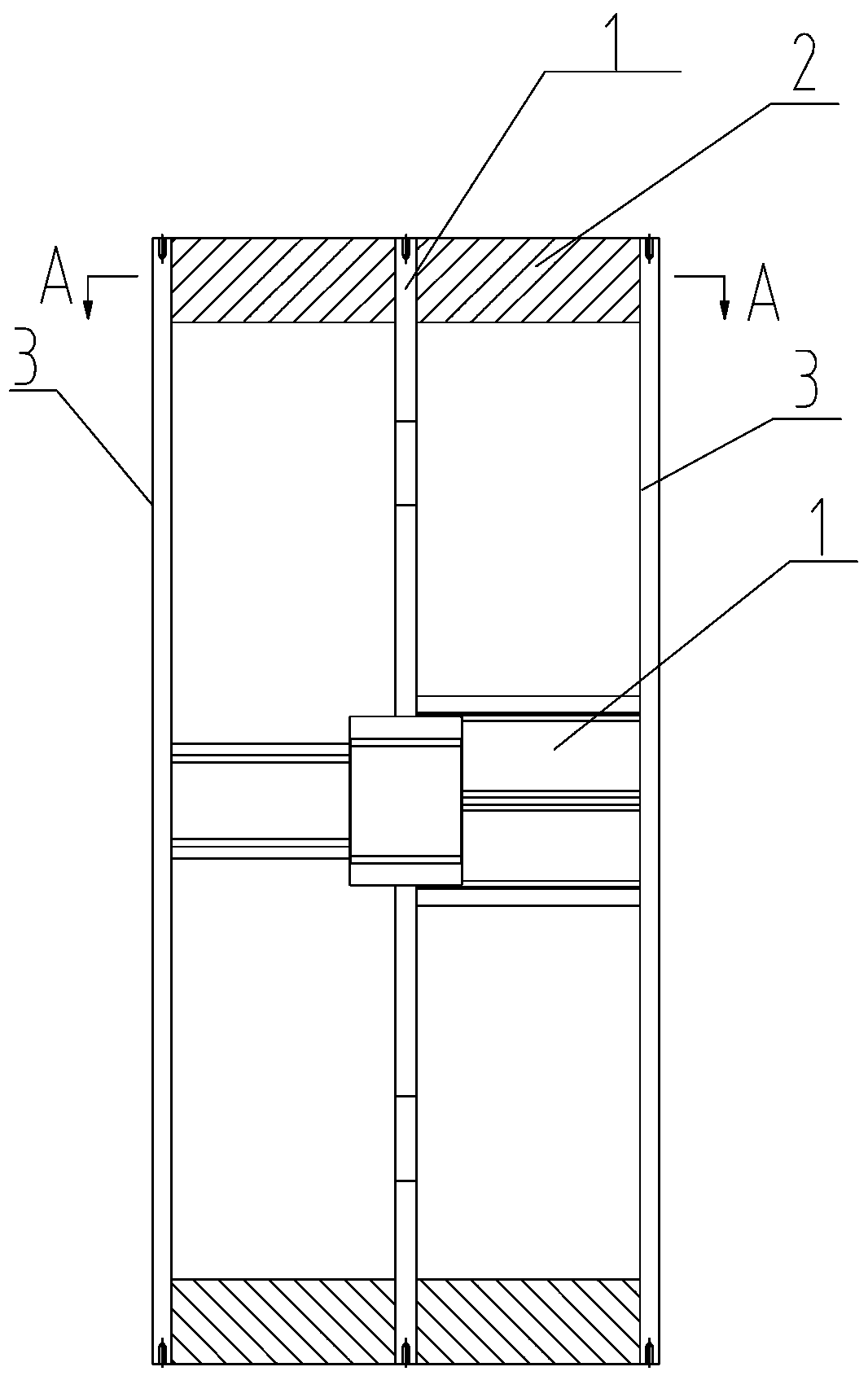

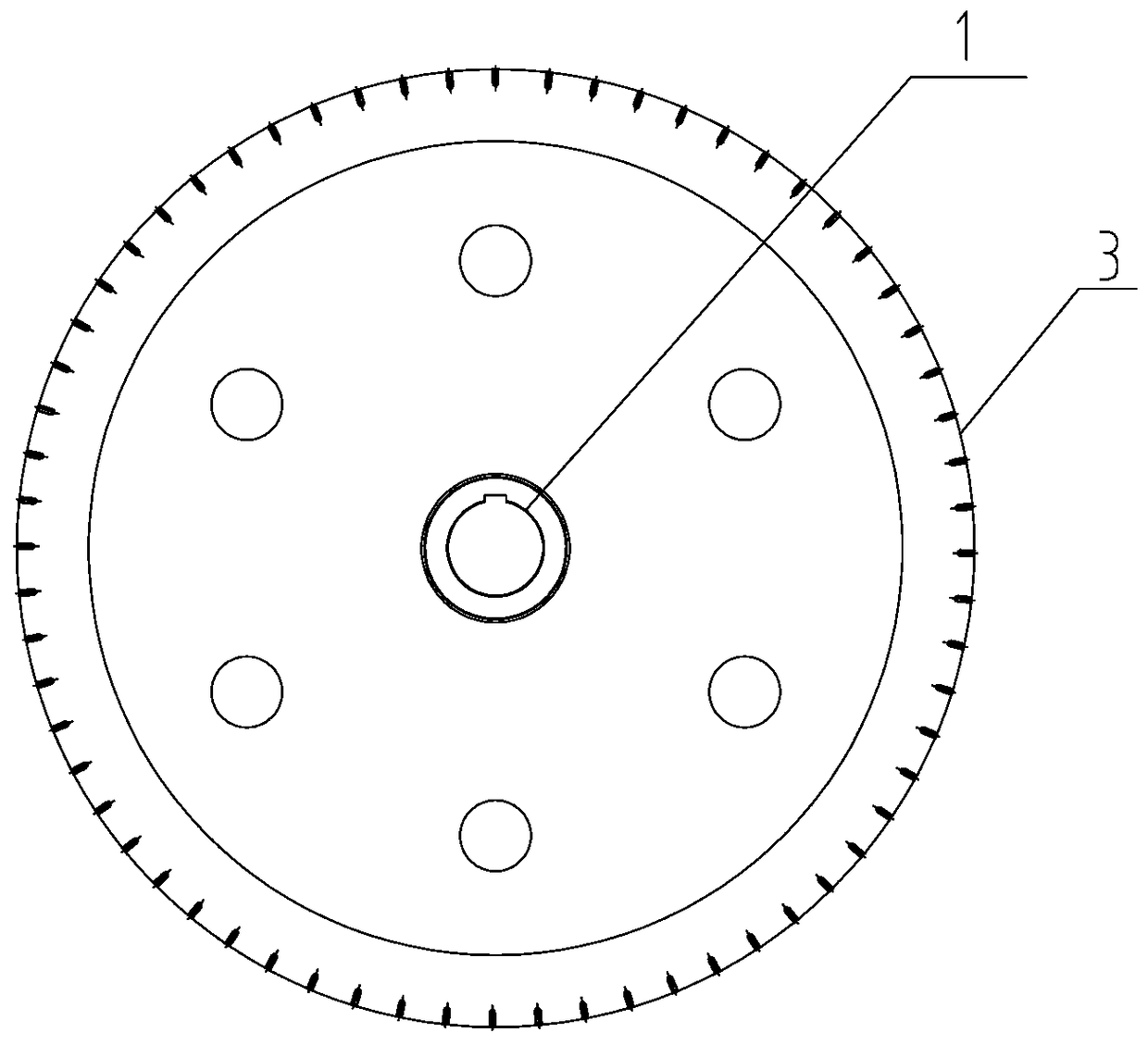

Vertical ring multi-gradient magnetic separator rotary ring structure

A multi-gradient and magnetic separator technology, applied in the direction of high-gradient magnetic separator, etc., can solve the problems of poor separation effect of fine mineral particles and high tailings grade, so as to increase equipment processing capacity, improve filling rate, reduce The effect of small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

