High-thermal-conductivity unfired alumina-carbon sliding plate brick and preparation method thereof

A sliding brick and high thermal conductivity technology, which is applied in the field of refractory materials for steelmaking, can solve the problems of reducing the internal bonding strength of materials, oxidized roughening, and poor thermal shock performance, so as to improve thermal conductivity and thermal shock performance, and improve heat resistance Impact performance and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

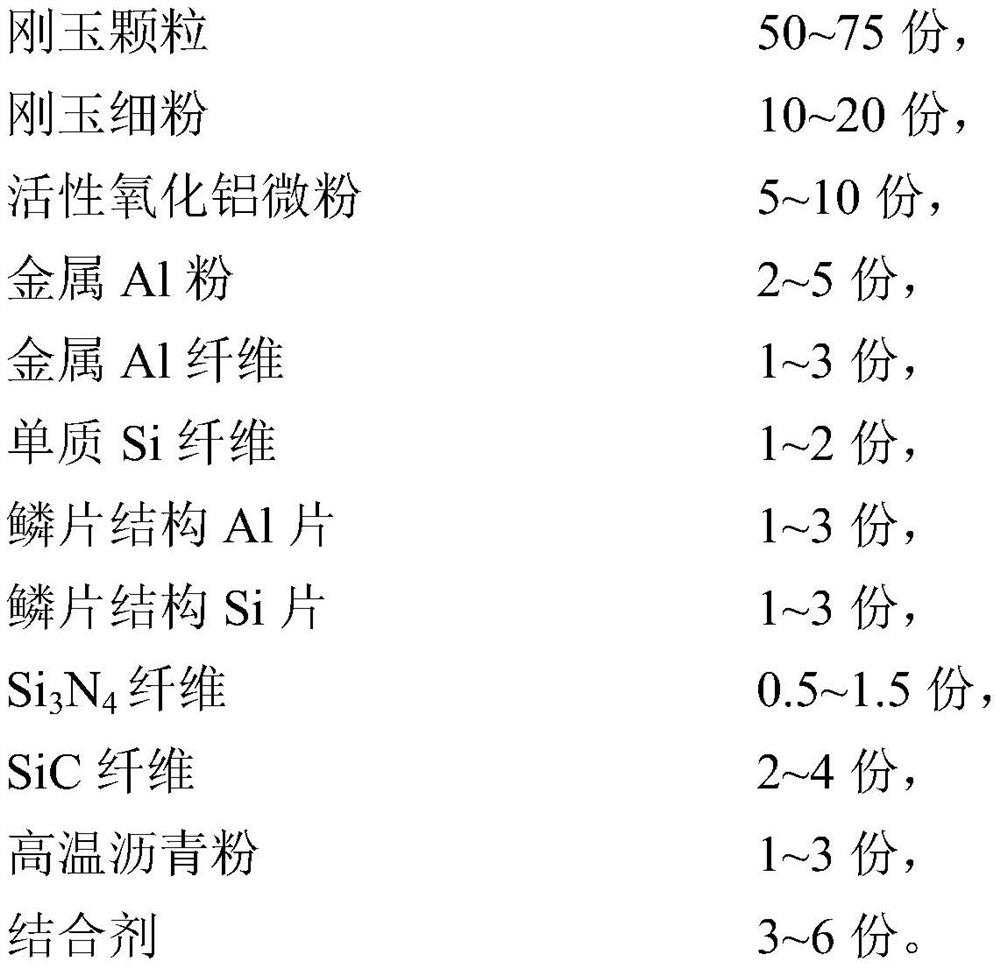

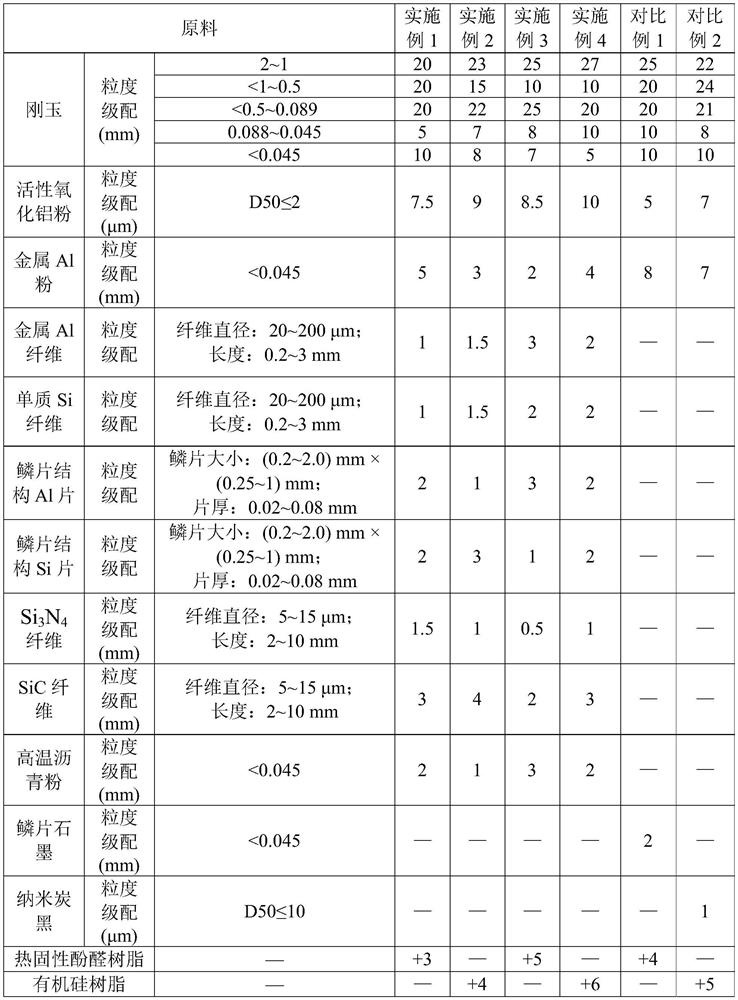

[0044] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

[0045] Each embodiment, the used part raw material description of comparative example are as follows:

[0046] The corundum is fused white corundum or sintered tabular corundum, Al 2 o 3 ≥99.0wt%;

[0047] Al in activated alumina micropowder 2 o 3 >99.0wt%;

[0048] Al>97.0wt% in metal Al powder;

[0049] Al>97.0wt% in metal Al fiber;

[0050] Si>97.0wt% in Si fiber;

[0051] Al>97.0wt% in the scale structure Al sheet;

[0052] Si>97.0wt% in Si flakes with scale structure;

[0053] Si 3 N 4 Si in fiber 3 N 4 >97.0wt%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com