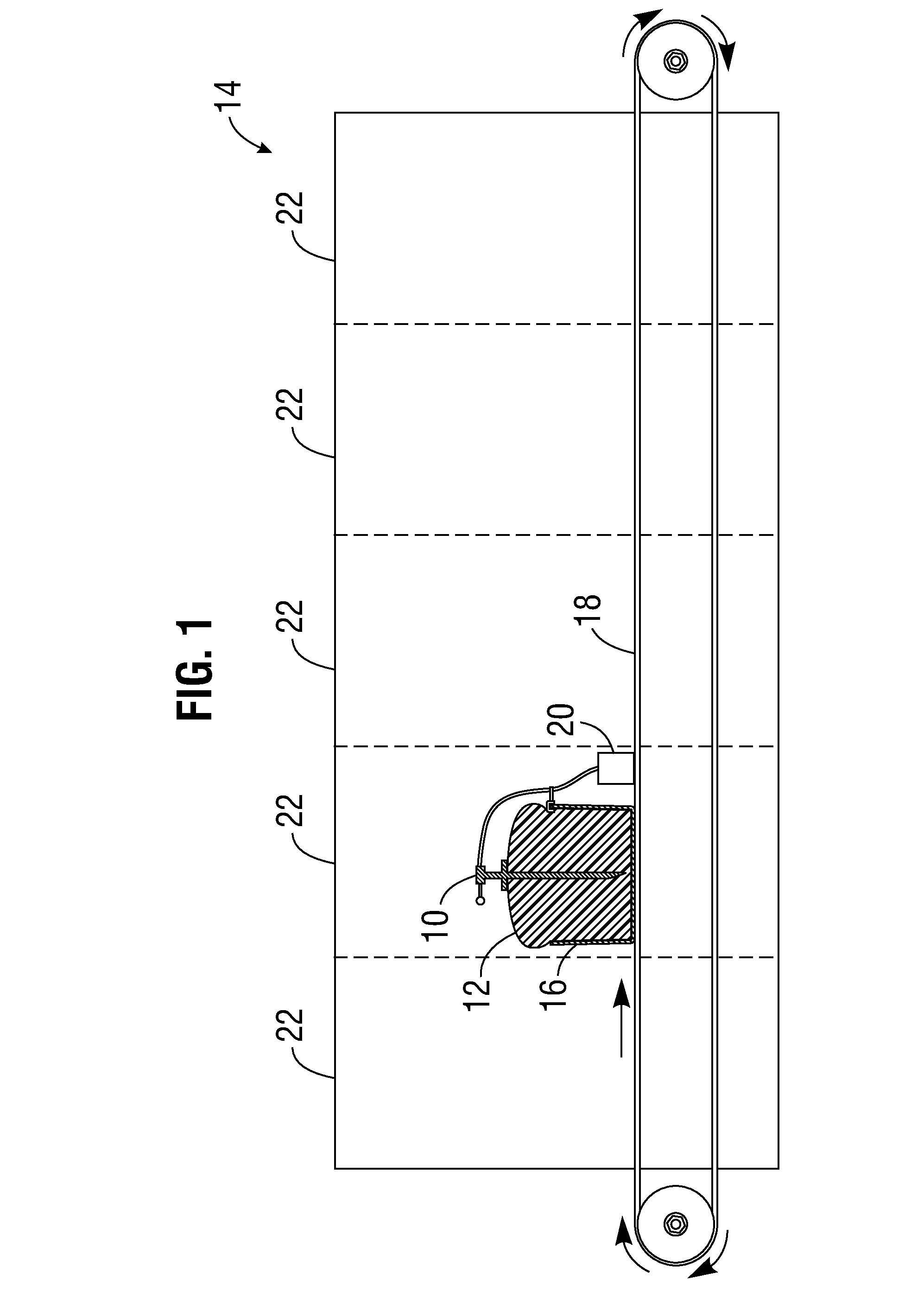

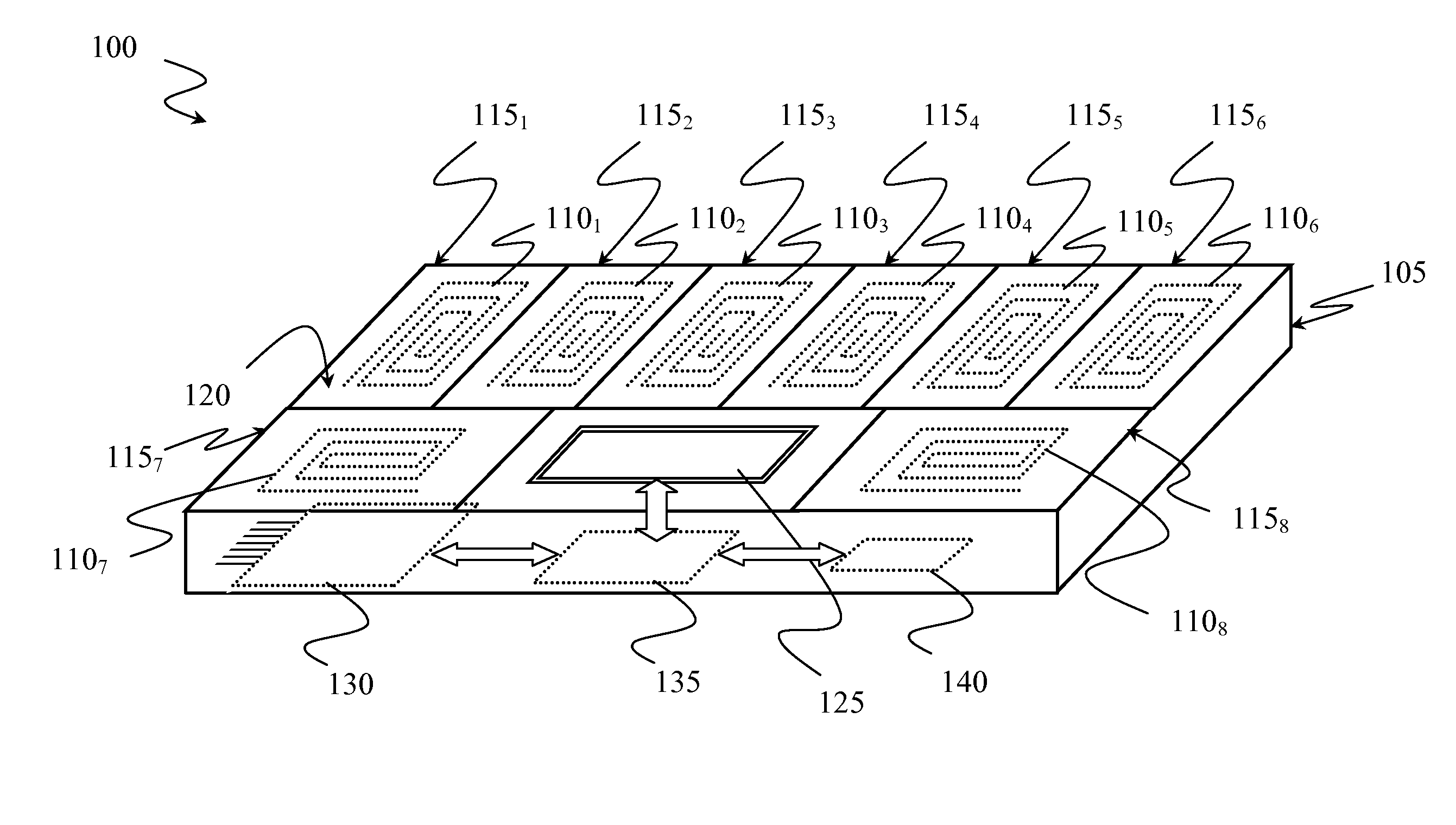

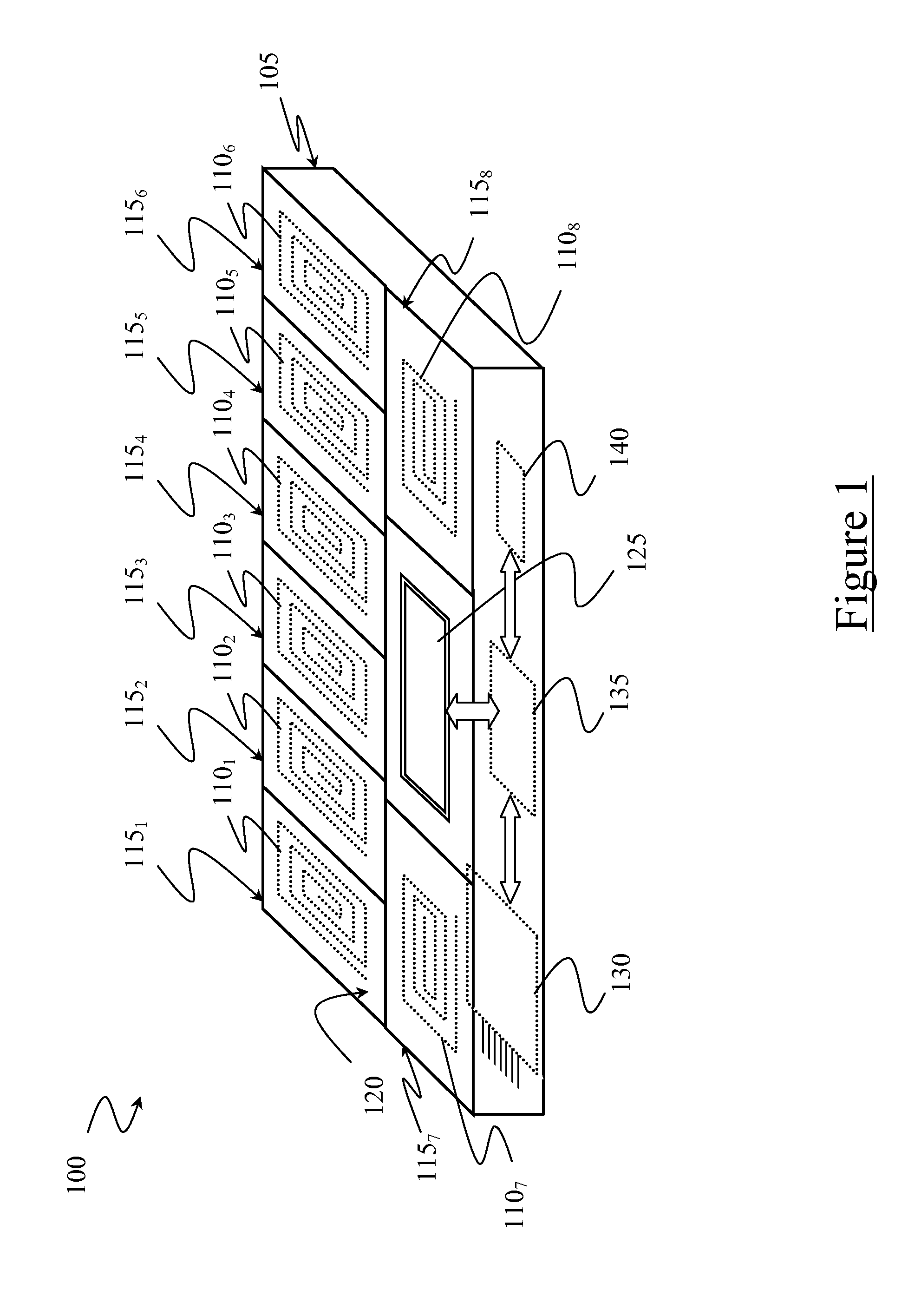

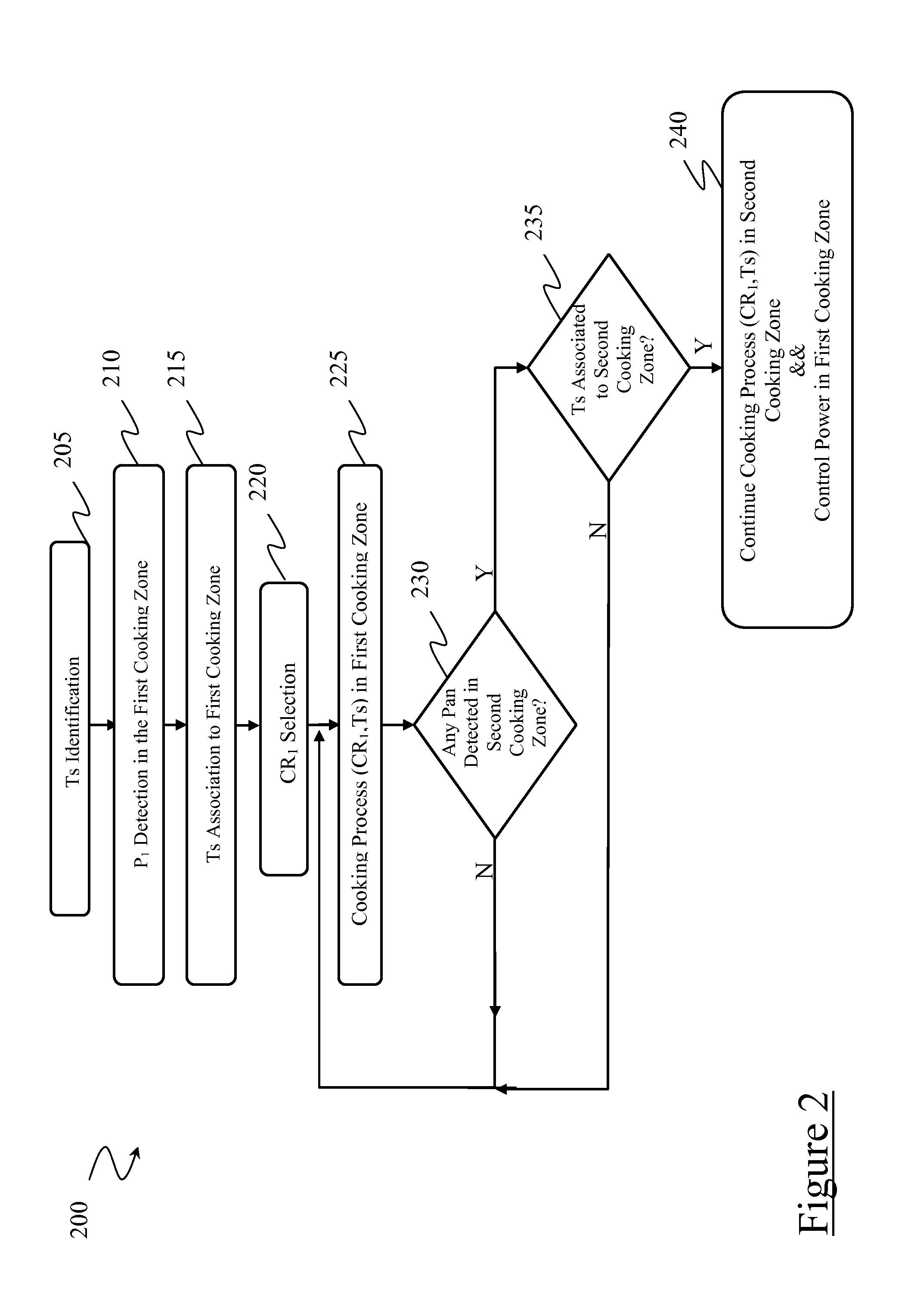

Cooking Hob and Operation Method Thereof

InactiveUS20150008216A1Quickly and efficiently and smartly recognizingImprove user experienceDomestic stoves or rangesLighting and heating apparatusProcess engineeringFood temperatures

A method (200;300;400) for operating a cooking hob (100) is proposed. The cooking hob comprises at least a first (1151) and a second (1156) cooking zones and a control unit (135) configured for controlling the first and second cooking zones. The method comprises the following steps executed by the control unit. A pan (P1) containing food to be cooked is associated (210;305;405) to the first cooking zone; a food temperature sensor (Ts) is associated (215;310;405) to the first cooking zone, the food temperature sensor being configured to be in direct contact with the food to be cooked and to communicate to the control unit an indication of the food temperature; a power level of the first cooking zone is automatically adjusted (225;320;420) according to a cooking recipe (CR1) and to the current food temperature provided by the food temperature sensor; food movement from the first cooking zone to the second cooking zone is inferred (230-235;325-330,345-360;425-430,445-460) based on a de-association (235;330,345;430,445) of the food temperature sensor from the first cooking zone and a re-association (235;330,355;430,455) of the food temperature sensor to the second cooking zone; and the power level of the second cooking zone is automatically adjusted (240;335,365;435,465) according to the cooking recipe and to the current food temperature provided by the food temperature sensor, starting from a progress status of the cooking recipe at the first cooking zone before moving the food.