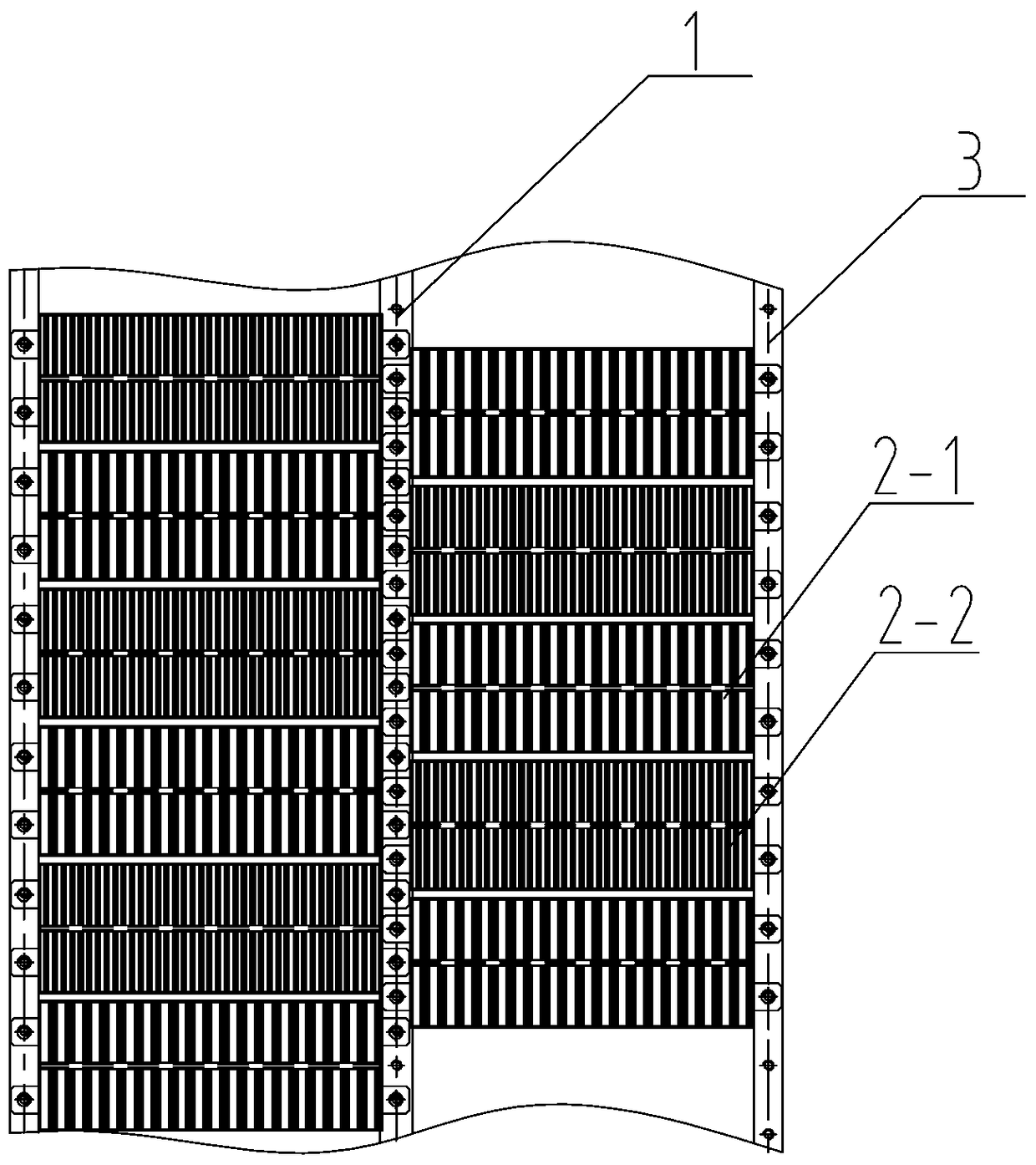

Embodiment 1

[0023] For the weak magnetic hematite ore with a particle size of -0.074mm and a content of 50%-60%, the multi-gradient conversion structure in the present invention is used for sorting, and the magnetic gathering medium rod 2-1 with a diameter of 2mm and a diameter of The 3mm magnetic gathering medium rods 2-2 are arranged alternately along the circumferential direction of the conversion, and the gap between the magnetic gathering medium sticks is 3mm. On the one hand, because the filling rate of the magnetic-gathering medium is 12% higher than that of the traditional conversion structure, the processing capacity per unit time is increased by 10.5% when the equipment model remains unchanged. On the other hand, due to the use of two kinds of magnetic gathering media with different diameters, compared with the traditional single magnetic gathering medium rod (only using a magnetic gathering medium with a diameter of 3mm), the fine particles with a particle size of ≤0.1mm in each...

Embodiment 2

[0025] For the fine-grained weak magnetic hematite ore with a particle size of -0.074mm and a content of 80%-90%, the multi-gradient conversion structure in the present invention is used for sorting, and the magnetic gathering medium rods with a diameter of 1.5mm are used for 2- 1 and magnetic gathering medium rods 2-2 with a diameter of 2 mm are arranged alternately along the circumferential direction of the conversion, and the gap between the magnetic gathering medium rods is 2 mm. On the one hand, because the filling rate of the magnetic-gathering medium is 14.5% higher than that of the traditional conversion structure, the processing capacity per unit time is increased by 11.9% when the equipment model remains unchanged. On the other hand, due to the use of two kinds of magnetic gathering medium rods with different diameters, compared with the traditional single magnetic gathering medium rod (only using a magnetic gathering medium with a diameter of 2mm), the fine particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com