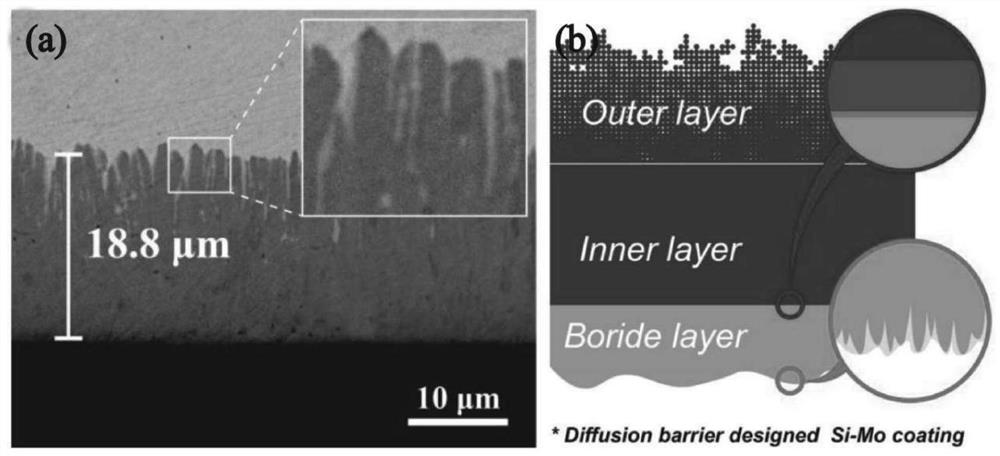

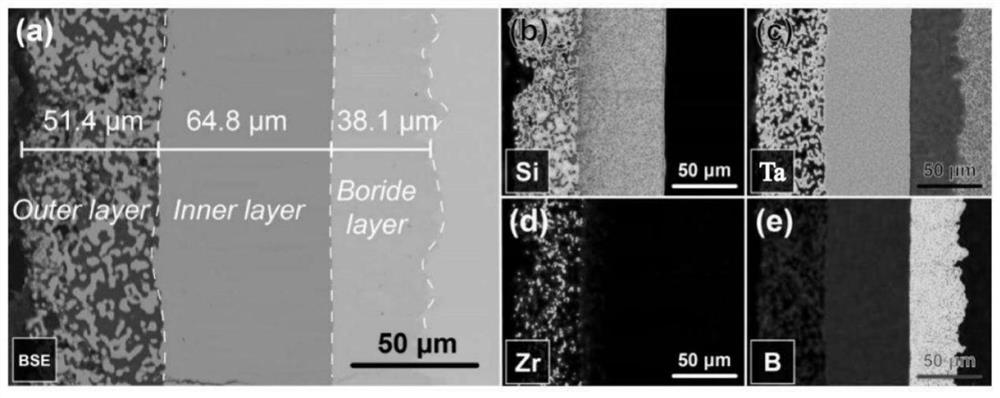

Novel tantalum-based Si-Mo-ZrB2 composite coating containing TaB diffusion barrier layer and three-step preparation method of novel tantalum-based Si-Mo-ZrB2 composite coating

A si-mo-zrb2, composite coating technology, applied in the field of high temperature anti-oxidation coating preparation, can solve the problems of mutual diffusion, the decline of anti-oxidation performance, etc., achieve low evaporation rate, good high-temperature anti-oxidation performance, prolonged high temperature use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

