Apparatus and method for heating objects with microwaves

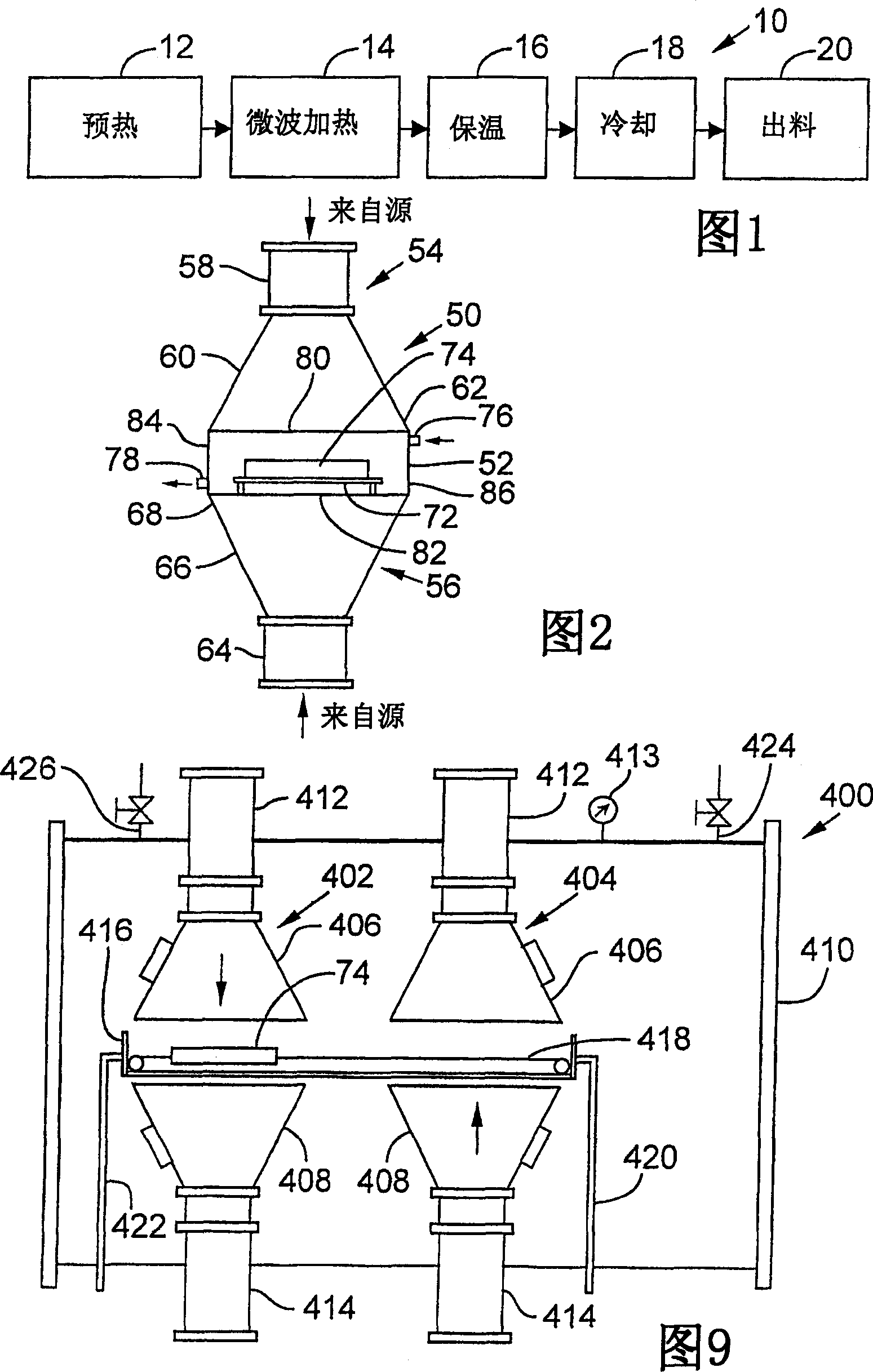

A microwave heating and microwave technology is applied to food pasteurization or high temperature sterilization. field, it can solve complex problems such as inability to guarantee packaging sterilization, uneven heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0116] Example 1: Computer simulation of a rectangular waveguide and cavity