Owner:ELECTROLUX PROFESSIONAL

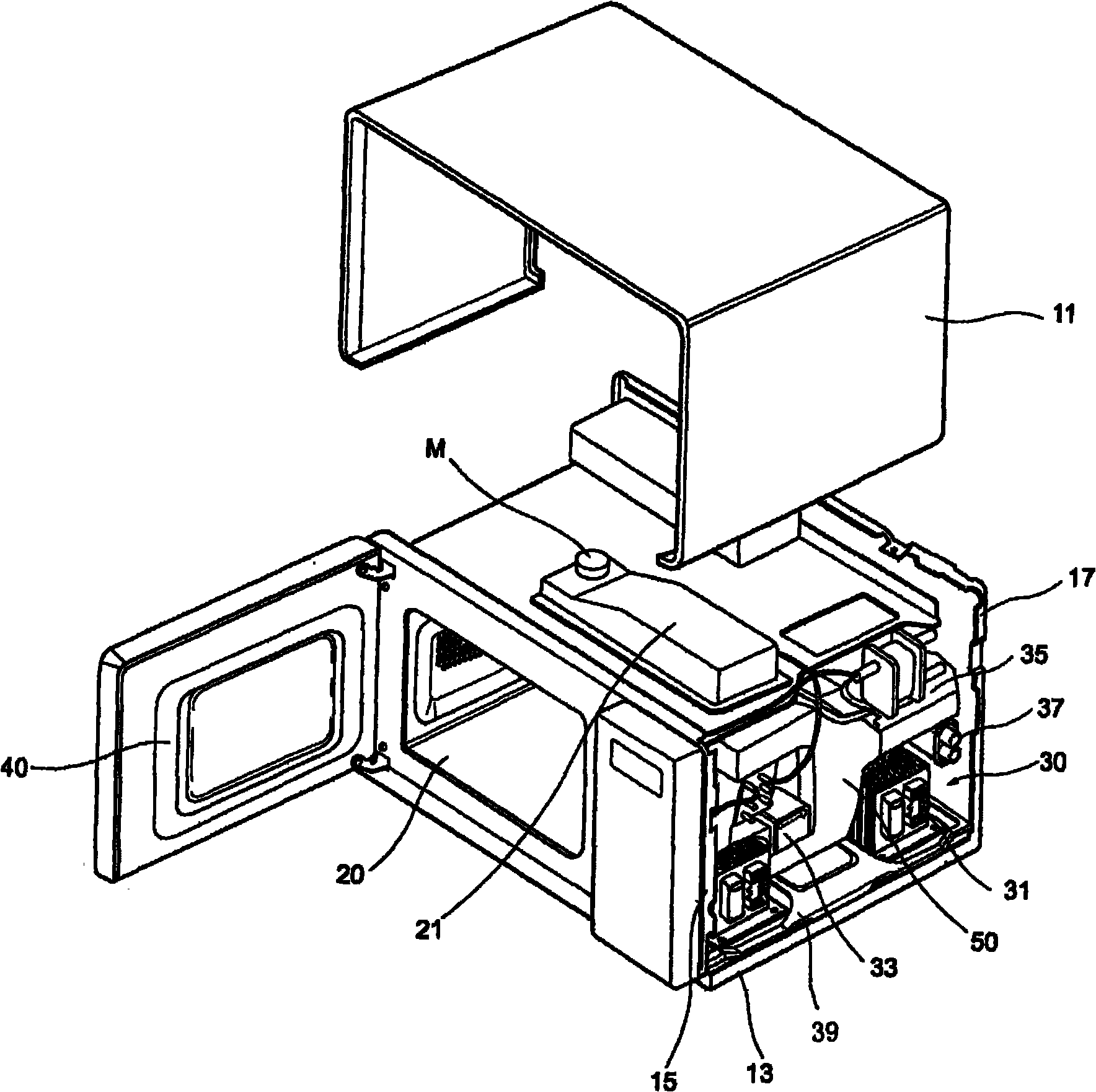

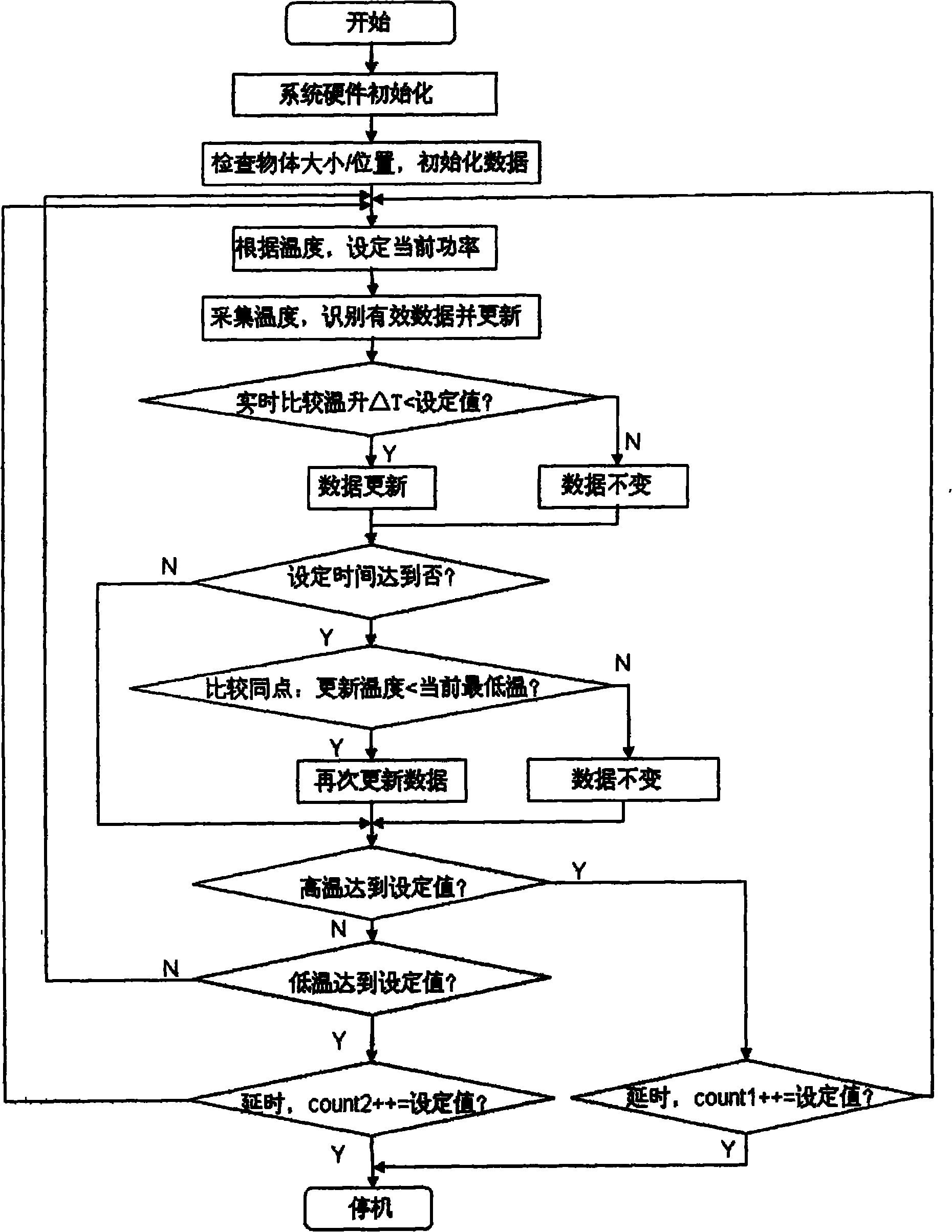

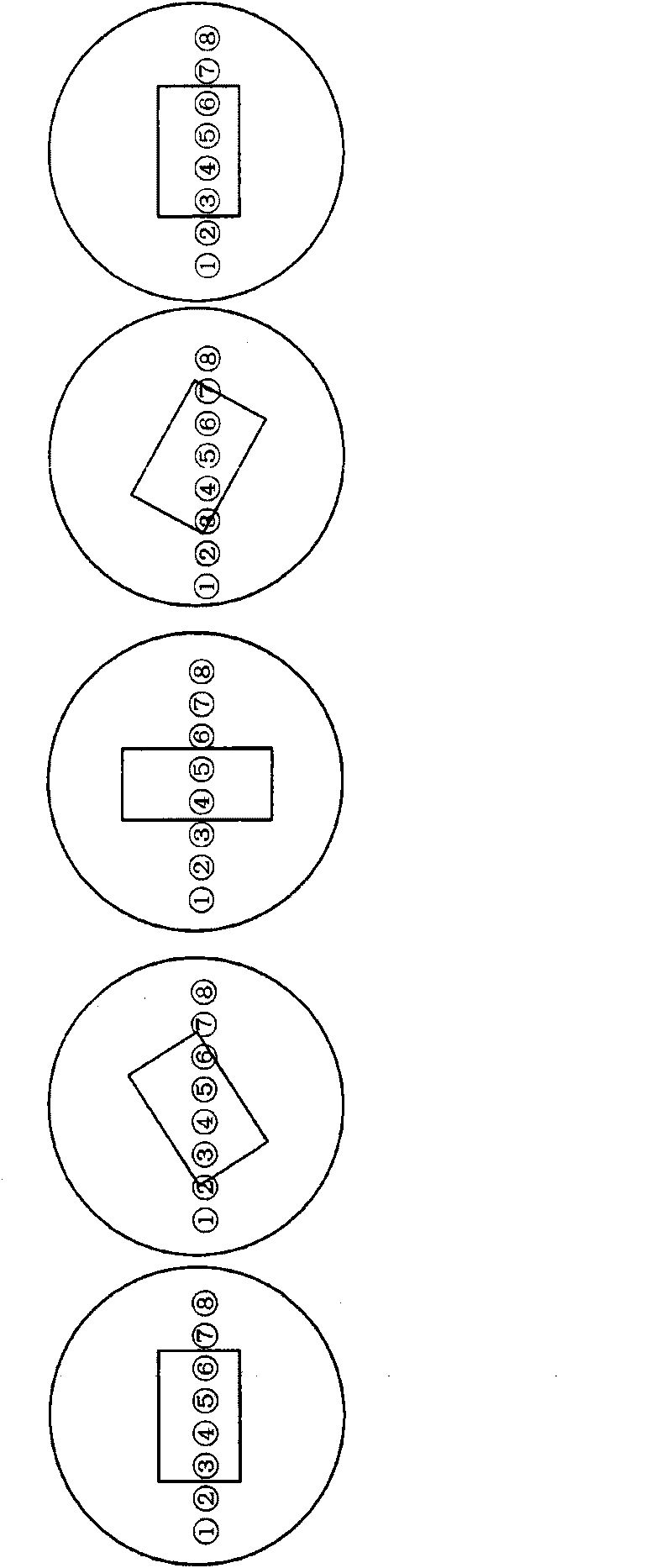

Food defrosting method for microwave oven

InactiveCN101940351AGood thawing effectDomestic stoves or rangesLighting and heating apparatusLower limitMicrowave oven

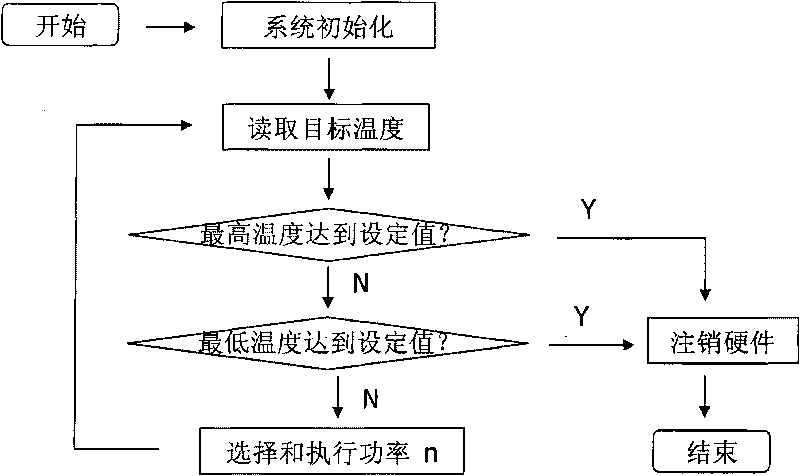

The invention discloses a food defrosting method for a microwave oven, wherein a sensor probe of the microwave oven measures the temperature of a food by using a plurality of sampling points. The method comprises the following steps of: initializing a temperature sensor and a controller, measuring the temperature from the plurality of sampling points by using the temperature sensor, obtaining thehighest temperature and the lowest temperature by contrast, comparing the highest temperature and the lowest temperature with a set upper limit temperature and a set lower limit temperature, controlling the running of the microwave oven according to the comparison result, and if the measured highest temperature is lower than the upper limit temperature and the measured lowest temperature is also lower than the lower limit temperature, continuing defrosting the food until the defrosting is stopped by regulating the power level of the microwave oven according to the lowest temperature to re-measure the temperate from the plurality of sampling points, so that the object can be defrosted with the optimum effect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

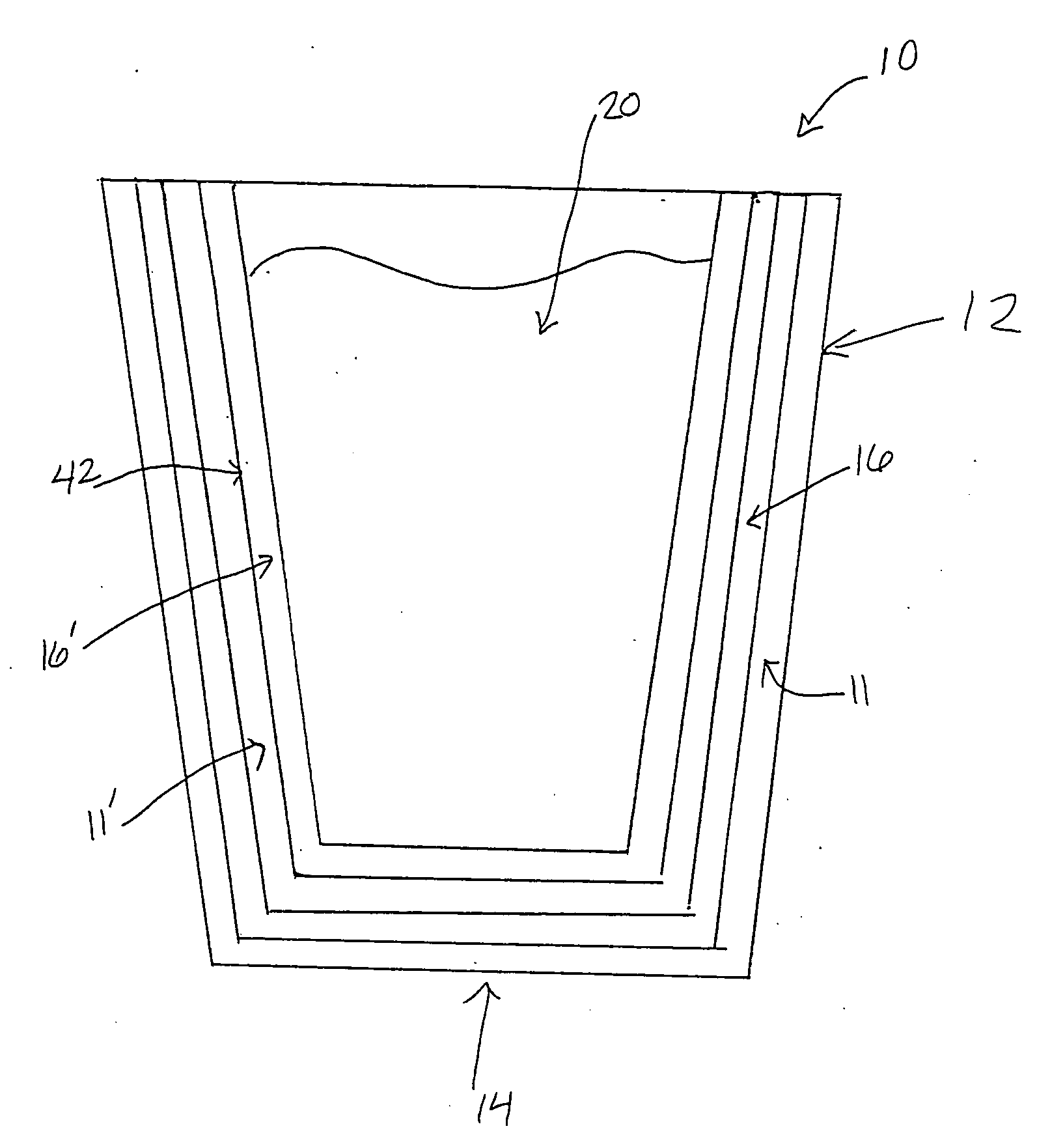

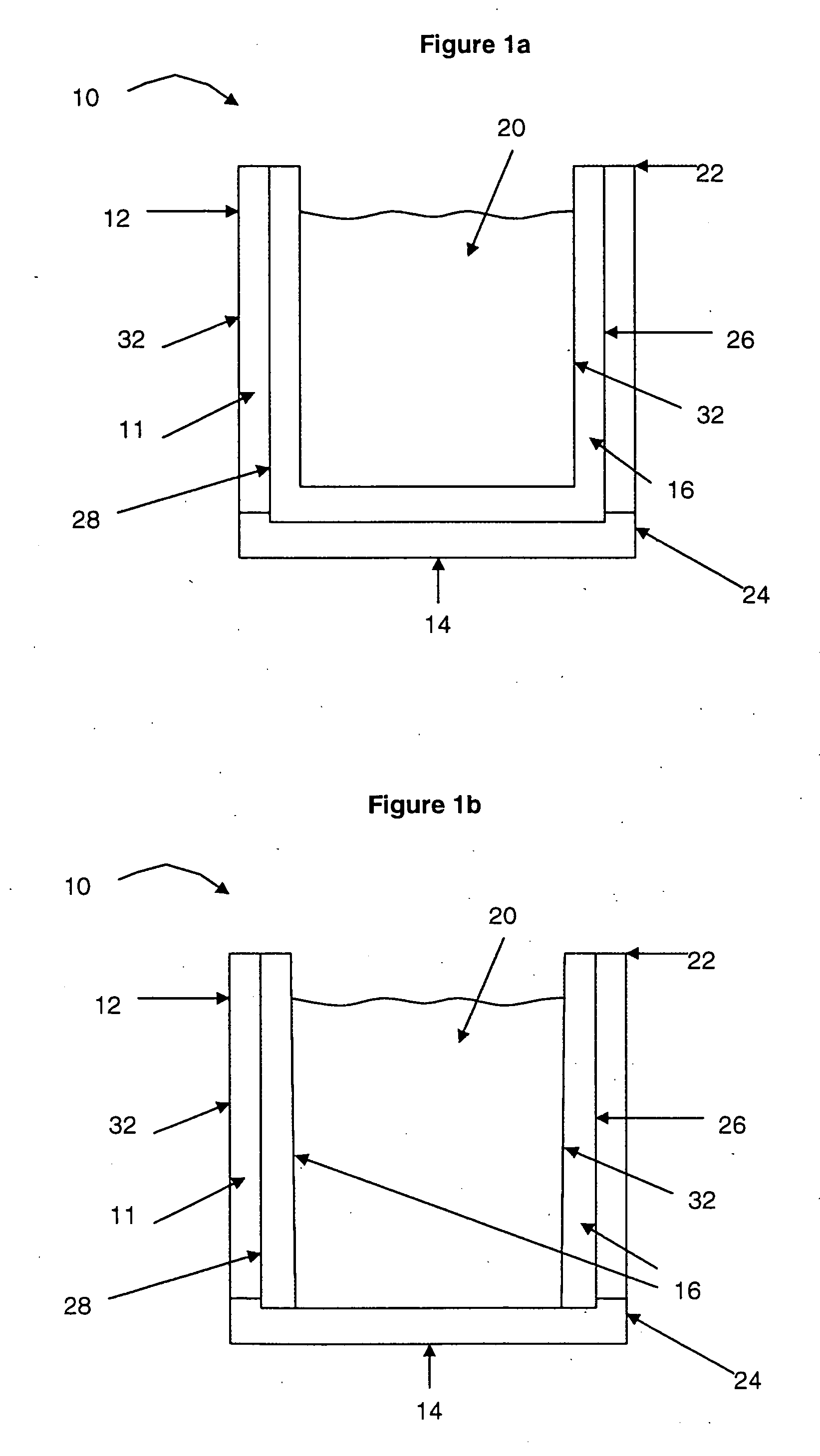

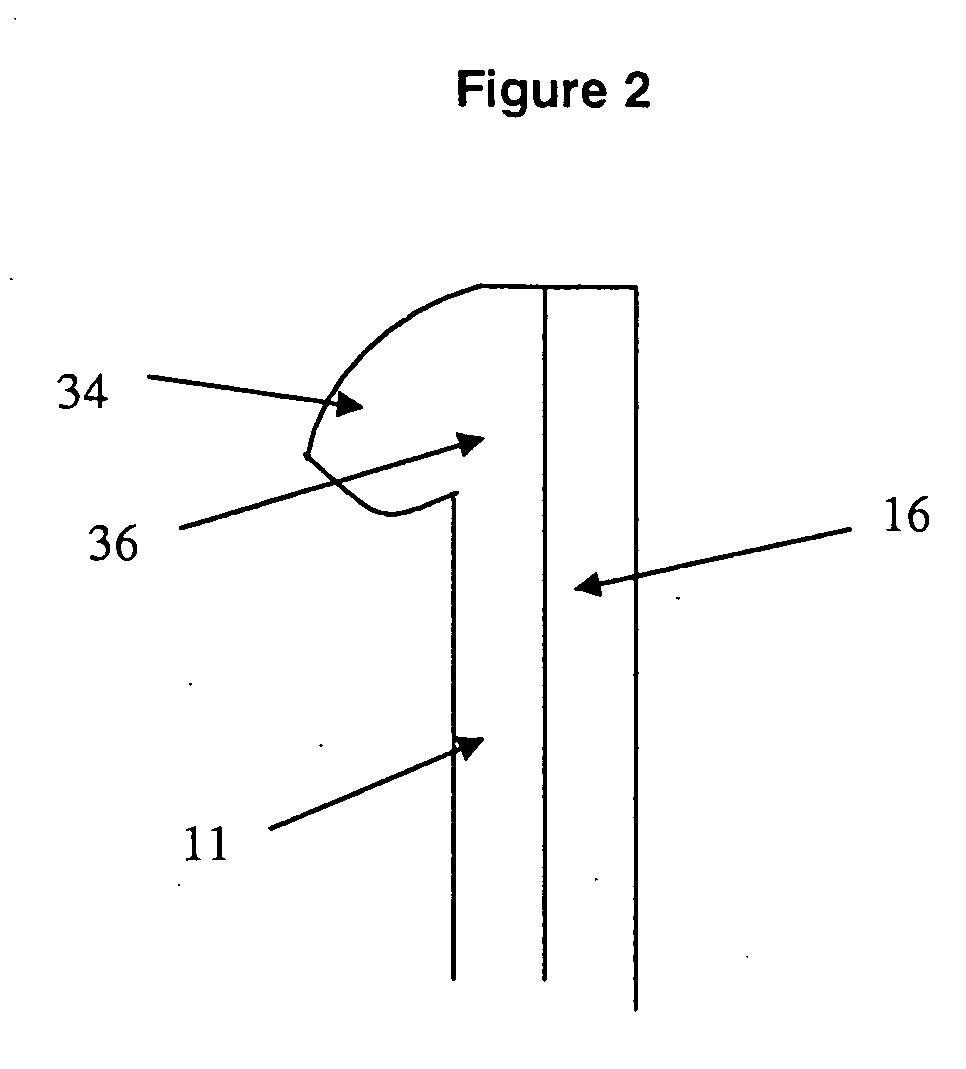

Disposable cup with Mylar insulation

InactiveUS20050199697A1Maintain temperatureDomestic cooling apparatusLighting and heating apparatusPolyesterDisposable cup

The present invention provides a disposable container comprising a container portion including at least one surface having a reflective layer for insulating food contained therein. Also included is a disposable container comprising a container portion including an outside surface, an inside surface, and a removable reflective layer covering at least a portion of one of said surfaces. A disposable sleeve for insulating a container is provided and includes a reflective layer for insulating food within the container. A disposable liner for insulating a container is provided and includes a reflective layer for insulating food within the container. A disposable lid for insulating a container is also provided and includes a reflective layer for insulating food within the container. Finally, the present invention includes a method of maintaining a food temperature, including the step of reflecting heat energy off of a reflective layer to maintain the temperature of the food.

