Preparation method for in-situ generation of (Ti, W) C reinforced WC-Ni3Al composite material by adding Ti powder

An in-situ generation, composite material technology, applied in the field of alloy materials, can solve the problems of easy softening, restricting the application of WC-Co cemented carbide, and WC-based cemented carbide, etc., and achieve the improvement of hardness and fracture toughness. Antioxidative properties, effects of excellent antioxidative properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

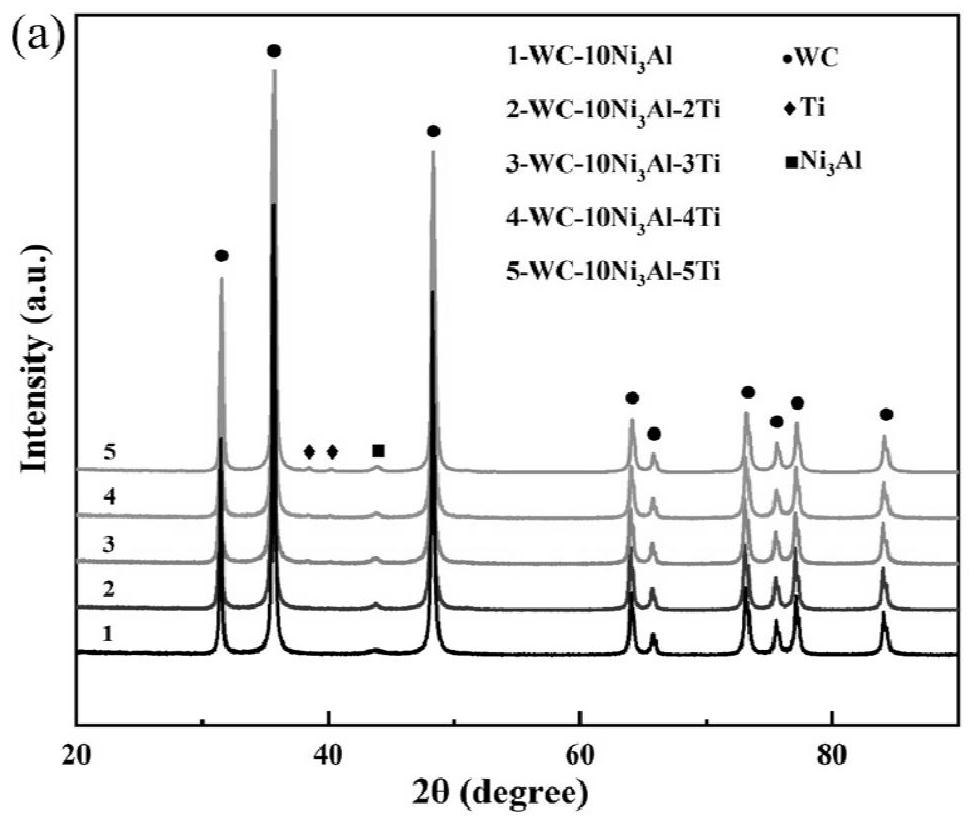

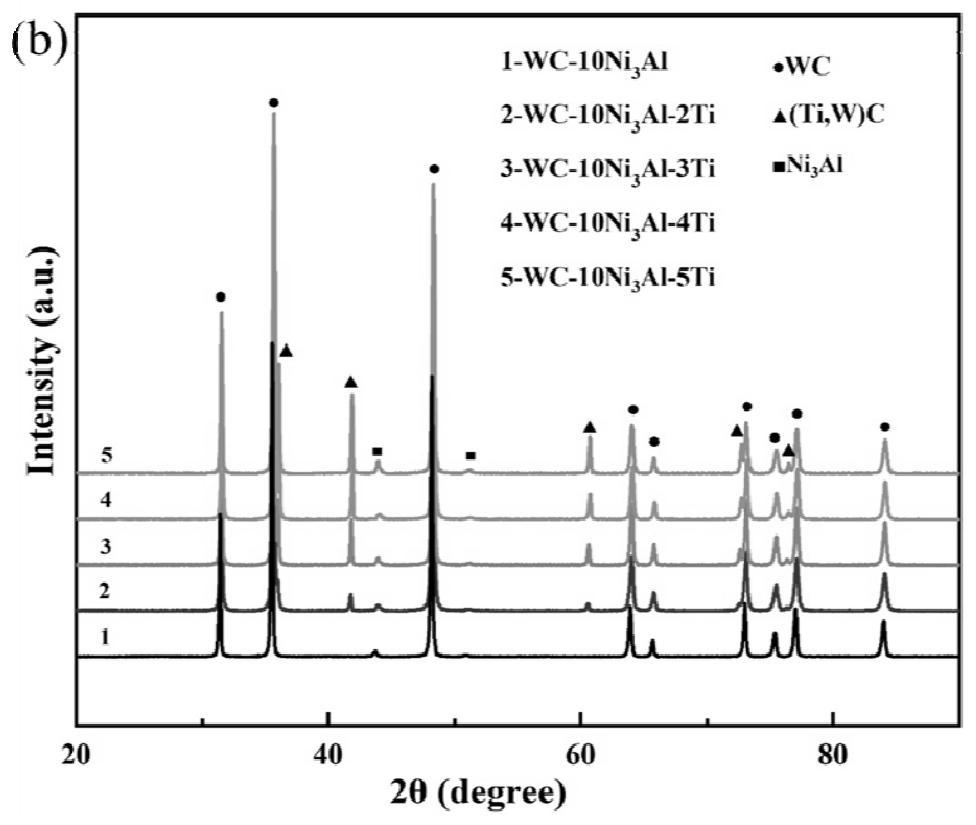

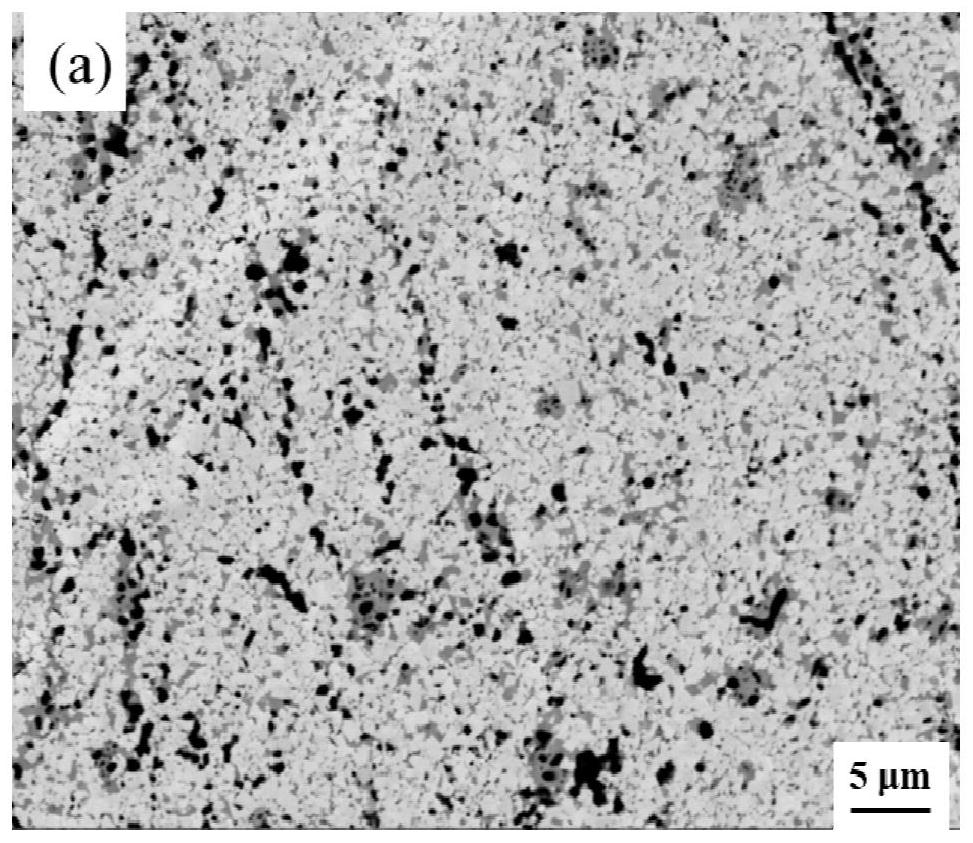

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of Ni by mechanical alloying 3 Al powder: Raw material powder ingredients according to the following mass percentage: Ni80%, Al10.70%, Cr7.85%, Mo 1.44%, B 0.01%, wherein Ni, Al, Cr, Mo powder purity ≥ 99.9%, particle size 1~ 3μm, B powder purity ≥ 99.1%, is amorphous high-purity boron powder; put the above raw material powder in a planetary ball mill for high-energy ball milling, the ball milling material is WC carbide, the ball-to-material ratio is 10:1, and the speed is 226r / min, and using high-purity Ar gas as a protective atmosphere, ball milling for 30 hours to produce Ni with a particle size of ≤250μm 3 Al intermetallic compound powder;