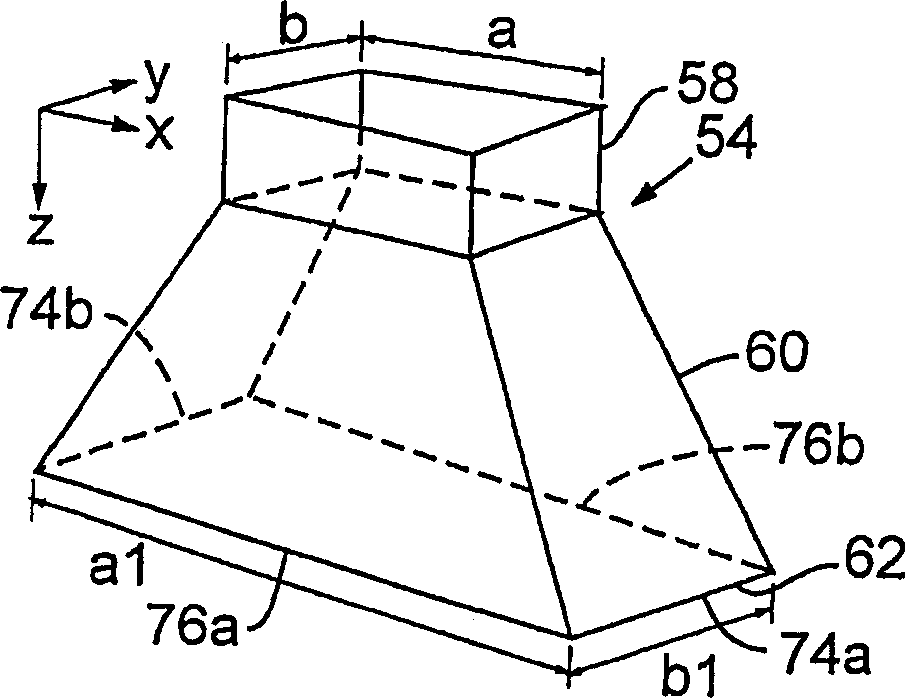

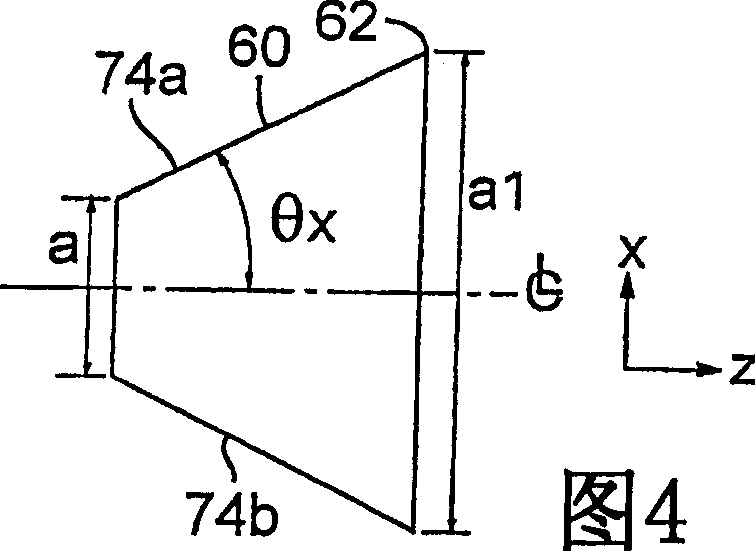

[0117] In this example, a computer model is used to demonstrate the effect of changing the size of the rectangular waveguide cavity on the field distribution and wave propagation characteristics in the cavity. The computer simulation is completed by using Quick-Wave software, which can be obtained from Warsaw, Poland, QWED. The requirements for computer hardware are 850MHz central processing unit, 256M memory, and Windows NT 4.0 as the operating system. Referring first to FIG. 14a, a cross-sectional view of a general rectangular waveguide 702 is shown here, and the length a is defined as the x direction and the width b as the y direction, and the x direction and the y direction are shown in FIG. 14a. In the computer simulation of this example, the value of a is 247.65mm and the value of b is 123.825mm, and the frequency of the microwave is 915MHz.

[0118] The lowest order propagation mode of wavegu...

example 2

[0132] Example 2: Computer Simulation of a Rectangular Waveguide and a Loaded Chamber

[0133] In this example, a computer model was used to evaluate the performance of the device of Figure 14a when heating a load 706 (eg, a food package) within a cavity 704 (Figure 19). As mentioned in the previous example, the length a of the waveguide 702 is 247.65 mm, and the width b is 123.825 mm. The cavity 704 in this example has a length a1 equal to 2.0a, a width b1 equal to 1.5b, and a depth z1 of 100mm. The dimensions of the load 706 are as follows: 140mm in the x-direction, 100mm in the y-direction, 30mm in the z-direction, and the comprehensive dielectric coefficient value, ε * =ε'-jε", the loading was 47.45-j38.55 and the model was whey gel. All simulations were performed at a frequency of 915MHz.

[0134] The energy distribution profile on the upper surface of the load 706 is calculated based on the following two conditions. In a first example, the load 706 is placed in the ce...

example 3

[0137] Example 3: Experimental results for rectangular waveguides and cavities

[0138] In this example, several experiments were carried out to verify the computer simulation results of Examples 1 and 2 described above. In these experiments, the load was heated in a rectangular microwave chamber made of an aluminum plate. These cavities are connected with the microwave power supply of 20kW, 915MHz produced by Ferrite Company, Inc., Hudson City, New Hampshire, and these cavities have rectangular waveguides, wherein the dimension of a is 247.65mm and the dimension of b is 123.825mm ( Figure 14a). The simulation results are obtained by simulating a chamber with dimensions a1=2.0a, b1=1.5b, and z1=100mm and a chamber with dimensions a1=2.0a, b1=1.5b, andz1=150mm. The reflected energy is measured with a directional coupler inside the power supply and an HP power meter. Applying a 6KW power to the load can achieve a heating time of 30 seconds to 2 minutes and raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com