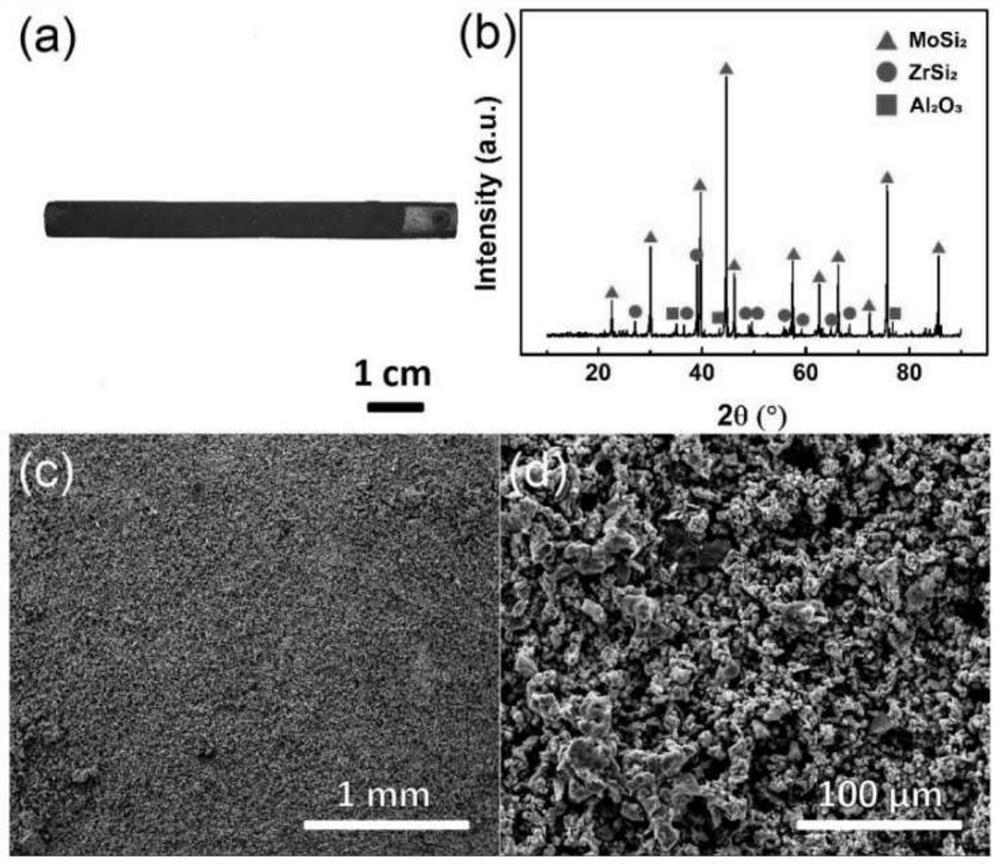

Embodiment 1

[0083] (1) Substrate pretreatment: select tantalum alloy as the substrate, the size is 2mm × 6mm × 80mm, sand the surface until there are no obvious sharp protrusions and wire cutting marks, and grind away the trace oxidized skin, wash with water after sandblasting , pickling, and alkali cleaning, clean them with alcohol ultrasonic waves, and put them in a drying oven for drying.

[0084] (2) Boronizing powder preparation: according to 95% Al 2 o 3 Powder, 4% NH 4 The mass fractions of F powder and 1% B powder are proportioned, the average particle sizes of the three are 3 μm, 1 μm and 1 μm respectively, and the purity of the three powders is not less than 99%. Put the prepared boronizing powder into the ball mill tank, the ball to material ratio is 2.5:1, the speed is 100r / min, and the ball milling time is 10h.

[0085] (3) Preparation of boride body: disperse and embed tantalum alloy with dry and clean surface in a corundum crucible filled with boronizing powder, compact ...

Embodiment 2

[0090] (1) Substrate pretreatment: select tantalum alloy as the substrate, the size is 2mm × 6mm × 80mm, sand the surface until there are no obvious sharp protrusions and wire cutting marks, and grind away the trace oxidized skin, wash with water after sandblasting , pickling, and alkali cleaning, clean them with alcohol ultrasonic waves, and put them in a drying oven for drying.

[0091] (2) Boronizing powder preparation: according to 94% Al 2 o 3 Powder, 4% NH 4 The mass fractions of Cl powder and 2% B powder are proportioned, and the average particle sizes of the three are 3 μm, 1 μm and 1 μm respectively, and the purity of the three powders is not less than 99%. Put the prepared boronizing powder into the ball mill tank, the ball to material ratio is 3:1, the speed is 100r / min, and the ball milling time is 10h.

[0092] (3) Preparation of boride body: disperse and embed tantalum alloy with dry and clean surface in a corundum crucible filled with boronizing powder, compa...

Embodiment 3

[0097] (1) Substrate pretreatment: select tantalum alloy as the substrate, the size is 2mm×7mm×70mm, sand the surface until there are no obvious sharp protrusions and wire cutting traces, and grind off trace oxidized skin, wash with water after sandblasting , pickling, and alkali cleaning, clean them with alcohol ultrasonic waves, and put them in a drying oven for drying.

[0098] (2) Boronizing powder preparation: according to 93% Al 2 o 3 Powder, 4% NH 4 The mass fractions of Cl powder and 3% B powder are proportioned, the average particle diameters of the three are 4 μm, 2 μm and 2 μm respectively, and the purity of the three powders is not less than 99%. Put the prepared boronizing powder into the ball mill tank, the ball to material ratio is 4:1, the rotation speed is 120r / min, and the ball milling time is 10h.

[0099] (3) Preparation of boride body: disperse and embed tantalum alloy with dry and clean surface in a corundum crucible filled with boronizing powder, comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com