Bi-component epoxy resin adhesive and preparation method thereof

A technology of epoxy resin glue and epoxy resin, which is applied in the direction of epoxy resin glue, adhesives, adhesive additives, etc., can solve the problems of poor comprehensive performance, change of fluidity, poor sealing performance, etc., and achieve stable fluidity, The effect of excellent bonding performance and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

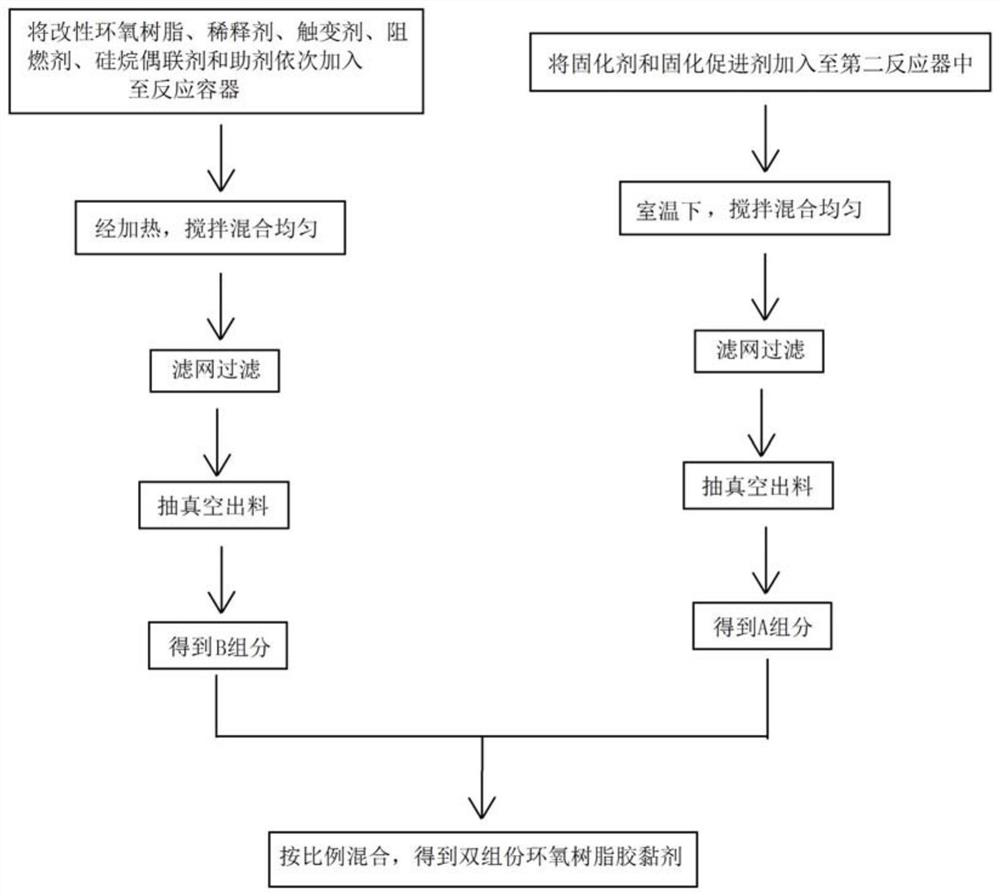

Method used

Image

Examples

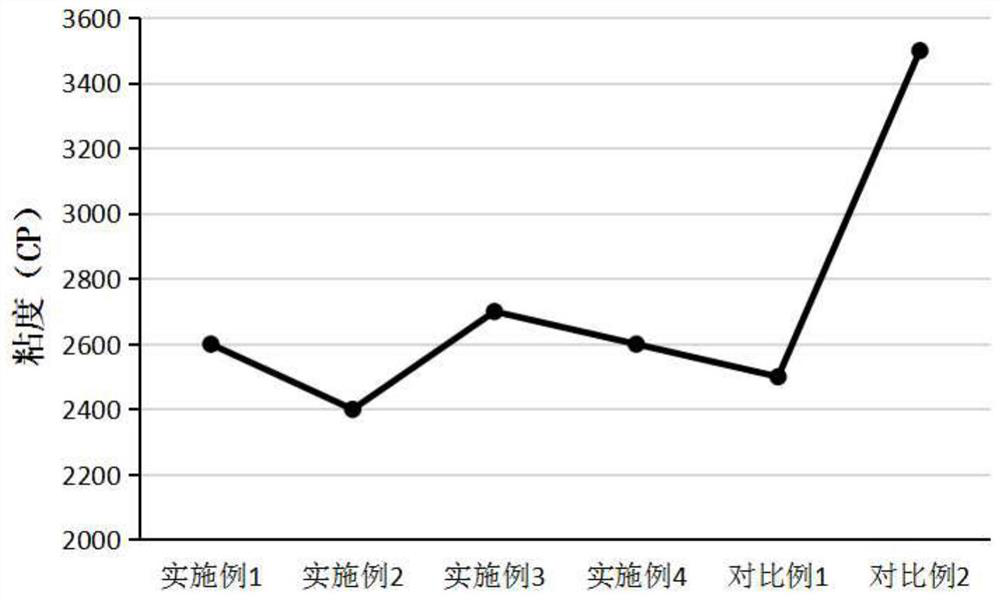

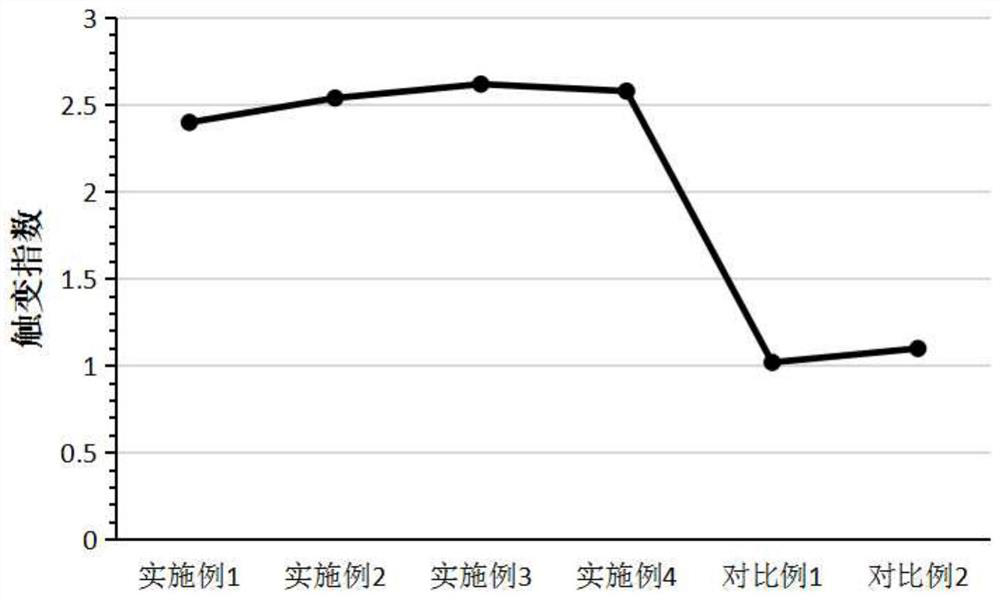

Embodiment 1

[0041] A two-component epoxy resin adhesive is prepared by mixing A component and B component with a volume ratio of 1:1.2;

[0042] Component A includes the following raw materials in parts by weight: 92 parts of modified epoxy resin, 3 parts of diluent (trimethylolpropane triglycidyl ether), thixotropic agent (weight ratio of 1:0.5 particle size of 2- 8μm fumed silica and nanoscale calcium carbonate) 6 parts, flame retardant (melamine) 3 parts, silane coupling agent (methyltrimethoxysilane) 5 parts, dispersing agent (sodium lauryl sulfate) 1 parts, 1 part of defoamer (polyoxyethylene polyoxypropanolamine ether), 1 part of UV light absorber (10nm titanium dioxide);

[0043] Component B includes the following raw materials by weight: 86 parts of curing agent (phthalic anhydride), 3 parts of curing accelerator (triethanolamine);

[0044] The preparation process of the modified epoxy resin is as follows: the hydrogenated bisphenol A epoxy resin and the hydroxyl-terminated polyb...

Embodiment 2

[0050] A two-component epoxy resin adhesive is prepared by mixing A component and B component with a volume ratio of 1:0.6;

