Spherical grinding material, preparation method, application and sapphire grinding fluid containing spherical grinding material

A spherical grinding and lapping fluid technology, applied in polishing compositions containing abrasives, chemical instruments and methods, other chemical processes, etc., can solve the problem of increasing the contact area between the diamond cutting acute angle and the sapphire wafer, the poor lapping effect of the lapping fluid, Problems such as low wafer roughness value, to achieve the effect of increasing the grinding rate, increasing the contact time, and increasing the grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0134] Embodiment 1-12 discloses a variety of sapphire lapping liquids, and its components and weight ratios are shown in Table 1:

[0135] Component and weight ratio of table 1 embodiment 1-12 sapphire grinding liquid

[0136]

[0137]

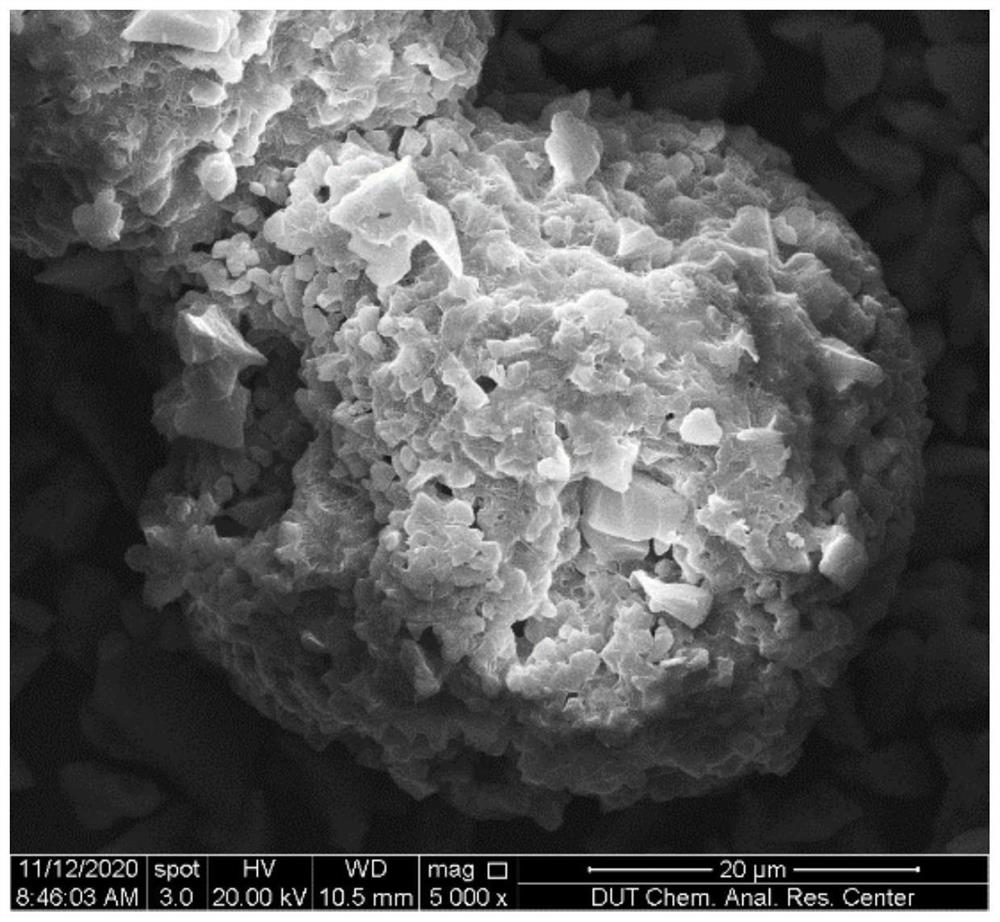

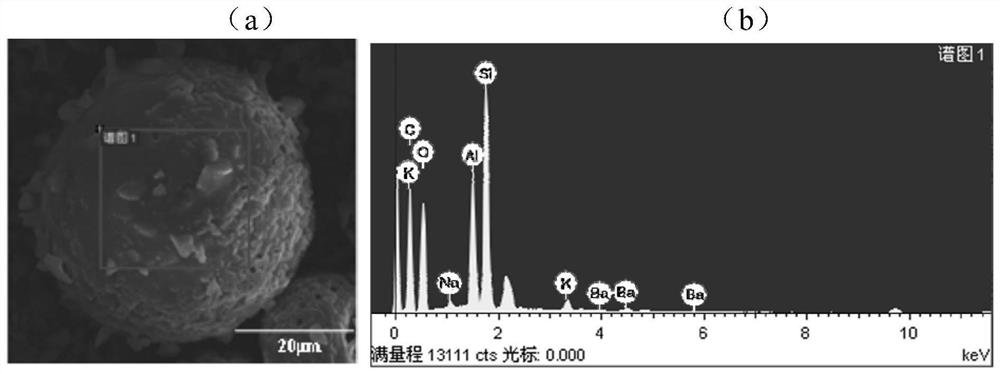

[0138] The spherical abrasive used in Examples 1-12 is prepared by the following preparation method:

[0139] 1) at first weigh three kinds of abrasives by table 2: alumina powder: silicon oxide powder: diamond micropowder, three kinds of abrasives add up to 1kg, add in the stirring kettle, add 1kg ethanol, stir 10min to make uniform slurry;

[0140] 2) in every 1kg slurry, add successively PVB, polyethylene glycol 400, polymethyl acrylate and dodecyl hydroxypropyl sulfobetaine described in table 2, stir 30min under 80rpm rotating speed to prepare mixed slurry;

[0141] 3) The mixed slurry obtained in step 2) was added to the planetary ball mill, the ball milling speed was set to 300rpm, the grinding ball and the ball mill tank were bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com