Owner:NUGENT DANIEL E

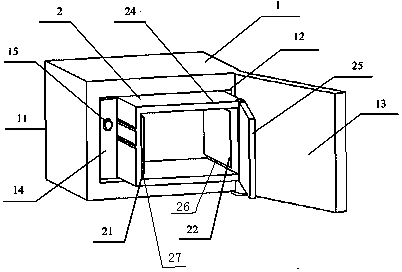

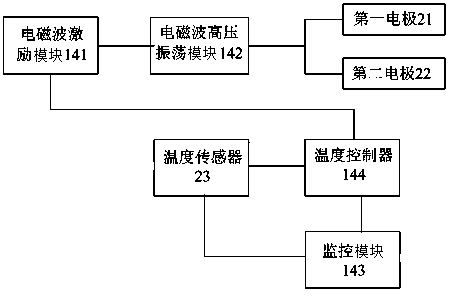

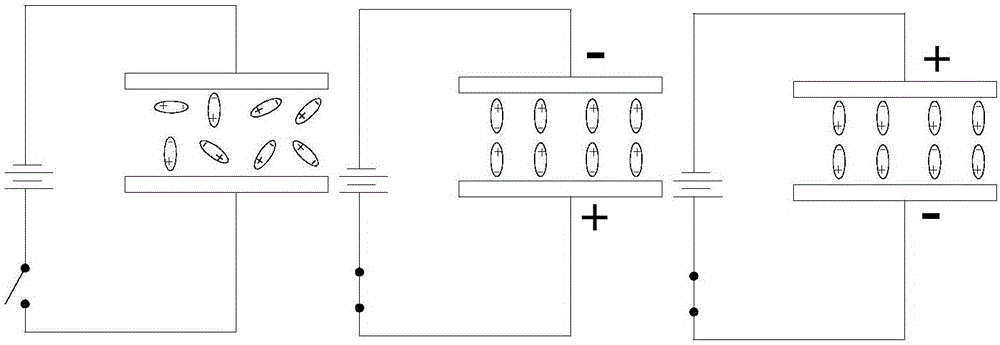

Thawing device of refrigerator

InactiveCN104186635AThaw evenlyEasy to control temperatureDomestic cooling apparatusLighting and heating apparatusElectricityHigh pressure

The invention relates to a refrigerator, and more specifically relates to a thawing device of a refrigerator. The thawing device of the refrigerator comprises a thawing chamber; the thawing chamber comprises a thawing chamber shell, a thawing chamber liner and a thawing chamber door; an electromagnetic wave excitation module, an electromagnetic wave high-pressure oscillation module and a monitoring module; the monitoring module is used for monitoring food temperatures; the electromagnetic wave excitation module is electrically connected with both of the electromagnetic wave high-pressure oscillation module and the monitoring module; a first electrode and a second electrode are arranged in the thawing chamber, are in contact with food, and are both electrically connected with the electromagnetic wave high-pressure oscillation module; a temperature sensor is further arranged in the thawing chamber and is electrically connected with the monitoring module. The first electrode and the second electrode in the thawing chamber are used for emitting high-frequency electromagnetic waves to food in contact with the two electrodes, and therefore, frozen food can be thawed quickly and evenly.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

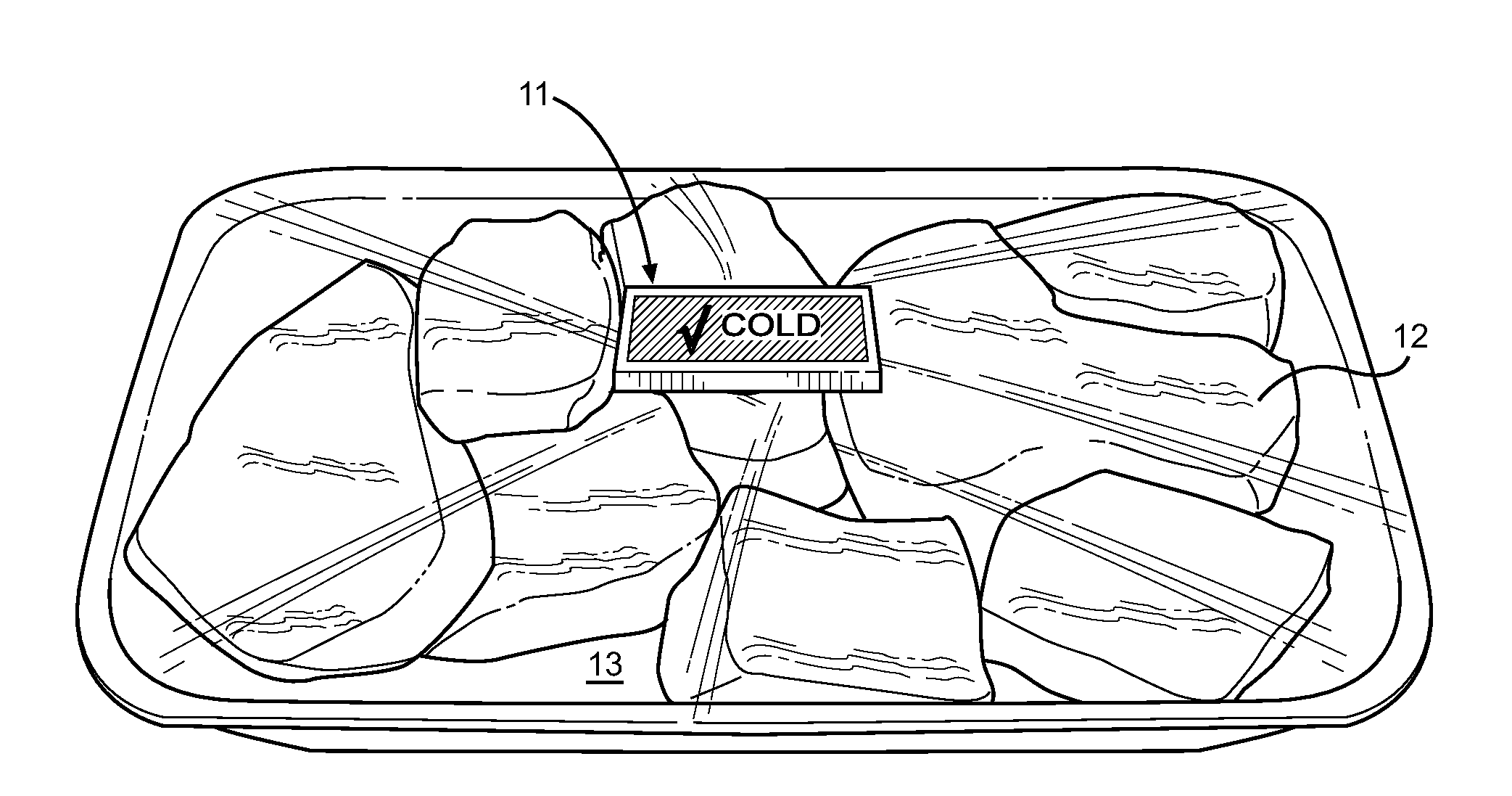

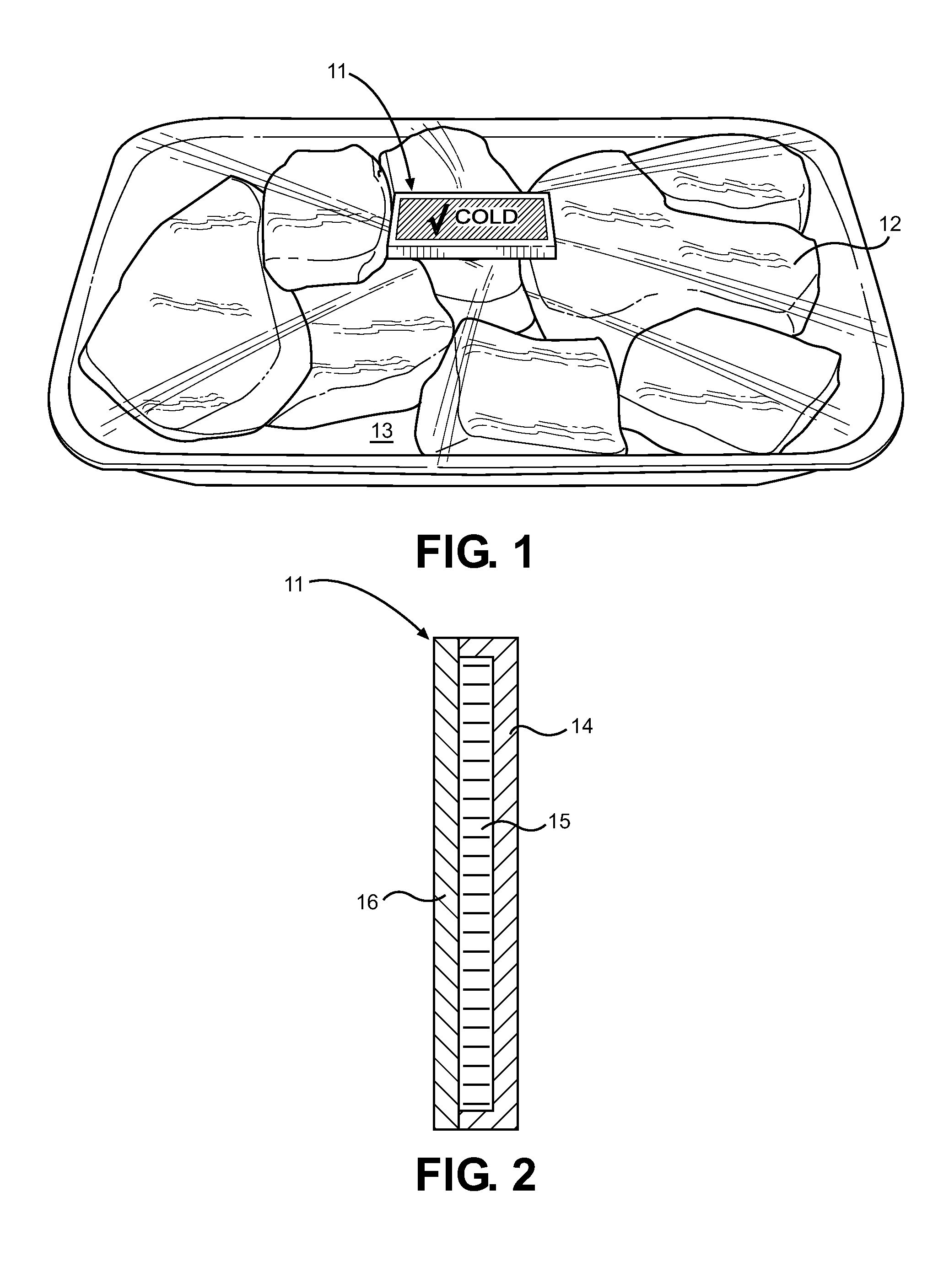

Temperature Sensing Food Stuff Label

InactiveUS20120174853A1Easy to measureEasy constructionInvestigating time/temperature historyRecording measured valuesConductive materialsEngineering

A food product temperature and freshness monitoring device and method is provided. The device comprises a thermochromic seal or label that monitors the temperature of food stuff and alters its appearance when the food temperature rises above a predefined limit for a given period of time. The present invention provides a device with a predefined temperature for which the pigment of an imbedded material alters its color from a first color to a second color, and does not revert to its original color after passing a threshold time-temperature. The pigment is sandwiched between a layer of thermally conductive material on a first, product-facing side, followed by a thermally insulative material on a second, outward-facing side. The seal provides an indicator to determine whether food stuff has been shipped and stored in an appropriate environment to prevent spoilage. The seal monitors the food temperature, as opposed to the ambient air temperature.

