Porous silicon/carbon composite material synthesized in situ by taking porous polymer microspheres as template, preparation method and lithium ion battery

A porous polymer, in-situ synthesis technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve problems such as unfavorable industrial production, unfavorable long-term circulation, complex preparation procedures, and achieve a safe and controllable reduction process. , the effect of shortening the diffusion path and improving the cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

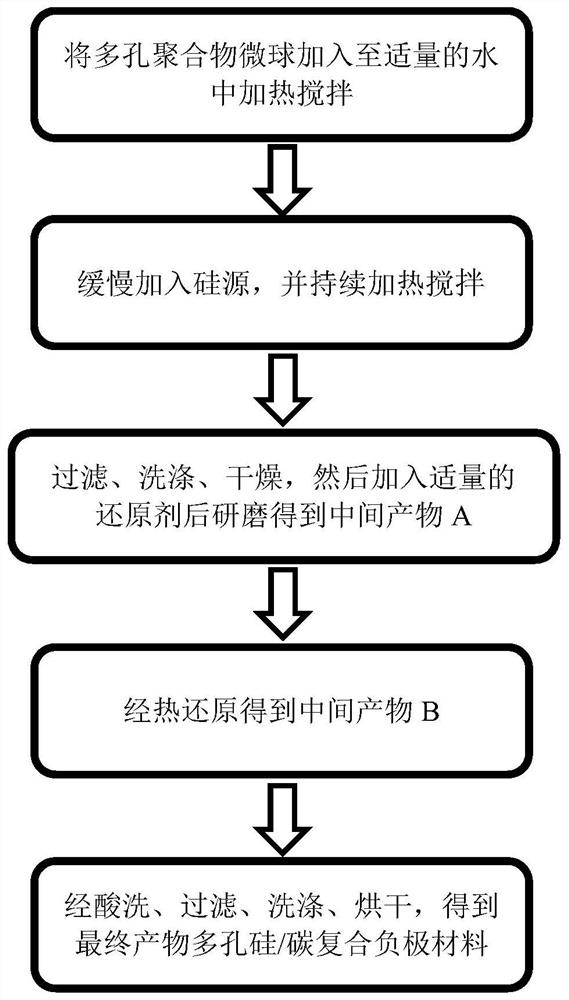

[0044] see figure 1 , take 50g of porous polystyrene microspheres with a particle size D50 of 500nm and a pore size of about 20nm, add an appropriate amount of water, heat to 40°C, and stir at 200r / min for 20min to disperse evenly; then slowly add to the obtained suspension solution Add 50g of ethyl silicate, and continue to stir at 200r / min at 40°C for 20min; then filter the mixed solution, wash with deionized water, and dry at 50°C for 1h, then add 250g of aluminum powder with a particle size of 3μm As a reducing agent, milling and mixing yielded Intermediate A.

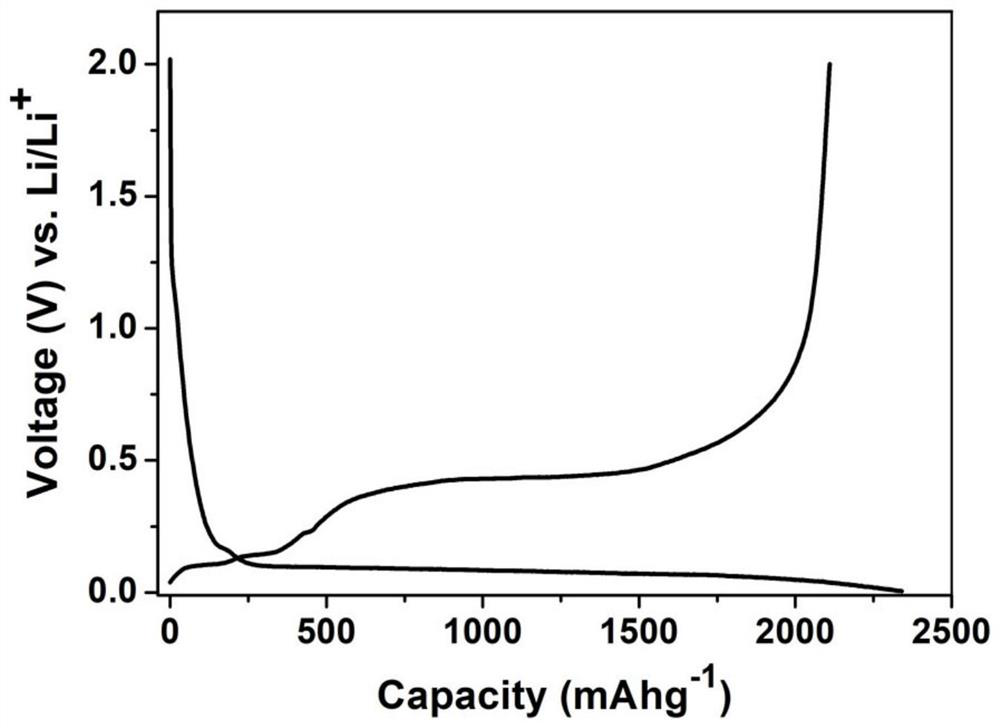

[0045] The temperature was raised to 800° C. at 2° C. / min, and kept for 1 h under vacuum atmosphere, and the intermediate product A was reduced to obtain the intermediate product B. Put the intermediate product B into 2.0mol / L hydrochloric acid for pickling for 0.5h, wash with deionized water, filter, and dry at 50°C for 1h to obtain a porous silicon / carbon composite material, see figure 2 .

[0046] The obtain...

Embodiment 2

[0048] Take 50g of porous polyvinyl chloride microspheres with a particle size D50 of 5μm and a pore size of about 70nm, add an appropriate amount of water, heat to 50°C, and stir at 500r / min for 30min to disperse evenly; then slowly add 600g of methyl silicate and 400g of sodium silicate, and continuously stirred at 50°C at 500r / min for 40min; then the mixed solution was filtered, washed with deionized water, and dried at 70°C for 2h, and then added 3000g of 5 μm aluminum powder was used as a reducing agent, and the intermediate product A was obtained by grinding and mixing.

[0049] The temperature was raised to 900°C at 5°C / min, and kept for 2h under an argon atmosphere, and the intermediate product A was reduced to obtain the intermediate product B. Put the intermediate product B into 3.0 mol / L sulfuric acid for pickling for 1 h, wash with deionized water, filter, and dry at 80° C. for 2 h to obtain a porous silicon / carbon composite material.

[0050] The obtained porous ...

Embodiment 3

[0052] Take 20g of porous polyethylene microspheres with a particle size D50 of 15μm and a pore size of about 90nm and 30g of porous polyurethane microspheres with a particle size of D50 of 15μm and a pore size of about 70nm. to disperse evenly; then slowly add 700g of methoxysilane and 800g of ethoxysilane to the resulting suspension solution, and continue stirring at 600r / min for 40min at 55°C; then the mixed solution is filtered, Wash with deionized water, dry at 80°C for 1.5 h, then add 650 g of aluminum powder with a particle size of 8 μm and 850 g of titanium hydride powder with a particle size of 10 μm as reducing agents, grind and mix to obtain intermediate product A.

[0053] The temperature was raised to 950°C at 10°C / min, and kept for 4h under a nitrogen atmosphere, and the intermediate product A was reduced to obtain the intermediate product B. The intermediate product B was put into 3.0 mol / L sulfuric acid for pickling for 2 hours, washed with deionized water, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com