Air passage and its control method

A control method and air duct technology, applied in the direction of electrical program control, electric temperature control, power supply test, etc., can solve the problems of high price, inconvenient movement, consuming test resources, etc., and achieve low manufacturing cost and mobile equipment Convenient, accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below according to the drawings and specific embodiments.

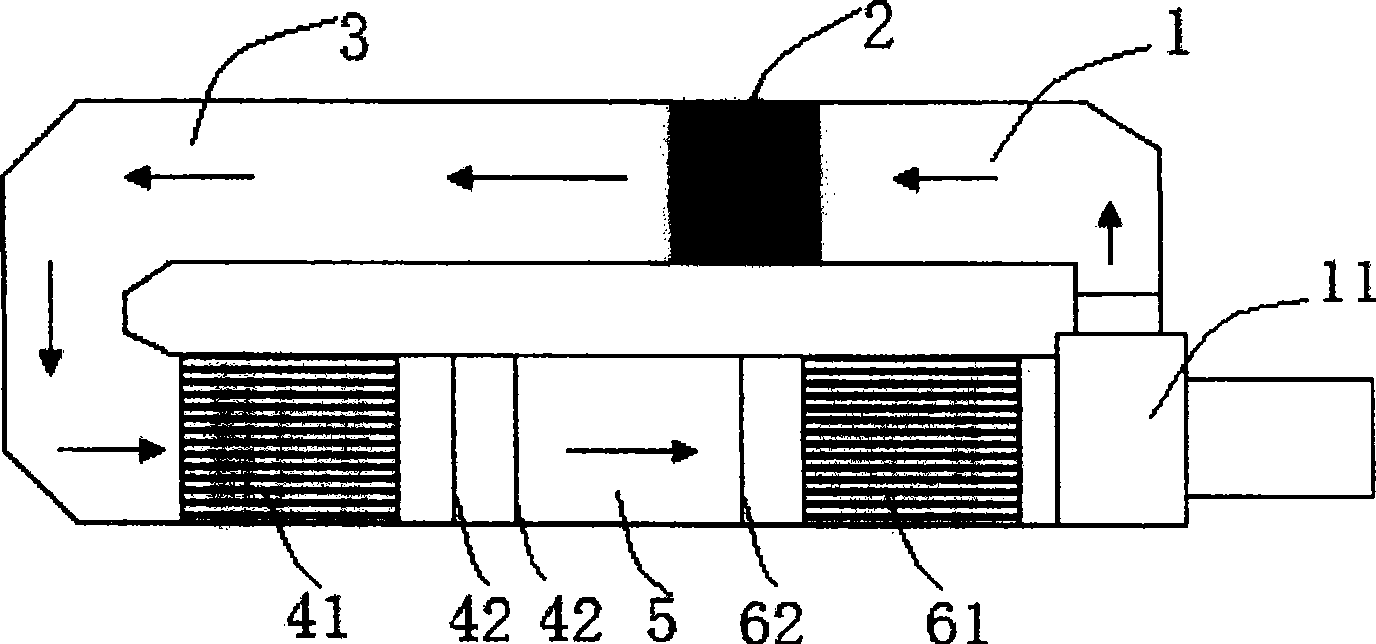