Owner:WILSON ROBERT

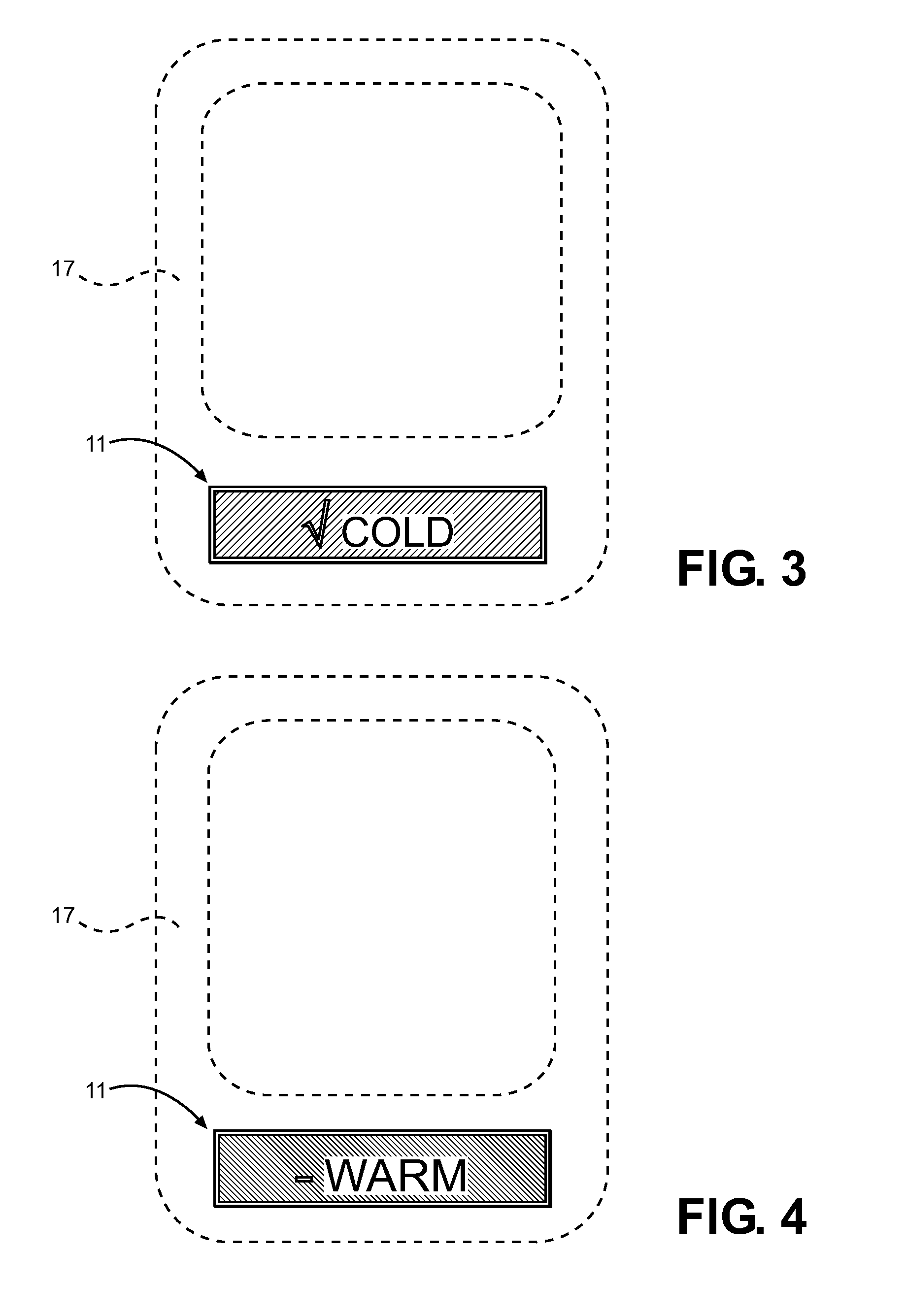

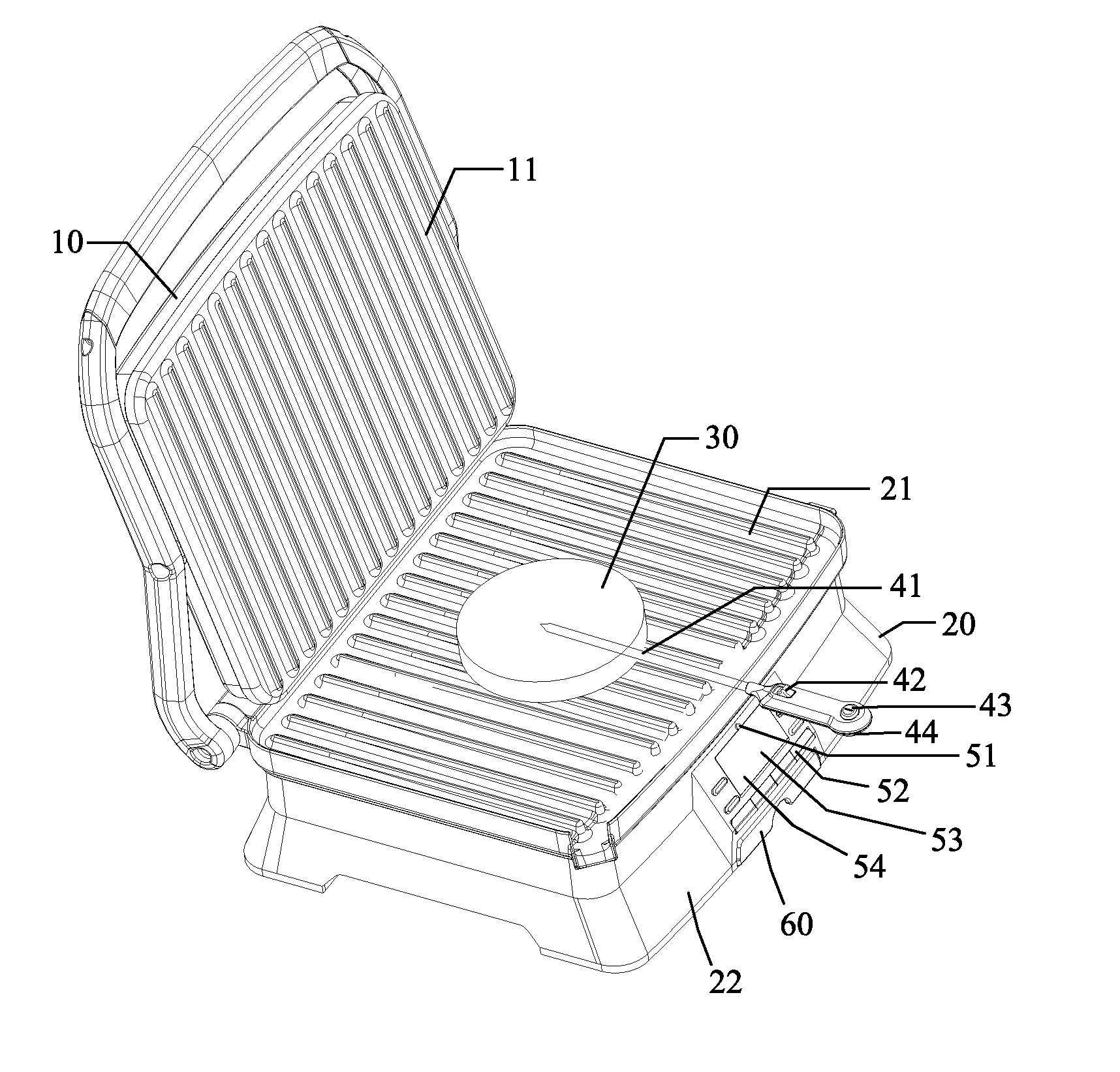

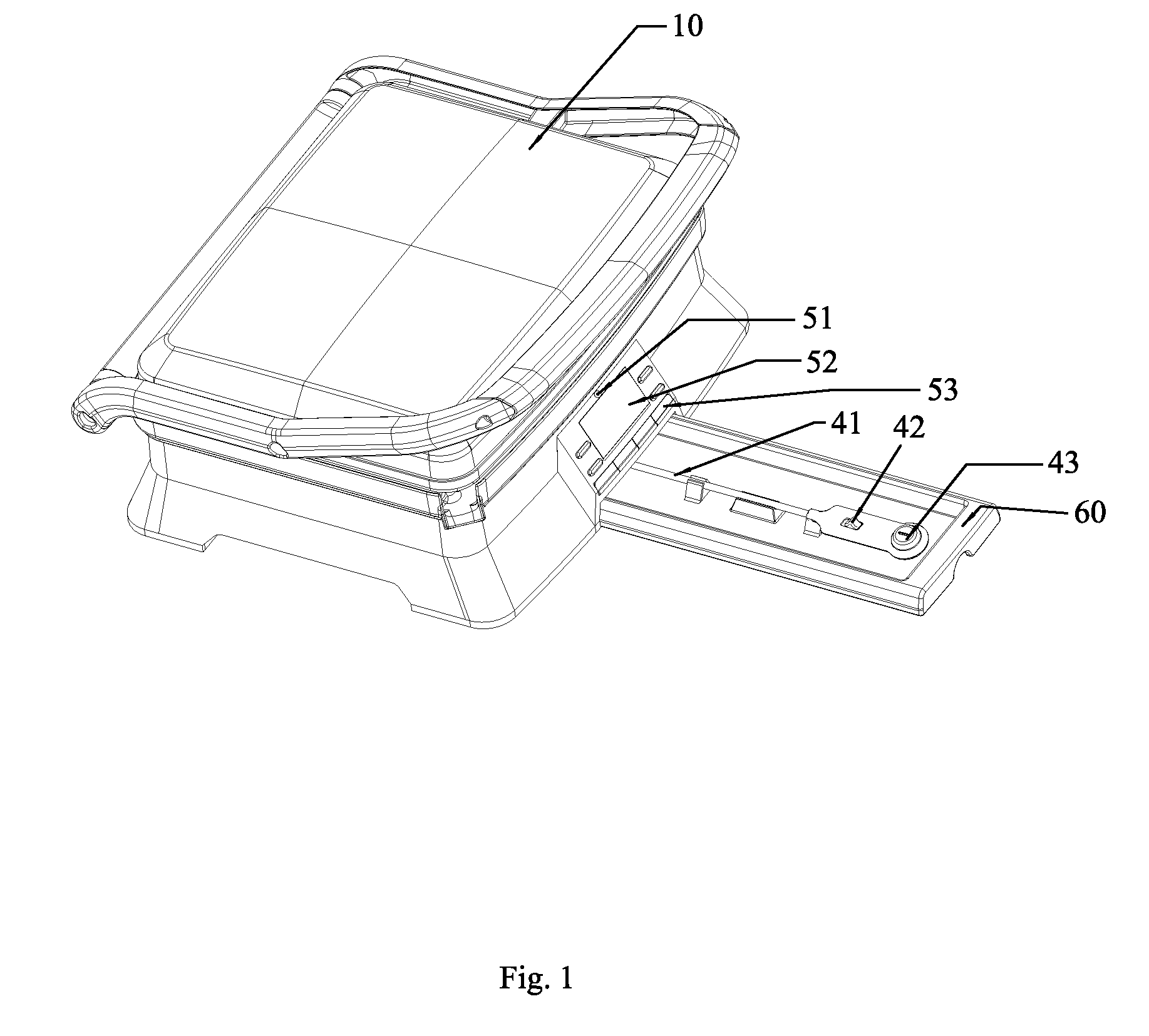

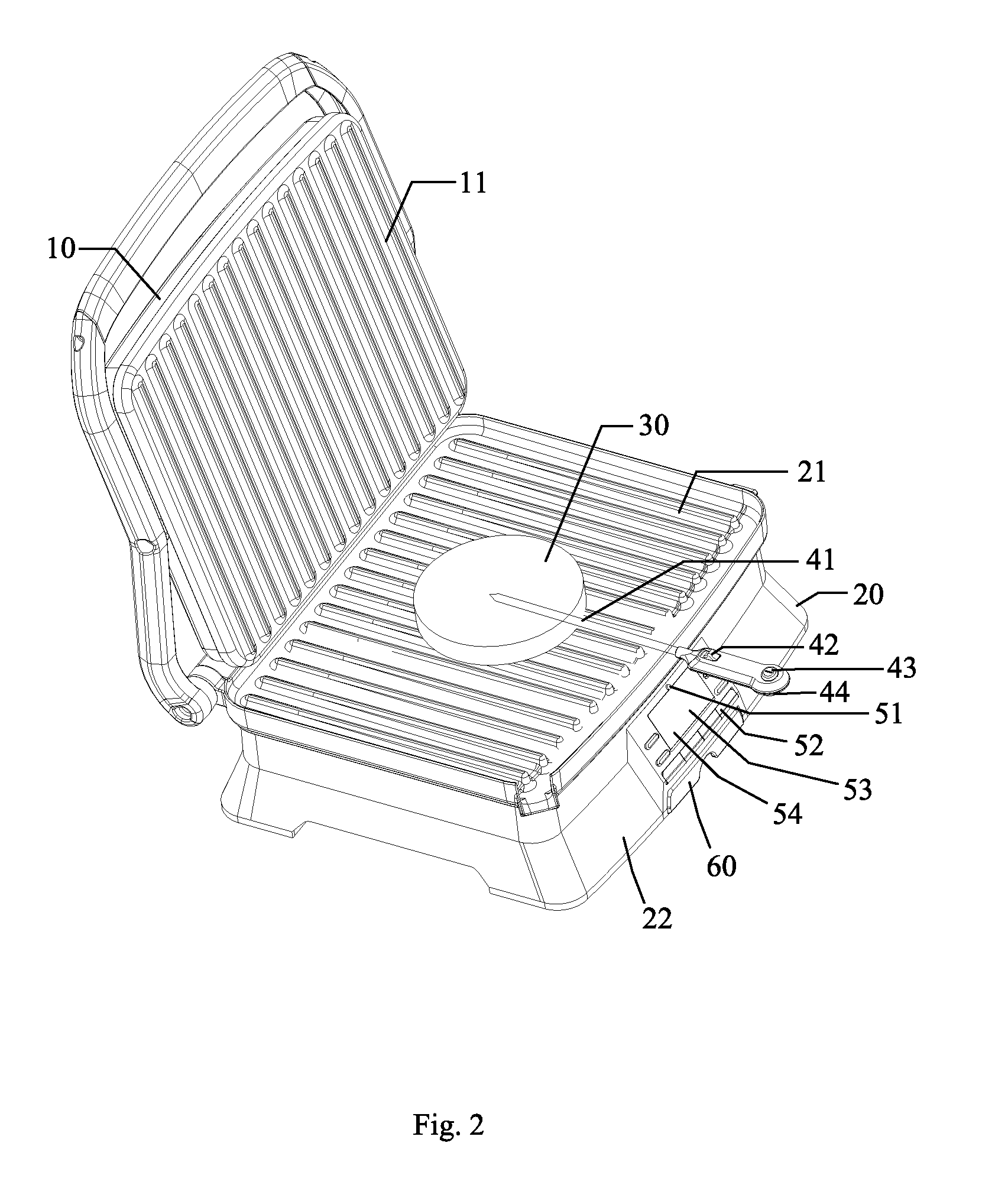

Wireless food temperature detecting device

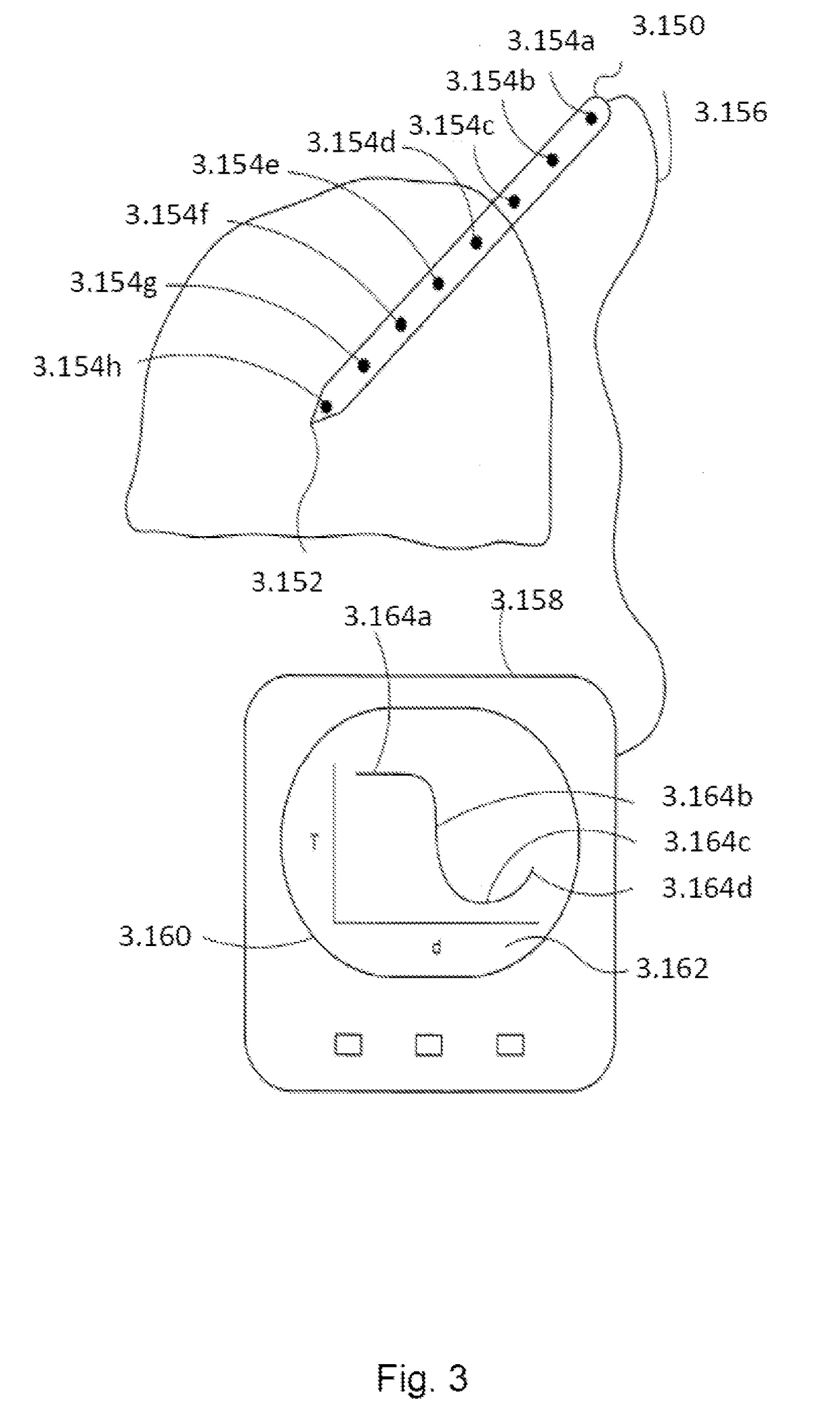

InactiveUS20100222938A1Easy to operateAutomatically judgingThermometer detailsTemperature measurement in household appliancesEngineeringFood temperatures

The present invention relates to a grilling device, especially relates to a wireless food temperature detecting device, comprising: a temperature detecting unit, a controlling unit disposed on the processor of grilling device; said temperature detecting unit has a temperature detecting stick for inserting into the food which is prepared to be fried or roasted, and has a wireless emitting element electrically connected to said temperature detecting stick; said controlling unit has a wireless receiving element; said temperature detecting unit is controlling by signals transmitted between said wireless emitting element and said wireless receiving element. Compared to the conventional technique, the present invention controls the doneness of food by detecting the inner temperature of food. It is greatly convenient for the consumers to operate.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

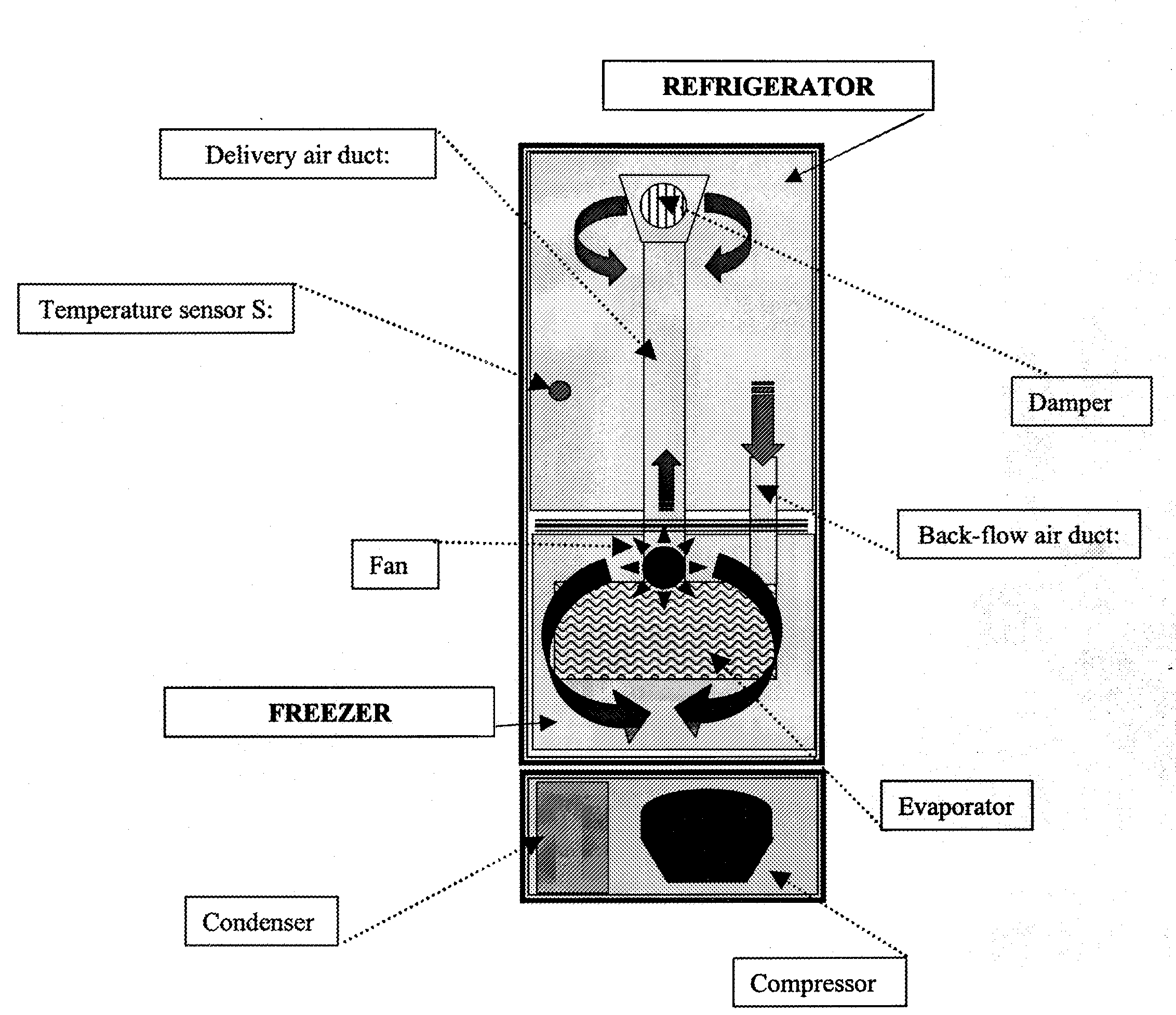

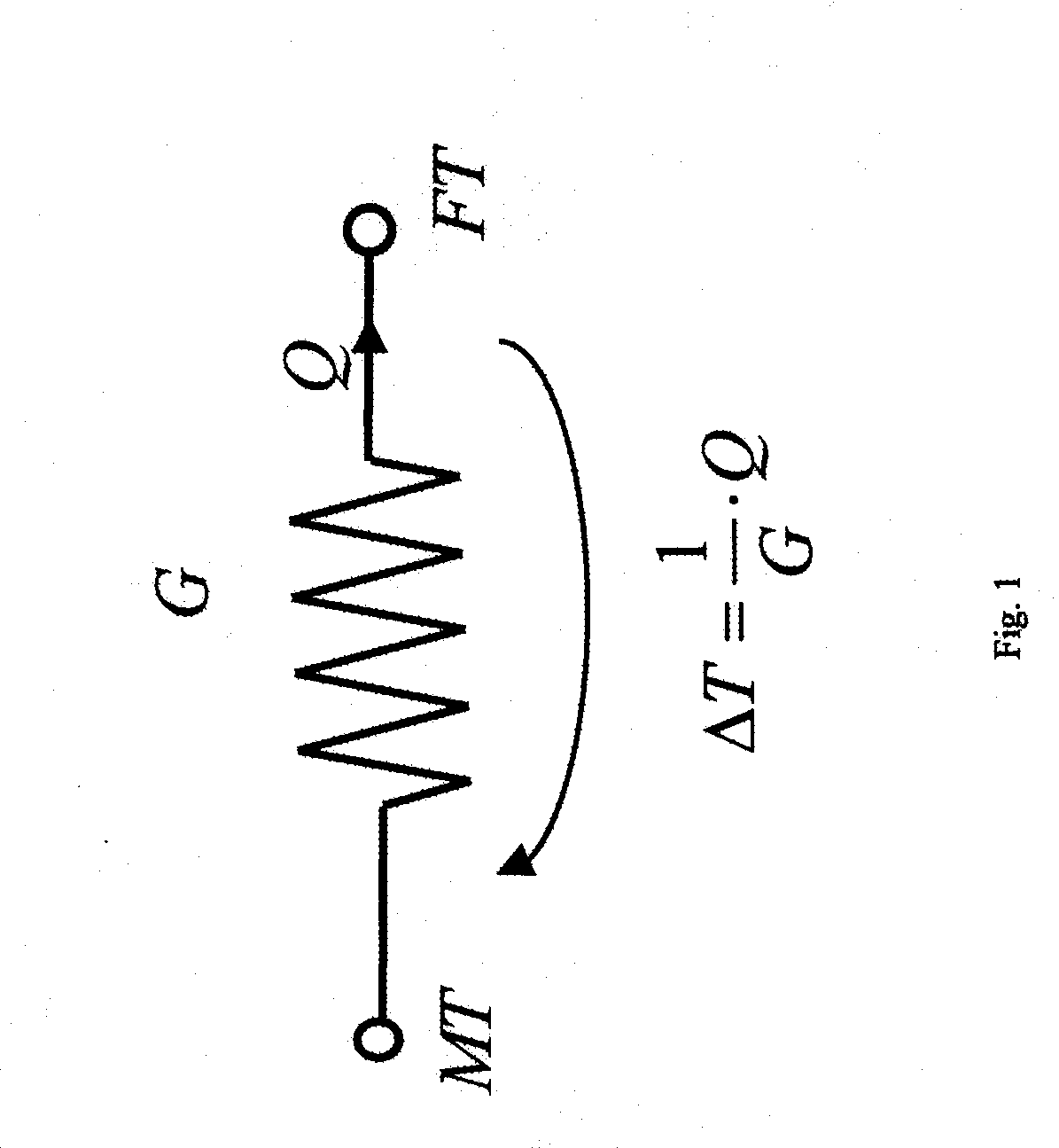

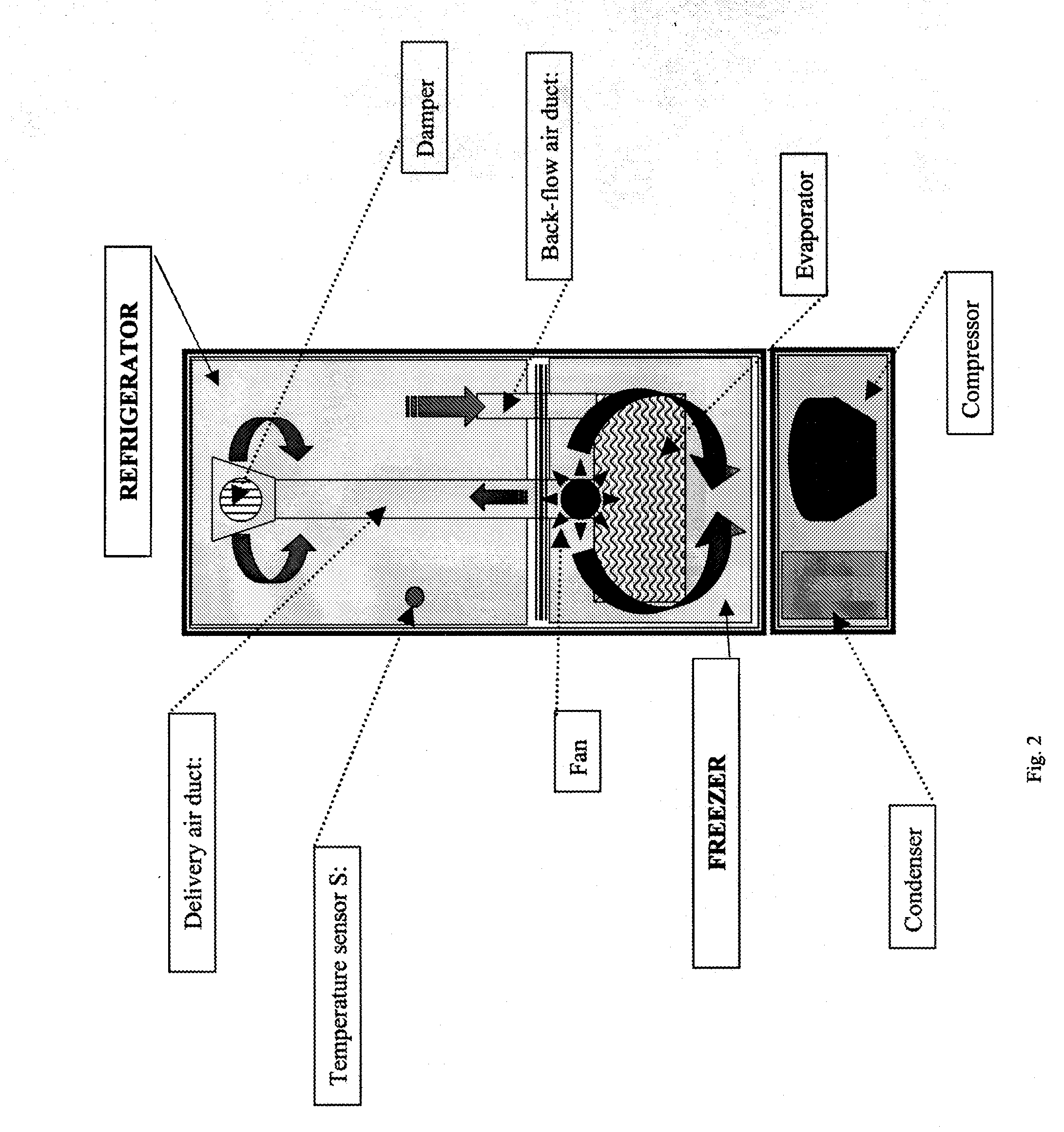

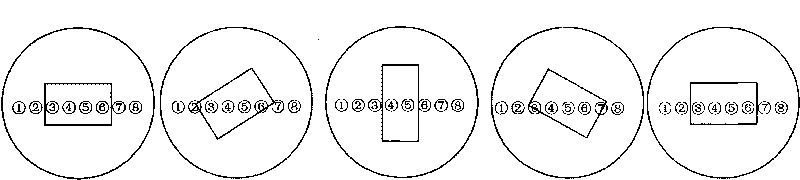

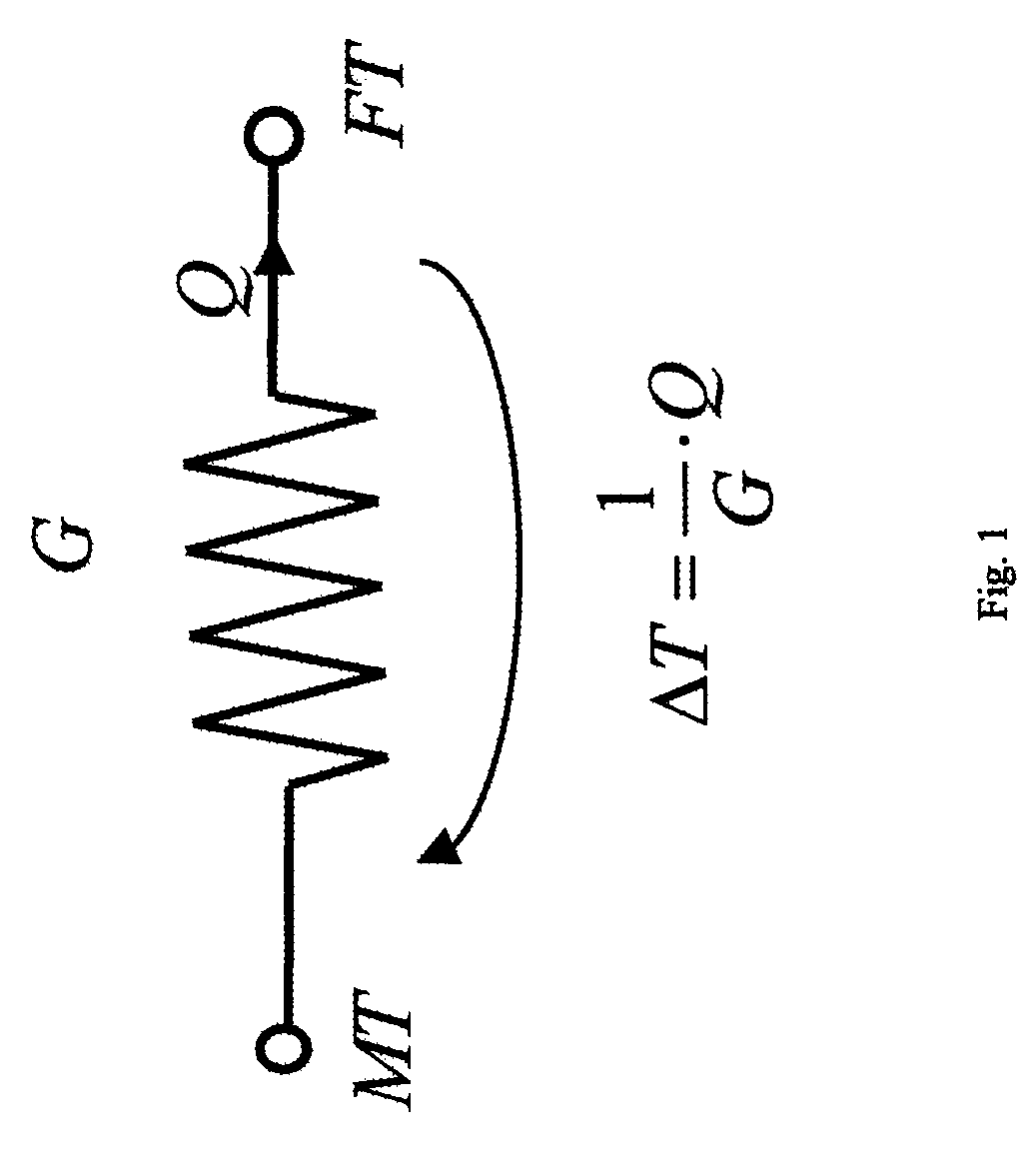

Method for Estimating The Food Temperature Inside a Refrigerator Cavity And Refrigerator Using Such Method

InactiveUS20080221740A1Risk minimizationTemperatue controlThermometers using electric/magnetic elementsProcess engineeringActuator

A method of controlling the temperature inside a cavity of a cooling appliance provided with a temperature sensor inside the cavity and with an actuator for adjusting the cooling capacity of the appliance, the food temperature is estimated on the basis of a value from the temperature sensor and on a predetermined function of a status of the actuator.

