Silicon/zinc ion doped biphase calcium phosphate ceramic scaffold and preparation method thereof

A biphasic calcium phosphate and ceramic stent technology, used in medical science, prostheses, coatings, etc., can solve the problem that the effect of promoting bone and promoting vascularization is not as good as that of silicon doping and silicon and zinc co-doping, pore connectivity and The mechanical properties are not as good and the content of silicon-doped hydroxyapatite is low, which can improve the ability of osteogenesis and angiogenesis, adjust the amount of ions easily, and speed up the process of bone repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

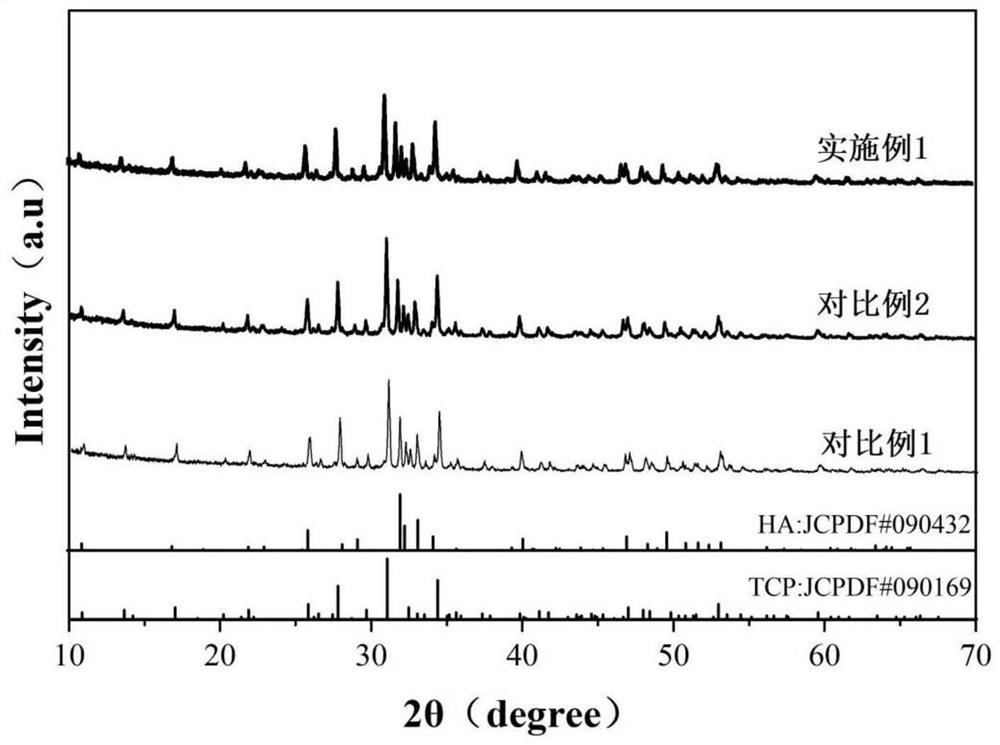

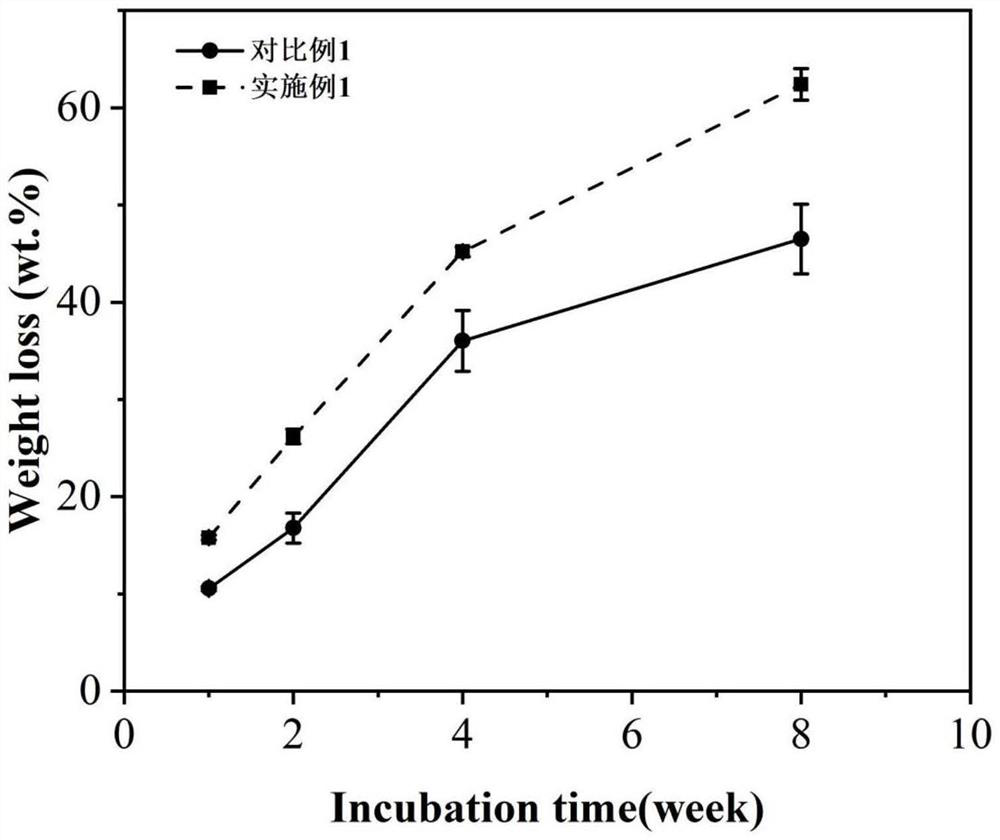

[0071] In this embodiment, hydroxyapatite powder with a silicon doping content of 4 mol.% and β-tricalcium phosphate powder with a zinc doping content of 2.5 mol.% are used as raw materials, and the specific process steps include:

[0072] 1) Synthesize silicon-doped hydroxyapatite powder by chemical precipitation method and hydrothermal method. Deionized water was used to obtain a phosphorus source solution, 2.72 mL of tetraethyl orthosilicate was mixed with an equal amount of anhydrous ethanol, and the phosphorus source solution was added to obtain a phosphorus / silicon mixed solution, and then the phosphorus / silicon mixed solution was added dropwise to the solution. Calcium source solution was obtained to obtain the reaction solution. During the dropping process, the stirring was continued at a speed of 600 r / min. Ammonia water was added to make the pH value of the reaction solution to be 10.5. The hydrothermal treatment was carried out in the autoclave, the hydrothermal tem...

Embodiment 2

[0082] In this embodiment, hydroxyapatite powder with silicon doping content of 4 mol.% and β-tricalcium phosphate powder with zinc doping content of 1.5 mol.% are used as raw materials, and the specific process steps include:

[0083] 1) Synthesize silicon-doped hydroxyapatite powder by chemical precipitation method and hydrothermal method. Deionized water was used to obtain a phosphorus source solution, 2.72 mL of tetraethyl orthosilicate was mixed with an equal amount of anhydrous ethanol, and the phosphorus source solution was added to obtain a phosphorus / silicon mixed solution, and then the phosphorus / silicon mixed solution was added dropwise to the solution. Calcium source solution was obtained to obtain the reaction solution. During the dropping process, the stirring was continued at a speed of 400 r / min. Ammonia water was added to make the pH value of the reaction solution to be 11. After the dropping was completed, the stirring was continued for 60 min (the stirring sp...

Embodiment 3

[0090] In this embodiment, hydroxyapatite powder with silicon doping content of 2 mol.% and β-tricalcium phosphate powder with zinc doping content of 3 mol.% are used as raw materials, and the specific process steps include:

[0091] 1) Synthesize silicon-doped hydroxyapatite powder by chemical precipitation method and hydrothermal method. Deionized water to obtain a phosphorus source solution, mix 1.36 mL of tetraethyl orthosilicate with an equal amount of anhydrous ethanol, add the phosphorus source solution to obtain a phosphorus / silicon mixed solution, and then add the phosphorus / silicon mixed solution dropwise to the solution. Calcium source solution was obtained to obtain the reaction solution. During the dropping process, the stirring was continued at a speed of 500 r / min. Ammonia water was added to make the pH value of the reaction solution to be 10.8. The hydrothermal treatment was carried out in the autoclave, the hydrothermal temperature was 160 °C, and the hydrothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com