Preparation method and application of high-purity rhenium standard sample for GD-MS component analysis

A GD-MS, standard sample technology, used in the preparation of test samples, analysis of materials, and testing of metal components, etc., to achieve the effect of long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the high-purity rhenium standard sample for GD-MS component analysis of the present invention, the obtained high-purity rhenium sample can be used for trace element analysis, comprising the following steps:

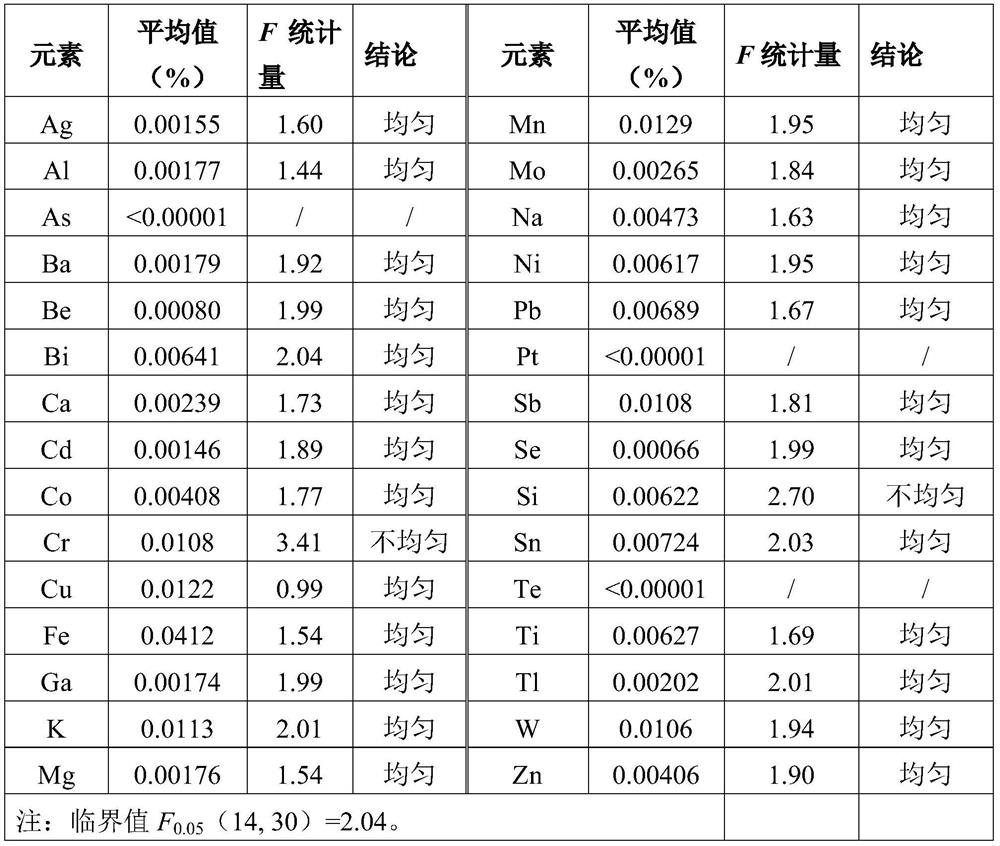

[0034] (1) High-purity rhenium standard sample composition design: design pure rhenium sample composition according to pure rhenium product standards, high-purity rhenium standard samples include Ag, Al, As, Ba, Be, Bi, Ca, Cd, Co, Cr, Cu , Fe, Ga, K, Mg, Mn, Mo, Na, Ni, Pb, Pt, Sb, Se, Si, Sn, Te, Ti, Tl, W, Zn a total of 30 trace impurity elements, each impurity element The content of 0.1mg / kg~500mg / kg;

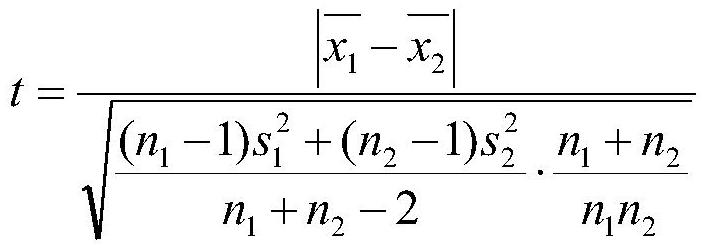

[0035] Ammonium rhenate with a purity of 99.95% is used as the raw material, and superior pure silver nitrate, aluminum nitrate, sodium arsenate, barium nitrate, beryllium carbonate, bismuth nitrate, calcium carbonate, cadmium nitrate, cobalt nitrate, nitric acid are quantitatively added to it according to the design value Chromium, co...

Embodiment

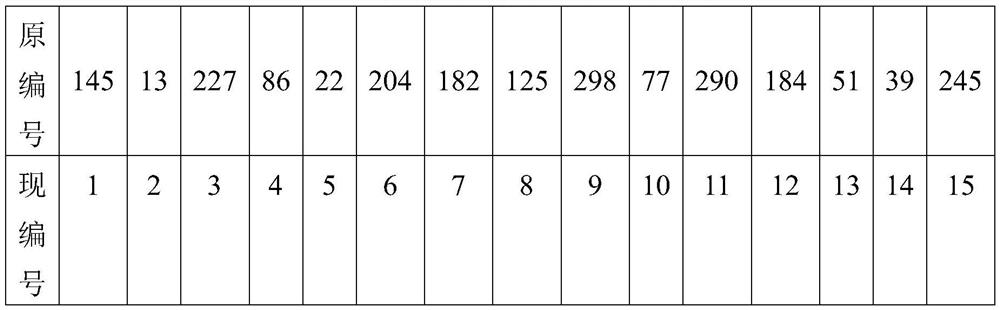

[0049] 1. Weigh 25kg of ammonium rhenate (purity>99.95%); 0.2g each of beryllium carbonate and thallium nitrate; 0.5g each of silver nitrate, barium nitrate, cadmium nitrate, gallium nitrate, and chloroplatinic acid; Magnesium, sodium arsenate, ammonium molybdate, sodium selenate, sodium telluride each 1g; bismuth nitrate, cobalt nitrate, nickel nitrate, lead nitrate, titanium powder, zinc chloride each 2g; chromium nitrate, copper nitrate, potassium nitrate, Manganese nitrate, antimony trioxide, sodium silicate, tin tetrachloride, ammonium paratungstate each 3g; ferrous sulfate 10g.

[0050] 2. Dissolve and mix the samples in step 1 with high-purity water, MOS-grade hydrochloric acid or nitric acid, place them in a vertical heating mixer for evaporation and crystallization for 24 hours, and then place them in a tubular reduction furnace for hydrogen reduction at 950°C for 6 hours. The hydrogen flow rate is 20L / h, and the rhenium powder standard sample candidate material is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com