Owner:WHIRLPOOL CORP

Food unfreezing method of microwave oven

InactiveCN101751055AGood thawing effectDomestic stoves or rangesLighting and heating apparatusLower limitMicrowave oven

The invention relates to a food unfreezing method of a microwave oven, wherein a sensor probe of the microwave oven measures the food temperature simultaneously with a plurality of sampling points; the food unfreezing method comprises the following steps: a temperature sensor and a controller are initialized; the temperature sensor measures through the plurality of the sampling points; the highest temperature and the lowest temperature are worked out through comparison; the measured highest temperature and the measured lowest temperature are respectively compared with the set upper limit and the set lower limit of the temperature, and the microwave oven is controlled to work according to the comparison results; and if the measured highest temperature is lower than the upper limit of the temperature and the measured lowest temperature is also lower than the lower limit of the temperature, an object needs to be continued to be unfrozen, the power level of the microwave oven is adjusted according to the lowest temperature, the step of measuring with the plurality of the sampling points is executed again, until the unfreezing is suspended, so as to ensure the object has the best unfreezing effect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

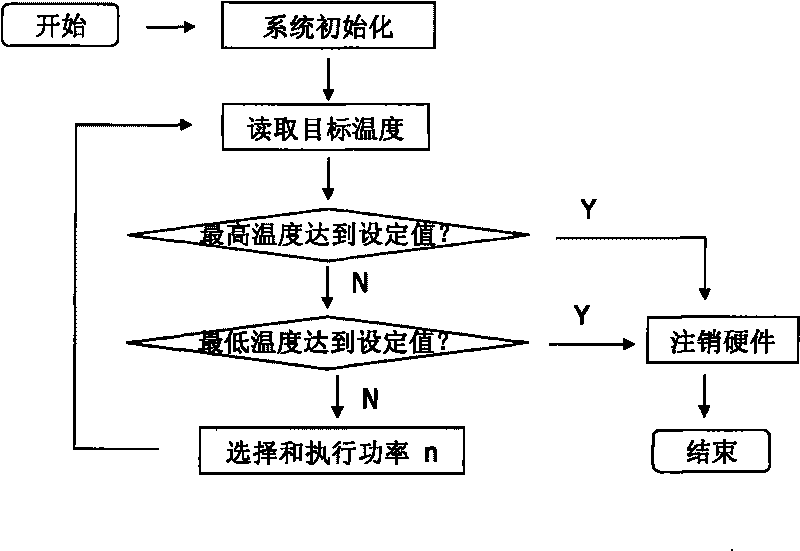

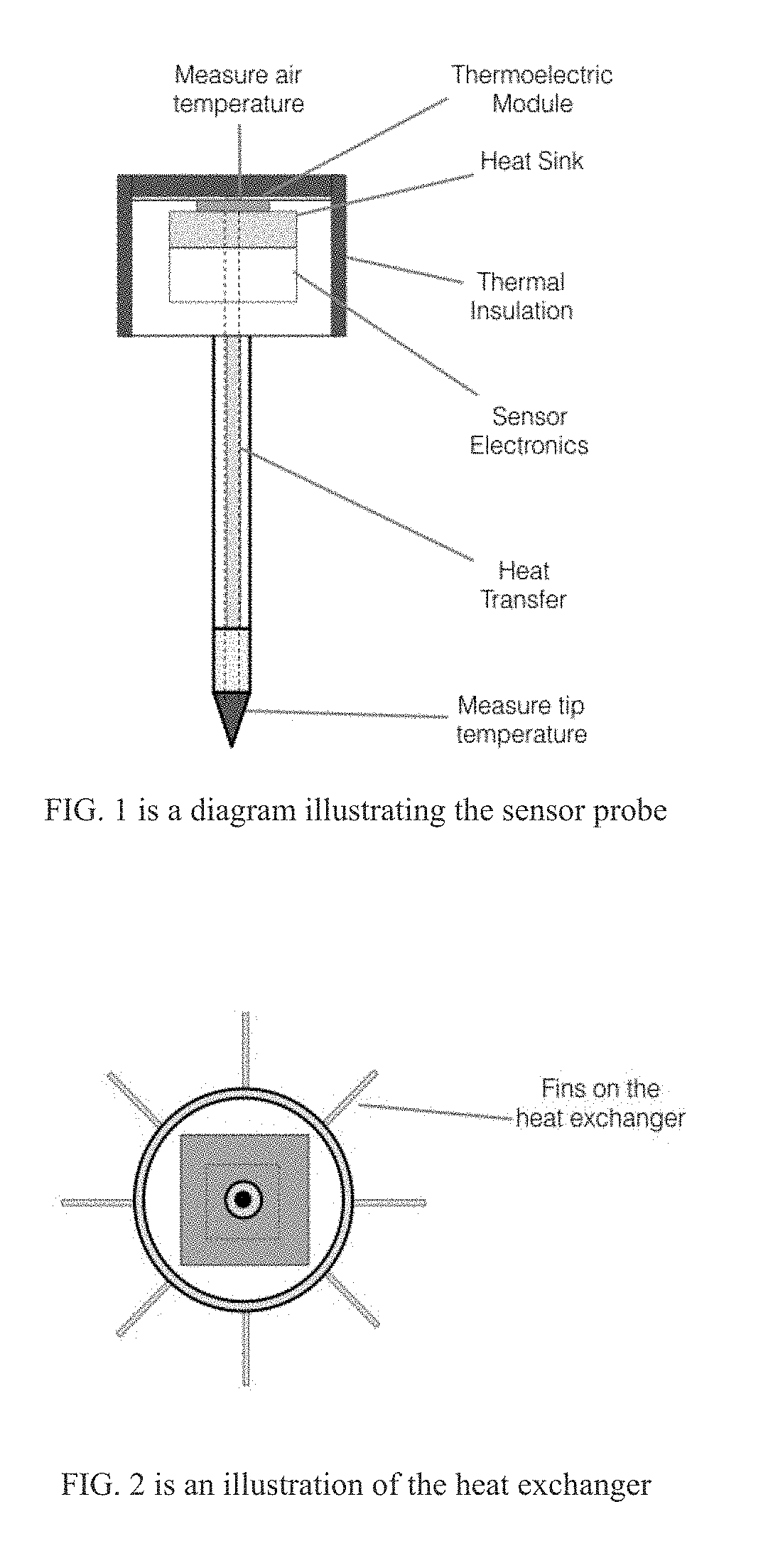

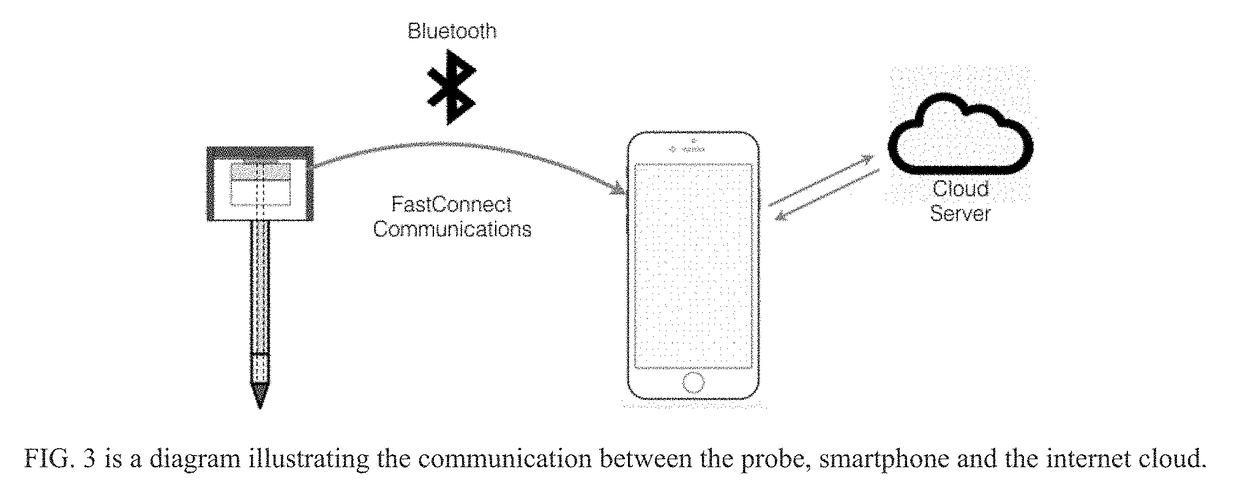

Novel Sensor Probe to Monitor Temperature during Cooking

InactiveUS20180353003A1Easy temperatureLow costThermometer detailsSub-station arrangementsTelecommunicationsThe Internet

Monitoring of food temperature during cooking for taste as well as to check if it is safe for consumption is well known, especially when grilling or bbqing or in professional kitchens. With smartphones and tablets, use of wireless thermometers that use bluetooth or WiFi are now available commercially. These thermometers use the internet cloud when needed and have apps that provide a lot of information to make cooking easier and fun. The present invention relates to an unique temperature monitoring system.

Owner:SABATA ASHOK +3

Unfreezing device, unfreezing method and refrigerator

InactiveCN106403482ADomestic cooling apparatusLighting and heating apparatusDissolutionFood temperatures

The invention provides an unfreezing device, an unfreezing method and a refrigerator. The unfreezing device comprises a cavity, a coupling window and a high-frequency generator, wherein the coupling window is arranged on the side wall of the cavity, the high-frequency generator is used for generating high-frequency waves, the high-frequency waves enter the cavity via the coupling window, and then multiple wave beams are emitted and irradiated to food to be unfrozen in the cavity so that the food can be unfrozen. According to the unfreezing device provided by the invention, all molecules of the unfrozen food bear the high-frequency waves, the polarity of polar molecules is changed at a high frequency, accordingly, the interior and the exterior of the unfrozen food are heated and unfrozen simultaneously, the temperature of the unfrozen food is uniform, the unfreezing speed is high, and the possibility of pollution caused by microorganisms is reduced. Meanwhile, the food to be unfrozen is dissolved fast through a largest ice crystal dissolution belt, the drop liquid loss is reduced, the loss of nutrients of the unfrozen food is effectively prevented, the quality of the unfrozen food is ensured, and large food can also be unfrozen, so that user experience is improved.

Owner:HEFEI HUALING CO LTD +2

Wireless cooking thermometer

InactiveUS20170248474A1High frequencyEasily be inserted into food itemThermometer detailsTemperature measurement in household appliancesEngineeringFood temperatures

The present invention provides a wireless cooking thermometer system, comprising: a food temperature indicator configured to provide a temperature reading, and a wireless transmitter unit operably connected to the food temperature indicator to receive a temperature reading therefrom and to wirelessly transmit an information representing the temperature reading.

Owner:NIELSEN NELS +1

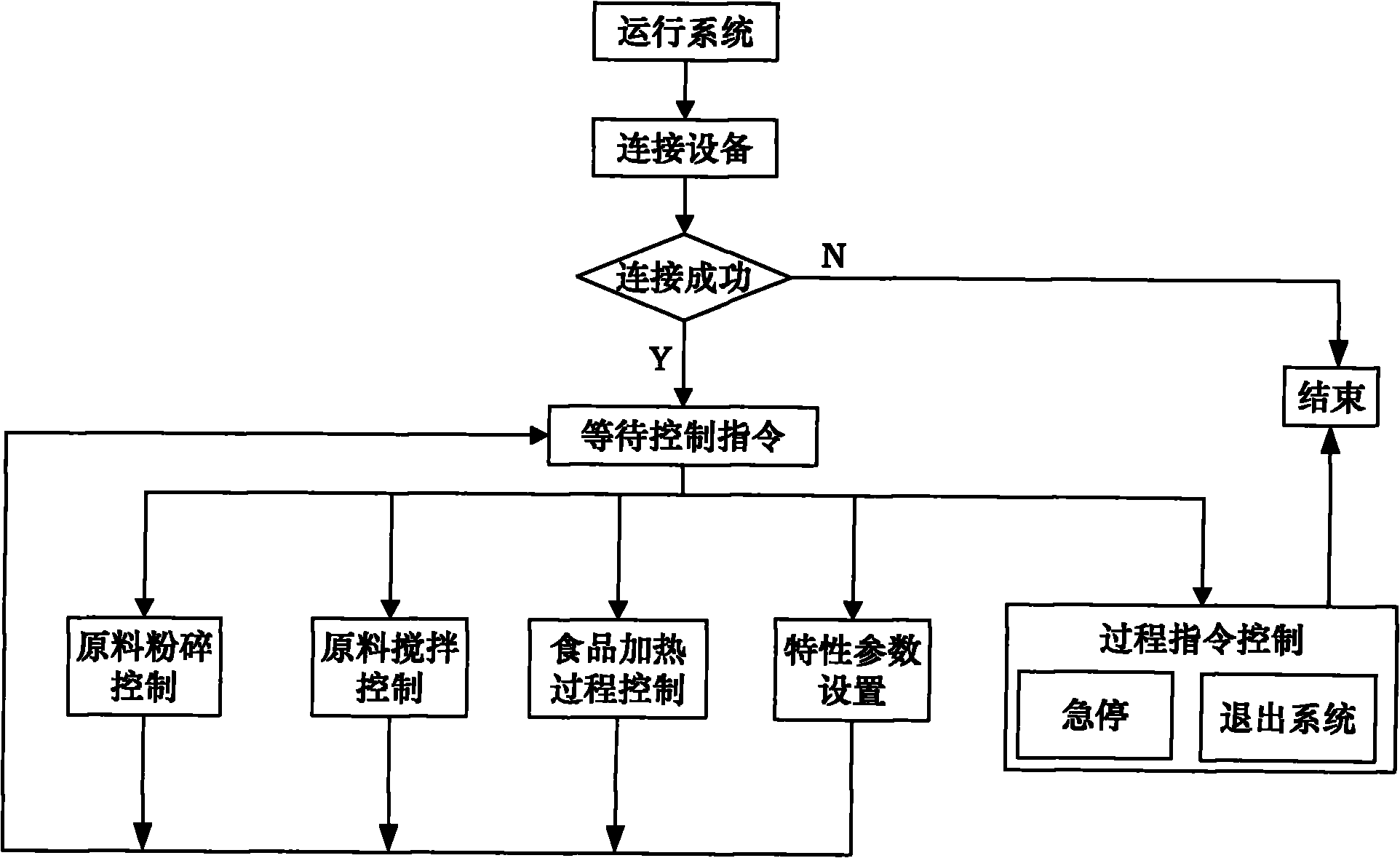

Man-machine interactive food processing control device capable of preprogramming

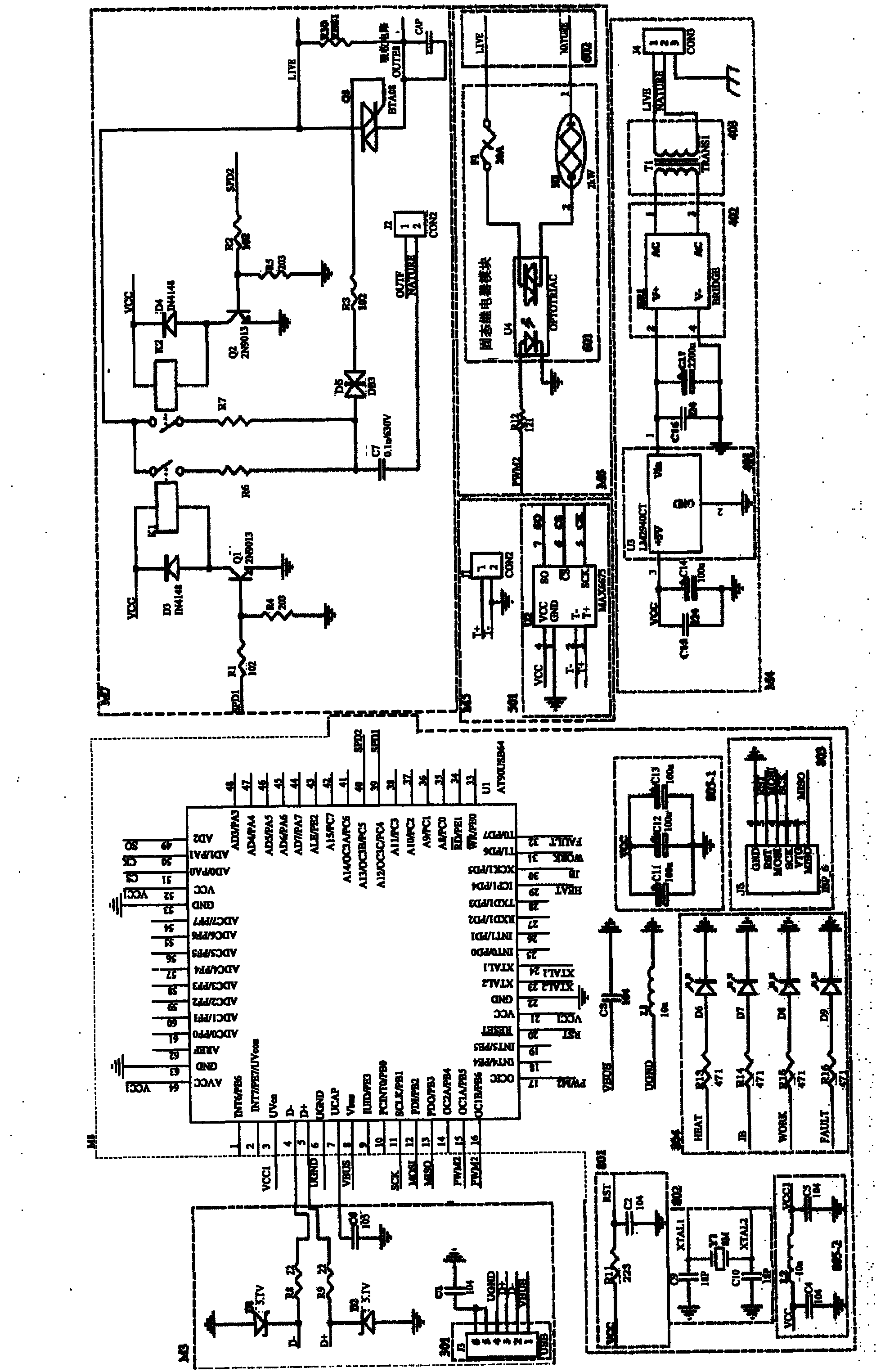

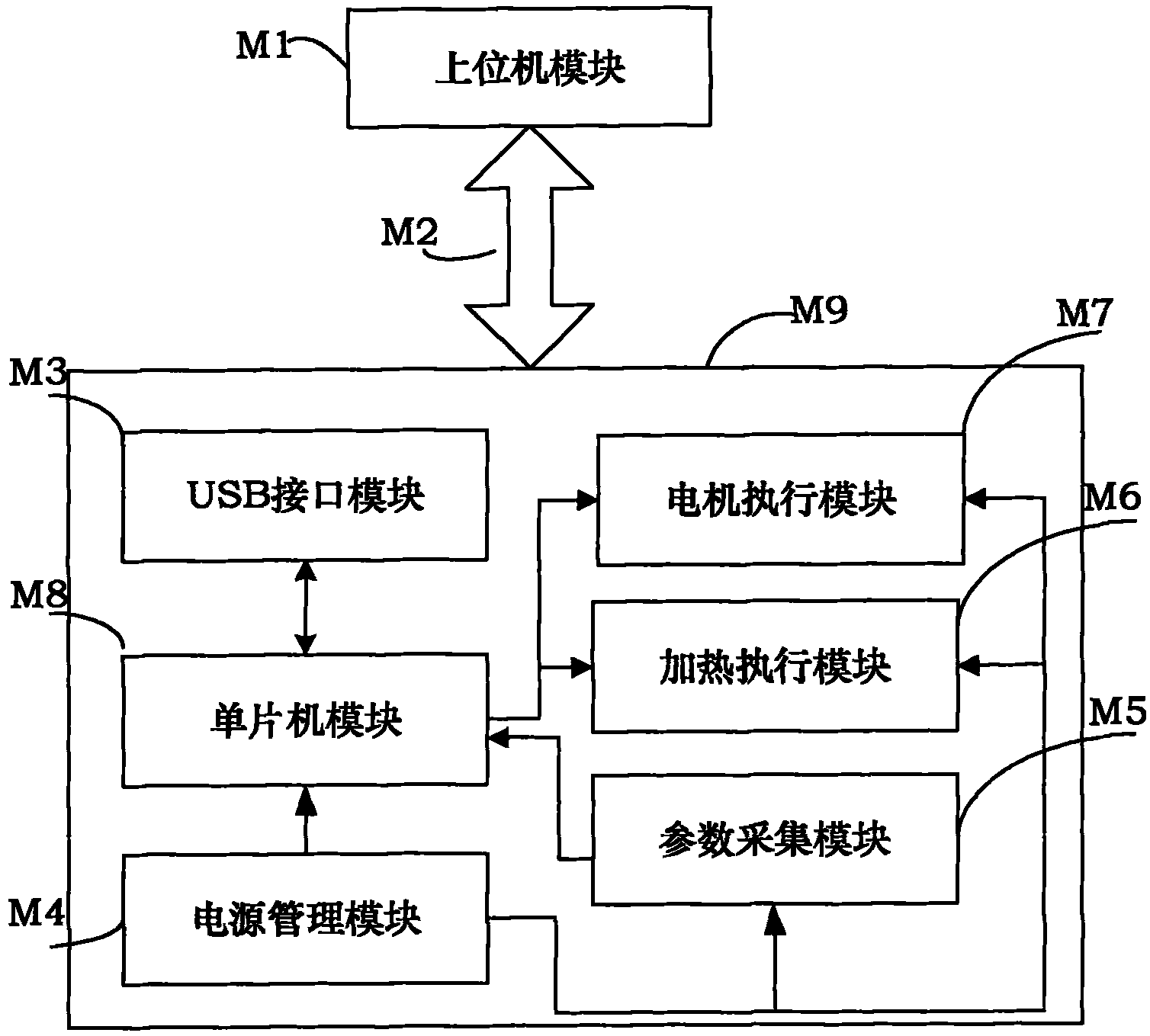

InactiveCN101833294AEasy to useImprove development efficiencyProgramme controlComputer controlMan machineFood temperatures

The invention discloses a man-machine interactive food processing control device capable of preprogramming, which comprises an upper computer, a USB connecting line and a lower computer. A user can preset expected processing procedures on the upper computer, the upper computer sends a processing procedure control instruction to the lower computer through a USB interface according to the USB communication protocol, the lower computer completes processing temperature tracking control, food crushing or stirring control according to the preset expected value and acquires food temperature parameters in real time in the food heating process to send the parameters to the upper computer, and the man-machine interactive terminal program of the upper computer shows and draws the food processing temperature parameters acquired in real time and stores processing procedure parameters, so that the user can observe the processing procedures and treat the conditions in the processing procedures.