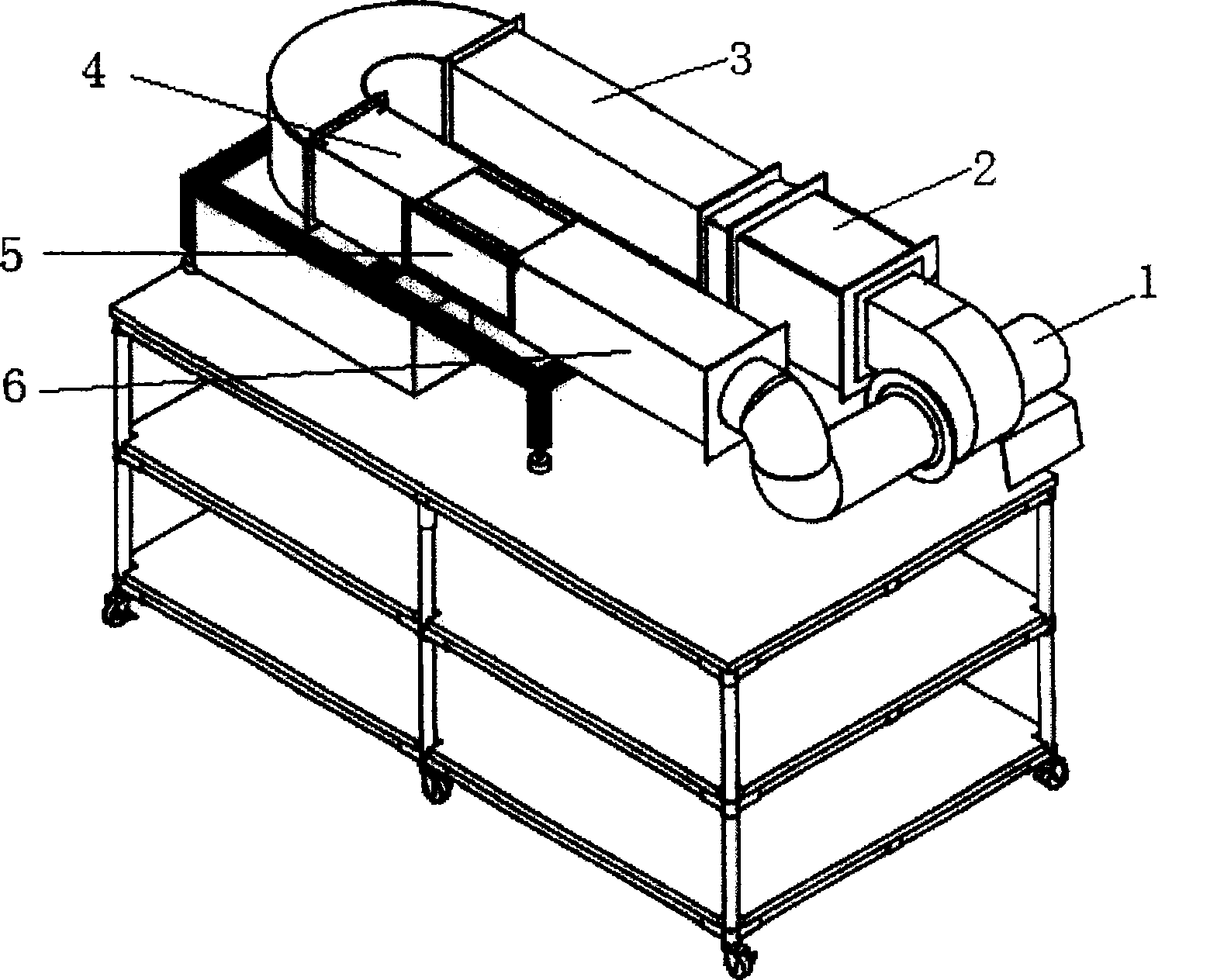

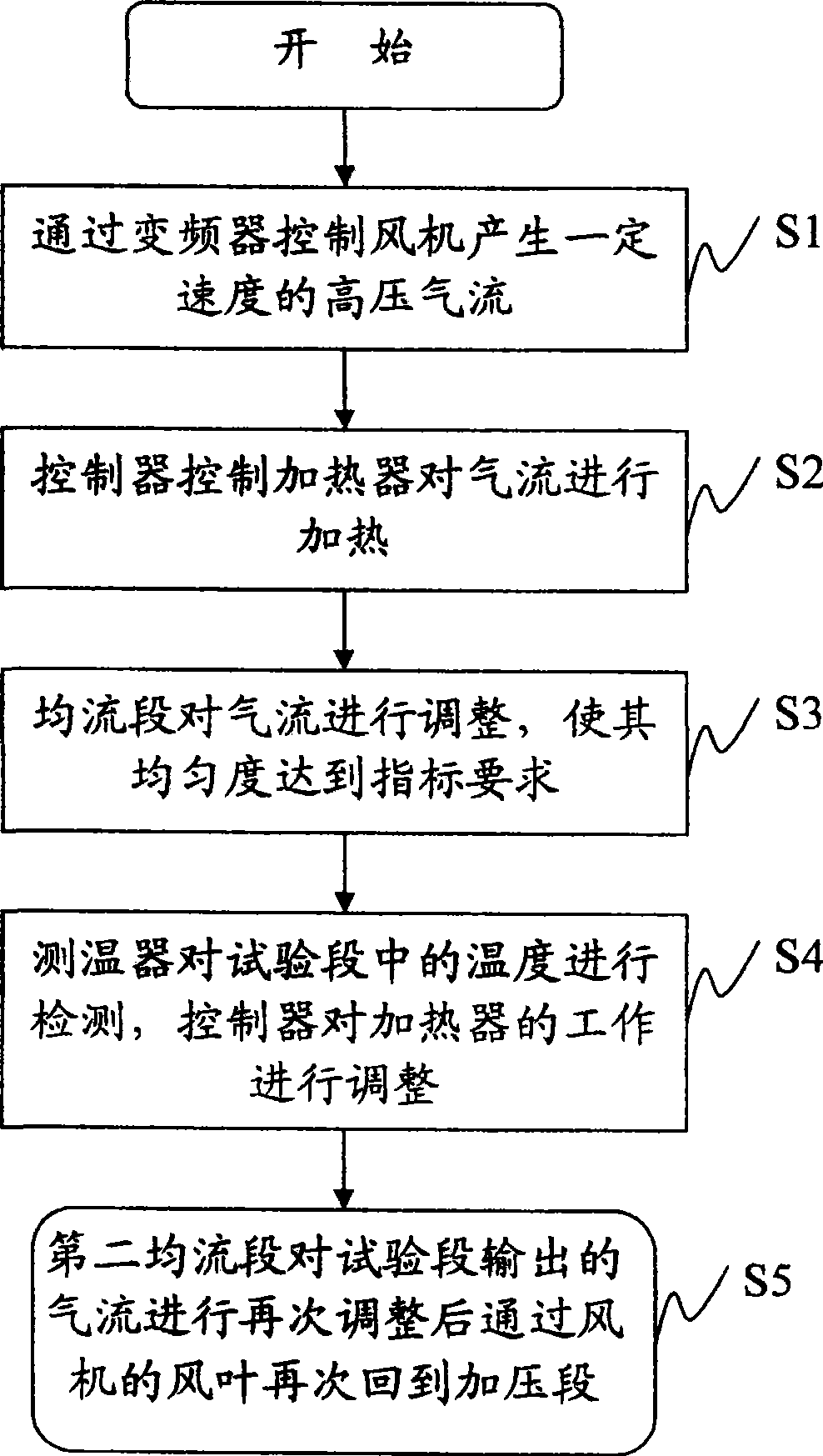

[0023] Such as figure 1 , figure 2 As shown, an air duct of the present invention is a closed-loop air duct, and the air duct part is mainly divided into a pressurization section 1, a heating section 2, a return air section 3, a flow equalization section 4 and a test section 5, and its control Part includes frequency converter (not marked in the figure) and controller (not marked in the figure).

[0024] Wherein, the pressurization section 1 adopts a centrifugal fan 11, the input end of the blade of the centrifugal fan 11 is connected with the output end of the test section 5, and the output end of the fan 11 outputs a high-pressure airflow with a certain wind speed to the heating section 2. The motor of the centrifugal fan 11 is arranged outside the air duct and connected with the frequency converter. Therefore, the speed of the fan 11 can be controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com