[0051] Component A includes the following raw materials by weight: 80 parts of modified epoxy resin, 9 parts of diluent (dodecyl glycidyl ether), thixotropic agent (weight ratio of 1:0.4, particle size of 2-8μm Fumed silica and nanoscale calcium carbonate) 8 parts, flame retardant (melamine) 5 parts, silane coupling agent (methyltrimethoxysilane) 3 parts, dispersing agent (sodium dodecyl sulfate) 0.2 parts, 0.3 part of defoamer (polyoxyethylene polyoxypropanolamine ether), 0.5 part of UV light absorber (10nm titanium dioxide);

[0052] Component B includes the following raw materials by weight: 80 parts of curing agent (maleic anhydride) and 1 part of curing accelerator (triethanolamine);

[0053] The preparation process of the modified epoxy resin is as follows: the hydrogenated bisphenol A epoxy resin and the hydroxyl-terminated polybutadiene (number...

Embodiment 3

[0059] A two-component epoxy resin adhesive is prepared by mixing A component and B component with a volume ratio of 1:1.5;

[0060] Component A includes the following raw materials in parts by weight: 96 parts of modified epoxy resin, 20 parts of diluent (tetradecyl glycidyl ether), thixotropic agent (weight ratio of 1:0.8, particle size of 2-8 μm) Fumed silica and nanoscale calcium carbonate) 10 parts, flame retardant (melamine uric acid) 10 parts, silane coupling agent (methyltrimethoxysilane) 12 parts, dispersing agent (sodium lauryl sulfate) 1 part , 3 parts of defoamer (polyoxyethylene polyoxypropanolamine ether), 6 parts of UV light absorber (10nm titanium dioxide);

[0061] Component B includes the following raw materials by weight: 93 parts of curing agent (maleic anhydride), 5 parts of curing accelerator (benzyl alcohol);

[0062] The preparation process of the modified epoxy resin is as follows: the hydrogenated bisphenol A epoxy resin and the hydroxyl-terminated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com