Owner:BEIHANG UNIV

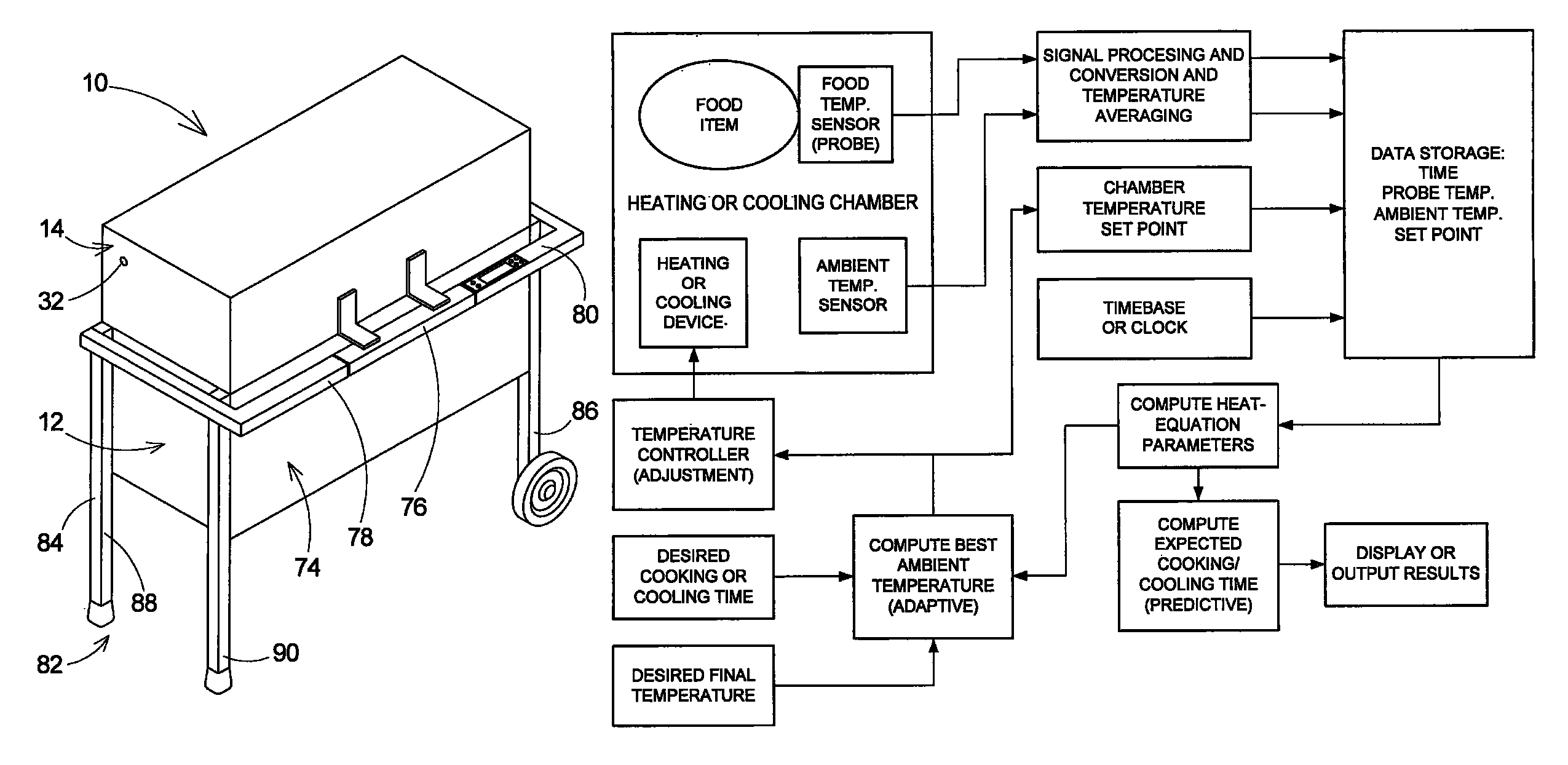

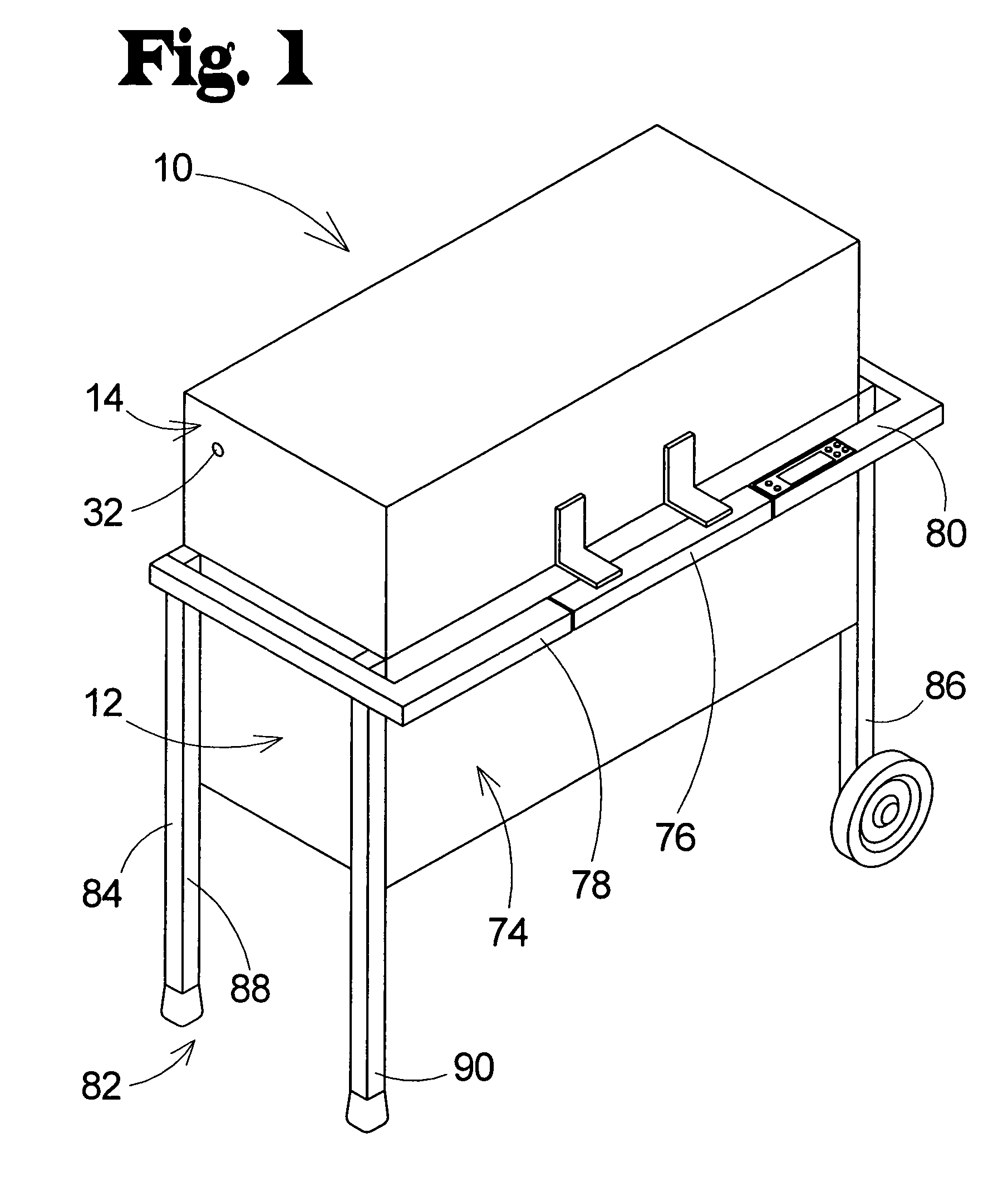

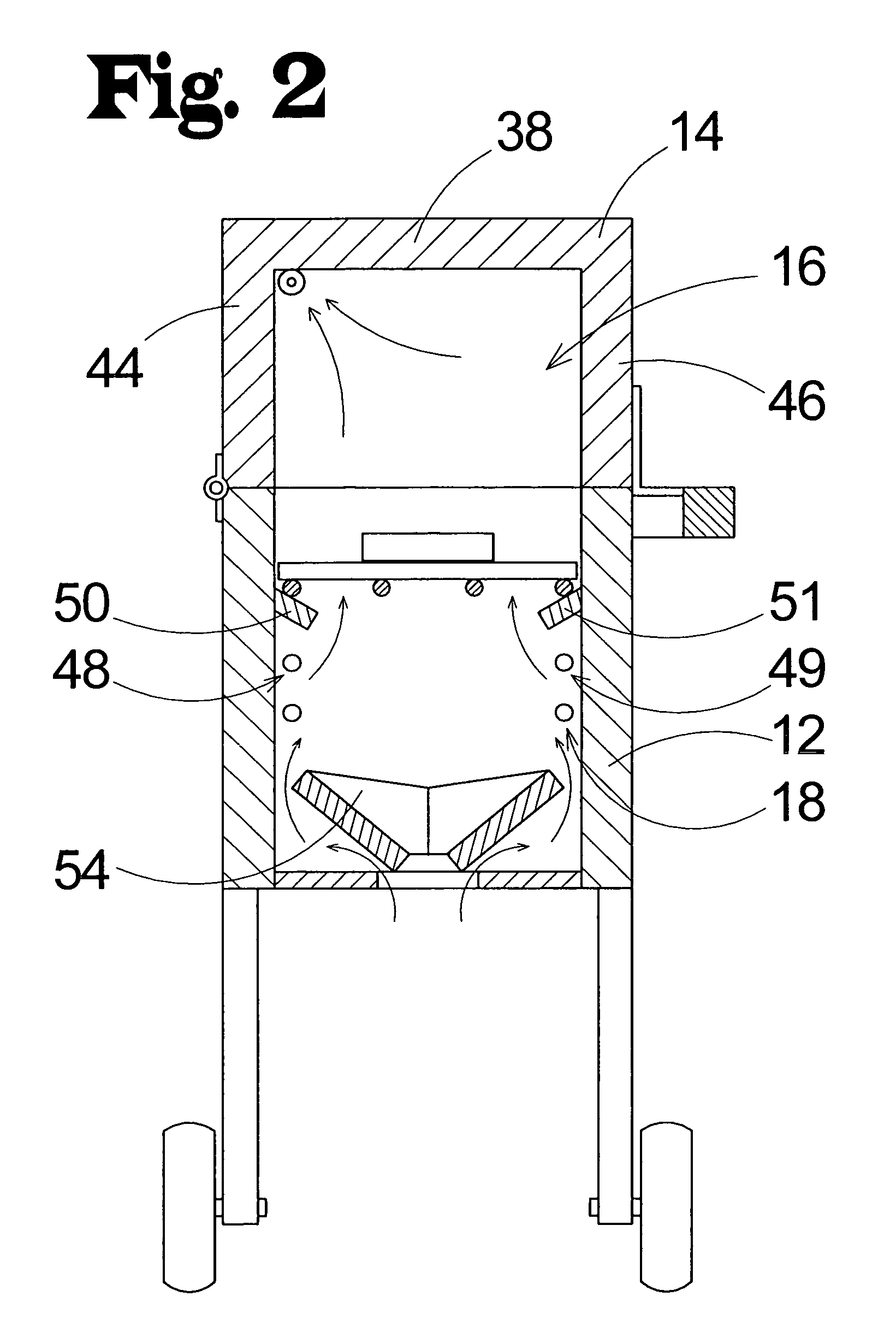

Electric grilling appliance

InactiveUS8624169B1Not overheat or burn or dry out the food being cookedEfficient heatingBoiling over preventionDomestic stoves or rangesFood temperaturesControl circuit

A heating appliance comprises a chamber portion defining a heating chamber, a lid portion, a heating apparatus to heat air in the heating chamber, a food temperature sensor to sense an internal temperature of an item located in the heating chamber, a user interface configured to receive designation of a desired time of completion of heating of the item from the user, and a control circuit configured to control the supply of power to the heating apparatus. The control circuit is in communication with the temperature sensor and the user interface. The control circuit may control the heating apparatus so that the internal temperature of the item reaches a predetermined temperature at the desired time of completion designated by the user. The control circuit may control the heating apparatus so that the internal temperature of the item is maintained at a predetermined temperature for a predetermined period of time before an end of the desired time of completion.

