A device and method for testing the adhesion between fiber and asphalt

A technology for testing devices and testing methods, applied in measuring devices, adopting mechanical devices, instruments, etc., can solve problems such as shortages, and achieve the effects of simple operation, convenient manufacture and operation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

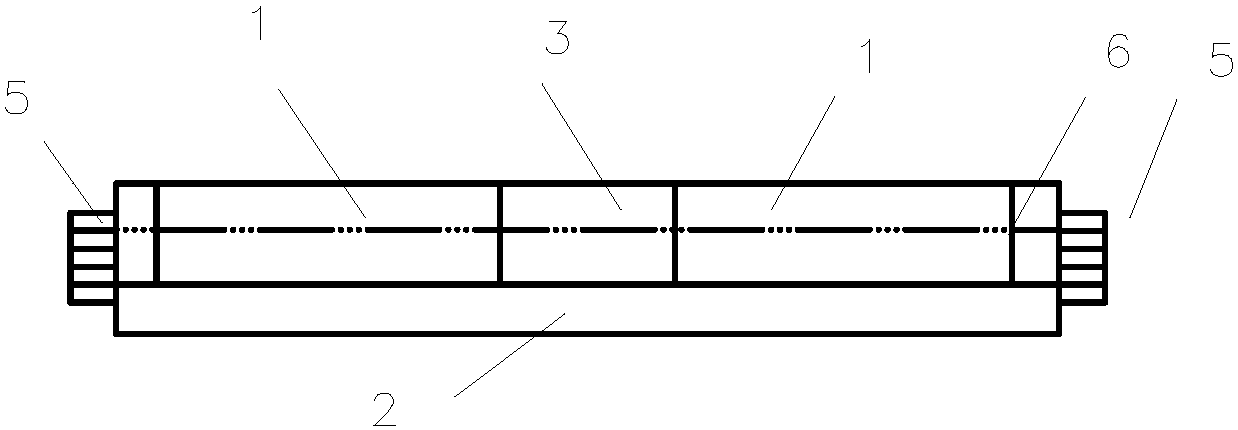

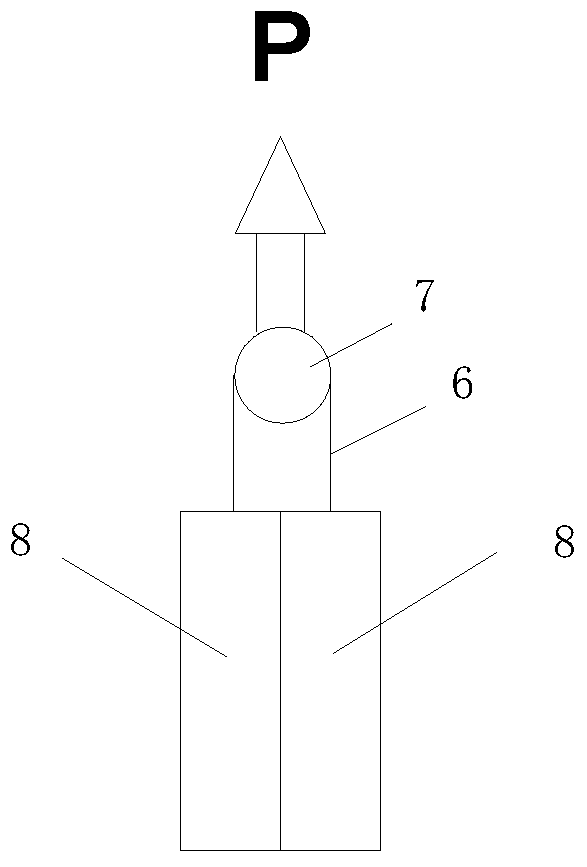

[0029] The fibrous asphalt adhesion performance testing device adopted in the present embodiment 1 comprises asphalt pouring groove 1, test form bottom plate 2, metal clip 3, fiber caulking 4 and bolt 5 (see figure 1 ), two pitch filling grooves 1 with a length of 6 cm are an axisymmetric octagonal notch container member with a bottom plate and an open side wall, and form a closed groove with the metal clamp block 3 at the end of the open side wall. The side wall of the opening is located on the vertical plane of the centerline of the axis of the container member. The width of the asphalt filling groove 1 is narrowed at the end of the opening side wall. On both sides of the metal clamp block 3, the total length of the three is about 19cm. The fiber caulking 4 is the groove at the intersection of the three and the axis centerline of the test device, and its depth is half the height of the asphalt pouring groove 1 (see Figure 4 ) with a width of 3mm. The fiber caulking 4 runs...

Embodiment 2

[0037] The fibrous asphalt adhesion performance testing device adopted in the present embodiment 2 comprises asphalt pouring groove 1, test mold bottom plate 2, metal clip 3, fiber caulking 4 and bolt 5 (see Figure 5 ). The asphalt pouring groove 1 is an axisymmetric octagonal notch container member with a bottom plate and an open side wall with a length of 6 cm, and forms a closed groove with the metal clamp block 3 positioned at the end of the open side wall, and the open side wall Located on the vertical plane of the center line of the container member axis, the width of the asphalt pouring groove 1 is narrowed at the end of its opening side wall, the asphalt pouring groove 1 is detachably placed on the bottom plate 2 of the trial mold, and the fiber caulking 4 is the asphalt pouring groove 1 The groove of the side wall and the metal clamp block 3 at the intersection with the center line of the shaft, its depth is half of the height of the asphalt pouring groove 1 (see F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com