[0036] (2) Ni 3 Pour 10wt.% of Al intermetallic compound powder and 90wt.% of WC powder (0.8μm, purity ≥99.9%, Jinlu Special Alloy Co., Ltd.) into a 250ml hard alloy tank, and then add cyclohexane as a solvent to obtain a mixed slurry ;Place the ball mill tank with the mixed slurry in a planetary ball mill for...

Embodiment 2

[0040] Step (1) is with embodiment 1;

[0041] (2) Ni 3Al intermetallic compound powder 10wt.%, Ti powder (10μm, purity ≥99.9%, Zhongnuo New Material (Beijing) Technology Co., Ltd.) 2wt.% and WC powder (0.8μm, purity ≥99.9%, Jinlu Special Alloy Co., Ltd. 88wt.% of the company) is poured into a 250ml cemented carbide tank, and cyclohexane is added as a solvent to obtain a mixed slurry; The material is WC-Co cemented carbide, the ratio of ball to material is 5:1, and the mixed slurry is prepared by ball milling for 24 hours at a speed of 180r / min, and then the above mixed slurry is dried in a drying furnace until the solvent Residue ≤ 1%, crushed and sieved to obtain mixed powder with particle size ≤ 250 μm;

[0042] (3) Weigh 28g of the mixed powder obtained in step (2) and put it into a graphite sintering mold with a diameter of φ20mm for one-step discharge plasma sintering. The sintering current type is DC pulse current, wherein the sintering pressure is 30MPa, and the sint...

Embodiment 3

[0045] Step (1) is with embodiment 1;

[0046] (2) Ni 3 Al intermetallic compound powder 10wt.%, Ti powder (10μm, purity ≥99.9%, Zhongnuo New Material (Beijing) Technology Co., Ltd.) 3wt.% and WC powder (0.8μm, purity ≥99.9%, Jinlu Special Alloy Co., Ltd. Company) 87wt.% is poured in the 250ml cemented carbide jar, then adds cyclohexane to obtain mixed slurry as solvent; The ball mill jar that mixed slurry is housed is placed in planetary ball mill and carries out low-energy ball milling, ball mill jar and ball mill The material is WC-Co cemented carbide, the ratio of ball to material is 5:1, and the mixed slurry is prepared by ball milling for 24 hours at a speed of 180r / min, and then the above mixed slurry is dried in a drying furnace until the solvent Residue ≤ 1%, crushed and sieved to obtain mixed powder with particle size ≤ 250 μm;

[0047] (3) Weigh 28g of the mixed powder obtained in step (2) and put it into a graphite sintering mold with a diameter of φ20mm for one-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com