Owner:SORENSON WALLY B +1

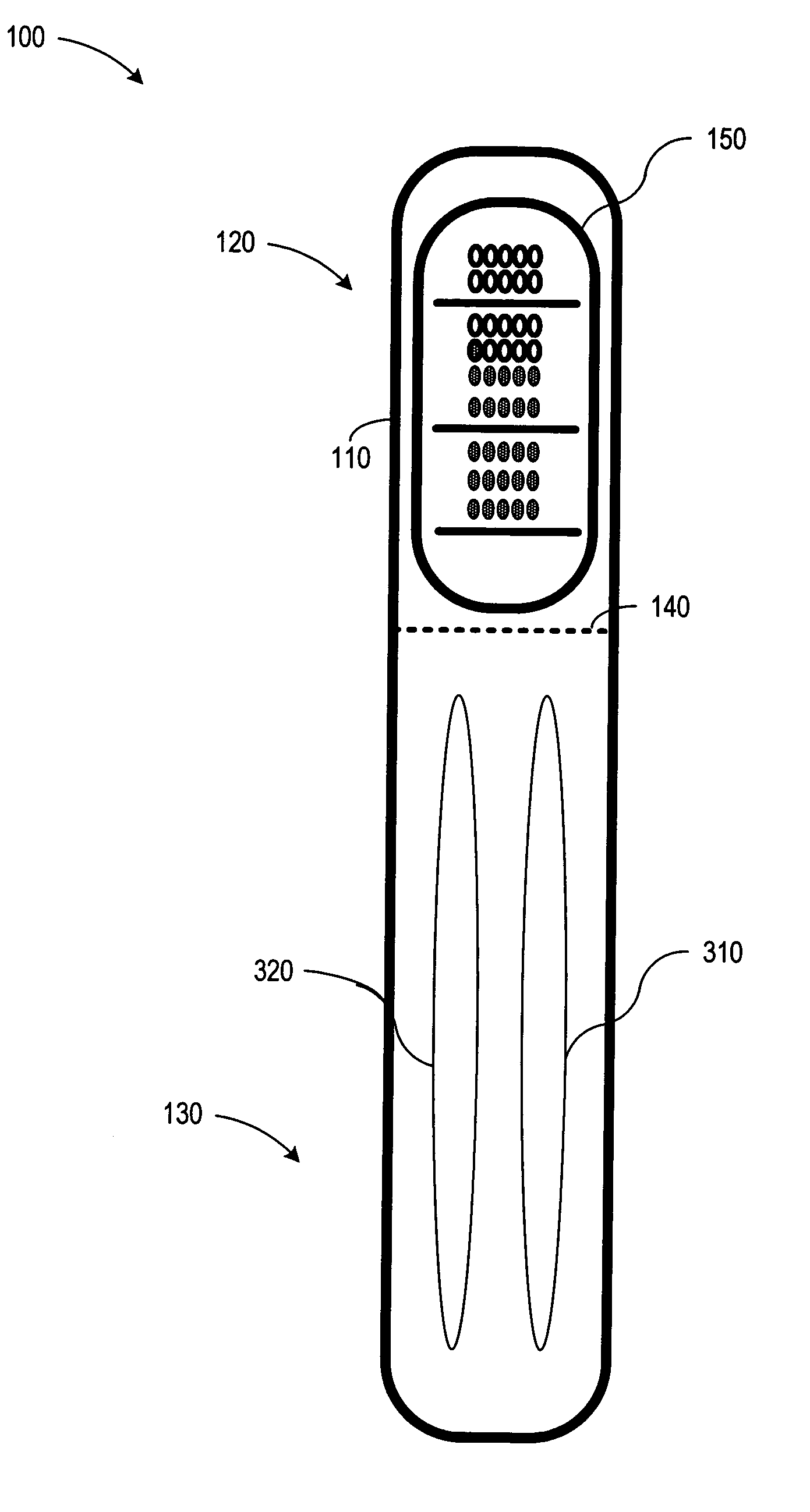

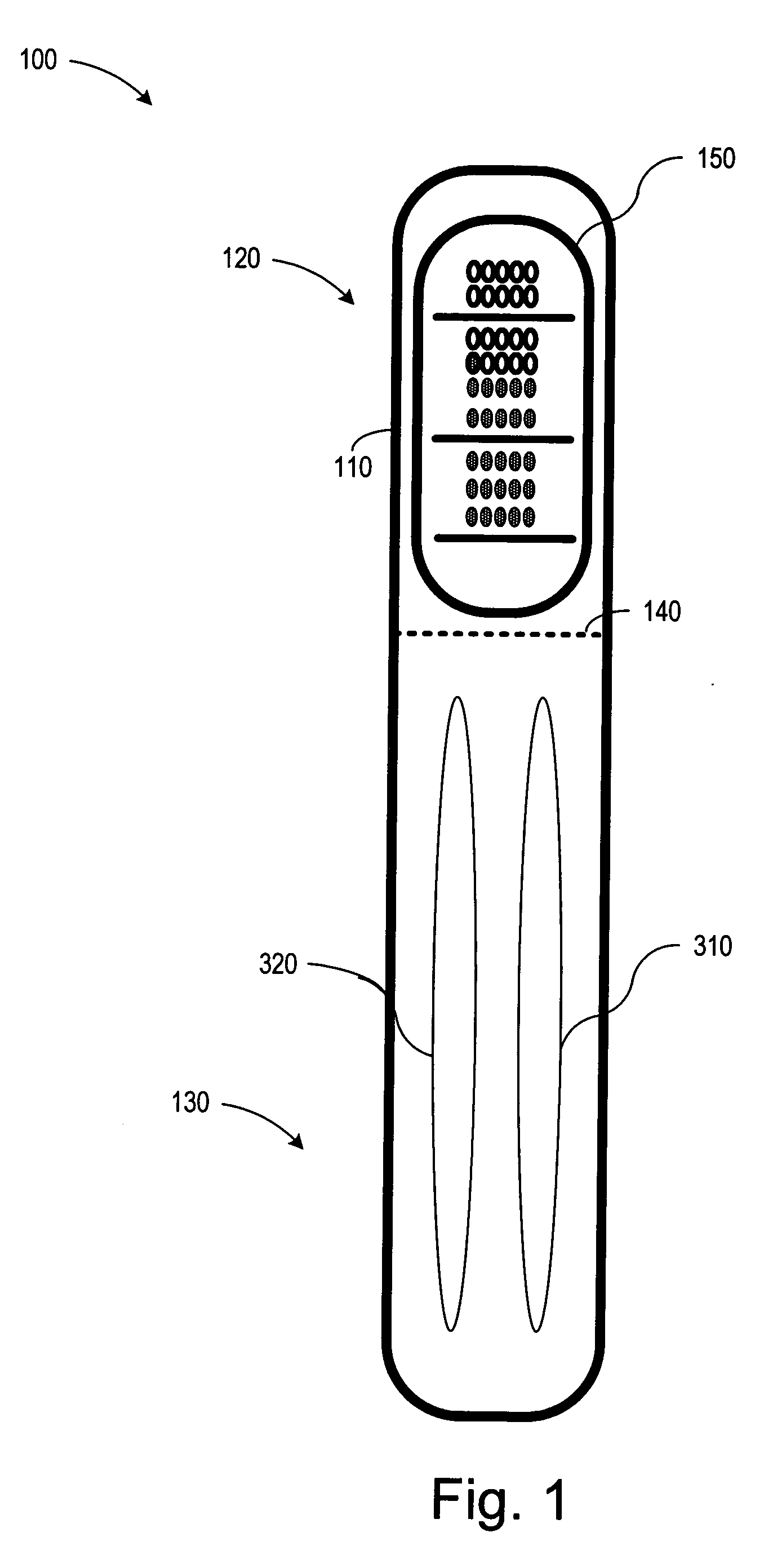

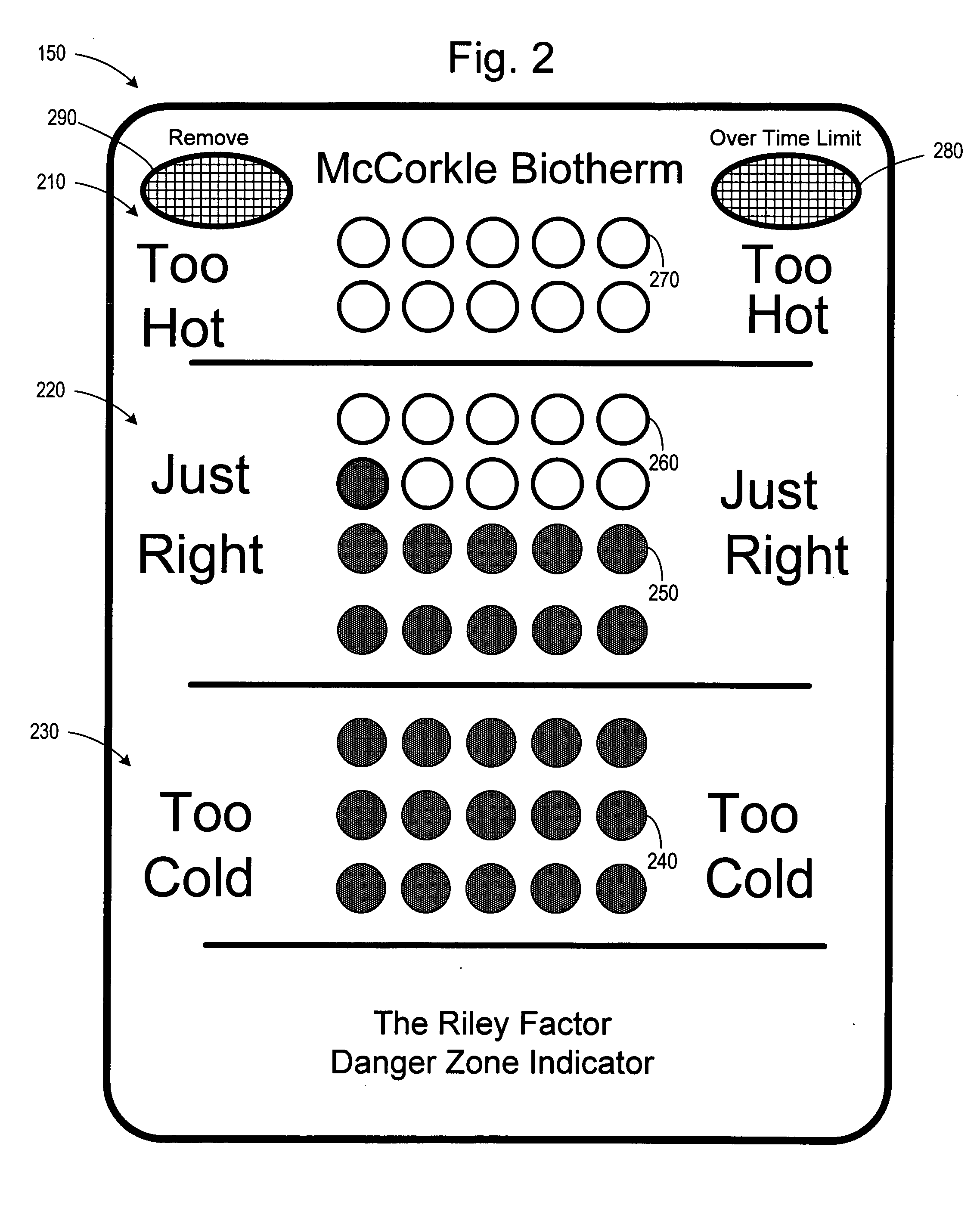

Single-use biotherm for reducing foodborne illnesses

InactiveUS20050188910A1Preventing food cross-contaminationReducing food borne illnessThermometer detailsThermometers using physical/chemical changesFoodborne IllnessesEngineering

A single use disposable thermometer / biotherm including devices and methods for preventing food cross-contamination and reducing foodborne illnesses. A single-use biotherm includes a biotherm body having a proximal end and a distal end, with a frangible portion fracturably attached to the biotherm body. A temperature sensitive arrangement is located in or on the biotherm body. A first temperature indicating arrangement is located in or on the frangible portion and coupled to the temperature sensitive arrangement. Fracturing the frangible portion from the biotherm body captures the temperature indicated by the temperature indicating arrangement. A method of reducing foodborne disease involves providing a single use biotherm; inserting the biotherm into a food product; and receiving an indication of the temperature of the food from the biotherm. The biotherm is then disposed after receiving the temperature indication from the food product.

Owner:MCCORKLE POLLY DEE

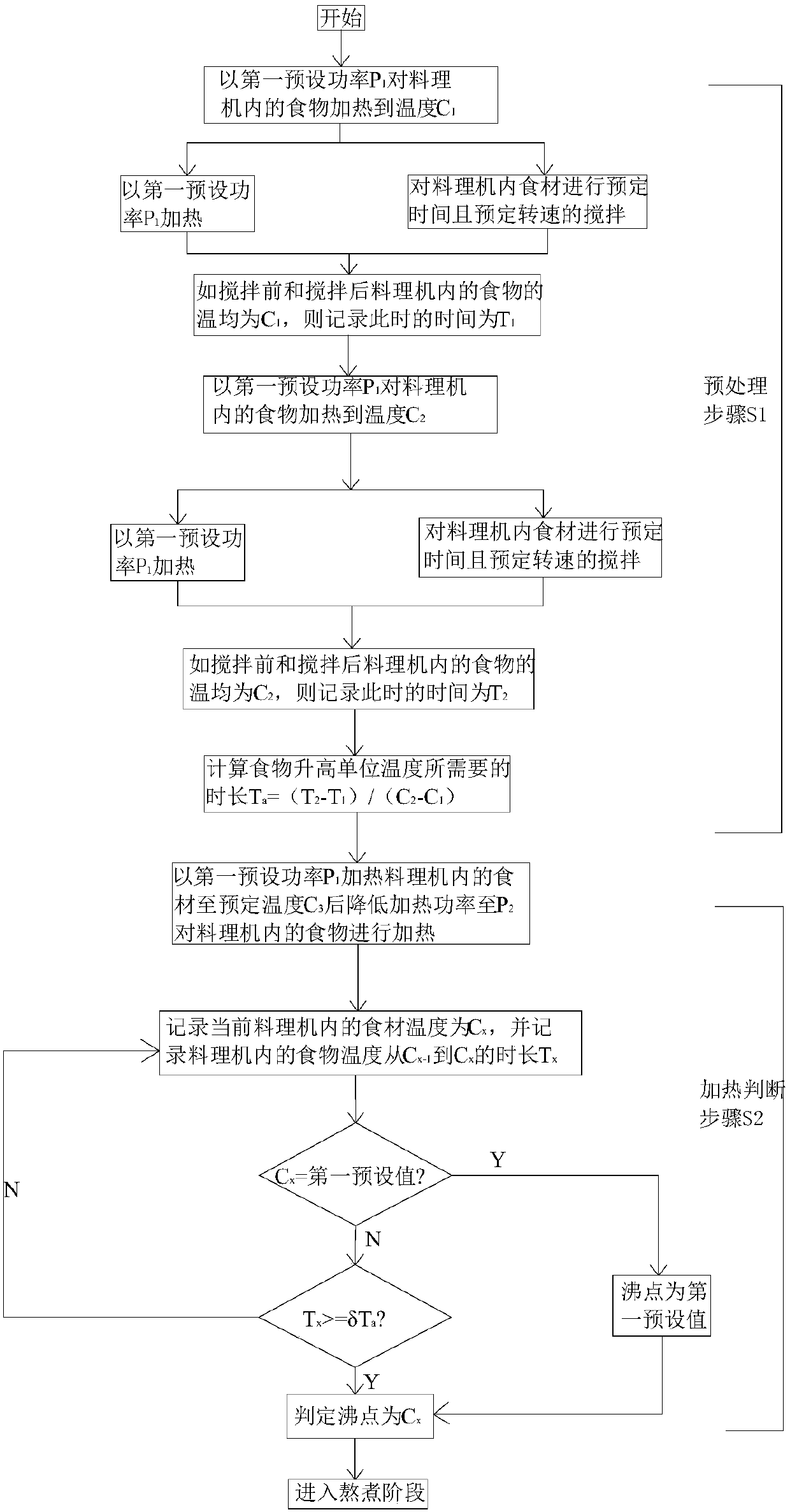

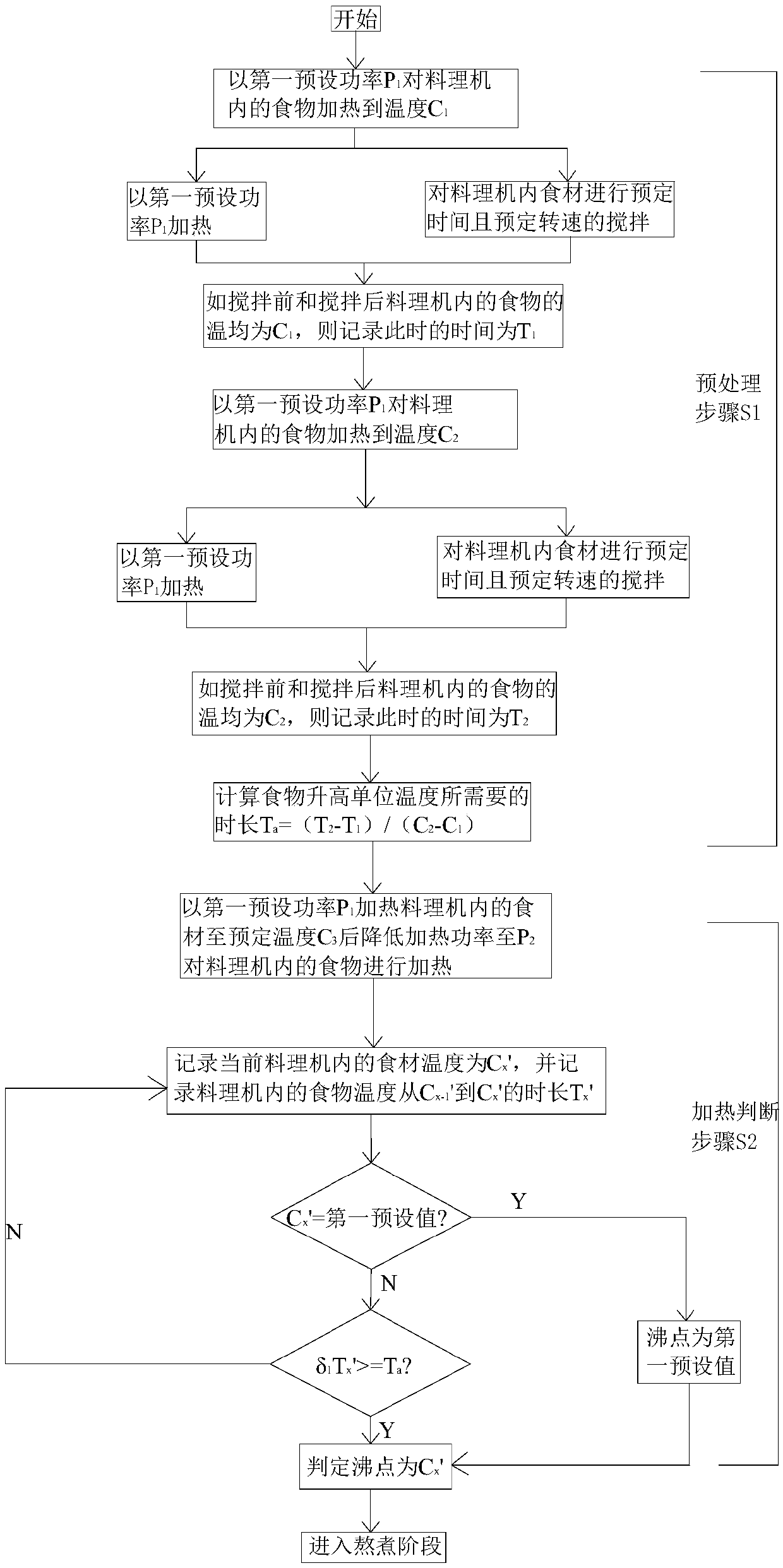

Method for determining food boiling point in food processer and food processer

ActiveCN107665003ANo additional costAvoid quality risksTemperatue controlVessels with intergral heatingBoiling pointEngineering

The invention provides a method for determining a food boiling point in a food processer and a food processer. The method comprises the following steps that: a time length Ta needed by raising a unittemperature of food is determined; the food is heated to be at a predetermined temperature C3 at a first preset power P1 and then the heating power is reduced to be P2 to heat the food, a current foodtemperature is recorded as Cx, and a time length Tx of the food temperature changing from a Cx-1 to the Cx is recorded; whether the Cx value is a first preset temperature is determined; if so, the food temperature is determined to reach a boiling point; if not, a Tx is compared with a delta Ta; if the Tx is larger than or equal to the delta Ta, the food temperature is determined to reach a boiling point; and if the Tz is less than the delta Ta, the first kind of determination behavior is executed continuously. With the method provided by the invention, food like soybean milk in a food processor is boiled and cooked fully without being affected by factors like the altitude of the current environment.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

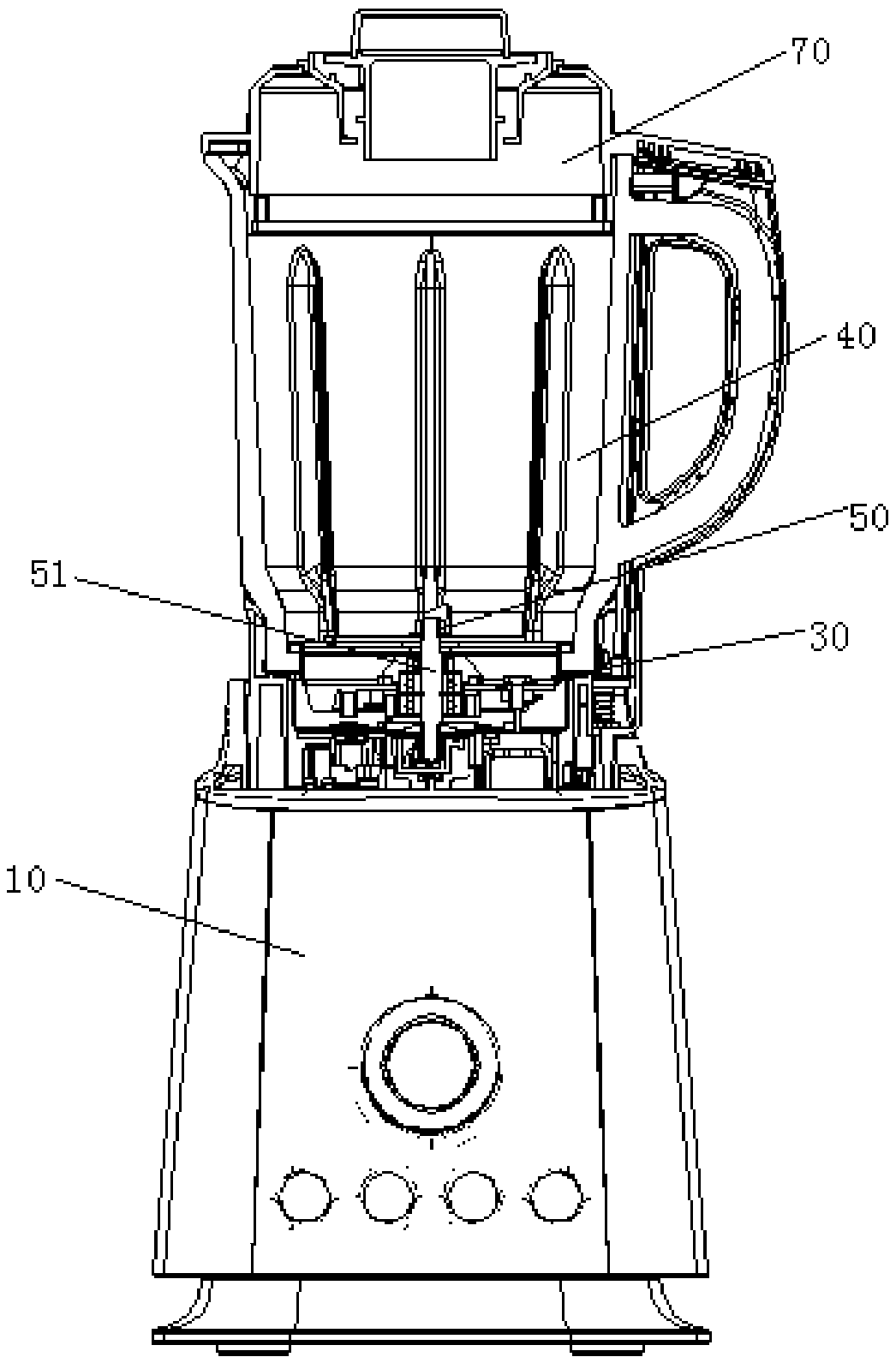

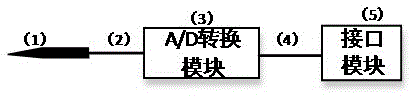

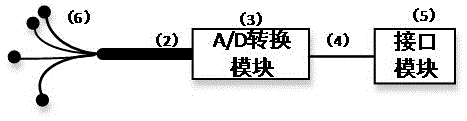

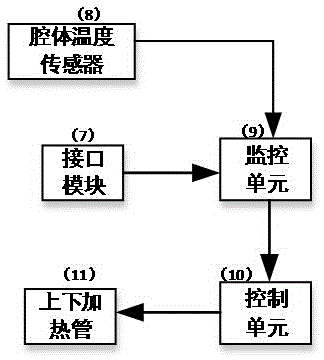

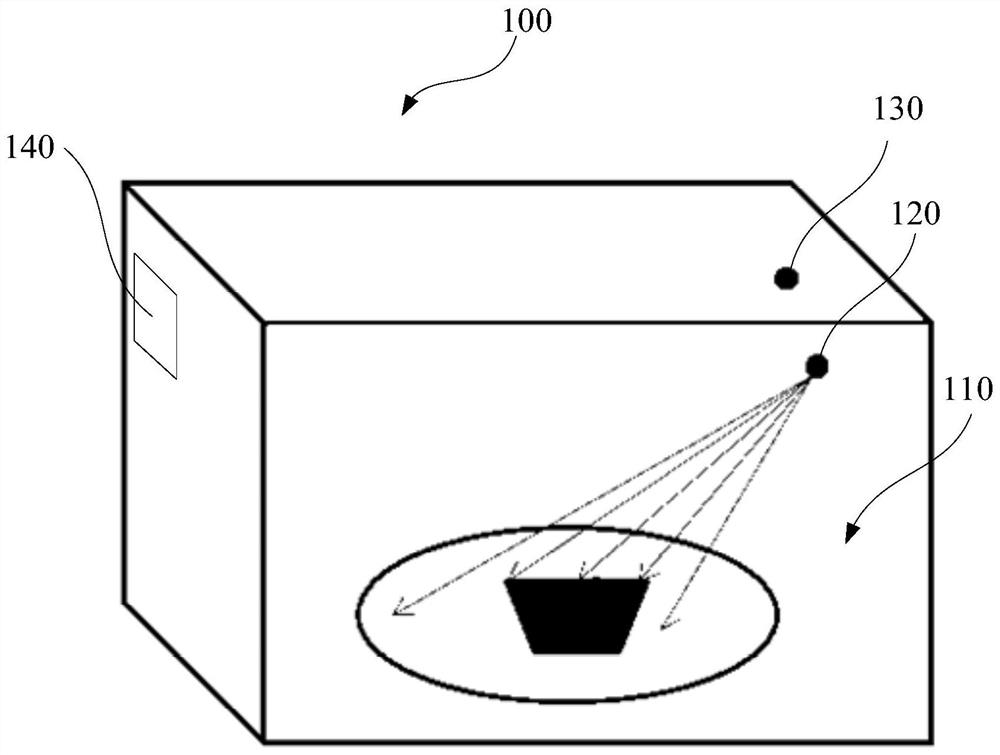

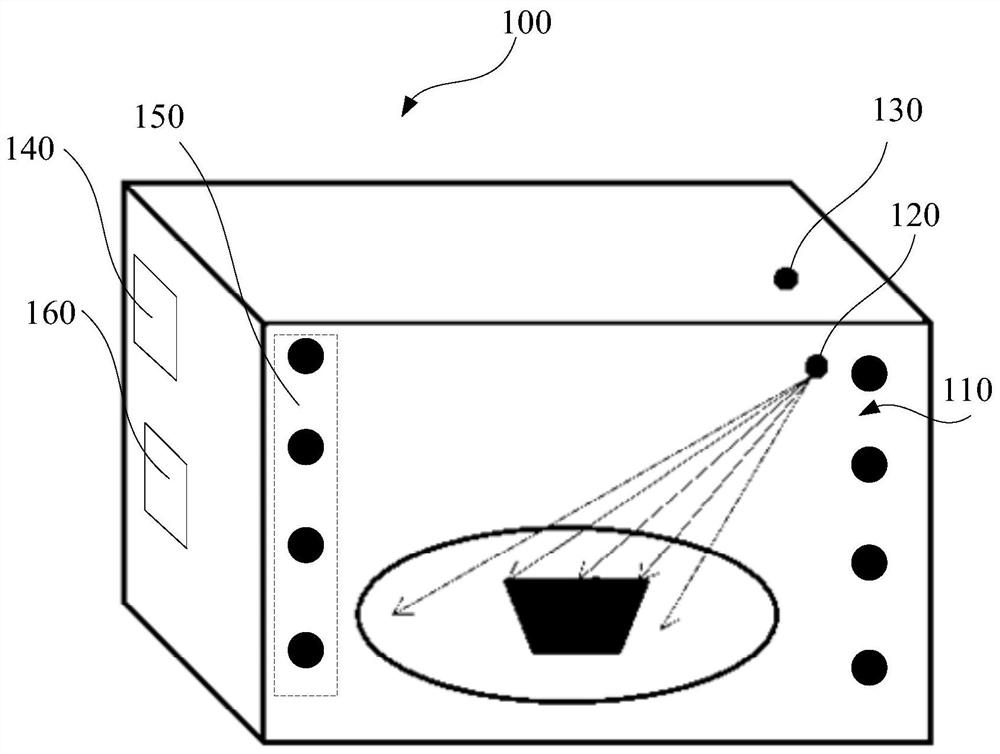

Food temperature sensor, electric oven and control method of electric oven

InactiveCN105628252AReal-time real temperature detectionImprove experienceRoasters/grillsThermometer applicationsCooking & bakingComputer module

The present invention provides a food temperature sensor, an electric oven and a control method of the electric oven. The food temperature sensor comprises a temperature detection probe for detecting the temperature of food in the electric oven in a baking process, a temperature transmission line which is connected to the temperature detection probe and is used for transmitting the temperature data detected by the temperature detection probe to an A / D conversion module, the A / D conversion module which is connected to the temperature transmission line and is used for carrying out analog and digital conversion of the temperature data to obtain a digital temperature signal, a signal transmission bus which is connected to the A / D conversion module and is used for transmitting the digital temperature signal to an interface module, and a first interface module for outputting the digital temperature signal. Through the food temperature sensor, the electric oven and the control method, the food temperature sensor can detect and output the real temperature of a food, and a user experience is improved.

