Array waveguide grating of organic polymer and its making process

An arrayed waveguide grating, polymer technology, used in light guides, optics, optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, a kind of preparation not containing fluoropolymer solution

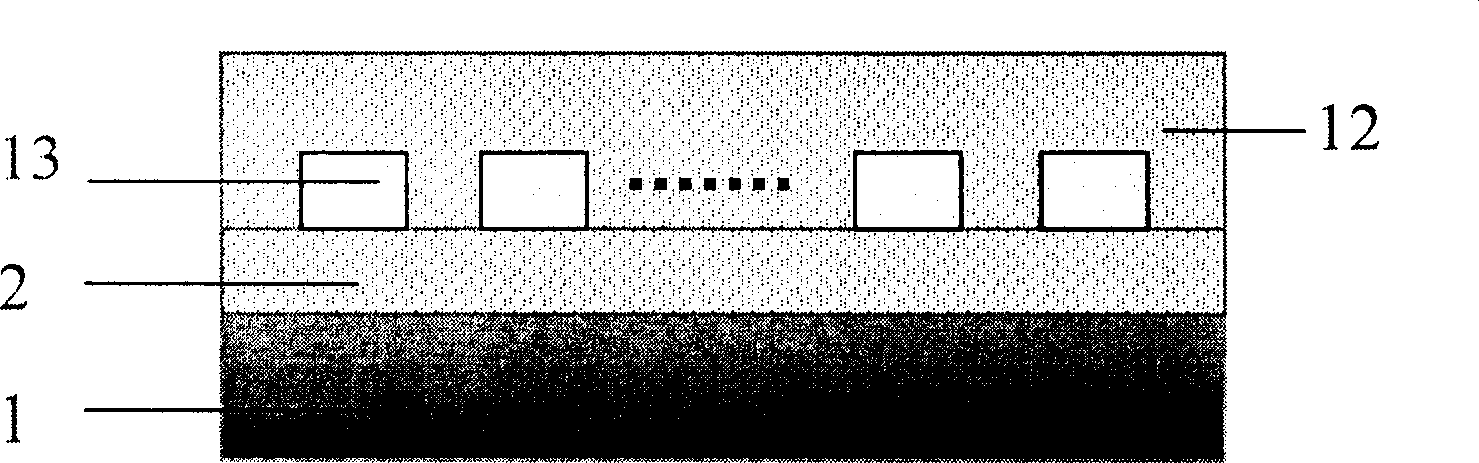

[0053] A copolymer of methyl methacrylate and glycidyl methacrylate is used as the cladding material (2) (as shown in the general formula VI). After testing, the refractive index of this material at 1.55 μm is 1.483. Bisphenol A epoxy resin is used as a high-refractive index regulator (as shown in general formula VII), mixed into the cladding material to form a core layer material (3), adjust the percentage of epoxy resin, and control the core layer The refractive index is 1.495, so that the waveguide formed is single-mode transmission. Add a certain amount of solvent to the cladding and core materials for dilution, mix and stir, filter with a 0.4 micron filter, adjust its concentration so that it can flow slowly, and set aside.

Embodiment 2

[0054] Embodiment 2: the polyester of synthesizing basic formula

[0055] Add 10g of 1,1,1,3,3,3,-hexafluorobisphenol A diacetate and 5.7g of 2,2,3,3,4,4,-hexafluoro Glutaric acid, then add 0.03g dibutyltin oxide as a catalyst. Put the pear-shaped bottle on a rotary evaporator and heat it to 200°C with an oil bath to react for 2 hours under a nitrogen atmosphere. The prepolymer was transferred to a test tube and reacted at 240° C. for 24 hours under the conditions of evacuating to 0.2 mmHg and filling with nitrogen. A transparent amber solid was obtained, which was dissolved in tetrahydrofuran and purified by precipitation with methanol to obtain a white powder as the product. After testing, the number average molecular weight of the sample was 9800, the Tg was 110° C., and the refractive index at 1.55 microns was 1.478.

Embodiment 3

[0056] Embodiment 3: synthesis adds terephthalic acid modified polyester on the basis of basic formula

[0057] Add 10g of 1,1,1,3,3,3,-hexafluorobisphenol A diacetate, 4.57g of 2,2,3,3,4,4,-hexafluoro Glutaric acid and 0.8g terephthalic acid, then add 0.03g dibutyltin oxide as a catalyst. Put the pear-shaped bottle on a rotary evaporator and heat it to 200° C. with an oil bath to react for 2 hours under nitrogen atmosphere. After the viscosity of the system increases, vacuumize to 0.1 mmHg and react for 11 hours. The prepolymer was transferred to a test tube and reacted at 240° C. for 24 hours under the conditions of evacuation and nitrogen gas. A transparent amber solid was obtained, which was dissolved in tetrahydrofuran and purified by precipitation with methanol to obtain a white powder as the product. After testing, the number average molecular weight of the sample is 9800, the Tg is 113° C., and the refractive index at 1.55 microns is 1.512. This material can be used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com