Method for selectively recycling lithium in waste lithium iron phosphate battery

A lithium iron phosphate battery and lithium iron phosphate technology, applied in battery recycling, waste collector recycling, secondary batteries, etc., can solve problems such as extensive operating conditions, equipment corrosion, and complicated processing procedures, and achieve easy control of reaction conditions, The effect of mild operating conditions and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

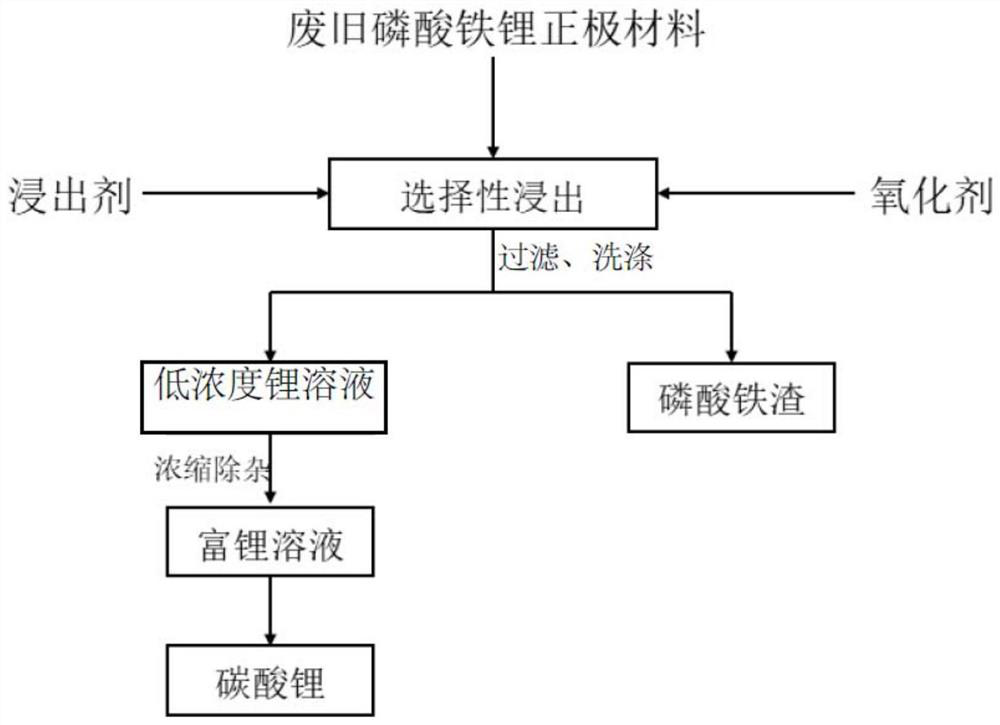

[0034] As mentioned above, in the existing selective leaching process of lithium from waste lithium iron phosphate, there are disadvantages such as a large amount of chemicals used, extensive operating conditions, inorganic salts generated during the leaching process, and complicated treatment procedures. In order to solve these problems, the inventors have conducted a lot of research on the selective recovery technology of lithium in waste lithium iron phosphate batteries.

[0035] The inventors found that in an acidic environment, in an oxidizing gas environment, the Fe 2+ in situ oxidation to Fe 3+ , with FePO 4 The form of lithium remains in the leaching residue, and the lithium is dissolved into the solution by the acidic solution without any inorganic salt by-products during the process. The present invention was thus obtained.

[0036] Therefore, the present invention provides a method for selectively recovering lithium from waste lithium iron phosphate batteries, wh...

Embodiment 1

[0081] Example 1: Selective recovery of lithium from waste lithium iron phosphate batteries

[0082] (1) Selective leaching of lithium

[0083] Take 8g of lithium iron phosphate electrode material (4.66% lithium content, 38.05% iron content) in a round bottom flask, add 134mL of 0.4mol / L dilute hydrochloric acid ( leaching agent), 10 mg / L of ozone (introduction rate: 1.5 L / min) was introduced, and reacted at 20° C. for 1 hour to obtain lithium-containing leaching solution.

[0084] (2) filter to obtain low concentration lithium solution

[0085] The lithium-containing leaching solution in step (1) was filtered to obtain a low-concentration lithium solution. At this time, the measured lithium ion concentration was 2.6286g / L, and the iron ion concentration was 8.292mg / L, and the filter residue was washed with water to obtain iron phosphate residue.

[0086] (3) concentrated to obtain lithium-rich solution

[0087] Concentrate the low-concentration lithium solution obtained in...

Embodiment 2

[0091] Example 2: Selective recovery of lithium from waste lithium iron phosphate batteries

[0092] (1) Selective leaching of lithium

[0093] Take 8g of lithium iron phosphate electrode material (lithium containing lithium 4.66%, iron content 38.05%) in a round bottom flask, add 125mL of 0.5mol / L dilute hydrochloric acid according to the molar ratio of hydrogen ions and lithium ions in lithium iron phosphate 1:1.12 (Leaching agent), 10 mg / L of ozone (1.5 L / min) was passed through, and reacted at 20° C. for 1 h to obtain a lithium-containing leaching solution.

[0094] (2) filter to obtain low concentration lithium solution

[0095] The lithium-containing leaching solution in step (1) is filtered to obtain a low-concentration lithium solution. The lithium ion concentration measured at this time was 2.9574g / L, and the iron ion concentration was 36.437mg / L, and the filter residue was washed with water to obtain iron phosphate residue.

[0096] (3) concentrated to obtain lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com