Owner:BEIJING XIAOBEI TECH CO LTD

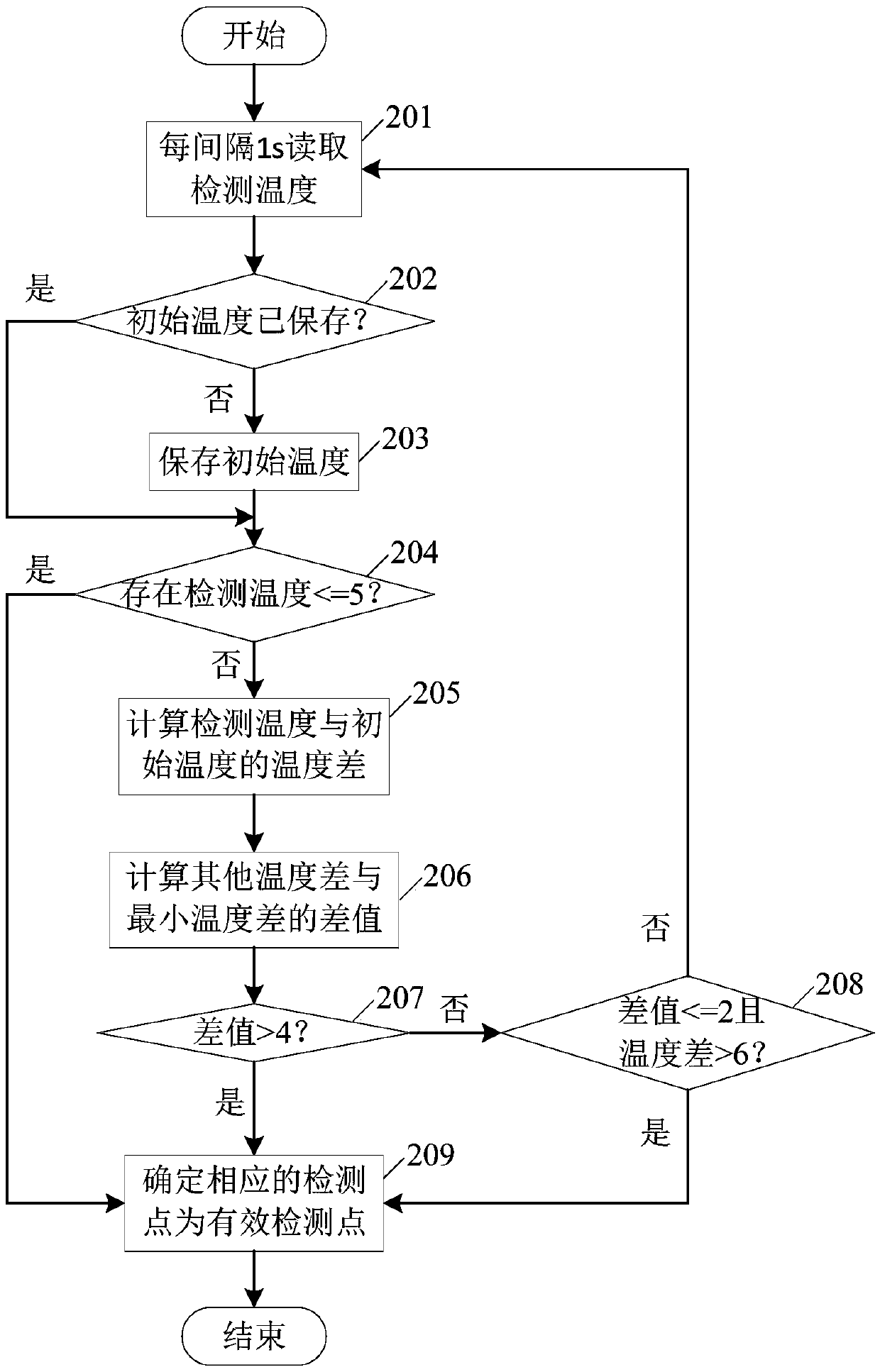

Device and method for determining food temperature, temperature control system and cooking device

ActiveCN105496216AControl heatingAccurate determination of temperatureCooking vesselsTemperature controlControl system

The invention relates to the technical field of determination of food temperature of a cooking device and discloses a device and method for determining food temperature, a temperature control system and the cooking device. The device comprises a temperature detection device used for detecting temperature of multiple detection points of the cooking device and obtaining multiple detection temperature, and a processing unit used for determining whether a detection point of the multiple detection points is an effective detection point based on detection temperature of the detection point and / temperature difference between detection temperature and initial temperature after the cooking device is started and also used for determining temperature of food based on determined detection temperature of effective detection points. By adoption of the technical scheme, the device and method for determining food temperature, the temperature control system and the cooking device can accurately determine temperature of food in the cooking device and better control heating of the cooking device such that food temperature cooked in the cooking device can precisely satisfy the temperature requirement.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Measuring method for unfrozen object in microwave oven

InactiveCN101750169AMake sure the feedback temperature differenceResolution target temperatureDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention relates to a measuring method for an unfrozen object in a microwave oven; a sensor probe of the microwave oven measures the food temperature with a plurality of sampling points simultaneously; a temperature sensor defines the initial position of the food as a measurement result at 0 DEG C, and simultaneously judges the number of the sampling points of the temperature sensor on the object; afterwards, a tray carries out the same judgment every time when rotating for a certain angle, until the tray rotates for one week, and the size of the food is finally worked out. The shape, the size and the position on the tray of the object are worked out by recording the position information of the sampling points on the object to be heated in the microwave over in different angles, and then the temperature rise of all the points is judged according to the positions of the effective sampling points of the tray in a first round, so as to effectively distinguish the target temperature and the background temperature in the unfreezing process.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Method for estimating the food temperature inside a refrigerator cavity and refrigerator using such method

InactiveUS7596432B2Risk minimizationTemperatue controlThermometers using electric/magnetic elementsRefrigerator carProcess engineering

A method of controlling the temperature inside a cavity of a cooling appliance provided with a temperature sensor inside the cavity and with an actuator for adjusting the cooling capacity of the appliance, the food temperature is estimated on the basis of a value from the temperature sensor and on a predetermined function of a status of the actuator.

Owner:WHIRLPOOL CORP

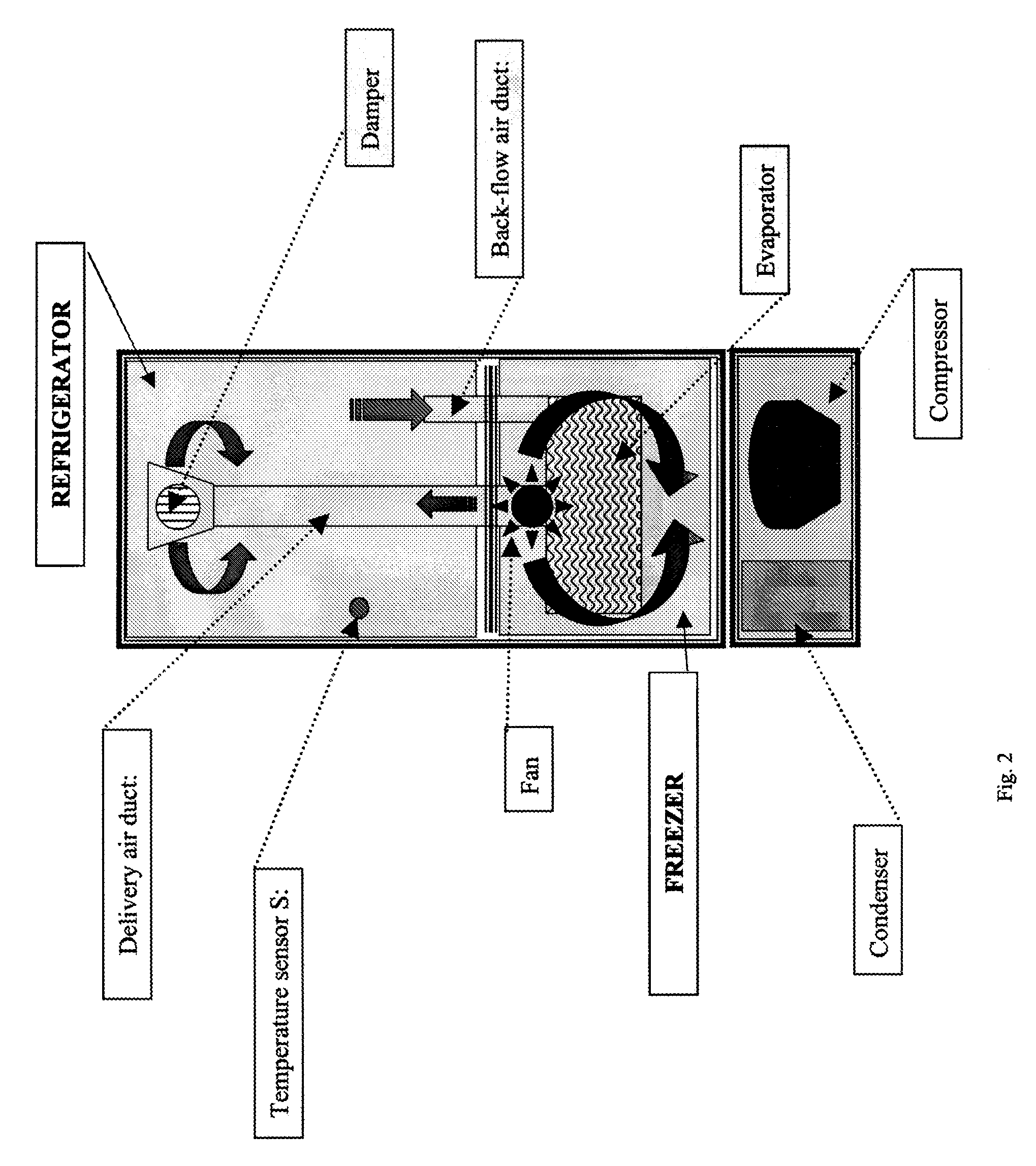

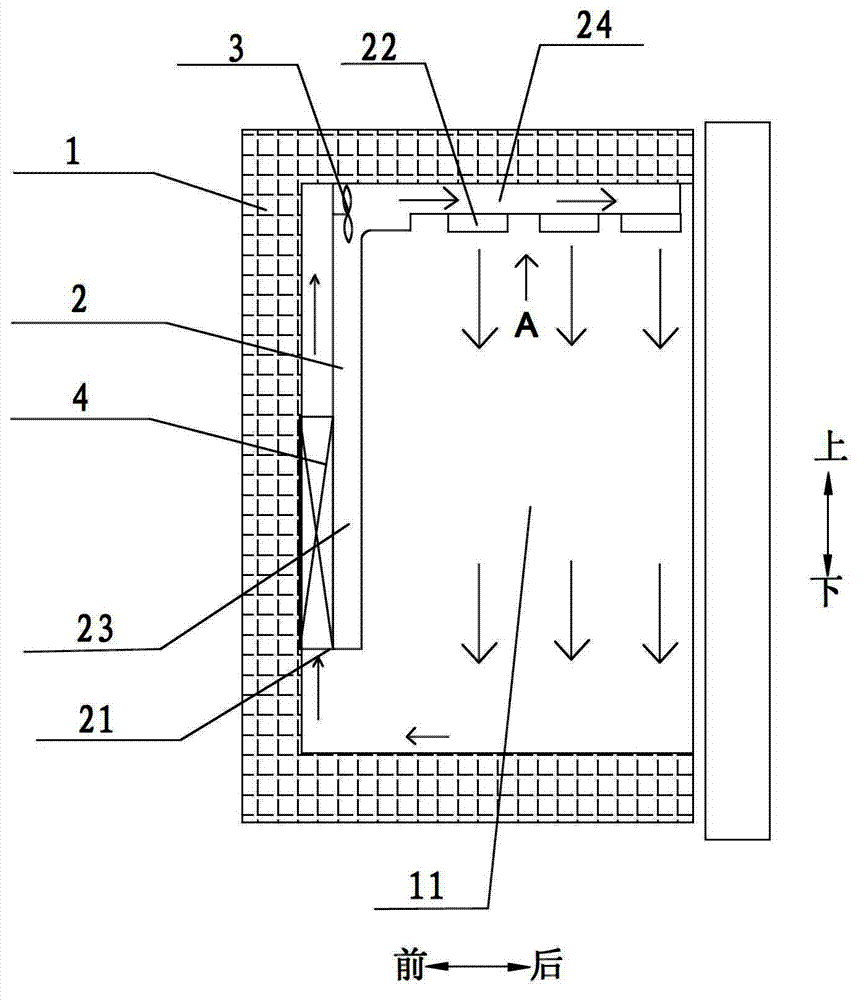

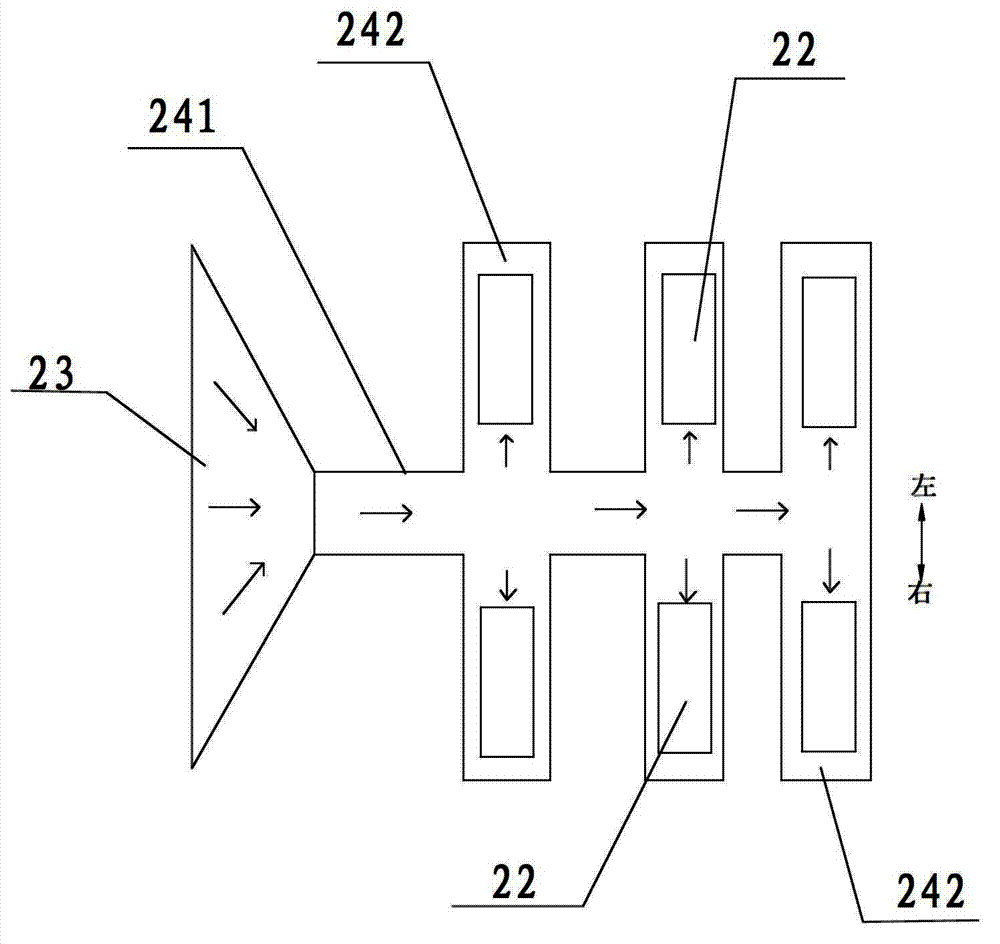

Refrigerator

InactiveCN102778095ASimple structureEasy to manufactureLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a refrigerator which comprises a refrigerator body, an air duct and a fan, wherein the refrigerator is internally provided with a refrigeration chamber; the air duct is arranged in the refrigeration chamber and is provided with an air return inlet and an air outlet; the air duct comprises a vertical section extending upwards along the rear wall of the refrigeration chamber and a horizontal section extending forwards along the top wall of the refrigeration chamber; the horizontal section comprises a main air duct directional along the front and back directions and a plurality of branch air ducts which are communicated with the main air duct and extend along left and right sides; and the fan is arranged in the air duct. Therefore, according the refrigerator provided by the embodiment of the invention, by arranging the branch air ducts on the left and right sides of the main air duct, cool air can be conveyed to each part of the refrigeration chamber, so that the attenuation of flowability of the cool air can be effectively avoided, the uniformity of an indoor refrigeration effect of the refrigeration chamber is improved, and the fluctuation of the food temperature is reduced, thereby being beneficial to the storing and nutrition maintenance of foods.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

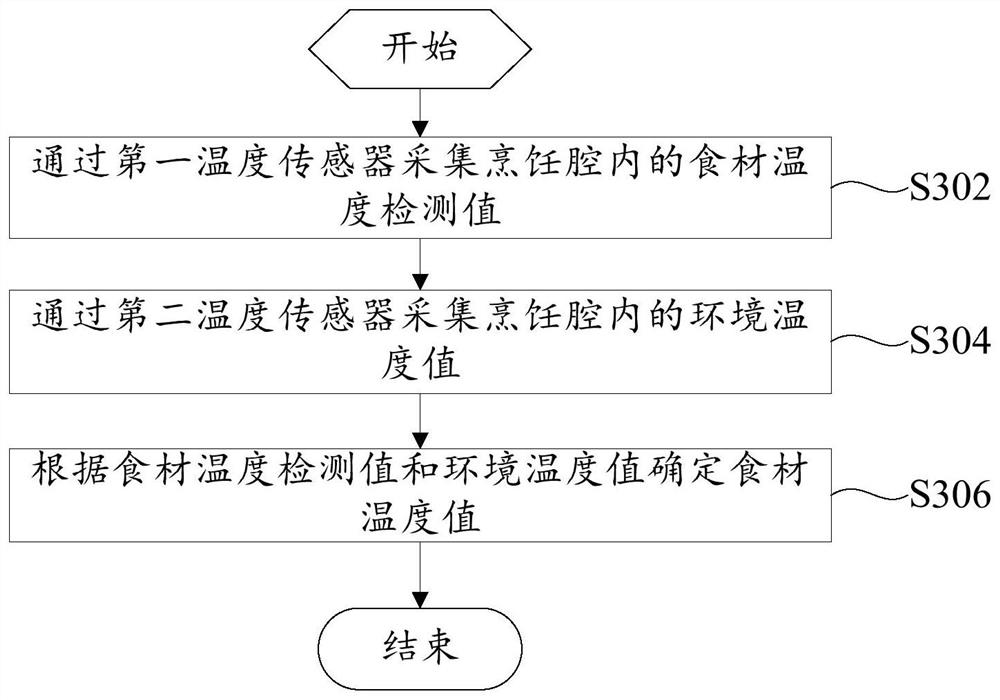

Cooking utensil, control method of cooking utensil and computer readable storage medium

The invention provides a cooking utensil, a control method of the cooking utensil and a computer readable storage medium. The cooking utensil comprises a cooking cavity, a first temperature sensor, asecond temperature sensor and a control device, wherein the first temperature sensor is arranged in the cooking cavity, the first temperature sensor is configured to collect a food material temperature detection value in the cooking cavity, the second temperature sensor is arranged in the cooking cavity, the second temperature sensor is configured to collect an environment temperature value in thecooking cavity, the control device is connected with a heating assembly, the first temperature sensor and the second temperature sensor, and the control device is configured to correct the food material temperature detection value according to the environment temperature value so as to determine the food material temperature value. According to the cooking utensil, the control method of the cooking utensil and the computer readable storage medium, the food material temperature value is corrected by using the environment temperature value in cooking cavity obtained through the second temperature sensor, then the food material temperature value is determined, and the food material temperature value is more accurate than the food material temperature value obtained through the first temperature sensor.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com